Patents

Literature

78results about How to "Save production energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

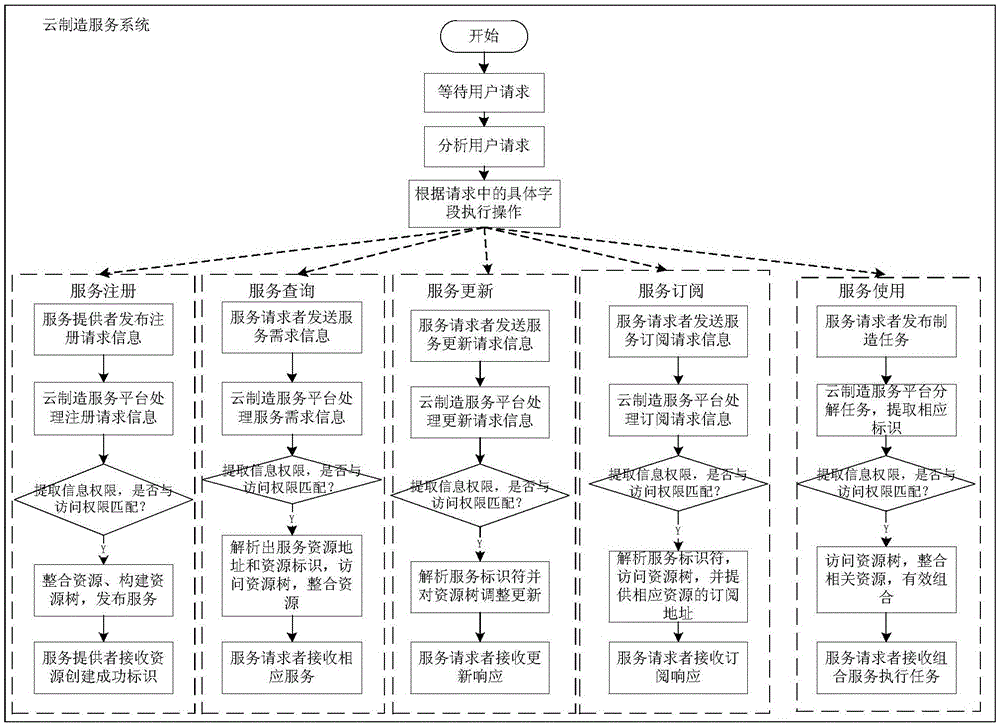

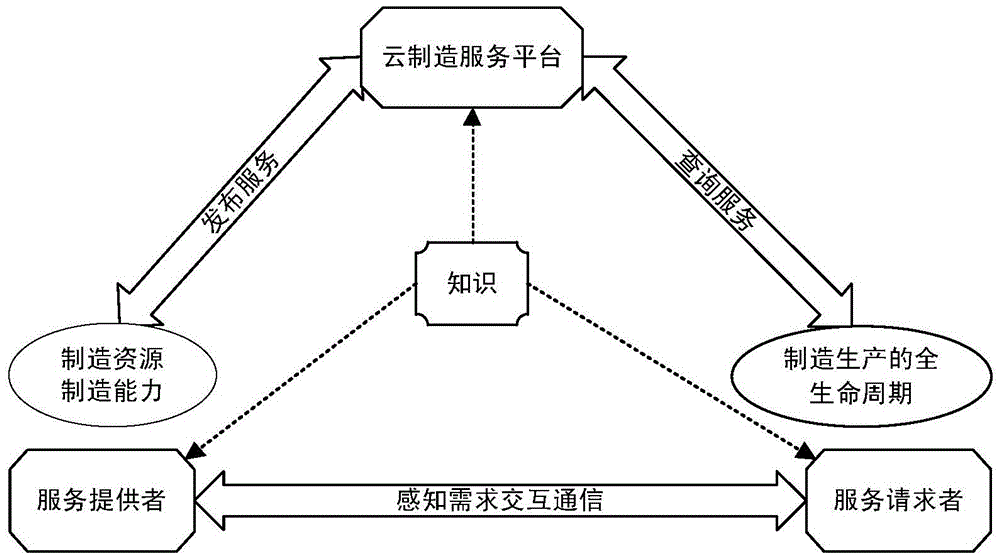

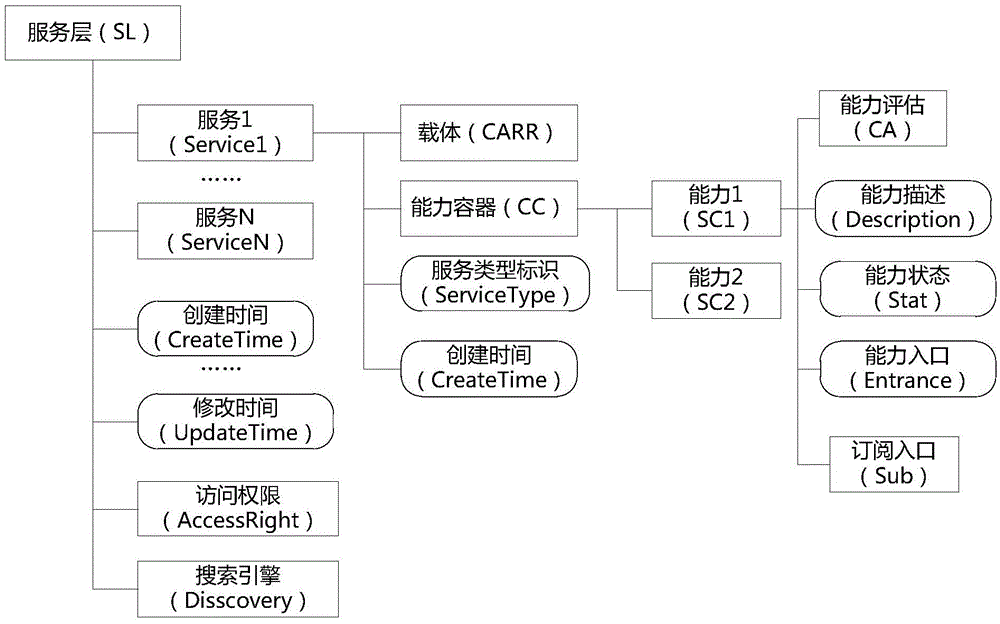

Organization and management and using method and system for cloud manufacturing service

InactiveCN105635283AEffective organizational managementActive service registrationTransmissionResource utilizationManagement efficiency

The invention discloses an organization and management and using method and system for a cloud manufacturing service. According to the method, on the basis of the internet of things technology and the cloud computing technology, interaction among a service provider, a service requester, and a cloud manufacturing service platform is described by using correlated network technologies like an XML language or an HTTP protocol; and modeling is carried out on the service based on description of the network technologies and a resource tree is constructed, so that the management efficiency and the resource utilization rate are effectively improved. Therefore, high-efficiency sharing of the resources and capabilities is realized; repeated building of the same kind of manufacturing resources and capability can be avoided; and the manufacturing energy and cost can be effectively saved. In a cloud manufacturing service system, a server is set to be in a user request waiting state; when a user request is received, the user request is analyzed; and corresponding operations of service registration, querying, updating, subscription, and usage are executed based on specific fields in the request.

Owner:NANJING UNIV OF POSTS & TELECOMM

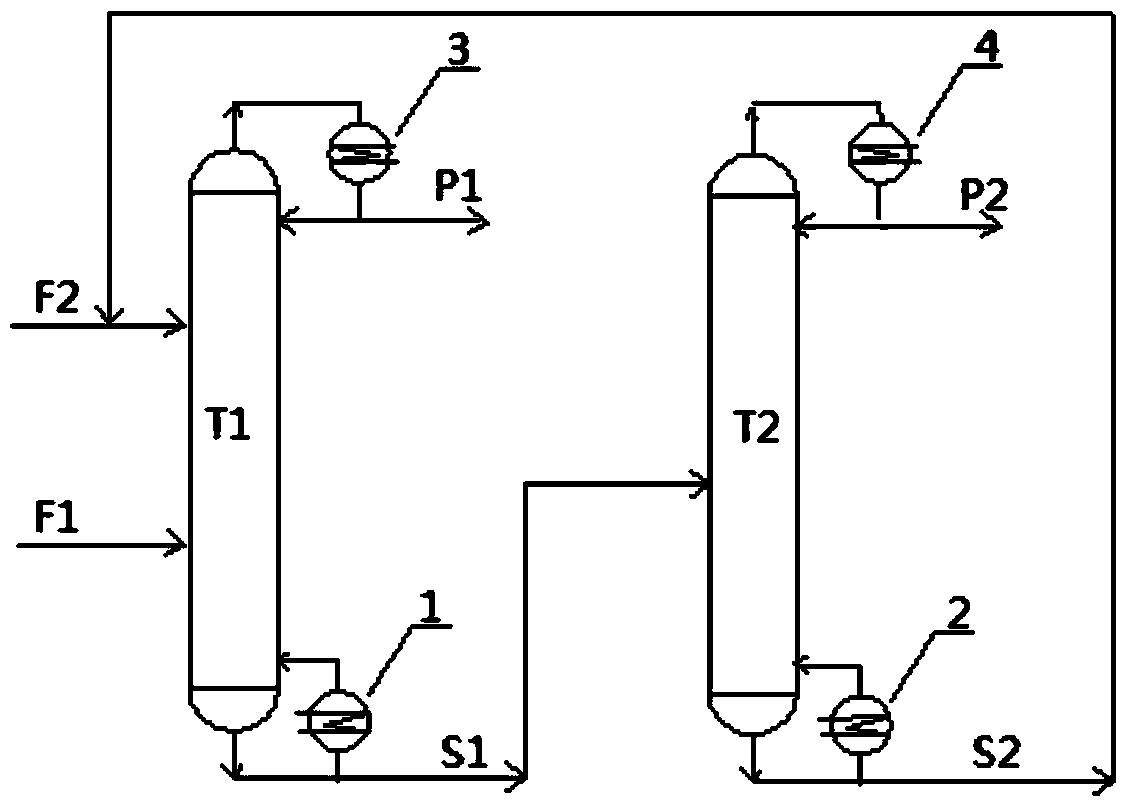

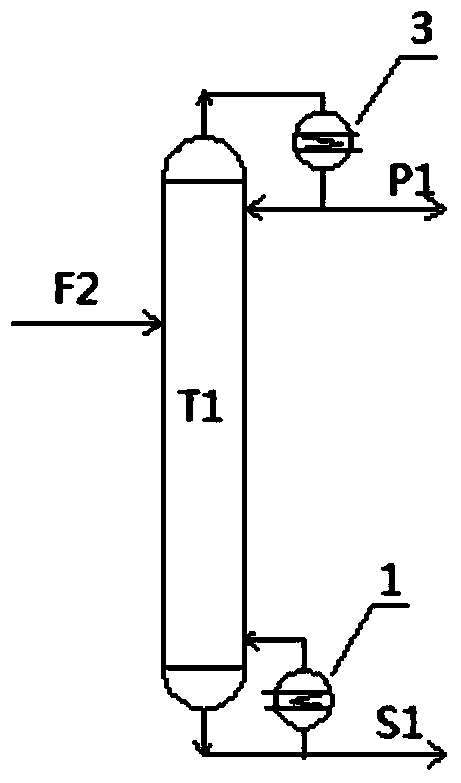

Method for separating isopropanol-water compound

InactiveCN103467246AIncrease relative volatilityEfficient separationOrganic compound preparationHydroxy compound preparationOrganic solventExtractive distillation

The invention provides a method for separating a isopropanol-water compound, which comprises the following steps: adopting an isopropanol-water compound in any proportion as a raw material, taking ionic liquid or a double solvent composed of ionic liquid and an organic solvent as an extraction agent, and extracting isopropanol and water in sequence after the raw material goes through an extractive distillation stage and an extraction agent recycle stage, wherein the extraction agent is used circularly after being extracted in the recycle stage. The method has the advantages that the energy consumption is low, environment pollution can be avoided, the product purity is high, the industrialization is facilitated, the equipment cost is low, and the economic benefit is good.

