Patents

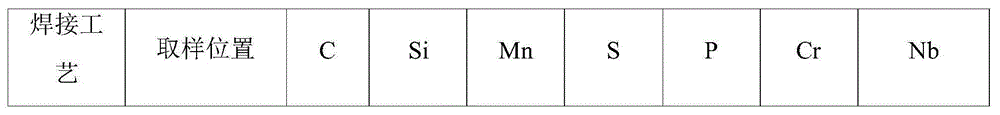

Literature

78results about How to "Reduce Si content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

600 MPa grade high-yield-ratio high-plasticity cold-rolled steel plate and manufacturing method thereof

A disclosed 600 MPa grade high-yield-ratio high-plasticity cold-rolled steel plate is characterized by comprising the following compositions in percent by mass: 0.06%-0.12% of C, 0.02-0.10% of Si, 1.40%-2.00% of Mn, 0.015% or less of P, 0.010% or less of S, 0.02%-0.10% of Al, 0.0050% or less of N, 0.015-0.045% of Nb, 0.020-0.055% of Ti, at the same time 0.035%<= Nb+Ti<= 0.100%, and the ferrite balance is Fe and other some unavoidable impurities.

Owner:ANGANG STEEL CO LTD

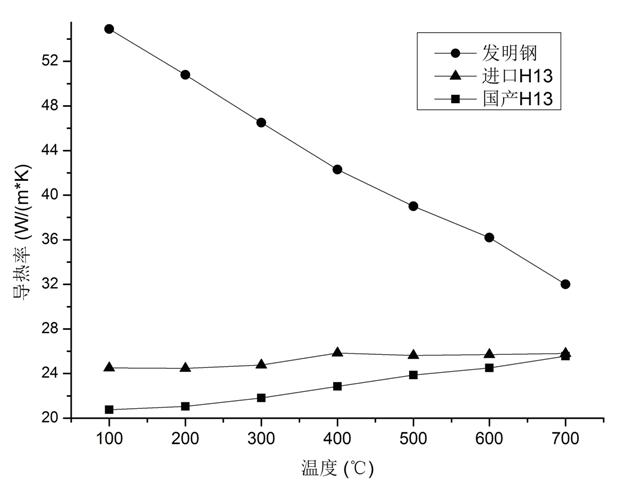

Ultrahigh thermal conductivity wear-resistant hot stamping die steel and manufacturing method thereof

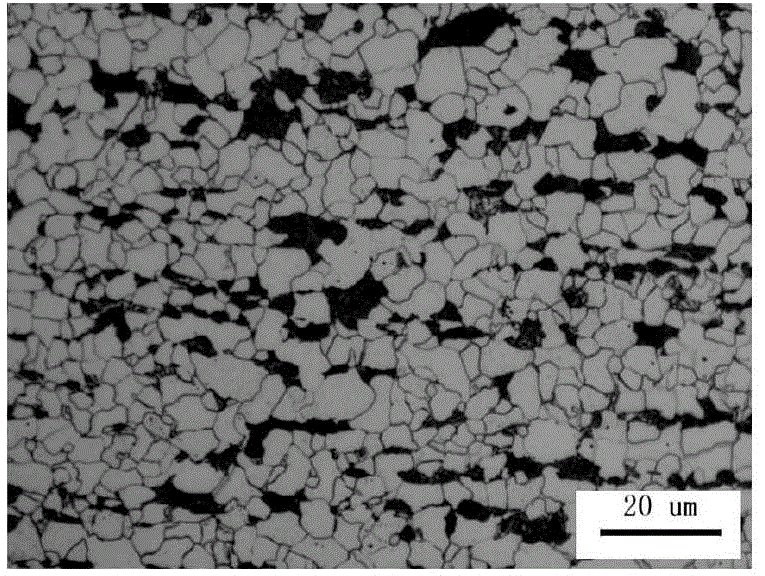

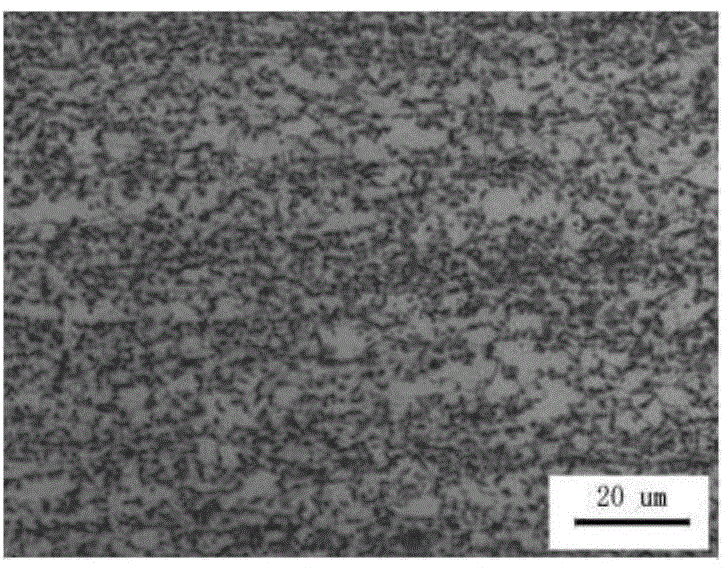

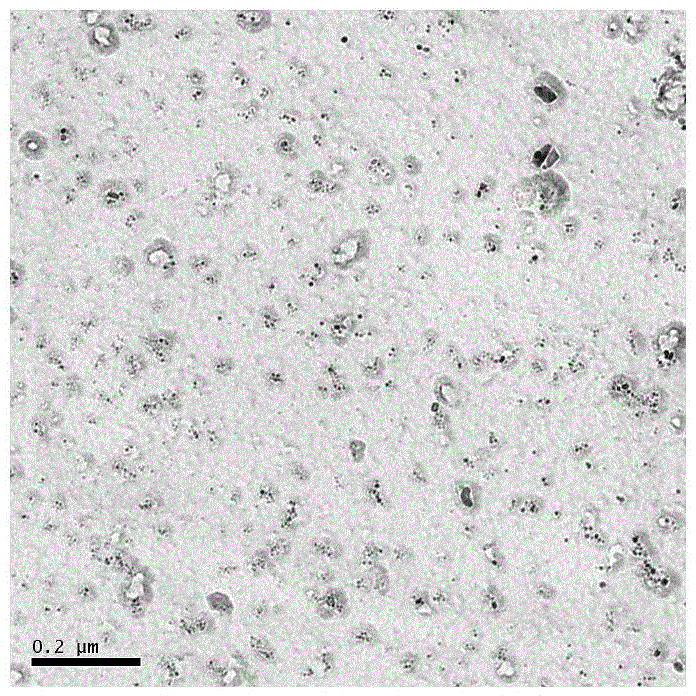

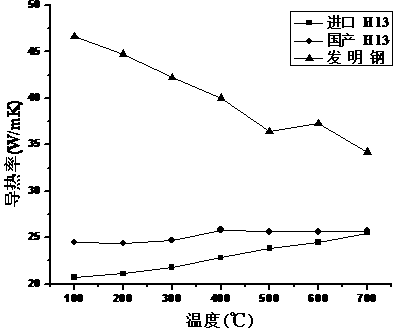

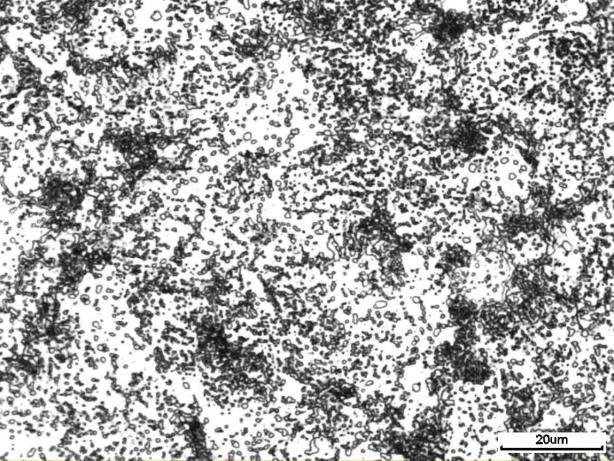

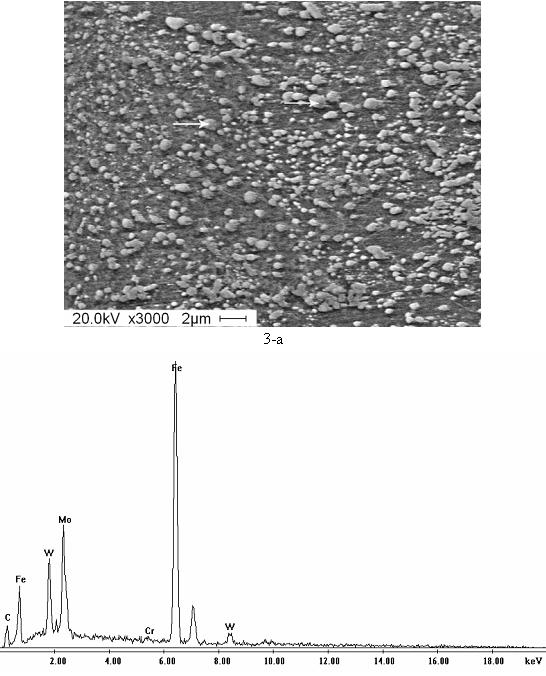

Belonging to the technical field of alloy steel preparation processes, the invention relates to an ultrahigh thermal conductivity wear-resistant hot stamping die steel and a manufacturing method thereof. Current hot stamping die steel on the market is mainly various improved H13, H11 and other high alloy hot work die steel. The steel provided by the invention comprises the following components by mass percent: 0.33-0.40% of C; less than 0.30% of Si; less than 0.30% of Mn; 1.0-2.0% of W; 4.0-5.0% of Mo; less than 0.30% of Cr; 0.10-0.20% of V; and the balance Fe and inevitable impurities. And in the impurity elements, S is smaller than or equal to 0.01%; P is smaller than or equal to 0.01%; and O is smaller than or equal to 30ppm. The steel is characterized in that: simple C, Mo and W are adopted as the main elements to coordinate the ratio of carbides; low Mn, low Cr and low Si content are maintained; after electric furnace smelting, electroslag remelting, annealing, high temperature homogenization, forging and annealing, the material has good machining properties; and after heat treatment, the material has excellent impact toughness, tempering stability and thermal fatigue performance. With ultrahigh thermal conductivity, the steel can be more suitable for hot stamping.

Owner:SHANGHAI UNIV +1

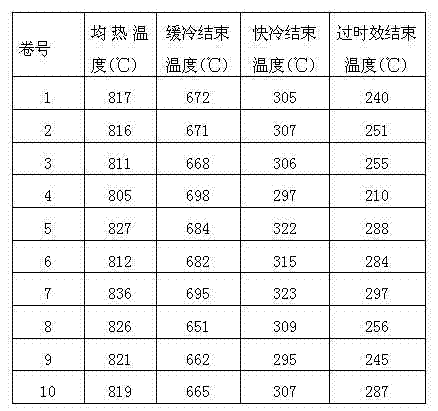

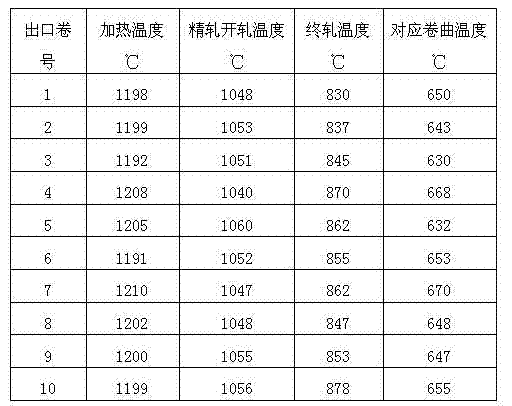

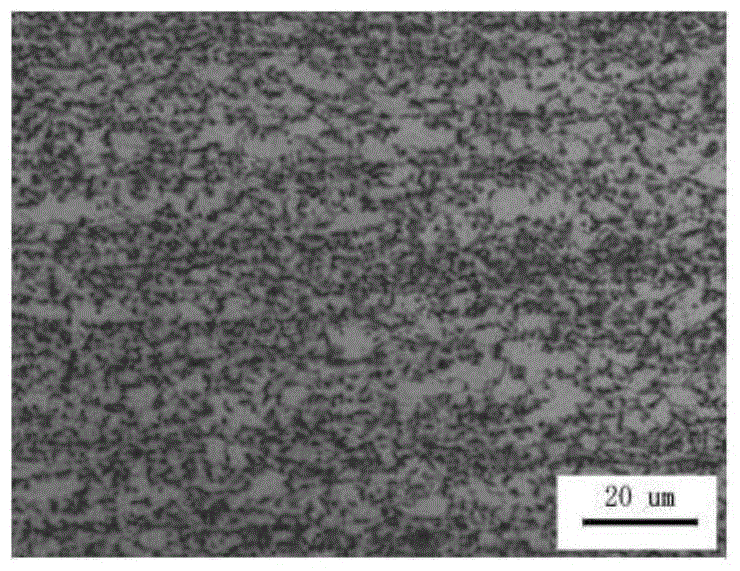

Production method of 600MPa grade cold rolling dual-phase steel

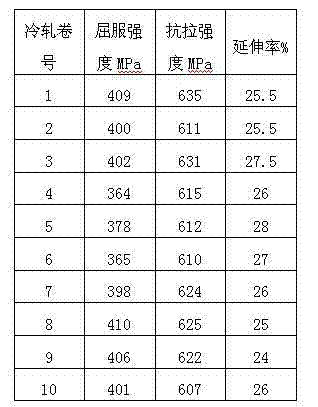

The invention relates to a production method of 600MPa grade cold rolling dual-phase steel and belongs to the technical field of metallurgical sheet material production. The technical scheme of the production method comprises working procedures of smelting in a converter, LF (ladle furnace) refining, continuous casting, hot rolling, cold rolling and continuous annealing. The final chemical components according to mass percent are as follows: 0.06-0.09% of C, 0.4-0.6% of Si, 1.65-1.75% of Mn, less than or equal to 0.01% of P, less than or equal to 0.015% of S, 0.025-0.06% of Als, less than or equal to 0.004% of N, and the balance of Fe. Molten iron requirements in the procedure of smelting in the converter are as follows: S is less than or equal to 0.040%, desulfurization target S is less than or equal to 0.010%, added steel scrap is 4-8% of total mass of the molten iron, and hot metal ratio is more than or equal to 85%. In the production method, no alloy element is added; composition of C-Si-Mn series dual-phase steel is improved; Si content is decreased; Al content is increased; and cold rolling dual-phase steel with low yield ratio and high elongation coefficient is produced by improving smelting, hot rolling, cold rolling and continuous annealing processes; the cost is low; the production procedures are continuous; and the product quality is stable. The mechanical property of the finished product is as follows: yield strength is about 360-430MPa, tensile strength is more than or equal to 600MPa, and elongation coefficient is more than or equal to 25%.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

Steel with ultra-high thermal conductivity for hot-stamping die and preparation method of steel

The invention relates to a novel material with ultra-high thermal conductivity for a hot-stamping die. The steels in the market for the hot-stamping die are mainly various types of improved H13 and H11 high-alloy hot work die steels. The steel in the invention comprises the following compositions in percentage by mass: 0.150-0.35% of C, less than or equal to 0.25% of Si, 0.08-0.20% of Mn,1.0-2.0% of W,2.0-4.5% of Mo, less than or equal to 0.30% of Cr,less than or equal to 0.02% of V and the balance of Fe and inevitable impurity elements, wherein S in the impurity elements is less than or equal to 0.005%, P in the impurity elements is less than or equal to 0.01 and O in the impurity elements is less than or equal to 30 ppm (parts per million). The invention is characterized in that simple elements i.e. C, Mo and W are used as the main elements, and proper proportion of carbide is adopted; the contents of Mn and Cr are maintained low, and the content of Si is maintained ultra-low; the steel has superior machining property after being subjected to electro-smelting, electro-slag remelting, annealing, high-temperature homogenization, forging and annealing; through thermal treatment (1060-1100 DEG C quenching and high-temperature annealing), the toughness of the steel can reach the toughness of common hot-stamping die steel such as H13, and the hardness, annealing stability and the fatigue property of the steel are more superior; particularly, the steel with lower coefficient of thermal expansion and ultra-high thermal conductivity is more suitable for hot stamping.

