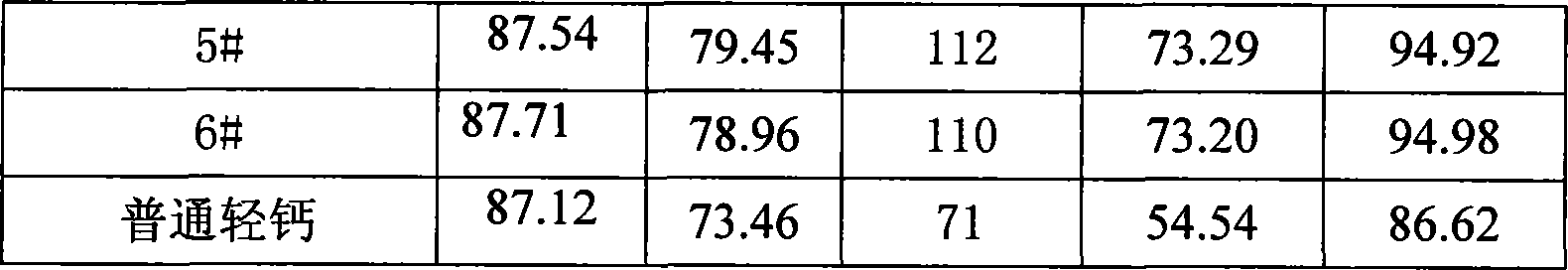

Patents

Literature

308 results about "Zirconium hydroxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nano-zirconium hydroxide is a white amorphous solid nanopowder, insoluble in water and alkali solution, soluble in hydrochloric acid and inorganic acids, non-toxic, odorless, density of 3.25, in the high temperature (500 ° C or so), it will decompose into zirconium oxide and water. Zirconium (IV) hydroxide is often called hydrous zirconia.

Solid acid catalyst and process for preparing the same

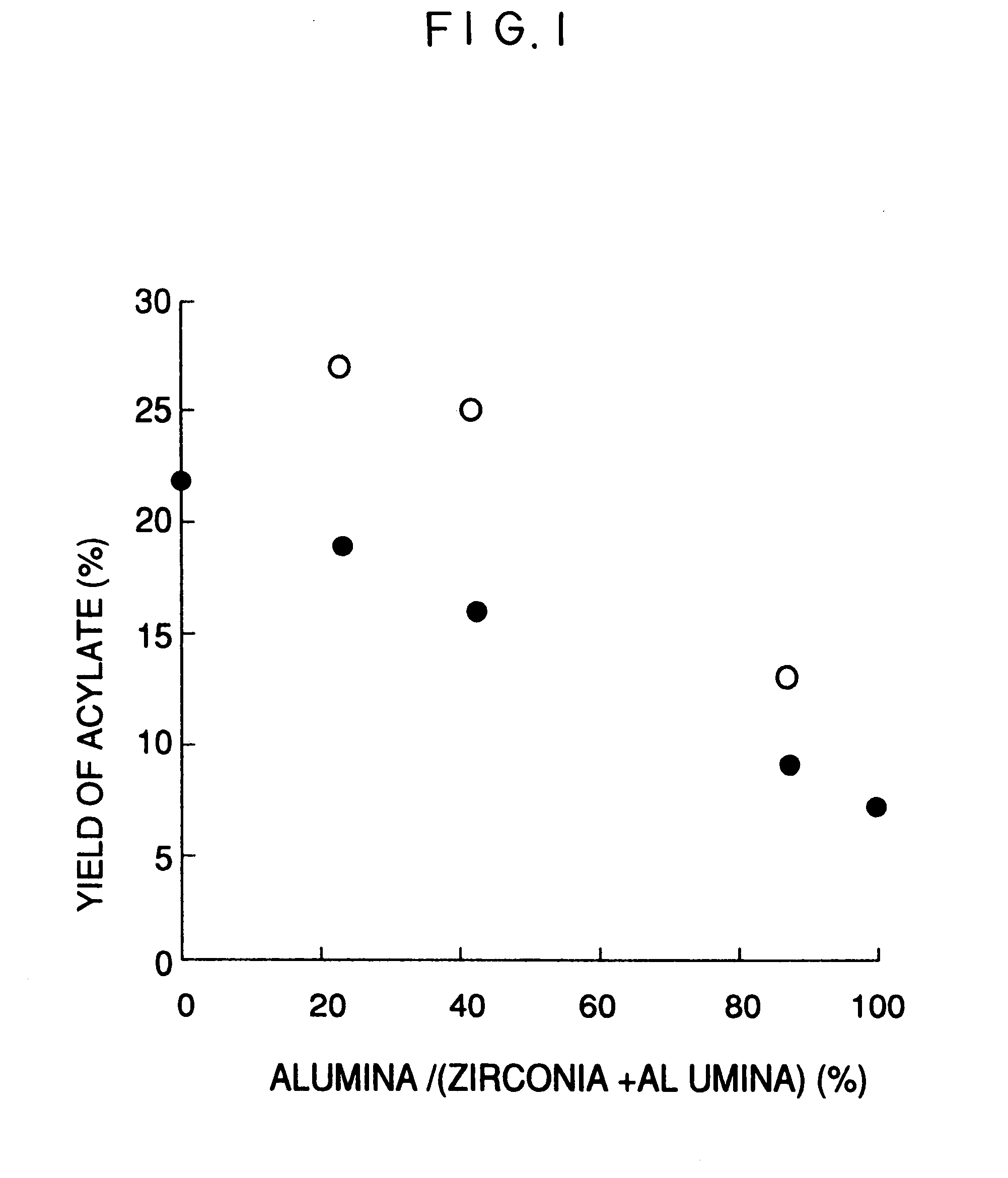

InactiveUS6326328B1High catalytic activityHigh activityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsIsomerizationPartial oxidation

The present invention relates to a shaped solid acid catalyst for the isomerization of hydrocarbons and so on, which has a high activity and is excellent in strength and easily handleable, and processes for the preparation thereof. This catalyst comprises a support comprising portions of zirconia having a tetragonal form and portions of alumina, and a sulfureous component and, if necessary, a Group 8, 9 or 10 metal component both being supported on the support, and has a specific surface area of 150 m2 / g or above. The catalyst can be prepared by kneading aluminum hydroxide, zirconium hydroxide and a sulfureous compound, shaping the kneaded mixture, calcining the shaped material at such a temperature as to form tetragonal zirconia and, if necessary, supporting a Group 8, 9 or 10 metal component on the calcined material and calcining the resulting molding at 300 to 700° C.

Owner:JAPAN ENERGY CORP

Method for recycling zirconium oxide and yttrium oxide from yttrium oxide steady zirconium oxide solid fused mass waste matter

ActiveCN101244843ASignificant progressTo achieve the effect of resource utilizationRare earth metal compoundsZirconium oxidesZirconium hydrideYttria-stabilized zirconia

The invention relates to a method for recovering zirconia and yttria from the yttria-stabilized zirconia solid solution waste, which comprises the following steps: mixing the solid solution waste powder, sulfate and salt; acidizing and calcining at 200 to 320 DEG C; leaching the acidizing water and / or mother liquor under self-heating conditions; concentrating the leaching solution to leach zirconium sulfate; dissolving the zirconium sulfate in the water and purifying; neutralizing the zirconium hydroxide with alkali and precipitating; calcining the zirconium hydroxide to obtain zirconia; precipitating zirconium mother liquor to produce by-product of ammonium sulfate; neutralizing yttrium rich mother liquor and precipitating to obtain yttrium; dissolving yttrium rich residue with acid and purifying; precipitating oxalate to obtain yttrium oxalate; calcining to obtain the yttria. The method has the advantages of effectively separating the yttria from the zirconia in stable zirconia solid solution waste with optional yttrium ion under low temperature condition, changing the zirconia solid solution waste into valuables and utilizing the resources.

