Patents

Literature

4337results about "Catalyst regeneration/reactivation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

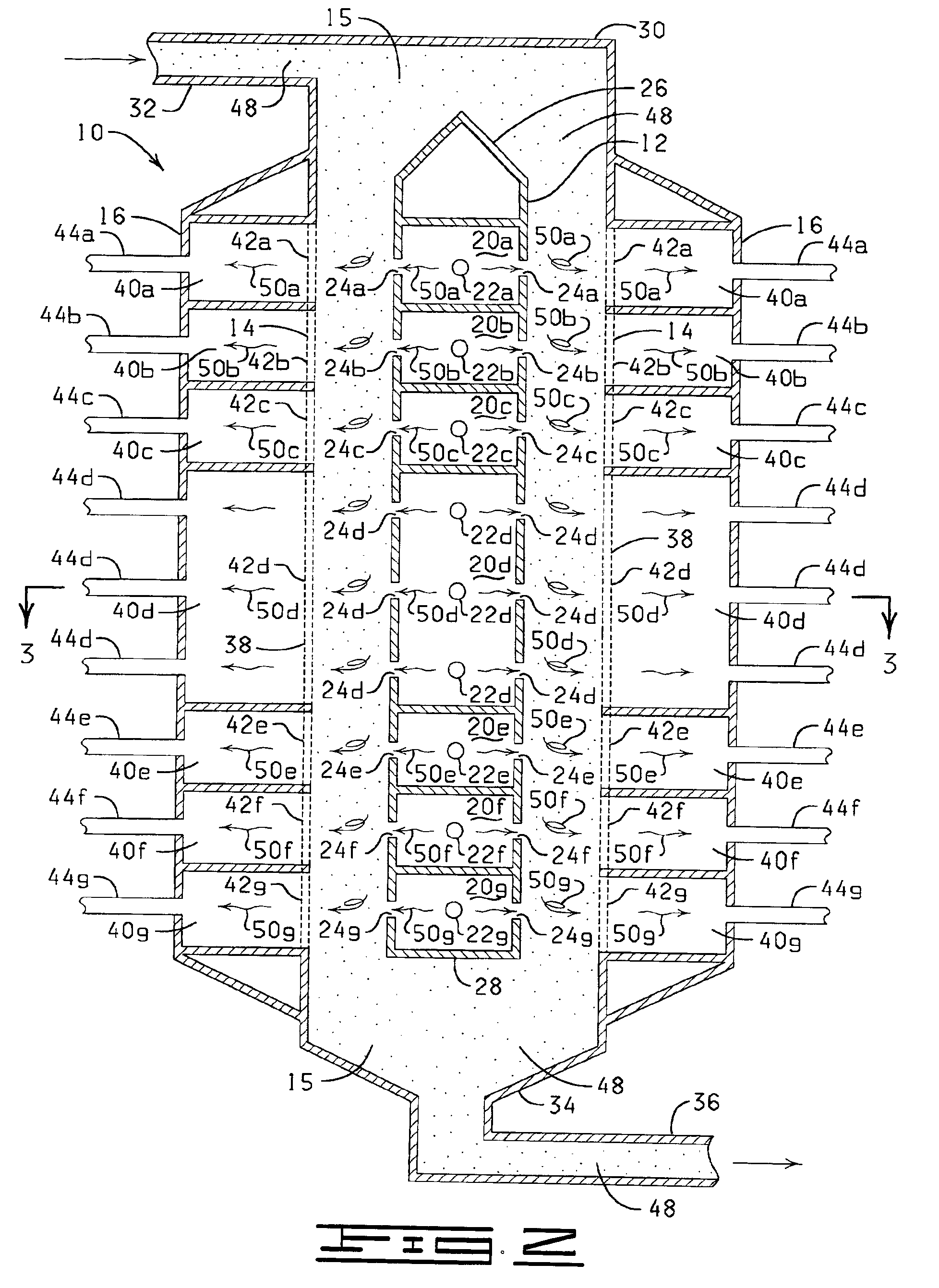

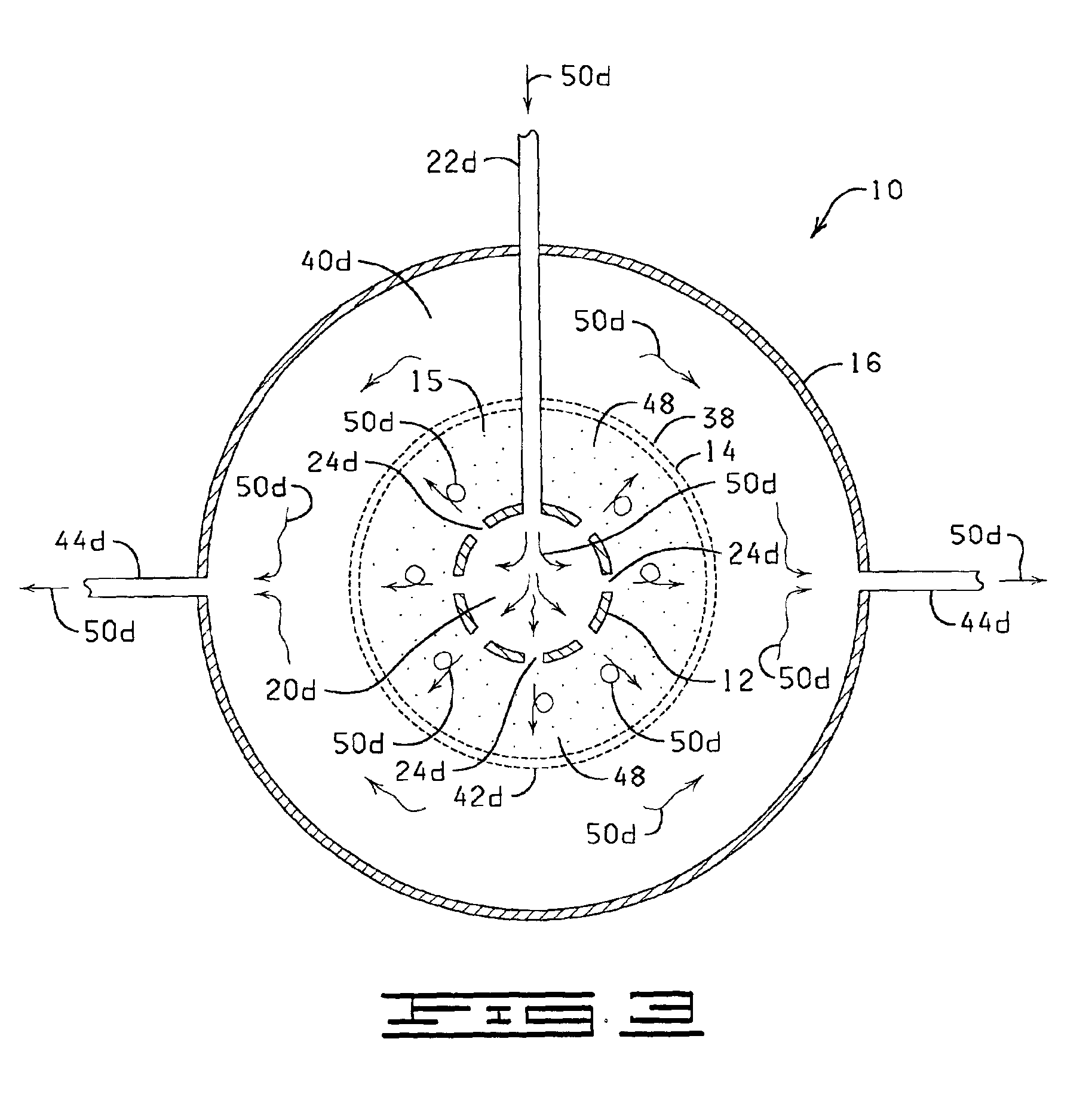

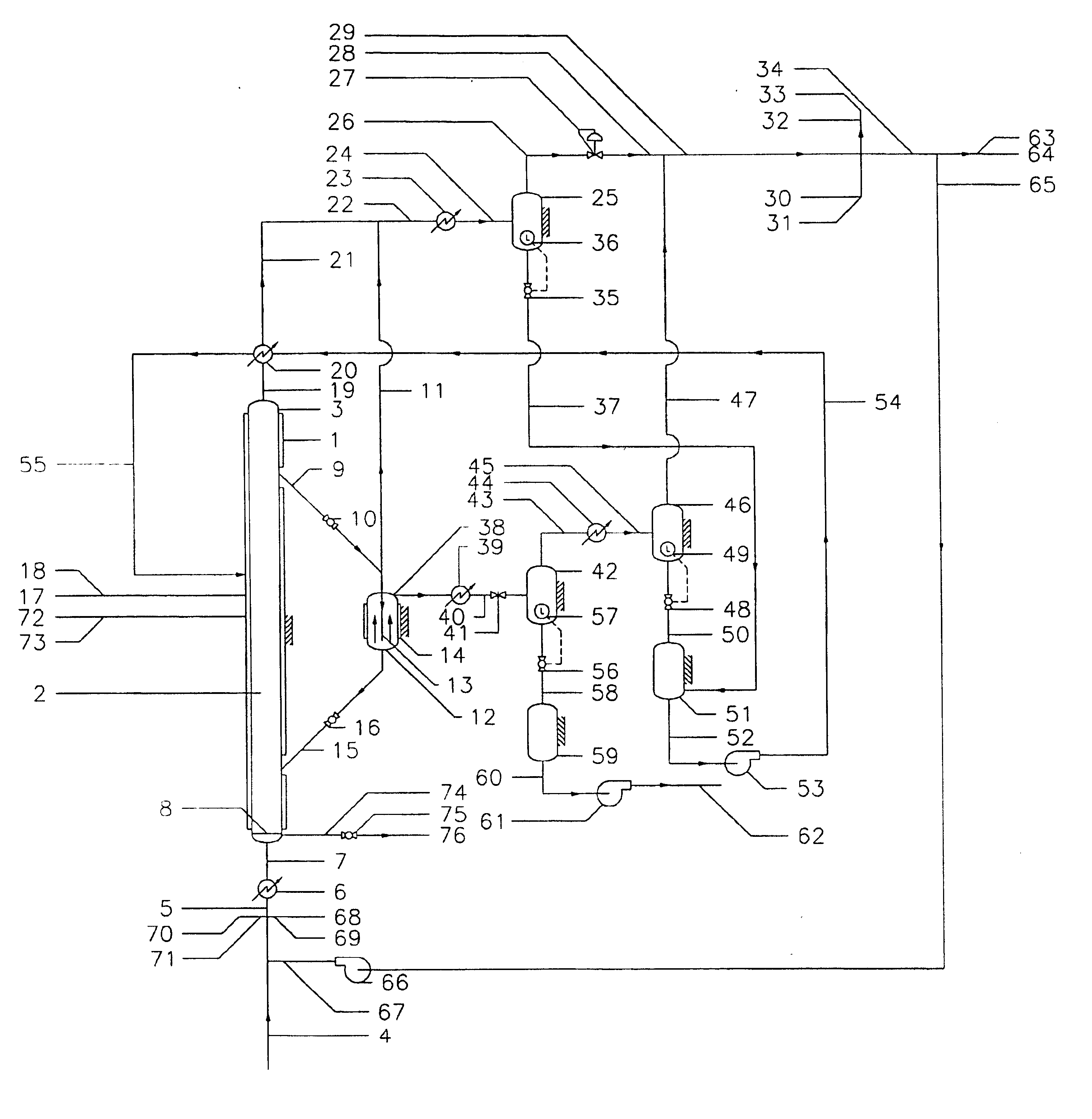

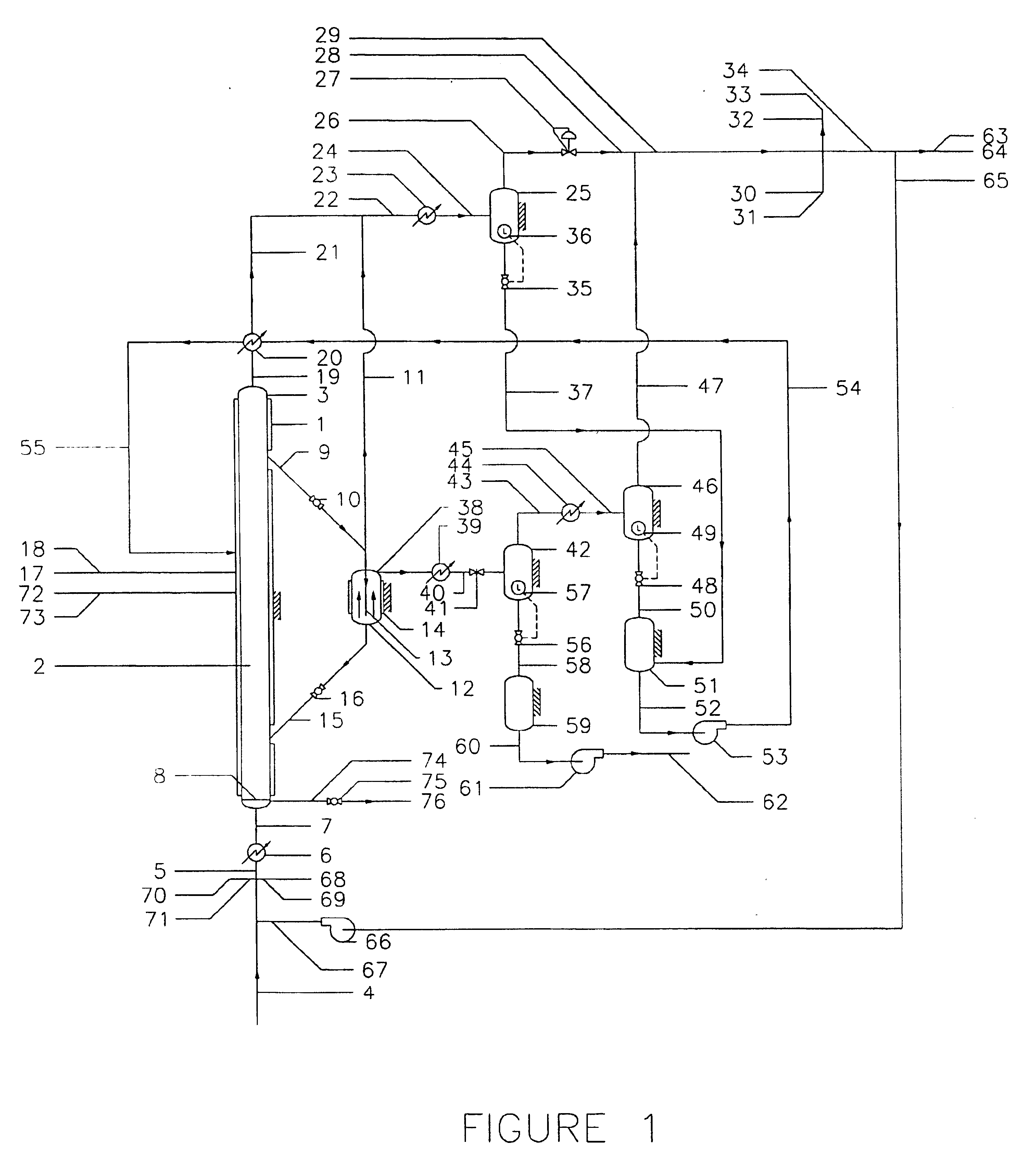

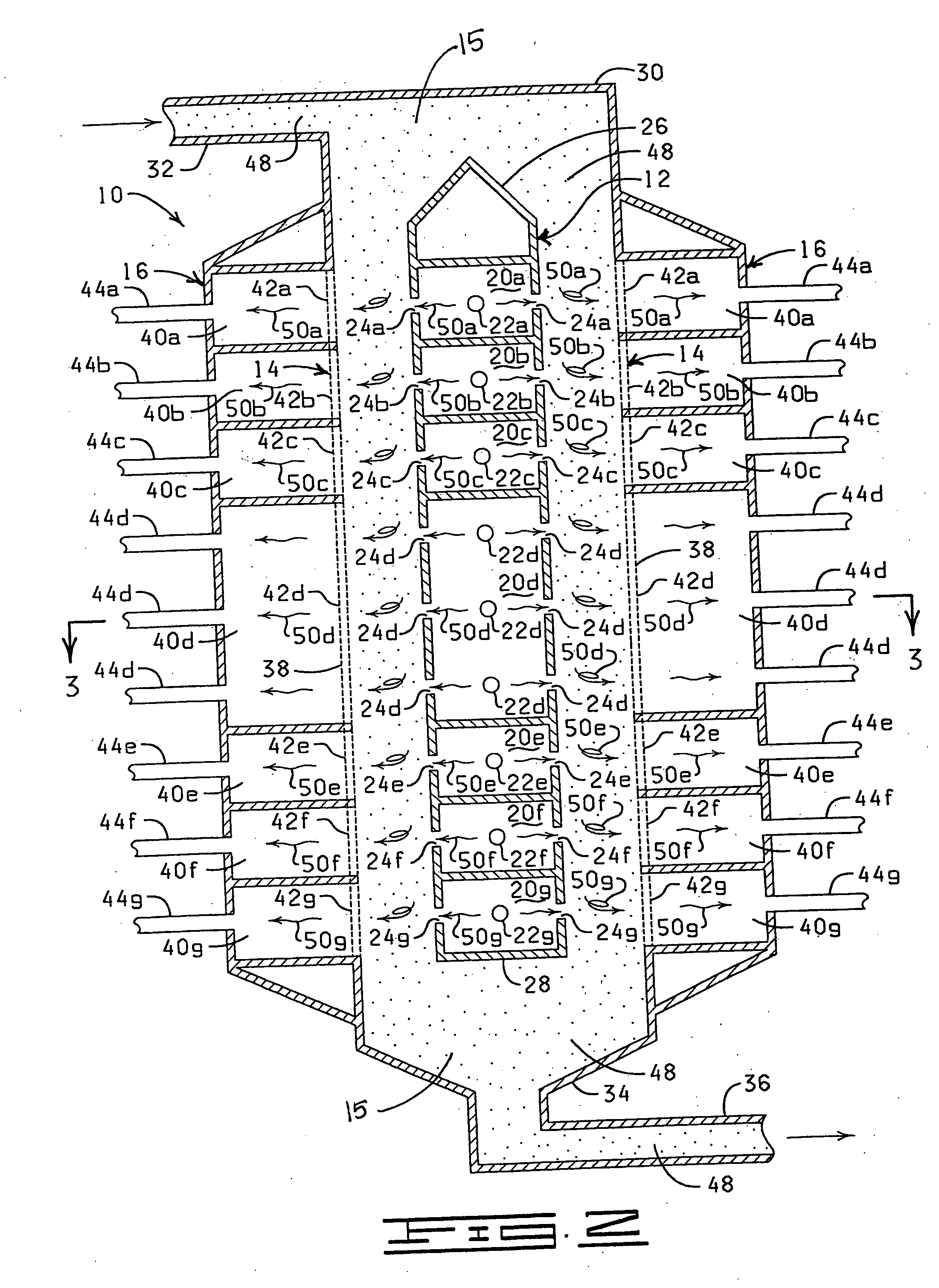

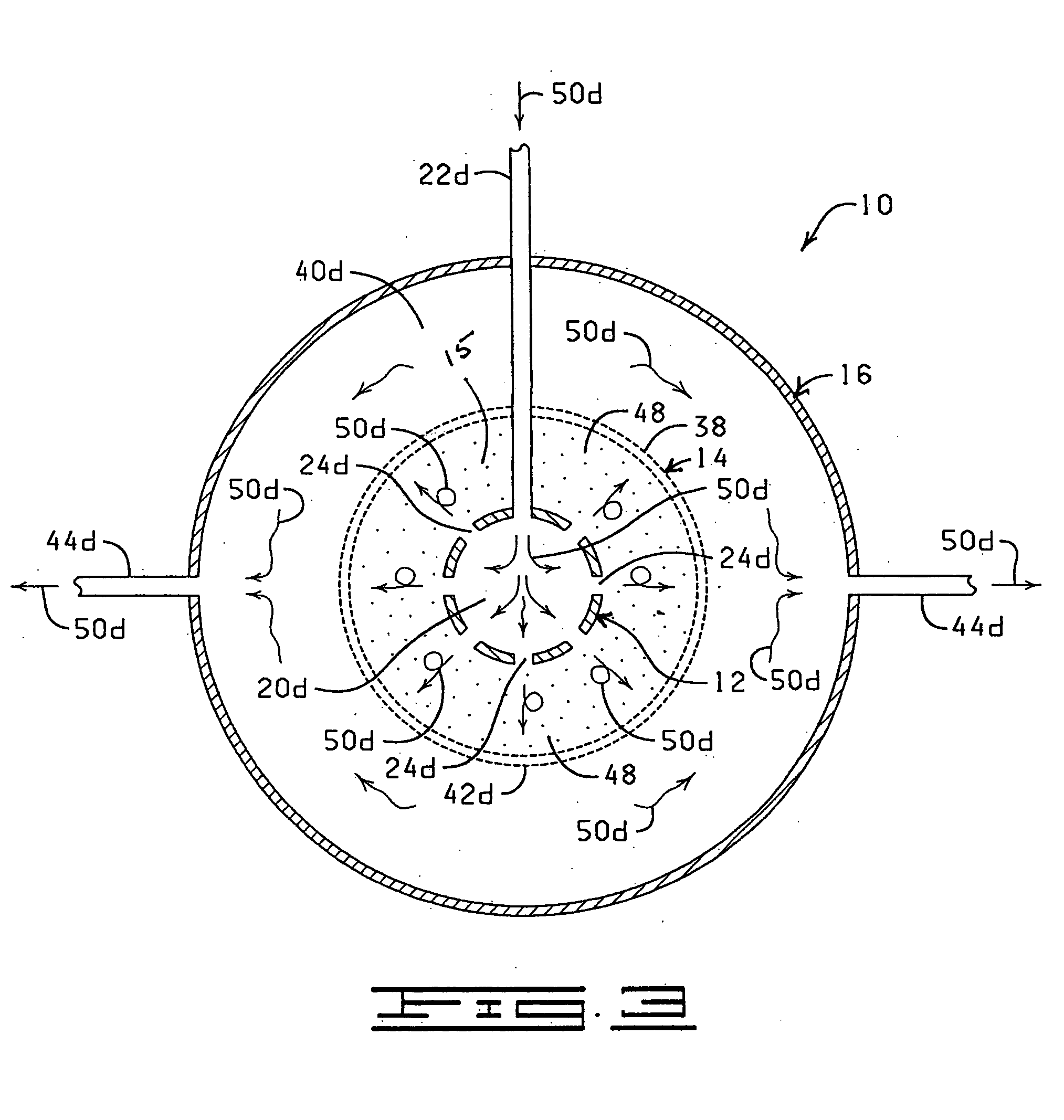

Continuous aromatization and catalyst regeneration device and method thereof

ActiveCN101244969ANo temperature fluctuationsDoes not affect aromatization reactionMolecular sieve catalystsCatalyst regeneration/reactivationFluidized bedAromatization

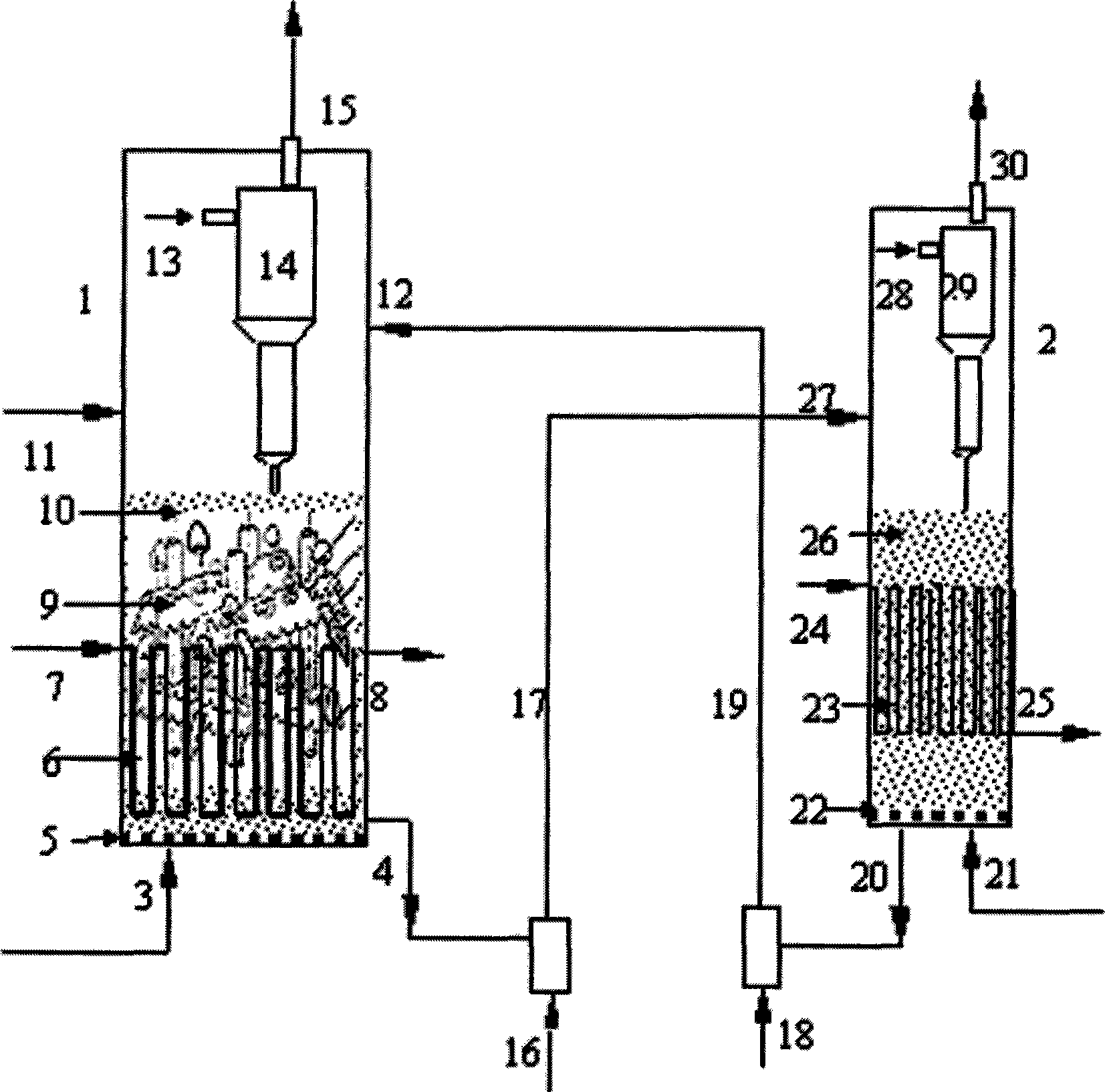

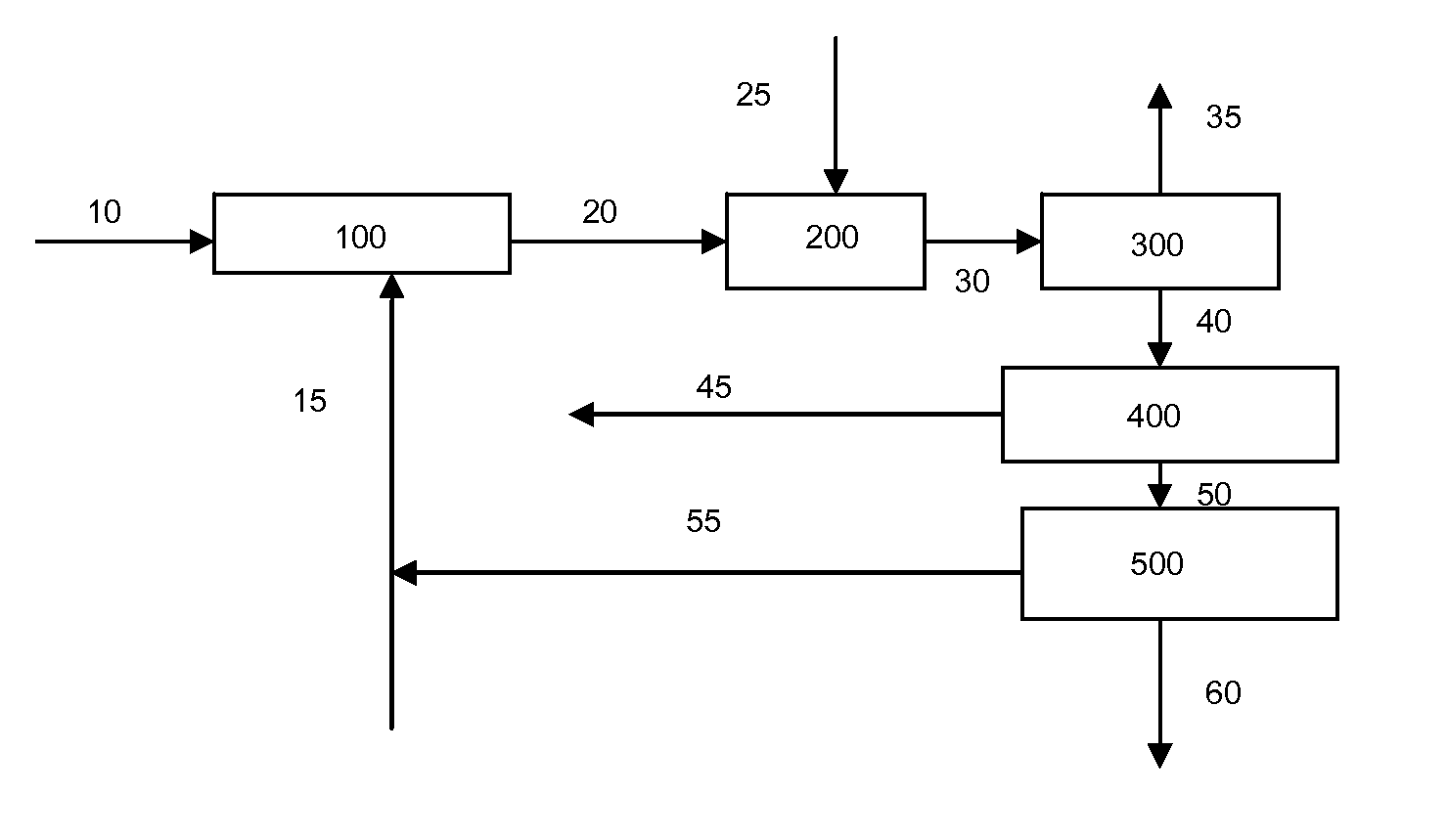

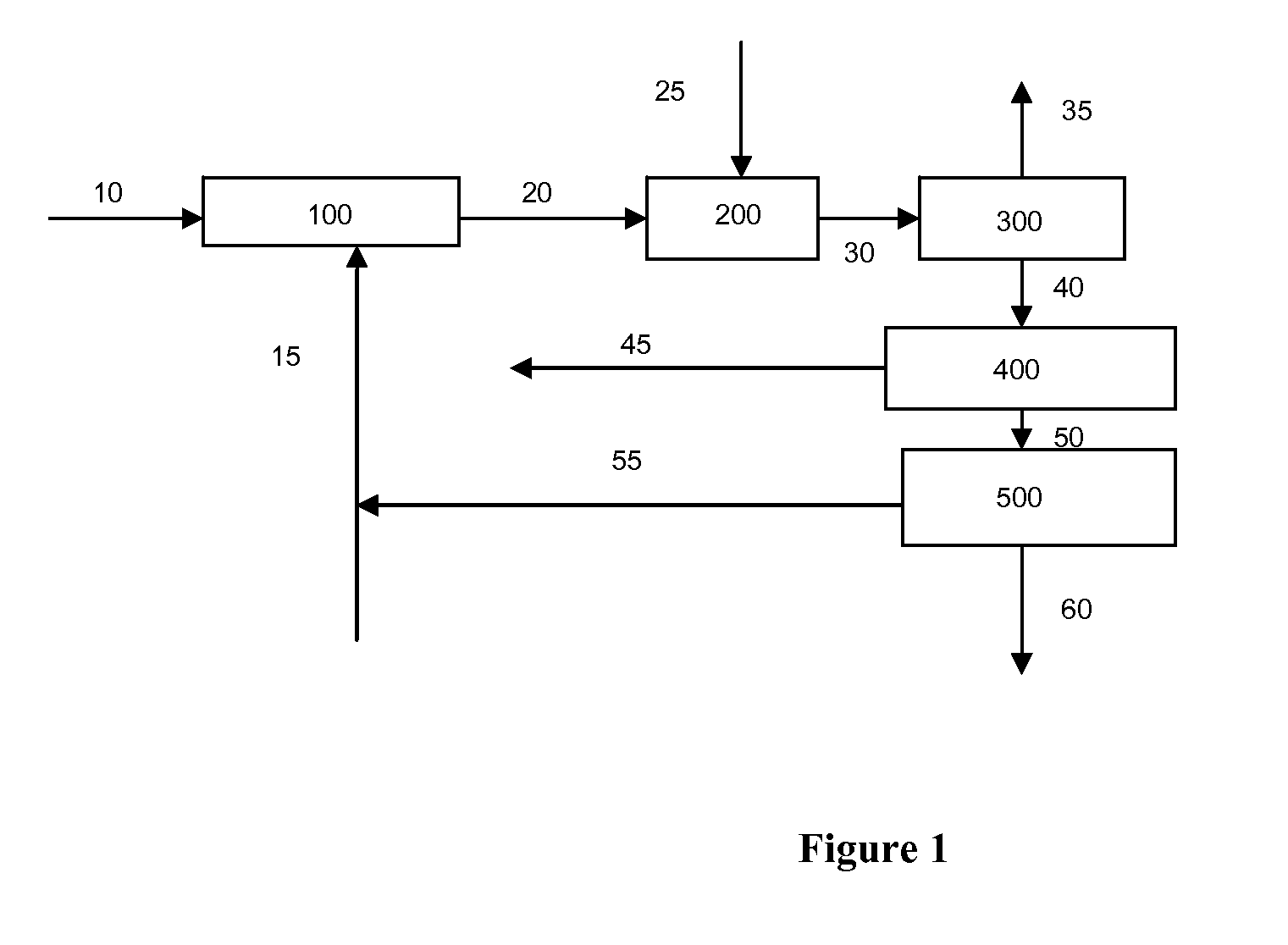

The invention discloses and belongs to the chemical equipment field, which more particularly relates to a C1-C2 hydrocarbon or methanol aromatization and catalyst regeneration fluidized bed device (comprising an aromatization fluidized bed, a catalyst continuous regeneration fluidized bed, a pipeline used for catalyst transportation and a solid transportation device which are arranged between the two fluidized beds), and an aromatization catalyst which is suitable for the fluidized bed operations and the operation methods of aromatization reaction, catalyst regeneration and the device. The device, the catalyst and the method are used for regulating the coking status of the catalyst in an aromatization reactor at any time, thus achieving the aim of transforming the C1-C2 hydrocarbon or the methanol continuously and efficiently and generating aromatics with high selectivity. The C1-C2 hydrocarbon or methanol aromatization and catalyst regeneration fluidized bed device of the invention with adjustable catalyst activity and selectivity can improve the purity and yield of the aromatics, can lead the aromatization reactor operates continuously without stopping at the same time, can improve the strength of aromatics production, and lower the operation cost of the catalyst regeneration when stopping and restarting the whole system.