Owner:SHANGHAI UNIV

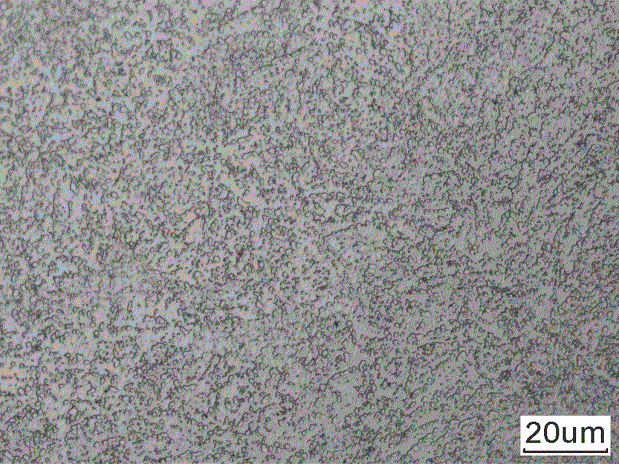

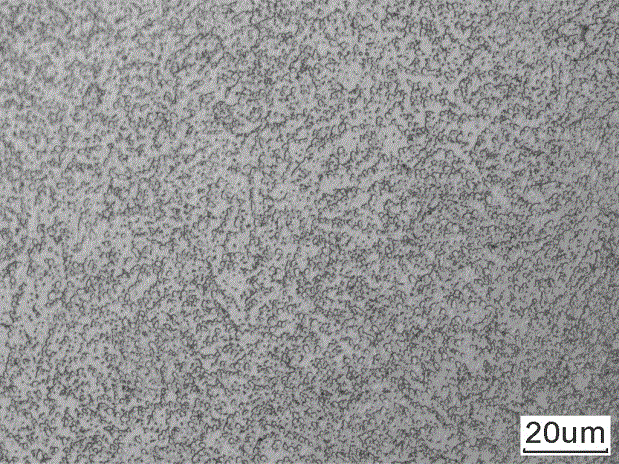

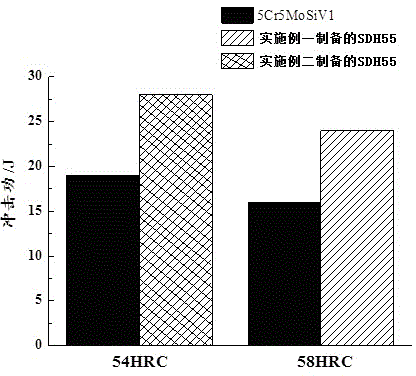

Alloy steel SDH55 for shield machine tools and production method thereof

The invention discloses alloy steel SDH55 for shield machine tools and a production method thereof. The alloy steel comprises, by weight, 0.4% to 0.55% of C, 0.10% to 0.40% of Si, 0.10% to 0.30% of Mn, 5.10% to 6.50% of Cr, 2.20% to 3.00% of Mo, 0.45% to 0.85% of V, the balance of Fe and unavoidable impurity elements, including not greater than 0.005% of S and not greater than 0.010% of P. The alloy steel high in wear resistance and high in toughness is made by means of matching, smelting, casting and electroslag remelting, by thermal feeding for high-temperature homogenous treatment after demolding, and by means of multidirectional forging, soft annealing and ultra-fining treatment; the problem that the current tools for shield machines are of short lives due to wear and failure and edges cracking caused by low toughness is solved; the alloy steel is of great significance to the development of the industry of special steels of shield machine tools.

Owner:SHANGHAI SHIJIN NEW MATERIAL TECH

600MPa class chromium/niobium-containing hot-rolled dual-phase steel plate and production method thereof

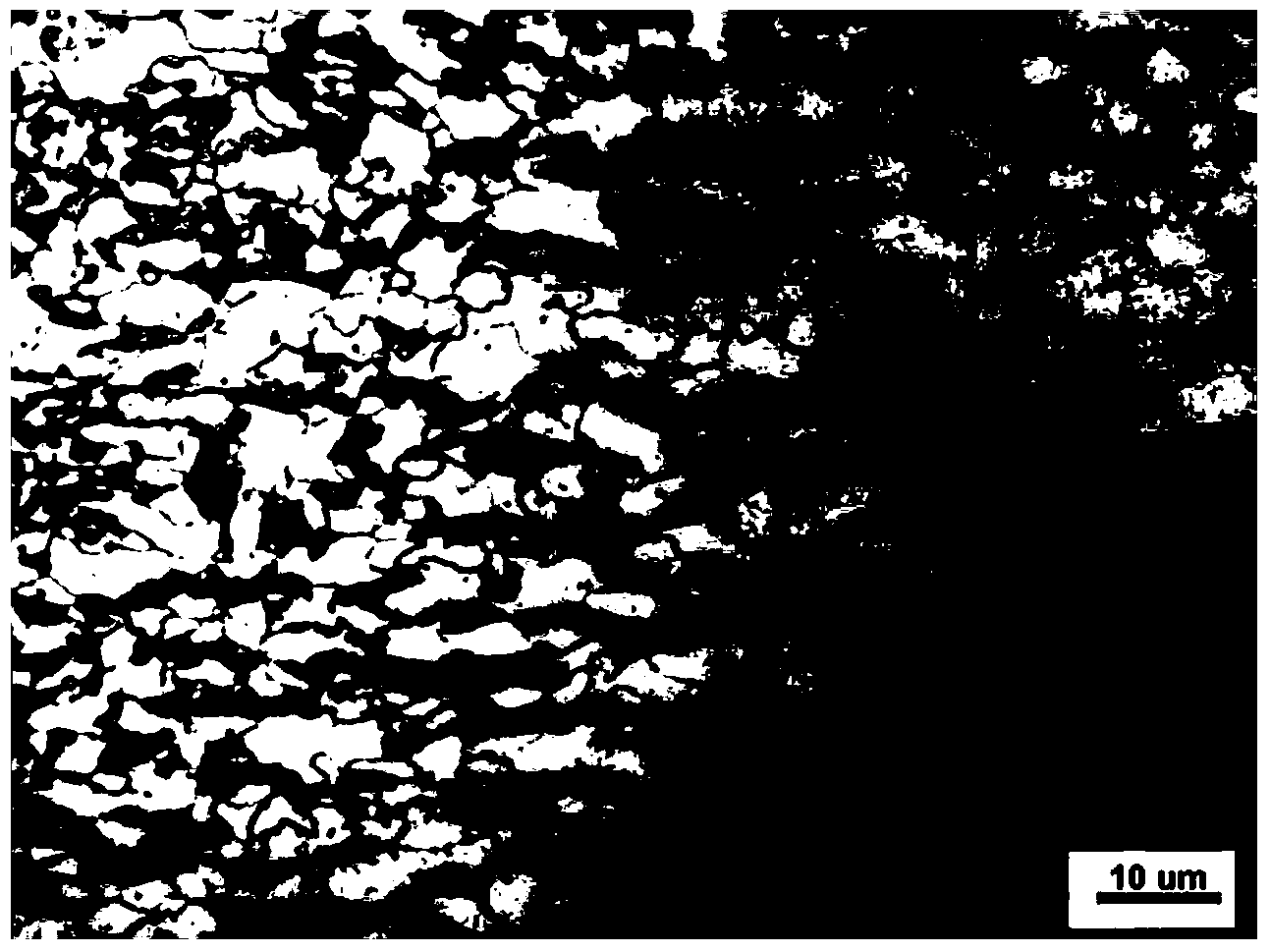

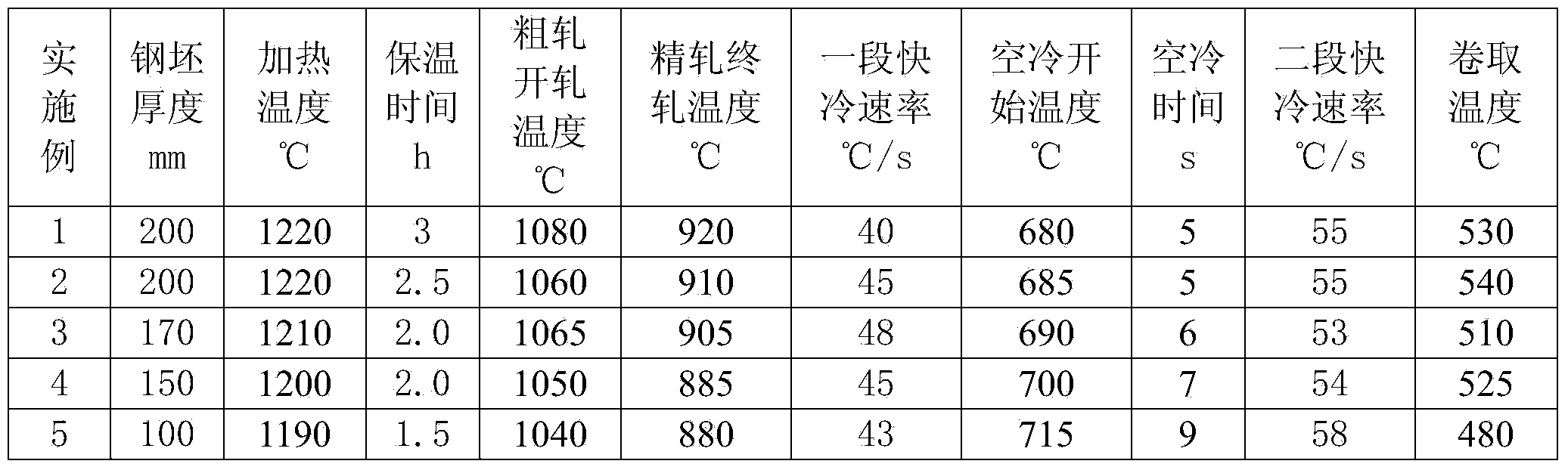

The invention provides a 600MPa class chromium / niobium-containing hot-rolled dual-phase steel plate and a manufacturing method thereof. The steel plate comprises the following chemical components in percentage by weight: 0.050-0.10 percent of C, 0.050-0.50 percent of Si, 1.0-1.80 percent of Mn, 0.010-0.080 percent of Als, 0.30-1.20 percent of Cr, 0.010-0.050 percent of Nb, less than 0.020 percent of P and less than 0.005 percent of S. The method comprises the following steps: heating a continuous casting billet to the temperature of 1200+ / -20 DEG C, and preserving heat for 1-3 hours, the rough rolling opening temperature is 1040-1100 DEG C, the finish rolling and finishing temperature is 860-920 DEG C; rapidly cooling the steel plate to ferrite for changing in a rapid temperature zone at a rapid cooling speed of more than 40 DEG C per second, wherein the air-cooling starting temperature is 680-720 DEG C, the time is 5-10 seconds; and rapidly cooling the steel plate to be 480-550 DEG C for rolling at a cooling rate of 50 DEG C per second after air cooling. According to the method, the cost can be greatly reduced, large-scale production of medium thin slabs on a continuous casting tandem rolling line is realized, the hot-rolled dual-phase steel plate of ferrite and martensite is obtained, Rp0.2 is 413MPa, Rm is 640MPa, A80 is 20.8 percent, and the n is 0.19.

Owner:ANGANG STEEL CO LTD

Mn and Nb added NiCrFe alloy surfacing solder strip for nuclear power and welding method

InactiveCN105215571AImprove deposition efficiencyLow dilution rateWelding/cutting media/materialsSoldering mediaCrack resistanceNuclear power

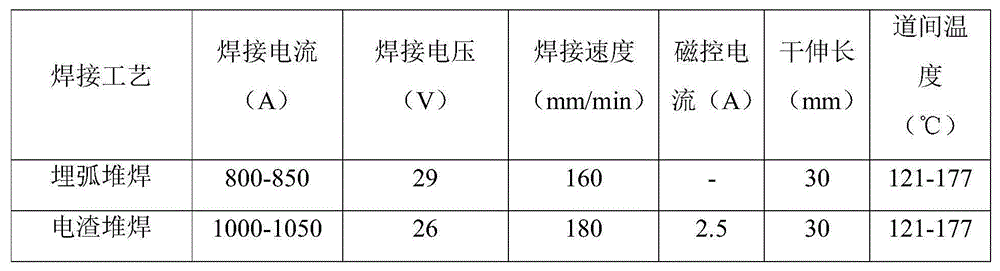

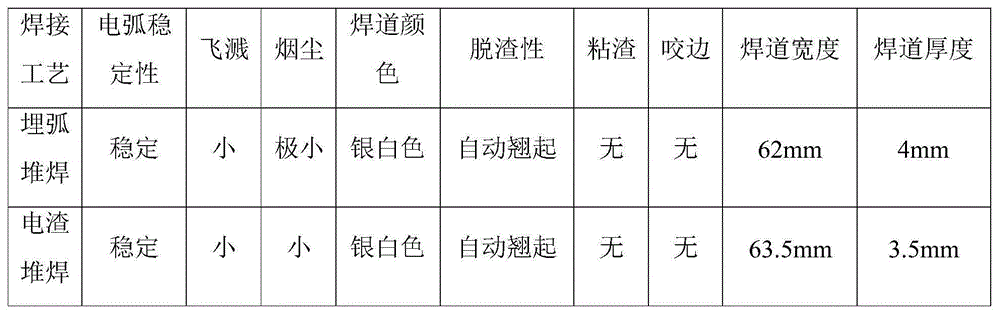

The invention provides a Mn and Nb added NiCrFe alloy surfacing solder strip for nuclear power and a welding method and belongs to NiCrFe nickel base alloy solder strips. The solder strip is composed of, by weight, less than 0.04% of C, less than 0.50% of Si, less than 5.0% of Mn, less than 0.015% of S, less than 0.020% of P, 28.0-31.5% of Cr, 7.0-12.0% of Fe, less than 2.5% of Nb, less than 0.30% of Cu, less than 0.50% of Al, less than 0.50% of Ti, and the balance nickel. The Mn and Nb added NiCrFe alloy surfacing solder strip for nuclear power can be applicable to a submerged arc overlay welding process and an electroslag surfacing process and can also be applicable to manufacturing of key components of a nuclear island of a nuclear power plant by being matched with corresponding soldering flux, the Mn element and the Nb element are added in the solder strip and improve the performance of resistance to high temperature plasticity-losing cracks of surfacing deposited metal, the surfacing deposited metal has high crystallization crack resistance and stress corrosion cracking resistance, the excellent corrosion resistance is achieved and integrated mechanical performance is good. By being matched with the soldering flux for surfacing, a weld pass is attractive in formation, corrugations are compact, deslagging is easy and welding defects are avoided.