Owner:TIANJIN CLEANTECH TECH

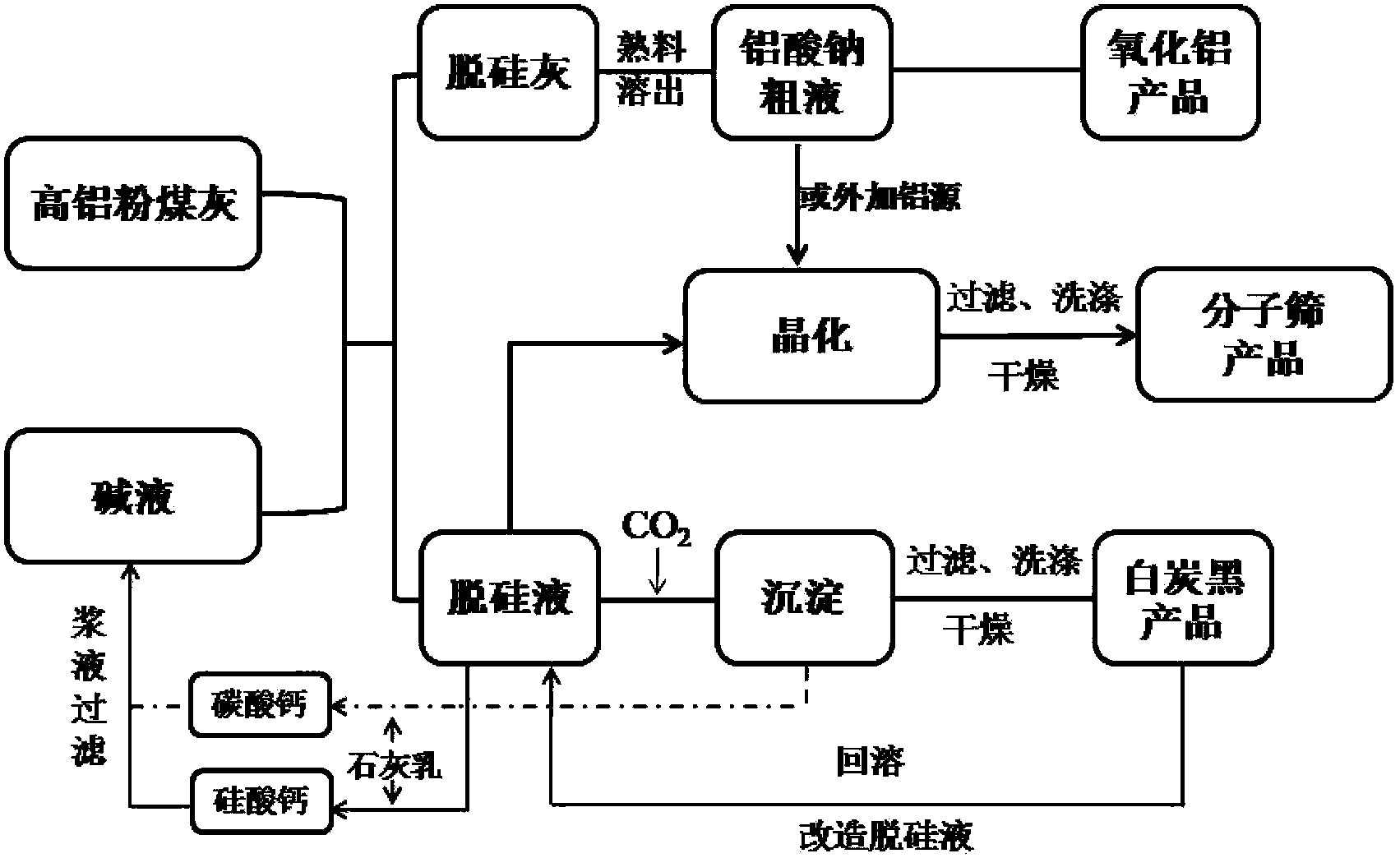

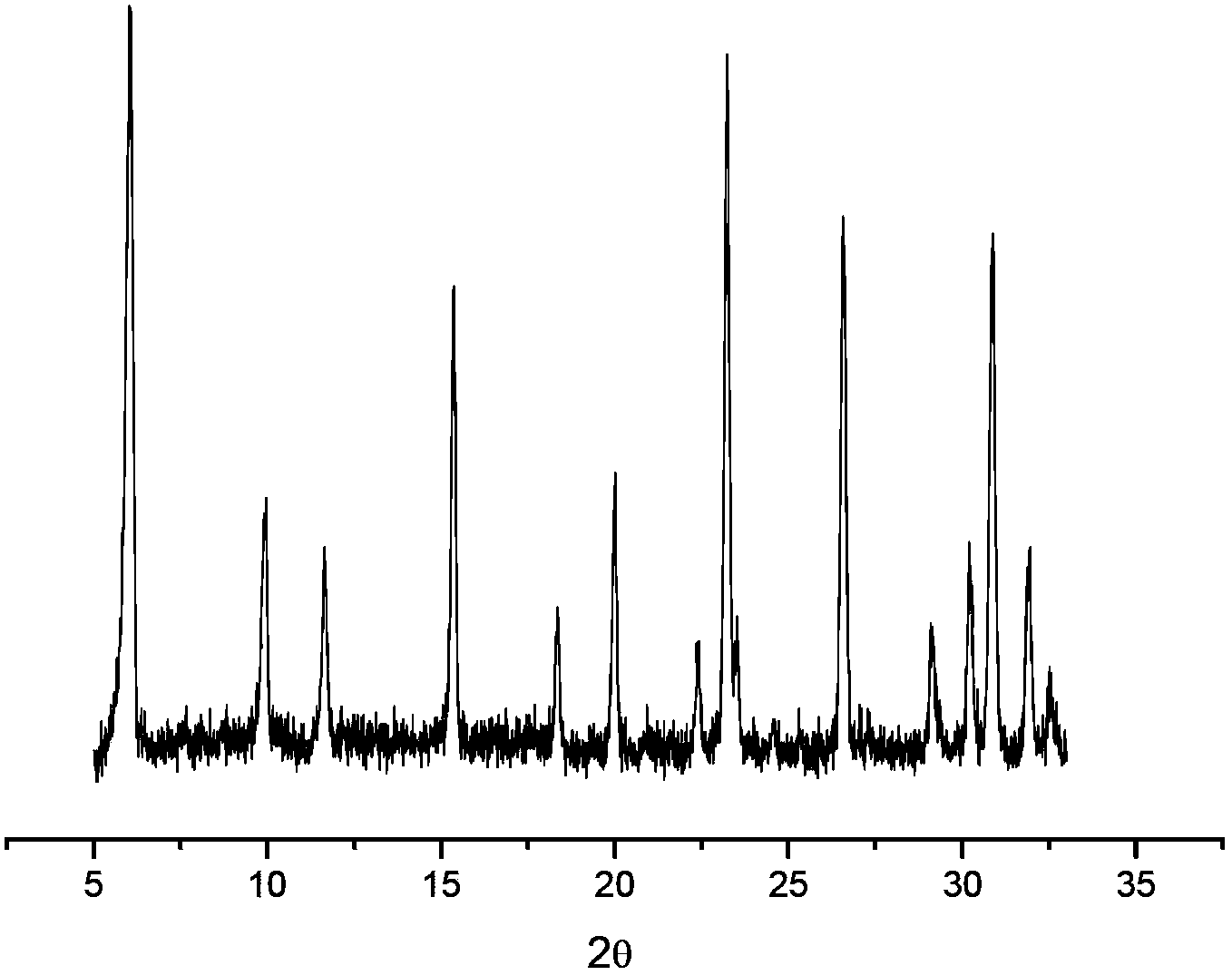

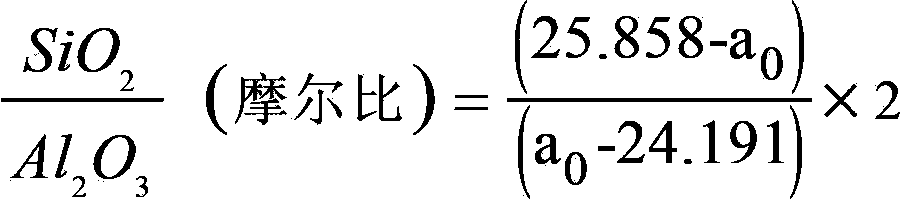

Method for preparing 13X molecular sieve through using high-alumina fly ash, and 13X molecular sieve

InactiveCN103449467ALow costAchieve environmental protectionSolid waste disposalFaujasite aluminosilicate zeoliteMolecular sieveFly ash

The invention provides a method for preparing a 13X molecular sieve through using high-alumina fly ash, and the 13X molecular sieve. The preparation method comprises the following steps: mixing the high-alumina fly ash with an alkali solution for a pre-desiliconization reaction, and filtering to obtain a desiliconized solution; mixing the desiliconized solution with white carbon black to obtain a modified desiliconized solution; mixing the modified desiliconized solution with an aluminum sauce to obtain a silicon and aluminum sol; and crystallizing the silicon and aluminum sol, filtering, washing, and drying to prepare the 13X molecular sieve. The invention also provides the 13X molecular sieve prepared through the preparation method.

