Patents

Literature

48 results about "Coal matrix" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

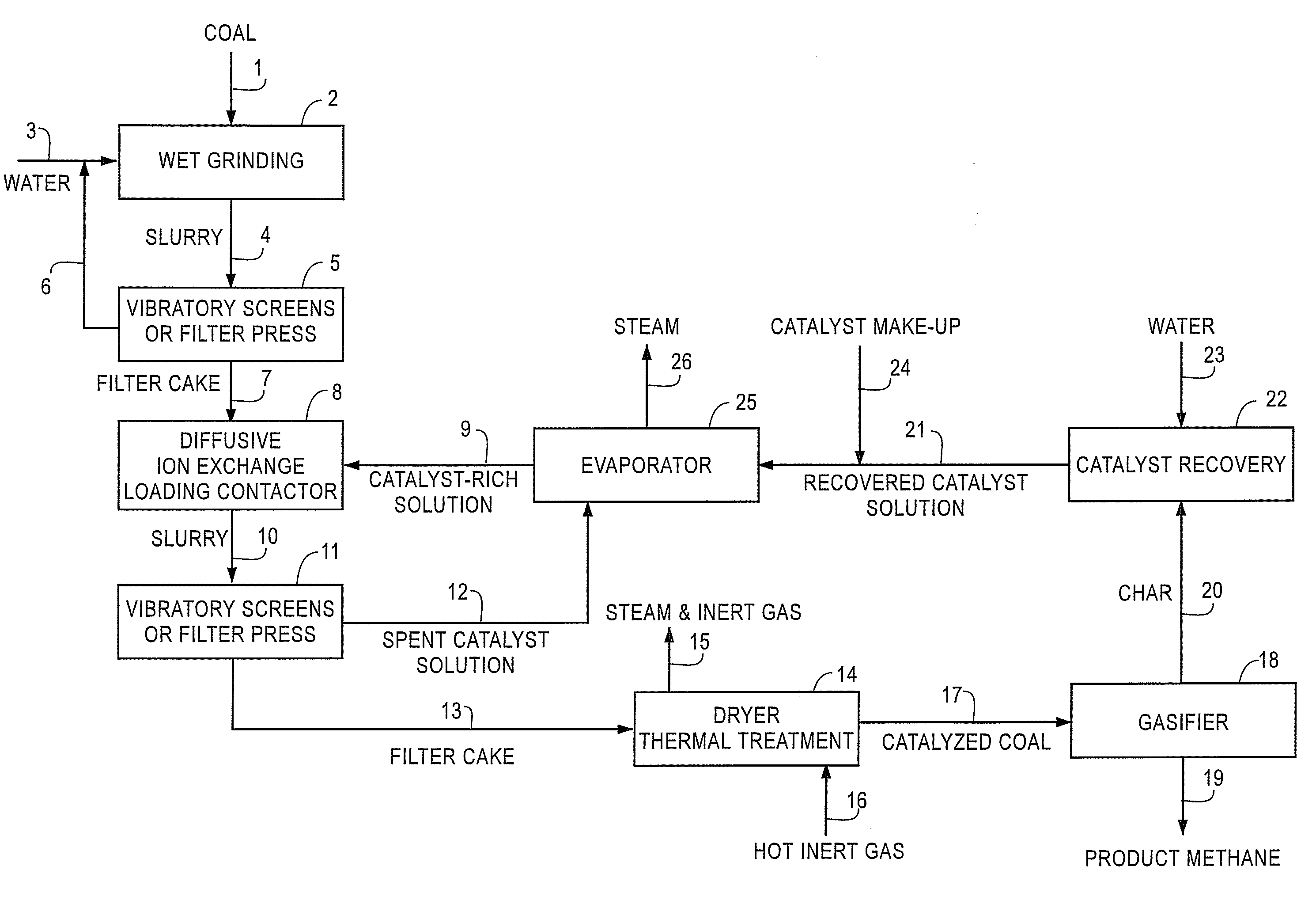

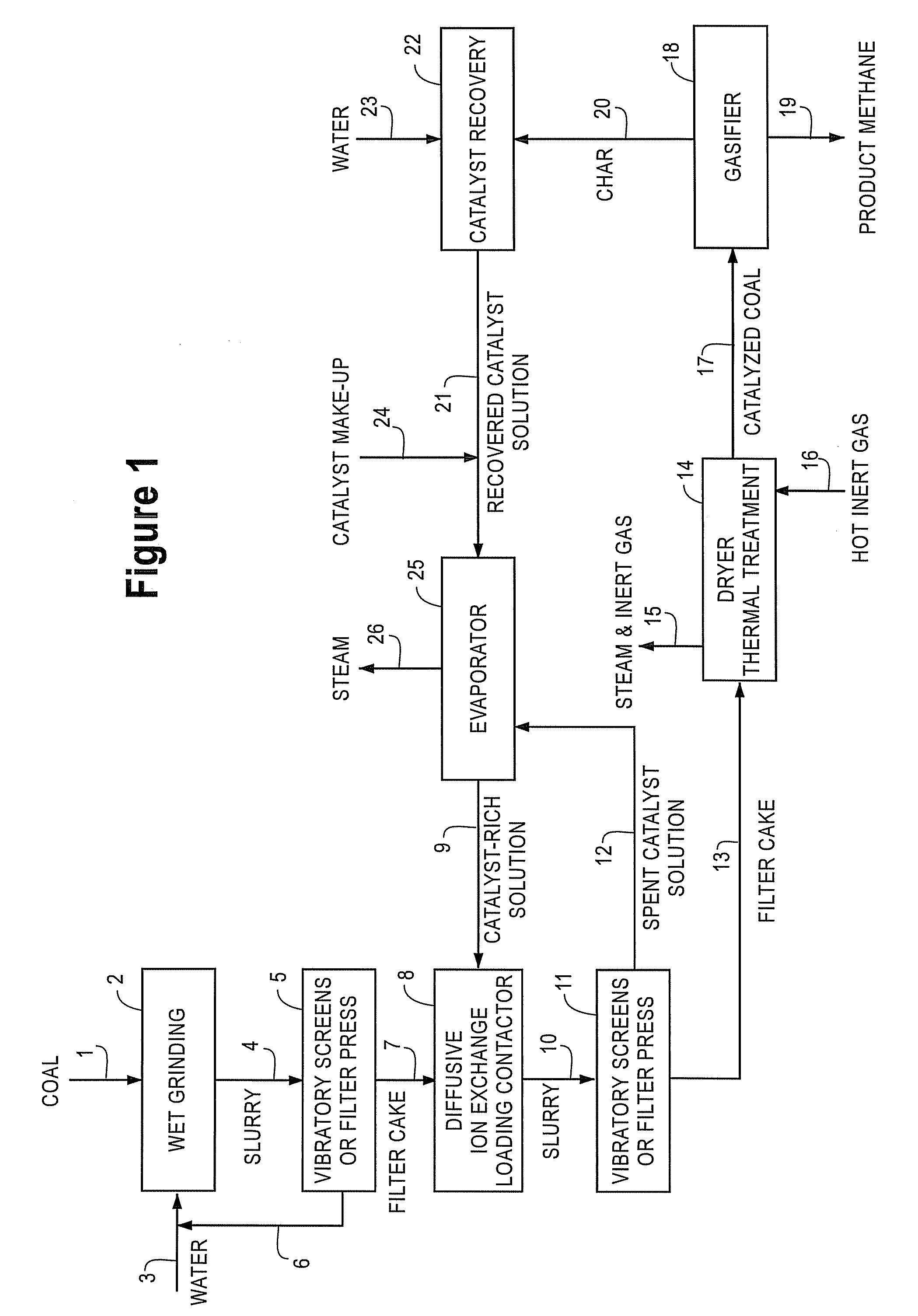

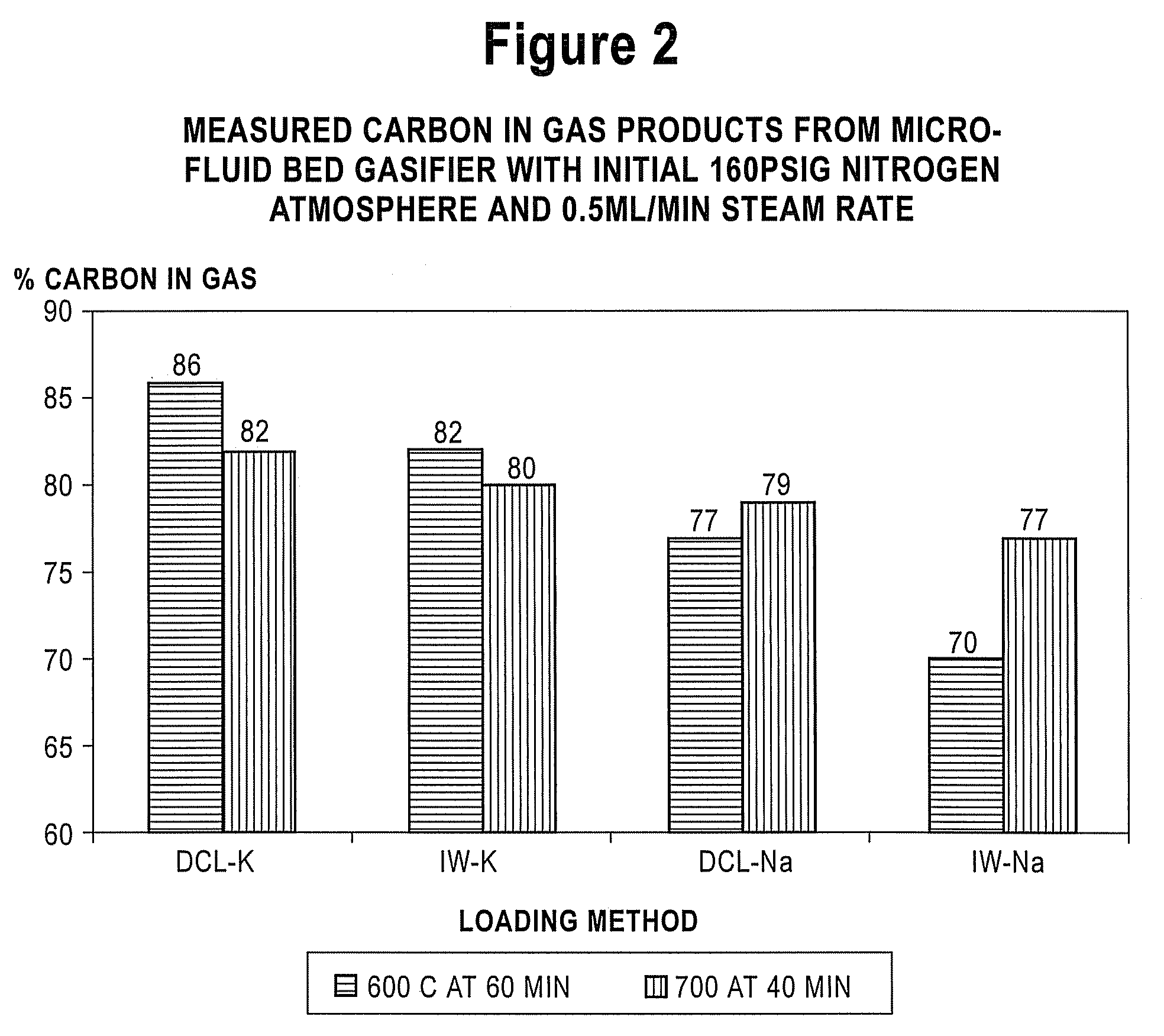

Catalyst-Loaded Coal Compositions, Methods of Making and Use

ActiveUS20090048476A1Efficient and high-yielding gasificationHigh yield productionCatalyst regeneration/reactivationSolid fuelsPtru catalystCoal matrix

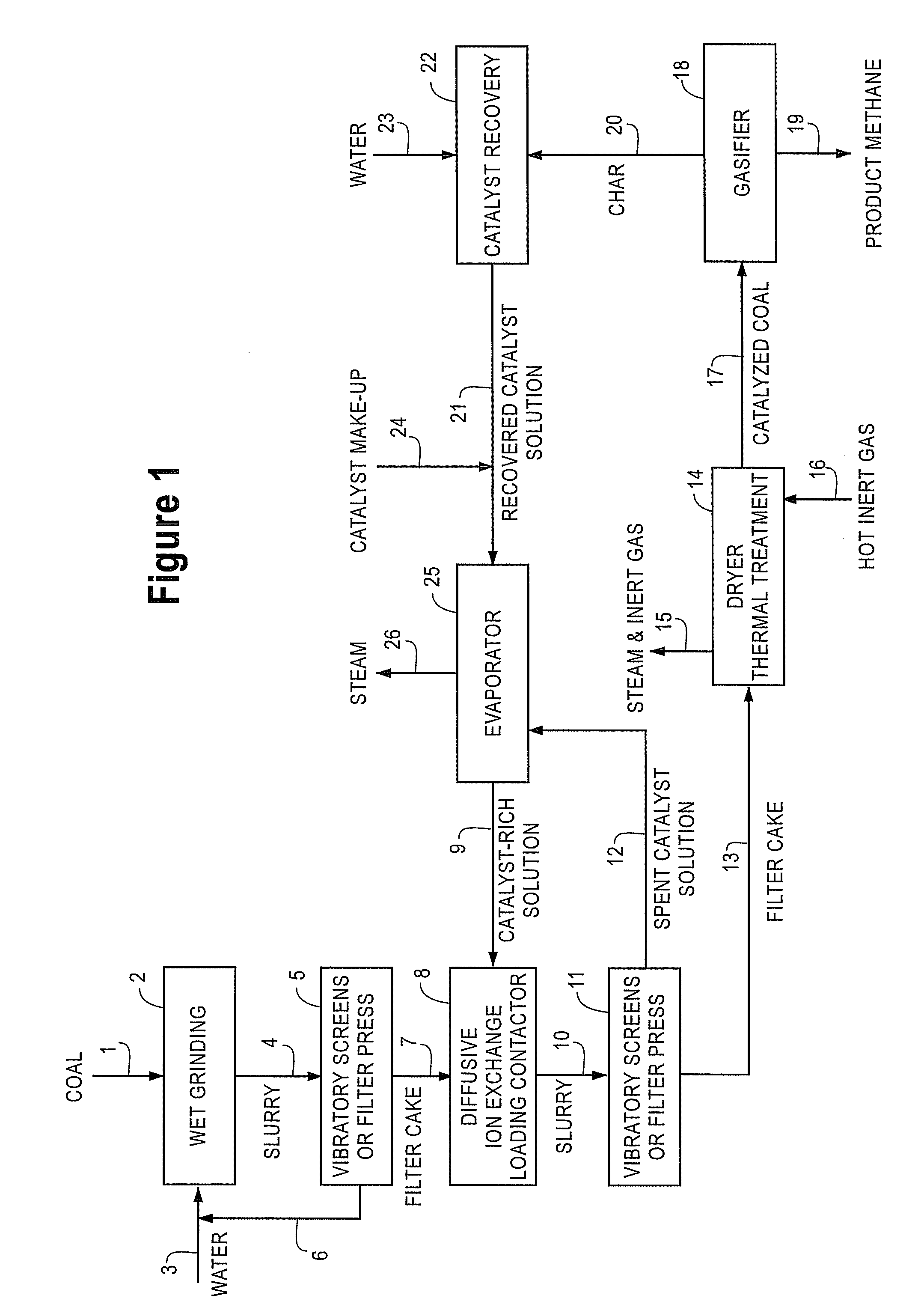

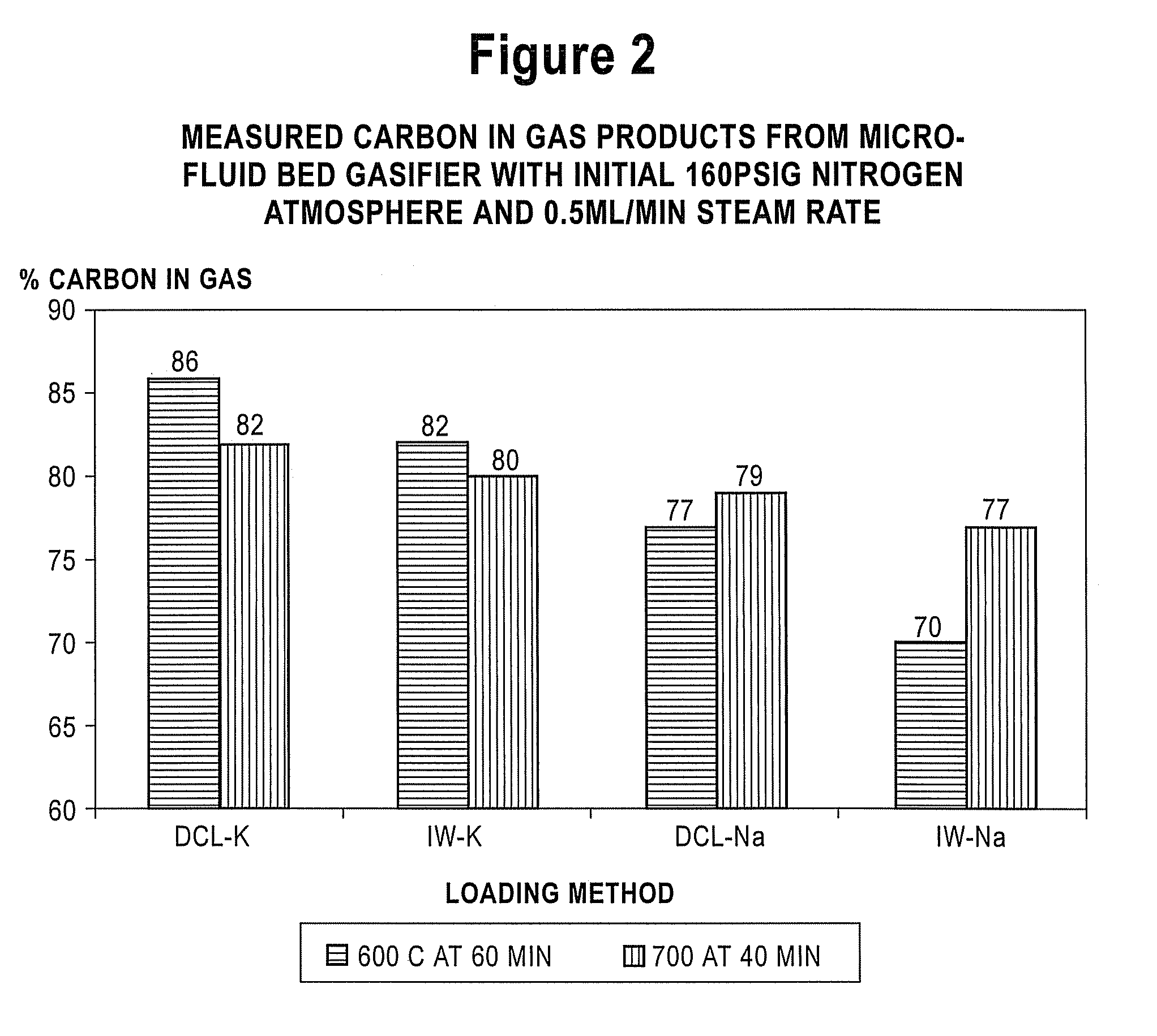

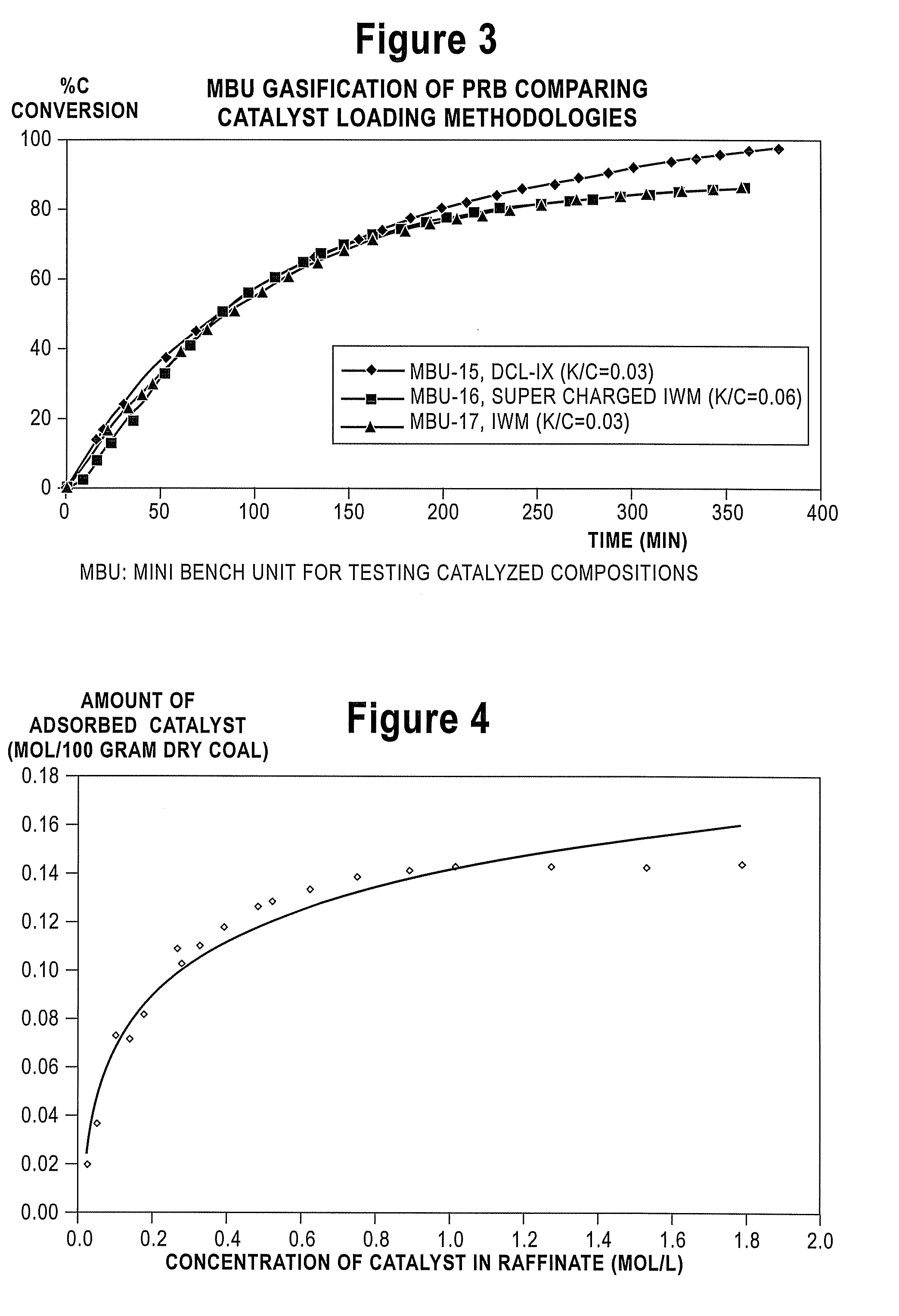

The present invention relates to catalyst-loaded coal compositions having a moisture content of less than about 6 wt %, a process for the preparation of catalyst-loaded coal compositions, and an integrated process for the gasification of the catalyst-loaded coal compositions. The catalyst-loaded coal compositions can be prepared by a diffusive catalyst loading process that provides for a highly dispersed catalyst that is predominantly associated with the coal matrix, such as by ion-exchange.