Owner:SHANDONG LEIBAO ZIRCONIUM SCI&TECH

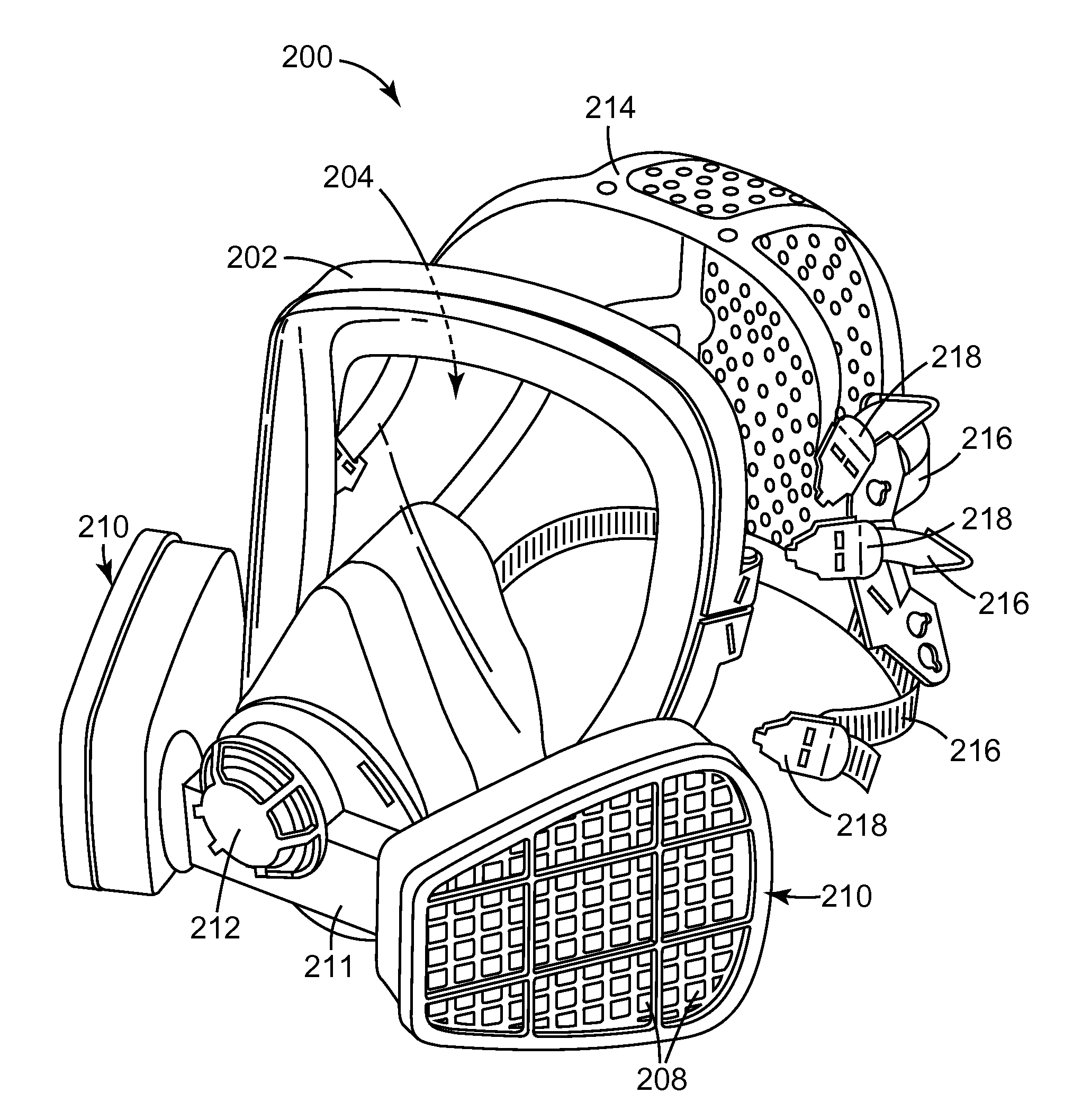

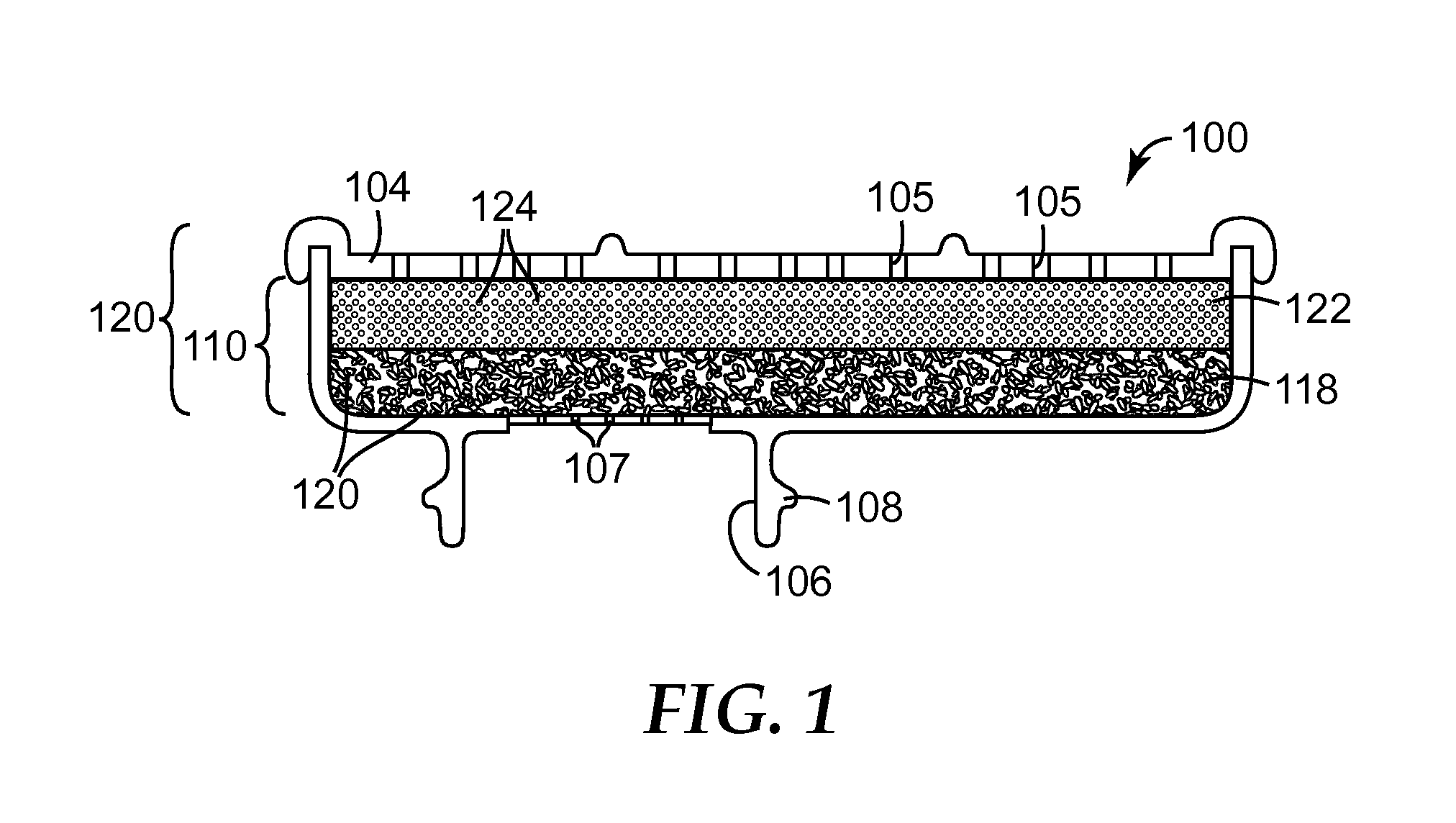

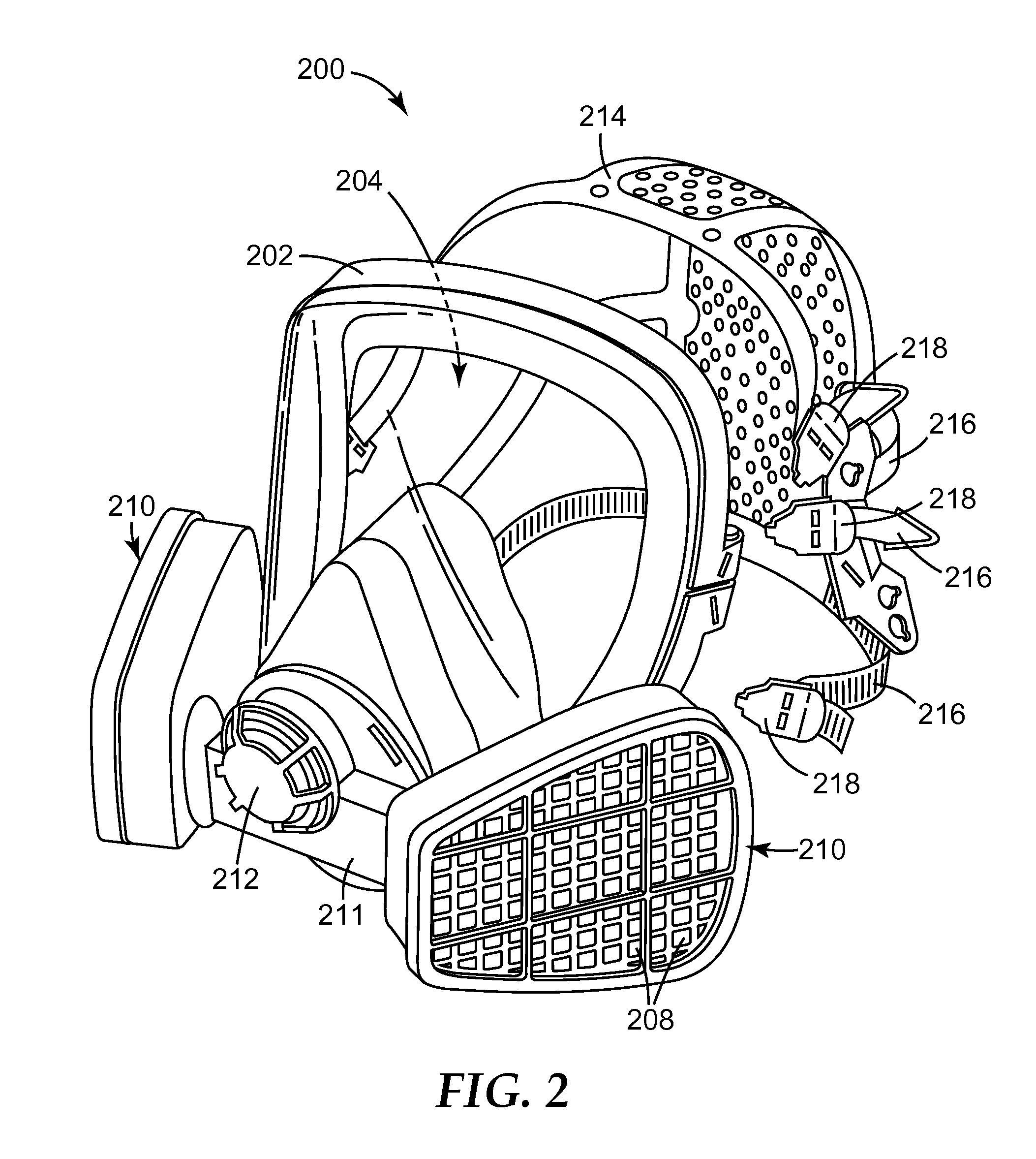

Layered Or Mixed Sorbent Bed Protective Filtration Device

InactiveUS20150306536A1Improve current performanceWeight controlGas treatmentDispersed particle filtrationBreakthrough timeFilter media

A filtration device including a fluid-impermeable housing having a gas inlet and outlet, and containing within the housing first filter media particles of an extended surface area substrate and containing at least one metal impregnant, and second filter media particles of an extended surface area zirconium hydroxide substrate and zinc (hydr)oxide. The device may be used in atmospheres containing various harmful gases, and may provide particularly useful improvements in NOx breakthrough times compared to a device containing only the first filter media particles or only the second filter media particles.

Owner:UNITED STATES OF AMERICA +1

Zirconia-alumina composite oxide carrier and method for preparing same

ActiveCN101890377AStrong penetrating powerExtended operating cycleCatalyst carriersCatalyst activation/preparationSolubilityPorosity

The invention discloses a zirconia-alumina composite oxide carrier and a method for preparing the same. The carrier is prepared from a zirconium hydroxide-aluminum hydroxide gel serving as a raw material by using a super-solubility micelle method. Because the gel contains a surfactant and hydrocarbon components, zirconia nanoparticles and alumina nanoparticles formed after dehydration of polymerized zirconium hydroxide and aluminum hydroxide still have rod-like basic structures after shaping and roasting, and the nanoparticles are disorderly stacked into a frame structure. The carrier has large pore volume, large aperture, high porosity, large orifices on outer surface and high pore penetrability, and particularly for high molecules, the carrier can prevent a catalyst from becoming inactivated due to blockage of the orifices, contribute to increasing the deposition of impurities and prolong the operating period of the catalyst because the carrier does not have orifices similar to ink bottle-shaped orifices. The carrier can be used in catalytic reactions comprising high molecular reactants or products.

Owner:CHINA PETROLEUM & CHEM CORP +1

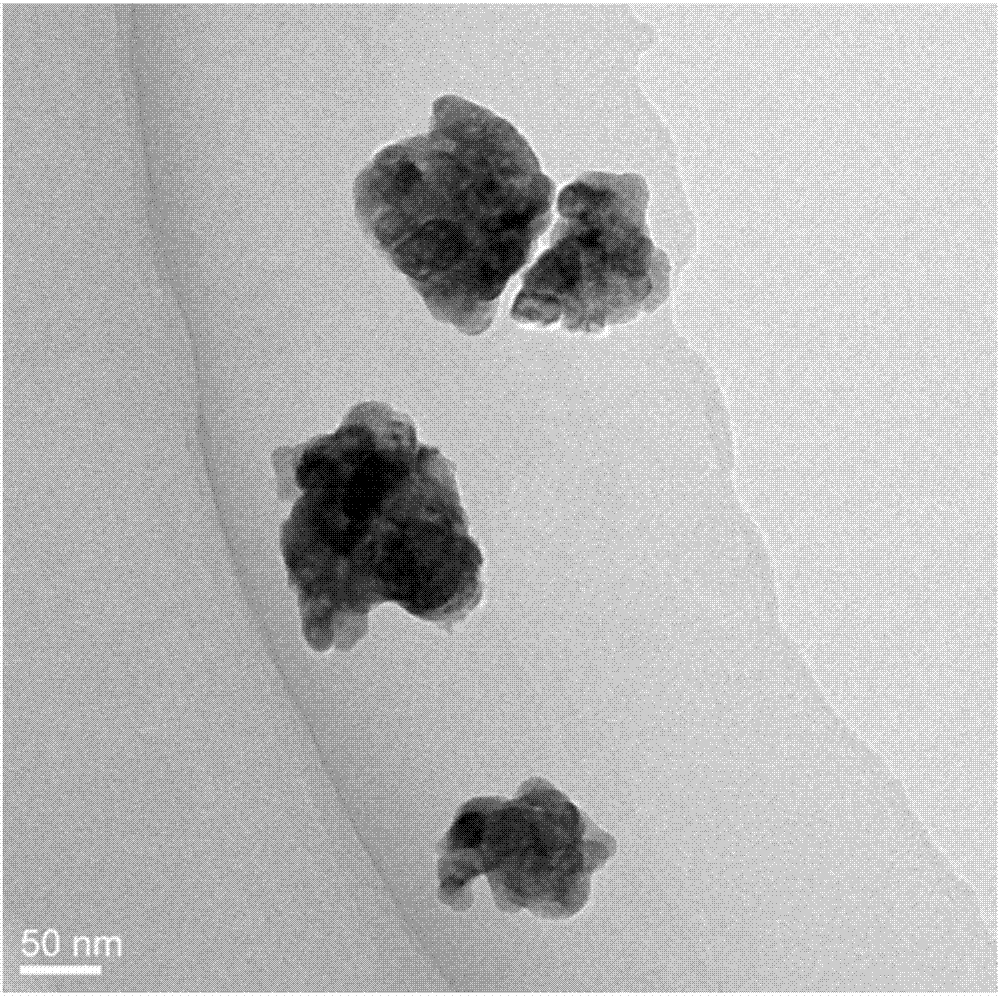

Composite toughening material of nanometer carbon pipe/nanometer zirconium exide and its preparation method

The invention provides a carbon nano tube / nano zirconium oxide composite toughening material and its preparing process, wherein the material is CNTs with nano zirconium oxide particles adhered on the surface, and the preparing process comprises, preparing CNTs suspending liquid, charging zirconium source and strong base to form CNTs / zirconium hydroxide colloid, heating the CNTs / zirconium hydroxide colloid to dehydrate the colloid, then transforming zirconium hydroxide into zirconium oxide under high temperature protection state, finally obtaining the carbon nano tube / nano zirconium oxide composite toughening material with controllable nano grade grain diameter, when used for alumina ceramics, the fracture toughness property can be improved appreciably.

Owner:TSINGHUA UNIV

Cerium oxide-zirconium oxide based composite rare-earth oxide with high specific surface area and high oxygen storage capacity and preparation method thereof

ActiveCN103191711ATotal pore volumeFresh specific surface area is highDispersed particle separationCatalyst activation/preparationZirconium hydrideSlurry

The invention discloses a method for preparing a cerium oxide-zirconium oxide based composite rare-earth oxide. The method comprises the following steps of: (1) heating a zirconium salt solution at room temperature, slowly adding sulfate ions, controlling the temperature rise rate so that the temperature is increased in the range of 90-95 DEG C when the sulfate ions are added completely, and then preserving heat for 20-100 minutes, thereby forming a zirconium basic sulfate composite salt precursor; (2) adding a cerium salt and a rare-earth metal salt to the precursor solution and stirring evenly, thereby obtaining a slurry; (3) settling the slurry by using basic carbonate and / or a basic oxalate solution, thereby obtaining a precipitate; and (4) filtering and washing the precipitate obtained in the step (3), removing purities, and calcining the washed precipitate. The cerium oxide-zirconium oxide based composite rare-earth oxide prepared by the method by controlling raw materials and process conditions has the characteristics of being high in total fine pore volume, high in fresh specific surface area, high in oxygen storage capacity and the like.

