Patents

Literature

117results about How to "Save investment costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

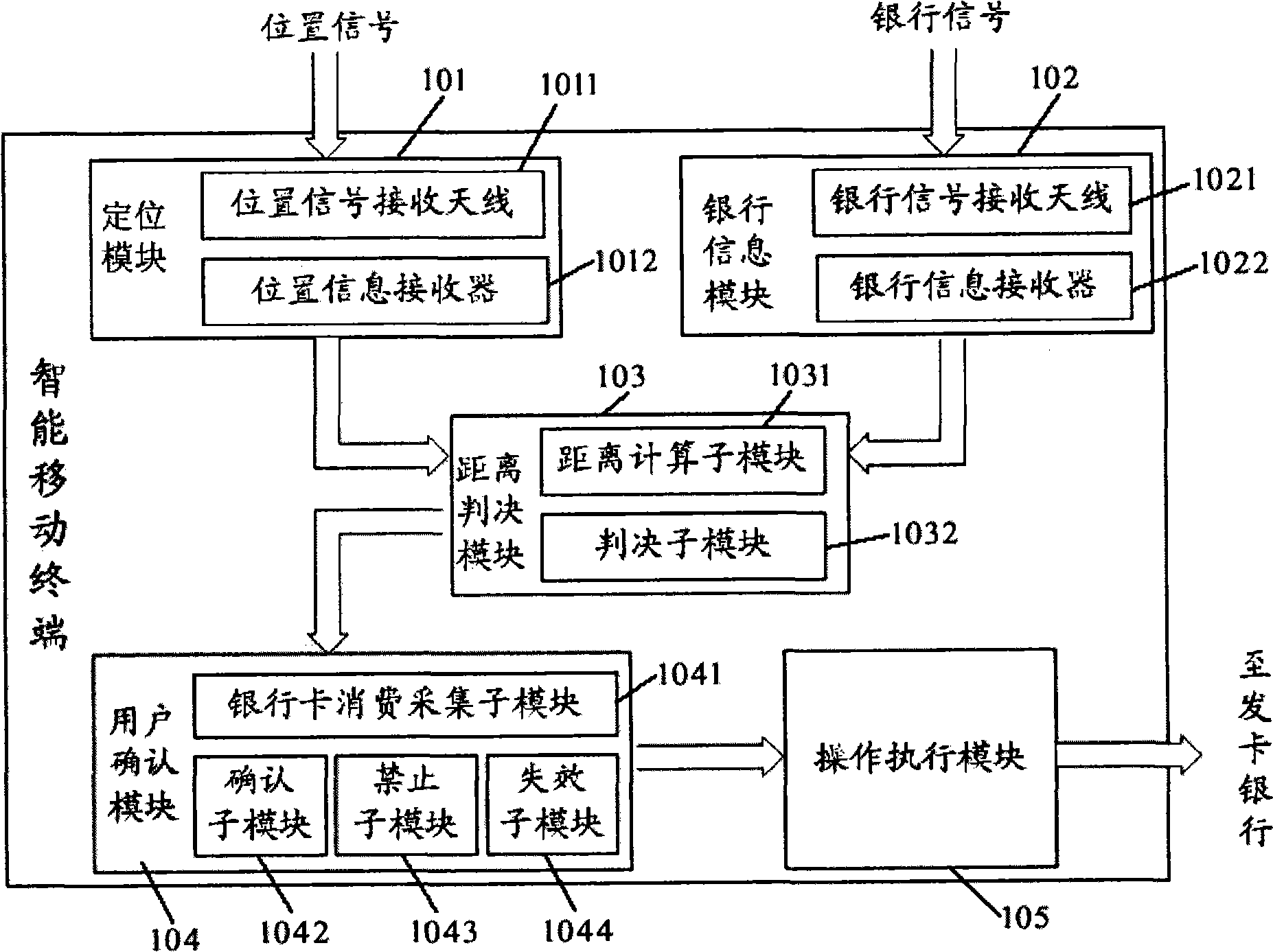

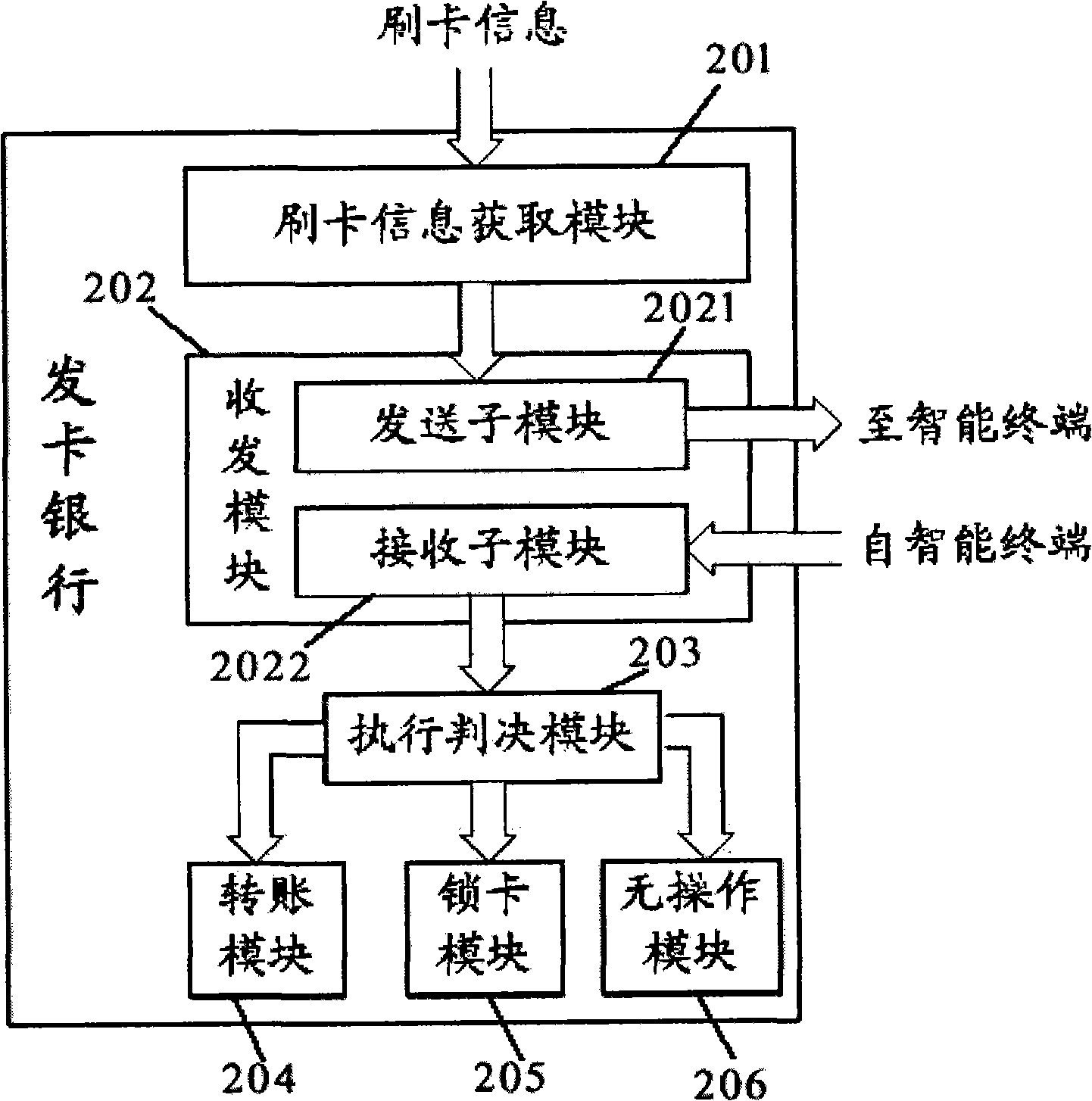

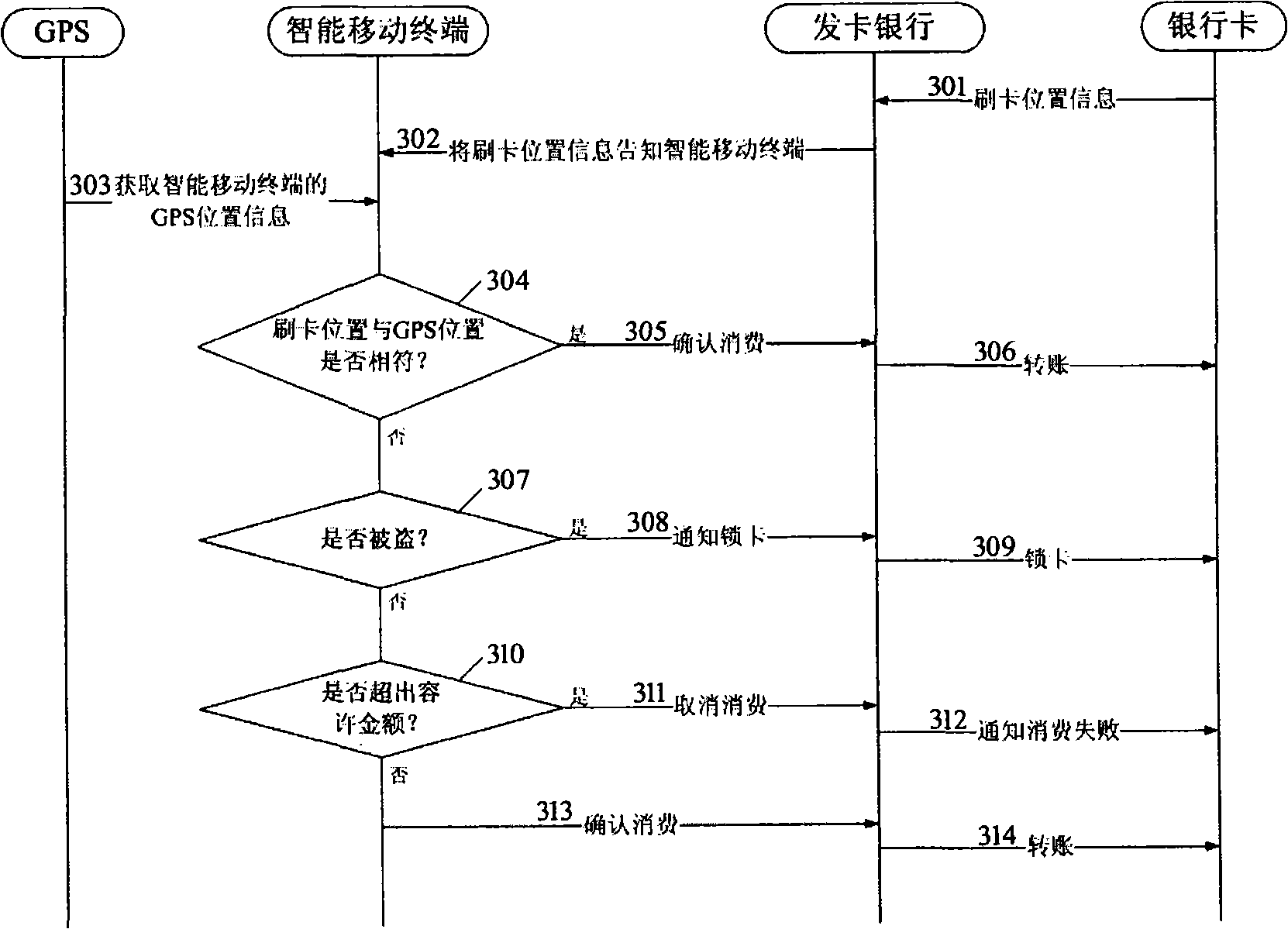

Method and equipment for preventing finance card from brushing deceptively

InactiveCN101303781APrevent theftWide coverageBeacon systems using radio wavesPosition fixationIssuing bankPunching

The invention discloses a method and a device for preventing the unauthorized use of a fiscal card; after a user stamps a card on the card punching terminal of a financial system, the value of the distance between an intelligent mobile terminal device of the fiscal card owner and the current card punching terminal is obtained. The value of the distance can be determined through the positioning information about the intelligent mobile terminal device and information about the position of the current card punching terminal provided by a bank. The obtained distance value is then compared with a predefined distance value; if the value of the distance between the intelligent mobile terminal device and the current card punching terminal is smaller than the predefined distance value, then the financial system automatically performs a remit account, and the consumption transaction is succeeded; if the value of the distance between the intelligent mobile terminal device and the current card punching terminal is larger than the predefined distance value, then the issuing bank takes further measures after taking the advice from the fiscal card owner. The scheme of the invention further enhances the safety of using the fiscal card.

