Patents

Literature

40 results about "Crystal size distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Energy-saving and synergizing wet desulfurization catalyst and using thereof

InactiveCN103191785AImprove solubilityPromote crystallizationOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationSodium saltWater content

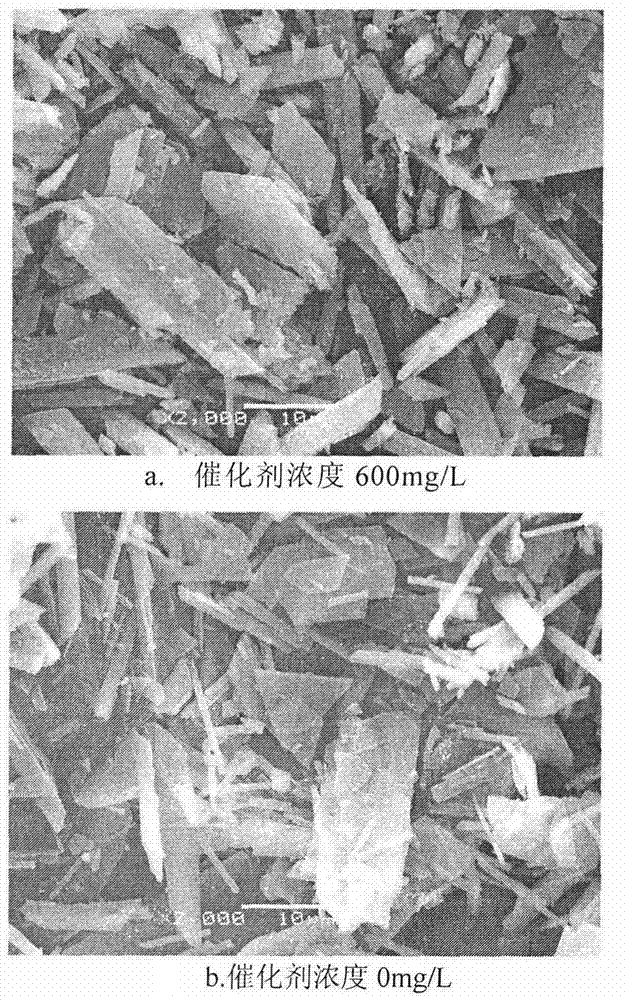

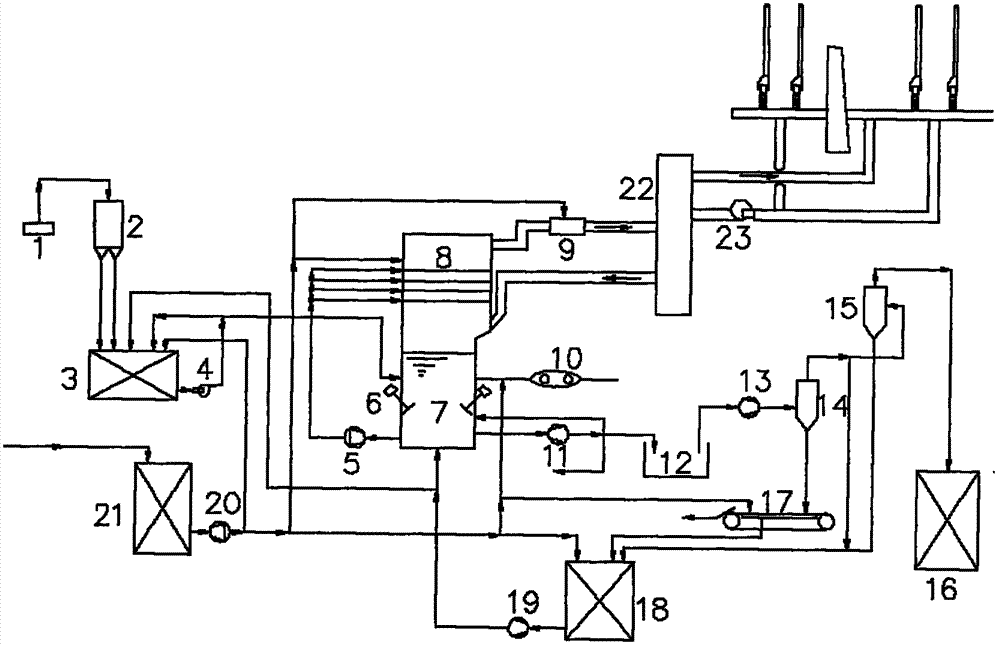

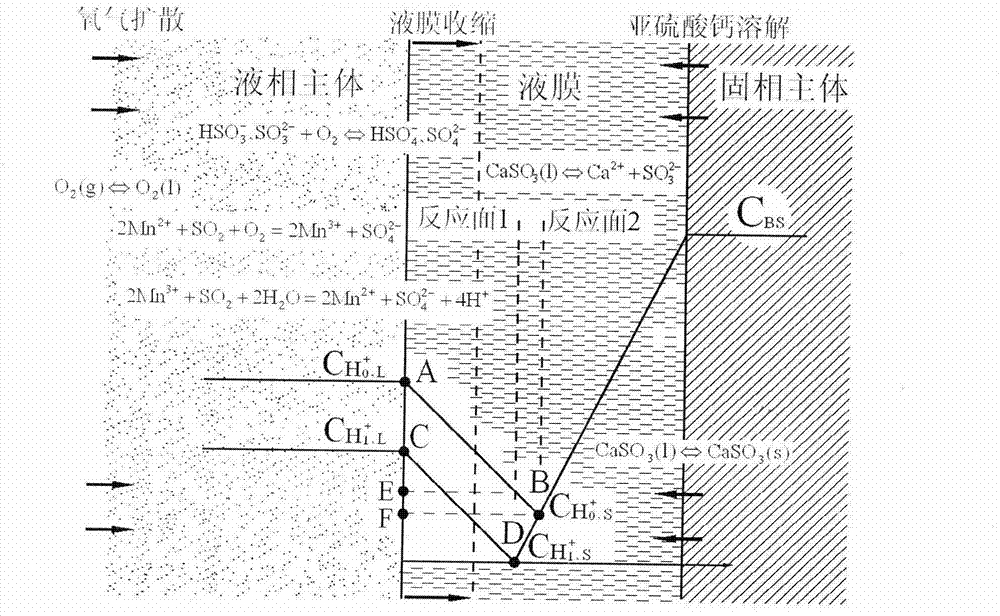

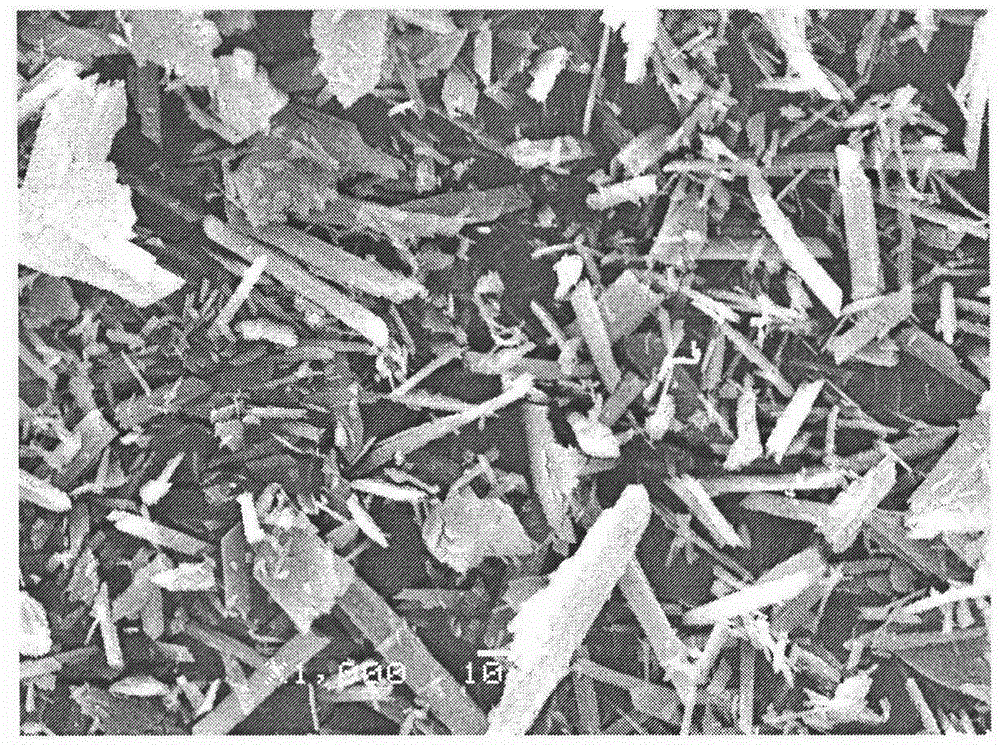

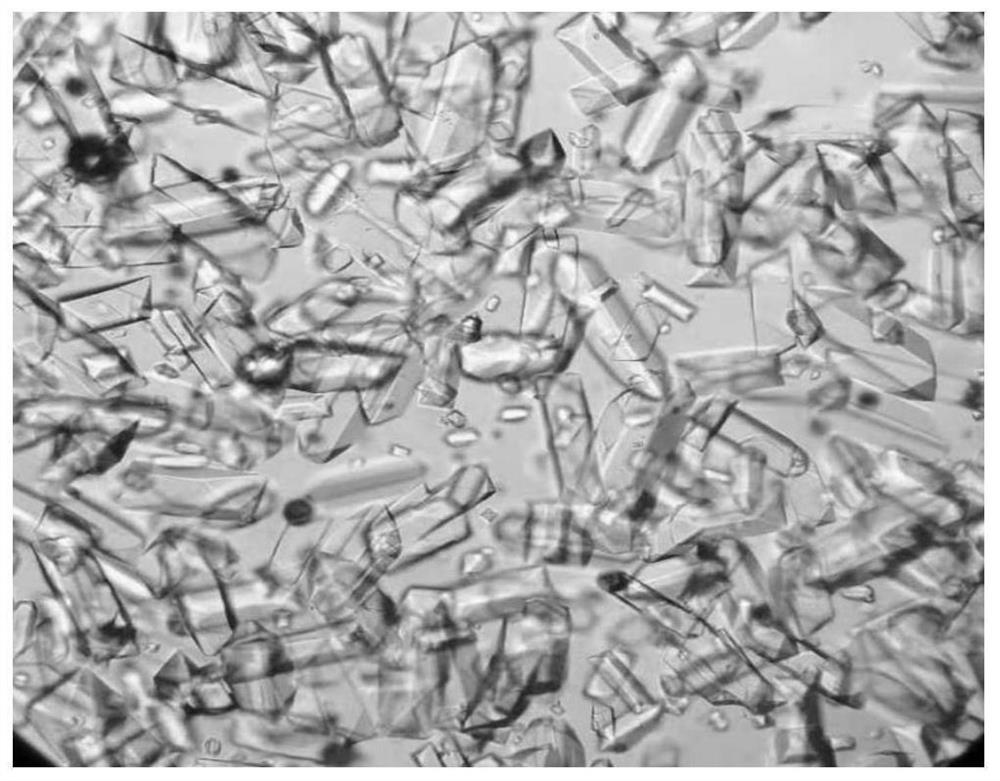

The invention provides a desulphurization catalyst which can substantially improve desulphurization efficiency, reduce system obstruction and fouling, prevent foaming and overflow of a slurry pump and reduce energy consumption of system, and a limestone-gypsum wet desulphurization technology used for large-scale thermal power, belonging to the technical field of environment protection. The catalyst comprises components by weight percent: 40-70 % of organic polyprotic acid or sodium salt thereof, 0.1-5 % of transition metal salts, 5-15 % of a pH buffering agent, 0.05-2 % of a surfactant and 5-20 % of a scale inhibitor. The catalyst is characterized in that a synergist can be directly added into a filtrate pit of an absorbing tower, uniformly stirred and dissolved and then pumped into the absorbing tower; or the synergist can be mixed with a limestone powder into a certain concentration and then added. By using the flue gas desulphurization catalyst, buffer capacity of a pH value of the slurry is relatively good, an oxidation rate of sulfite is accelerated by more than 30 %, a desulphurization efficiency is improved by 10 %, residual CaCO3 in the gypsum is reduced to be less than 1 %, a water content is reduced to be more than 2 %, distribution of crystal size is relatively uniform, share of rhombic crystal shapes and columnar shapes are increased, a specific surface area of the crystal is increased and a dehydrated performance of the gypsum is relatively good.

Owner:NANJING INST OF TECH

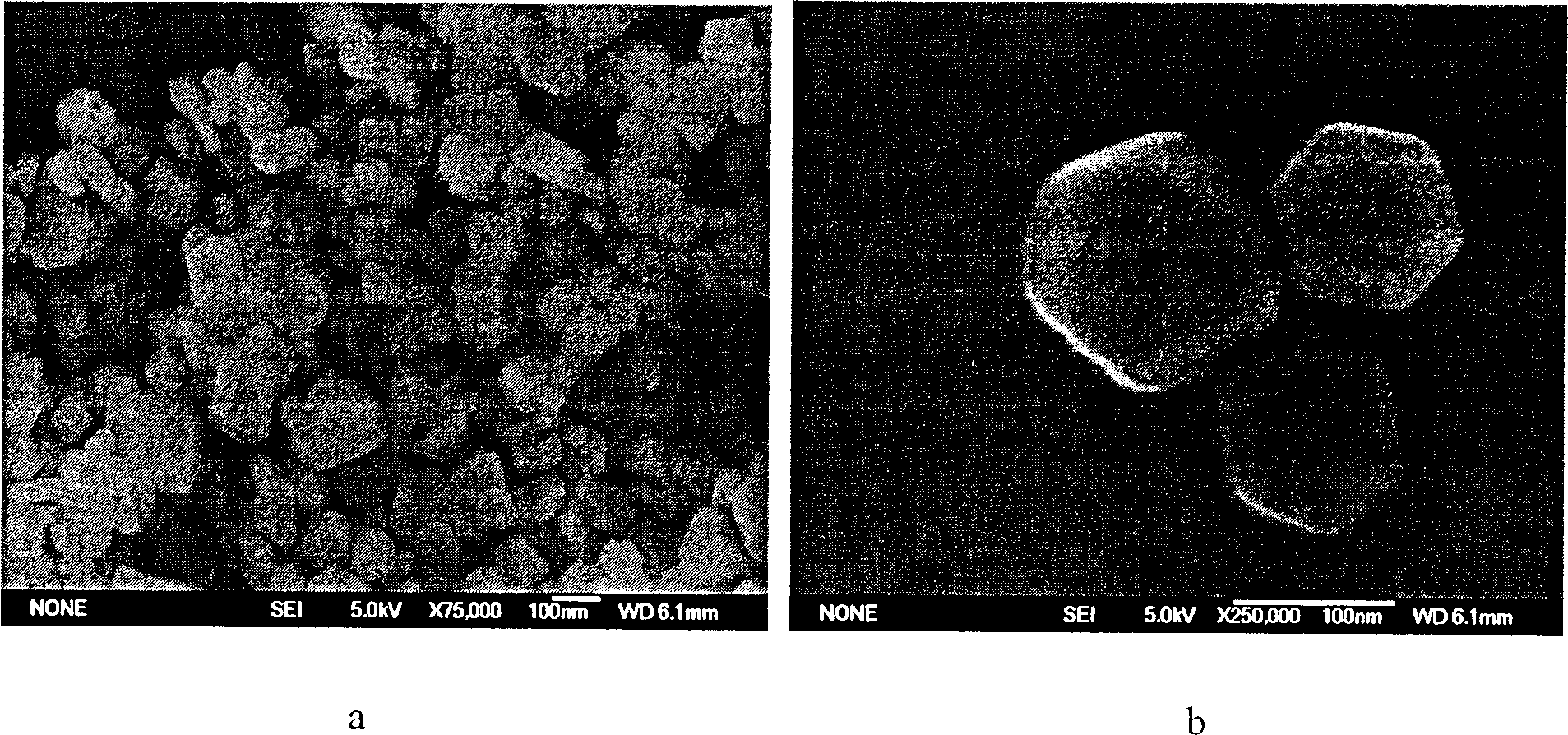

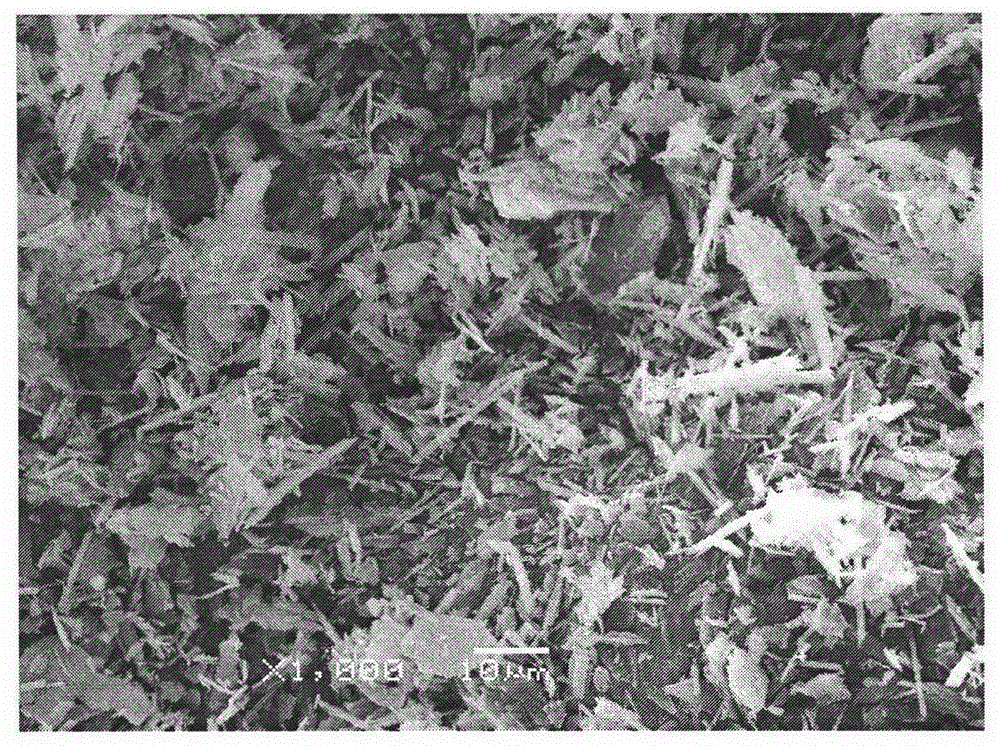

Prepn of magnesium hydroxide for fire retardant

InactiveCN1810927AHigh crystallinityUniform particle size distributionFireproof paintsAqueous sodium hydroxideFree cooling

The preparation process of magnesium hydroxide for fire retardant belongs to the field of chemical material technology. The preparation process includes the steps of: mixing the main material light burnt magnesia and water in the weight ratio of 0.5-3 to 3-7, dropping sodium hydroxide aqua while stirring to ultimate sodium hydroxide concentration in the system of 4-6 M, stirring for 10-60 min before transferring to a high pressure reactor to a filling degree of 70-80 %, hydrothermal reaction at 140-180 for 6-10 hr, cooling the product naturally, water washing and stoving to obtain the flake magnesium hydroxide for fire retardant. The preparation process has the advantages of simplicity and low cost, and the prepared magnesium hydroxide product has excellent crystallization, regular shape and homogeneous crystal size distribution and is suitable for use in fire retardant.

