Patents

Literature

732results about "Crystallization by component evaporation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

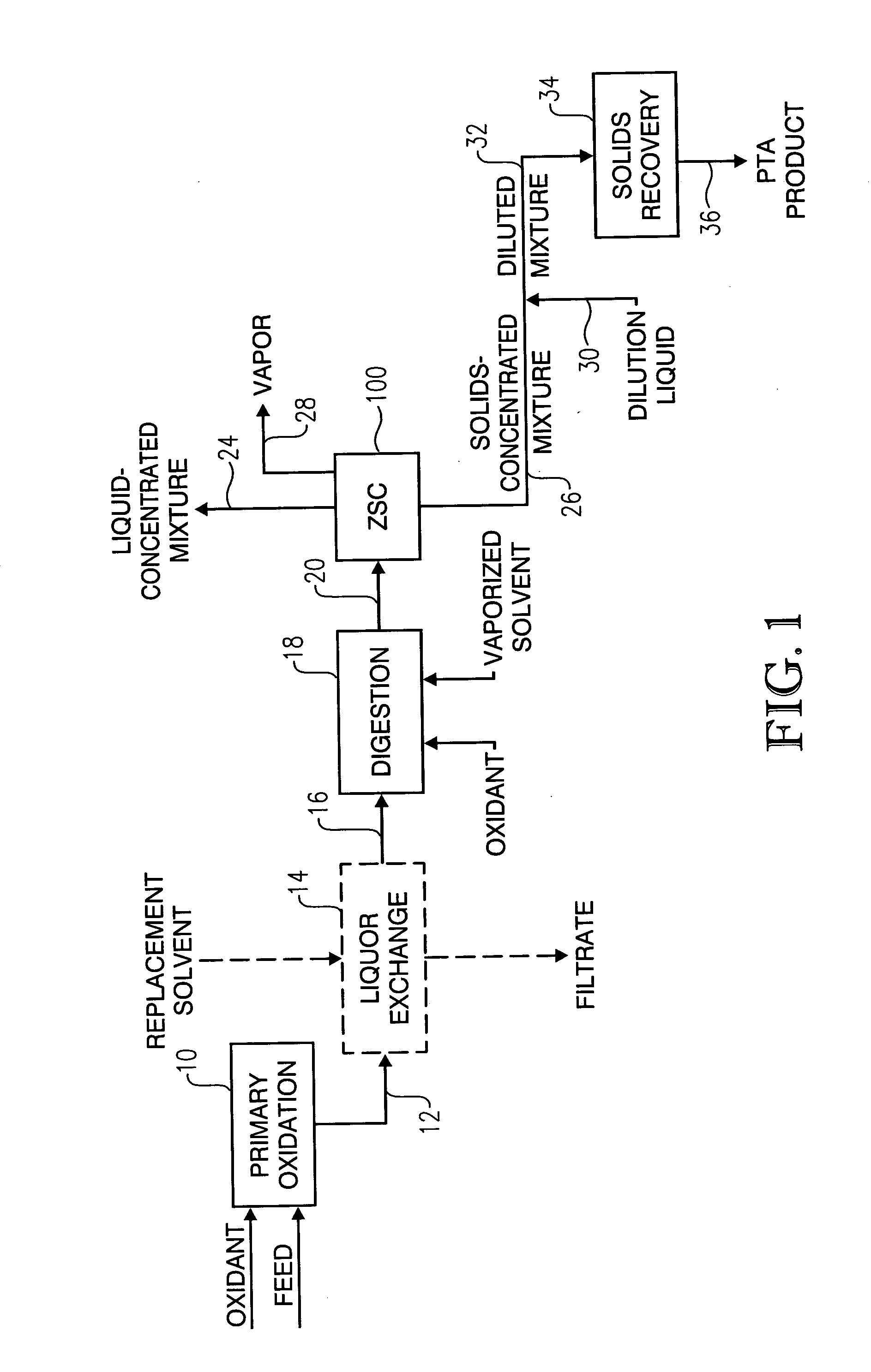

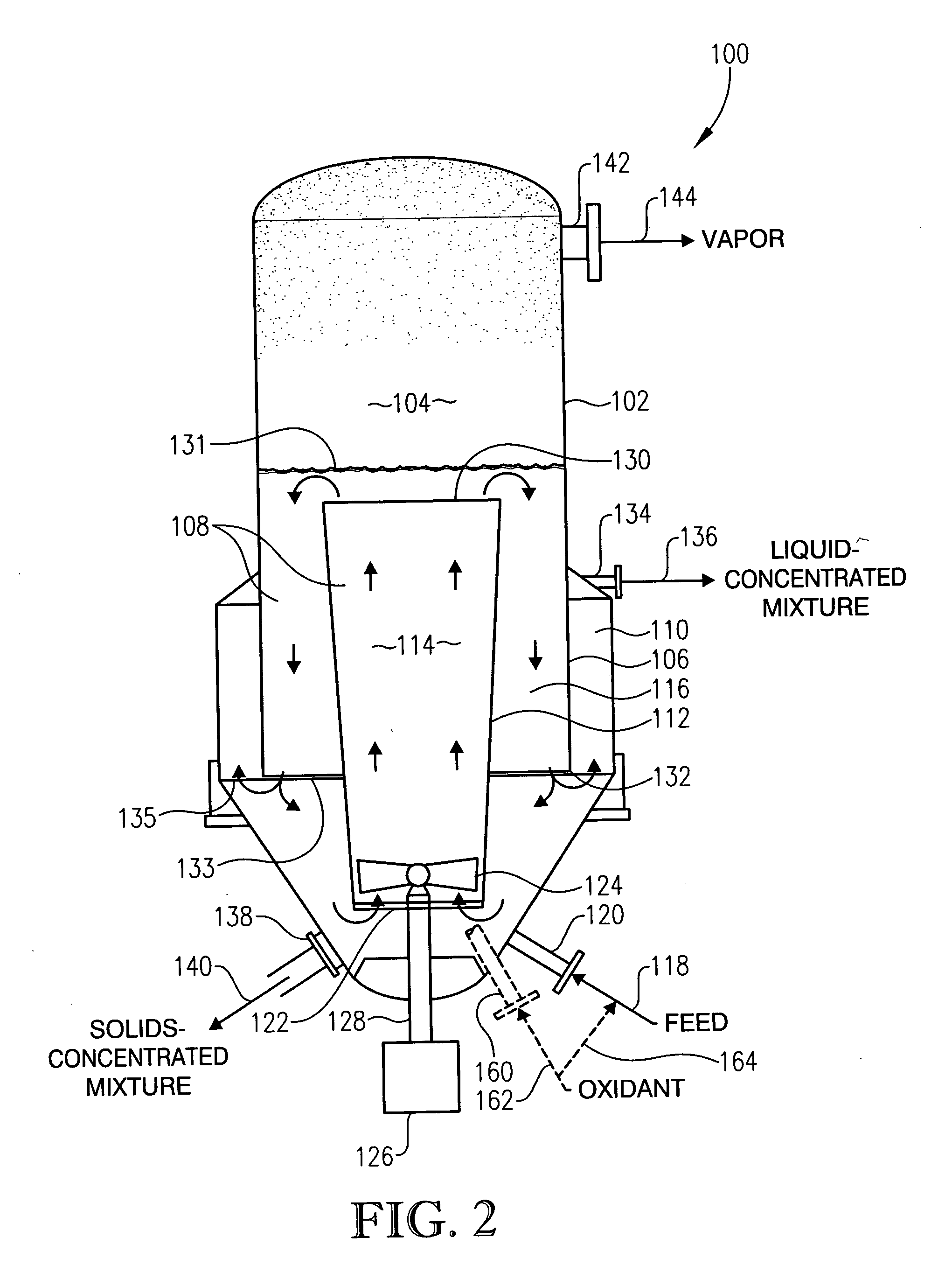

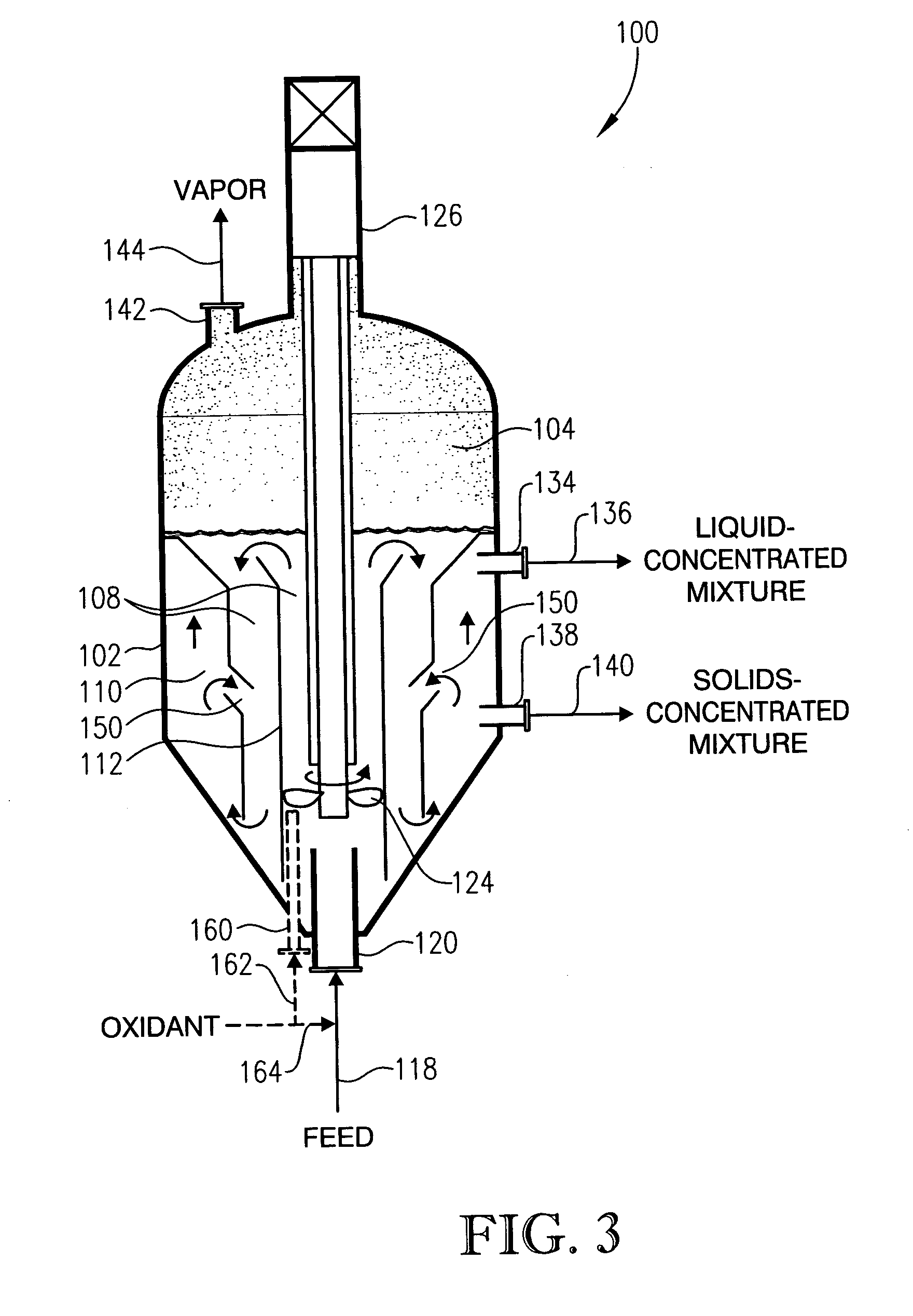

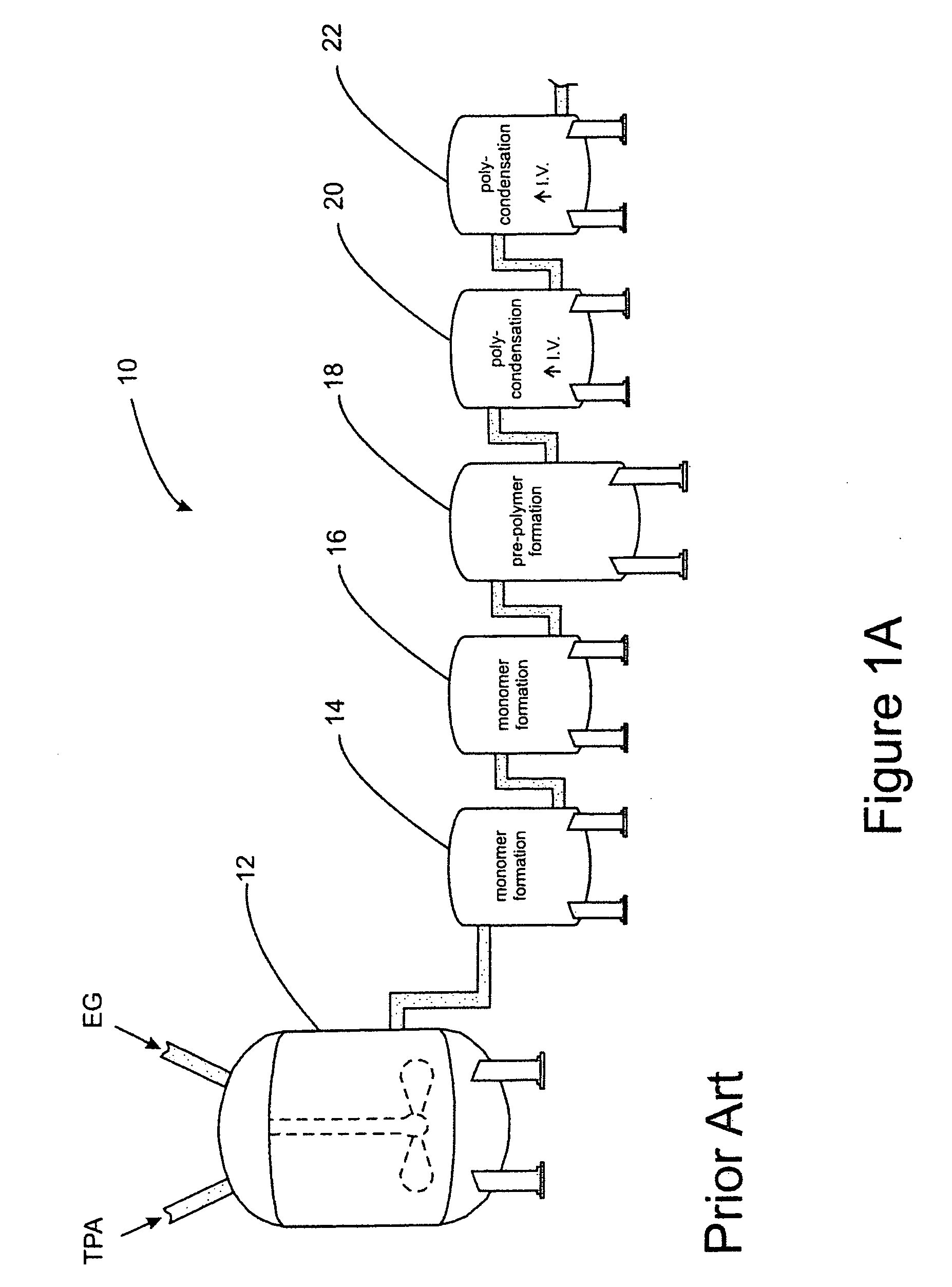

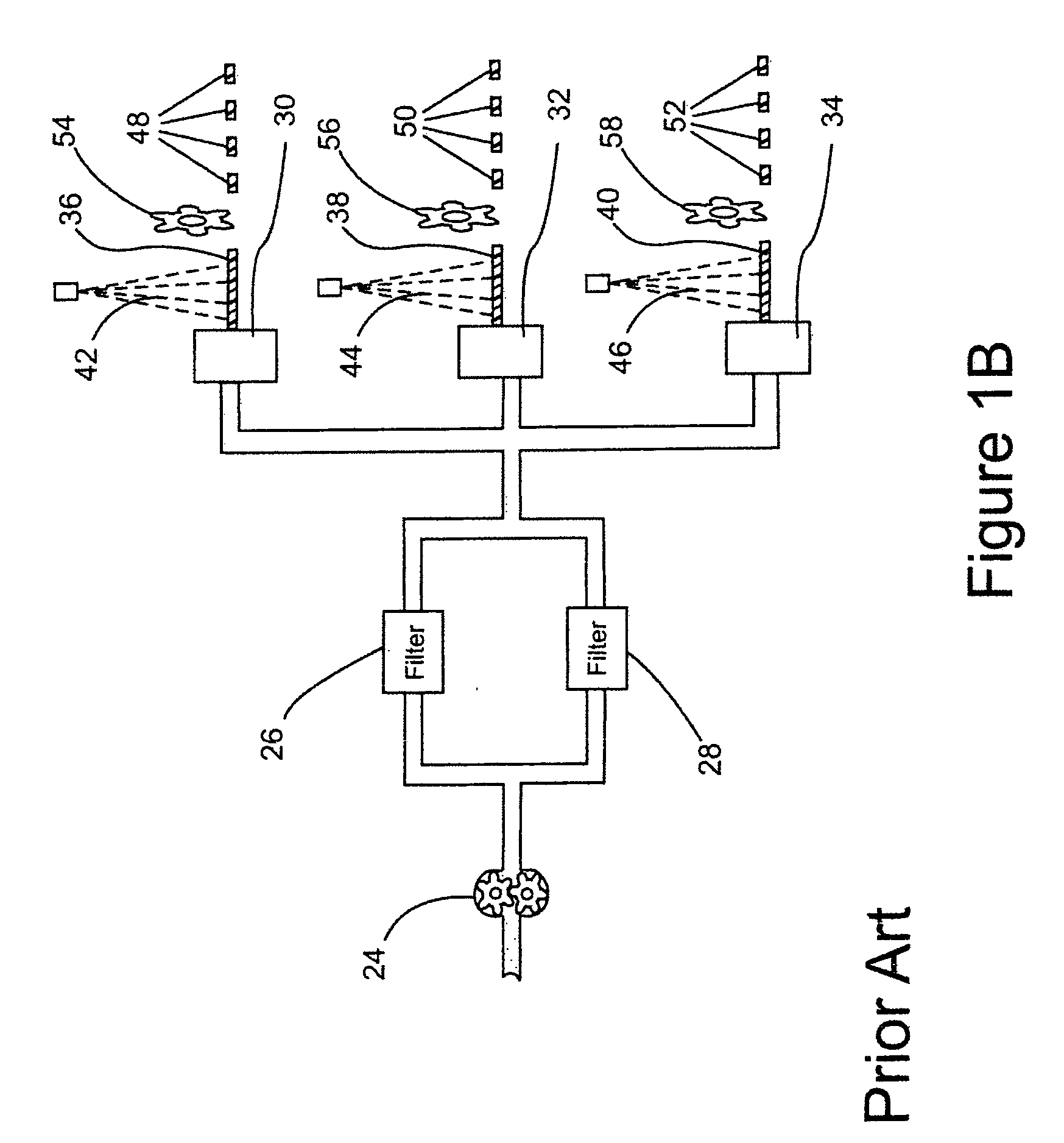

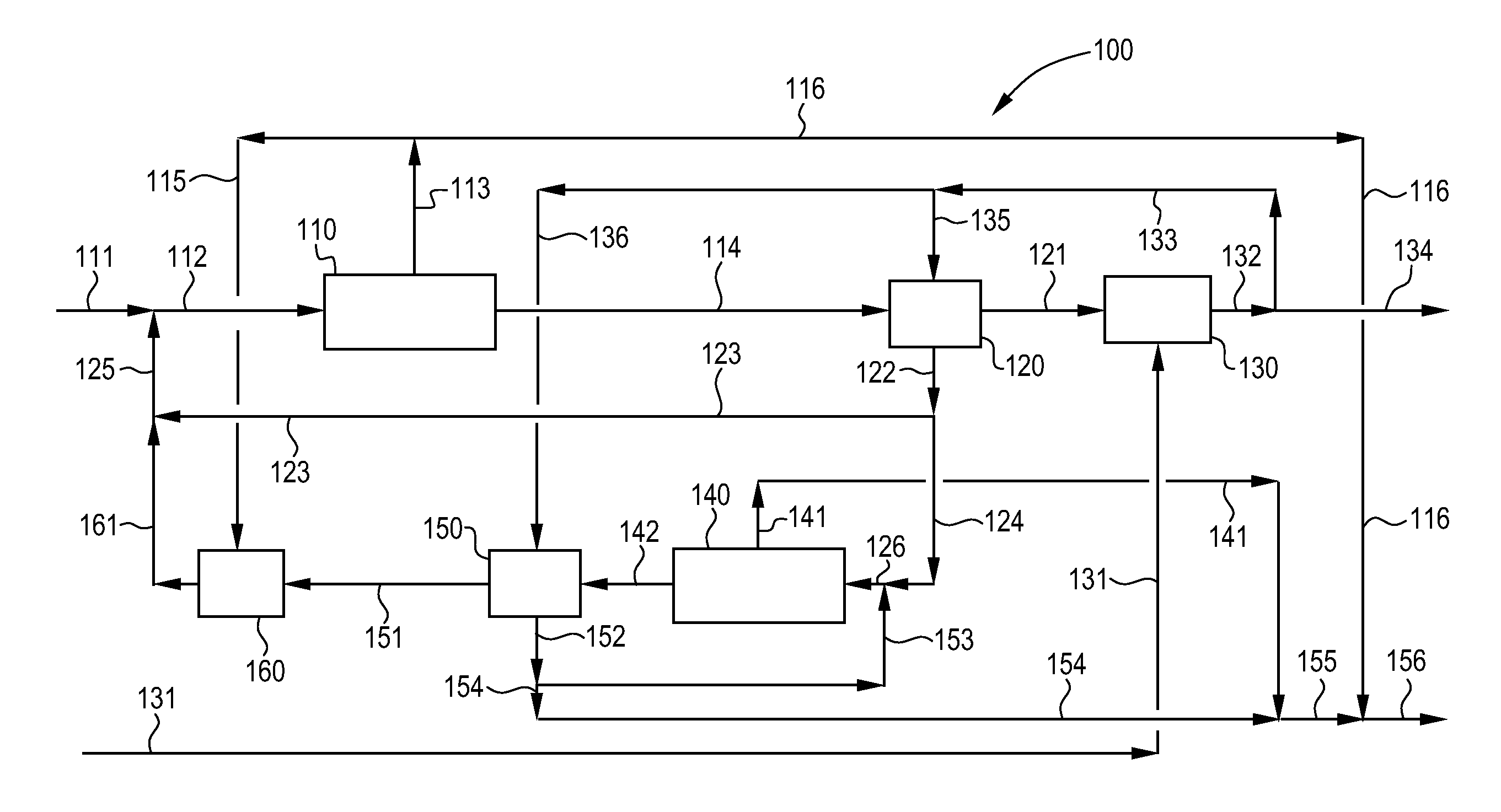

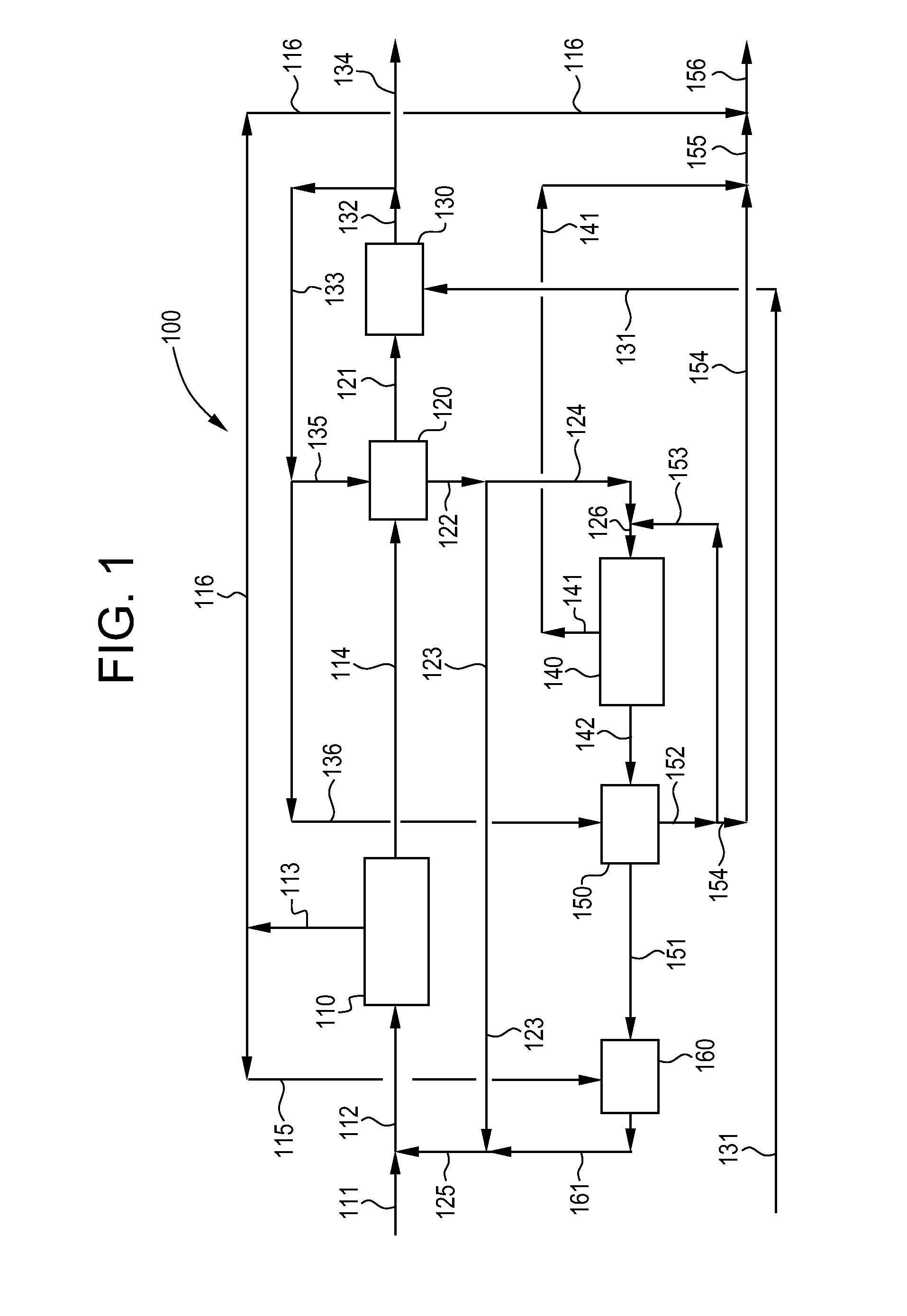

Optimized production of aromatic dicarboxylic acids

ActiveUS20060047166A1Organic compound preparationCrystallization by component evaporationDicarboxylic acidCarboxylic acid

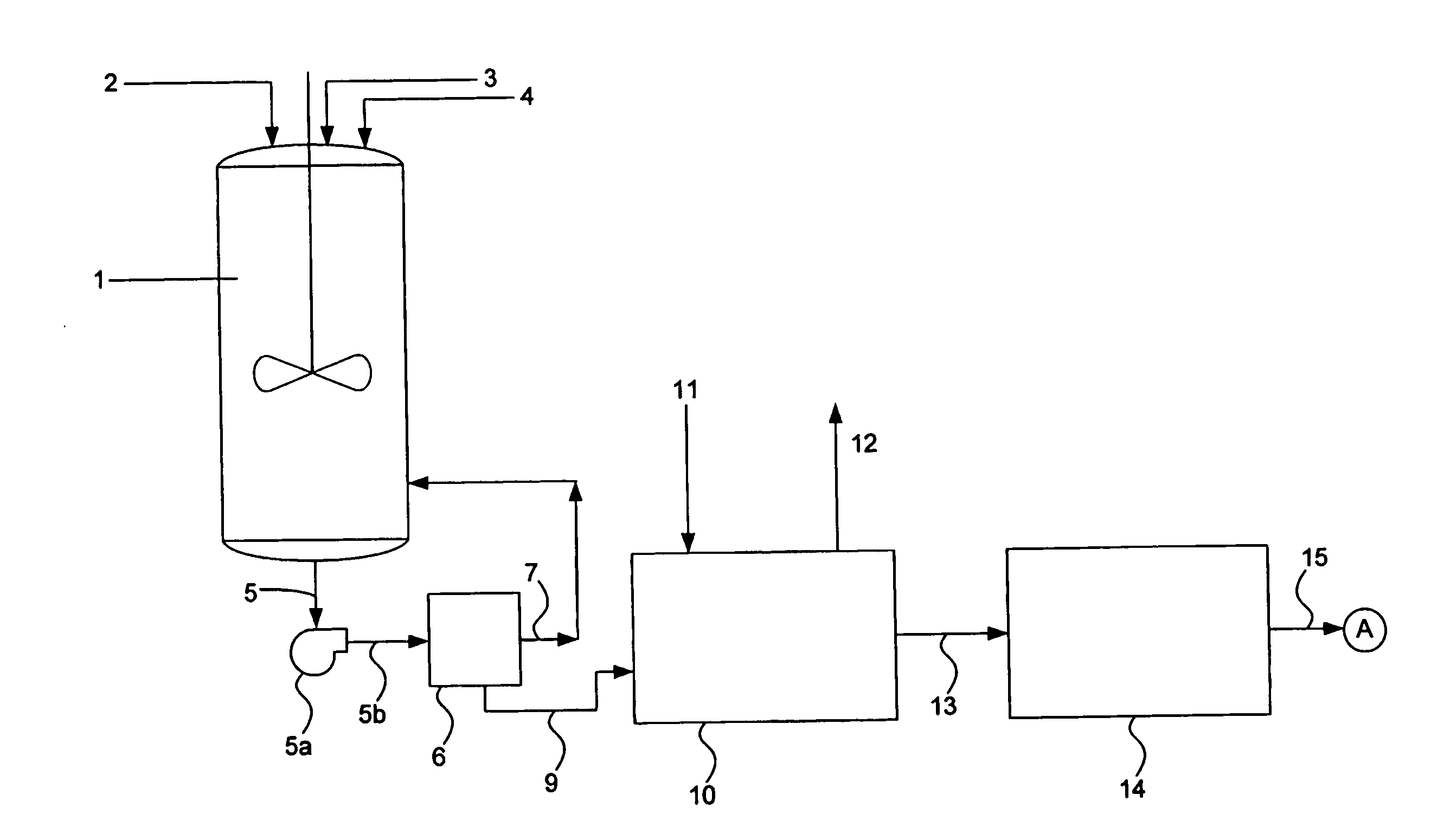

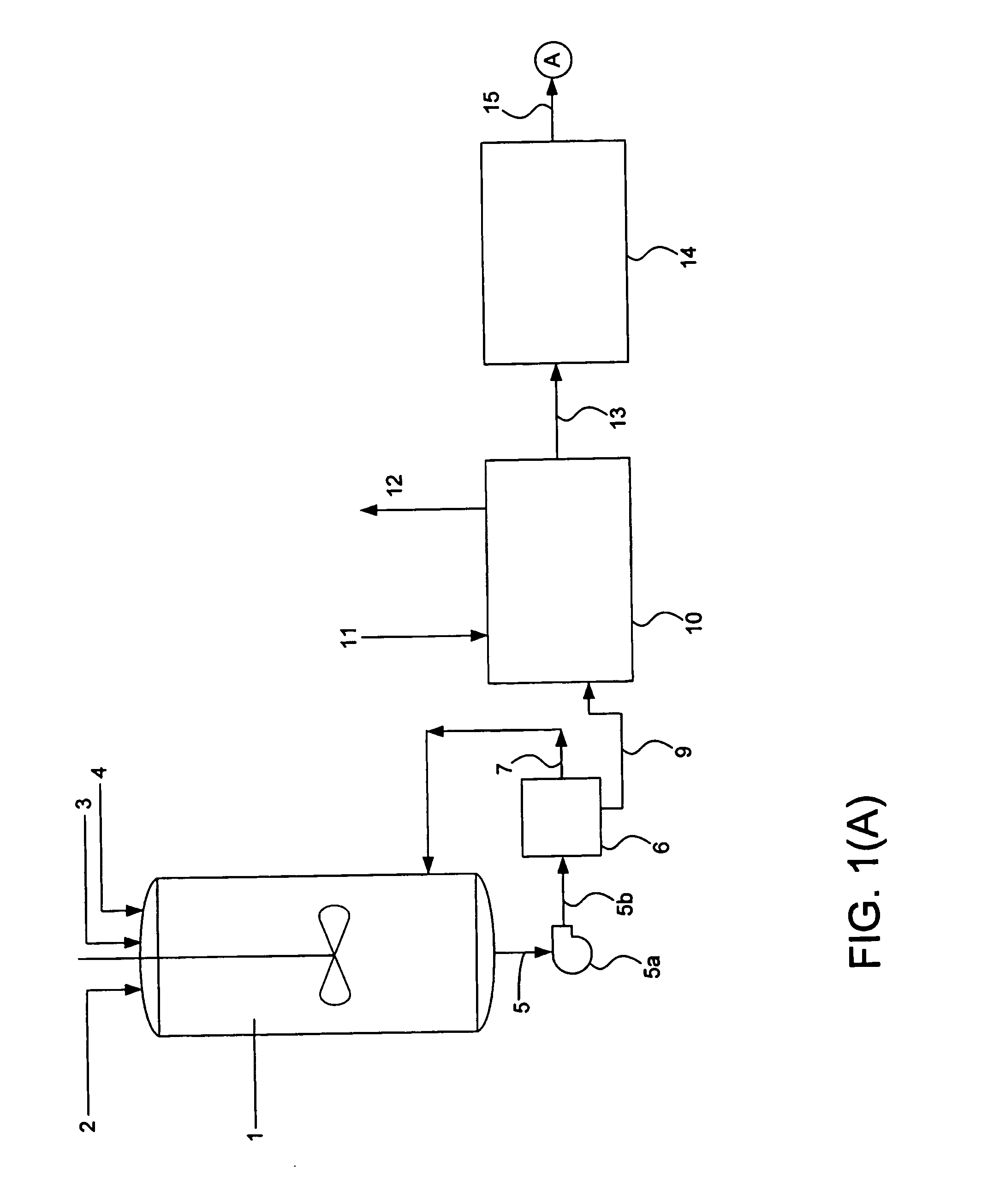

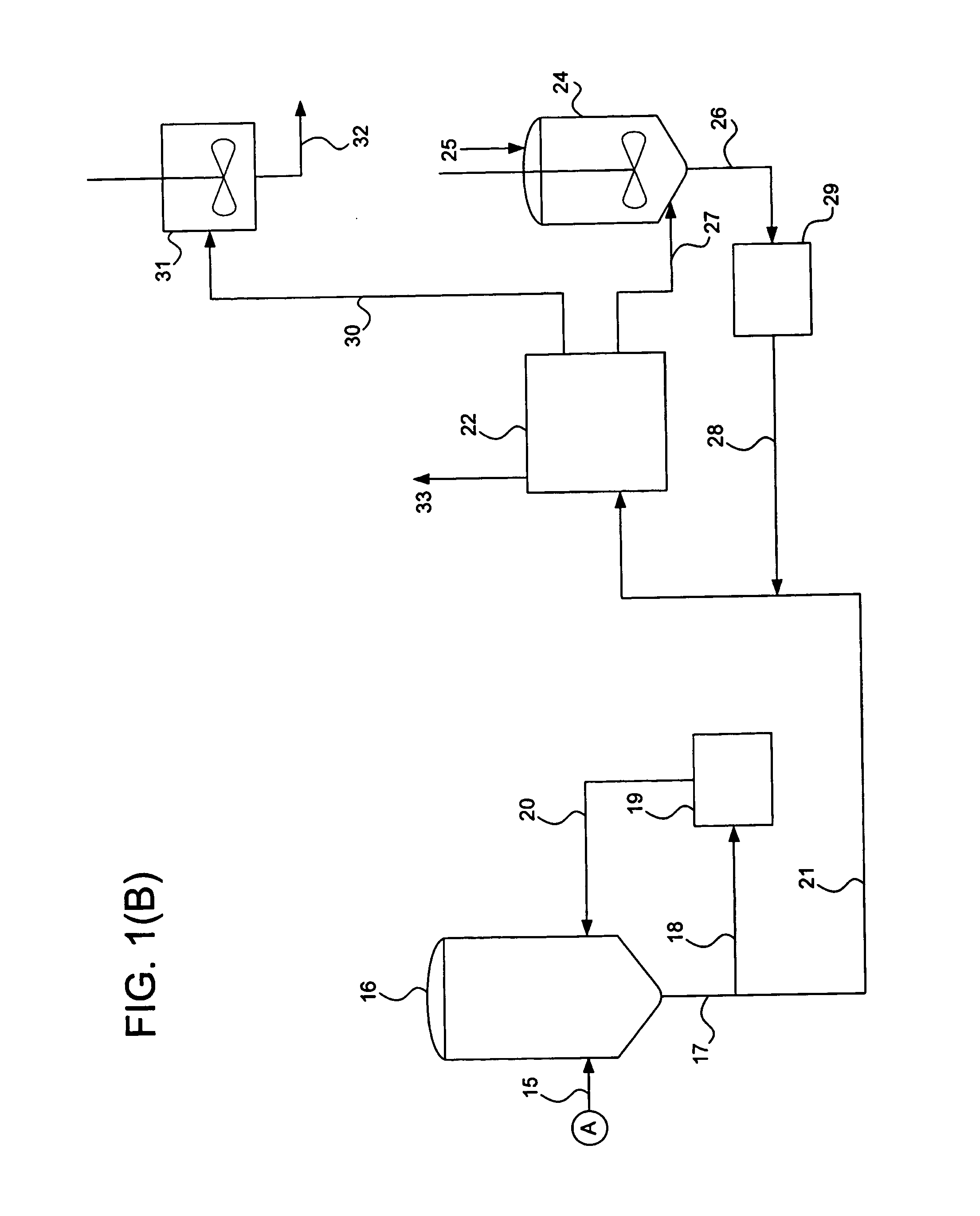

Disclosed is an optimized process and apparatus for more efficiently producing and purifying aromatic dicarboxylic acids (e.g., terephthalic acid). The optimized system employs at least one zoned slurry concentrator to enhance purification of the aromatic dicarboxylic acid.

