Patents

Literature

708results about "Preparation from chlorides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

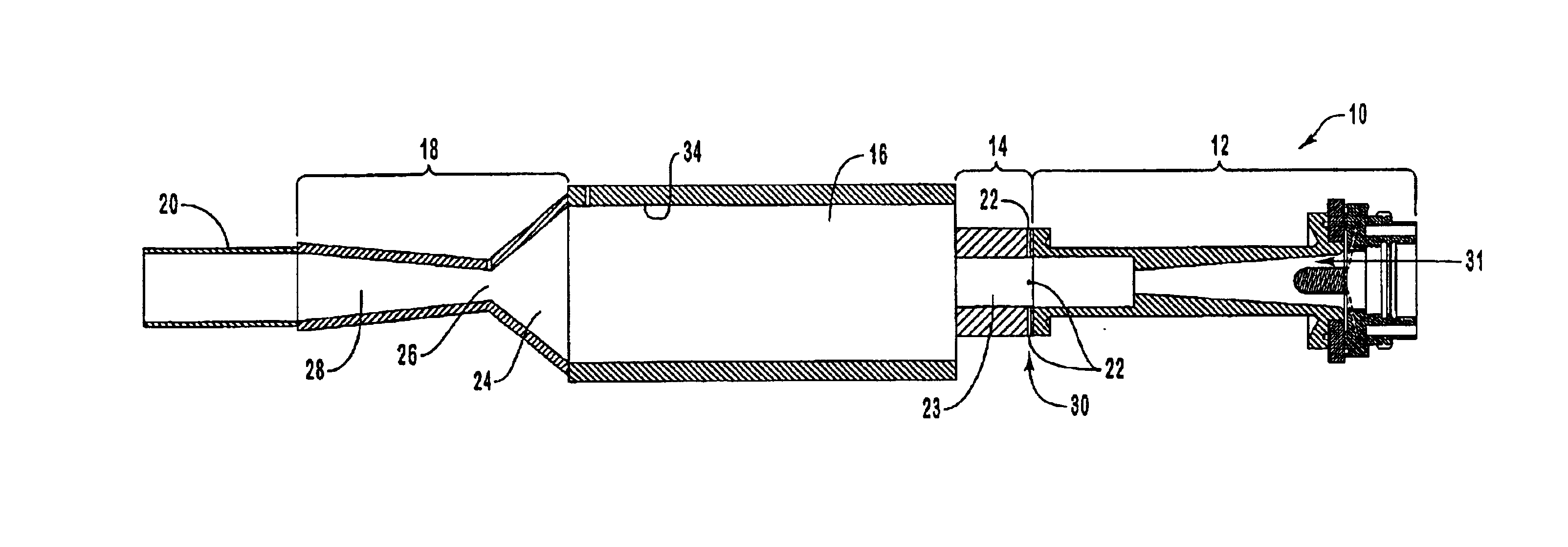

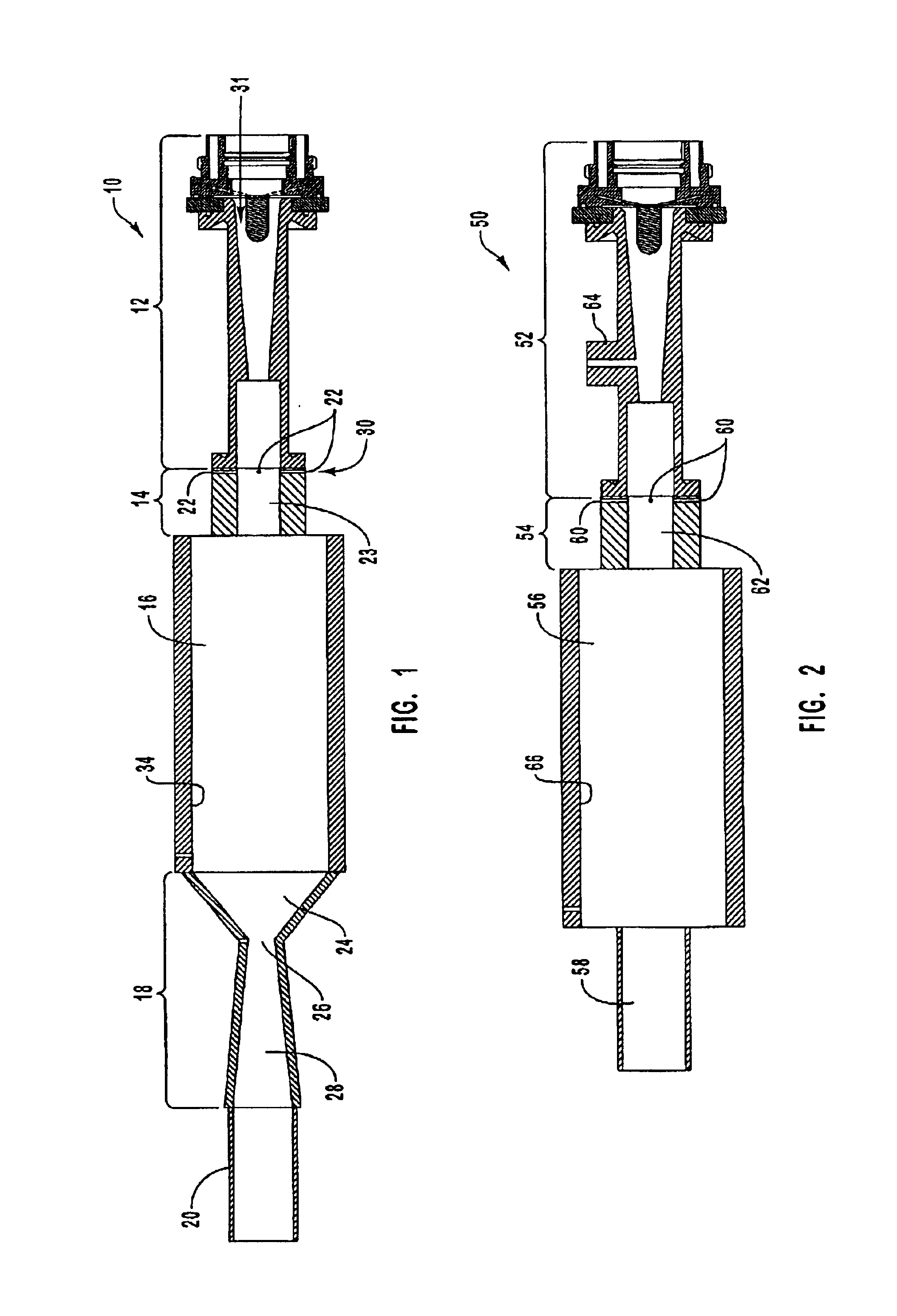

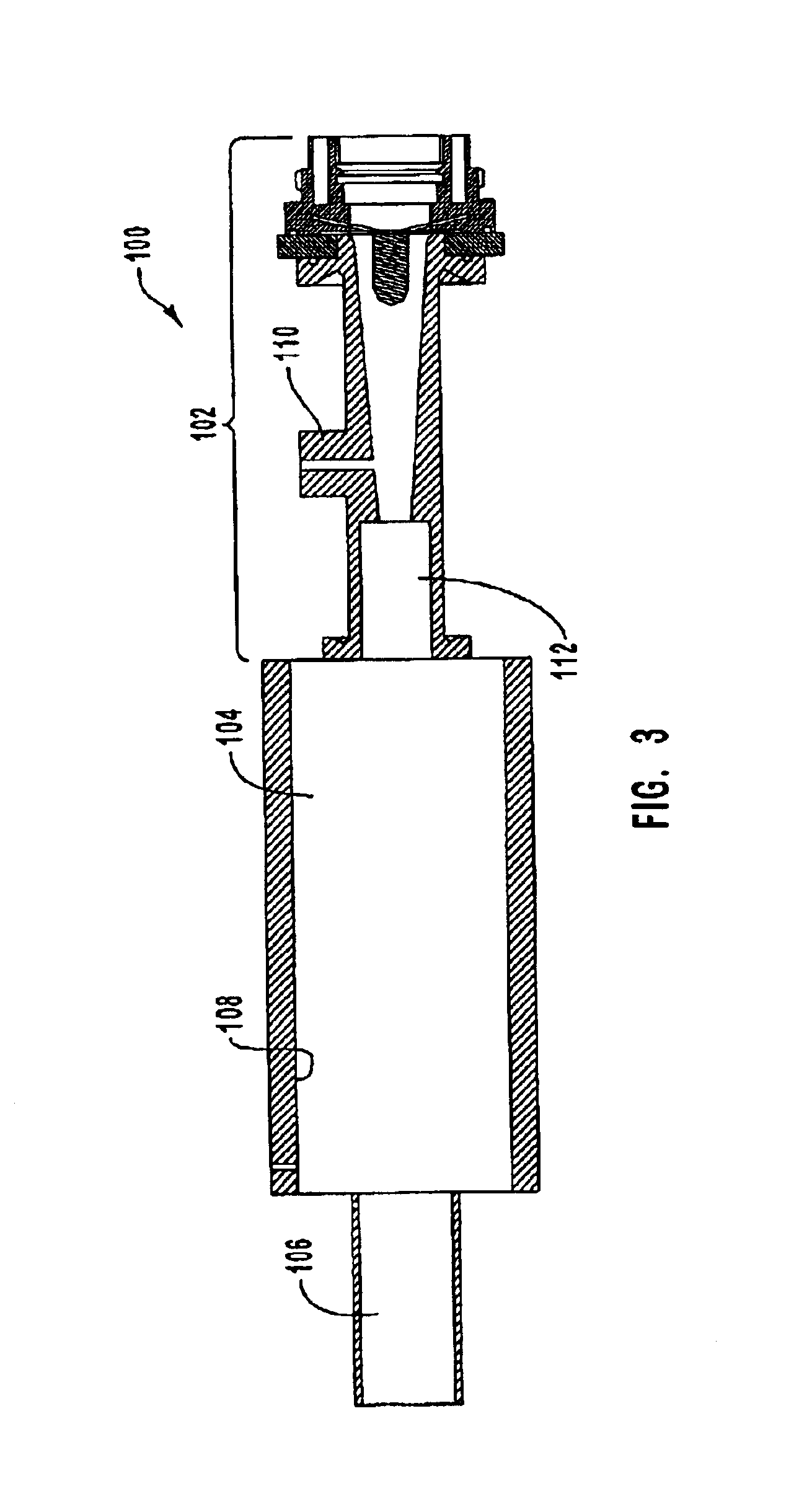

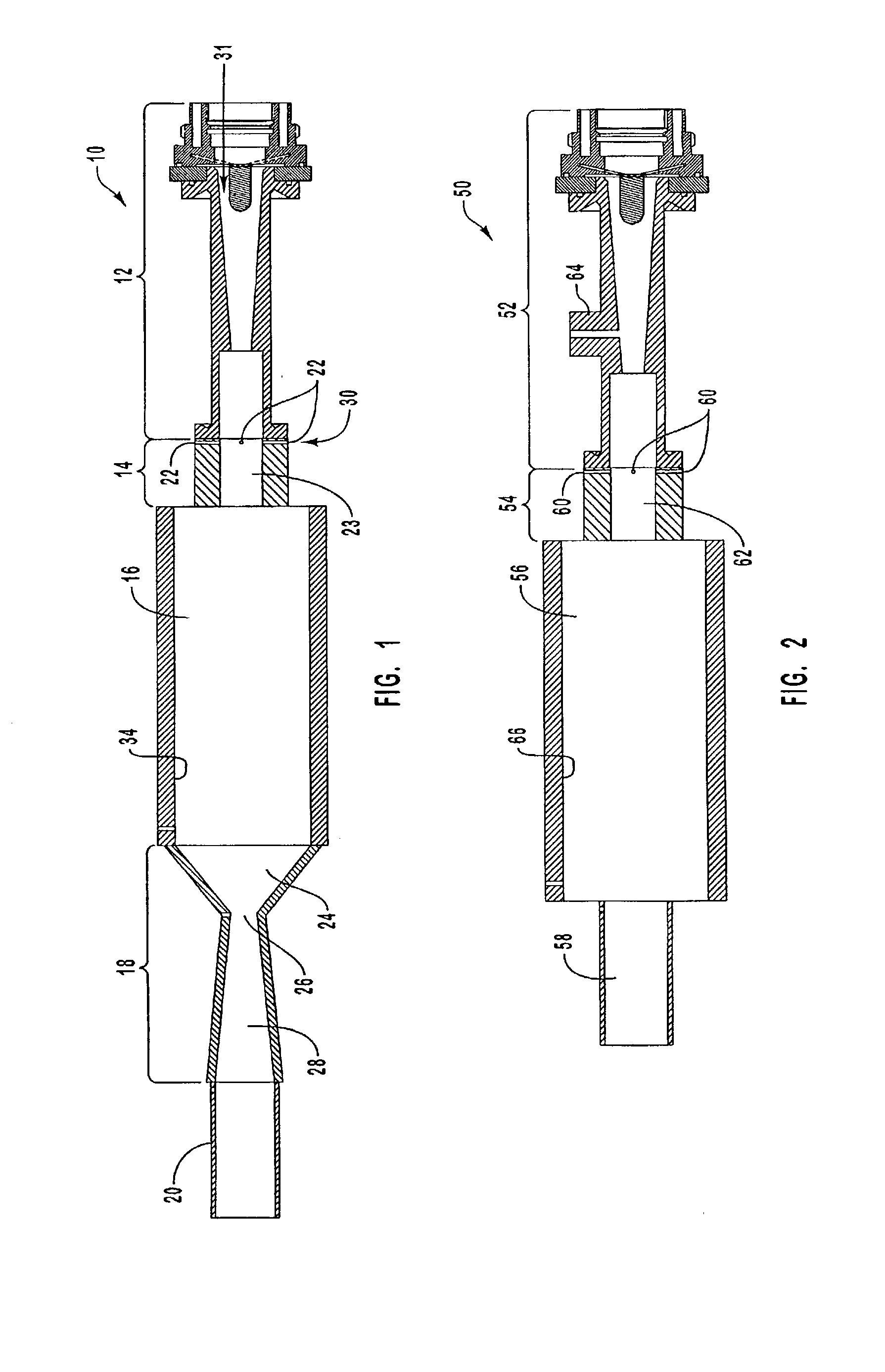

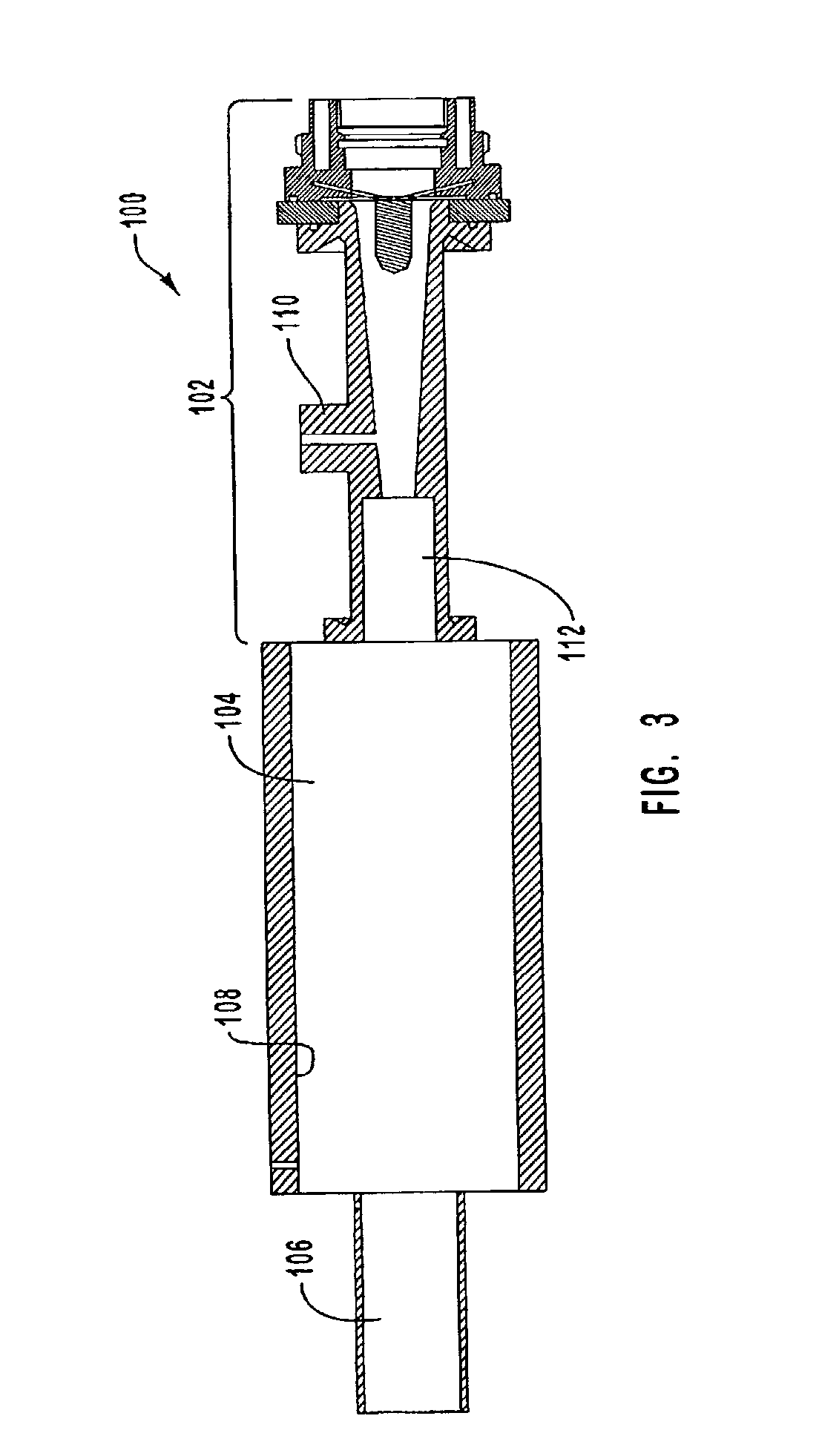

Thermal synthesis apparatus and process

InactiveUS6821500B2Improve efficiencyHigh yieldCarbon monoxideIndirect heat exchangersNuclear engineeringReaction zone