Owner:CHAOZHOU THREE CIRCLE GRP

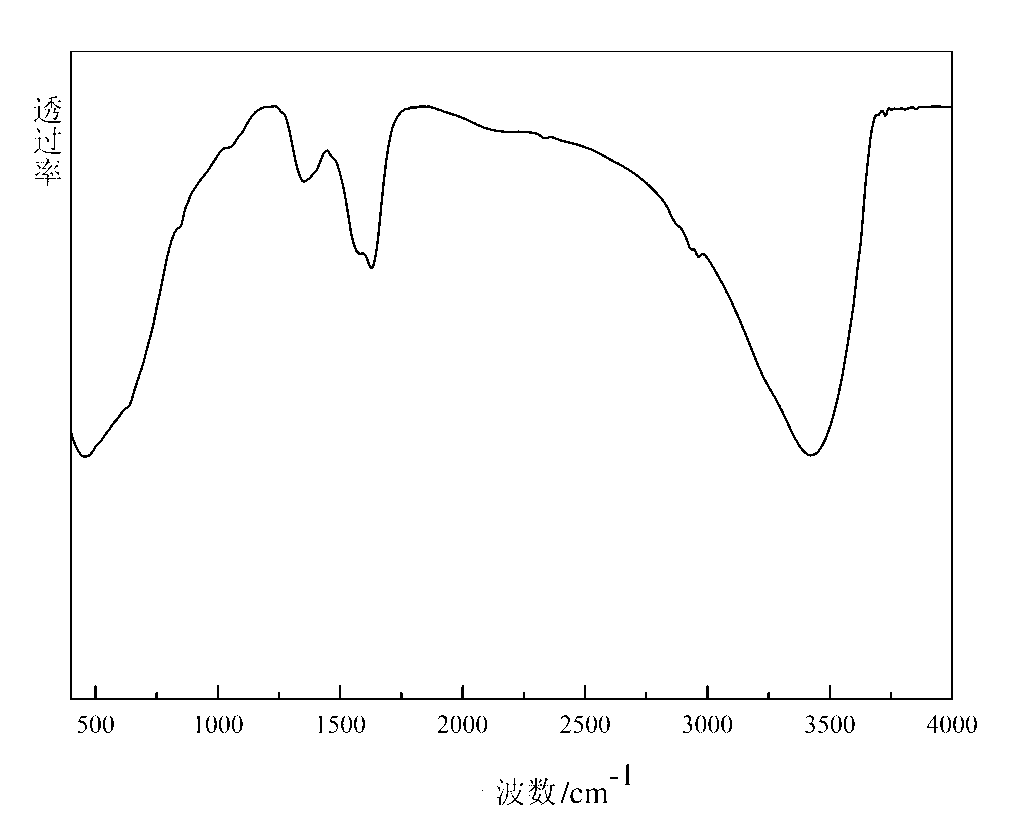

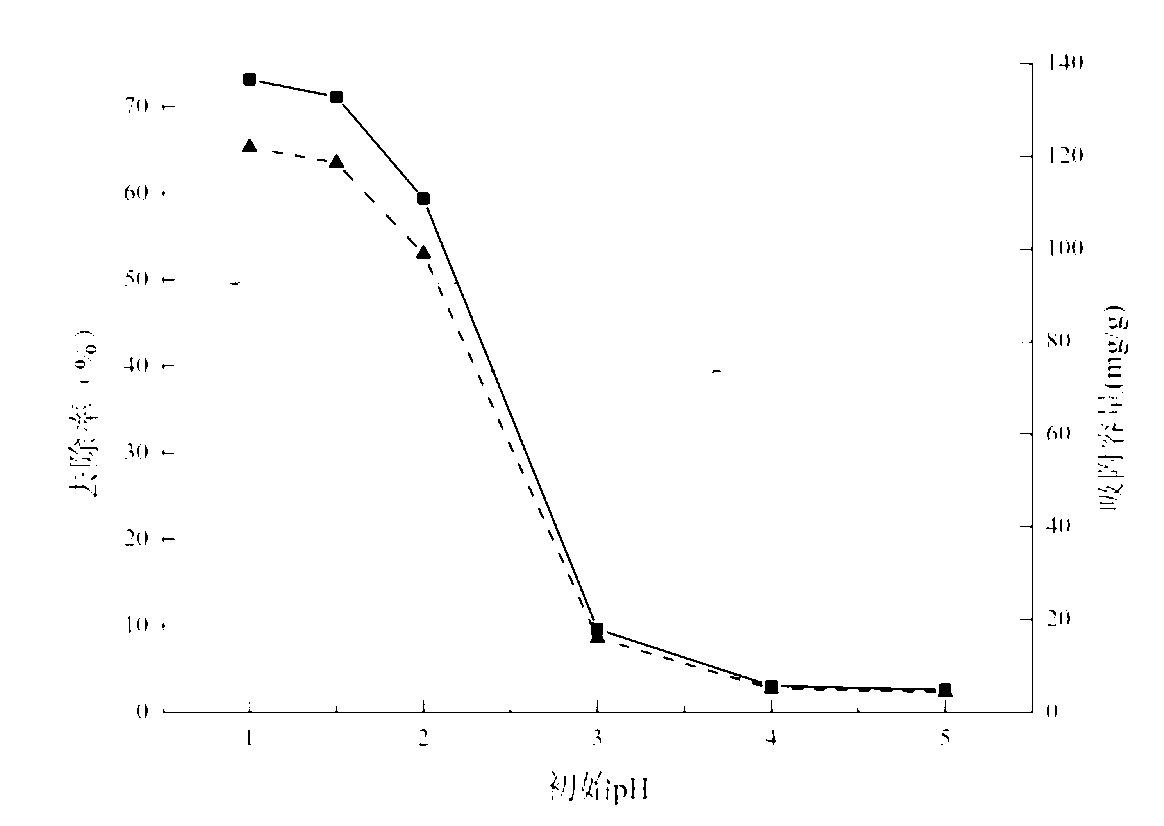

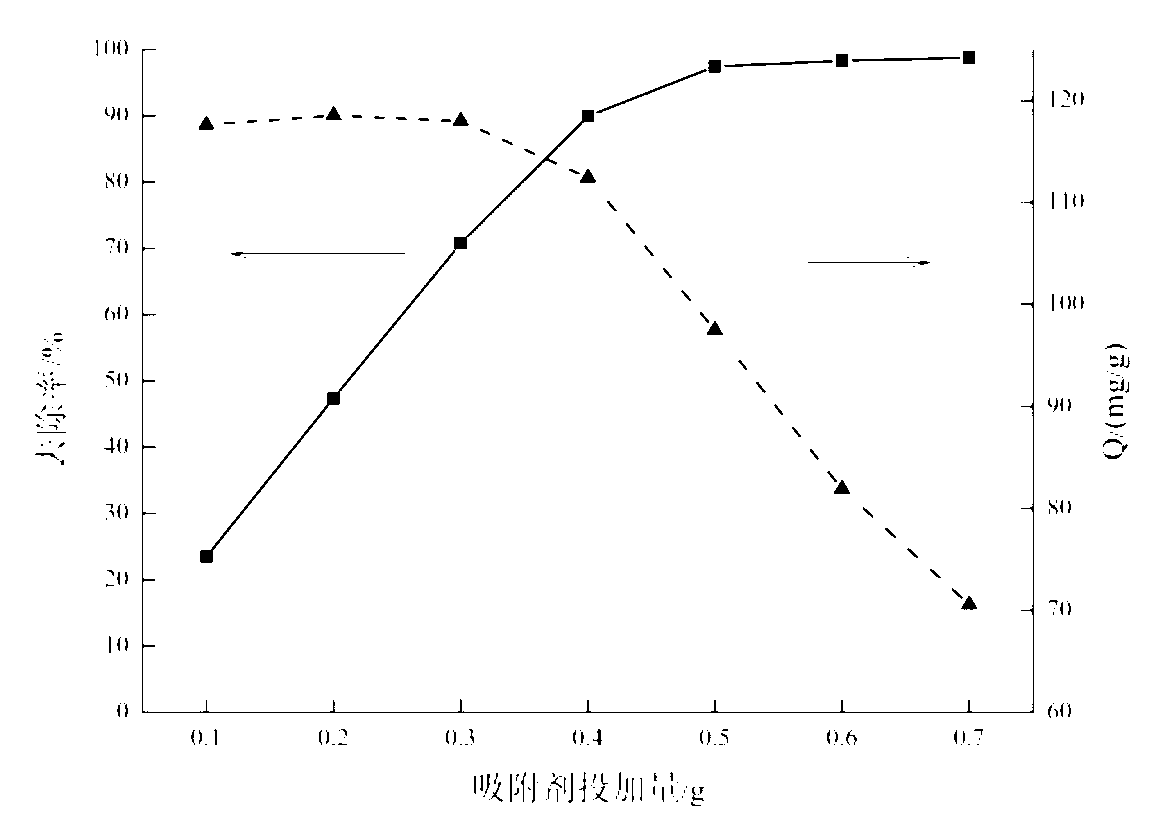

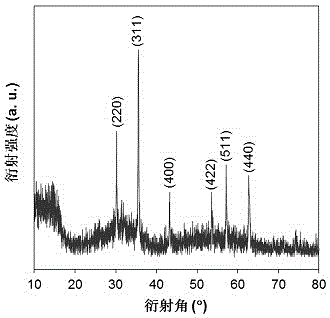

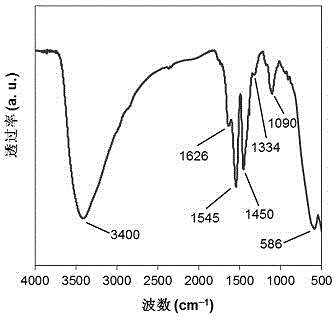

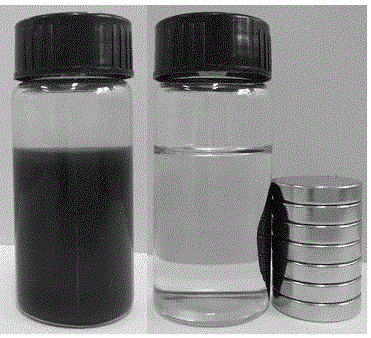

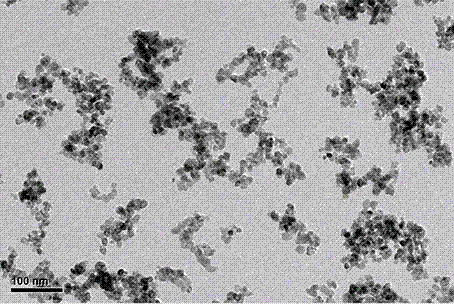

Sulfate radical sorbent magnetic nanometer zirconium hydroxide and preparation method thereof

InactiveCN102872790AFacilitate solid-liquid separationSolid-liquid separation is simple and convenientOther chemical processesAlkali metal oxides/hydroxidesSulfate radicalsFiltration

The invention relates to a sulfate radical sorbent magnetic nanometer zirconium hydroxide and a preparation method thereof. The preparation method comprises the following steps: (1), modifying magnetic Fe3O4 nanoparticles; (2), under mechanical stirring, firstly, quickly dripping a ZrOC12 solution in a Fe3O4 suspending liquid, then slowly dripping an ammonia solution until the pH value is 9-10, followed by standing and aging so as to obtain wet sol sedimentation, and finally performing sedimentation washing and suction filtration; and (3), dissolving the wet sol in a n-butanol for azeotropic distillation, vacuum drying after the termination of the distillation, and extracting for grinding and sieving so as to obtain the sulfate radical sorbent magnetic nanometer zirconium hydroxide. According to the invention, the solid-liquid separation is easily realized after the adsorption of the sulfate radical sorbent; the magnetic field solid-liquid separation is simpler and convenient; and the water basically has no residual after the sulfate radical is desorbed, and the adsorption effect is good.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Zirconium hydroxide for decontaminating toxic agents

ActiveUS8530719B1Effective and rapid in decontaminating toxic agentFire extinguisherZirconium hydroxideEnvironmental chemistry