Owner:ALPEK POLYESTER SA DE CV

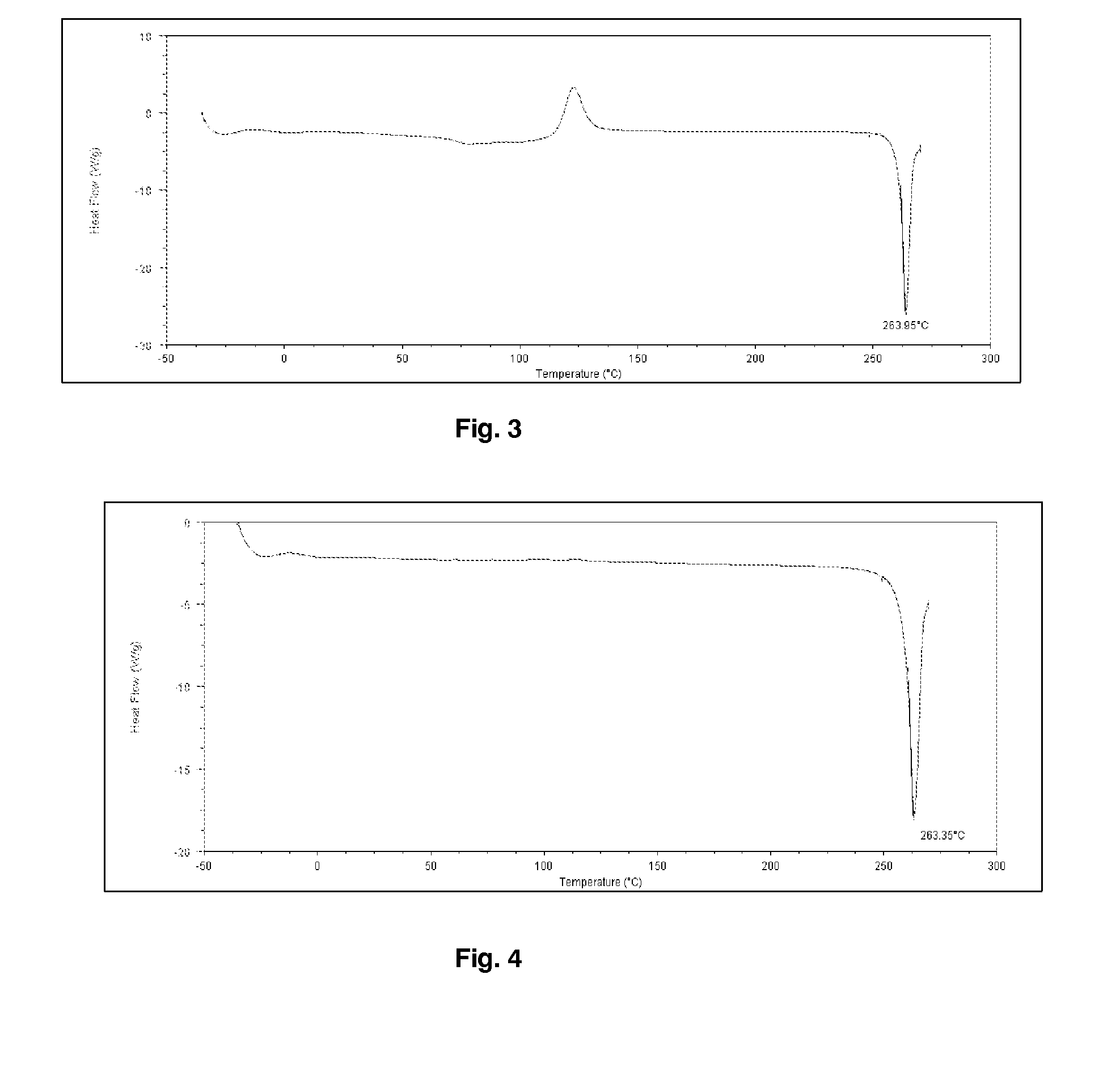

Process for improving crystallinity

ActiveUS20110146678A1High crystallinityPrevent leakageOrganic active ingredientsPowder deliveryNon solventCrystallinity

This invention provides a process for increasing the crystallinity of at least one solid material which is less than 100% crystalline, comprising contacting said solid material with solvent in which the solid material is insoluble or poorly soluble (a non-solvent); and applying ultrasound to the solid material when in contact with said non-solvent.

Owner:CIRCASSIA

Brine purification

InactiveUS20100219372A1Increase contentLower levelTreatment using aerobic processesIsotope separationSaline waterCarbon adsorption

Process and apparatus for reducing organic content of brine comprising subjecting a brine solution to at least two purification treatments selected from electrochemical treatment, chlorinolysis, or other chemical oxidation treatment, carbon adsorption, extraction, biological treatment and chrystallizing treatment; wherein the organic content of purified brine is sufficiently low to enable sense of the purified brine in an industrial process.

Owner:DOW GLOBAL TECH LLC

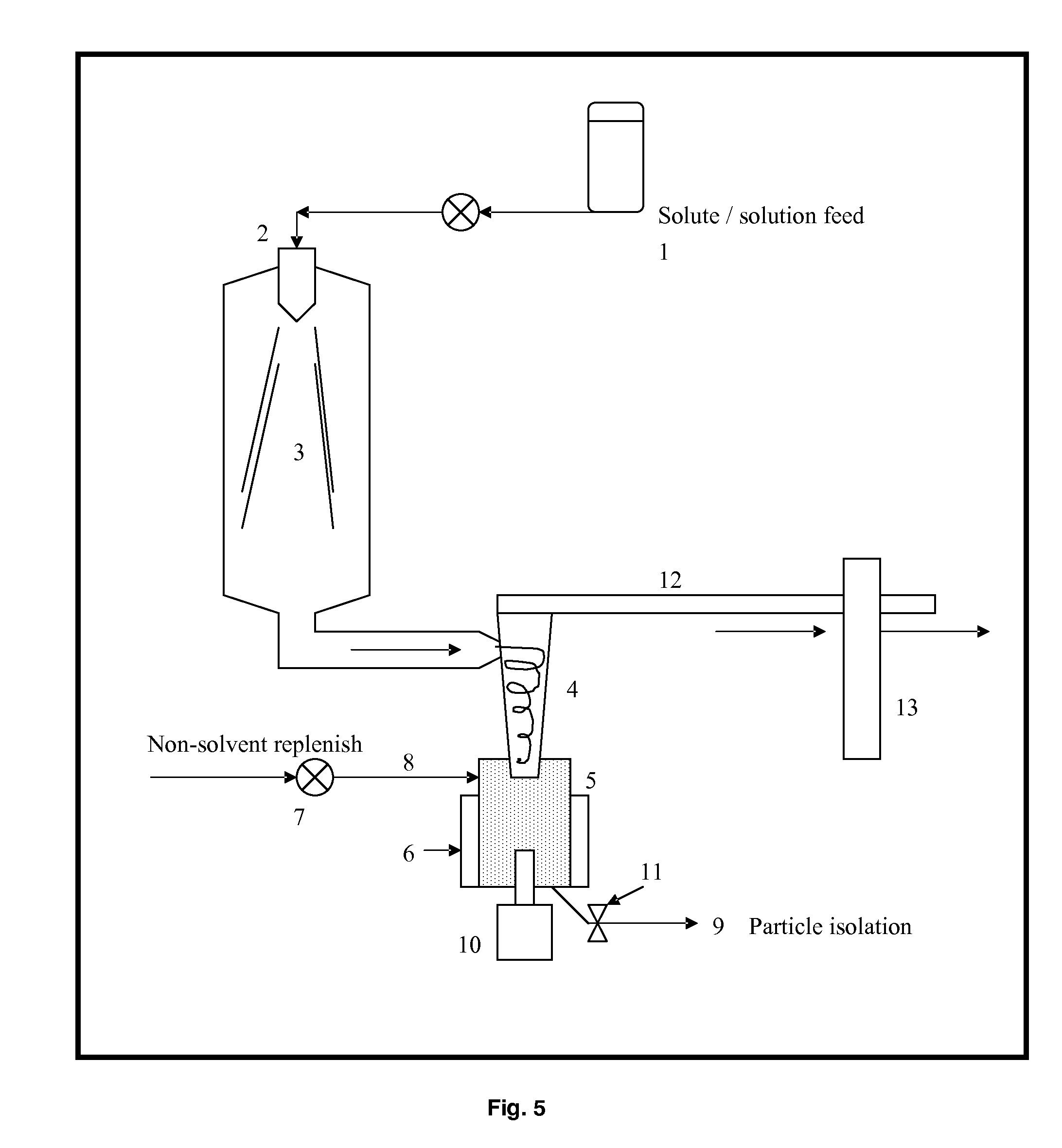

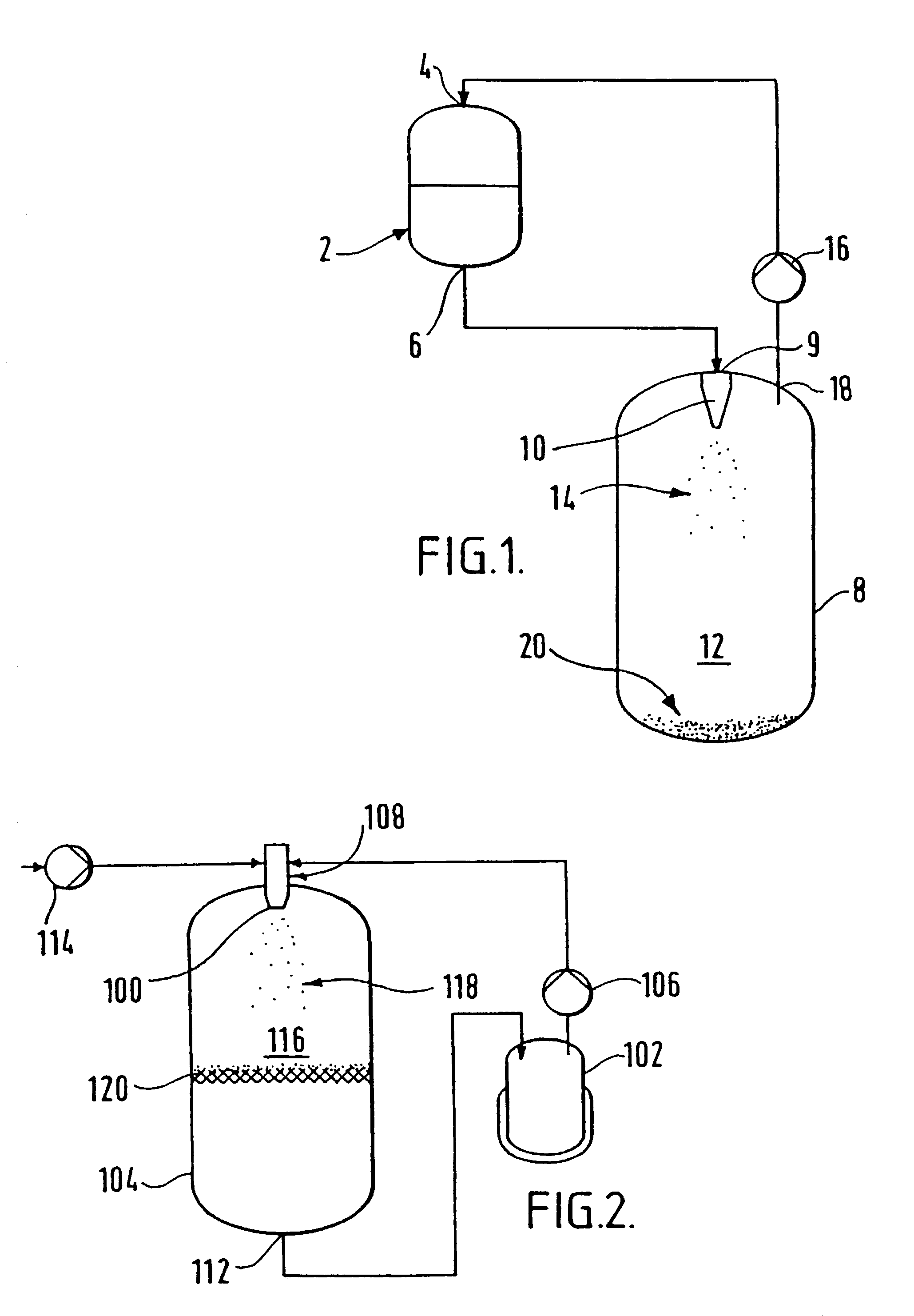

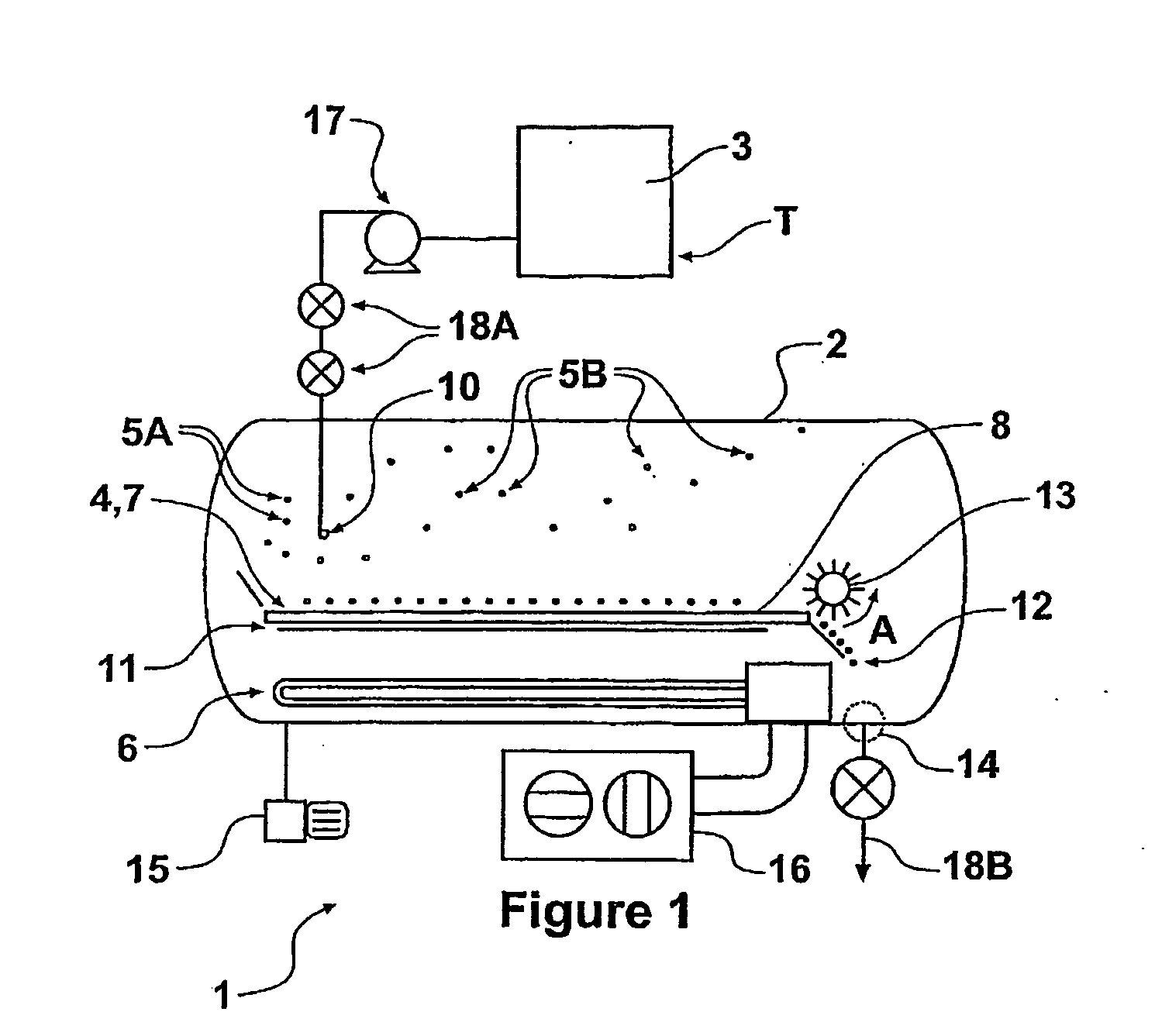

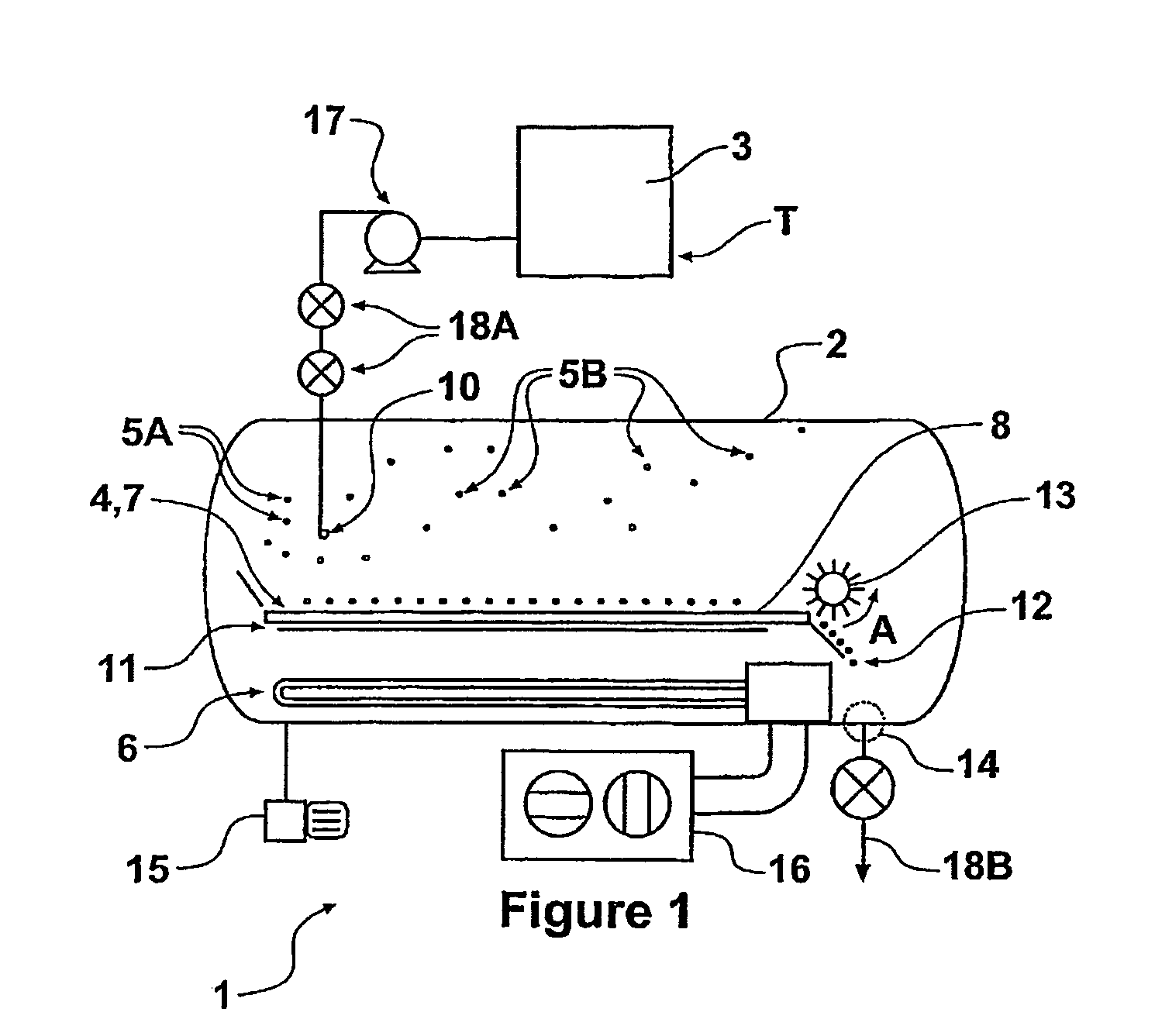

Method for the production of particles

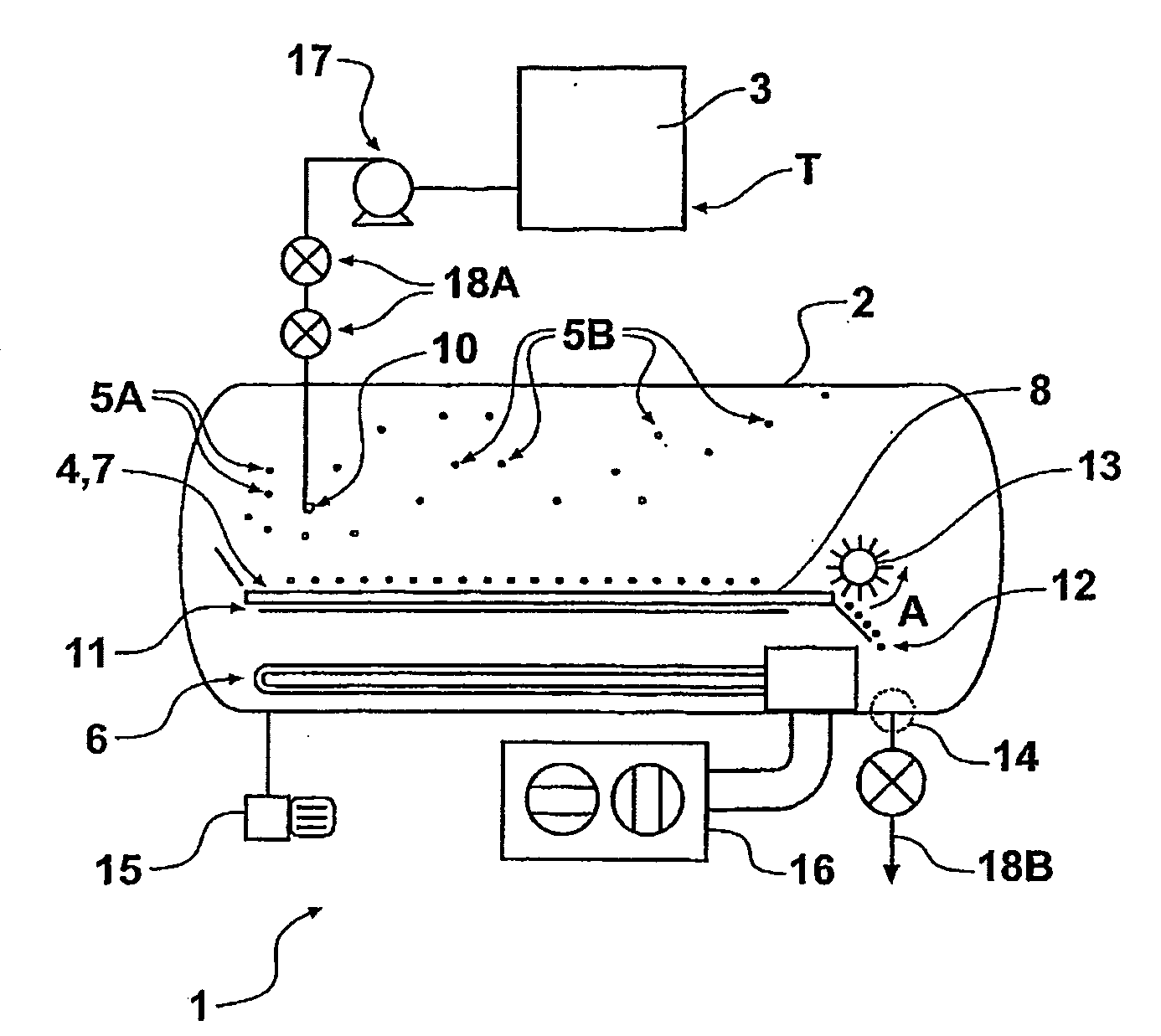

InactiveUS7404828B1Powder deliveryOrganic compounds purification/separation/stabilisationPlastic materialsHigh pressure

A method of preparing particles of a substance, for example selected from a flavor, fragrance, pigment, dye, biologically active compound or a plastics material, comprises contacting the substance of a formulation (which may include the substance in conjunction with a second solvent) with a first solvent which comprises a C1-C4 hydrofluorocarbon, especially tetrafluoroethane, and subjecting the resultant mixture to a separation process, for example, by allowing the mixture to be sprayed as a mist (14) from a high pressure environment in a first vessel (2) to a low pressure environment in a second vessel (8), thereby to cause separation of a least some of the substance from the first solvent and the formation of fine particles (20) of the substance.

