Patents

Literature

976results about How to "Facilitate solid-liquid separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrometallurgical process of nickel oxide ore

InactiveUS20050265910A1Simple and efficient processSimplified leaching stageSolvent extractionIron compoundsSlurryHydrometallurgy

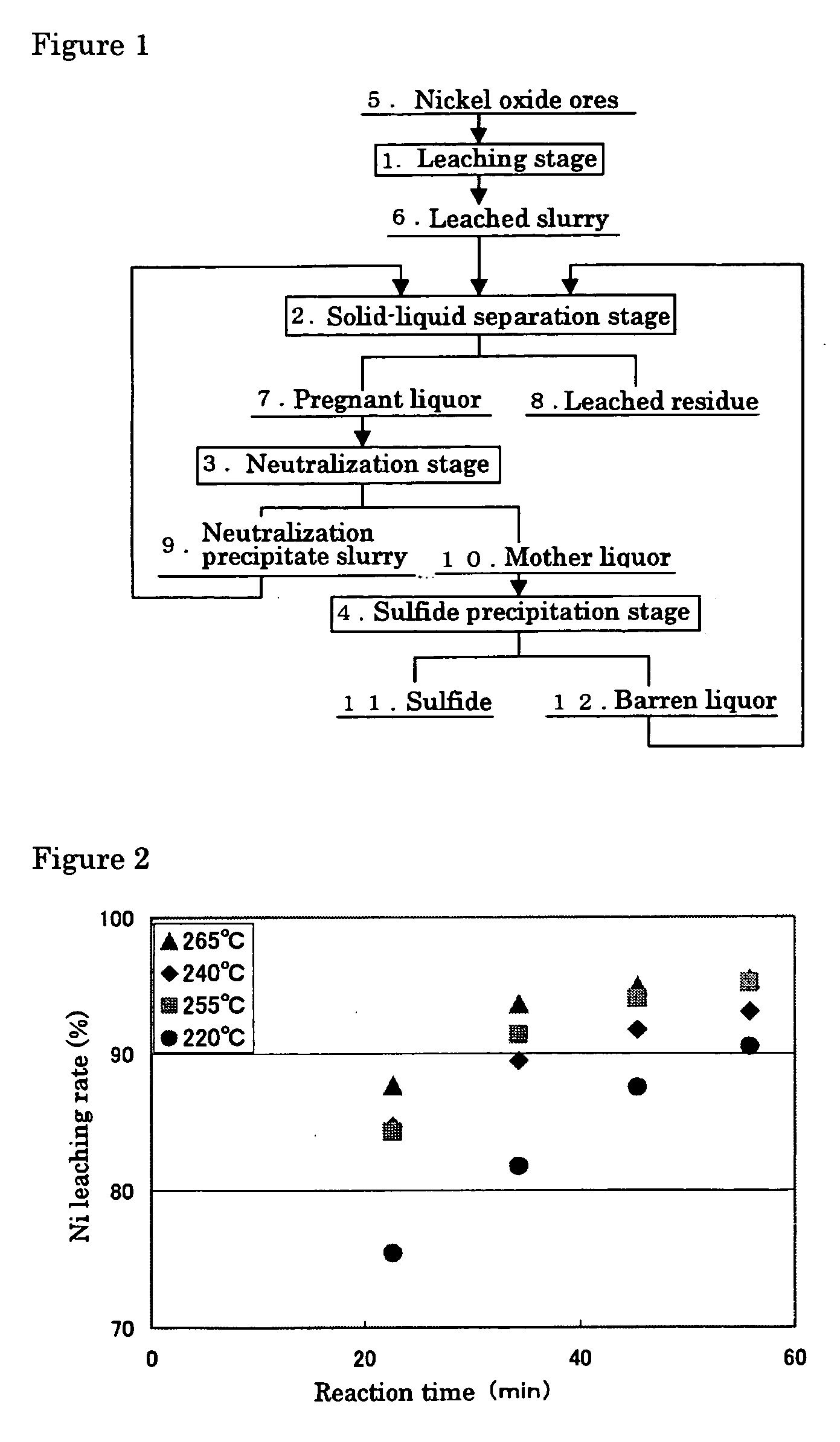

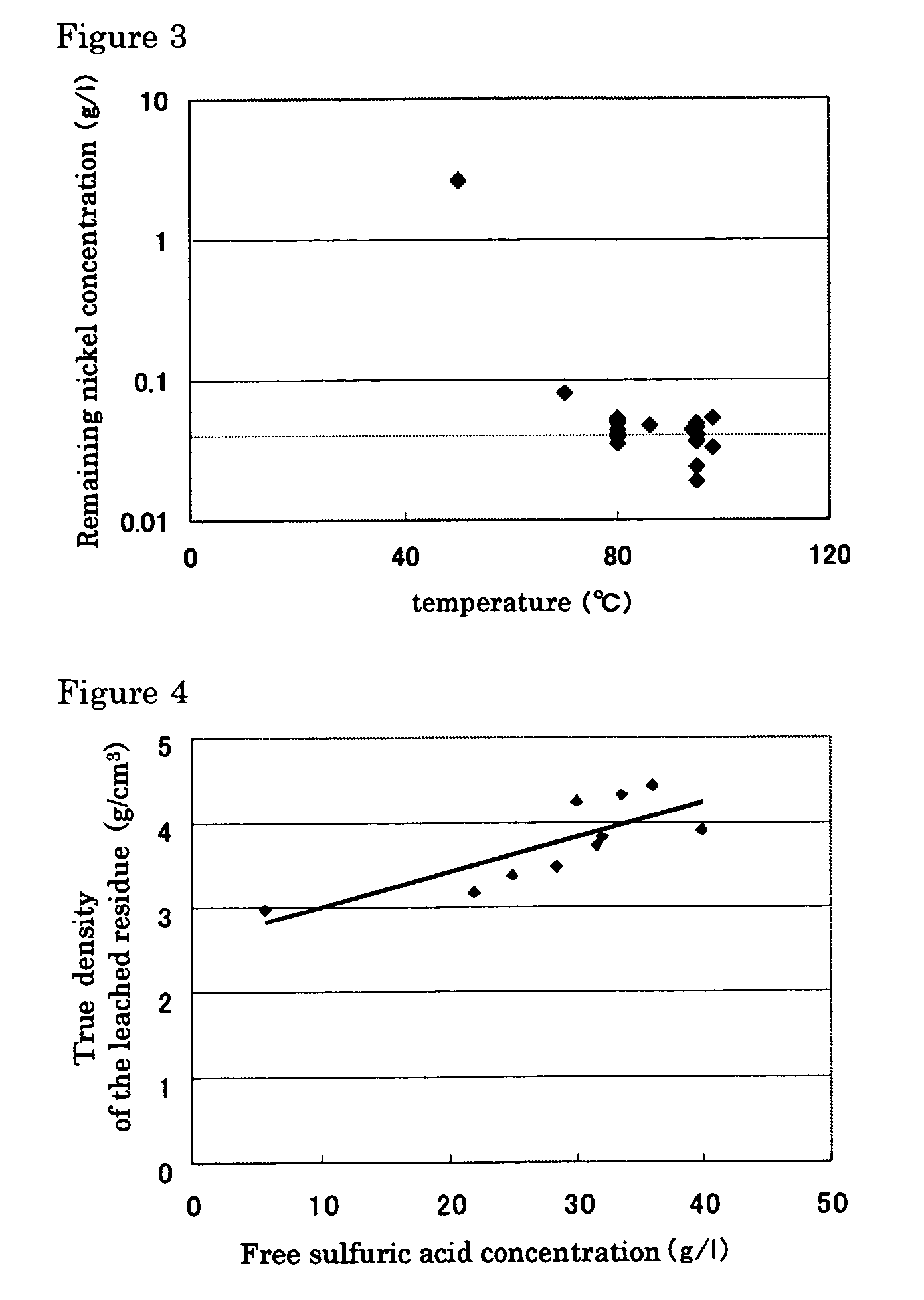

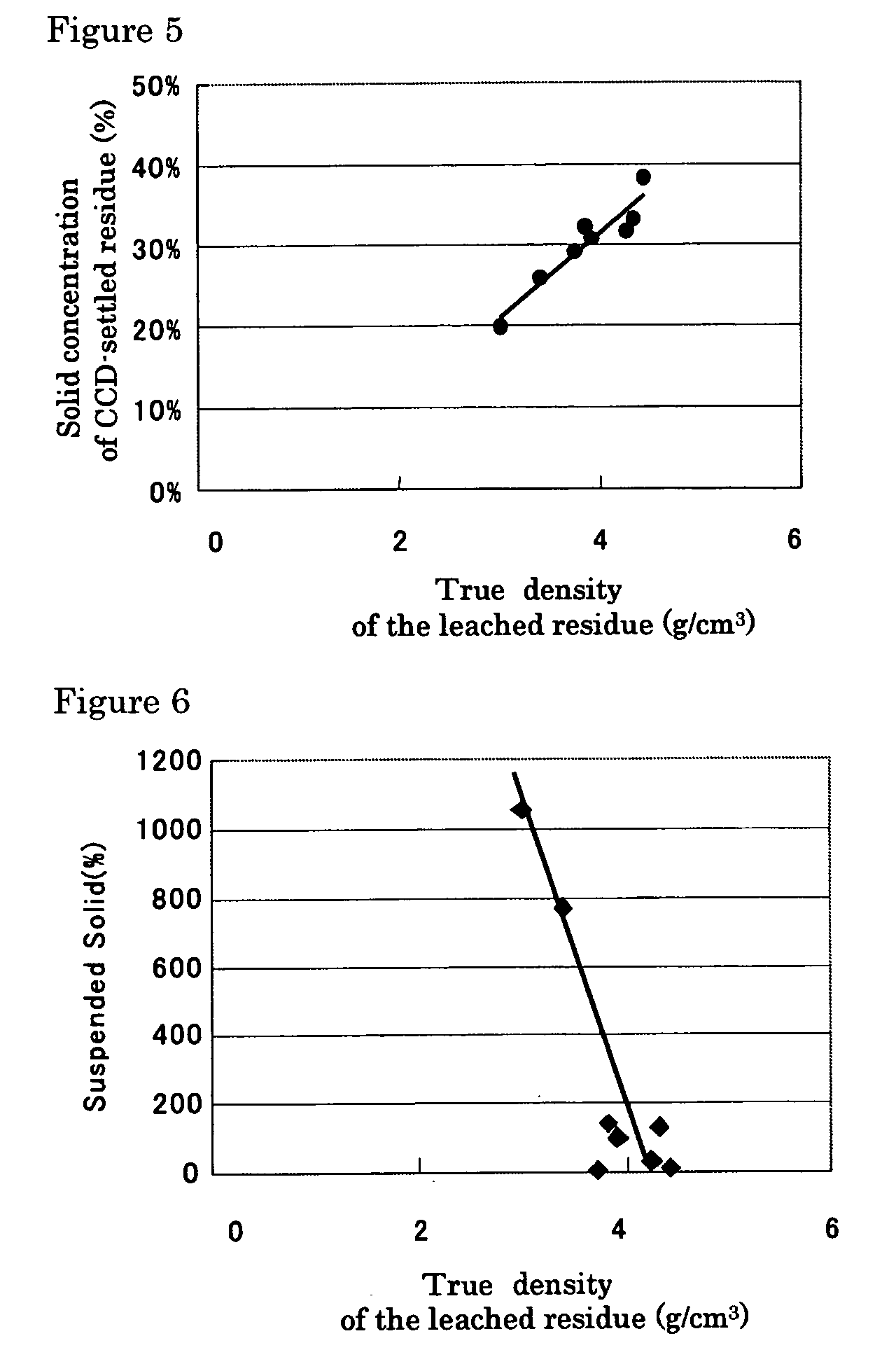

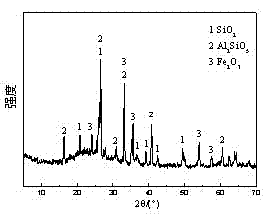

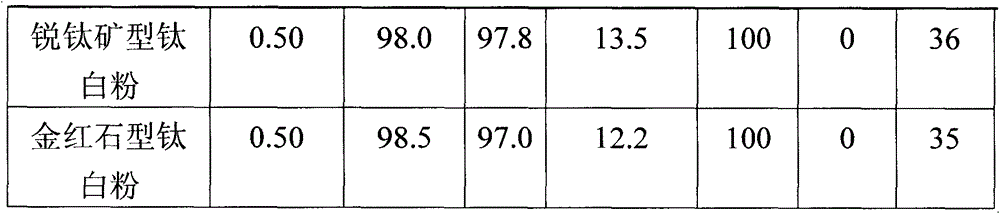

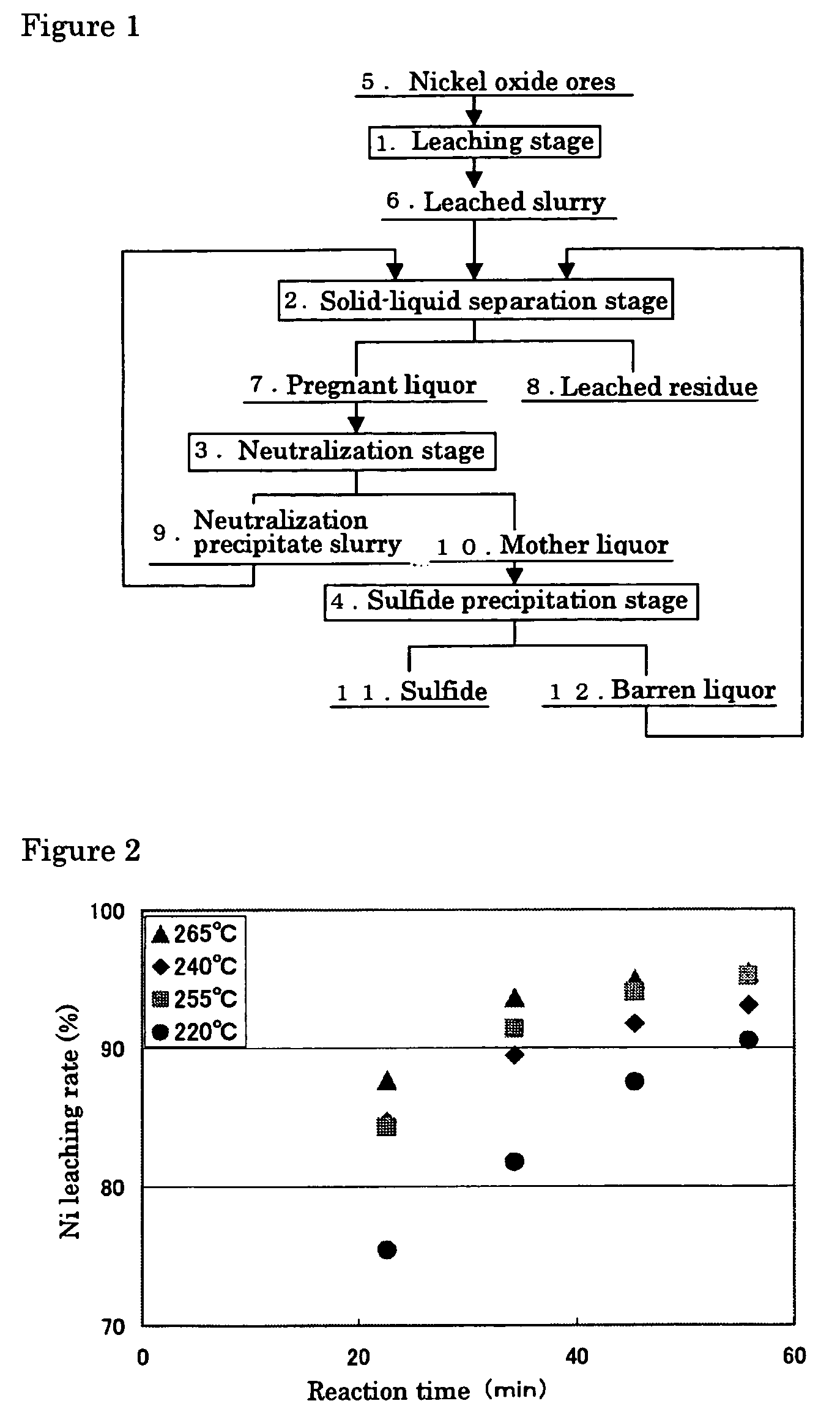

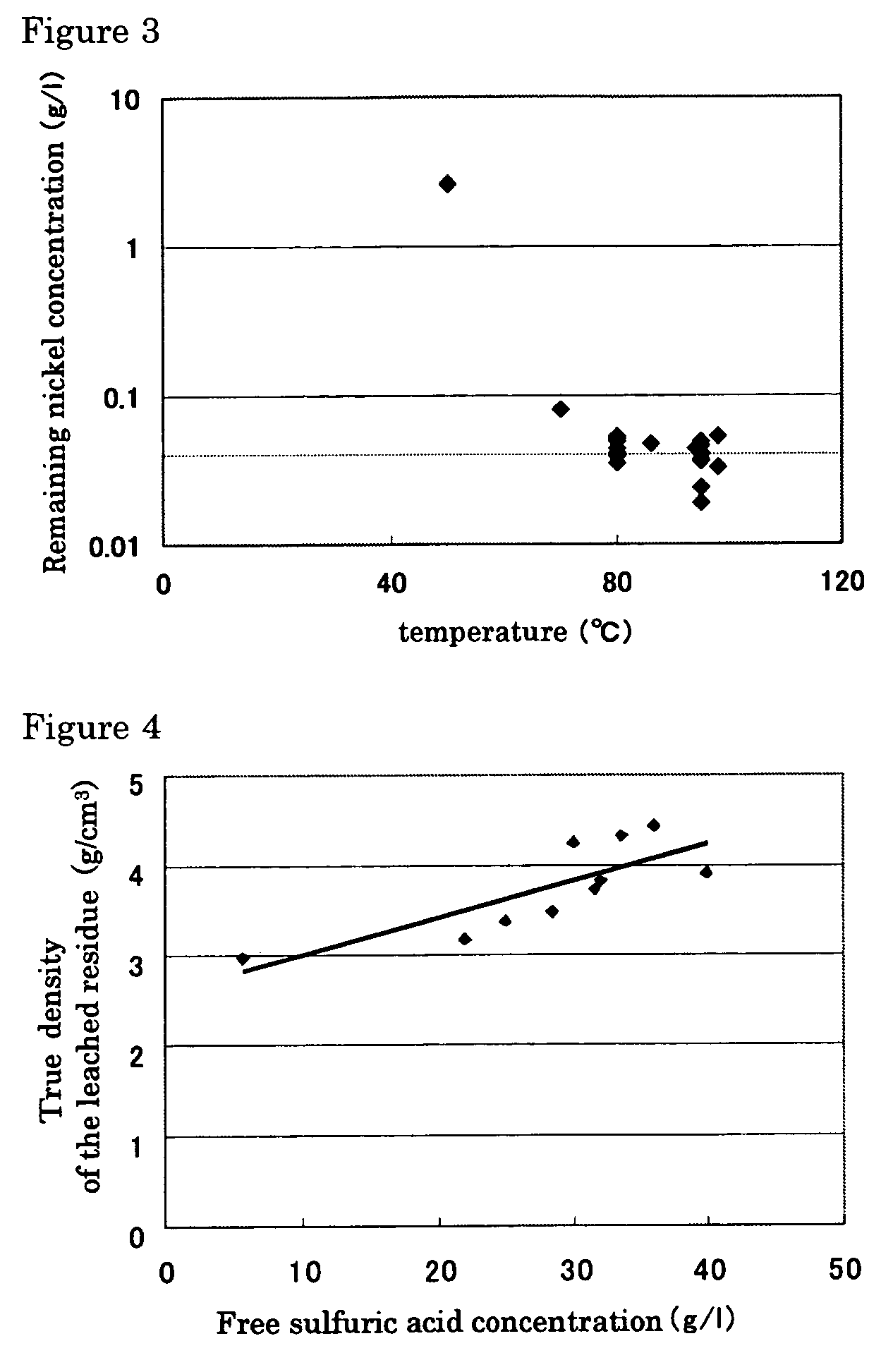

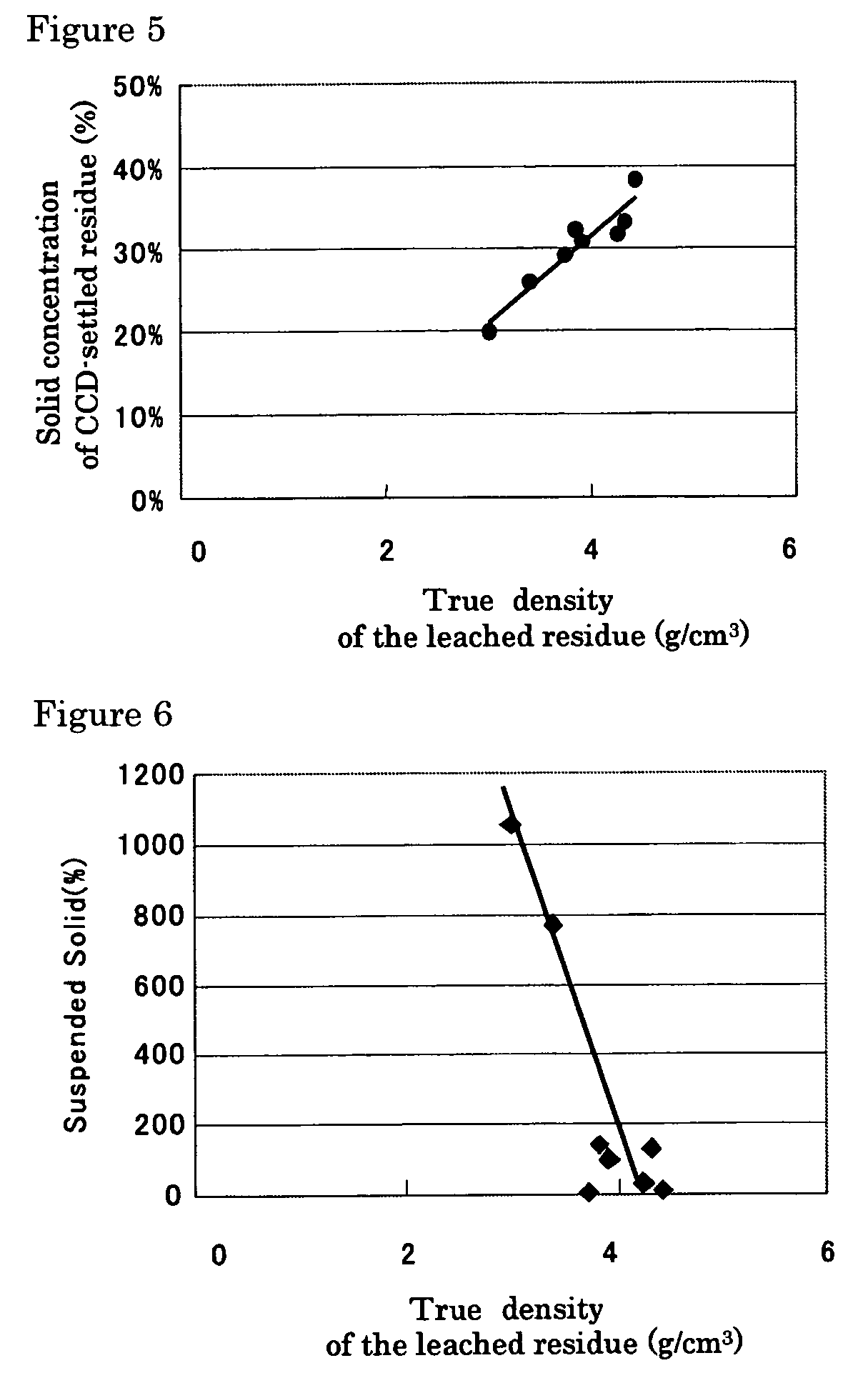

A hydrometallurgical process based on pressure leaching at elevated temperature for recovering nickel from nickel oxide ores, characterized by a simplified and efficient process as a whole, realizing a simplified leaching stage, reduced neutralizer consumption and precipitate production in the neutralization stage, and efficient use of recycled water. The hydrometallurgical process of the present invention, comprising a leaching stage which stirs the slurried ore in the presence of sulfuric acid at 220 to 280° C. to produce the leached slurry; solid-liquid separation stage which washes the leached slurry in multi-stages to produce the pregnant liquor and leached residue, the former containing nickel and cobalt; neutralization stage which treats the pregnant liquor in the presence of calcium carbonate incorporated to keep the pH level at 4 or less, while suppressing oxidation of the liquor, to produce the neutralization precipitate slurry and mother liquor for nickel recovery, the former containing trivalent iron; and a sulfide precipitation stage which blows hydrogen sulfide gas into the mother liquor to produce the sulfide solution and barren liquor, the former containing nickel and cobalt.

Owner:SUMITOMO METAL MINING CO LTD

Reproducible phosphorus-uptake ceramsite and preparation method thereof

InactiveCN102515830AStrong phosphorus removal capacityAdaptableOther chemical processesCeramic materials productionHydration reactionWastewater

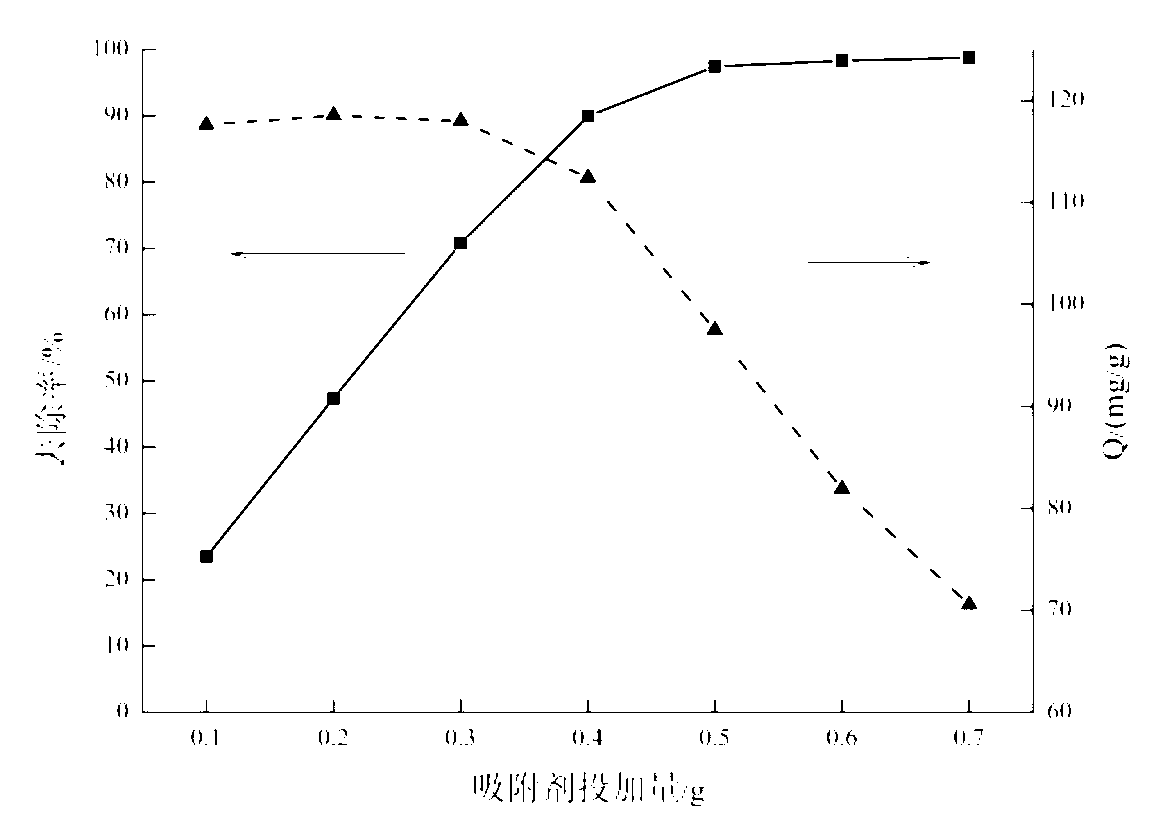

The invention discloses a reproducible phosphorus-uptake ceramsite and a preparation method thereof. The technical scheme provided by the invention comprises the following steps of: respectively drying 70-85 wt% of fly ash, 10-16 wt% of pore-forming agent and 5-14 wt% of clay powder and uniformly mixing the raw materials; after balling the mixture, baking at a temperature in a range of 950-1100 DEG C for 30-50 min to obtain a baked porous ceramsite; sequentially