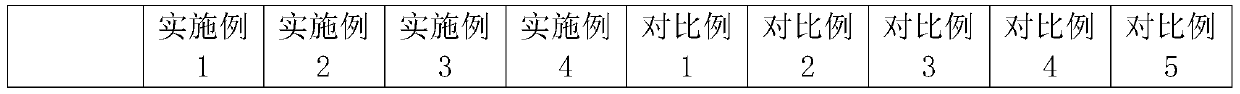

Patents

Literature

81results about How to "Prevent temper brittleness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

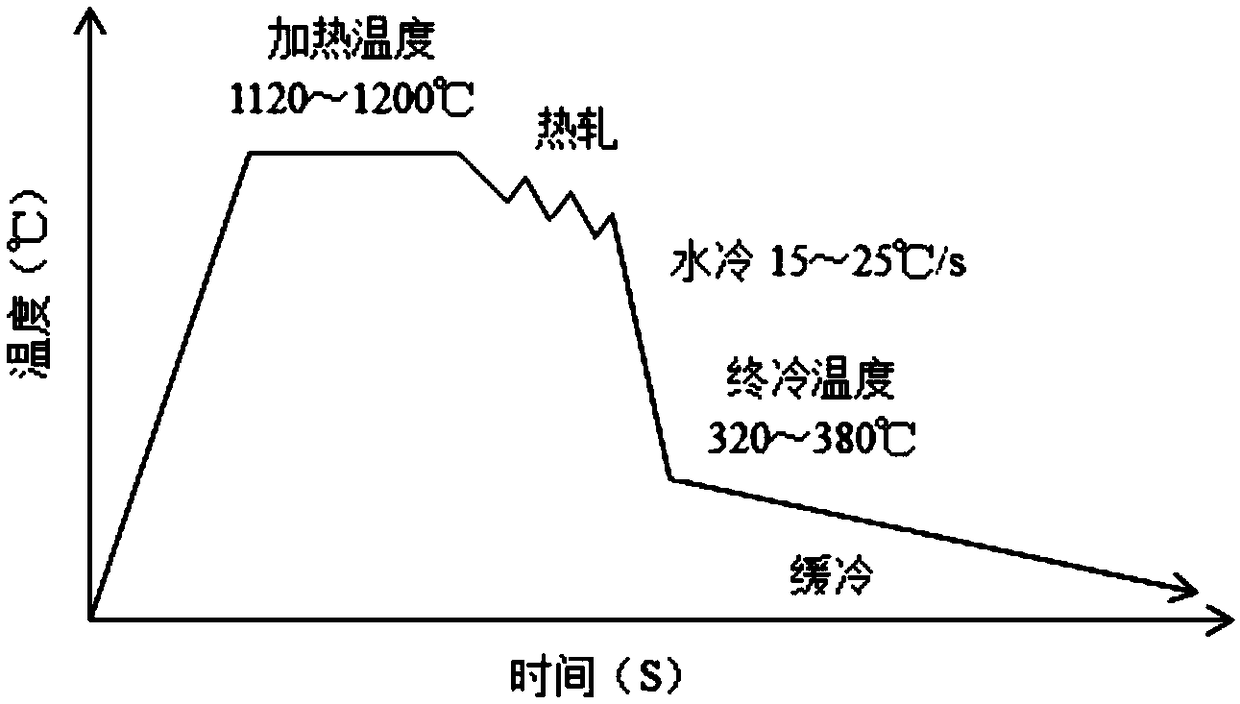

High-performance bridge weathering steel containing Mo and preparation method thereof

The invention belongs to the field of manufacture of low-alloy steel, in particular to high-performance bridge weathering steel containing Mo and a preparation method thereof. The invention provides bridge weathering steel containing Mo with the high performance, which comprises the following chemical components by mass percent: 0.02-0.05 percent of C, 0.20-0.30 percent of Si, 1.0-1.50 percent of Mn, at most 0.02 percent of P, at most 0.010 percent of S, 0.20-0.40 percent of Cu, 0.40-0.60 percent of Cr, 0.20-0.40 percent of Ni, 0.1-0.30 percent of Mo, 0.04-0.07 percent of Nb, 0.005-0.015 percent of Ti, at most 0.02 percent of Al and the balance of Fe and inevitable impurities. The high-performance bridge weathering steel containing Mo adopts two stages of rolling. The rough rolling and bloom rolling temperature of the first stage is 1050-1070 DEG C, the precision rolling and bloom rolling temperature of the second stage is 900-950 DEG C, and the finish rolling temperature is 800-850 DEG C. The high-performance bridge weathering steel containing Mo disclosed by the invention has good mechanical property, welding performance and atmospheric-corrosion resistance performance. The high-performance bridge weathering steel containing Mo adopts an Ultra-low carbon design, and the production cost is low.