Owner:BEIJING UNIV OF POSTS & TELECOMM

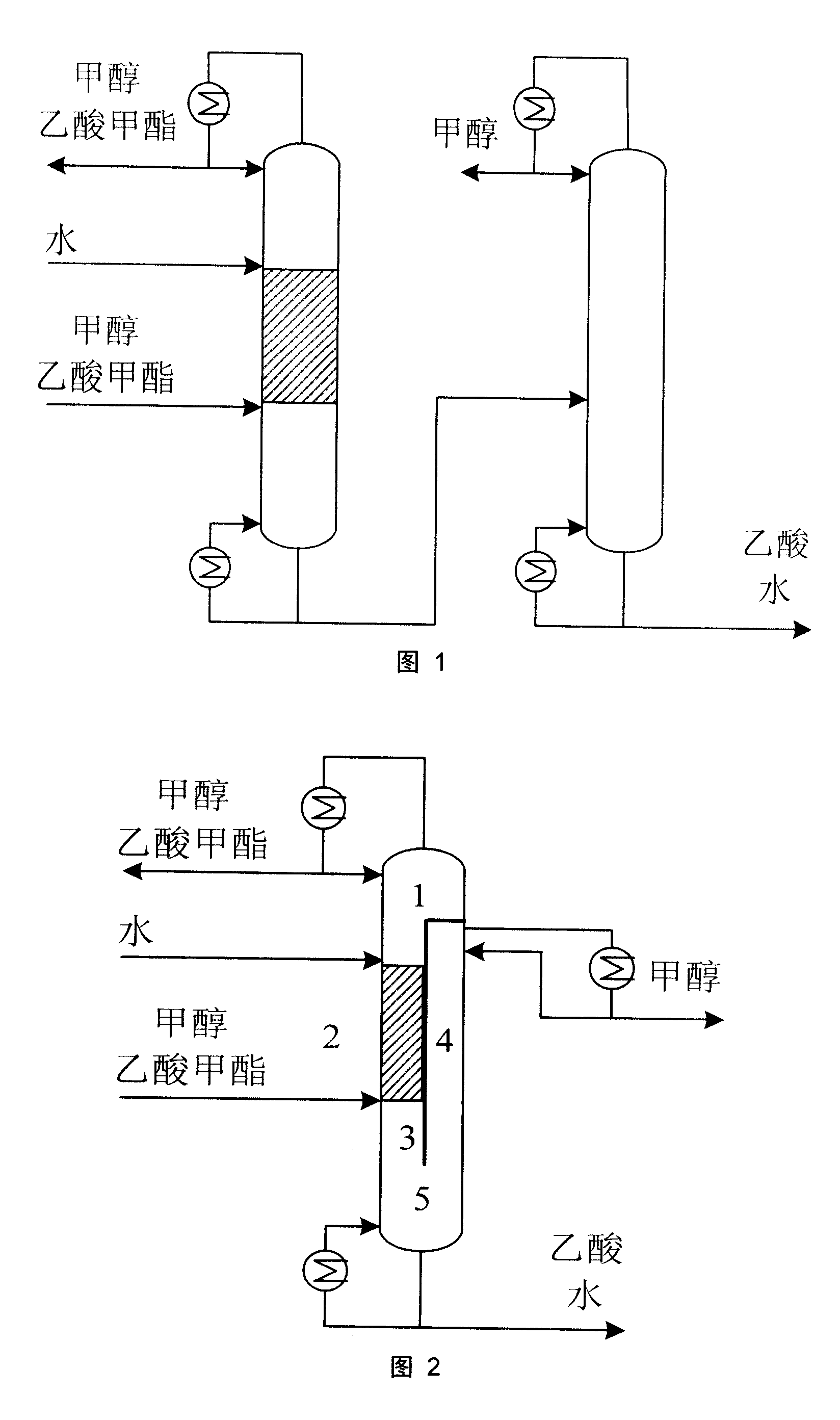

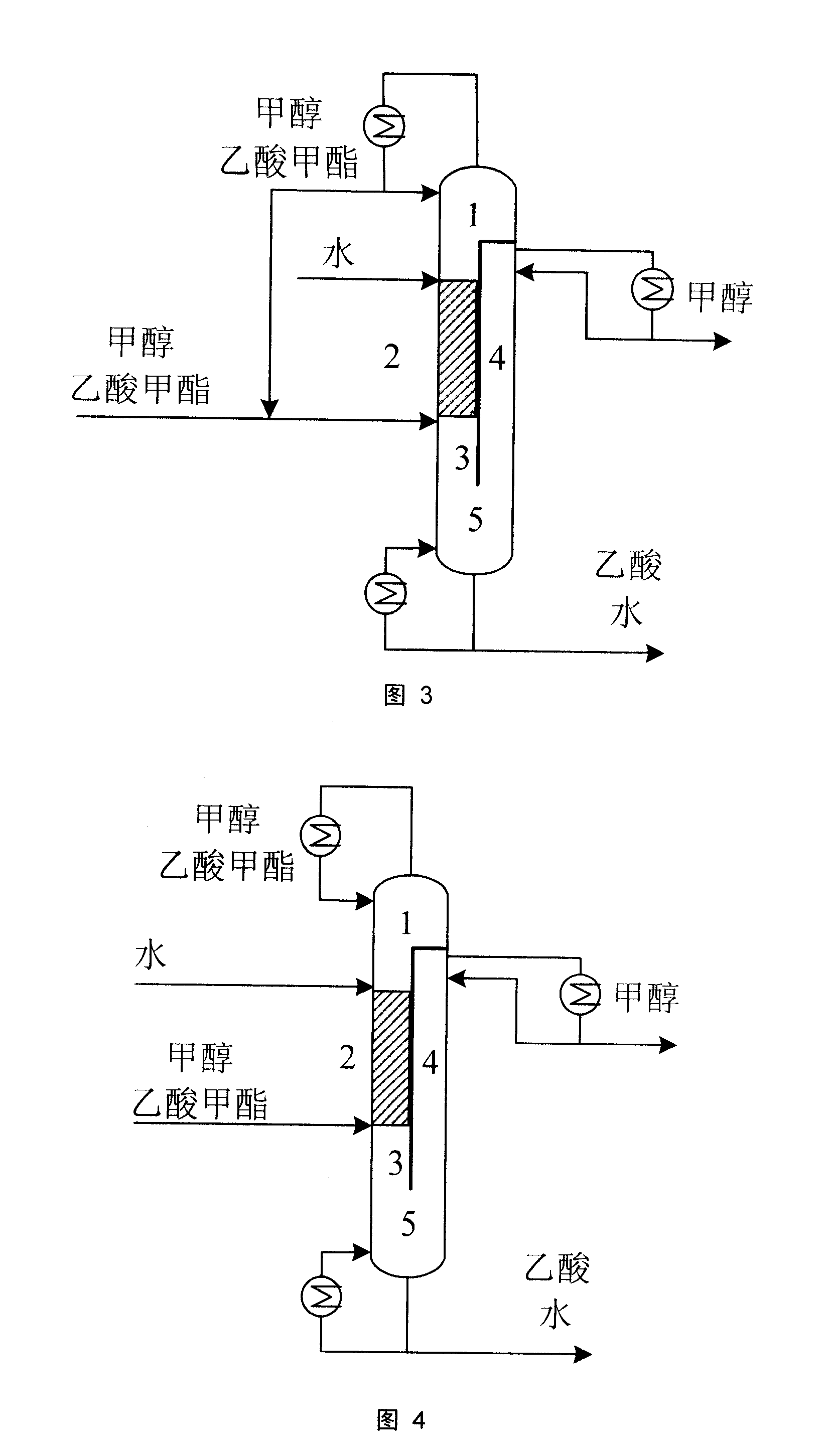

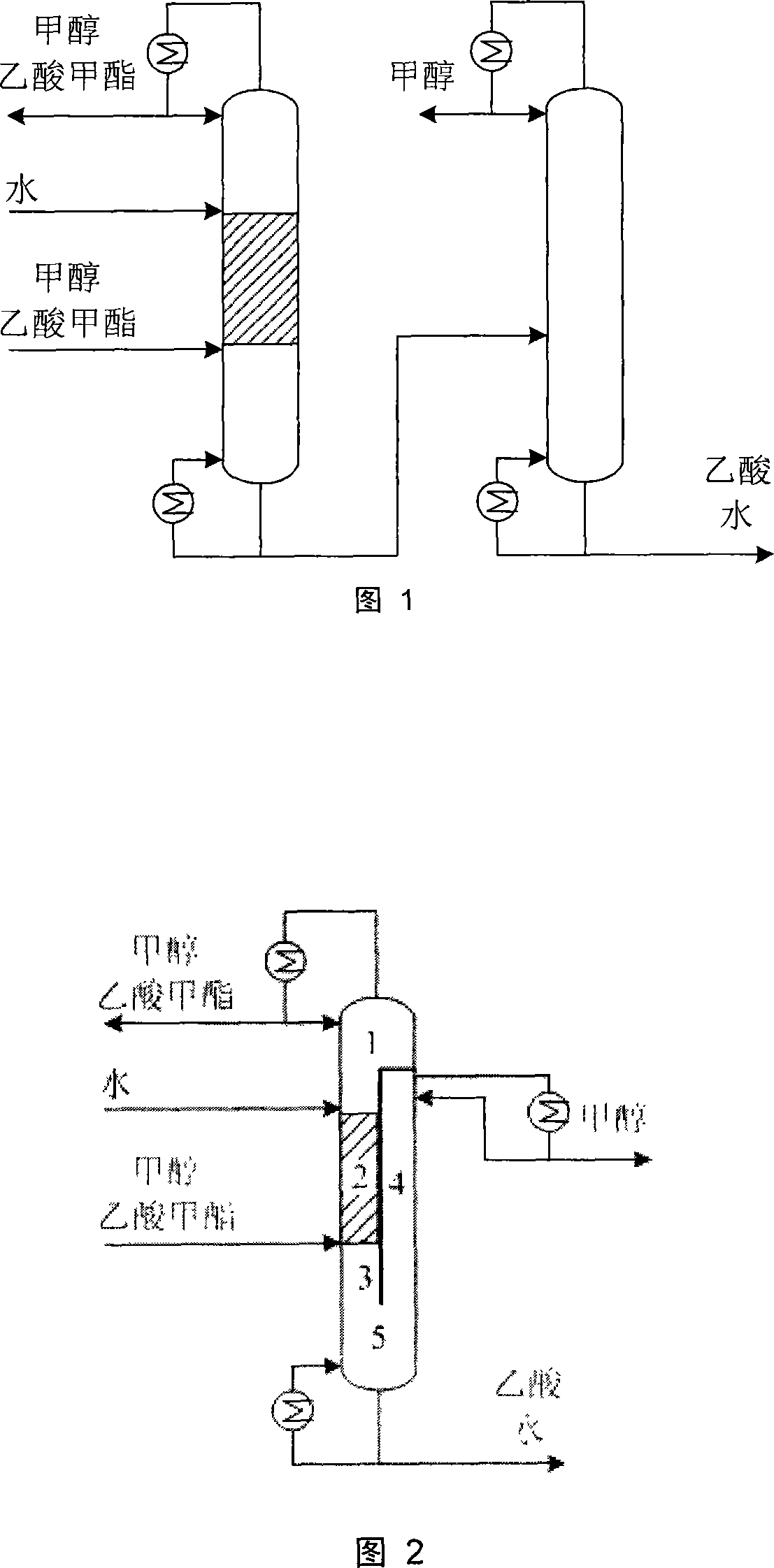

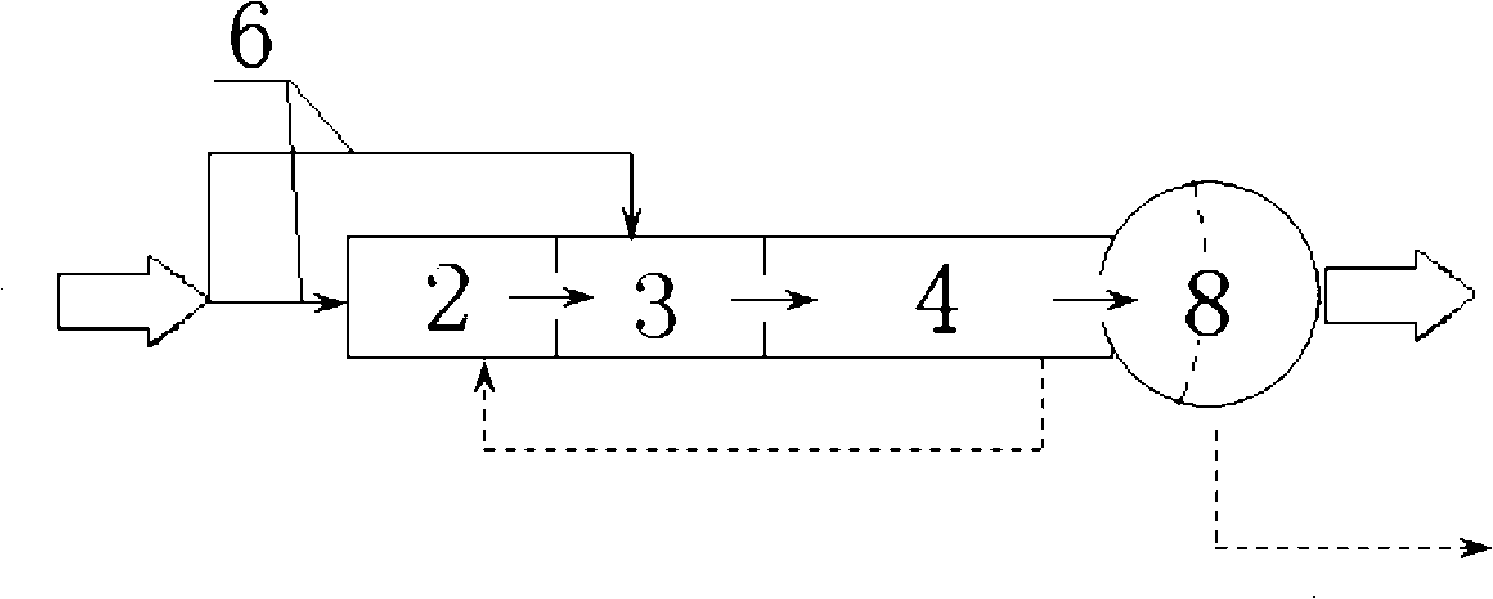

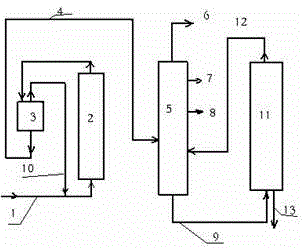

Hydrolyzation separation apparatus for methyl acetate and technique

InactiveCN101244982AIncrease hydrolysis rateAvoid remixingOxygen-containing compound preparationOrganic compound preparationSide effectDistillation

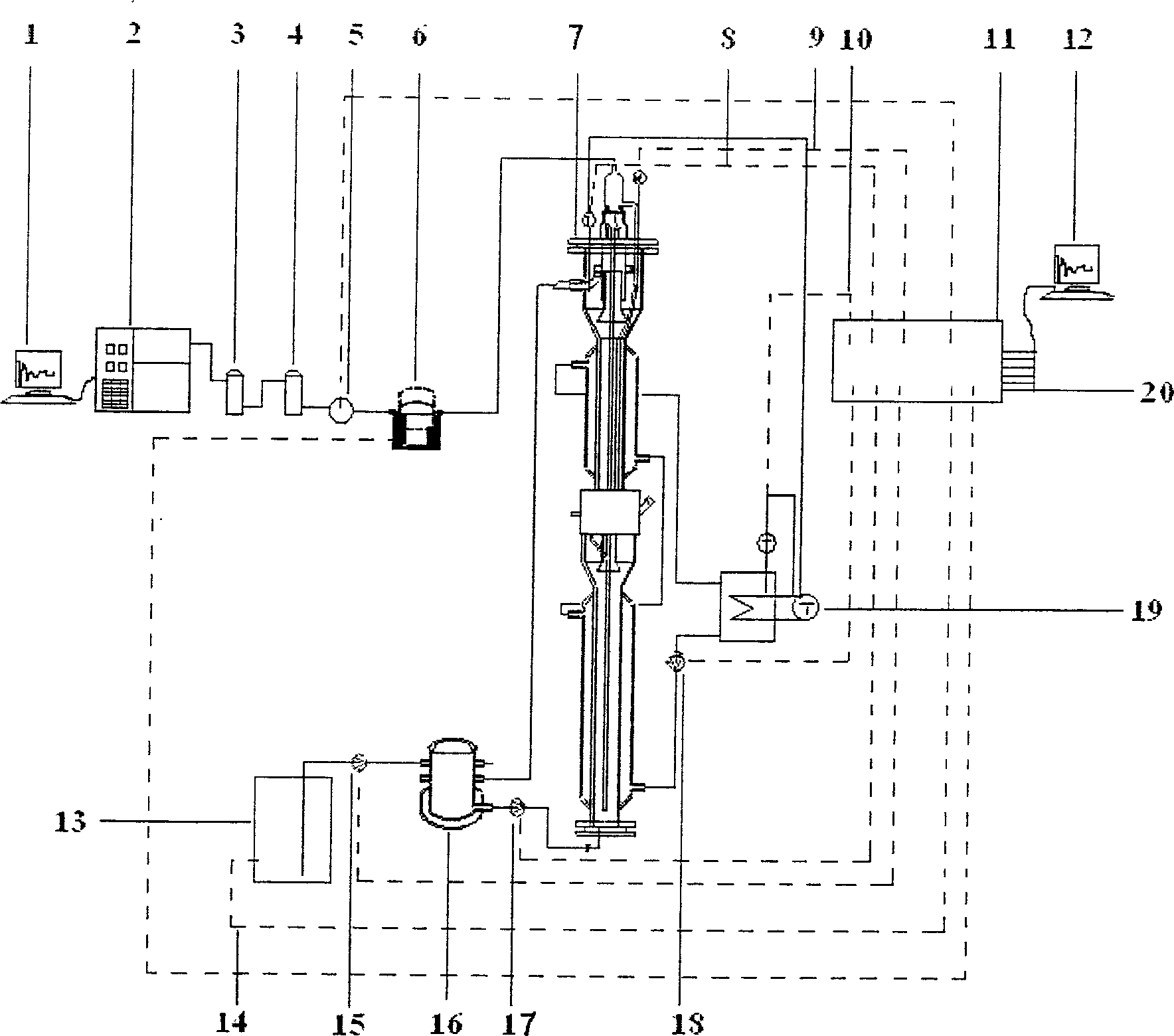

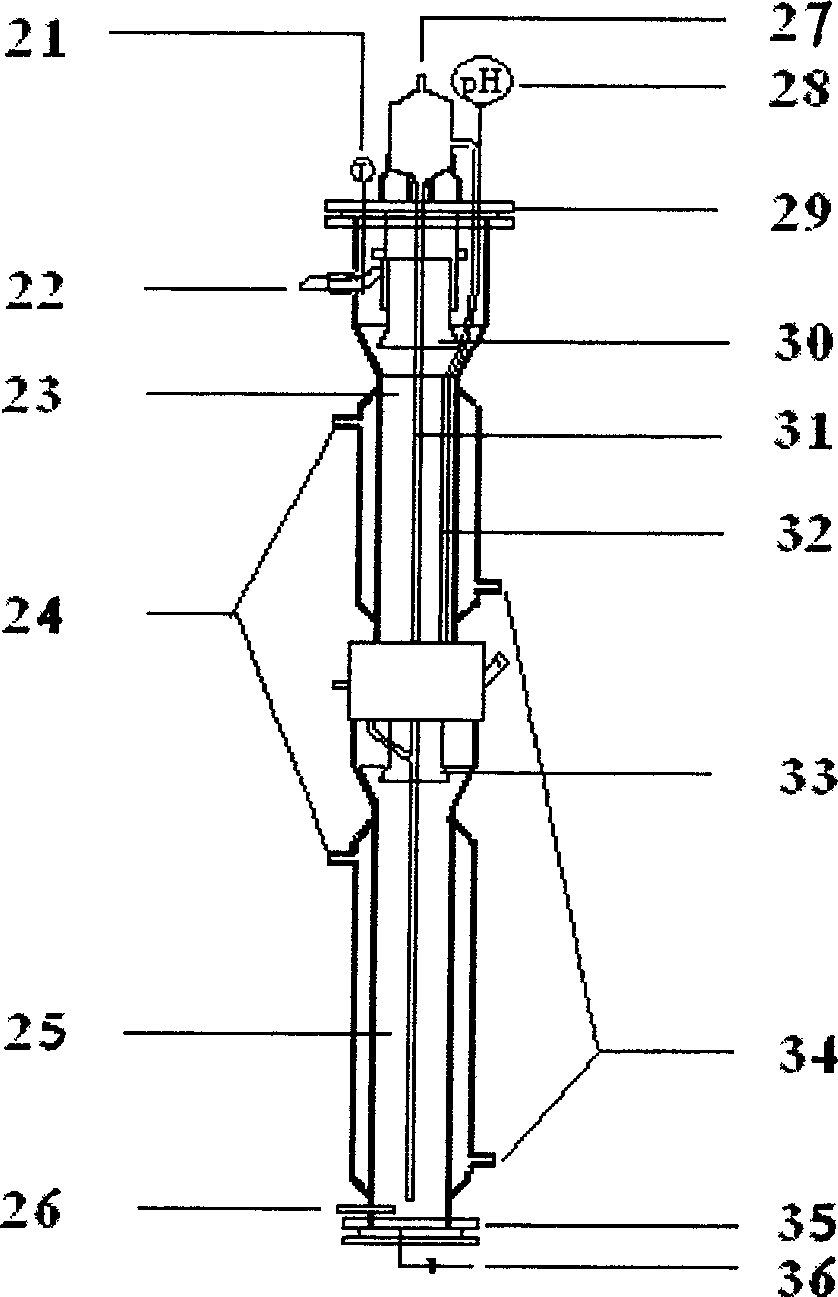

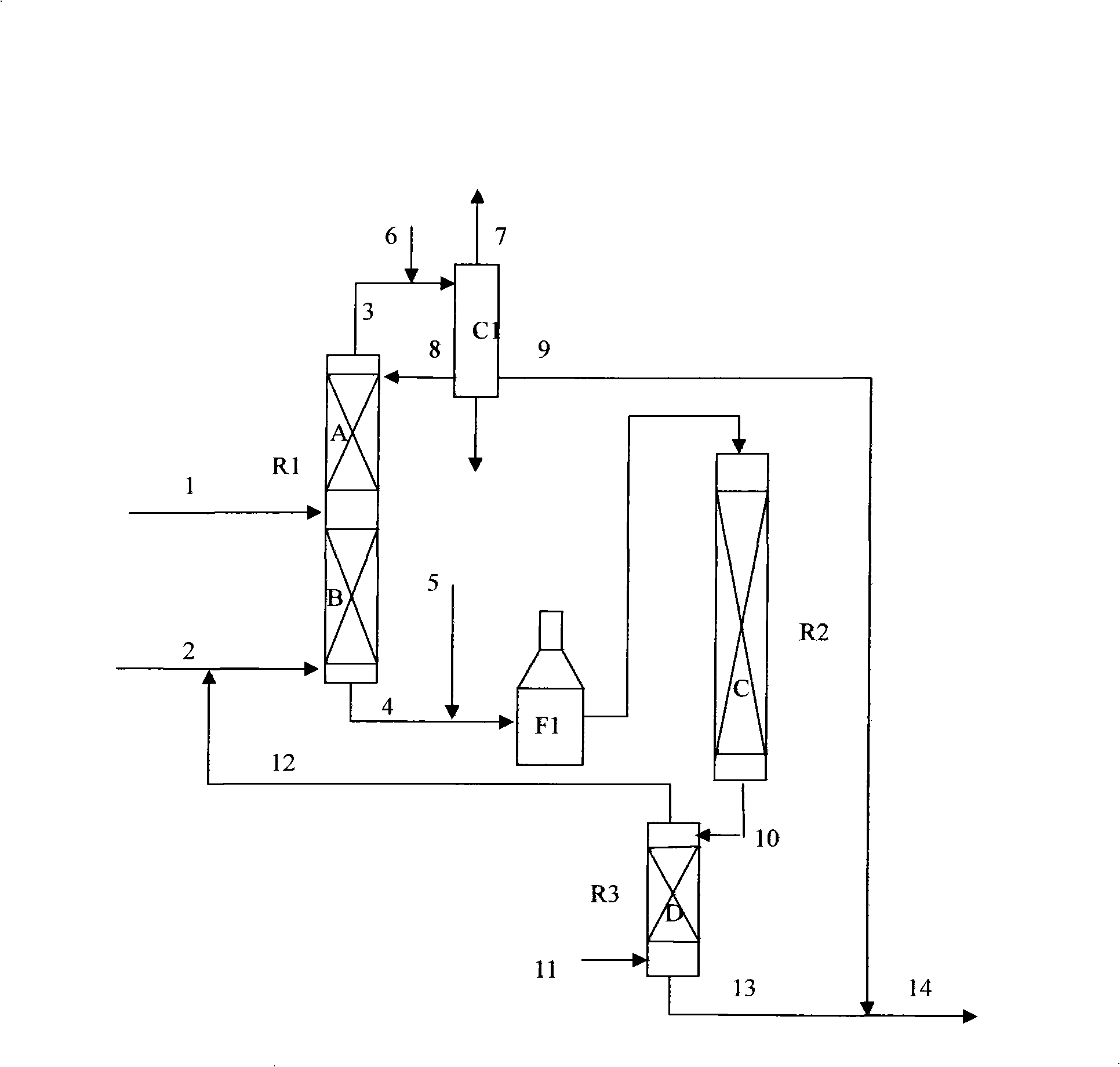

The invention provides a hydrolyzing and separation device of methyl acetate and a technique method thereof, which more particularly relates to a novel technique to catalyze and hydrolyze methyl acetate by a reaction bulkhead distillation tower, which can organically combine reaction process, product separation and recovery of no reactant into the tower. A separator extending from the upper part of the tower to the lower part of the tower is arranged on the vertical direction in the conventional distillation tower, the upper part of one side of which is covered and the other side of which is filled with a catalyst; therefore, the inner space of the reaction bulkhead distillation tower is divided into five regions with different functions. The hydrolyzing and separation device of methyl acetate can fully unleash the advantage of bulkhead tower and reaction distillation, and can cause hydrolysis reaction, product separation and recovery of non reactant to be realized in the same tower. The device provided by the invention and the technique process thereof can obtain the methyl acetate with 60 percent to 99.99 percent hydrolysis rate and products with high purity, restrain side effect effectively, reduce the volume of equipment markedly, simplify process, and reduce energy consumption and operation cost.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