immersing the baked porous ceramsite with HCl, washing with water and drying; and loading zirconium oxide hydrate to obtain the phosphorus-uptake ceramsite. The phosphorus-uptake ceramsite prepared by the invention can be directly added into or filled as a filtering column to remove phosphorus in the water and the adsorbed phosphorus-uptake ceramsite can be desorbed by a NaOH solution to be reproduced; the saturated adsorption capacity to the phosphorus is 10-11 mg / g and the adaptability to the change of the phosphorus concentration in the water is good; after the treatment, the solid-liquid separation is easy to realize and the water quality of the discharged water is better. The reproducible phosphorus-uptake ceramsite provided by the invention has the advantages of strong phosphorus-uptake capability, easiness of realizing the solid-liquid separation, good cyclic usability and higher cost performance, so that the reproducible phosphorus-uptake ceramsite is applicable to phosphorous removal of various types of wastewater and surface water.

Owner:WUHAN UNIV OF SCI & TECH

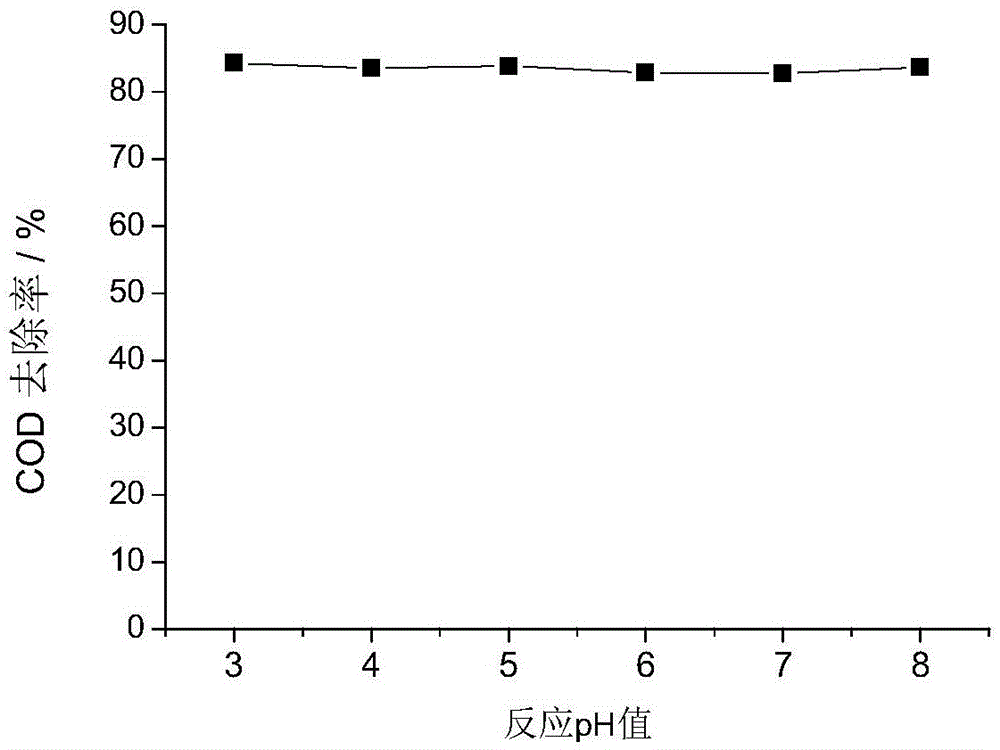

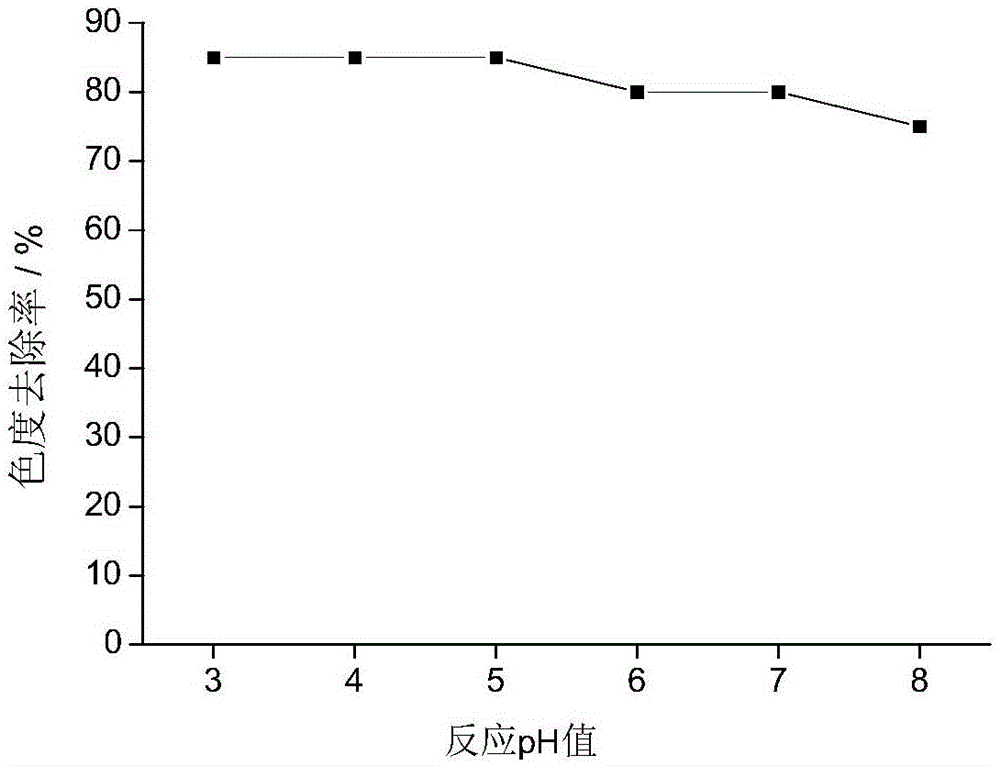

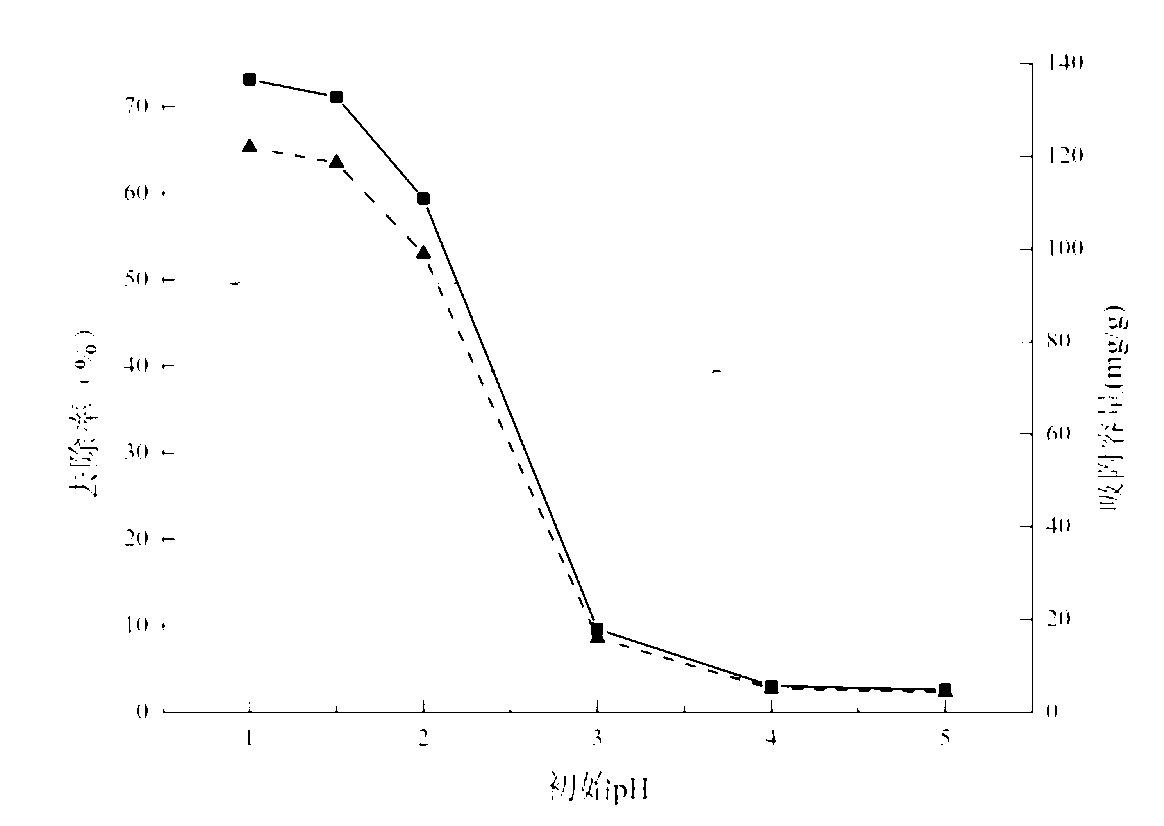

Method of treating refractory pollutants through catalyzing H2O2 oxidation by pyrite cinder

ActiveCN101745197AApplicable to a wide range of pHImprove responseSolid waste disposalWater contaminantsCinderPollutant

A method of treating refractory pollutants utilizes the pyrite cinder as catalyst which forms a heterogeneous Fenton system with H2O2 to catalyze H2O2 to generate hydroxyl radical (.OH) with strong oxidability and degrade the organic pollutants efficiently and quickly. The method comprises the following steps: (1) after the waste water is added in a reactor, a given amount of pyrite cinder original sample or activated and pretreated cinder is added in the waste water; (2) H2O2 solution is added in a mixed liquid of the waste water and the pyrite cinder so as to form an analogous Fenton reagent with the pyrite cinder; (3) stirring is carried out so as to lead the pyrite cinder, the H2O2 solution and the waste water to be mixed for reaction, and the stirring is stopped at the set reaction time; and (4) standing is carried out, the pyrite cinder is quickly precipitated and the supernate is discharged, so that the pyrite cinder can be reused. The invention discovers a novel analogous Fenton oxidation catalyst, extends the resource utilization ways of the pyrite cinder, achieves the purpose of controlling waste by waste and realizes the comprehensive utilization of the waste.