Owner:SURE CHAMPION INVESTMENT LTD

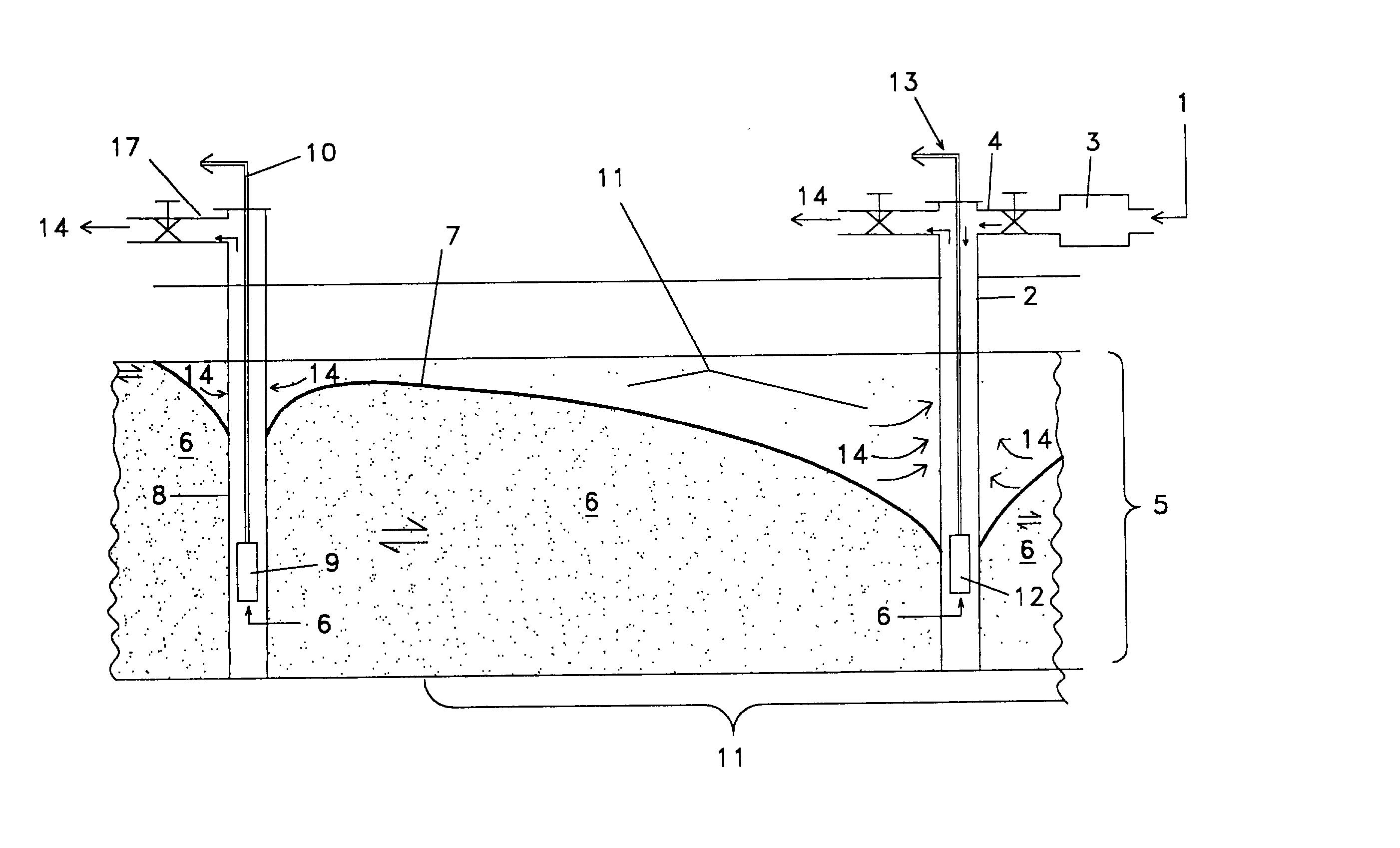

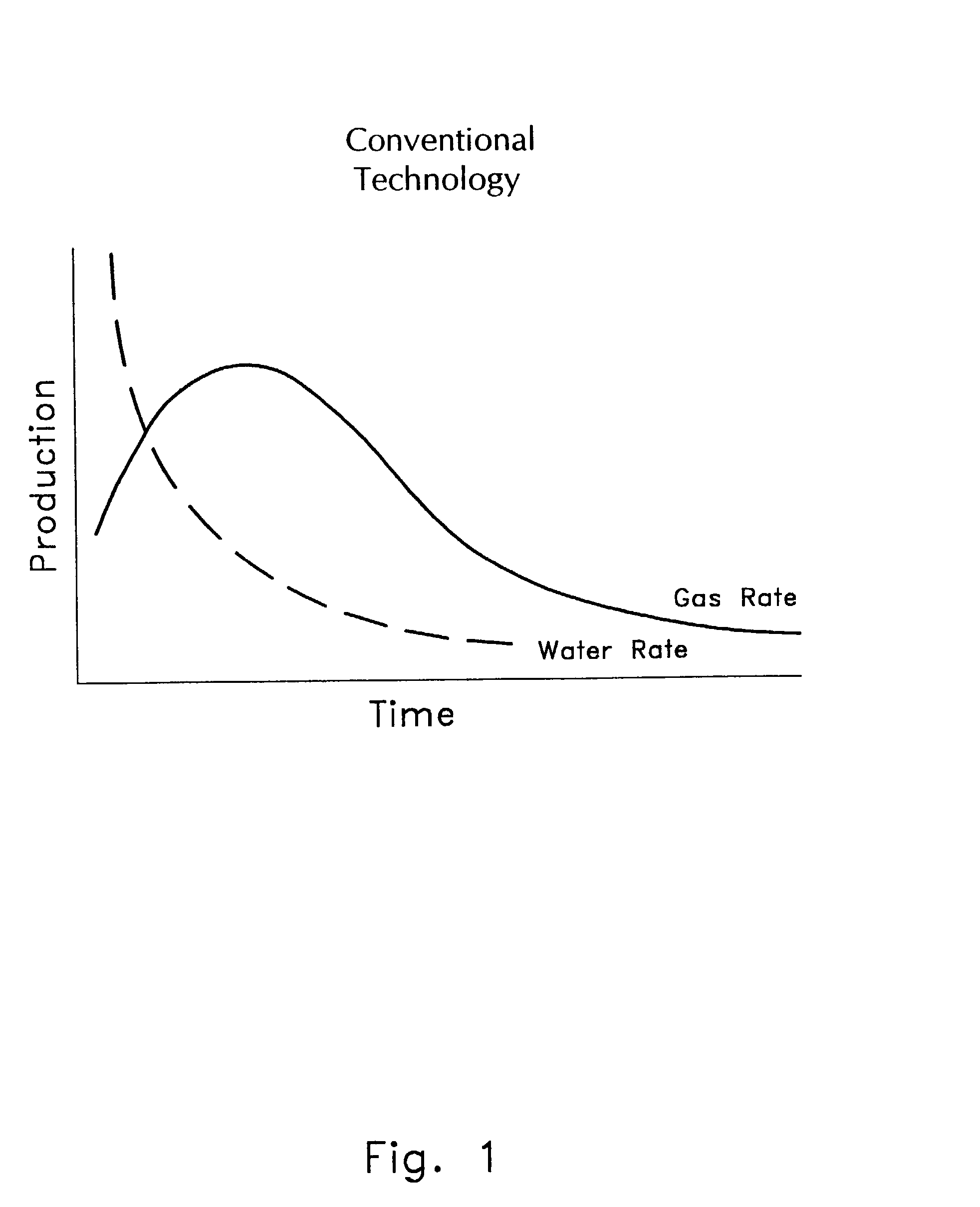

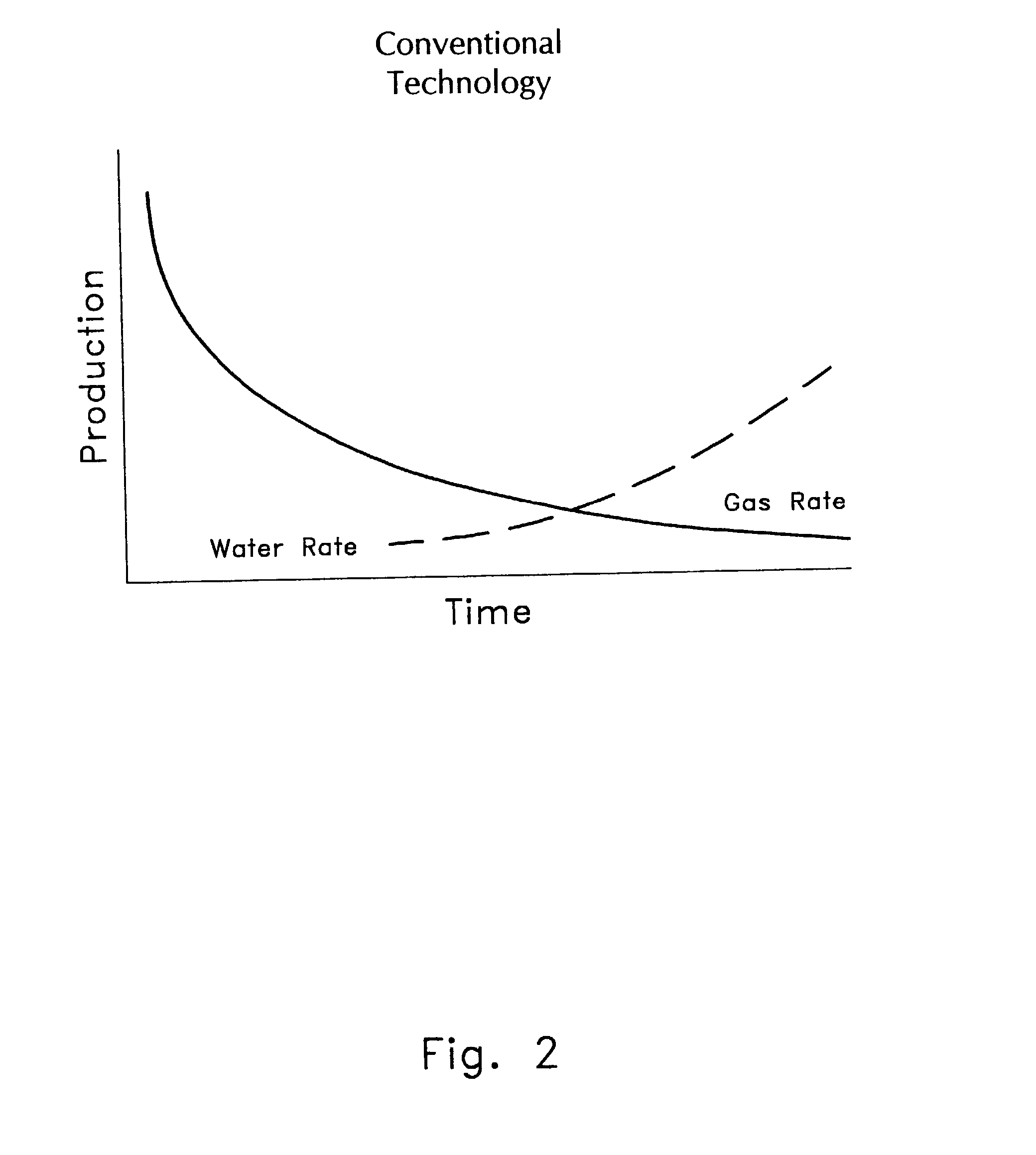

System for improving coalbed gas production

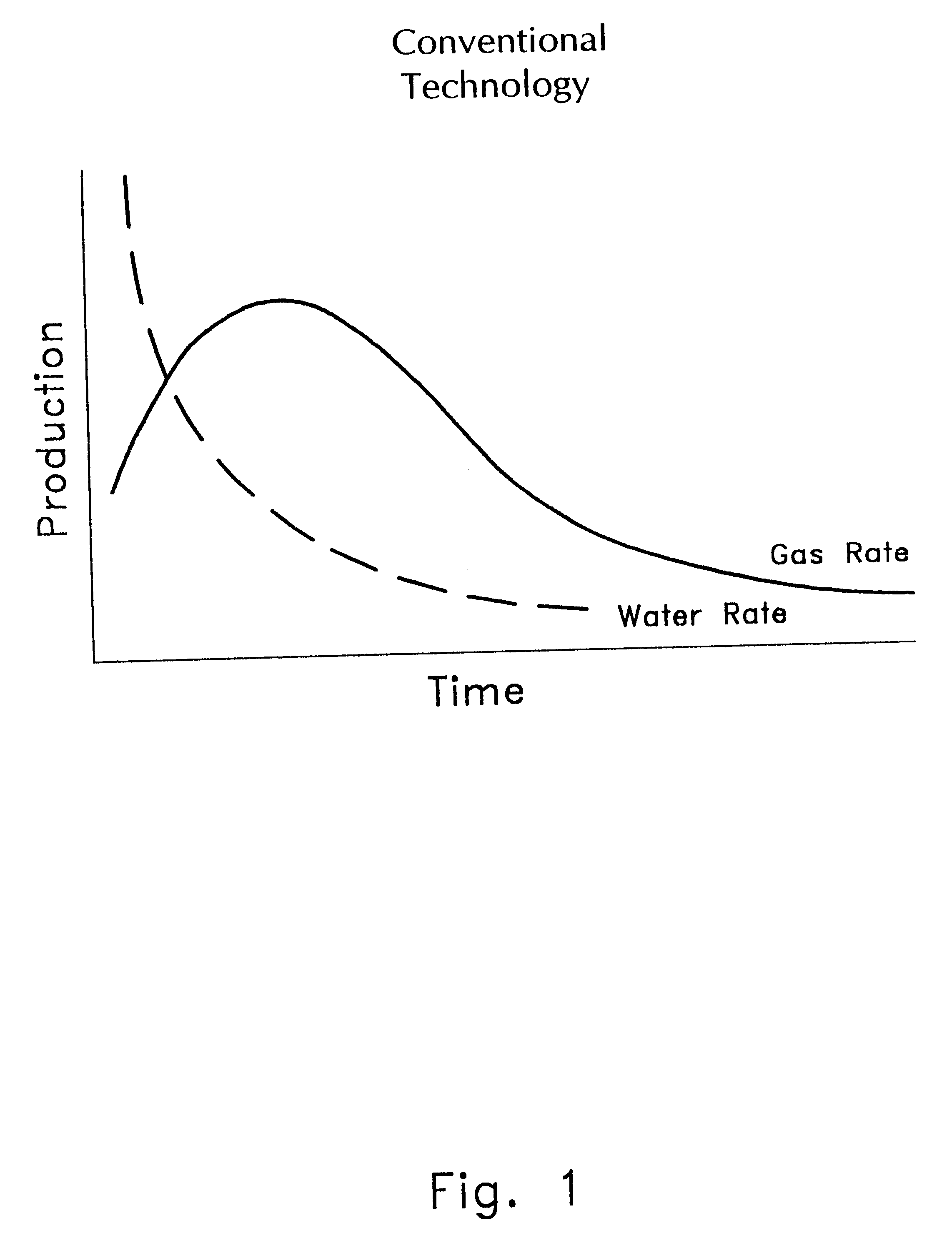

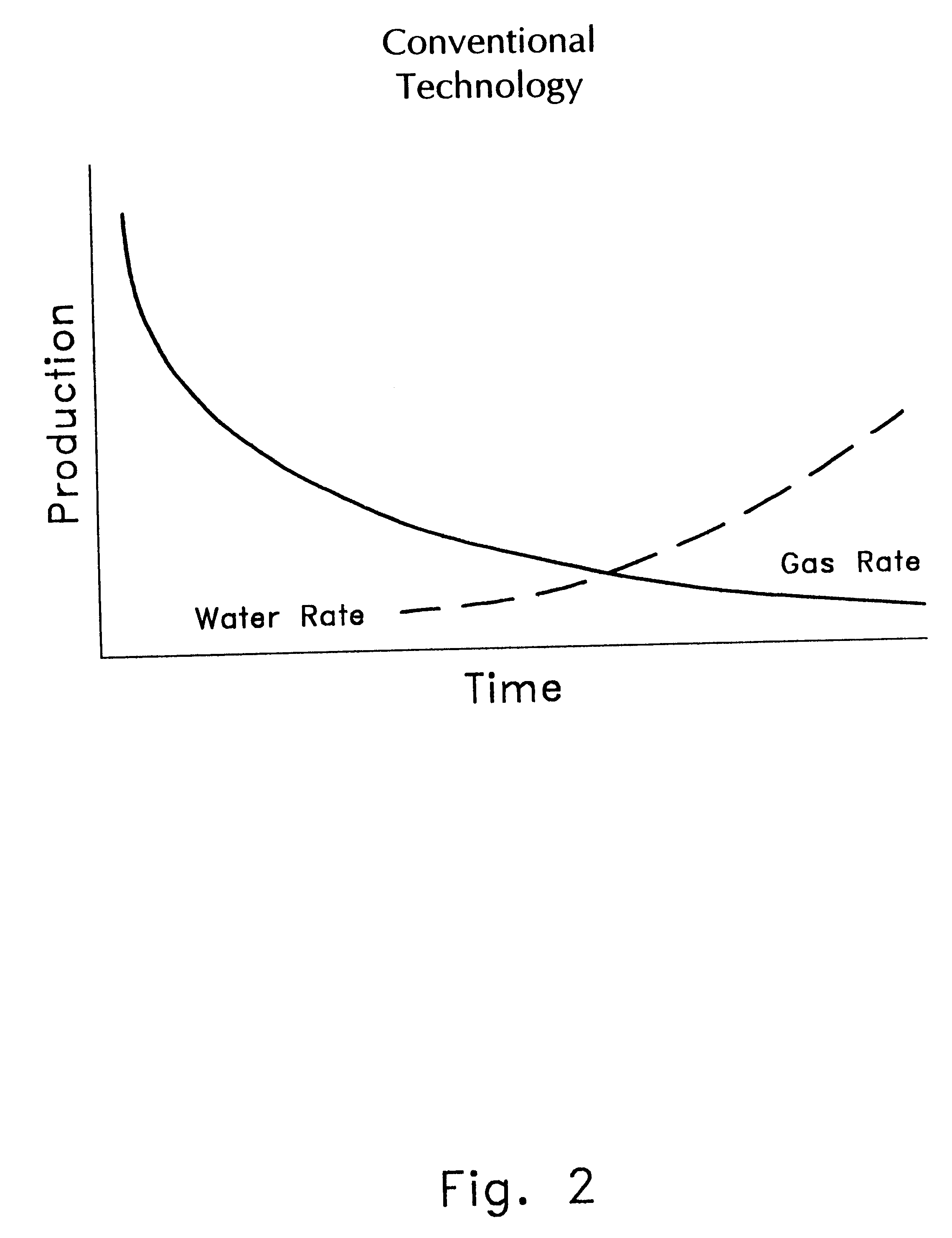

InactiveUS6244338B1Change in permeabilityPromote recoverySurveyDrilling rodsCoal matrixWater production

A method of stimulating coalbed methane production by injecting gas into a producer and subsequently placing the producer back on production is described. A decrease in water production may also result. The increase in gas production and decrease in water production may result from: (1) the displacement of water from the producer by gas; (2) the establishment of a mobile gas saturation at an extended distance into the coalbed, extending outward from the producer; and (3) the reduction in coalbed methane partial pressure between the coal matrix and the coal's cleat system.

