Sulfate radical sorbent magnetic nanometer zirconium hydroxide and preparation method thereof

A magnetic nano, zirconium hydroxide technology, applied in chemical instruments and methods, alkali metal oxide/hydroxide, adsorbed water/sewage treatment, etc., can solve problems such as difficulty in solid-liquid separation, achieve good dispersion stability, The effect of easy adsorption and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

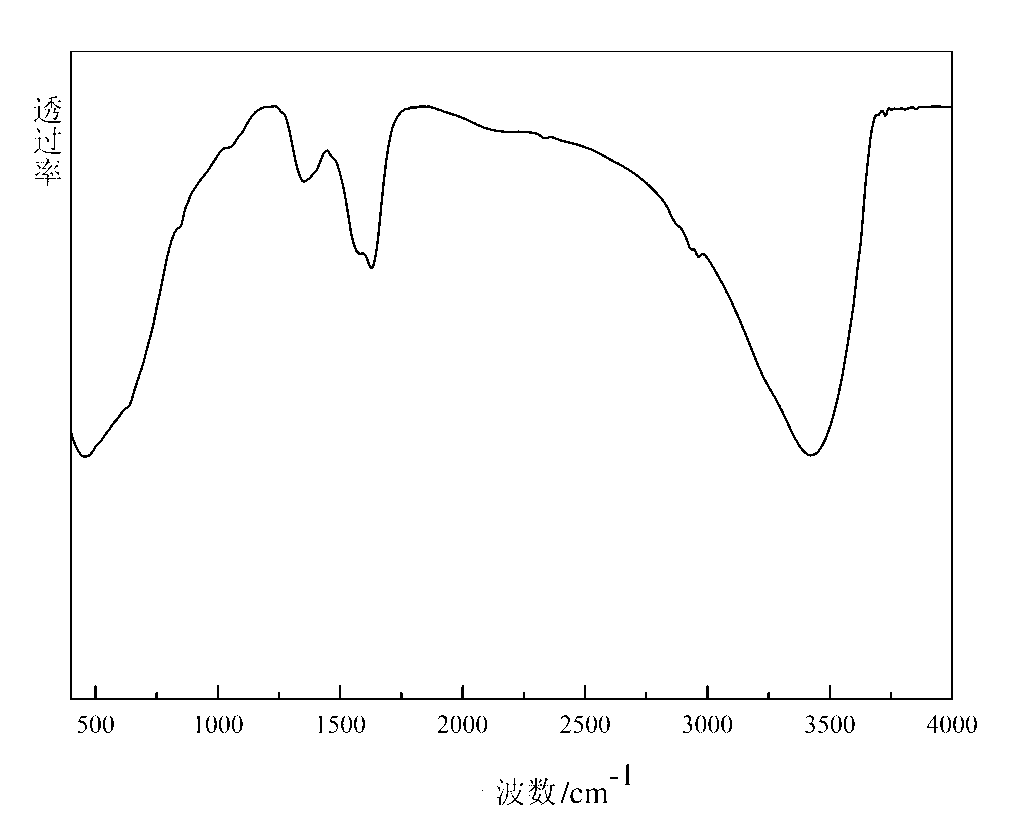

[0030] A kind of sulfate radical adsorbent magnetic nano zirconium hydroxide, it is prepared according to the following steps:

[0031] (1) Weigh 0.5262g Fe 3 o 4 Add nanoparticles to 40mL0.2mol / L sodium citrate solution for ultrasonic dispersion for 40min, then shake for 30min, magnetically separate the modified nano-magnetic ferric oxide, wash twice with absolute ethanol, and transfer to a three-necked flask , and then add 20mL deionized water, that is, water-based Fe 3 o 4 suspension;

[0032] (2) to Fe 3 o 4 Add 0.2674g polyethylene glycol to the suspension to dissolve; add 50mL0.5mol / LZrOCl dropwise at 9mL / min at a water bath temperature of 60°C and a stirring speed of 900rpm 2 Solution, then slowly add 2mol / L ammonia solution at a rate of 3mL / min until the pH is maintained at 10, then stop the dropwise addition; let it stand for aging for 30min to obtain sol precipitation, magnetically separate the solid product, and wash repeatedly with deionized water until the p...

Embodiment 2

[0044] A kind of sulfate radical adsorbent magnetic nano zirconium hydroxide, it is prepared according to the following steps:

[0045] (1) Modification of magnetic iron ferric oxide nanoparticles: Weigh the Fe prepared in Example 1 3 o 4 Add 0.8269g of nanoparticles into 50mL0.2mol / L sodium citrate solution and ultrasonically disperse for 30min, then vibrate for 15min, magnetically separate the modified magnetic ferric iron tetroxide nanoparticles, wash twice with absolute ethanol, transfer to the three-necked flask, and then add 20mL deionized water, which is the water-based Fe 3 o 4 suspension;

[0046] (2) to water-based Fe 3 o 4 Add 0.2087g polyethylene glycol to the suspension to dissolve. At a water bath temperature of 60°C and a stirring speed of 1000 rpm, 50 mL of 0.5 mol / L ZrOCl was added dropwise at 7.5 mL / min 2 Solution, then slowly add 2mol / L ammonia solution at a rate of 2.5mL / min, until the pH is maintained at 10, stop the dropwise addition; let it stand ...

Embodiment 3

[0052] Magnetic Fe 3 o 4 Preparation of nanoparticles: 0.5mol / L ferrous sulfate solution and 0.5mol / L ferric chloride solution are added to a three-necked flask at a molar ratio of 1:1.75, nitrogen gas is introduced, placed in a 65°C constant temperature water bath, Stir at 1200rpm while slowly adding analytically pure ammonia water dropwise, stop dropping when the pH is maintained at 9, continue to stir at a constant temperature for 30min, and obtain a black suspension. After magnetically separating the precipitate, wash it repeatedly with deionized water until the pH is neutral. Dry the precipitate under vacuum at 60°C for 12 hours, grind and pass through a 200-mesh sieve to obtain Fe 3 o 4 Nanoparticles.

[0053] A kind of sulfate radical adsorbent magnetic nano zirconium hydroxide, it is prepared according to the following steps:

[0054] (1) Modification of magnetic Fe3O4 nanoparticles: Weigh 1.9294g of the above-prepared Fe 3 o 4 Add nanoparticles into 80mL0.2mol / L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com