Owner:TONGJI UNIV

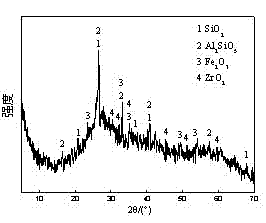

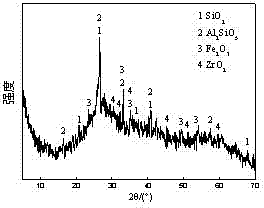

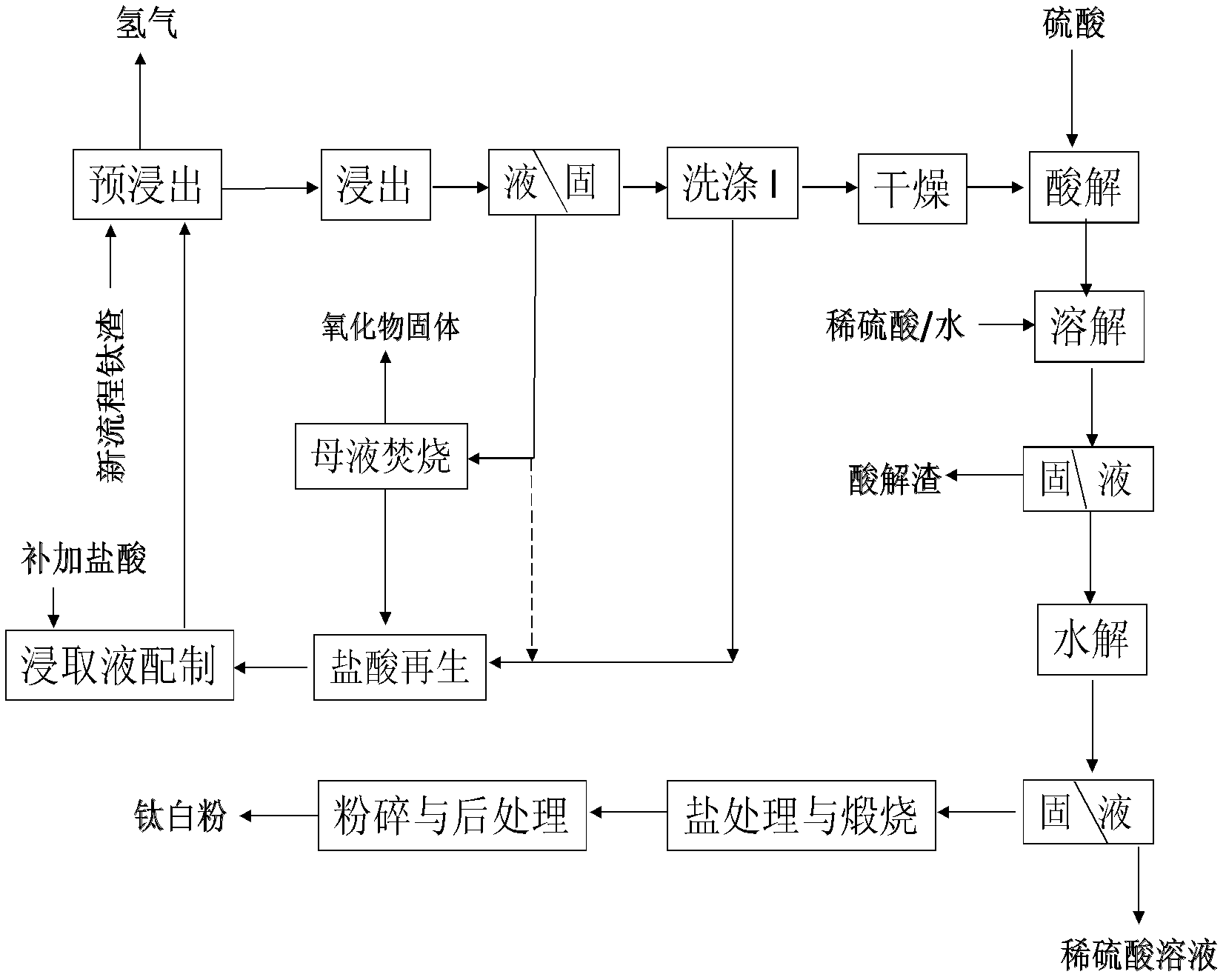

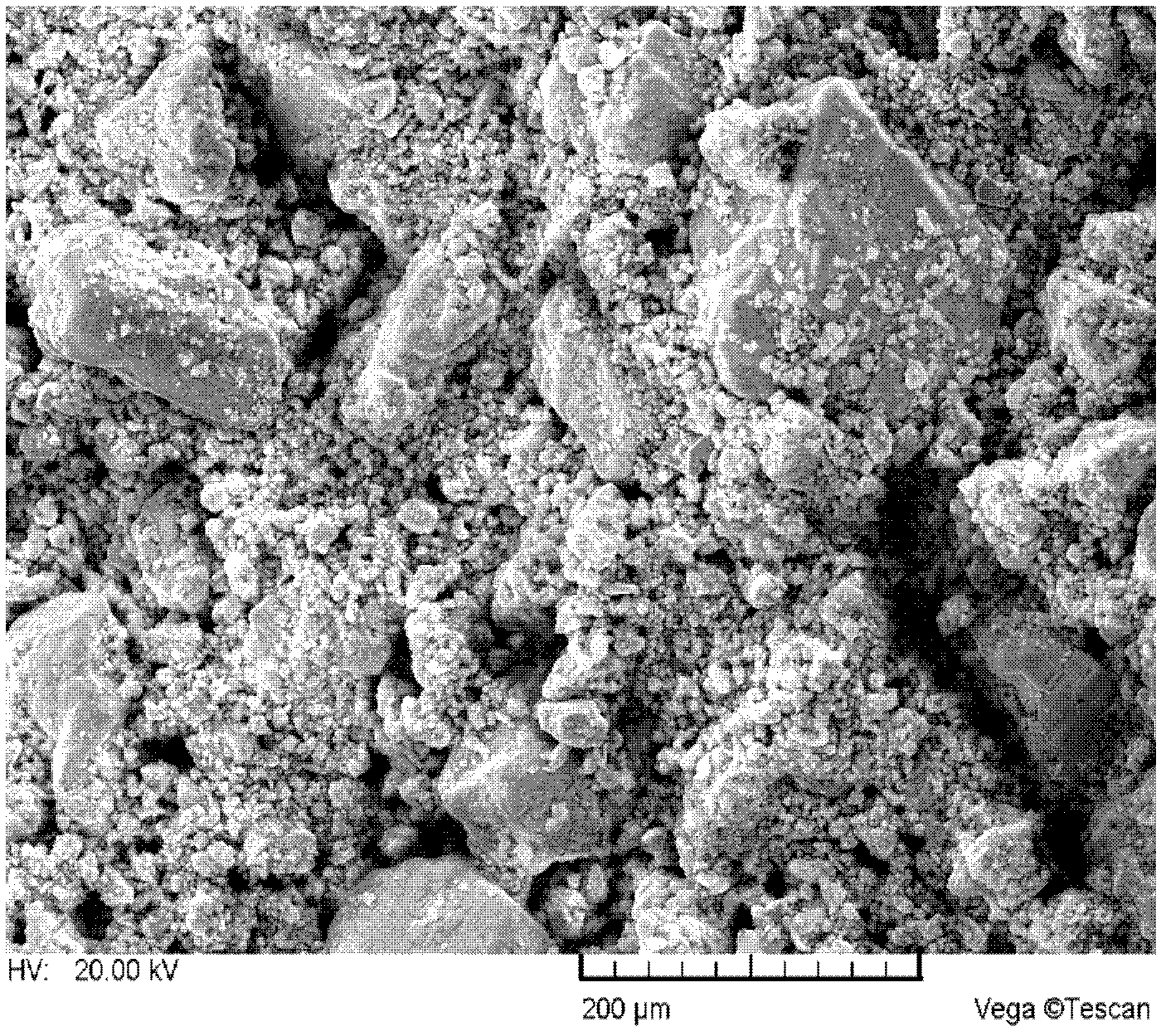

Method for preparing titanium pigment by using titanium residues obtained by directly reducing titanium-iron oxide

InactiveCN102627321AEfficient removalLow impurity contentTitanium dioxideProcess efficiency improvementBrown iron oxideScrap

The invention provides a method for preparing a titanium pigment by adopting a novel direct reduction flow. A novel raw material is provided for the production of a titanium pigment with a sulfuric acid process, and a process flow is provided for downstream utilization of a direct reduction product of vanadium titano-magnetite simultaneously. A novel hydrochloric acid pretreatment process with a novel direct reduction flow for titanium residues is adopted, so that dyeing elements such as aluminum, calcium, magnesium, iron, chromium, vanadium and the like in the titanium residues in the novel process are removed effectively, pretreated titanium-rich hydrochloric acid leaching residues are directly applied to production of a titanium pigment with a sulfuric acid process, the conventional refrigeration iron removing and concentration purifying processes are not required, special aluminum, chromium and vanadium processes are not required, ferrous sulfate is not produced, and ammonia alum waste as well as chromium, vanadium and ferrous sulfide residues which are difficult to treat are not produced. Moreover, the used hydrochloric acid and sulfuric acid are completely recycled in an enclosed loop, and a diluted waste acid liquid is not produced.

Owner:沙立林 +1

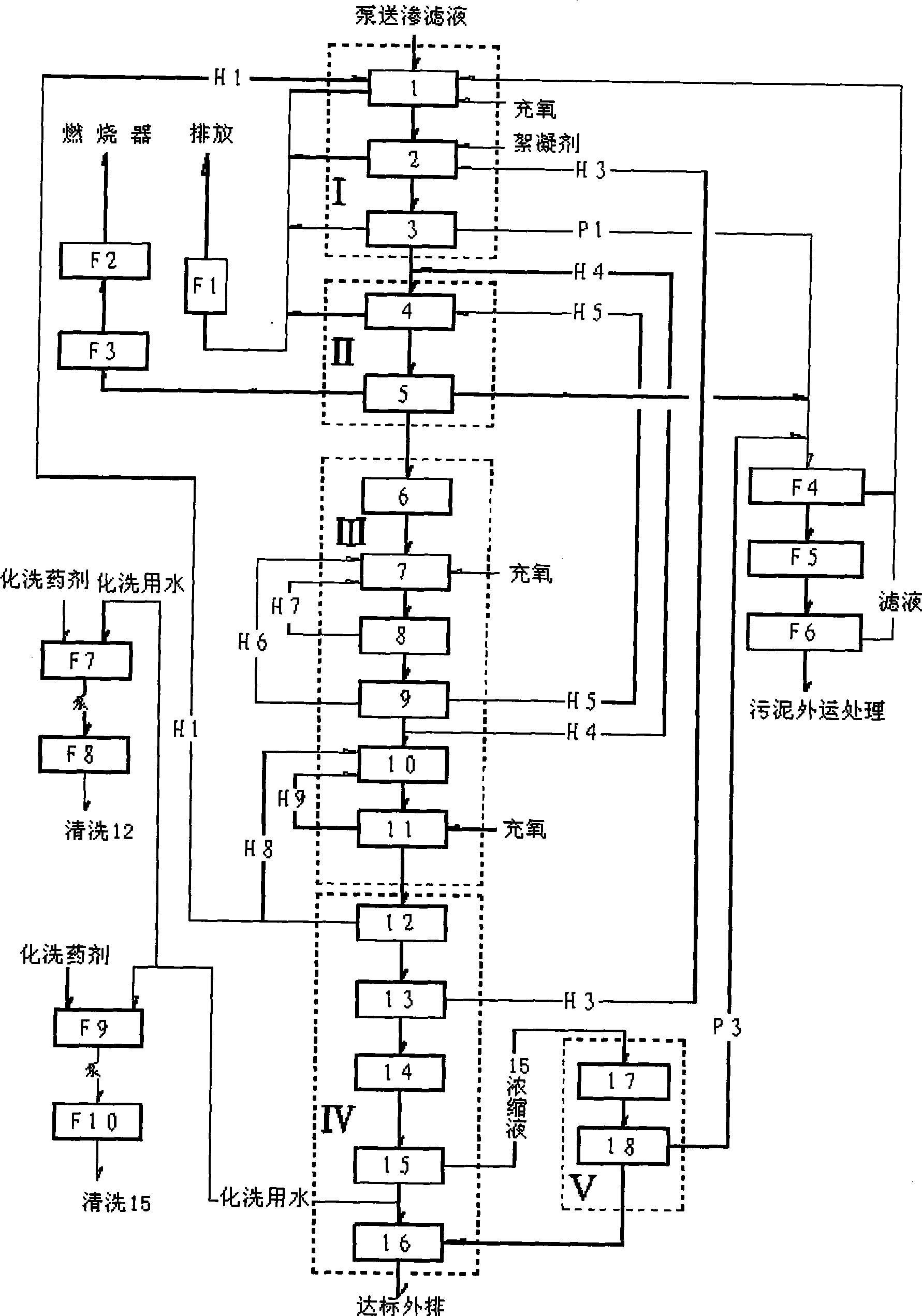

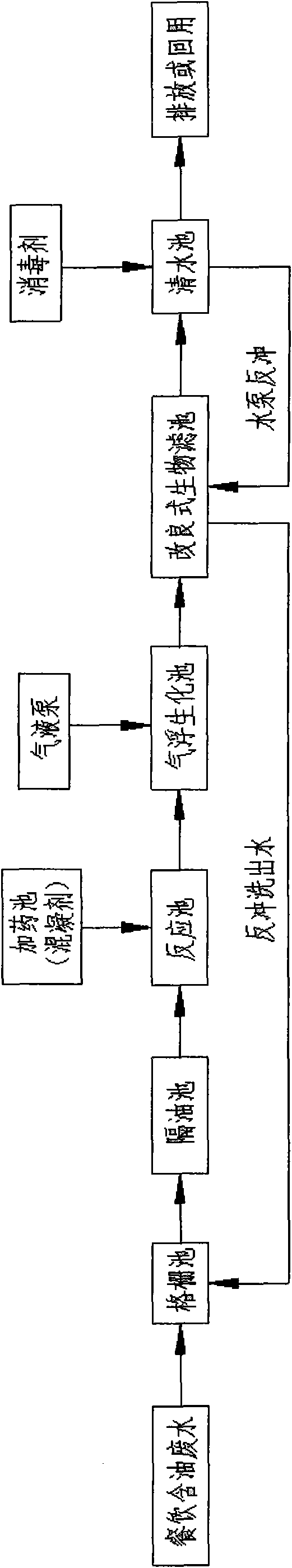

Treatment process for garbage leachate

ActiveCN101428938AImprove biodegradabilityPrevent rancidityTreatment with aerobic and anaerobic processesWater/sewage treatment bu osmosis/dialysisFlocculationHydrolysis

The invention discloses a method for treating landfill leachate, which orderly comprises flocculation precipitation pretreatment, hydrolysis pre-acidification treatment, anaerobic treatment, aerobic treatment comprising shortcut nitrification-denitrification and secondary nitrification-denitrification, membrane separation treatment and oxidation flocculation treatment. The method has the advantages of having higher removal rate of ammonia nitrogen and lower energy consumption, realizing the up-to-standard discharge of leachate concentrated solution, ensuring sound operation of the whole system, greatly lowering the oxidation-reduction potential in the anaerobic reaction, and improving the anaerobic treatment effect, thereby making the landfill leachate fully meet the first-level discharge standard of the Integrated Wastewater Discharge Standard.

Owner:浙江永峰环保科技股份有限公司 +1

Plastic-skeleton bentonite bentonite composite adsorbent and its production

InactiveCN101073764AEasy to recycleHigh strengthOther chemical processesWater/sewage treatment by sorptionPorositySodium Bentonite

The invention is concerned with the plastic framework-style bentonite composite sorbent and the preparation method. The crude bentonite or the character-changed bentonite is the main material for the composite sorbent, the thermoplastic macromolecule polymer is as the framework connecting material and also add the assistant selective material, the blowing hole-make material by the working procedure such as mixture, model melt extrude, dryness and cut grain. The preparation method is dry preparation method with simple process and without secondary pollution, the product can adjust the powder intensity, the size of the hole, the porosity, the density and the adsorbing selectivity according to the change of the selected group and dosage. The sorbent is not easy pulverization in water which can use for waste water dispose with heavy metal ion and organic infectant.

Owner:GUANGXI UNIV

Method for purifying oil-containing waste water of catering and complete equipment thereof

ActiveCN101643301AFacilitate solid-liquid separationImprove production efficiencyFatty/oily/floating substances removal devicesMultistage water/sewage treatmentBio filtrationFiltration

The invention belongs to the technical field of water processing, and in particular relates to a method for purifying oil-containing waste water of catering and complete equipment thereof. The methodcomprises the following steps: mechanical-type oil-dirt separation, coagulation treatment of suspended substances, air floatation biochemical treatment, and biological filtration and sterilization. Compared with the prior art, the method of the invention has the characteristics of high removal efficiency, simple equipment, low running cost, convenient operation, management and maintenance, and caneffectively remove large amount of organic substances and grease in the waste water, the mmonian and chroma of the waste water, and the like, and enables every outlet water index to satisfy the requirement of recycle water.

