Patents

Literature

77results about How to "Lower the discharge temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

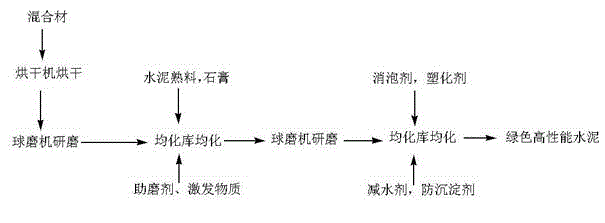

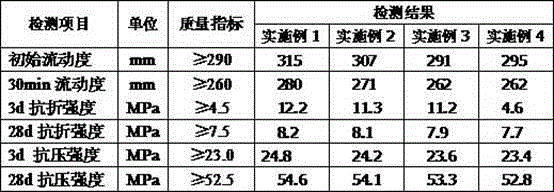

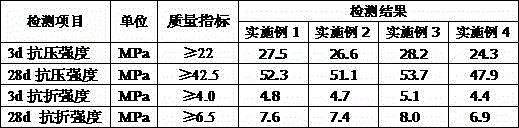

Environment-friendly high-performance cement and production method thereof

ActiveCN103601381AReduce crushing efficiencyImprove liquidityCement productionPlasticizerCement slurry

The invention provides environment-friendly high-performance cement which is characterized by consisting of the following raw materials in parts by weight: 50-60 parts of admixture, 32-40 parts of cement clinker, 6-8 parts of gypsum, 0.03-0.05 part of grinding aid, 3-5 parts of excitation substance, 0.05-0.1 part of antifoaming agent, 0.05-0.1 part of plasticizer, 0.03-0.05 part of anti-precipitating agent and 0.2-0.4 part of water reducing agent. In the environment-friendly high-performance cement provided by the invention, a large mixing amount of cement slurry can be realized by adopting a mechanical-chemical excitation production process, a great quantity of industrial waste residues can be consumed, the yield is increased, and the production cost is lowered; moreover, by adding a functional additive, the performance of the product is improved, and the needs of civil engineering are met.

Owner:广西云燕特种水泥建材有限公司

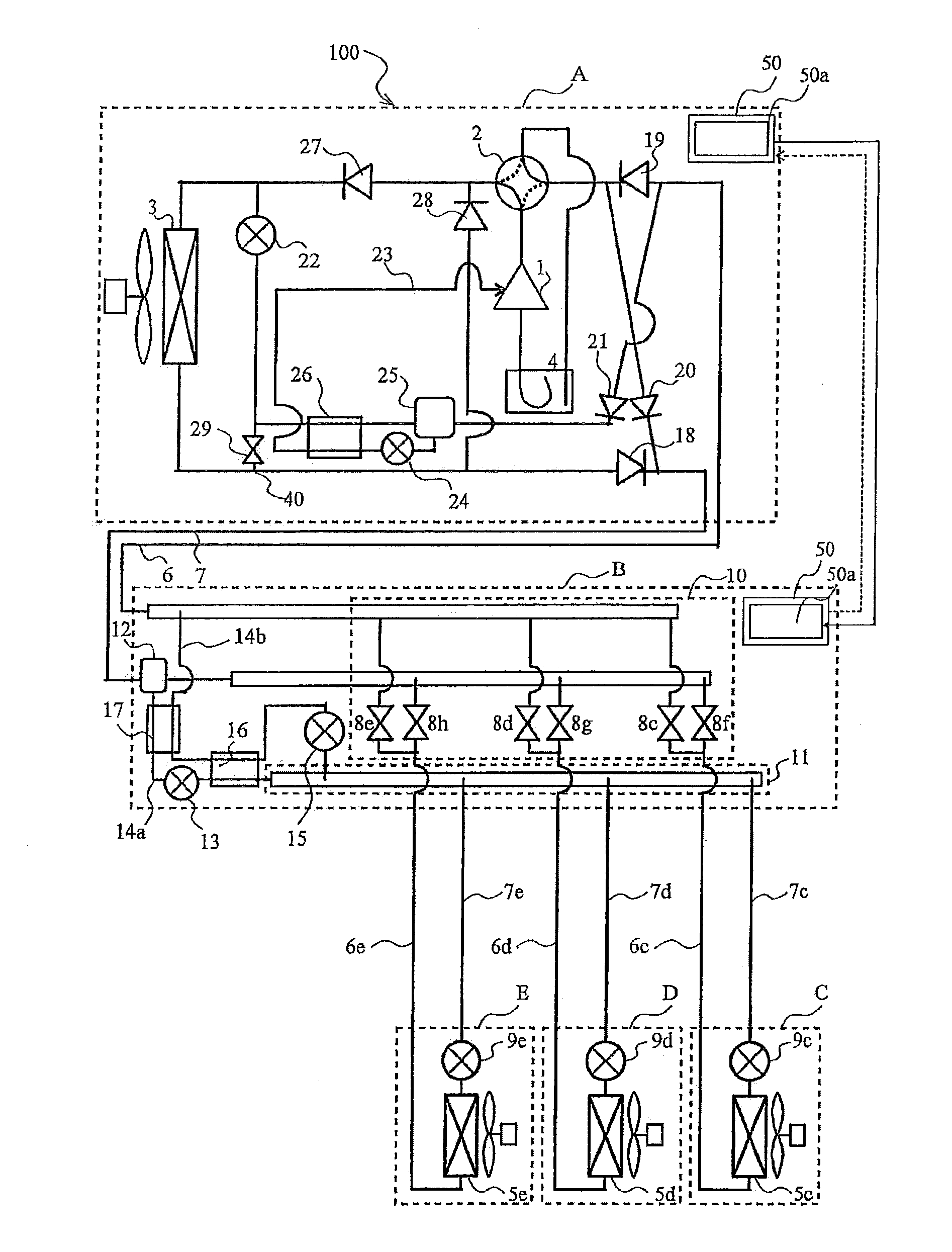

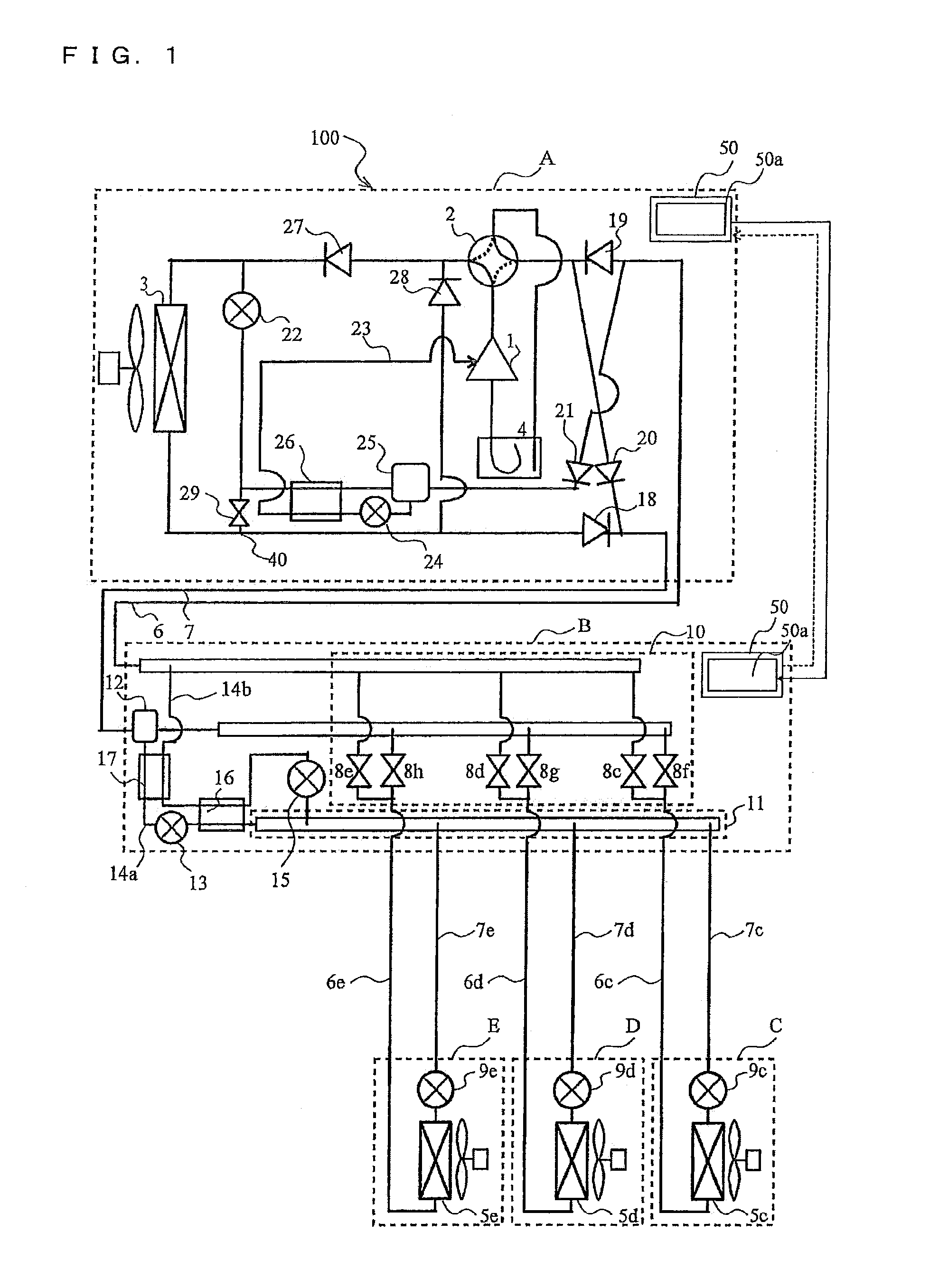

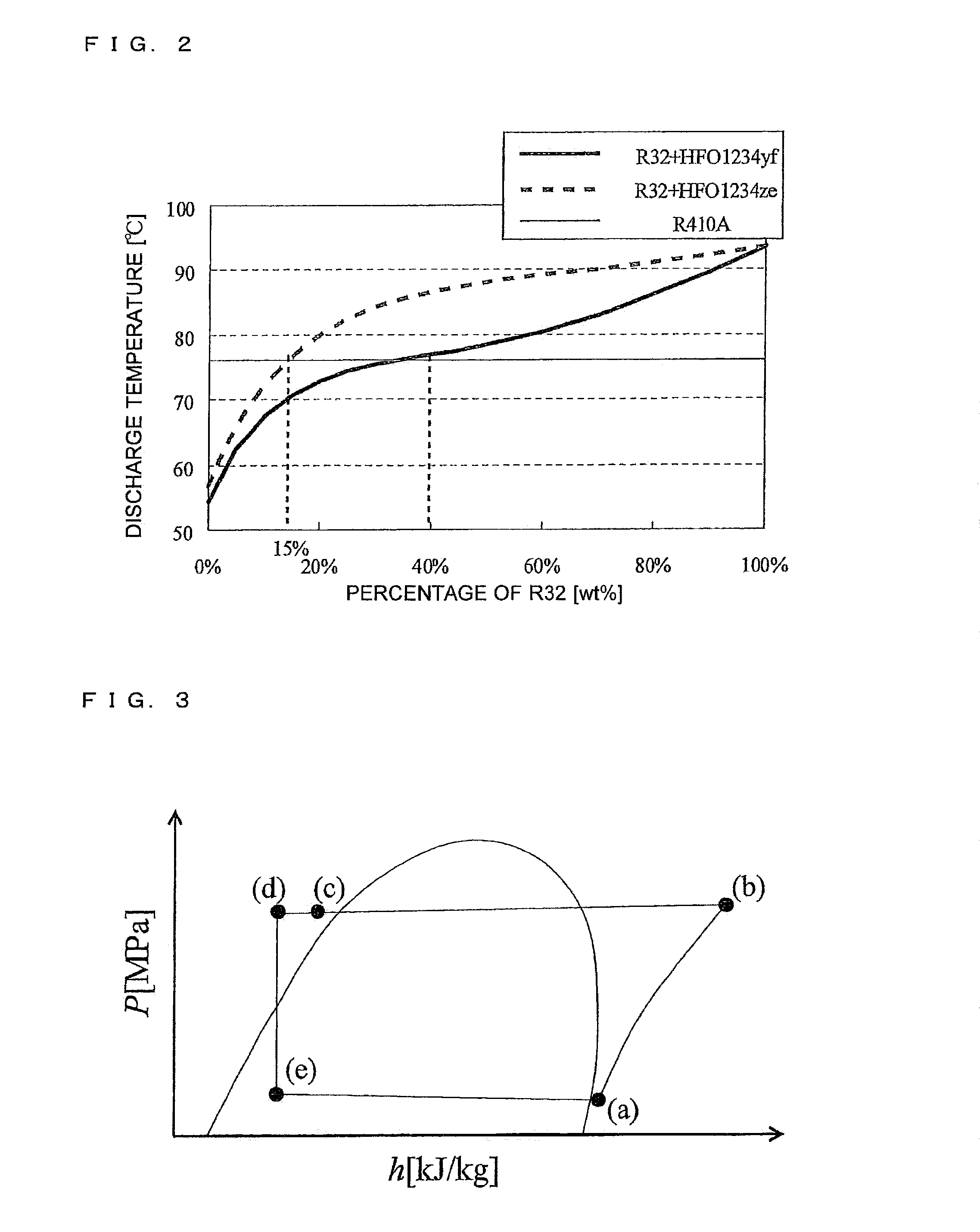

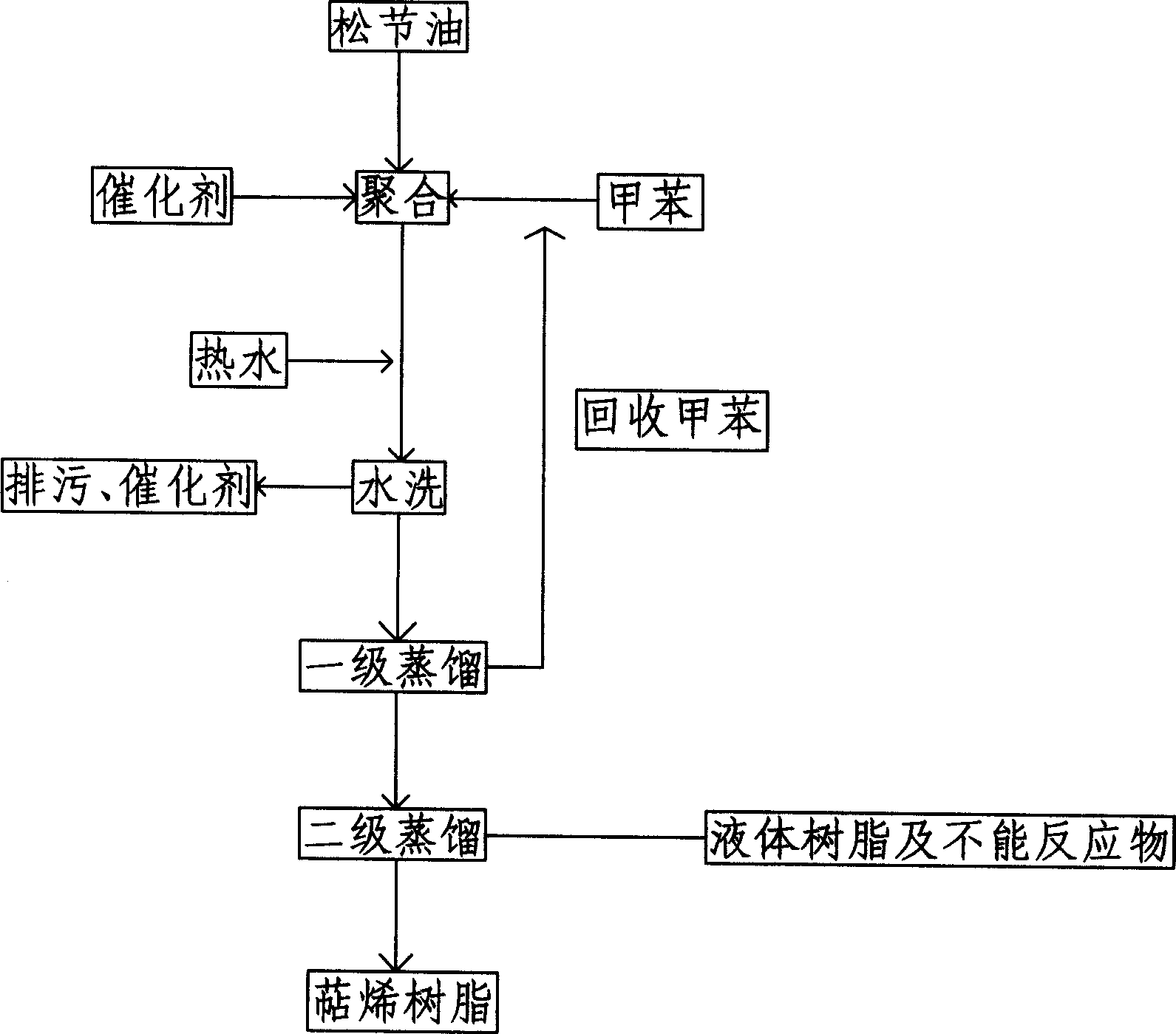

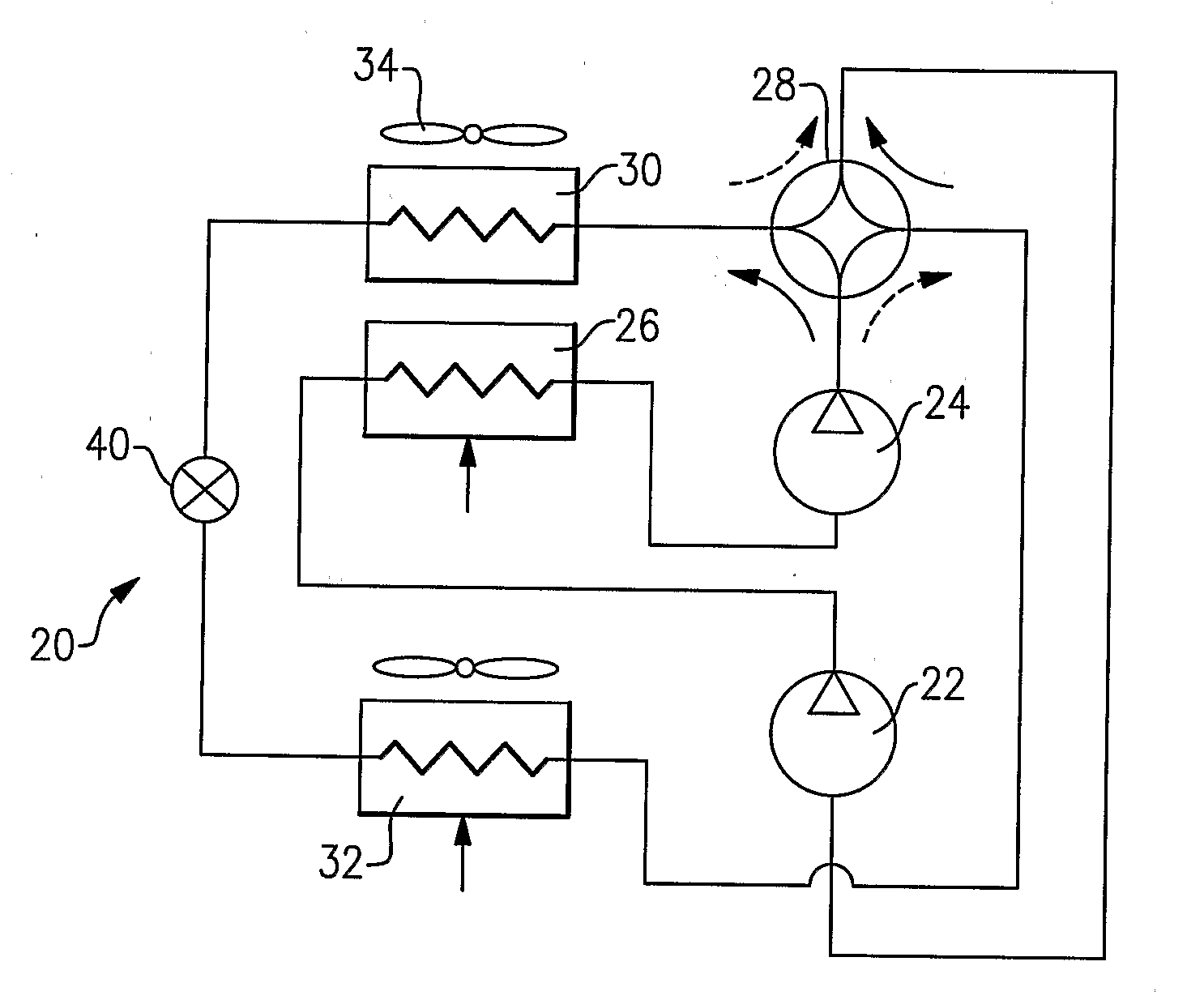

Air-conditioning apparatus

ActiveUS20130283843A1Lower the discharge temperatureStable operation of compressorCompression machines with reversible cycleRefrigeration componentsEngineeringAir conditioning

An air-conditioning apparatus uses R32, a refrigerant mixture containing R32 and HFO1234yf in which R32 has a mass percentage of 40% or higher, or a refrigerant mixture containing R32 and HFO1234ze in which R32 has a mass percentage of 15% or higher, as a heat-source refrigerant. The air-conditioning apparatus includes a low-pressure shell-structure compressor, a first flow switching valve, a heat-source-side heat exchanger, first flow control devices, and plural use-side heat exchangers connected by refrigerant pipes, forming a refrigeration cycle. The compressor includes a compression chamber within a sealed container including an opening extending between inside and outside of the sealed container. The air-conditioning apparatus can perform only a heating at the use-side heat exchangers, only a cooling at the use-side heat exchangers, and a mixed cooling and heating in a mixed fashion at the use-side heat exchangers.

Owner:MITSUBISHI ELECTRIC CORP

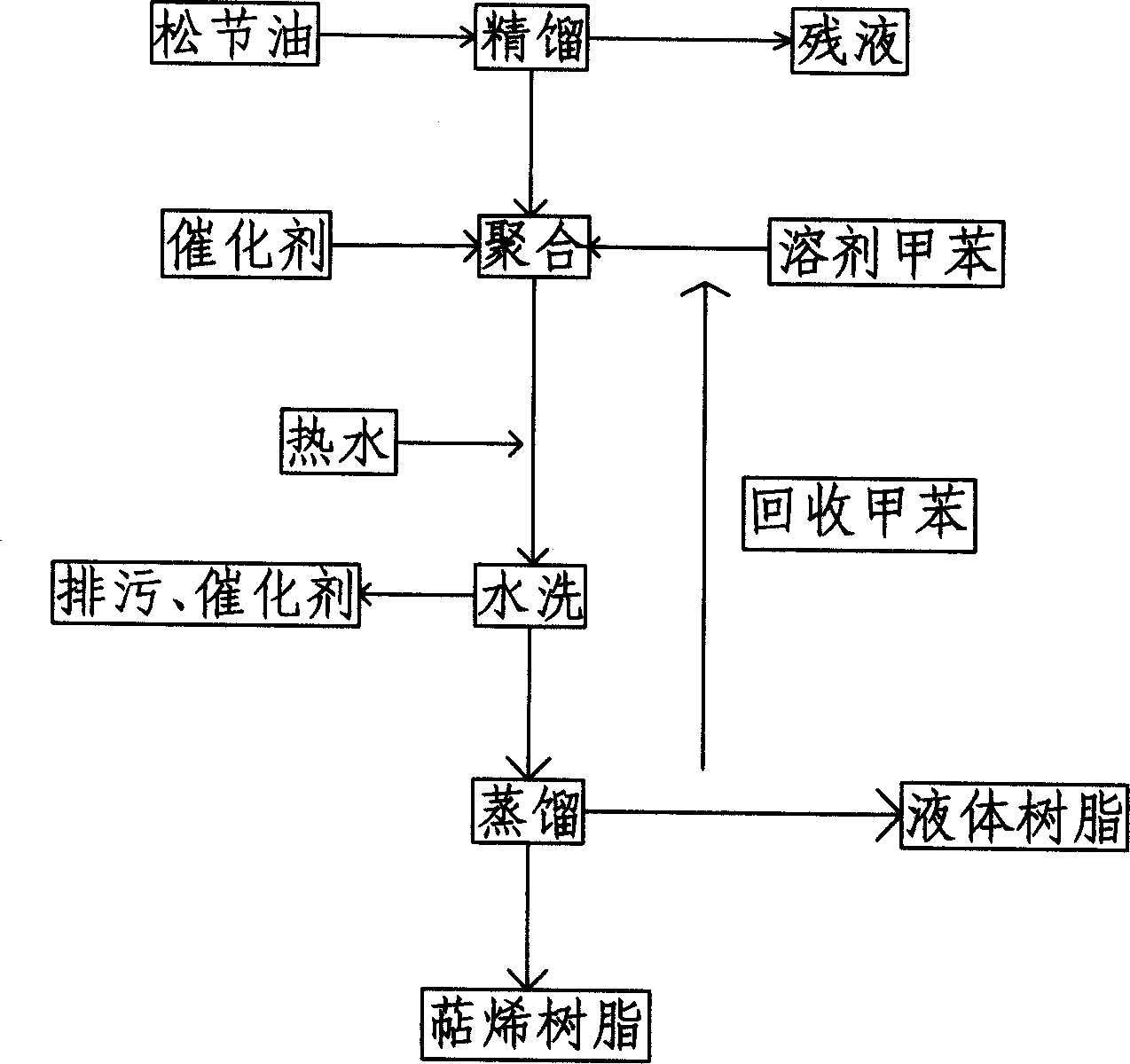

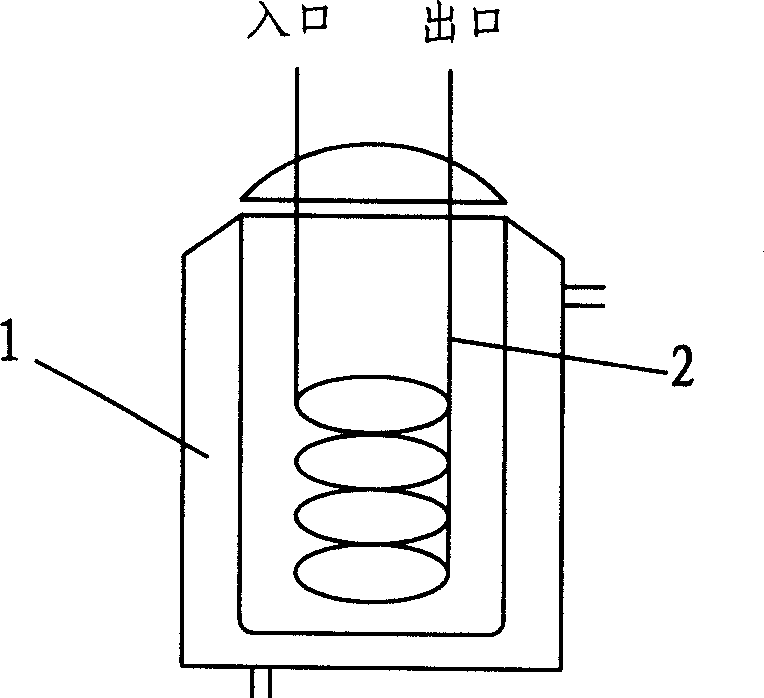

Production method of terpene resin

InactiveCN1631916AMild and even reactionThe reaction temperature fluctuation range is smallAluminium chlorideDistillation

A method for producing terpine resin has the steps follows: turpentine oil, toluene, catalyst aluminium chloride have polymerization in the wash the mixed outcome with hot water for draining the catalyst and waste out, then distil the outcome, recycle toluene and clear the liquid resin and the material which did not join the reaction in the course of distillation, then the toluene is made. The reactor includes enamel glass and inside cooling device which is steelless pipe groups filled with saturated salt solution of indoor temperature in the polymerization. The invention has friendly reaction, small fluctuating range of temperature, stable operation, productiving being raised by 20%, fewer equipments, low cost fir energy and production good economic benefit.