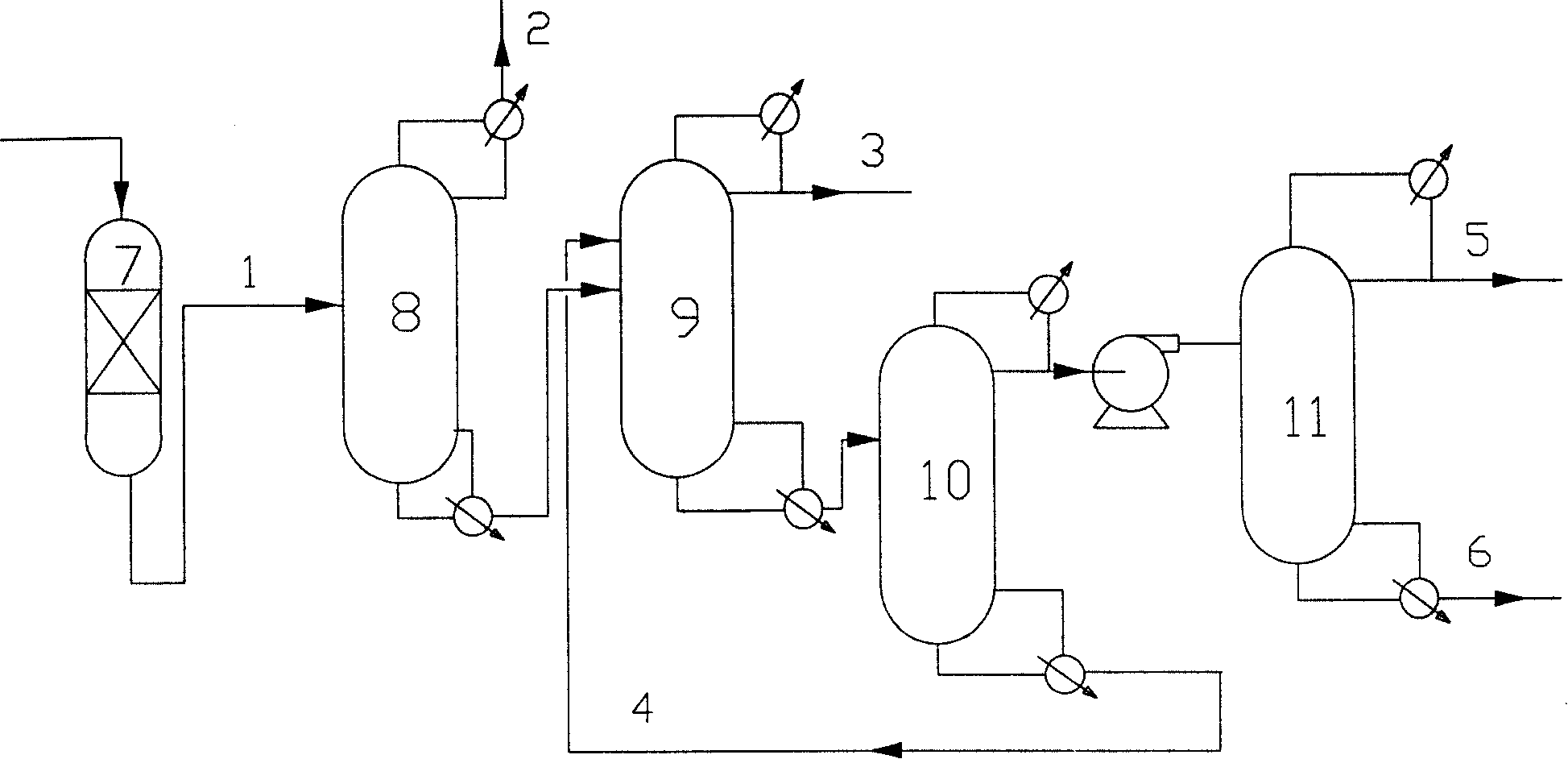

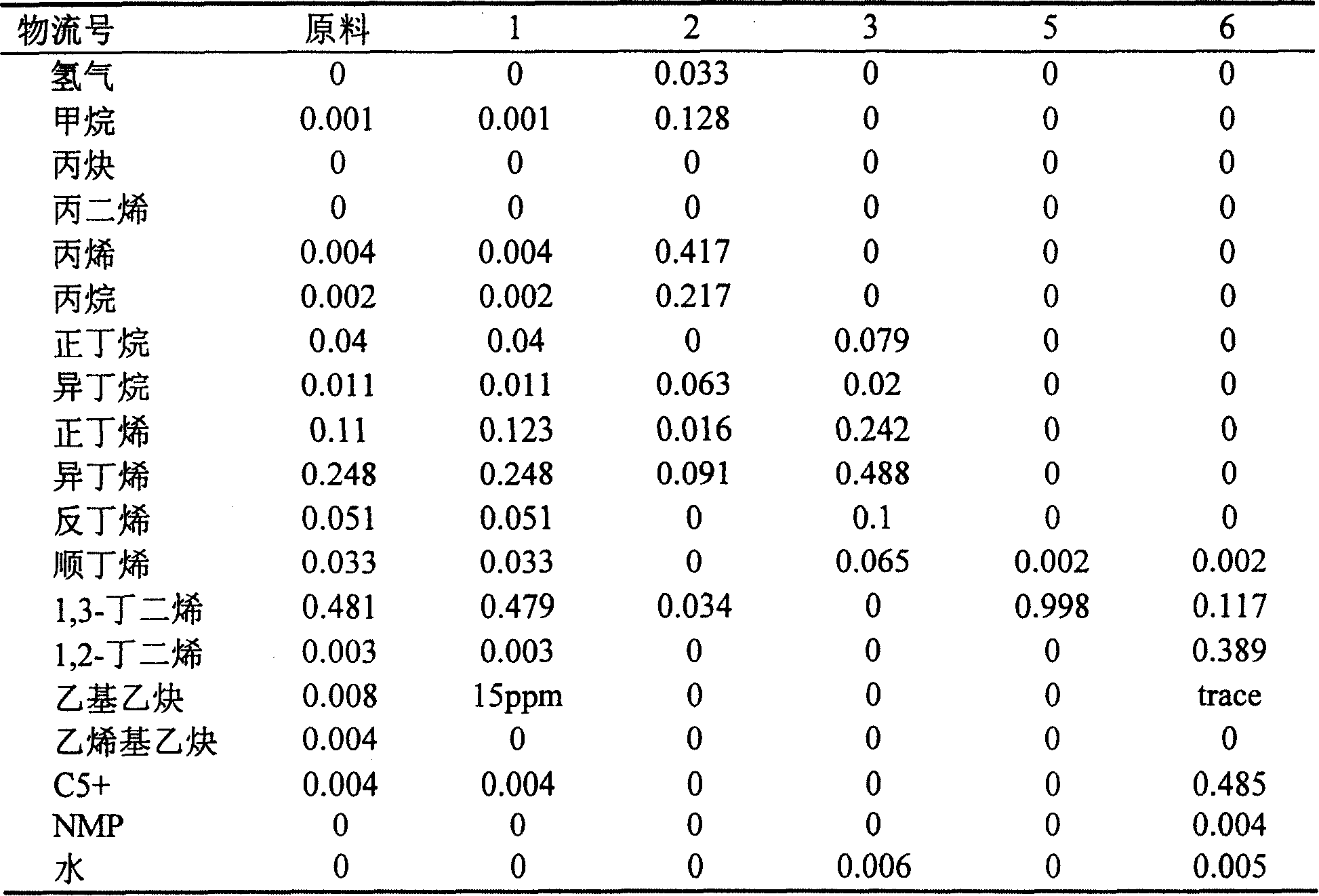

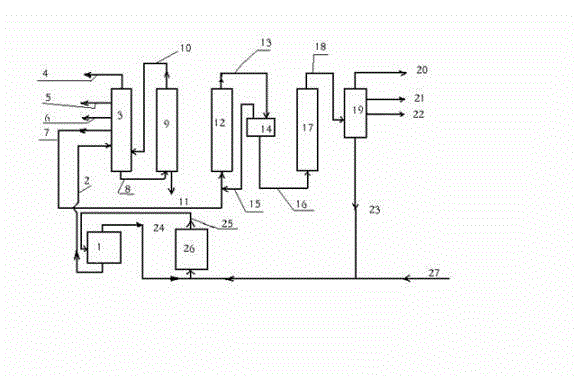

Extraction method for a segment of butadiene with NMP method

ActiveCN101172929ASimple processLess investmentDistillation purification/separationHydrocarbonsEngineeringTower

The invention discloses a NMP butadiene sectional extraction method with a forward hydrogenation technology. The invention solves the problems existed in the prior NMP butadiene sectional extraction method that the tower top of a leaching and rectifying tower has large load, needs a circulated pressure compressor and has high requirement on the grade of refrigerant. The invention provides a butadiene section extraction method of leading a slight tower and canceling the circulated pressure compressor in the sectional extraction technology, and the invention comprises the steps of hydrogenation,releasing the slight components, leaching and rectifying, adsorption stripping, refining and so on. The invention is characterized in that the forward hydrogenation technology is adopted so that theacetylene hydrocarbon is released before leaching and rectifying, thereby increasing the operational safety, and the slight components are released in advance before leaching and refining so that thematerial positioned on the tower top of the adsorption stripping tower can be condensed to liquid phase, thereby being able to be transported to a refining tower through a pump; the invention cancelsthe compressor, thereby saving the device investment, decreasing the energy consumption, simplifying the operation, and being high in safety. Besides, with strong adaptive capacity on raw material, the operation of the device is not influenced by the regeneration period of catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

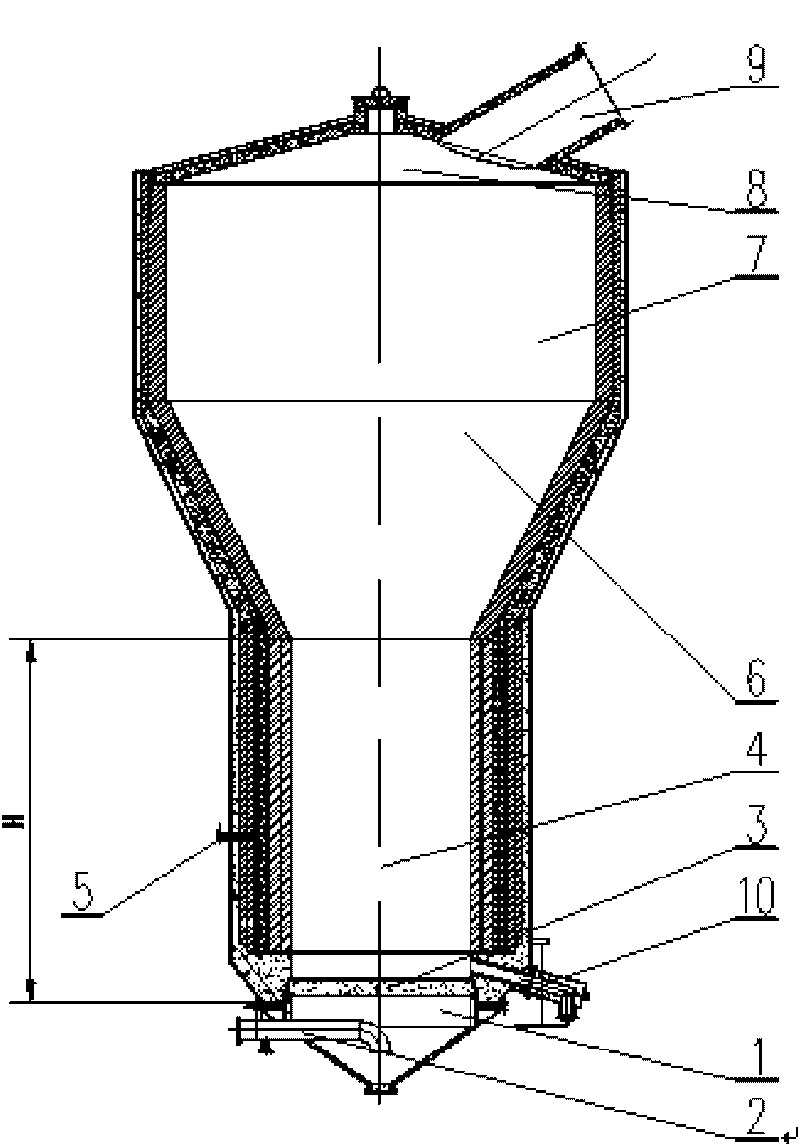

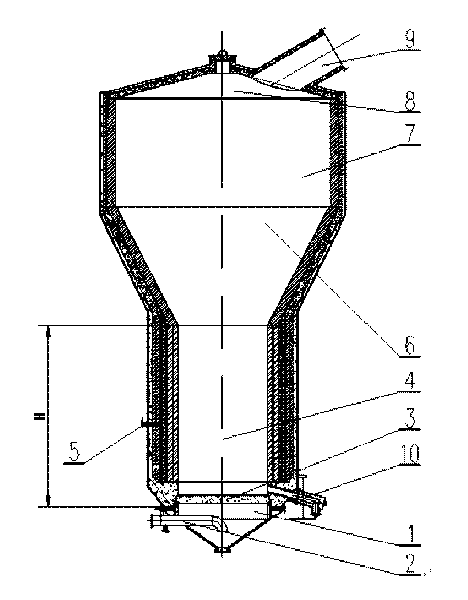

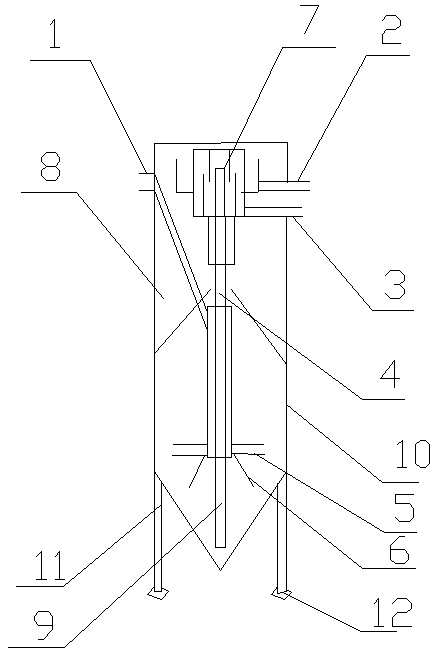

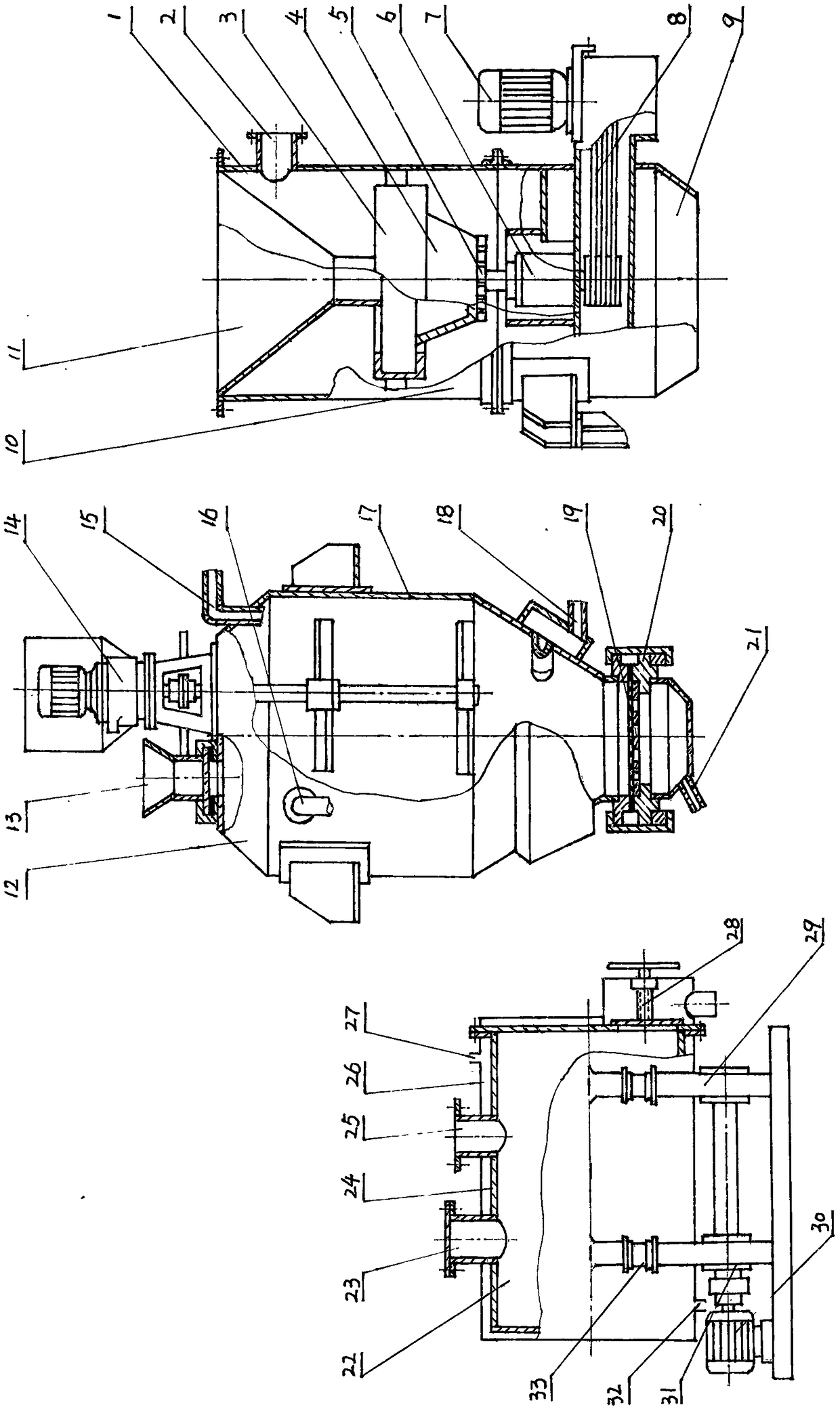

Boiling chlorination furnace for preparing titanium tetrachloride by using natural rutile

