Patents

Literature

96results about How to "Prevent blocking phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

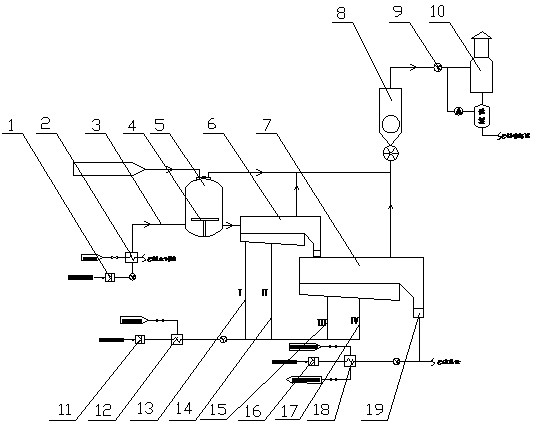

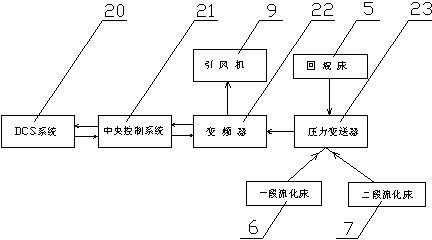

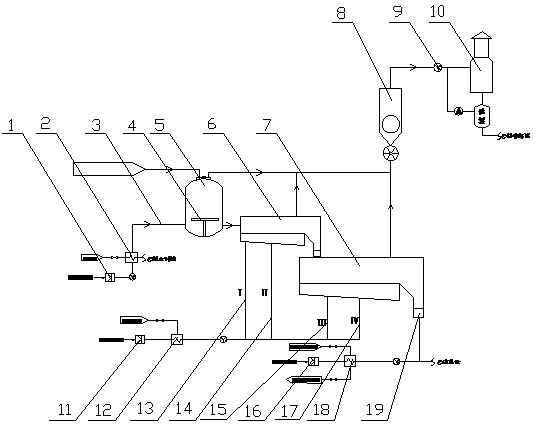

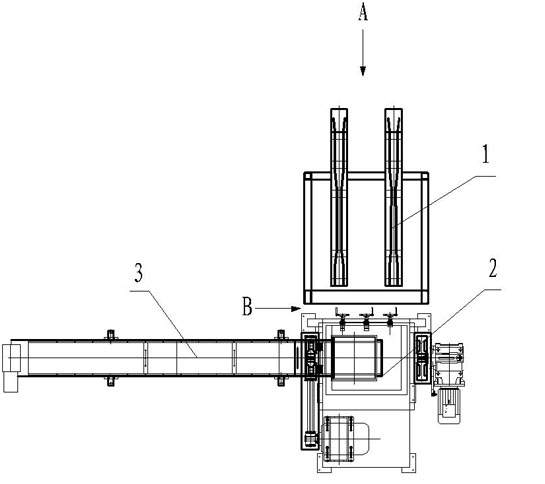

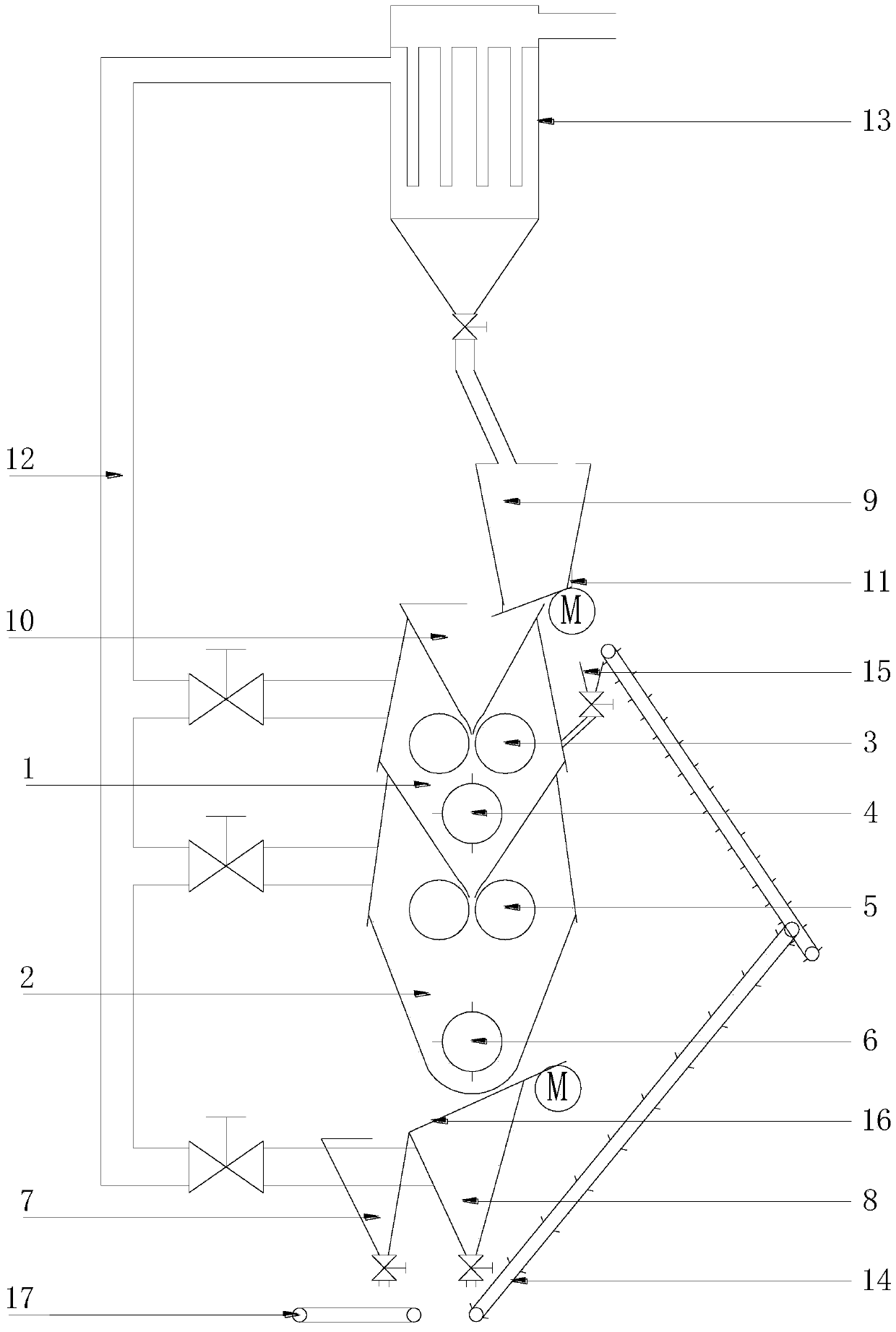

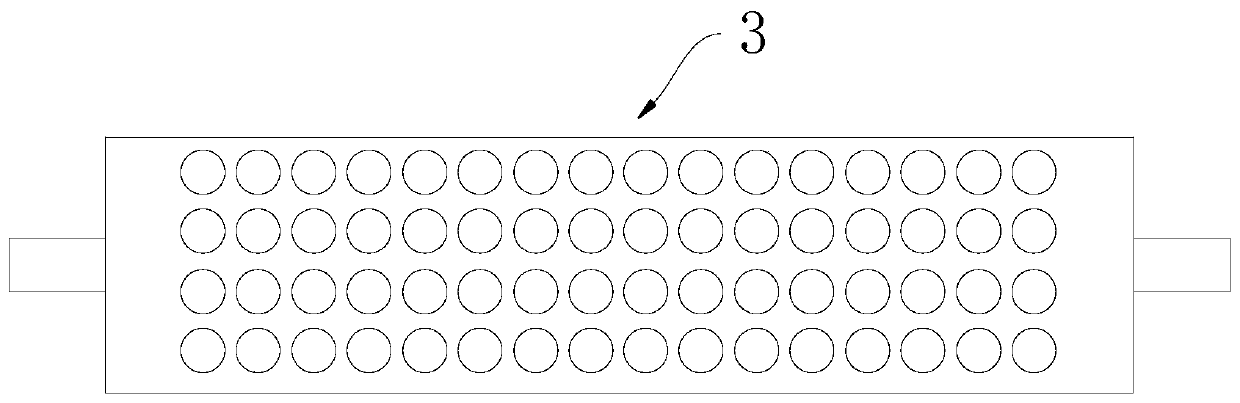

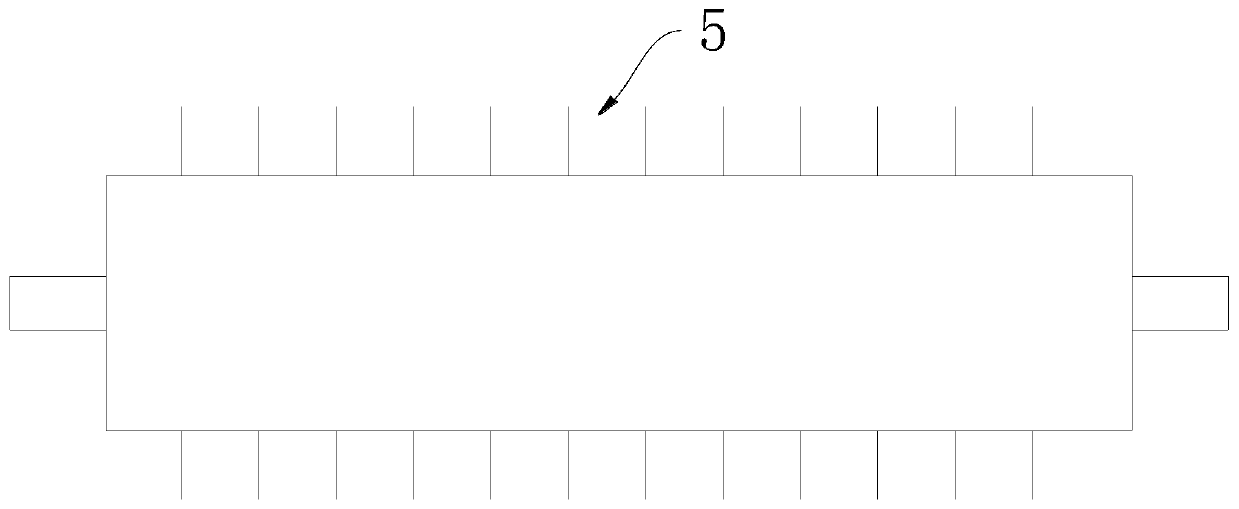

Anhydrous dextrose drying device and drying process

ActiveCN102435049AImprove continuityGuaranteed boiling effectDrying solid materials with heatHearth type furnacesFluidized bedChange color

The invention belongs to the technical field of biomedicine, in particular relates to an anhydrous dextrose drying device and a drying process. The technical scheme is that the anhydrous dextrose drying device comprises a fluidized bed and a back mixing bed. The fluidized bed comprises a first-section fluidized bed and a second-section fluidized bed. The lower portion of the back mixing bed is connected with an air inlet pipe I through an air feeder I, a heater I is arranged on the air inlet pipe I, an air inlet pipe II and an air inlet pipe III are respectively connected with the first-section fluidized bed, an air inlet pipe IV and an air inlet pipe V are respectively connected with the second-section fluidized bed, an air feeder II is respectively connected with the air inlet pipe II, the air inlet pipe III, the air inlet pipe IV and the air inlet pipe V through a heat exchanger II, so that the phenomena that finished products are apt to change colors and blocked caused by high temperature of materials caused by continuous drying can be avoided.

Owner:XIWANG PHARMA

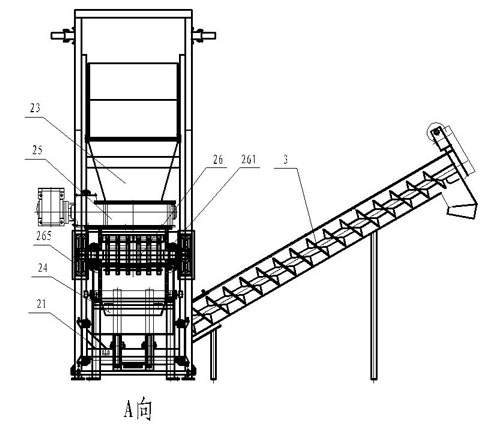

Garbage crushing machine

InactiveCN102319610ASolving Recycling ProblemsPrevent blocking phenomenonGrain treatmentsEngineeringCrusher

The invention discloses a garbage crushing machine. The garbage crushing machine comprises a charging conveying mechanism, a crushing mechanism and a discharging conveying mechanism, wherein the crushing mechanism comprises a machine frame; a box body is arranged on the machine frame; a charging hopper and a discharging hopper are arranged on the box body; and a double-shaft tearing device, a single-shaft breaking device and a discharging screen are arranged in the box body in turn from the charging hopper and the discharging hopper. Because the double-shaft tearing device is arranged for breaking garbage into blocks, and then the garbage is broken thoroughly by the single-shaft breaking device, the garbage is broken and deformed to prevent from being recycled; a material blockage phenomenon in the process of using is avoided; and the service efficiency s improved. Moreover, because of the arrangement of the charging conveying mechanism and the discharging conveying mechanism, the garbage crushing machine is not only convenient to use, but also greatly reduces human input in an operation process.

Owner:ZHANGJIAGANG AMSTAR SANWA MACHINERY

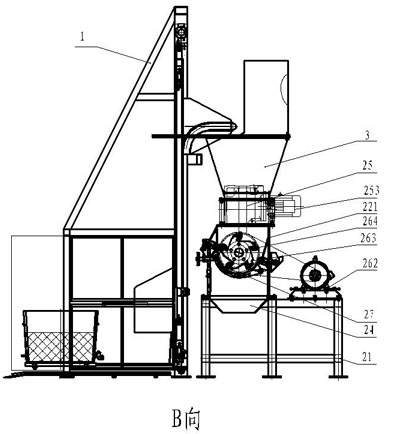

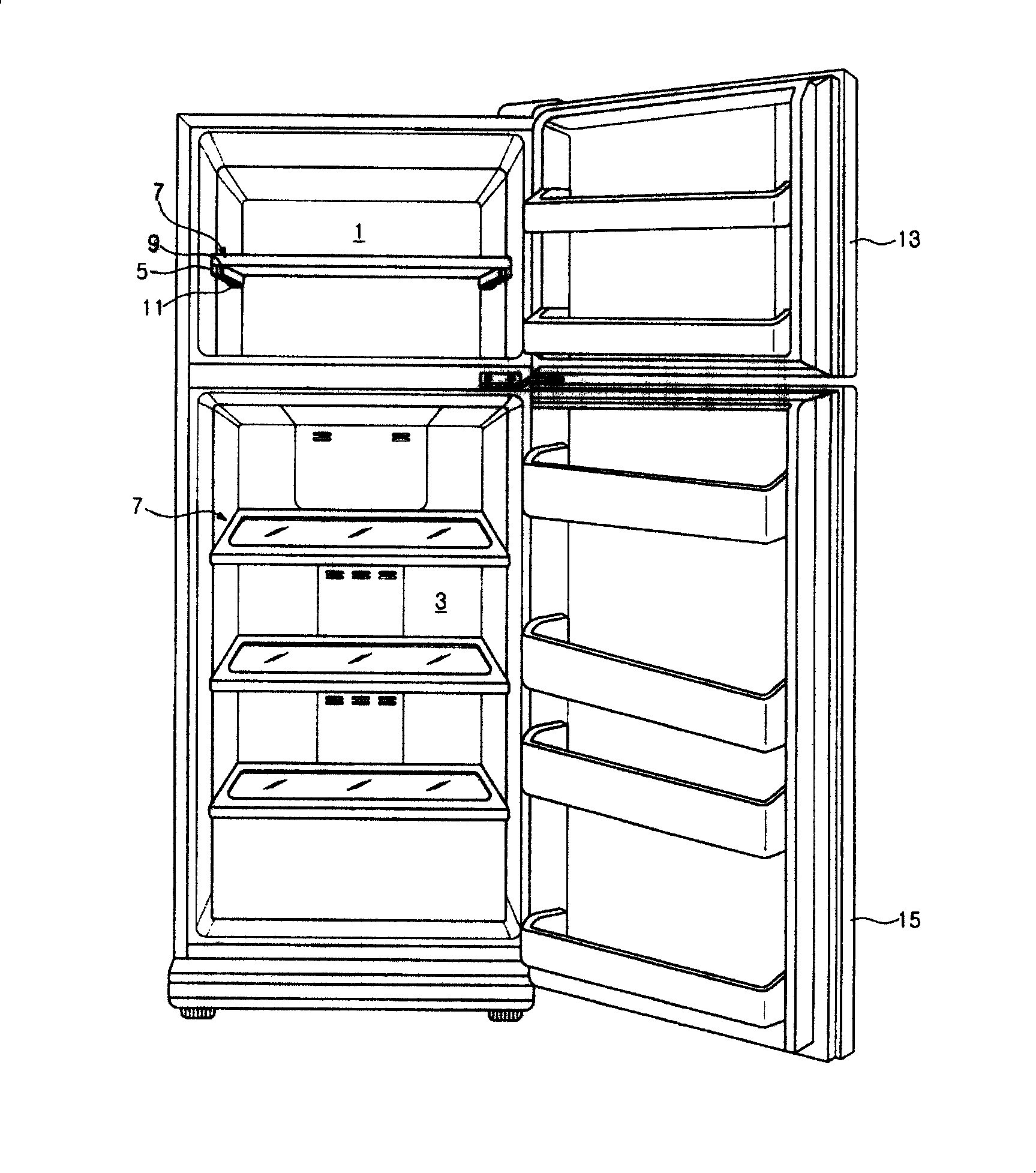

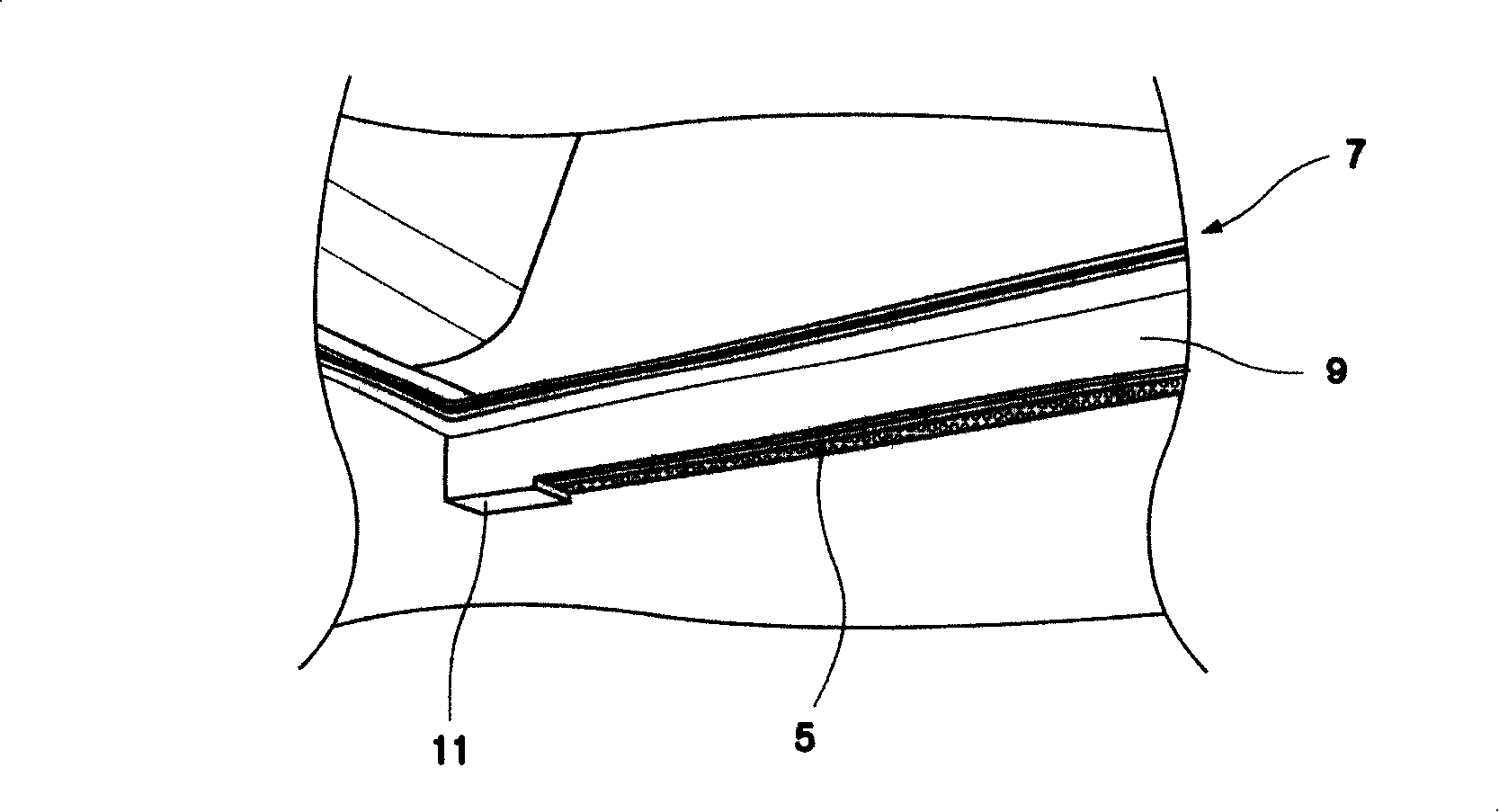

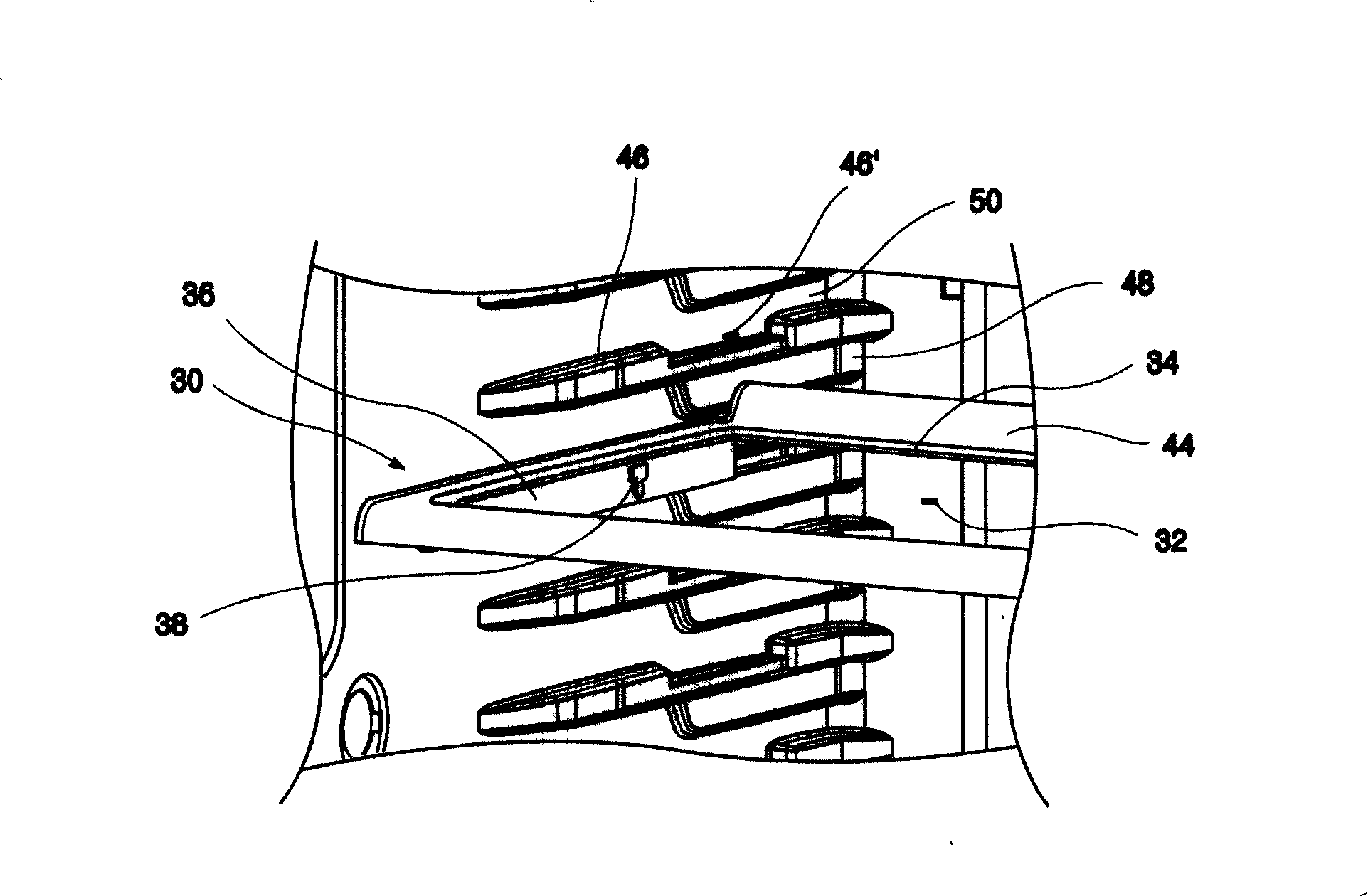

Installation structure of shelf assembly for refrigerator

InactiveCN101231074AAvoid shakingPrevent blocking phenomenonLighting and heating apparatusSupportEngineeringRefrigerated temperature

The invention relates to a mounting structure of shelf assembly parts used for a refrigerator, and the mounting structure comprises shelf assembly parts on which food can be positioned; a plurality of supporting parts which are arranged on both sides of storage space and are formed at certain intervals, and can support the two ends of the shelf assembly parts in the demountable way; a bulging rib which is adjacent to the support parts and is formed on both sides of the storage space and is closely attached on both ends of the upper side of the shelf assembly parts. the mounting structure also comprises a shielding rib which is formed along the edge of a through-hole which is formed at the inner side of the shelf assembly parts and extends from the mounting end arranged at the edge of mounting support parts, and is used for shielding the support parts; an inserting rib is formed a distance away from the shielding rib and inserted into the space between the supporting parts and the bulging rib; a braking device which is formed at one side of the inserting rib used for limiting the shelf assembly parts to be arranged at the position of the support parts, and is formed via bulging downwards. The invention has the advantages that the mounting structure can avoid the problem of separation of shelf assembly parts and cut-off of a cold air flow path caused by the inadvertence of the user.

