Patents

Literature

110 results about "Carbonless copy paper" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbonless copy paper (CCP), non-carbon copy paper, or NCR paper (No Carbon Required, taken from the initials of its creator, National Cash Register) is a type of coated paper designed to transfer information written on the front onto sheets beneath. It was developed by chemists Lowell Schleicher and Barry Green, as an alternative to carbon paper and is sometimes misidentified as such.

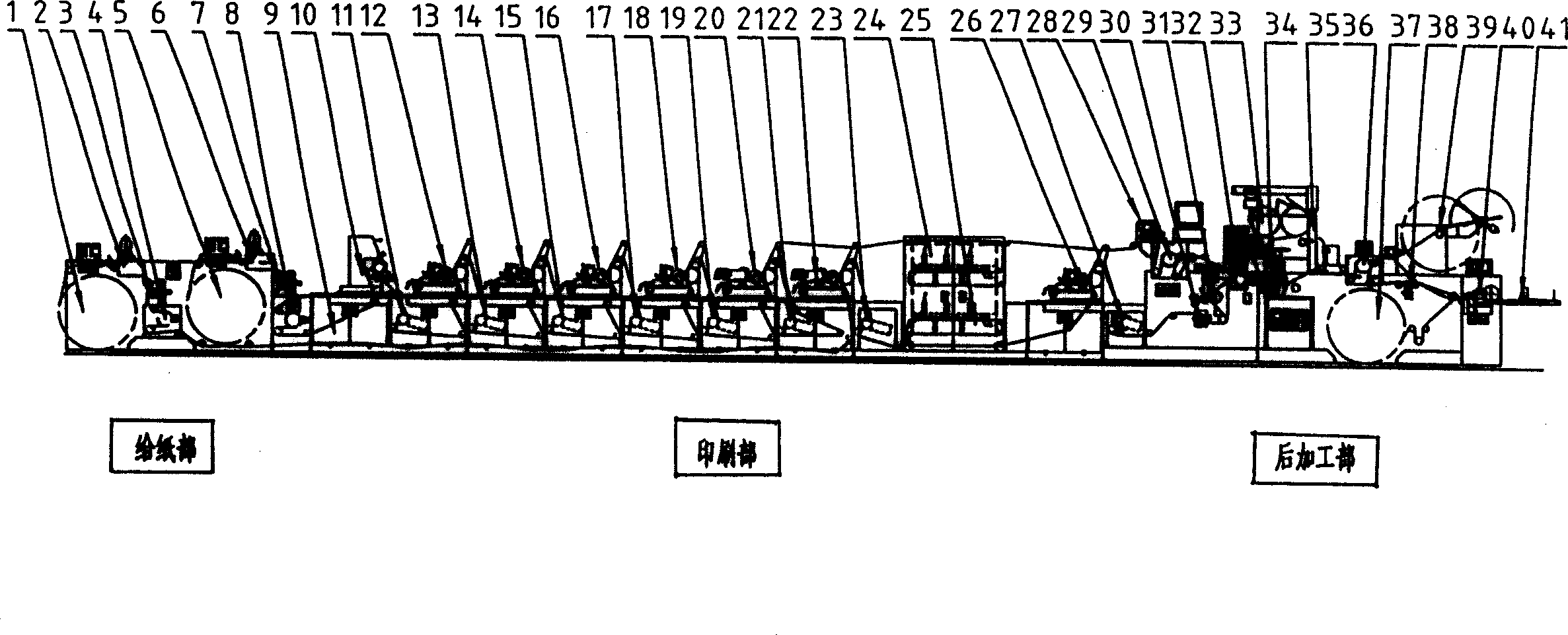

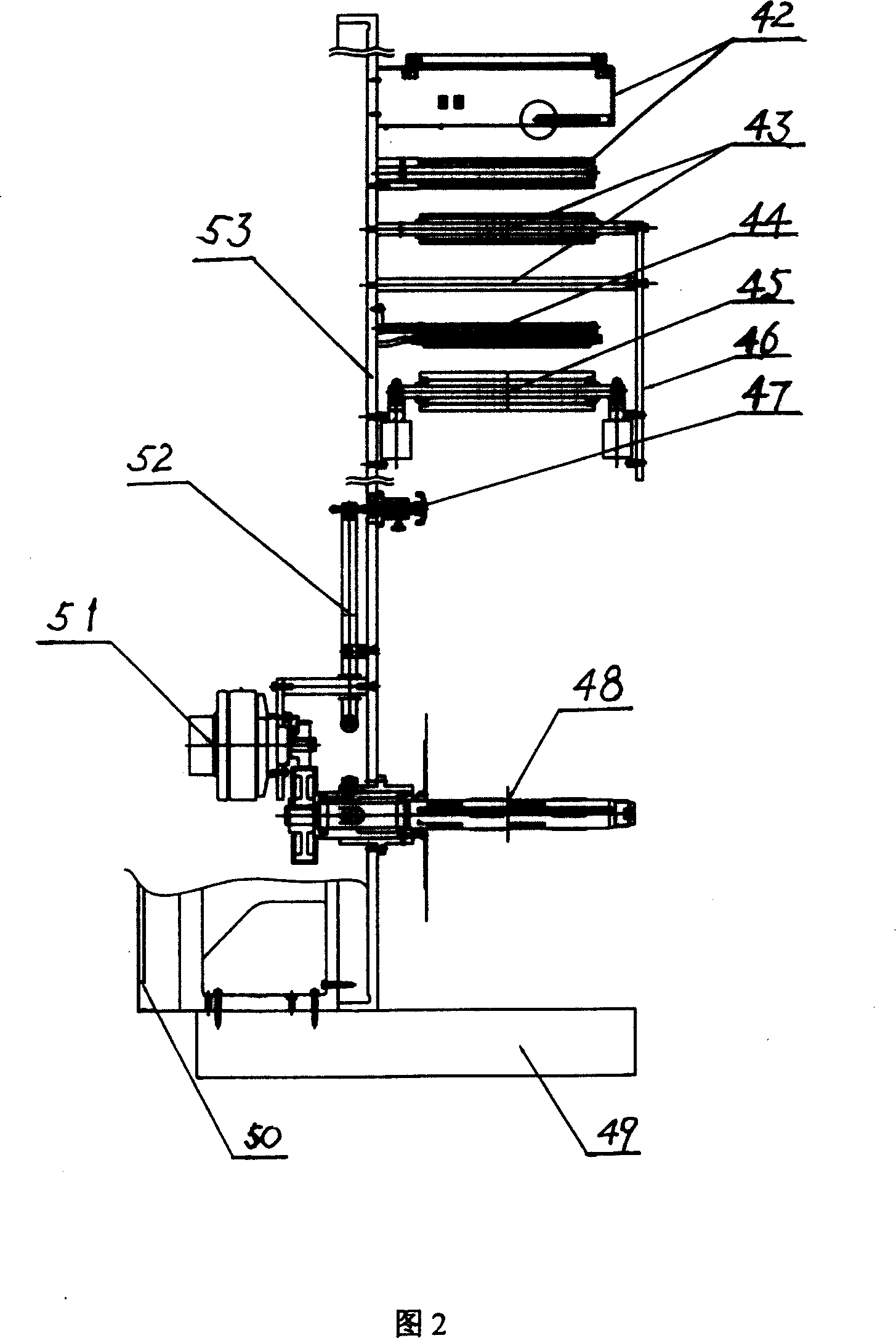

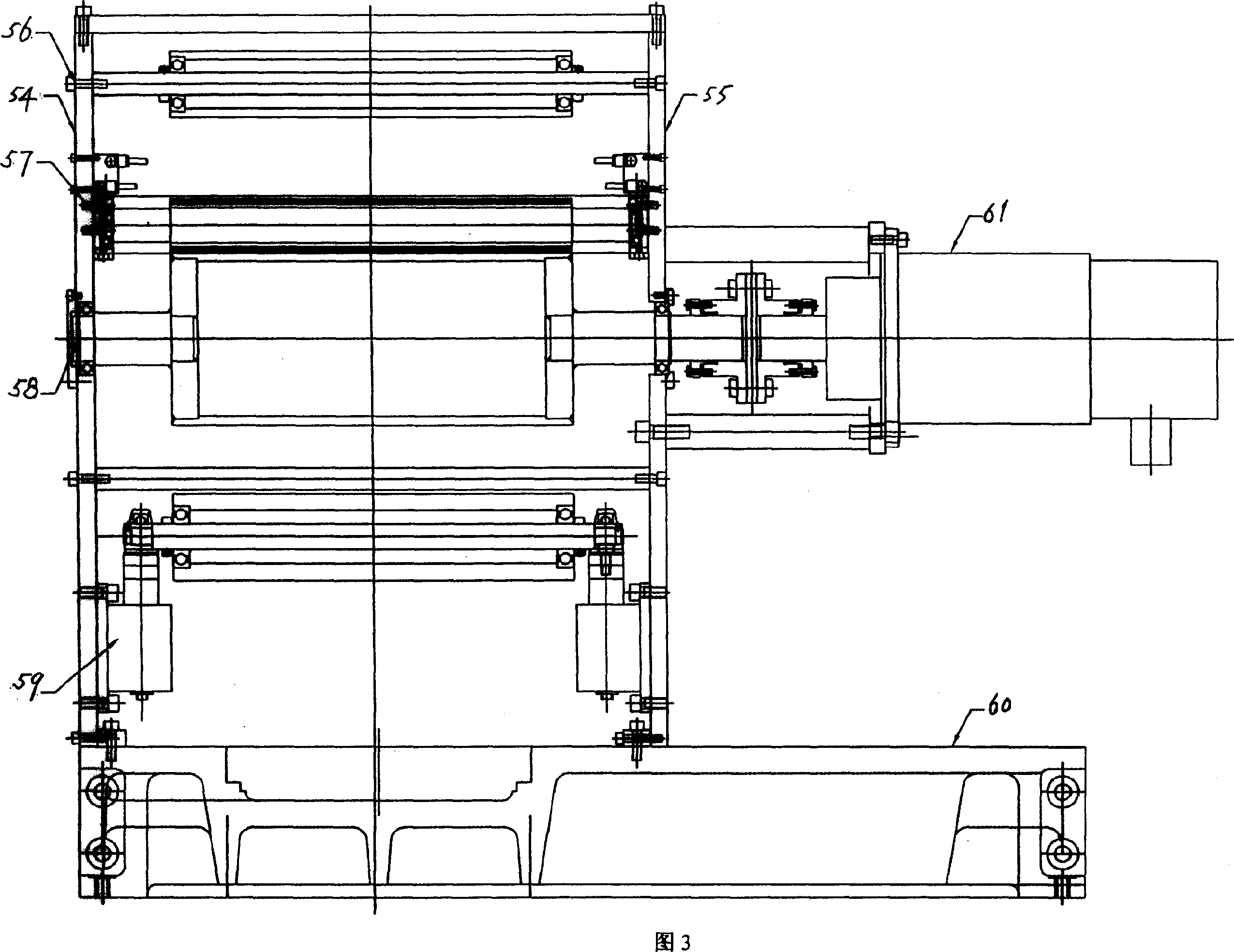

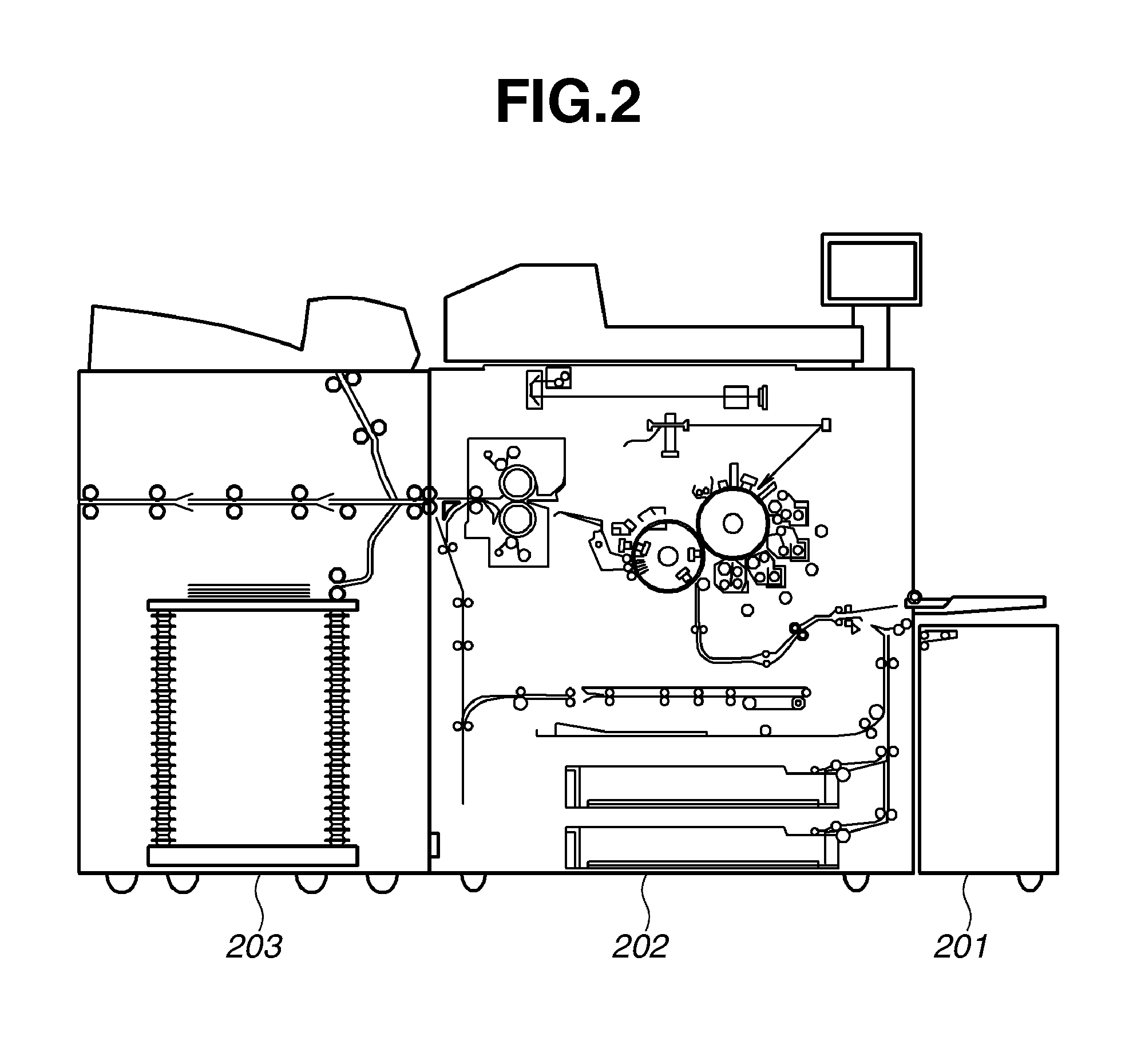

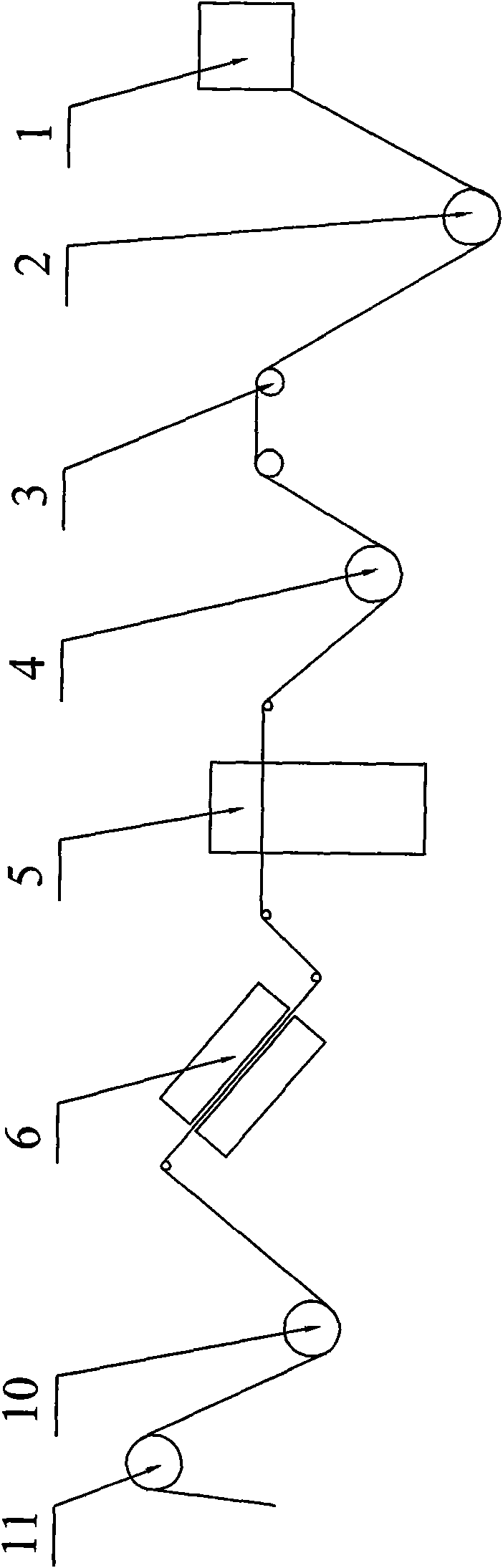

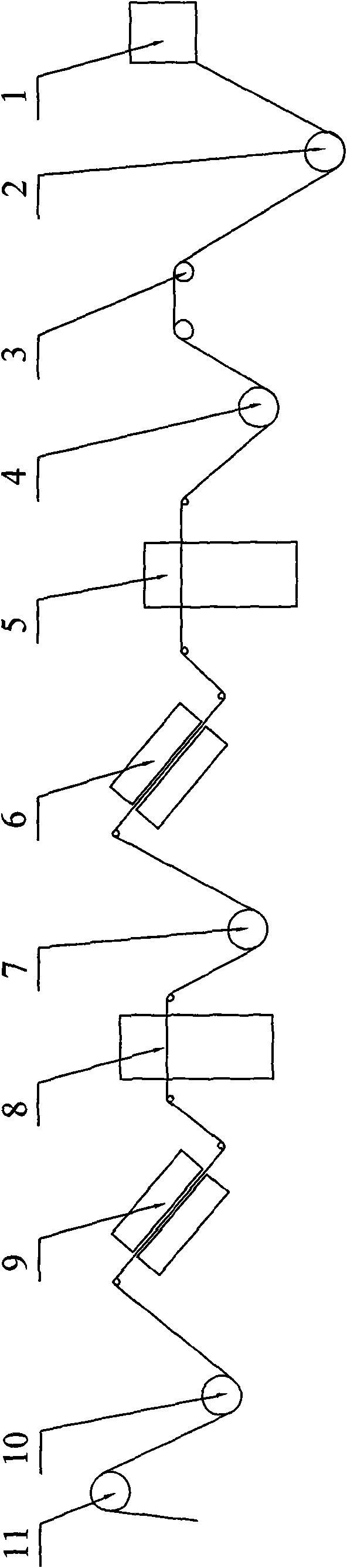

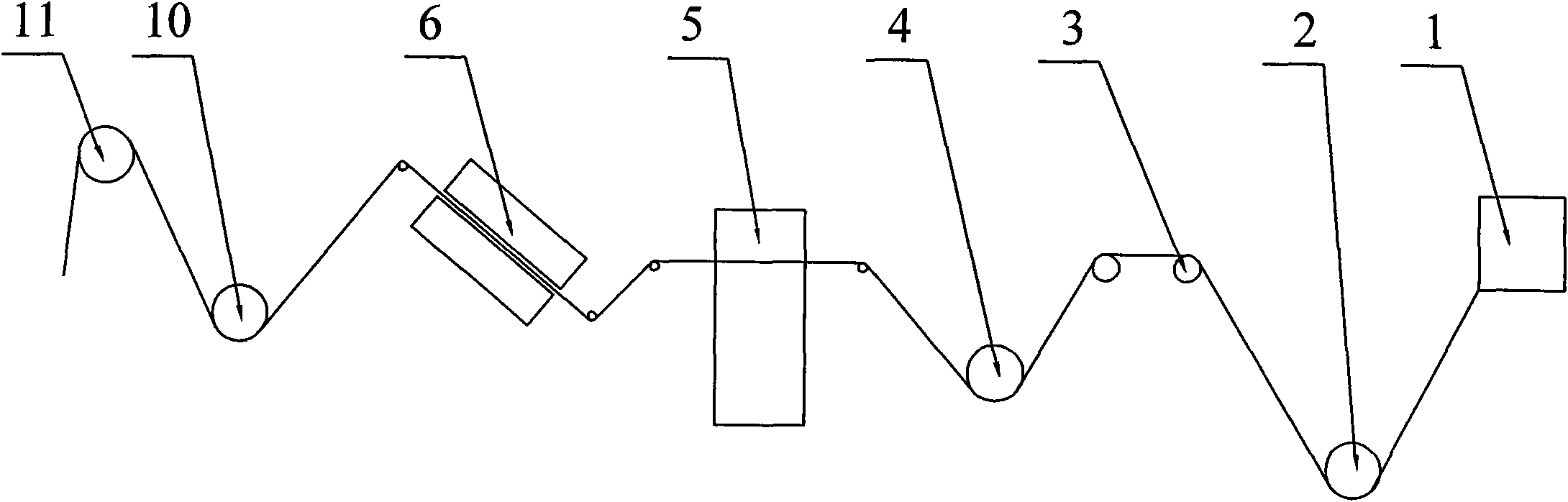

Label wheel rotary printing machine

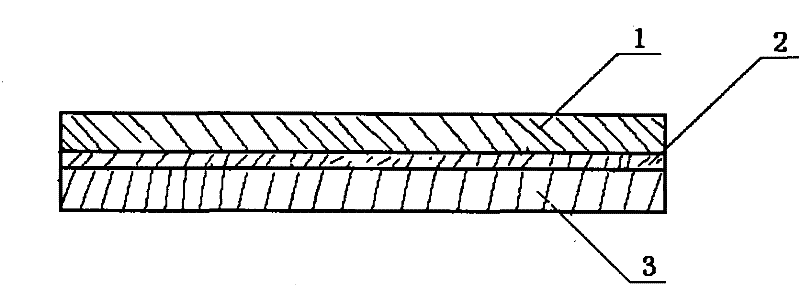

InactiveCN101054011AImprove matchDry in timeLamination plant layoutStampsPlastics industryEngineering

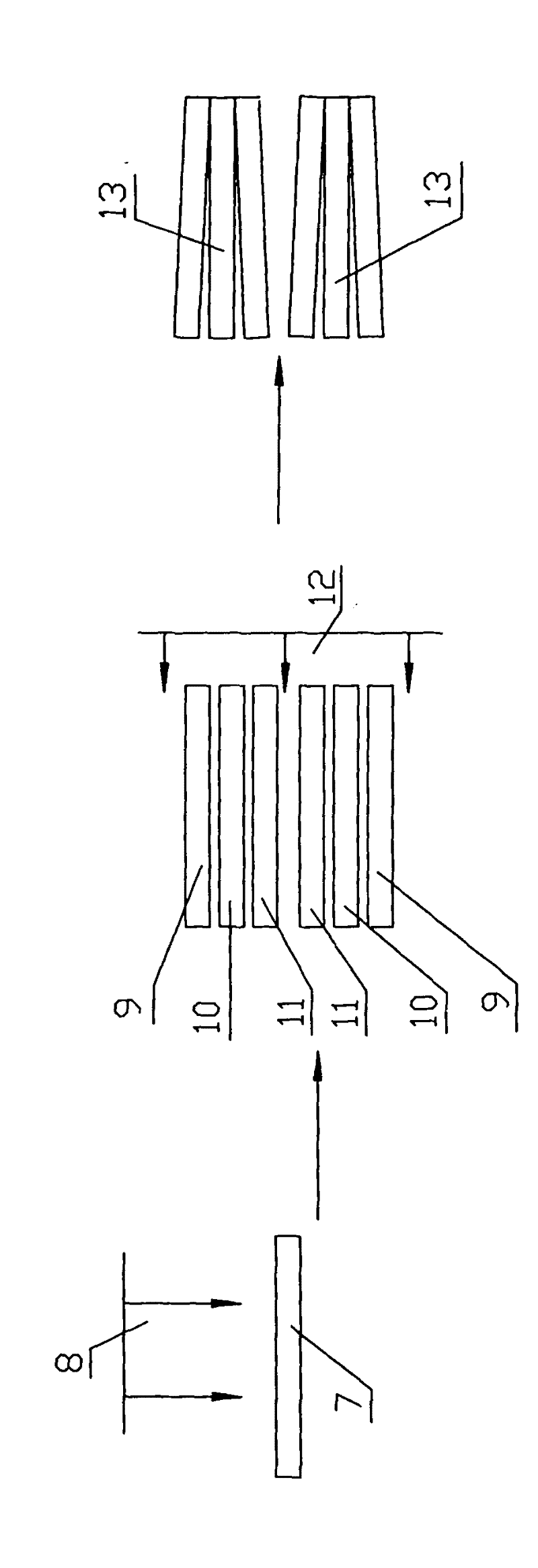

The invention relates to a label rotary printing which is characterized by that: it is mainly comprised by paper feeding device, printing section, post-process portion, and can be linked with relief printing, flexographic printing, offset printing, and can be further linked with code spray, silicon oil coating, hot melting glue coating to make multi-layer anti-counterfeiting label, and two paper feeding portions can simultaneously print two rolls of stocks, and coats hot melting glue between the two rolls of stocks, and compounds them to obtain the non-drying glue label, and the invention is applicable in plastic industry for plastic film printing, and can be also used in printing commercial table and printing non-carbon impact paper; because the invention has five flexo printing color classes, it can be regarded as a pure five-color rotary flexo printing used in commercial packing printing field. The advantage of the invention is that: the invention can print single roll of stock as well as two rolls of stocks and can compound the two rolls of stocks, multi-layer non-drying glue label can be processed by multiple printings and ink jet printing on same device.

