Patents

Literature

102 results about "Vacuum sublimation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

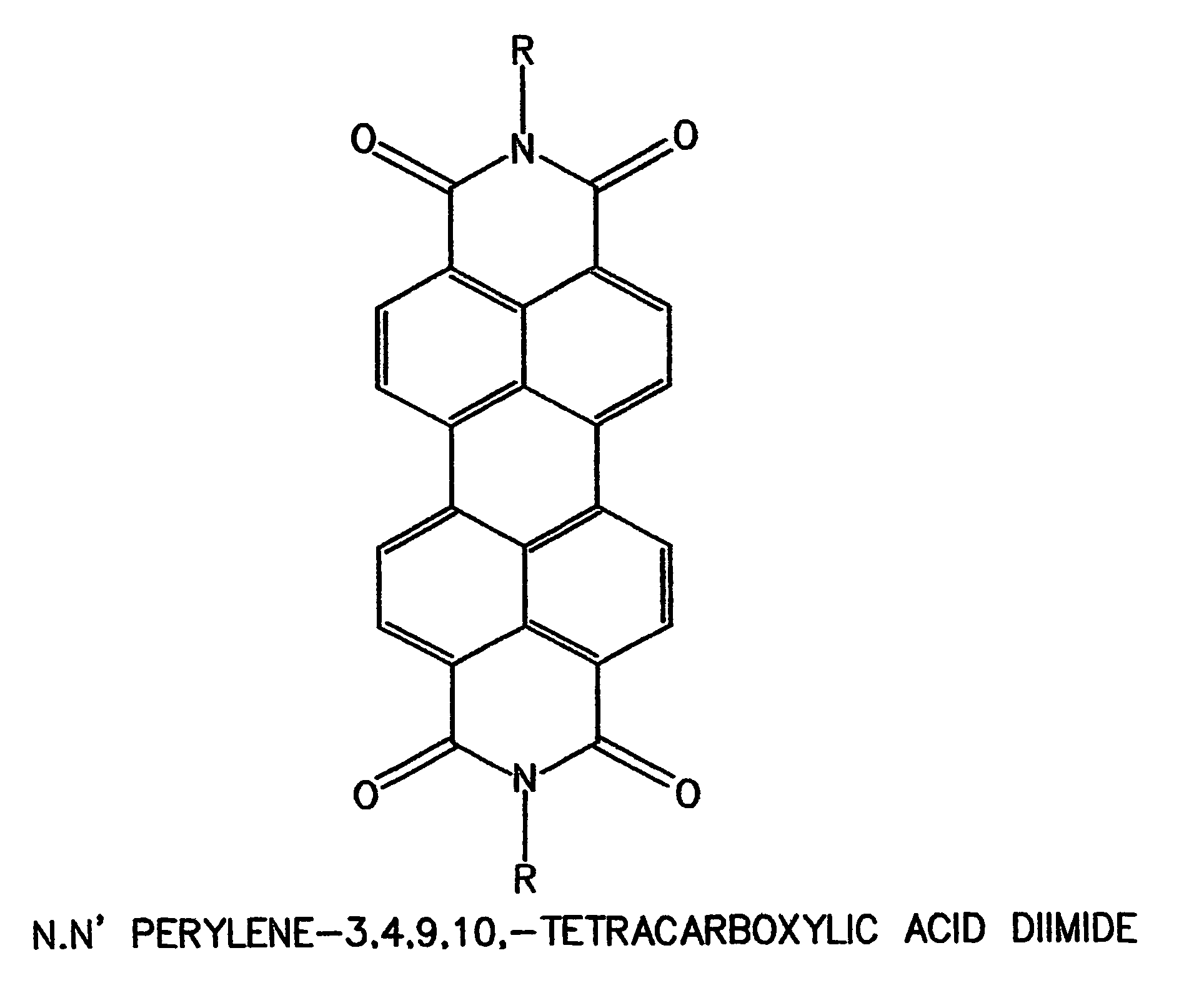

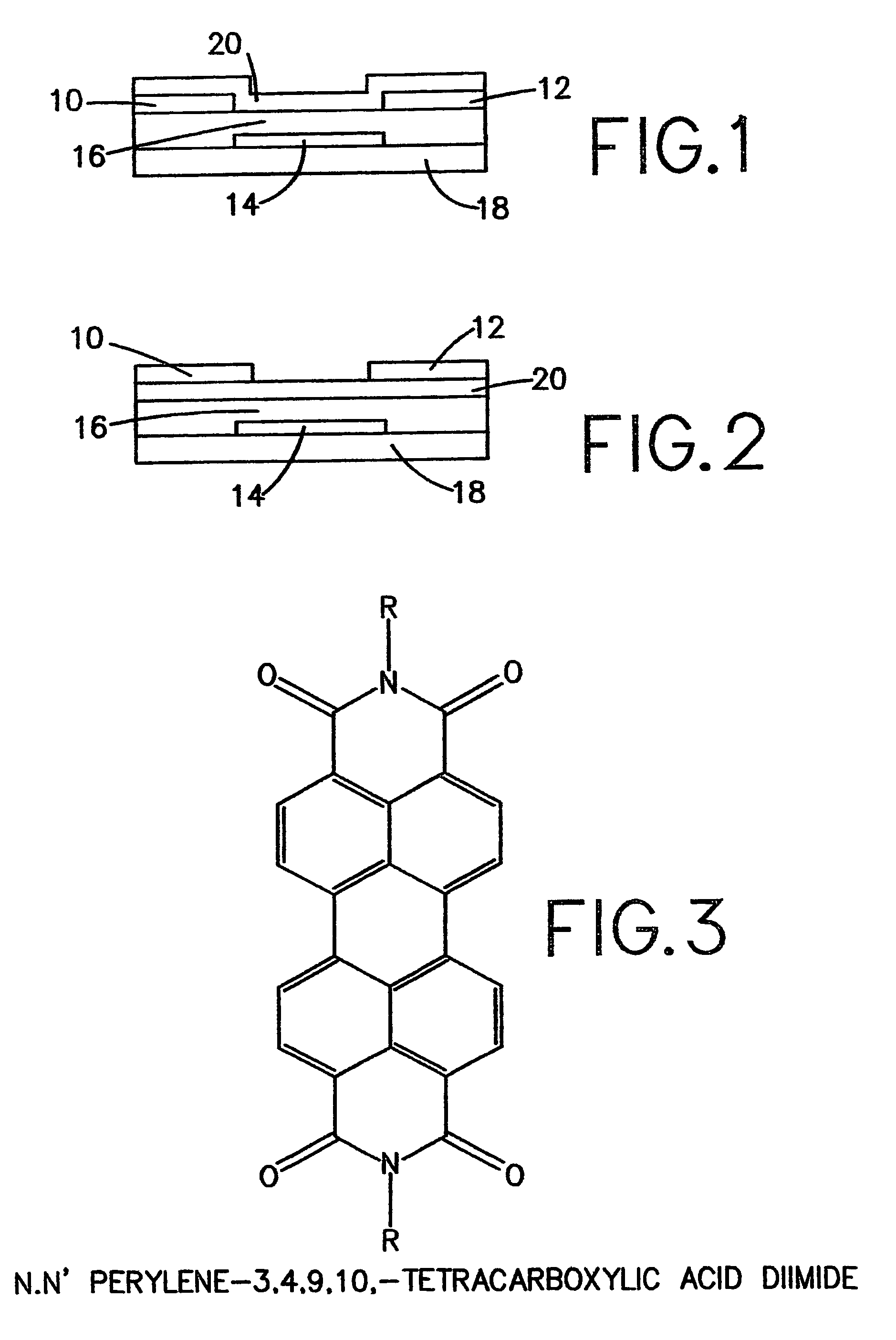

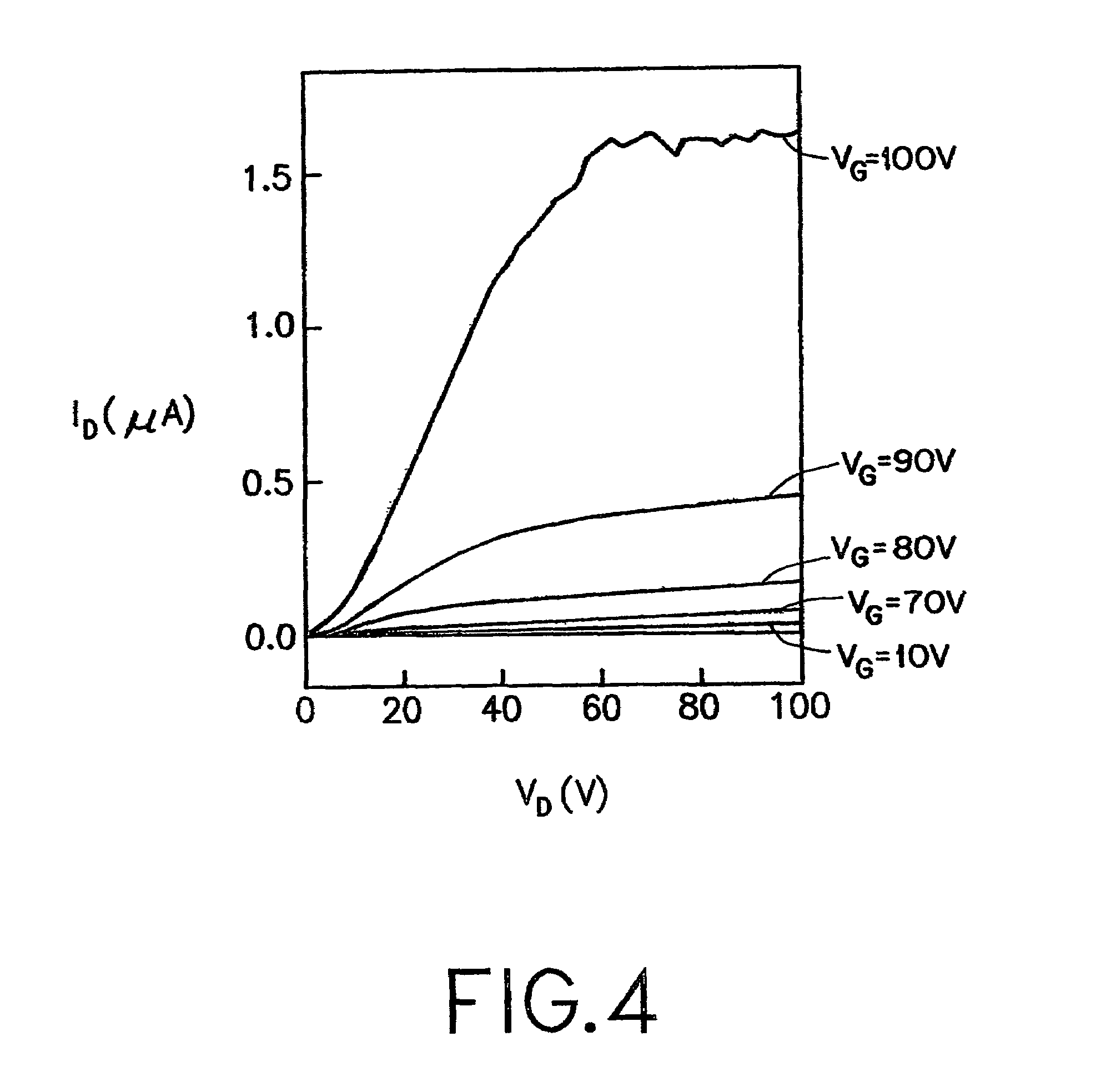

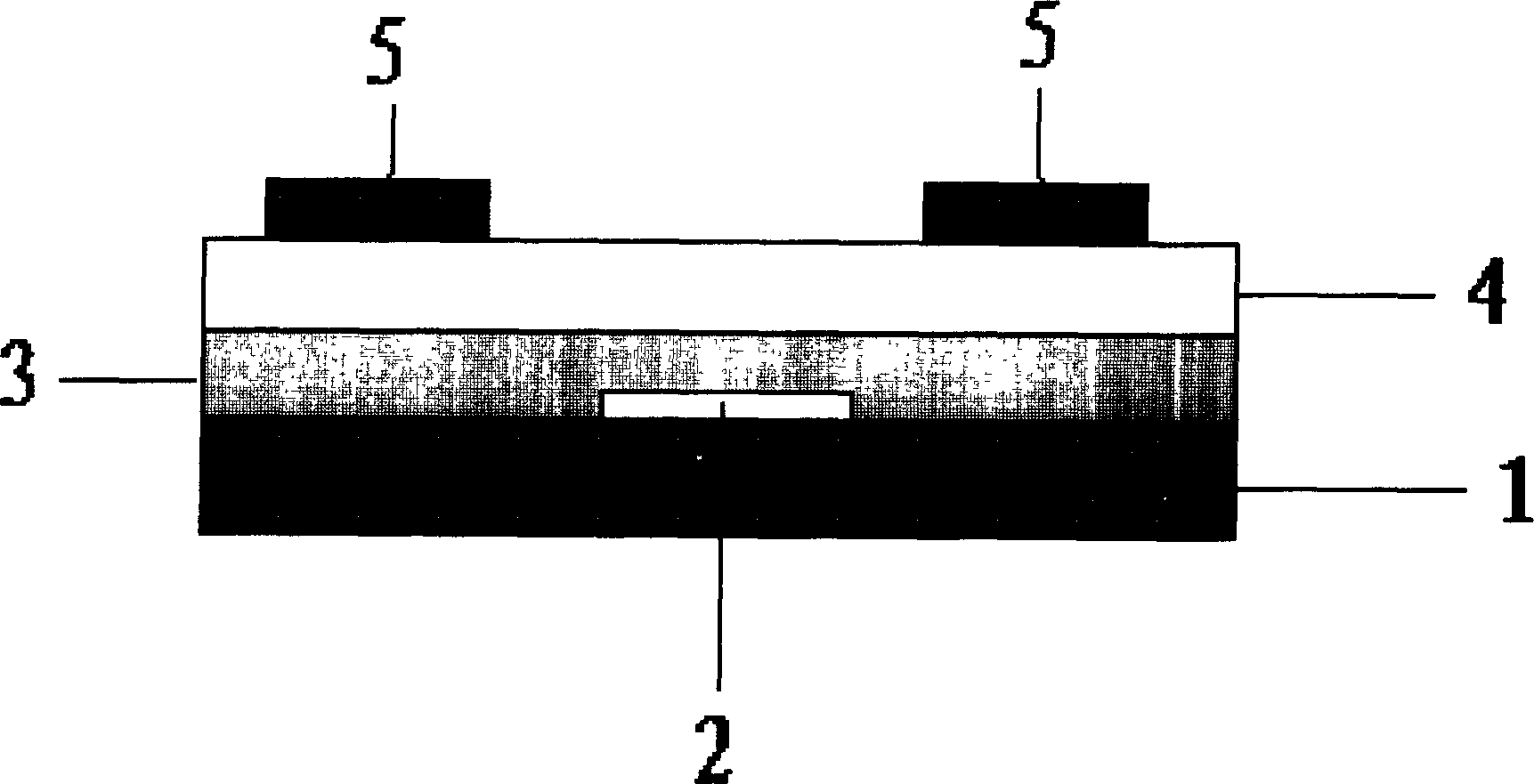

Organic n-channel semiconductor device of N,N' 3,4,9,10 perylene tetracarboxylic diimide

InactiveUS7026643B2Solid-state devicesSemiconductor/solid-state device manufacturingPeryleneVacuum sublimation

The invention provides a device comprising an improved n-channel semiconducting film. This film consists of a perylene tetracaboxylic acid diimide compound and was deposited onto substrates by vacuum sublimation. Thin film transistor devices comprising such films as the semiconducting channel exhibit a field effect electron mobility greater than 0.01 cm2 / Vs and an on / off ratio of 10000 and higher.

Owner:GLOBALFOUNDRIES US INC

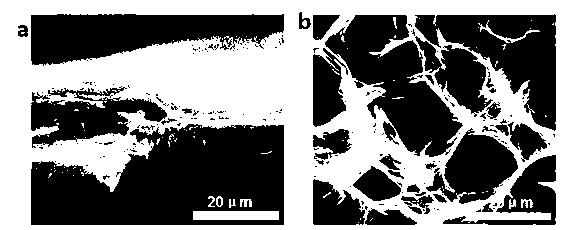

Manufacturing method of graphene foam

ActiveCN103213978ANo generationEasy control of mechanical propertiesGrapheneGraphene flakeEngineering

The invention provides a manufacturing method of graphene foam. The manufacturing method comprises the following steps of: 1) reducing an aqueous dispersion of graphene oxide through a hydrothermal method, and performing self-assembly on graphene sheets to obtain a graphene wet gel block body; 2) freezing the graphene wet gel block body obtained in the step 1) on a metal tray, wherein the metal tray has preset freezing temperature which is controlled within a range of -196 DEG C to -10 DEG C, and the graphene wet gel block body after freezing is completely crystallized to form a gel crystalline solid; and 3) performing vacuum sublimation and drying on the gel crystalline solid obtained in the step 2). The manufacturing method has the advantages of simple process and capability of regulating and controlling a hole structure of the graphene foam, thus the graphene foam has different properties.