Owner:山东凯利隆化工有限公司

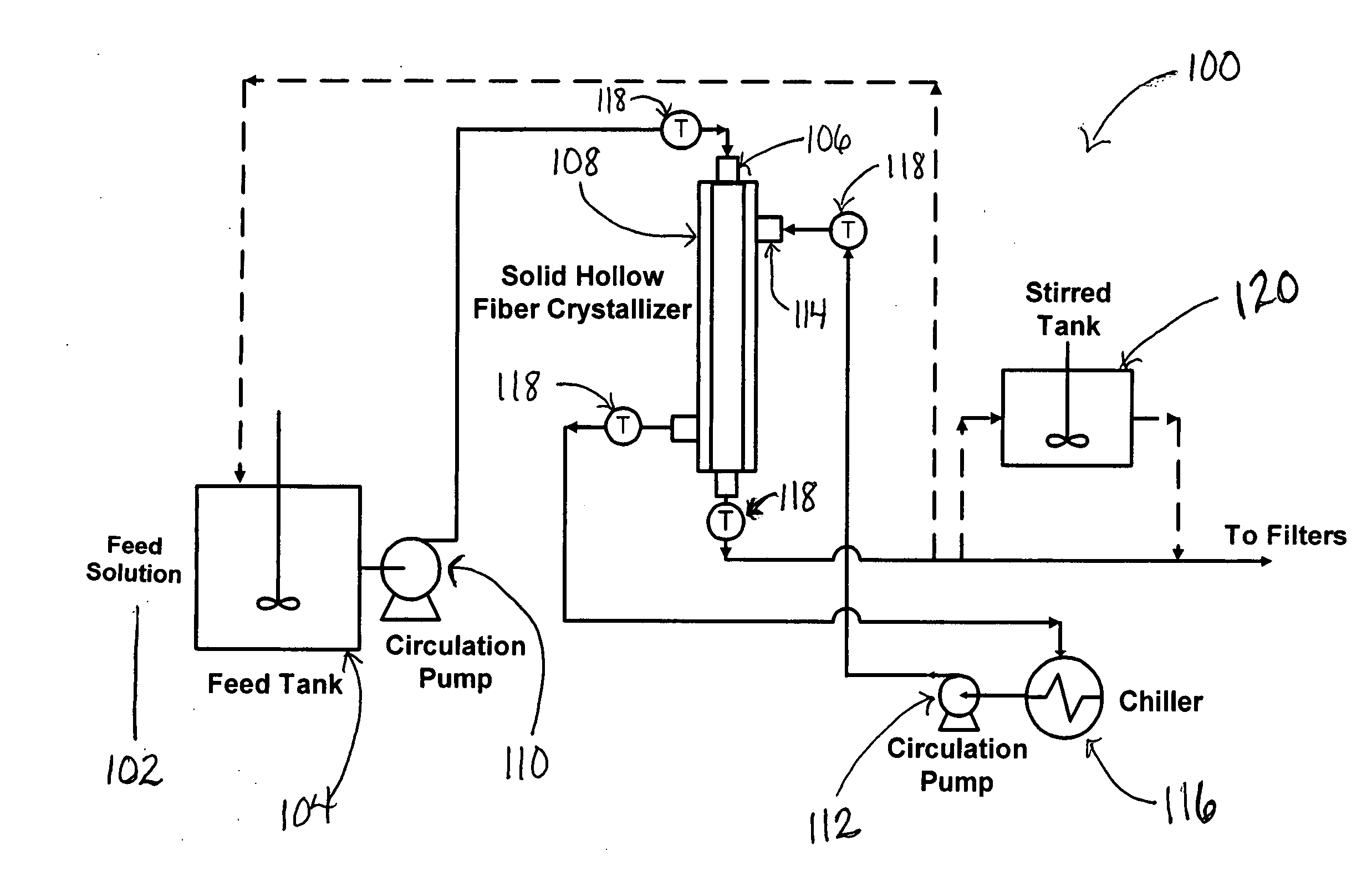

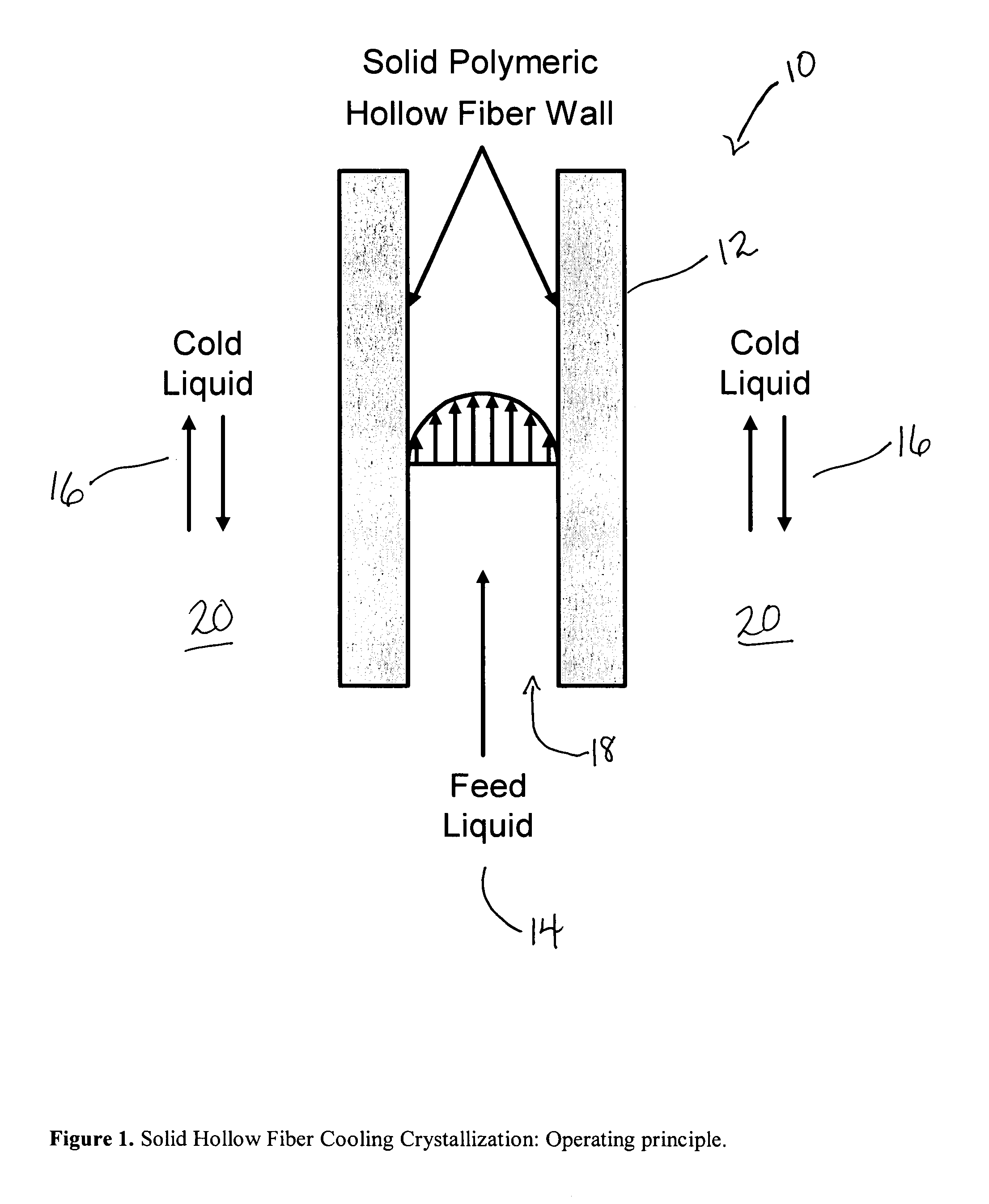

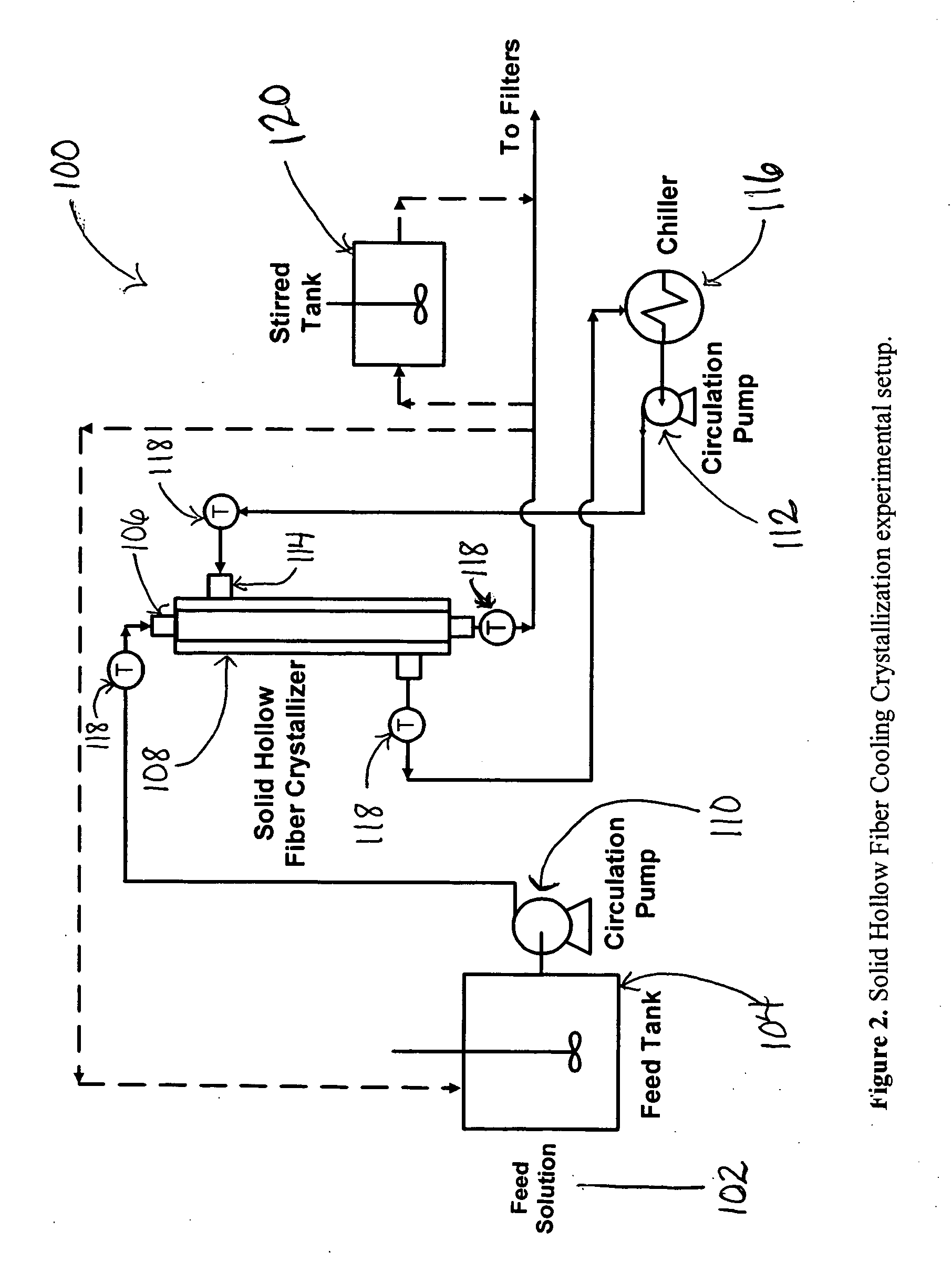

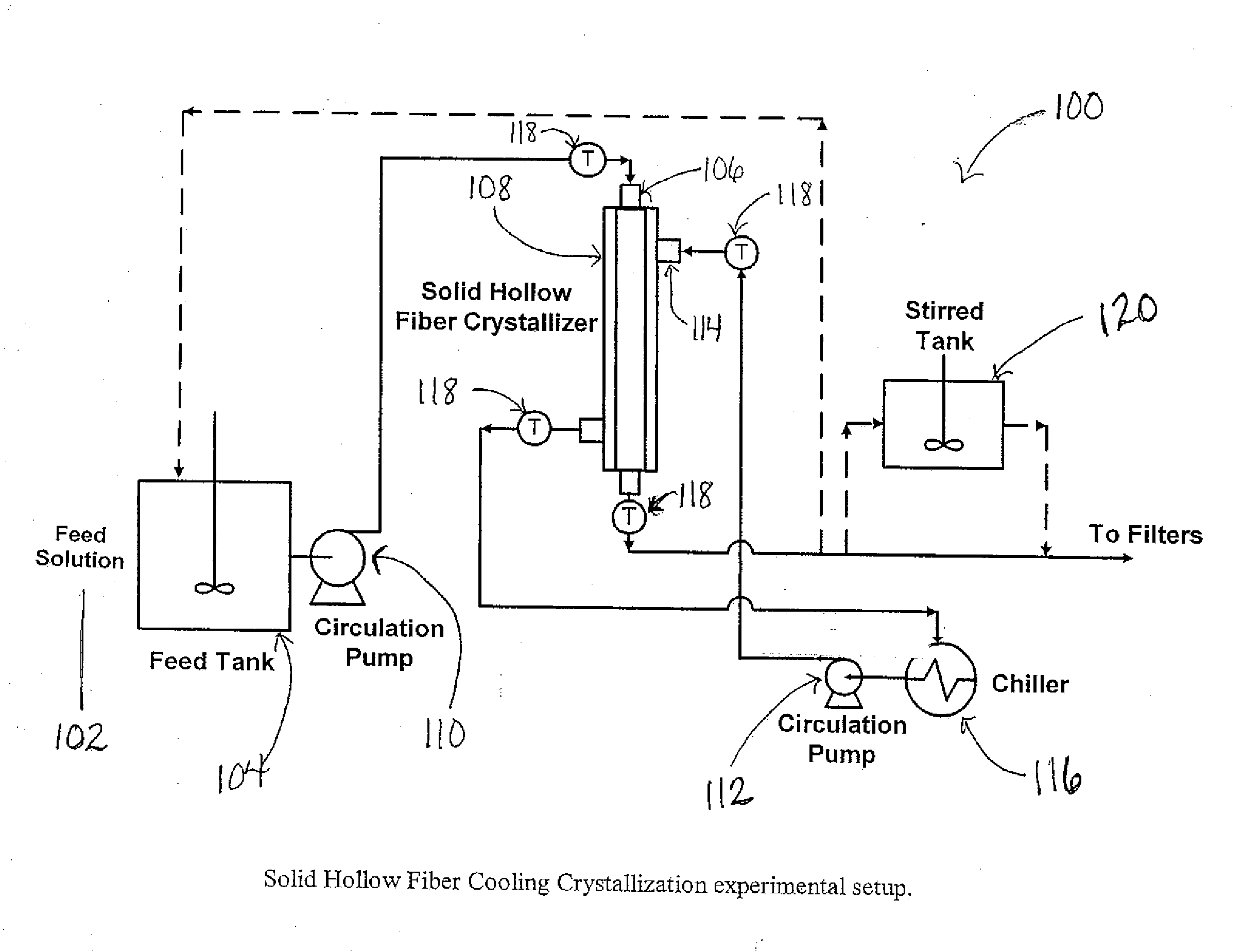

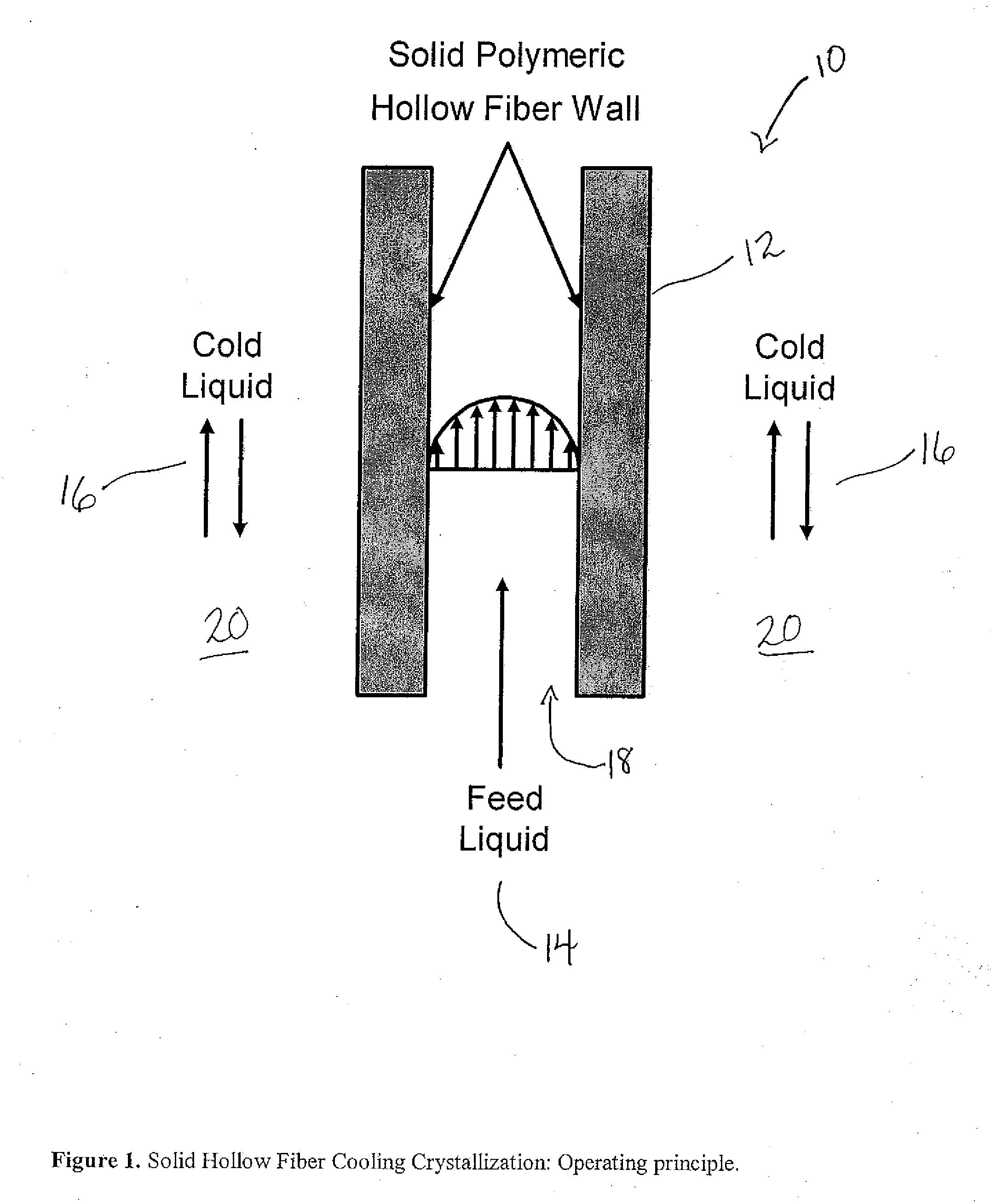

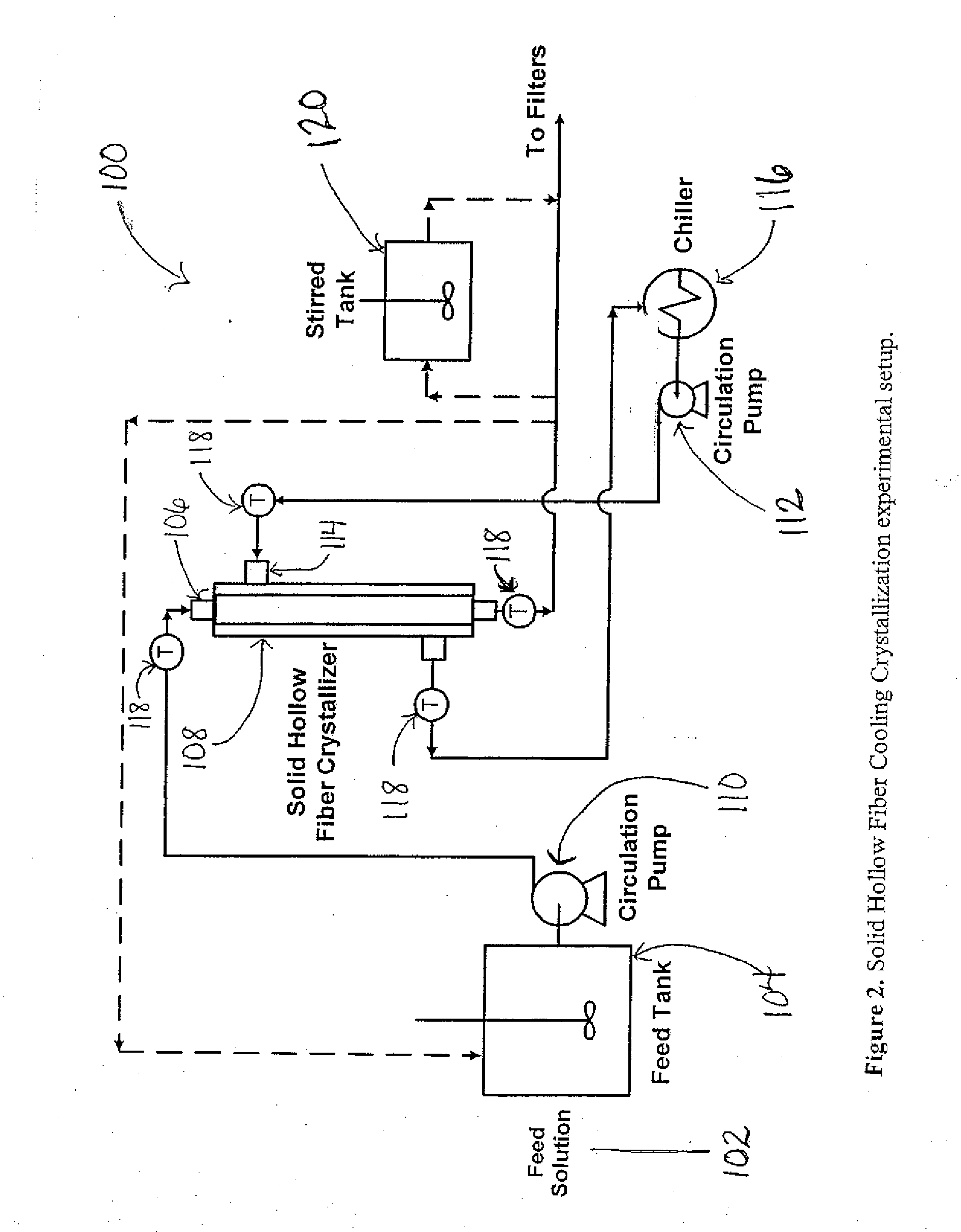

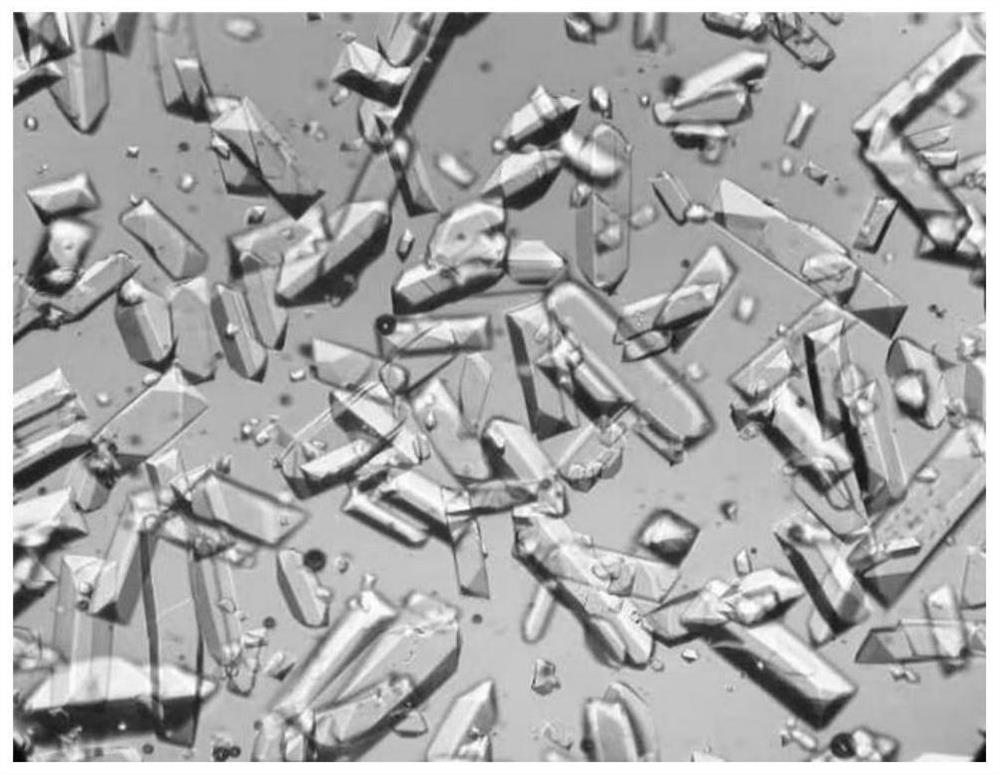

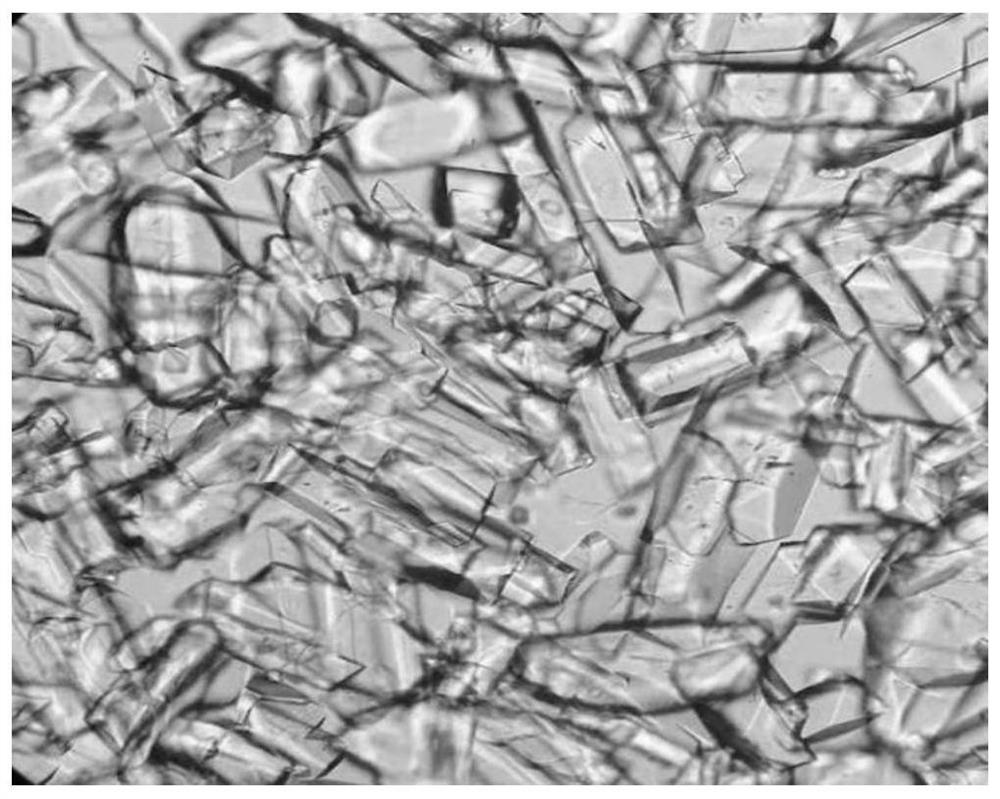

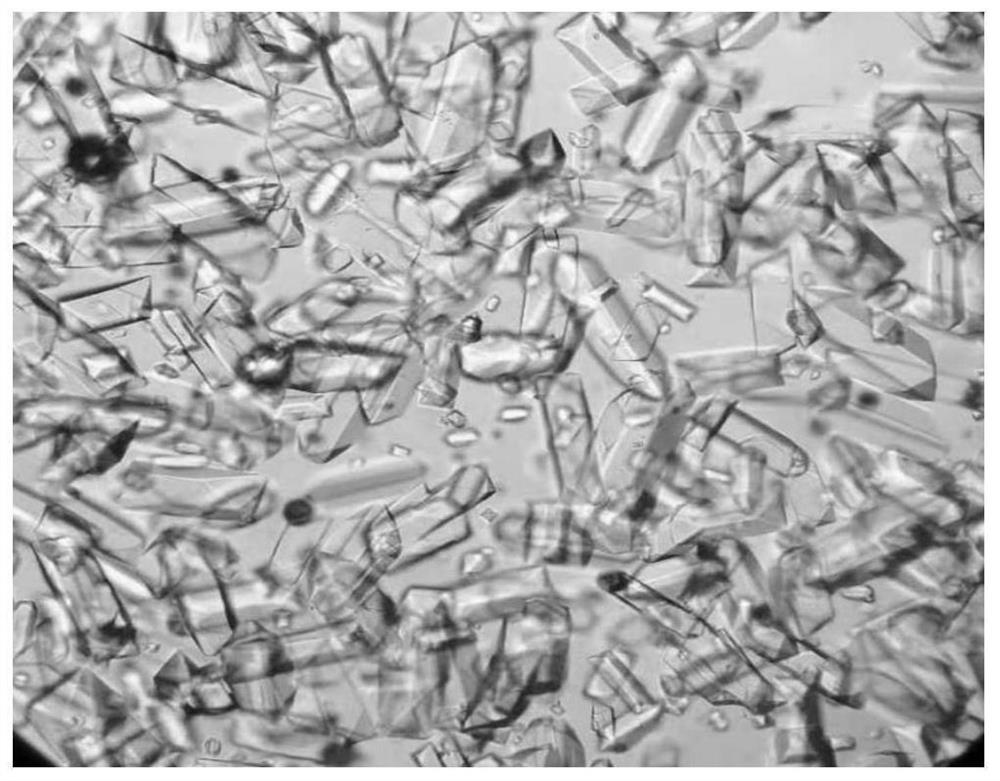

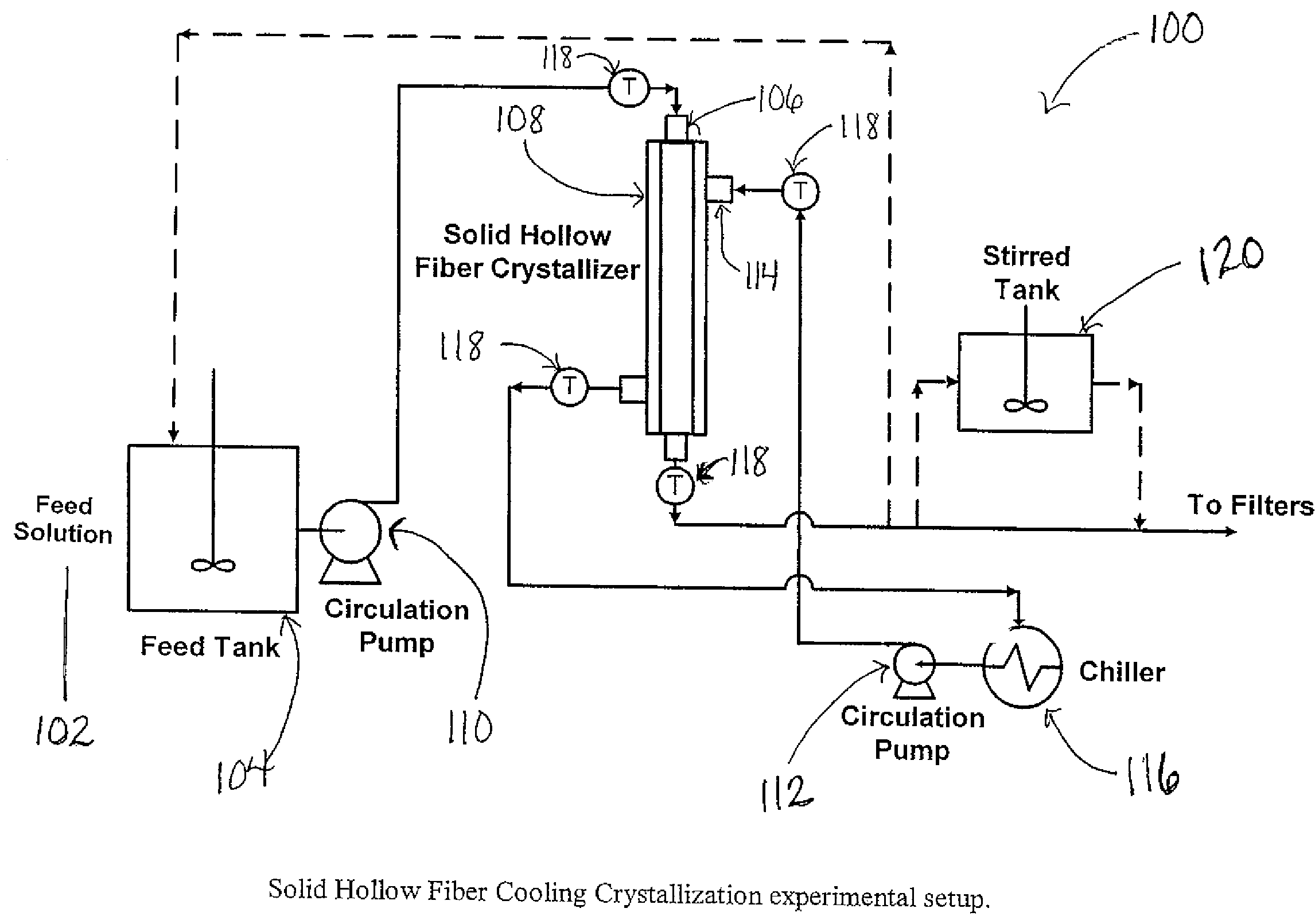

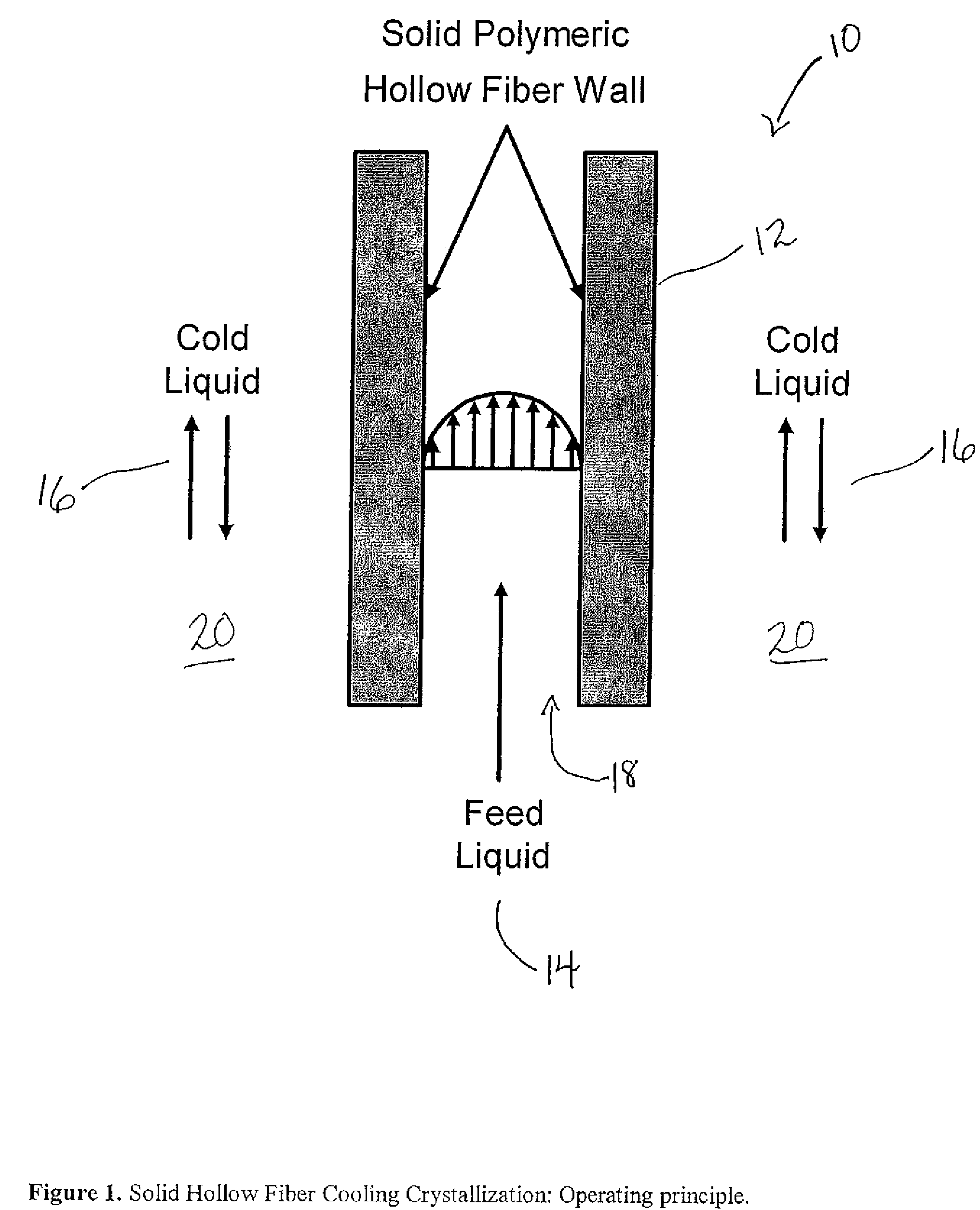

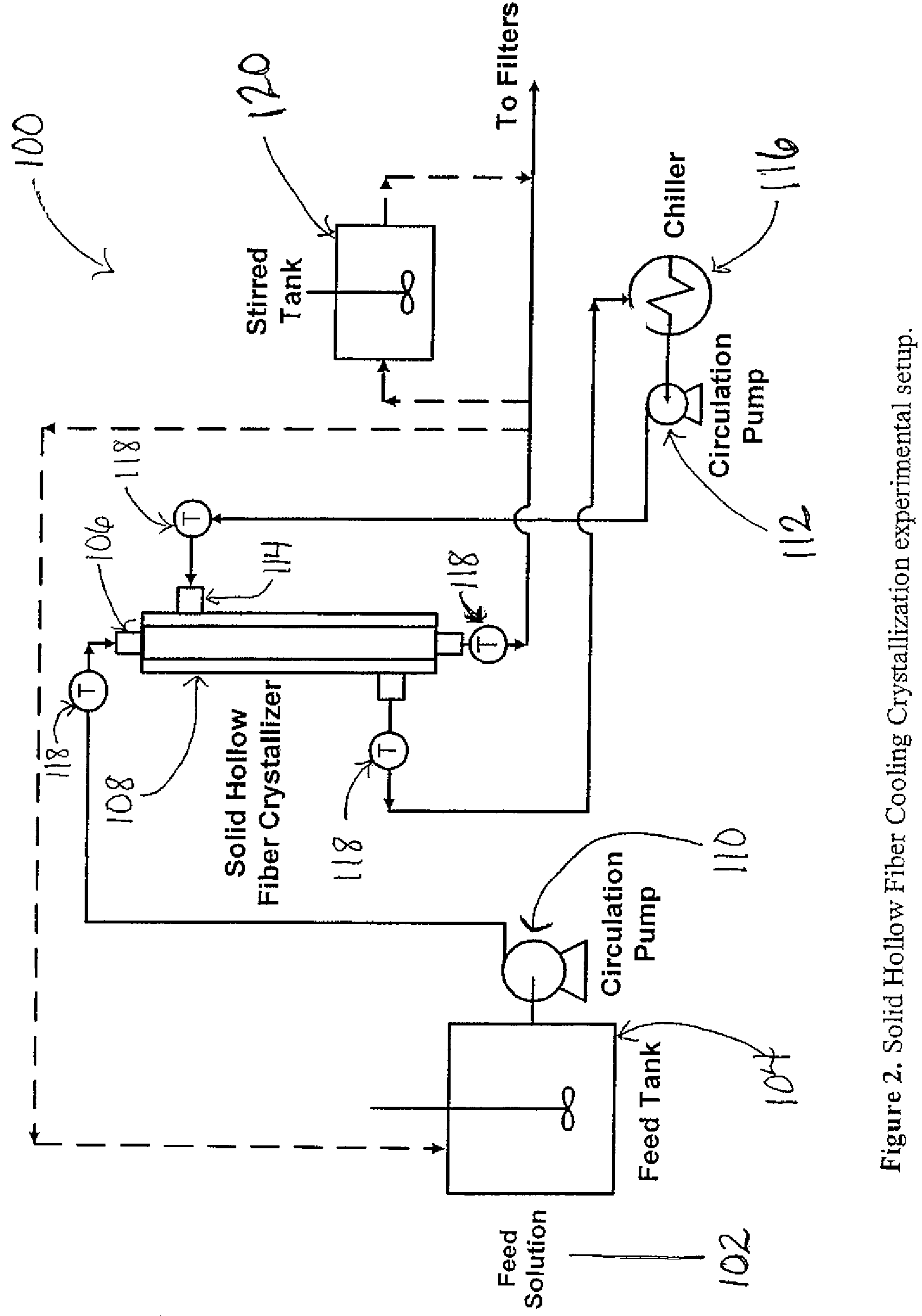

Solid hollow fiber cooling crystallization systems and methods

InactiveUS20060096525A1Increase nucleation rateNarrow crystal size distributionAfter-treatment apparatusPolycrystalline material growthFiberHollow fibre

A solid hollow fiber cooling crystallizer and method for crystallizing aqueous and organic solutions are provided. The solid hollow fiber crystallizer (SHFC) for carrying out cooling crystallization of inorganic / organic microsolutes / macrosolutes from solution generally includes a bundle of non-porous hollow fibers mounted within a shell where a feed solution for crystallization flows through the lumen side of the hollow fibers and a cooling solution flows through the shell side to form nuclei and subsequently crystals in the feed solution at a temperature below its saturation temperature. The solid hollow fiber crystallizer may be combined with a mixing device, such as a completely stirred tank or static mixer, to further effectuate crystallization. The solid hollow fiber crystallizer may be operated in a number of modes including feed recycle mode, once through mode, SHFC-in-line static mixer in series mode, and SHFC-CST in series mode. The advantages of solid hollow fiber cooling crystallization in comparison to conventional crystallization processes include improved temperature control between crystallizing solution and coolant, higher nucleation rates, improved control of crystal size and crystal size distribution, smaller crystal size, capability for decoupling crystal nucleation and crystal growth, decreased fouling of process equipment, and improved process scale-up.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

