Prepn process of magnetic composite organic bentonite as water treating material

A technology of bentonite and water treatment, which is applied in the direction of adsorption of water/sewage treatment, clay products, and other household appliances. It can solve the problems of reducing use value, increasing investment in infrastructure and human capital, and slow settlement speed, achieving strong practicality. Value, good solid-liquid separation effect, effect of improving adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

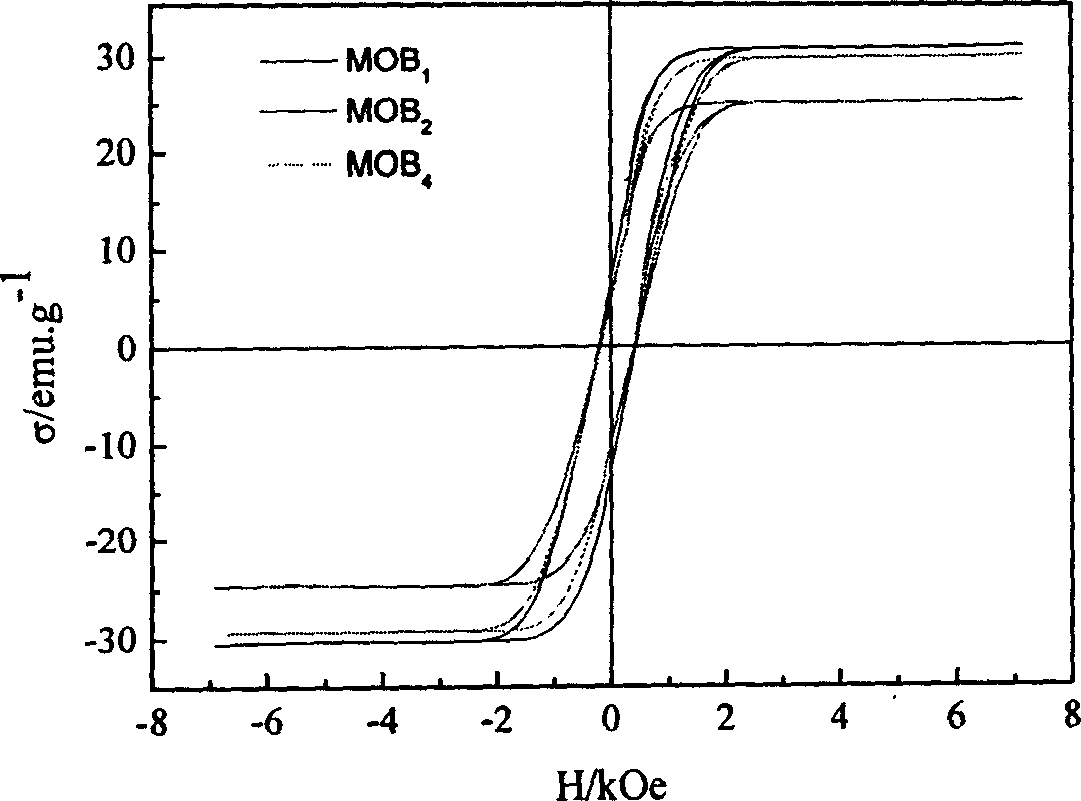

[0018] The dried and crushed bentonite raw soil, FeCl 3 and FeSO 4 Each 20g, 8.2g, and 4.1g was added distilled water to 700mL to make a suspension, placed in a constant temperature water bath at 70°C, and 100mL of a 5mol / L NaOH solution was added dropwise with stirring, and the stirring was continued for 3 hours. The product was washed with distilled water for 3 times and dried at 110°C. After grinding, it was added to 600 mL of 2 mmol / L cetyltrimethylammonium bromide solution, stirred for 5 hours, and aged at room temperature for 12 hours. The product was washed and filtered several times, dried at 60°C, and ground to obtain magnetic composite organic bentonite (MOB 1 ).

[0019] In the 50mL iodine bottle, add 20mL of the mixed solution of phosphate and phenanthrene, wherein the concentration of phosphate is 20mg / L (in PO 4 3- meter), the concentration of phenanthrene is 50mg / L, then add 0.05g of MOB 1 , shake at a constant temperature of 25°C for 2 hours, and measure t...

Embodiment 2

[0021] 20g of bentonite raw soil and FeCl that were dried and crushed through a 100-mesh sieve 3 , FeSO 4 Each 7.9g and 3.9g was added distilled water to 600mL to form a suspension, placed in a constant temperature water bath at 70°C, and 100mL of 5mol / L NaOH solution was added dropwise with stirring. Stirring was continued for 4 hours; the product was washed with distilled water for 4 times and then dried at 100°C. After grinding, it was added to 400 mL of 3 mmol / L dodecyltrimethylammonium bromide solution, stirred for 5 hours, and aged at room temperature for 12 hours. hours, the product was washed and filtered several times, dried at 60°C, and ground to obtain magnetic composite organobentonite (MOB 2 ).

[0022] In the typical measuring bottle of 50mL, add the mixed solution of 20mL phosphate radical and ethyl naphthol, wherein the concentration of phosphate radical is 15mg / L (in PO 4 3- meter), the concentration of ethyl naphthol is 20mg / L, then add the MOB of 0.05g ...

Embodiment 3

[0024] 15g of bentonite raw soil and FeCl that were dried and crushed through a 150-mesh sieve 3 , FeSO 4 Each 7.8g and 3.9g was added distilled water to 600mL to form a suspension, placed in a constant temperature water bath at 80°C, and 80mL of 6mol / L NaOH solution was added dropwise under stirring. Stirring was continued for 3 hours; the product was dried at 120°C, and after grinding, it was added to 400 mL of 3 mmol / L octadecyltrimethylammonium bromide solution, stirred for 6 hours, and aged at room temperature for 10 hours. After washing and filtering, dry at 80°C and grind to obtain magnetic composite organobentonite (MOB 3 ).

[0025] In the typical measuring bottle of 50mL, add the mixed solution of 20mL phosphate radical and ethyl naphthol, wherein the concentration of phosphate radical is 25mg / L (in PO 4 3- meter), the concentration of ethyl naphthol is 20mg / L, then add the MOB of 0.05g 3 , shake at a constant temperature of 25° C. for 2 hours, and measure the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com