Method for preparing large-particle baking soda by secondary carbonization method and obtained baking soda

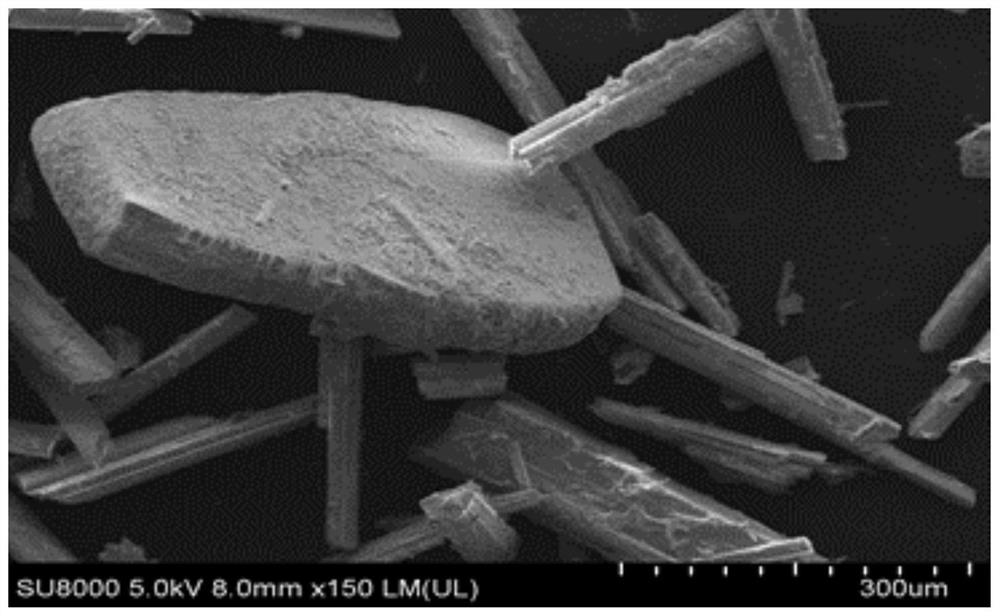

A secondary carbonization, baking soda technology, applied in the preparation of bicarbonate, the preparation of alkali metal carbonate shape, reagents and other directions, can solve the problems of poor product quality, long reaction time, difficult to control the operation process, etc., to achieve particle size Large, easy to operate, and the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

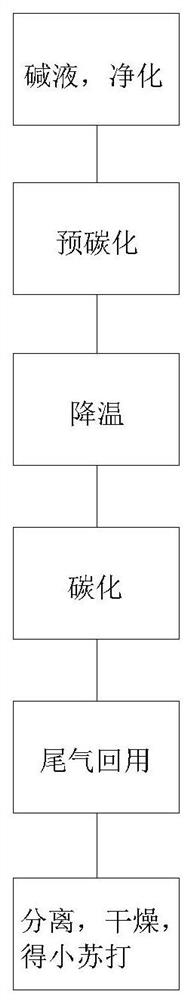

[0044] See attached figure 1 , a kind of secondary carbonization method of the present invention prepares the method for large particle sodium bicarbonate, comprises the following steps:

[0045] 1) get sodium carbonate and sodium bicarbonate, mix, add water, the concentration that makes sodium carbonate is 172g / L and the concentration of sodium bicarbonate is the lye of 84g / L, purifies, standby;

[0046] 2) Using a flow pump to 0.25m 3 The flow rate of step 1) is transported to the top of the pre-carbonization tower by the flow rate of step 1), so that the lye enters the pre-carbonization tower from the top of the pre-carbonization tower, and the carbon dioxide gas is 1m from the bottom of the pre-carbonization tower 3 The / h flow rate enters the pre-carbonization tower, and the lye and carbon dioxide gas undergo a pre-carbonization reaction at a reaction temperature of 10°C to obtain pre-carbonized lye;

[0047] 3) Emit the pre-carbonized lye from the bottom of the pre-car...

