Method for extracting lithium hydroxide by salt lake brine

A lithium hydroxide, salt lake brine technology, applied in chemical instruments and methods, energy wastewater treatment, water/sewage multi-stage treatment, etc., can solve problems such as unreported

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

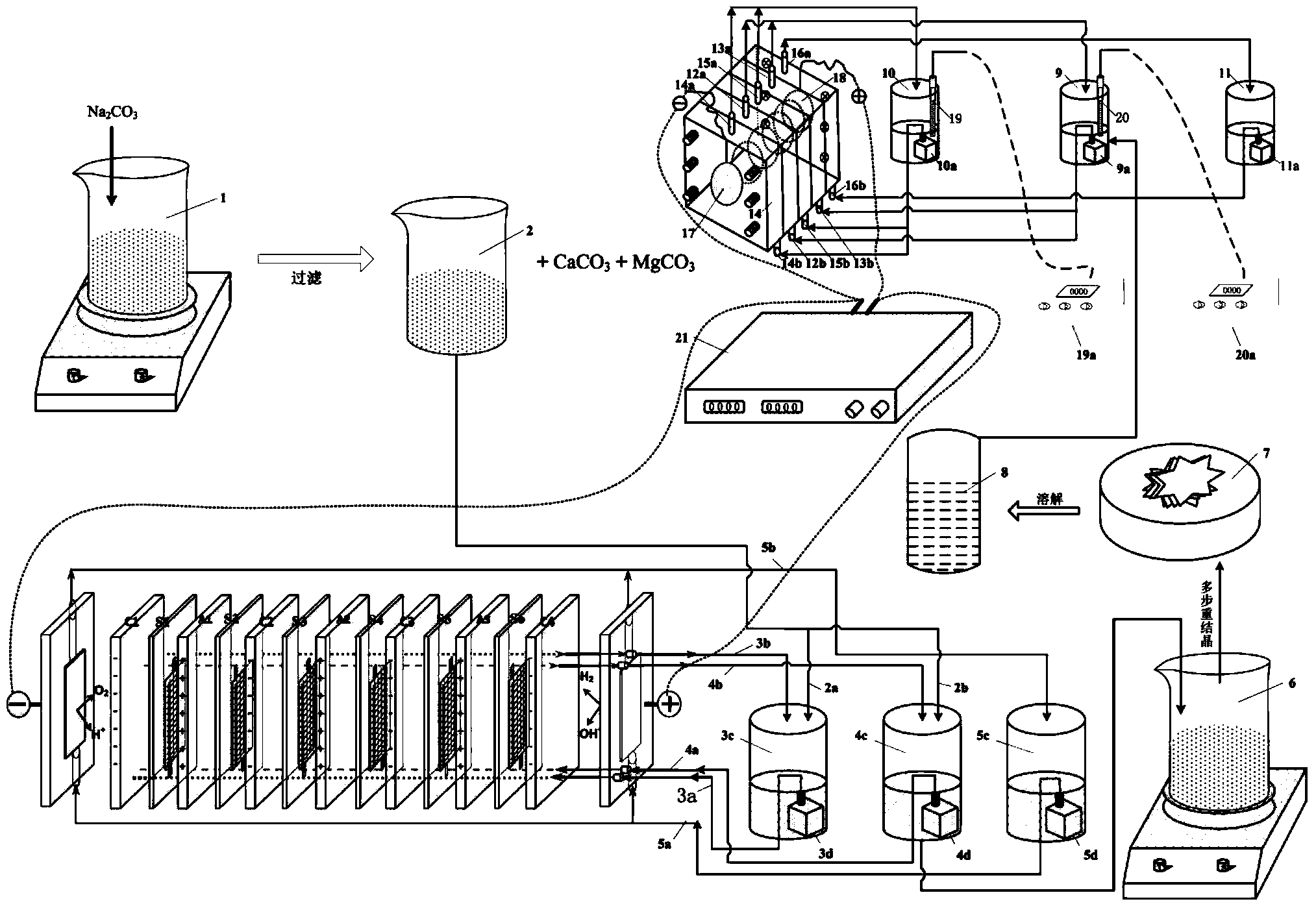

[0068] a. Add 2500ml of salt lake brine into the beaker (see Table 1 for specific ingredients), and place it on the first stirring device 1, add 5ml of saturated sodium carbonate solution into the salt lake brine and stir for 4 hours to remove magnesium ions and Calcium ions to obtain low-magnesium-lithium ratio brine, and import the low-magnesium-lithium ratio brine into the low-magnesium-lithium ratio brine storage tank 2;