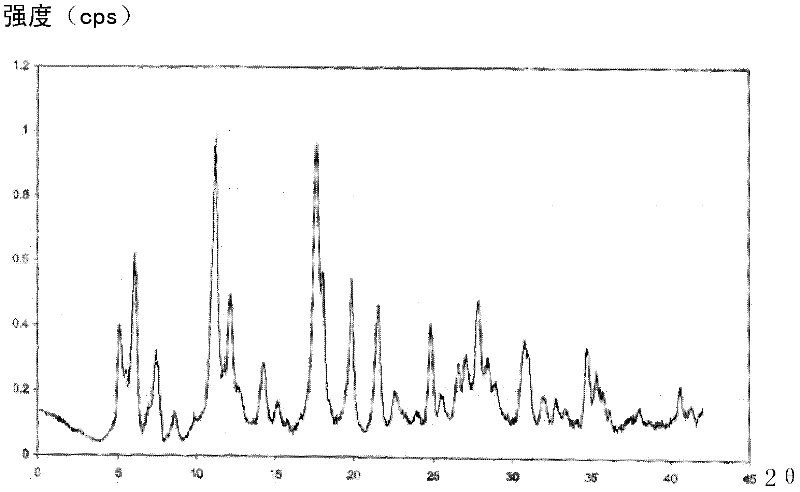

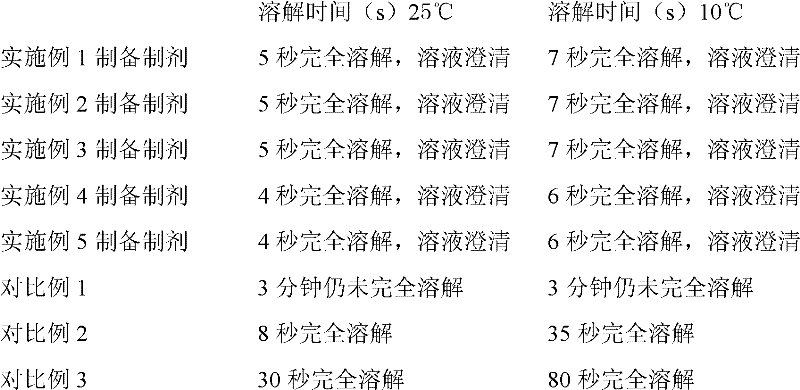

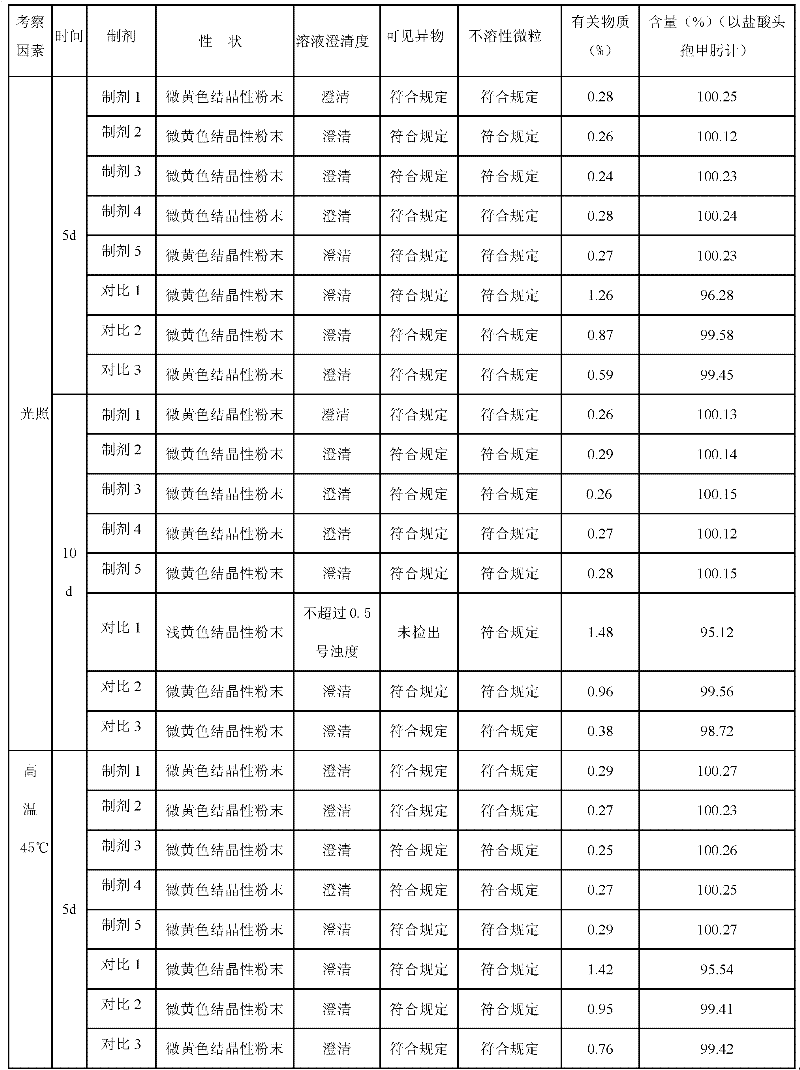

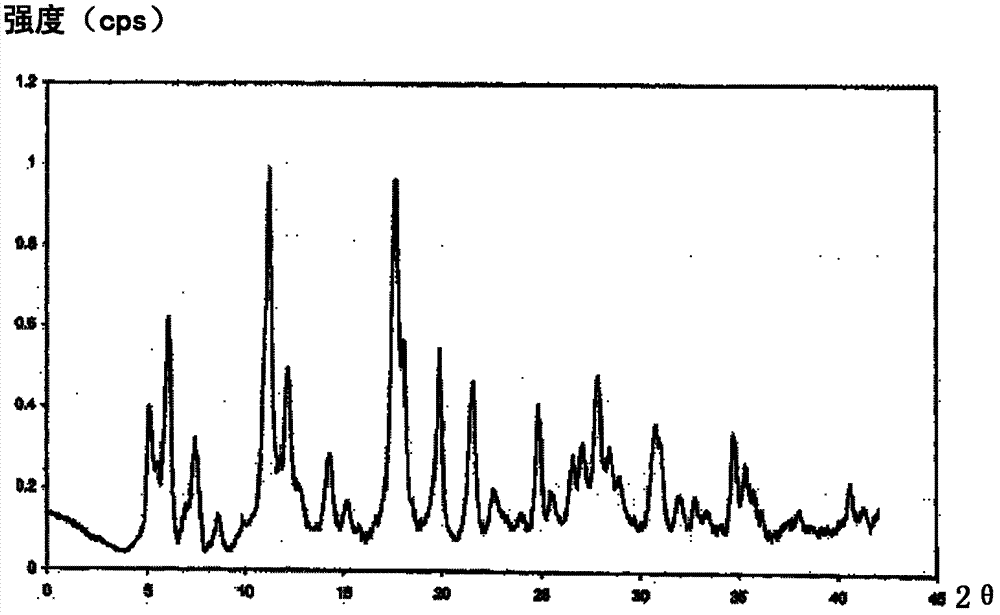

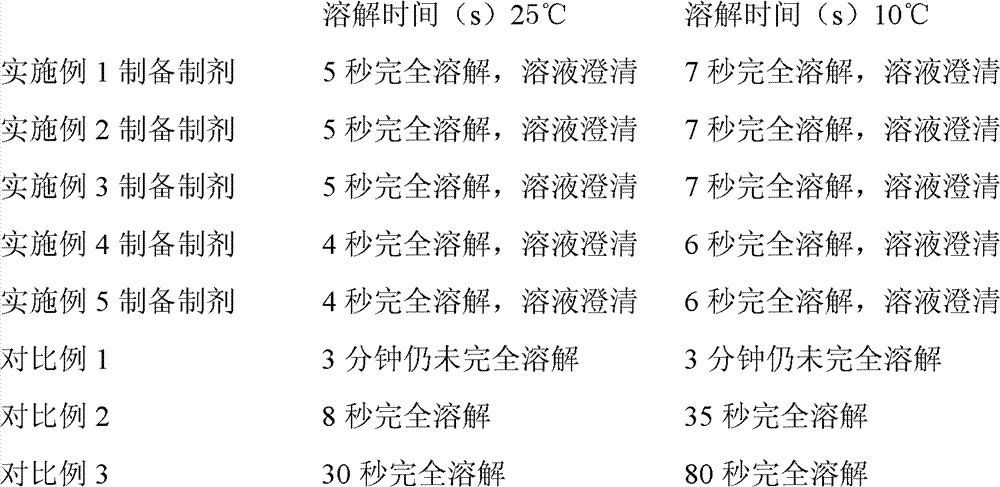

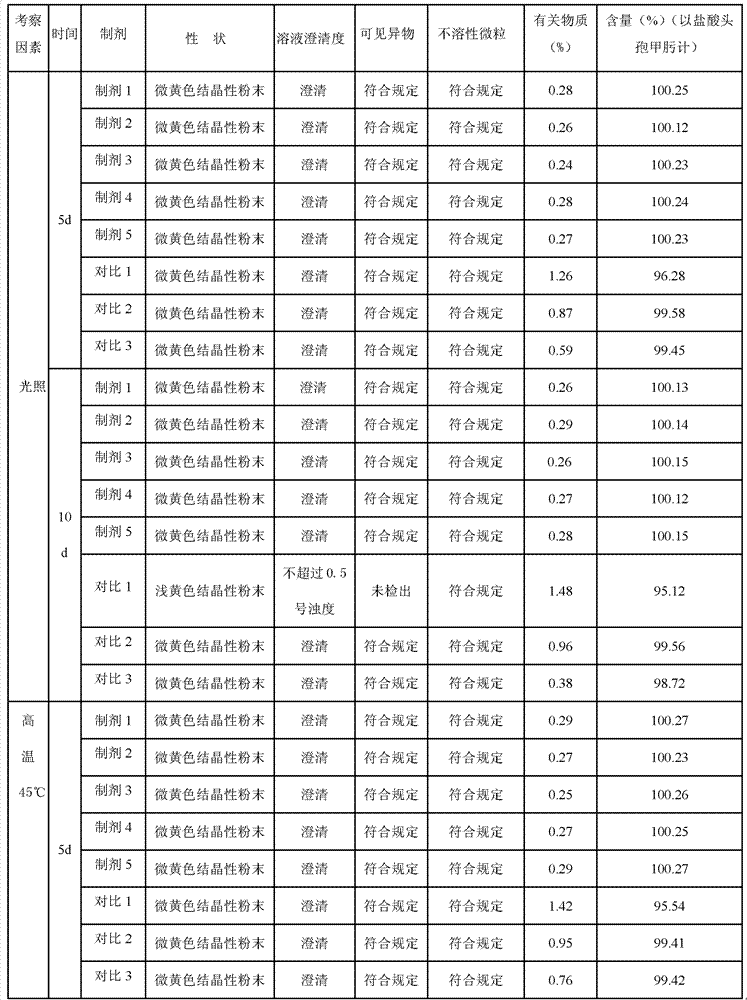

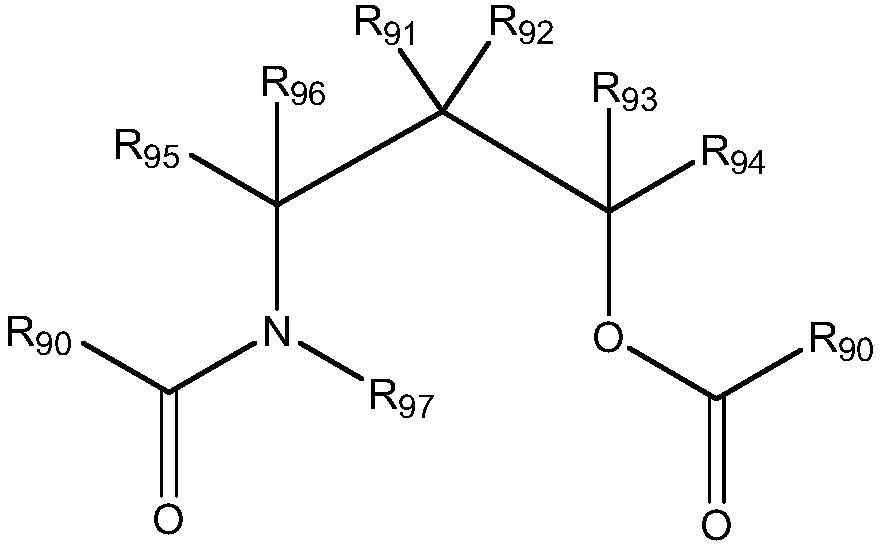

Cefmenoxime hydrochloride composition for injection and preparation thereof

ActiveCN102499922AParticle stabilityPromote generationAntibacterial agentsOrganic active ingredientsCrystal size distributionK-alpha

The invention relates to a cefmenoxime hydrochloride composition for injection which consists of 10 parts by weight of cefmenoxime hydrochloride and 1.5 to 2.5 parts by weight of anhydrous sodium carbonate, preferably 10 parts by weight of cefmenoxime hydrochloride and 1.75 to 1.8 parts by weight of anhydrous sodium carbonate. The cefmenoxime hydrochloride is crystal, having characteristic peaks at the diffraction angles 2 theta of 6.0 degrees, 7.4 degrees, 11.0 degrees, 12.2 degrees, 17.5 degrees, 19.8 degrees, 21.6 degrees, 24.8 degrees and 27.7 degrees in the X-ray powder diffraction measured using a Cu K-alpha ray. The main crystal size of cefmenoxime hydrochloride is 30 to 45 microns and the crystal size distribution width is 25 to 75 microns. The cefmenoxime hydrochloride composition of the invention is in the dosage form of injection which is dissolved quickly, suitable for clinic application, good in stability and reliable in safety.

Owner:桂林澳林制药有限责任公司

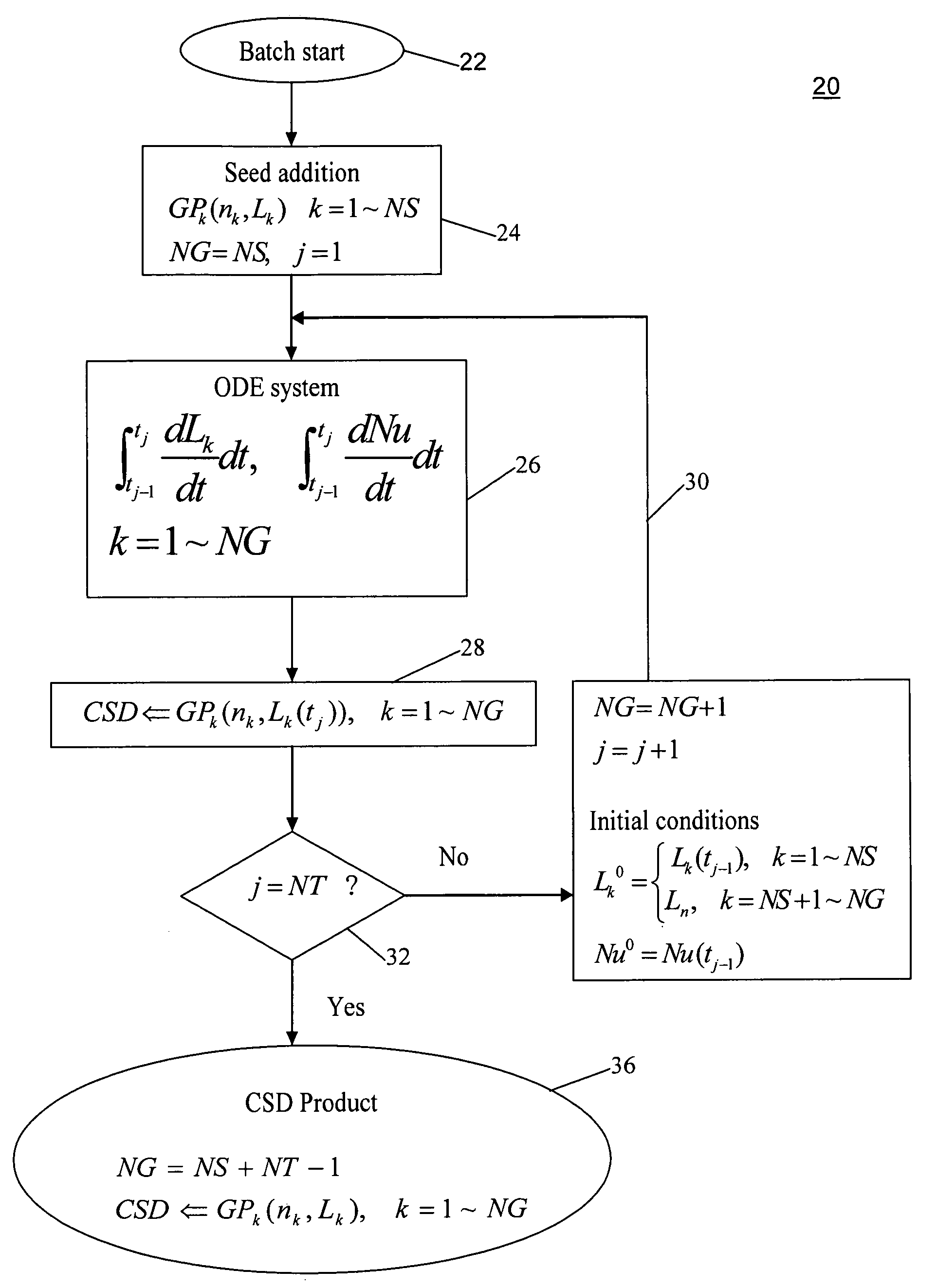

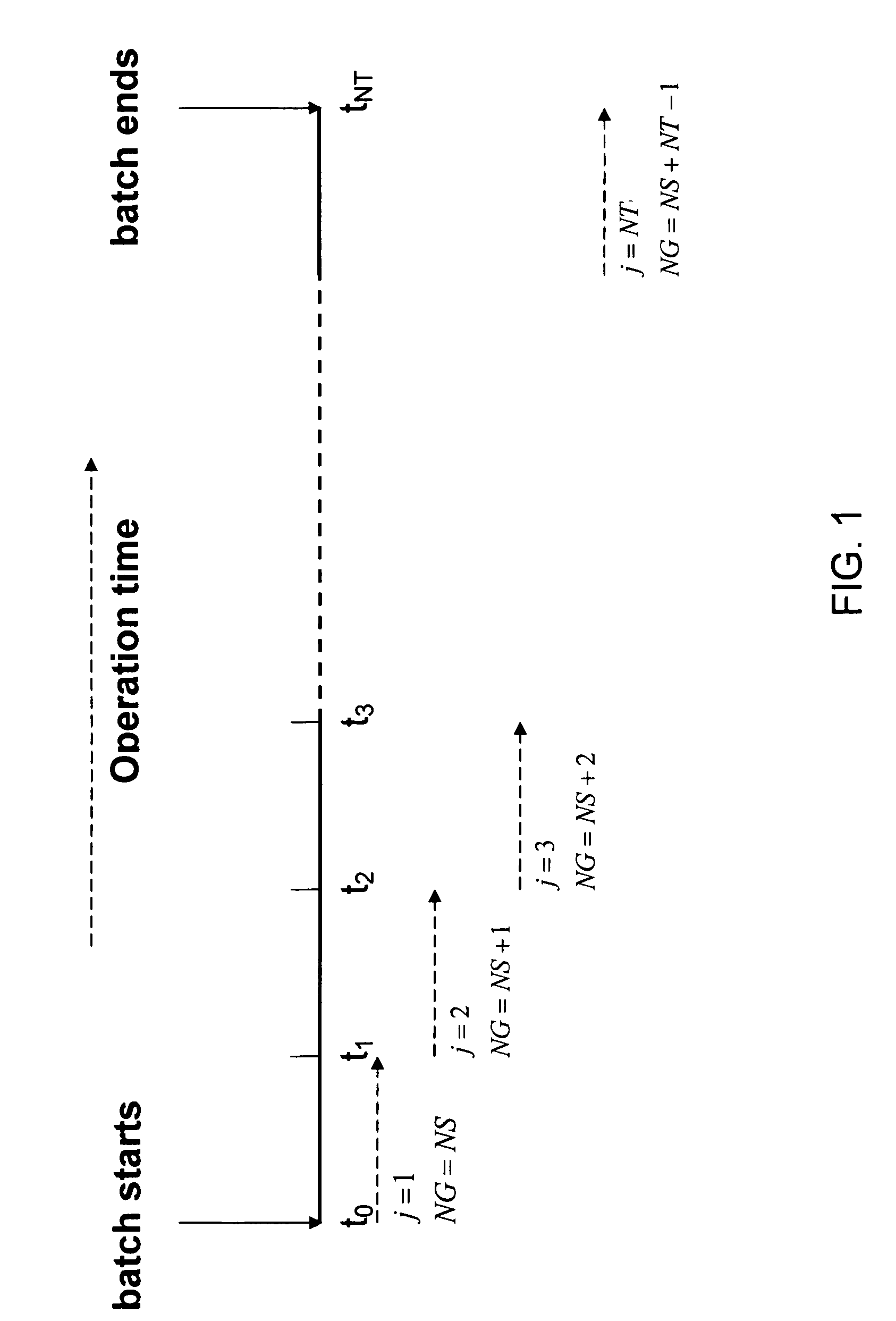

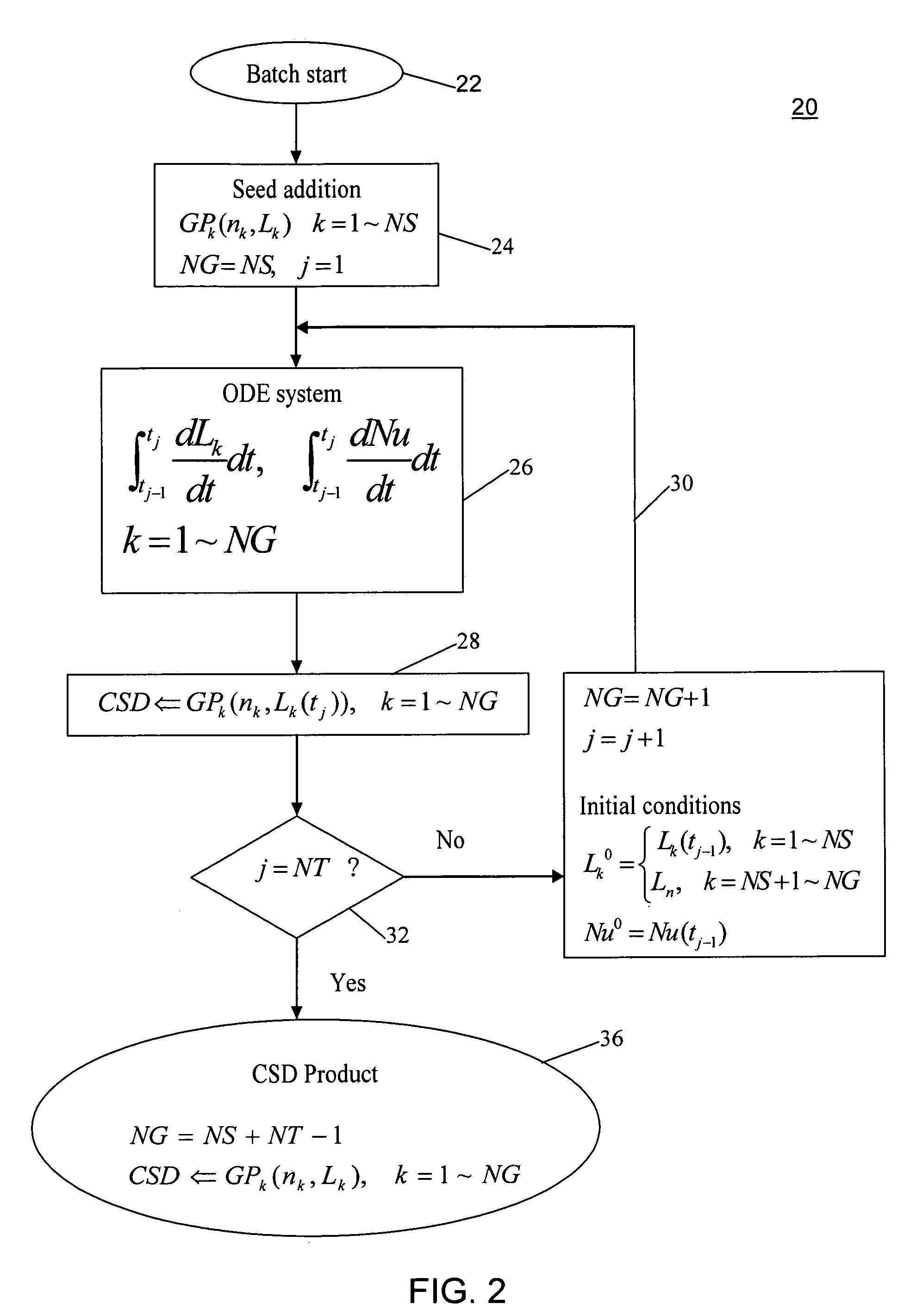

Systems and methods for modeling of crystallization processes

ActiveUS20100063783A1Crystallization separationAnalogue computers for chemical processesCharacteristic lengthComputerized system

A computer system and method of modeling a crystallization process includes representing a plurality of crystals in a solution by different subsets of the plurality, tracking increase of the respective characteristic length of each crystal group, and determining a crystal size distribution to output a model to a user. Ech subset forms a respective crystal group characterized by group attributes of (i) a number of crystals and (ii) a characteristic length. Additionally, the system and method track generation of new crystal groups generated by seeding, nucleation and / or breakage.

Owner:ASPENTECH CORP

Solid Hollow Fiber Cooling Crystallization Systems and Methods

InactiveUS20090000080A1Improve cooling effectEffective decouplingFrom normal temperature solutionsSolvent extractionFiberHollow fibre

A solid hollow fiber cooling crystallizer and method for crystallizing aqueous and organic solutions are provided. The solid hollow fiber crystallizer (SHFC) for carrying out cooling crystallization of inorganic / organic microsolutes / macrosolutes from solution generally includes a bundle of non-porous hollow fibers mounted within a shell where a feed solution for crystallization flows through the lumen side of the hollow fibers and a cooling solution flows through the shell side to form nuclei and subsequently crystals in the feed solution at a temperature below its saturation temperature. The solid hollow fiber crystallizer may be combined with a mixing device, such as a completely stirred tank or static mixer, to further effectuate crystallization. The solid hollow fiber crystallizer may be operated in a number of modes including feed recycle mode, once through mode, SHFC-in-line static mixer in series mode, and SHFC-CST in series mode. The advantages of solid hollow fiber cooling crystallization in comparison to conventional crystallization processes include improved temperature control between crystallizing solution and coolant, higher nucleation rates, improved control of crystal size and crystal size distribution, smaller crystal size, capability for decoupling crystal nucleation and crystal growth, decreased fouling of process equipment, and improved process scale-up.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

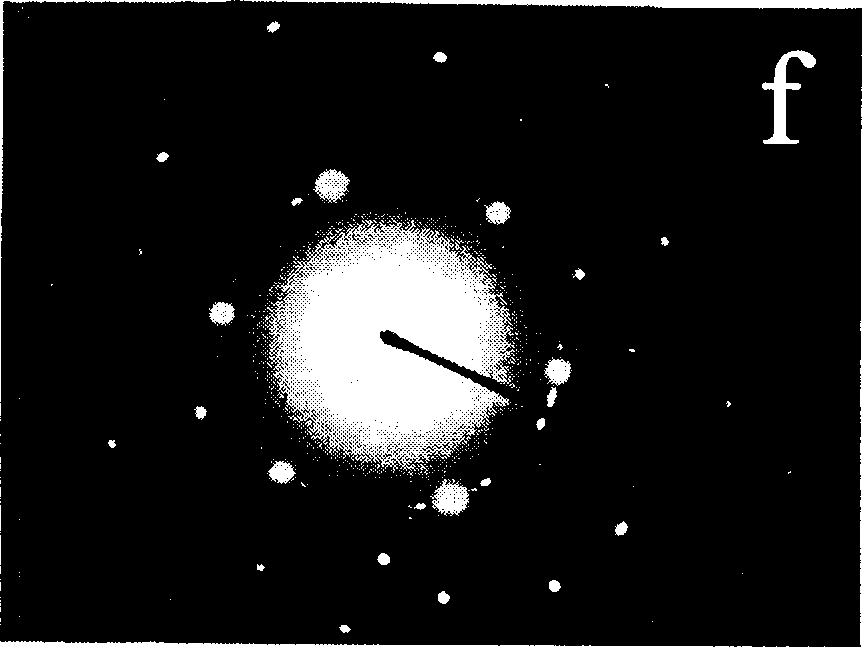

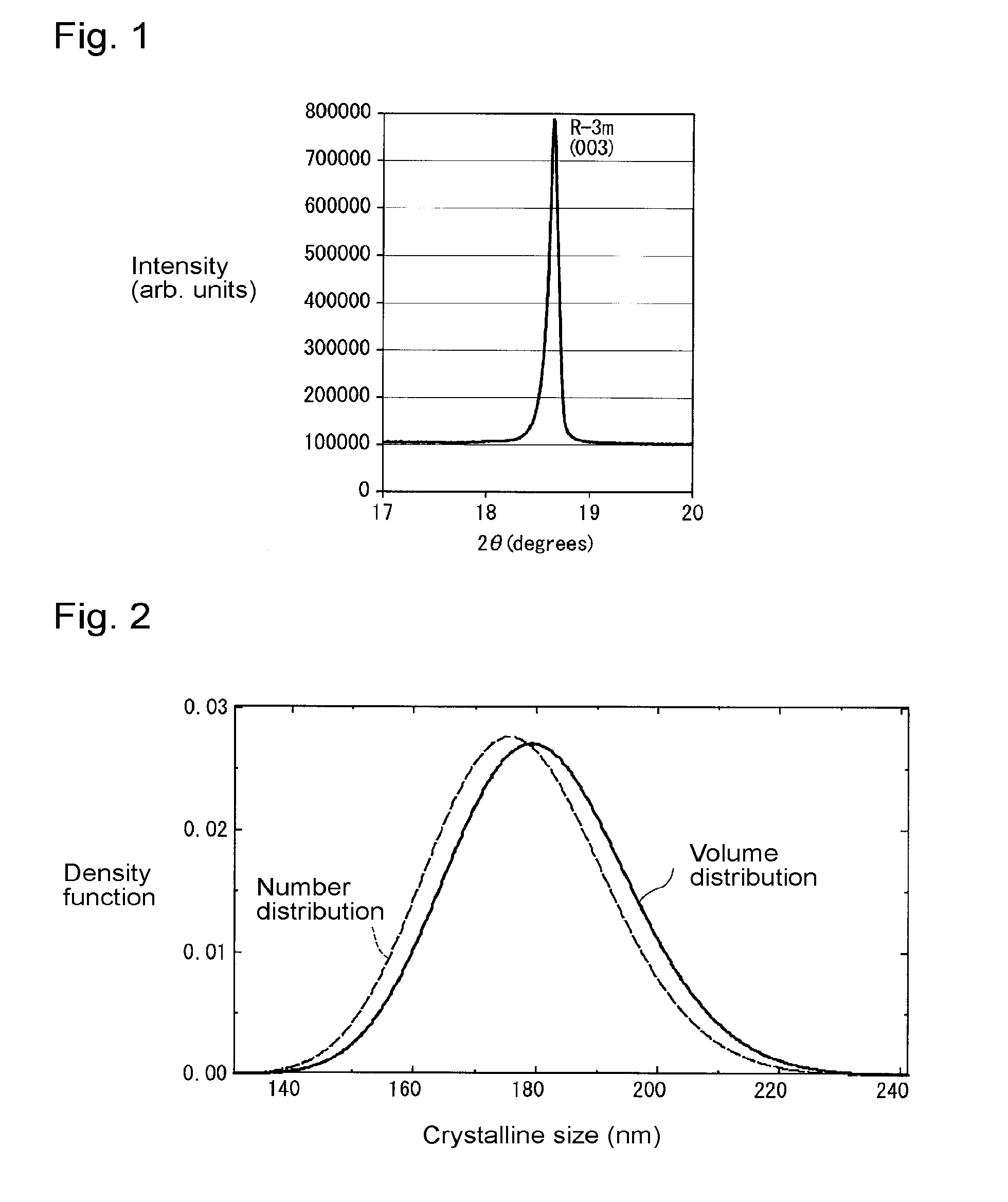

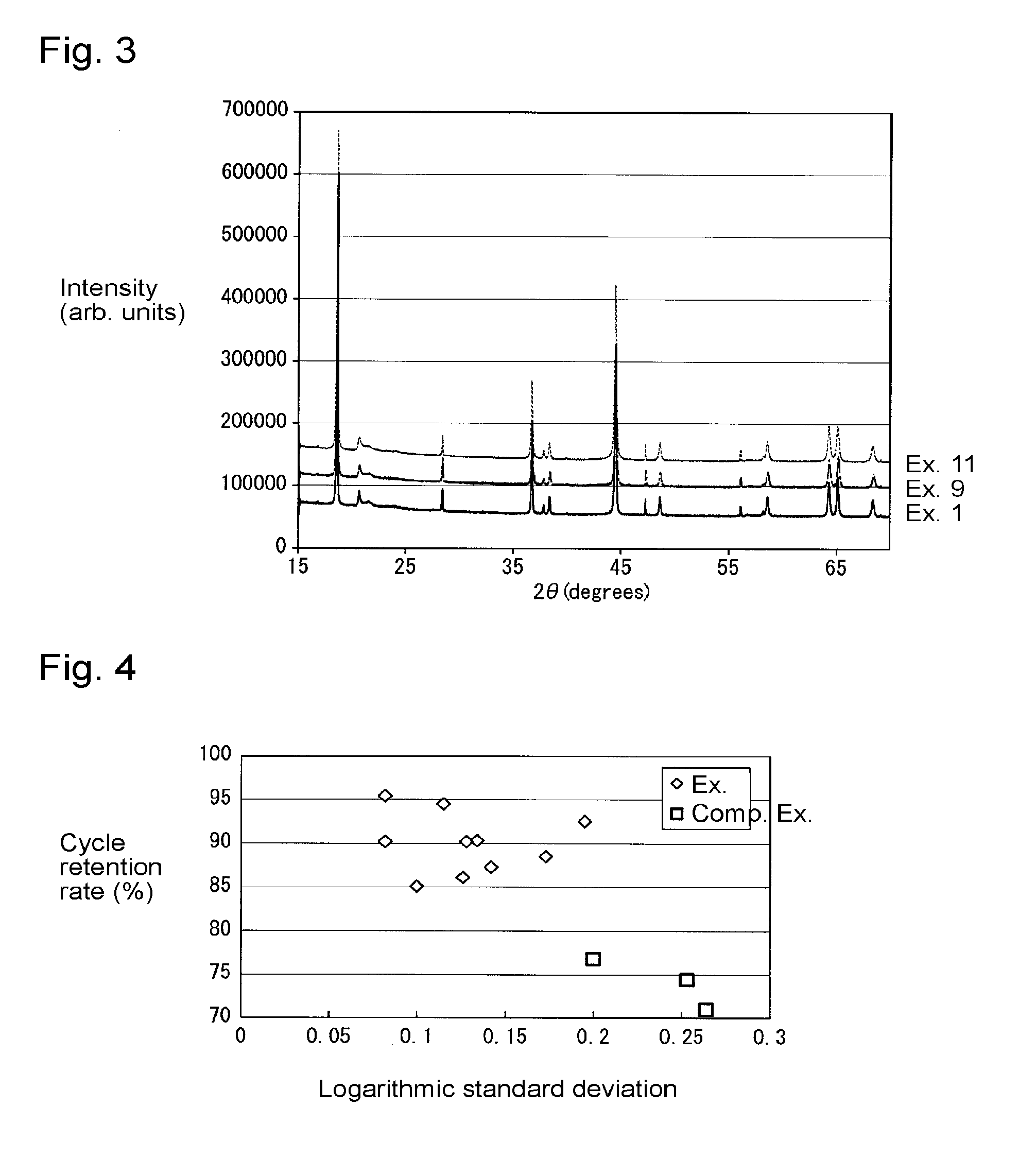

Lithium-containing composite oxide, its production process, cathode active material, positive electrode for lithium ion secondary battery, and lithium ion secondary battery