Owner:SOUTHEAST UNIV

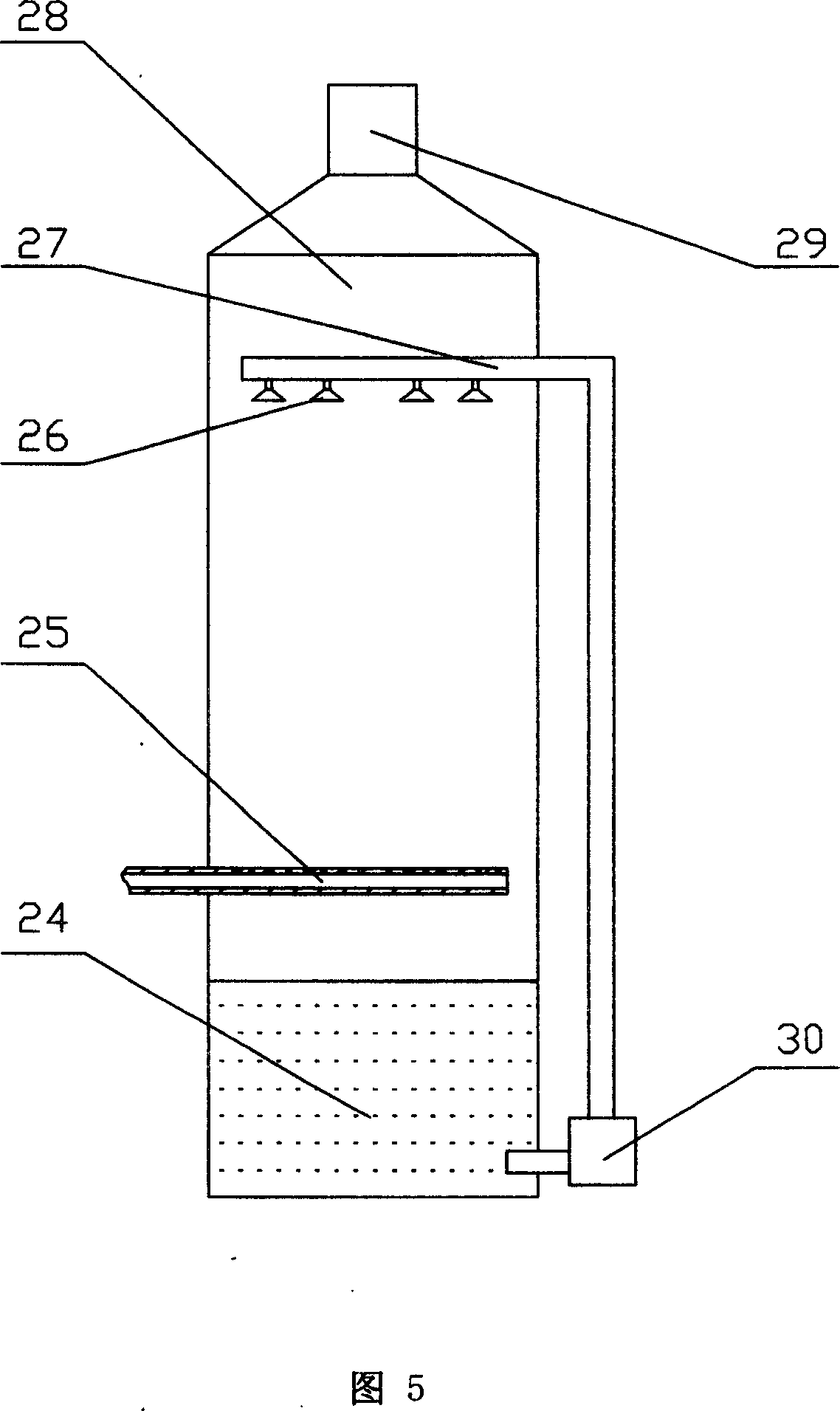

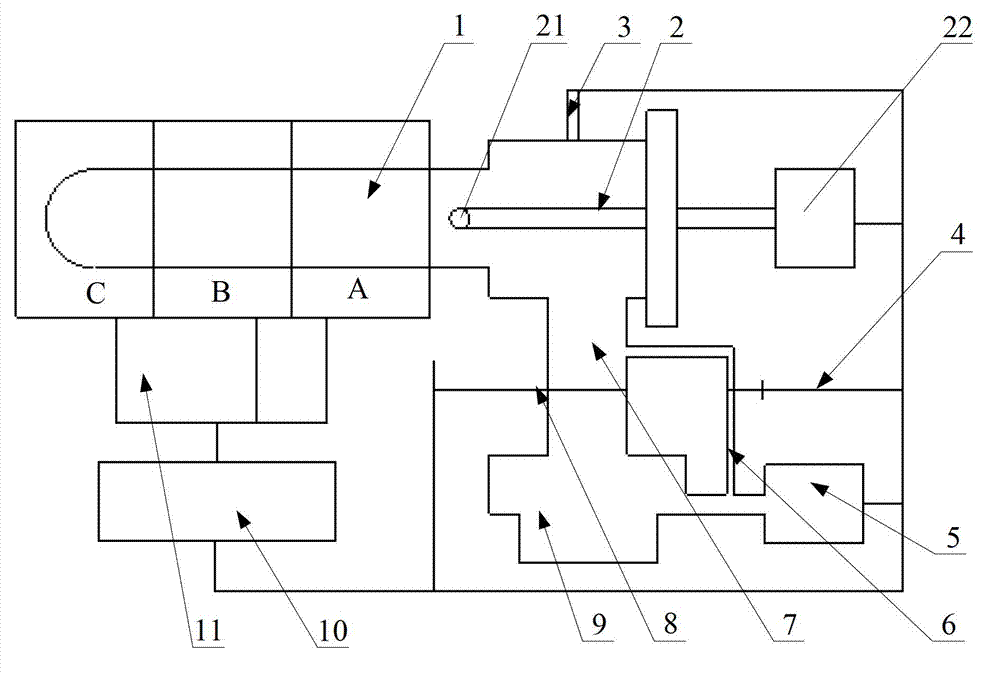

Production method for high-purity arsenic and its equipment

The invention discloses a manufacturing method and specific equipment of semiconductor basic material hyperhigh-purity alpha-typed arsenic with purify at 99.99999% through once vacuum sublimation and twice hydrogen sublimations, which consists of vacuum sublimator and hydrogen sublimator, wherein the vacuum sublimator contains heater A, heater B, vacuum tank, water jacket, copple, obstruct board, conical titanium condenser, low-boiling collecting board and vacuum pump; the hydrogen sublimator includes hydrogen input device, argon input device, casing, quartz tube A, quartz tube B, quartz tube C, heater, scrubbing device and spray device.

Owner:杨华民

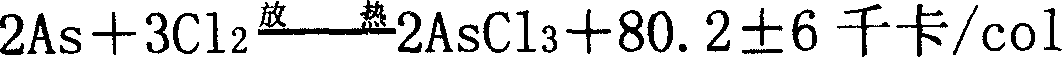

Industrialized producing method for high-purity arsenic

ActiveCN101144125AIncrease productionIncrease production capacityProcess efficiency improvementArsenic compoundsHydrogenVacuum sublimation

The industrialized production method for preparing simple substance and high purity arsenic disclosed by the present invention relates to a method for industrialized arsenic production, in particular to a high purity (the purity is above 99.9999 percent) continuous industrialized production method. The concrete method is realized by: first, using industrial arsenic with the purity of 99 percent the raw material, to be sublimated; second, performing chlorination reaction and synthetizing AsCl 3 ; third, distilling; fourth, dechlorinating; fifth, performing fractional dictillation through a first tower, a second tower, and a third tower; sixth, performing hydrogen reduction to obtain the end product, and packing in a non-oxygen condition. The present invention has the advantages that the vacuum sublimation is adopted, the purity of the raw material can reach 99.99 percent from 99 percent of the industrial arsenic through once sublimation, and the production capacity can be improved; the dechlorinating and the distilling processes of the present invention can eliminate various impurities with only one step, can reduce the waste material, and improve the yield rate. The other remarkable advantage of the present invention is continuous production, thereby overcoming the severe abuses of heavy pollution, unstable quality, etc.

Owner:昆明鸿世达高技术材料有限责任公司

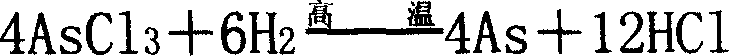

Fresh-preserving and storage technology of cordyceps sinensis

The invention discloses a fresh-preserving and storage technology of cordyceps sinensis. The technology includes following steps: (1) selecting fresh cordyceps sinensis; (2) cleaning the cordyceps sinensis through an ultrasound cleaning machine; (3) performing water-retention shaping; (4) homogenizing and classifying the raw material; (5) decreasing the temperature in a freezing tank to -45 - -50 DEG C, and pre-freezing the homogenized cordyceps sinensis in the freezing tank for 3 hours; (6) performing vacuum sublimation drying at -30 - -40 DEG C with the pressure in a freezing chamber being 28-10 Pa, the temperature of a heating disk being controlled to be not higher than 18 DEG C, the thickness of the material being not more than 10mm and a drying time being 10-15 hours; and performing desorption drying with the temperature being 20-25 DEG C, the pressure in the freezing chamber being 30-10 Pa and a time being at least 2 hours; (7) performing sterilization with the concentration of ozone being more than 120 ppm and a sterilization being 60 min; and (8) feeding the cordyceps sinensis in a special glass bottle with nitrogen filled to packaging the cordyceps sinensis. The technology is sanitary and safe. The cordyceps sinensis is convenient to carry, is good in reconstitution property and is suitable for long-period storage in normal situation.

Owner:齐生伟

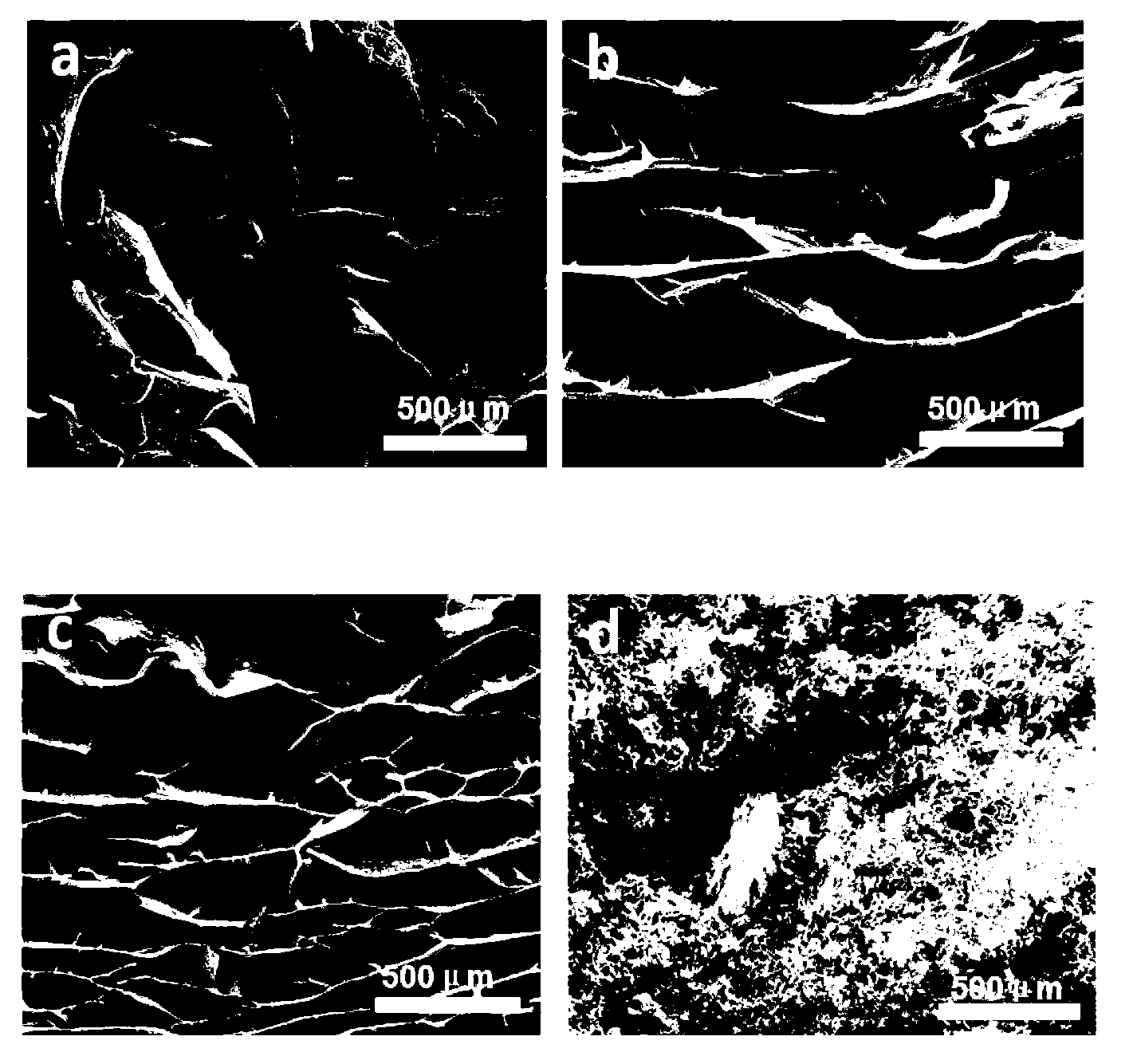

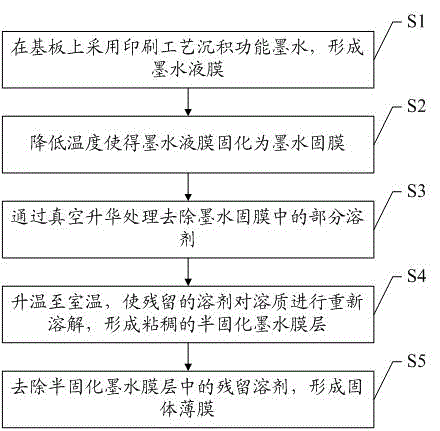

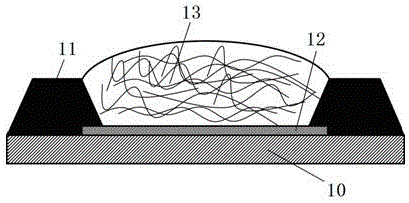

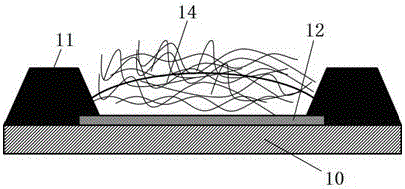

Method for inhibiting formation of coffee ring in printing process and solid thin film

The invention discloses a method for inhibiting formation of a coffee ring in the printing process and a solid thin film. The method comprises the following steps: A, depositing a functional ink on a substrate by use of a printing technology to form an ink liquid film; B, reducing the temperature to enable the ink liquid film to be cured into an ink solid film; C, removing part of a solvent in the ink solid film through vacuum sublimation treatment; D, raising the temperature to room temperature, and enabling the residual solvent to redissolve solute so as to form a thick semi-cured ink film layer; and E, removing the residual solvent in the semi-cured ink film layer to form a solid thin film. After the liquid film is deposited by ink jet printing, the sublimation process is combined with the heating or vacuum process to remove the solvent, so that formation of the 'coffee ring' in the printing process is inhibited, meanwhile, an even and compact film layer structure is formed, follow-up progressing of the printing process is facilitated, the quality of the film layer prepared by the printing process is improved, and the performance of display devices is also improved finally.

Owner:深圳市TCL高新技术开发有限公司

Method for making a nanoporous granular material and a detergent composition

InactiveUS6627597B1Inorganic/elemental detergent compounding agentsOrganic detergent compounding agentsSolubilityControlled release

A process for producing a starting material in a granular form and in a nanoporous anhydrous state, a process for improving the water-solubility and controlled release characteristics of a detergent material, and a detergent composition are disclosed. In one aspect, a process for producing a starting material in a granular form and in a nanoporous anhydrous state includes obtaining a starting material in a form of a dispersion or solution in a sublimable solvent or mixtures of sublimable solvents, forming graded droplets by atomization, freezing the graded droplets in a freezing medium at a controlled freezing rate of a least 100° C. per second to form frozen droplets and drying the frozen droplets by vacuum sublimation to obtain freeze-dried granules of the starting material in a nanoporous anhydrous state. The starting material in dispersion or solution form has a viscosity suitable for atomization and formation of graded droplets.

