Patents

Literature

97results about "Alkali metal carbonates shape formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

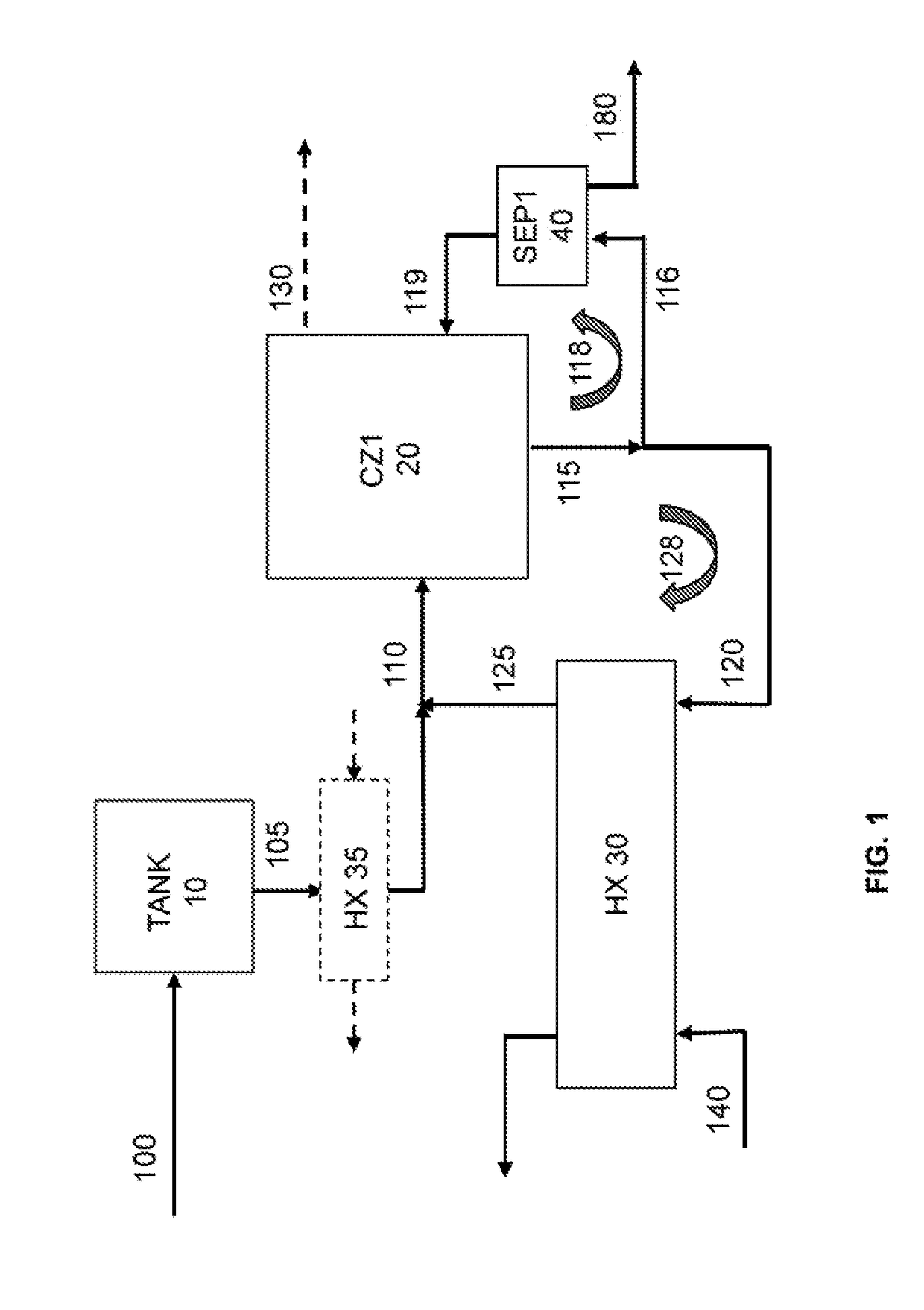

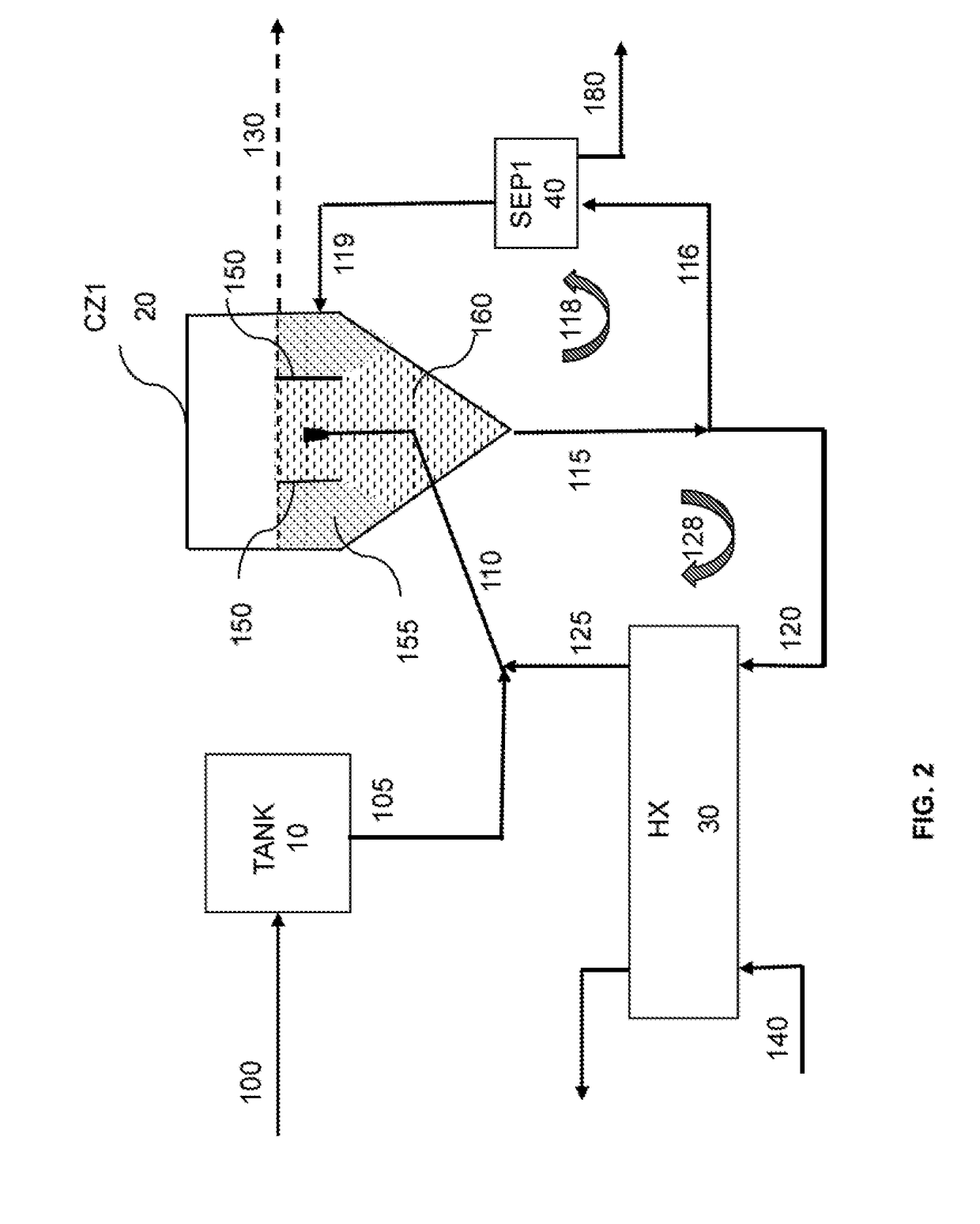

Method of making pure salt from FRAC-water/wastewater

ActiveUS8158097B2Yield maximizationQuality improvementCalcium/strontium/barium carbonatesCalcium/strontium/barium chloridesWater useParticulates

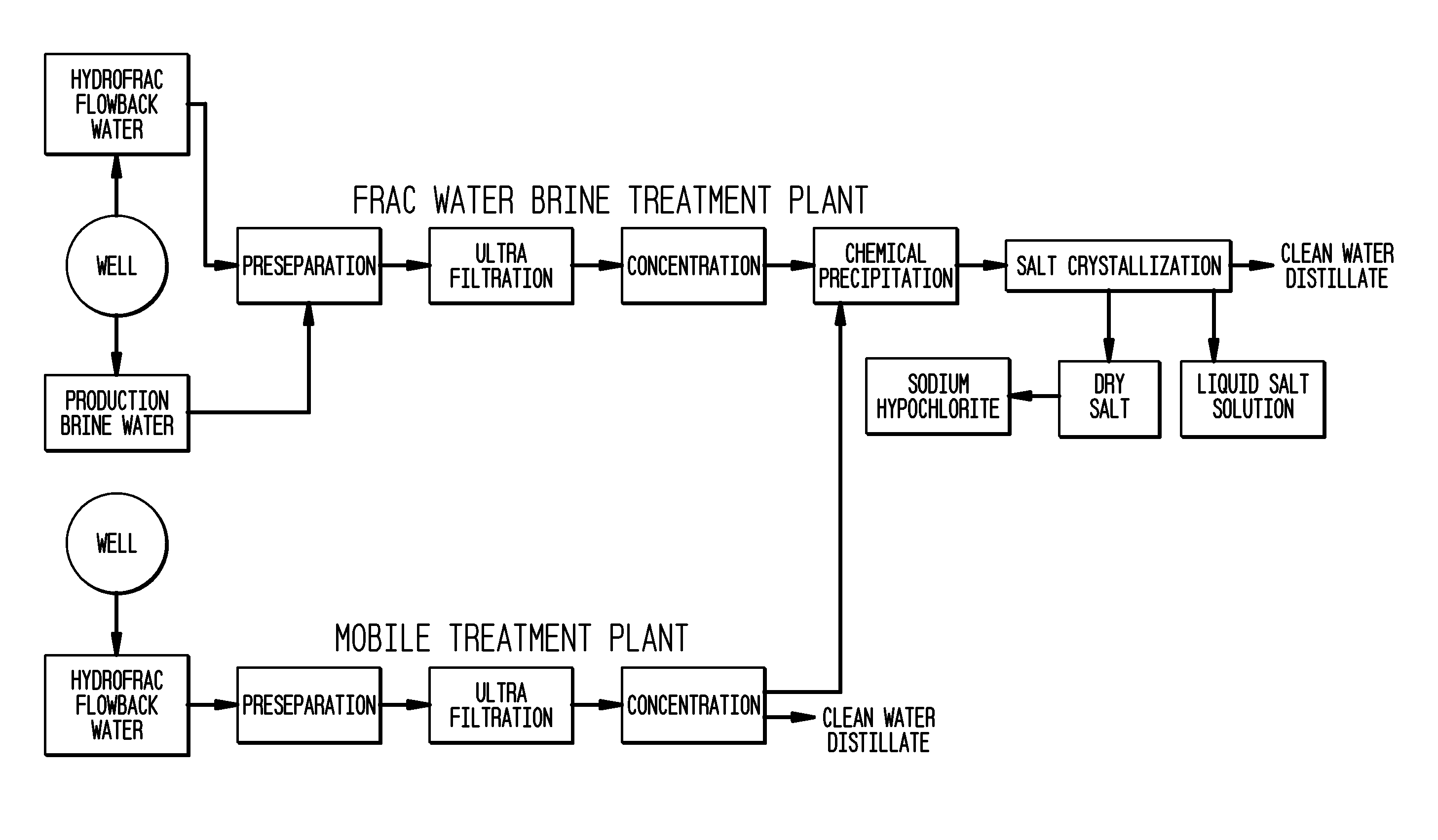

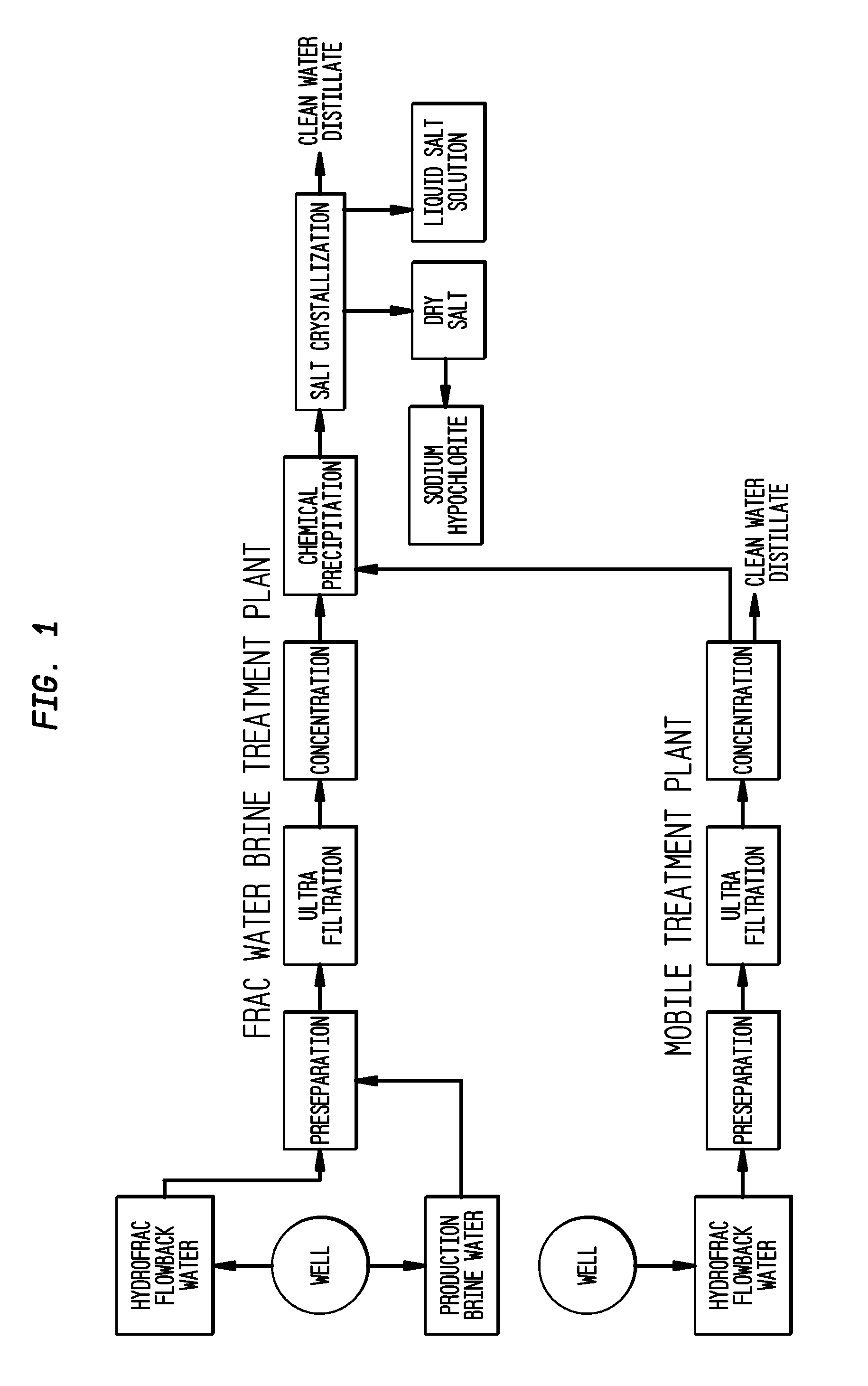

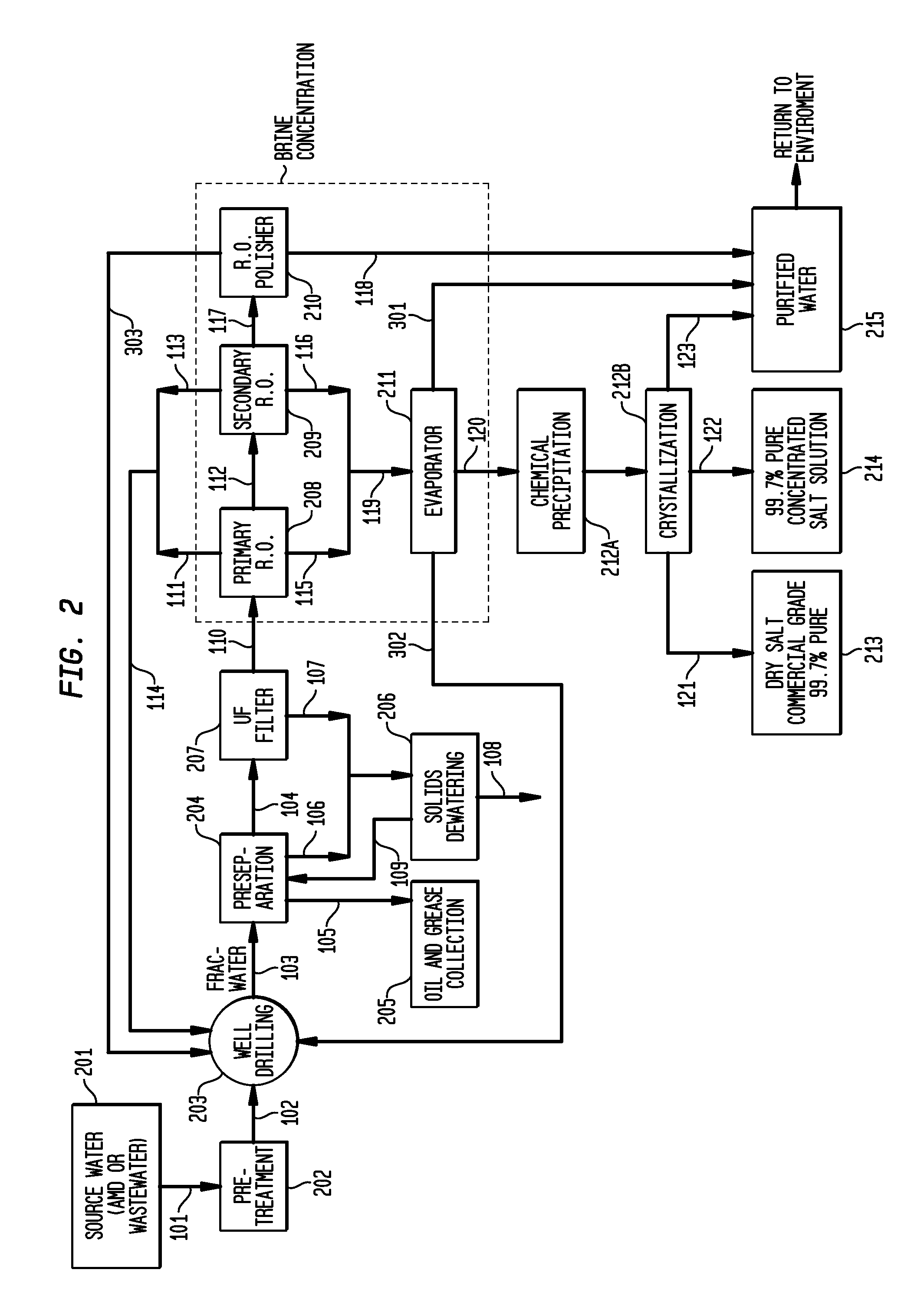

The present invention relates to a method for making pure salt comprises recapturing post-drilling flowback water from hydro-fracturing; removing oil from the flowback water; filtering the flowback water using an ultra filter with a pore size of about 0.1 microns or less to remove solid particulates and large organic molecules, such as benzene, ethylbenzene, toluene, and xylene, from the water; concentrating the flowback water to produce a brine that contains from about 15 wt % to about 40 wt % of salt relative to the total weight of the flowback brine; performing one or more chemical precipitation process using an effective amount of reagents to precipitate out the desired high quality commercial products, such as, barium sulfate, strontium carbonate, calcium carbonate; and crystallizing the chemically treated and concentrated flowback brine to produce greater than 99.5% pure salt products, such as sodium and calcium chloride.

Owner:FRACPURE HLDG

Simultaneous recovery of potassium chloride and KCL enriched edible salt

The present invention relates to recovery of industrial grade potassium chloride and low sodium edible salt from bittern as part of an integrated process. The process comprises, mixing low sulphate concentrated feed bittern (a by-product of salt industry) of density 31.5 to 32.5° Be (sp.gr. 1.277–1.289) with high density end bittern of density 36.5 to 37.5° Be′ (sp.gr. 1.336–1.35), thereby producing low sodium carnallite, from which industrial grade potassium chloride is produced. The resultant bittern is evaporated in forced evaporation system, thereby producing crude carnallite, from which low sodium salt that would be beneficial to persons suffering from hypertension is produced. When sulphate-rich bittern is used, such bittern is desulphated with CaCl2 that is generated from carnallite decomposed liquor through reaction with lime, and wherein low B2O3-containing Mg(OH)2 is a by-product. The entire content of potassium in feed bittern is recovered in the process of the invention.

Owner:COUNCIL OF SCI & IND RES

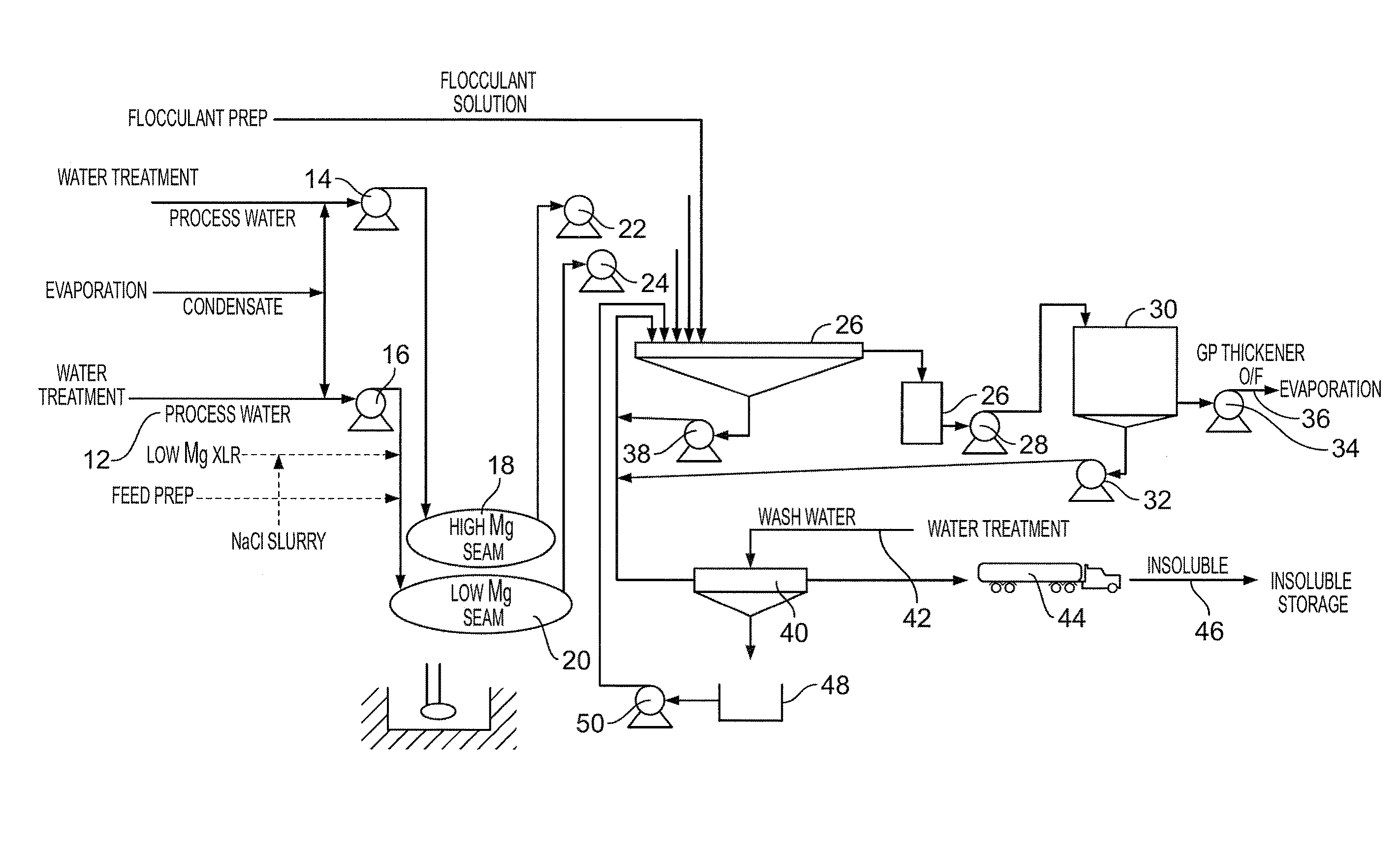

Process for the formulation of potassium chloride from a carnallite source

A process for formulating high purity potassium chloride from a carnallite source. The process takes advantage of solubility differences and saturation levels in a multiple salt system generated upon dissolution of carnallite. In the system, the sodium chloride is kept in solution and the magnesium chloride present in the system is controlled to be in a concentration range of between 12% and 25% by weight. This avoids co-precipitation of sodium chloride with the potassium chloride during crystallization and therefore prevents the sodium chloride from contaminating the potassium chloride. The result is high grade potassium chloride.