Owner:DATANG INT CHEM TECH RESINST

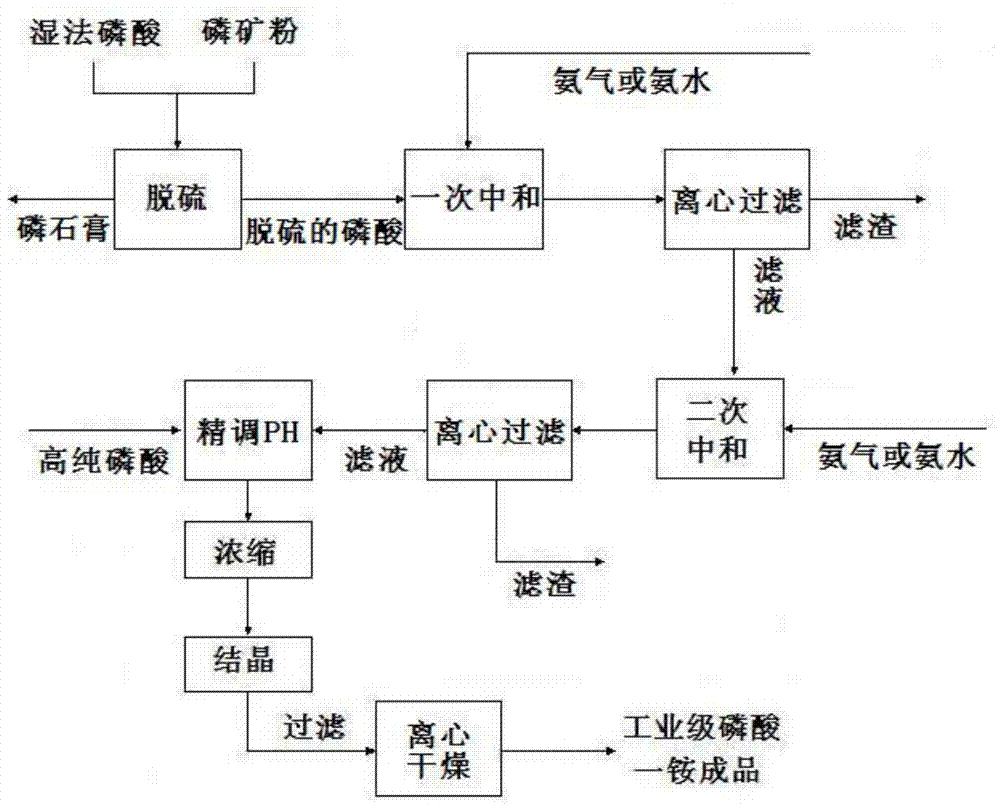

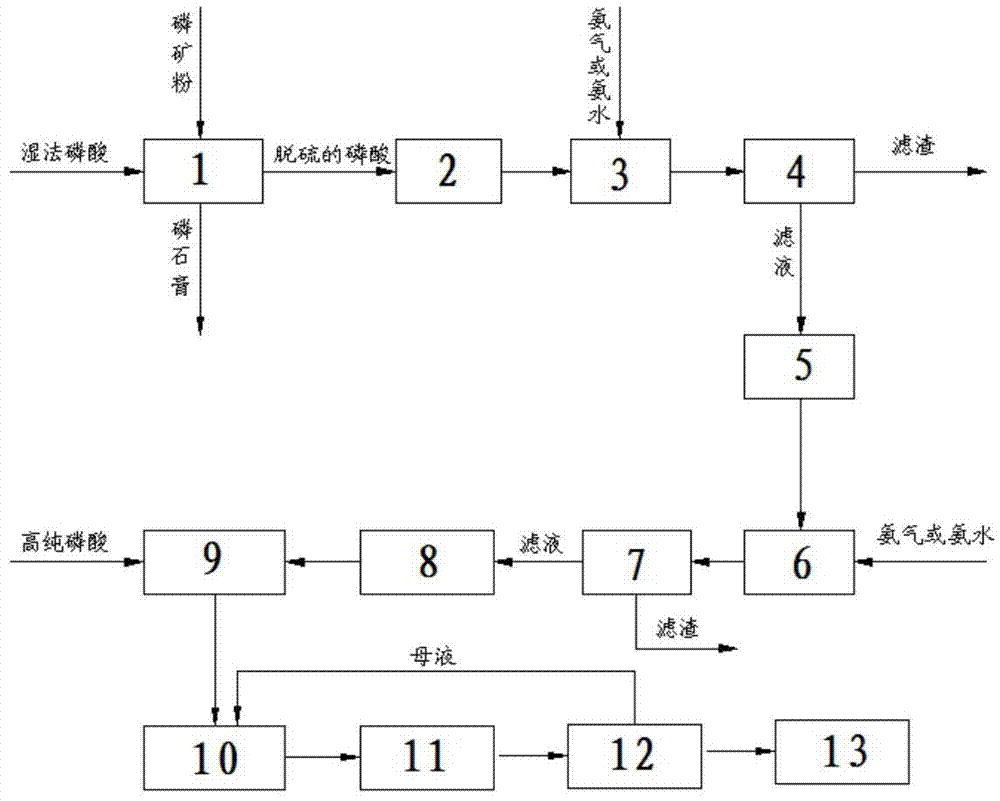

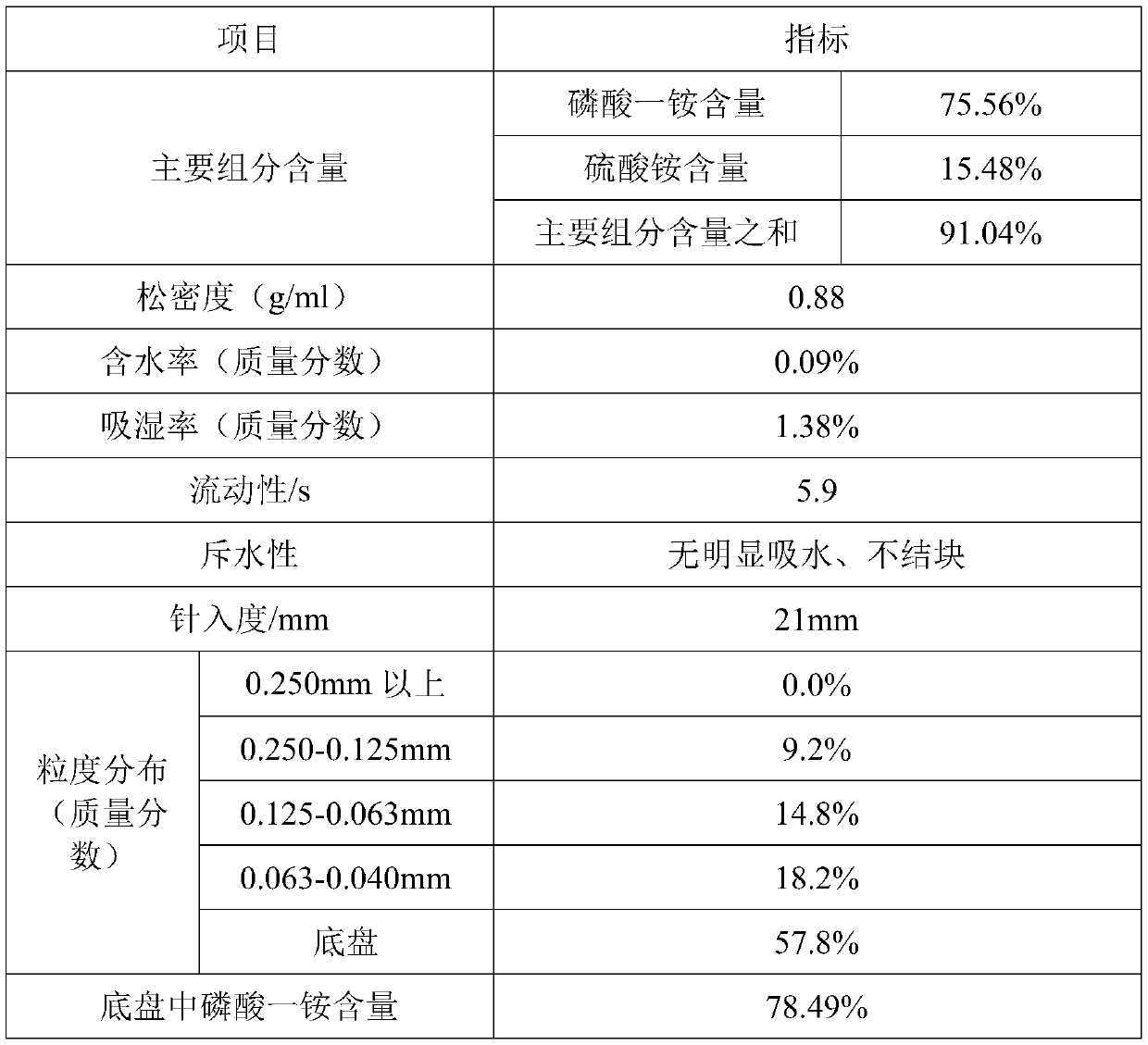

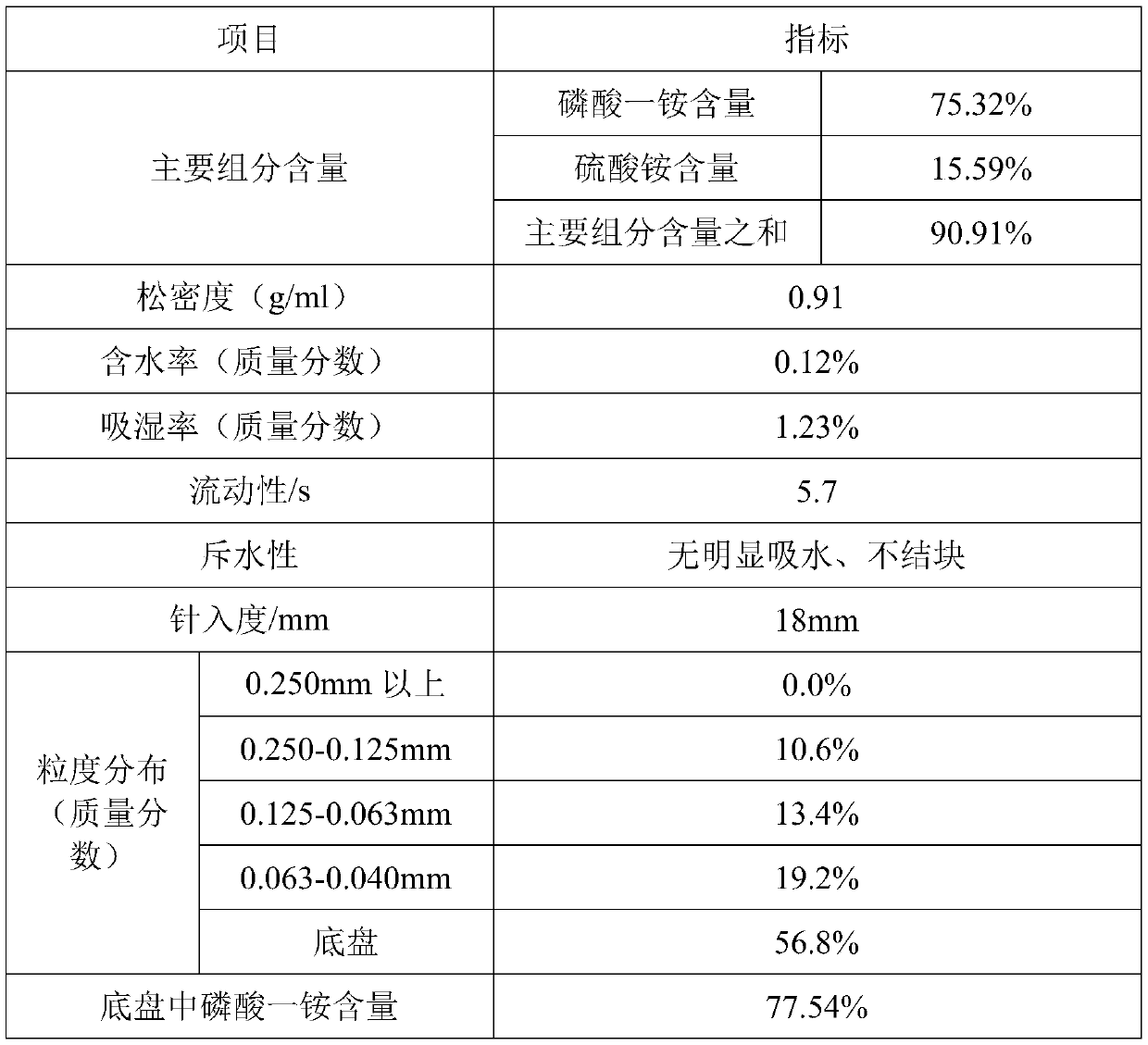

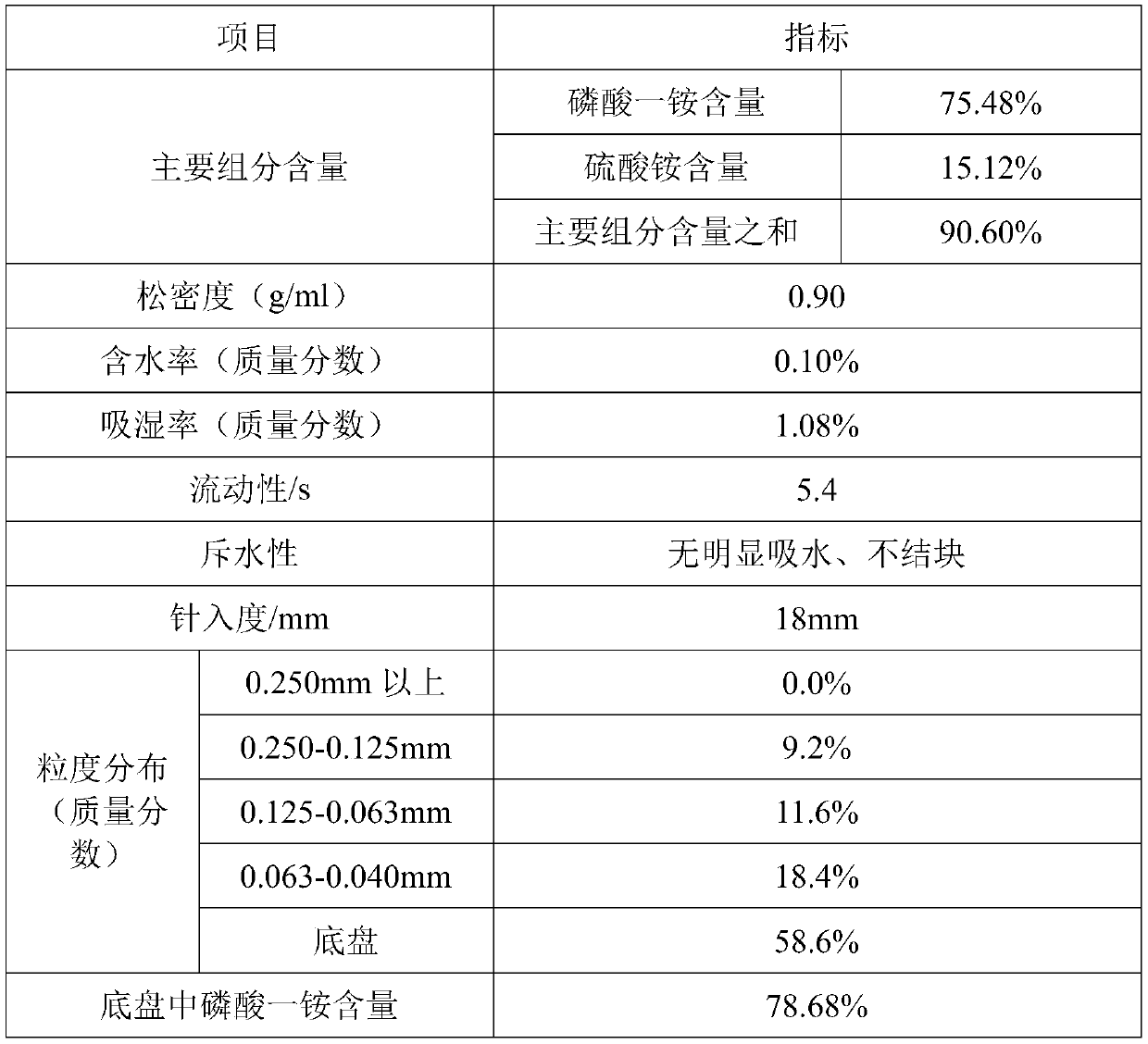

Method for producing industrial grade monoammonium phosphate through combination of wet process phosphoric acid and high-purity phosphoric acid

The invention discloses a method for producing industrial grade monoammonium phosphate through combination of wet process phosphoric acid and high-purity phosphoric acid. The method comprises the steps of performing neutralization reaction for two times on filtrate and ammonia gas or ammonia water to obtain ammonium phosphate slurry, wherein the filtrate is obtained by performing desulfurization reaction on phosphate rock powder and wet process phosphoric acid; performing concentration, crystallization and drying by using filtrate which is obtained by adjusting the pH value with high-purity phosphoric acid to obtain an industrial grade monoammonium phosphate product; removing most of impurity ions when the pH value is neutralized to 4.0-5.0 by the first neutralization reaction, then performing the second neutralization reaction to remove impurities in the wet process phosphoric acid, finely adjusting the pH value to 3.9-4.4 by using the high-purity phosphoric acid, and performing concentration and crystallization to obtain the industrial grade monoammonium phosphate. The method disclosed by the invention reduces the production cost and energy consumption and is environment-friendly and pollution-free; the obtained product is stable in quality, the process flow is short, the device construction investment is saved, the needed operators are less, the energy consumption is reduced, the pollution is reduced, and the quality of monoammonium phosphate is ensured through effective impurity removal, so that the method has a very good economic benefit.

Owner:GUIZHOU KAILIN GRP CO LTD

Preparation method of palladium-platinum bimetallic catalyst

InactiveCN103071486AHigh activityExtend your lifeOrganic compound preparationAmino compound preparationActivated carbonPlatinum

The invention relates to a preparation method of a palladium-platinum bimetallic catalyst. The preparation method is characterized by using active carbon as a carrier, pretreating the active carbon respectively by hydrochloric acid and nitric acid before preparation, then simultaneously loading palladium and platinum on the pretreated active carbon, and adding an activating agent into the active carbon with palladium and platinum for reduction to finally obtain the palladium-platinum bimetallic catalyst. According to the invention, the preparation method is simple; and the obtained palladium-platinum bimetallic catalyst disclosed herein has the advantages of high activity, long life, etc, and is especially suitable for preparing o-phenylenediamine by solvent-free hydrogenation.

Owner:JIANGSU YANGNONG CHEM GROUP +1

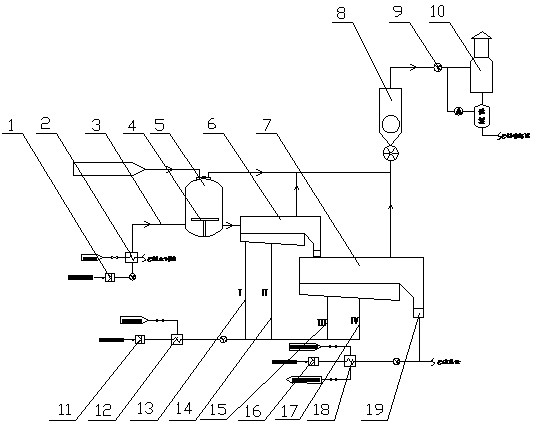

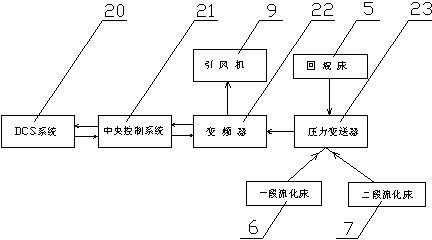

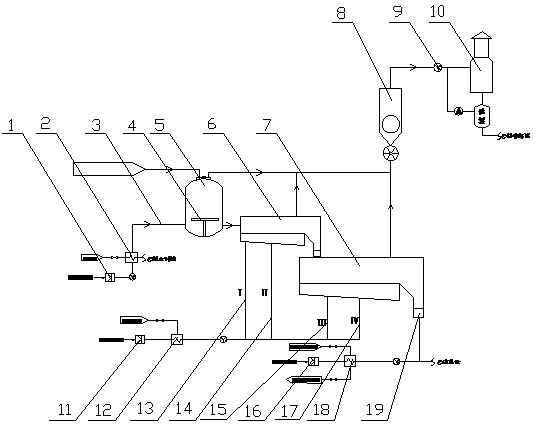

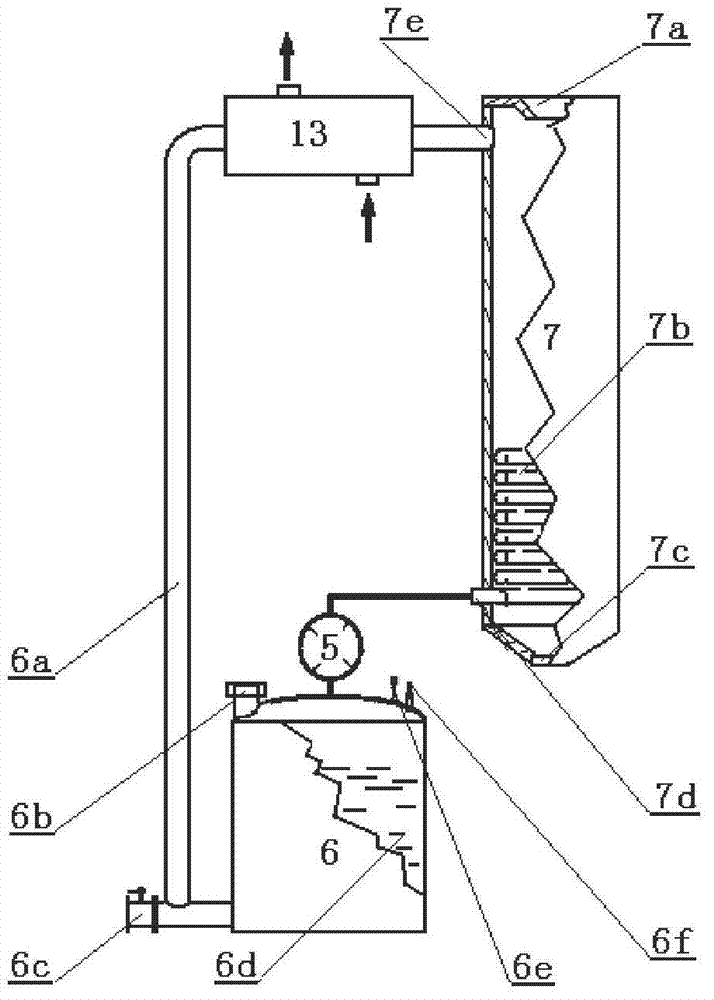

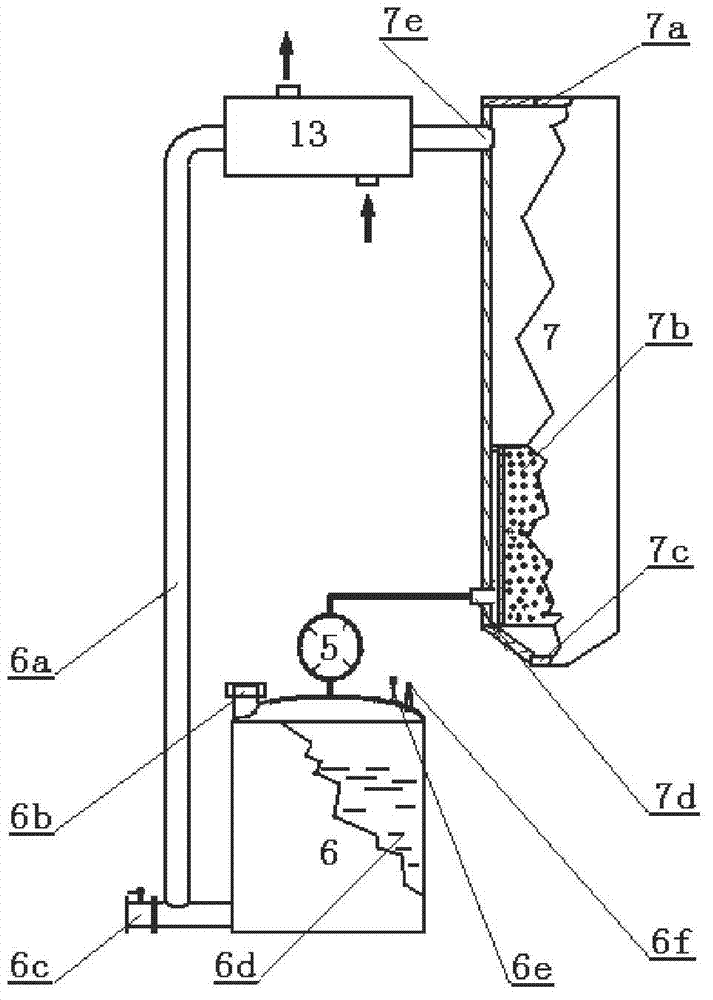

Anhydrous dextrose drying device and drying process

ActiveCN102435049AImprove continuityGuaranteed boiling effectDrying solid materials with heatHearth type furnacesFluidized bedChange color

The invention belongs to the technical field of biomedicine, in particular relates to an anhydrous dextrose drying device and a drying process. The technical scheme is that the anhydrous dextrose drying device comprises a fluidized bed and a back mixing bed. The fluidized bed comprises a first-section fluidized bed and a second-section fluidized bed. The lower portion of the back mixing bed is connected with an air inlet pipe I through an air feeder I, a heater I is arranged on the air inlet pipe I, an air inlet pipe II and an air inlet pipe III are respectively connected with the first-section fluidized bed, an air inlet pipe IV and an air inlet pipe V are respectively connected with the second-section fluidized bed, an air feeder II is respectively connected with the air inlet pipe II, the air inlet pipe III, the air inlet pipe IV and the air inlet pipe V through a heat exchanger II, so that the phenomena that finished products are apt to change colors and blocked caused by high temperature of materials caused by continuous drying can be avoided.

Owner:XIWANG PHARMA

Method for preparing active pseudo-ginseng

InactiveCN101961361ANot transgenderHigh content of active ingredientsNervous disorderMetabolism disorderVacuum pressureHeat conducting

The invention relates to a drying process of a specific plant. The process comprises the following steps of: 1. pretreatment: sorting prepared fresh pseudo-ginsengs; after separating and removing pruning openings, fibrous roots and flocking roots attached to the fresh pseudo-ginseng roots, obtaining main pseudo-ginseng roots; cleaning and removing surface attachments and leaching surface water; 2. pre-freezing: directly placing the whole main pseudo-ginseng roots into a pre-freezing chamber at minus 15-minus 20 DEG C and pre-freezing for 6-7 hours; 3. sublimation drying: spreading the pre-frozen main pseudo-ginseng roots on a table disk made of heat conducting materials, controlling the thickness of a paving material to be below 5cm and shifting to a vacuum drying chamber; after sealing, vacuumizing, maintaining internal vacuum pressure at 30-70Pa, setting the temperature of the table disk to be 40 DEG C, continuously supplying heat to the table disk and carrying out sublimation drying in vacuum for 10-15 hours till the table disk is heated to 40 DEG C; 4. analysis: maintaining the temperature of the table disk to be 40 DEG C and continuously supplying heat to the table disk and vacuumizing for 10-12 hours till the material is heated to 40 DEG C and material water is controlled to be below 3 percent; and 5. discharging and packaging. The invention provides a method for preparing active pseudo-ginseng.