Owner:GLAXO GROUP LTD

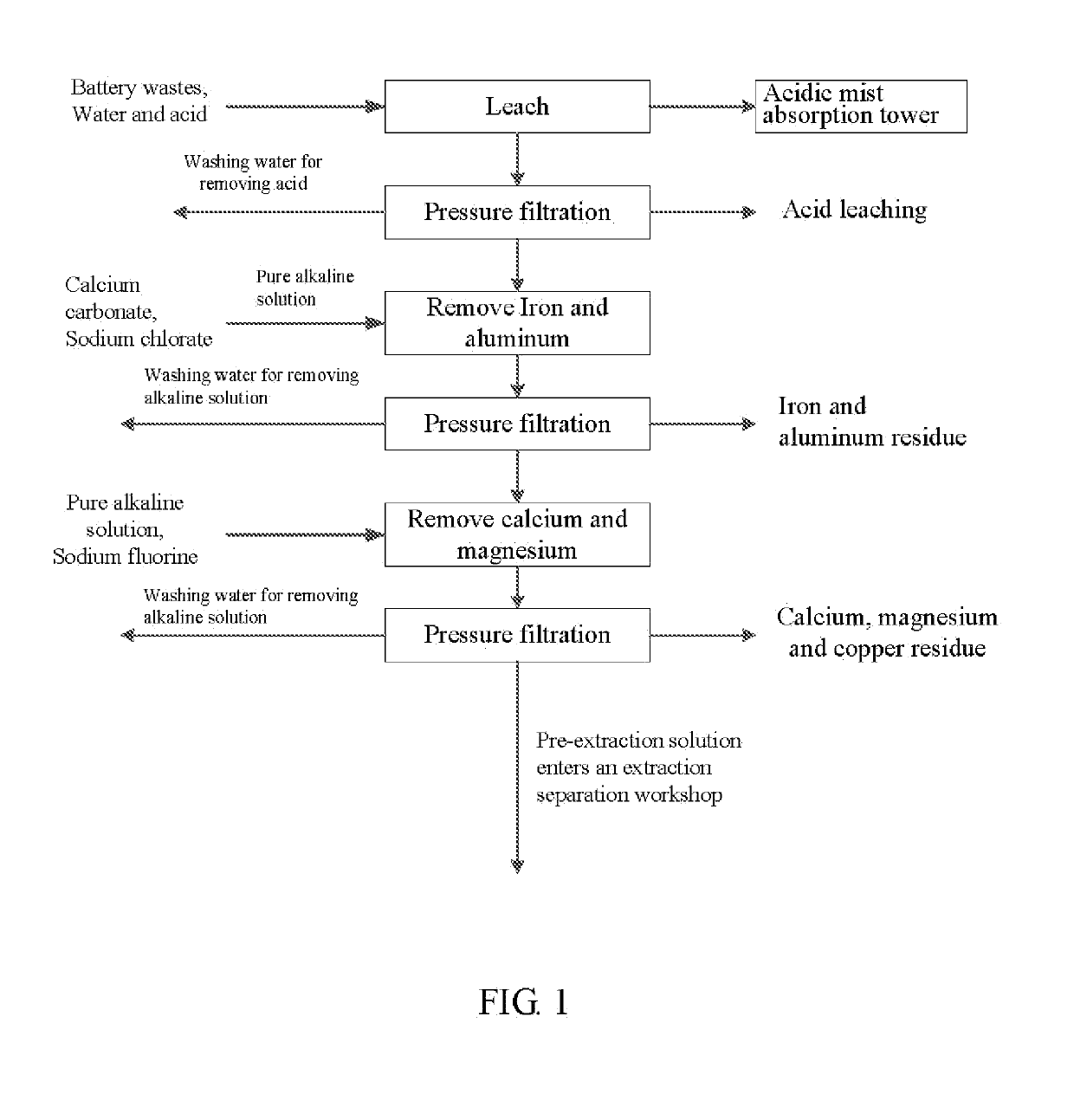

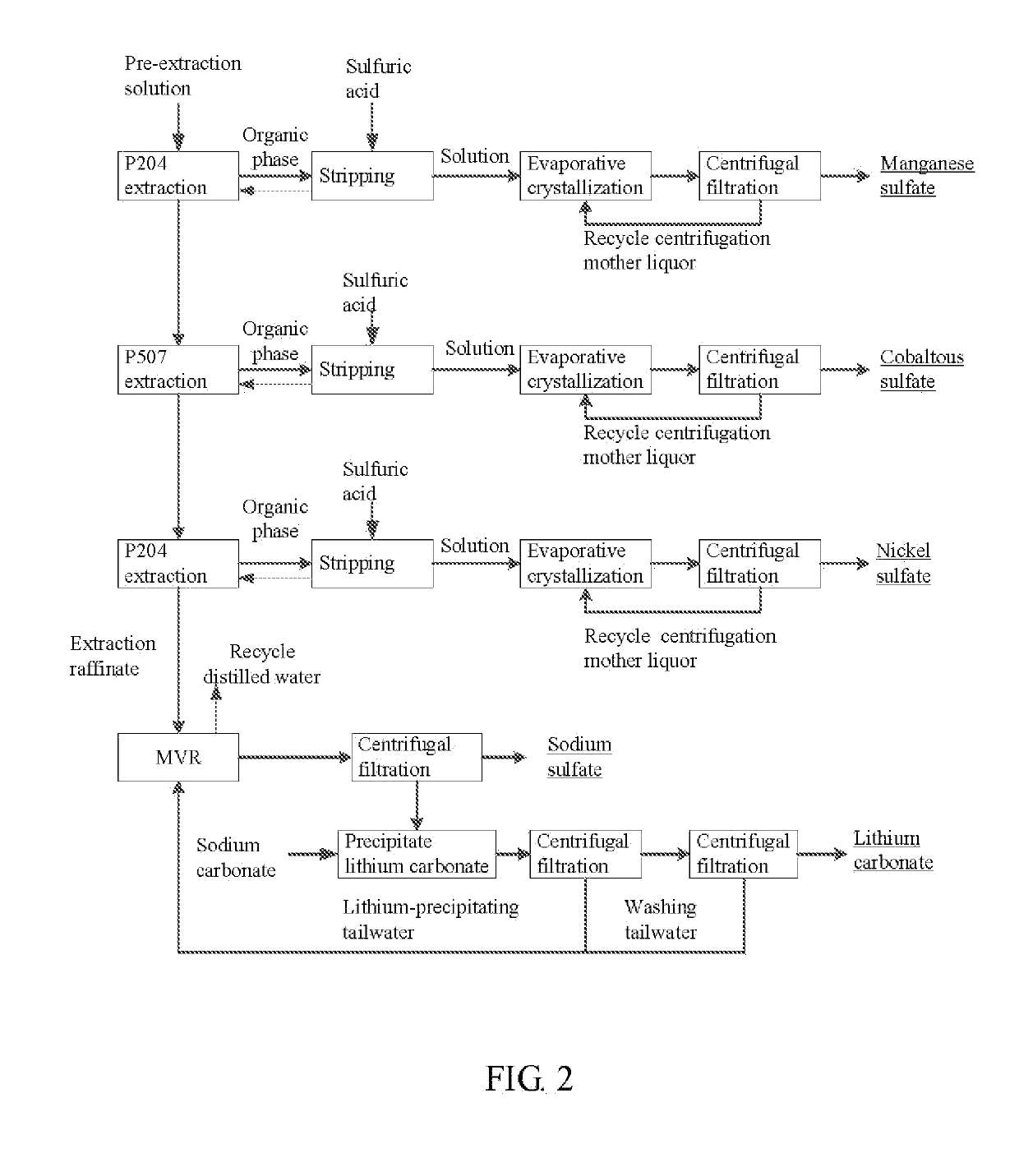

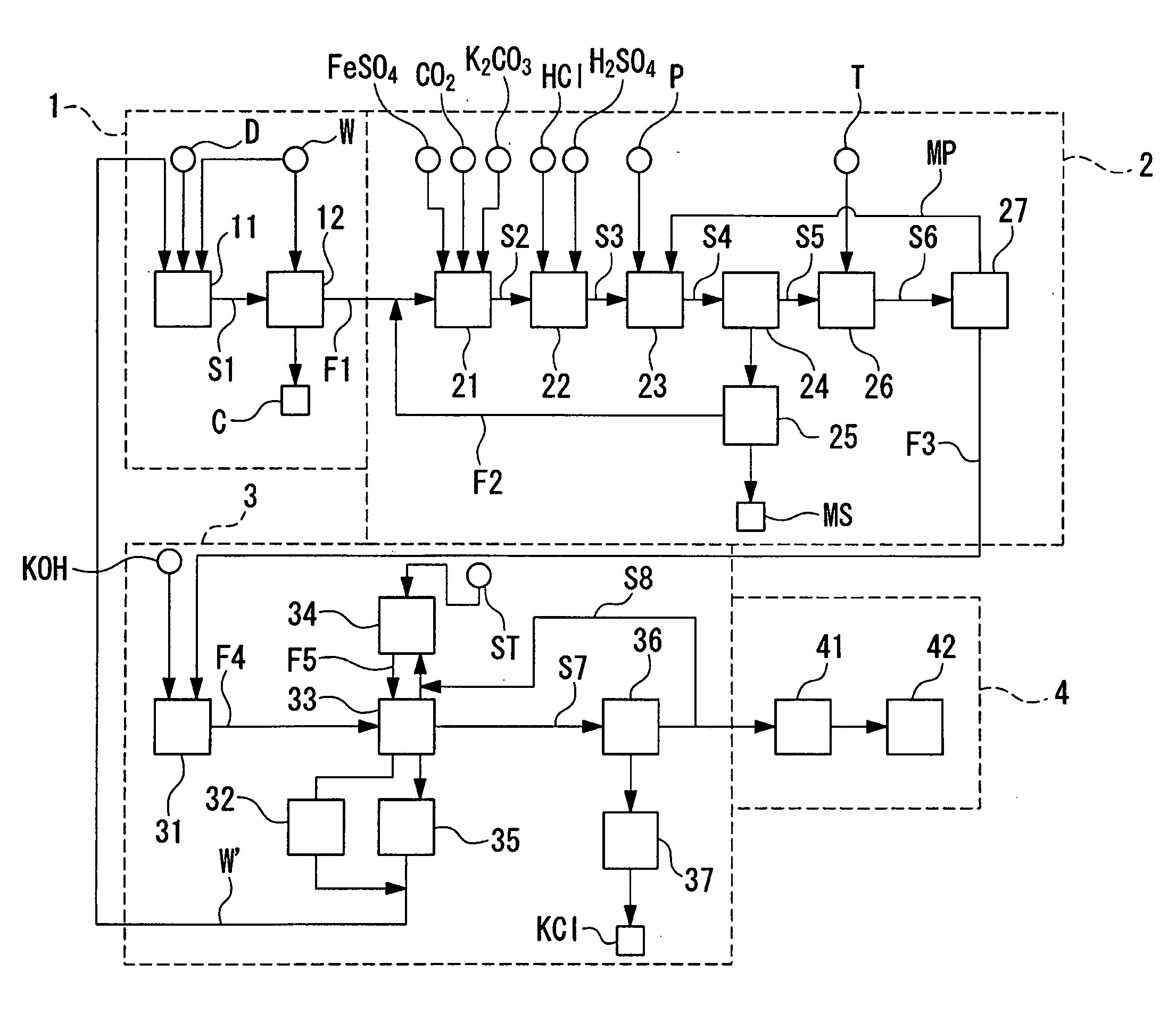

Method for preparing nickel/manganese/lithium/cobalt sulfate and tricobalt tetraoxide from battery wastes

ActiveUS20190152797A1Reduce productionHigh puritySolvent extractionCobalt sulfatesManganeseCobalt Sulfate

A method for preparing nickel / manganese / lithium / cobalt sulfate and tricobalt tetraoxide from battery wastes adopts the following process: dissolving battery wastes with acid, removing iron and aluminum, removing calcium, magnesium and copper, carrying extraction separation, and carrying out evaporative crystallization to prepare nickel sulfate, manganese sulfate, lithium sulfate, cobalt sulfate or / and tricobalt tetraoxide. By using the method, multiple metal elements, such as nickel, manganese, lithium and cobalt, can be simultaneously recovered from the battery wastes, the recovered products are high in purity and can reach battery grade, battery-grade tricobalt tetraoxide can also be directly produced. The method is simple in process, low in, energy consumption and free in exhaust gas pollution, and can realize zero release of wastewater.

Owner:HUNAN JINYUAN NEW MATERIALS CO LTD

Method for extracting nylon from waste materials

InactiveUS20060031997A1Shorten the dissolution timeReduce the temperaturePlastic recyclingRotary piston pumpsNylon materialSolvent

The invention relates to a method for recovering nylon from a nylon-containing material by contacting the nylon-containing material with an alkanol-containing solvent at elevated temperature and at a pressure higher than the equilibrium pressure of the alkanol-containing solvent at the elevated temperature, thereby dissolving the nylon in the alkanol-containing solvent, removing the alkanol-containing solvent containing dissolved nylon from any undissolved solids, and decreasing the temperature of the alkanol-containing solvent containing dissolved nylon to precipitate the dissolved nylon.

Owner:INTERFACE INC

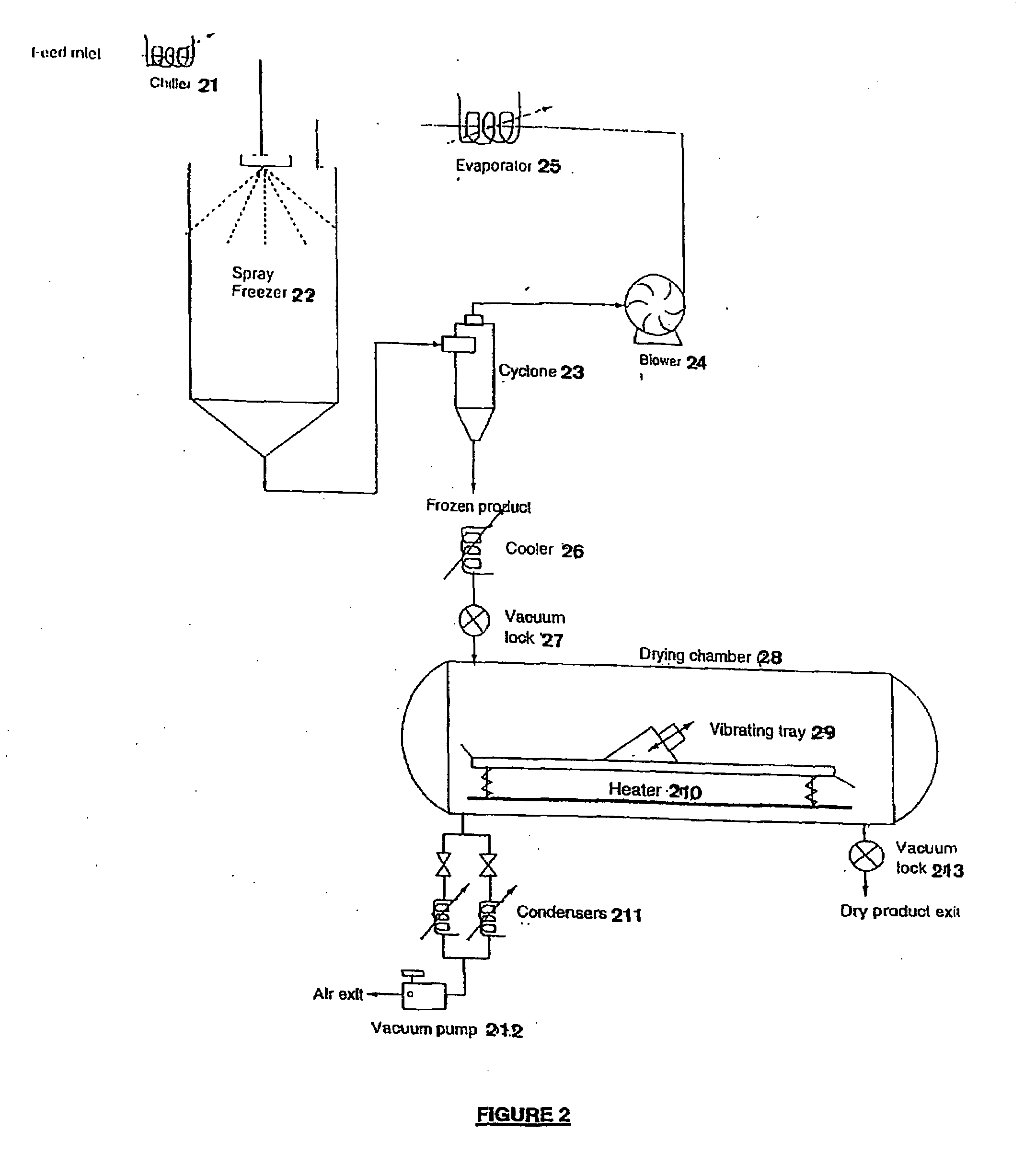

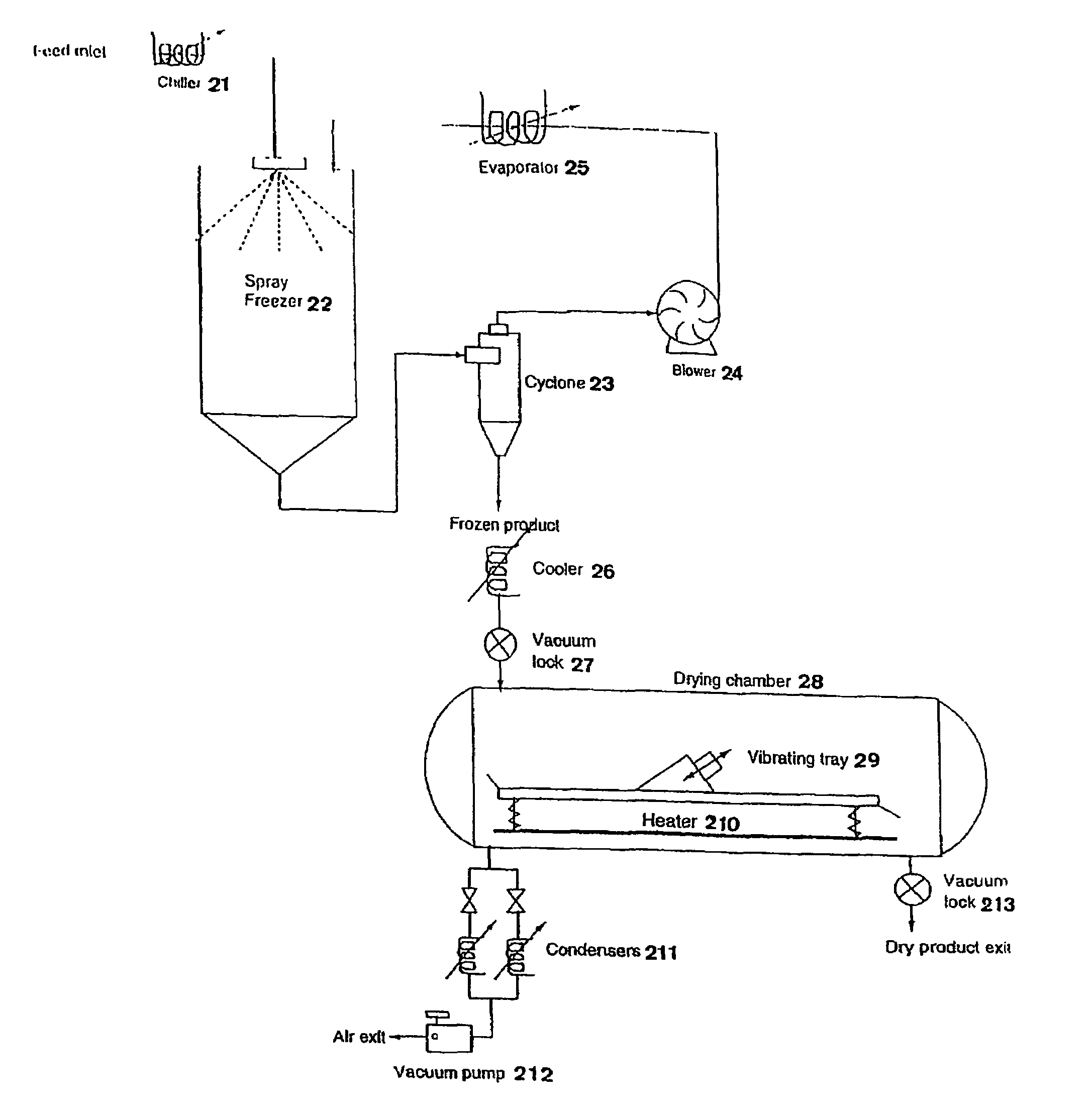

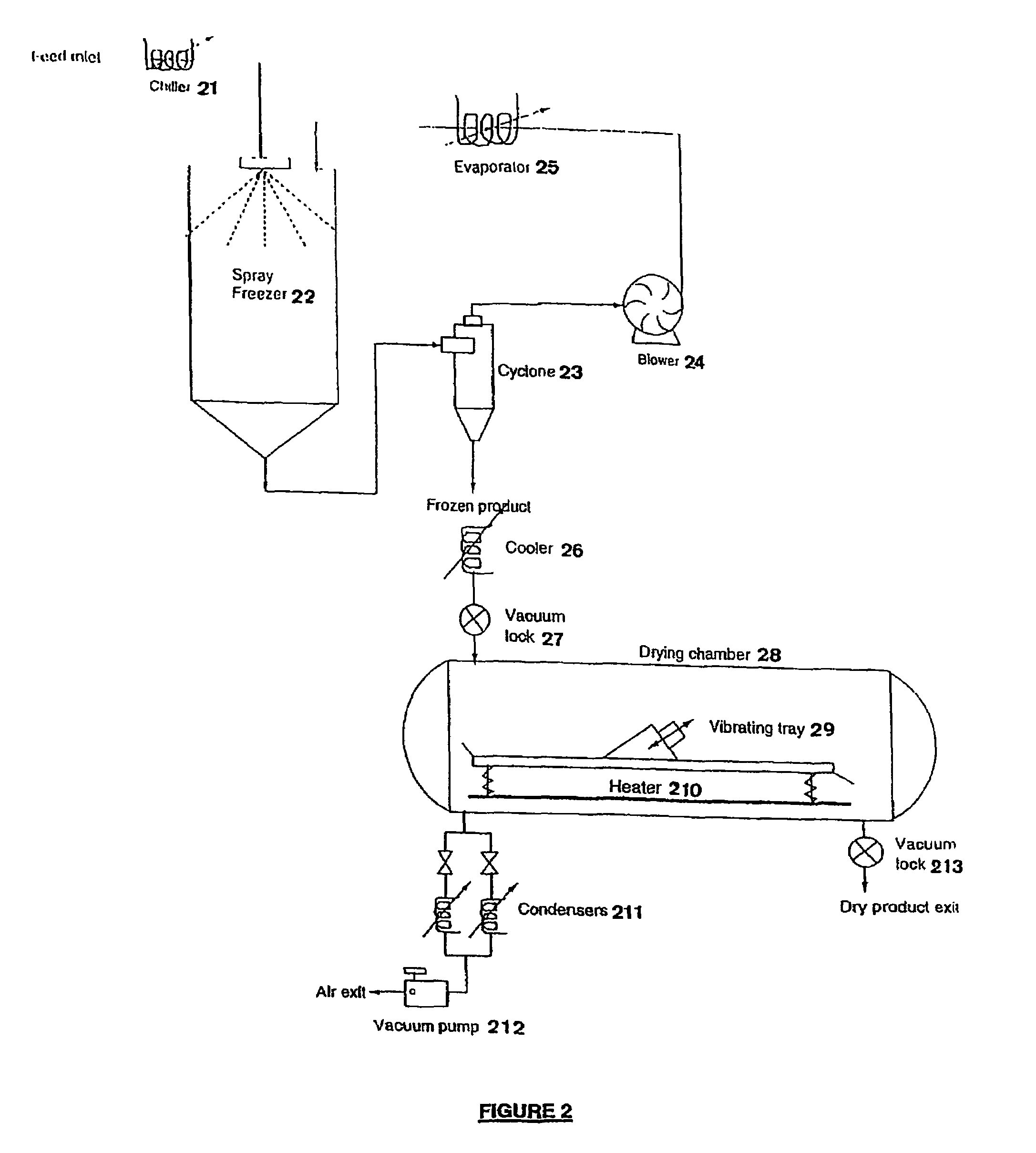

Drying Process and Apparatus

InactiveUS20080142166A1Control thicknessImprove throughputDrying solid materials without heatOther dairy technologyFruit juiceFreeze-drying

This invention relates to a process and / or method and associated apparatus for use in spray freeze drying a fluid substance such as fruit juice, pharmaceuticals, nutraceuticals, tea and coffee. A fluid substance is sprayed (atomised) and reduces in temperature to below its eutectic temperature; thereby inducing a phase change of fluids in the fluid substance. The atomised fluid substance (AFS) is then subjected to a vacuumous drying chamber in which the AFS is subjected to an energy source to assist sublimation of fluid from the AFS as it is conveyed through the chamber. Such an energy source can provide a temperature gradient through which the AFS passes and is exposed to, all carried out so as to preferably minimise or reduce the likelihood of degradation of the substance being dried (reducing the fluid content).

Owner:AGRESEARCH LTD

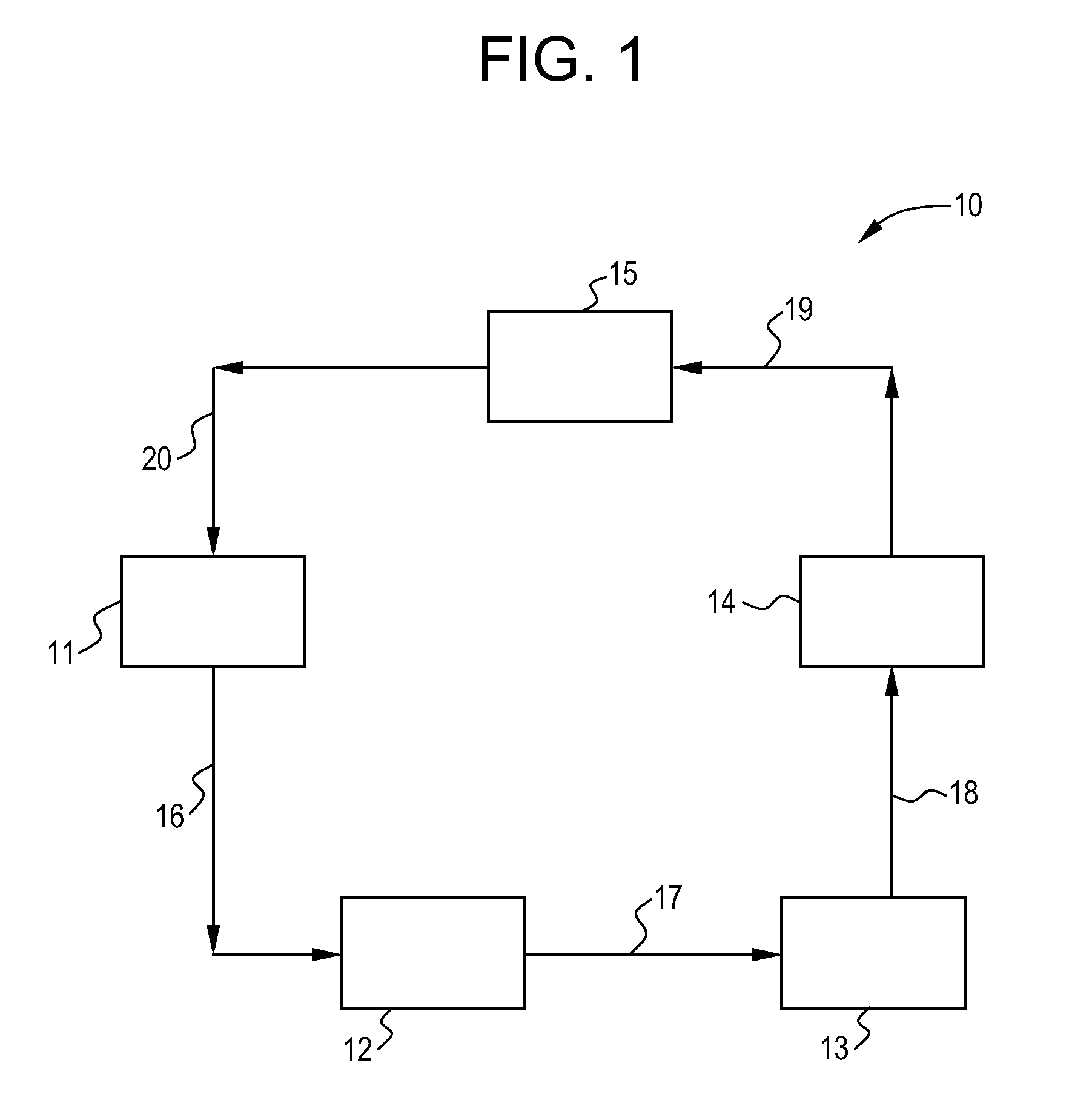

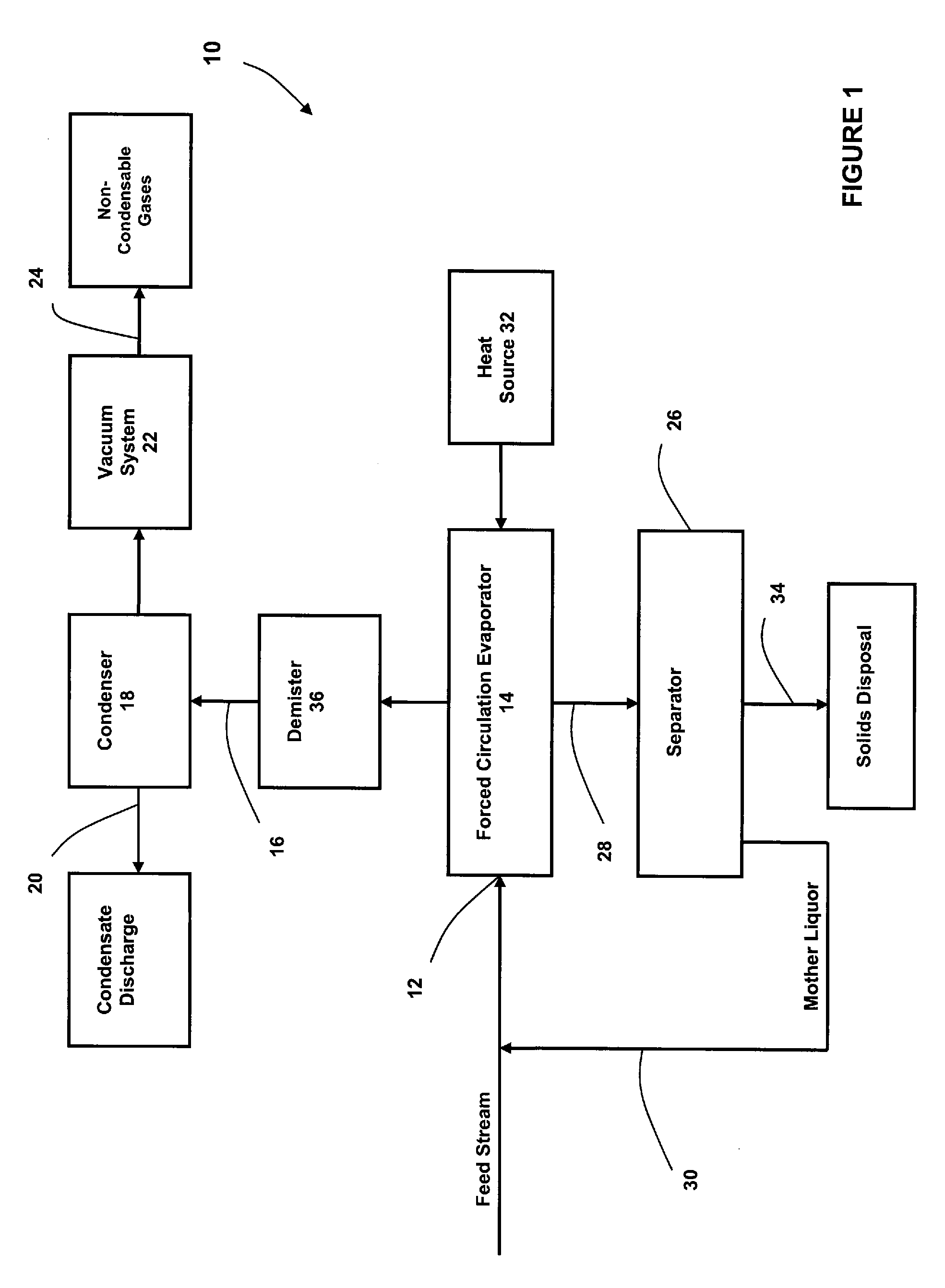

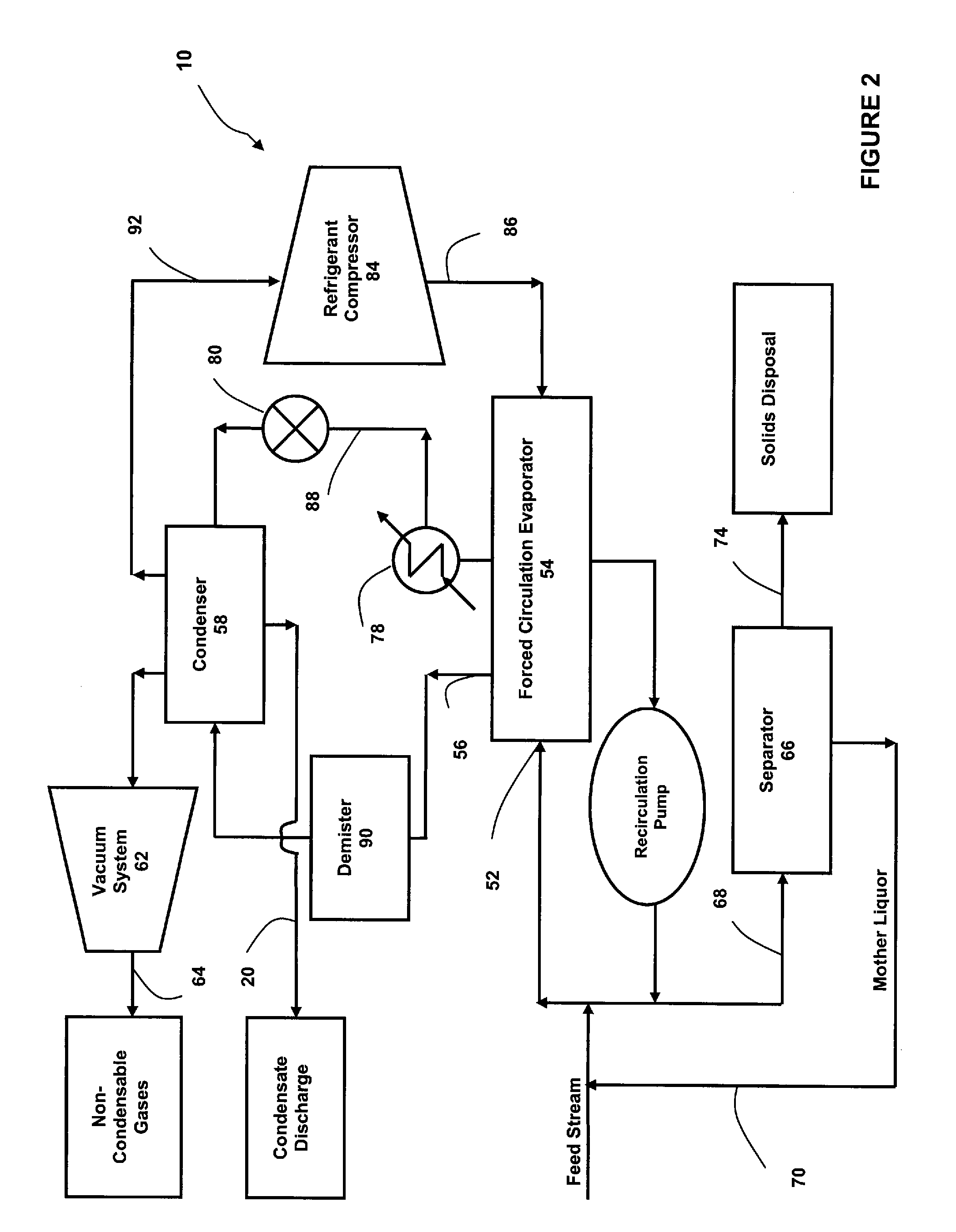

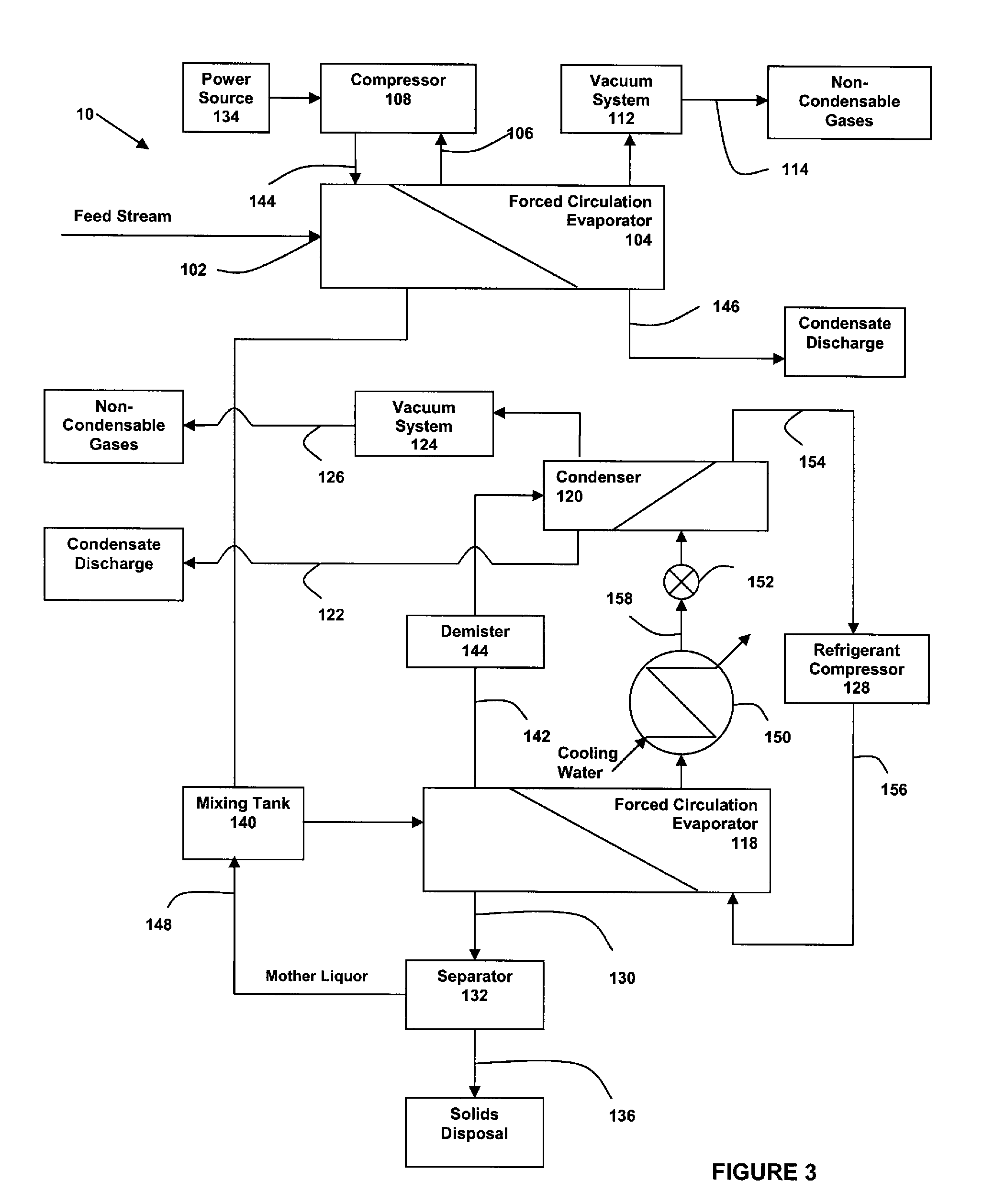

Method for removing dissolved solids from aqueous waste streams

ActiveUS8052763B2Sedimentation separationWaste water treatment from gaseous effluentsWaste streamBoiling point

A method for removing dissolved solids from a waste stream, such as that produced in flue gas scrubbing, through an evaporation-crystallization process operated at relatively low temperature. A waste stream is directed into an evaporator and heated at a temperature of less than 60° C. at a pressure below atmospheric pressure. The waste stream is concentrated through the evaporation process and forms a slurry stream having crystallized solids. At the low temperature of evaporation, the solids crystallize at substantially lower temperature and the solution has a substantially lower boiling point elevation than at atmospheric pressure. The slurry stream is directed to a solid-liquid separator where the crystallized solids in the slurry stream are separated, producing a solid cake and mother liquor.

