Patents

Literature

85results about How to "Crystallization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

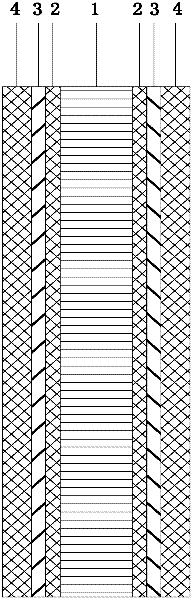

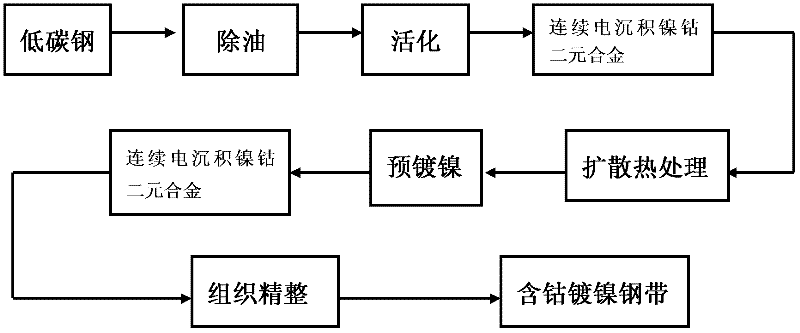

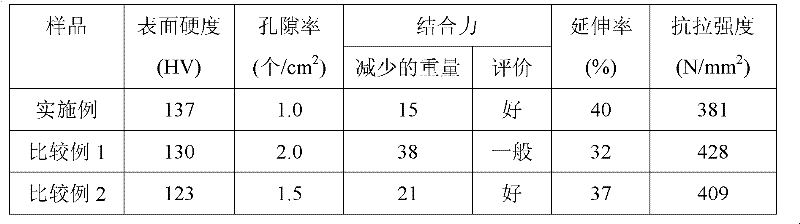

Cobalt-containing nickel plated steel strip serving as lithium battery shell material and preparation method thereof

InactiveCN102230200AImprove performanceTimely supplementCell component detailsElectrical batteryNitrogen

The invention discloses a cobalt-containing nickel plated steel strip serving as a lithium battery shell material and a preparation method thereof. The preparation method comprises the following procedures of: (1) pretreating a base material; (2) continuously electrodepositing a nickel-cobalt alloy plating layer on the pre-treated base material; (3) carrying out diffusion annealing treatment on the nickel-cobalt alloy plating layer under a protective atmosphere like high-purity nitrogen; (4) plating a nickel-cobalt alloy plating layer on the metal subjected to the diffusion annealing treatment again; and (5) rolling the plated nickel-cobalt alloy plating layer in a cold manner. The cobalt containing nickel plated steel strip disclosed by the invention is prepared by a special process of tightly combining the nickel-cobalt alloy plating layer and a low-carbon steel strip and then electroplating the nickel-cobalt alloy plating layer and the low-carbon steel strip, shows better corrosion resistance and can be used for shell materials of primary batteries, secondary batteries and lithium ion power cells such as 18650, 26650 and the like.