Owner:THE PROCTER & GAMBLE COMPANY

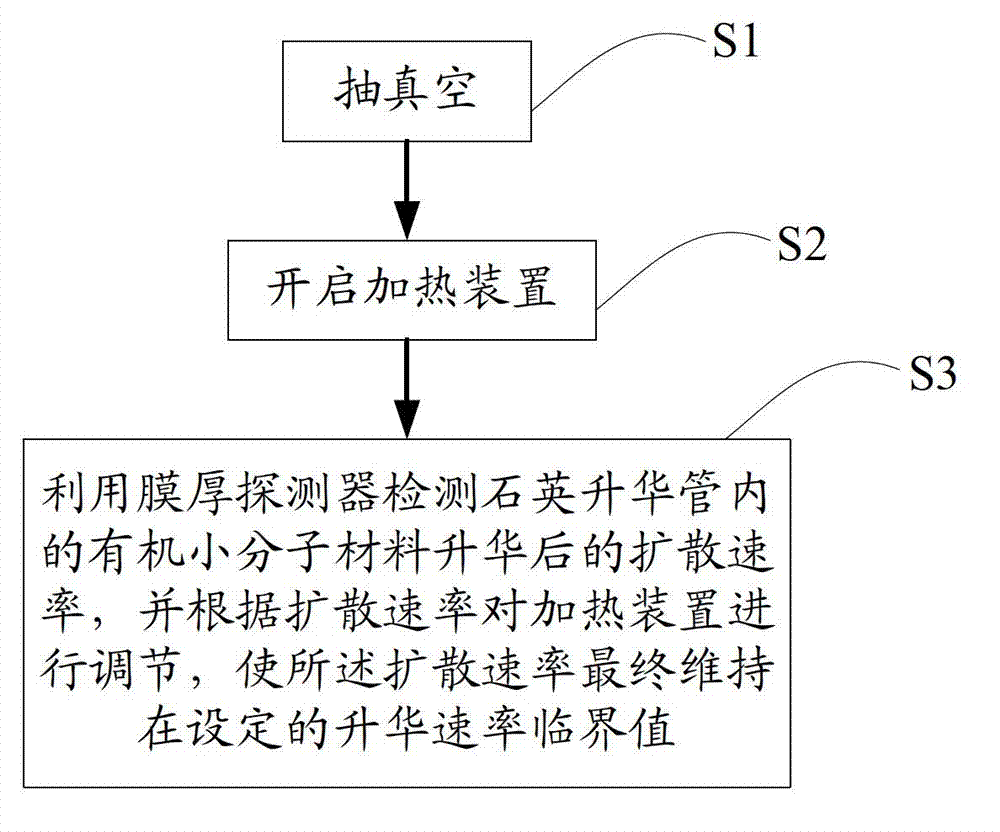

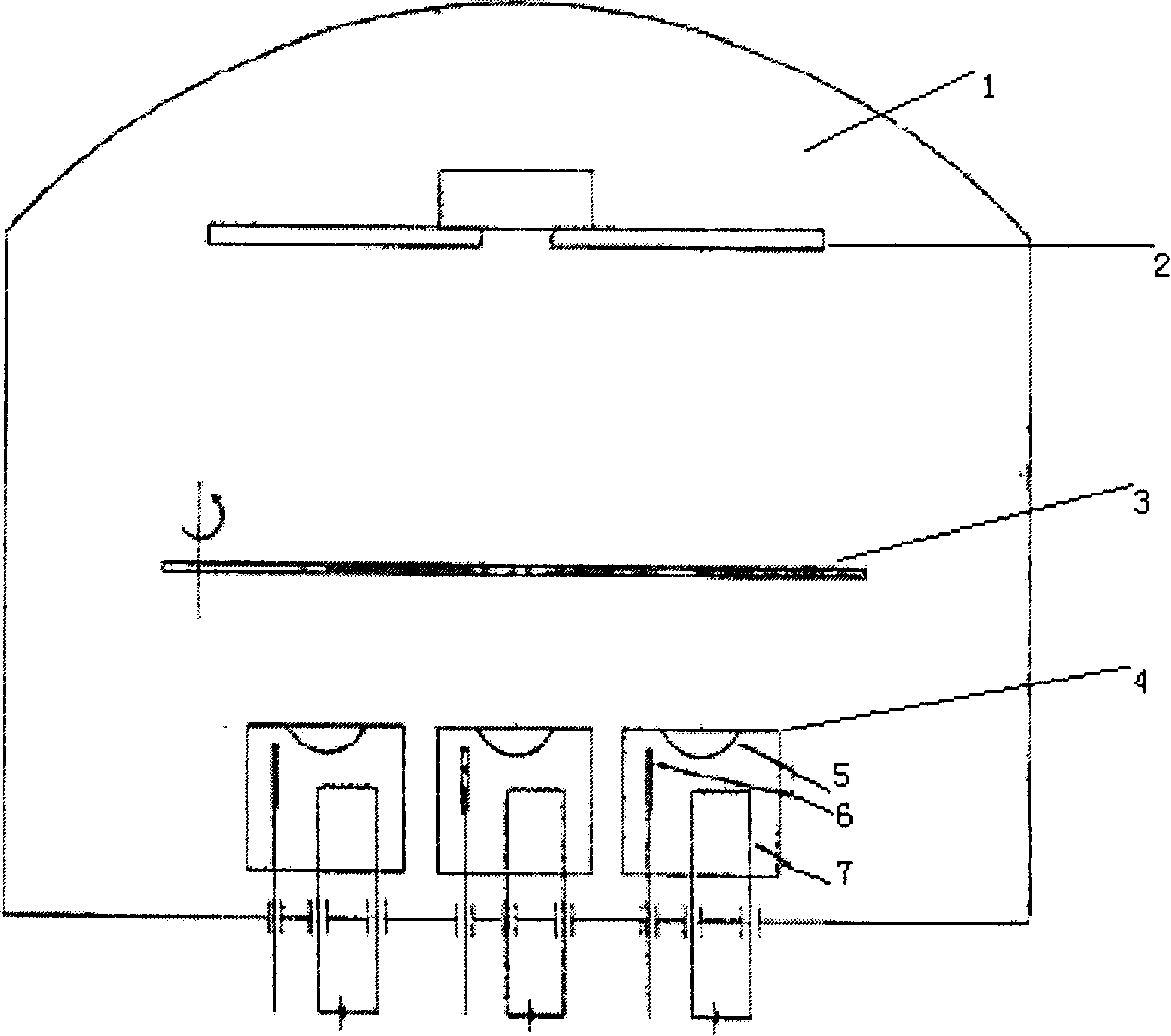

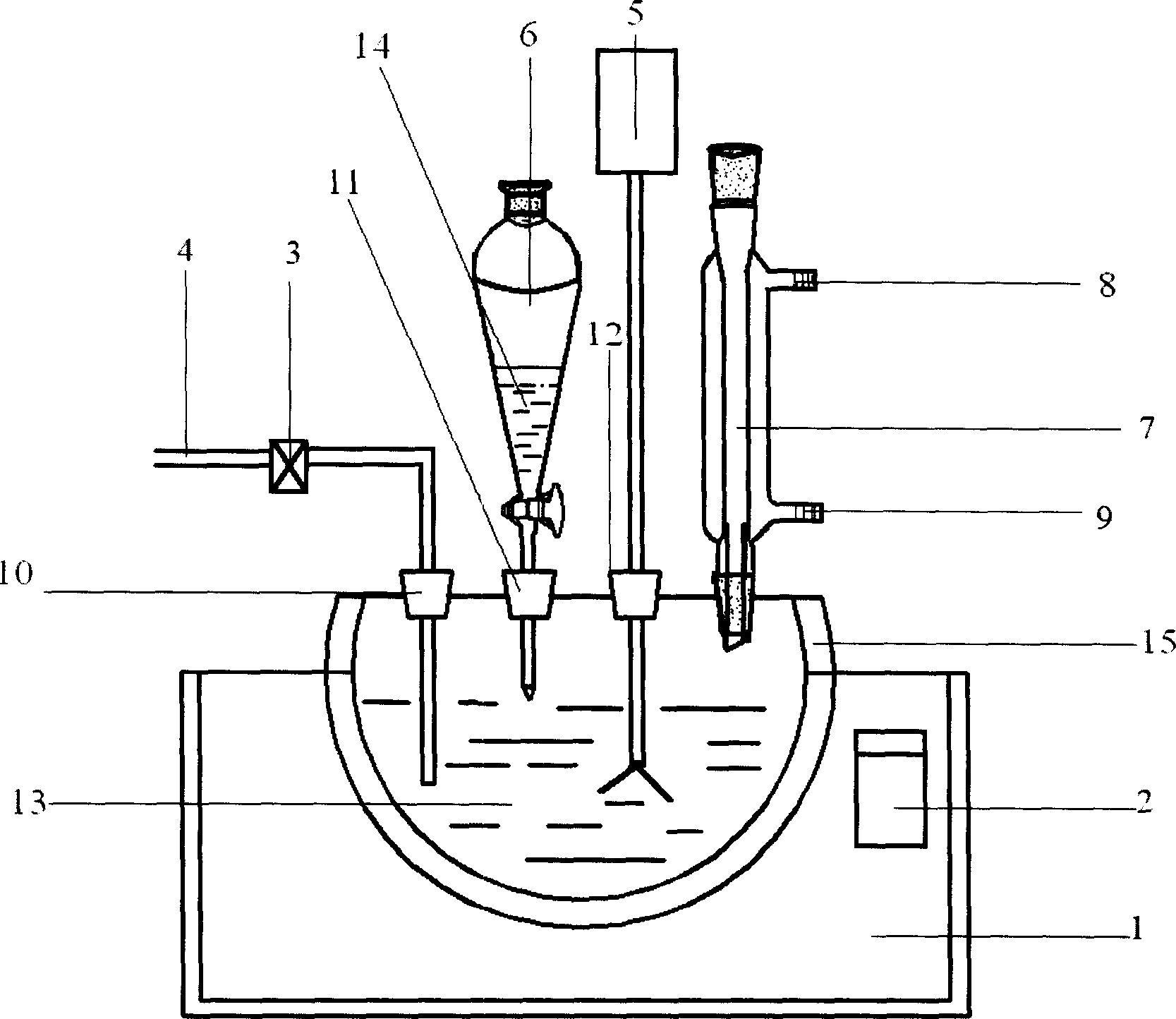

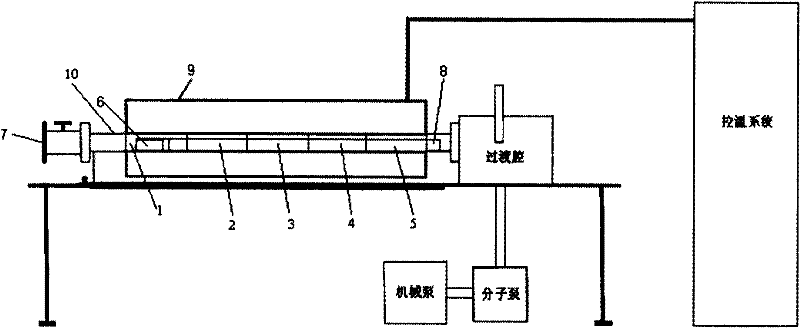

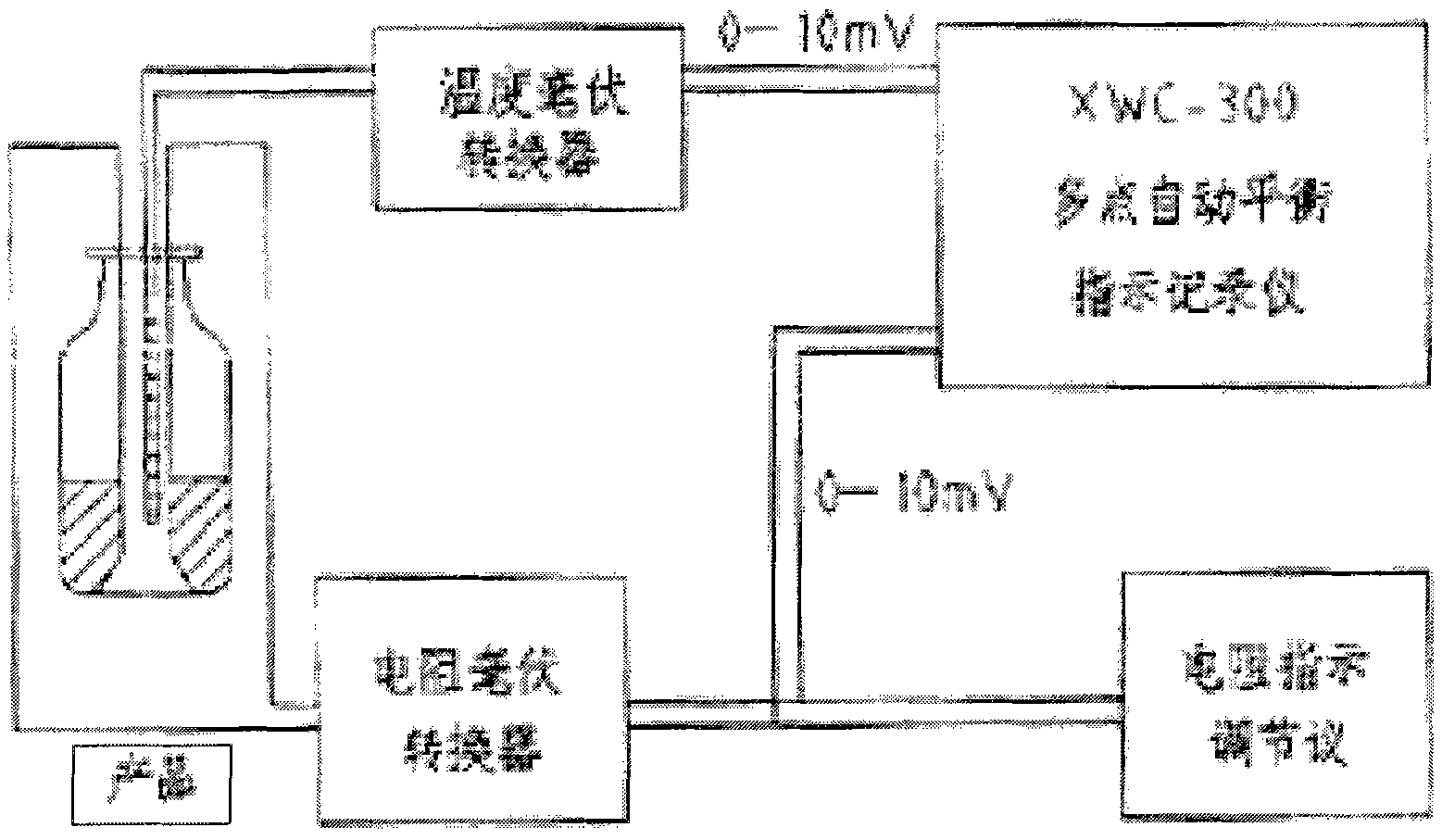

Equipment and process for vacuum sublimation purification of small organic molecule material

ActiveCN102961890AStable temperatureReduce the temperatureSublimationVacuum sublimationOrganic chemistry

The invention provides equipment for vacuum sublimation purification of a small organic molecule material. The equipment comprises a quartz sublimation pipe, a vacuumizing device for vacuumizing the quartz sublimation pipe, a film thickness detector and a heating device, wherein the film thickness detector is capable of detecting the diffusion rate of the small organic molecule material after sublimation in the quart sublimation pipe and comprises a probe capable of contacting small organic molecules, and a signal processor which is connected with the probe and used for sending out a diffusion rate signal; and the heating device is used for heating each temperature zone of the quartz sublimation pipe and adjusting according to the diffusion rate. The equipment provided by the invention realizes effective control on the vacuum sublimation purification process of the small organic molecule material, and further realizes reduction of pollution and waste while improving the purification speed and the purity and quality of the material. The invention also provides a process for the vacuum sublimation purification of the small organic molecule material, which is implemented by the equipment for the vacuum sublimation purification of the small organic molecule material provided by the invention.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

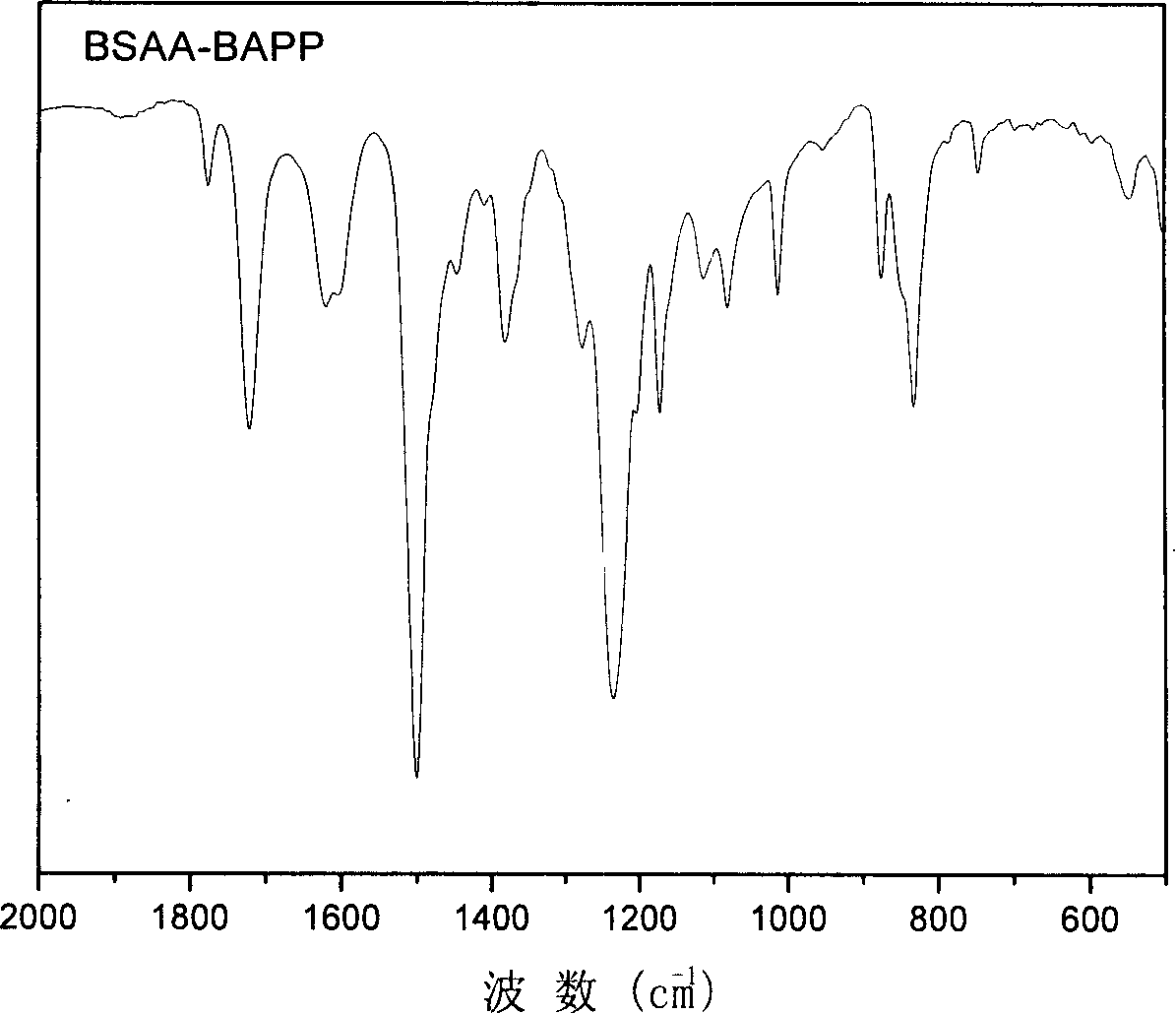

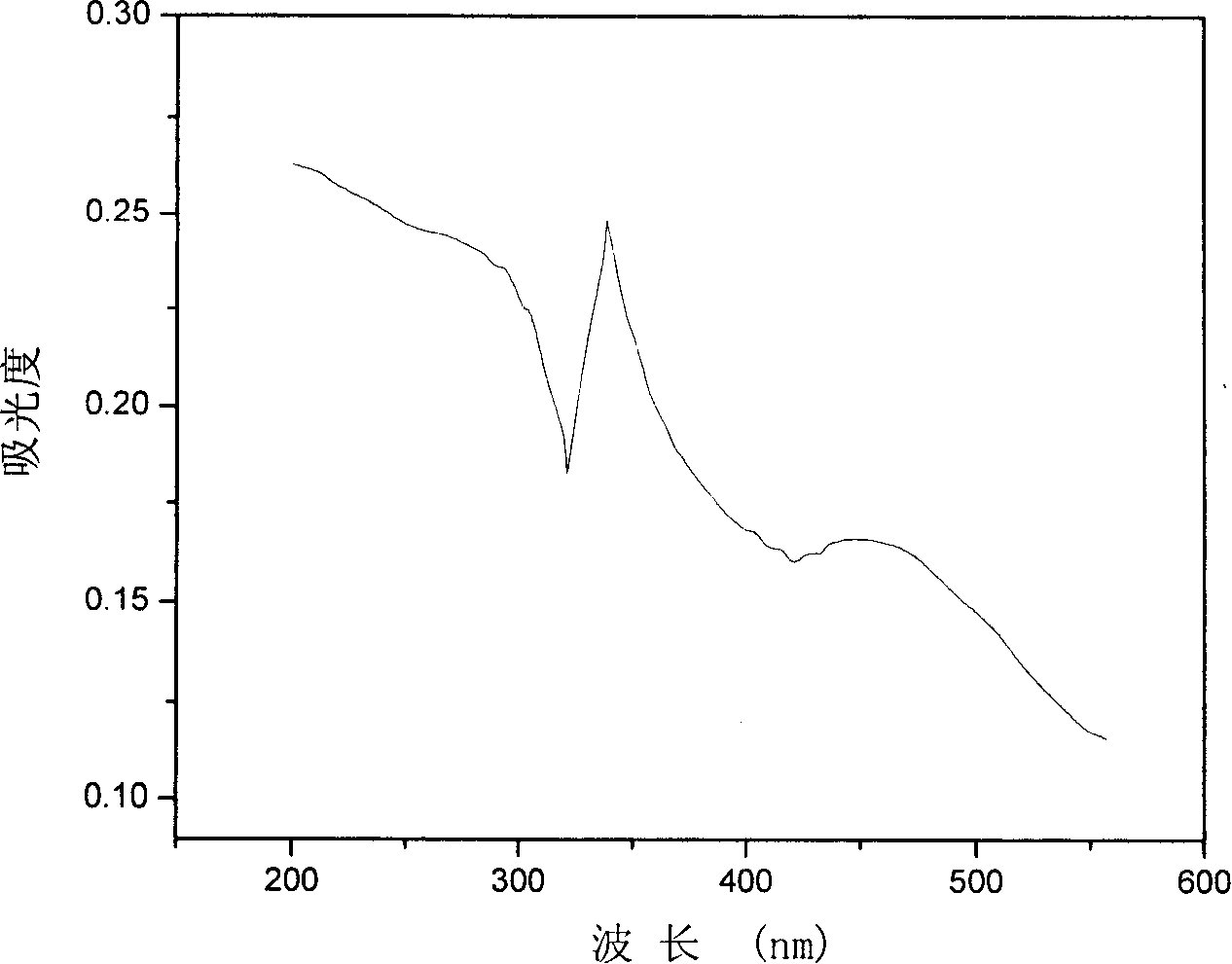

Bisphenol A-type polyimide material and method for making same

The invention belongs to the technical field of macromolecular materials and macromolecular synthesis, and in particular relates to the preparation of bisphenol A polyimide film by vapor deposition polymerization. The method for preparing polyimide is characterized in that bisphenol A dianhydride and diamine monomers are sublimated in vacuum and polymerized during vapor phase deposition. The polyimide prepared by this method not only maintains the good thermal stability and chemical stability of polyimide prepared by the traditional method, but also overcomes the shortcomings of the traditional method. The prepared polyimide film is uniform and dense, No pinholes, no catalyst, no solvent residue, high purity, and simplified reaction steps.