Owner:上海青溪环保科技有限公司

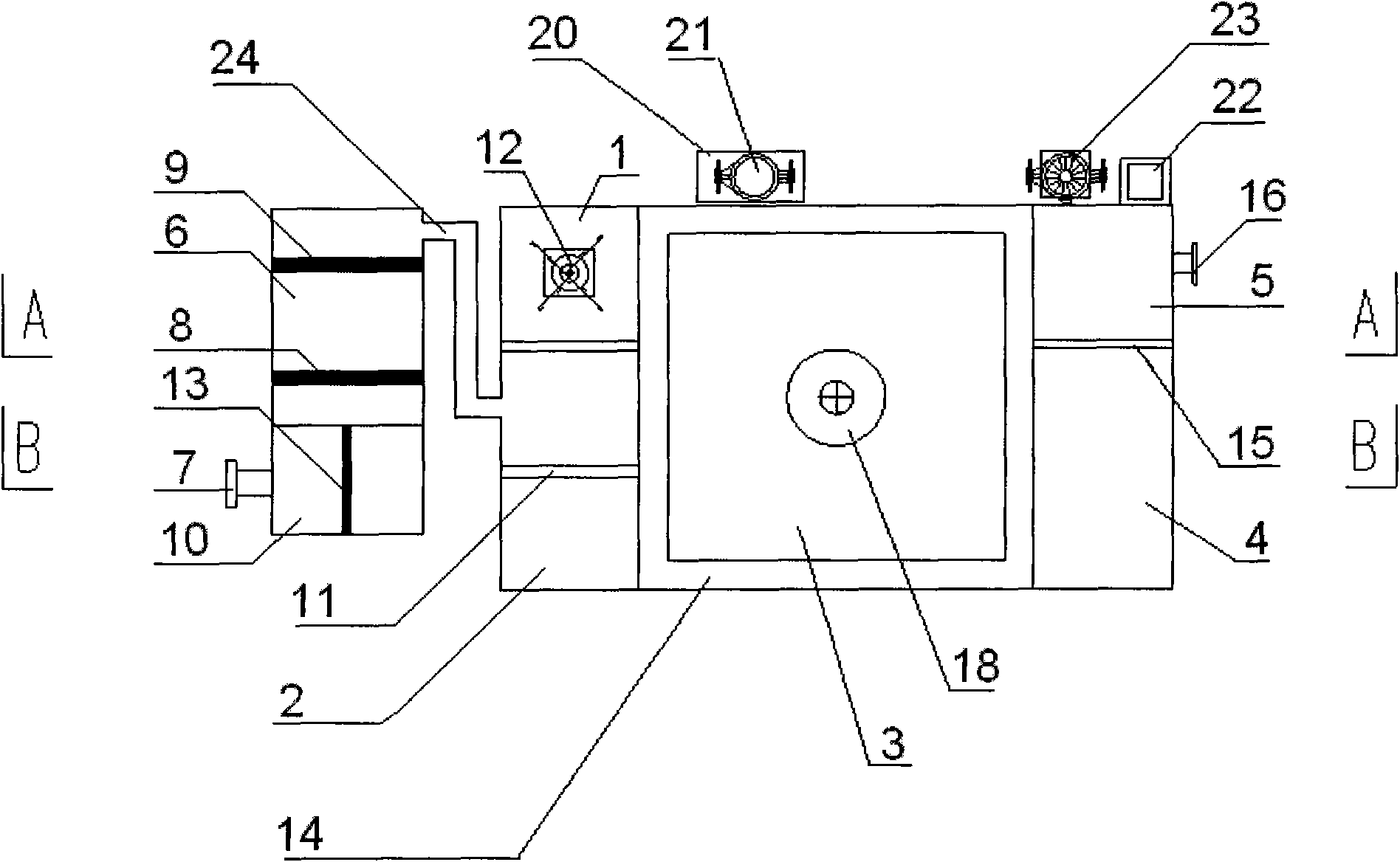

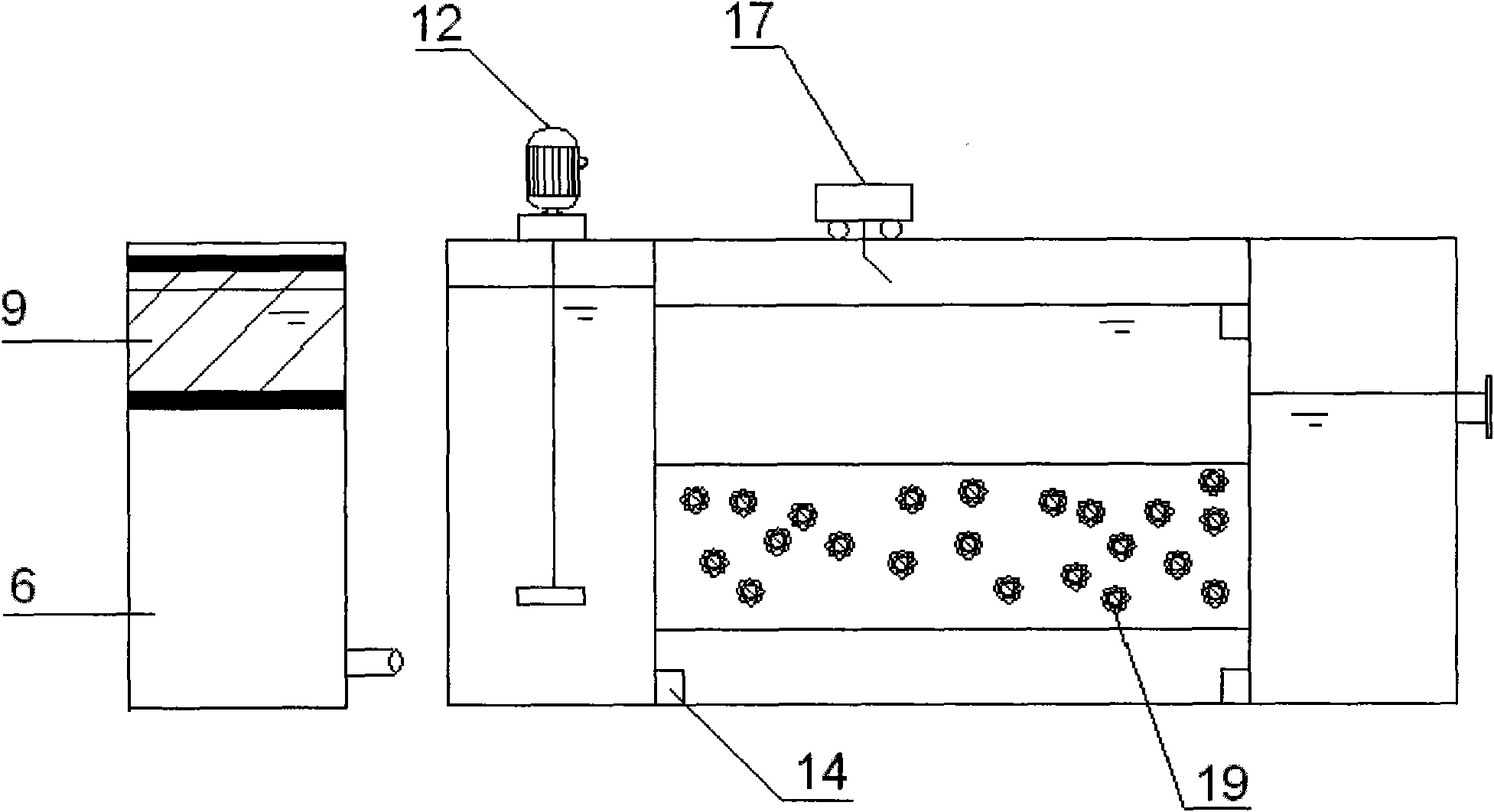

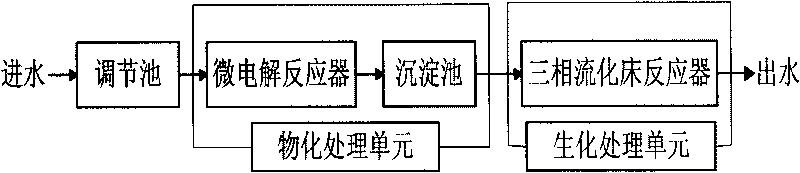

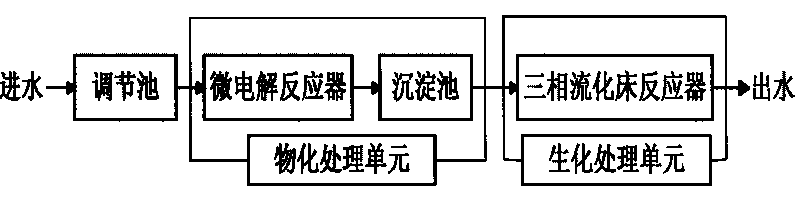

Process method for treating coking wastewater

InactiveCN101734826ALow densityReduce processing costsWaste water treatment from metallurgical processMultistage water/sewage treatmentVolatile phenolsActivated sludge

The invention discloses a process method for treating coking wastewater. The process method solves the technical problems that a micro-electrolysis method has hardening, channeling and narrow applicability of a pH range and a biochemical treatment process has long flow, large occupied area, poor impact load resistance and high expense. The method comprises a physical-chemical treatment unit consisting of a micro-electrolysis reactor and a settling tank; in the micro-electrolysis reactor, scrap iron, scrap copper and a lightweight blocky material are used as fillers; the pH of inlet water is between 2.0 and 6.0; the waterpower retention time is between 20 and 60 minutes; the method adopts air aeration; the method also comprises a filtering type inner circulating three-phase fluidized bed reactor biochemical treatment unit, and immobilized activated sludge balls are utilized to realize simultaneous denitrification and decarburization; the pH of inlet water is between 7.2 and 8.5; the concentration of dissolved oxygen is between 2 and 6mg / L; the temperature is between 28 and 32 DEG C; the waterpower retention time is between 20 and 40h; the COD of outlet water reaches secondary standard of integrated wastewater discharge standard; and volatile phenol, ammonia nitrogen and chroma reach primary standard of integrated wastewater discharge standard.

Owner:NANJING UNIV OF SCI & TECH

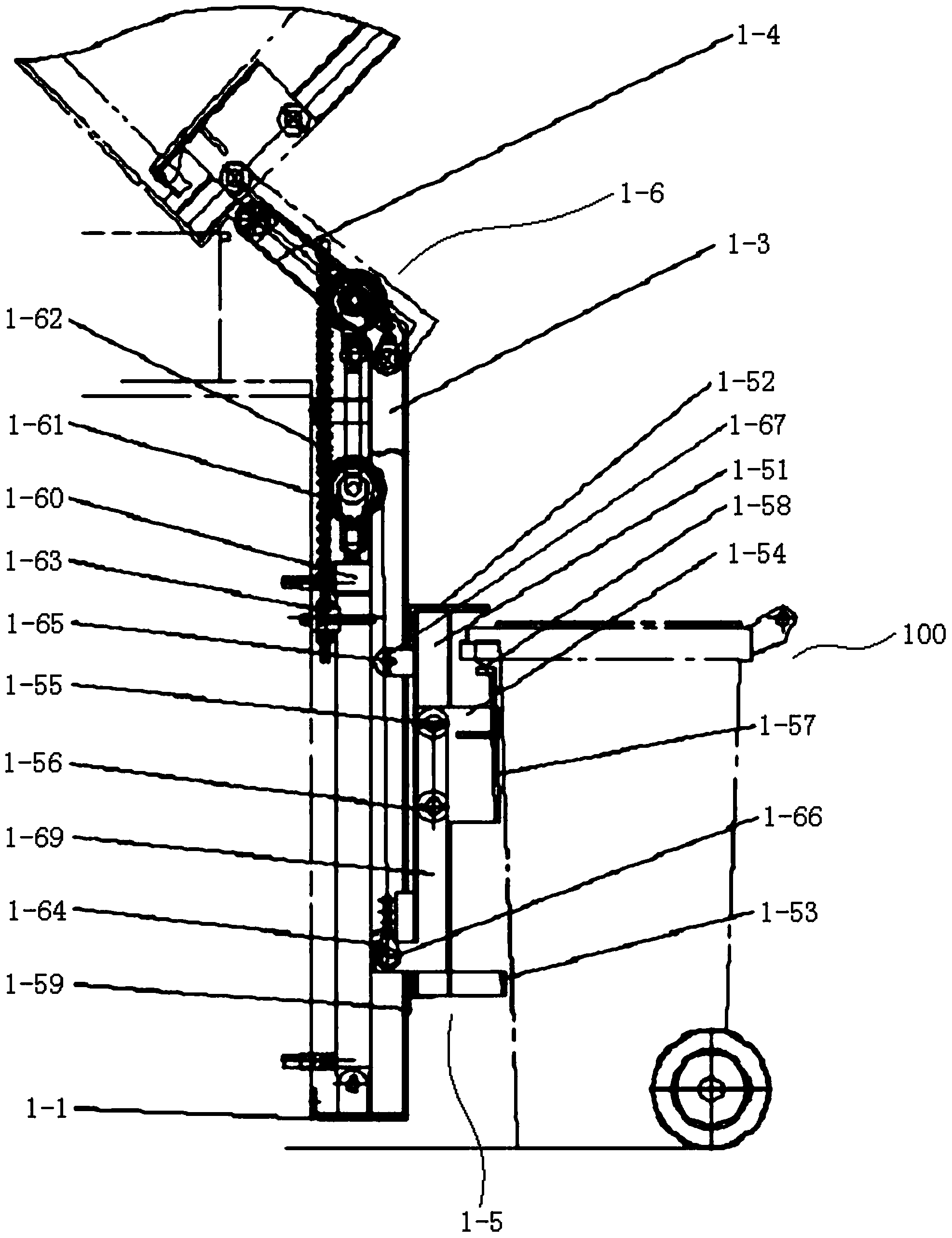

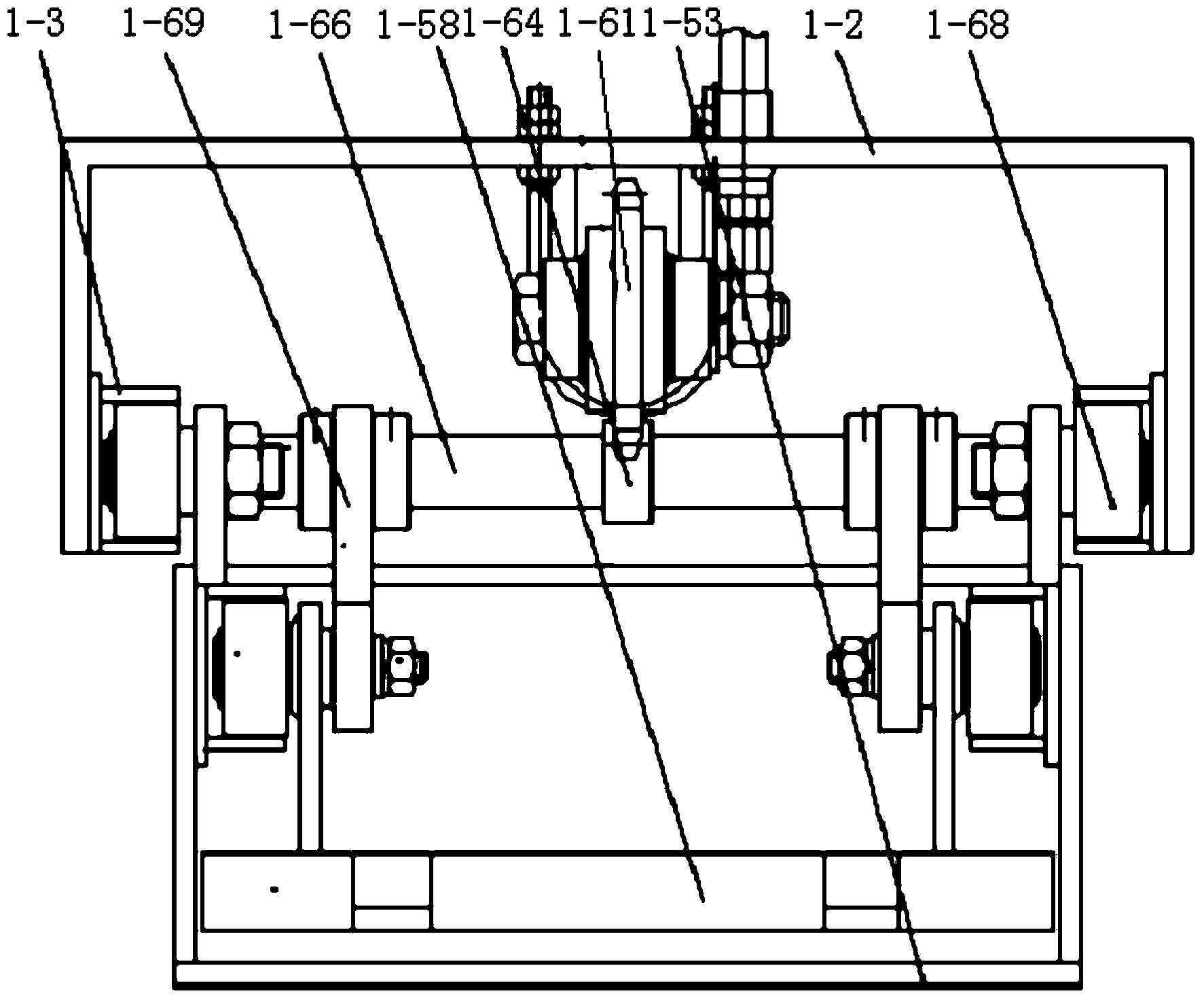

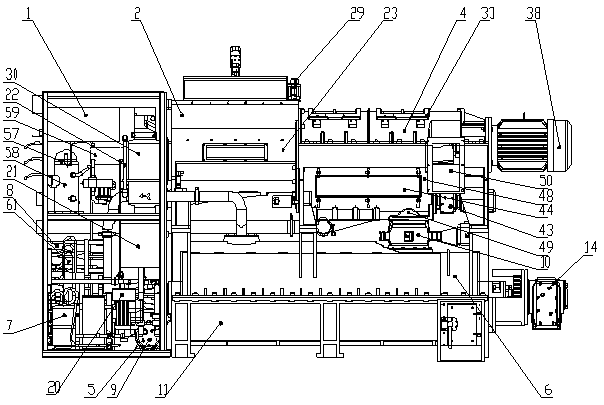

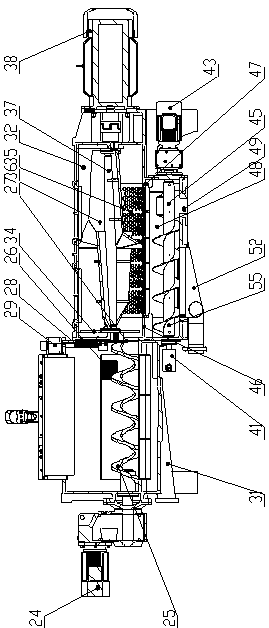

Kitchen waste pretreatment equipment and technology

The invention relates to a kitchen waste pretreatment equipment and technology. The equipment is characterized by comprising a shell body, a garbage can lifting device mounted on one side of the shell body, a feeding device mounted on the upper portion of the shell body, an automatic separation device mounted in the shell body, an extrusion device mounted in the shell body, a smashing device mounted in the shell body, a fermenting and drying device mounted in the shell body and an ionization deodorization device mounted in the shell body. The kitchen waste pretreatment equipment and technology has the advantages of feeding and sorting automatically, being good in solid-liquid separation effect, high in efficiency, high in dehydration rate, high in fermentation treatment speed, even in fermentation, high in heating speed, capable of oxygenating automatically during fermentation, up to standard on gas deodorization, environmentally friendly, free of pollution and convenient to operate, saving manpower and the like, can process the kitchen waste generated by 300 to 500 people in 24 hours, and output 150kg to 200kg organic fertilizer with the moisture content not more than 25%.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

Fixed microbe rubber granule filler, preparation and application thereof

InactiveCN101693775AFully contactedIncrease concentrationBiological water/sewage treatmentPolyvinyl alcoholSewage

The invention discloses a fixed microbe rubber granule filler which comprises rubber granules as carriers, embedding medium and microbe enzyme preparation for providing microbes, wherein the rubber granules can mutually act with the embedding medium and the microbe enzyme preparation to form composite macromolecular gel, microbes in the microbe enzyme preparation are embedded in a gel network to form the fixed microbe rubber granule filler. The invention further discloses a preparation process of fixed microbe rubber granule filler and an application thereof in sewage treatment. As adding polyvinyl alcohol and the microbe enzyme preparation in the rubber granules, the fixed microbe rubber granule filler has light weight than common rubber granules, and is easy to form circulating fluidization state in a biological reactor, and enables sewage to fully contact with the fixed microbe filler, and the stability of a biological film is excellent.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV

