Method and system for decrement of concentrated solution in nuclear industry

A concentrate and nuclear industry technology, applied in the field of nuclear industry concentrate reduction, can solve the problems of affecting the treatment efficiency, reducing the decontamination factor, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

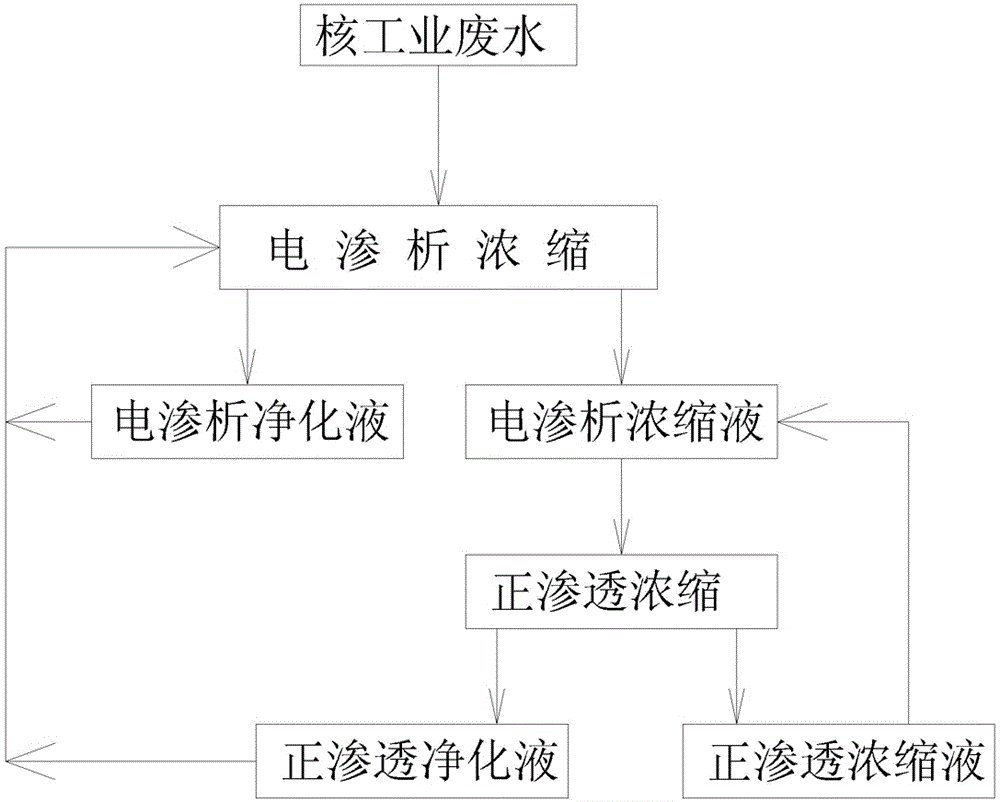

[0026] like figure 1 Shown, a kind of method that is used for nuclear industry concentrate reduction, concrete steps are as follows:

[0027] 1) Concentration by electrodialysis: the pH value is 6-9, the salt content is 15-20g / L, and the radioactive level is 3.7×10 4 Bq / L nuclear industry radioactive wastewater is treated by electrodialysis to obtain electrodialysis concentrate and electrodialysis purification solution; among them, the main ions of nuclear industry radioactive wastewater include sodium, chloride, magnesium, calcium, sulfate, strontium, cesium, cobalt, silver etc.

[0028] 2) Forward osmosis concentration: The electrodialysis concentrated solution is separated and treated by forward osmosis technology; after forward osmosis, the forward osmosis purification solution and the forward osmosis concentration solution are returned to step 1) the electrodialysis process, the forward osmosis purification solution is combined with the The electrodialysis purification...