Owner:云南特安呐制药股份有限公司

Thin vermicelli and/or vermicelli vertical cooler

ActiveCN102726784AImprove flexibilityHigh strengthFood shapingFood preparationCold airEconomic benefits

The invention discloses a thin vermicelli and / or vermicelli vertical cooler, which is provided with a cold air blower, a cooling tank, a cooler and a heat exchanger, wherein the cooler is provided with an air distributor, a bean vermicelli inlet, a bean vermicelli outlet, a cooling air inlet and a cooling air outlet, wherein the air distributor is arranged at the lower end of the cooler, and is adisk circular tube provided with even air distribution holes, or an air distribution card provided with even air outlet holes; the upper and lower ends of the air distribution card are welded with the cooler; the cooling air outlet is arranged at the upper end of the cooler; the top part of the cold air blower is provided with an exhaust opening, a liquid feeding opening, a vacuum meter and a thermometer; an air pipe and a cooling liquid are arranged at the lower end of the cooling tank; and the cooler, the cold air blower, the cooling tank and the heat exchanger are circularly connected in turn. With the adoption of the vertical cooler, the bean vermicelli is cooled in time, the flexibility and strength of the bean vermicelli are enhanced due to vertical stretching; a frequency modulation variable speed motor is automatically controlled by a computer, so that the operation is easy, the safety is high, the apparatus failure rate is low, the production efficiency and the product quality thin vermicelli and / or vermicelli are enhanced, and the thin vermicelli and / or vermicelli vertical cooler is suitable for industrial production, and has high economic benefit.

Owner:广西崇左天赐生物科技有限公司

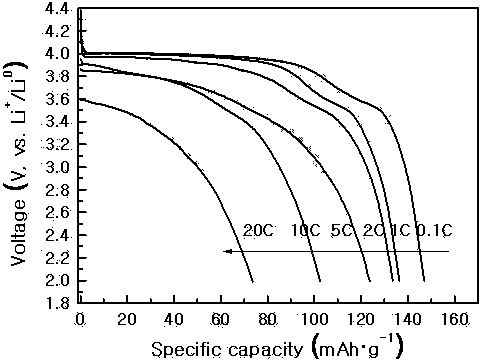

Preparation method for positive electrode material of iron, lithium and manganese phosphate battery

InactiveCN103985871AIncrease profitWith ultra-microporous structureCell electrodesSecondary cellsShielding gasManganese

The invention provides a method for synthesizing a positive electrode material of a nano-level iron, lithium and manganese phosphate battery (Li(FeyMn1-y)XzPO4 / C) which is high in energy density, is provided with a high-discharge-voltage platform and is excellent in conductivity by combining a sol-gel method with a microwave drying method. The method comprises the following steps of a, adding a lithium source, an iron source, a manganese source and metal X salt into ethyl alcohol to prepare sol A; b, adding citric acid into a phosphorus source-containing ethyl alcohol aqueous solution, and adding a carbon source into the phosphorus source-containing ethyl alcohol aqueous solution to obtain a solution B, wherein the carbon source added into the solution B contains 1-5 percent of carbon elements by mass; c, mixing and heating the sol A and the solution B, and adjusting the pH to form gel C; d, performing microwave drying on the gel C to obtain a precursor; e, preparing powder from the precursor, and pre-burning, sintering and screening the powder under protection gas to obtain the positive electrode material of the iron, lithium and manganese phosphate battery.

Owner:宁波艾能锂电材料科技股份有限公司

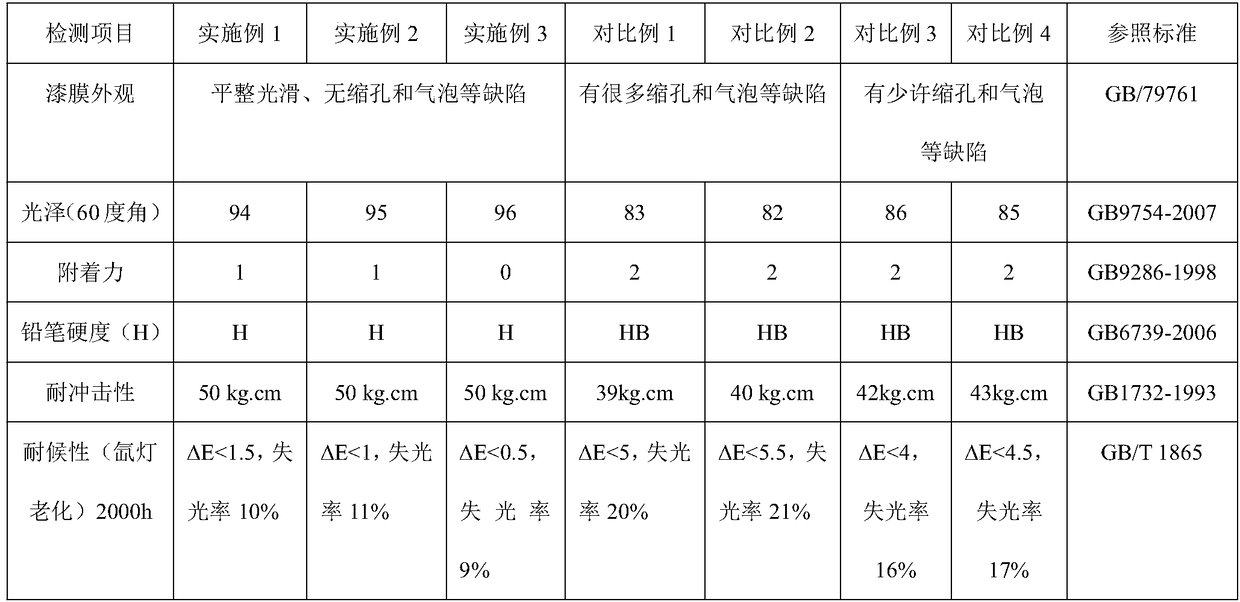

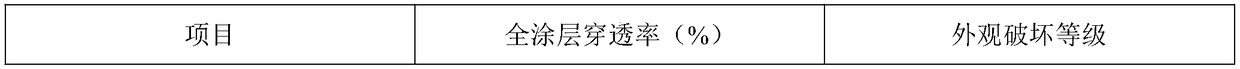

Single-component middle coating can be used for wet-on-wet and dry jet wet, and preparation method thereof

InactiveCN109181433AExtension of timeImprove efficiencyPolyurea/polyurethane coatingsPriming paintsWater basedPolyol

The invention belongs to the technical field of paint, and more specifically relates to a single-component middle coating can be used for wet-on-wet and dry jet wet. The single-component middle coating can be used for wet-on-wet and dry jet wet comprises, by mass, 35 to 45% of a grinding component slurry, 15 to 25% of a water-based acrylic polyol dispersion, 5 to 15% of a water-based polyurethanedispersion, 3 to 7% of an aqueous auxiliary agent, 0.5 to 1.5% of an amine neutralizer, 0.5 to 2% of ethylene glycol monobutyl ether, 0.3 to 0.7% of a wetting leveling agent, 2 to 8% of a methylated amino resin, 0.3 to 0.7% of a thickening agent, and 8 to 14% of water. The single-component middle coating can be used for wet-on-wet and dry jet wet is capable of increasing production efficiency greatly, is universal in et-on-wet and dry jet wet, is capable of saving production time and baking energy consumption greatly, and reducing research and development cost.

Owner:GUANGDONG YATU CHEM

Preparation method of active pseudo-ginseng slices

ActiveCN101961363AHigh content of active ingredientsEasy to storeNervous disorderMetabolism disorderSurface moistureInternal pressure

The invention relates to a drying process method of a specific plant. The method comprises the following steps of: (1) pretreatment: sorting and selecting prepared fresh pseudo-ginseng, separating and removing snips, fibrous roots and flocking roots attached to the fresh pseudo-ginseng roots to obtain pseudo-ginseng main roots, cleaning and removing surface attachments, draining surface moisture, and cutting into 0.2-2 mm slices by using a slicing machine; (2) pre-freezing: directly placing the slices in a pre-freezing room with the set temperature of subzero 15 to subzero 20 DEG C, and pre-freezing for 5-6h; (3) sublimation drying: spreading the pre-frozen slices out on a desk tray made of a conducting material, controlling the spreading thickness to be below 5 cm, and moving to a vacuum drying room; sealing, starting vacuumizing, maintaining the internal vacuum pressure at 30-70 pascals, setting the temperature of the desk tray to be 40 DEG C, keeping supplying heat for the desk tray, and carrying out vacuum sublimation drying for 7-10h until the temperature of the desk try reaches 40 DEG C; (4) analysis: maintaining the temperature of the desk tray to be 40 DEG C, keeping supplying heat for the desk tray and vacuumizing for 6-12h until the temperature of the material reaches 40 DEG C, and controlling the moisture of the material at 3-5%; and (5) discharging and packaging.

Owner:云南特安呐制药股份有限公司

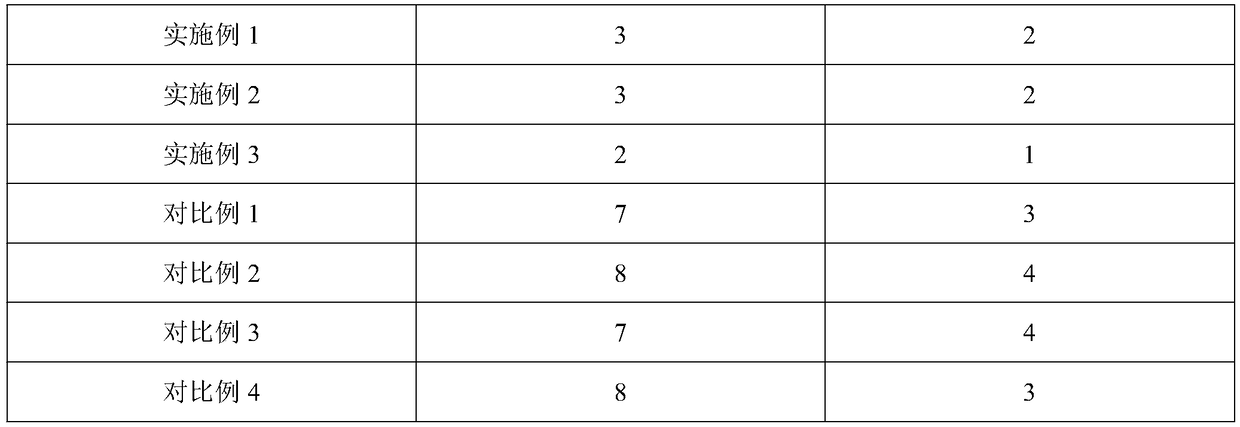

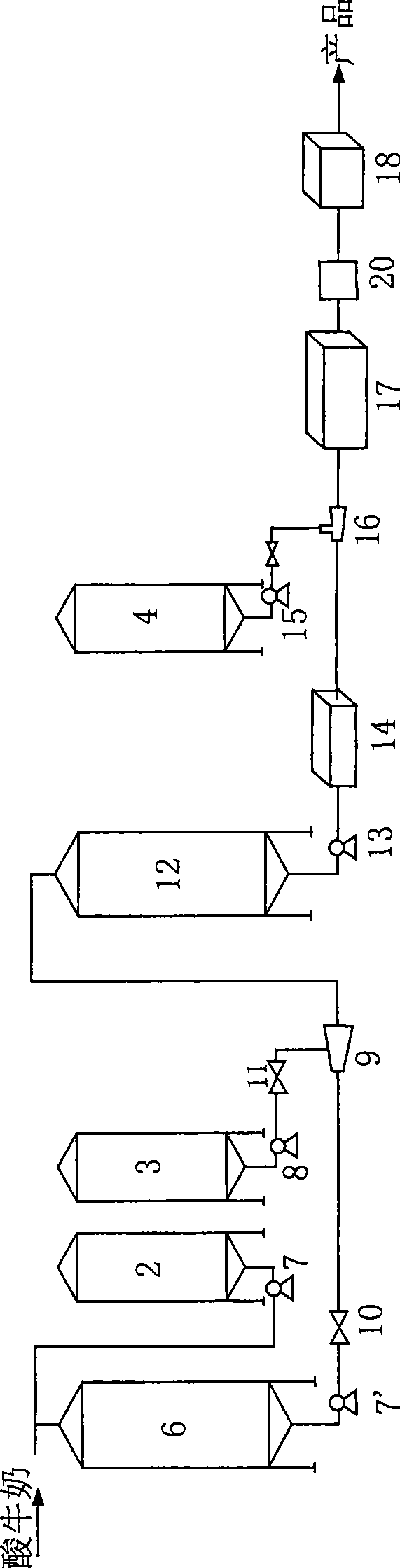

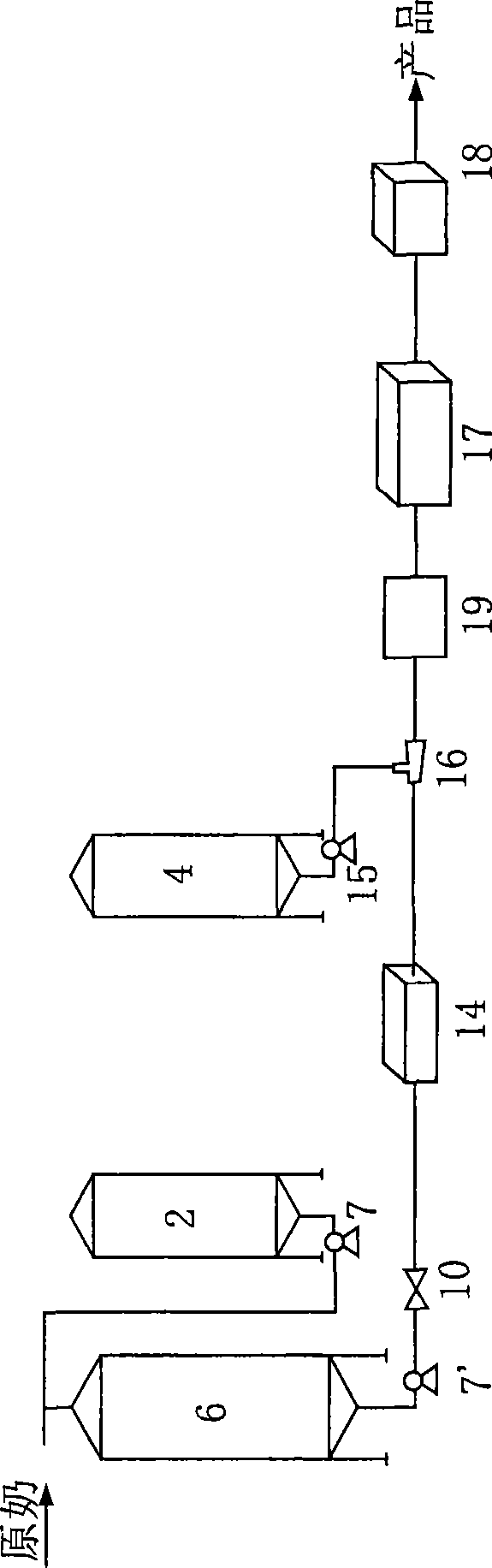

Method for producing milk beverage with added garden stuff fiber

The present invention provides a method for producing a milk drink added with fruit vegetable fiber. The milk drink comprises the following components: milk, fruit vegetable fiber material, stabilizing agent, sugar and water. The method for producing the milk drink comprises the following steps: 1. preparing the milk liquid base stock: mixing the fermented or unfermented milk, stabilizing agent, sugar and appropriate amount of water to uniform, adjusting the acidity degree according to requirement for obtaining the milk liquid base stock and homogenizing the milk liquid base stock; 2. preparing the fruit vegetable fiber material liquid: mixing the fruit vegetable fiber material with appropriate amount of water for dispersing the fruit vegetable fiber material in the water and obtaining the fruit vegetable fiber material liquid; and 3. pumping the fruit vegetable fiber material liquid into a producing pipe for on-line contacting and mixing the homogenized milk liquid base stock, delivering the mixed material liquid into a sterilization machine for sterilizing and then pouring-in, and the milk drink product is obtained. The method according to the invention can add the fruit vegetable fiber material into the drink of each packaging unit more uniformly, and simultaneously the production cost can be saved.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

