Cladding die repair technology by laser coaxial and synchronous power feeding method

A technology of synchronous powder feeding and cladding, applied in the coating process and coating of metal materials, can solve the problems of easy distortion and cracking, low life, poor thickness uniformity, etc., to improve production efficiency and processing quality, and reduce production costs , the effect of small heat-affected zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

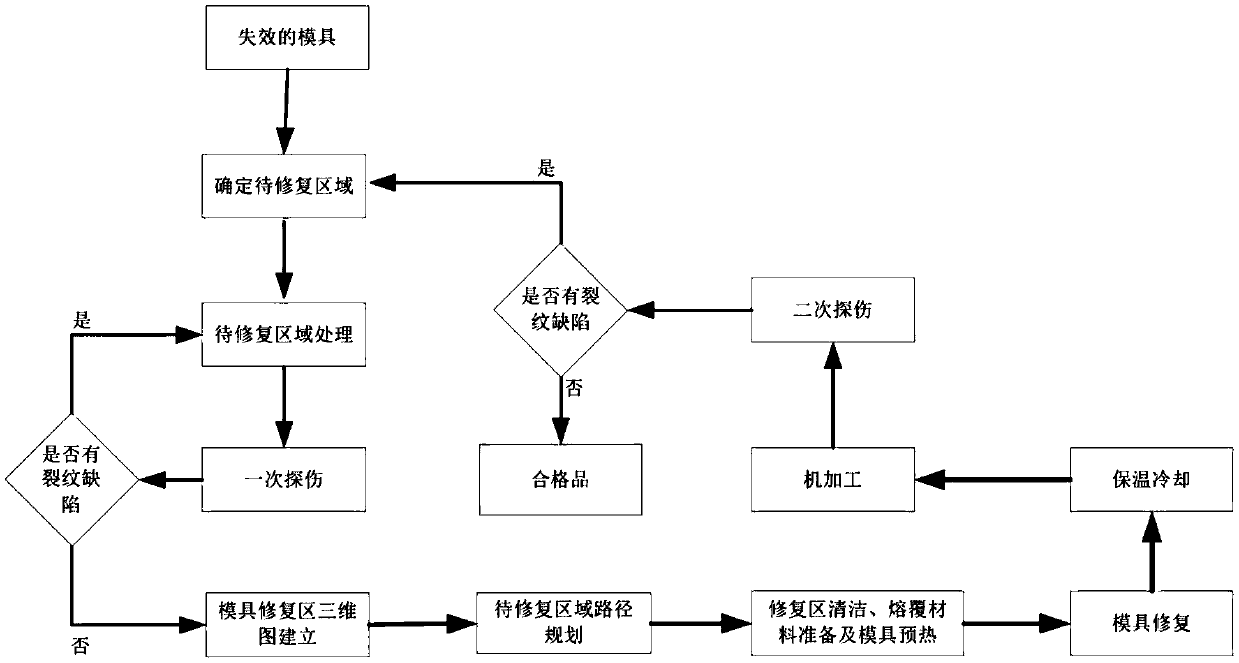

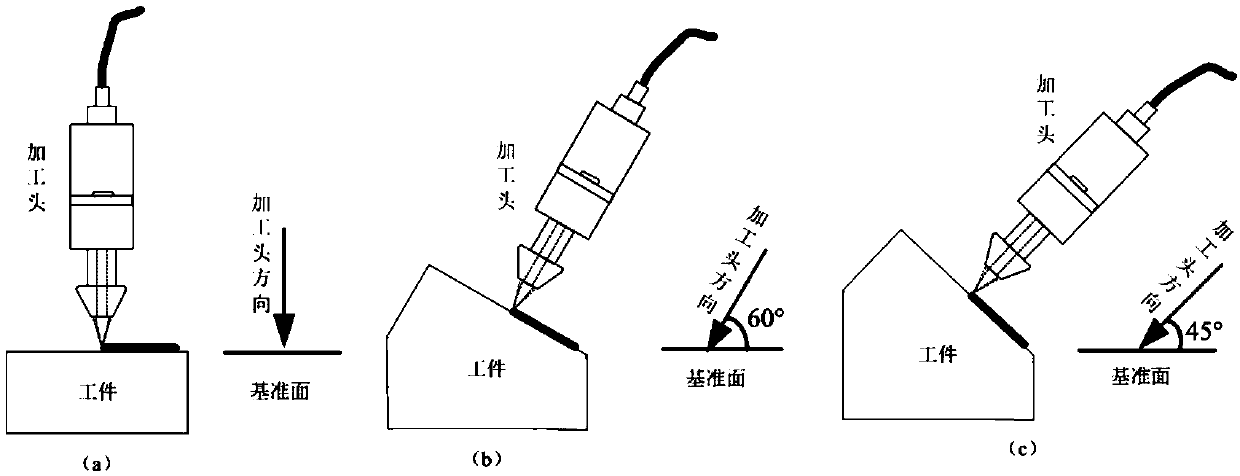

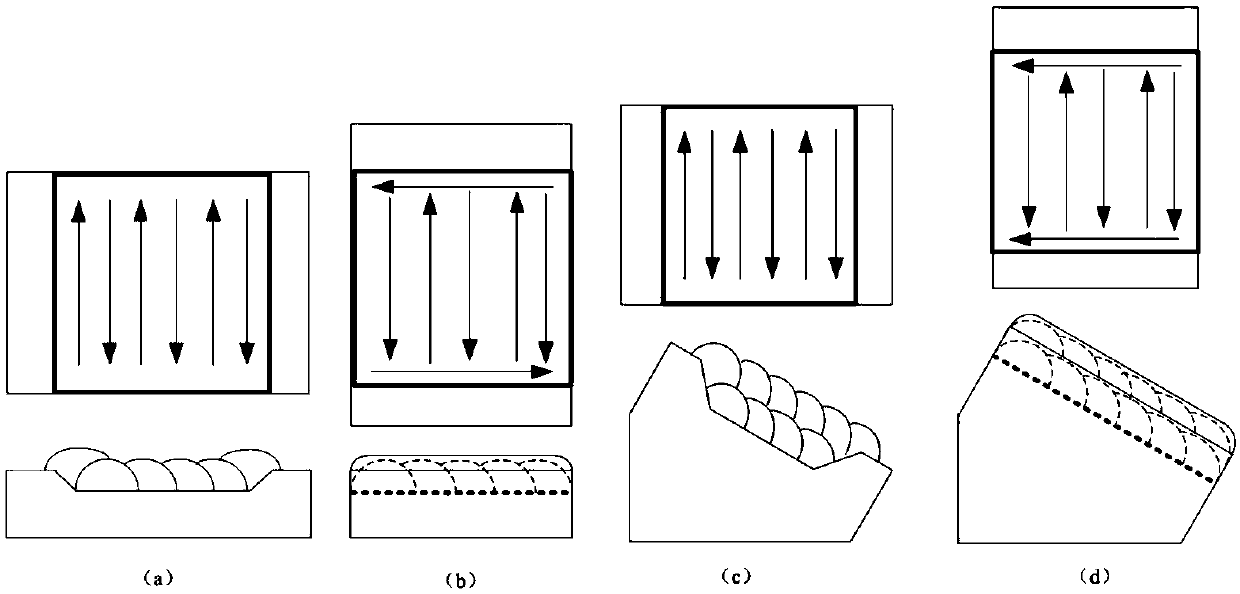

[0058] In this embodiment, the microcracks on the surface of the 5CrNiMo hot-worked mold are implemented as objects and the crack or defect depth is 1 mm under the condition that the surface coincides with the reference plane.

[0059] The first step is to evaluate the damage of the failed mold and determine the area of the failed mold to be repaired. The surface of the area to be repaired is treated, and the oxide scale and fatigue layer existing on the surface are removed by mechanical processing, and the groove is processed on the cracked place, and the groove angle is 45°.

[0060] The second step is to carry out the first flaw detection, using magnetic particle flaw detection and ultrasonic non-destructive flaw detector to carry out surface and internal flaw detection on the surface of the treated area to be repaired respectively, if the flaw detection results show that there is no crack defect, then enter the third step, otherwise execute the first step again One step;...

Embodiment 2

[0067] In this embodiment, microcracks on the surface of a 5CrNiMo hot-working mold are used as objects and there is an angle between the surface and the reference plane (the deflection angle between the laser head and the reference plane is (60-90°) and the depth of the crack or defect is 2mm.

[0068] The first step is to evaluate the damage of the failed mold and determine the area of the failed mold to be repaired. The surface of the area to be repaired is treated, and the oxide scale and fatigue layer existing on the surface are removed by mechanical processing, and the groove is processed at the place with cracks, and the groove angle is 45°.

[0069] The second step is to use penetrant testing and ultrasonic non-destructive testing to detect surface and internal flaws, respectively, and use magnetic particle testing and ultrasonic non-destructive testing to detect surface and internal flaws on the surface of the treated area to be repaired. If the testing results show no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com