Array type microplasma generating device based on conductive coating

A conductive coating, plasma technology, applied in the direction of plasma, electrical components, etc., can solve the problems of complex discharge structure design, uneven plasma, high discharge requirements, and achieve exquisite device structure, fully uniform propagation, and low discharge temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

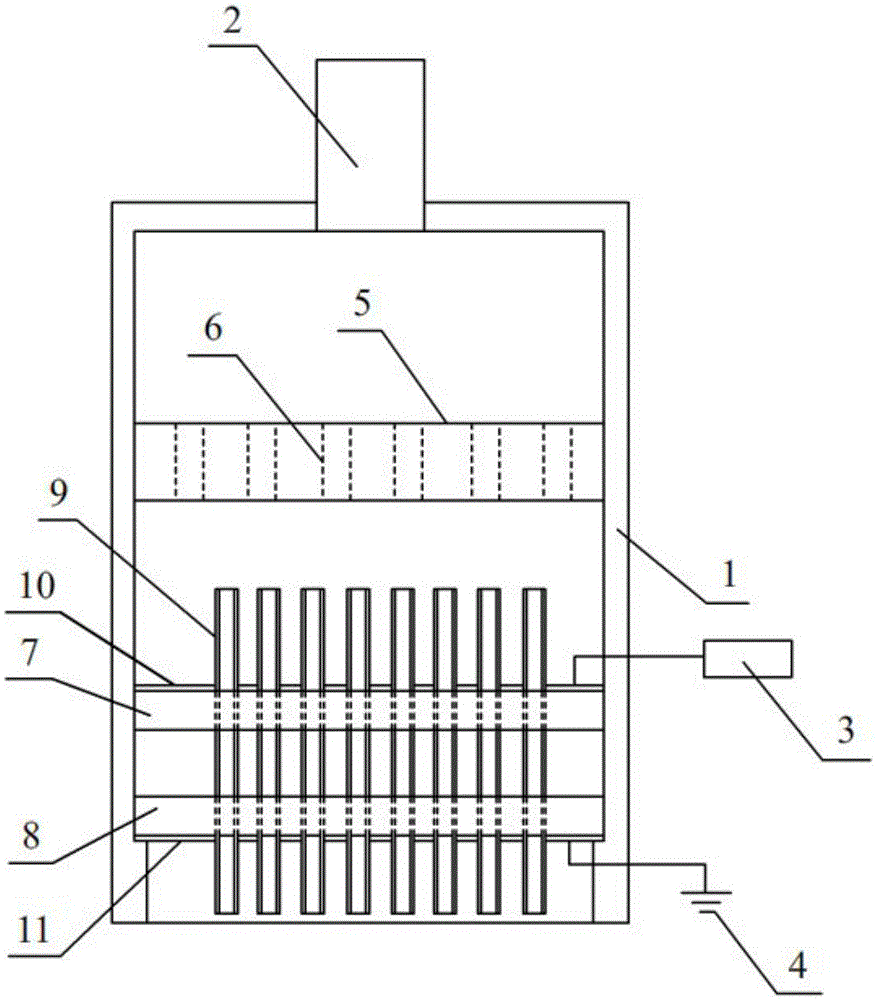

Method used

Image

Examples

Embodiment 1

[0039] Conductive coatings A and B are made of graphite materials, which are respectively used as high-voltage electrodes and ground electrodes, and the thickness of conductive coatings A and B are both 300 microns.