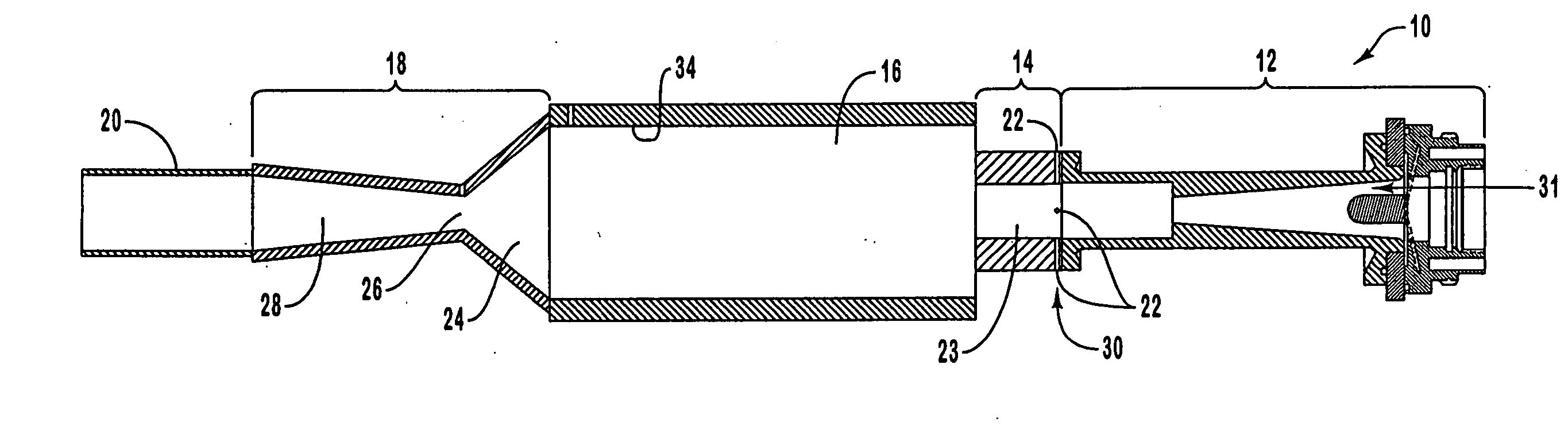

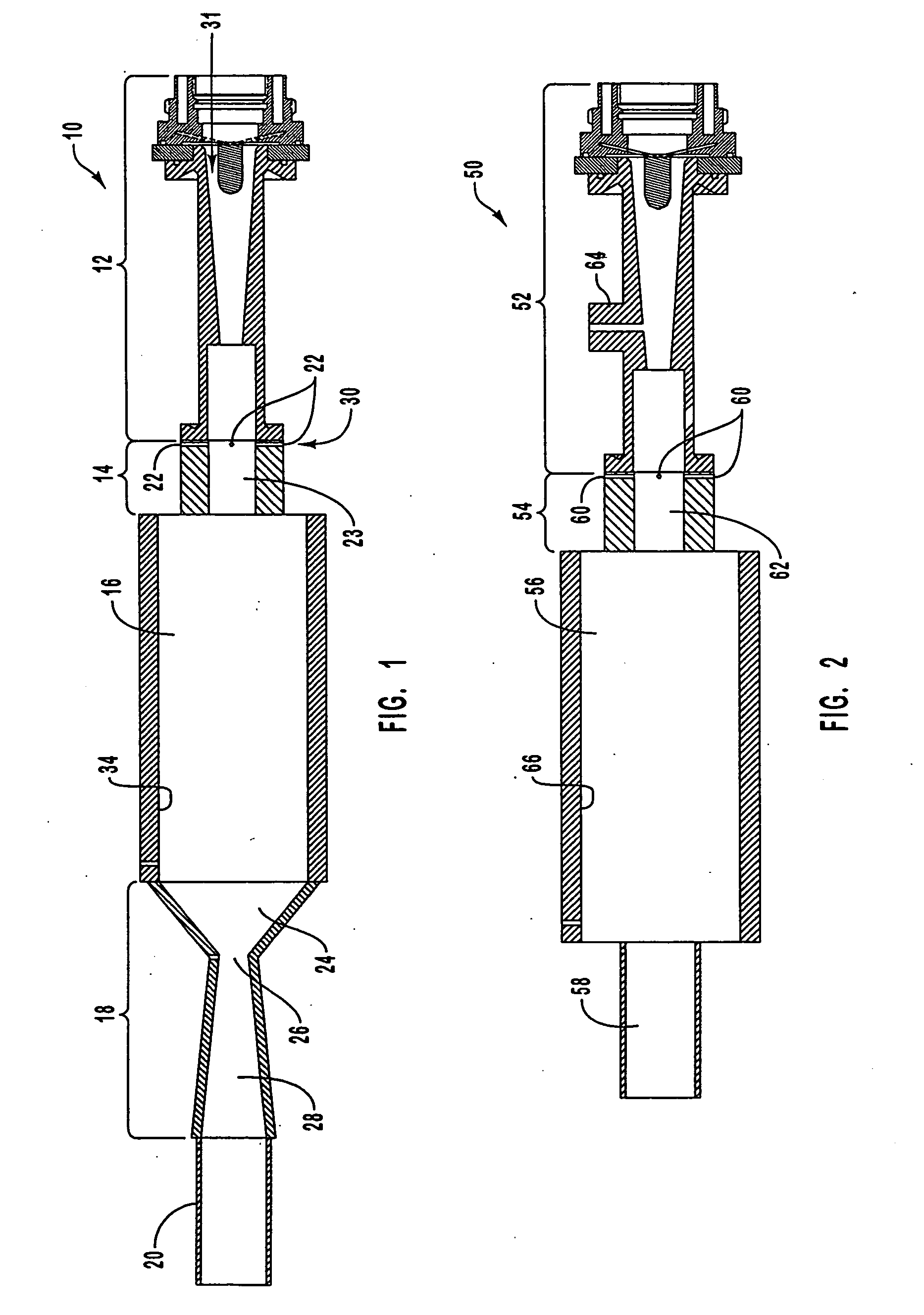

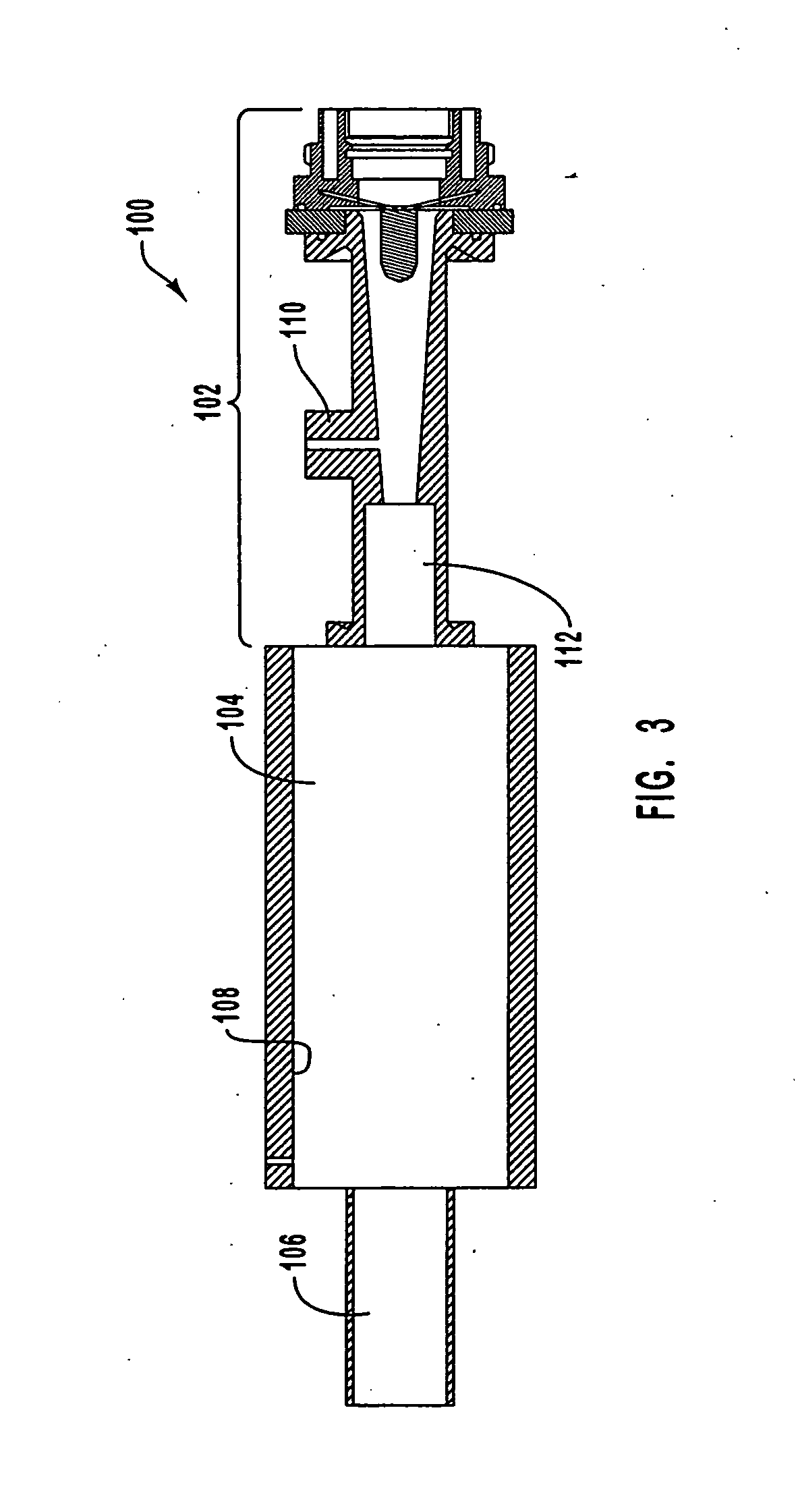

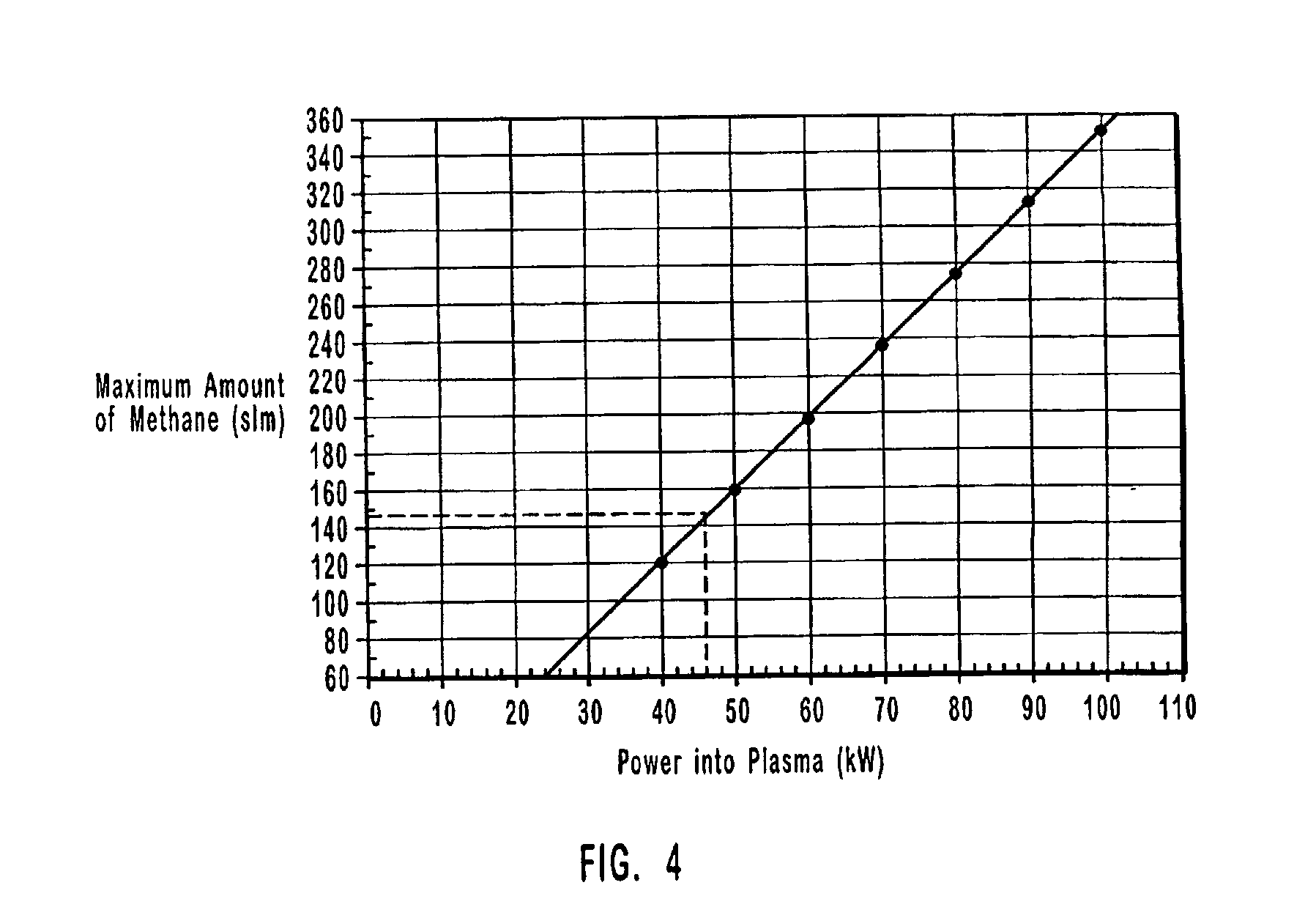

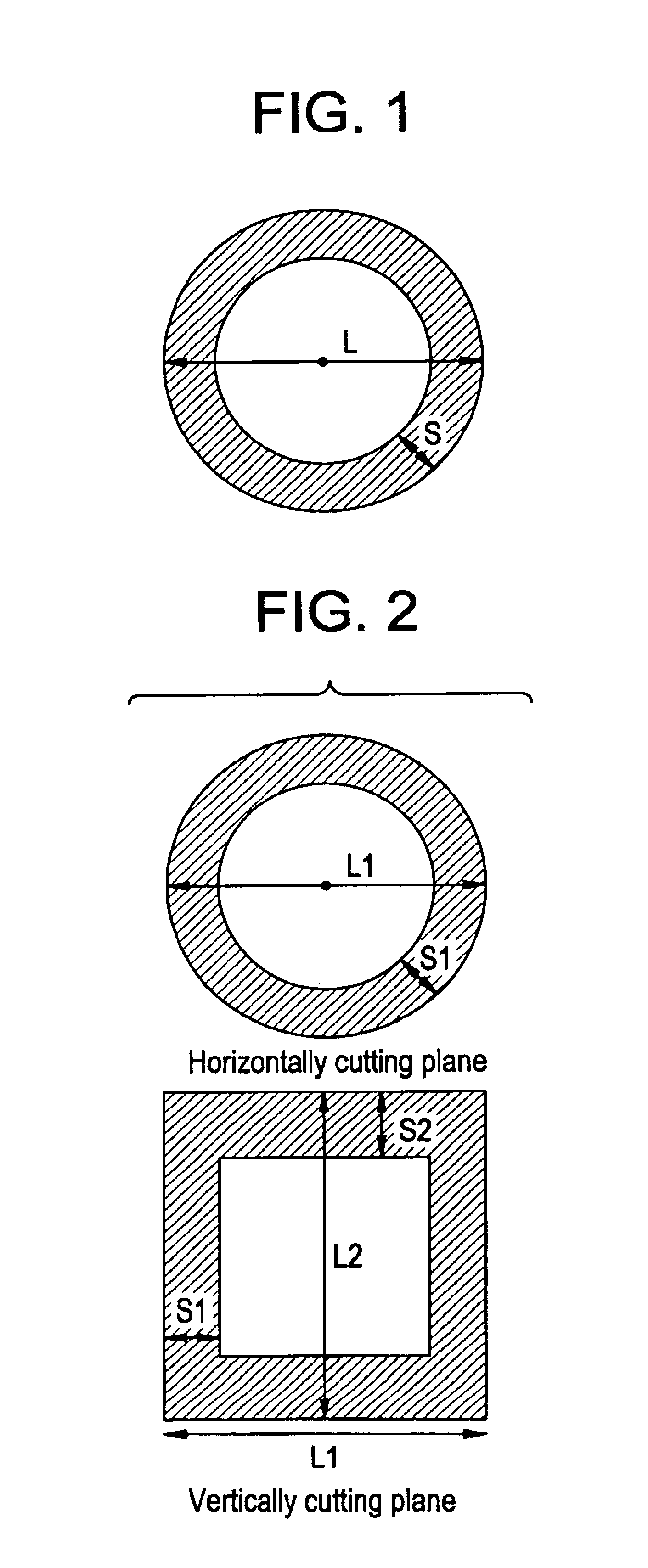

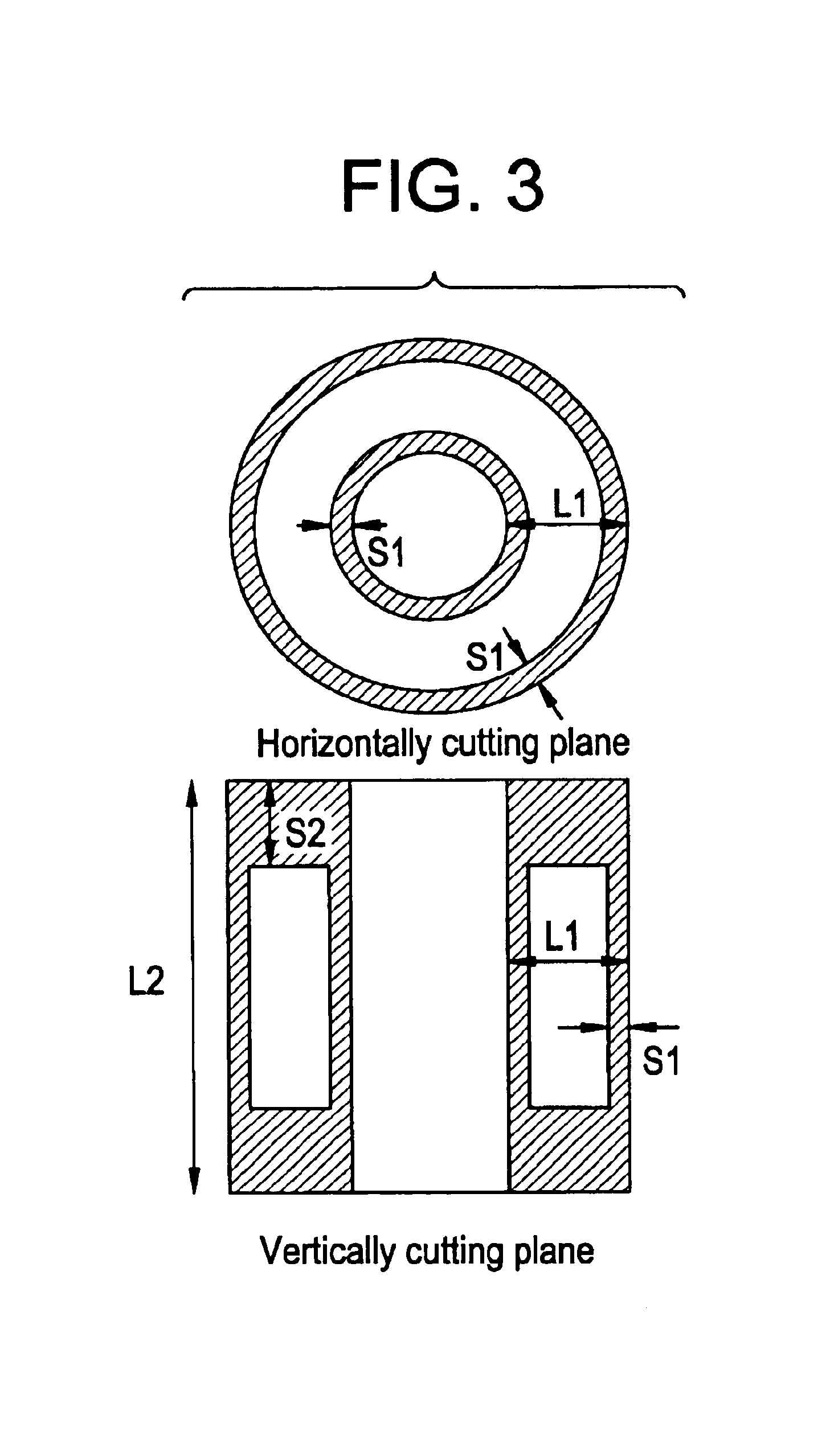

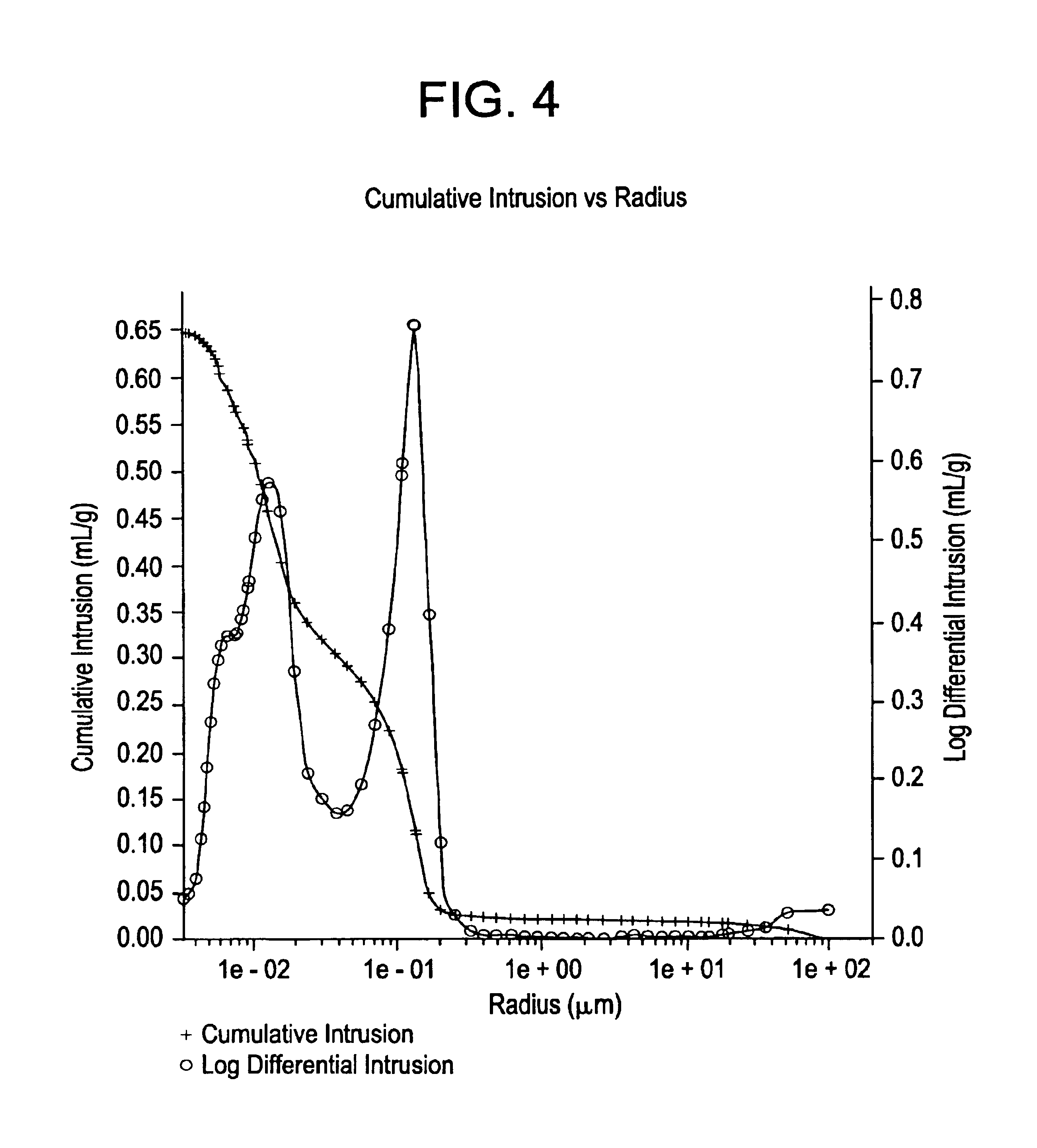

An apparatus for thermal conversion of one or more reactants to desired end products includes an insulated reactor chamber having a high temperature heater such as a plasma torch at its inlet end and, optionally, a restrictive convergent-divergent nozzle at its outlet end. In a thermal conversion method, reactants are injected upstream from the reactor chamber and thoroughly mixed with the plasma stream before entering the reactor chamber. The reactor chamber has a reaction zone that is maintained at a substantially uniform temperature. The resulting heated gaseous stream is then rapidly cooled by passage through the nozzle, which "freezes" the desired end product(s) in the heated equilibrium reaction stage, or is discharged through an outlet pipe without the convergent-divergent nozzle. The desired end products are then separated from the gaseous stream.