Owner:THE UNIVERSITY OF WYOMING RESEARCH CORPORATION DBA WESTERN RESEARCH INSTITUTE

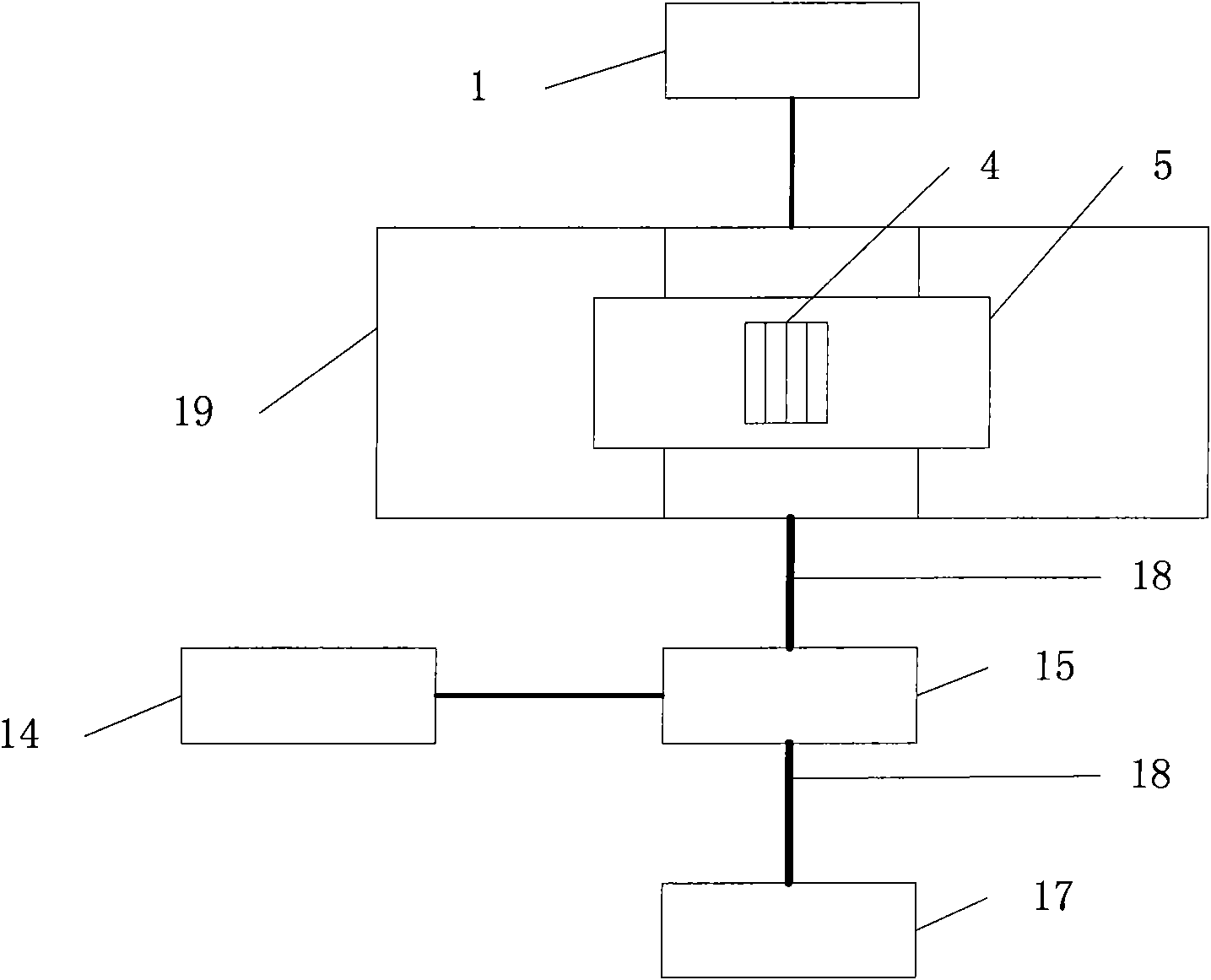

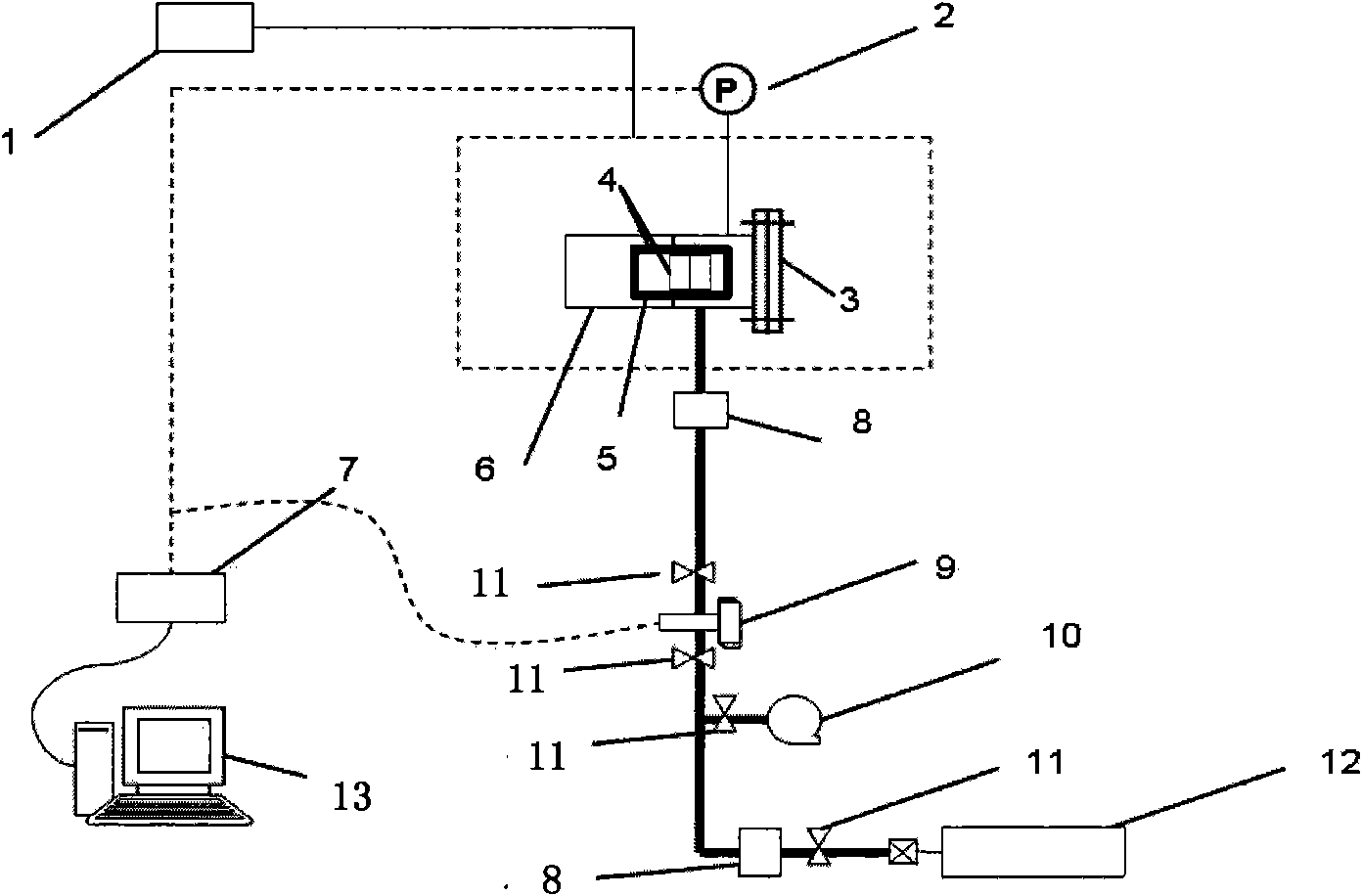

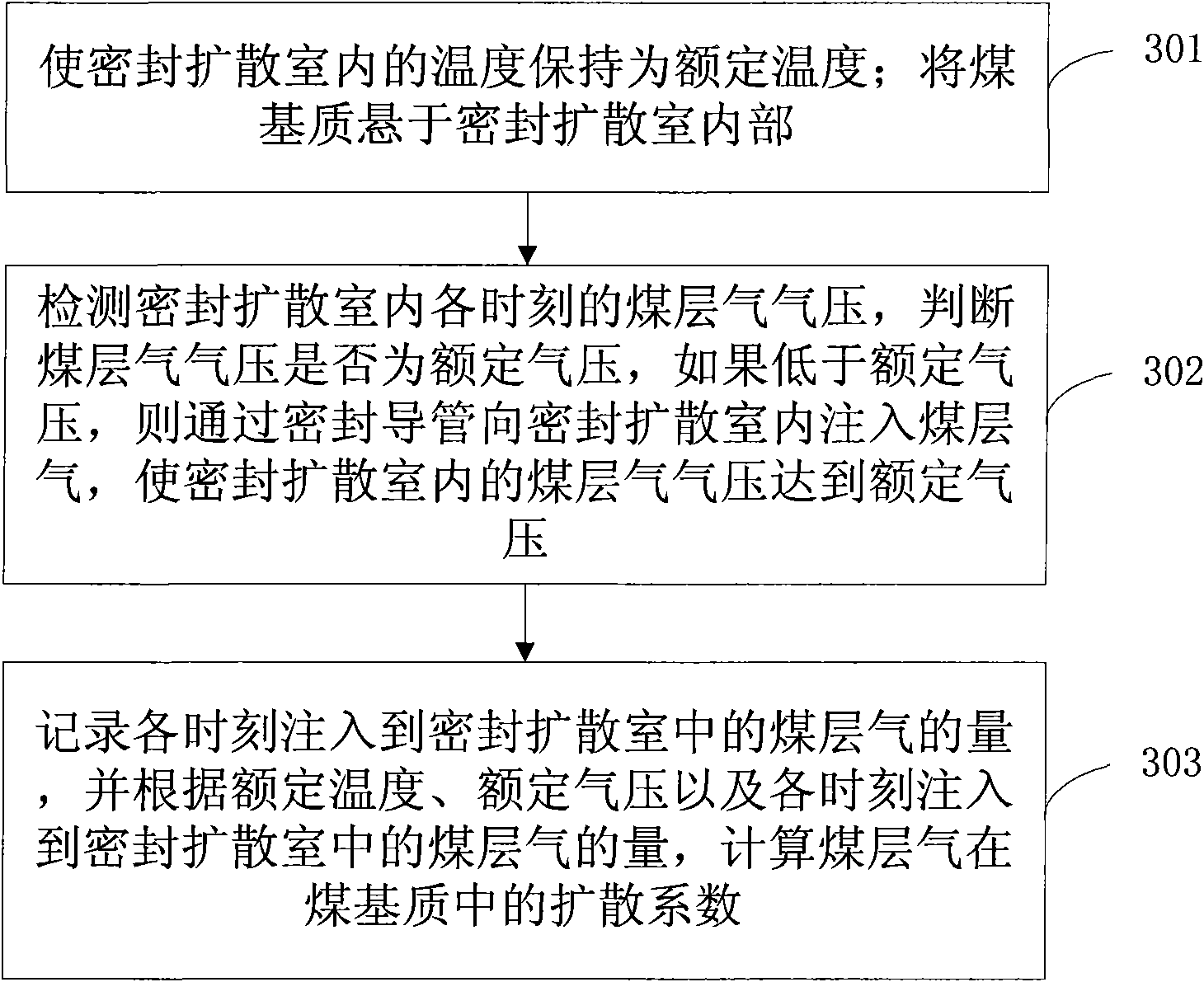

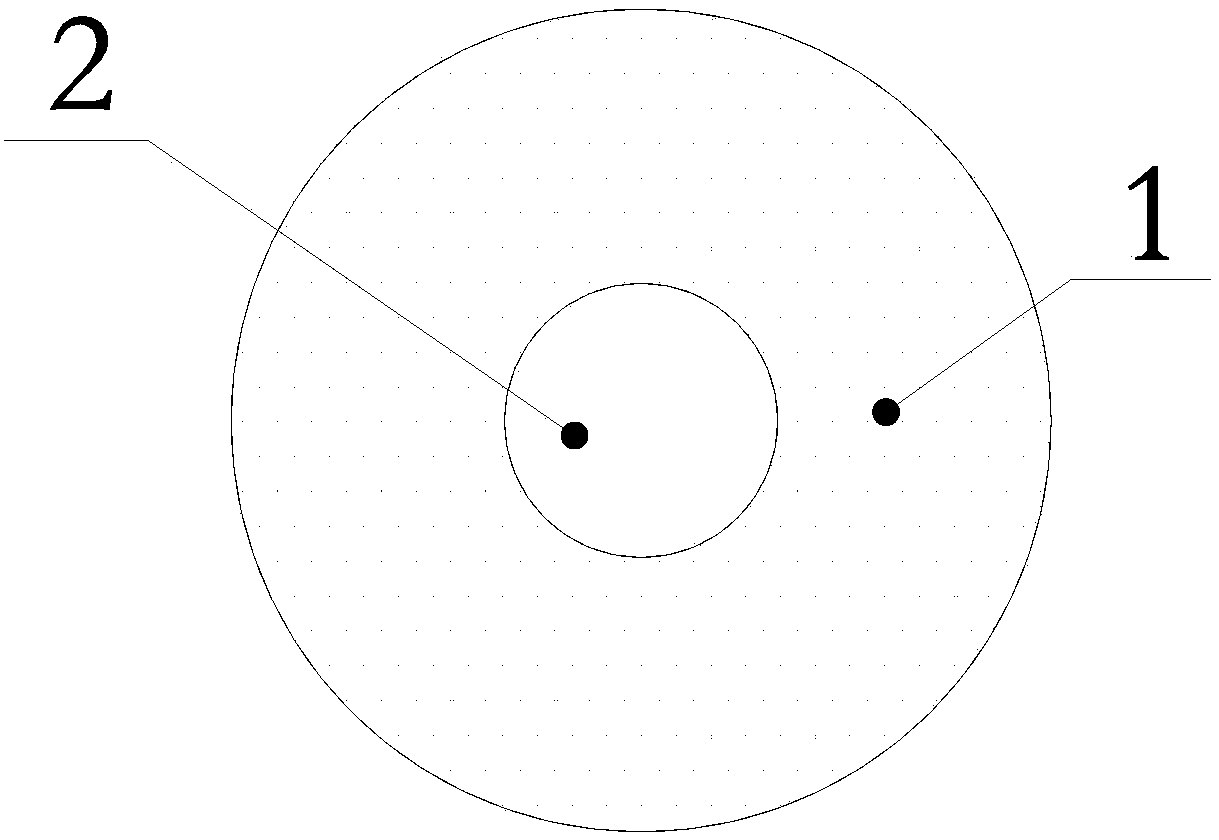

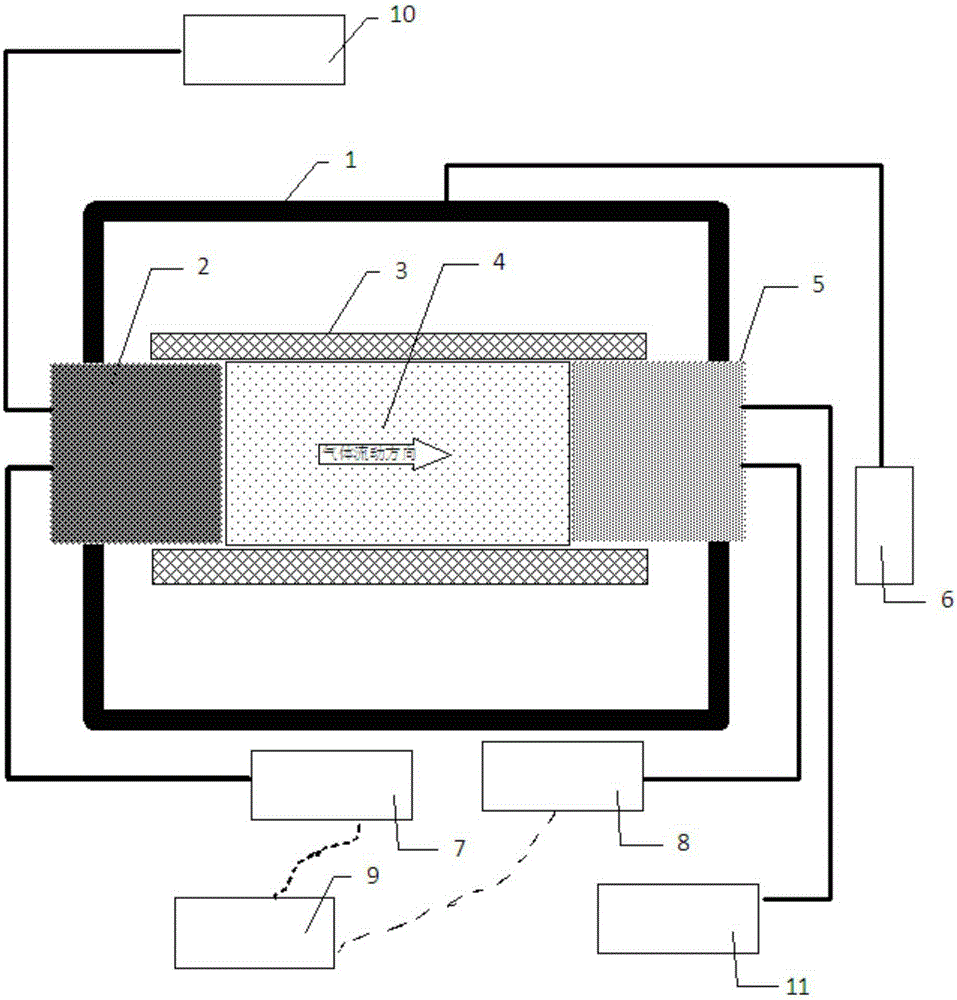

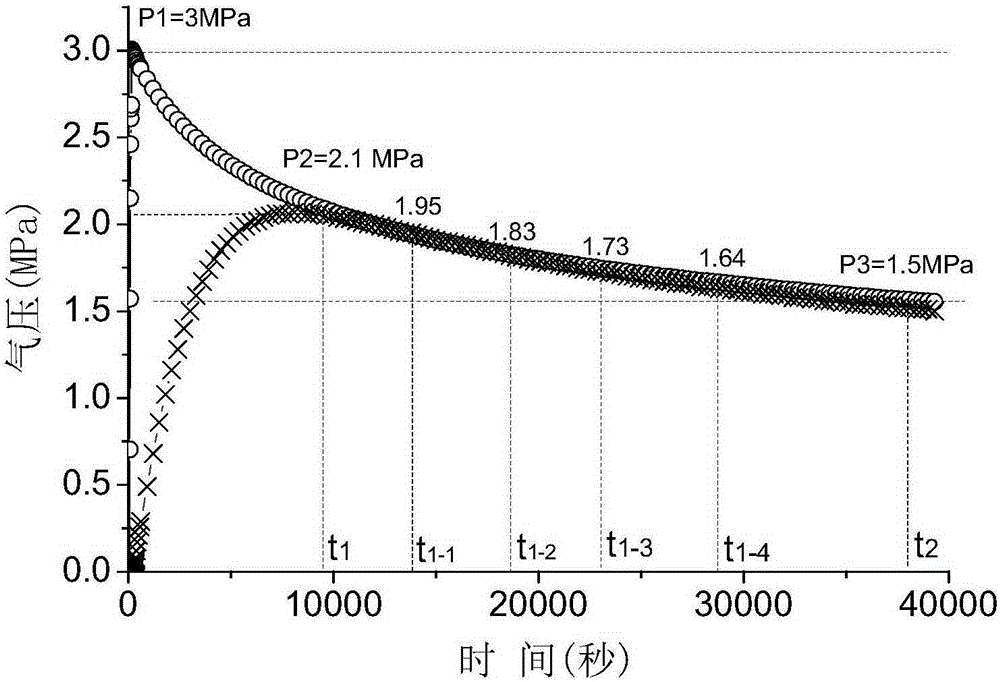

Device and method for detecting diffusion coefficient of coal bed gas in coal matrix

ActiveCN101929939AMaintain spatial structureDiffuse fullySurface/boundary effectDiffusionCoal matrix

The invention discloses a method for detecting diffusion coefficient of coal bed gas in coal matrix. The method comprises the following steps: keeping temperature in a sealed and diffused chamber to rated temperature; suspending coal matrix in the sealed and diffused chamber; detecting the air pressure of coal bed gas at each moment in the sealed and diffused chamber; judging whether the air pressure of coal bed gas is rated air pressure; if the air pressure of coal bed gas is lower than the rated air pressure, injecting the coal bed gas into the sealed and diffused chamber by a sealed conduit to cause the air pressure of coal bed gas in the sealed and diffused chamber to reach the rated air pressure; recording the amount of the coal bed gas injected into the sealed and diffused chamber at each moment; and according to the rated temperature, the rated air pressure and the amount of the coal bed gas injected into the sealed and diffused chamber at each moment, calculating the diffusion coefficient of the coal bed gas in the coal matrix. The technical scheme of the invention can detect the diffusion coefficient of the coal bed gas in the coal matrix, which is much closer to the true value compared with the prior art.

Owner:CHINA UNITED COALBED METHANE NAT ENGRES CENT +1

Catalyst-loaded coal compositions, methods of making and use

ActiveUS8163048B2Efficient and high-yielding gasificationHigh degreeSolid fuelsEnergy inputCoal matrixIon exchange

The present invention relates to catalyst-loaded coal compositions having a moisture content of less than about 6 wt %, a process for the preparation of catalyst-loaded coal compositions, and an integrated process for the gasification of the catalyst-loaded coal compositions. The catalyst-loaded coal compositions can be prepared by a diffusive catalyst loading process that provides for a highly dispersed catalyst that is predominantly associated with the coal matrix, such as by ion-exchange.

Owner:SURE CHAMPION INVESTMENT LTD

Method for enhancing methane production from coal seams

InactiveUS20050082058A1Reduce effective stressEnhancing fracture void volumeFluid removalCoal matrixMethane production

Discloses a three step process to stimulate well production of methane from coal seams, wherein step one provides for injection of a treating gas into a well bore intersecting a coal seam, step two includes a shut-in period and step three comprises the placement of a propped fracture treatment. In step one, the injection of the treating gas physically opens pre-existing paths of weakness in the coal. As the treating gas travels along these planes of weakness, it preferentially adsorbs onto the coal and displaces the methane. This displacement process induces shrinkage of the coal matrix, which further increases the size of the intervening existing fractures. The second step, or shut-in period, allows time for this gas exchange process to substantially complete, thereby maximizing the effect of matrix shrinkage and enhancement of the intervening fractures. The third step provides for placement of a propped fracture treatment into this enhanced fracture system. Propping of the enhanced fractures ensures that they remain open, even as removal of water and methane work to close the fractures by increasing effective stress within the coals. The result is a stimulated coal seam that maintains enhanced permeability during production operations.

Owner:BUSTIN ROBERT MARK +1

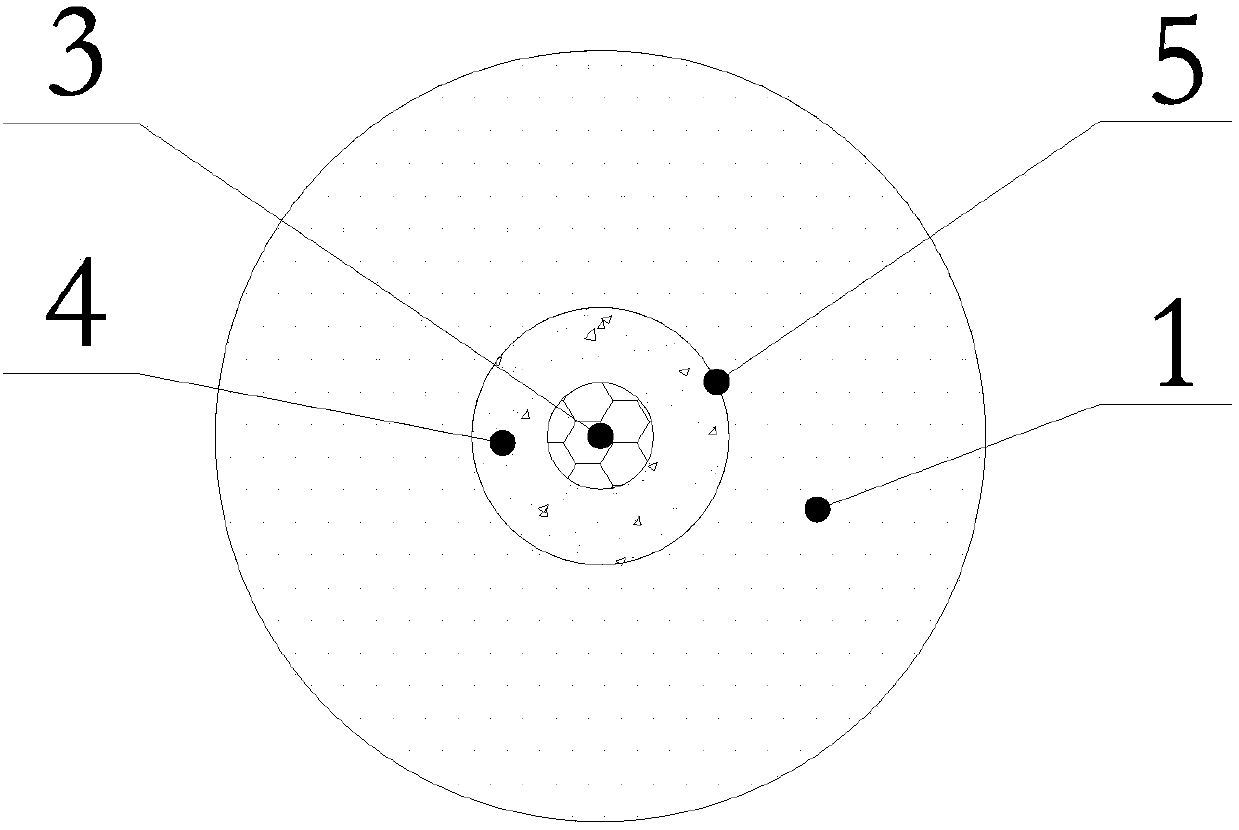

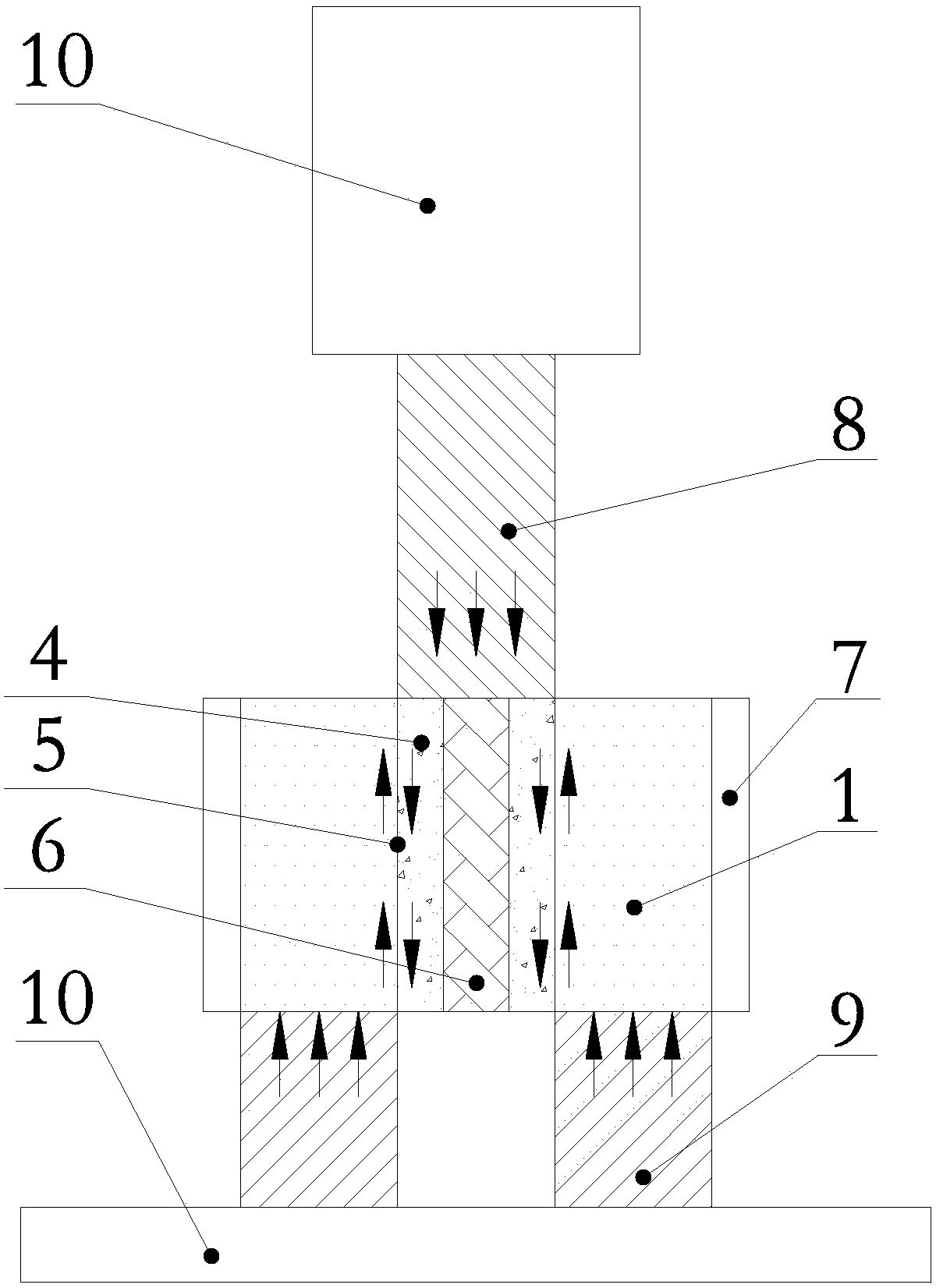

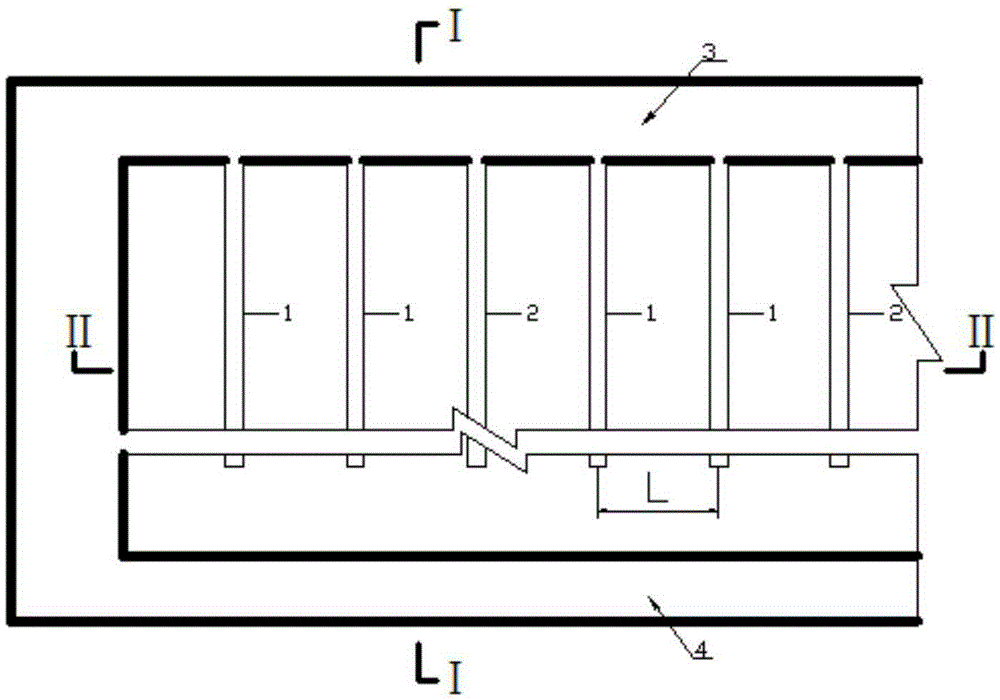

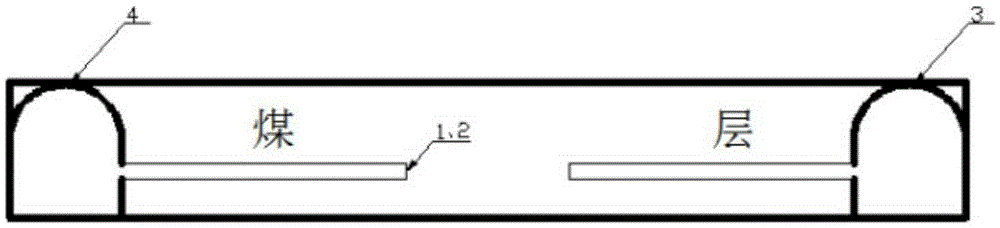

Coal body and anchoring agent interface bonding strength testing method

ActiveCN107843553AEfficient simulation of squeeze situationsAvoid situations that are difficult to process into specimensUsing mechanical meansMaterial analysisCoal matrixAtmospheric pressure

The invention discloses a coal body and anchoring agent interface bonding strength testing method. The method is characterized in that according to coal body existing conditions, a coal matrix (1) iscompacted, a through hole (2) is formed at middle of the coal matrix (1), an elastic circular column (3) is placed at the middle of the through hole (2), an anchoring agent cylinder (4) is formed by injecting an anchoring agent in the through hole (2), the elastic circular column (3) is subjected to pneumatic compression, after the anchoring agent is completely acted while a certain air pressure is kept, the elastic circular column (3) is changed to a rigid cylinder (6), two ends of the through hole (2) are plugged to form a test piece, then the test piece is placed on a servo press (10), an aperture same with the through hole (2) is placed at a lower part of the test piece, the aperture is aligned with the through hole (2), a pressure head (8) is a cylinder having a same diameter with theanchoring agent cylinder (4), the pressure head (8) is lowered for testing the bonding strength, and finally data is collected for analysis. The real coal body is taken as an anchoring matrix, and the testing result is more close to on-site condition.