Owner:TAIZHOU LG ELECTRONICS REFRIGERATOR CO LTD

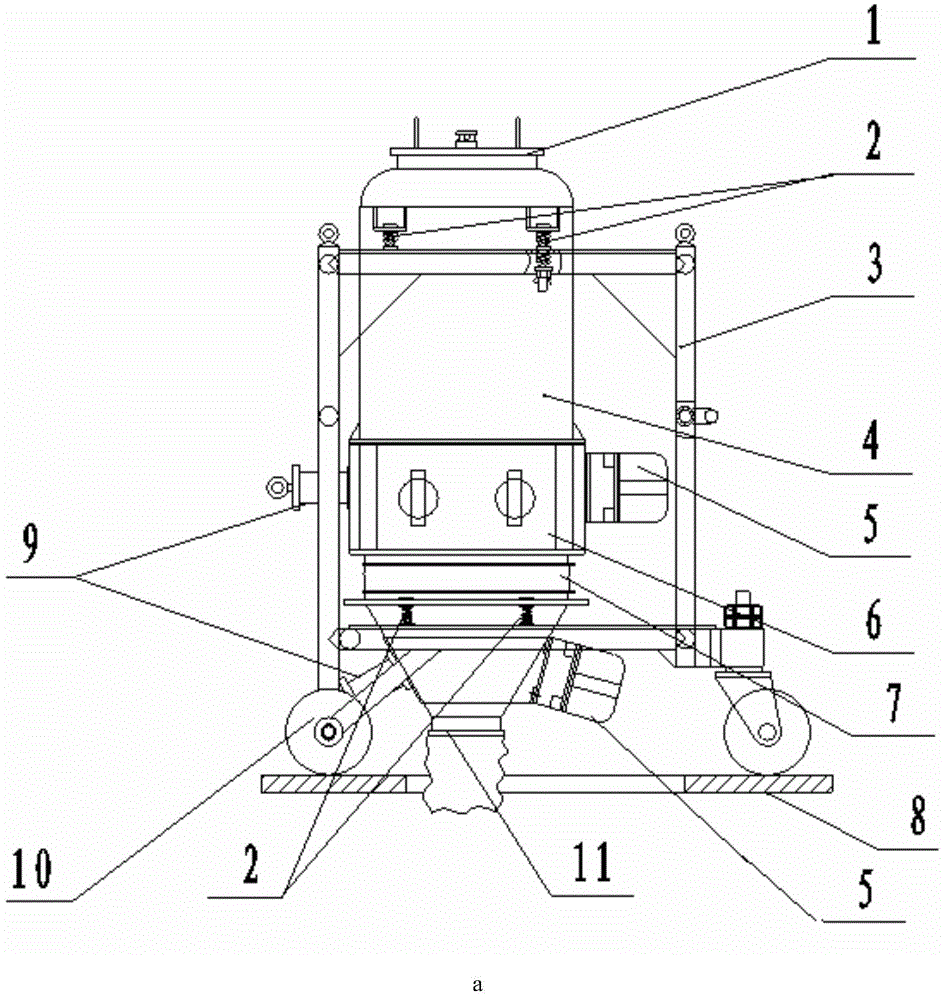

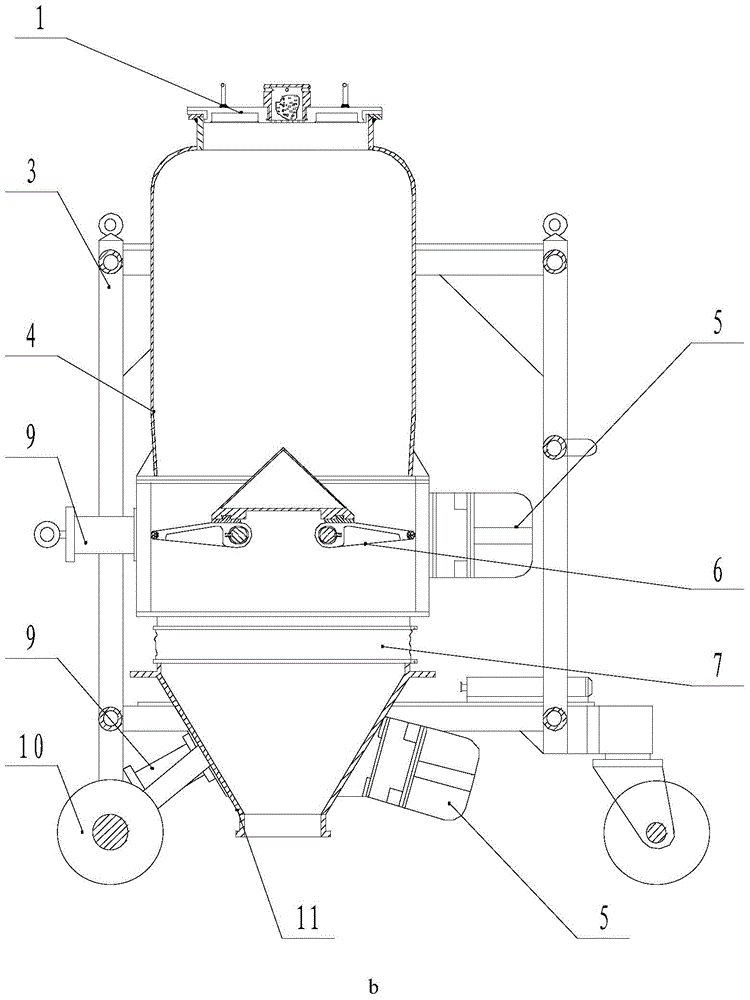

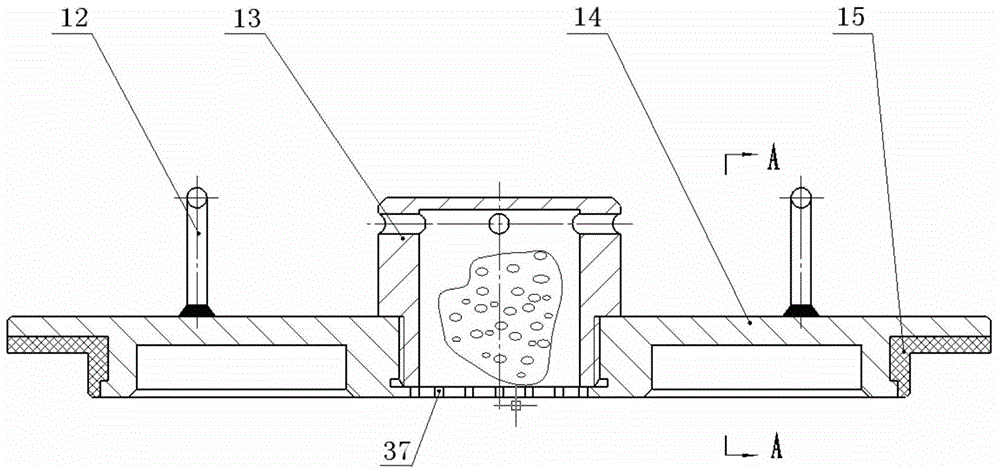

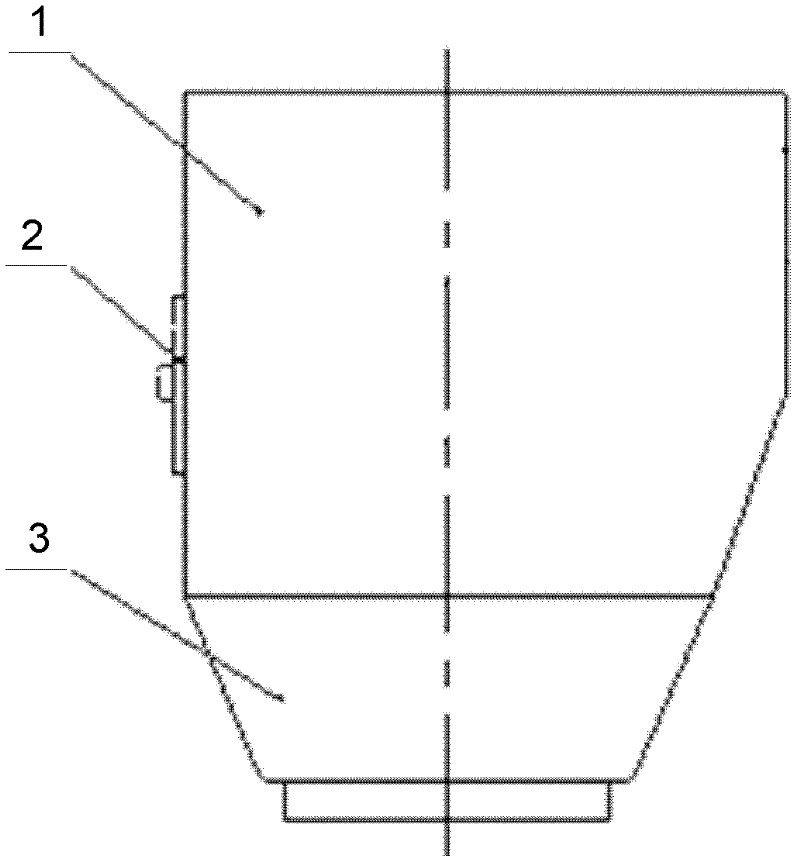

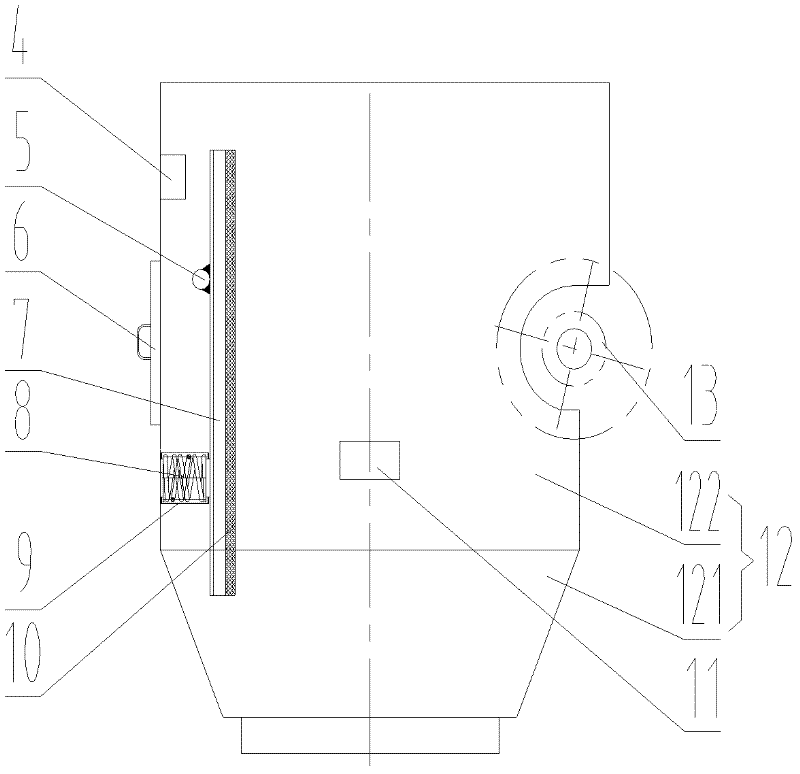

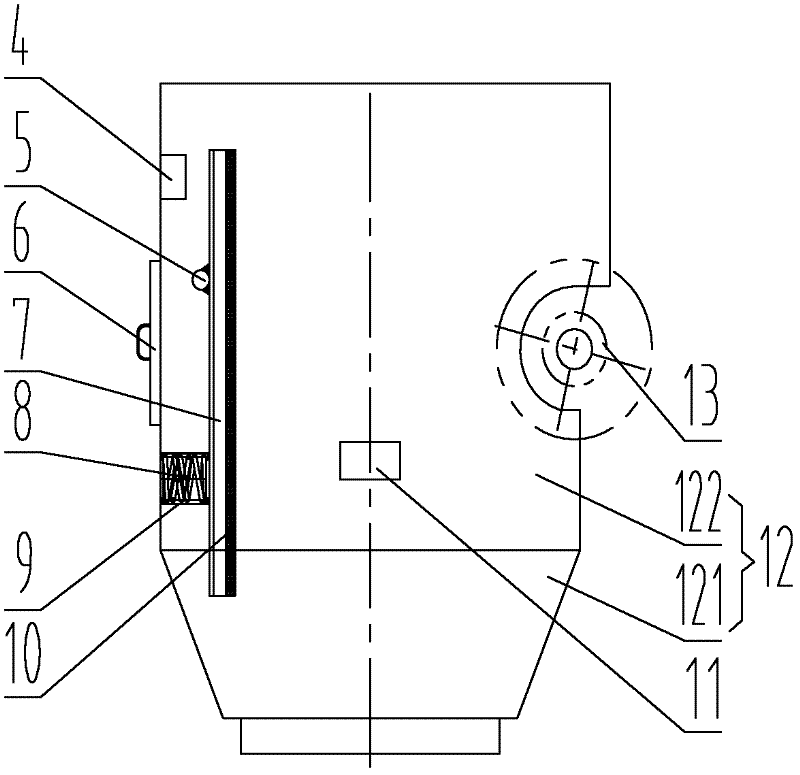

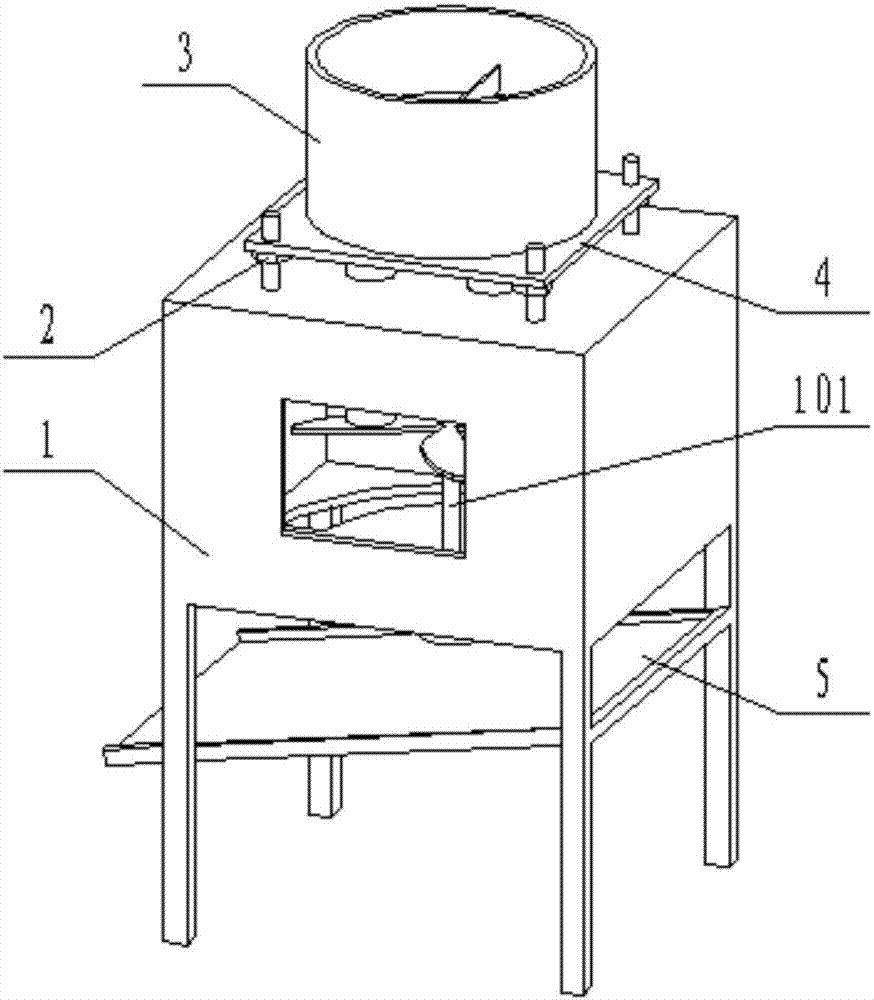

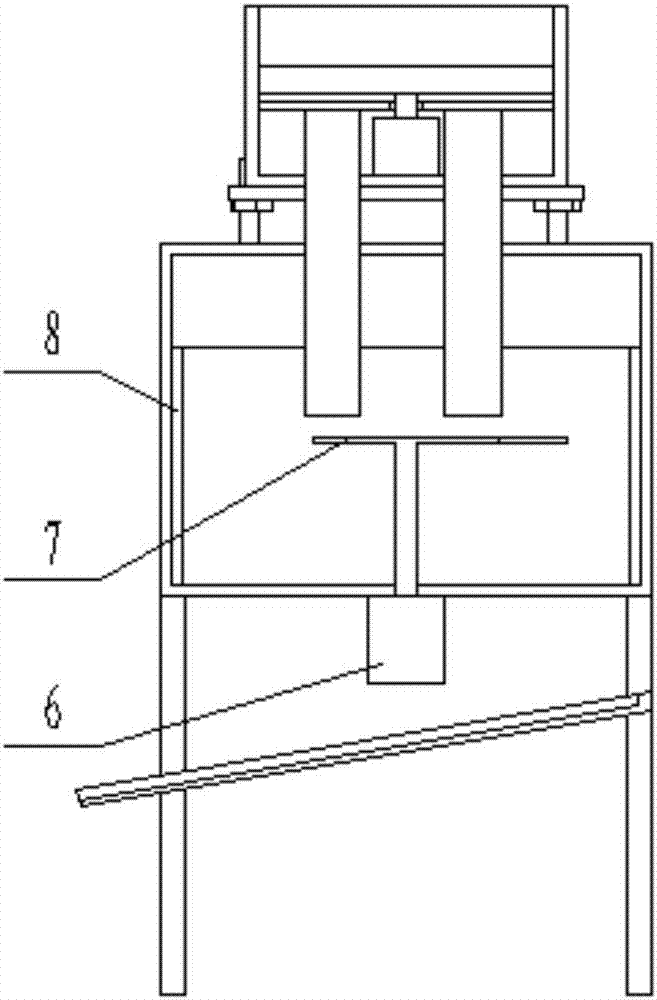

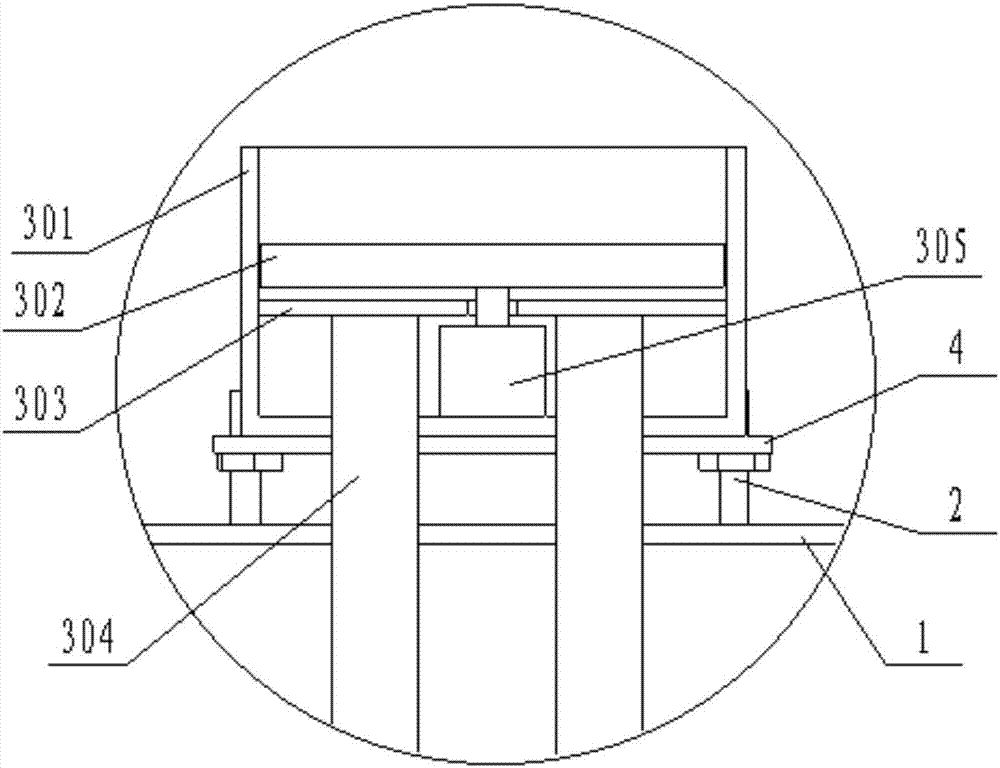

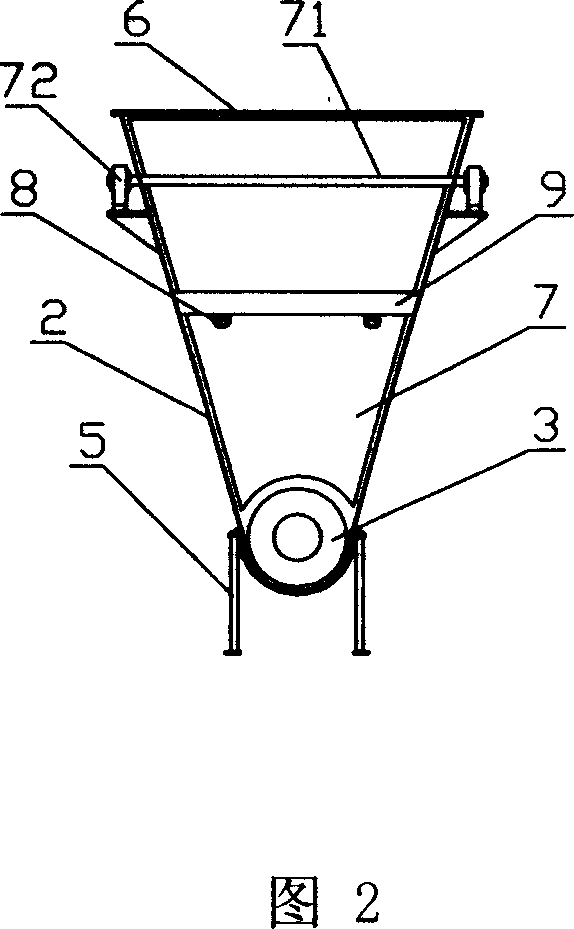

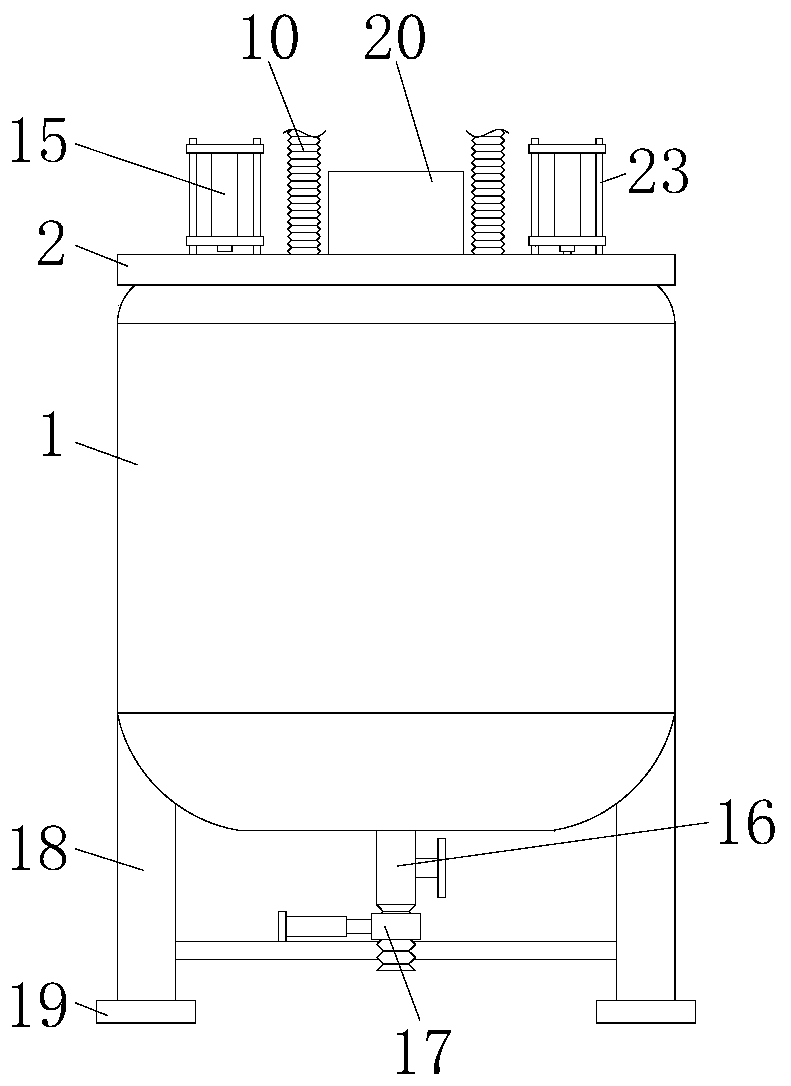

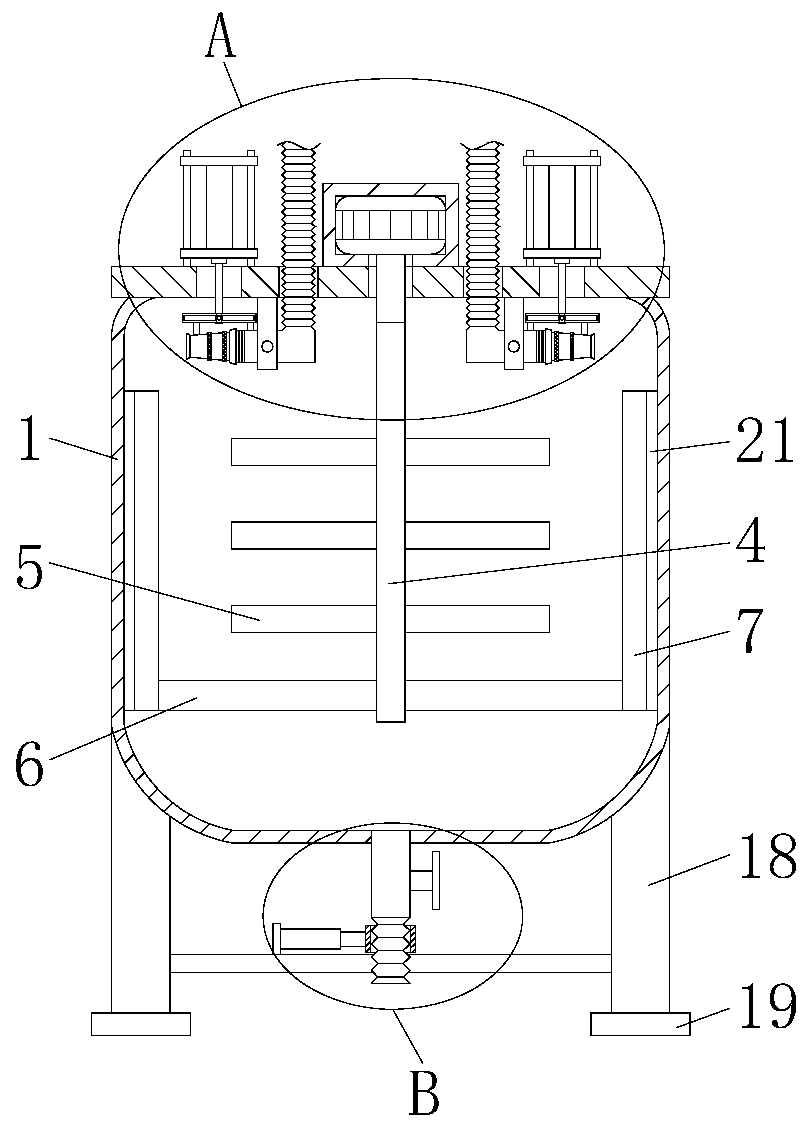

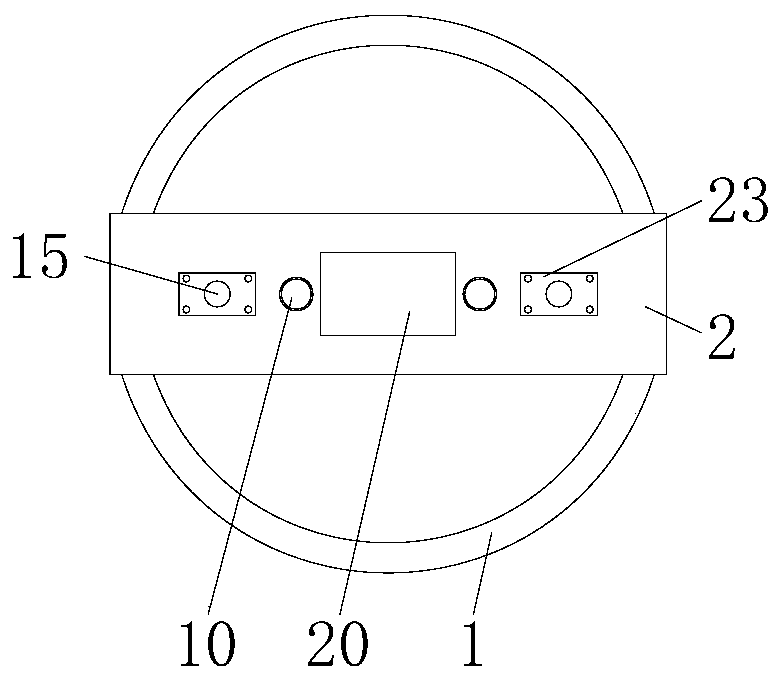

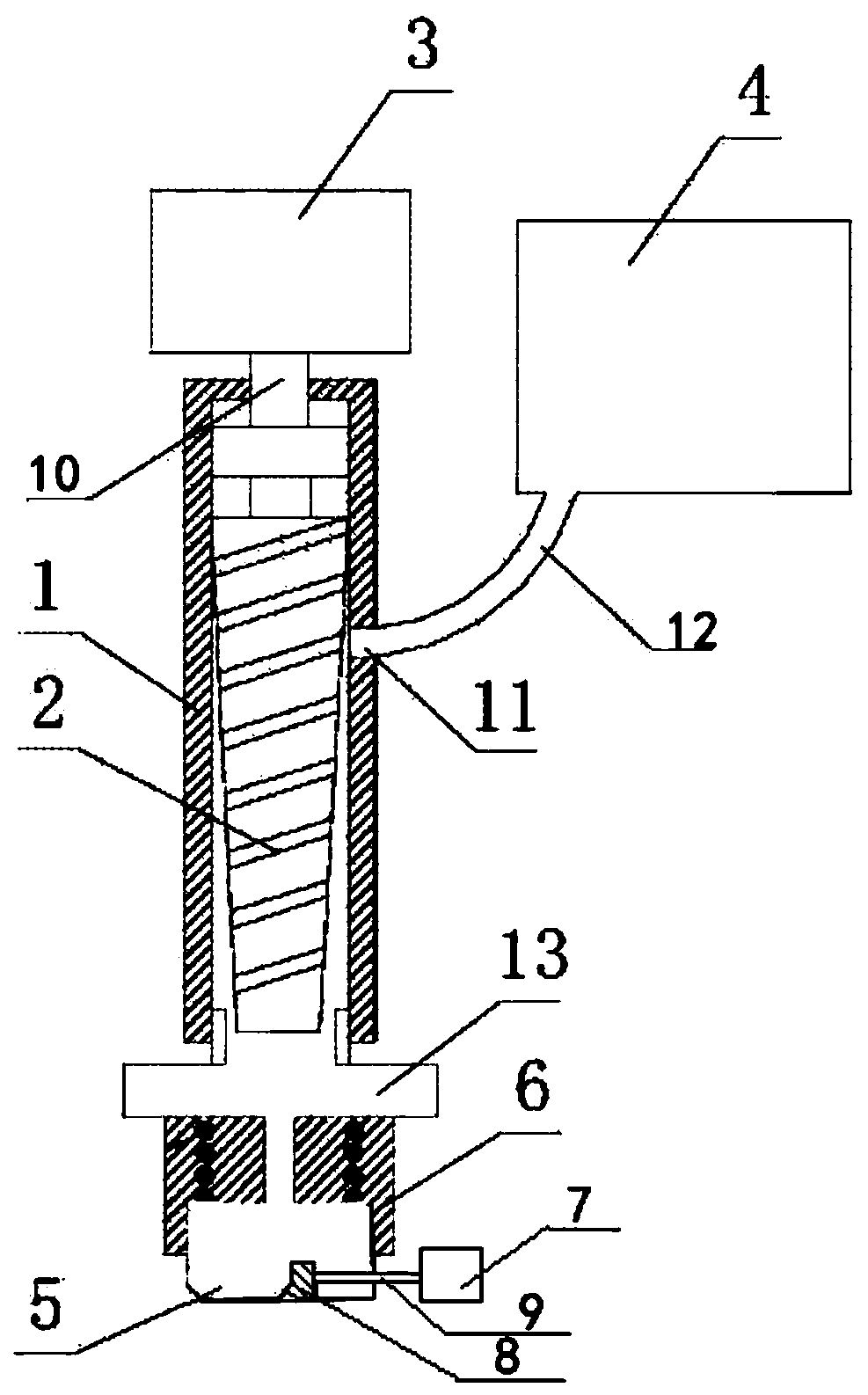

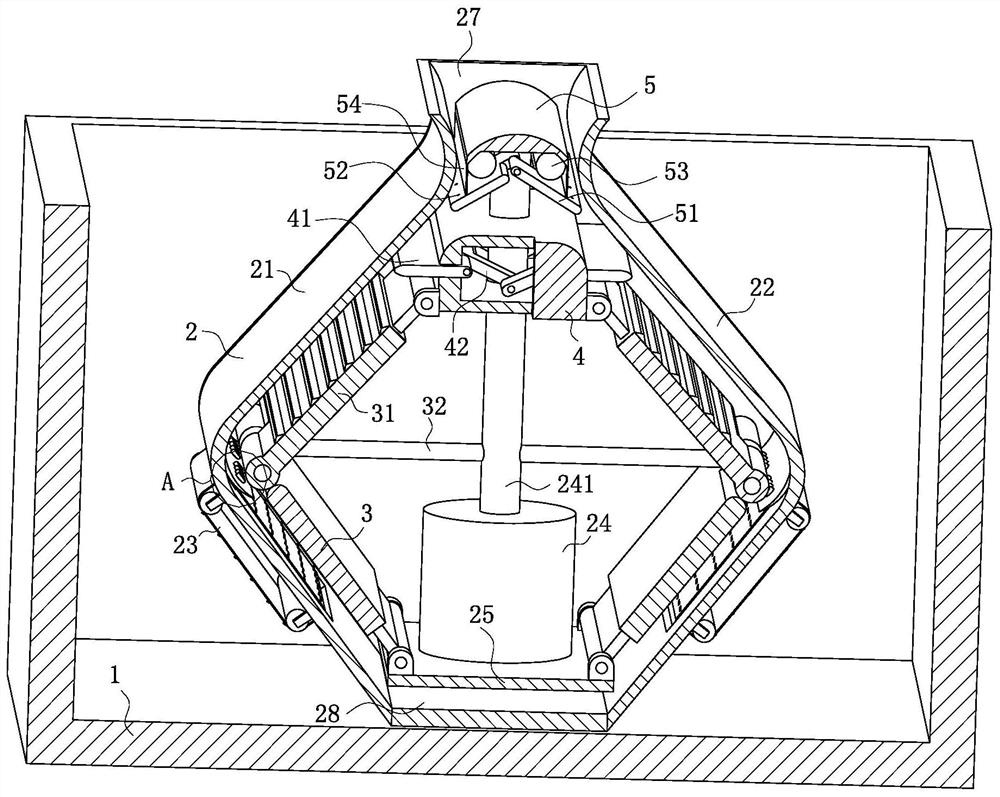

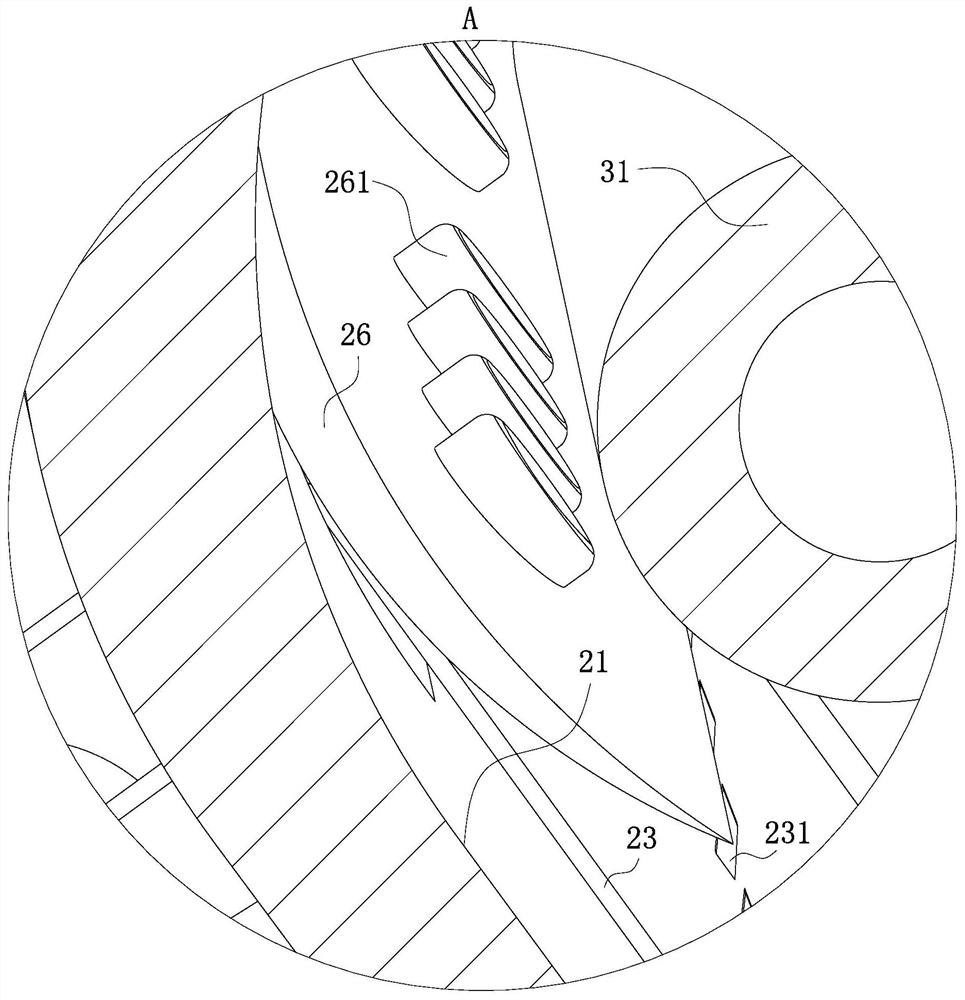

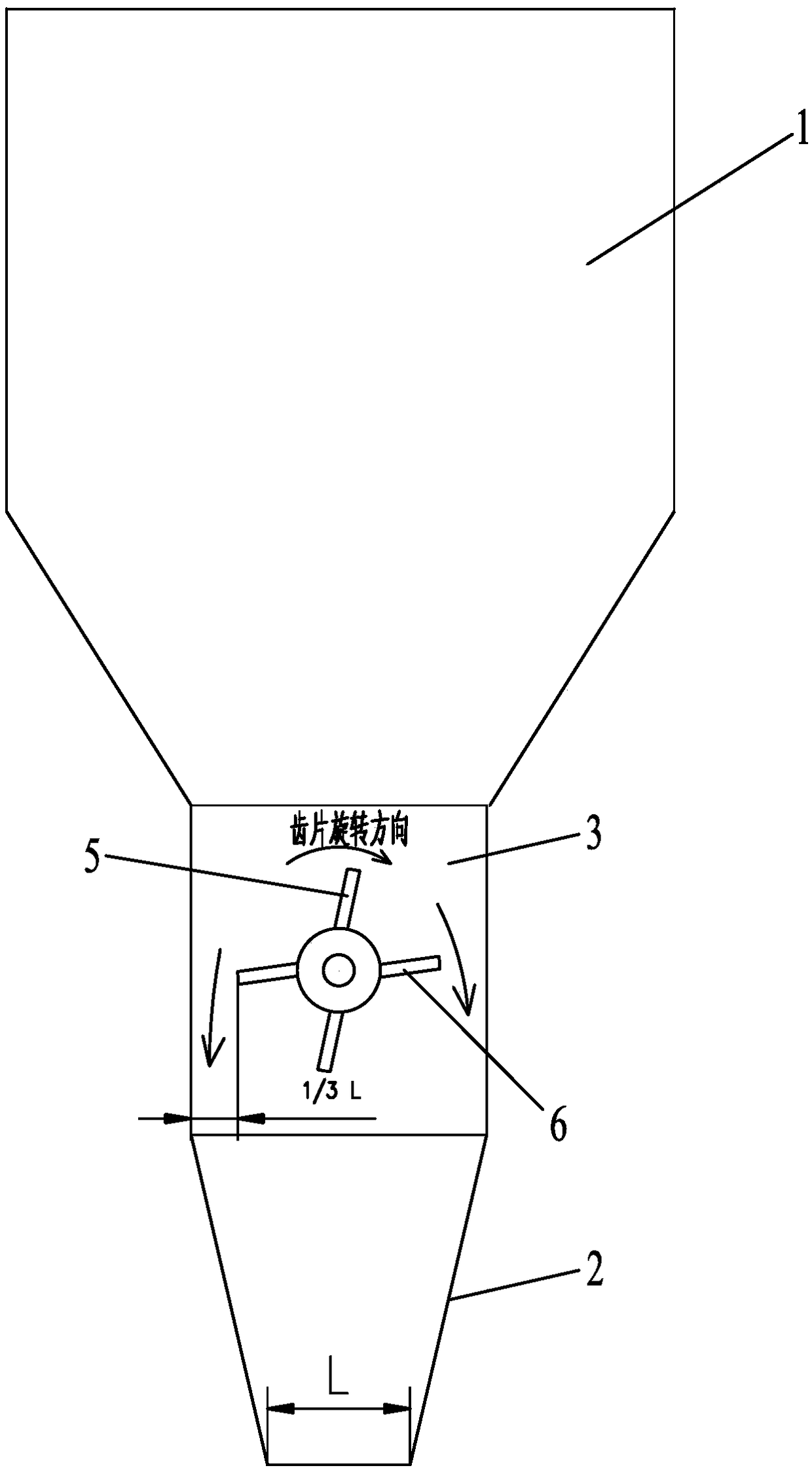

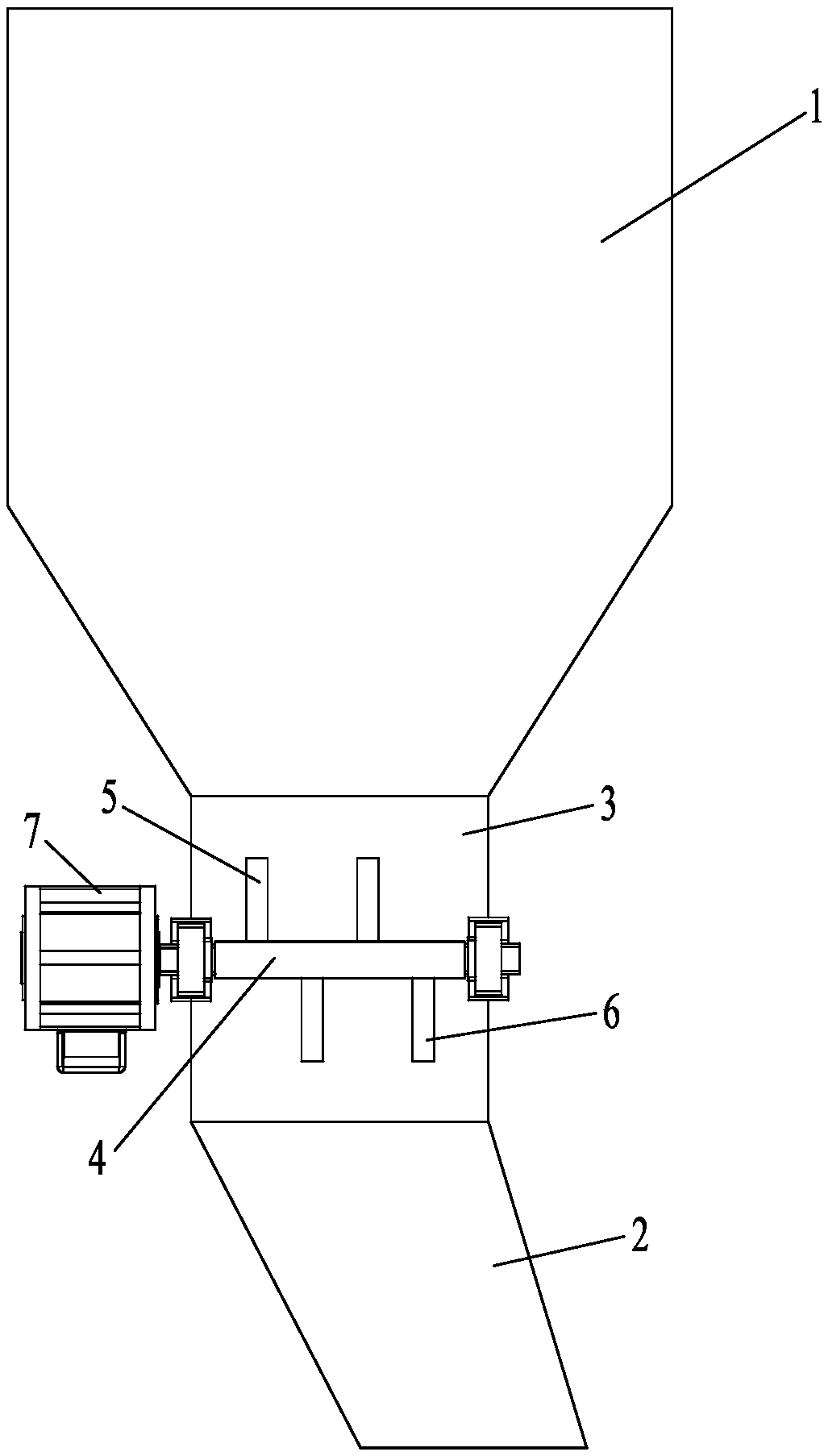

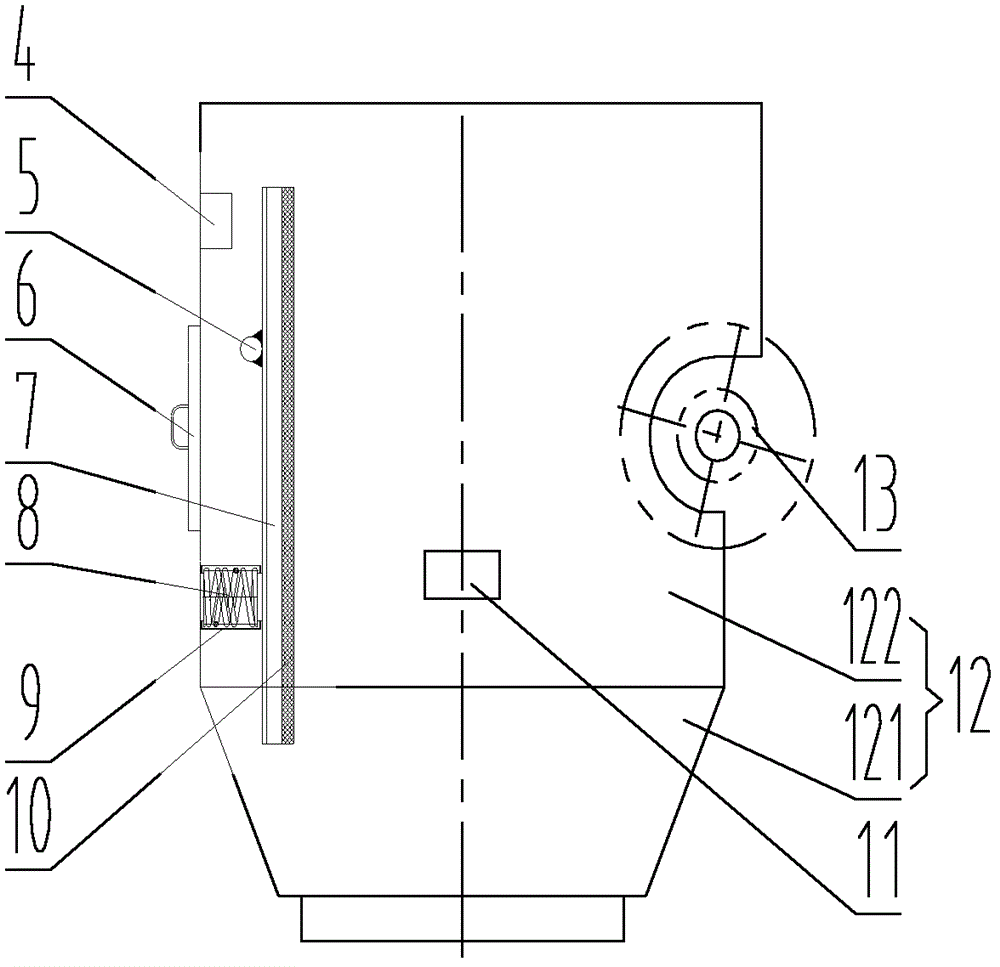

Powder storage device with quantitative discharging function

ActiveCN104309956APrevent blocking phenomenonUniform feedingLarge containersMechanical engineeringEngineering

The invention relates to a powder storage device with a quantitative discharging function. The powder storage device is characterized in that a material containing barrel is mounted on an upper cross beam of a frame through a flexible connector; a quantitative discharging device is fixedly arranged below the material containing barrel; a discharging hopper is fixedly arranged below the quantitative discharging device; a dustproof cover is arranged on the discharging hopper in a sleeving way; the number of explosion-proof electromagnetic vibrators is two, the two explosion-proof electromagnetic vibrators are respectively mounted on a supporting base of the quantitative discharging device and a connecting base of the discharging hopper; the number of air hammers is two, one of the air hammers is mounted on the supporting base of the quantitative discharging device, and the other air hammer is mounted on a connecting plate of the discharging hopper. The powder storage device has the benefits that the powder storage device can be used for automatic quantitative discharging, transportation and storage of a lot of power stored; through the design of the structure and the adjustment of the vibration frequency of the explosion-proof electromagnetic vibrators, the arching and agglomeration phenomenon of the powder in the blanking process can be greatly reduced, so that smooth blanking is ensured; the power quantitative discharging is realized through real-time monitoring of power weight in the discharging process.