Owner:BATTELLE ENERGY ALLIANCE LLC

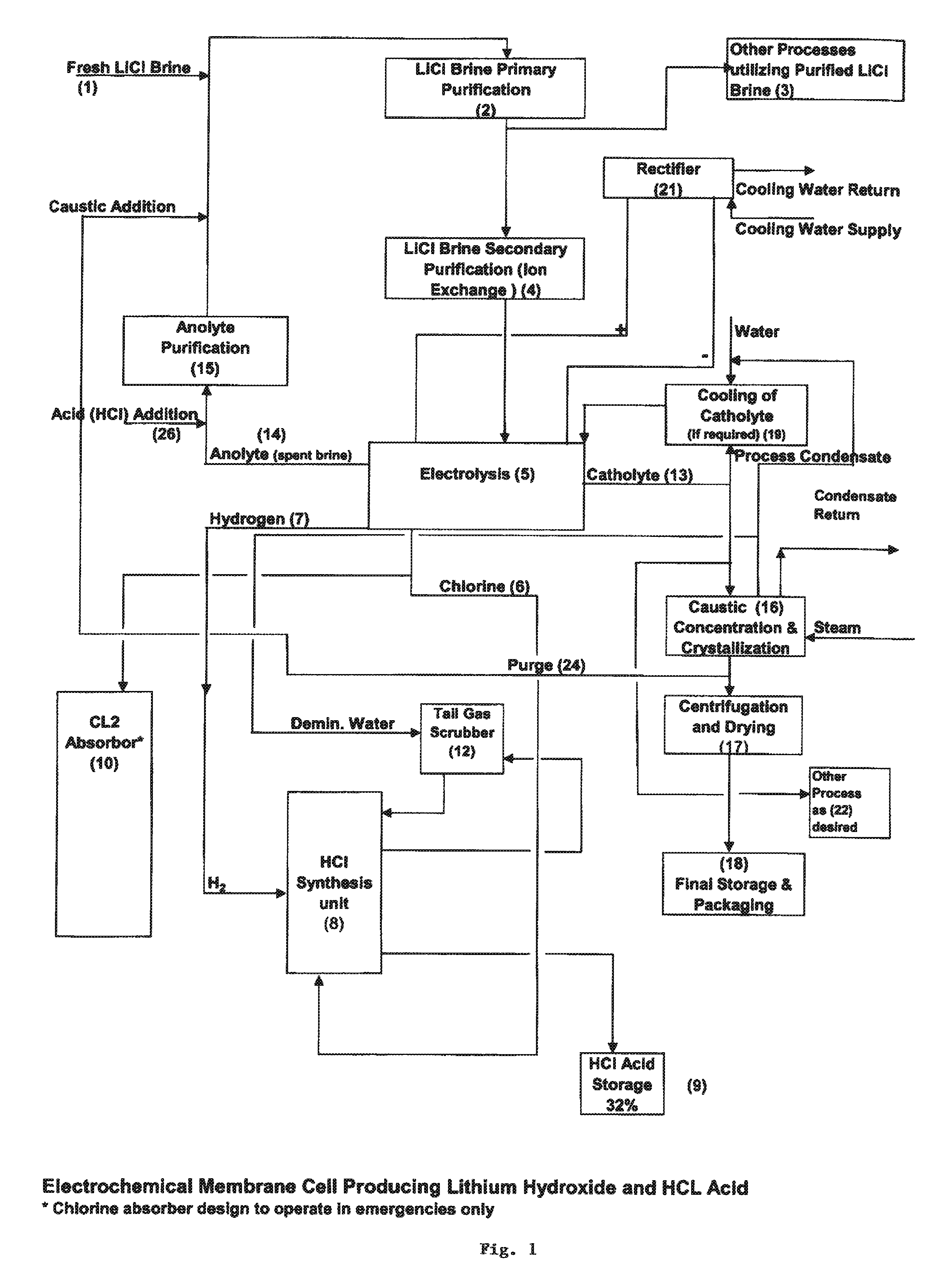

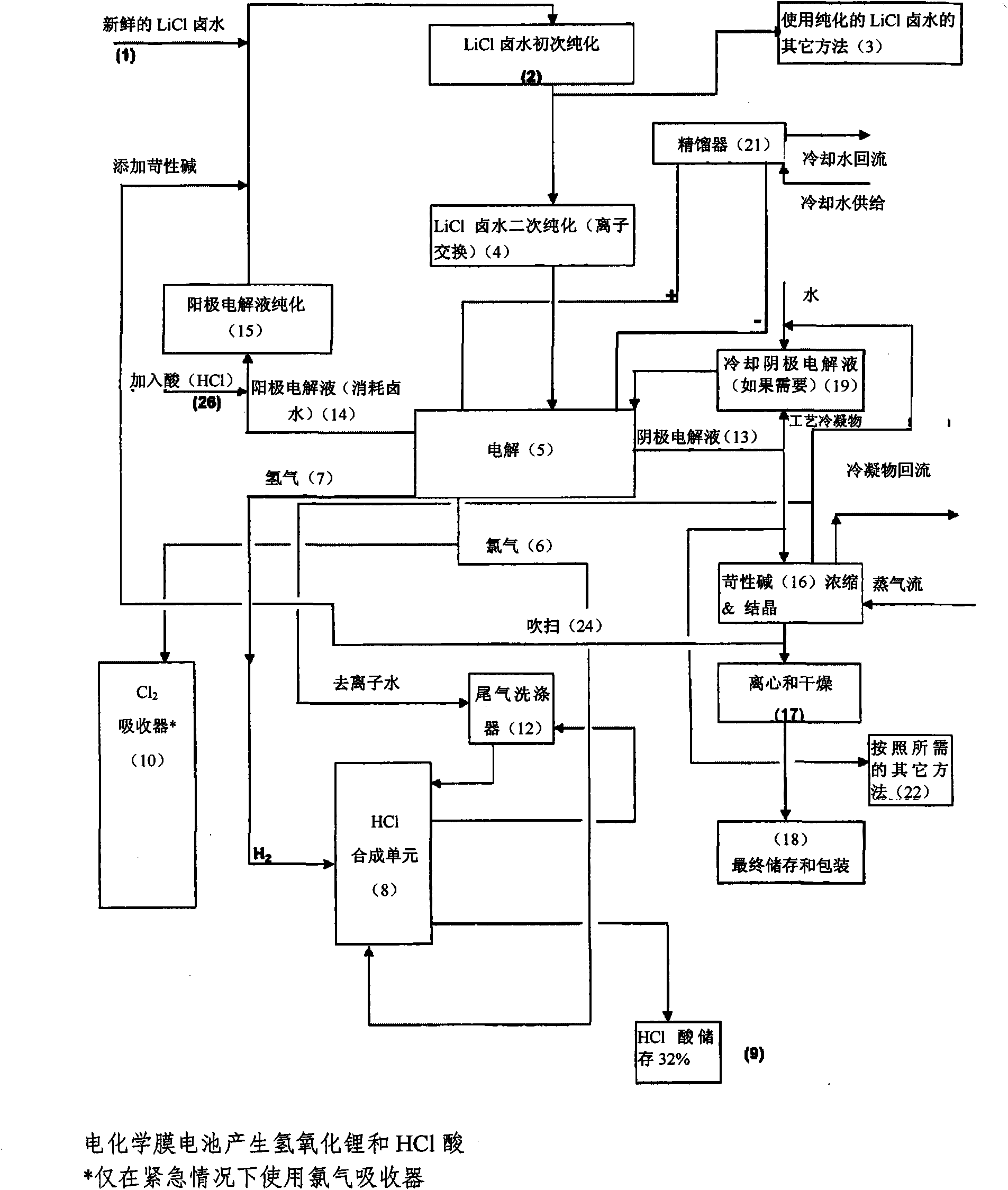

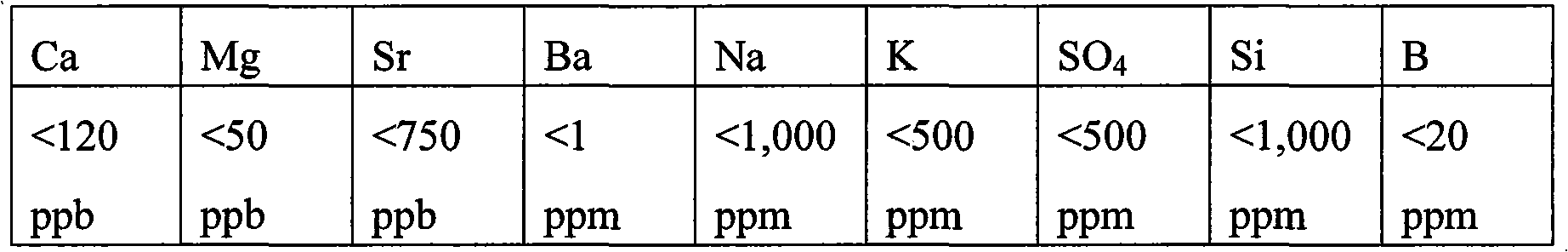

Method of making high purity lithium hydroxide and hydrochloric acid

InactiveUS20110044882A1Simple and economical processEasy to convertElectrolysis componentsEnergy inputElectrolysisIon exchange

The present invention relates to a process for producing high purity lithium hydroxide monohydrate, comprising following steps: concentrating a lithium containing brine; purifying the brine to remove or to reduce the concentrations of ions other than lithium; adjusting the pH of the brine to about 10.5 to 11 to further remove cations other than lithium, if necessary; neutralizing the brine with acid; purifying the brine to reduce the total concentration of calcium and magnesium to less than 150 ppb via ion exchange; electrolyzing the brine to generate a lithium hydroxide solution containing less than 150 ppb total calcium and magnesium, with chlorine and hydrogen gas as byproducts; producing hydrochloric acid via combustion of the chlorine gas with excess hydrogen and subsequent scrubbing of the resultant gas stream with purified water, if elected to do so; and concentrating and crystallizing the lithium hydroxide solution to produce lithium hydroxide monohydrate crystals.

Owner:ROCKWOOD LITHIUM INC

Thermal synthesis apparatus

InactiveUS20040208805A1Smoothly accelerateExpand smoothlyHydrogenCarbon monoxideNuclear engineeringReaction zone

An apparatus for thermal conversion of one or more reactants to desired end products includes an insulated reactor chamber having a high temperature heater such as a plasma torch at its inlet end and, optionally, a restrictive convergent-divergent nozzle at its outlet end. In a thermal conversion method, reactants are injected upstream from the reactor chamber and thoroughly mixed with the plasma stream before entering the reactor chamber. The reactor chamber has a reaction zone that is maintained at a substantially uniform temperature. The resulting heated gaseous stream is then rapidly cooled by passage through the nozzle, which "freezes" the desired end product(s) in the heated equilibrium reaction stage, or is discharged through an outlet pipe without the convergent-divergent nozzle. The desired end products are then separated from the gaseous stream.

Owner:BATTELLE ENERGY ALLIANCE LLC

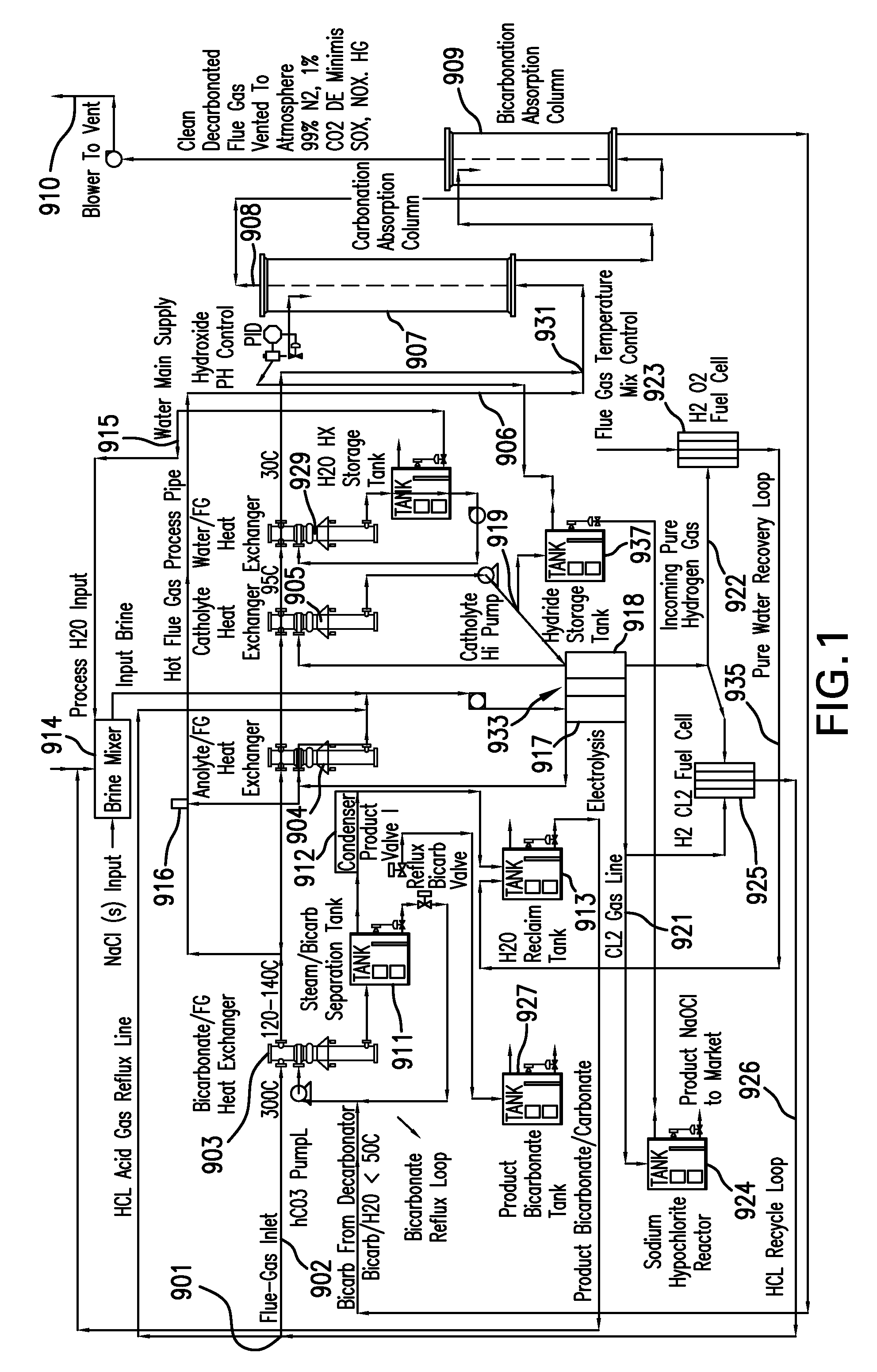

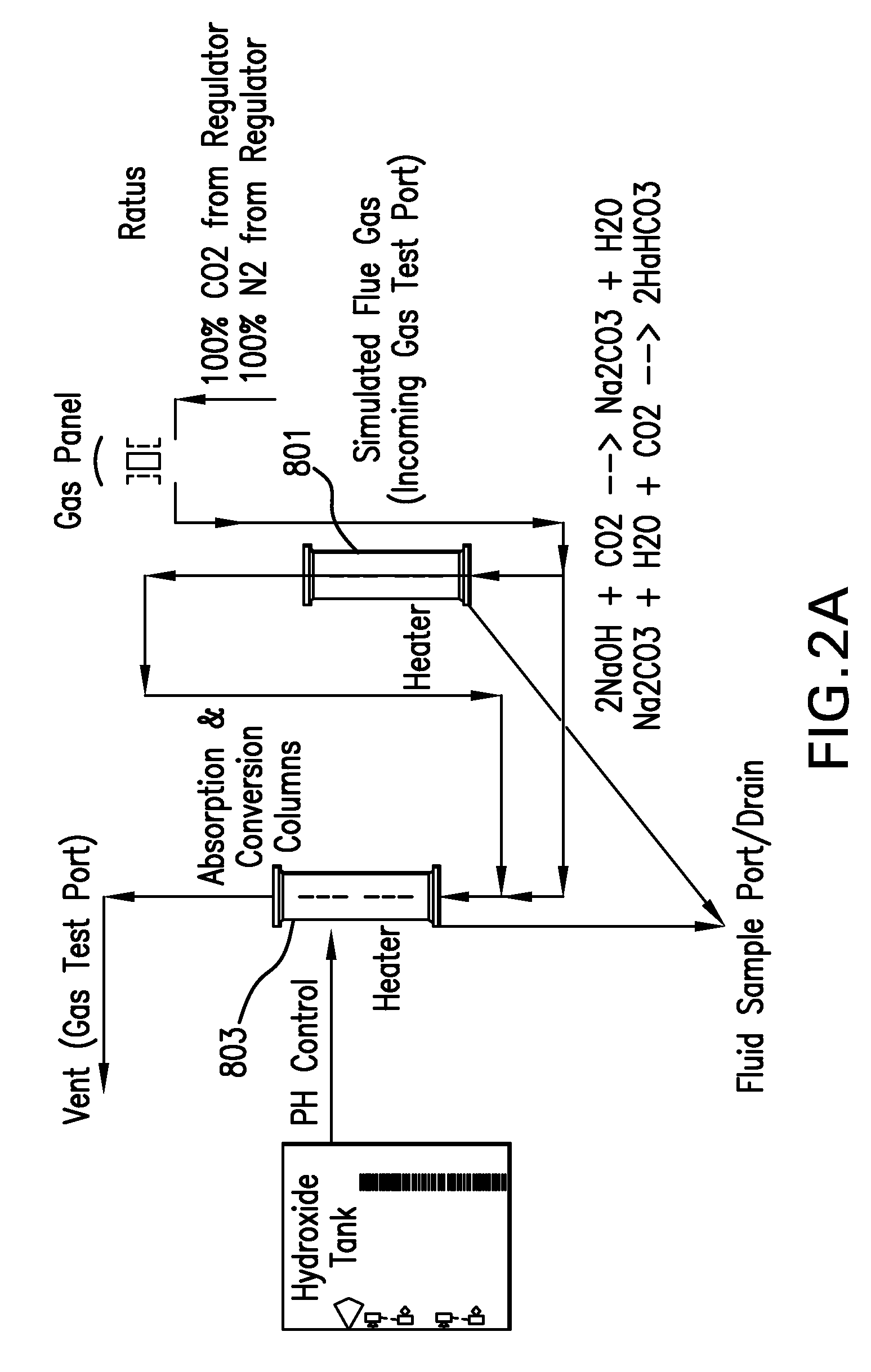

Removing Carbon Dioxide From Waste Streams Through Co-Generation of Carbonate and/or Bicarbonate Minerals

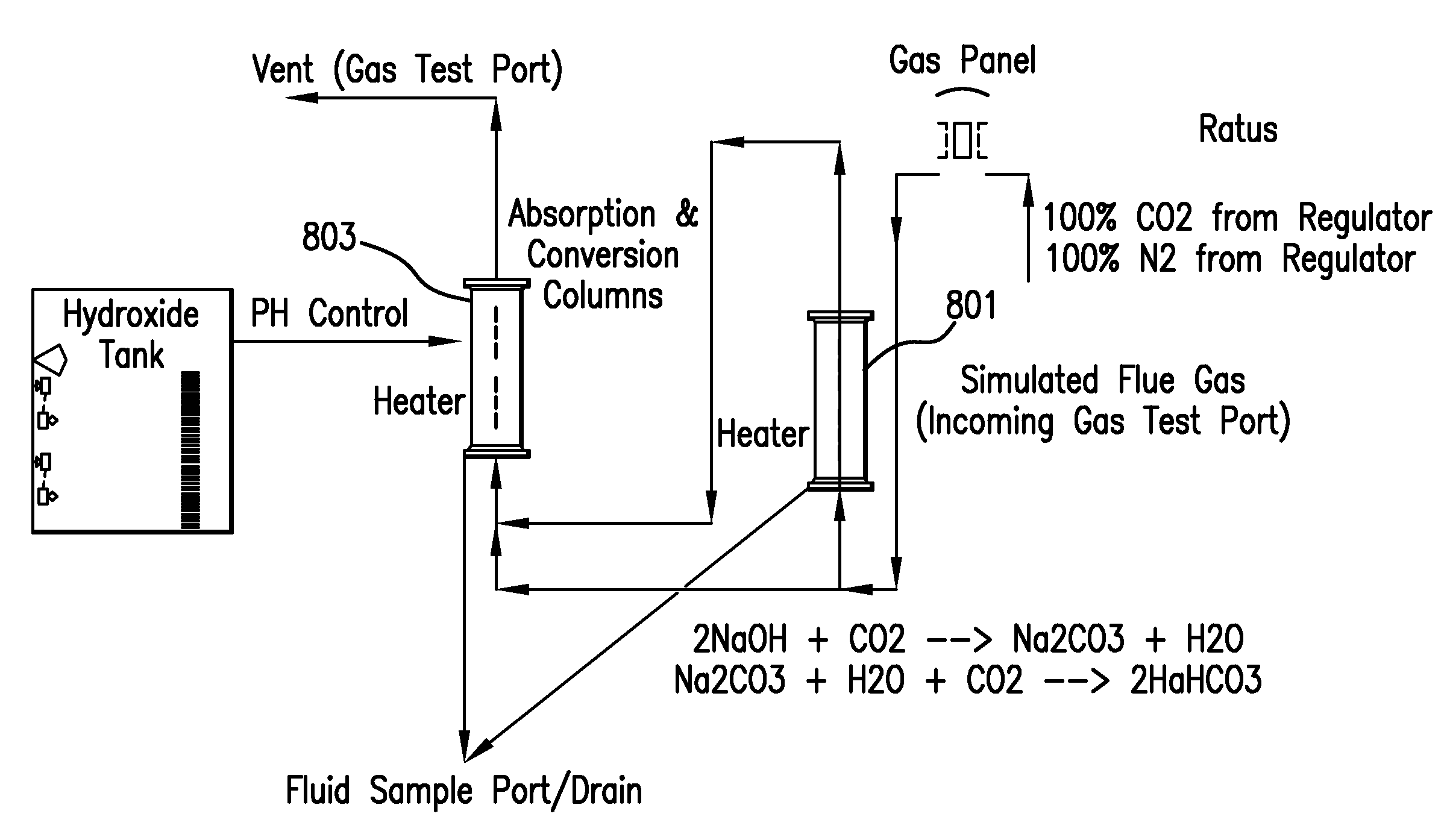

ActiveUS20090127127A1Prevent returnChloride preparationCalcium/strontium/barium chloridesDicarbonateElectrolysis

Apparatuses and methods for removing carbon dioxide and other pollutants from a gas stream are provided. The methods include obtaining hydroxide in an aqueous mixture, and mixing the hydroxide with the gas stream to produce carbonate and / or bicarbonate. Some of the apparatuses of the present invention comprise an electrolysis chamber for providing hydroxide and mixing equipment for mixing the hydroxide with a gas stream including carbon dioxide to form an admixture including carbonate and / or bicarbonate.