Owner:HARBIN WELDING INST LTD +2

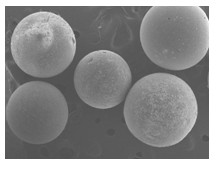

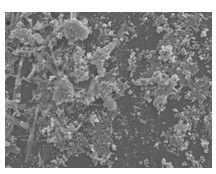

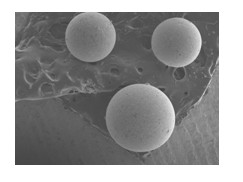

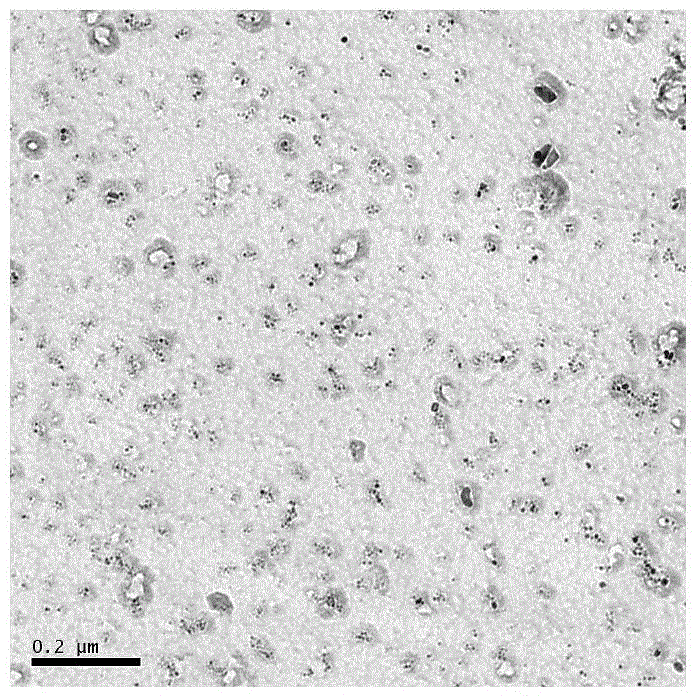

Chemical plating Ni-P alloy technology of glass micro beads

The invention discloses a chemical plating Ni-P alloy technology of glass micro beads. A common chemical plating nickel liquid formula is adopted, the temperature is controlled to be 50-60 DEG C in the chemical plating nickel process, the plating application time is 30 minutes, and finally the chemical plated Ni-P alloy of glass micro bead with an even Ni-P deposition layer is obtained. After chemical plating, the contents of surface elements O and Si of the micro beads are lowered, but the contents of Ni and P are maximum, wherein the content of Ni reaches 58.76-68.41wt%, and the content of P reaches 8.87-10.04wt%. Compared with the chemical plating Ni-P alloy technology in the prior art, the content of Ni on the surface of the micro beads of the technology optimized by the invention is improved by 21.68-31.33wt%, and the content of P is improved by 8-9wt% compared with those of the technology which is not optimized.

Owner:SHANGHAI INST OF TECH

High-temperature carburizing steel, high-temperature carburizing steel component and preparation method thereof

ActiveCN110373607ASuppress grain coarseningHigh fatigueProcess efficiency improvementSteelmakingChemical composition

The invention designs low-cost high-temperature carburizing steel for a high-temperature carburizing environment with a temperature higher than 1000 DEG C. The low-cost high-temperature carburizing steel consists of the following chemical components in percentage by weight: 0.16-0.20% of C, less than or equal to 0.04% of Si, 0.75-0.90% of Mn, 1.15-1.25% of Cr, 0.20-0.30% of Mo, 0.040-0.050% of Al,0.0120-0.0180% of N, less than or equal to 0.025% of P, 0.015-0.025% of S, less than or equal to 0.0010% of O and the balance of Fe and inevitable impurities. An Al / N ratio is controlled to be 2.0-4.0, Si content is controlled to be relatively low, and a deoxidation process in steelmaking and a stopper rod curve control process in continuous casting are combined, so that large-scale production and continuous casting can be realized, extra process treatment does not need to perform before high-temperature carburizing, a steel structure before carburizing does not need to strictly control and the process is greatly simplified. Grade of a B-class rough system, fine system impurities and Ds impurities of high-temperature carburizing steel is lower than 0.5, carburizing can be simulated for 2-6 hours at a temperature of 1000-1030 DEG C and mixed crystal is avoided. The carburizing steel can be effectively guaranteed in fatigue life after being applied to parts such as a gear.

Owner:SGIS SONGSHAN CO LTD

Automobile beam steel plate with tensile strength of 750MPa grade and heavy gauge, and preparation method of automobile beam steel plate

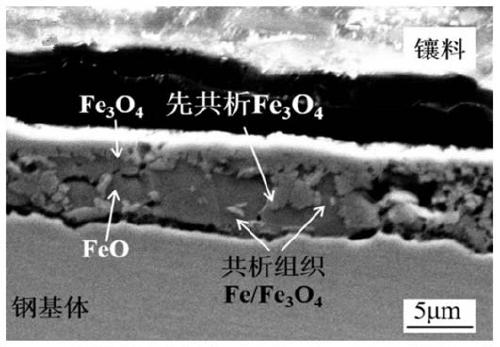

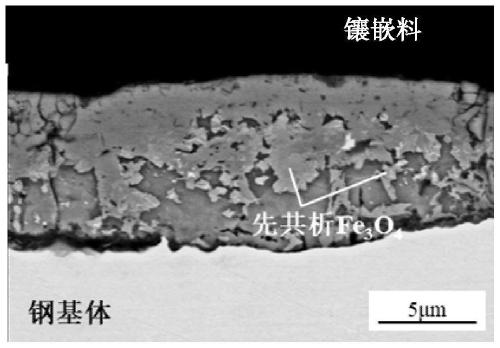

The invention relates to an automobile beam steel plate with tensile strength of 750MPa grade and heavy gauge, and a preparation method of the automobile beam steel plate. The steel plate comprises, by mass, 0.03 to 0.12% of C, 0.05 to 0.60% of Si, 0.2 to 1.0% of Cr, 1.0 to 2.5% of Mn, not greater than 0.015% of S, not greater than 0.025% of P, 0.015 to 0.045% of Als, 0.07 to 0.15% of Ti, 0.02 to0.08% of Nb, and the balance being Fe and impurities that are unavoidable during smelting. During preparation, a steel billet adopting the above chemical composition proportion is subjected to reasonable process design, so as to prevent the pickling preparation process from replacing the original process, reduce the thickness of the scale, and obtain the scale complex structure of Fe3O4, FeO and eutectoid Fe3O4 coexisting with alpha-Fe, so that the surface quality of the steel plate is significantly improved, and the requirements of the use of pickling-free direct stamping or roll forming andeliminate the pickling process can be met, production efficiency is improved, environmental pollution is reduced and production cost is reduced.

Owner:NORTHEASTERN UNIV

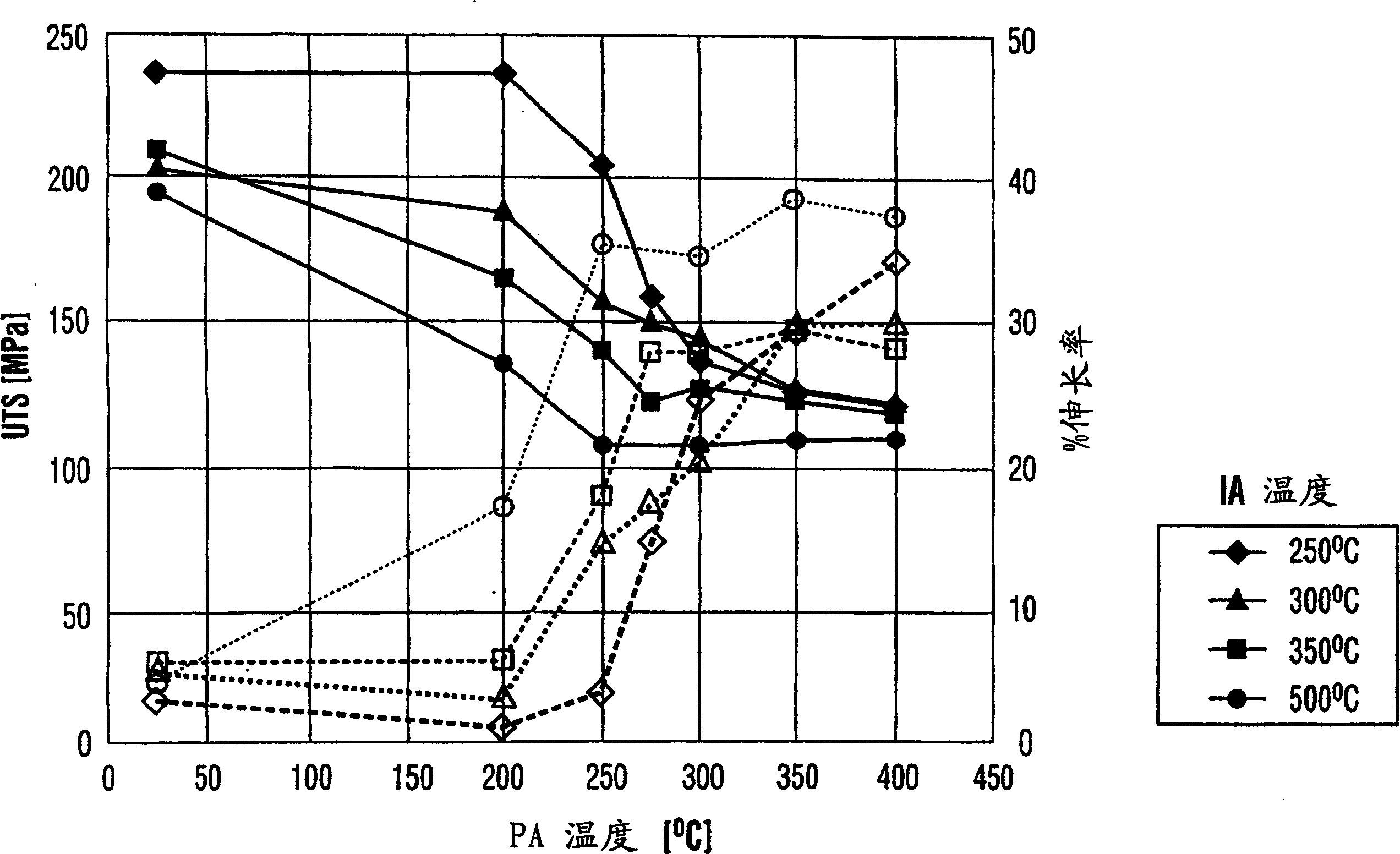

Preparation method of delta-ferrite-containing TRIP (transformation induced plasticity) steel

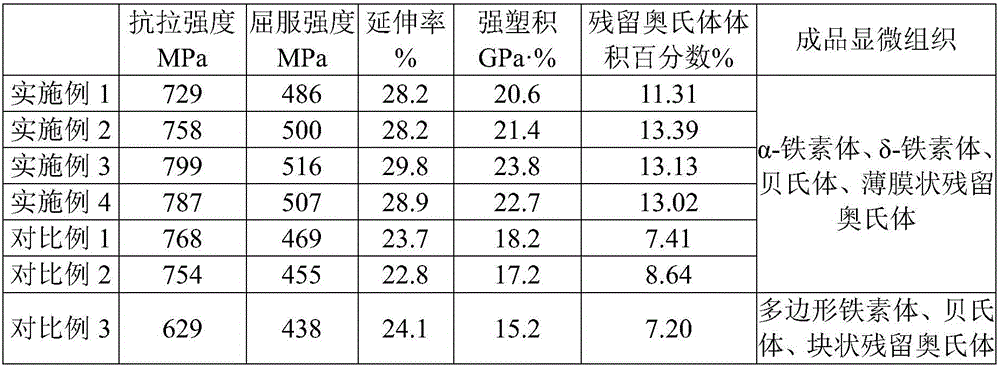

The invention discloses a preparation method of delta-ferrite-containing TRIP (transformation induced plasticity) steel, and belongs to the technical field of high-strength steel for automobiles. The delta-ferrite-containing TRIP steel comprises the following chemical components in percentage by mass: 0.24-0.28% of C, 0.5-1.0% of Si, 1.8-2.5% of Mn, 2.9-3.7% of Alt, no more than 0.01% of P, no more than 0.008% of S+N and the balance of Fe and inevitable impurities. The preparation method comprises the following steps: hot rolling, induction heating, ultra-fast cooling and heat treatment. The steel structure disclosed by the invention contains delta-ferrite, thereby improving the weldability. During composition design, the Al content is increased, thereby obtaining high elongation percentage, lowering the density of the steel, and effectively realizing lightweight development. The structure of the steel finished product comprises alpha-ferrite, delta-ferrite, bainite, thin-film retained austenite (or martensite / austenite island), wherein the volume percent of the retained austenite is 11.31-13.39%. The yield strength of the steel is 486-516 MPa, the tensile strength is 729-799 MPa, the elongation percentage is 28.2-29.8%, and the product of strength and elongation is 20.6-23.8 GPa.%.

Owner:UNIV OF SCI & TECH BEIJING

Aluminum alloy material for hot precision forging connection rod and preparation method thereof

The invention discloses an aluminum alloy material for a hot precision forging connection rod. The aluminum alloy material comprises the following components in percentage by weight: 0.6-1.2% of Si, 0.1-0.7% of Fe, 3.8-4.7% Cu, 0.4-1% of Mn, 0.4-0.8% of Mg, 0.01-0.3% of Zn, 0.01-0.15% of Ti, 89.5-93.6% of Al, 0.05-0.1% of impurities and 0.65-1.45% of a rare earth composite additive containing a mixture of Re, Er and Zr. The rare earth composite additive is the mixture of Re, Er and Zr. The Re contains 75-80% of Ce and 20-25% of La. The invention also discloses a preparation method of the material, comprising the following steps: smelting at the temperature of 710-750 DEG C; adding the rare earth composite additive into the solution, stirring, preserving heat and pouring; fetching out the casting and forging at 400-420 DEG C; and finally performing annealing, solution treatment, quenching and artificial aging. The invention has the advantage that the mechanical performance of the casting by forging at low cost.