Owner:TONGJI UNIV

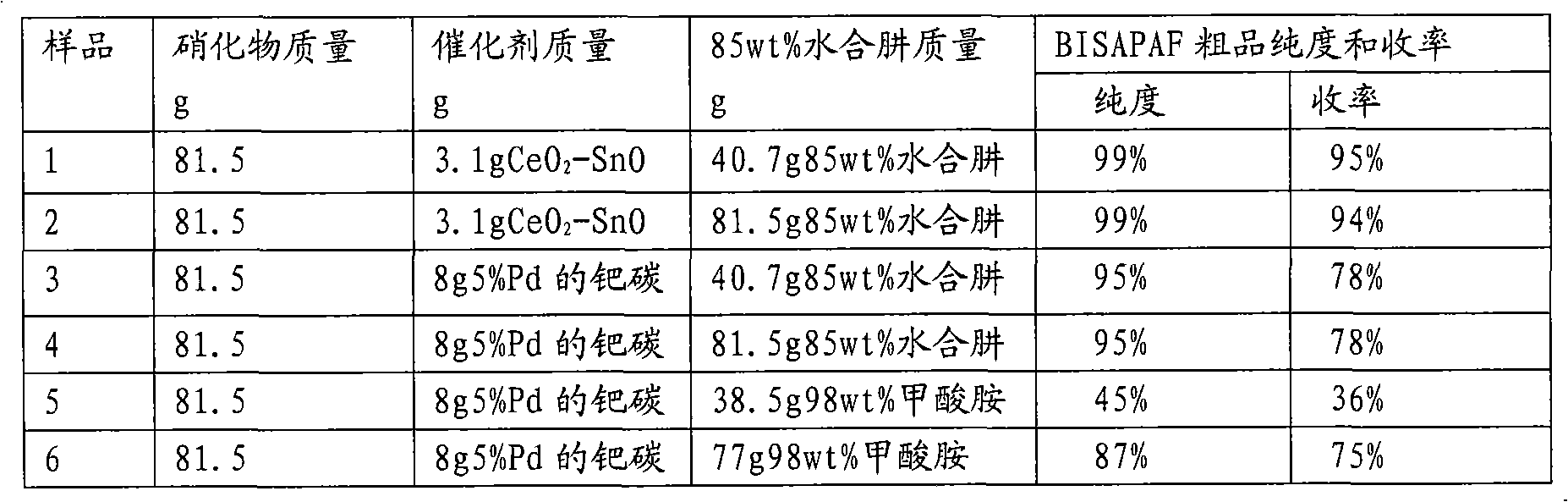

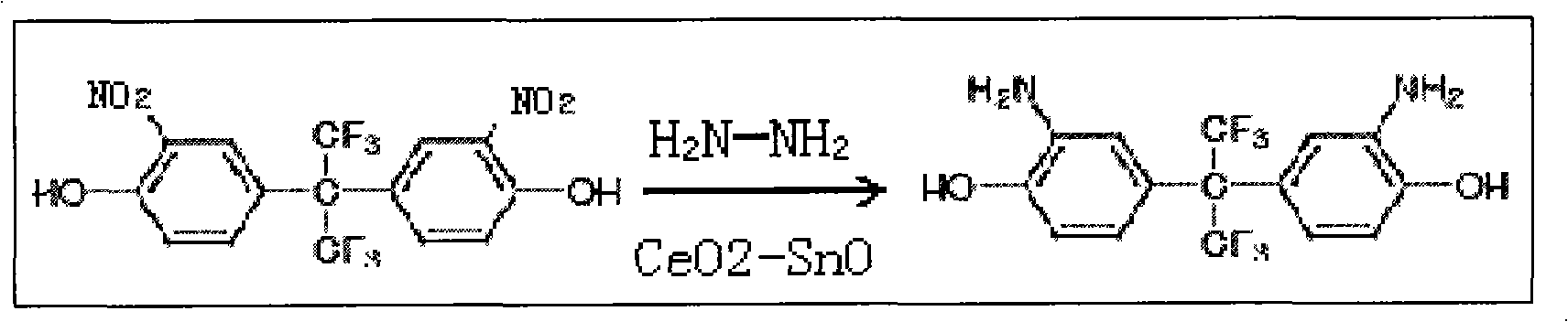

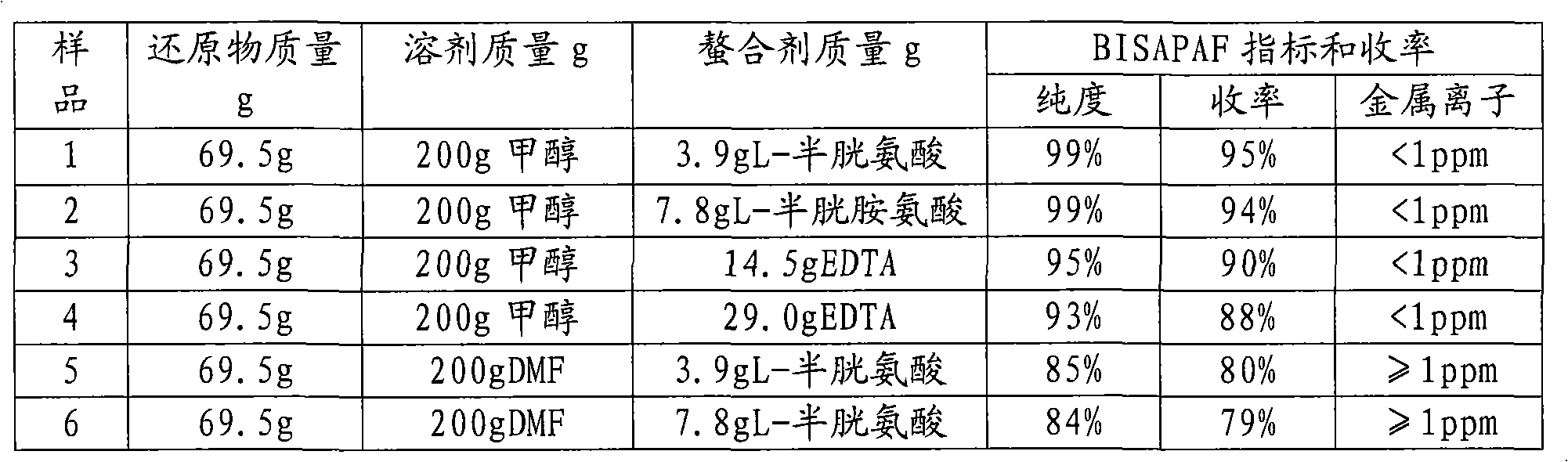

Preparation method of 2,2-bis(3-amino-4-hydroxylphenyl)hexafluoropropane

ActiveCN101643427APrevent oxidationNon-toxic and harmless Low boiling pointOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsHydrazine compoundVacuum sublimation

The invention discloses a preparation method of 2,2-bis(3-amino-4-hydroxylphenyl)hexafluoropropane, belonging to the technical field of electronic chemical materials. The preparation method comprisesthe following steps: adopting 2,2-bis(3-nitro-4-hydroxylphenyl)hexafluoropropane as raw material and hydrazine hydrate dissolved in methanol as reductant to reduce 2,2-bis(3-nitro-4-hydroxylphenyl)hexafluoropropane under the action of catalyst CeO2-SnO and obtain raw 2,2-bis(3-amino-4-hydroxylphenyl)hexafluoropropane, using chelating agent to remove metal ions in the raw product and performing vacuum sublimation and purification to the obtained 2,2-bis(3-amino-4-hydroxylphenyl)hexafluoropropane in which metal ions are removed and finally obtaining the target product. The method has low production cost, high product purity, low contents of metal ions and high yield.

Owner:自贡中天胜新材料科技有限公司

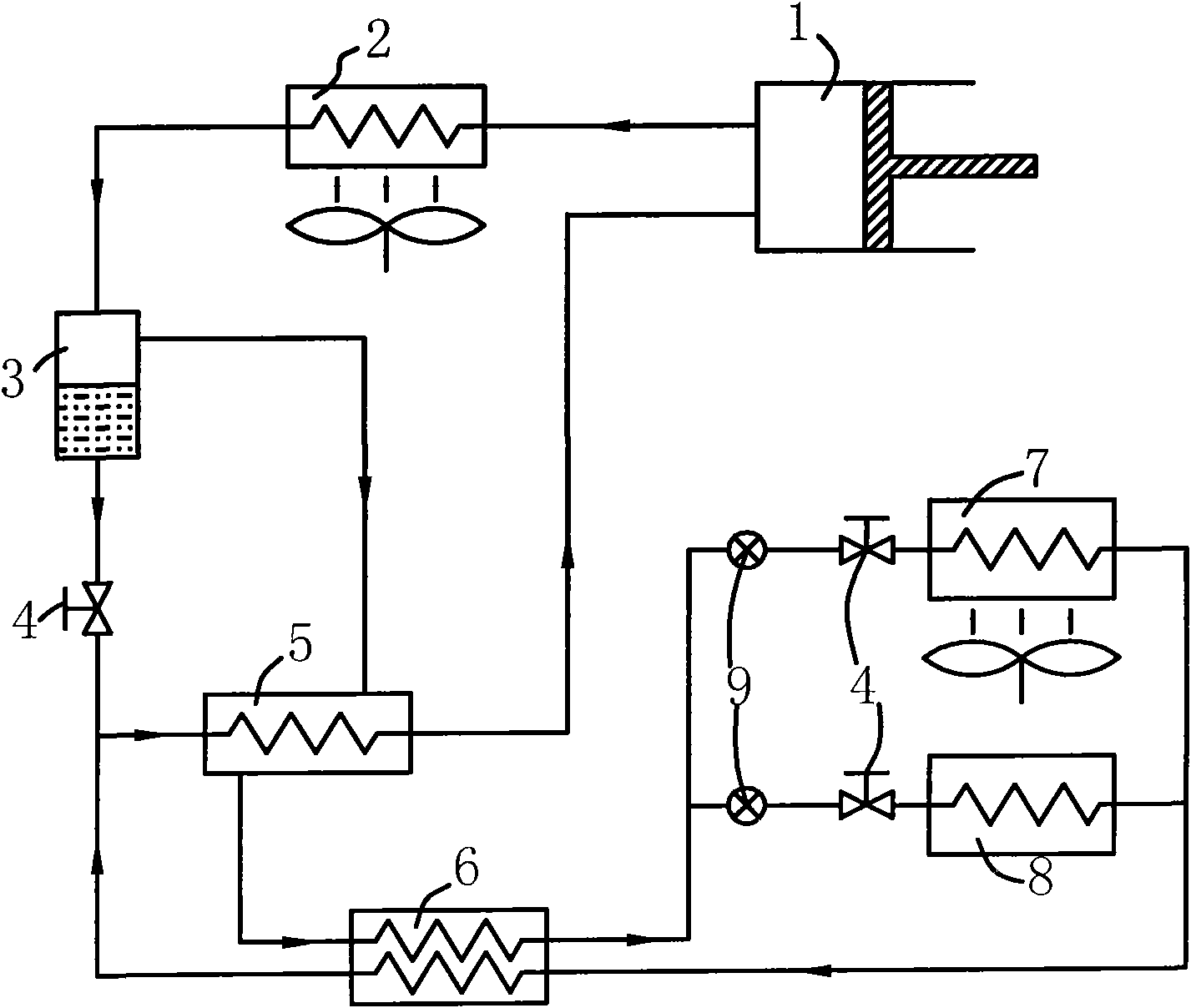

Vacuum sublimation purifying method for high-purity arsenic and vacuum sublimation furnace thereof

InactiveCN101225479AGood separation and condensation effectAvoid dischargeTemperature controlPurification methods

The invention relates to a vacuum sublimation purification method of high-purity arsenic, sublimating in vacuum sublimation sealed furnace, which comprises a heating furnace, a vacuum tank and a sublimation inner sleeve; wherein, a circular water jacket is arranged on the top of the vacuum tank; the vacuum tank under the circular water jacket is arranged in the heating furnace; the sublimation inner sleeve is arranged in the vacuum tank and comprises a bottom charging crucible, a middle high-purity arsenic implantation condenser and a top gas impurity condensing collector. A high boiling point high melting point element condensing ring is arranged between the charging crucible and the high-purity arsenic implantation condenser. A baffle is arranged between the high-purity arsenic implantation condenser and the gas impurity condensing collector. The gas impurity condensing collector is arranged in the circular water jacket on the top of the vacuum tank. The vacuum sublimation purification method of high-purity arsenic, sublimating in vacuum sublimation sealed furnace has the advantages of having rational structure, three segments of balance furnace temperatures, certain vacuum degree, precise temperature control, finished warming curve, uniform temperature field distribution, good repeatability, high product quality of the same arsenic after sublimating one time, good impurity separating condensing results, and low purification cost.

Owner:郑桂昌

Method for preparing high-purity Hangzhou white chrysanthemum essential oil

The invention discloses a method for preparing high-purity Hangzhou white chrysanthemum essential oil. The method comprises the following steps: (1) carrying out spraying treatment on Hangzhou white chrysanthemum raw materials by using water; (2) pre-freezing the Hangzhou white chrysanthemum after being subjected to the spraying treatment and carrying out vacuum sublimation drying; (3) smashing the Hangzhou white chrysanthemum after being subjected to the freeze drying; (4) putting the smashed Hangzhou white chrysanthemum raw materials and a fluid in a super-critical state into an extraction kettle and extracting to obtain Hangzhou white chrysanthemum crude oil through supercritical fluid extraction; and (5) purifying and separating the Hangzhou white chrysanthemum crude oil obtained through the supercritical fluid extraction through secondary molecular distillation to collect the high purity Hangzhou white chrysanthemum essential oil. The method has the advantages that the shortages of traditional extraction methods are avoided and effective constituents of plants are protected from being heated and damaged to the maximum limit; the extraction requirements of rapidness, high efficiency, fullness and completeness are achieved; and the method is simple and convenient in operation and high in separating speed and the working efficiency is greatly increased.