Owner:CARBONFREE CHEM HLDG LLC

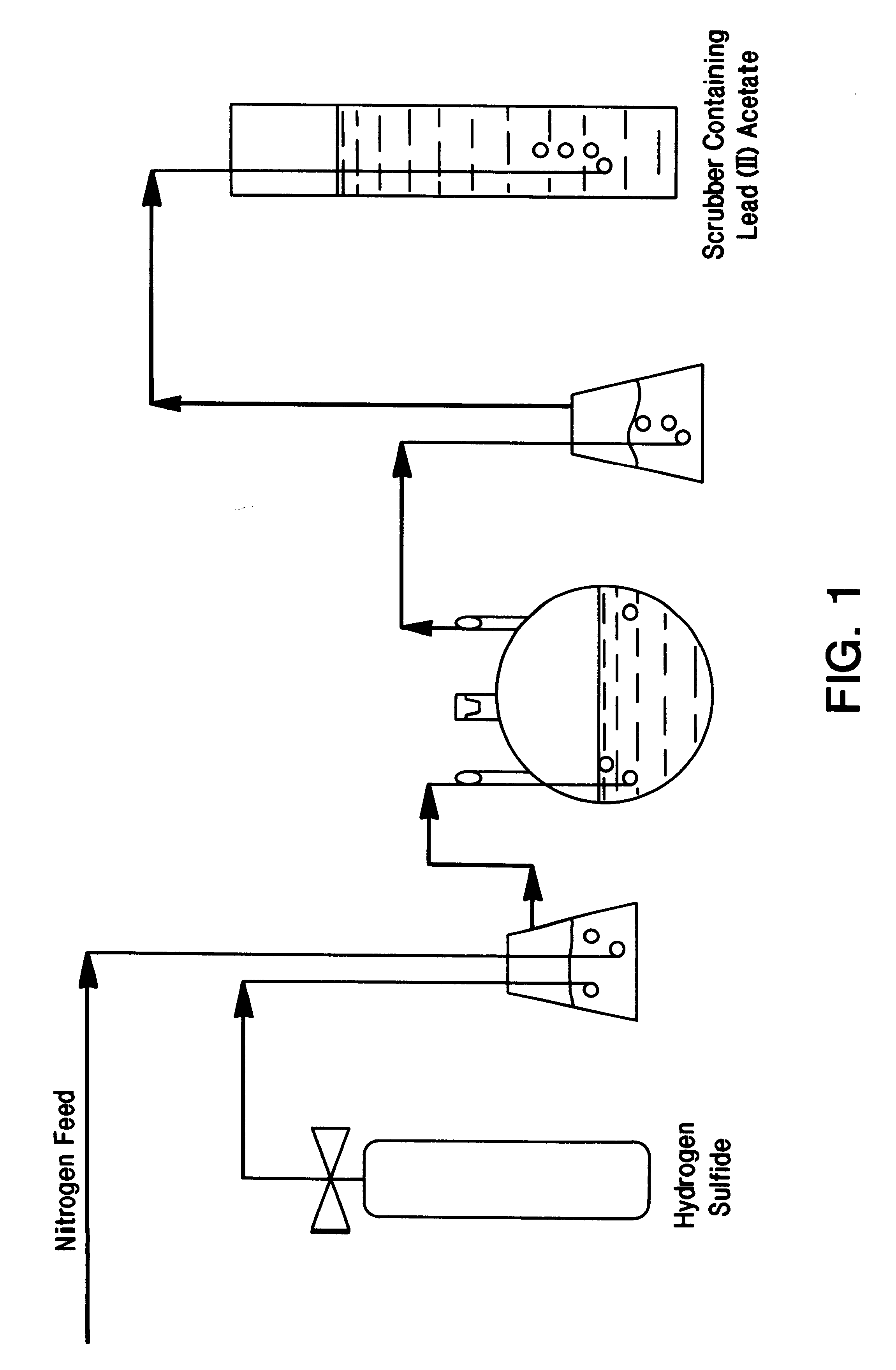

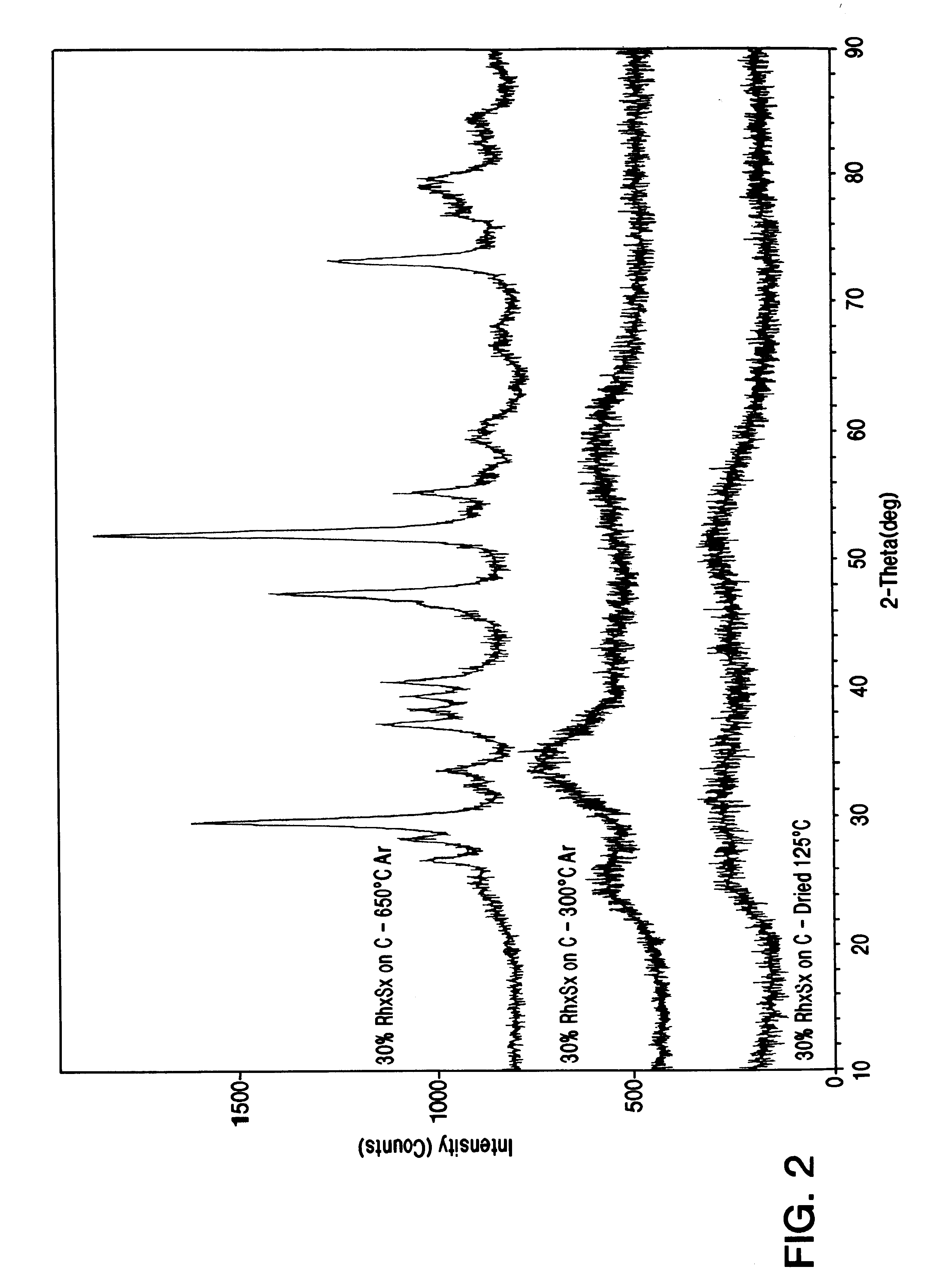

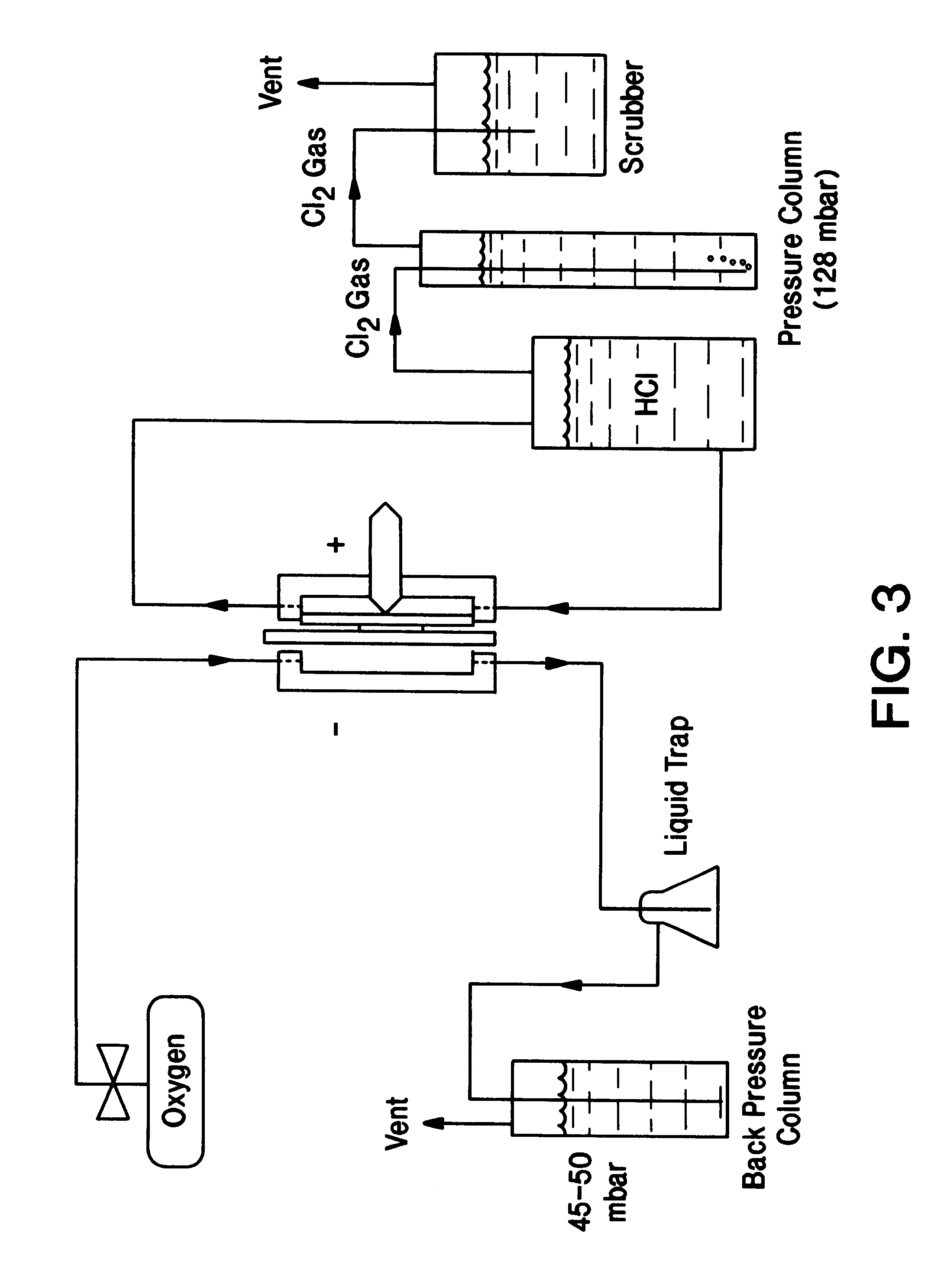

Process for the electrolysis of technical-grade hydrochloric acid contaminated with organic substances using oxygen-consuming cathodes

InactiveUS6402930B1Prevent further reactionHighly corrosive mediaCellsPhysical/chemical process catalystsElectrolysisCoating

A process for electrolyzing an aqueous solution of hydrochloric acid to chlorine in an electrochemical cell provided with an anode compartment and a cathode compartment including at least one gas diffusion cathode comprising an electrically conductive web provided on at least one side thereof with a coating of a catalyst for the electroreduction of oxygen comprising rhodium sulfide and optionally containing at least one fluorinated binder incorporated therein, comprising introducing aqueous hydrochloric acid containing contaminant species into the anode compartment and oxygen into the cathode compartment while impressing a direct electric current on the cell.

Owner:COVESTRO DEUTSCHLAND AG +1

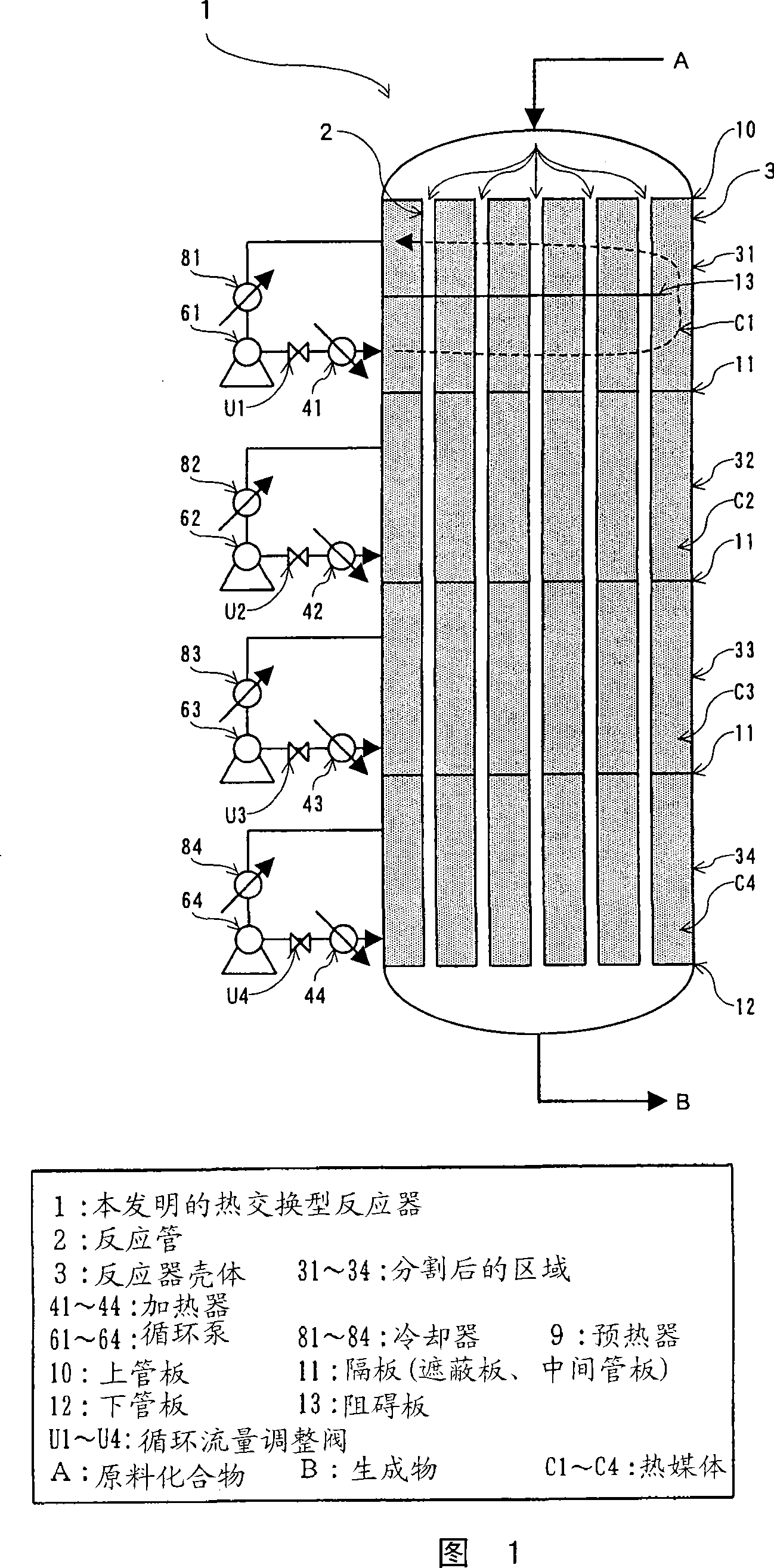

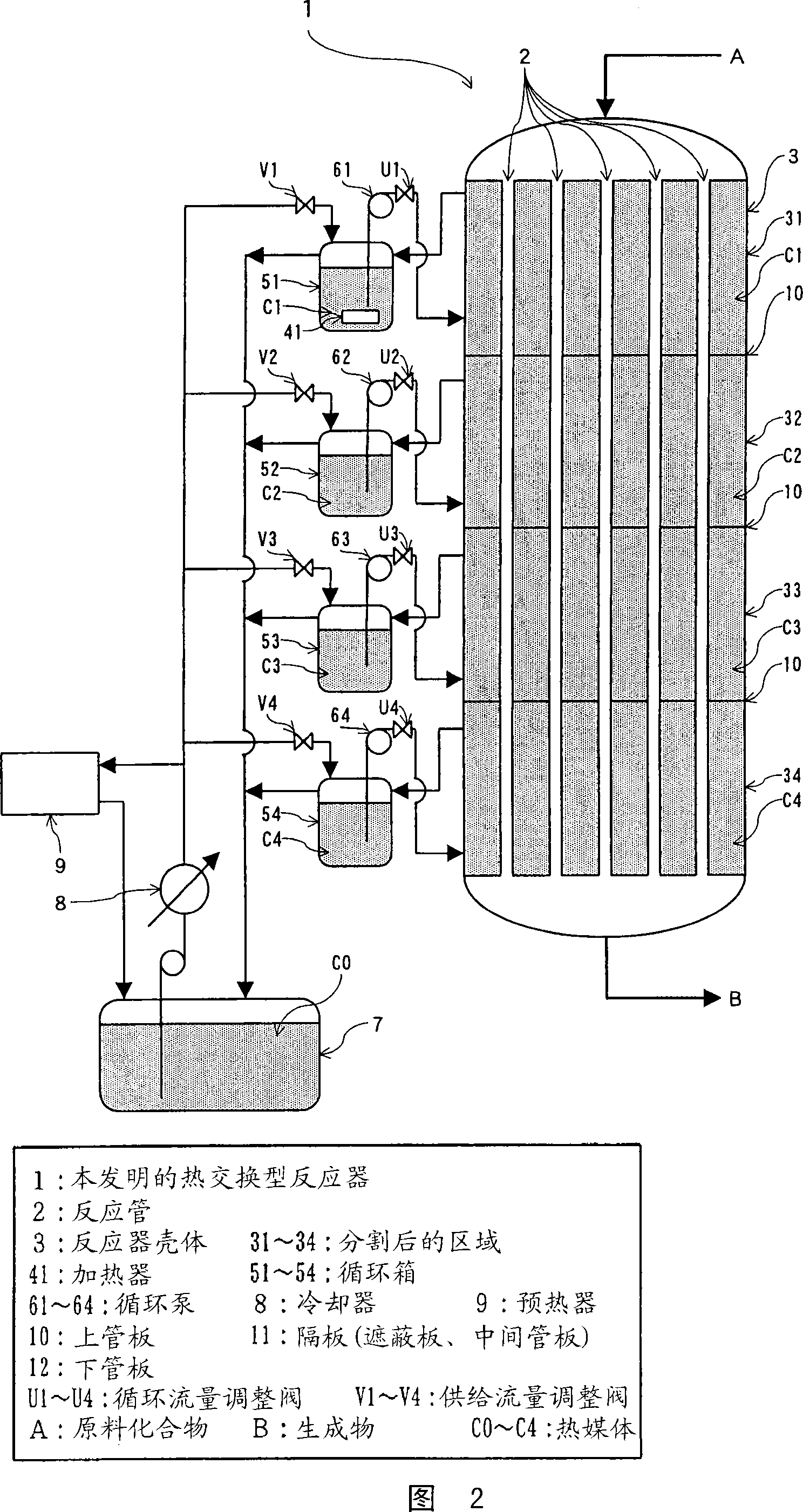

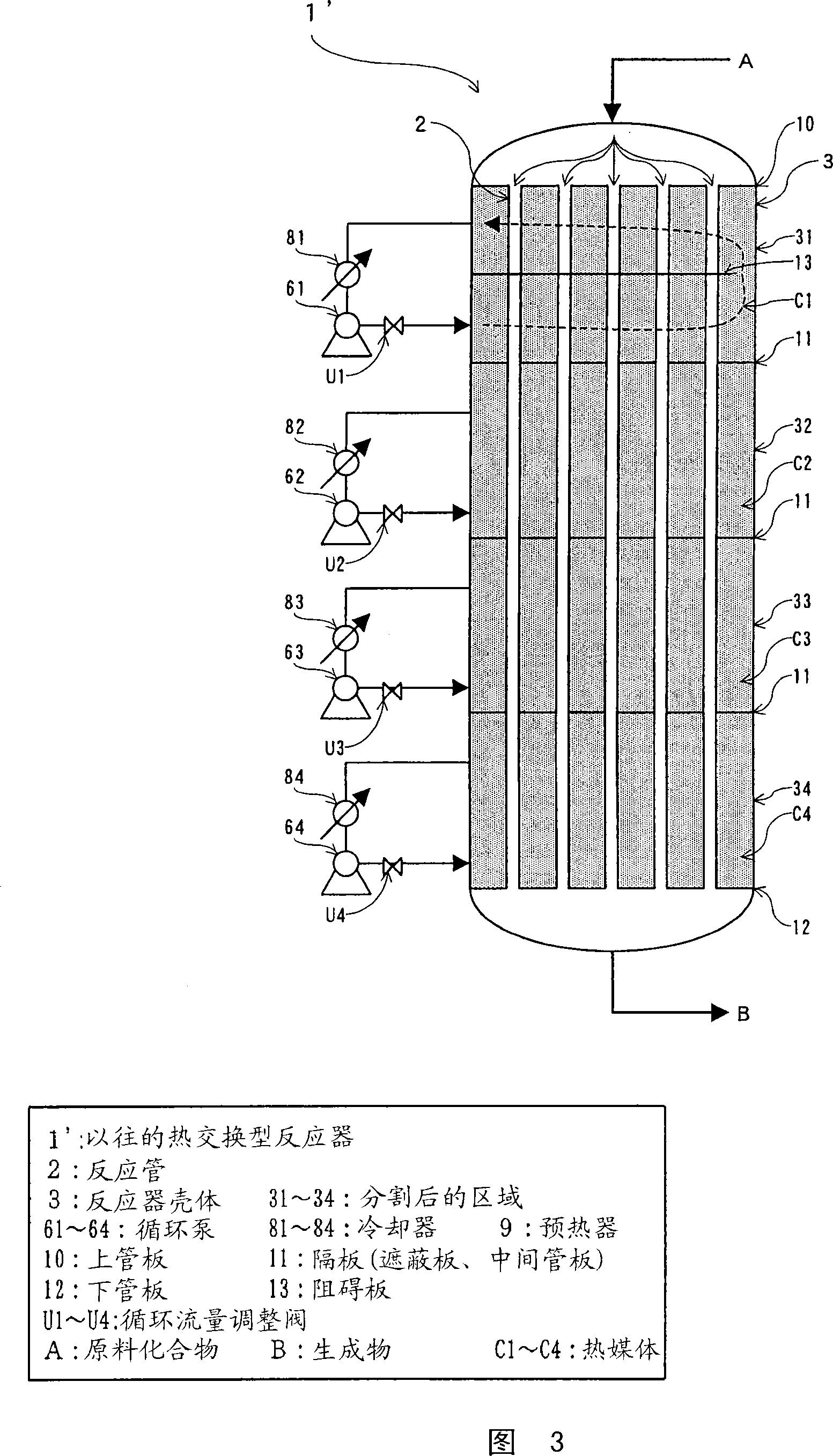

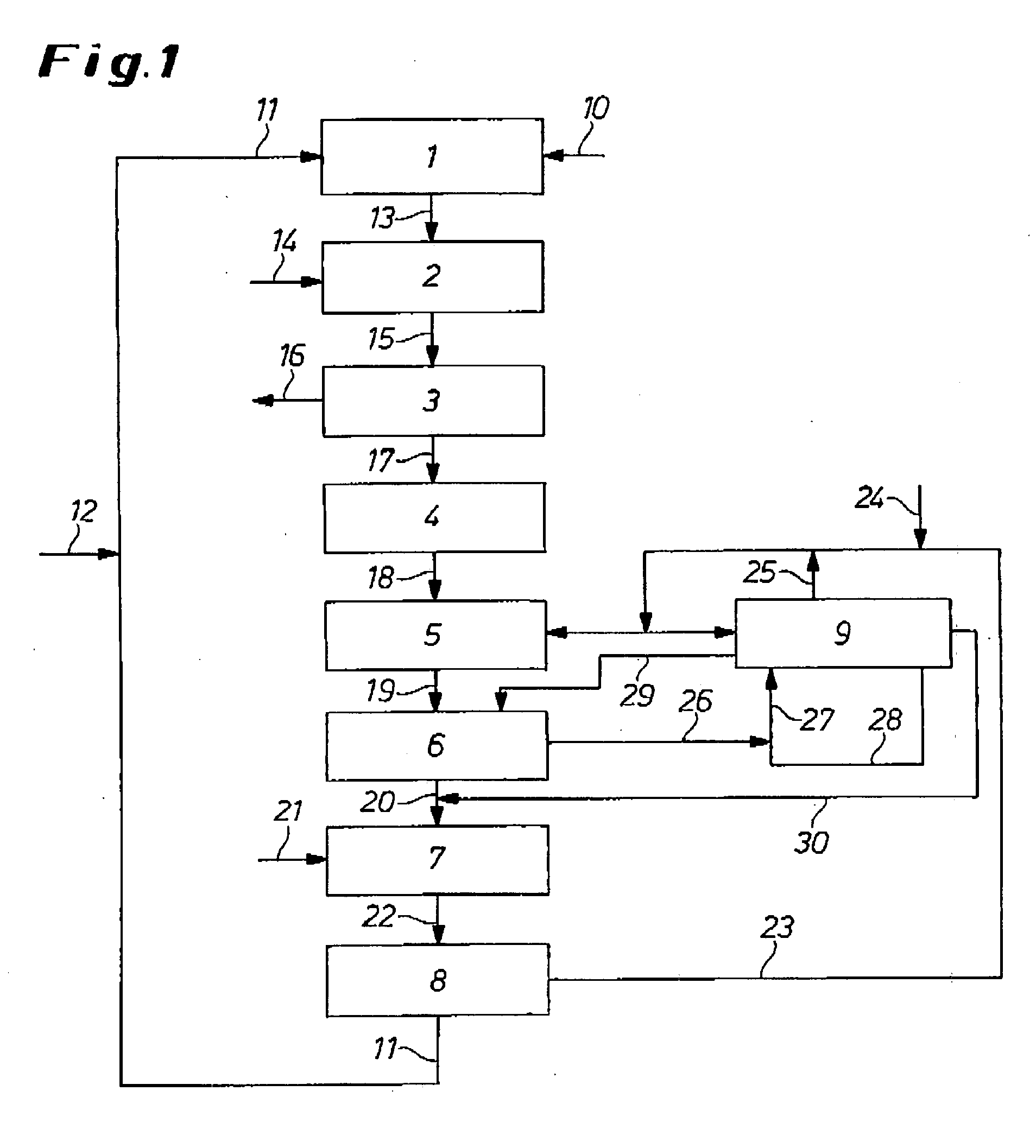

Heat exchange type reactor

ActiveCN1988950AReaction Yield ReducedGas-gas reaction processesChemical/physical/physico-chemical stationary reactorsExothermic reactionReaction tube