Owner:VEOLIA WATER TECH INC

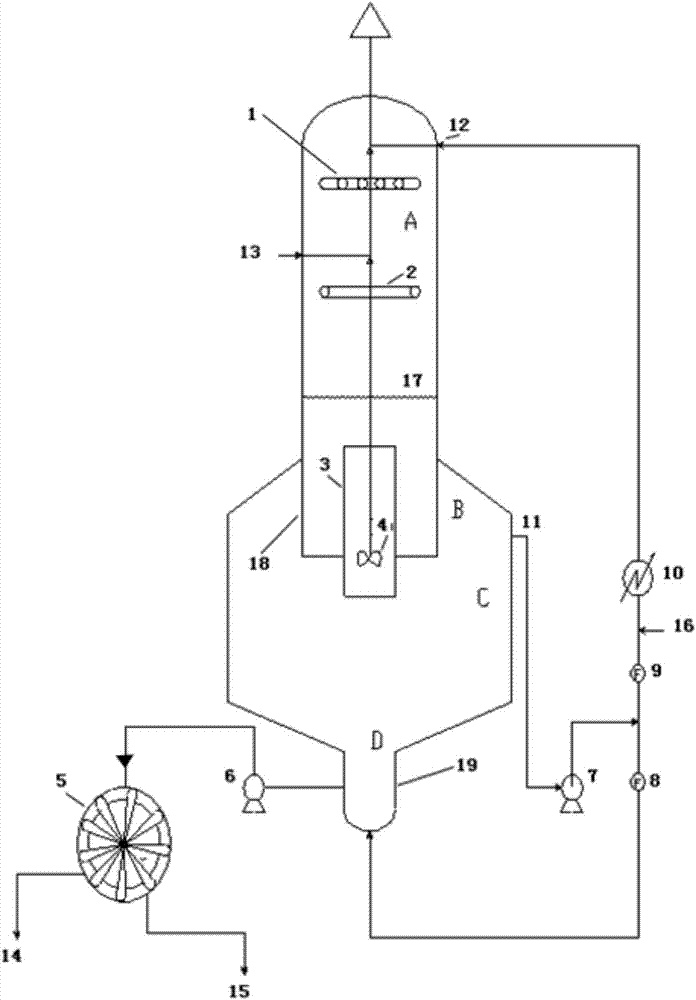

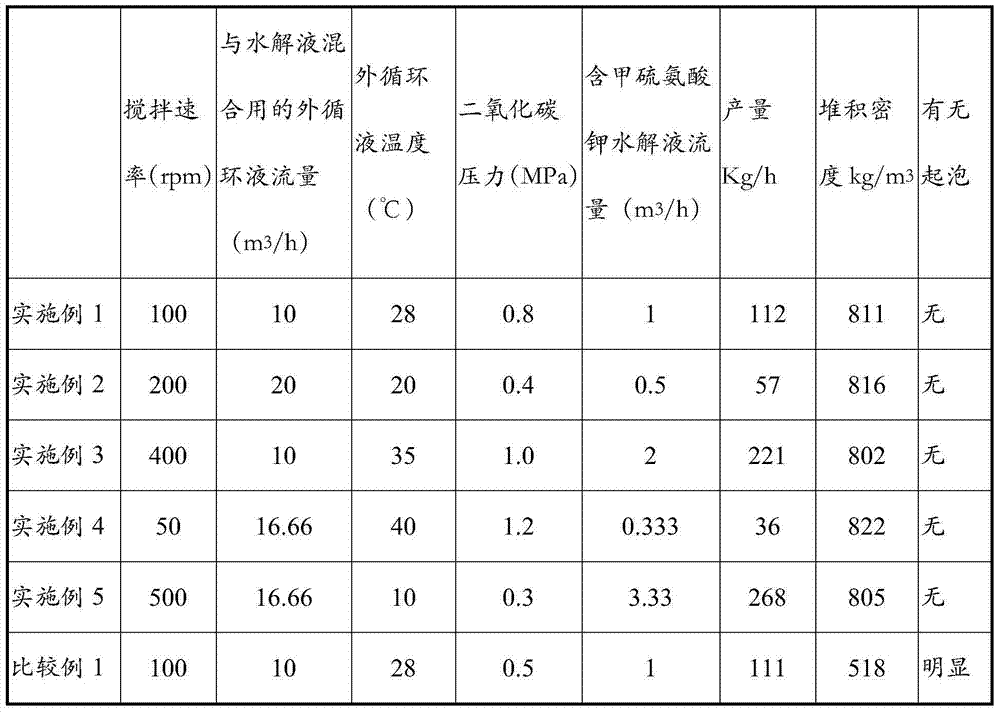

Method for continuously preparing high-bulk density methionine crystals

ActiveCN104744326AImprove product qualityImprove efficiencyOrganic chemistryOrganic compound preparationHydantoin derivativesHydrolysate

The invention relates to a method for continuously preparing high-bulk density methionine crystals. The process of the method is as follows: a hydrolysate, which is obtained from reaction of 5-(beta-methylthioethyl)hydantoin and a potassium carbonate solution, is mixed with an outside circular material from a DTB neutralization crystallizer with a gas phase neutralization section, the mixture is cooled and enters a liquid distributor in a neutralization area in the upper part of the crystallizer, the mixture is sprayed in drops or trickles into carbon dioxide gas for neutralization reaction, and then falls naturally into a crystallization area in the lower part to be mixed with a material in the area, the mixture grows on tiny crystals in a system to form crystals with larger grain sizes, and meanwhile new crystal nucleuses are formed; in a deposition area in the middle part of the crystallization area, the crystals with larger grain sizes sink into a washing leg, the tiny crystals circulate along with the outside circular material, a part of the outside circular material is used for washing the crystals in the washing leg, and the other part of the outside circular materials is mixed with the hydrolysate; the crystals in the washing leg are separated, washed and then dried to obtain the high-bulk density methionine product.

Owner:SHANDONG XINHECHENG AMINO ACID +2

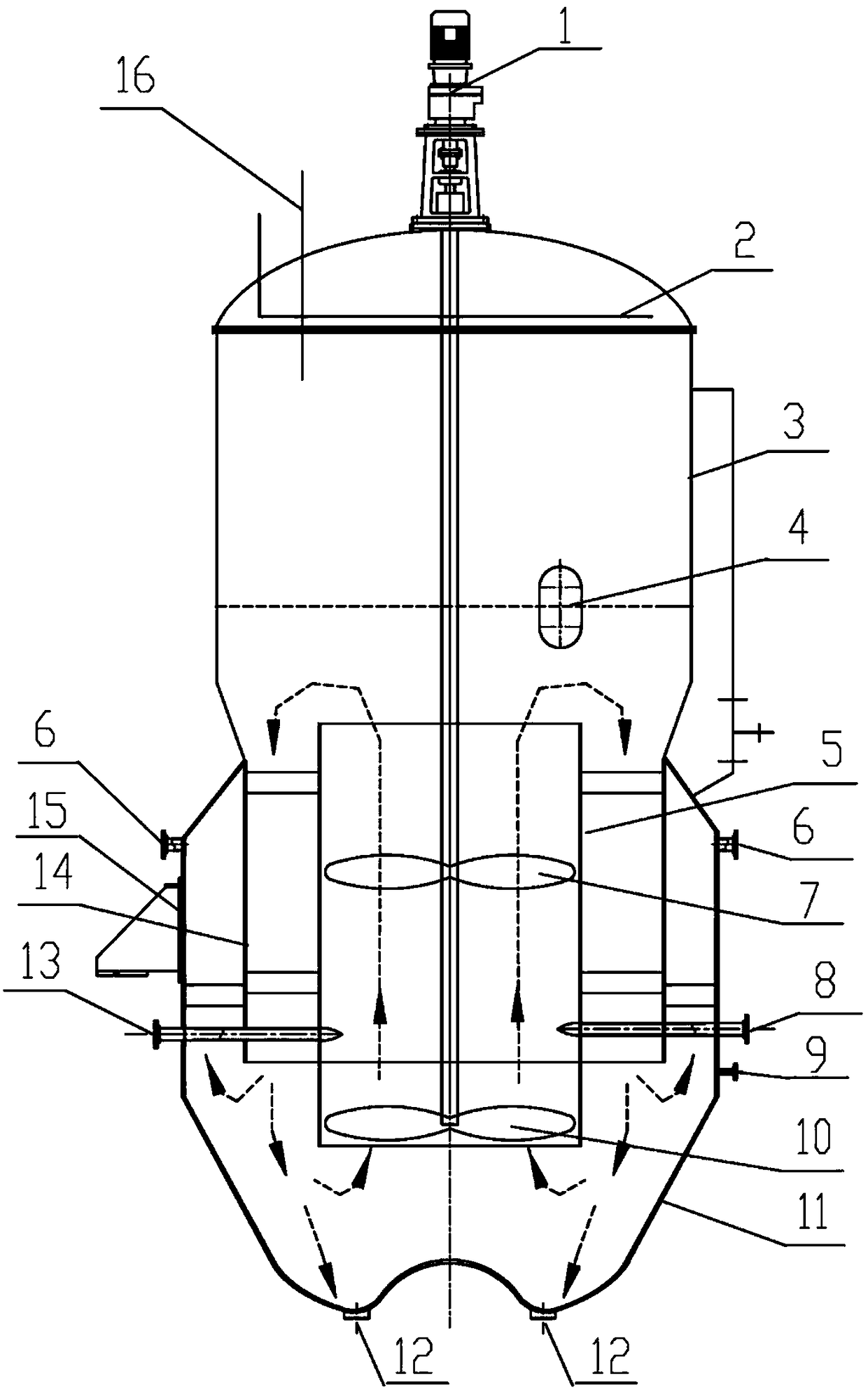

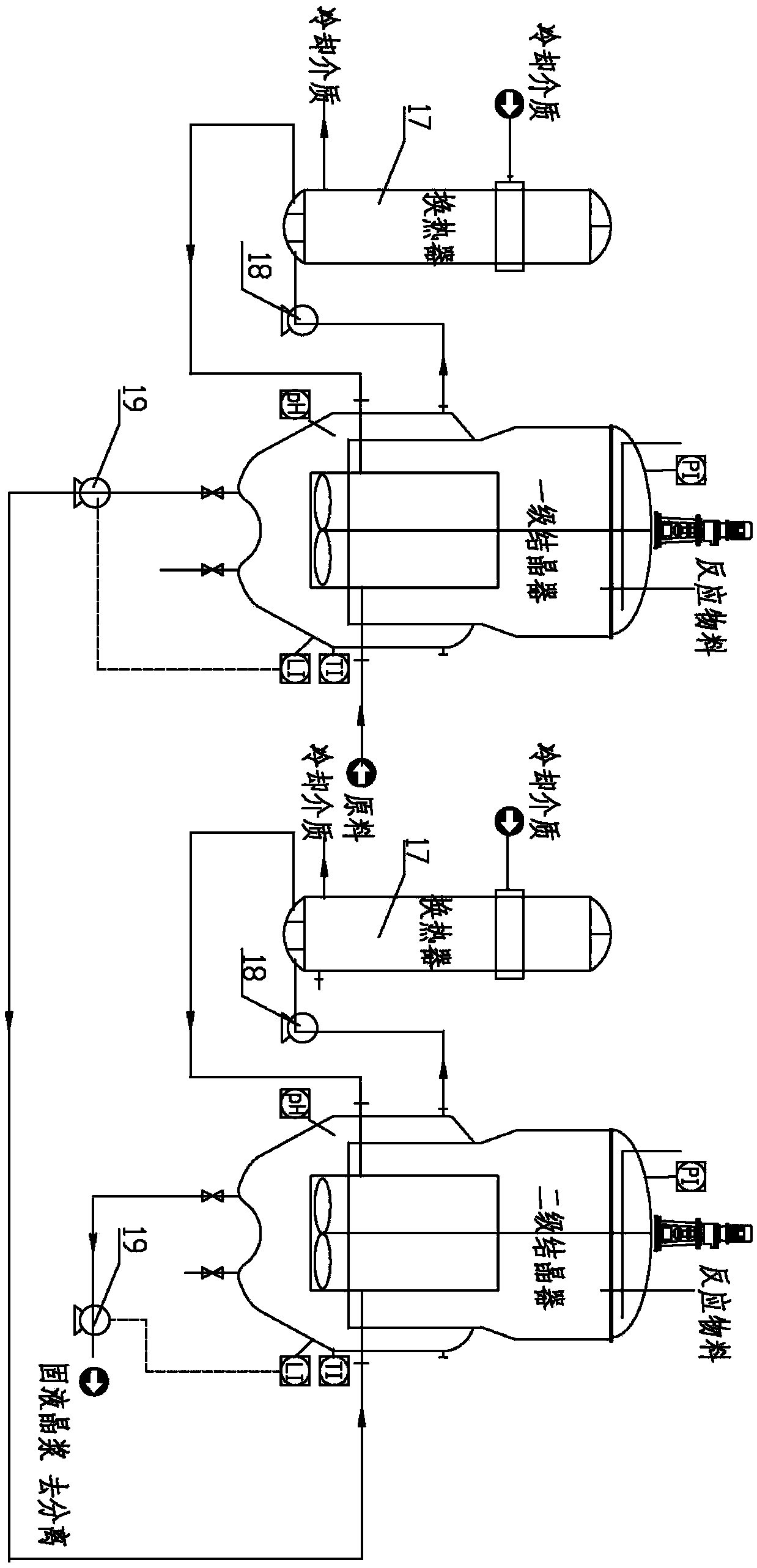

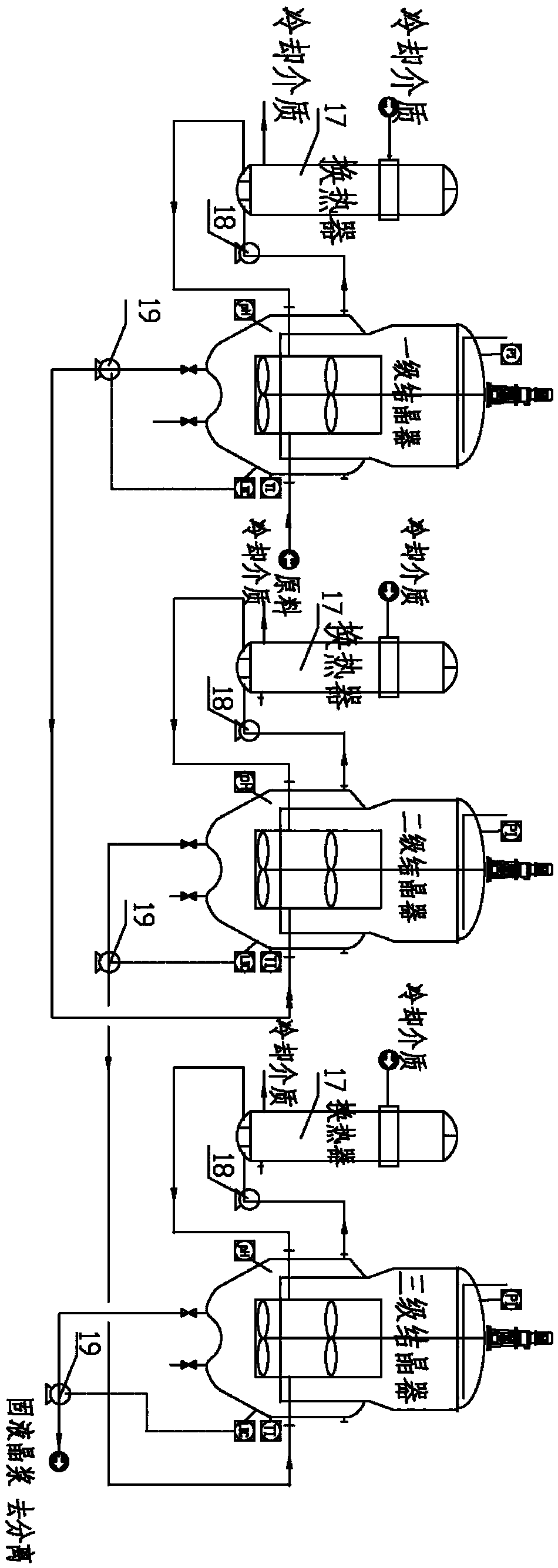

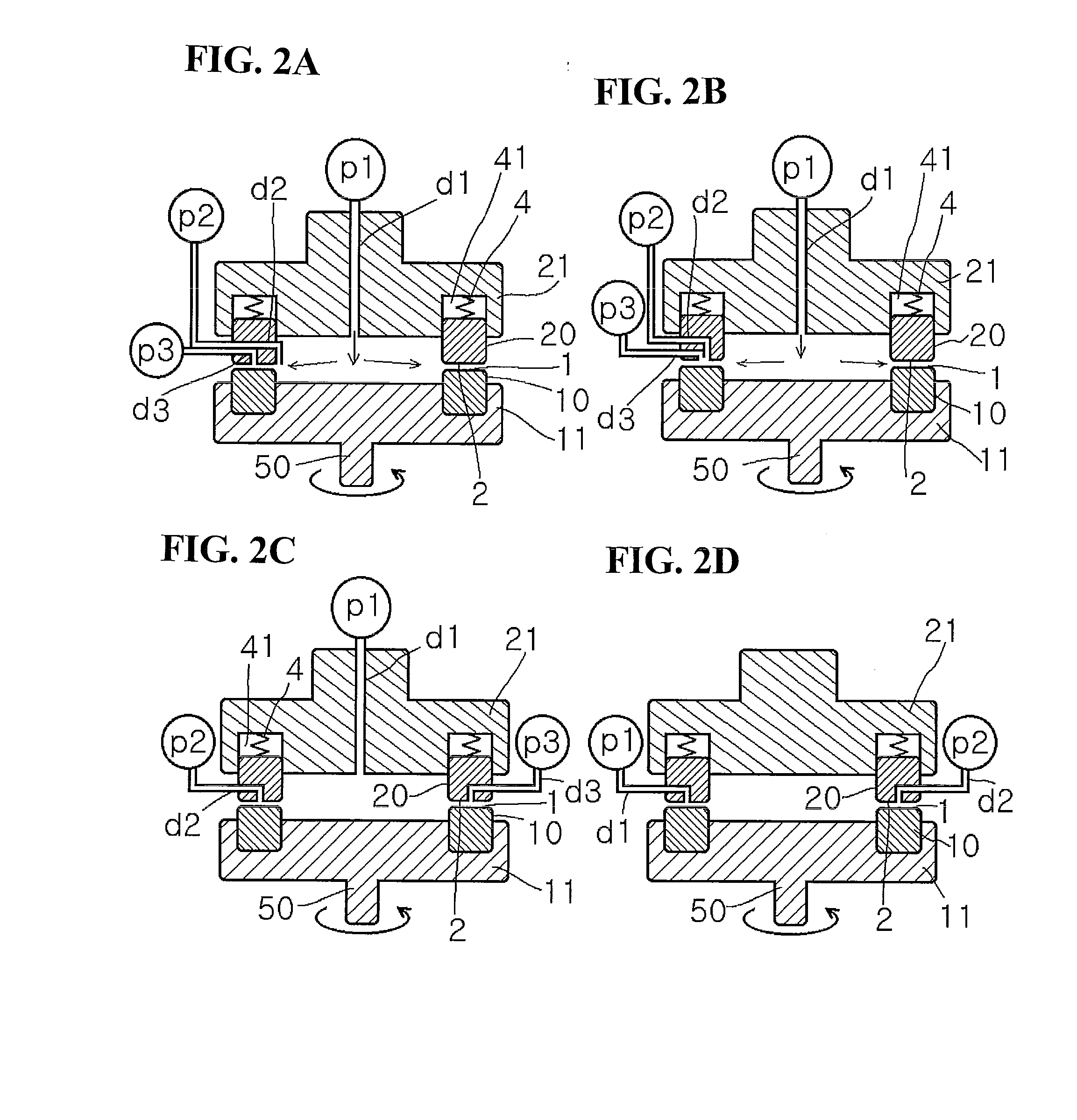

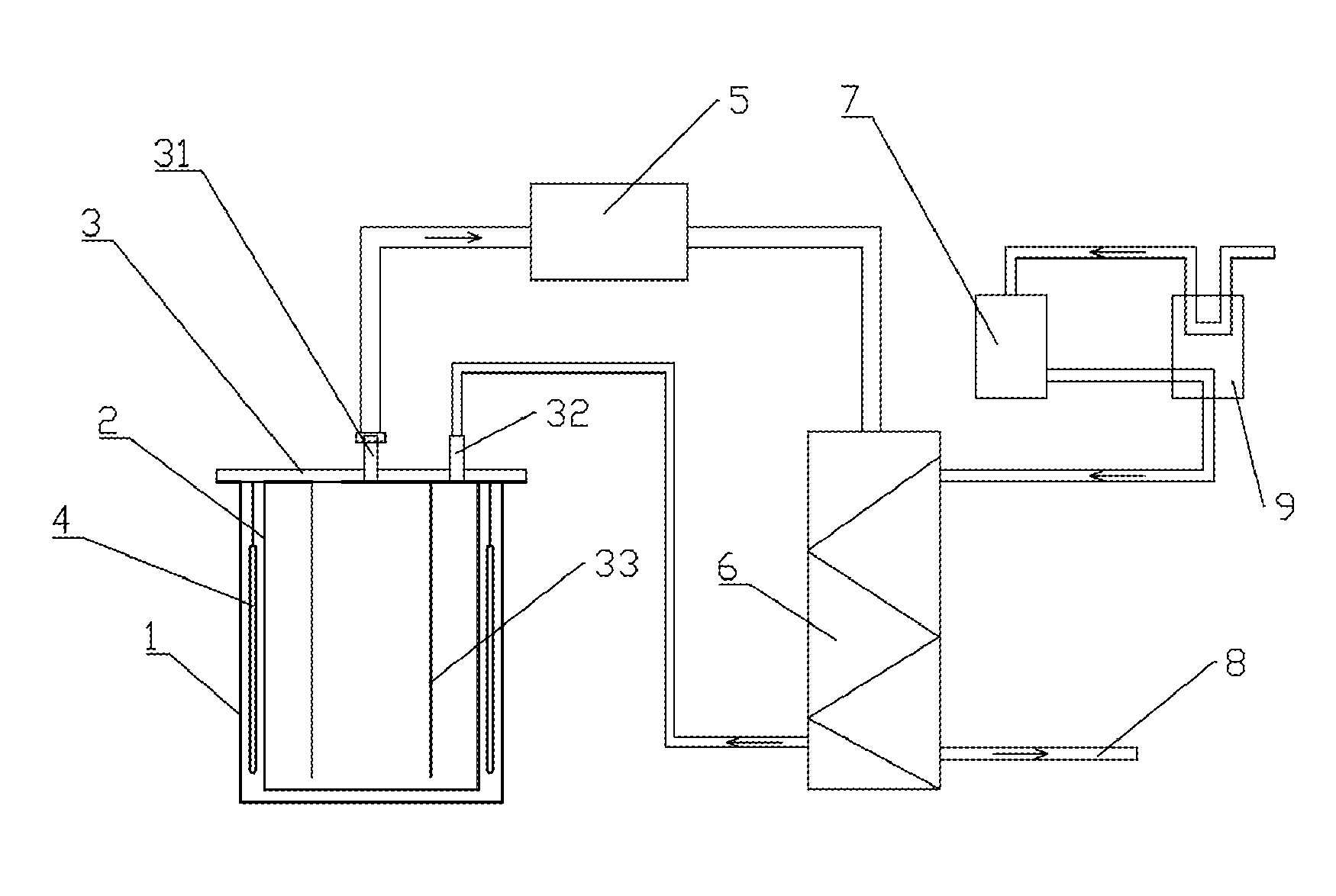

Self-circulating crystallizer and multistage continuous crystallization method

ActiveCN108939599AReduce the chance of collision nucleationStable particle sizeEvaporator accessoriesSolution crystallizationGranularityEvaporation

The invention relates to a self-circulating crystallizer and a multistage continuous crystallization method. The crystallizer sequentially comprises a kettle head, an upper cylinder body, a middle cylinder body and a bottom hole-shrinkage cylinder body with a W-shaped bottom from top to bottom, wherein a steam outlet and / or a feeding hole are / is arranged on the kettle head, an annular spraying pipe is arranged at the lower part of the kettle head; a middle straight cylinder section is arranged in the middle cylinder body, a flow guiding cylinder is arranged in the middle straight cylinder section, and a stirrer is arranged in the flow guiding cylinder; the diameter of the middle cylinder body is larger than that of the upper cylinder body, and the diameter of the upper cylinder body is larger than that of the middle cylinder body; and the lower part of the upper cylinder body and the upper part of the middle cylinder body are respectively connected with the circumference of the top ofthe middle straight cylinder section via a hole-shrinkage transition section, and a discharging hole is formed in the W-shaped bottom. The invention provides the method for realizing multistage continuous evaporation, cooling or reaction crystallization through the series connection of the crystallizer, the prepared crystals are large in granularity and uniform in particle size, the problems thatthe product granularity is small, equipment is seriously scaled, a pipeline is blocked, and the like in the continuous crystallization process are improved, and the operation period of the continuouscrystallization process is prolonged.

Owner:TIANJIN UNIV

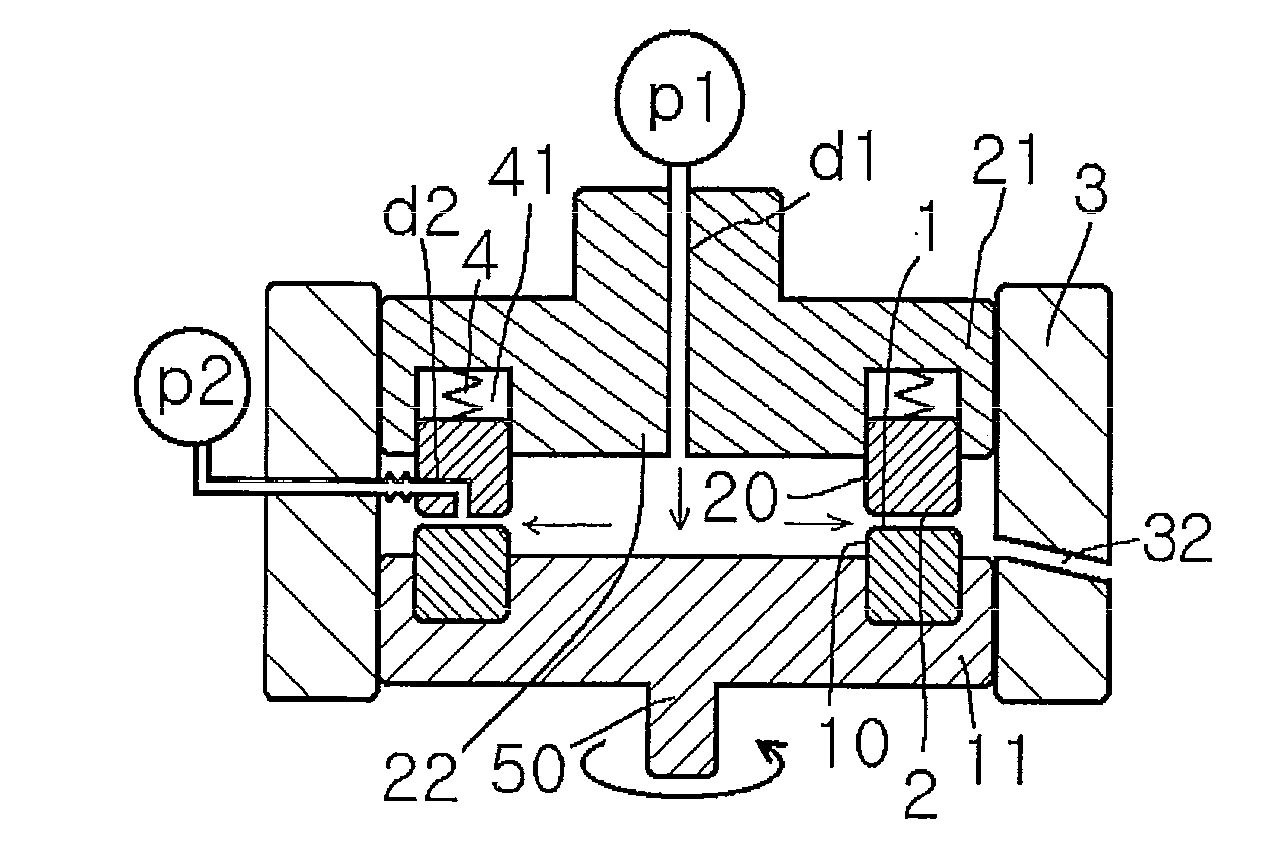

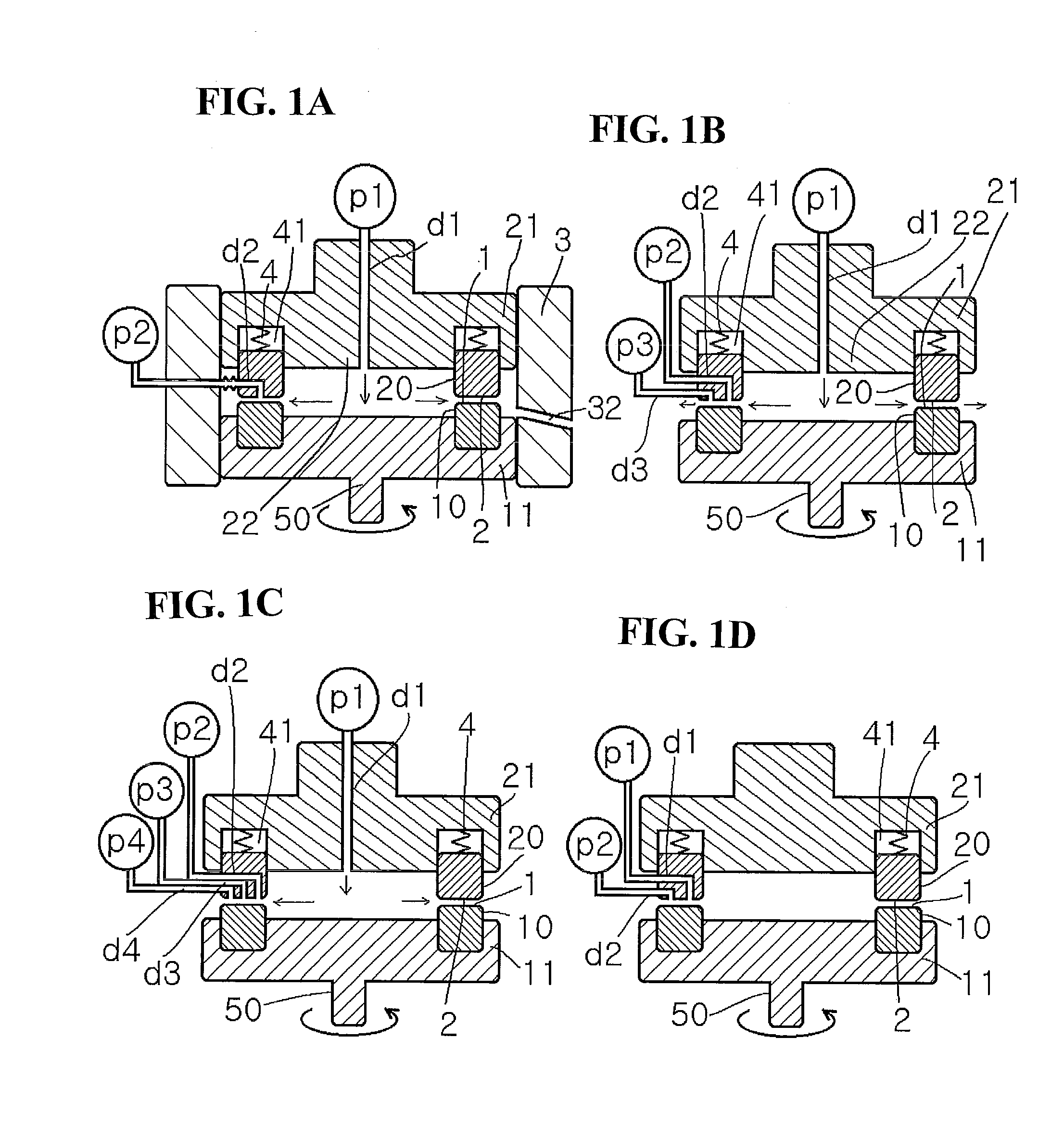

Method for producing microparticles and the microparticles

ActiveUS20100215958A1Good redispersibilityLow costPowder deliveryAntiviralsProduction rateEngineering

It is an object of the present invention to provide a method for producing microparticles, which can produce monodispersed microparticles, causes no clogging with a product due to self-dischargeability, requires no great pressure, and is excellent in productivity, wherein a fluid in which at least one kind of microparticle materials is dissolved is introduced between two processing surfaces arranged to be opposite to each other to be able to approach to and separate from each other, at least one of which rotates relative to the other, to be formed into a thin film fluid, and the thin film fluid is cooled or heated (warmed) to allow saturation solubility to change, thereby separating microparticles.