The invention discloses a boiling chlorination furnace for preparing titanium tetrachloride by using natural rutile. The boiling chlorination furnace comprises a boiling section (4). The boiling section (4) is connected with an expanded section (7) through a transitional section (6). A slag discharge port (10) and a hearth sealing cover (1) are arranged at the lower end of the boiling section (4). A chlorine inletting pipe (2) is inserted into the hearth sealing cover (1). A chorine distribution plate (3) is arranged between the hearth sealing cover (1) and the slag discharge port (10). A feeding pipe (5) is arranged on one side of the boiling section (4). A furnace top cover (8) is arranged at the upper end of the expanded section (7). A gas outlet (9) is arranged on the furnace top cover (8). The invention has the advantages that the normal operation of the boiling chlorination furnace is guaranteed, and the investment and the maintenance expense of the boiling chlorination furnace are saved. Moreover, since the chlorine distribution plate is placed at the bottom of the boiling section, the elasticity of the boiling chlorination furnace is good, the operation and the control are easy, the sieve openings are not blocked and the chlorine is evenly distributed.

Owner:GUIYANG AL-MG DESIGN & RES INST

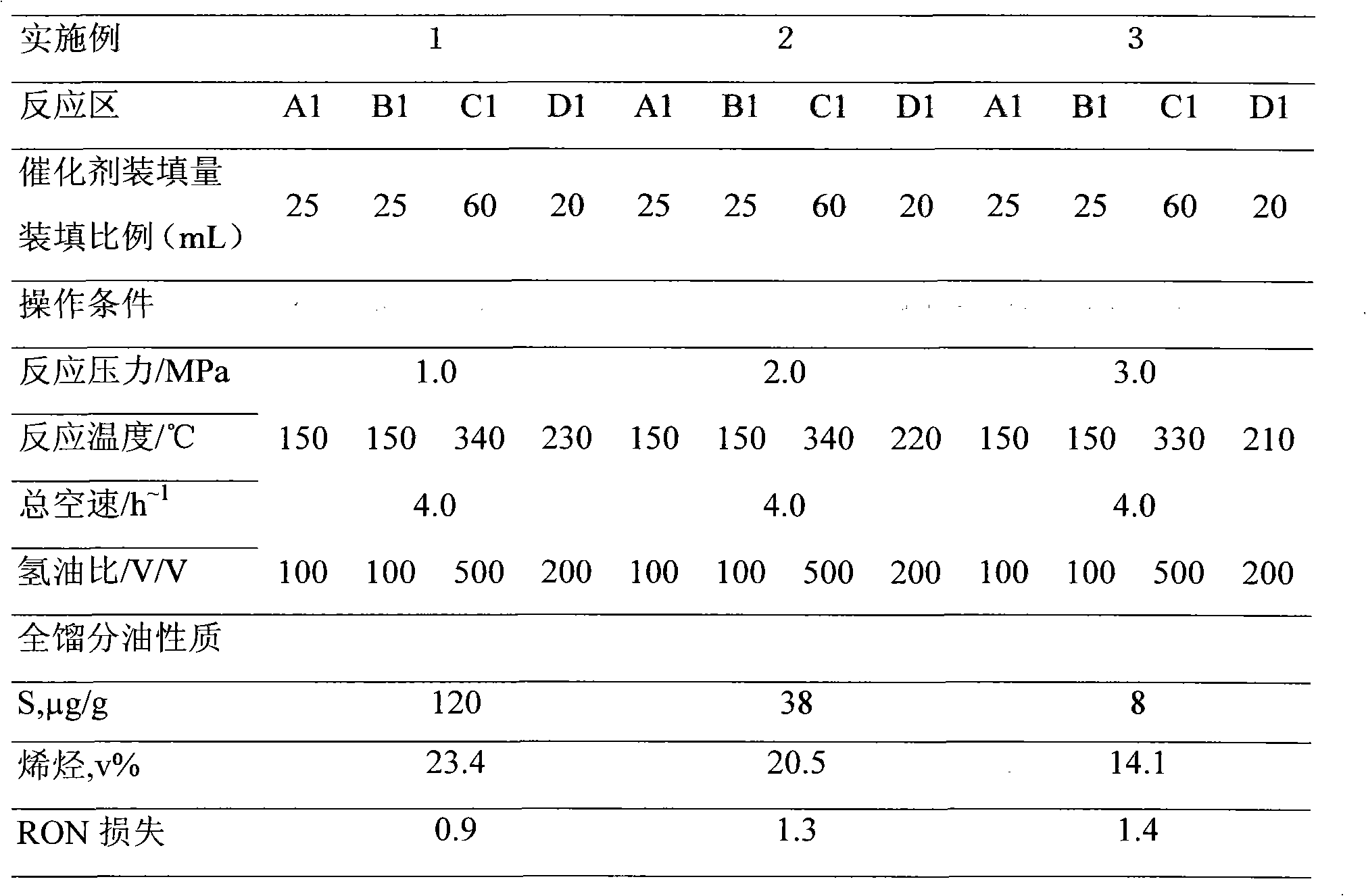

Hydrogenation conversion method for poor ignition quality fuel distillate

ActiveCN101280221ASave investment costsSave operating costsTreatment with hydrotreatment processesNaphthaHydrogen

The invention discloses a hydrogenation transformation method of poor quality diesel distillate. The poor quality diesel distillate and hydrogen pass the reaction area which contains hydrorefining catalyst; the obtained material is separated to obtain hydrogen-rich gas and diesel distillate; the hydrogen-rich gas and the diesel distillate is fed into the hydrogenation cracking reaction area; the separated aviation kerosene distillate is fed into the aviation kerosene hydrorefining reaction area; the gas obtained in the hydrogenation cracking area through the separation of the material stream is for recycle use; naphtha and diesel product are obtained; the obtained aviation kerosene distillate is fed into the aviation kerosene hydrorefining reaction area; the gas obtained through the separation of aviation kerosene hydrorefining material steam is for recycle use and the aviation kerosene product is obtained. The hydrogenation transformation method of poor quality diesel distillate adopts the combination process of hydrorefining and hydrogenation cracking to transform the diesel distillate into high quality naphtha, aviation kerosene and diesel products directly.

Owner:CHINA PETROLEUM & CHEM CORP +1

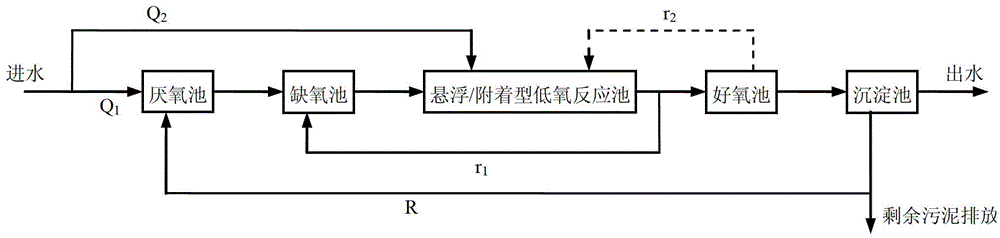

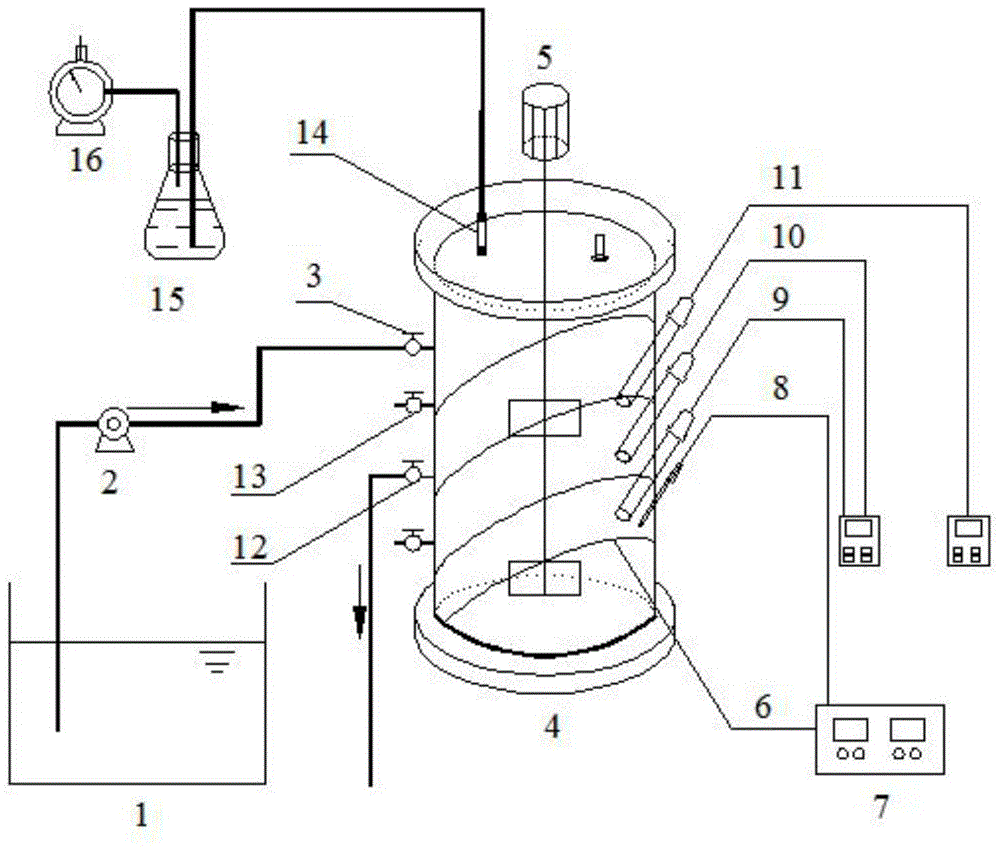

AALOO multipoint water feeding synchronization denitrification and dephosphorization process, operation method thereof, and used biological reaction tank

InactiveCN102718313ASimple processFlexible control and adjustmentTreatment with aerobic and anaerobic processesSludgeWater quality

The invention provides an AALOO multipoint water feeding synchronization denitrification and dephosphorization process. All pretreated wastewater Q1 enters an anaerobic tank, then flows through an anoxic tank, a low oxygen tank, a short-term aerobic tank and a precipitation tank sequentially, and then is discharged from the precipitation tank. Partial pretreated wastewater Q2 directly enters the low oxygen reaction tank, then flows through the short-term aerobic tank and the precipitation tank sequentially, and then is discharged from the precipitation tank. One part of precipitated sludge flows back to the anaerobic tank, and the other part of the precipitated sludge is discharged from the precipitation tank as excess sludge. Mixed liquid return channels are arranged between the low oxygen reaction tank and the anoxic tank, and the mixed liquid return channels are also arranged between the short-term aerobic tank and the low oxygen reaction tank. A returned sludge contact reaction region is arranged on the front end of the anaerobic tank, and water feeding points are arranged both on the front end region and the rear end region of the anaerobic tank. The method has a simple flow, and is adaptable to wastewater quality change, and is capable of removing nitrogen and phosphorus from wastewater with low carbon source and low oxygen consumption. The method is applicable to rebuilding or building of a municipal wastewater treatment plant which has nitrogen and phosphorus removing requirements.