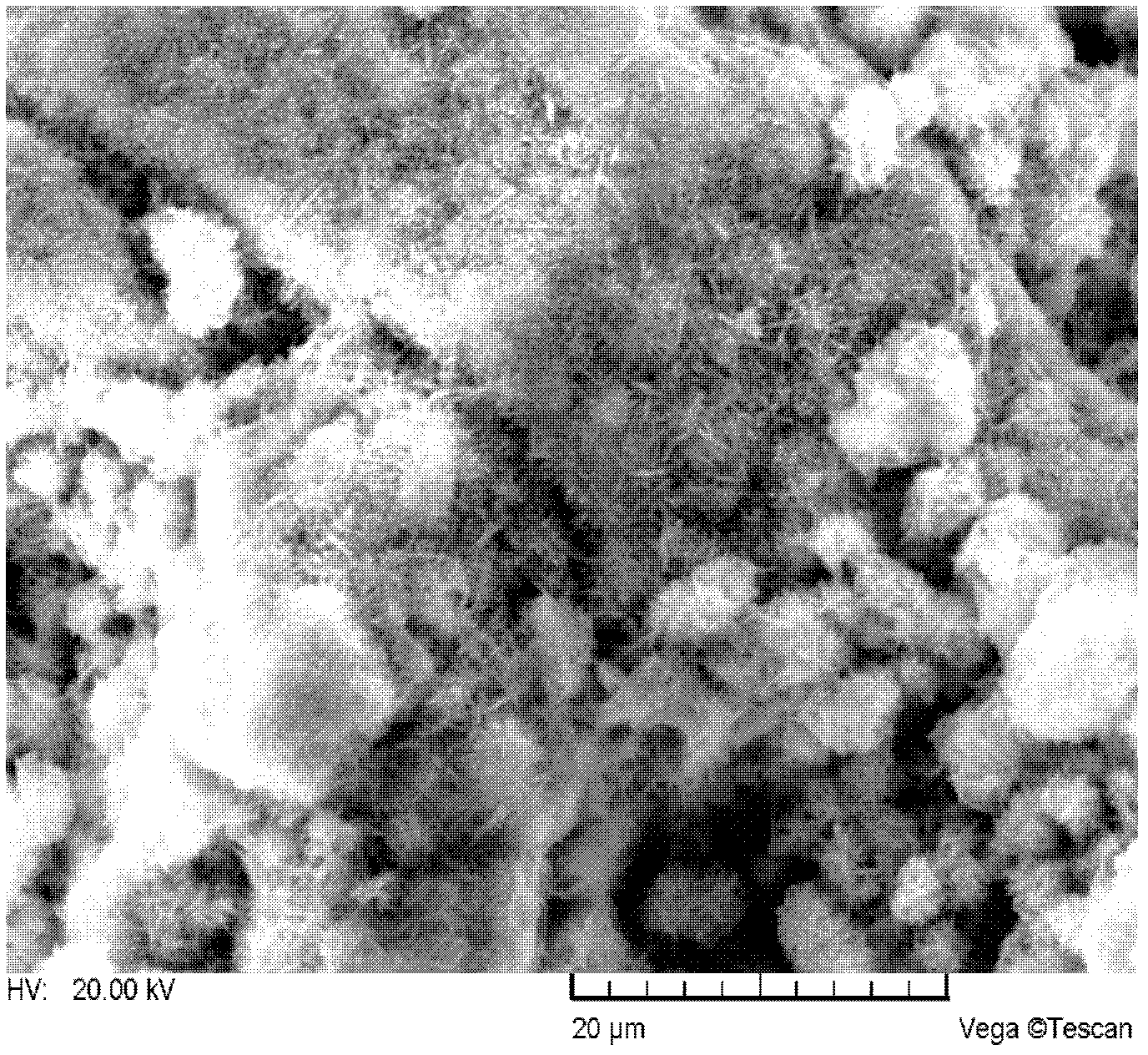

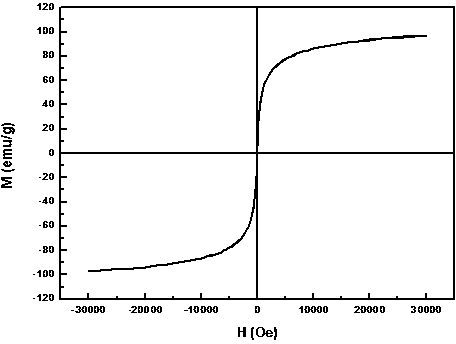

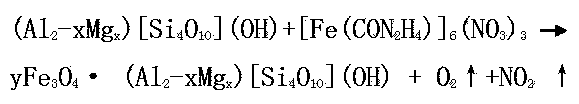

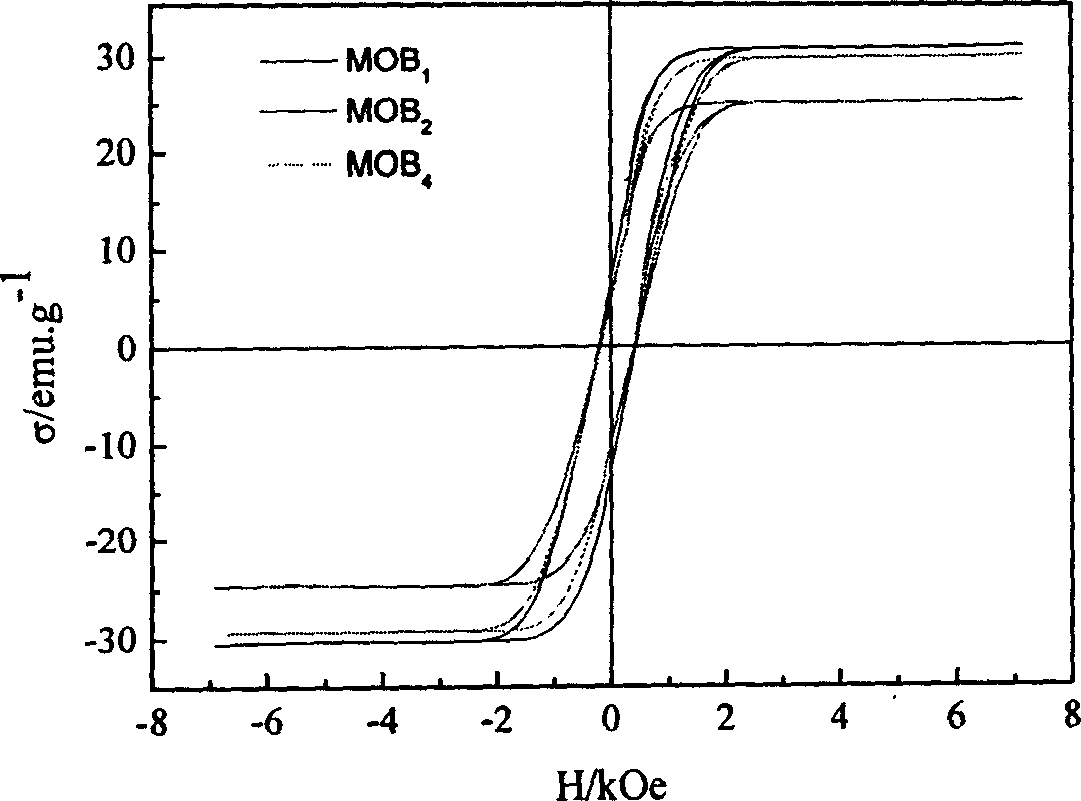

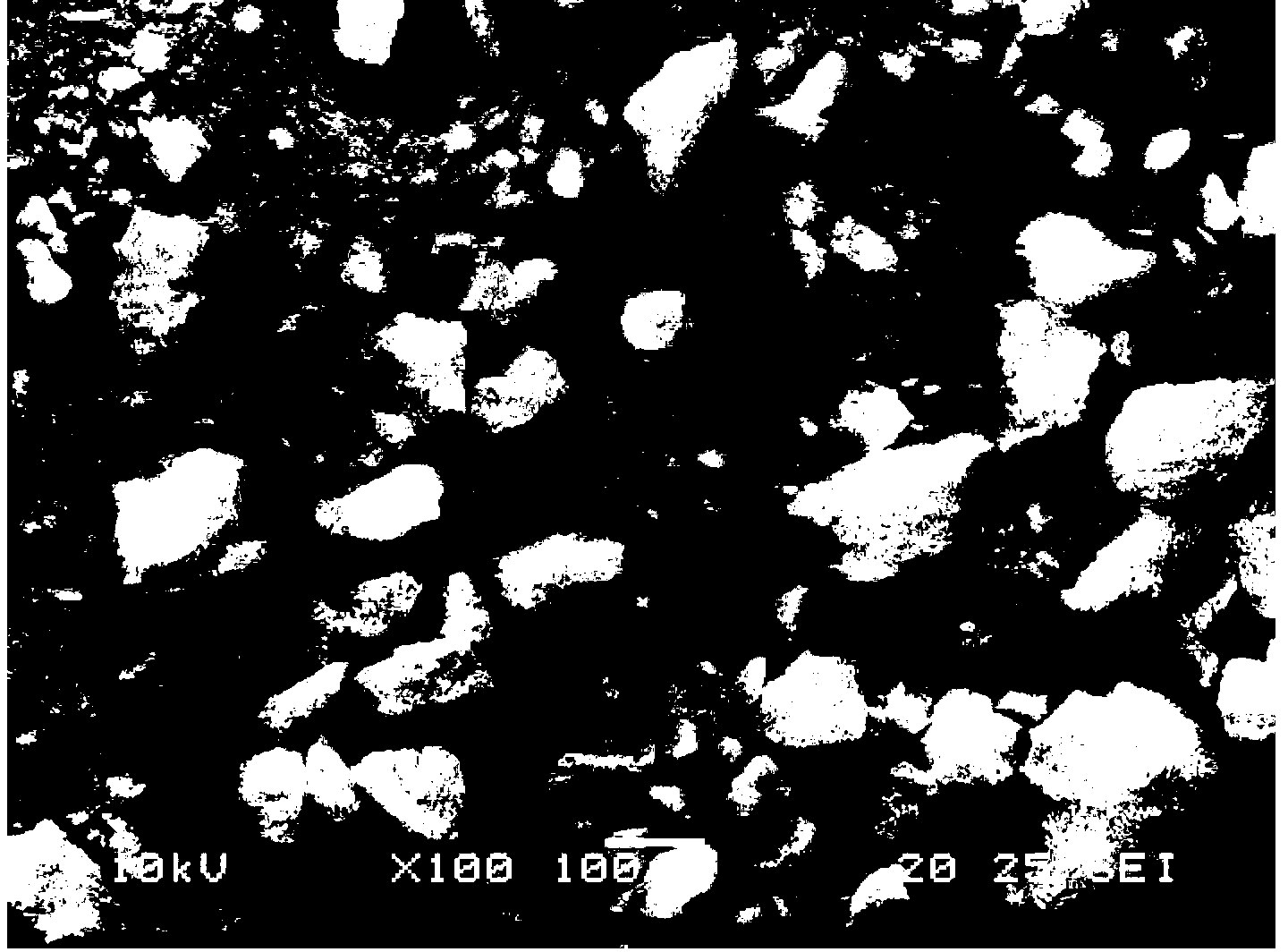

Preparation method of superparamagnetic bentonite-based water treating agent

ActiveCN104174354AGood adsorption and purification of industrial wastewaterFacilitate solid-liquid separationOther chemical processesWater/sewage treatment by sorptionSodium BentoniteBentonite suspension

The invention discloses a preparation method of a superparamagnetic bentonite-based water treating agent and belongs to the field of environmental protection and adsorbing-method water treatment. The preparation method comprises the following steps: (1) preparing modified bentonite suspension; (2) preparing a mixed aqueous solution of deionized water or distilled water of an inorganic or organic iron source containing Fe<2+> and Fe<3+>; (3) preparing an alkaline-substance aqueous solution; (4) carrying out synthesis in a reaction container; and (5) cleaning, drying and grinding. The preparation method disclosed by the invention has the advantages that the adsorptivity is good, the magnetic separation and recycling are easy, the preparation process is simple, materials are easily available, the reaction is mild and the effect of adsorbing coal slime and other impurities in coal-slime water is relatively good.

Owner:TAIYUAN UNIV OF TECH

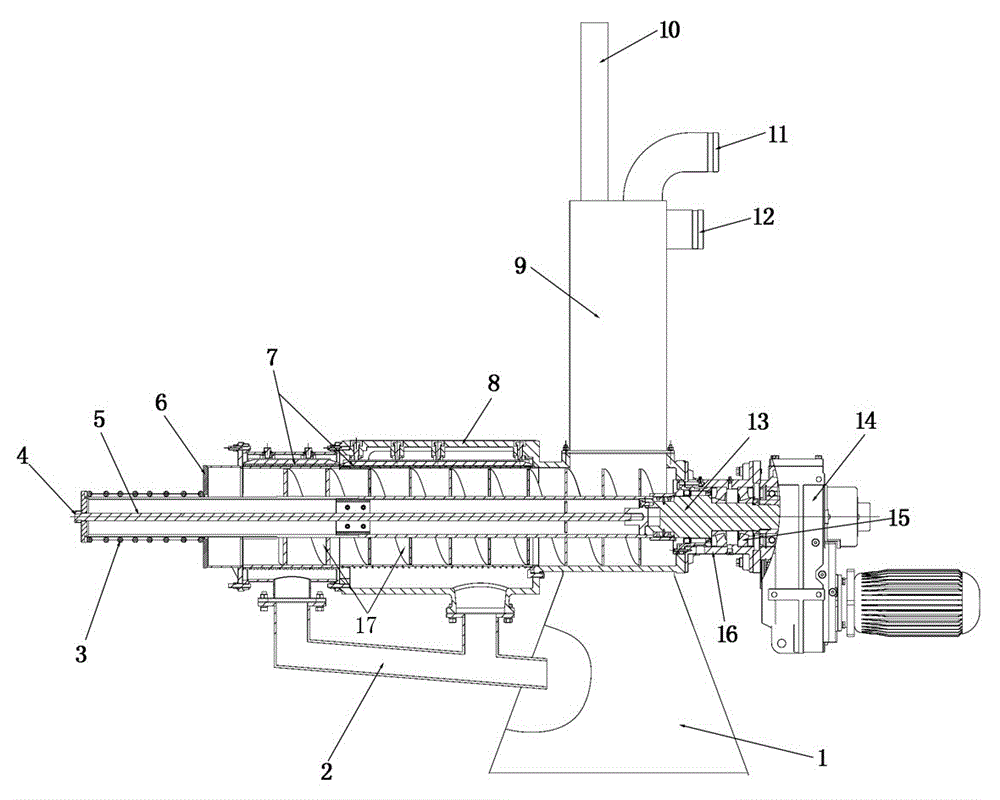

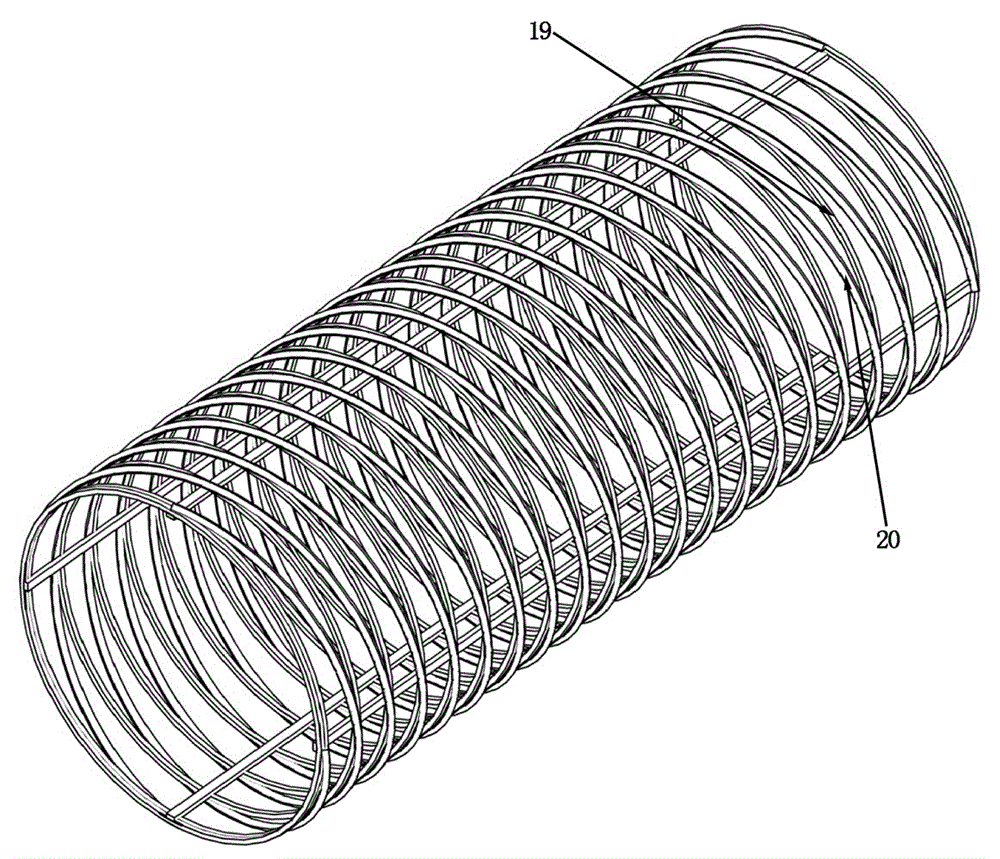

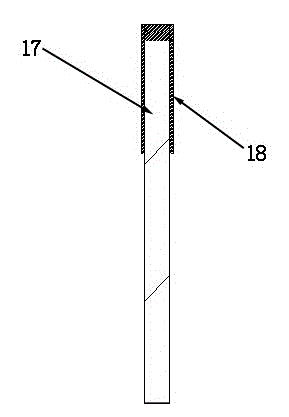

Spiral extrusion type solid-liquid separator and solid-liquid separating method

The invention discloses a spiral extrusion type solid-liquid separator. The spiral extrusion type solid-liquid separator comprises a feeding mechanism, a power mechanism, a spiral extrusion mechanism, a solid discharging mechanism and a liquid discharging mechanism, wherein the spiral extrusion mechanism comprises a main body sleeve, a filter screen cylinder and a packing auger; the filter screen cylinder is arranged in the main body sleeve, and the packing auger is arranged in the filter screen cylinder; blades of the packing auger are composed of spiral blade bodies and high-wear-resisting rubber coating strips coated on the outer edges of the spiral blade bodies; the packing auger comprises a front section packing auger body and a rear section packing auger body; the filter screen cylinder comprises a front section filter screen cylinder body and a rear section filter screen cylinder body; and the solid discharging mechanism is characterized in that an annular cover plate is arranged at the position of a discharging port of the main body sleeve, and the annular cover plate is connected with a compression spring in an abutting manner. Meanwhile, the invention further discloses a solid-liquid separating method using the spiral extrusion type solid-liquid separator. The spiral extrusion type solid-liquid separator has multiple good effects when being used for conducting solid-liquid separation on feces of beasts and birds, biogas residue and the like.

Owner:DINGZHOU SIFENG ENVIRONMENTAL PROTECTION TECH

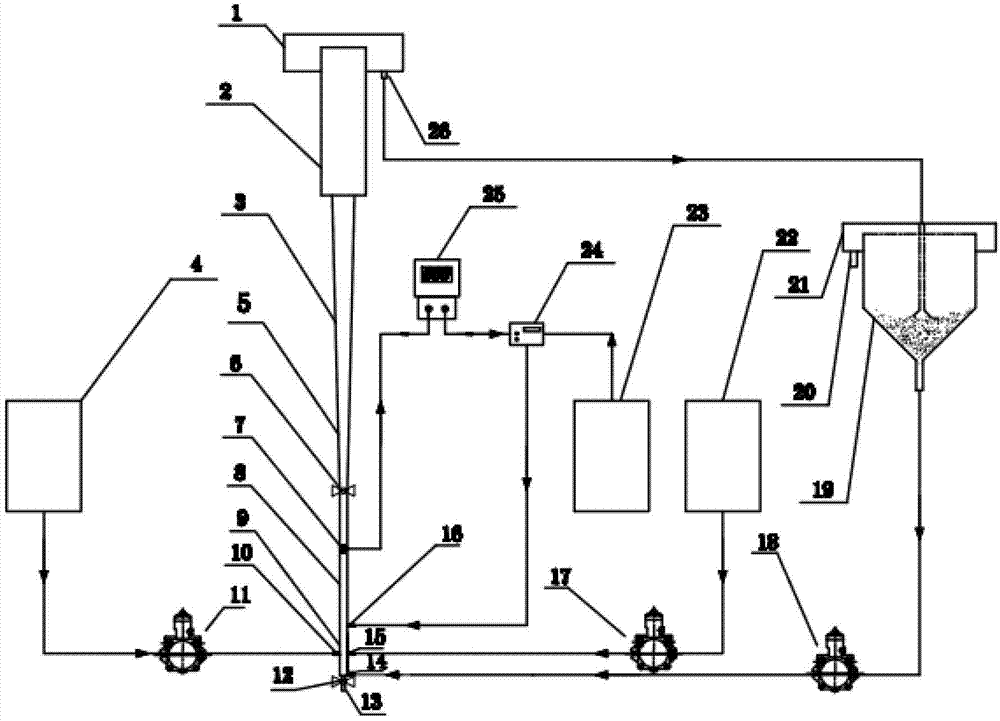

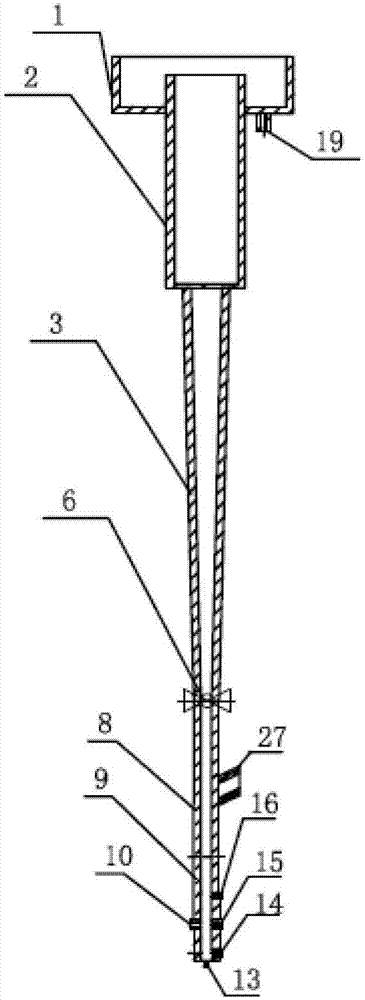

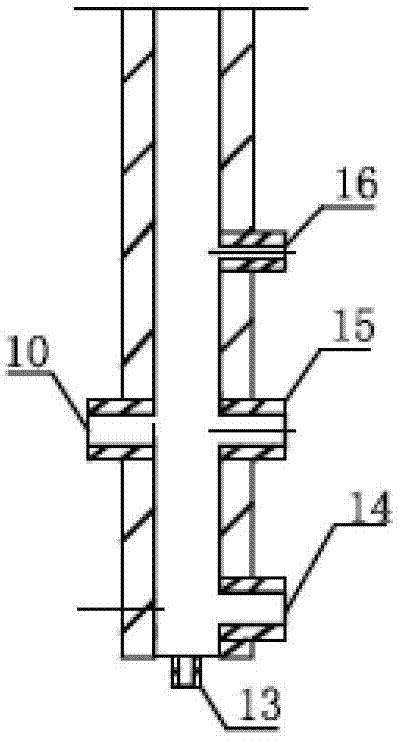

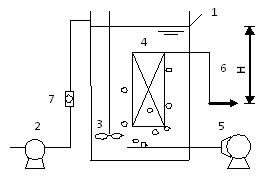

Device and process for preparing struvite crystals from nitrogen and phosphorus in sewage

InactiveCN102963970AIncreased turbulence intensityCompact structureWater/sewage treatment by flocculation/precipitationPhosphorus compoundsStruvite CrystalsSmall footprint

The invention relates to a device and a process for preparing struvite crystals from nitrogen and phosphorus in sewage. The device comprises a reactor (5), a pH (potential of Hydrogen) controller (25), a pH regulating pump (24), an alkali liquor tank (23), a nitrogen and phosphorus containing waste water tank (22) and a secondary sedimentation tank (19), wherein the reactor (5) is composed of a reactor feed pipe (9), a reactor crystal collecting pipe (8), a reactor growth tube (3) and a reactor sediment tube (2) from bottom to top. The process comprises the steps of pumping nitrogen and phosphorus containing wastewater into the reactor (5) and pumping a magnesium chloride solution into the reactor (5) to ensure that the molar ratio of NH3-N to PO43-P to Mg <2+> in the reactor (5) is (1:1:1)-(1:1:1.3); controlling the reflux ratio between 14 and 28 and the pH equal to 6.4-9.2; and forming the struvite crystals in the reactor (5) by using the nitrogen, phosphorus and magnesium containing solution. The device disclosed by the invention has the advantages of simple structure and small floor space, is simple and easy to operate and difficult to scale, can be widely applied to preparation of the struvite crystals from the nitrogen and phosphorus containing wastewater such as coking wastewater, pig manure wastewater or sludge fermentation liquor, and is capable of realizing the resource recycling of nitrogen and phosphorus.