Owner:NORTHEASTERN UNIV LIAONING +1

Alloy steel SDH55 for shield machine tools and production method thereof

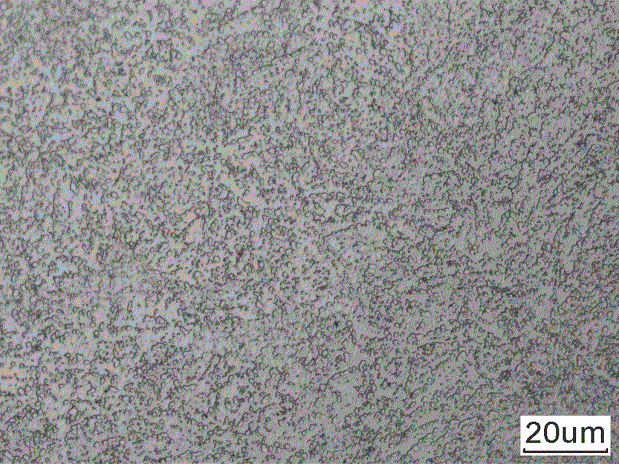

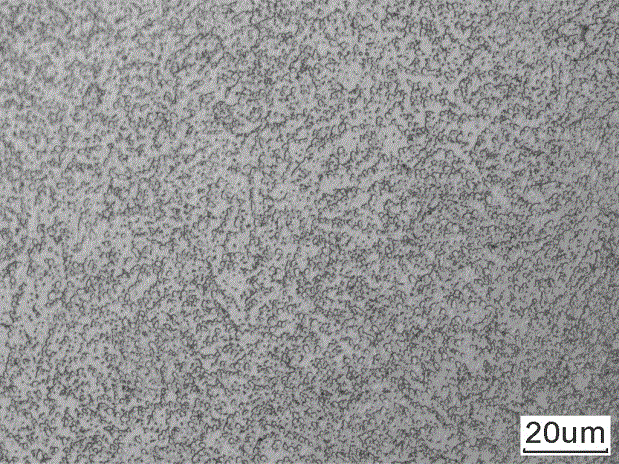

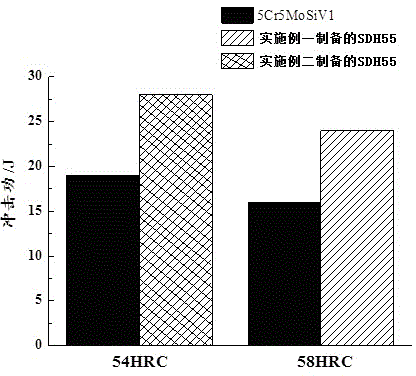

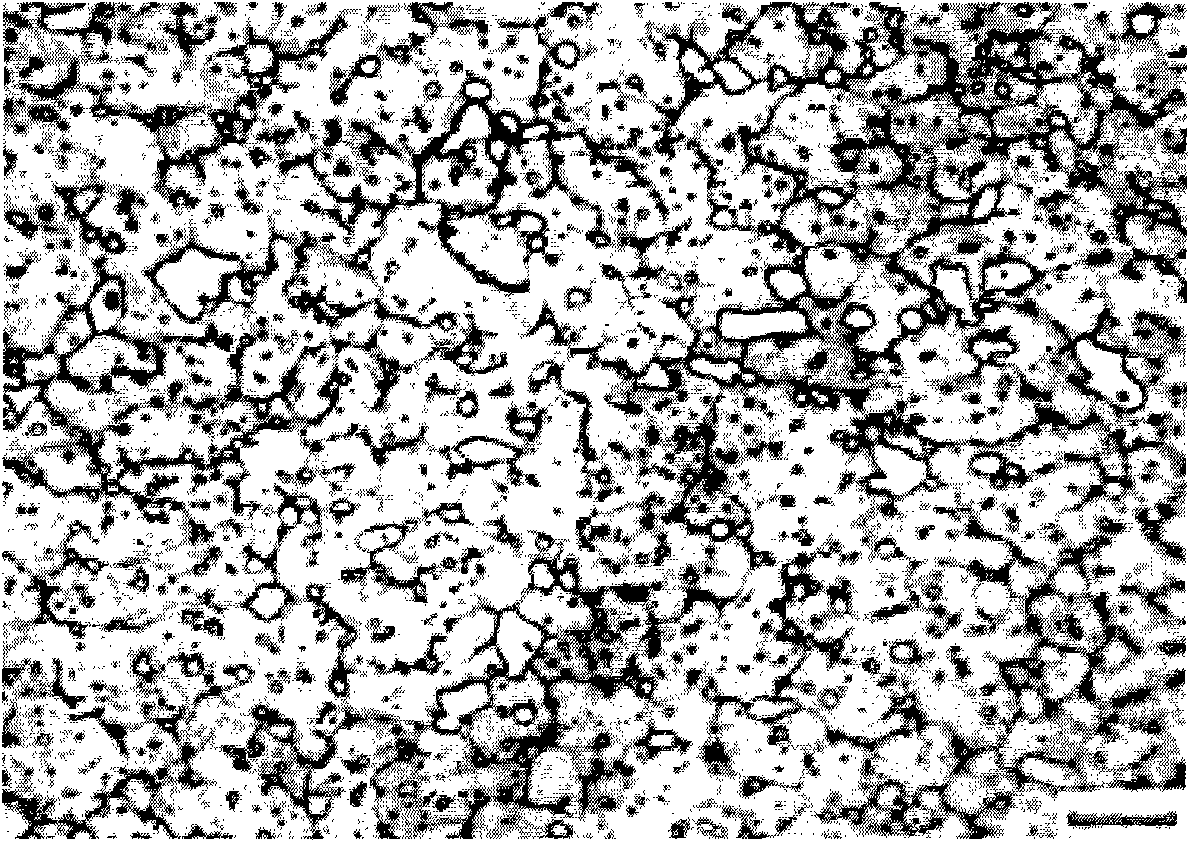

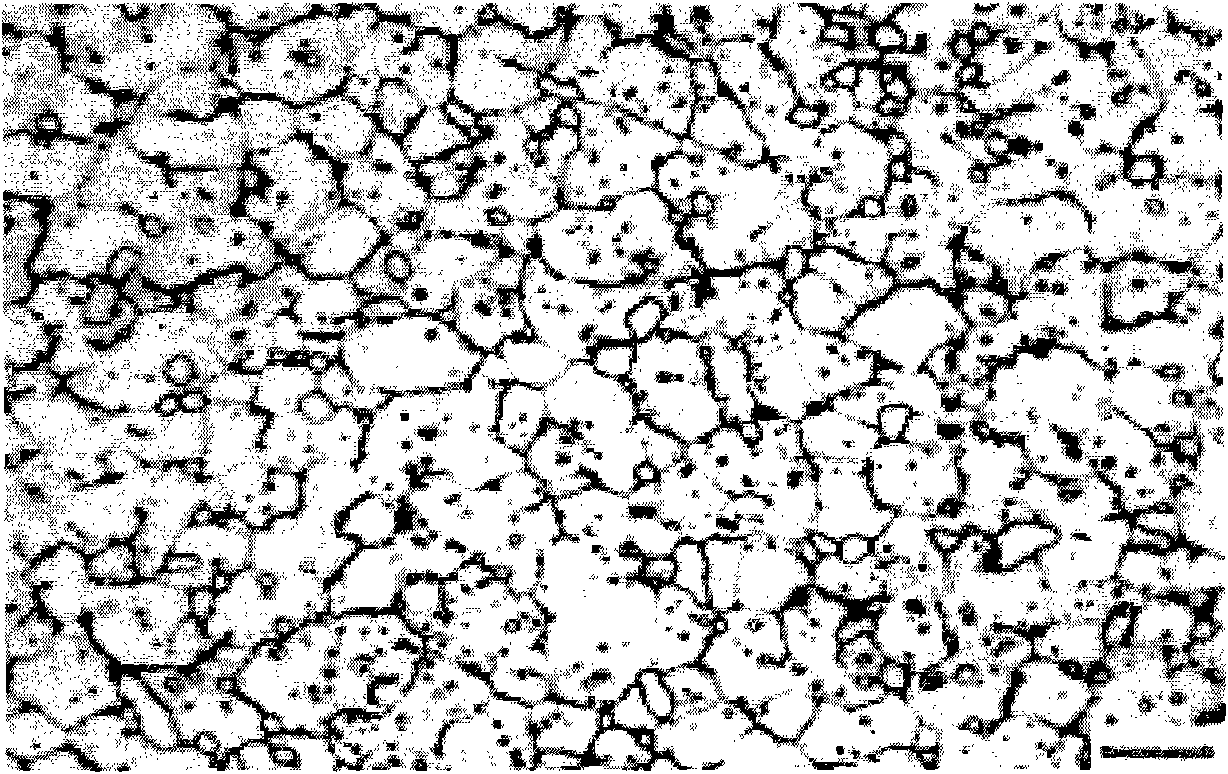

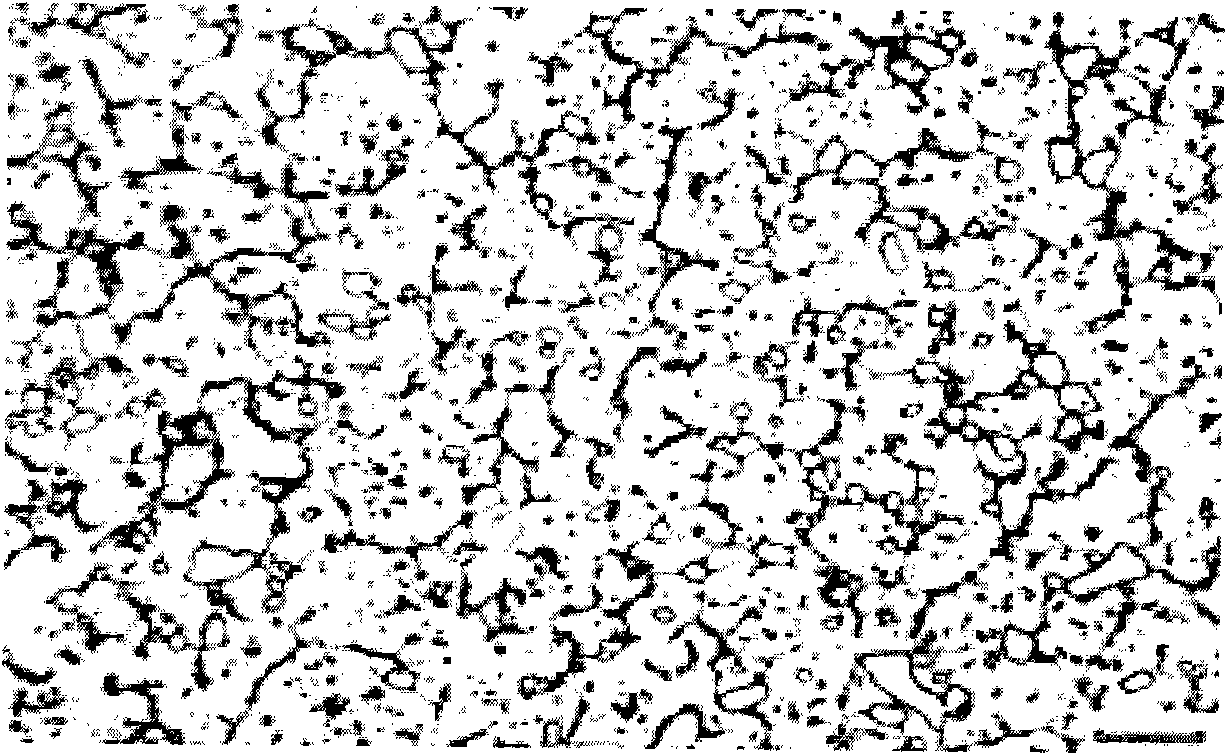

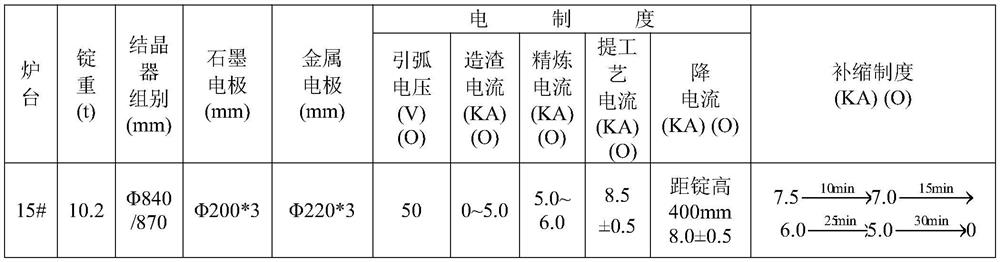

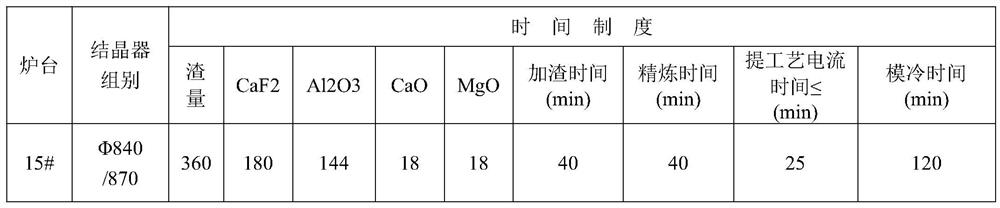

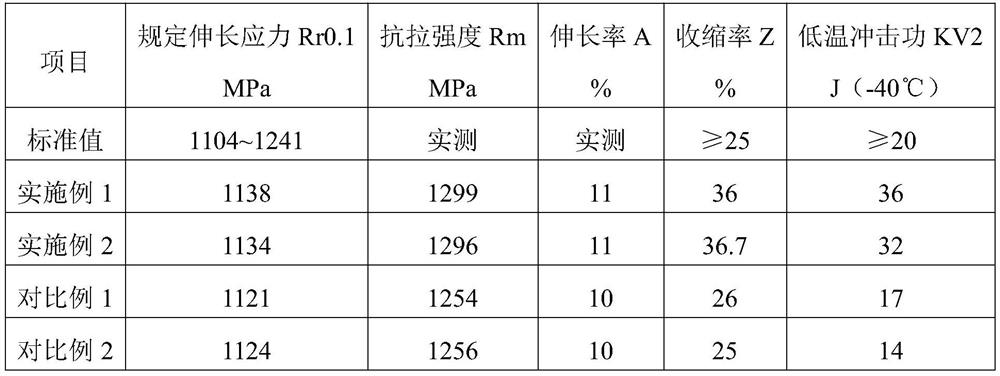

The invention discloses alloy steel SDH55 for shield machine tools and a production method thereof. The alloy steel comprises, by weight, 0.4% to 0.55% of C, 0.10% to 0.40% of Si, 0.10% to 0.30% of Mn, 5.10% to 6.50% of Cr, 2.20% to 3.00% of Mo, 0.45% to 0.85% of V, the balance of Fe and unavoidable impurity elements, including not greater than 0.005% of S and not greater than 0.010% of P. The alloy steel high in wear resistance and high in toughness is made by means of matching, smelting, casting and electroslag remelting, by thermal feeding for high-temperature homogenous treatment after demolding, and by means of multidirectional forging, soft annealing and ultra-fining treatment; the problem that the current tools for shield machines are of short lives due to wear and failure and edges cracking caused by low toughness is solved; the alloy steel is of great significance to the development of the industry of special steels of shield machine tools.

Owner:SHANGHAI SHIJIN NEW MATERIAL TECH

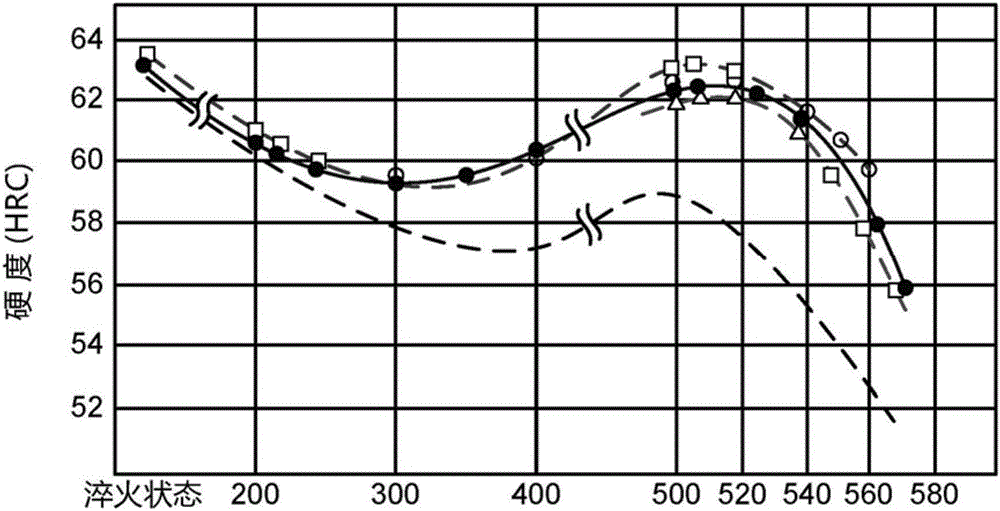

High-performance cold extrusion die steel and metallurgical manufacturing method thereof

ActiveCN101649419AReduced brittle tendencyImprove metallurgical qualitySteelmakingChemical composition

The invention provides high-performance cold extrusion die steel and metallurgical manufacturing method thereof. The high-performance cold extrusion die steel comprises the following chemical components in percentage by mass: 0.95 to 1.02 percent of C, 0.20 to 0.40 percent of Mn, 8.60 to 9.00 percent of Cr, 0.87 to 1.10 percent of Si, 1.80 to 2.00 percent of Mo, 0.40 to 0.60 percent of V, less than or equal to 0.30 percent of Cu, less than or equal to 0.25 percent of Ni, less than or equal to 0.025 percent of P, less than or equal to 0.010 percent of S, and the balance of Fe and inevitable impurities. According to the component proportion, the toughness performance of the high-performance cold extrusion die steel can be greatly improved. The metallurgical manufacturing method comprises theprocesses of electric furnace steel making, electroslag remelting and steel forging by a radial forging press. In the process of electroslag remelting, the voltage is between 57 and 59V, and the current is between11,000 and 12,000A; and in the process of steel forging by the radial forging press, steel ingots are heated to between 1,150 DEG C and 1,170 DEG C, and the temperature keeps for 2 to 4hours. The method is simple and convenient, and can remarkably improve the performance index of the steel.

Owner:宝武特种冶金有限公司

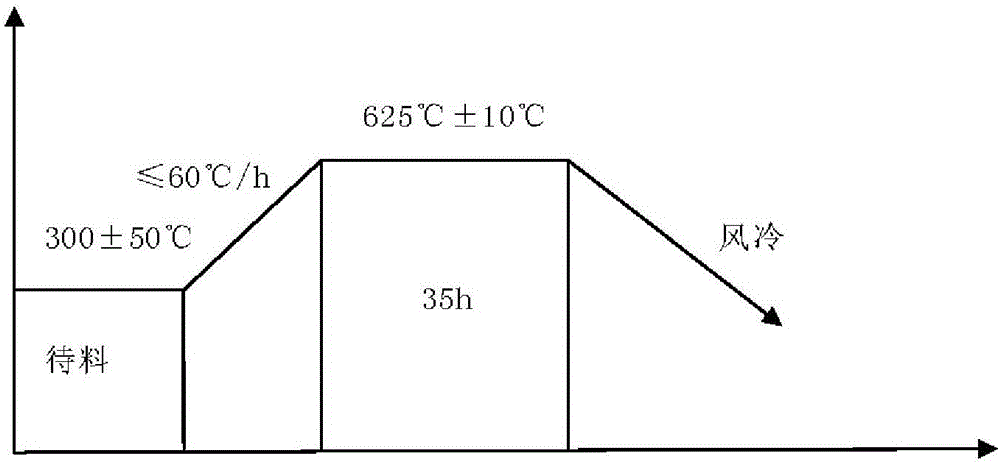

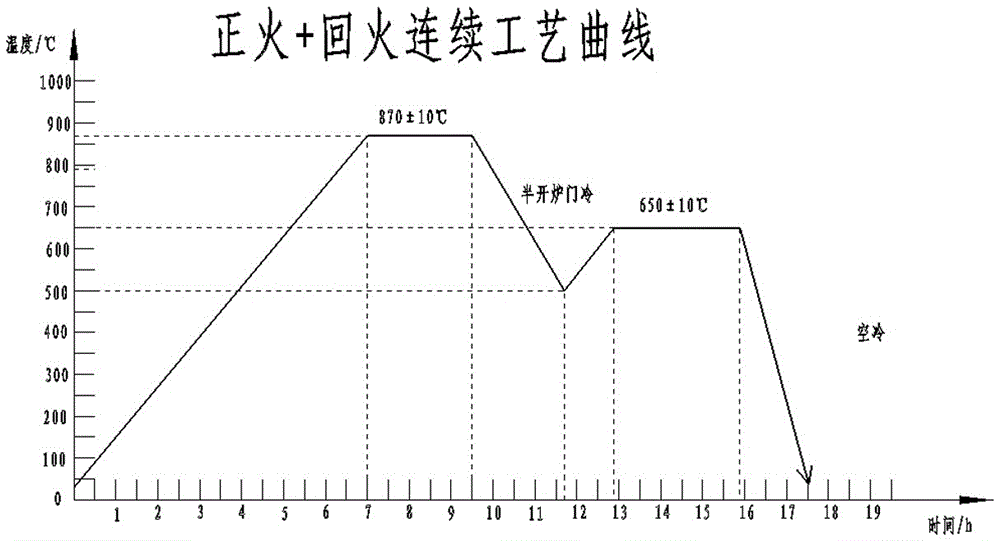

Large-size 42 CrMo4 hardened and tempered steel manufacturing process for wind power gearbox outer main shaft

The invention discloses a tempered steel 42 CrMo4 manufacturing process for a wind power main shaft with the diameter not smaller than 450 mm, and the technical aims of high intensity, high tenacity and stable mechanical property of large and round tempered steel are achieved. According to the technical scheme, the manufacturing process is characterized in that (1) the process route includes operation through electric furnace + LF + VD, die casting, forging (through a 3500t high-speed forging machine), normalization and tempering; and (2) by optimizing the internal control ingredients, the mechanical property of the steel is guaranteed to be stable, intensified elements such as vanadium, niobium and nickel are added into smelting ingredients, and the steel intensity is improved; through pretreatment before tempering, normalizing is carried out the steel to homogenize the texture and refine grains, and the good impact toughness is obtained after tempering; and temper brittlement is avoided through air cooling of tempered furnace discharge steel. The tempered steel 42 CrMo4 manufacturing process has the beneficial effects that the stable and qualified mechanical property of the large and round tempered steel is achieved, the strength of extension (Rm) ranges from 760 MPa to 910 MPa, the yield strength (Re) is not smaller than 535 MPa, the percentage reduction of area (A) is not smaller than 15%, the impact absorbing energy (AkV) is not smaller than 38 J; and the impact toughness is improved.