Owner:HUBEI CHINA TOBACCO IND +1

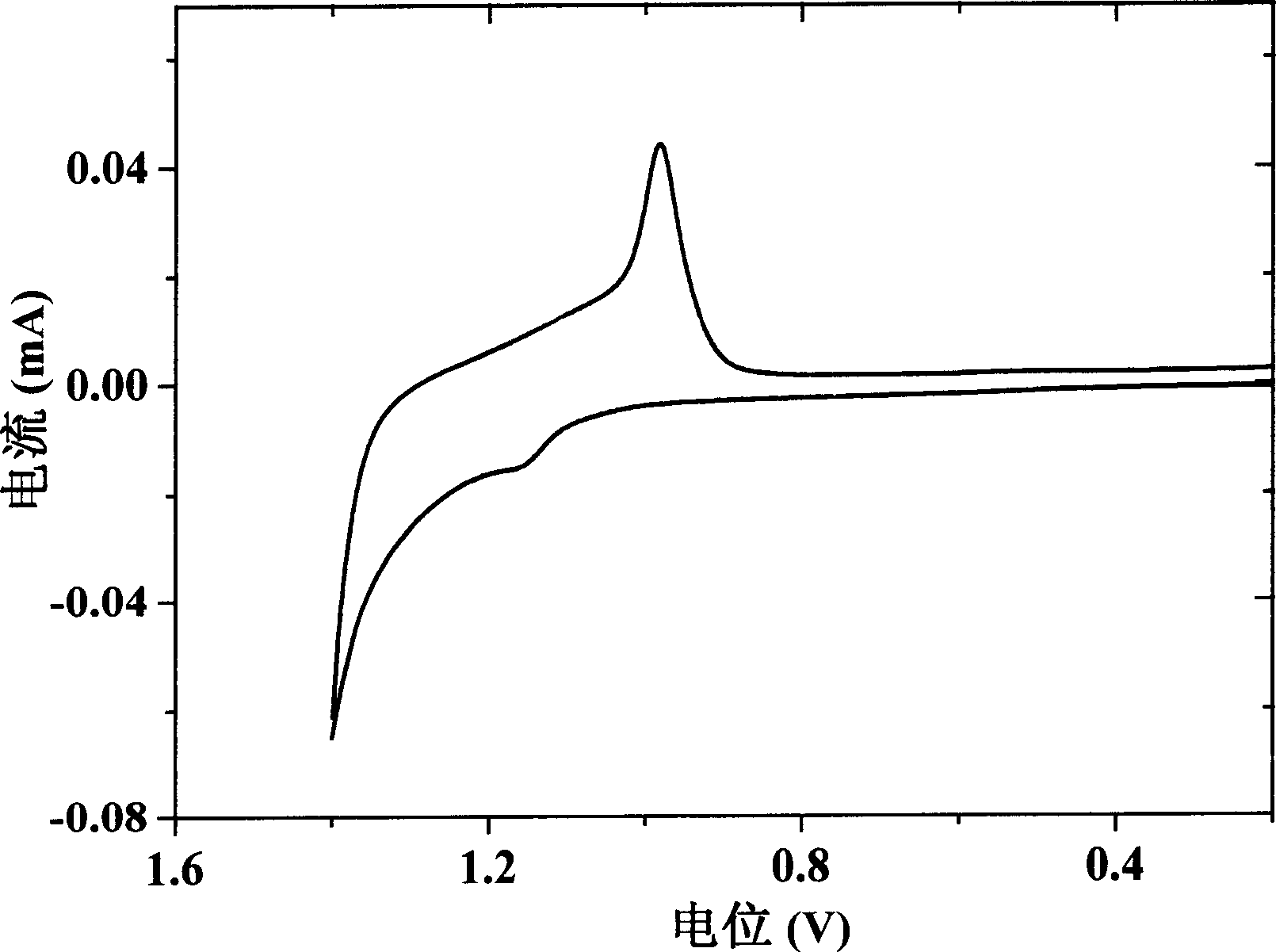

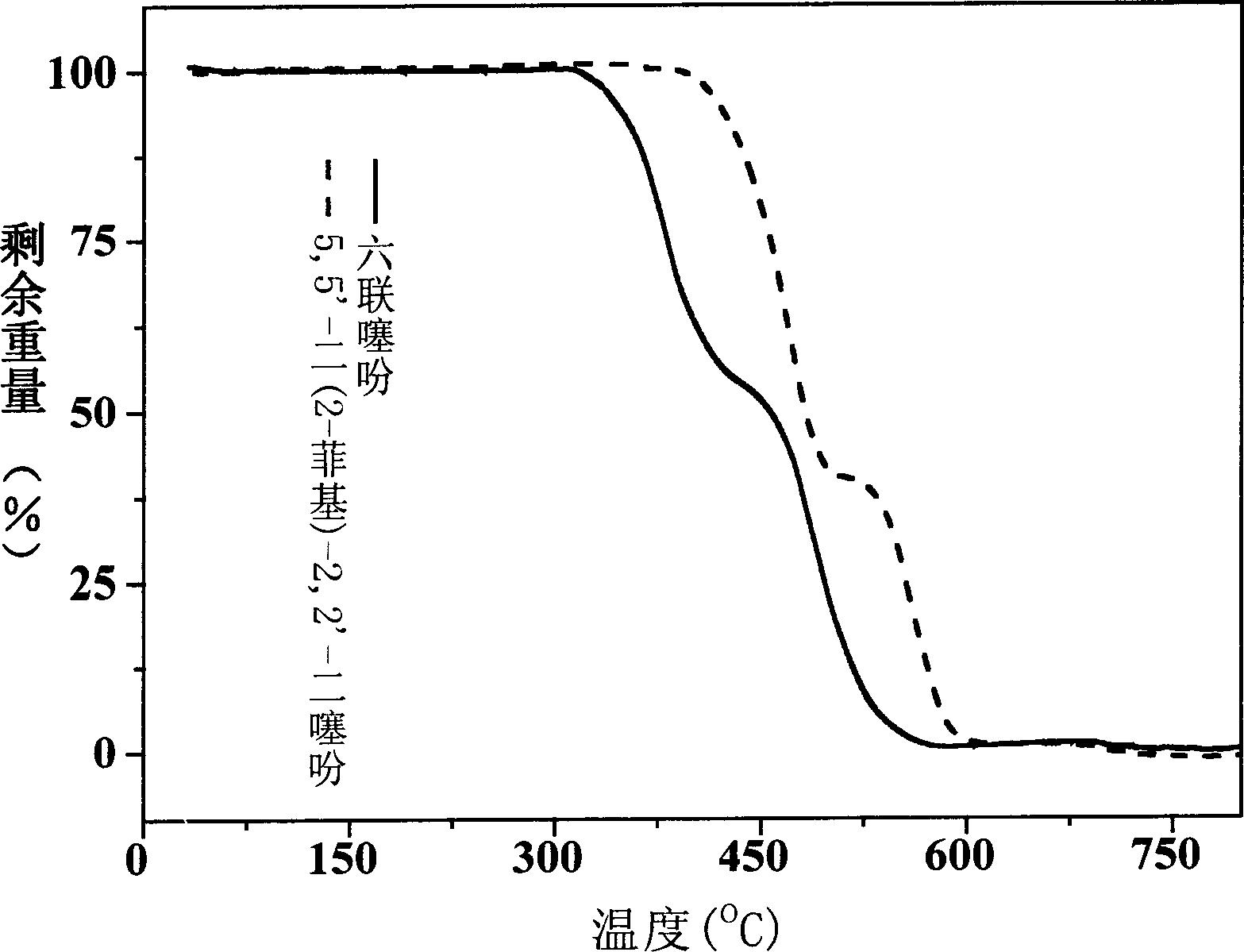

Phenanthrene/thiophene hybridized high-mobility organic semiconductor and application thereof

InactiveCN1803792AImprove mobilityImprove thermal stabilityOrganic chemistrySolid-state devicesSolubilityVacuum sublimation

The related phenanthrene / thiophene hybridized organic semiconductor with high mobility and general structural formula as the right has high thermal and environmental stability, can be purified by vacuum sublimation, dissolves very little in organic solvent, and can be used as transport layer in organic TFT.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