Owner:XIAN AEROSPACE CHEM PROPULTION PLANT

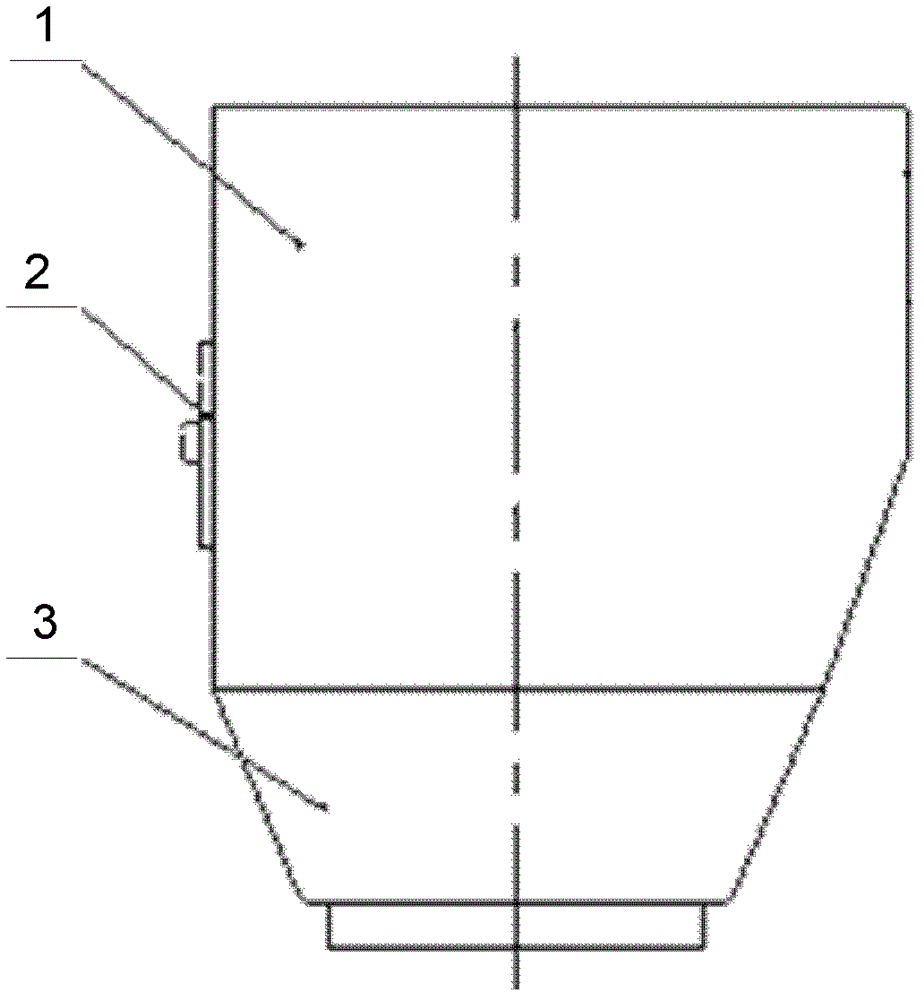

Bucket-wheel stacker reclaimer and hopper thereof

The invention discloses a hopper, which is connected with a rotary drum of a belt conveyor of a bucket-wheel stacker reclaimer and comprises a material baffle and a hopper body. The hopper body consists of an upper hopper body and a lower hopper body which are fixedly connected with each other, and the material baffle is detachably connected to the inner wall of the upper hopper body and is opposite to a discharge end of the rotary drum of the belt conveyor. The invention further discloses the bucket-wheel stacker reclaimer comprising the hopper. When the bucket-wheel stacker reclaimer operates, materials thrown out from the discharge end of the rotary drum of the belt conveyor enter the upper hopper body, directly contact with the material baffle, flow out from an outlet end of the lower hopper body under the action of the material baffle and enter a next working procedure. The material baffle replaces the upper hopper body to be used as a direct material contacting component of the hopper, abrasion of the materials to the upper hopper body is transferred from the upper hopper body to the material baffle, the material baffle can be replaced conveniently when abraded to a limit degree, accordingly, the abrasion of the materials to the hopper body is reduced remarkably due to the structure, and the service life of the hopper is prolonged.

Owner:SANY MARINE HEAVY IND

Low moisture coke quenching device and coke quenching method adopting same

The invention provides a low moisture coke quenching device. A low moisture coke quenching method adopting the device is characterized in that firstly primary coke quenching is carried out on high temperature coke formed after carbonization by spraying cold water, then secondary coke quenching is carried out on coke by utilizing massive water vapour produced during water spraying, and low moisture coke is formed after coke quenching is completed. Compared with the coke quenching method in the prior art, which has the problems that accurate control on temperature of semi coke after coke quenching is finished can not be realized, moisture content of the semi coke after the coke quenching is finished is still high and quality of the coke is poor, the low moisture coke quenching method adopting the low moisture coke quenching device can realize the effects that the temperature of the coke after the coke quenching is finished is accurately controlled to be 70-80 DEG C, water consumption in a coke quenching process can be effectively reduced, the moisture content of the coke after the coke quenching is finished is low and is about 1-2%, secondary drying is avoided, and no coal gas consumption is needed; besides, the produced water vapour as well as dust and toxic gas which are carried can be returned to a furnace and utilized again, excessive water vapour is led out through a pipeline for centralized treatment, and secondary pollution is eliminated.

Owner:HUADIAN HEAVY IND CO LTD

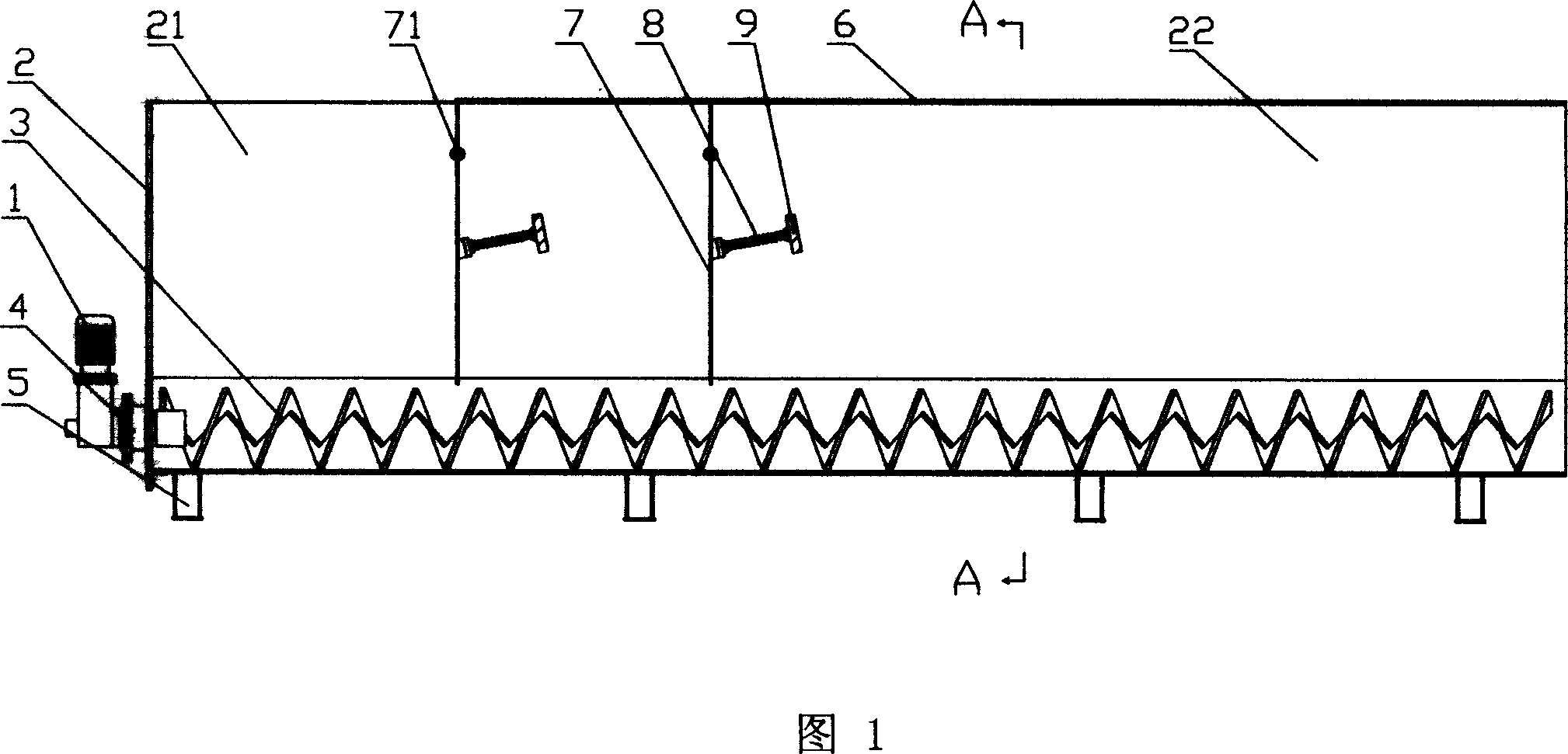

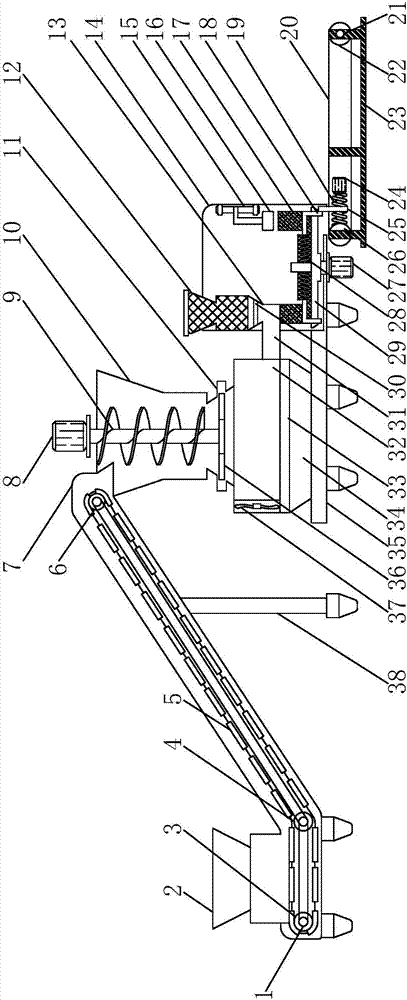

Dried sweet potato slicing and conveying integrated machine

PendingCN107457822APrevent blocking phenomenonImprove slice qualityMetal working apparatusMotor driveEngineering

The invention discloses an integrated machine for conveying dried sweet potato slices, which comprises a slicing box, a slicing motor is installed at the lower end of the slicing box, and a cutter disc is fixedly installed at the output end of the slicing box; a discharge port is arranged at the bottom of the slicing box , the outer side of the discharge port is provided with side guards; the upper end of the slicing box is fixed with a support plate through height-adjusting bolts, and a feeding device is installed at the upper end of the support plate. The beneficial effect is that: the feed motor drives the feed scraper to rotate to achieve stirring, and cooperates with the feed vibrating plate to realize the vibration, stirring and feeding of raw materials, which can prevent the phenomenon of material blocking; the raw materials enter the inside of the material guide tube under the action of vibration and stirring , to realize the adjustment of the feeding direction of the raw material, so as to ensure the consistent cutting direction and improve the cutting quality; the height of the support plate can be adjusted by adjusting the height of the bolt, so as to adjust the height of the feeding device and change the distance between the outlet of the guide tube and the cutter head. Adjust the slice thickness to meet different thickness requirements.

Owner:绍兴云疆网络科技服务有限公司

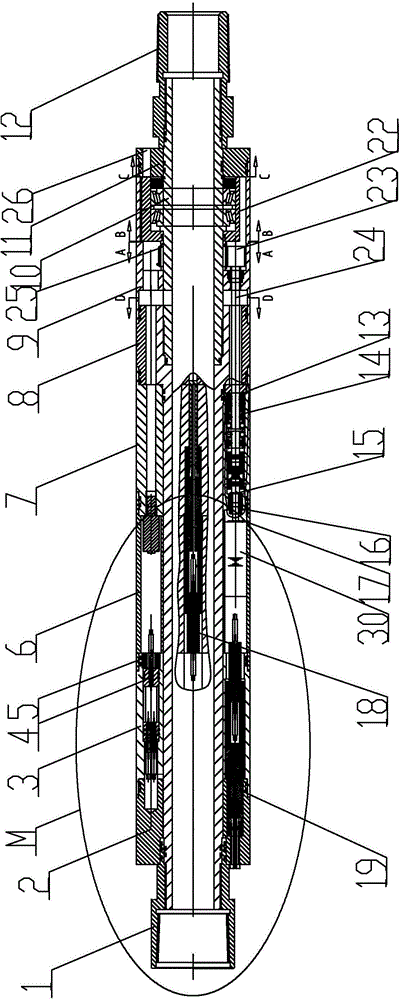

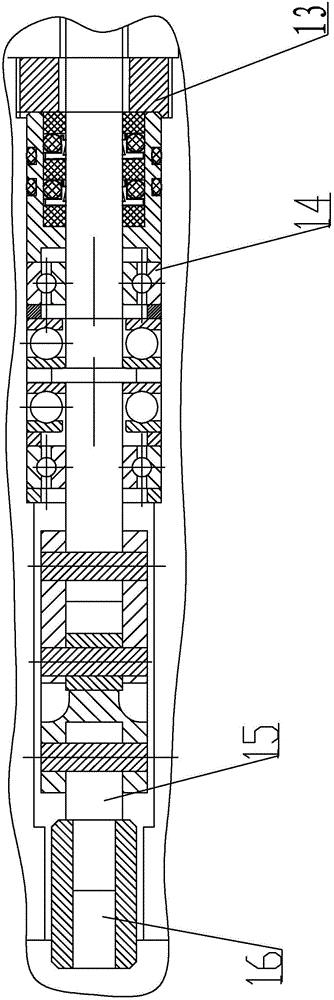

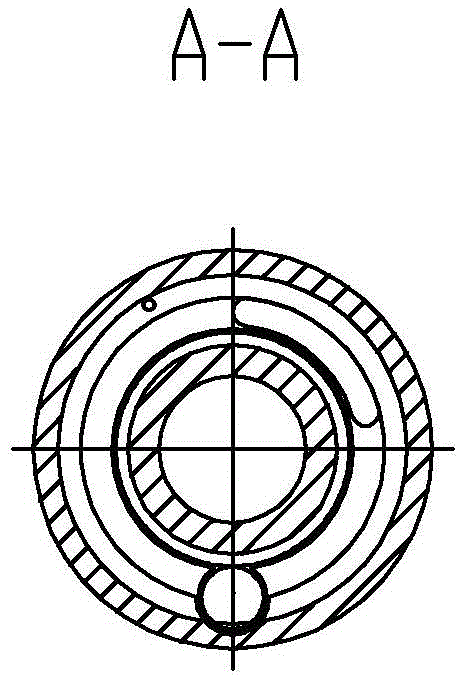

Gear adjusting type injection allocation device for polymer injection well

ActiveCN104153747AIncrease the areaPrevent blocking phenomenonFluid removalEngineeringInjection well

The invention relates to an injection allocation device, in particular to a gear adjusting type injection allocation device for a polymer injection well. The problems that the structure of an existing polymer injection allocation device is complex, the polymer injection amount is inconvenient to adjust, and an outlet is prone to being blocked are solved. An upper connector body, an upper cable body, an contact pin body, a motor shell body and a bearing shell body are sequentially arranged on the outer surface of a connecting body of the device from top to bottom, the connecting body and the upper connector body are connected through threads, an upper outer shell body, a lower outer shell body and a lower connector body are sequentially arranged on the outer surface of a central tube from top to bottom, the central tube is connected with the lower connector body through threads, the connecting body is connected with the central tube through threads, a motor is arranged in the motor shell body, the central tube is sleeved with a large gear, one end of a small gear shaft is connected with the motor, the other end of the small gear shaft is sleeved with a small gear, the large gear is meshed with the small gear, and the central tube is sleeved with a blocking sheet. The gear adjusting type injection allocation device is used for oil exploitation.

