Built-in multi-coating carbonless paper production process

A technology of carbonless copying paper and production process, which is applied in coating, paper, papermaking, etc., can solve the problems of inability to coat carbonless copying paper in the machine and production, and achieve the effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

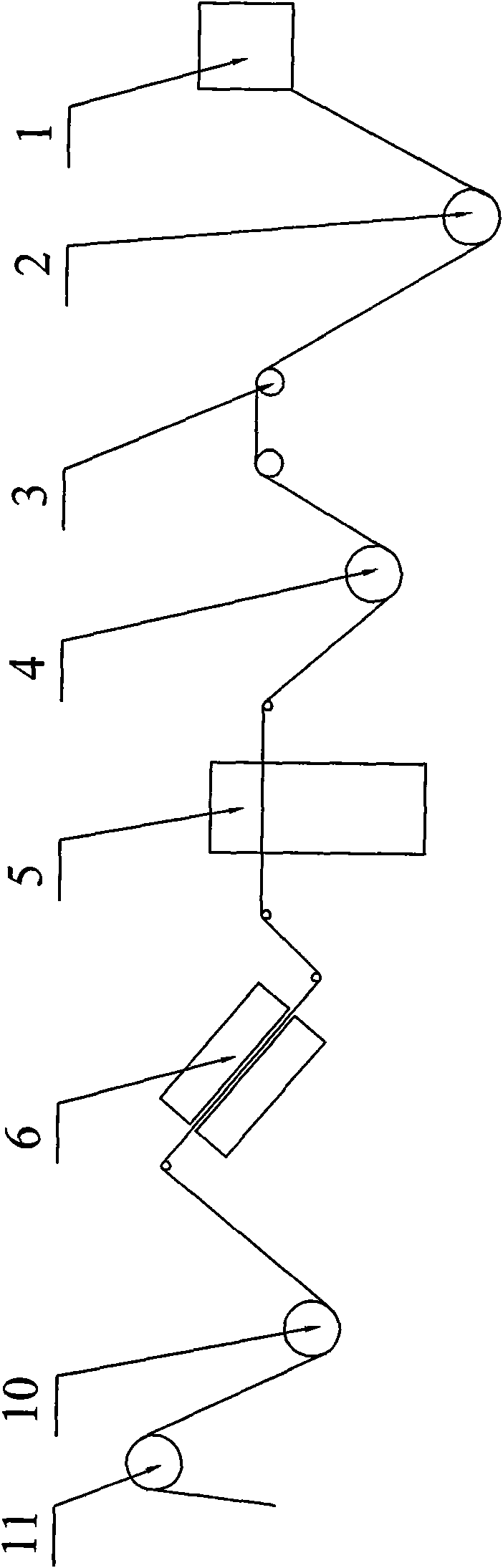

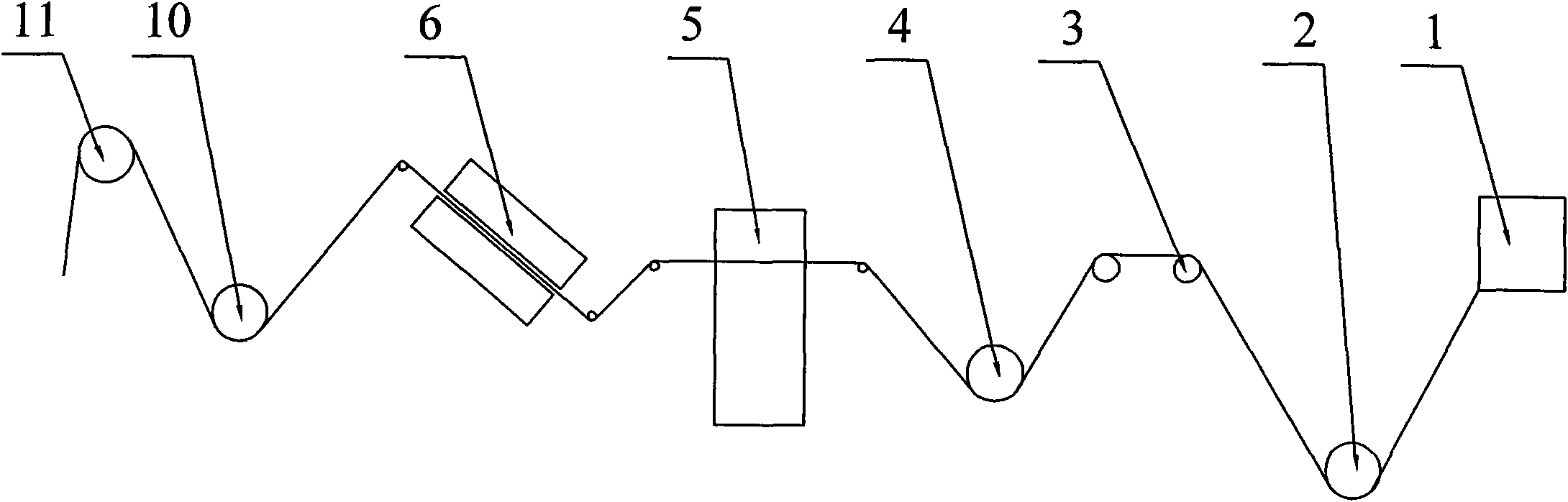

[0023] like figure 1 As shown, the carbonless copy paper coating production device of the present invention includes a carbonless copy paper coating production line, and the carbonless copy paper coating production line is sequentially equipped with a headbox 1, a wire section 2, a pressing device 3, and a front drying Equipment 4, curtain coater 5, drying oven 16, post-drying equipment 10 and calendering coiling equipment 11.

[0024] It works as follows:

[0025] When coating paper (CB paper) paper, the slurry flowing out from the headbox 1 passes through the wire part 2 to form the initial paper, and then passes through the pre-drying equipment 4 to obtain semi-finished paper, and the semi-finished paper is coated with a curtain coater 5 The layer of CB paint is dried through the air flotation drying oven 6, and then dried through the post-drying equipment (drying cylinder) 10, and then rolled up by the calendering coiling equipment 11 to produce the upper paper (CB paper)...

Embodiment 2

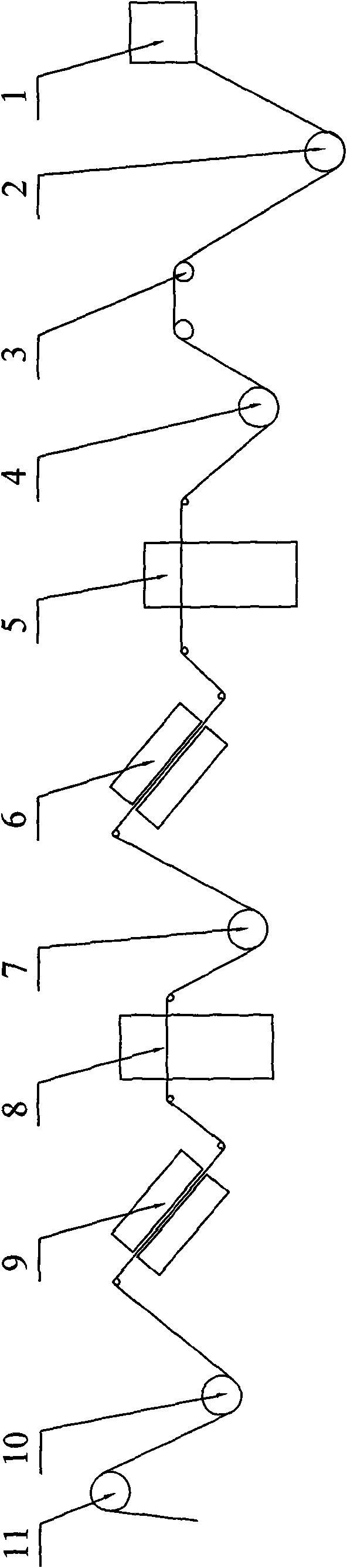

[0027] like figure 2 As shown, the carbonless copy paper coating production device of the present utility model includes a carbonless copy paper coating production line, and the carbonless copy paper coating production line is successively equipped with a headbox 1, a wire section 2, a pressing device 3, a pre-drying Drying equipment 4, film transfer coating machine 5, drying box I 6, middle drying equipment 7, curtain coater 8, drying box II 9, post-drying equipment 10 and calendering coiling equipment 11.

[0028] It works as follows:

[0029] When producing medium paper (CFB paper), the slurry flowing out from the headbox 1 passes through the wire part 2 to form the initial paper, and then passes through the pre-drying equipment 4 to obtain semi-finished paper. The semi-finished paper first passes through the film transfer coating machine 5 to coat a A layer of CF paint is dried through the air flotation drying oven 6, and then dried through the middle drying equipment (d...

Embodiment 3

[0031] like figure 1 As shown, the carbonless copy paper coating production device of the present invention includes a carbonless copy paper coating production line, and the carbonless copy paper coating production line is sequentially equipped with a headbox 1, a wire section 2, a pressing device 3, and a front drying Equipment 4, film transfer coating machine 5, drying oven 16, post-drying equipment 10 and calendering coiling equipment 11.

[0032] It works as follows:

[0033] When producing the bottom paper (CF paper), the slurry flowing out from the headbox 1 passes through the wire part 2 to form the initial paper, and then passes through the pre-drying equipment 4 to obtain semi-finished paper, and the semi-finished paper first passes through the film transfer coating machine 5 to coat a The layer of CF paint is dried through the air flotation drying oven 6, and then dried through the post-drying equipment (drying cylinder) 10 and decoiled by the decoiler 11 to produce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com