Owner:江苏万里活塞轴瓦有限公司

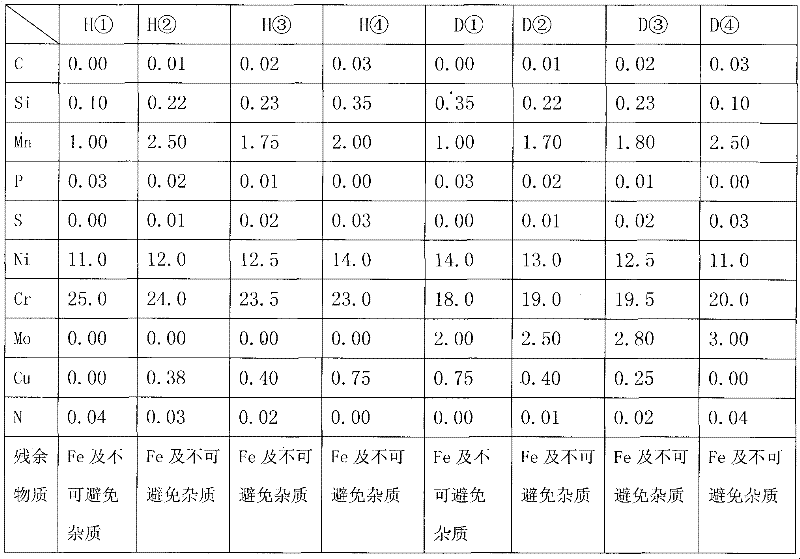

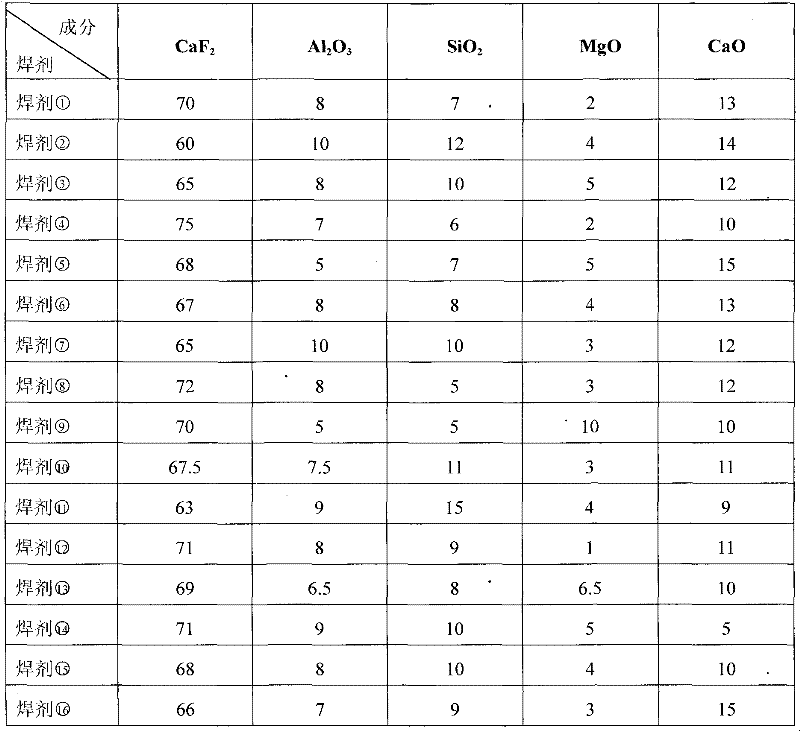

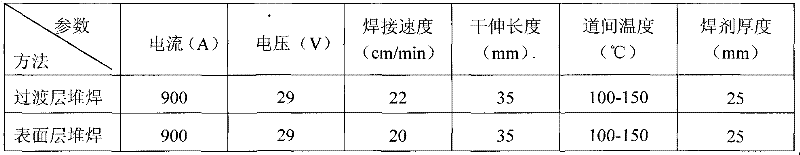

Stainless steel band electrode electroslag surfacing welding strip and welding flux

ActiveCN102233494AWeld firmlyImprove efficiencyWelding/cutting media/materialsSoldering mediaSlagCorrosion resistant

The invention discloses a stainless steel band electrode electroslag surfacing welding strip and a welding flux. The Mo element is not added into a transition layer welding strip, but the surfacing metal has sufficient Mo; and the welding strip and the welding flux can be matched to be applied to large-scale surfacing on the inner wall or the outer wall of a container and can meet corrosion-resistant and high-temperature-resistant requirements. When the welding strip and the welding flux are matched for surfacing, the dilution rate is ultralow and is 5 to 12 percent and the production efficiency is high; slag is easy to remove, a formed welding bead is attractive and welding defects do not exist; the intergranular corrosion resistance is excellent; and cracks do not exist during surfacingbending.

Owner:KUSN GINTUNE WELDING

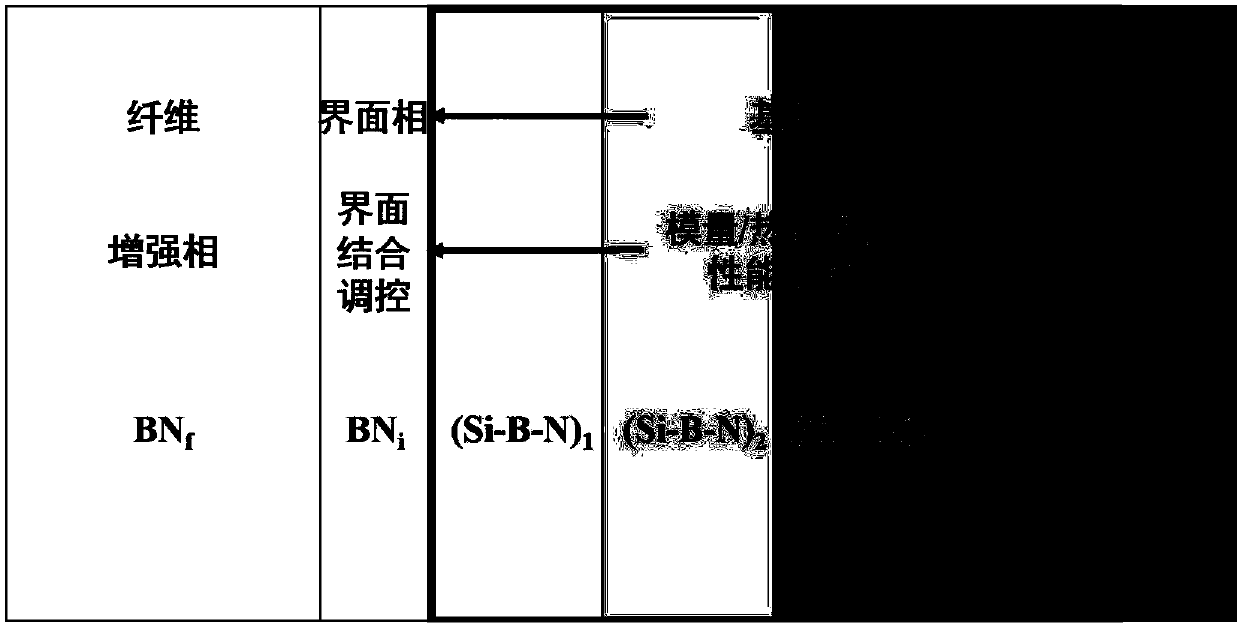

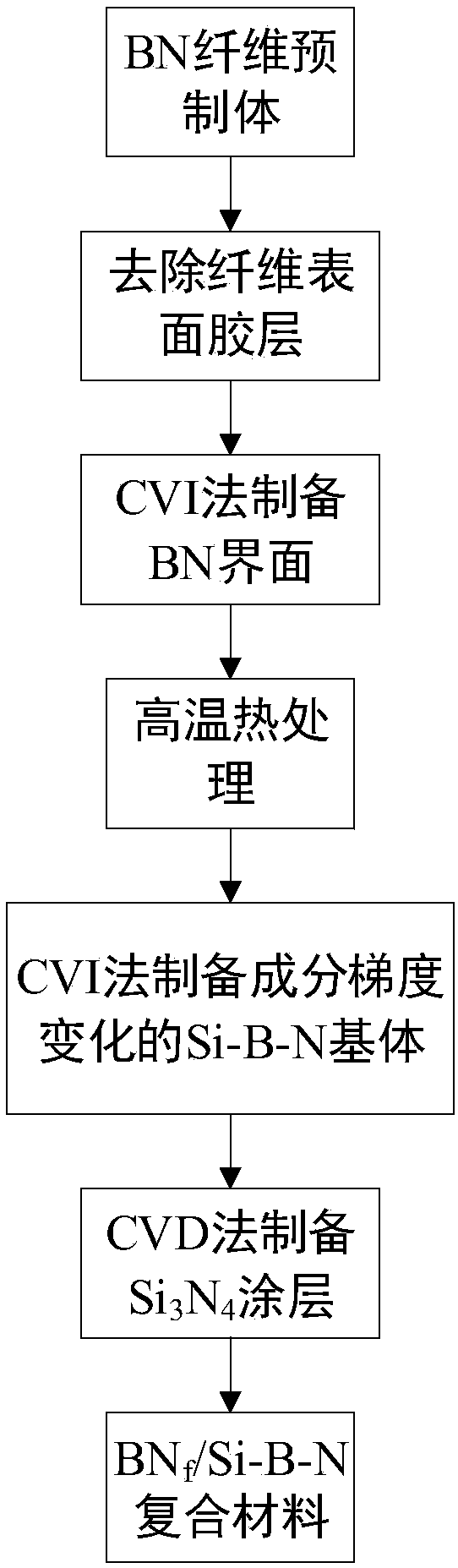

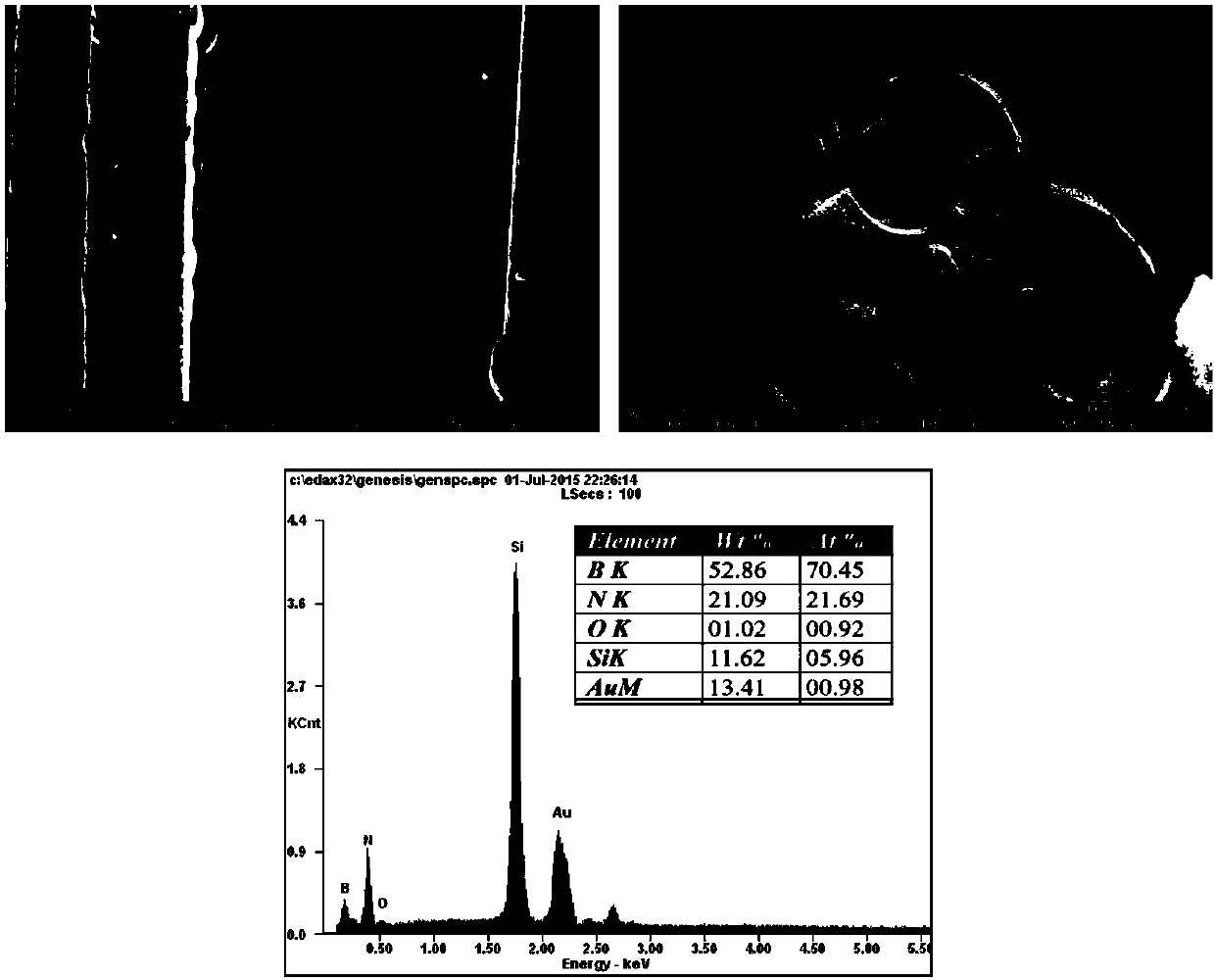

Method for preparing wave-transmitting BN fiber toughened Si-B-N ceramic-based composite material through CVD/CVI

The invention relates to a method for preparing a wave-transmitting BN fiber toughened Si-B-N ceramic-based composite material through CVD / CVI method. First, a uniform, continuous BN interface with aspecific thickness is prepared in a pretreated BN fiber preform through CVD / CVI method; then, a reaction gas proportion of an Si source, a B source and an N source in a precursor system is controlledin a proper temperature arrange so as to prepare an Si-B-N substrate with a multi-layer component gradient structure in the BN fiber preform with the BN interface through CVD / CVI method, components ofeach layer of substrate are in gradient distribution, the content of Si increases gradually and the content of B decreases gradually from the BN interface to a composite material surface; and finally, a uniform, continuous Si3N4 coating with a specific thickness is prepared on the composite material surface through CVD / CVI method. The method prepares the wave-transmitting BNf / Si-B-N composite material with controllable dielectric and mechanical properties.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