Owner:FUSHUN SPECIAL STEEL SHARES

Production method of 8630 super-long forge piece for deep sea Christmas tree equipment

The invention discloses a production method of an 8630 super-long forge piece for deep sea Christmas tree equipment. The production method comprises the following steps: feeding, namely taking 8630# steel as a raw material steel ingot, wherein the steel ingot comprises the following chemical components: 0.3-0.33% of C, 0.15-0.35% of Si, 0.75-0.95% of Mn, less than or equal to 0.025% of P, less than or equal to 0.025% of S, 0.8-1.0% of Cr, 0.35-0.45% of Mo, 0.70-0.90% of Ni, 0.015-0.03% of Al, less than or equal to 0.35% of Cu, less than or equal to 0.06% of Nb, less than or equal to 0.06% of Ti, 0.03-0.06% of V, less than or equal to 0.0005% of B, less than or equal to 0.005% of Ca, less than or equal to 2 ppm of H, less than or equal to 20 ppm of O, less than or equal to 100 ppm of N, greater than or equal to 0.77% of CEV and the balance of Fe; carrying out forging; carrying out heat treatment; carrying out UT flaw detection; and carrying out machining.

Owner:ZHANGJIAGANG HAIGUO HEAVY FORGING

690 MPa-grade low-carbon medium-manganese high-strength medium-thickness plate and quenching-dynamic blending production process preparation method

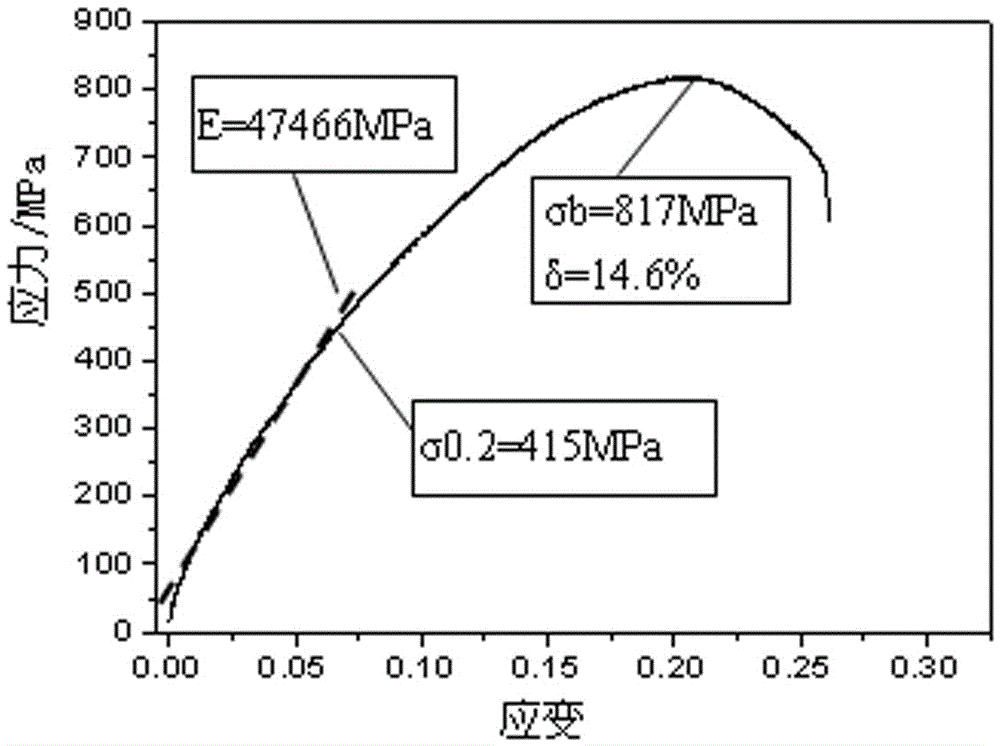

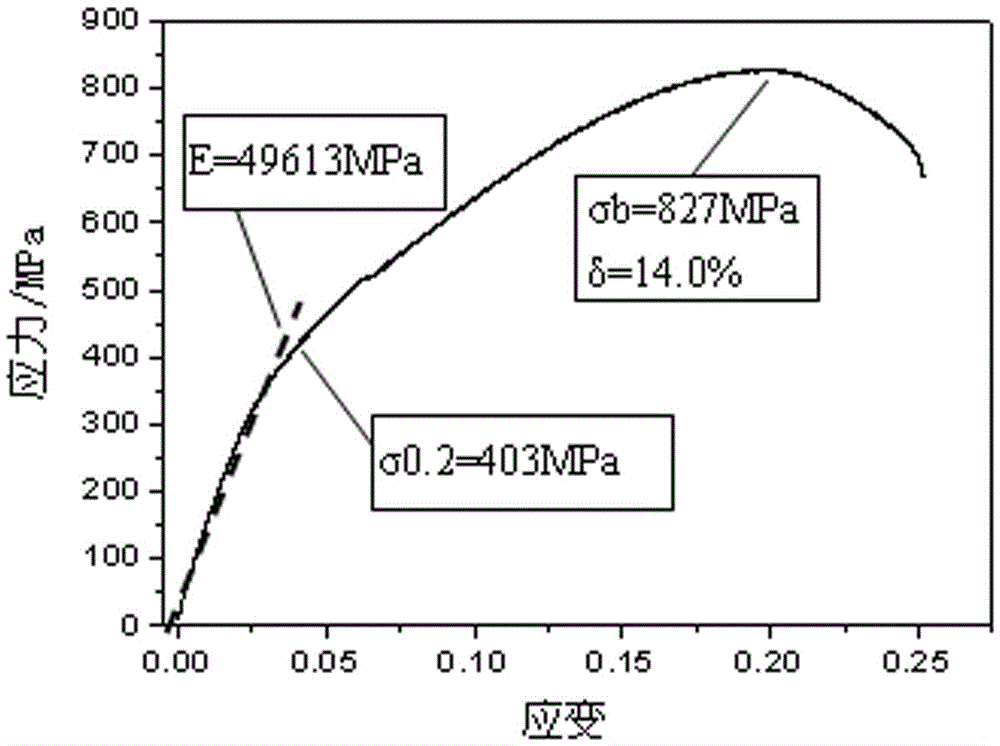

The invention discloses a 690 MPa-grade low-carbon medium-manganese high-strength medium-thickness plate and a quenching-dynamic blending production process preparation method. The 690 MPa-grade low-carbon medium-manganese high-strength medium-thickness plate comprises, by weight: 0.04-0.09 % of C, 4.9-5.45 % of Mn, 0.19-0.20 % of Si, 0.0012-0. 0006 % of S, 0.004-0.009 % of P, 0.01-0.023 % of Al,0.12-0.31 % of Cu, 0.21-0.32 % of Ni, 0.16-0.23 % of Mo, 0.39-0.42 % of Cr, the balance Fe and other inevitable impurities; and the thickness of a steel plate ranges from 20 mm to 80 mm, and the metallographic structure is lath martensite and thin-film-like carbon-rich residual austenite. The prepared low-carbon medium-manganese high-strength medium-thickness plate is excellent in performance, andthe yield strength is 780-820 MPa, the tensile strength ranges from 1000 MPa to 1150 MPa, the elongation percentage ranges from 15.78 % to 17.36 %, and the impact power at the temperature of 40 DEG Cis greater than or equal to 59 J.

Owner:NORTHEASTERN UNIV

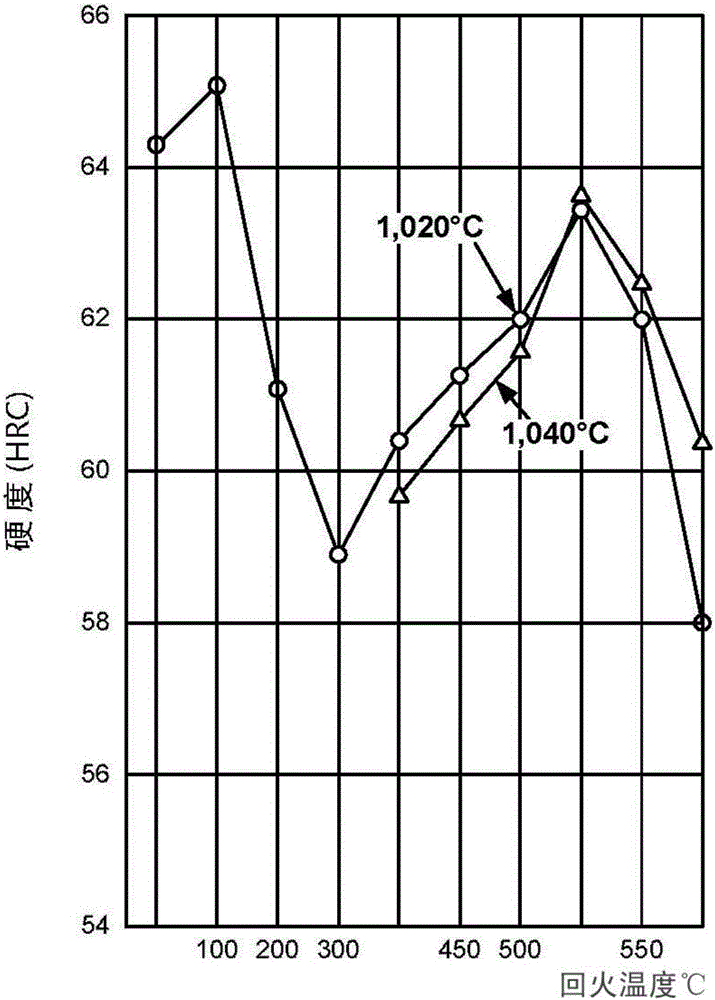

High-performance and high-speed-stamping cold work die steel and preparation method thereof

The invention relates to high-speed-stamping cold work die steel and a preparation method thereof. The high-speed-stamping cold work die steel is characterized by primarily comprising, by mass, 0.85%-0.95% of C, 0.80%-1.20% of Si, 0.30%-0.60% of Mn, 0.025% or less of P, 0.015% or less of S, 7.90%-8.40% of Cr, 1.40%-1.70% of Mo, 1.90%-2.20% of W, 2.20%-2.50% of V, 0.90%-1.20% of Al, 0.20% or less of Cu, 0.25% or less of Ni, and the balance Fe. By adding the alloy element, namely Al, the hardness, red hardness and the surface hardness and heat stability after nitriding of the steel are further improved; through addition of Mo, the hardenability, heat resistance, temper embrittlement resistance and temper softening resistance of the steel can be improved; and the high-speed-stamping cold work die steel has the remarkable beneficial effects of having high hardness, heat hardness and heat stability, meeting the development demand of modern industry, reducing consumption and increasing social benefits.

