Low-temperature selective catalytic reduction denitration catalyst and preparation method thereof

A denitration catalyst and selective technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, chemical instruments and methods, etc., can solve the problems of difficult control of catalyst preparation conditions, serious high temperature ablation of activated carbon, and high cost of catalytic preparation, To achieve the effect of improving denitration activity and efficiency, large adsorption capacity, and improving catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

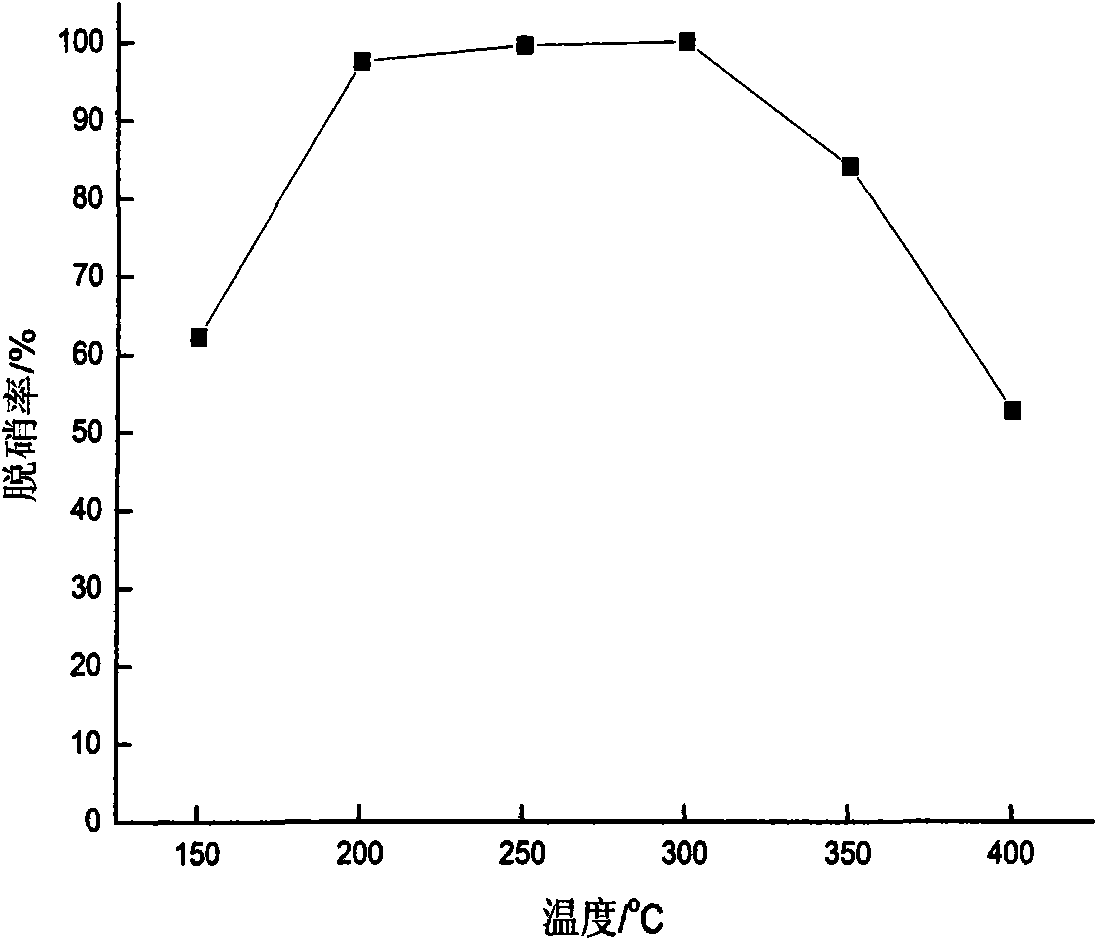

Embodiment 1

[0017] Store and homogenize the attapulgite clay ore in advance;

[0018] Add the piled attapulgite clay to the water for stirring. The mass percentage of the attapulgite clay and water is 65%: 35%. Then the evenly stirred attapulgite clay is cut by a pair of rollers and a multi-roll extruder. Cut and extrude attapulgite clay flakes to promote the depolymerization and dispersion of attapulgite crystal bundles;

[0019] Dry the attapulgite clay flakes, and then pulverize them into attapulgite clay powder passing through a 200-mesh sieve;

[0020] Add 100g of attapulgite clay powder into 2L of water, age for 10h, stir at high speed for 20min to make the attapulgite clay powder into a uniform slurry, and then add 50mL of sulfuric acid with a mass concentration of 10% and 100mL with a concentration of 100g / L manganese nitrate solution, keep stirring for 30 minutes to obtain a suspension, and then slowly add 4mol / L sodium hydroxide solution until the pH value of the suspension is 8-10, ...