Owner:CHINA UNIV OF MINING & TECH

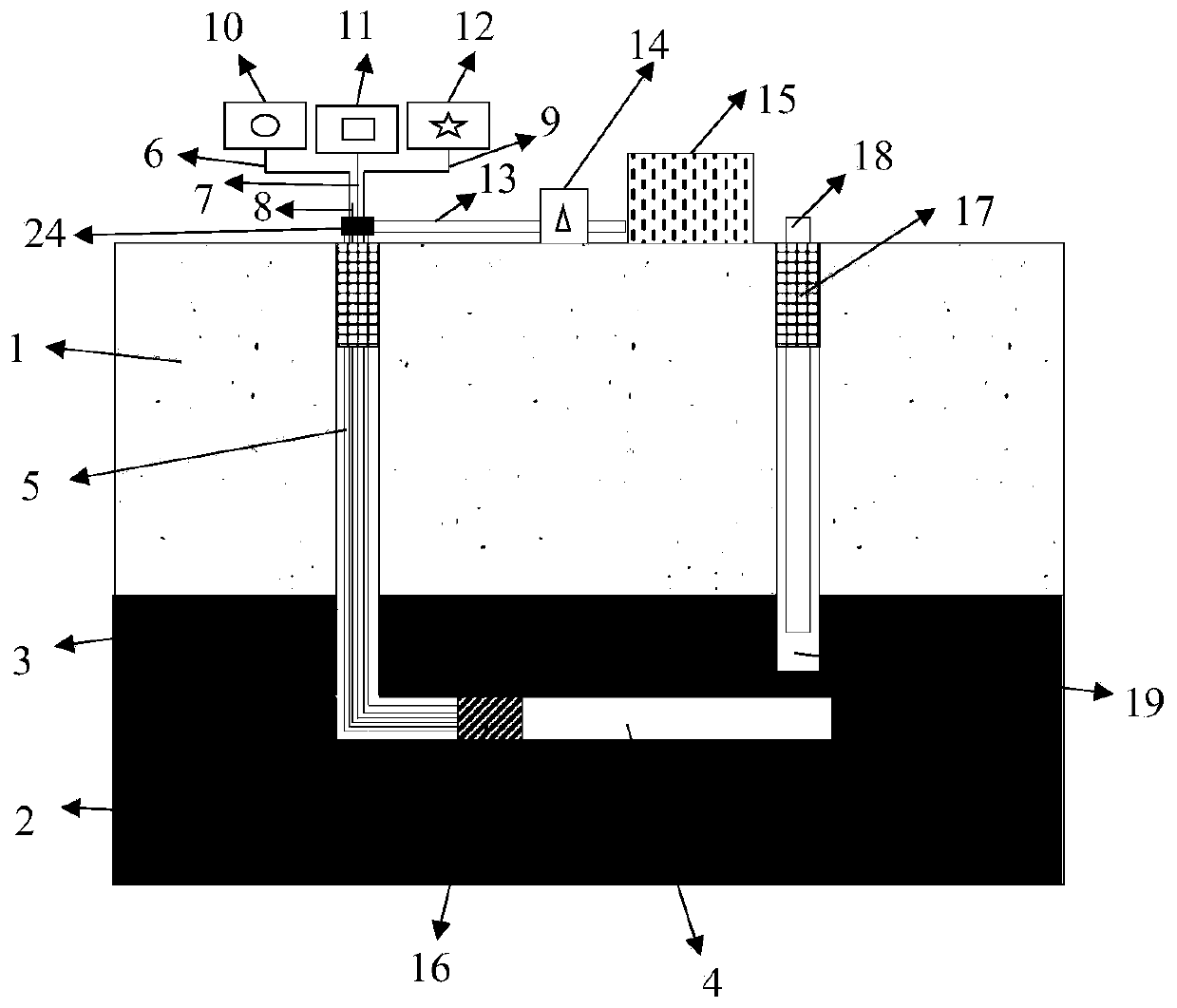

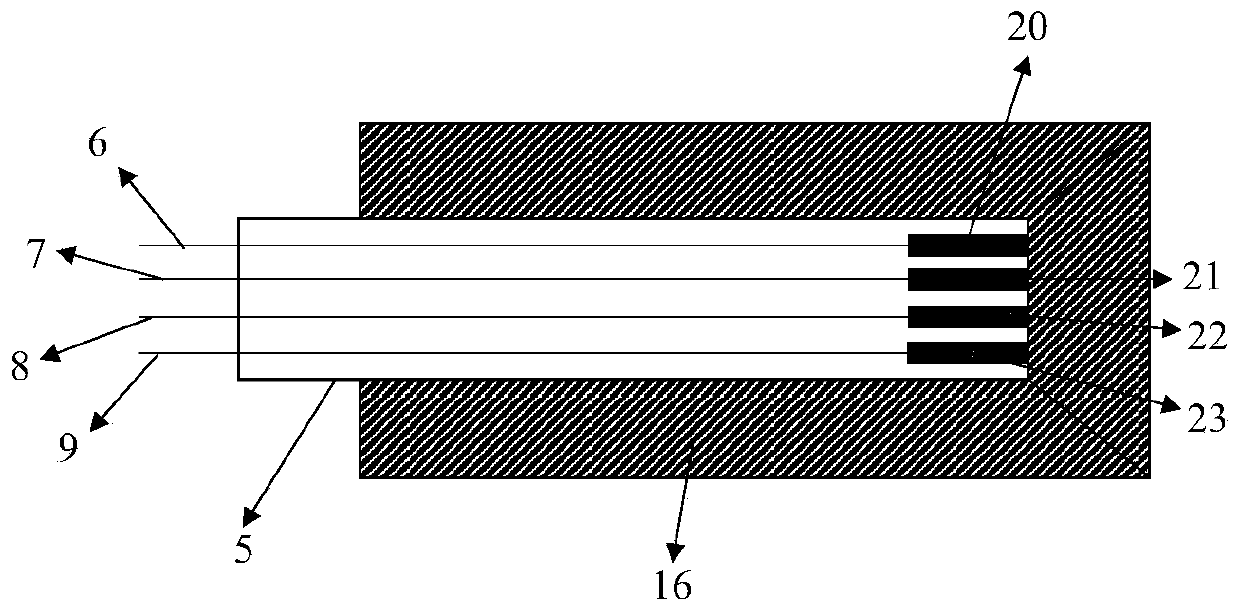

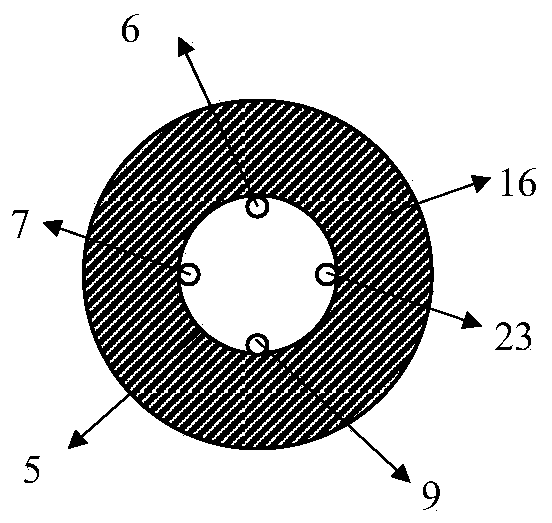

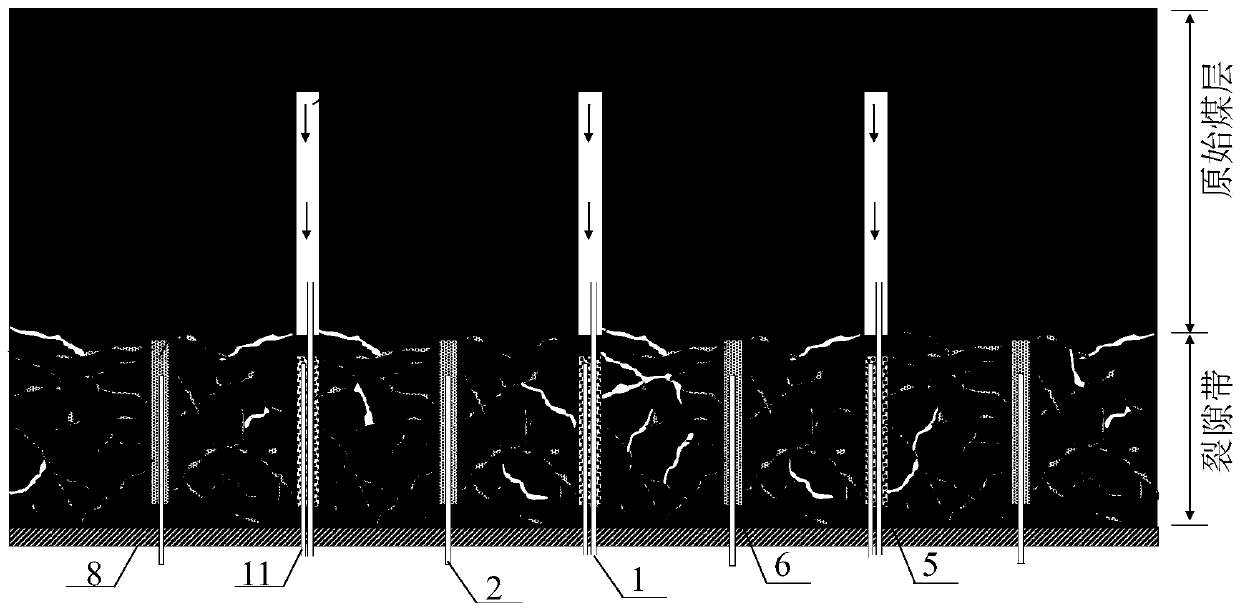

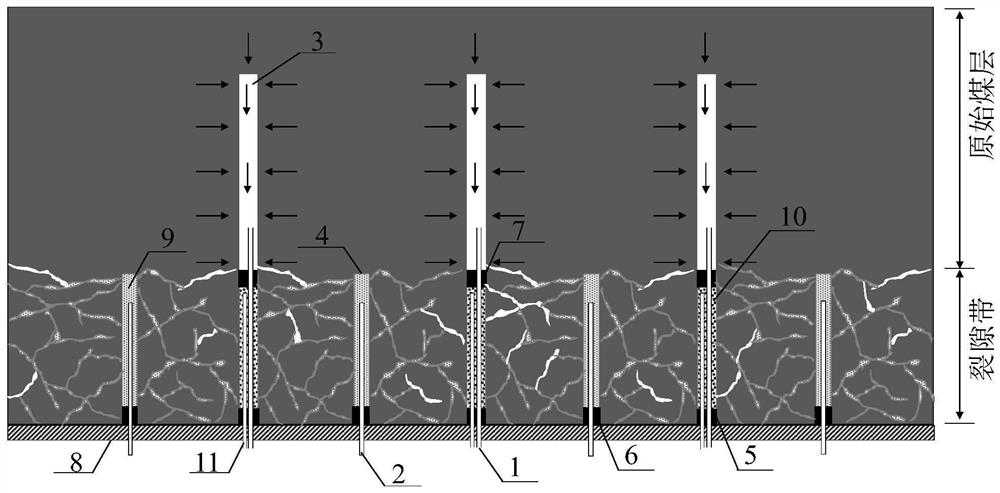

Method for mining coal seam gas

InactiveCN102587958ABreakthrough drainage is affected by the complex constraints of geological structureImprove the extraction effectGas removalCoal matrixCoal

The invention discloses a method for mining coal seam gas, belonging to the field of coal seam gas mining. The method comprises the steps of: drilling a gas injection hole downwards from the ground; injecting gas into the gas injection hole; displacing the coal seam gas by the injected gas; drilling an underground pumping hole; and pumping the coal seam gas from the underground pumping hole. Through the method provided by the invention, the gas injection has a large influence range, effects are exerted on adjacent and non-adjacent drilled holes, and the coal seam gas in coal seams can be displaced to ensure that the coal seam gas adsorbed on the inner surfaces of coal matrix holes are changed from an adsorbed state to a detached state, so that the pumping effect of the coal seam gas is improved.

Owner:山西蓝焰煤层气工程研究有限责任公司

Test method for coal matrix deformation mechanical parameters

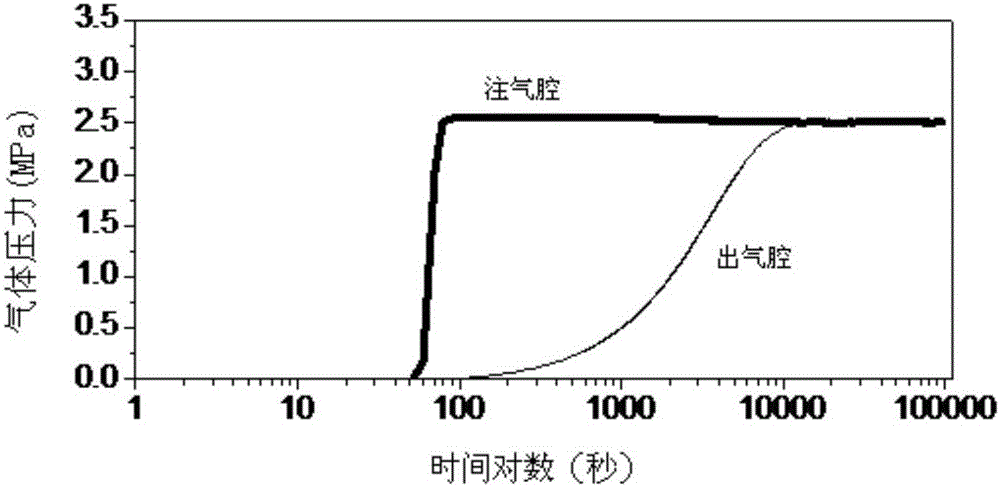

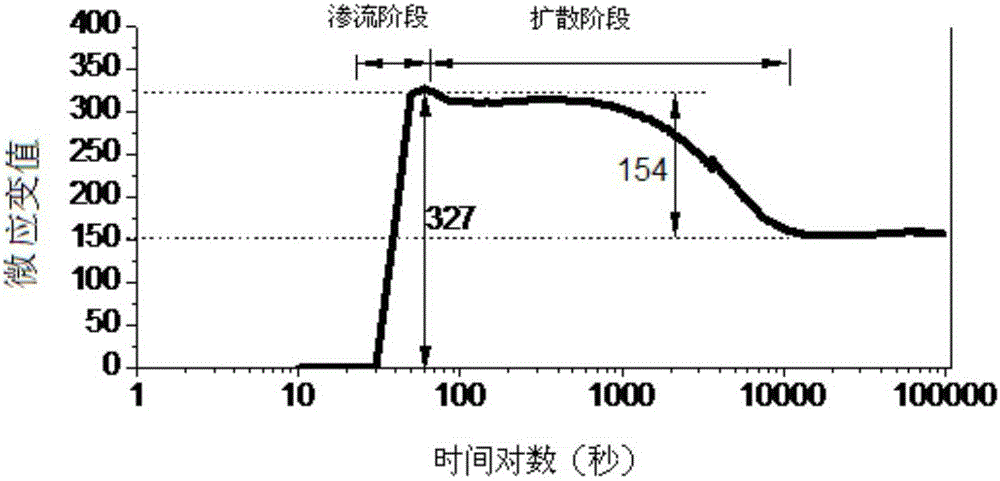

The invention discloses a test method for coal matrix deformation mechanical parameters. A coal sample test piece is placed into a closed clamping chamber body, a gas injection cavity and a gas outlet cavity are formed in two ends of a coal sample respectively, helium is guided into the gas injection cavity, the helium is firstly seeped into a coal fracture and then start to diffuse into a coal matrix, relations of a pressure value and a strain value as well as log time are drawn into graphs respectively, and a strain value and a fracture pore pressure value at the end of seepage and a strain value at the end of diffusion are obtained according to the graphs; finally, the coal matrix volume modulus in the seepage stage and the pore pressure variation in the matrix in the diffusion stage are calculated. A test method for deformation parameters of coal in all directions under the triaxial stress state condition is provided aiming at the high adsorption characteristic of coal-seam gas and considering the effect of pore pressure to a coal pore structure in the flowing process of gas and the effect of coal matrix deformation to permeability, and a new research means is provided for in-depth study of a coal-gas coupling problem.

Owner:SHANDONG UNIV OF SCI & TECH

Broken and soft low-permeability coal bed horizontal well staged fracturing technology

InactiveCN104863562AImprove buried depthImprove heterogeneityFluid removalPrincipal stressCoal matrix

The invention belongs to the coal-bed gas well fracturing motivation technology, and particularly relates to a broken and soft low-permeability coal bed horizontal well staged fracturing technology. The broken and soft low-permeability coal bed horizontal well staged fracturing technology aims at improving the broken and soft low-permeability coal bed mining benefits and adopts the fracturing technology mode that sealing and fracturing are carried out section by section. The previous sealed section produces induction stress for the fracture initiation of the rear fracturing section. By optimizing the sectioning distance, the maximum horizontal principal stress difference caused by coal reservoir burial depth, heterogeneity and aeolotropism is improved, the manual fracture initiation direction and natural fracture initiation included angle are enlarged, coal bodies can form joint nets more easily, natural fractures are communicated, and the fracture complexity degree is improved; different kinds of pressure are distributed for different sections, the contact area between the fracture wall face and the coal matrix face is enlarged, a complex crossed fracture network system is built finally, the seepage distance from the coal matrix in any direction to the fracture is the shortest, and the low-permeability coal reservoir can achieve economic output.

Owner:山西蓝焰煤层气集团有限责任公司 +2

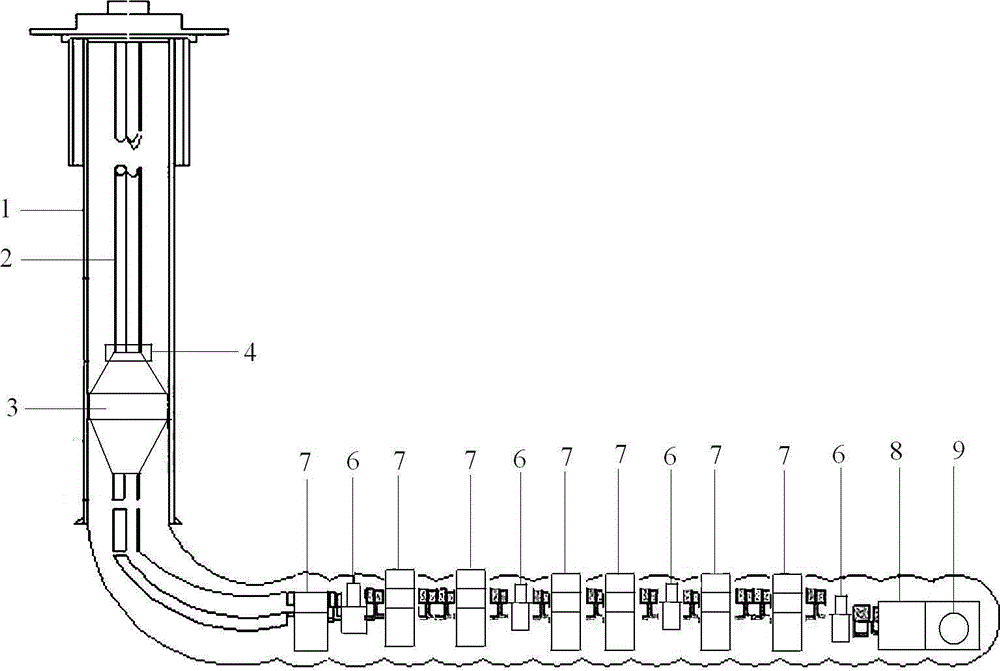

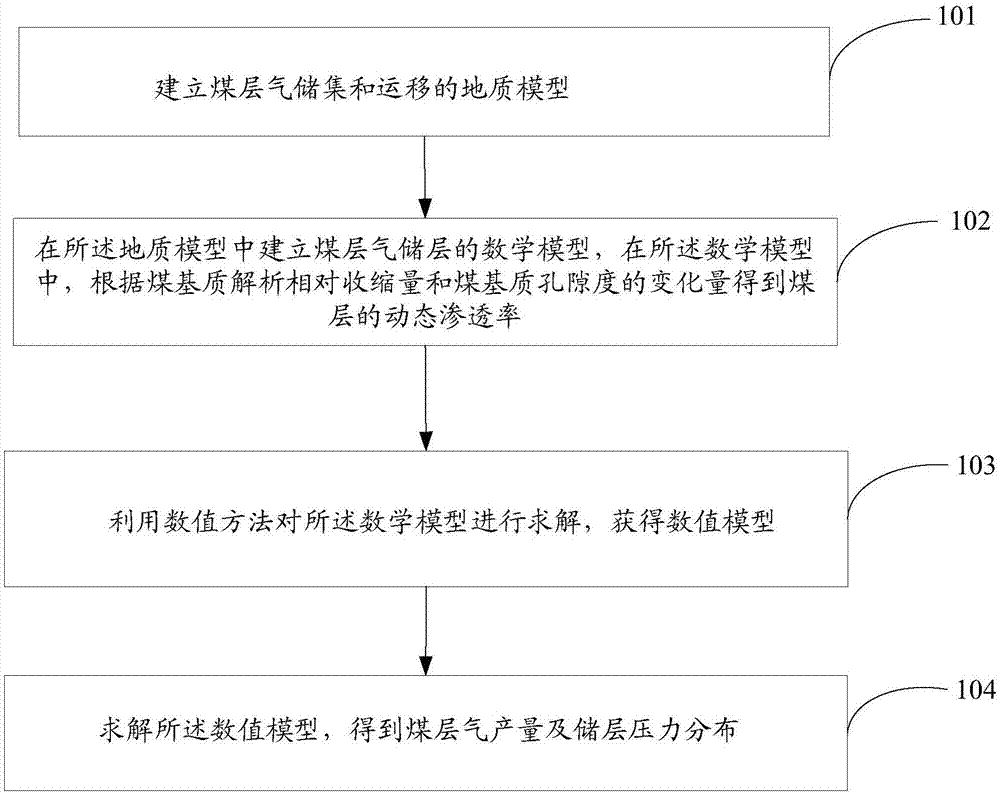

Coal bed gas yield forecasting method

The invention discloses a coal bed gas yield forecasting method which comprises the following steps: establishing a geological model for coal bed gas storage and migration; establishing a mathematical model of a coal bed gas reservoir in the geological model and obtaining the dynamic permeability of a coal bed according to the relative shrinkage of coal matrix desorption and the variation of coal matrix porosity in the mathematical model; solving the mathematical model by utilizing a numerical method to obtain a numerical model; solving the numerical model to obtain coal bed gas yield and reservoir pressure distribution. The coal bed gas yield forecasting method disclosed by the invention has the benefits that through comprehensive improvement in coal fissure compression factors and coal volume shrinkage factors, the accuracy of the forecasting method is improved; further, the influence of pulverized coal in a near well zone is considered, the pulverized coal in the near bore zone is converted into coal powder pollution skin, and the coal bed gas yield forecasting method is suitable for a coal bed gas well in which the pulverized coal is easy to go out, and geological conditions are not clearly understood.