Owner:XIANGTAN UNIV

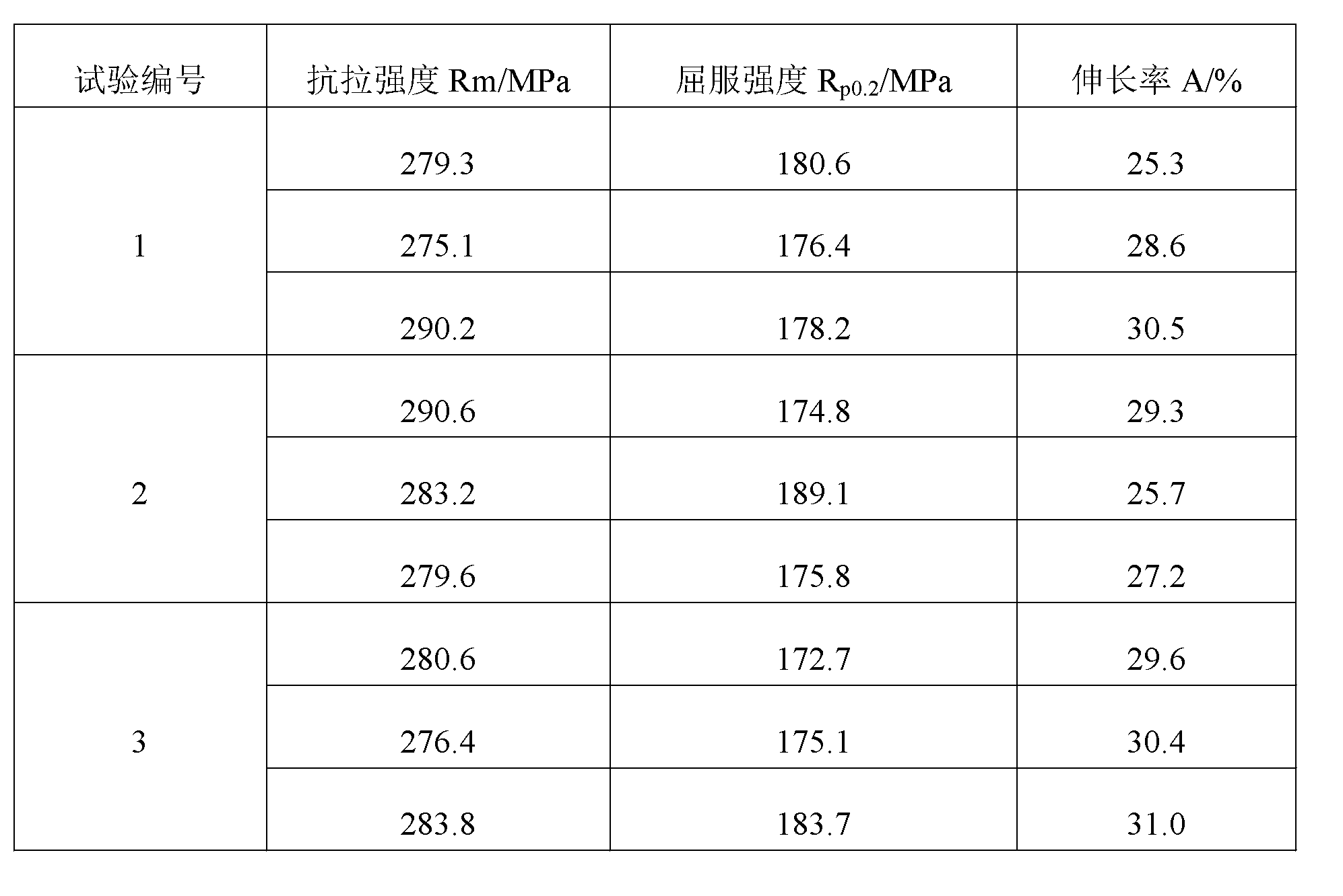

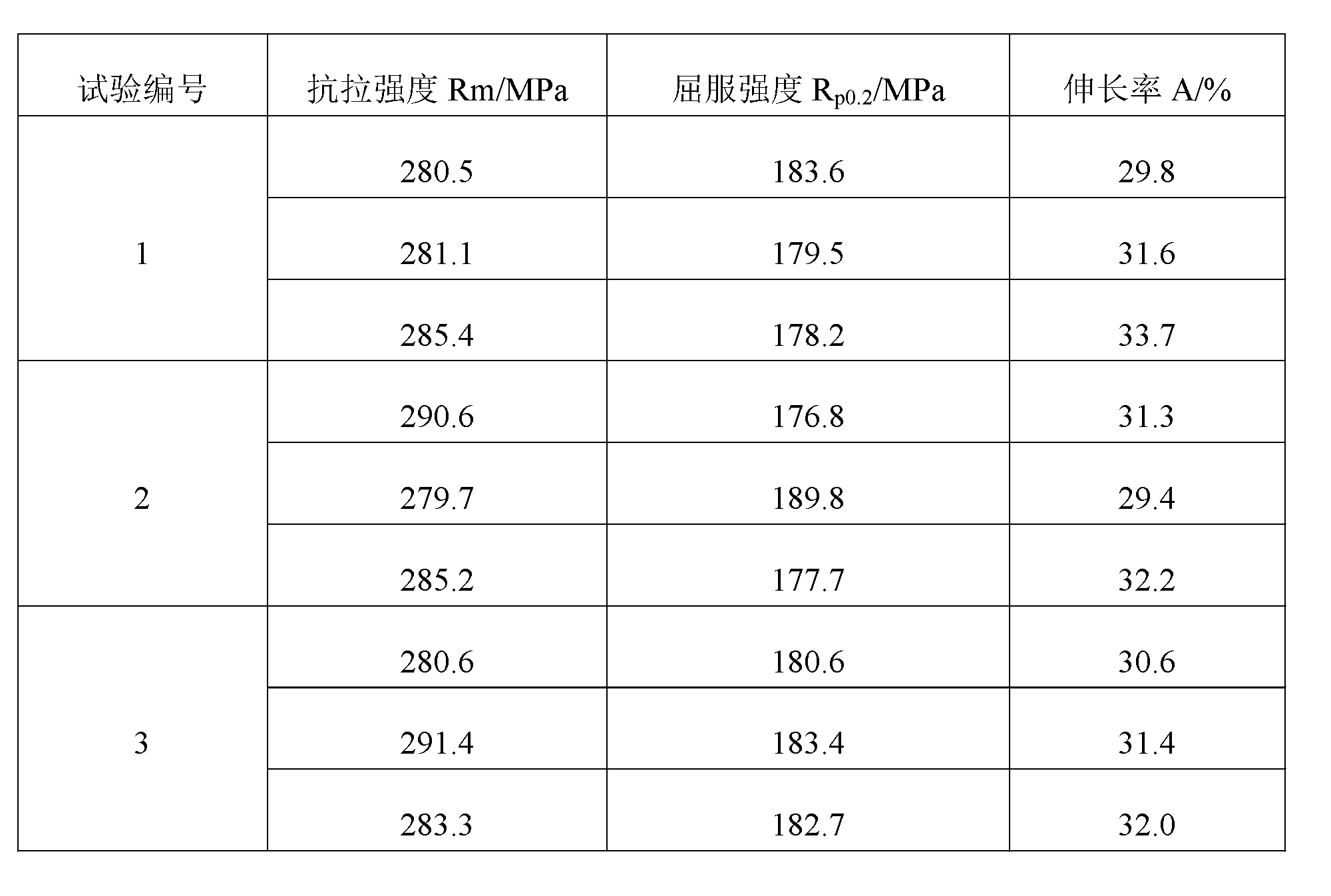

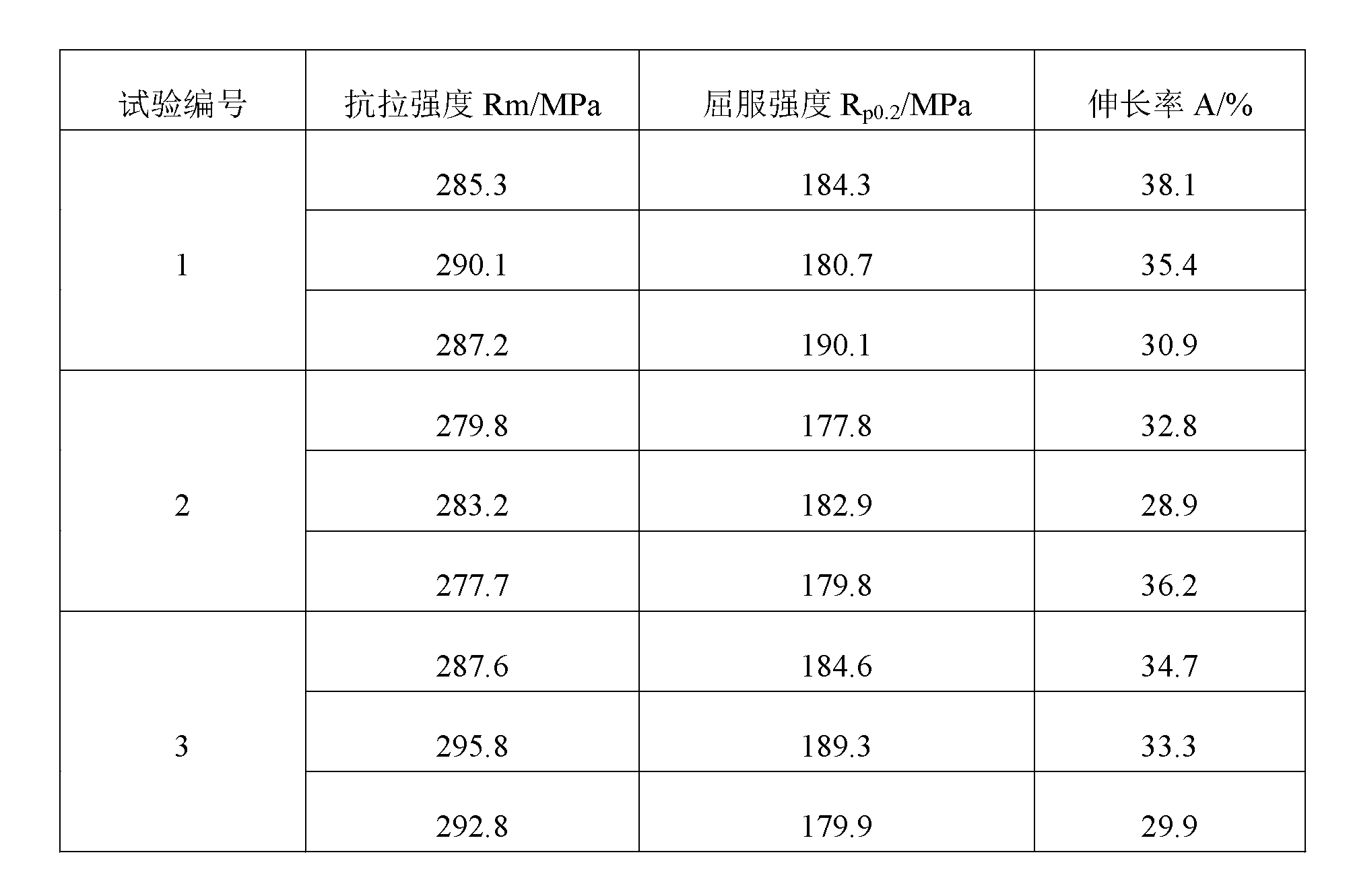

Rare earth magnesium-lithium alloy sheet and preparation method thereof

The invention discloses a rare earth magnesium-lithium alloy sheet and a preparation method thereof, belonging to the field of metal processing. The rare earth magnesium-lithium alloy sheet is characterized by comprising the following components in percentage by weight: 11-15% of Li, 0.5-2% of Y, 0.5-2% of Gd, 0.1-1% of Sc, 7-9% of Al and the balance of magnesium. The preparation method comprises the following steps of: melting magnesium and intermediate alloy by using an industrial medium-frequency or line-frequency induction melting furnace, adjusting the furnace temperature for heat preservation treatment, sampling from the furnace and carrying out rapid on-the-spot sample analysis after the heat preservation time is reached, and detecting whether the components are qualified; and hot rolling and cold rolling a pouring and rolling sheet, carrying out T6 treatment, then, making a mechanical sample, and measuring the mechanical property. By using the rare earth magnesium-lithium alloy sheet and the preparation method thereof, the strength of magnesium-lithium alloy is ensured, the plastic deformation capability of the magnesium-lithium alloy is also greatly enhanced, the production difficulty of the deformed magnesium-lithium alloy sheet is lowered, and the production efficiency is increased. The alloy smelting process is simple, convenient and reliable, convenient to operate and free of special processing process and alloy adding methods. A cast ingot is fine and uniform in tissue, free of meshy and thick sheet-like Mg17Al12 phase and uniform in precipitated phase. The rolling process is simple, convenient, reliable and feasible, and the sheet has favorable comprehensive mechanical property.

Owner:INNER MONGOLIA 52 SPECIAL MATERIAL ENG TECH RES CENT

Electrolytic tinning annexing agent

The invention belongs to the technical field of chemical tinning, in particular to an electrolytic tinning annexing agent. The electrolytic tinning annexing agent is formed by matching of following ingredients. The ingredients comprise 25-55 g / l of tin methanesulfonate, 90-140 g / l of methanesulfonic acid, 15-20 g / l of a stabilizing agent, 10-15 g / l of brightening agent, 15-25 g / l of polyacrylamide and aluminium polychlorid, 3-8 g / l of a rare earth annexing agent and the balance deionized water. The electrolytic tinning annexing agent has the advantages that the plating solution property is stable, a plating solution can be maintained to be clear and free of turbidity, a cladding layer crystal is refining, the brightness area is large, the evenness is good, lead does not exist, and the environment is further protected.