Owner:蓝运泉

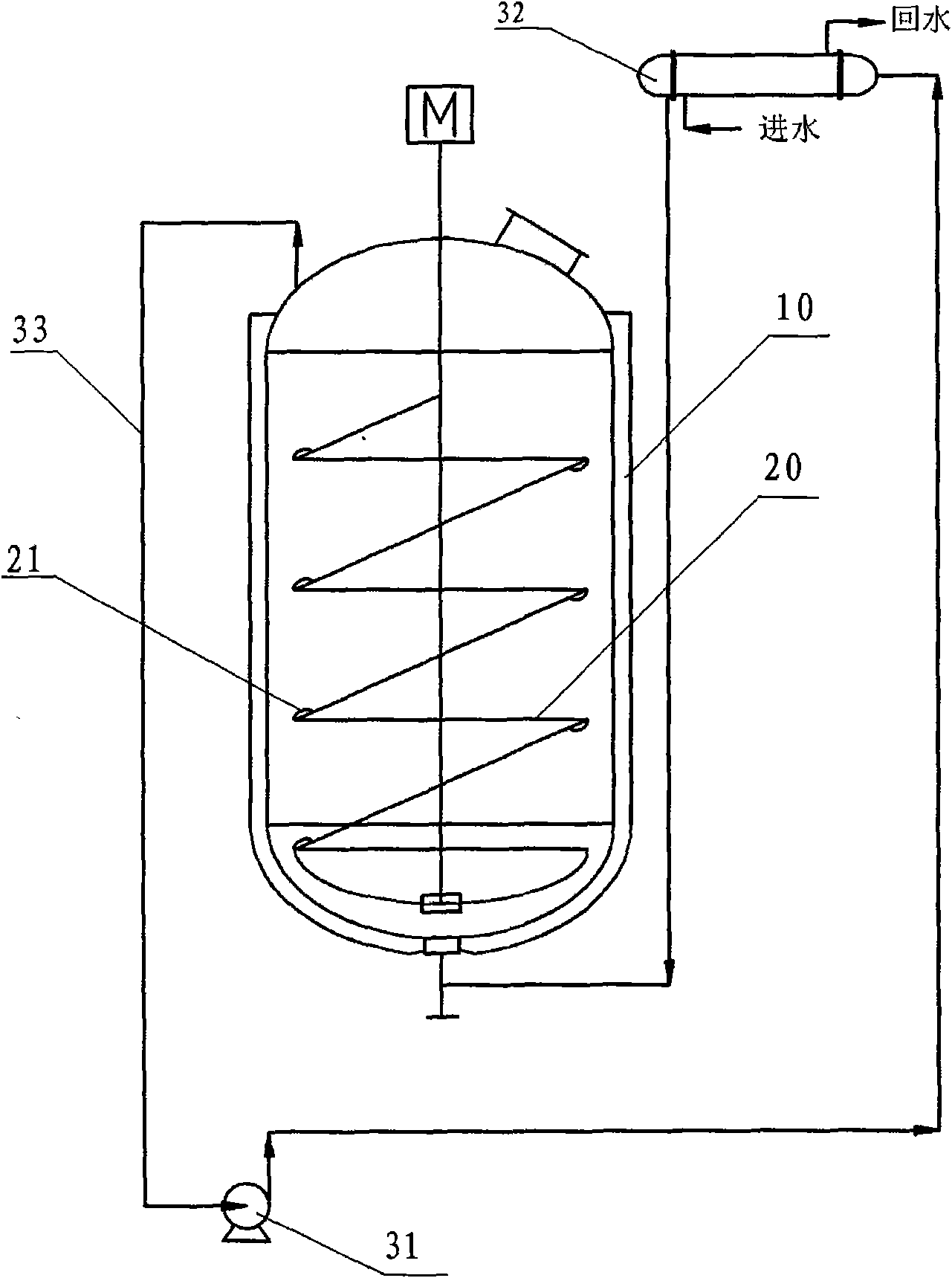

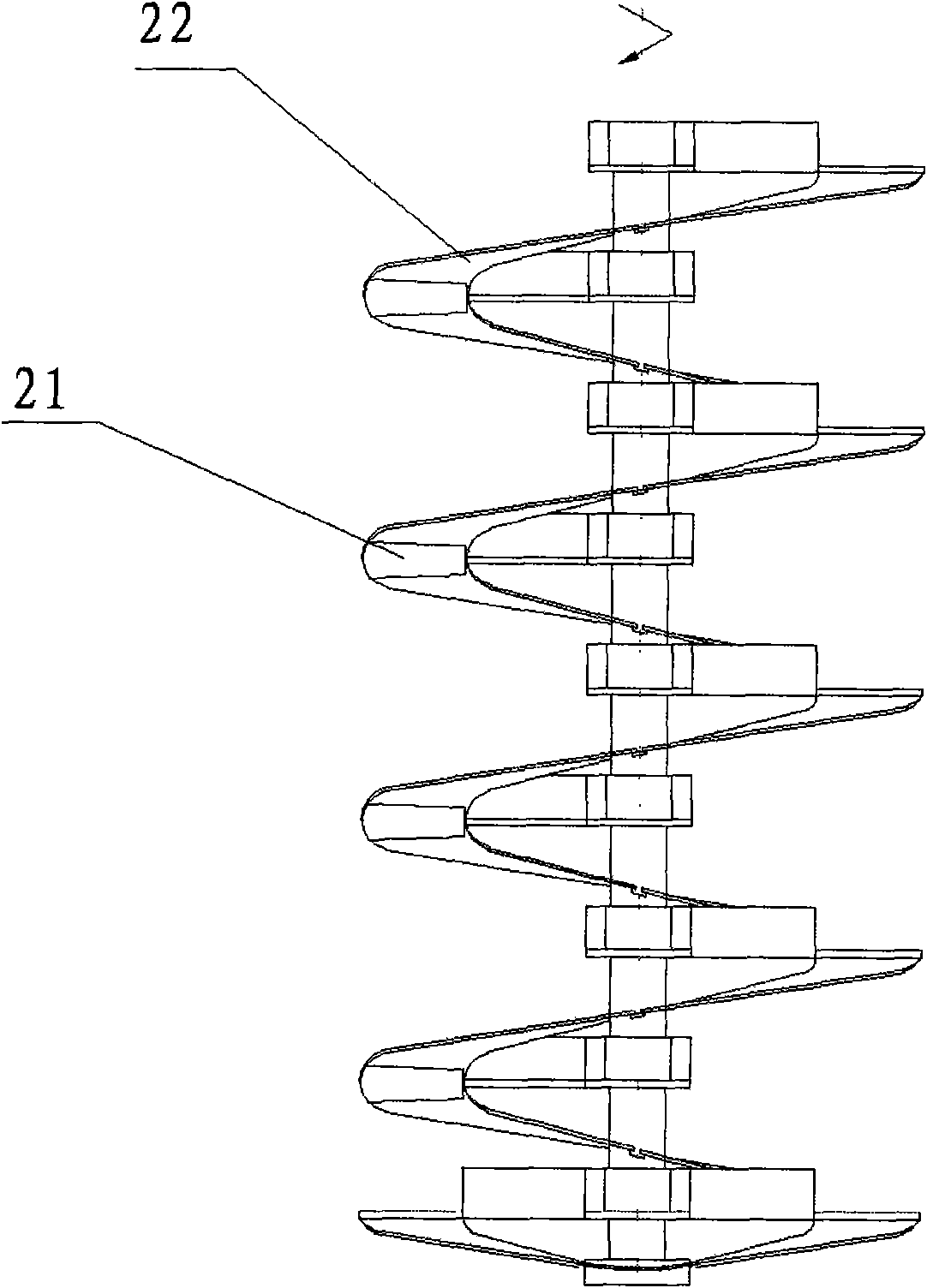

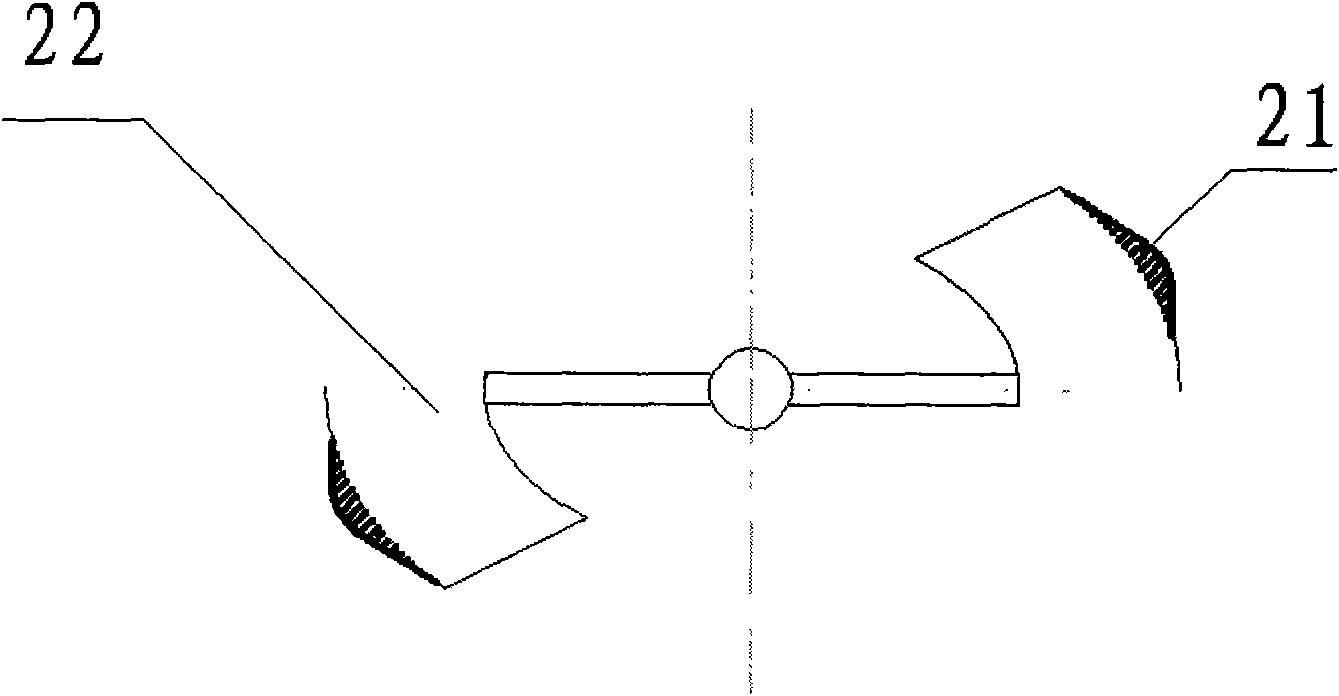

Polymeric kettle and thermal withdrawal mode thereof

InactiveCN101618310AIncrease cooling capacityGood yieldRotary stirring mixersChemical/physical/physico-chemical stationary reactorsGas phaseDiameter ratio

The invention discloses a polymeric kettle and a thermal withdrawal mode thereof. The polymeric kettle comprises a kettle body and a stirrer arranged in the kettle body, an outer cycle condensing system used for enhancing thermal withdrawal of the polymeric kettle is also arranged outside the kettle body, the volume of the kettle body is 12m<3> to 70m<3>, and the height-diameter ratio of the kettle body is 2 to 3. The thermal withdrawal mode comprises the following steps: propylene steam released from a gas outlet of the upper end of the polymeric kettle is condensed by the outer cycle condensing system at the outer side of the polymeric kettle; and the condensed liquid phase and gas phase flow back to the polymeric kettle under the action of the deadweight and the circulating fan. The invention utilizes the outer cycle condensing system to solve the problems of large scale of the polymeric kettle and insufficient thermal withdrawal capacity for producing copolymer polypropylene in a batch bulk method, the large scale of the polymeric kettle is ensured to be viable, single kettle output and product quality are both enhanced, the stirring and thermal withdrawal properties of the polymeric kettle are enhanced, the production capacity of the polymeric kettle, the single kettle output and the product quality are all greatly enhanced, the production capacity is especially enhanced when an efficient catalyst is used, and product added value and economic benefits are increased.

Owner:南京金陵塑胶化工有限公司

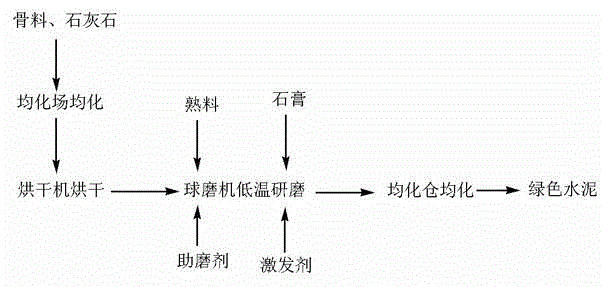

Environment-friendly cement and production method thereof

ActiveCN103601382AReduce crushing efficiencyImprove liquidityCement productionMethods of productionToxic industrial waste

The invention discloses environment-friendly cement. The raw materials include various industrial waste residues, limestone, cement clinker, gypsum, a grinding aid and an excitation substance. The environment-friendly cement is characterized in that the weight parts of the raw materials are as follows: 50-60 parts of admixture, 32-40 parts of cement clinker, 4-8 parts of gypsum, 0.03-0.05 part of grinding aid and 3-5 parts of excitation substance. Since the production process of the environment-friendly cement adopts a low-temperature mechanical-chemical co-excitation technology, the mixing amount of the admixture is large, multiple industrial waste residues can be used as raw materials, the raw materials are widely available, the cost is low, a great quantity of industrial waste residues can be consumed, the waste is turned into wealth, and the performance of the obtained product is remarkably improved from the quality index.

Owner:广西云燕特种水泥建材有限公司

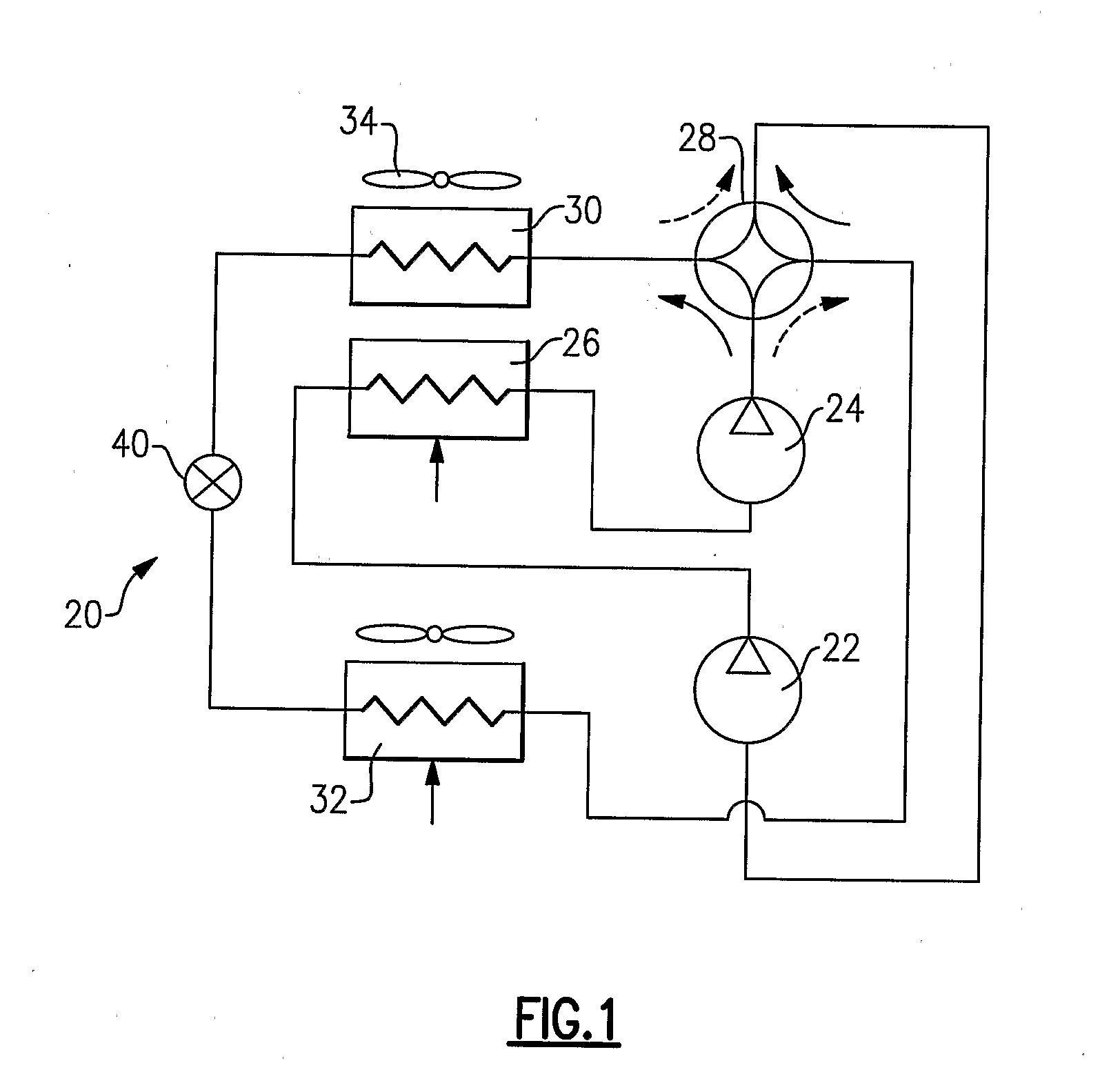

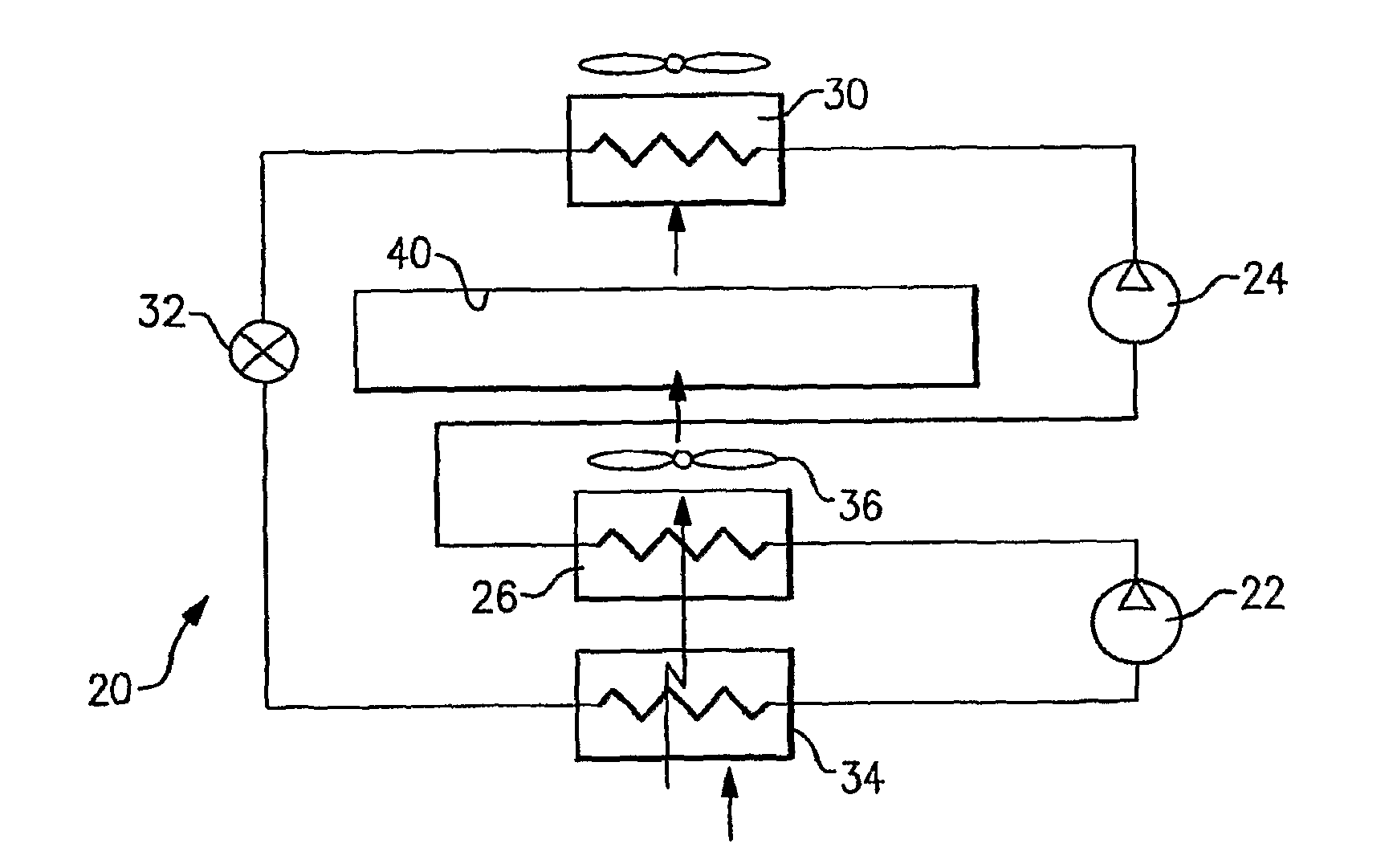

Heat pump with intercooler

ActiveUS20100032133A1Increase system capacityImprove efficiencyCompression machines with non-reversible cycleFluid circulation arrangementTranscritical cycleSystem configuration

A heat pump refrigerant system is provided with at least two sequential stages of compression. An intercooler is positioned intermediate the two stages. The refrigerant flowing through the intercooler. is cooled by a secondary fluid such as ambient air. The intercooler is positioned to be in a path of air flow passing over an outdoor heat exchanger, and preferably upstream of the outdoor heat exchanger, in relation to this air flow. Benefits with regard to efficiency and capacity are achieved due to proposed system configuration in both heating and cooling modes of operation, while no additional circuitry or components are required to provide the intercooler function for the heat pump refrigerant system. This invention is particularly important for the CO2 heat pump refrigerant systems operating in the transcritical cycle.

Owner:CARRIER CORP

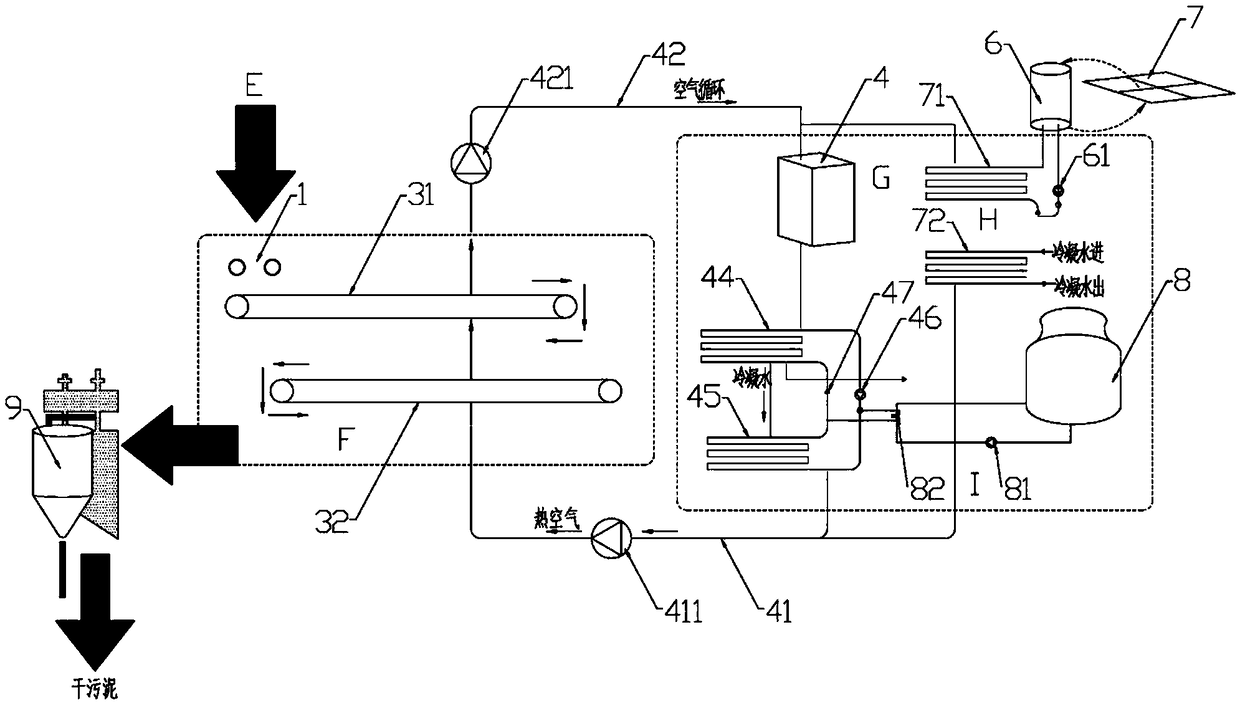

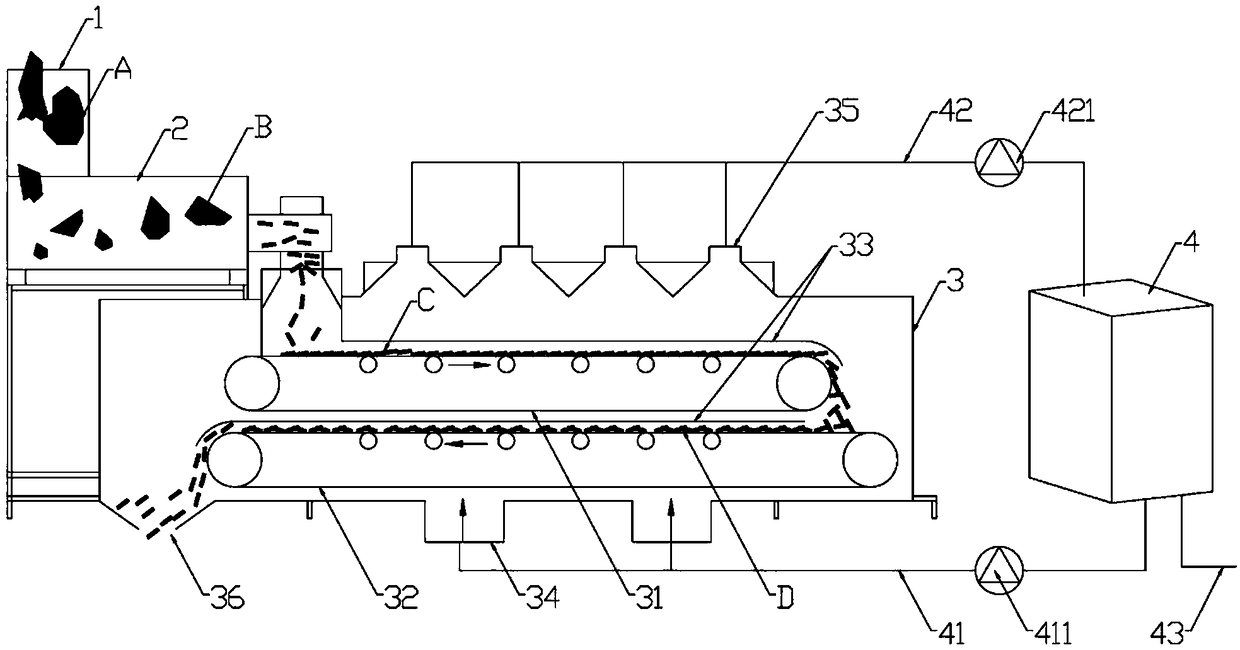

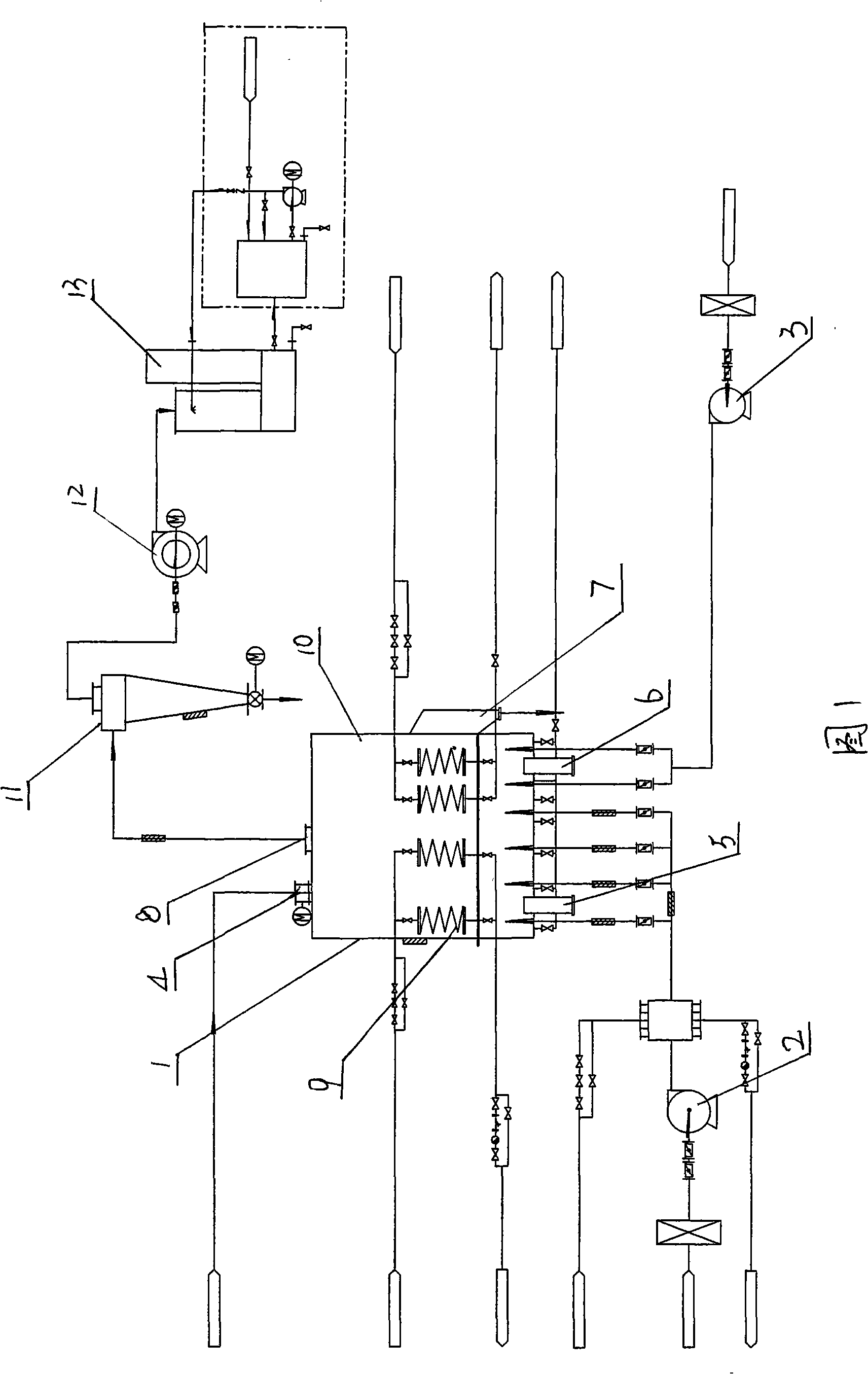

Energy-saving belt type sludge low-temperature drying device

PendingCN109399891ASystem operation is safe and reliableNo explosion hazardSludge treatment by de-watering/drying/thickeningHeat pumpSludge

The invention provides an energy-saving belt type sludge low-temperature drying device, and belongs to the technical field of sludge drying method processing devices. The drying device comprises a sludge feeding and forming zone, a drying zone, a heat pump heating zone, a clean energy heating zone, a circulating condensing zone and a discharging zone, wherein the drying zone is provided with a sludge outlet, and the sludge outlet is located at the end of the conveyor belt running direction. Dried sludge is delivered to the discharging zone through the sludge outlet and discharged. The drying device not only achieves continuous drying of the sludge, but also effectively uses the clean energy to achieve low-temperature low-energy drying of the sludge.