Owner:TONGJI UNIV

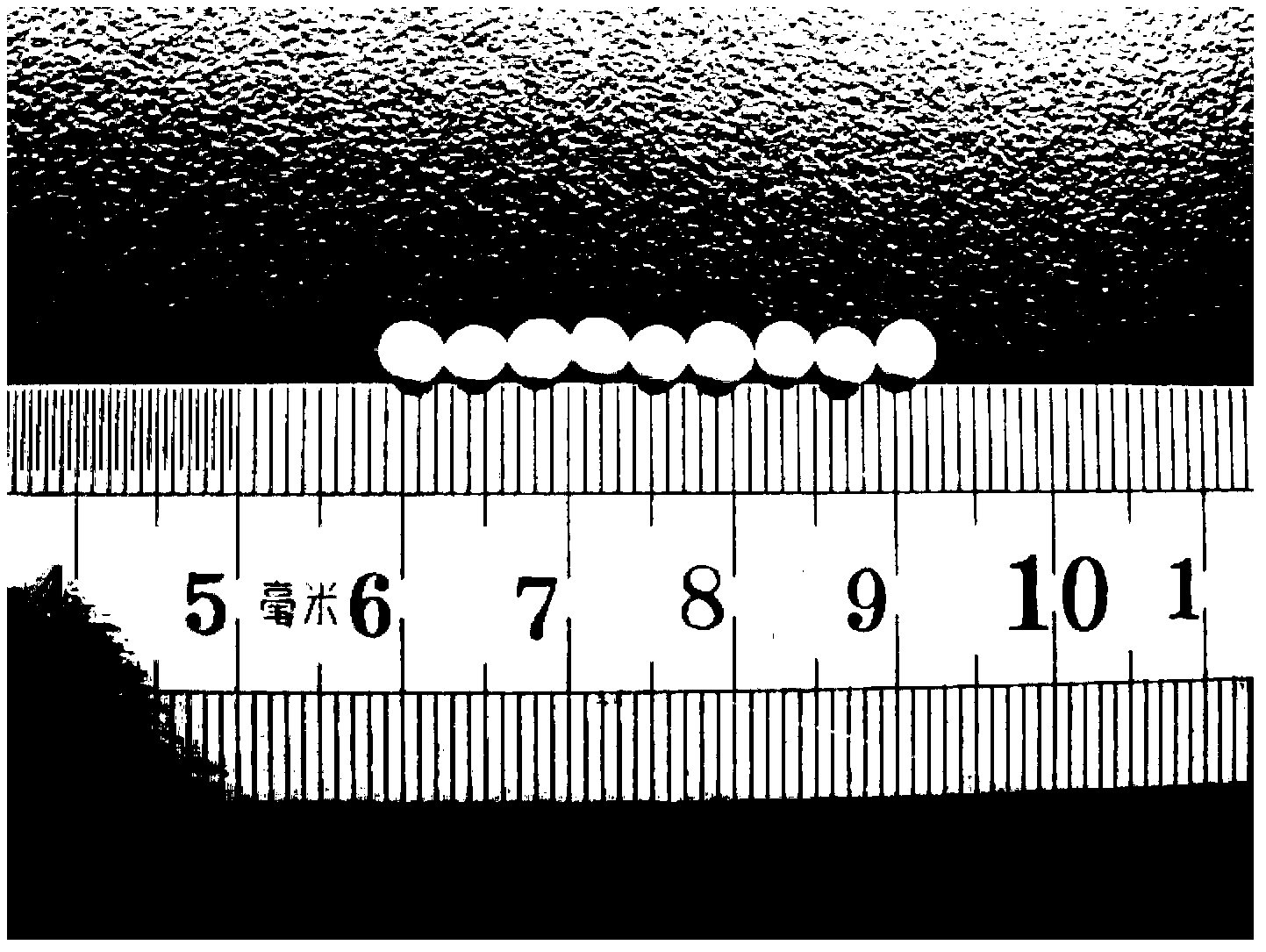

Mould biosorbent and preparation method thereof

InactiveCN101797497AReduce manufacturing costEase of industrial applicationFungiOther chemical processesDisperse dyeSorbent

The invention relates to a mould biosorbent and a preparation method thereof, belonging to the field of environment governance. The biosorbent is mycelial pellets formed by winding mould mycelia, wherein the diameter thereof is about 2.0mm, and the mycelial pellets have uniform size and certain mechanical strength. The preparation method comprises the following steps: taking food production waste water as a culture medium, inoculating a mould spore suspension under the sterilized or non-sterilized condition of pH 3.5-6.5, shaking culturing for 60-72h at 28-35 DEG C and at the speed of 150-200rpm, and filtering the collected mycelial pellets to obtain the mould biosorbent. The mould biosorbent prepared in the invention has low cost and simple preparation process, has good adsorbing and decoloring effects on reactive dyes, reducible dyes, disperse dyes, direct dyes, sulfur dyes and the like, can also be used for removing metal ions in the waste water, and has the characteristics of economy, high efficiency, easy solid-liquid separation, no secondary pollution, capability of recovering the metal ions, environment friendliness and the like.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

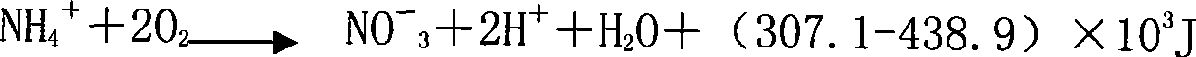

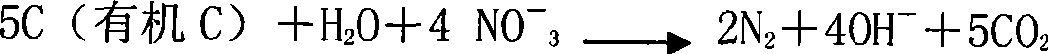

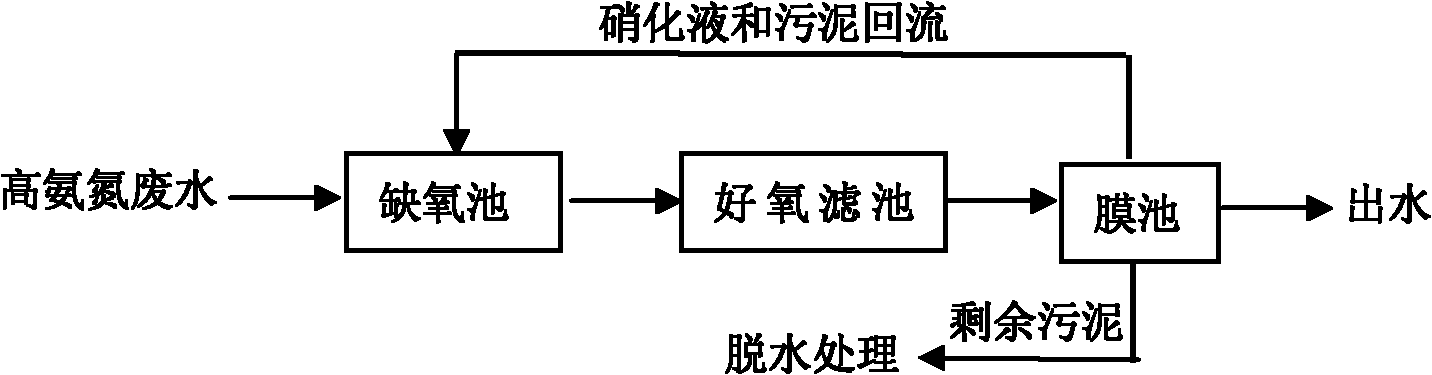

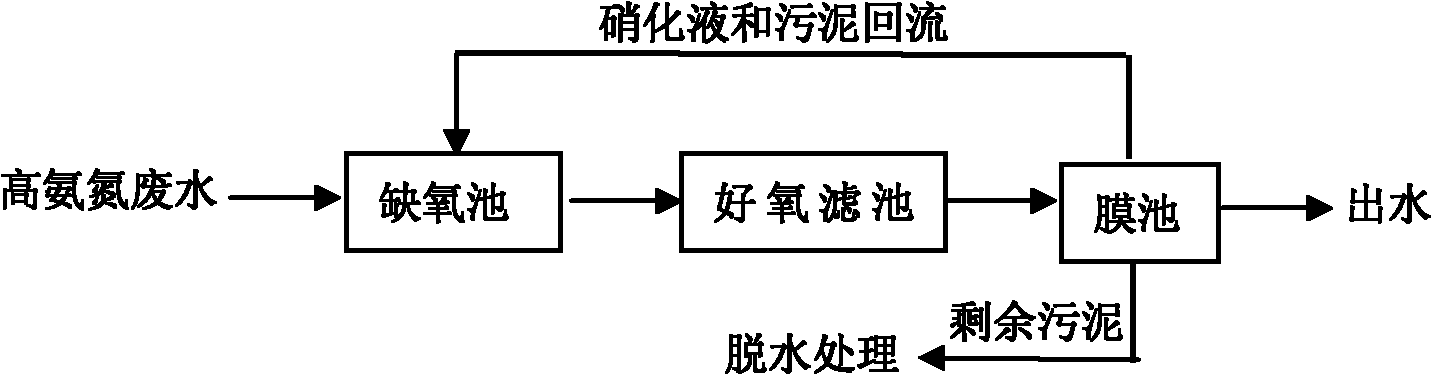

Bioaugmentation treatment technology of high ammonia nitrogen wastewater

InactiveCN101973678AIncrease the number ofSmall footprintMultistage water/sewage treatmentHigh concentrationSludge

The invention relates to a bioaugmentation treatment technology of the high ammonia nitrogen wastewater. The treatment technology is characterized in that under the condition that dissolved oxygen exists in the high ammonia nitrogen wastewater, an aerobic pool, an aerobic filter and a membrane pool are established, wherein by utilizing the metabolism of the aerobic microorganism, high concentration of organic substances are degraded, the organic substances with high molecular weight and energy are converted to substances with low molecular weight and energy; the aerobic pool adopts internal circulation and large-scale external circulation hydraulic agitation; and the aerobic filter is filled with novel fixed enzyme-floating filler and immobilized microorganism and microporous aeration and jet aeration are combined for aeration, thus the flow pattern of the nitrification filter is improved. Compared with the prior art, the system of the invention has high sludge concentration and the corresponding volume loading is also high, thus the floor space is small and the capital cost is low; the conversion rate and utilization rate of atmospheric oxygen is high, the effect of mass transfer is good, the anti-shock loading capability of the system is high, the effluent quality is stable; the operating cost is low; the density is increased relatively, the solid-liquid separating effect is good and the yield of excess sludge is low.

Owner:SHANGHAI HONESS ENVIRONMENTAL TECH CORP

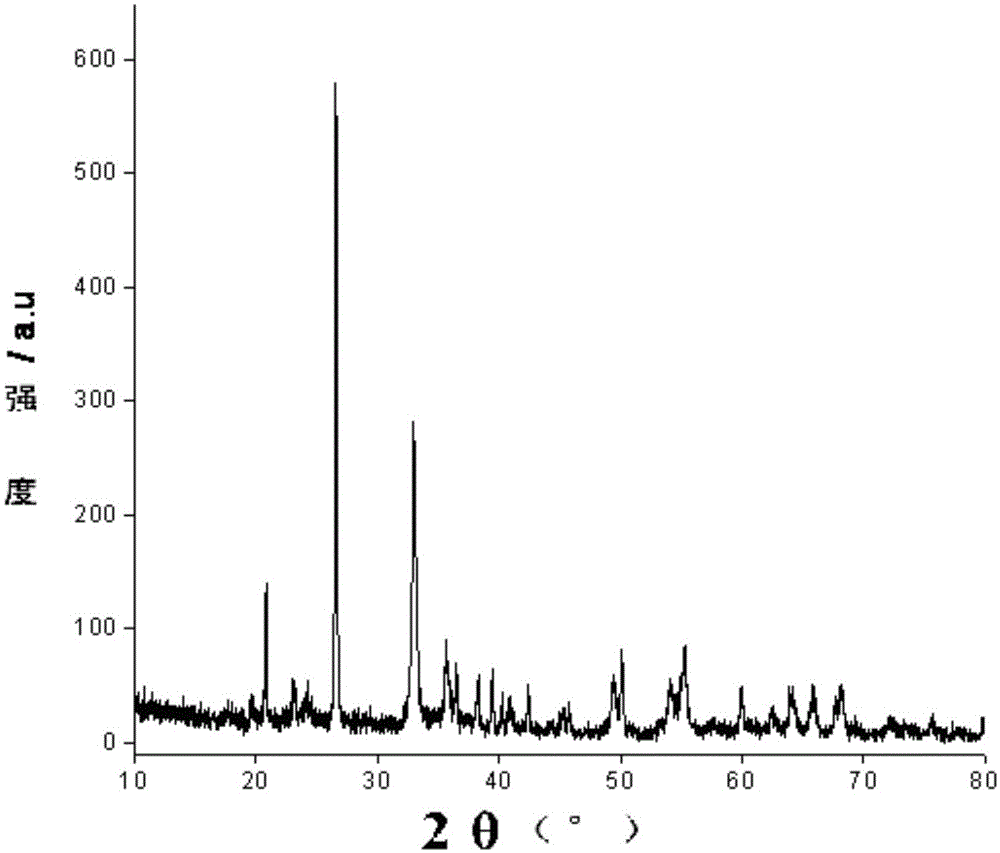

Ferro-manganese composite oxide catalyst and preparation method thereof

ActiveCN105107522APromote degradationLow costWaste water treatment from plant processingMetal/metal-oxides/metal-hydroxide catalystsPolyvinyl alcoholSludge

The invention relates to a ferro-manganese composite oxide catalyst and a preparation method thereof. The ferro-manganese composite oxide catalyst is granular and is prepared by calcining polyvinyl alcohol, sodium dodecyl benzene sulfonate (SDBS), ferrous sulfate, sodium carbonate and natural ferro-manganese ore after reaction. The catalyst can be used for advanced degradation of papermaking wastewater after biochemical treatment. The catalyst disclosed by the invention is changed to ferro-manganese composite oxide particles from conventional ferrous sulfate, can be reused after calcination, is low in chemical sludge output, can save sludge treatment cost, can reduce production of secondary pollution, and can easily realize solid-liquid separation.

Owner:W STARTECH BEIJING ENVIRONMENTAL TECH

Dynamic membrane automatic water flow-out solid-liquid separation method applicable to domestic sewage treatment

ActiveCN102616986ACompact structureReduce energy consumptionMultistage water/sewage treatmentActivated sludgeWater flow

The invention provides a dynamic membrane automatic water flow-out solid-liquid separation method applicable to domestic sewage treatment. The method includes: adding powder particles with fine water permeable performance into activated sludge to form biological intensified powder mixed liquid to structurally improve the activated sludge; combining with the dynamic membrane separation technique to greatly improve the filtering capacity and water permeability of dynamic membrane filter cakes; performing solid-liquid separation of discharged water by allowing a dynamic membrane component to be driven by a water head having lower fixed gravity action and formed by liquid level waterhead between the upper liquid level of the immersed dynamic membrane component in a reaction device and a wateroutlet, stably controlling the unit area membrane filter flux of the dynamic membrane component to be more than 20-60L / m2h and the continuous operating time to be longer than 120h without action of external power; and allowing the dynamic membrane to completely shed with the air backwashing time being 1min-2min and the air inlet pressure being 9.8-49kPa. The dynamic membrane component does not need to be chemically cleaned regularly, and control and operation of the method can be automatically controlled in the whole process. The dynamic membrane solid-liquid separation technique can realize automatic water flowing out under differential pressure of low-liquid-level waterhead, energy consumption is greatly reduced, operation process is simplified, and discharged water is high in quality.

Owner:TONGJI UNIV

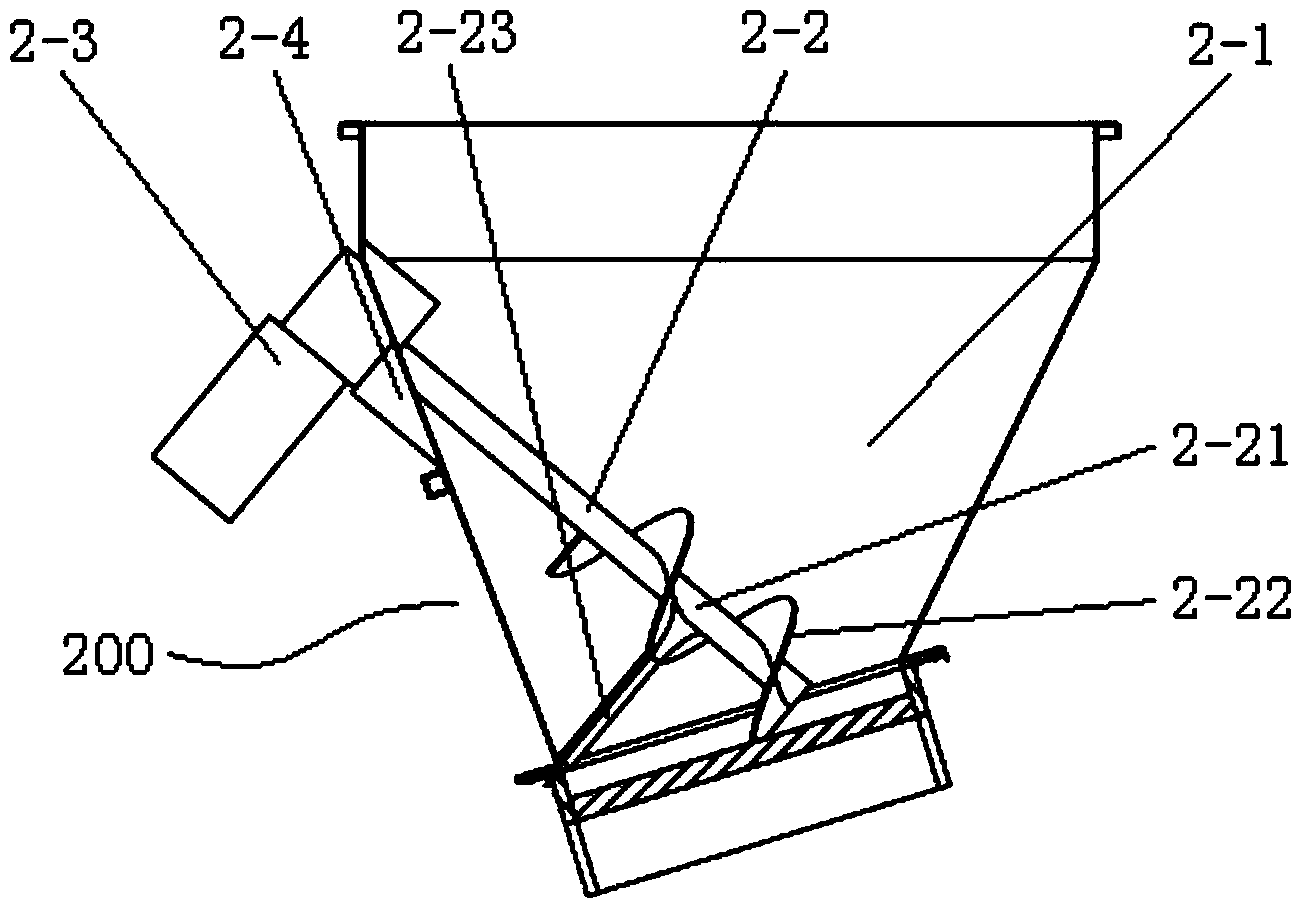

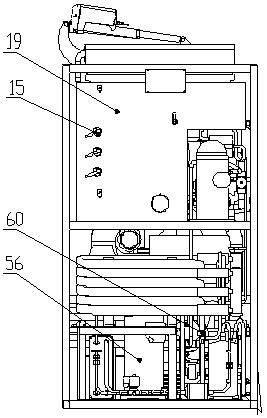

Kitchen waste treatment method and treatment device

PendingCN109485466ANovel structureHigh degree of automationFatty/oily/floating substances removal devicesGas current separationControl systemProcess engineering

The invention discloses a kitchen waste treatment method and treatment device. The treatment device comprises an automatic feeding lifting device, a desalting and degreasing device, an oil-water separation device, an automatic sorting device, a drying device, a waste heat recovery device and a control system. The treatment device is characterized in that a water outlet of the desalting and degreasing device is connected with the oil-water separation device while a discharging port is connected with a feeding port of the automatic sorting device; a discharging port of the automatic sorting device is connected with a feeding port of a drying tank of the drying device through an electric ball valve; a steam outlet of the drying tank is connected with a vacuum pump through the waste heat recovery device, and vacuum negative pressure is formed in the drying tank through operation of the vacuum pump. Due to adoption of the structure, the treatment device has advantages of novel structure, high automation level, remarkable solid-liquid separation effect, short drying time, energy saving, low power consumption, environmental friendliness, odorless emission, high stability in operation andthe like.