Owner:M TECHN

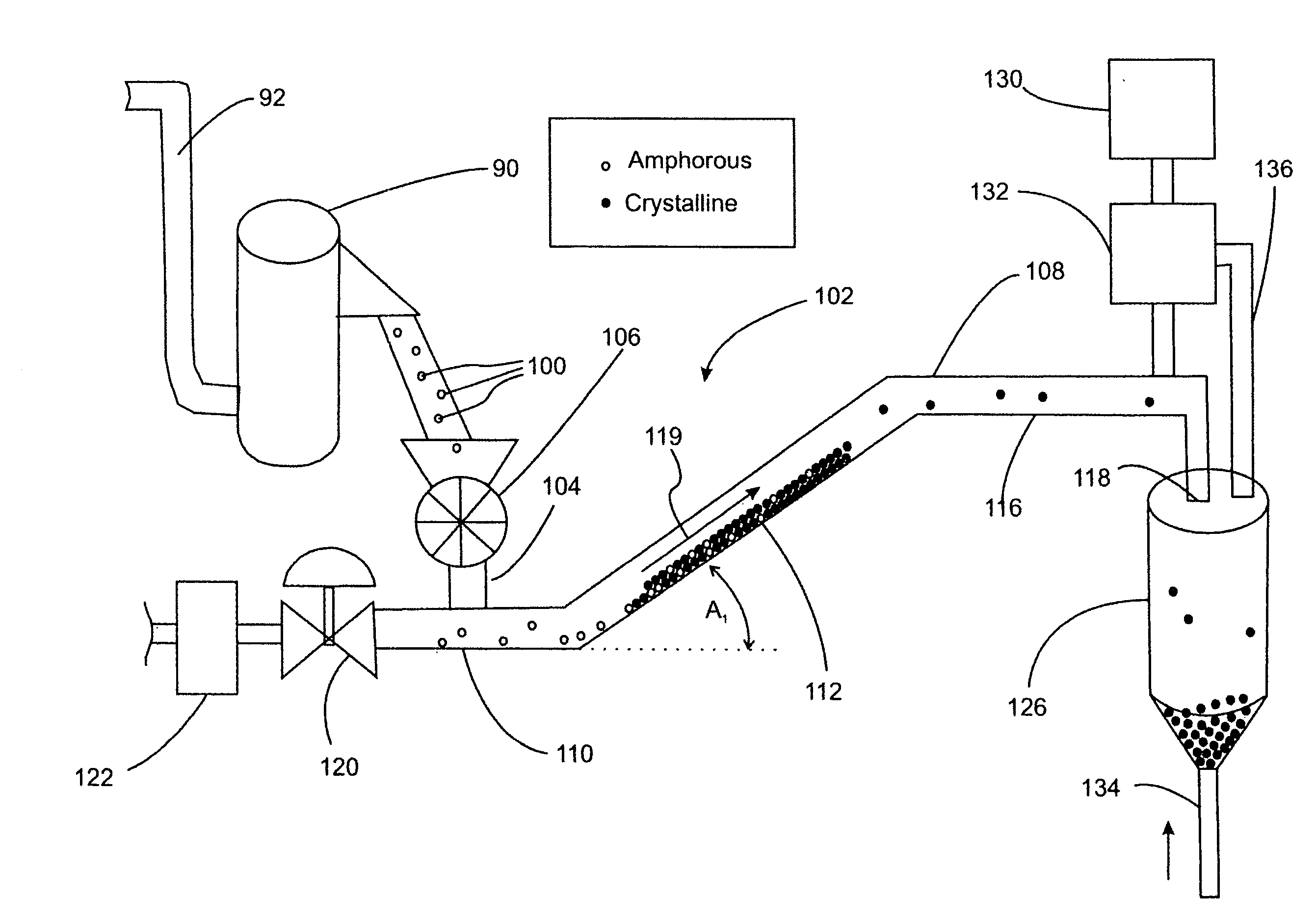

Crystallizing conveyor

ActiveUS20070274789A1Promote crystallizationSave a lot of costCrystallization by component evaporationBulk conveyorsProduct gasEngineering

A method of crystallizing a plurality of polymeric pellets includes a step of introducing the pellets into a pneumatic conveying system with an initial average temperature. The plurality of polymeric pellets are pneumatically transferred from the inlet to an outlet with a conveying gas. While residing within the conveying system, the pellets have a sufficient temperature for crystallization to occur. A pneumatic conveying system implementing the methods of the invention is also provided.

Owner:ALPEK POLYESTER SA DE CV

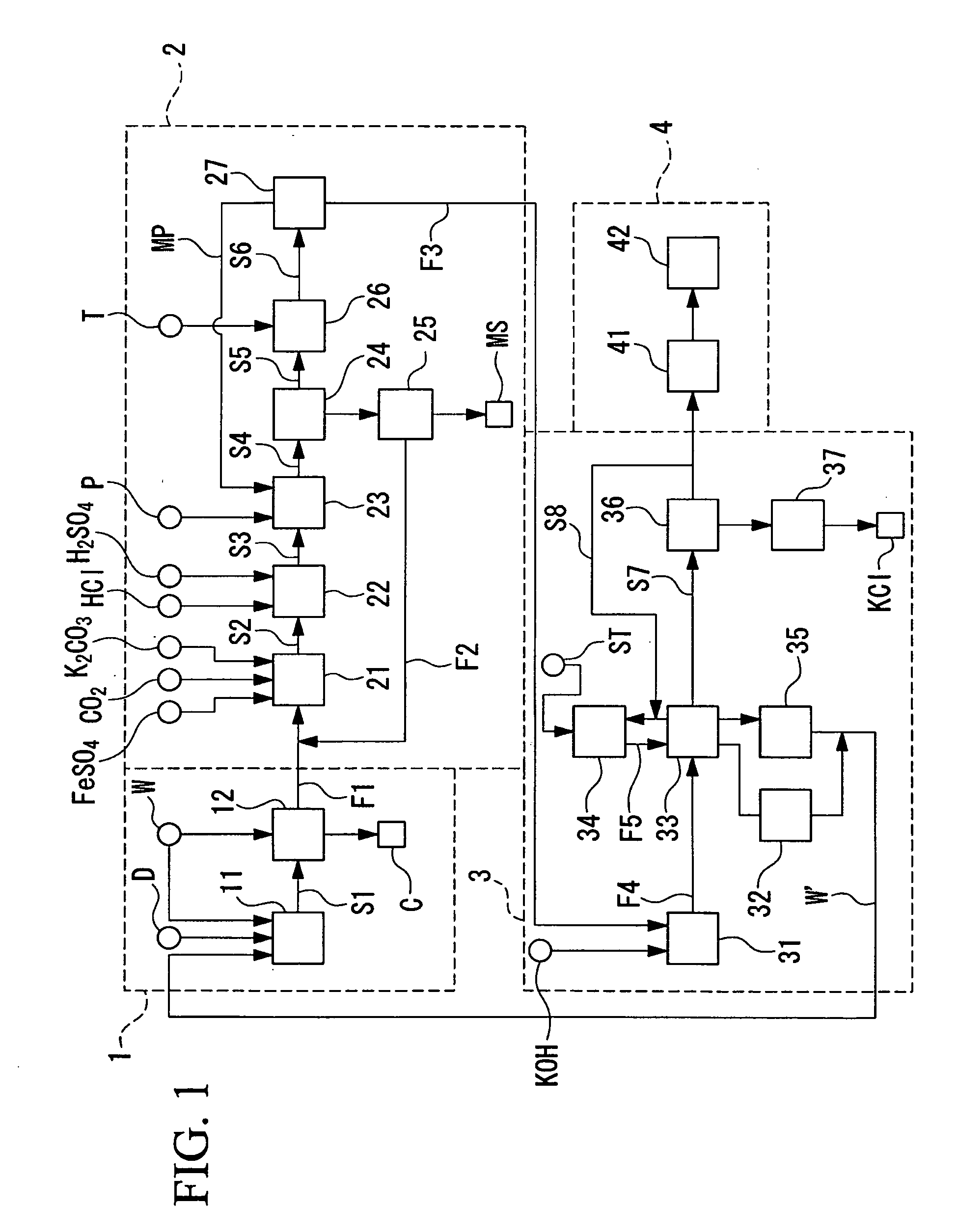

Method of and Apparatus for Treating Chlorine-Containing Waste

The present invention provides a method and an apparatus for treating a chlorine-containing waste, which can separate and recover a chlorine component from a chlorine-containing waste, and also can achieve a high chlorine removal thereby obtaining a high purity chlorine compound, and can decrease the amount of water for recovering chlorine. The method for treating a chlorine-containing waste of the present invention comprises a washing / filtrating step of adding water to the chlorine-containing waste, followed by mixing to form a first slurry, separating the first slurry into a solid and a filtrate through filtration, and using the resulting solid as a cement raw material; a filtrate treating step of adding a reducing agent and a pH adjustor to the filtrate to form a sediment containing heavy metal and calcium contained in the filtrate, and separating the sediment through filtration; a crystallization step of concentrating the filtrate, from which the sediment has been removed, through heating and evaporation to form a second slurry in which a chlorine compound contained in the filtrate has been crystallized, separating the second slurry into a solid containing a chlorine compound and a mother liquor, and recovering the solid; and a separated mother liquor treating step of returning a portion of the mother liquor to a cement manufacturing facility.

Owner:JAPAN WATER SYST CORP +1

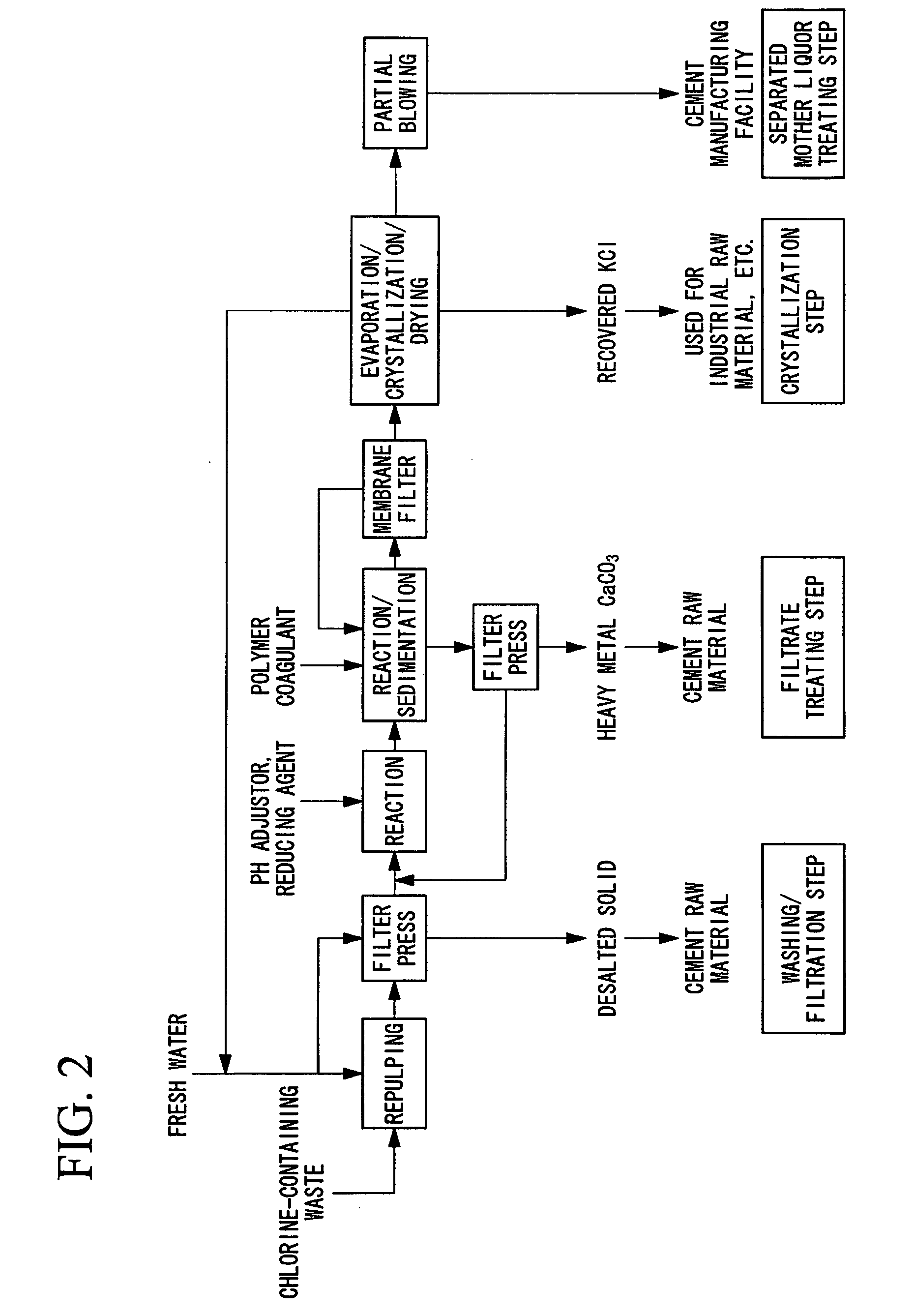

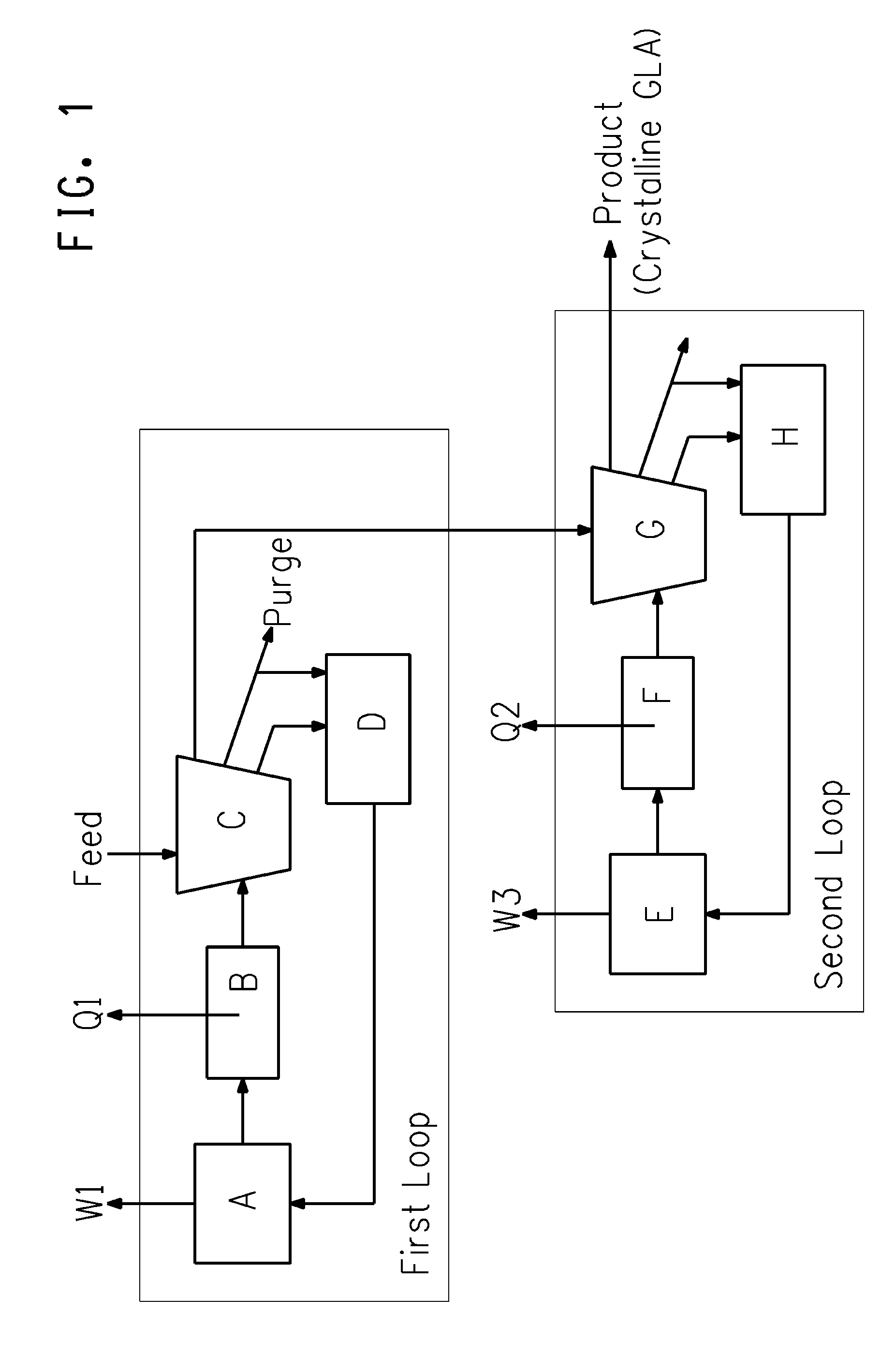

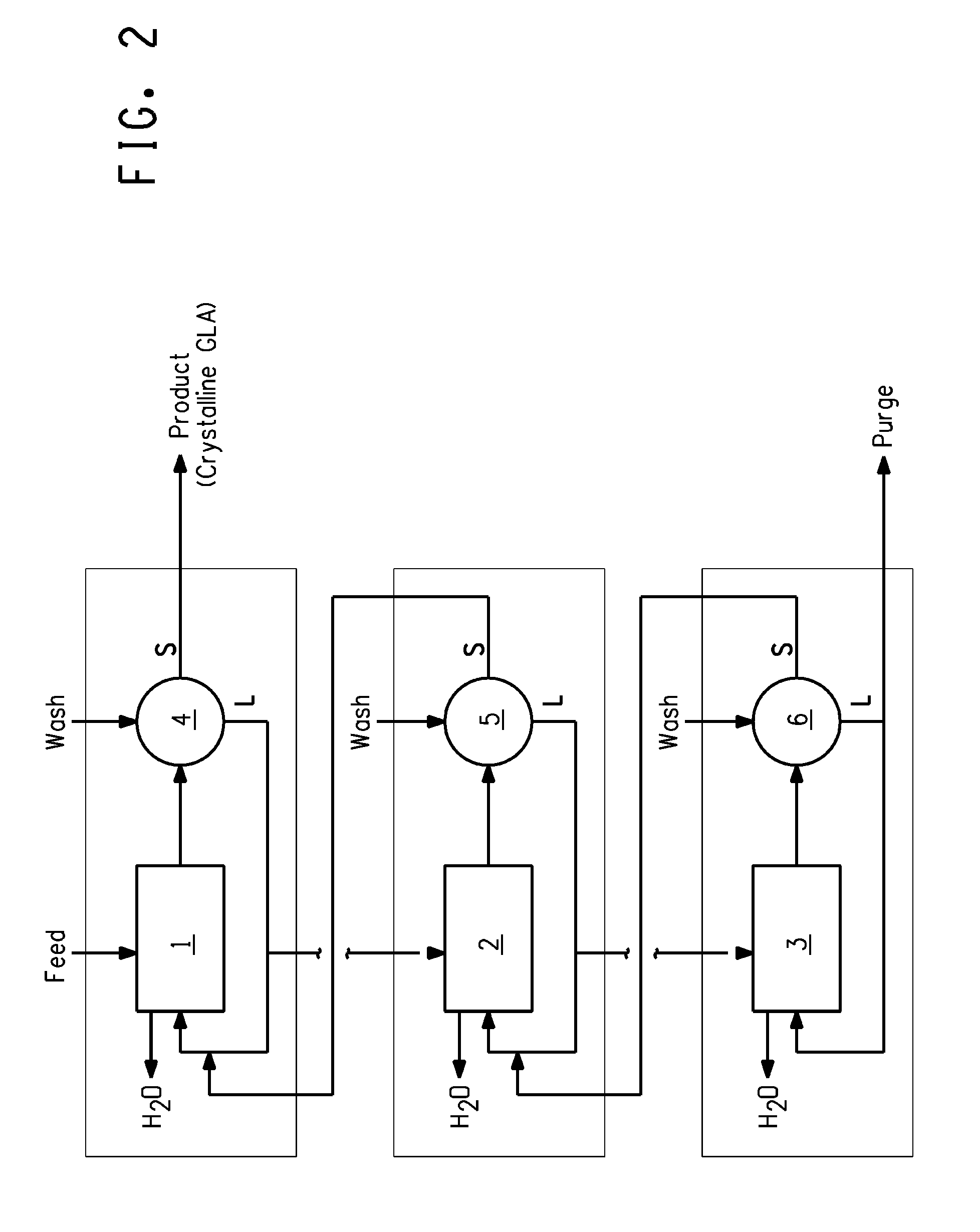

Multi-stage glycolic acid crystallization

ActiveUS7439391B2High yieldLow levelOrganic compound preparationCrystallization by component evaporationGlycollic acidCrystallization

The present invention relates to a high yield process to prepare high purity crystalline glycolic acid using a multi-loop crystallization process characterized by high liquid and / or solid recycle, said process suitable for large scale purification and producing high purity glycolic acid with low diglycolic acid content.

Owner:PURETECH SCI LLC

Process and apparatus for purification of industrial brine

Processes and apparatus for purifying brine are provided including (1) providing an aqueous brine solution comprising one or more inorganic salts and one or more organic compounds and (2) conducting at least one unit operation for removing organic compounds from the brine solution to obtain a purified brine solution.

Owner:BLUE CUBE IP

Methods of processing polyhalite ore, methods of producing potassium sulfate, and related systems

ActiveUS20130121900A1Improve concentrationLimit economic riskSolution crystallizationCrystallization by component evaporationWater solublePotassium sulfate

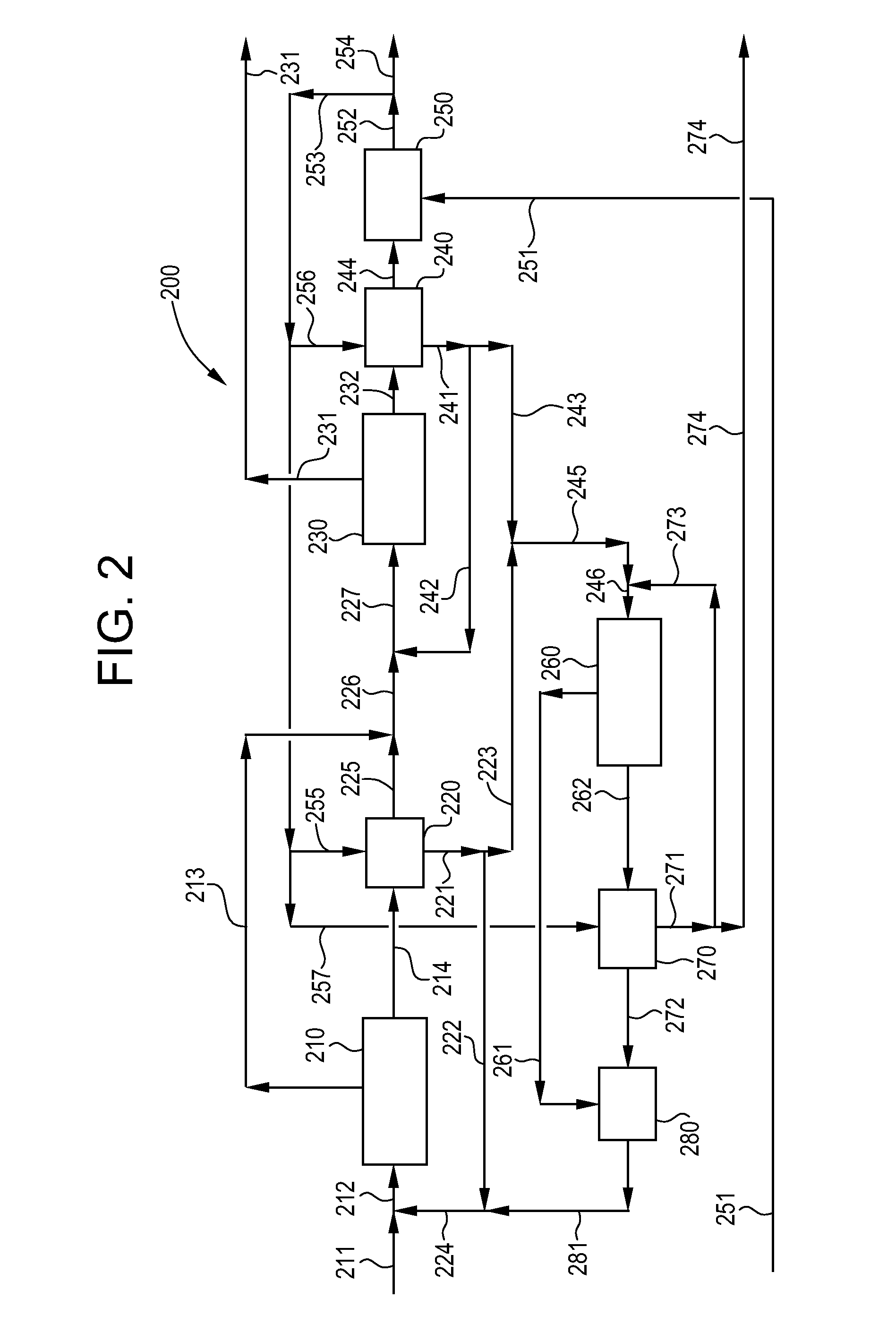

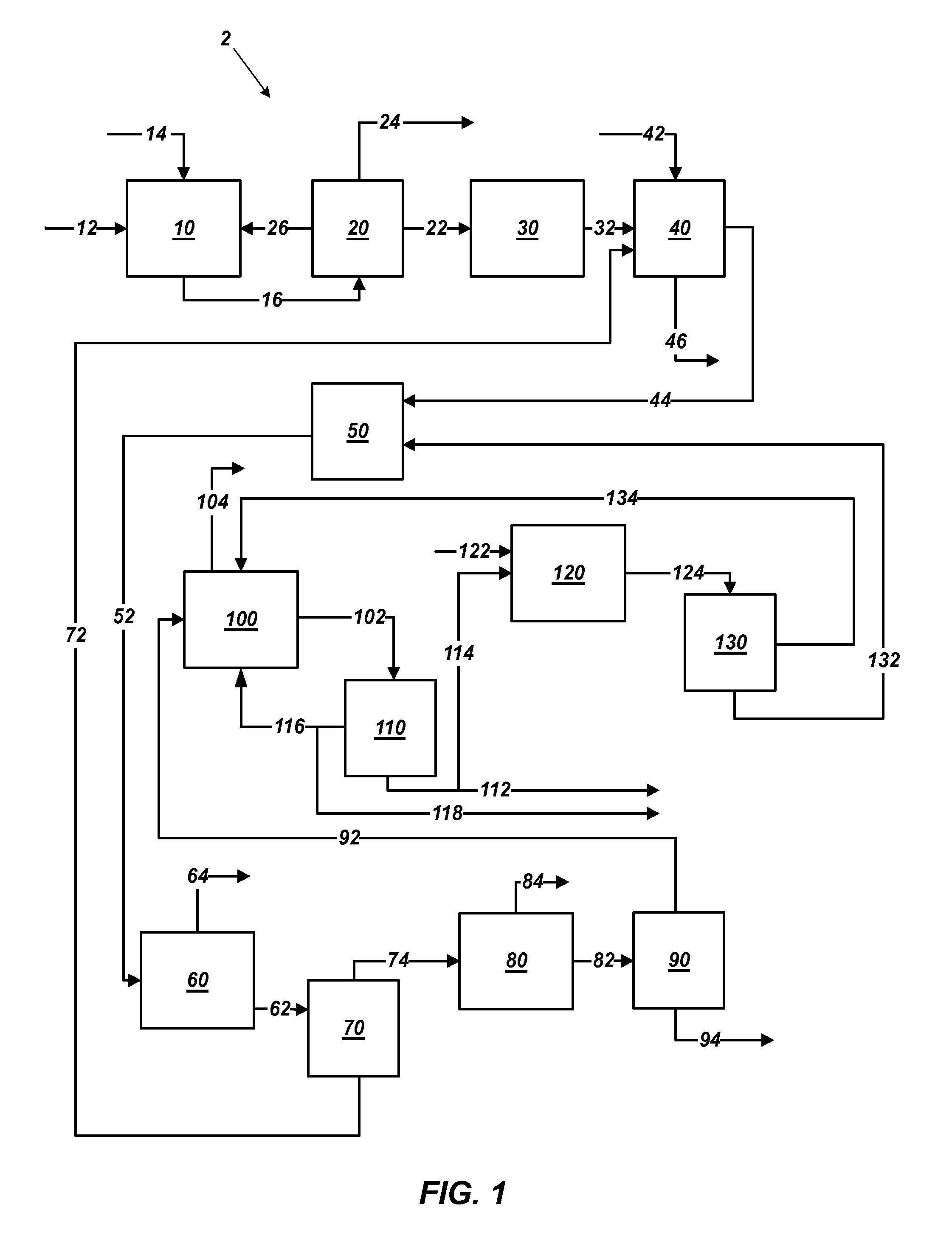

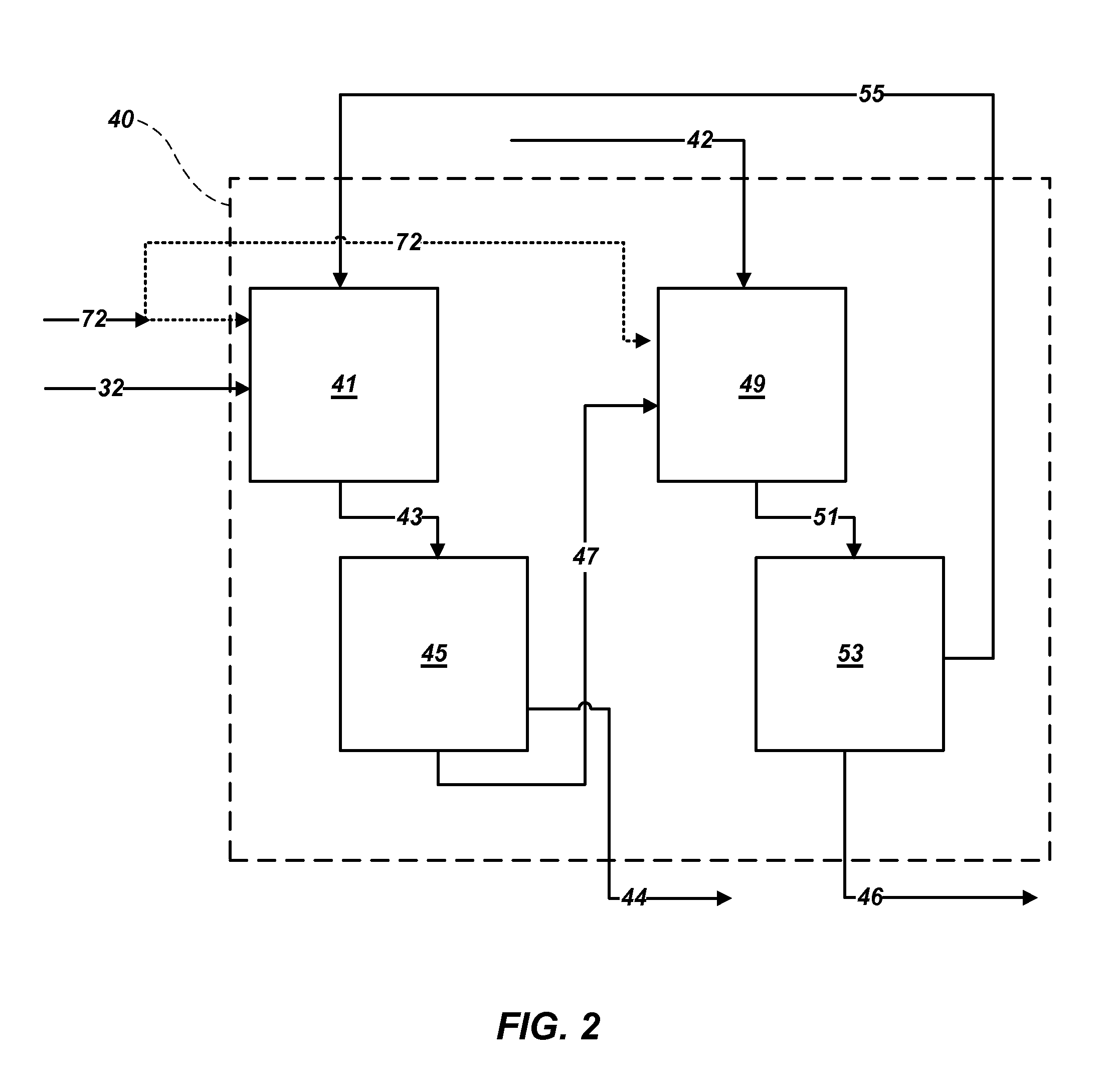

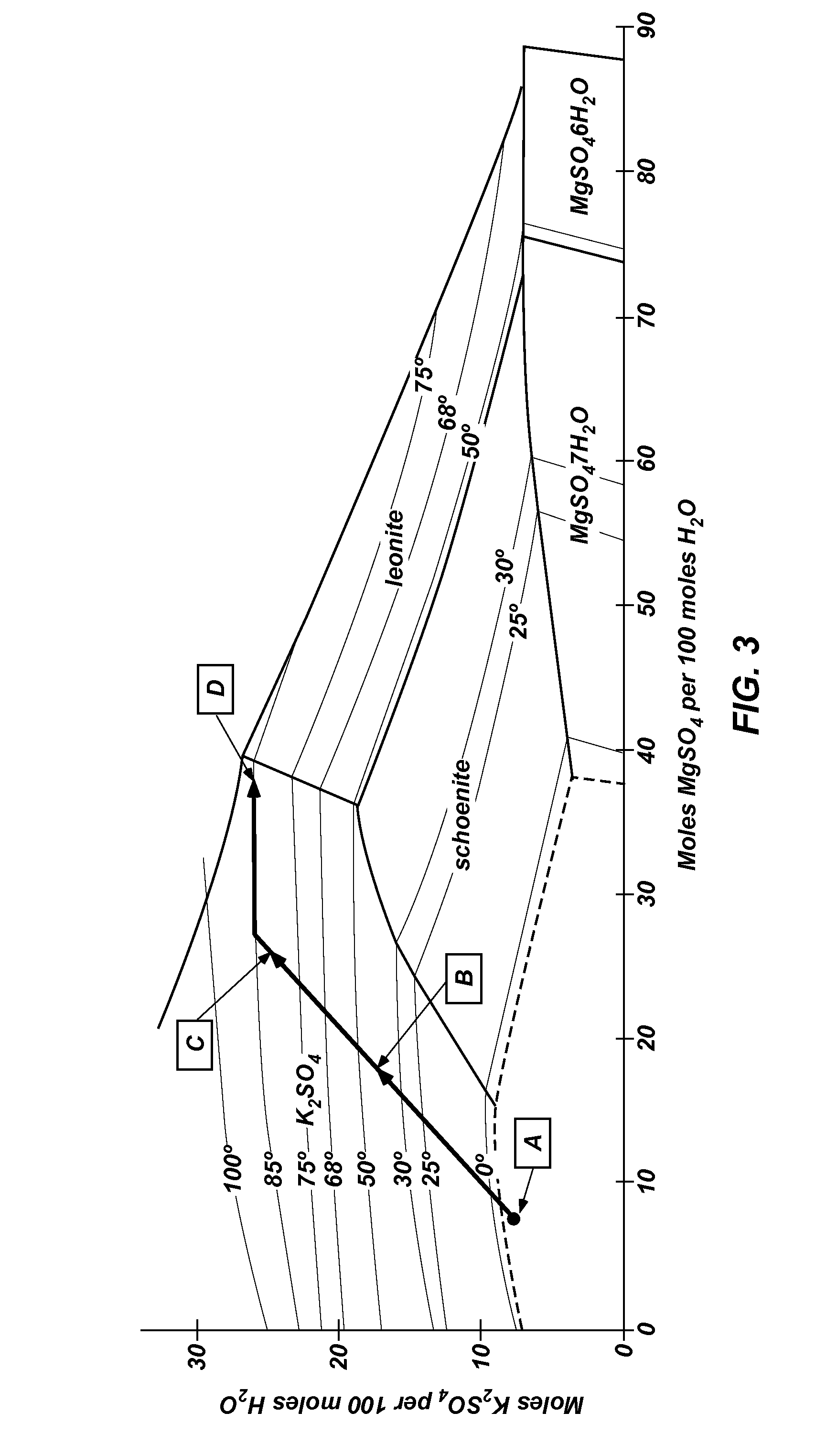

Methods of forming potassium sulfate include calcining polyhalite ore particles to convert the polyhalite ore particles to a water-soluble composition. At least a portion of the water-soluble composition is dissolved in an aqueous medium to form an aqueous solution comprising K+, Mg2+, and SO42− ions and a calcium-containing solid. The calcium-containing solid is separated from the aqueous solution to form a filtrate comprising K+, Mg2+, and SO42− ions. A potassium-containing salt is dissolved in the filtrate to increase the concentration of K+ and SO42− ions to from a concentrated liquor, and K2SO4 is crystallized from the concentrated liquor. A system for processing polyhalite ore includes a countercurrent leaching apparatus, a first mix tank, an evaporator, and at least one crystallizer.