Owner:KARNALYTE RESOURCES

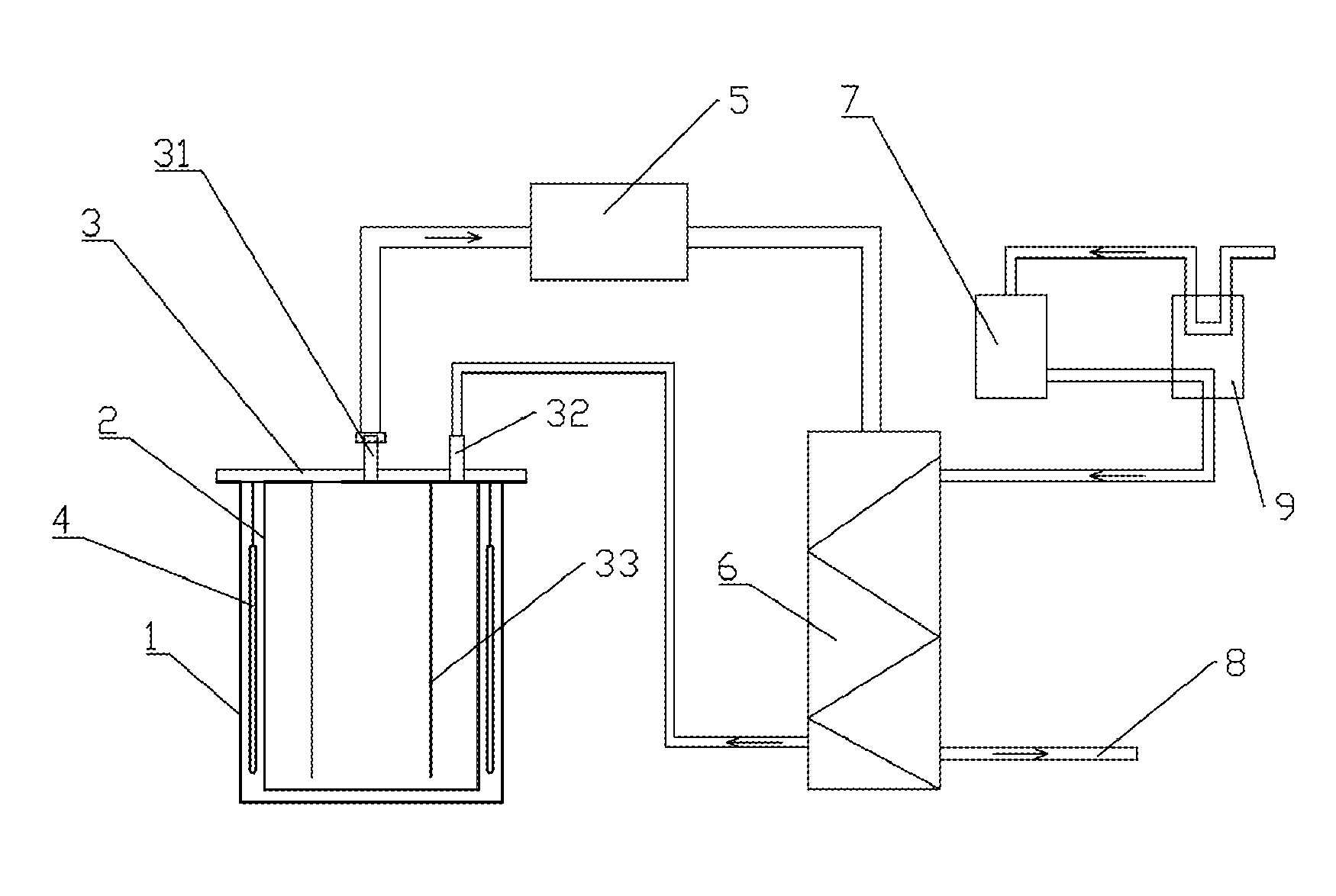

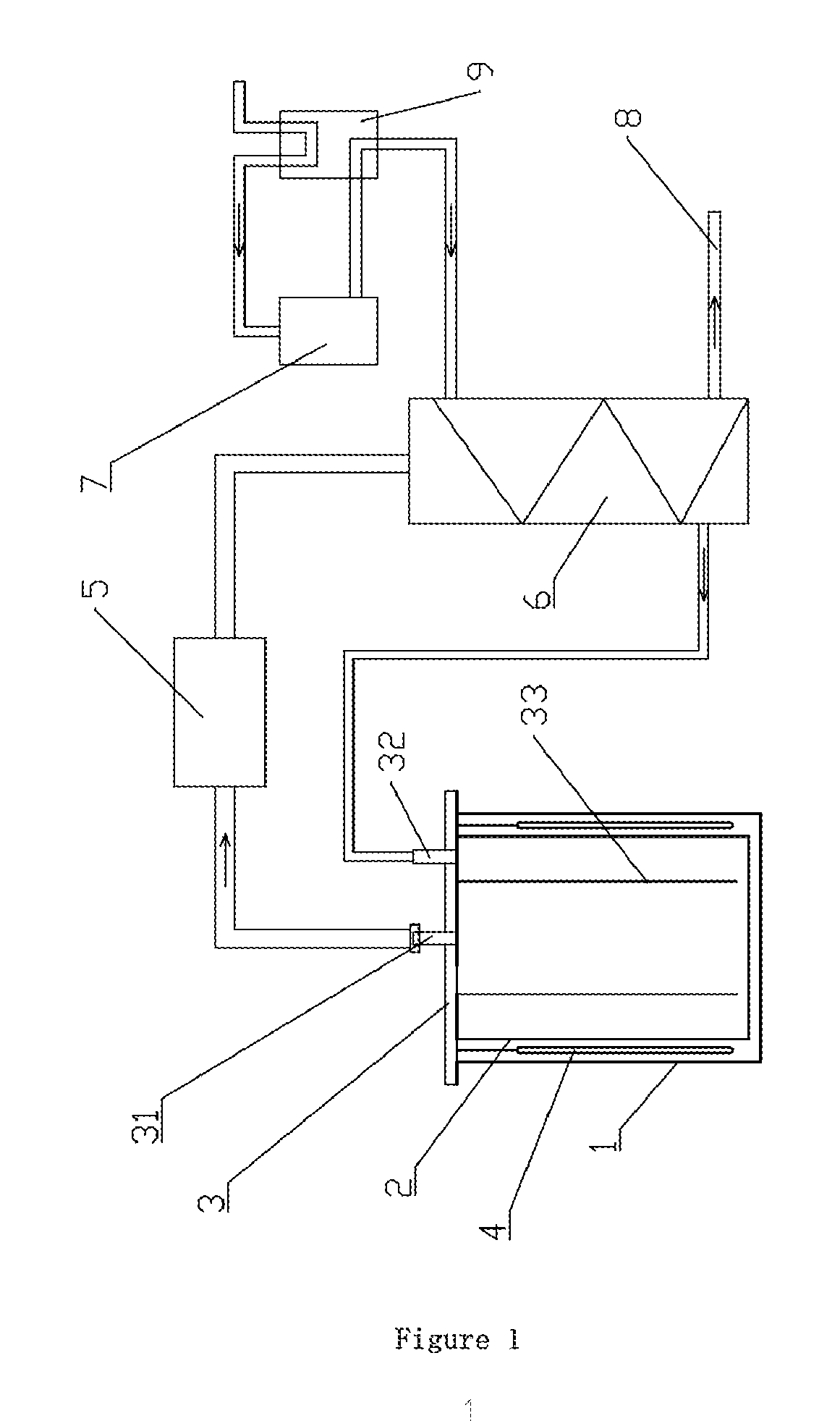

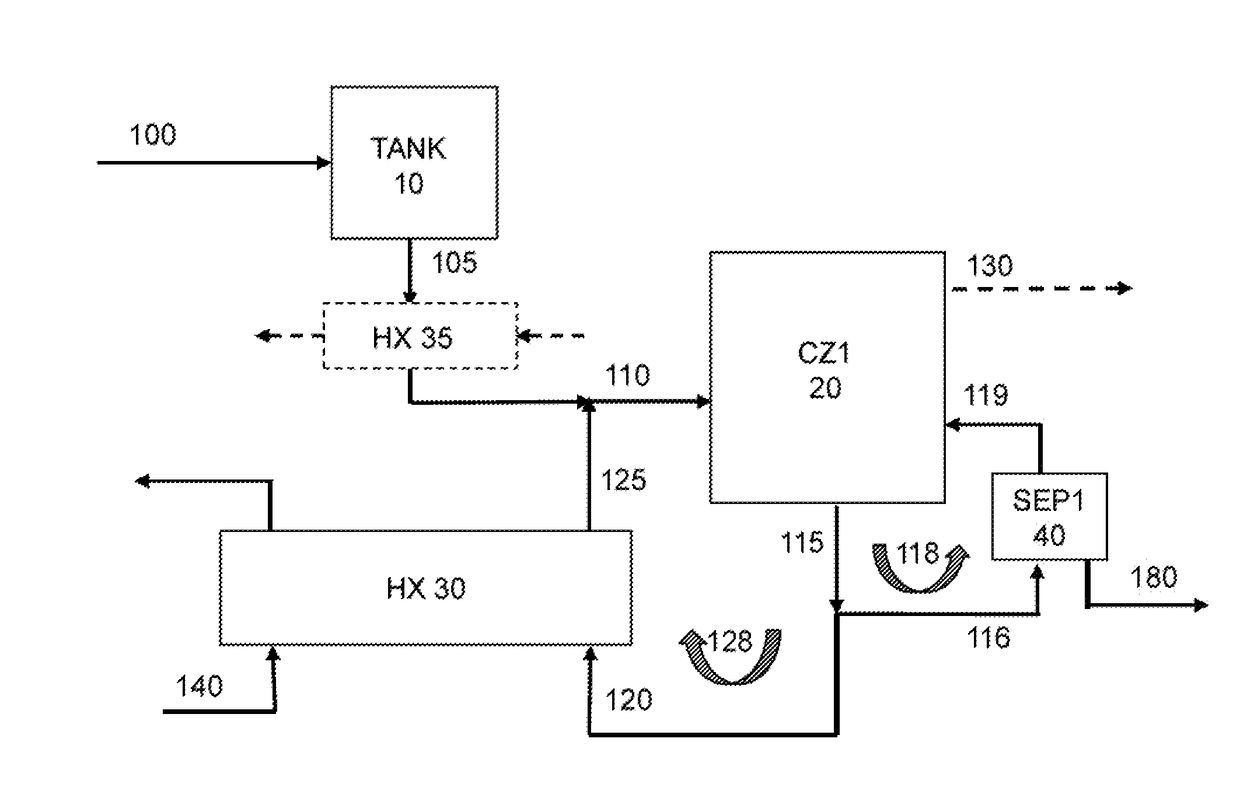

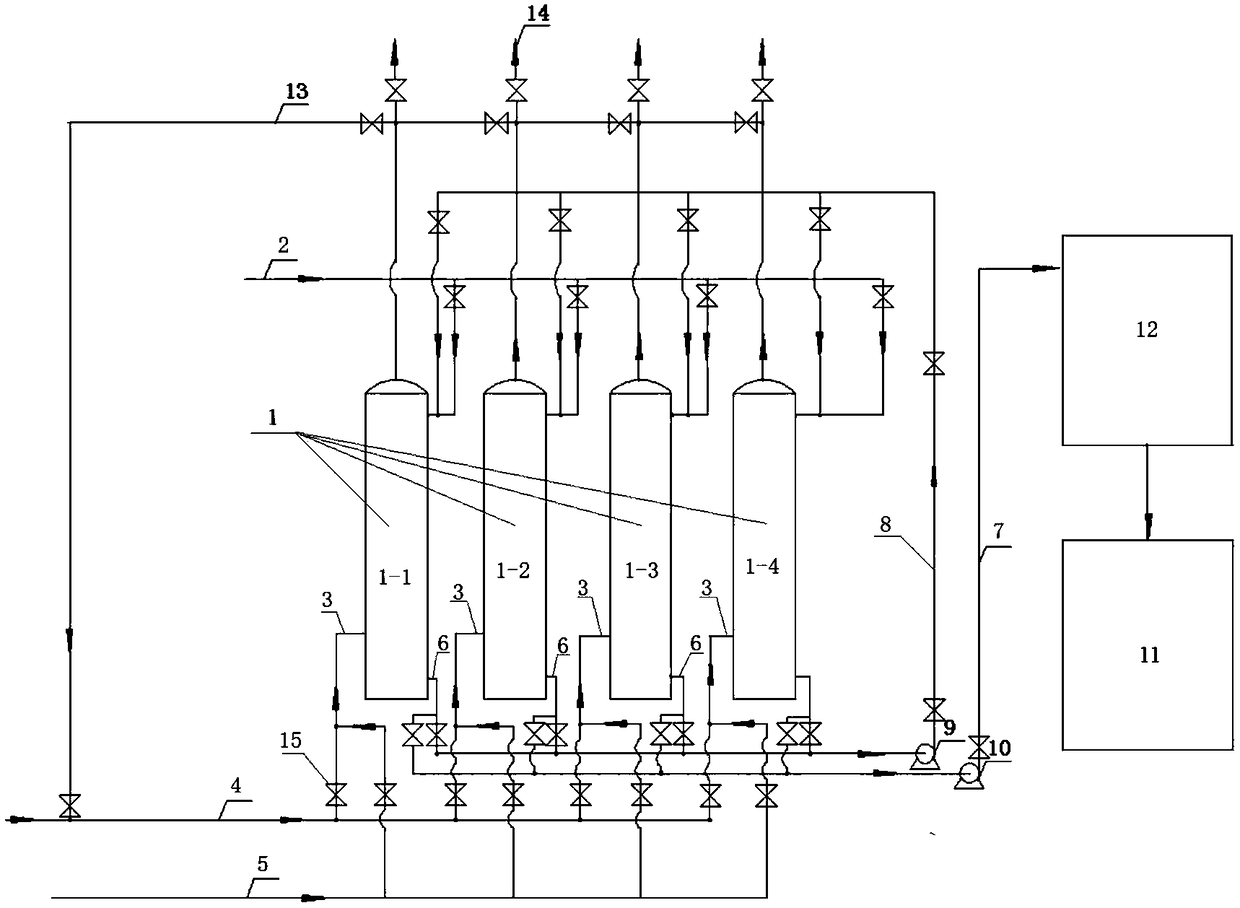

Method and System for Quickly Extracting Lithium Carbonate from Saline Lake Water

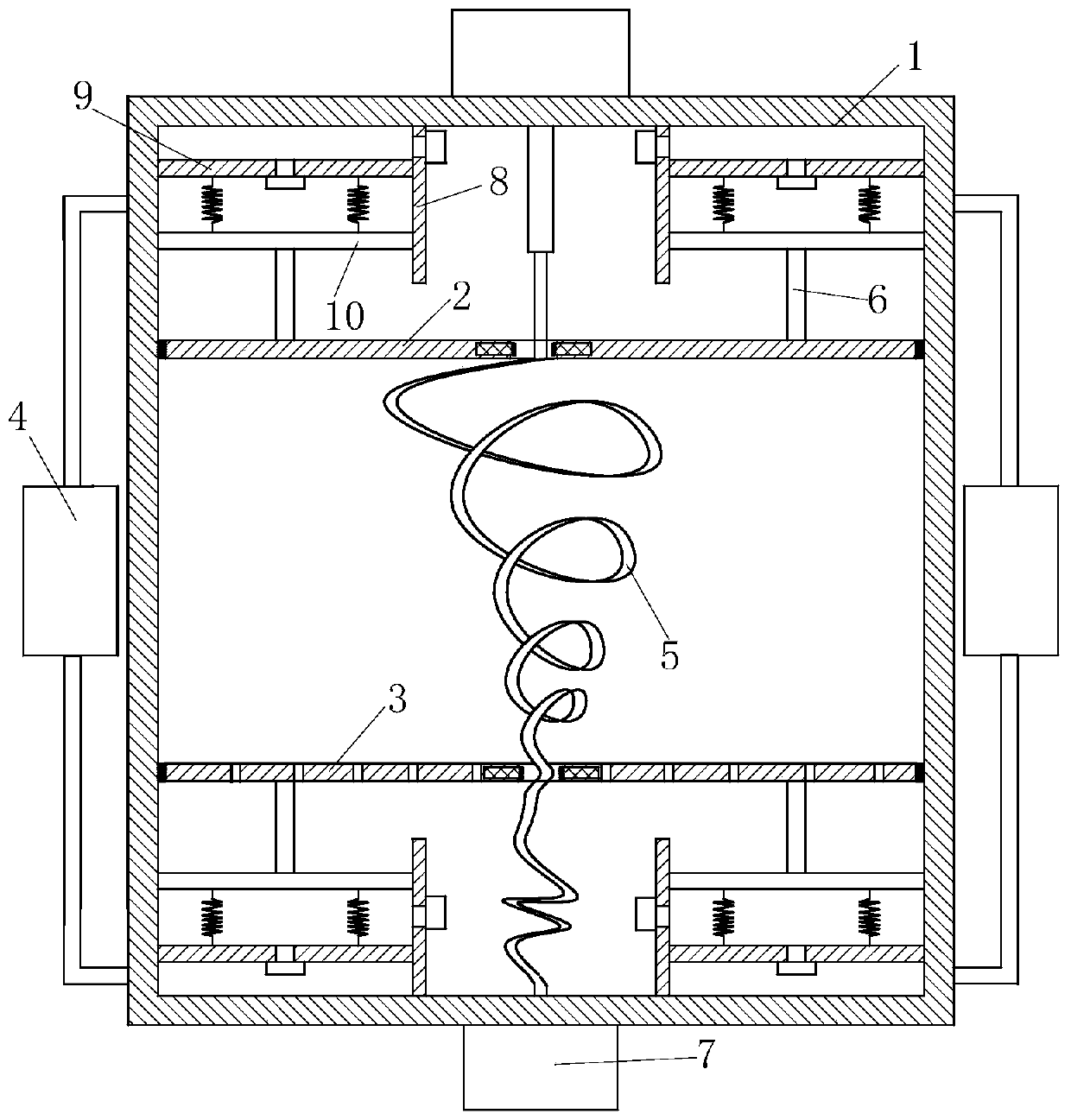

ActiveUS20160115040A1Excess saturationIncrease the areaAlkali metal carbonates shape formationCrystallization by component evaporationSaline waterVacuum pumping

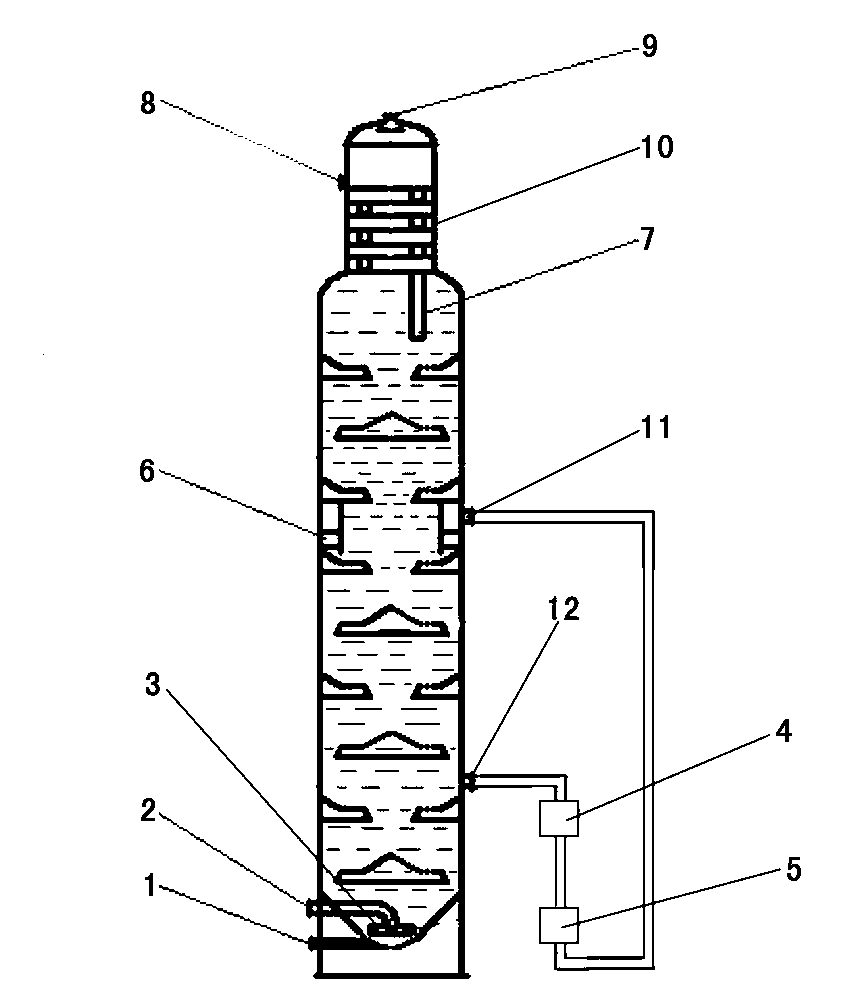

The present invention discloses a method for quickly extracting lithium carbonate from saline lake water and a system for the same. The method comprises: first quick-freezing the saline lake water to obtain lithium-rich brine, then evaporating under reduced pressure to enable lithium carbonate to be rapidly precipitated out. The method has advantages of short process flow and less labor consumption, thereby enabling continuous automatic operation, high energy utilization and environment-friendly. Further, the crystallization rate is several times faster than that of the salt-pan process and the grade of lithium carbonate salt mine obtained can reach 95% or more, therefore the method of the present invention is particularly suitable for industrial production in the remote saline lake region. The system comprises a reduced-pressure evaporation crystallizer, a vacuum-pumping apparatus, a brine preheating apparatus and a brine cooling apparatus, which concentrates the brine by quick-evaporation of the water, promotes lithium carbonate to form non-uniform nucleus, and improves the crystallization efficiency.