Owner:UNITED STATES OF AMERICA

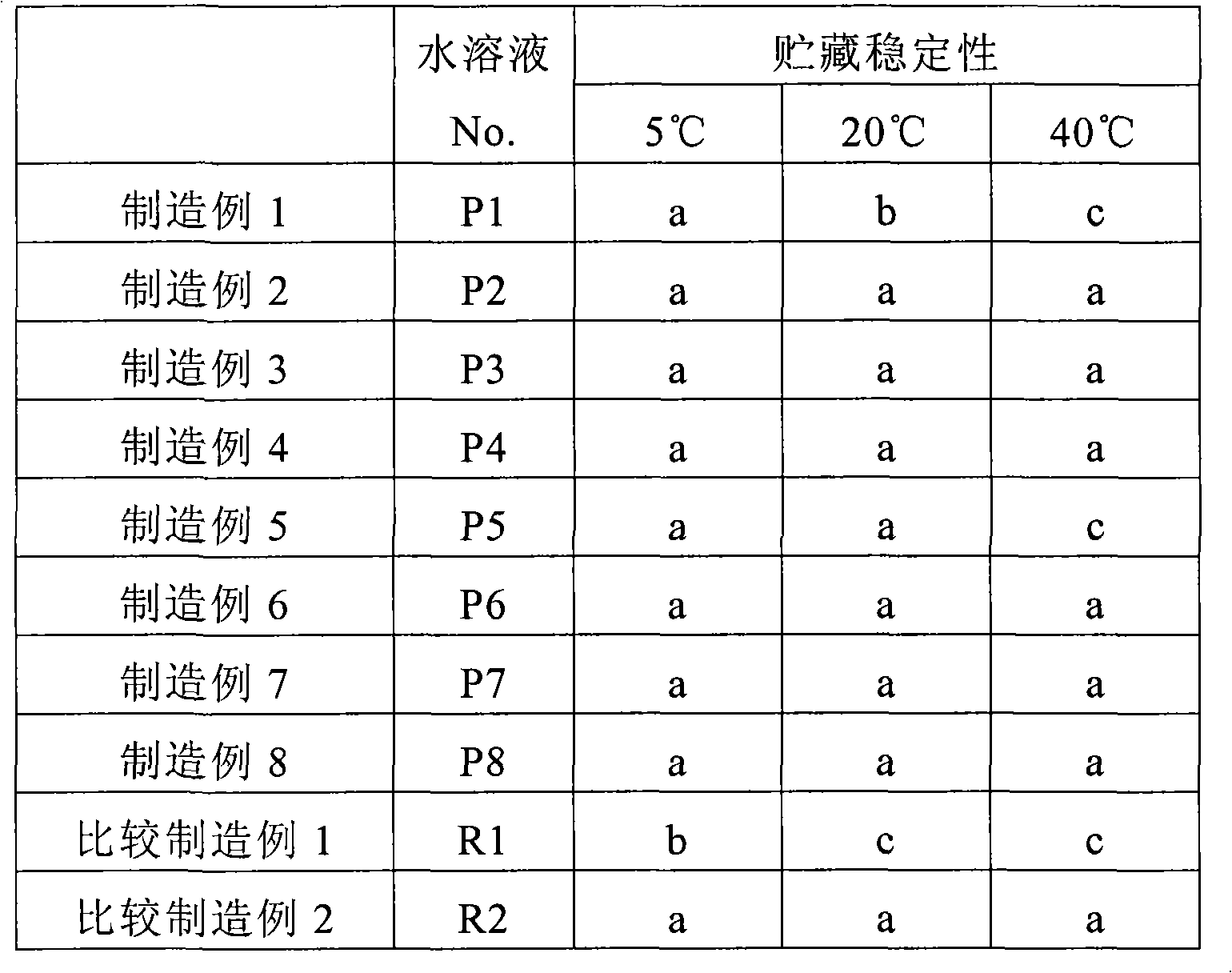

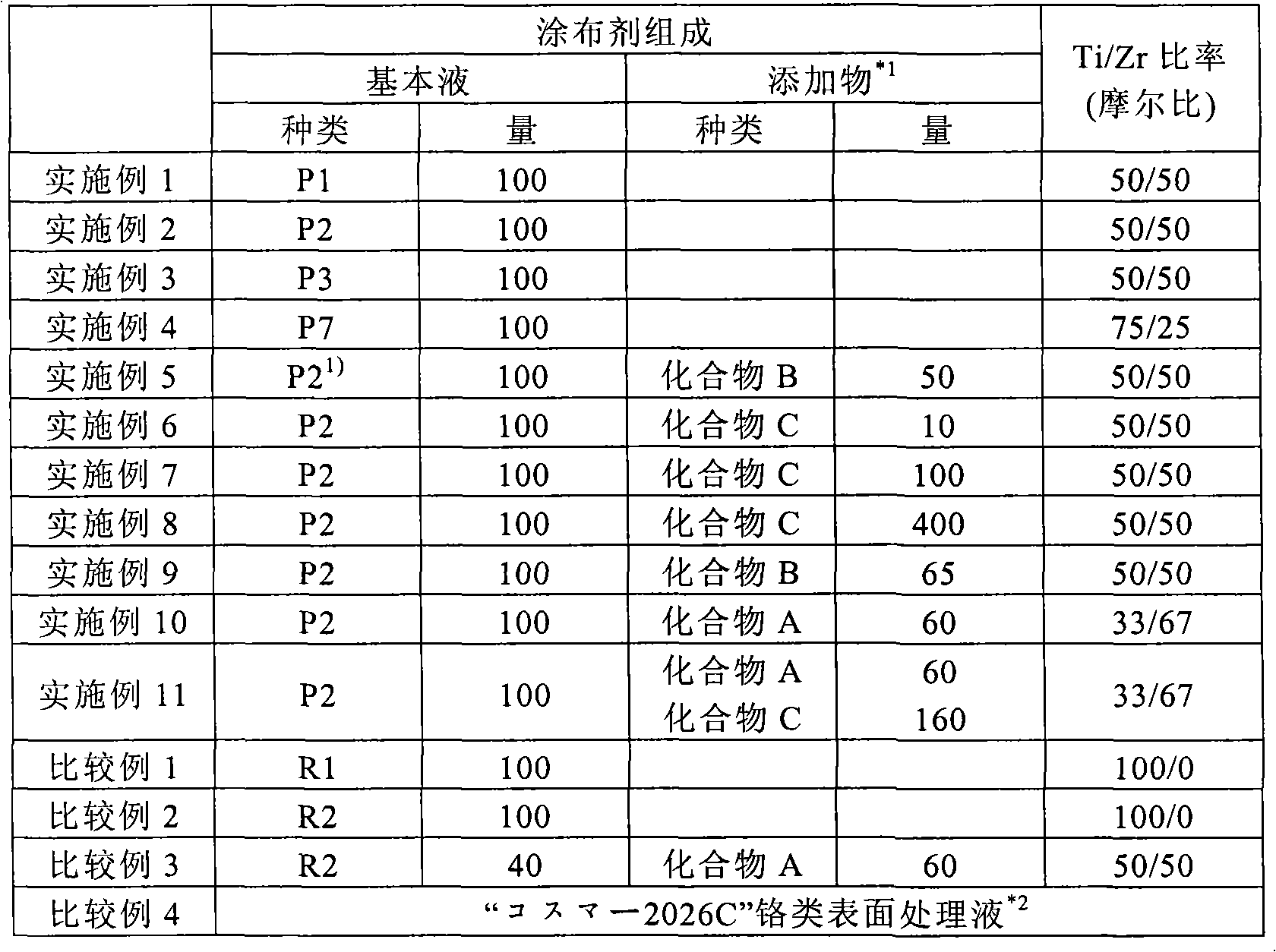

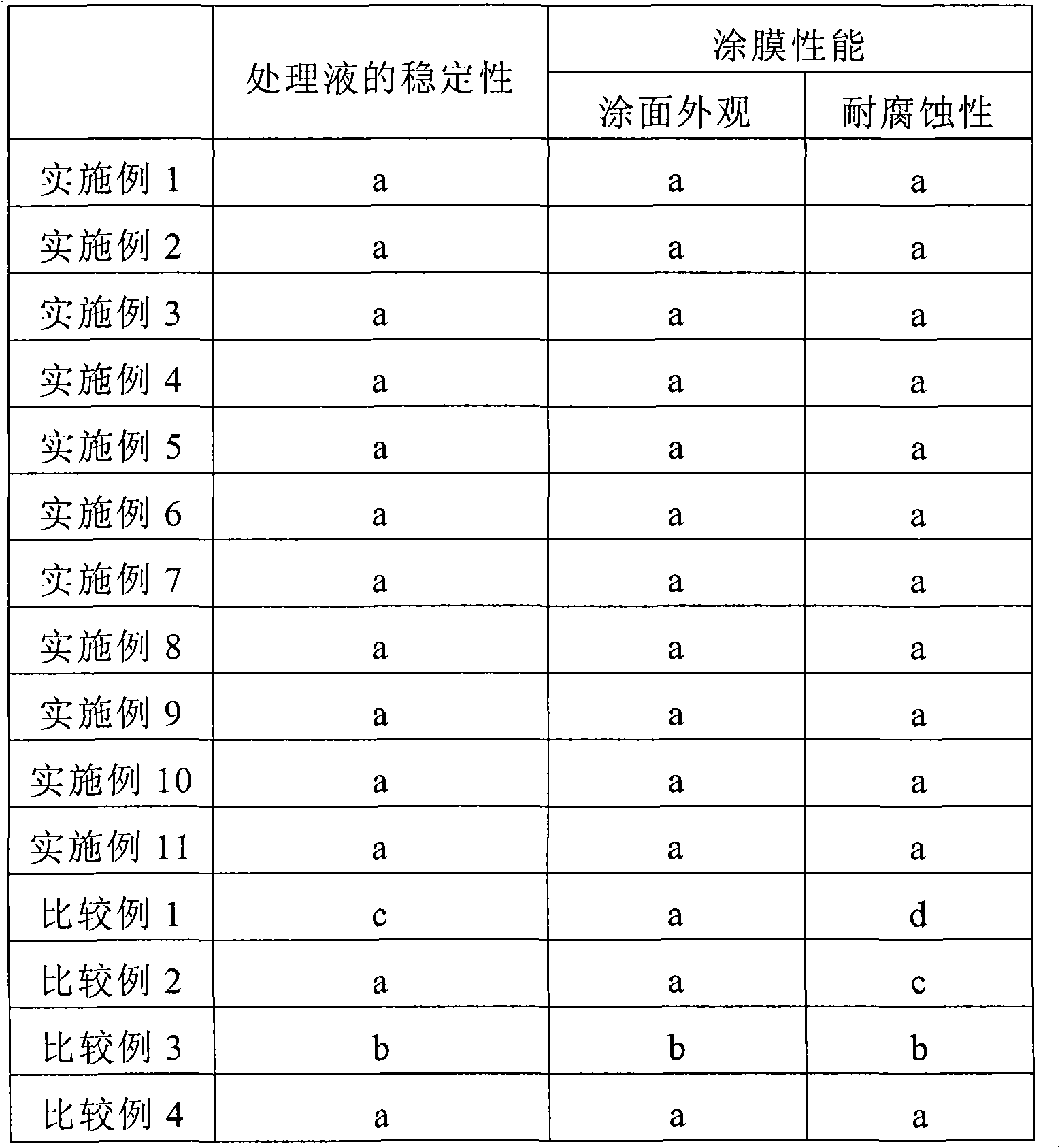

Coating agent for forming titanium/zirconium film, method for forming titanium/zirconium film and metal substrate coated with titanium/zirconium film

The invention provides a titanium / zirconic containing coating agent for film-forming that contains a titanium / zirconic aqueous solution obtained by reaction of (A) titanium compound and (B) zirconic compound with oxyful; wherein the (A) titanium compound is at least one selected from low condensate of hydrolytic titanium compound, hydrolytic titanium compound and low condensate of titanic hydroxide and titanic hydroxide. The (B) zirconic compound is at least one selected from low condensate of hydrolytic zirconic compound, hydrolytic zirconic compound and low condensate of zirconic hydroxide and zirconic hydroxide. In addition, the invention further provides a titanium / zirconic film forming method and coated metal basal material of capsule formed by coating agent.

Owner:KANSAI PAINT CO LTD

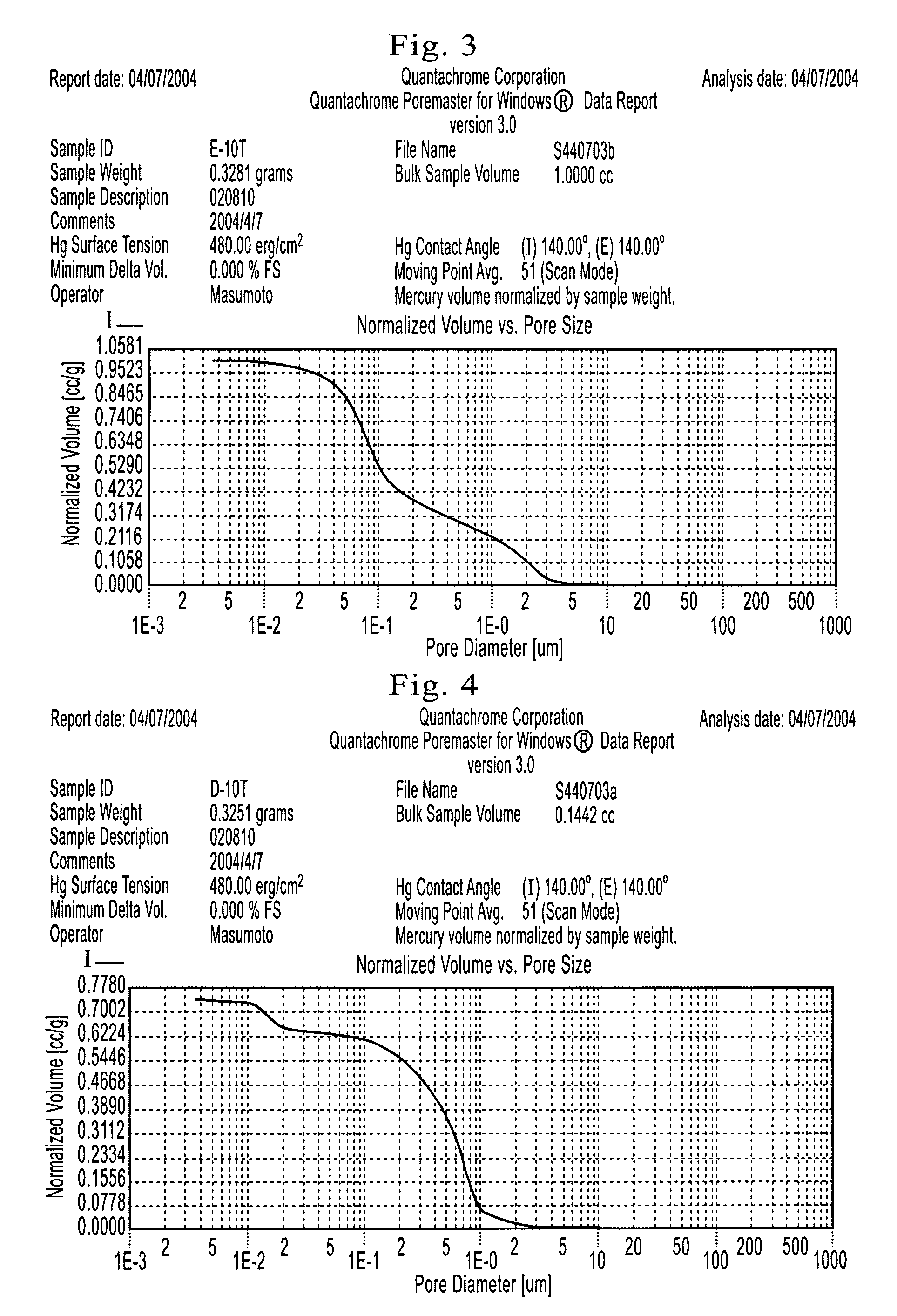

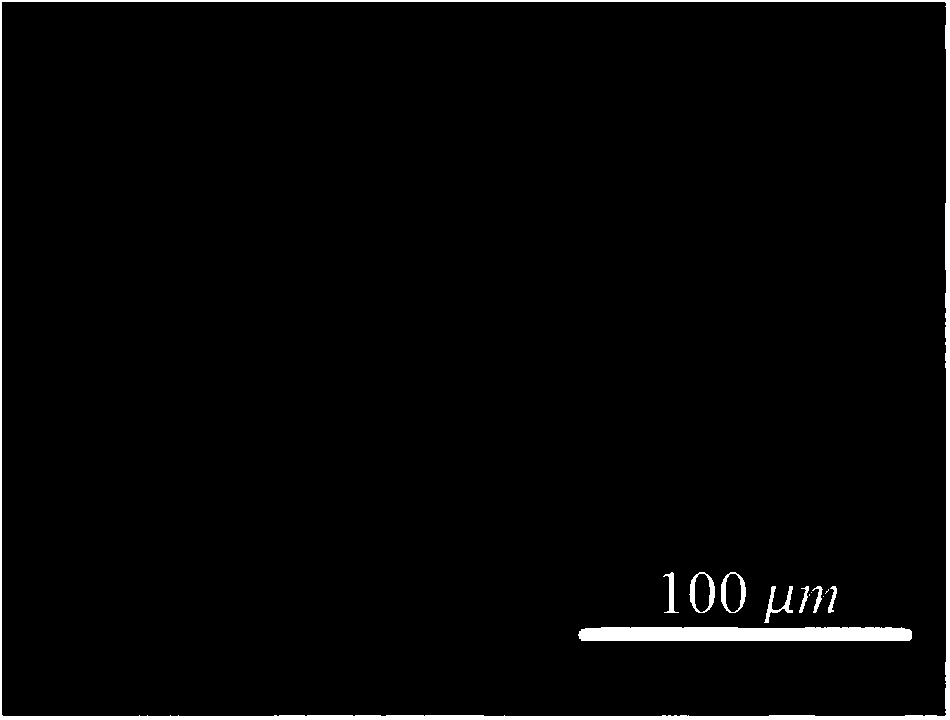

Porous zirconia powder and production method of same

ActiveUS7927699B2Improve heat resistanceEasy to getSynthetic resin layered productsCellulosic plastic layered productsHeat resistanceSulfate

The present invention provides a porous zirconium powder having improved heat resistance of total pore volume, and a simple production method thereof. More specifically, the present invention provides:(1) a porous zirconium powder in which total pore volume following heat treatment for three hours at 1000° C. is at least 0.75 ml / g, and total volume of pores having a diameter of 10 to 100 nm following heat treatment for three hours at 1000° C. is at least 30% of the total pore volume, and(2) a production method of a porous zirconia powder comprising: forming a basic zirconium sulfate by adding a sulfating agent to a zirconium salt solution; forming zirconium hydroxide by neutralizing the basic zirconium sulfate; and heat-treating the zirconium hydroxide, wherein, when adding the sulfating agent to the zirconium salt solution, the sulfating agent is added to the zirconium salt solution having a temperature of 100° C. or higher in an autoclave.

