Method for preparing coal-based chelating adsorbent by taking diethylenetriamine as raw material

A technology of diethylenetriamine and chelating adsorbent, which is applied in chemical instruments and methods, adsorption water/sewage treatment, and other chemical processes, can solve the problems of high manufacturing cost and complexity, and achieve good adsorption performance and good adsorption Performance, the effect of excellent physical and chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The present embodiment takes 10g of coal dust as an example, and the method for preparing a coal-based chelating adsorbent with diethylenetriamine as a raw material is realized by the following steps:

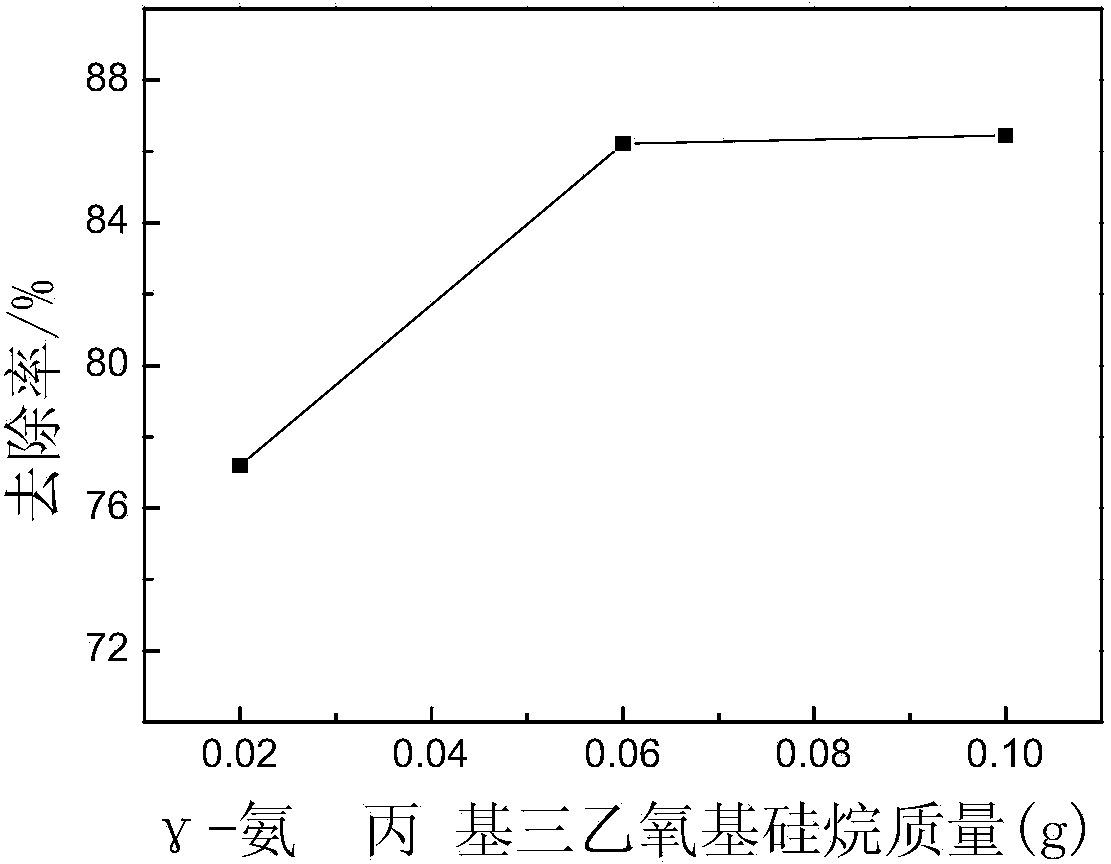

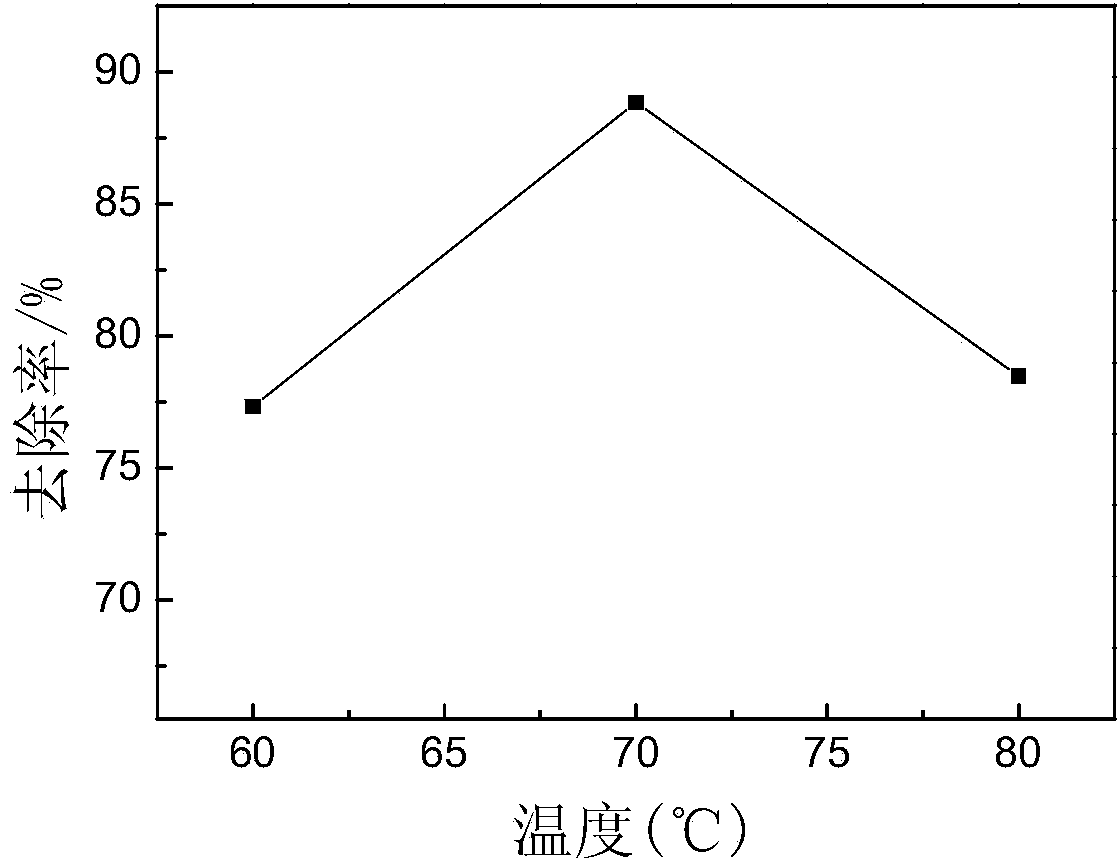

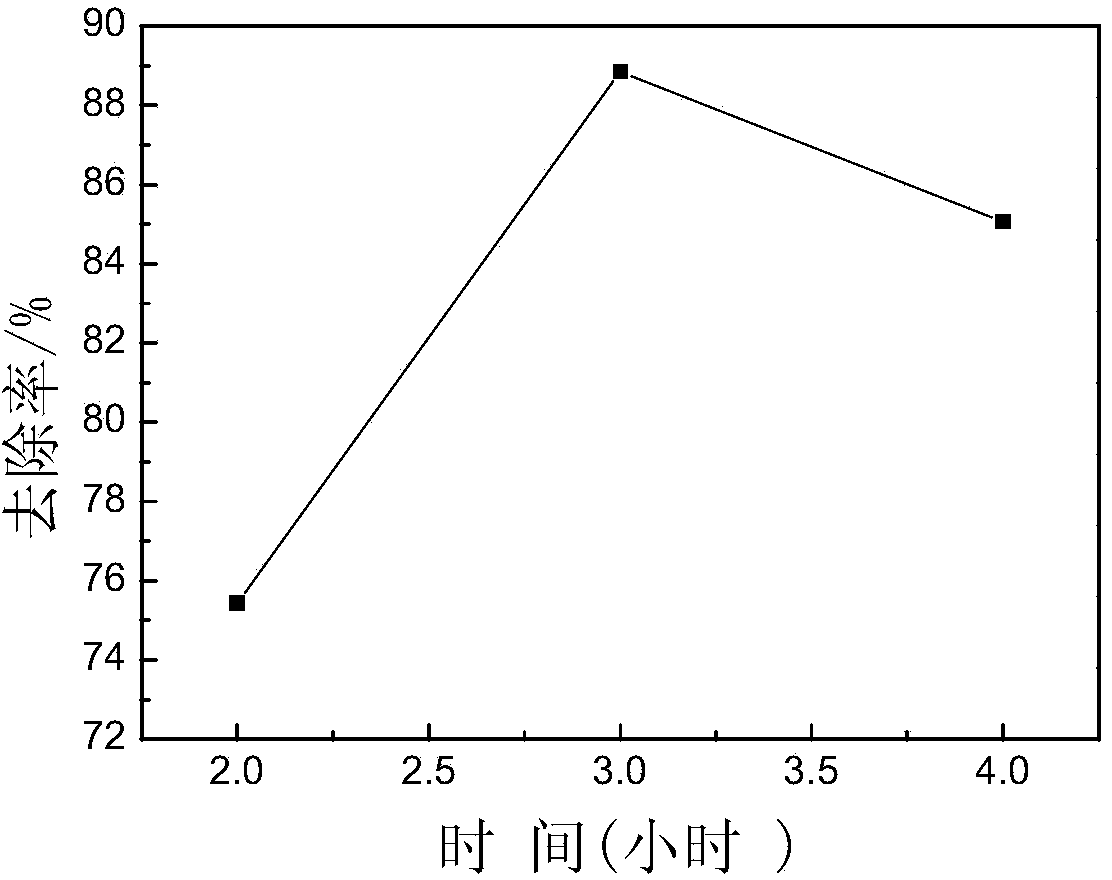

[0029] (1) Weigh 10 g of raw coal powder with a particle size of 0.075 to 0.113 mm, add it to 100 mL of distilled water, mix well, weigh 0.3 g γ-aminopropyltriethoxysilane and add it to the coal powder solution to make the raw