Owner:国家城市给水排水工程技术研究中心 +1

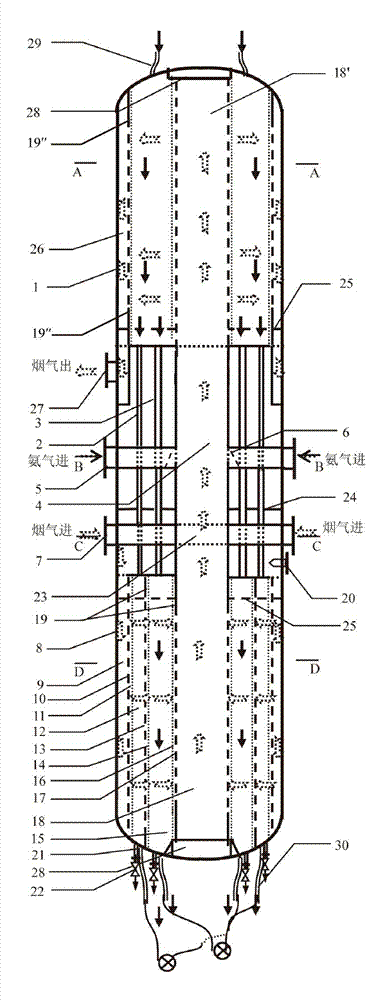

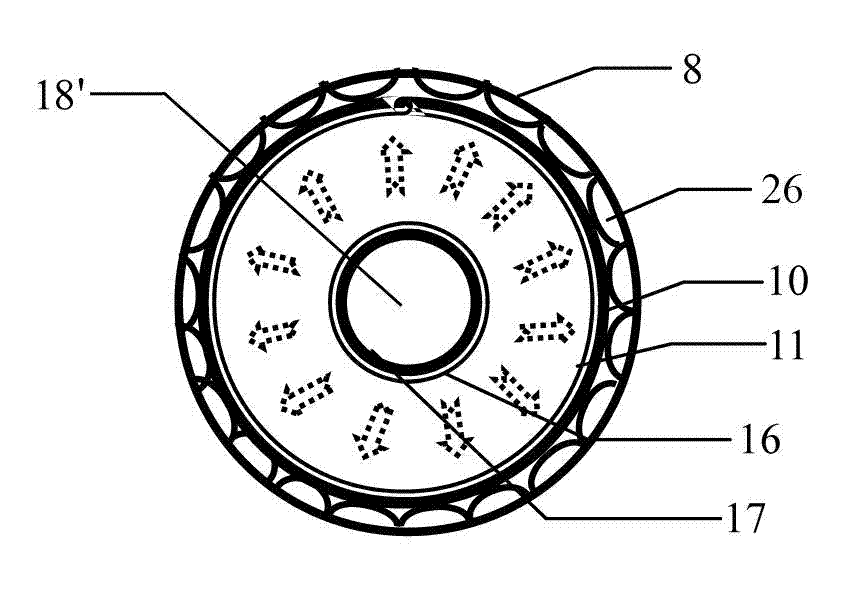

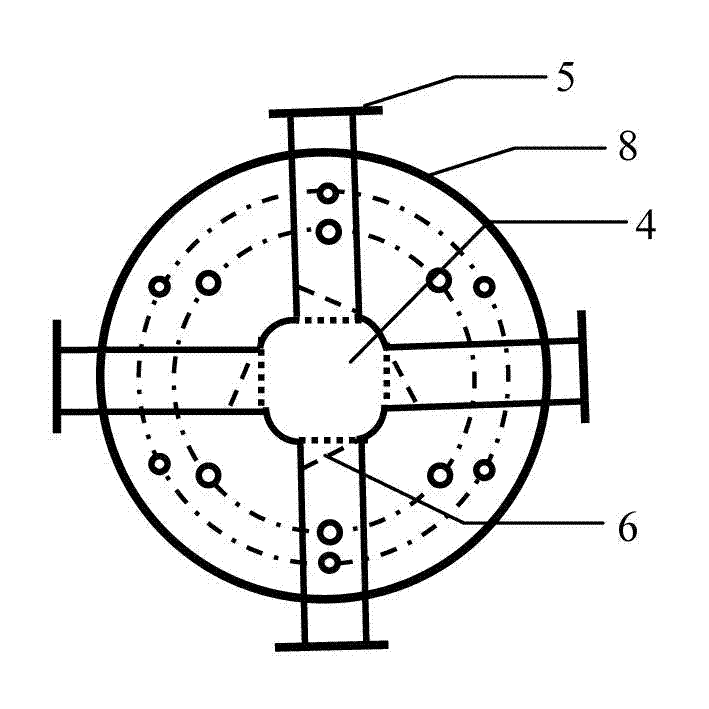

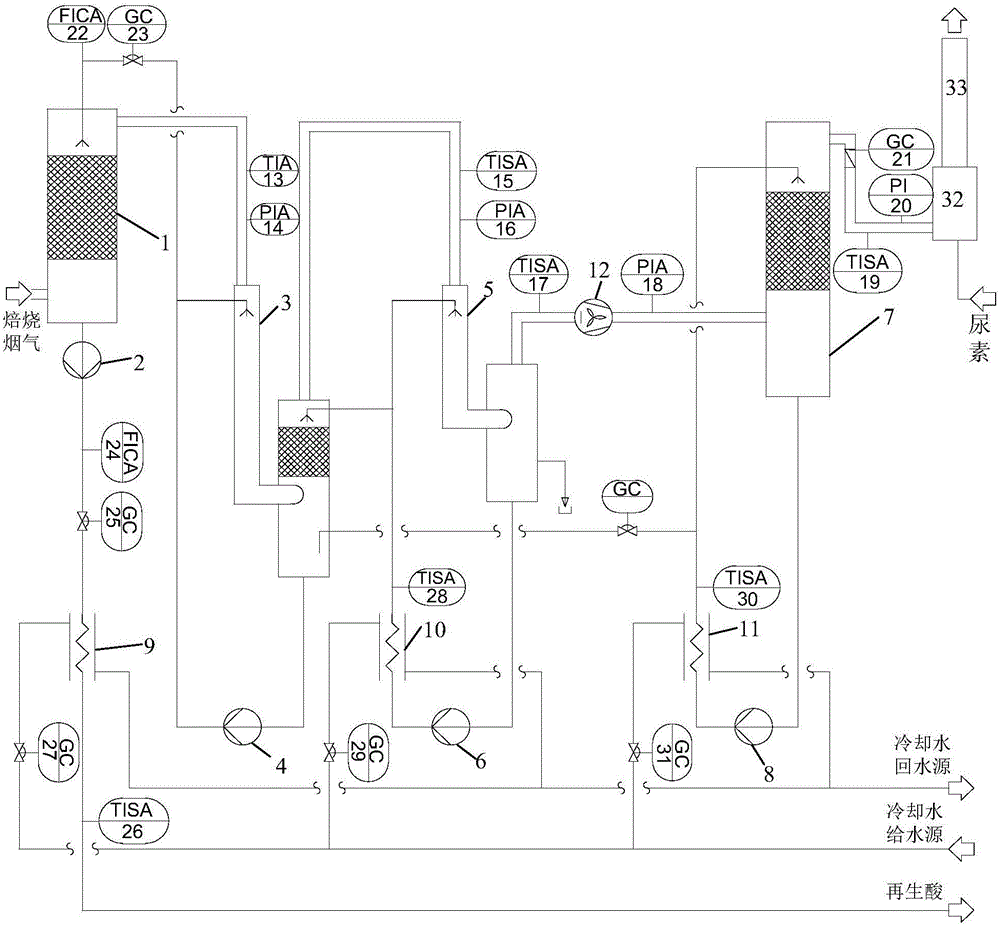

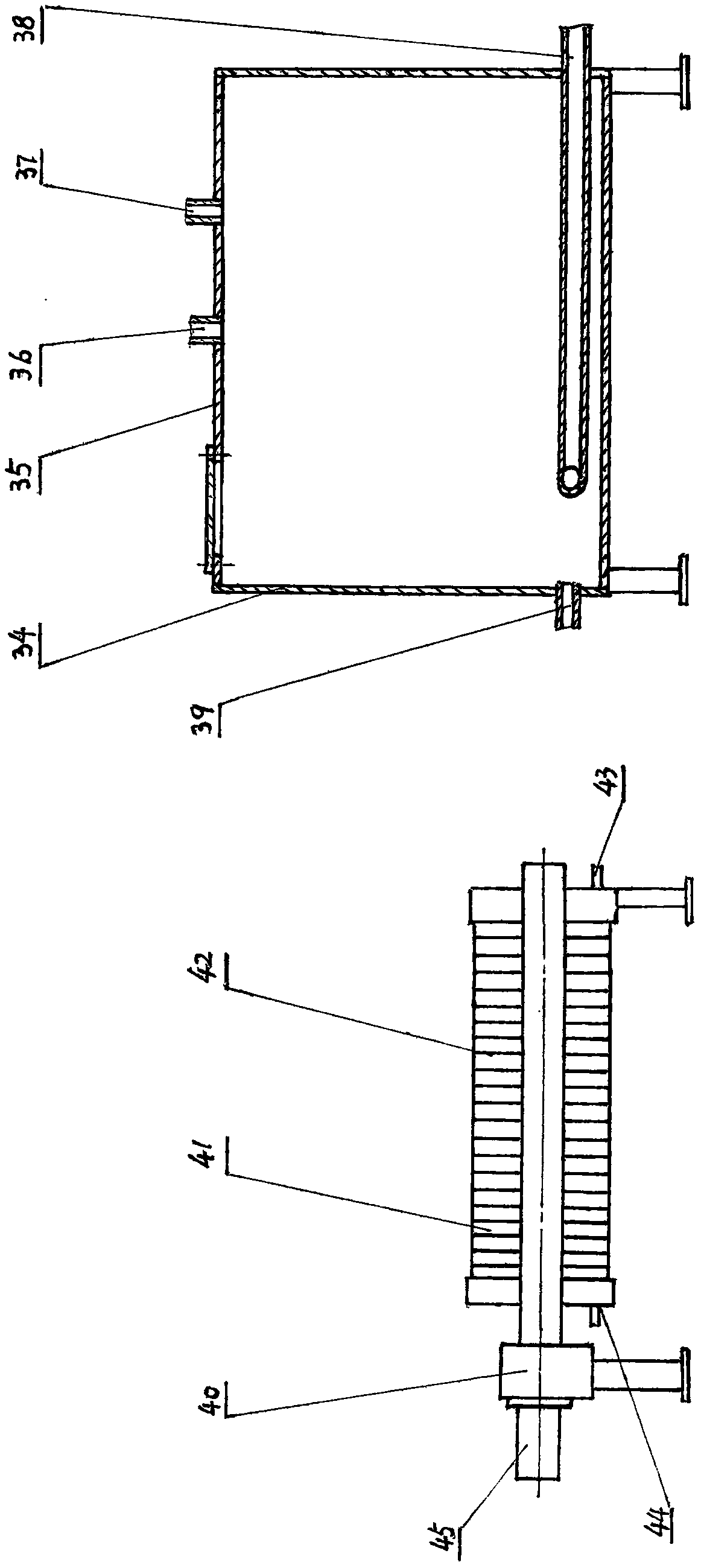

Axial and radial cross flow moving bed reactor and activated coke flue gas desulfurization and denitration technology thereof

ActiveCN102824846ACombined removalAchieve efficient utilizationDispersed particle separationAir quality improvementThermodynamicsFlue gas

An axial and radial cross flow moving bed adsorption reactor and an activated coke flue gas desulfurization and denitration technology thereof are used for realizing the purposes that SO2, NOx, mercury, dioxin and other pollutants in flue gas are unitedly removed and integrally purified in an adsorption reactor, and belong to the technical field of comprehensive waste flue gas treatment. The adsorption reactor is a combined type double-section double-inverse U-type axial and radial cross flow moving bed, awherein desulfurization area is arranged at a lower section of the axial and radial cross flow moving bed, an annular internal activated coke particle layer and an annular external activated coke particle layer are arranged, and the desulfurization area is divided into a coarse desulfurization area and a fine desulfurization area; a denitration area is arranged at an upper section of the axial and radial cross flow moving bed, and an activated coke particle layer is arranged; an ammonia spray pipe is arranged between the upper section and the lower section; and flue gas is filled along a double-port counter annular gas flow channel structure, the flue gas of the lower section centripetally flows to be desulfurized, and the flue gas of the upper section centrifugally flows to be denitrated. According to the reactor and the technology, desulfurization and denitration are realized in one adsorption reactor, so the adsorption reactor has the advantages of efficient utilization of activated coke, uniform flue gas mixing, sufficient gas-solid contact, stability and reliability in operation, operation cost saving and the like.

Owner:SHANGHAI LONGKING ENVIRONMENTAL PROTECTION

Zero residual base normal-pressure or low-pressure boiling high-concentration pulp preparing method by using base process

InactiveCN101215794ARapid responseNo residual alkaliDigestersNon-macromolecular organic additionHigh concentrationSodium metasilicate

The invention relates to a method for boiling high concentration pulping in normal pressure or low pressure by an alkaline method with zero residual alkaline, and the method comprises adding accelerating agent in the boiling process and utilizing a double screw to rub and squeeze a pulper, leading pulp making and boiling process with an alkaline method to go on in normal pressure or low pressure, and leaving no residual alkaline in black liquor, leading pulp to always keep a higher density in the pulping process of boiling, washing and bleaching, and the pulp which is prepared can meets the requirement of paper making. Accelerating agent chooses one or a plurality of magnesium hydrate, potassium hydrate, sodium metasilicate, sodium sulfide, sodium sulfite, ammonium sulfite and carbamide. Special-purpose pulping boiling equipment and high-pressure boilers are not needed by pulping paper mills through utilizing the invention, in the process of pulping, pulp always keeps higher density, and black liquid has high density, little numbers and low energy consumption, alkaline recovery project with great investment is not needed to be built, and the invention enables black liquid to prepare fertilizer or other chemical products with high quality, and the invention is suitable for popularizing and applying.

Owner:晏永祥

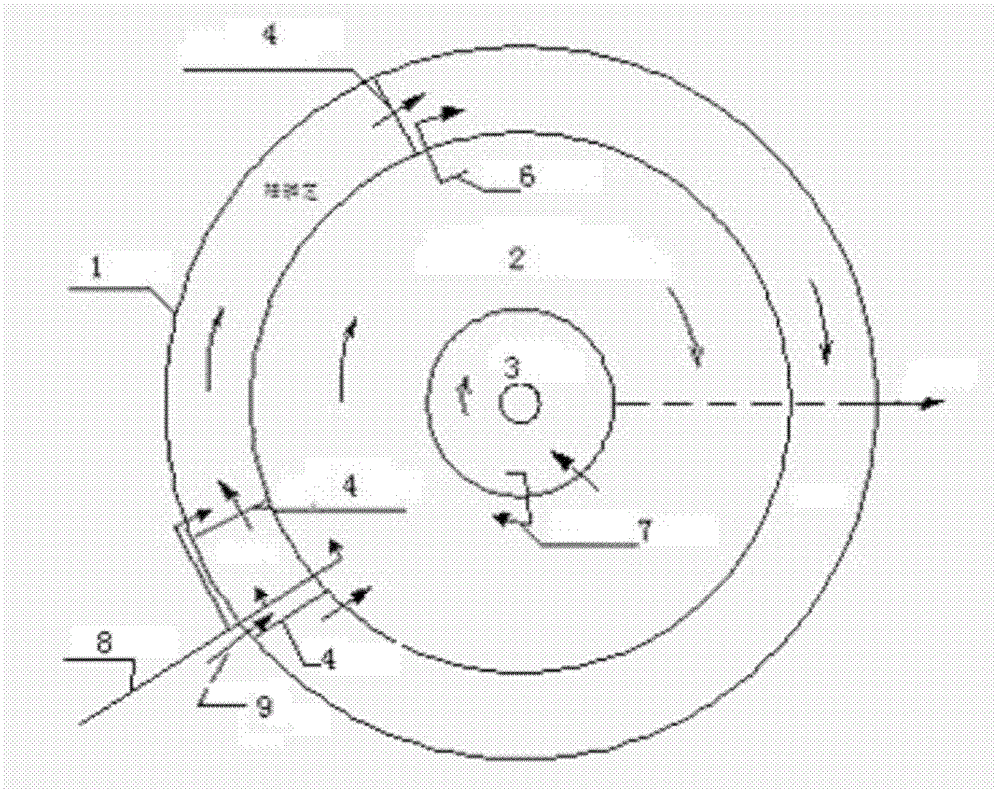

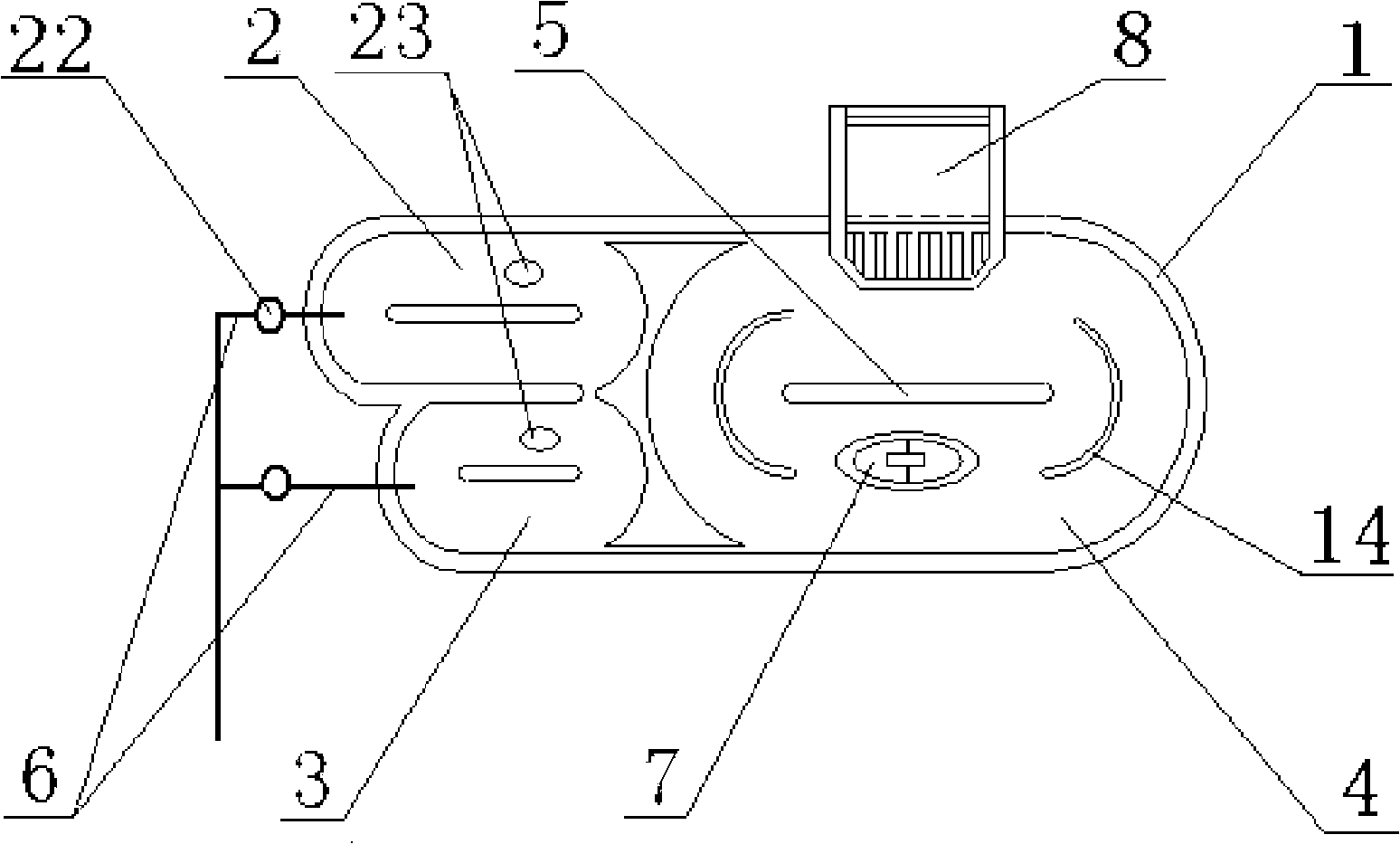

Integrated oxidation ditch, construction and operation method

InactiveCN101269882AImprove settlement performanceIncrease concentrationTreatment with aerobic and anaerobic processesSewageSmall footprint

The invention discloses an integrated oxidation ditch and a construction and operation method thereof. The construction and operation method has the technical proposal that the integrated oxidation ditch is divided into an anoxic zone, an anaerobic zone and an aerobic zone, which are communicated mutually, the anoxic zone and the anaerobic zone are arranged at one end of the integrated oxidation ditch in common, the aerobic zone is arranged at the other end of the integrated oxidation ditch, and a water-retaining wall is arranged at the middle part of each zone to cause each zone to be formed a single annular channel, water inlet pipes used for feeding water by the division point way are arranged at the anoxic zone and the anaerobic zone, an aeration device is arranged in a circulation channel at one side of the aerobic zone communicated with the anoxic zone, and a mud-water separation device used for the mud-water separation and the water emission is built on the side wall of the aerobic zone for the water emission. The aeration device is started, and the sewage passes through the anoxic zone, the anaerobic zone, the aerobic zone, and the mud-water separation device in sequence, so the dephosphorization and the denitrification as well as the decarbonization treatments of the sewage are realized. The integrated oxidation ditch has the advantages of simple structure, lower cost, small occupation area, and good sewage treatment effect, and can particularly and effectively perform the dephosphorization and the denitrification simultaneously.