Owner:TSINGHUA UNIV

Catalyst-Loaded Coal Compositions, Methods of Making and Use

ActiveUS20090048476A1Efficient and high-yielding gasificationHigh yield productionCatalyst regeneration/reactivationSolid fuelsPtru catalystCoal matrix

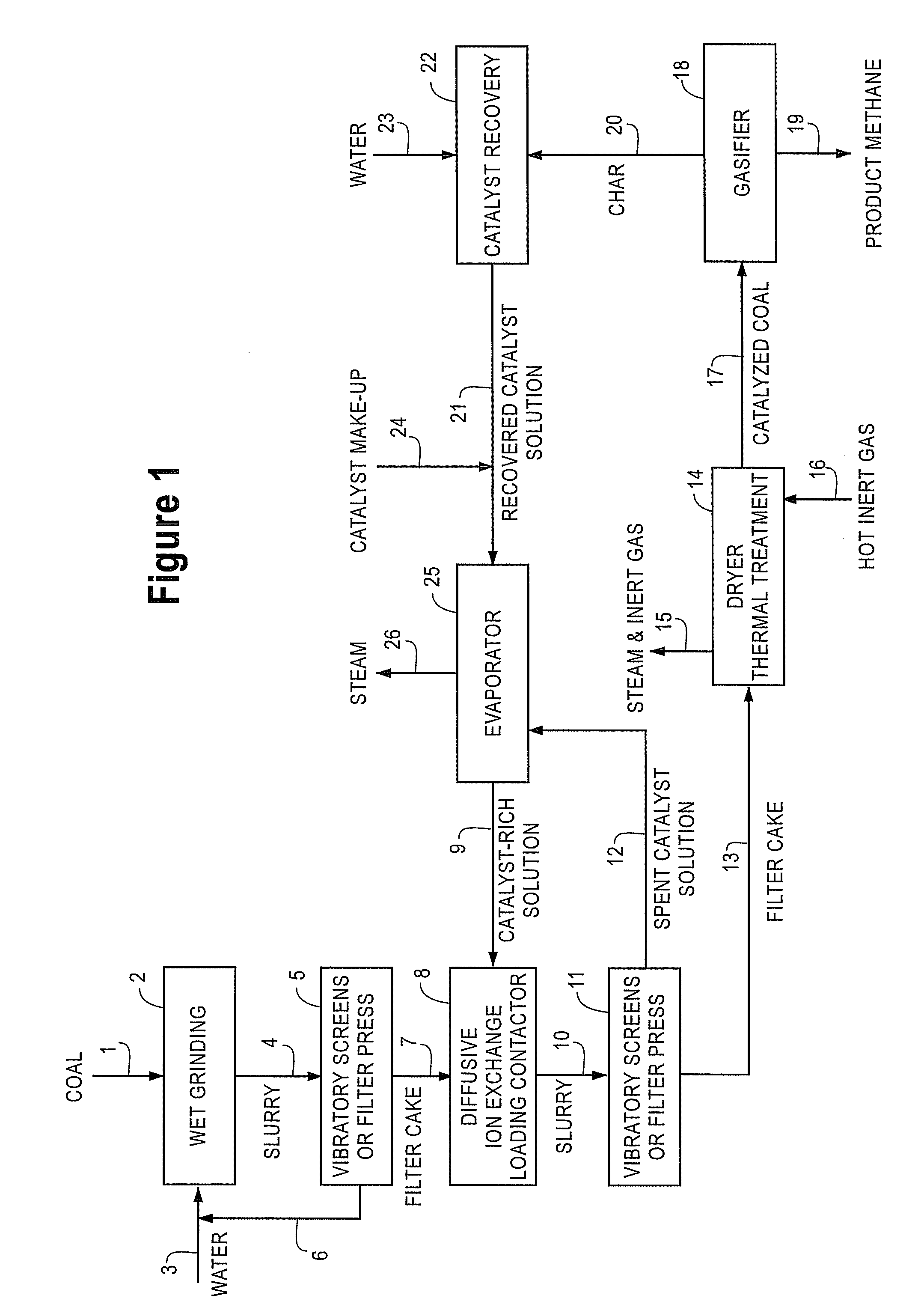

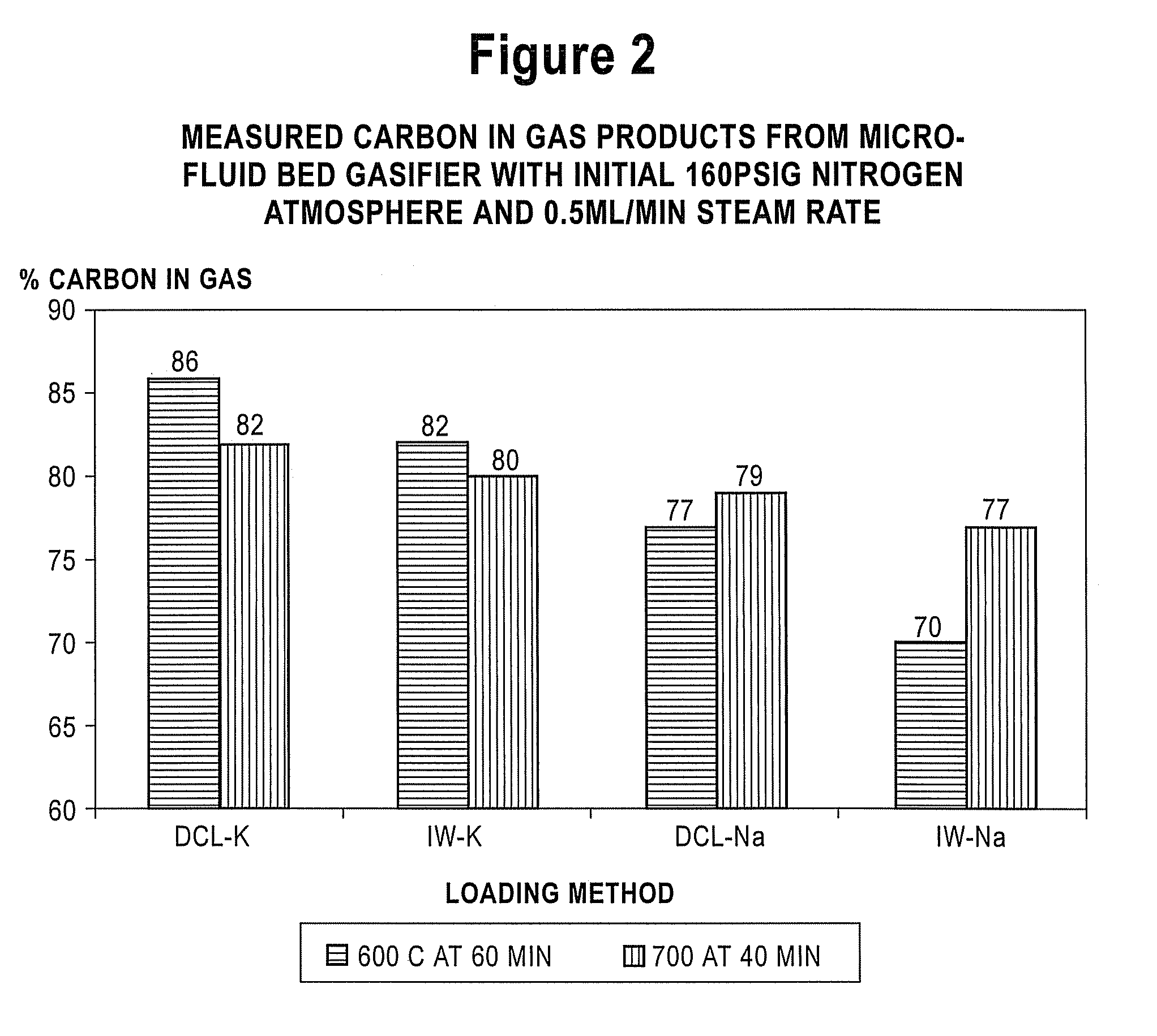

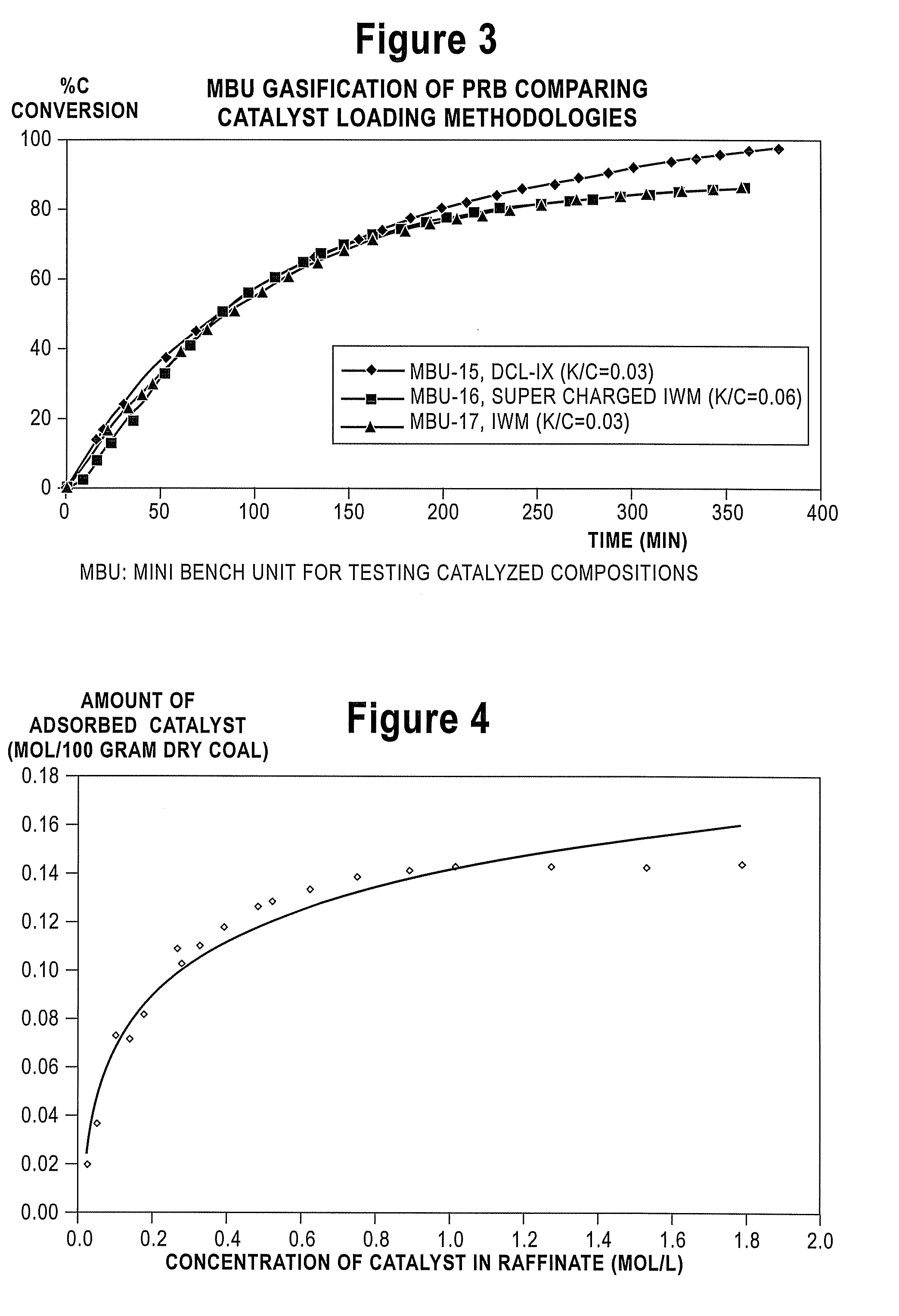

The present invention relates to catalyst-loaded coal compositions having a moisture content of less than about 6 wt %, a process for the preparation of catalyst-loaded coal compositions, and an integrated process for the gasification of the catalyst-loaded coal compositions. The catalyst-loaded coal compositions can be prepared by a diffusive catalyst loading process that provides for a highly dispersed catalyst that is predominantly associated with the coal matrix, such as by ion-exchange.

Owner:SURE CHAMPION INVESTMENT LTD

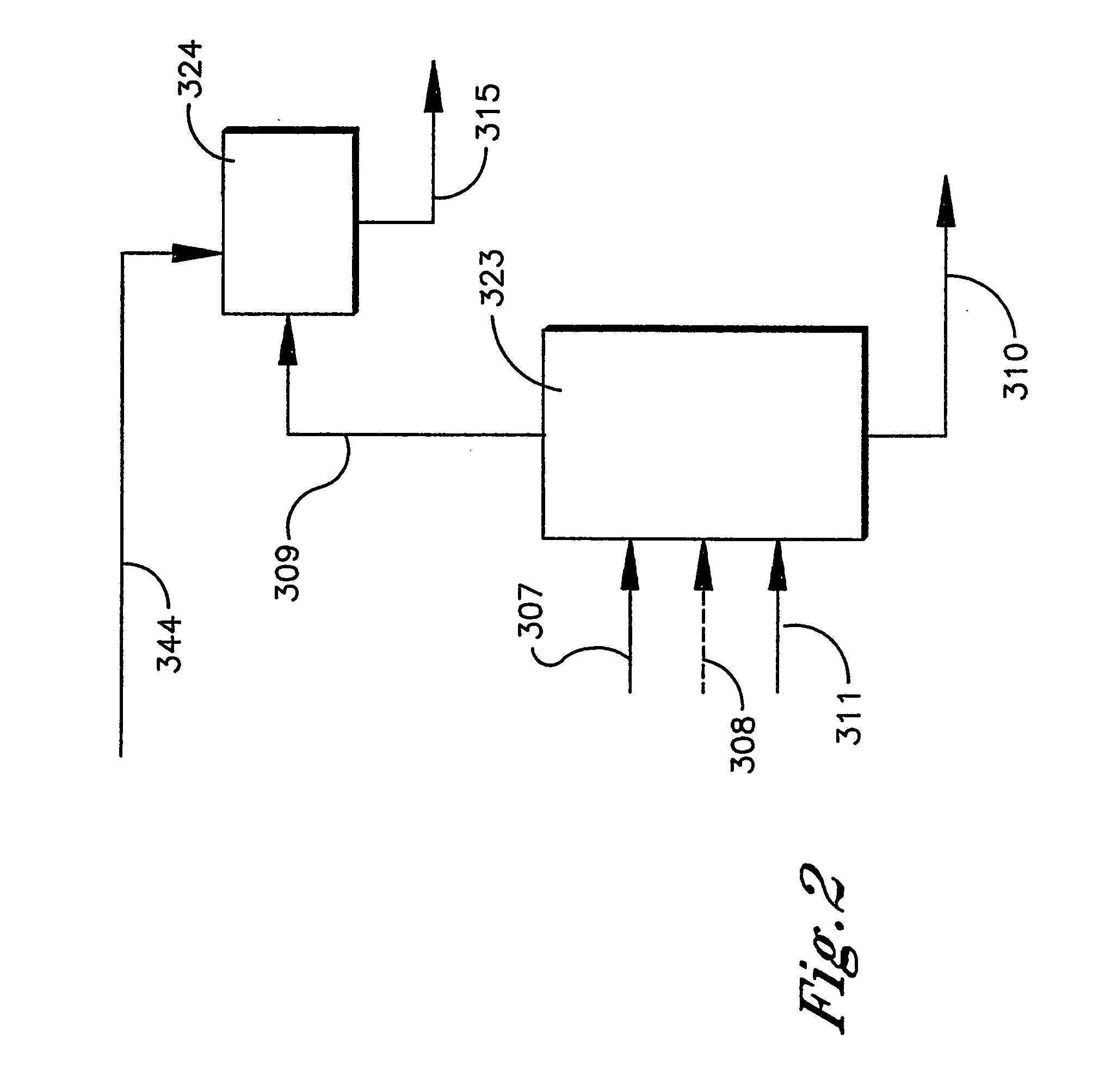

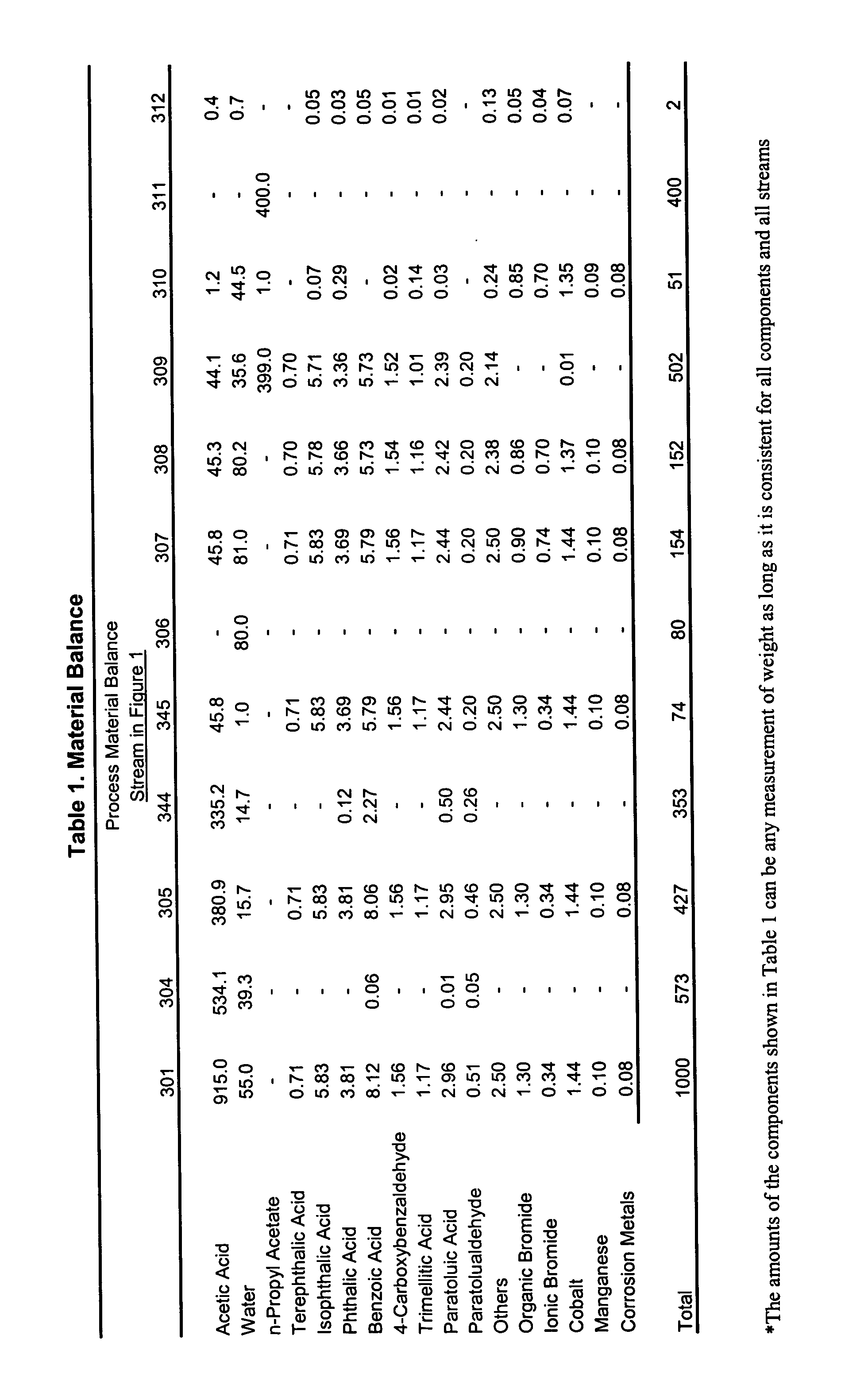

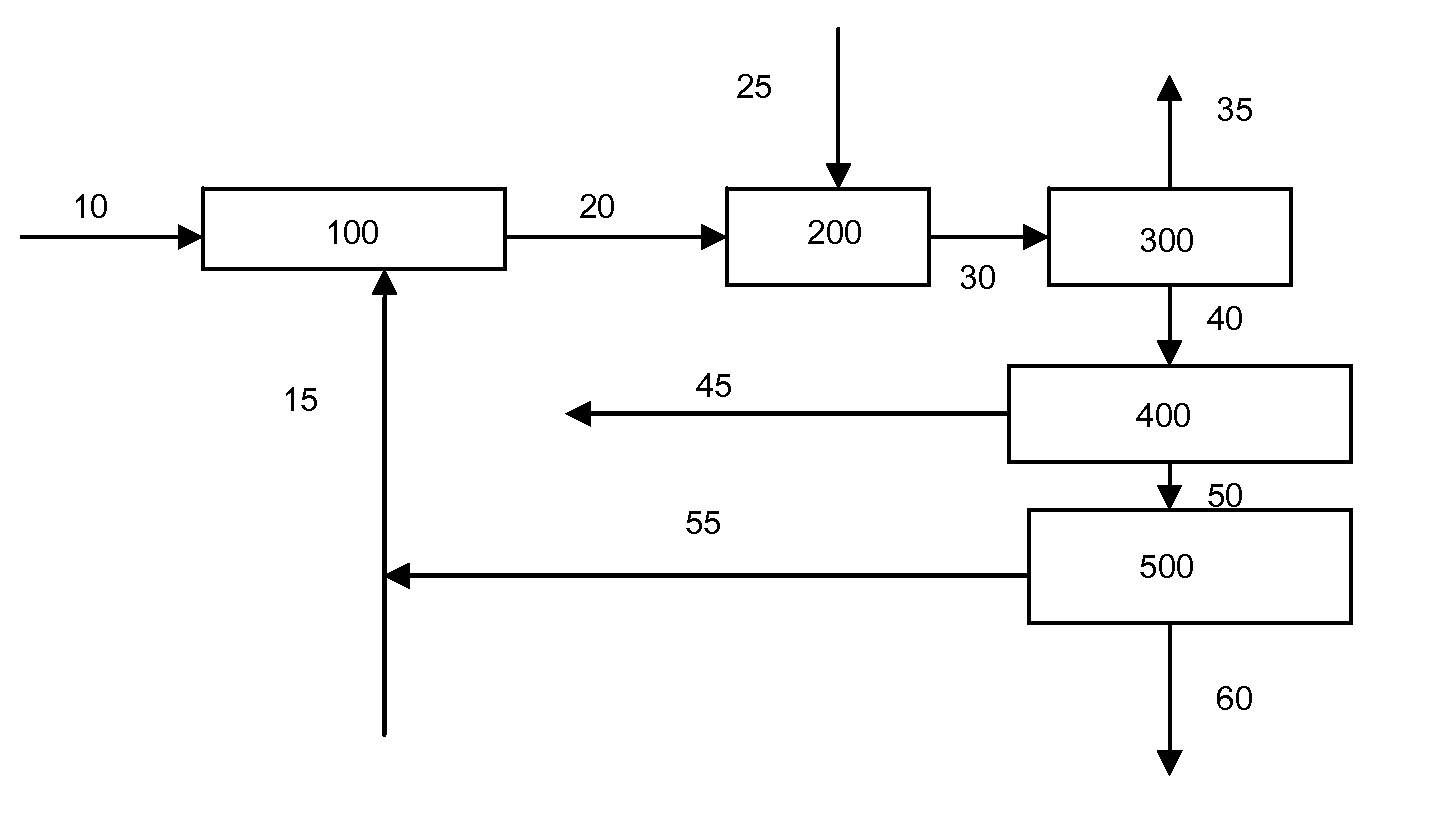

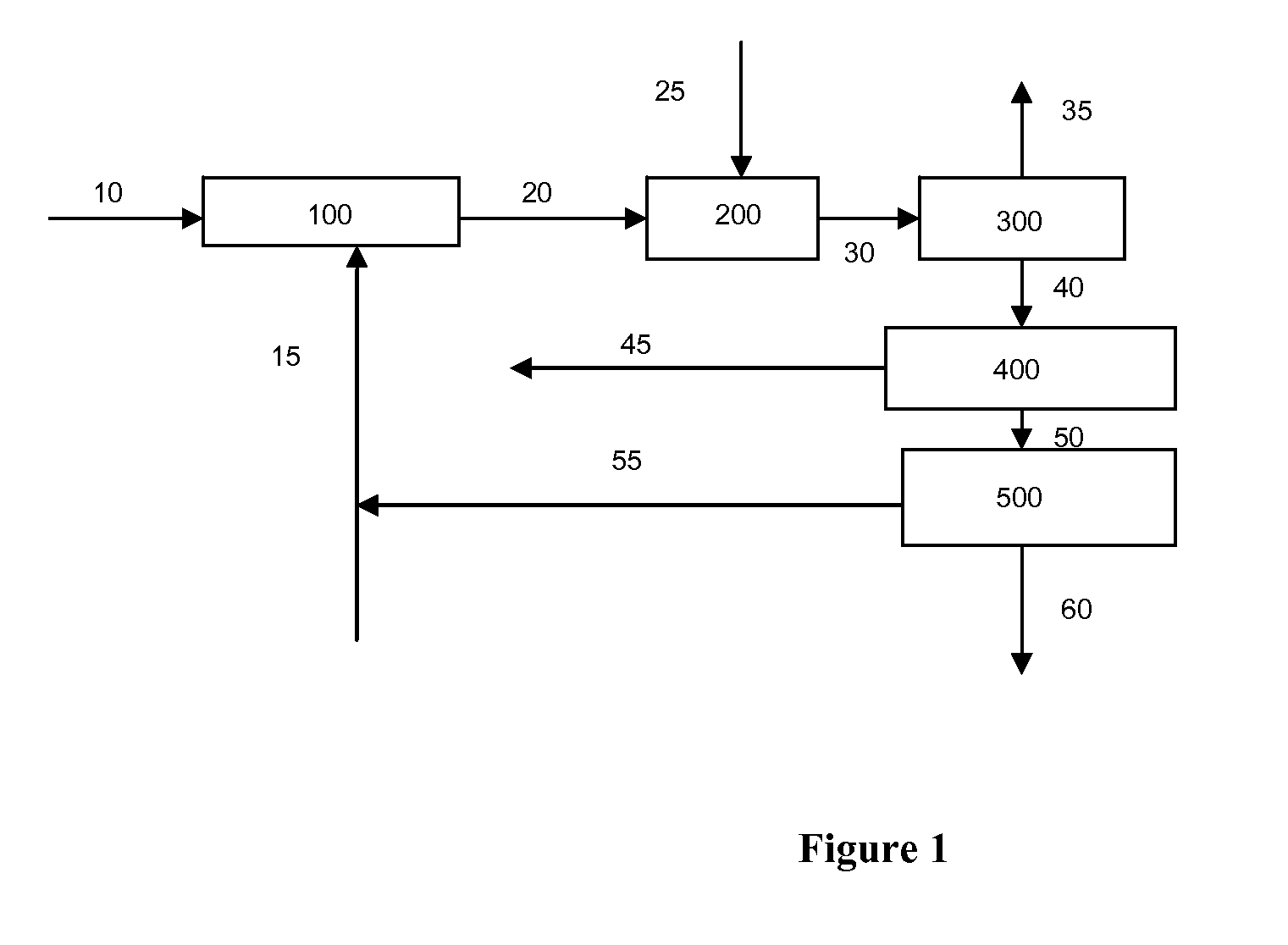

Extraction process for removal of impurities from an oxidizer purge stream in the synthesis of carboxylic acid

InactiveUS20050038288A1Easy to operateImprove reliabilityOrganic compound preparationOrganic chemistry methodsSingle stageMetal catalyst

Disclosed is a process that relates to the recovery of a metal catalyst from an oxidizer purge stream produced in the synthesis of carboxylic acid, typically terephthalic acid. The process involves the addition of a wash solution to a high temperature molten dispersion to recover the metal catalyst and then subjecting an aqueous mixture or purified aqueous mixture so formed to a single stage extraction to remove organic impurities to produce an extract stream and a raffinate stream comprising the metal catalyst.