Owner:GUANGDONG STRONG METAL TECH

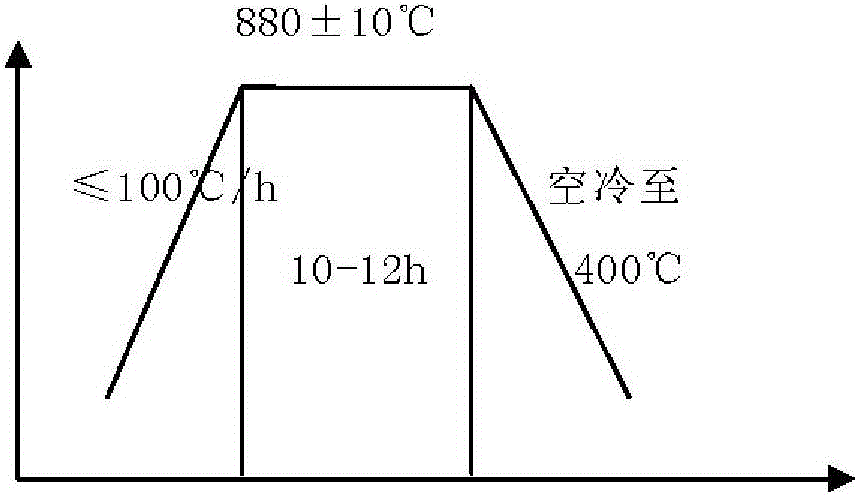

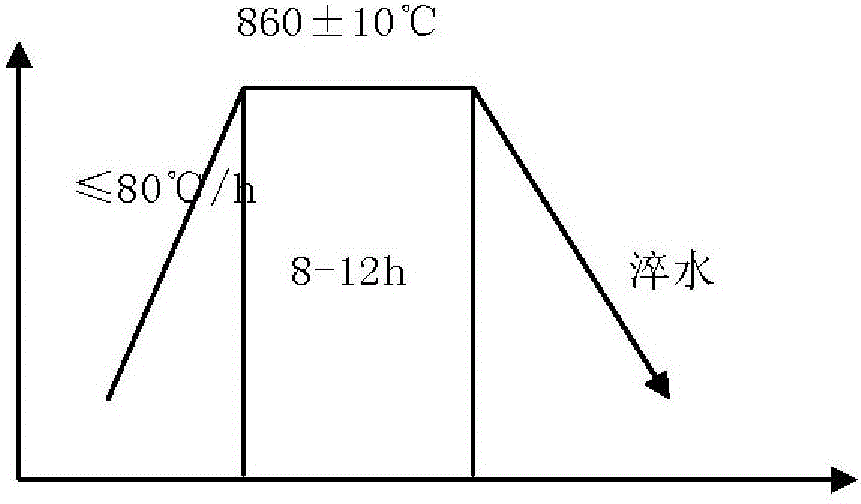

Production method of 18CrNiMo7-6 forging for wind power equipment gear

The invention discloses a production method of a 18CrNiMo7-6 forging for a wind power equipment gear. The production method includes the following steps of feeding, forging, normalizing, tempering, rough turning, UT flaw detecting and finish turning. In feeding, 18CrNiMo7-6 steel is taken and used as a raw materials steel ingot; in forging, a forging is formed after three times of upsetting and drawing, the sum of the forging ratios of three times of upsetting and drawing is larger than 7:1, the initial forging temperature is 1,220 DEG C, and the final forging temperature is 850 DEG C; in normalizing, the forging is heated to 710+ / -5 DEG C and heat-preserved for 2-2.5 h, then the forging is heated to 960+ / -5 DEG C at the heating rate being smaller than or equal to 150 DEG C / h and heat-preserved for 6-6.5 h, and then the forging is air-cooled below 300 DEG C; in tempering, the forging is heated to 680 DEG C at the heating rate being smaller than or equal to 150 DEG C / h and kept for 10-12 h, and then the forging is air-cooled to room temperature; and in finish turning, the forging is finish-turned into the wind power equipment gear meeting the dimension requirements.

Owner:ZHANGJIAGANG HAIGUO HEAVY FORGING

Ultrahigh strength die steel with good corrosion resistance and toughness

An ultrahigh strength die steel with good corrosion resistance and toughness is characterized by comprising the following chemical components by weight: 0.08-0.32% of C, no more than 0.8% of Si, no more than 0.5% of Mn, 5-10% of Cr, 6.0-8.0% of Ni, 1.3-1.8% of Co, 0.9-1.1% of W, 0.2-0.5% of V, 0.08-0.15% of Nb, no more than 0.002% of N, no more than 0.0015% of O, 0.9-1.4% of Mo, 0.05-0.4% of Ti, 0.011-0.025% of S, and the balance of Fe and inevitable impurities. The die steel subjected to forging and other processing methods can be widely applied to industrial steel such as automobile steel with the requirements of high strength and toughness.

Owner:威海九鼎金属制品股份有限公司

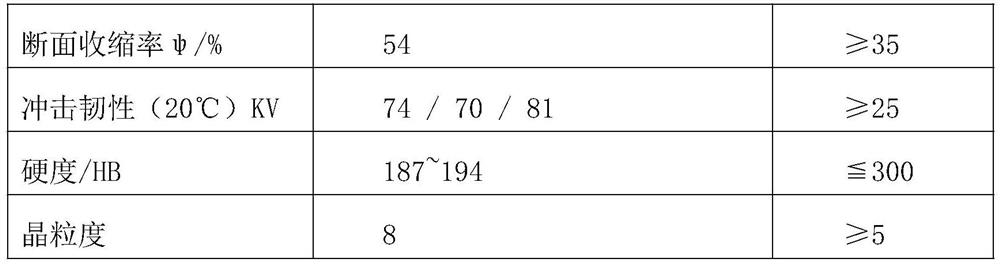

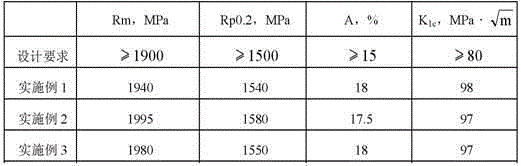

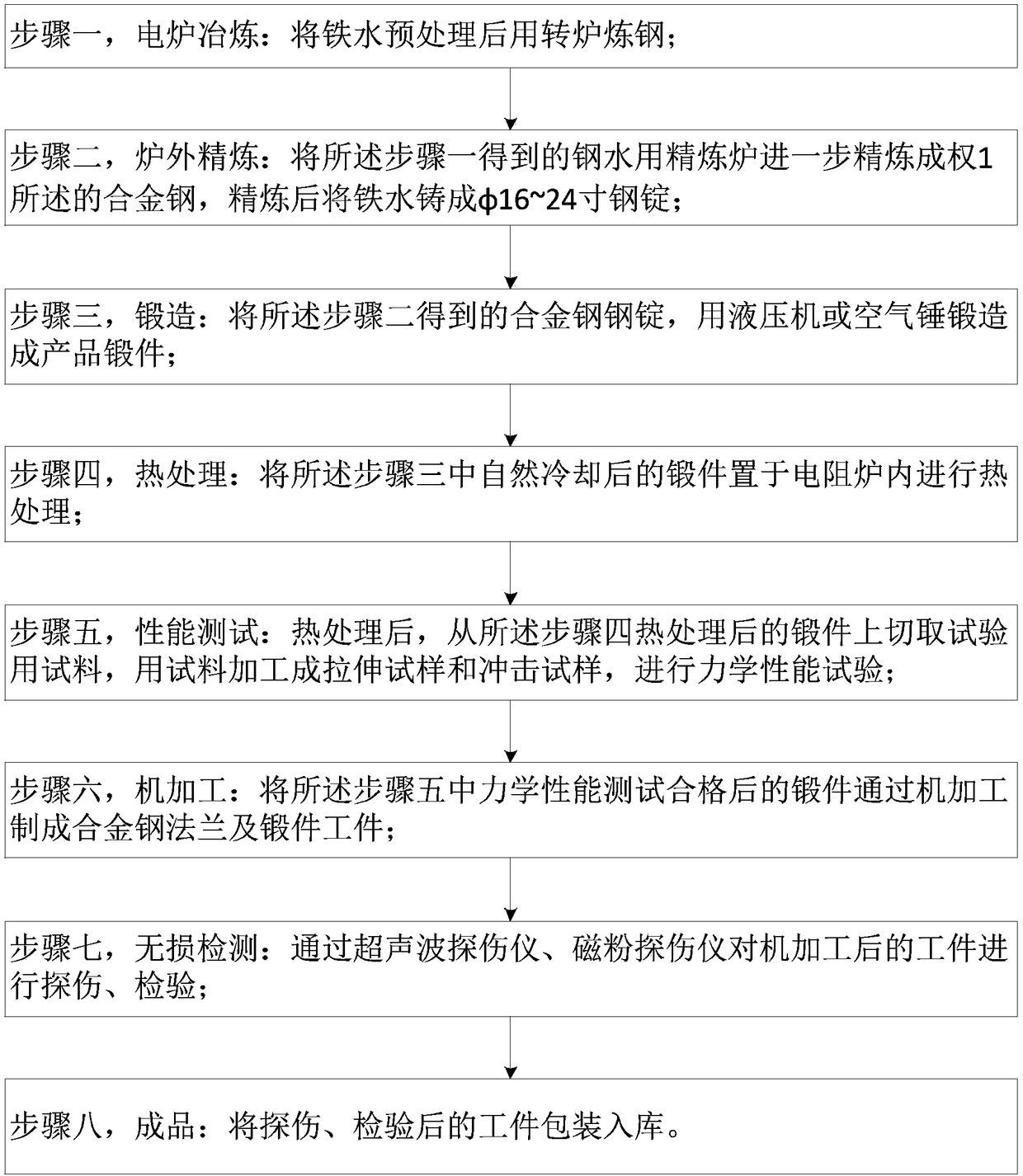

High-performance alloy steel flanges and forgings and manufacturing method thereof

The invention relates to the technical field of alloy steel forging and discloses high-performance alloy steel flanges and forgings and a manufacturing method thereof. Alloy steel comprises the components of, by weight, 0.14%-0.17% of carbon, 0.10%-0.60% of silicon, 0.60%-0.80% of manganese, 0-0.005% of phosphorus, 0-0.003% of sulfur, 1.00%-1.25% of chromium, 0.55%-0.65% of molybdenum, and the balance iron. The forgings produced through the manufacturing process are excellent in performance, the performance index of the forgings far exceeds that of forgings produced through a traditional process, and the defect number and size found in forging nondestructive testing are also far superior to those of the traditional process.

Owner:无锡市法兰锻造有限公司

High-tenacity wear-resisting overlaying alloy welding wire for cold-rolling support roller

InactiveCN102240868AMeet the surfacing requirementsNo thermal cracksArc welding apparatusWelding/cutting media/materialsNiobiumSulfur

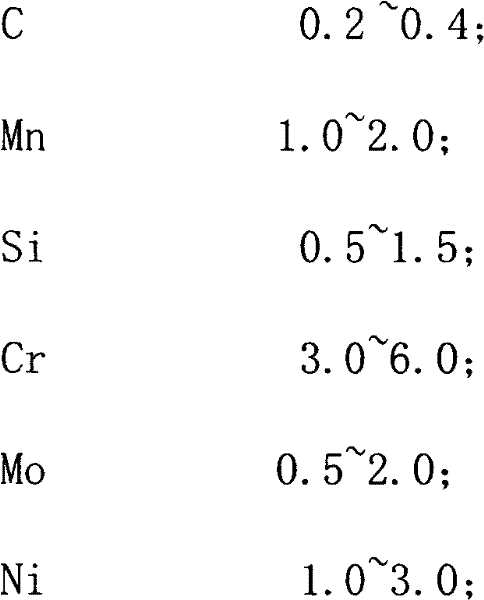

The invention relates to a high-tenacity wear-resisting overlaying alloy welding wire for a cold-rolling support roller, and the overlaying alloy welding wire provided by the invention has excellent tenacity and suitable hardness. The alloy welding wire comprises the following chemical components by weight percent: 0.2-0.4% of C, 1.0-2.0% of Mn, 0.5-1.5% of Si, 3.0-6.0% of Cr, 0.5-2.0% of Mo, 1.0-3.0% of Ni, less than or equal to 0.02% of P, less than or equal to 0.01% of S, and impurities, wherein the impurities comprise mineral substances and alloy powder; the mineral substances, the content of which is 2-5%, comprises one or more than one of CaF2, CaCO3, Na3SiF6 and LiF2; the alloy powder, the total content of which is 0.3-2.0%, comprises one or more than one of vanadium, tungsten, niobium, titanium, aluminum, and the like; and 0.1-0.5% of rare earth is additionally added. The welding wire is matched with a suitable welding process, thereby acquiring the hardness of HRC (Rockwell hardness) 48-53. A low-carbon steel belt is used for wrapping the alloy powder and the mineral substances and then rolling and drawing are performed, thereby forming the welding wire. A reasonable component design is matched with HJ107, grains are refined and sulfur-removing components are added, so that the high-tenacity wear-resisting overlaying alloy welding wire is free from hot crack in an overlaying process, has the hardness and tenacity suitable for cold-rolling rollers, and meets the demand of overlaying a cold roller.