Embodiment 2

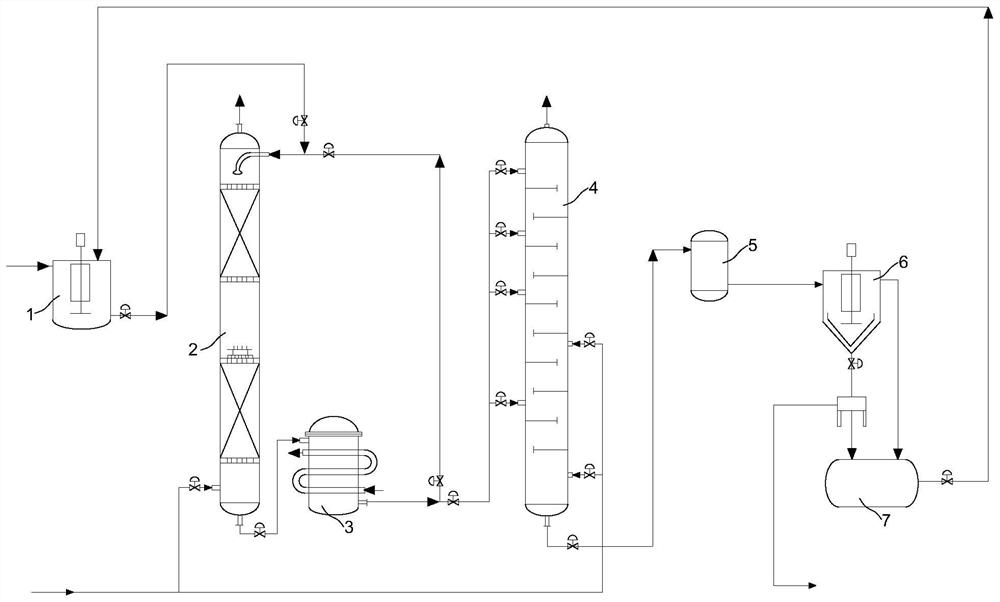

[0052] A kind of secondary carbonization method of the present invention prepares the method for large particle sodium bicarbonate according to attached figure 2 The shown technological process is carried out, at first, the lye after the mixing of sodium carbonate and sodium bicarbonate is stored in the lye storage tank 1, simultaneously, the mother liquor of return liquid tank 7 is also circulated to the lye storage tank 1, three common Form lye, after the lye is purified, enter the pre-carbonization tower 2 from the upper part of the pre-carbonization tower 2, and carry out pre-carbonization reaction with carbon dioxide gas, and the carbon dioxide absorbs and reacts with the raw material sodium carbonate in the pre-carbonization tower 2; the lye after the reaction , flows into the cooling tank 3 with coil cooling from the bottom of the pre-carbonization tower 2, and drops to a suitable temperature; the lye after cooling can be returned to the pre-carbonization tower 2, and t...

Embodiment 3

[0061] A kind of secondary carbonization method of the present invention prepares the method for large particle sodium bicarbonate, comprises the following steps:

[0062] 1) get sodium carbonate, add water, make the concentration of sodium carbonate and be the soda ash solution of 150g / L, add the sodium polystyrene sulfonate of 10ppm, purify, standby;

[0063] 2) Using a flow pump to 0.26m 3 The flow rate of step 1) is transported to the upper part of the pre-carbonization tower by the flow rate of step 1), so that the solution enters the pre-carbonization tower from the upper part of the pre-carbonization tower, and the carbon dioxide gas flows from the bottom of the pre-carbonization tower at 1.5m 3 The / h flow rate enters the pre-carbonization tower, and the solution and carbon dioxide gas undergo a pre-carbonization reaction at a reaction temperature of 60°C to obtain a pre-carbonized solution;

[0064] 3) Release the pre-carbonized solution from the bottom of the pre-ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com