Owner:SUMITOMO CHEM CO LTD

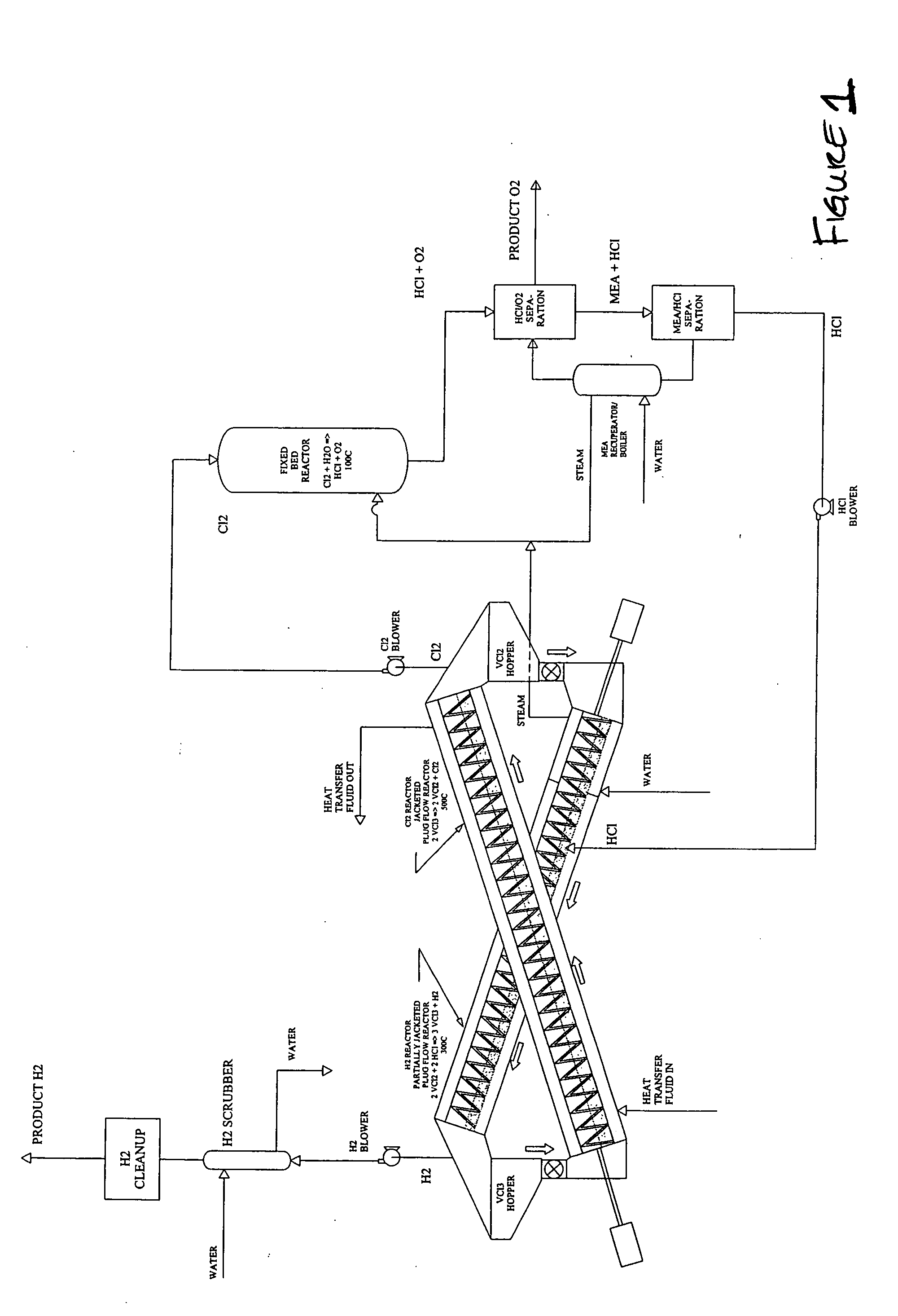

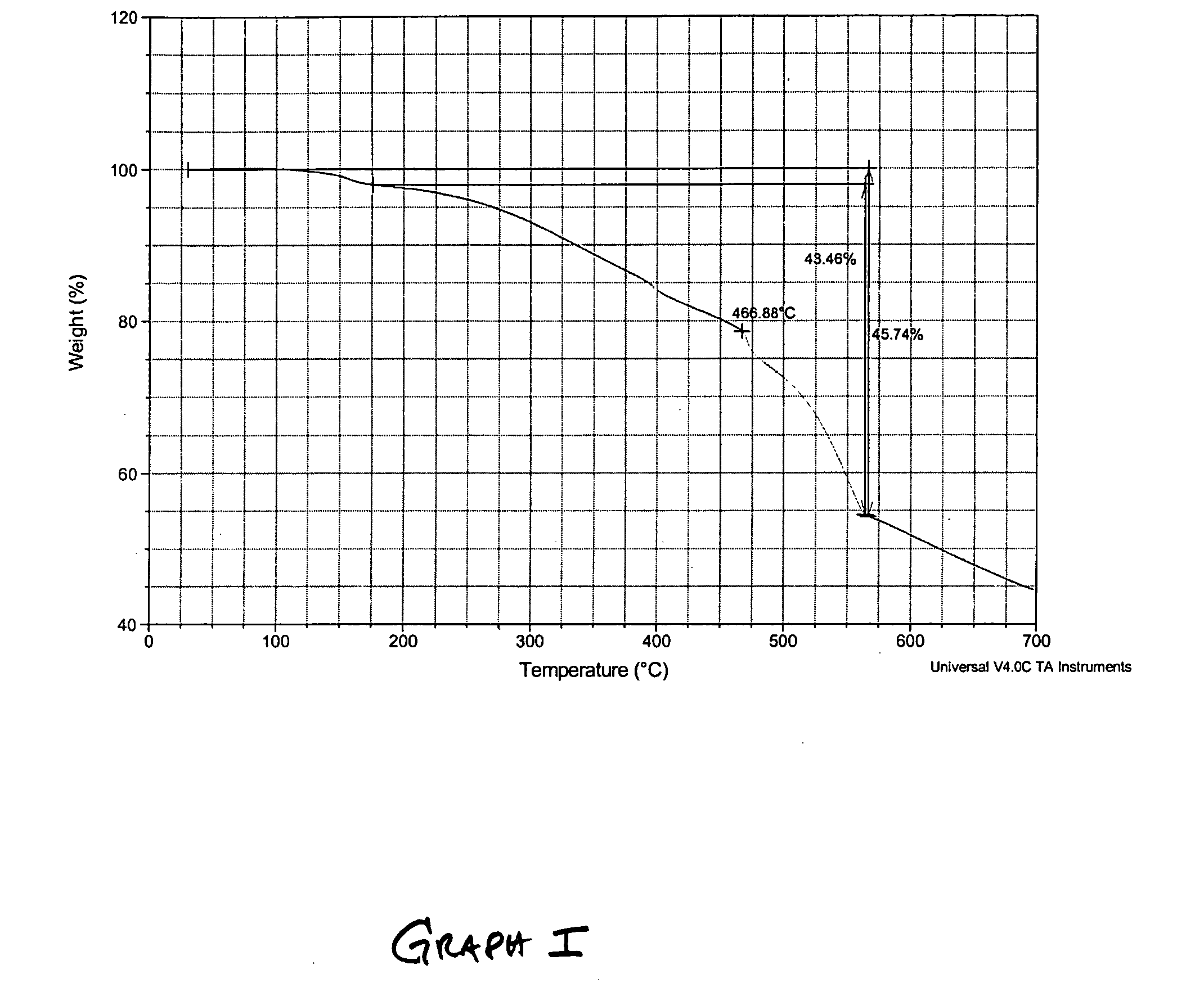

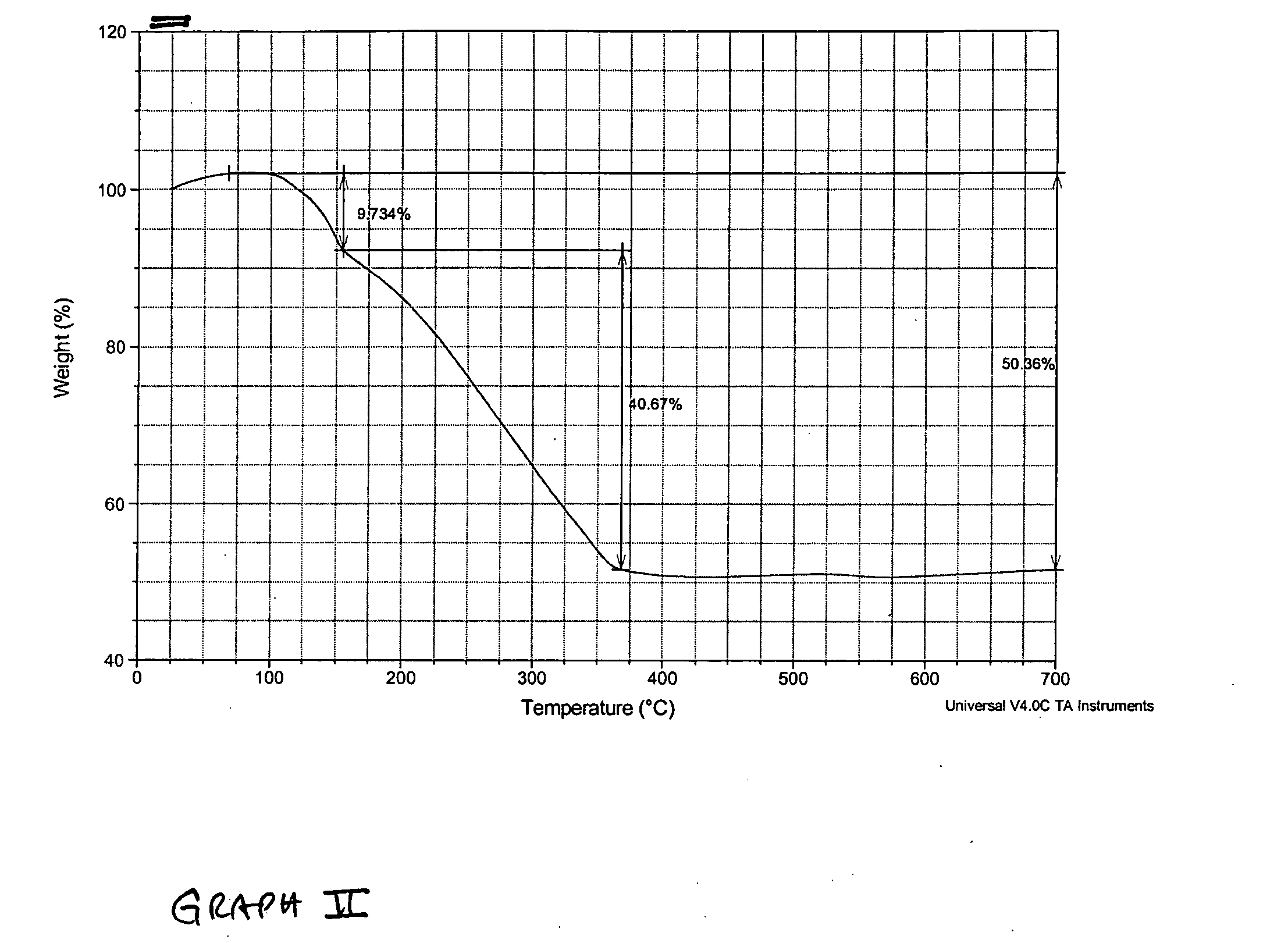

Thermochemical hydrogen produced from a vanadium decomposition cycle

InactiveUS20050013771A1Improve reliabilityHydrogen separation using liquid contactEnergy inputHydrogenDecomposition

A thermochemical water-splitting process all reactions of which operate at relatively low temperatures and high efficiencies, and in which relatively inexpensive materials and processing methods are made possible. This invention involves the decomposition of a metal halide compound, i.e., one which is capable of being reduced from a higher oxidation state to lower oxidation state, e.g. vanadium chloride III→vanadium dichloride. The process is cyclic and regenerative, and the only net inputs are water and heat; and the only net outputs are hydrogen and oxygen. The process makes it possible to utilize a wide variety of available heat, including solar, sources for the energy input.

Owner:AMENDOLA STEVEN

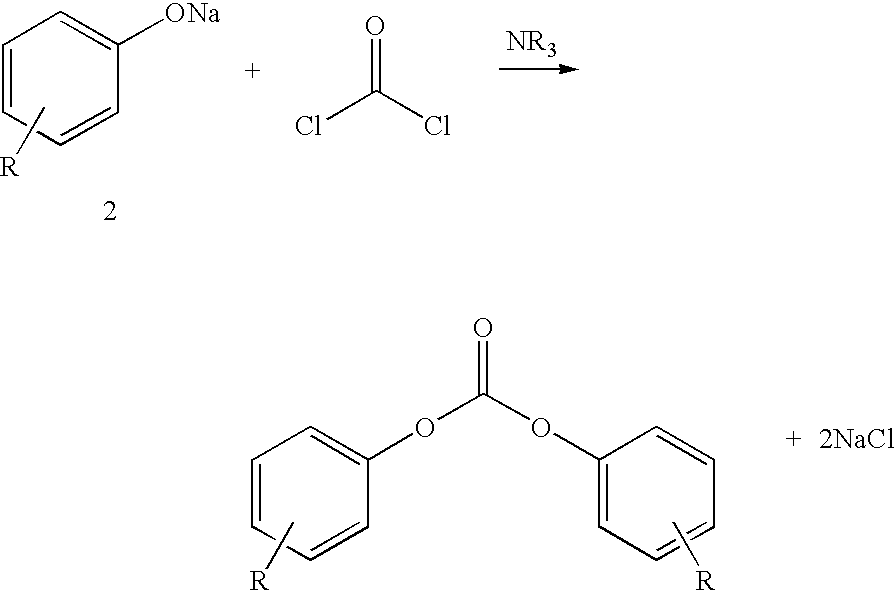

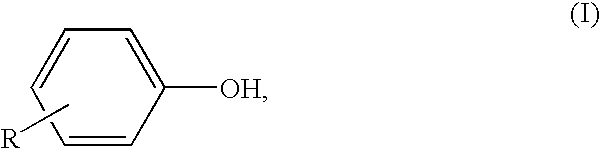

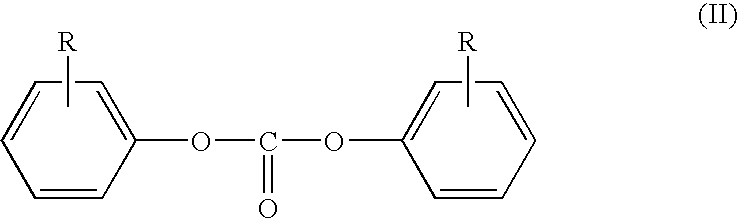

Process for production of diaryl carbonate

The invention relates to a process for production of diaryl carbonate combined with the electrolysis of the resultant alkali metal chloride-containing process wastewater. The process according to the invention makes possible, inter alia, improved utilization in electrolysis of the alkali metal chloride-containing solution obtained in the production of diaryl carbonate.

Owner:BAYER MATERIALSCIENCE AG

Thermal synthesis apparatus and process

InactiveUS20030021746A1Improve efficiencyHigh yieldTantalum compoundsIndirect heat exchangersNuclear engineeringReaction zone

An apparatus for thermal conversion of one or more reactants to desired end products includes an insulated reactor chamber having a high temperature heater such as a plasma torch at its inlet end and, optionally, a restrictive convergent-divergent nozzle at its outlet end. In a thermal conversion method, reactants are injected upstream from the reactor chamber and thoroughly mixed with the plasma stream before entering the reactor chamber. The reactor chamber has a reaction zone that is maintained at a substantially uniform temperature. The resulting heated gaseous stream is then rapidly cooled by passage through the nozzle, which "freezes" the desired end product(s) in the heated equilibrium reaction stage, or is discharged through an outlet pipe without the convergent-divergent nozzle. The desired end products are then separated from the gaseous stream.

Owner:BATTELLE ENERGY ALLIANCE LLC

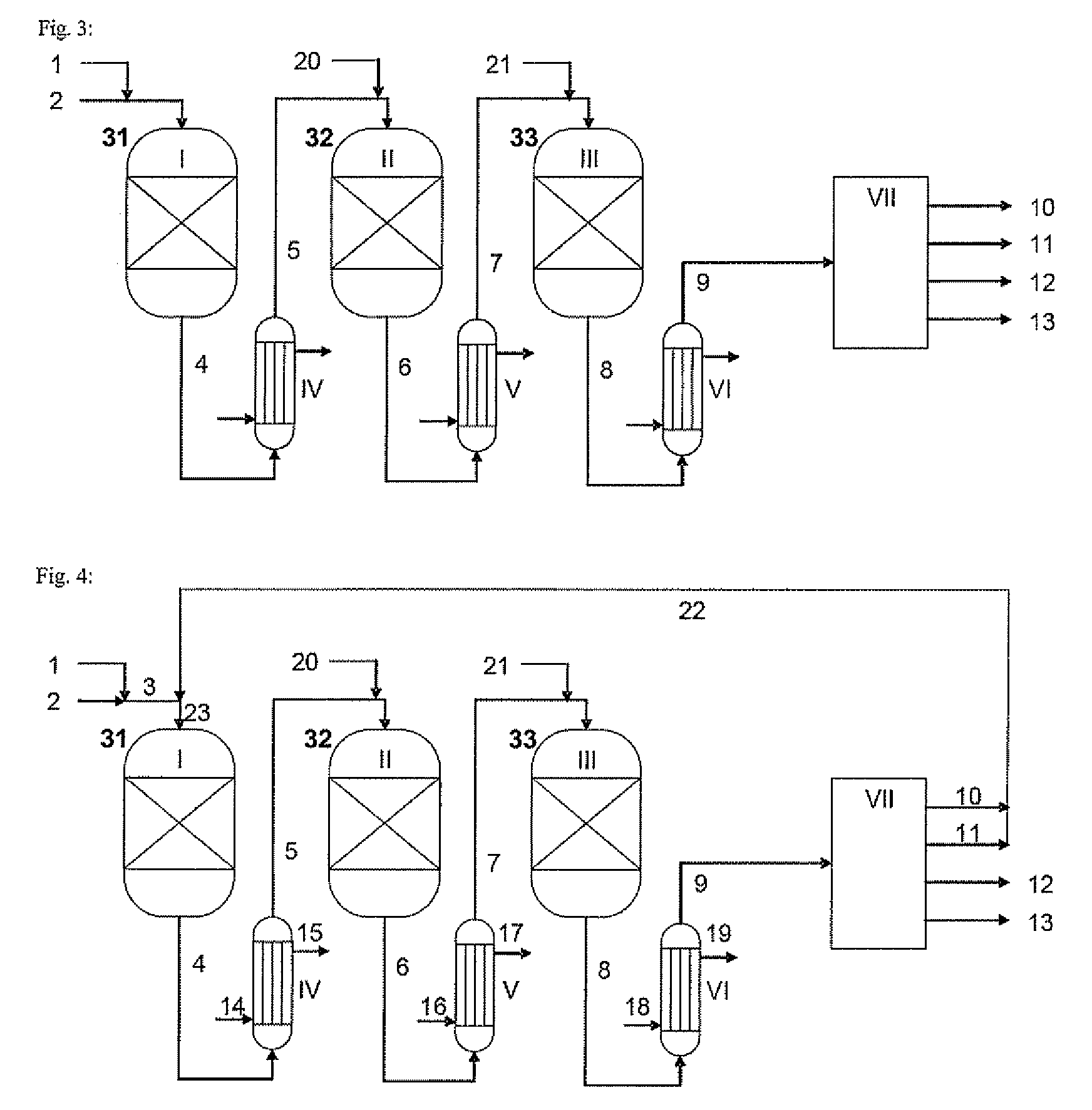

Process for producing chlorine

InactiveUS6852667B2High activityEasy to controlCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsActive componentOxygen

A process for producing chlorine by oxidizing hydrogen chloride with oxygen. The process uses various supported ruthenium catalysts or a catalyst system containing (A) an active component of a catalyst and (B) a compound having thermal conductivity of a solid phase measured by at least one point within a range from 200 to 500° C. of not less than 4 W / m. ° C.

Owner:SUMITOMO CHEM CO LTD

Hydrolysis method for material containing hydrolysable halogen atom

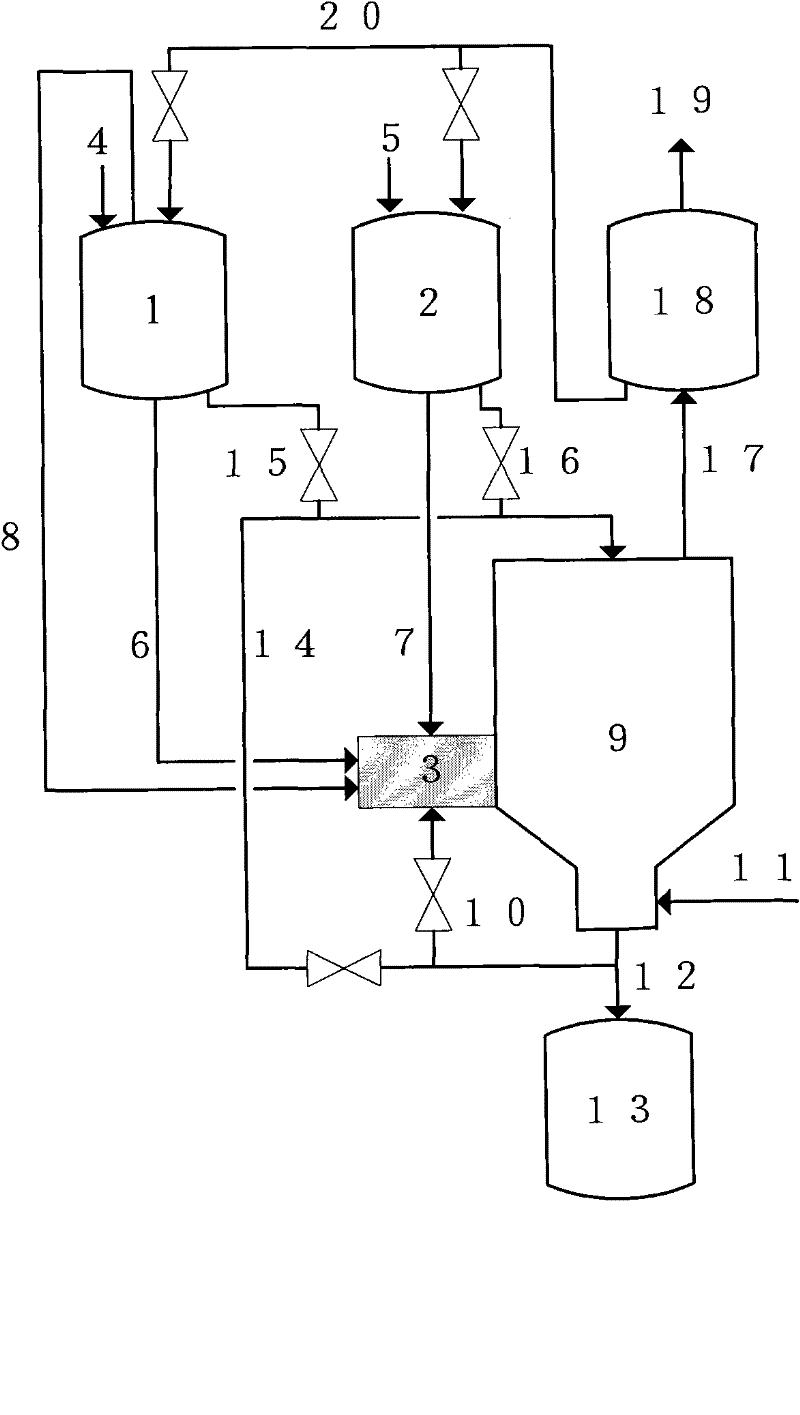

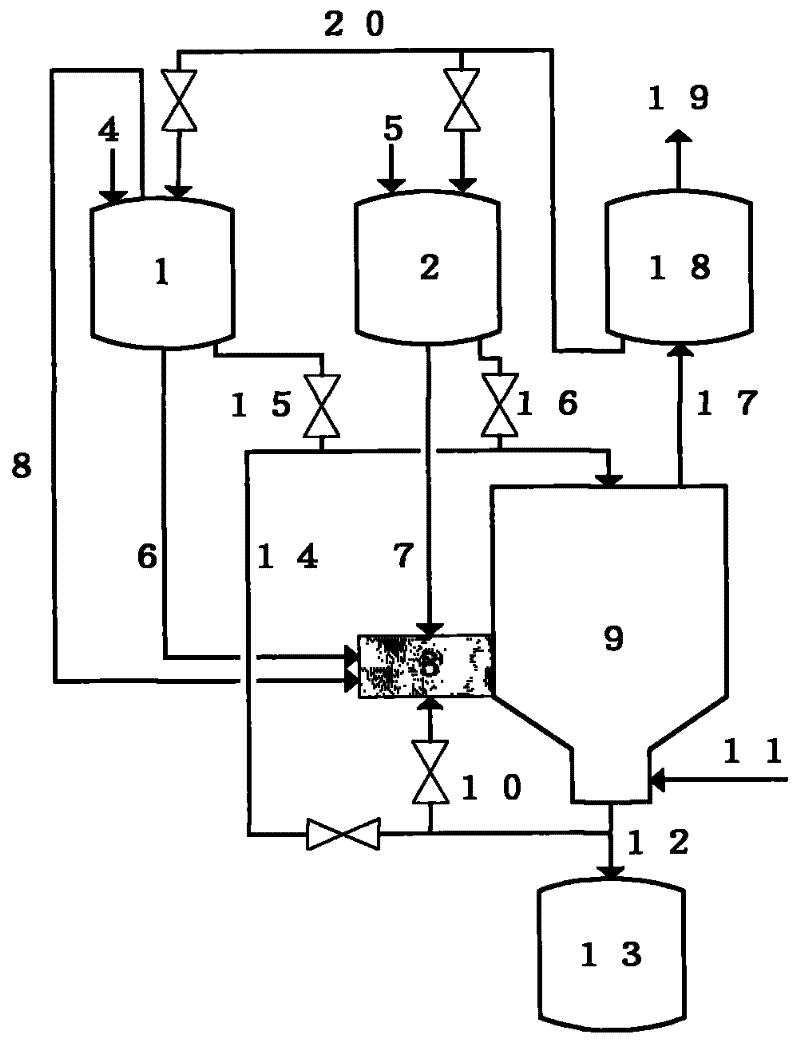

ActiveCN102234117AAvoids problems with clogging gaseous product channelsRelieve stressSilicaPreparation from chloridesHalogenGaseous hydrogen

The invention discloses a short-procedure, less-investment and simple-operation hydrolysis method for a material containing hydrolysable halogen atom. The method is characterized in that: a material containing hydrolysable halogen atom and a material containing water are subjected to mixing and reacting in a mixing and reaction unit; at least one reactant reacts as completely as possible through controlling reaction conditions, in particular, a key point is that the resulting reaction products are dried solid oxide and gaseous hydrogen halide, then the solid oxide is removed from a gas-solid separation and purification unit, and the gaseous hydrogen halide is processed through a gas product cleaning unit. The solid oxide and the gaseous hydrogen halide prepared through the method are valuable commodities, and the gaseous hydrogen halide further can be applicable for a synthesis process of halide. In addition, the method can be applicable for processing industrial waste containing the hydrolysable halogen atom, and producing solid oxides and hydrogen halide through adopting compounds containing the hydrolysable halogen atom.

