Device and production method for increasing particle size of baking soda by adopting pre-carbonization method

A technology of pre-carbonization method and production method, which is applied in the direction of bicarbonate preparation, alkali metal carbonate shape preparation, etc., and can solve the problem that the extension of the alkali production cycle of the carbonization tower is not obvious, and the tail gas is not well utilized, operated and industrialized Difficulty in promotion and other problems, to achieve the effect of increasing product size, reducing cost, and solving the problem of mother liquor expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

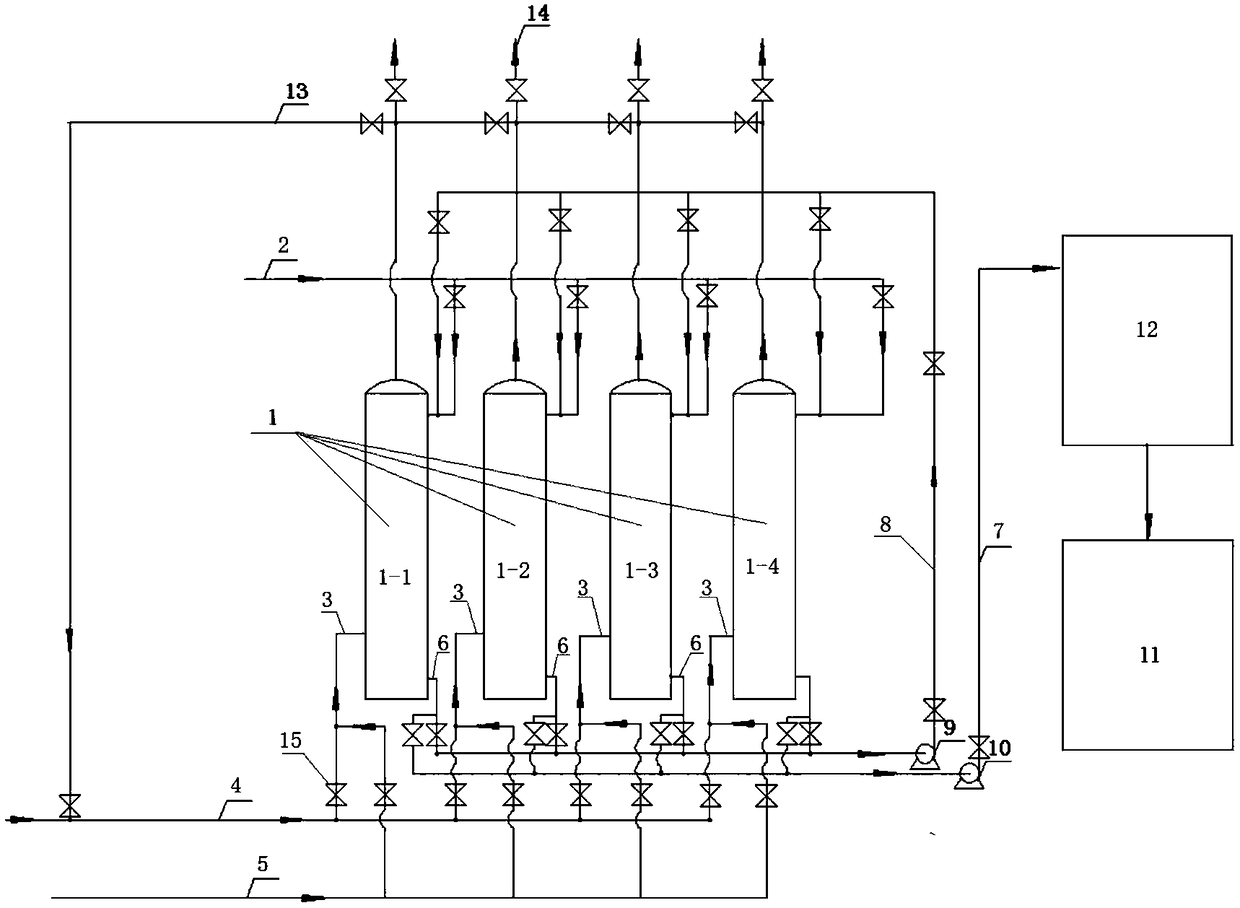

[0052] The pre-carbonization method of the present invention improves the production method of baking soda product granularity, and concrete process is as follows:

[0053] (1) The mixture of industrial defective sodium carbonate and heavy ash fine powder is dissolved to form a mixed solution with a total alkalinity of 80-85tt, followed by clarification tanks and microporous filters to reduce the calcium and magnesium content in the solution to 20ppm Next, store it in the lye storage tank to obtain the lye, and then use 80-110m 3 The flow rate of / h is sent to a cleaning tower feed port, and a pre-carbonization reaction is carried out with low-concentration carbon dioxide (20%-35%) in the cleaning tower to form a supersaturated solution at a corresponding temperature, and continue to extend the reaction residence time to make the mixture A small amount of crystals are produced in the liquid until the solid-liquid ratio reaches 5%. Wherein, lye lye can be the centrifugal mothe...

Embodiment 2

[0059] The pre-carbonization method of the present invention improves the production method of baking soda product granularity, and concrete process is as follows:

[0060] (1) dissolving industrial defective sodium carbonate is made into the mixed solution that total alkalinity is 80-85tt, adopts clarifier barrel and microporous filter purification successively to make the calcium and magnesium content in the solution drop below 20ppm, obtains lye. The lye solution that industrial defective product sodium carbonate raw material dissolving adopts comes from the centrifuge mother liquor that centrifuge gets rid of in step (3)

[0061] The cleaning tower in the method of embodiment 1 is switched to a soda-making tower, replaces one of three soda-making towers, and simultaneously the soda-making tower replaced is cleaned with chemical lye, because there is residual in this soda-making tower Sodium bicarbonate crystallization, the low-concentration carbon dioxide used at this time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com