Owner:HARBIN INST OF TECH

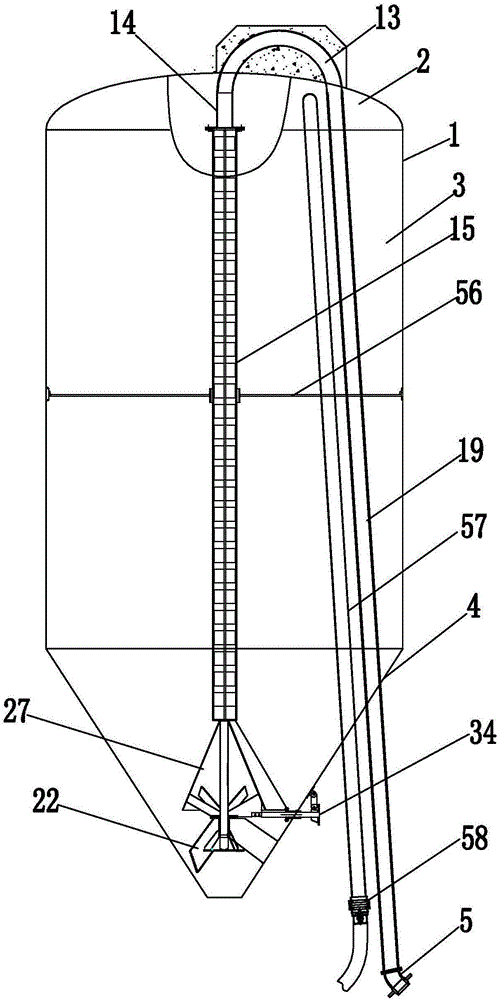

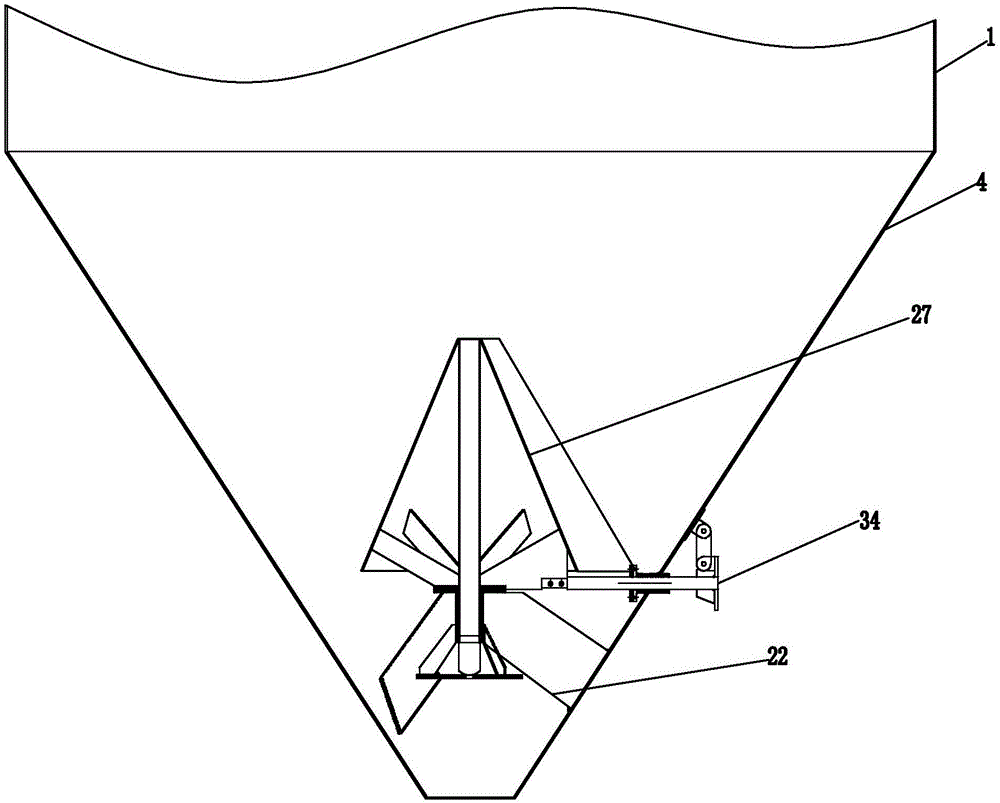

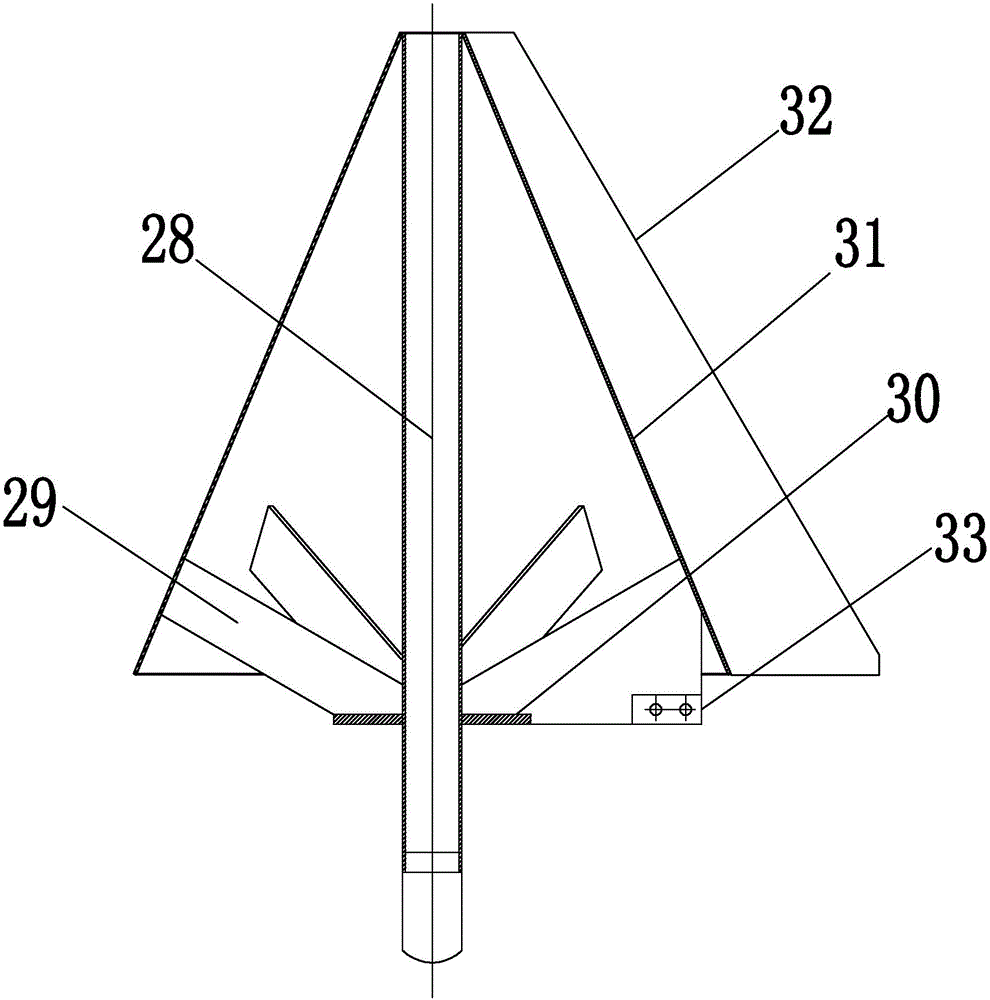

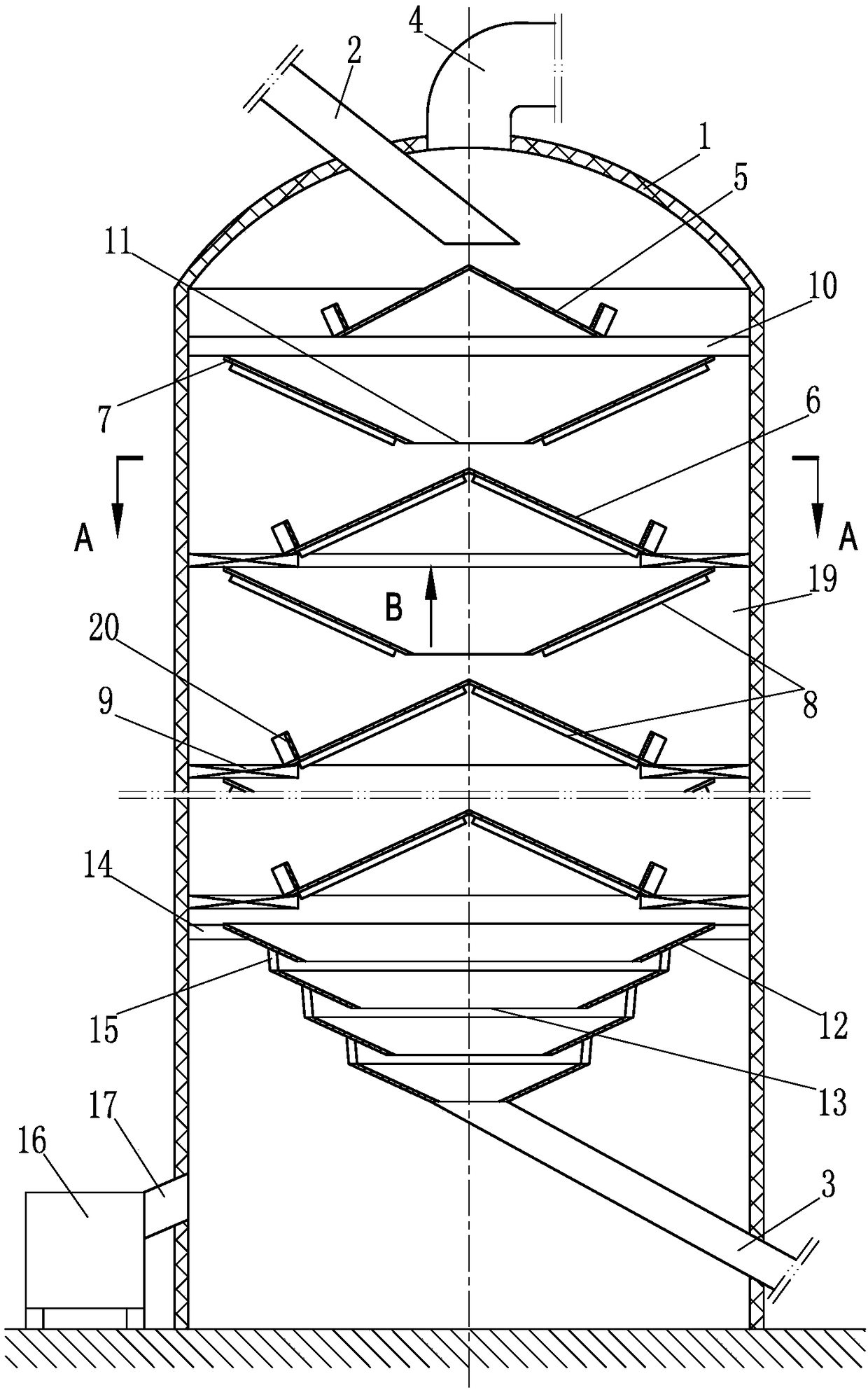

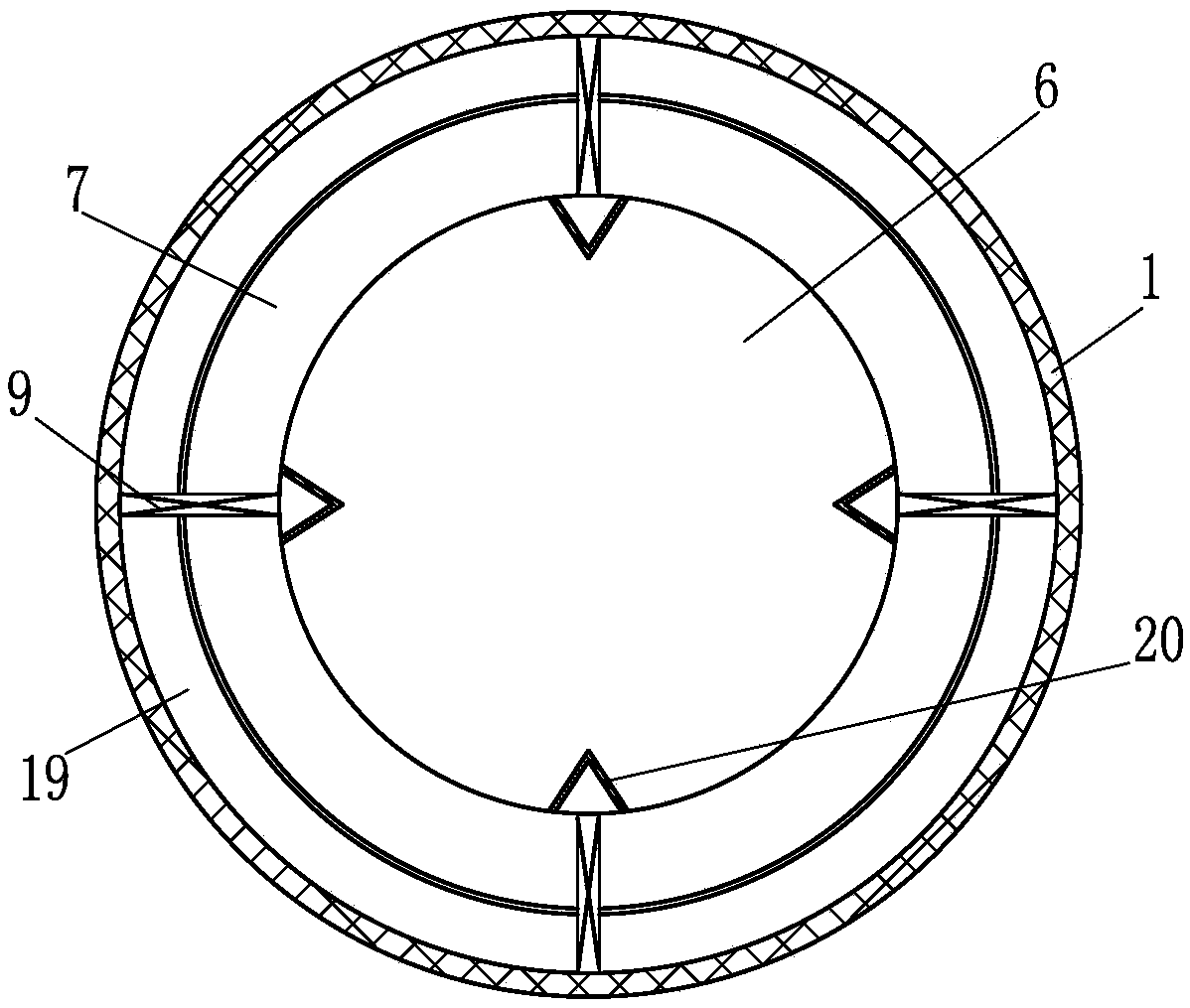

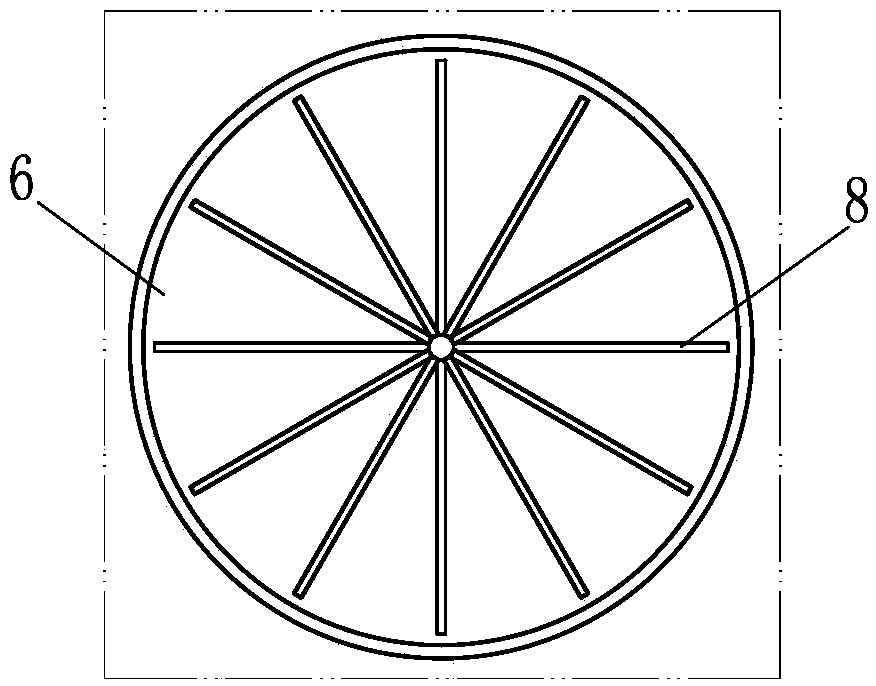

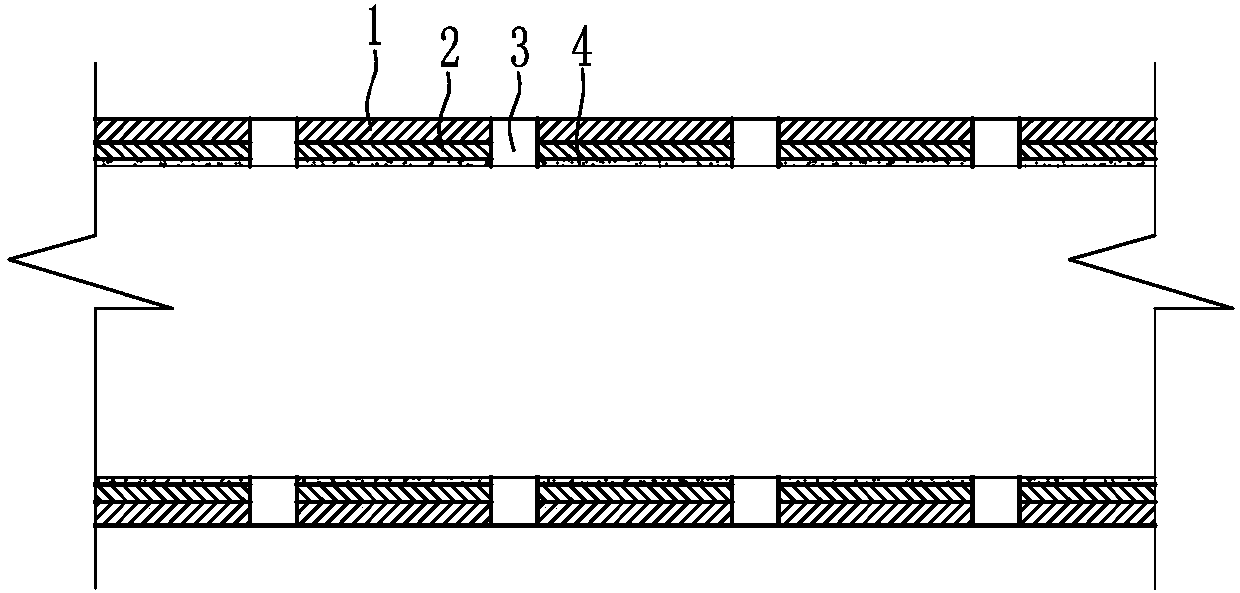

Novel movable silo for dry-mixed mortar

InactiveCN106395172AReduce segregationReduce extrusion pressureLarge containersBulk conveyorsEngineeringSilo

The invention relates to a novel movable silo for dry-mixed mortar. The novel movable silo comprises a movable silo body which is provided with an air-blowing feeding structure, a discharging structure and an air outlet structure. The air-blowing feeding structure comprises a straight feeding pipe; one end of the straight feeding pipe is connected with a steering pipe connection assembly; the other end of the straight feeding pipe is connected with a bend feeding pipe; and the end of the bend feeding pipe is connected with a material guide pipe which is connected with a cage-shaped discharging pipe. The movable silo body comprises a silo cone; the discharging structure comprises a supporting part installed in the silo cone; a conical device is installed on the supporting part and connected with a vibration device which is connected to the side wall of the silo cone; and the conical device is connected with the cage-shaped discharging pipe. The air outlet structure comprises an air outlet pipe which penetrates through the interior of the movable silo body and is connected with a reducing valve. The novel movable silo is simple in structure, convenient to use, durable and convenient to operate, has no vulnerable part and has high practical value.

Owner:浙江益森久城环保设备有限公司 +1

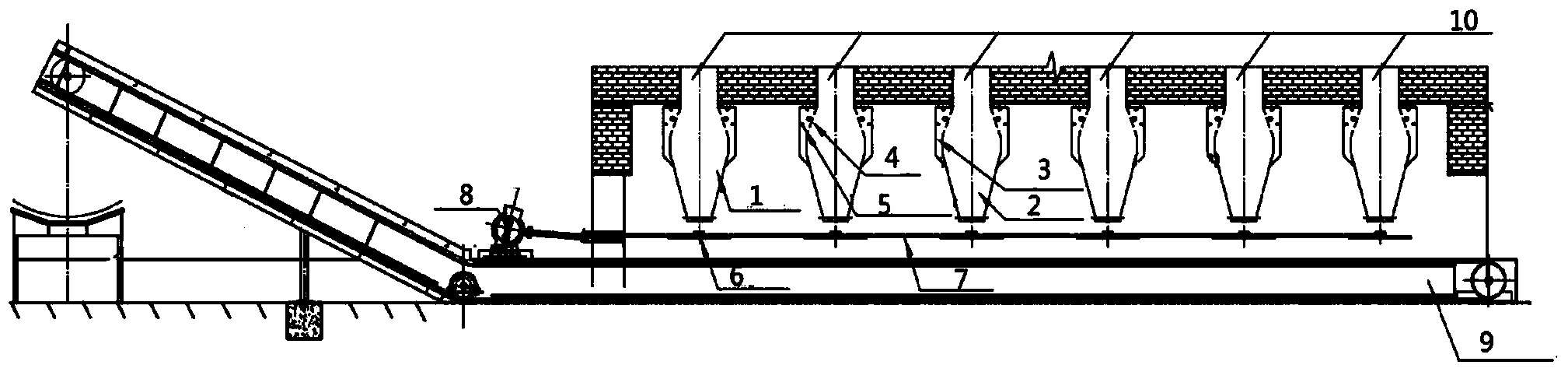

Non-axial screw conveyor for burning refuse

InactiveCN1927678AConvey evenlyIncrease effective spacePackagingIncinerator apparatusHelical bladeElectric machine

The invention discloses an axis-free screw conveyor for burning refuses, which includes electric machine, store bodies and axis-free helical blades. The store bodies comprise of feeding part and conveyor part, two actively rotating baffles are installed in said conveyor part, one side of said baffles link with compressed springs. When the garbage enter from the feeding mouth, first the garbage are rolled in by axis-free helical blades to transporting forwards, then the garbage enter the garbage incineration evenly after balanced by two baffles, while the baffles block off the dissemination of heats, smokes and the smell of the garbage incineration. It increases the effective delivery channel space, basically avoids the phenomenon of blocking and gets rid of the manual dredge by using the axis-free helical blades. The invention solves the problems of plugging, arching, heat leaking and garbage stench dissemination in the garbage transfer process effectively, ensures the uniform transportation of the garbage and incineration fully, so improves the working environment.

Owner:钱尧翎

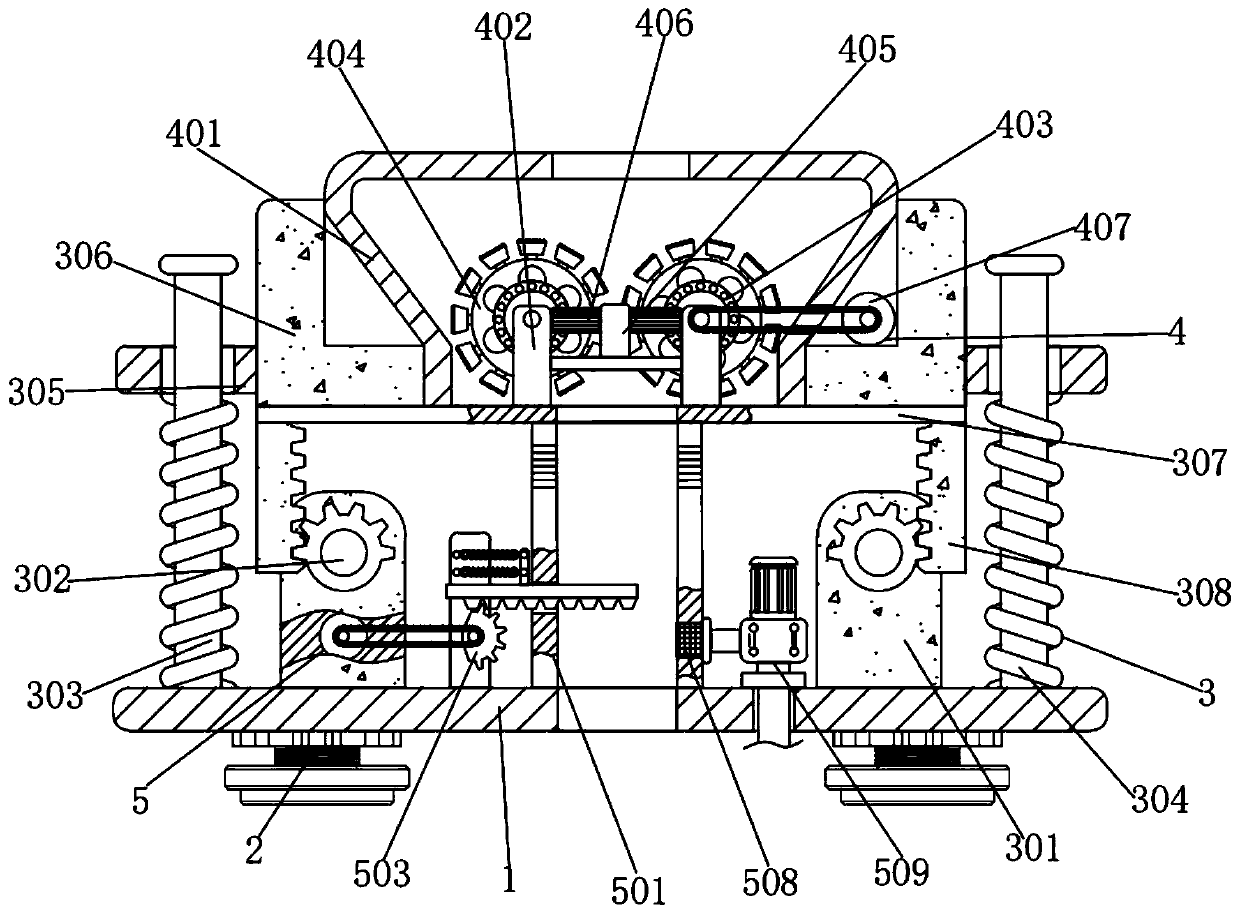

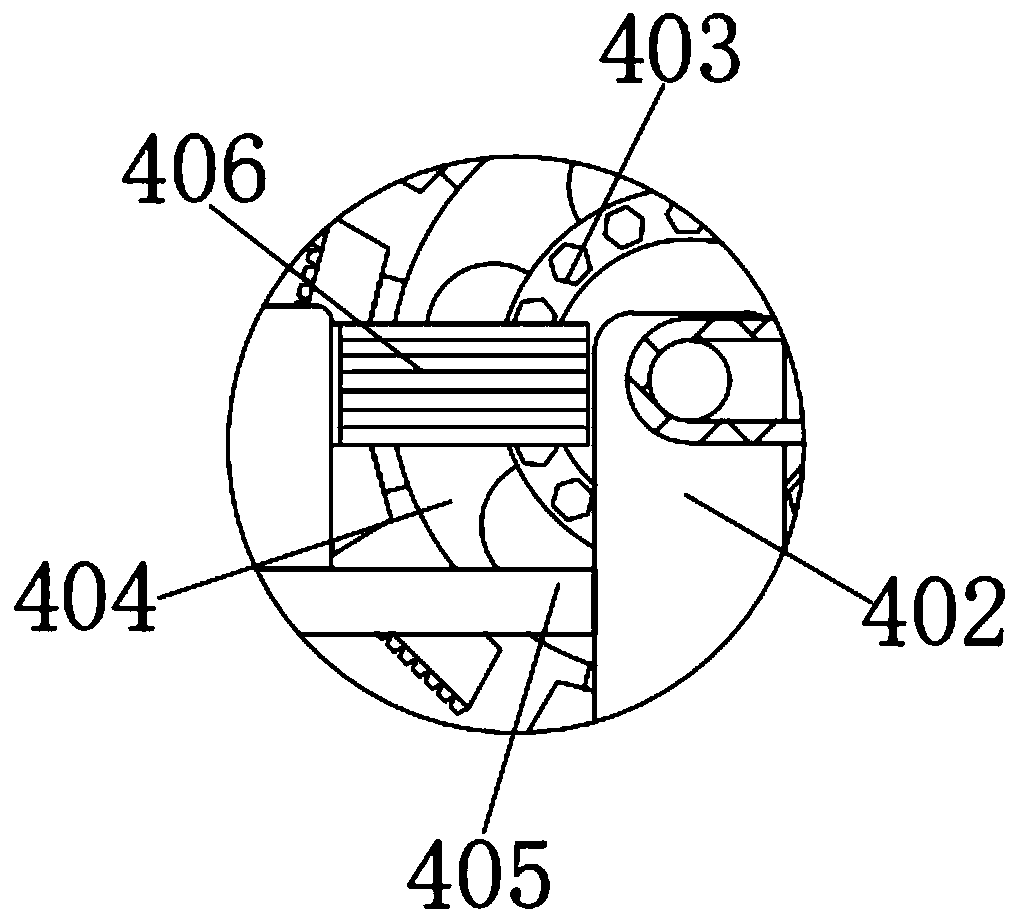

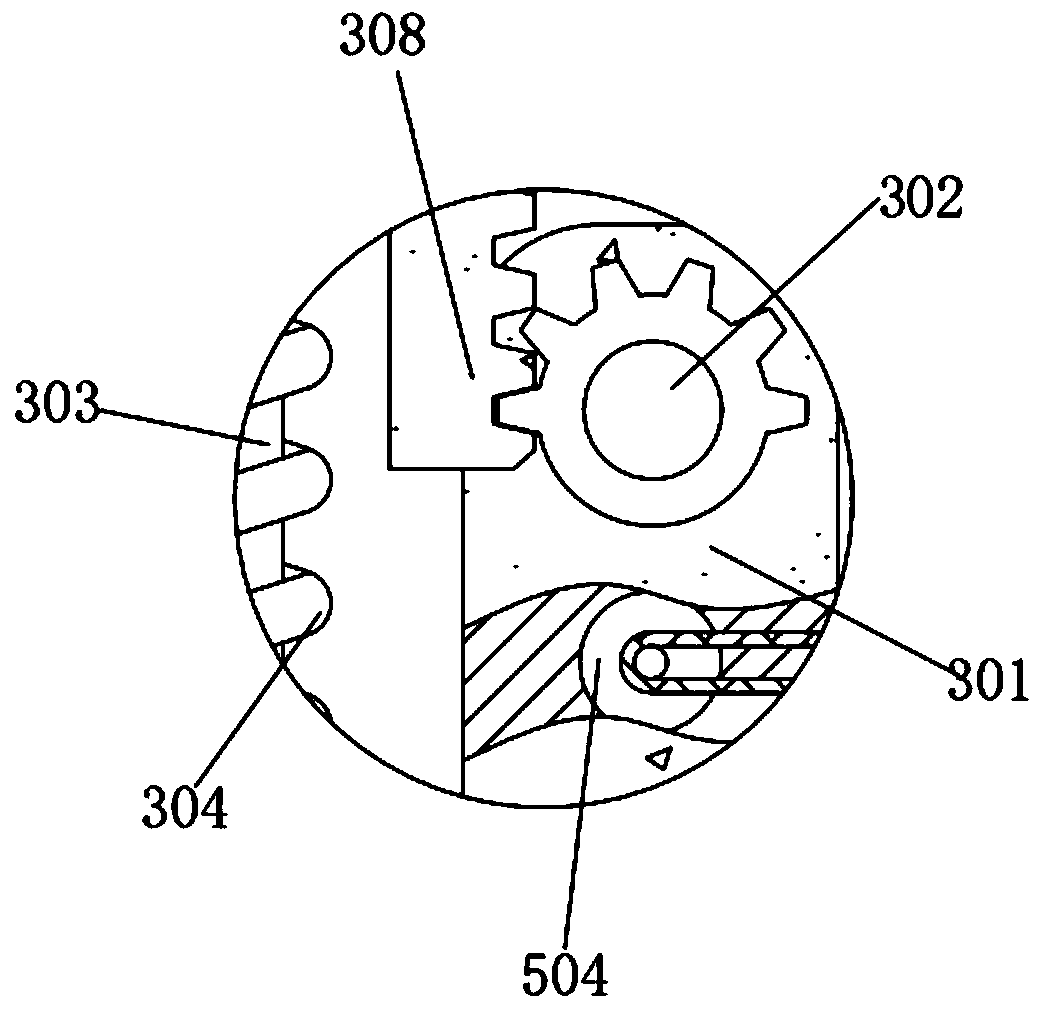

Cement smashing device

ActiveCN111151339AReduce vibrationExtended service lifeNon-rotating vibration suppressionDirt cleaningVibration amplitudeGear wheel

The invention discloses a cement smashing device comprising a first cross plate and bases fixedly connected with the lower surface of the first cross plate. A damping device is installed on the uppersurface of the first cross plate. According to the cement smashing device, by means of mutual cooperation of vertical rods, first half-ring gears, first tooth plates, second cross plates, first springs, L-shaped plates and other structures, the vibration amplitude can be lowered when the cement smashing device works, so that the service life of the cement smashing device is prolonged. By means ofmutual cooperation of a second motor, a second half-ring gear, a second toothed plate, a second spring, a pipe and other structures, a material blockage phenomenon is avoided, the work efficiency is improved and the labor cost is reduced; by means of mutual cooperation of a filtering net, a third cross plate, a pipe, a fan, the first cross plate and other structures, dust generated during smashingcan be sucked for centralized treatment, and therefore the health of operation personnel is protected.