Owner:ZHEJIANG TIANXINGJIAN WATER SERVICE CO LTD

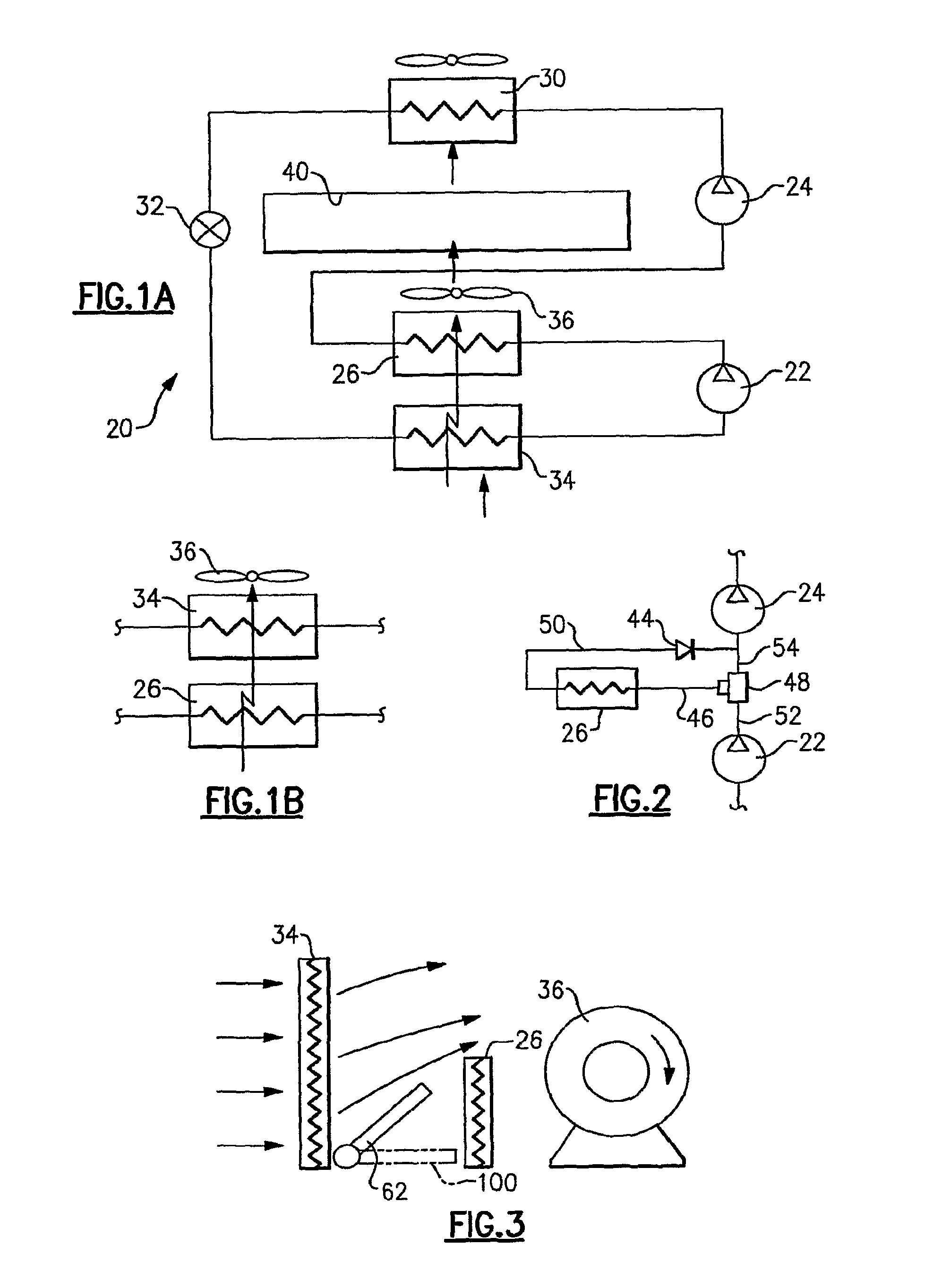

Refrigerant system with intercooler utilized for reheat function

ActiveUS20100071407A1Increase refrigerant system capacityImprove efficiencyCompression machines with non-reversible cycleEvaporators/condensersTranscritical cycleEngineering

A refrigerant system is provided with at least two stages of compression connected in series. An intercooler is positioned intermediate the two stages and is cooled by an indoor air stream. The intercooler is positioned to be in a path of air flow passing over an indoor heat exchanger, and preferably downstream of the indoor heat exchanger, in relation to this airflow. The intercooler cools the refrigerant flowing between the two compression stages as well as provides the reheat function. Benefits with regard to system performance (efficiency, capacity and reliability) are achieved with no additional circuitry or components required to provide the intercooler and reheat functions. This invention is particularly important for the CO2 refrigerant systems operating in the transcritical cycle. Methods of control are presented for both the intercooler and reheat functions.

Owner:CARRIER CORP

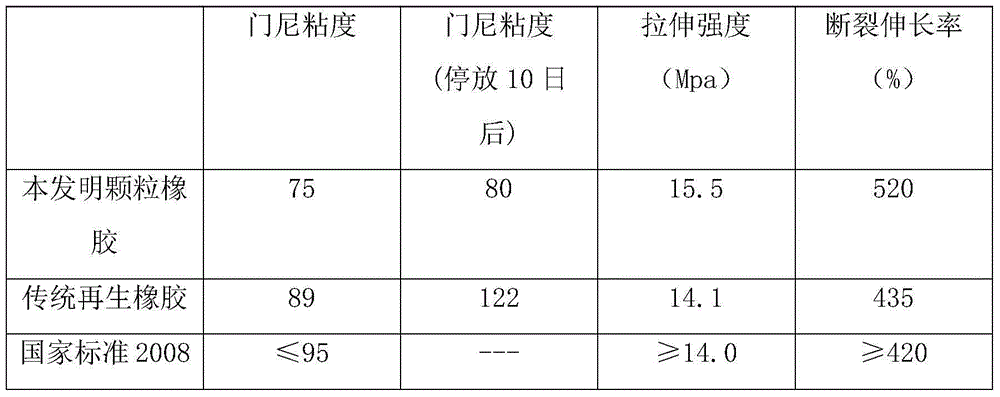

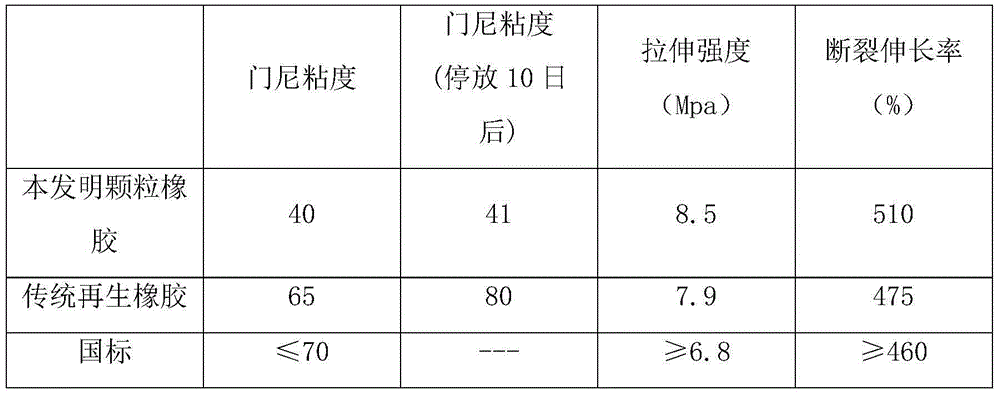

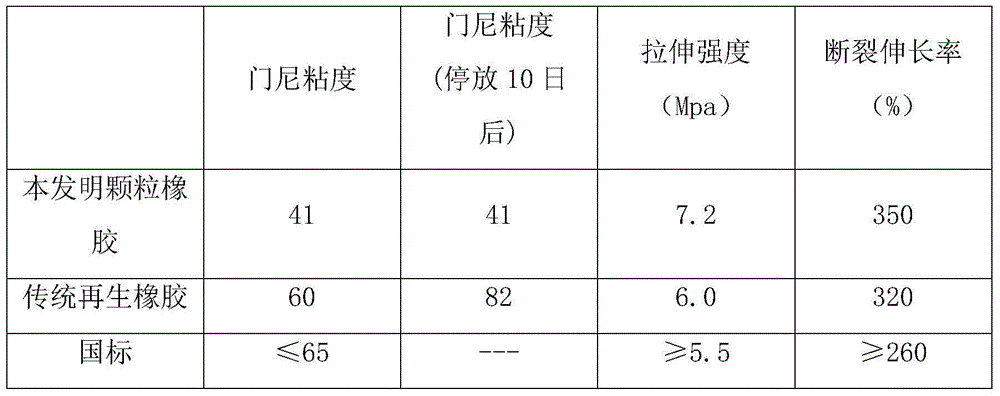

Method for preparing granular rubber by adopting three screw rods to continuously extrude devulcanized rubber powder

ActiveCN104690844AImprove safe continuous productionImprove working environmentCross-linkEnvironmental resistance

The invention discloses a method for preparing granular rubber by adopting three screw rods to continuously extrude devulcanized rubber powder, and belongs to the field of waste rubber cyclic regeneration. Devulcanized rubber powder which is preliminarily and thoroughly cooled is added into a three-screw-rod extruder through a metering feeding device, high shearing, stretching and compression effects are applied on the devulcanized rubber powder on the lower temperature condition by means of the strong material conveying capability, the shearing and mixing capability and the high productivity ratio of the three-screw-rod extruder, a cross-linked network in the devulcanized rubber powder is damaged further, the Mooney viscosity of the devulcanized rubber powder is lowered on the premise of not lowering the mechanical property, a granular rubber product is obtained, and a traditional refiner is replaced. Operation is continuously completed by the adoption of the three-screw-rod extruder on the closed, low temperature and high shearing conditions. The devulcanized rubber powder Mooney viscosity lowering effect which is originally achieved by the traditional refiner is achieved, the production process is environmentally friendly and continuous and saves energy, the stability of the mechanical property and the Mooney viscosity of the obtained granular rubber product is better than that of a product obtained by the traditional refiner.

Owner:NANJING L J R RUBBE & PLASTIC CO LTD +1

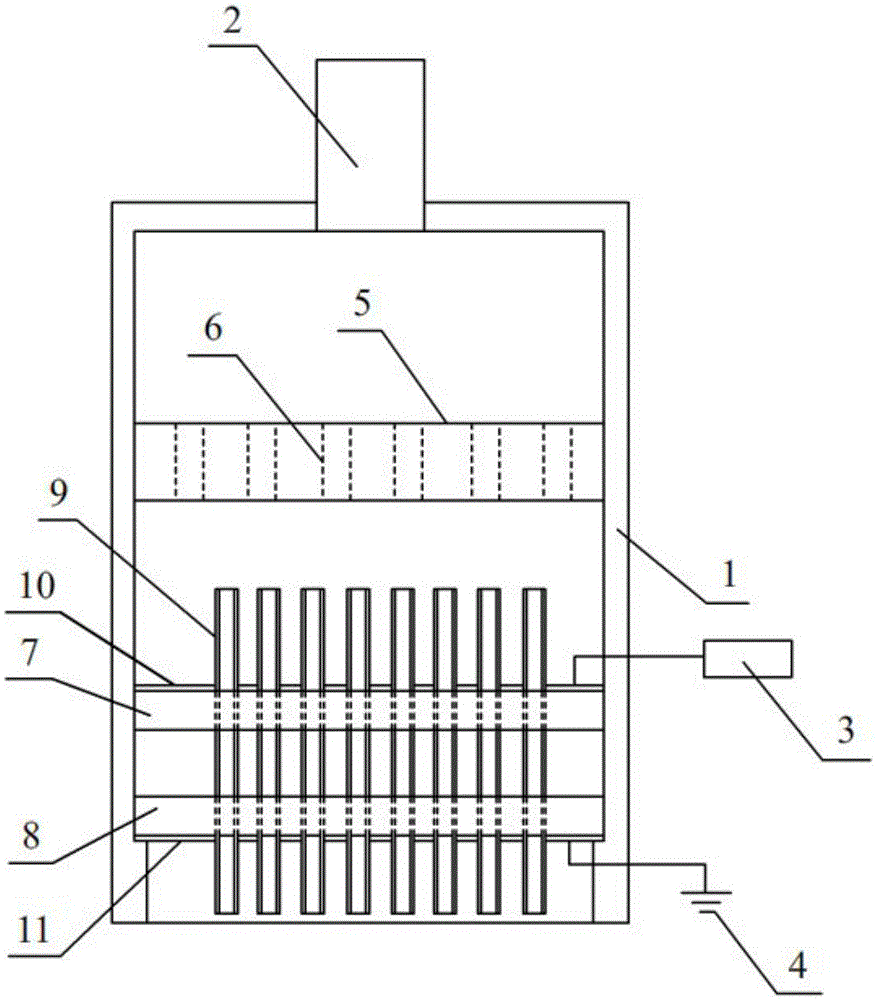

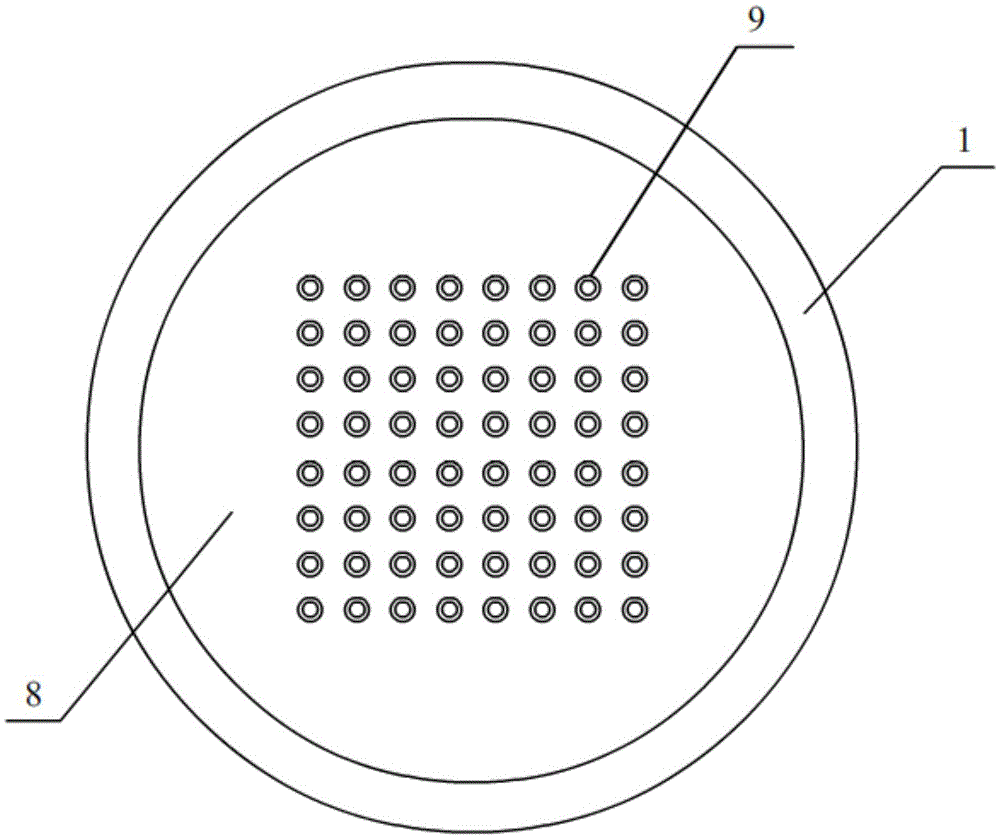

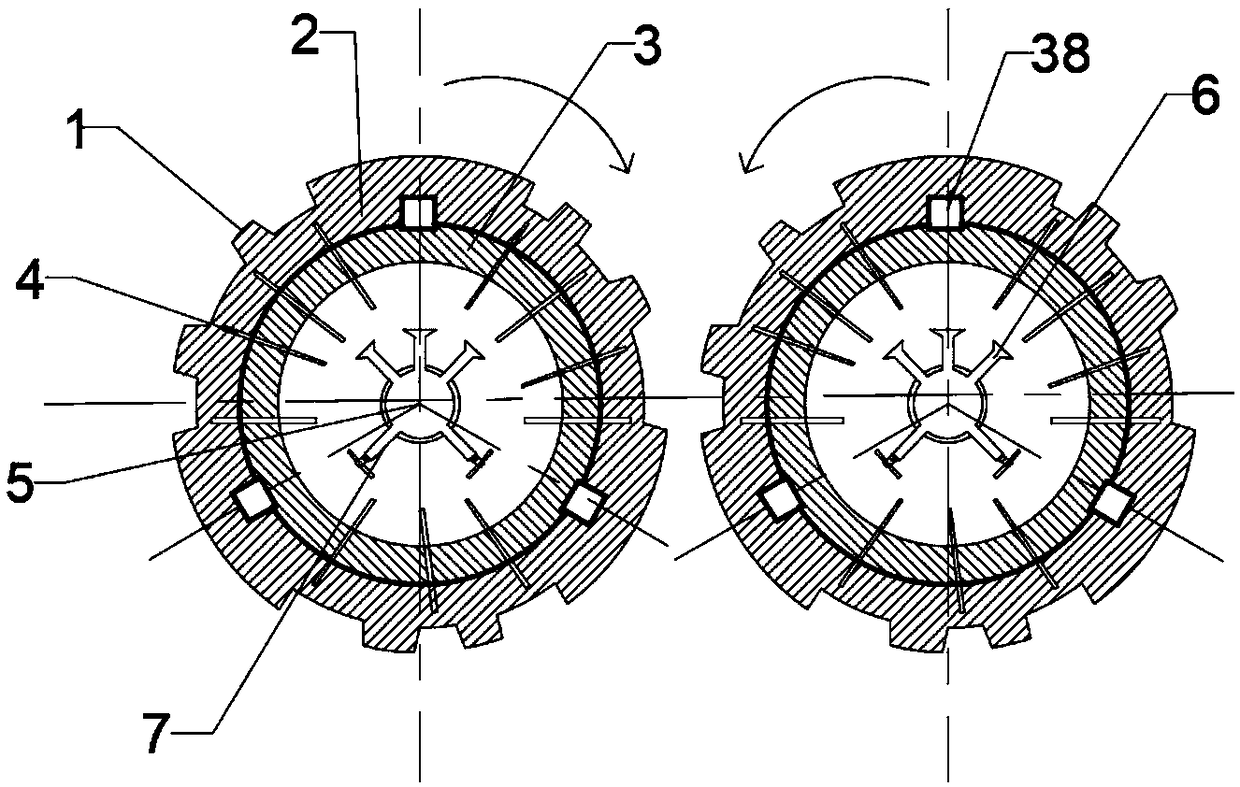

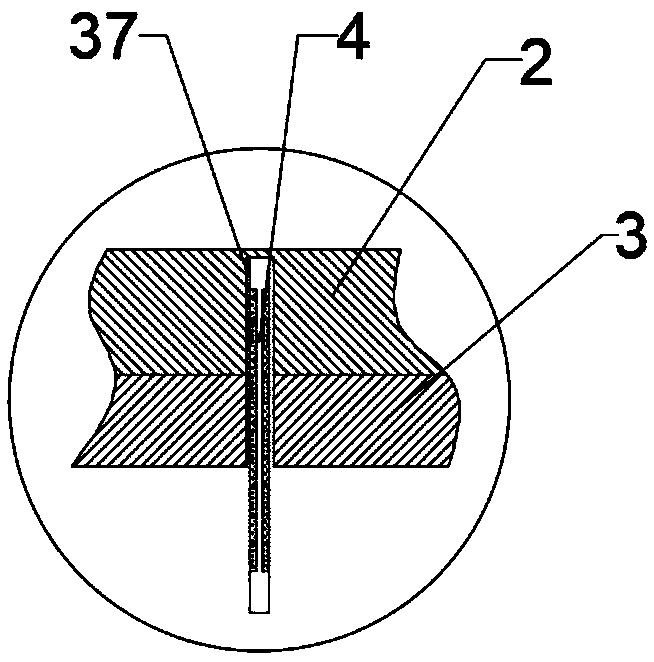

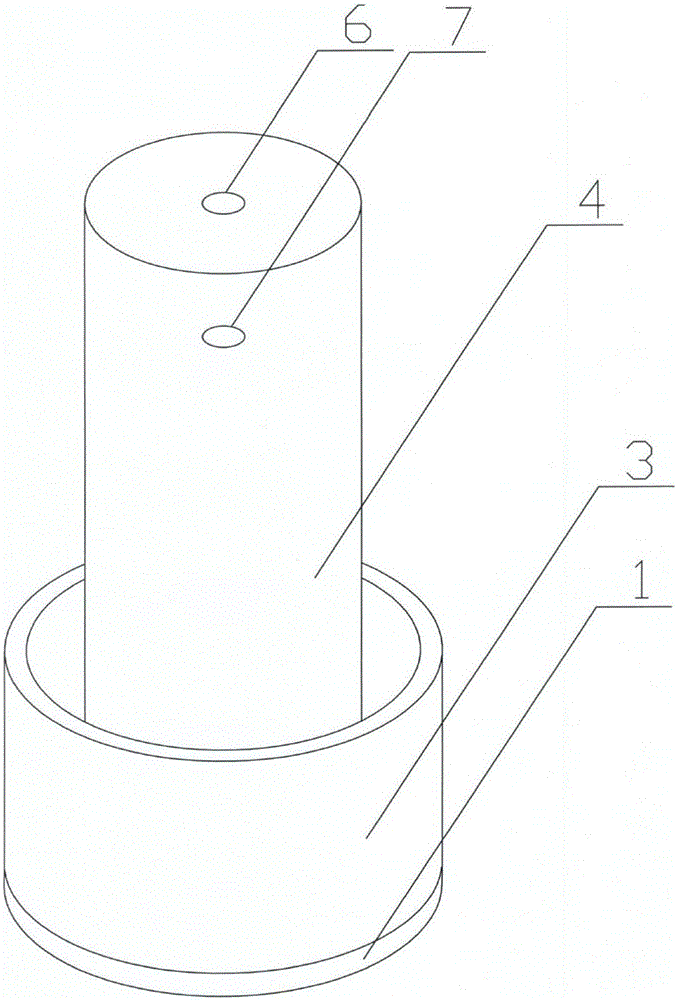

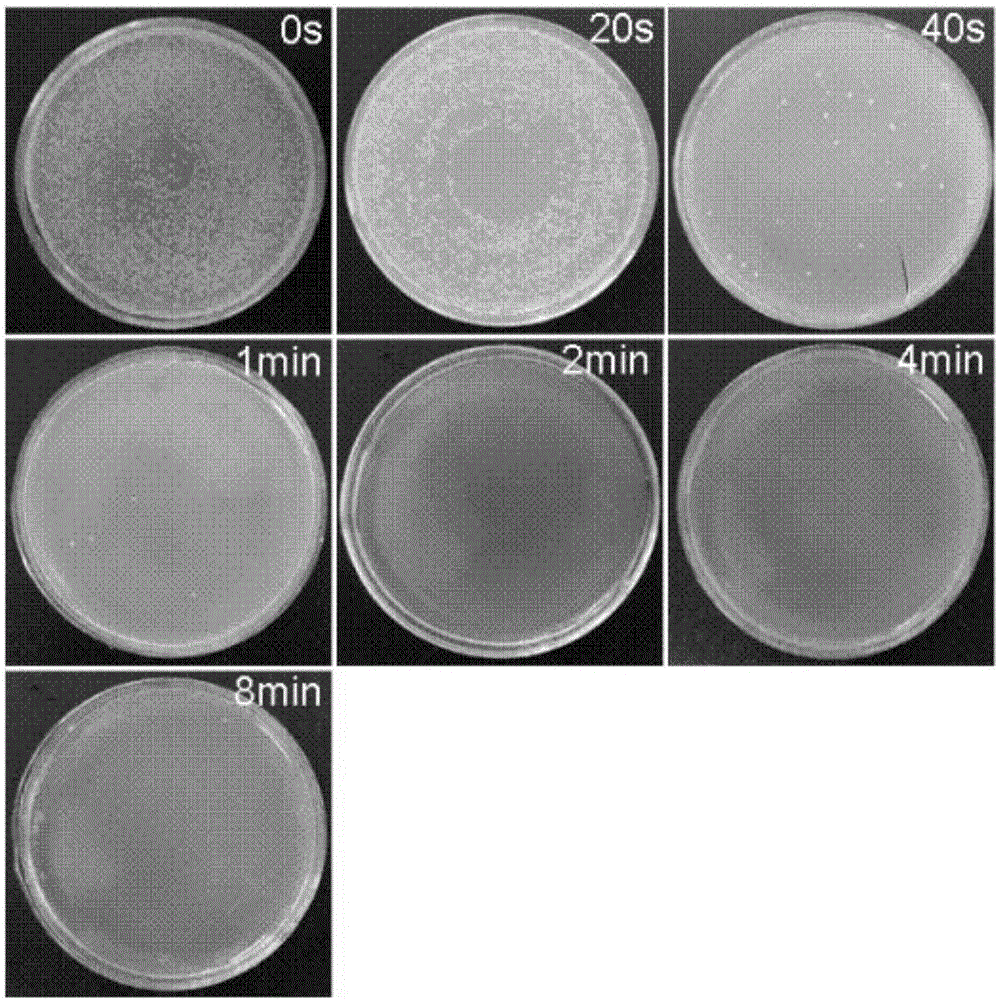

Array type microplasma generating device based on conductive coating

InactiveCN105491774AIncrease the areaLower the discharge temperaturePlasma techniqueDielectricConductive coating

An array type microplasma generating device based on a conductive coating comprises the components of an insulating housing, an inlet pipe, a high-voltage power supply and a ground electrode. The insulating housing has a cylindrical structure. One end of the insulating housing is closed, and the other end is open. The closed end of the insulating housing is communicated with the inlet pipe. The middle part of the insulating housing is provided with a circular flow sharing plate in radical direction. The flow sharing plate is provided with flow sharing holes which are arranged uniformly. A dielectric board A and a dielectric board B are mounted below the flow sharing plate, and furthermore a space is kept between the dielectric board A and the dielectric board B. The surfaces of the dielectric board A and the dielectric board B are provided with jacks which correspond with one another in the vertical direction. Insulating dielectric pipes are inserted and fixed between the jacks of the two dielectric boards, wherein the jacks correspond with one another in the vertical direction. Each insulating dielectric pipe has a pipe structure with an upper opening and a lower opening. The upper surface of the dielectric board A is provided with a conductive coating A which is connected with the high-voltage power supply through a lead. The lower surface of the dielectric board B is provided with a conductive coating B which is connected with the ground electrode through a lead. The array type microplasma generating device has advantages of high uniformity, concise structure, low cost, etc.