Owner:吕小方

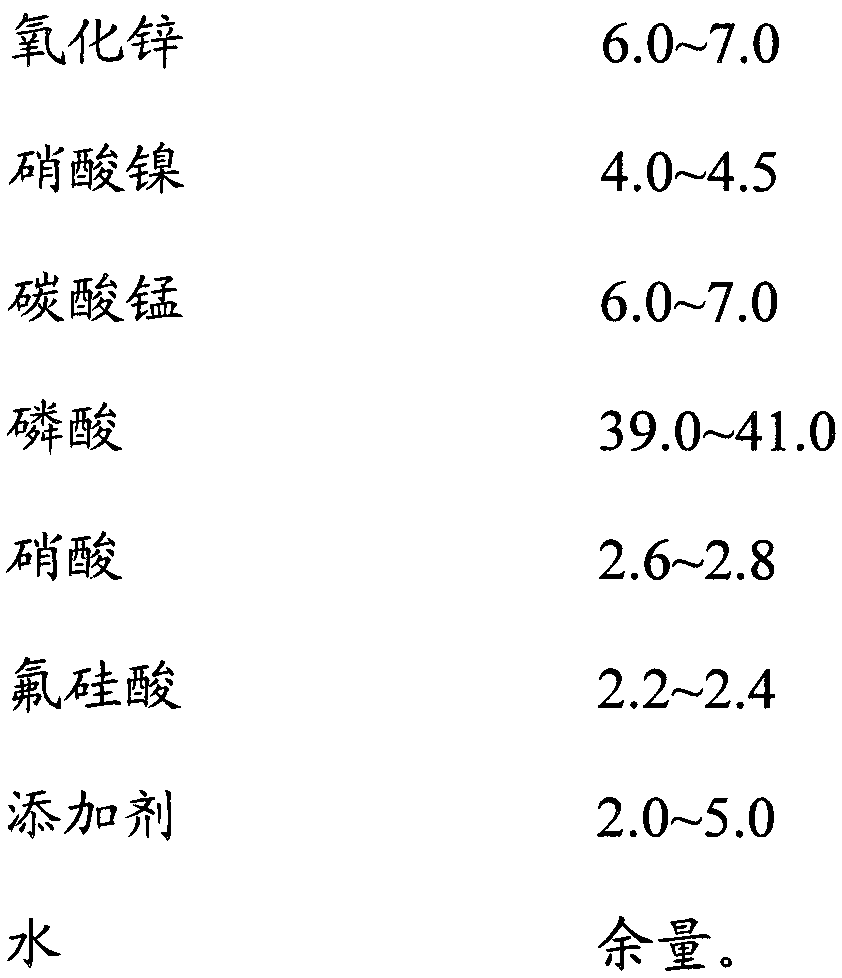

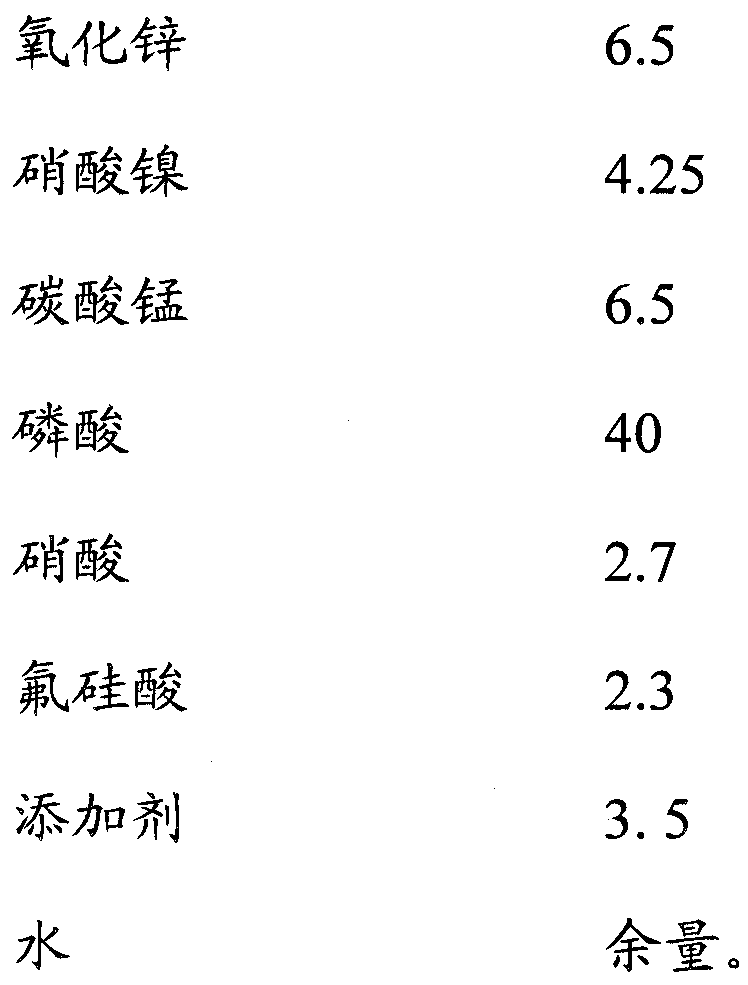

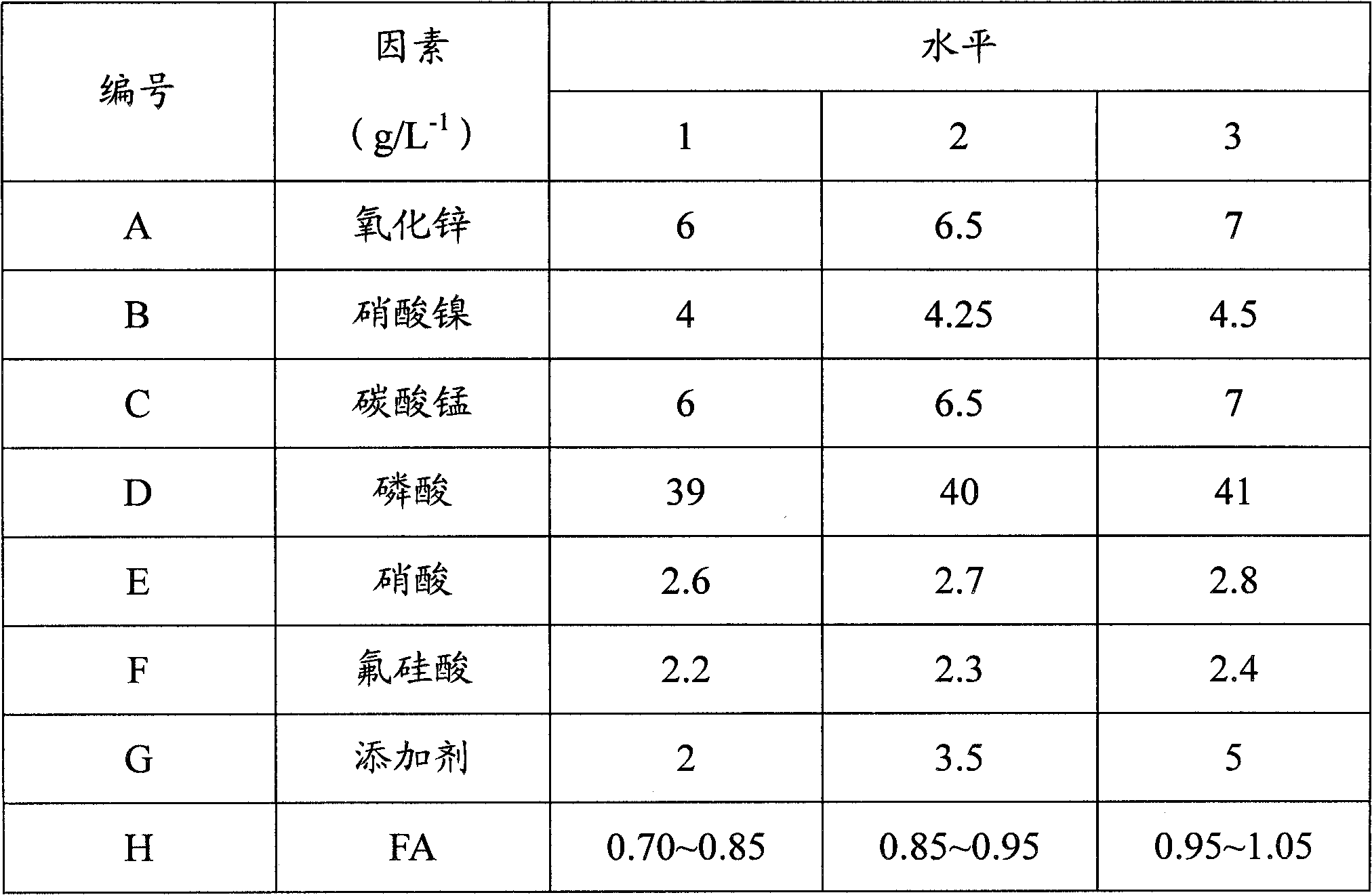

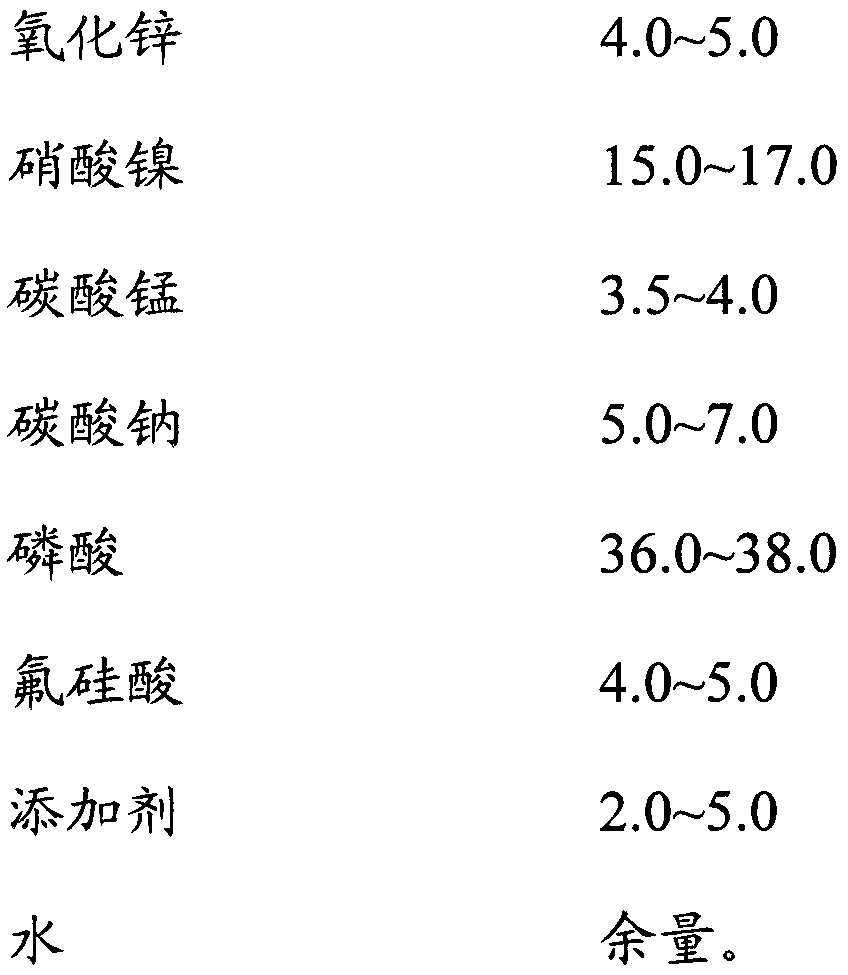

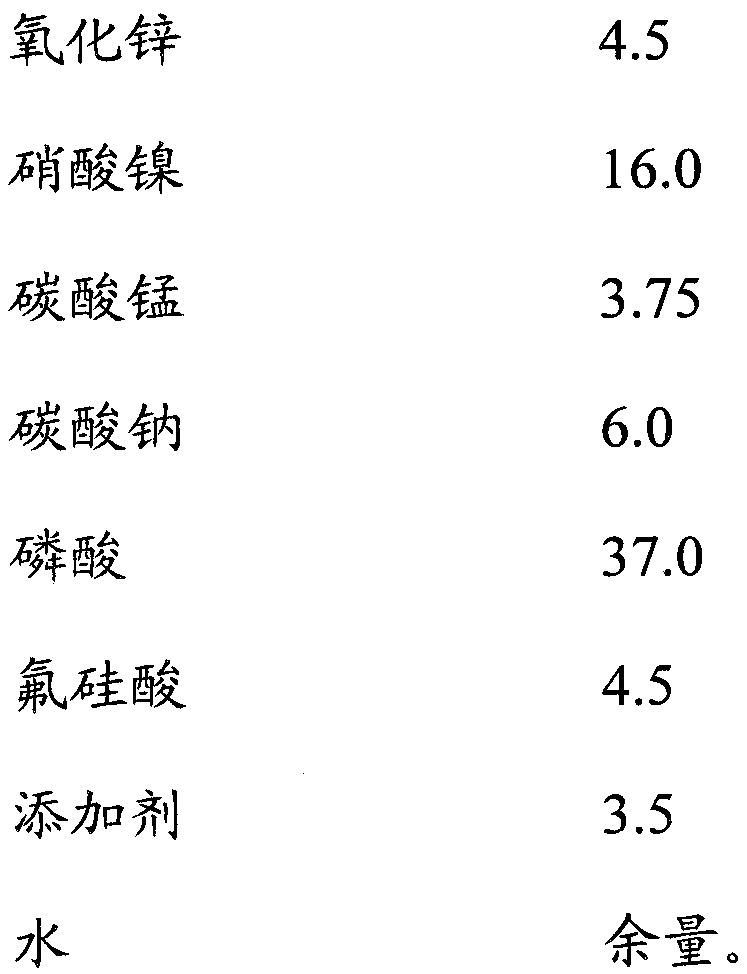

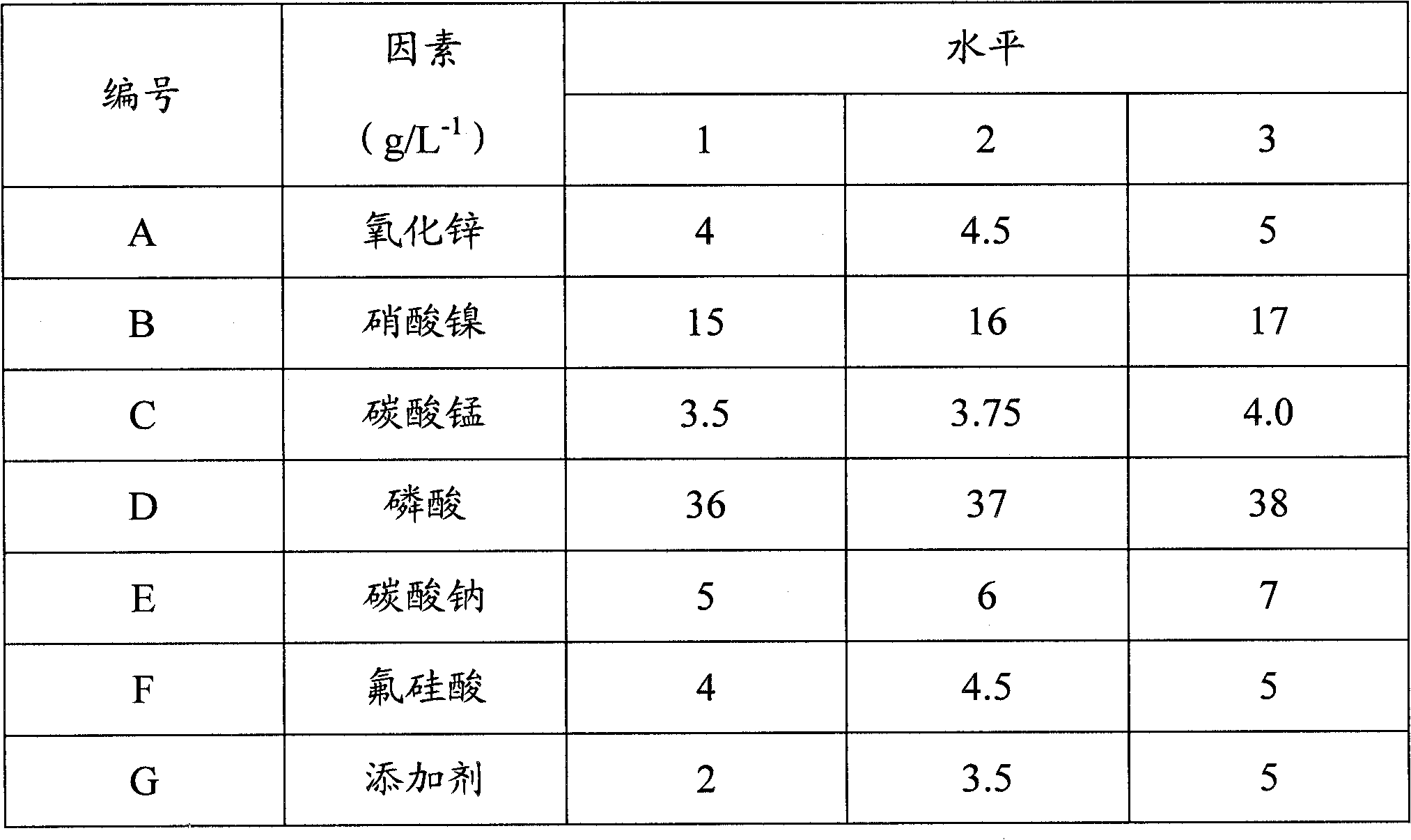

General phosphating agent

InactiveCN102719819AEasy to handlePrevent rustMetallic material coating processesNitratePhosphoric acid

The invention relates to the technical field of surface treatment technologies of metal materials and discloses a general phosphating agent which is suitable for surface treatment of metal materials such as steel, aluminium, zinc and the like. The general phosphating agent contains the following components: zinc oxide, nicdel nitrate, manganese carbonate, phosphoric acid, nitric acid, fluosilicic acid, an additive and water. The invention aims to provide the general phosphating agent with good versatility. The general phosphating agent can be widely used in surface treatment of metal such as steel, aluminium, zinc and the like and can be used to raise anticorrosion performance of metal surface.

Owner:CHONGQING RONGSHI METAL SURFACE TREATMENT AGENT

Polyester/mesoporous molecular sieve composite material and its preparing material

This invention relates to polyester / mesoporous molecular sieve composite material and its preparing method. Using mesoporous molecular sieve fine particles with definite grain size, aperture and acid-base value, after drying, mixing with liquid polyesters, esterifying to obtain esterified mixed product, during reaction combining with ultrasonic dispersion technology to make monomer and molecular sieve fine partticles mix uniformly, by precondensation and endcondensation under constant temperature and pressure esterified product to obtain a product, by granulating and drying to be agglomerates. During prparation, under vacuum and ultrasonic action, monomer can enter to particle aperture, by in-situ polymerization, particles inside and outside is coated with polymer, bonding polyester and molecular sieve interface well to form polyester / mesoporous molecular sieve composite material with inorganic-organic interpenetrating network structure. The material properties, such as melt crystallization temperature, crystallinity, glass-transition temperature and bending strength, storage modulus elasticity modulus are obviously improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Automobile air conditioner compressor planetary plate and production method thereof

ActiveCN104789826AHigh strengthEasy to useMetal-working apparatusAfter treatmentUltimate tensile strength

The invention provides an automobile air conditioner compressor planetary plate. The planetary plate is prepared from an aluminum alloy which comprises the following components in percentage by weight: 8%-9% of Si, 1%-1.5% of Cu, 0.4%-0.7% of Mg, 0.1%-0.3% of C, 0.8%-1.5% of Ni, 0-0.1% of Mn, 0-0.2% of Fe, 0-0.1% of Zn, 0.3%-0.4% of Ti, 0.1%-0.2% of RE and the balance of Al. The invention also provides a production method of the automobile air conditioner compressor planetary plate. The elements in the aluminum alloy for the planetary plate are selected and controlled, a forging technique is further used instead of the casting technique, the pretreatment before forging and after-treatment after forging are optimized, and the technological parameters in each treatment process are optimized, thereby enhancing the strength of the planetary plate and further improving the service performance and service life of the planetary plate.

Owner:SHANDONG HUICHUAN AUTO PARTS

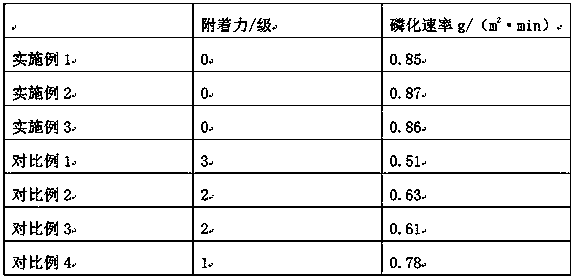

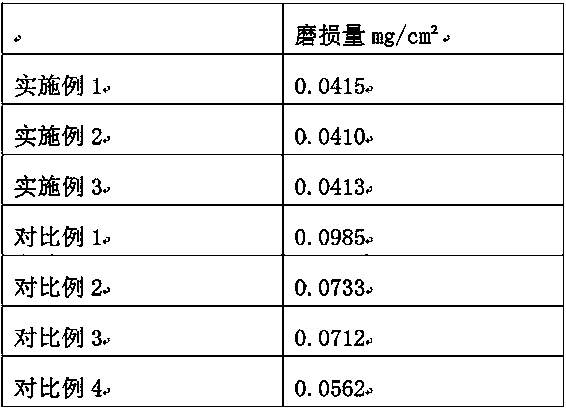

NdFeB zinc series phosphating solution and application method thereof

InactiveCN105695974AImprove corrosion resistancePrevent precipitationMetallic material coating processesSaline waterTime range

The invention discloses an NdFeB zinc series phosphating solution. The NdFeB zinc series phosphating solution is composed of Zn2+, PO43-, NO3-, F-, an accelerant and Ni2+, wherein the amount-of-substance concentration ratio of Zn2+ to PO43- to NO3- to F- to the accelerant is (54-74) :(163-183) :(126-146) :(50-70) :(3-5), the concentration of the accelerant ranges from 0.1 g / L to 1.3 g / L, and the concentration of Ni2+ ranges from 0.01 g / L to 0.2 g / L. The phosphating solution and water are prepared into a work solution according to the ratio of 1:10. According to work parameters, the free acidity ranges from 5% to 8%, the total acidity ranges from 30% to 40%, the phosphating temperature ranges from 50 DEG C to 55 DEG C, the phosphating time ranges from 10 minutes to 15 minutes, NdFeB is treated to generate a light grey or grey phosphating film, the soaking time of 3% neutral saline water is three hours or above, the cross-cut test of a paint film obtained after cathode electrophoresis is the degree 0, and the time of the neutral salt spray test of the paint film obtained after cathode electrophoresis is 550 hours or above. The phosphating solution is high in film-forming thickness and fine in film layer crystallization on treated workpieces, the surface is smooth and dense, the corrosion resistance is excellent, the solution is stable, less sediment is generated, and the time of the salt spray test is longer; and meanwhile no organic complexing agent is included in the formula, the enterprise cost is reduced, and the environment is protected.