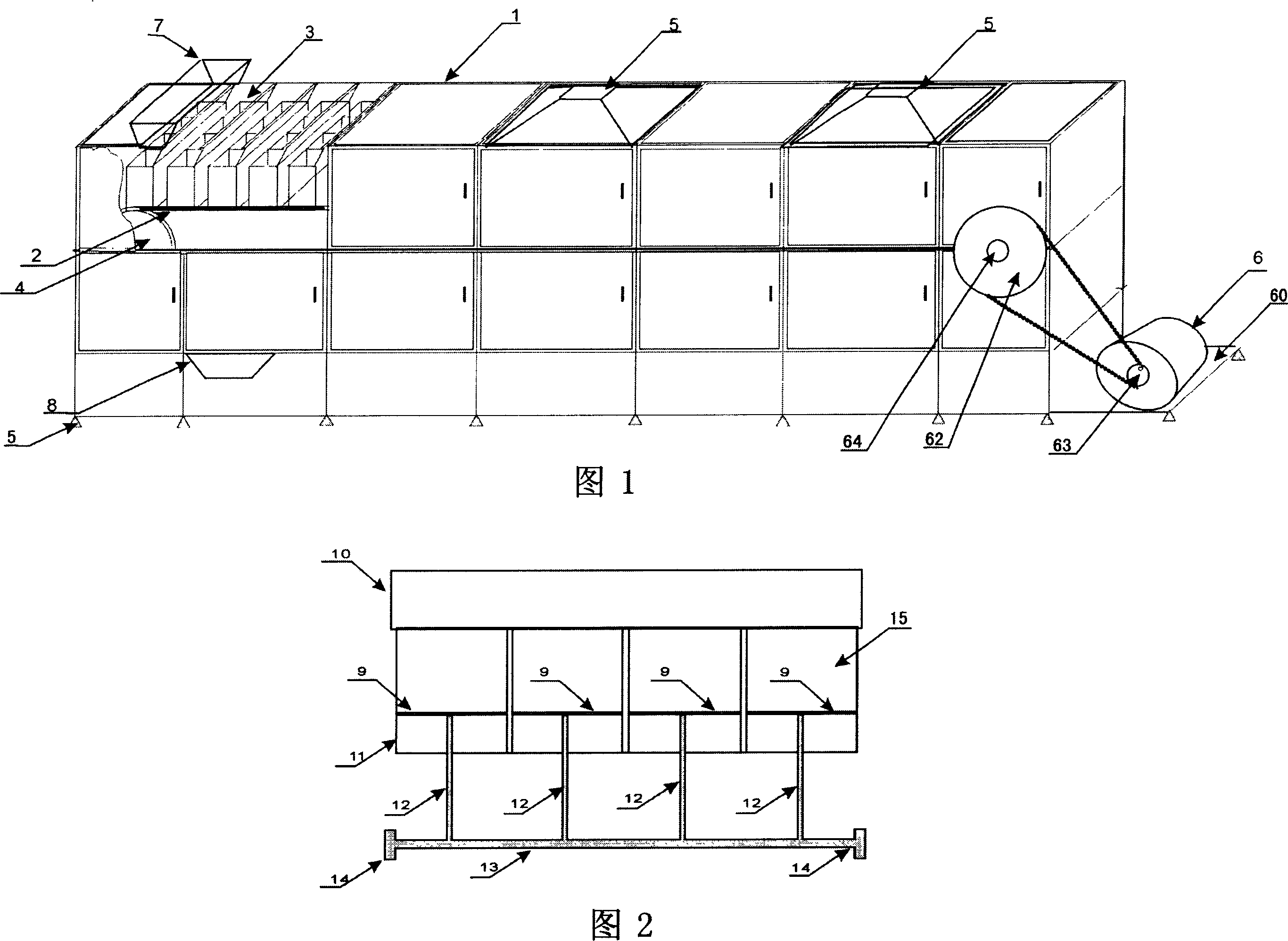

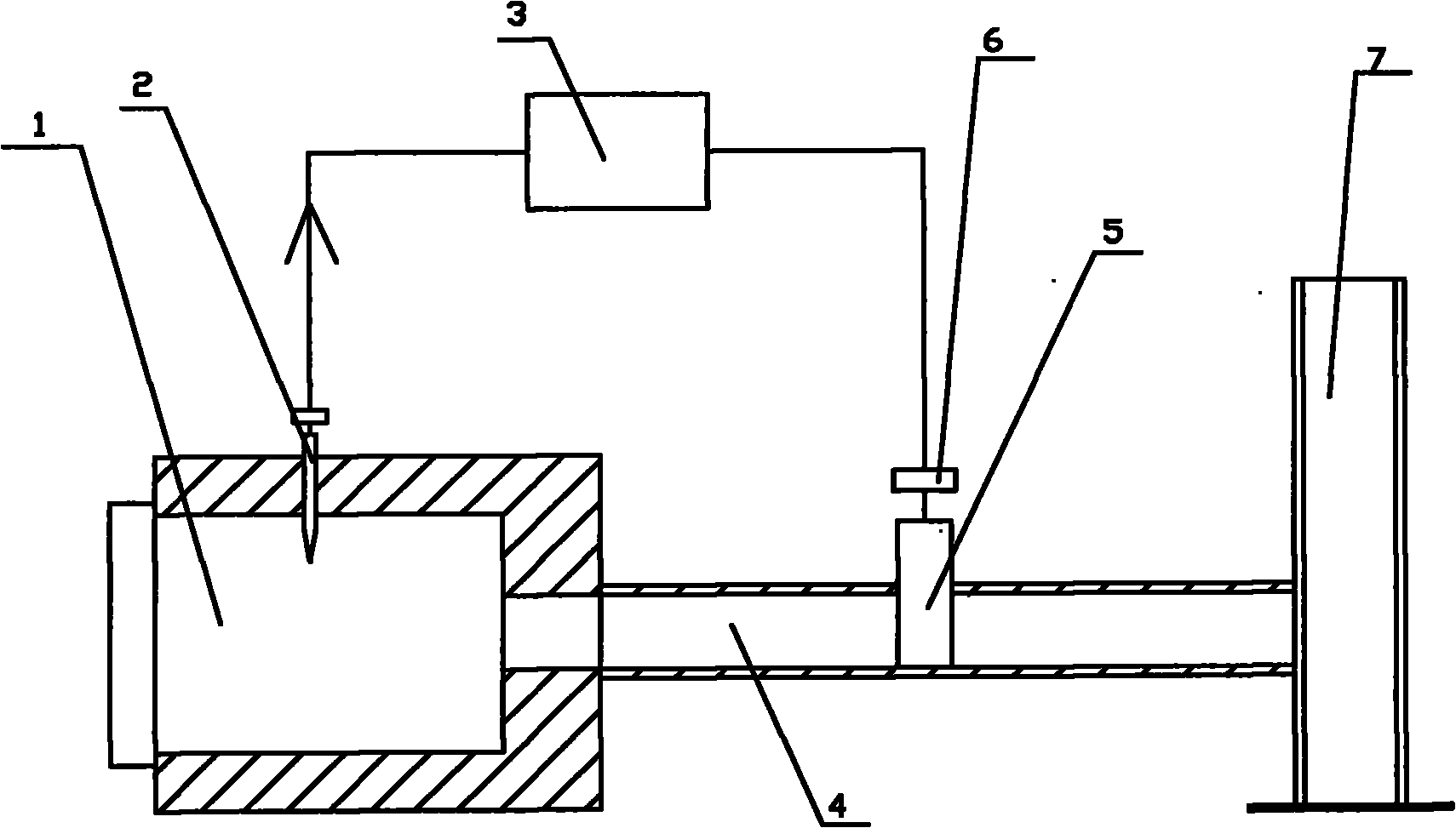

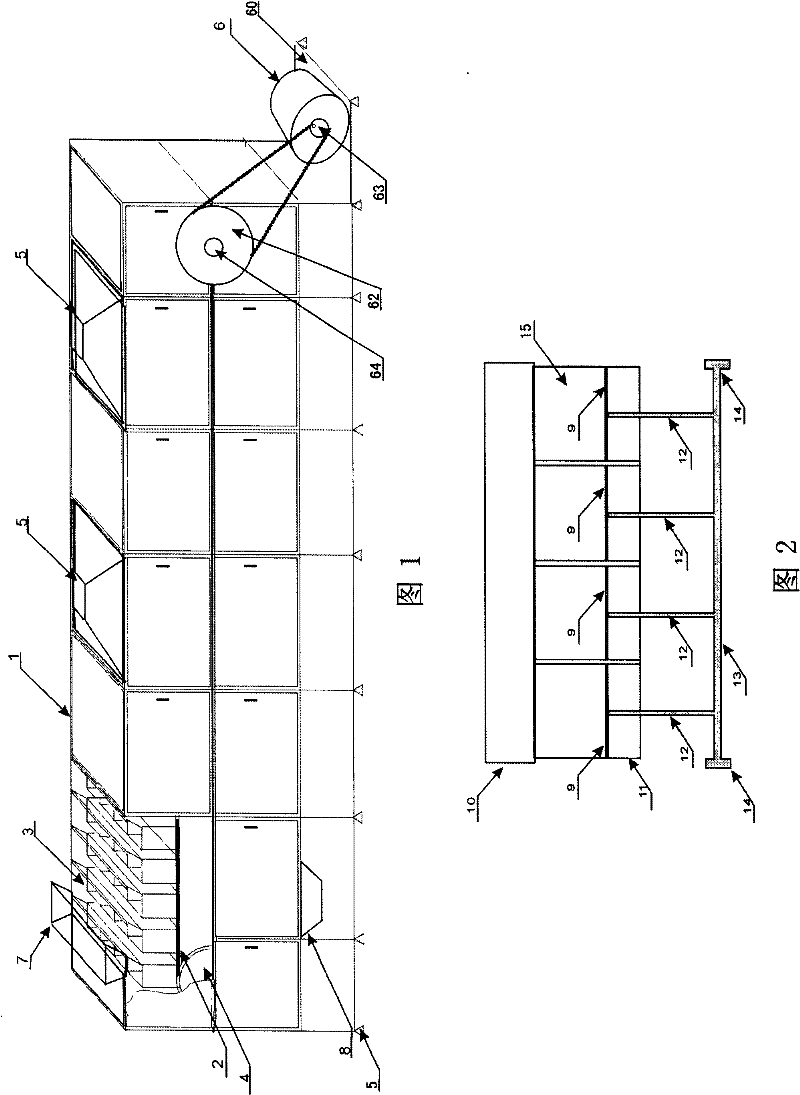

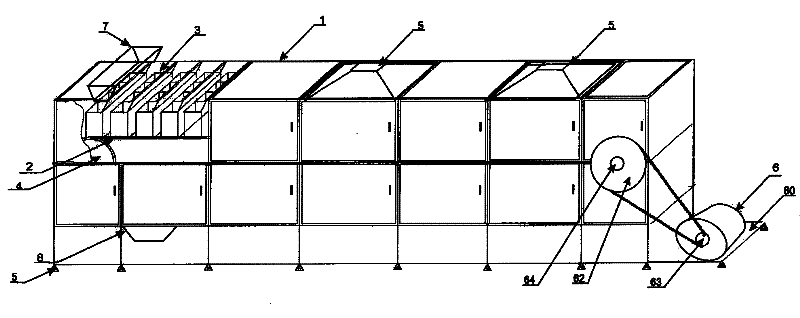

Technological process and apparatus for fast shaping instant rice noodle cake

The present invention is technological process and apparatus for fast shaping instant rice noodle cake. The technological process includes the ageing, dispersing and metering of instant rice noodle; setting inside the sealed shaping box of the shaping apparatus and high temperature heating to convert water inside instant rice noodle into vapor to cook and soften; and further heating for the instant rice noodle to evaporate water, harden and shape. The present invention realizes the automatic production of instant rice noodle cake in high efficiency.

Owner:东莞市一家人食品有限公司

Preparation method of pentaerythritol tristearate

InactiveCN104529766AHigh activityHigh catalytic activityPhysical/chemical process catalystsOrganic compound preparationChemical synthesisPentaerythritol

The invention belongs to the field of chemical synthesis and relates to a preparation method of pentaerythritol tristearate. The preparation method comprises the following steps of adding stearic acid and pentaerythritol into a reactor according to a mole ratio of 1.0-1.2: 1, carrying out stirring mixing to obtain a uniform mixture, adding solid super acid into the mixture to cause a reaction lasting for 2-3h under the conditions of a temperature of 150-180 DEG C and pressure of 5-50Pa so that a pentaerythritol tristearate crude product is obtained by the reaction, and carrying out decoloring treatment on the pentaerythritol tristearate crude product to obtain a pentaerythritol tristearate finished product. The preparation method utilizes solid super acid SO4<2-> / ZrO2-SiO2 as a pentaerythritol tristearate synthesis catalyst, reduces the existing reaction high-temperature from 200 DEG C to 150-180 DEG C, reduces reaction time by 1-2h and greatly saves a production cost and energy consumption. The preparation method of pentaerythritol tristearate has a high esterification rate of 92% and good product indexes.

Owner:GUANGZHOU CARDLO BIOCHEM TECH

Dehydration process of multi-water sodium sulfide during polyphenyl thioether resin synthesis

The invention discloses a dehydration process of multi-water sodium sulfide during polyphenyl thioether resin synthesis. The dehydration process comprises the following steps of heating and stirring the multi-water sodium sulfide, a catalyst and an NMP (N-Methyl Pyrrolidone) solution in a reaction kettle in the dehydrating stage of the raw material multi-water sodium sulfide, continuously increasing temperature to 150-200 DEG C, and introducing nitrogen. The dehydration process disclosed by the invention can reduce the dewatering time of the multi-water sodium sulfide in the synthetic process of polyphenyl thioether, increase the dehydration efficiency, reduce the energy consumption, prevent the problems of easiness for decomposition and oxidation and the like of NMP (N-Methyl Pyrrolidone) and sodium sulfide at high temperature in air, generate extremely less NMP gas and other foreign gas in the dehydration process, can be used for carrying away the nitrogen through water vapors and is simplified in process flow and favorable to industrialized production and environmental protection.

Owner:ZHUHAI CHANGXIAN CHEM TECH

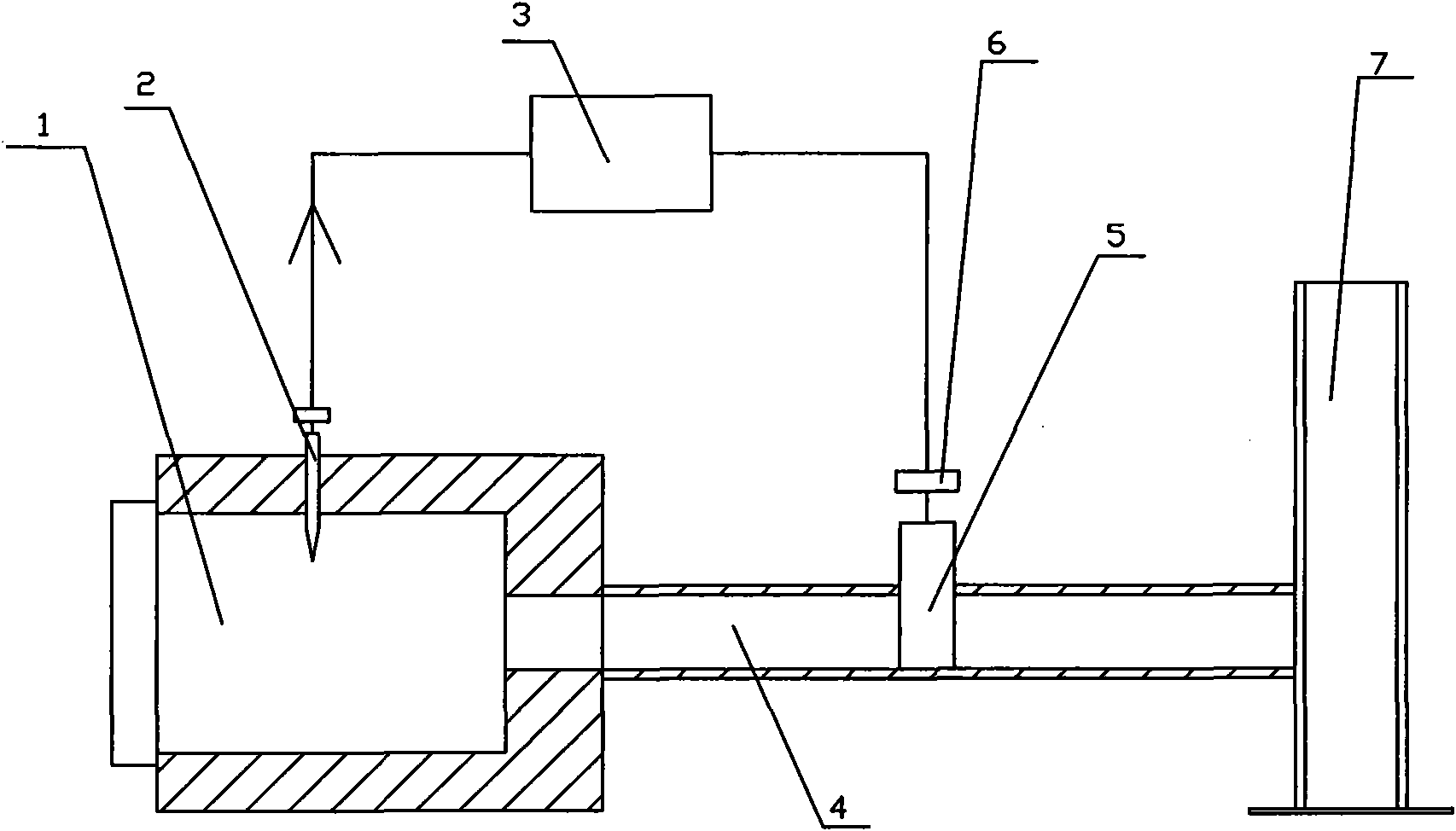

Automatic lifting device for flue damper of kiln

InactiveCN102384480AImprove work efficiencyExtended service lifeOperating means/releasing devices for valvesChimneysProgrammable logic controllerHearth

The invention relates to an automatic lifting device for a flue damper of a kiln. The kiln is communicated with a chimney through a flue; a damper is arranged in the flue. The automatic lifting device comprises a pressure gauge and an electric device, wherein the pressure gauge is arranged in a hearth of the kiln; a PLC (Programmable Logic Controller) is arranged between the pressure gauge and the electric device; and the electric device is connected with the damper. The automatic lifting device is simple in structure and can automatically lift the flue damper according to the pressure intensity in the hearth of the kiln and ensure that the pressure in the hearth is within the best working scope, thereby improving the work efficiency of the kiln, saving the produced energy resources, also prolonging the service life of the kiln and related equipment and greatly reducing the labor intensity of workers.