Owner:SHANGHAI XINMIN TAIYO KIKAI

Thermochromic paint and carbonless copy paper containing same

ActiveCN103603229ADoes not affect printingDoes not affect functionPaper coatingPaper/cardboardRoom temperatureSolid content

The invention discloses a thermochromic paint. The thermochromic paint comprises one or more of starch, a microcapsule, a rheological water retention agent, a latex, a water repellent agent, a lubricating agent, a dispersing agent, an interfacial agent and a thermochromic capsule, wherein the solid content of the paint is 20-30 percent; the thermochromic capsule accounts for 0.0997-0.2997% of the total weight of the paint. According to the paint, the limitation of the prior art is broken through; the paint is colored when carbonless paper with the reversible thermochromic capsule is added at the constant temperature so as not to influence the printing and normal coloring functions of paper; when a product has a temperature of more than 40 DEG C or is contacted with an object at the temperature of 40 DEG C or more, the surface paint of the paper can be gradually faded from coloring until the paint becomes colorless and can be automatically recovered into the original color at the room temperature.

Owner:GOLD EAST PAPER JIANGSU

Color developer pigment for carbonless copying paper

InactiveUS6277490B1Improve rheologyLiquid surface applicatorsDuplicating/marking methodsMontmorillonitePaper based

A color developer pigment for carbonless copying papers based on acid-activated smectitic layered silicates, wherein a phenolic resin is condensed on the acid-activated layered silicate. The invention also concerns a coating composition based on the color developer pigment as well as a copying paper containing the color developer pigment.