Owner:DAIICHI KIGENSO KAGAKU KOGYO CO LTD

Coarse-grained sphere-like zirconium hydroxide with large specific surface area and preparation method of zirconium hydroxide

ActiveCN105502490ALow impurity contentUniform particle sizeZirconium compoundsZirconium hydridePotassium hydroxide

The invention discloses coarse-grained sphere-like zirconium hydroxide with large specific surface area. Zirconium hydroxide adopts a sphere-like structure in shape, the grain size D10 is larger than or equal to 8 mu m, the diameter D50 is larger than or equal to 30 mu m and smaller than or equal to 40 mu m, the diameter D90 is smaller than or equal to 80 mu m, the specific surface area is larger than or equal to 550 m<2> / g, the pore volume is 0.20-0.25 cm<3>, the pore diameter is 2.0-2.4 nm, and the phosphorus / sulfur dynamic adsorption capacity of zirconium hydroxide is larger than 1 mmol / g. The invention further provides a preparation method of coarse-grained sphere-like zirconium hydroxide with the large specific surface area. According to the method, zirconium oxychloride reacts with SO4<2->, a product reacts with potassium hydroxide or sodium hydroxide, and zirconium hydroxide is directly prepared; ammonium ions are avoided effectively, and the prepared product contains few impurities and is uniform in grain size, large in specific surface area and high in activity. With adoption of the coarse-grained sphere-like structure, the product can be applied to phosphorous removal through dynamic adsorption for hemodialysis and can effectively reduce osmotic pressure.

Owner:JIANGXI KINGAN HI TECH

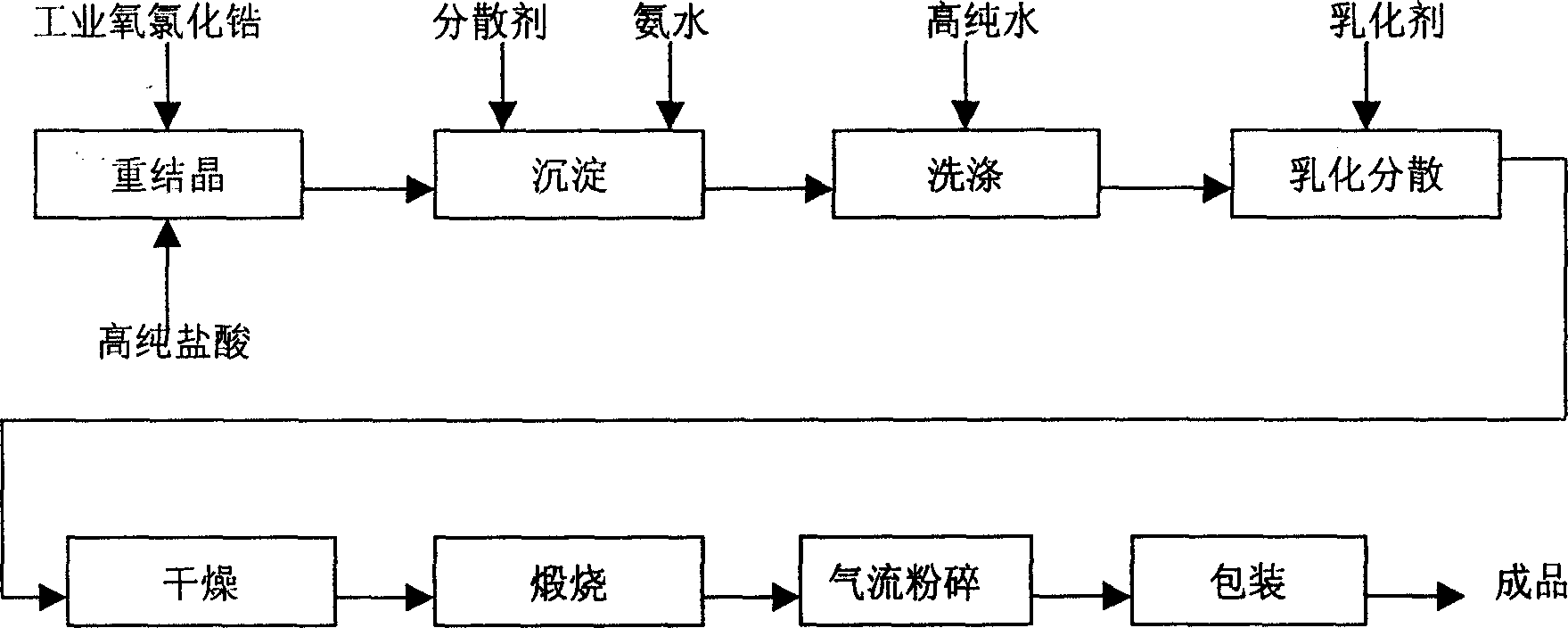

Process for preparing high-purity superfine zirconia by zirconium oxychloride

Disclosed is a process for preparing high-purity superfine zirconia by zirconium oxychloride, which comprises recrystallization purifying, charging ammonia for sedimentation, obtaining zirconium hydroxide colloid that is easy for filtration and washing, after filtering and washing, charging minute quantity of emulsifying agent, carrying out high shearing emulsification and high-energy ball grinding, thus obtaining stable hydrated zirconium dioxide with good dispersity, then drying with spraying drying apparatus, calcining to obtain crude product of high purity ultra-fine zirconium dioxide, finally subjecting the crude product to high pressure disintegration.

Owner:宜兴新兴锆业有限公司

Preparation method of high-coating-ratio zirconium silicate coated ceramic pigment and product prepared therethrough

The invention discloses a preparation method of a high-coating-ratio zirconium silicate coated ceramic pigment. The preparation method includes the steps of: dispersing and wetting a to-be-coated substance in a zirconium tetrachloride ethanol solution to prepare a suspension liquid, and volatilizing the ethanol and drying the liquid, and performing a reaction with ammonia gas to form a zirconium hydroxide coating layer on the surface of the to-be-coated substance; mixing the to-be-coated substance with a silicon source solution, and performing gelatination / precipitation to form a silicic acid coating layer on the surface of the zirconium hydroxide coating layer; and drying the substance, mixing the substance with a mineralizing agent and calcining the substance to form the zirconium silicate coated ceramic pigment. The invention also discloses a product prepared through the method. In the invention, a core-shell structure with the to-be-coated substance as a core and the zirconium silicate as a coating layer is formed, so that the coating ratio and the coloring intensity of the coated substance are significantly increased. Meanwhile, applicability of the zirconium silicate as a coating layer material is developed, so that application and development of the zirconium silicate coating ceramic pigment are effectively promoted.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Process for preparing punching die by using ZTA material

InactiveCN101289320AAvoid reunionEvenly dispersedMixing operation control apparatusClay processing apparatusHigh fractureTemperature resistance

The invention discloses a method for preparing press tool by using ZTA material. The method of the invention has the following procedures: a coprecipitation method is adopted to prepare zirconium hydroxide and yttrium hydroxide collosol; yttrium stable zirconia collosol and nano-alumina powder are mixed evenly according to the mixture ratio of 75 to 95 percent weight content of A12O3 in ZTA powder materials, and calcined at the temperature of 500 to 900 DEG C to obtain the ZTA powder in which zirconia is evenly distributed; then zirconia-toughened alumina ceramics is formed by baking at the temperature of 1500 to 1600 DEG C after the isostatic pressing at the pressure of 150MPa to 250MPa. The ZTA material prepared by the method has the advantages of high strength, high fracture toughness property, high hardness, high temperature resistance, corrosion resistance and anti-abrasive property, etc. By using ZTA ceramics materials to prepare alkaline cells and tablet press tool used in pharmaceuticals industry, the abrasive resistance property of the tool is greatly increased and the life service is prolonged.

Owner:SOUTH CHINA UNIV OF TECH

3D printing method of zirconium dioxide powder material, 3D printing device with binder injection device and binder injection device used for 3D printing method of zirconium dioxide powder material

InactiveCN105881695AHigh densityLow costAdditive manufacturing apparatusCeramic shaping apparatusZirconium dioxideInjection device

The invention discloses a 3D printing method of zirconium dioxide powder material. The method comprises the following steps: (1) slicing up and stratifying the 3D model of the product which needs to be printed to form multi-layered profile information; (2) paving a layer of zirconium dioxide powder material, movably injecting binder liquid with zirconium hydroxide nano-particles according to set procedure by an injection nozzle, and then bonding the zirconium dioxide powder material to form a profile of a layer of a part; (3) injecting binder after paving another layer of zirconium dioxide powder material on the formed profile, and then according to the above mentioned method, superimposing profiles layer by layer to form a 3D green body; (4) degreasing and sintering the green body and then conducting surface treatment to obtain a finished product. The invention further discloses a binder injection device used for the 3D printing method and a 3D printing device with the binder injection device. The invention is beneficial to obtain a 3D printed product which is high in density and reduce cost.

Owner:GUANGDONG JANUS SMART GRP CO LTD

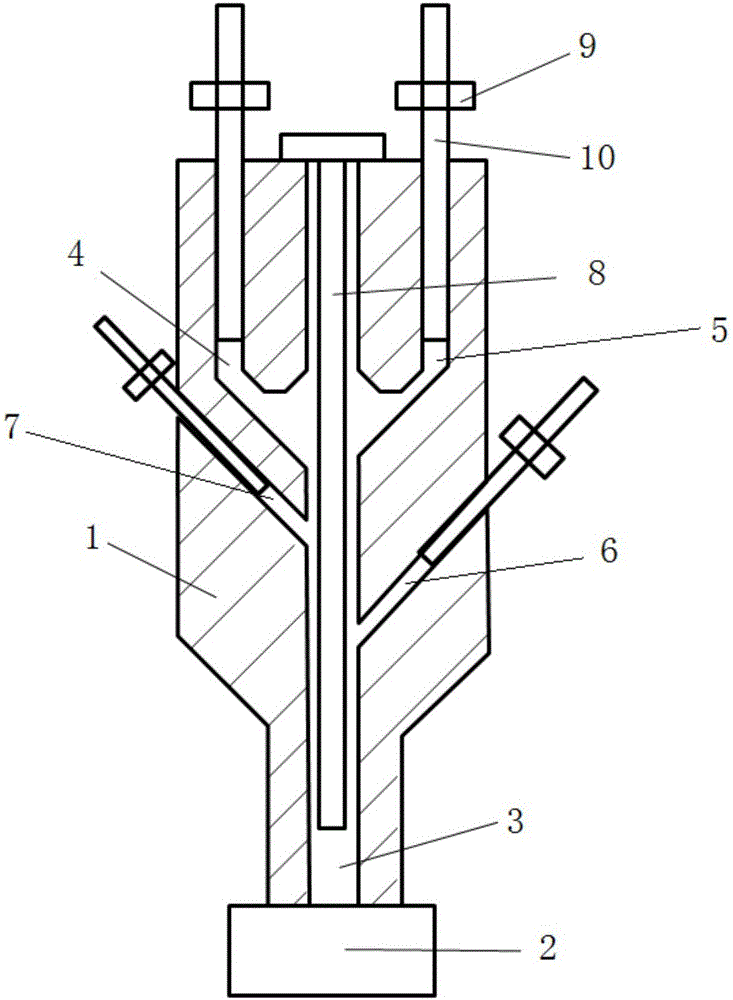

Method for producing nano zirconia

InactiveCN101698509AThe production method is scientific and reasonableMeet quality requirementsNanostructure manufactureZirconium oxidesHigh pressureAqueous solution

The invention relates to a method for producing nano zirconia, and belongs to the technical field of fine chemical engineering. The method comprises the following steps: reacting aqueous solution of zircon salt with an alkaline precipitator to form zirconium hydroxide precipitate; and filtering, washing, dehydrating, drying, and sintering the zirconium hydroxide precipitate to obtain zirconia powder. The method is characterized in that: the aqueous solution of zircon salt and the alkaline precipitator are respectively subjected to high pressure to form high speed fluid for jet mixing reaction to form the zirconium hydroxide precipitate. The method is scientific and reasonable, is convenient to implement, and can produce the nano zirconia meeting quality requirement.