Owner:GRUPO PETROTEMEX DE C V

Catalytic Gasification Process with Recovery of Alkali Metal from Char

ActiveUS20090169448A1Quantity minimizationThermal non-catalytic crackingMuffle furnacesPhysical chemistryAlkali metal

Processes are described for the extraction and recovery of alkali metal from the char that results from catalytic gasification of a carbonaceous material. Among other steps, the processes of the invention include a hydrothermal leaching step in which a slurry of insoluble particulate comprising insoluble alkali metal compounds is treated with carbon dioxide and steam at elevated temperatures and pressures to effect the conversion of insoluble alkali metal compounds to soluble alkali metal compounds. Further, processes are described for the catalytic gasification of a carbonaceous material where a substantial portion of alkali metal is extracted and recovered from the char that results from the catalytic gasification process.

Owner:SURE CHAMPION INVESTMENT LTD

Catalytic Gasification Process with Recovery of Alkali Metal from Char

ActiveUS20090169449A1Quantity minimizationThermal non-catalytic crackingMuffle furnacesParticulatesSlurry

Processes are described for the extraction and recovery of alkali metal from the char that results from catalytic gasification of a carbonaceous material. Among other steps, the processes of the invention include a hydrothermal leaching step in which a slurry of insoluble particulate comprising insoluble alkali metal compounds is treated with carbon dioxide and steam at elevated temperatures and pressures to effect the conversion of insoluble alkali metal compounds to soluble alkali metal compounds. Further, processes are described for the catalytic gasification of a carbonaceous material where a substantial portion of alkali metal is extracted and recovered from the char that results from the catalytic gasification process.

Owner:SURE CHAMPION INVESTMENT LTD

Sorbent composition, process for producing same and use in desulfurization

A particulate adsorbent composition comprising a mixture of zinc oxide, silica, alumina and substantially reduced valence cobalt for use in desulfurizing a cracked gasoline or diesel fuel feed stream in a desulfurization zone by: The desulfurization zone contacts the feed stream, then separates the resulting low sulfur content stream and the sulfurized adsorbent, regenerates and activates the separated adsorbent, and then returns to the desulfurization zone.

Owner:CHINA PETROLEUM & CHEM CORP

Reclamation of a Titanosilicate, and Reconstitution of an Active Oxidation Catalyst

InactiveUS20080064591A1Acceptable product selectivityAcceptable selectivityMolecular sieve catalystsOther chemical processesCatalytic metalTitanium

A method of reclaiming a titanosilicate from a deactivated or spent oxidation catalyst containing a titanosilicate having deposited thereon one or more catalytic metals, such as gold, and optionally, one or more promoter metals, the method involving treating the deactivated catalyst with an oxidant; contacting the oxidant-treated catalyst with acid, preferably aqua regia; washing the titanosilicate to remove residual acid; and optionally drying and / or calcining. A method of reconstituting an active oxidation catalyst from a spent or deactivated oxidation catalyst, the method involving reclaiming the titanosilicate as noted above, and then depositing one or more catalytic metals and, optionally, one or more promoter metals onto the reclaimed titanosilicate.

Owner:DOW GLOBAL TECH LLC

Separation of carbon dioxide (CO2) from gas mixtures

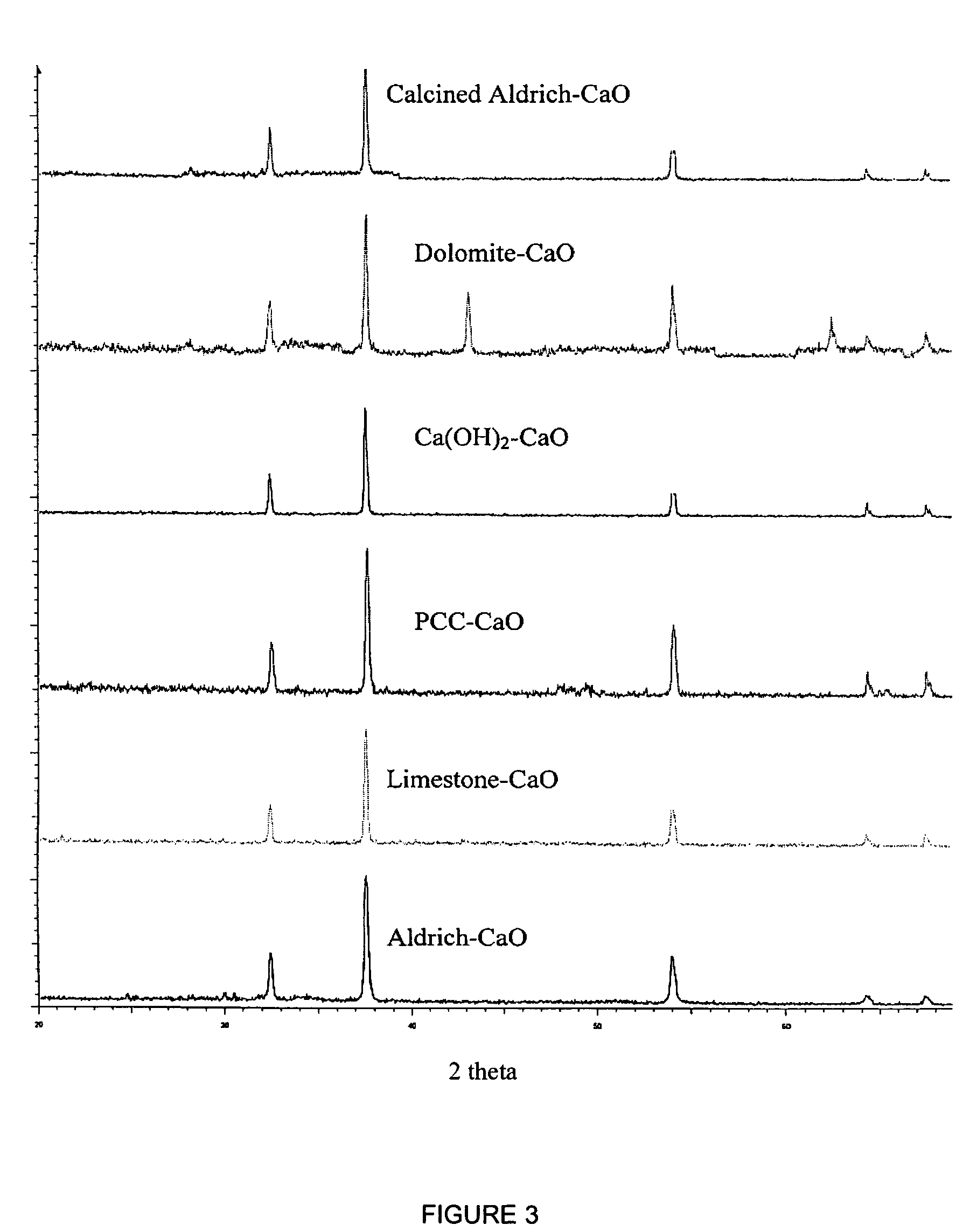

ActiveUS7618606B2Good repeatabilityMaterial nanotechnologyCombustible gas catalytic treatmentCo2 removalSorbent

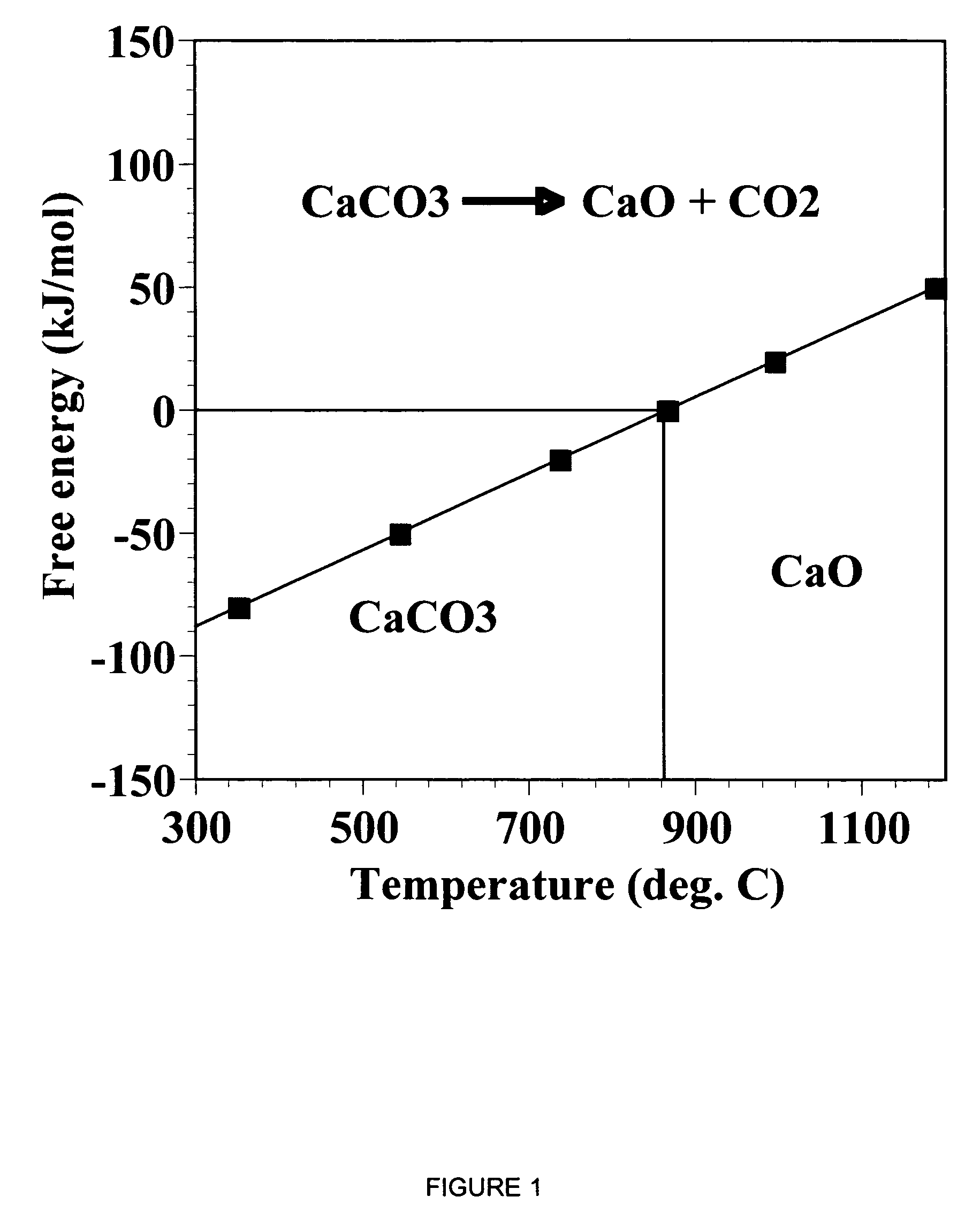

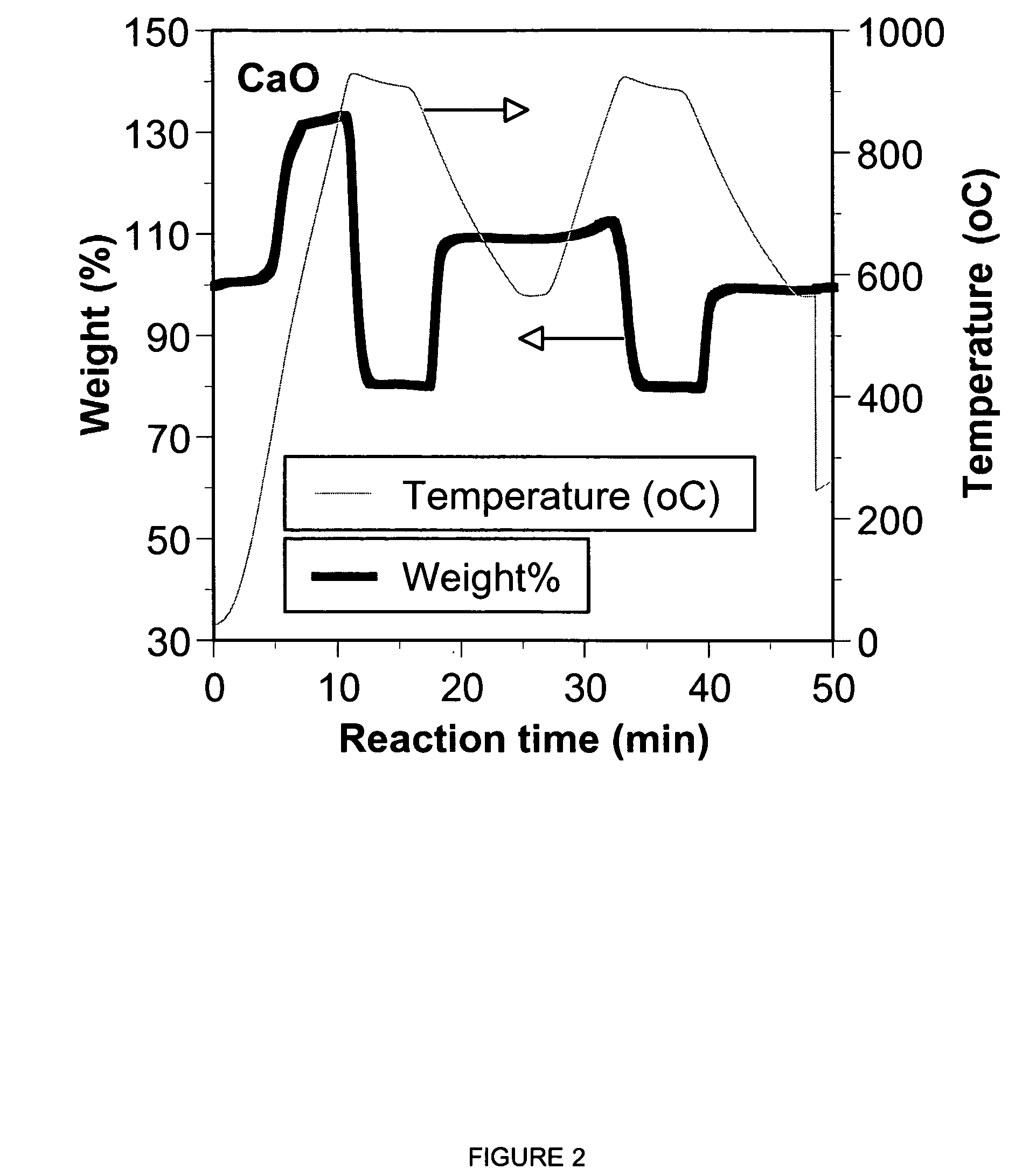

A reaction-based process has been developed for the selective removal of carbon dioxide from a multicomponent gas mixture. The proposed process effects the separation of CO2 from a mixture of gases by its reaction with metal oxides. The Calcium based Reaction Separation for CO2 process consists of contacting a CO2 laden gas with calcium oxide in a reactor such that CaO captures the CO2 by the formation of calcium carbonate. Once “spent”, CaCO3 is regenerated by its calcination leading to the formation of fresh CaO sorbent. The “regenerated” CaO is then recycled for the further capture of more CO2. This process also identifies the application of a mesoporous CaCO3 structure, that attains >90% conversion over multiple carbonation and calcination cycles. Lastly, thermal regeneration (calcination) under vacuum provided a better sorbent structure that maintained reproducible reactivity levels over multiple cycles.

Owner:THE OHIO STATES UNIV

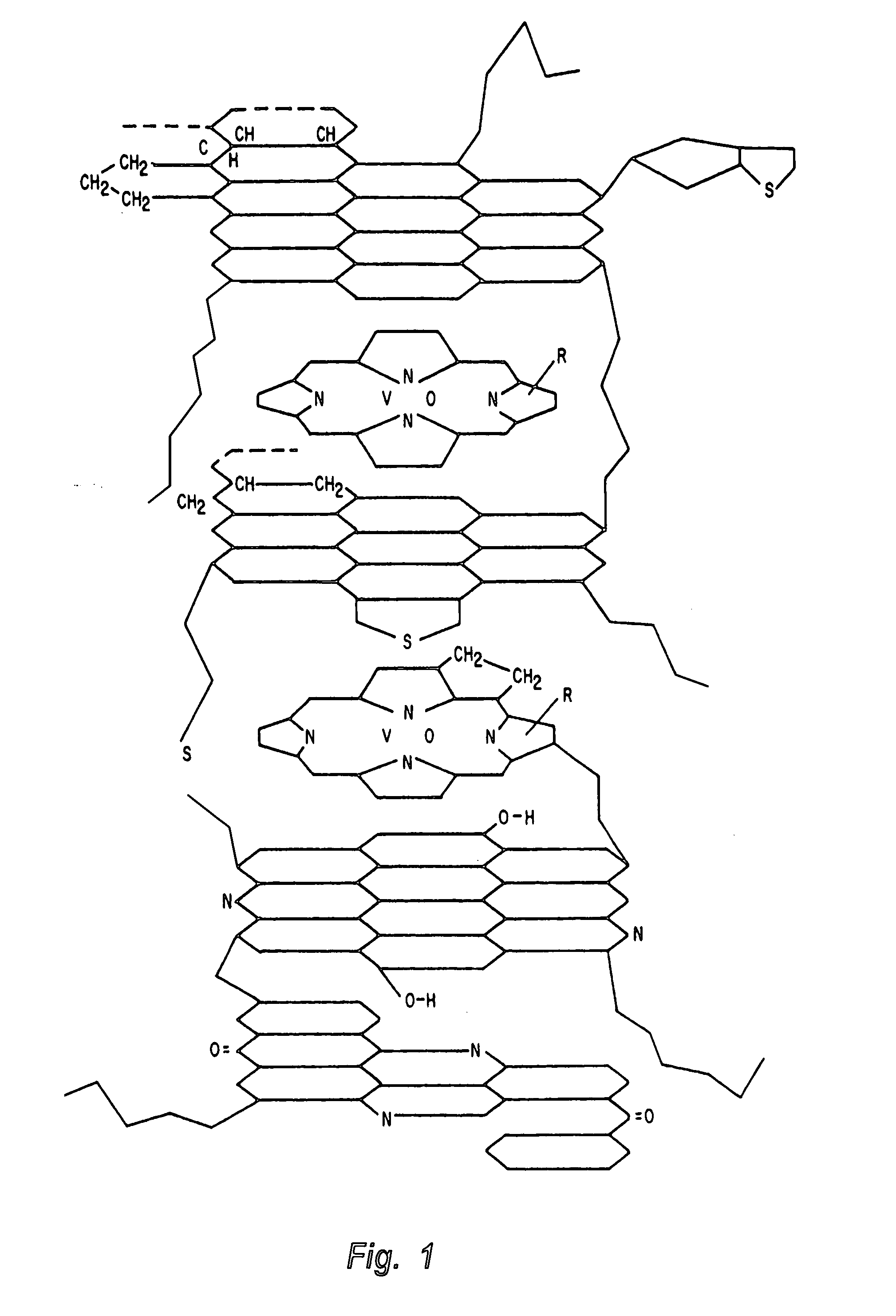

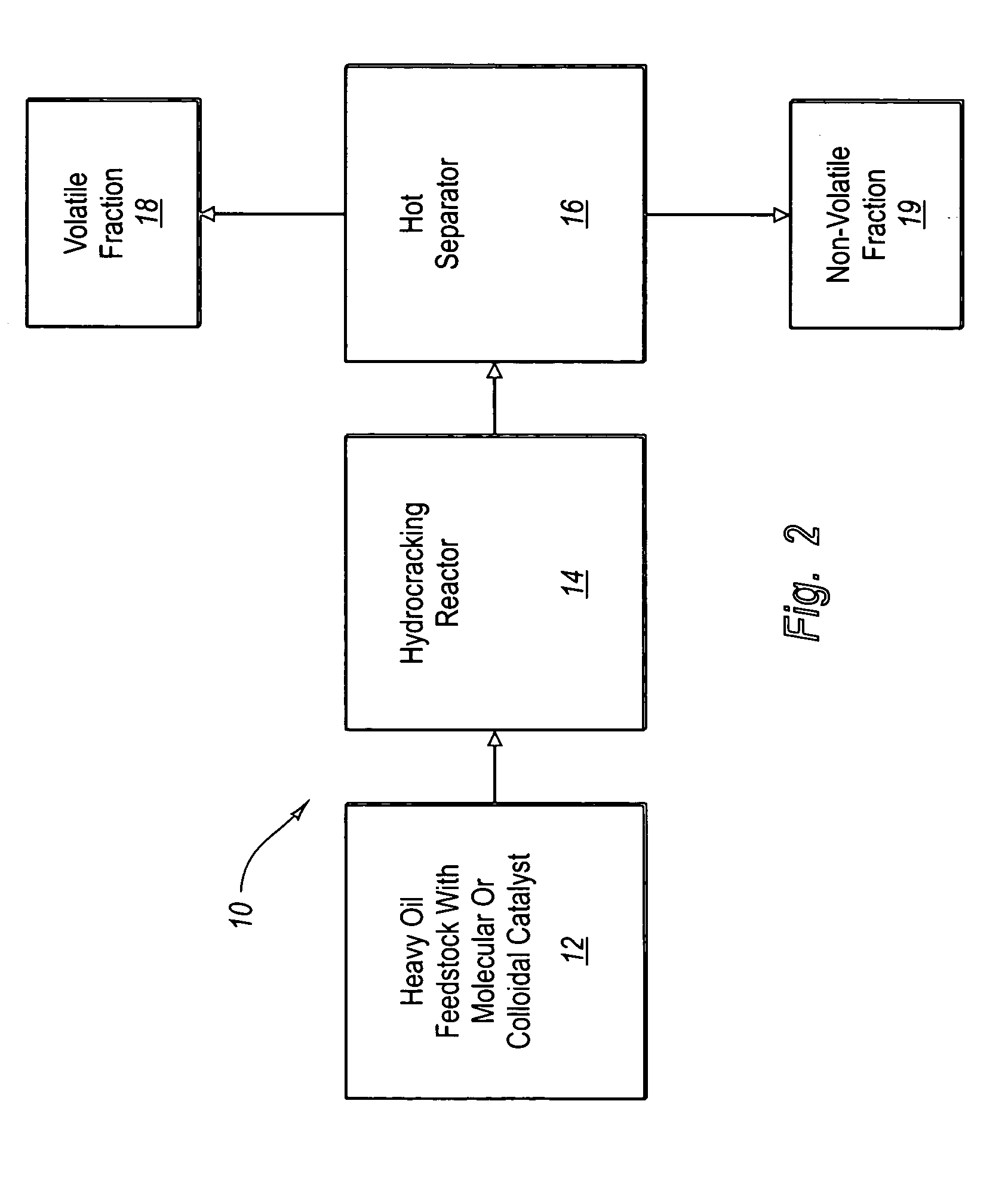

Hydroprocessing method and system for upgrading heavy oil using a colloidal or molecular catalyst

ActiveUS20050241993A1Inhibits eliminates formationEasy to useCatalyst regeneration/reactivationCatalyst activation/preparationColloidFuel oil

Methods and systems for hydroprocessing heavy oil feedstocks to form an upgraded material involve the use of a colloidal or molecular catalyst dispersed within a heavy oil feedstock, a hydrocracking reactor, and a hot separator. The colloidal or molecular catalyst promotes hydrocracking and other hydroprocessing reactions within the hydrocracking reactor. The catalyst is preferentially associated with asphaltenes within the heavy oil feedstock, which promotes upgrading reactions involving the asphaltenes rather than formation of coke precursors and sediment. The colloidal or molecular catalyst overcomes problems associated with porous supported catalysts in upgrading heavy oil feedstocks, particularly the inability of such catalysts to effectively process asphaltene molecules. The result is one or more of reduced equipment fouling, increased conversion level, and more efficient use of the supported catalyst if used in combination with the colloidal or molecular catalyst.