Owner:天津雷公焊接材料有限公司

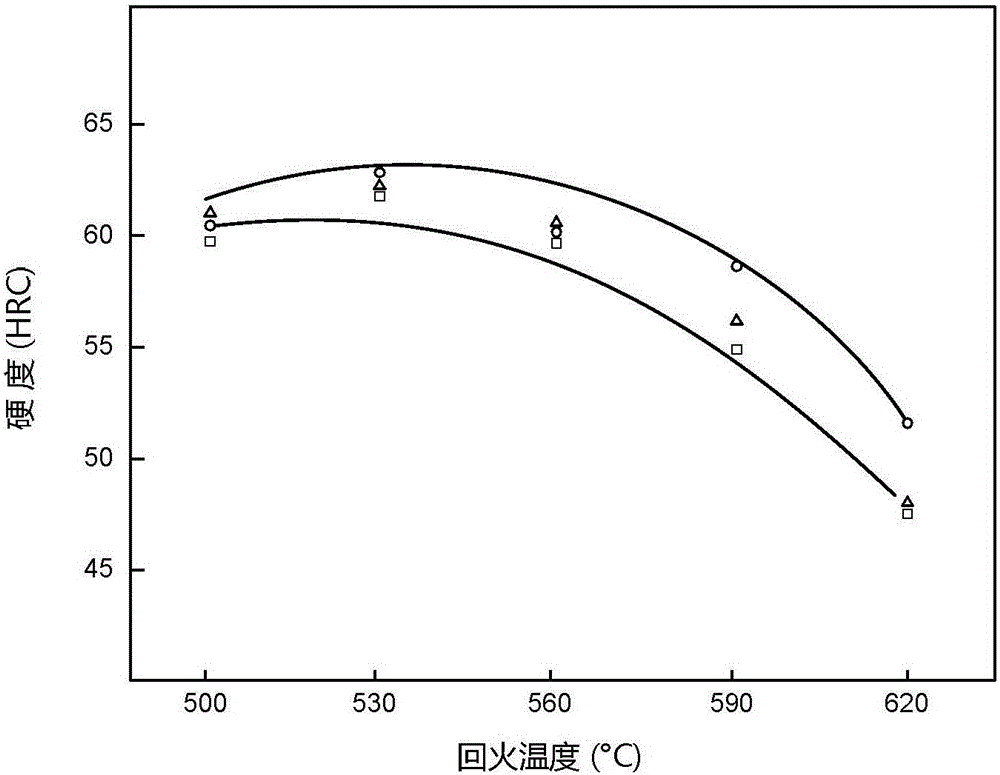

Casting medium alloy steel for cold stamping mould of automobile

The invention relates to casting medium alloy steel for a cold stamping mould of an automobile. The casting medium alloy steel is characterized by comprising the following chemical components in percentage by weight: 0.50-0.65% of C, 0.90-1.20% of Si, 0.60-0.90% of Mn, 4.50-5.50% of Cr, 0.75-0.90% of Mo, 0.70-0.80% of V, less than or equal to 0.02% of S or less than or equal to 0.03% of P. The casting medium alloy steel has high wear resistance and strong toughness, is low in production cost, is easy to process, has the overall quenching hardness of HRC59-62 and can meet the use requirements of the mould.

Owner:CHINA FIRST AUTOMOBILE +1

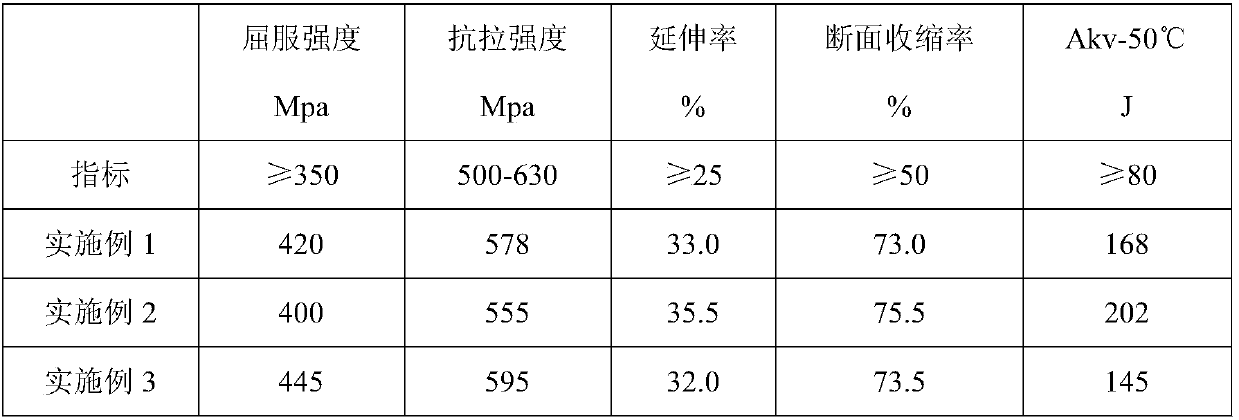

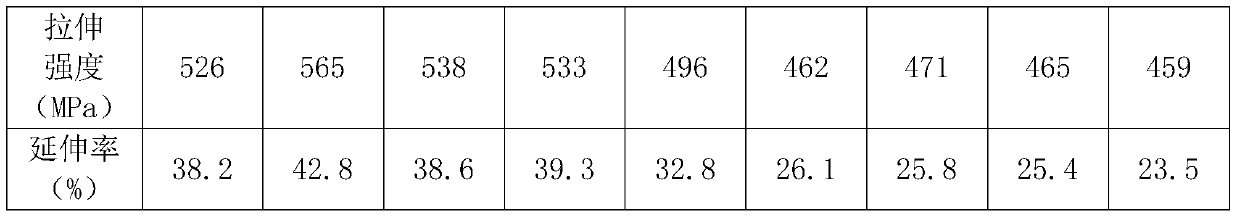

Normalized cryogenic steel at temperature of -50 DEG C and manufacturing method thereof

The invention provides a steel for normalizing -50°C low temperature. The composition of the steel plate is as follows by weight percentage: C: 0.09%-0.15%, Si: 0.16%-0.50%, Mn: 0.60%-1.18%, Ni: 0.10 %~0.50%, Mo: 0.01%~0.09%, Cr: 0.15%~0.30%, V: 0.06%~0.10%, Ti: 0.015%~0.030%, S: ≤0.005%, P: ≤0.008%, remainder The amount is Fe and unavoidable impurities, Ceq≤0.36. Manufacturing method: converter smelting, refining, continuous casting, slow cooling of slab, cleaning, rolling, heat treatment. Adopting the invention to produce low-temperature steel has yield strength ≥ 350MPa, tensile strength 500-630MPa, elongation ≥ 25%, and the strength is about 15% higher than that of 09MnNiDR steel of the same level.

Owner:ANGANG STEEL CO LTD

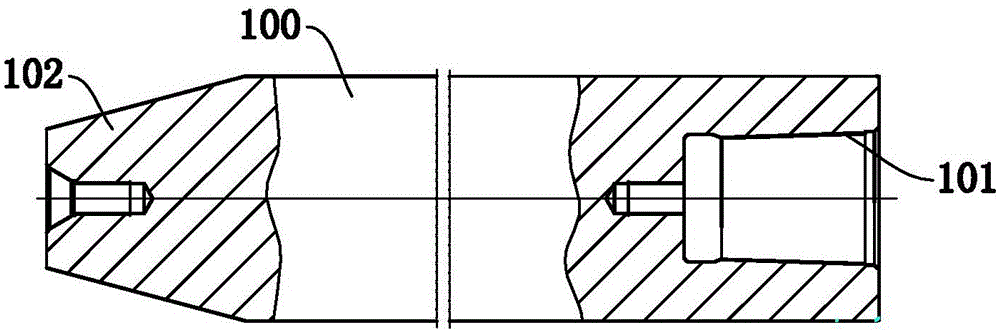

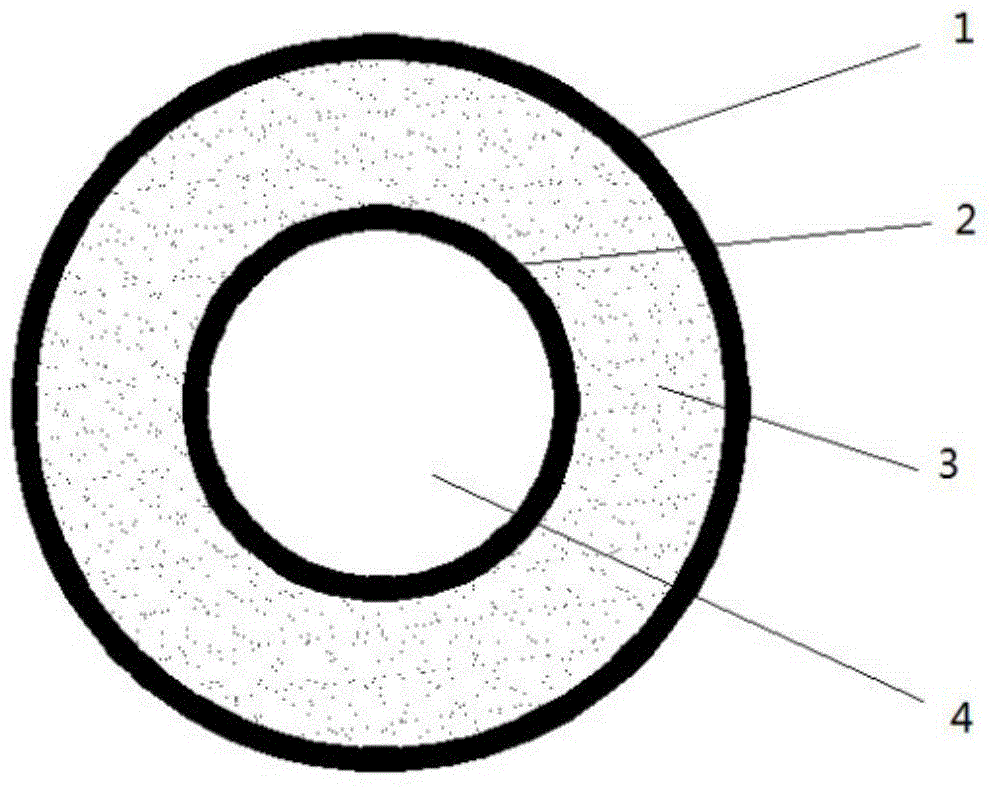

Alloy steel, retained mandrel and production method of retained mandrel

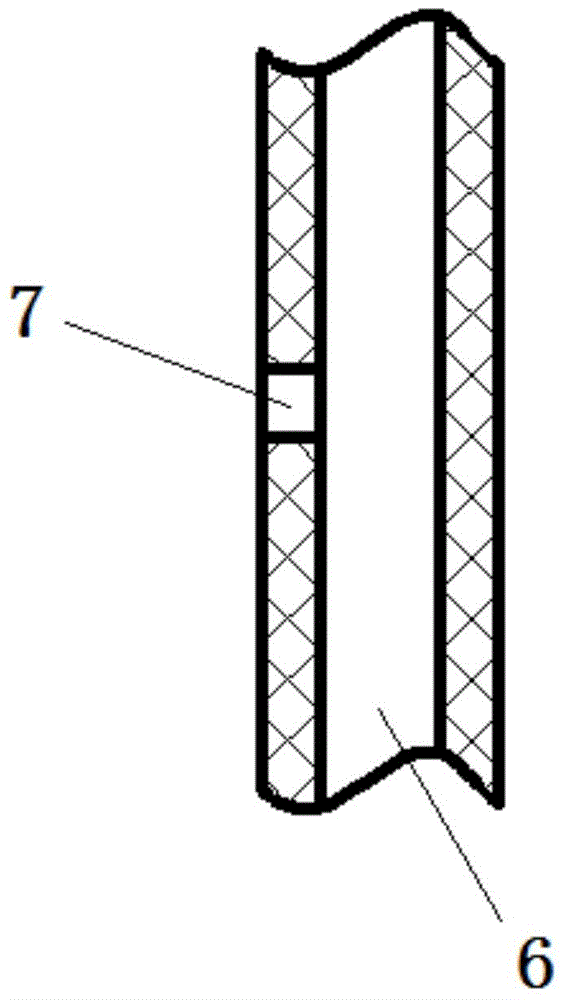

InactiveCN104998905AImprove purityImprove wear resistanceMandrelsMetal rolling arrangementsAlloy steelHeat treated

The invention discloses alloy steel and belongs to the technical field of continuous rolling units. The alloy steel comprises components in percentage by mass as follows: 0.27%-0.31% of C, 0.60%-0.80% of Si, 0.7%-0.9% of Mn, smaller than or equal to 0.015% of P, smaller than or equal to 0.005% of S, 3.50%-3.70% of Cr, 0.20%-0.30% of Ni, 0.40%-0.50% of V, 0.50%-0.58% of Mo, smaller than or equal to 0.025% of Al and the balance of iron and impurity elements. The invention discloses a retained mandrel adopting the alloy steel. The retained mandrel comprises a plug, a connecting rod and a hollow cylindrical retained mandrel body. The invention further discloses a production process for manufacturing the retained mandrel. The process comprises steps of steel making, rolling, heat treatment, machining and assembling. On the premise that the use requirements are met and the product quality is guaranteed, the cost is reduced.

