Process for preparing high-purity superfine zirconia by zirconium oxychloride

A technology of ultra-fine zirconia and zirconium oxychloride, which is applied in the direction of zirconia, can solve the problems of high equipment requirements, low product grade, and small specific surface area of zirconia, and achieve low equipment requirements, high product grade, and high specific surface area. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

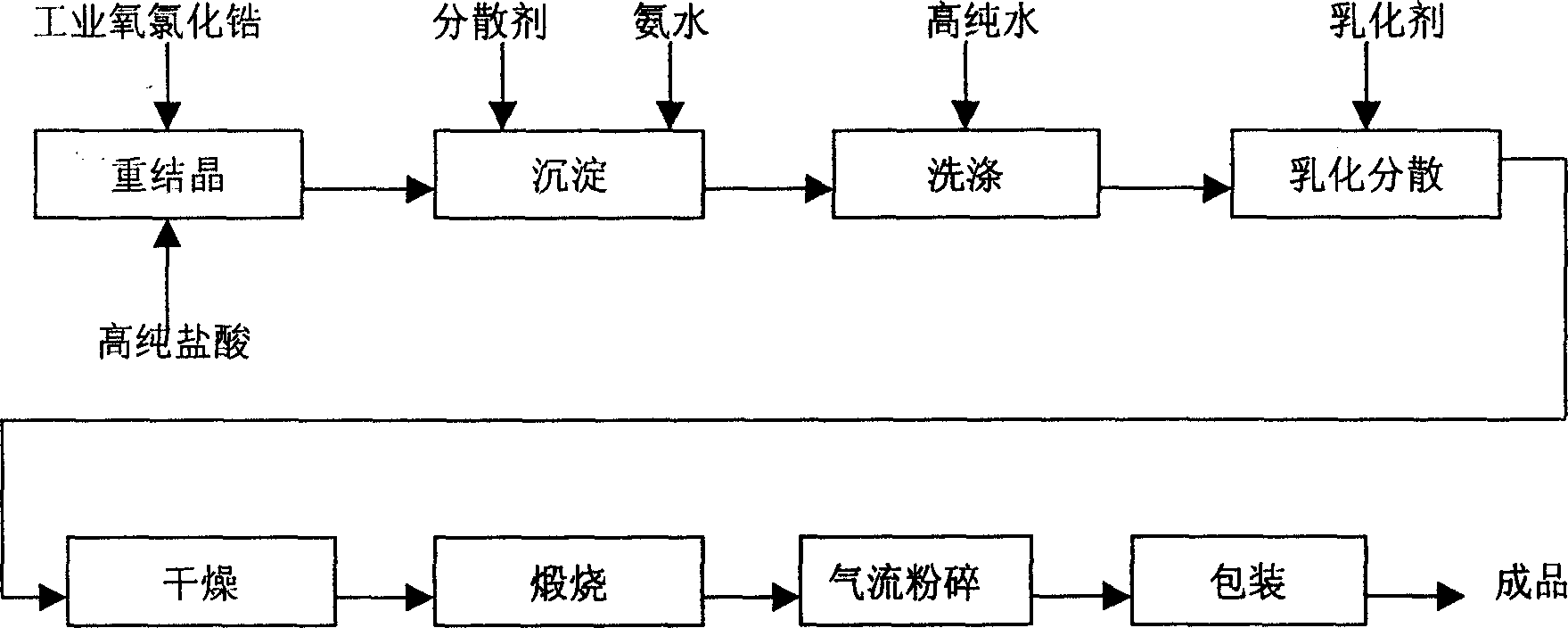

[0017] Example 1, the production process of zirconium oxychloride to prepare high-purity ultra-fine zirconia, the manufacturing steps are:

[0018] 1) Purification by recrystallization. Dissolve industrial zirconium oxychloride in purified hydrochloric acid at 80-95°C with an acidity of 5.5-6.5N until the concentration of zirconium oxychloride in the solution is 160-220g / L in terms of zirconia, stir and cool to room temperature;

[0019] 2) coprecipitation reaction. Pass the recrystallized zirconium oxychloride solution into 4-6N purified ammonia water and stir until the pH reaches 8-9 and terminate;

[0020] 3) washing and filtering with pure water;

[0021] 4) Add Tween 20 emulsifier to the filter cake for emulsification and dispersion treatment, the weight ratio of the ingredients is zirconia: emulsifier = 100: 0.1-0.5, and the emulsification time is 10-20 minutes.

[0022] 5) The emulsified material is spray-dried to obtain a semi-finished powder;

[0023] 6) The semi-...

Embodiment 2

[0025] Embodiment 2, reference example 1, also add polyethylene glycol dispersant during co-precipitation reaction, add weight and be zirconia: polyethylene glycol=100: 0.1-0.5, the emulsification dispersant of emulsification dispersion process filter cake is Composition of Tween 60 and Tween 80.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com