Owner:HEADWATERS TECH INNOVATION LLC

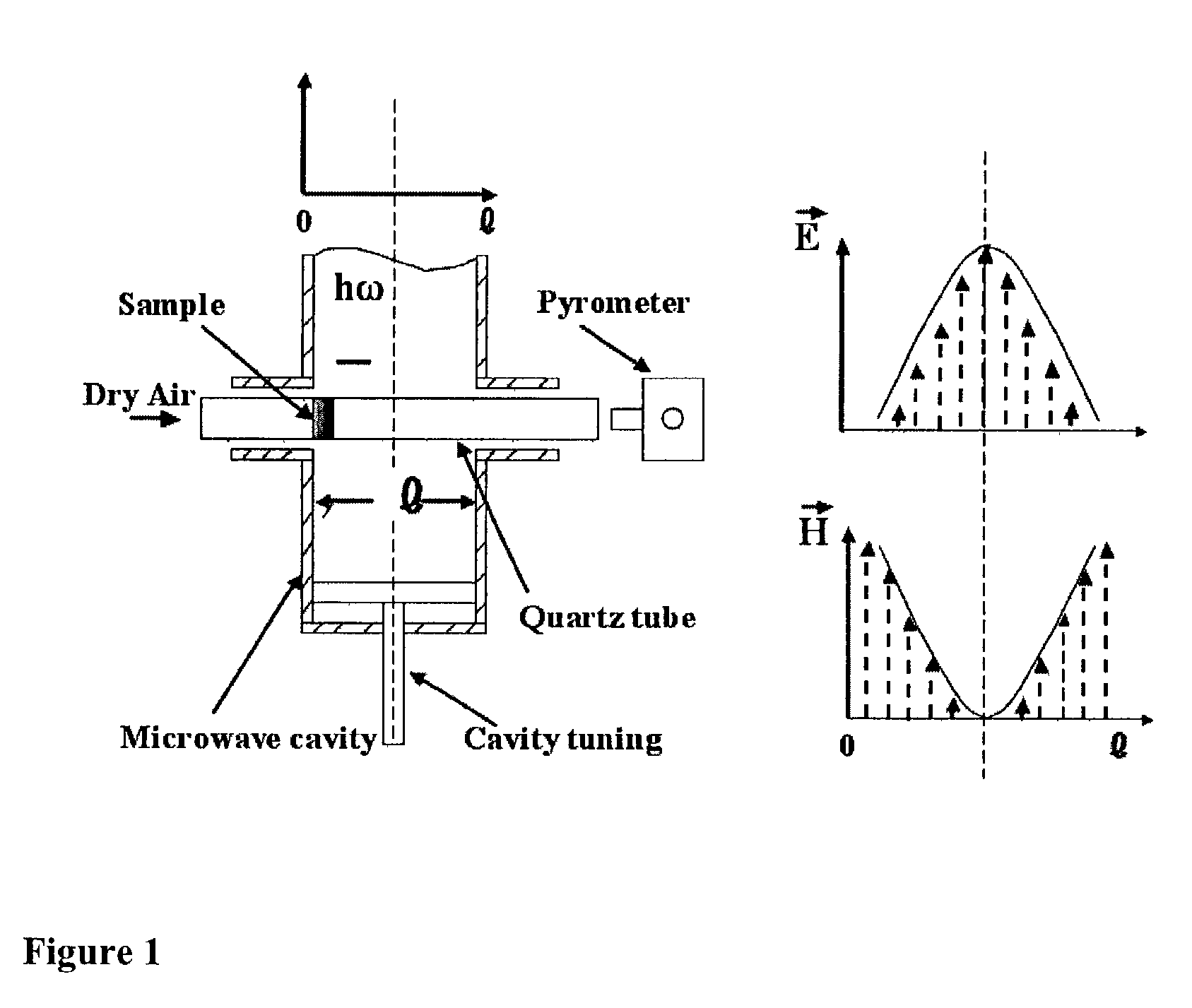

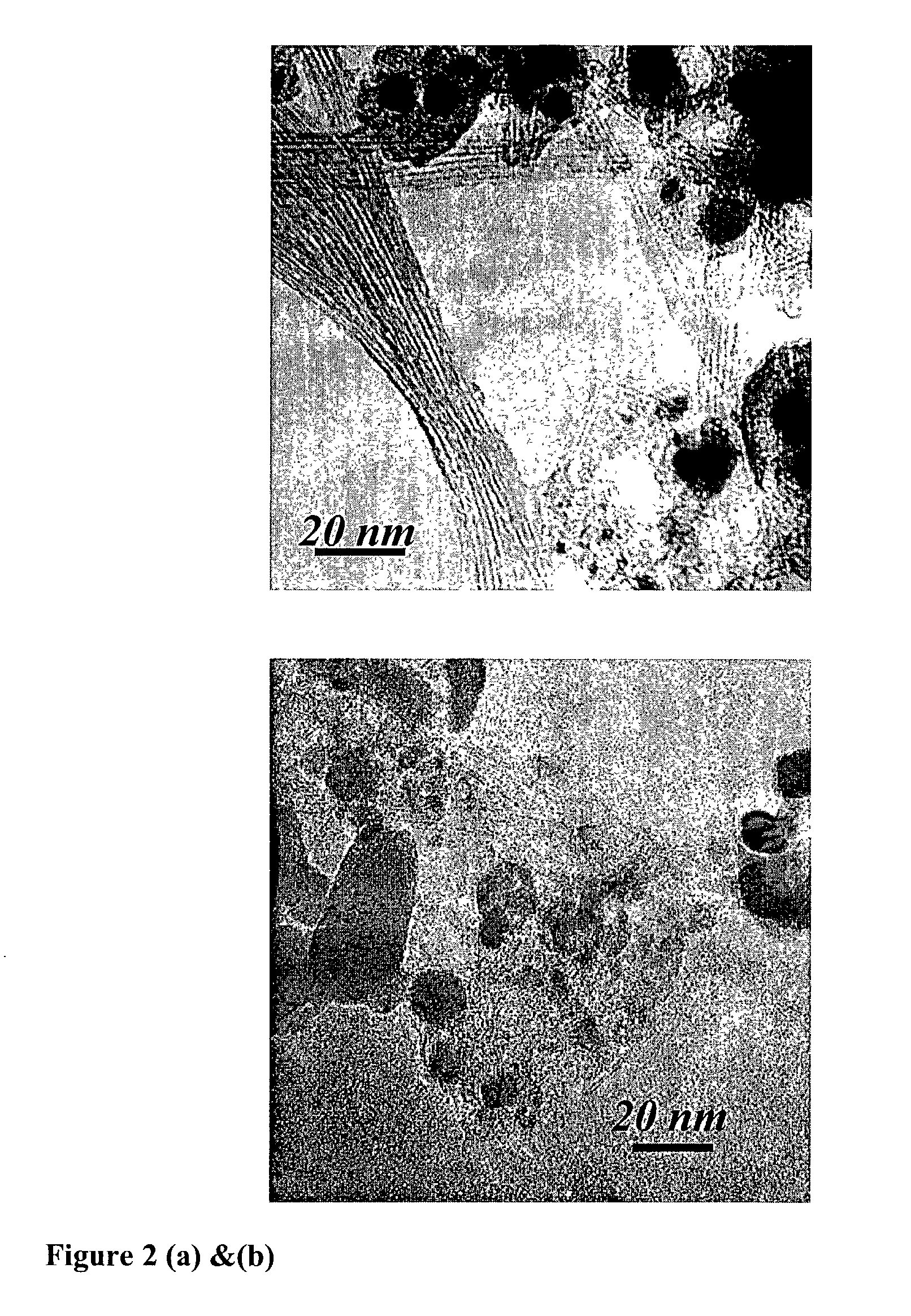

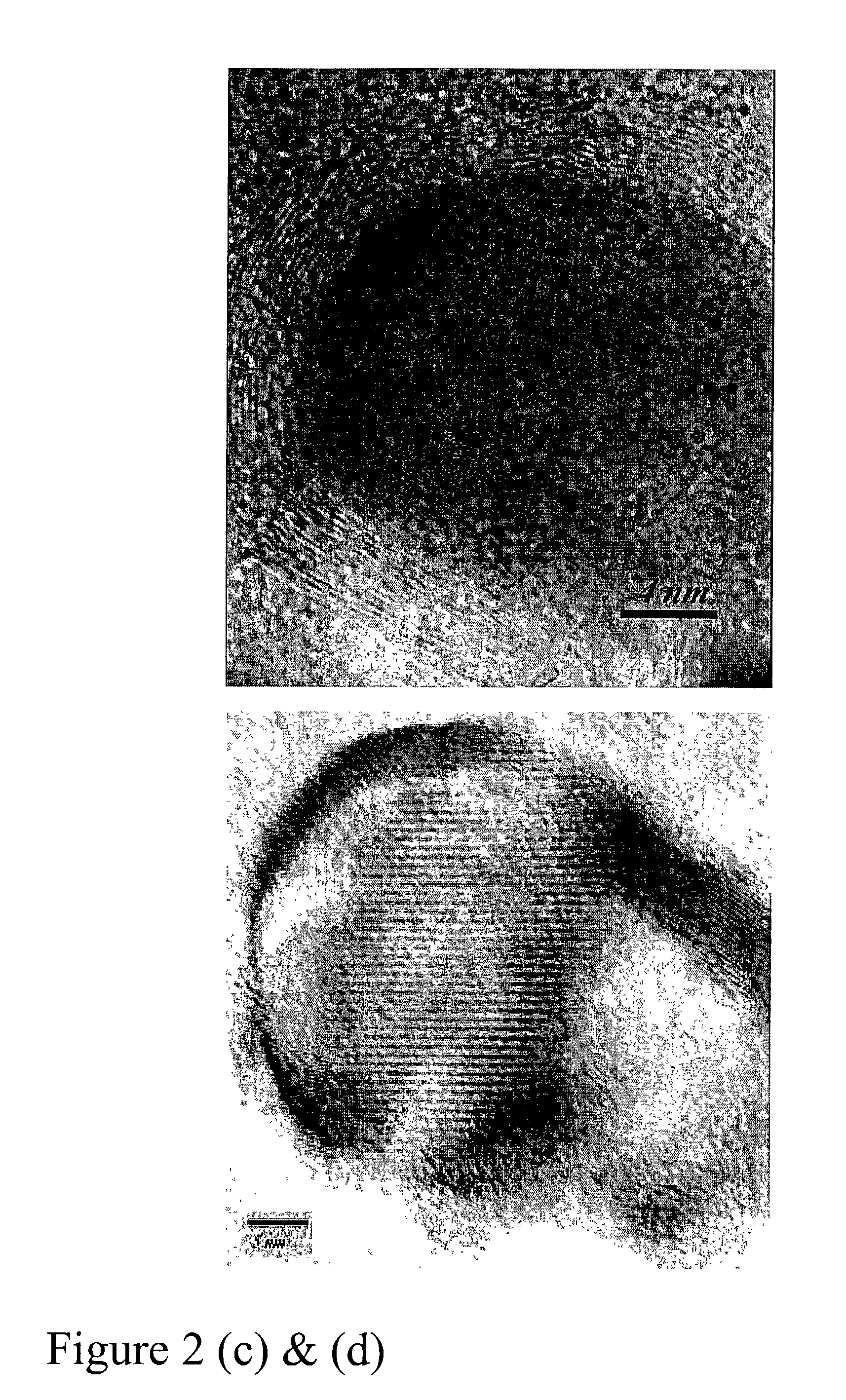

Method of purifying nanotubes and nanofibers using electromagnetic radiation

Disclosed are methods of purifying mixtures comprising nanofibers and / or nanotubes and residual catalyst particles that are covered by outer layers of the nanotube or nanofiber material. The mixtures are exposed to electromagnetic radiation, which induces localized heating in the residual catalyst particles. The localized heating creates breaches in the outer layers. Thereafter, the residual catalyst particles may be removed under relatively mild conditions that do not significantly affect the structural integrity of the nanotubes or nanofibers. The methods of the invention have been used to particular advantage in the purification of single wall carbon nanotubes (SWNTs) synthesized using metal catalysts. For these SWNTs, microwave radiation is preferably used to induce the localized heating, the outer layers are preferably removed at least in part by carrying out the localized heating under air, and the residual catalyst may be removed by exposure to relatively dilute aqueous acid.

Owner:PENN STATE RES FOUND

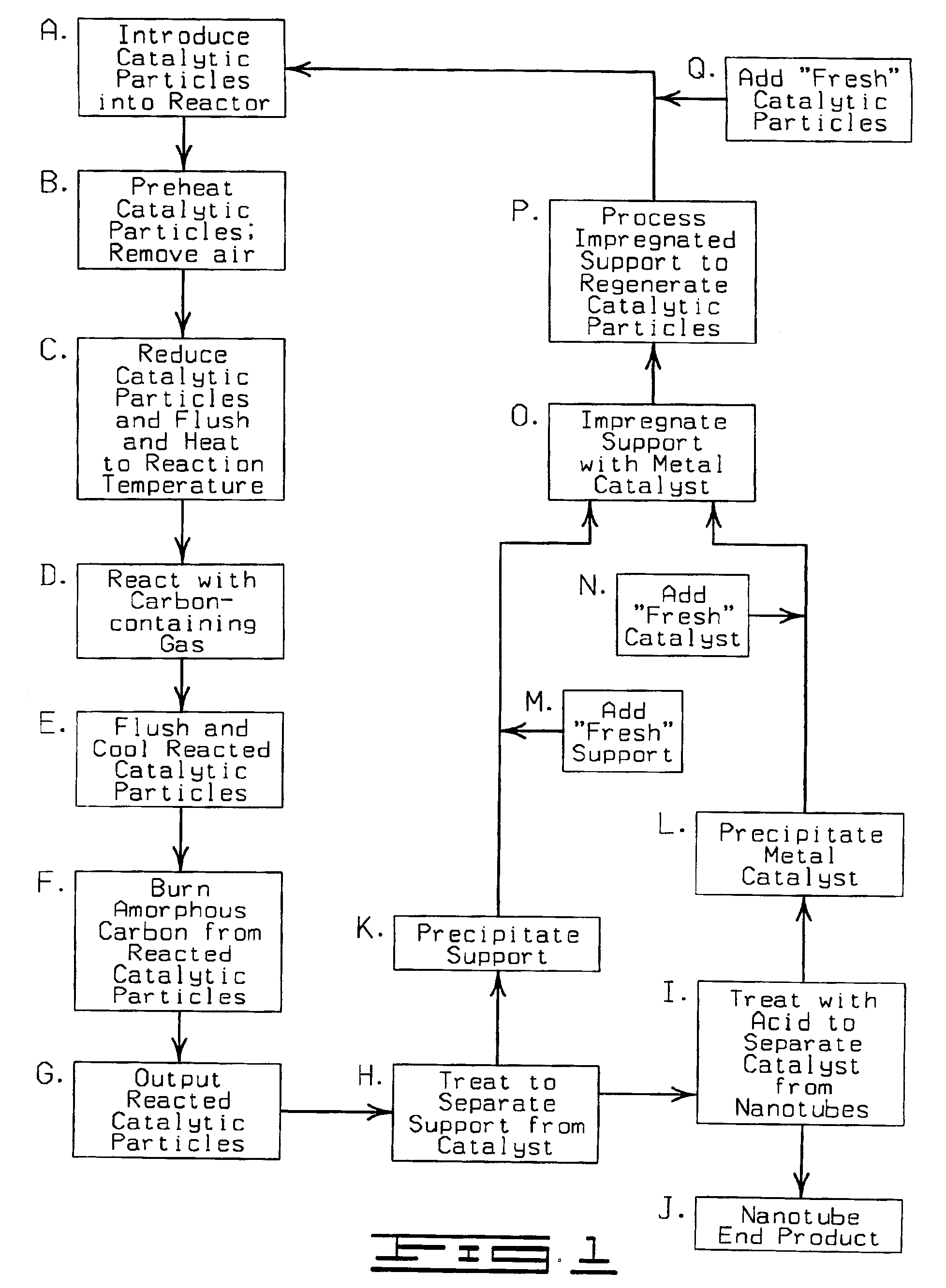

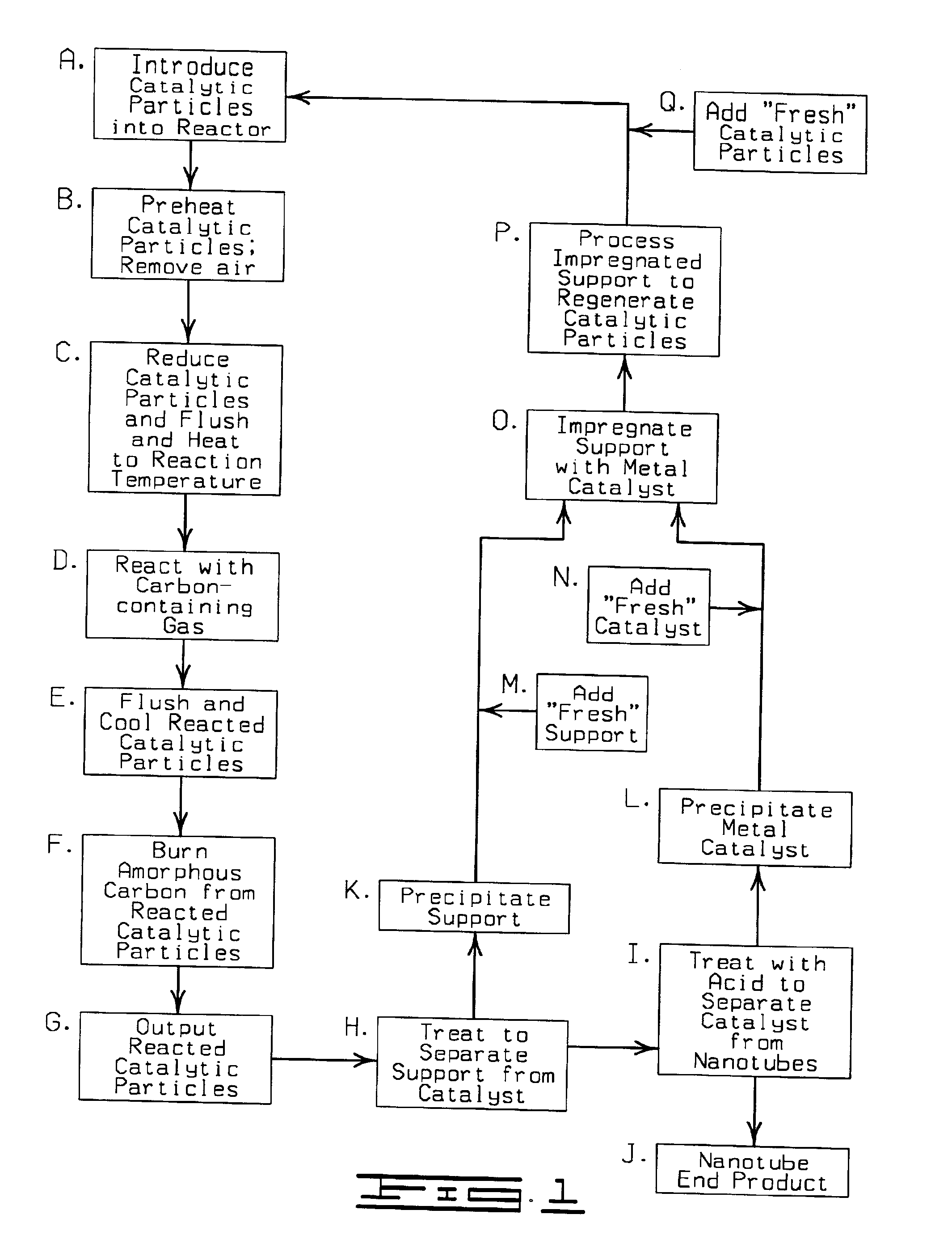

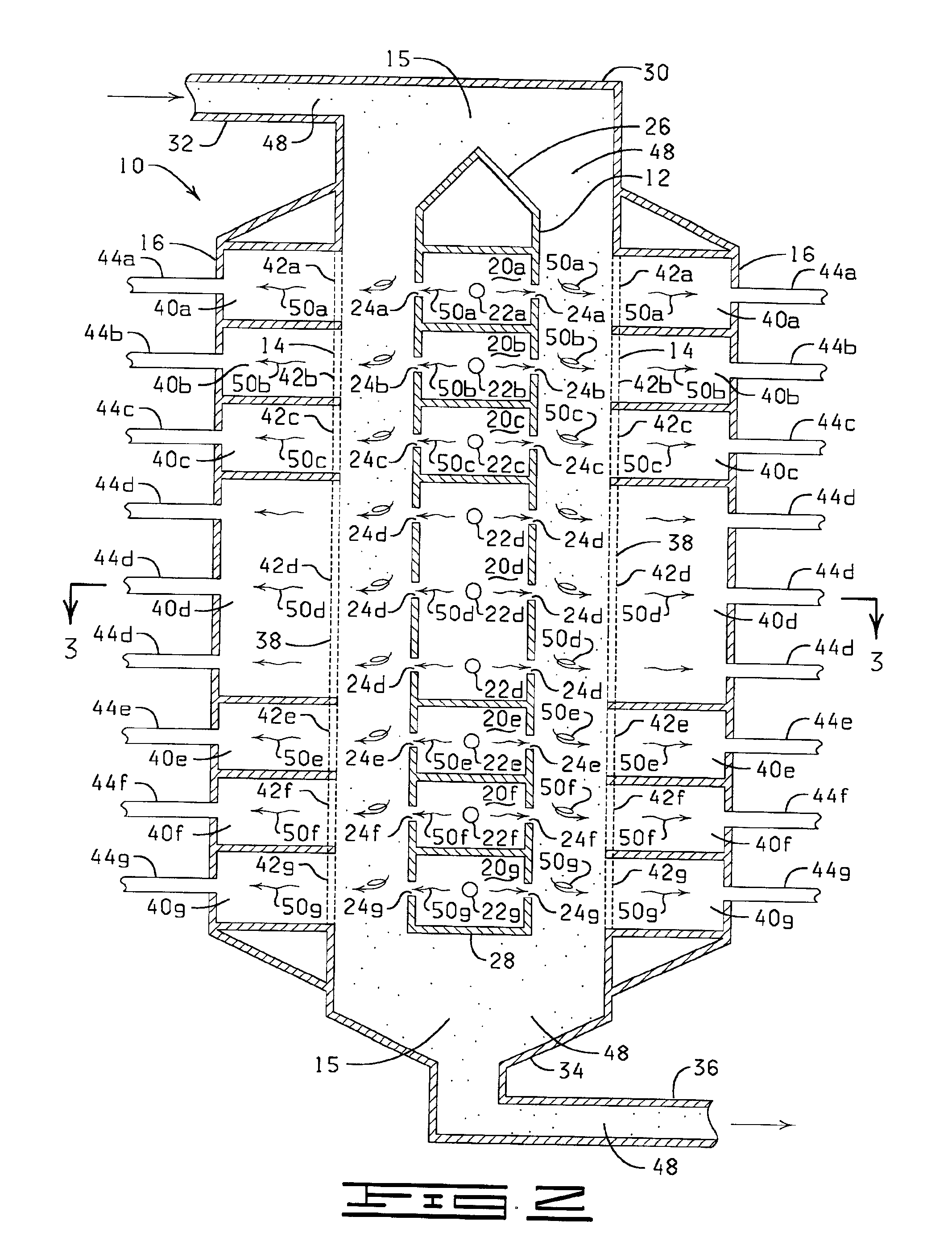

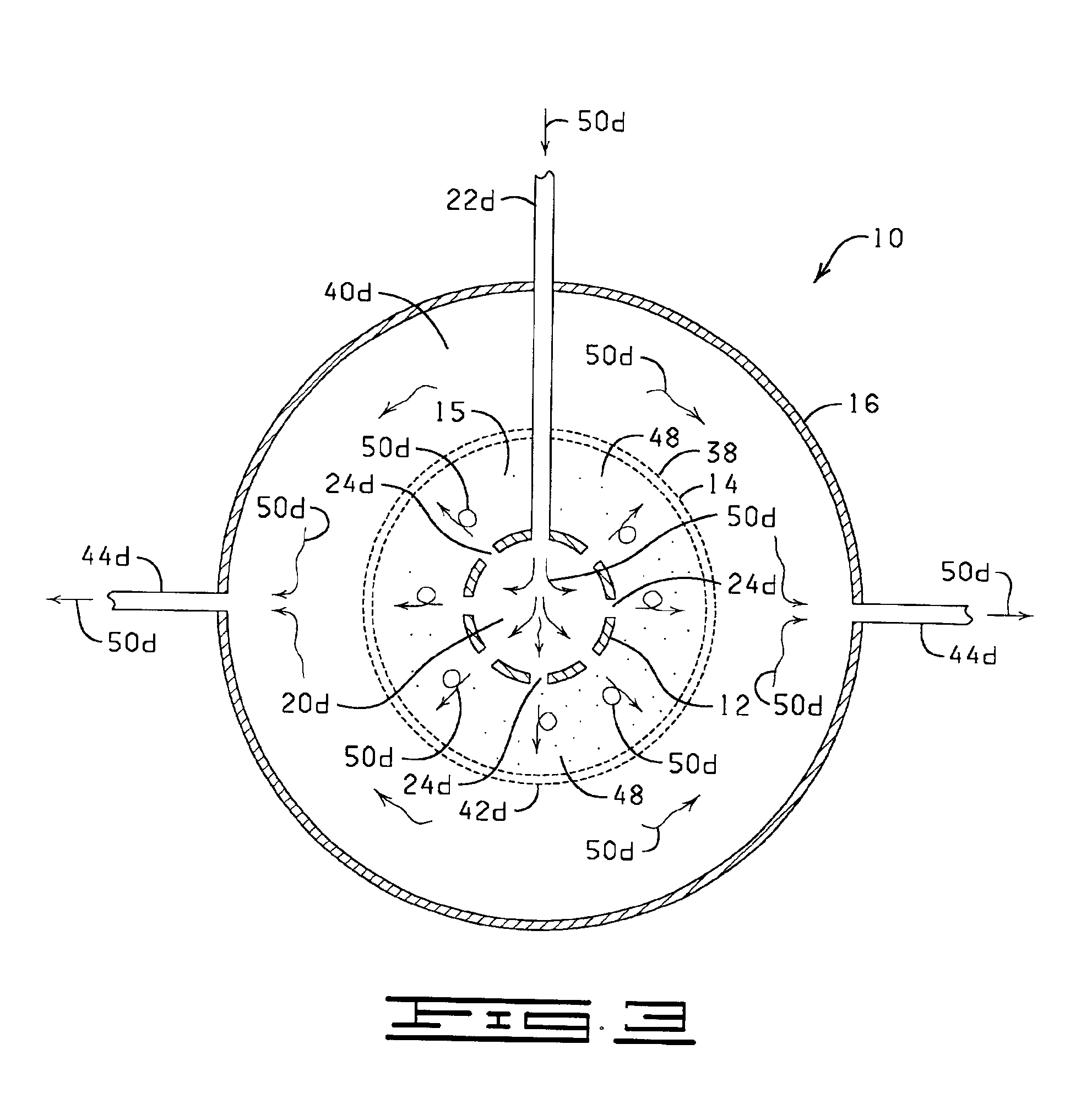

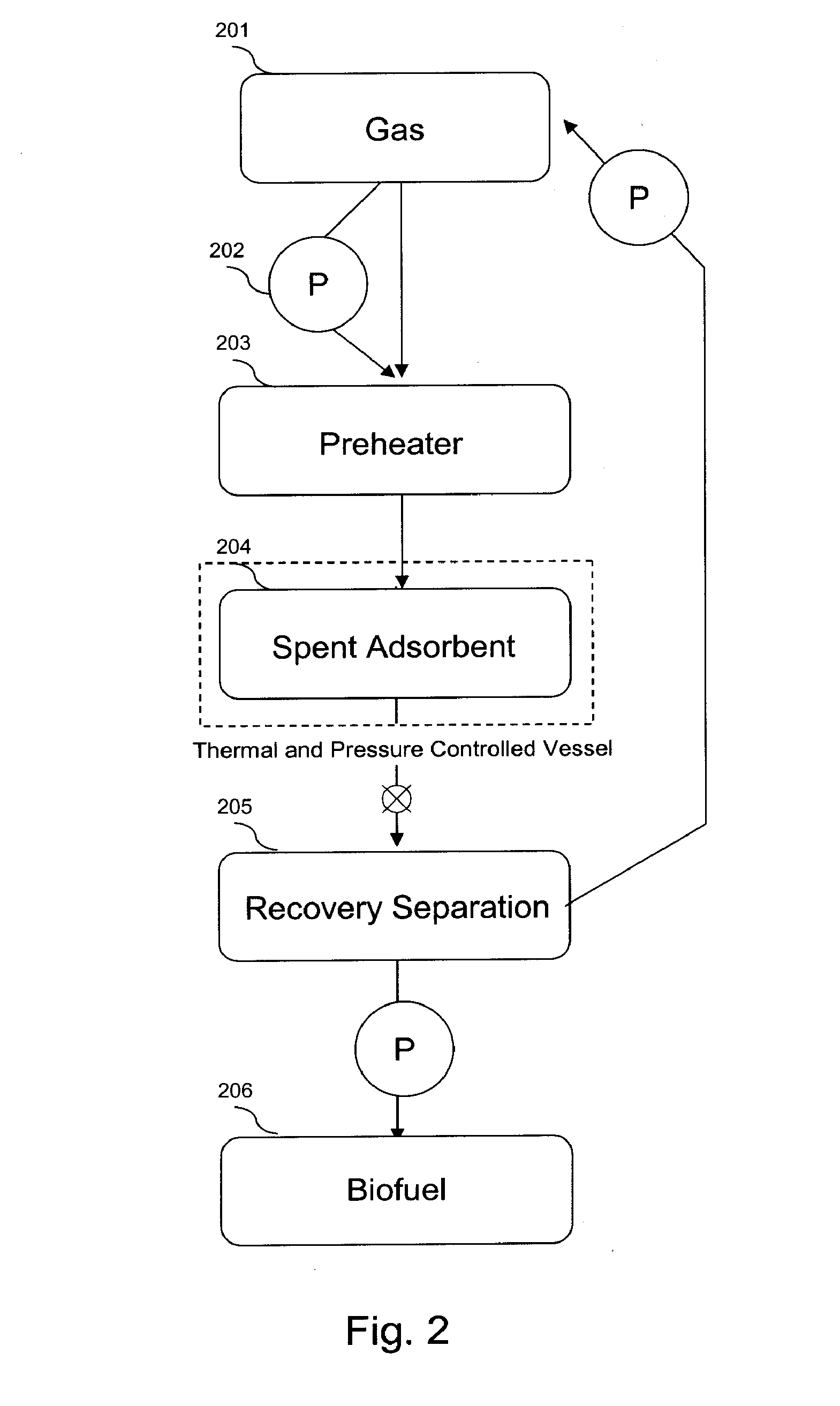

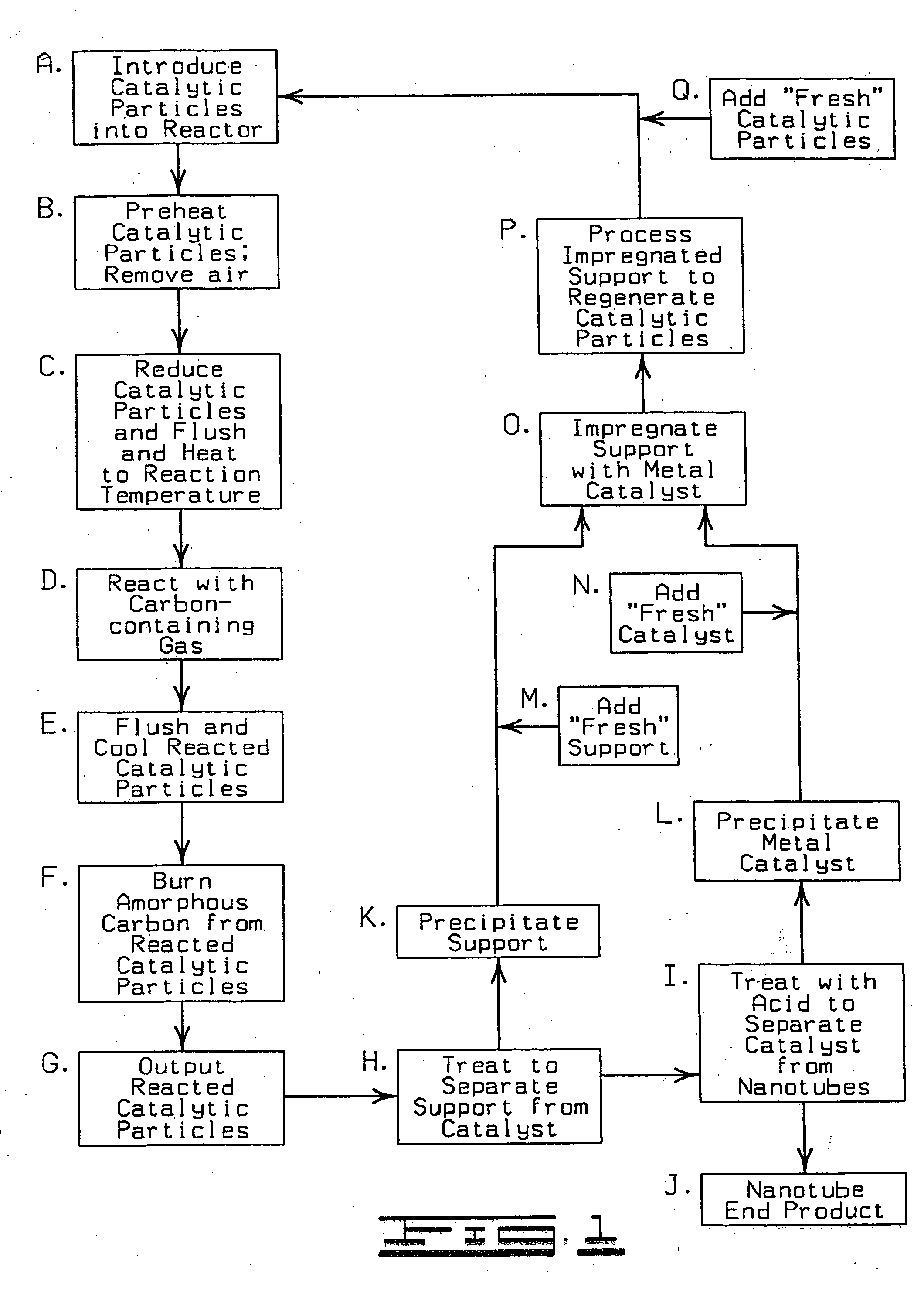

Method and apparatus for producing carbon nanotubes

InactiveUS6955800B2Avoid disadvantagesAvoid defectsMaterial nanotechnologyCatalyst regeneration/reactivationParticulatesCarbon nanotube

A method and apparatus for catalytic production of carbon nanotubes. Catalytic particles are exposed to different process conditions at successive stages wherein the catalytic particles do not come in contact with reactive (catalytic) gases until preferred process conditions have been attained, thereby controlling the quantity and form of carbon nanotubes produced. The method also contemplates methods and apparatus which recycle and reuse the gases and catalytic particulate materials, thereby maximizing cost efficiency, reducing wastes, reducing the need for additional raw materials, and producing the carbon nanotubes, especially SWNTs, in greater quantities and for lower costs.