Owner:刘基扬

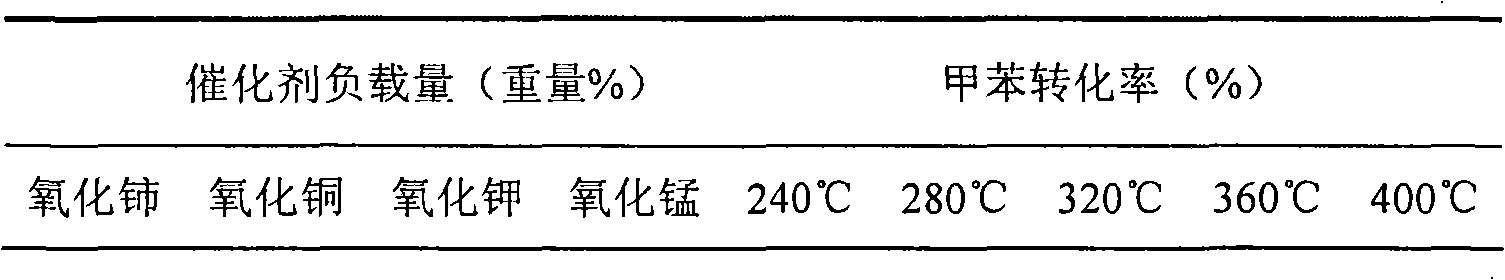

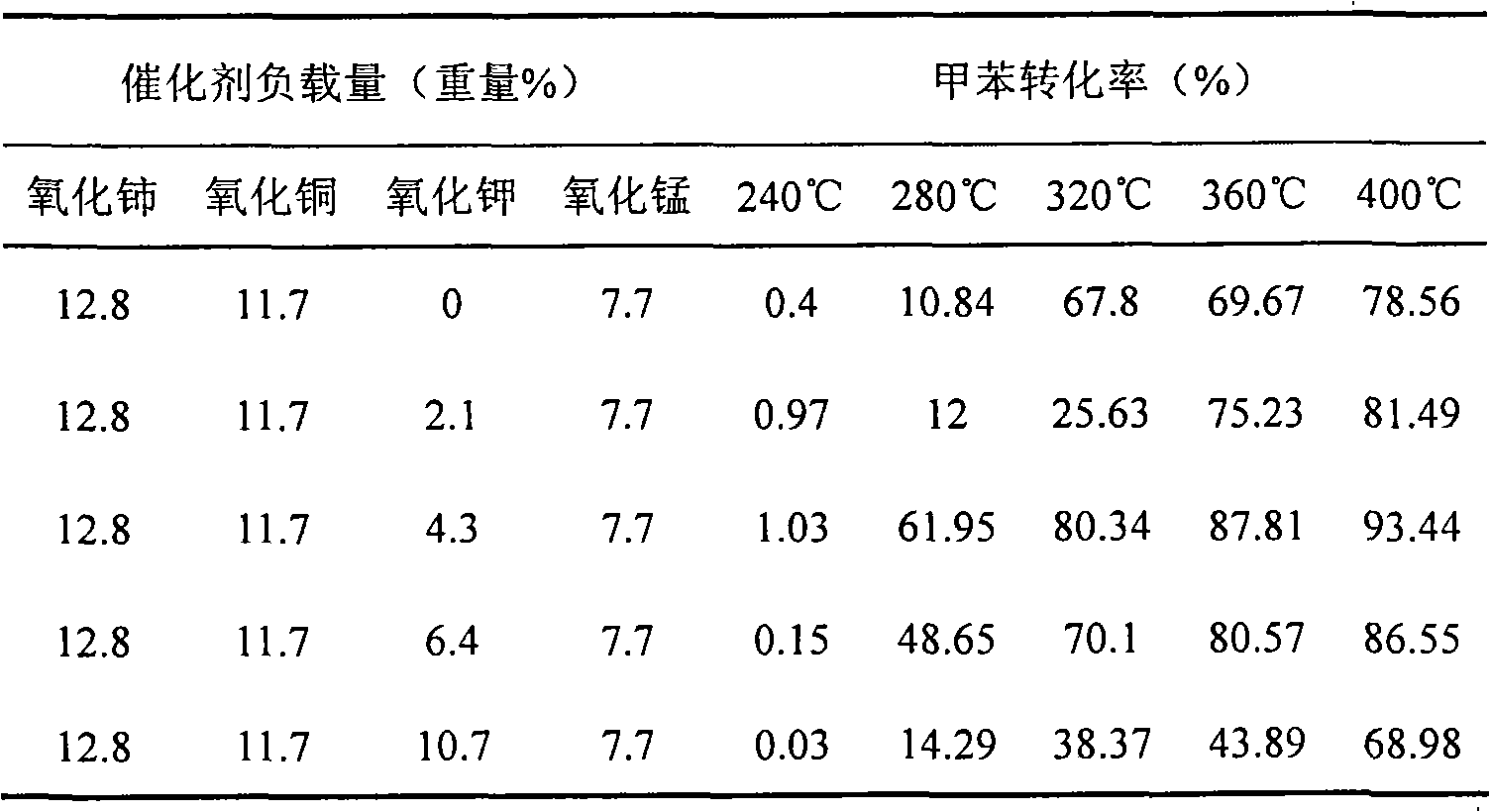

Bifunctional catalyst and preparation method and application thereof

ActiveCN101559374ASimple preparation processLow priceDispersed particle separationCatalyst activation/preparationAdhesivePotassium

The invention belongs to the field of environmental protection and catalyst, disclosing a bifunctional catalyst and a preparation method and an application thereof. The catalyst is prepared in a manner that substance containing rare earth metal element cerium, substance containing alkali metal element potassium and substance containing transition metal elements are loaded on a carrier under the action of adhesive to be baked; wherein transition metal elements are 1-3 elements of Cu, Mn, Fe, V, Co. The catalyst has low cost and high catalytic activity, does not cause secondary pollution, is suitable for preparation of chlorine by oxidation of hydrogen chloride to realize the recycling of chlorine resource, and is also suitable for deep oxidation combustion of organic impurities such as cyclohexane, benzene, toluene and the like in industrial waste gas.

Owner:南京资环工程技术研究院有限公司

Method of making high purity lithium hydroxide and hydrochloric acid

The present invention relates to a process for producing high purity lithium hydroxide monohydrate, comprising following steps: concentrating a lithium containing brine; purifying the brine to remove or to reduce the concentrations of ions other than lithium; adjusting the pH of the brine to about 10.5 to 11 to further remove cations other than lithium, if necessary; neutralizing the brine with acid; purifying the brine to reduce the total concentration of calcium and magnesium to less than 150 ppb via ion exchange; electrolyzing the brine to generate a lithium hydroxide solution containing less than 150 ppb total calcium and magnesium, with chlorine and hydrogen gas as byproducts; producing hydrochloric acid via combustion of the chlorine gas with excess hydrogen and subsequent scrubbing of the resultant gas stream with purified water, if elected to do so; and concentrating and crystallizing the lithium hydroxide solution to produce lithium hydroxide monohydrate crystals.

Owner:ROCKWOOD LITHIUM INC

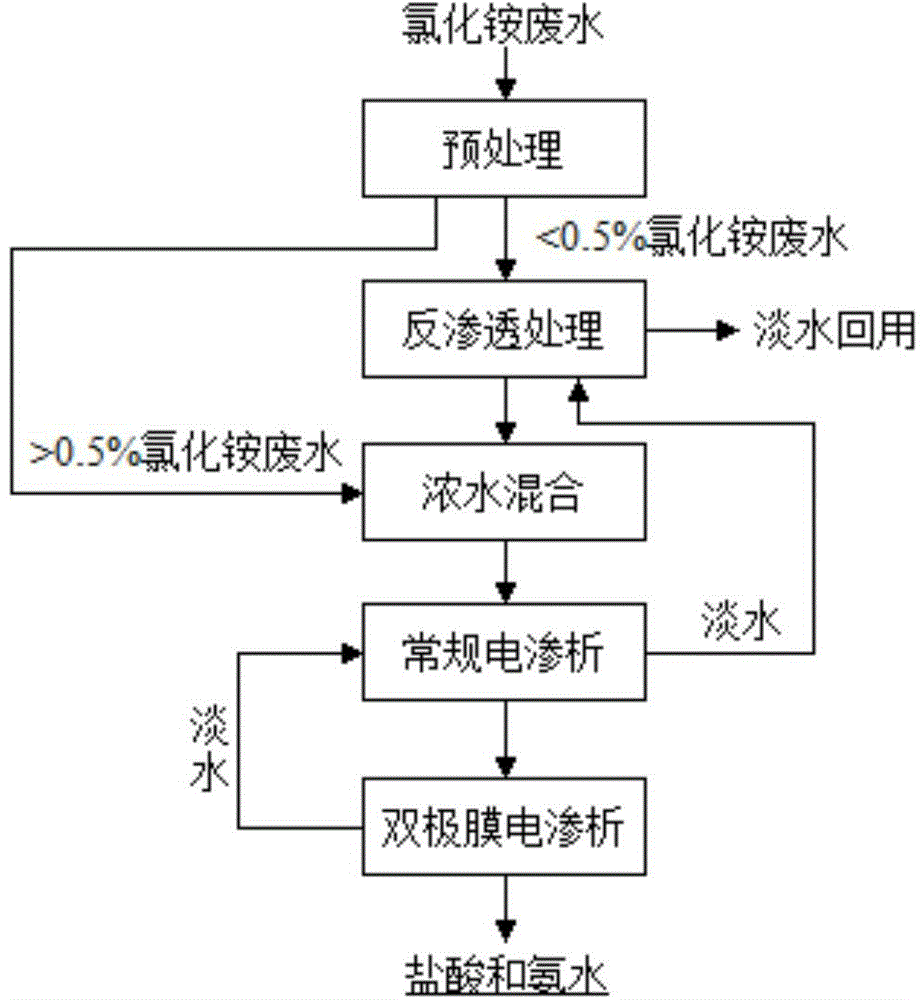

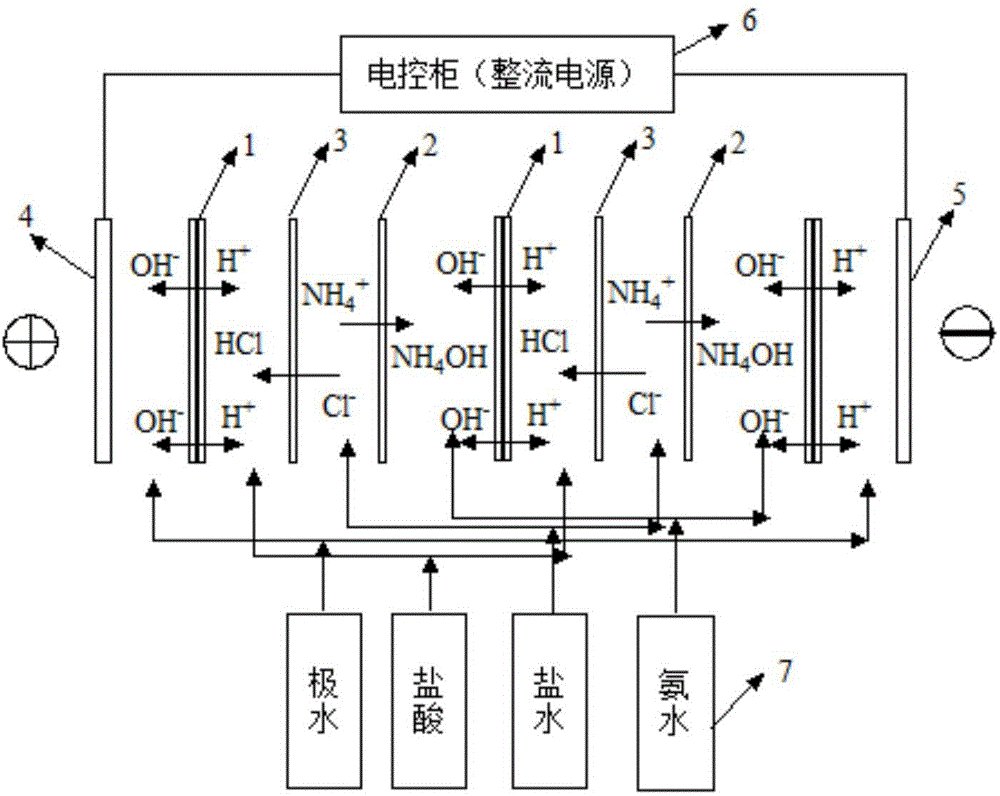

Method for resourceful treatment of ammonia chloride wastewaters

ActiveCN104445755ARealize resource processingAchieving processing powerGeneral water supply conservationWater contaminantsReverse osmosisImpurity

The invention relates to a method for resourceful treatment of ammonia chloride wastewaters. The method comprises the following steps: (1) respectively carrying out pretreatment on ammonia chloride wastewater with different concentrations for removing impurities; (2) carrying out reverse osmosis treatment on a clear liquor of the ammonia chloride wastewater, which is obtained in the step (1), with the concentration being lower than 0.5%; (3) mixing obtained reverse osmosis concentrated water with a clear liquid of the ammonia chloride wastewater, which is obtained in the step (2), with the concentration being higher than 0.5% so as to obtain ammonia chloride mixed wastewater; (4) carrying out conventional electrodialysis treatment on the obtained ammonia chloride mixed wastewater so as to obtain electrodialysis fresh water; (5) returning the obtained electrodialysis fresh water, carrying out reverse osmosis treatment the obtained electrodialysis fresh water to obtain electrodialysis concentrated water, and carrying out acid-alkali regeneration on the electrodialysis concentrated water by adopting bipolar membrane electrodialysis; and (6) converting ammonia chloride in the wastewater into hydrochloric acid and ammonium hydroxide by adopting the bipolar membrane electrodialysis to obtain low-concentration ammonia chloride wastewater, simultaneously returning the obtained low-concentration ammonia chloride wastewater and carrying out the conventional electrodialysis treatment on the obtained low-concentration ammonia chloride wastewater. According to the method, the resourceful treatment and the zero emission of the ammonia chloride wastewater can be really achieved.

Owner:JIANGXI INST OF RARE EARTHS CHINESE ACAD OF SCI

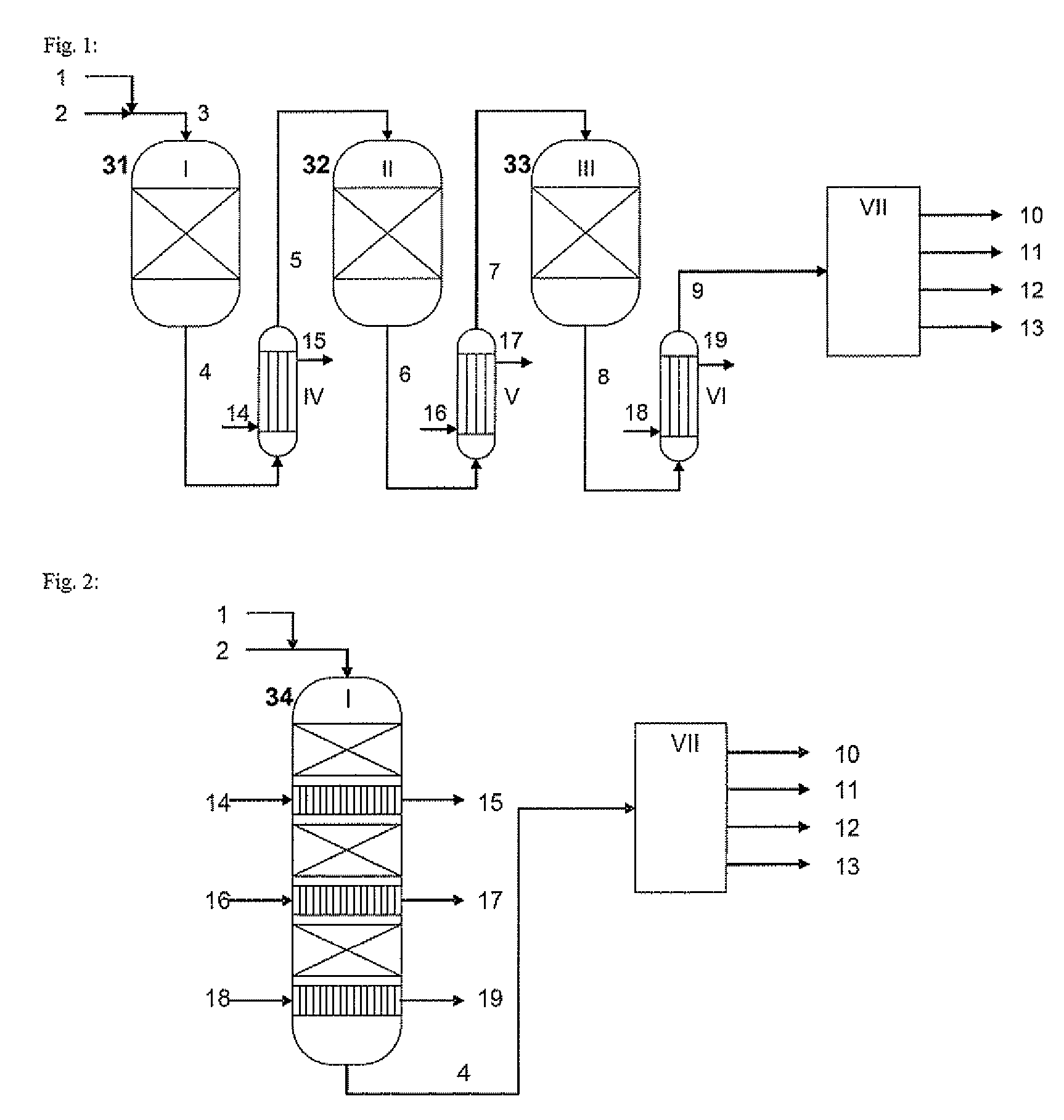

Method for producing chlorine

InactiveUS6977066B1High activityEquipment and operational costPreparation from chloridesChlorine productionReaction zoneOxygen

A process for producing chlorine comprising the step of oxidizing hydrogen chloride in a gas containing hydrogen chloride with a gas containing oxygen in the presence of a catalyst, wherein the oxidation of hydrogen chloride is carried out in at least two reaction zones each comprising a catalyst-packed layer, which are arranged in series, and a temperature in at least one of said reaction zones is controlled with a heat exchange system. According to this process, the stable activity of the catalyst is maintained and chlorine can be stably obtained at a high yield since the excessive hot spot in the catalyst-packed layer is suppressed and the catalyst-packed layer can be effectively used.

