Preparation method of psicose crystals

A technique of psicose and psicose sugar, which is applied to the preparation field of psicose crystallization, can solve the problems of unconcentrated crystal mesh distribution, cumbersome production process, low product yield and the like, and saves energy consumption. , The effect of simplifying the preparation process and high crystal yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A method for preparing psicose crystals, comprising the following steps:

[0049] (1) Evaporation and crystallization: take allulose sugar liquid, the solid content of the allulose sugar liquid is 73%, and the purity is ≥ 95%, add allulose seed crystals, allulose seed crystals The dosage of the allulose syrup is 1‰ of the quality of the allulose syrup, the size of the allulose seed crystal is 250 mesh, evaporated and crystallized under the conditions of 41°C and a vacuum of -0.01MPa, until the solid state of the allulose syrup is The substance content is 81%;

[0050] (2) Crystallization: Add water to the allulose syrup system obtained in step (1), and at the same time continue to evaporate and crystallize at 41°C and a vacuum of -0.01MPa, so that the allulose syrup The solid content is always between 82% and 83%, and the crystallization time is 4h;

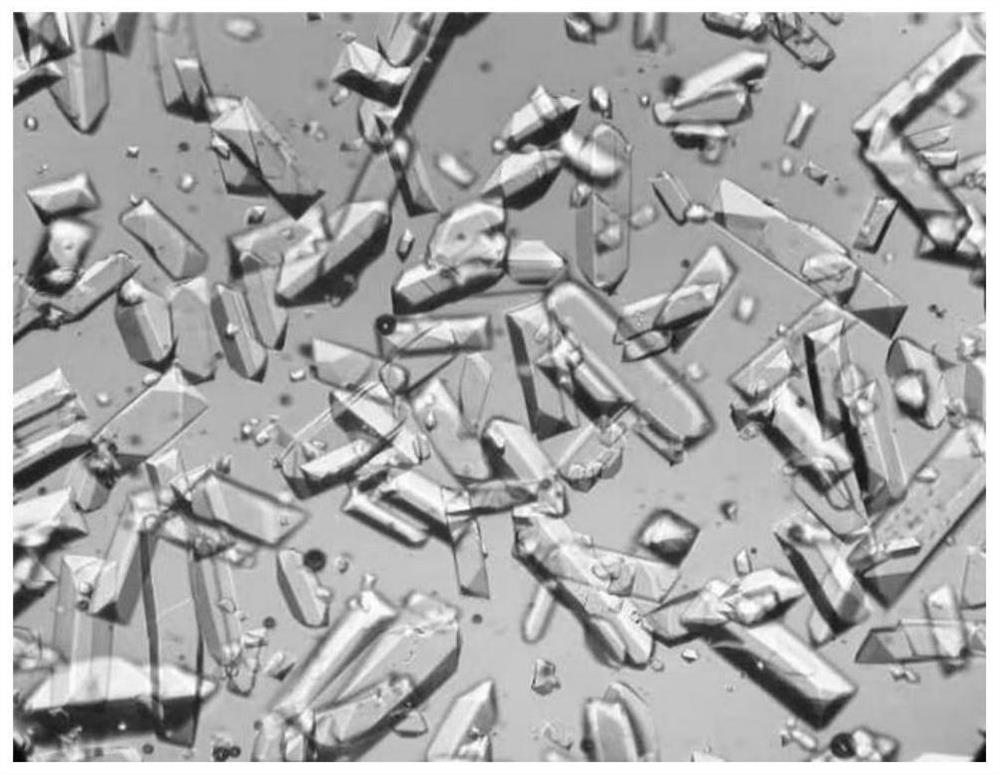

[0051] After the whole crystal is finished, the micrograph (100 times) of gained crystal is as follows figure 1 As sh...

Embodiment 2

[0059] A method for preparing psicose crystals, comprising the following steps:

[0060] (1) Evaporation and crystallization: take allulose sugar solution, the solid content of the allulose sugar solution is 74%, and the purity is ≥ 95%, add allulose seed crystals, allulose seed crystals The addition amount of the allulose syrup is 1.2‰ of the quality of the allulose syrup, the size of the allulose seed crystal is 260 mesh, evaporated and crystallized under the conditions of 45°C and a vacuum of -0.01MPa, until the solid state of the allulose syrup is The substance content is 82%;

[0061] (2) Crystallization: Add water to the allulose syrup system obtained in step (1), and at the same time continue to evaporate and crystallize at 45°C and a vacuum of -0.01MPa, so that the allulose syrup The solid content is always between 82% and 83%, and the crystallization time is 6h;