Owner:DALIAN NATIONALITIES UNIVERSITY

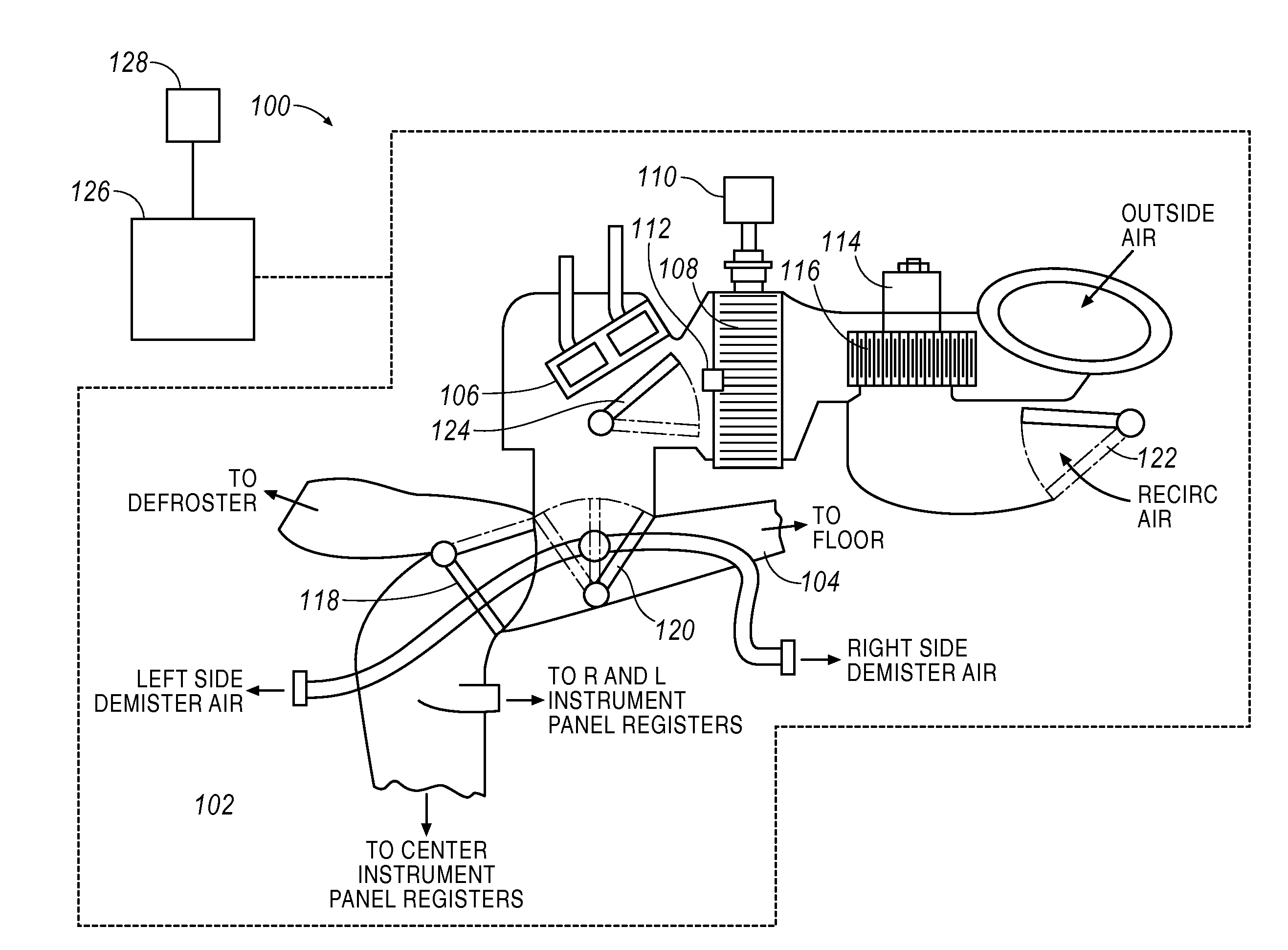

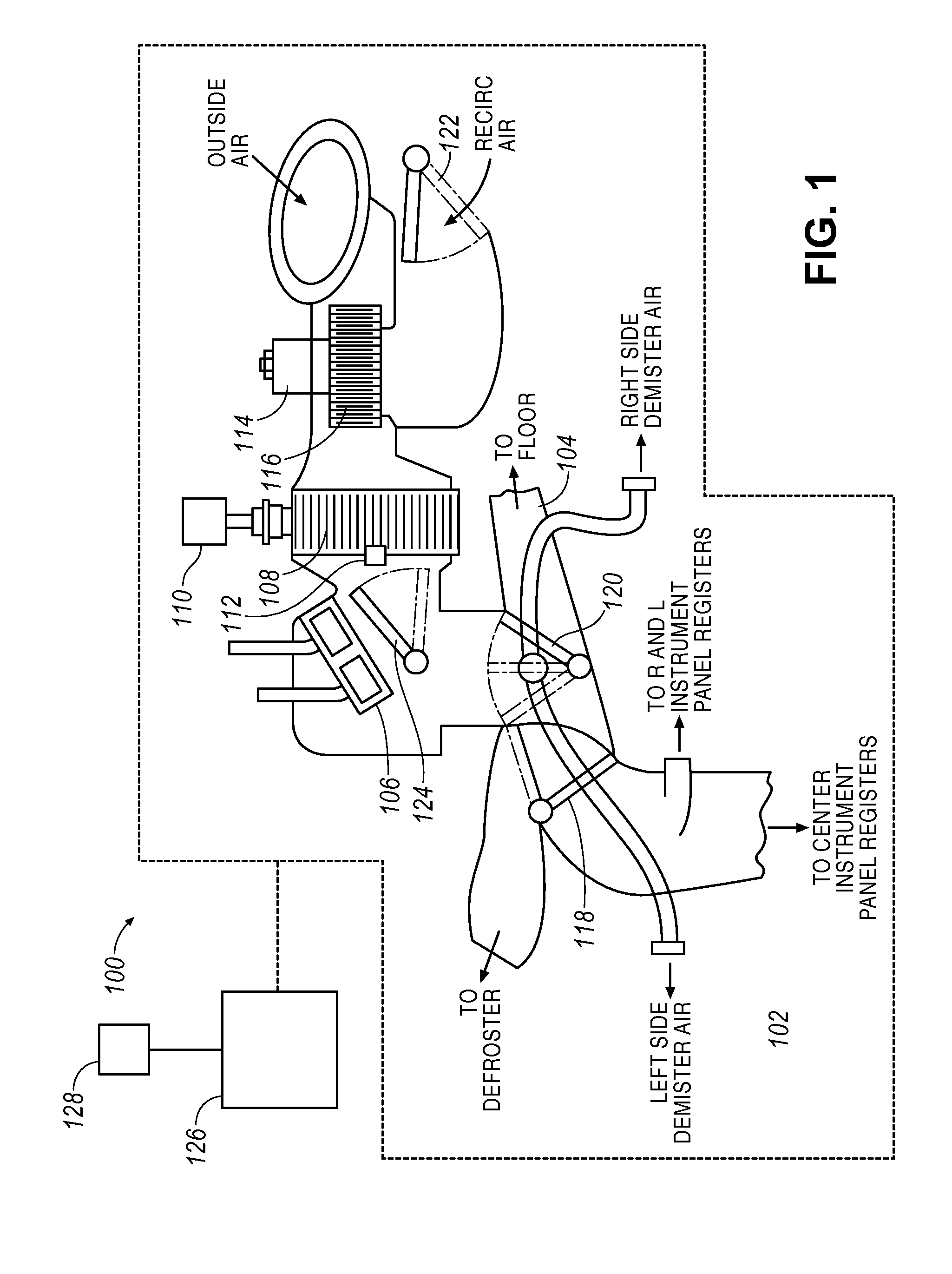

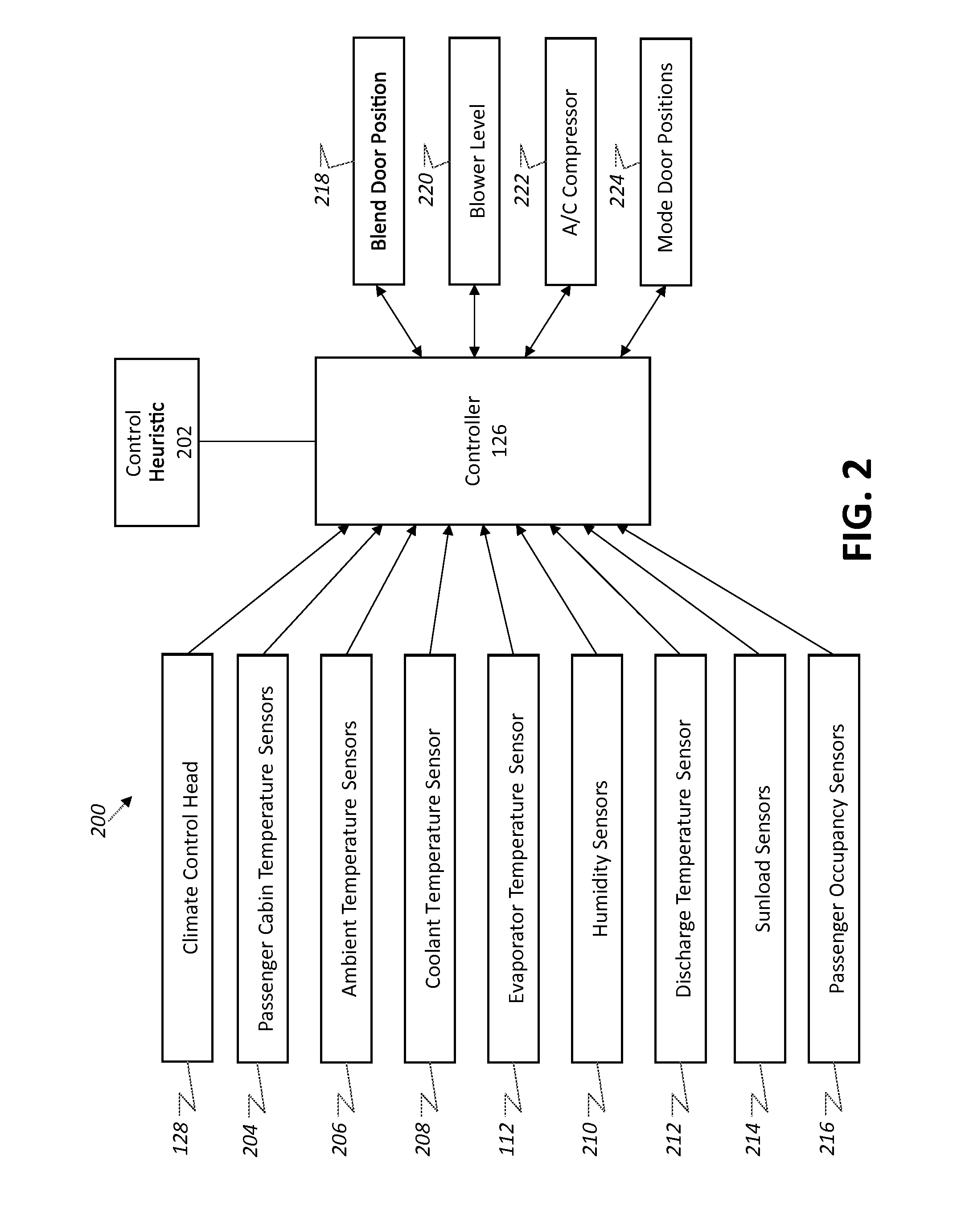

Coolest a/c discharge temperature for all operating conditions

ActiveUS20140216705A1Reduce the possibilityIncrease speedAir-treating devicesVehicle heating/cooling devicesControl systemEngineering

An automatic climate controller device may be configured to perform operations including identifying, by an automatic climate controller device, an operating zone of the climate control system according to at least two input factors; identifying a discharge temperature of the climate control system; determining, based on the operating zone and the discharge temperature, whether to perform at least one override action to override a climate control system setting to reduce the possibility of evaporator core icing; and adjusting an evaporator set point according to the at least one override action to reduce the discharge temperature. The input factors may include evaporator temperature and cabin relative humidity. The actions may include to increase blower speed and to increase use of recirculated air.

Owner:FORD GLOBAL TECH LLC

Medium and high temperature roller crusher with high efficiency composite cooling system

ActiveCN109277131AFast heat transferImprove heat transfer performanceGrain treatmentsControl systemHigh pressure water

The invention relates to a medium and high temperature roller crusher with a high efficiency composite cooling system. The medium and high temperature roller crusher with the high efficiency compositecooling system comprises a transmission device, a crushing unit, a miniature heat pipe cooling system, a water cooling system, a driven end sealing system and a measurement and control system, wherein the miniature heat pipe cooling system efficiently dissipates heat to a cavity of a roller through a miniature heat pipe, and symmetric fluid grooves of a micropore accelerate the cooling of the roller; in the water cooling system, a part of high pressure water is sprayed onto the inner wall of the upper part of the cavity of a roller shaft and a condensation section of the heat pipe for heat transfer through a high pressure cooling water spray head, and a part of high pressure water is sprayed out through axial small spray pipes and a radial small spray pipes of an immersion type spray headto generate high-speed jet flow and rotational flow which are in opposite directions, so that accumulated water highly forms turbulence flow; recesses of the inner surface of the roller shaft strengthens the surface heat dissipation; the cooling systems endow the medium and high temperature roller crusher with high efficiency cooling performance; and the driven end sealing system is provided witha reverse thread groove seal, an air cavity seal, and a ring-shaped air bag air seal, so that the good shaft end seal can be realized. The high efficiency cooling sealing characteristic of the mediumand high temperature roller crusher can ensure the safe and reliable operation of the medium and high temperature roller crusher in the medium and high temperature region of a grate cooler.

Owner:XIANGTAN UNIV

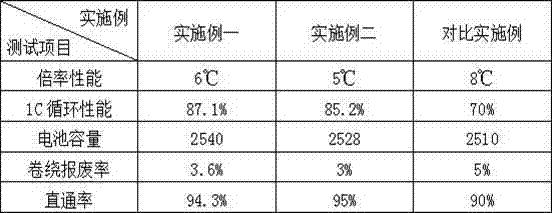

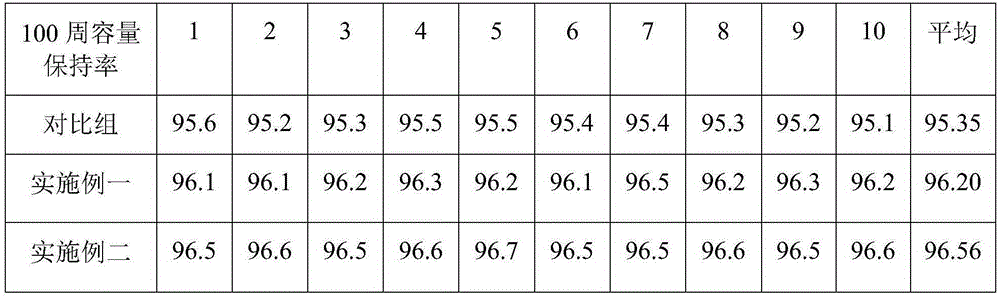

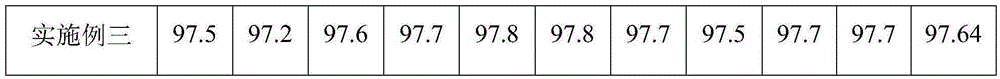

Preparation method of lithium ion battery positive plate and lithium battery manufactured thereby

ActiveCN104779368AReduce the problem of easy breakageGood flexibilitySecondary cellsElectrode screen printingScreen printingPhysical chemistry

The invention discloses a preparation method of a lithium ion battery positive plate. The method comprises the following steps: 1, adding dry powder containing polyoxyethylene PEO into a solvent to prepare a glue solution; 2, adding the glue solution into a mixture of a positive active material and a conductive agent and stirring to prepare positive paste; and 3, coating the positive paste by means of silk-screen printing coating and drying. According to the preparation method of the lithium ion battery positive plate and the lithium ion battery positive plate manufactured by using the preparation method, PEO softening positive paste is added to prevent the crisping of the positive plate; by using a silk-screen printing coating way, the phenomenon that powder falls down during slicing is avoided, and the performance of the lithium ion battery is greatly improved.