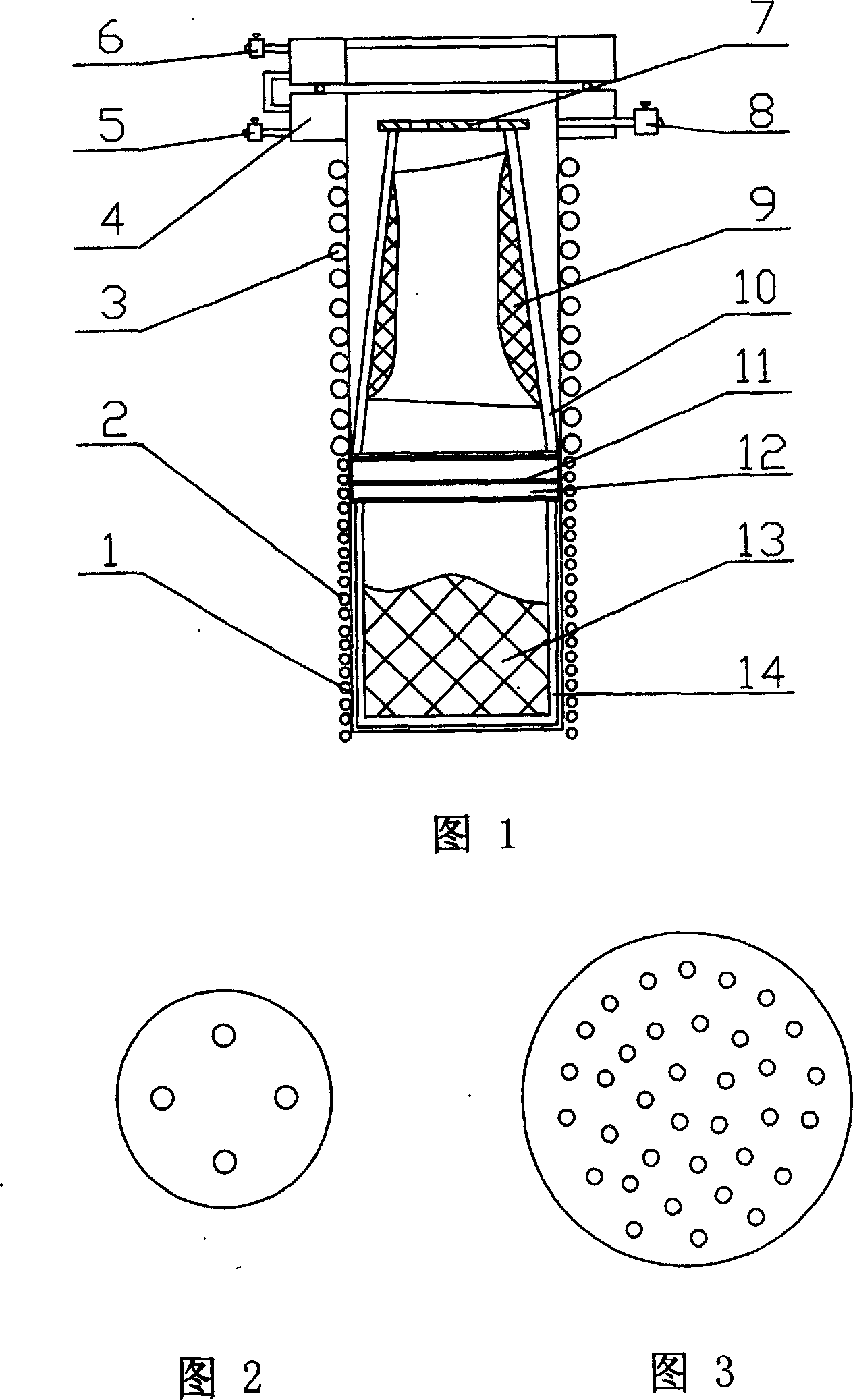

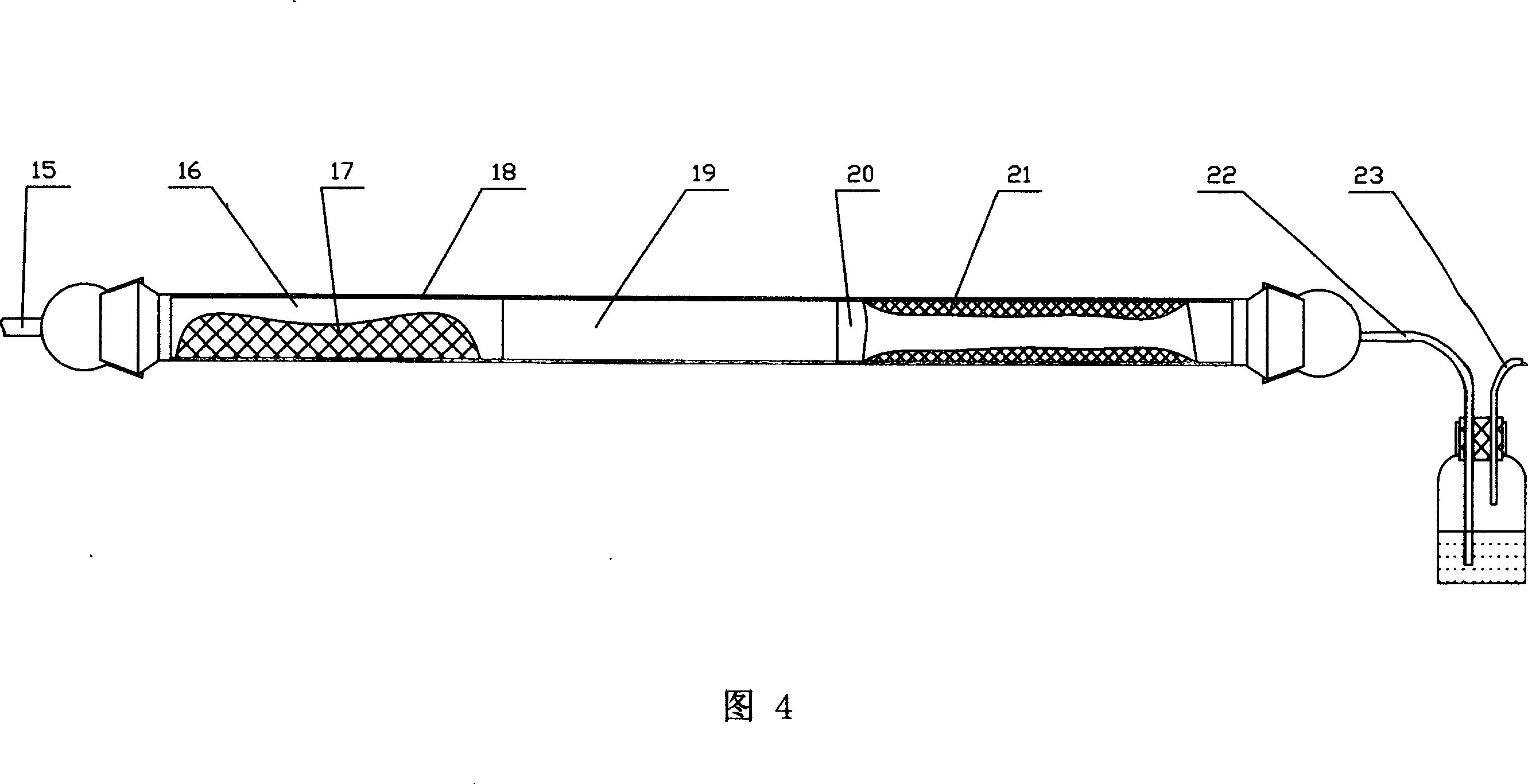

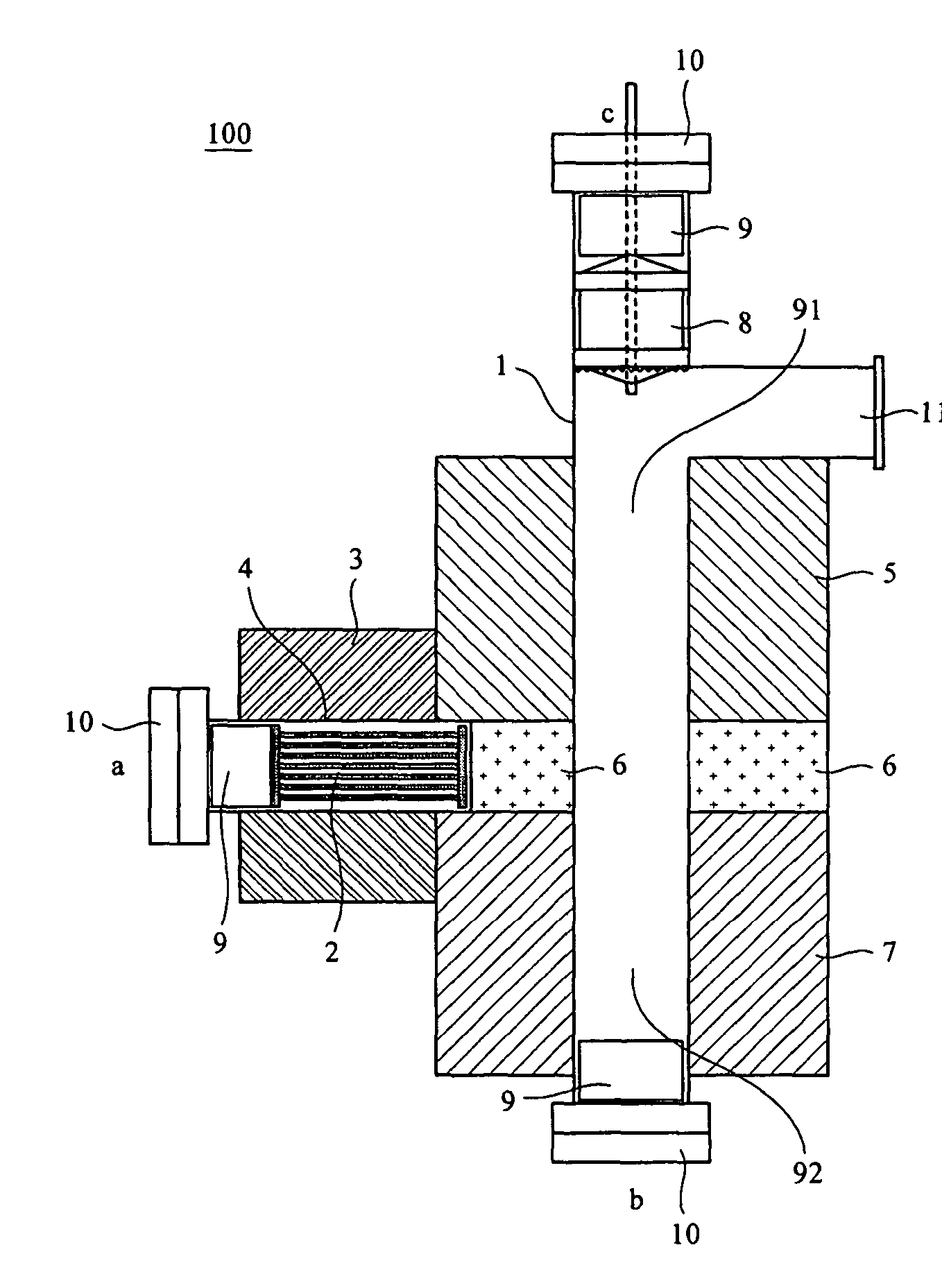

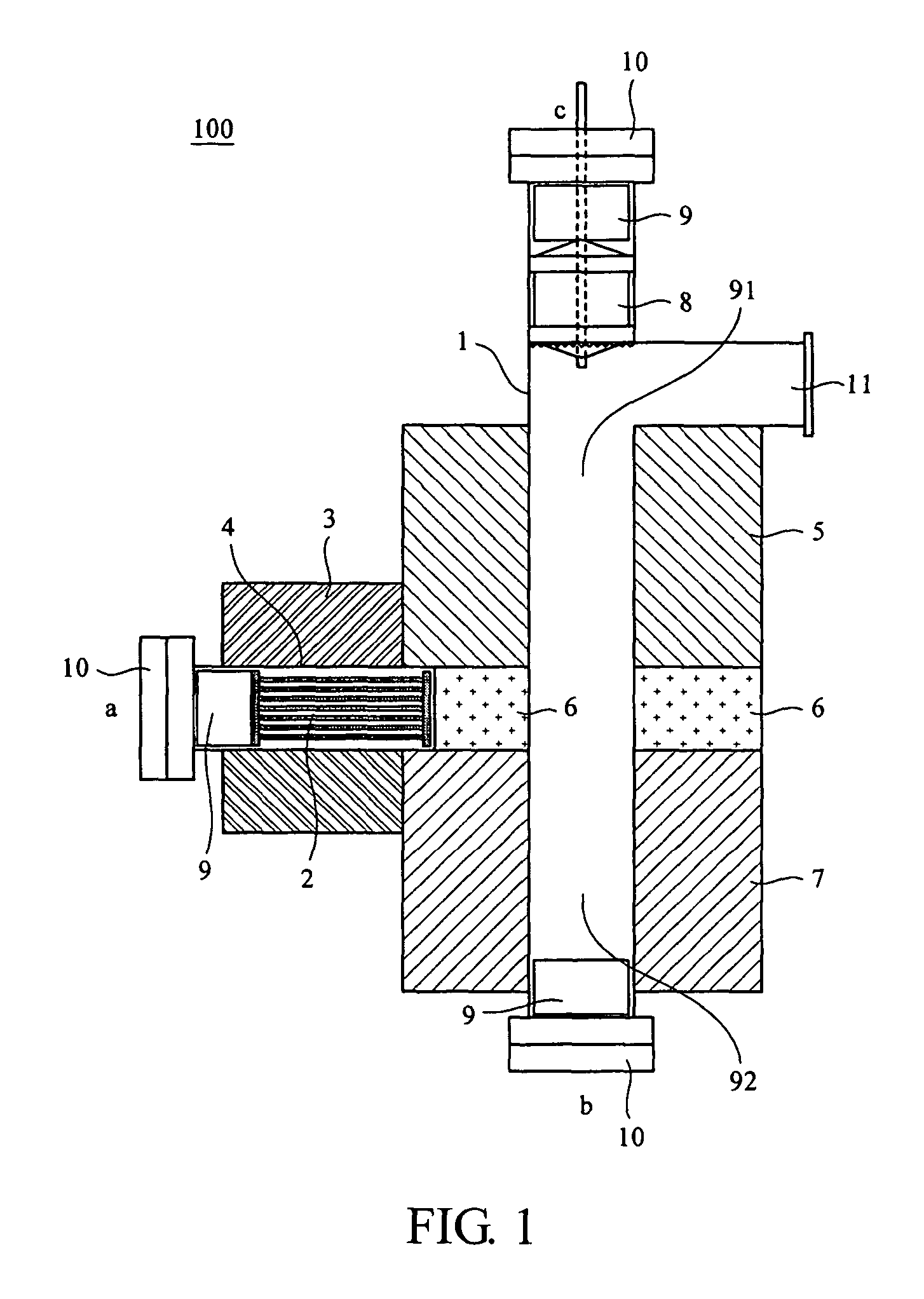

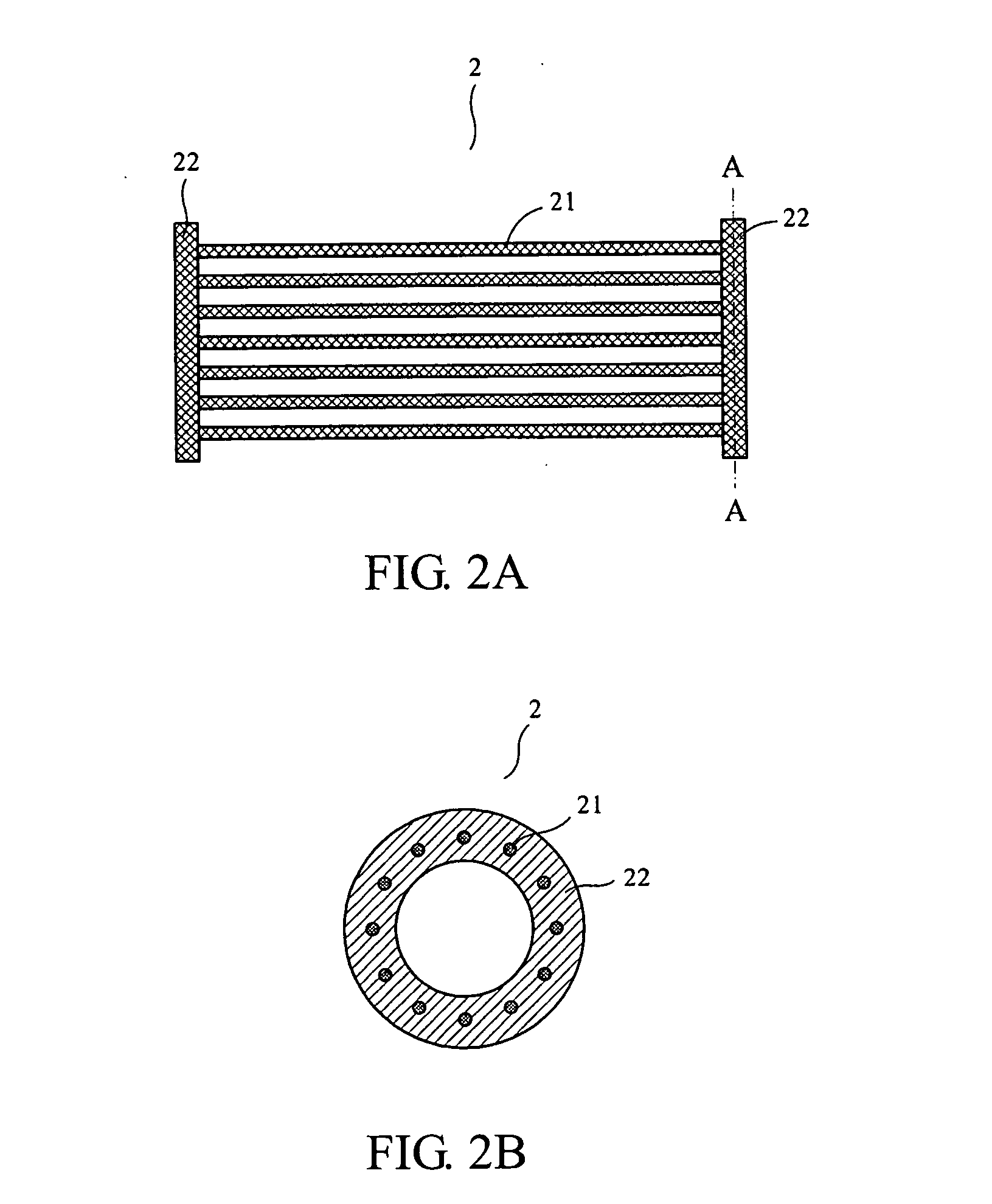

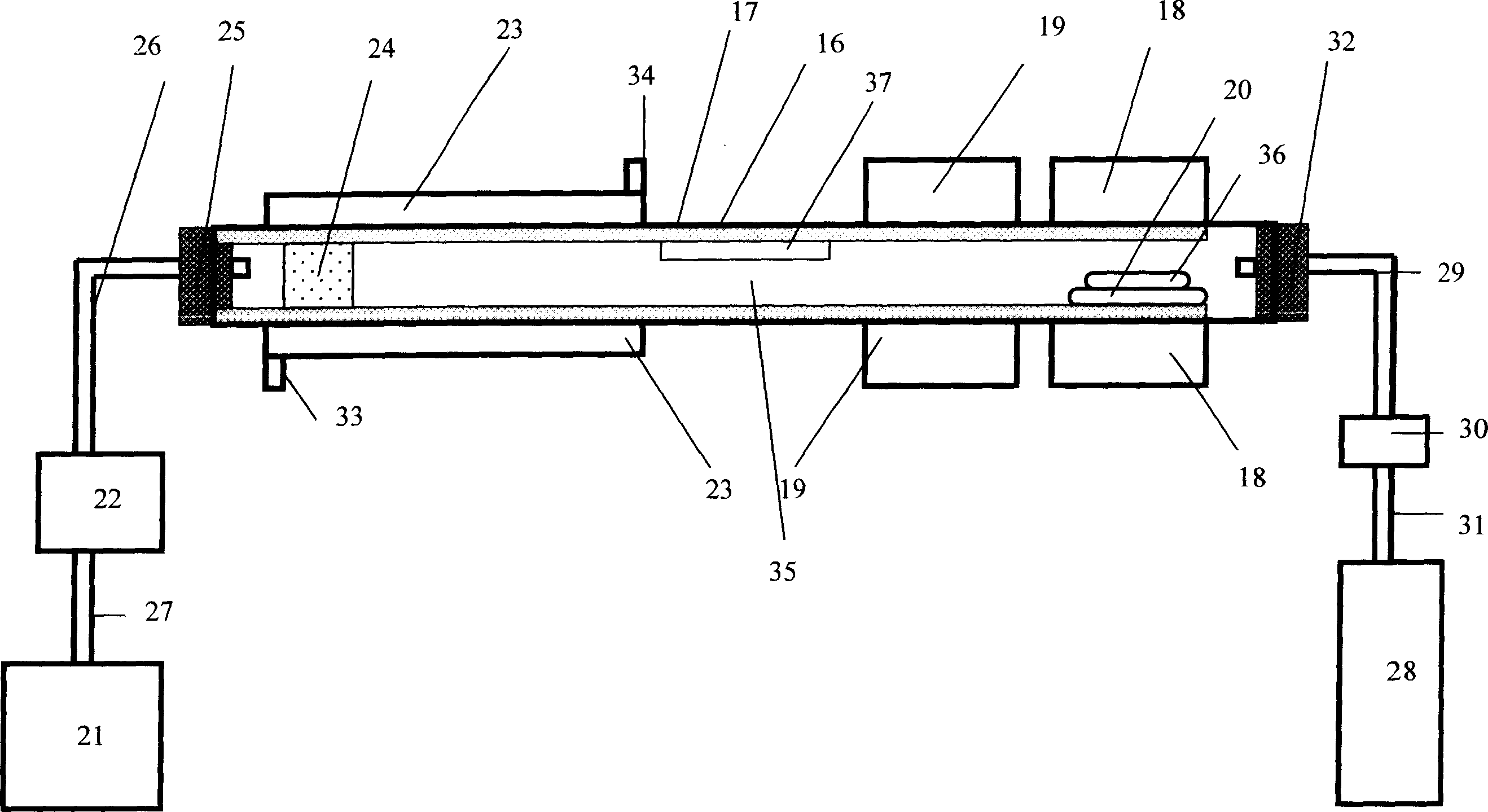

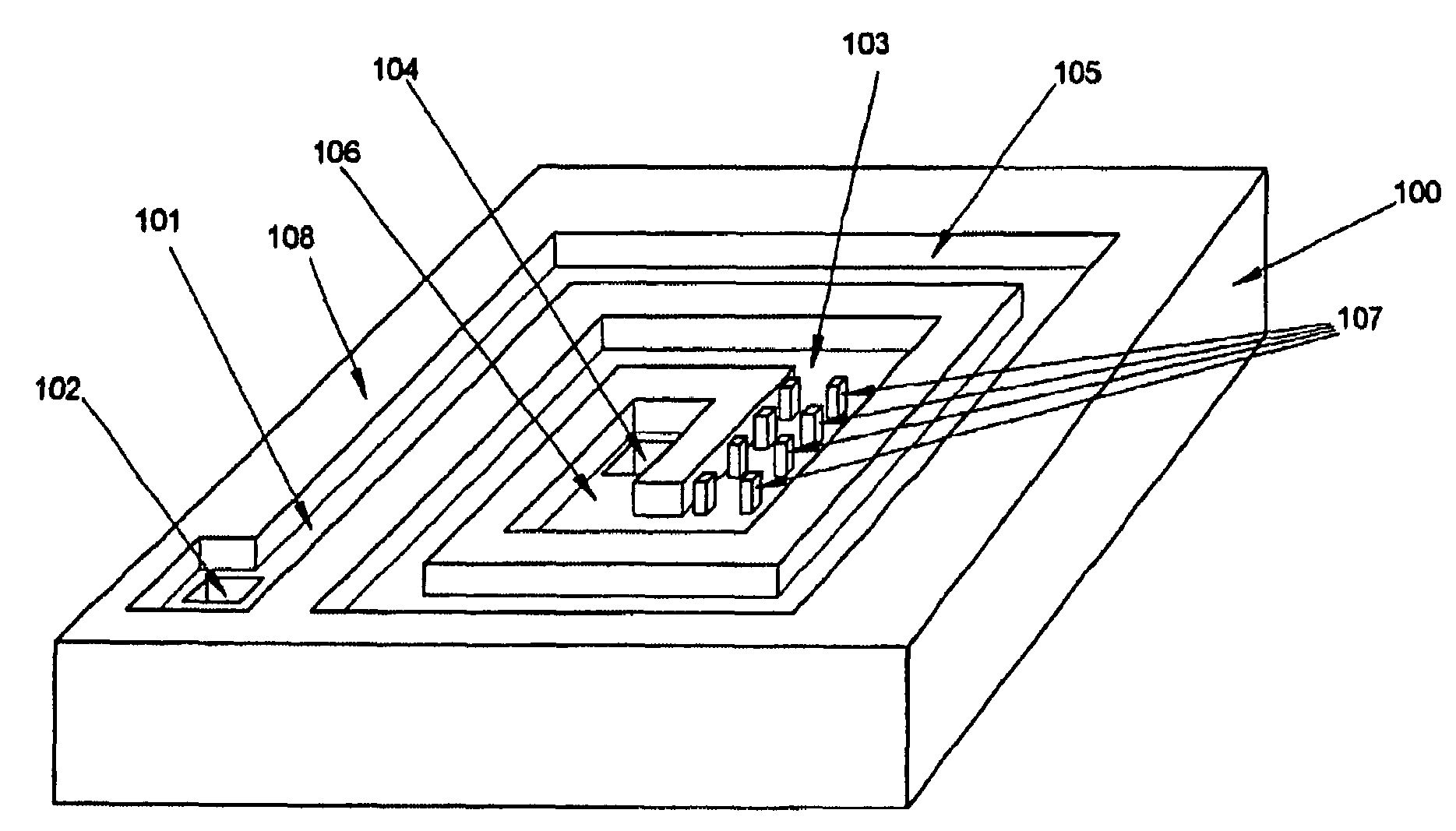

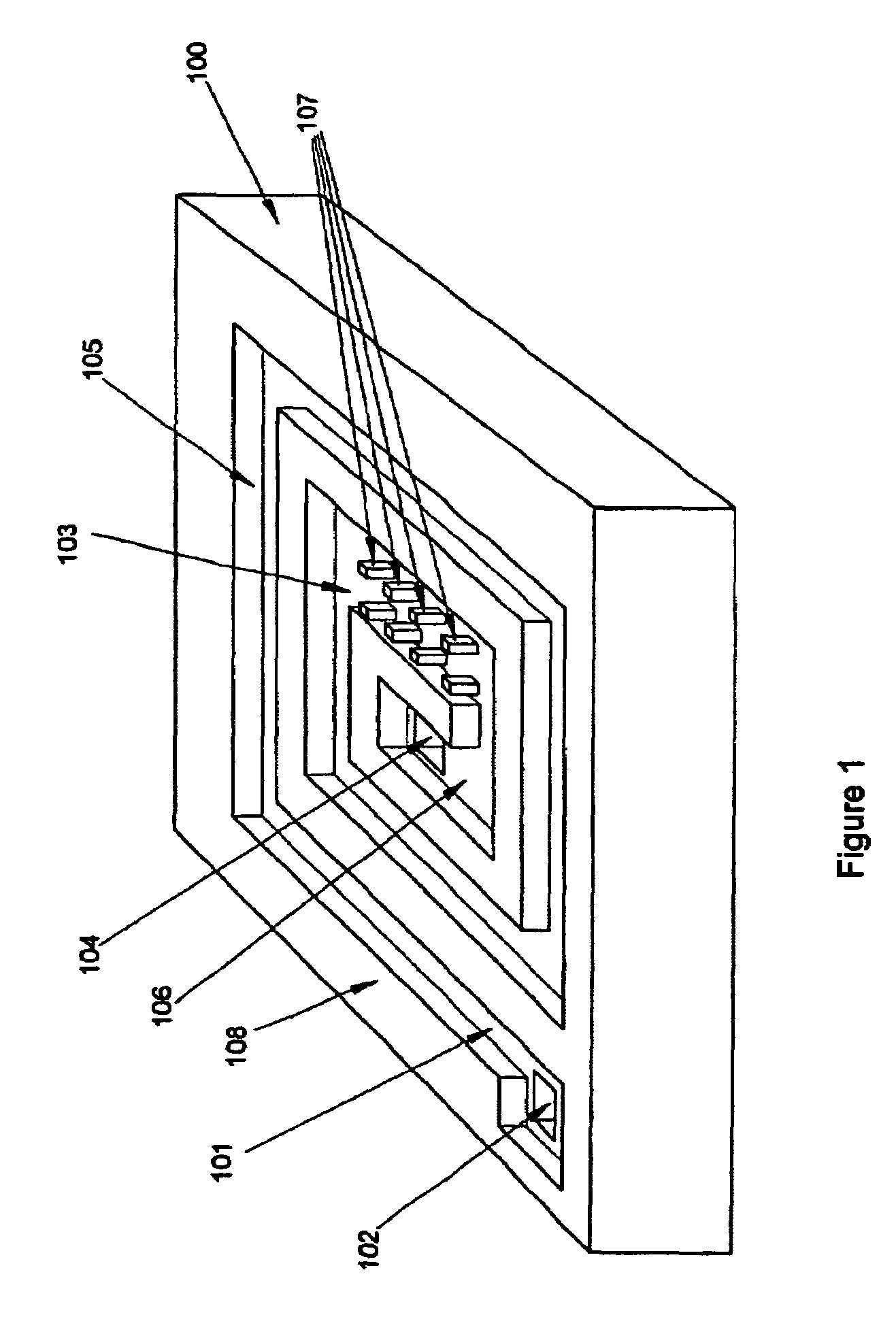

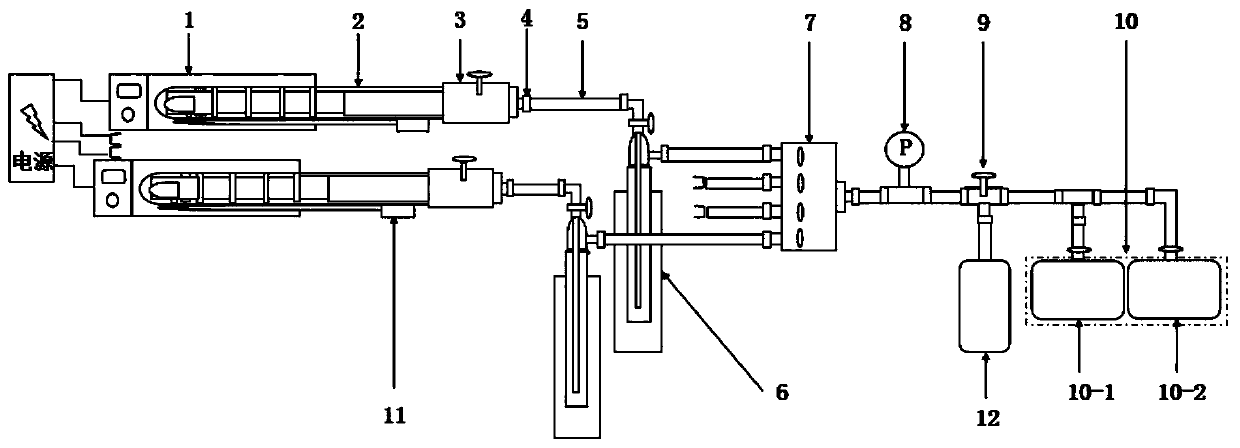

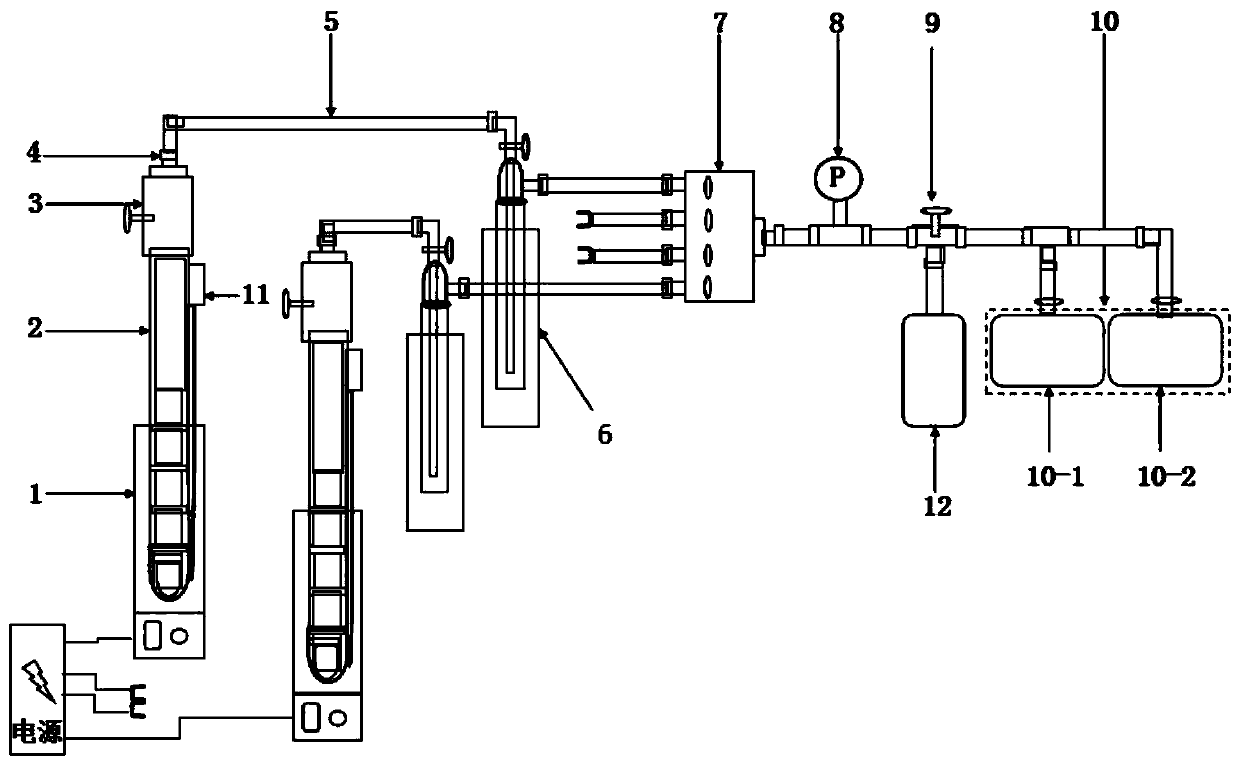

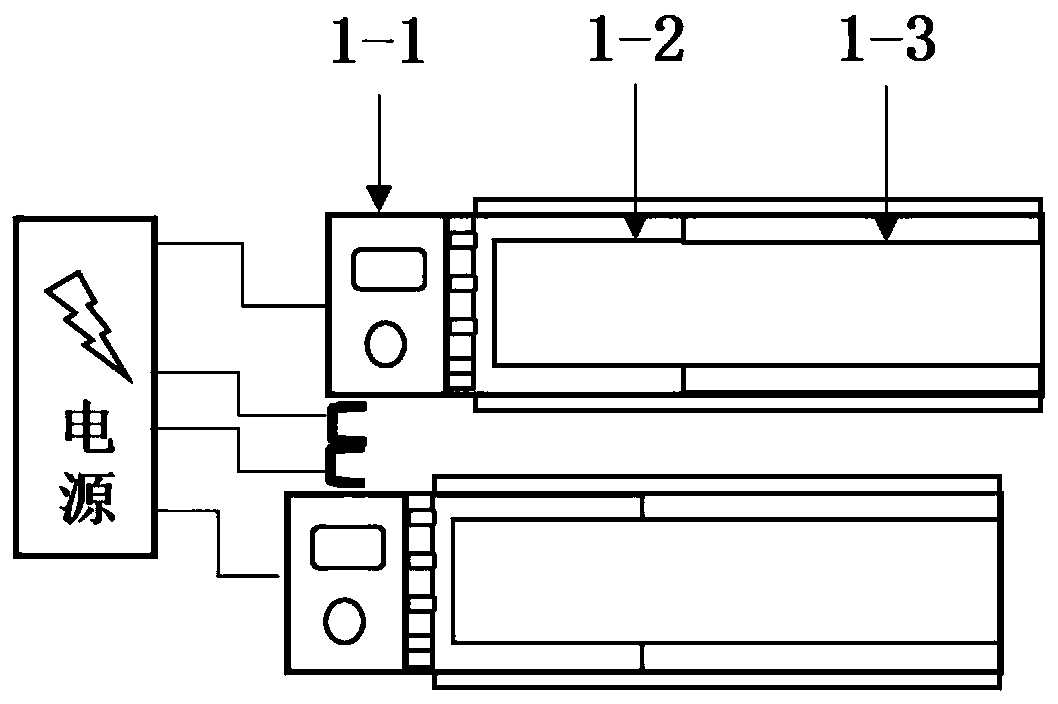

Apparatus and process for vacuum sublimation

InactiveUS20050047979A1High purity productAppropriate product purityVapor condensationSublimationEvaporationCompound (substance)

A vertical and a horizontal vacuum sublimation apparatus with high efficiency and processes thereof are provided, especially for the materials having high melting point and low vapor pressure. The vertical sublimation purification apparatus comprises a sublimation channel body, a material rack, a heating evaporation device, a condensation device, an incubating device and a product scratching device. The horizontal sublimation purification apparatus comprises a sublimation channel body, a material carrier, a heating evaporation device and two end pipes. The apparatuses of the present invention can be applied on high purity chemicals from mass production, and are capable of sublimating and purifying OLED illumination layer materials including ALq3, NPB and CuPc, which have high melting temperature and low vapor pressure.

Owner:IND TECH RES INST

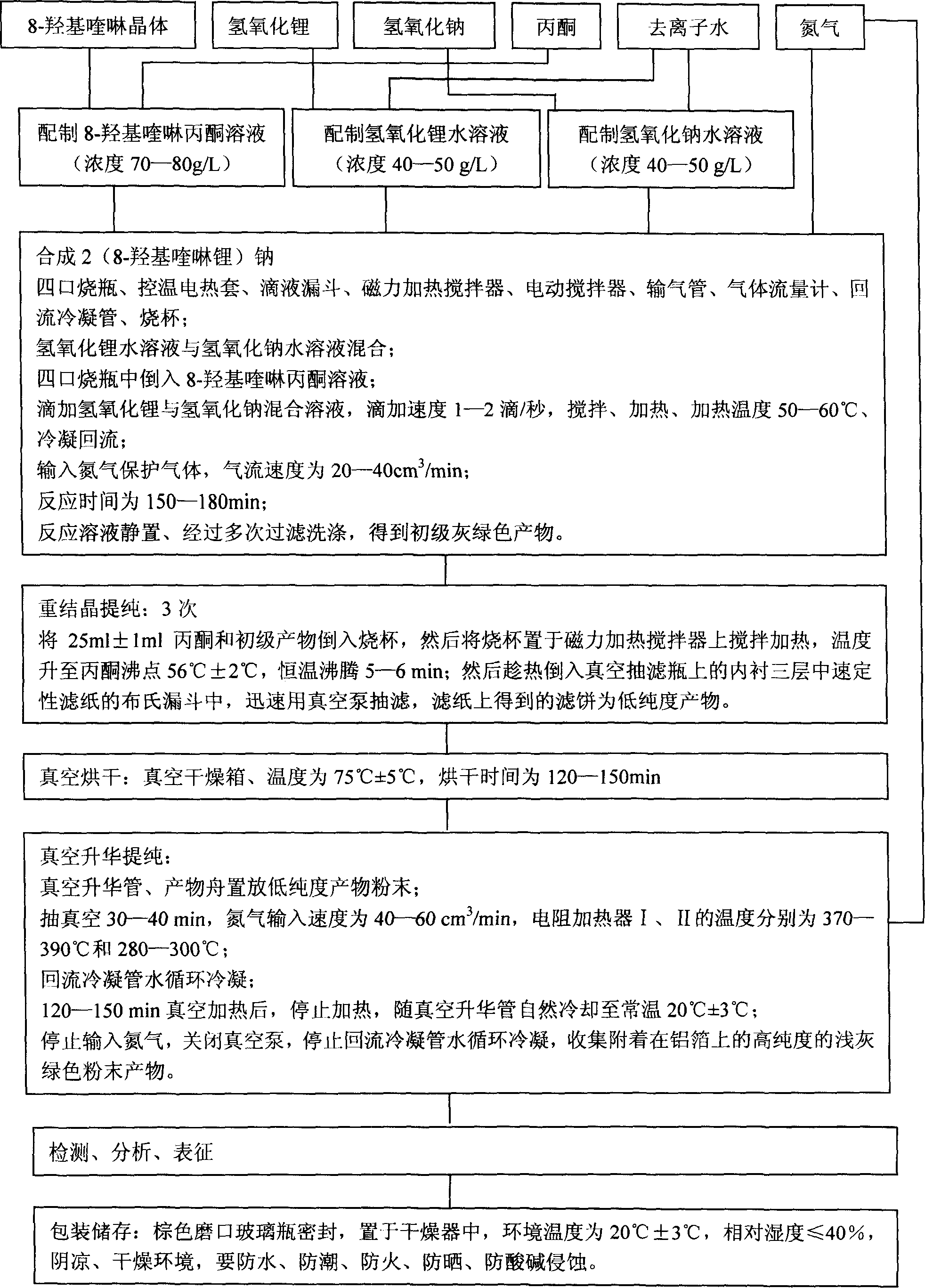

Process for preparing organic electroluminescence material bis (8-hydroxy quinoline lithium sodium)

InactiveCN1900213AHigh purityLong fluorescence lifetimeLuminescent compositionsElectron injectionLithium hydroxide

The present invention relates to a kind of organic electroluminescent material bis(8-hydroxy quinoline lithium sodium), which is prepared with 8-hydroxy quinoline, lithium hydroxide and sodium hydroxide as materials, acetone and deionized water as solvent, and nitrogen as protecting gas, and through the steps of compounding solution, synthesis reaction, washing and filtering, re-crystallization to purify, vacuum stoving and final vacuum sublimation to purify to obtain blue light emitting high purity bis(8-hydroxy quinoline lithium sodium) powder. Owing to sodium ion for emitting light and electron injection, the bis (8-hydroxy quinoline lithium sodium) material is superior to 8-hydroxy quinoline lithium and has the features of good filming performance, long fluorescence life, high color purity, high light emitting efficiency, etc. The present invention may be used widely in electronic information display and lighting technology.

Owner:TAIYUAN UNIV OF TECH +1

Preparation method of active pseudo-ginseng slices

ActiveCN101961363AHigh content of active ingredientsEasy to storeNervous disorderMetabolism disorderSurface moistureInternal pressure