Owner:江苏腾达环境工程有限公司

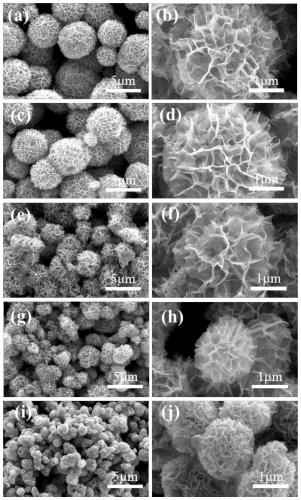

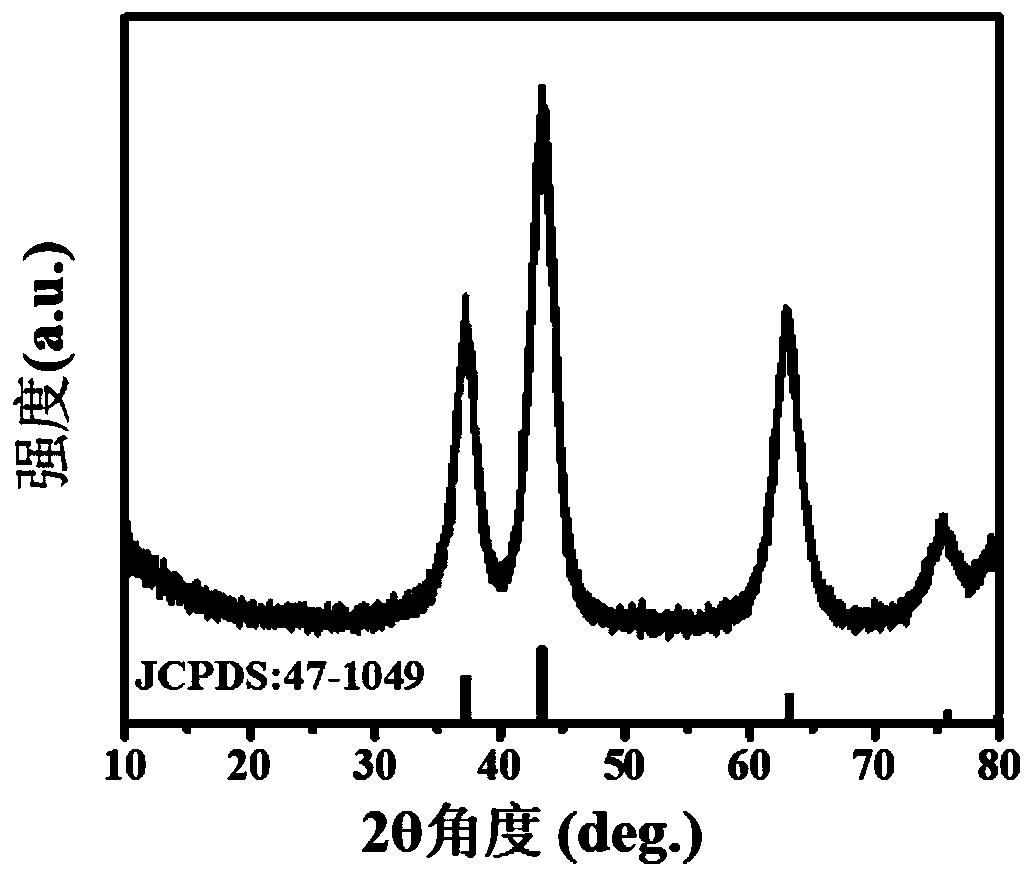

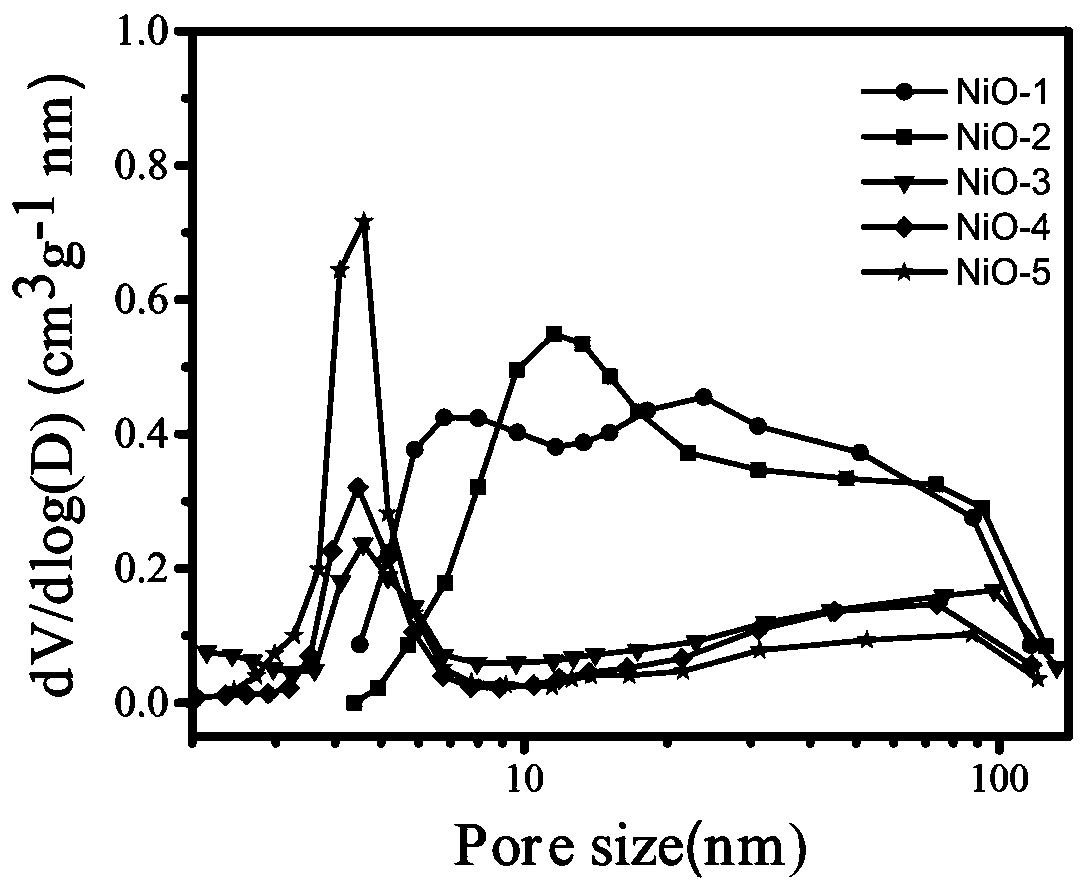

Graded porous honeycomb nickel oxide microsphere and preparation method thereof

ActiveCN111333127ALow reaction temperatureShort reaction timeNickel oxides/hydroxidesMicrosphereGlycerol

The invention provides a preparation method of hierarchical porous honeycomb nickel oxide microspheres, and belongs to the field of micro-nano material preparation. In the hydrothermal reaction of thepresent invention, in the first stage of the growth process, glycerol and Ni<2+> in a reaction system form coordination, and react with CO3<2-> and OH<-> generated by urea hydrolysis to form a primary core; in the second stage of the growth process, the original primary core is adsorbed by a chelating agent of glycerol and nickel, is used as an end-capping reagent to adjust the form by reducing the surface energy, and finally is converted into a highly symmetrical flower-shaped structure; and in a urea-glycerol mixture system, the adopted non-surfactant organic small molecule glycerol template contains more hydroxyl groups, glycerol is firstly gathered through the hydrogen bond effect, then a mesoporous structure is formed through the interaction of the hydrogen bond and the hydroxyl group of the urea hydrolysis inorganic phase, and finally the hierarchical porous honeycomb-shaped nickel oxide microspheres are obtained through calcination.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Base steel resin carbon fibre synchronization device cone ring matrix material component and production process thereof

The invention discloses a conical ring matrix material component of steel-based resin carbon fiber synchronizer and a production process thereof. According to weight percentage, 95.32 percent to 97.85 percent of atomized iron powder-100 meshes, 1 percent to 3 percent of copper powder -200 meshes, 0.5 percent to 1.0 percent of carbon powder -325 meshes, 0.6 percent of zinc stearate -325 meshes and 0.05 percent to 0.08 percent of No.20 industrial engine oil are adopted, fully mixed and die-casted to shape through a presser; after the sintering of atmosphere protection net belt, the metallic phase requirement can be met, vapor treatment, mechanical process and secondary vapor treatment are then carried out and the production process is completed. The components and the production process of the invention have the advantages of less cutting or no cutting, saving material and energy, high production efficiency and being suitable for bulk production.

Owner:陕西华夏粉末冶金有限责任公司

Straw compound foamed shoe material and production processing method thereof

InactiveCN102229751AImprove protectionLow heat setting temperatureFootwearLow-density polyethyleneVulcanization

The invention discloses a straw compound foamed shoe material and a production processing method thereof, and relates to the technical field of plastic raw materials and products. After natural straw, low-density polyethylene, calcium carbonate and plastic aid are mixed, the mixed materials are placed in a compression roller and sheeted, and raw material sheets of the straw compound foamed shoe material can be obtained. The raw material sheets can be directly shaped; and after the raw material sheets of the straw compound foamed shoe material are heated, shaped products of different shapes can be obtained by closed vulcanization foaming of a die press. The heat setting temperature of the straw compound foamed shoe material is much lower than that of the conventional non-degradable plastic, the production energy is saved, the equipment and the environment are protected, the disintegration period of the shoe material under the conditions of strong sunlight and severe temperature difference is 180 days, and the disintegration period of a compost is 120 days.

Owner:殷正福

Method for preparing active pseudo-ginseng granule

InactiveCN101961362ANot transgenderReduce moisture contentNervous disorderMetabolism disorderVacuum pressureHeat conducting

The invention relates to a drying process of a specific plant, which comprises the following steps of: 1. pretreatment: sorting prepared fresh pseudo-ginsengs; after separating and removing pruning openings, fibrous roots and flocking roots attached to the fresh pseudo-ginseng roots, and then obtaining main pseudo-ginseng roots; cleaning and removing surface attachments, leaching surface water and mincing by a mincer to obtain granules of 10-20 meshes; 2. pre-freezing: directly placing the granules into a pre-freezing chamber at minus 15-minus 20 DEG C and pre-freezing for 4-5 hours; 3. sublimation drying: spreading the pre-frozen granules on a table disk made of heat conducting materials, controlling the thickness of the spread material to be below 5cm and shifting to a vacuum drying chamber; after sealing, vacuumizing, maintaining internal vacuum pressure at 30-70Pa, setting the temperature of the table disk to be 40 DEG C, continuously supplying heat to the table disk and carrying out sublimation drying in vacuum for 5-7 hours till the table disk is heated to 40 DEG C; 4. analysis: maintaining the temperature of the table disk to be 40 DEG C and continuously supplying heat to the table disk and vacuumizing for 4-6 hours till the material is heated to 40 DEG C and material water is controlled to be below 3 percent; and 5. discharging and packaging.