Owner:CHINA NAT OFFSHORE OIL CORP +1

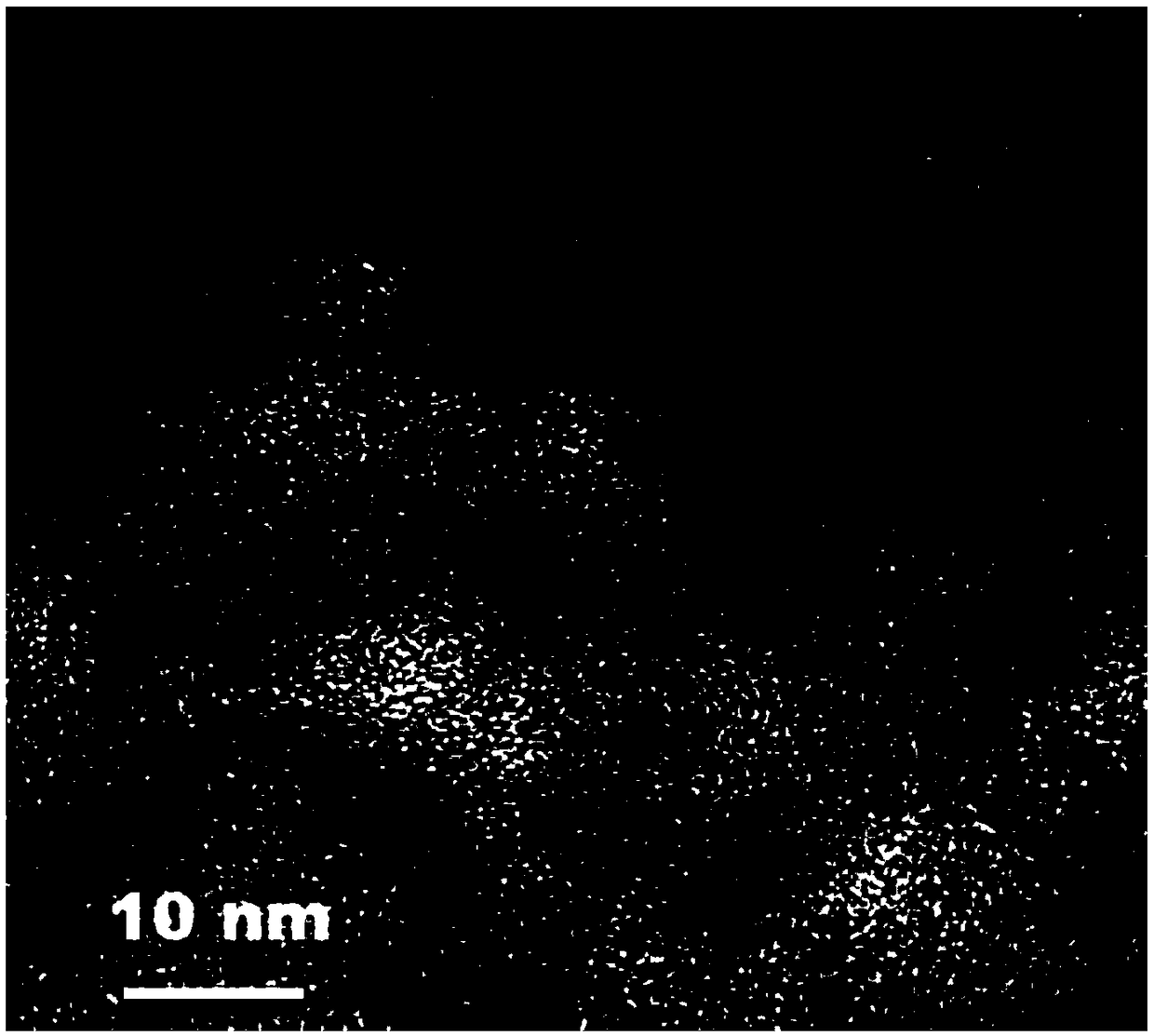

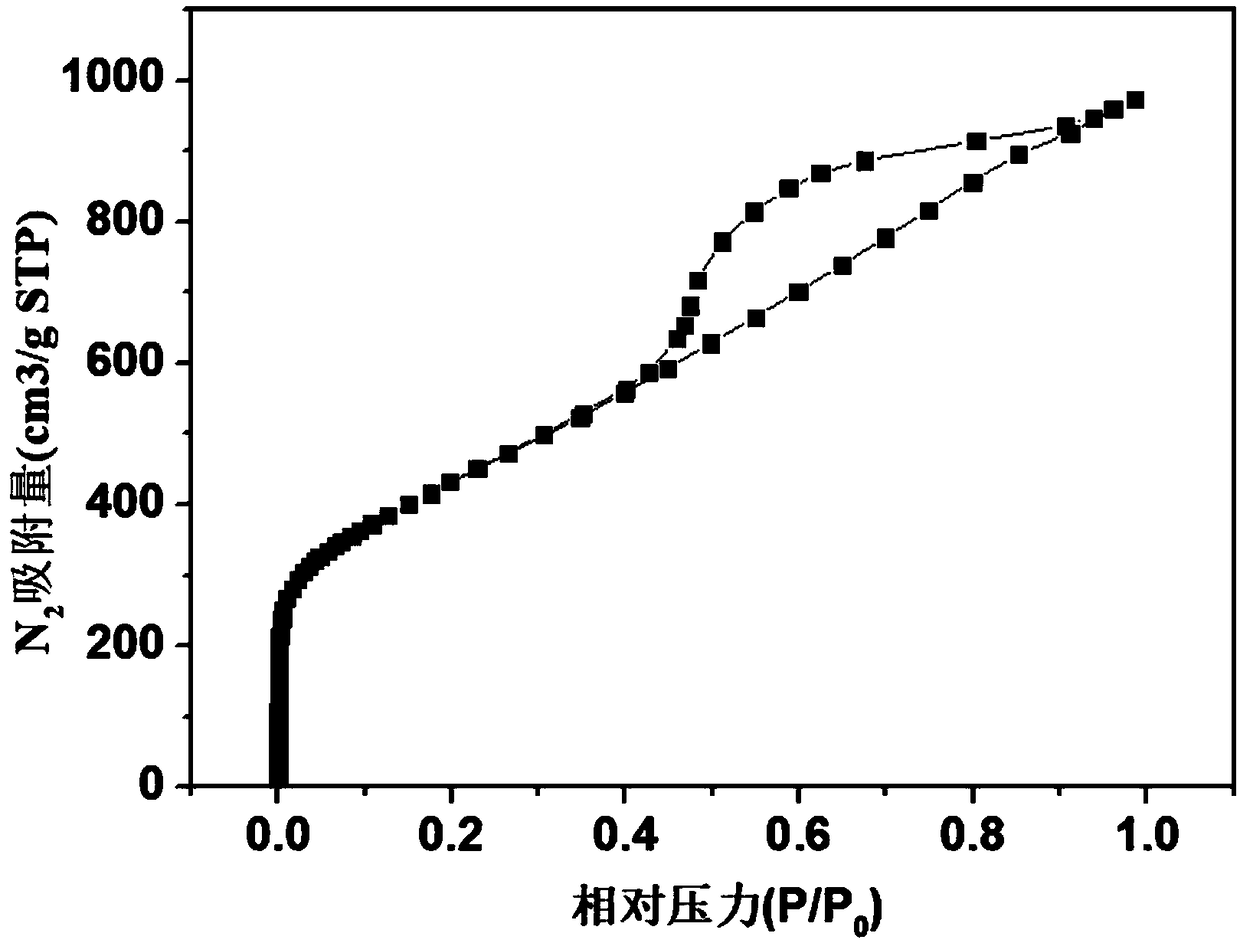

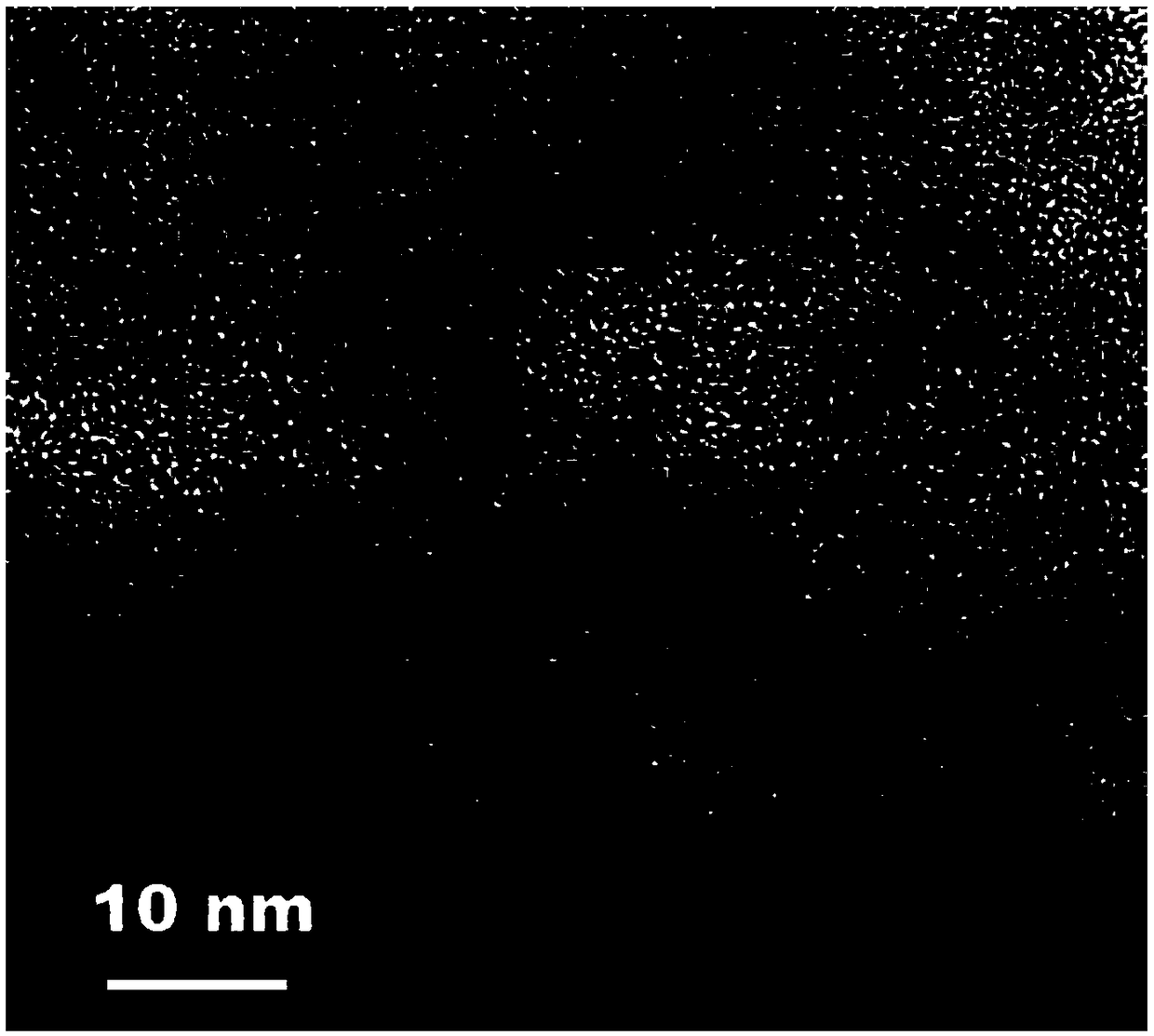

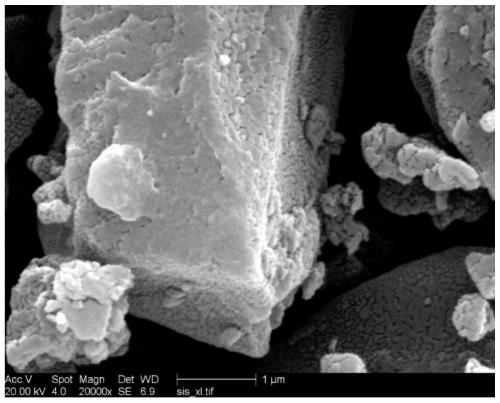

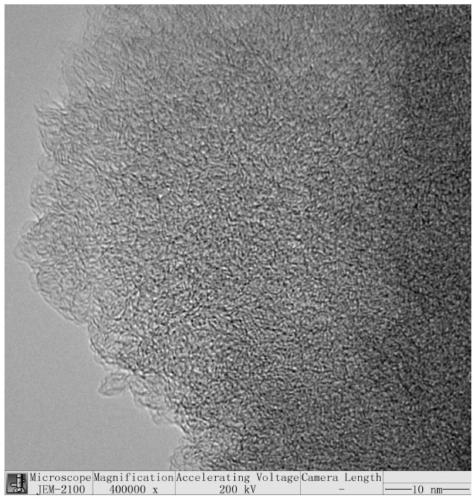

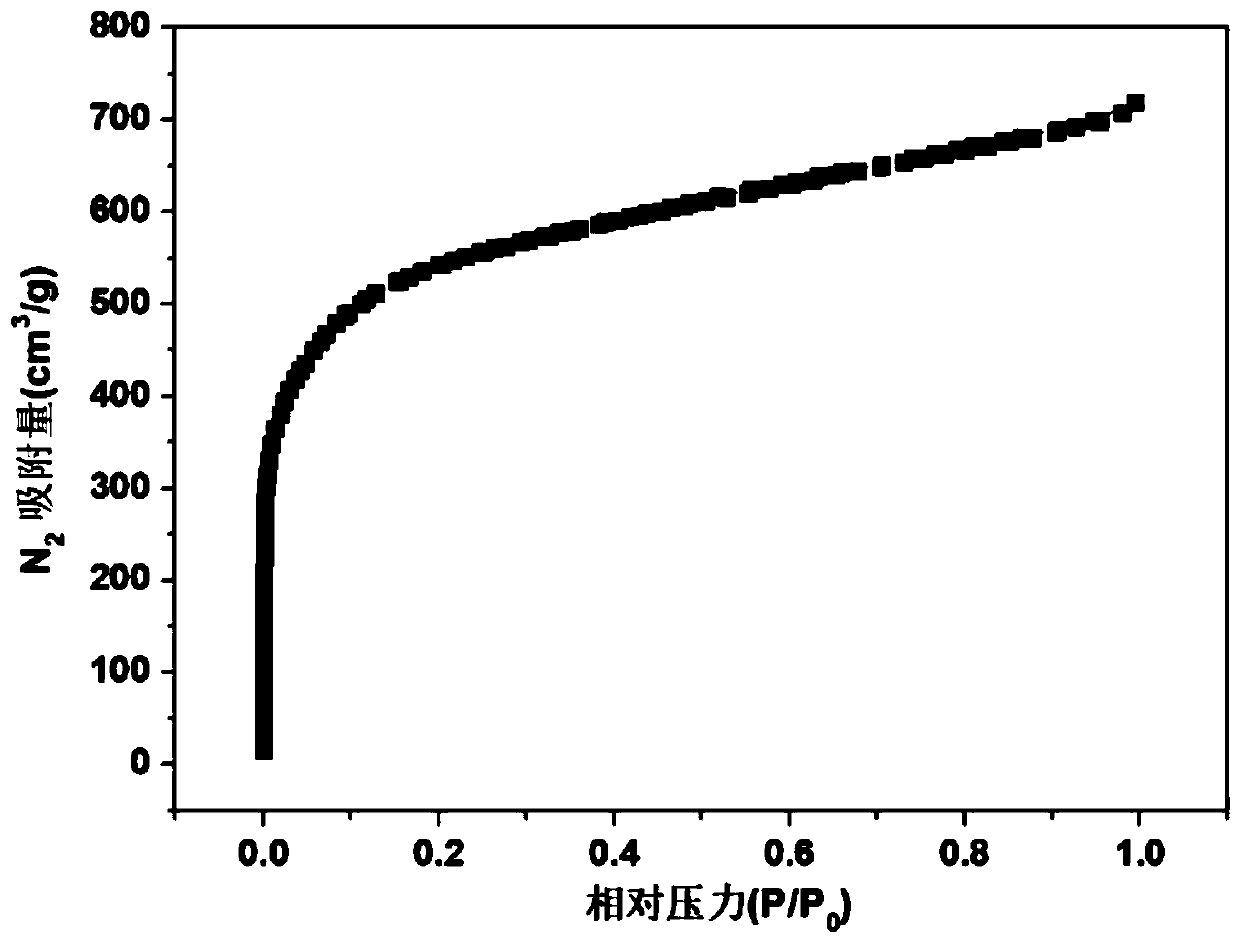

Method for preparing coal-based porous carbon material through trace calcium addition and catalytic activation

The invention discloses a method for preparing a coal-based porous carbon material through trace calcium addition and catalytic activation and relates to a preparation method of a porous carbon material. The invention aims to solve the problems in the traditional preparation method of the coal-based porous carbon material that the porous carbon material obtained by physical activation is under-developed in pore structure and the usage amount of an activating agent needed in the chemical activation preparation process is great. The preparation method disclosed by the invention comprises the following steps: taking coal as a raw material, enabling a calcium source to be distributed in a coal matrix by virtue of a ball-milling mixing process of trace organic or inorganic calcium source and coal, obtaining a coal-based porous carbon material by virtue of a catalytic activation process and a process of removing calcium containing compounds, and regulating the pore matching and pore parameters of the obtained coal-based porous carbon by virtue of the calcium source and the content, thereby obtaining the micro-porous carbon material and hierarchical pore carbon material. The specific surface area of the obtained coal-based hierarchical pore carbon can reach 1535m<2> / g, and the pore volume can reach 1.66cm<3> / g. The method disclosed by the invention is applicable to deep regulation ofthe porous carbon material pore structure, and has application prospects in the fields of adsorption of gas molecules and liquid molecules and super capacitor energy storage.

Owner:HARBIN INST OF TECH

Preparation method of coal-based porous carbon based on potassium carbonate cyclic activation and preparation method of biomass-based porous carbon

PendingCN109835900AAchieve recyclingReduce manufacturing costCarbon compoundsActivation methodCoal matrix

The invention discloses a preparation method of coal-based porous carbon based on potassium carbonate cyclic activation and a preparation method of biomass-based porous carbon, relates to a preparation method of the coal-based porous carbon and a preparation method of the biomass-based porous carbon, and aims to solve the problems that the pore structure of a porous activated carbon material obtained by a physical activation method is not developed, and the amount of an activating agent required by a chemical activation method is large. The preparation method comprises the following steps: sequentially crushing, grinding and screening raw materials, then carrying out ball milling mixing or liquid phase impregnation to mix a small amount of K2CO3 with a coal matrix, carrying out high-temperature activation on the obtained mixture in an atmosphere furnace, and cleaning and drying the activated product. According to the preparation method, the potassium carbonate can catalyze the activation reaction of an activation gas and the carbon matrix, so that the pore forming process is enhanced; in addition, the cyclic regeneration of the potassium-based component can be realized in the reaction process, so that coal or biomass-based porous carbon with developed pores can also be obtained under the addition of a small K2CO3 adding amount. The method is suitable for preparing the porous carbon.

Owner:HARBIN INST OF TECH

Fluidized mining method for on-situ pyrolyzed gas of high gas coal seam

ActiveCN111119982AImprove utilization efficiencyFacilitate desorptionMining devicesGas removalMining engineeringCoal matrix

The invention relates to a fluidized mining method for on-situ pyrolyzed gas of a high gas coal seam. The method is suitable for being used in a low-permeability, low-temperature strong oxidability and high gas content coal seam or a remnant coal seam in a closed goaf. The method comprises the following steps of drilling a horizontal drilling well and a gas extraction drilling well from the groundto a target coal seam or the remnant coal same in the closed goaf; generating a lot of cracks around the horizontal drilling well by way of detonation; sealing a hole of a shaft; injecting air at a proper flow rate into the horizontal drilling well; after the target coal seam or the remnant coal seam is in contact with a small amount of air for a certain time, carrying out smoldering on the coalseam by using a fire striker, wherein raised temperature can induce penetration among a lot of multi-scale hole cracks to accelerate desorption of adsorbed gas in the coal seam, and meanwhile, CO2 gasgenerated by smoldering can displace the adsorbed gas in a coal matrix effectively, so that the gas seeps and is diffused along a crack network; and finally, carrying out negative pressure extractionby the gas extraction drilling well. The method is high in feasibility and simple to operate, and can achieve efficient utilization of a coal resource to the maximum extent.

Owner:CHINA UNIV OF MINING & TECH

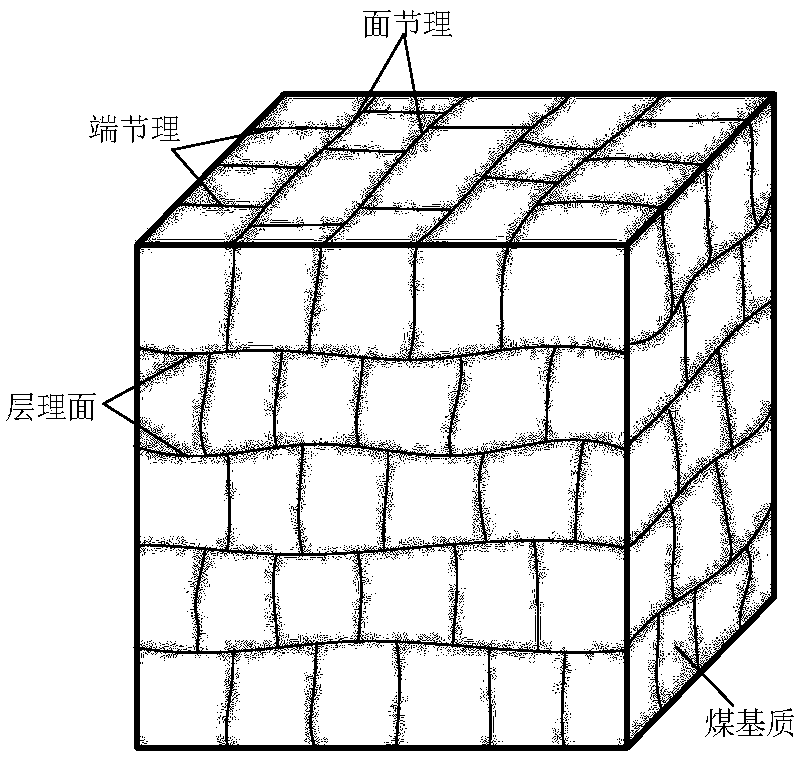

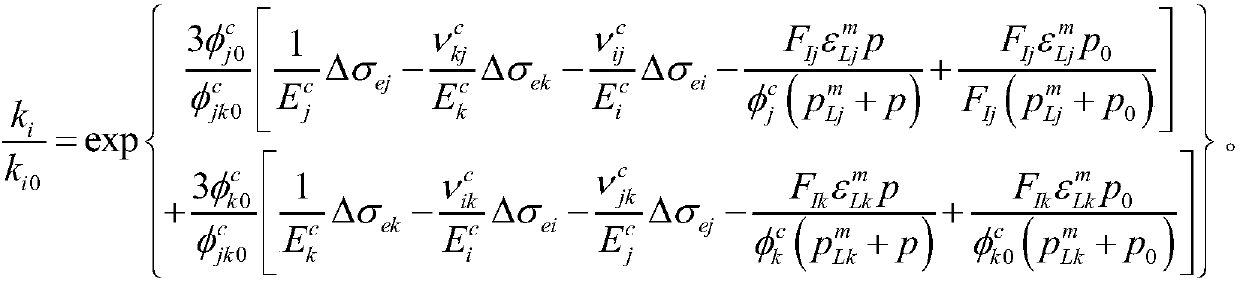

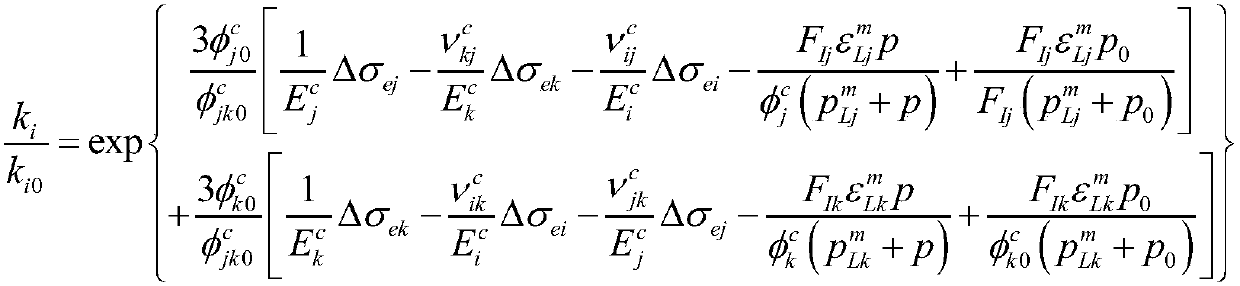

Method for calculating the absolute permeability of orthogonal anisotropic coal seam cracks

According to the method, it is assumed that cracks in a coal seam are three groups of joints which are mutually orthogonal; By considering the anisotropy of fracture structure, joint mechanics parameters, coal matrix adsorption / desorption deformation and ground stress, evolution model of absolute permeability of orthotropic coal seam fissures under effective stress change and gas adsorption / desorption under the dual action is set up. The invention is closer to the real coal seam fissure structure than the previous coal seam absolute permeability model, so it can more accurately predict the evolution law of the absolute permeability in the coalbed methane mining and coal seam gas drainage process.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Accurate time-delay presplitting blasting reinforcement coal seam gas extraction method

ActiveCN105275435AImprove breathabilityIncrease desorption rateFluid removalGas removalDetonatorDetonation

The invention discloses an accurate time-delay presplitting blasting reinforcement coal seam gas extraction method. By use of an accurate time-delay presplitting blasting technology, a blast hole detonation sequence is reasonably arranged, a reasonable time-delay interval of an electronic detonator is adjusted, the master oscillator frequency of explosion seismic waves is enabled to be similar to or the same as the inherent frequency of a coal seam, and as a result, a coal body quite far away from a blast hole and a coal body nearby the blast hole generate resonance together. Due to the resonance effect of coal bodies around the blast hole, the coal body quite far away from the blast hole and the coal body medium nearby the blast hole are subjected to effects of stress, shearing forces and compression stress which are alternatively changed, size fluctuation of apertures and cracks in a coal matrix is caused, a new crack network is generated in the coal body quite far away from the blast hole, the crack growth degree of the coal body nearby the blast hole is further improved, the crack expansion scope and the expansion degree of the coal body nearby the blast hole are increased, the influence scope and the influence degree of presplitting blasting antireflection are enlarged, and accordingly, the scope and the amplitude of increase of coal seam permeability are further improved.