Owner:DONGGUAN CHUANGMING BATTERY TECH

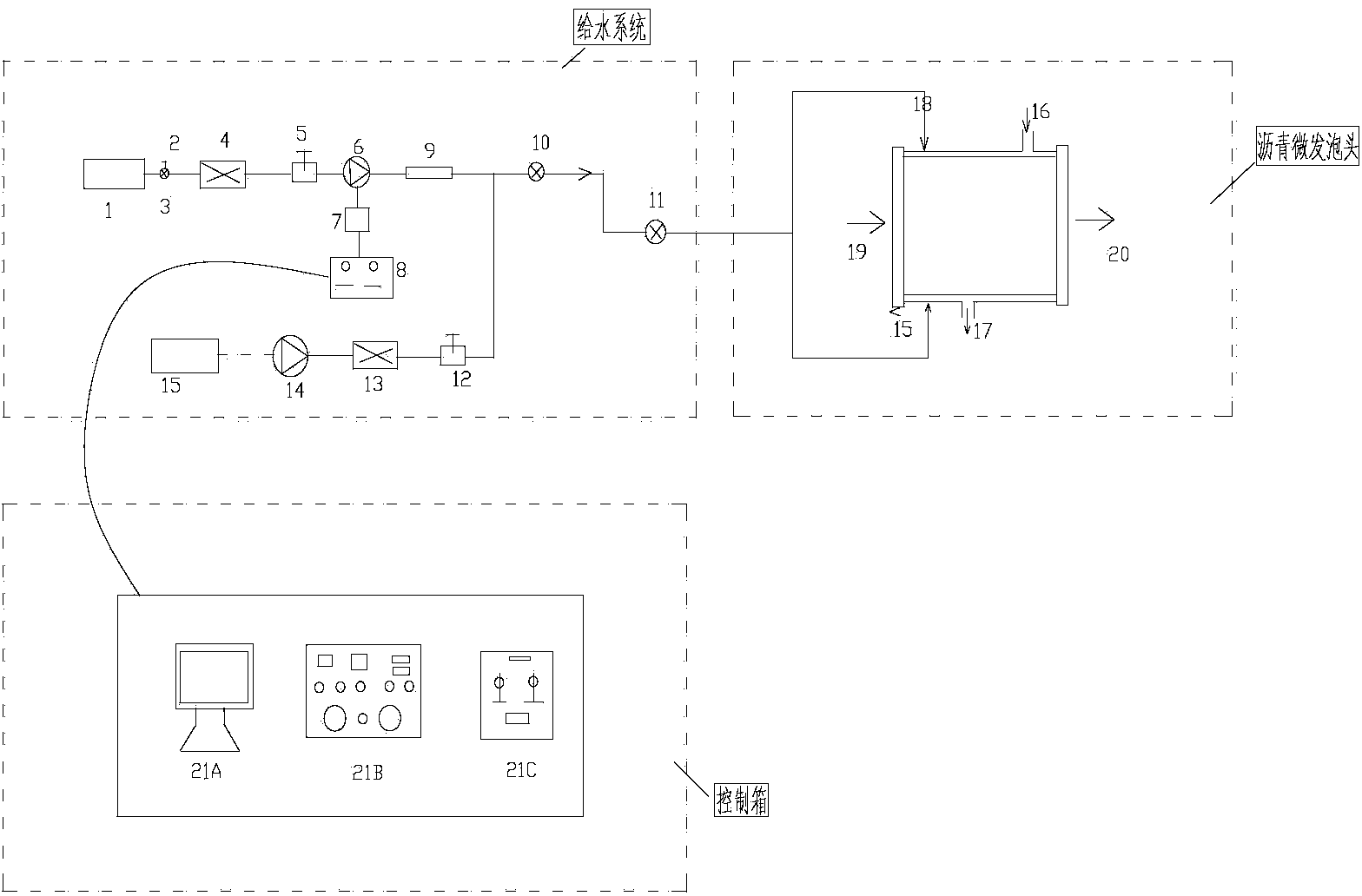

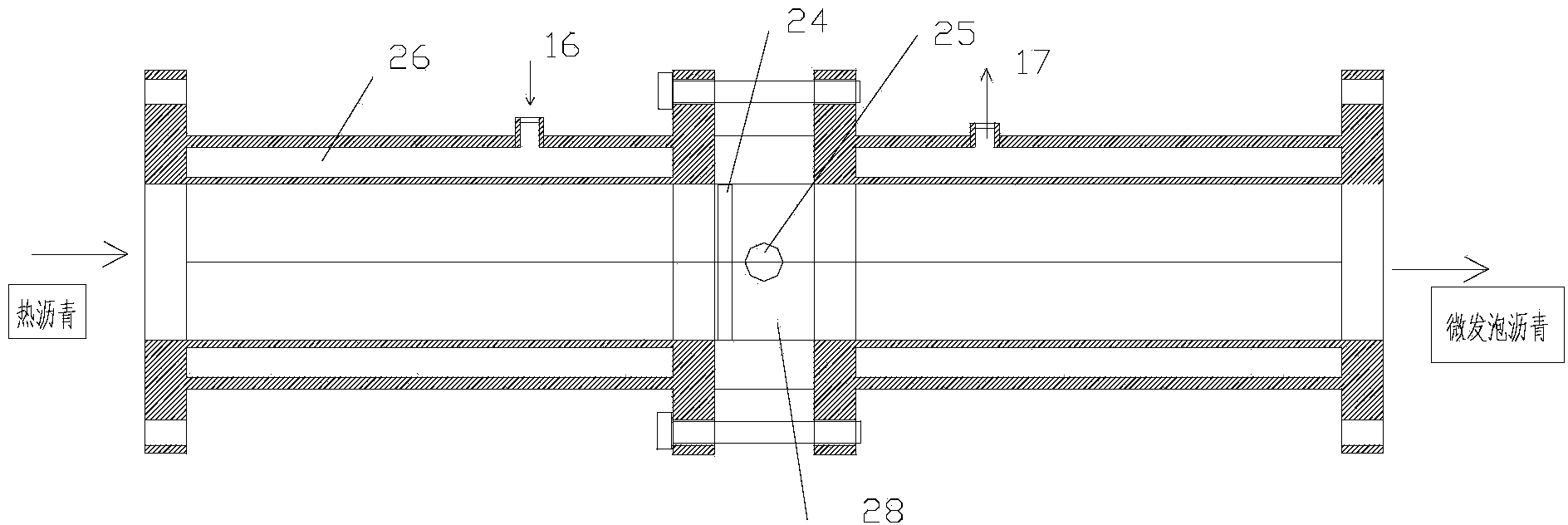

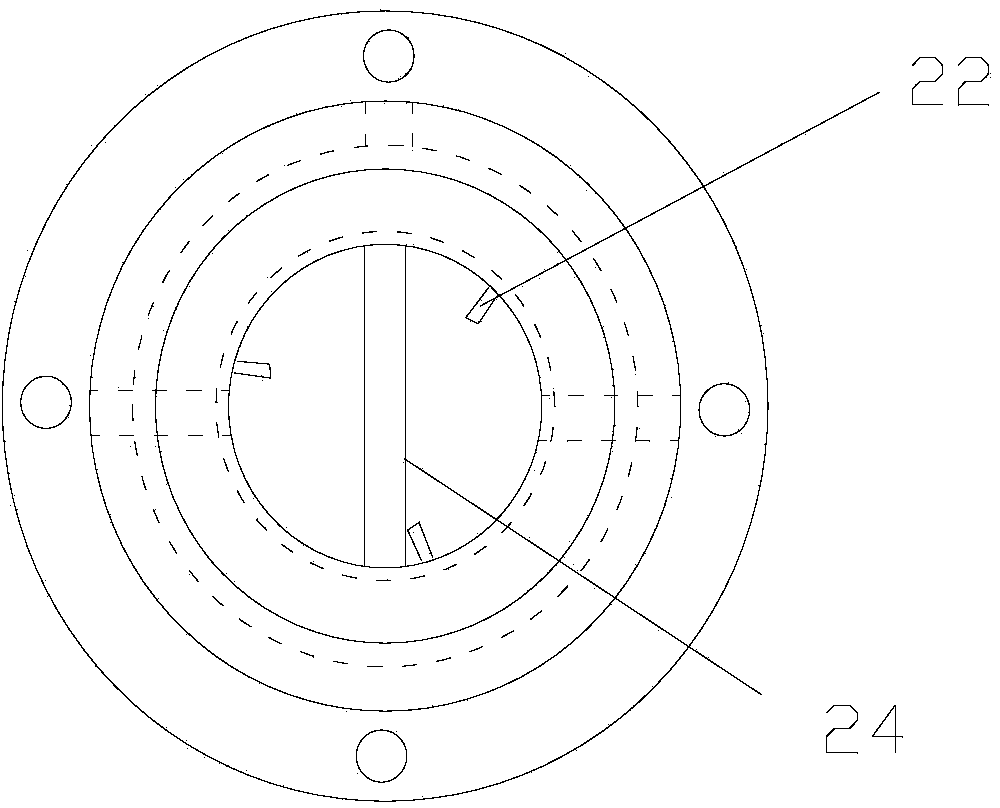

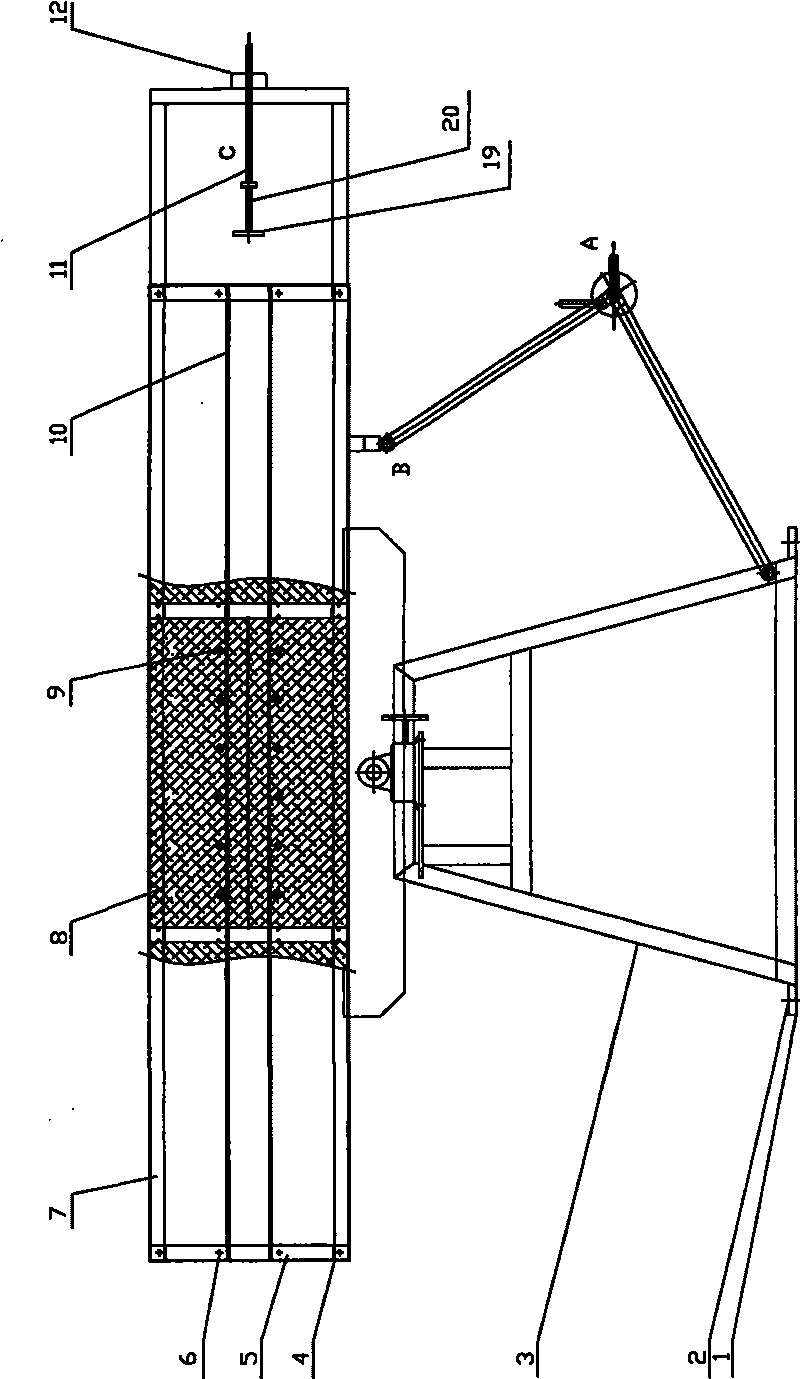

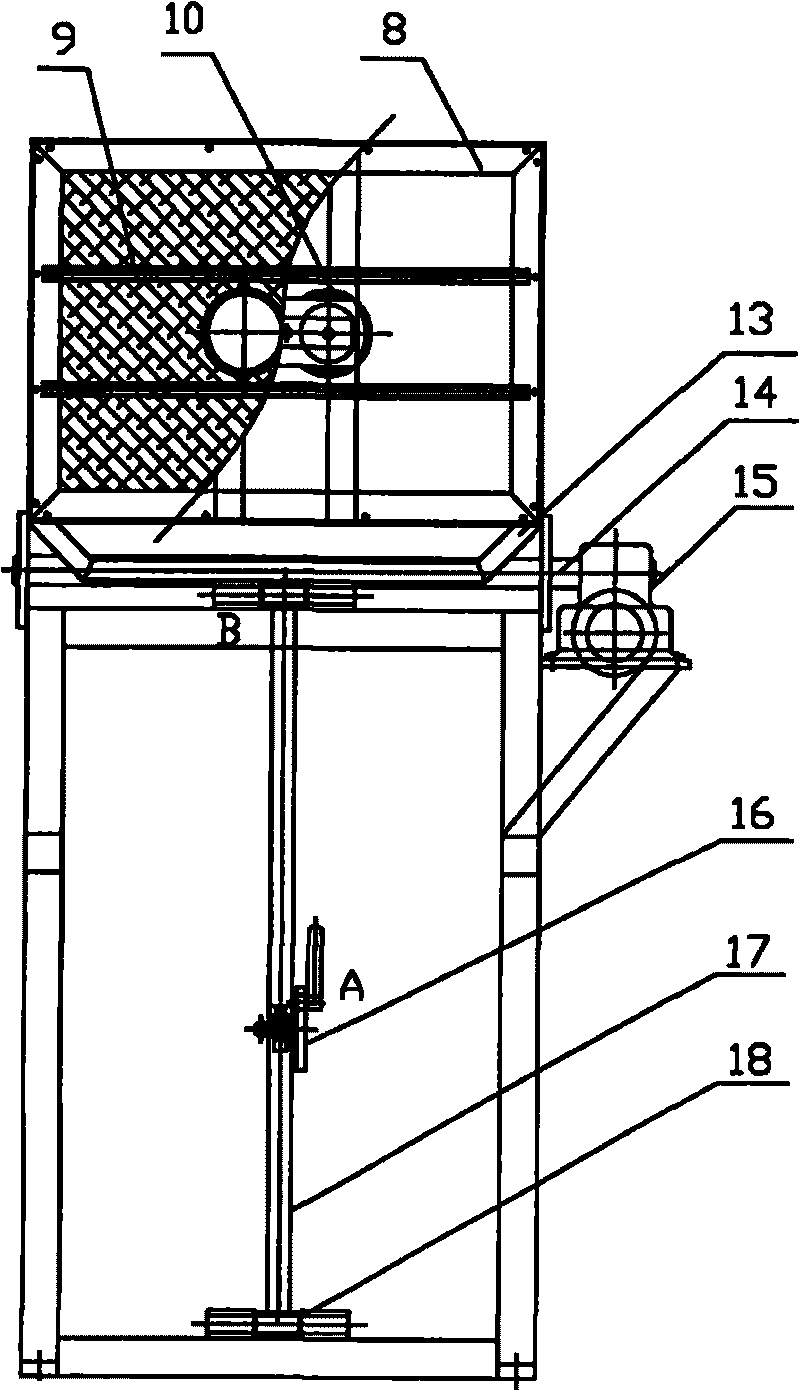

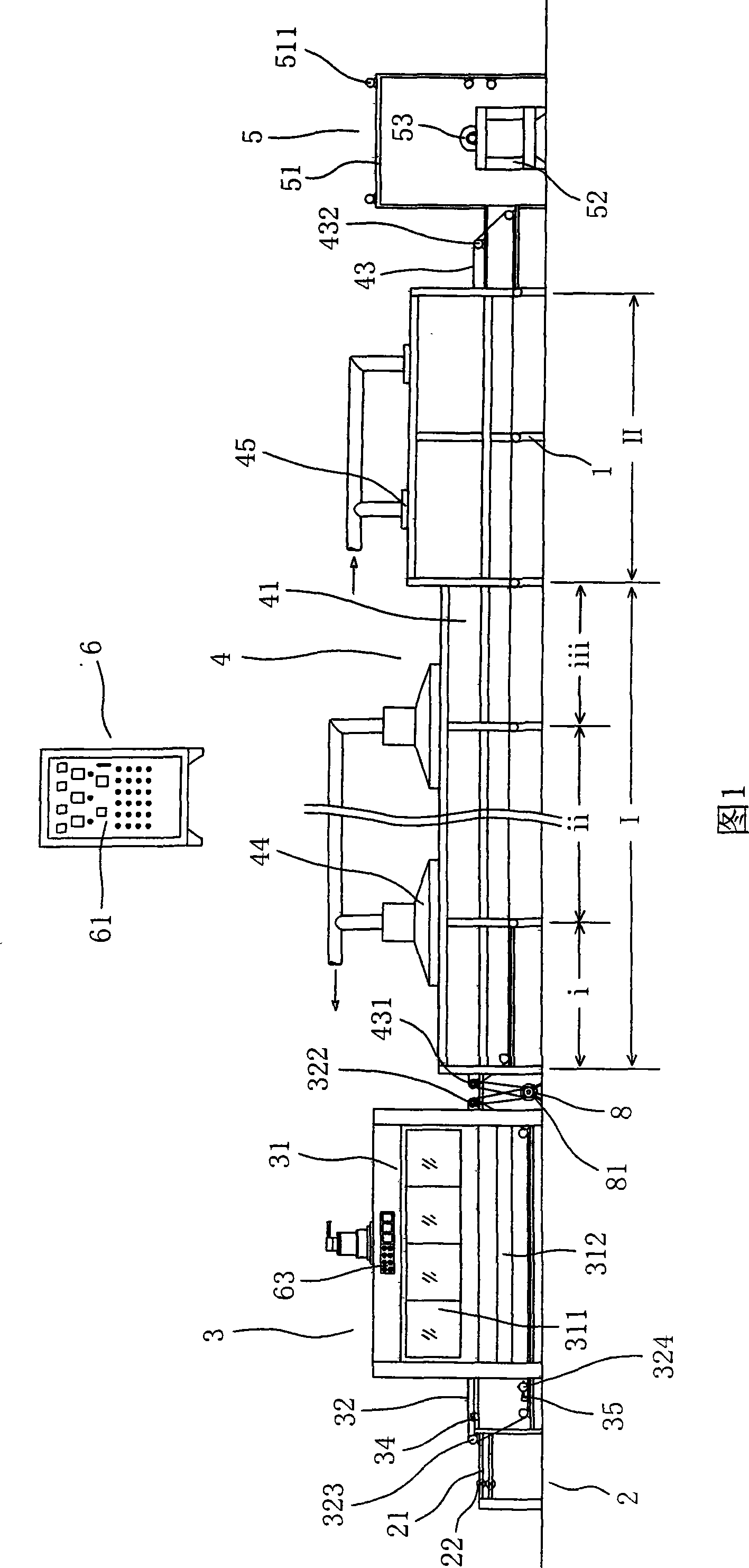

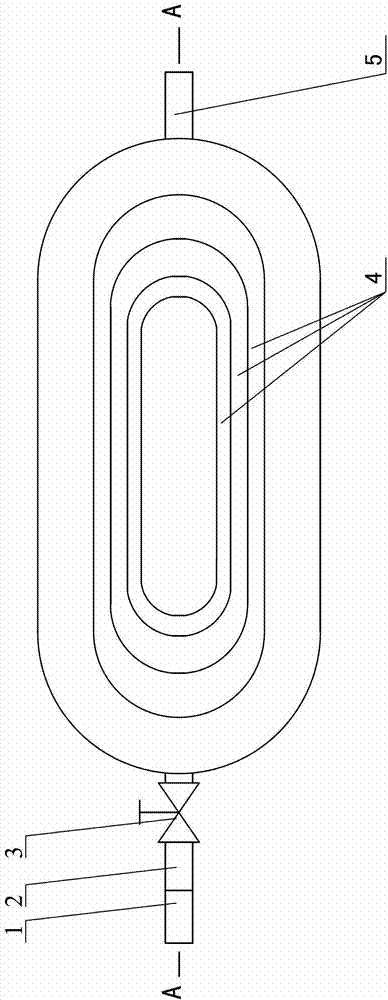

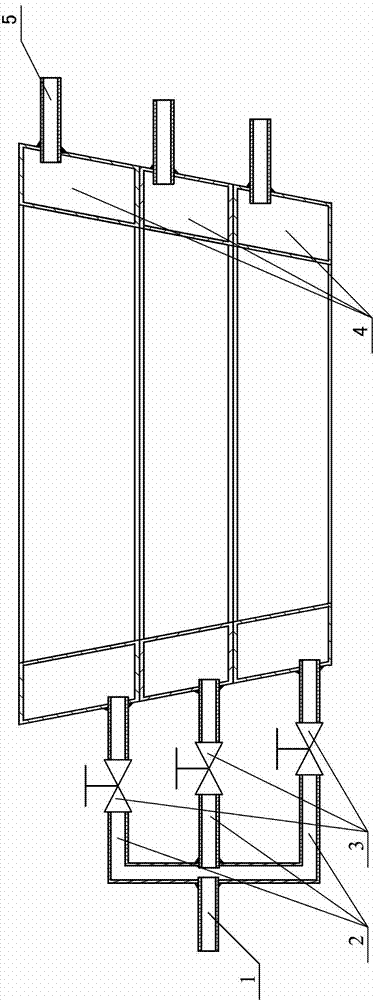

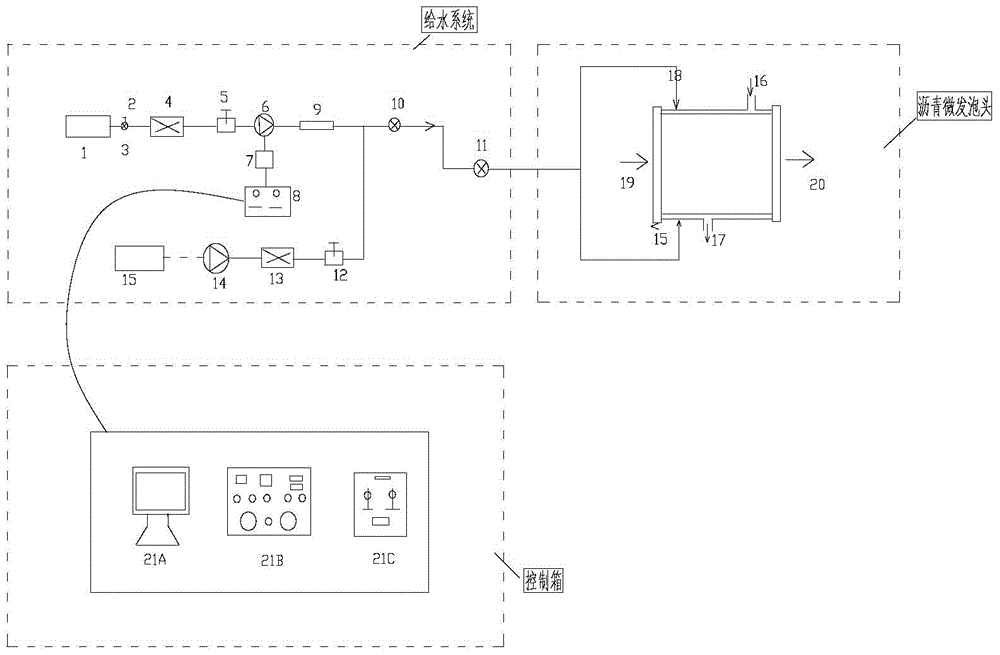

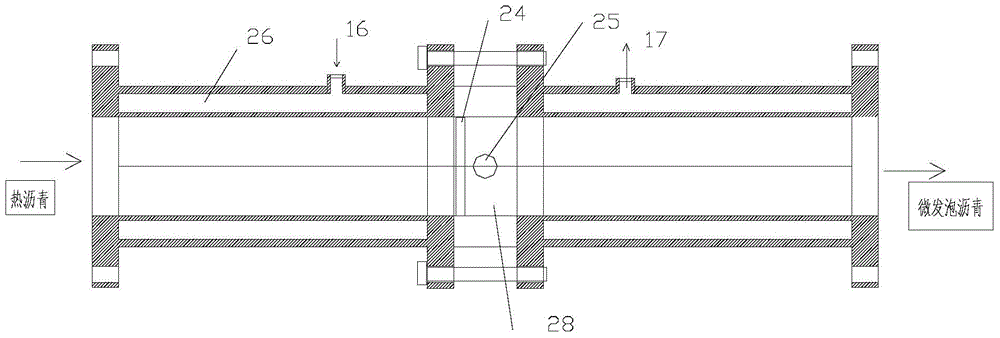

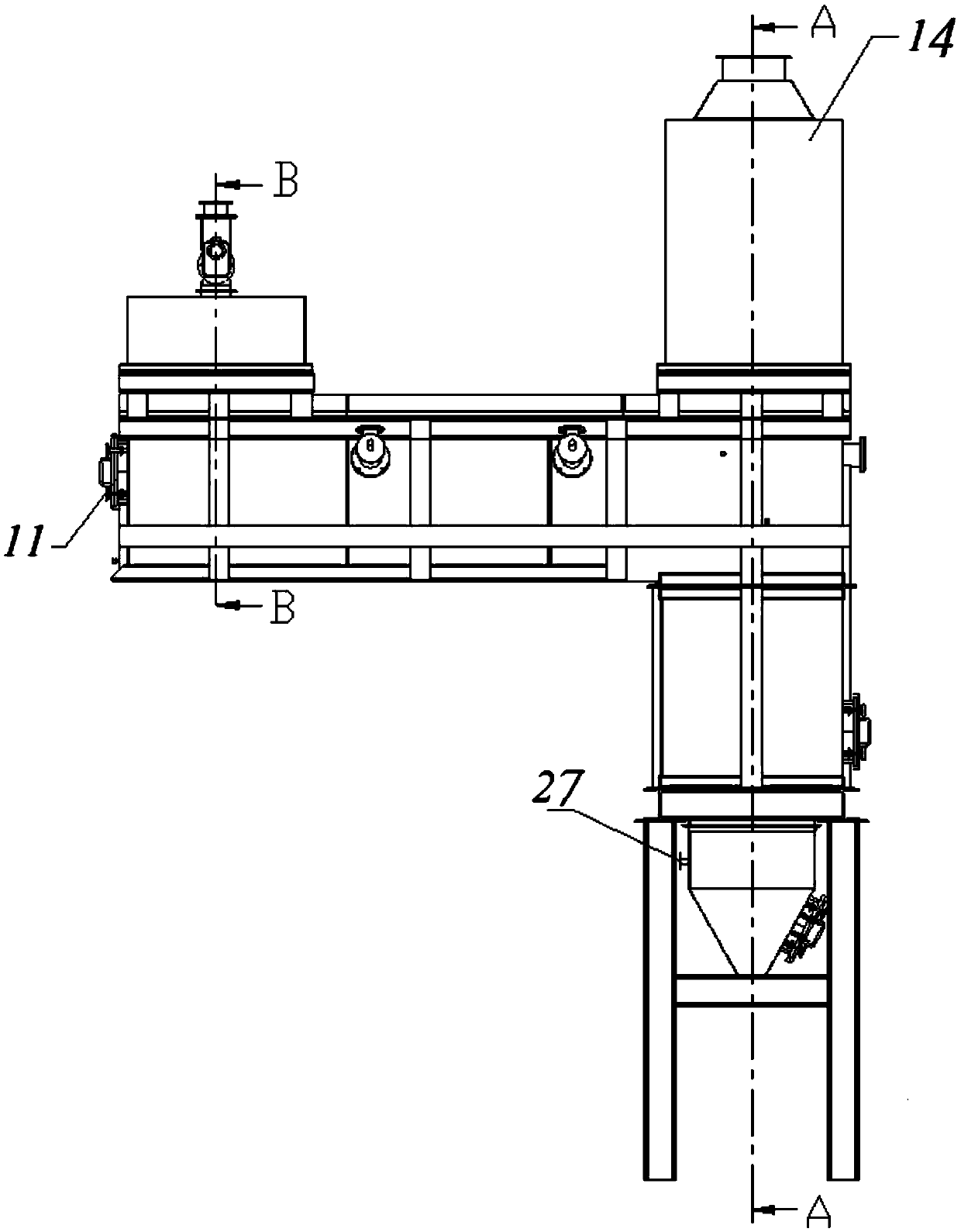

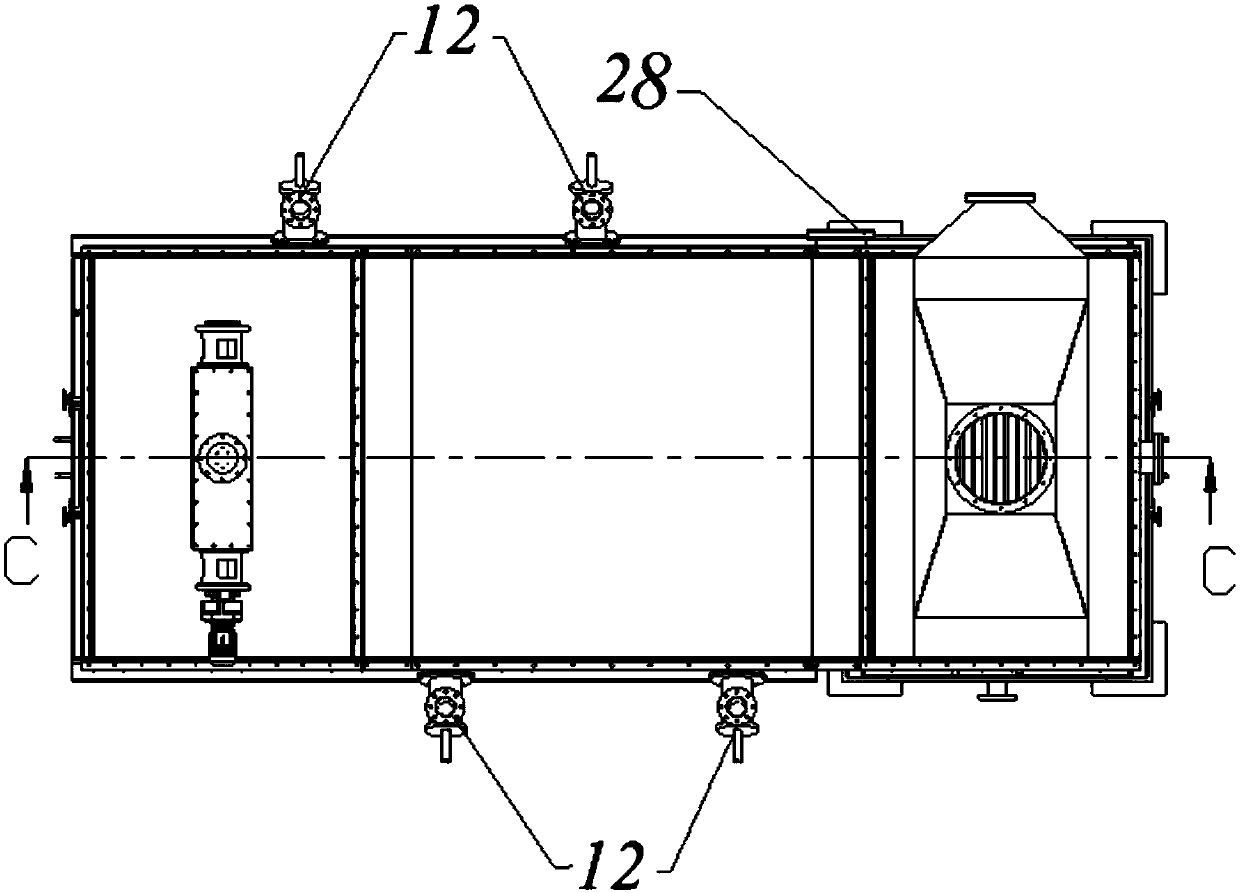

Micro-foamed warm mix asphalt mixture as well as preparation method and equipment thereof

ActiveCN104355568AReduce consumptionEmission reductionClimate change adaptationRoads maintainenceViscosityAsphalt

The invention relates to a warm mix asphalt mixture as well as a preparation method and equipment thereof, in particular to a micro-foamed warm mix asphalt mixture as well as a preparation method and equipment thereof, and belongs to the technical field of engineering. An asphalt micro-foaming formula and the equipment are matched for use. During mixture production, by the aid of the equipment, asphalt is fully foamed, a binder is sprayed into a mixing cylinder in the form of foamed asphalt and mixed with aggregate to form the warm mix asphalt mixture, the foamed asphalt is lower than the asphalt in viscosity and higher in workability and can fully cover the aggregate at the lower temperature, the mixing temperature of the warm mix asphalt mixture is reduced, and the micro-foamed warm mix asphalt mixture is produced. The micro-foamed warm mix asphalt mixture as well as the preparation method and the equipment thereof have benefits as follows: warm mixing of the warm mix asphalt mixture is realized by the aid of micro-foaming equipment, the cost for purchasing the equipment is only input once, and a small amount of water is sprayed in production. The production cost of the warm mix asphalt mixture is reduced, the once-and-for-all effect can be realized, and the method is more energy-saving and environment-friendly when compared with a traditional technology that warm mix materials are added for warm mixing.

Owner:江苏东交工程设计顾问有限公司

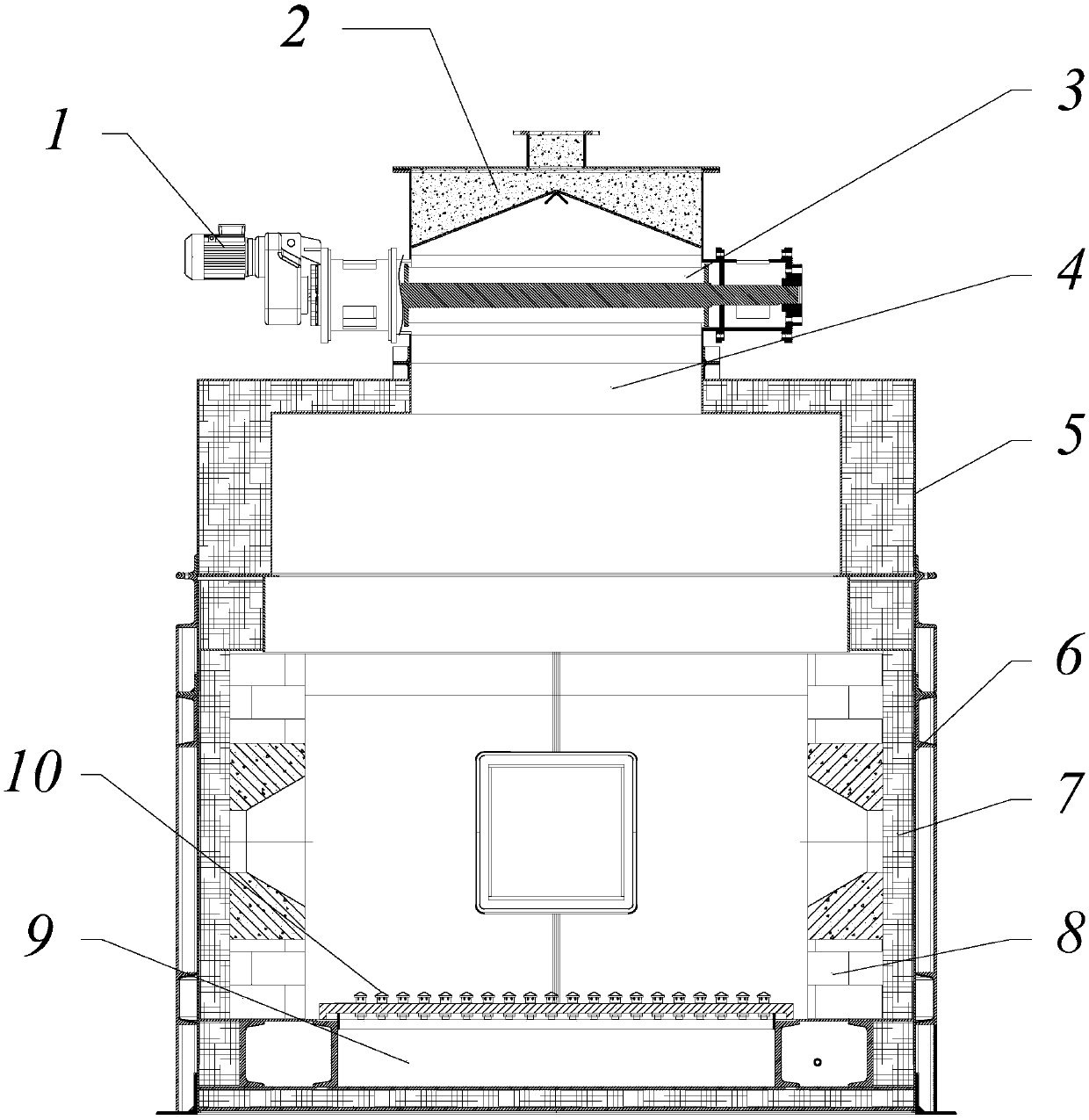

High-efficiency energy-saving high-technology ceramic material synthesis pre-burning kiln

InactiveCN101762155AReduce energy consumptionReduce burn-in costFurnace typesTunnel kilnMaterial synthesis

The invention relates to a high-efficiency energy-saving high-technology ceramic material synthesis pre-burning kiln, which is characterized in that: the high-efficiency energy-saving high-technology ceramic material synthesis pre-burning kiln is composed of a kiln body made of fireproofing material, a run-through fireproofing material pipe passage arranged in the kiln body and an electrical heating body, the electrical heating body is arranged between the kiln body and the fireproofing material pipe passage; in the invention, compared with the existing tunnel kiln and the continuous pushed slab kiln, the high-efficiency energy-saving high-technology ceramic material synthesis pre-burning kiln has simple structure without a sagger, a pushing plate and a guide rail; in addition, the high-technology ceramic material pre-burning powder is completely placed in the fireproofing material pipe, the heating space is compact, the heat dissipation area is greatly reduced and the heat energy efficiency is greatly improved; the placement angle of the high-efficiency energy-saving high-technology ceramic material synthesis pre-burning kiln can be adjusted and the kiln can be placed horizontally or obliquely, the inclined angle is convenient for leading the high-technology ceramic material to flow and convey in the fireproofing material pipe, so as to realize that when the high-technology ceramic material is cooled, the emitted waste heat flows back upwards along the fireproofing material pipe, so as to improve the utilization rate of heat energy.