The invention relates to a drying process method of a specific plant. The method comprises the following steps of: (1) pretreatment: sorting and selecting prepared fresh pseudo-ginseng, separating and removing snips, fibrous roots and flocking roots attached to the fresh pseudo-ginseng roots to obtain pseudo-ginseng main roots, cleaning and removing surface attachments, draining surface moisture, and cutting into 0.2-2 mm slices by using a slicing machine; (2) pre-freezing: directly placing the slices in a pre-freezing room with the set temperature of subzero 15 to subzero 20 DEG C, and pre-freezing for 5-6h; (3) sublimation drying: spreading the pre-frozen slices out on a desk tray made of a conducting material, controlling the spreading thickness to be below 5 cm, and moving to a vacuum drying room; sealing, starting vacuumizing, maintaining the internal vacuum pressure at 30-70 pascals, setting the temperature of the desk tray to be 40 DEG C, keeping supplying heat for the desk tray, and carrying out vacuum sublimation drying for 7-10h until the temperature of the desk try reaches 40 DEG C; (4) analysis: maintaining the temperature of the desk tray to be 40 DEG C, keeping supplying heat for the desk tray and vacuumizing for 6-12h until the temperature of the material reaches 40 DEG C, and controlling the moisture of the material at 3-5%; and (5) discharging and packaging.

Owner:云南特安呐制药股份有限公司

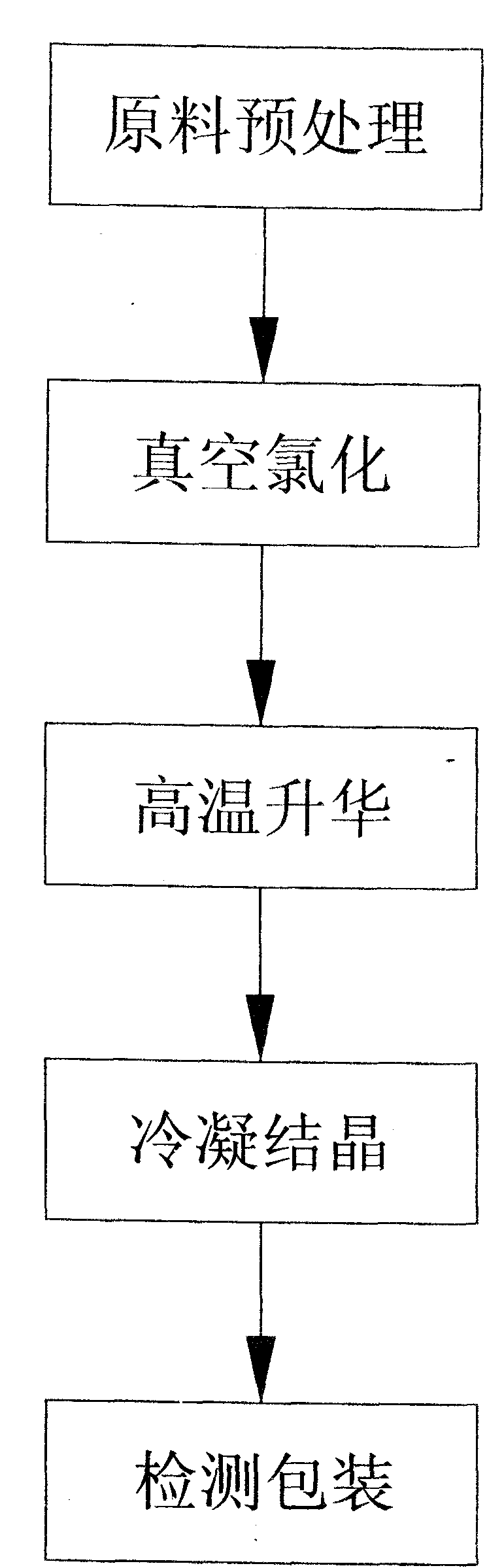

Anhydrous indium chloride synthesizing method

ActiveCN101792174AHigh purityIncrease productionChloride preparationGallium/indium/thallium compoundsVacuum sublimationPre treatment

The invention relates to an anhydrous indium chloride synthesizing method. The method adopts the following process steps: pre-treatment, vacuum chlorination, sublimation and purification, and formation of a finished anhydrous indium chloride product. According to the method, the high-purity anhydrous indium chloride is synthesized by adopting totally nontoxic agents and raw materials by using vacuum high-temperature chlorination and distilled purification technology; the product has high purity, high yield and no toxicity; by detecting the synthesized high-purity anhydrous indium chloride product, the impurity content is below 5ppm, and the purity reaches above 99.995 percent; and the trace impurity produced in the synthesizing process is blown out in a form of dust and then is hydrolyzed and absorbed under the sealed condition, the liquid enters an indium metal reclaiming link, the process flow avoids toxic agents, and the product is further purified by the unique vacuum sublimation technology.

Owner:SHAOGUAN JINYUAN INDAL

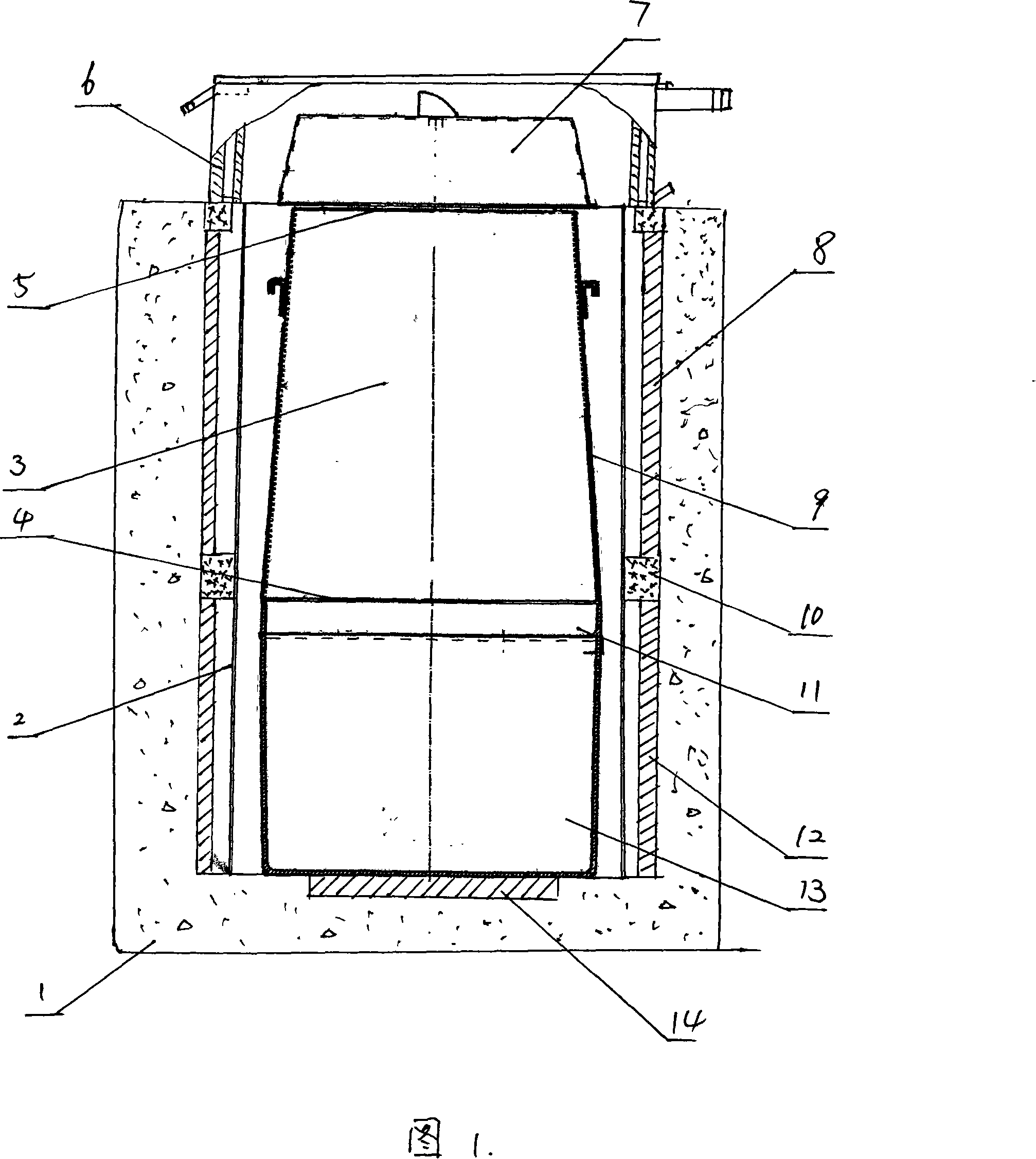

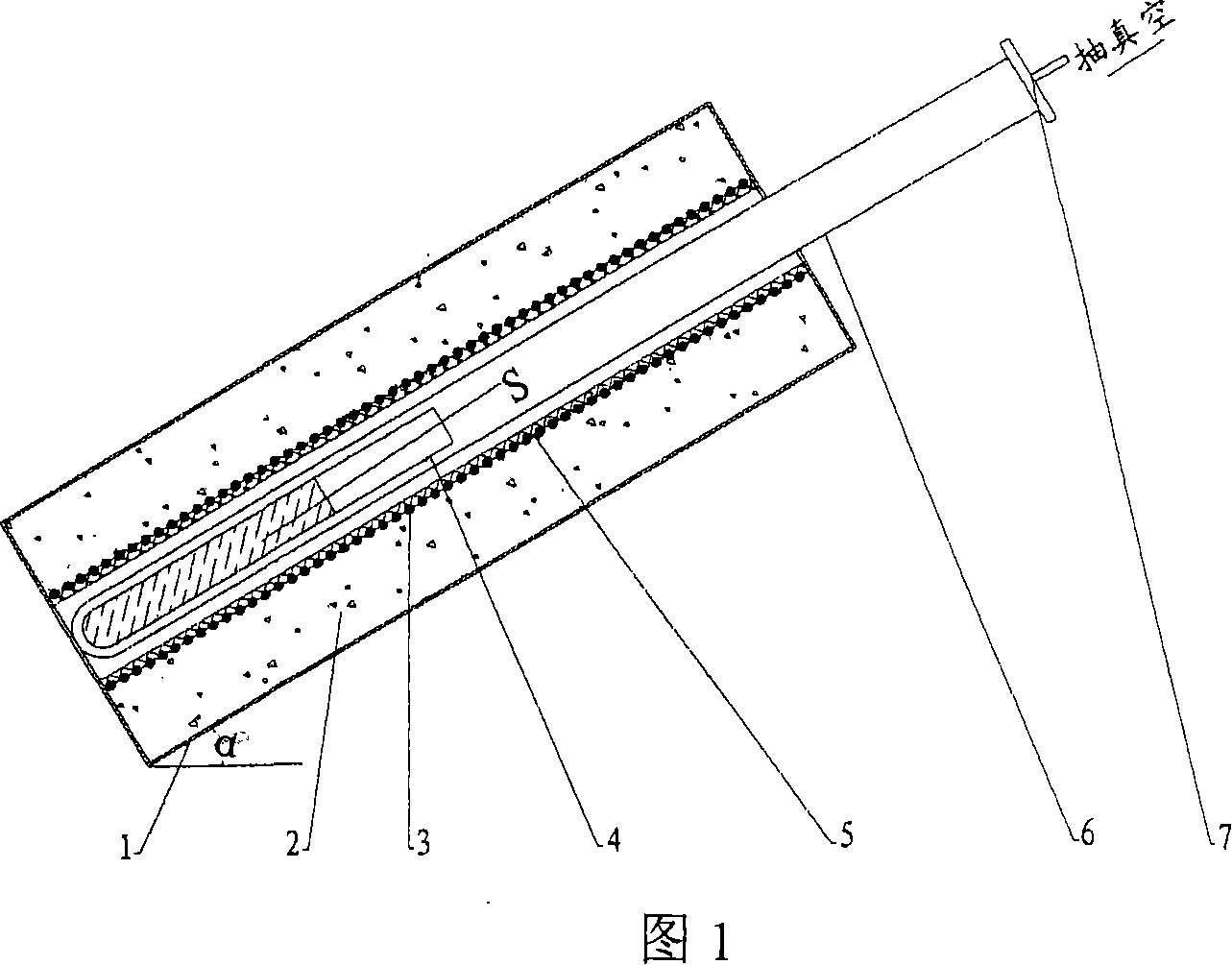

Method of producing high-pure sulfur

InactiveCN101125640AProduction method safetyProduction methods are environmentally friendlySulfur preparation/purificationInsulation layerVacuum pressure