Owner:ZIBO GUANGTONG CHEM

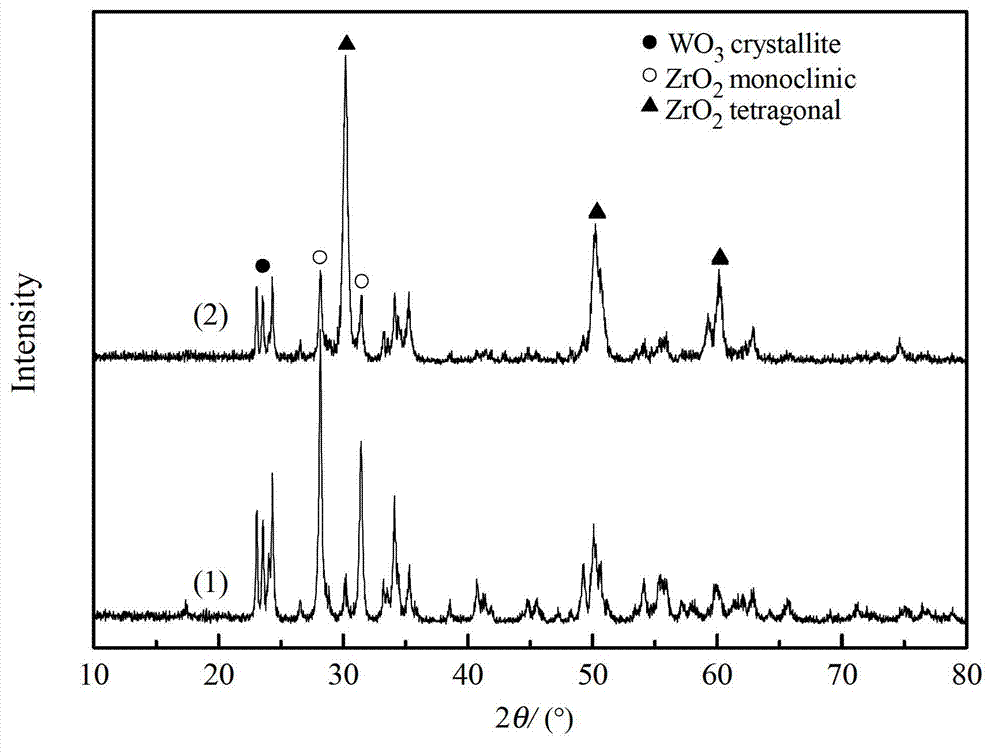

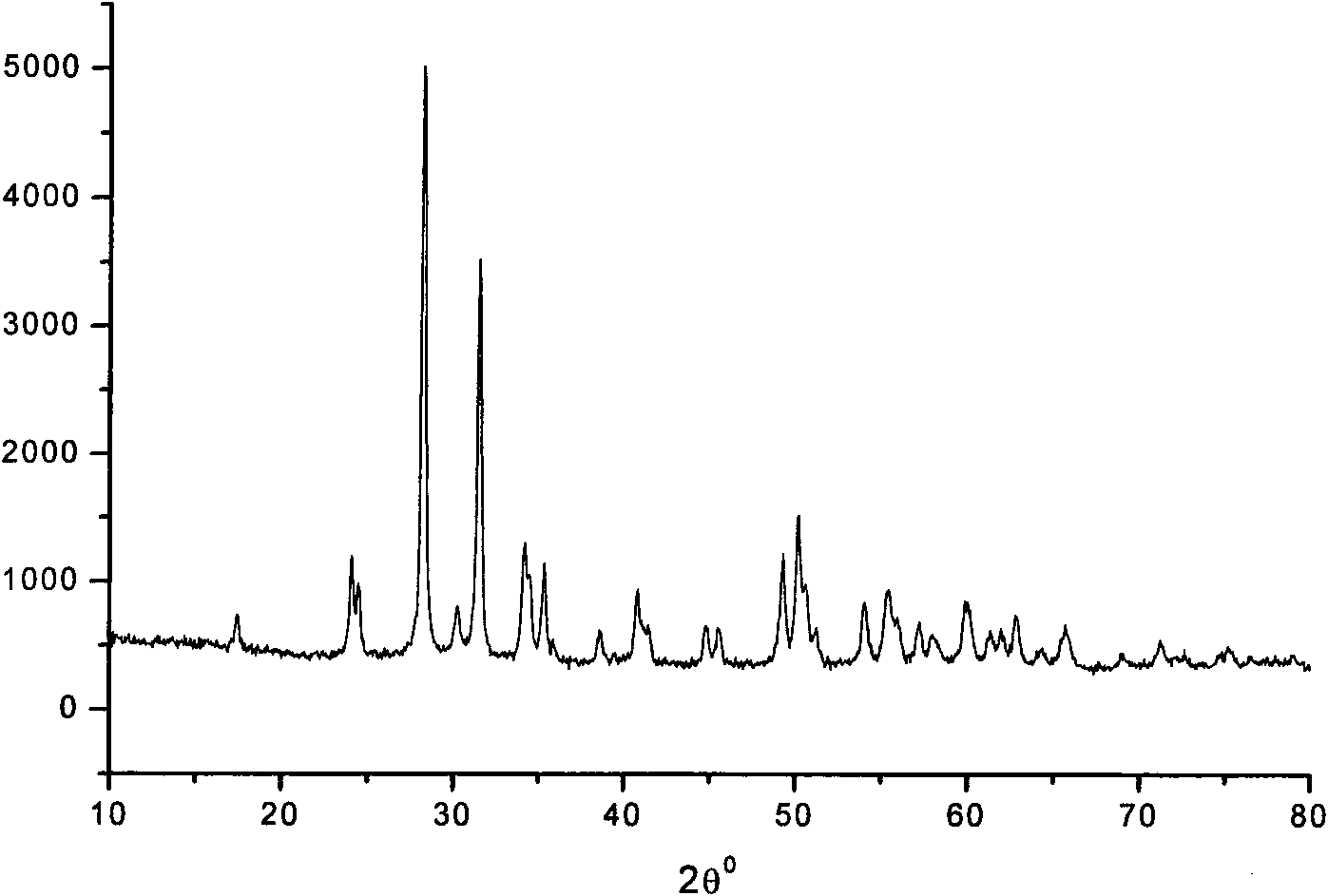

Preparation method of WO3/ZrO2 solid super acidic catalyst

InactiveCN103041800ARaise the ratioEvenly distributedHydrocarbon by isomerisationMetal/metal-oxides/metal-hydroxide catalystsEmulsionReaction temperature

The invention relates to a preparation method of a WO3 / ZrO2 solid super acidic catalyst. The method comprises the following steps that a zirconium hydroxide emulsion is heated in a round-bottom flask with a condenser pipe for 1-24h; a zirconium hydroxide solution is repeatedly leached and washed till a pH value of a filtrate is 6-8 and no chlorion exists; a zirconium hydroxide filter cake is soaked in C2H5OH with the concentration of 99% in a constant-temperature drying oven; drying is conducted after C2H5OH is removed; powdery zirconium hydroxide is obtained, and ground till a particle size is less than 80 meshes; and then ammonium metatungstate serves as a raw material, and is impregnated by an equal-volume method, dried and roasted to form the WO3 / ZrO2 solid super acidic catalyst. The method has the advantages of easiness and simplicity in operation, low reaction temperature, good stability and the like; in addition, in the WO3 / ZrO2 solid super acidic catalyst prepared by the method, the proportion of a tetragonal phase of zirconium dioxide is increased; a specific surface area is increased; the activity of catalytic reaction is improved obviously; and the cost is lowered effectively.

Owner:NORTHEAST GASOLINEEUM UNIV

Preparation method of zirconium dioxide powder

The invention relates to a preparation method of zirconium dioxide powder, comprising the following steps: A. dissolving zirconium oxychloride into deionized water, and controlling mass ratio of the zirconium oxychloride and the deionized water to be 4:(21-35); B. dropwise adding ammonia water into mixed solution in the step A, and controlling mole ratio of the ammonia water and the zirconium oxychloride to be (1.8-3.7):1; C. carrying out washing, pressing and filtering or centrifugal separation on zirconium hydroxide hydrogel in the step B to obtain zirconium hydroxide gel; D. drying the zirconium hydroxide gel of the step C to obtain zirconium hydroxide, and calcining the zirconium hydroxide to obtain zirconium dioxide; E. mixing the zirconium dioxide in the step D with grinding medium and water and carrying out wet grinding on the mixture; and F. drying the zirconium dioxide slurry in the step E to prepare the zirconium dioxide powder. The zirconium dioxide powder product produced by the method has good particle monodispersity, complete particle form, concentrating distribution of particle size, high purity and controllable particle size and can realize low cost when in large-scale production of the zirconium dioxide.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

Method for preparing 2,5-dihydroxymethyl furan through 5-hydroxymethyl furfural catalytic transfer hydrogenation

The invention discloses a method for preparing 2,5-dihydroxymethyl furan through 5-hydroxymethyl furfural catalytic transfer hydrogenation. The method uses magnetic zirconium hydroxide as a catalyst, uses low carbon alcohol as a reaction solvent and a hydrogen donor, 5-hydroxymethyl furfural is selectively converted into the 2,5-dihydroxymethyl furan through Meerwein-Ponndorf-Verley (MPV) transfer hydrogenation reaction in a high-pressure reaction kettle, and the highest yield is up to 91.5%. The raw materials for the used catalyst are low in price, the preparation process is simple, and the catalytic performance is good. In addition, the 2,5-dihydroxymethyl furan has strong magnetism and is easy to separate, recycle and reuse. Furthermore, the used low carbon alcohol can serve as the in-situ hydrogen donor, hydrogen usage is omitted, and the safety of the reaction process is further improved. Moreover, the 2,5-dihydroxymethyl furan can also serve as a reaction solvent, introduction of exogenous substances is reduced, the production costs are further reduced, and the method has a high application value and a good industrialized prospect.

Owner:HUAIYIN TEACHERS COLLEGE

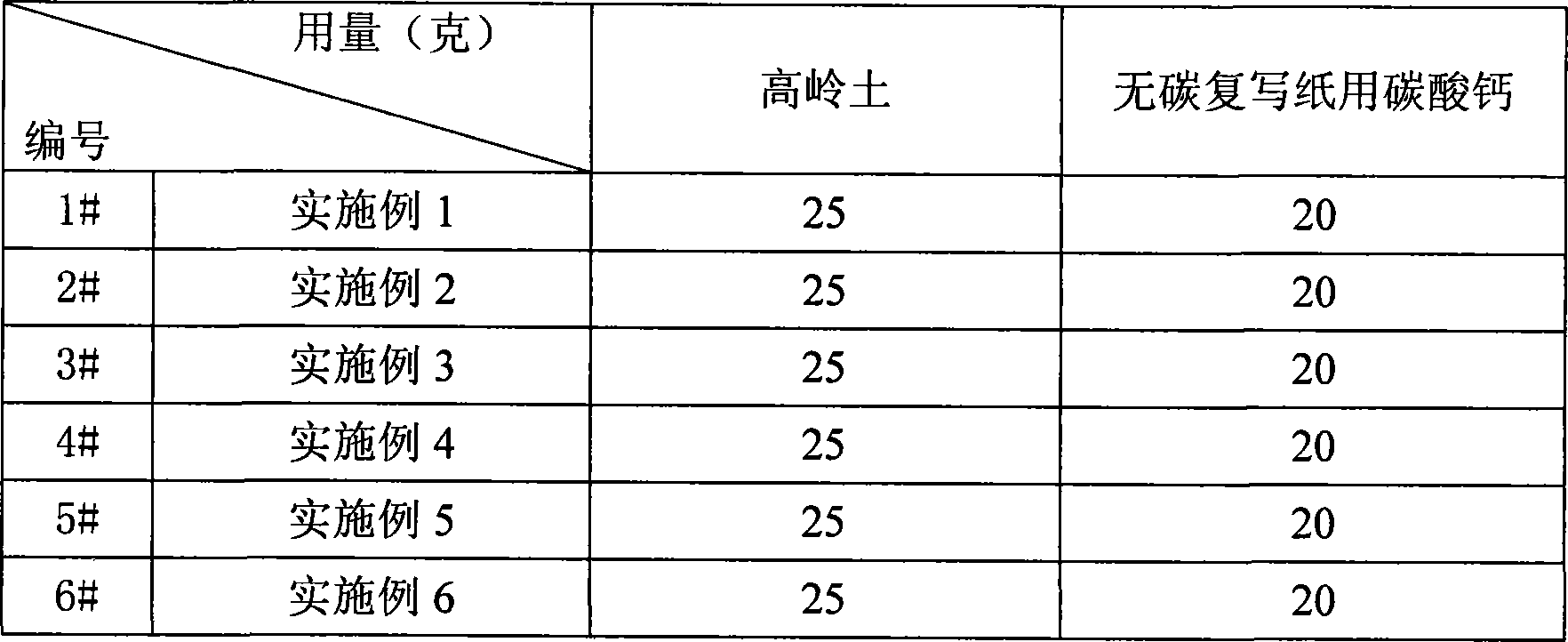

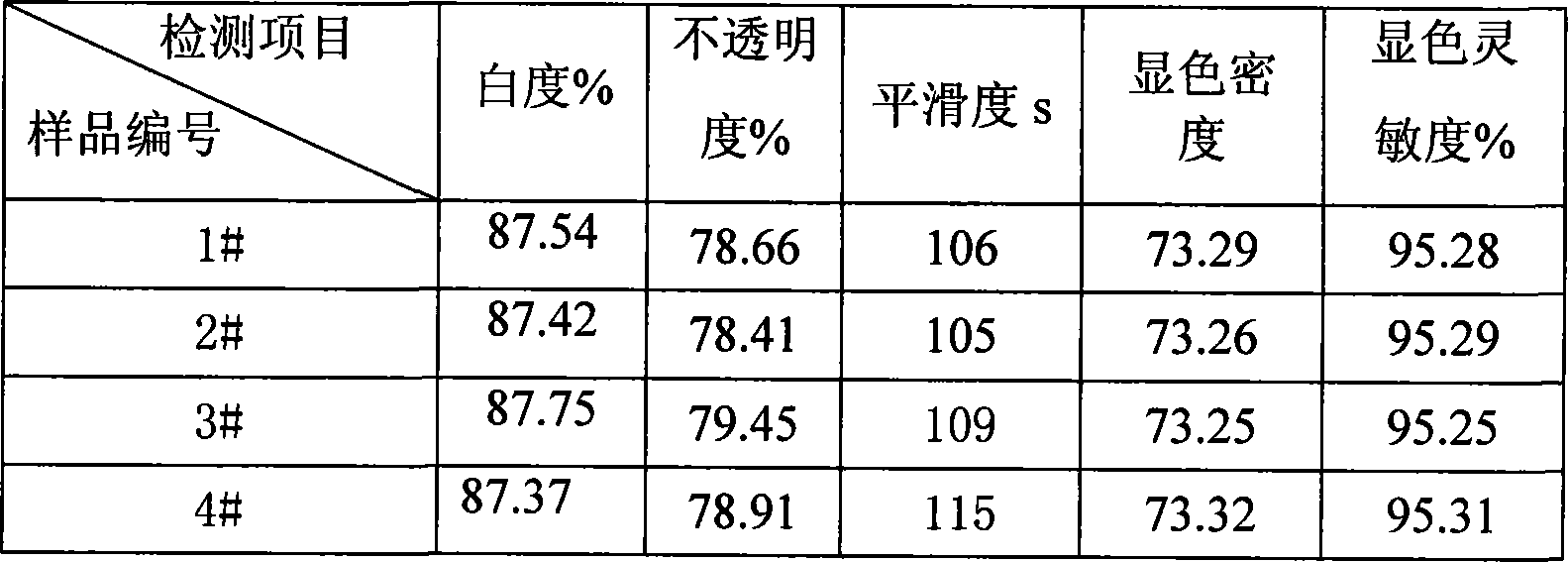

Preparation and application of calcium carbonate for carbon-free copying paper paint