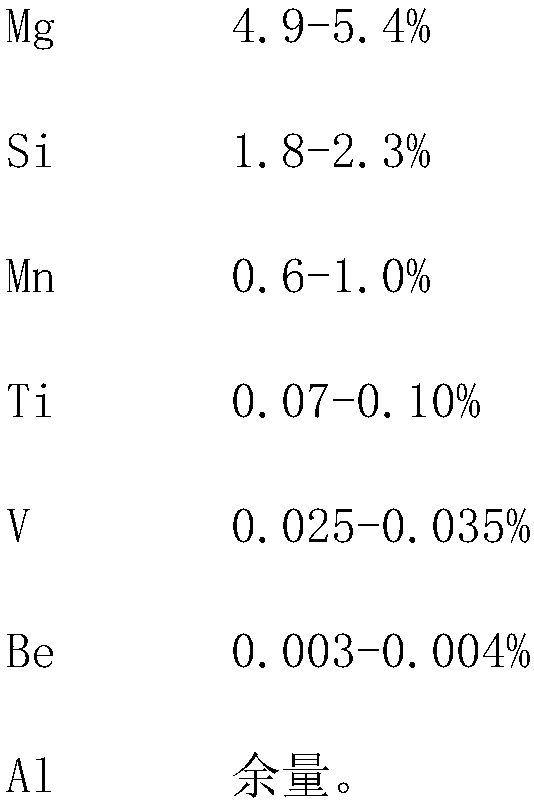

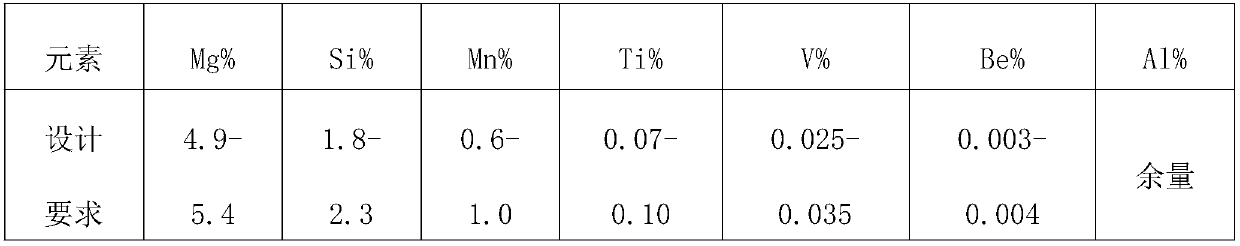

Aluminum magnesium alloy for casting two-breadth-type steering wheel framework and preparation method thereof

The invention belongs to the field of metal materials and relates to the field of preparation of aluminum magnesium alloys, in particular to an aluminum magnesium alloy for casting a two-breadth-typesteering wheel framework and a preparation method thereof. The alloy comprises the following components in percentages by weight: 4.9-5.4% of Mg, 1.8-2.3% of Si, 0.6-1.0% of Mn, 0.07-0.10% of Ti, 0.025-0.035% of V, 0.003-0.004% of Be and the balance of Al; impurity elements are controlled as follows: less than or equal to 0.13% of Fe, less than or equal to 0.03% of Zn, less than or equal to 0.01%of Cu, less than or equal to 0.0005% of Cr, less than or equal to 0.001% of P, less than or equal to 0.0005% of Na, less than or equal to 0.0005% of Ca, less than or equal to 0.01% of Li and the balance of Al.

Owner:保定隆达铝业有限公司 +1

Low-silicon and low-impurity pre-melting slag for electro-slag remelting and preparing method and application thereof

The invention provides low-silicon and low-impurity pre-melting slag for electro-slag remelting through the optimal design of a formula scheme and a technical preparing method of pre-melting slag. The low-silicon and low-impurity pre-melting slag consists of 24-34% of F, 35-58% of Ca, 6-19% of Al, 0-3% of Mg, 10-26% of O and not more than 0.28% of Si in percentage by mass. The granularity is distributed between 0 and 15mm. The preparing method comprises the processing steps of mixing, electric furnace smelting, cooling, crushing, granularity sieving and aluminum foil vacuum packaging. The low-silicon electro-slag re-melting slag has low impurity content and even ingredients and can meet the electro-slag re-melting technical requirements of various high-temperature alloys and special steel, such as stainless steel.

Owner:刘天成

2,000 MPa-grade acid pickling steel plate for hot stamping wheel rim and manufacturing method of acid pickling steel plate