Owner:承德冀东水泥有限责任公司

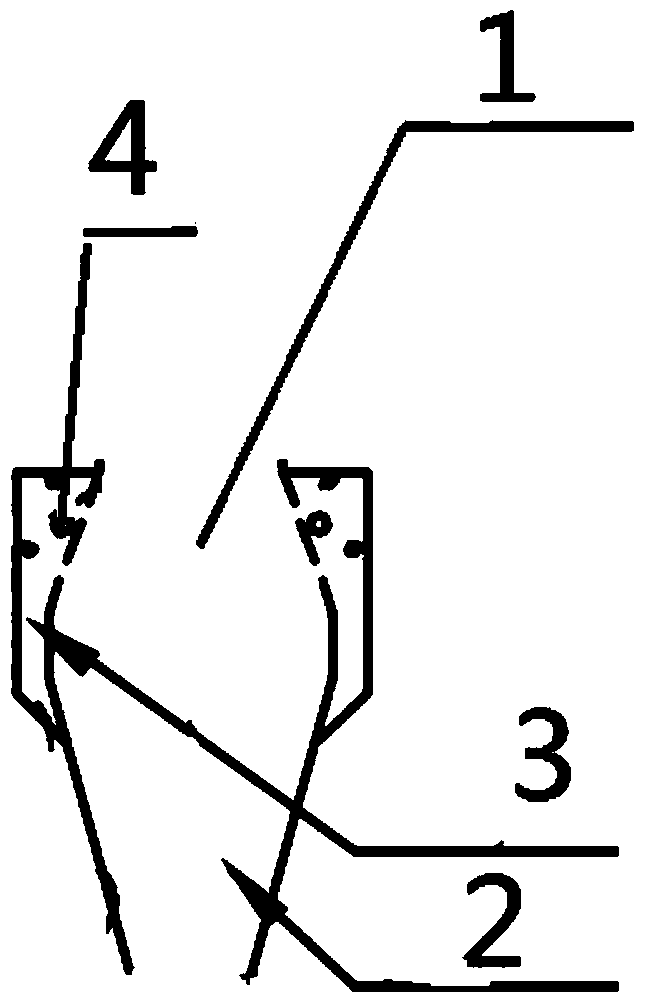

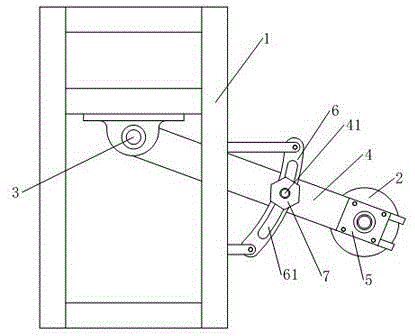

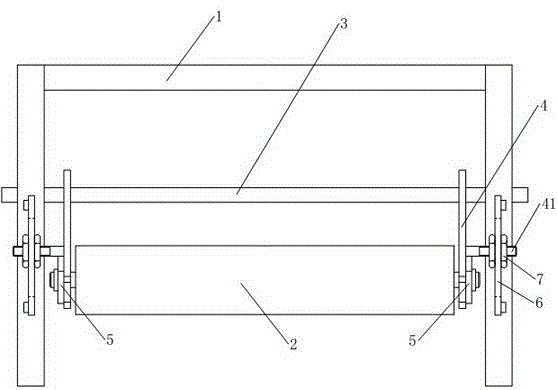

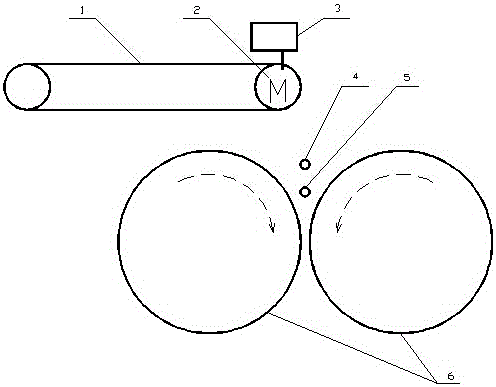

Material bag shaping and flattening device

The invention relates to a material bag shaping and flattening device. The material bag shaping and flattening device comprises a machine frame and a pressure roller which is arranged horizontally, wherein a rotatable rotating shaft is hung at the lower part of the machine frame; two rotating arms are vertically and fixedly connected to the rotating shaft; a mounted bearing is arranged at one end, far away from the rotating shaft, of each rotating arm; each mounted bearing is connected with a shaft head of the pressure roller; guide rails are respectively and fixedly arranged on the two sides of the machine frame; each guide rail is provided with an arc-shaped guide groove; a guide post which is provided with external screw threads is arranged on each rotating arm; each guide post penetrates through the corresponding guide groove; screwing nuts which are matched with the guide posts are respectively arranged on the two sides of each guide rail; the screwing nuts are clamped and fixed to the guide rails. By the structure, the material bag shaping and flattening device is simple in structure; the guide posts are arranged on the rotating arms, the guide rails provided with the arc-shaped guide grooves are arranged on the machine frame, and the height of the guide posts are adjusted through the screwing nuts, so that the height of the pressure roller is adjusted; therefore, the shaping effect is enhanced, and the phenomenon of material blockage is avoided.

Owner:WUXI XINAN TAIHU CHEM MACHINERY FACTORY

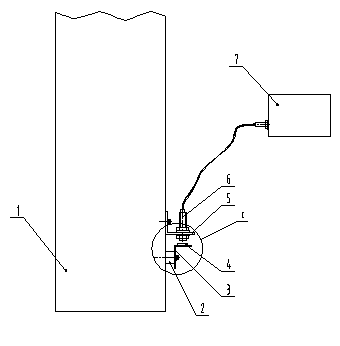

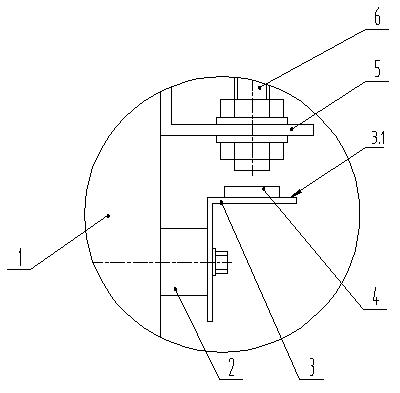

Belt slippage detection device of grain hoister

InactiveCN103043393AAdjust the tightness in timeGuaranteed to proceed normallyControl devices for conveyorsDrive shaftAgricultural engineering

The invention discloses a belt slippage detection device of a grain hoister. The belt slippage detection device is arranged at the shaft end of a driven shaft of the grain bucket hoister and comprises a strong magnet, a Hall sensor, a controller, a magnet support and a sensor support. The magnet support is a right-angled member, one right-angled side of the magnet support is fixedly connected at the shaft end of the driven shaft and rotates coaxial to the driven shaft, and the strong magnet is fixedly connected onto a magnet installation plane serving as the other right-angled side. The sensor support is fixedly connected onto the outer wall of a lateral plate of the grain bucket hoister, a sensor installation hole corresponding to the strong magnet in position is arranged on the sensor support, the Hall sensor is fixedly connected onto the sensor support, corresponds to the strong magnet and is connected with the controller through a cable wire, and the Hall sensor transmits pulse signals to the controller. The belt slippage detection device of the grain hoister can timely detect the belt slippage conditions of the grain bucket hoister and timely adjust belt tightness, ensures normal operation of grain hoisting, and can be widely used on the grain bucket hoister.

Owner:JIANGSU TIANYU AGRI MACHINERY

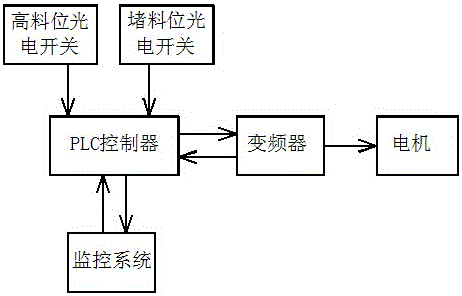

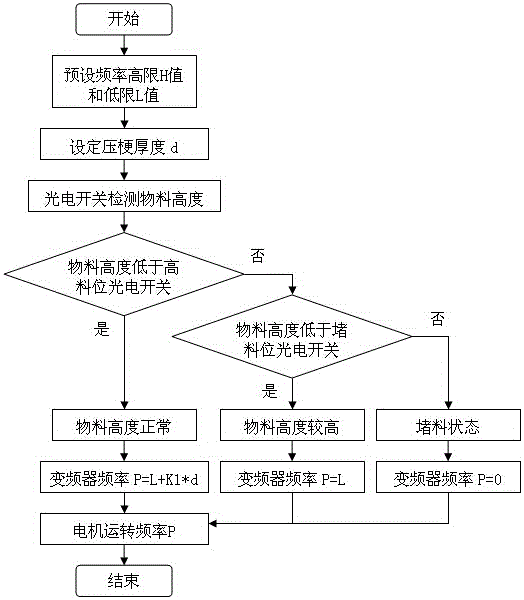

Automatic flow regulating device and method for stem pressing machines

InactiveCN105124746AGuaranteed uniformityPrevent blocking phenomenonTobacco treatmentFrequency changerEngineering

The invention discloses an automatic flow regulating device and method for stem pressing machines. The method includes: setting an upper limit value H and a lower limit value L for operating frequency of a frequency converter; setting required amount d for current stem pressing thickness; judging material piling to be within a normal range and output frequency of the frequency converter to be P value when material height is smaller than a high-level photoelectric switch, and performing automatic regulation according to change of pressed stems in thickness according to the formula of P=L+K1*d; when the material height is larger than the high-level photoelectric switch but smaller than a material-plugging-level photoelectric switch, judging material piling to be over high, lowering the output frequency of the frequency converter to be the low limit value L to reduce flow of the materials; when the material height is larger than the material-plugging-level photoelectric switch, judging material piling to be in material plugging state, setting the output frequency of the frequency converter to be zero, shutting down a feeding conveyor, and enabling a monitoring unit to send an alarm. By the arrangement, the operating frequency of the frequency converter can be automatically regulated, in other words, material flow of the feeding conveyor can be regulated, evenness of the pressed stems in thickness is guaranteed, and plugging is prevented.

Owner:CHINA TOBACCO JIANGSU INDAL

Low-moisture coke quenching box and coke quenching method using same

The invention provides a low-moisture coke quenching box which firstly carries out primary coke quenching on high-temperature coke spraying cold water formed after carbonization, and then carries out secondary coke quenching on the coke by utilizing much vapor produced in spraying water, so that low-moisture coke is formed after coke quenching is completed; compared with the problems that the coke quenching method in the prior art cannot carry out precise control on temperature of coke-quenched semi coke, the moisture content of the coke-quenched semi coke is still higher and the coke quality is poor, the low-moisture coke quenching method disclosed by the invention can be used for not only precisely controlling the temperature of the coke-quenched coke at 70-80 DEG C, but also effectively reducing the water consumption in a coke-quenching process, so that the moisture content of the coke-quenched semi coke is low and is about 1-2%, secondary drying is avoided, and coal gas consumption is not needed; besides, produced vapor and carried dust and poisonous gas can be returned to a furnace for utilization, and excessive vapor is guided out by a pipeline and intensively treated, so that secondary pollution is avoided.

Owner:HUADIAN HEAVY IND CO LTD

Chemical dissolving device for reduction, recycling and harmless treatment of sludge

PendingCN111453952AHigh degree of mechanizationLow costShaking/oscillating/vibrating mixersSludge treatmentSludgeProcess engineering

The invention discloses a chemical dissolving device for reduction, recycling and harmless treatment of sludge, belonging to the technical field of sludge treatment. The chemical dissolving device comprises a crushing assembly and a conveying assembly, wherein the conveying assembly comprises a feeding shell; a feeding cylinder is arranged at the upper end of the feeding shell; a discharging cylinder is arranged at the bottom of the right side of the feeding shell; the discharging cylinder is positioned right above a hopper; the hopper is arranged at the center of the top of a case body; a material stirring assembly is arranged in the hopper; a driven crushing roller and a driving crushing roller are arranged in the case body; a material guiding plate is obliquely and movably arranged below the case body; the right end of the material guiding plate is located in a discharging port; a vibration assembly is arranged at the bottom of the material guiding plate; a stirring rotating shaft is arranged on the right side of the discharging port; a combined stirring assembly is arranged on the stirring rotating shaft; and a dosing assembly is arranged above the combined stirring assembly. According to the invention, automatic feeding operation of river sludge can be realized, crushed sludge and a sludge treatment chemical are fully mixed and uniformly stirred, the waste of the sludge treatment chemical is avoided, and sludge treatment cost is reduced.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

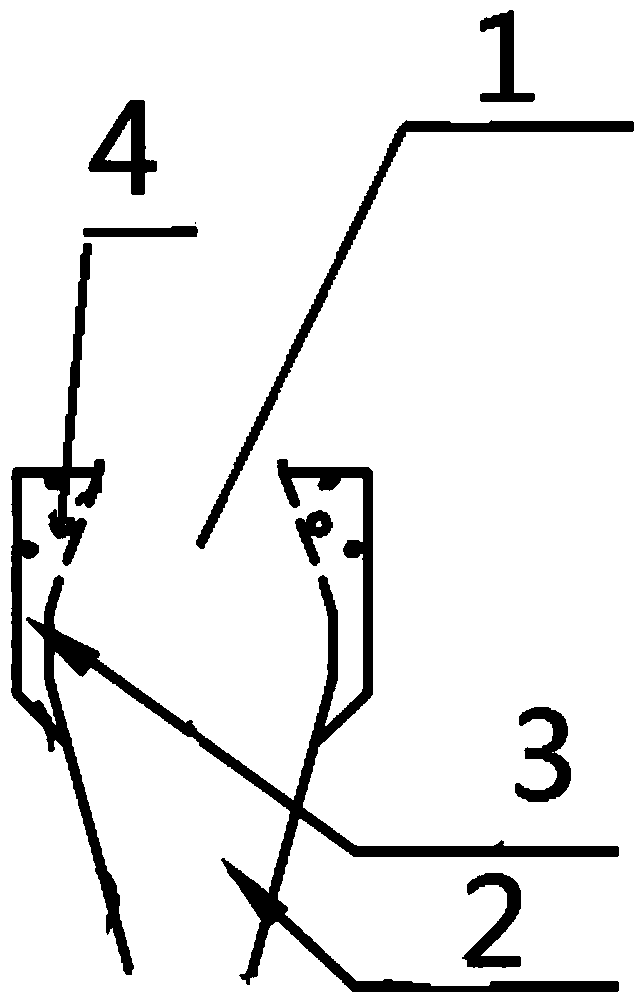

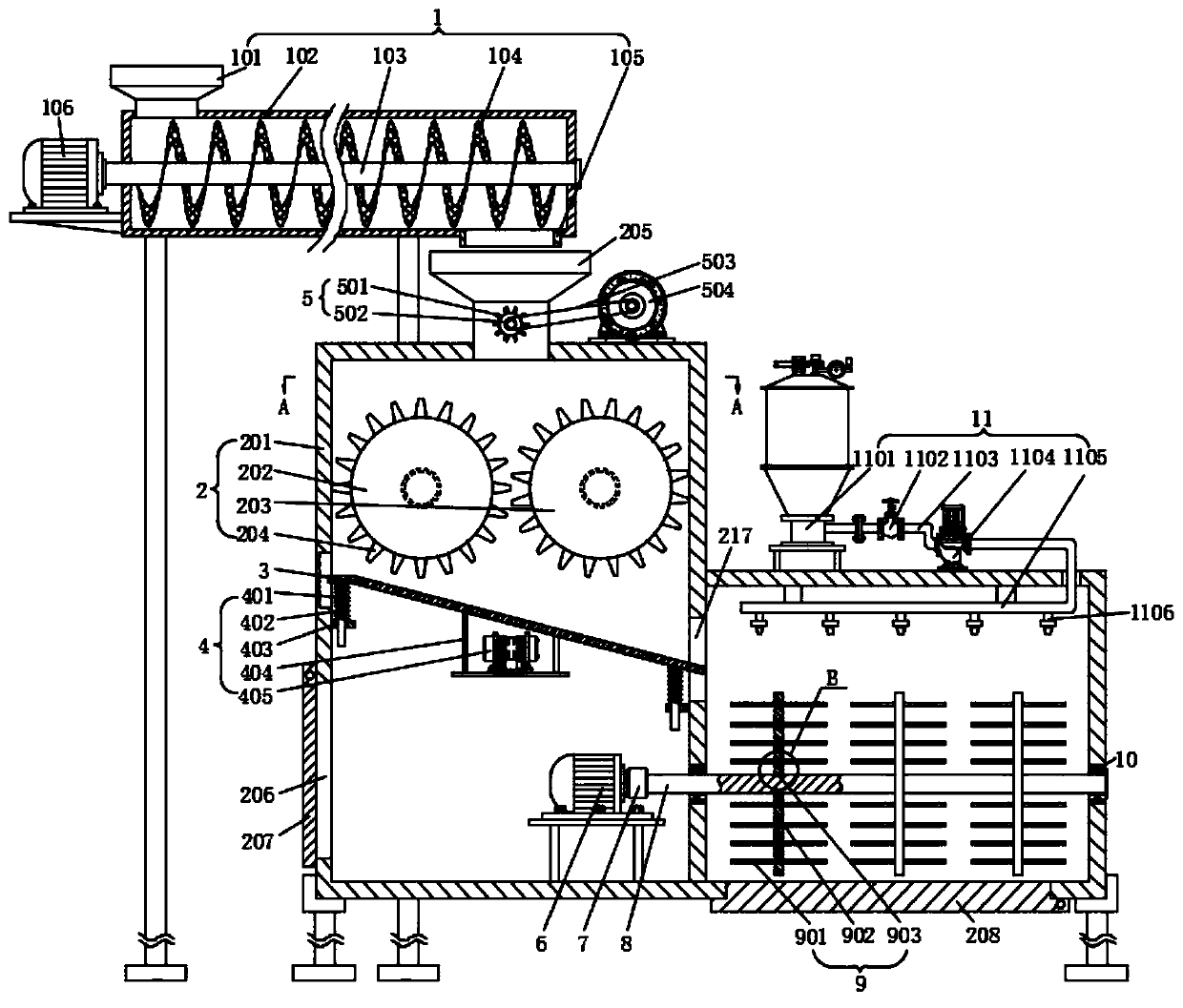

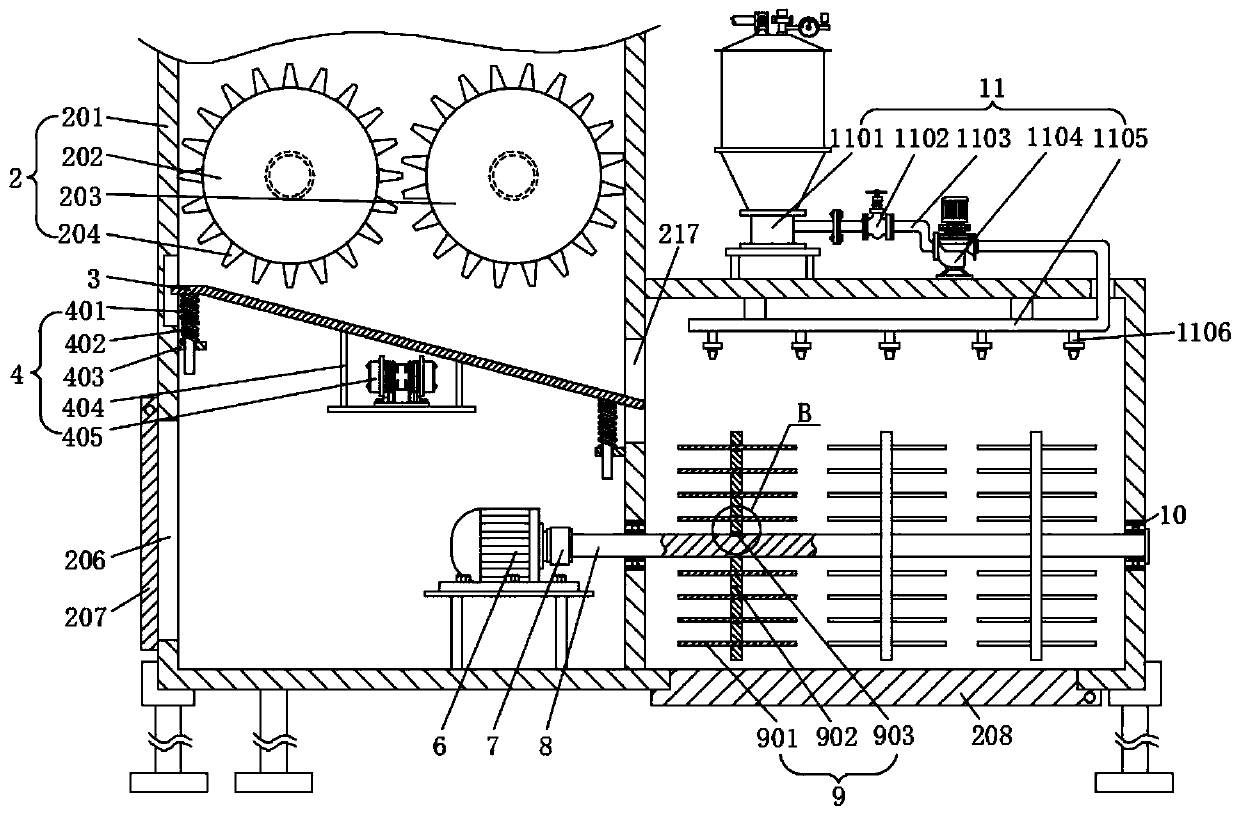

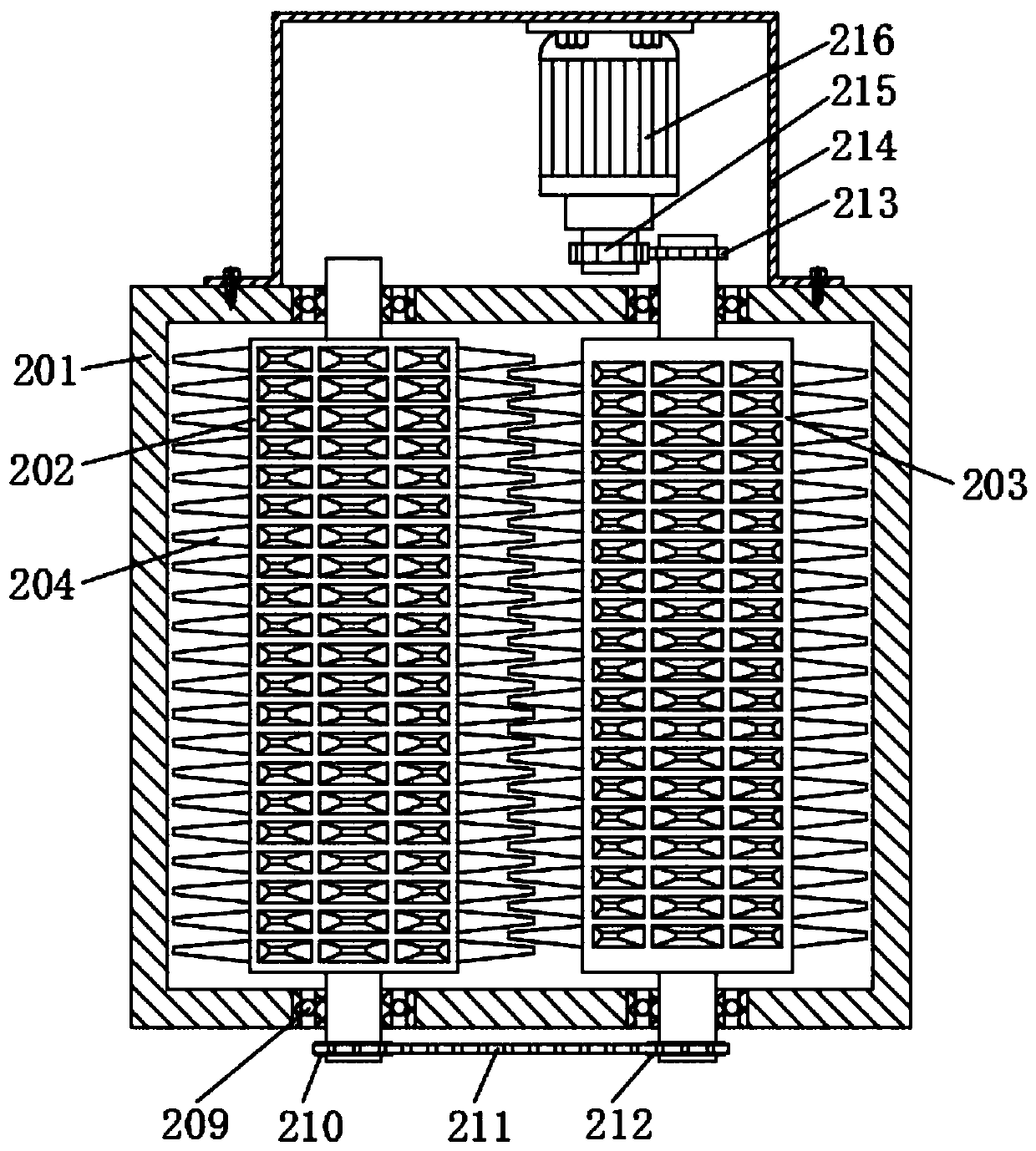

Vanadium slag pelleting device

InactiveCN109999721AImprove Particle UniformityReduce labor intensityGranulation by pressingSlagPre compression

The invention discloses a vanadium slag pelleting device, and relates to the technical field of metallurgy. The problem that vanadium slag pellets prepared by a disc granulator are poor in uniformityand low in pelletizing rate is solved. According to the technical scheme, the vanadium slag pelleting device comprises a feeding system, a pre-pressing forming system and a screening system; the pre-pressing forming system comprises a pre-pressing hopper and a forming hopper; the feeding system is used for supplying materials to the pre-pressing hopper; a pre-pressing roller press and a first edgecutting machine are arranged in the pre-pressing hopper, wherein a discharging opening of the feeding system directly faces a gap between two pressing rollers of the pre-compression roller press, andthe first edge cutting machine is arranged below the pre-compression roller press; a forming pressing roller and a second edge cutting machine are arranged in the forming hopper, wherein a discharging opening of the pre-pressing hopper directly faces a middle line between two pressing rollers of the forming roller press, and the second edge cutting machine is arranged below the forming pressing machine; the screening system is arranged below a discharging opening of the forming hopper; and a finished product bin is connected on a screen of the screening system and a fine powder bin is arranged below the screen. The vanadium slag pelleting device is applicable to vanadium slag pelleting.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES

Cleaning mechanism for pulper used for production of base corrugated paper with low basis weight and high strength

InactiveCN109722928AEasy to useImprove practicalityHollow article cleaningRaw material divisionWater flowMechanical engineering

The invention discloses a cleaning mechanism for a pulper used for production of base corrugated paper with low basis weight and high strength. The cleaning mechanism comprises the pulper, wherein thetop part of the pulper is fixedly connected with a fixed plate; and the top part of the fixed plate is fixedly connected with a motor. According to the invention, each first air cylinder is started to drive a lift-drop plate to move up and down; each lift-drop plate drives a sliding column to move up and down; each sliding column drives a sliding rail to sway up and down; each sliding rail drivesa fixed block to sway up and down; each fixed block drives a spray head to sway up and down to enable water to flush the interior of the pulper; meanwhile, the water flows downward through gravity and flows out through a discharging mechanism; thus, the problems of low cleaning efficiency, the increase of labor force of a worker and the waste of a large amount of time of the worker due to main adoption of a manual cleaning manner for a conventional pulper are solved. The cleaning mechanism for the pulper used for production of the base corrugated paper with low basis weight and high strengthhas the advantage of automatic cleaning, improves the practicability of the pulper, and is convenient for a user to use.