Owner:ARCHITECTURAL DESIGN RES INST OF GUIZHOU +1

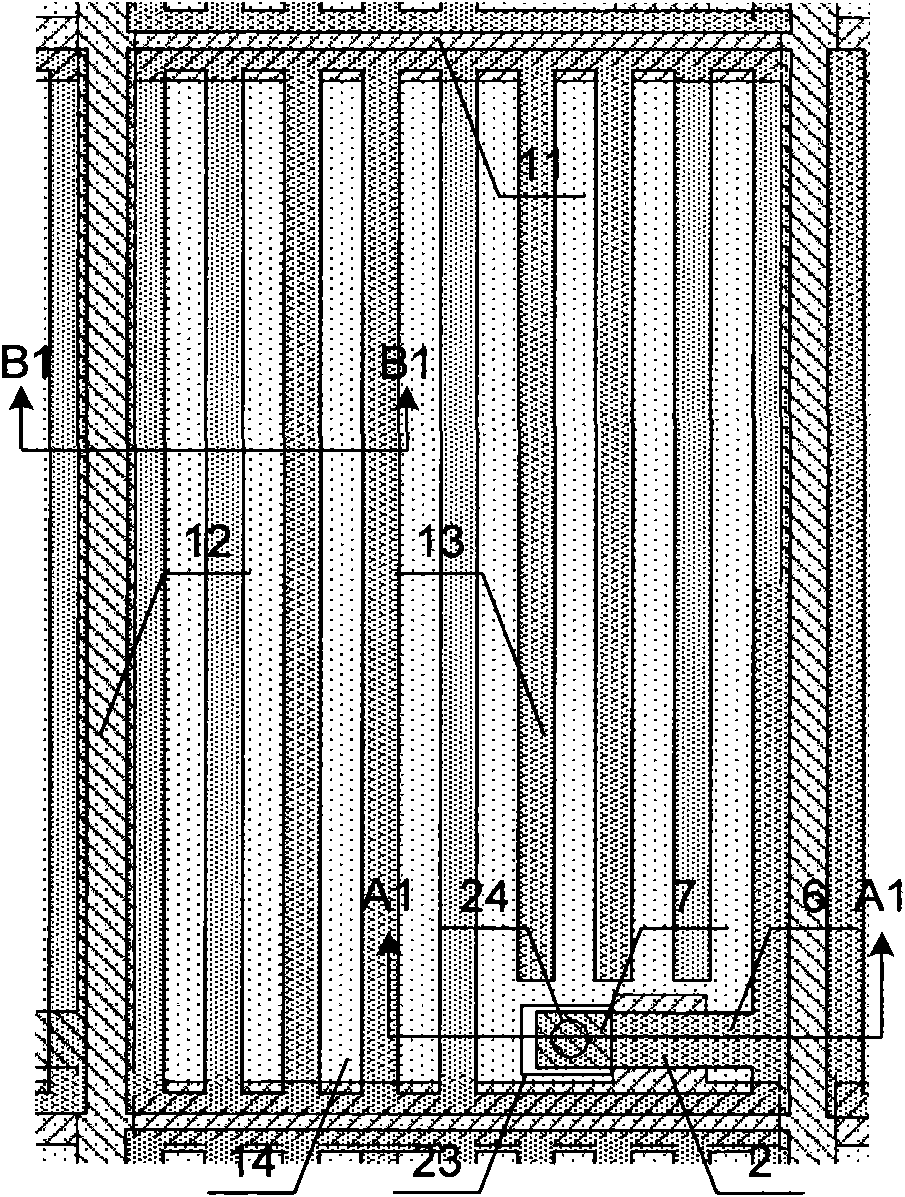

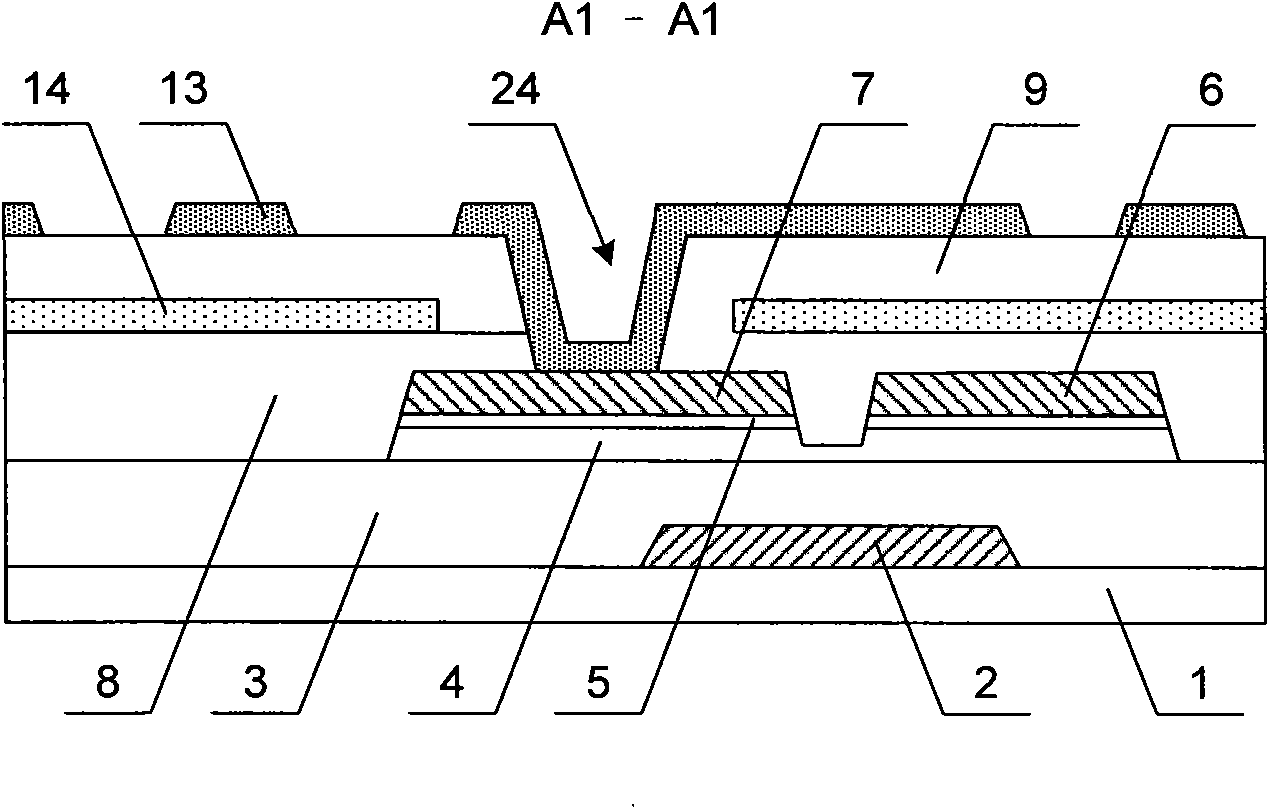

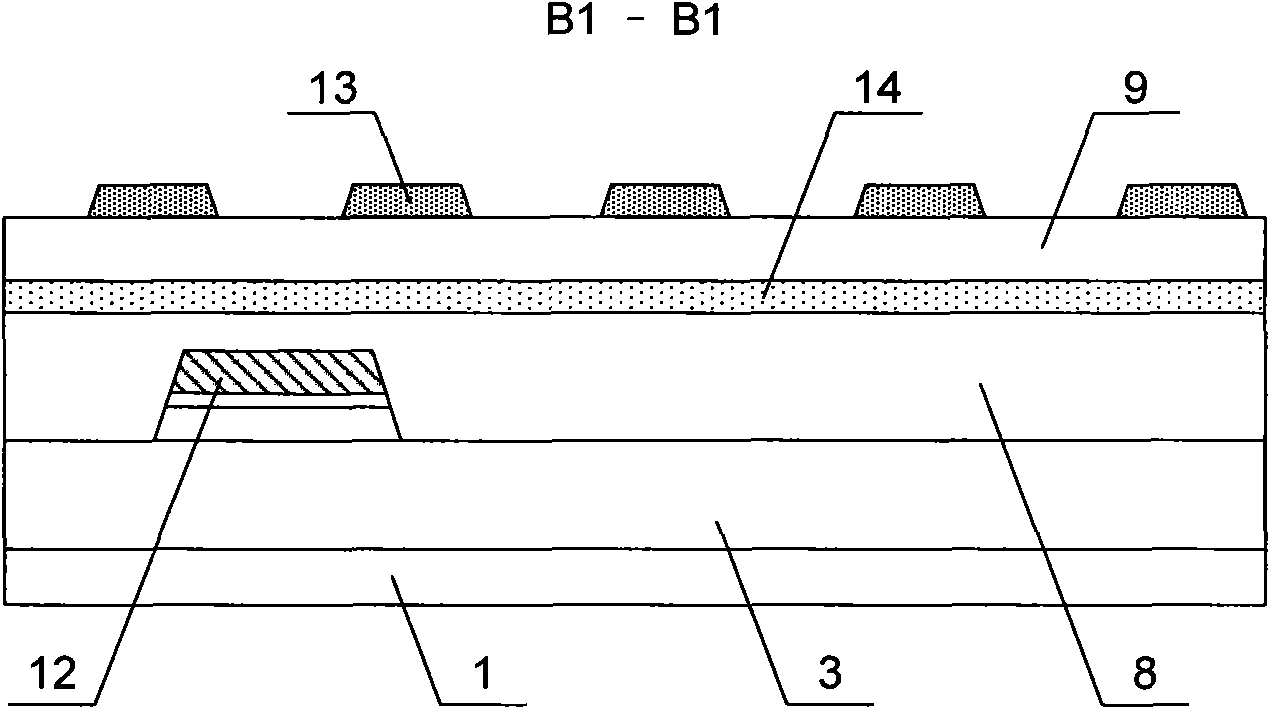

Thin film transistor liquid crystal display (TFT-LCD) array substrate and manufacturing method thereof

ActiveCN102156369AIncrease the areaImprove the efficiency of driving liquid crystalSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringThin-film-transistor liquid-crystal display

The invention relates to a thin film transistor liquid crystal display (TFT-LCD) array substrate and a manufacturing method thereof. The array substrate comprises grid lines and data lines which define a pixel region, wherein a TFT, common electrodes and pixel electrodes of electrode strip structure are formed in the pixel region; the common electrodes are formed on a second insulating layer covering the data lines; and the pixel electrodes are formed on a third insulating layer covering the common electrodes. The array substrate and the manufacturing method have the following beneficial effects: by forming the common electrodes on the second insulating layer covering the data lines, forming the pixel electrodes of electrode strip structure on the third insulating layer covering the common electrodes and driving all the liquid crystals in the regions between the edges of the pixel electrodes and the edges of the data lines with a regular electric field, the efficiency of driving the liquid crystals is improved and the region becomes a display region, thus farthest increasing the area of the display region and effectively improving the aperture opening ratio.

Owner:BOE TECH GRP CO LTD +1

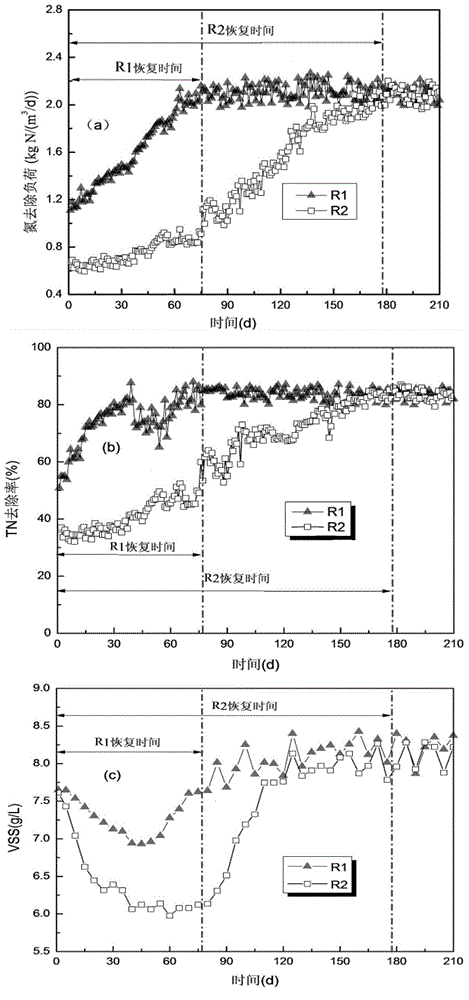

Method for relieving anaerobic ammonium oxidation system salinity shock with betaine as additive

ActiveCN104909455AShorten the timeImprove removal rateTreatment with anaerobic digestion processesBetaineSludge

The invention relates to a method for relieving anaerobic ammonium oxidation system salinity shock with betaine as an additive. According to the invention, a successfully started anaerobic ammonium oxidation SBR reactor is used for processing salt-containing wastewater, wherein a volatile suspended sludge concentration is maintained at 6-9g / L, an inlet water NH4<+>-N concentration is 180-220mg / L, and the molar ratio of NH4<+>-N to NO2<->-N is controlled at 1:1-1:1.32 through adding (NH4) 2SO4 and NaNO2; the betaine concentration in the reactor is maintained at 0.1-5mmol / L through adding betaine; with a heating band, the temperature of the reactor is controlled at 30-35 DEG C; DO is controlled at 0-0.1mg / L; inlet water pH is stabilized at 7.0-8.5 through dropping NaOH / HCl; anoxic stirring is carried out for 4-8h after water feeding; when stirring is finished, the material is allowed to stand and to precipitate; when precipitation is finished, a supernatant is discharged. With the method provided by the invention, anaerobic ammonium oxidation activity recovery time when the anaerobic ammonium oxidation system is under salinity load shock can be effectively shortened, nitrogen removal rate can be improved, and a higher total nitrogen removal rate can be realized.

Owner:BEIJING UNIV OF TECH

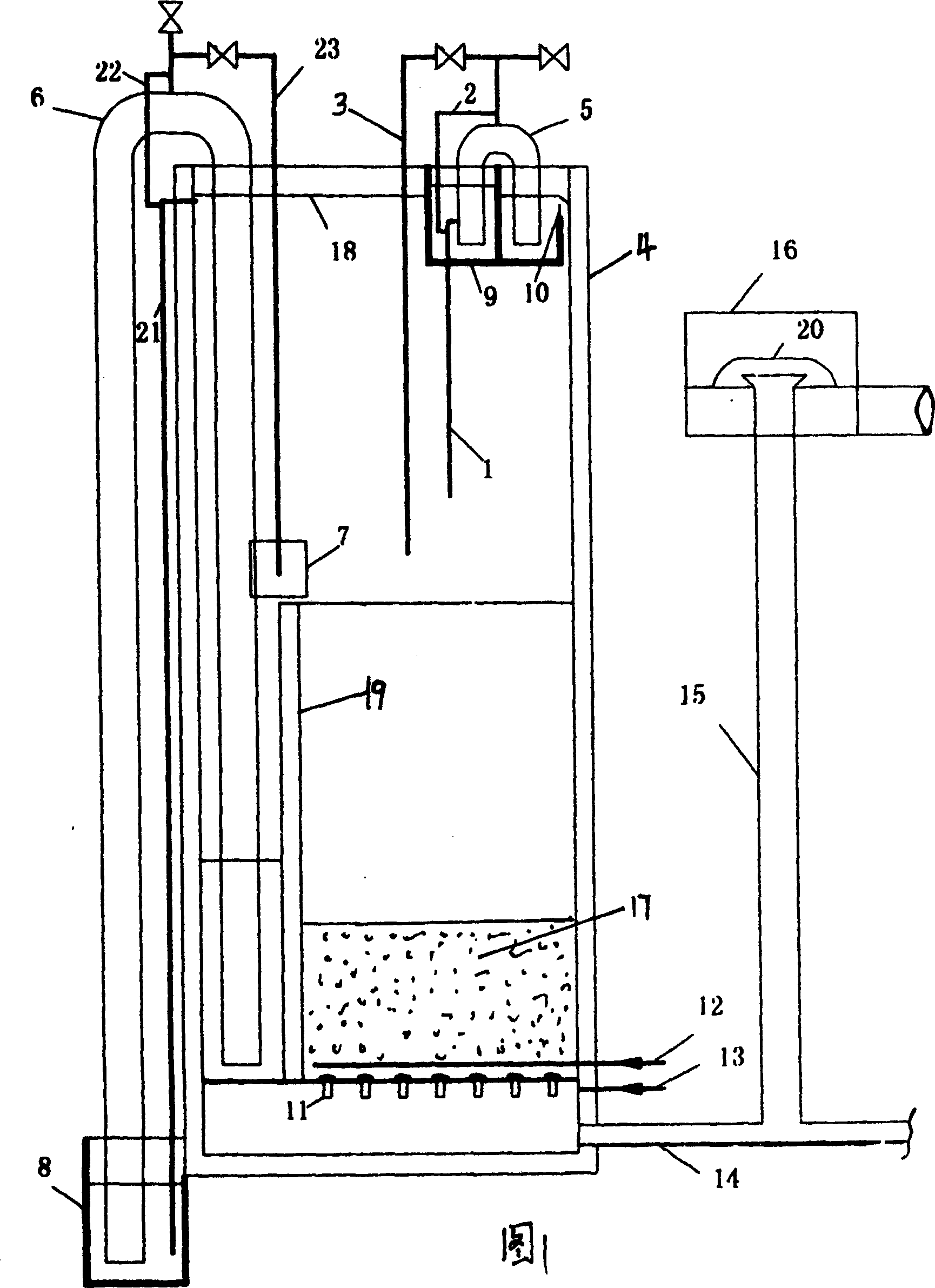

Siphon type full automatic aeration biologicall filtering chamber

InactiveCN1911832AGuaranteed uptimeEasy to manageTreatment using aerobic processesSustainable biological treatmentSiphonAutomatic control

The siphoning automatic aerating biofilter includes filter basin with filtering material, inlet channel, water outlet weir and timing water tank. It has also water outlet pipe connected to the lattices of the filter basin and water outlet tank, draining siphon pipe connected to the water seal well, water inlet siphon pipe connected to the water inlet channel, auxiliary water inlet siphon pipe connected to the water inlet siphon pipe, water inlet exhaust pipe, water inlet siphonage eliminating pipe, auxiliary water drainage siphon pipe connected to the draining siphon pipe, draining exhaust pipe, draining siphonage eliminating pipe, etc. The present invention has the advantages of completely hydraulic controlling, easy running, no need of clear water tank, no need of back flush pump, low cost, etc.