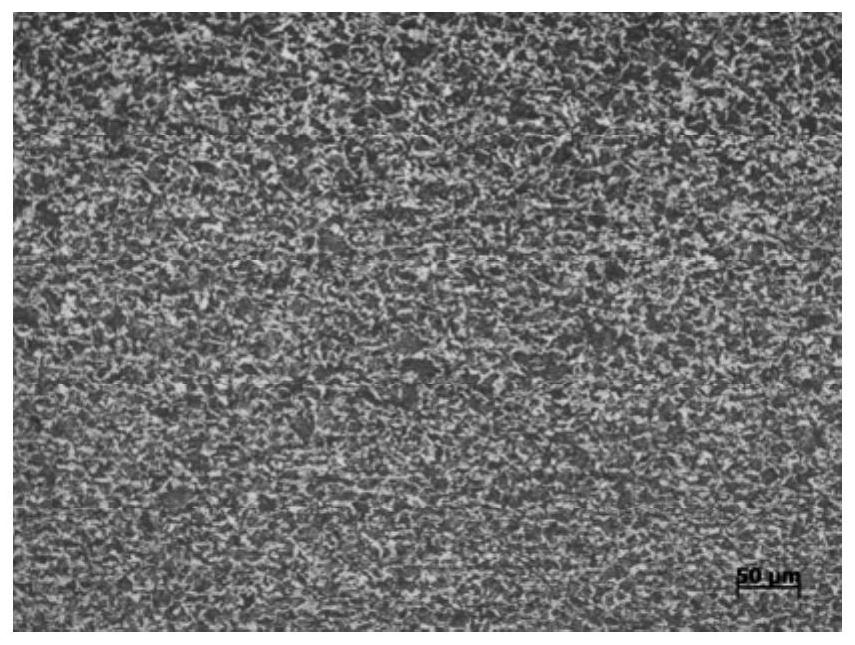

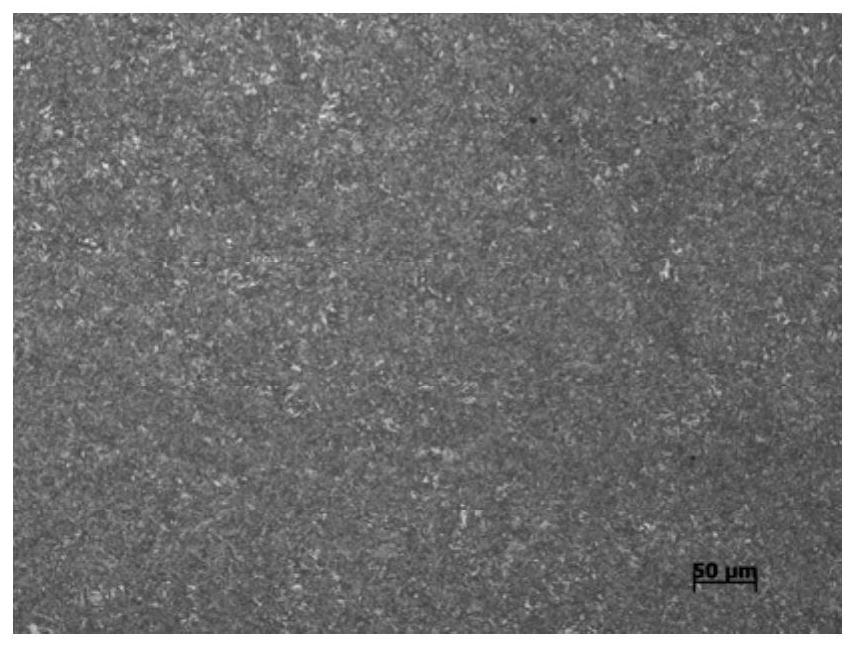

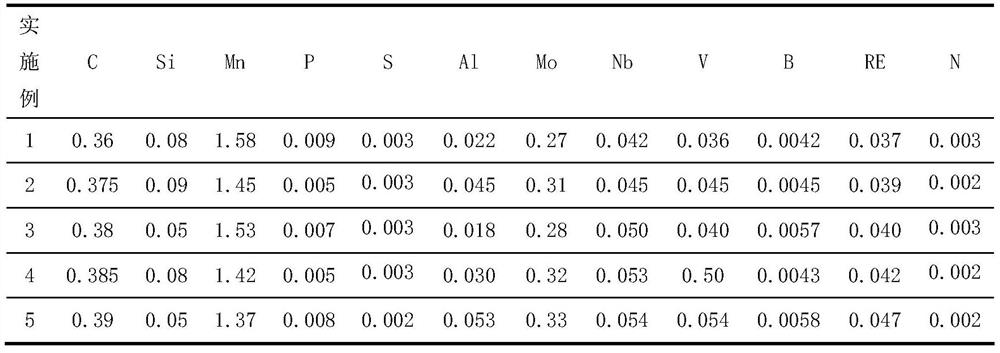

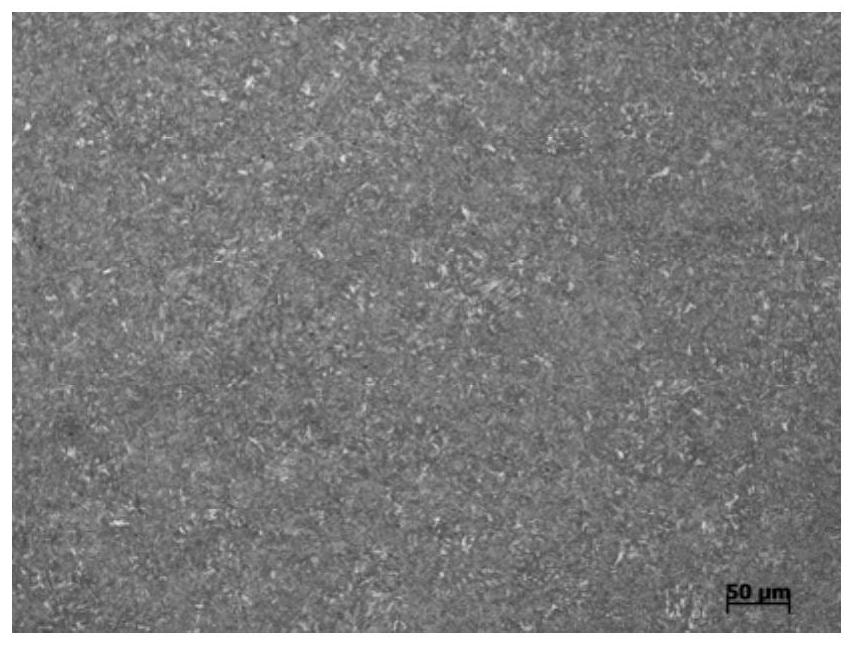

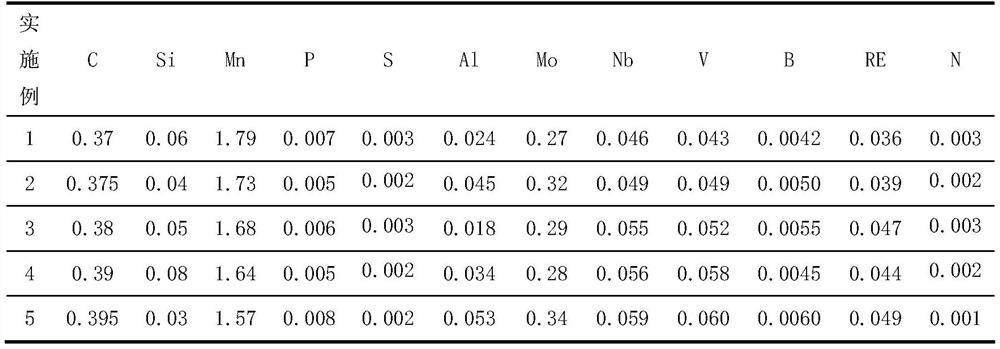

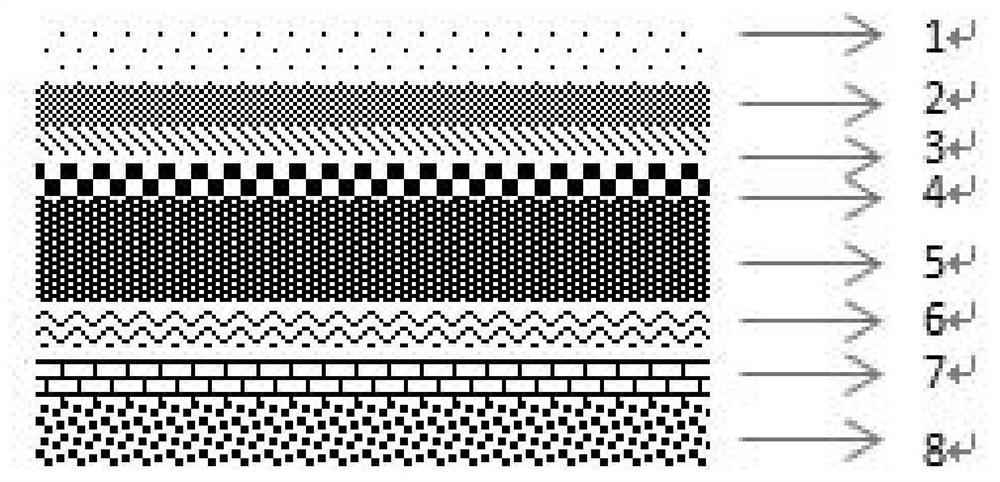

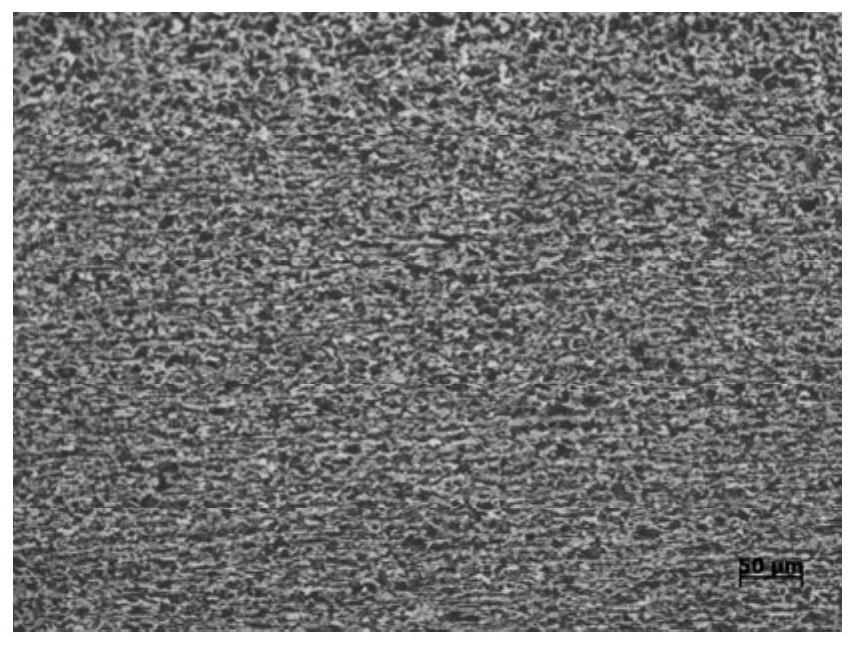

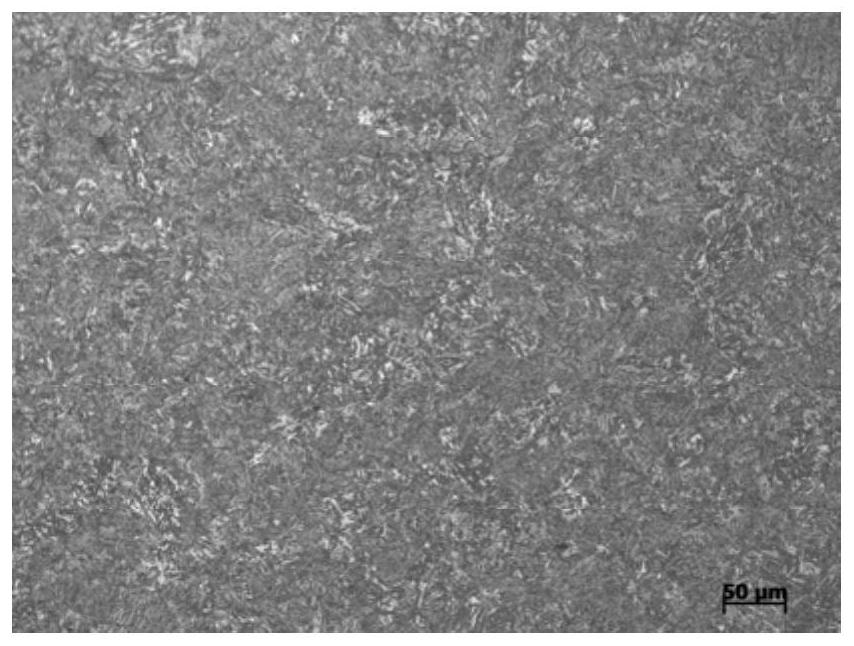

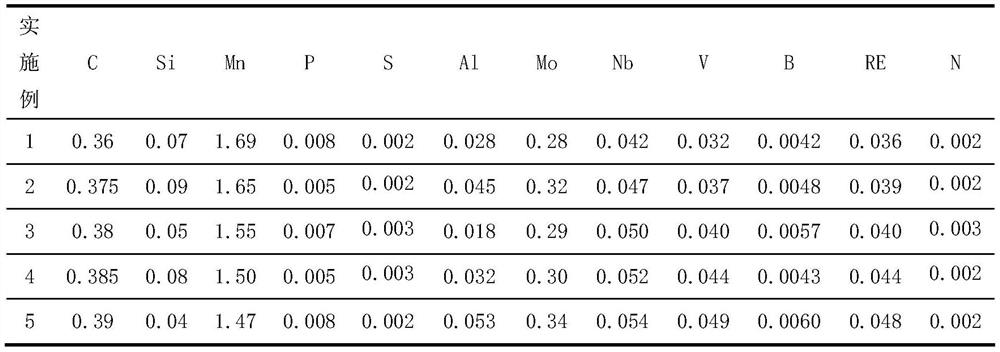

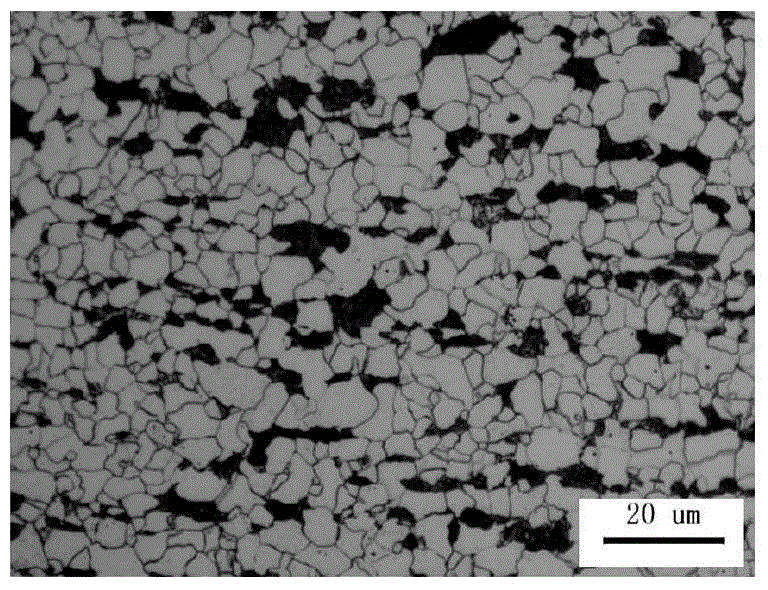

The invention discloses a 2,000 MPa-grade acid pickling steel plate for a hot stamping wheel rim and a manufacturing method of the acid pickling steel plate. The 2,000 MPa-grade pickled steel plate comprises 0.36%-0.39% of C, 0.01%-0.10% of Si, 1.36%-1.60% of Mn, less than or equal to 0.010% of P, less than or equal to 0.004% of S, 0.015%-0.055% of Al, 0.041%-0.055% of Nb, 0.035%-0.055% of V, 0.26%-0.35% of Mo, 0.0041%-0.006% of B, 0.035%-0.050% of rare earth elements La and Ce, equal to or less than 0.003% of N and the balance of Fe and unavoidable impurities.

Owner:ANGANG STEEL CO LTD

High-conductivity flexible aluminium alloy material preparation method

The invention relates to a high-conductivity flexible aluminum alloy material preparation method. The high-conductivity flexible aluminum alloy material preparation method comprises the following steps: heating and fusing aluminum ingots of which the impurity content meets the requirement, heating and fusing boron-aluminum alloy and ferro-aluminum alloy of which the mass percents are respectively 3 and 22 together with the aluminum ingots to form a mixed aluminum liquid, keeping the temperature of the aluminum liquid to be 700-720 DEG C in the fusing process, adding 10% rare earth-aluminum alloy in batches for melting, stirring the mixed aluminum liquid at the speed of 40 r / min; adopting nitrogen gas to uniformly blow a refining agent into the aluminum liquid; stirring, insulating, standing, removing impurities and casting to form aluminum ingot blanks; rolling the ingot blanks into aluminum alloy bars with the diameter of 9.5 mm through a rolling mill, and controlling the bar discharging temperature to be 250 DEG C-300 DEG C so as to prepare an aluminum alloy material. According to the invention, through the processes of melting, alloying, purifying, casting, rolling, quenching and the like, the aluminum conductivity is improved, the aluminum mechanical property is improved, and the aluminum alloy material for high-conductivity flexible cables are manufactured.

Owner:ANHUI SHUANGCHENG WIRE & CABLE CO LTD

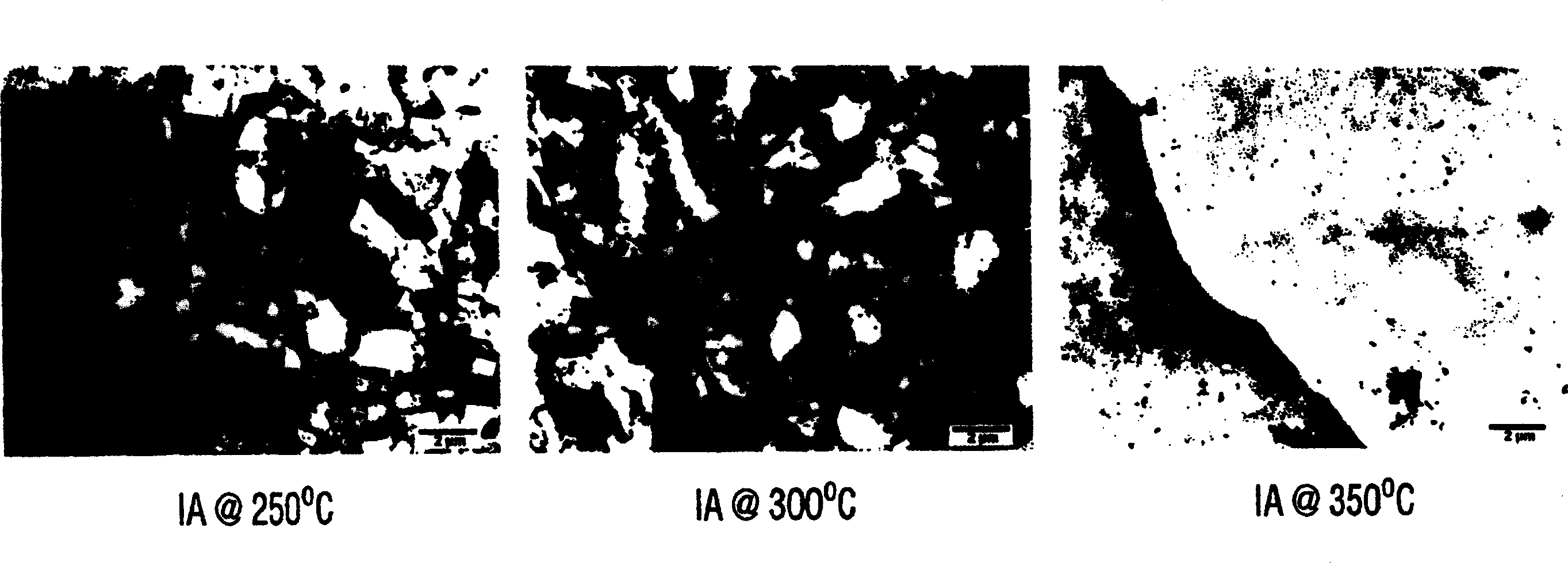

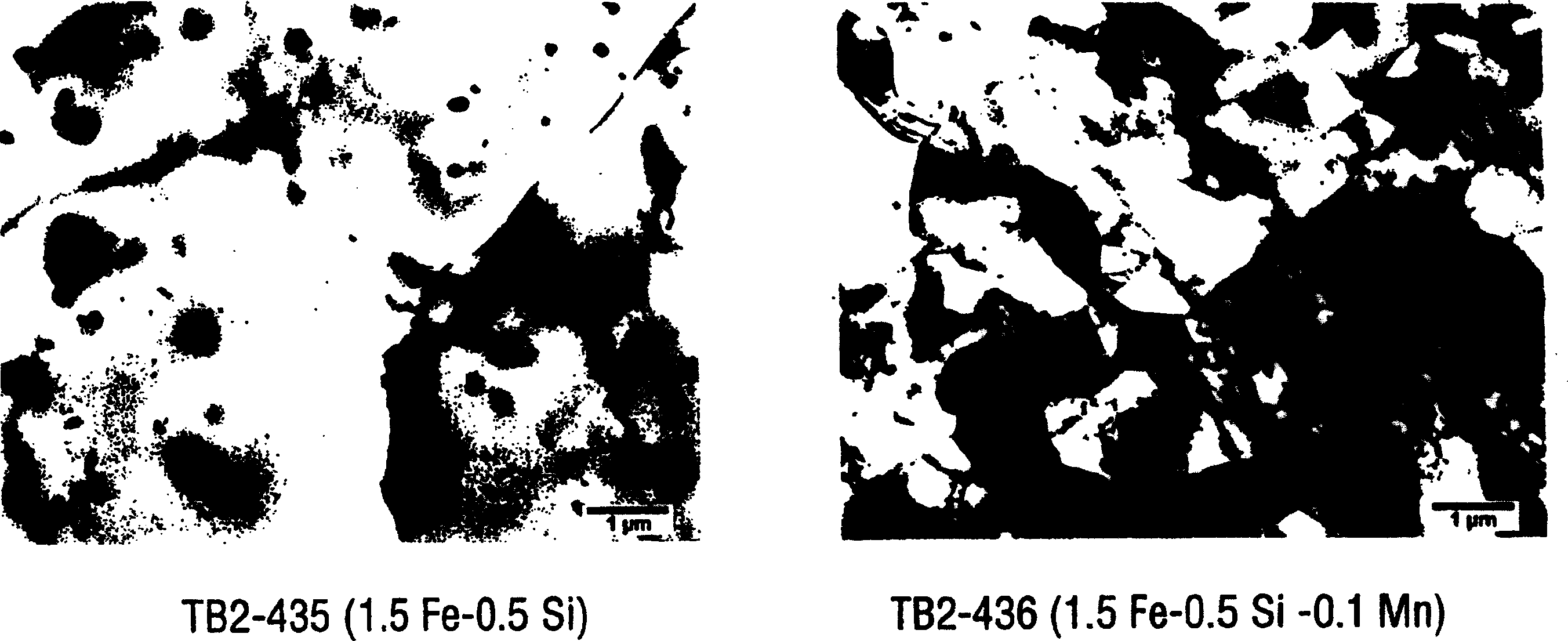

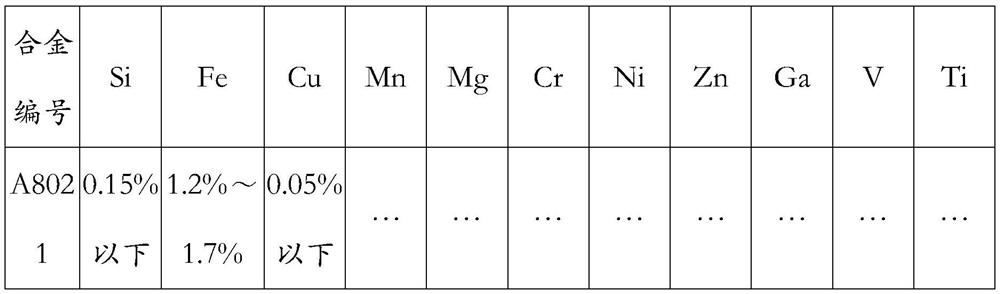

Production of high strength aluminum alloy foils

InactiveCN1491289ASolve the problem of uneven localized coolingSi content increasedMetal rolling arrangementsManganeseHigh intensity

An aluminum alloy foil is formed from an alloy containing about 1.2 to 1.7% by weight iron, about 0.4 to 0.8% by weight silicon and about 0.07 to 0.20% by weight manganese, with the balance aluminum and incidental impurities. The alloy is continuously strip cast, e.g. on a belt caster, to form a strip having a thickness of less than about 25 mm, which is then cold rolled to interanneal gauge followed by interannealing at a temperature of about 280 to 350 DEG C. The interanneal strip is cold rolled to final gauge and further annealed to form the final foil product, having high strength and excellent quality.