Owner:YIWU YINAN PAPER IND CO LTD

Novel quick printing spray head

InactiveCN110421851AChange lengthExpand the printing rangeApplying layer meansSpray nozzleEngineering

The invention discloses a novel quick printing spray head. The novel quick printing spray head comprises an extruding tube which is vertically arranged, a screw which is inserted into the extruding tube, a stock holder for storing printing materials, a ring-shaped spray nozzle, a movable valve, a motor for driving the screw to rotate, a motor for driving the valve to move, and a heating apparatuson the outer wall of the spray nozzle, wherein the movable valve is mounted inside the spray nozzle; the movable valve is connected to the motor for driving the valve to move through a rolling ball lead screw, and the motor can be controlled to drive the movable valve to move, so that the opening dimension of the spray nozzle can be changed. The novel quick printing spray head can change length ofthe spray nozzle in real time according to dimension changes of a model, increases the printing range of the spray nozzle, changes conventional dot printing into linear printing, and realizes once printing forming of each layer, so that printing speed is greatly increased; cooling time, in air, of each layer of the printing materials sprayed out by the spray nozzle is greatly reduced, and layerscan be guaranteed to be connected more tightly, so that strength of a printed part is greatly improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

High-efficiency and environment-friendly construction waste crushing device

ActiveCN111921585AEasy accessBroken fastConstruction waste recoveryGrain treatmentsHydraulic cylinderRebar

The invention belongs to the technical field of construction waste treatment, and specifically discloses a high-efficiency and environment-friendly construction waste crushing device. The high-efficiency and environment-friendly construction waste crushing device comprises a collection box and a crushing mechanism, and the crushing mechanism is mounted in the collection box; the crushing mechanismcomprises a lower baffle; the lower baffle is fixedly connected with left, right, front and back baffles; the crushing mechanism is internally provided with a mounting board fixedly connected with the front and back baffles; a lower crushing board is in hinge joint on the mounting board; an upper crushing board is in hinge joint on an upper end of the lower crushing board; a platform board fixedly connected on the front and back baffles and connected with the upper crushing board through hinge joint is mounted in the crushing mechanism; a hydraulic cylinder is mounted on the mounting board; apiston rod of the hydraulic cylinder is fixedly connected with a driving rod in hinge joint with the upper and lower crushing boards; a conveyor belt, of which a surface is provided with hook teeth,is mounted on an external side wall of the left baffle; and the high-efficiency and environment-friendly construction waste crushing device is simple in structure, can separate steel bars from crushedcement blocks, and can avoid manual secondary treatment.

Owner:中建四局华南建设有限公司

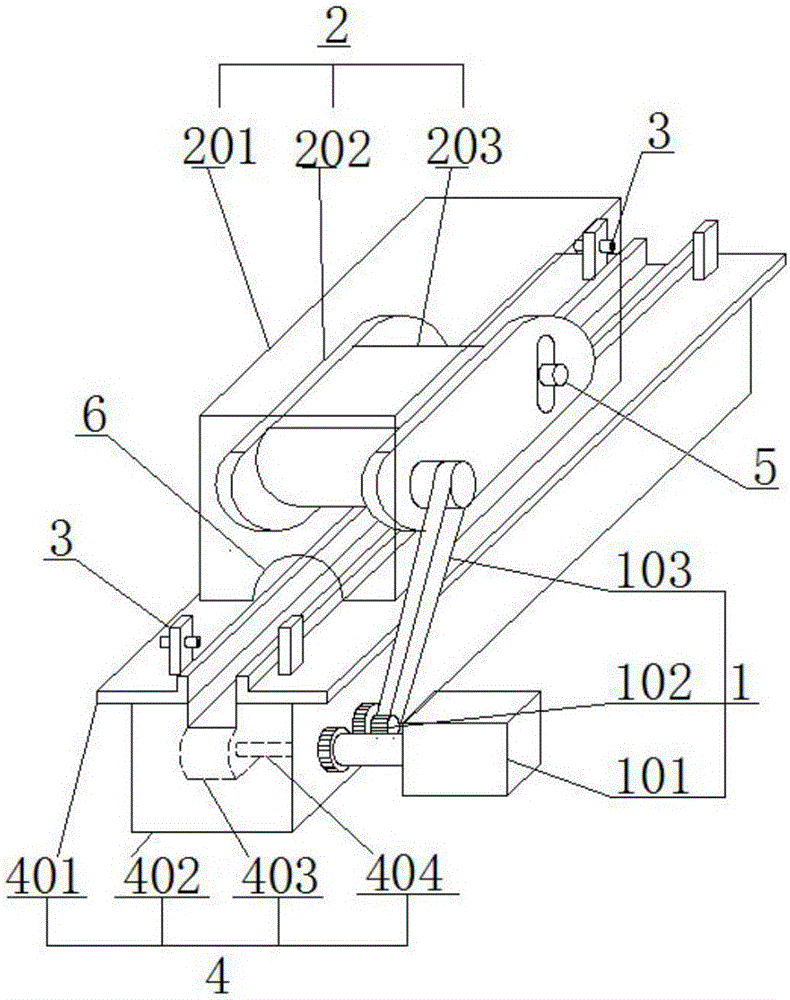

Novel control device for door seal rubber sleeve cutting remnants

ActiveCN105710918APrevent blocking phenomenonImprove controllabilityMetal working apparatusProcess lossEngineering

The invention discloses a novel control device for door seal rubber sleeve cutting remnants. The novel control device is characterized by comprising a power mechanism, a remnant control mechanism, a rubber sleeve conveying mechanism and two photoelectric sensors. The power mechanism comprises a servo motor, a transmission gear and a toothed belt. The remnant control mechanism is composed of a rotational belt, a supporting plate and a protection shell. The rubber sleeve conveying mechanism comprises a rotary shaft, a fixing plate, a conveying belt and a baffle. The two photoelectric sensors are mounted at the two ends of the rubber sleeve conveying mechanism. The remnant control mechanism is fixed to the upper portion of the rubber sleeve conveying mechanism through bolts. The power mechanism is mounted at the right side of the rubber sleeve conveying mechanism. According to the novel control device, controllability of the rubber sleeve cut corner length is achieved, process losses are reduced, the phenomenon of blocking caused by too long cut corner in the rubber sleeve cutting process is eliminated, and the novel control device is suitable for controlling the length of the rubber sleeve cutting remnants

Owner:ANHUI HIGASKET PLASTICS CO LTD

Biomass straw briquetting machine for efficiently producing

ActiveCN107033981APrevent blocking phenomenonIncrease feeding rateBiofuelsSolid fuelsEngineeringImpurity

The invention discloses a biomass straw briquetting machine for efficiently producing. The biomass straw briquetting machine comprises a stirring housing, pressing moulds, a dust collecting box, a base and a smashing blade. The dust collecting box is installed at one side above the base. The top end of the dust collecting box is fixedly provided with a cooling housing. A fan is installed at one side in the cooling housing. A smashing housing is fixed above the cooling housing. The top end of the smashing housing is provided with the stirring housing. A briquetting housing is installed on the base at one side of the dust collecting box. A workbench is installed at the central position of the bottom end of the briquetting housing. An annular material storage is installed above the workbench. The interior of the material storage is provided with four pressing moulds of which the neighboring included angle is 90 degrees. The biomass straw briquetting machine is capable of realizing the efficient briquetting discharge function of the biomass straw, and has the advantages of no blocking situation of the device, rapid feeding speed, large material storage, high briquetting efficiency, good briquetting effect, long service life of the device, simple and convenient operation and high working efficiency. In addition, the impurities cannot enter into the mould.

Owner:新沂城北新区城市建设发展有限公司

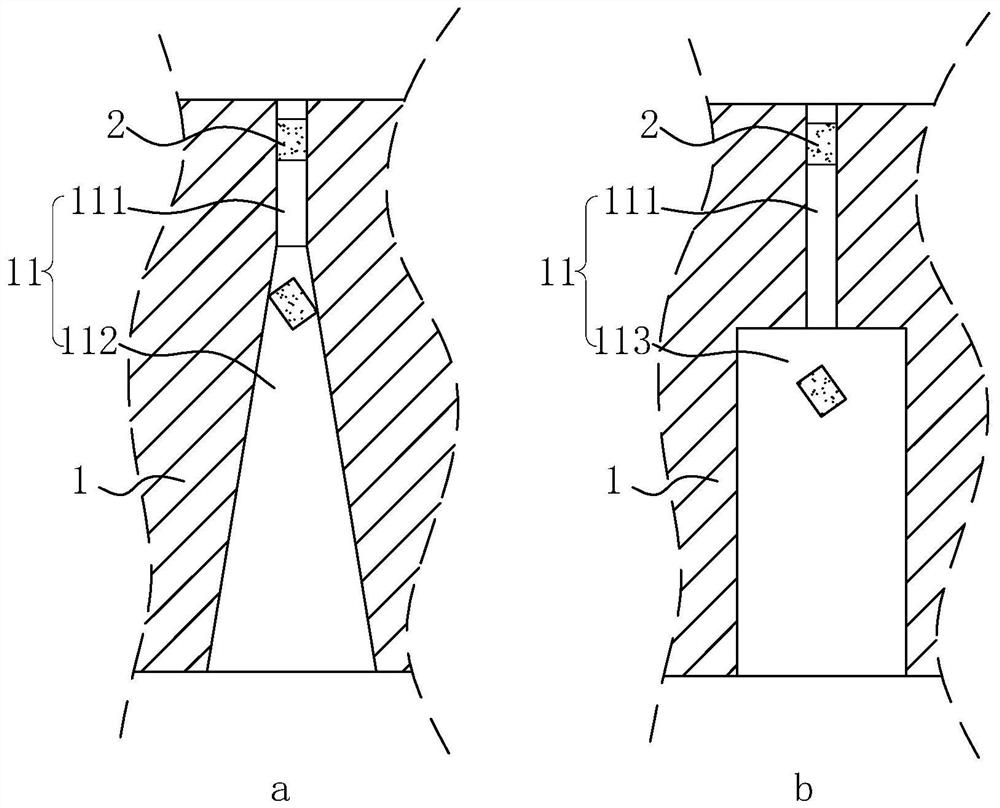

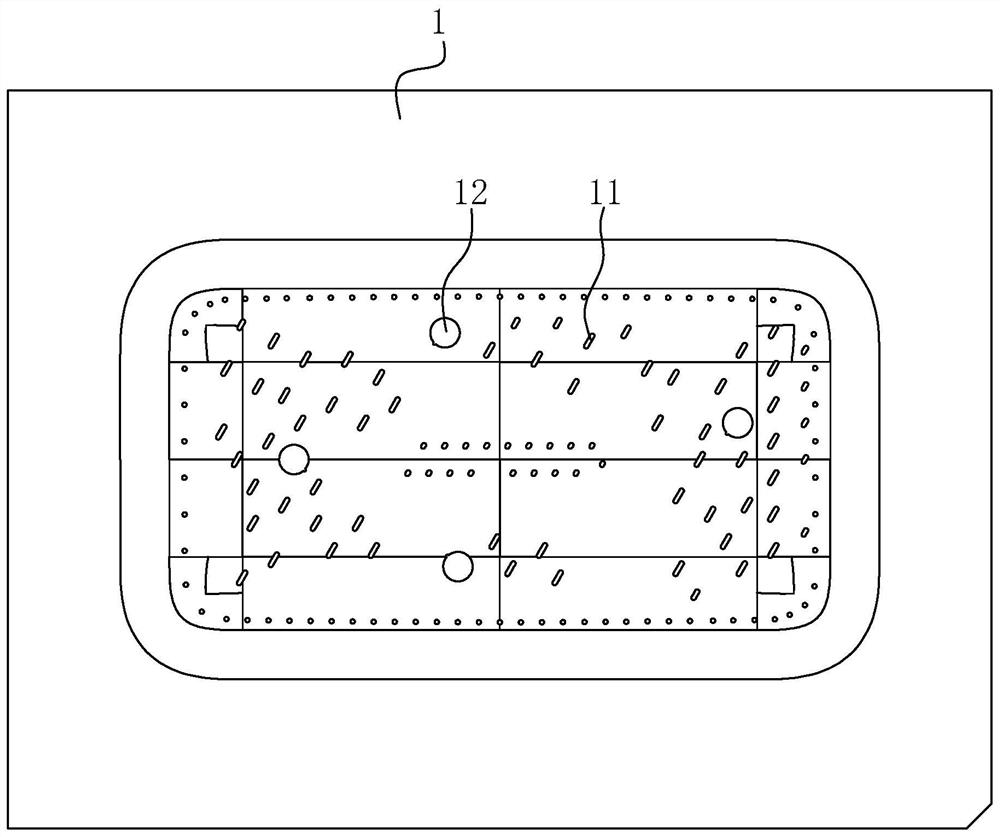

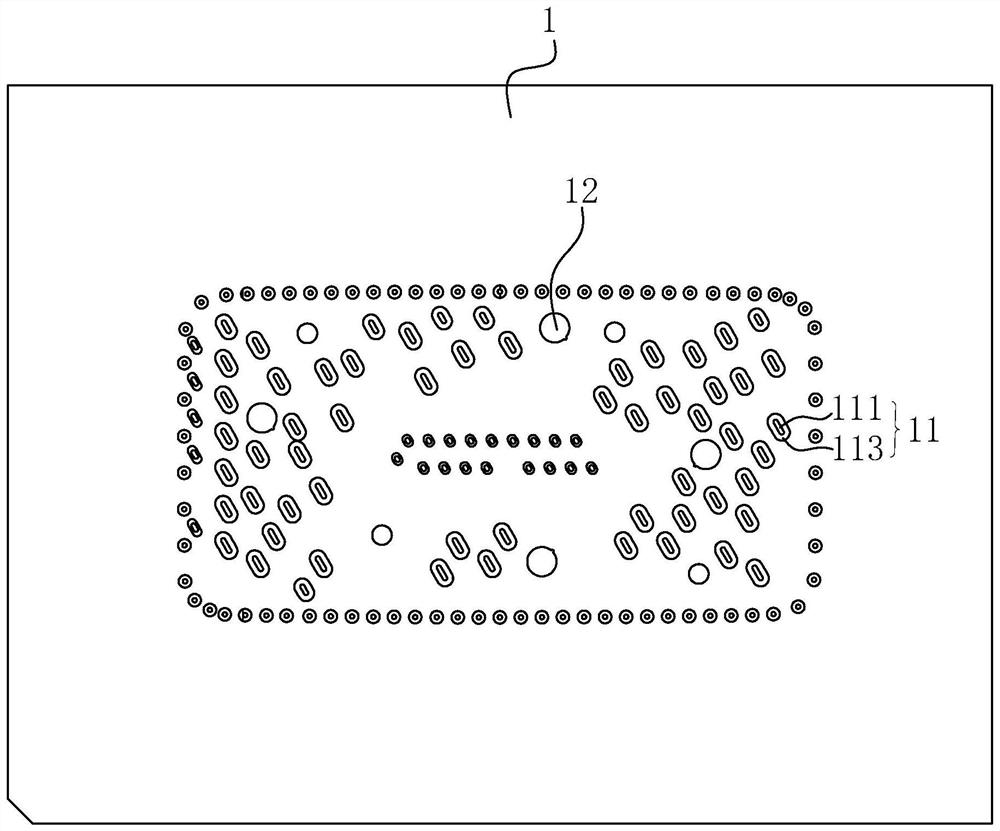

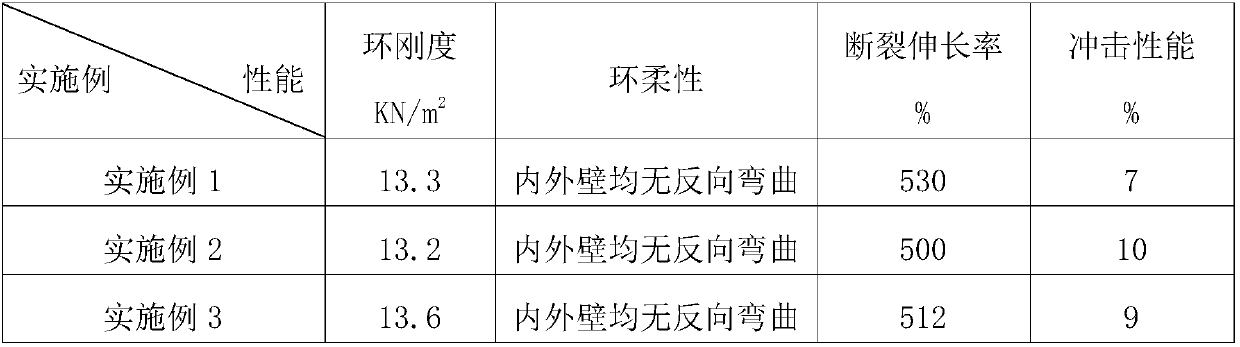

Anti-blocking die hole structure, stamping lower die and machining technology of dense small meshes

ActiveCN113102618AGuaranteed patencyPrevent blocking phenomenonPerforating toolsStripping-off devicesStampingEngineering

The invention belongs to the technical field of punching machining, and relates to an anti-blocking die hole structure, a stamping lower die and a machining technology of dense small meshes. The anti-blocking die hole structure comprises an initial cylindrical section on the upper portion and an externally-expanded discharging cylindrical section on the lower portion, wherein the horizontal section of the initial cylindrical section is matched with the horizontal section of a to-be-machined mesh of a workpiece, and the width of the section of the discharging cylindrical section is larger than the depth of the to-be-machined mesh of the workpiece. A die hole of the stamping lower die adopts the anti-blocking die hole structure. In the machining process of the dense small meshes, the stamping lower die is adopted, and a scattered multi-time punching machining mode is adopted, that is, the meshes in the machining face of the workpiece are formed through multiple times of stamping, the area stamped each time is staggered from the area where stamping is completed, and the area stamped each time is distributed on the machining face of the workpiece in a scattered mode. The lower die is suitable for machining dense small meshes of soft metal plates, the material blocking phenomenon can be almost completely avoided, burrs are not generated during punching, and the structural strength of the lower die can be guaranteed.

Owner:深圳市鹏福创新实业有限公司

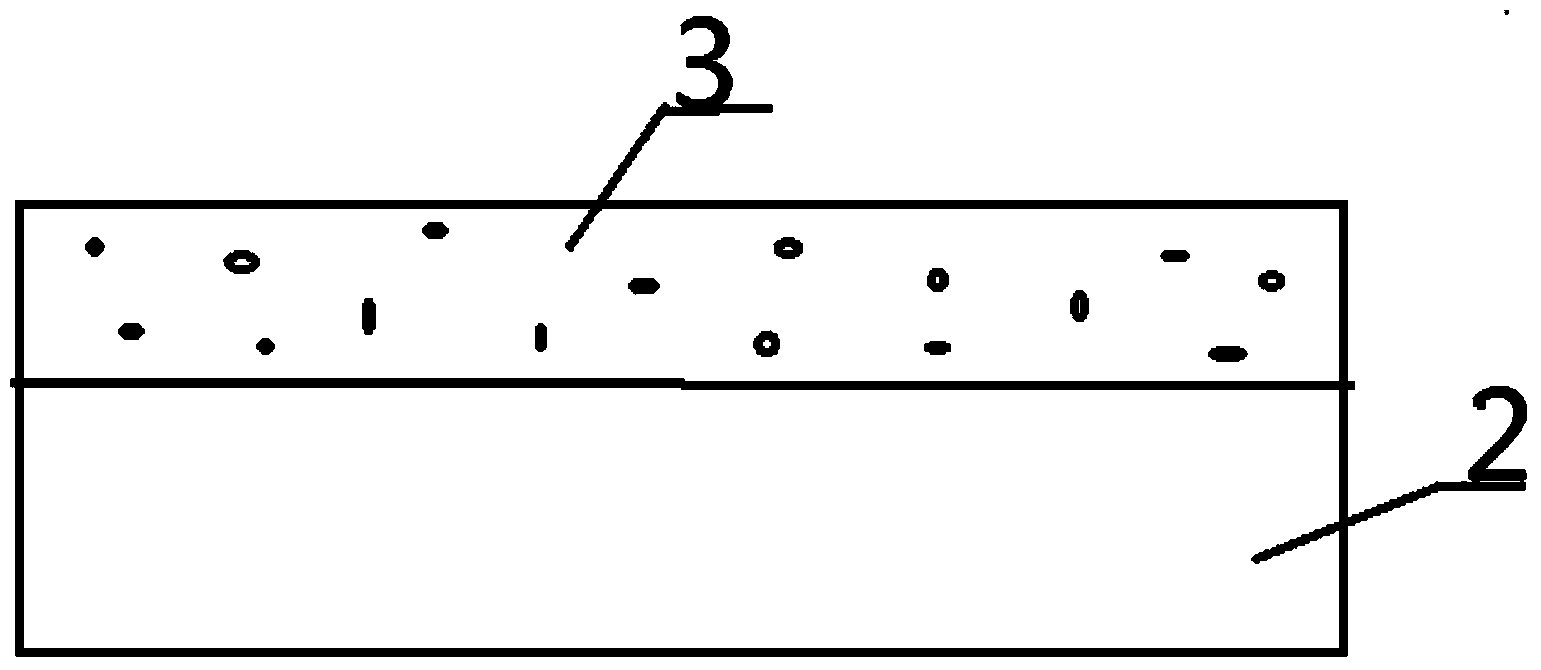

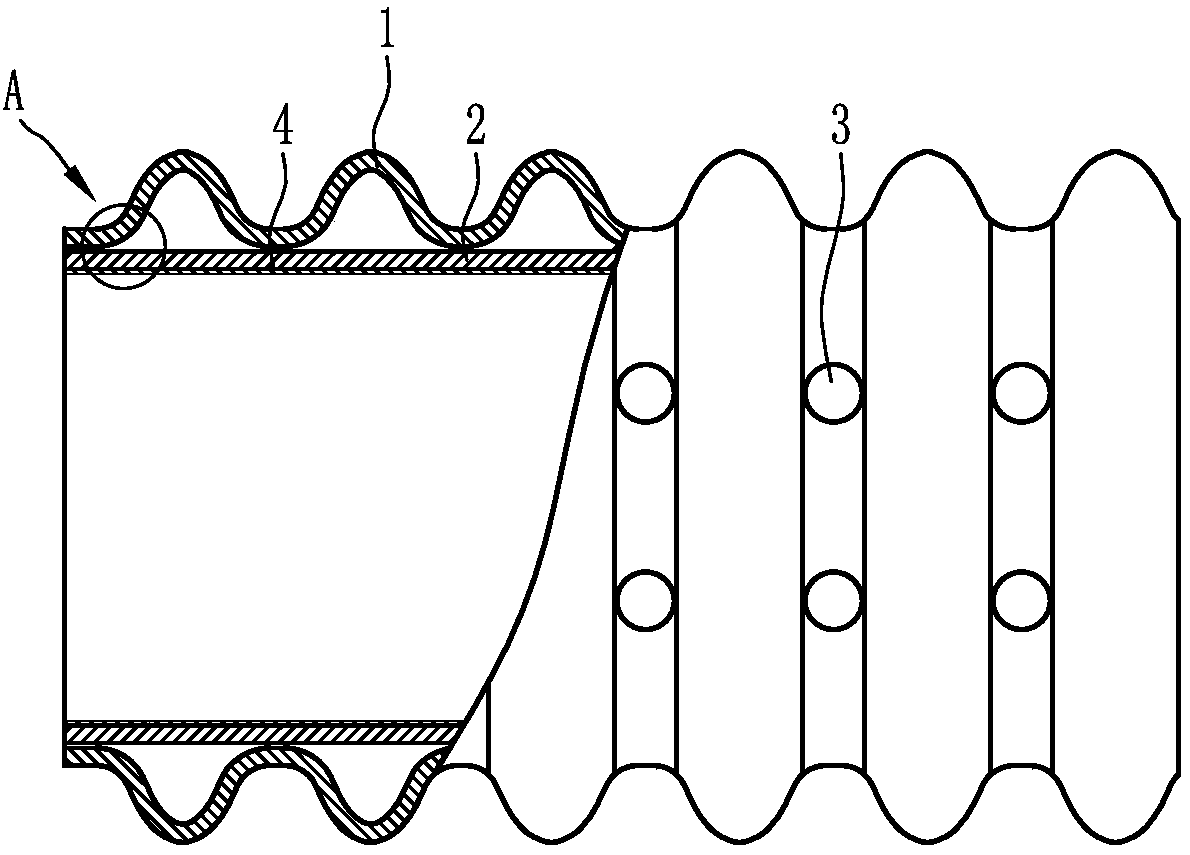

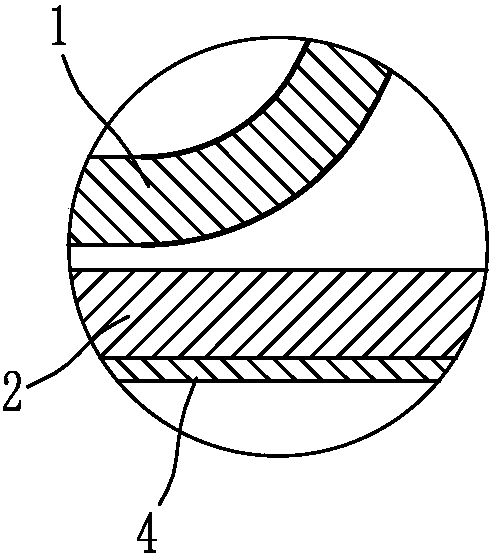

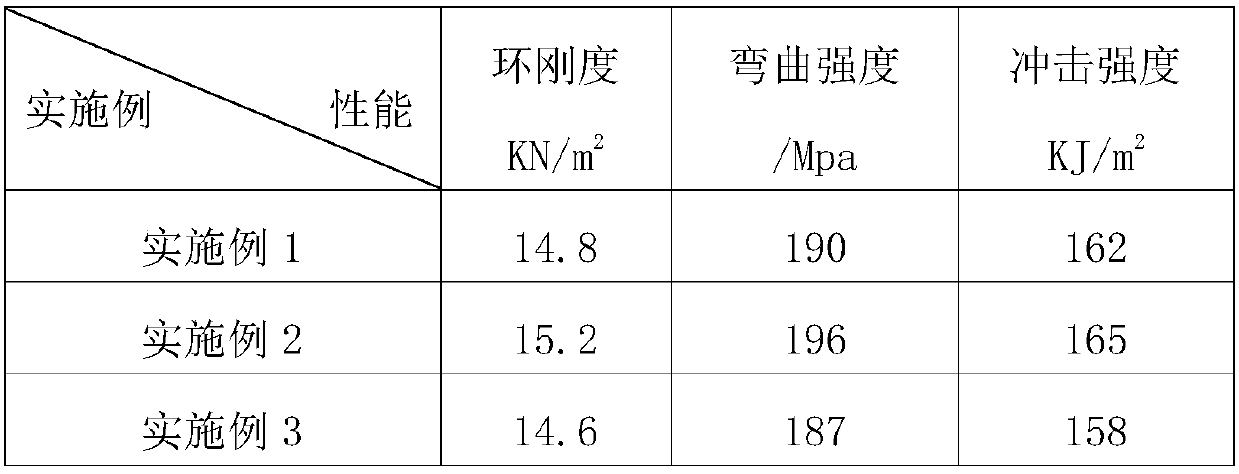

Scale-resistant type salt elimination material-filtering corrugated tube in saline alkali soil and preparation method thereof

The invention discloses a scale-resistant type salt elimination material-filtering corrugated tube in saline alkali soil and a preparation method thereof. The material-filtering corrugated tube comprises an outer wall tube which is of a corrugated structure and an inner wall tube which is of a smooth structure; a functional hydrophobic layer is sprayed on the inner wall of the inner wall tube; theouter wall tube comprises the following components of high density polyethylene, petroleum resin, organic fiber, calcium carbonate, rosin, calcium stearate, zinc oxide, thiodipropionic acid and chlorinated paraffin; and the inner wall tube comprises the following components of rigid polyvinyl chloride, petroleum resin, calcium carbonate, zinc stearate, vinyl ester resin and talcum powder. The outer wall tube of the material-filtering corrugated tube is both flexible and rigid, so that the corrugated tube has high resistance to a soil load and good flexibility and can be conveniently and continuously laid in the soil; and the functional hydrophobic layer is sprayed on the inner wall, so that the smooth surface of the inner wall tube simultaneously has dual-hydrophobic performance, low adhesion and self-cleaning performance, and the problem that scale deposition is prone to occurring on the inner wall of the material-filtering corrugated tube in the salt elimination process is solved.