Owner:NANJING WEINENG KILN TECH

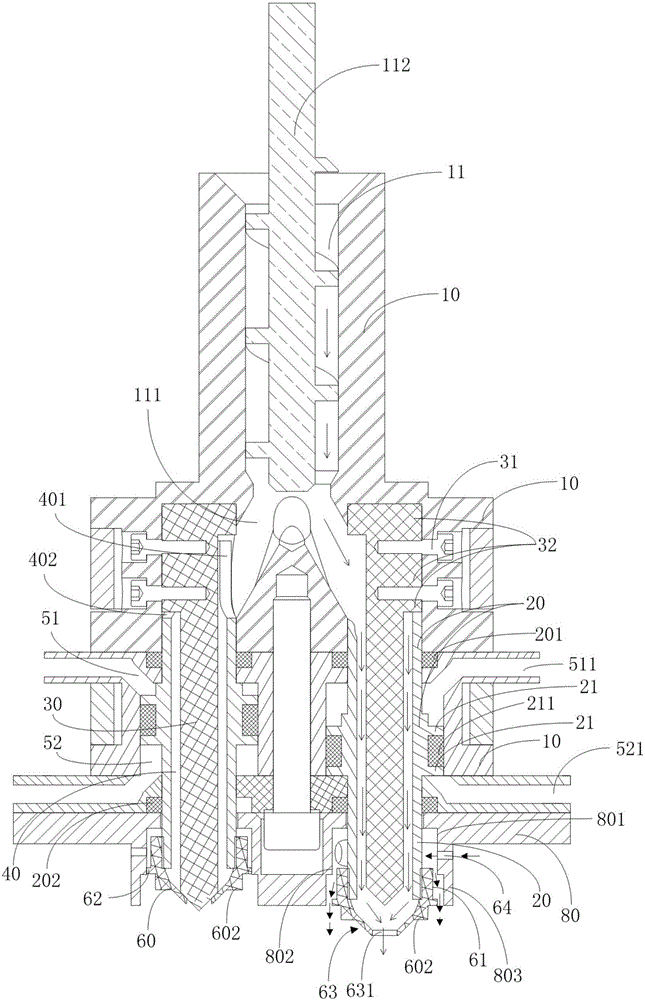

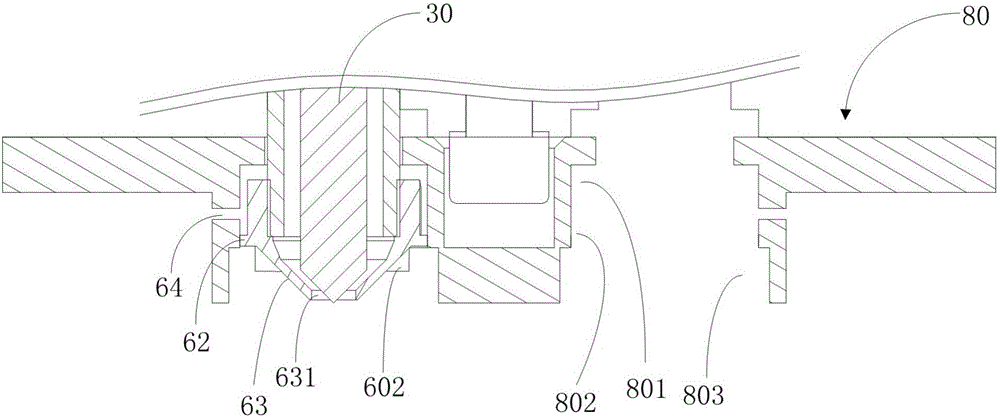

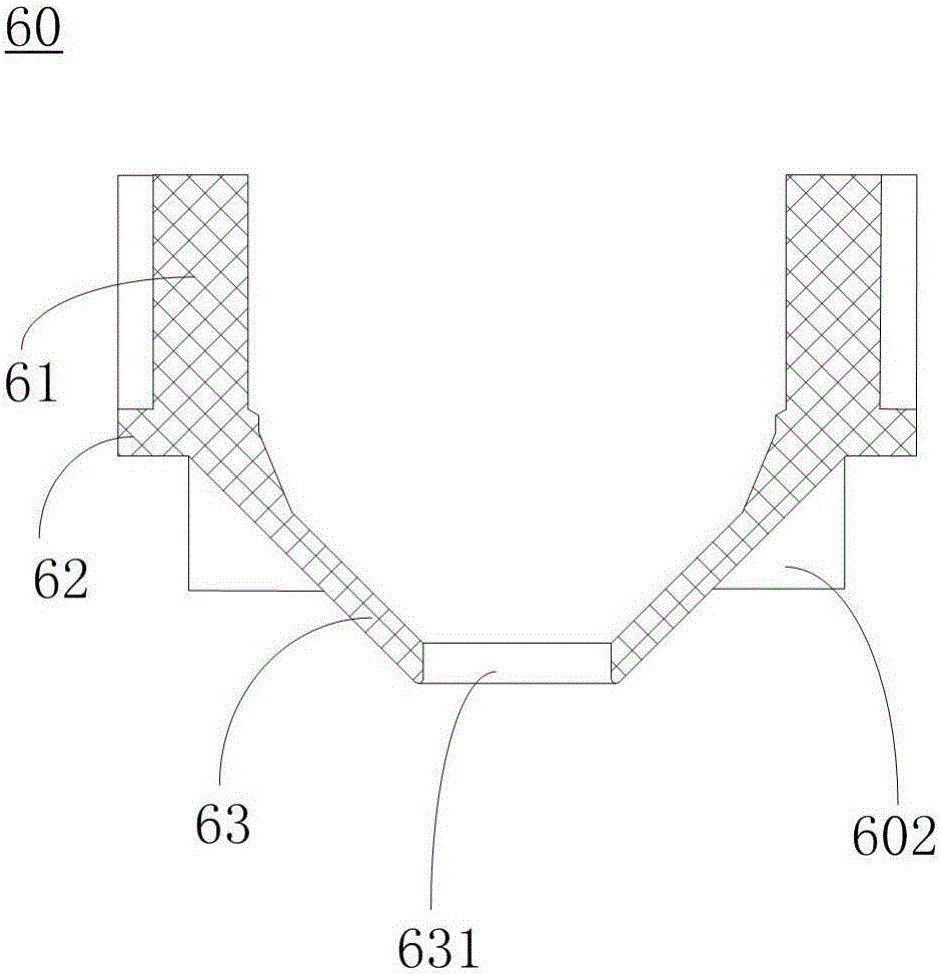

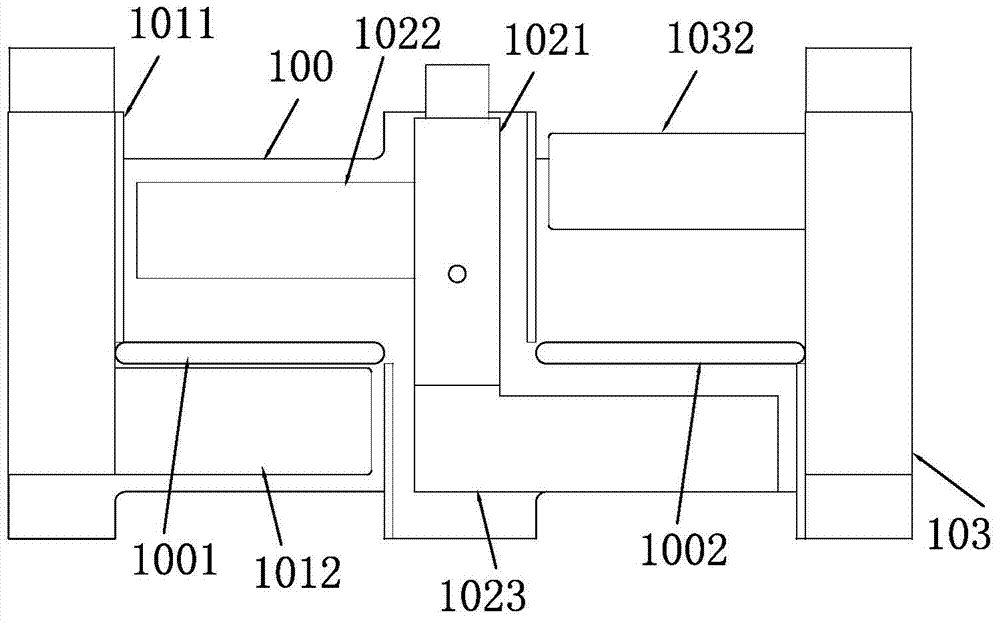

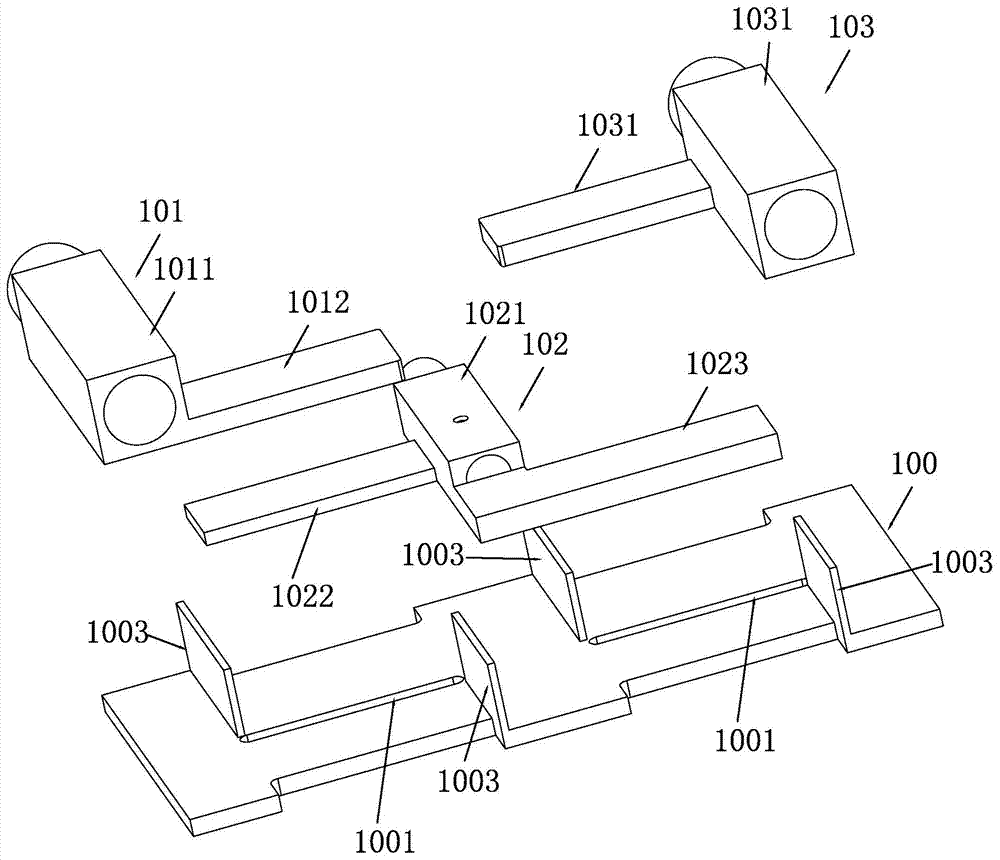

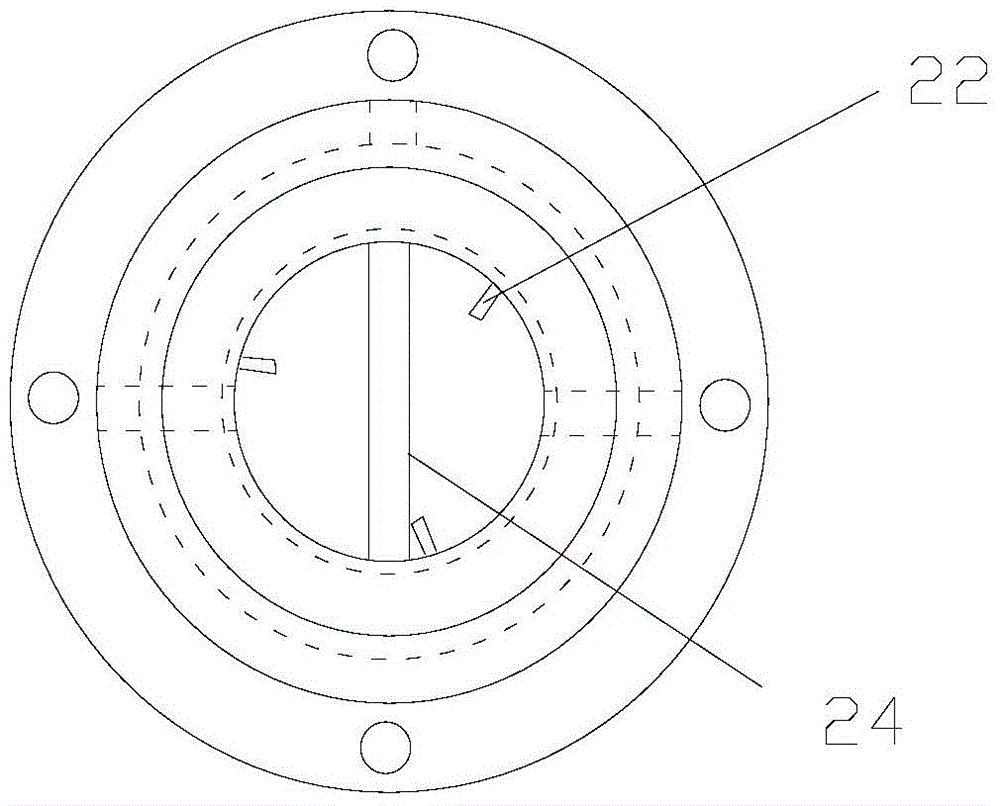

3D printing air nozzle and multi-channel telescopic nozzle valve provided with air nozzle

ActiveCN105922590AUniform cooling effectIncrease the windAdditive manufacturing apparatusMultiple way valvesEngineeringEnergy consumption

The invention discloses a 3D printing air nozzle. The air nozzle comprises a hollow air nozzle structure and a 3D printing nozzle, wherein the air nozzle structure comprises an air nozzle sealing section and an air outlet section, a nozzle hole is formed in the tail portion of the 3D printing nozzle, the 3D printing nozzle comprises a nozzle sealing section and a nozzle protruding section which are matched with the air nozzle sealing section, and the air nozzle structure installed around the outer side of the 3D printing nozzle. The invention further discloses a multi-channel telescopic nozzle valve provided with the air nozzle. The multi-channel telescopic nozzle valve comprises the 3D printing air nozzle and further comprises an installation base, cylinders and a valve needle, wherein the upper section of the installation base is provided with a feeding channel, the lower section of the installation base is provided with inner holes, and discharge ports are formed in the tops of the inner holes; the cylinders are installed in the inner holes and extend out from the open ends of the inner holes, and cylinder feed inlets are formed in the top ends of the cylinders; a hollow valve cavity is formed in each cylinder; the valve needle penetrates through the valve cavities and is installed on the installation base, and discharge channels are formed between the valve needle and the valve cavities. The 3D printing nozzle is arranged on the tail portions of the cylinders, and the air nozzle structure is arranged on the lower portion of the installation base. Air outflow is uniform, precision is high, energy consumption is low, noise is low, and environment protection and energy conservation are achieved.

Owner:浙江光镀智造科技有限公司

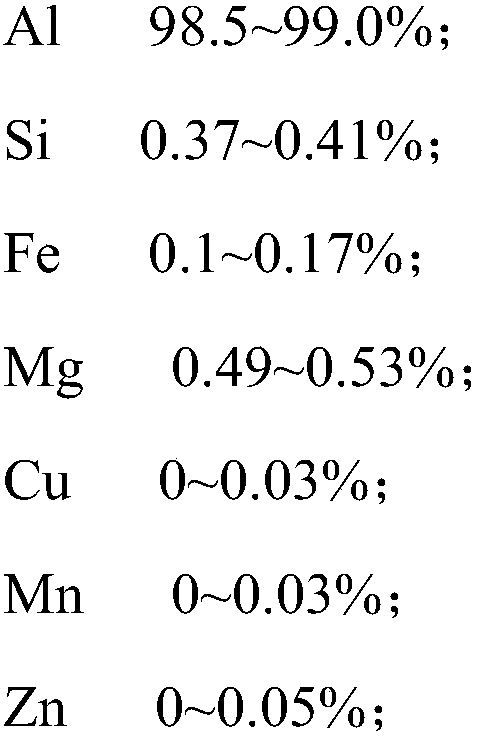

Processing technology of aluminum alloy profile and aluminum alloy profile

InactiveCN108359859AReduced amount of microscopic gapsSmall particle sizeConductive materialMetal/alloy conductorsIngotMechanical property

The invention provides a processing technology of an aluminum alloy profile. The processing technology at least comprises the following steps that an aluminum alloy ingot, an extrusion die and an extrusion barrel are respectively heated so that the temperatures of the aluminum alloy ingot, the extrusion die and the extrusion barrel are 480-500 DEG C, 435-445 DEG C and 410-420 DEG C correspondingly; the heated aluminum alloy ingot is placed in the heated extrusion barrel for extrusion treatment, and the heated aluminum alloy ingot is extruded from a die hole of the heated extrusion die to obtain a first extrusion profile; the first extruded profile is sequentially subjected to on-line quenching treatment, sawing treatment and tension straightening treatment, and finally, artificial aging treatment is carried out under the aging conditions of 195-205 DEG C for 5-8h to obtain the aluminum alloy profile. The aluminum alloy profile obtained by the technology is small in grain size, micro gap amount is reduced and micro gap size is reduced, the conductivity reaches 56% or more, and the comprehensive mechanical properties are good.

Owner:深圳市华加日西林实业有限公司

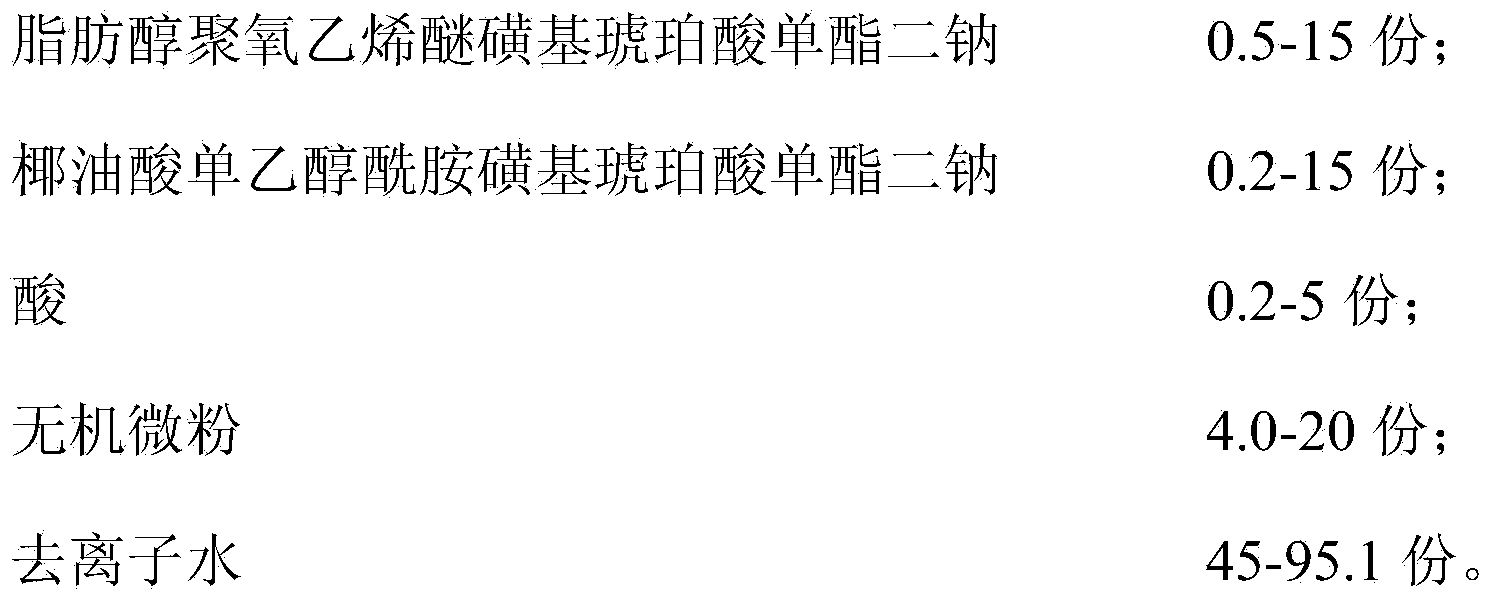

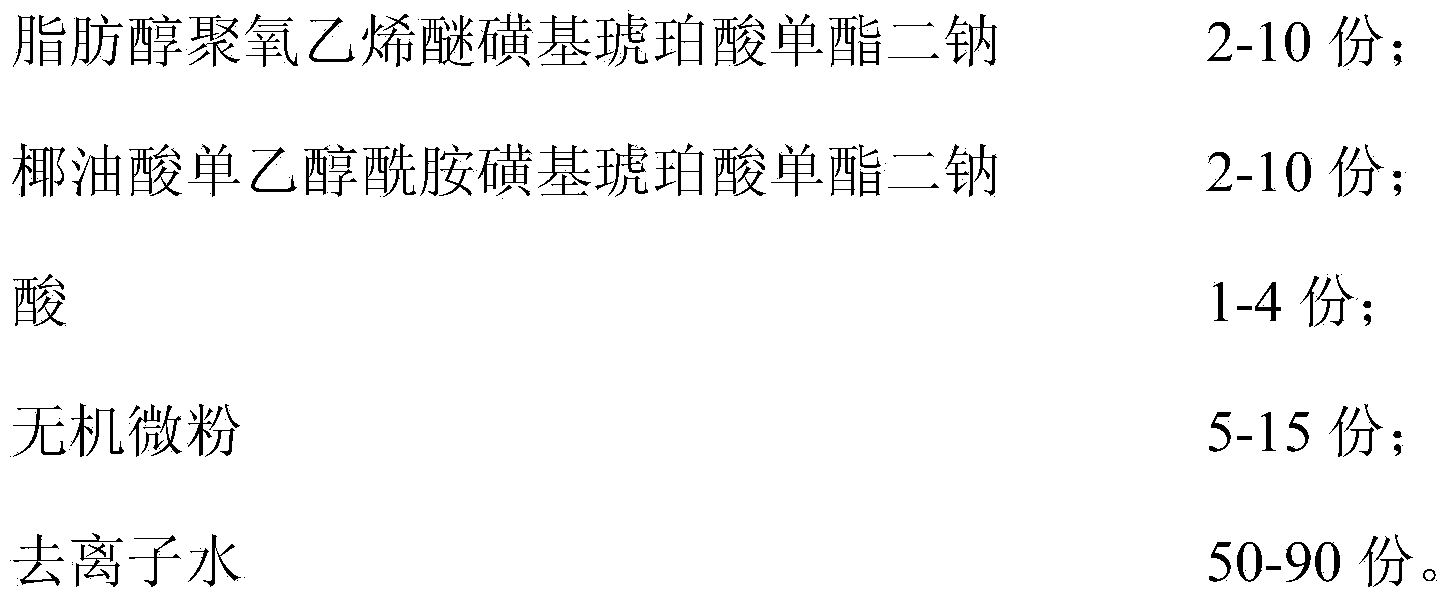

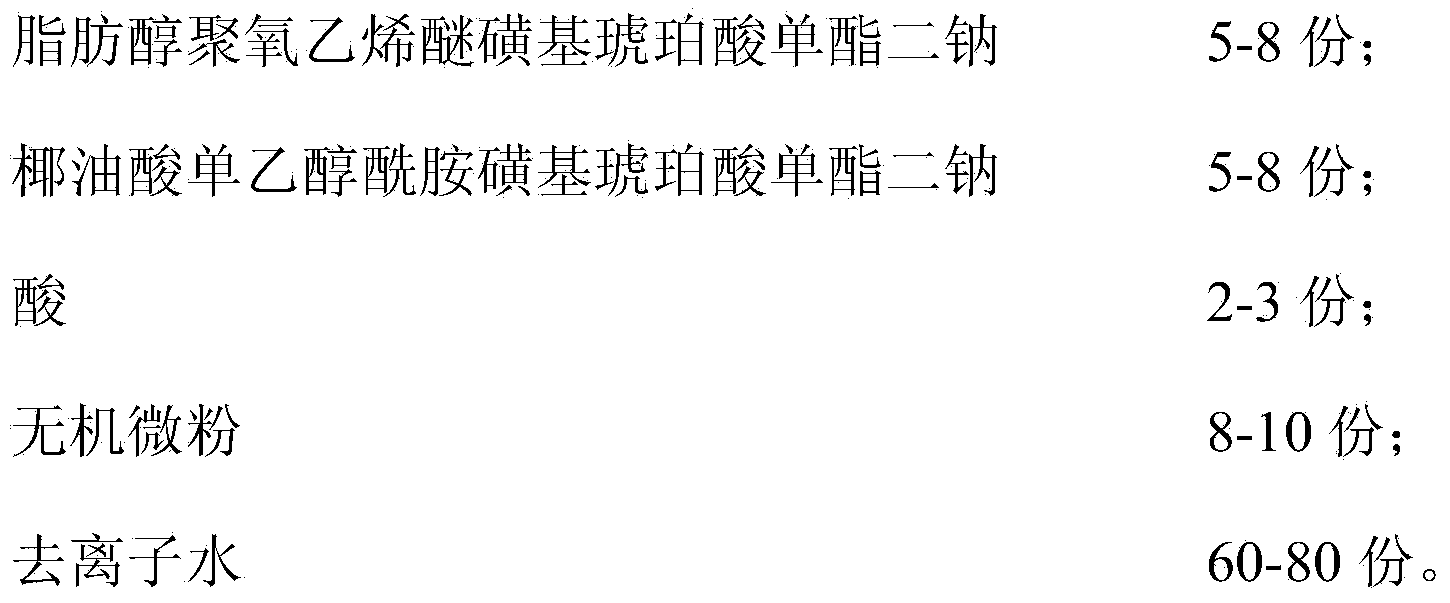

Warm asphalt modifier and preparation method and application thereof

InactiveCN104250446ALow preparation temperatureAchieve coolingClimate change adaptationBuilding insulationsAsphaltRoad construction

The invention relates to a warm asphalt modifier. The warm asphalt modifier comprises the following raw materials in parts by weight: 0.5-15 parts of disodium laureth sulfosuccinate, 0.2-15 parts of disodium cocoyl monoethanolamide sulfosuccinate, 0.2-5 parts of acid, 4.0-20 parts of inorganic micropowder and 45-95.1 parts of deionized water. The invention further relates to a method and application of the warm asphalt modifier as well as an asphalt mix containing the warm asphalt. The warm asphalt modifier well meets the requirements of road construction.

Owner:BEIJING ZHONGJIE WEIYE TECH DEV

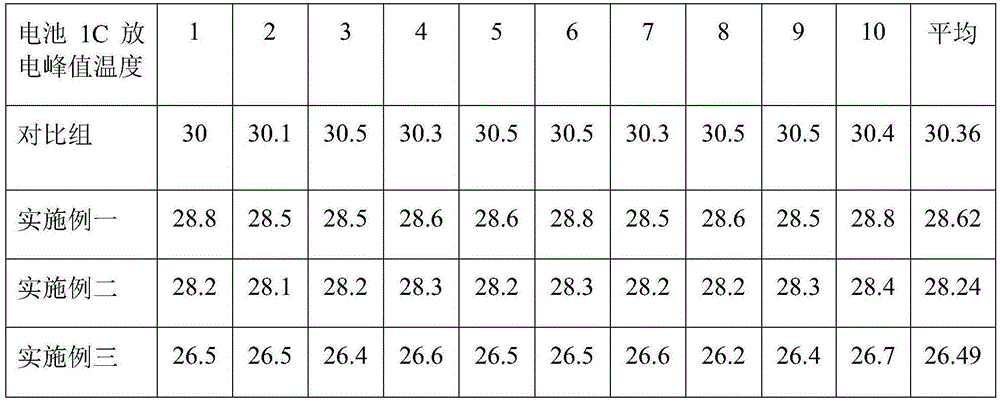

Polyindole crosslinked polyvinylidene fluoride binder and lithium ion battery applying the same

InactiveCN105355922AImprove conductivityImprove performanceFinal product manufactureCell electrodesInternal resistanceLithium-ion battery

Belonging to the technical field of lithium ion batteries, the invention provides a polyindole crosslinked polyvinylidene fluoride binder. The binder is formed by crosslinking polymerization of polyindole and polyvinylidene fluoride. The preparation method of the polyindole crosslinked polyvinylidene fluoride binder comprises the steps of: (1) premixing polyindole with polyvinylidene fluoride to obtain mixed powder A; (2) pouring the mixed powder A into N-methyl pyrrolidone under stirring, then conducting vacuum pumping, maintaining the pressure to obtain mixed colloid B; (3) adding a coupling agent into the colloid B and performing stirring to obtain mixed colloid C; (4) weighing crosslinking agent diisocyanate and N-methyl pyrrolidone, performing stirring at room temperature to obtain a solution D; and (5) adding the solution D rapidly into the mixed colloid C, and conducting stirring to obtain the binder F. The invention also provides a lithium ion battery applying the binder. The invention can solve the actual problems that the high battery internal resistance caused by high dielectric constant of the binder can affect the discharge capacity, the discharge temperature is high and the like.

Owner:百顺松涛(天津)动力电池科技发展有限公司

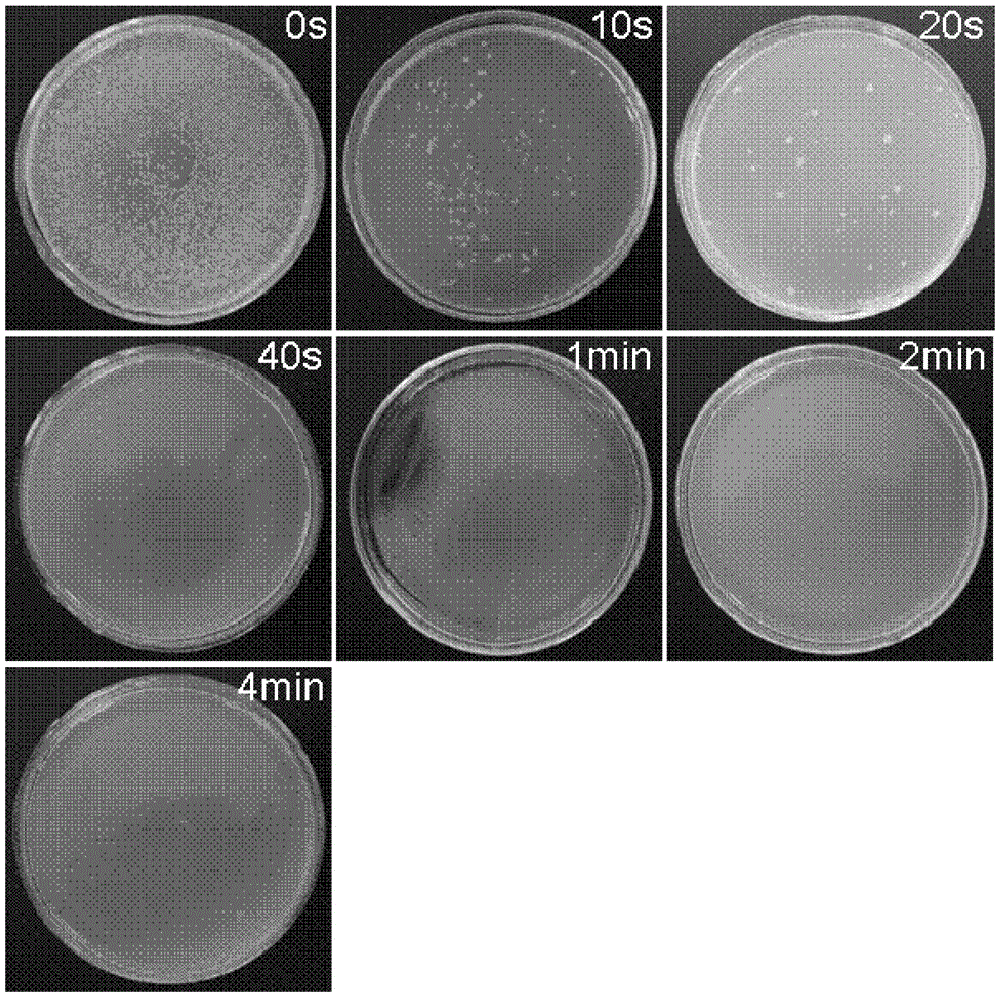

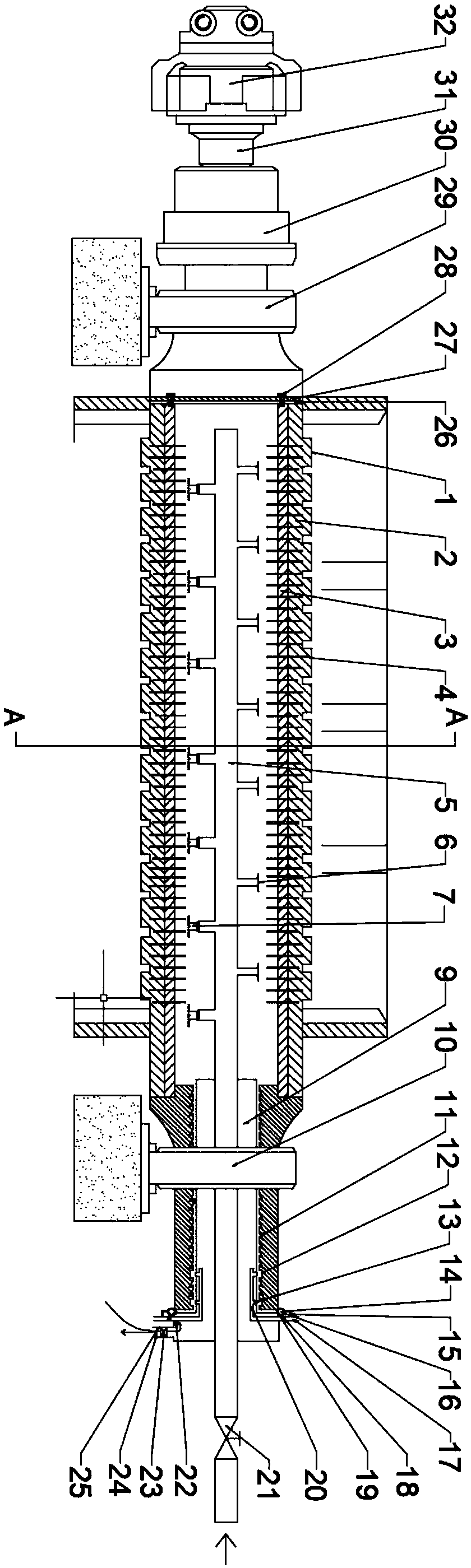

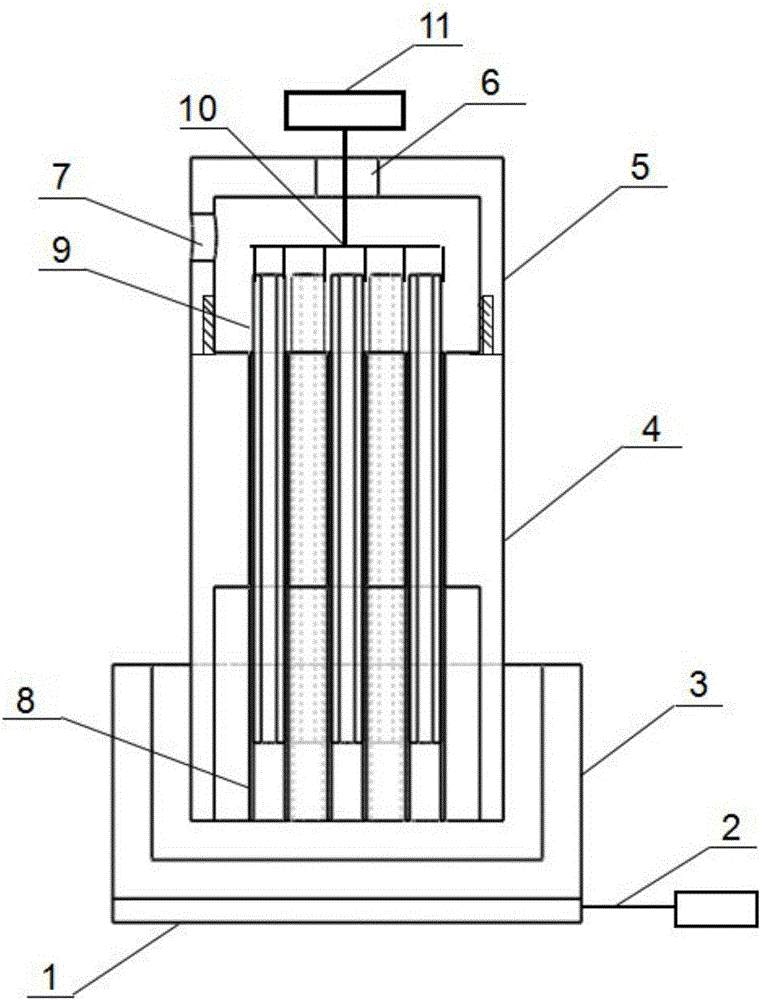

Array needle-board type liquid phase plasma jetting generation apparatus

InactiveCN105744713ALower the discharge temperatureImprove uniformityPlasma techniquePlasma jetEngineering

Disclosed is an array needle-board type liquid phase plasma jetting generation apparatus. The apparatus mainly comprises a metal board, a dielectric body, a ventilating mechanism, insulating dielectric tubes and conductive metal tubes. The liquid phase plasma jetting generation apparatus adopts a dielectric block discharging technology in the liquid phase; uniform low-temperature plasma jet is generated in the liquid; the liquid phase plasma jetting generation apparatus is low in discharging temperature and high in uniformity; and compared with the conventional liquid phase plasma discharging apparatus, the apparatus provided by the invention is more delicate and simpler in structure, higher in concentration of the generated plasma active materials, convenient and rapid to install, low in discharging requirement, high in stability, low in energy consumption and high in efficiency.