Owner:THE BOARD OF RGT UNIV OF OKLAHOMA

Method and apparatus for regenerating an iron-based Fischer-Tropsch catalyst

ActiveUS6838487B1Reduce concentrationMaintain standardOrganic compound preparationOther chemical processesWaxContinuous flow

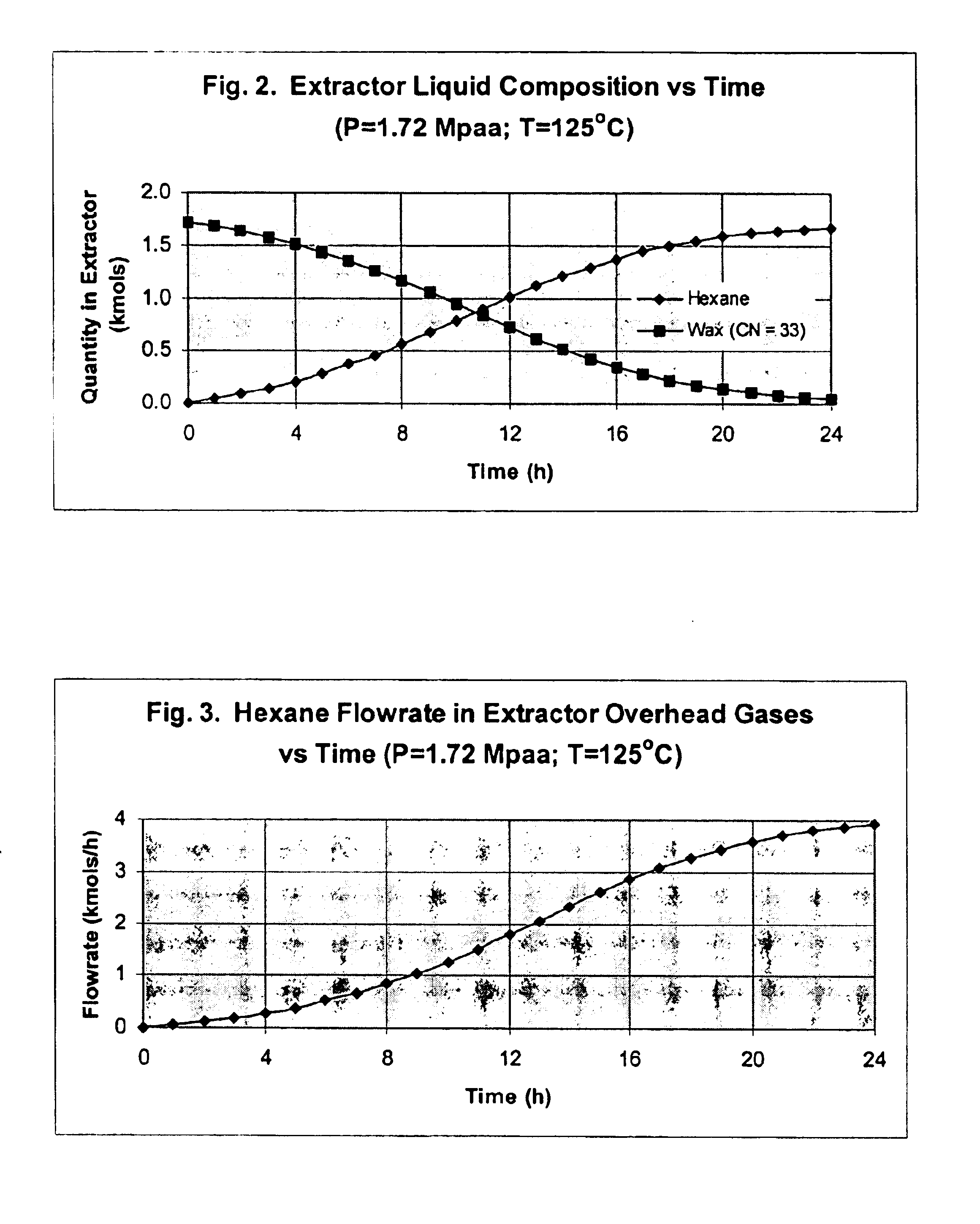

Solvent extraction is used to remove wax and contaminants from an iron-based Fischer-Tropsch catalyst in a natural circulation continuous-flow system. The wax-free catalyst is then subjected to controlled oxidation to convert the iron to its initial oxidized state, Fe2O3. Reactivation of the oxide catalyst precursor is carried out by addition of synthesis gas.

Owner:RES USA LLC

Electrical, Plating And Catalytic Uses Of Metal Nanomaterial Compositions

ActiveUS20080020304A1Improve absorption rateReduce reflectivityOptical radiation measurementMangetographic processBiological activationElectroplating

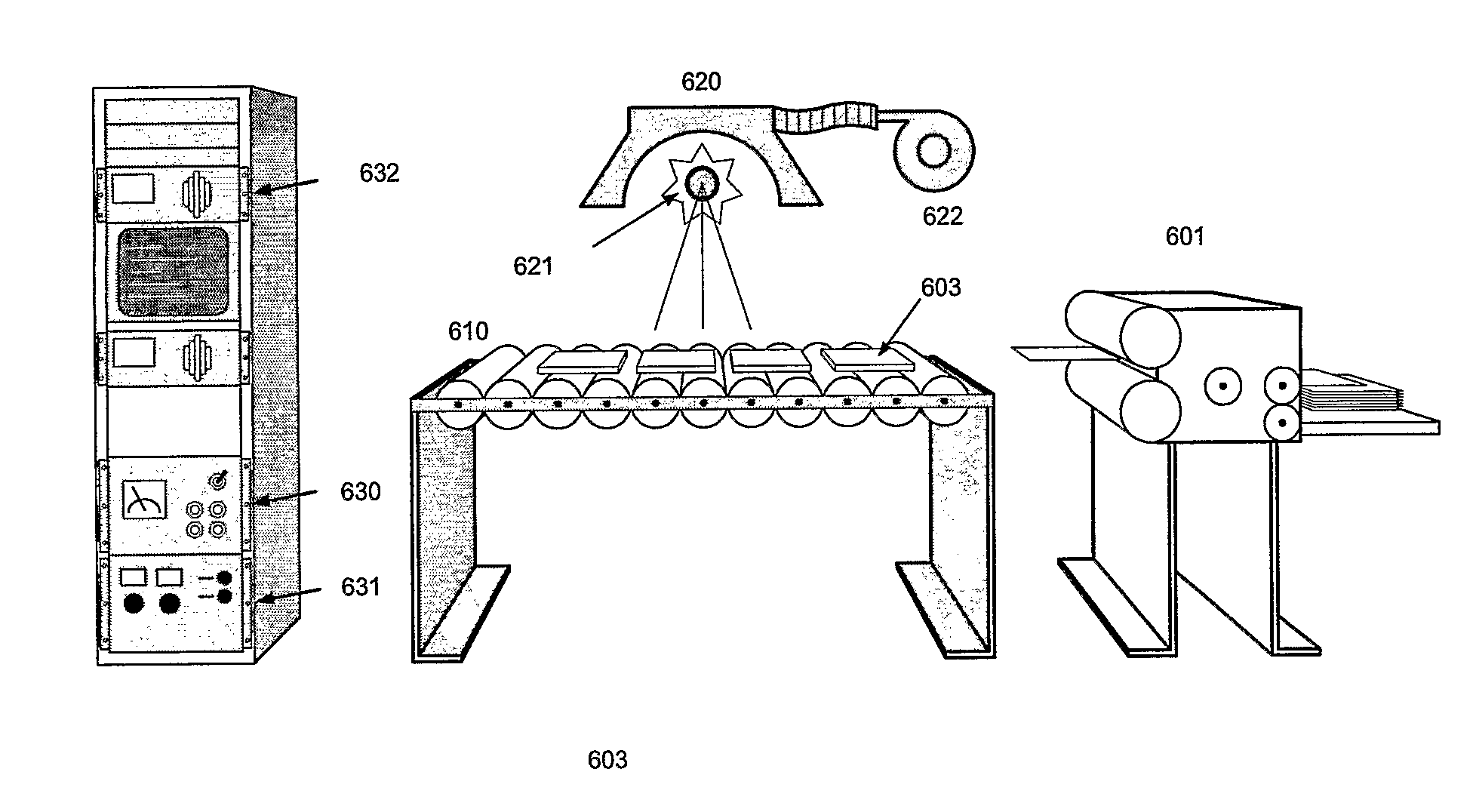

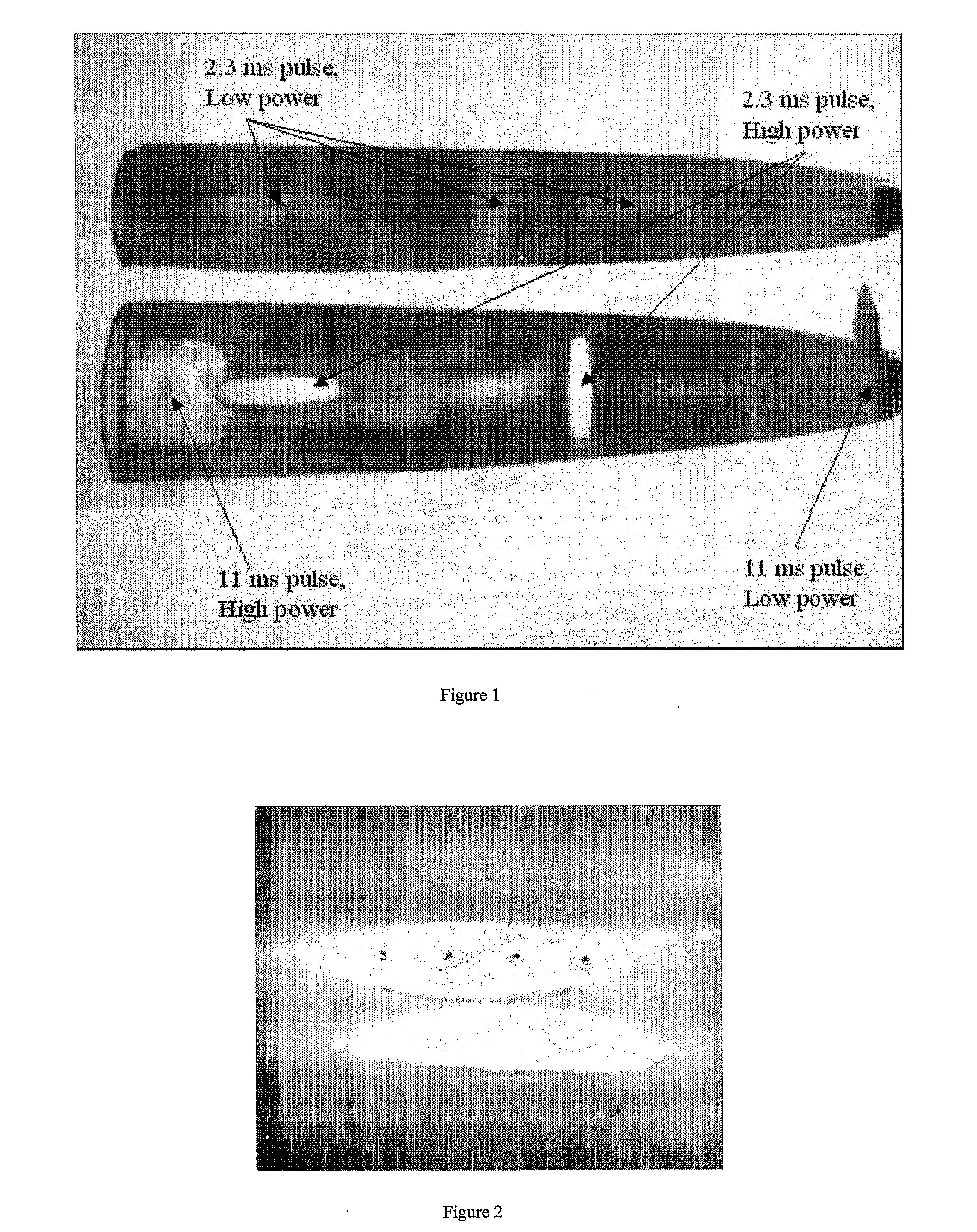

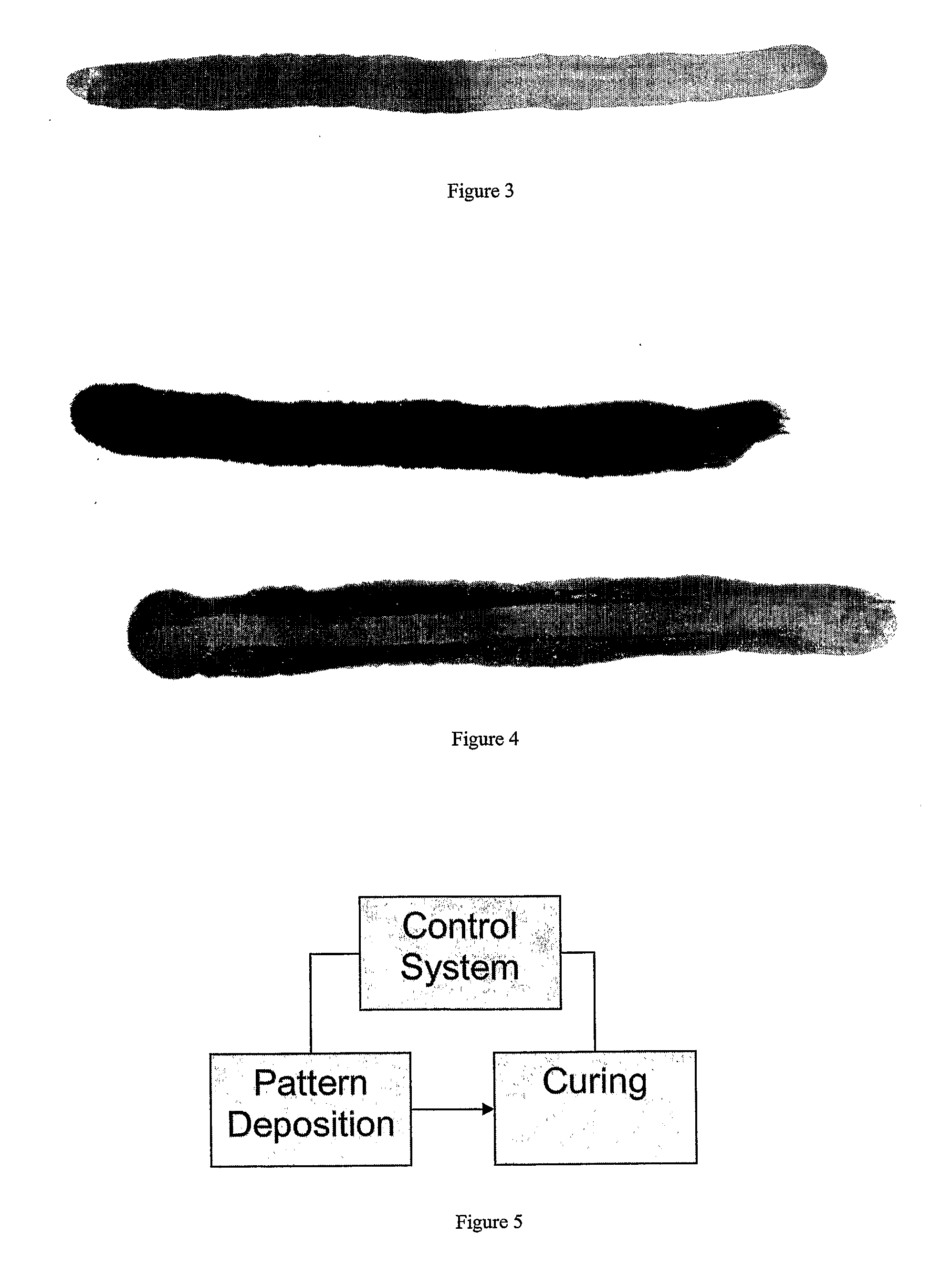

This invention relates generally to uses of novel nanomaterial composition and the systems in which they are used, and more particularly to nanomaterial compositions generally comprising carbon and a metal, which composition can be exposed to pulsed emissions to react, activate, combine, or sinter the nanomaterial composition. The nanomaterial compositions can alternatively be utilized at ambient temperature or under other means to cause such reaction, activation, combination, or sintering to occur.

Owner:NCC NANO LLC

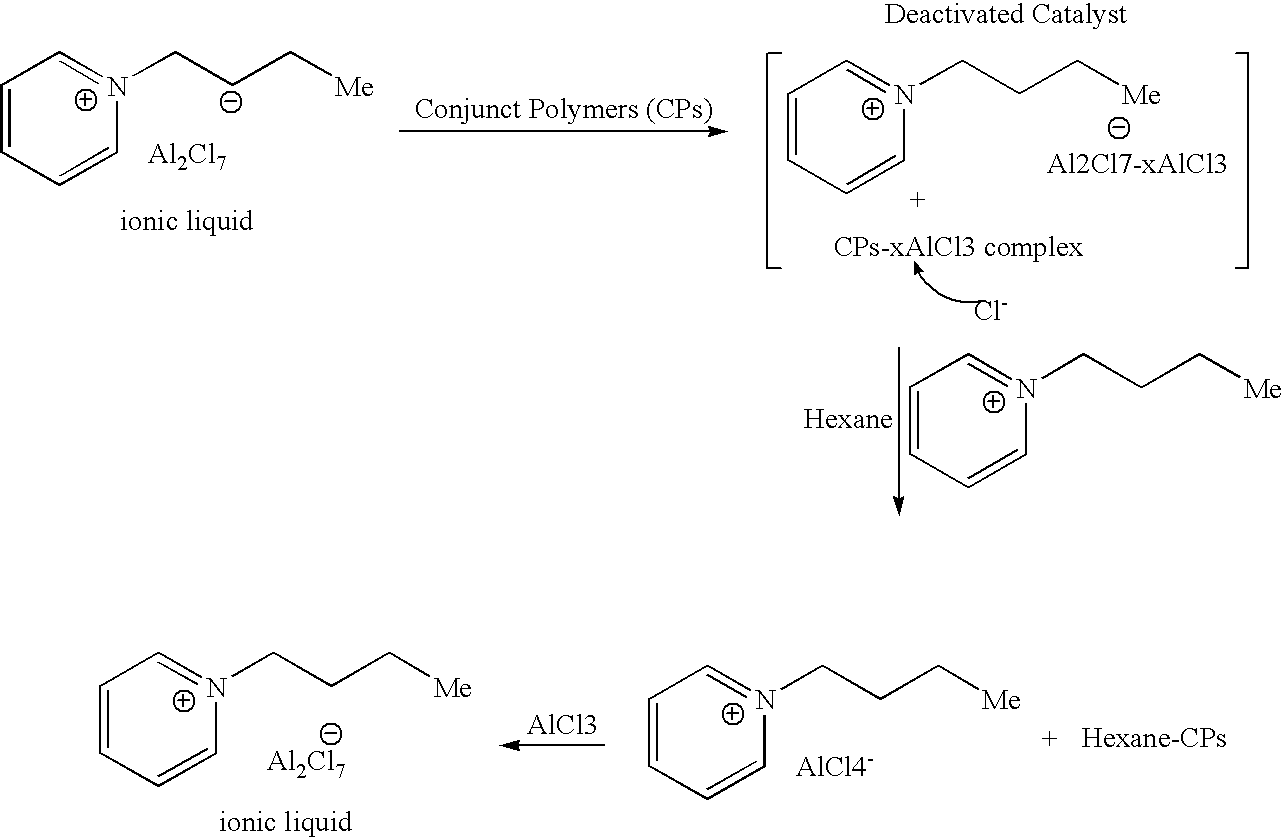

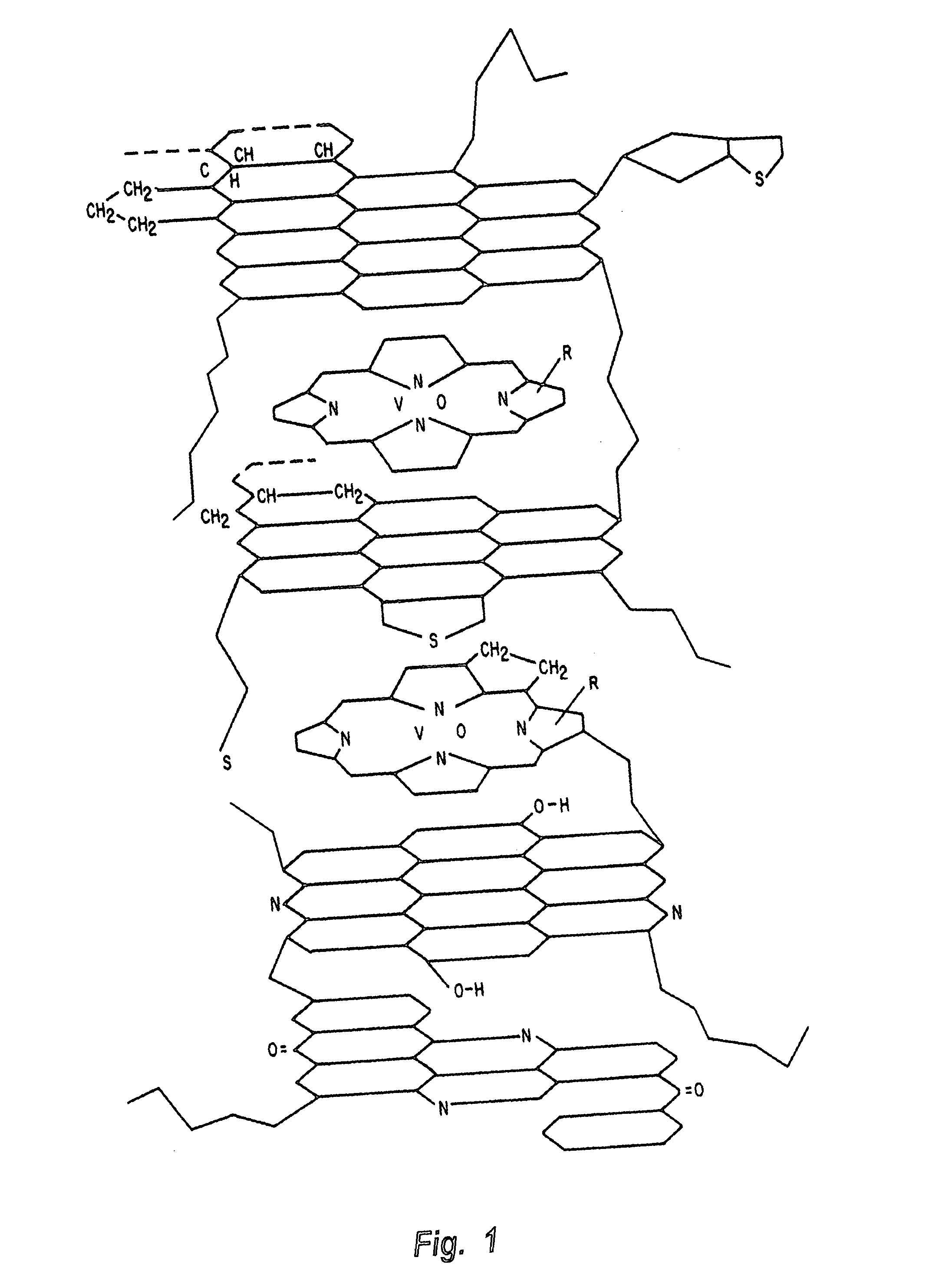

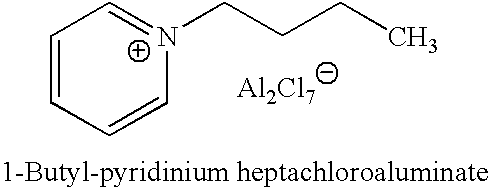

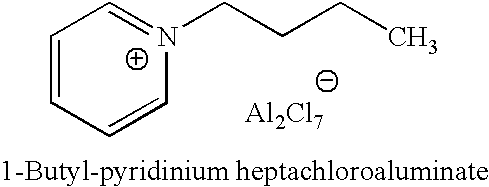

Regeneration of acidic catalysts

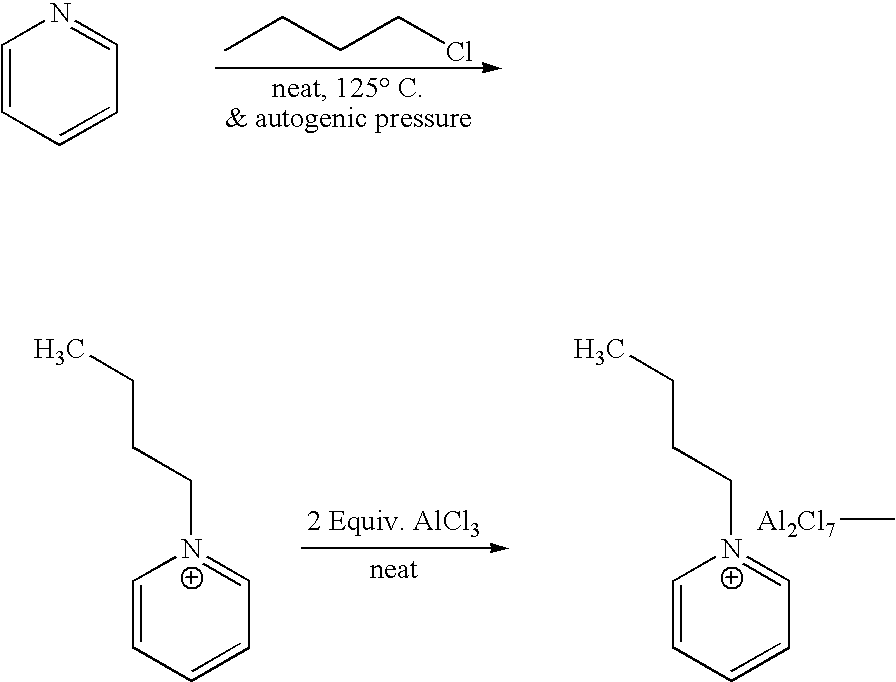

ActiveUS20070142213A1High activityChlorine/hydrogen-chloride purificationSulfur compoundsAlkyl transferIonic liquid

A process for regenerating a used acidic catalyst which has been deactivated by conjunct polymers by removing the conjunct polymers so as to increase the activity of the catalyst is disclosed. Methods for removing the conjunct polymers include hydrogenation, addition of a basic reagent and alkylation. The methods are applicable to all acidic catalysts and are described with reference to certain ionic liquid catalysts.

Owner:CHEVROU USA INC

Regeneration fluid for SCR denitration catalyst

InactiveCN101574671AHigh activityEasy to cleanDispersed particle separationCatalyst regeneration/reactivationAdditive ingredientAmmonium paratungstate

The invention discloses a regeneration fluid for an SCR denitration catalyst, which comprises the following components: 0.001 to 1 weight percent of penetration enhancer JFC, 0.001 to 1 weight percent of surfactant OP-10, 0 to 1 weight percent of peregal, 0.6 to 4 weight percent of ammonium metavanadate, 5.5 to 12.5 weight percent of ammonium paratungstate, 0 to 6.5 weight percent of ammonium paramolybdate, and the balance of deionized water and acid. The regeneration fluid has the advantages that the regeneration fluid can also supplement active ingredients during the washing, and the activity recovery of the catalyst after the regeneration is up to between 90 and 105 percent; a nonionic surfactant is added into the regeneration fluid, so that the regeneration fluid improves the cleaning capability on the catalyst and cannot cause the damage to a catalyst carrier and other effective ingredients; and the regenerated catalyst fully can continue to be normally used, and the service life can reach more than 95 percent of that of a new catalyst.