The invention provides a producing method of high pure sulfur, which is characterized in filling 3 to 4 weight parts of 99 wt percent sulfur into a pot(4), then putting the pot with 99 wt percent sulfur into a quartz tube(6) which is put into a vacuum sublimation heating furnace(1). Wherein, the heating furnace is internally provided with an insulation layer(2), a heating wire(3), a pot(4), a furnace lining(5), a quartz tube(6) and a vacuum pressure cover(7), whose mounting obliquity Alpha is 30 to 45 degrees; moreover, one end of the quartz tube is sealed with the vacuum pressure cover(7) which is provided with an extraction vacuum hole; once the vacuum is extracted to 1 multiplies by 10-3 to 9 multiplies by 10-3Pa, the heating system of the vacuum sublimation heating furnace is opened, after that, waiting till the temperature of the heating furnace is up to 135 to 145 DEG C, the vacuum sublimation purifying is performed for 3.5 to 4.5 hours; after that, the vacuum and heating system is closed for cooling and discharging, thus, obtaining 2.3 to 3.0 weight parts of 5N sulfur product and having a yield of 75 to 78 percent.

Owner:四川鑫龙碲业科技开发有限责任公司

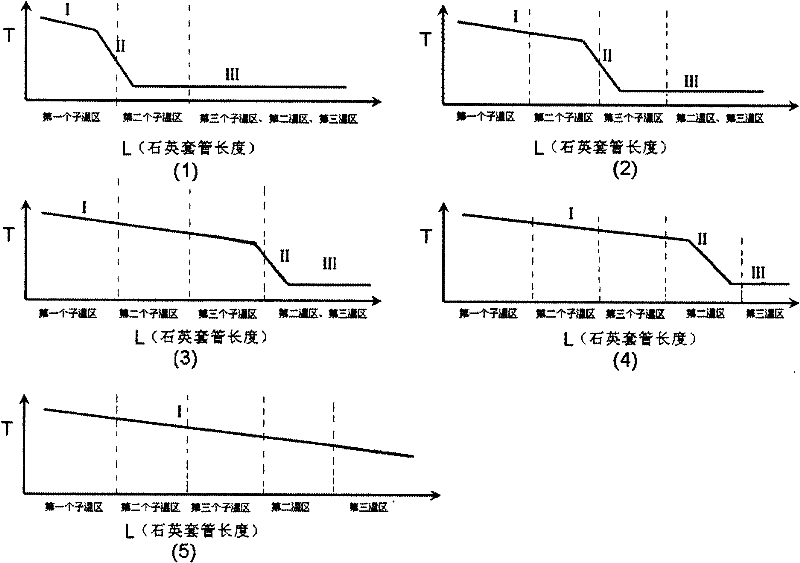

Vacuum sublimation purifying method of OLED (organic light emitting diode) material

ActiveCN102527076AImprove purification efficiencyHigh puritySublimationVacuum sublimationLight-emitting diode

The invention relates to a vacuum sublimation purifying method of OLED (organic light emitting diode). The method comprises the following steps of: placing the crude product of OLED in a first temperature area; heating the first temperature area to the first temperature area heating temperature, and keeping the temperatures of the second and third temperature areas lower than the lowest sublimation temperature of OLED material at the same time, and depositing after sublimation; heating the second temperature area to the second temperature area heating temperature, and keeping the temperatures of the first and third temperature areas at the same time, and further depositing after sublimation; heating the third temperature area to the third temperature area heating temperature, and keeping the temperatures of the first and second temperature areas at the same time, and further depositing after sublimation; reducing the temperatures of all temperature areas; and taking out the deposits on the second temperature area and on the interface area between the second temperature area and the third temperature area. The method provided by the invention can well prevent the removed impurities from returning to the purified material so as to realize higher purity and purifying efficiency; and the method has good effect in removing various impurities, and can realize simple continuous operations.

Owner:驻马店韵光科技有限公司

Method for debittering color protection and low-temperature processing of ginkgoes

InactiveCN104397509AReduce the temperatureReduce oxygen concentrationFood preparationQuick FreezeFreeze-drying

The invention discloses a method for debittering color protection and low-temperature processing of ginkgoes. The method comprises the following steps: 1, preparing a ginkgo raw material at first, screening the raw material, then peeling after pre-cooking the ginkgo raw material to obtain ginkgo nuts, and then performing debittering color protection and hardening on the ginkgo nuts; 2, quick-freezing the hardened ginkgo nuts by virtue of a low-temperature freeze-drying technology to ensure that compact tissues of the ginkgo nuts form micro-crystalline structures, performing vacuum sublimation under the quick-freezing condition to ensure that the ginkgo nuts become crisp, then unfreezing, putting into vacuum to perform immersion and cleaning, and draining after cleaning; and 3, performing vacuum frying on the drained nuts, performing vacuum oil removing during the vacuum frying, then performing product seasoning, and finally warehousing.

Owner:徐志扬

Pilose antler activity comprehensive processing and production technology

ActiveCN101642471AReduce biological activityLow chemical activityDigestive systemUnknown materialsVacuum sublimationBULK ACTIVE INGREDIENT

The invention relates to a pilose antler activity comprehensive processing and production technology, which comprises the following steps: washing fresh pilose antler, placing the fresh pilose antlerinto boiling water, and cooking and frying for 33 seconds for standby; slicing the cooked and fried fresh pilose antler, putting the fresh pilose antler into a drying oven with the temperature of minus 27 DEG C, and rapidly freezing for 2 hours; starting a condenser for refrigerating for 30 minutes at the temperature of minus 25 DEG C; starting a vacuum pump shovel until the vacuum degree in the oven is 7 Pa; continuously refrigerating in the condenser for 30 minutes at the temperature of minus 42 DEG C; putting the prepared fresh pilose antler into a heating device, and heating to the temperature of 60 DEG C; drying for 23 hours; pulverizing and sieving to acquire fine powdery pilose antler with the granularity of 110 meshes; and sterilizing and encapsulating. When in use, the moisture inthe pilose antler is rapidly frozen into ice for direct sublimation by adopting low-temperature freezing and vacuum sublimation principles, the moisture in the pilose antler is removed, and the active ingredients containing amino acid, protein and the like in the pilose antler are kept, thereby the pilose antler has high biological activity and chemical activity, high nutrition and high curativeeffect, and is easily absorbed.

Owner:BENXI LONGBAO GROUP GINSENG & VELVET

(Wood grain) surface treatment process for conducting laser radium on metal surface

InactiveCN102501713ASurface three-dimensional effect is obviousClose to the original ecological effect of solid woodNatural patternsDecorative surface effectsCooking & bakingSolid wood

The invention provides a (wood grain) surface treatment process for conducting laser radium on a metal surface. According to the process, the surface of a product is subjected to two times of coating, two times of baking and one time of transferring, the textures of the wood grains on the surface are sublimated into a semi-transparent coating of the surface of a base material, the textures of thewood grains on the surface of the product is weather resistant for about 10 years, and the base material is processed substantially due to the convex-concave effect on the surface of the base material, so that the three-dimensional effect of the surface of the product processed by the process is remarkable, wear-resistant and vivid, and is close to the original ecology effect of solid wood. According to the process, a section bar is subjected to radium radiation, so that the surface of the section bar shows the primary wood grain texture effect before the substantial coating, after the surface of the section bar is changed by the key process steps, the section bar is subjected to powder coating treatment and wood grain vacuum sublimation (two times of coating and two times of baking), andfinally, the extremely strong three-dimensional effect can be formed.

Owner:梁志华

Freeze drying for gas chromatography stationary phase deposition

The present disclosure relates to methods for deposition of gas chromatography (GC) stationary phases into chromatography columns, for example gas chromatography columns. A chromatographic medium is dissolved or suspended in a solvent to form a composition. The composition may be inserted into a chromatographic column. Alternatively, portions of the chromatographic column may be exposed or filled with the composition. The composition is permitted to solidify, and at least a portion of the solvent is removed by vacuum sublimation.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Method for processing bee larva and bee pupae through microwave vacuum freezing drying

The invention relates to a novel method for processing fresh bee larva and bee pupae through microwave vacuum freezing drying, which is mainly characterized in that the technology of adopting microwaves for providing heat required by the sublimation drying and the resolution drying in the vacuum freezing drying, adopting optical fiber / infrared rays for temperature measurement control and the like for carrying out deep processing on the bee larva and bee pupae. The technical processes comprise fresh bee larva and bee pupae pretreatment or pulping treatment, disc loading, pre-freezing, vacuum sublimation drying, vacuum resolution drying and the like, the ordinary vacuum freezing drying process generally adopts the surface heating, the heat resistance is great, and the drying speed rate is low, so the whole freeze drying process lasts for a long time, and the defects can be overcome when the microwave heating is used for providing the heat required by sublimation. The processing method has the advantages that nutrient contents of biological substances of the bee larva and the bee pupae and the like can be effectively preserved, and the shapes of the bee larva and the bee pupae can be perfectly maintained. The microwaves have the penetrating performance, the heat efficiency is high, the energy sources are saved, the processing speed is greatly accelerated, the drying time is shortened, and the efficiency is improved.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Preparation method of dendrobium officinale lozenge

ActiveCN103751556AFresh colorStrong fragranceDigestive systemAntinoxious agentsFlavorMechanical crushing

The invention discloses a preparation method of a dendrobium officinale lozenge. The preparation method comprises the following steps of ultrasonically processing fresh dendrobium officinale lozenge strips; taking out and drying in the air; crushing the fresh dendrobium officinale lozenge strips together with water in a mass ratio of 1: (10-15) for 3 to 5 minutes; emulsifying for 25 to 35 minutes; performing ultrasonic cell wall breaking, wherein the ultrasonic frequency is 20 to 25kHz, the slot time is 2 to 4 seconds, the ultrasonic processing needs 2 to 4 seconds, and the whole process needs 50 to 70 minutes; freezing at an ultralow temperature of -50 to -35 DEG C; and carrying out vacuum sublimation and drying for 24 to 36 hours to obtain the lozenge. According to the preparation method of the dendrobium officinale lozenge, mechanical crushing and ultrasonic cell wall-breaking enable sped-up release of effective ingredients of dendrobium officinale, and the obtained lozenge can contain 60% of dendrobium polysaccharides. The dendrobium officinale lozenge has bright color and luster, and aromatic flavor, just melts in the mouth, tastes great, is long in shelf line, and enables the effective ingredients of dendrobium polysaccharides to be fully absorbed by a human body, and thus the bioavailability of dendrobium polysaccharides can be greatly improved.

Owner:宁波易中禾生物技术有限公司

Preparation method of high-purity citrus aurantium flower essential oil and flavor addition essence used for cigarettes and blended with high-purity citrus aurantium flower essential oil

InactiveCN106635418AFree from pollutionEasy to separateTobacco preparationTobacco treatmentDistillationVacuum sublimation

The invention discloses a preparation method of high-purity citrus aurantium flower essential oil and flavor addition essence used for cigarettes and blended with the high-purity citrus aurantium flower essential oil. The preparation method of the high-purity citrus aurantium flower essential oil takes fresh citrus aurantium flowers as raw material and comprises the following steps: carrying out atomizing, pre-freezing, vacuum sublimation and drying and crushing treatment on the raw materials in sequence, and filling the crushed citrus aurantium flower raw material and fluid at a supercritical state into an extraction kettle; extracting to obtain crude oil extracted from the citrus aurantium flower supercritical fluid; and carrying out secondary molecular distillation on the citrus aurantium flower crude oil and purifying and separating to obtain the high-purity citrus aurantium flower essential oil. Then the high-purity citrus aurantium flower essential oil is blended with California lemon oil, Brazilian sweet orange oil, caraway oil and alcohol to prepare the flavor addition essence used for the cigarettes. According to the preparation method disclosed by the invention, the citrus aurantium flower oil can be rapidly, efficiently and sufficiently extracted and separated; the operation is simple and convenient, the separation speed is rapid and the production efficiency is greatly improved; and the prepared flavor addition essence used for the cigarettes and blended with the citrus aurantium flower essential oil has soft, fine and smooth smoke and the effect of increasing the sweet taste of the smoke is enhanced.

Owner:HUBEI CHINA TOBACCO IND

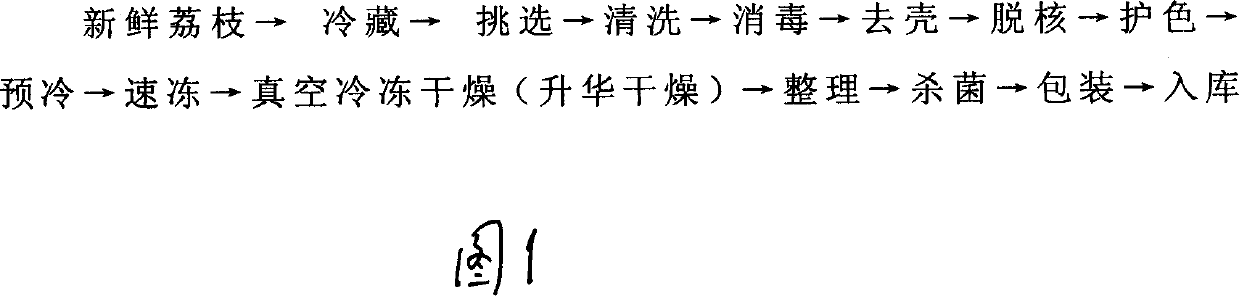

Method of vacuum freezing drying litchi pulp

InactiveCN1493210AQuality improvementMuch lossFood preservationFood preparationFreeze-dryingAdditive ingredient

A method for preparing the vacuum freeze dried litchi pulp includes mixing the fresh litchi pulp with citric acid and ascorbic acid for protecting color, prefreezing, quickly freezing, and vacuum sublimation drying. It can retain origional color, smell and taste of litchi pulp.

Owner:ZHENZHOU GROUP HUIZHOU CITY

Solidification method and equipment for unearthed bamboo and wooden wares

InactiveCN101890746ASolve problems such as dehydrationSimple structureWood impregnation detailsCold airHigh concentration

The invention relates to a solidification method and equipment for unearthed bamboo and wooden wares. The solidification method comprises the following steps of: (a) pre-treating: cleaning a ware to be treated, weighing the ware and recording the weight; (b) performing hot-dip replacement: dipping the ware in a closed vessel which is filled with solution of antibacterial solidifying agent for the hot-dip replacement, wherein the solution of the solidifying agent consists of multiple parts of PEG solution from low concentration to high concentration; (c) measuring an eutectic point: detecting the eutectic point of the solution of the solidifying agent and the solution in the ware to determine a pre-freezing temperature after the hot-dip replacement is finished; and (d) performing freezing sublimation: reducing the temperature of the ware to the pre-freezing temperature by cold air freezing and performing vacuum sublimation for dehydration. The equipment comprises a pre-freeze drying device, wherein the pre-freeze drying device comprises a sealed tank in which multiple layers of shelves are arranged, and provided with a condensing device, a heating device, a vacuum device, a refrigerating device, a weighing device and an electric control device. Through the method and the equipment, integrated operation of the pre-freezing device and the sublimation dehydration device is realized, and the problems such as dehydration of large-sized wooden cultural relics and the like are solved while the structure of the equipment is simplified through the overall coordinated operation of the electric control device and by matching the ware shelves.

Owner:浙江省博物馆 +1

Multichannel vacuum sublimation apparatus and using method thereof

PendingCN110354525APrecisely control the heating partPrecise temperature controlSublimationSimple Organic CompoundsVacuum sublimation

Owner:ZHENGZHOU UNIV

Production method of solid rice wine

InactiveCN107653147ASweet and mellow tasteDecreased alcohol contentAlcoholic beverage preparationAlcohol contentFreeze-drying

The invention relates to a production method of solid rice wine. The method comprises the following steps: directly adding purified water or aqueous extract of flowers, Chinese herbal medicines, fruits or tea while mechanically crushing and stirring rice wine; carrying out medium-high microwave sterilization for 90-120 s, sub-packaging the obtained rice wine in a container, placing the container in a vacuum freeze-drying machine cold trap, pre-freezing the rice wine at -45 to -50 DEG C for 10-15 h to form ice crystal blocks; and carrying out vacuum sublimation drying at -45 to 25 DEG C and gradually changing the pressure to 20 pa from 200 pa within 36-60 h to obtain the white crystal solid rice wine or nutritional health preserving solid wine. Rice grains of the rice wine are adopted as afreeze-drying molding supporter, so the produced solid rice wine or nutritional health preserving solid rice wine keeps the sweet and mellow mouthful of the original rice wine after being rehydrated;the amino acid content does not change basically, and the alcohol content is reduced; the solid rice wine can be instantly eaten after being dissolved in fresh boiled water; and the solid rice wine isportable, is easy to store, and is suitable for being promoted and applied at home and in restaurants and bars.

Owner:武汉东保科技开发有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com