Preparation method and application of transition metal phosphide used for hydrogenating dechlorination

A transition metal, hydrodechlorination technology, applied in the direction of chloride preparation, chemical instruments and methods, non-metallic elements, etc., can solve the problems of small catalyst surface area, low catalytic activity, etc., to improve hydrodechlorination activity, Good repeatability and stable catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Weigh 4.0 g of ammonium molybdate tetrahydrate and 3.0 g of diammonium hydrogen phosphate, mix and dissolve in 30 ml of deionized water, and dissolve 5.0 g of polyethylene glycol with a molecular weight of 8000 in the above solution to obtain a mixed aqueous solution. The aqueous solution was stirred at 80° C. for 3 h, evaporated to dryness at 100° C., dried at 120° C. for 12 h, and calcined at 500° C. for 5 h to prepare the catalyst precursor in oxidation state. The precursor is ground, pressed into tablets and sieved to obtain 20-40 mesh particles.

[0022] in H 2 Under the atmosphere, after raising the particle to 350°C in 0.5h, at 1°C min -1 The rate was increased to 650°C and kept at this temperature for 2h. h 2 Under the atmosphere, after the temperature was lowered to room temperature, the catalyst was prepared.

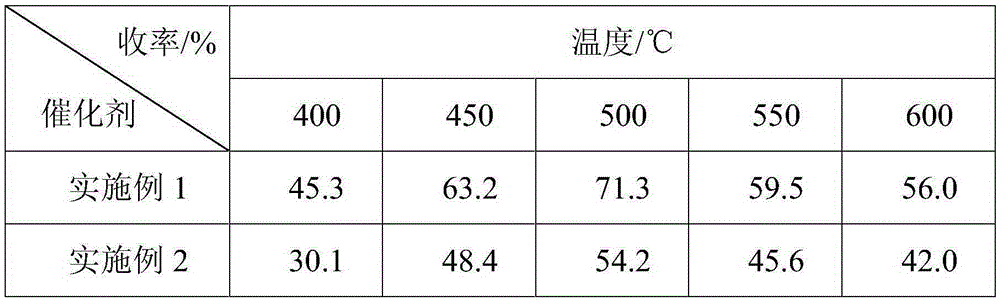

[0023] Under a hydrogen atmosphere, the catalyst is placed in a quartz tube, and trichlorethylene is carried by hydrogen into the quartz tube to ca...

Embodiment 2

[0025] Weigh 4.0 g of ammonium molybdate tetrahydrate and 3.0 g of diammonium hydrogen phosphate, mix and dissolve in 30 ml of deionized water, and dissolve 1.0 g of polyethylene glycol with a molecular weight of 8000 in the above solution to obtain a mixed aqueous solution. Subsequent operations are the same as in Example 1. The catalyst prepared by this method is used in the hydrodechlorination reaction of trichlorethylene, and the hydrogen chloride yield can reach up to 54.2%.

Embodiment 3

[0027] Weigh 4.0 g of ammonium molybdate tetrahydrate and 3.0 g of diammonium hydrogen phosphate, mix and dissolve in 70 ml of deionized water, and dissolve 15.0 g of polyethylene glycol with a molecular weight of 8000 in the above solution to obtain a mixed aqueous solution. Subsequent operations are the same as in Example 1. The catalyst prepared by this method is used in the hydrodechlorination reaction of trichlorethylene, and the hydrogen chloride yield can reach up to 68.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com