Owner:SHANDONG MOLONG PETROLEUM MACHINERY

Cast steel material and manufacturing method for castings of cast steel material

ActiveCN106282787AIncrease load capacityExtended service lifeProcess efficiency improvementManufacturing cost reductionElement analysis

The invention provides a cast steel material with high strength, good toughness and low cost. The cast steel material is composed of, in weight percentage, 0.32-0.40% of C, 0.25-0.45% of Si, 0.50-0.80% of Mn, smaller than or equal to 0.035% of P, smaller than or equal to 0.035% of S, 0.02-0.03% of N, 0.020-0.060% of Al, smaller than or equal to 0.10% of Mo, smaller than or equal to 0.05% of V, smaller than or equal to 0.20% of Ni, smaller than or equal to 0.20% of Cu, smaller than or equal to 0.25% of Cr and the balance Fe and inevitable impurities. According to the cast steel material, on the premise of not increasing the wall thickness and the section ratio of engineering vehicle axle housings and suspensions and not increasing the manufacturing cost, the strength and the toughness of the axle housings and suspension supports are improved, and therefore the bearing capacity can be improved; and according to finite element analysis, the thickness of castings of products can be reduced appropriately, the purpose of light weight can be realized, and the manufacturing cost can be lowered.

Owner:卢森加

Steel for heat-resistant high-strength sleeve and preparation process of steel

The invention discloses steel for a heat-resistant high-strength sleeve and a preparation process of the steel. The steel consists of the following chemical components in percentage by weight: 0.10-0.25% of C, 0.10-0.30% of Si, 0.70-1.30% of Mn, 0.05-0.30% of Hf, 0.001-0.006% of B, 0-0.20% of Mo, 0-0.25% of W, 0-0.15% of Nb, 0-0.20% of Ta, 0-0.18% of Ti, 0-0.18% of Zr, 0.01-0.20% of RE, not greater than 0.008% of P, not greater than 0.004% of S and the balance of Fe. According to the steel for the heat-resistant high-strength sleeve and the preparation method of the steel, a high-temperature deformation quenching process is adopted for the whole sleeve, so that a relatively high dislocation density and other deformation defects are kept to obtain the sleeve with uniform tissue and high toughness; a medium-temperature section long-time thermal insulation process and a high-temperature section short-time thermal insulation process are adopted, so that relatively high strength is kept and the toughness is remarkably improved; elements such as Nb, W, Hf, Mo, Re and the like are added and quickly cooled to a temperature lower than 260 DEG C to preserve the heat for a long time, so that heat resistance, high strength, high toughness and high impact resistance of the sleeve are effectively guaranteed.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Automobile semi-axle forging and stamping die

InactiveCN106591685APrevent temper brittlenessReduce heat sensitivityForging/hammering/pressing machinesFerromanganeseFerrosilicon

The invention relates to a forging and stamping die, in particular to an automobile semi-axle forging and stamping die. The automobile semi-axle forging and stamping die is formed by smelting following materials including, by weight, 90-110 parts of 45# steel, 0.8-1.5 parts of silicon iron, 0.6-1.2 parts of ferrovanadium, 5-10 parts of tungsten carbide powder, 0.6-1 part of mid-carbon ferromanganese and 0.05-0.1 part of low-carbon ferrochromium. The automobile semi-axle forging and stamping die provided by the invention is good in material matching and casting density, even in structure, high in strength, resistant to high temperature and long in service life.

Owner:LIUZHOU TONGWEI MACHINERY

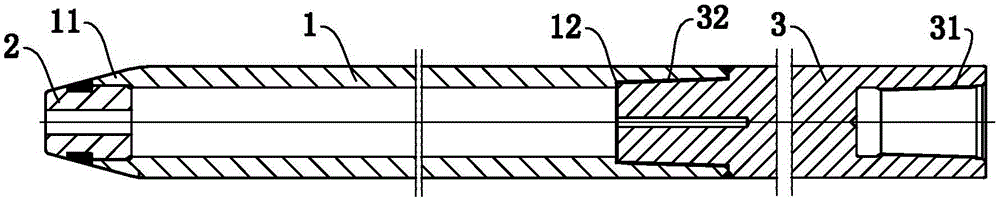

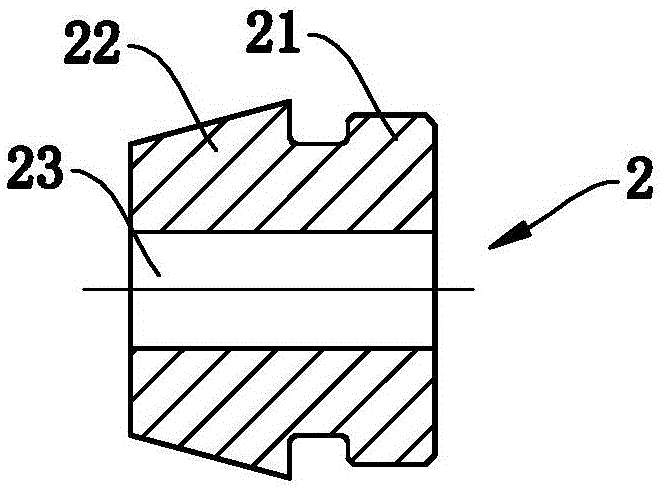

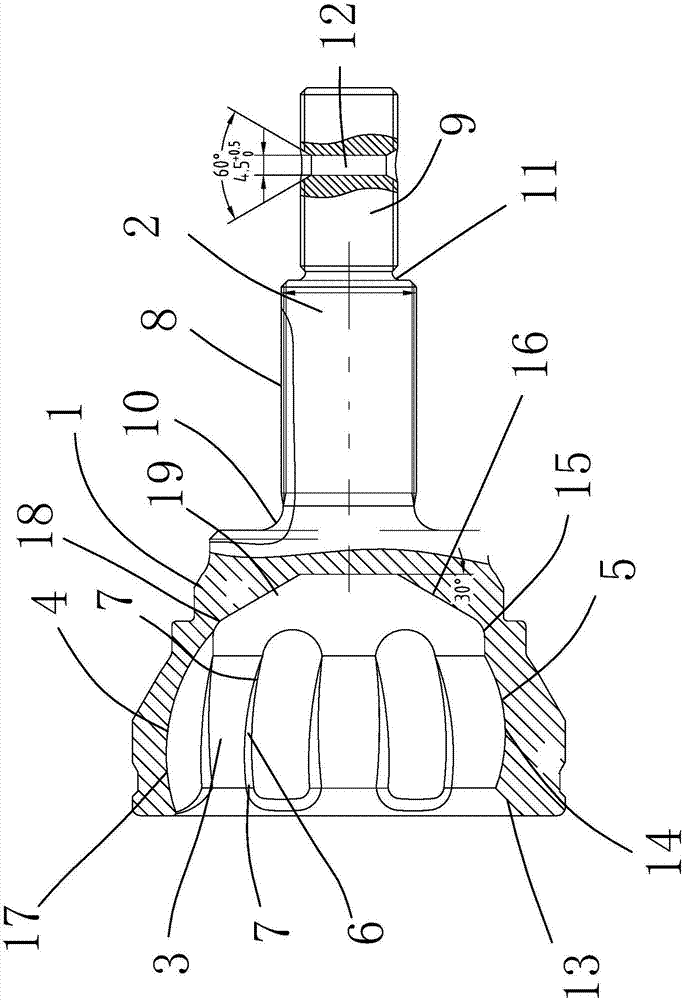

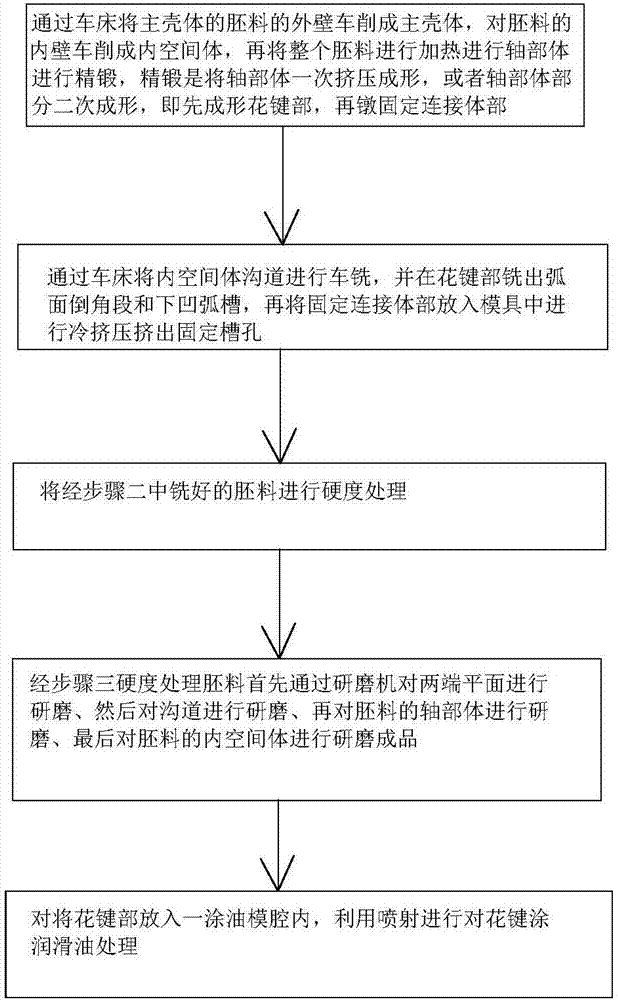

Driving shaft bell-shaped housing structure and process treatment method thereof

PendingCN107120357AImprove carrying capacityPrevent temper brittlenessYielding couplingFurnace typesStructural engineeringIndustrial engineering

The invention belongs to the technical field of automobile driving accessories, and provides a driving shaft bell-shaped housing structure and a process treatment method of the driving shaft bell-shaped housing structure. The driving shaft bell-shaped housing structure comprises a main housing and a shaft body; each channel chamfer angle is reduced from the left end to the right end; the shaft body comprises a spline part and a fixed connection body part; a cambered chamfer section is arranged between the left end of the spline part and the main housing; and a lower concave arc groove is formed between the right end of the spline part and the fixed connection body part. The process treatment method is characterized in that the inner wall of a blank is lathed into an inner space body, then the whole blank is heated and precision forging of the shaft body is carried out, precision forging means the shaft body is subjected to extrusion forming at one time or is partly subjected to secondary forming, that is the spline part is formed first, and the milled blank is subjected rigidity treatment and a spline is subjected to lubricating oil treatment. The driving shaft bell-shaped housing structure has the advantages that due to the channel chamfer angles, steel balls can be kept in the centers to the greatest extent when the steel balls rotate, the carrying capacity is improved, a situation that ballistic work is lowered due to temper brittleness is avoided, and the integral torque performance is high, thus the rigidity requirement is met.

Owner:NINGBO V SHINE AUTO PARTS

Production method of S42Cr1S forge piece for piston rod of marine diesel engine

The invention discloses a production method of a S42Cr1S forge piece for a piston rod of a marine diesel engine. The method comprises the following steps of 1) blanking, 2) forging, 3) quenching and tempering, 4) rough turning, 5) UT flaw detection and 6) finish turning, wherein during blanking, S42Cr1S #steel serves as a raw material steel ingot comprising 0.41-0.45% of C, 0.15-0.35% of Si, 0.70-0.80% of Mn, 0-0.015% of P, 0-0.015% of S, 1.05-1.20% of Cr, 0.20-0.25% of Mo, 0-0.25% of Ni, 0.015-0.030% of Al, 0-0.20% of Cu, 0-2 ppm of H, 0-15 ppm of O, 0-70 ppm of N, larger than or equal to 0.81% of CEV and the balance Fe.

Owner:ZHANGJIAGANG HAIGUO HEAVY FORGING

Heat treatment method of transmission metal chain

InactiveCN107447093AImprove wear resistanceLess prone to stickingSolid state diffusion coatingFurnace typesTime rangeHeating furnace

The invention discloses a heat treatment method for a transmission metal chain, which relates to the technical field of chains; it includes the following steps: A. Carburizing treatment: each component of the transmission metal chain is put into a carburizing furnace for carburizing treatment, and the carburizing temperature is 750 ℃ ~ 800 ℃, carburizing time 50 minutes ~ 70 minutes, tempering temperature 360 ℃ ~ 400 ℃, tempering time 40 minutes ~ 50 minutes; B, quenching: put each part of the transmission metal chain into two heating Oil cooling after heating in the furnace; C. Tempering: Temper and heat all parts at medium temperature and then air cool with the furnace. Compared with the prior art, the present invention can solve the problem in the prior art that parts are easily damaged when heat treatment is performed to improve the wear resistance of the transmission metal chain.

Owner:河池桂嘉知识产权服务有限公司

Heat treatment normalizing process

The invention discloses a heat treatment normalizing process suitable for small-size parts of 40 CrH steel and similar alloy constructional steel, which comprises the following steps of: step 1, enabling the rigidity of materials to be more than or equal to 26 HRC through normalizing, so that pearlite and upper bainite occur in material tissue, wherein the materials are heated to a first temperature which is at least above 50 DEG C more than the critical temperature Ac3 of the materials; step 2, decomposing the pearlite and the upper bainite in the normalizing tissue through tempering to adjust the rigidity of the materials to 20 to 26 HRC, wherein the tempering temperature is a second temperature; and step 3, cooling the materials through water-cooling after tempering and tapping. The heat treatment normalizing process can realize that the normalizing rigidity of the parts of the 40 CrH steel and the similar alloy constructional steel is controlled to be between 20 and 26 HRC, eliminate imbalanced tissue and realize the combination of the stable strength, toughness and mechanical properties of the materials.