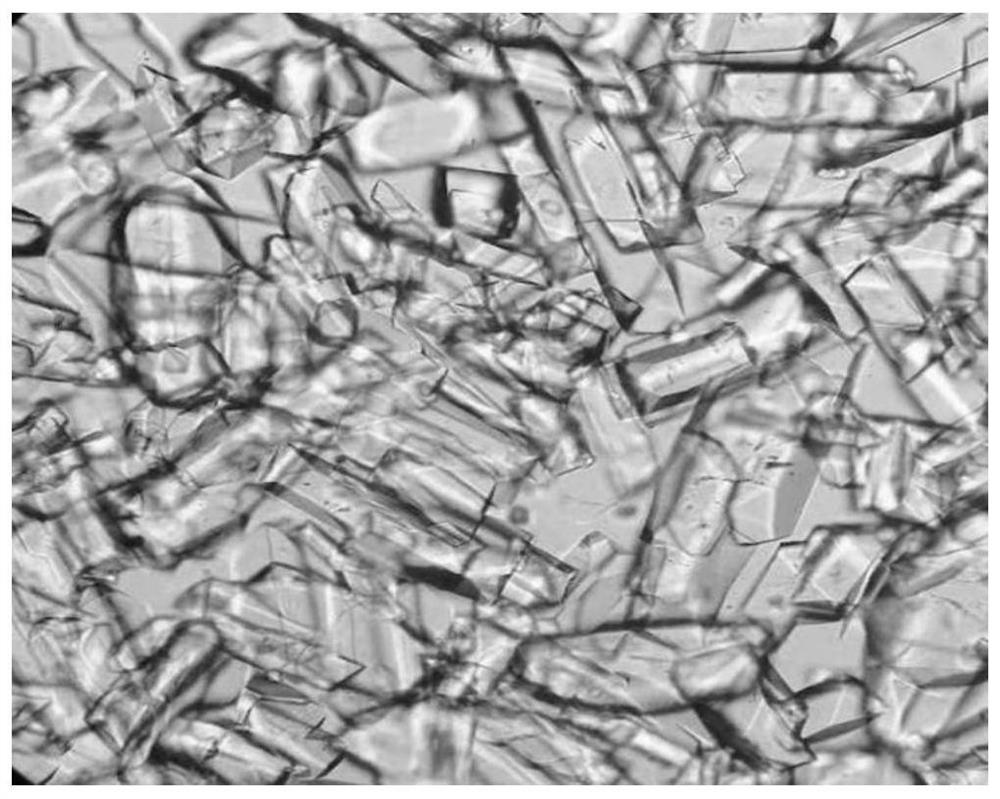

[0062] After the whole crystal is finished, the micrograph (100 times) of gained crystal is as follows ...

Embodiment 3

[0070] A method for preparing psicose crystals, comprising the following steps:

[0071] (1) Evaporation and crystallization: take allulose sugar solution, the solid content of the allulose sugar solution is 75%, and the purity is ≥ 95%, add allulose seed crystals, allulose seed crystals The dosage of the allulose syrup is 1.5‰ of the quality of the allulose syrup, the size of the allulose seed crystal is 280 mesh, evaporated and crystallized under the conditions of 50°C and a vacuum of -0.01MPa, until the solid state of the allulose syrup is The substance content is 83%;

[0072] (2) Crystallization: Add water to the allulose syrup system obtained in step (1), and at the same time continue to evaporate and crystallize under the conditions of 50°C and a vacuum of -0.01MPa, so that the allulose syrup The solid content is always between 82% and 83%, and the crystallization time is 8 hours;

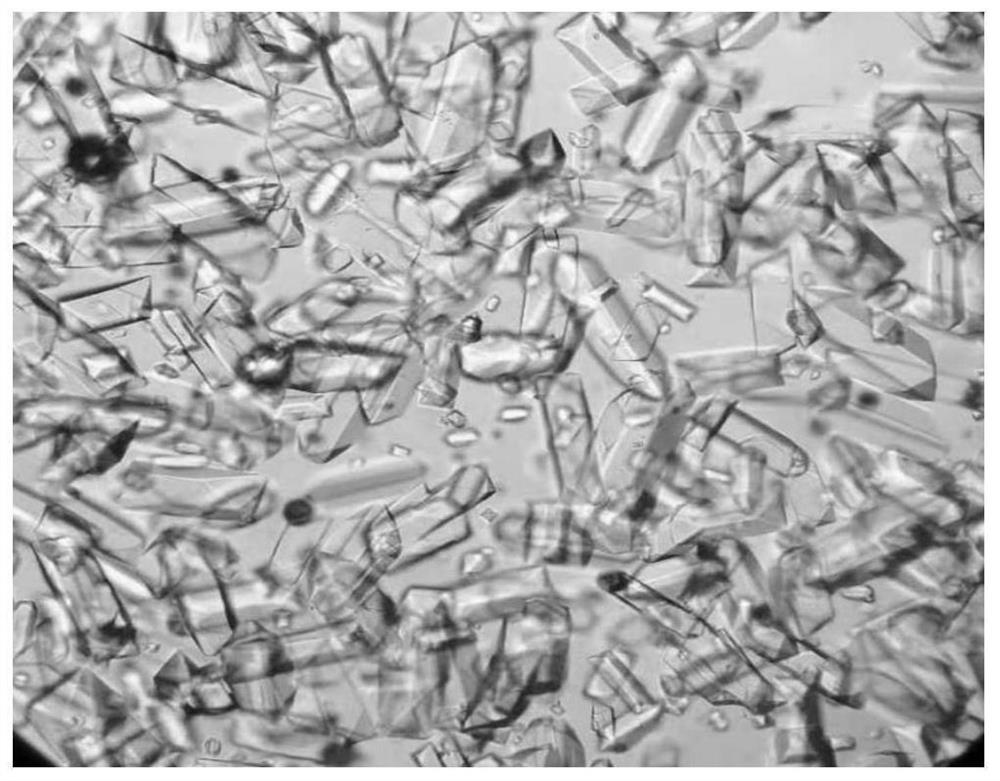

[0073] After the whole crystal is finished, the micrograph (100 times) of gained cryst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com