Forward osmosis absorption liquid using and recycling method and forward osmosis absorption device

A recovery method and a technology for extracting liquid, which are applied in chemical instruments and methods, permeation/dialysis water/sewage treatment, semi-permeable membrane separation, etc., can solve the problems of high energy consumption, low extraction capacity, waste of resources, etc. in distillation, and achieve saving The effect of investment and operating costs, increasing the concentration factor, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

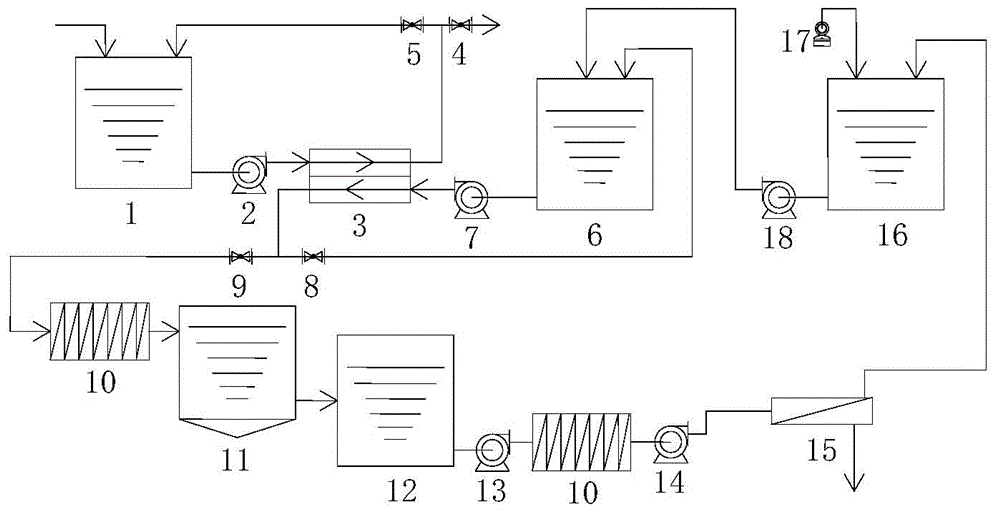

[0027] Embodiment 1: use sodium sulfate solution alone as drawing liquid

[0028] Such as figure 1 As shown, at first, the concentration of 60000ppm sodium chloride raw material solution flows into the raw material tank 1, and is transported to the forward osmosis device 3 by the raw material pump 2, and the raw material solution is concentrated to 110000 ppm through the concentration of the forward osmosis device 3, and the qualified raw material solution The material is discharged through the qualified valve 4, and the unqualified valve 5 is opened when it is unqualified, and the raw material liquid is returned to the raw material box 1. Sodium sulfate is added into the salt-dissolving tank 16 through the sodium sulfate adding device 17 and purified water in a certain proportion, and the melting ratio becomes a drawing solution with a concentration of 35% and a temperature of 40°C, and is transported to the drawing tank 6 by a feeding pump 18 , and then the drawing liquid i...

Embodiment 2

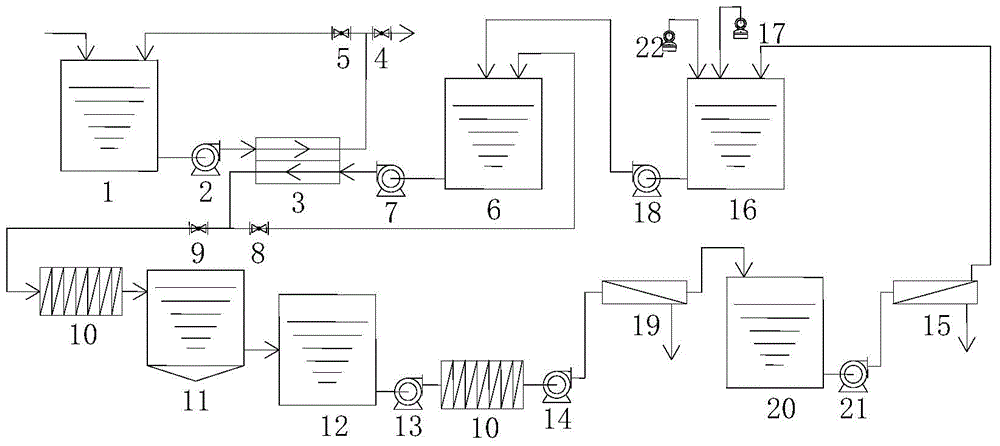

[0029] Embodiment 2: use sodium sulfate+sodium chloride solution as drawing liquid

[0030] Such as figure 2 As shown, at first, the concentration of 80000ppm sodium chloride raw material solution flows into the raw material tank 1, and is transported to the forward osmosis device 3 by the raw material pump 2, and the raw material solution is concentrated to 140000 ppm through the concentration of the forward osmosis device 3, and the qualified raw material solution The material is discharged through the qualified valve 4, and the unqualified valve 5 is opened when it is unqualified, and the raw material liquid is returned to the raw material box 1. Sodium sulfate and sodium chloride are passed through sodium sulfate adding device 17 and salt adding device 22 respectively, and are added in a certain proportion in the salt-dissolving tank 16 filled with pure water at 40°C, and the melting ratio becomes a concentration of 32% sodium sulfate and 6% sodium sulfate. The mixed dra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com