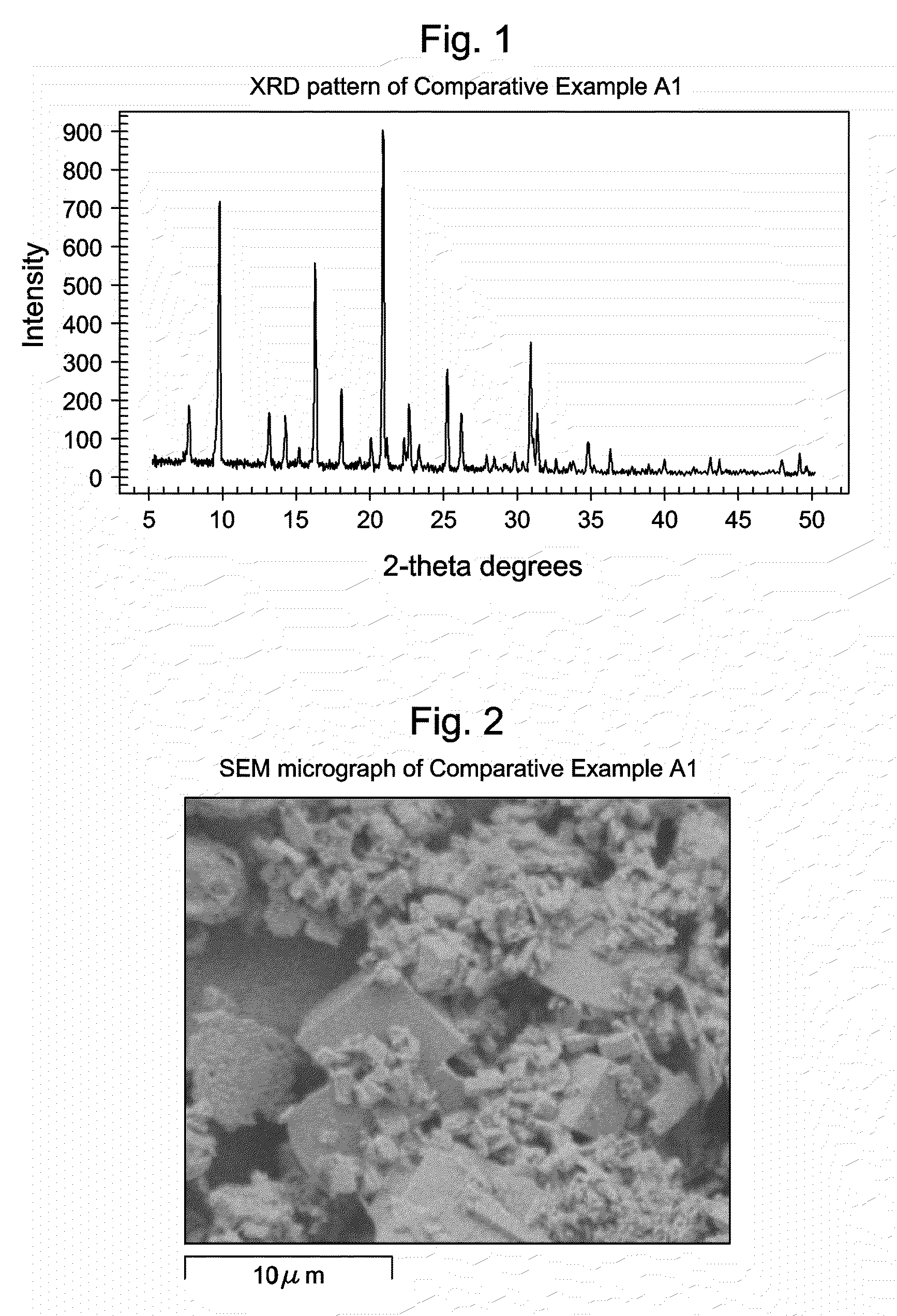

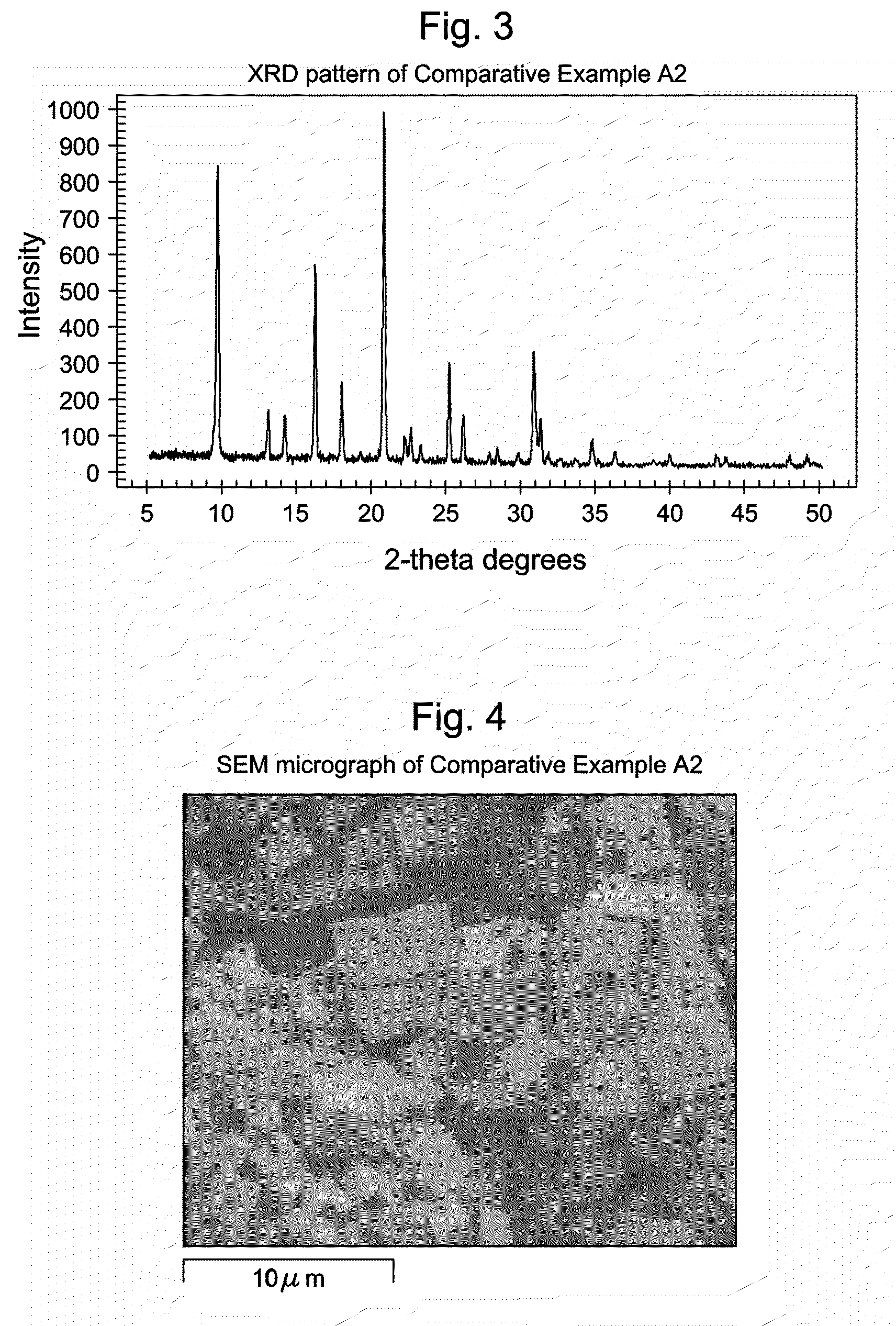

InactiveUS20160301065A1Improve discharge capacityExcellent cycle characteristicsPositive electrodesCobalt compoundsX-rayCrystal structure

To provide a lithium-containing composite oxide capable of obtaining a lithium ion secondary battery excellent in the discharge capacity and cycle characteristics and its production process, a cathode active material, a positive electrode for a lithium ion secondary battery which contains the lithium-containing composite oxide and a lithium ion secondary battery.A lithium-containing composite oxide, which is represented by aLi(Li1 / 3Mn2 / 3)O2.(1−a)LiNiαCoβMnγO2 (wherein 0<a<1, 0<α<1, 0≦β<1, 0<γ≦0.5, and α+β+γ=1), wherein in its X-ray diffraction pattern, the logarithmic standard deviation of the crystalline size distribution obtained from a peak of (003) plane assigned to a crystal structure with space group R-3m is at most 0.198.