Owner:ZHU BINYUAN +1

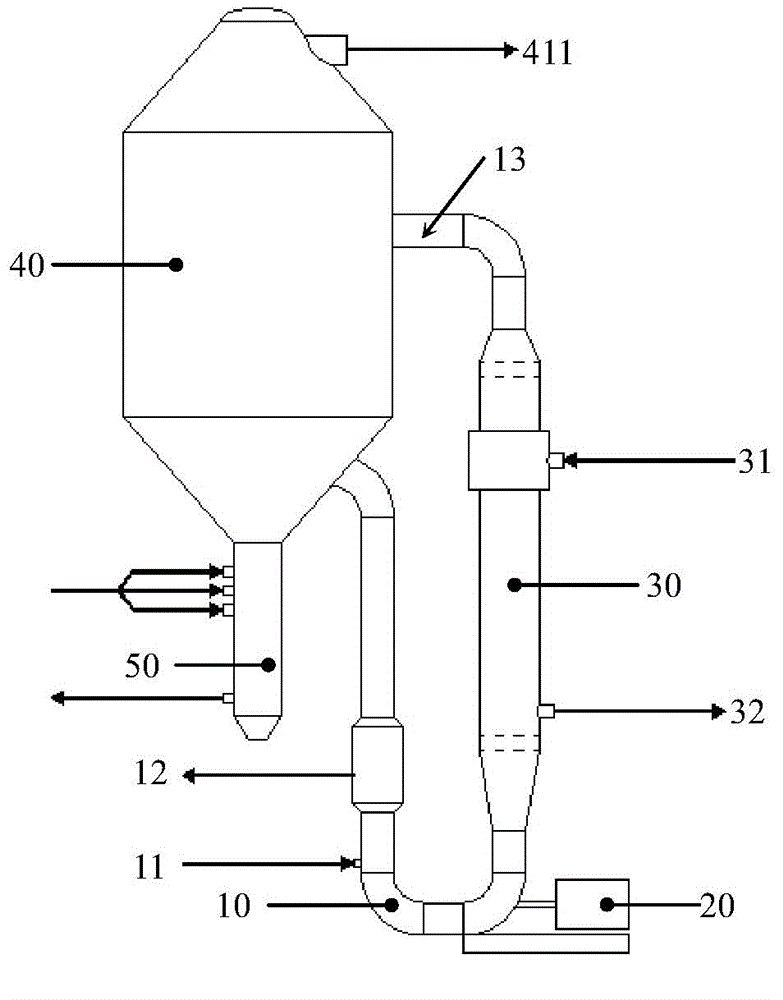

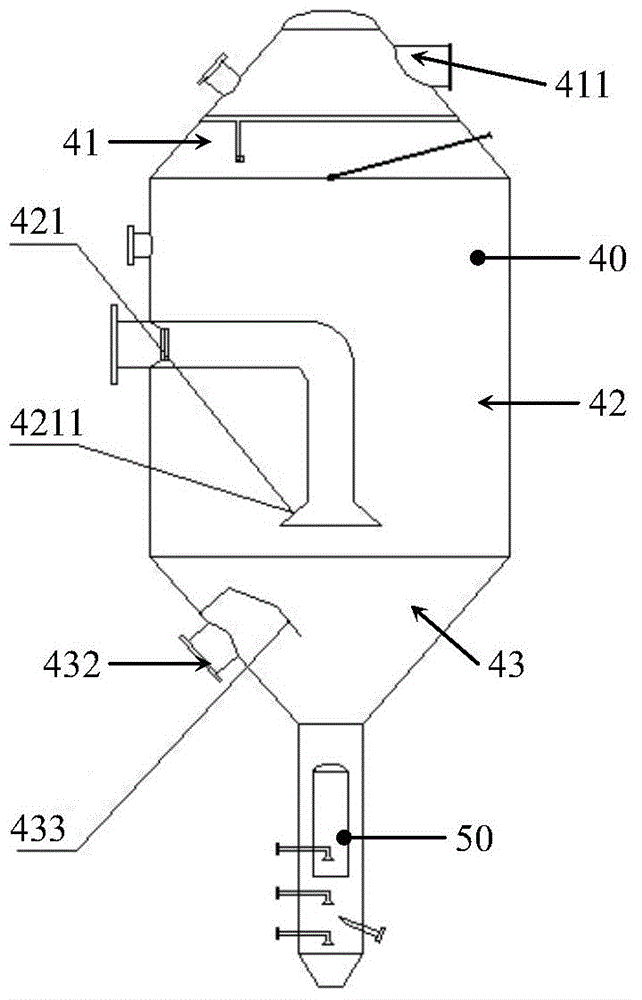

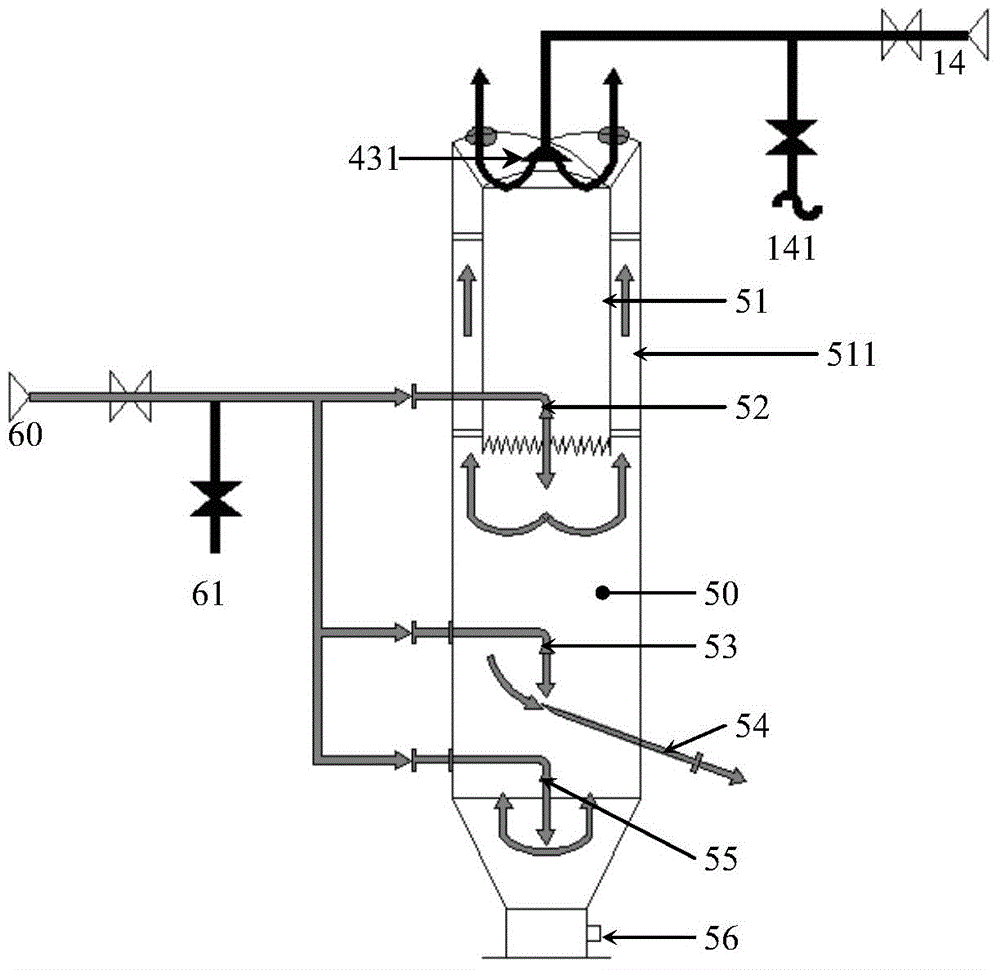

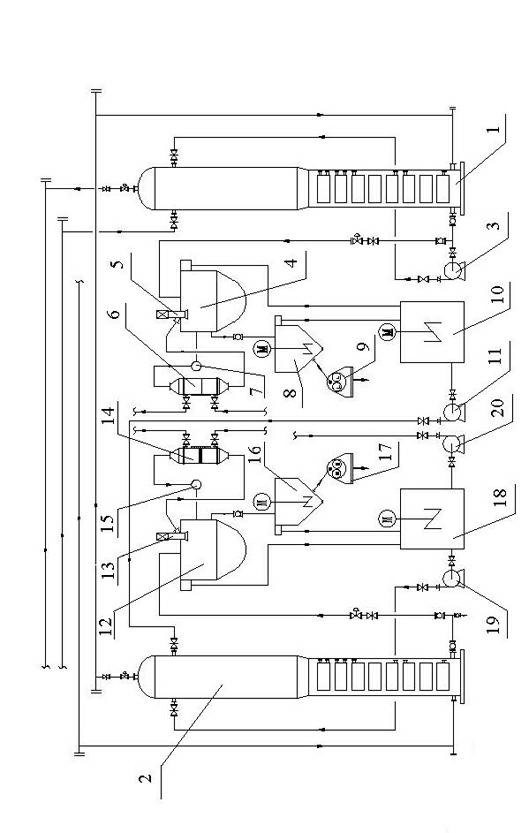

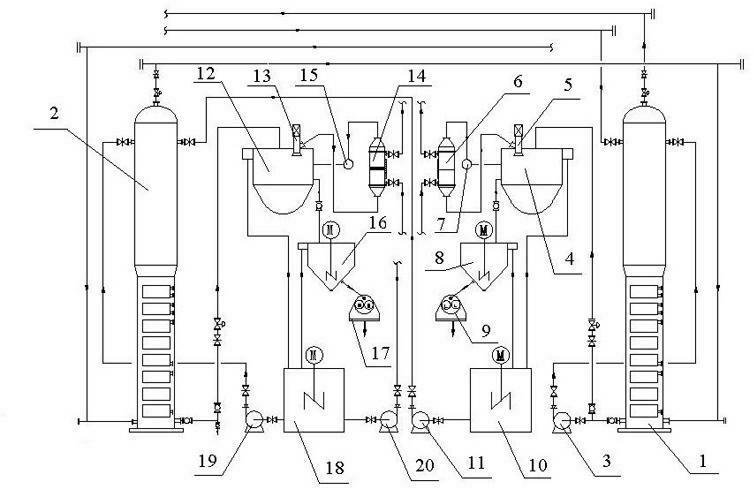

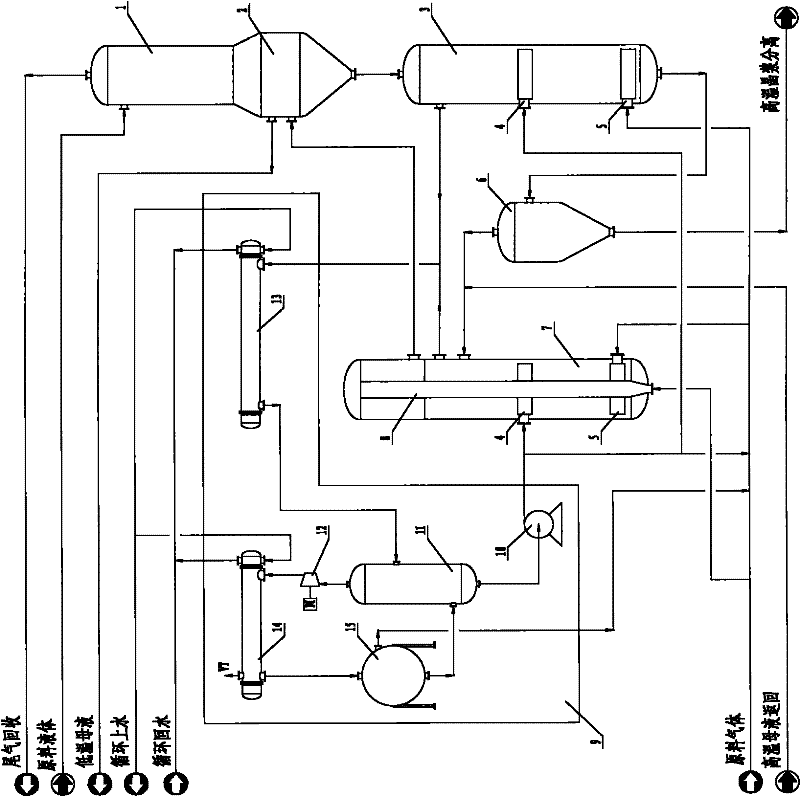

Evaporative-crystallization salt making equipment and wastewater treatment system for treating high-salt organic wastewater

ActiveCN104445477ASimple structureImprove processing efficiencyWater contaminantsAlkali metal carbonates shape formationRotational flowTreatment system

The invention provides a wastewater treatment system and evaporative-crystallization salt making equipment for treating high-salt organic wastewater. The evaporative-crystallization salt making equipment comprises a flash tank; the flash tank is provided with a first circulating water inlet and a circulating water outlet which is arranged below the first circulating water inlet; the circulating water outlet is connected with the first circulating water inlet by a circulating pipe; and the circulating pipe is provided with a heating device. The evaporative-crystallization salt making equipment further comprises a salt washing leg, and the salt washing leg is connected with and penetrates through the bottom of the flash tank and comprises an upper water inlet, a middle water inlet and a salt outlet, wherein the upper water inlet is arranged in the salt washing leg, the water inlet direction of the upper water inlet is downward, the middle water inlet is arranged below the upper water inlet and is designed to enable the wastewater in the salt washing leg to generate rotational flow, and the salt outlet is arranged below the middle water inlet. The wastewater treatment system and the evaporative-crystallization salt making equipment can be used for washing the crystalloid salt particles repeatedly under the condition that the crystalloid salt particles are mixed with the wastewater, are simple in structure, low in cost, high in wastewater treatment efficiency and can ensure that the obtained crystalloid salt particles have high purity.

Owner:广州汉泰环境技术有限公司

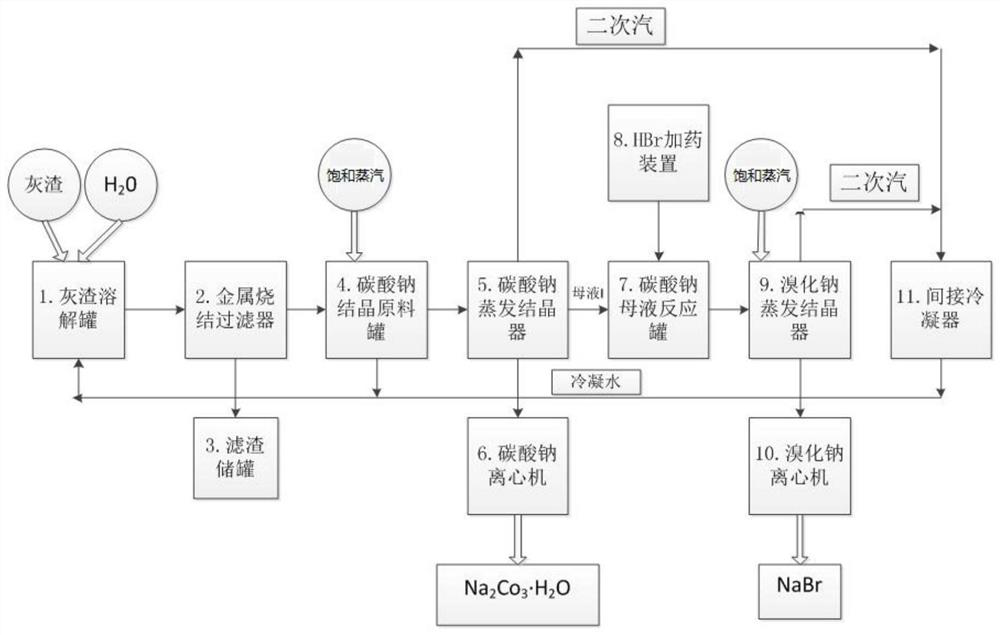

PTA incineration boiler ash residue solution salt separation crystallization process

ActiveCN112811444AFulfill quality requirementsRealize resourcesAlkali metal carbonates shape formationEnergy inputPhysical chemistryWastewater

The invention relates to a PTA incineration boiler ash residue solution salt separation crystallization process, and belongs to the technical field of evaporative crystallization. The process comprises the following steps of: dissolving ash of the PTA incineration boiler with waste heat into a nearly saturated solution of sodium carbonate and sodium bromide, and removing metals and other insoluble substances from the solution by adopting a metal sintering filter, separating the obtained filtrate by adopting an evaporative crystallization method to obtain sodium carbonate monohydrate crystals, removing sodium carbonate from the mother liquor by adopting a replacement method, and then separating by adopting an evaporative crystallization method to obtain sodium bromide crystals. Sodium carbonate and sodium bromide in the PTA boiler ash are separated and recovered by adopting an evaporative crystallization method, the process flow is simple, the operation conditions are simple, convenient and stable, and industrialization is facilitated; the high-purity sodium carbonate and sodium bromide recovered by the method can meet the quality requirements of industrial-grade products and can be directly recovered and reused or sold as by-products, so that the purpose of treating waste residues and wastewater is achieved, the requirements of the current environmental protection situation are met, waste can be turned into wealth, recycling of salt is realized, and the benefits of factories are improved.

Owner:河北工大晟珂工程科技有限公司

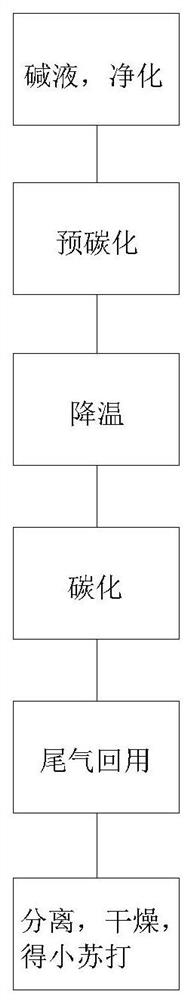

Carbonization crystallization technology in process for producing sodium carbonate through Hou's method

ActiveCN102502718AIncrease effective volumeProlong the carbonization reaction residence timeAlkali metal carbonates shape formationCarbonizationSlurry

The invention relates to a carbonization crystallization technology in the process for producing sodium carbonate through a Hou's method. The technology is characterized in that the technology comprises the following steps: sending an ammonia II mother solution to a carbonization cleaning tower, and countercurrent-contacting and reacting with a cleaning gas output by a sodium carbonate preparation tower to precarbonize; injecting a precarbonization solution to a cleaning pump connected to the carbonization cleaning tower to clean the cycle of the carbonization cleaning tower; sending the precarbonization solution taken from the bottom of the carbonization cleaning tower to a primary crystallizer, cooling the precarbonization solution by allowing it to go through a primary cooler, allowingit to go through a collection tank and then return to the primary crystallizer, sending the generated crystal slurry to a primary thickener by the primary crystallizer to thick, and centrifuging; sending the obtained overflow solution to the soda preparation tower, and countercurrent-contacting and reacting with a transformation gas to prepare soda; sending the solution from the soda preparation tower to a secondary crystallizer, crystallizing again, thickening again, and separating again; and sending parts of the overflow solution to the soda preparation tower, and contacting with the transformation gas to carry out cycle soda preparation. The technology of the invention, which adopts above two-time carbonization two-time crystallization external-cooling process, allows the crystallization residence time of the carbonization tower to be prolonged, the carbonization conversion rate to be improved, the working time of the carbonization tower to be prolonged and the production capacity of the carbonization tower to be increased.

Owner:赵祥海 +1

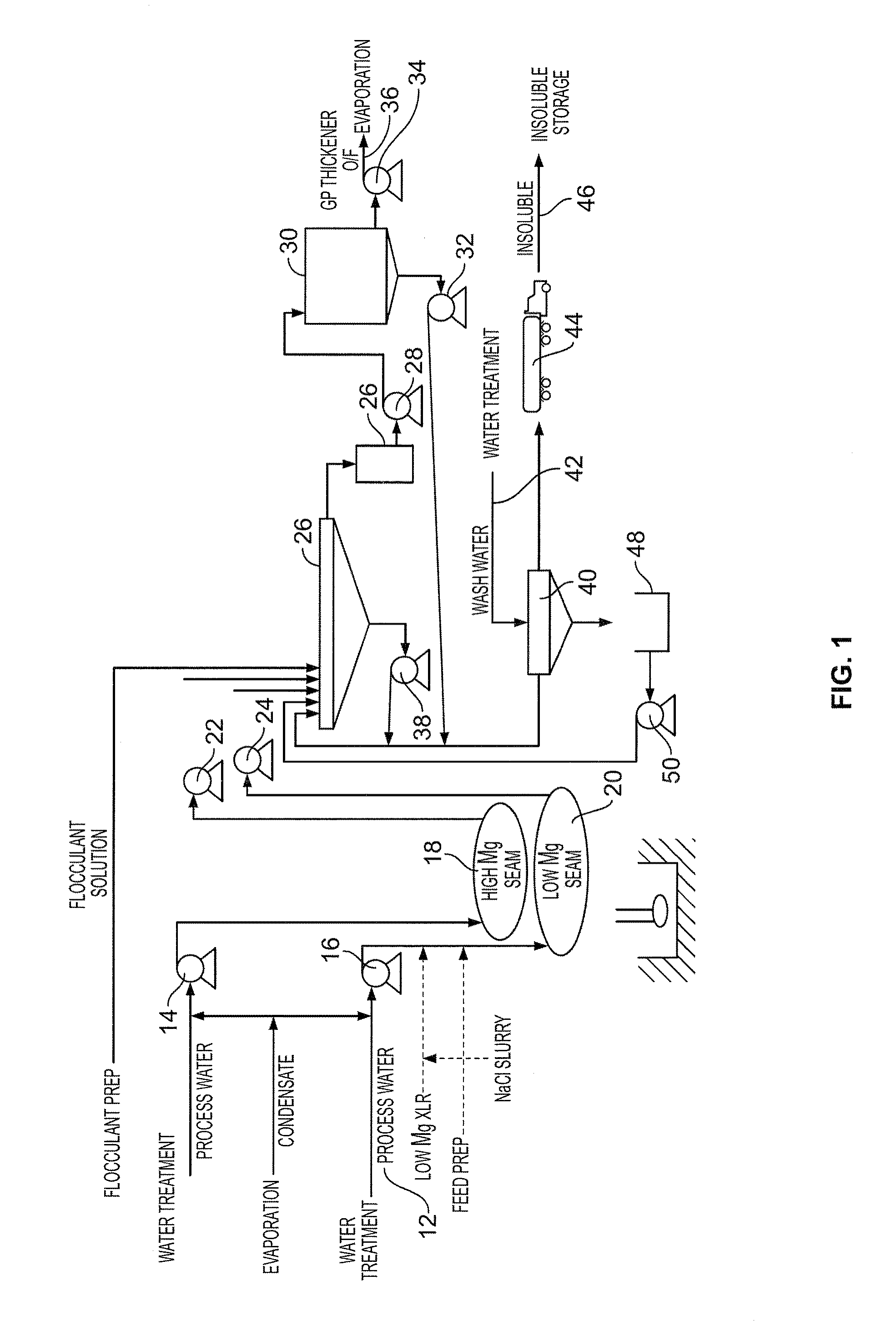

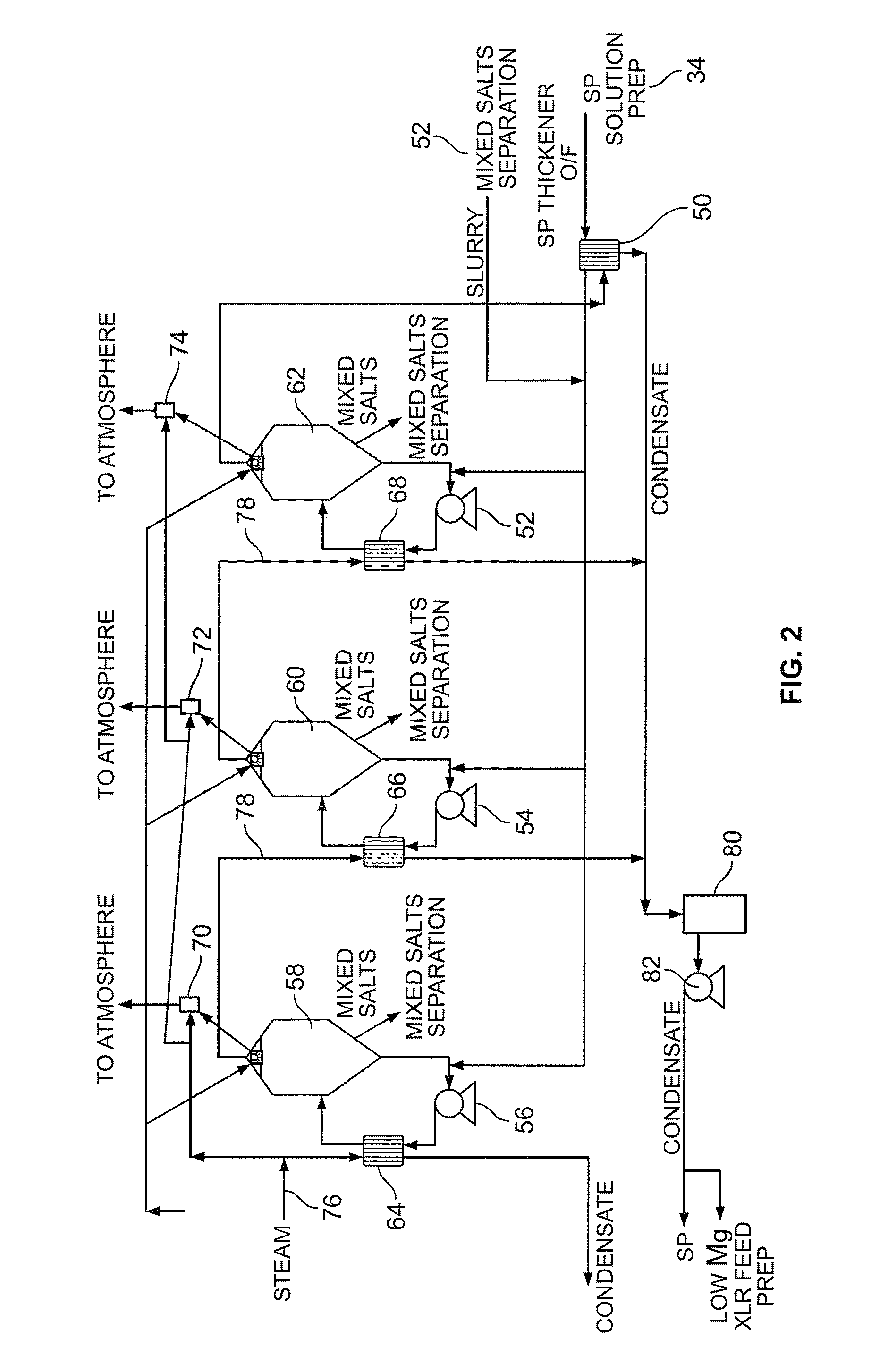

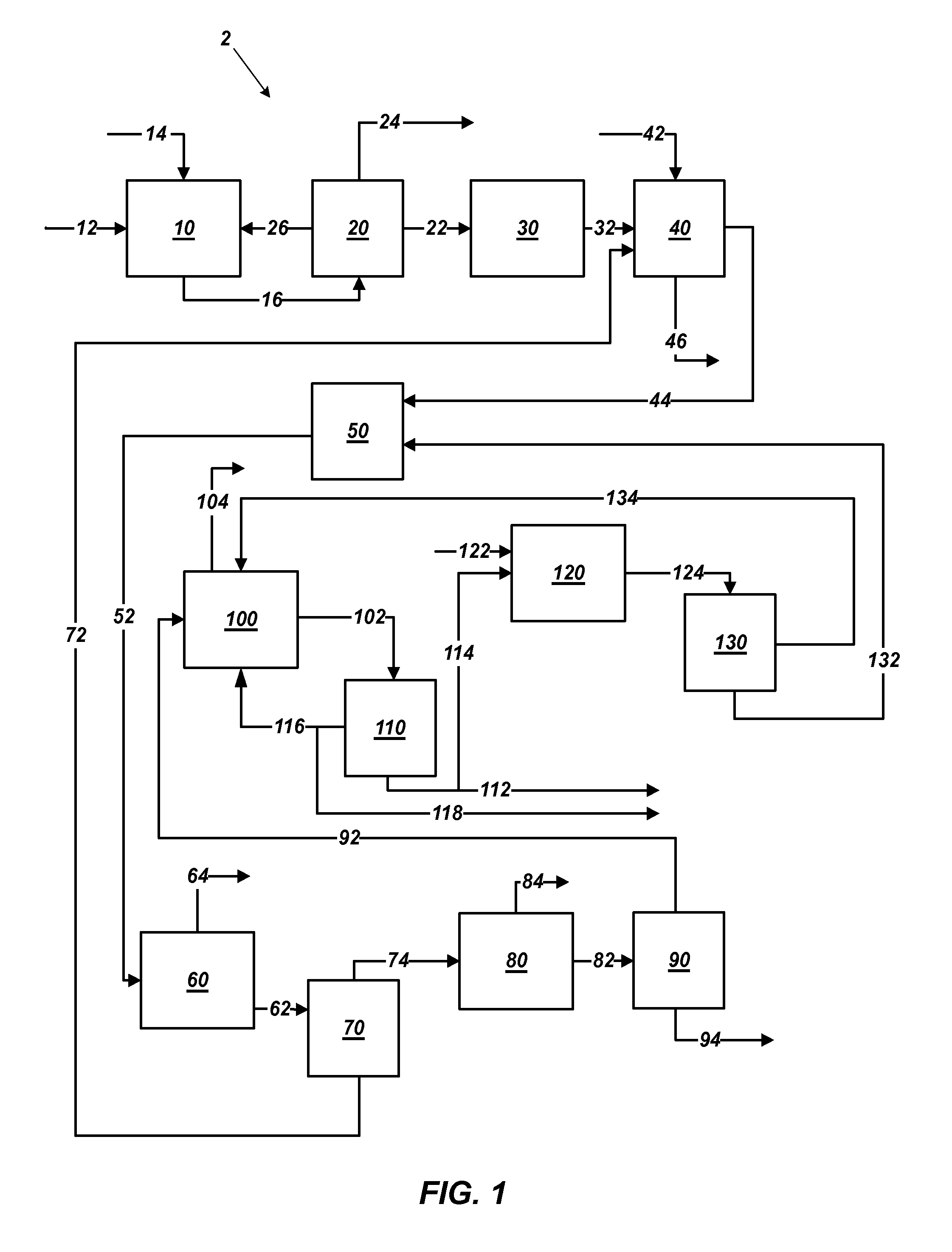

Methods of processing polyhalite ore, methods of producing potassium sulfate, and related systems