Owner:SHANGHAI GKN DRIVE SYST

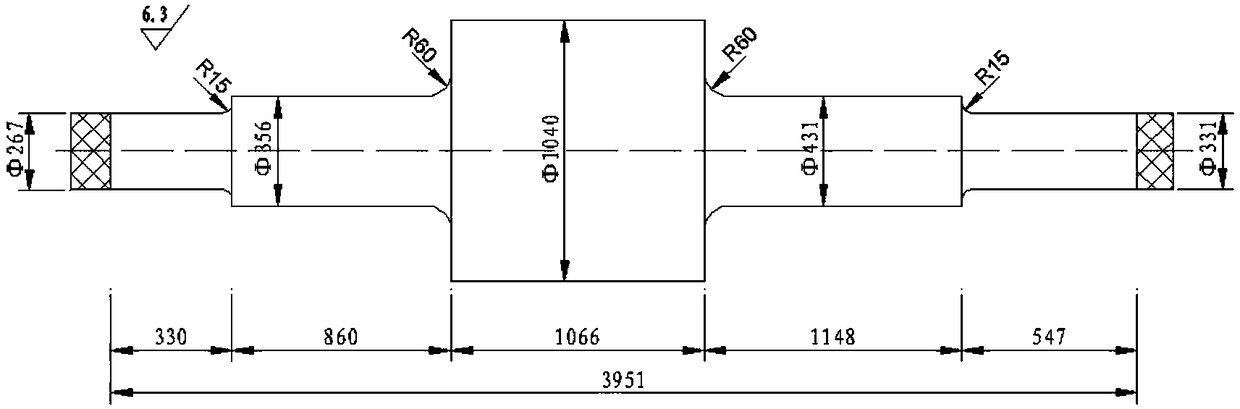

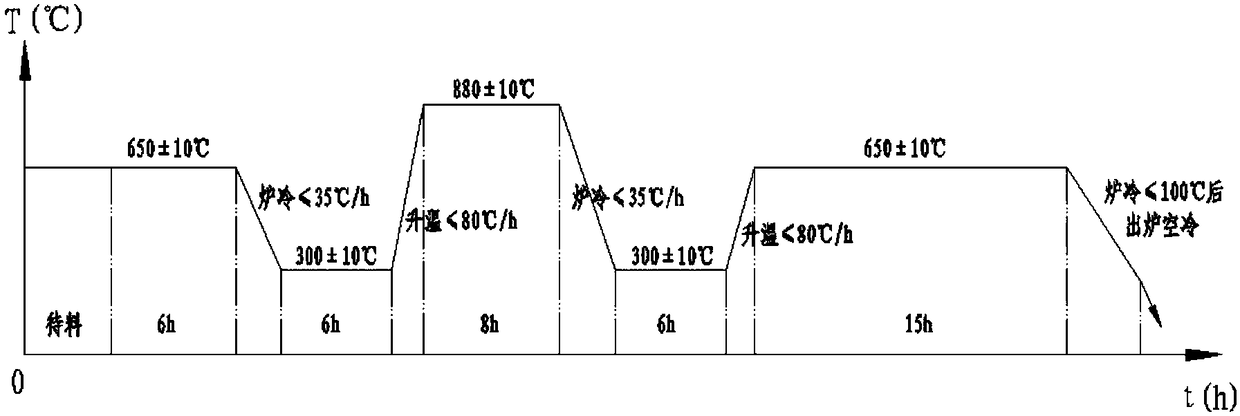

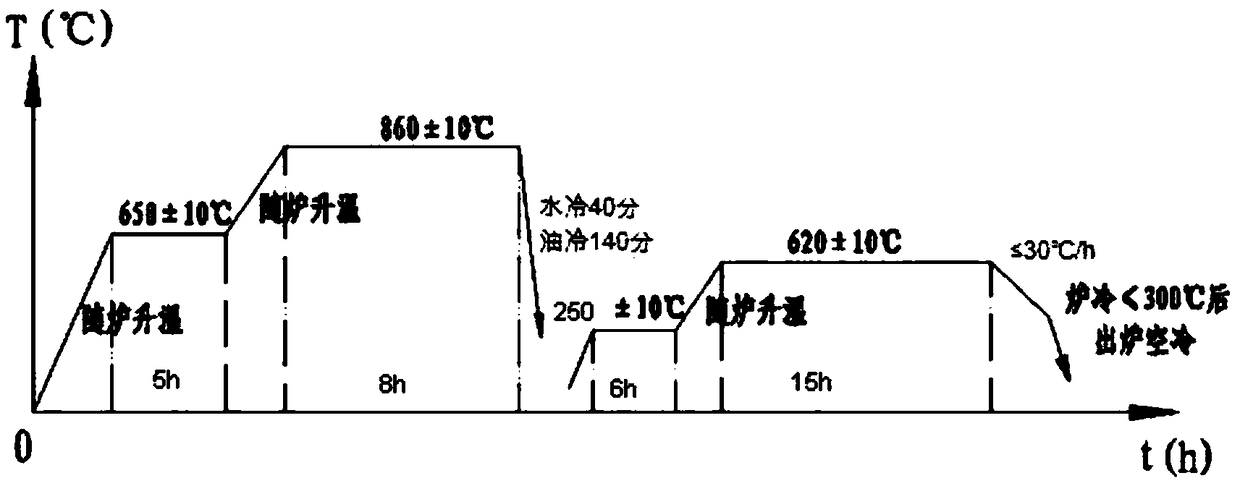

High strength rotor shaft forging for high voltage motor and heat treatment machining method

ActiveCN108149154APrevent temper brittlenessEvenly heatedFurnace typesHeat treatment furnacesEngineeringHigh pressure

The invention discloses relates to a machining method for a high strength rotor shaft for a high-voltage motor, and the machining method can meet the requirements of operating stability of a rotor shaft of a high-voltage motor under the premise of the diameter of the rotor shaft of the high-voltage motor up to 1040 mm. The rotor shaft machining method comprises the steps that 1, the roundness of abearing guard are required to be controlled at 0.006 mm, when a numerical control lathe is machined, a center frame support roller tooling is improved to be a planar bearing bush made of babbitt alloy, and a friction mode is changed from rolling friction to sliding friction; and after a process is transferred to a grinding machine for fine grinding, when the amount to be grinded is 0.3 mm, staticaging treatment is carried out for 1 week, and the machining is in place according to a required size; 2, at a bearing guard area with the highest axial requirements, namely, when the plane degree is0.012 mm, the vertical degree is 0.012 mm relative to the bearing guard, and the roughness of the end surface of a bearing bush is below 0.63, integrated combined machining of the plane and the end surface is adopted, grinding wheel positioning is adopted for precise control, the surface of a grinding wheel is trimmed to a small contact surface of an inverted cone with a diamond grinding wheel cutter, and during machining, the surface of the bearing bush is grinded by a feeding mode to ensure that the planeness is controlled at 0.008 mm and the verticality is controlled at 0.005 mm; and 3, atotal of 144 threaded holes with chamfered angles are arranged on the large outer surface of the rotor shaft, using a combination drill one-time machining and forming technology, and pre-positioning,drilling chamferings, and drilling thread bottom holes are completed in one step.

Owner:宝鼎重工有限公司

Hardening and tempering method in pump body manufacturing

InactiveCN101892362AIncreased impact valueImprove hardenabilityQuenching agentsPotassium nitrateManufacturing technology

The invention discloses a hardening and tempering method in pump body manufacturing, and belongs to the technical field of pump body machining and manufacturing. The method comprises the processes of normalizing, hardening, primary high-temperature tempering, secondary high-temperature tempering and medium-temperature tempering, namely two-time high-temperature tempering and once medium-temperature tempering are performed after hardening. Simultaneously, sodium nitrate, sodium nitrate and potassium nitrate serve as a medium, namely a mixed solution consisting of 25 weight percent of the sodium nitrate, 20 weight percent of the sodium nitrite, 20 weight percent of the potassium nitrate and 35 weight percent of water, so as to improve the hardenability of a product, and simultaneously reduce a surface pulling stress to be crucially effective in stopping hardening cracks. The method of the invention effectively improves an impact value of a pump body at the temperature of -40 DEG C and the mechanical property of the pump body, has high safety in a hardening and tempering processes, improves working environment and reduces the labor intensity of production staff.

Owner:JINXI IND GRP

High-tenacity steel automobile hardware stamping part and preparation process thereof

ActiveCN106011628AImprove mechanical propertiesGuaranteed solid solution boron contentSolid state diffusion coatingQuenchingSmelting

The invention discloses a high-tenacity steel automobile hardware stamping part. The high-tenacity steel automobile hardware stamping part is prepared from, by mass percent, 0.21%-0.32% of C, 0.35%-0.52% of Si, 1.1%-1.3% of Mn, 0.001%-0.005% of B, 0.02%-0.05% of V, 0.01%-0.05% of Ni, 0.02%-0.06% of Mo, 0.05%-0.12% of Cu, 0.03%-0.08% of Co, 0.01%-0.05% of Ta, not larger than 0.02% of P, not larger than 0.02% of S, not larger than 0.002% of N and the balance Fe and inevitable impurities. A preparation process of the high-tenacity steel automobile hardware stamping part comprises the steps of smelting, casting, machining forming, surface treatment, nickelizing, quenching and tempering. The prepared hardware stamping part is good in quality, high in tenacity and strength, good in machining performance, not prone to breaking and long in service life and has wide application prospects.

Owner:ANHUI HONGQIAO METAL MFG

Seawater corrosion resistant austenitic stainless steel and application thereof

The invention relates to seawater corrosion resistant austenitic stainless steel and application thereof, belonging to field of the metallurgical alloy and the application thereof. The matrix materials of the seawater corrosion resistant austenitic stainless steel comprise the following components by weight percent in addition to allowed trace impurities: 0.08 percent of C or more, 0.10 percent of Si or more, 2.00 percent of Mn or more, 0.04 percent of P or more, 0.03 percent of S or more, 7-10 percent of Ni, 17-19 percent of Cr, 1-2 percent of Cu, 0.05 percent of Nb or more and the balance of Fe. The seawater corrosion resistant austenitic stainless steel is used for manufacturing the floating production storage and offloading (FPSO) system and the air valve matched with the oil tanker. The austenitic stainless steel can resist the long-time corrosion of the seawater and the seawater vapor so as to ensure that the air valve operates safely and is free from the accident.

Owner:盐城中油船舶海洋工程科技有限公司

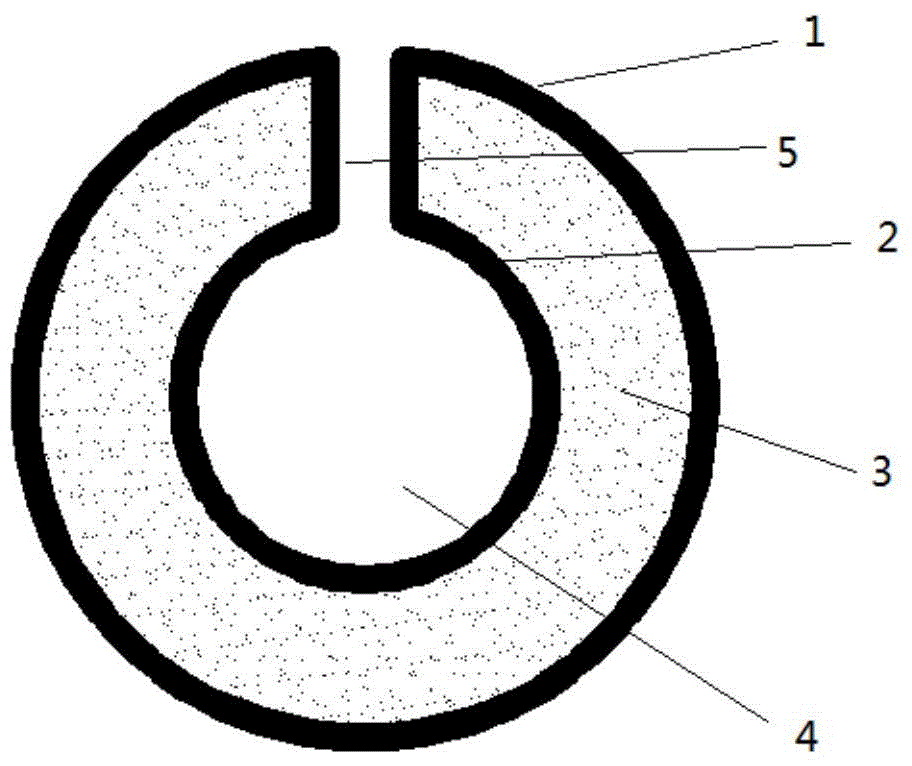

Flux-cored wire for surfacing repair

ActiveCN104551436AAchieve high temperature performanceAchieving wear resistanceWelding/cutting media/materialsSoldering mediaCarbideWeld seam

The invention relates to the technical field of welding, and discloses a flux-cored wire for surfacing repair. The flux-cored wire comprises a flux-cored wire main body, wherein the flux-cored wire main body comprises a metal layer wrapping a flux core; the flux core comprises the following components in percentage by weight: 0.1 to 5 percent of C, 0.8 to 3 percent of Mn, 0.5 to 2 percent of Si, 3 to 25 percent of Cr, 1 to 4 percent of Mo, 1 to 10 percent of W and the balance of Fe. According to the flux-cored wire, Mo is added into a conventional flux core formula, so that the performance of high temperature resistance and abrasion resistance of a welding material is achieved, the strength of a welding seam is ensured, and a welding layer is favorably prevented from being stripped in large scale; by Mo in steel, the hardenability and the thermal strength can be improved, the temper brittleness is prevented, and the residual magnetism and the coercive force are improved; silicon does not form carbide, so that a powerful function of promoting the graphitization of carbon is realized.