Owner:ROCKWOOD ADDITIVES

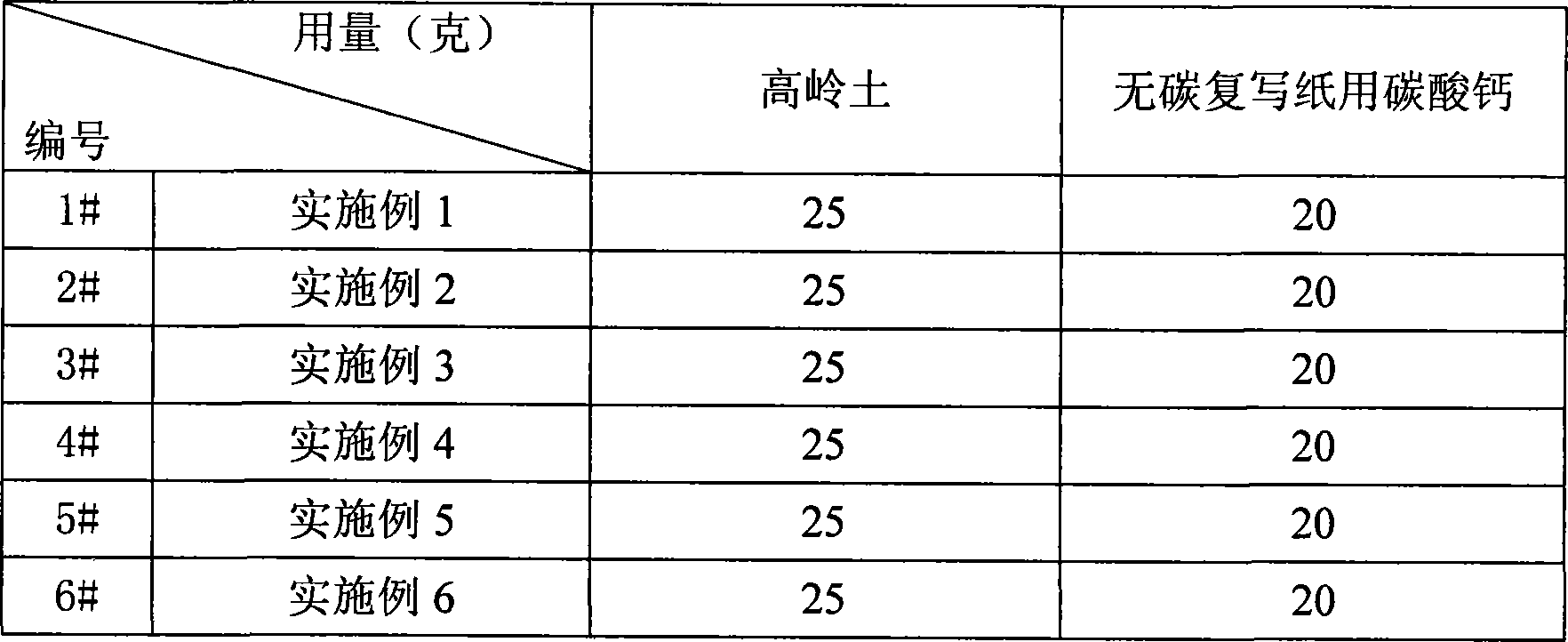

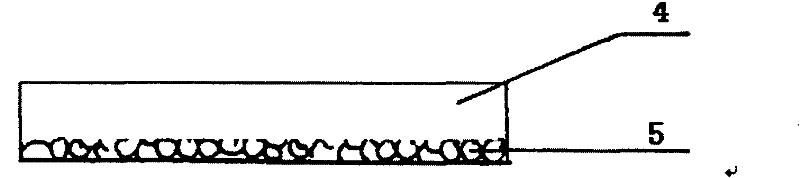

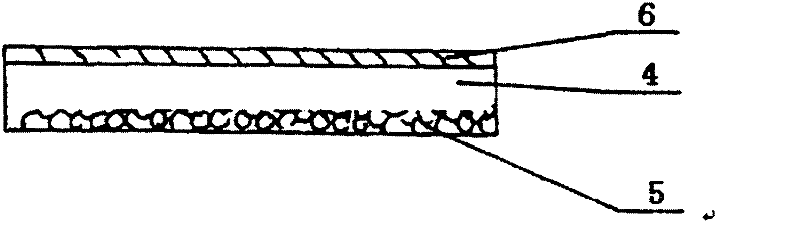

Coating for carbon-free paper with developer layer and use thereof

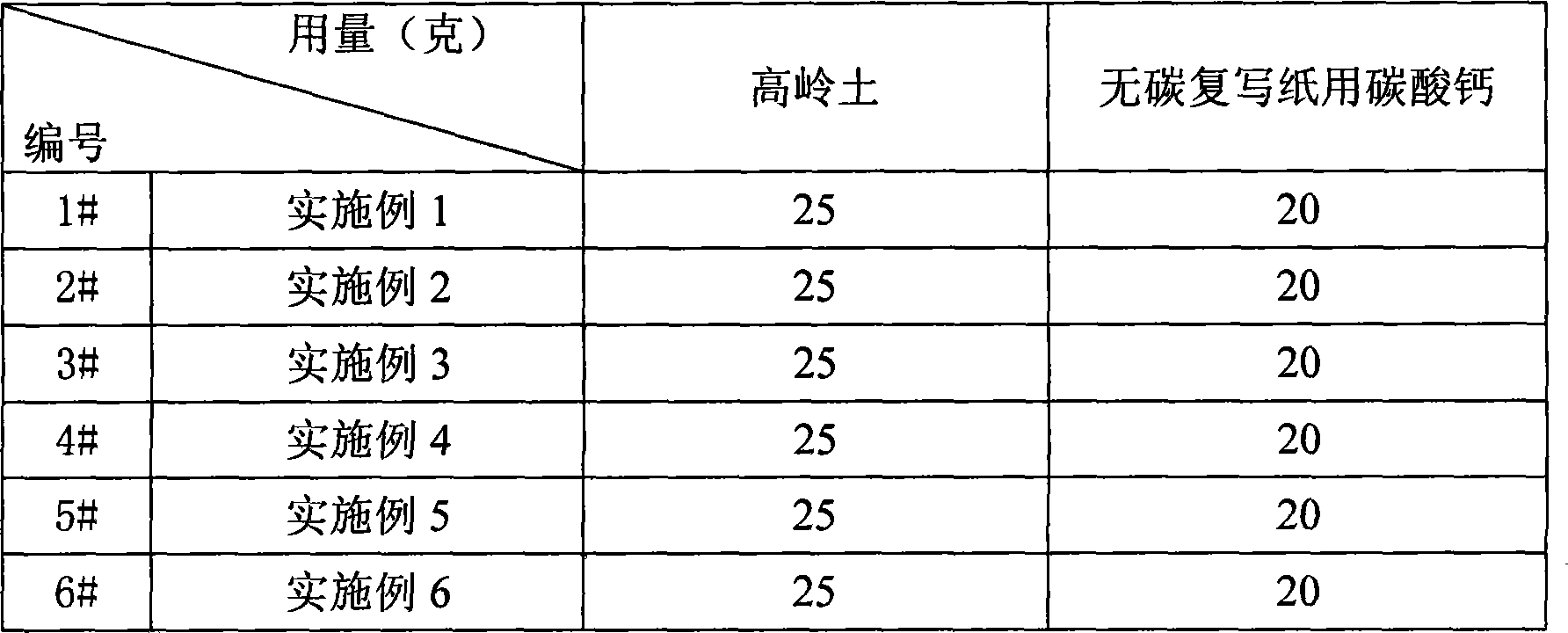

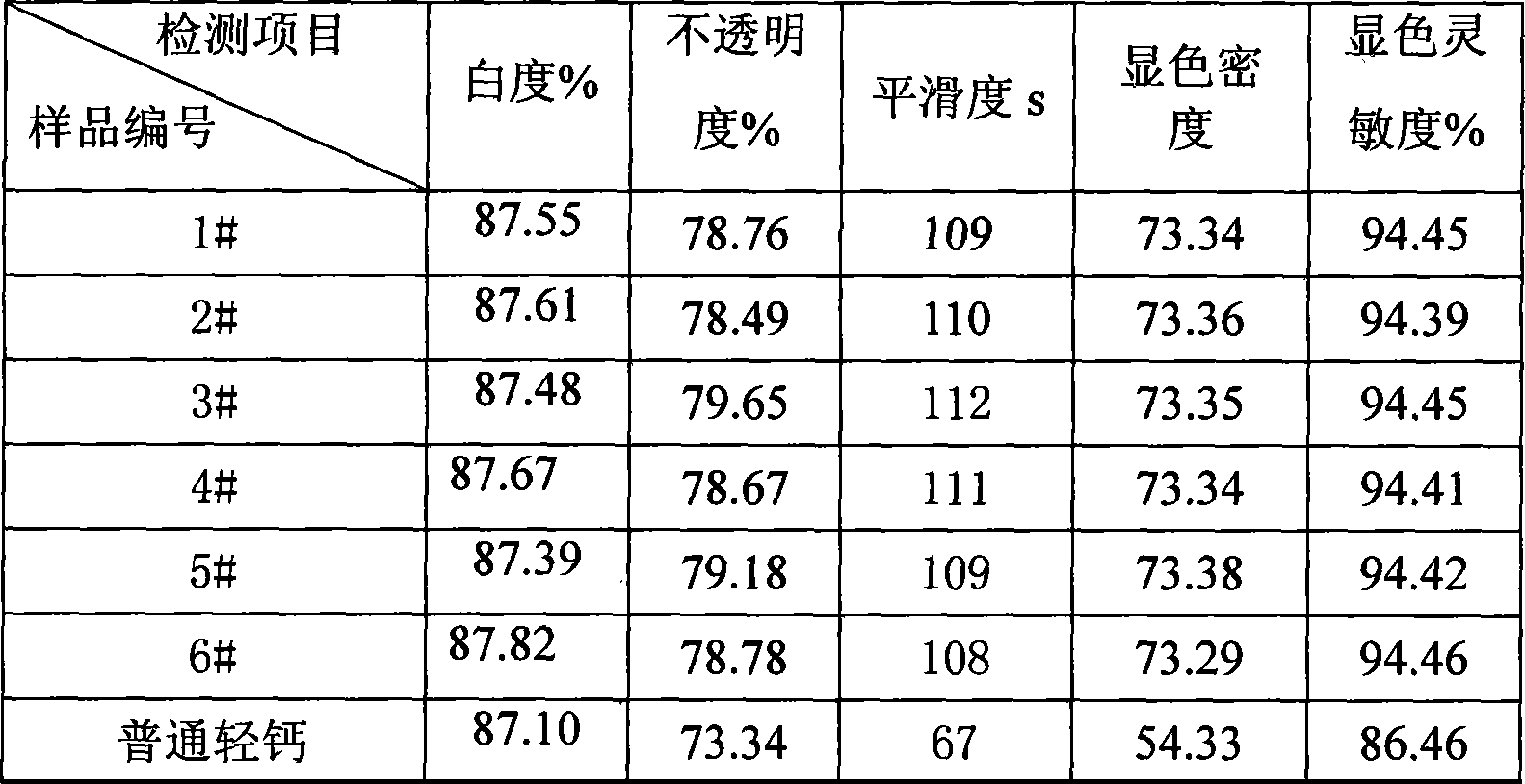

ActiveCN101381973ALow viscosityReduce the presence of air bubblesCoatings with pigmentsCoatingsViscosityPolymer chemistry