ActiveUS8551429B2Limit economic riskLess energyChemical/physical/physico-chemical processesAlkali metal oxides/hydroxidesWater solublePotassium sulfate

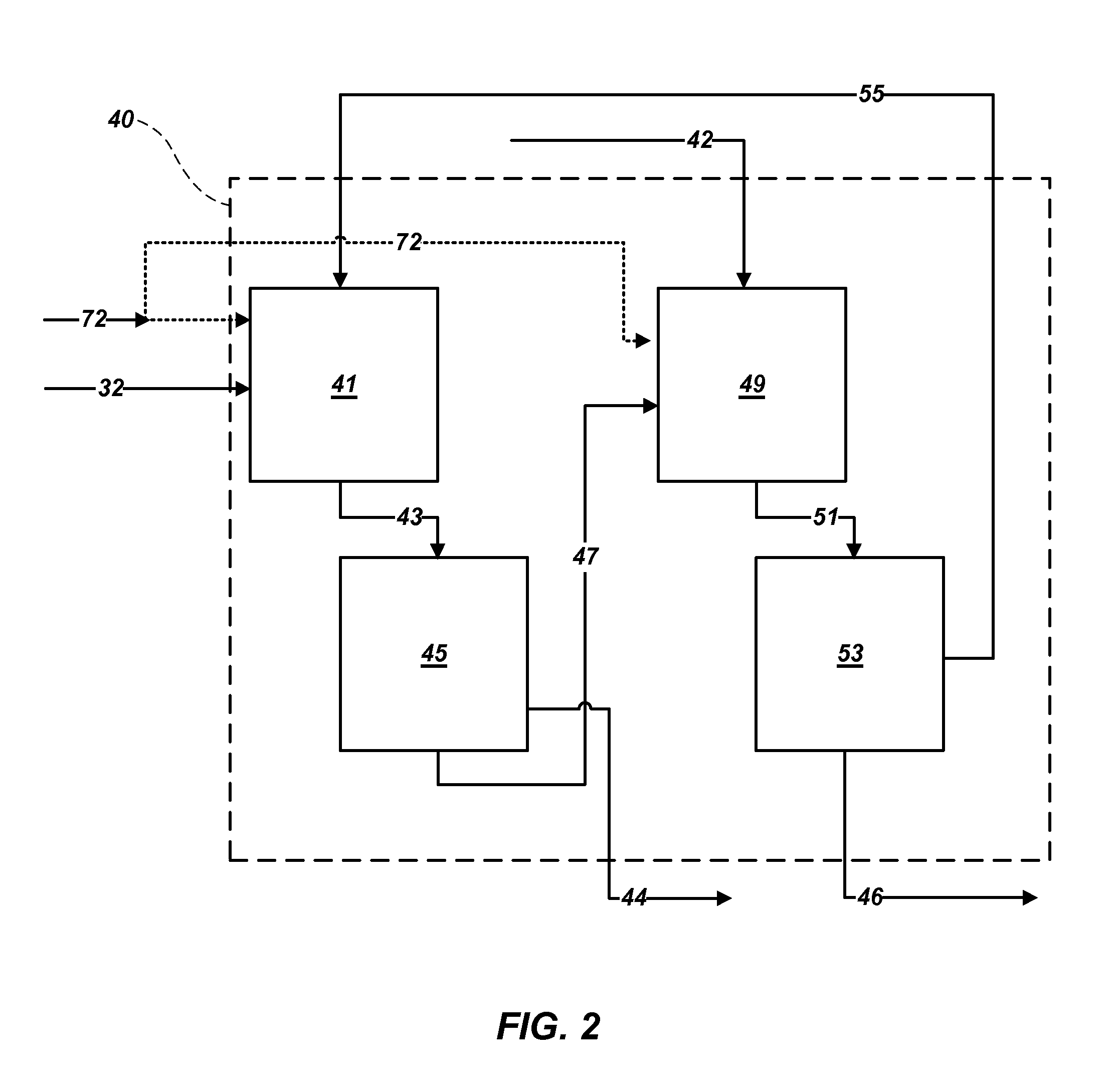

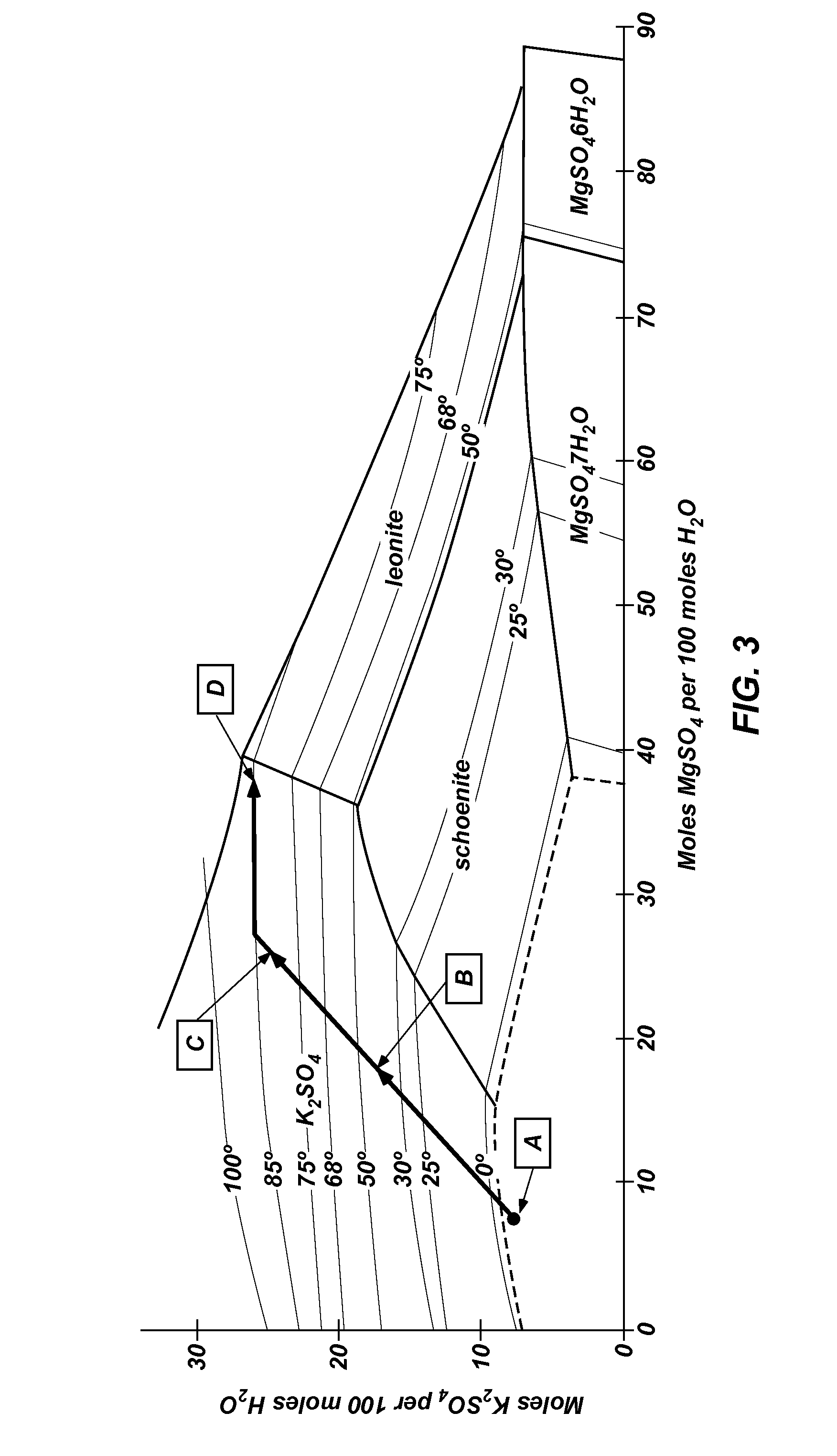

Methods of forming potassium sulfate include calcining polyhalite ore particles to convert the polyhalite ore particles to a water-soluble composition. At least a portion of the water-soluble composition is dissolved in an aqueous medium to form an aqueous solution comprising K+, Mg2+, and SO42− ions and a calcium-containing solid. The calcium-containing solid is separated from the aqueous solution to form a filtrate comprising K+, Mg2+, and SO42− ions. A potassium-containing salt is dissolved in the filtrate to increase the concentration of K+ and SO42− ions to from a concentrated liquor, and K2SO4 is crystallized from the concentrated liquor. A system for processing polyhalite ore includes a countercurrent leaching apparatus, a first mix tank, an evaporator, and at least one crystallizer.

Owner:INTERCONTINENTAL POTASH CORP USA

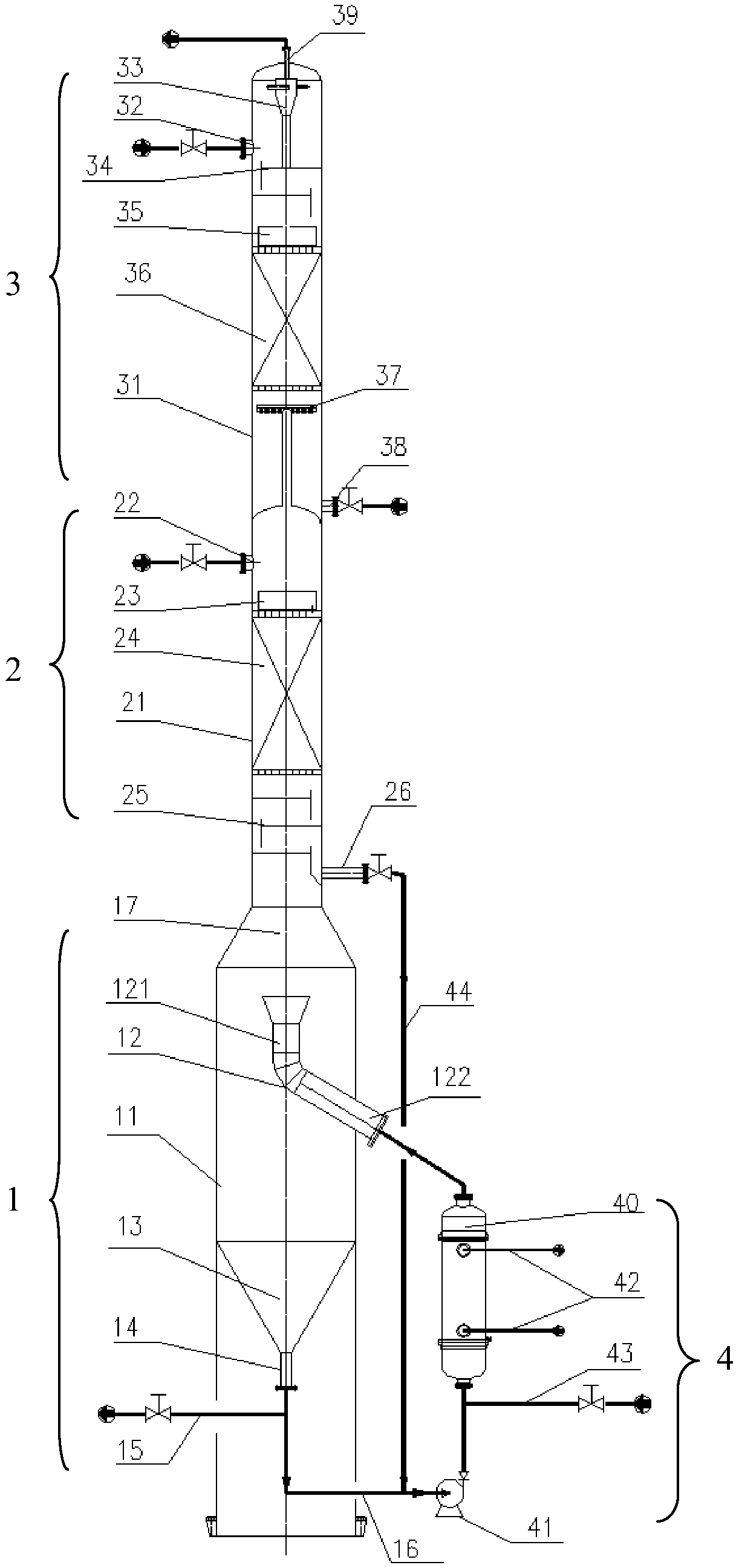

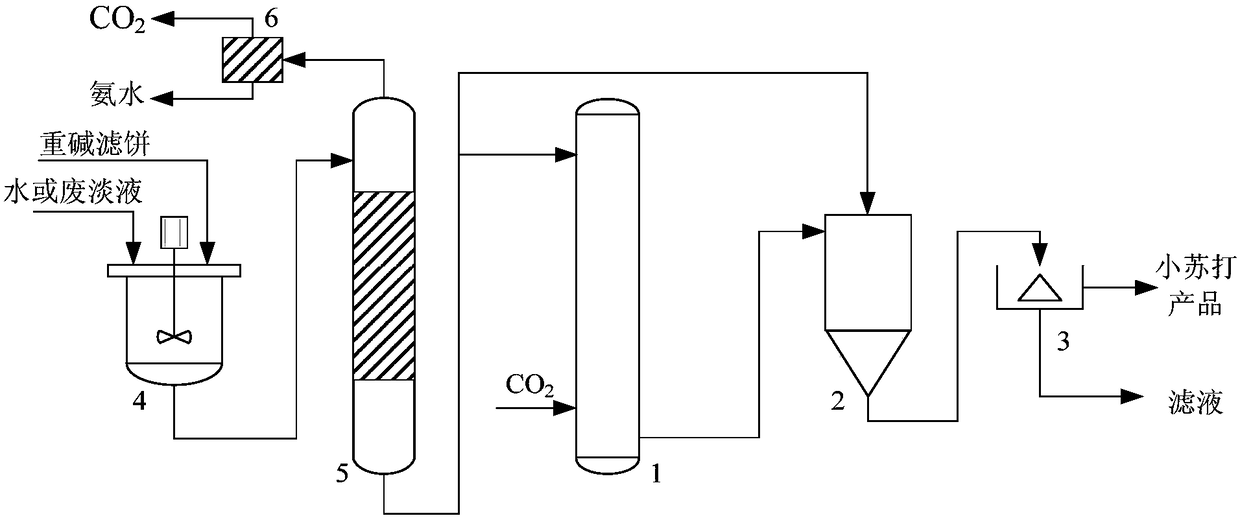

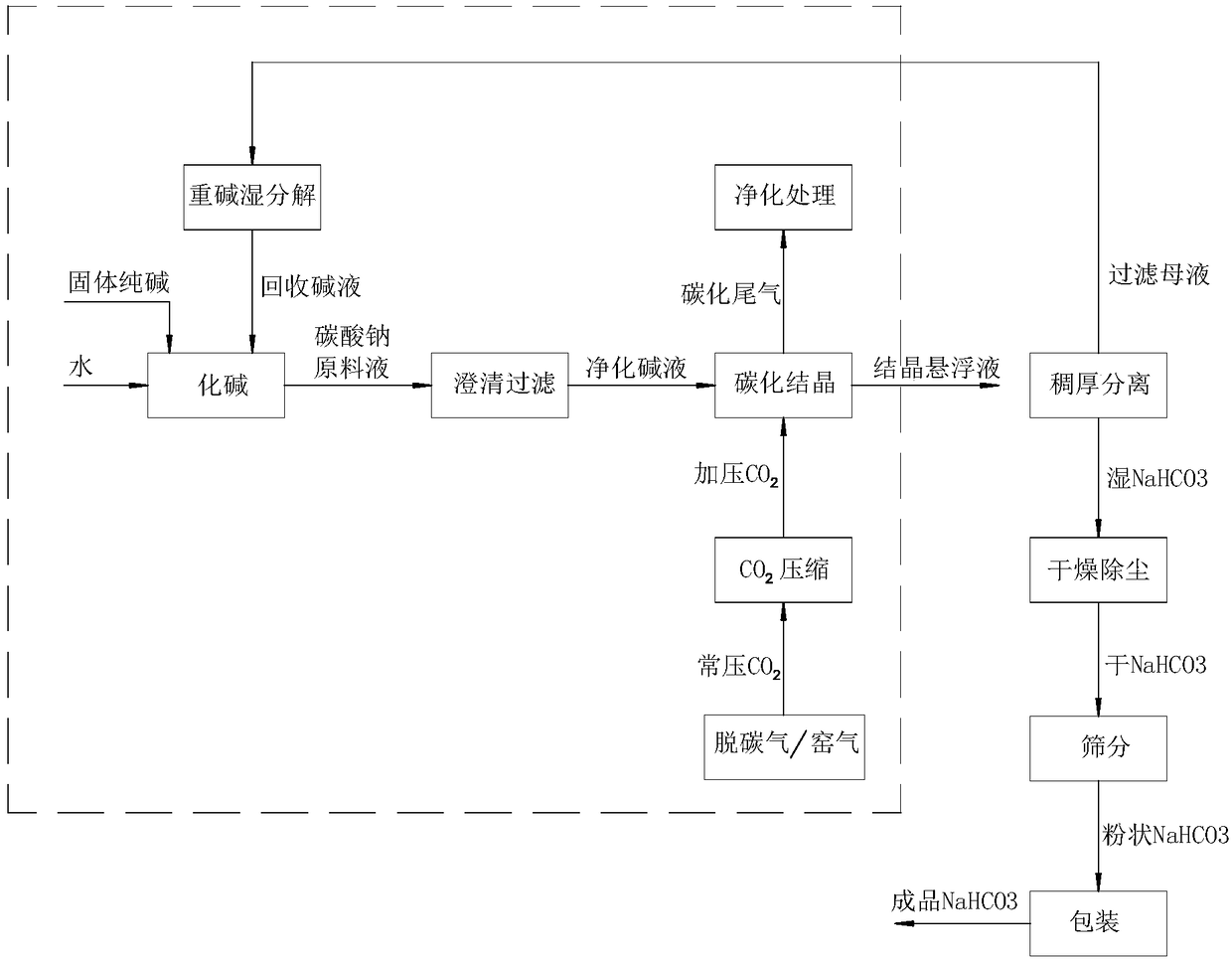

Sodium bicarbonate crystal preparation equipment and process for preparing sodium bicarbonate crystals by utilizing same

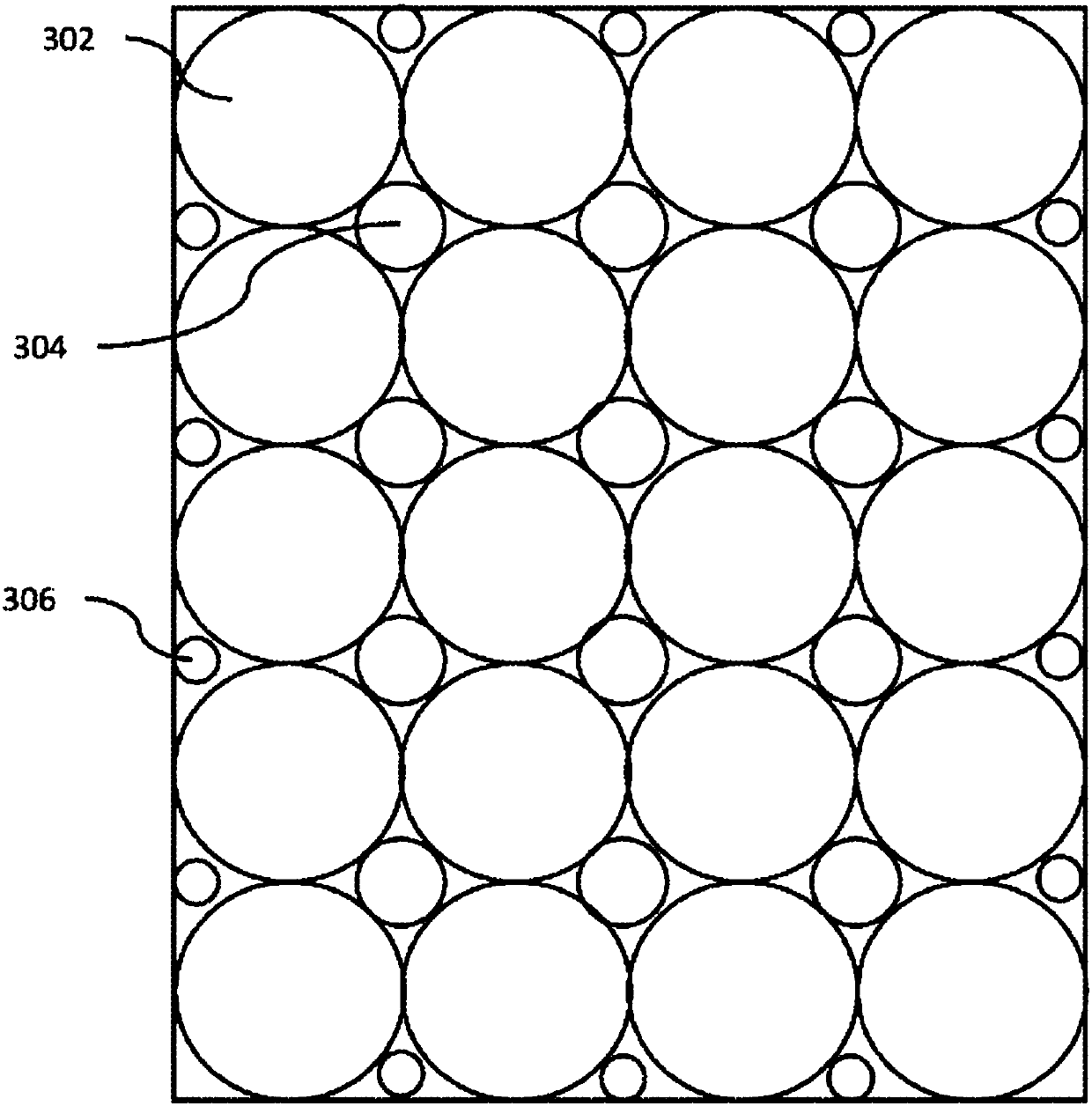

ActiveCN103303946ANot easy to scarOvercome the illsAlkali metal carbonates shape formationSodium bicarbonateCarbonization

The invention discloses sodium bicarbonate crystal preparation equipment and a process for preparing sodium bicarbonate crystals by utilizing the same. The equipment comprises a carbonizer, wherein a tail gas absorption section is arranged at the top of the carbonizer; the part (below the tail gas absorption section) is divided into a first reaction zone, a second reaction zone and a third reaction zone in sequence; and a plurality of ring-shaped tower plates are arranged in each reaction zone. The process is characterized by comprising the following steps: firstly carrying out first-step carbonization and crystallization, then carrying out crystal-slurry separation on reaction solution and enabling the product to leave from the carbonizer and pass through an ammoniating apparatus for ammoniating so that sodium bicarbonate enters an unsaturated zone; then cooling with water and finally sending sodium bicarbonate back to the carbonizer for further carbonization and crystallization. Therefore, the problem of water cooler scabbing is solved, no standby coolers are needed for alternate operation, the prepared sodium bicarbonate crystals have good crystal form, big particles and low moisture content and the energy consumption of the subsequent calcining procedure is also obviously reduced.

Owner:SHIJIAZHUANG TIANREN CHEM EQUIP GRP

Process for the time recovery of sulphate of potash (SOP) from sulphate rich bittern

InactiveUS8182784B2Eliminate DPA losses in gypsumPromote recoveryChemical industryAlkali metal carbonates shape formationSulfateAqueous solution

The present invention relates to a process for the recovery of sulphate of potash (SOP) from bittern. Kainite is obtained by fractional crystallization of the bittern. Kainite is converted into schoenite with simultaneous removal of NaCl and the filtrate (SEL) is used for production of KCl. Schoenite is reacted with aqueous KCl to yield SOP and the filtrate (KEL) is recycled in the kainite to schoenite conversion step. The production of KCl from SEL is carried out with the aid of dipicrylamine (DPA). Lime is treated with DPA in water for the production of highly soluble Ca (DPA)2, which in turn treated with SEL to produce insoluble K(DPA). K(DPA) is treated with HCl to produce KCl and insoluble DPA, which can be recycled for the production of Ca (DPA)2. The aqueous KCl thus obtained is treated with schoenite to prepare SOP. The KEL obtained along with SOP is recycled to generate schoenite.

Owner:COUNCIL OF SCI & IND RES

Process for recovery of low sodium salt from bittern

InactiveUS6890509B2Calcium/strontium/barium sulfatesAlkali metal carbonates shape formationEvaporationChloride

A new process for recovery of Low Sodium Salt from bittern has been described in the present invention, the said process comprising desulphatation of bittern (by-product of salt industry), evaporation of bittern in solar pans and processing of solid mixture with water to produce a mixture of sodium and potassium chlorides and optionally preparing “free flowing” and iodized, by known techniques.