Owner:INTERCONTINENTAL POTASH CORP USA

Method for extracting lithium from salt lake brine and preparing aluminum hydroxide simultaneously

ActiveCN109336142AEfficient use ofReduce lossesAluminium hydroxide preparationCrystallization by component evaporationSolid phasesLayered structure

The invention provides a method for extracting lithium from salt lake brine and preparing aluminum hydroxide simultaneously. The method comprises process steps as follows: aluminum salt is added to brine and subjected to a coprecipitation reaction with alkali liquor to obtain MgAl-LDH and lithium-containing brine; the lithium-containing brine is subjected to evaporation concentration, solid aluminum chloride is added to the lithium-containing brine and subjected to a coprecipitation reaction with a sodium hydroxide solution, a lithium-containing layered structure material is prepared and dispersed in deionized water, heating is performed under full stirring, so that lithium ions are removed from solids of the lithium-containing layered structure material to enter an aqueous solution, and the solution is concentrated to reach the lithium carbonate preparation concentration; aluminum is still retained in a solid phase and an aluminum hydroxide product is obtained. Lithium is extracted from the lithium-containing layered structure material, the reaction is mild, the equipment is simple, the lithium loss is low, mass production is easy, and an important way is provided for extraction of the lithium resource. The sodium hydroxide product is coproduced while the lithium is extracted efficiently, and comprehensive utilization of lithium and aluminum resources is realized.

Owner:BEIJING UNIV OF CHEM TECH

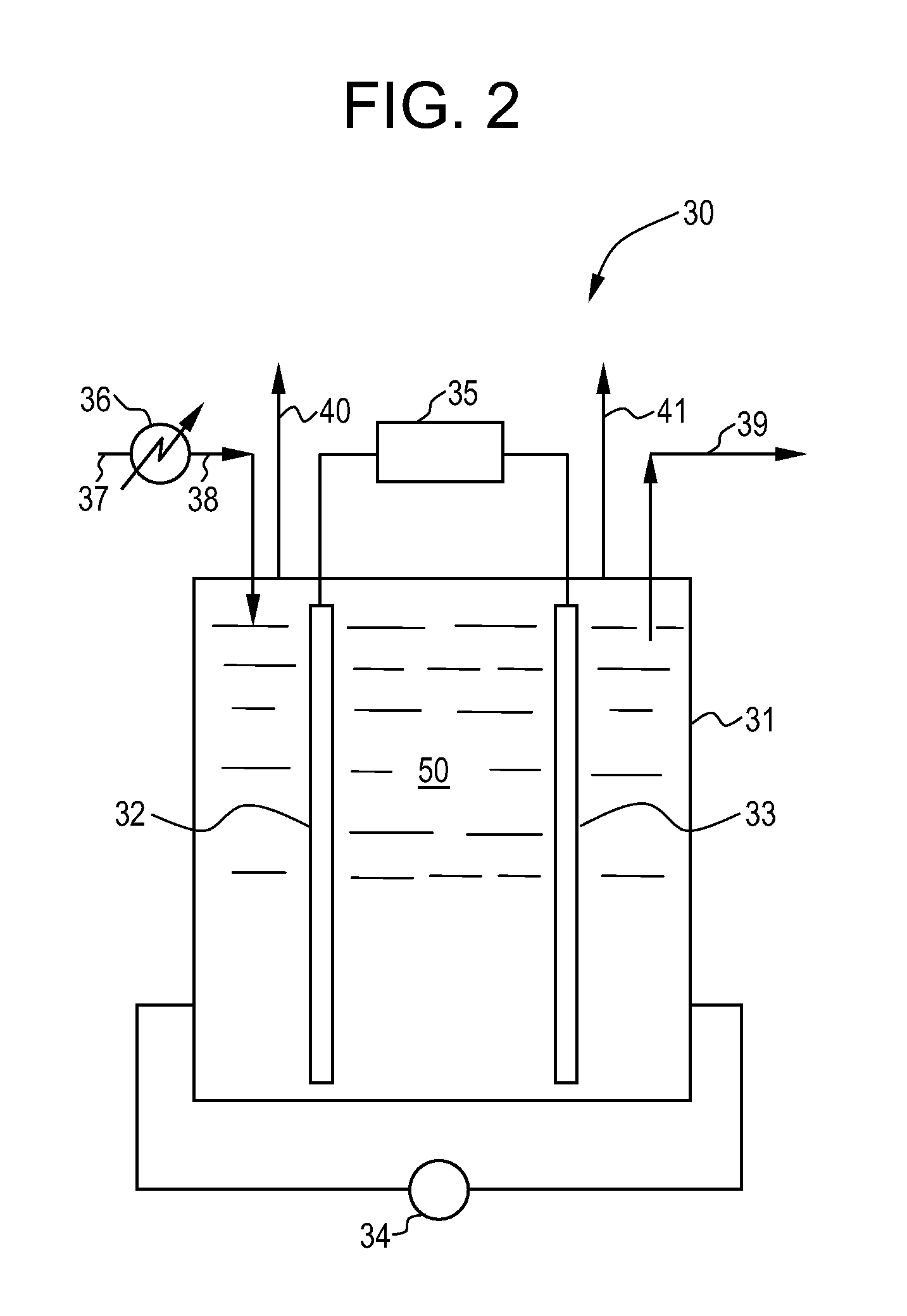

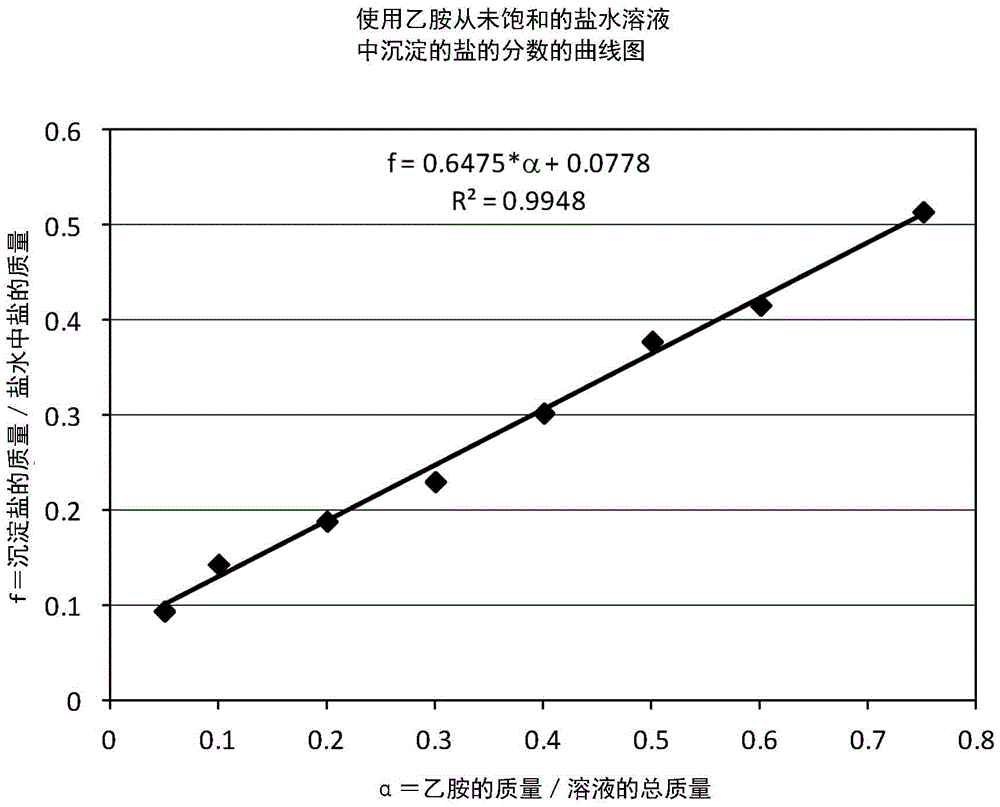

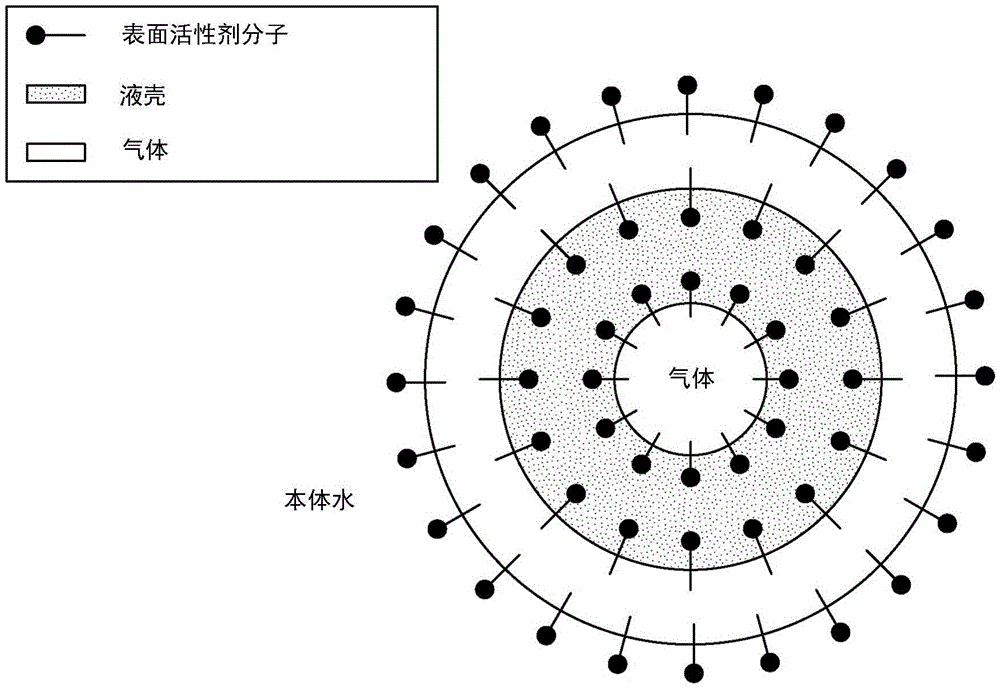

Dissolved air flotation, antisolvent crystallisation and membrane separation for separating buoyant materials and salts from water

InactiveCN105451888AAchieve separationIncrease in sizeWaste water treatment from quariesSeawater treatmentInorganic saltsStrontium

Provided are systems, methods, and apparatus for removing materials from liquid, such as water. The system, methods, and apparatus allow for separation of neutrally buoyant materials from liquid via flotation to or near the surface of the liquid via air bubbles. The system, methods, and apparatus allow for the selective separation of an element, such as strontium, from the liquid. The system, methods, and apparatus allow for precipitating a water soluble salt or water soluble salts from water, including adding a water-miscible solvent to a water solution including an inorganic salt. And, the system, method and apparatus also allow for the separation of the precipitated salt, and for separation of the solvent from the water.

Owner:ADVANCED WATER RECOVERY

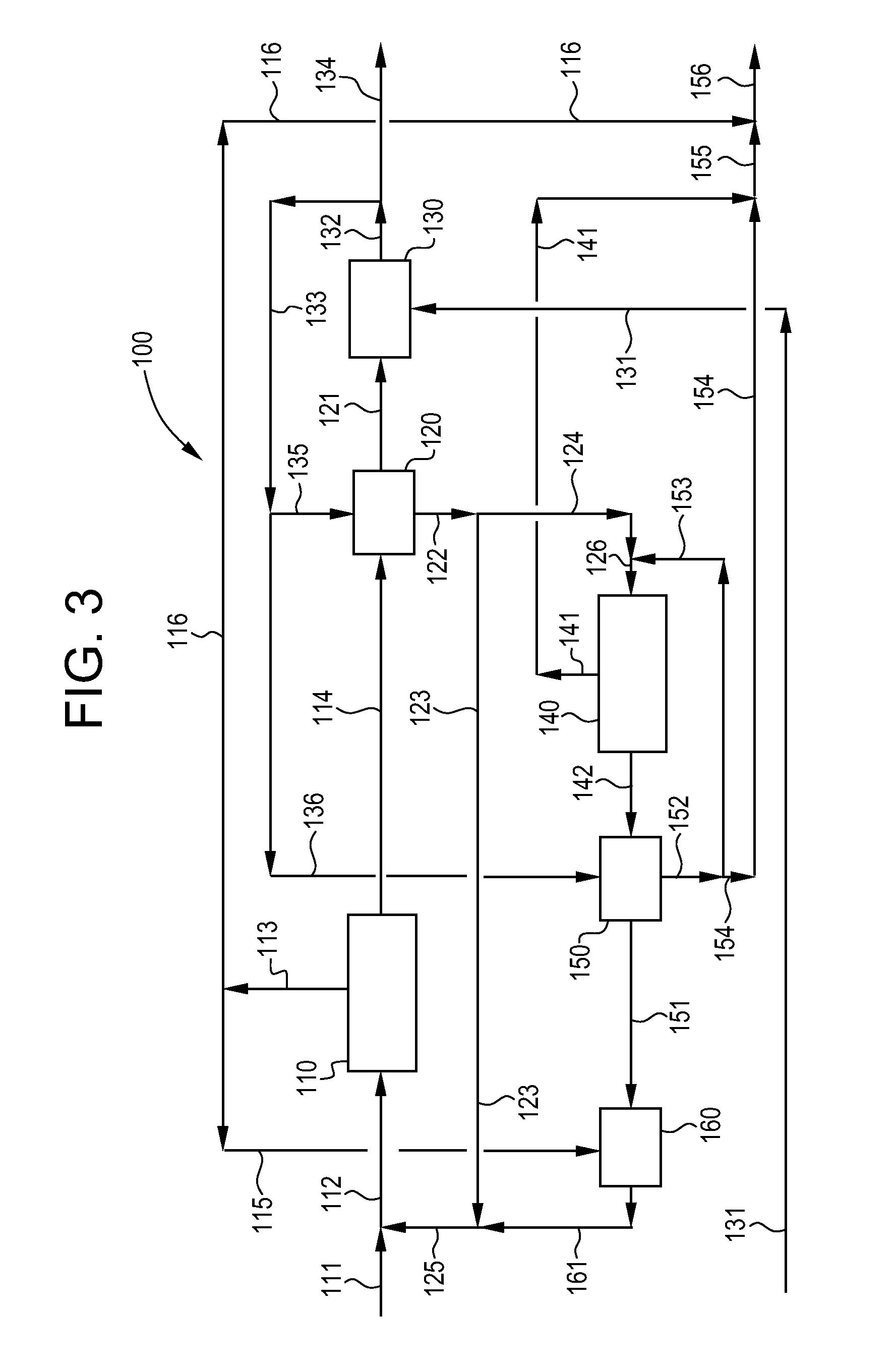

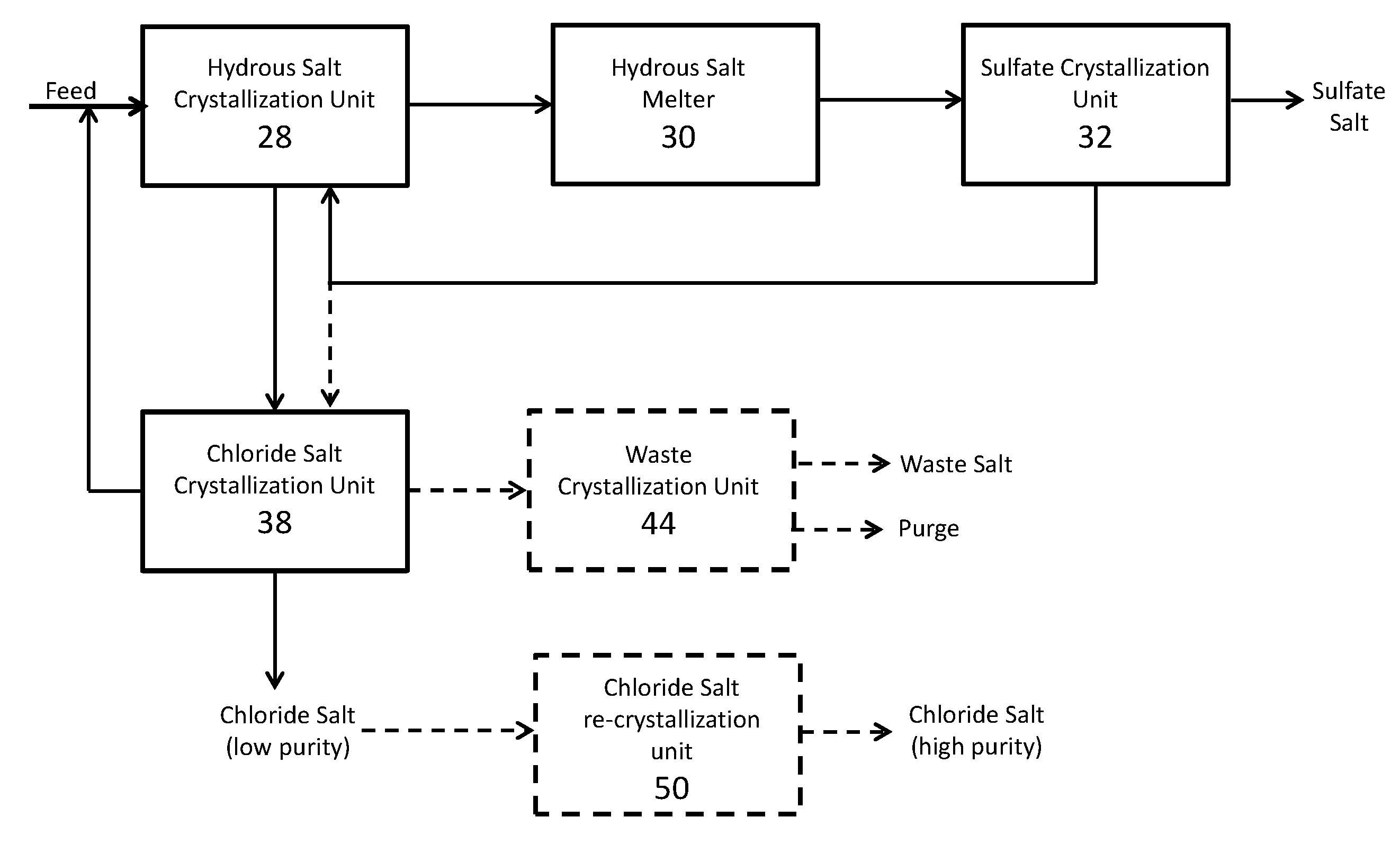

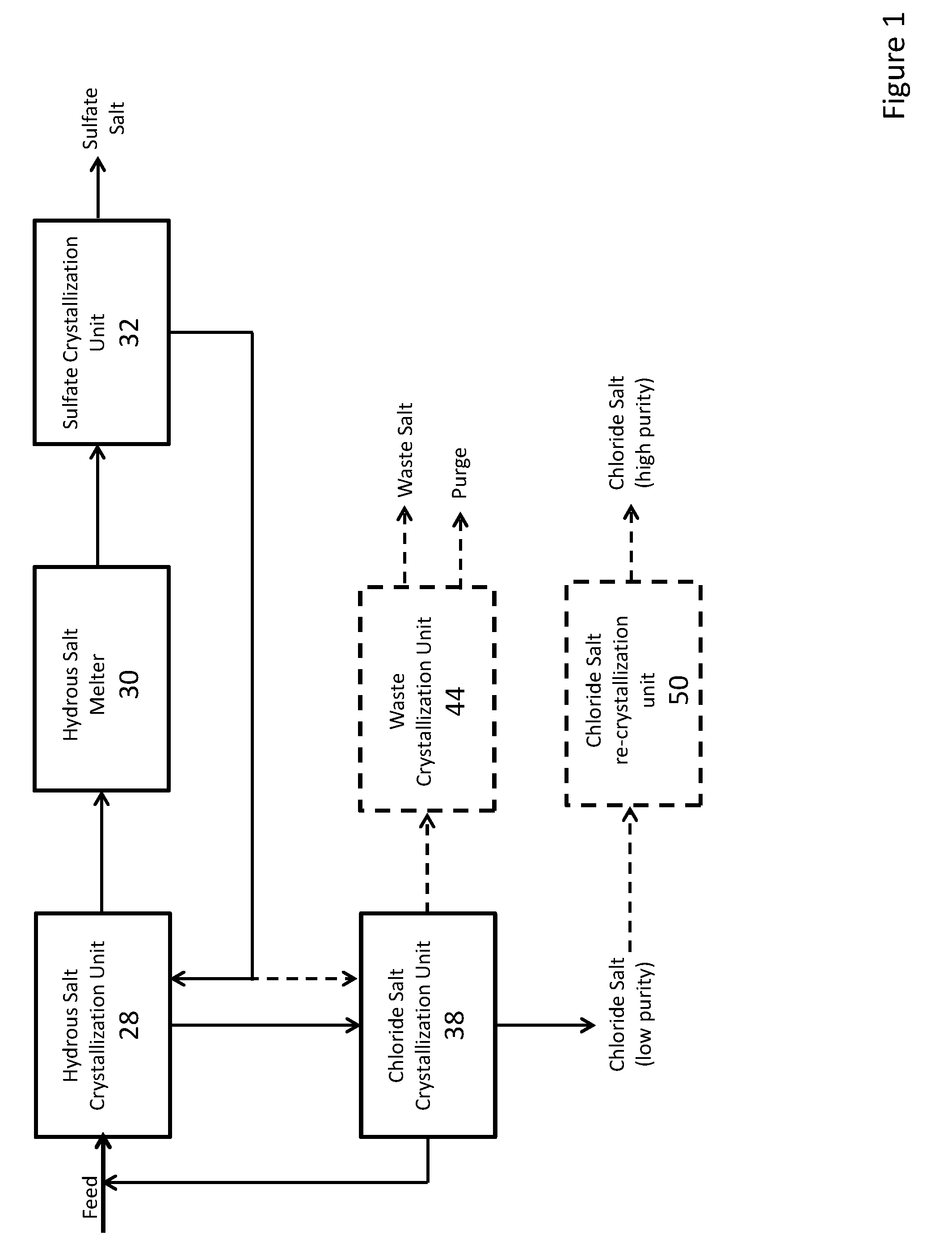

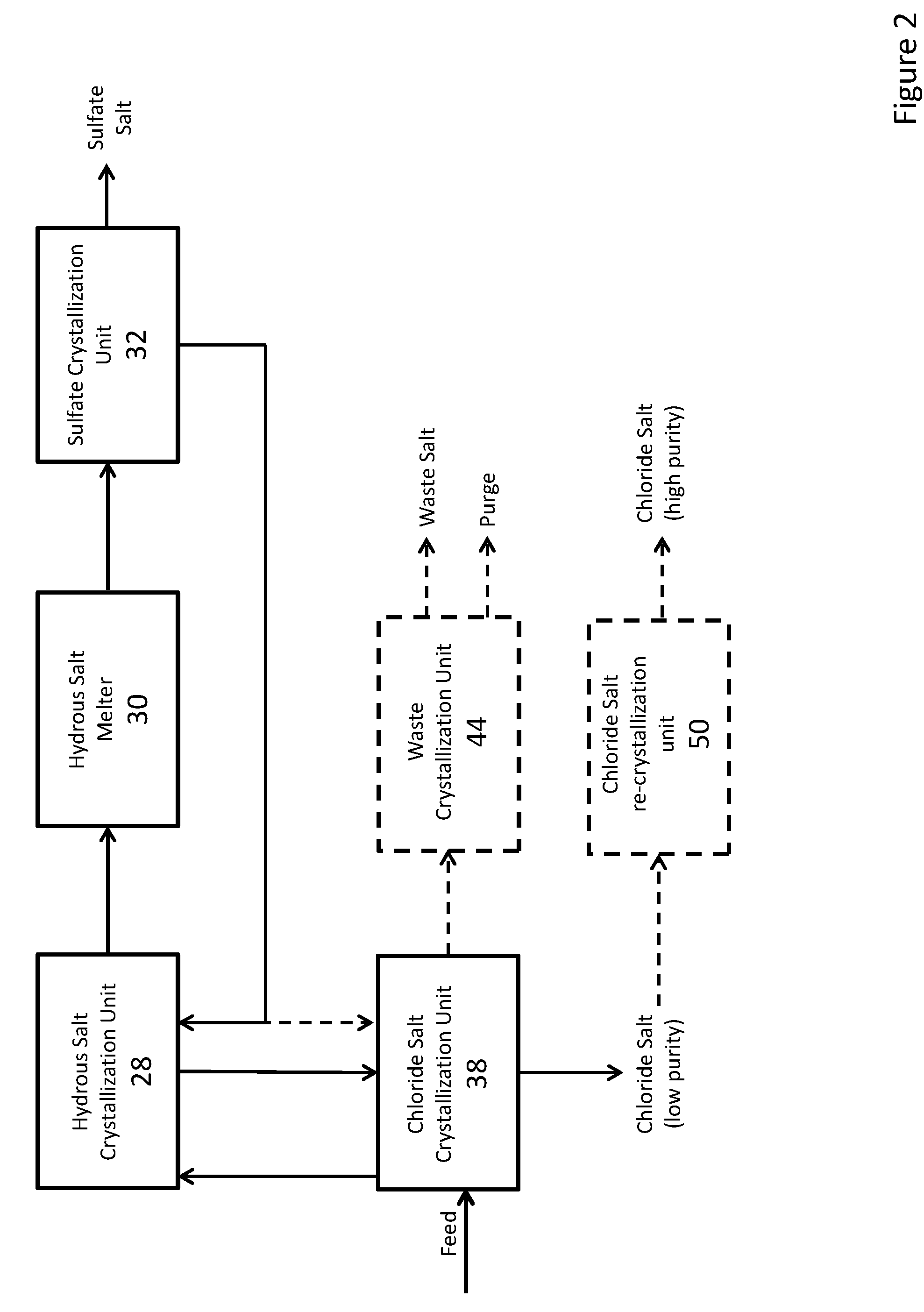

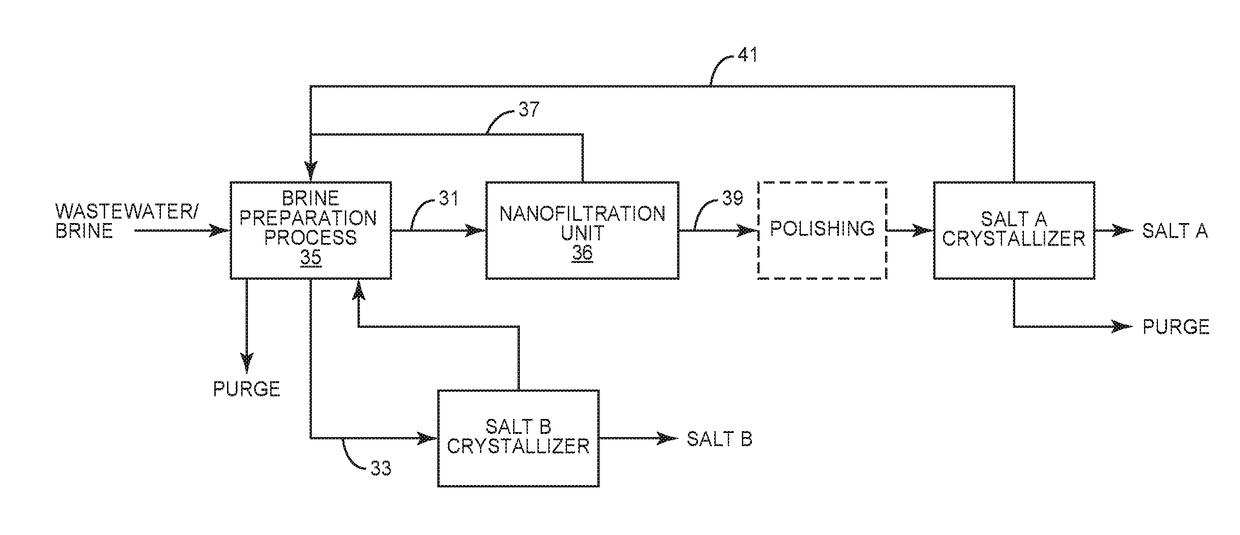

Process for recovering sulfate and chloride salts from wastewater, mixed salts, and brines

ActiveUS20160280571A1Reduce the amount requiredSafe releaseWaste water treatment from quariesSulfate preparationMetal chlorideChloride salt

A process is described for recovering alkali-chloride and alkali-sulfate salts from a salt solution. The salt solution comprises alkali metal, chloride and sulfate ions and is directed to a hydrous salt crystallization unit which crystallizes hydrated sulfate salts that comprise sulfate and at least one alkali metal. A purged solution from the hydrous salt crystallization unit is directed to a chloride salt crystallization unit while the hydrated sulfate salt crystals are melted to form an aqueous sulfate solution which is directed to a sulfate crystallization unit. Anhydrous sulfate salts are crystallized from the aqueous sulfate solution to form sulfate salt crystals comprising sulfate and at least one alkali metal. In the chloride salt crystallization unit, chloride salt is crystallized to form chloride salt crystals. A purge from the chloride salt crystallization unit is directed to the hydrous salt crystallization unit.

Owner:VEOLIA WATER TECH INC

Drying process and apparatus

InactiveUS8012313B2Improve throughputReduce harmPhysical/chemical process catalystsDistillation regulation/controlInjection portTriple point

This technology relates to a process and associated apparatus for use in spray freeze drying a fluid substance such as fruit juice, pharmaceuticals, nutraceuticals, tea and coffee. The method includes the steps of: holding a chamber at a temperature and pressure below the triple-point of the liquid substance; injecting and / or atomizing the liquid substance into the chamber through at least one injection port to generate a frozen liquid substance portion having a predetermined particle size and a first evaporated liquid substance portion; collecting the FLS portion as a layer on a conveying surface; and exposing the collected layer of FLS portion to a heating means thereby inducing sublimation and generation of a second evaporated liquid substance portion and a product, wherein the conveying surface conveys the collected FLS portion at a rate which achieves substantially a monolayer thickness of the FLS portion to accumulate on the conveying surface.

Owner:AGRESEARCH LTD

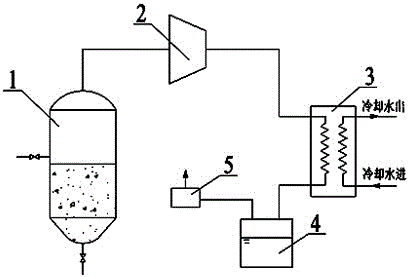

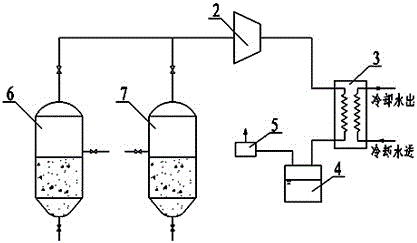

Constant-gradient cooling crystallization system and operation method thereof

InactiveCN106492499AImprove work efficiencyReduce vacuumSolution crystallizationCrystallization by component evaporationVacuum pumpingEngineering

The invention relates to a constant-gradient cooling crystallization system and an operation method thereof and belongs to the technical field of crystallization. The constant-gradient cooling crystallization system comprises a crystallizer, a compressor, a condenser, a condensation water tank and a vacuum pump; an exhaust of the crystallizer is connected with an entry of the compressor, an exit of the compressor is connected with an air-side entry of the condenser, the air-side entry of the condenser is connected to the condensation water tank, and the vacuum pump is connected to the condensation water tank. By the arrangement that the compressor is taken as vacuum-pumping equipment of the condenser, control on crystal size and cooling rate is realized through matching of compression ratio of the compressor and sucking rate; the constant-gradient cooling crystallization system is simple in structure, few in accessory equipment, convenient in regulating and controlling of crystallization process, and uniform in crystal size.