Owner:QINGDAO XINPURUI DETECTION TECH CO LTD

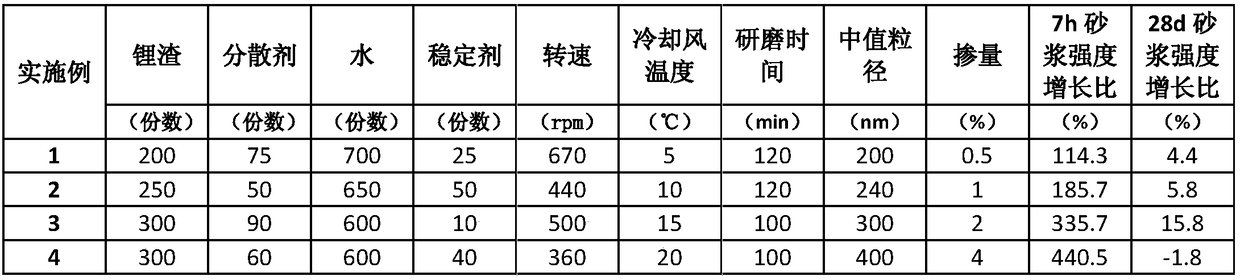

Early strength agent using nanometer lithium slag for sulphoaluminate cement and preparation method thereof

The invention relates to an early strength agent using nanometer lithium slag for sulphoaluminate cement and a preparation method thereof. The early strength agent is prepared from the following raw materials and components in percentage by mass: 20 to 30% of lithium slag, 5 to 9% of dispersant, 1 to 5% of stabilizer, and 60 to 70% of deionized water. The preparation method comprises the followingsteps of adding the lithium slag, the dispersant, the stabilizer and the deionized water into a planetary ball mill according to a ratio, adding zirconium oxide grinding balls, and performing ball grinding, so as to obtain the early strength agent using the nanometer lithium slag for sulphoaluminate cement, wherein the medium particle size is 200 to 400nm. The early strength agent using the nanometer lithium slag is doped into the sulphoaluminate cement according to the doping amount of 0.5 to 4.0%, the 7d strength of the mortar of the sulphoaluminate cement can be increased by 110 to 140%, and the later strength can avoid shrinkage. The preparation method has the advantages that the technology process is simple, and the technology parameters are easy to control; the used lithium slag isindustrial waste, so that the cost is low, and the preparation method is suitable for environment protection.

Owner:WUHAN UNIV OF TECH

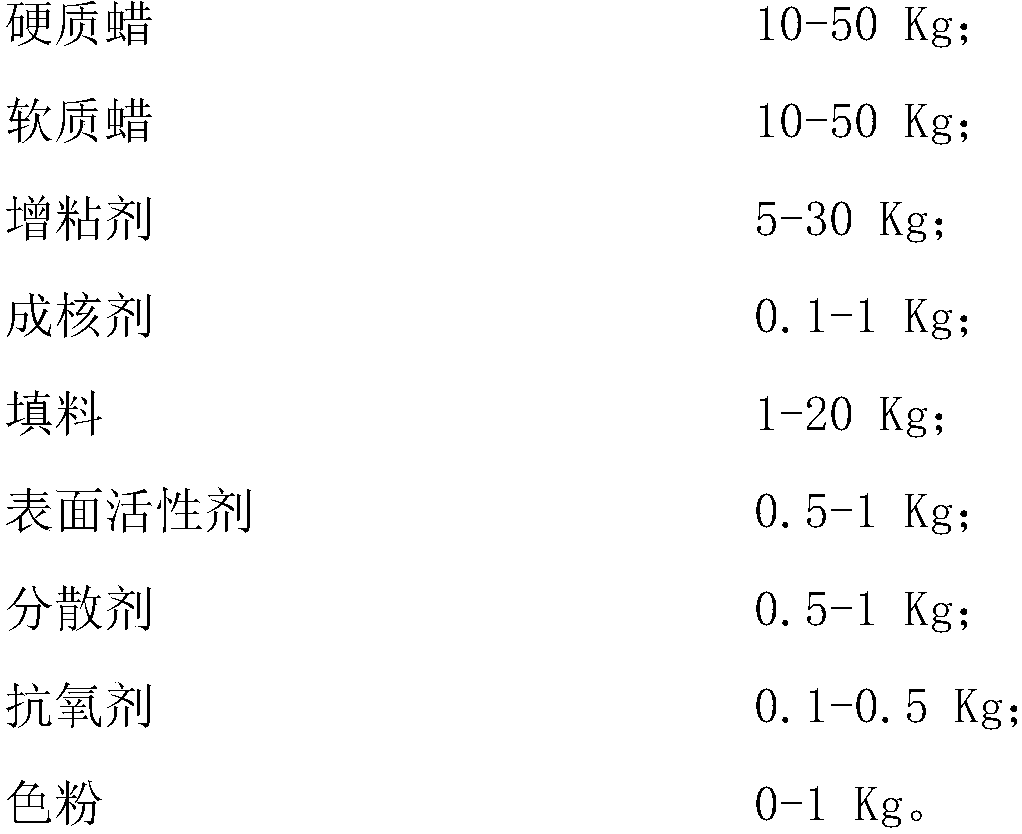

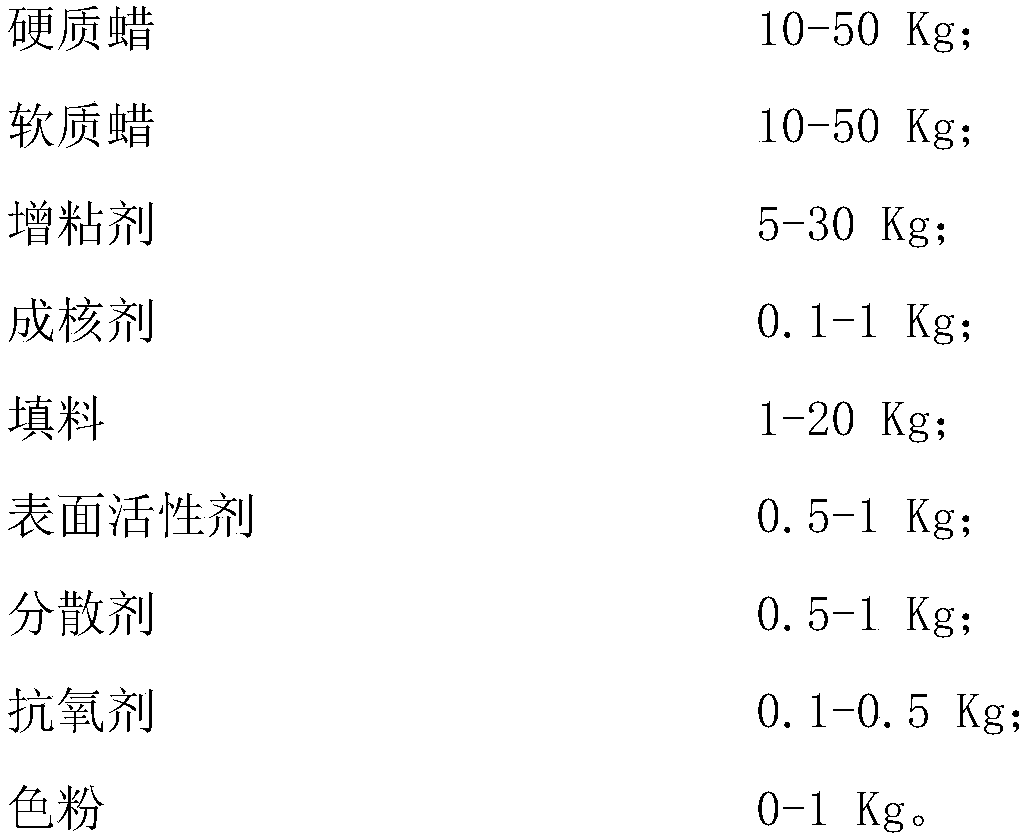

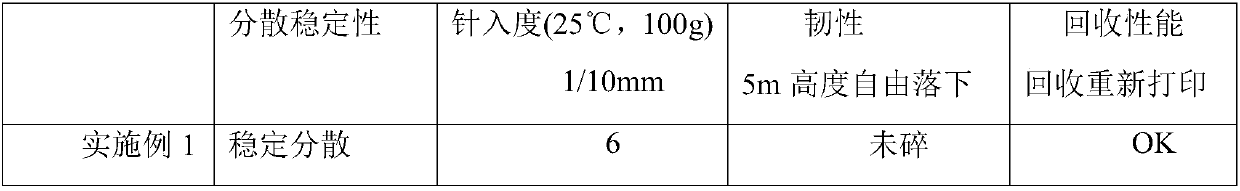

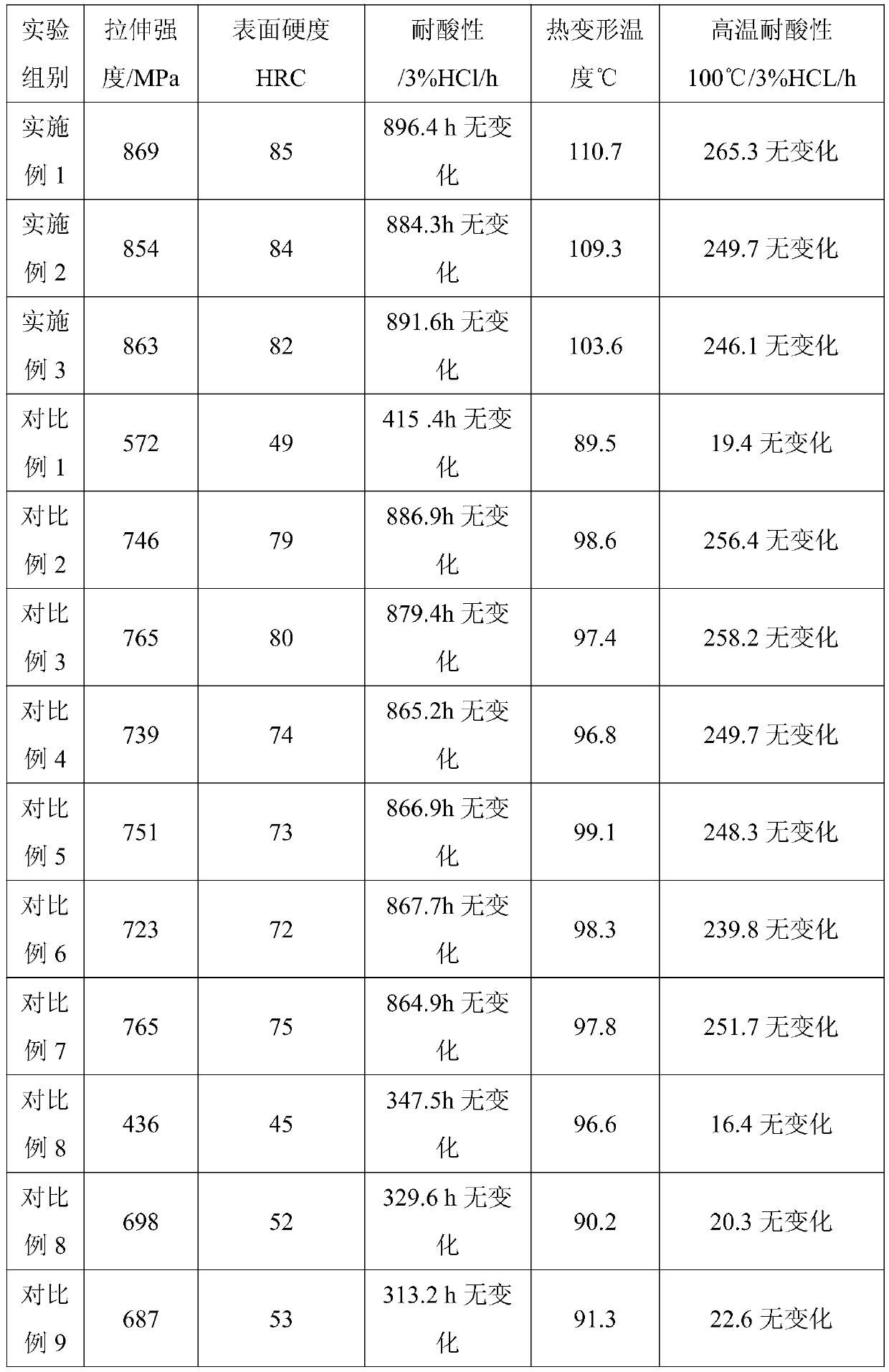

3D printing molding wax with high rigid-tough balance and preparation method thereof

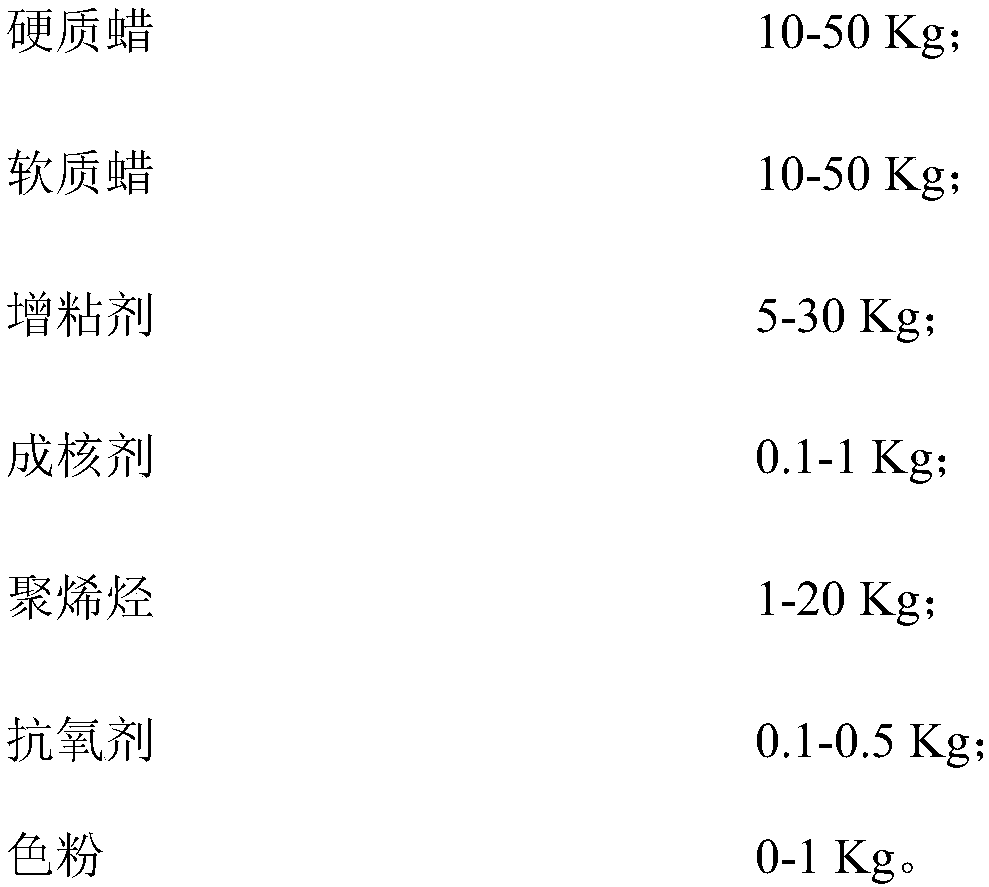

ActiveCN107936582APromote crystallizationCrystallizationAdditive manufacturing apparatusMicrosphereTackifier