Embodiment 2

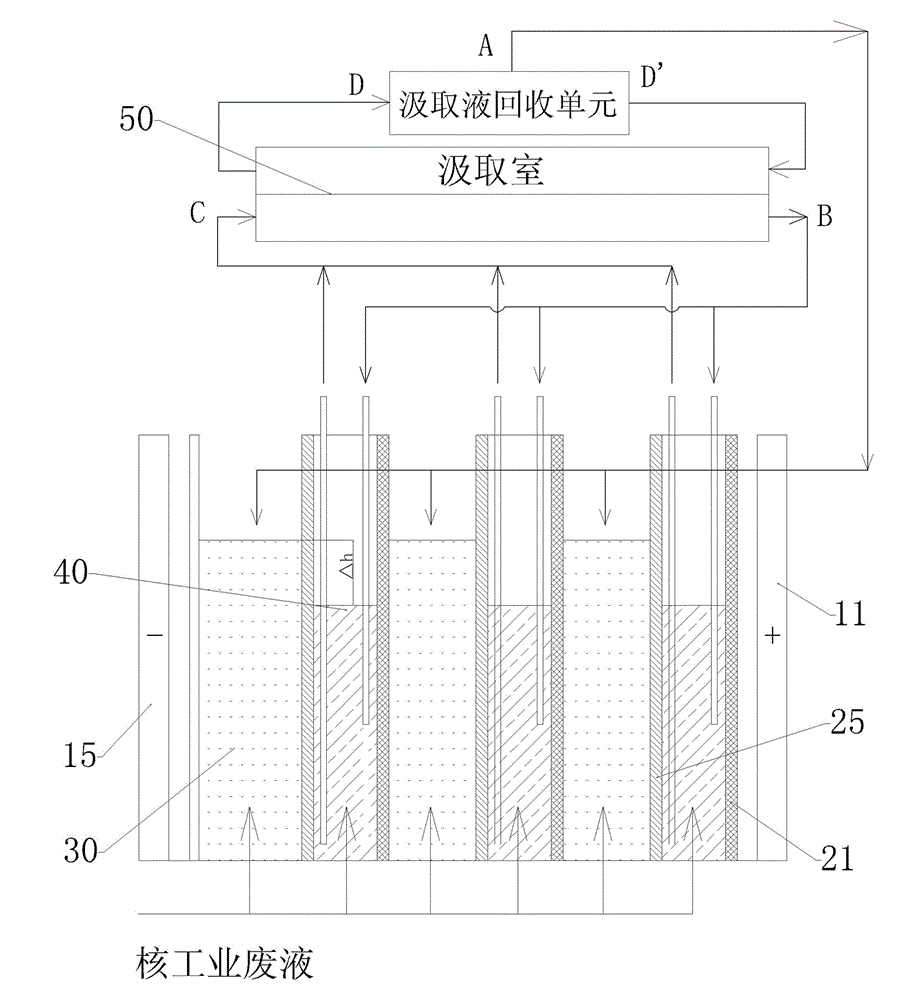

[0039] like figure 2Shown, a kind of system that is used for nuclear industry concentrate reduction, it comprises electrodialysis unit and forward osmosis unit, electrodialysis unit comprises waste water treatment chamber, and waste water treatment chamber two ends are respectively provided with cathode 15 and anode 11, from cathode to Anion exchange membranes 25 and cation exchange membranes 21 are alternately arranged between the anodes, and the alternately arranged anion exchange membranes 25 and cation exchange membranes 21 divide the wastewater treatment chamber into several small chambers; nuclear industry waste liquid enters each small chamber through pipelines Finally, under the action of a direct current electric field, the ions migrate in a directional manner, and the positive and negative ions are intercepted by the anion exchange membrane 25 and the cation exchange membrane 21 respectively, so that the several small chambers are differentiated to form an electrodia...

Embodiment 3

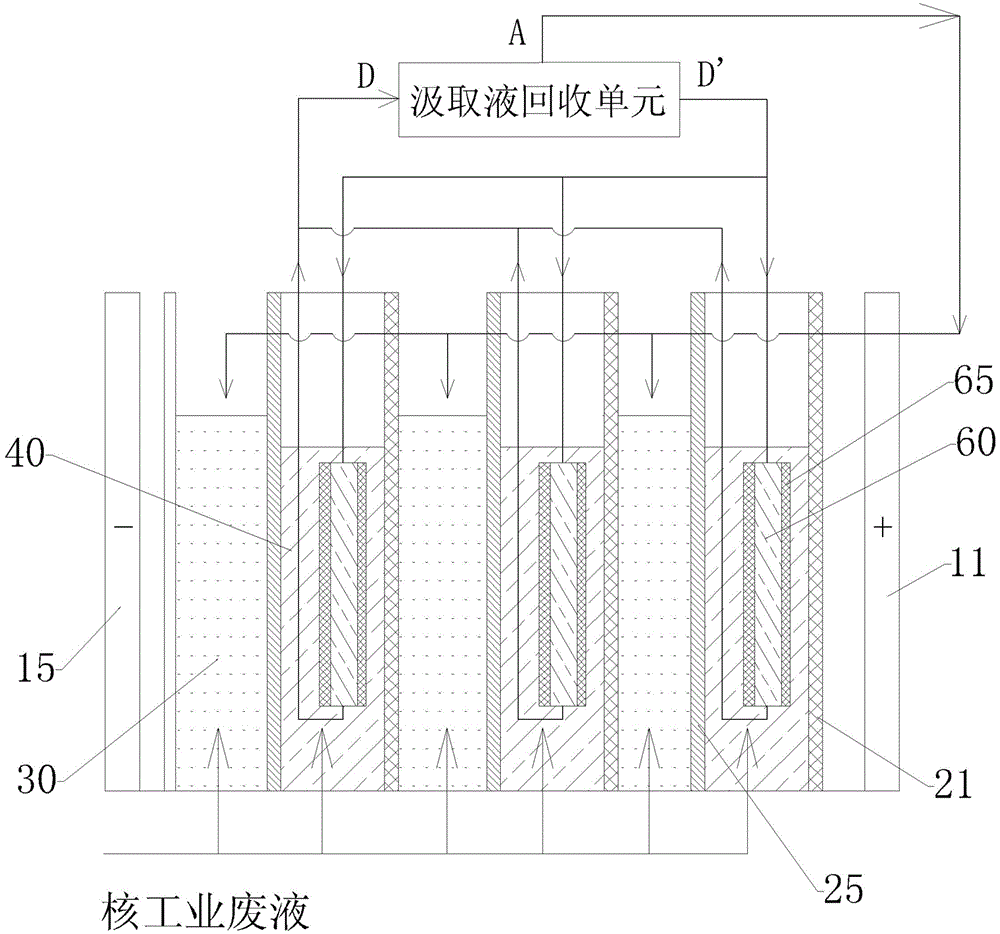

[0045] like image 3 As shown, this embodiment is basically the same as Embodiment 2, the difference is that the forward osmosis device includes a forward osmosis membrane, a drawing unit 60 and a draw solution recovery unit, and the water outlet A arranged on the draw solution recovery unit passes through the pipeline and the fresh water chamber 30 connection; the drawing unit 60 is set in the concentrated water chamber 40, and the forward osmosis membrane 65 of the drawing unit 60 is directly in contact with the electrodialysis concentrate in the concentrated water chamber. The drawing unit 60 can be cylindrical, spherical, rectangular and other shapes surrounded by the forward osmosis membrane 65. The upper and lower sides of the drawing unit are respectively provided with inlets and outlets for the forward osmosis drawing liquid. The water chamber draws fresh water, and the fresh water is separated out in the drawing solution recovery unit and returns to the fresh water ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com