Preparation method of light calcium carbonate for carbon-free copying paper

A light calcium carbonate, carbon-free copy paper technology, applied in the direction of calcium carbonate/strontium/barium, inorganic compound addition, etc., can solve the problems of low smoothness, slow color development speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

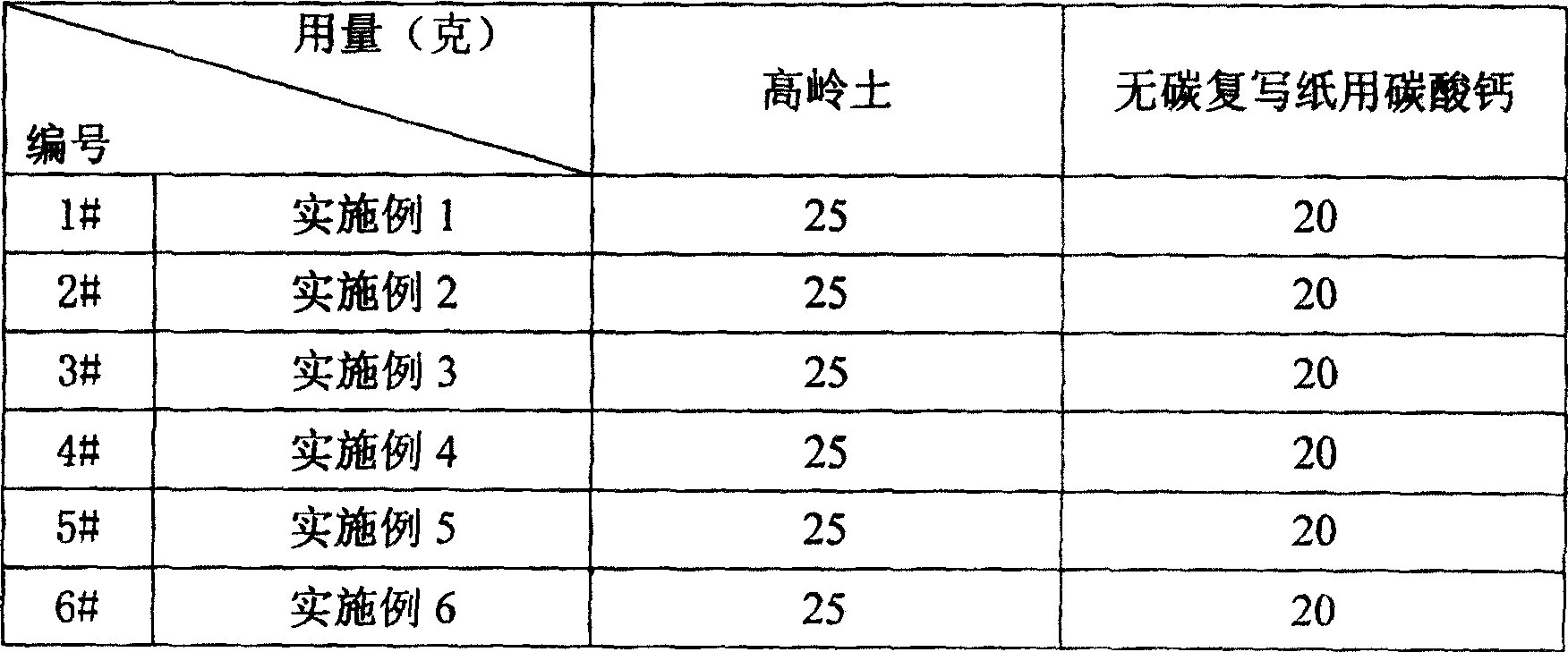

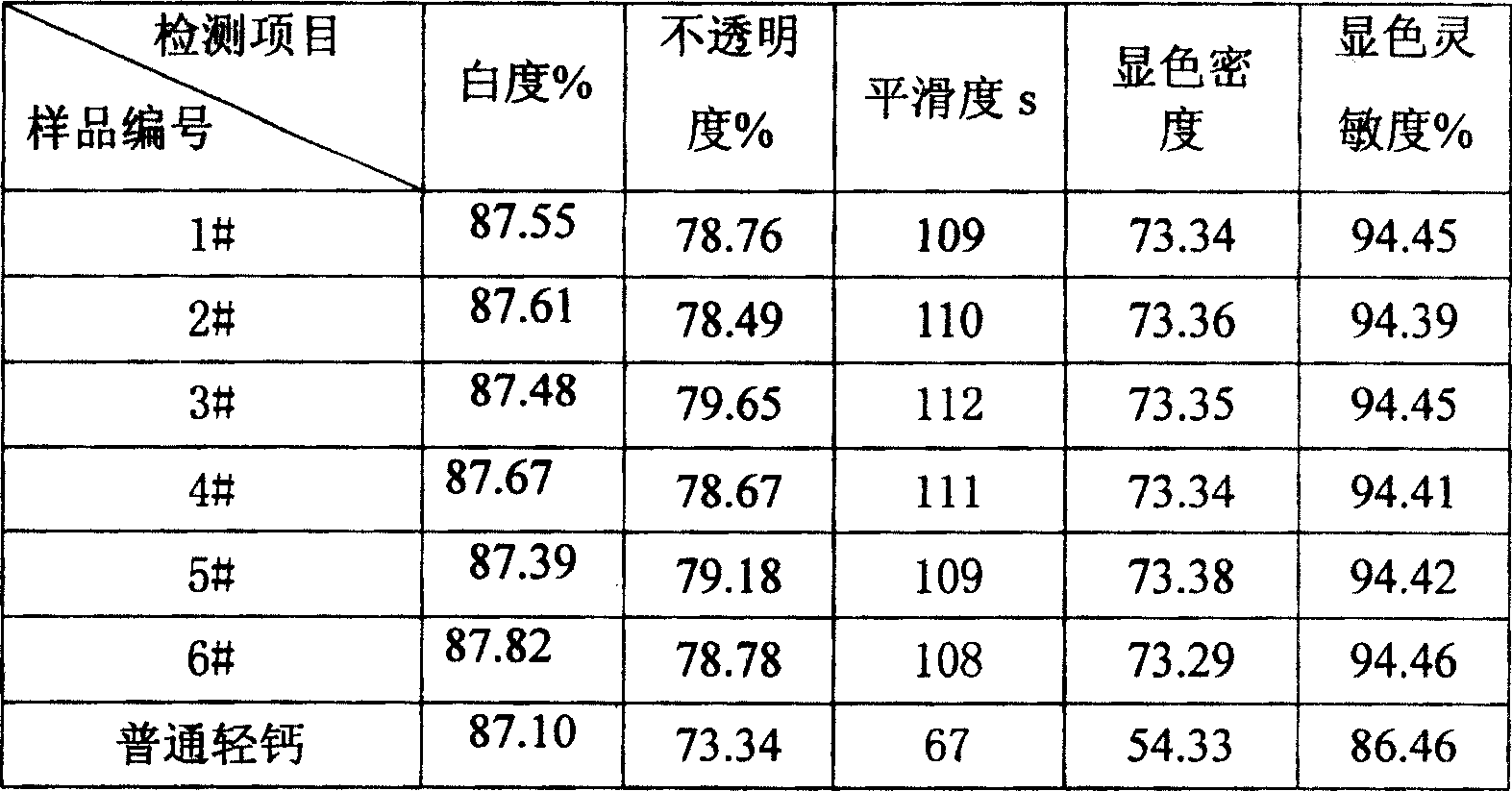

Examples

Embodiment 1

[0027] Ultrafine precipitation silica slurry:

[0028] Weigh 200kg of precipitated silica, add 300kg of water into a 1 cubic meter reactor, add 200kg of precipitated silica into a stirred 1 cubic meter reactor, and then add 2kg of dodecyl phosphate mixed ester sodium salt dispersant , the molar ratio of dodecyl phosphate monoester to dodecyl diester phosphate is 1:1, and the silicon oxide slurry is prepared, stirred, and then 80 liters of wet-type ultra-fine peeling machine is used to carry out the precipitation method silicon oxide slurry ultra fine grind. A silicon oxide slurry is prepared, wherein the weight content of particles with a particle size less than 2 μm is 70%.

[0029] The calcium hydroxide slurry that 8000kg solid content is 15% joins in the carbonization tower of 12 cubic meters, adds above-mentioned superfine precipitation method silicon oxide slurry 300kg in the carbonization tower, passes into the carbonation tower containing carbon dioxide 27% ( volume) ...

Embodiment 2

[0031] Ultrafine precipitation silica slurry:

[0032] Weigh 100kg of precipitated silica, add 1900kg of water into a 3 cubic meter reactor, add 100kg of precipitated silica into a stirred 3 cubic meter reactor, and then add 3kg of dodecyl phosphate mixed ester sodium salt dispersant , the molar ratio of dodecyl phosphate monoester to dodecyl diester is 1:0.5, and the precipitated silicon oxide slurry is prepared. Stir, and then use an 80-liter wet ultrafine sand mill to ultrafinely grind the precipitated silicon oxide slurry. An ultra-fine precipitation silicon oxide slurry is prepared, wherein the weight content of particles with a particle size less than 2 μm is 100%.

[0033] The calcium hydroxide slurry that 8000kg solid content is 9% joins in the carbonization tower of 12 cubic meters, adds above-mentioned superfine precipitation method silicon oxide slurry 720kg in the carbonization tower, passes into carbon dioxide 28% ( volume) mixed gas, carbonized to pH 6.8 to obt...

Embodiment 3

[0035] Ultrafine precipitation silica slurry:

[0036] Weigh 500kg of precipitated silica, add 2000kg of water into a 3 cubic meter reactor, add 500kg of precipitated silica into a stirred 3 cubic meter reactor, and then add 0.5kg of cetyl phosphate mixed ester sodium salt Powder, the molar ratio of cetyl phosphate monoester to cetyl phosphate diester is 1:1.2, and the precipitated silicon oxide slurry is prepared. Stir, and then use an 80-liter wet ultrafine sand mill to ultrafinely grind the precipitated silicon oxide slurry. An ultra-fine precipitation silicon oxide slurry is prepared, wherein the weight content of particles with a particle size less than 2 μm is 70%.

[0037] The calcium hydroxide slurry that 6000kg solid content is 10% joins in the carbonization tower of 12 cubic meters, adds above-mentioned superfine precipitation method silicon oxide slurry 2000kg in the carbonization tower, passes into carbon dioxide 34% ( volume) mixed gas, carbonized to pH 6.9 to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com