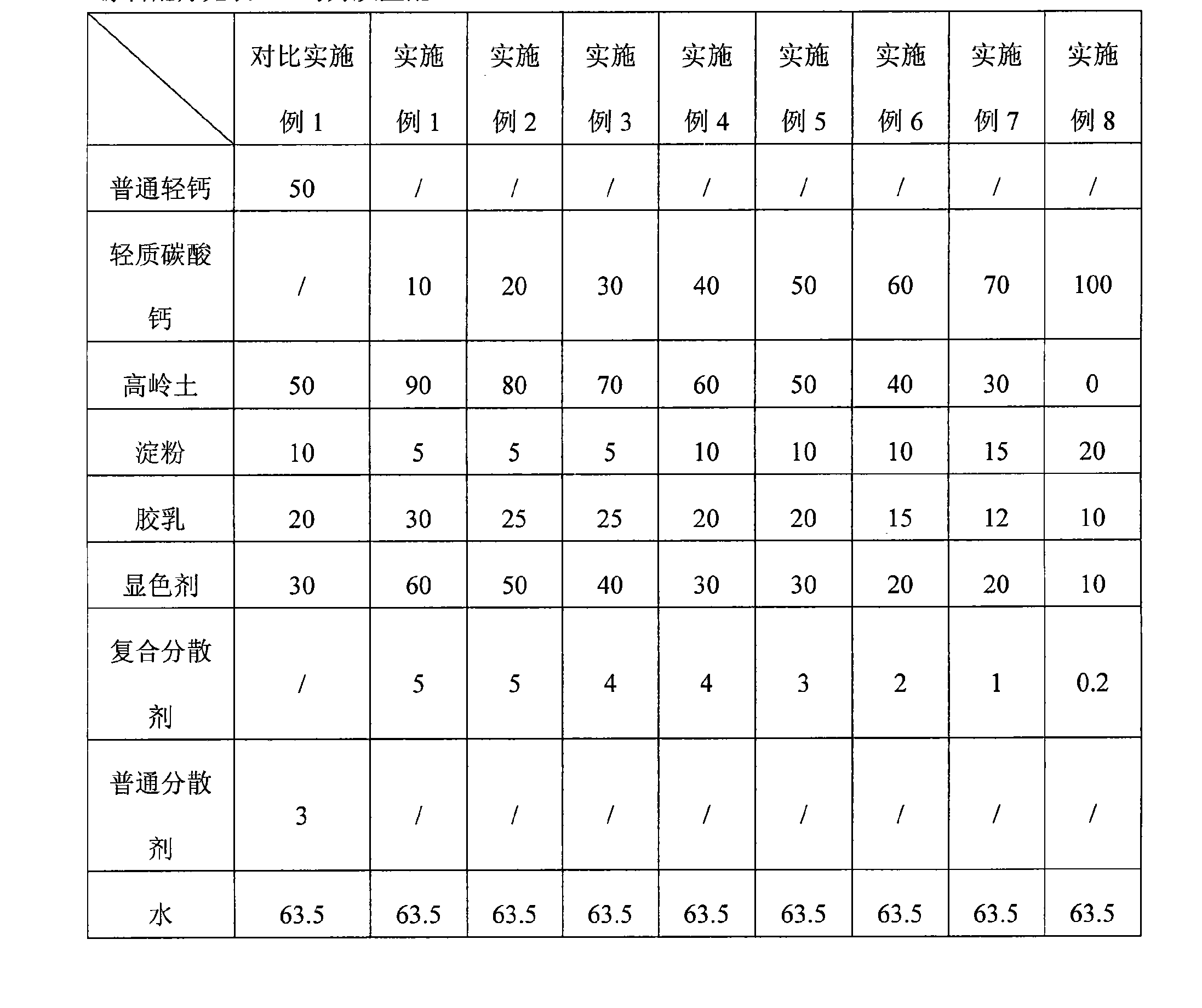

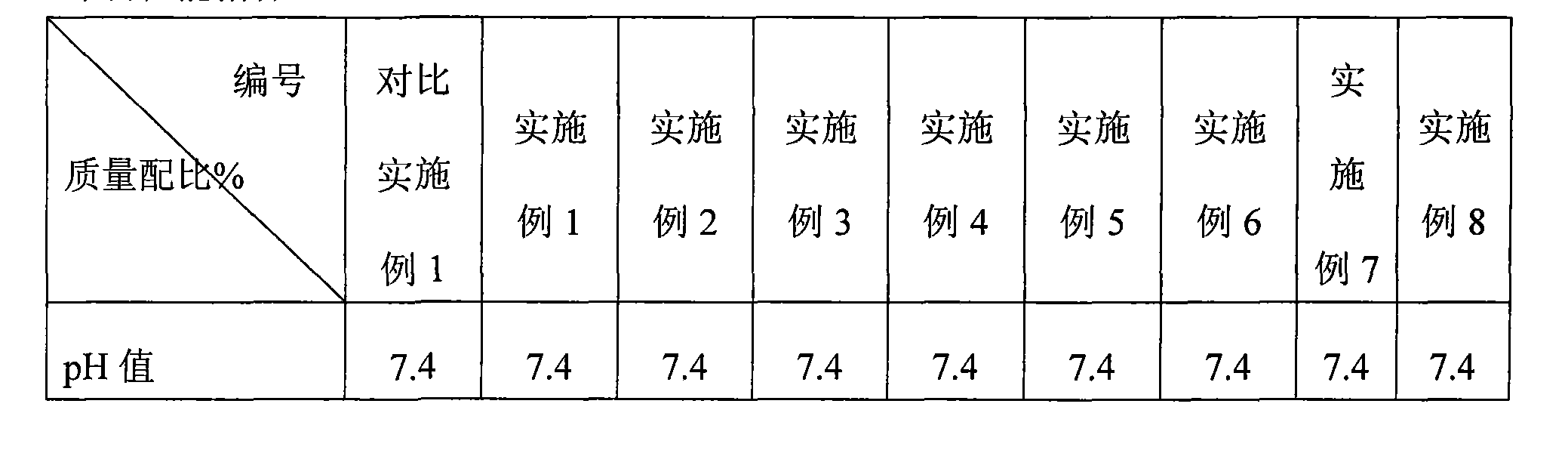

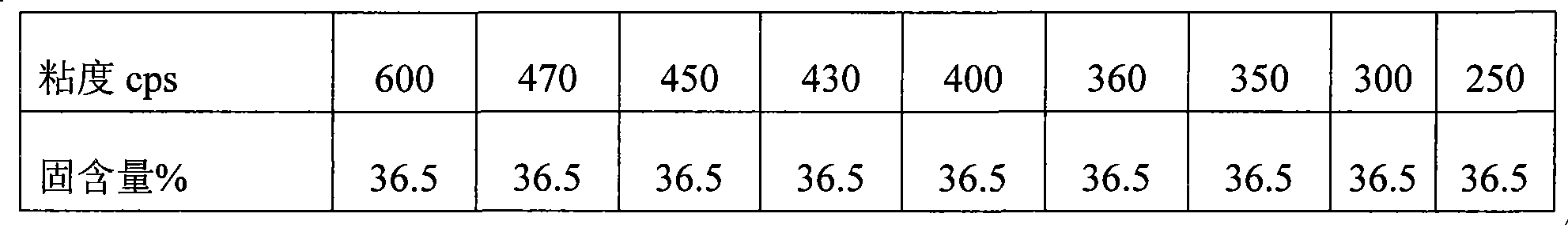

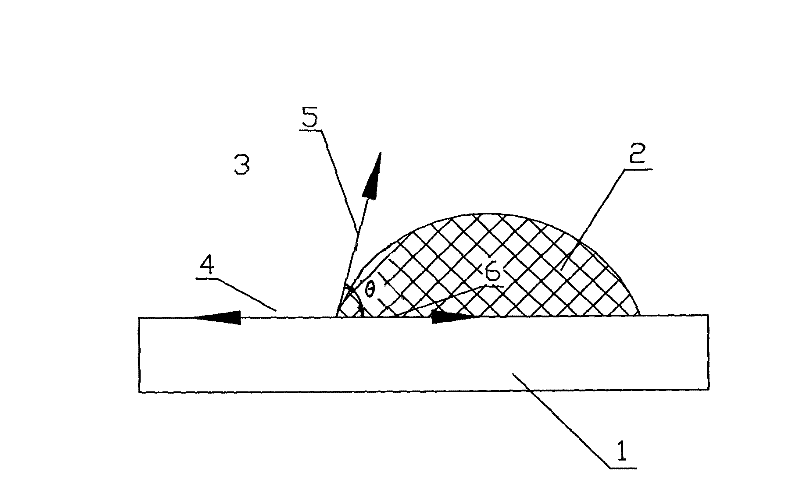

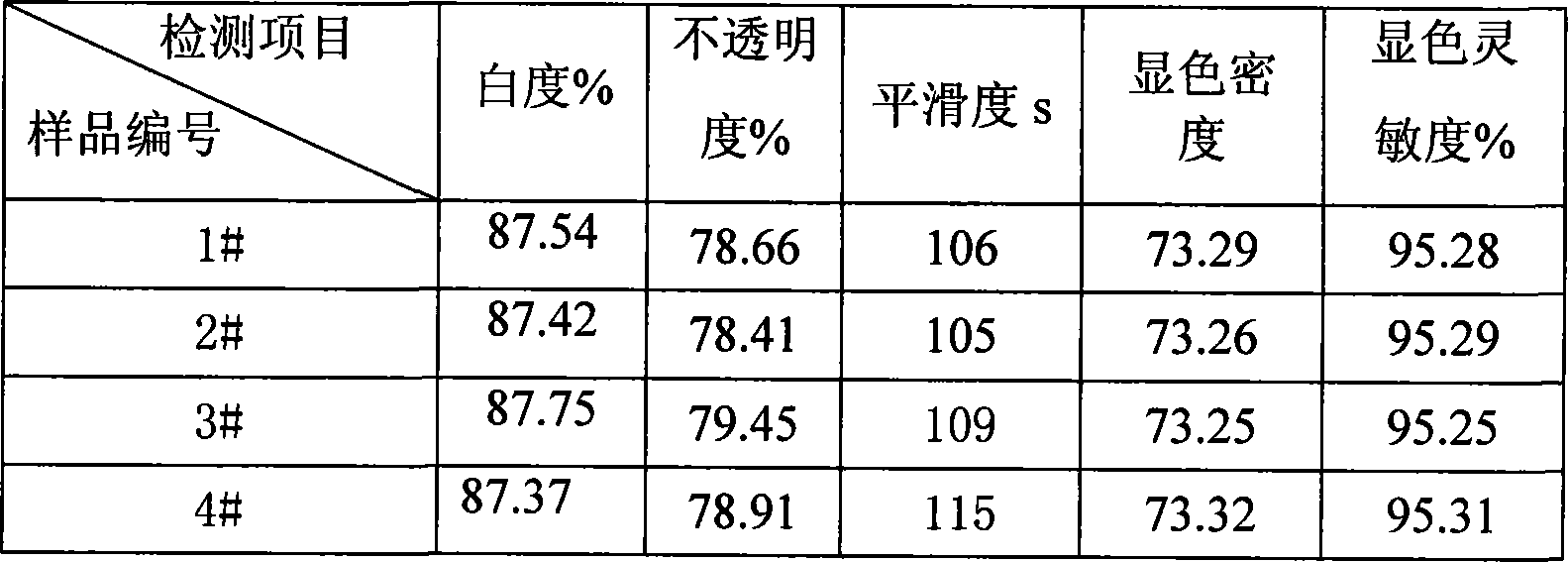

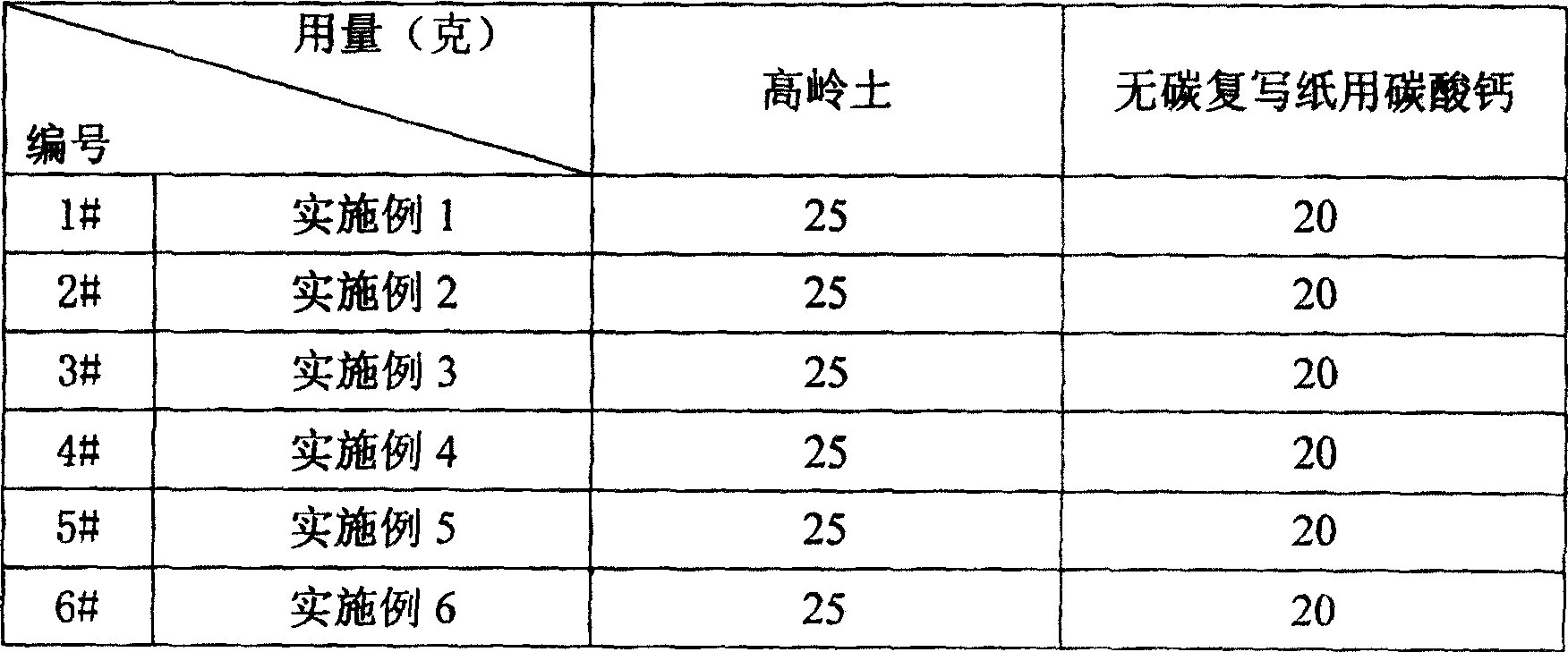

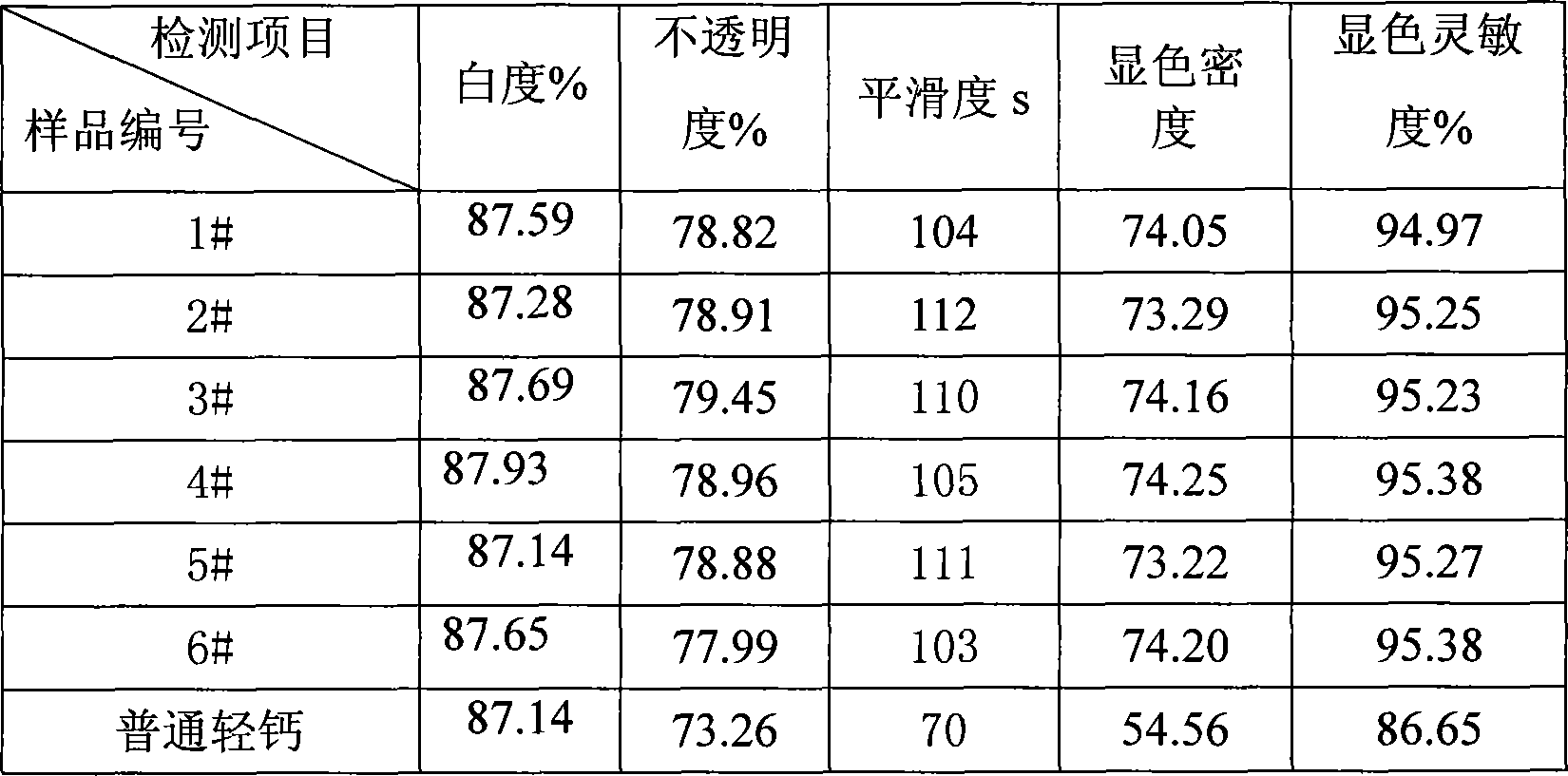

The invention discloses a painting containing a reagent layer for carbonless paper and application thereof. The painting comprises the following compositions in weight portion: 10 to 100 portions of lightweight calcium carbonate, 0 to 90 portions of kaolin, 5 to 20 portions of starch, 10 to 30 portions of rubber latex, 10 to 60 portions of a reagent, 0.2 to 5 portions of a composite dispersant and 50 to 80 portions of water. The formula of the carbonless paper CF layer painting adopts the lightweight calcium carbonate with thin and even particle diameter; in the formula, the composite dispersant is used to ensure that the prepared painting has low viscosity, few bubbles and low stress on the dynamic surface; coating paper is applied to ensure rapid chromogenic speed, high chromogenic density, high white content, even hue, good coating quality and uniform thickness of the coating layer, is suitable for the requirements on high-speed curtain coating and has good coating effect.

Owner:JIANGSU KANGAITE ENVIRONMENTAL ENG GRP CO LTD

Digital carbonless copy paper

ActiveCN102230300AImprove compactnessImprove hydrophobicityCoatings with pigmentsCoatingsPulp and paper industryWater resistant

The invention relates to a digital carbonless copy paper, particularly a digital carbonless copy paper which can be matched with separation gel. Curtain coating is carried out on the carbonless copy paper which is 40-170g / m<2>, and the paint comprises pigment, starch, rheologic water retention agent, latex, water-repellent agent, water-resistant agent, lubricant, dispersant and interfacial agent. The optimized paint is coated on the digital carbonless copy paper pages, and the separation gel is matched, so that the printing product with pages can automatically become separate into several parts, and the pages in each part are firmly bound, thereby completely satisfying the demands of the client.