Owner:SHANDONG MINGLIU KITCHEN WASTE TREATMENT EQUIP CO LTD

Preparation and application for nanometer SiO2 strengthened calcium alginate-xanthan gum composite absorbent

InactiveCN102671641ALarge specific surface areaFacilitate solid-liquid separationOther chemical processesAlkali metal oxides/hydroxidesMicrosphereDigestion

The invention discloses preparation and application for a nanometer SiO2 strengthened calcium alginate-xanthan gum composite absorbent. At first, calcium alginate-xanthan gum composite microballoon spheres are prepared by a cross-linking method, nanometer SiO2 is led into the calcium alginate-xanthan gum composite microballoon spheres by a sol-gel method, and accordingly the absorbent is prepared. The specific surface area of the absorbent is large, solid and liquid separation is easy, the mechanical strength of the corresponding microballoon spheres can be effectively improved after the microballoon spheres are modified and strengthened by the nanometer SiO2, the problem that the microballoon spheres are expanded after absorbing water is solved, digestion of calcium ions of the microballoon spheres is controlled to be reduced, preparation cost is low, and preparation is green and safe. The microballoon spheres are actually applied to absorbing and removing heavy metal pollutants, the utilization quantity of the microballoon spheres is low, selectivity and absorption removal rate are high, operation is simple, convenient and fast, and the microballoon spheres can be regenerated and recycled. 0.07g of microballoon spheres can absorb and remove 20ml, 2mg / lPb2+ of artificial waste water, and lead removal rate is higher than 90%.

Owner:SHANGHAI JIAO TONG UNIV

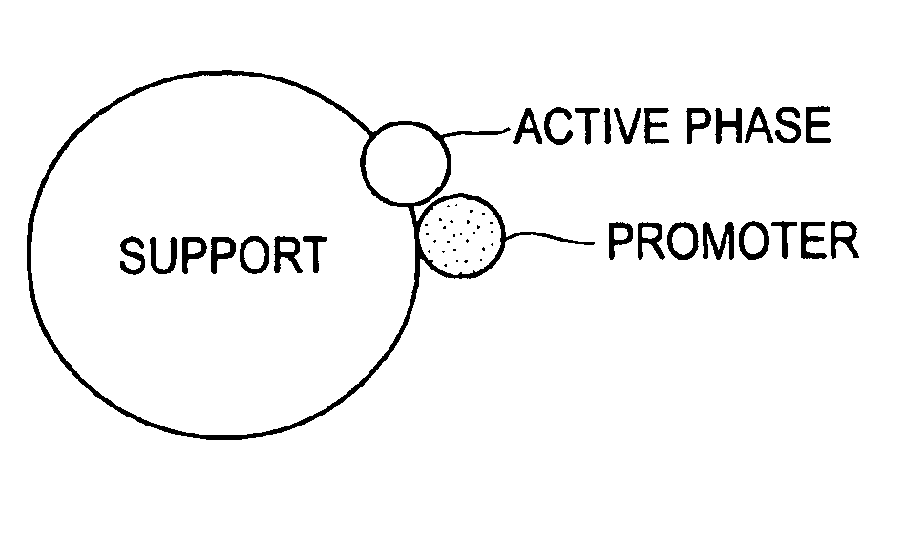

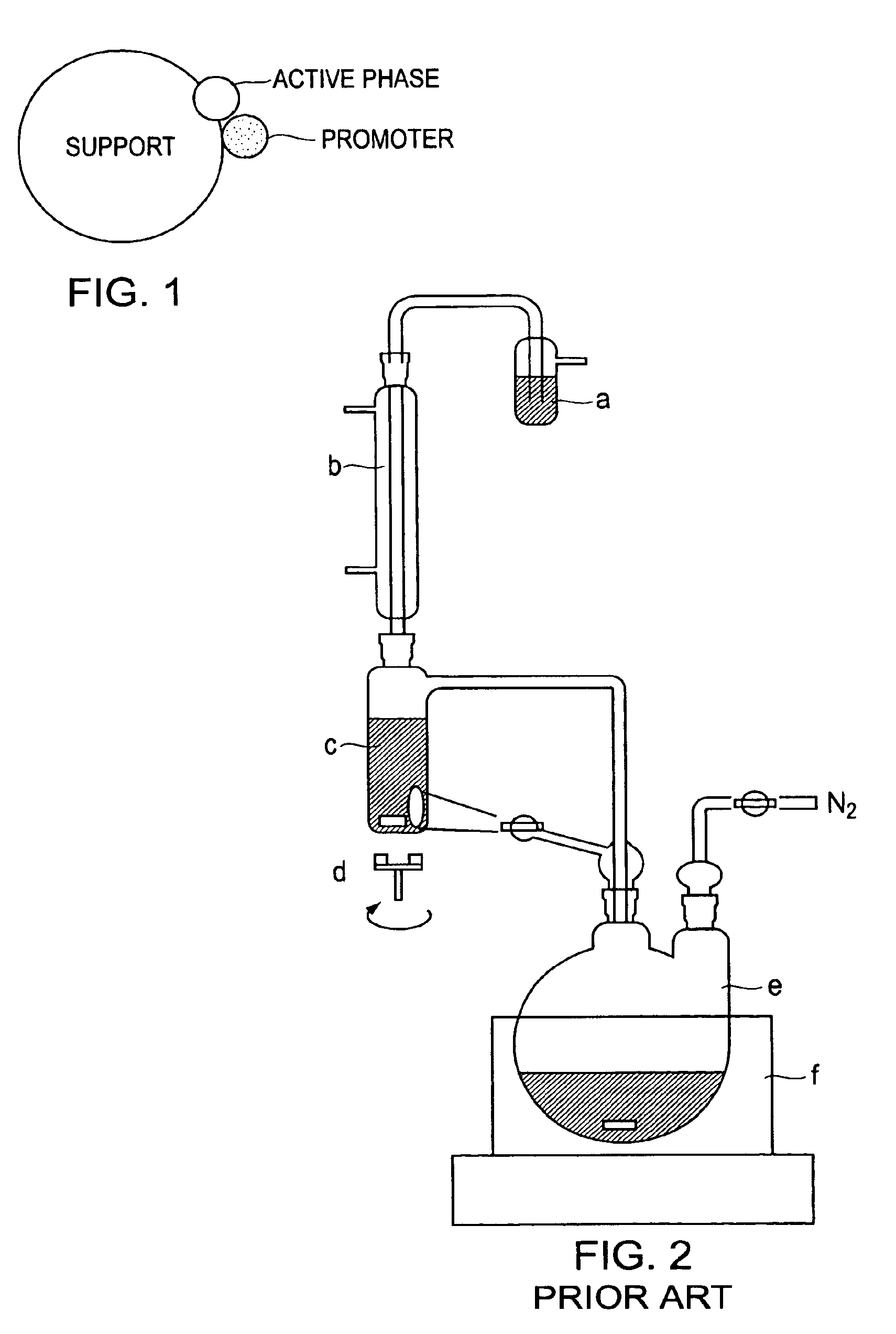

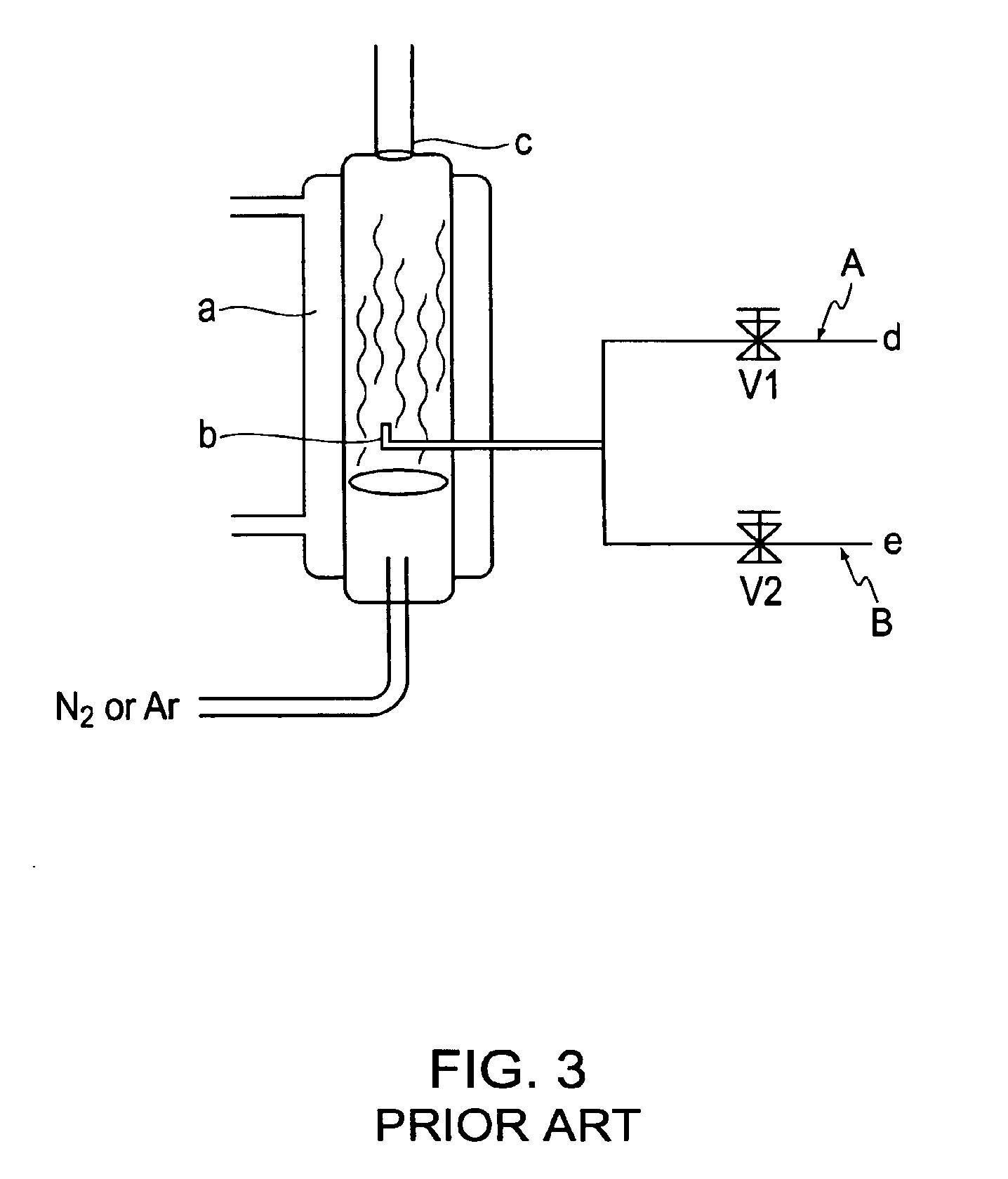

Catalytic formulation and its preparation

InactiveUS7026266B2Facilitate solid-liquid separationOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsLiquid mediumActive component

A hetergeneous catalyst includes a solid support having deposited thereon a catalyticaly active material, which is substantially insoluble in organic and aqueous liquid media. The insoluble material is constructed from secondary building blocks derived from suitable organometallic active components, and the organometallic active component may be molecularly modified so as to introduce two or more anionic functional groups. These molecularly modified organometallic components, upon interaction with salts of Ca2+, Sr2+ and Ba2+, provde the practically insoluble solid material. Methods of formuatling the organometallic active materials on a solid support as a solid catalyst are also provided. The catalysts are capable of catalyzing diverse reactions in polar and nonpolar reaction media, and the overall integrity of the formulation as a solid material in a liquid phase provides easy catalyst and product separation.

Owner:COUNCIL OF SCI & IND RES

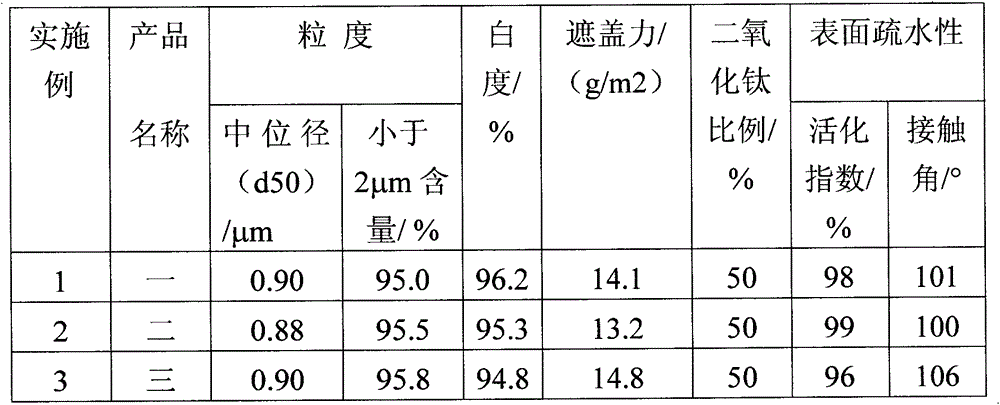

Preparation method for white mineral-titanium dioxide composite powder pigment

InactiveCN104098932AHydrophobicGood compatibilityPigment treatment with non-polymer organic compoundsSlurryEnergy consumption

The invention discloses a preparation method for a white mineral-titanium dioxide composite powder pigment. The white mineral-titanium dioxide composite powder pigment is prepared by firstly preparing slurries respectively from a white mineral powder and pigment-grade titanium dioxide with water, employing an organic modifier to perform surface modification, regulating the pH value, then uniformly mixing the prepared slurries, and performing strong stirring, press filtering and drying. The preparation method comprises the following advantages that 1) energy consumption is relatively low in the preparation process; 2) the surface of the prepared composite particle has hydrophobicity, and the particle is good in compatibility with organic matrix; 3) the preparation technology is simple, especially solid-liquid separation is easy to realize, and large-scale production is easy to realize; and 4) the production process is clean, no three wastes (waste gas, waste water and industrial residue) are discharged, and environment is not polluted.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Multifunctional ore dressing chemical, synthesis method thereof and using method thereof

ActiveCN101890398AImprove protectionIncrease productivityFlotationSynthesis methodsOrganic synthesis

The invention discloses a multifunctional ore dressing chemical, and a using technique thereof. The chemical can be widely used for treating various ore resources. A synthesis method of the multifunctional ore dressing chemical comprises the following steps: preparing colloidal solution of an inorganic oxide and a hydroxide; dissolving an organic monomer in the colloidal solution of the inorganicoxide and the hydroxide; adding an initiator into the solution to complete organic synthesis a reaction kettle. The obtained multifunctional ore dressing chemical which has a selective flocculation function is added into the flotation pulp to help ore separation in ore flotation and solid-liquid separation in tailing processing. The using technique comprises: the flotation and tailing processing.The multifunctional ore dressing chemical also can be used in tailing processing alone. The multifunctional ore dressing chemical can improve production efficiency, improve mine environmental protection, greatly improve the economic benefits of the mine, improve the return water recovery effect and reduce mine environment pollution.

Owner:李海红

Hydrometallurgical process of nickel oxide ore

InactiveUS7563421B2Simple and efficient processSimplified leaching stageSolvent extractionIron compoundsSulfideSlurry

A hydrometallurgical process based on pressure leaching at elevated temperature for recovering nickel from nickel oxide ores, characterized by a simplified and efficient process as a whole, realizing a simplified leaching stage, reduced neutralizer consumption and precipitate production in the neutralization stage, and efficient use of recycled water.The hydrometallurgical process of the present invention, comprising a leaching stage which stirs the slurried ore in the presence of sulfuric acid at 220 to 280° C. to produce the leached slurry; solid-liquid separation stage which washes the leached slurry in multi-stages to produce the pregnant liquor and leached residue, the former containing nickel and cobalt; neutralization stage which treats the pregnant liquor in the presence of calcium carbonate incorporated to keep the pH level at 4 or less, while suppressing oxidation of the liquor, to produce the neutralization precipitate slurry and mother liquor for nickel recovery, the former containing trivalent iron; and a sulfide precipitation stage which blows hydrogen sulfide gas into the mother liquor to produce the sulfide solution and barren liquor, the former containing nickel and cobalt.

Owner:SUMITOMO METAL MINING CO LTD

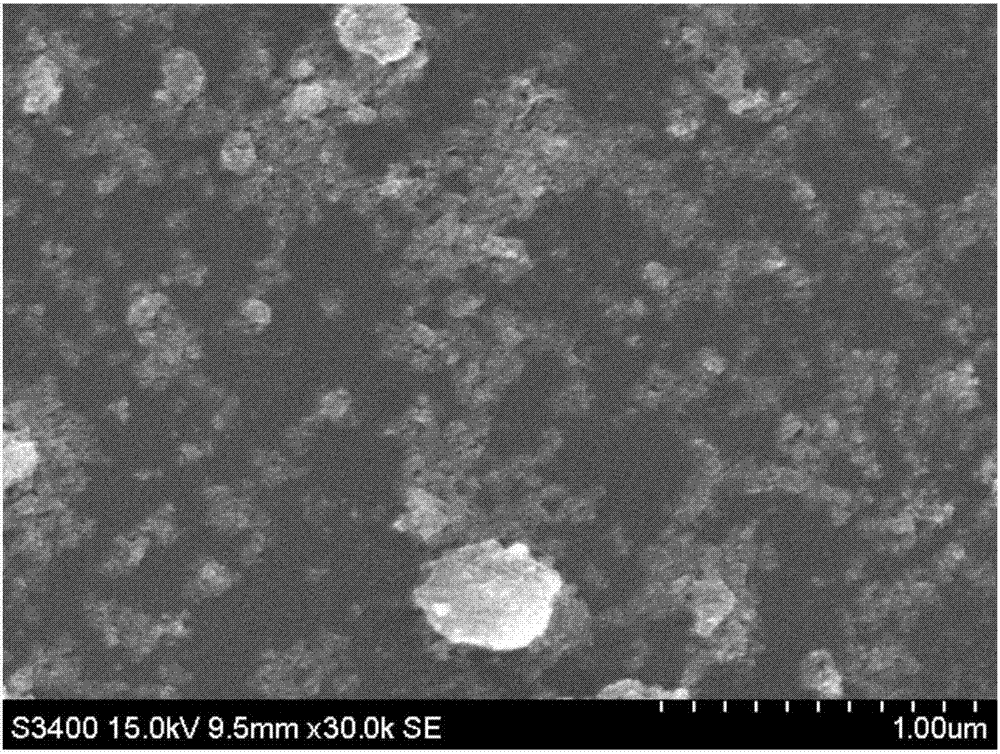

Magnetic mesoporous silica surface-imprinted polymer adsorbing material and preparation method thereof

InactiveCN106334537AEasy to separate and recycleFacilitate solid-liquid separationIon-exchange process apparatusOther chemical processesRare earth ionsAtom-transfer radical-polymerization

The invention discloses a magnetic mesoporous silica surface-imprinted polymer adsorbing material and a preparation method thereof. The preparation method comprises the following steps: firstly, modifying magnetic mesoporous silica with a silane coupling agent; then grafting an initiator; finally, preparing a surface-imprinted adsorbing material through a surface imprinting technology and an activator generated by electron transfer atom transfer radical polymerization (AGET ATRP). The adsorbing material prepared in the invention is fast to adsorb rare earth ions, strong in selective adsorption, easy to separate and recover, and applicable to the adsorption and separation of the rare earth ions.