The invention discloses a 3D printing molding wax with high rigid-tough balance. The 3D printing molding wax comprises the following components by weight: 10-50Kg of hard wax; 0-50Kg of soft wax, 5-30Kg of a tackifier; 0.1-1Kg of a nucleating agent, 1-20Kg of a filler, 0.5-1Kg of a surfactant, 0.5-1Kg of a dispersant, 0.1-0.5Kg of an antioxidant and 0-1Kg of a toner. The invention also provides apreparation method of the molding wax. According to the invention, the rigidity and toughness of the 3D printing molding wax are regulated through the hard wax and the soft wax; with the addition of the nucleating agent, the crystallization of the wax is promoted and the wax crystallization is refined, so that the cooling speed of the 3D printing molding wax is fast, the surface finish of the 3D printing molding wax is high, and the rigid-tough balance of the material is improved; the monodisperse polystyrene microspheres can stably disperse and exist in the wax through the surfactant and thedispersing agent, and sedimentation is prevented, so that a spraying head is prevented from being blocked. The components in the 3D printing molding wax provided by the invention volatilize easily ata casting temperature, and the MJP 3D printing fineness is high, so that the fineness of cast metal products is high.

Owner:HUIZHOU YOUHENGKE 3D MATERIAL TECH CO LTD

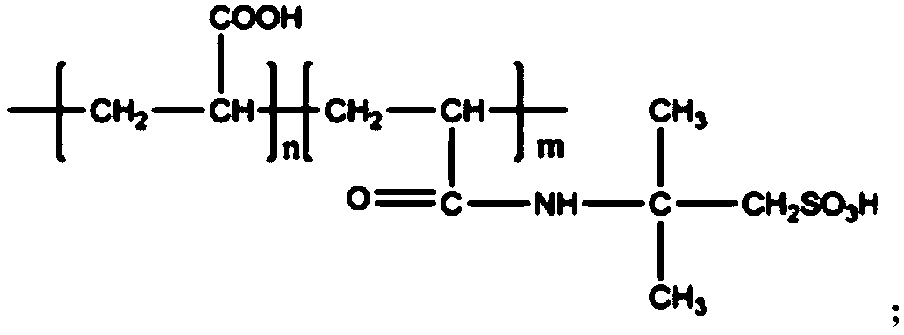

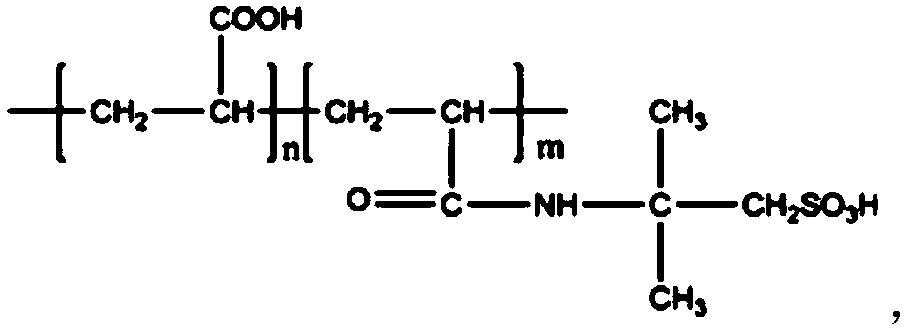

Cathode electrophoretic phosphatizing agent

InactiveCN102719874AImprove corrosion resistancePromote formationElectrophoretic coatingsMetallic material coating processesPhosphateManganese

The present invention relates to a cathode electrophoretic coating technology field and discloses a cathode electrophoretic phosphatizing agent for pretreatment of cathode electrophoretic coating. The cathode electrophoretic phosphatizing agent comprises the following components: zinc oxide, nickel nitrate, manganese carbonate, sodium carbonate, phosphoric acid, fluosilicic acid, an additive and water. The invention aims to provide a cathode electrophoretic phosphatizing agent with high phosphorus ratio but simple components. When the Cathode electrophoretic phosphatizing agent is used in the pretreatment of cathode electrophoretic coating, a phosphate coating obtained has excellent adhesion and corrosion resistance.

Owner:CHONGQING RONGSHI METAL SURFACE TREATMENT AGENT

Cyanide-free alkaline cuprous plating additive

The invention relates to the technical field of metal corrosion protection and surface treatment, in particular to a cyanide-free alkaline cuprous plating additive. The additive comprises 50-200 partsof complexing agent, 0.1-20 parts of stabilizer, 0.01-0.5 part of brightener, 0.1-5 parts of leveling agent, 10-20 parts of NaOH, 5-20 parts of Na2CO3 and 15-50 parts of cuprous compound. The additive does not contain cyanide and organic phosphonate, is suitable for cyanide-free alkaline copper plating electroplating solution taking cuprous salt as main salt, and effectively solves the problem that traditional cyanide-free alkaline copper plating generates a loose plating layer with poor binding force due to displacement reaction; meanwhile, a certain activation effect can be generated on a steel substrate, a copper coating with good binding force can be obtained on the steel substrate, and the additive is safe, efficient and environmentally friendly.

Owner:武汉奥邦表面技术有限公司

Abrasion-resisting and high-temperature-resisting power box housing and preparation method thereof

InactiveCN107686939AHigh hardnessChange the shape of the organizationSubstation/switching arrangement detailsMetallic material coating processesCeramic coatingImpurity

The invention discloses an abrasion-resisting and high-temperature-resisting power box housing and a preparation method thereof. The housing comprises a power box housing metal substrate and a ceramiccoating. Raw materials of the power box housing metal substrate comprise the following components of C, Al, B, Si, Mn, Cr, Ni, Cu, Ti, Zr, Nb, Mo, Sc, Nd, Y, La and the balance Fe and inevitable impurities. Raw materials of the ceramic coating comprise BC, SiC, Cr3C2, B2O3, ZrO2 and BN. The abrasion-resisting and high-temperature-resisting power box housing and the preparation method thereof havethe advantages of being resistant to a high temperature and creep deformation, good in tenacity, good in corrosion resistance, long in service life and the like.