Owner:GOLD EAST PAPER JIANGSU

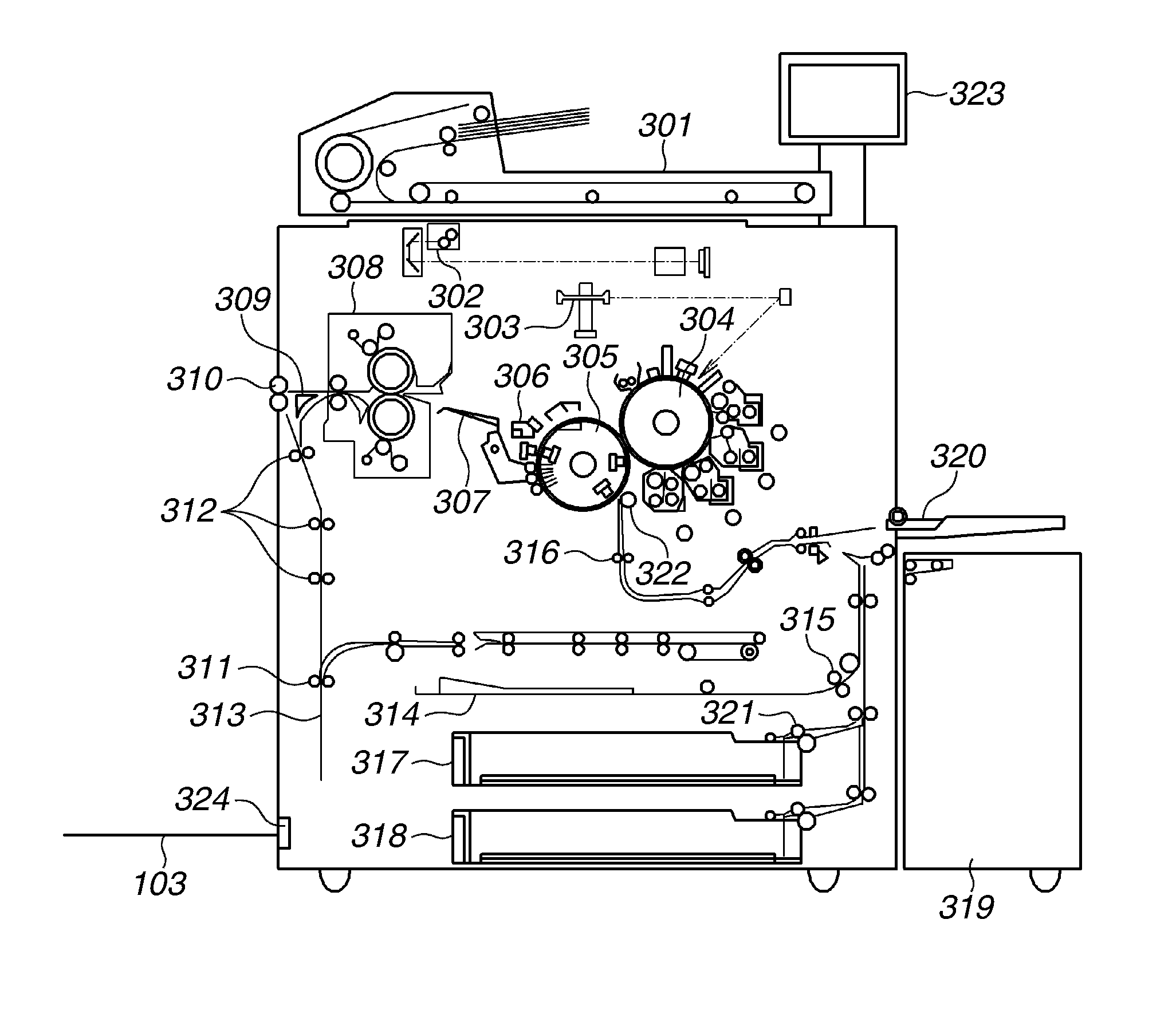

Image forming apparatus, output control method, and program

An image forming apparatus includes a specifying unit configured to, when a user operation for instructing checking of printing is performed during printing, specify, according to a type of carbonless copy paper of a page being printed, carbonless copy paper for checking corresponding to the carbonless copy paper being printed, and an output unit configured to output the carbonless copy paper being printed and the carbonless copy paper for checking specified by the specifying unit.

Owner:CANON KK

Method for preparing calcined kaolin with high oil absorption value by utilizing coal gangues

The invention belongs to the technical field of coal gangue processing and provides a method for preparing calcined kaolin with high oil absorption value by utilizing coal gangues, aiming at solving the problem that the oil absorption quantity of existing common calcined kaolin is low and overcoming the defects in an existing method for preparing the calcined kaolin with the high oil absorption value. The method comprises the following steps: carrying out beneficiation, screening and iron removal, crushing and smashing, carrying out superfine grinding, calcining and cooling and scattering and disaggregating. An inorganic dispersant sodium hexametaphosphate is replaced with an organic dispersant sodium polyacrylate and sintering is correspondingly reduced in a calcining process of the kaolin. The requirements of customers of carbonless copy paper on a high oil absorption performance are met and the oil absorption quantity can reach 80g / 100g; furthermore, the additional value of the waste coal gangues is improved so that the utilization of the waste resource coal gangues reaches a new stage. The product has relatively high market competitiveness; on one hand, the requirements of the customers of the carbonless copy paper, heat-sensitive paper and the like are met; the calcined kaolin has the outstanding oil absorption performance so that the additional value of the waste resource coal gangues is greatly improved and the waste resource coal gangues are really changed into valuable things.

Owner:山西晋坤矿产品股份有限公司

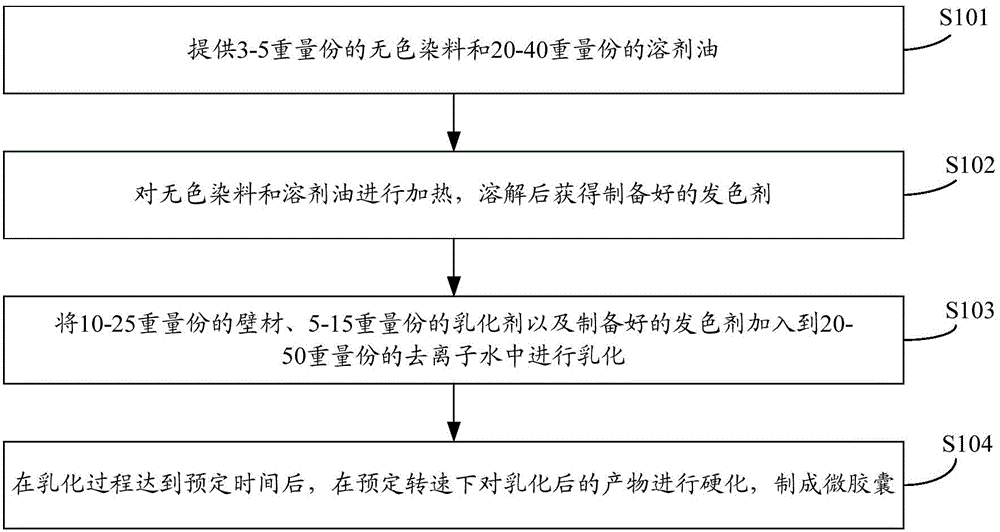

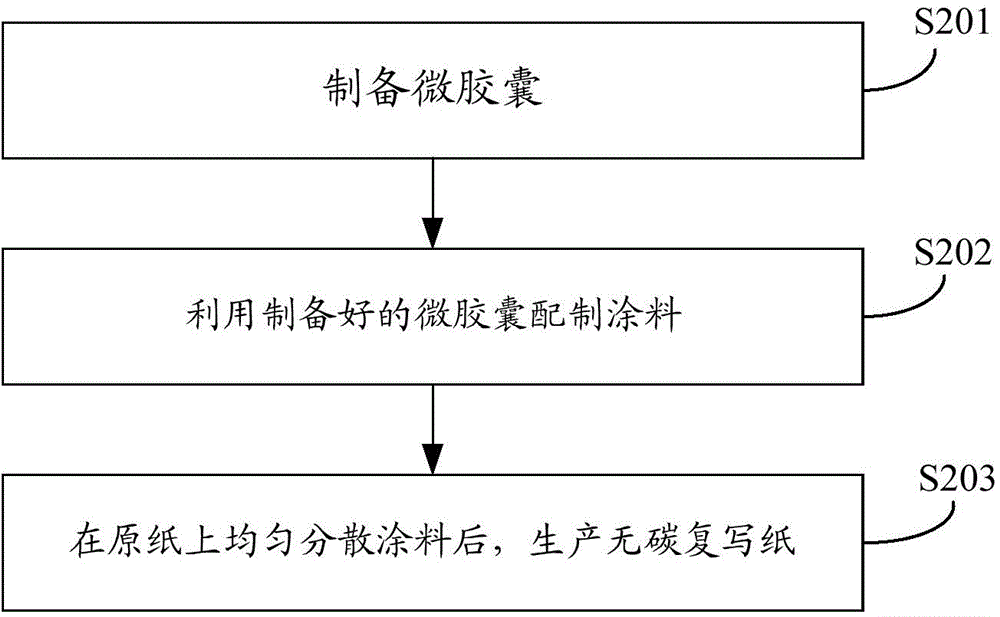

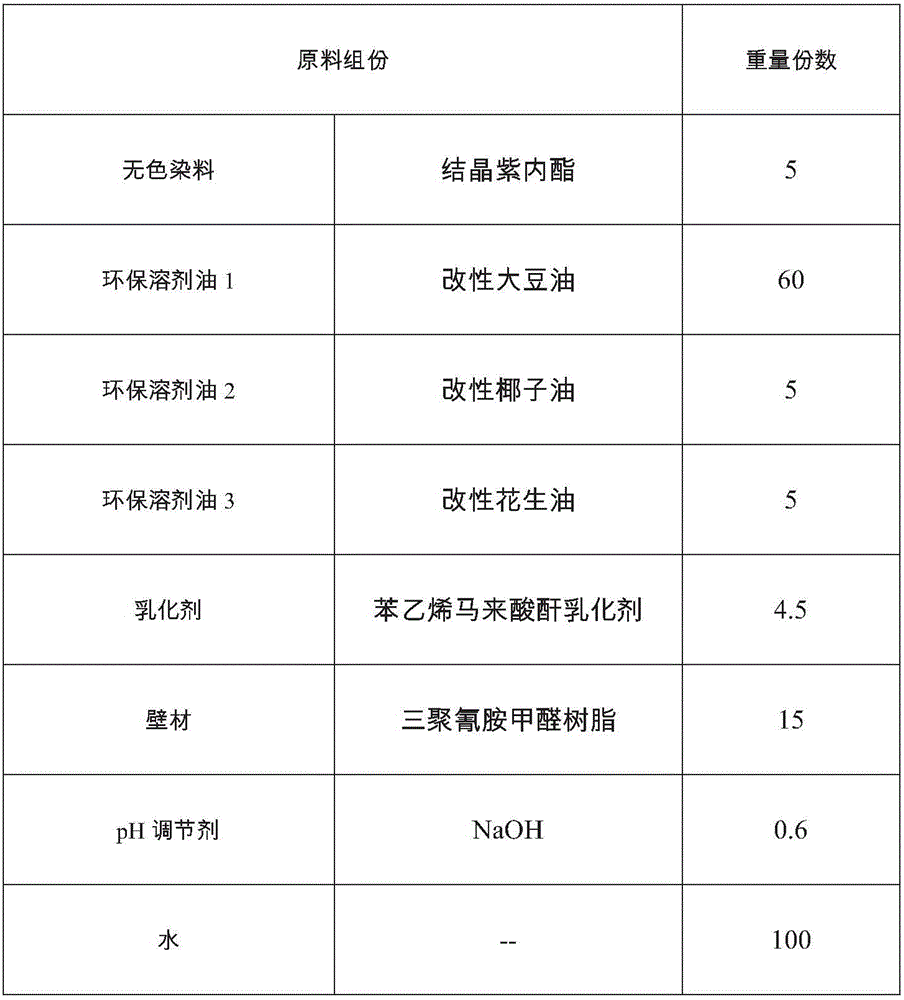

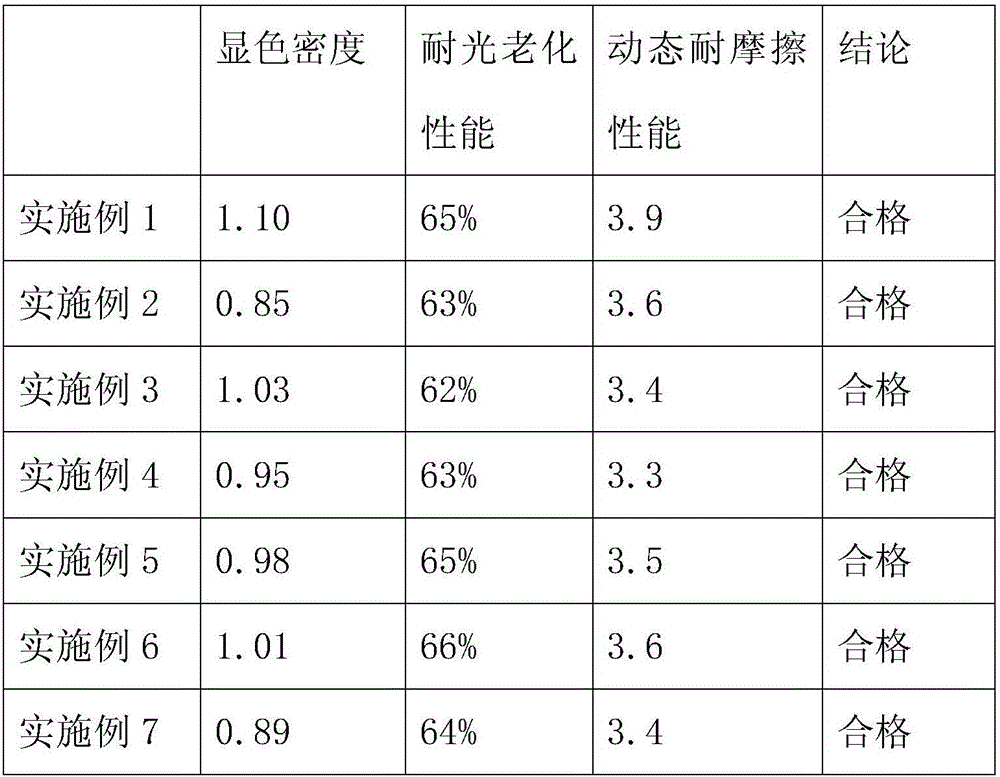

No carbon required paper microcapsule and coating, and preparation methods of no carbon required paper and microcapsule

InactiveCN104005263AHigh color densityReduce usage ratioCoatings with pigmentsCoatingsLeuco dyeSolvent

The invention discloses a no carbon required paper microcapsule and coating, and preparation methods of no carbon required paper and the microcapsule. The method of the microcapsule includes the steps: providing 3-5 parts by weight of an colorless dye and 20-40 parts by weight of a solvent oil; heating the colorless dye and the solvent oil, and dissolving to obtain a prepared chromogenic agent; adding 10-25 parts by weight of a wall material, 5-15 parts by weight of an emulsifier and the prepared chromogenic agent into 20-50 parts by weight of deionized water, and emulsifying; and after the duration of the emulsification process reaches a predetermined time, hardening the emulsified product at a predetermined rotation speed, and thus obtaining the microcapsule. Through the above way, while the microcapsule is guaranteed not to be easily broken because of extrusion or friction, the coloration density of the no carbon required paper is improved.