Owner:DALIAN NATIONALITIES UNIVERSITY

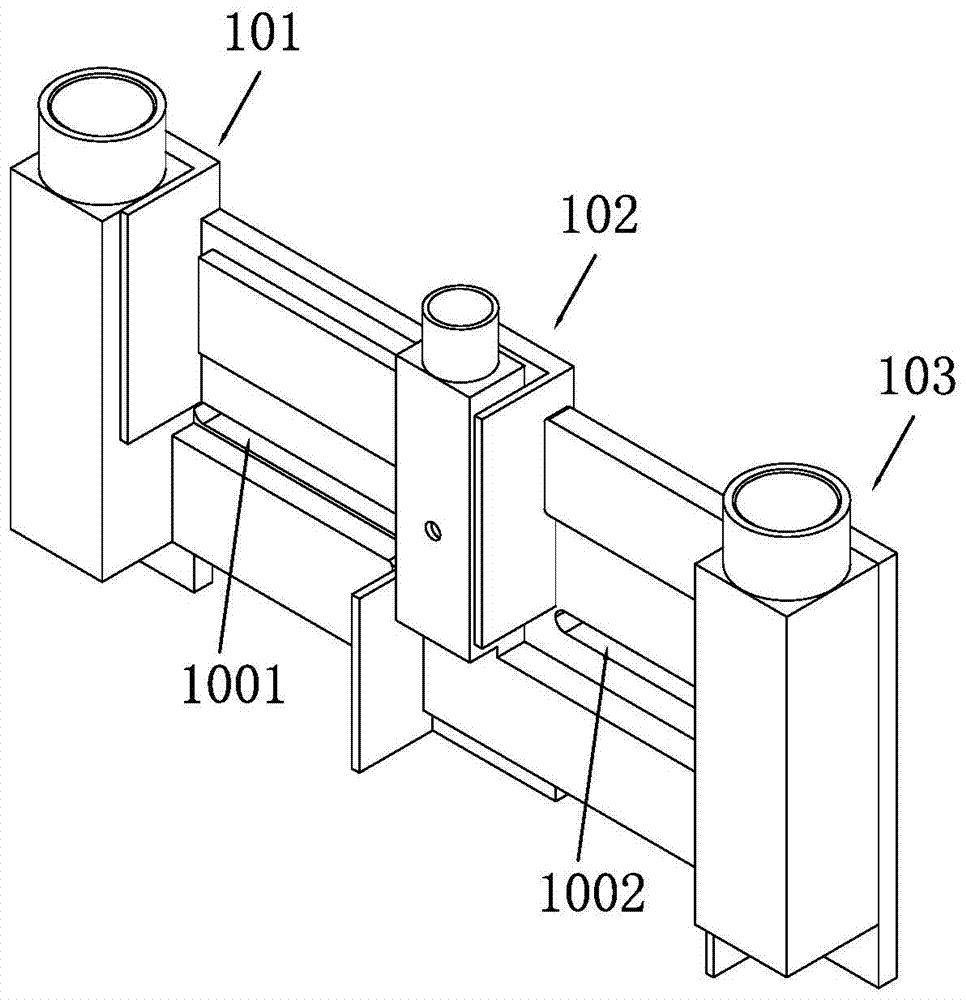

Adapter plate and lithium ion battery pack with adapter plate

ActiveCN104752672AEasy to assemble and connectFast connection and assemblySecondary cellsCell component detailsElectrical batteryEngineering

The invention relates to the field of lithium ion batteries, and discloses an adapter plate and a lithium ion battery pack with the adapter plate; the adapter plate comprises an insulating substrate; a first tab through hole and a second tab through hole are respectively formed in the insulating substrate; the adapter plate further comprises a first metal component, a second metal component and a third metal component fixed on the surface of the insulating substrate; the first metal component comprises a first metal pipe and a first metal plate extending at the right side of the first metal pipe; the second metal component comprises a second metal pipe, a second metal plate and a third metal plate, wherein the second metal plate and the third metal plate respectively extend at the left and right sides of the second metal pipe; the third metal component comprises a third metal pipe and a fourth metal plate extending at the right side of the third metal pipe; the first metal plate and the second metal plate are just aligned and parallel to each other and respectively positioned at the front and back of the first tab through hole; and the third metal plate and the fourth metal plate are just aligned and parallel to each other and respectively positioned at the front and back of the second tab through hole. The cycle performance of the battery pack is easily increased.

Owner:SHENZHEN GREPOW BATTERY CO LTD

Method for making nitre and drying and drying apparatus thereof

InactiveCN101275804AImprove working environmentLess nitrateDrying solid materials with heatHearth type furnacesFluidized bed dryingProcess engineering

The invention discloses a processed saltpeter drying method and a drying device thereof, comprising: through real time control of warm wind and cool wind in a dryer of a fluidized bed, drying anhydrous sodium sulphate with a certain volume of water entering the dryer of the fluidized bed which is divided into a drying section and a cooling section, in the drying section, wet saltpeter entering the dryer of the fluidized bed undergoes sufficient heat energy exchange with warm air entering the dryer of the fluidized bed, the dried material enters the cooling section for sufficient heat energy exchange with cool air entering the dryer of the fluidized bed, and cool saltpeter is discharged from the dryer of the fluidized bed for packaging. The method and device of the invention are provided with the following advantage of convenient to operate and manage with low energy consumption, low travel cost, good dry effect and stable dry effect.

Owner:江苏白玫化工有限公司

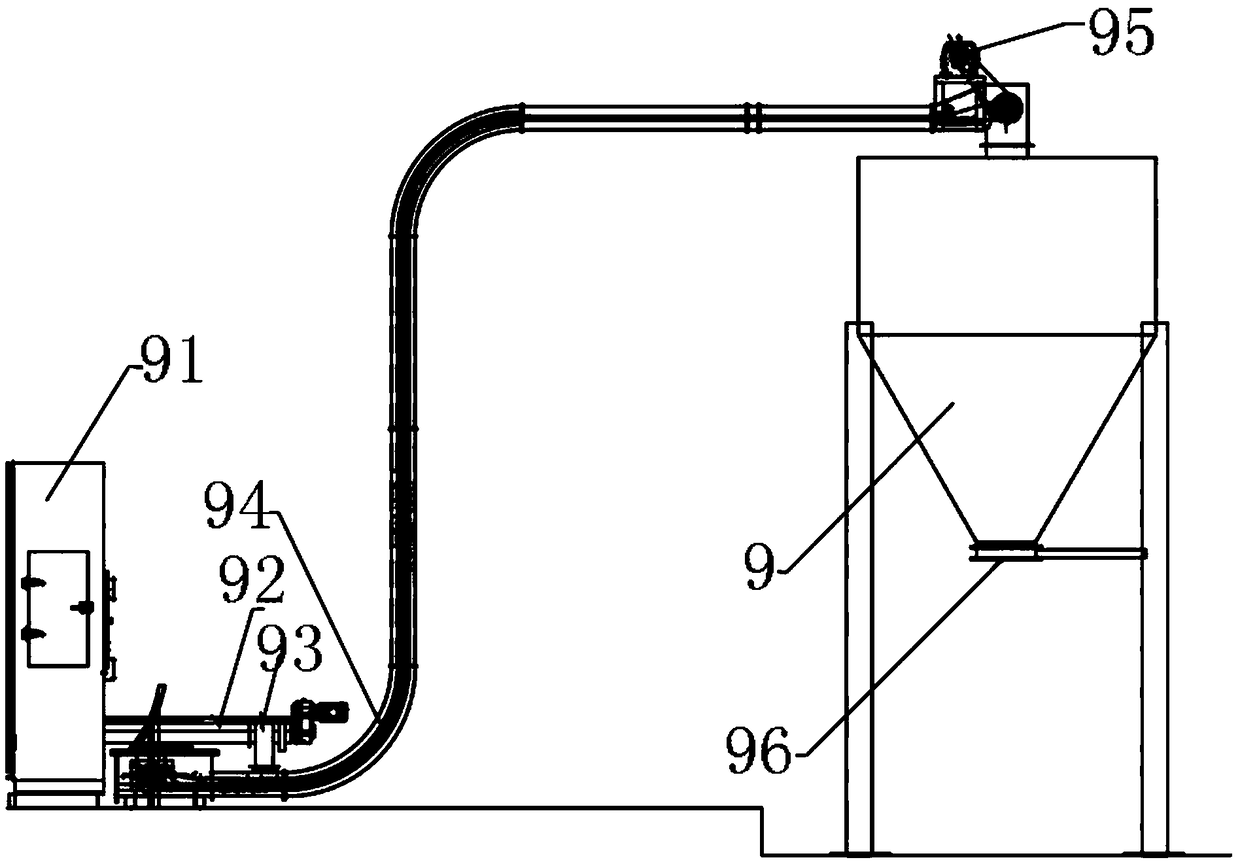

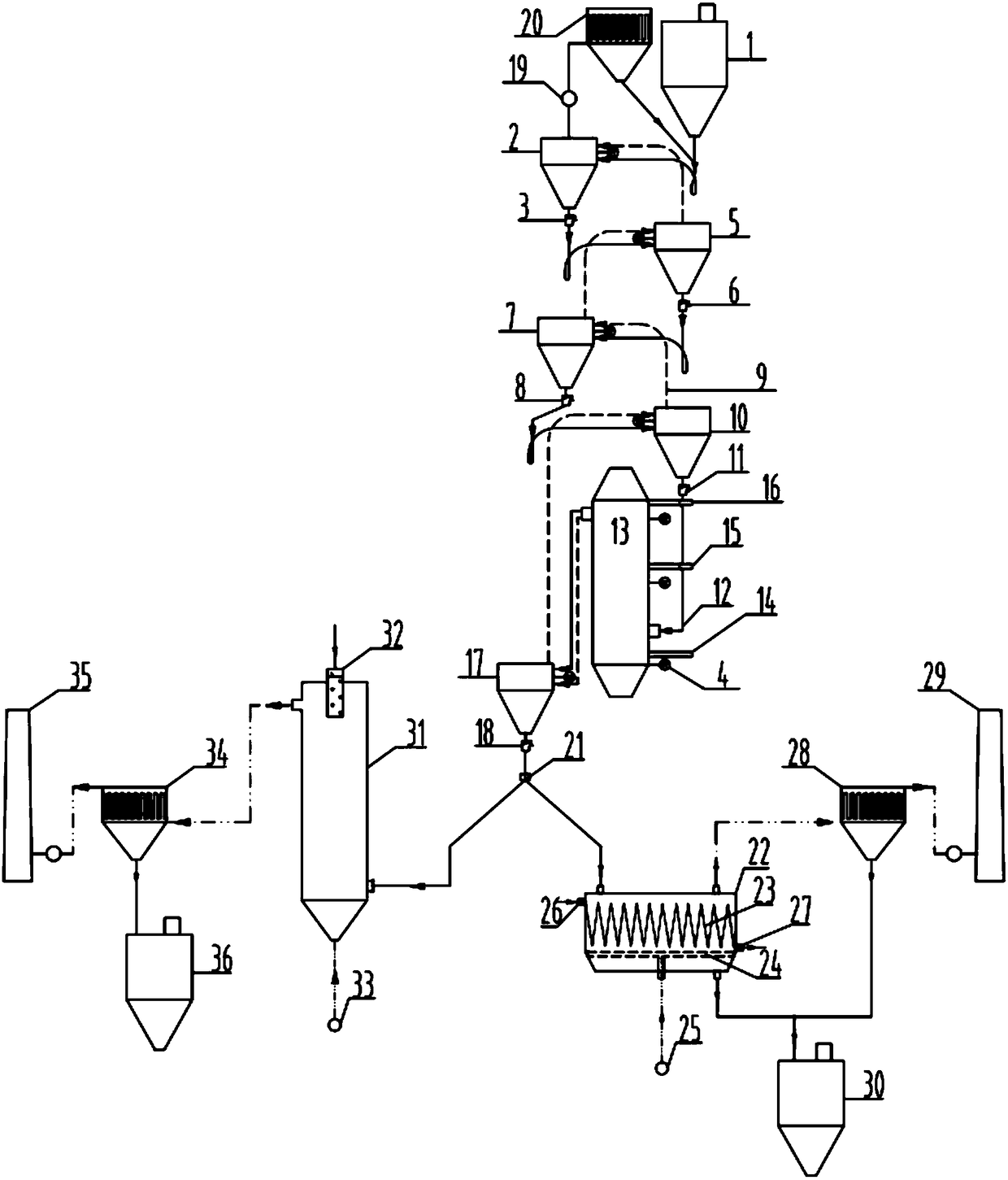

Production process and device for co-producing light-burned MgO and Mg(OH)2 through suspension kiln

PendingCN108314335AImprove stabilityLarge adjustment rangeEnergy inputMagnesium hydroxideHydration reactionCyclone

The invention discloses a production process and a production device for co-producing light-burned MgO and Mg(OH)2 through a suspension kiln. The device comprises a raw material bin, a four-stage cyclone preheater, a decomposing furnace, a cyclone separator, a fluidifying and cooling bed, a hydration reaction tower, a finished product collecting and dust collector, a finished product bin and the like. After a magnesium carbonate powder material is sintered, an MgO clinker is obtained; after gas-solid separation, the MgO clinker is fed into the fluidifying and cooling bed through a switching gate so as to be cooled, and a light-burned MgO finished product can be prepared, or the MgO clinker is fed into the hydration reaction tower through the switching gate so as to be subjected to hydration reaction with distilled water, and an Mg(OH)2 finished product can be prepared. According to the production process and the production device for co-producing the light-burned MgO and the Mg(OH)2 through the suspension kiln provided by the invention, the characteristic of single product of an existing light-burned MgO roasting device is changed, and a technological process of high-temperature sintered MgO is changed through the switching gate of the device, so that without additionally arranging the production device, the aims of co-producing the light-burned MgO and the Mg(OH)2 at the sametime can be realized, the equipment utilization ratio is effectively improved, the energy is saved, and the production cost is reduced.

Owner:ZHENJIANG SOBUTE NEW MATERIAL CO LTD +1

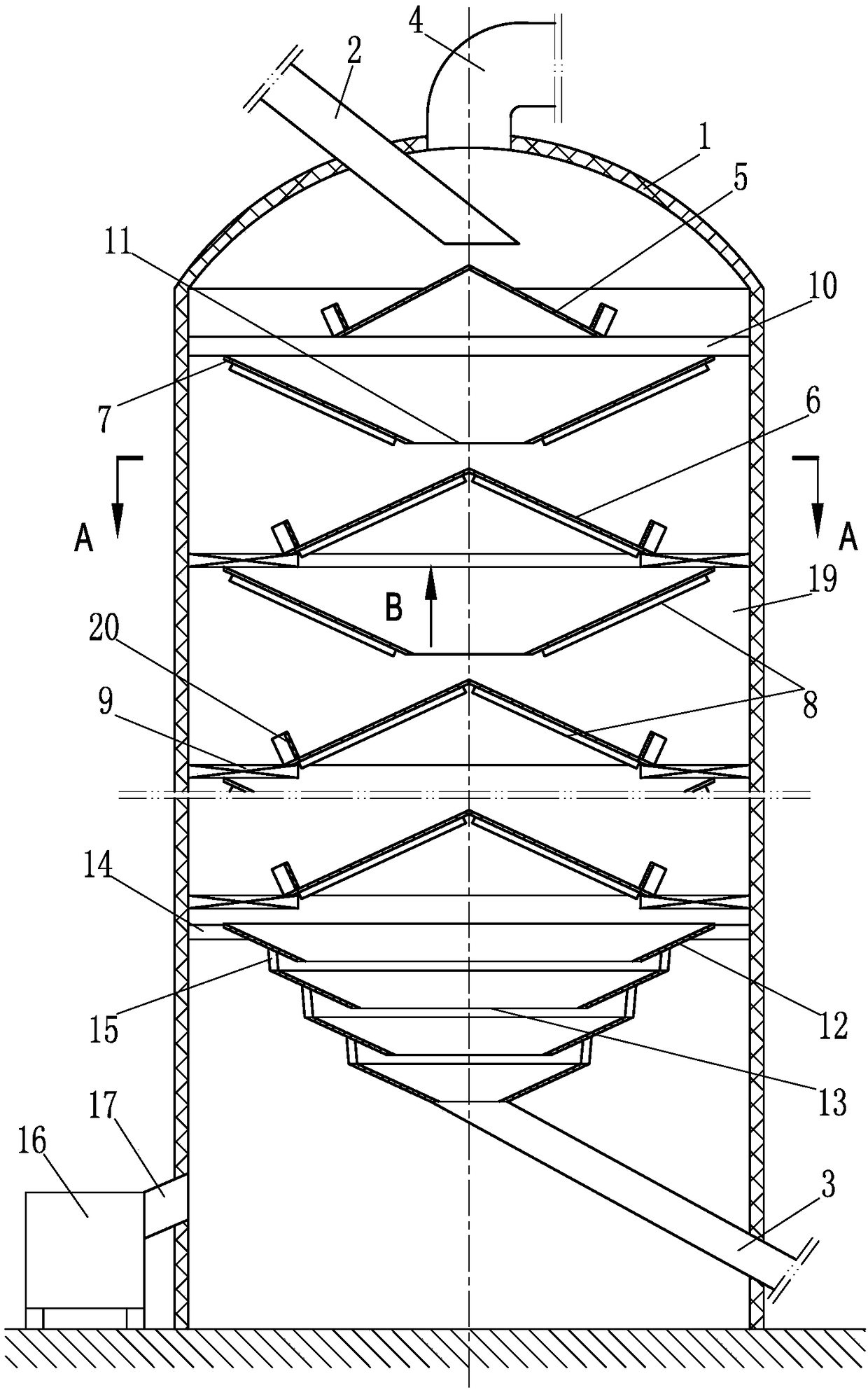

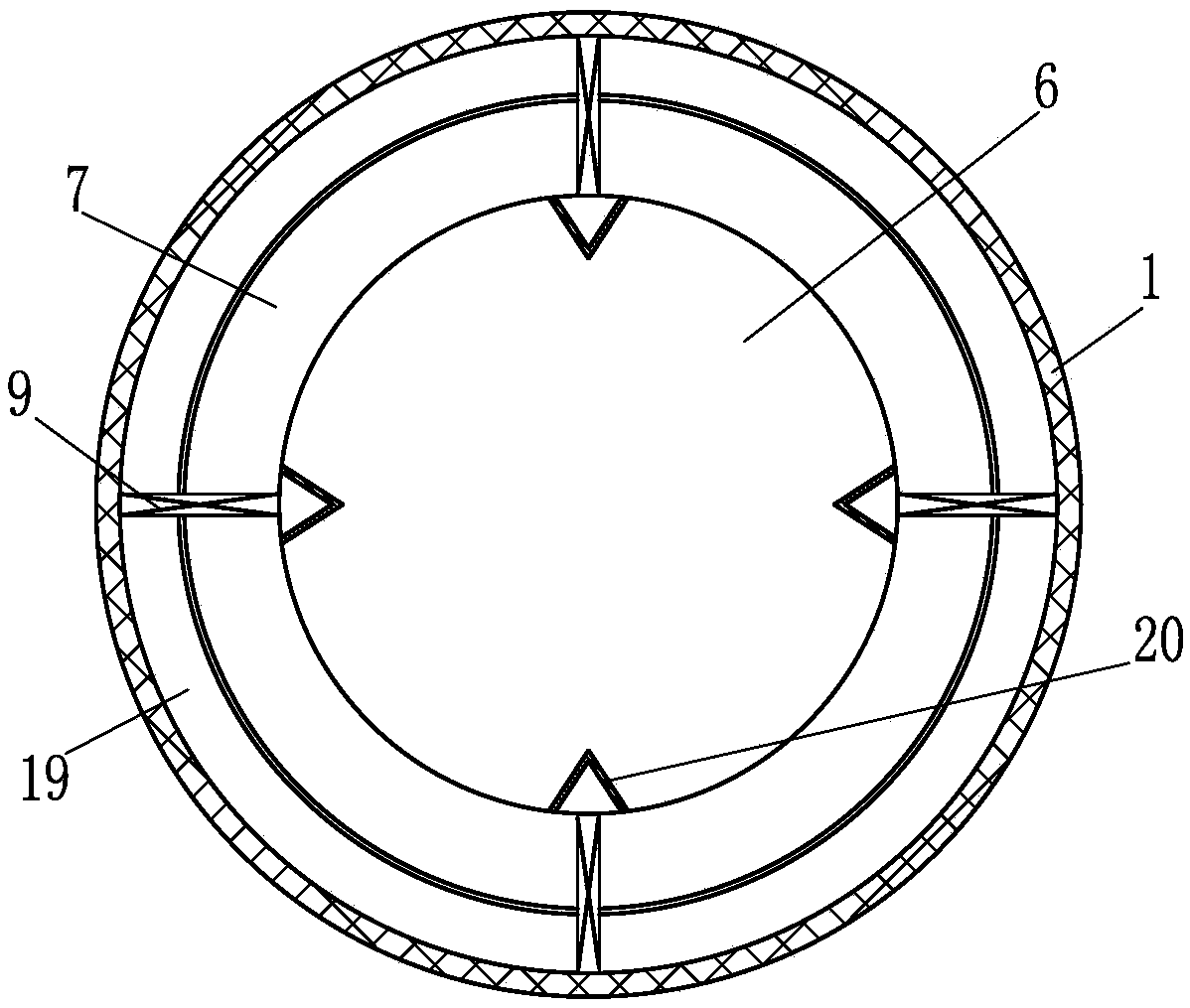

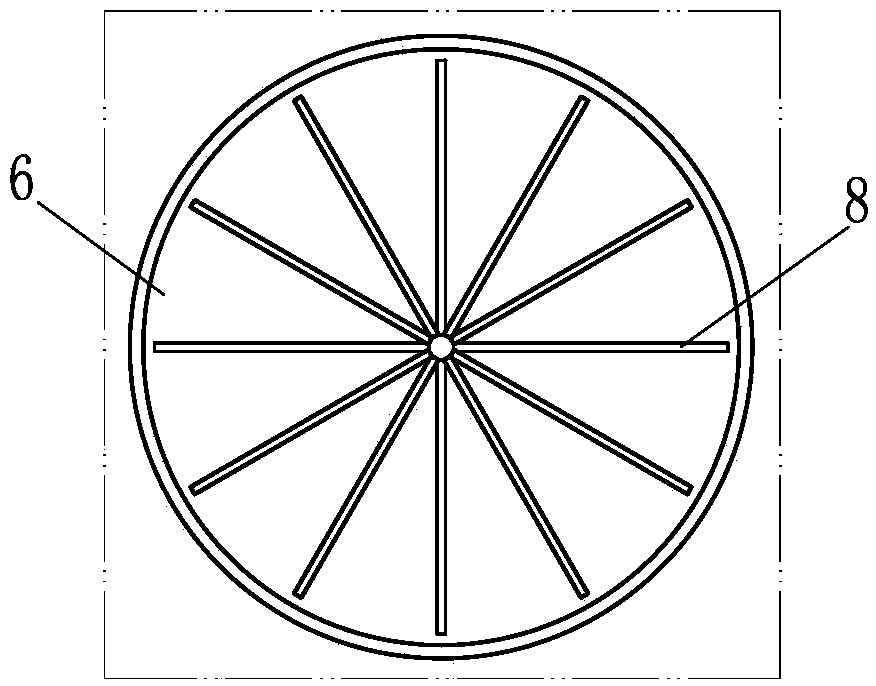

Vertical-type electric dryer

InactiveCN108088221ASolve the problem of not being able to saveNo pollution in the processGranular material dryingDrying gas arrangementsElectricitySlag

The invention discloses a vertical-type electric dryer. The vertical-type electric dryer comprises a drying barrel, a feeding channel, a discharging channel and an air exhausting pipe. The feeding channel and the air exhausting pipe are arranged at the top of the drying barrel. The vertical-type electric dryer is characterized in that an electric heating cone combination device, a cooling cone combination device and a convection ventilating device are further sequentially arranged inside the drying barrel from top to bottom; the electric heating cone combination device, the cooling cone combination device and the convection ventilating device are connected with the drying barrel; gaps are both reserved between the electric heating cone combination device and the drying barrel as well as between the cooling cone combination device and the drying barrel; and the upper area and the lower area, corresponding to the gaps, of the inside of the drying barrel form a convection channel. The vertical-type electric dryer has the remarkable advantages of being high in heat exchange efficiency, small in energy consumption, high in applicability, economical, environmentally friendly and the like. The vertical-type electric dryer can effectively replace various sorts of existing vertical-type dryers and is suitable for drying various block-shaped or granular powdered raw materials like cementraw materials, slag, pulverized fuel ash and coke, and the application prospects are broad.