Owner:云南特安呐制药股份有限公司

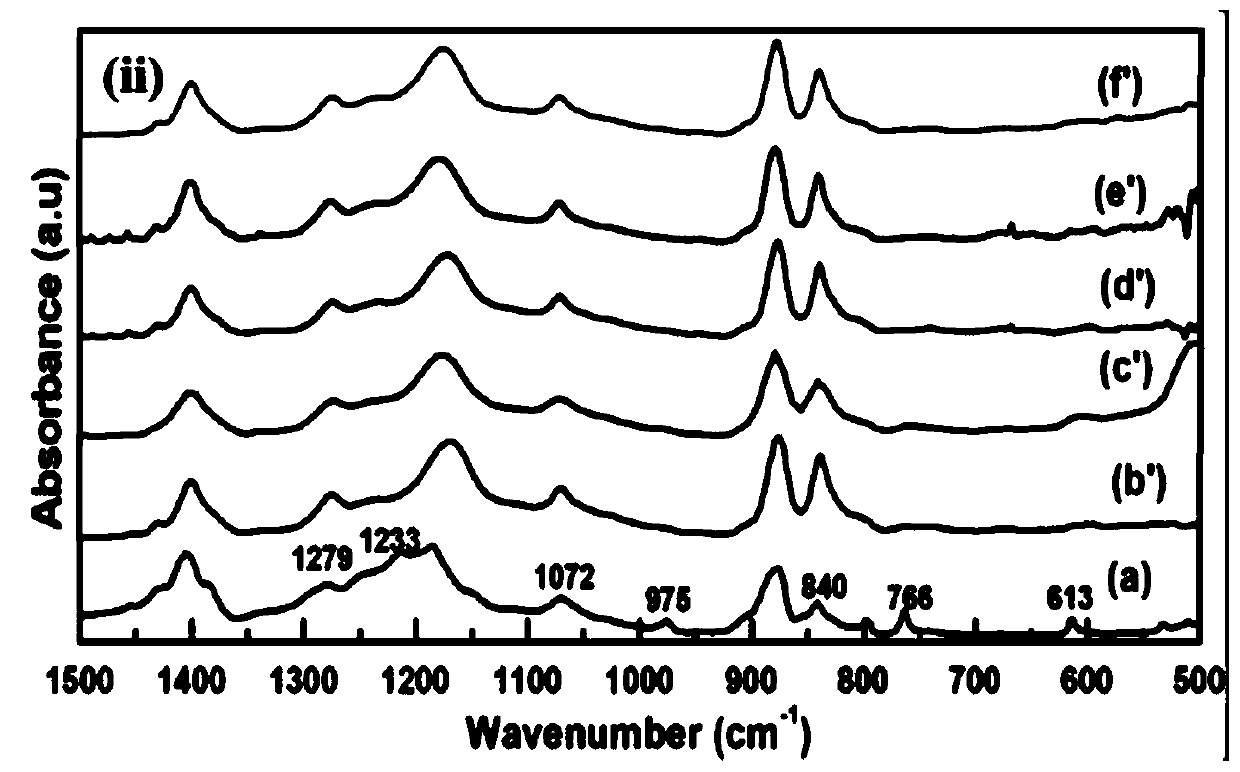

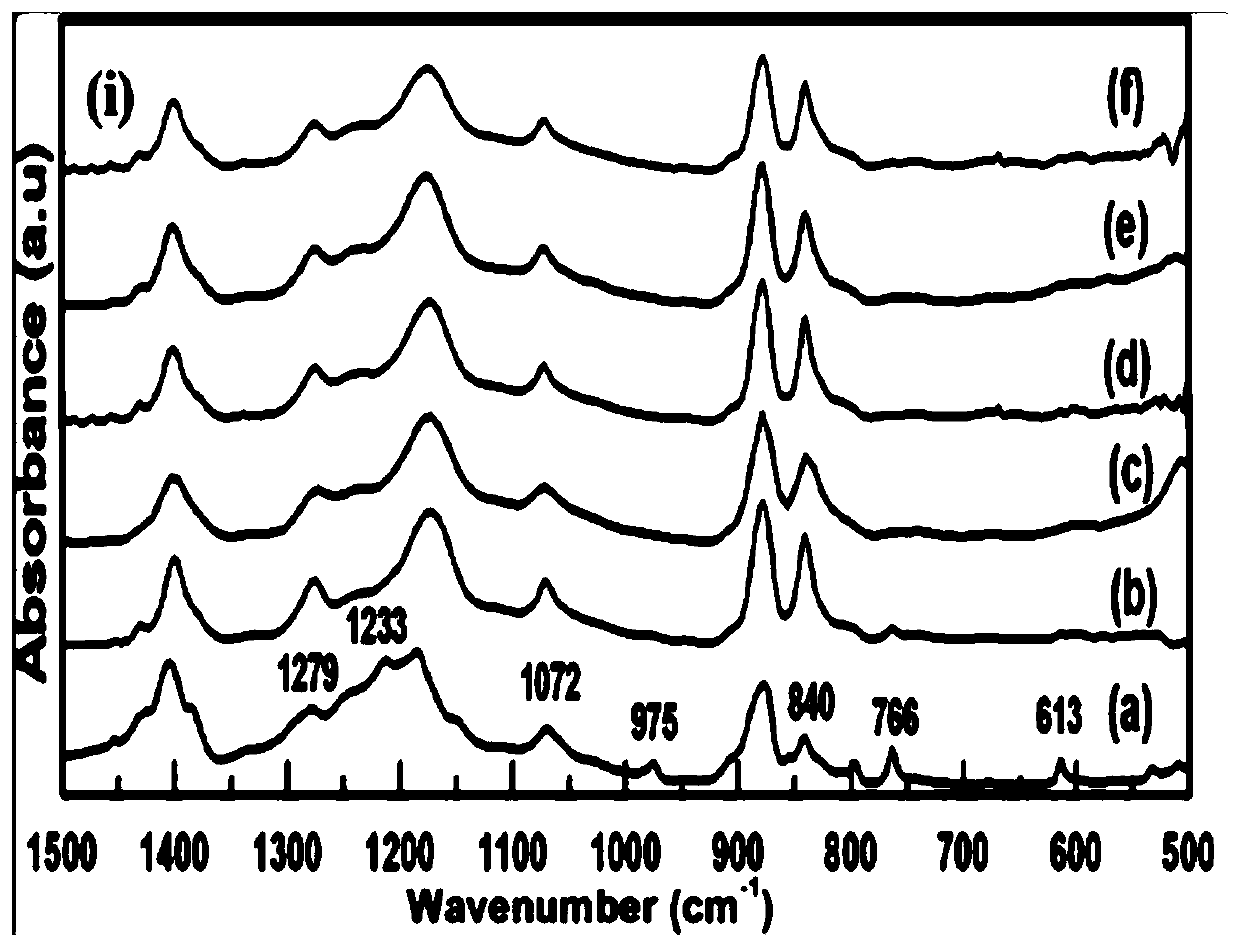

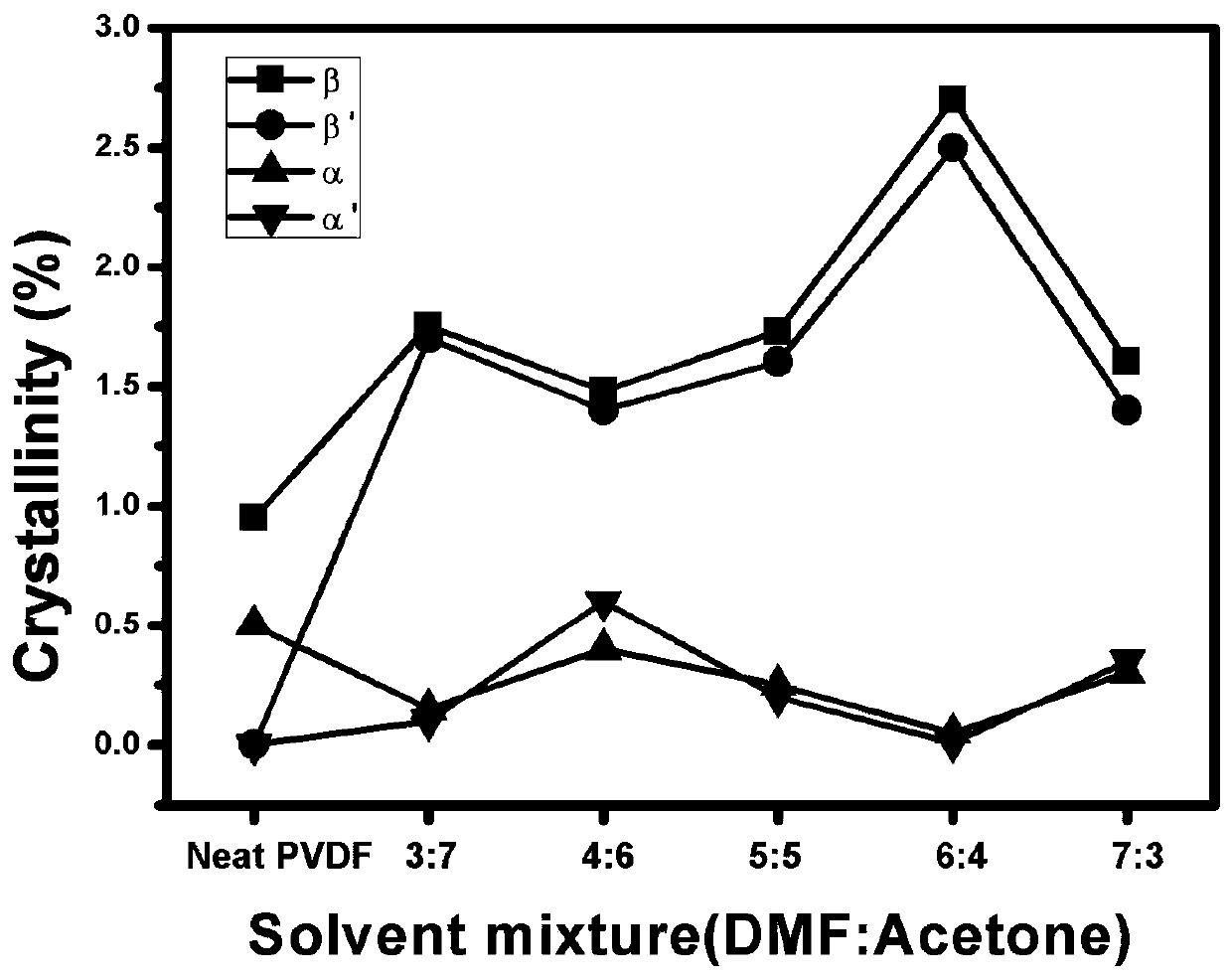

Composite piezoelectric film and preparation method and application thereof

PendingCN111063794AUniform distribution of piezoelectric effectLarge output piezo voltagePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionFiberSpinning

The invention belongs to the technical field of piezoelectric materials, and particularly relates to a composite piezoelectric film and a preparation method and application thereof. The preparation method comprises the following steps: adding inorganic piezoelectric powder into a polymer solution to obtain a precursor solution; and carrying out electrostatic spinning on the precursor solution andperforming collection in a water medium to obtain the composite piezoelectric film. The composite piezoelectric film is a porous structure fiber film and is filled with inorganic piezoelectric powder,and a polymer piezoelectric material and a rigid piezoelectric material are well compounded. Moreover, the composite piezoelectric film is a beta-phase enhanced flexible composite film, can generatea relatively large output piezoelectric voltage, has a relatively high piezoelectric constant, is uniform in piezoelectric effect distribution, and can solve the problem that an existing polymer piezoelectric film cannot be effectively combined with an inorganic piezoelectric material to form a flexible device with high piezoelectric performance. In addition, the preparation method is simple in preparation process and beneficial to large-scale production.

Owner:GUANGDONG UNIV OF TECH

A homogeneous base-catalyzed method for rapid preparation of biofuels at normal temperature and pressure

InactiveCN102296000ASave consumptionSave production energyFatty acid esterificationFatty-oils/fats refiningWater bathsPolymer science

The invention is a homogeneous alkali-catalyzed method for rapidly preparing biofuel at normal temperature and pressure. The method comprises the following steps: taking the oil raw material, and then sequentially adding a cosolvent and a short-chain alcohol solution dissolved with an alkaline catalyst, wherein the amount of the co-solvent is 10% to 100% of the mass of the oil raw material, and the molar ratio is short-chain alcohol: oil = 3 to 4.5:1, the amount of basic catalyst is 0.5 to 5% of the mass of the oil raw material, placed in a temperature-controlled reciprocating water bath shaker, at a temperature of 20 to 30 ° C, and under low-speed oscillation conditions, the transesterification reaction is carried out for 5 to 15 minutes to obtain Biofuel, biofuel yield up to 99.4%. The preparation of the biofuel by the invention does not require high temperature and high pressure, high-speed stirring and excessive short-chain alcohol to promote the reaction, and the reaction between the oil and the short-chain alcohol can be completed within 15 minutes under the homogeneous condition. Not only the amount of short-chain alcohol and production energy consumption are saved, but also the reaction time is shortened and the production efficiency is improved.

Owner:HEBEI UNIV OF TECH

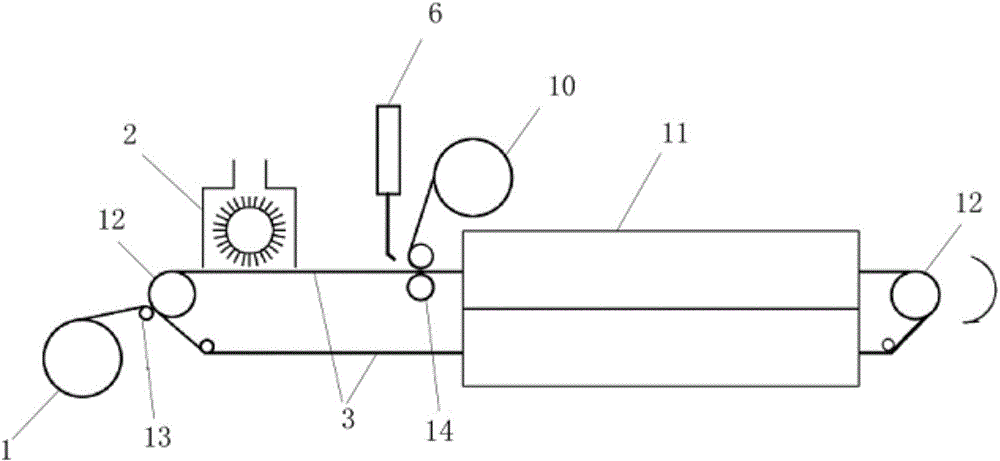

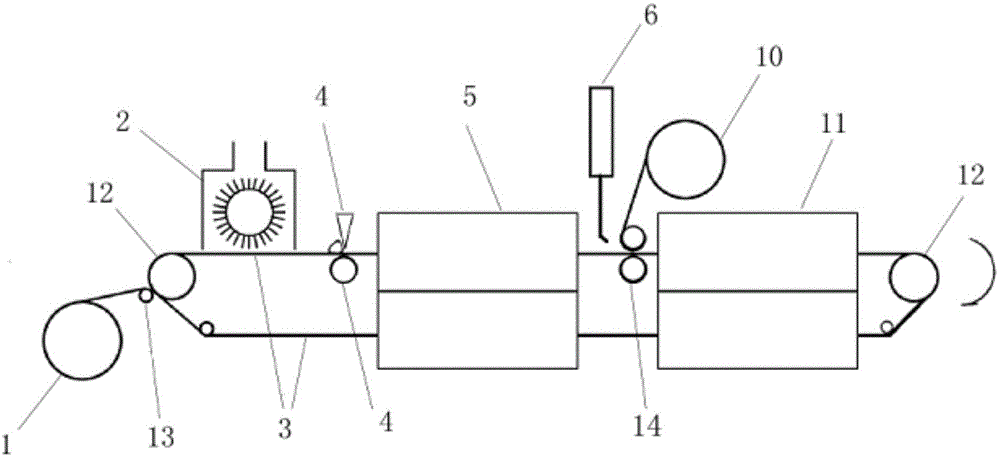

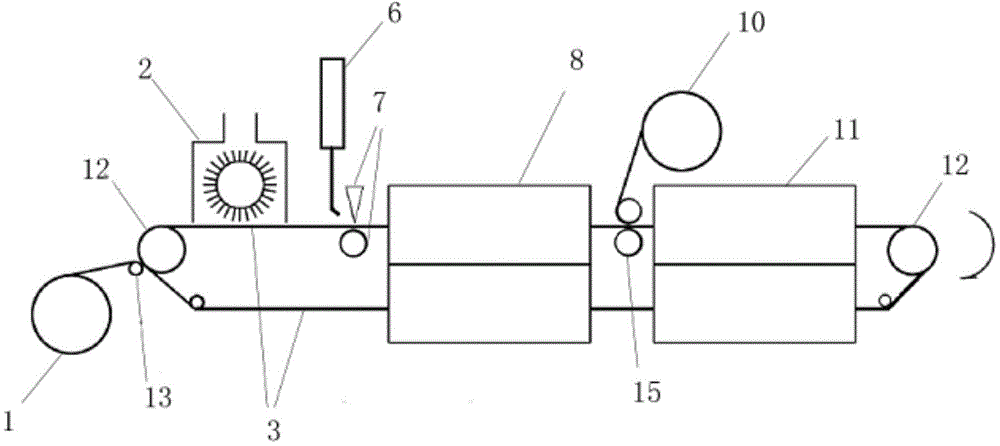

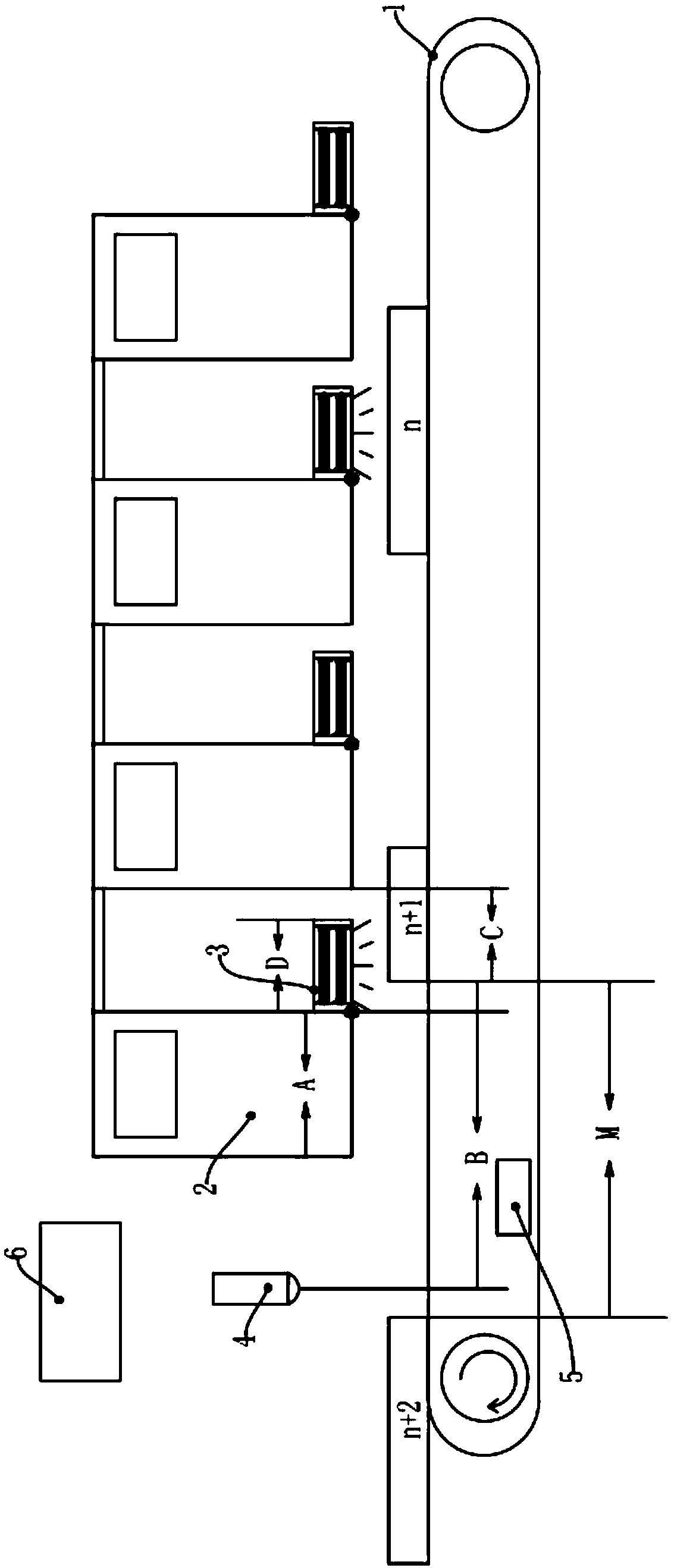

Solvent-free synthetic leather production method using rotation teflon and specially-used production line

InactiveCN104878615AAvoid pollutionEasy to operateLamination ancillary operationsLaminationProduction lineSolvent free

The invention provides a solvent-free synthetic leather production method using rotation teflon. According to the method, the teflon is used as a circulation type continuous conveying belt. The method includes the following steps that (1) the teflon conveying belt is coated with a synthetic leather raw material, so that a processing layer is obtained; (2) a base material is pressed and compounded onto the processing layer so that a composite layer can be obtained, and first-time heating curing is conducted; (3) the composite layer is stripped and coiled through the rotation of the teflon conveying belt, so that a finished synthetic leather product is obtained; (4) dust on the teflon conveying belt is cleaned in an on-line mode, and the first step is executed again or halting is carried out. The invention further provides a solvent-free synthetic leather specially-used production line using rotation teflon. According to the method, production resources are greatly saved, energy consumption is greatly reduced, environmental pollution is avoided, and the environmental protection effect is achieved; the number of operation steps can be reduced, and the production cost is lowered. The production line is simple and compact in structure and small in occupied space, an existing intermittent production mode can be replaced, and accordingly circulation continuous type synthetic leather production can be realized.

