Industrialized producing method for high-purity arsenic

A high-purity arsenic and elemental technology, applied in chemical instruments and methods, arsenic compounds, preparation with chloride, etc., can solve the problems of high cost, long process, and large pollution, so as to increase production capacity, overcome large pollution, and improve production capacity. The effect of success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Purification and sublimation for the first time: Firstly, the raw material industrial god (99%) is sublimated under a state of vacuum of 0.1×10Pa and temperature of 540°C to obtain 3--4N arsenic with relatively small impurity content.

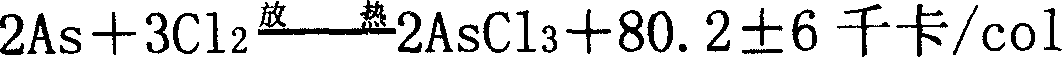

[0032] Secondary purification distillation: let arsenic and chlorine react chemically to obtain liquid AsCl 3 , and then make the liquid AsCl 3 Initially evaporate at 133°C to remove impurities with a boiling point higher than this temperature to obtain 4-5N liquid AsCl 3 .

[0033] Dechlorination: making liquid AsCl 3 The free excess chlorine, sulfur and selenium impurities are removed at 133°C. Get Better Liquid AsCl 3 .

[0034] Three times of purification and rectification: AsCl after dechlorination 3 After many times and repeated exchanges of vapor and liquid in the first tower, the second tower, and the third tower, 7N-8N high-purity liquid AsCl is obtained 3 .

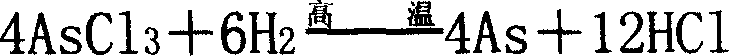

[0035] Hydrogen reduction: making liquid AsCl 3 Reduction re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com