Owner:COUNCIL OF SCI & IND RES

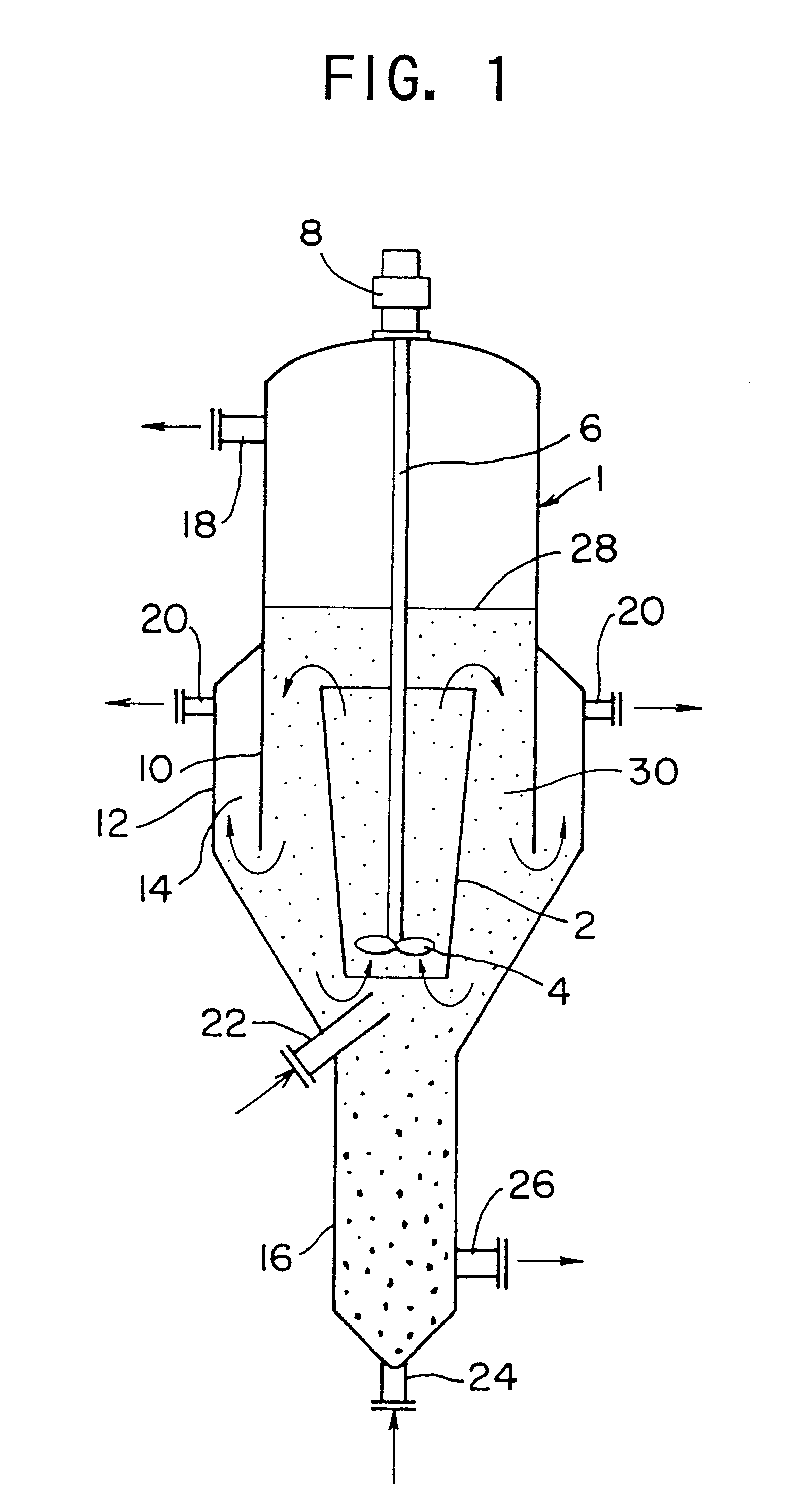

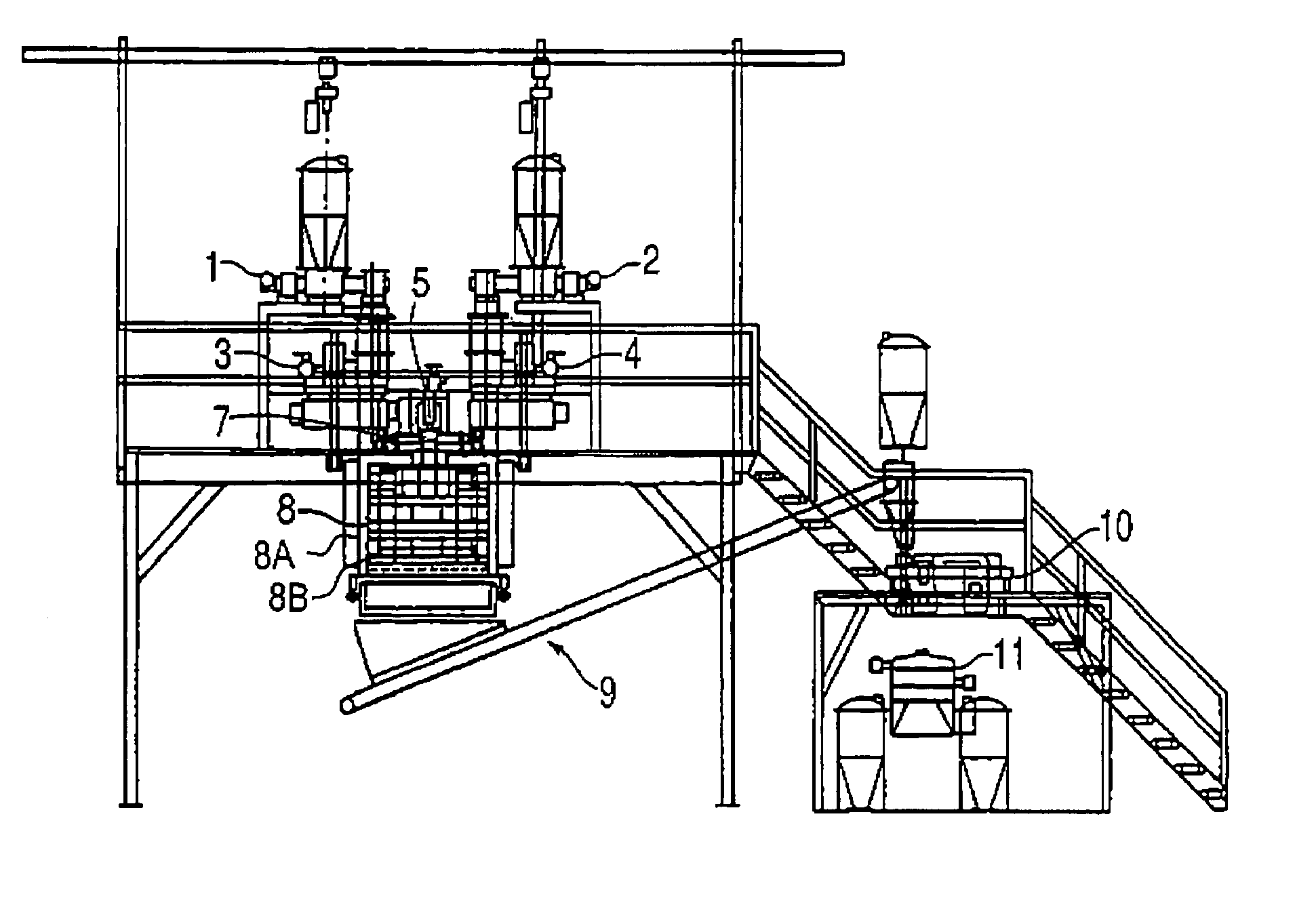

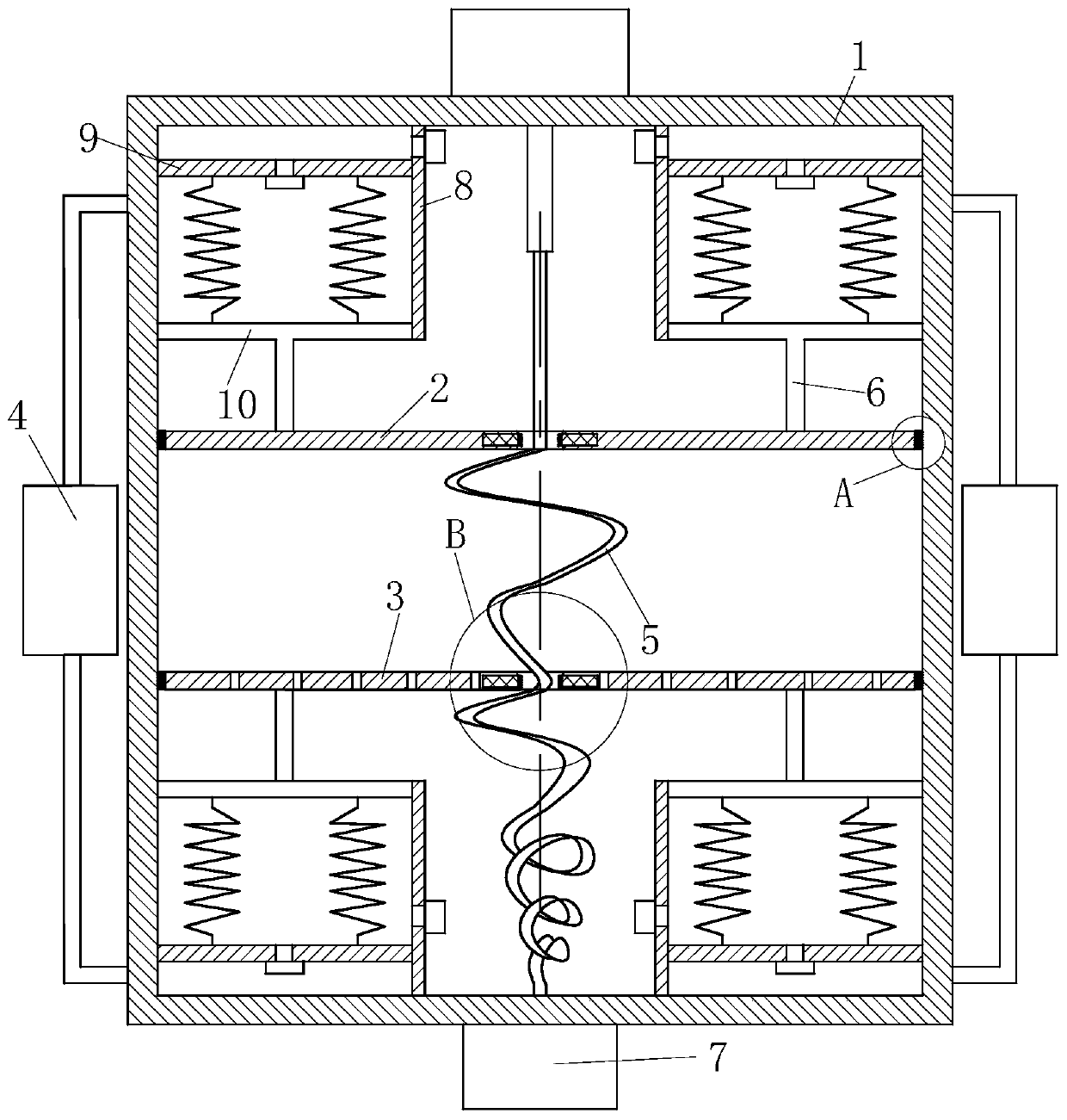

Apparatus and method for crystallization

InactiveUS6334878B1From normal temperature solutionsAlkali metal carbonates shape formationSlurryEngineering

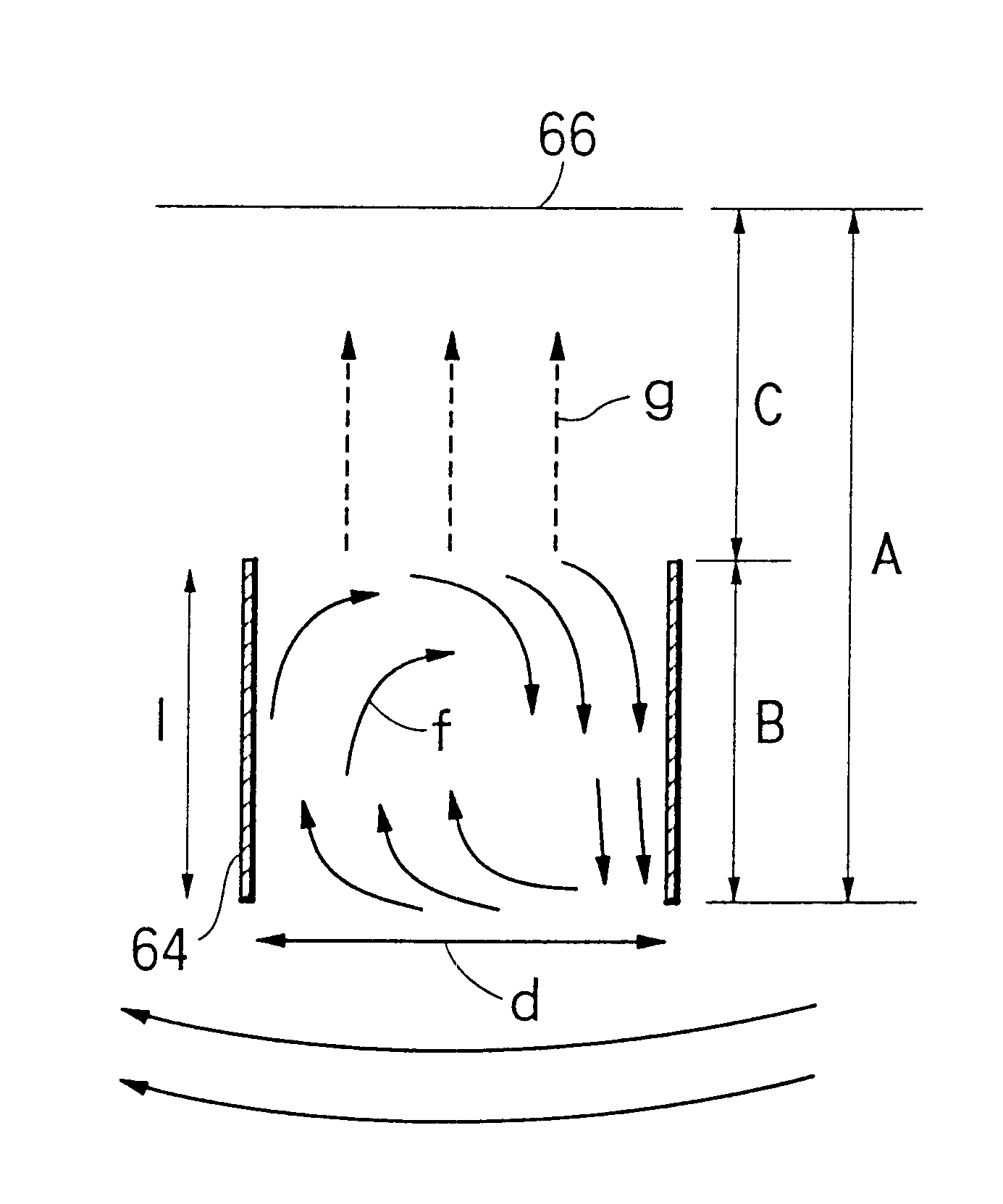

An apparatus for crystallization, which contains a crystallization vessel, a seed supplying device, a feed solution supplying device and a tube baffle disposed within the crystallization vessel. The tube baffle is provided with a crystallization portion in an inner area and a lower area thereof, and the tube baffle and the crystallization vessel define a classification portion there between. The apparatus further contains an agitating fan for agitating the seed crystals and the feed solution, and a plurality of plate baffles disposed within the classification portion which define a buffer portion and a gravitational settling portion. The apparatus further contains a device for generating a rising velocity of a slurry containing fine crystals in the gravitational settling portion by discharging the slurry so that the rising velocity of the slurry is greater than a settling velocity of the fine crystals and an outlet for discharging the crystallized material.

Owner:AJINOMOTO CO INC

Carbonation and crystallization equipment, application thereof and preparation method for sodium bicarbonate

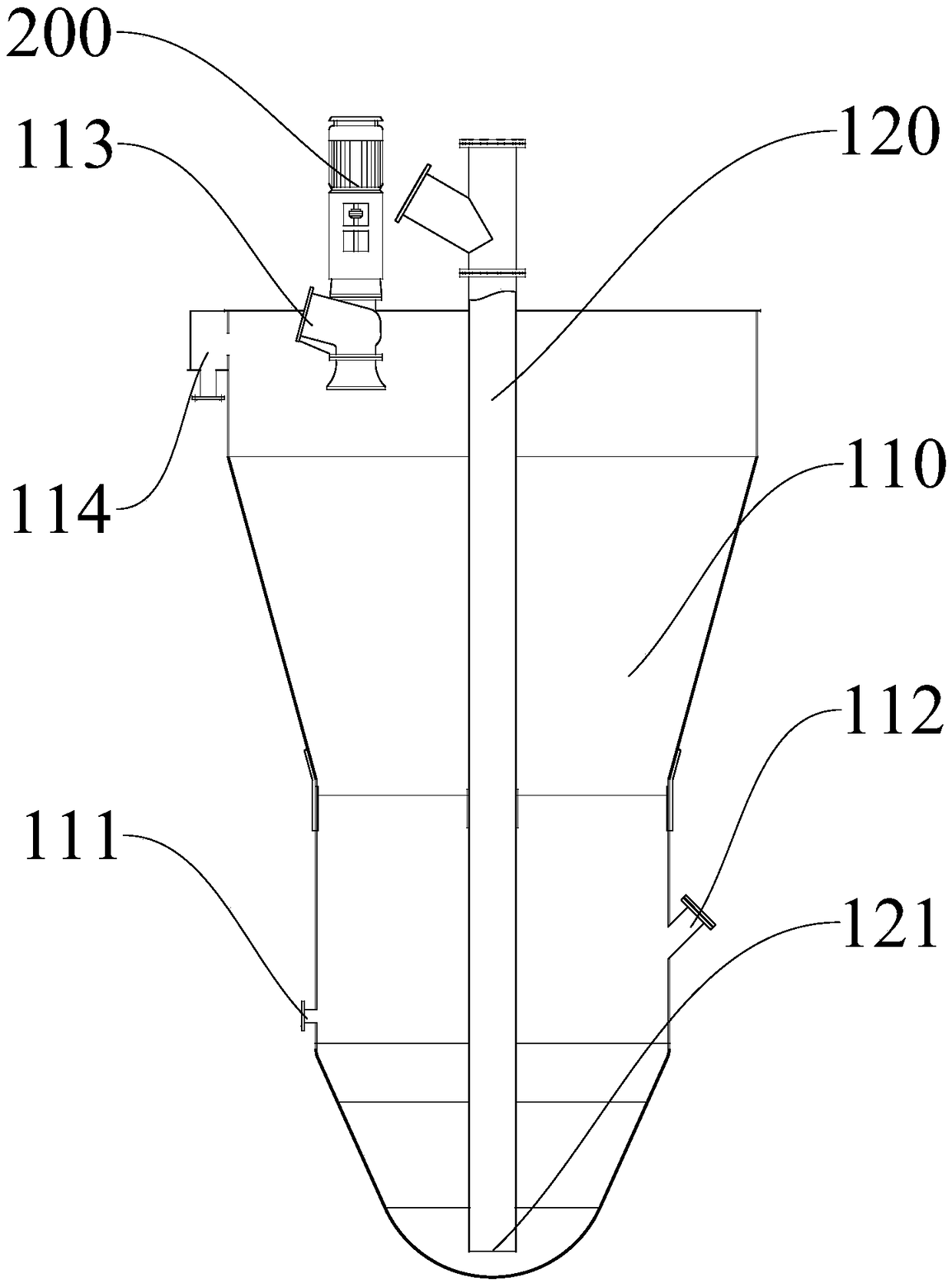

PendingCN108862332AAvoid cloggingRealize large-scale developmentBicarbonate preparationAlkali metal carbonates shape formationSodium bicarbonateCarbonization

The invention provides carbonation and crystallization equipment, application thereof and a preparation method for sodium bicarbonate, and relates to the field of chemical equipment. The carbonation and crystallization equipment comprises a crystallization barrel and a carbonization reactor, the carbonization reactor is arranged outside the crystallization barrel and is communicated with the crystallization barrel, and reaction final liquid in the carbonization reactor can enter the crystallization barrel for crystallization treatment. The carbonation nad crystallization equipment has the advantages that the technical problems that an existing carbonation tower is low in production efficiency and large in energy loss due to cleaning can be solved, and the technical effects that the operation efficiency and the production efficiency of the equipment are improved, and the energy consumption is reduced can be achieved.