Owner:芜湖锐华暖通科技股份有限公司

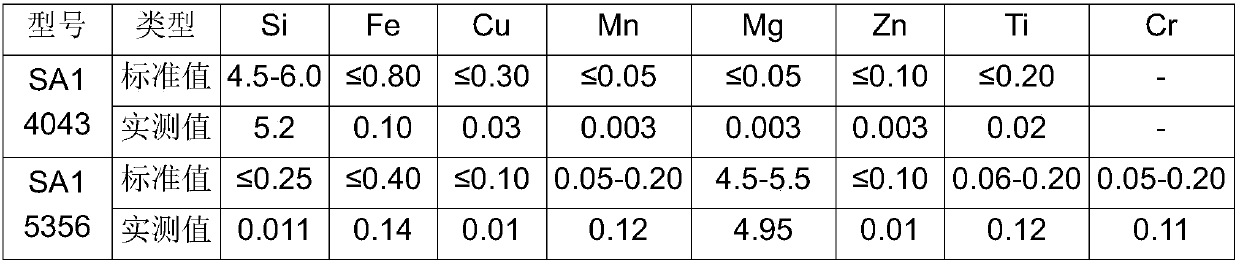

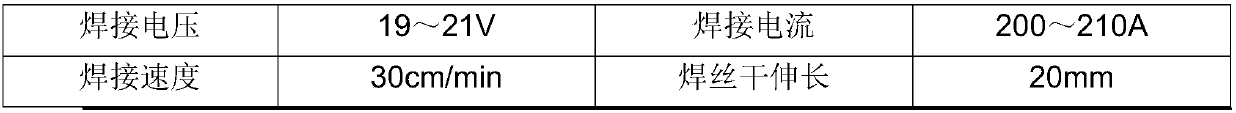

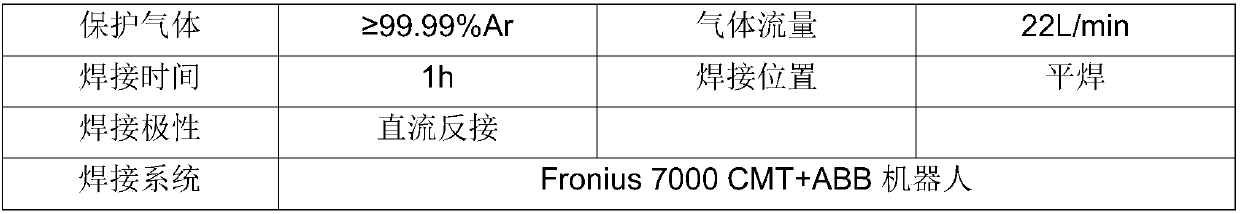

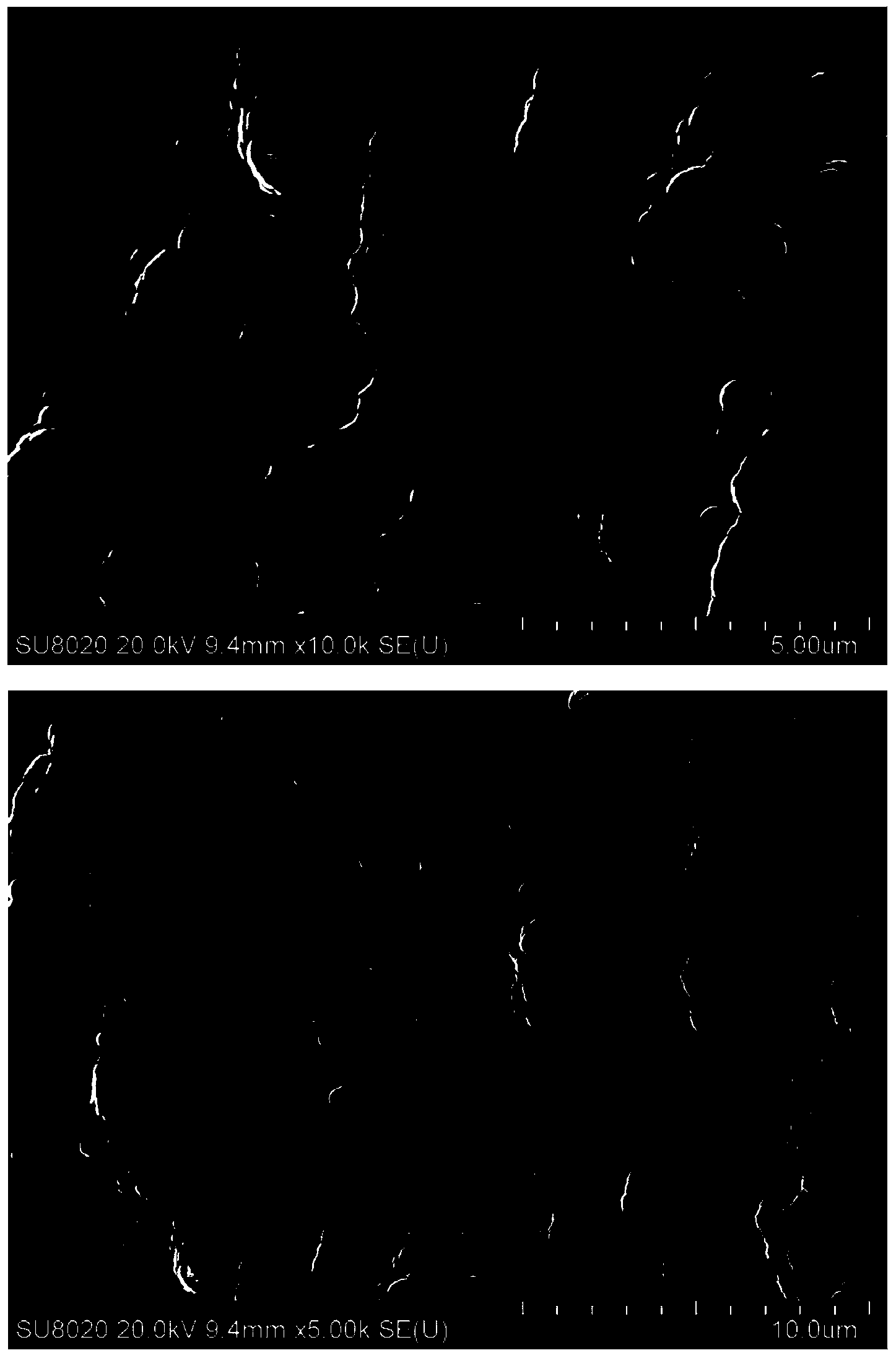

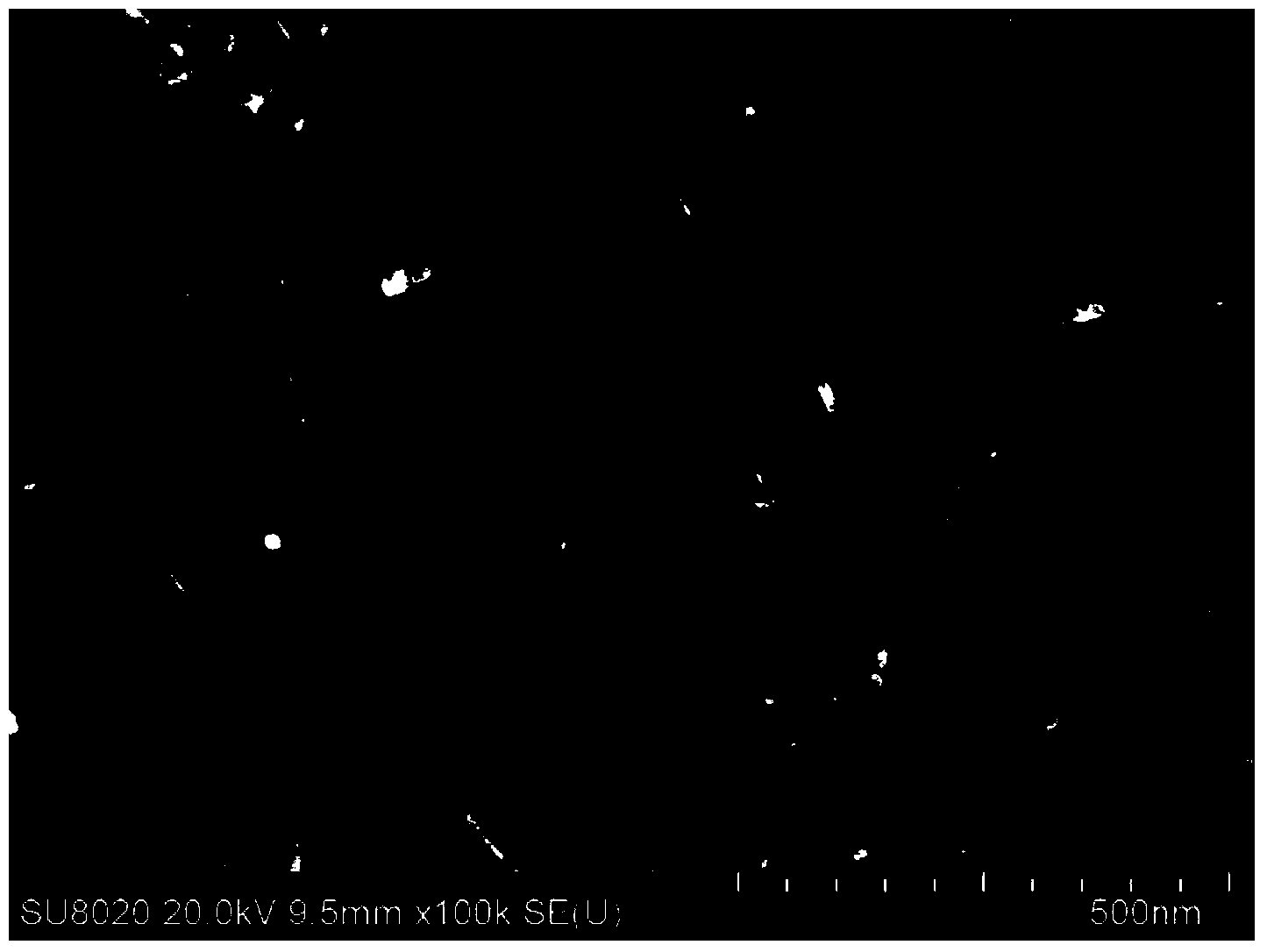

Preparation method of aluminum and aluminum alloy welding wire electrochemically plated with Zn+Cu/Re composite coating and applied to robot welding

ActiveCN107904576AImprove the lubrication effectCrystallizationLiquid/solution decomposition chemical coatingPorosityMolten bath

The invention relates to the field of welding wire manufacturing, in particular to a preparation method of an aluminum and aluminum alloy welding wire electrochemically plated with a Zn+Cu / Re composite coating and applied to robot welding. A pure aluminum or aluminum alloy wire rod is used as the matrix. Pretreatment, electrochemical plating of the Zn+Cu / Re composite coating and post-treatment areconducted on the surface. The electrochemically plated Zn+Cu / Re composite coating has the functions of reducing welding smoke, improving the porosity resistance of the welding wire and improving solid lubrication and meanwhile fills up pits in the surface of the welding wire matrix, and the electric conductivity and surface quality of the welding wire are improved; the bonding force and strengthof the Zn+Cu / Re composite coating are high, the aluminum or copper peeling phenomenon is avoided, the Zn+Cu / Re composite coating is high in compactness, good in rust resistance and resistant to wear,Zn can reduce welding smoke and splashes, and Re can refine plating layer crystals and reduce the void ratio; and meanwhile, molten bath stirring is enhanced, a molten bath is purified, crystals are refined, pores on the surface and on the inner portion of a welding joint are thoroughly eradicated, and the porosity resistance of the welding wire is improved.

Owner:江苏恒熠金属制品有限公司

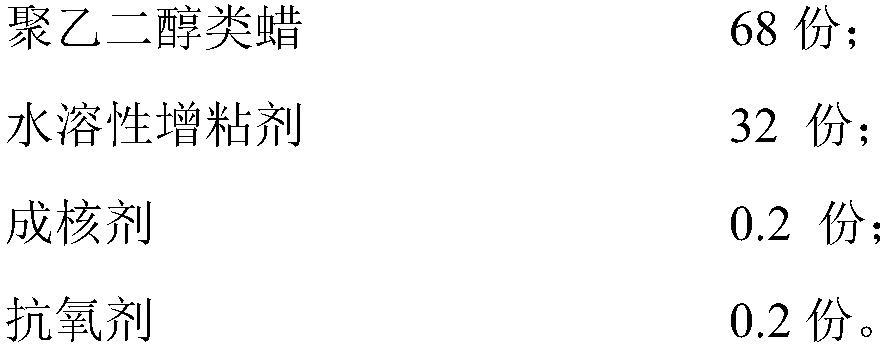

Water-soluble 3D-printing supporting wax and preparation method thereof

The invention discloses a water-soluble 3D-printing supporting wax. The water-soluble 3D-printing supporting wax comprises the following components in parts by weight: 20-90 parts of polyethylene glycol wax, 5-50 parts of a water-soluble tackifier, 0.1-1 part of a nucleating agent, and 0.1-0.5 part of an antioxidant. The invention further provides a preparation method of the supporting wax. The supporting wax has the characteristics of being fast in dissolving speed in water, high in printing accuracy, simple in removing processes, safe, environmentally friendly, and suitable for massive application; meanwhile, a printing wax die cannot be damaged, so that the wax die printing accuracy and the casting accuracy are improved.

Owner:HUIZHOU YOUHENGKE 3D MATERIAL TECH CO LTD

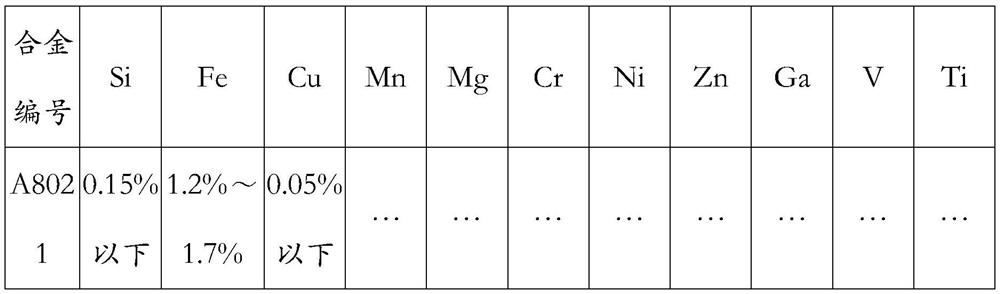

High-conductivity rare earth aluminum alloy wire and manufacturing method thereof

ActiveCN106710663AGrain refinement and crystallizationImprove heat resistanceConductive materialMetal/alloy conductorsRare-earth elementAlloy element

The invention provides a rare earth aluminum alloy wire high in electrical conductivity, corrosion resistance, wear resistance and toughness, and a manufacturing method of manufacturing the rare earth aluminum alloy wire. The rare earth aluminum alloy material comprises silver, silicon, iron, zinc, gallium, a rare earth element, aluminum and inevitable elements. The contents of all the above elements are as follows: 0.05-0.5 wt% of Ag, 0.01-0.1 wt% of Si, 0.01-0.2 wt% of Fe, 0.01-0.1 wt% of Zn, 0.01-0.03 wt% of Ga, 0.05-0.25 wt% of rare earth element, and the balance of aluminum and inevitable impurities. According to the technical scheme of the method for manufacturing the rare earth aluminum alloy wire, firstly, an aluminum ingot is melted. Secondly, corresponding alloying elements are added into the molten aluminum liquid. Thirdly, through the continuous-casting, continuous-rolling and drawing process, an aluminum alloy wire is finally manufactured. The manufactured aluminum alloy wire is excellent in electrical conductivity, and the conductivity of the aluminum alloy wire can reach or exceed 101. 2% IACS. Meanwhile, the manufactured aluminum alloy wire is excellent in flexibility, corrosion resistance and wear resistance.

Owner:靖江市新万国标准件制造有限公司

Method for preparing carbon nano-tube modified palladium-loaded electrode through electrophoresis-pulse deposition

ActiveCN104005046AAcid-resistant and corrosion-resistantImprove stabilityElectrolytic organic productionElectrophoretic coatingsPolypyrrolePalladium catalyst

The invention discloses a method for preparing a carbon nano-tube modified palladium-loaded electrode through electrophoresis-pulse deposition, belonging to the technical field of electrochemical water treatment. Polypyrrole is used as a cocatalyst, and a carbon nano tube is used as a catalyst carrier, so that the dispersibility of a catalyst is improved, and utilization ratio of the catalyst is increased; a pulse plating process is used as a catalyst deposition technology, and crystals on a plating layer are refined, so that the catalytic performance of the electrode is enhanced. According to the invention, a titanium mesh is used as the substrate, the oxidized carbon nano tube is modified on the surface of the substrate by using an electrophoresis method after a layer of polypyrrole film is polymerized on the surface of the substrate, and then, a layer of uniform carbon nano-tube carrier film is formed. Compared with a Pdped / Ti electrode prepared under the same condition and a Pdded / Ti electrode prepared through direct-current electroplating, a Pd / CNTs / PPy / Ti electrode prepared by depositing a palladium catalyst by using the pulse plating process is higher in catalytic performance.

Owner:BEIJING UNIV OF TECH

Machining method for improving abrasion and corrosion resistance of valve

InactiveCN107385433AImprove mechanical propertiesImprove fatigue resistanceMetallic material coating processesProcess optimizationSand blasting

The invention discloses a machining method for improving abrasion and corrosion resistance of a valve. The machining method comprises the following steps that firstly, the valve is arranged in activation liquid to be immersed, then the valve is washed to be neutral, grinding is conducted, then washing is conducted, drying is conducted, and a material A is obtained; secondly, the material A is subjected to sand blasting treatment, and a material B is obtained; thirdly, the material B is subjected to plasma cladding treatment, and a material C is obtained; and fourthly, the material C is subjected to heat treatment. According to the provided machining method for improving abrasion and corrosion resistance of the valve, through process optimization, a plating material and a base body are tightly combined, distribution is uniform, the high temperature resistance, corrosion resistance and creeping resistance of the valve are effectively improved, and the service life of the valve is effectively prolonged.

Owner:ANHUI WODE VALVE MFG

Aluminum alloy profile for firefighting truck and preparation method thereof

The invention discloses aluminum alloy profile for a firefighting truck and a preparation method thereof, and relates to the technical field of aluminum alloy. The aluminum alloy profile comprises thefollowing components of, by mass, 0.1-0.3% of Cu, 0.3-0.5% of Si, 0.25-0.4% of Fe, 0.1-0.2% of Cr, 0.55-0.85% of Mg, 0.3-0.5% of Mn, 0.1-0.3% of Zn, 0.2-0.4% of Ti, 0.04-0.08% of Li, 0.12-0.18% of Ni, 0.06-0.12% of Y, 0.04-0.08% of Ca and the balance Al. According to the aluminum alloy profile for the firefighting truck and the preparation method thereof, all the elements of the aluminum alloy profile and the content of the elements are reasonably optimized, the preparation technology is optimized, the prepared aluminum alloy profile has excellent mechanical properties and is high in strengthand hardness, good in ductility and excellent in impact resistance and fatigue resistance, and cracking and other phenomena are not prone to occurring when firefighting truck body parts are subjectedto punch forming.