Owner:NOVELIS INC

800mpa grade cold-rolled dual-phase steel and production method thereof

The invention discloses 800 MPa grade cold-rolled double-phase steel and a production method thereof. The production method comprises a hot rolling process and a cold rolling continuous annealing process. The chemical compositions of a casting entering the hot rolling process comprise, in percent by mass, 0.14-0.17% of C, 0.45-0.55 of Si, 1.6-1.8 of Mn, 0.55-0.65% of Cr, P<=0.016%, S<=0.008%, 0.02-0.05% of Als, N<=0.004%, and the balance Fe. In the double-phase steel, the Si content is increased and the Mn content is reduced on the basis of the compositions of C-Si-Mn-Cr, so that the strength is increased without adding Al, Nb, Mo, Ti and other high-cost elements, and the purposes of reducing production difficulty and production cost while not influencing smelting castability are realized. The method improves the Si content, reduces the Mn content, improves the composition system of the C-Si-Mn-Cr system and realizes the purpose of reducing production cost. By improving the smelting, hot rolling and cold-rolling continuous annealing technologies, the cold-rolled double-phase steel with the tensile strength of 800-850 MPa, the yield strength of 450-550 MPa and the elongation percentage of 15-17% is produced, and the production method has the characteristics of simple technology, low cost and stable product quality.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

High-impact-toughness foamed aluminum based on A356 aluminum alloy and production process of high-impact-toughness foamed aluminum

The invention relates to a foamed aluminum material, in particular to high-impact-toughness foamed aluminum based on A356 aluminum alloy and a production process of the high-impact-toughness foamed aluminum. The production process comprises the steps that (1) 12-20 parts, by weight, of a foaming agent is ground and screened through a sieve with 100-180 meshes; (2) 100 parts, by weight, of A356 aluminum alloy ingots are crushed, ground into particles and then evenly mixed with 8-15 parts, by weight, of inorganic nano-whiskers and 10-12 parts, by weight, carbon nano-tubes, then a mixture is placed into a smelting furnace and completely molten in an inert gas atmosphere, afterwards, the foaming agent is sucked in to the smelting furnace under negative pressure, and a molten aluminum mixture is obtained after uniform mixing; (3) the molten aluminum mixture obtained in the step (2) is poured into a mold, the mold is then pushed into a foaming furnace, and heat preservation is conducted for1-2h at the temperature of 680-700 DEG C; and (4) the mold enters a cooling system to be cooled, and thus the foamed aluminum is obtained. According to the high-impact-toughness foamed aluminum basedon the A356 aluminum alloy and the production process of the high-impact-toughness foamed aluminum, the mixture of the inorganic nano-whiskers and the carbon nano-tubes is added in the forming processof the foamed aluminum, and thus the impact toughness of the aluminum is remarkably improved.

Owner:JIESHOU JINGHUA TECH INFORMATION CONSULTING SERVICE CO LTD +1

Novel alumina bubble brick

The invention belongs to a refractory material and relates to a novel alumina bubble brick. The novel alumina bubble brick comprises, by weight, 97-98% of Al2O3 with particle size of 1.5-8mm and spontaneous stacking density of 0.7-1.0g / m<3>, 2-1% of SiO2 with particle size of 1.5-8mm and spontaneous stacking density less than 0.6g / m<3>, and 1% of calcium carbonate with spontaneous stacking density less than 0.2g / cm<3> and corresponding density of 1.2-2.0g / cm<3>. The novel alumina bubble brick has high chemical component purity, low impurity content and low Si content. The novel alumina bubble brick is free of the traditional method for preparing a mullite bonding phase by specifically introducing SiO2, effectively reduces SiO2 content, improves a material use temperature, has high strength, can satisfy kiln building and use requirements and can guarantee coal water slurry vapourizing furnace normal operation.

Owner:长兴县新宏信耐火材料有限公司

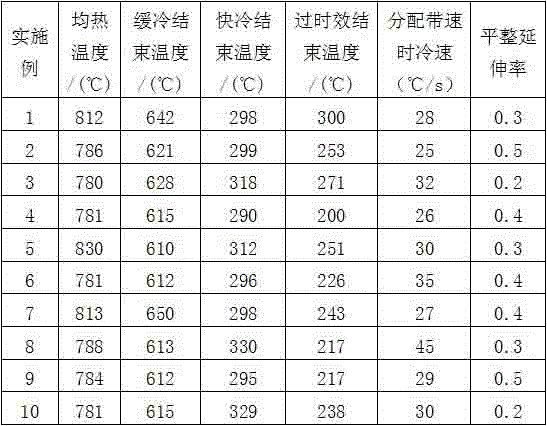

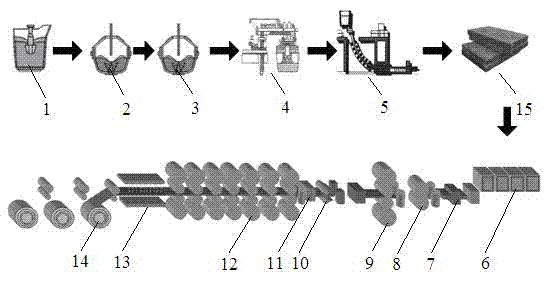

Strip steel and production method and system thereof

InactiveCN102345064AReduce Si contentImprove surface qualityManufacturing convertersMetal rolling arrangementsChemical compositionOxide

The invention discloses strip steel and a production method and system thereof, belonging to the technical field of steel products. The strip steel produced by using the production method and system comprises the following chemical components in percentage by weight: 0.12-0.18% of C, not more than 0.30% of Si, 1.20-1.40% of Mn, not more than 0.020% of P, not more than of 0.012% of S, 0.02-0.06% of Alt, 0.010-0.025% of V, 0.010-0.025% of Ti and the balance of Fe and impurities. Combined with different processing conditions of a hot continuous rolling mill in the hot continuous rolling process, the production system is capable of respectively producing the steels of the Q345q series bridges and Q370q series bridges with the chemical components in the same percentage of weight. The diversified production is realized while simplifying the smelting and continuous casting operations and management. The strip steel has lower content of Si and ensures that the generated ferric oxide sheet is easy to remove, and the content of P as an impurity element is also lower.

Owner:SHOUGANG CORPORATION

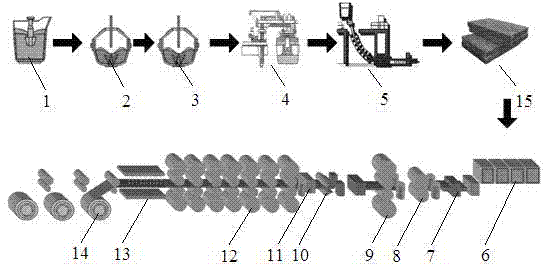

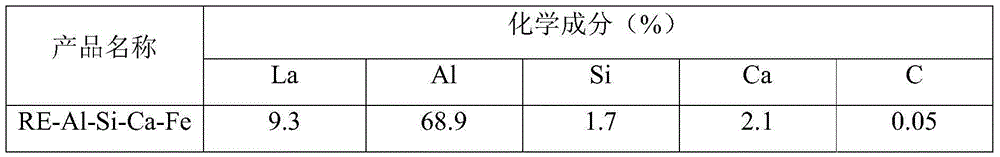

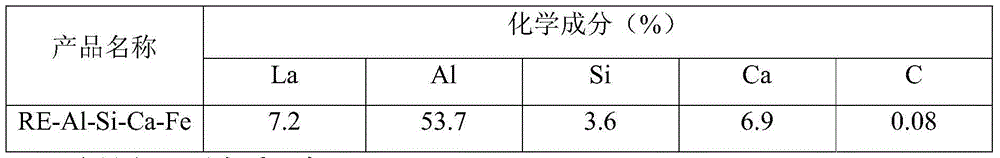

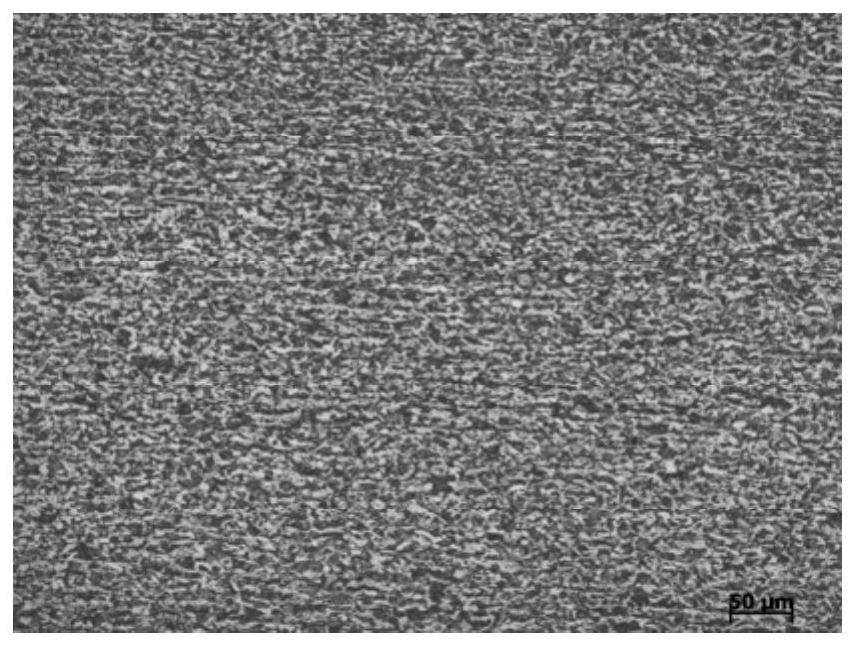

Rear-earth aluminum, silicom and calcium ferroalloy and preparation method of rear-earth aluminum, silicom and calcium ferroalloy

The invention discloses a rear-earth aluminum, silicom and calcium ferroalloy and a preparation method of the rear-earth aluminum, silicom and calcium ferroalloy and belongs to the technical field of a steel-making deoxidizer. The rear-earth aluminum, silicom and calcium ferroalloy comprises the following components in percentage by weight: 40 to 70 percent of aluminum, 1 to 4 percent of silicon, 1 to 10 percent of rear earth, 5 to 10 percent of calcium, smaller than or equal to 0.2 percent of carbon, smaller than or equal to 0.03 percent of sulfur, smaller than or equal to 0.03 percent of phosphor, smaller than 1 percent of inevitable impurity elements, and the balance of iron. Pure aluminum ingot, rear earth, high-quality silicon iron, metal calcium and low-carbon and high-quality waste steel are prepared into a finished alloy meeting requirements through a two-step melting process in an induction furnace. The alloy has the advantages that Mn element is not contained, so that a low-Mn steel variety can be produced; the alloy simultaneously contains Si and Al, so that a better complex deoxidation effect to molten steel is achieved when the alloy is added in a steel-making process; inclusion modification and removal effects are enhanced by relatively higher Ca content and certain RE; in an alloy preparation process, after the waste steel is molten into molten steel, at first, a Si alloy is added to deoxidize, the yield of Al is obviously improved, and the alloy cleanness is also improved.

Owner:UNIV OF SCI & TECH BEIJING +1

2000MPa-grade hot-stamped vehicle wheel spoke hot-rolled steel plate and fabrication method thereof

The invention discloses a 2000MPa-grade hot-stamped vehicle wheel spoke hot-rolled steel plate and a fabrication method thereof. The hot rolled steel plate comprises the chemical ingredients of, in percentage by mass, 0.37-0.40% of C, 0.01-0.10% of Si, 1.56-1.80% of Mn, less than or equal to 0.010% of P, less than or equal to 0.004% of S, 0.015-0.055% of Al, 0.046%-0.060% of Nb, 0.041-0.060% of V,0.26-0.35% of Mo, 0.0041-0.006% of B, 0.035-0.050% of rare earth elements La+Ce, less than or equal to 0.003% of N and the balance Fe and inevitable impurities.

Owner:ANGANG STEEL CO LTD

Method for smelting austenite antirust steel through converter desilicication solution

InactiveCN107760976AReduce Si contentImprove furnace conditionsManufacturing convertersProcess efficiency improvementAustenitic stainless steelNickel

The invention relates to a method for smelting austenite antirust steel through a converter desilicication solution, belongs to the technical field of steel smelting, and solves the technical problemthat AOD smelting time is increased after a medium-frequency furnace or an electric furnace uses chromium iron with high Si content. According to the scheme adopted by the invention, the method comprises the following steps: a, filling a chromium-nickel alloy or chromium iron into the medium-frequency furnace to melt; b, filling waste steel or raw iron containing molybdenum, nickel and chromium into an electric furnace to smelt; c, mixing pre-melting solutions prepared in the step a and the step b, and transferring the mixed solution into a converter to blown by an oxygen lance, and lifting the lance when mass percentage content of Si in the pre-melting solution is 0.65%-0.75, blowing argon gas to the bottom of the medium converter in a blowing process for continuously stirring and reducing until mass percentage content of Si in the pre-melting solution is reduced to be lower than 0.50%; and d, mixing the pre-melting solutions in the step c into an AOD furnace to smelt, thereby preparing austenite antirust steel. The austenite antirust steel smelted by the method has a yield increased to be 0.25% or more, AOD smelting time is not increased, and the whole-line production efficiencyis obviously improved.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