Owner:SUMITOMO CHEM CO LTD

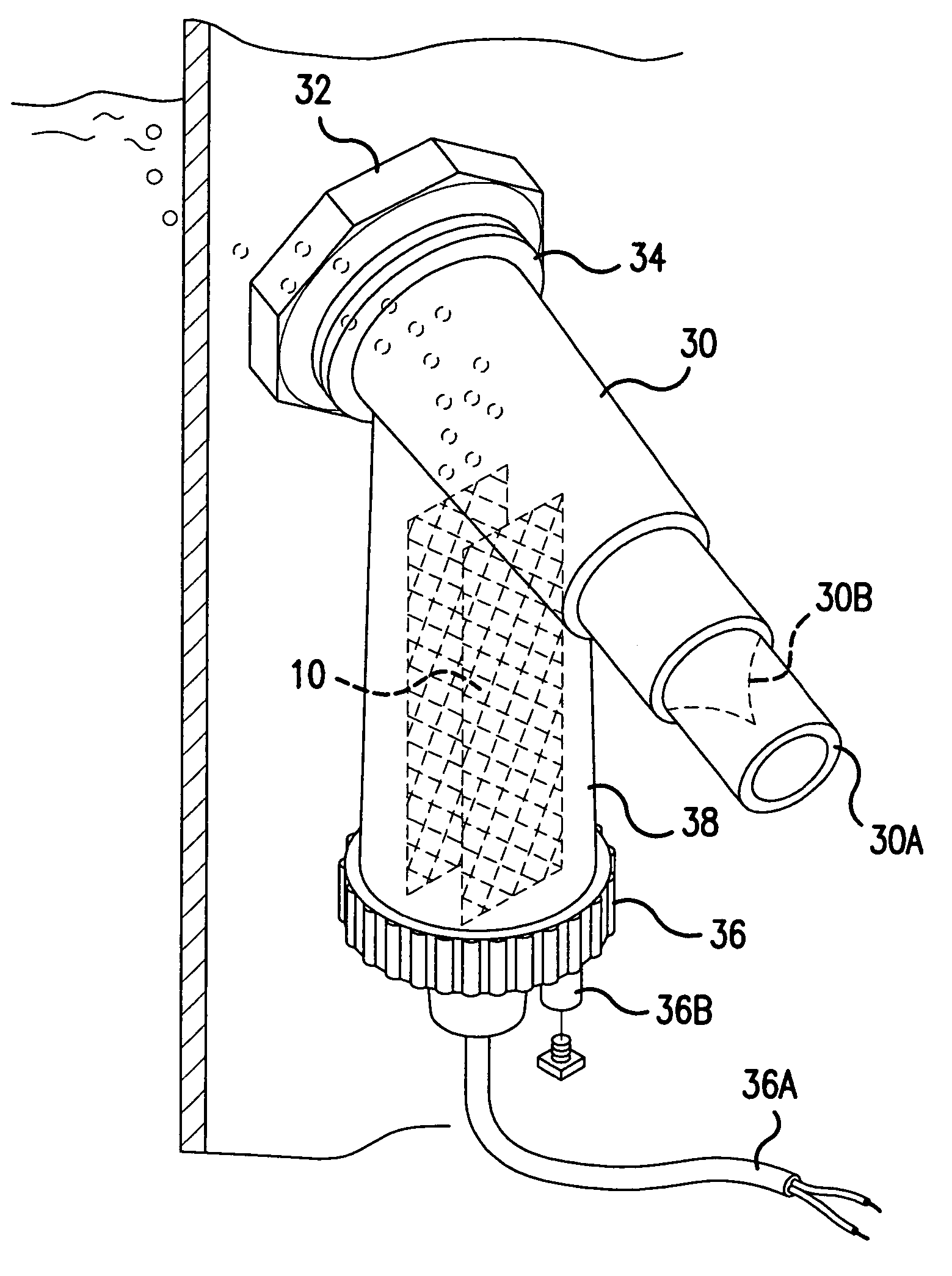

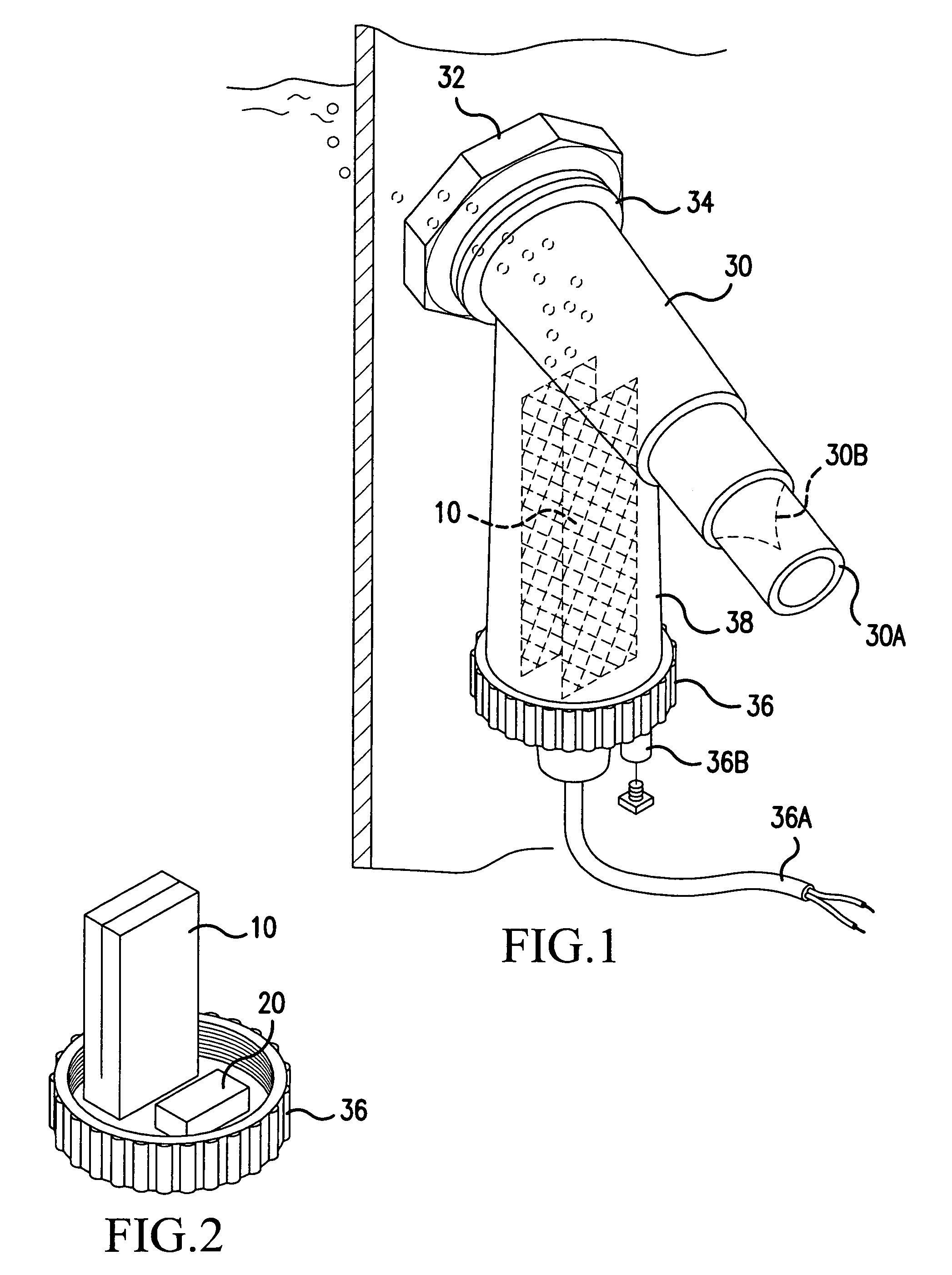

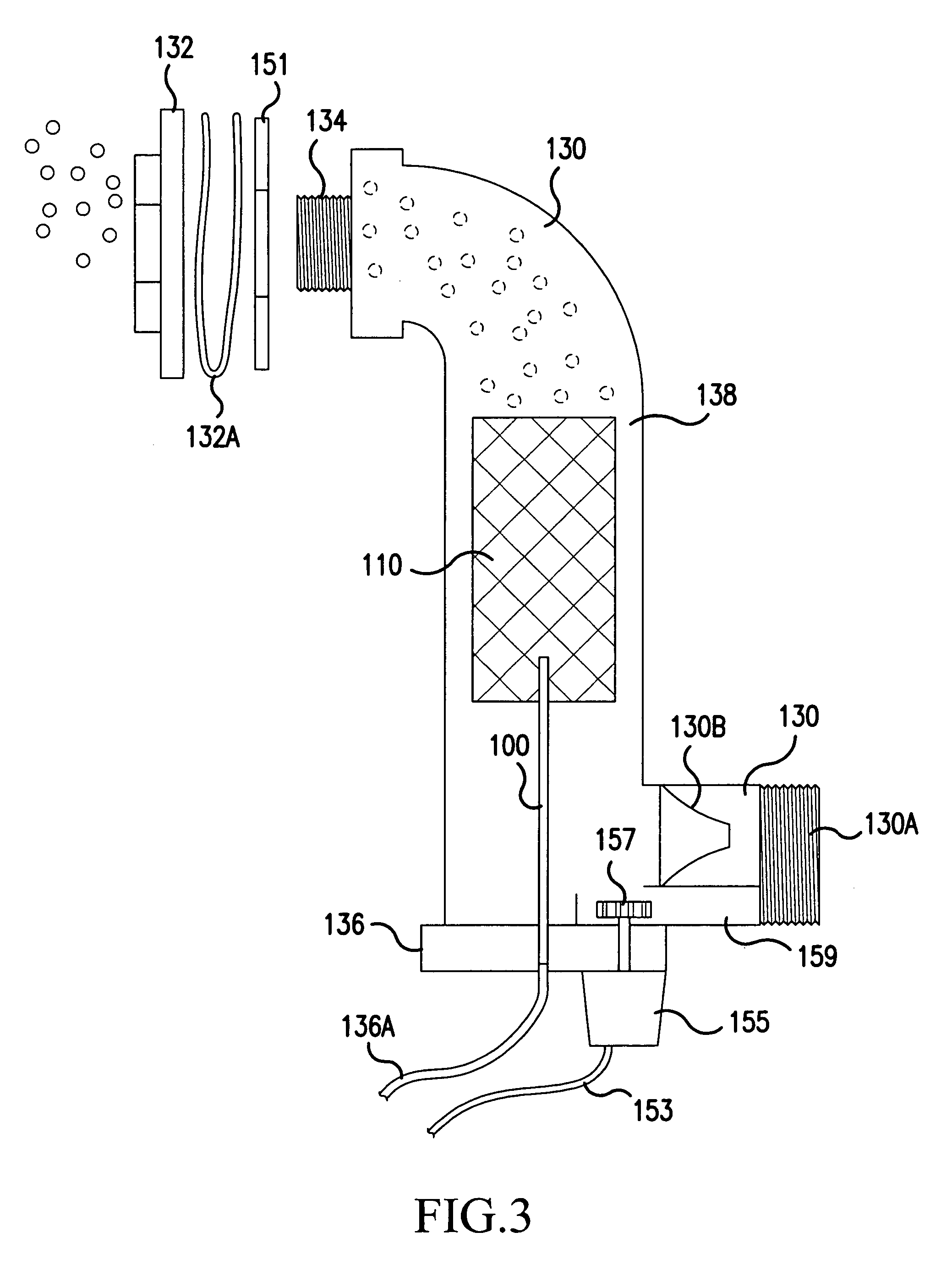

Salt chlorine generator

ActiveUS7014753B2Low costEasy to installSludge treatmentPhotography auxillary processesFiltrationEngineering

An electrolytic cell combined into a unitary structure with a liquid circulation fitting, which purifies water by electrode plates inside the cell when an aqueous solution is present. The unitary structure replaces the existing water return fitting. This integrated structure is well suited for use in pools, tubs, spas, fountains or similar large liquid containers. The production of halogen inside the structure is not required to coincide with the cycle of the existing pool filtration system. Rather, the electrodes receive a continuous supply of low level power and the halogen produced inside the structure is disbursed back into the body of water through the fitting using an integrated, dedicated circulation pump, special channels in the surface and a check valve to insure one directional flow from the pool pump and natural convection. Using fresh water drawn from the vessel, halogen is then disbursed back into the vessel with the water at a location different from where the fresh water was drawn. The level of halogen production may be regulated using a timing mechanism and / or sensors in the circuitry.

Owner:SMARTPOOL

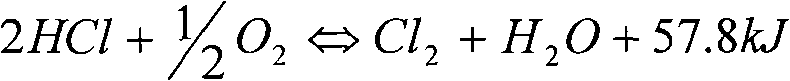

Processes for the production of chlorine from hydrogen chloride and oxygen

ActiveUS20080029404A1Overcome disadvantagesElectrolysis componentsPreparation from chloridesNitrogen gasOxygen

Processes for the production of chlorine by multi-stage oxidation, for example, by thermal reaction of hydrogen chloride with oxygen using catalysts or by non-thermal activated reaction of hydrogen chloride with oxygen, in which the gas mixture formed in the reaction, comprising the target products chlorine and water, unreacted hydrogen chloride and oxygen, and possibly other secondary constituents, such as carbon dioxide and nitrogen, (a) is cooled to condense hydrochloric acid as an aqueous solution of hydrogen chloride and (b) the aqueous solution of hydrogen chloride formed is separated from the gas mixture, characterised in that (c) the separated aqueous solution of hydrogen chloride is fed at least partially to an electrochemical oxidation in which at least part of the hydrogen chloride is oxidised to chlorine, (d) the chlorine gas occurring in step d) is optionally added to the gas mixture occurring in step c), (e) the residues of water present in the gas mixture from steps c) and e), in particular by washing with sulfuric acid, are removed, (f) the chlorine-rich gas mixture forming is freed of oxygen and optionally of secondary constituents.

Owner:COVESTRO DEUTSCHLAND AG

Catalyst used for catalytic oxidation of hydrogen chloride for preparing chlorine gas and preparation method thereof

InactiveCN101862663AHigh activityImprove stabilityPhysical/chemical process catalystsPreparation from chloridesRare earthCatalytic oxidation

The invention discloses a catalyst used for the catalytic oxidation of hydrogen chloride for preparing chlorine gas and a preparation method thereof. The catalyst comprises the following components in percentage by weight: 1 to 30 percent of CuCl2, 1 to 15 percent of KCl, 1 to 25 percent of rare earth chloride and 55 to 95 percent of carrier and is prepared by adopting an immersion method. The catalyst of the invention does not contain a toxic component Cr, belongs to an environmental-friendly low-cost catalyst and has the advantages of simple and practical preparation method, high catalyst activity, high stability and long service life.

Owner:SHANGHAI CHLOR ALKALI CHEM +1

Processes and apparatus for the production of chlorine by gas phase oxidation

InactiveUS20070274901A1Simple design and processingEasy to operateLiquid-gas reaction processesMetal/metal-oxides/metal-hydroxide catalystsReactor systemGas phase

Owner:COVESTRO DEUTSCHLAND AG

Processes for the preparation of chlorine by gas phase oxidation

InactiveUS20070292336A1High activityHigh catalytic activityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsTin dioxideGas phase

Owner:BAYER MATERIALSCIENCE AG

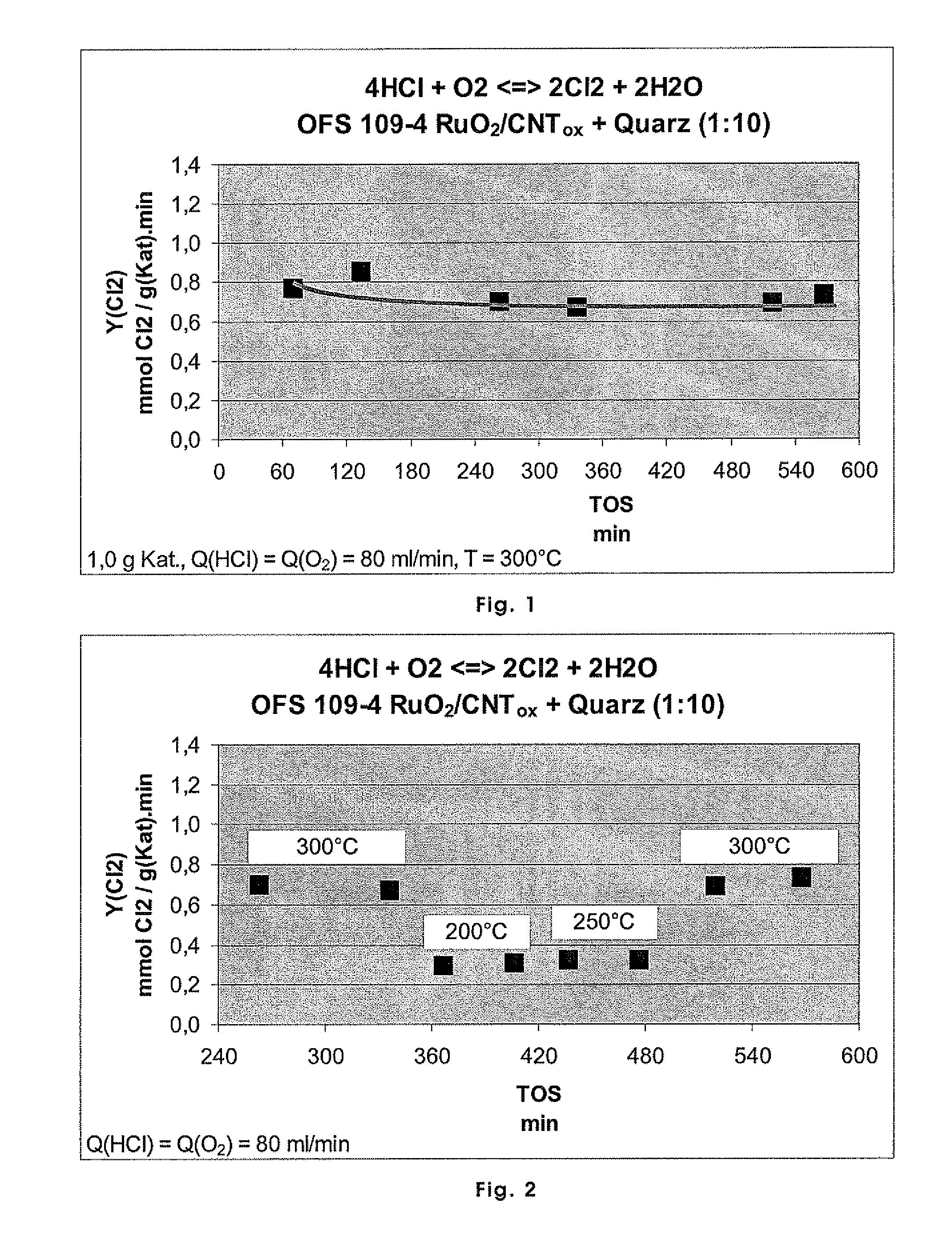

Temperature-stable catalysts for gas phase oxidation, and processes for using the same

InactiveUS20070274899A1High catalytic activityImprove stabilityMaterial nanotechnologyOrganic oxidationGas phaseCarbon nanotube

Oxidation catalysts which comprise at least one constituent active in the catalysis of oxidation reactions, and a support for said constituent, characterized in that the support includes carbon nanotubes; are disclosed along with processes for their use including the oxidation of hydrogen chloride. Such catalysts can exhibit a higher stability and activity than that of catalysts of the state of the art.

Owner:BAYER MATERIALSCIENCE AG

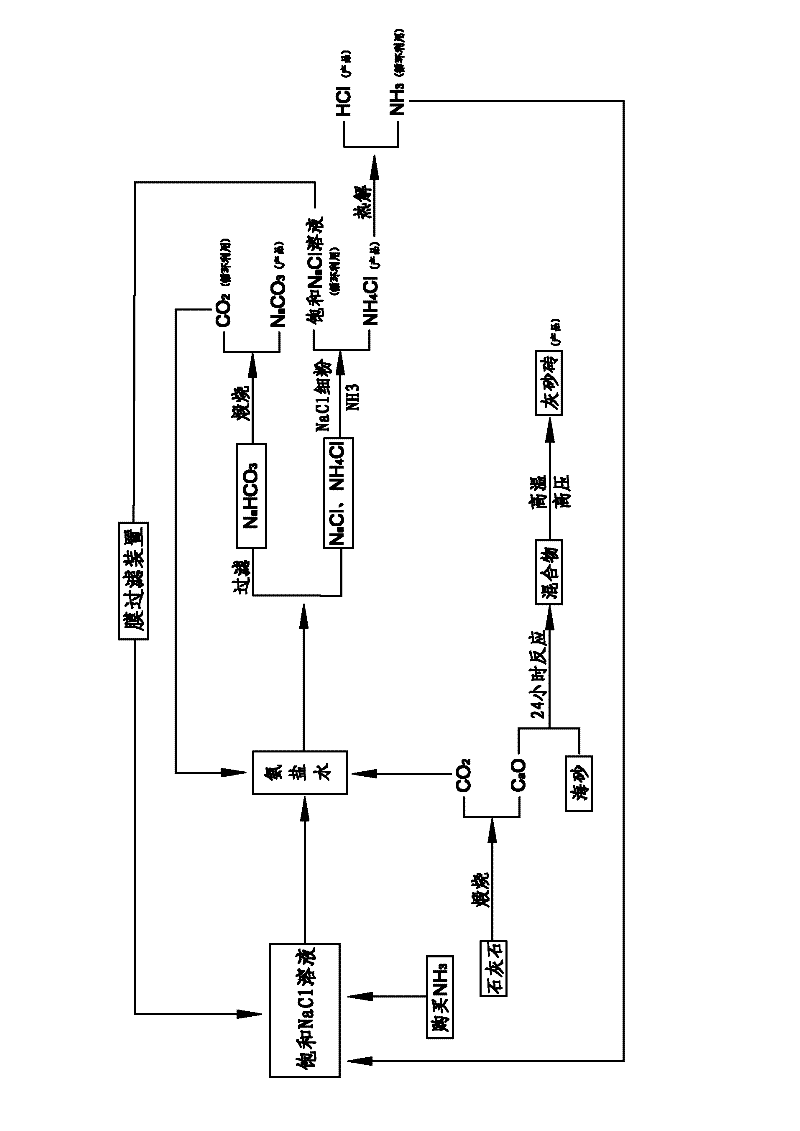

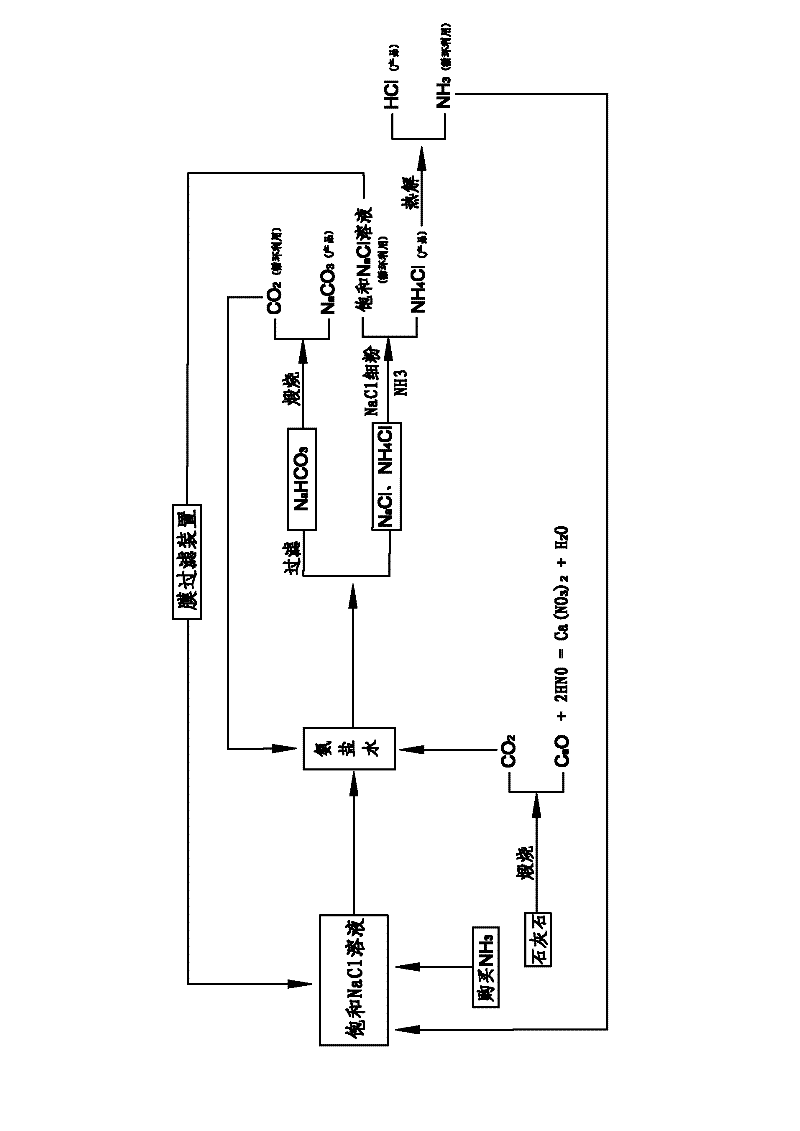

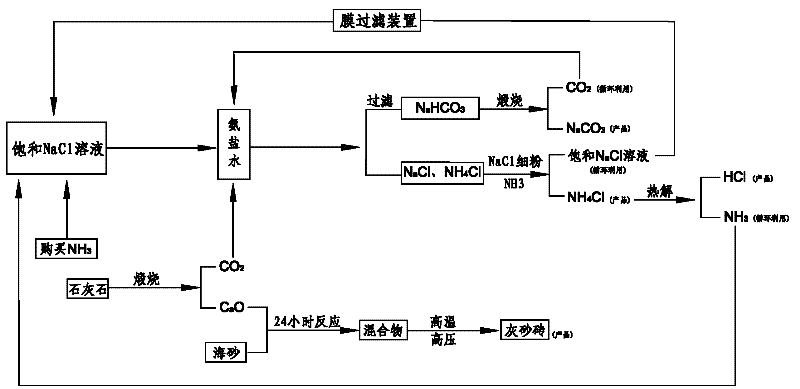

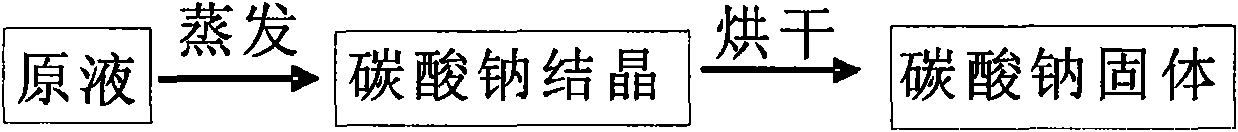

Comprehensive soda ash producing process and product application thereof

ActiveCN102531001AIncrease profitReduce manufacturing costCalcium/strontium/barium nitratesAmmonium halidesSodium bicarbonateProcess engineering

The invention relates to the technical field of soda ash production, and especially relates to a comprehensive soda ash producing process and product applications thereof; the process comprises the following process steps: introducing ammonia gas into a saturated sodium chloride solution to prepare ammoniacal brine; introducing carbon dioxide generated in limestone calcination into the ammoniacal brine to generate a mixture of sodium bicarbonate, sodium chloride and ammonium chloride; filtering the mixture to obtain sodium bicarbonate, sodium chloride and ammonium chloride; calcining the sodium bicarbonate to generate soda ash and carbon dioxide, recycling the carbon dioxide; adding sodium chloride fine powder and ammonia gas into the mixed filtrate of ammonium chloride and sodium chloride to generate ammonium chloride and sodium chloride solutions; separating impurities from the sodium chloride solution by a membrane filter, recycling the sodium chloride solution. The process has the advantages of low production cost, high soda ash whiteness, high sodium chloride utilization rate, no water waste or solid waste generation, environment protection, safety, simple processes, full use of geographic advantages in our country, low raw material purchase cost, waste change into things of value, high economic benefits, and good social benefits.

Owner:GUANGDONG DAZHONG AGRI SCI CO LTD

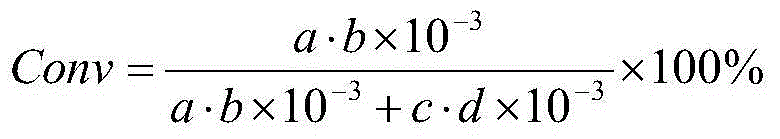

Preparation method and application of transition metal phosphide used for hydrogenating dechlorination

ActiveCN105344368AImprove hydrodechlorination activityImprove catalytic performancePhysical/chemical process catalystsPreparation from chloridesParticulatesDiammonium phosphate

The present invention discloses a preparation method and application of transition metal phosphide used for hydrogenating dechlorination. The preparation method comprises the following steps: 1. dissolving soluble metallic salt and diammonium phosphate in water, and dissolving polyethylene glycol in the solvent; 2. stirring an aqueous solution obtained in the step 1 at a temperature of 80 DEG C for 3 hours, then heating up the stirred aqueous solution to the temperature of 100 DEG C to dry the aqueous solution in a steaming manner, then drying at a temperature of 120 DEG C for 12 hours, and then calcining at a temperature of 500 DEG C for 5 hours to obtain an oxidizing precursor; and 3. grinding and tabletting the oxidizing precursor obtained in the step 2 into pieces, screening to obtain particulate matters with meshes of 20-40, and performing reduction on the particulate matters by a heating reduction method to obtain modified transition metal phosphide. When used as a catalyst, the phosphide performs hydrogenating dechlorination and has an significantly improved catalytic activity compared with an unmodified catalyst. The method is simple and easy to operate, and meanwhile can effectively improve hydrogenating dechlorination catalytic activity of the transition metal phosphide.