Owner:CHINA UNIV OF MINING & TECH

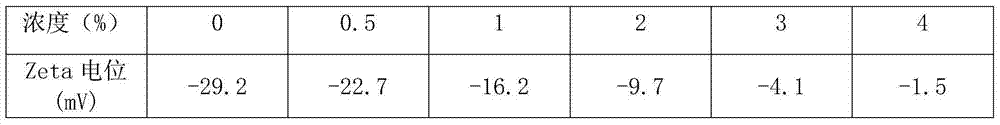

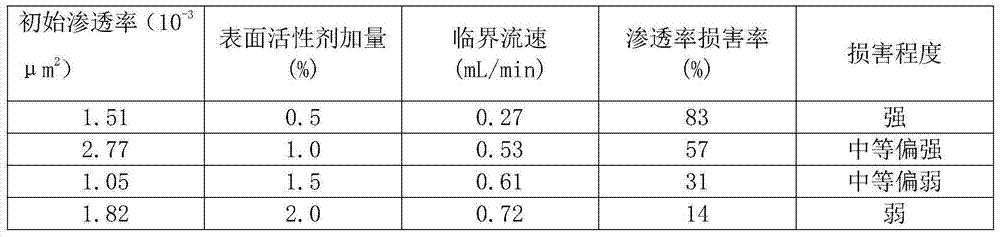

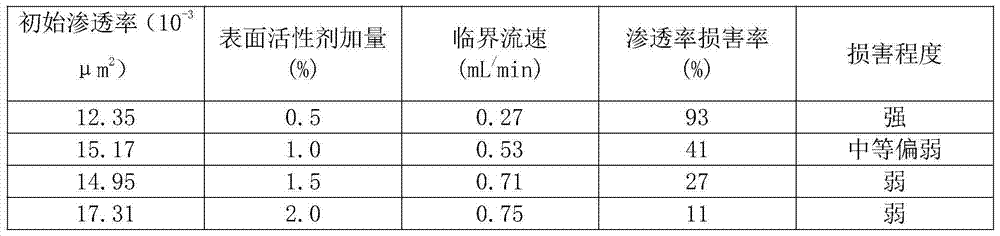

Pulverized coal stabilizer for coal bed gas reservoir and application method thereof

InactiveCN104745172AStable in natureGood weather resistanceFluid removalDrilling compositionZeta potentialAlcohol

The invention discloses a pulverized coal stabilizer for a coal bed gas reservoir and an application method thereof. The pulverized coal stabilizer disclosed by the invention consists of the following components in percentage by weight: 20-40% of an organic quaternary ammonium surfactant or polyquaternary ammonium surfactant, 1-10% of an inorganic cationic polymer, 5-30% of alcohol and the balance of water. In the backflow stage or drainage stage during and after fracturing construction, a large amount of pulverized coal stabilizer solution can be injected, and cations are adsorbed on the negative-charge coal surface, so that the Zeta potential of the coal rock is increased to about zero, and the repulsive force of the negative charges in the pulverized coal and between the pulverized coal and a coal matrix is reduced to fix the pulverized coal. The pulverized coal stabilizer disclosed by the invention has the characteristics of convenience and easiness to get, no toxicity, convenience in transportation and easiness in field construction; and the applicable temperature is 10-60 DEG C, and the application range is wide.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

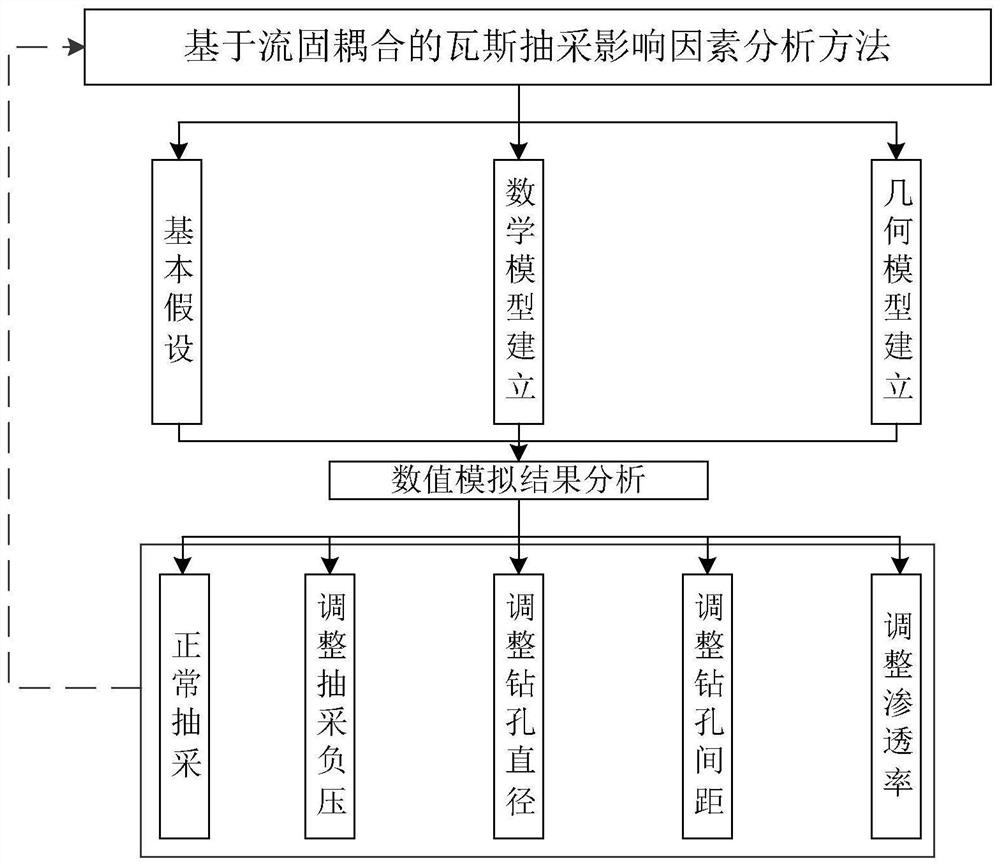

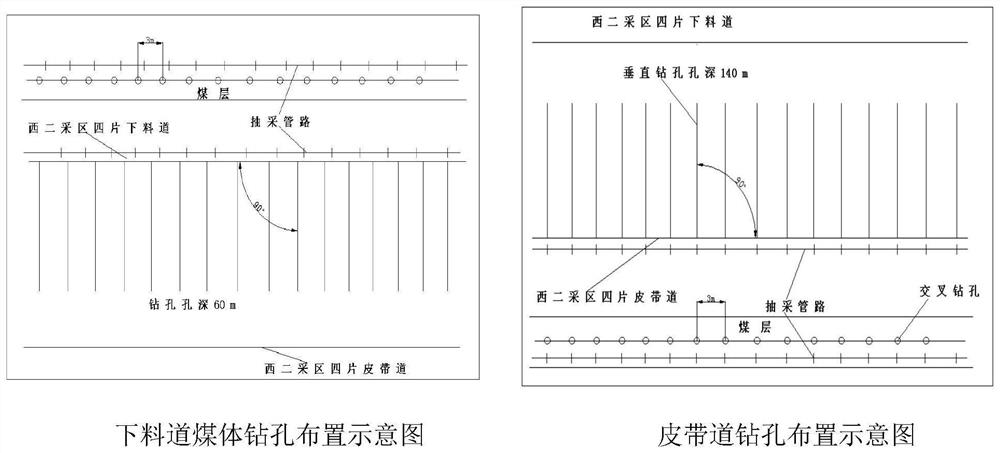

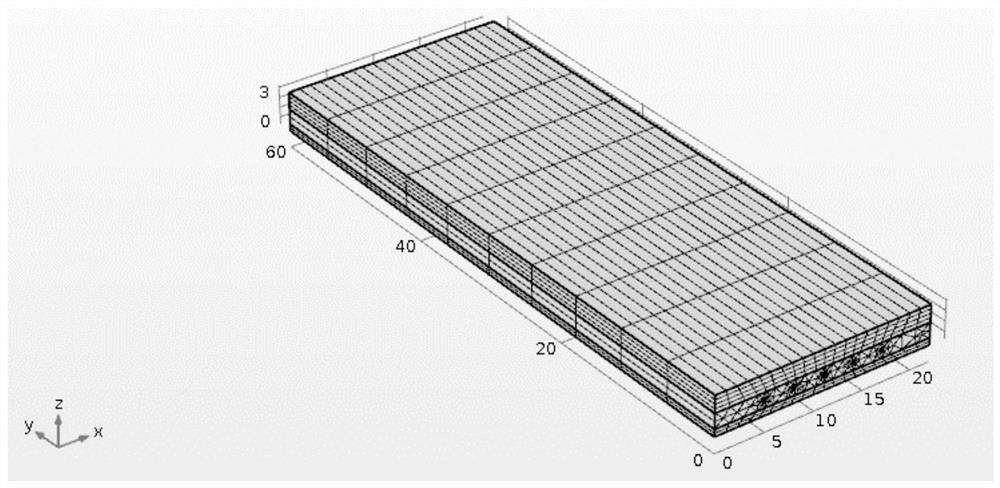

Gas extraction influence factor analysis method based on fluid-solid coupling

The invention discloses a gas extraction influence factor analysis method based on fluid-solid coupling. The method comprises the following steps: firstly, assuming that coal rock is an elastic medium with double porosity and single permeability, wherein the elastic medium is composed of coal matrix pores and fractures; in the gas extraction process, along with reduction of the coal seam gas pressure, adsorbed gas in matrix pores is desorbed into free gas, the free gas is transported into cracks through the diffusion effect and permeates into drill holes through the cracks, a gas extraction model based on fluid-solid coupling is established according to the transportation law of the coal seam gas, and the gas extraction model based on fluid-solid coupling is established by means of comsol multiphysics numerical simulation software. Numerical simulation analysis is carried out in combination with actual conditions of a certain mine working face, and main control factors influencing the gas extraction effect are obtained. According to the analysis method, the gas extraction fluid-solid coupling model is established on the basis of the geological background of a certain mine project in combination with the gas migration rule in the gas extraction process, numerical simulation is conducted on different gas extraction schemes, and a theoretical basis is provided for coal mine gas control.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

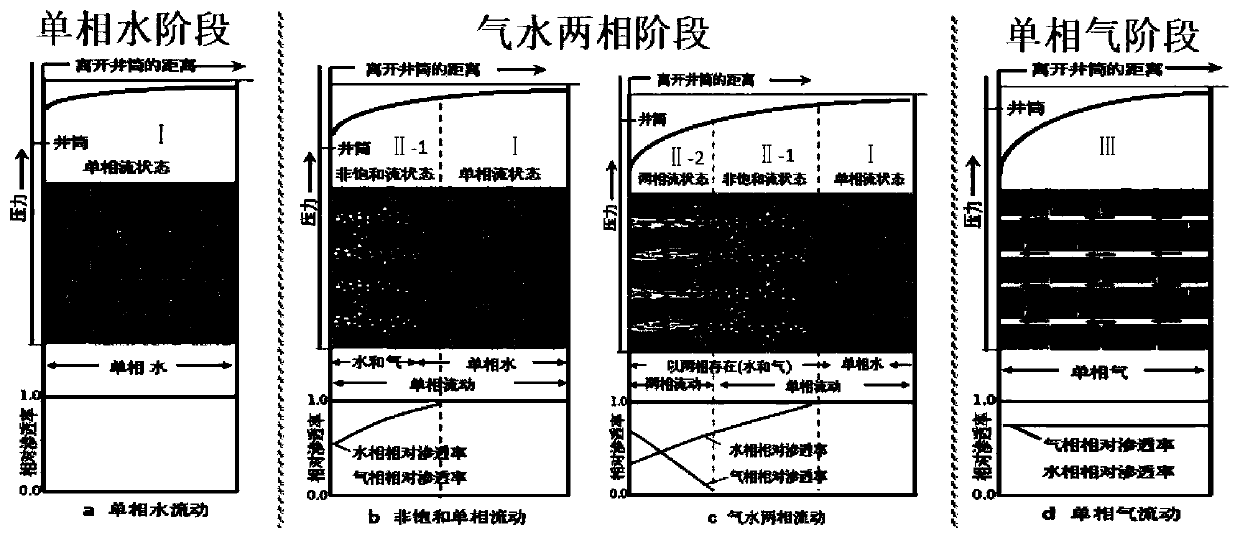

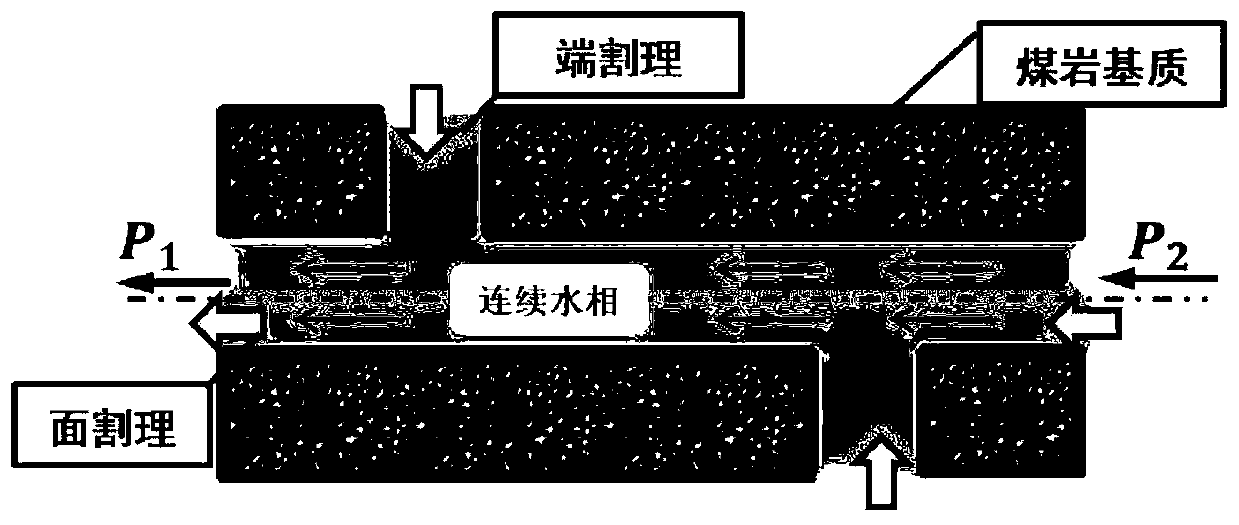

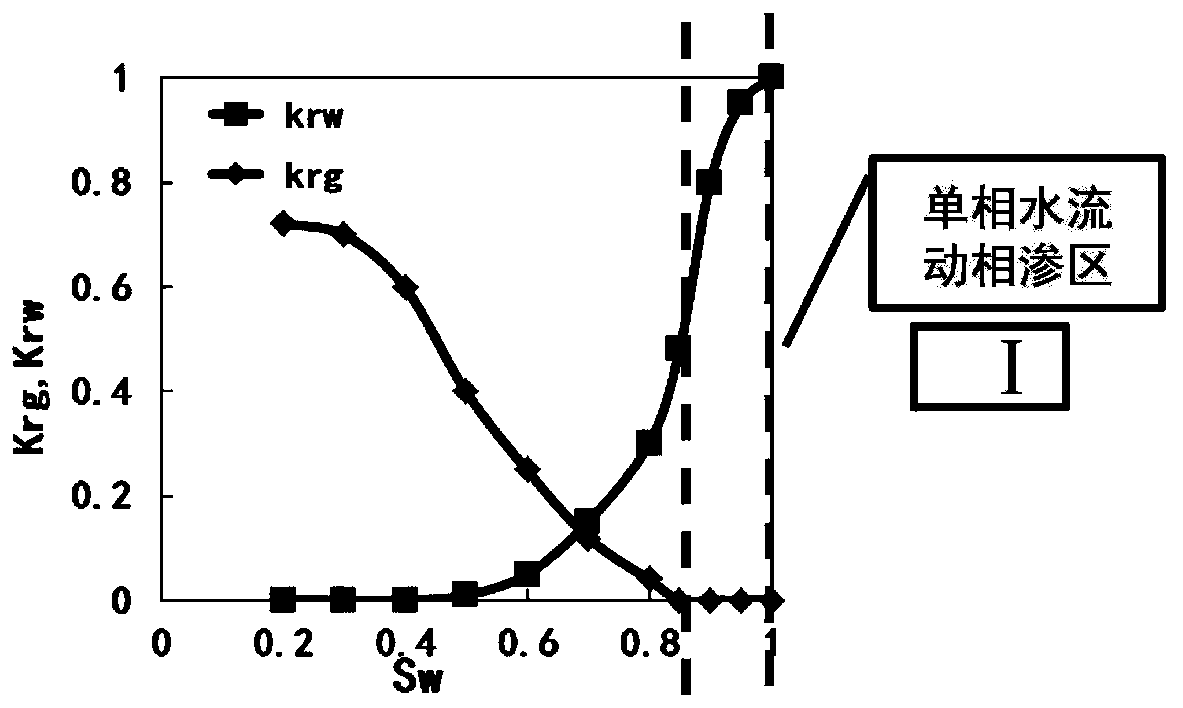

Method for calculating gas-water permeability of coal-bed methane in different production stages

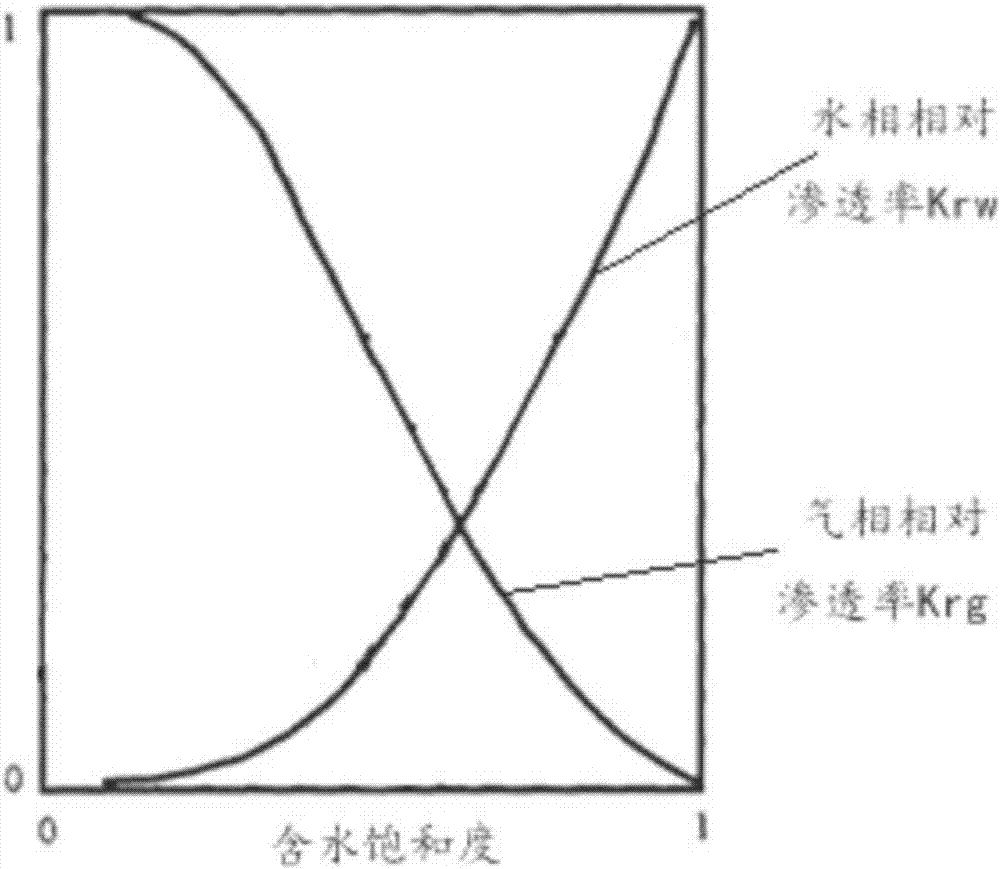

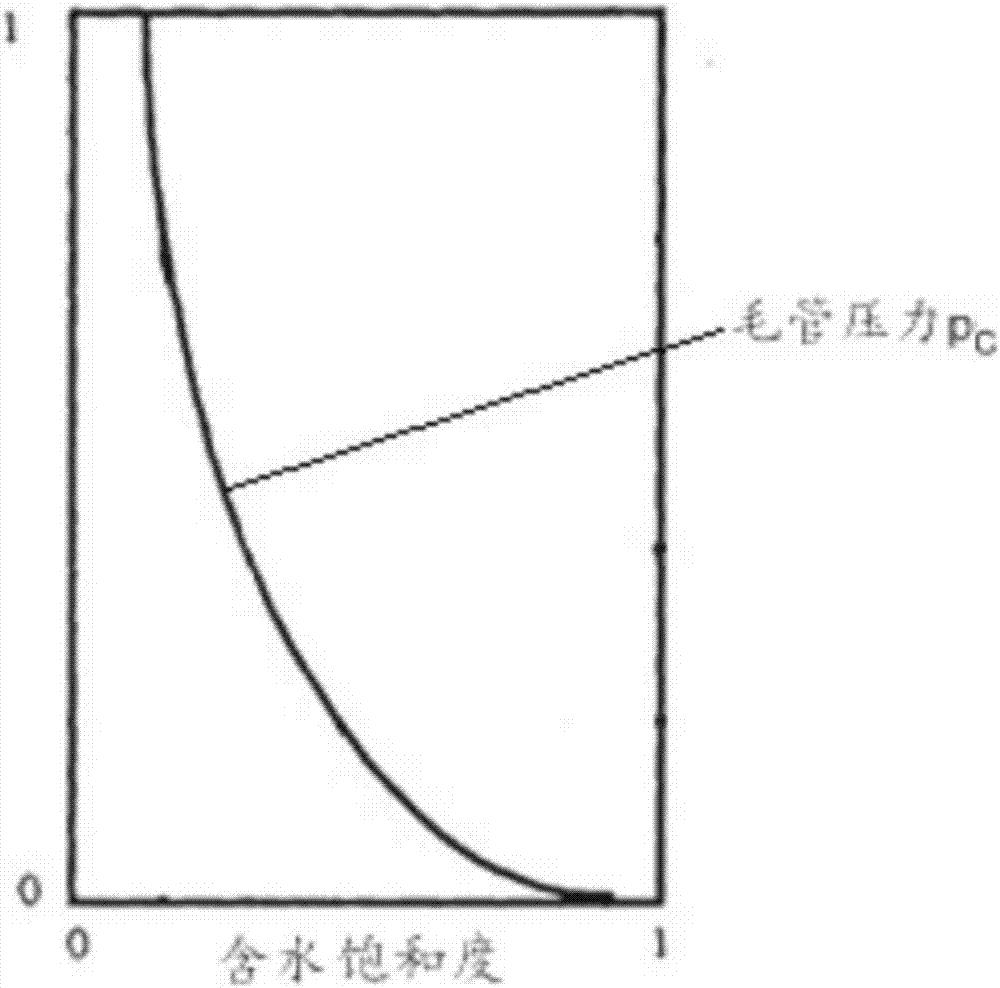

PendingCN110984972AQuick monitoringAccurate monitoringData processing applicationsFluid removalThermodynamicsSoil science

The invention discloses a method for calculating gas-water permeability of coal-bed methane in different production stage. The method involves that according to different mining stages, the productionstage can be divided into the following four stages including a single-phase water flowing stage, a near-wellbore unsaturated single-phase flowing stage, a near-wellbore gas-water two-phase flowing stage and a single-phase gas flowing stage; and the permeability is calculated through combining a permeability-pressure empirical model according to restrictions of an effective stress effect, a coalmatrix shrinkage effect caused by gas desorption, a coal matrix shrinkage effect caused by hydrolysis desorption as well as a Klinkenberg effect on the permeability. According to the method, aiming atthe four production stages of a coal-bed gas well for the first time, a gas-water permeability calculation model which comprehensively considers the influence of "the four effects" in the coal-bed gas well drainage and recovery process is provided, and therefore the dynamic permeability of the coal-bed gas well can be predicted more accurately and quickly.

Owner:PETROCHINA COALBED METHANE +1

System for displacement of water in coalbed gas reservoirs

InactiveUS20030000696A1Change in permeabilityPromote recoverySurveyDrilling rodsCoal matrixWater production

A method of stimulating coalbed methane production by injecting gas into a producer and subsequently placing die producer back on production is described. A decrease in water production may also result The increase in gas production and decrease in water production may result from: (1) die displacement of water from die producer by gas; (2) die establishment of a mobile gas saturation at an extended distance into the coalbed, extending outward from the producer; and (3) the reduction in coalbed methane partial pressure between the coal matrix and die coal's cleat system.

Owner:UNIV OF WYOMING RES

Coal seam spraying reinforcing and grading grouting cooperative hole sealing method

ActiveCN110725700AEffective blockingPrevent air leakageUnderground chambersGas removalMining engineeringCoal matrix

The invention discloses a coal seam spraying reinforcing and grading grouting cooperative hole sealing method, and relates to the technical field of coal seam cooperative hole sealing methods. The hole sealing method comprises the following steps that firstly, spraying reinforcing is carried out on the wall surface; then a bedding extraction drilling hole is constructed, and grouting hole sealingis carried out; and finally a colloid under pressure is injected into a colloid injecting drilling hole on the two sides of the extraction drilling hole by a colloid injecting pipe to block a fractureregion; and when the gas concentration is gradually reduced to a certain value along with extraction, the colloid is injected into the colloid injecting drilling hole again by the colloid injecting pipe to block secondary fractures. According to the coal seam spraying reinforcing and grading grouting cooperative hole sealing method, drilling and blocking are achieved through the mode of wall spraying reinforcing in combination with drilling grouting, the operation is simple, the cost is low, the safety is high, and the effect is good; meanwhile, the two-stage grouting mode is adopted, the secondary fractures generated by the coal matrix shrinkage are caused due to desorption flow of coal seam gas, good blocking is carried out, and the extraction effect and the extraction concentration ofthe coal seam drilling gas are further improved.