Owner:BEIJING EDGEIN TECH +1

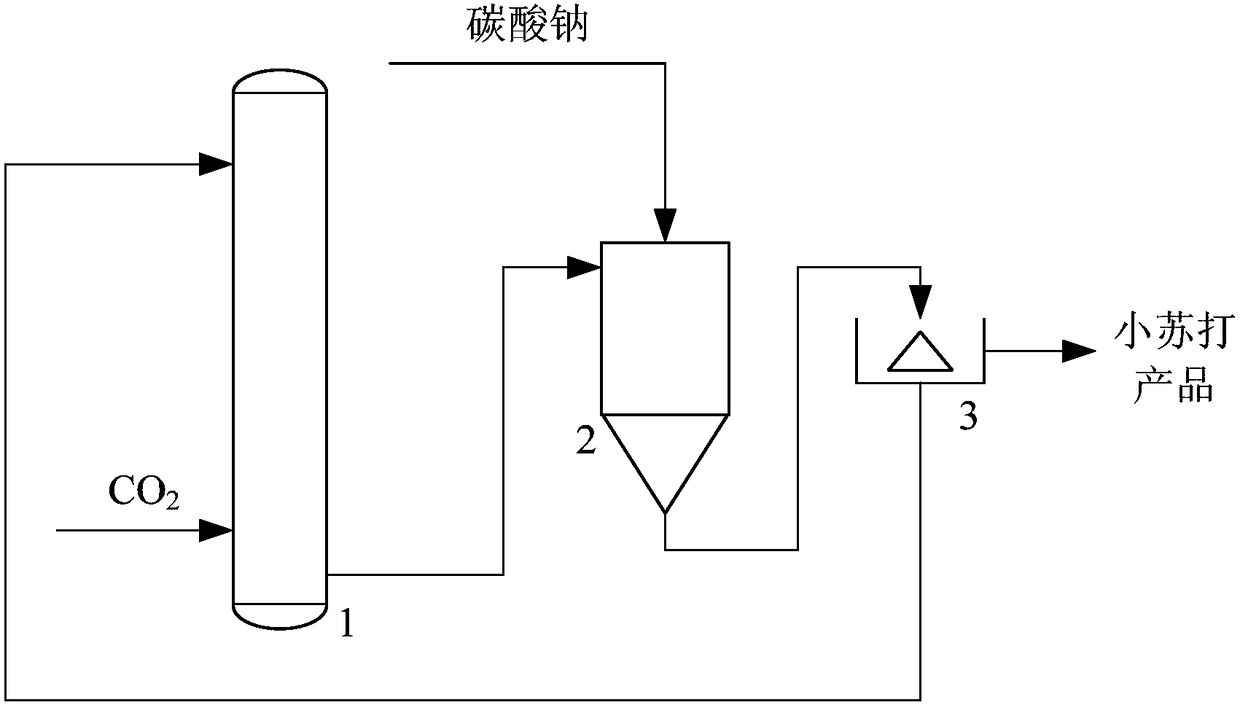

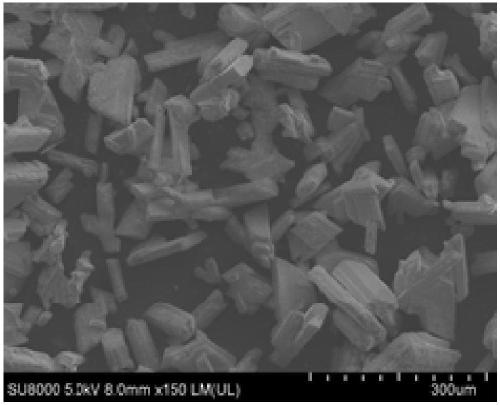

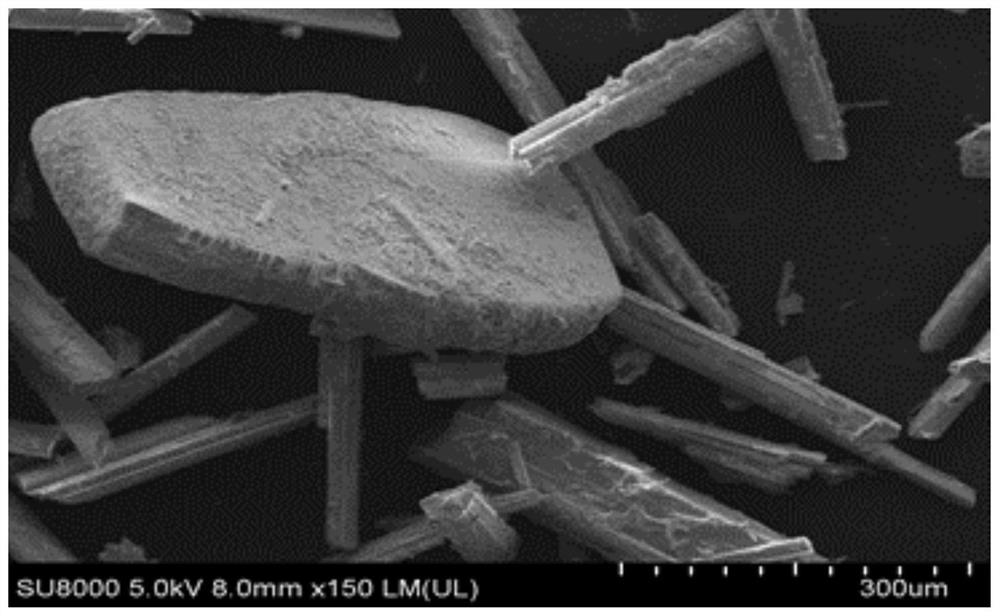

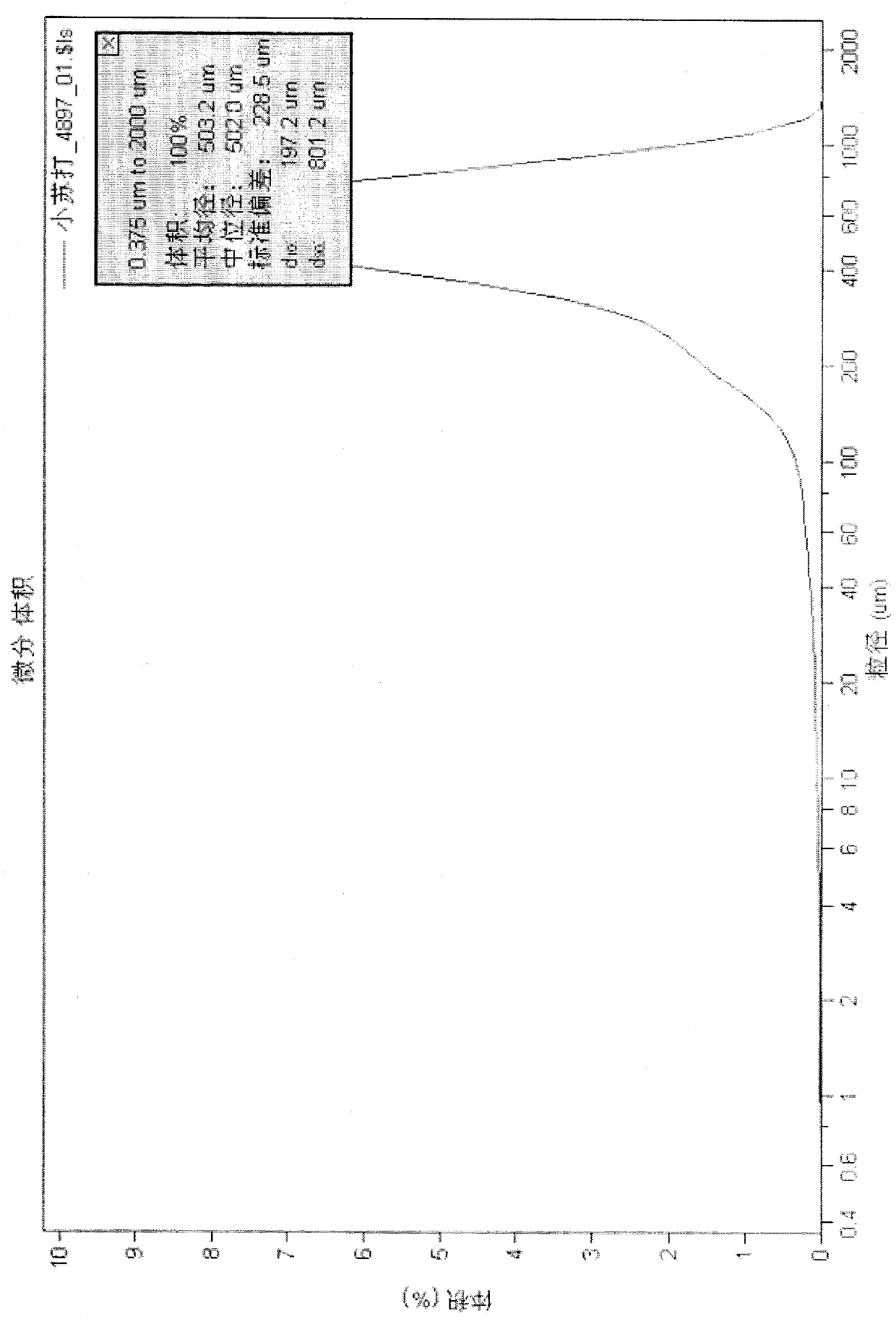

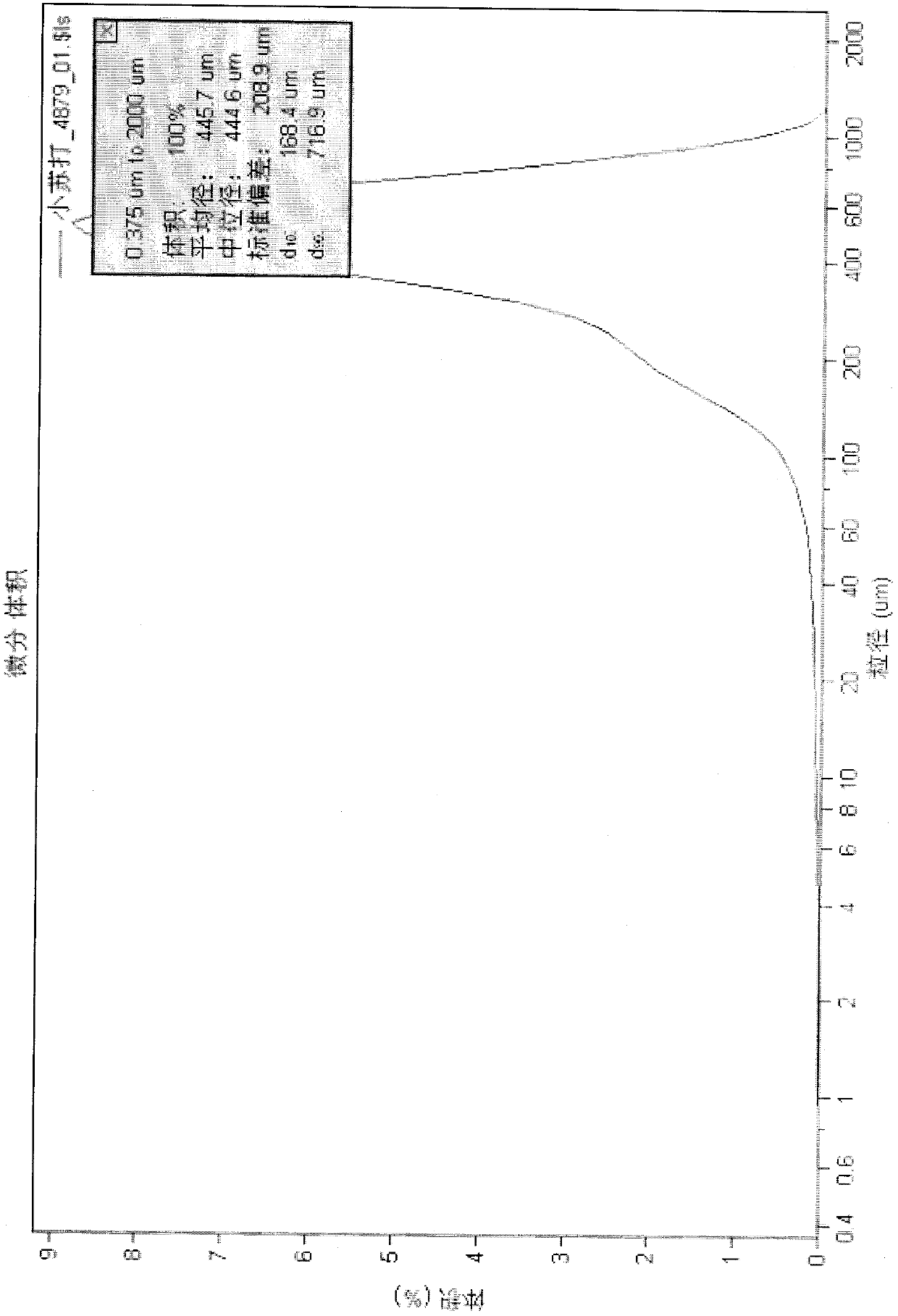

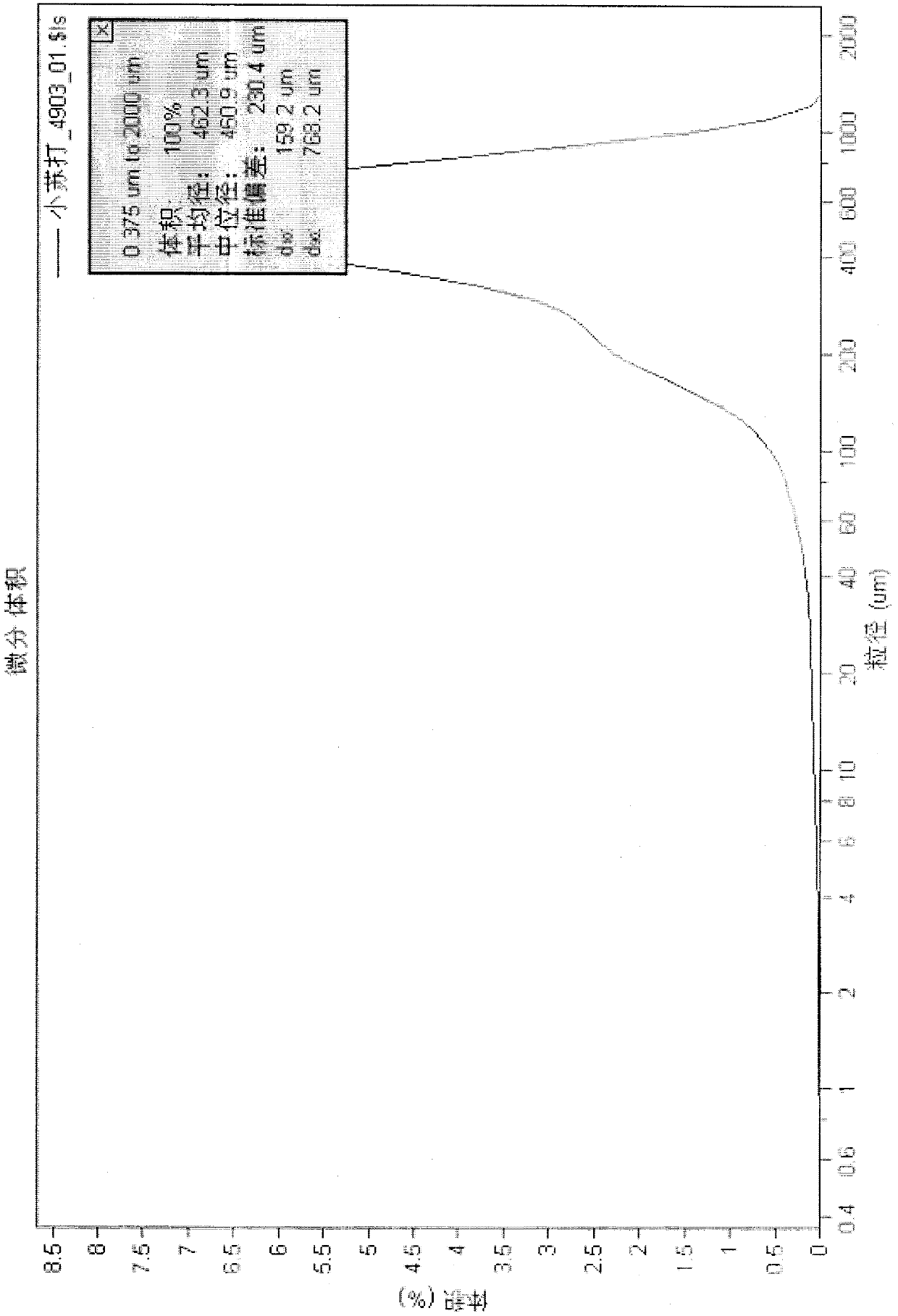

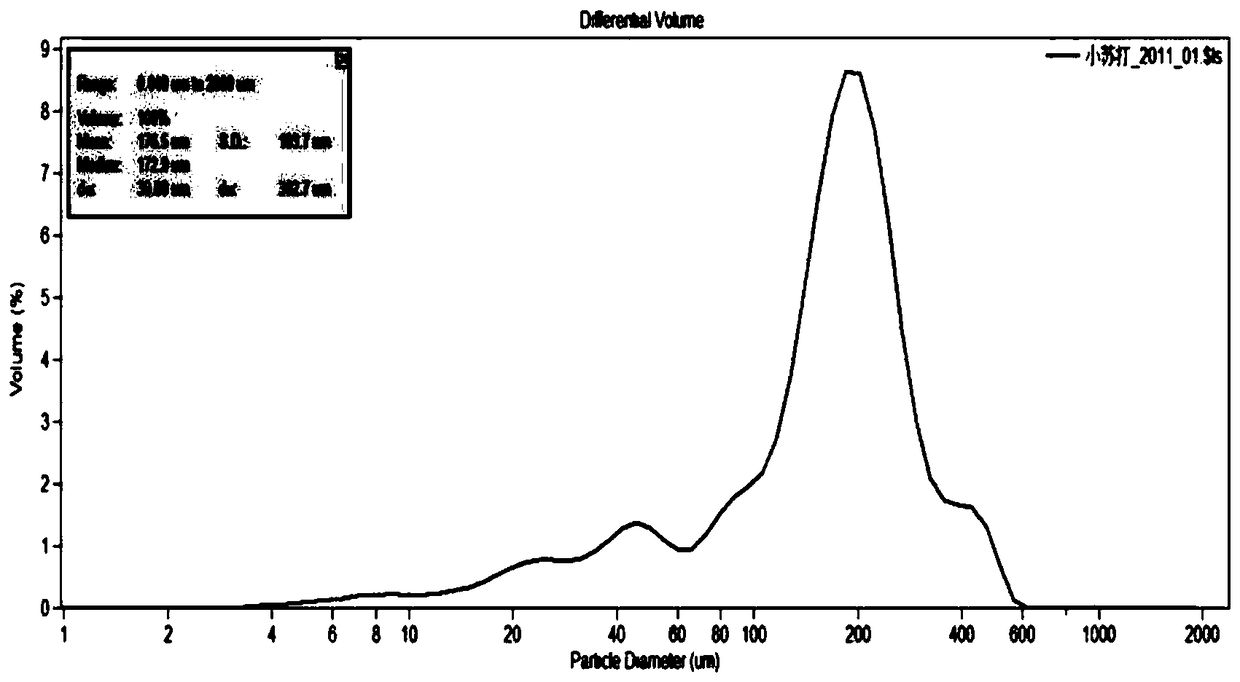

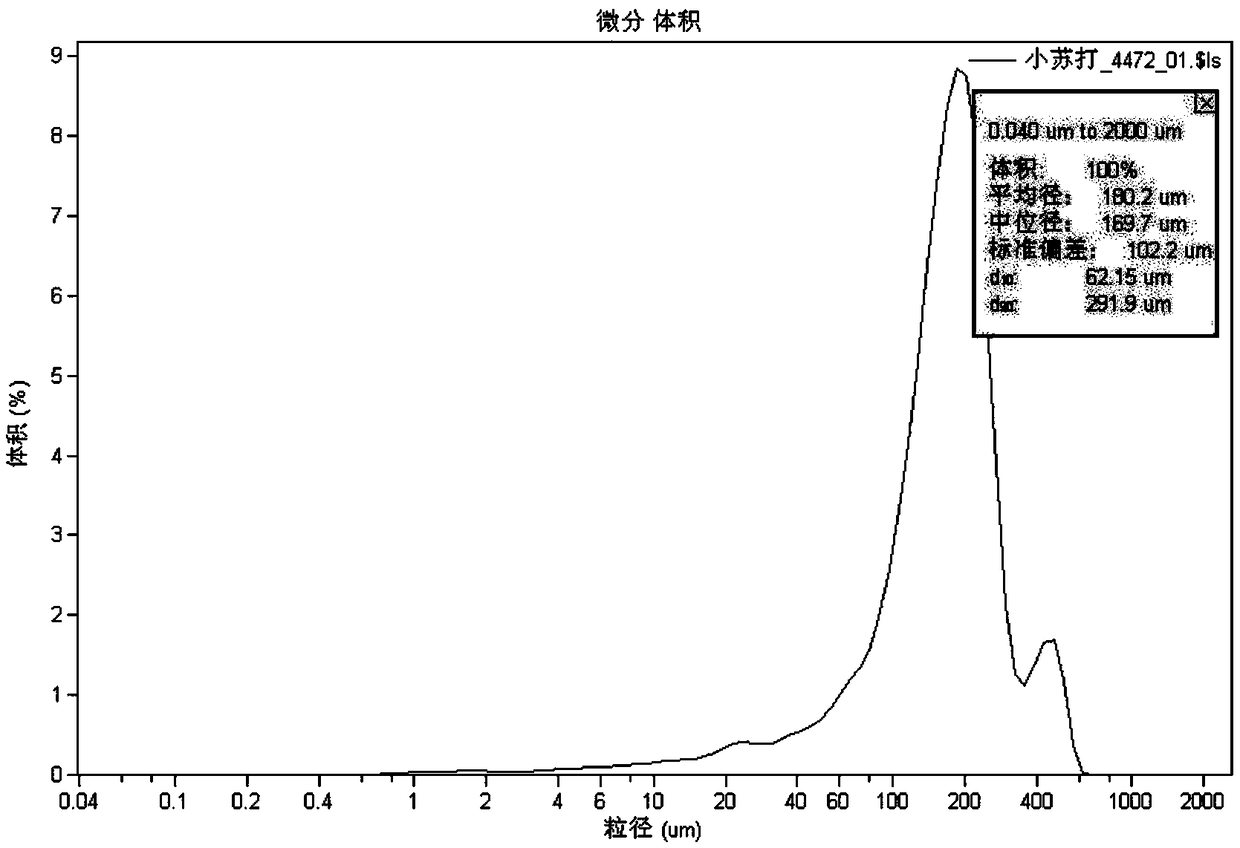

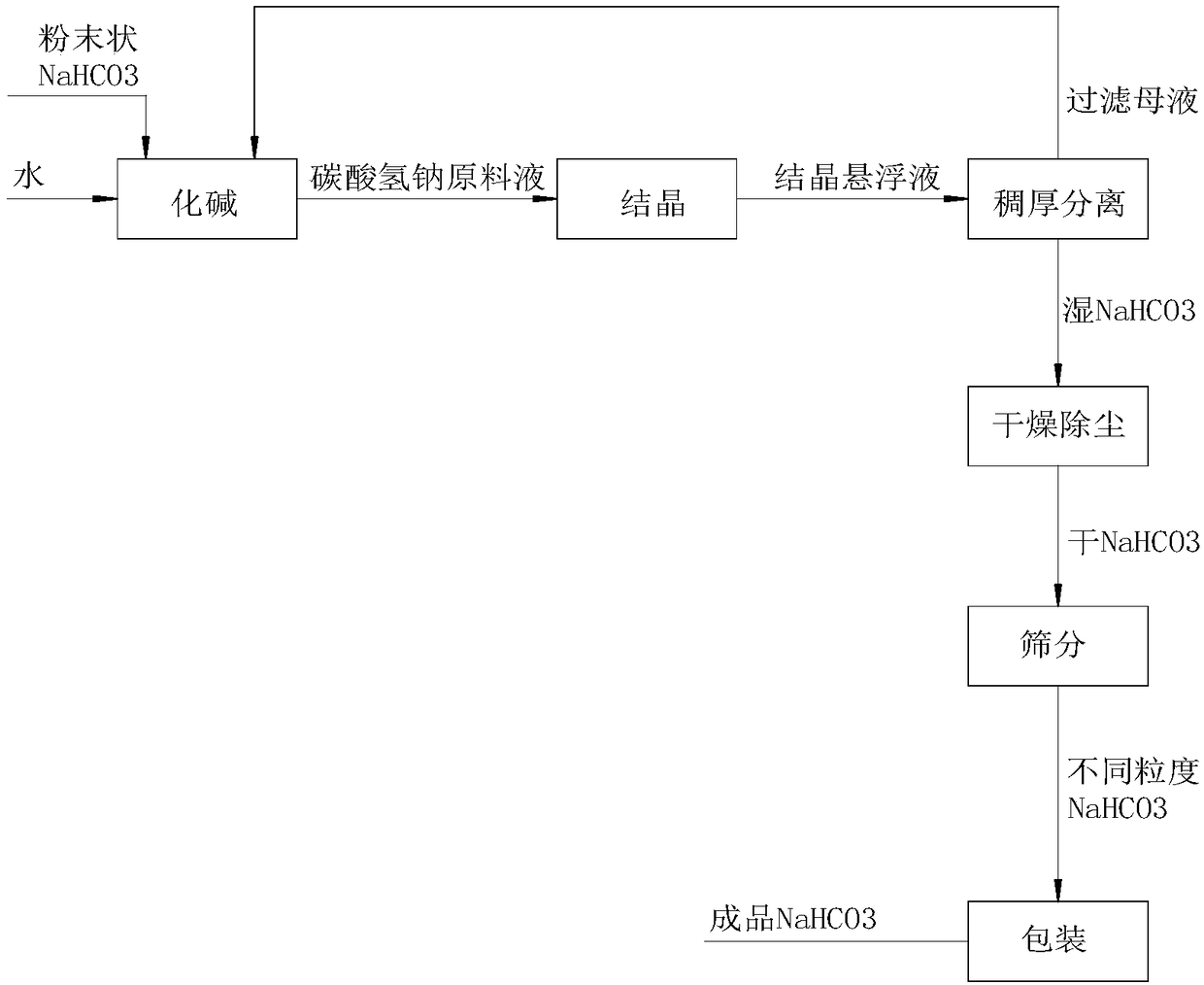

Preparation method of large-particle heavy baking soda

ActiveCN108996526AReduce solubilityLarge particlesBicarbonate preparationAlkali metal carbonates shape formationSodium bicarbonateCarbonization

The invention relates to a preparation method of large-particle heavy baking soda. The method comprises the following steps: performing a carbonization reaction on a sodium carbonate solution or a mixed solution of sodium carbonate and sodium bicarbonate and CO2, so as to obtain a mixture; and adding sodium carbonate and / or a solid and / or a solution of a mixture of sodium carbonate and sodium bicarbonate into the obtained mixture for crystallization and solid-liquid separation, so as to obtain the large-particle heavy baking soda. The sodium carbonate solution or the mixed solution of sodium carbonate and sodium bicarbonate can be prepared from heavy alkali in soda production. The preparation method is suitable for different baking soda manufacturing plants; and the baking soda is high inyield and large in particle size.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Process for the preparation of common salt of high purity from brines in solar salt pans

ActiveUS8021442B2High purityFormation of such insoluble magnesium compounds is minimizedCrystallization separationMagnesium chloridesAlumAqueous solution

The process of the invention is an improvement over the existing process of producing salt of high purity from alum-treated brine disclosed recently in the prior art. More particularly, the invention rectifies the ratio of Ca2+ to Mg2+ from a value <1 to a value in the range of 2-3 desired by chlor-alkali and soda ash industries. The improved process involves the adjustment of pH of clarified brine with aqueous HCl so as to carry out salt crystallization at a pH of 6.5 instead of at the natural pH of 7. The pH adjustment reduces the Mg2+ impurity in salt while slightly raising the Ca2+ impurity in the salt and thereby achieving the desired ratio.

Owner:COUNCIL OF SCI & IND RES

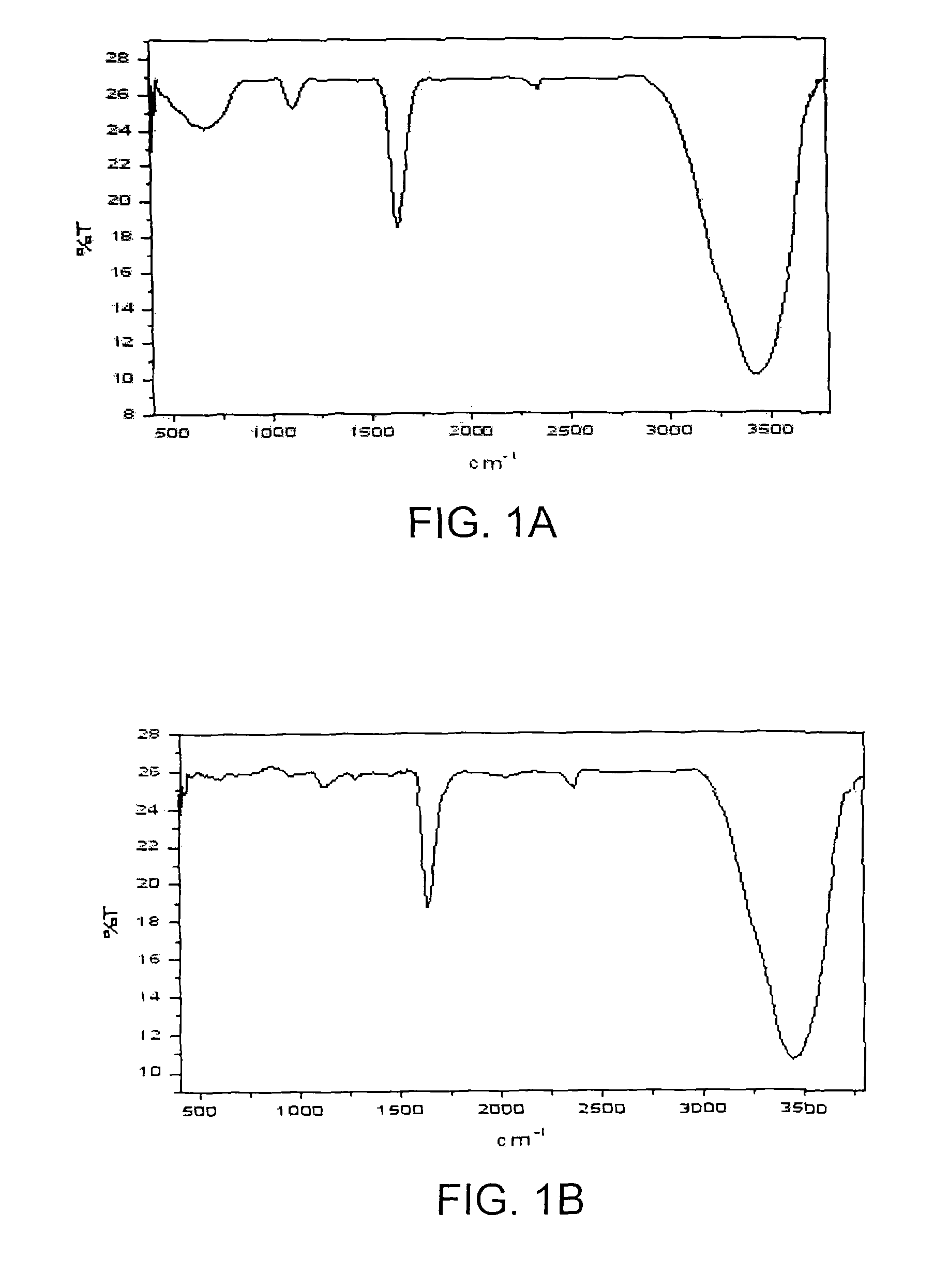

Production of crystalline sodium bicarbonate

ActiveUS20180230018A1Increases usable pond lifetimeIncrease capacityBicarbonate preparationAlkali metal carbonates shape formationSodium bicarbonateAqueous solution

A process for producing crystalline sodium bicarbonate, comprising: providing an aqueous sodium-bicarbonate containing liquor originating from a reactive crystallization step in which first sodium bicarbonate crystals are produced and recovered; feeding at least a portion of said aqueous sodium-bicarbonate containing liquor to a cooling crystallization unit to form second sodium bicarbonate crystals and produce a crystals slurry comprising the second sodium bicarbonate crystals; and withdrawing a portion of the crystals slurry from the cooling crystallization unit for the withdrawn second sodium bicarbonate crystals to be further processed. A portion of the second sodium bicarbonate crystals withdrawn from the cooling crystallization unit may be fed to a sodium bicarbonate reactive crystallization unit, to a caustic unit, or may be separated and dried. The reactive crystallization, separation and / or drying units where the second sodium bicarbonate crystals are further processed may be the same units where the first sodium bicarbonate crystals are processed.