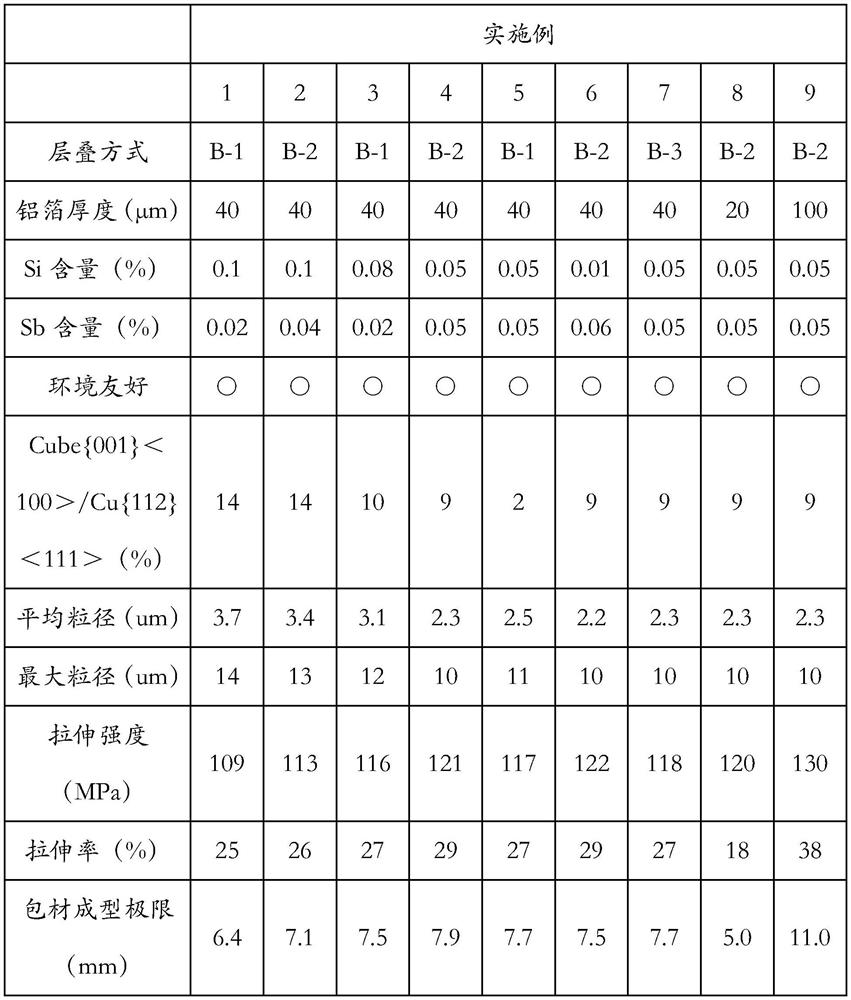

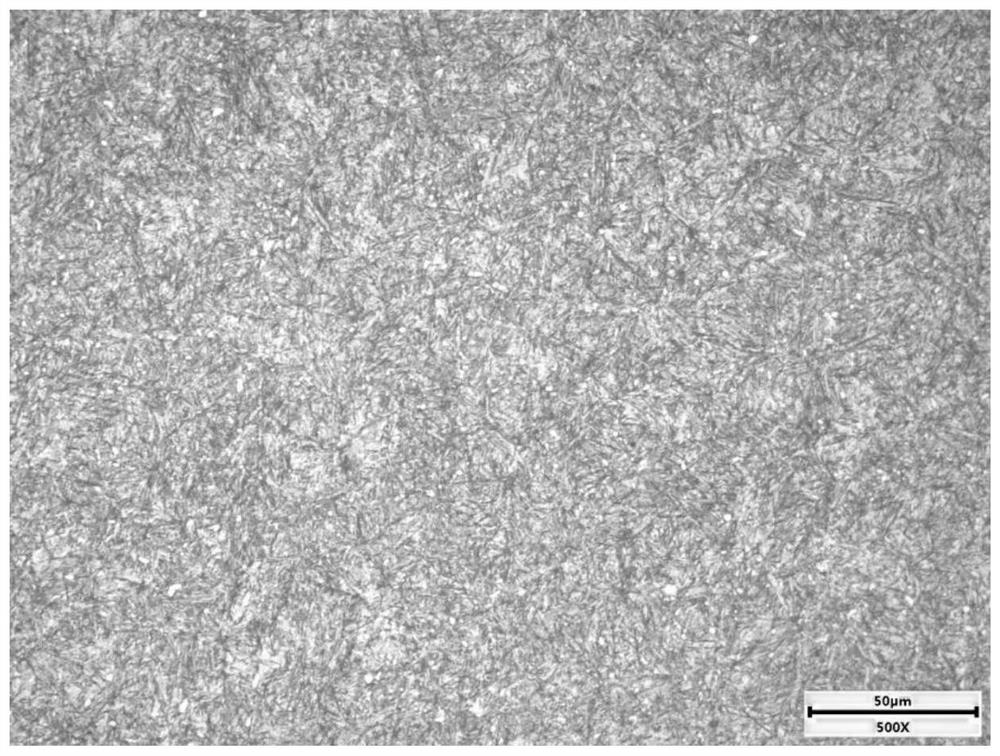

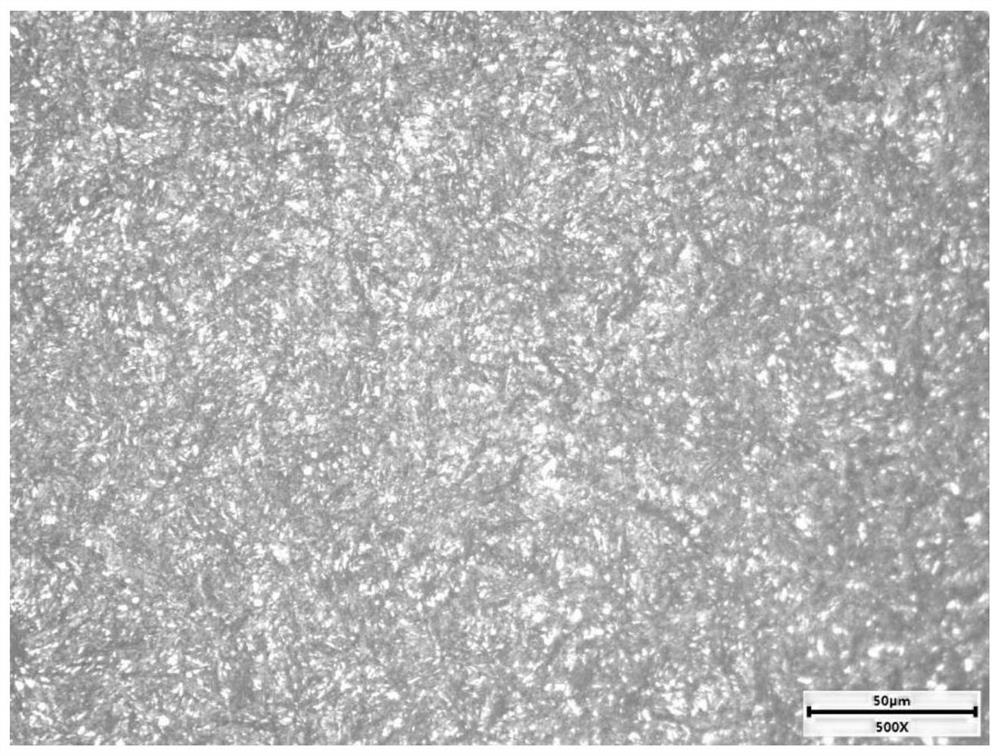

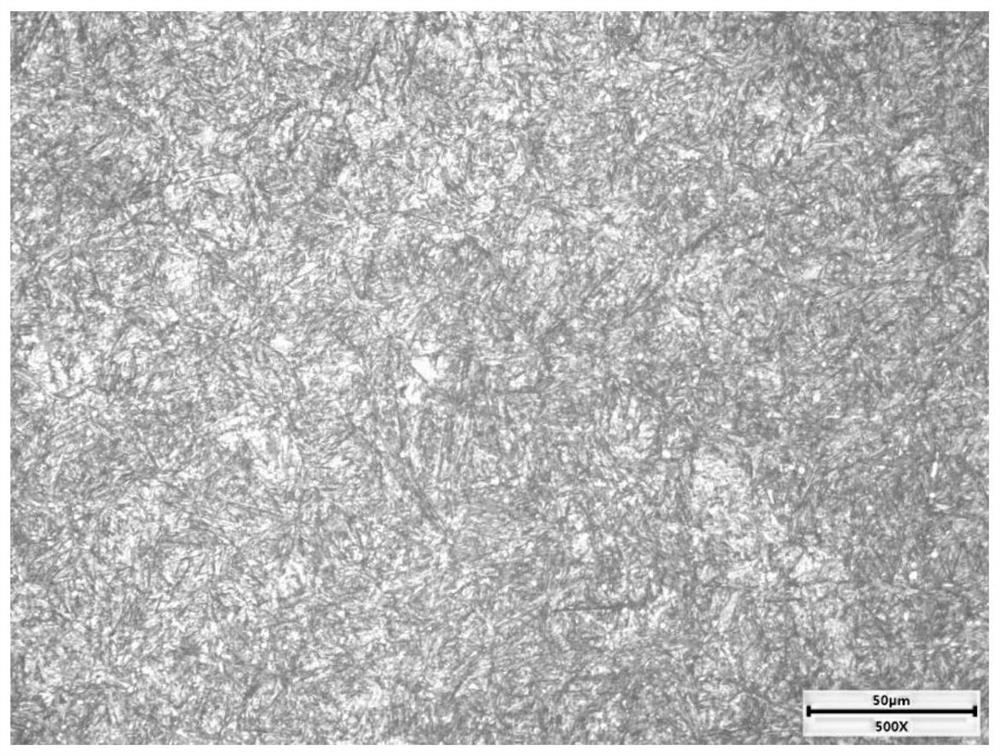

Outer packaging material for high-punching-depth battery device and battery

PendingCN112848577AReduce Si contentCrystallizationSynthetic resin layered productsElectrical equipmentCrystal size distributionAluminum foil

The invention relates to an outer packaging material for a high-punching-depth battery device and a battery. The outer packaging material comprises a base material layer, a barrier layer and a hot melting layer; the outer packaging material is characterized in that the barrier layer is an aluminum alloy foil; the distribution of the optimal plane orientation of the aluminum alloy foil is the ratio of Cube {001} < 100 > orientation to Cu {112} < 111 >, i.e., Cube {001} < 100 > / Cu {112} < 111 > = 1.6-20%, and the proportion of S {123} < 643 > orientation in the entire aluminum alloy foil is 15% or more. The material has the positive effects that the proportion of Cube {001} < 100 > / Cu {112} < 111 > is reduced within a certain range, so that the crystal size distribution in the aluminum foil can be reduced, the crystal uniformity is improved, and the forming limit depth is deepened.

Owner:WUXI ENERGY NEW MATERIALS TECH CO LTD

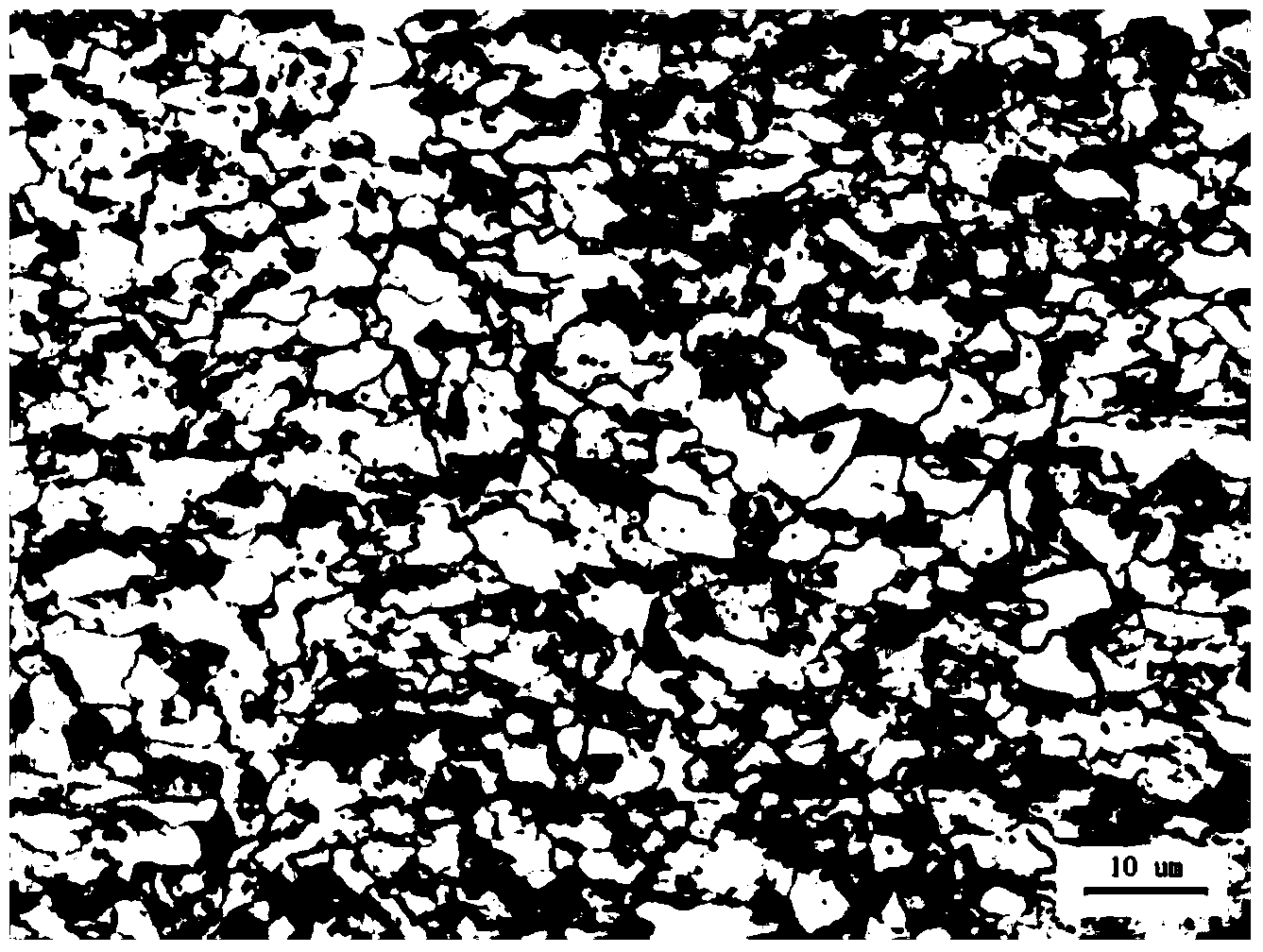

High-toughness and high-hardness die steel and preparation method thereof

The invention provides high-toughness and high-hardness die steel. The high-toughness and high-hardness die steel is prepared from the components in percentage by mass: 0.70%-0.85% of C, 0.10%-0.40% of Si, 0.30%-0.70% of Mn, 4.85%-5.30% of Cr, 2.25%-2.55% of Mo, 0.40%-0.70% of V, less than 0.02% of P, less than 0.003% of S and the balance of Fe. According to the high-toughness and high-hardness die steel, the content of C is set between the components of the hot-work and cold-work die steel, so that the hardenability and hardenability of the material can be improved, alloy carbide can furtherbe formed, and the wear resistance is improved; the Si content is reduced, so that the toughness of the material is improved; and the content of Cr is kept the same as that of Cr in the hot-work die steel H13, meanwhile, the content of V is reduced, the content of Mo is increased, generation of V-containing eutectic carbide can be reduced, the influence on toughness is reduced, and it is guaranteed that the material has good tempering softening resistance.

Owner:TIANJIN CISRI HARDER MATERIALS & TECH

2000MPa-grade hot-rolled steel plate for hot-stamped wheel rim and manufacturing method of 2000MPa-grade hot-rolled steel plate

The invention discloses a 2000MPa-grade hot-rolled steel plate for a hot-stamped wheel rim and a manufacturing method of the 2000MPa-grade hot-rolled steel plate. The 2000MPa-grade hot-rolled steel plate comprises 0.36%-0.39% of C, 0.01%-0.10% of Si, 1.46%-1.70% of Mn, less than or equal to 0.010% of P, less than or equal to 0.004% of S, 0.015%-0.055% of Al, 0.041%-0.055% of Nb, 0.030%-0.050% of V, 0.26%-0.35% of Mo, 0.0041-0.006% of B, 0.035%-0.050% of of rare earth elements La+Ce, less than or equal to 0.003% of N, and the balance Fe and inevitable impurities.

Owner:ANGANG STEEL CO LTD

600mpa grade high yield strength ratio high plasticity cold-rolled steel plate and its manufacturing method

A disclosed 600 MPa grade high-yield-ratio high-plasticity cold-rolled steel plate is characterized by comprising the following compositions in percent by mass: 0.06%-0.12% of C, 0.02-0.10% of Si, 1.40%-2.00% of Mn, 0.015% or less of P, 0.010% or less of S, 0.02%-0.10% of Al, 0.0050% or less of N, 0.015-0.045% of Nb, 0.020-0.055% of Ti, at the same time 0.035%<= Nb+Ti<= 0.100%, and the ferrite balance is Fe and other some unavoidable impurities.

Owner:ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com