Owner:CHINA UNIV OF MINING & TECH

Diffusivity testing method for gas in coal on triaxial stress condition

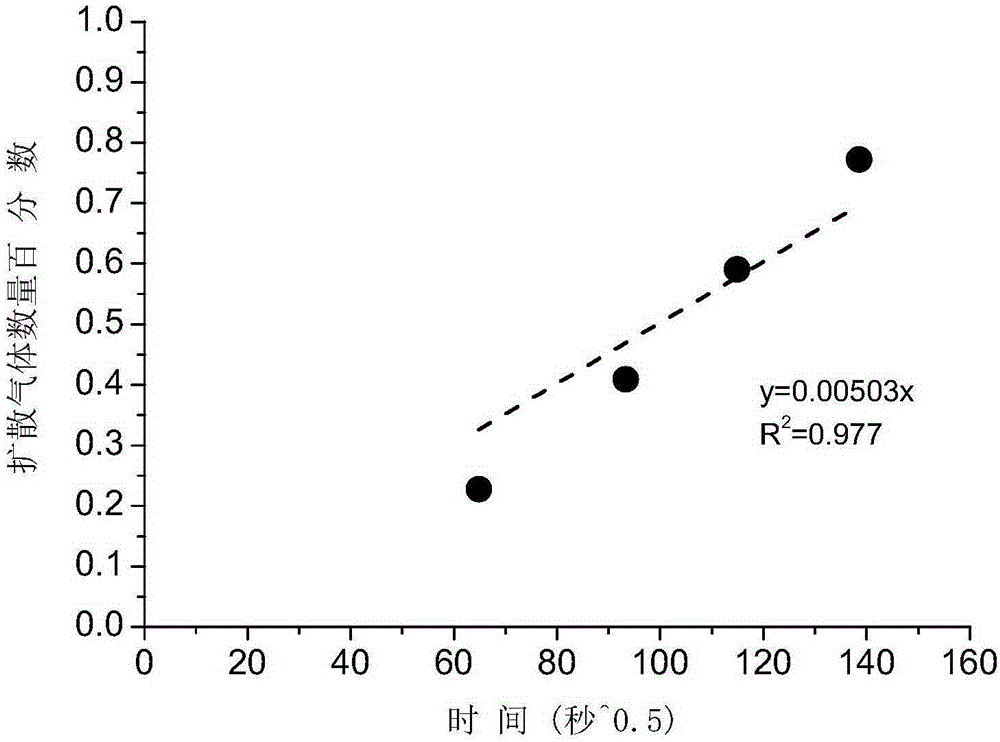

ActiveCN105181556APore structure retentionOutstanding FeaturesPermeability/surface area analysisDiffusionStress conditions

The invention discloses a diffusivity testing method for gas in coal on a triaxial stress condition. The method comprises the steps that a coal sample testing specimen is put into a closed clamping cavity, and therefore a gas injection cavity and a gas outlet cavity are formed in the two ends of the coal sample respectively; helium gas is guided into the gas injection cavity, and the helium gas is firstly infiltrated into coal cracks and then diffused into coal matrixes; a curve chart of gas quantity percentages and square roots of the diffusion time is drawn, the curve slope is fit through a least square method according to a relational expression between the effective diffusivity and the diffusion gas quality, and then the gas diffusivity is calculated. According to the method, a whole coal block is adopted to serve as the coal sample, the special pore structure of a coal body is retained, the influence condition of the complex pore structure of the coal on gas diffusion can be really reflected, and the tested and calculated gas diffusivity can supply important technical support to deeply understanding and grasping of the coal bed gas migration mechanism.

Owner:SHANDONG UNIV OF SCI & TECH

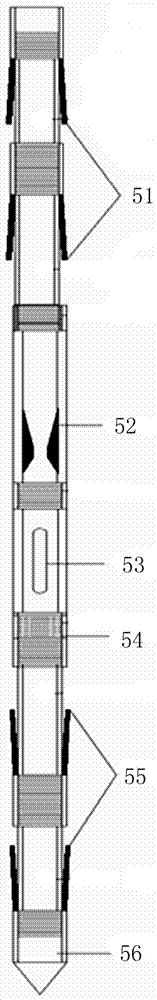

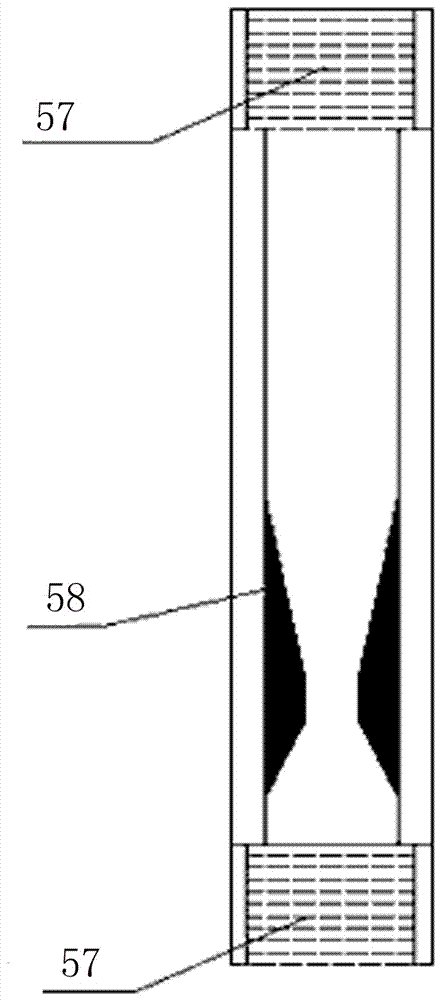

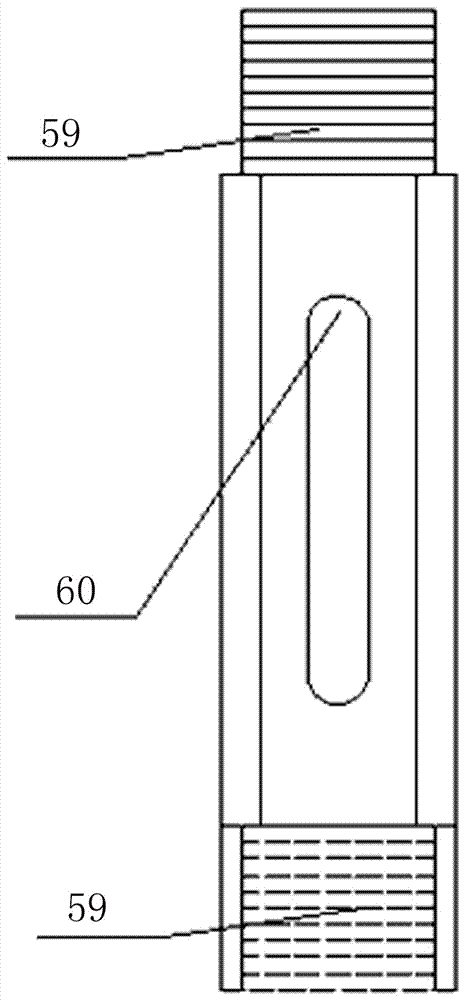

Ball-throwing type high energy gas fracturing device

InactiveCN106978999AFracturing RealizedRealize the vibration triggering effectSurveyFluid removalCoal matrixHigh energy

The invention belongs to a coal seam gas well fracturing technology, and provides a ball-throwing type high energy gas fracturing device aiming to solve the problem that the proportion of rupture cracks formed by a hydraulic fracturing method is low, and the coal seam methane is difficult to be effectively exploited. The ball-throwing type high energy gas fracturing device comprises an upper sealing unit, a vibration trigger unit, an energy releasing unit, a pressure recording unit, a lower sealing unit and a guide shoe which are connected from the top to bottom in sequence; and the vibration trigger unit completes vibration of a pitching sealing ball, the energy releasing unit completes release of high energy gas generated by burst of the sealing ball, and the top of the upper sealing unit is connected with a ground fracturing truck pumper through a succession oil pipe. The vibration trigger unit of the device can realize an effect of shocking and trigger of the sealing ball, the high energy released by the sealing ball explosion can enter a target coal reservoir through a pressure relief hole of the energy releasing unit, vibration of the area near a well is conducted, an abnormal micro fracturing network system can be developed in coal matrix and communicate with original fracture, the permeability of the coal reservoir is improved, the reservoir is transformed, and increased production is achieved.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

Anti-collapse drilling fluid for coal bed methane horizontal well and method for preparing anti-collapse drilling fluid

ActiveCN102807846AReduce pollutionDoes not affect original permeabilityDrilling compositionCoal matrixPotassium

The invention provides anti-collapse drilling fluid for coal bed methane horizontal well. The drilling fluid is used for preventing the collapse of the wall of the well in the well drilling process. The drilling fluid is characterized by comprising the following components in percentage by weight: 0.1 to 0.3 percent of potassium polyacrylate, 0.1 to 0.5 percent of sodium lignosulfonates, 0.1 to 0.3 percent of GHA-5 type coal water slurry additive, 0.5 to 3 percent of potassium chloride, 0.4 to 0.6 percent of potassium humate, 0.3 to 0.5 percent of sulfonated lignite, 1 to 3 percent of graphite powder and the balance of water. The sum of weight percent of the components is 100 percent. The drilling fluid has the advantages of effectively preventing the expansion of the coal matrix, inhibiting the collapse of the wall of the well due to the immersion of the coal bed in clean water, dissolving macromolecules adsorbed in the coal bed, lowering the surface tension of the coal matrix on the premises of keeping the normal physical characteristics unchanged, facilitating the flowback of the drilling fluid and lowering the pollution of the coal bed; the drilling fluid is prevented from being absorbed on the surface of coal, so that a gas channel cannot be blocked; and by adjusting the proportion of additives, the well-drilling construction is guaranteed.

Owner:PETROCHINA CO LTD

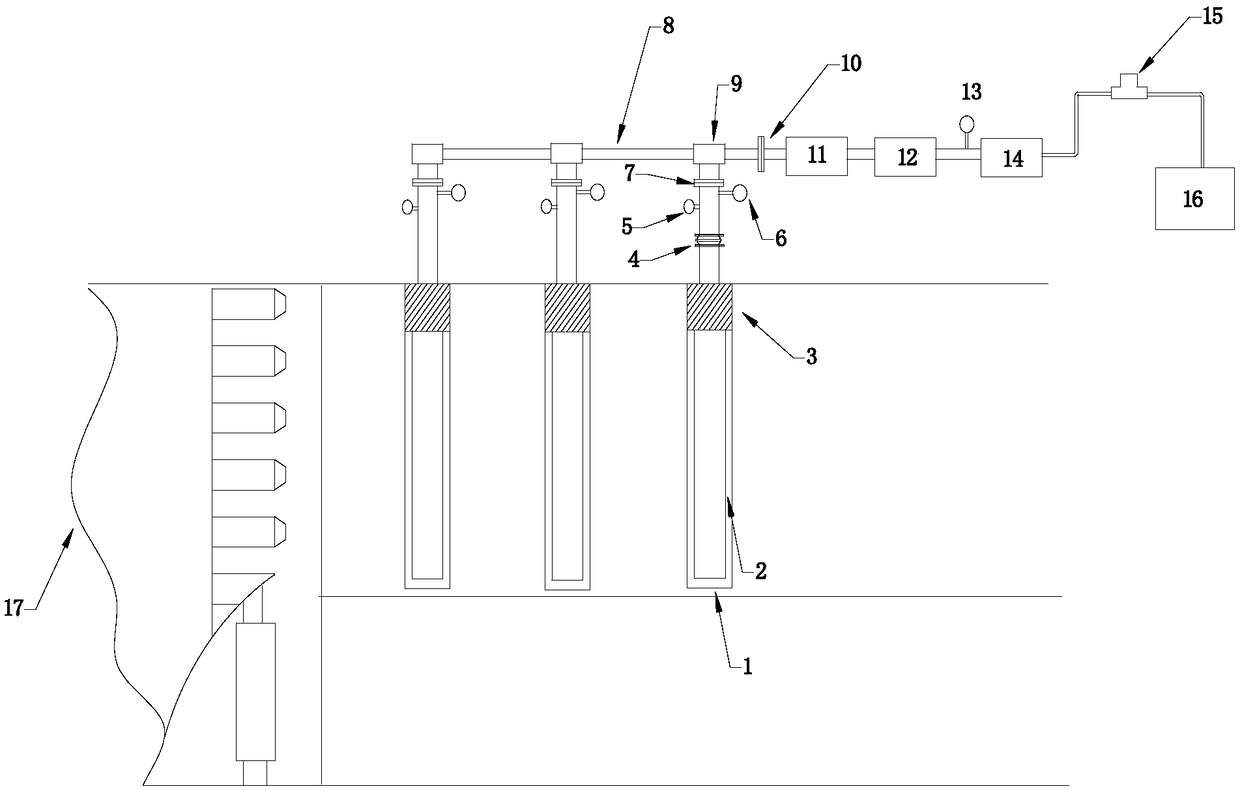

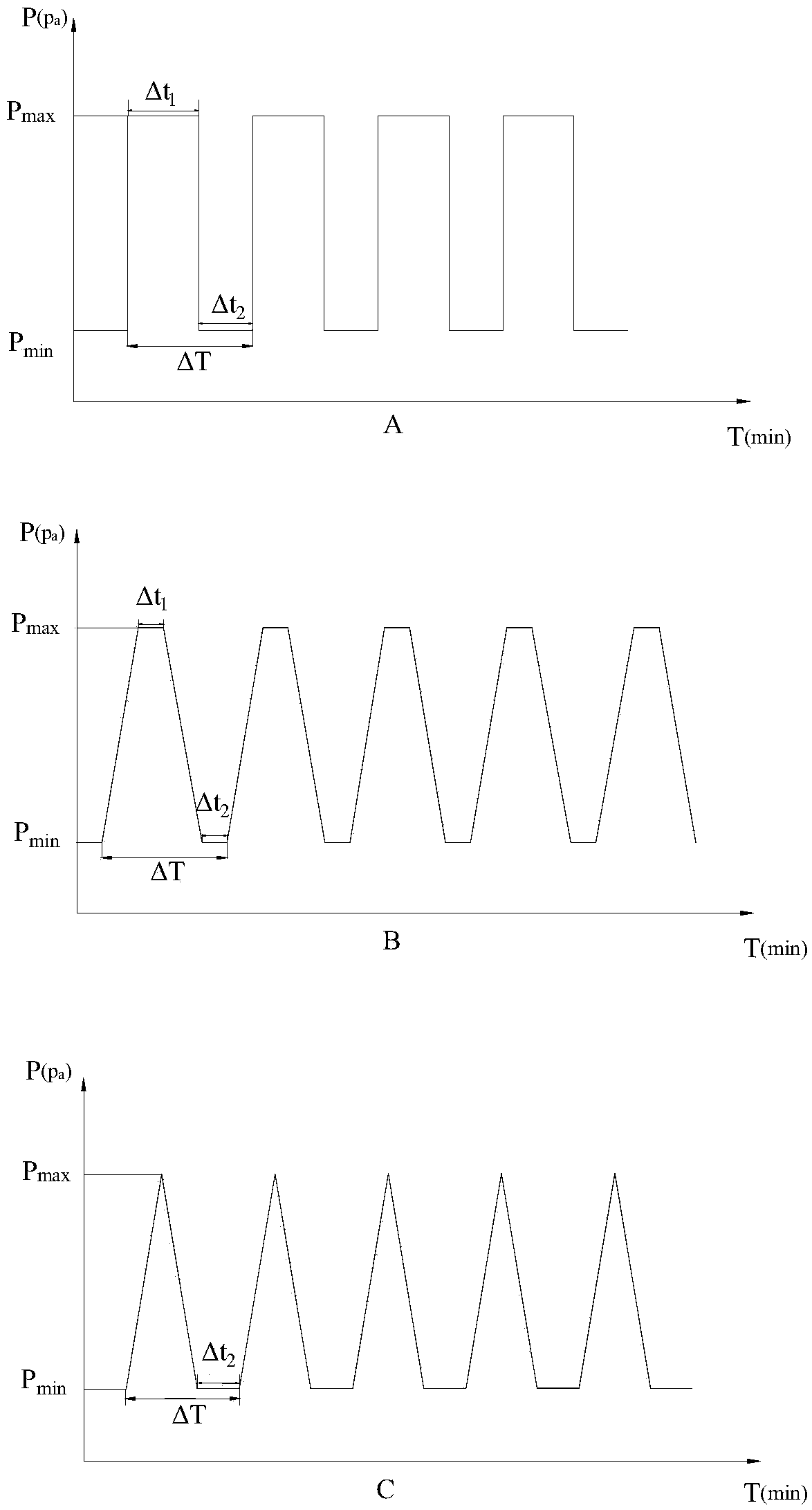

Device and method for alternating reinforced water injection permeation strengthening and wetting of low-porosity coal seam

InactiveCN108708702AImprove water injection effectHigh porosityDust removalFire preventionPorosityFatigue damage

The invention provides a device and method for alternating reinforced water injection permeation strengthening and wetting of a low-porosity coal seam. The device comprises a dynamic pressure water injection device, a high-pressure water injection rubber hose, a flow divider and a water injection drill hole, wherein the dynamic pressure water injection device comprises a water tank, an injection pump, a motor, a water injection frequency converter and a water outlet end which are connected in sequence; a shut-off valve is arranged between the water outlet end and the high-pressure water injection rubber hose, and the high-pressure water injection rubber hose is connected with the water injection drill hole through the flow divider. A plurality of water injection drill holes are formed in acoal seam area not affected by mining, and pipe laying and hole sealing are carried out; the dynamic pressure water injection device is connected to one water injection drill hole or above through the high-pressure water injection rubber hose and the flow divider to carry out alternating reinforced water injection permeation strengthening and wetting on the coal seam, so that under the impact ofhigh and low alternating cyclic water pressure, obvious fatigue damage of a coal body is generated, the pores and fractures of the alternating reinforced water-injected coal body are increased, then pressurized water penetrates into a coal matrix along the pores and the fractures, and finally, the purpose of improving the effects of wetting, dust suppression and scour prevention of coal seam waterinjection is achieved.

Owner:SHANDONG UNIV OF SCI & TECH

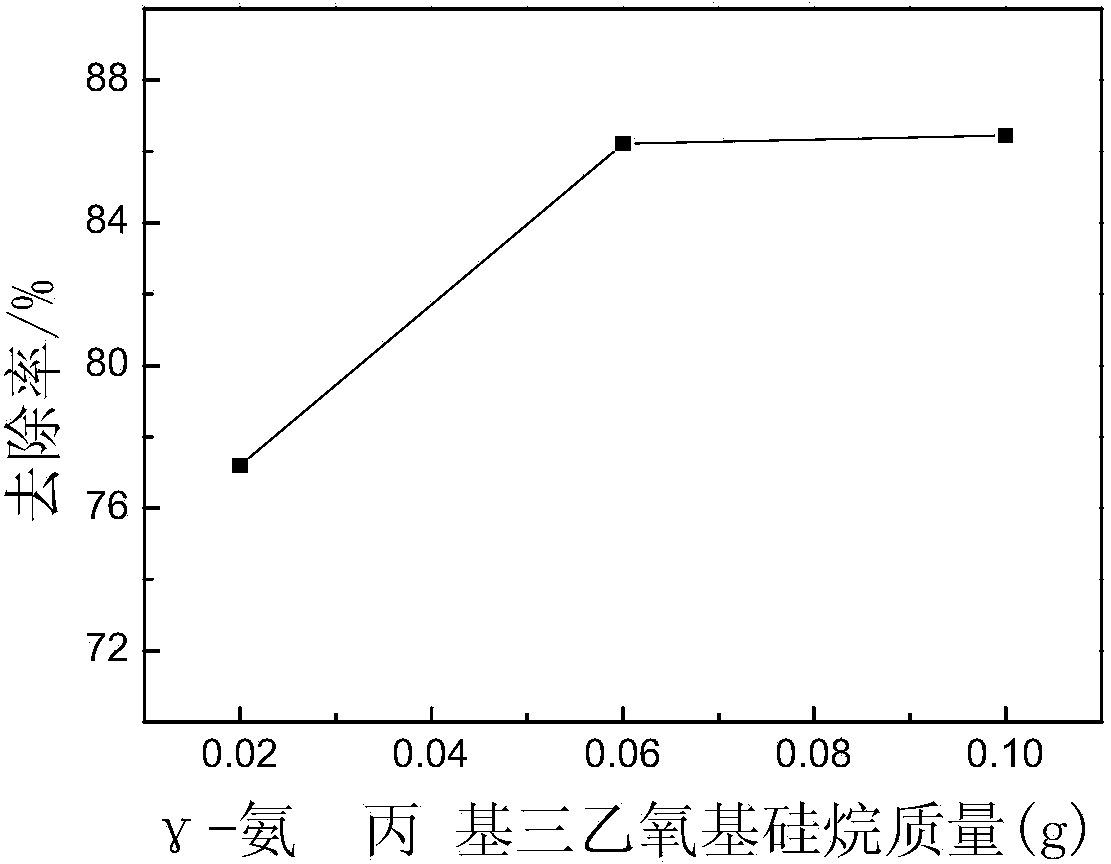

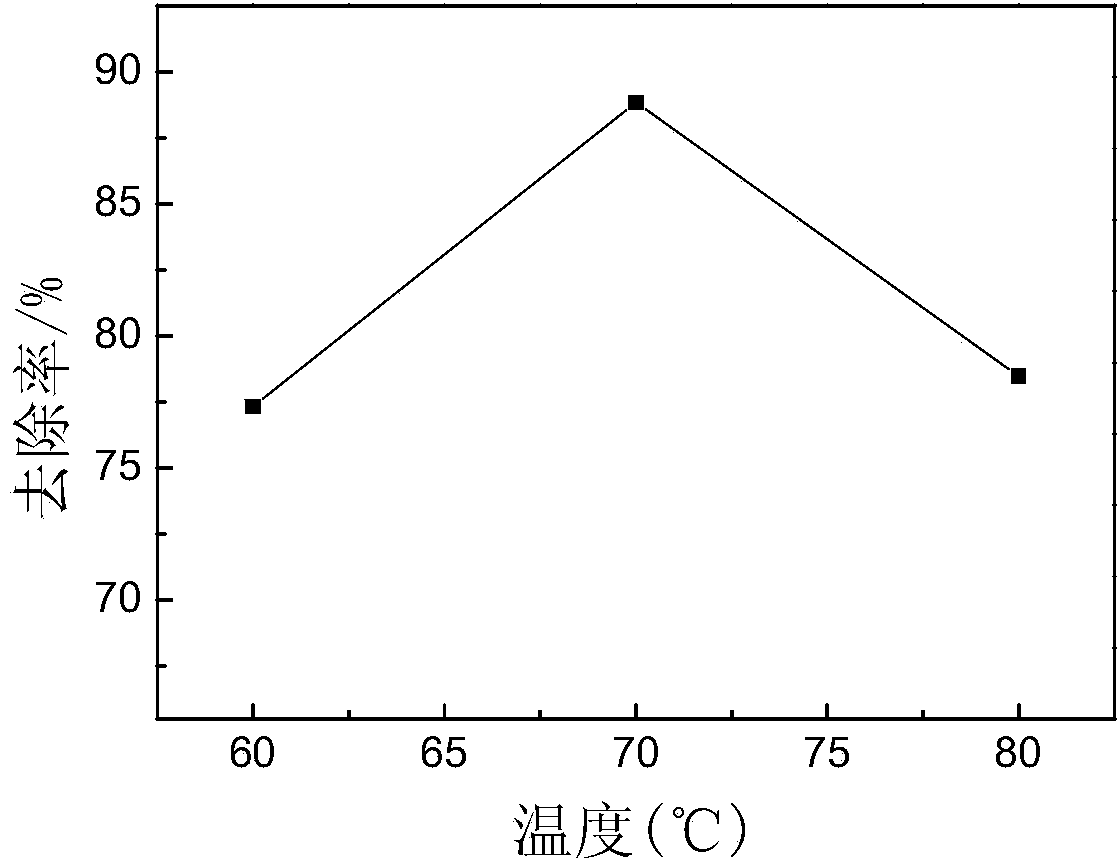

Method for preparing coal-based chelating adsorbent by taking diethylenetriamine as raw material

InactiveCN103933955APromote chelationStable physical and chemical propertiesOther chemical processesWater/sewage treatment by sorptionCoal matrixSorbent

The invention relates to a method for preparing a coal-based chelating adsorbent by taking diethylenetriamine as a raw material. The method comprises the following steps: first, adding gamma-aminopropyl triethoxysilane into a raw coal powder solution to obtain coupling modified coal powder; then, adding diethylenetriamine into the coupling modified coal powder for reacting to obtain aminated coal powder; later, adding sodium hydroxide and carbon disulfide into the aminated coal powder one after another, and reacting to obtain the coal-based chelating adsorbent. The coal-based chelating adsorbent which has high adsorption performance and stable physical and chemical properties is prepared by coupling and grafting diethylenetriamine to the surfaces of coal powder particles, and reacting the modified coal powder with sodium hydroxide and carbon disulfide to generate dithiocarbamate with high chelating performance on the surface of the coal powder. The invention provides the novel preparation method of the coal-based chelating adsorbent. The preparation is simple and feasible; the coal-based chelating adsorbent has the characteristics of high adsorption performance and high physical and chemical properties of a coal matrix, easiness in solid-liquid separation, wide application range and the like.

