Vertical-type electric dryer

A drying machine, vertical technology, applied in the direction of drying machine, drying, drying solid materials, etc., can solve the problems of material pollution, poor discreteness, high viscosity, etc., to reduce production costs, improve discreteness, The effect of low discharge temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

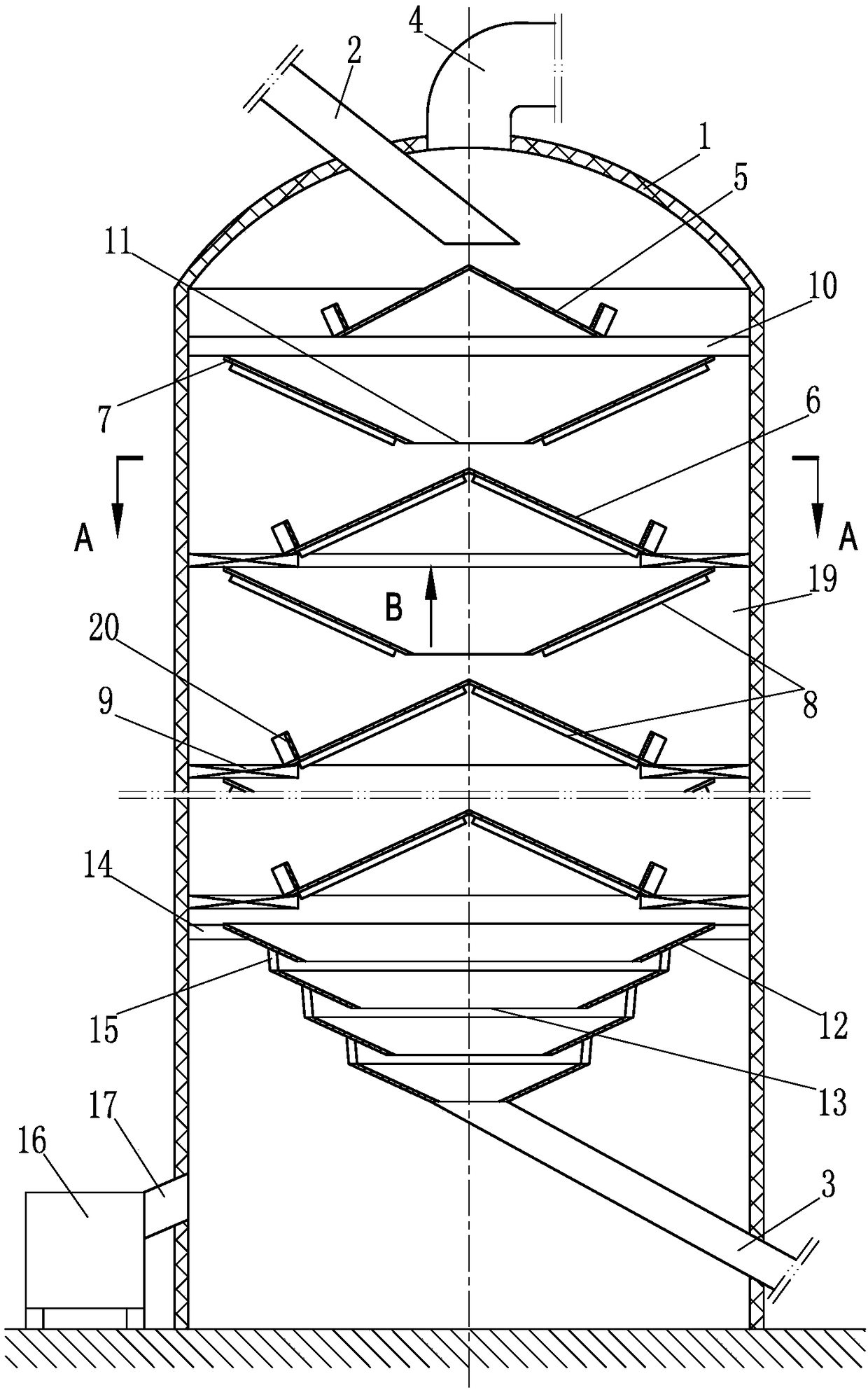

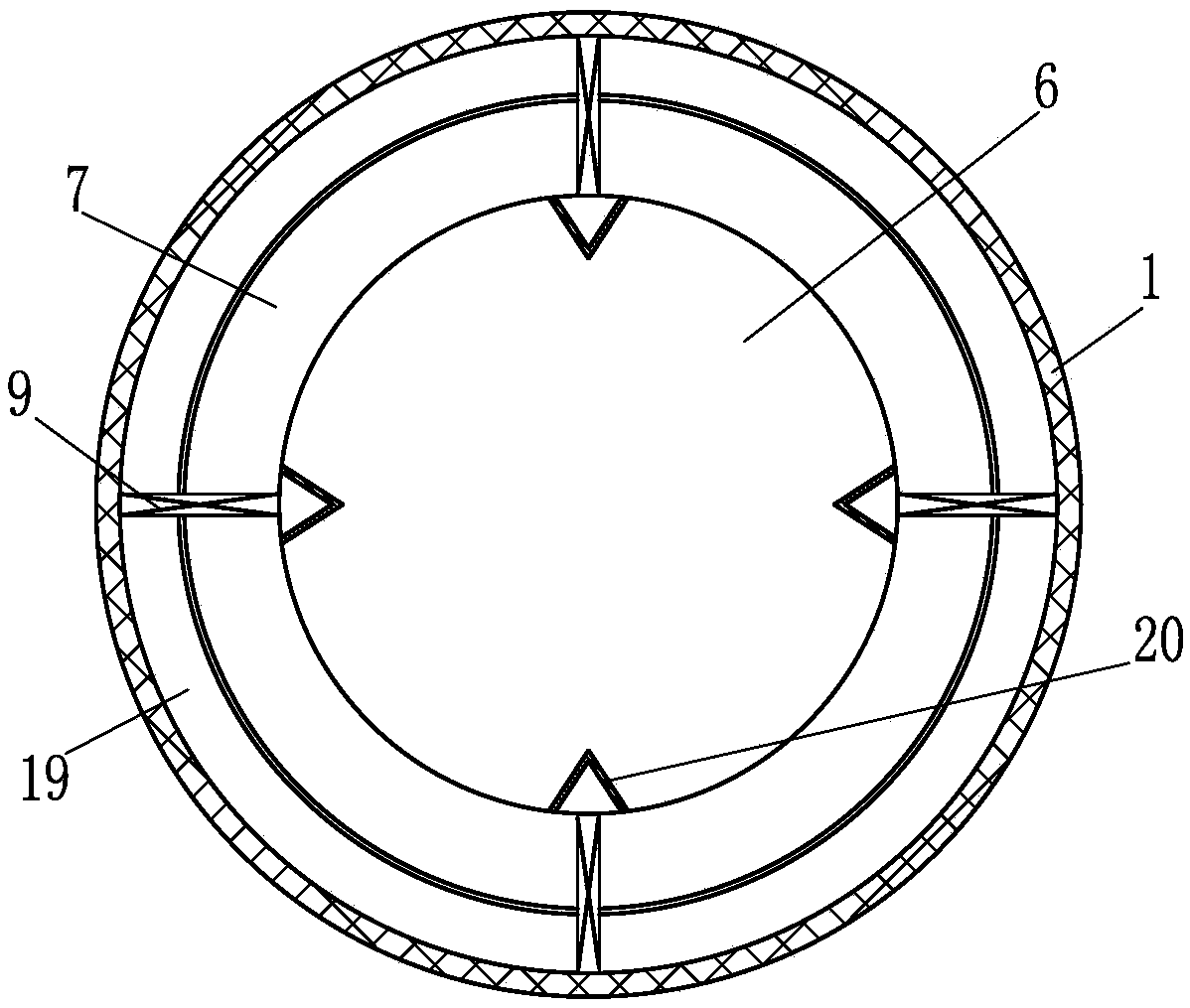

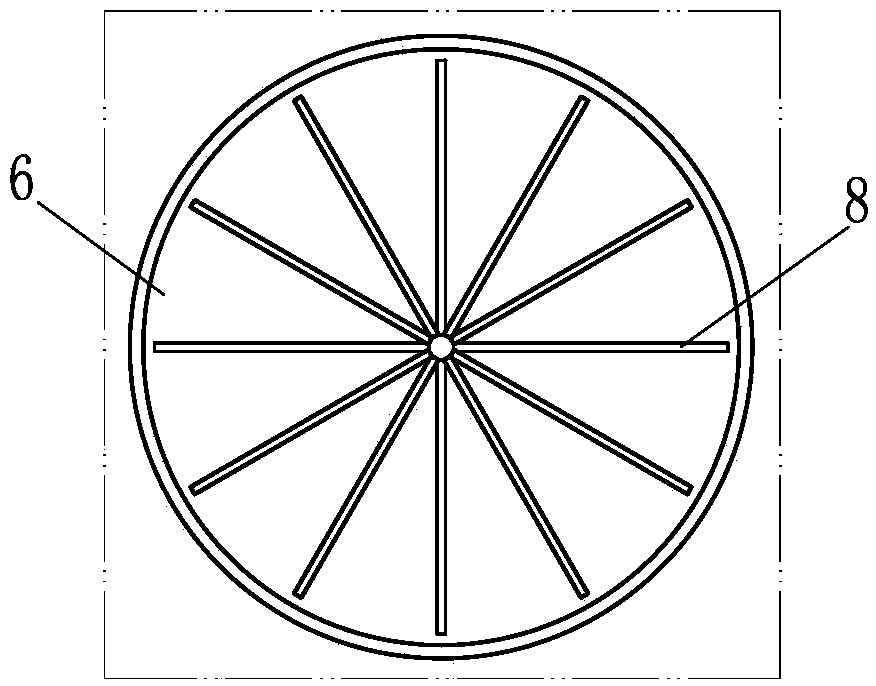

[0033] Such as figure 1 , figure 2 and image 3 The vertical electric dryer shown in the present invention includes a drying cylinder 1, a feed channel 2, a discharge channel 3, an air outlet pipe 4 and a bulk material device 5, and the feed channel 2 and the air outlet pipe 3 are arranged On the top of the drying cylinder 1, the bulk material device 5 is specifically an umbrella-shaped bulk material cone, and the umbrella-shaped bulk material cone is arranged corresponding to the opening that the feed channel 2 communicates with the inside of the drying cylinder 1; in addition, the drying The electric heating cone combination device, the cooling cone combination device and the