Owner:GOLD HUASHENG PAPER SUZHOU IND PARK

Preparation and application of calcium carbonate for carbon-free copying paper paint

ActiveCN101113004ACalcium/strontium/barium carbonatesNon-fibrous pulp additionCalcium hydroxideSlurry

The invention discloses a calcium carbonate for carbonless copy paper coating as well as the preparation and application thereof and the preparation method comprises the steps that: 1. the preparation of crystal seed zirconium hydroxide: alkaline material aqueous solution in zirconium salt aqueous solution is added to produce crystal seed zirconium hydroxide slurry; 2. the crystal seed zirconium hydroxide slurry is added into calcium hydroxide slurry, carbonized through carbon dioxide gas until pH is between 6.5-7.5 to get calcium carbonate slurry for carbonless copy paper coating, and then calcium carbonate for carbonless copy paper coating is collected. The calcium carbonate for carbonless copy paper coating can be applied to carbonless copy paper coating, which results in high smoothness of carbonless copy paper and high coloring speed.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Color veiled-image anti-fake paper and its making process

The present invention is one kind of color veiled-image anti-fake paper and its making process. The anti-fake paper is developed based on available carbon-free duplication paper and pressure-sensitive paper. Two or more kinds of colorless dye microcapsule to form pattern of different colors are painted to paper base via form overlay printing technological process. The seal pattern and cipher are also hidden in the color changing pattern to raise the anti-fake capacity. The present invention may be used widely in the middle coupon of various bills, anti-fake document and other special paper.

Owner:康文朝

Color anti-fraud watermark paper and its producing method

InactiveCN1431367AImprove anti-counterfeiting performanceReflect individualitySurface covering paperPaper sheetCarbonless copy paper

Owner:胡传辉

Antifalse copying paper and detector possessing memory cipher and is detecting method

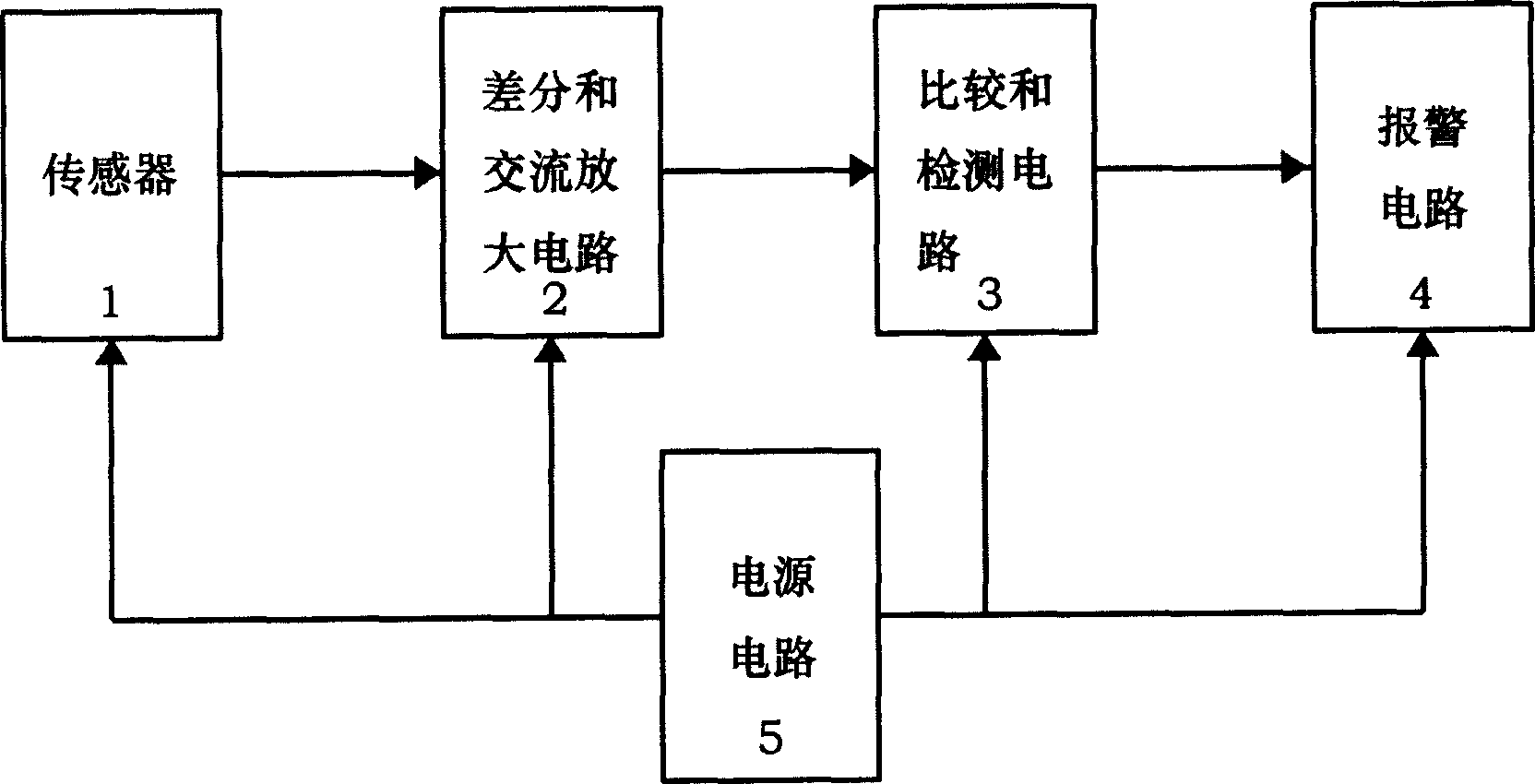

InactiveCN1538360ASimple methodSave memoryCoding/ciphering apparatusDuplicating using carbon paperMagnetic memoryCopying

The invention includes manometric copying paper, carbon free copying paper, magnetic memory material and detector. Magnetic memory material as a well magnetic metallic oxide is capable of storing, inputting and saving electromagnetic cryptographical information. Detecting method is as following: non-contacting type detector scans handwriting on paper; converted memorized cryptographical information in magnetic memory material is magnified; comparing detecting and discriminating cryptographical information by IC chip; informing tested result to alarm buzzer. Advantages of the invention are good effect of anti false and duplicable suitable to finance, insurance, tax affairs and custom etc.

Owner:熊春宁

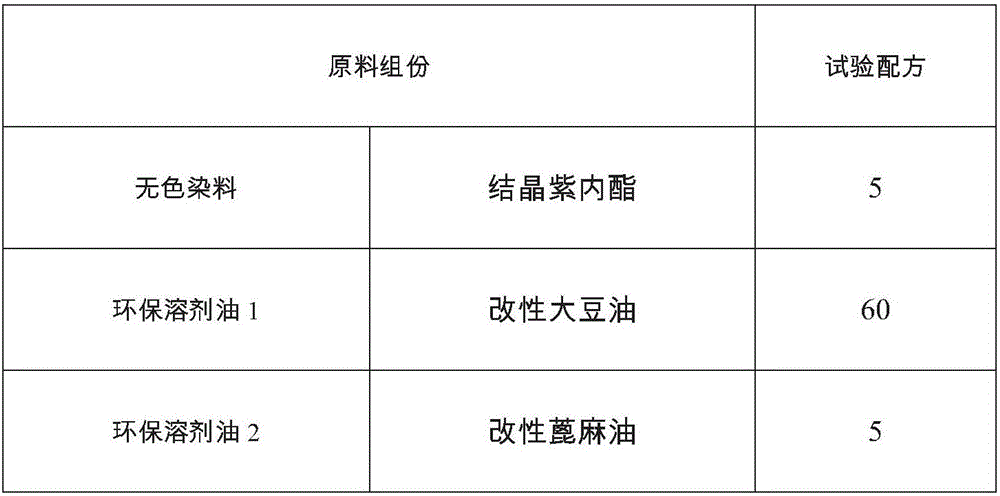

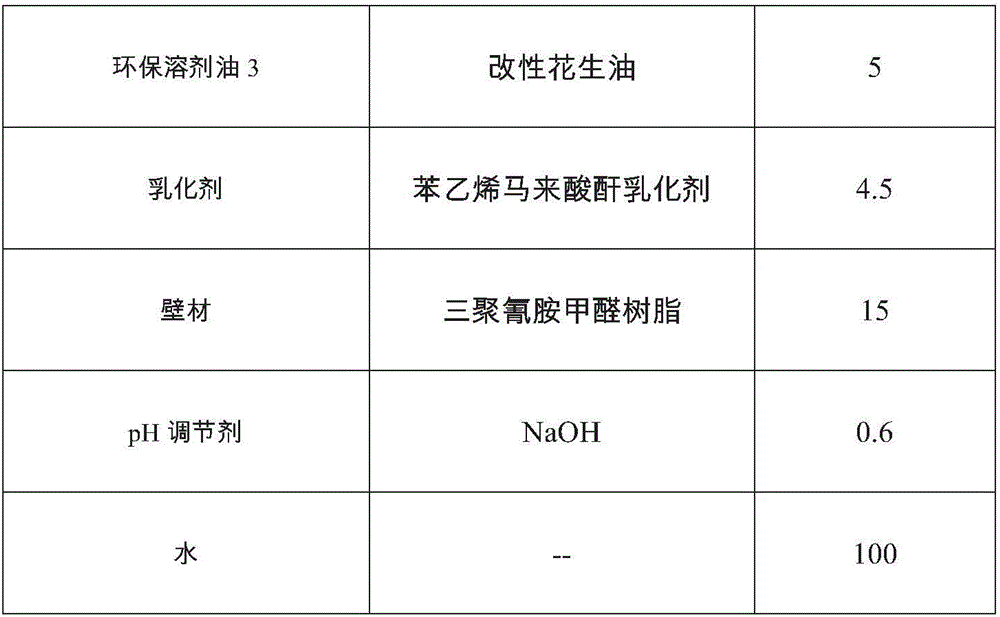

Environment-friendly microcapsule of carbonless copy paper and preparing method thereof, coating of carbonless copy paper

The invention discloses environment-friendly microcapsule of carbonless copy paper. The environment-friendly microcapsule for carbonless copy paper is prepared from, by weight, 2-10 parts of leuco dye, 20-80 parts of environment-friendly solvent oil, 2-10 parts of emulsifier, 6-15 parts of wall material and 10-100 parts of water. The microcapsule conducts reasonable optimization and compound of plant-based and animal-based environment-friendly solvent oil, to replace general benzene series solvent oil. The invention is applied to microcapsule for carbonless copy paper. The carbonless copy paper prepared from the microcapsule is more environment-friendly, innocuous and nonpoisonous, which reduces pollution, and makes writing of copy more clear. The invention also discloses a preparing method for microcapsule of carbonless copy paper and coating of microcapsule of carbonless copy paper.

Owner:GOLD HUASHENG PAPER SUZHOU IND PARK

Coating formula of non-carbon carbon paper color development face for aqueous ink jet printing bar code symbol

ActiveCN101377066AEasy to storeSolving Diffusion ProblemsCoatings with pigmentsCoatingsAdhesiveNational standard

The present invention relates to the technical field of carbonless papers, in particular to a coating formula for a color-developing side of a carbonless paper used in the aqueous ink jet printing of bar code symbols. Calculated according to weight portions, the coating formula contains the following ingredients: 700 to 900 portions of water, 2 to 10 portions of dispersant, 15 to 40 portions of activated clay, 50 to 70 portions of kaoline, 90 to 110 portions of calcium carbonate, 125 to 140 portions of laminating adhesive, 20 to 30 portions of color-developing resin, 3 to 10 portions of polyvinylpyrrolidone, 3 to 5 portions of optical brightener and 2 to 5 portions of foam suppressor. The carbonless paper coated with the coating formula can be easily stored, and when aqueous ink is adopted to jet-print the carbonless paper coated with the coating formula to print bar code symbols, the problems of the diffusion and deep permeation of the aqueous ink on the coating of the carbonless paper and the nicks on the edges of ink lines can be effectively resolved, so that the quality of the reflection curve of a bar code can come up to the class A of the national standard.