Owner:WEIFANG YOURONG IND

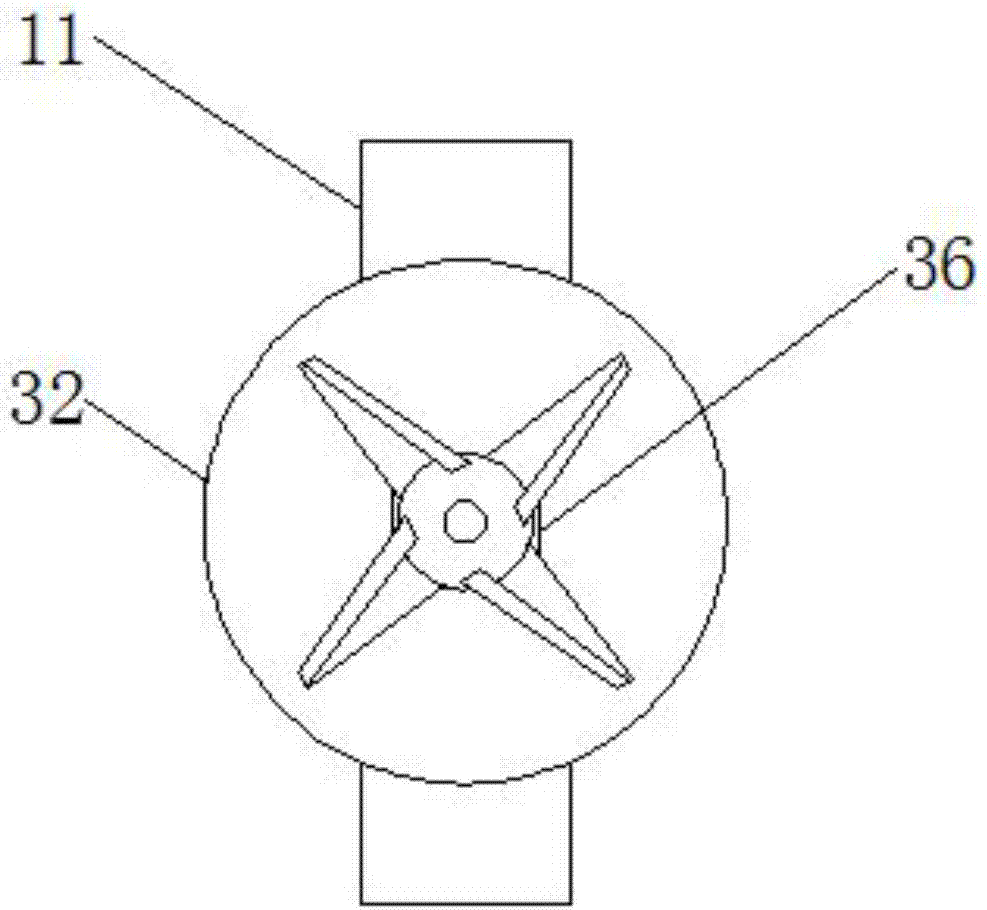

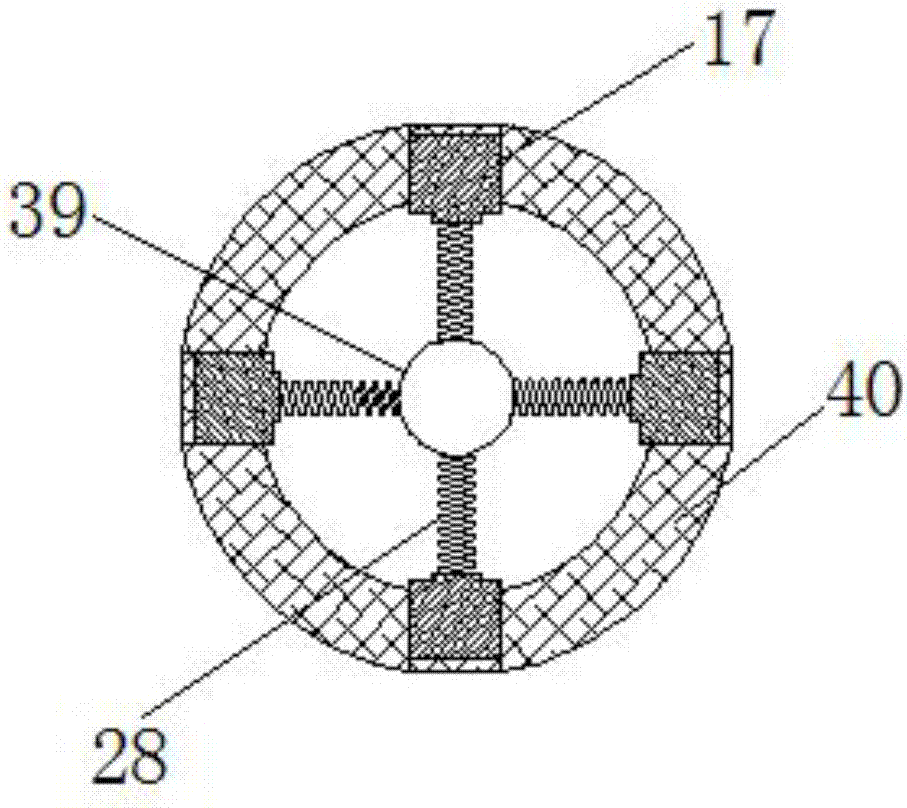

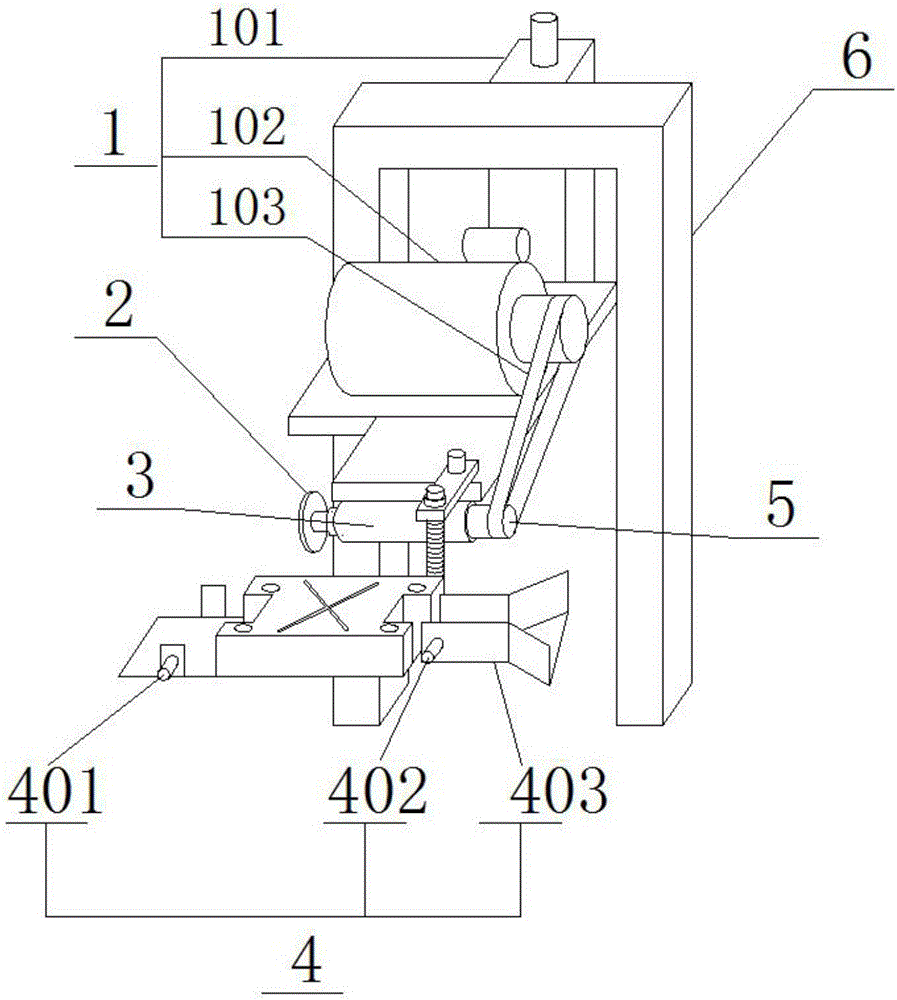

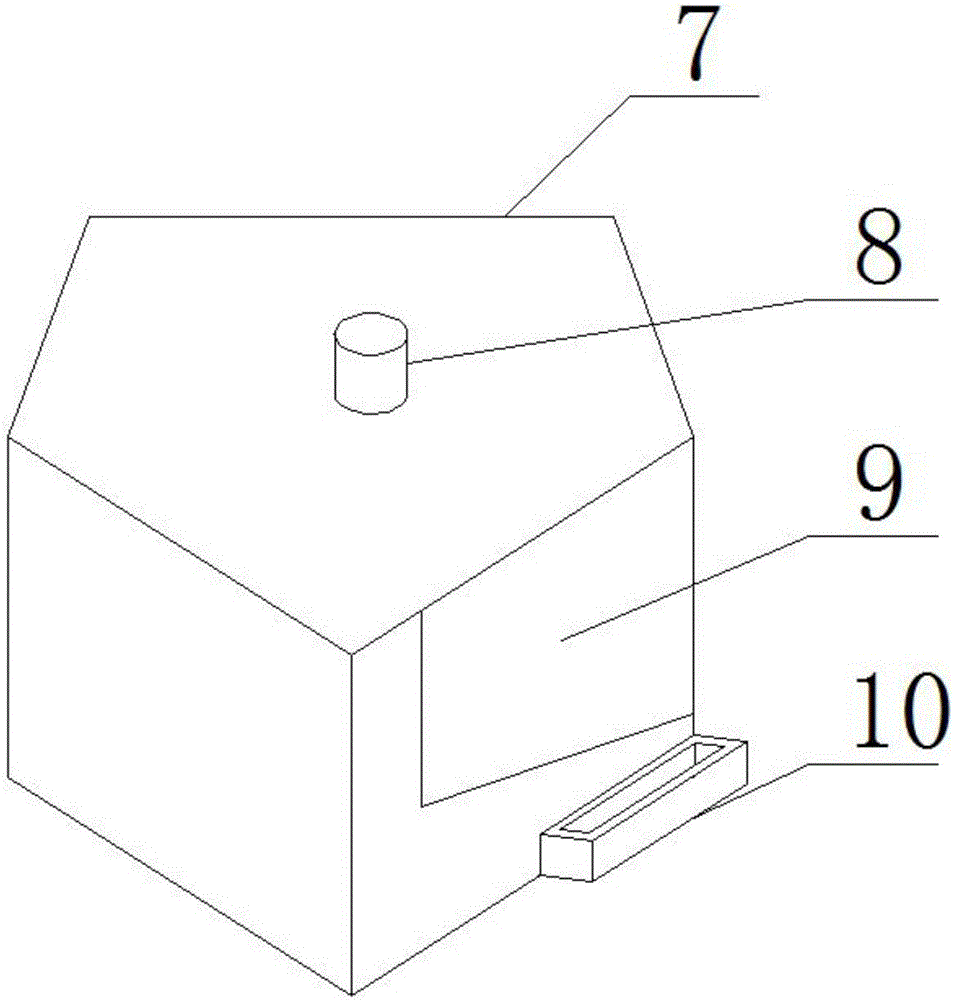

Material return anti-blocking device and smoke circulation semidry method desulfurization system with same

ActiveCN108114784AThe return conveying channel is smoothAvoid blockingGas treatmentDispersed particle filtrationEngineeringSmoke

The invention discloses a material return anti-blocking device comprising a crushing barrel and a crushing cutter. The crushing barrel is arranged between a material return ash bucket of a desulfurization bag-type dust collector, and a discharge hopper. The crushing cutter is rotationally arranged in the crushing barrel and is used for crushing block materials entering the crushing barrel. Throughthe material return anti-blocking device, block lime falling from the material return ash bucket of the desulfurization bag-type dust collector can be crushed, the completely crushed materials fall smoothly from the discharge hopper, normal passing of circulation nitration lime on a subsequent channel is ensured, a material return conveying channel of a smoke circulation semidry method desulfurization system is smooth, and normal operation of the desulfurization system is ensured. The invention further provides the smoke circulation semidry method desulfurization system.

Owner:MAANSHAN IRON & STEEL CO LTD

Novel door seal rubber sleeve cutting device

InactiveCN105773689AImprove securitySolve the following defects when usingMetal working apparatusMotor driveTransmission belt

The invention discloses a novel door seal rubber sleeve cutting device. The novel door seal rubber sleeve cutting device has the characteristics that the novel door seal rubber sleeve cutting device comprises a cutting unit, a power unit, a safety protection unit and a support; the cutting unit comprises a cutter assembly and a cutting mold; the cutter assembly comprises a cutter, a braking device and a rotary shaft; a mold inlet of the cutting mold is provided with a photoelectric sensor and a guide part; an outlet of the cutting mold is provided with a photoelectric sensor; the power unit comprises a telescopic device, a power motor and a transmission belt; the telescopic device controls the safety protection unit through a connection part; the power motor drives the cutter assembly through the transmission belt; and the safety protection unit is provided with a trapezoidal monitoring window and a warning device. The novel door seal rubber sleeve cutting device is stable in structure, reasonable in design, high in production efficiency, good in size precision, high in safety, and suitable for application and popularization to mass production for continuous and automatic cutting of door seal rubber sleeves in the production process of refrigerator door seals.

Owner:ANHUI HIGASKET PLASTICS CO LTD

Vertical-type electric dryer

InactiveCN108088221ASolve the problem of not being able to saveNo pollution in the processGranular material dryingDrying gas arrangementsElectricitySlag

The invention discloses a vertical-type electric dryer. The vertical-type electric dryer comprises a drying barrel, a feeding channel, a discharging channel and an air exhausting pipe. The feeding channel and the air exhausting pipe are arranged at the top of the drying barrel. The vertical-type electric dryer is characterized in that an electric heating cone combination device, a cooling cone combination device and a convection ventilating device are further sequentially arranged inside the drying barrel from top to bottom; the electric heating cone combination device, the cooling cone combination device and the convection ventilating device are connected with the drying barrel; gaps are both reserved between the electric heating cone combination device and the drying barrel as well as between the cooling cone combination device and the drying barrel; and the upper area and the lower area, corresponding to the gaps, of the inside of the drying barrel form a convection channel. The vertical-type electric dryer has the remarkable advantages of being high in heat exchange efficiency, small in energy consumption, high in applicability, economical, environmentally friendly and the like. The vertical-type electric dryer can effectively replace various sorts of existing vertical-type dryers and is suitable for drying various block-shaped or granular powdered raw materials like cementraw materials, slag, pulverized fuel ash and coke, and the application prospects are broad.

Owner:赵世青

High-strength saline-alkali soil salt draining filter tube and manufacturing method thereof

The invention discloses a high-strength saline-alkali soil salt draining filter tube and a manufacturing method thereof. The salt draining filter tube comprises a chlorinated polyvinyl chloride tube layer at the outer layer and a polyvinyl chloride tube layer at the inner layer, wherein the chlorinated polyvinyl chloride tube layer comprises the following components: chlorinated polyvinyl chloride, polyvinyl chloride resin, organic fibers, calcium carbonate, dibasic lead phosphite, calcium stearate, zinc oxide, thiodipropionic acid and chlorinated paraffin; and the polyvinyl chloride tube layer comprises the following components: rigid polyvinyl chloride, polyvinyl chloride resin, calcium carbonate, zinc stearate, vinyl ester resin and talcum powder. The filter tube is high in strength, isgood in compression resistance, and has excellent flexibility. Water scales are very difficult to form as a result of surface tension of the inner wall of the filter tube, so that salt draining and conveying ability is favorably improved.

Owner:WEIFANG YOURONG IND

Bucket-wheel stacker reclaimer and hopper thereof

The invention discloses a hopper, which is connected with a rotary drum of a belt conveyor of a bucket-wheel stacker reclaimer and comprises a material baffle and a hopper body. The hopper body consists of an upper hopper body and a lower hopper body which are fixedly connected with each other, and the material baffle is detachably connected to the inner wall of the upper hopper body and is opposite to a discharge end of the rotary drum of the belt conveyor. The invention further discloses the bucket-wheel stacker reclaimer comprising the hopper. When the bucket-wheel stacker reclaimer operates, materials thrown out from the discharge end of the rotary drum of the belt conveyor enter the upper hopper body, directly contact with the material baffle, flow out from an outlet end of the lower hopper body under the action of the material baffle and enter a next working procedure. The material baffle replaces the upper hopper body to be used as a direct material contacting component of the hopper, abrasion of the materials to the upper hopper body is transferred from the upper hopper body to the material baffle, the material baffle can be replaced conveniently when abraded to a limit degree, accordingly, the abrasion of the materials to the hopper body is reduced remarkably due to the structure, and the service life of the hopper is prolonged.

Owner:SANY MARINE HEAVY IND

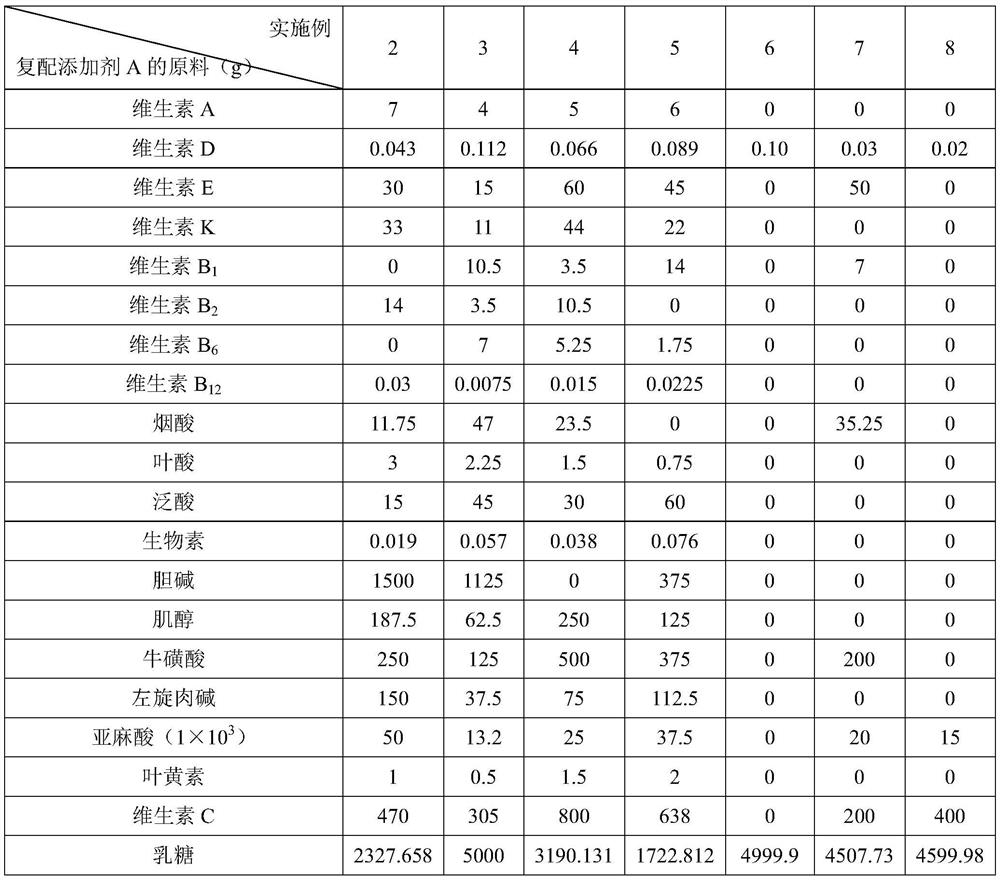

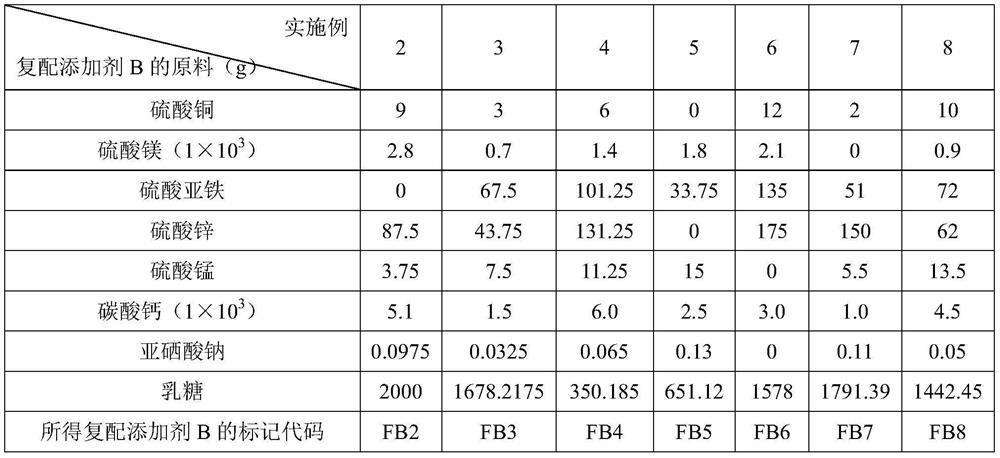

Nutritional supplement modified milk tablet and preparation method thereof

The present invention belongs to the field of dairy product processing and discloses a nutritional supplement modified milk tablet and a preparation method thereof. The nutritional supplement modifiedmilk tablet is prepared from milk powder, auxiliary materials composed of xylitol, tricalcium phosphate, protein powder, edible essence and fruit and vegetable powder, and a nutritional agent. The preparation method comprises steps of evenly mixing the auxiliary materials with the nutritional agent and the milk powder, and conducting tabletting. The milk powder is used as a main raw material, a proper amount of the xylitol and tricalcium phosphate are added to be matched to be used as a flow aid, the milk tablet meeting nutritional ingredients and material standards of the modified milk powder is prepared through the simple process method, the milk solid content in the obtained milk tablet reaches 70% or above and is far larger than 60% specified by an existing milk tablet, and a repose angle of the obtained milk tablet is smaller than 42 degrees. The tabletting is smooth and the prepared milk tablet is complete, good in glossiness and stable in gram weight. The milk tablet is suitable for various people to eat.

Owner:JUNLEBAO DAIRY GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com