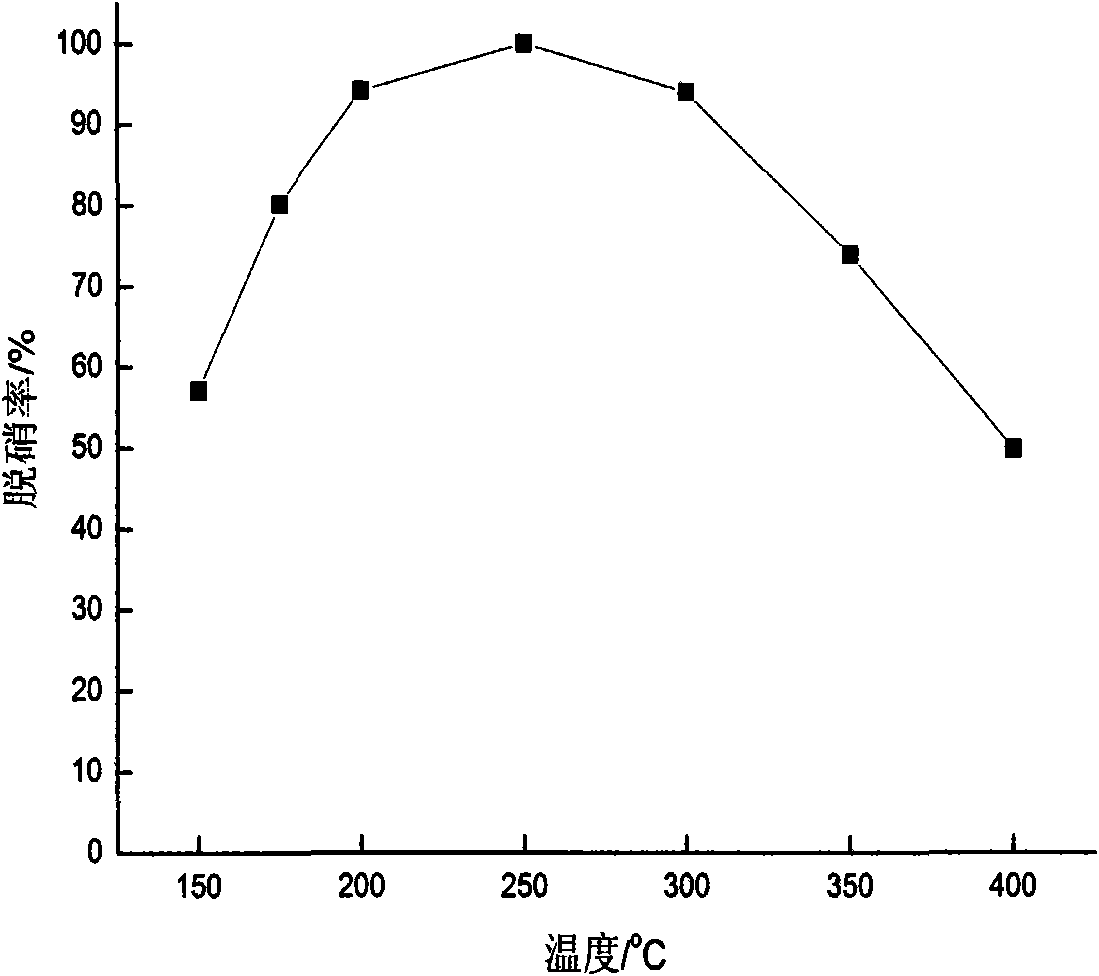

Embodiment 2

[0024] Store and homogenize the attapulgite clay ore in advance;

[0025] Add the piled attapulgite clay to the water for stirring. The mass percentage of the attapulgite clay and water is 65%: 35%. Then the evenly stirred attapulgite clay is cut by a pair of rollers and a multi-roll extruder. Cut and extrude attapulgite clay flakes to promote the depolymerization and dispersion of attapulgite crystal bundles;

[0026] Dry the attapulgite clay flakes, and then pulverize them into attapulgite clay powder passing through a 200-mesh sieve;

[0027] Add 100g of attapulgite clay powder into 2L of water, age for 10h, stir at high speed for 20min to make the attapulgite clay powder into a uniform slurry, and then add 50mL sulfuric acid with a mass concentration of 10% and 200mL with a concentration of 10g / L of copper nitrate and 100mL of 100g / L manganese nitrate solution, continue to stir for 30min to obtain a suspension, then slowly add 4mol / L of sodium hydroxide solution until the pH of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com