Owner:赵世青

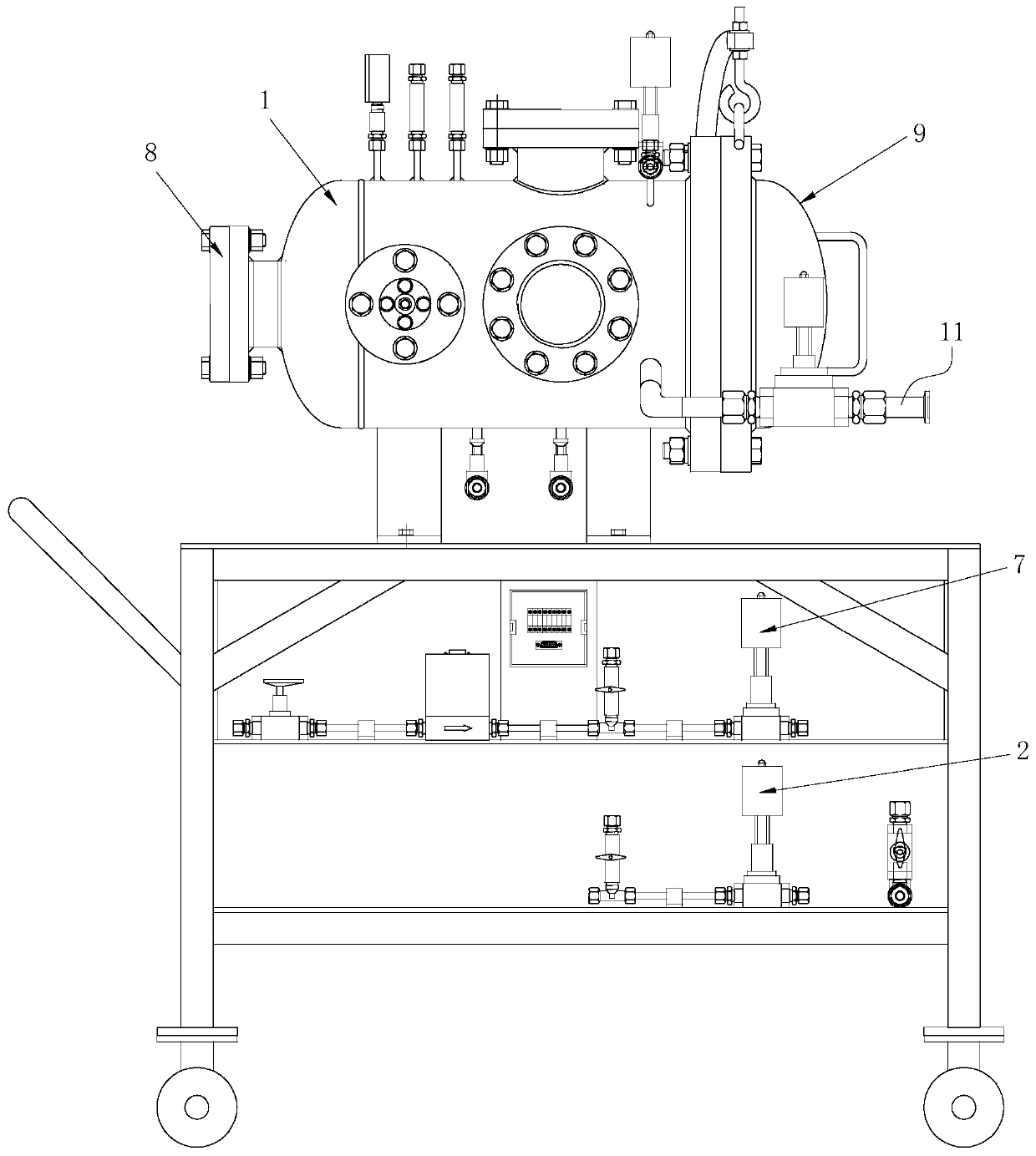

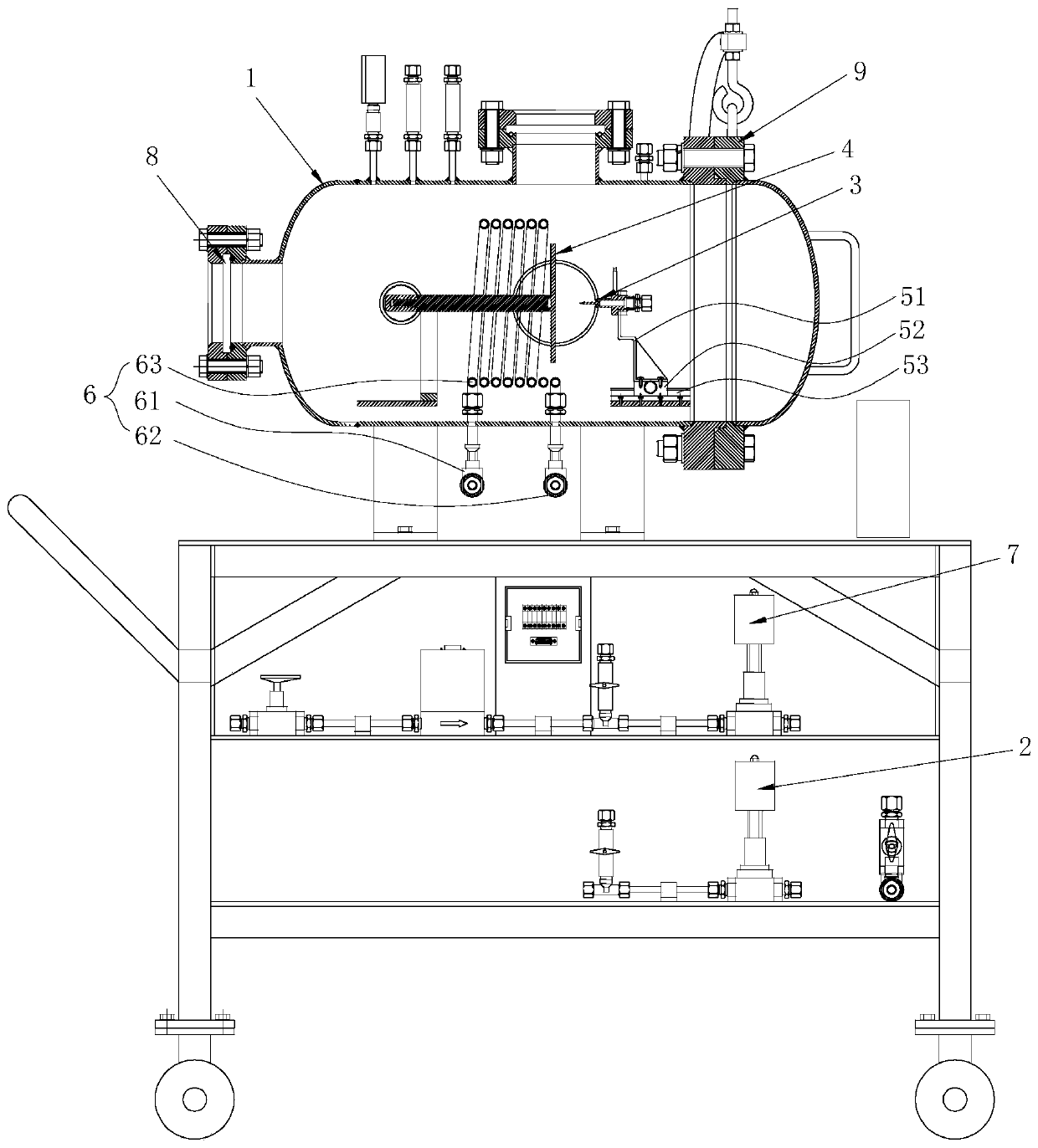

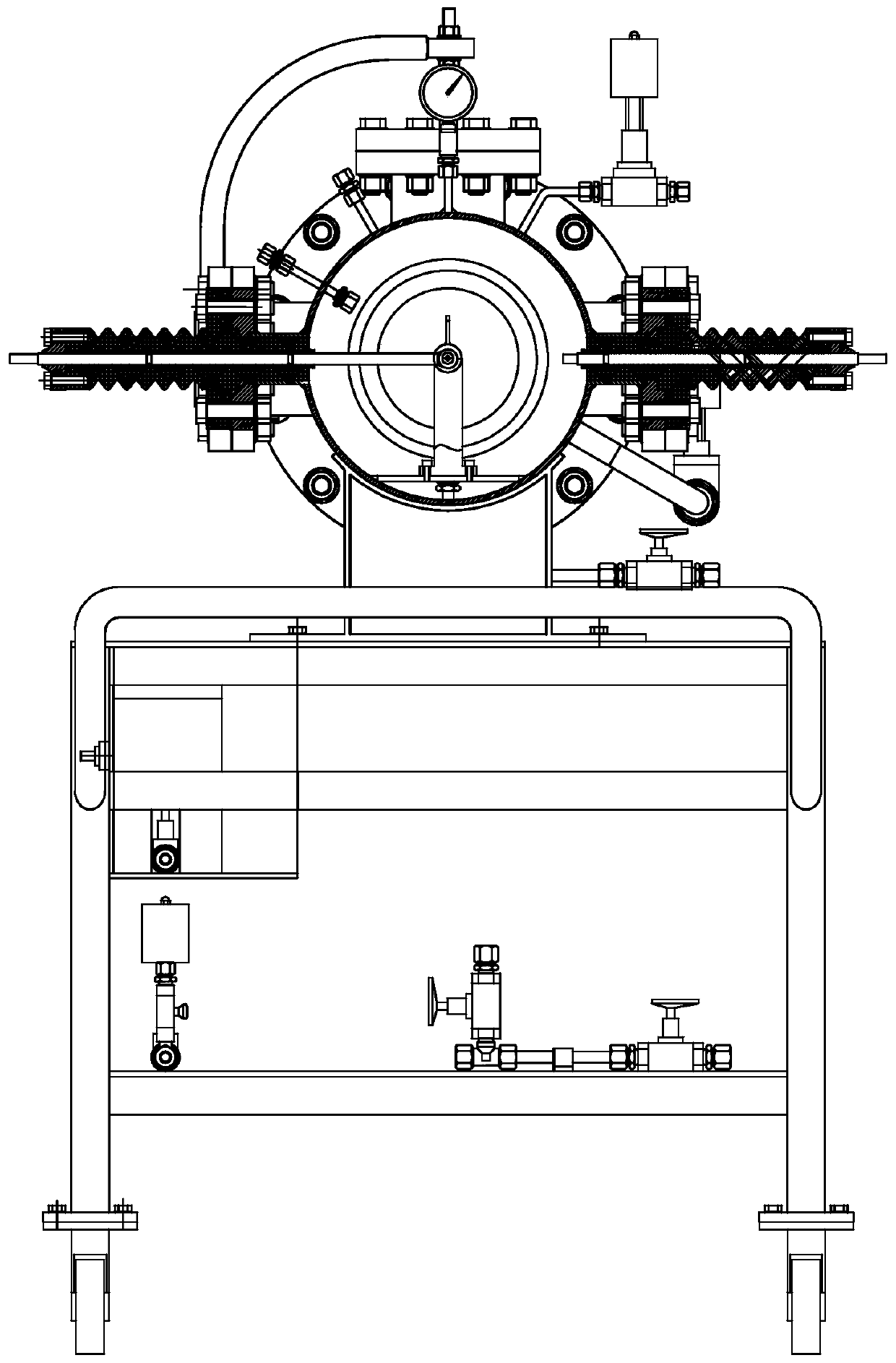

Sulfur hexafluoride electro-decomposition intermediate product extraction device and extraction method

ActiveCN111595991AInhibitory responseLower the discharge temperatureComponent separationSulfur hexafluorideGas supply

The invention belongs to the technical field of sulfur hexafluoride decomposition product extraction, and particularly relates to a sulfur hexafluoride electro-decomposition intermediate product extraction device. Aiming at the defect that an intermediate product in a sulfur hexafluoride decomposition process is difficult to reliably extract due to the fact that existing sulfur hexafluoride discharge test equipment simulates a real discharge working condition and the decomposition temperature is relatively high, the invention adopts the following technical scheme: the sulfur hexafluoride electro-decomposition intermediate product extraction device comprises: a closed pressure-resistant tank body; the vacuumizing device that is communicated with the tank body; the gas supply device that iscommunicated with the tank body and is used for conveying sulfur hexafluoride gas into the tank body; the first electrode and the second electrode that are arranged in the tank body; and the cooling device that is used for cooling the tank body. The invention has the beneficial effects that by additionally arranging the cooling device, the discharge temperature is reduced, and the reaction of theintermediate product can be inhibited compared with the normal temperature or higher temperature, so that the sulfur hexafluoride electro-decomposition intermediate product can be stored for a largeramount and longer time.

Owner:ELECTRIC POWER RES INST OF STATE GRID ZHEJIANG ELECTRIC POWER COMAPNY

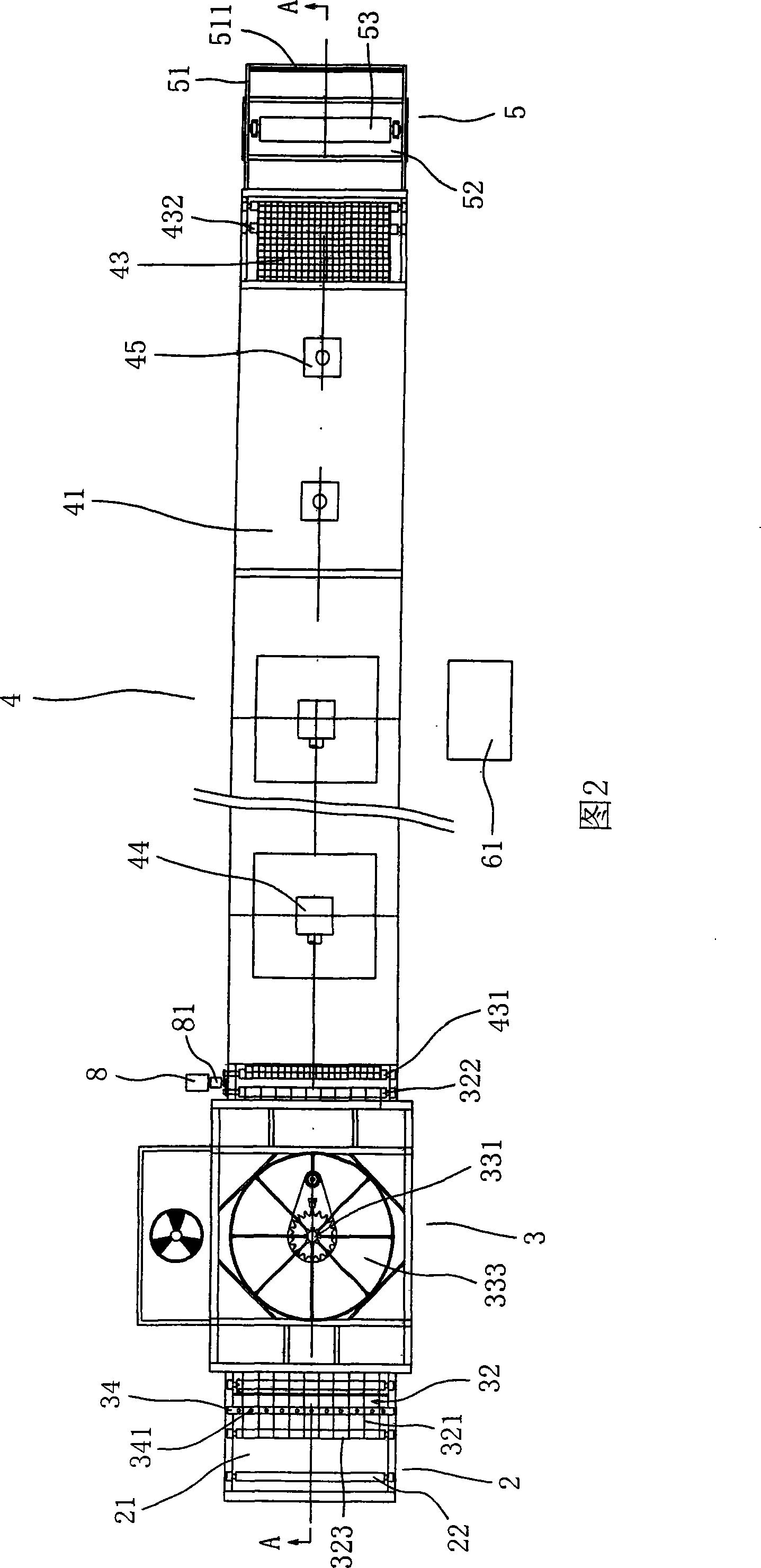

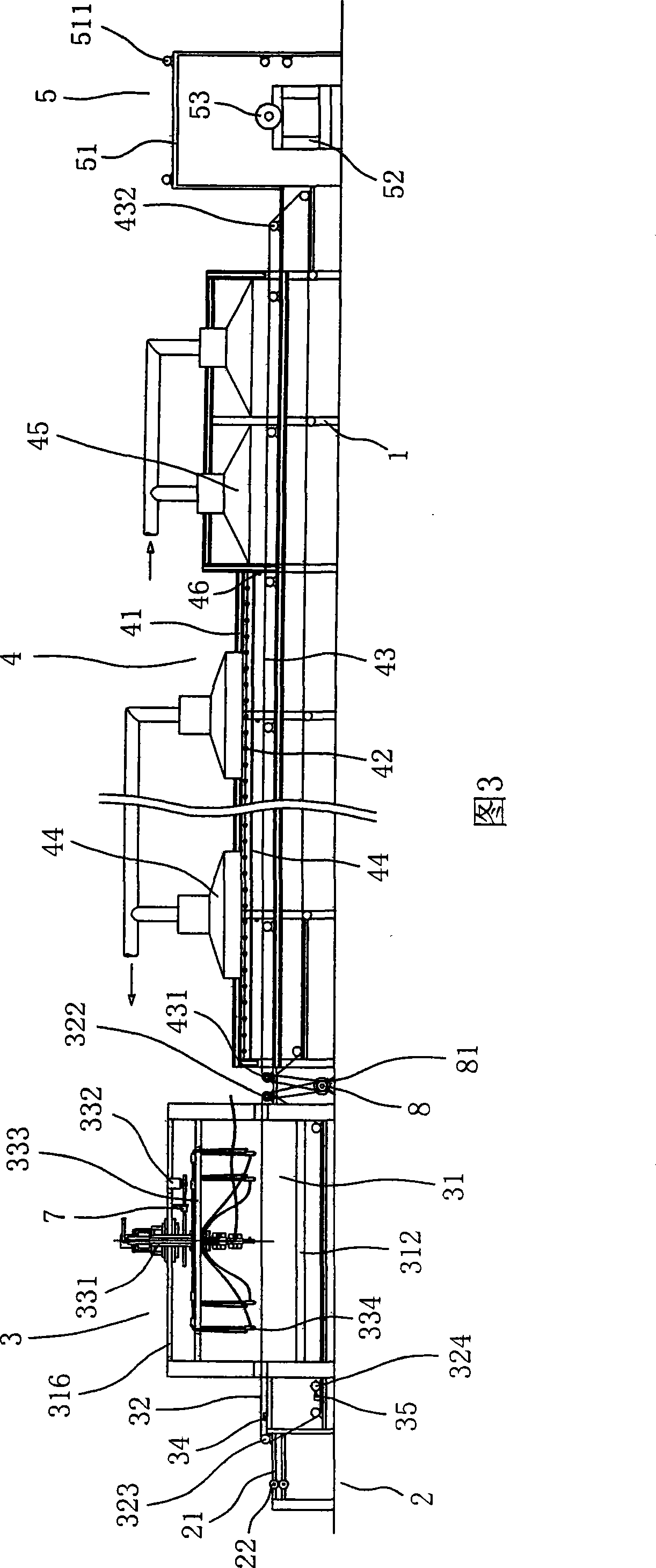

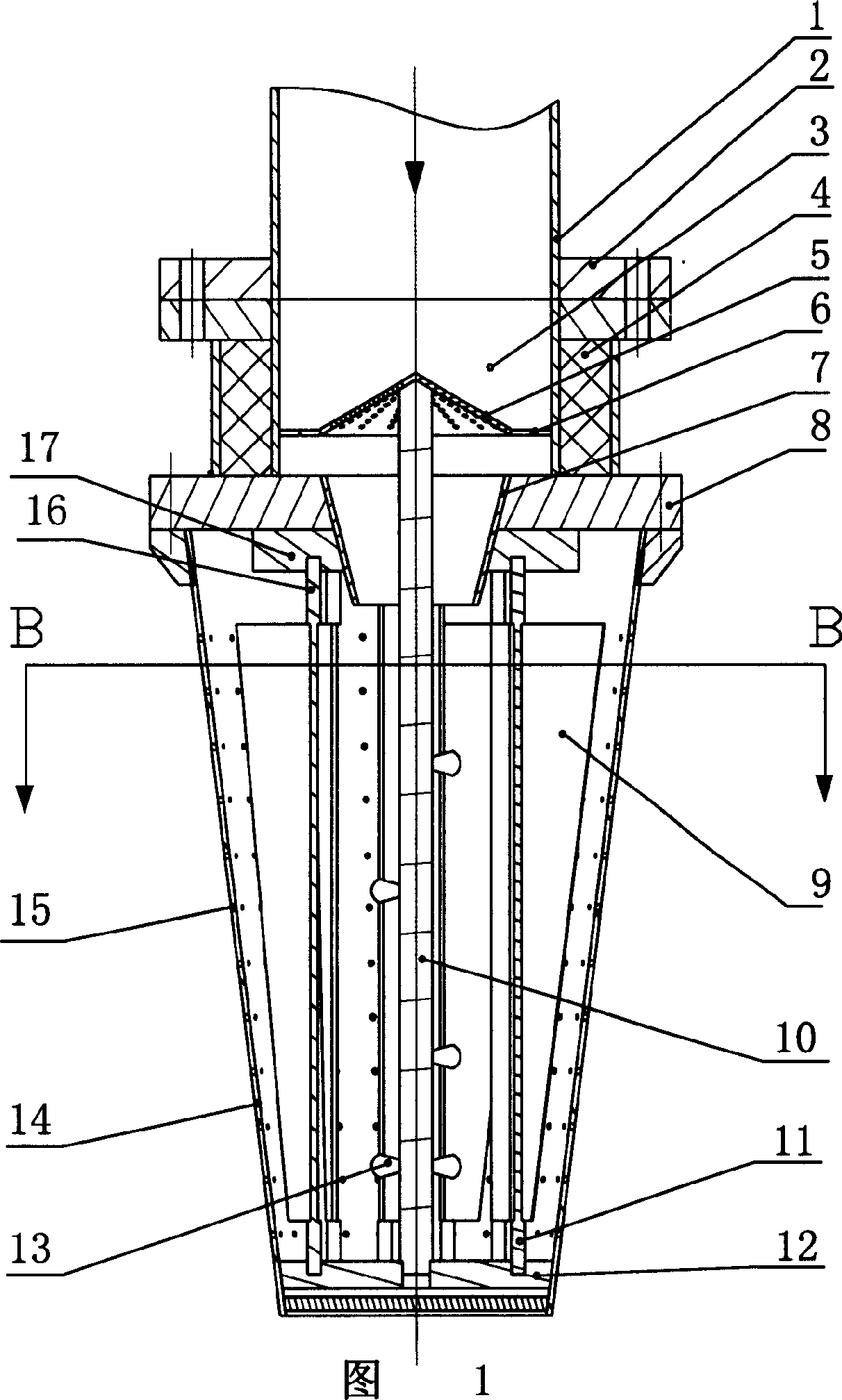

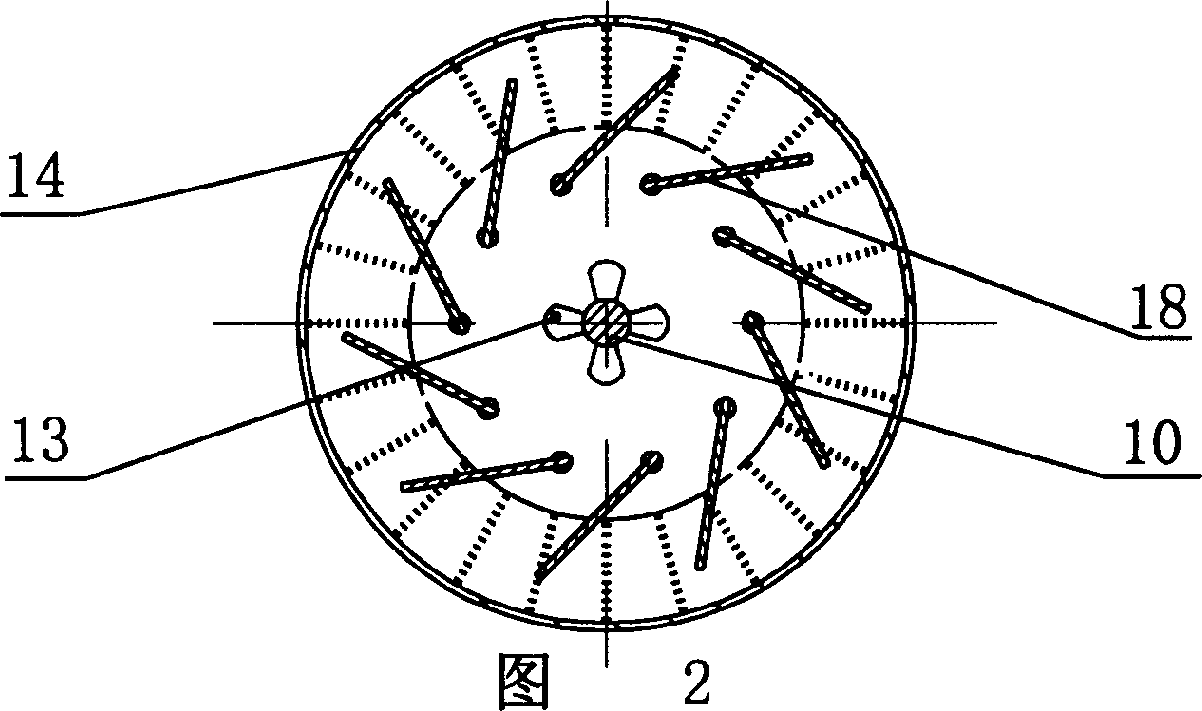

Swinging automatically spraying and drying machine

ActiveCN101406867BSpeed up dryingLower the discharge temperatureLiquid surface applicatorsDrying solid materials with heatMicrocomputerControl system

The invention provides a rotary type automatic spraying drier, which comprises a frame, as well as a feeding mechanism, a spraying system, a drying system, a receiving mechanism and a microcomputer control system which are arranged on the frame in sequence, wherein a spraying room conveying belt of the spraying system accurately and evenly sprays a sprayed object through an automatic spraying pistol which rotates along the central rotating shaft; and a drying conveying belt continuously conveys the sprayed object to pass through a drying case which is provided with a drying area and a cooling area in time with even spraying, quick drying and low discharging temperature. Each drive mechanism is intensively controlled by a microcomputer data processing center CPU of the control system, so the rotary type automatic spraying drier has the advantages of high automation degree, great improvement of work efficiency, accurate spraying, paint conservation and cost reduction.

Owner:XTEPCHINA

Cushioning internal rotation equipressure urea granulating injector

InactiveCN1546215APrevent shock wavesLower the discharge temperatureGranulation by liquid drop formationSpray nozzleInjector

The invention discloses a kind of buffer inner rotation equal-pressure ureophil pelleting spray, which includes spray body which has a spraying hole, there sets a buffer room on top of the spraying body, there has a small spraying hole on the buffer body; there fixes a flow spraying muzzle in the middle of the spray cup through connection board; there sets a ring separation equal-pressure distribution device, there sets a flow guiding pole in the middle of the spray cup, on top of the guiding pole is fixed with the buffer body through the flow cup, the bottom is fixed on the bottom of the spray cup.

Owner:金持中

Multi-stage parallel cooling device for high-temperature calcined coke of pot-type calcining furnace

InactiveCN102774827AHigh working reliabilityLarge heat transfer temperature differenceCarbon preparation/purificationHandling discharged materialEngineeringWater jacket

The invention relates to a multi-stage parallel cooling device for high-temperature calcined coke of a pot-type calcining furnace. The multi-stage parallel cooling device comprises a water inlet system and annular water cooling sleeves, and is characterized in that a plurality of the water cooling sleeves are superposed and fixedly connected; the water inlet system comprises a water inlet header tube which is communicated with a water supply system and a plurality of water inlet branch tubes; a regulating valve is arranged on each water inlet branch tube; a water outlet tube is arranged on one end of each water cooling sleeve, and the other end of the water cooling sleeve is communicated with a water inlet branch tube; and the water outlet tube and the water inlet branch tube are arranged on the two ends of the water cooling sleeve. According to the multi-stage parallel cooling device, the high-temperature calcined coke provided by the invention has the advantages of quick cooling speed, controllable cooling water amount, low discharging temperature, high working reliability and the like.

Owner:SHANDONG UNIV OF TECH

A micro-foaming warm mix asphalt mixture equipment

ActiveCN104355568BReduce consumptionEmission reductionClimate change adaptationRoads maintainenceViscosityAsphalt

The invention relates to a warm mix asphalt mixture as well as a preparation method and equipment thereof, in particular to a micro-foamed warm mix asphalt mixture as well as a preparation method and equipment thereof, and belongs to the technical field of engineering. An asphalt micro-foaming formula and the equipment are matched for use. During mixture production, by the aid of the equipment, asphalt is fully foamed, a binder is sprayed into a mixing cylinder in the form of foamed asphalt and mixed with aggregate to form the warm mix asphalt mixture, the foamed asphalt is lower than the asphalt in viscosity and higher in workability and can fully cover the aggregate at the lower temperature, the mixing temperature of the warm mix asphalt mixture is reduced, and the micro-foamed warm mix asphalt mixture is produced. The micro-foamed warm mix asphalt mixture as well as the preparation method and the equipment thereof have benefits as follows: warm mixing of the warm mix asphalt mixture is realized by the aid of micro-foaming equipment, the cost for purchasing the equipment is only input once, and a small amount of water is sprayed in production. The production cost of the warm mix asphalt mixture is reduced, the once-and-for-all effect can be realized, and the method is more energy-saving and environment-friendly when compared with a traditional technology that warm mix materials are added for warm mixing.

Owner:江苏东交工程设计顾问有限公司

Method for recycling waste foundry sand through compound roasting device

ActiveCN109654882AImprove heat transfer effectReduce heat lossMould handling/dressing devicesFluidised-bed furnacesFoundryCold air

The invention discloses a method for recycling waste foundry sand through a compound roasting device. The method for recycling the waste foundry sand through the compound roasting device comprises thefollowing steps that S1, materials enter a receiving tank through a material uniformizing plate, then enter a feeding protection device through an impeller and finally enter a horizontal combustion chamber; S2, the materials are blown and boiled through hot air from the bottom of the combustion chamber to flow from one end of the combustion chamber to the other end of the combustion chamber, andthree-stage roasting is conducted in the flowing process of the materials, wherein the temperature for the first stage of roasting is 300-400 DEG C, and the time for the first stage of roasting is 10-20 s; the temperature for the second stage of roasting is 600-800 DEG C, and the time for the second stage of roasting is 180-240 s; and the temperature for the third stage of roasting is 850-900 DEGC, and the time for the third stage of roasting is 10-20s; and S3, the roasted materials enter an air preheating chamber, exchange heat with cold air to be cooled to 200-300 DEG C and then are discharged, and high-temperature waste gas is exhausted after heat exchange. According to the method for recycling the waste foundry sand through the compound roasting device, the discharge temperature is lower than 300 DEG C, and the furnace temperature can be increased rapidly and can be increased to the material roasting temperature within 30 min; and the exhausted waste gas has a low temperature andcontains few hazardous substances.

Owner:广西兰科资源再生利用有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com