Microcapsule for self-repair concrete and preparation method of self-repair concrete

A technology for microcapsules and concrete, applied in the directions of microcapsule preparation and microsphere preparation, etc., can solve the problems of inability to track the development of cracks in time, poor intelligence, etc., and achieve the effect of easy implementation and simple preparation process operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

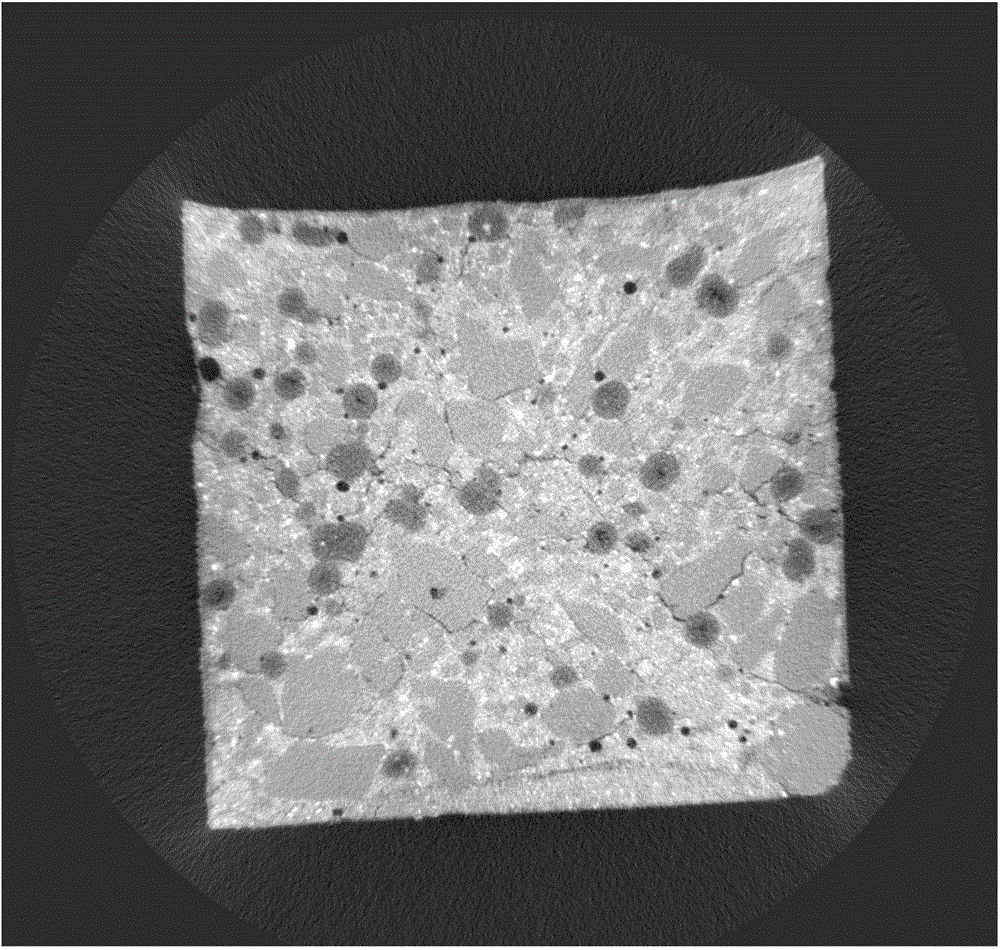

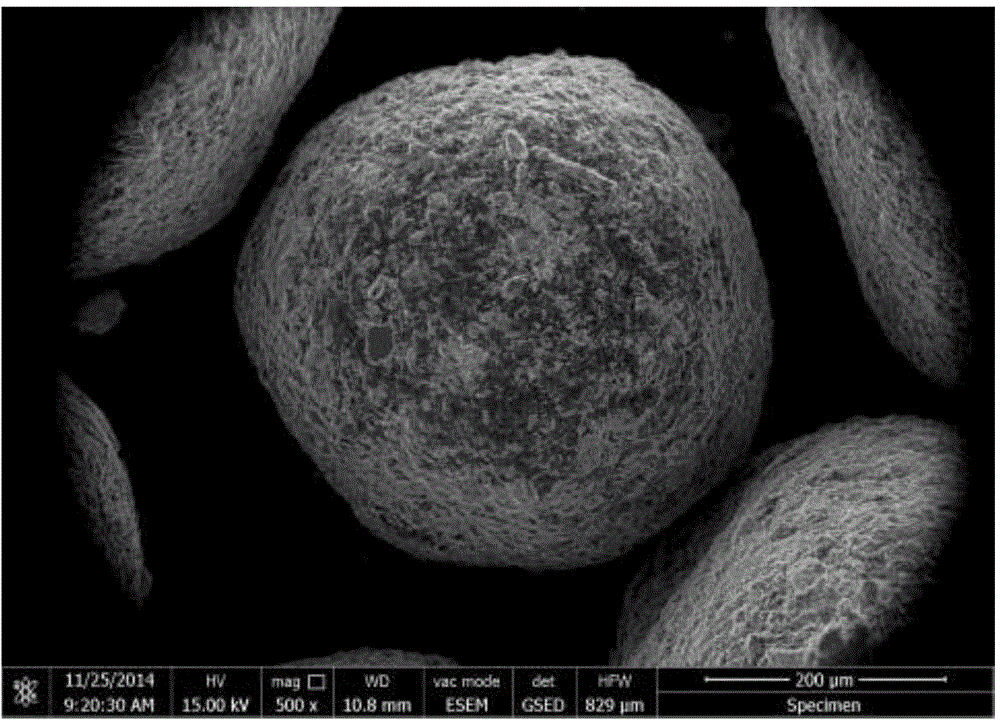

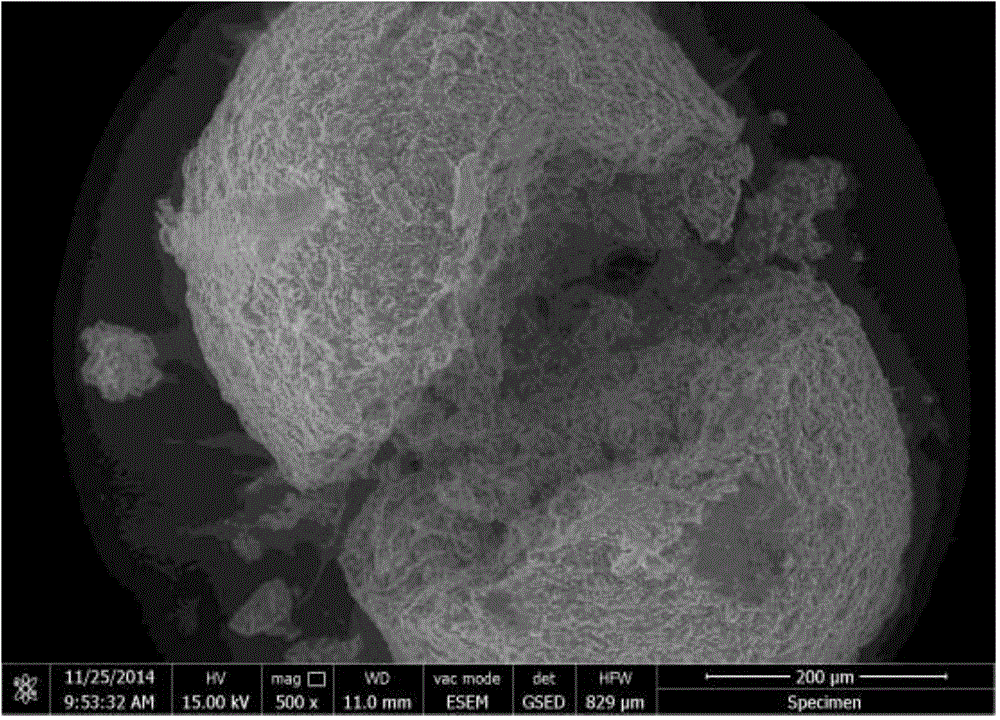

Image

Examples

Embodiment 1

[0046] Example 1: Preparation of ethyl cellulose-coated sulphoaluminate self-healing concrete

[0047] Microcapsule preparation:

[0048] 1) Capsule core preparation:

[0049] Capsule core raw material mass ratio (parts by weight):

[0050] recipe number

Sulphoaluminate cement

Tween 80

30% ethanol

Formulation Ⅰ

100

90

8

100

Formulation II

100

90

10

110

Formula III

100

95

9

110

Formula IV

100

95

10

115

Formulation V

100

100

10

120

[0051] Wherein, 30% ethanol refers to ethanol with a concentration of 30% by volume.

[0052] According to the mass ratio of the above five kinds of capsule core formula raw materials, the obtained mixture is respectively put into the extrusion equipment for extrusion and thinning, and the rice strip-shaped capsule core material is extruded, and the rice strip-shaped capsule co...

Embodiment 2

[0069] Example 2: Preparation of polystyrene-wrapped sulphoaluminate self-healing concrete

[0070] Microcapsule preparation:

[0071] 1) Capsule core preparation:

[0072] Capsule core raw material mass ratio (parts by weight):

[0073] recipe number

Sulphoaluminate cement

Tween 80

30% ethanol

Formulation Ⅰ

100

90

8

100

Formulation II

100

90

10

110

Formula III

100

95

9

110

Formula IV

100

95

10

115

Formulation V

100

100

10

120

[0074] According to the mass ratio of the raw materials of the above five capsule core formulations, put the obtained mixture into the extrusion equipment for extrusion and thinning, extrude the rice strip-shaped capsule core material, and pour the rice strip-shaped capsule core material into the drum of the spheronizing equipment , roll out the capsule core particles, and dry t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com