ActiveCN101113004ACalcium/strontium/barium carbonatesNon-fibrous pulp additionCalcium hydroxideSlurry

The invention discloses a calcium carbonate for carbonless copy paper coating as well as the preparation and application thereof and the preparation method comprises the steps that: 1. the preparation of crystal seed zirconium hydroxide: alkaline material aqueous solution in zirconium salt aqueous solution is added to produce crystal seed zirconium hydroxide slurry; 2. the crystal seed zirconium hydroxide slurry is added into calcium hydroxide slurry, carbonized through carbon dioxide gas until pH is between 6.5-7.5 to get calcium carbonate slurry for carbonless copy paper coating, and then calcium carbonate for carbonless copy paper coating is collected. The calcium carbonate for carbonless copy paper coating can be applied to carbonless copy paper coating, which results in high smoothness of carbonless copy paper and high coloring speed.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Production of superfine mono-dispered nano-zirconium dioxide

Process of mono-dispersing nano-superfine zirconium anhydride is carried out by dissolving zirconium oxychloride into de-ionized water, adding into zirconium oxychloride solution into ammonia water slowly while agitating to obtain zirconium hydroxide hydrosol, transferring it to filter press, adding into water, washing to obtain zirconium hydroxide powder, putting it into kiln, burning for 4-5 hrs, and crushing by air flow to obtain final product. The mono-crystal granular diameter is 60-100 nm. It has excellent purity, activity and mono-dispersion.