Owner:SOLVAY SA

Method for preparing large-particle baking soda by secondary carbonization method and obtained baking soda

ActiveCN111634928ALarge particle sizeLower the discharge temperatureProductsBicarbonate preparationCarbonizationMaterials science

Owner:山东海天生物化工有限公司

Large-particle (granular) semi-batch baking soda crystallization method

InactiveCN107739038ALow costHigh purityAlkali metal carbonates shape formationAccessory food factorsSodium bicarbonateParticulates

The invention provides a large-particle (granular) semi-batch baking soda reactive crystallization process method. The method comprises the following steps: taking a saturated aqueous solution of sodium bicarbonate and a saturated solution of base (with a principle component of sodium carbonate) as raw materials, and controlling the degree of supersaturation by utilizing a gas-liquid reaction by virtue of a seed crystal adding method, thereby obtaining the large-particle (granular) baking soda crystal product. The specific process comprises the following four steps: preparing the solution, adding the seed crystal, performing reactive crystallization and discharging fine grains. According to the method, the large-particle (granular) baking soda crystal product can be prepared.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

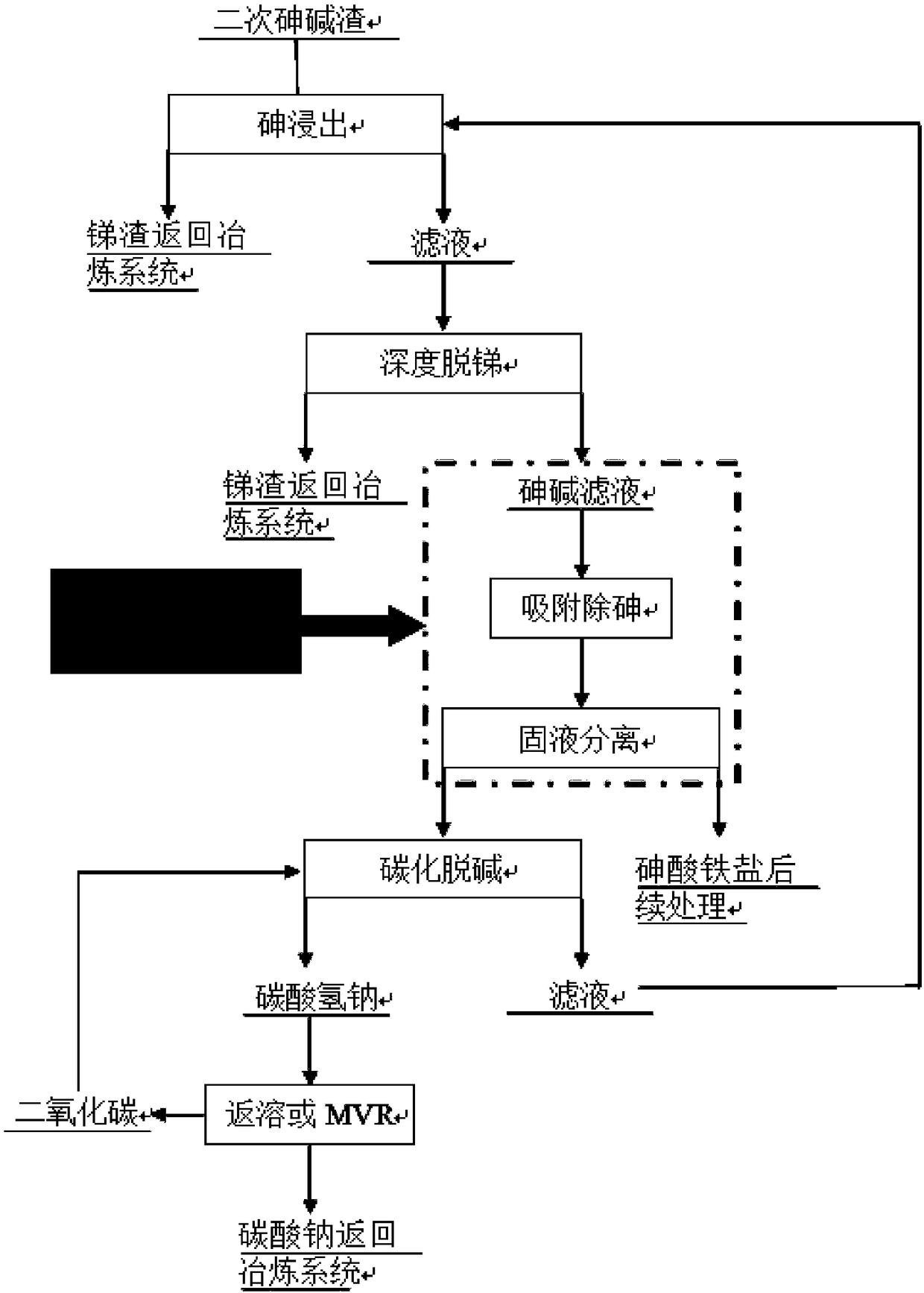

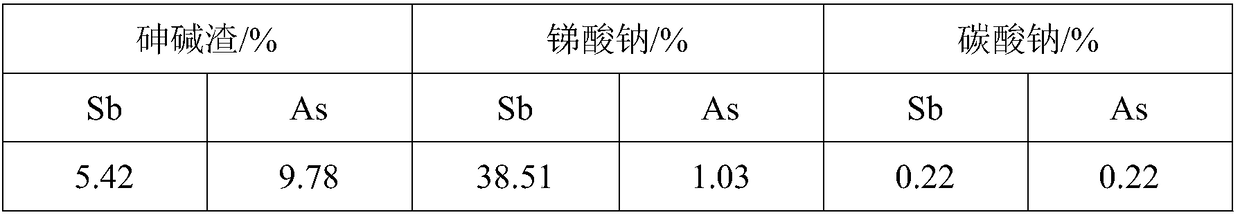

Method for separating arsenic and alkali in arsenic and alkali residues based on superfine ferric hydroxide colloid

ActiveCN108585057AReduce energy consumptionLow costIron oxides/hydroxidesAlkali metal carbonates shape formationSolubilityFerric hydroxide

The invention discloses a method for separating arsenic and alkali in arsenic and alkali residues based on a superfine ferric hydroxide colloid. The method includes the steps: leaching the arsenic andalkali residues by water, and performing antimony removal on leaching solution through oxidation to obtain solution containing sodium carbonate and sodium arsenate; adding iron arsenate crystal nucleus and the superfine ferric hydroxide colloid to perform reaction to obtain iron arsenate crystals, and performing solid-liquid separation to obtain solution containing sodium carbonate and an iron arsenate product; leading carbon dioxide into the solution containing the sodium carbonate to perform reaction to separate out sodium hydrogen carbonate crystals, and performing thermal decomposition onthe sodium hydrogen carbonate crystals to obtain a sodium carbonate product. According to the method, arsenate in arsenic and alkali residue leaching solution is adsorbed and converted by the superfine Fe (OH)3 colloid with high activity to generate stable iron arsenate precipitation with low solubility and good crystal property, arsenic and alkali in arsenic and alkali residue leaching solutionare effectively separated, and the method overcomes the shortcomings of low iron salt arsenic removal utilization efficiency, incomplete purification and the like under the strong alkaline condition,is simple in process and convenient to operate and meets industrial production.

Owner:CENT SOUTH UNIV

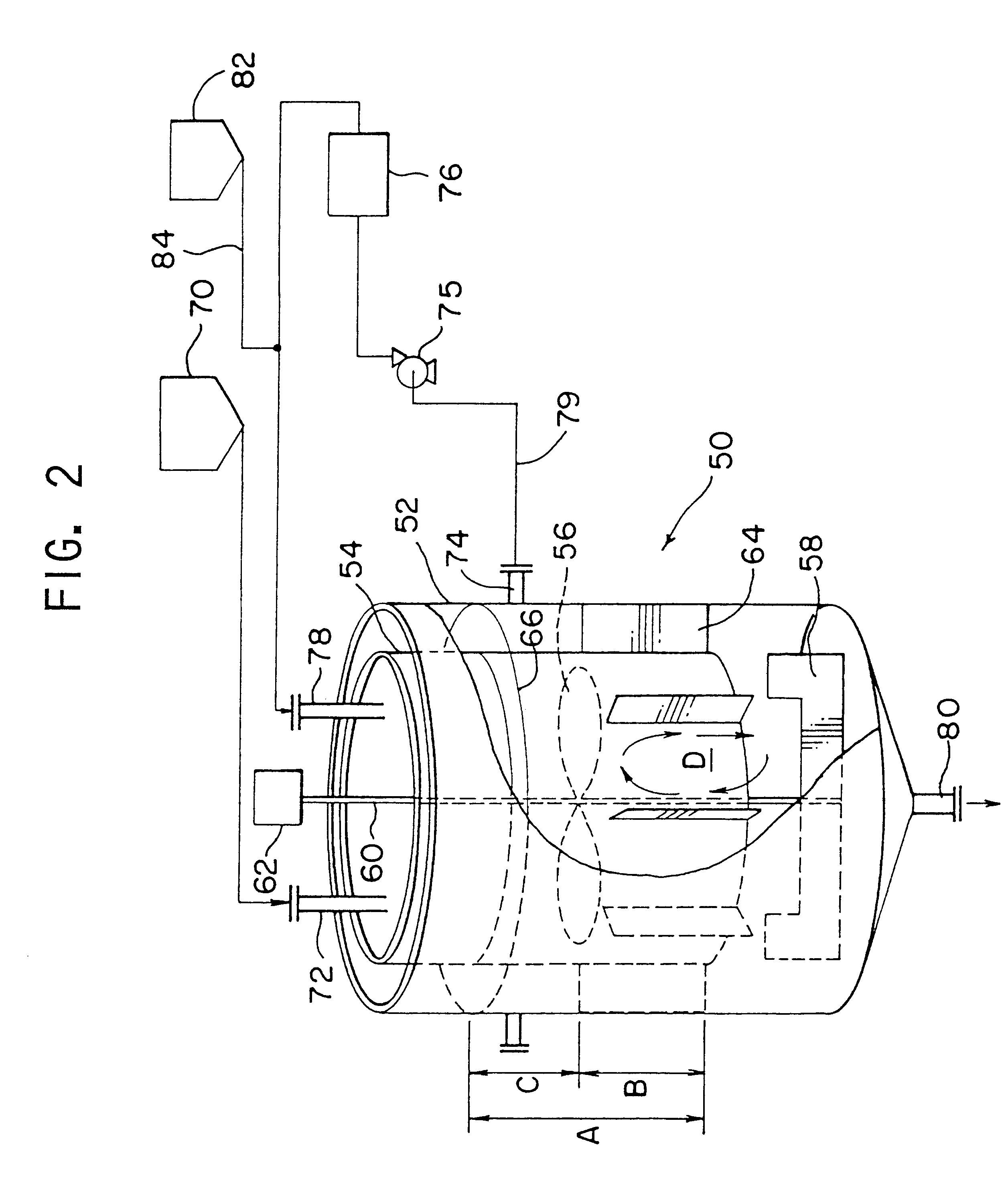

Crystallization method through gas-liquid biphasic reaction and apparatus thereof

ActiveCN102188940AHigh purityReduce production consumptionCrystallization separationAlkali metal carbonates shape formationChemical reactionControl system

A crystallization method through gas-liquid biphasic reaction is disclosed. Liquid materials react with gas phase materials to produce solid phase crystals. The method includes the following steps that: in a low temperature crystallizer, liquid materials and gas phase materials are subjected to chemical reactions so as to realize generation and growth of crystal nucleuses, wherein the chemical reaction process is a biphasic continuous reaction process that comprises a chemical reaction process of which the liquid materials are continuous phase and the gas phase materials are dispersed phase and a chemical reaction process of which the gas phase materials are continuous phase and the liquid materials are dispersed phase; then in a high temperature crystallizer, a reaction process of using a liquid phase as a continuous phase and a gas phase as a dispersed phase on the crystal nucleuses is performed so as to crystallize and make the crystal nucleuses become bigger; a high temperature crystal plasma separator is used to obtain solid phase crystallized products. The crystal nucleuses can be automatically returned in a crystal nucleus system so that formation and quantity of the crystal nucleuses can be controlled. The grown crystals are taken out in a high temperature area of an apparatus and the crystal nucleuses are formed in a low temperature area of the apparatus. The processes of generation and growth of the crystal nucleuses are performed in different containers of a gas-liquid biphasic response apparatus provided in the invention.

Owner:武奋超

Process for the joint production of sodium carbonate and sodium bicarbonate

ActiveUS20130095011A1Reduce amountImproved dwell time distributionElectrolysis componentsThiosulfates/dithionites/polythionitesSodium bicarbonatePhosphate

A process for the production of sodium carbonate and sodium bicarbonate out of trona, comprising crushing trona ore and dissolving it in a leaching tank containing a solution comprising sodium carbonate and sodium bicarbonate, and an additive selected from the group consisting of: phosphates, phospholipids, carboxylates, carboxilic acids, and combinations thereof, saturated in sodium bicarbonate, in order to produce solid particles suspended in a production solution comprising sodium carbonate, the solid particles containing insoluble impurities and at least 65% by weight of sodium bicarbonate. The solid particles are separated from the production solution containing sodium carbonate. At least part of the production solution containing sodium carbonate is taken out of the leaching tank.

Owner:SOLVAY SA

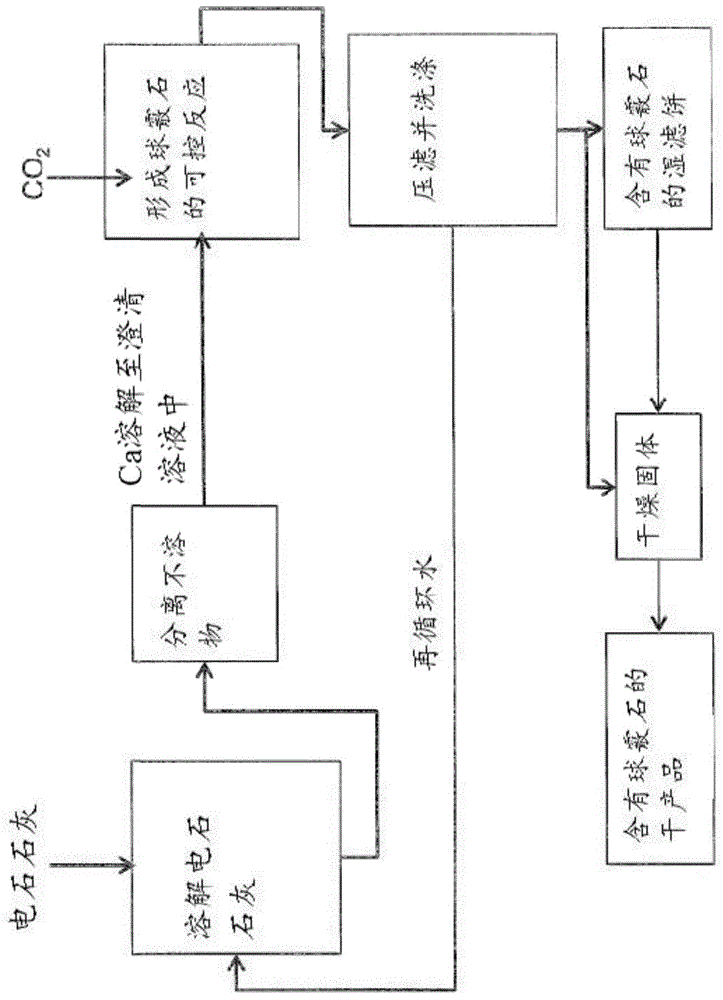

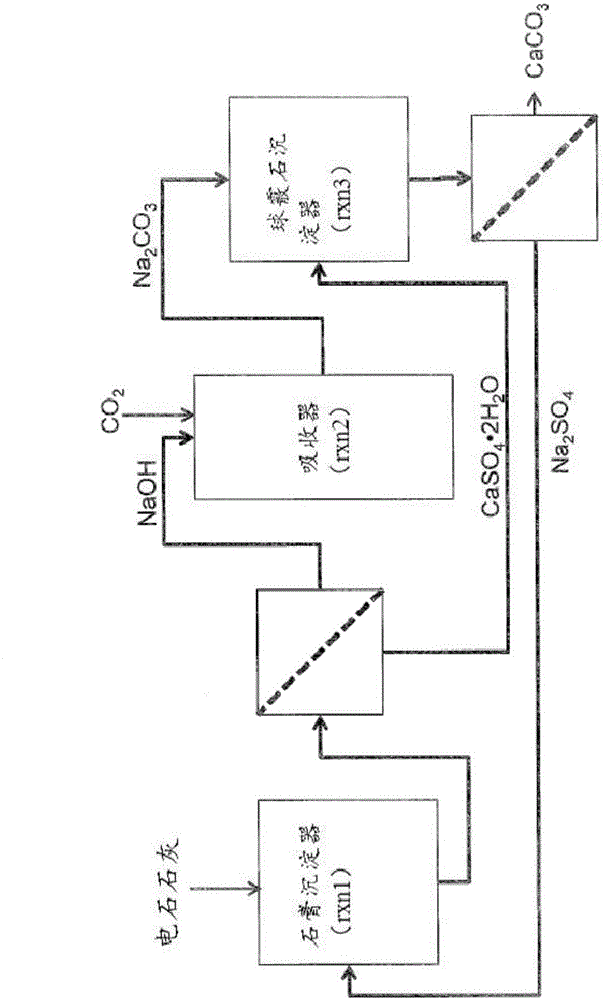

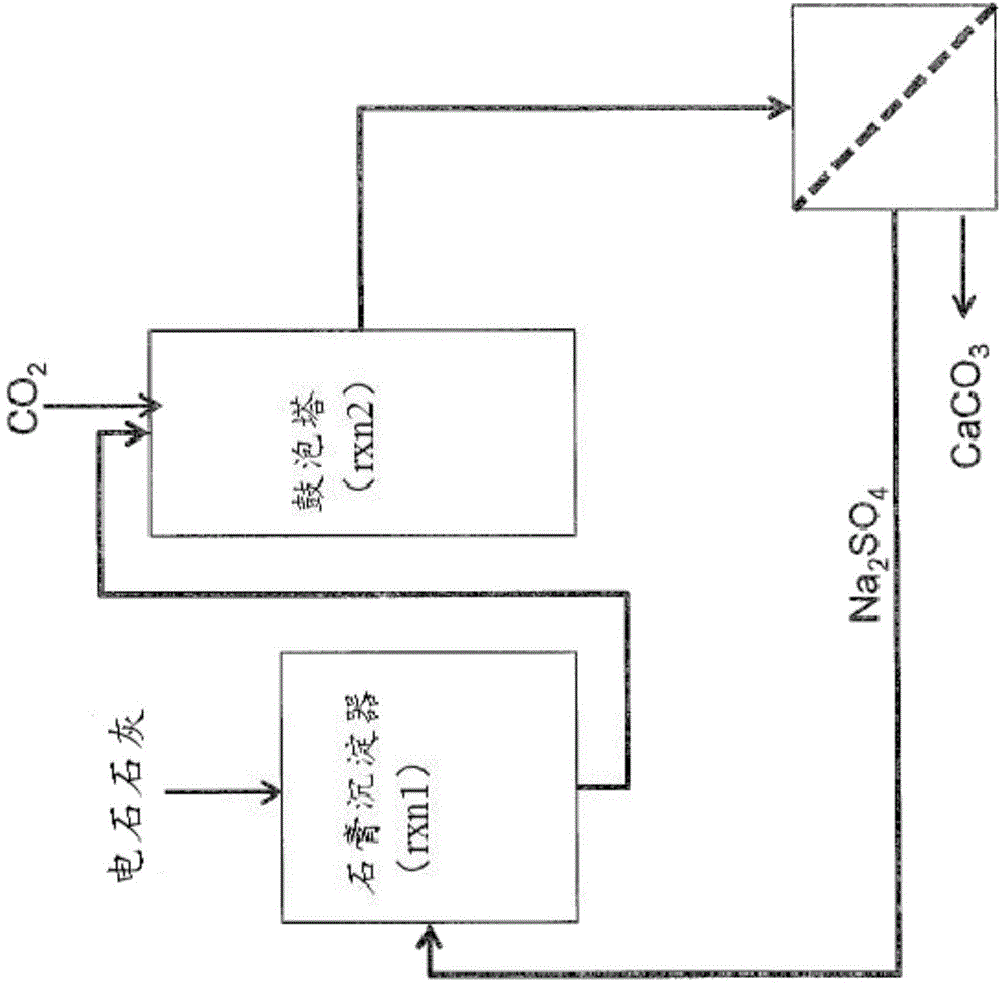

Methods and systems for utilizing carbide lime

ActiveCN104487458ACalcium/strontium/barium compoundsAlkali metal carbonates shape formationChemistryCarbon dioxide

Methods and systems are provided for producing a carbonate precipitation material comprising stable or reactive vaterite from carbide lime that provides both a source of divalent cations (Ca divalent cations, Mg divalent cations, etc.) and a source of proton removing agent. A method of forming drywall, comprising a) contacting an aqueous solution comprising carbide lime with carbon dioxide from an industrial process; b) producing a precipitation material comprising reactive vaterite; c) setting and hardening the precipitation material by transforming the reactive vaterite to aragonite, and d) forming the drywall.

Owner:ARELAC INC

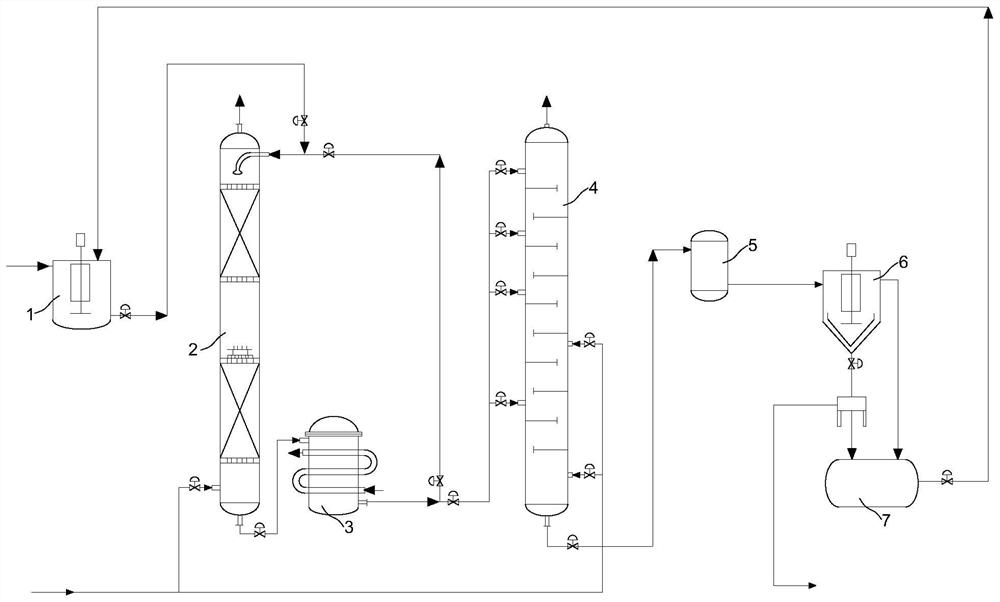

Device and production method for increasing particle size of baking soda by adopting pre-carbonization method

PendingCN108975355AAlkali making cycle increasedEfficient use ofBicarbonate preparationAlkali metal carbonates shape formationHigh concentrationCarbonization

The invention discloses a device and production method for increasing the particle size of baking soda by adopting a pre-carbonization method. The device comprises carbonization towers, the carbonization towers are divided into cleaning towers and alkali making towers, the tops of the carbonization towers are provided with tail gas discharge ports, the side surfaces of the tops of the carbonization towers are provided with feed ports, the side surfaces of the bottoms of the carbonization towers are provided with mixed gas inlets and liquid outlets, the mixed gas inlets of the carbonization towers are connected to a mixed gas inlet pipeline, the mixed gas inlet pipeline is formed by converging a low-concentration carbon dioxide pipeline and a high-concentration carbon dioxide pipeline, theliquid outlets of the carbonization towers are connected to a carbonized liquid outlet pipeline, the carbonized liquid outlet pipeline is branched into a carbonized crystal mush pipeline and a pre-carbonized crystal mush pipeline, the carbonized crystal mush pipeline is connected to a thickener through a crystal mush pump, the pre-carbonized crystal mush pipeline is connected to the feed ports ofthe carbonization towers through an alkali liquid pump; the feed ports of the carbonization towers are connected to an alkali liquor pipeline, and the tail gas discharge ports are connected to tail gas emptying pipelines and a carbonized tail gas recycling pipeline. According to the device and the production method, the production cost is lowered, the process operation is simple, and the popularization is convenient.