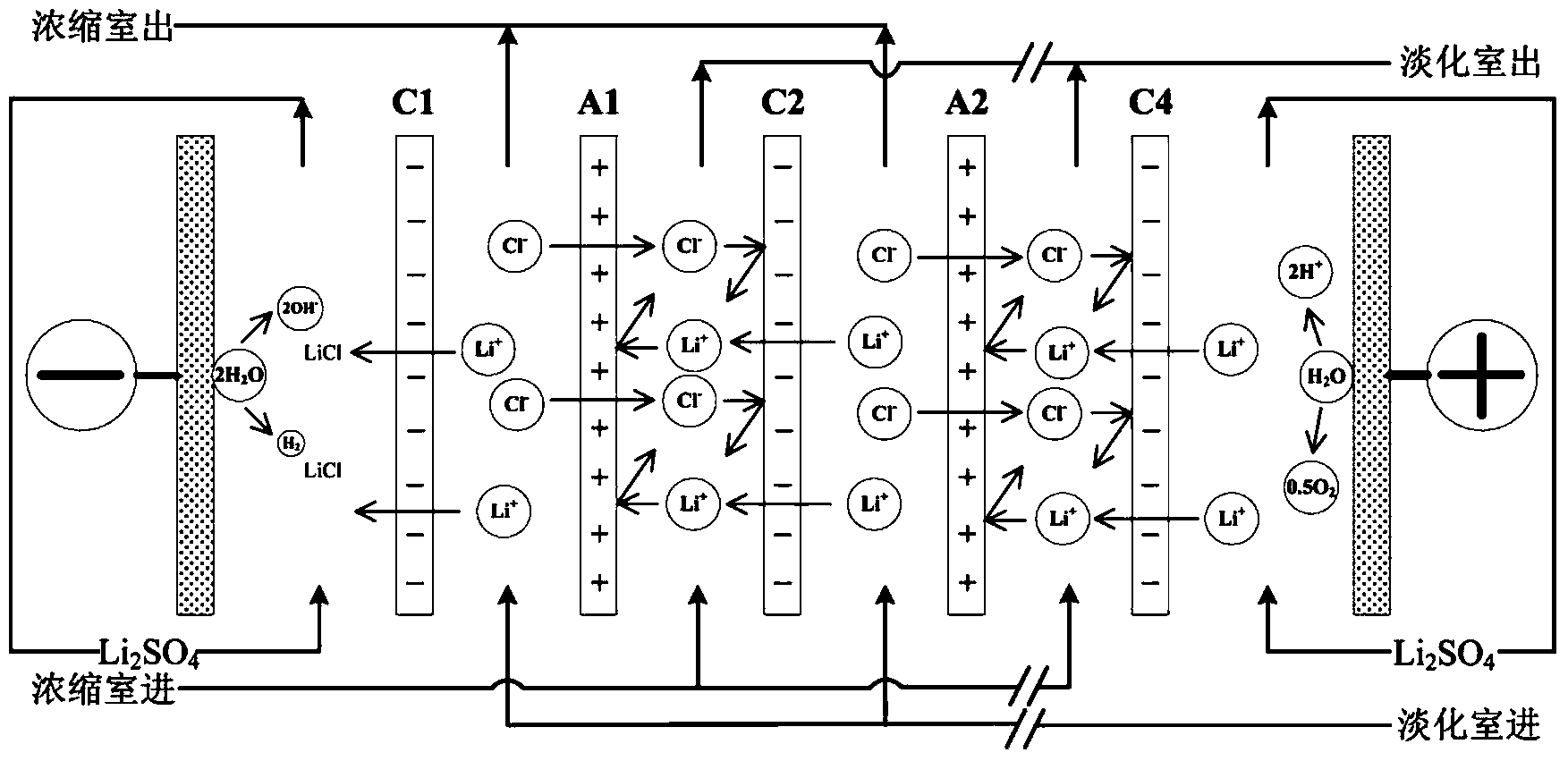

[0069] b. Concentrate the low-magnesium-lithium-ratio brine using an ordinary electrodialysis membrane stack to obtain lithium-ion concentrated brine;

[0070] The specific process is:

[0071] Firstly, the low-magnesium-lithium ratio brine is introduced into the desalinated liquid storage tank 3c and the concentrated liquid storage tank 4c by the low-magnesium-lithium ratio brine storage tank 2 respectively through the desalinated liquid storage tank conduit 2a and the concentrated liquid storage tank conduit 2b, respectively as the desalinated liquid (...