Owner:SUMITOMO CHEM CO LTD

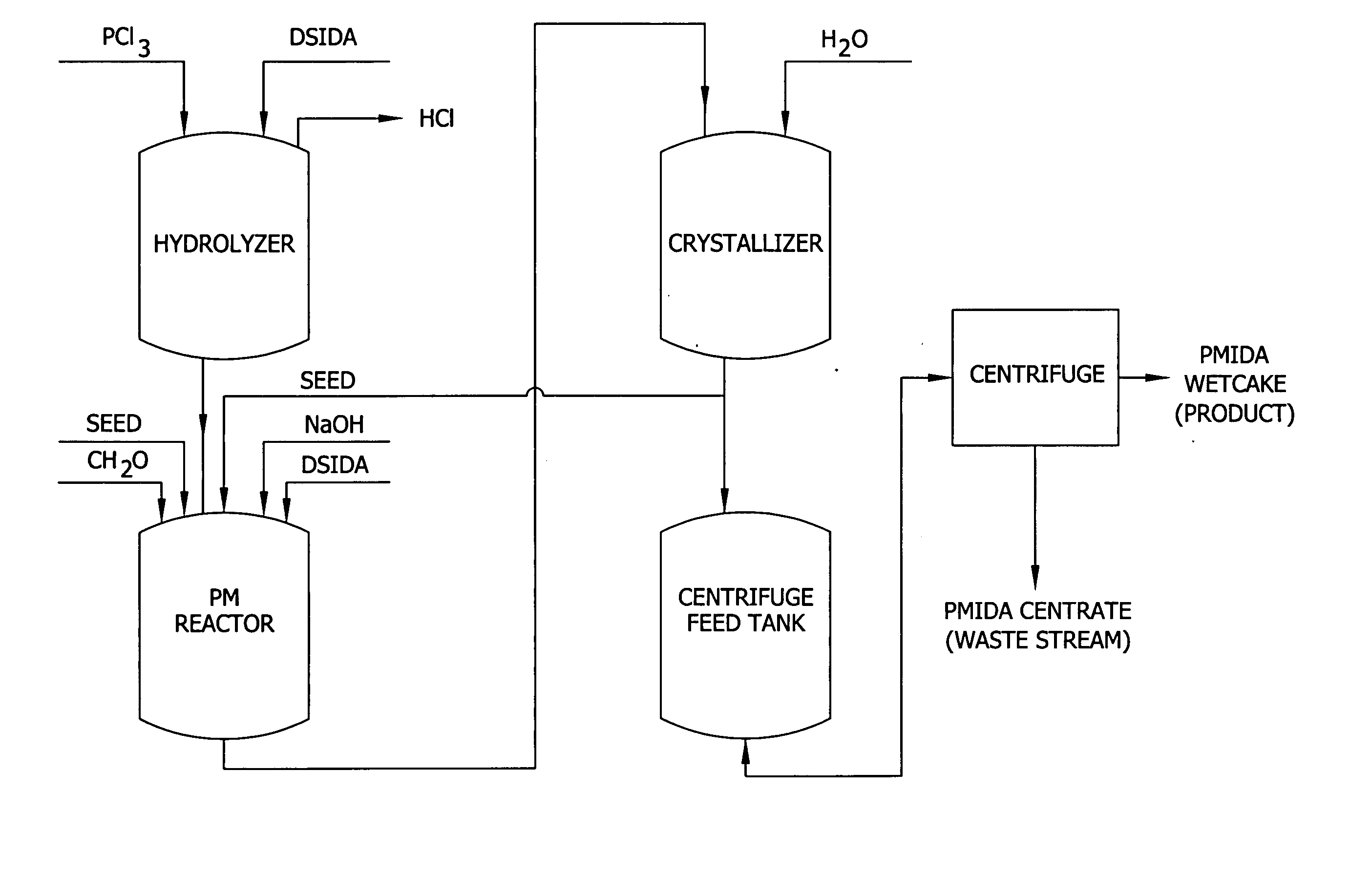

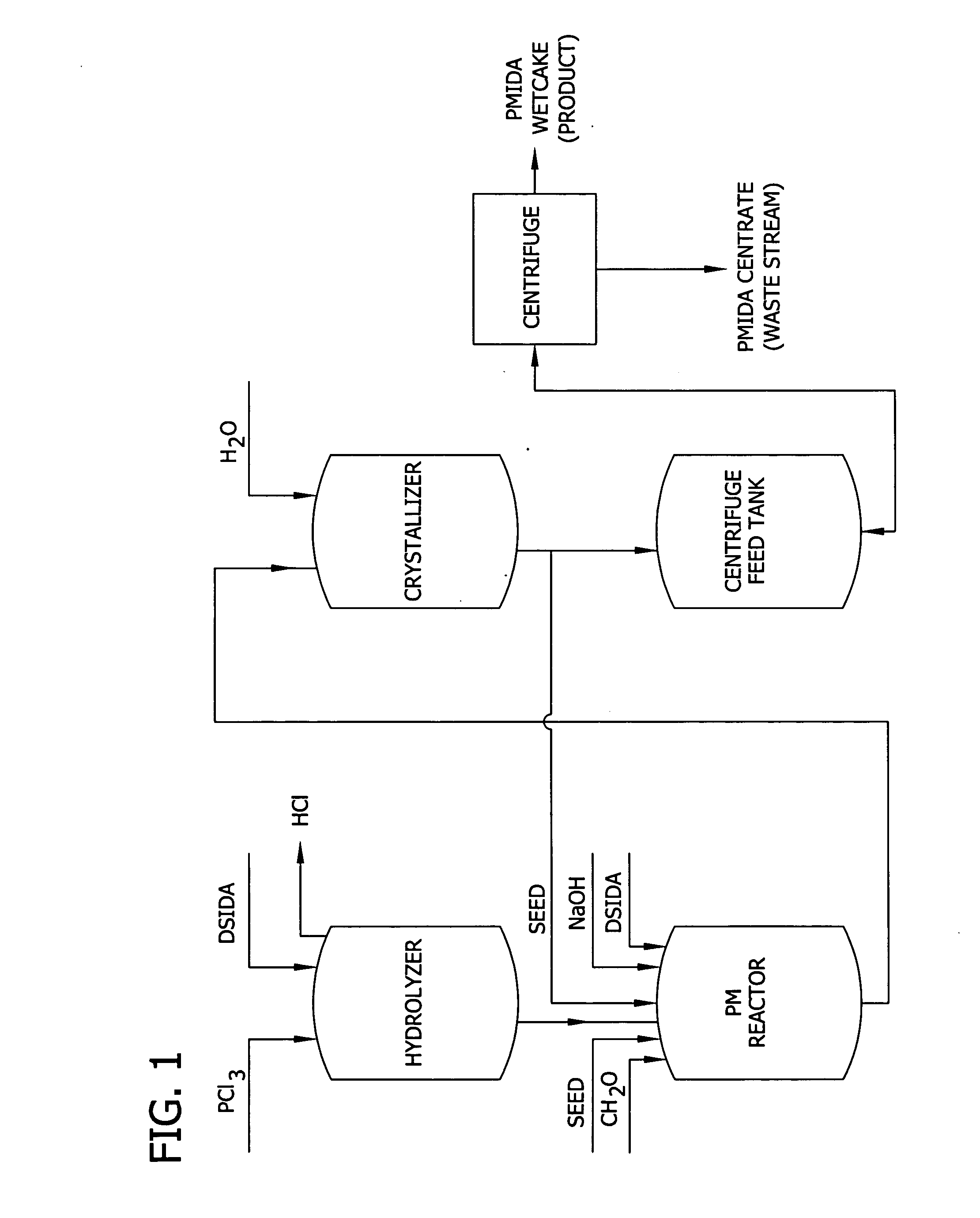

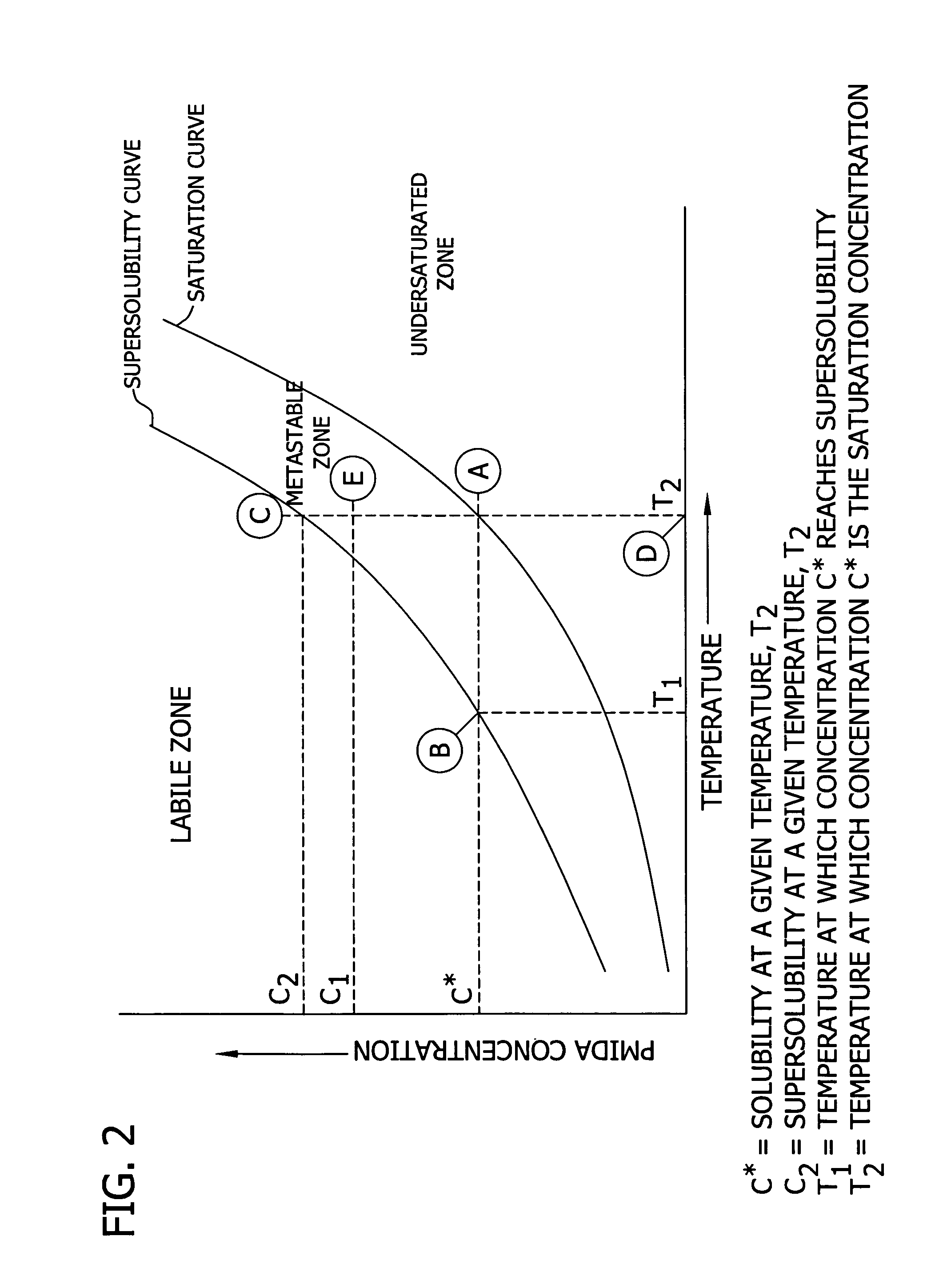

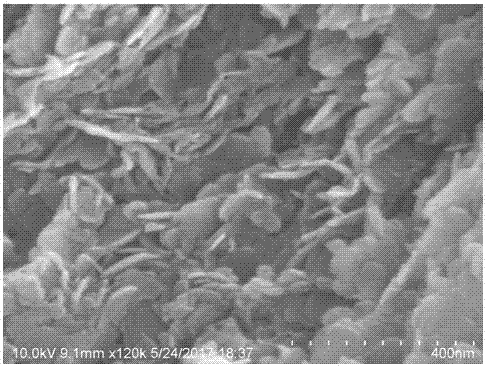

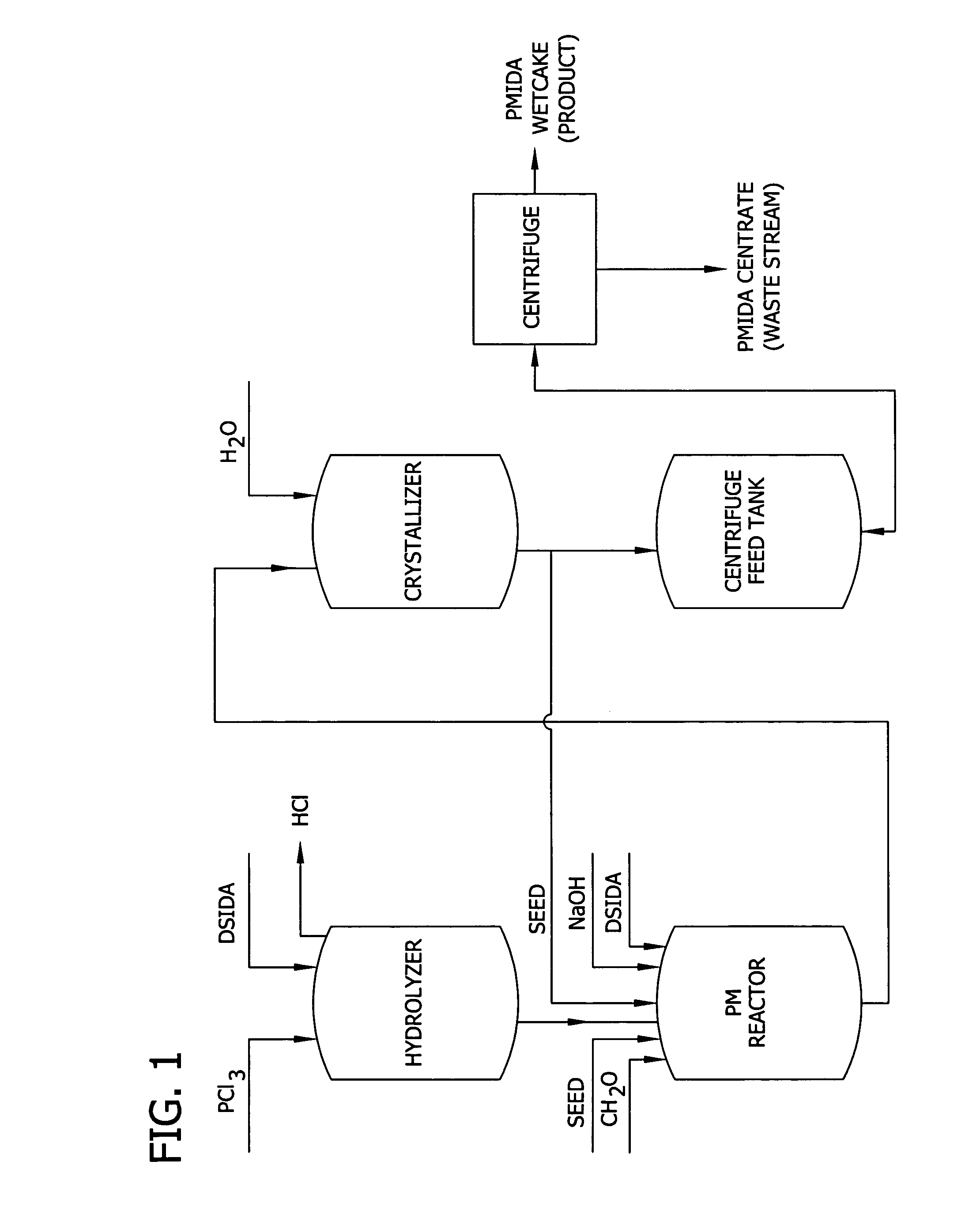

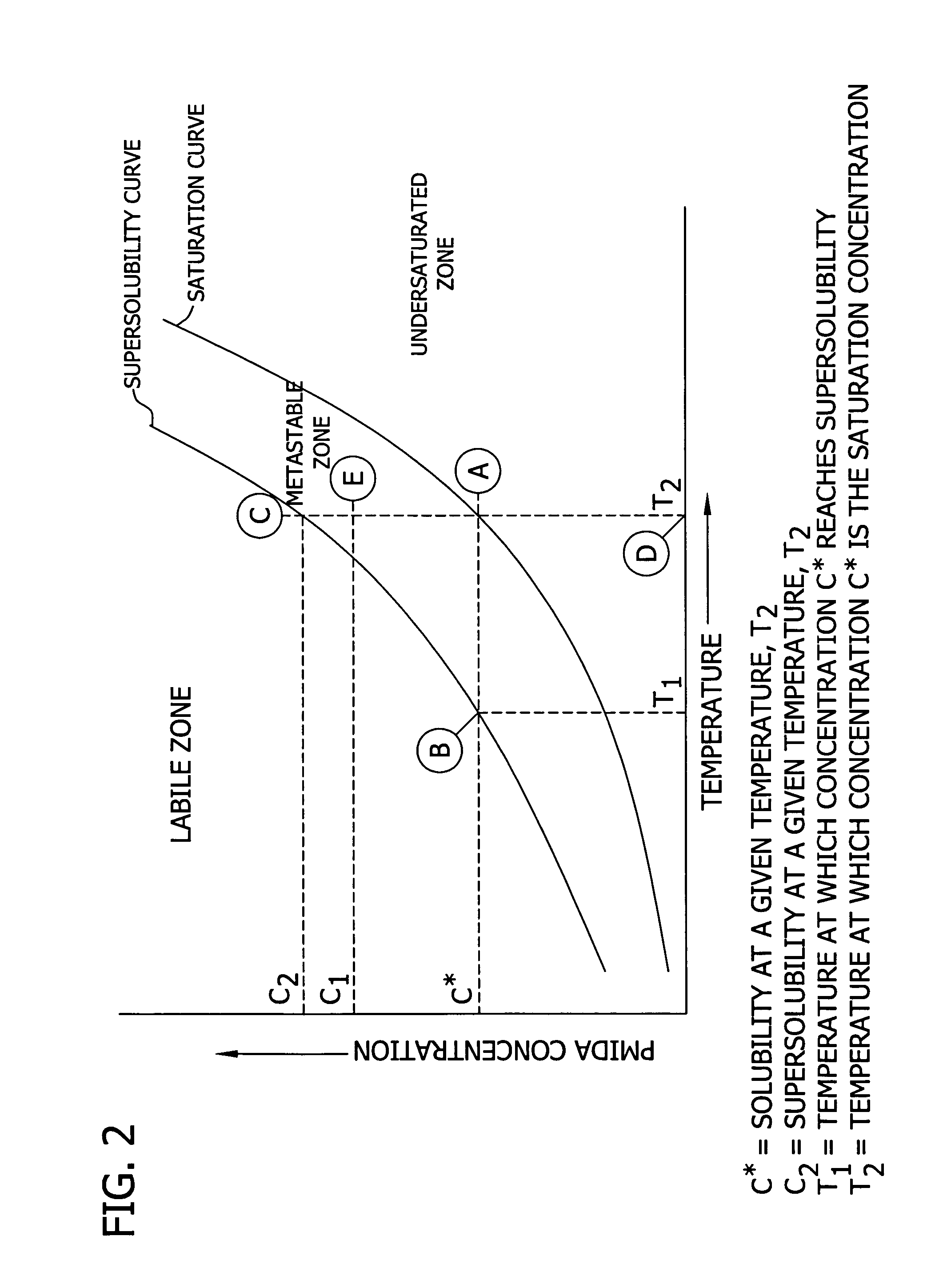

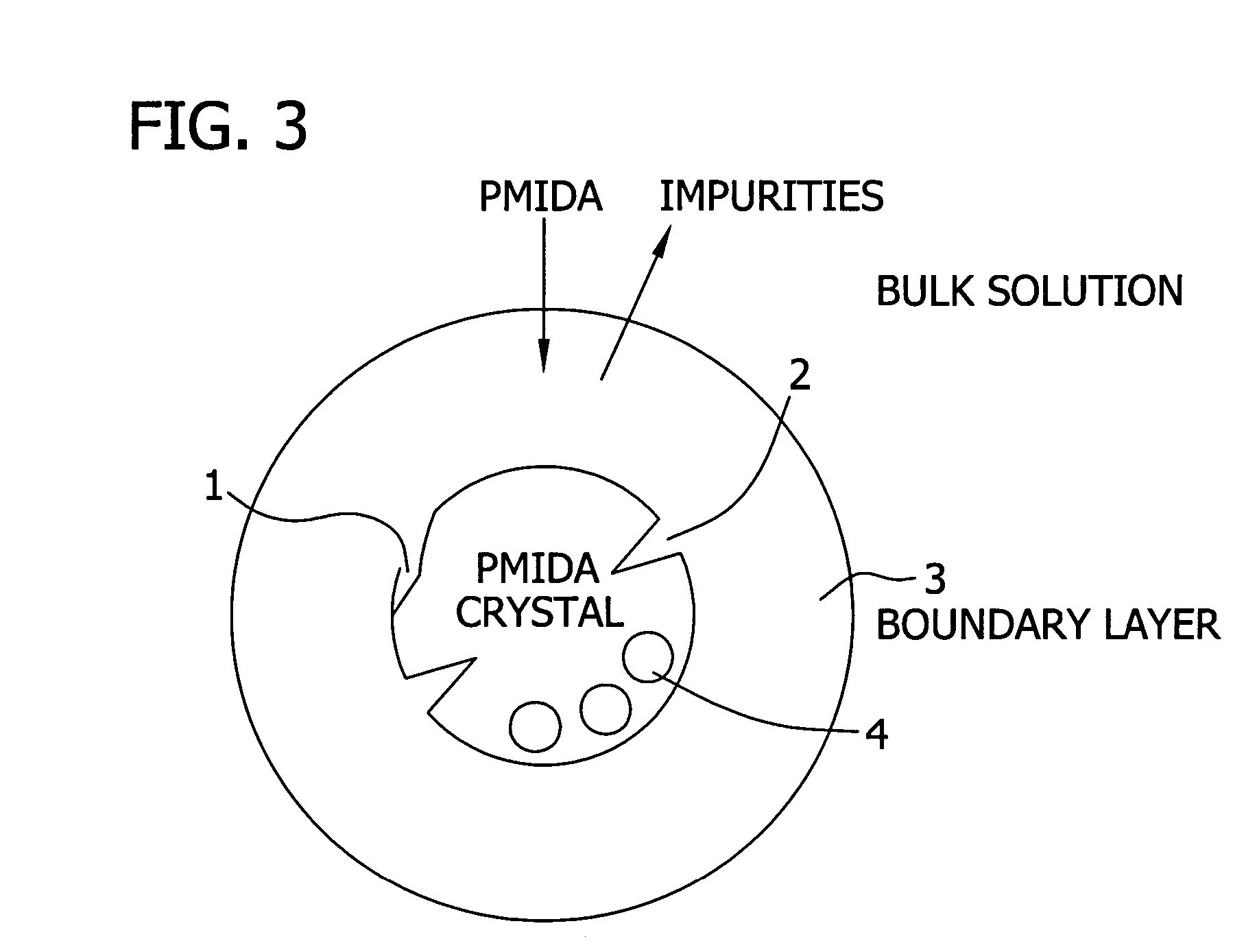

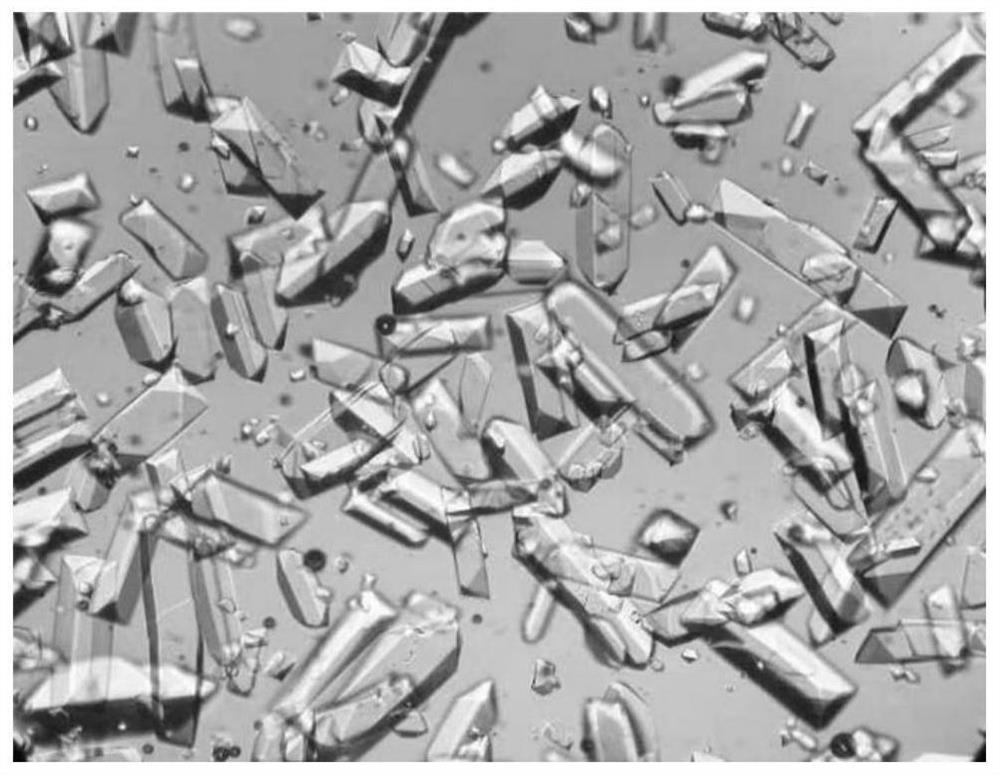

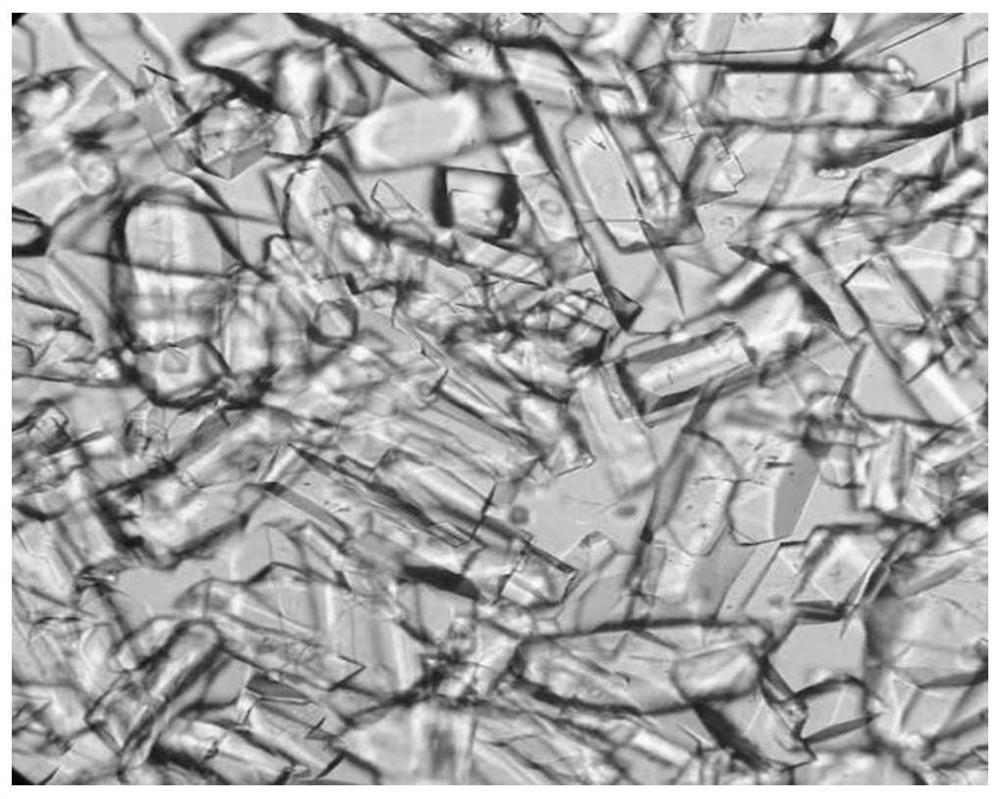

Altering the crystal size distribution of N-(phosphonomethyl) iminodiacetic acid for improved filtration and product quality

ActiveUS20060247463A1Increase filtration rateImprove permeabilityGroup 5/15 element organic compoundsProduct crystals bed crystallizationIminodiacetic acidFiltration

Improved processes for preparing and crystallizing N-(phosphonomethyl)iminodiacetic acid are provided. The processes include adding N-(phosphonomethyl)iminodiacetic acid seed crystals to N-(phosphonomethyl)iminodiacetic acid reaction solutions. Provided are beds of crystallized N-(phosphonomethyl)iminodiacetic acid having improved permeability and filtration rate and reduced impurities.

Owner:MONSANTO TECH LLC

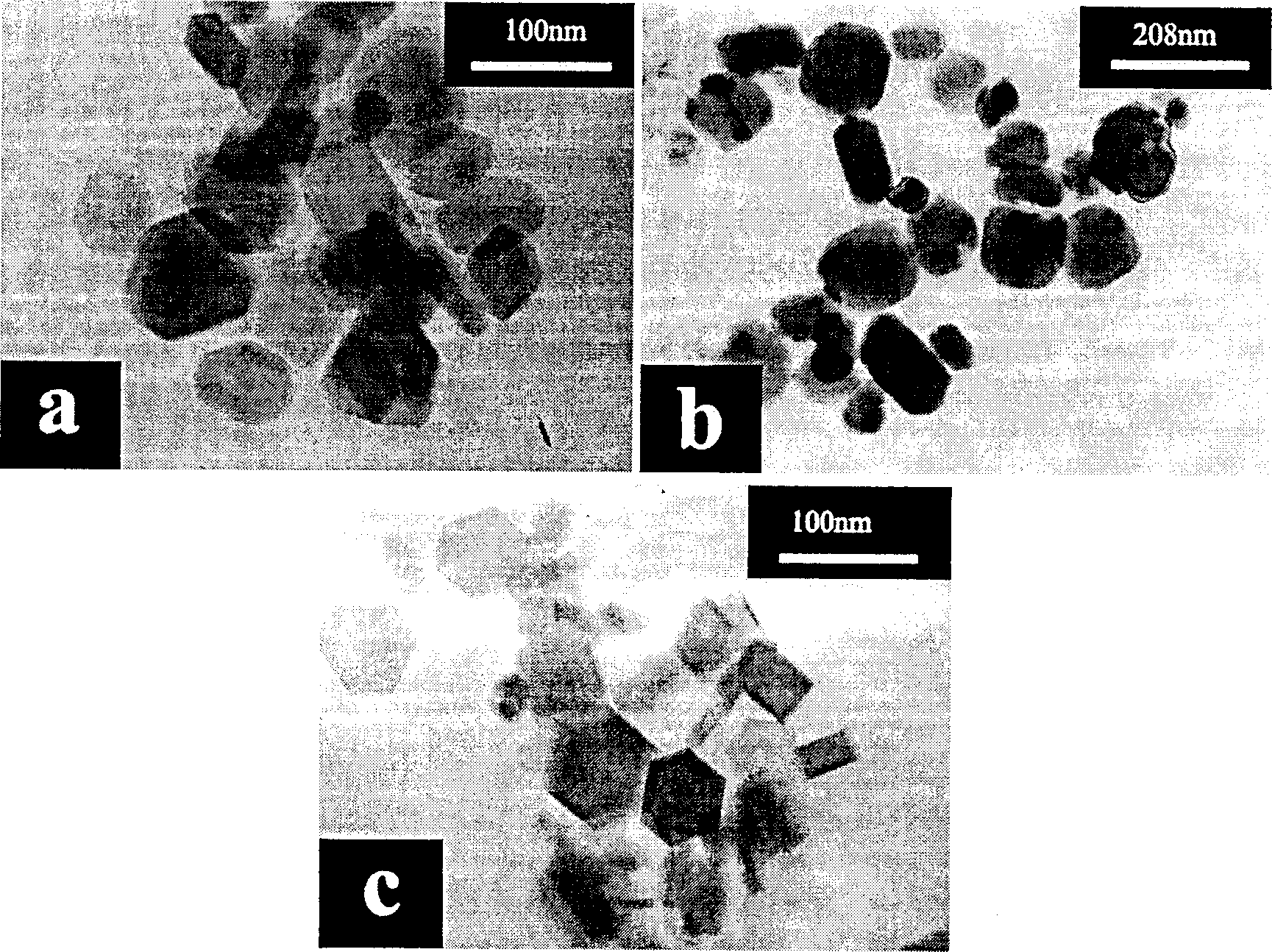

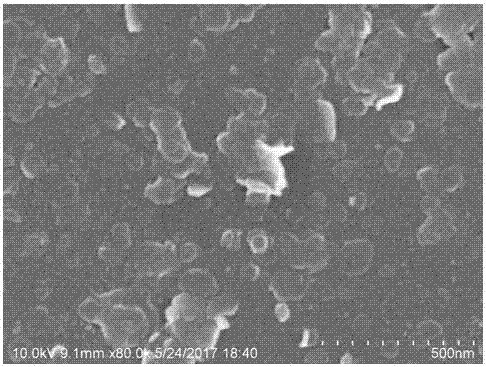

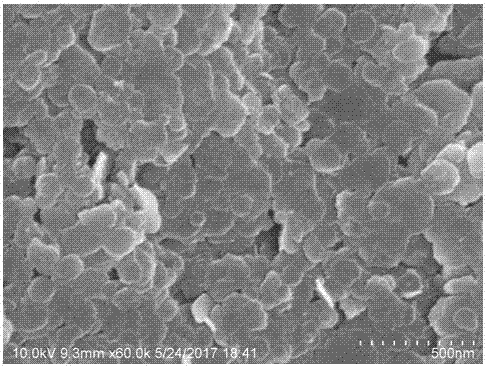

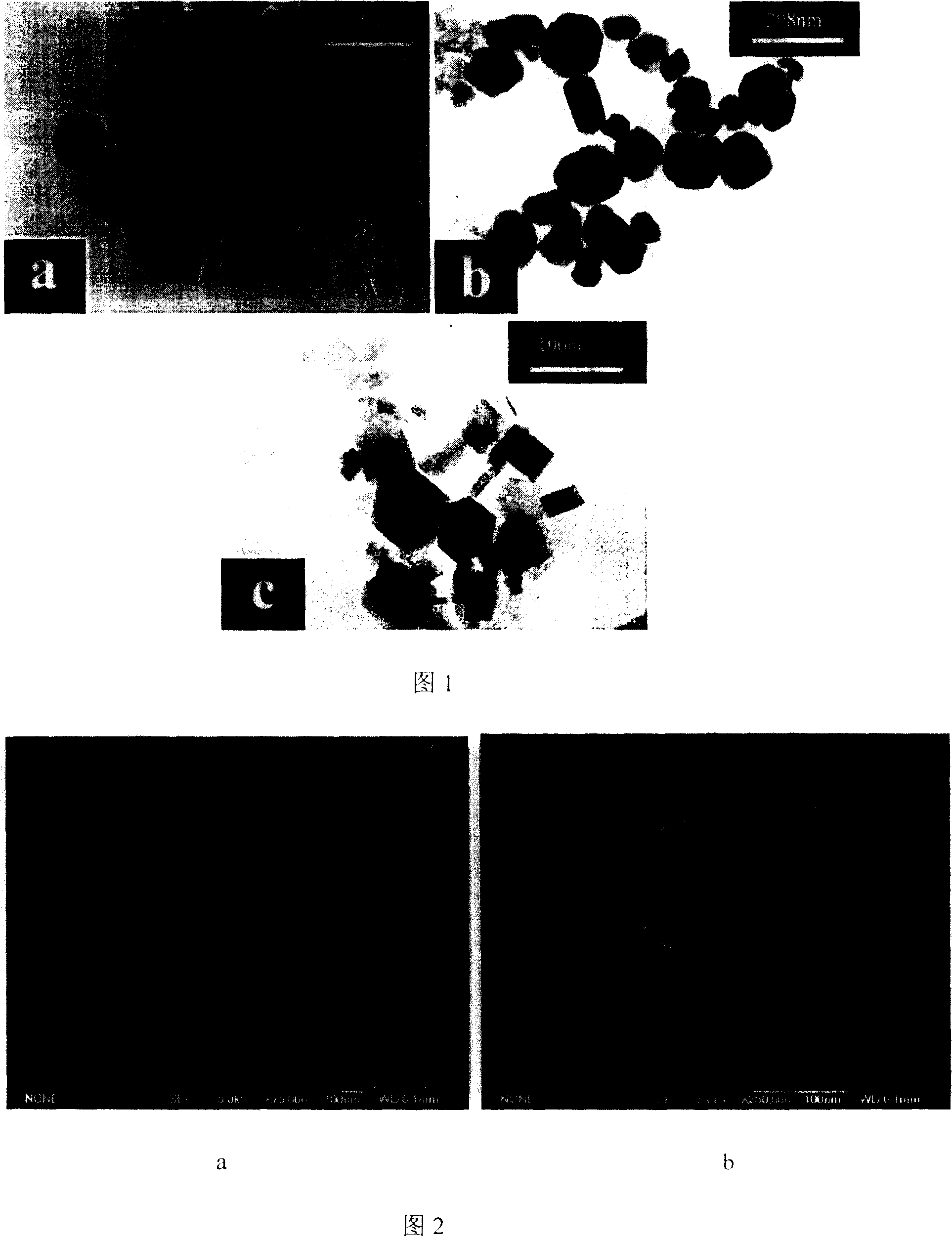

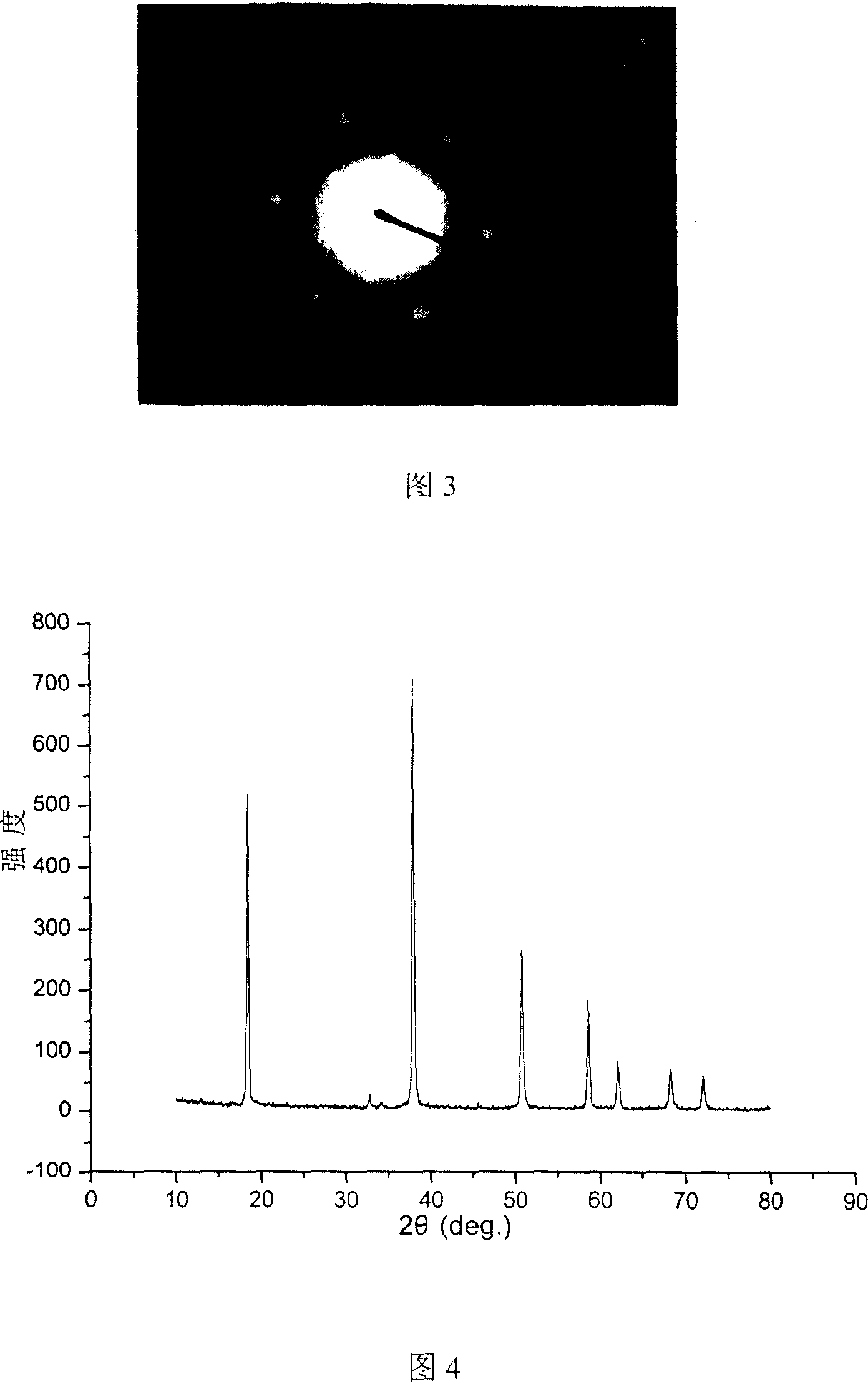

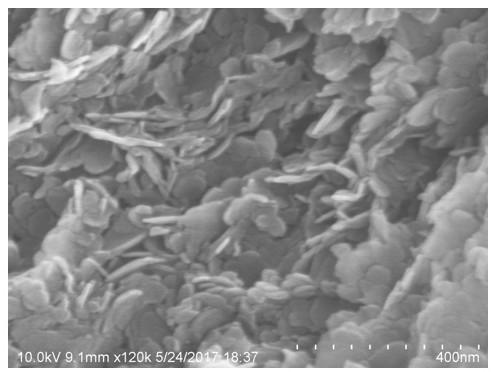

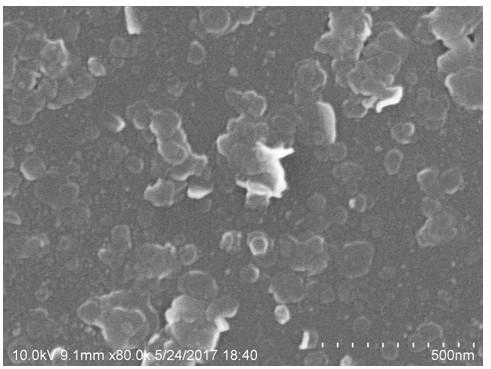

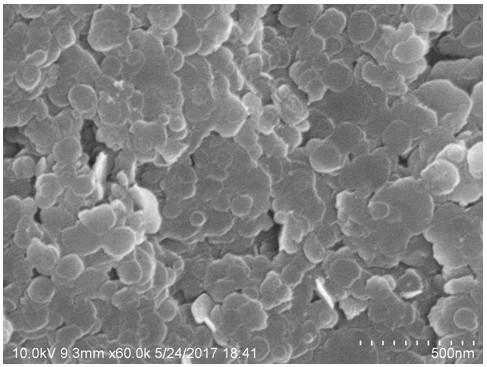

Regulating method of nano layered MgFe hydrotalcite grain growth process

InactiveCN107879377ALarge specific surface areaInhibit aggregate growthNanotechnologyIron compoundsHydrotalciteHydrothermal synthesis

The invention relates to a regulating method of a nano layered MgFe hydrotalcite grain growth process. The regulating method of the nano layered MgFe hydrotalcite grain growth process comprises the steps as follows: (1) an Mg(NO3)2 solution and a Fe(NO3)3 solution are prepared and uniformly mixed, so that the molar ratio of Mg to Fe in the solution is (1:10)-(10:1); (2) a NaOH precipitant is dropwise added to the prepared solution in step (1), and the solution is continuously stirred, so that the pH of the solution is 8-12; (3) crystallization is performed at 40-220 DEG C for 0.5-6 h, crystallization is continuously performed at 70-120 DEG C for 12-36 h, the addition quantity of organic steric hindrance agents in a hydrothermal synthesis system is 0.1%-20.0% of the total mass of the solution, a solid product is obtained through separation after the reaction, washed and separated, the obtained solid product is dried, and nano layered MgFe hydrotalcite can be obtained. The nano MgFe hydrotalcite with the narrower crystal size distribution range can be prepared.

Owner:NORTHEAST GASOLINEEUM UNIV

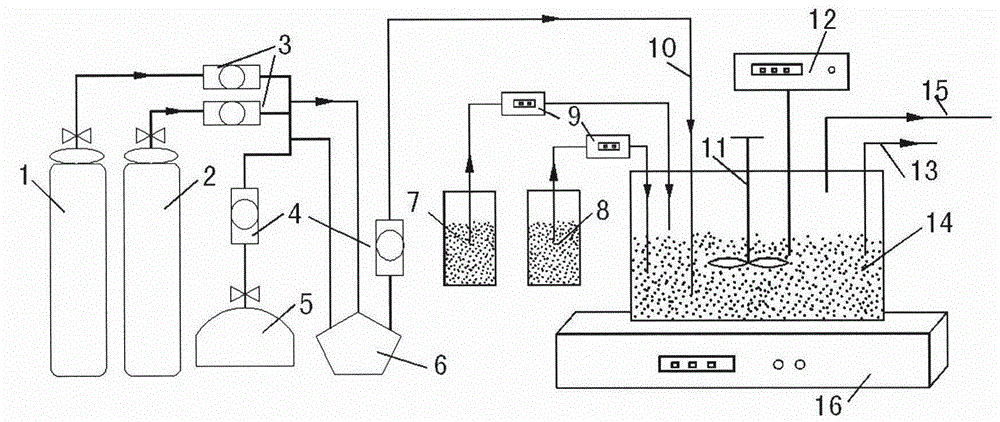

Gypsum crystallization regulator suitable for wet type calcium-based flue gas desulphurization poisoning slurry

InactiveCN104147910AReduce mass transfer rateImprove the crystallization processDispersed particle separationSlurryContamination

The invention discloses a gypsum crystallization modifier suitable for wet type calcium-based desulphurization of a thermal power generating unit, and the gypsum crystallization modifier can effectively eliminate the impact of heavy metal ions and oil contaminations in gypsum slurry on gypsum crystallization process to obtain gypsum crystals with coarse and large particles and low water content, increases stability of the desulfurization system, and belongs to the technical field of environmental protection. The gypsum crystallization modifier comprises the following components by weight: 0.1-5% of an oil-removing agent, 85-95% of a metal complexing agent and 5-10% of a surfactant, and is characterized in that the gypsum crystallization modifier can be directly added into an absorption tower or an absorption tower filtrate pit, then mixed evenly and dissolved for pumping. The gypsum crystallization modifier can accelerate the oxidation of sulfites and the gypsum crystallization process, is appropriate to improve the efficiency of the desulfurization system. In the embodiment, the gypsum crystallization modifier concentration is increased from 0% to 0.1%, the by-product gypsum purity is improved from 78% to 93%, the gypsum water content is reduced from 19% to 10%, the crystal size distribution is more uniform, acicular gypsum crystals are decreased, rhombic crystal share and columnar crystal share increase, the crystal specific surface area increases, and the gypsum dewatering performance is better.

Owner:NANJING INST OF TECH

External circulating DTB fluidized bed crystallizer

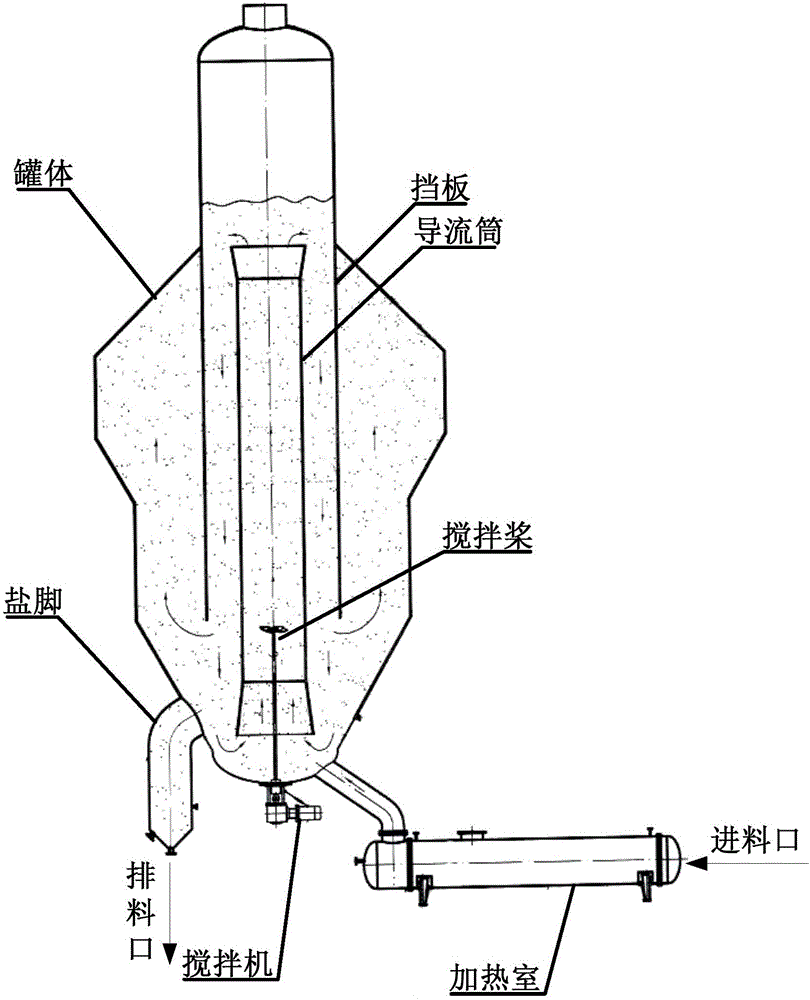

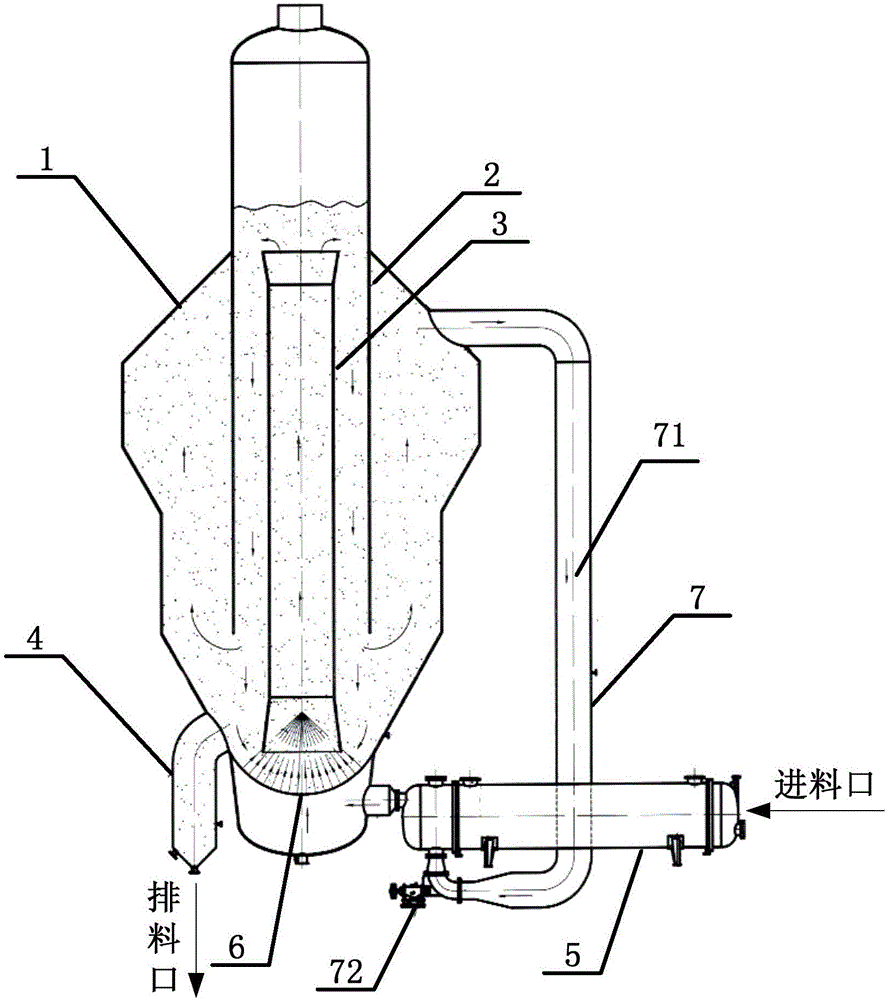

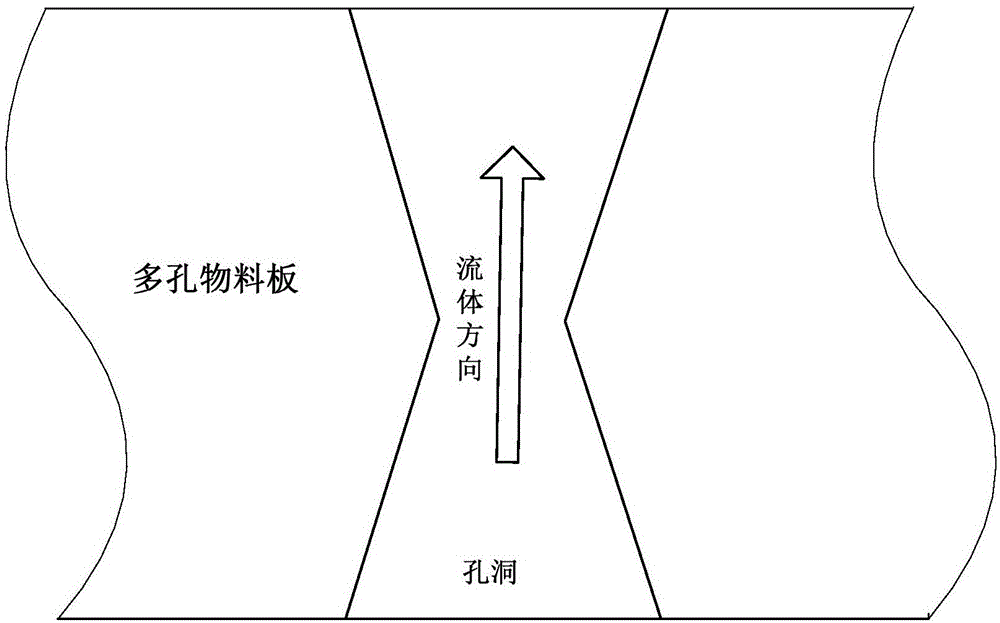

InactiveCN106215454AOuter loop implementationGood suspensionSolution crystallizationCrystallization by component evaporationFluidized bedSlurry

The invention discloses an external circulating DTB fluidized bed crystallizer. A porous distributing plate is arranged below a guide cylinder to accelerate fluid entering the guide cylinder from the bottom of a tank, the material fluid is sprayed into the guide cylinder at high speed, crystal suspending is promoted, and crystal slurry in the crystallizer forms a uniform fluidized layer. The degree of supersaturation is effectively eliminated, crystal size distribution is even, meanwhile, an external circulating device is adopted, fluid flowing to the area between a baffle and the tank flows back to a heating chamber in the crystallization process, and external circulation of the fluid is achieved. The circulating mode is optimized, circulating efficiency is improved, and therefore crystallization efficiency is improved.