Owner:SOUTHEAST UNIV

Catalyst for oxidation of hydrogen chloride to prepare chlorine and application thereof

InactiveCN103920507AIncrease surface oxygen concentrationHigh catalytic activityPhysical/chemical process catalystsPreparation from chloridesReaction temperatureRare earth

Belonging to the field of catalysts, the invention relates to a catalyst for oxidation of hydrogen chloride to prepare chlorine and application thereof. The catalyst takes a rare earth oxysulfate or a compound composed of the rare earth oxysulfate and other auxiliary materials as a carrier, and adopts the transition metal element chromium, nickel, ruthenium, copper or gold and an alkali metal element as active components. The reaction of oxidizing hydrogen chloride to prepare chlorine is carried out in a fixed bed reactor, the volume ratio of oxygen to hydrogen chloride is 1 / 8-2 / 1, the reaction pressure is 1-10atm, the reaction temperature is 300-430DEG C, and the reaction capacity of hydrogen chloride on unit mass of the catalyst is 0.22-2.38mmol / (g.min).

Owner:NANJING UNIV OF TECH

Portable gas generating device and electrical fuel cell power supply comprising such a device

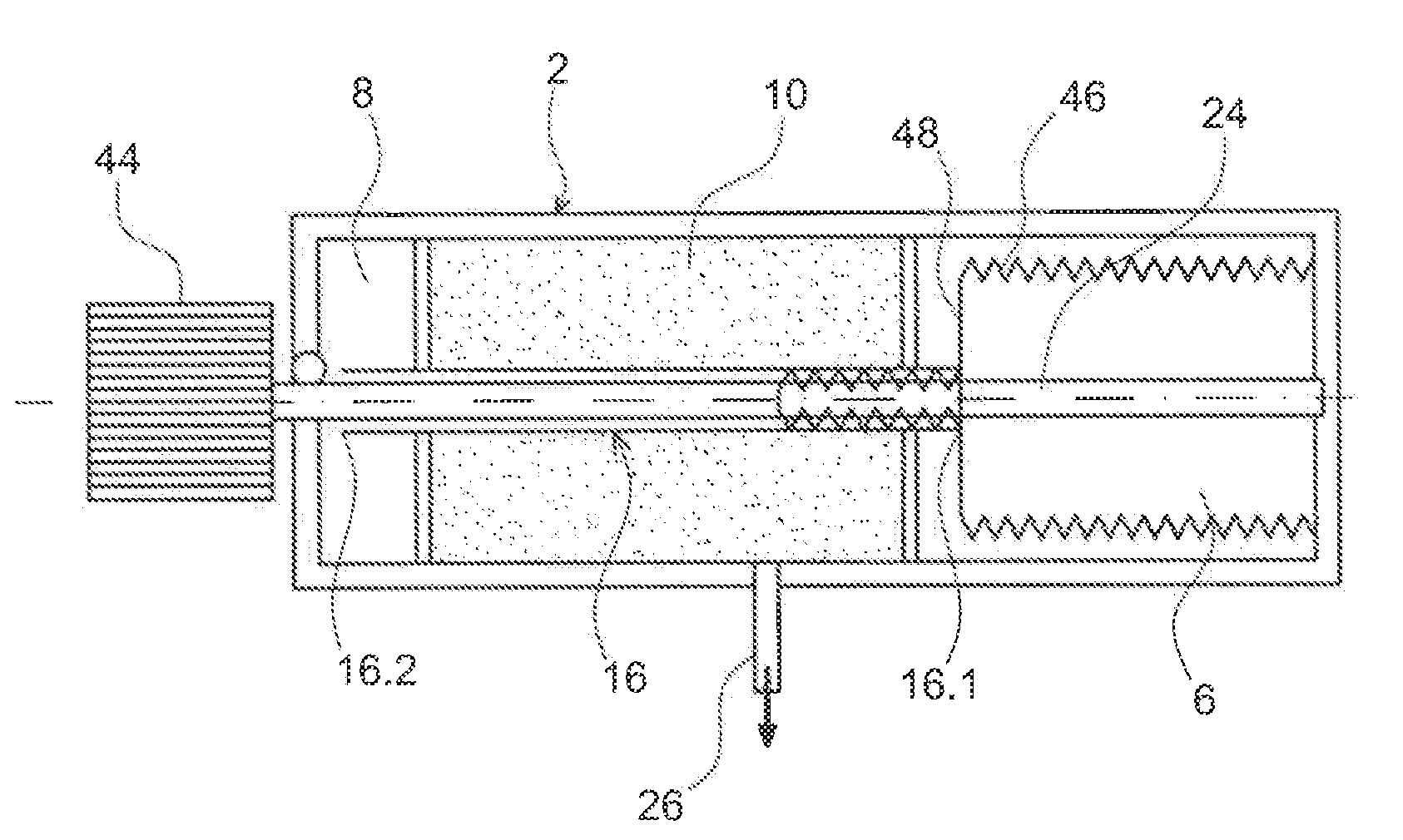

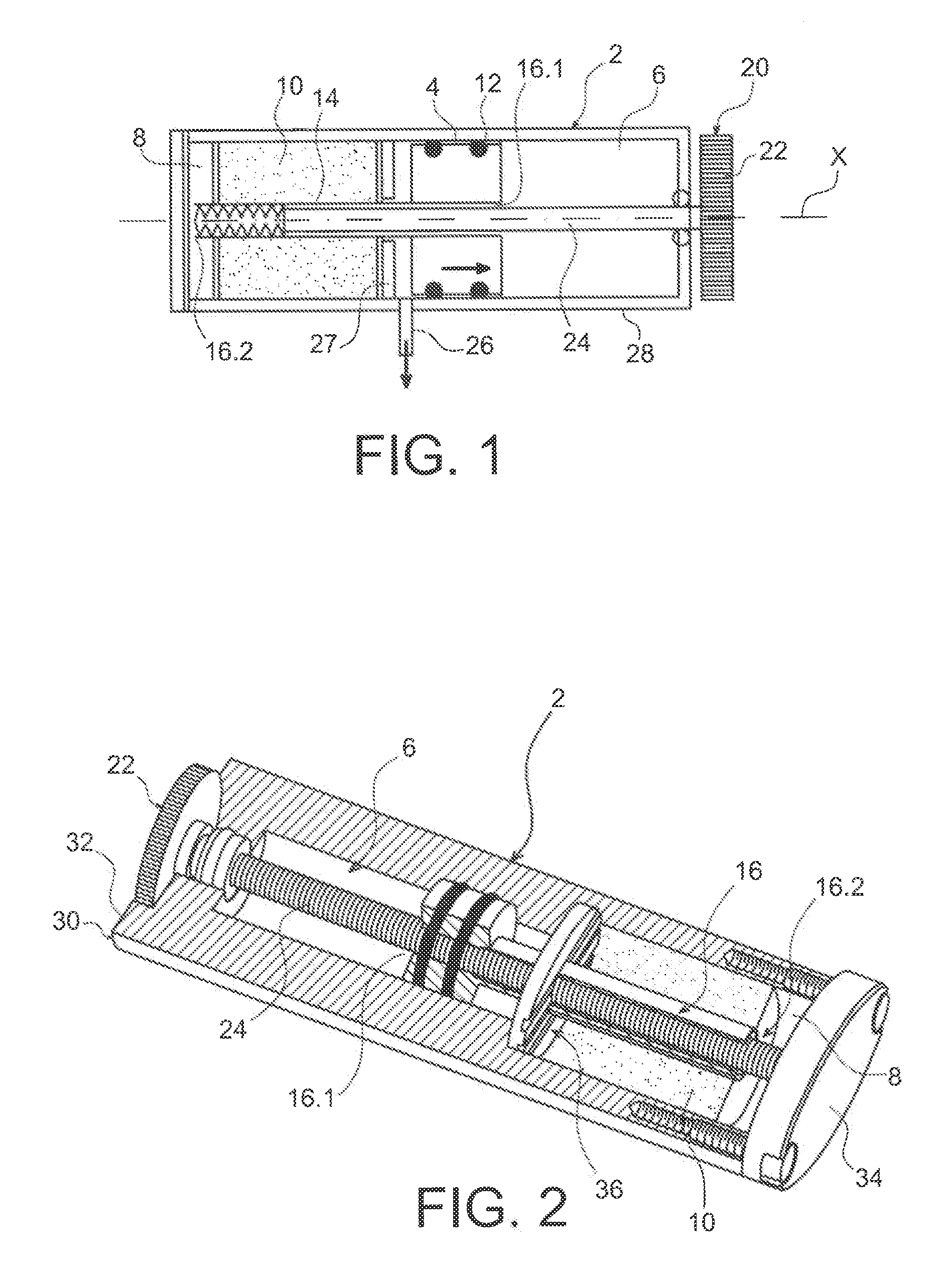

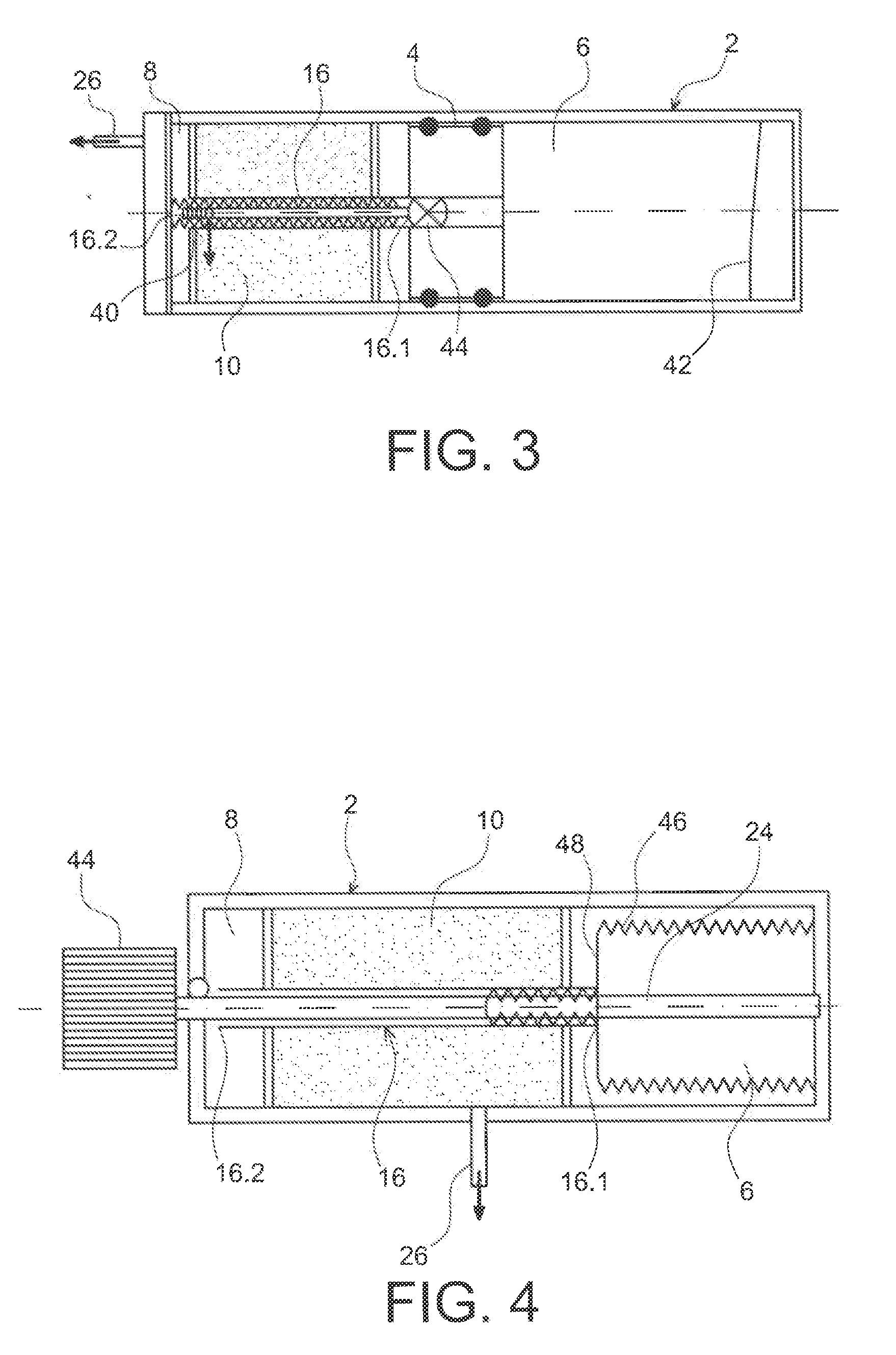

ActiveUS20090017347A1Keep for a long timeConstant volumeGenerators with non-automatic water feedAcetylene gas generator detailsFuel cellsEngineering

Device for generating gas by placing a liquid reactant in contact with a solid element, comprising a liquid reactant tank (6) and a reaction chamber (8) intended to contain the solid element, wherein the tank (6) and the reaction chamber (8) are separated in a sealed manner by a mobile wall (4), with an outlet port (26) for collecting the gas generated in the reaction chamber and means (14) for injecting the liquid reactant onto the solid element, which injection means (14) pass through the mobile wall (4) and are capable of moving into the solid element.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Method for treating titanium tetrachloride-containing waste liquid

ActiveCN106277046ALow costHas industrial valueTitanium dioxidePreparation from chloridesSocial benefitsPolyolefin

The invention relates to a method for treating titanium tetrachloride-containing waste liquid. The waste liquid comprises titanium tetrachloride, an organic solvent and halogenated alkoxy titanium and / or titanium alkoxide. The method comprises a step (1) of contacting the titanium tetrachloride-containing waste liquid with water to perform hydrolysis; a step (2) of distilling the hydrolysed waste liquid, and after an oil phase is evaporated by 20 volume% or above, a titanium-containing compound is collected from remaining materials. Through the method, resource treatment of the polyolefin production waste liquid can be performed simply, not only can the industrial waste treatment problem in the polyolefin catalyst production process be solved, but also the polyolefin catalyst production cost is reduced; useful materials in the polyolefin production waste liquid can be recycled to facilitate reutilization, and thus the method has long-term economic and social benefits.

Owner:CHINA PETROLEUM & CHEM CORP +2

Copper oxide catalyst for preparing chlorine gas from chlorine hydride by catalytic oxidation, and preparation method and application thereof

InactiveCN102658149AHigh activityImprove stabilityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsAir atmosphereChlorine dioxide

The invention provides a copper oxide catalyst for preparing chlorine gas from chlorine hydride by catalytic oxidation, and a preparation method and application thereof. The catalyst is prepared from the following components in percentage by weight: 1-20% of CuO, 1-15% of K2O and 65-98% of support, wherein the support is rare-earth oxide modified activated alumina. The invention belongs to an environment-friendly low-cost catalyst; and the rare-earth oxide modified activated alumina is used as the support to enhance the activity and stability of the catalyst and prolong the service life of the catalyst. An isometric impregnation method is utilized to directly support copper and potassium chloride onto the rare-earth oxide modified activated alumina support, and roasting is carried out in an air atmosphere to obtain the supported copper oxide catalyst. The preparation method is simple and easy to implement, and has the advantages of high catalyst activity and high stability.

Owner:SHANGHAI CHLOR ALKALI CHEM +1

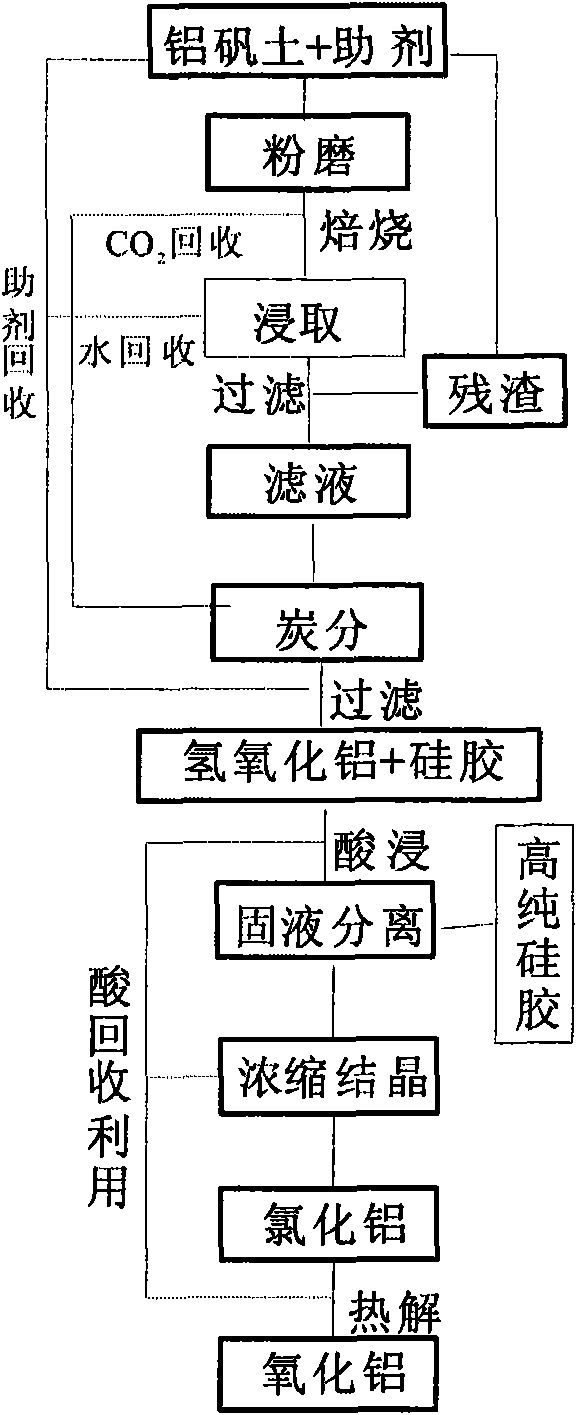

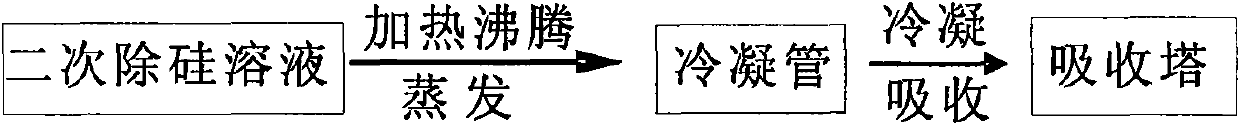

Method for extracting high-purity aluminum oxide and silica gel from beauxite

ActiveCN101767807ALower taste requirementsBreakthrough costAluminium compoundsSilicaProcess engineeringSilica gel

The invention discloses a method for extracting aluminum oxide and silica gel from beauxite (aluminum bauxite). In the method, steps such as cyclic activation, leaching, recovery of carbon, sodium carbonate and water, separation of silicon from aluminum, thermal decomposition and recovery of hydrochloric acid are employed to obtain high-purity aluminum oxide; in addition, CO2 produced in the whole technological process and alkaline, acid and water used in the process of extraction can all be recovered and recycled. The method of the invention features high extraction efficiency of aluminum oxide, simple technological process, high-purity obtained silica gel and major breakthroughs in solving the technical problem that a great deal of waste residue is produced in the process of traditionally extracting aluminum bauxite and deironing is costly.

Owner:北京蔚然欣科技有限公司

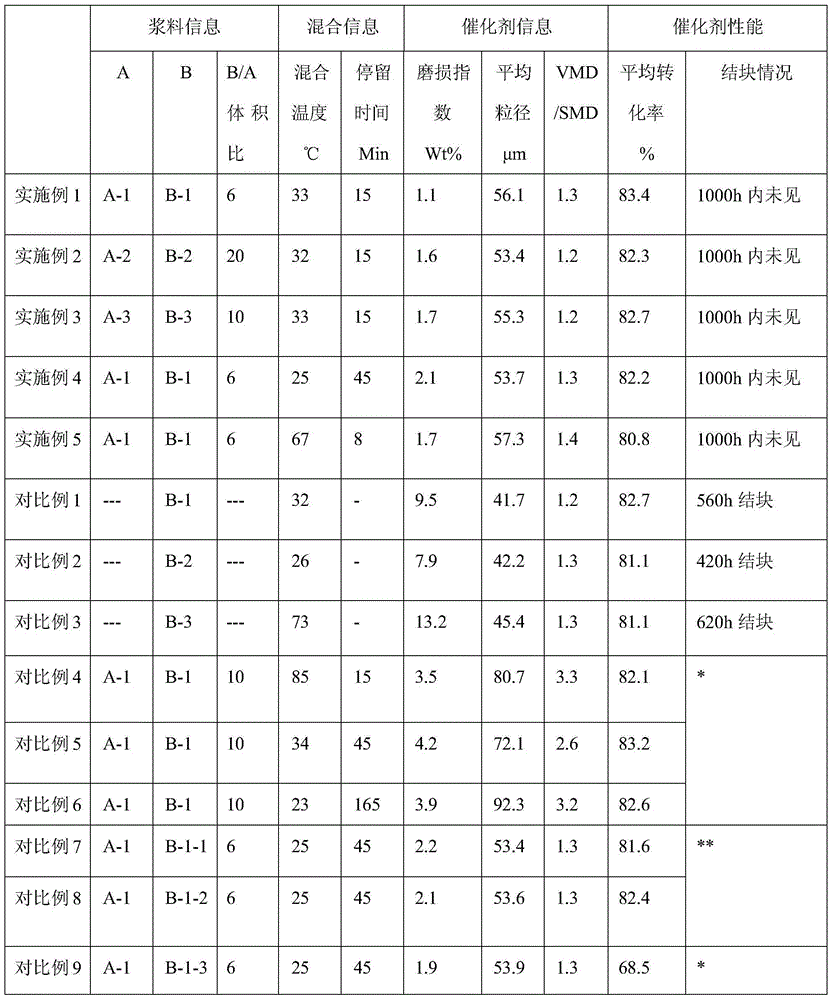

Preparation method of catalyst used for chlorine preparation, catalyst, and method used for preparing chlorine

ActiveCN104785271AImprove liquidityHigh activityHeterogenous catalyst chemical elementsCatalyst activation/preparationRare-earth elementPtru catalyst

The present invention relates to a method for preparing catalyst used for preparing chloride by oxidizing hydrogen chloride. The method is mixing a slurry mainly containing boron and chromium with a slurry mainly containing copper, boron, alkali-metal elements, rare-earth elements, aluminum sol, silica sol, carrier and optionally other metal elements, the mixing temperature being not more than 100℃, and the residence time being not more than 120 minutes, the mixed slurry is successively treated with spray drying, high temperature calcination and the like, so that catalyst particles is obtained. The present invention also relates to the catalyst prepared through the method, uses of the catalyst used in the process of preparing chloride by oxidizing hydrogen chloride and a method for preparing chlorine by using the catalyst. The catalyst is used for preparing chlorine by oxidizing hydrogen chloride with oxygen or air in fluidized bed reactor, and has an excellent activity and anti-caking property, a relatively good mechanical strength and a relatively long service life.

Owner:WANHUA CHEM GRP CO LTD

Heavy oil hydrogenating treatment catalyst and preparation method thereof

ActiveCN101357337ASimple manufacturing methodExtended service lifeMolecular sieve catalystsPreparation from chloridesLoss rateAlkali metal oxide

Owner:NANJING UNIV OF TECH

Popular searches

Hydrocarbon by hydrocarbon condensation Hydrocarbon by hydrocarbon cracking Hydrocarbons from unsaturated hydrocarbon addition Hydrocarbons Chemical/physical/physico-chemical nozzle-type rreactors Electric furnace Energy based chemical/physical/physico-chemical processes Plasma technique Rubidium/caesium/francium compounds Alkali metal oxides/hydroxides

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com