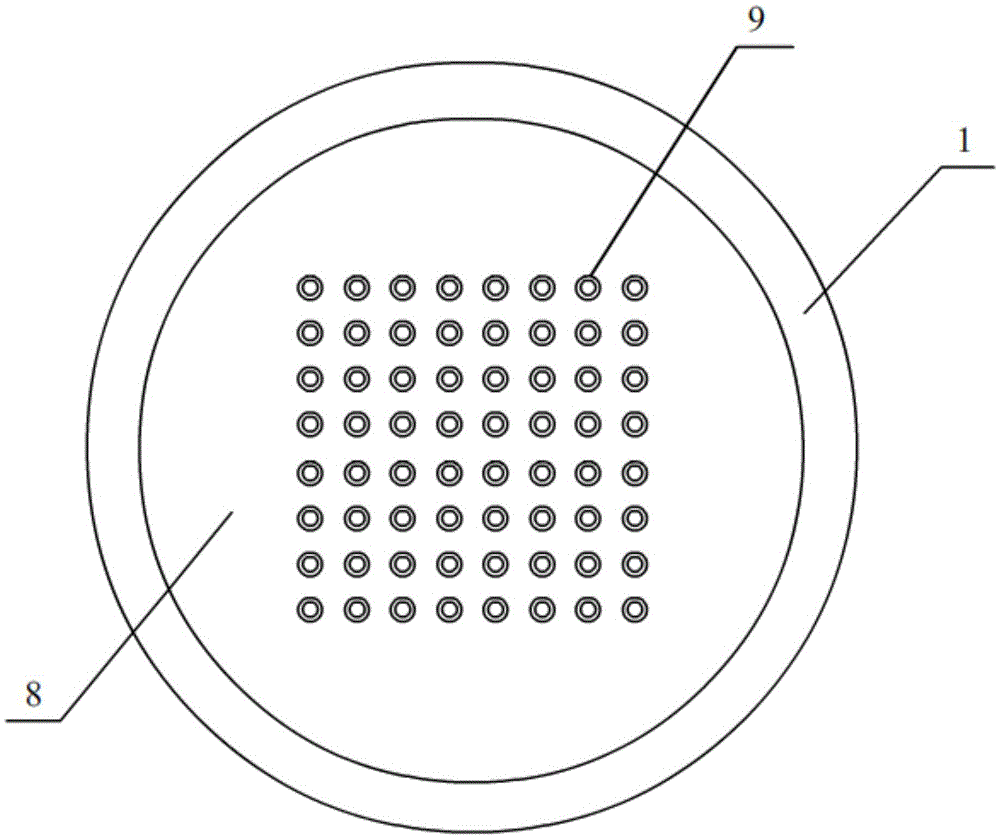

[0040] The insulating dielectric tube is made of quartz material, the length of the insulating dielectric tube is 20 mm, the inner diameter of the insulating dielectric tube is 100 microns, the outer diameter is 300 microns, and the thickness of the tube wall is 100 microns. The selected insulating medium tubes form an array form of 8*8 with a total of 64 pieces, and the distance between the tubes is 1mm.

[0041] Use plexiglass to make dielectric boards A and B, both of which have a length of 50 mm, a width of 50 mm, and a thickness of 5 mm.

[0042] Helium was selected as the discharge gas, and the gas flow rate was 2L / min.

[0043] The pulse power supply is selected as the power supply, the discharge voltage of the pulse power supply is 15kV, and the discharg...

Embodiment 2

[0047] Graphite is selected as the conductive coating A and B as the high-voltage electrode and the ground electrode respectively, and the thickness of the conductive coating is 500 microns.

[0048] The insulating medium tube is made of quartz material, the length of the insulating medium tube is 17 mm, the inner diameter of the insulating medium tube is 300 microns, the outer diameter is 500 microns, and the thickness of the tube wall is 100 microns. The selected insulating medium tubes form an array of 100 pieces in total of 10*10, and the distance between the tubes is 1.5mm.

[0049] Use plexiglass to make dielectric boards A and B, the length of dielectric boards A and B are both 80 mm, the width is 80 mm, and the thickness is 7 mm.

[0050] Air is selected as the discharge gas, and the gas flow rate is 3L / min.

[0051] The AC power is selected as the power source, the discharge voltage of the AC power is 10kV, and the discharge frequency is 8kHz.

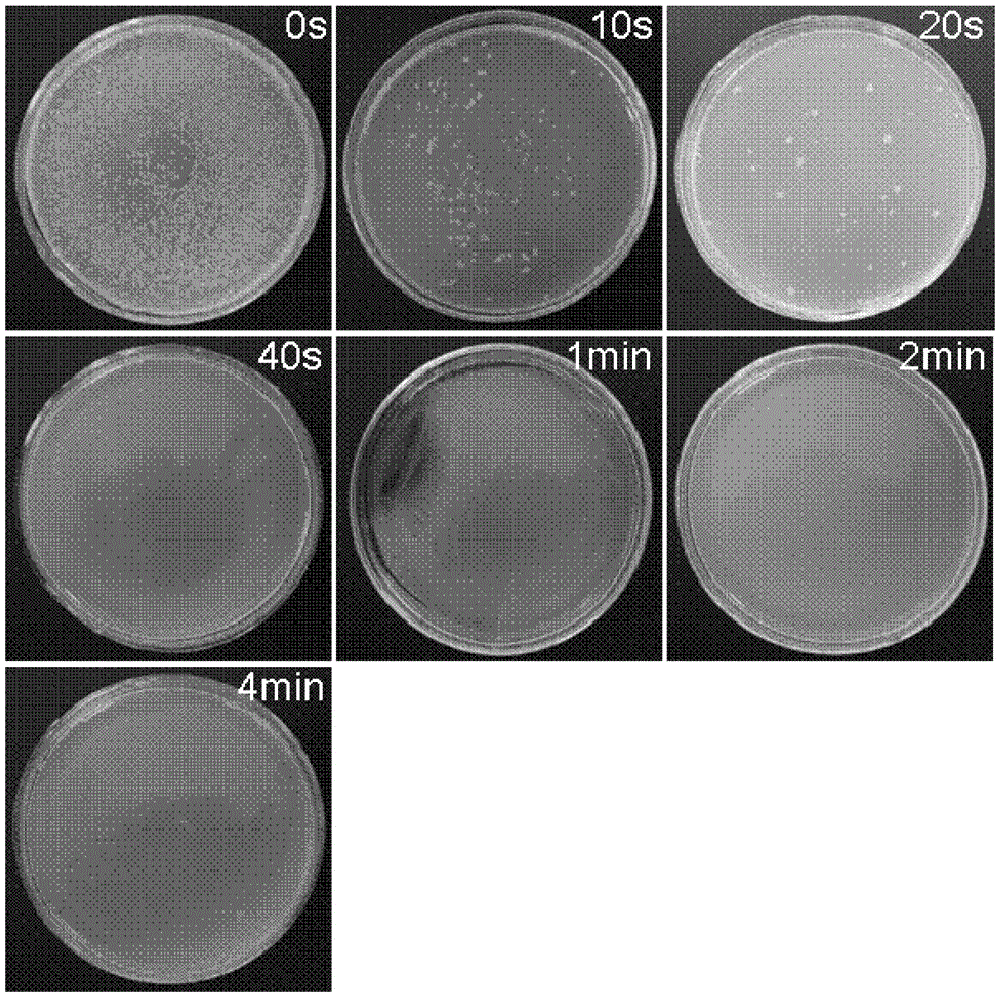

[0052] During the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com