Owner:YIYANTANG YINGCHENG HEALTH SALT MFG

Preparation method of psicose crystals

ActiveCN112574263ASimple preparation processEasy to operateSugar derivativesOrganic chemistry methodsCrystal morphologyCrystal size distribution

The invention relates to a preparation method of psicose crystals. According to the method, the psicose crystal is prepared by combining an evaporative crystallization method and a cooling crystallization method, the preparation process is simple, the operation is easy, and the crystallization period is short. According to the method, the seed crystal is added when the solid content is low (70-75%) in the evaporative crystallization process, so that the crystallization process is facilitated, the growth speed of the crystal in each direction is more uniform, the whole crystallization period can be shortened, and the energy consumption is reduced; after the evaporative crystallization is finished, crystal rectification is carried out, so that the crystal size tends to be equalized, the crystal surface grows to be smooth, and the crystal form is perfected; cooling crystallization is carried out after crystal rectification, and the cooling frequency of different cooling intervals is designed in the cooling process according to the metastable region curve of psicose. After crystallization according to the preparation method disclosed by the invention is finished, the obtained crystal is high in yield, centralized in crystal size distribution, smooth in crystal surface, mirror-like, good in reflectivity and regular in crystal form.

Owner:SHANDONG BAILONG CHUANGYUAN BIO TECH

Solid hollow fiber cooling crystallization systems and methods

InactiveUS7754083B2Improve cooling effectEffective decouplingFrom normal temperature solutionsSolvent extractionFiberProcess equipment

A solid hollow fiber cooling crystallizer and method for crystallizing aqueous and organic solutions are provided. The solid hollow fiber crystallizer (SHFC) for carrying out cooling crystallization of inorganic / organic microsolutes / macrosolutes from solution generally includes a bundle of non-porous hollow fibers mounted within a shell where a feed solution for crystallization flows through the lumen side of the hollow fibers and a cooling solution flows through the shell side to form nuclei and subsequently crystals in the feed solution at a temperature below its saturation temperature. The solid hollow fiber crystallizer may be combined with a mixing device, such as a completely stirred tank or static mixer, to further effectuate crystallization. The solid hollow fiber crystallizer may be operated in a number of modes including feed recycle mode, once through mode, SHFC-in-line static mixer in series mode, and SHFC-CST in series mode. The advantages of solid hollow fiber cooling crystallization in comparison to conventional crystallization processes include improved temperature control between crystallizing solution and coolant, higher nucleation rates, improved control of crystal size and crystal size distribution, smaller crystal size, capability for decoupling crystal nucleation and crystal growth, decreased fouling of process equipment, and improved process scale-up.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

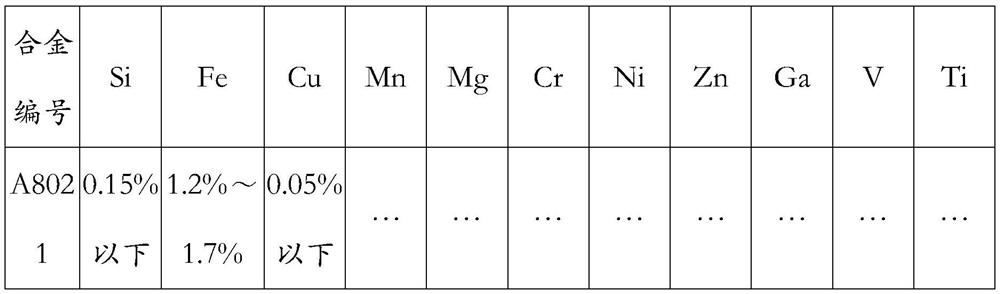

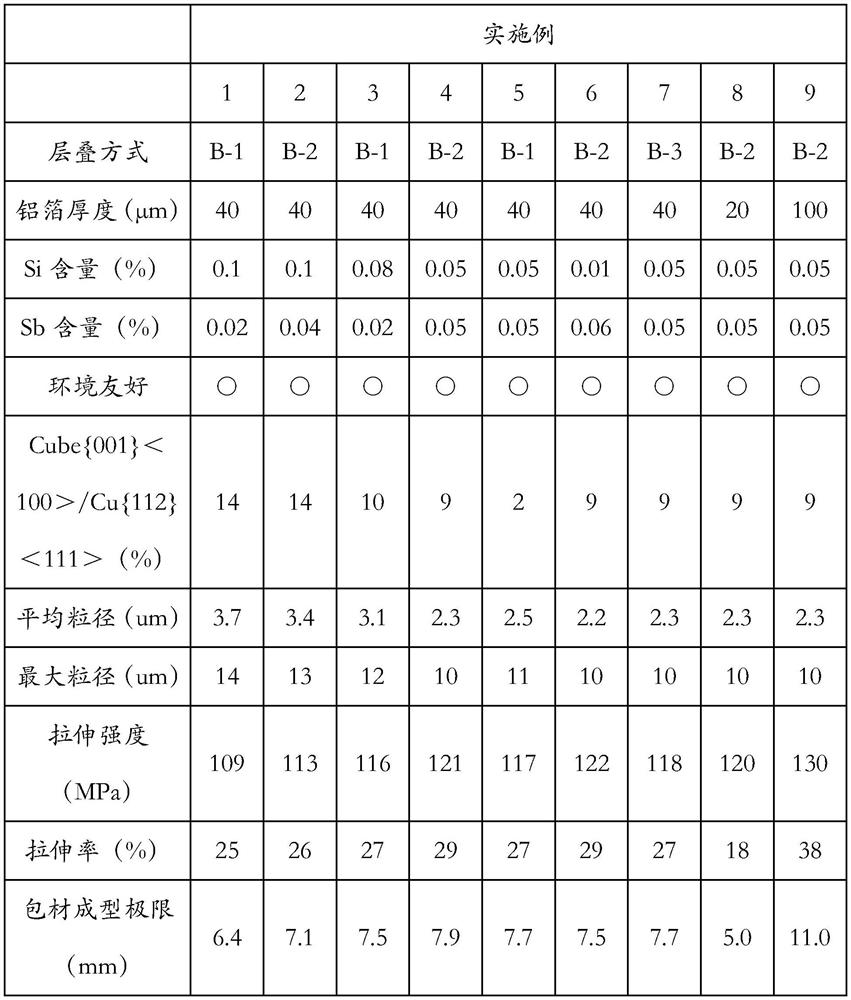

Outer packaging material for high-punching-depth battery device and battery

PendingCN112848577AReduce Si contentCrystallizationSynthetic resin layered productsElectrical equipmentCrystal size distributionAluminum foil

The invention relates to an outer packaging material for a high-punching-depth battery device and a battery. The outer packaging material comprises a base material layer, a barrier layer and a hot melting layer; the outer packaging material is characterized in that the barrier layer is an aluminum alloy foil; the distribution of the optimal plane orientation of the aluminum alloy foil is the ratio of Cube {001} < 100 > orientation to Cu {112} < 111 >, i.e., Cube {001} < 100 > / Cu {112} < 111 > = 1.6-20%, and the proportion of S {123} < 643 > orientation in the entire aluminum alloy foil is 15% or more. The material has the positive effects that the proportion of Cube {001} < 100 > / Cu {112} < 111 > is reduced within a certain range, so that the crystal size distribution in the aluminum foil can be reduced, the crystal uniformity is improved, and the forming limit depth is deepened.

Owner:WUXI ENERGY NEW MATERIALS TECH CO LTD

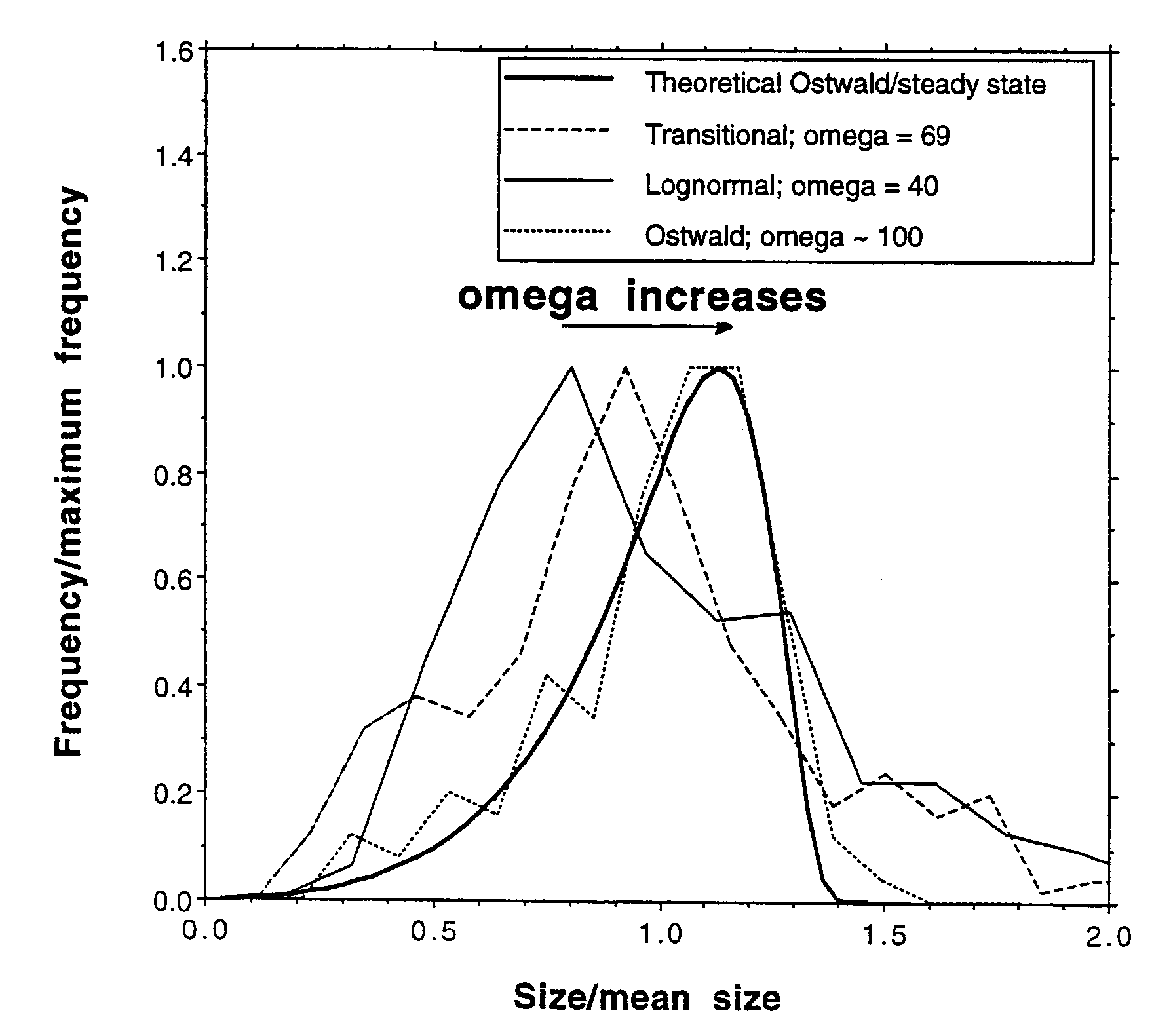

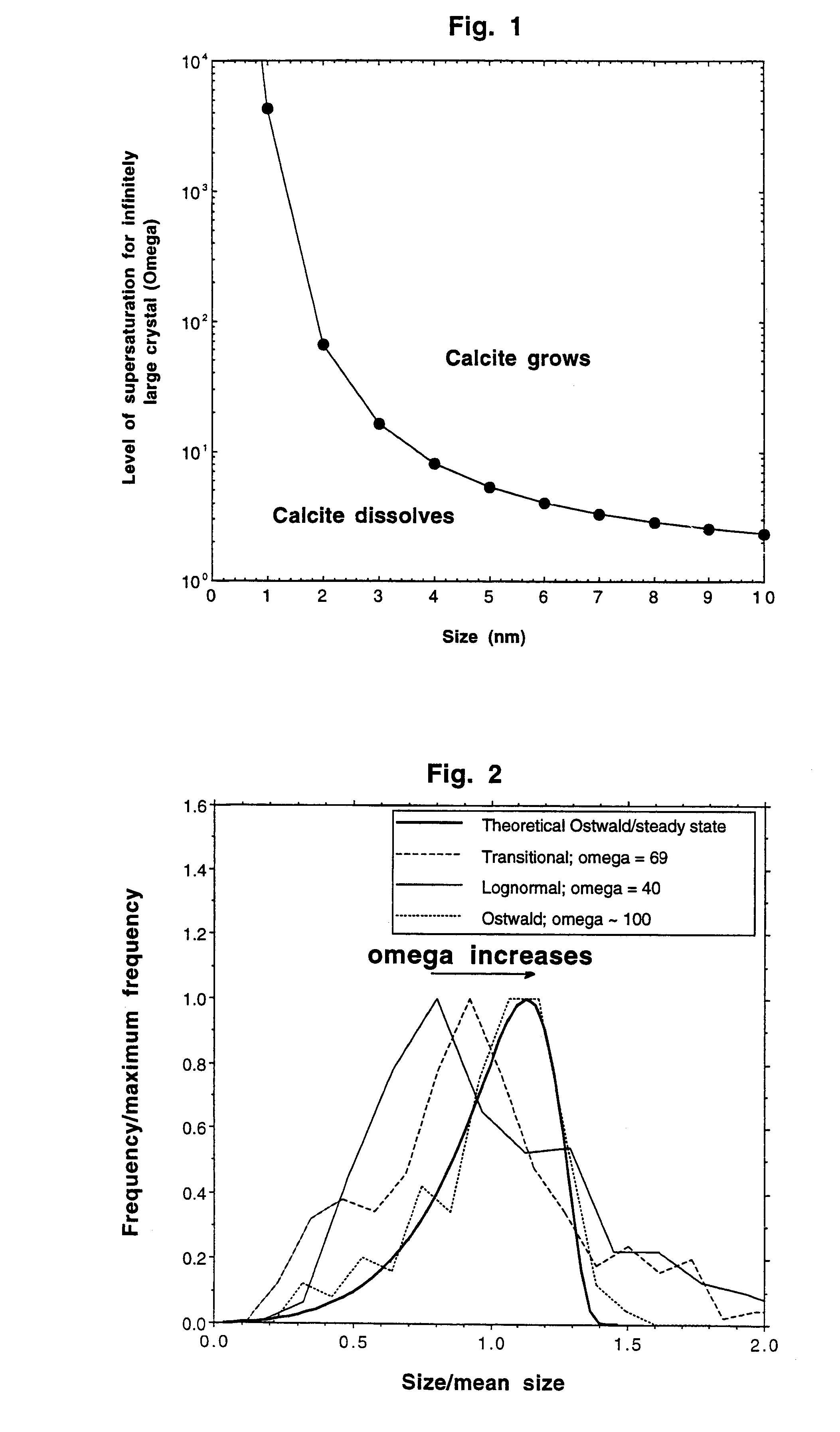

Crystallization of powders having uniform particle sizes by Ostwald ripening at large levels of supersaturation

InactiveUS6379459B1Calcium/strontium/barium carbonatesPolycrystalline material growthEngineeringCrystal size distribution

A method is provided for the manufacture of mineral power crystals having a uniform mean size. The method includes forming a solution which is highly supersaturated with respect to the crystals. The crystals of the solution are Ostwald ripened at a level of supersaturation that produces an Ostwald steady state crystal size distribution shape wherein the crystals are of a uniform size. After Ostwald ripening ceases, the crystals further grow by supply controlled growth which uniformly increases the size thereof. This enables the supply controlled growth to be terminated at a selected, controlled point so as to produce a desired mean crystal size.

Owner:INTERIOR UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC

Synthesis of chabazite-containing molecular sieves and their use in the conversion of oxygenates to olefins

In a method of synthesizing a silicoaluminophosphate molecular sieve having 90%+CHA framework type character, a reaction mixture is prepared comprising first combining a reactive source of aluminum with a reactive source of phosphorus to form a primary mixture that is aged. A reactive source of silicon and a template for directing the formation of the molecular sieve can then be added to form a synthesis mixture. Crystallization is then induced in the synthesis mixture. Advantageously, (i) the source of silicon comprises an organosilicate, (ii) the source of phosphorus optionally comprises an organophosphate, and (iii) the crystallized silicoaluminophosphate molecular sieve has a crystal size distribution such that its average crystal size is not greater than 5 μm. The molecular sieve can then preferably be used in a hydrocarbon (oxygenates-to-olefins) conversion process.

Owner:EXXONMOBIL CHEM PAT INC

Prepn of magnesium hydroxide for fire retardant

InactiveCN1331984CHigh crystallinityUniform particle size distributionFireproof paintsAqueous sodium hydroxideFree cooling

Owner:山东凯利隆化工有限公司

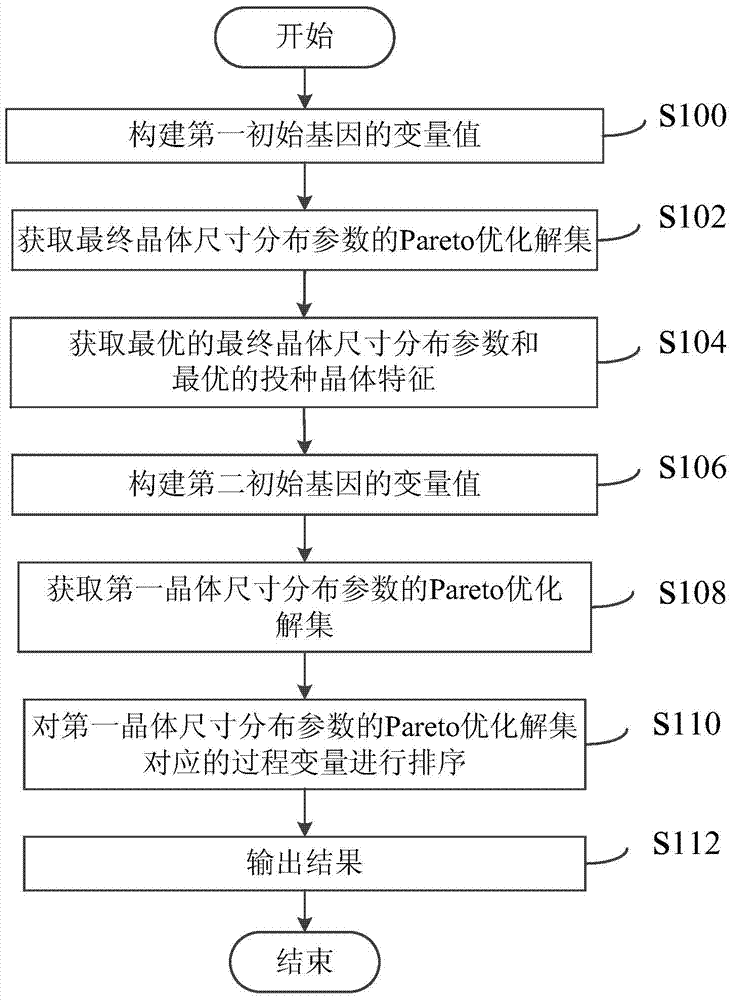

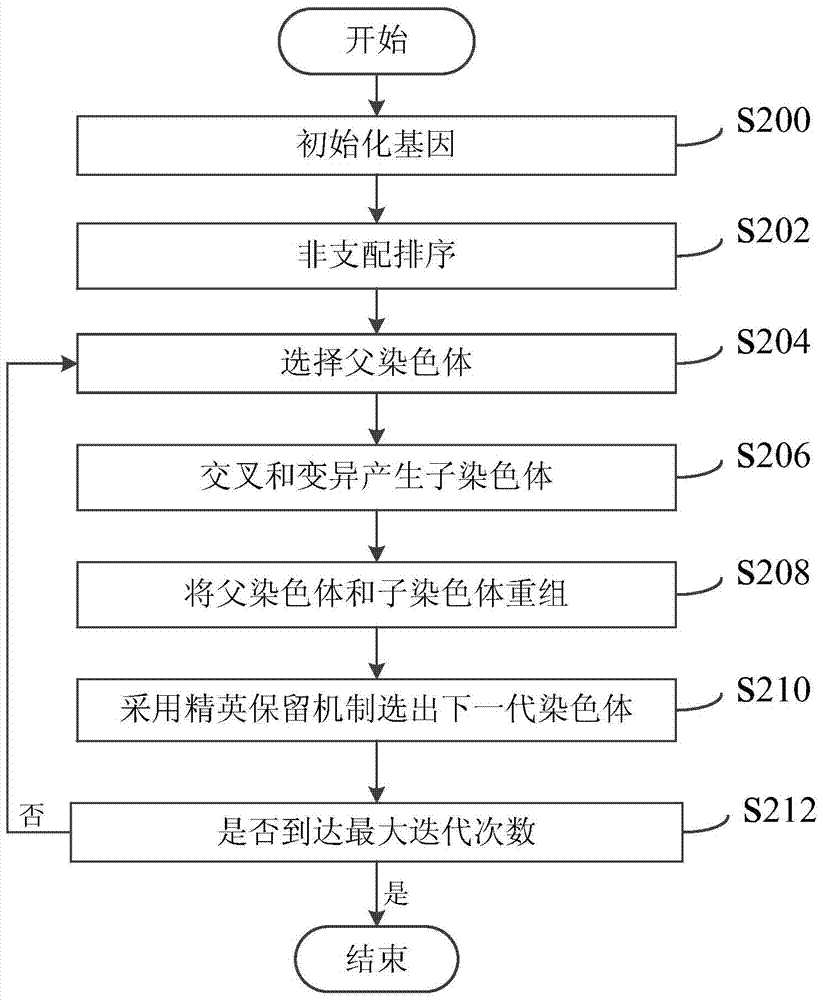

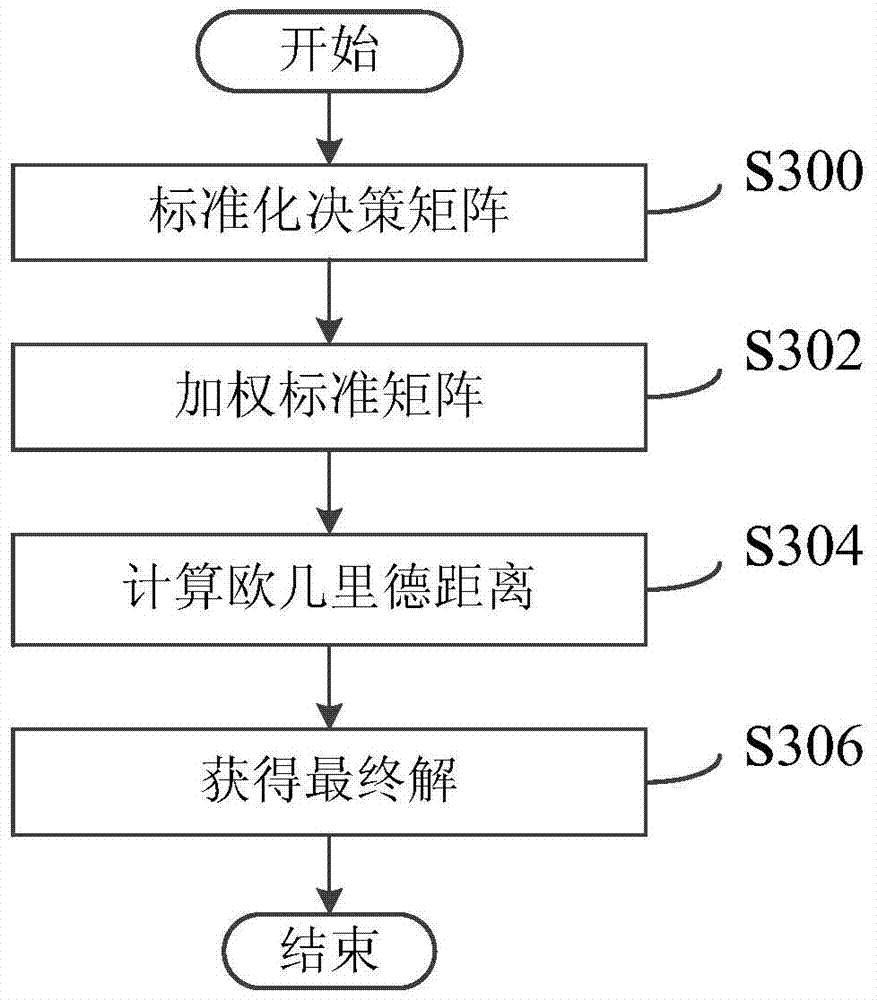

Intermittent sugarcane sugar boiling and crystallization process multi-objective optimization method

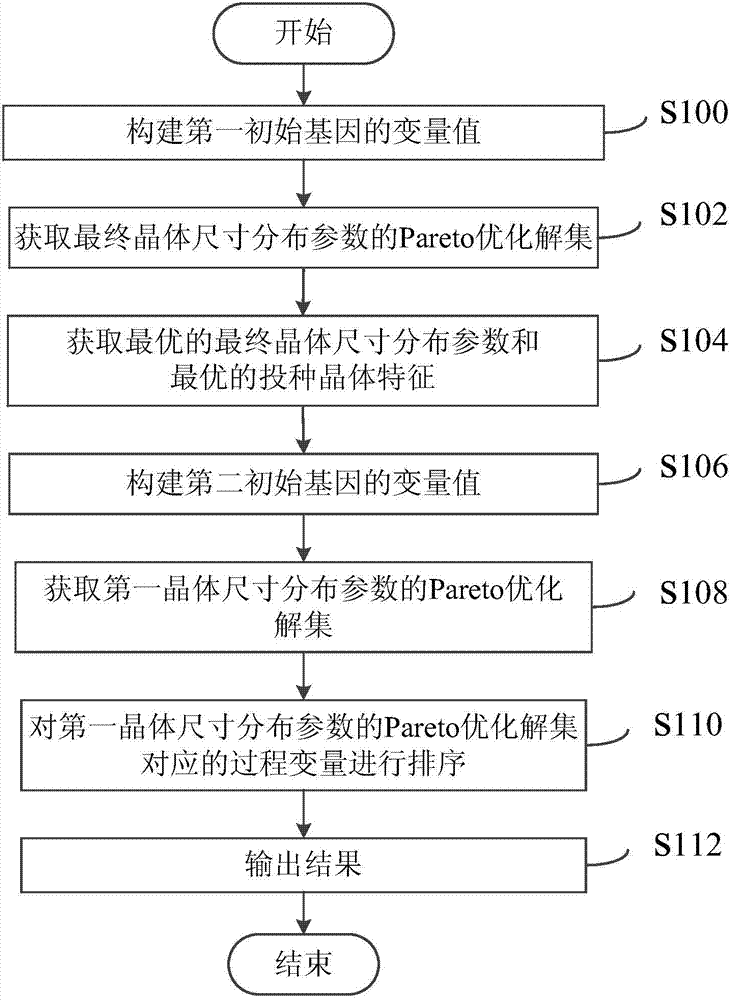

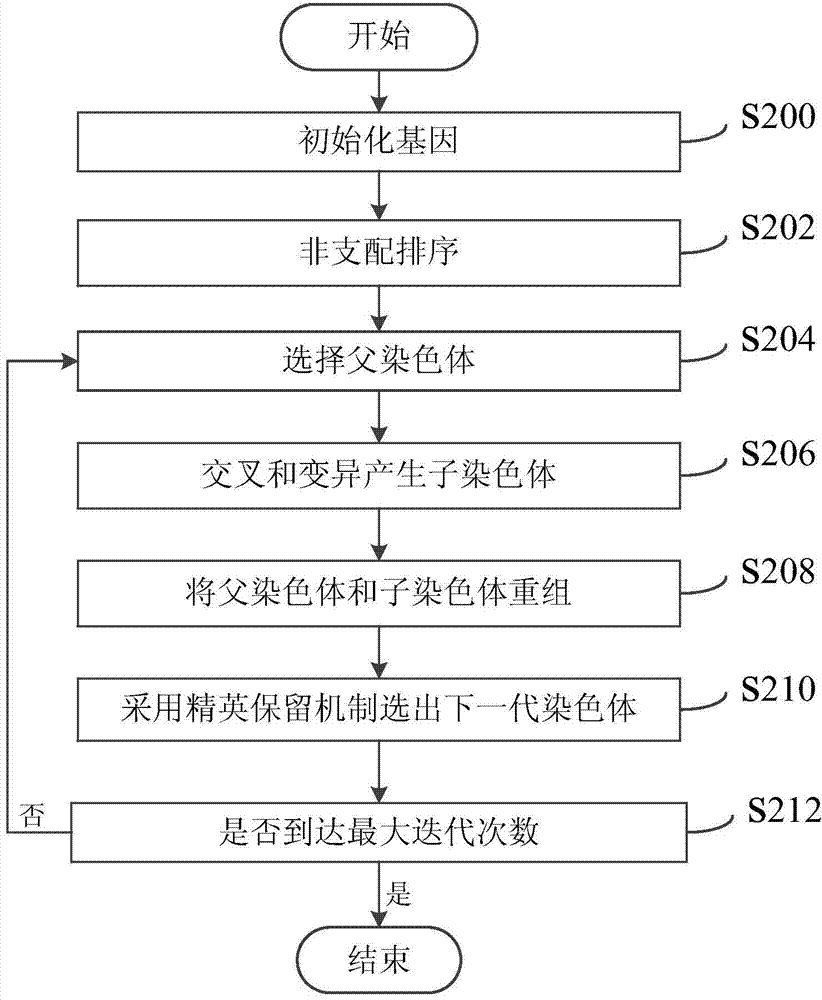

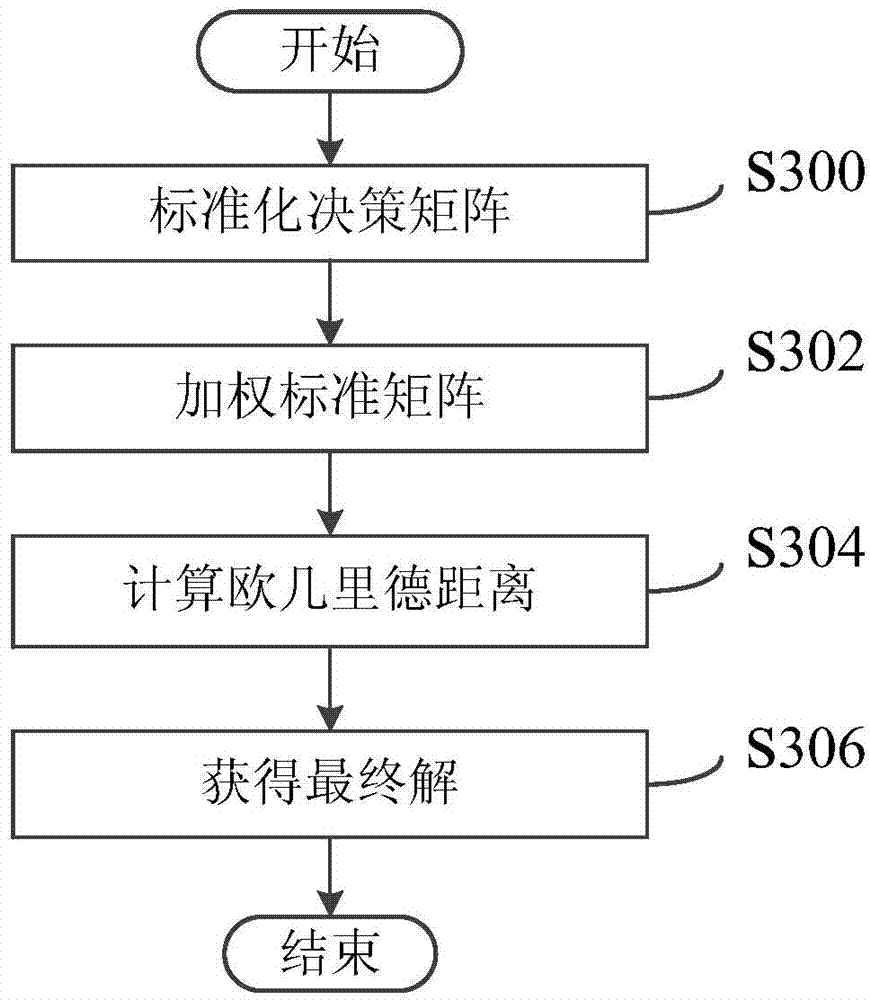

ActiveCN104778314AComprehensive multi-objective optimizationMulti-objective optimization is accurate and reliableSpecial data processing applicationsGenetic algorithmCrystal size distribution

The invention discloses an intermittent sugarcane sugar boiling and crystallization process multi-objective optimization method. The method comprises the following steps: 1) establishing a variable value of a first initial gene; 2) performing optimization to the first initial gene in step 1) by using a non-dominated sorting genetic algorithm to obtain a Pareto optimal solution set of final crystal size distribution parameters; 3) performing multi-objective decision making to the Pareto optimal solution set of the final crystal size distribution parameters in step 2) to obtain an optimal final crystal size distribution parameter; 4) establishing a variable value of a second initial gene; 5) performing optimization to the second initial gene in step 4) by using the non-dominated sorting genetic algorithm to obtain a Pareto optimal solution set of first crystal size distribution parameters; 6) ordering process variables corresponding to the Pareto optimal solution set of the first crystal size distribution parameters; 7) outputting results. By using the intermittent sugarcane sugar boiling and crystallization process multi-objective optimization method, better optimization results can be obtained so as to better guide the optimization control of a sugarcane sugar boiling and crystallization process.