Owner:COUNTRY JIANGSU CATALYST REGENERATION TECH

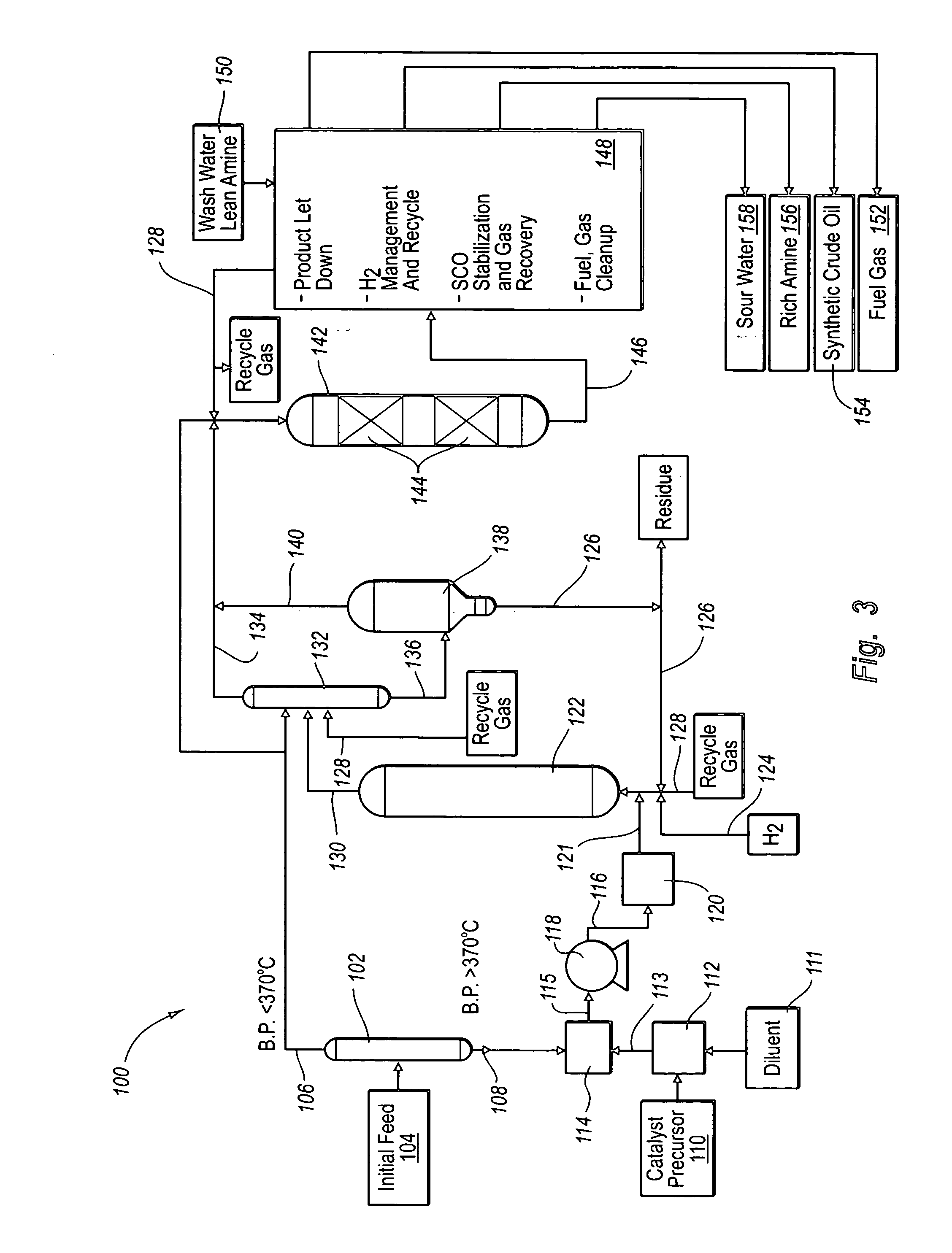

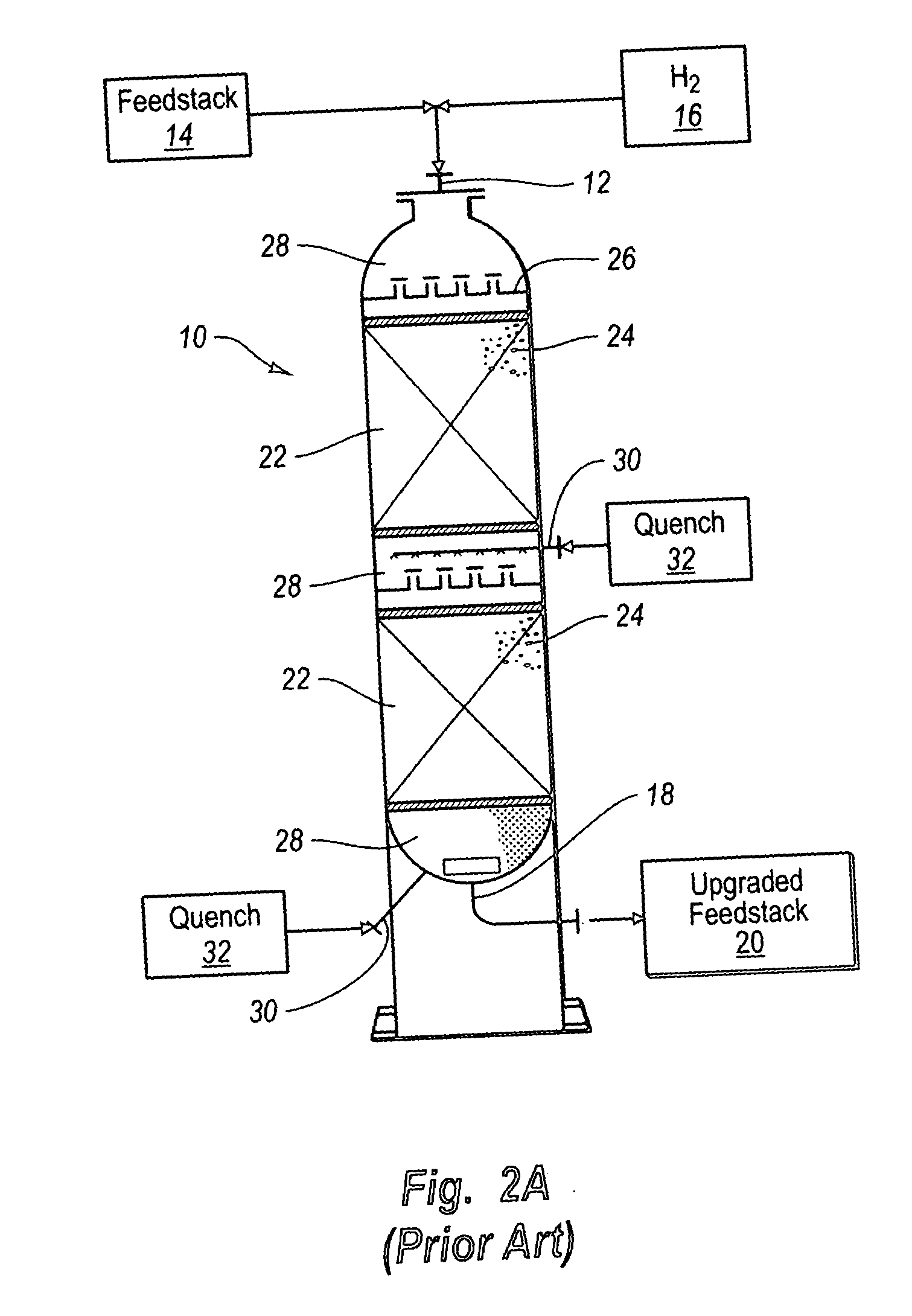

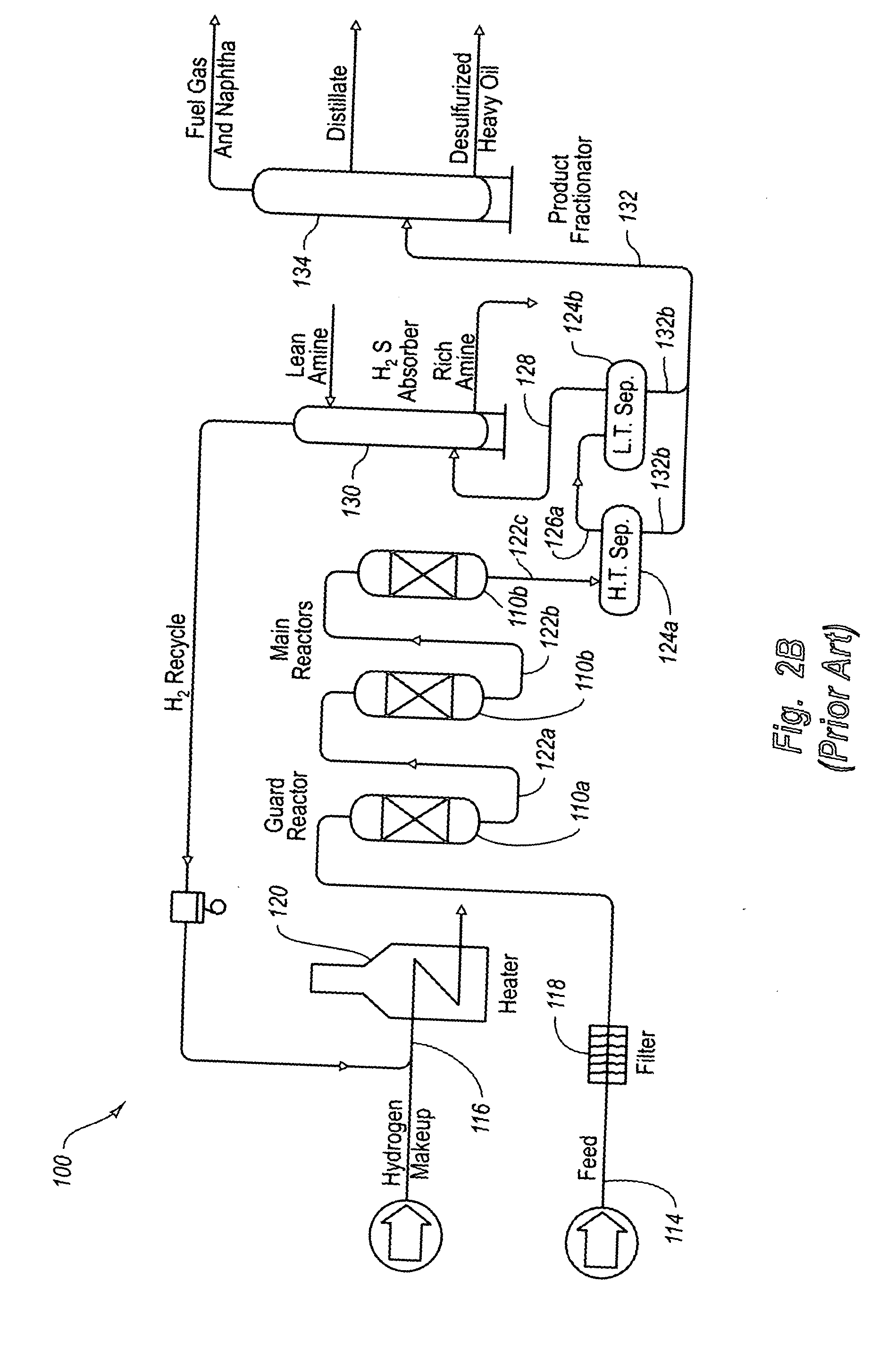

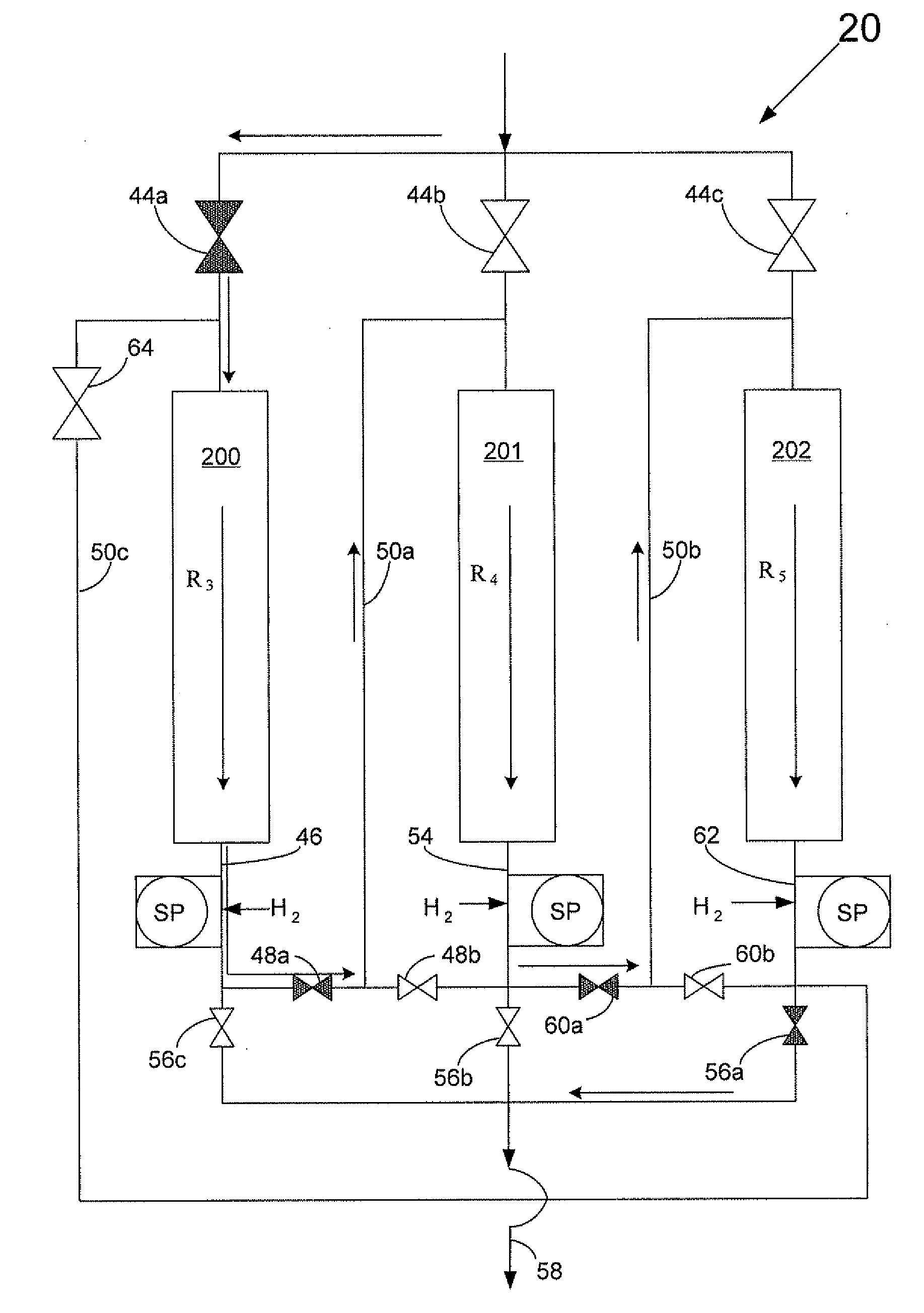

Fixed bed hydroprocessing methods and systems and methods for upgrading an existing fixed bed system

ActiveUS20050241992A1Quality improvementReduce formationCatalyst regeneration/reactivationCatalyst activation/preparationDecompositionFixed bed

A fixed bed hydroprocessing system, and also a method for upgrading a pre-existing fixed bed hydroprocessing system, involves preliminarily upgrading a heavy oil feedstock in one or more slurry phase reactors using a colloidal or molecular catalyst and then further hydroprocessing the upgraded feedstock within one or more fixed bed reactors using a porous supported catalyst. The colloidal or molecular catalyst is formed by intimately mixing a catalyst precursor composition into a heavy oil feedstock and raising the temperature of the feedstock to above the decomposition temperature of the precursor composition to form the colloidal or molecular catalyst in situ. Asphaltene or other hydrocarbon molecules otherwise too large to diffuse into the pores of the fixed bed catalyst can be upgraded by the colloidal or molecular catalyst. One or more slurry phase reactors may be built and positioned upstream from one or more fixed bed reactors of a pre-existing fixed bed system and / or converted from one or more pre-existing fixed bed reactors.

Owner:HEADWATERS TECH INNOVATION LLC

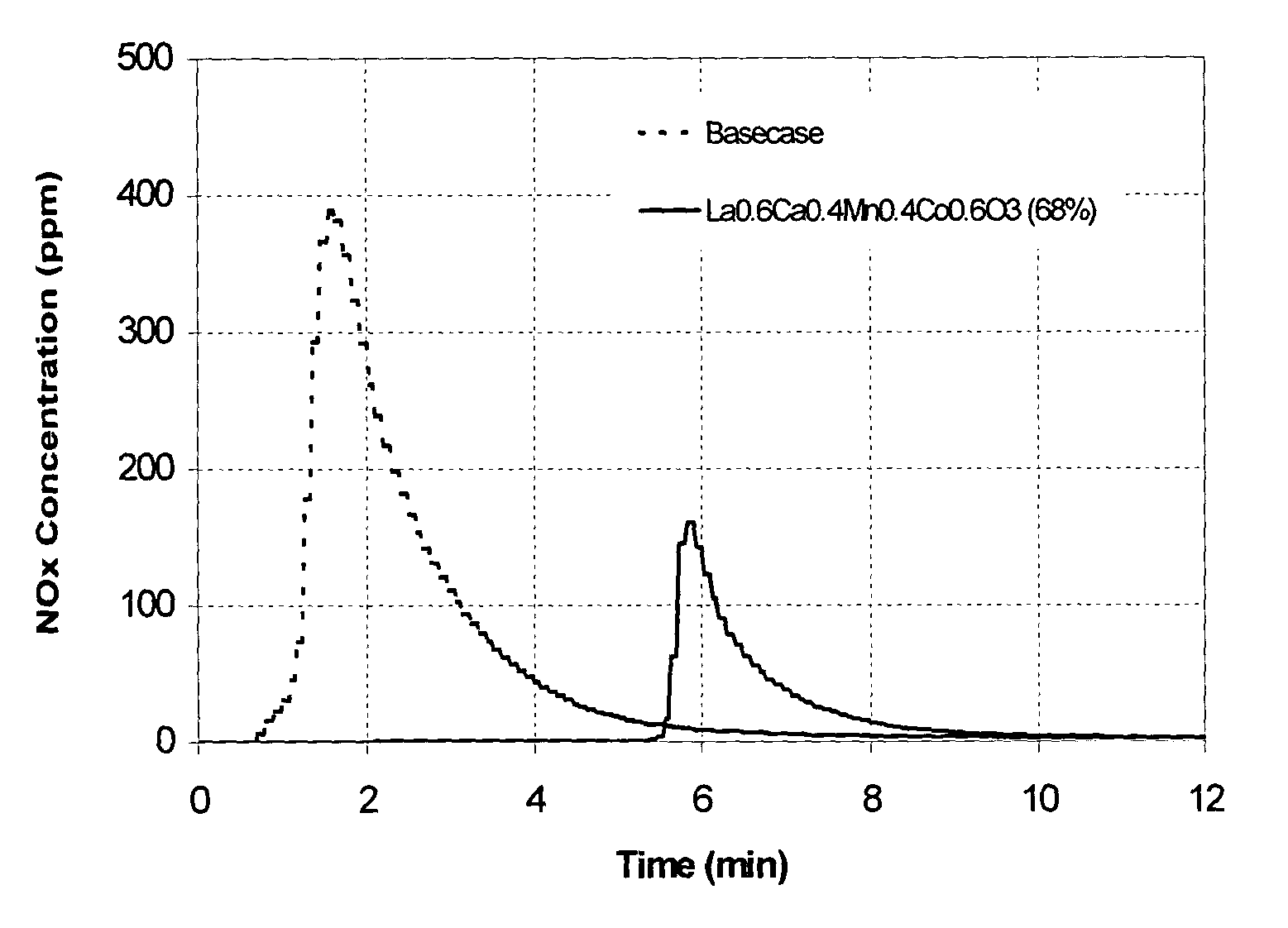

Combined cracking and selective hydrogen combustion for catalytic cracking

A catalyst system and process for combined cracking and selective hydrogen combustion of hydrocarbons are disclosed. The catalyst system contains at least one solid acid component and at least one metal-based component which consists of (a) oxygen and / or sulfur and (b) a metal combination selected from the group consisting of: i) at least one metal from Group 3 and at least one metal from Groups 4-15 of the Periodic Table of the Elements; ii) at least one metal from Groups 5-15 of the Periodic Table of the Elements, and at least one metal from at least one of Groups 1, 2, and 4 of the Periodic Table of the Elements; iii) at least one metal from Groups 1 and 2, at least one metal from Group 3, and at least one metal from Groups 4-15 of the Periodic Table of the Elements; and iv) two or more metals from Groups 4-15 of the Periodic Table of the Elements, wherein the at least one of oxygen and sulfur is chemically bound both within and between the metals and, optionally, (3) at least one of at least one support, at least one filler and at least one binder. The process is such that the yield of hydrogen is less than the yield of hydrogen when contacting the hydrocarbons with the solid acid component alone. Further the emissions of NOx from the regeneration cycle of the catalyst system are reduced.

Owner:EXXONMOBIL CHEM PAT INC

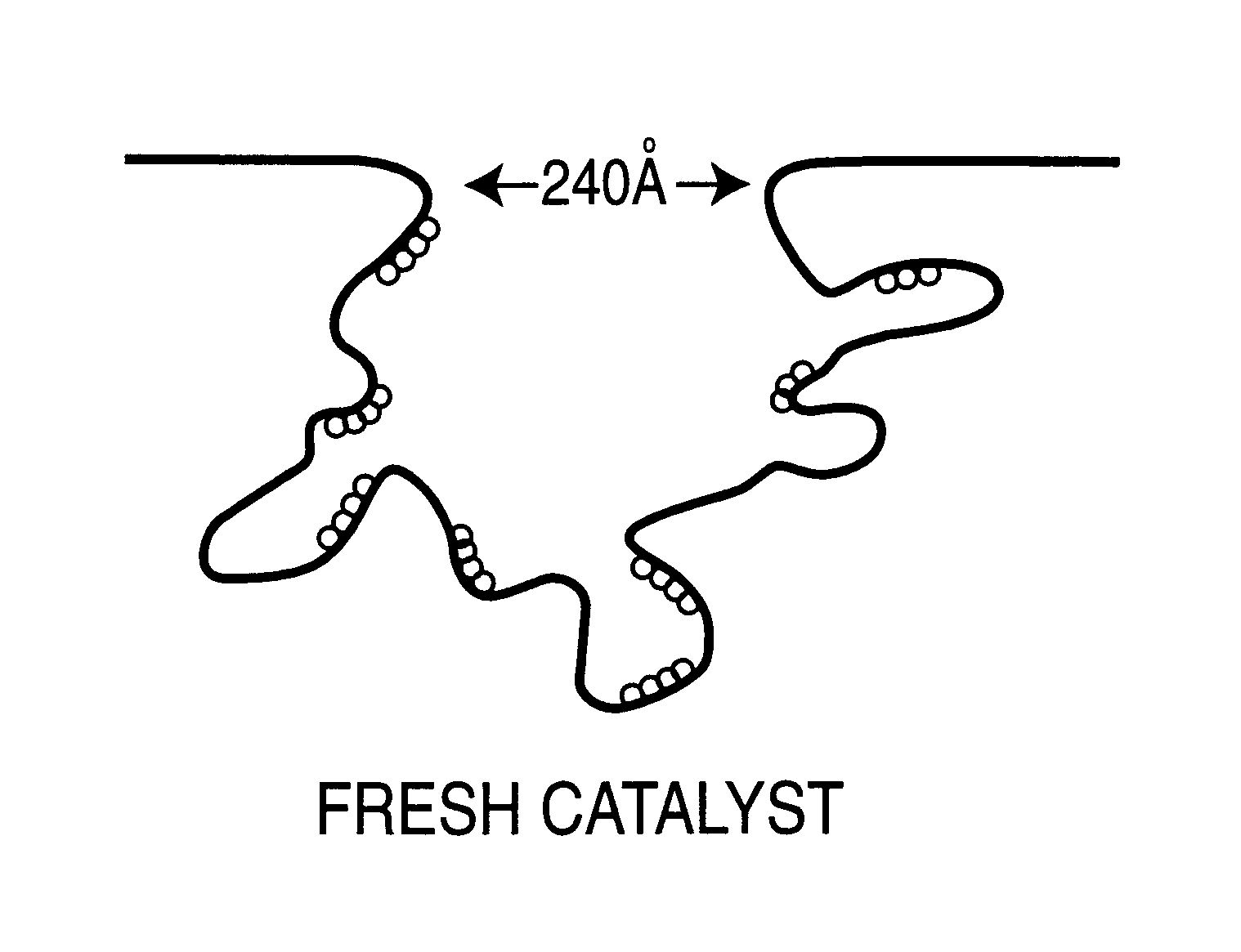

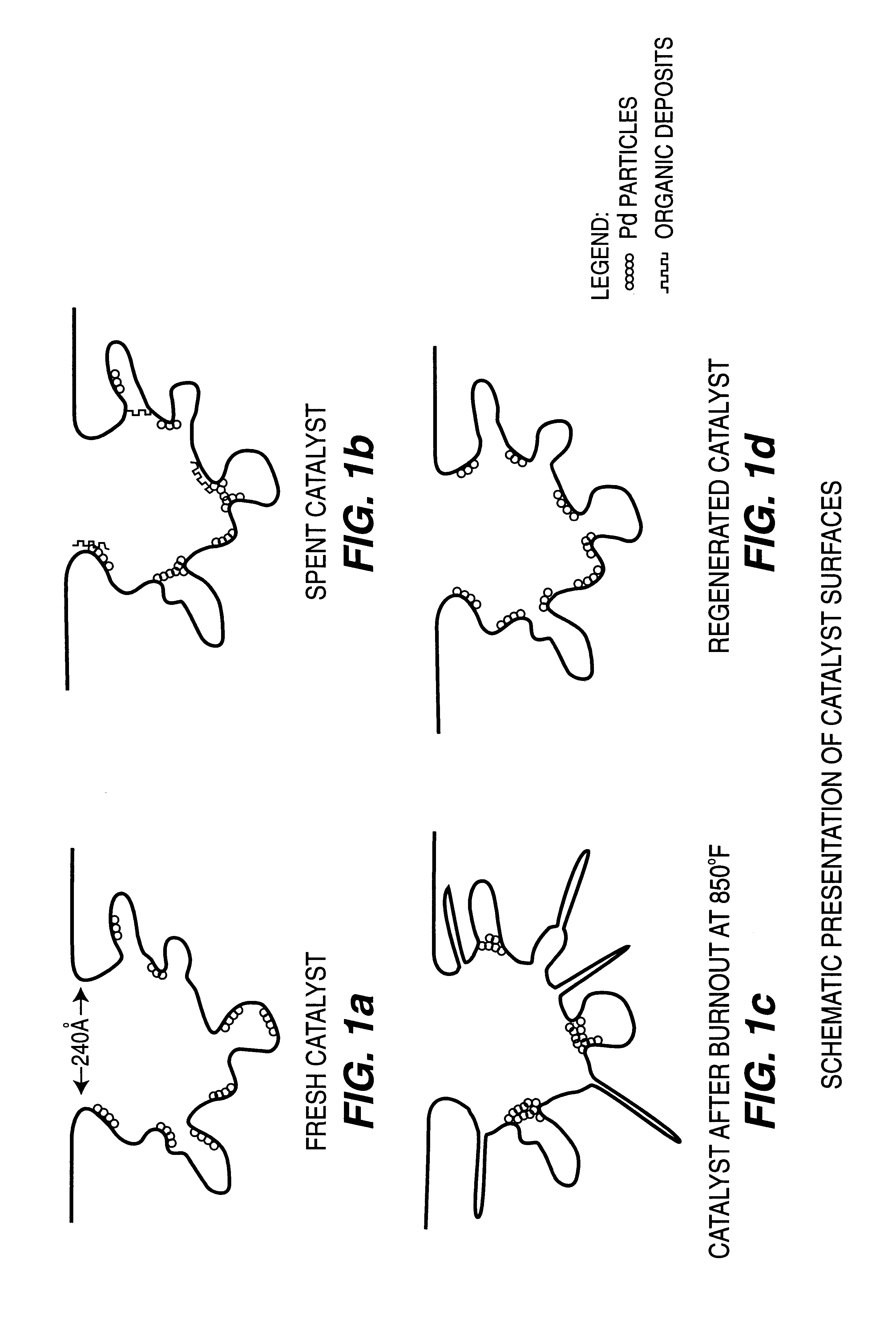

Regeneration of used supported noble metal catalysts

InactiveUS6740615B2Efficient removalImproves expositionHydrogen peroxideOther chemical processesPalladium catalystMetal particle

A method for regenerating used supported noble metal catalysts, which method includes solvent cleaning the used catalyst by contact with a suitable organic liquid cleaning solvent such as alcohols, ketones and such to remove organic deposits from the catalyst, followed by drying and calcining at elevated temperature to remove any remaining organic deposits from the catalyst, then treating the catalyst with an organo-metallic complex forming agent having ionization constant pK1 greater than about 2.5, such as glycolic acid and the like. The organic-metallic complex forming agent acts to break down large clusters of noble metal particles such as palladium (Pd) and redistributes the metal particles on the catalyst support such as alumina (Al2O3) in the same or other larger pores, so as to increase catalyst surface area and catalytic activity to provide a catalytic activity level at least 80% or even exceeding that of the fresh catalyst. This regeneration method is particularly useful for regenerating used supported palladium catalysts utilized for hydrogenation of ethyl anthraquinone (EAQ) for producing hydrogen peroxide (H2O2) product.