Embodiment 2

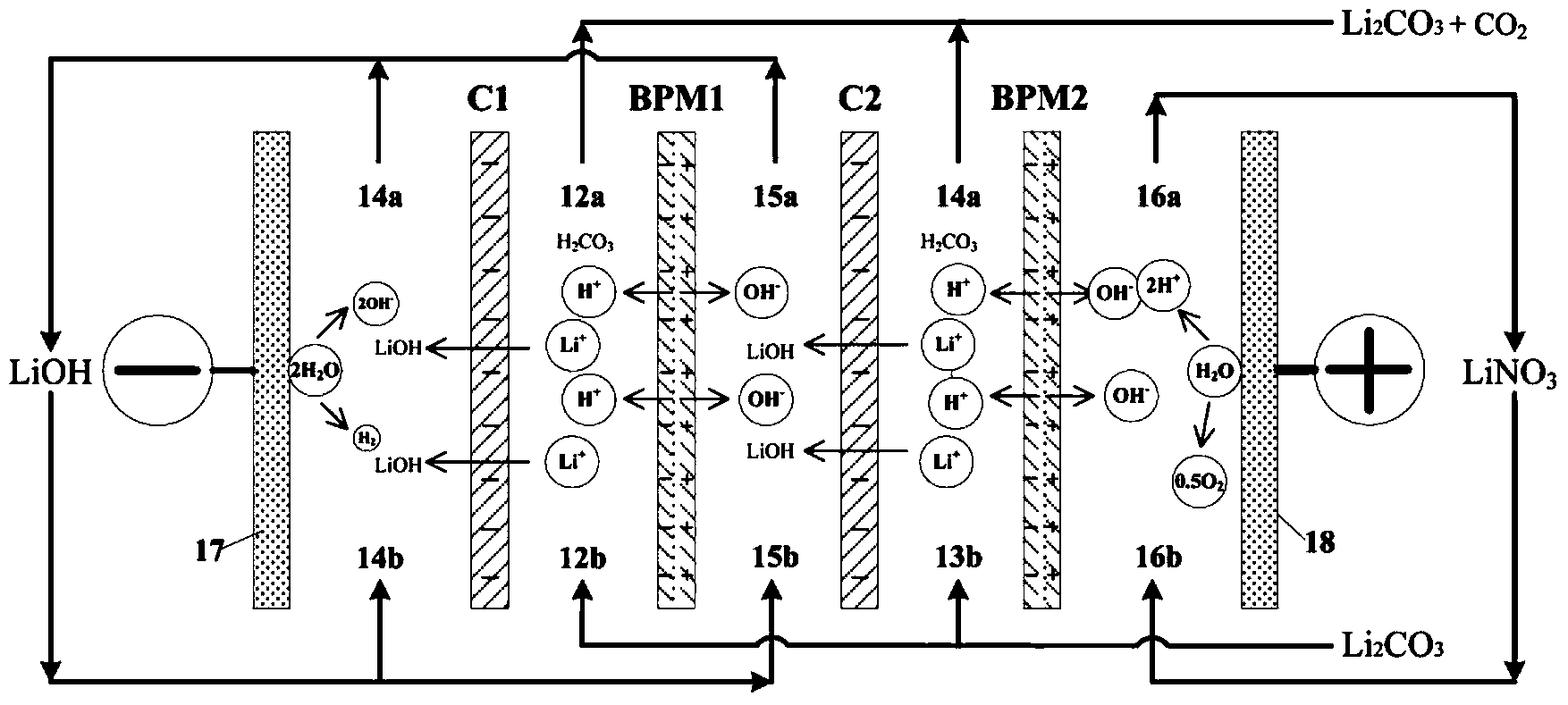

[0091] Adopt the same method of step a, b, c, d, e in embodiment 1 to prepare lithium carbonate solution, and utilize electrolysis-bipolar membrane electrodialysis system to carry out the electrolysis and dissociation of water to obtain hydrogen by the lithium carbonate solution obtained lithium oxide. The specific process is:

[0092] First, add 200ml of lithium hydroxide solution with a concentration of 0.1mol / L in the lye tank 10; mol / L lithium nitrate solution 200ml;

[0093] Then, control the lithium hydroxide solution between the lye tank and the first alkali chamber and between the lye tank and the second alkali chamber, carbonic acid by the alkali chamber drive pump 10a, the material chamber drive pump 9a and the anode chamber drive pump 11a respectively The lithium solution is circulated between the liquid tank and the first liquid chamber and between the liquid tank and the second liquid chamber, and the lithium nitrate solution is circulated between the electrolyte ...

Embodiment 3

[0099] Adopt the same method of step a, b, c, d, e in embodiment 1 to prepare lithium carbonate solution, and utilize electrolysis-bipolar membrane electrodialysis system to carry out the electrolysis and dissociation of water to obtain hydrogen by the lithium carbonate solution obtained lithium oxide. The specific process is:

[0100] First, add 200ml of lithium hydroxide solution with a concentration of 0.1mol / L in the lye tank 10; mol / L lithium nitrate solution 200ml;

[0101] Then, control the lithium hydroxide solution between the lye tank and the first alkali chamber and between the lye tank and the second alkali chamber, carbonic acid by the alkali chamber drive pump 10a, the material chamber drive pump 9a and the anode chamber drive pump 11a respectively The lithium solution is circulated between the liquid tank and the first liquid chamber and between the liquid tank and the second liquid chamber, and the lithium nitrate solution is circulated between the electrolyt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com