Owner:XIAN UNIV OF SCI & TECH

Method and system for predicting coalbed methane of double-pore coal body

ActiveCN113392567AIncrease productionImprove the extraction effectForecastingDesign optimisation/simulationThermodynamicsCoal matrix

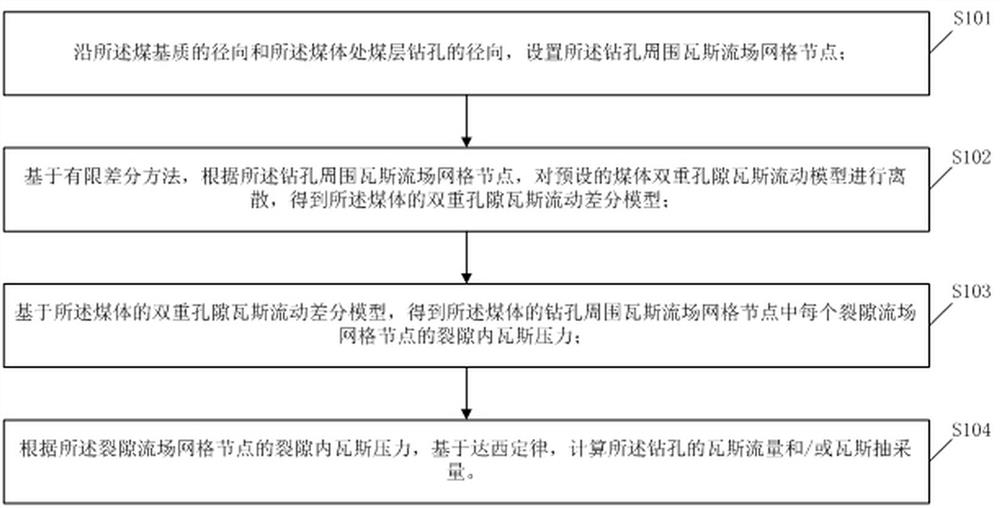

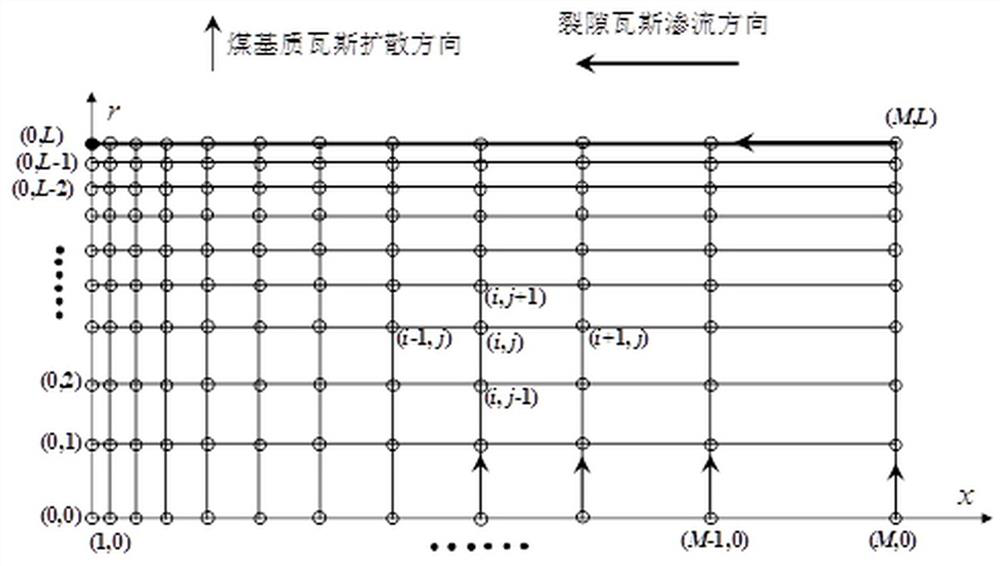

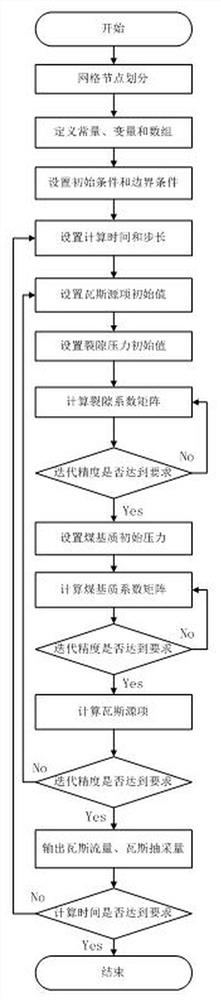

The invention belongs to the technical field of testing or analyzing materials by means of measuring chemical or physical properties of the materials, and provides a coal bed gas prediction method and system for a double-pore coal body. The method comprises the steps: arranging gas flow field grid nodes around drill holes in the radial direction of a coal matrix and the radial direction of the coal seam drill holes in a coal body; based on a finite difference method, according to the grid nodes of the gas flow field around the drill hole, discretizing a preset coal body double-pore gas flow model, and obtaining a coal body double-pore gas flow difference model; on the basis of a double-pore gas flow difference model of the coal body, obtaining the fracture internal gas pressure of each fracture flow field grid node in the gas flow field grid nodes around the coal seam drill hole; and according to the gas pressure in the fracture of the fracture flow field grid nodes, based on the Darcy law, calculating the gas flow and / or the gas extraction amount of the drill hole. Therefore, the dynamic change of the extraction quantity of the coal bed gas in a long time period and the accurate prediction of the production quantity of the coal bed gas are realized.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

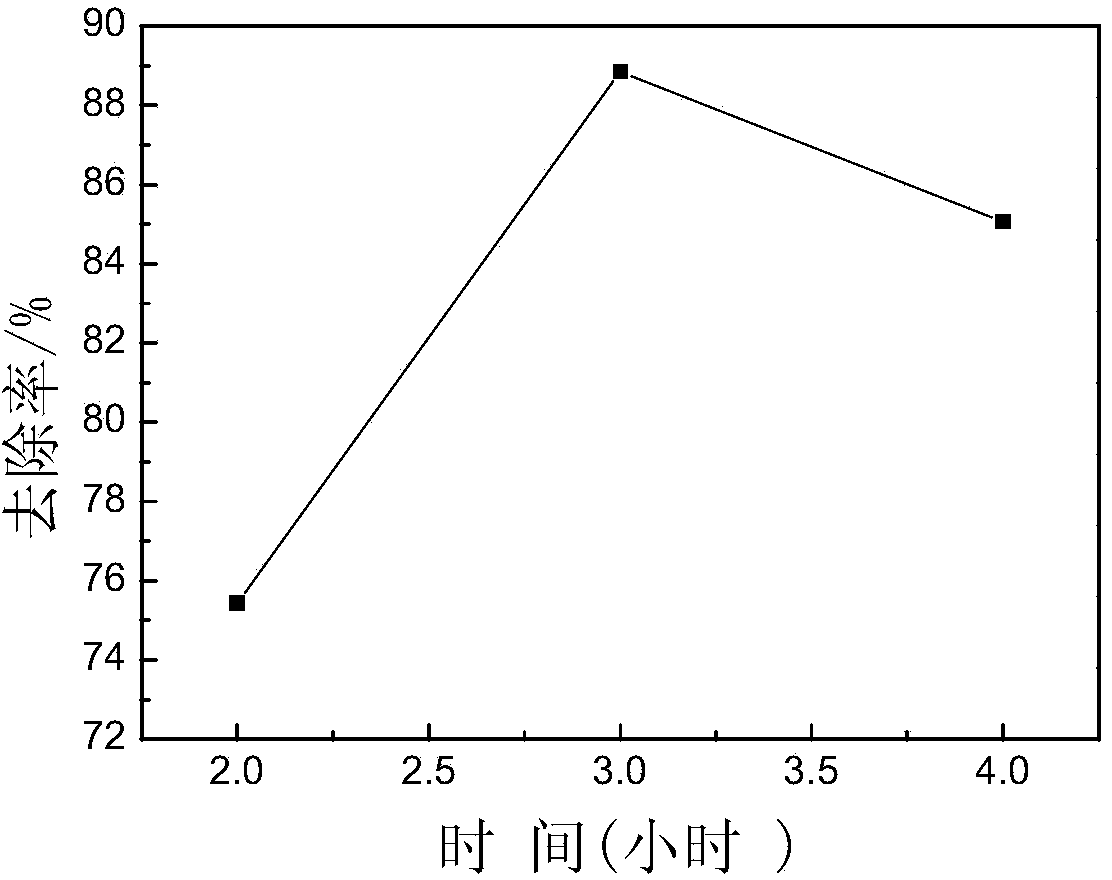

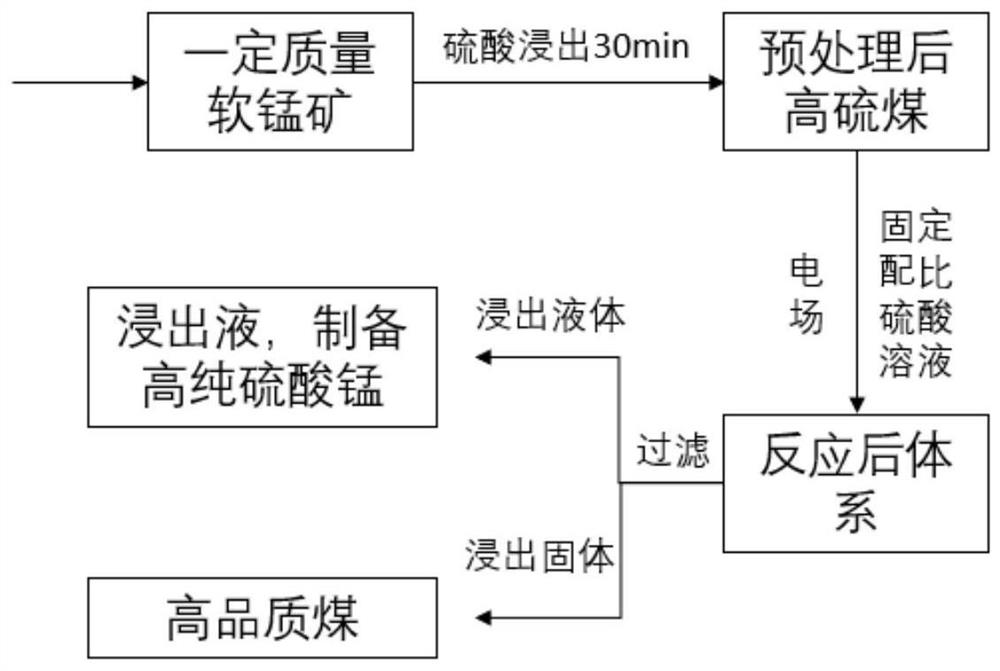

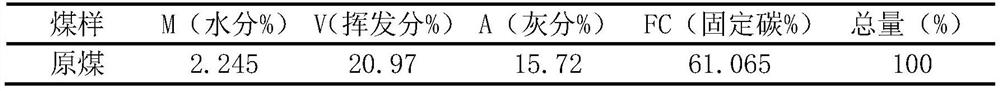

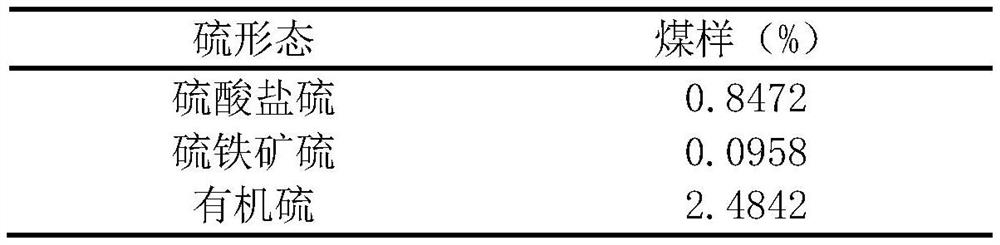

Method for strengthening oxidative desulfurization and deashing of high-sulfur coal by coupling effect of electric field and pyrolusite

The invention belongs to the field of strengthening desulfurization of high-sulfur coal before combustion under the coupling action of an electric field and an oxidizing agent, and discloses an experimental method for improving the quality of the high-sulfur coal by utilizing the strong oxidizing property of manganese dioxide. According to the method, pyrolusite and high-sulfur coal are uniformlymixed and subjected to acid leaching. The pyrolusite preferentially oxidizes a sulfur-containing inorganic phase in a coal matrix under the action of an electric field, and then after part of organiccompounds are hydrogenated, iron ions and manganese ions produced after the pyrite is dissolved can help to oxidize and desulfurize the sulfur-containing organic phase in the coal. Under the auxiliaryaction of an electric field, the desulfurization effect of organic sulfur in coal is better. The whole set of technological process is simple, convenient to operate, low in pollution, low in energy consumption, high in efficiency and green, and an environment-friendly and efficient desulfurization method is provided for coal desulfurization before combustion.

Owner:CHONGQING UNIV

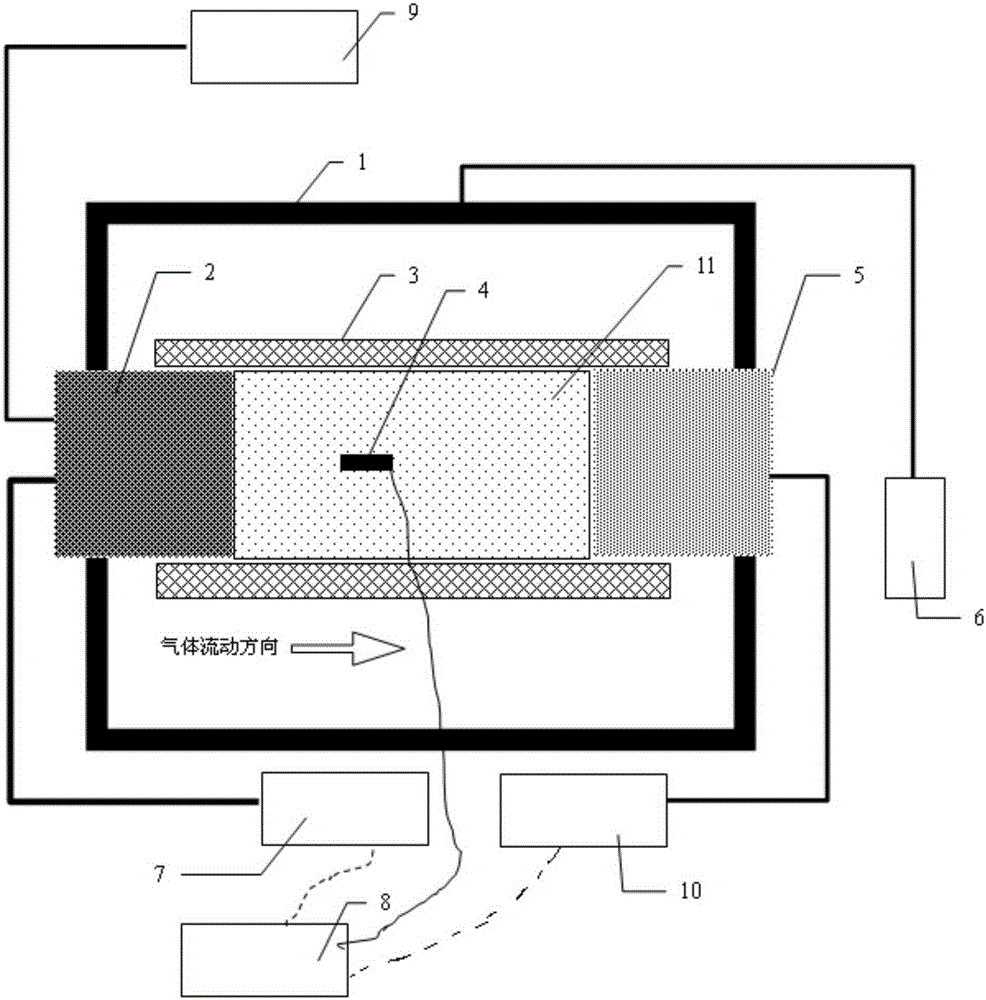

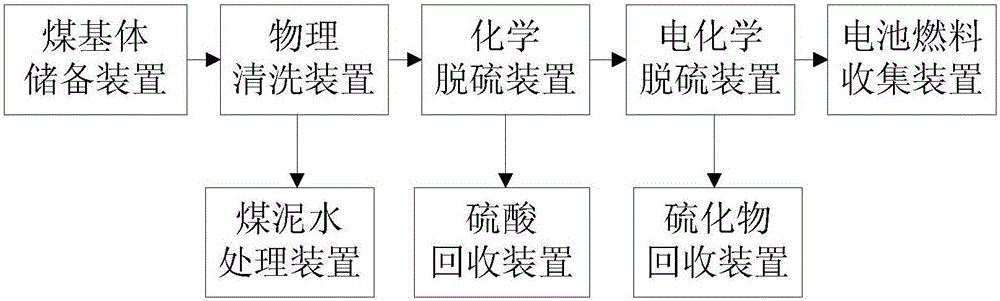

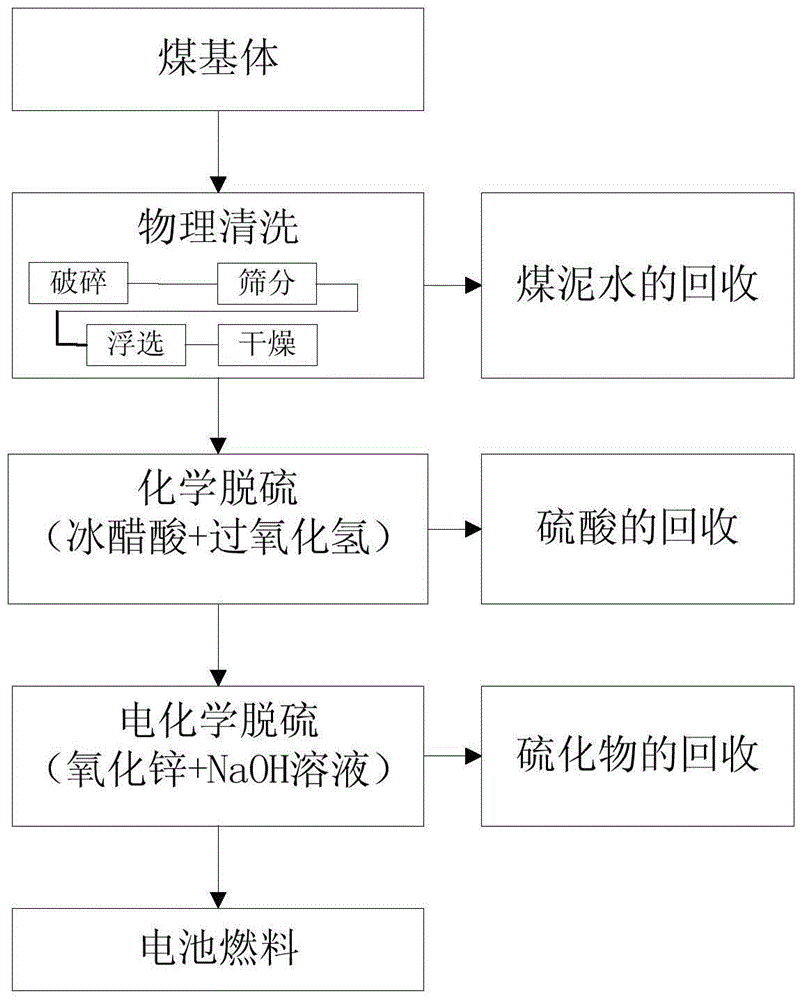

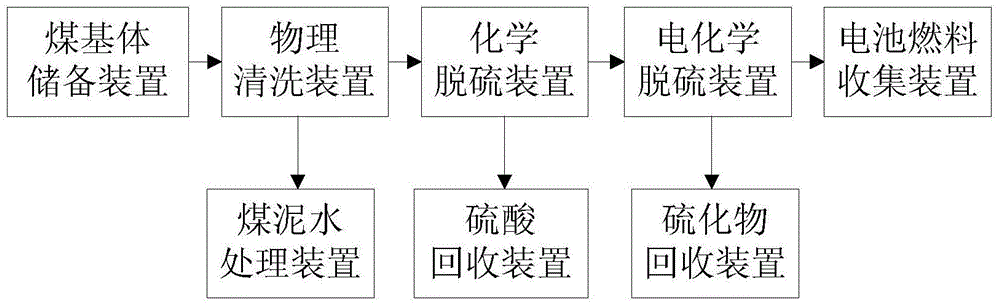

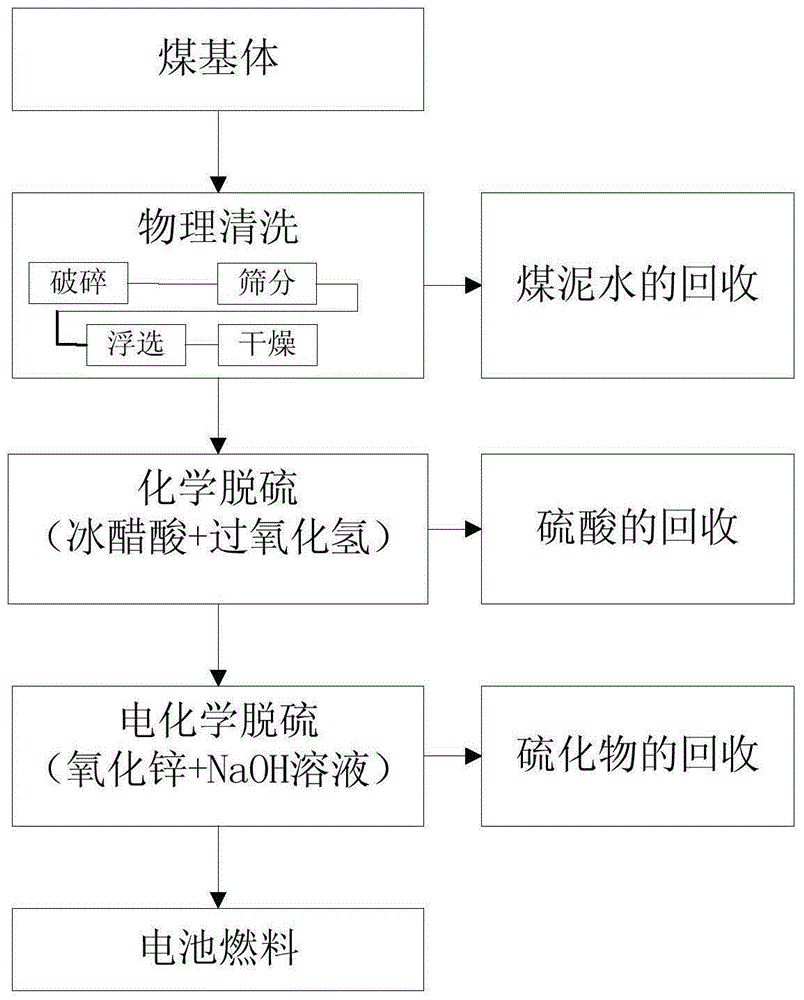

A carbon fuel cell coal-based fuel combined processing device and processing method thereof

ActiveCN105186019BEfficient removalMeet purity requirementsSolid fuelsFuel cellsMicro structureChemical reaction

Owner:SHANXI YUXIANG INFORMATION TECH CO LTD +2

Combined processing device of coal-based fuel of carbon fuel cell and processing method thereof

ActiveCN105186019AImprove microstructureEfficient removalSolid fuelsFuel cellsFuel cellsChemical reaction

The invention discloses a combined processing device of a coal-based fuel of a carbon fuel cell and a processing method thereof. The combined processing device disclosed by the invention comprises a coal matrix storage device, a physical cleaning device, a chemical desulphurization device, an electrochemical desulphurization device, a cell fuel collecting device, a coal slurry processing device, a sulphuric acid recovery device and a sulfide recovery device. A PCE combined processing process is provided in the invention; the micro-structure of coal is improved, so that anodic electrochemical reactions are convenient to generate; more than 99% of ash components and volatile components in a coal matrix can be effectively removed; more than 90-95% of total sulphur is removed; requirements of the fuel cell to the carbon purity can be satisfied; the complete set of coal-based fuel cell fuel device is provided; reference of a raw material processing device is provided for future industrial popularization of the fuel cell; and the PCE combined processing process is simple in principle and low in equipment cost and has important significances for solving sulphur poisoning and sulphur pollution of the carbon fuel cell and realizing industrial popularization of the fuel cell.

Owner:SHANXI YUXIANG INFORMATION TECH CO LTD +2

Coal seam spray reinforcement and graded glue injection collaborative sealing method

ActiveCN110725700BEffective blockingPrevent air leakageUnderground chambersGas removalThermodynamicsCoal matrix

The invention discloses a coal seam spraying reinforcing and grading grouting cooperative hole sealing method, and relates to the technical field of coal seam cooperative hole sealing methods. The hole sealing method comprises the following steps that firstly, spraying reinforcing is carried out on the wall surface; then a bedding extraction drilling hole is constructed, and grouting hole sealingis carried out; and finally a colloid under pressure is injected into a colloid injecting drilling hole on the two sides of the extraction drilling hole by a colloid injecting pipe to block a fractureregion; and when the gas concentration is gradually reduced to a certain value along with extraction, the colloid is injected into the colloid injecting drilling hole again by the colloid injecting pipe to block secondary fractures. According to the coal seam spraying reinforcing and grading grouting cooperative hole sealing method, drilling and blocking are achieved through the mode of wall spraying reinforcing in combination with drilling grouting, the operation is simple, the cost is low, the safety is high, and the effect is good; meanwhile, the two-stage grouting mode is adopted, the secondary fractures generated by the coal matrix shrinkage are caused due to desorption flow of coal seam gas, good blocking is carried out, and the extraction effect and the extraction concentration ofthe coal seam drilling gas are further improved.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com