Owner:GUANGXI UNIV

Altering the crystal size distribution of N-(phosphonomethyl) iminodiacetic acid for improved filtration and product quality

ActiveUS7705178B2Improve filtering effectImprove permeabilityGroup 5/15 element organic compoundsProduct crystals bed crystallizationFiltrationCrystal size distribution

Improved processes for preparing and crystallizing N-(phosphonomethyl)iminodiacetic acid are provided. The processes include adding N-(phosphonomethyl)iminodiacetic acid seed crystals to N-(phosphonomethyl)iminodiacetic acid reaction solutions. Provided are beds of crystallized N-(phosphonomethyl)iminodiacetic acid having improved permeability and filtration rate and reduced impurities.

Owner:MONSANTO TECH LLC

A kind of preparation method of psicose crystal

ActiveCN112574263BSimple preparation processEasy to operateSugar derivativesOrganic chemistry methodsCrystal morphologyPsicose

The invention relates to a method for preparing psicose crystals. The present invention adopts the combination of evaporation crystallization method and cooling crystallization method to prepare allulose crystals, the preparation process is simple, easy to operate, and the crystallization period is short. In the present invention, during the evaporation crystallization process, the seed crystals are added at a lower solid content (70-75%), which is beneficial to the crystallization process, and the crystal growth rate in all directions is more uniform, which can shorten the entire crystallization period and save energy. Consumption; crystallization is carried out after evaporation and crystallization. The crystallization makes the crystal size tend to be averaged, and at the same time the crystal surface grows to be smooth, and the crystal shape is improved; after the crystallization, cooling crystallization is carried out. Zone curve, design the cooling frequency of different cooling intervals. According to the preparation method of the present invention, after the crystallization is completed, the yield of the obtained crystals is high, the crystal size distribution is concentrated, and the crystal surface is smooth and mirror-like, with good light reflection and regular crystal forms.

Owner:SHANDONG BAILONG CHUANGYUAN BIO TECH

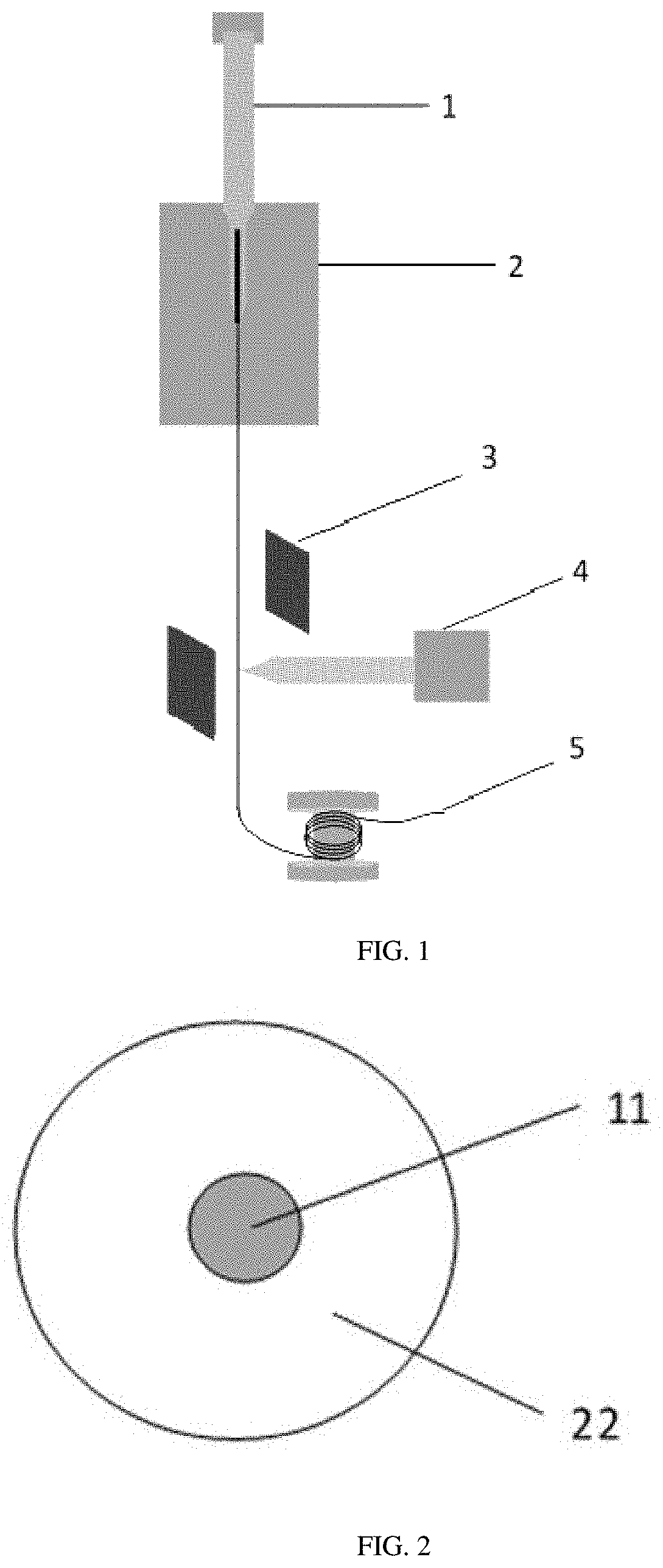

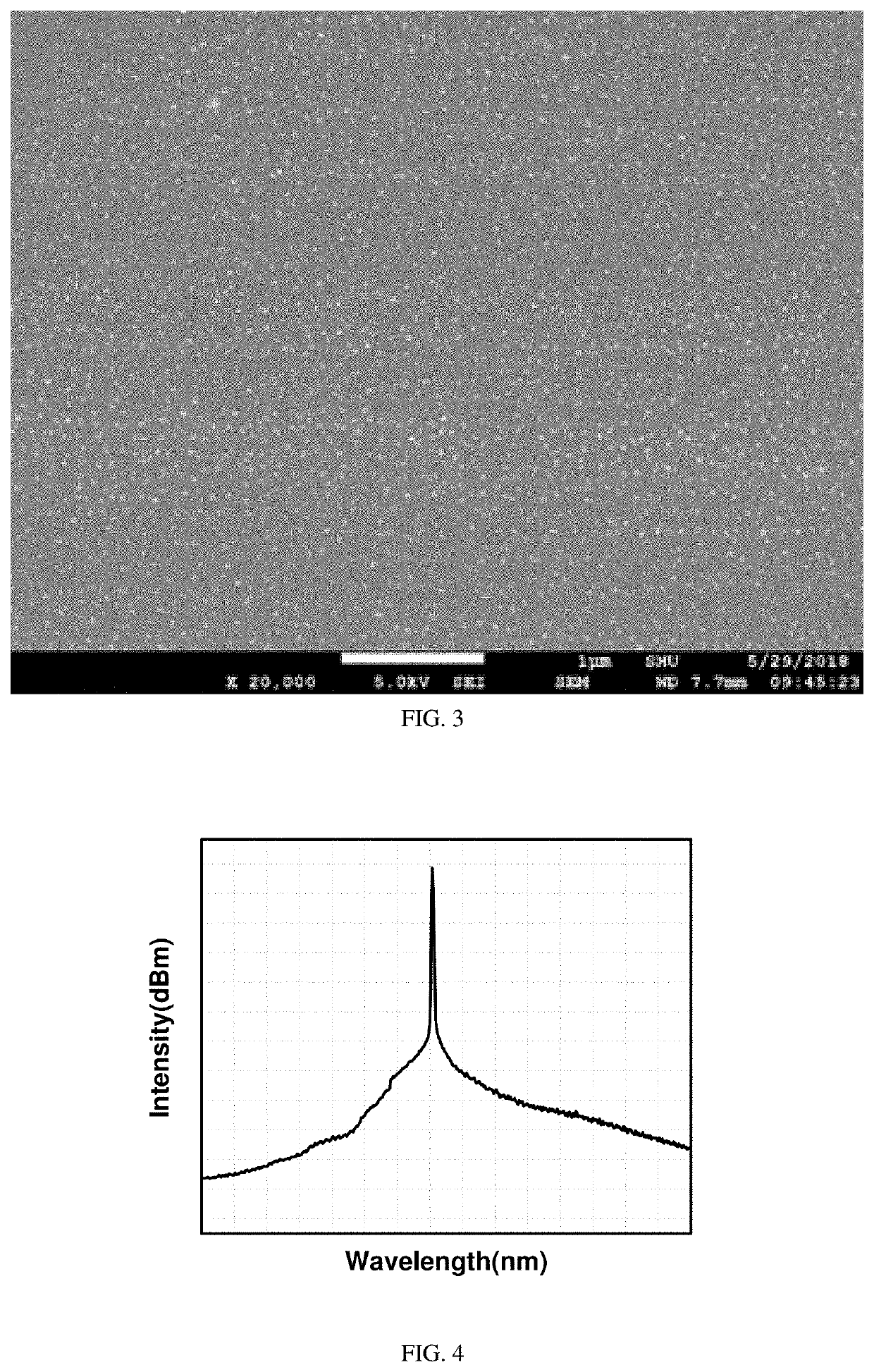

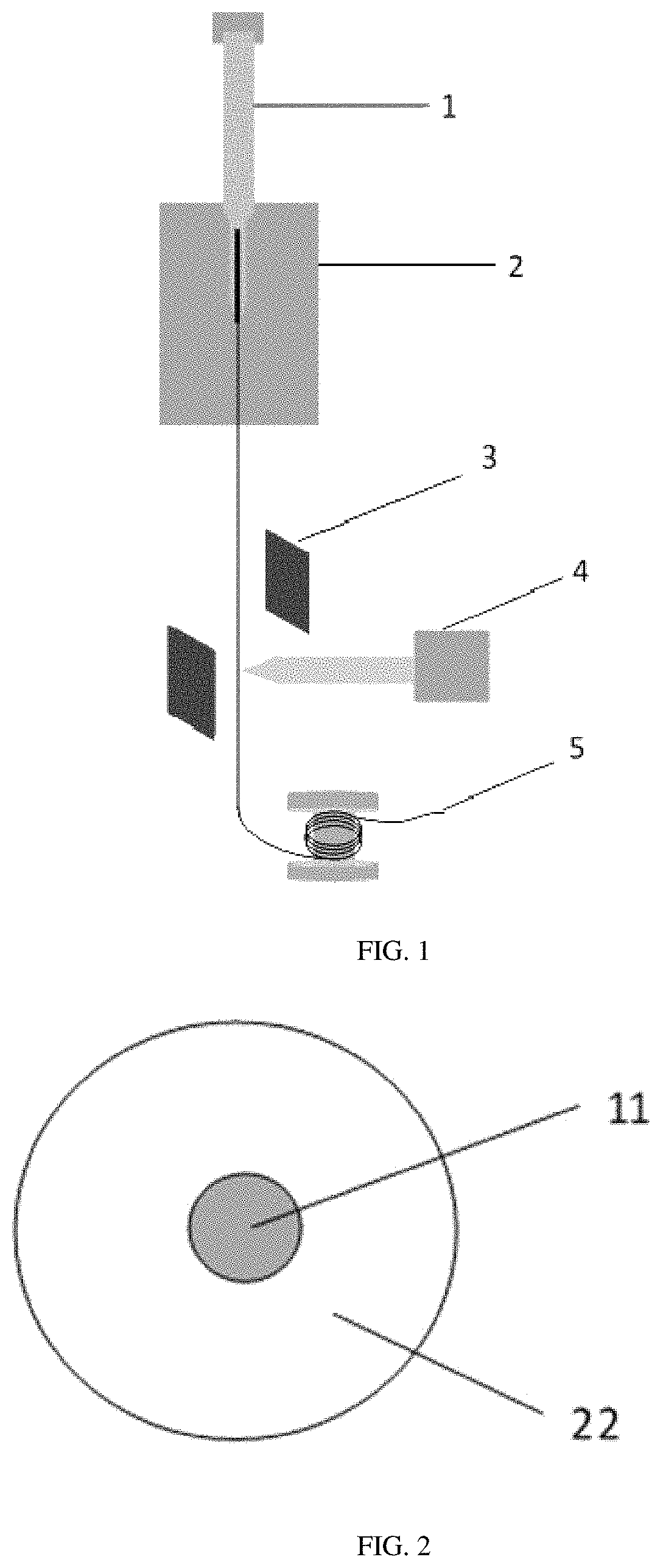

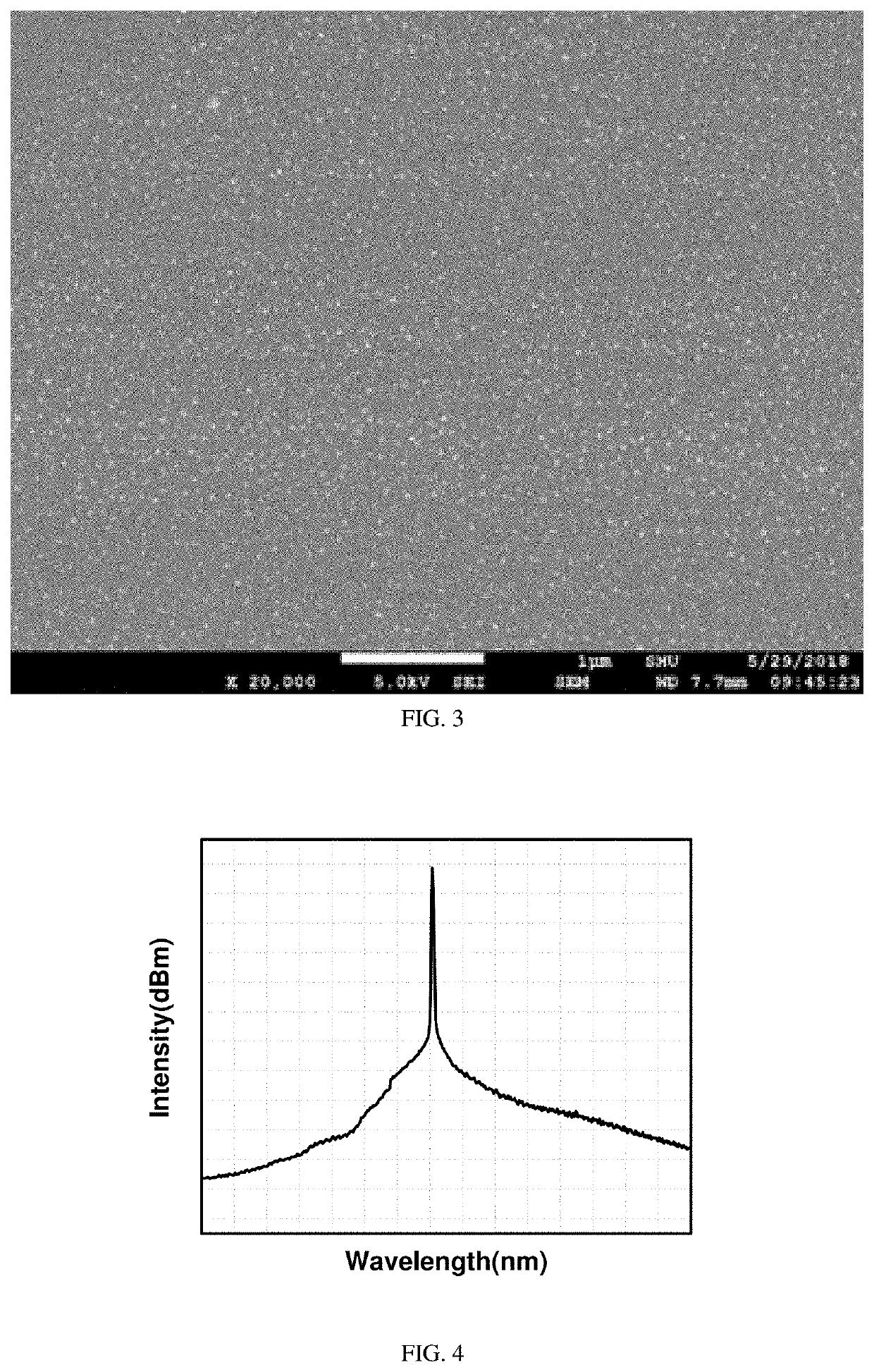

Method and device for processing active microcrystalline fiber by magnetic field induction and laserit

ActiveUS20220149581A1Easy to controlControl grain growthGlass making apparatusActive medium materialFiberCrystallinity

The invention discloses a preparation method and device of active microcrystalline fiber, place the prefabricated rod in the drawing furnace for wire drawing, the drawn fiber is induced by magnetic field in uncoated state and combined with laser treatment technology, the laser beam is focused on the fiber and recrystallized after laser treatment to obtain active microcrystalline fiber. Appropriate laser processing power directly affects the silicate glass fiber in the crystal structure, type, degree of crystallinity, grain size, content, and how much residual phase of glass. Induced by external magnetic field, the thermodynamics and dynamics of crystallization process are changed, make the crystal size distribution is better and uniform, reduce the phenomenon of condensation and makes the grain size is smaller.

Owner:SHANGHAI UNIV

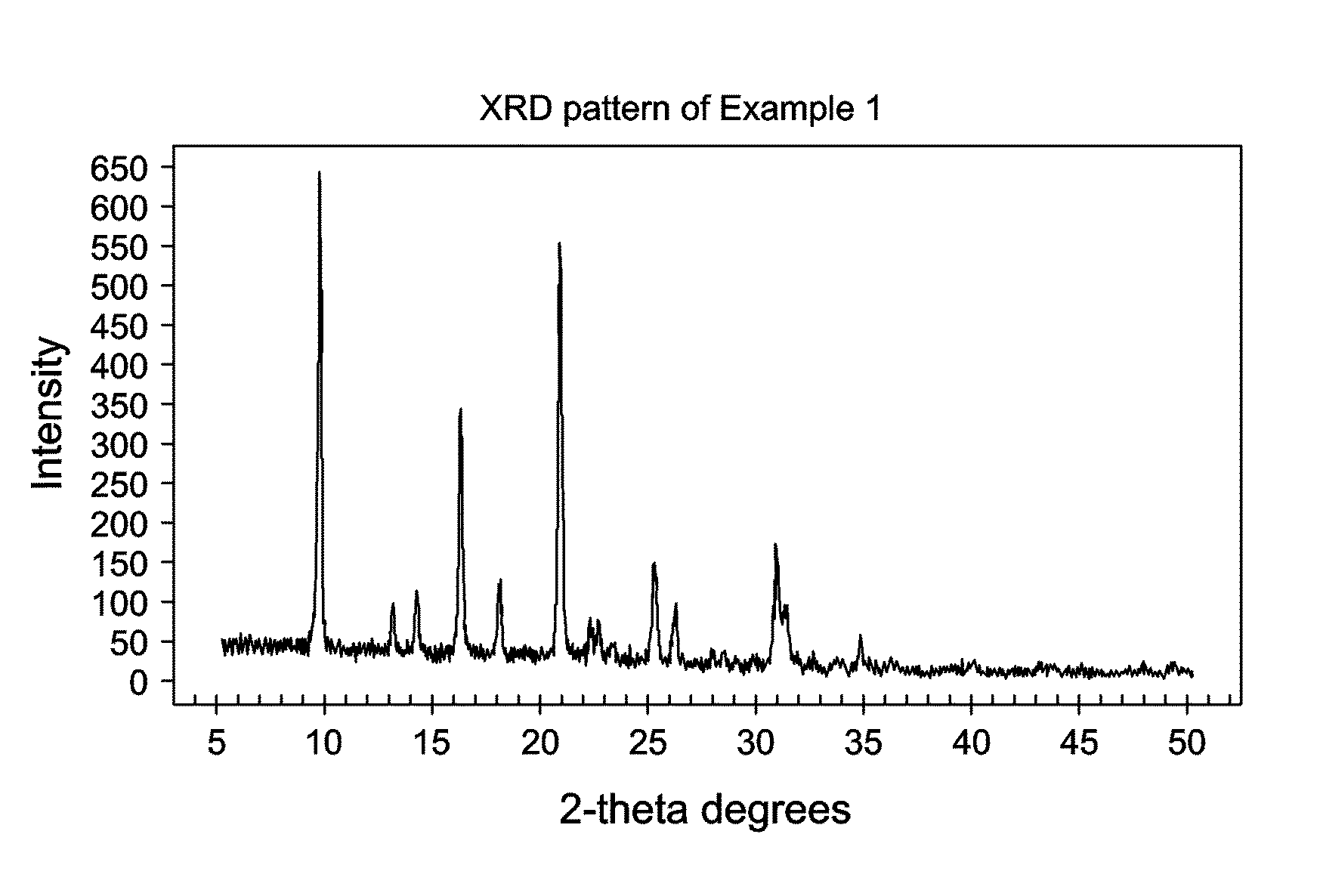

Cefmenoxime hydrochloride composition for injection and preparation thereof

ActiveCN102499922BImprove solubilityImprove stabilityAntibacterial agentsOrganic active ingredientsCrystal size distributionK-alpha

The invention relates to a cefmenoxime hydrochloride composition for injection which consists of 10 parts by weight of cefmenoxime hydrochloride and 1.5 to 2.5 parts by weight of anhydrous sodium carbonate, preferably 10 parts by weight of cefmenoxime hydrochloride and 1.75 to 1.8 parts by weight of anhydrous sodium carbonate. The cefmenoxime hydrochloride is crystal, having characteristic peaks at the diffraction angles 2 theta of 6.0 degrees, 7.4 degrees, 11.0 degrees, 12.2 degrees, 17.5 degrees, 19.8 degrees, 21.6 degrees, 24.8 degrees and 27.7 degrees in the X-ray powder diffraction measured using a Cu K-alpha ray. The main crystal size of cefmenoxime hydrochloride is 30 to 45 microns and the crystal size distribution width is 25 to 75 microns. The cefmenoxime hydrochloride composition of the invention is in the dosage form of injection which is dissolved quickly, suitable for clinic application, good in stability and reliable in safety.

Owner:桂林澳林制药有限责任公司

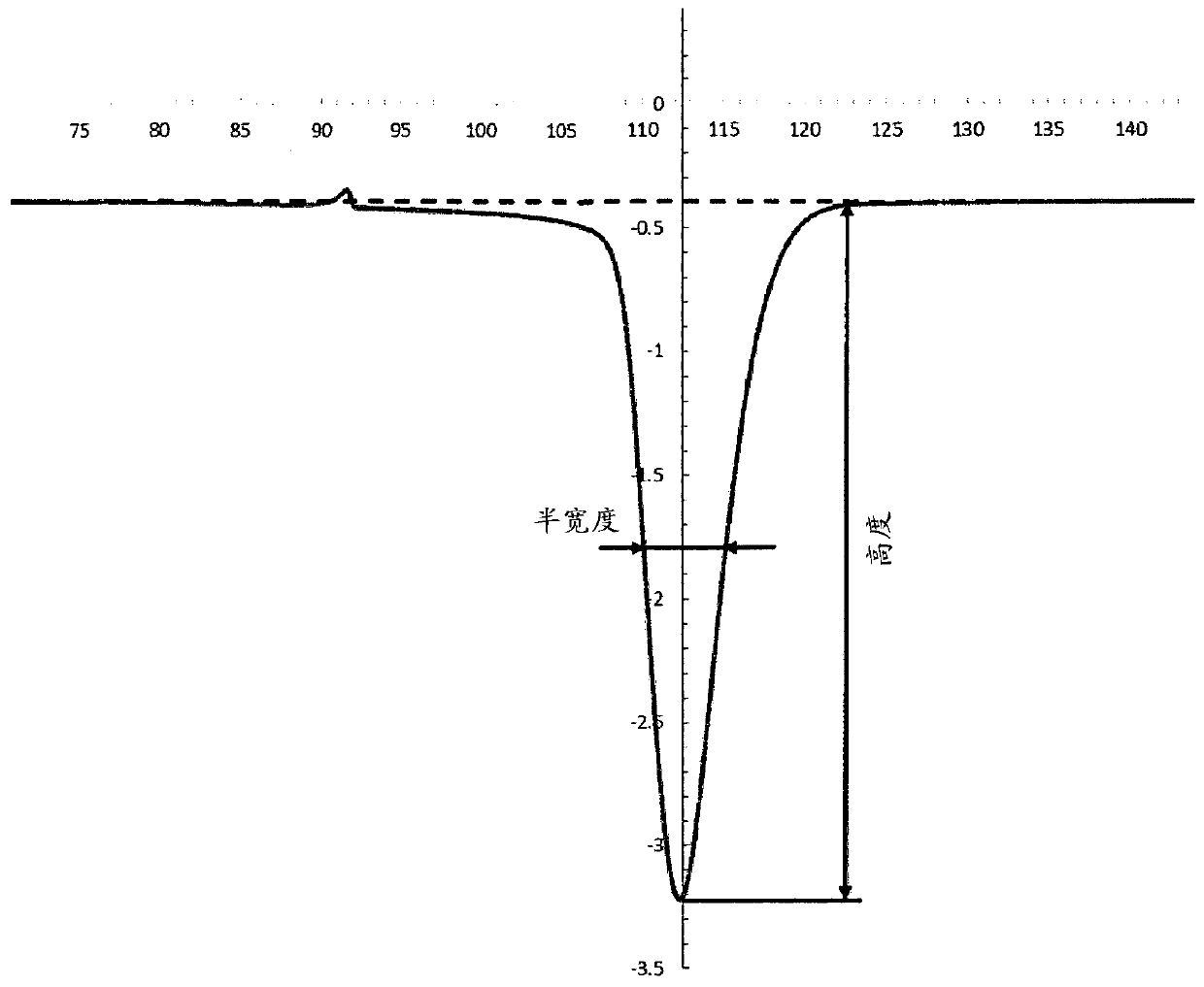

Polypropylene for use in bopp applications

The invention relates to a biaxially oriented polypropylene (BOPP) film comprising a propylene homopolymer or propylene-ethylene copolymer having an ethylene content of at most 1.0 wt% based on the propylene-ethylene copolymer having an Mw / Mn in the range from 5.0 to 12, wherein Mw stands for the weight average molecular weight and Mn stands for the number average weight and wherein Mw and Mn aremeasured according to ASTM D6474-12, an XS in the range from 1.0 to 6.0 wt%, wherein XS stands for the amount of xylene solubles which are measured according to ASTM D 5492-10, a melt flow rate in therange of 1 to 10 dg / min as measured according to IS01133 (2.16 kg / 230 DEG C) and a crystal size distribution as indicated by a height / width ratio of the highest peak of the first cooling curve of atleast 0.70 W / g DEG C as determined by ASTM D3418-08 using a heating and cooling rate of 10 DEG C / min.