Owner:JIANGSU LEKE ENERGY SAVING TECH CO LTD

Method and System for Quickly Extracting Lithium Carbonate from Saline Lake Water

ActiveUS20160115040A1Excess saturationIncrease the areaAlkali metal carbonates shape formationCrystallization by component evaporationSaline waterVacuum pumping

The present invention discloses a method for quickly extracting lithium carbonate from saline lake water and a system for the same. The method comprises: first quick-freezing the saline lake water to obtain lithium-rich brine, then evaporating under reduced pressure to enable lithium carbonate to be rapidly precipitated out. The method has advantages of short process flow and less labor consumption, thereby enabling continuous automatic operation, high energy utilization and environment-friendly. Further, the crystallization rate is several times faster than that of the salt-pan process and the grade of lithium carbonate salt mine obtained can reach 95% or more, therefore the method of the present invention is particularly suitable for industrial production in the remote saline lake region. The system comprises a reduced-pressure evaporation crystallizer, a vacuum-pumping apparatus, a brine preheating apparatus and a brine cooling apparatus, which concentrates the brine by quick-evaporation of the water, promotes lithium carbonate to form non-uniform nucleus, and improves the crystallization efficiency.

Owner:ZHU BINYUAN +1

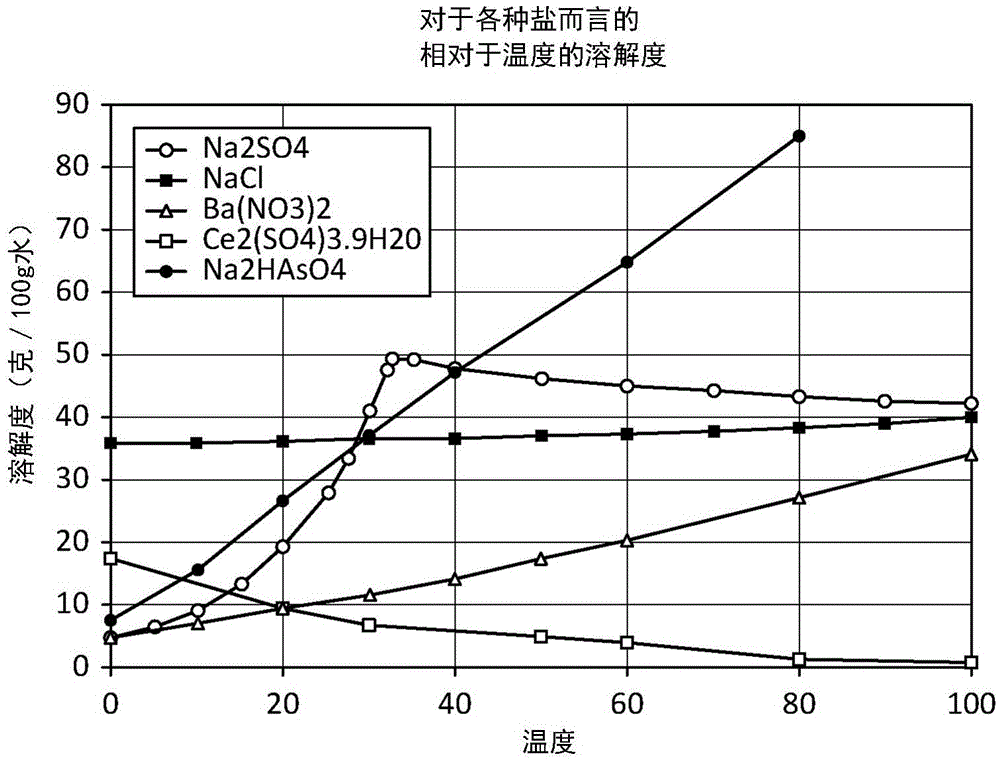

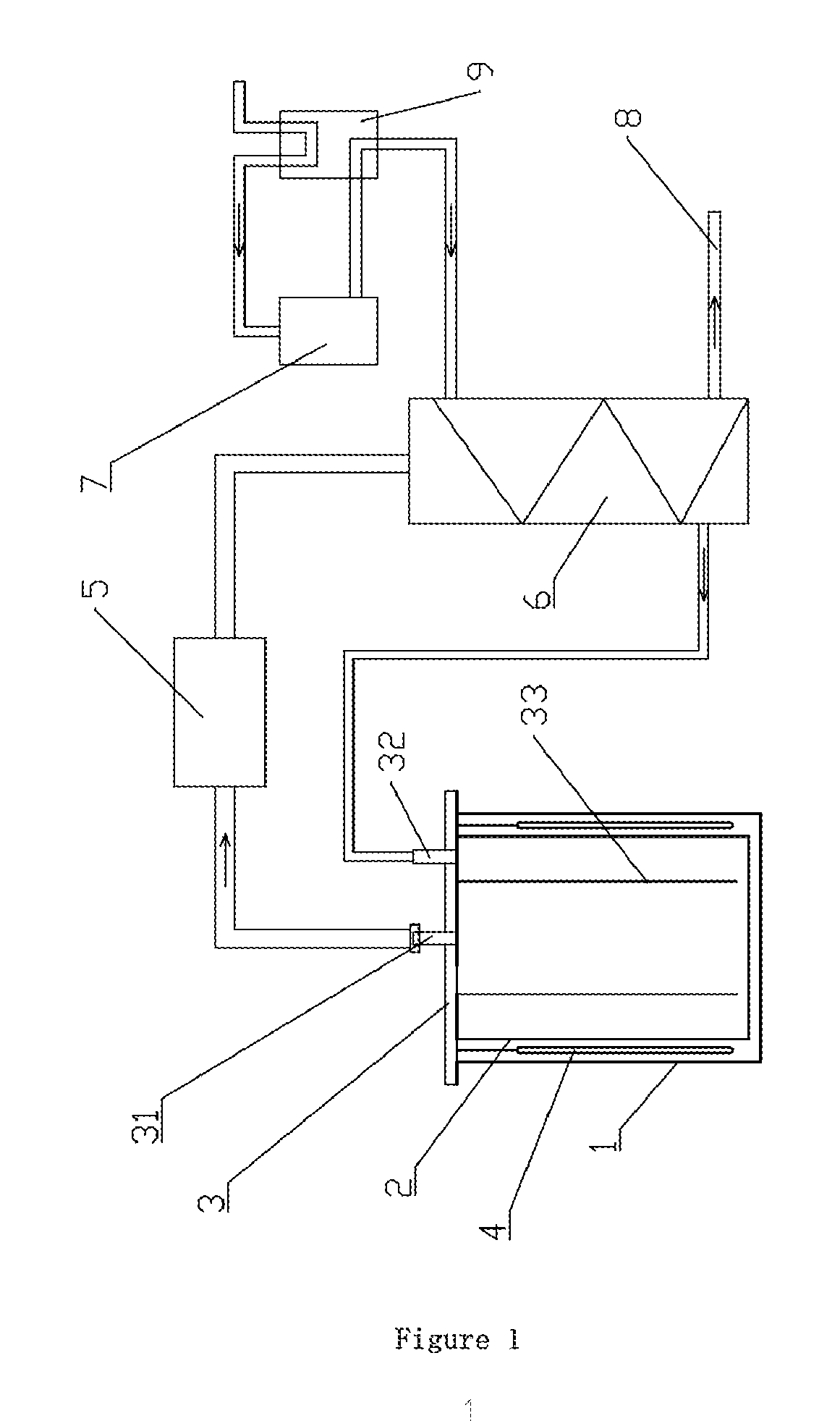

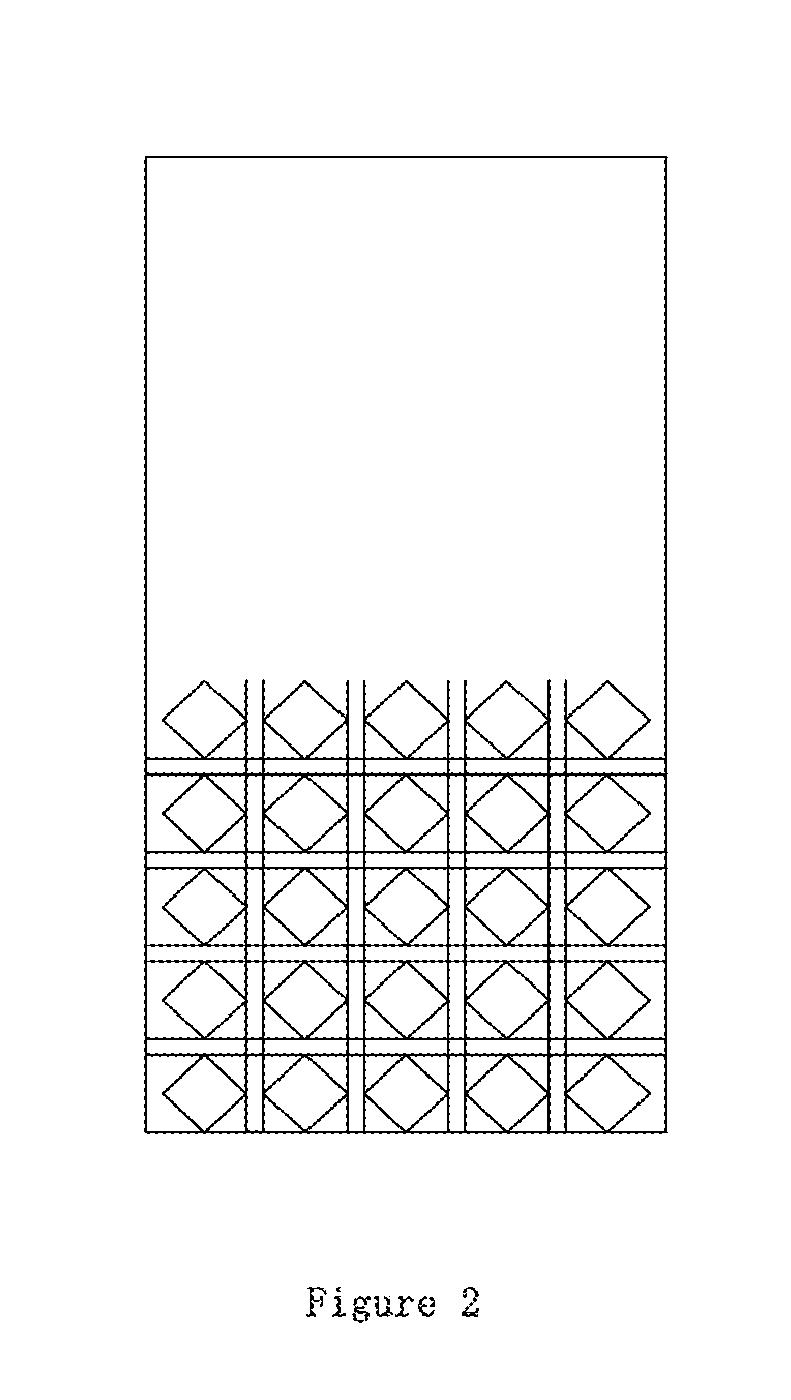

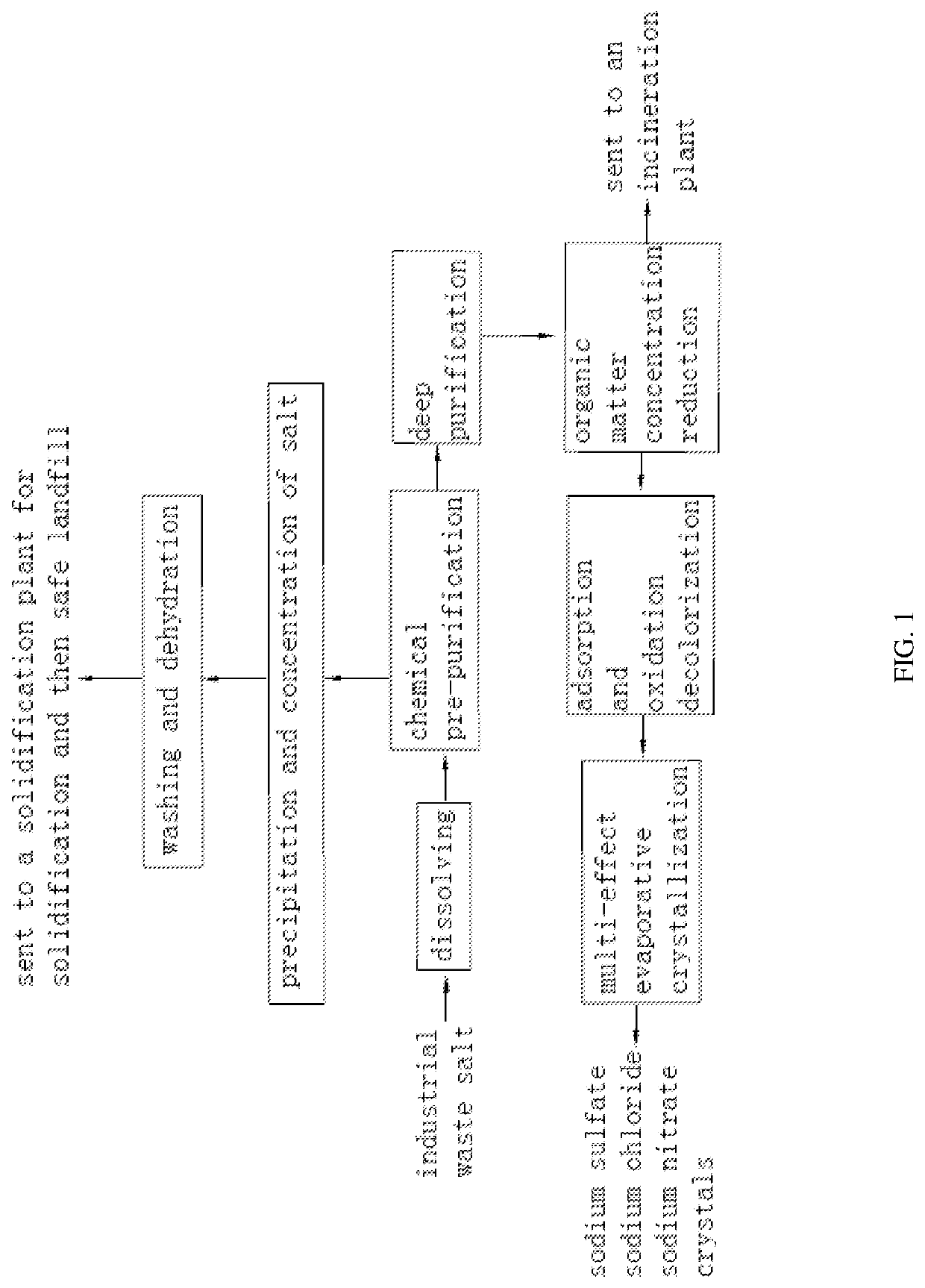

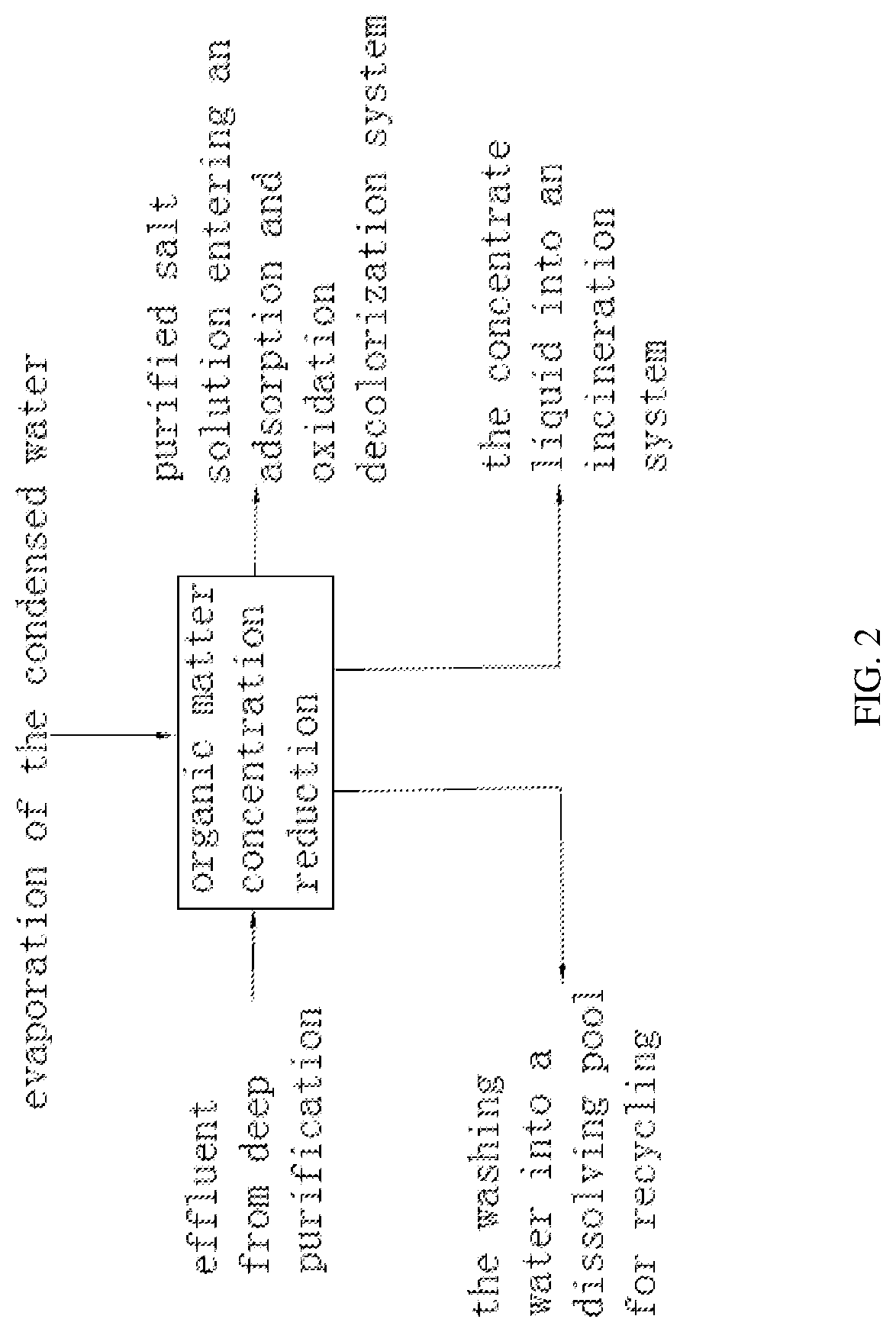

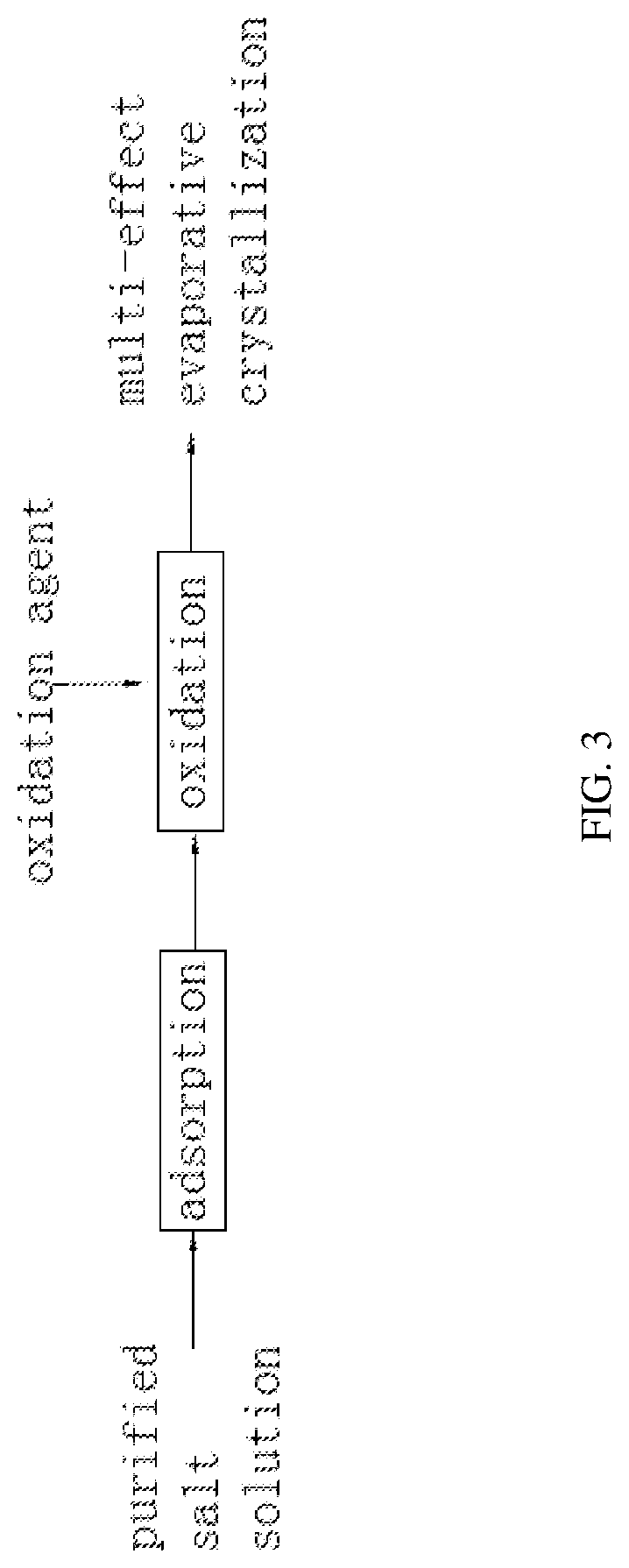

Industrial waste salt resourceful treatment method and device

ActiveUS20210347649A1Reduce difficultyReduce pretreatment costsSludge treatmentUltrafiltrationEnvironmental engineeringCrystallization temperature

An industrial waste salt resourceful treatment method comprises the following steps: the industrial waste salt is sequentially subject to dissolving, chemical pre-purification, deep purification, organic matter concentration reduction, adsorption and oxidation decolorization and multi-effect evaporative crystallization to respectively obtain sodium sulfate, sodium chloride and sodium nitrate crystals; the crystallization temperature of sodium sulfate is in a range of 75° C. to 85° C.; the crystallization temperature of sodium chloride is in a range of 60 to 70° C.; and the crystallization temperature of sodium nitrate is in a range of 45° C. to 55° C. An industrial waste salt resourceful treatment device is further provided.

Owner:GO HIGHER ENVIRONMENT GRP CO LTD

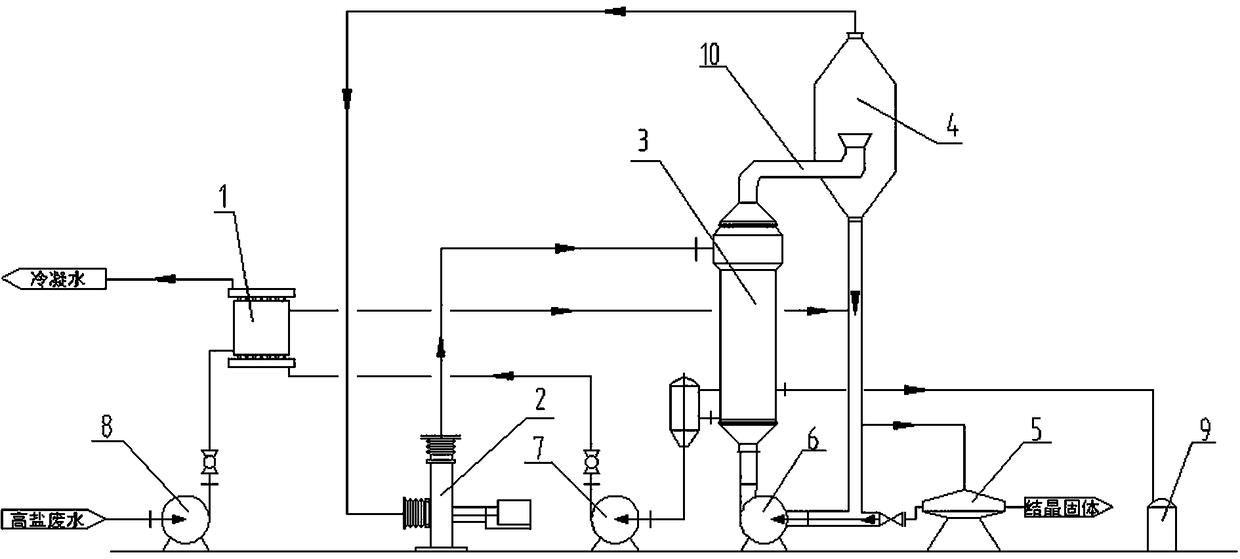

High salinity wastewater energy-saving evaporative crystallization system and technology thereof

PendingCN108910997AGood energy saving effectLess investmentSolution crystallizationCrystallization by component evaporationWastewaterCondensate pump

The invention provides a high salinity wastewater energy-saving evaporative crystallization system and a technology thereof. The system comprises a wastewater preheater, a heating chamber, an evaporation chamber, a steam compressor, a vacuum system, a solid-liquid separation device, a circulating pump, a feed pump, and a condensate water pump. High salinity wastewater enters the heating chamber for preheating, enters the evaporation chamber for steam heating, and undergoes flash evaporation under vacuum and at low pressure; the evaporated steam enters the steam compressor for compression and warming, and the compressed steam enters the heating chamber again to heat the wastewater; condensate water is then used to preheat the high salinity wastewater, and the heat taken away by the evaporated water is further recovered. The heating chamber and the evaporation chamber of the invention adopt an integrated structure, the wastewater directly enters the evaporation chamber for flash evaporation after being heated, the concentrated liquor enters the circulating pump through the bottom of the evaporation chamber to be circulated to the heating chamber for continuous heating, and the liquidforms an inner circulation until the crystallization starts. The invention has the advantages of energy conservation and high efficiency, small equipment occupation, less equipment investment, etc.,and zero discharge of wastewater is finally achieved.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

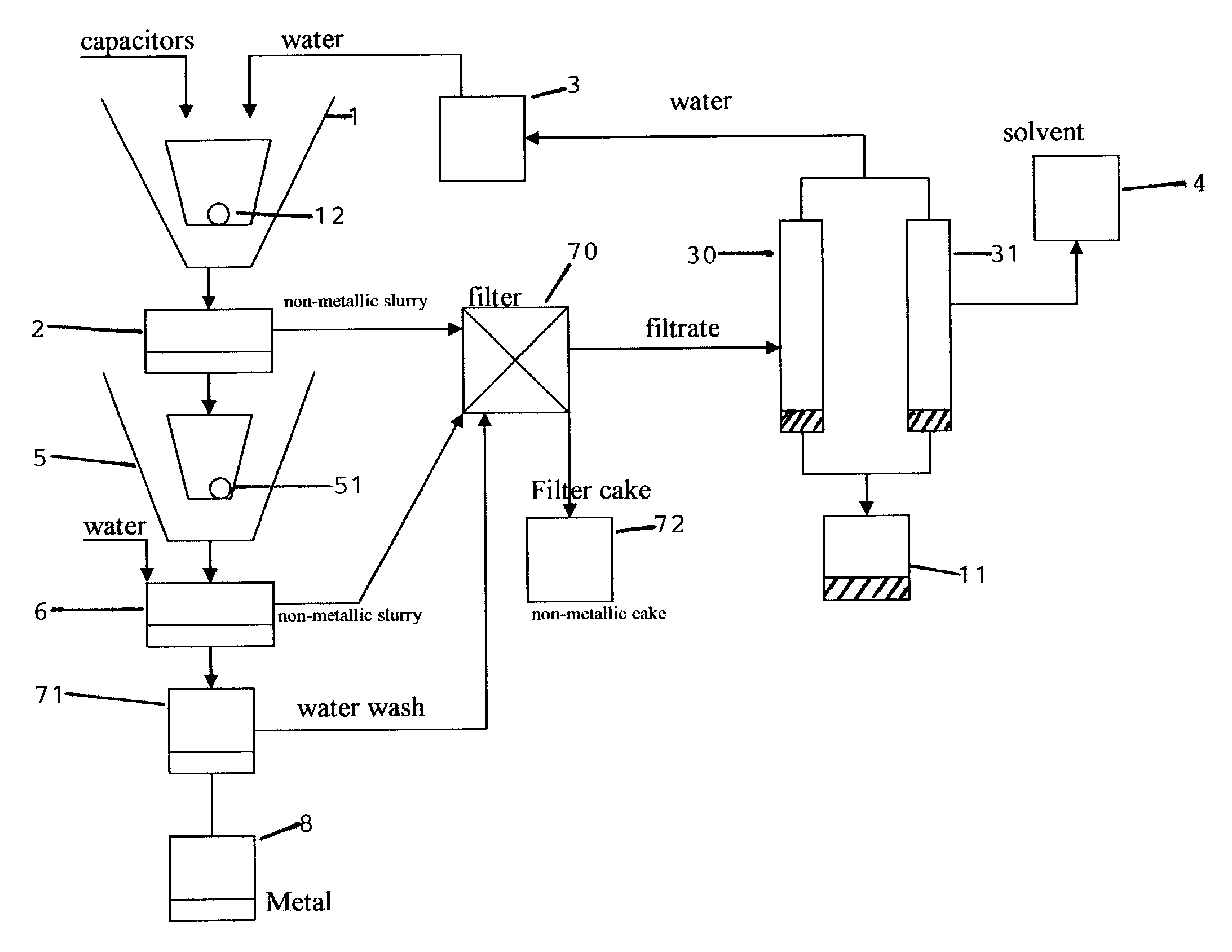

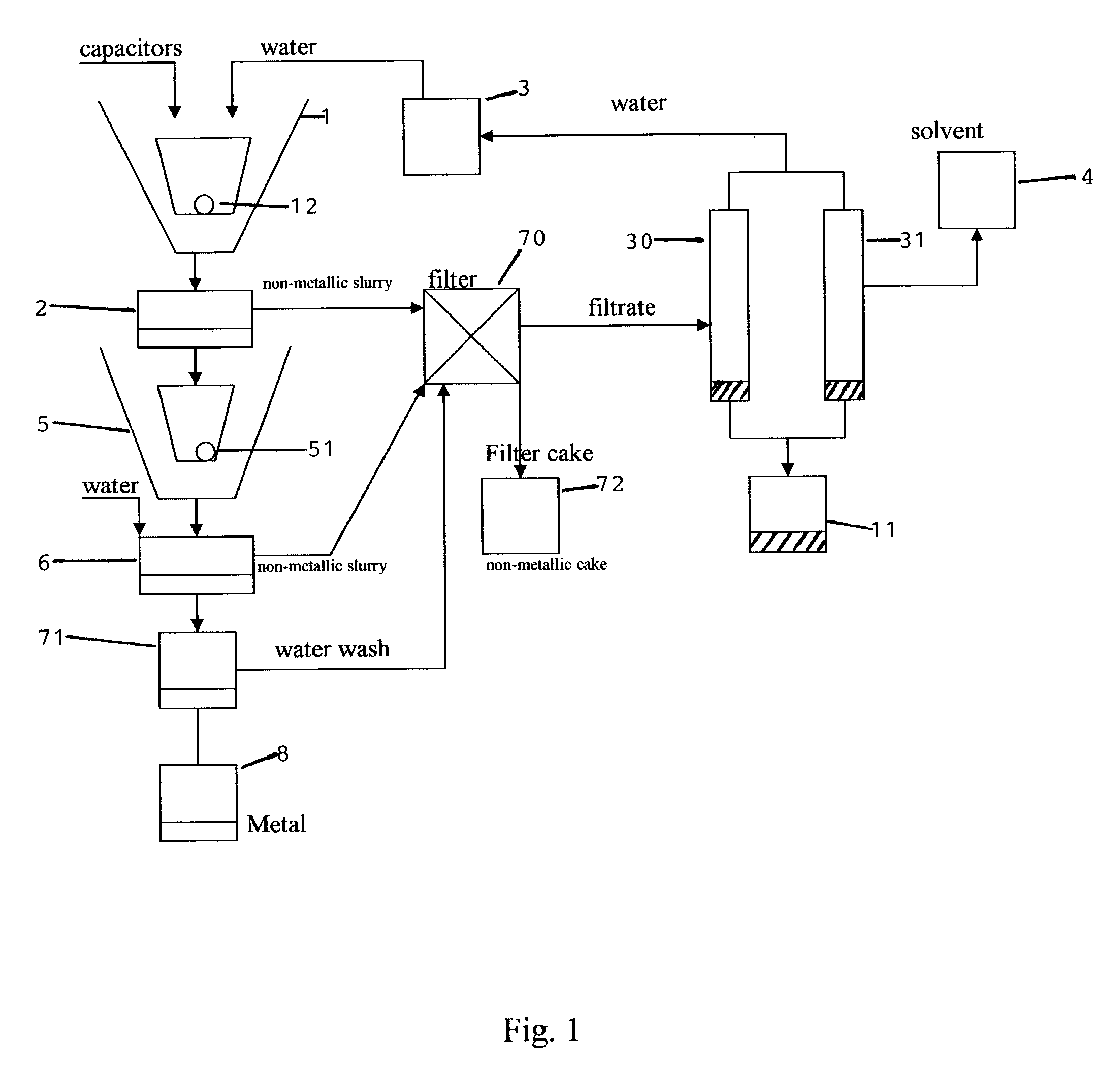

Capacitor electrolyte recovery

ActiveUS6896807B1Avoiding waste disposal problemSafe and economical and efficientElectrolytic capacitorsLiquid solutions solvent extractionOrganic solventWater insoluble

A method for recovering and recycling expensive and hazardous components from capacitors containing an electrolyte salt dissolved in an aprotic organic solvent. The method includes disintegrating a plurality of capacitor casings and their contents into fragments and forming an aqueous slurry of water insoluble fragments, filtering fractionally distilling the filtrate to remove the solvent as a distillate and recovering the electrolyte salt.