Owner:YANCHENG INST OF TECH

Prepn process of magnetic composite organic bentonite as water treating material

InactiveCN1673108AStrong magnetismImprove adsorption capacityWater/sewage treatment by sorptionClaywaresWater bathsDistilled water

The preparation process of magnetic composite organic bentonite as waste water treating material includes the following steps: 1) drying, crushing and sieving bentonite, mixing with FeCl3, FeSO4 and water in certain proportion to obtain suspension, and dropping sodium hydroxide solution while stirring; 2) washing the deposit with distilled water and stoving at 110-120 deg.c; and 3) grinding, adding cationic surfactant solution while stirring, ageing at room temperature for 10-12 hr, washing and filtering, stoving at 60-80 deg.c, grinding and 60-100 mesh sieving. The waste water treating material of the present invention can eliminating organic pollutant and acid radical pollutant from waste water and has excellent deposition separating performance.

Owner:ZHEJIANG UNIV

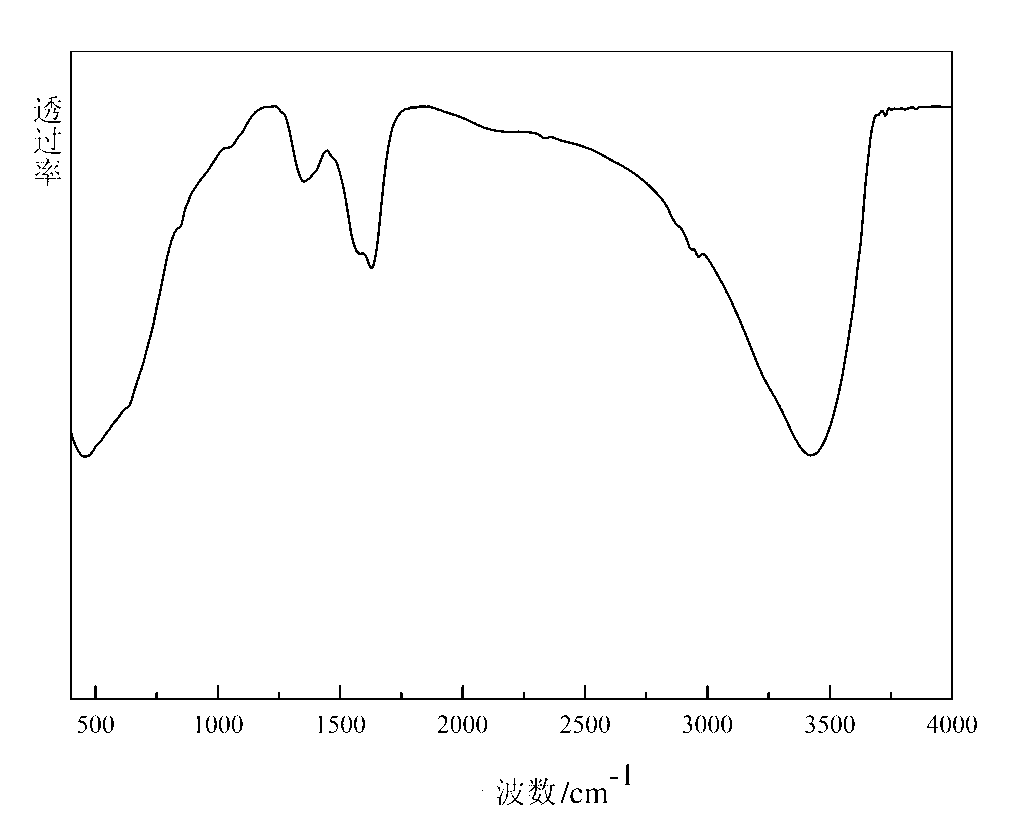

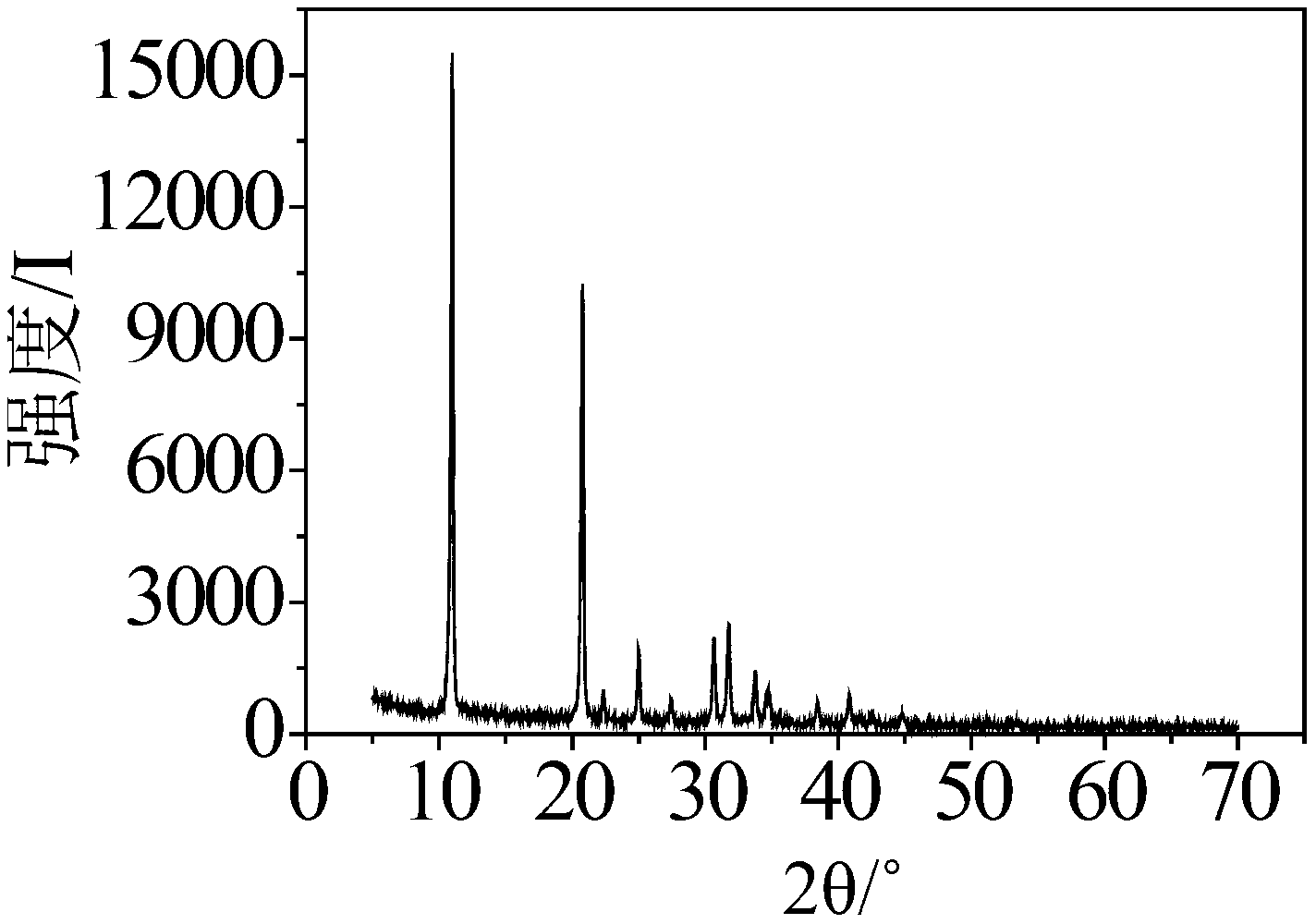

Sulfate radical sorbent magnetic nanometer zirconium hydroxide and preparation method thereof

InactiveCN102872790AFacilitate solid-liquid separationSolid-liquid separation is simple and convenientOther chemical processesAlkali metal oxides/hydroxidesSulfate radicalsFiltration

The invention relates to a sulfate radical sorbent magnetic nanometer zirconium hydroxide and a preparation method thereof. The preparation method comprises the following steps: (1), modifying magnetic Fe3O4 nanoparticles; (2), under mechanical stirring, firstly, quickly dripping a ZrOC12 solution in a Fe3O4 suspending liquid, then slowly dripping an ammonia solution until the pH value is 9-10, followed by standing and aging so as to obtain wet sol sedimentation, and finally performing sedimentation washing and suction filtration; and (3), dissolving the wet sol in a n-butanol for azeotropic distillation, vacuum drying after the termination of the distillation, and extracting for grinding and sieving so as to obtain the sulfate radical sorbent magnetic nanometer zirconium hydroxide. According to the invention, the solid-liquid separation is easily realized after the adsorption of the sulfate radical sorbent; the magnetic field solid-liquid separation is simpler and convenient; and the water basically has no residual after the sulfate radical is desorbed, and the adsorption effect is good.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

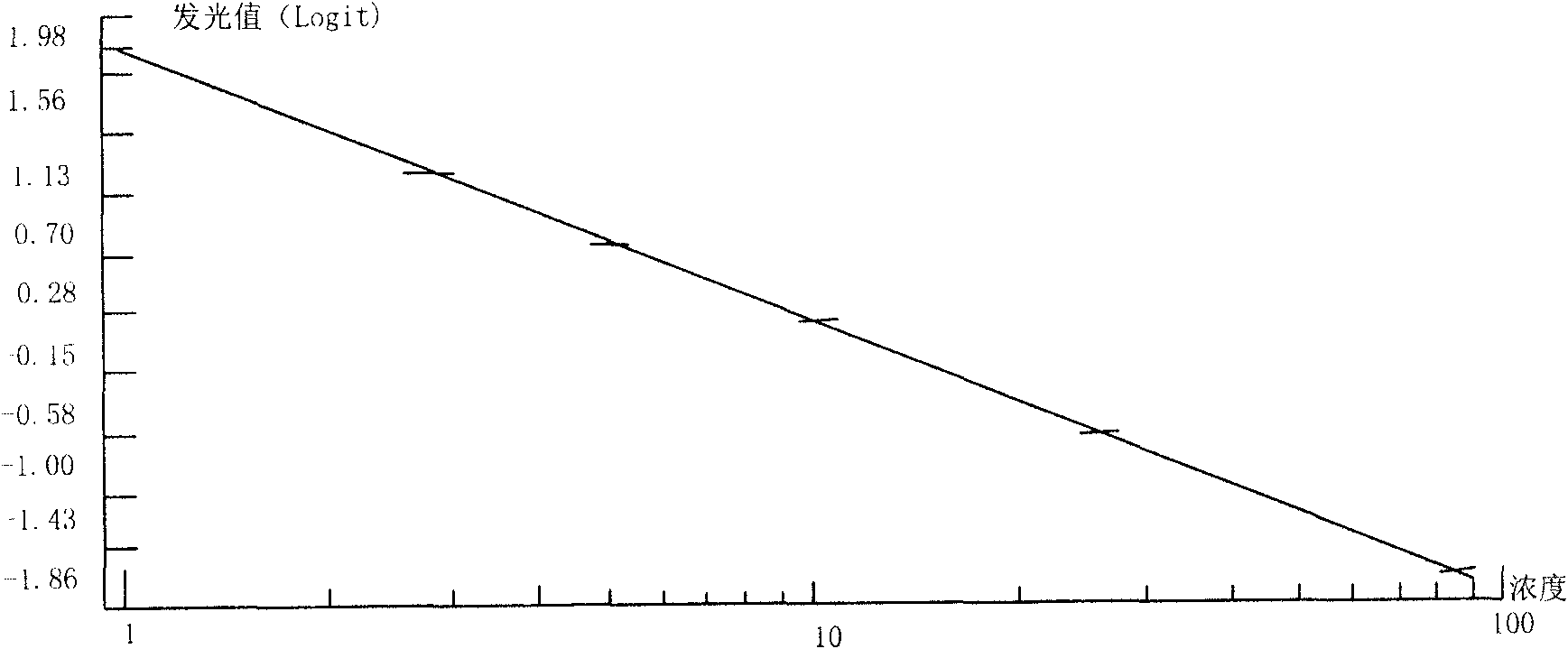

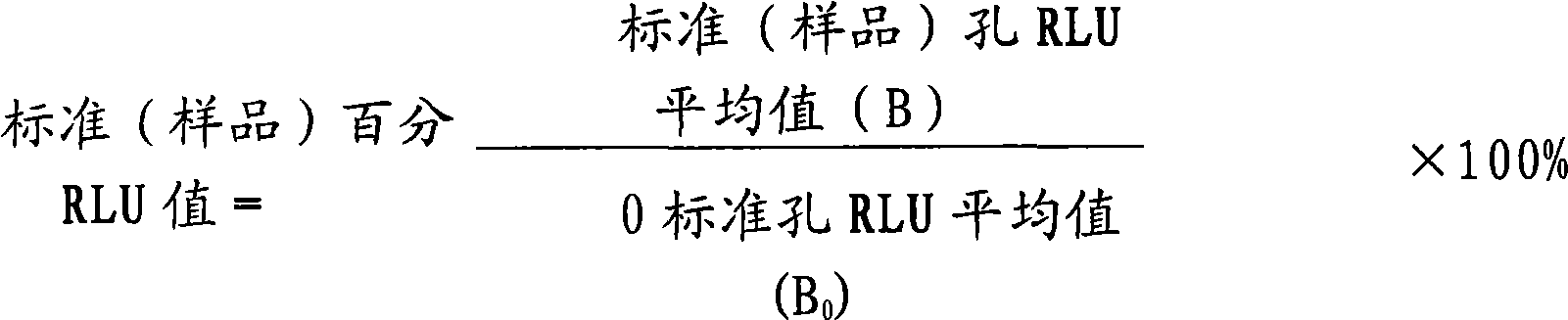

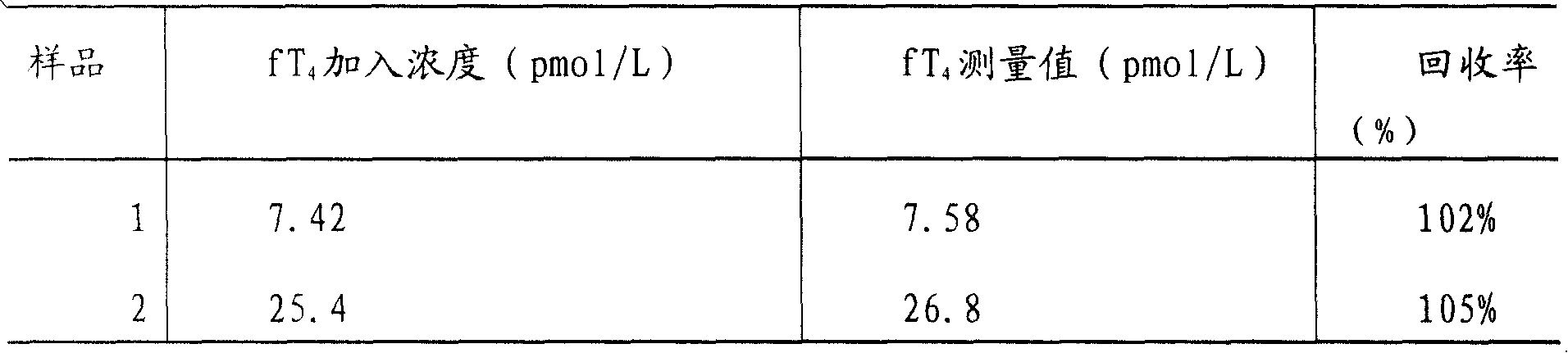

Magnetic particle chemiluminescence detection kit of free thyroxine and application thereof

InactiveCN101551389AReduce manufacturing costIncrease surface areaChemiluminescene/bioluminescenceAntigenMicrosphere

The present invention discloses a quantitative detection kit of free thyroxine (fT4) and a method for detecting the free thyroxine with the detection kit. The detection kit comprises a free thyroxine standard, a free thyroxine antigen marked by horseradish peroxidase, an antibody, a magnetic bead separating agent, luminescence substrate reagent and wash liquid. The method for detecting free thyroxine comprises the following steps: adding the free thyroxine standard and sample to be measured into the test tube, adding the free thyroxine antigen marked by horseradish peroxidase and antibody, after mixing to uniform, incubating for one hour in 37 DEG C, then adding magnetic bead separating agent for stewing for 5 minutes, separating for obtaining the immune magnetic microspheres, discarding the supernate, washing the deposit for two times; adding the luminescence substrate reagent, measuring and analyzing the concentration of free thyroxine in sample to be measured. The quantitative detection kit of free thyroxine and the detection method provided by the invention have the advantages of higher stability, higher sensitivity and higher accuracy, and belong to the technical field of immunodiagnosis.

Owner:天津九鼎医学生物工程有限公司 +1

Gel ball type rubidium/caesium ion adsorbent, and preparation method and application thereof

InactiveCN103212388ASimple processReduce manufacturing costOther chemical processesRadioactive decontaminationIonPotassium tetraphenylborate

The invention discloses a gel ball type rubidium / caesium ion adsorbent, and a preparation method and application thereof. The gel ball type rubidium / caesium ion adsorbent is prepared by the following steps of: preparing sodium alginate hydrosol, mixing potassium tetraphenylborate powder and the sodium alginate hydrosol to form a sol mixing solution, dropping the sol mixing solution into a calcium chloride or strontium chloride solution and performing aging and separation. The preparation method is simple and low in production cost. The obtained rubidium / caesium ion adsorbent is high in adsorption capacity for rubidium / caesium ions and is high in selectivity. The gel ball type rubidium / caesium ion adsorbent can be used for removing the caesium ions from radioactive nuclear waste and is used for extracting the rubidium / caesium ions from an alkali metal competition system.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Preparation of waste water treating agent by using active calcium silicate and treatment method for papermaking waste water

InactiveCN103204560AFacilitate solid-liquid separationPurifyWaste water treatment from plant processingWater/sewage treatment by flocculation/precipitationWater treatmentWastewater disposal

The invention provides preparation of a waste water treating agent by using active calcium silicate and a treatment method for papermaking waste water, belonging to the technical field of environment protection. The waste water treating agent comprises, by weight, 60 to 98 parts of active calcium silicate, 0.5 to 40 parts of an inorganic flocculating agent and 0.01 to 0.5 part of an organic polymeric flocculant. The above-mentioned components are blended in a composition modification device so as to prepare the waste water treating agent. The treatment method for papermaking waste water comprises the following steps: adding the treating agent accounting for 0.2 to 2% of the weight of waste water to be treated into the papermaking waste water; stirring the waste water for 5 to 30 min so as to realize adsorption treatment; stopping stirring and carrying out standing for 5 to 30 min; and subjecting the treated waste water to solid-liquid separation, wherein separated water can be used as water for pulping and paper making, and separated solids can be used as a paperboard filling material after purification. According to the invention, an application scope of active calcium silicate is broadened, comprehensive utilization of resources is realized, investment and operation cost of a waste water treatment facility is greatly reduced, and the treatment method is especially applicable to medium-sized and small enterprises.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT +1

Magnetic iron-based composite catalyst and preparation method thereof

InactiveCN107262111AEfficient degradationImprove the activation effectWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsNanoparticleSulfate

The invention relates to a preparation method of a magnetic iron-based Fe3O4 / MnO2 composite catalyst and a method for treating wastewater by taking the magnetic iron-based Fe3O4 / MnO2 composite catalyst as a high-grade oxidation technology catalyst. The magnetic iron-based catalyst is prepared from a nano manganese dioxide material cladded on magnetic ferroferric oxide nanoparticles; and the magnetic iron-based composite catalyst is synthesized by taking ferrous sulfate and potassium permanganate as raw materials through a one-step reaction at room temperature. Raw materials used by the preparation method are cheap and easy to obtain; a synthesis process is simple and environmentally friendly; a treatment effect on dyestuff wastewater is good; and the catalyst is easily separated and recycled from water under an external magnetic field and has a certain application prospect.

Owner:JIANGSU UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com