Owner:安徽鑫铂铝业股份有限公司

Repairing wax for investment casting and preparation method of repairing wax

ActiveCN110205092AModerate surface hardnessGood flexibilityFoundry moulding apparatusOil/fat/wax adhesivesWaxSurface finish

The invention provides a repairing wax for investment casting. The repairing wax for investment casting is prepared from, by weight, 65%-87% of cerate, 5%-28% of resin and 3%-10% of a high molecular material. According to the repairing wax, the cerate is used as a main material, the resin and the high molecular material are added for improving initial adhesion and persistent adhesion, and the prepared repairing wax is proper in surface hardness and good in flexibility, adhesion performance and workability; heating for melting is not needed, surface defects such as air holes, sunken parts or cracks of the surface of a wax pattern for investment casting are directly smeared with the repairing wax, and the repairing wax can adhere to the surfaces of various wax patterns for investment castingof different manufacturers and brands,; the surfaces of the repaired parts are high in smooth degree and have resistance to scratching, and the repairing wax has high applicability.

Owner:苏州泰尔航空材料有限公司

Rust-removing phosphating solution for wire rod drawing, and preparation method thereof

ActiveCN108048826AHigh hardnessImprove adhesionMetallic material coating processesPhosphatePhosphoric acid

The invention aims to solve the problems that wire rod pickling and phosphating procedures are implemented separately, resulting high treatment cost of waste water generated by washing, phosphating films are not secure enough, the fracture phenomenon occurs during drawing, and the content of corrosive components in phosphating agents is high. The invention provides a rust-removing phosphating solution for wire rod drawing, and a preparation method thereof, and belongs to the technical field of rust removal and phosphating treatment of metal surfaces. The rust-removing phosphating solution forthe wire rod drawing comprises, by mass, 20%-50% of concentrated phosphoric acid, 1%-10% of concentrated nitric acid, 1%-10% of zinc oxide, 2%-10% of dihydric phosphate, 1%-10% of nitrate, 0.5%-5% ofmanganese carbonate, 0.2%-5% of complexing agents, 0.05%-1% of fluorine-containing surfactants and the balance water. After treatment by the rust-removing phosphating solution provided by the invention, a gray-black uniform and dense phosphating film is formed on the surfaces of steel wires and welded steel tubes, and has better lubrication effects in the drawing and cold working process.

Owner:鞍山晨雷科技有限公司

3D printing wax wire applied to lost foam casting and preparation method thereof

InactiveCN108102392AAdjust rigidityRegulatory toughnessAdditive manufacturing apparatusWaxPolyolefin

The invention relates to a 3D printing wax wire applied to lost foam casting and a preparation method thereof. The material is prepared from 10 to 50Kg of hard wax, 10 to 50Kg of soft wax, 5 to 30Kg of tackifier, 0.1 to 1Kg of nucleating agent, 1 to 20Kg of polyolefin, 0.1 to 0.5Kg of antioxidant and 0 to 1Kg of toner. The preparation method comprises the following specific steps: weighing all ingredient raw materials according to ingredient proportions; mechanically and evenly mixing all the ingredients; then adding all the evenly-mixed ingredient raw materials into an extruding machine; drawing under 50 DEG C to 120 DEG C, cooling, air drying, diameter measuring, pulling, storing wires and winding to obtain the 3D printing wax wire with the uniform wire diameter. The material has the advantages of good strength, no easiness in being broken, good wax lost performance, small shrinkage, large-size printing, good antioxidant performance, recyclable and the like, and the material can replace traditional wax molds to be widely applied to the industrial field of lost foam casting.

Owner:吴丹

Lead-free tin-soldering wire applied to automatic soldering robot and preparation method thereof

InactiveCN105252163AReduce and resolve defectsImprove high temperature resistanceWelding/cutting media/materialsSoldering mediaFurnace temperatureAlloy

The invention relates to a lead-free tin-soldering wire applied to an automatic soldering robot and a preparation method thereof. The lead-free tin-soldering wire is characterized by comprising Cu, Se, Ni, P, Nd and Sn. The preparation method of the lead-free tin-soldering wire applied to the automatic soldering robot comprises the following steps: respectively preparing a Sn-Cu alloy, a Sn-Ge alloy, a Sn-Ni alloy, a Sn-P alloy and a Sn-Nd alloy through Cu, Ge, Ni, P, Nd and Sn according to a ratio; then heating the prepared Sn-Cu alloy in a smelting furnace, adding the Sn-Ni alloy, stirring, preserving heat, then adding the Sn-Ge alloy and the Sn-Nd alloy, then cooling, adding the Sn-P alloy, finally reducing the temperature of the furnace to 300-340 DEG C, preserving heat, discharging the alloys out of the furnace to prepare a soldering flux column; extruding and drawing to obtain the lead-free tin-soldering wire. The lead-free tin-soldering wire can be suitable for the soldering flux of various automatic soldering robots in a large range; the defects of continuous tin, lcicles and tin balls can be reduced and solved to a maximum extent; the lead-free tin-soldering wire is high in corrosion resistance; crystals are thinned; the resistance to high temperature of the welding flux is improved; the advantage and the effect of oxidation resistance of soldering points are improved.

Owner:广东中实金属有限公司

Stamping die surface phosphating processing method

InactiveCN110042376AExcellent high temperature corrosion resistanceGood adhesionMetallic material coating processesHigh-temperature corrosionHot Temperature

The invention discloses a stamping die surface phosphating processing method, and relates to the technical field of mold processing. The stamping die surface phosphating processing method includes thefollowing steps of polishing, heating, phosphating, twice soaking and twice drying processing and pressurizing processing. By means of the stamping die surface phosphating processing method, a uniform and compact phosphating film can be formed on the surface of a stamping die, the surface of the stamping die can be better protected, and the processed stamping die has excellent high-temperature corrosion-resistant performance.

Owner:长沙而道新能源科技有限公司

Method for performing pulse chromium plating based on trivalent chromium in sulfate system

The invention discloses a high-efficiency environment-friendly pulse plating metallurgy method for performing thick chromium plating based on trivalent chromium in a sulfate system. The method is characterized by comprising the following steps: dissolving rare earth oxides in an acid, so as to obtain a rare-earth salt solution; dissolving chromium sulfate salt, aluminum sulfate, boric acid, a complexing agent and methanol with water, and adding the rare-earth salt solution, so as to obtain a chromium sulfate salt-aluminum sulfate-boric acid-complexing agent-methanol-rare-earth salt plating solution; electroplating a to-be-plated plating piece into the electroplating solution; controlling the electroplating process conditions as follows: the distance between a pulse electroplating power supply and a plating tank is 2-3m, a wire refers to a multi-stranded core wire, and an anode refers to a Cu-matrix coating electrode plate; the current density of a connecting wire is 28-90A / dm<2> and needs to be far higher than the average current, the pH value of the electroplating solution is 2-4, the temperature refers to 25-60 DEG C, the stirring speed is 100-600rpm, the plating time refers to 30-90 minutes, the pulse frequency refers to 100-500Hz, and the duty ratio is 5-100 percent; and washing the plating piece subjected to complete electroplating, and airing. The method disclosed by the invention has the advantages of coating flatness and compactness, good adhesiveness, high current efficiency, high environmental friendliness and the like.

Owner:TIANJIN BINYONGSHENG ELECTRICAL LEAD TECH

Corrosion-resistant and wear-resistant high strength electrophoretic aluminum profile and preparation process thereof

InactiveCN110453119AImprove wear resistanceImprove corrosion resistanceAnodisationElectrophoretic coatingsWear resistantThermal stability

The invention discloses a corrosion-resistant and wear-resistant high strength electrophoretic aluminum profile and a preparation process thereof and belongs to the field of aluminum profile preparation. The corrosion-resistant and wear-resistant high strength electrophoretic aluminum profile is prepared from the following raw materials in percent by weight: 0.8-1.2% of Mg, 0.4-0.6% of Si, 0.2-0.4% of Ti, 0.22-0.3% of Fe, 0.06-0.1% of Cu, 0.08-0.12% of Zn, 0.06-0.08% of Cr, 0.12-0.18% of Mo and the balance of Al and inevitable impurities. The preparation process is simple and effective and convenient and rapid in process operation. By controlling the contents of Mg, Si, Fe, Cu and Zn reasonably, strengthening phases such as Al2Cu, Al2CuMg, Mg2Si, MgZn2 and the like are formed in the electrophoretic aluminum profile to strengthen the synergistic effect, refine crystals and improve grain distribution, so that performance, such as wear resistance and corrosion resistance, of the electrophoretic aluminum profile is improved. By matching Si, Ti, Fe, Cr and Mo, the grains are refined, the cast structure and the weld joint structure are refined, the recrystallization temperature is increased, the thermal stability of a material is improved, the intergranular corrosion is avoided, and the corrosion performance of the electrophoretic aluminum profile is improved.

