High-performance and high-speed-stamping cold work die steel and preparation method thereof

A technology of cold work die steel and high-speed stamping, which is applied in the field of iron and steel smelting, can solve the problems of cold work die steel red hardness, insufficient thermal stability and wear resistance, and achieve the effect of improving hardenability and preventing temper brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0041] A high-speed stamping cold work die steel involved in this embodiment, the main material components include C, Si, Mn, P, S, Cr, Mo, W, V, Al, Cu and Ni, the mass percentage of each material component Contents are: C 0.85-0.95%, Si 0.80-1.20%, Mn 0.30-0.60%, P≤0.025, S≤0.015, Cr 7.90-8.40%, Mo 1.40-1.70%, W 1.90-2.20%, V 2.20 -2.50%, Al 0.90-1.20%, Cu≤0.20, Ni≤0.25; the balance is Fe.

[0042] The preparation method of a kind of high-speed stamping cold working die steel that this embodiment relates to is characterized in that:

[0043] 1) Prepare raw materials for high-speed stamping cold work die steel according to the set material composition, and prepare basic electric arc furnace or induction melting furnace;

[0044] 2) The smelting process adopts the oxidation method or the return method;

[0045] When the oxidation method is used for smelting, the melted carbon is more than 0.40% of the finished carbon in the batching, and the sulfur and phosphorus content of ...

specific Embodiment 2

[0075] The characteristics of the specific embodiment 2 of the present invention are: the high-speed stamping cold work die steel involved, the main material component is to reduce Cu and Ni on the basis of claim 1, that is, the main material component includes C, Si, Mn, P, S , Cr, Mo, W, V and Al, the mass percentages of each material component are: C 0.85-0.95%, Si 0.80-1.20%, Mn0.30-0.60%, P≤0.02, S≤0.015, Cr 7.90-8.40%, Mo 1.40-1.70%, W 1.90-2.20%, V 2.20-2.50%, Al 0.90-1.20%; the balance is Fe. Its preparation method is with specific embodiment 1.

[0076] Compared with the existing high toughness and high wear resistance cold working die steel, the new steel type of the present invention has the following outstanding advantages:

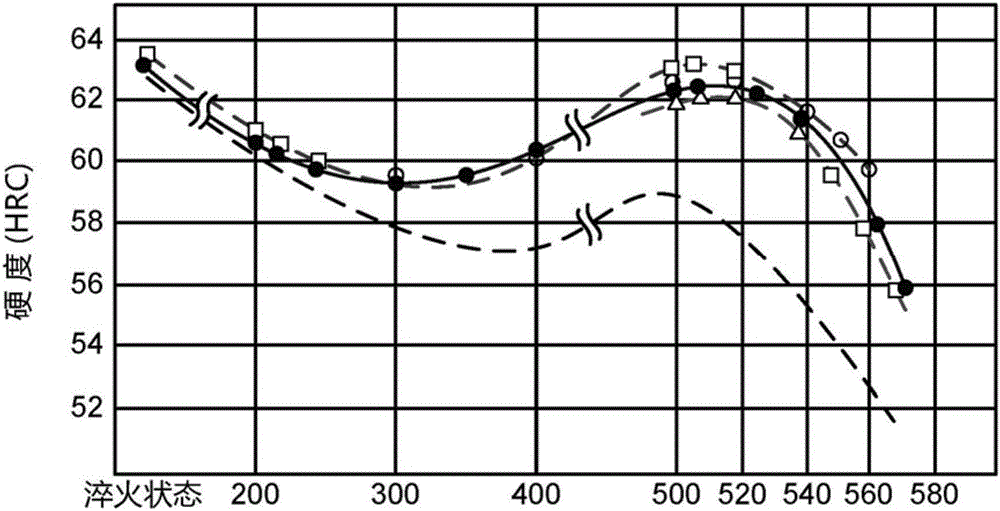

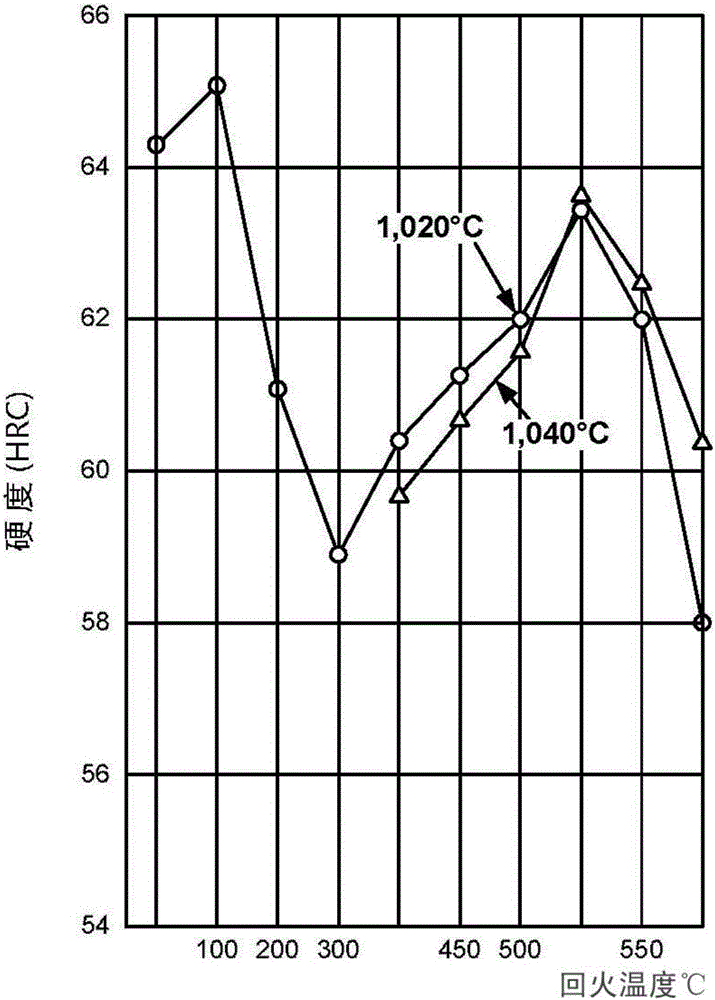

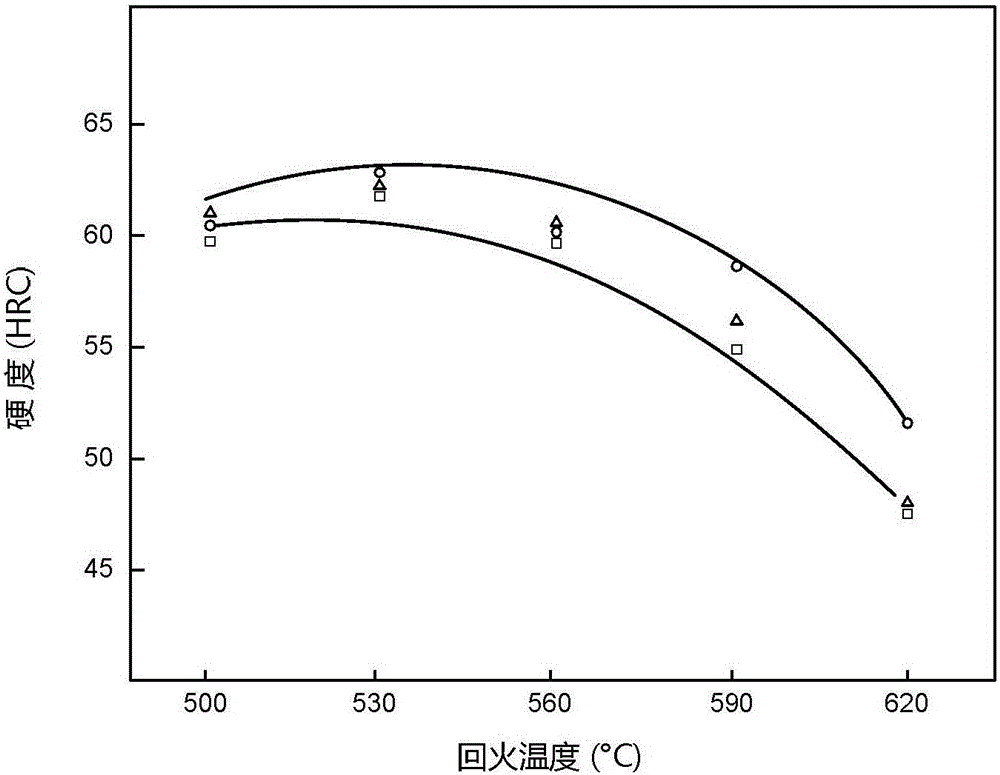

[0077] 1. Compared with my country's 7Cr7Mo3V2Si steel, the DC53 steel of Datong Company of Japan and the SLD-8 steel of Hitachi Metal Company have higher tempering hardness; see Figure 9 , quenched at 1130-1150°C, and tempered at 530°C, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com