Owner:SABIC GLOBAL TECH BV

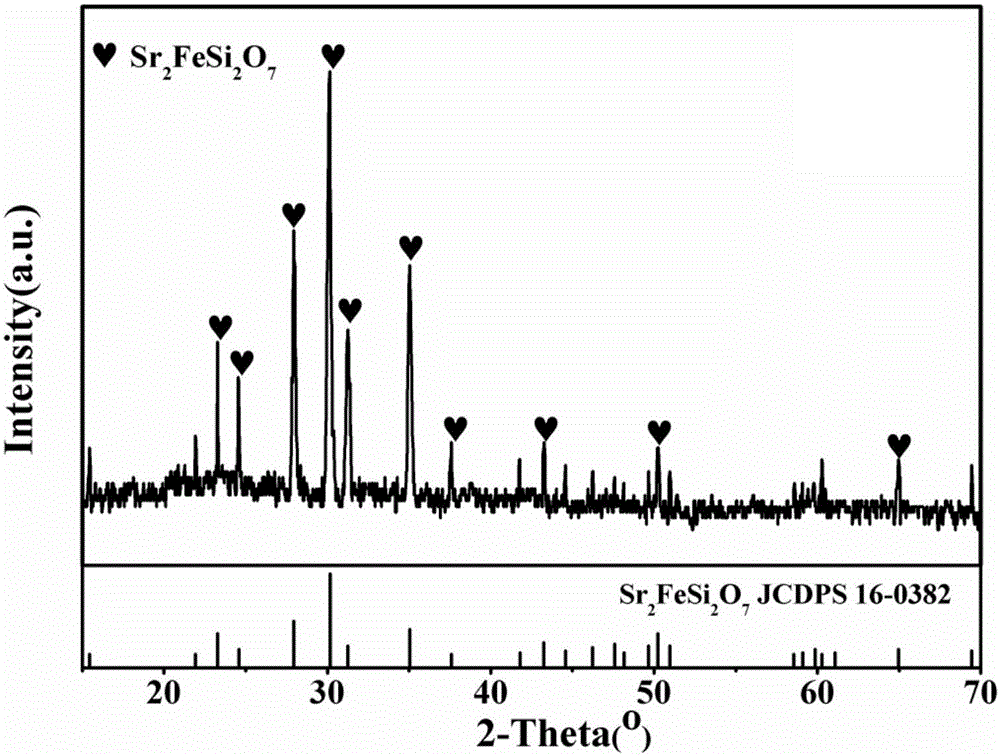

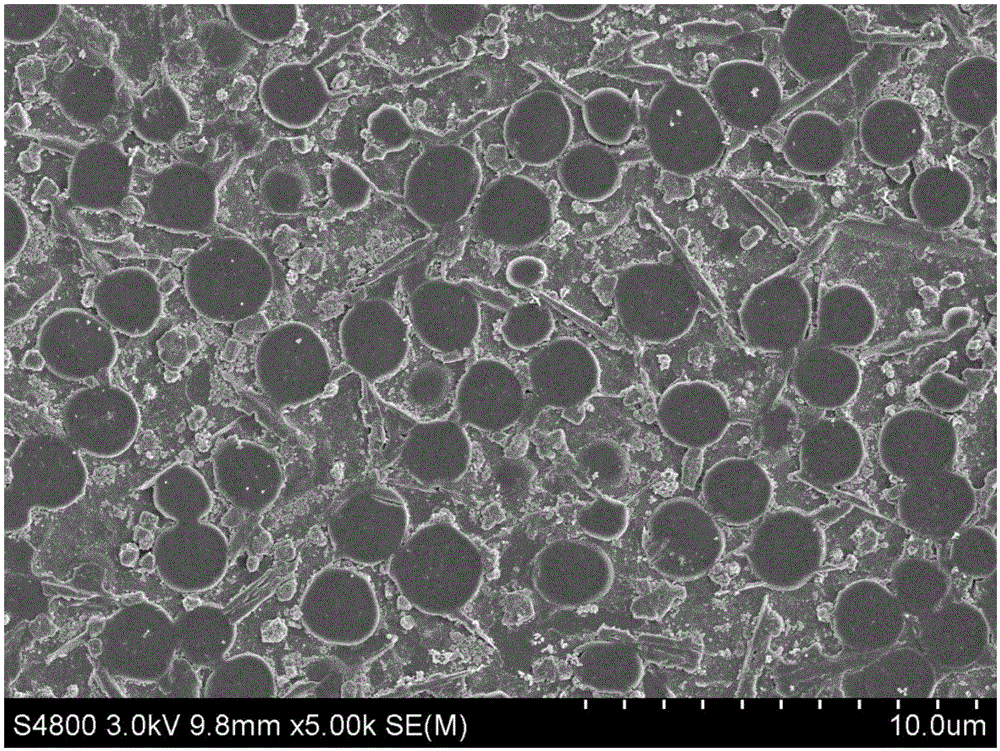

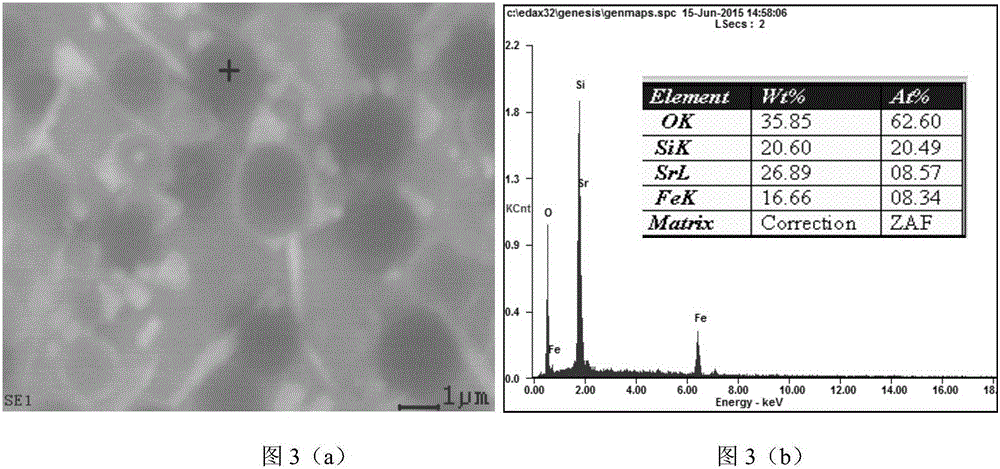

Ferromagnetic Sr2FeSi2O7 microcrystal glass and preparation method thereof

The invention discloses ferromagnetic Sr2FeSi2O7 microcrystal glass and a preparation method thereof. The preparation method comprises the following steps of proportioning strontium oxide, ferric oxide, boron oxide, silicon dioxide, cerium oxide and antimony oxide according to a certain chemical ratio, then, melting to form molten glass, and carrying out heat insulation on the molten glass; then, rapidly pouring the molten glass into a heated die for forming, rapidly transferring the molten glass to an annealing furnace after forming to carry out precise annealing treatment, and then, carrying out furnace cooling to obtain strontium-ferrum-boron-silicon glass; and after cutting the glass, placing the glass on an aluminum oxide board, heating to the required temperature, and carrying out heat insulation treatment. The preparation method is low in adopted raw material price, energy-saving, environment-friendly, suitable for industrial production, simple in operation, short in preparation period and low in cost, and the raw materials used in the preparation process are environment-friendly; and the prepared ferromagnetic Sr2FeSi2O7 is small in size (about submicron-order), relatively high in crystal purity, extremely low in impure phase content, compact in component, uniform in crystal size distribution and excellent in ferromagnetic performance.

Owner:SHAANXI UNIV OF SCI & TECH

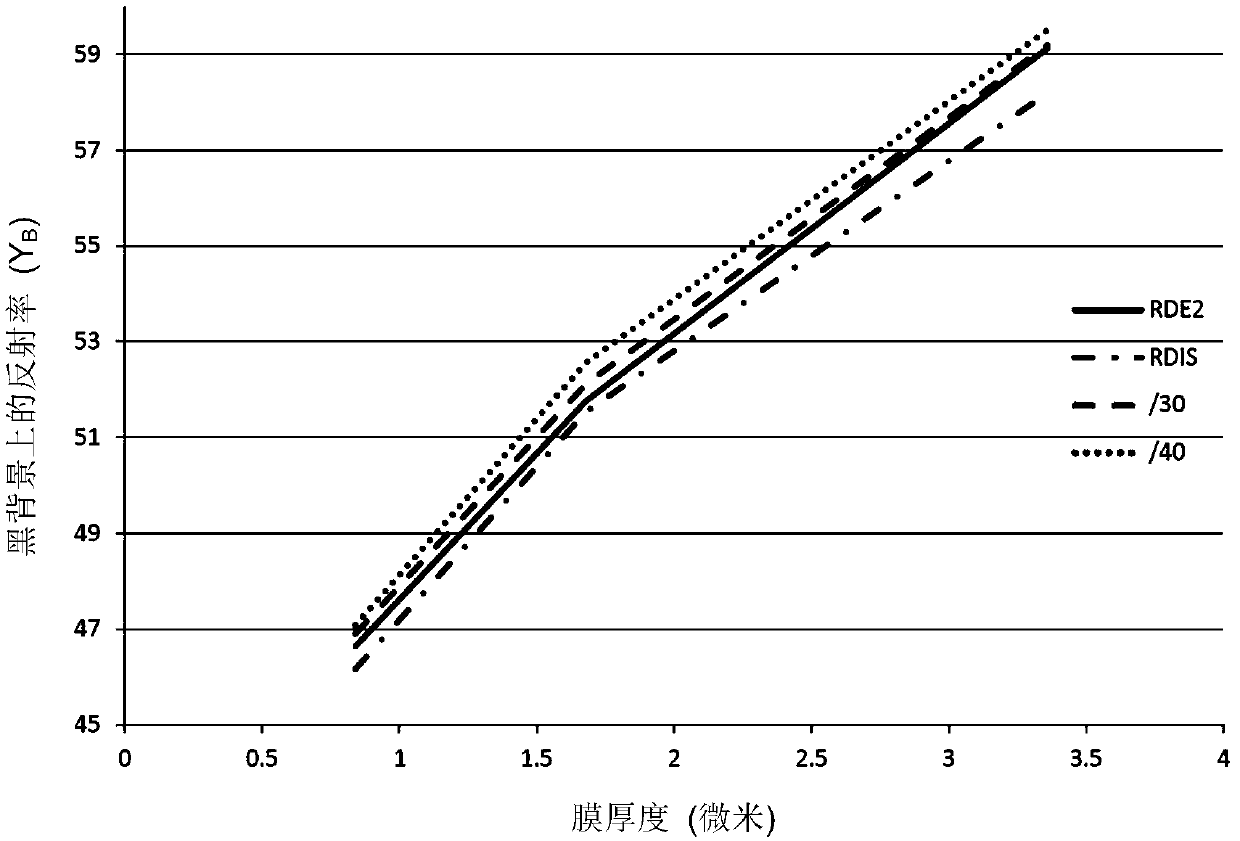

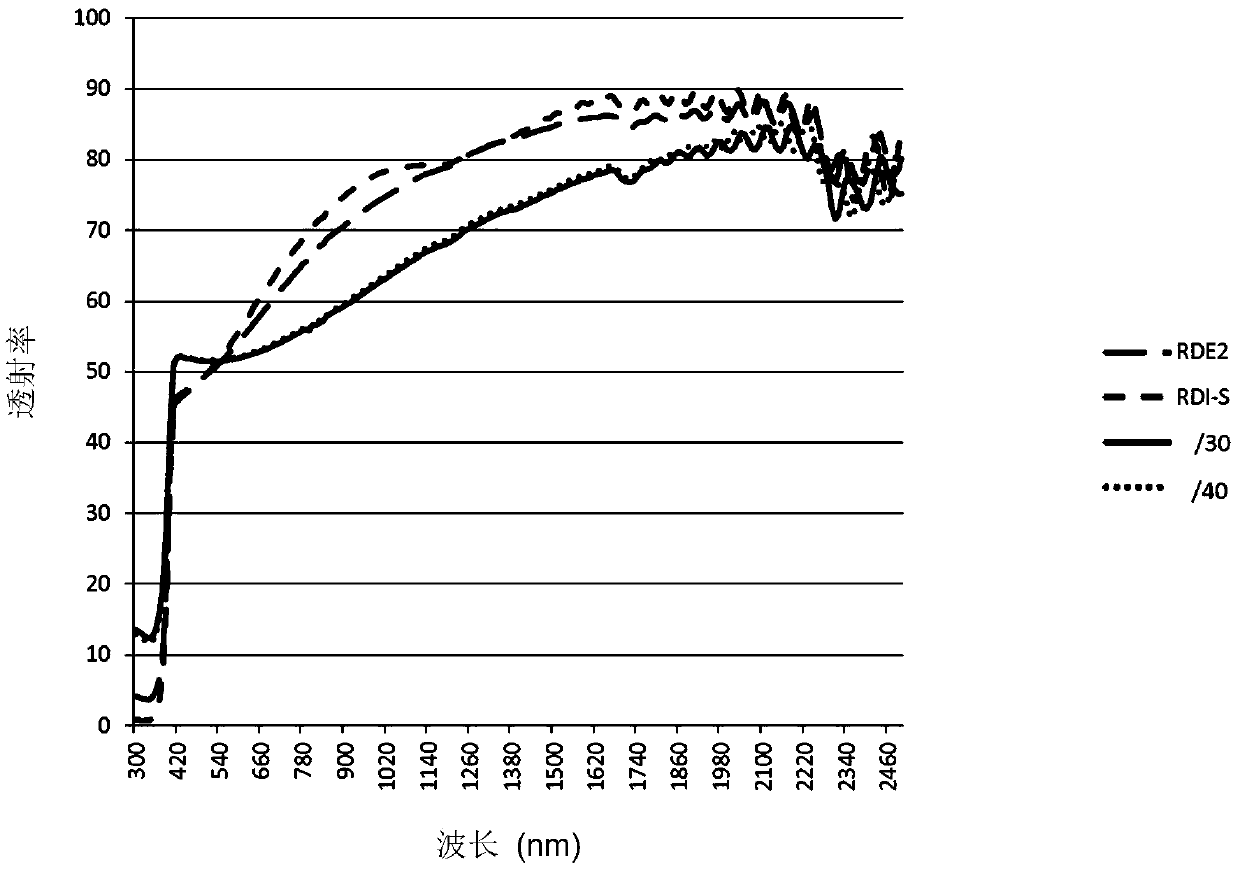

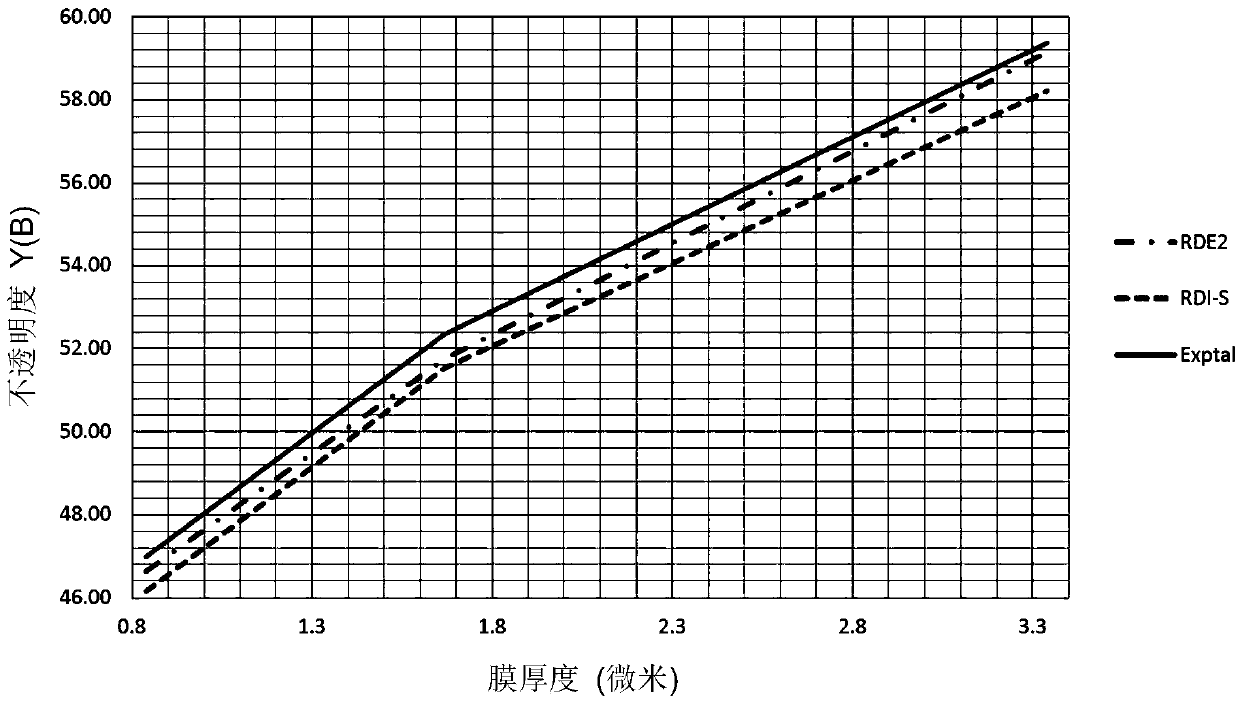

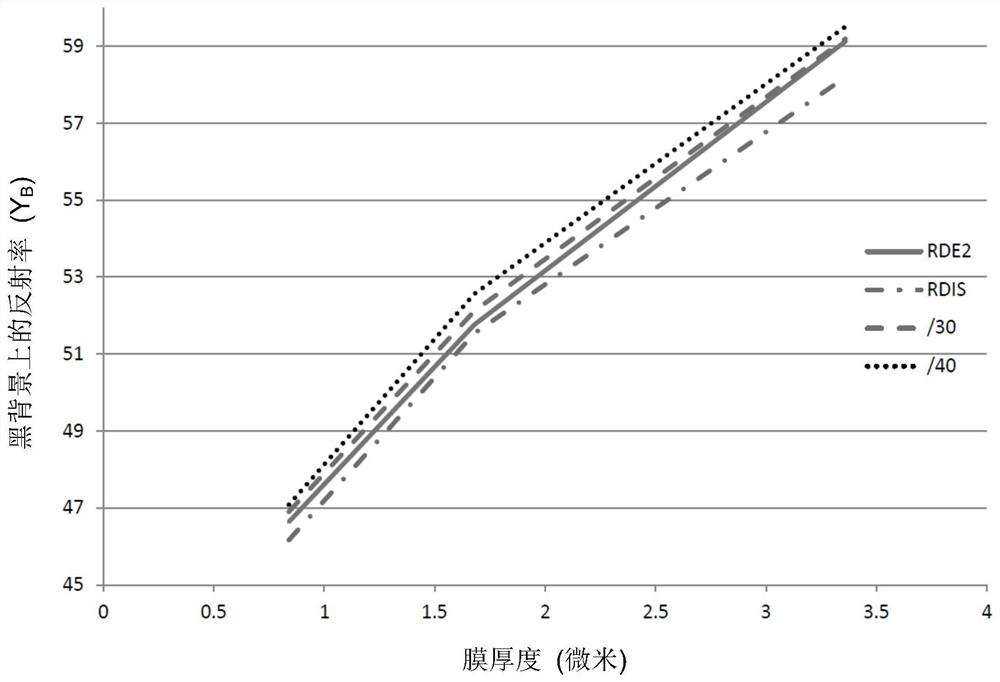

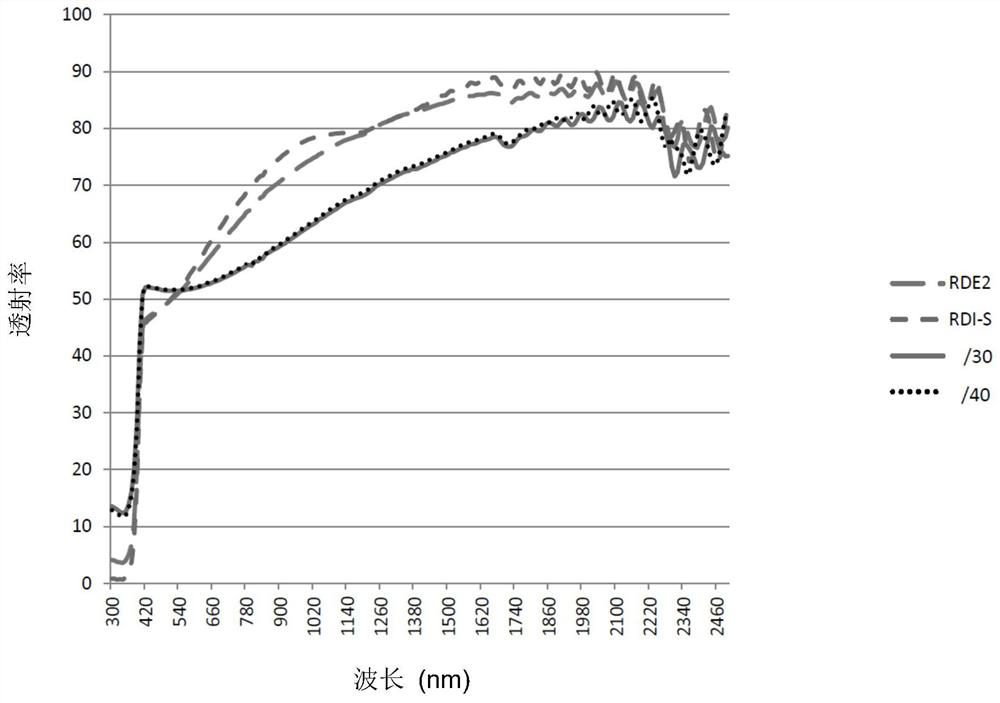

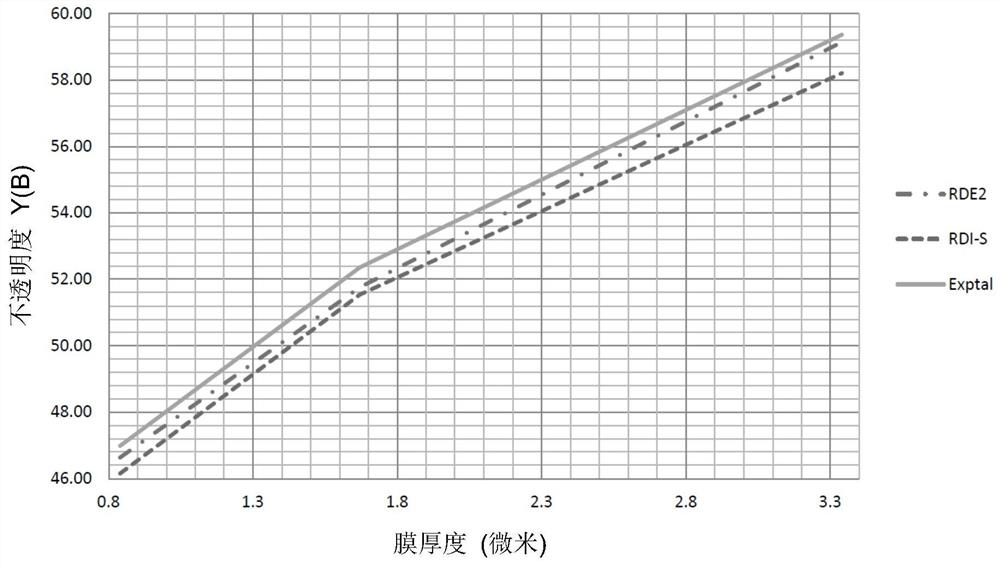

Titanium dioxide product

ActiveCN109689576AHigh opacityLow costPigmenting treatmentInksCrystal size distributionTitanium dioxide

The invention provides a pigmentary particulate material selected from the group consisting of titanium dioxide, doped titanium dioxide and a mixture thereof, wherein the particulate material has a mean crystal size in the range of from0.3 to 0.5 microns and a crystalsize distribution such that 40wt% or more of the particulate material has a crystal size in the range of from0.3to 0.5microns, and wherein theratio of the meanparticle size to the mean crystal size is 1.25 or less. Theparticulate material may be used in a composition comprising pigmentary material dispersed in a vehicle, to provide improved opacity for said composition.

Owner:VENATOR MATERIALS UK LTD

Multi-objective optimization method for intermittent sugarcane boiling and crystallization process

ActiveCN104778314BComprehensive multi-objective optimizationMulti-objective optimization is accurate and reliableSpecial data processing applicationsAlgorithmGenetic algorithm

The invention discloses a multi-objective optimization method for intermittent sugarcane boiling and crystallization process, comprising the following steps: 1) constructing the variable value of the first initial gene; Carry out optimization to obtain the Pareto optimization solution set of the final crystal size distribution parameter; 3) carry out multi-objective decision-making to the Pareto optimization solution set of the final crystal size distribution parameter in step 2), and obtain the optimal final crystal size distribution parameter; 4) Construct the variable value of the second initial gene; 5) use the non-dominated sorting genetic algorithm to optimize the second initial gene in step 4), and obtain the Pareto optimization solution set of the first crystal size distribution parameter; 6) optimize the first crystal size Sorting the process variables corresponding to the Pareto optimization solution set of the distribution parameters; 7) outputting the result. The invention can obtain better optimization results to better guide the optimal control of the crystallization process of sugar cane boiling.

Owner:GUANGXI UNIV

Method and device for processing active microcrystalline fiber by magnetic field induction and lasering

ActiveUS11502475B2Easy to controlIncrease concentrationGlass making apparatusActive medium materialFiberCrystallinity

The invention discloses a preparation method and device of active microcrystalline fiber, place the prefabricated rod in the drawing furnace for wire drawing, the drawn fiber is induced by magnetic field in uncoated state and combined with laser treatment technology, the laser beam is focused on the fiber and recrystallized after laser treatment to obtain active microcrystalline fiber. Appropriate laser processing power directly affects the silicate glass fiber in the crystal structure, type, degree of crystallinity, grain size, content, and how much residual phase of glass. Induced by external magnetic field, the thermodynamics and dynamics of crystallization process are changed, make the crystal size distribution is better and uniform, reduce the phenomenon of condensation and makes the grain size is smaller.

Owner:SHANGHAI UNIV

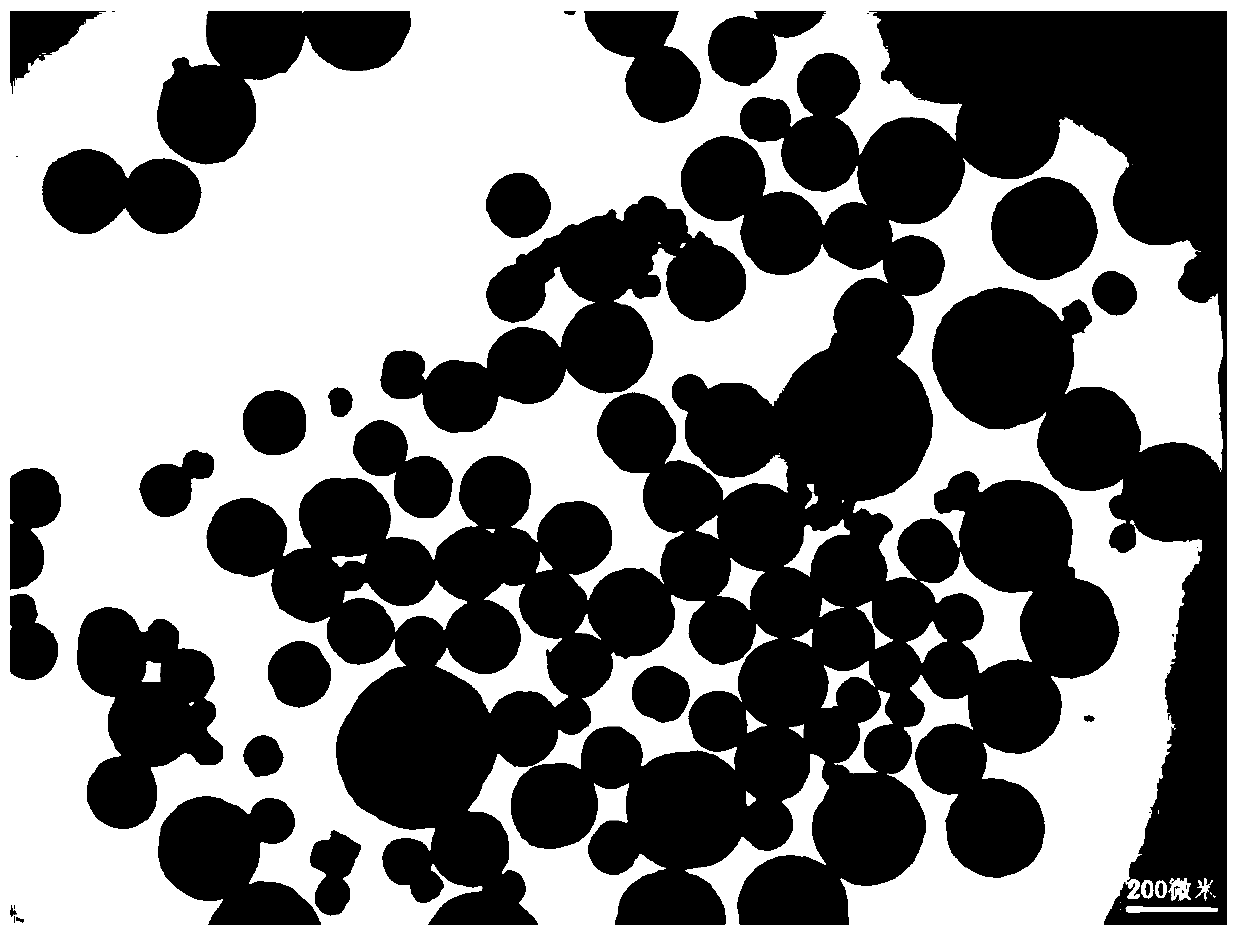

A kind of high crystal density spheroidized NTO crystal and preparation method

InactiveCN105274625BReduce dosageControl shapePolycrystalline material growthFrom normal temperature solutionsHigh densityCrystal plane

The invention provides a high crystal density spheroidized NTO crystal and a preparation method thereof, wherein the NTO content in the crystal is ≥99.9%, the crystal density is ≥1.92g / cm3, the short-to-long axis ratio of the crystal is ≥0.90, and the crystal The median particle size ranges from 150 to 200 μm. The preparation method of the high crystal density spheroidized NTO crystal comprises the following steps: (1) adding NTO and a solvent into a reactor to fully dissolve, and the temperature of the reactor is 40-80°C; (2) lowering the reactor while stirring Temperature, after the formation of a supersaturated solution, crystal nuclei are formed and grow; (3) After the crystals are completely precipitated, stir at a low temperature of -5-0°C for 1-5 hours; (4) Filter, dry, and weigh. The crystal particle size distribution is narrow, the appearance observation crystal sphericity is high, the surface is smooth, and the crystal plane has no cracks.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Titanium Dioxide Products

The present invention provides a pigment particulate material selected from titanium dioxide, doped titanium dioxide and mixtures thereof, wherein said particulate material has an average crystal size of 0.3-0.5 microns and a crystal size distribution such that 40% by weight or more of the particulate material Having a crystal size of 0.3-0.5 microns, and wherein the ratio of average particle size to average crystal size is 1.25 or less. The pigmentary material is useful in compositions comprising the pigmentary material dispersed in a vehicle to provide improved opacity to the composition.

Owner:VENATOR MATERIALS UK LTD

A method for controlling the grain growth process of nano-layered mgFe hydrotalcite

InactiveCN107879377BLarge specific surface areaInhibit aggregate growthNanotechnologyIron compoundsHydrotalciteCrystal size distribution

The present invention relates to a method for controlling the growth process of nano-layered MgFe hydrotalcite grains. The method for controlling the growth process of nano-layered MgFe hydrotalcite grains: (1) preparing Mg(NO 3 ) 2 solution, Fe(NO 3 ) 3 Solution, mix evenly, so that the Mg / Fe molar ratio in the solution is 1:10‑10:1; (2) Add NaOH precipitant dropwise to the solution prepared in step (1), and stir continuously, so that the pH of the solution is 8 -12; (3) Crystallize at 140°C-220°C for 0.5h-6h, then continue to crystallize at 70°C-120°C for 12h-36h, the amount of organic steric hindrance added in the hydrothermal synthesis system is the total mass of the solution 0.1%-20.0%, after the reaction, the solid product is isolated, washed and separated, and the obtained solid product is dried to obtain nano-sized layered MgFe hydrotalcite. The invention can prepare MgFe hydrotalcite with nanometer size and narrow crystal size distribution range.

Owner:NORTHEAST GASOLINEEUM UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com