Owner:GUANGDONG QIAOSHENG ANTI COUNTERFEITING MATERIALS CO LTD

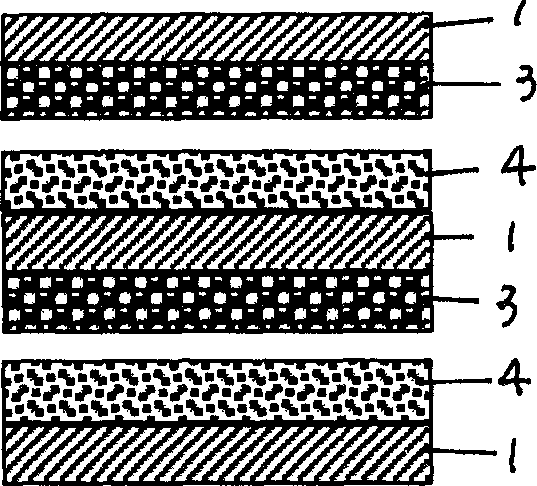

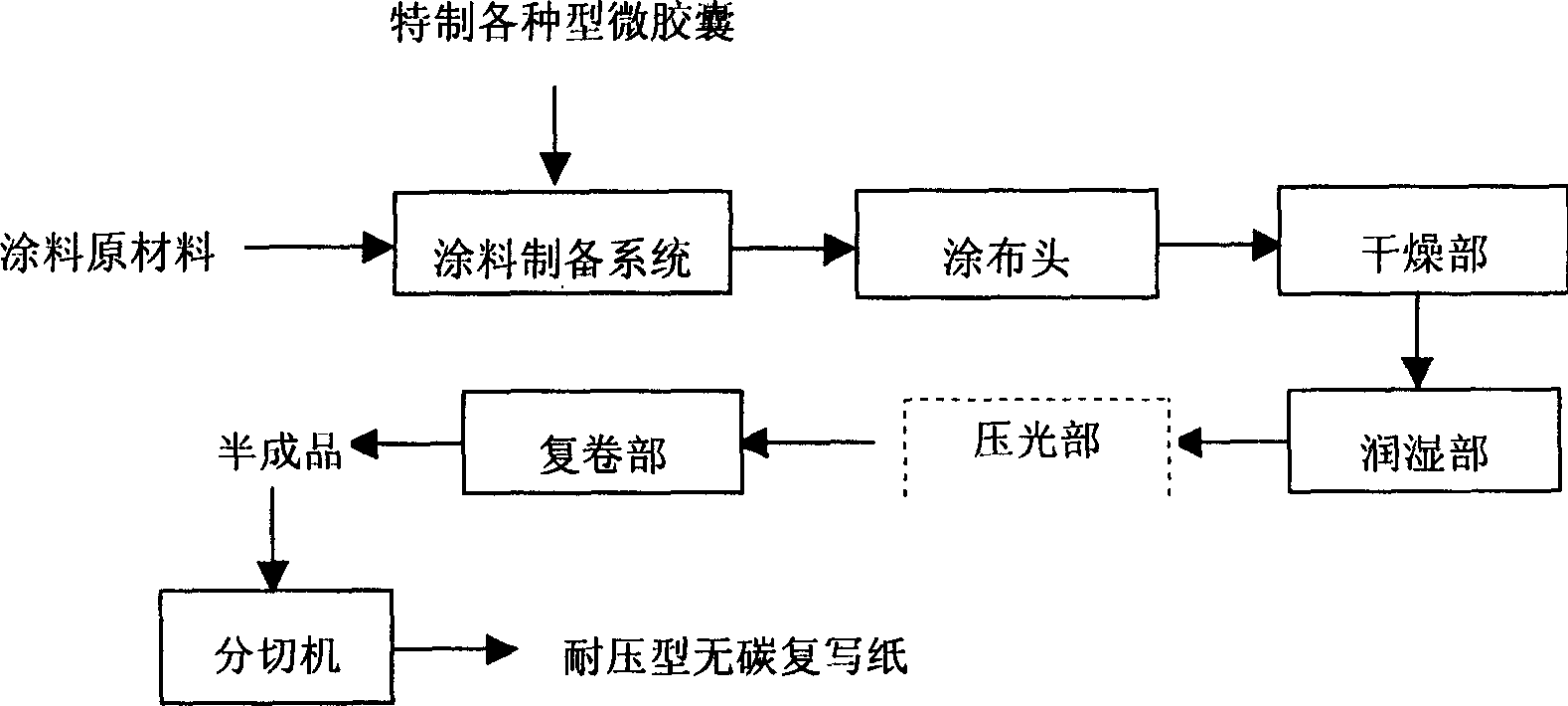

Pressure-resistant carbon-free duplicating paper and production thereof

InactiveCN1779071AImprove stress resistanceHigh opacityPaper/cardboardPaper/cardboard layered productsPulp and paper industryCarbonless copy paper

The invention is about a pressure carbon-free paper and its process. The aim of the invention is to solve the paper turning blue and skew ness in the roll-up printing process. The microcapsule is treated specially in the invention. The mean particle diameters about 3 microns and the opacity are about 75%. So it can be used for the double-sided printing and the word in the printing face is clear.

Owner:GUANGDONG GUANHAO HIGH TECH

Two-color anti-counterfeiting carbonless CB (coated back)/CFB (coated front and back) paper and production process for same

Disclosed are two-color anti-counterfeiting carbonless CB (coated back) / CFB (coated front and back) paper and production process for the same. Second developed dye is emulsified and packaged by the capsulation technique, or further processed by the grinding technique, the processed second developed dye is added into CB coatings in different colors, and the coatings are coated to the back of raw paper or CF (coated front) paper to produce two-color carbonless CB / CFB paper. The original developed color of the carbonless paper can be retained on the CF side when the carbonless CB / CFB paper is gathered and printed with CFB / CF paper sheets. When the paper sheets are recognized by friction operations such as scribing and the like on the CB side, a second developed color line can appear clearly on the CB side. The two developed marks are mutually independent of each other about developing conditions, so that the new anti-counterfeiting function of carbonless copy paper is realized.

Owner:GUANGDONG GUANHAO HIGH TECH

False proof particle non-carbon manifold paper CF paper and producing method thereof

ActiveCN101294362ASimple production processFlexible production processNon-fibrous pulp additionCoatings with pigmentsFluorescenceUltraviolet lights

The invention belongs to the carbonless copy paper processing technology field, in particular to an anti-counterfeiting particle carbonless copy CF paper as well as the production method thereof. The anti-counterfeiting particle carbonless copy CF paper has the technical proposal that anti-counterfeiting particles are added in the CF coating of the carbonless copy paper, while colorful anti-counterfeiting particles can be clearly seen under visible light, colorless fluorescent anti-counterfeiting particles can be easily observed under ultraviolet light, and the color change of temperature-changing anti-counterfeiting particles can be observed according to the temperature changing range when the condition is satisfied. The anti-counterfeiting particles with different colors can be used by being mixed according to a certain proportion. During identification, observation can be carried out or certain instruments can be used for determining whether the anti-counterfeiting particles accord with the proportion, thereby realizing the anti-counterfeiting purpose.

Owner:GUANGDONG GUANHAO HIGH TECH

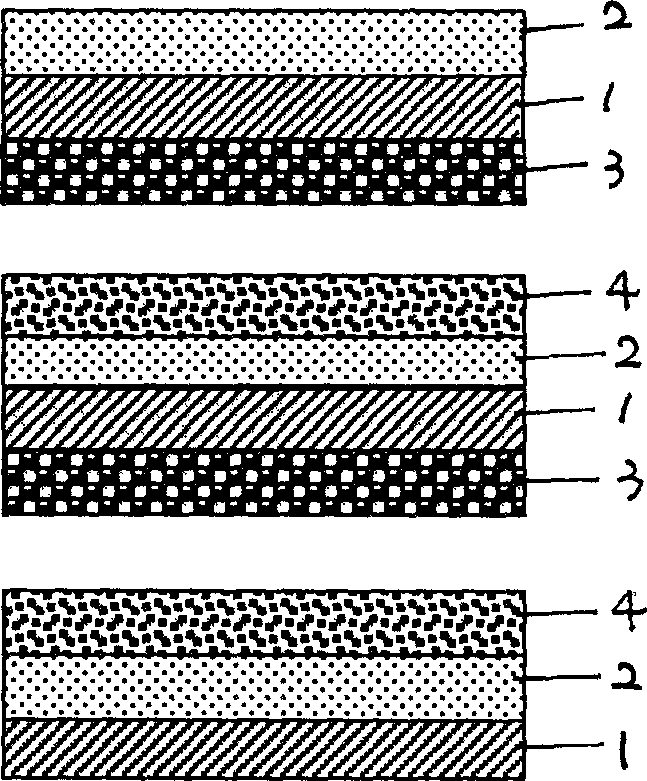

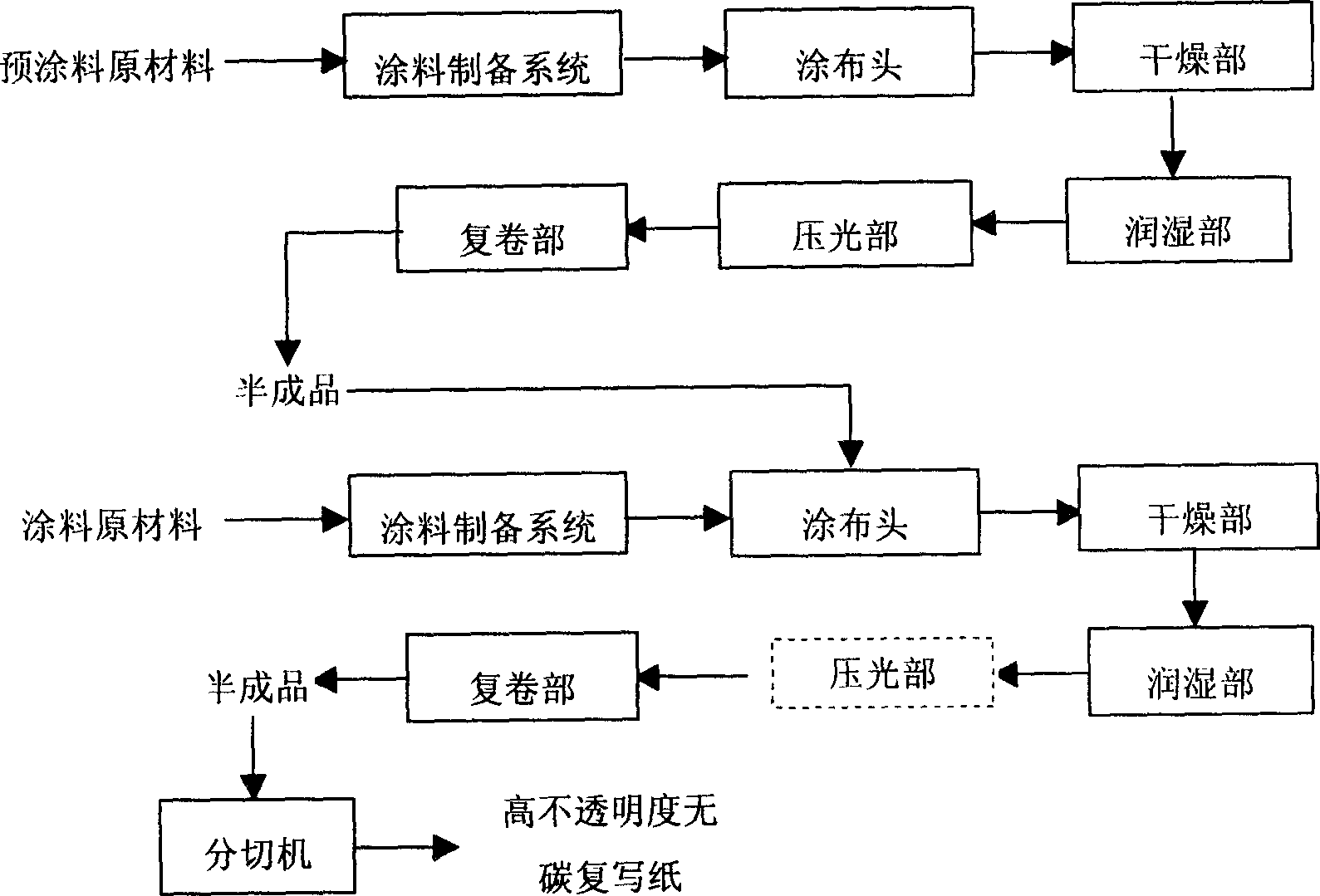

High non-transparent carbon-free duplicating paper and production thereof

InactiveCN1779072AClear writing on the printing surfaceAdapt to the requirements of high-speed printingInorganic fibres/flakesPaper/cardboardPulp and paper industryEngineering

The invention is about high opaque carbon-free paper and its process. The paper of high opaque (about 85%) with big quantity (above 100g / m2) caní»t be copied; the paper of low quantity (lower than 60 g / m2) has the low opaque (about 70%). The invention is to cover a high opaque paint on the paper, then to coat using the carbon-free paper, so its opacity reaches above 85%.

Owner:GUANGDONG GUANHAO HIGH TECH

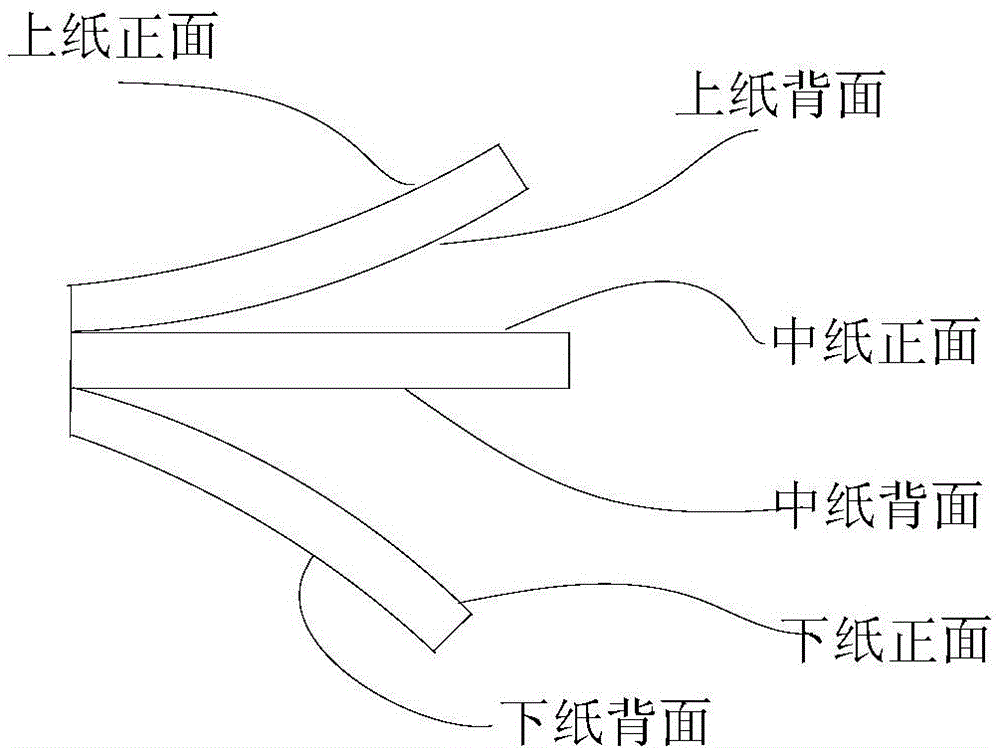

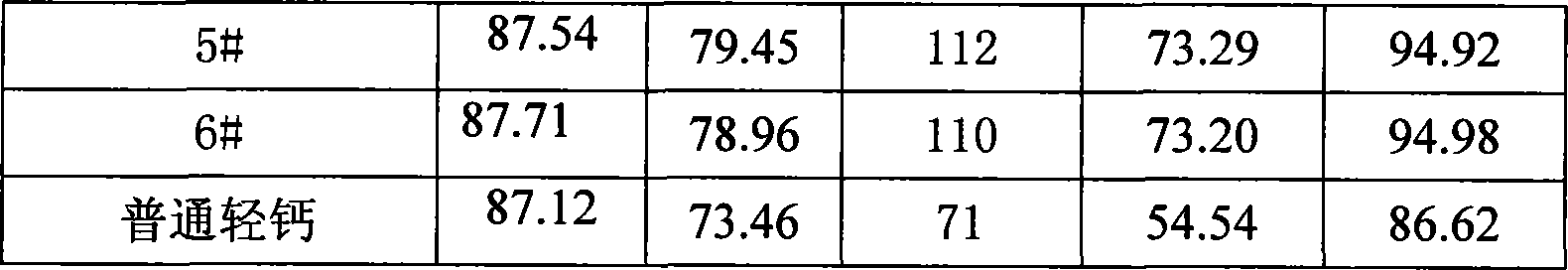

Built-in multi-coating carbonless paper production process

InactiveCN101899798AWon't breakReduce energy consumptionPaper coatingPaper/cardboardSlurryPulp and paper industry

The invention relates to a built-in multi-coating carbonless paper production process belonging to the technical field of paper-making coating. The process comprises the following steps: enabling pulp from a head box to pass through a wire section to form raw paper, baking the raw paper on a pre-baking apparatus to obtain semi-finished paper, coating the semi-finished paper with a layer of paint by a coating apparatus, drying in a drying box, then drying on a post-baking apparatus, and coiling in a calendering and coiling apparatus to complete the one-time production of carbonless paper. The invention can realize the built-in multiple coating of raw paper of the carbonless paper, i.e. upper paper (CF paper), intermediate paper (CFB paper) and lower paper (CF paper) can be produced by one-time coating on the paper-making machine in the process of the producing raw paper of the carbonless paper without carrying out off-machine coating, thereby effectively saving energy consumption and human power.