Owner:仙桃市中星电子材料有限公司

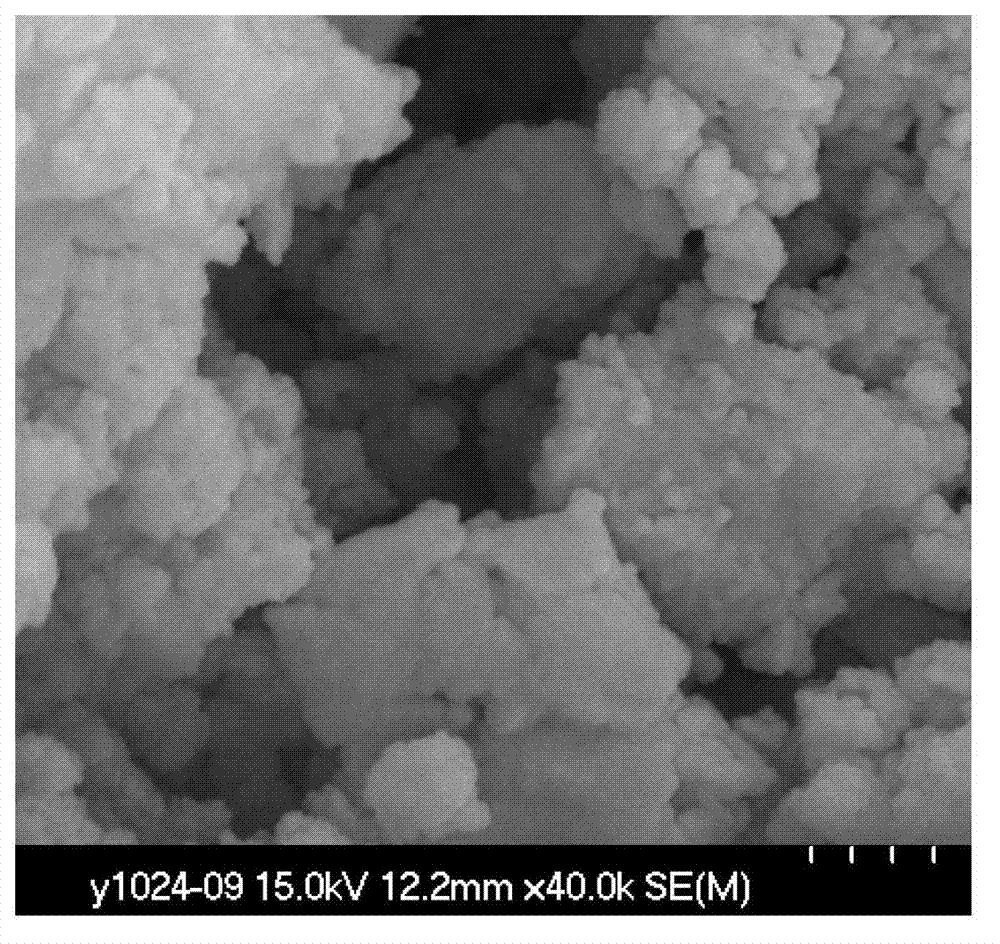

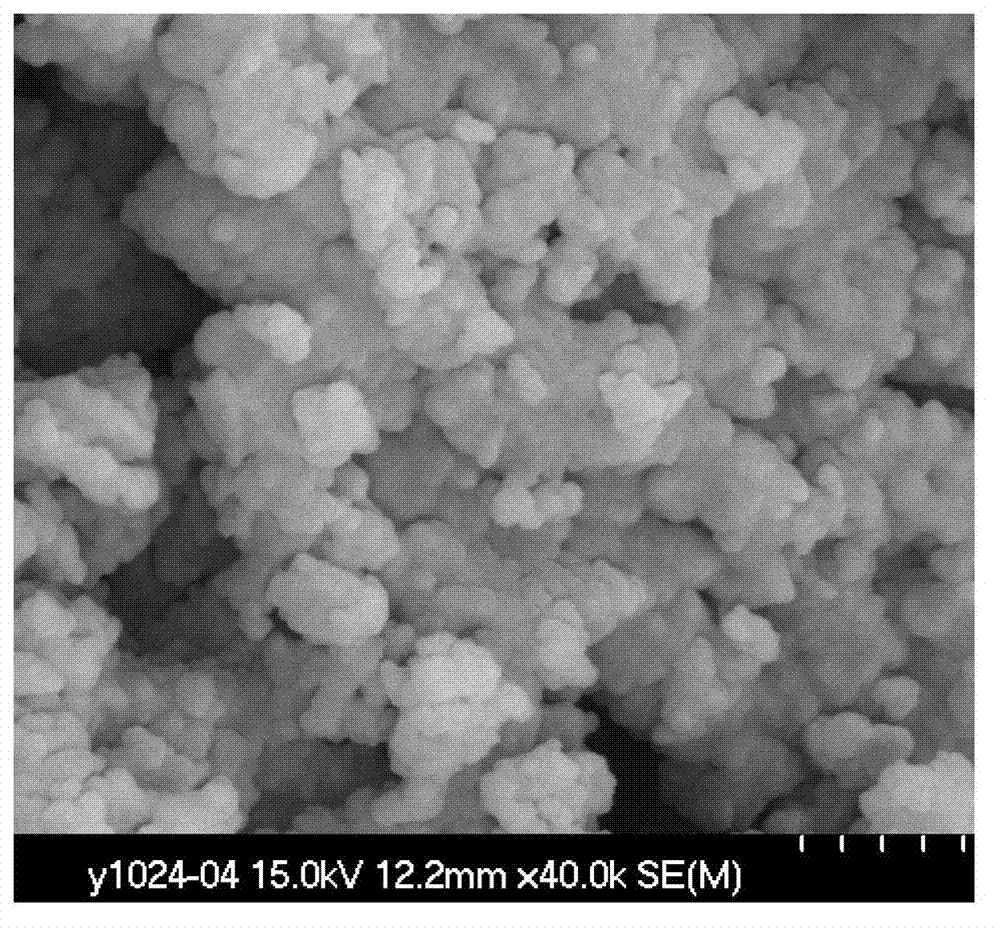

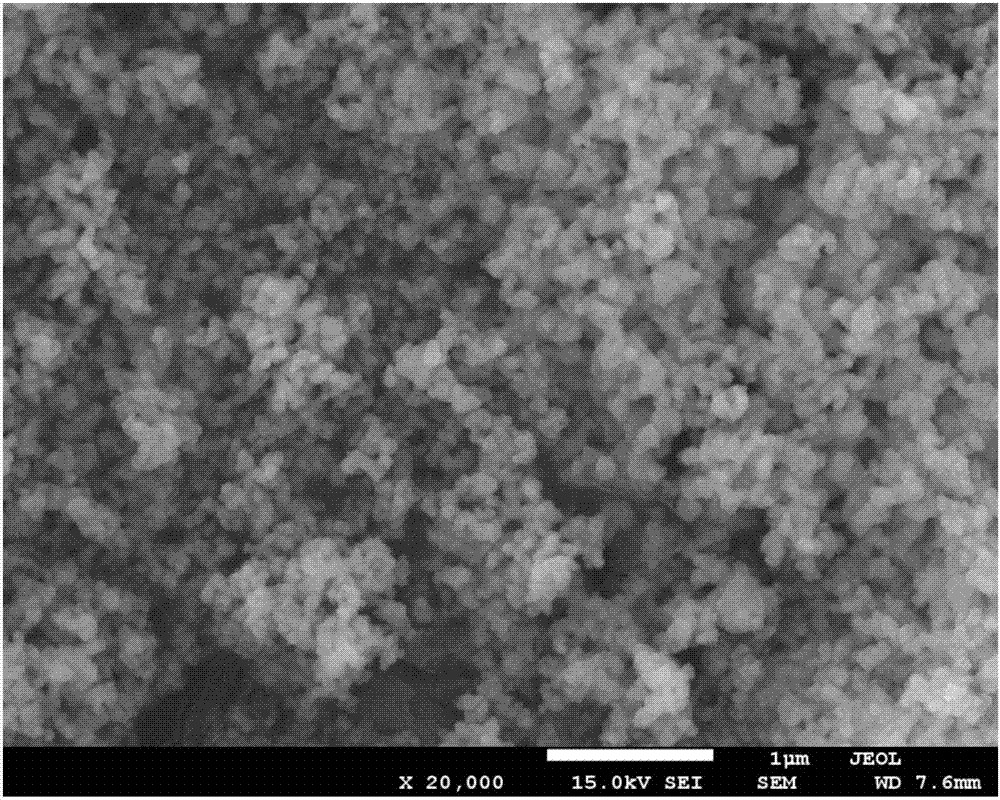

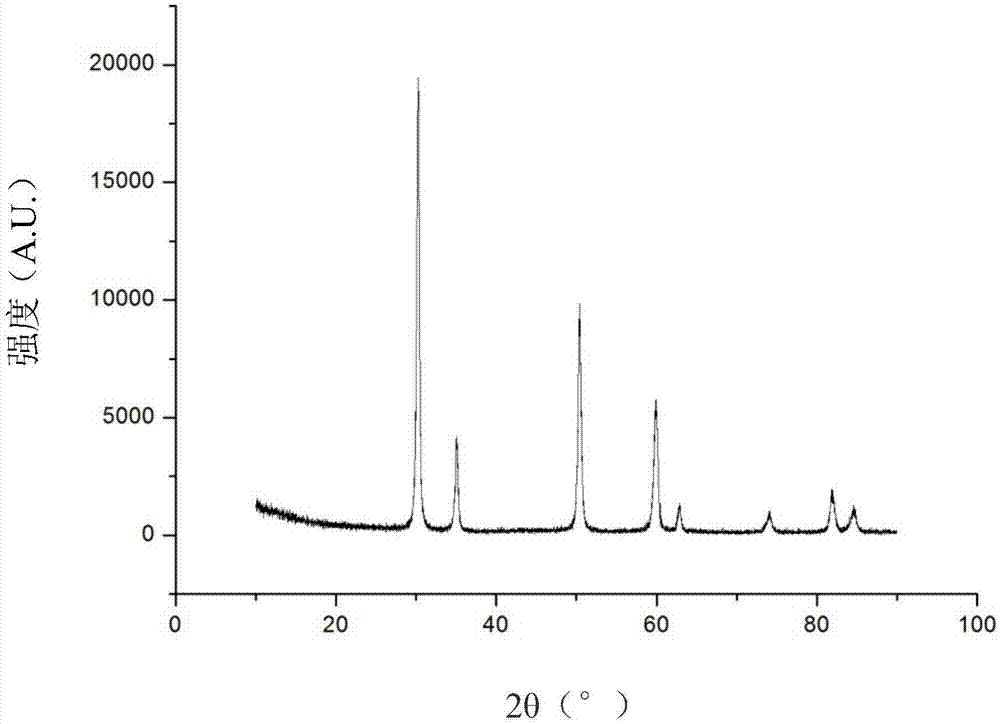

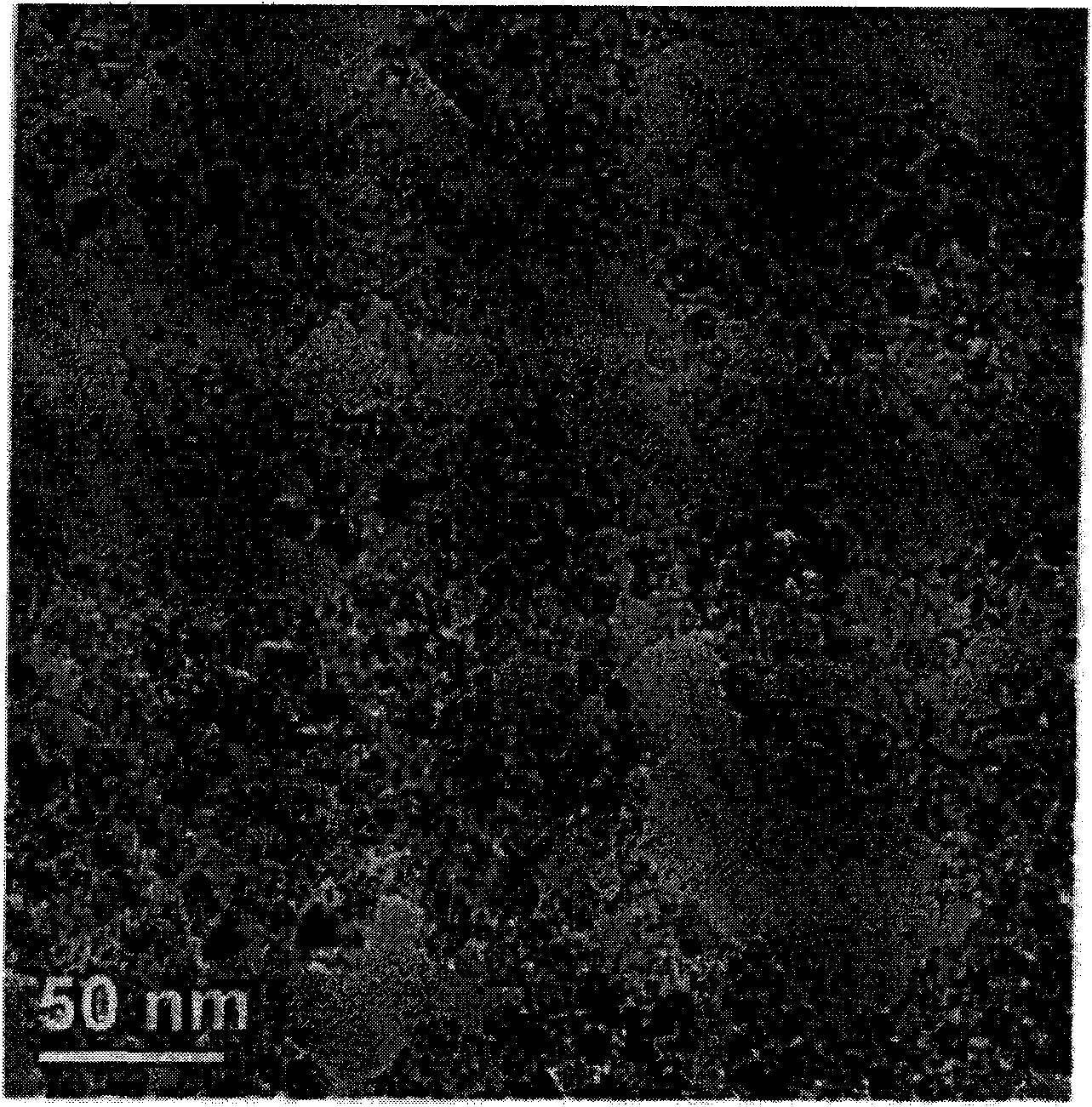

Preparation method of loose zirconium hydroxide or zirconium oxide nano powder

The invention relates to a preparation method of a loose zirconium hydroxide or zirconium oxide nano powder, and belongs to the field of inorganic nano powder preparation. The preparation method comprises the steps of preparing a precipitant A solution and a precipitant B solution which have different pH (potential of hydrogen) values, adding a zirconium salt solution to the precipitant A solution at a certain flow rate, keeping the flow rate of the zirconium salt solution and simultaneously adding the precipitant B solution to the precipitant A solution at a certain flow rate after the solution becomes clarified from turbid, ageing, filtering, cleaning and drying to obtain the loose zirconium hydroxide nano powder, and then performing roasting and cooling to obtain the zirconium oxide nano powder. Zirconium hydroxide precursor slurry prepared by the method has no colloidality and is easy to filter; the dried zirconium hydroxide nano powder has no hard aggregation; the zirconium oxide powder generated after the roasting reaches a nanoscale; the particle size is 60-100nm; a pattern is regular; the distribution is narrow; the cleaning is easy; a ball milling process is not required; technological operation is simple and convenient; an equipment requirement is low; the preparation method is suitable for large-scale industrial production.

Owner:GUOBIAO BEIJING TESTING & CERTIFICATION CO LTD

Production method of nanoscale high-purity zirconium dioxide composite powder

InactiveCN106866142AImprove particle size uniformityEfficient removalMaterial nanotechnologyZirconium halidesDistillationIon exchange

The invention relates to a production method of nanoscale high-purity zirconium dioxide composite powder. The method comprises the following steps: taking zirconium tetrachloride as the raw material, drying the raw material, then removing impurity with boiling point being lower than that of zirconium tetrachloride and impurity with boiling point being higher than that of zirconium tetrachloride through a two-step distillation crystallization method, dissolving zirconium tetrachloride by using a mixed solution of deionized water and alcohol, carrying out separation of zirconium and hafnium in the solution through an MIBK extraction-elution resin filled extraction chromatographic column, then further purifying zirconium tetrachloride through an ion exchange mode, adding chloride into a high-purity zirconium tetrachloride solution to form a zirconium tetrachloride compound solution, then obtaining zirconium hydroxide gel through an ammonia water spraying co-precipitation manner, carrying out hydrothermal reaction of the zirconium hydroxide gel in a high-pressure reactor, and finally filtering, washing and drying to obtain the nanoscale high-purity zirconium dioxide composite powder. The nanoscale high-purity zirconium dioxide composite powder prepared by the method has the advantages of high purity, uniform particle size, high dispersibility and the like and is applicable to industrial production.

Owner:南京金鲤新材料有限公司

Preparation method and phosphorus removal method of zirconium oxide-loading phosphorus removal biological composite material

InactiveCN103706333AImprove work efficiencyExpand application spaceOther chemical processesWater/sewage treatment by sorptionWater bathsZirconium hydride

The invention relates to a preparation method and a phosphorus removal method of a zirconium oxide-loading phosphorus removal biological composite material. The preparation method comprises: dissolving zirconium oxychloride in dehydrated alcohol, adding brine shrimp egg shell, carrying out ultrasonic and magnetic stirring at a room temperature to make the zirconium oxychloride gradually diffuse to the inner surface of egg shell pore channels, placing into a water bath pot to evaporate the ethanol, taking the egg shell out, adding the zirconium oxychloride-loading egg shell to a NaOH solution, carrying out mechanical stirring at a room temperature, carrying out in situ precipitation to produce zirconium hydroxide in the egg shell pore channels, filtering, washing the shell egg complex a plurality of times with distilled water until achieving the neutral state, and drying in a drying oven to prepare the zirconium oxide-loading brine shrimp egg shell biological composite material. The phosphorus removal method comprises that: phosphate-containing sewage passes through a cylindrical fixed bed absorption device filled with the zirconium oxide-loading brine shrimp egg shell biological composite material in a forward flow manner so as to efficiently purify the phosphate-containing sewage; the composite material after absorption is subjected to desorption by using a NaOH and NaCl mixing solution, and the desorbed composite material is subjected to water washing by using deionized water to achieve the neutral state so as to be recycled.

Owner:YANSHAN UNIV

Preparation method and application of active zirconium dioxide

The invention discloses a preparation method of active zirconium dioxide. The preparation method comprises the steps of firstly mixing zircon sand with a carbon reducing agent and then performing electric smelting calcining to obtain desiliconized zirconium; adding alkali and performing alkali fusion calcining to obtain sodium zirconate; hydrolyzing sodium zirconate and adding acid for neutralizing to form zirconium hydroxide and sodium salt; then adding sodium hydroxide and controlling the pH value to be 8-9; and finally washing to remove sodium salt and drying materials to obtain active zirconium dioxide. The active zirconium oxide prepared by adopting the preparation method contains zirconium dioxide of tetragonal crystal phase, has high activity and is suitable for manufacturing ferrozirconium pigment; in addition, side products generated in the preparation process does not pollute the environment and thus the environment-friendly and pollution-free effects are achieved; silicon is converted into silicon dioxide to be recycled after being subjected to electric smelting calcining; after the preparation is completed, all sodium is converted into sodium chloride or sodium sulfate to be recycled.

Owner:SHENGQUAN FUJIAN GLAZE MAKING CO LTD

Process of preparing zirconium oxide nano powder by supersonic sol-gel process

InactiveCN1559915AAcceleration and control of forming speedControl formation speedZirconium oxidesAlcoholDistilled water

The invention discloses a method of preparing ZrO2 nano powder by ultrasonic sol-gel method, including the following steps: adding a certain amount of ammonia water to a reactor, and during continuously stirring, dropping in zirconium oxychloride solution at a proper speed; making ultrasonic action; ageing; washing zirconium oxychloride colloid by distilled water until no residual ions exist, and in washing, applying ultrasonic action; drying the prepared wet gel by anhydrous alcohol and grinding, burning at temperature 500-750 deg.C for 2 h and obtaining ZrO2 nano powder. It combines the ultrasonic technique with the sol-gel method to prepare ZrO2 nano powder, achieving remarkable effect and able to produce obvious social and economical benefits.

Owner:SOUTH CHINA UNIV OF TECH

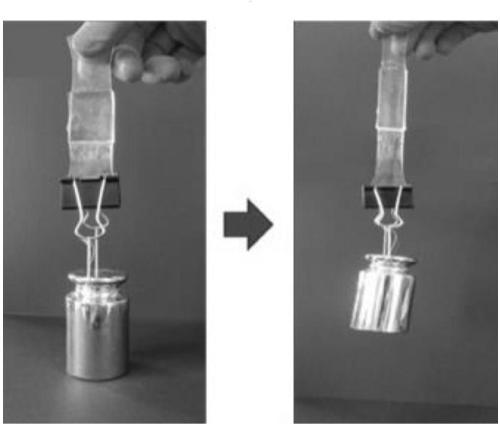

Method for simple and rapid preparation of hydrogel bilayer film with high adhesion acting force

The invention relates to a method for simple and rapid preparation of a hydrogel bilayer film with high adhesion acting force, and belongs to the field of functional polymer materials. According to the method, nano aluminum hydroxide sol, nano zirconium hydroxide sol, nano clay and the like are used as crosslinkers, acrylic acid, N,N-dimethacrylamide, acrylamide, N-isopropyl acrylamide and the like are used as monomers, and in-situ free radical polymerization is used for preparing various nano complex hydrogels; based on high-strength hydrogels, a bridged polymer is prepared by activation reaction of chitosan, sodium alginate and other macromolecules with carboxyl of EDC / NHS, and the bridged polymer is bonded by self or with other hydrogels to prepare the hydrogel bilayer film with high adhesion acting force in a wet environment; the bilayer film has extremely strong adhesion acting force, simple preparation method and easy operation in preparation process, greatly expands the application of the hydrogels, and has strong application potential in intelligent bionic drive, flexible sensing parts, biomedical materials and other fields.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Method for preparing superfine zirconia powder

The invention provides a method for preparing superfine zirconia powder, wherein the superfine zirconia powder is prepared by using quaternary ammonium base as a precipitator and adopting a special precipitation method. In the special precipitation method, two types of solutions are rapidly stirred and simultaneously added into a reaction kettle to react rapidly for nucleation without ageing, and the nucleuses are directly washed with water so as to achieve the purpose of controlling the growing of the nucleuses. The quaternary ammonium base is an alkaline substance which can be used for precipitating aqueous zirconia (zirconium hydroxide gel) from a zirconium salt solution, and is also a surfactant which can change interfacial tension so as to achieve a dispersion effect, therefore the addition of a dispersing agent is omitted and the cost is saved; and meanwhile, tetragonal-phase and cubic-phase zirconia powder can be prepared as required by controlling the addition of a yttrium-containing compound.

Owner:LUMING SCI & TECH GRP

Process of preparing atomic energy level zirconium dioxide and hafnium oxide by methyl isobutanone double solvent extraction method

The methyl isobutyl ketone (MIBK) double solvent extraction process of prepare zirconia and hafnium oxide in atomic energy level includes the following steps: 1. preparing dilute hydrochloric acid solution, dilute sulfuric acid solution, ammonia solution, zirconium oxychloride solution and ammonium thiocyanate solution; setting in high-level tanks separately; washing and reverse extracting; 2. mixing MIBK and extractant and extracting; 3. mixing ammonium thiocyanate solution, zirconium oxychloride solution and dilute hydrochloric acid solution; and setting the mixture in high-level tank; 4. reaction through stirring for 8 hr and multistage extraction to obtain zirconium hydroxide solution and hafnium hydroxide solution; 5. depositing zirconium hydroxide and hafnium hydroxide in ammonia water; and 6. high temperature roasting zirconium hydroxide and hafnium hydroxide to obtain zirconia and hafnium oxide. The process has high separating effect and less environmental pollution.

Owner:JIANGXI KINGAN HI TECH

Process for synthesizing calcium zirconate by liquid-phase and solid-phase mixed calcination method

InactiveCN102001705AOvercome uneven mixingOvercoming reactivityZirconium compoundsTunnel kilnZirconate

The invention relates to a process for synthesizing calcium zirconate by a liquid-phase and solid-phase mixed calcination method. The process comprises the following steps of: 1, mixing zirconium carbonate or zirconium hydroxide and CaCO3 or Ca (OH) 2 in a metallic oxide molar ratio of 1:1.0-1.2 by using refined water; 2, performing centrifugal separation and dehydration on the slurry; 3, loading the dehydrated mixture into a quartz crucible, feeding the quartz crucible into a tunnel kiln of which the central highest temperature is between 850 and 1,200 DEG C, and slowly warming up; and 4, discharging, cooling, crushing, and packing to obtain finished products. The moisture content of the dehydrated materials is between 40 and 50 percent. By the process, the defects of nonuniform mixing, incomplete reaction, nonuniform particles and super high energy consumption by a dry method are overcome, and the process problems of difficulty in cleaning impurities, a large amount of wastewater, drying and the like by a wet method are solved. The whole production process has short flow and simple equipment, is easy to operate and control, is suitable for large-scale production, and has high product quality and lower cost.

Owner:JIANGXI KINGAN HI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com