Owner:佛山市飞凌皮革化工有限公司

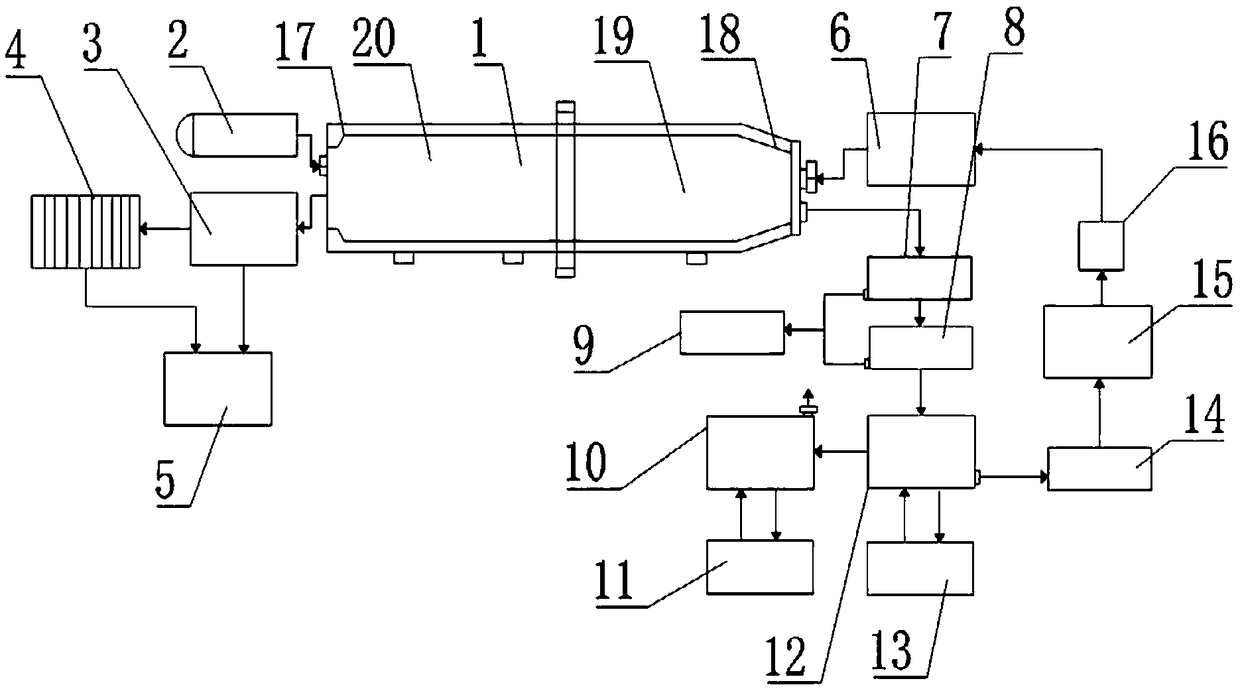

UV curing machine and control method thereof

The invention provides a UV curing machine. The UV curing machine comprises a conveying belt, a plurality of hanging cages, a plurality of UV lamps, an electric eye, a bottom belt servo driver and a PLC; the plurality of hanging cages are arranged above the conveying belt at equal intervals; each UV lamp is arranged between every two corresponding hanging cages, and one ends of the UV lamps are connected to the hanging cages; the electric eye is arranged on the left sides of the hanging cages, and the electric eye is electrically connected with the PLC; and the bottom belt servo driver is arranged on the conveying belt, and the bottom belt servo driver is electrically connected with the PLC. According to the UV curing machine, the starting and stopping time of the UV lamps can be controlled according to the width of printed materials, and the opening time of the UV lamps can be adjusted according to the distance between every two adjacent printed materials.

Owner:HOPE CERAMICS MACHINERY

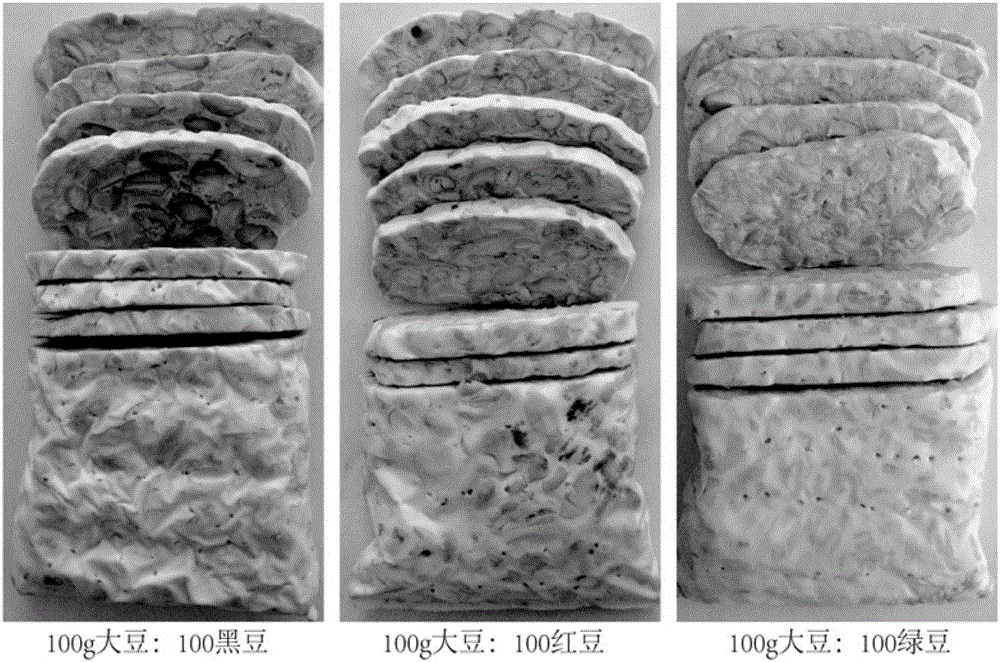

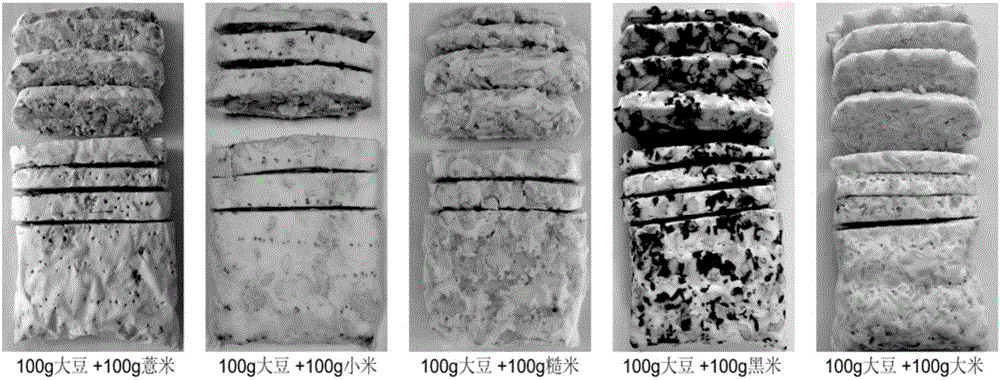

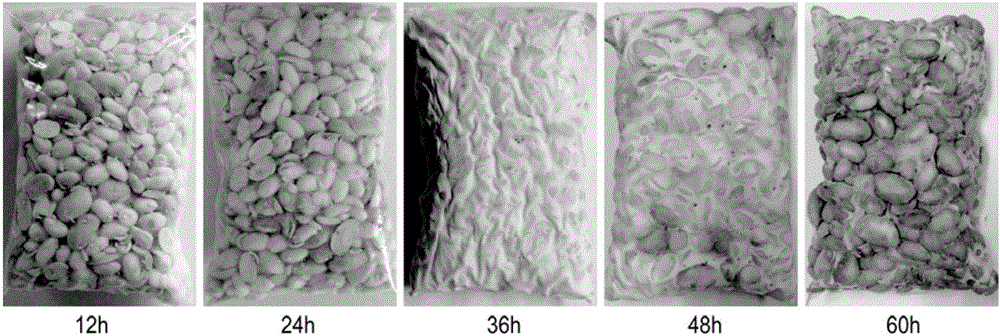

Cereal tempeh product and production method thereof

The invention provides a method for taking cereals as raw materials for producing tempeh. A new high-activity bacterial strain is taken as zymophyte; the techniques of fermentation time, raw material ratio and categories are optimized; the tempeh made from cereals can be prepared into high-quality products; white hypha are uniformly distributed on the surface; the elasticity is high; the cross section is smooth; the hypha are obvious; the tempeh is tasty, has the fermented sauce flavor and is free from ammonia flavor; the tempeh product can be freshly taken, mixed coldly, cooked as assistant sauce or used for preparing snack food and extracting functional components.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

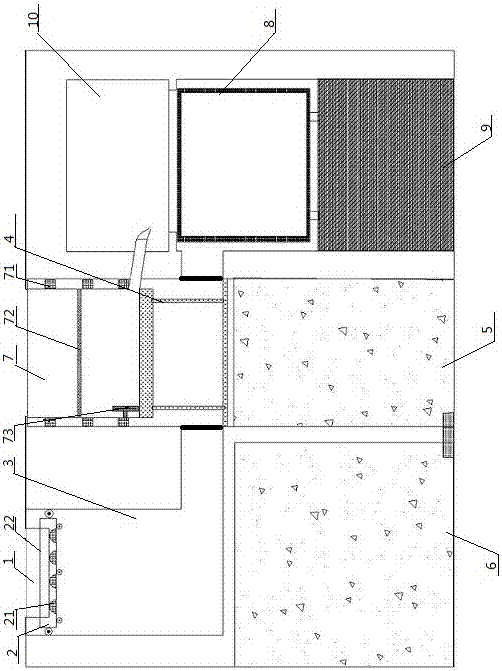

Production methods of fire-fighting monoammonium phosphate and ABC dry powder extinguishing agent

ActiveCN111115596AImprove liquidityHigh bulk densityPhosphatesFire extinguisherO-Phosphoric AcidPhosphate

The invention provides a production method of fire-fighting monoammonium phosphate. The production method comprises the following steps: step a, mixing wet-process phosphoric acid with a sulfur-containing compound; b, adding liquid ammonia into the mixture obtained in the step a for neutralization to obtain slurry; and c, atomizing and drying the slurry obtained in the step b to obtain the fire-fighting monoammonium phosphate. The invention further provides a production method of an ABC dry powder extinguishing agent. The method disclosed by the invention has the advantages of low requirementson production equipment, process technology and auxiliary materials and the like, and the fire-fighting monoammonium phosphate and the ABC dry powder extinguishing prepared by the method disclosed bythe invention have the characteristics of good fluidity, high bulk density and low water absorption rate.

Owner:GUIZHOU CHANHEN CHEM CO LTD

Fruit ferment black tea and making equipment thereof

ActiveCN107494816AMaintain biological activityQuality assurancePre-extraction tea treatmentFreeze-dryingBlack tea

The invention provides fruit ferment black tea, and belongs to the technical field of tea making. A fruit ferment stock solution is processed through a freeze-drying technology so that fruit ferment powder which can be stably stored at normal temperature is obtained, besides, the biological activity of the fruit ferment is guaranteed, and then the fruit ferment powder and tea leaf powder are mixed according to a certain proportion so that the fruit ferment black tea which can be stored at normal temperature is obtained. The invention further provides making equipment of the fruit ferment black tea based on a liquid nitrogen freezing technology, and the making equipment is used for cooperating production of the fruit ferment black tea which is long in storage life and has health-care health-preservation effects.

Owner:清远市何公桥茶叶有限公司

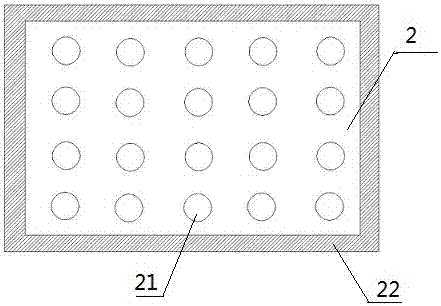

Zinc calcine production and fume treating system and method

PendingCN109266845AAccurate processingReduce resource gapsHuman health protectionCombination devicesComing outSludge

The invention discloses a zinc calcine production and fume treating system. The system comprises a zinc calcine production unit and a fume treating unit, wherein the zinc calcine production unit comprises a rotary kiln, the tail of the rotary kiln is provided with a feeding port and a fume outlet, wherein the feeding port is provided with a feeding device, the fume outlet is connected with the fume treating unit, the fume treating unit comprises a settling chamber and a water purification spray tower which are sequentially connected, the water purification spray tower is provided with a gas discharging port and a liquid discharging port, wherein the gas discharging port is connected with an alkali liquor spray tower through a pipeline, fume discharged from the fume discharging port is discharged after being treated by the alkali liquor spray tower, the liquid discharging port is sequentially connected with a stirring pond and a sedimentation pond, zinc precipitation reaction is conducted on liquid coming out from the liquid discharging port in the stirring pond, the liquid enters the sedimentation pond to be precipitated, precipitated sludge is pressed and filtered by a pressing filtering machine and delivered to a feeding machine to be taken as the raw material and recycled. The system has the advantages of reasonable structural design and massive production, and environmentalpollution is reduced while a zinc smelting raw material of zinc calcine with stable quality and high zinc containing rate is provided.

Owner:桂阳银龙科技有限责任公司

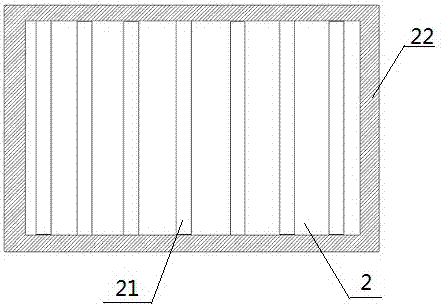

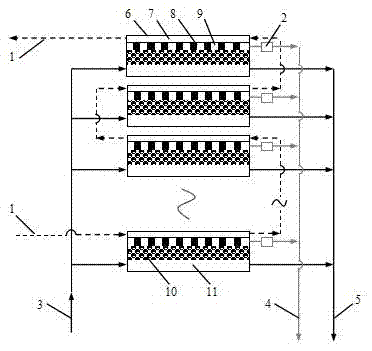

Sea water desalination treatment system

InactiveCN105439229AImprove efficiencySave production energyGeneral water supply conservationSeawater treatmentSeawaterPorous medium

The invention relates to a sea water desalination treatment system. The sea water desalination treatment system comprises a plurality of sea water desalination devices. Each sea water desalination device comprises a heat exchange flow channel, a steam channel, porous media and a sea water flow channel. The sea water flow channel is located at the bottom of the sea water desalination device. One end of the sea water flow channel is connected with a sea water inflow pipeline, and the other end of the sea water flow channel is connected with a sea water outflow pipeline. The porous media are located at the position above the sea water flow channel. The heat exchange flow channel is located at the position of the top of the sea water desalination device. The steam channel is located at the position below the heat exchange flow channel. The steam channel is internally provided with a plurality of heat conduction fins. The heat exchange flow channels of the sea water desalination devices are connected through high temperature heat source pipelines. Outlets of the steam channels of the sea water desalination devices are connected with fresh water pipelines. The end of each fresh water pipeline connected with each steam channel is provided with a condenser. The sea water desalination devices are utilized to perform sea water desalination, the sea water desalination efficiency can be improved greatly, the same heat source pipeline can be used for many times, and the production energy is saved.

Owner:RUNHAI ENERGY TECH INC JIANGSU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com