Owner:HENAN JIANGHE PAPER

Temperature-range false-proof non-carbon CB/CFB paper and producing method thereof

ActiveCN101294363AWith "fixing" functionRealize anti-counterfeitingNon-fibrous pulp additionCoatings with pigmentsRoom temperaturePulp and paper industry

Owner:GUANGDONG GUANHAO HIGH TECH

Preparation method of environmental-friendly type pressure-sensitive oil for carbonless copying paper

ActiveCN106400589AImprove stabilityImprove solubilityPaper coatingPaper/cardboardWater bathsDissolution

The invention discloses a preparation method of environmental-friendly type pressure-sensitive oil for carbonless copying paper. The preparation method comprises the following steps: 1) pretreatment: compounding and heating solvent oil, and stirring uniformly; 2) dissolution: heating and dissolving colorless dye and the solvent oil to obtain a color forming agent; 3) pre-emulsification: adding and mixing an emulsifying agent, a wall material and deionized water into the color forming agent in the step 2) to obtain emulsified liquid; 4) emulsification: shearing and emulsifying at a high speed to the particle diameter needed by capsules, so as obtain emulsified liquid; 5) curing: carrying out curing on the emulsified liquid in the step 4) to form microcapsules; 6) hardening: carrying out water-bath insulation on the microcapsules in the step 5); 7) oil formation: adding an adhesive and an isolating agent into the microcapsules in the step 6) to obtain the pressure-sensitive oil. The environmental-friendly type pressure-sensitive oil for the carbonless copying paper, prepared by the preparation method, is non-toxic and non-irritating, is good in safety and wide in application range and is environmental-friendly and pollution-free.

Owner:SUZHOU FENGBEI BIOTECH CO LTD

Preparation method for oxidation cross-linked-carboxymethyl composite modified starch, and oxidation cross-linked-carboxymethyl composite modified starch

ActiveCN102690362AReduce manufacturing costEasy to popularize productionPaper coatingCoatingsOrganosolvMONOCHLOROACETIC ACID

The invention discloses a preparation method for oxidation cross-linked-carboxymethyl composite modified starch and the oxidation cross-linked-carboxymethyl composite modified starch. According to the preparation method, starch raw materials are subjected to oxidation cross-linking to form cross-linked starch, and the cross-linked starch which is used as a reaction raw material is subjected to carboxymethylation in a microwave reaction system and an infrared heat preservation system to form the required oxidation cross-linked-carboxymethyl composite modified starch. The preparation method is simple, low in cost and high in comprehensive cost performance; an organic solvent is not needed to be adopted; and the prepared oxidation cross-linked-carboxymethyl composite modified starch is high in performance, and coating slurry with high concentration of more than 30 percent can be prepared by using the modified starch, is high in flowability and water-retaining property, can meet the coating requirements of high-end products such as carbonless copy paper, coated paper and the like in papermaking industry well, and the oxidation cross-linked-carboxymethyl composite modified starch has good development and application prospect.

Owner:GUANGDONG HUIMEI STARCH SCI & TECH

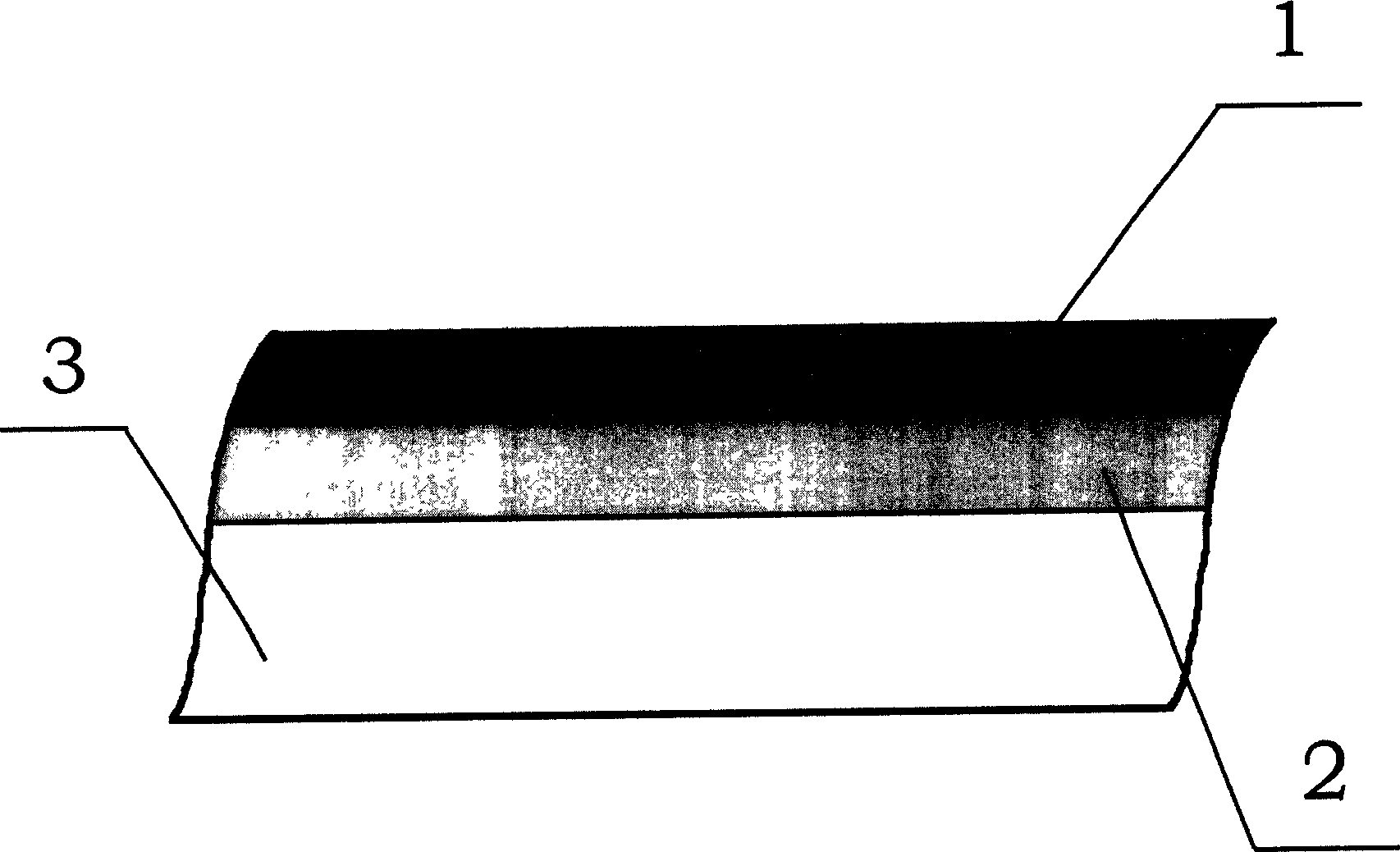

Carbonless copying paper with guard wires and making method thereof

InactiveCN102182113ATo achieve the purpose of printing can not be counterfeitedNon-fibrous pulp additionSpecial paperEngineeringPulp and paper industry

The invention relates to carbonless copying paper with guard wires and a making method thereof, belonging to the technical field of paper making. The carbonless copying paper with guard wires is characterized by consisting of 3-5 pieces of converted paper with different structures, i.e. upper carbonless paper, middle carbonless paper and lower carbonless paper, wherein an anti-counterfeit guard wire is embedded in each base paper, and the topmost paper is converted paper formed by arranging a coating at the back side of base paper; each of the multiple pieces of middle paper is converted paper formed by arranging coatings at both sides of base paper; and the lowermost paper is converted paper formed by arranging a coating at the front side of base paper. The making method comprises the following steps: a, production of the base paper: 1) pulping, 2) beating and preparing, 3) forming paper, 4) squeezing and dewatering, 5) drying, 6) carrying out top sizing, and 7) calendering; and b, coating and processing: 1) preparing paint, 2) coating, 3) drying, and 4) calendering. The invention has the advantages that the base paper is provided with the guard wires for anticounterfeiting, and the guard wires are visible to the naked eyes and can be directly separated from the paper in a tearing manner, thereby achieving the purpose of no counterfeiting for printing.

Owner:莱阳银通纸业有限公司

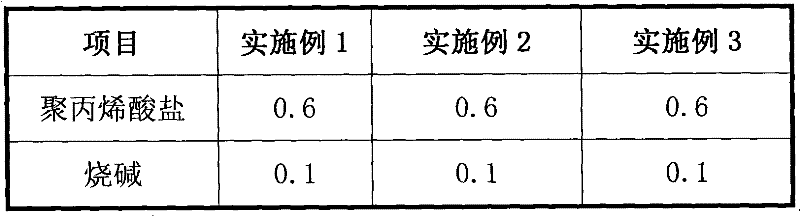

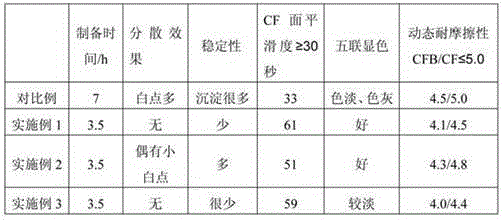

Paint of carbonless copy paper

The invention provides paint of carbonless copy paper. A CB material is prepared by 22-23 parts of glue, 6-7 parts of a dispersant, 20-22 parts of microcapsule, 0.3-0.5 part of a binder and 50-52 parts of water; and a CF material is prepared by 23-24 parts of glue, 33-34 parts of a white material, 0.2-0.3 part of a dispersant, 7-8 parts of a developer, 1.5-2.0 parts of a binder, 0.4-0.5 part of a lubricant and 33-35 parts of water, wherein the while material is prepared by 60-62 parts of kaolin, 9-10 parts of light calcium carbonate, 0.9-1.0 part of a dispersant, 27-28 parts of water and 0.4-1.0 part of alkali. According to the invention, preparation time is obviously shortened and production efficiency can be effectively improved; the paint has a good dispersion effect, a good rheological property, and less foam; and carbonless copy paper prepared by the paint is high in strength, good in printing adaptability, and is not likely to warp.

Owner:湖北金民纤维材料科技有限公司

Preparation method of light calcium carbonate for carbon-free copying paper

ActiveCN100509631CCalcium/strontium/barium carbonatesPaper coatingCalcium hydroxidePrecipitated calcium carbonate

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Coating and method capable of decreasing uncoated areas of curtain

InactiveCN105002774AImprove running stabilityMeet the viscosityPaper coatingPaper/cardboardViscosityPolymer chemistry

The invention discloses a coating and method capable of decreasing uncoated areas of a curtain. The coating capable of decreasing the uncoated areas of the curtain comprises separation agents, starch, latex, extension agents, microcapsules, water repellent agents, interfacial agents and pH modifiers. The coating has good extension viscosity, so the operation stability of the curtain is obviously improved; when stretched vigorously at the moment when the coating is in contact with a paper web, the coating can bear certain deformation and cannot break easily, the covering quality of the coating can be easily improved, and the uncoated areas existing on the surface of coated carbonless copy paper are obviously decreased.

Owner:GOLD HUASHENG PAPER SUZHOU IND PARK

Preparation method of light calcium carbonate for carbon-free copying paper

The invention discloses a preparation method of light calcium carbonate for carbonless copy papers, comprising the steps that: 1. dispersant is added in silicon oxide slurry and then is sent into a grinder to be grinded; the dispersant is the mixture of phosphoric acid monoester salt and phosphoric acid diester salt; 2. the products in step 1 is put into calcium hydroxide slurry, is carbonized through carbon dioxide gas until pH is between 6.5-7.5 to get light calcium carbonate slurry, and then the light calcium carbonate is collected from the light calcium carbonate slurry. The light calcium carbonate produced by the invention can be applied to carbonless copy paper coating, which results in high coloring speed of the carbonless copy papers.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Carbonless copying paper

InactiveCN103046433AImprove adhesionMeet needsCoatings with pigmentsCoatingsPolyvinyl alcoholMelamine formaldehyde resin

The invention provides digital carbonless copying paper. Curtain coating is carried out on the carbonless copying paper. A coating comprises the following components in parts by weight: 2-5 parts of light calcium carbonate, 5-9 parts of sodium carboxymethyl cellulose, 4-9 parts of styrene-butadiene emulsion, 5-10 parts of polyamine polyepoxy resin, 10-15 parts of melamino-formaldehyde resin, 11-14 parts of styrene-acrylic copolymer, 10-18 parts of carboxylic butadiene-styrene latex, 1-3 parts of sulphonated castor oil, 7-16 parts of sodium polyacrylate, 12-18 parts of polyvinyl alcohol, 1-5 parts of kaolin, 1-4 parts of corn starch, 1-3 parts of pigment, 4-7 parts of emulation, 3-5 parts of argil, 5-12 parts of titanium dioxide and 4-12 parts of talcum powder. According to the invention, after the technical measures are adopted, as the digital carbonless copying paper parts can be automatically separated and leaves of each paper part are firmly bonded, requirements of clients are satisfied.

Owner:QINGDAO ADVANCED MARINE MATERIAL TECH

Preparation of calcium carbonate for carbon-free copying paper paint

InactiveCN101113008ACalcium/strontium/barium carbonatesCoatings with pigmentsCalcium hydroxideSlurry

The invention provides a preparation method of calcium carbonate for carbonless copy paper coating, comprising the steps that: soluble aluminum salt aqueous solution is added in calcium hydroxide slurry, then the calcium hydroxide slurry is carbonize through carbon dioxide gas until pH is between 6.5-7.5 to get calcium carbonate slurry for carbonless copy paper coating, and then calcium carbonate is collected for carbonless copy paper coating from the calcium carbonate slurry. Detection results show that the calcium carbonate for carbonless copy paper coating produced by the method can be applied to producing the carbonless copy paper coating, which results in high smoothness of carbonless copy paper and high coloring speed.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Developer for use with carbonless copy paper and photo imaging system

An electron accepting developer useful for producing visible images by reaction with an electron donor in carbonless paper and photo- imaging systems, the developer comprising an acid-treated, water insoluble alkali metal-modified, inorganic oxide or an acid-treated molecular sieve.

Owner:RENTECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com