Owner:POROCEL INT LLC +1

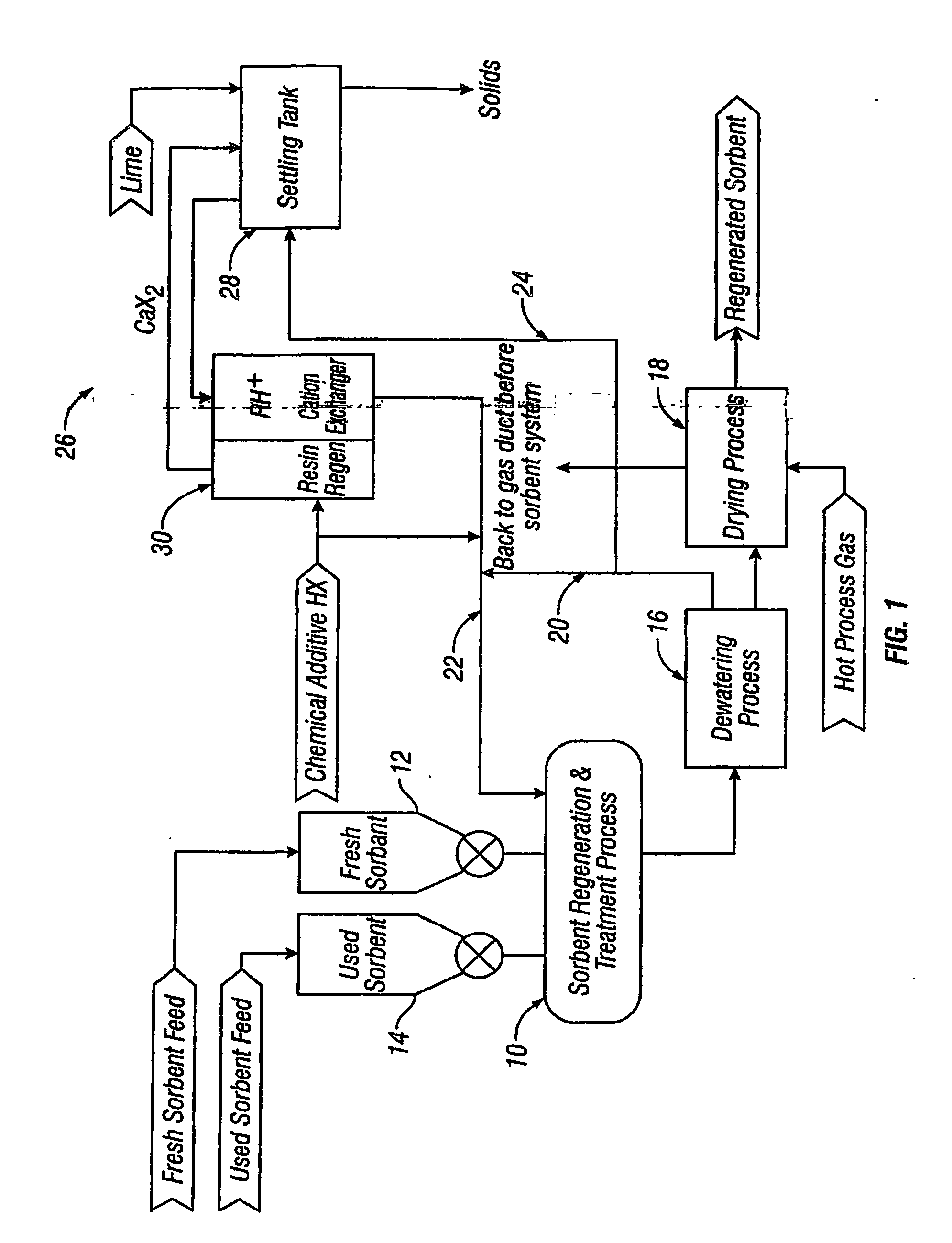

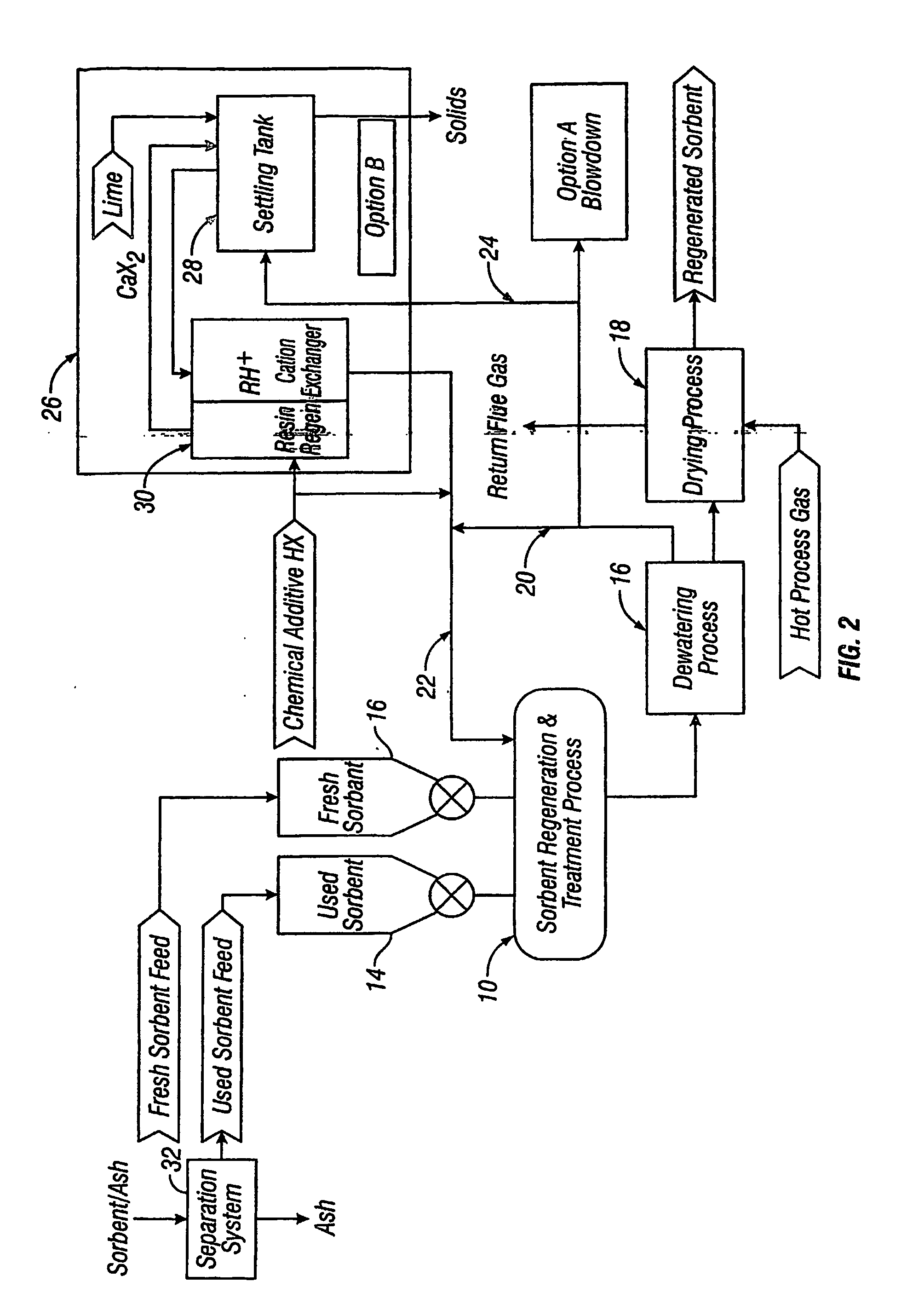

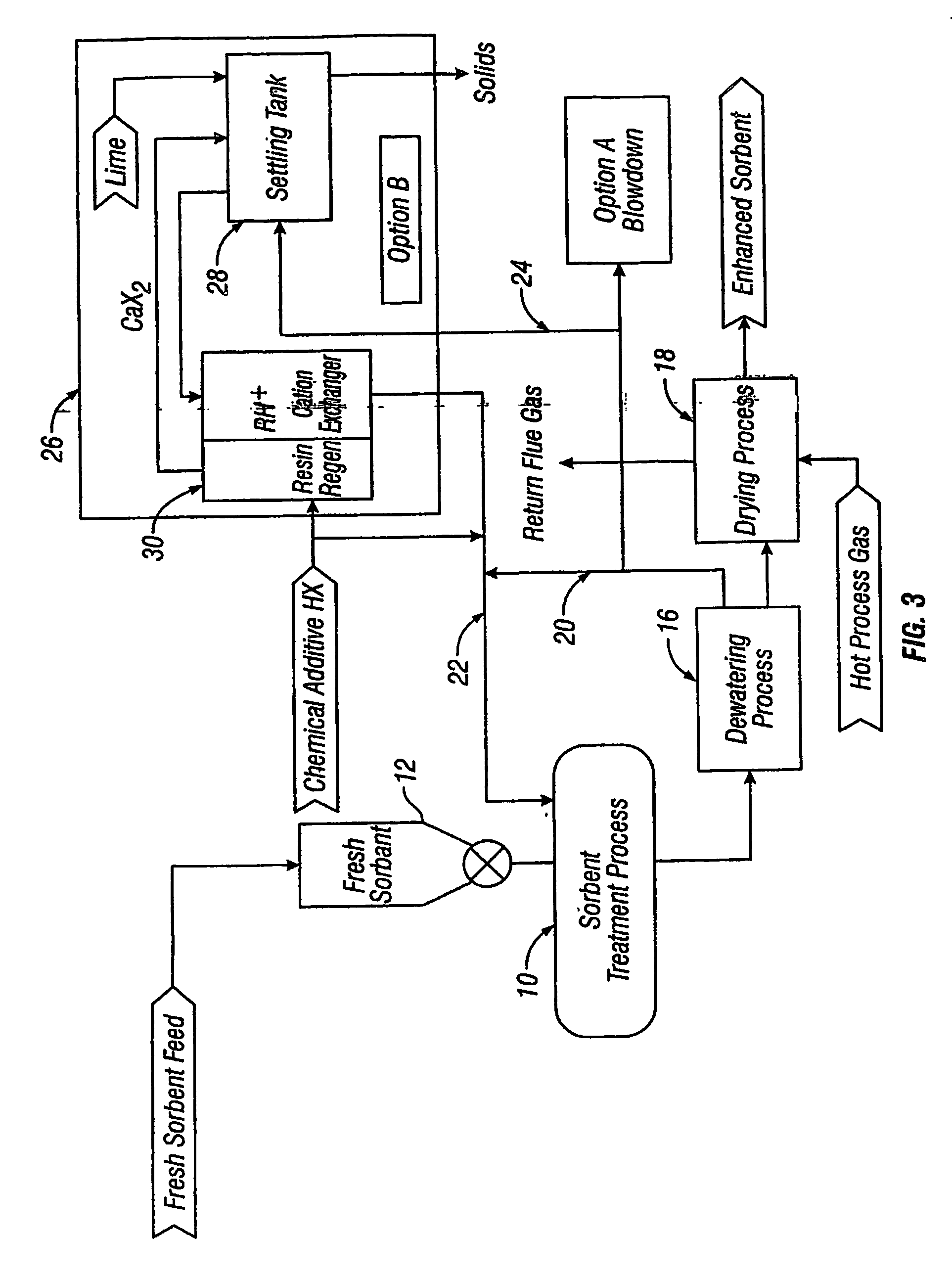

Process for regenerating a spent sorbent

ActiveUS20070167309A1Improve efficiencyOther chemical processesUsing liquid separation agentFlue gasSorbent

A method and apparatus is provided for regenerating a sorbent that has been poisoned by components derived from flue gas. The sorbent is treated with an agent to remove the poisoning components and introduce a promoting agent into the sorbent. The method and apparatus can also be used to enhance the effectiveness of a new sorbent.

Owner:MIDWEST ENERGY EMISSIONS CORP

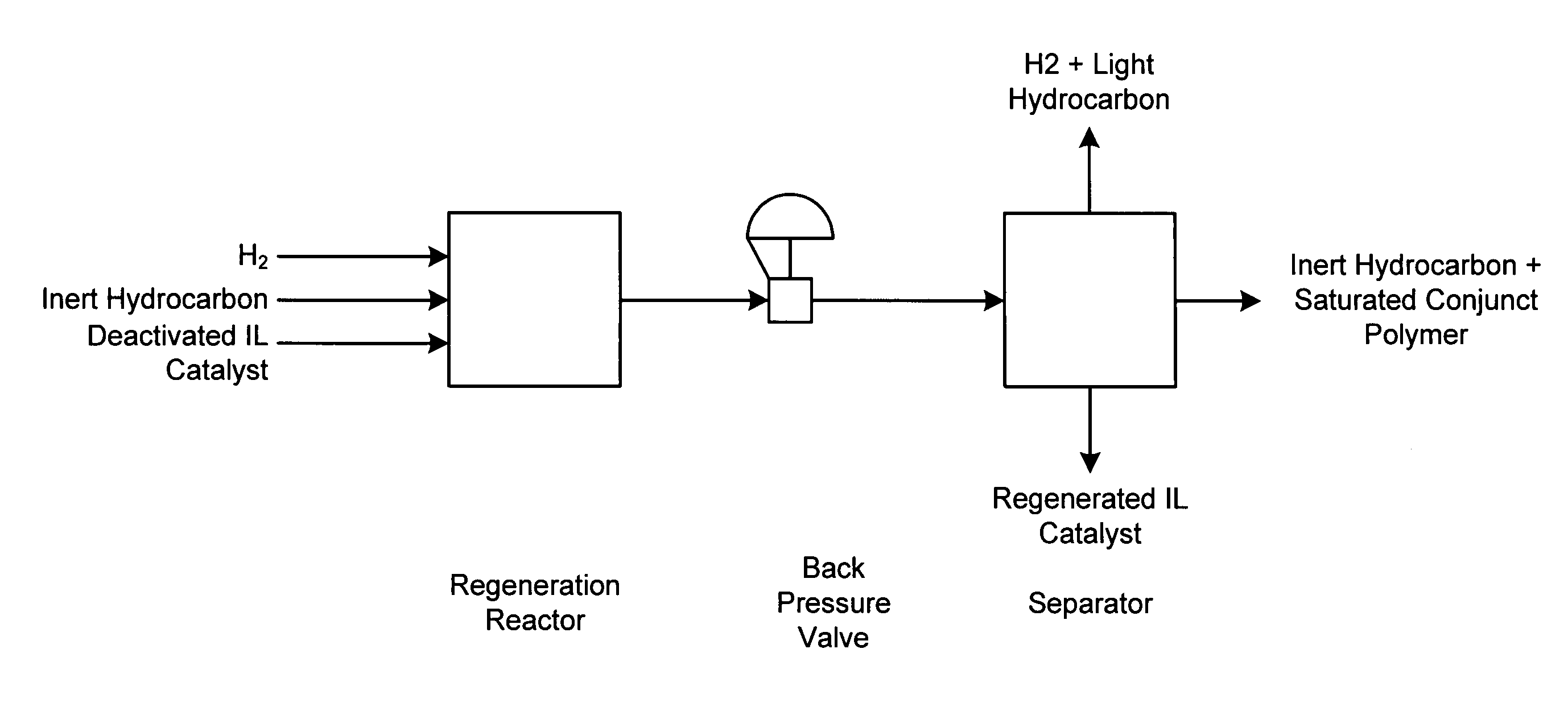

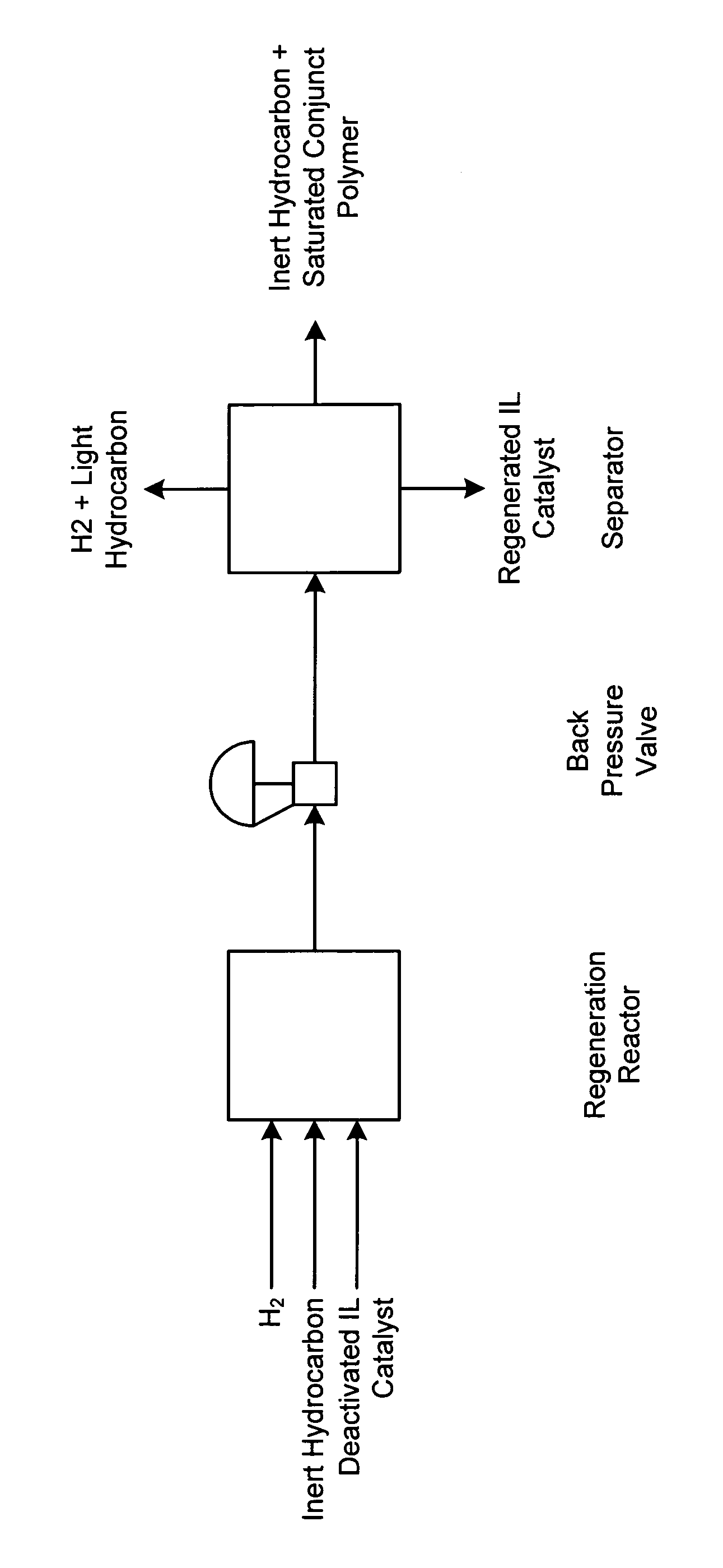

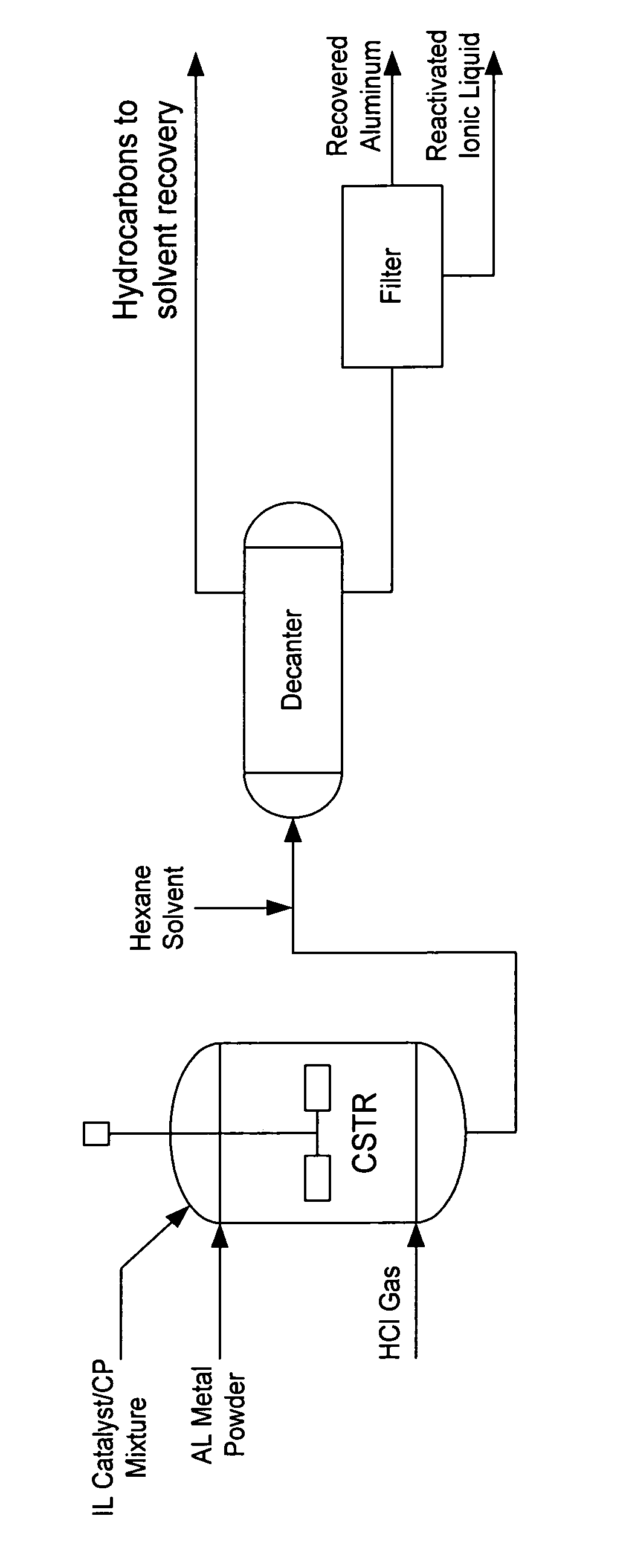

Regeneration of ionic liquid catalyst by hydrogenation using a supported catalyst

A process for regenerating a used acidic ionic liquid catalyst comprising the steps of contacting the used ionic liquid catalyst and hydrogen with a supported hydrogenation catalyst comprising a hydrogenation component on a support in a reaction zone under hydrogenation conditions for a time sufficient to increase the activity of the used catalyst is disclosed.

Owner:CHEVROU USA INC

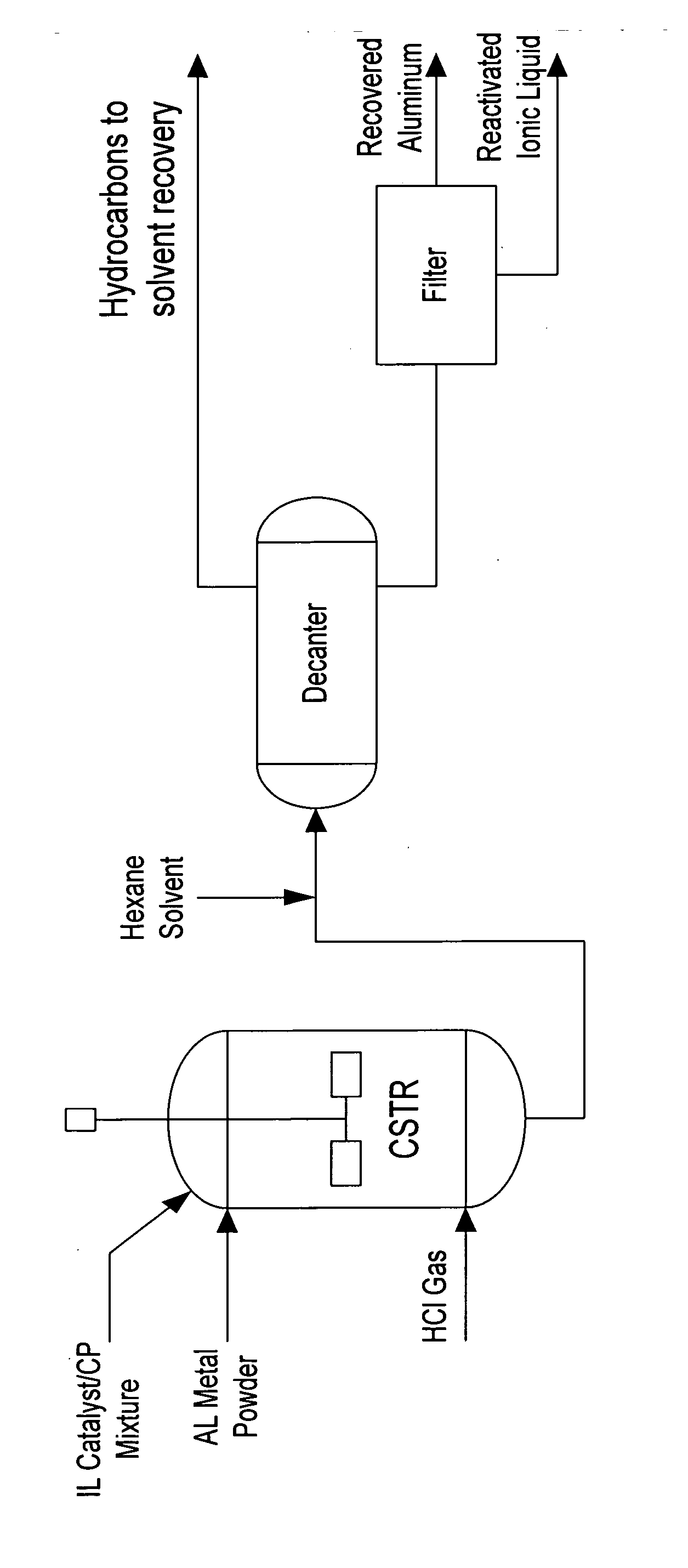

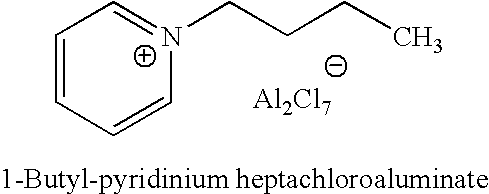

Regeneration of ionic liquid catalyst using a metal in the absence of added hydrogen

ActiveUS20070249485A1High activityMolecular sieve catalystsOther chemical processesHydrocarbon solventsHydrogen

A process for regenerating a used acidic ionic liquid catalyst comprising contacting the used ionic liquid catalyst with at least one metal in a regeneration zone in the absence of added hydrogen under regeneration conditions for a time sufficient to increase the activity of the ionic liquid catalyst is described. In one embodiment, regeneration is conducted in the presence of a hydrocarbon solvent.

Owner:CHEVROU USA INC

Process and apparatus for producing single-walled carbon nanotubes

InactiveUS6919064B2Avoid defectsOptimize quantityMaterial nanotechnologyCatalyst regeneration/reactivationParticulatesCarbon nanotube

Owner:THE BOARD OF RGT UNIV OF OKLAHOMA

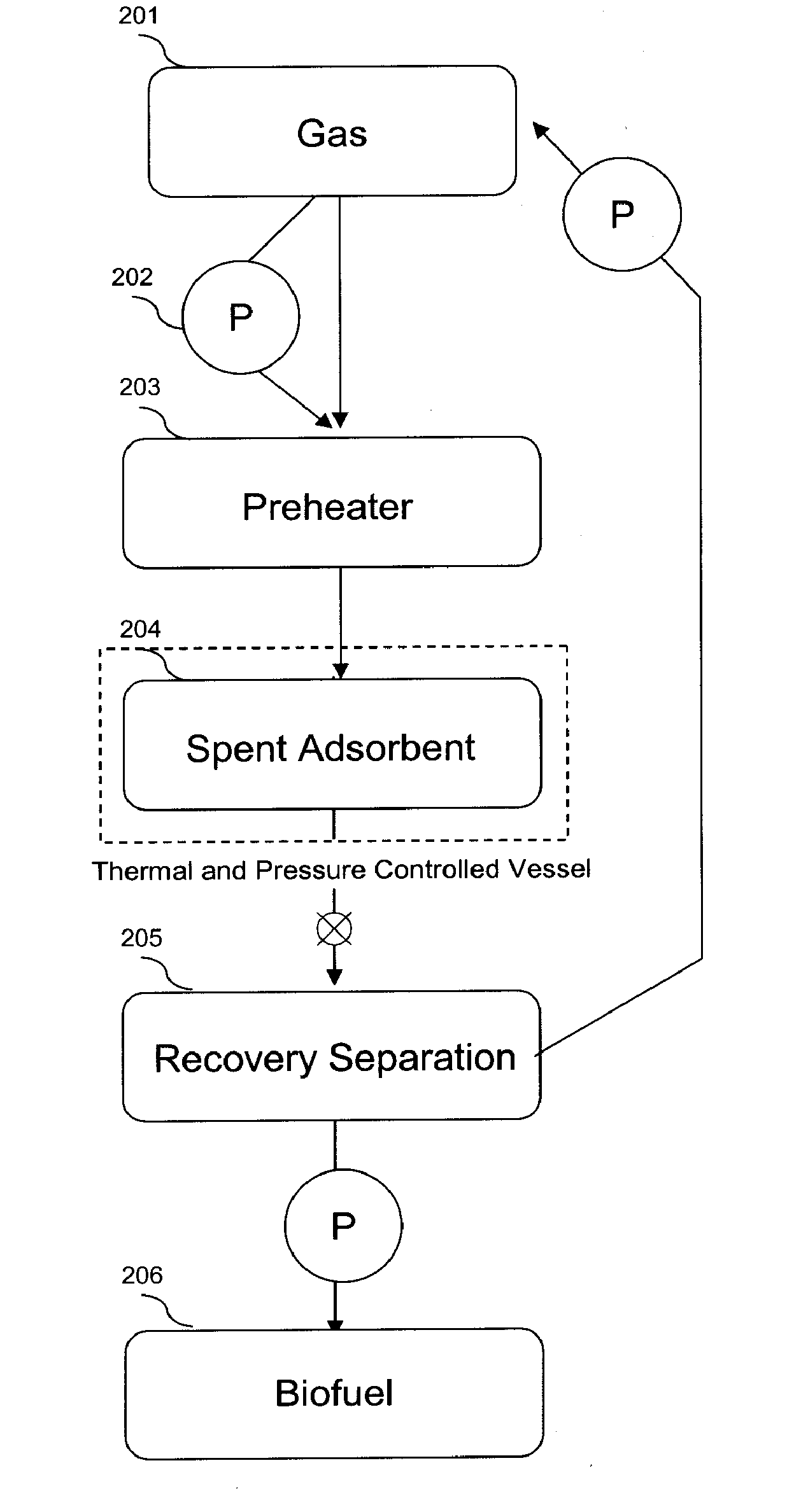

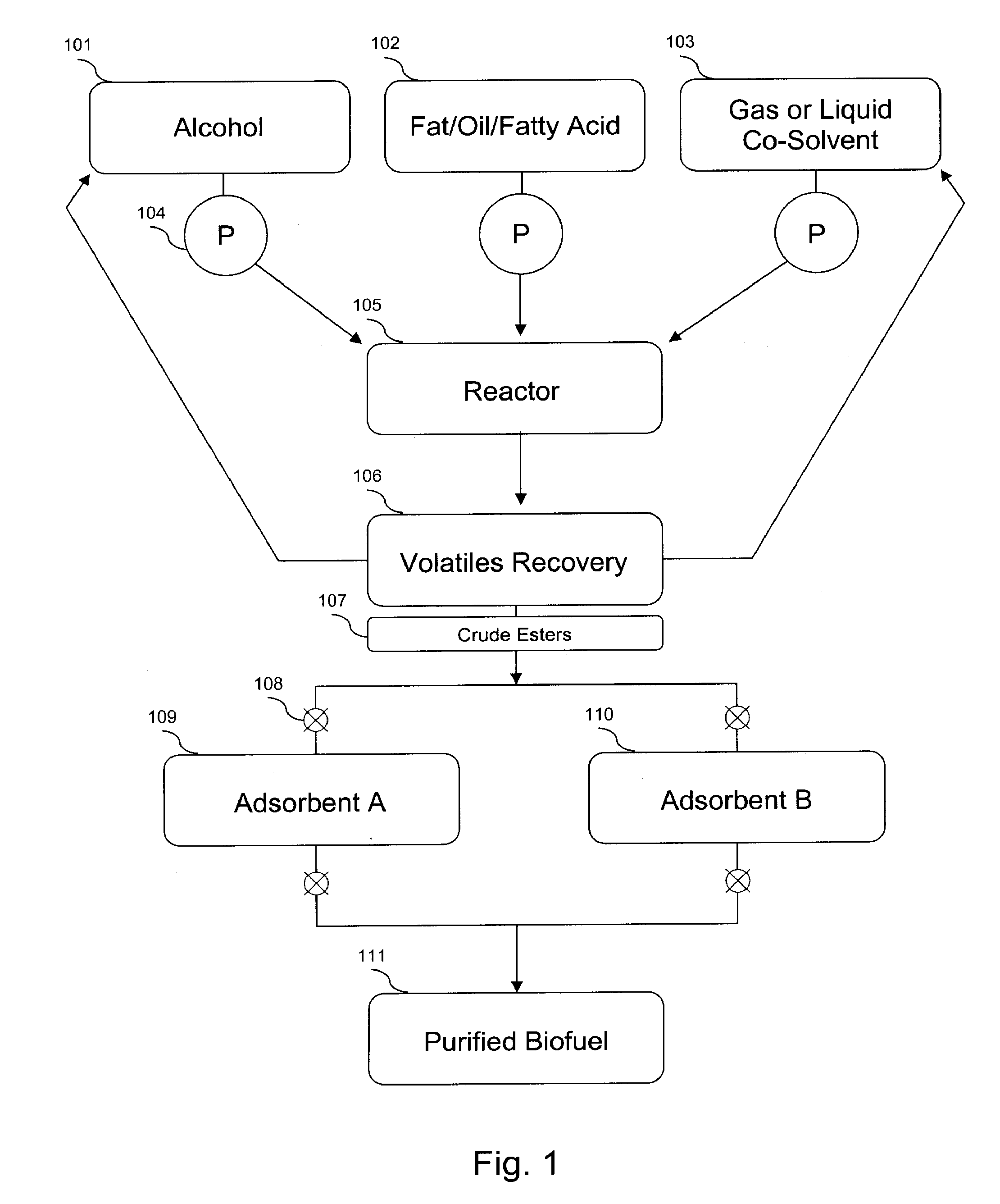

System for production and purification of biofuel

Systems and methods are provided for the regeneration of adsorbent medium and the production of additional fatty acid esters, i.e., biofuel, in particular, by means of discharging adsorbed contaminants from an adsorbent medium such as an inorganic catalytic medium by methods that convert the contaminants into additional biofuel or biofuel intermediates, thereby increasing production efficiency, conserving labor, and reducing material waste and environmental contamination.

Owner:BIOFUELBOX

Process and apparatus for producing single-walled carbon nanotubes

InactiveUS20050042162A1Avoid disadvantagesOptimize quantityMaterial nanotechnologyCatalyst regeneration/reactivationParticulatesCarbon nanotube

A process and apparatus for catalytic production of single walled carbon nanotubes. Catalytic particles are exposed to different process conditions at successive stages wherein the catalytic particles do not come in contact with reactive (catalytic) gases until preferred process conditions have been attained, thereby controlling the quantity and form of carbon nanotubes produced. The process also contemplates processes and apparatus which recycle and reuse-the gases and catalytic particulate materials, thereby maximizing cost efficiency, reducing wastes, reducing the need for additional raw materials, and producing the carbon nanotubes, especially SWNTs, in greater quantities and for lower costs.

