Automatic lifting device for flue damper of kiln

A technology of flue shutter and electric device, applied in valve device, exhaust gas device, valve operation/release device, etc., can solve the problem that the furnace wall and related accessories are easily burnt out, the heating time is prolonged, and it is difficult to guarantee the furnace Pressure and other problems, to achieve the effect of simple structure, prolong service life and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

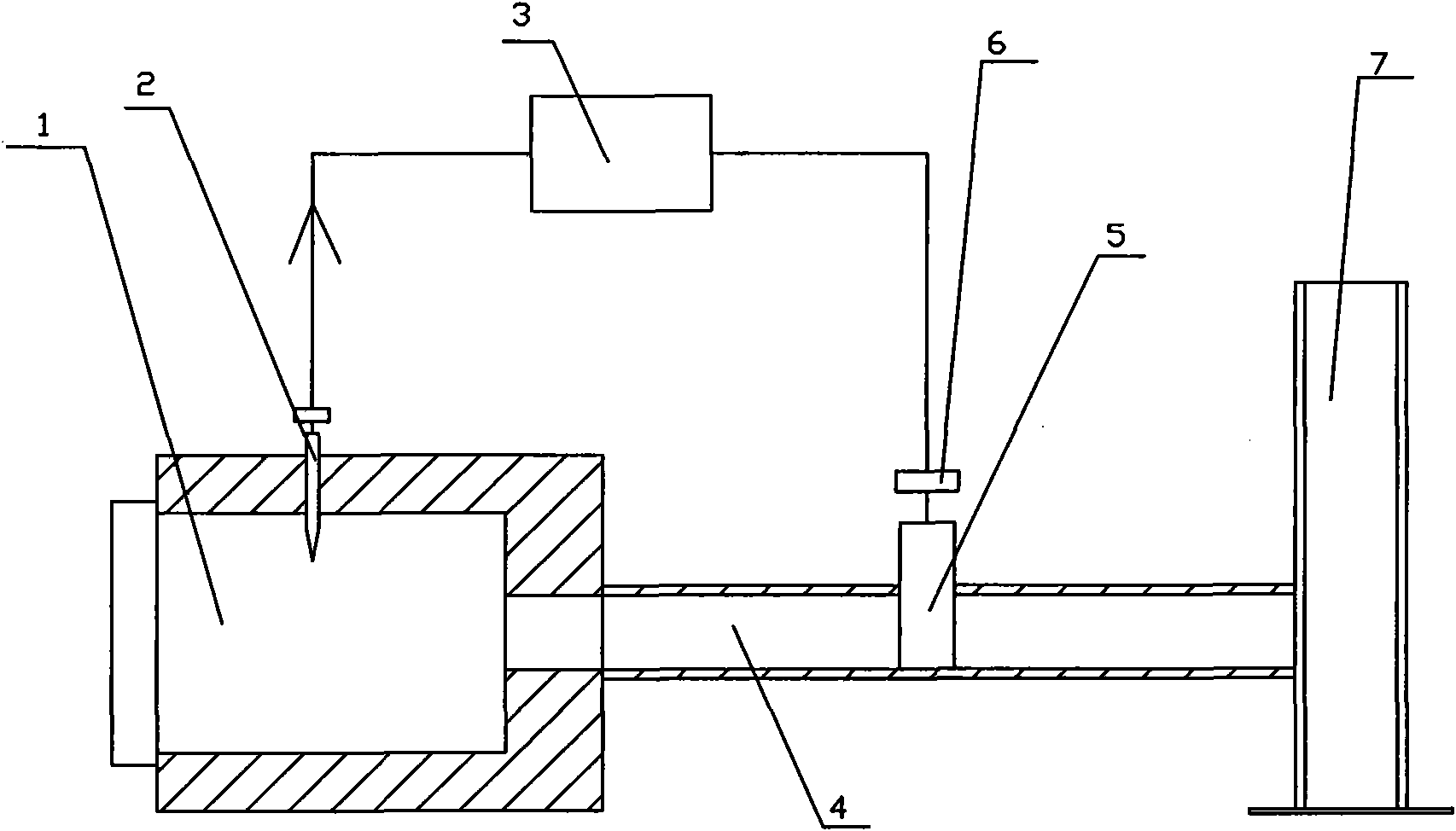

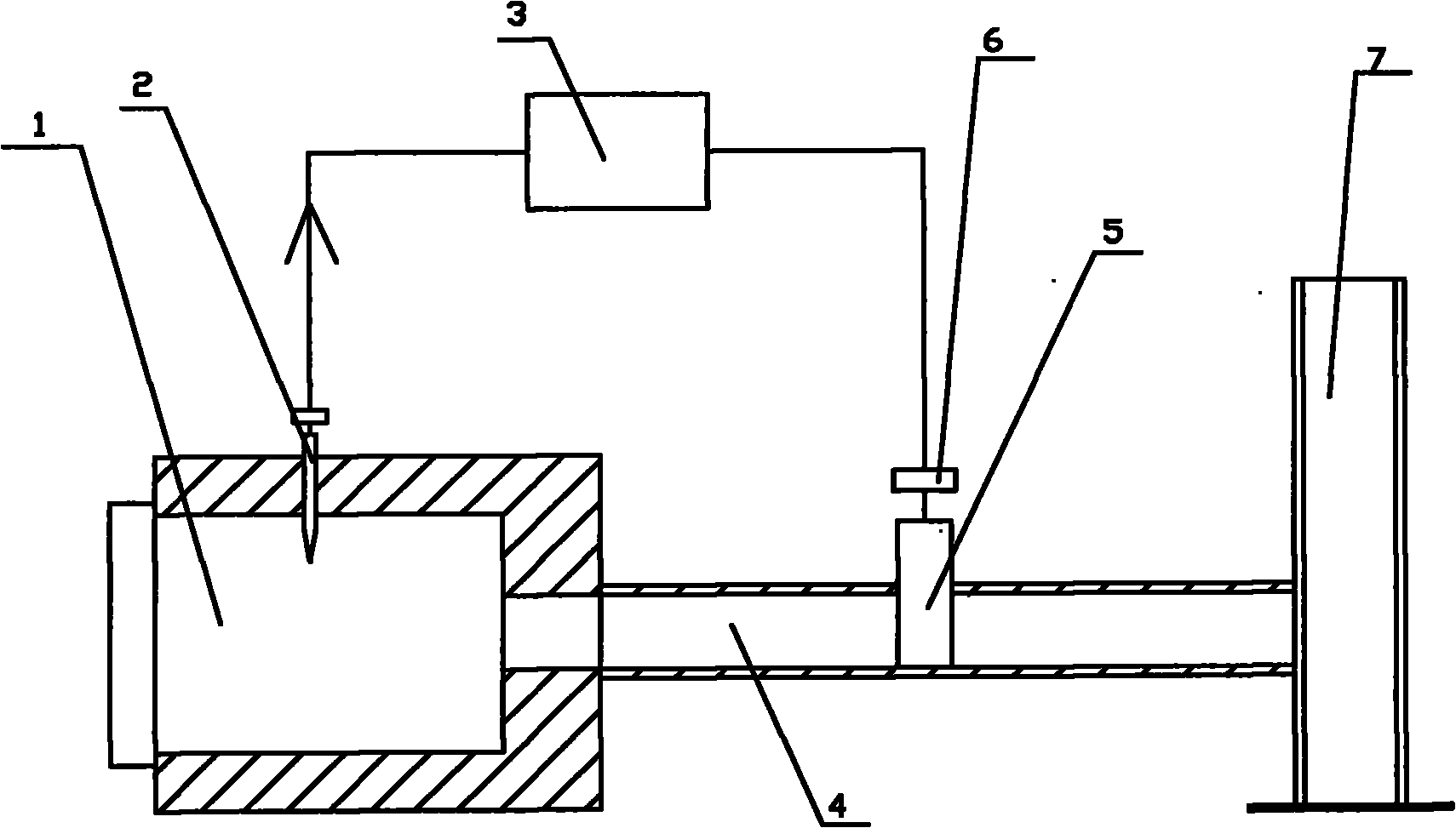

[0008] A kiln flue gate automatic lifting device, the kiln 1 communicates with the chimney 7 through the flue 4, the flue 4 is provided with a gate 5, the device includes a pressure device 2, an electric device 6, the The pressure device 2 is arranged in the hearth of the kiln 1, and the PLC control device 3 is provided between the pressure device 2 and the electric device 6, and the electric device 6 is connected with the gate plate 5. When the pressure in the hearth of kiln 1 is not within the optimum working pressure range, the pressure device 2 sends a signal to the PLC control device 3, and the PLC control device 3 starts the electric device 6 to open the gate 5, thereby controlling the pressure in the furnace to return to the maximum Good working pressure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com