convection ventilation device are arranged in sequence from top to bottom in the drying cylinder body 1, and the electric heating cone combination device, the cooling cone combination device and the convection ventilation device are respectively connected with the drying cylinder body 1 Connected, wh...

Embodiment 2

[0048] Such as Figure 5 The difference between the vertical electric dryer of the present invention shown in Embodiment 1 is that the forward feeding heating cone 6 is used instead of the umbrella-shaped bulk material cone as a bulk material device. The guide heating cone 7 is fixedly connected with the drying cylinder 1 through the short connecting frame 9; in addition, the lowest end of the electric heating cone assembly is a reverse feed guide heating cone, and the corresponding cooling cone assembly consists of multiple forward blanking The cone 22 and a plurality of reverse blanking cones 12 are formed, and the forward blanking cones 22 are all arranged above the reverse blanking cones 12, and the contour dimensions of the multiple forward blanking cones 22 increase sequentially from top to bottom. Large, the outline size of multiple reverse blanking cones 12 decreases sequentially from top to bottom, and the adjacent forward blanking cones 22 or / and reverse blanking con...

Embodiment 3

[0052] Such as Figure 6 The difference between the shown vertical electric dryer of the present invention and the second embodiment is that in the electric heating cone combination device, the adjacent reverse feeder heating cone 7 and the forward feeder heating cone 6 are connected into one body through a connecting bracket. The connecting bracket includes a short connecting bracket 23 and a long connecting bracket 24 , the forward feeding heating cone 6 at the top and the reverse feeding heating cone 7 at the bottom are respectively fixedly connected to the drying cylinder 1 through the short connecting frame 9 .

[0053] The advantages and application methods of the technical solution described in this example are similar to those in Embodiment 2, and will not be repeated here. It should be pointed out that, in the technical solution described in this example, since the short connecting bracket 23 and the long connecting bracket 24 are used in the electric heating cone com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com