Owner:THE BOARD OF RGT UNIV OF OKLAHOMA

Regeneration of ionic liquid catalyst by hydrogenation using metal and acid

A process for regenerating a used acidic ionic liquid catalyst which has been deactivated by conjunct polymers comprising combining the used catalyst, a metal and a Broensted acid which acts a source of hydrogen in a reaction zone under hydrogenation conditions for a time sufficient to hydrogenate at least a portion of the conjunct polymer is disclosed. An embodiment of a process for regenerating a used acidic ionic liquid catalyst which has been deactivated by conjunct polymers comprising the steps of combining the used ionic liquid catalyst, a metal and HCl in a reaction zone under hydrogenation conditions for a time sufficient to hydrogenate at least a portion of the conjunct polymer; removing reaction product from the reaction zone; mixing the removed reaction product with a hydrocarbon solvent in which the hydrogenated conjunct polymers are soluble; allowing the mixture to separate into two phases, a lighter phase which contains the hydrogenated conjunct polymers and a heavier phase which contains a regenerated ionic liquid catalyst; and recovering at least a portion of the heavier phase is also disclosed.

Owner:CHEVROU USA INC

Catalytic gasification process with recovery of alkali metal from char

ActiveUS7897126B2Quantity minimizationThermal non-catalytic crackingMuffle furnacesParticulatesSlurry

Processes are described for the extraction and recovery of alkali metal from the char that results from catalytic gasification of a carbonaceous material. Among other steps, the processes of the invention include a hydrothermal leaching step in which a slurry of insoluble particulate comprising insoluble alkali metal compounds is treated with carbon dioxide and steam at elevated temperatures and pressures to effect the conversion of insoluble alkali metal compounds to soluble alkali metal compounds. Further, processes are described for the catalytic gasification of a carbonaceous material where a substantial portion of alkali metal is extracted and recovered from the char that results from the catalytic gasification process.

Owner:SURE CHAMPION INVESTMENT LTD

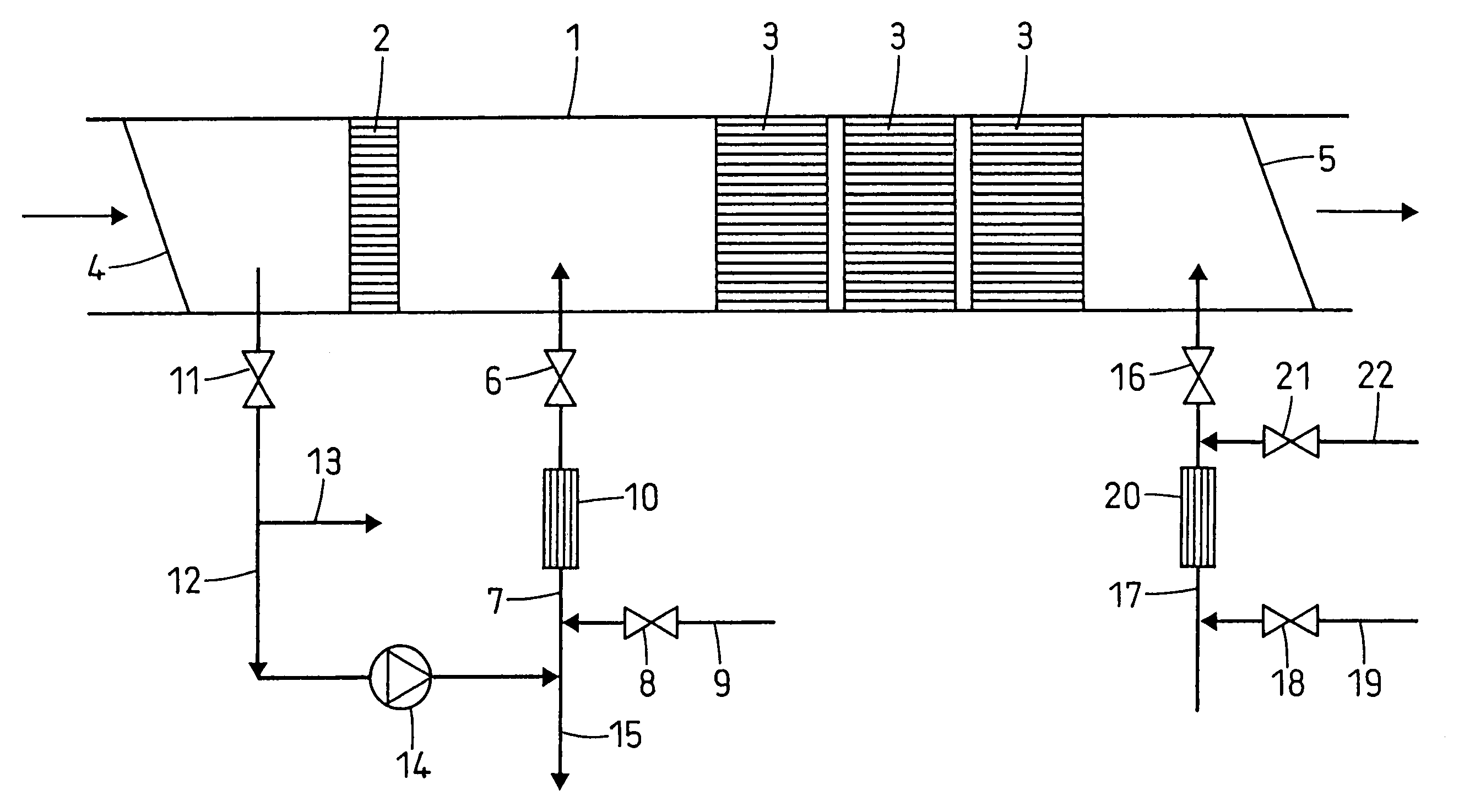

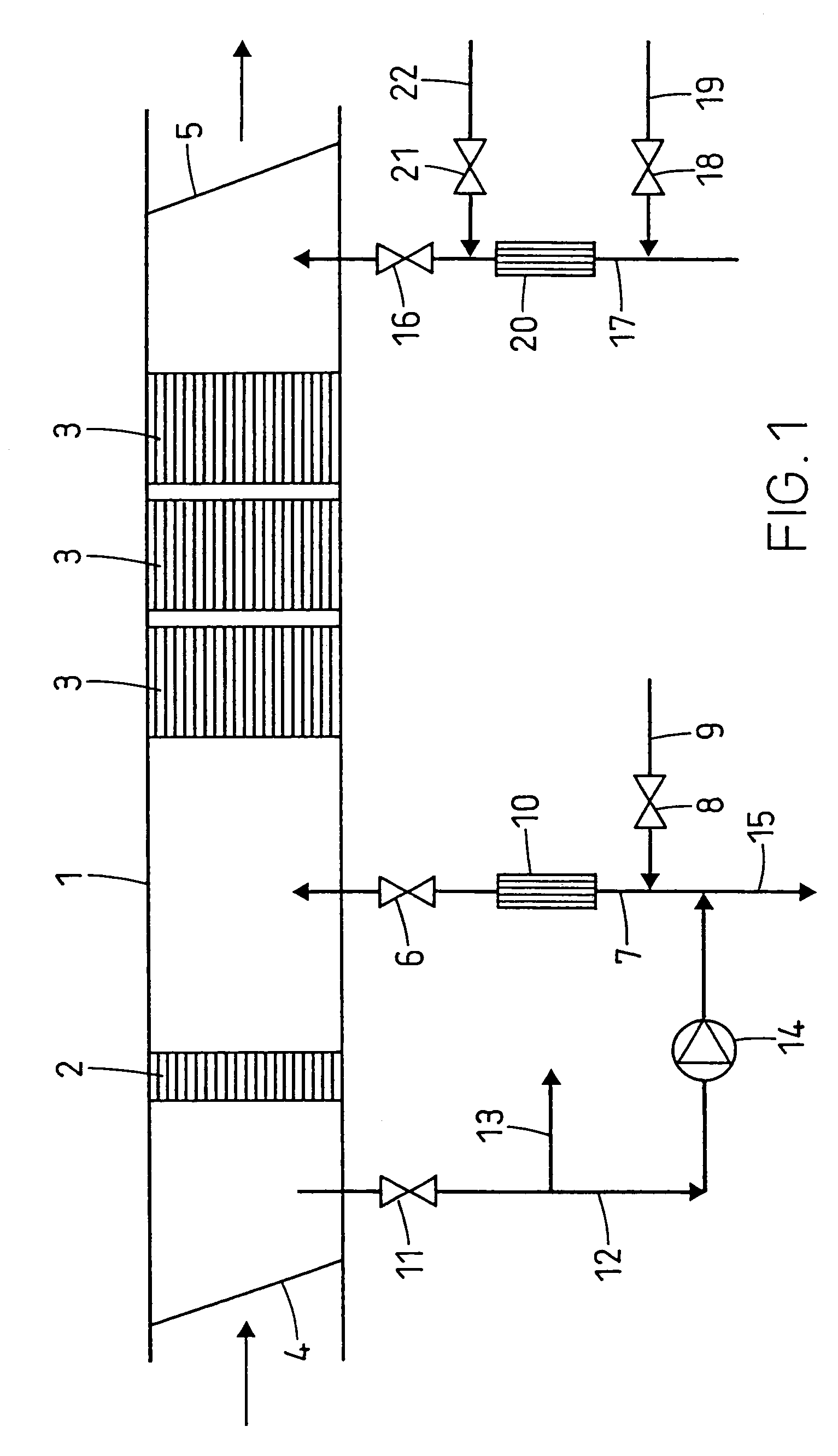

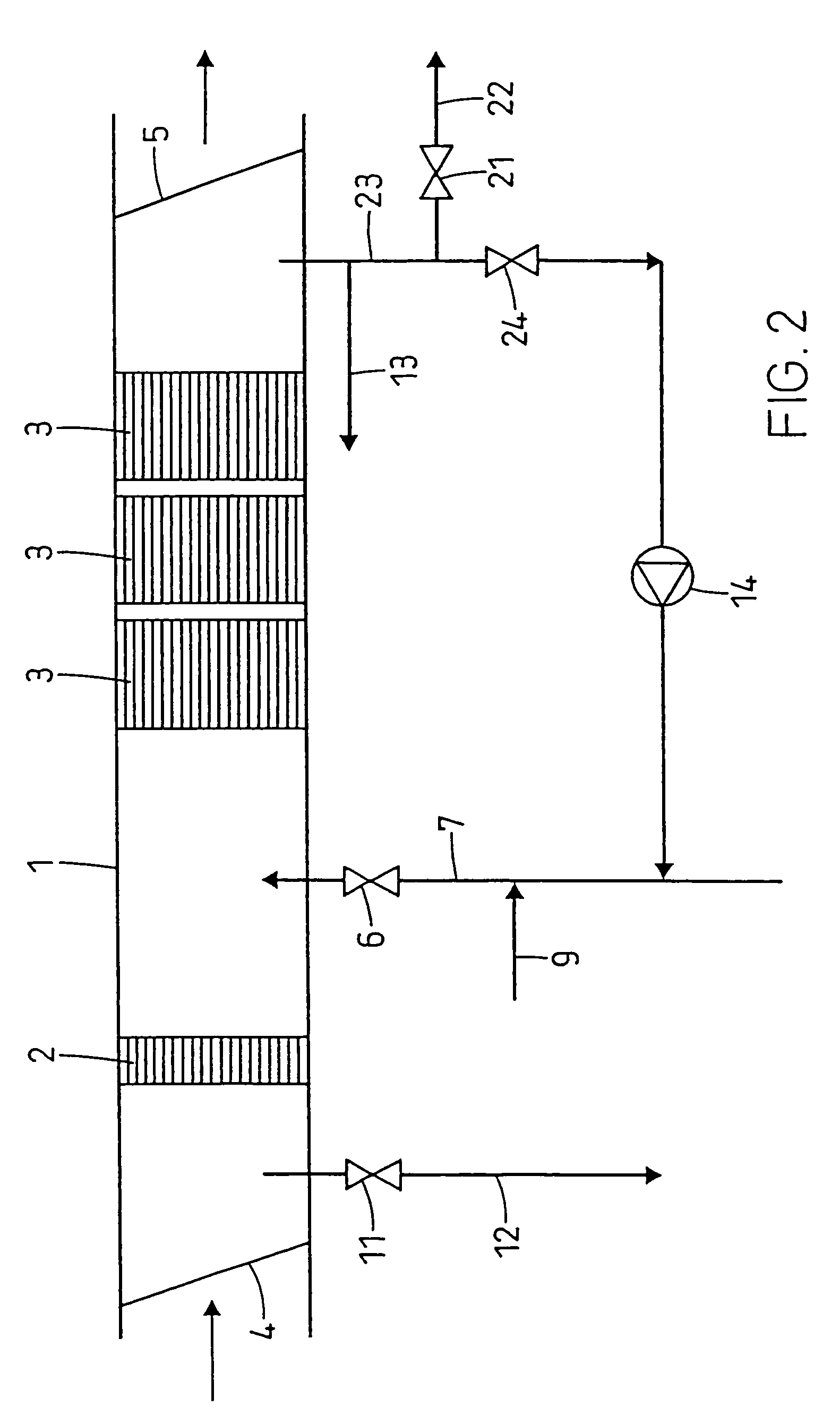

Process for the regeneration of a catalyst plant and apparatus for performing the process

InactiveUS7611681B2Reduce consumptionLow costCombination devicesOther chemical processesHydrogenFlue gas

A gas stream containing e.g. molecular hydrogen is used for the regeneration of a catalyst for NOx and SO2 removal from the flue gas of a gas turbine. In order to reduce the consumption of regeneration gas, the gas inlet is located between the SCOSOx catalyst (2) and the SCONOx catalyst (3). The regeneration gas leaves the catalyst chamber upstream of the SCOSOx catalyst and is recycled. For the regeneration of the SCONOx catalyst and to keep SO2 containing gas from entering the SCONOx catalyst, a second regeneration gas inlet is located downstream of the SCONOx catalyst. The regeneration gas entering the catalyst chamber through this port passes the SCONOx (3) and the SCOSOx catalyst (2). The direction of the flow in the SCONOx catalyst can also be reversed. In another example, regeneration gas outlets are located both upstream of the SCOSOx and downstream of the SCONOx catalyst. But, only the regeneration gas from the SCONOx catalyst is recycled.

Owner:ANSALDO ENERGIA IP UK LTD

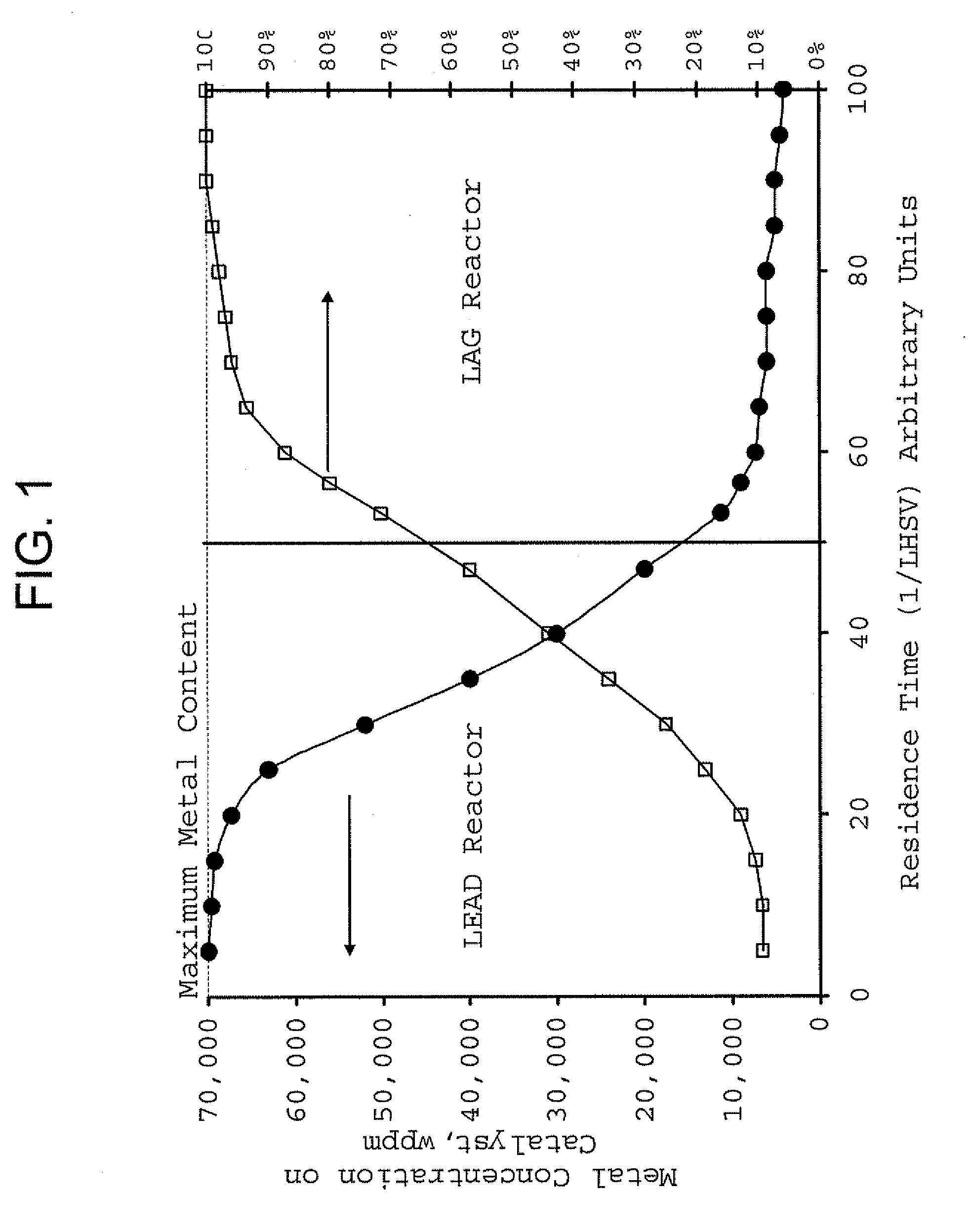

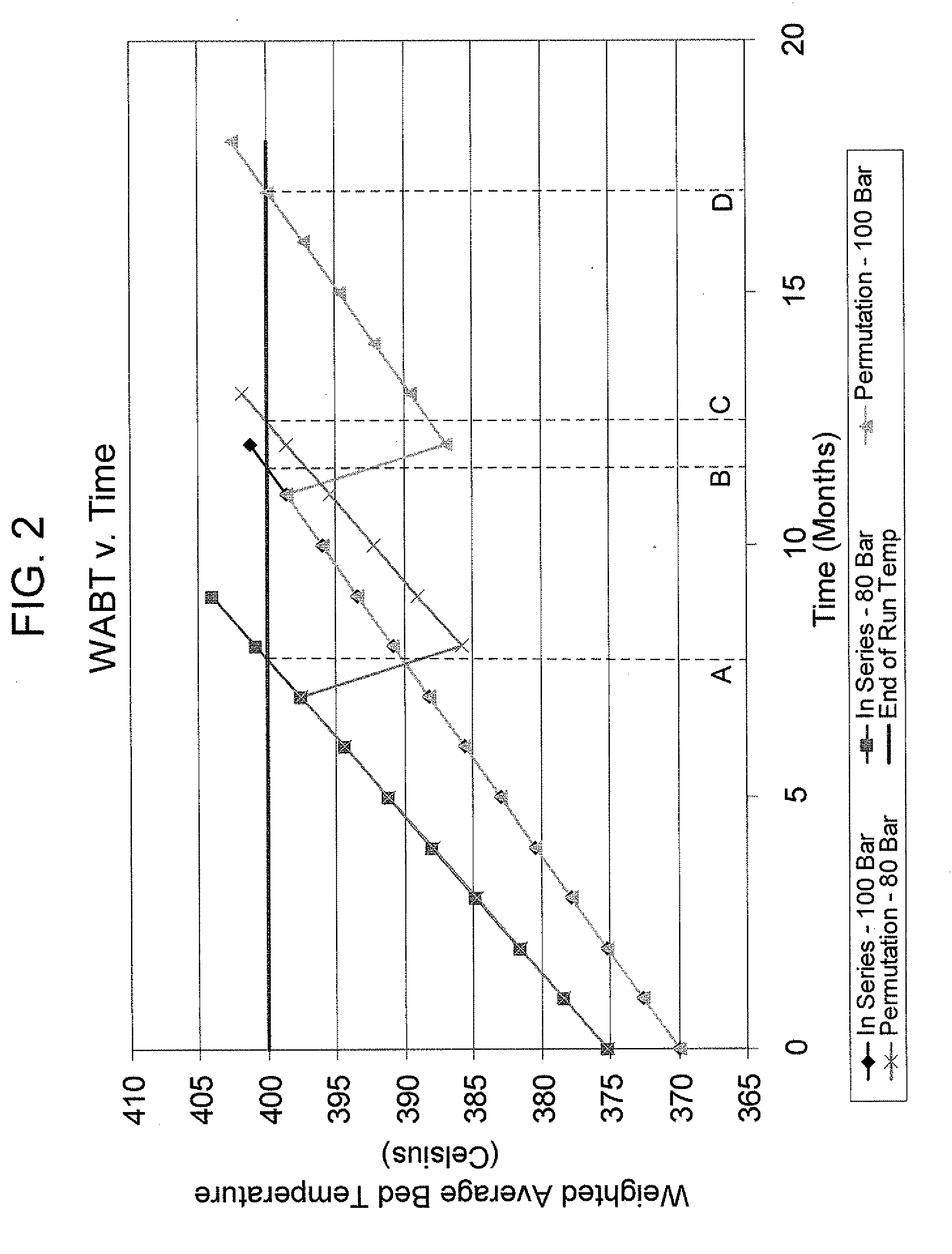

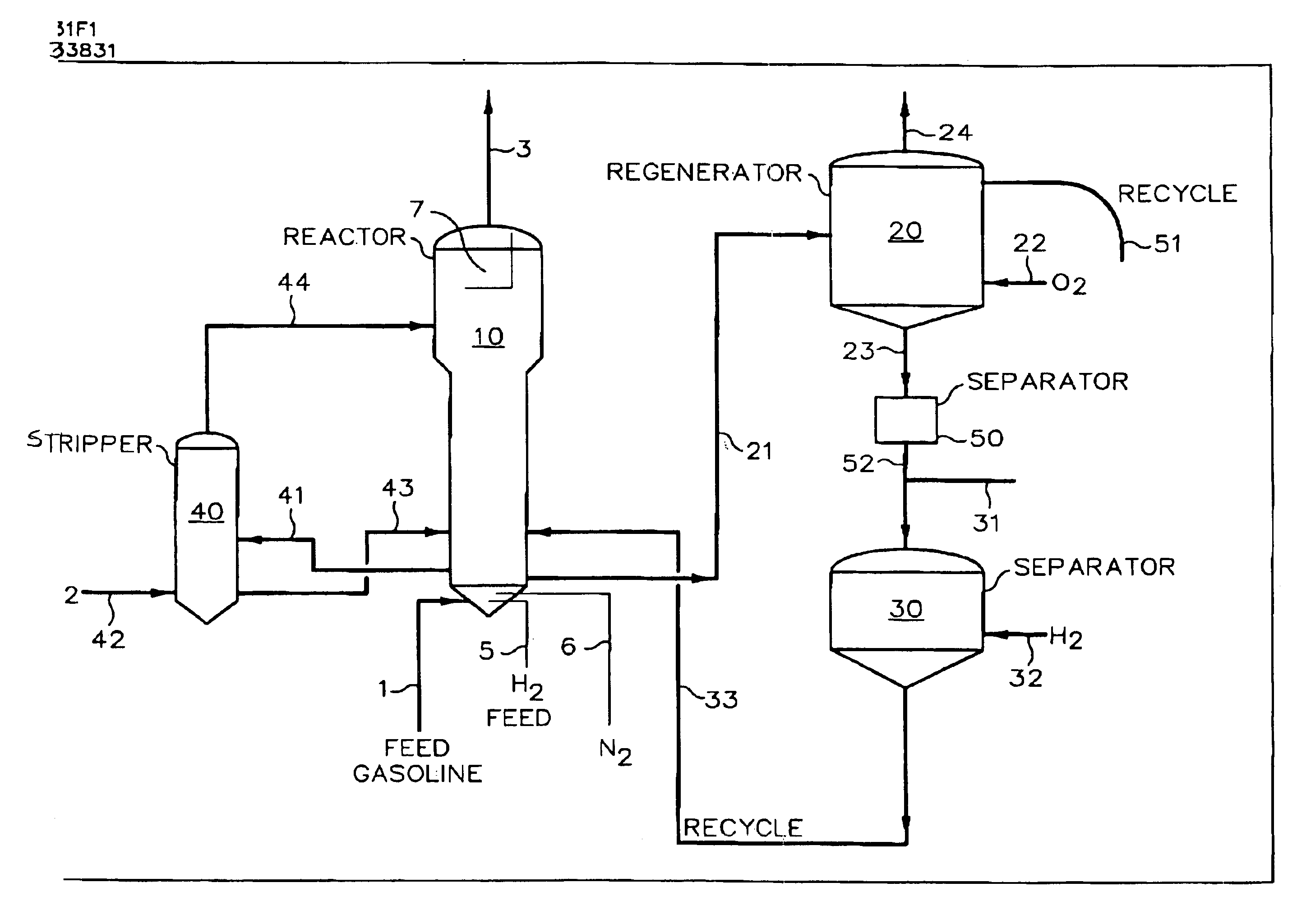

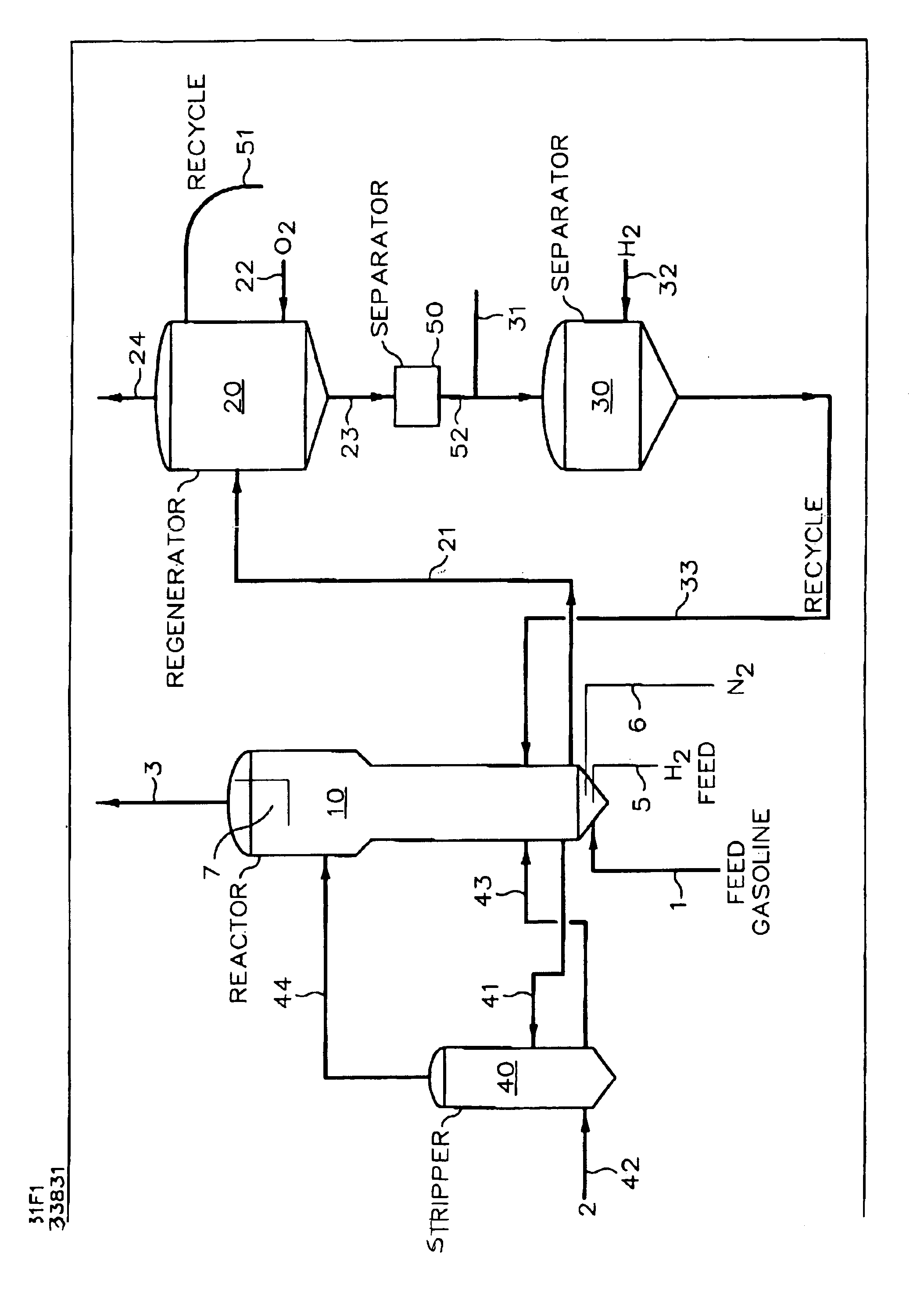

High temperature naphtha desulfurization using a low metal and partially deactivated catalyst

InactiveUS6231754B1Catalyst regeneration/reactivationMetal/metal-oxides/metal-hydroxide catalystsNaphthaThiol

A high temperature naphtha desulfurization process with reduced olefin saturation employs a partially spent and low metals content hydrodesulfurization catalyst having from 2-40% the activity of a new catalyst. The catalytic metals preferably include Co and Mo in an atomic ratio of from 0.1 to 1. The catalyst is preferably at least partially regenerable, has less than 500 wppm of a total of one or more of nickel, iron and vanadium and preferably has no more than 12 wt. % catalytic metal calculated as the oxide. This permits selective deep desulfurization, with reduced olefin saturation, low product mercaptan levels and little or need for downstream mercaptan removal.

Owner:EXXON RES & ENG CO

Process for catalytic hydrotreating of sour crude oils

ActiveUS20090139902A1Improve catalyst utilizationImproves HDS activityTreatment with hydrotreatment processesFilter regenerationHydrodesulfurizationSulfur

A continuous process for upgrading sour crude oil by treating the sour crude oil in a two step process that includes a hydro-demetallization section and a hydro-desulfurization section, both of which are constructed in a permutable fashion so as to optimize the operating conditions and catalyst lifespan to produce a high value crude oil having low sulfur and low organometallic impurities.

Owner:SAUDI ARABIAN OIL CO

Desulfurization process

InactiveUS6869522B2Extended service lifeReduced valenceOther chemical processesZirconium compoundsSorbentOrganosulfur compounds

In a desulfurization process for the removal of organosulfur compounds from a hydrocarbon fluid stream such as cracked-gasoline or diesel fuel wherein a bifunctional sorbent system is employed, surface treatment of the bifunctional sorbent during the use of same for desulfurization results in an extension of the useful life of the bifunctional sorbent prior to the regeneration and reactivation of same for further use in the desulfurization of the hydrocarbon fluid stream.

Owner:CHINA PETROCHEMICAL CORP

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com