Owner:RETRIEV TECH

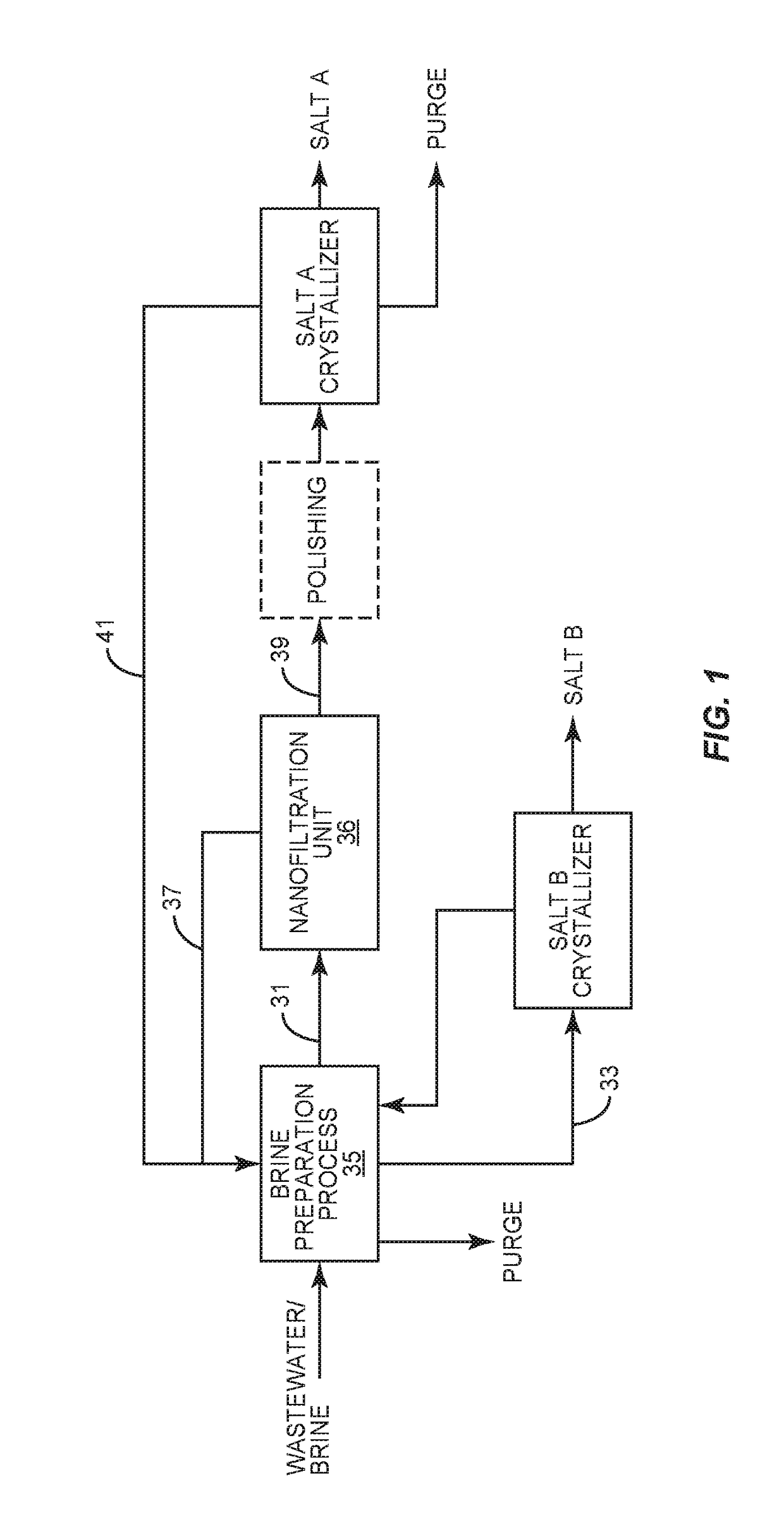

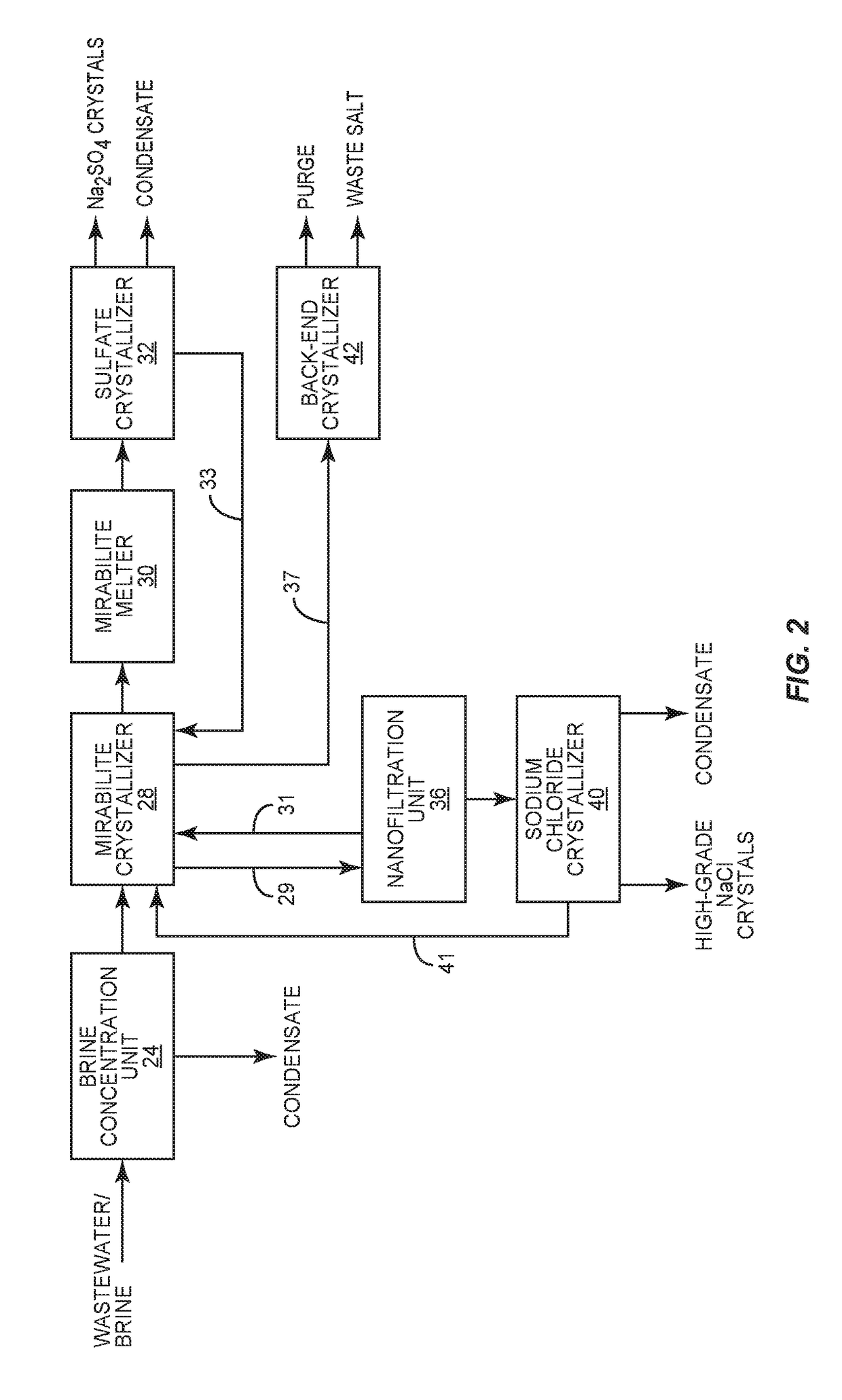

Enhanced process for selective salt recovery from wastewater, waste salts, and brines

ActiveUS20180029904A1Enhances sulfate depletionFacilitating hydrated salt crystallizationWater contaminantsAlkali metal sulfite/sulfate purificationSulfateSalt water

A process for treating wastewater or waste brines that include sodium and chloride ions. The waste brine is concentrated and thereafter directed to a Mirabilite crystallizer that produces hydrated sulfate salt crystals and a first solution. The hydrated crystals are melted to form an aqueous sulfate solution that is directed to a sodium sulfate crystallizer which produces sodium sulfate salt crystals. The first solution produced by the Mirabilite crystallizer is directed to a nanofiltration device which produces a permeate stream and a reject stream containing sulfate removed by the nanofiltration device. The permeate stream is directed to a sodium chloride crystallizer that produces sodium chloride salt crystals. The reject stream is recycled to the Mirabilite crystallizer.

Owner:VEOLIA WATER TECH INC

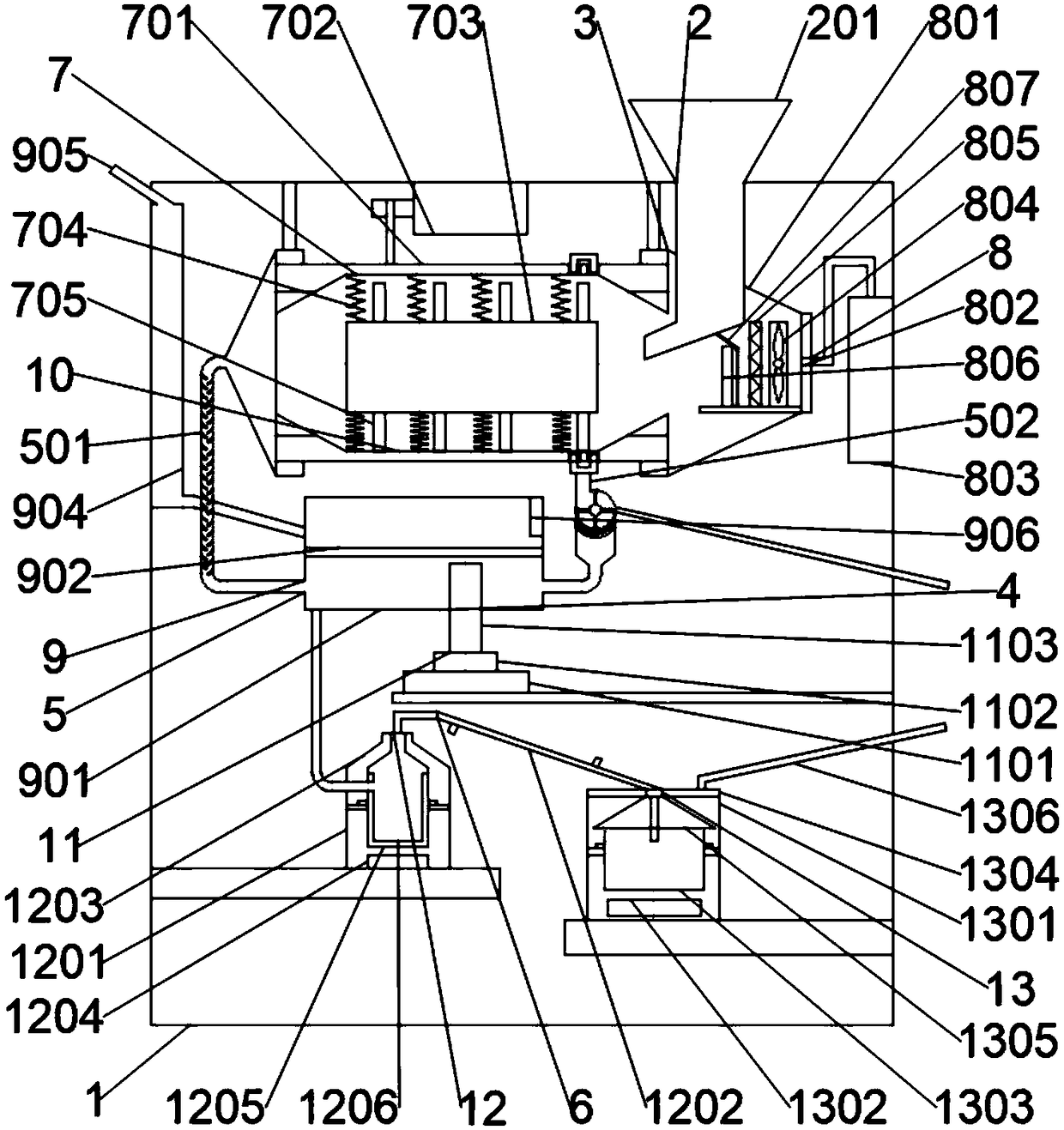

Plant effective component extraction equipment for medical material preparation

ActiveCN108525341AReduce lossHigh extraction rateVapor condensationSolution crystallizationMaterials preparationHas active ingredient

The invention discloses plant effective component extraction equipment for medical material preparation. An ultrafine grinding mechanism is arranged in a mounting case, and an effective component extraction mechanism is arranged on the lower portion of the ultrafine grinding mechanism and comprises a leacher and an efficient cleaning device. The leacher comprises a leaching vessel, the bottom of the leaching vessel is connected with a dry powder guide pipe and a water pulp guide pipe through pipes, and the upper portion of the leaching vessel is connected with a leach liquid adding box which is connected with a filling pipe. The efficient cleaning device comprises an ultrasonic wave generator, an ultrasonic transducer and an ultrasonic amplification rod. An output end of the ultrasonic wave generator is electrically connected with an input end of the ultrasonic transducer, an output end of the ultrasonic transducer is electrically connected with an electric energy input end of the ultrasonic amplification rod, and the ultrasonic amplification rod penetrates the lower bottom surface of the leaching vessel to extend into the leaching vessel. The plant effective component extraction equipment has advantages that separation of impurities and effective components in to-be-extracted plants is realized, and the step of subsequent separation of the effective components in the to-be-extracted plants is simplified.

Owner:南京泽朗医药技术有限公司

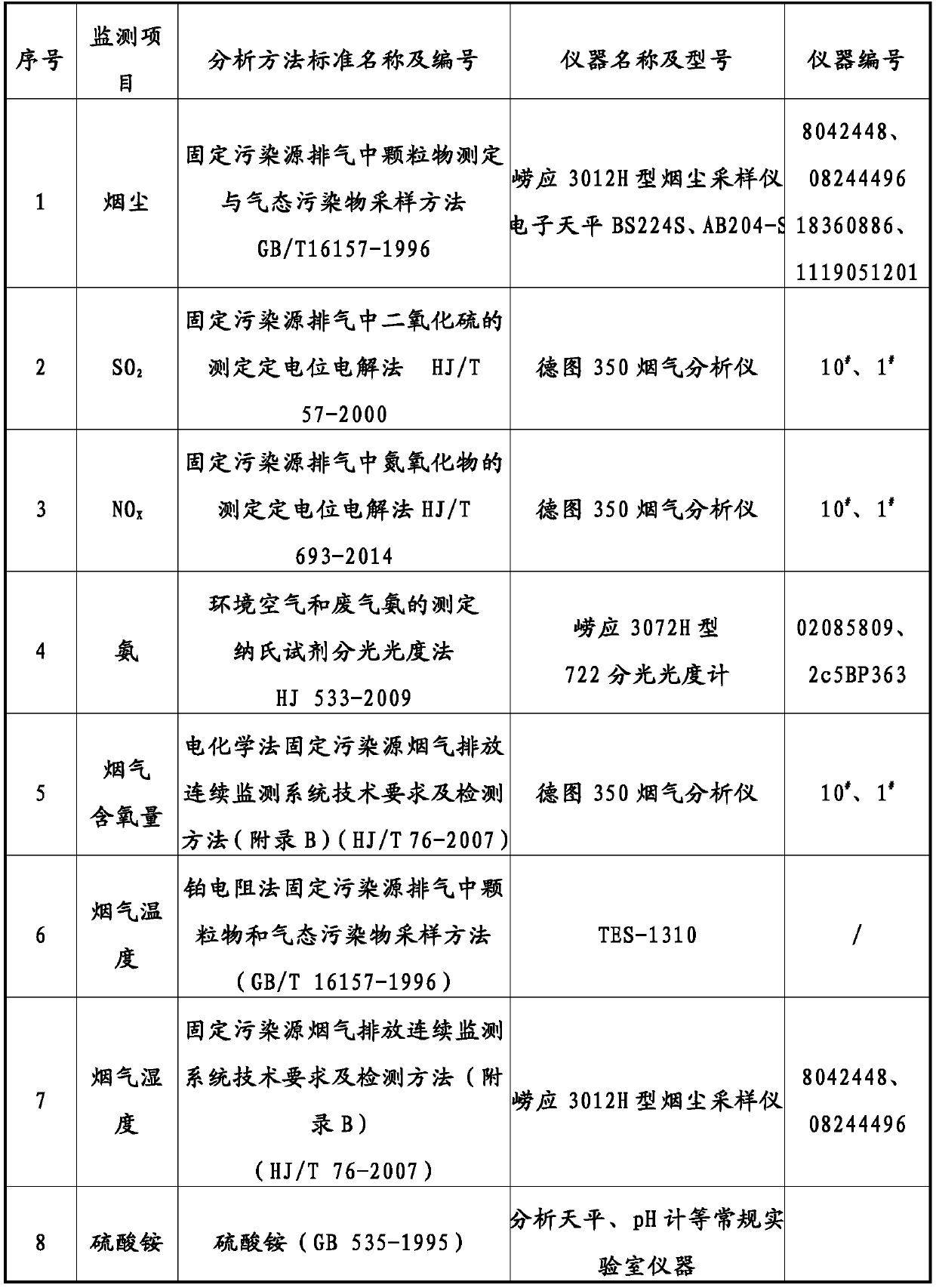

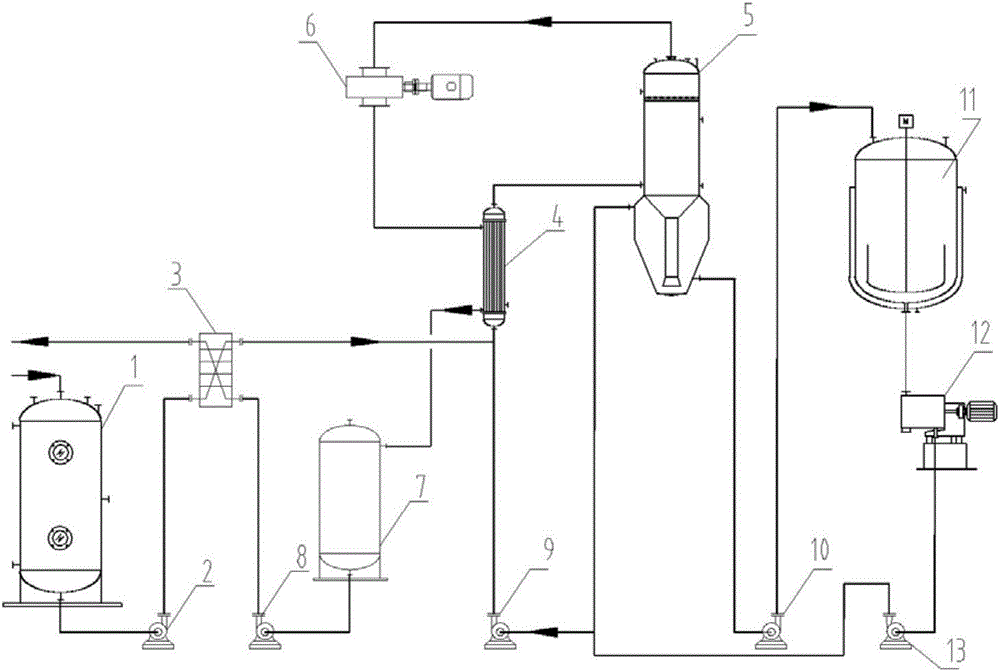

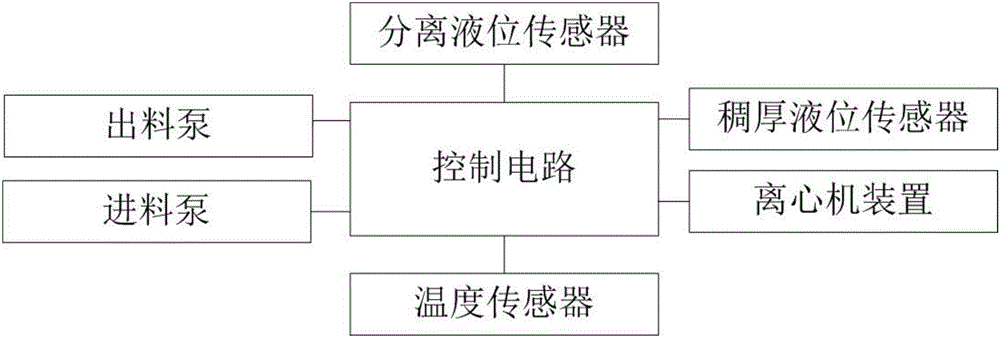

An improved method for controlling aerosol generation in an absorption process of ammonia desulfurization

ActiveCN110975546AAvoid emissionsLower pHGas treatmentDispersed particle separationParticulatesDust control

An improved method for controlling aerosol generation in an absorption process of ammonia desulfurization is disclosed. The absorption reaction temperature and the process gas oxygen and water contents are controlled, and an absorption circulating liquid containing ammonium sulfite is utilized to remove sulfur dioxide in flue gas in order to control aerosol generation during the absorption processof ammonia desulfurization. Through graded solution composition control and reaction condition control, high-efficiency desulfurization and dust removal are achieved, ammonia escape and aerosol generation in the absorption process are controlled at the same time of high-efficiency desulfurization, the flue gas purified and cooled preliminary by pre-washing circulating liquid is brought into contact with absorption circulating liquid and micro particle washing circulating liquid in order, components of solutions of each stage, the reaction temperature and flue gas components are controlled, synergistic control of absorption, oxidation and concentration is achieved, and therefore, investment and energy consumption are reduced at the same time of ensuring the absorption efficiency of the absorption process, controlling ammonia escape and controlling aerosol generation, and long-term stable operation of equipment is achieved.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION +1

Energy-saving evaporative crystallization equipment for sodium chloride solution and control method thereof

InactiveCN106334333AGood evaporation and crystallization effectLow costChemical industrySolution crystallizationPhysical chemistryEnergy conservation

The invention discloses energy-saving evaporative crystallization equipment for a sodium chloride solution. The energy-saving evaporative crystallization equipment for the sodium chloride solution comprises a preheating device, an evaporating device, a crystal separating device and a control device. After adoption of the energy-saving evaporative crystallization equipment for the sodium chloride solution, the conventional steam-heating evaporative crystallization way is replaced, a compressor is used for compressing secondary steam separated by an OSLO separator, the compressed secondary steam is used as heating steam, and the own cycle of the equipment is achieved by setting a circuit, so that steam is not generated for heating, condensing equipment is not needed, and a good evaporative crystallization effect can be achieved only by using a small amount of electric energy. Therefore, the energy-saving evaporative crystallization equipment for the sodium chloride solution opens up a new way for reducing the cost, saving the energy and protecting the environment during treatment of the sodium chloride solution, and has the advantages of cleanness, energy conservation, intelligence, automatism, high working efficiency and the like.

Owner:深圳市捷晶科技股份有限公司

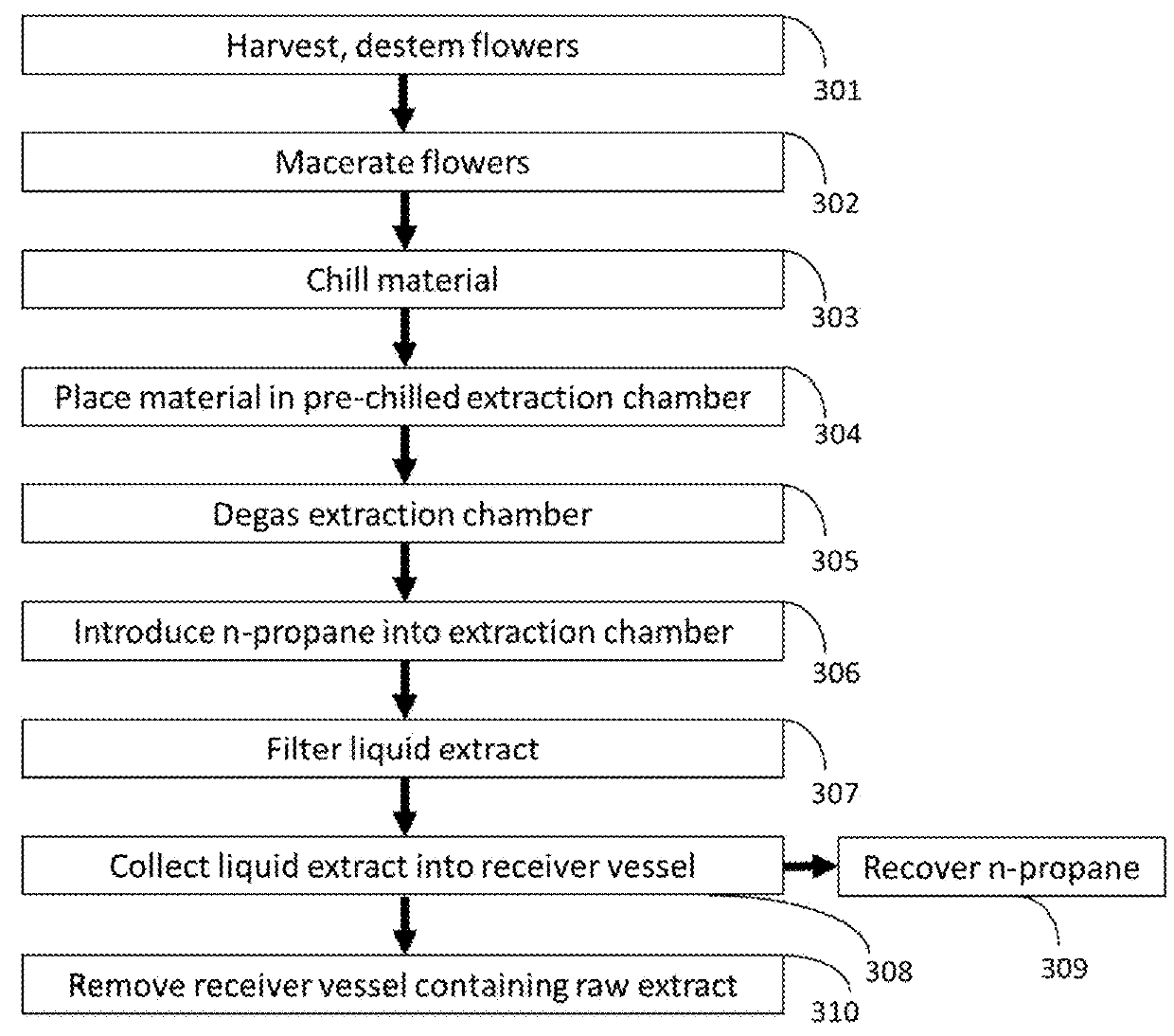

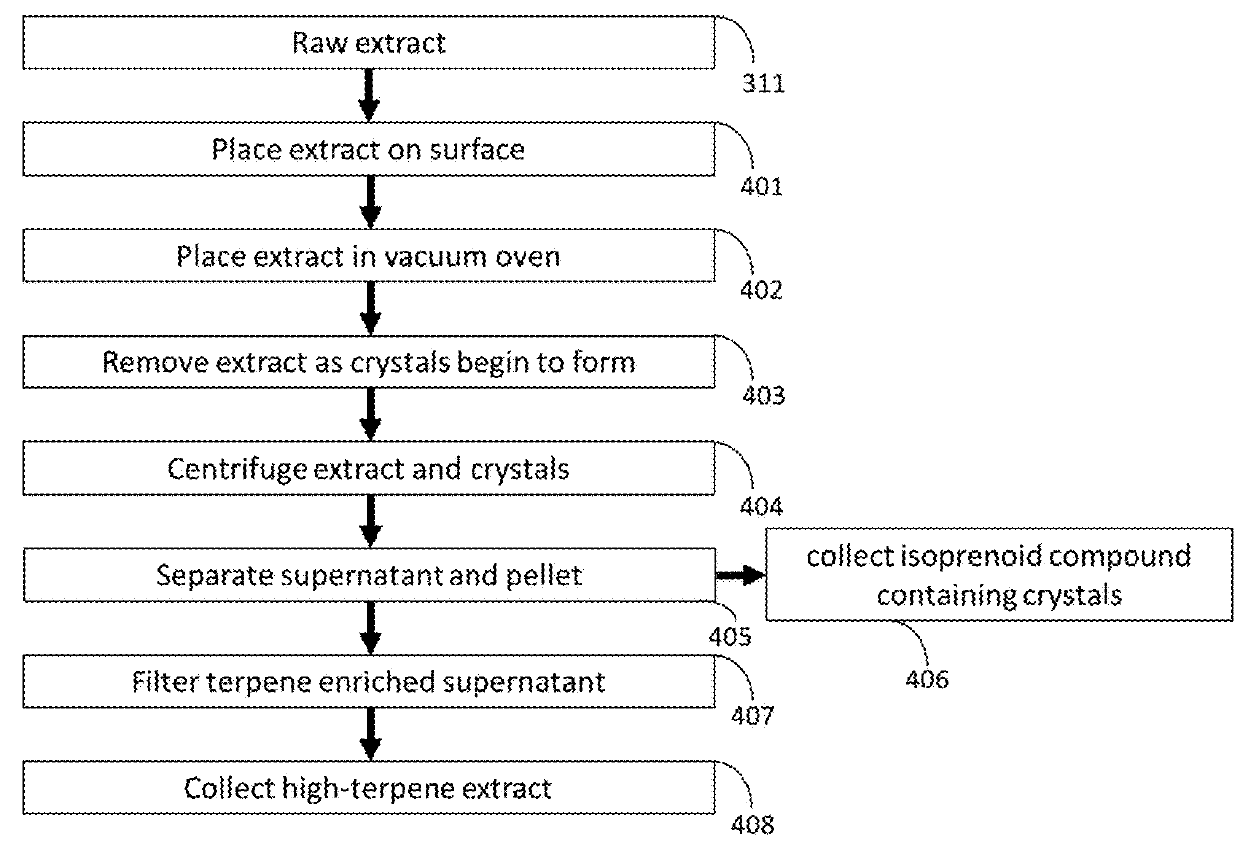

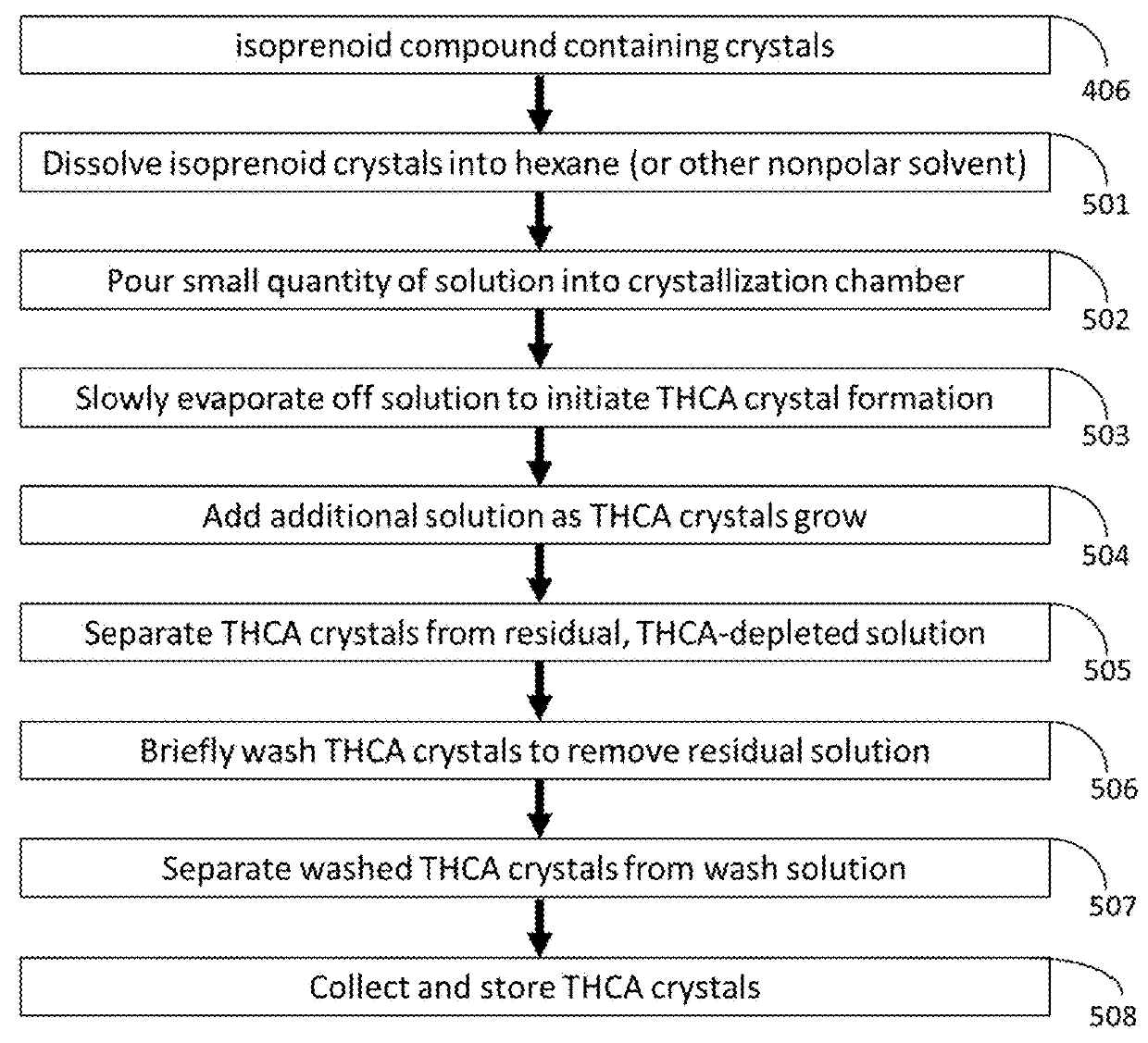

Methods for Purification of Non-Psychoactive Isoprenoid Compounds from Biological Extracts

ActiveUS20180273501A1Improve stabilityPrevent degradationOrganic chemistry methodsCentrifugal force sediment separationCannabisPrenylation

A method for the extraction and isolation of the terpene and isoprenoid compounds from plant material, followed by a centrifugal force induced selective crystallization of isoprenoids resulting in a separation of terpene and isoprenoid fractions. This this method is suitable for the extraction of cannabinoids from Cannabis and the enrichment tetrahydrocannabinolic acid and reduction of tetrahydrocannabinol in an extract. The purity of tetrahydrocannabinolic acid resulting from centrifugal crystallization is such that dissolution and selective recrystallization of tetrahydrocannabinolic acid is possible resulting in >99.9% pure tetrahydrocannabinolic acid, w / w.

Owner:CONCENTRATED CONSULTING GRP LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com