Owner:NANCHANG UNIV

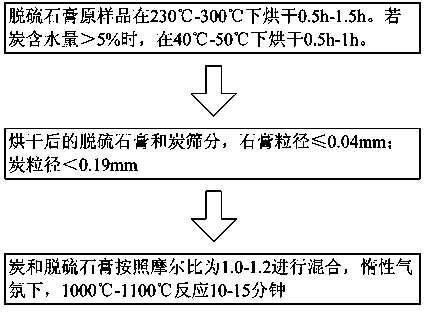

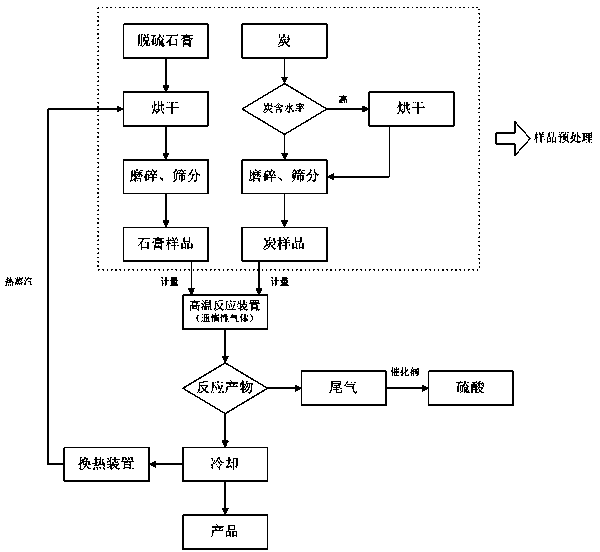

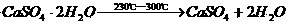

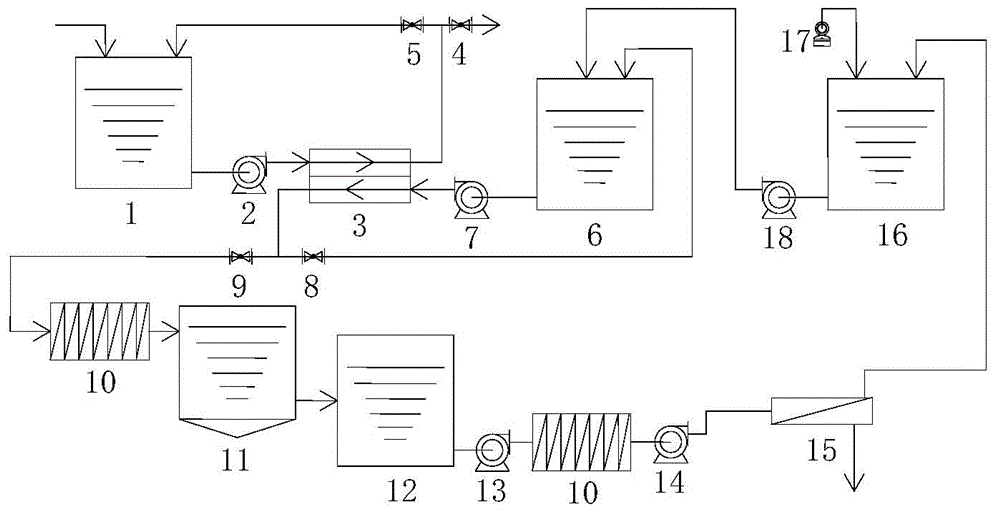

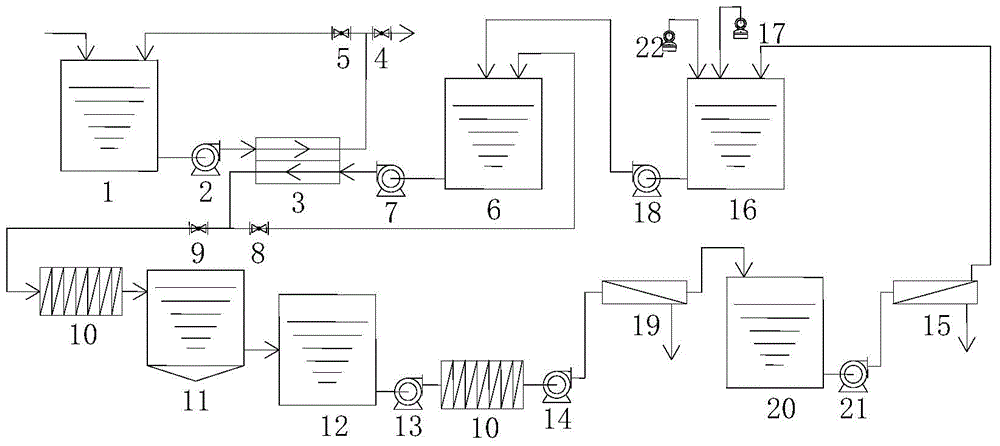

Production technology for preparing calcium oxide and sulfur dioxide through utilizing desulfurized gypsum

ActiveCN103482584AAvoid secondary pollutionReduce miningSulfur compoundsCalcium/strontium/barium oxides/hydroxidesNitrogen gasAtmospheric pollution

The invention discloses a production technology for preparing calcium oxide and sulfur dioxide through utilizing desulfurized gypsum. The technology comprises the following steps: drying desulfurized gypsum at 230-300DEG C for 0.5-1.5h, wherein drying pretreatment is carried out at 40-50DEG C for 0.5-1h if the water content of carbon is above 5%; screening the desulfurized gypsum and the carbon for controlling the gypsum particle size below 40mum and the carbon particle size below 187.5mum; and mixing the screened carbon and the screened desulfurized gypsum according to a carbon-to-calcium sulfate mole ratio of 1:1-1.2:1 to obtain a mixed sample, putting the mixed sample in a high temperature reaction device, and reacting at 1000-1100DEG C under the protection of nitrogen or an inert gas under a gas flow velocity of 4-10m / s for 10-15min. The technology has the advantages of high reaction efficiency, fast reaction speed, less carbon consumption, high finally-obtained product quality, and no atmospheric pollution.

Owner:NANJING UNIV OF SCI & TECH

Hydrogenation process for coal direct liquefaction circulation solvent

InactiveCN1844318AUniform temperature distributionHomogenization of temperature distributionLiquid hydrocarbon mixture productionBrown coalChemical reaction

The invention adopts a catalyst grading technology and installs adequate chemical reaction environment to carry out incompletely saturated hydrogenation in a mild technological condition, which not only mildly hydrogenates the unsaturated compound in dissolvent, but also mildly hydrogenates the saturated compound. The affected compounds of the hydrogenated dissolvent reach even degree of unsaturation on molecular structure, which improves transferable hydrogen content of molecule, accordingly the free hydrogen(-H) released by cycle dissolvent just can meet the need of hydrogen consumption of direct liquefaction of brown coal in a mild technological condition. The invention can simplify the industrial process of lignite liquification and solvent hydrogenation, reduce the device requirement, and save investment and operating cost.

Owner:ZHAOQING SHUNXIN COAL CHEM TECH

Forward osmosis absorption liquid using and recycling method and forward osmosis absorption device

InactiveCN104353361AReduce concentrationIncrease the concentration factorSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisHigh concentrationRecovery method

The invention discloses a forward osmosis absorption liquid using and recycling method and a forward osmosis absorption device, and belongs to the field of water treatment. According to the forward osmosis absorption liquid using and recycling method, raw material liquid is absorbed by the absorbing liquid in a forward osmosis device, so that in a raw material liquid concentration process, the absorbing liquid is an inorganic saline water solution and comprises dissolved sodium sulfate; the concentration of sodium sulfate is greater than 20wt%, and the temperature is 35-45 DEG C; the osmosis pressure of the absorbing liquid is 110-150bar; the recycling of the absorbing liquid comprises the processes of cooling crystallization and concentration recycling. By the use of the characteristic that the sodium sulfate solution is greatly different in dissolving degree due to different temperatures, the high-concentration sodium sulfate solution is used as the absorbing liquid, so that the concentration factor of the raw material liquid is increased as much as possible; when the absorbing liquid is recycled, a cooling crystallization device is added, and the concentration of sodium sulfate is reduced; under a condition of relative low pressure, the absorbing liquid is recycled by nano filtration or / and reverse osmosis concentration, and therefore, the energy consumption is low, and the cost is low; the investment and operation cost of equipment is lowered.

Owner:山东泰禾环保科技股份有限公司

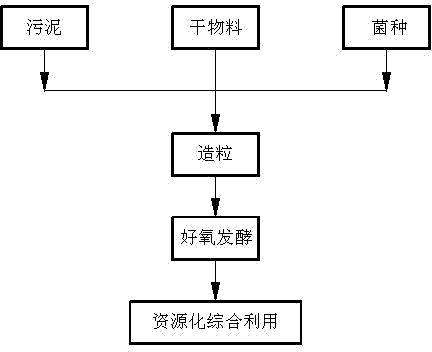

Dehydration method for reducing water content of sludge in microbial fermentation way

ActiveCN103496834AReduce moisture contentAchieving processing powerSludge treatment by de-watering/drying/thickeningSludge processingSimple Organic CompoundsSludge

The invention belongs to the technical field of sludge treatment, and particularly relates to a dehydration treatment method for reducing the water content of sludge. The method comprises the two procedures of mixing and granulating the sludge, a dry material, straws and a composite strain BYM, and performing stacking fermentation. According to a principle for the dehydration method for reducing the water content of the sludge in a microbial fermentation way, a great amount of heat can be produced in a microbial fermentation process, and can be used for reducing the water content of the sludge with low cost. Compared with the prior art, the method has the advantages of low energy consumption, low material consumption and low cost; the water content of the fermented sludge is reduced to be lower than 30 percent, the sludge has great development potential, and can be used as an organic compound fertilizer or a building material, and the resource utilization of a product is facilitated.

Owner:HENAN JINGU IND DEV

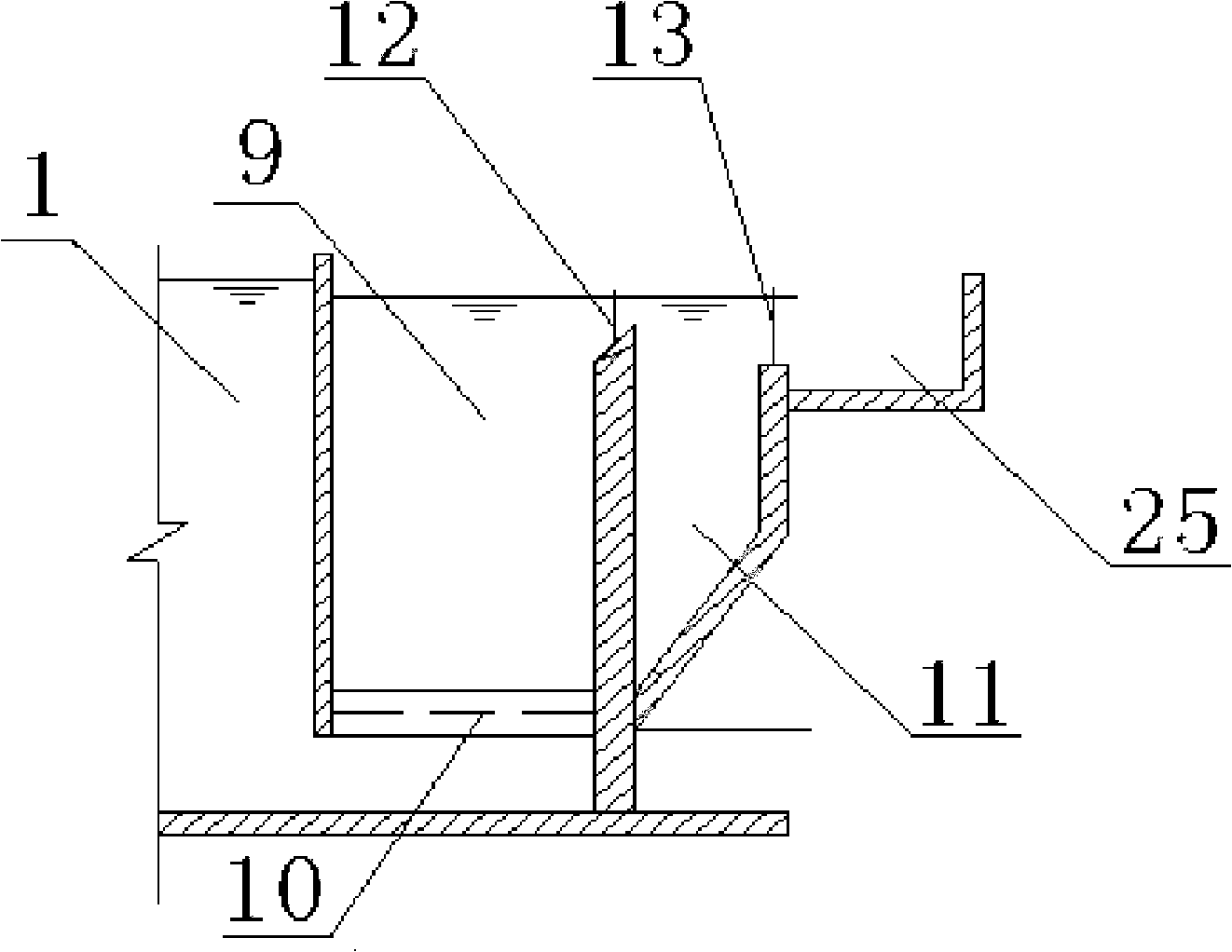

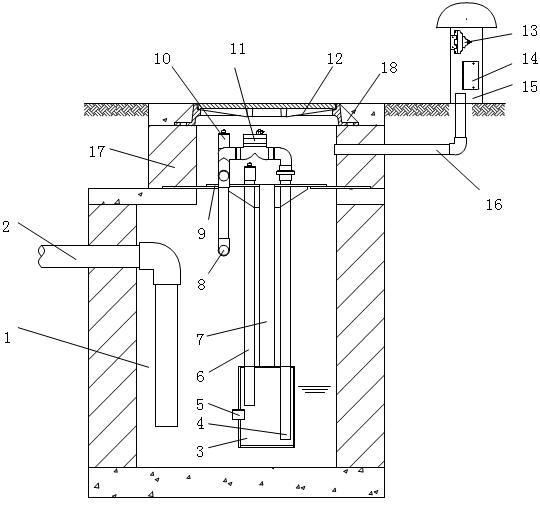

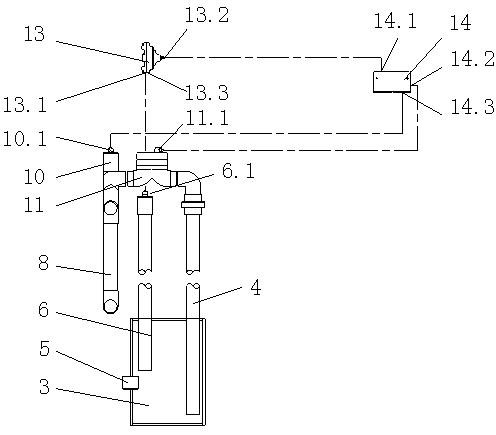

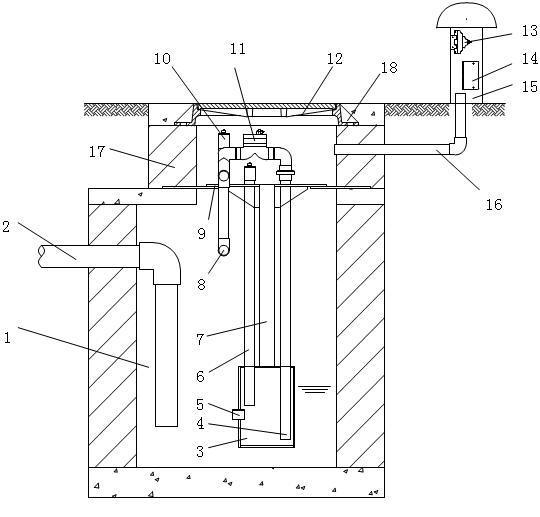

Sump well for vacuum drainage system

ActiveCN102121271ARemove balanceEliminate shockCesspoolsSewerage structuresEngineeringMultiple point

The invention relates to a sump well for a vacuum drainage system. The sump well comprises a collection well, a sewage pumping pipe, a drainage pipe, a vacuum valve, a controller for controlling connection and disconnection of the vacuum valve and a water level sensor for collecting water level information, wherein the outlet of the drainage pipe is connected into a vacuum pipeline, and the inletof the drainage pipe is connected with the outlet of the sewage pumping pipe through the vacuum valve; the inlet of the sewage pumping pipe extends into a sewage pumping level in the collection well;and a signal output end of the water level sensor is connected with a signal input end of the controller. Along with sewage collection in the well, the sump well drains automatically and intermittently to the vacuum drainage system, has a simple structure, and does not require a lift pump, so that the problems of being low in safety, easy in blockage, difficult in cleaning, high in power consumption and the like caused by assembling the lift pumps on multiple points can be avoided, and sewage collected by gravity flow can be lifted to the vacuum drainage system without extra additional power,and the sump well is convenient to check and maintain.

Owner:ENVIROSYST BEIJING ENVIRONMENTAL ENG & TECH CO LTD

Continuous suspended dirt filtering device and filtering and back-flushing method

InactiveCN108236800ALess investmentReduce energy consumptionLoose filtering material filtersGravity filtersMultiple formsFilter media

The invention relates to a continuous suspended dirt filtering device and a filtering and back-flushing method. Traditional sand filtration devices comprise rapid filter tanks, double-layer filter tanks and pressure filters, are in multiple forms but have common problems, namely halting back-flushing problems that filtering mediums are fixed in the filtering process and are blocked by suspended solids after being used for filtration for a period of time, the filtration speed is reduced, the filtration resistance is increased, and the water production capacity is reduced. The continuous suspended dirt filtering device comprises a sand filtration tank (10) connected with a clean water outlet pipe (3), wherein the clean water outlet pipe is connected with a sand-water separator (7), the sand-water separator is connected with a dirt discharging pipe (2) and an air sand lifting pipe (4) respectively, the air sand extraction pipe is connected with a water inlet pipe (1), an air lifting pump(9) and a water inlet distribution pipe (5) respectively, and the water inlet distribution pipe is connected with a backflow sand hopper (6). The continuous suspended dirt filtering device is appliedto the further purification of sewage in the subsequent sewage treatment process.