Owner:TIANJIN BOHUA YONGLI CHEM IND

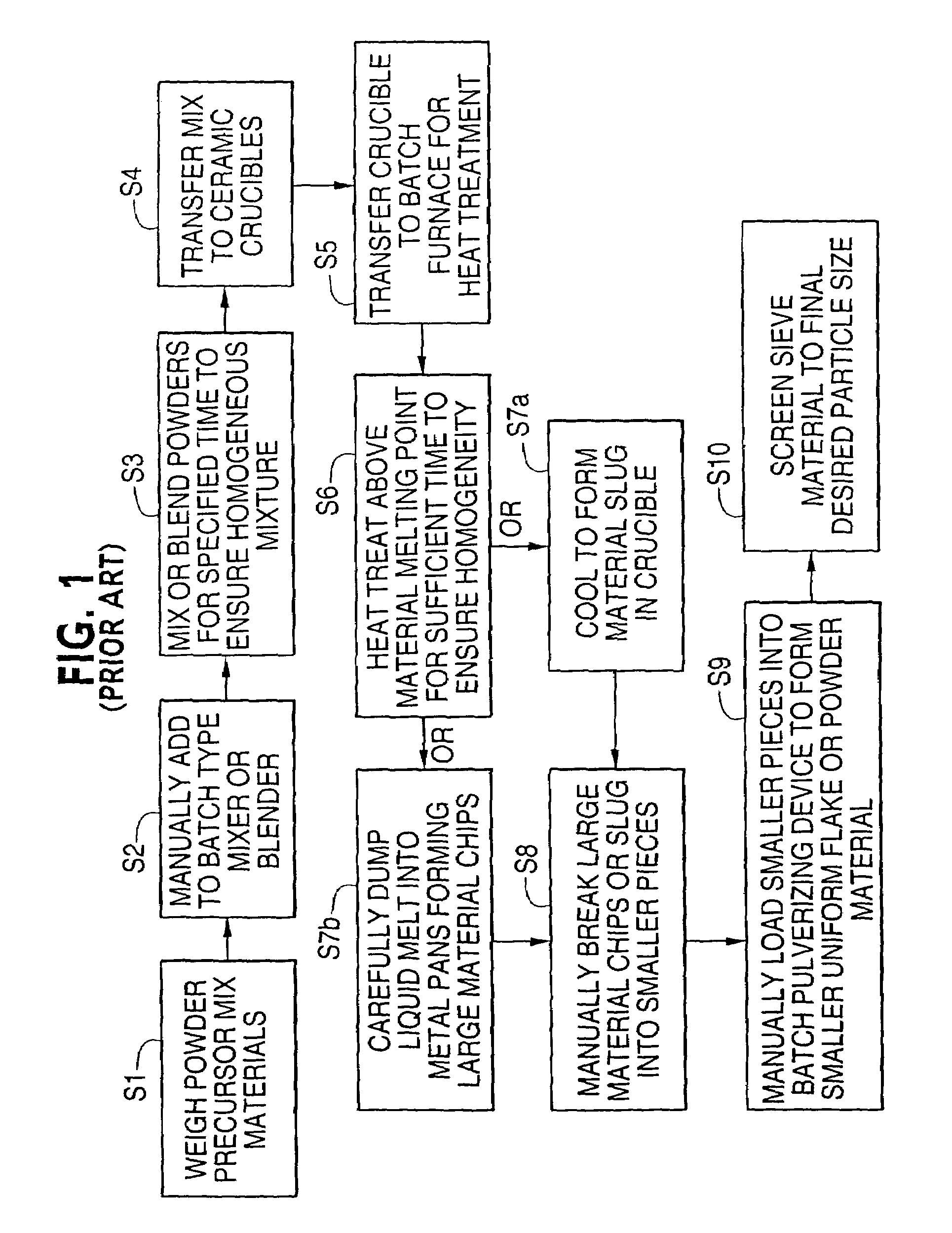

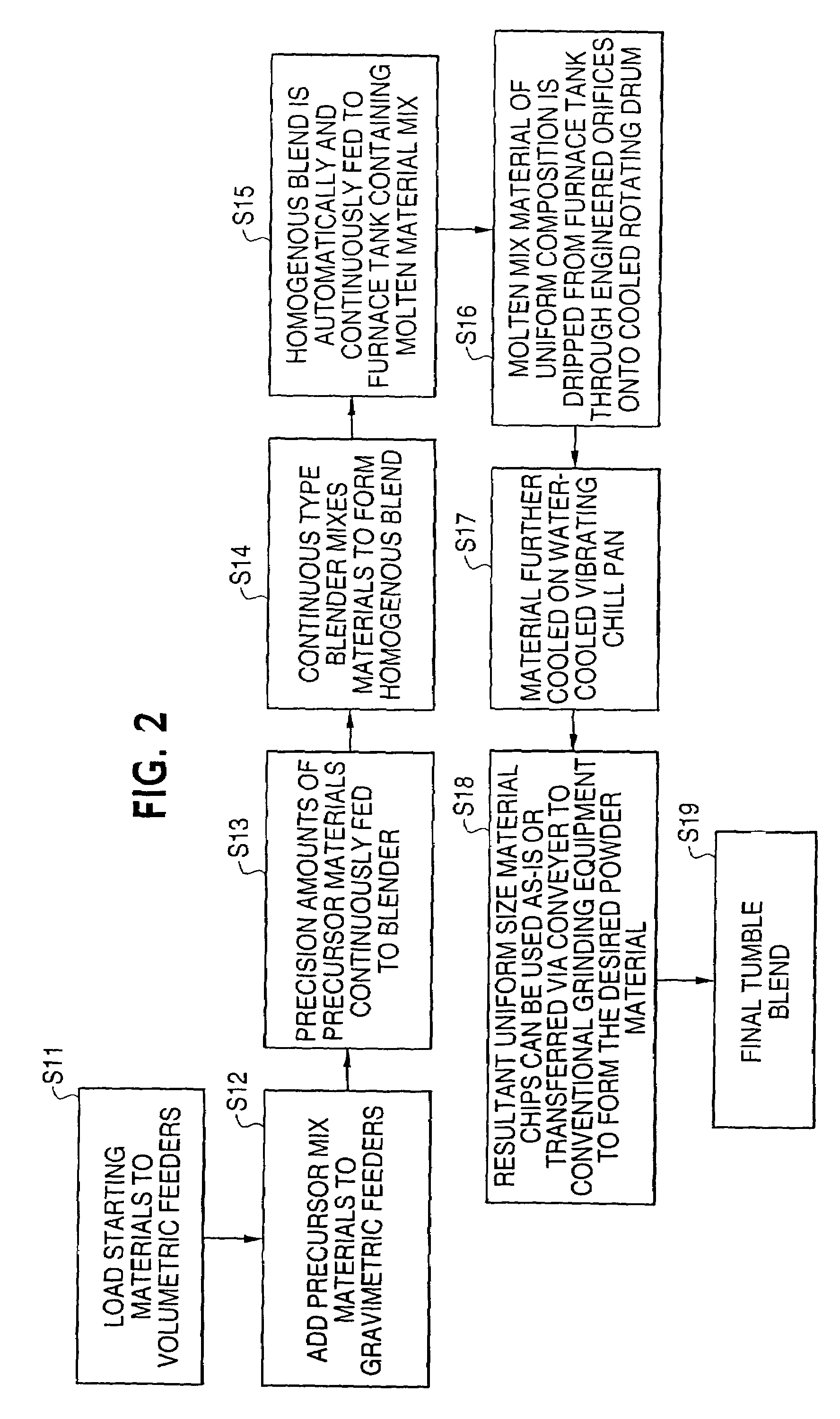

Continuous method and apparatus for manufacture of uniform size flake or powder

InactiveUS7060219B2Cost effectiveMinimal labor requirementCalcium/strontium/barium carbonatesElectrolyte holding meansMelting tankInorganic salts

A method and apparatus for continuous fabrication of homogeneous thin flake or powder electrolyte material from inorganic salt, metallic or similar materials or from mixtures of such materials for use in Carbonate Fuel Cell (“CFC”) power plants. Electrolyte precursor powders are fed to a continuous blender type mixer using precision metering equipment that controls material feed rates. The homogenous mixture of blended powders is then fed into a high temperature melting tank in which the mixture is melted, forming the desired molten eutectic composition. The liquid eutectic melt drips from the melting tank through ceramic or metallic nozzles and splat-cools on a rotating, water-cooled metal cylinder to produce uniform size, thin flake material. The thin flake electrolyte material can be used as-is, or it may be further processed using continuous grinding and powder fabrication equipment.

Owner:FUELCELL ENERGY INC

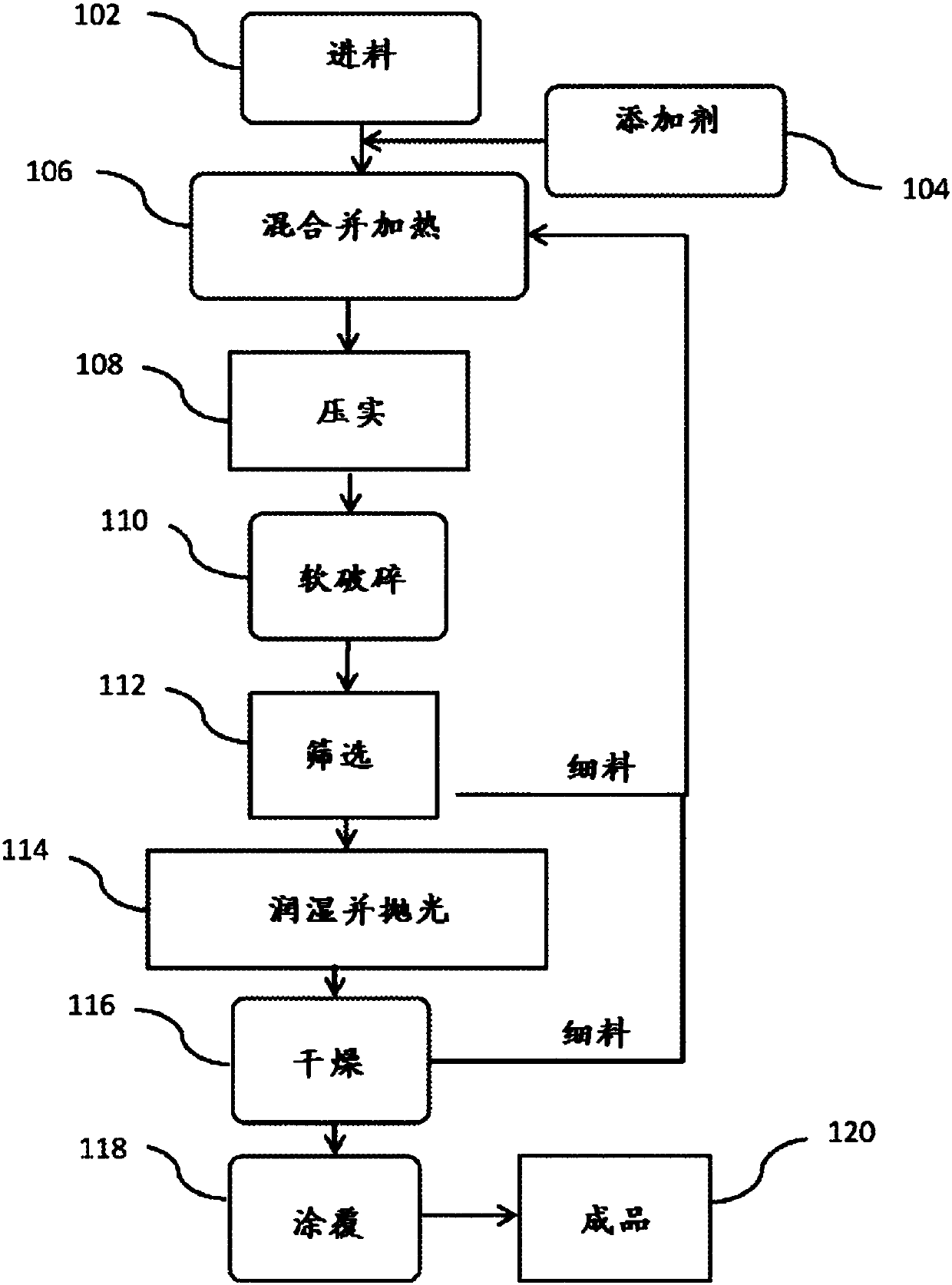

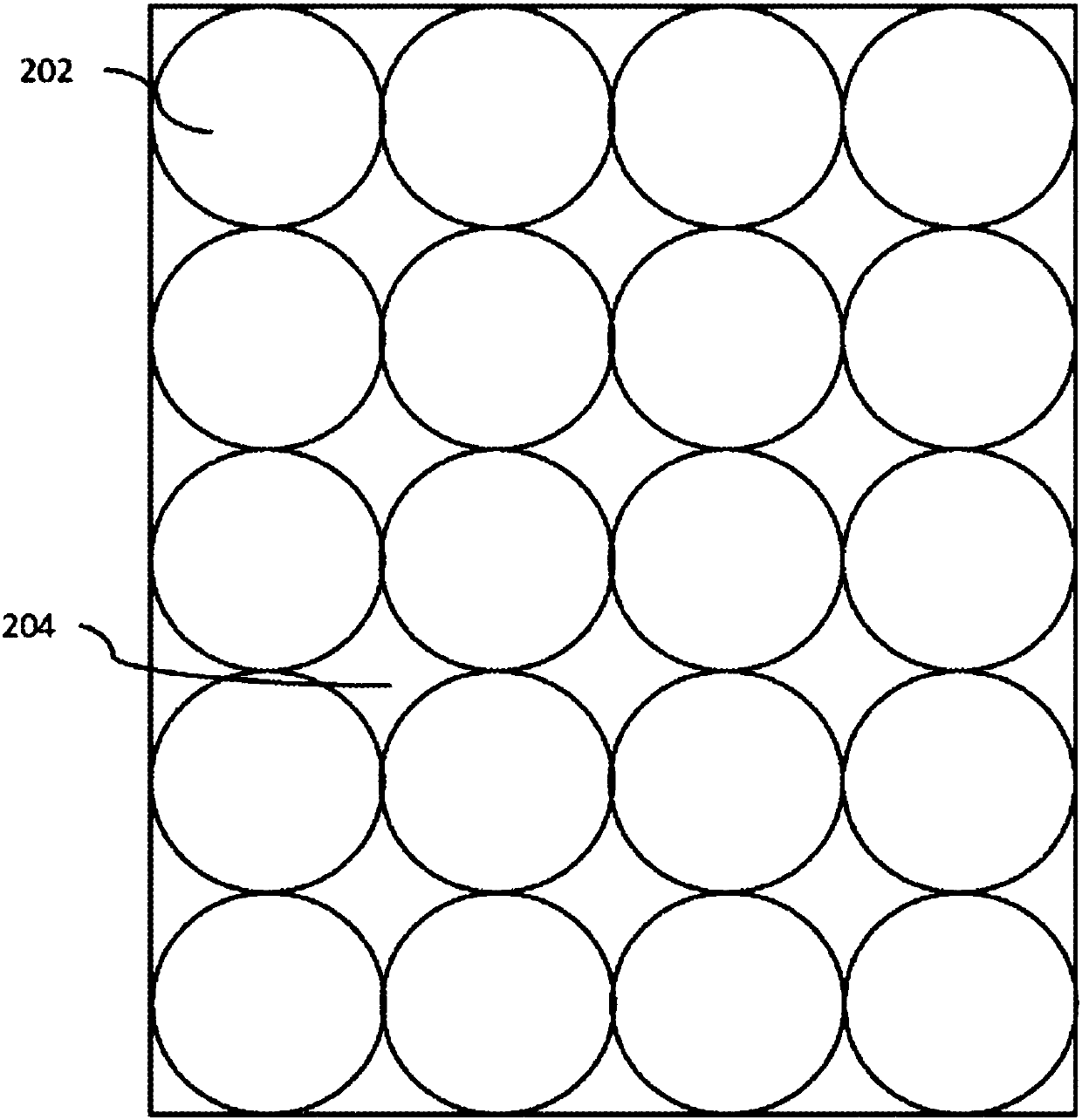

Spherical fertilizers and process for the production thereof

According to some demonstrative embodiments, there is provided herein a spherical fertilizer granule having a specific gravity of more than 1.94 g / cm2 and less than 3% porosity.

Owner:DEAD SEA WORKS

Method of producing potassium sulfate via cation exchange

InactiveUS6986878B2Improve efficiencyEfficient exchangeSolvent extractionSulfate/bisulfate preparationPotassium sulfateSodium sulfate

Owner:DIRDAL RAND TECH

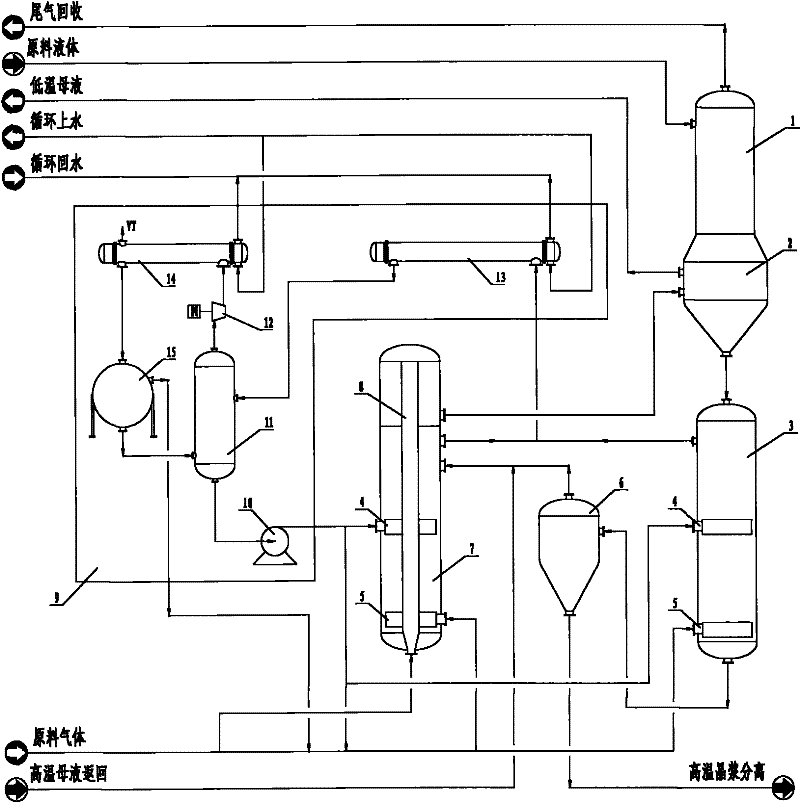

Method for increasing crystal size of sodium bicarbonate

ActiveCN108751233AIncrease the crystal sizeMeet needsAlkali metal carbonates shape formationSolution crystallizationAxial-flow pumpSodium bicarbonate

The invention discloses a method for increasing a crystal size of sodium bicarbonate. The method comprises the following steps: preparing a saturated solution or a supersaturated solution of sodium bicarbonate, introducing the saturated solution or the supersaturated solution of the sodium bicarbonate in an apparatus for increasing the crystal size of sodium bicarbonate through a raw material liquid inlet. The apparatus comprises a tank and a center back flow; and the raw material liquid inlet, a crystal mush outlet, a cycle cooling material liquid axial-flow pump outlet and an overflow port are arranged in the tank. the cycle cooling material liquid axial-flow pump outlet is arranged at an upper and upper part of the tank, and is used for leading the material liquid in the tank and cooling the material liquid; the center back flow is used for introducing the cooled material liquid in the tank, an outlet of cooling material liquid back flow pipe of the center back flow is arranged at amiddle and lower part of the tank, the cycle cooling of the material liquid is realized, a sodium bicarbonate product with a particle size being 180-380 [mu]m is prepared, and the requirement of thesodium bicarbonate product with the large particle size is satisfied.

Owner:JIANGSU BAIJIAN ENVIRONMENTAL PROTECTION TECH CO LTD

Preparation method of hydrophobic oleophobic BC superfine dry powder extinguishing agent base material carbonate

ActiveCN108314063AImprove hydrophobicityGood compatibilityAlkali metal carbonates shape formationFire extinguisherSilanesCarbonate

Owner:UNIV OF SCI & TECH OF CHINA

Dense soda ash high-efficiency crystallization production device

ActiveCN109704370AExtended service lifeScrub cleanAlkali metal carbonates shape formationSlurryEngineering

The invention belongs to the field of chemical low-salt dense soda ash equipment, and particularly relates to a dense soda ash high-efficiency crystallization production device, a motor is started torotate to drive a stirring belt to rotate, a gas flow generated by the rotation of a gas in a crystallization furnace along with the stirring belt spirally ascends, the gas on the upper side of the crystallization furnace extrudes a pressure valve on a second fixing plate through an one-way valve, the gas pressure is increased, at the moment the gas pressure breaks down the pressure valve, the gaspressure pushes a sliding plate and a first pressure plate on the upper side of the crystallization furnace to slide downwards, and a spring is stretched; steam in a steam chamber enters the crystallization furnace, the gas pressure is increased, at the moment the gas pressure breaks down a pressure valve at the lower side of the crystallization furnace, the gas pressure pushes a sliding plate and a second pressing plate on the lower side of the crystallization furnace to slide upwards, the spring is stretched, the spring rebounds to drive the sliding plate to slide back, and the sliding plate, the first pressing plate and the second pressing plate slide back and forth to stir crystal slurry in the crystallization furnace, so that the slurry is continuously circulated, and crystal grainsgrow continuously.

Owner:台州市路桥凯通管业有限公司

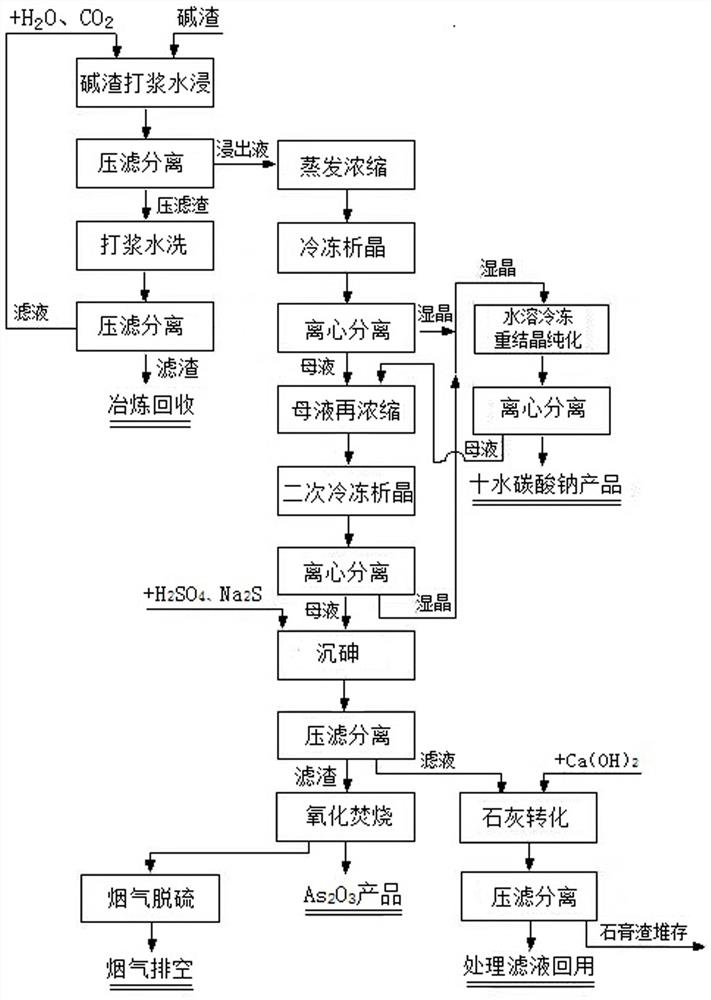

A method for recycling and processing arsenic slag resources by freezing and separating arsenic and alkali in the immersion solution of alkali slag

ActiveCN111118301BImprove recycling ratesReduce manufacturing costArsenic oxides/hydroxides/oxyacidsCalcium/strontium/barium sulfatesSlagSlurry

The invention relates to a method for recycling and treating arsenic slag resources by freezing and separating arsenic and alkali in alkaline slag water extract. The method comprises the following steps of adding water into alkaline slag, pulping, leaching with water, introducing CO<2> gas to convert NaOH in the slurry into Na<2>CO<3>, evaporating and concentrating the separated Na<2>CO<3>-containing arsenic alkaline water extract, cooling, freezing and crystallizing, dissolving the separated wet crystals, cooling, freezing and recrystallizing again to obtain sodium carbonate, concentrating the separated arsenic-containing mother liquor, carrying out secondary freezing crystallization treatment, precipitating arsenic by using a Na<2>S saturated aqueous solution, maintaining the pH value at1-2 by using H<2>SO<4>, adding pulverized coal into filter residues separated from an arsenic precipitation mixed solution, and carrying out oxidation incineration to obtain As<2>O<3>, and convertingthe filtrate with lime. According to the method, arsenic and alkali in the alkaline slag water extract are separated through freezing crystallization, Na<2>CO<3>.10H<2>O is obtained through freezingrecrystallization, and Na<2>S is used for precipitating arsenic, so that arsenic slag resources can be well recycled.

Owner:YAN XIN ENVIRONMENTAL PROTECTION & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com