Owner:SHANGHAI SHIWEI WELDING IND

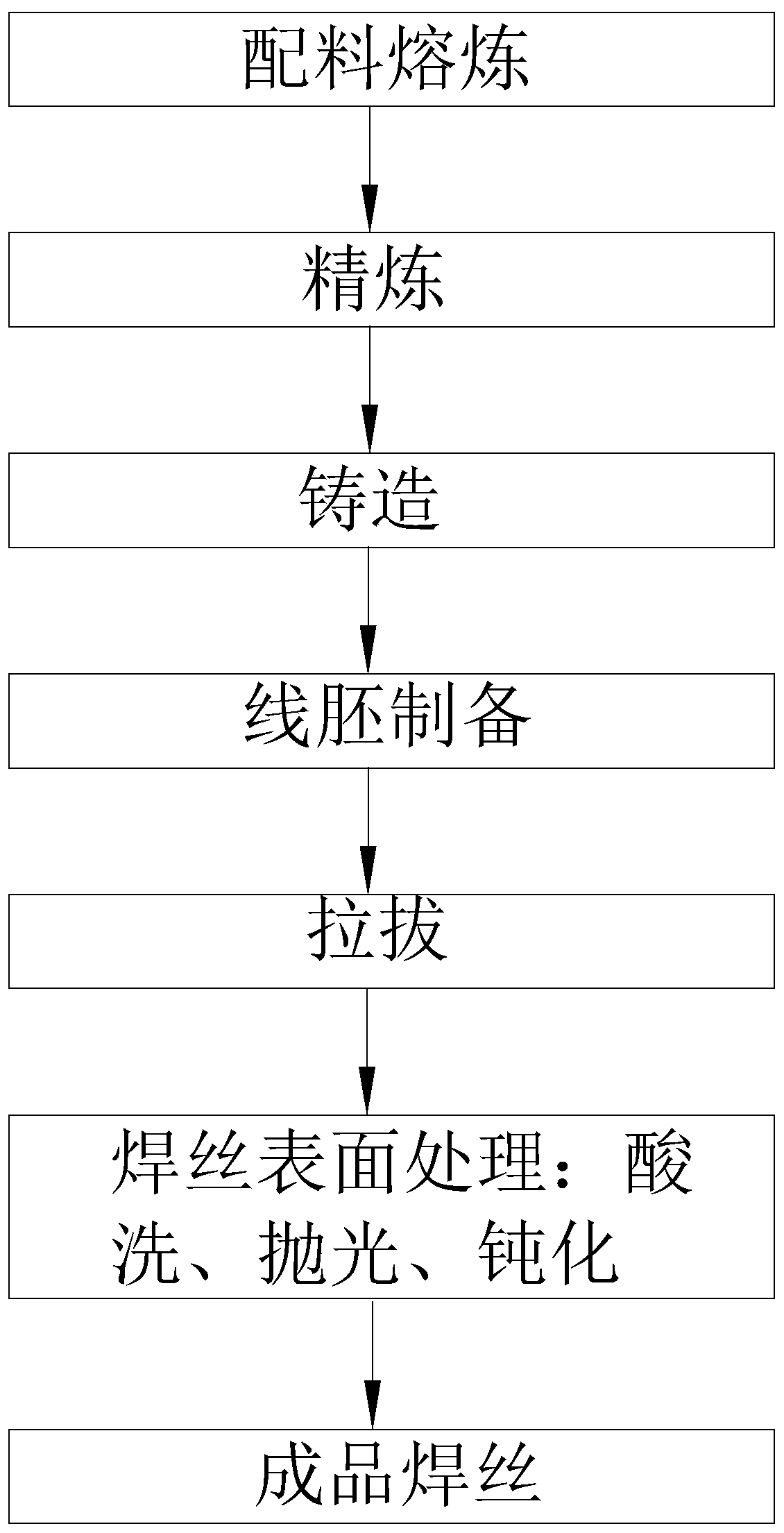

Ultralow-carbon high-temperature-resistant welding wire and preparation method thereof

ActiveCN110551951AReduce formationReduce intergranular corrosionWelding/cutting media/materialsSoldering mediaMechanical propertyImpurity

The invention relates to an ultralow-carbon high-temperature-resistant welding wire and a preparation method thereof. The ultralow-carbon high-temperature-resistant welding wire comprises the following chemical components, in percentage by mass, of 0.01%-0.04% of C, 22.0%-24.0% of Cr, 1.5%-3.5% of Si, 12.0%-14.0% of Ni, 0.5%-1.2% of Ti, 0.1%-0.4% of Mn, 0.2%-0.5% of Zr, 0.3%-0.6% of Sc, 0.1%-0.3%of Mo, 0.3%-0.5% of Nb, 3.0%-5.0% of Mg, 0.6%-1.2% of Al, 0.03%-0.07% of P, 0.02%-0.05% of S, 0.2%-0.4% of V, 1.3%-1.6% of B, and the balance Fe and other inevitable impurity elements. According to the method, the mechanical property of the welding wire can be improved while the low carbon of the welding wire is ensured.

Owner:常州长海焊材有限公司

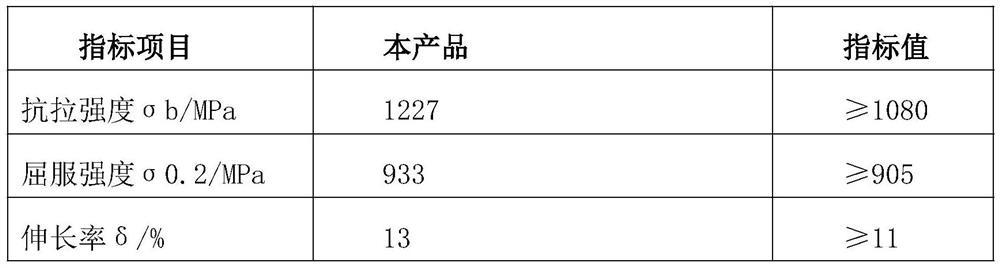

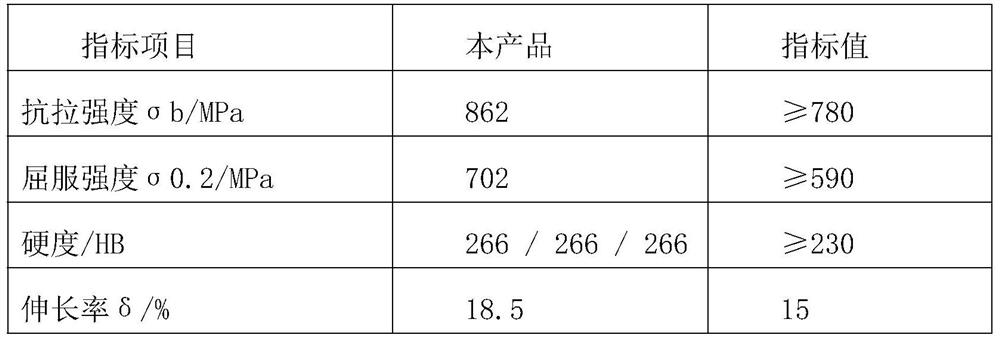

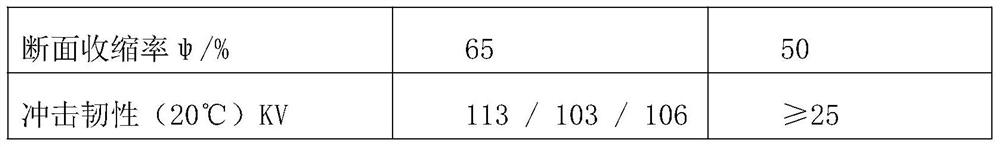

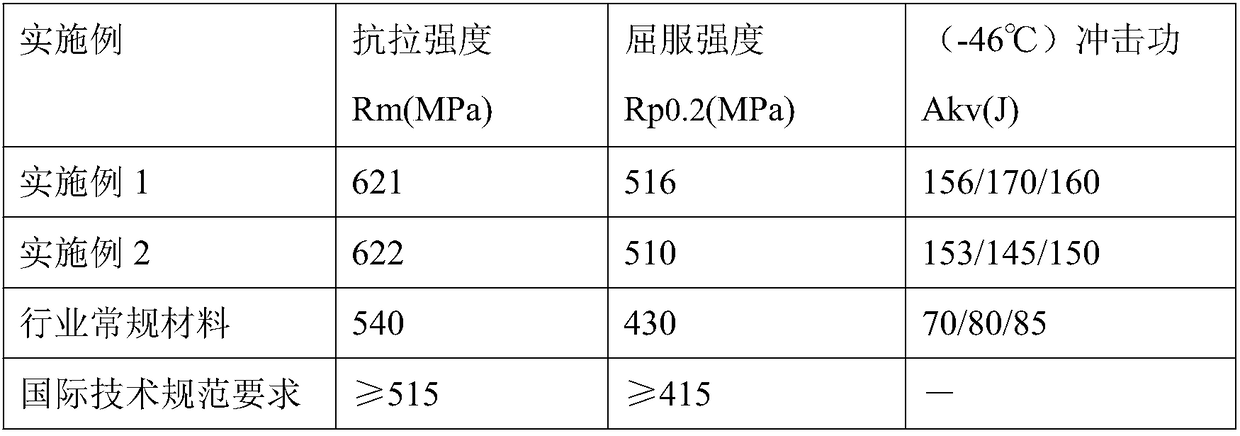

A694GRF60 carbon steel forging and preparation method thereof

The invention provides an A694GRF60 carbon steel forging and a preparation method thereof. According to a texture of the A694GRF60 carbon steel forging, alloy elements such as Cr, Ni, Mo, Nb and V areadded in a trace amount on the basis of common low-carbon structural steel, and the content of each component is optimized; moreover, the preparation process conditions are further optimized, so thata product of the A694GRF60 carbon steel forging has the advantages of higher strength, good plastic toughness, low-temperature impact toughness and the like, and each performance index exceeds ASTM A694 F60 standard of the American iron and steel association and reaches the advanced level of similar products at home and abroad.

Owner:ZHANGJIAGANG HAIGUO HEAVY FORGING

Bearing material and preparation method thereof

The invention discloses a bearing material composed of tungsten, cobalt, titanium, carbon, boron and ferrum and also discloses a preparation method of the material. The bearing material of the invention is composed of W, Co, Ni, Ti, C, B and Fe, wherein W, Co, Ni and Ti account for 95% of total weight, and C, B and Fe account for 5% of total weight; the weight ratio of W to sum of Co and Ni to Ti is 6:1.9:1.5, and weight relative ratio is 6:2:1.5 (the weight of Ni); the weight ratio of C to B to Fe is 5.1:3.2:1.7; and the weight ratio of Co to Ni is 1.87:0.03-1.8:0.1.

Owner:INST OF MAGNETIC DEVICES GANSU ACAD OF SCI

Method for solving too low low-temperature ballistic work after tempering of high alloy structure steel

InactiveCN111647721APrevent temper brittlenessAvoid lostHeat treatment process controlTemperingWater cooling

The invention relates to a method for solving too low low-temperature ballistic work after tempering of high alloy structure steel, and belongs to the technical field of metallurgy. In order to solvethe problem that the low-temperature ballistic work is too low after tempering of the high alloy structure steel, the method for solving the too low low-temperature ballistic work after tempering of the high alloy structure steel is provided and comprises the tempering processes of quenching and high-temperature hardening and tempering. According to the high-temperature hardening and tempering process, a quenched and cooled steel material is heated to be 590+ / -5 DEG C, and heat preservation is carried out for 8 h after temperature equalization; and then water cooling is adopted for cooling thesteel material to range from 50 DEG C to 100 DEG C, the second kind of temper brittleness is avoided, the too low low-temperature ballistic work caused by temper brittleness is avoided, the -40DEG Cballistic work of the high alloy structure steel is qualified, the product delivery cycle is shortened, and inner losses of steel are avoided.

Owner:建龙北满特殊钢有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com