Owner:ANHUI XIN FA ALUMINUM PROD

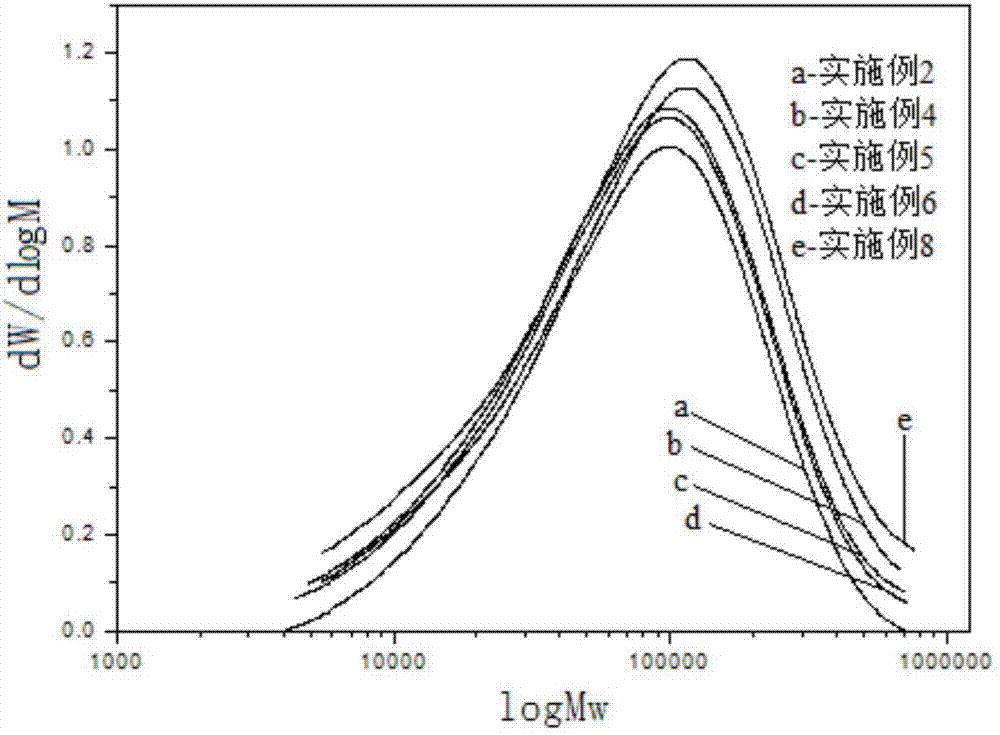

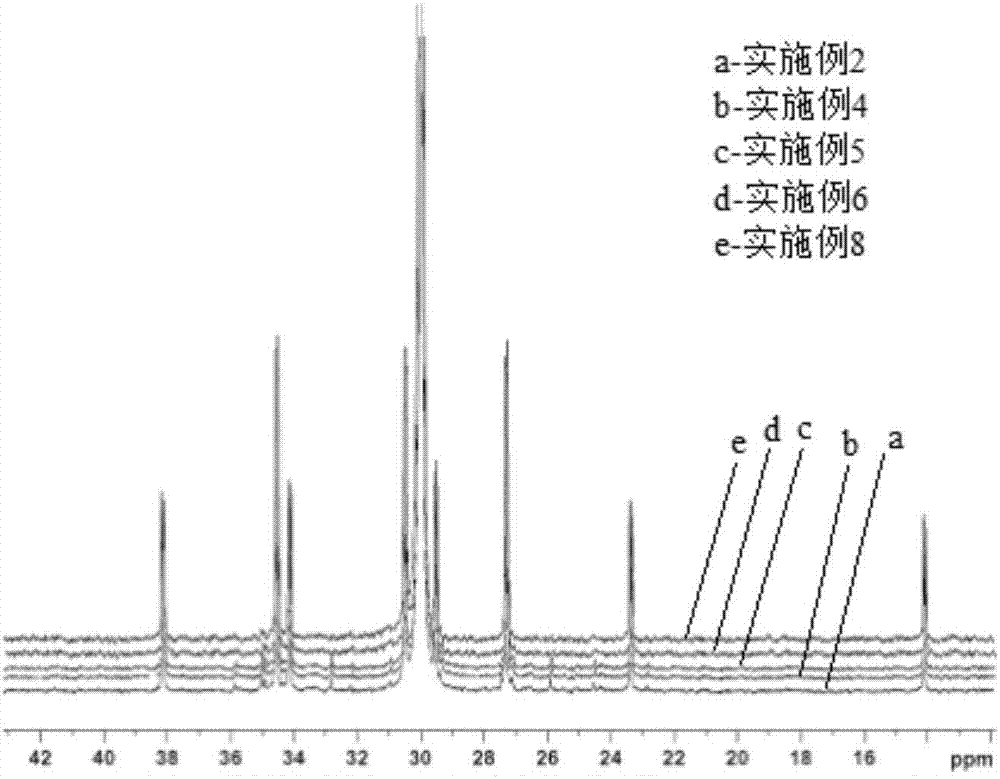

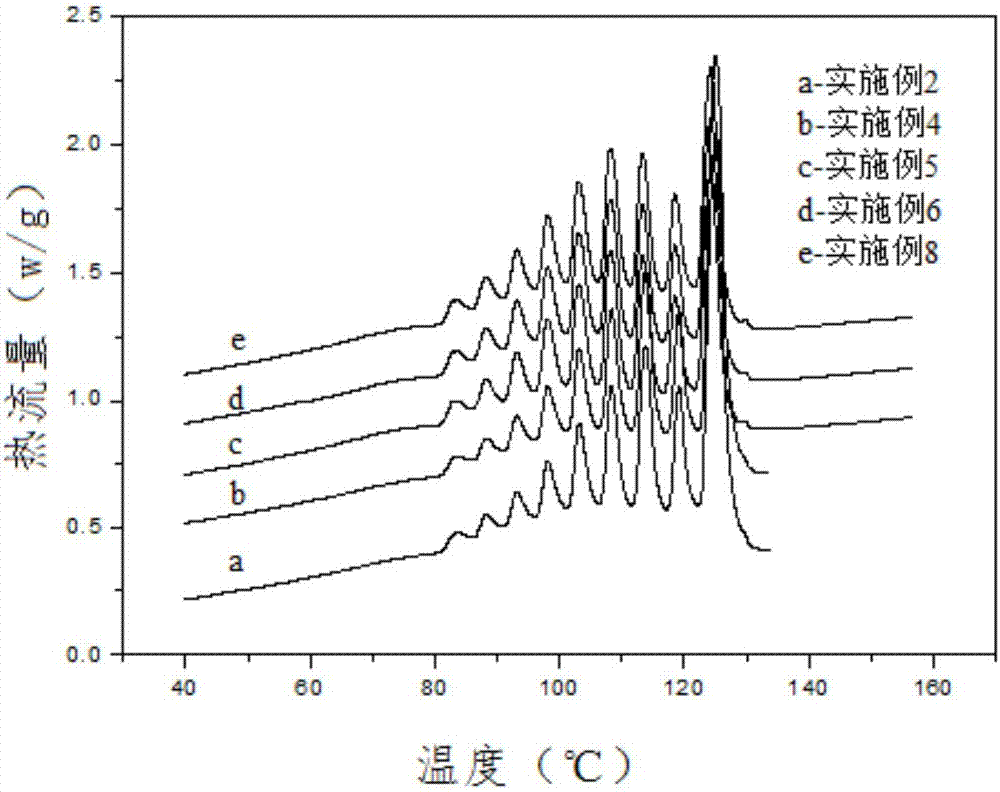

Transparent LLDPE (linear low density polyethylene) thin-film resin and thin film prepared from same

InactiveCN107987201AHigh activityIncrease contentLow-density polyethyleneLinear low-density polyethylene

The invention discloses transparent LLDPE (linear low density polyethylene) thin-film resin and a thin film prepared from the same. The resin is prepared from ethylene and 1-butene through copolymerization, the structure of a resin compound is shown in the description, wherein n1 is larger than or equal to 20 and smaller than or equal to 25, n2 is larger than or equal to 25 and smaller than or equal to 250, n3 is larger than or equal to 1 and smaller than or equal to 20, R1 is -CH2CH3, R2 is -(CH2)mCH3, and m is larger than or equal to 100. The thin-film resin has a structure with broad molecular weight distribution, unique short branched chains and a few long branched chains, and by means of the structure, shear sensitivity of a product and crystallization morphology can be improved, so that the resin shows better transparency and machinability, has good overall performance, can be used in the thin-film fields of packaging films, wrapping films and the like with special requirements and is practical and functional thin-film resin.

Owner:PETROCHINA CO LTD

Steel rim vehicle wheel surface phosphating treatment method

InactiveCN108914110AImprove compactnessImprove uniformityAnti-corrosive paintsMetallic material coating processesHigh phosphateWear resistance

The invention discloses a steel rim vehicle wheel surface phosphating treatment method and relates to the technical field of steel treatment. The method comprises: (1) grinding, (2) cleaning, (3) plasma treatment and (4) phosphating treatment. The method can well protect the steel rim vehicle wheel surface, improve the film forming stability, greatly improve the compactness and uniformity of the phosphated film, realize high phosphated film adhesion, improve the corrosion resistance and wear resistance of the surface of the steel rim vehicle wheel surface, realize high phosphated film purity,facilitate precipitate removal, shorten the conventional high-temperature surface phosphating treatment time, realize fast phosphating treatment at the normal temperature, prevent heating, solve the problem that the conventional high-temperature phosphating treatment method easily causes phosphated film impurities and precipitates difficult to remove, and improve the phosphating efficiency.

Owner:ANHUI JIANGHUAI WHEEL CO LTD

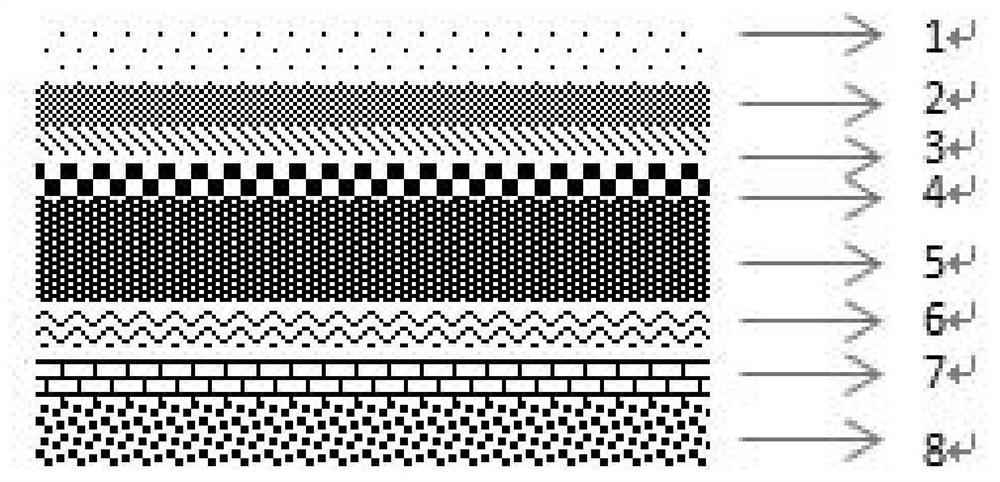

Outer packaging material for high-punching-depth battery device and battery

PendingCN112848577AReduce Si contentCrystallizationSynthetic resin layered productsElectrical equipmentCrystal size distributionAluminum foil

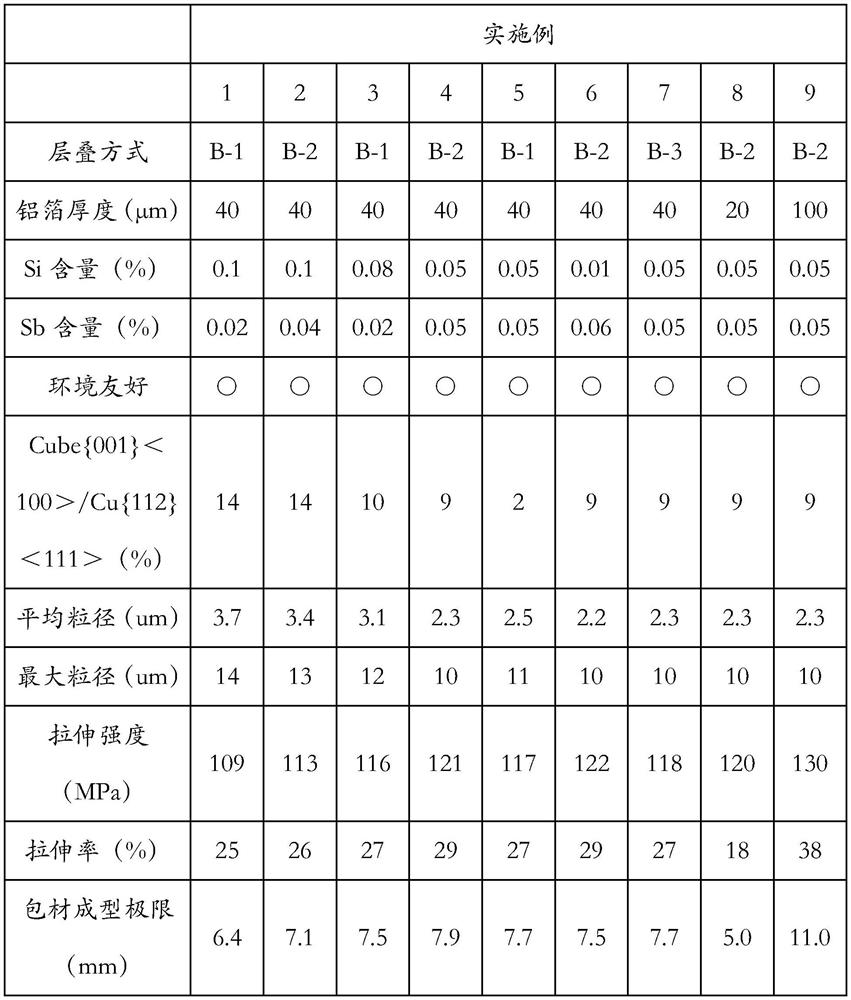

The invention relates to an outer packaging material for a high-punching-depth battery device and a battery. The outer packaging material comprises a base material layer, a barrier layer and a hot melting layer; the outer packaging material is characterized in that the barrier layer is an aluminum alloy foil; the distribution of the optimal plane orientation of the aluminum alloy foil is the ratio of Cube {001} < 100 > orientation to Cu {112} < 111 >, i.e., Cube {001} < 100 > / Cu {112} < 111 > = 1.6-20%, and the proportion of S {123} < 643 > orientation in the entire aluminum alloy foil is 15% or more. The material has the positive effects that the proportion of Cube {001} < 100 > / Cu {112} < 111 > is reduced within a certain range, so that the crystal size distribution in the aluminum foil can be reduced, the crystal uniformity is improved, and the forming limit depth is deepened.

Owner:WUXI ENERGY NEW MATERIALS TECH CO LTD

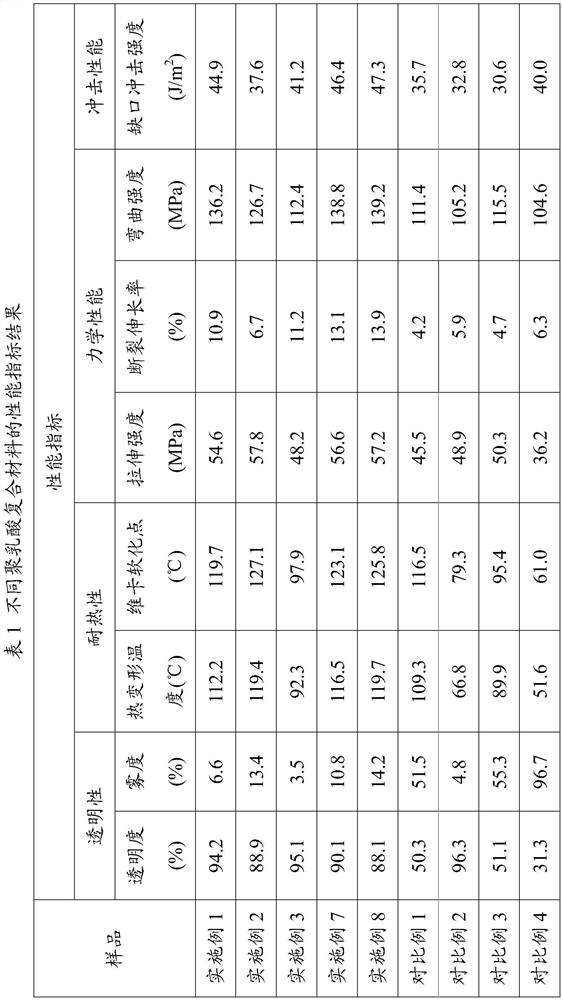

Transparent heat-resistant fully-degradable component polylactic acid composite material and preparation method thereof

The invention relates to the technical field of polylactic acid modification, and discloses a transparent heat-resistant fully-degradable component polylactic acid composite material and a preparation method thereof. The composite material comprises polylactic acid and nucleating masterbatch; the nucleating masterbatch comprises high-molecular-weight polylactic acid and a beta-nucleating agent; the composite material comprises the following components in parts by weight: 100 parts of polylactic acid, 3-15 parts of high-molecular-weight polylactic acid and 1-10 parts of the beta-nucleating agent. The invention also discloses a preparation method of the composite material. According to the polylactic acid composite material, the adopted process is simple and easy to operate, and after the transparency-heat resistance is optimized, the polylactic acid composite material can be widely applied to high-performance PLA-based composite materials and manufacturing of important industrial products including medical materials, high-temperature sterilization, degradable packaging and the like.

Owner:XIHUA UNIV

Efficient plating solution additive

InactiveCN106119904AStable bath propertiesCoating crystallization refinementEnvironmental chemistryPolyacrylamide

The invention discloses an efficient plating solution additive. The efficient plating solution additive contains the following components per kilogram: 30 to 60 g of tetraethylenepentamine, 1 to 5 g of pyridinium, 20 to 30 g of methanesulfonic acid, 0.1 to 1 g of vanillin, 1 to 3 g of saccharin sodium, 20 to 30 g of polyacrylamide, 10 to 20 g of diethyl hexyl sodium sulfate, 1 to 5 g of polyoxy alkyl phenol sodium sulfate, 20 to 30 g of lauryl sodium sulfate, 15 to 25 g of polymeric aluminium, 10 to 20 g of hydroxy sodium sulfonate, 10 to 20 g of polyoxyethylene, 10 to 20 g of trichloride ammonium and deionized water as the rest.

Owner:太仓市凯福士机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com