Magnesium alloy for staged fracturing of petroleum exploitation and preparation method of magnesium alloy

A magnesium-based alloy and alloy technology, which is applied in the fields of fluid mining, earth-moving drilling, wellbore/well components, etc., can solve the problems of strong pressure bearing capacity, insufficient fracturing ball strength, substandard dissolution rate, etc., and achieves good mechanics. performance, attenuating electrochemical corrosion rates, improving mechanical/electrochemical and machinability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0035] This embodiment provides a soluble magnesium-based alloy for preparing fracturing balls for oil and gas development, including the following components in weight percentages: Gd: 8%, Al: 5%, Zn: 2%, Y: 2%, Ca: 0.3%, Mg: 82.7%.

[0036] The preparation method of the above-mentioned soluble magnesium-based alloy is as follows:

[0037] Take pure Mg as raw material and Mg-Zn, Mg-Gd, Mg-Al, Mg-Ca and Mg-Y master alloys with powder particles of 20~200μm prepared by powder metallurgy method according to the ratio, and dry all raw materials ;

[0038] S1: Smelting: in CO 2 with SF 6 In a mixed gas atmosphere with a ratio of 300:1, first melt pure magnesium, then add Mg-Zn, Mg-Al and Mg-Ca master alloys with a purity ≥ 99.9% at 680ºC, stir evenly, keep warm for 25min, and cool down to 665ºC. Add Mg-Gd and Mg-Y master alloys with a purity of ≥99.9%, stir evenly, keep warm for 4 minutes, and raise the temperature to 675ºC; inject 0.3MPa, 0.05m 3 / min of argon gas, stir while...

Embodiment approach 2

[0045] This embodiment is roughly the same as Embodiment 1, the difference is only that (1) during S3 homogenization heat treatment, the heat treatment temperature is 350°C, and the treatment time is 40 hours; (2) the extrusion ratio during S4 extrusion is 5 ; (3) Among the components of the soluble magnesium-based alloy, Gd: 10%, Y: 1%, Mg: 81.7%. .

[0046] Apart from this, this embodiment is completely the same as Embodiment 1, and details are not repeated here.

Embodiment approach 3

[0048] This embodiment is roughly the same as Embodiment 1, the difference is only that (1) during S3 homogenization heat treatment, the heat treatment temperature is 420°C, and the treatment time is 20 hours; (2) the extrusion ratio during S4 extrusion is 15 ; (3) Among the components of the soluble magnesium-based alloy, Gd: 5%, Y: 3%, Mg: 84.7%.

[0049] Apart from this, this embodiment is completely the same as Embodiment 1, and details are not repeated here.

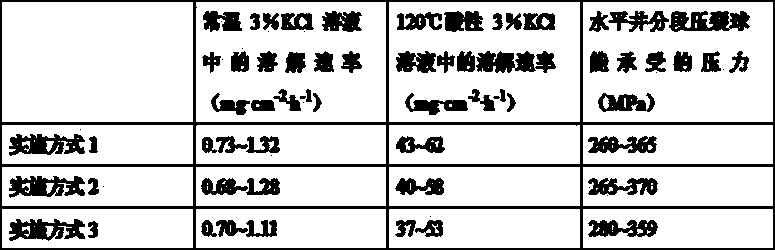

[0050] The dissolution rate of the soluble magnesium-based alloy prepared in Embodiments 1 to 3 above in a 3% KCl solution at room temperature, the dissolution rate in a 3% acidic KCl solution at 120°C, and the pressure parameters that the staged fracturing balls of a horizontal well can withstand are as follows Table 1.

[0051] Table 1

[0052]

[0053] It can be seen from Table 1 that the dissolution rate in 3% acidic KCl solution at room temperature and 120°C is low, and the mechanical properties are good, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com