coal powder The mass ratio of γ-aminopropyltriethoxysilane to γ-aminopropyltriethoxysilane is 1:0.03, and the coupling reaction is stirred at 70°C for 3 hours to obtain coupled modified coal powder.

[0030] (2) Measure 5.15g of diethylenetriamine, add it to the coupling modified coal powder, make the mass ratio of raw coal powder and diethylenetriamine 1:0.515, and react at 60°C for 2 hours to obtain amine pulverized coal;

[0031] (3) Add 6g sodium hydroxide and 7.6g carbon disulfide to the aminated coal powder of step (2), that is, the mass rat...

Embodiment 2

[0033] The present embodiment takes 10g of coal dust as an example, and the method for preparing a coal-based chelating adsorbent with diethylenetriamine as a raw material is realized by the following steps:

[0034] (1) Same as step (1) of Example 1.

[0035] (2) Measure 4g of diethylenetriamine, add it to the coupling modified coal powder, make the mass ratio of raw coal powder and diethylenetriamine 1:0.4, and react at 50°C for 3 hours to obtain amination pulverized coal;

[0036] (3) Add 5g sodium hydroxide and 6.3g carbon disulfide to the aminated coal powder of step (2), make the mass ratio of raw coal powder, sodium hydroxide and carbon disulfide be 1:0.5:0.63, react for 1 hour at 35°C, A coal-based chelating adsorbent is obtained.

Embodiment 3

[0038] The present embodiment takes 10g of coal dust as an example, and the method for preparing a coal-based chelating adsorbent with diethylenetriamine as a raw material is realized by the following steps:

[0039] (1) Same as step (1) of Example 1.

[0040] (2) Measure 6g of diethylenetriamine, add it to the coupling modified coal powder, make the mass ratio of raw coal powder and diethylenetriamine 1:0.6, and react at 65°C for 2 hours to obtain amination pulverized coal;

[0041] (3) Add 7g sodium hydroxide and 8.32g carbon disulfide to the aminated coal powder of step (2), make the mass ratio of raw coal powder, sodium hydroxide and carbon disulfide be 1:0.7:0.832, react for 4 hours at 35°C, A coal-based chelating adsorbent is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com