Owner:HARBIN SHUNZHI TECH CO LTD

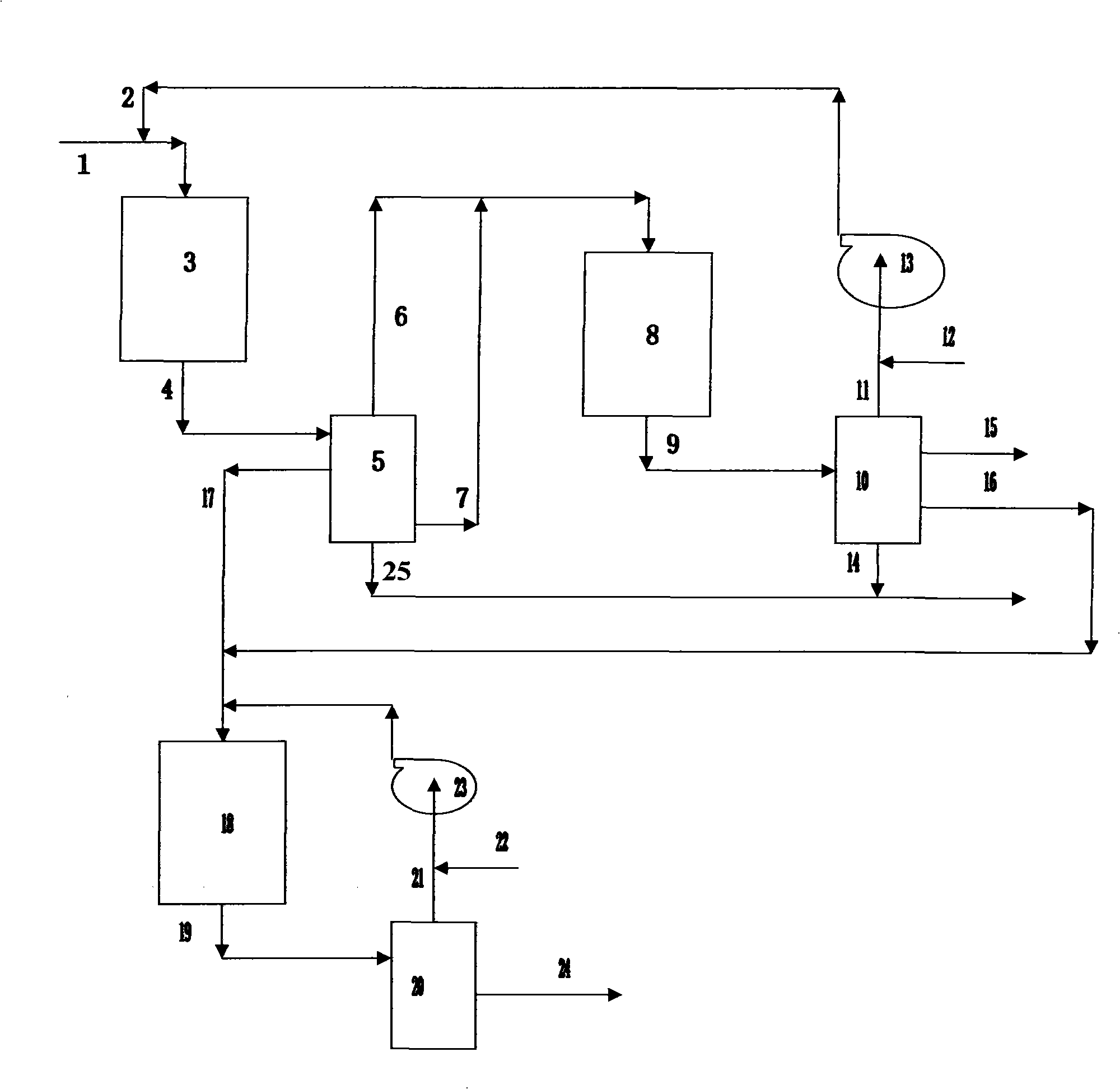

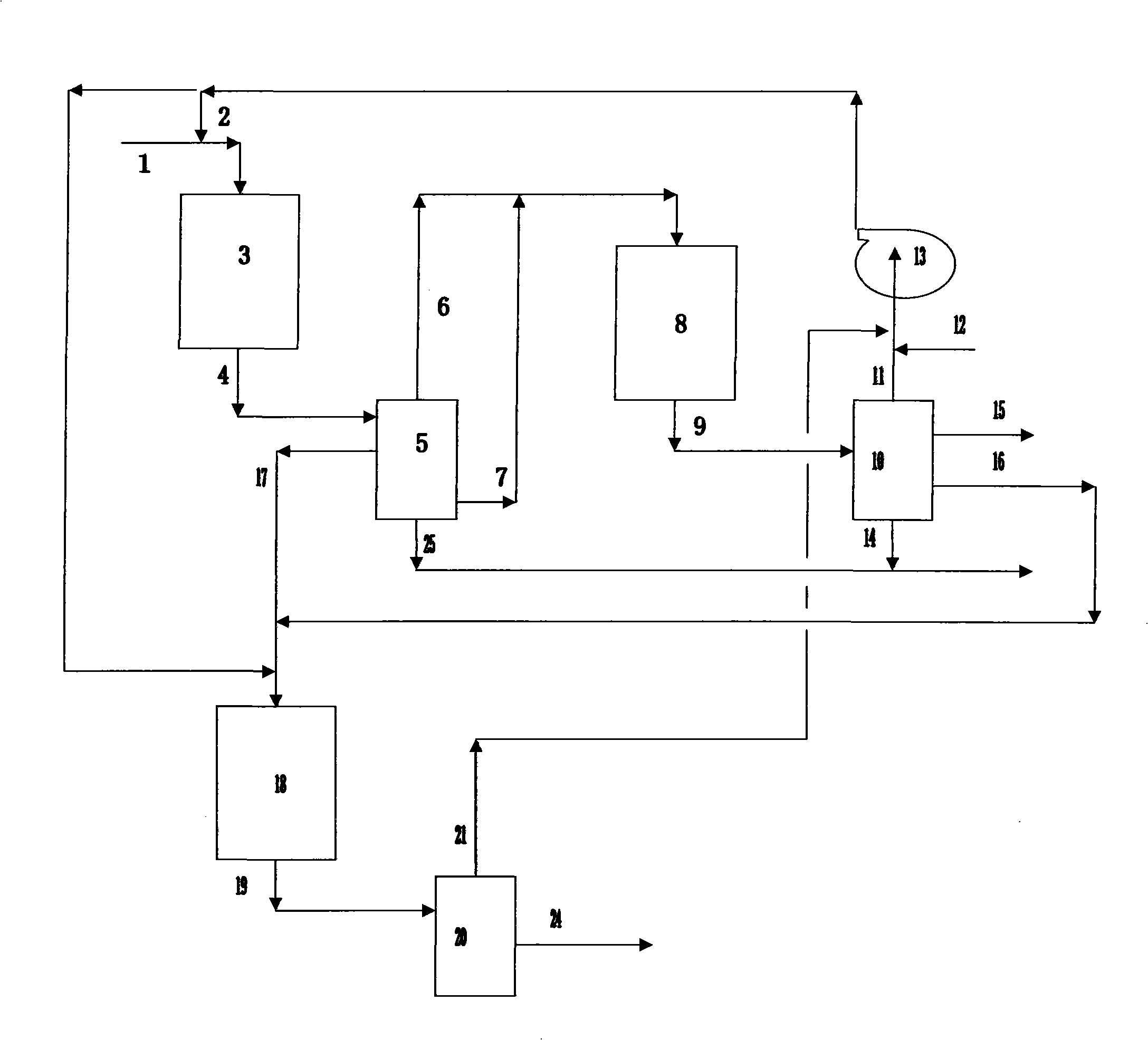

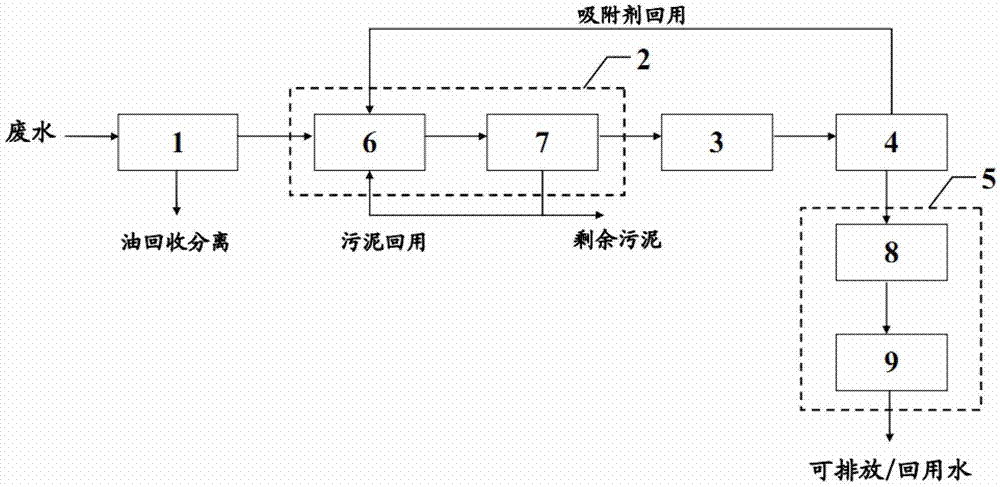

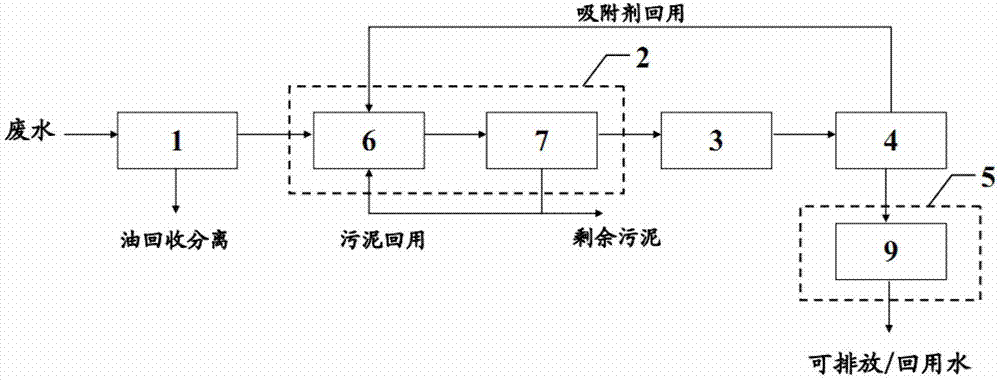

Slack coal pressure gasification wastewater resourceful treatment method and treatment system as well as application

InactiveCN103288311AAchieve reuseProportionally largeMultistage water/sewage treatmentFlocculationSludge

The invention provides a slack coal pressure gasification wastewater resourceful treatment method. The treatment method sequentially comprises the following steps of: (1) performing oil-water separation on the wastewater to obtain wastewater after the oil-water separation treatment; (2) treating the wastewater obtained by the step (1) by use of active sludge, and performing mud-water separation to obtain wastewater after the active sludge treatment; (3) adding an adsorbent into the wastewater obtained by the step (2), and performing solid-liquid separation to obtain wastewater after the adsorption separation treatment; (4) adding a flocculating agent and / or flocculation aid into the wastewater obtained by the step (3), and precipitating to obtain wastewater after the coagulation clarifying treatment; and (5) treating the wastewater obtained by the step (4) by use of a filter material loaded with microorganisms to obtain dischargeable / recyclable water. The invention also provides a system for the method to realize resourceful treatment on the wastewater, and application of the treatment method or treatment system in treating slack coal pressure gasification wastewater.

Owner:DATANG INT CHEM TECH RESINST

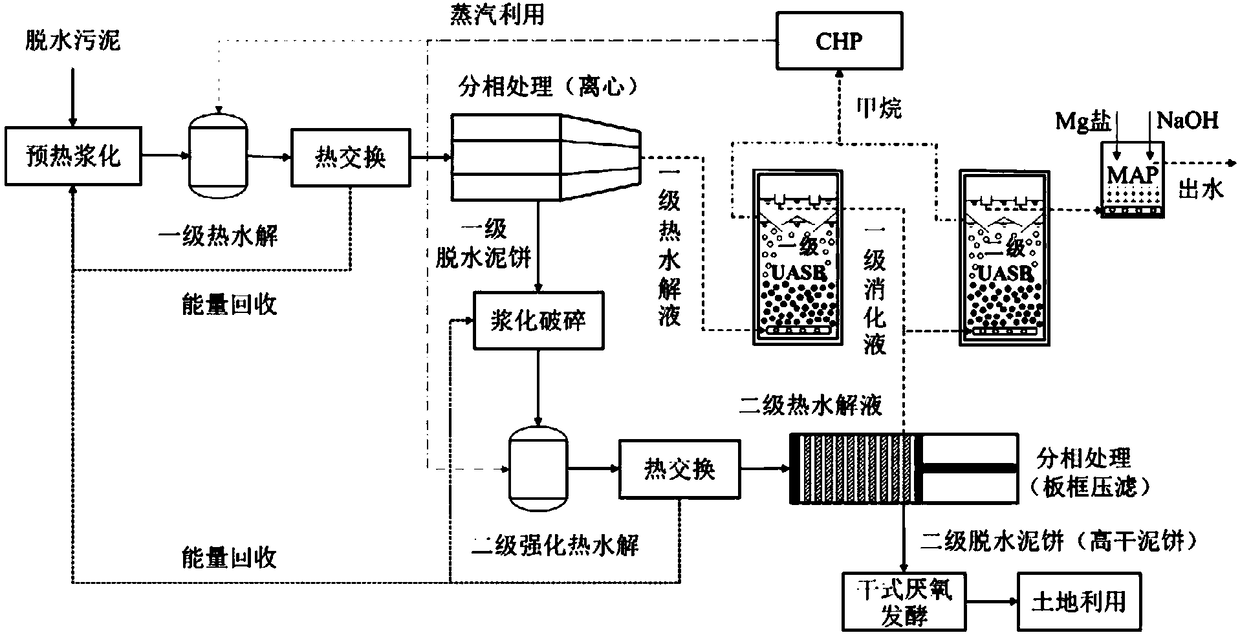

Method for matter and phase divided resource recovery of sludge

ActiveCN108423957AReduce volumeImprove conversion efficiencySludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisSludge cakeHydrolysate

The invention relates to a method for matter and phase divided resource recovery of sludge. The invention creatively proposes a method of "two-stage high solid-content thermal hydrolysis+synchronous solid-liquid separation+efficient methane production by liquid / solid dry anaerobic fermentation+land utilization". Compared with the prior art, the method provided by the invention can effectively realize degradable organic matter and hardly degradable organic matter divided and solid-liquid phase divided high efficiency treatment in sludge, organic matter-rich thermal hydrolysate is subjected to anaerobic digestion by a two-stage UASB high-efficiency anaerobic reactor, the residence time is greatly shortened, the volume of a digestion tank is obviously reduced, and the conversion efficiency oforganic matter anaerobic digestion is significantly improved. At the same time, thermal-hydrolyzed sludge high dryness dehydration can be realized without adding chemicals under a high temperature condition, the filter cake dehydration performance and quality are both significantly improved, the energy consumption and material consumption level of the sludge treatment and disposal process can besignificantly reduced, finally, the dehydrated sludge cake makes use of the afterheat of itself for dry anaerobic fermentation to recover biogas energy and realize sludge cake stabilization, and the discharged material is applied to land utilization.

Owner:TONGJI UNIV

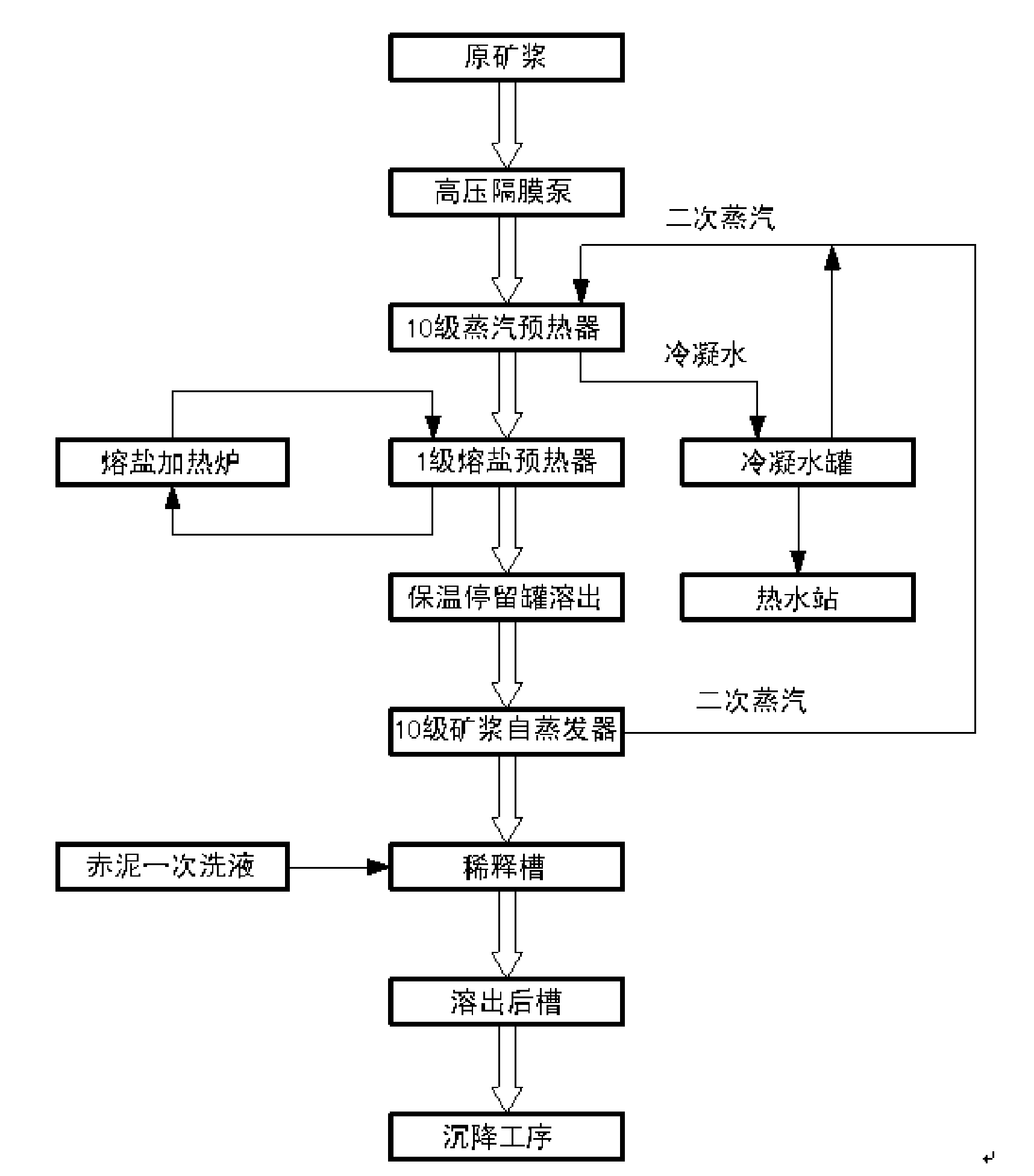

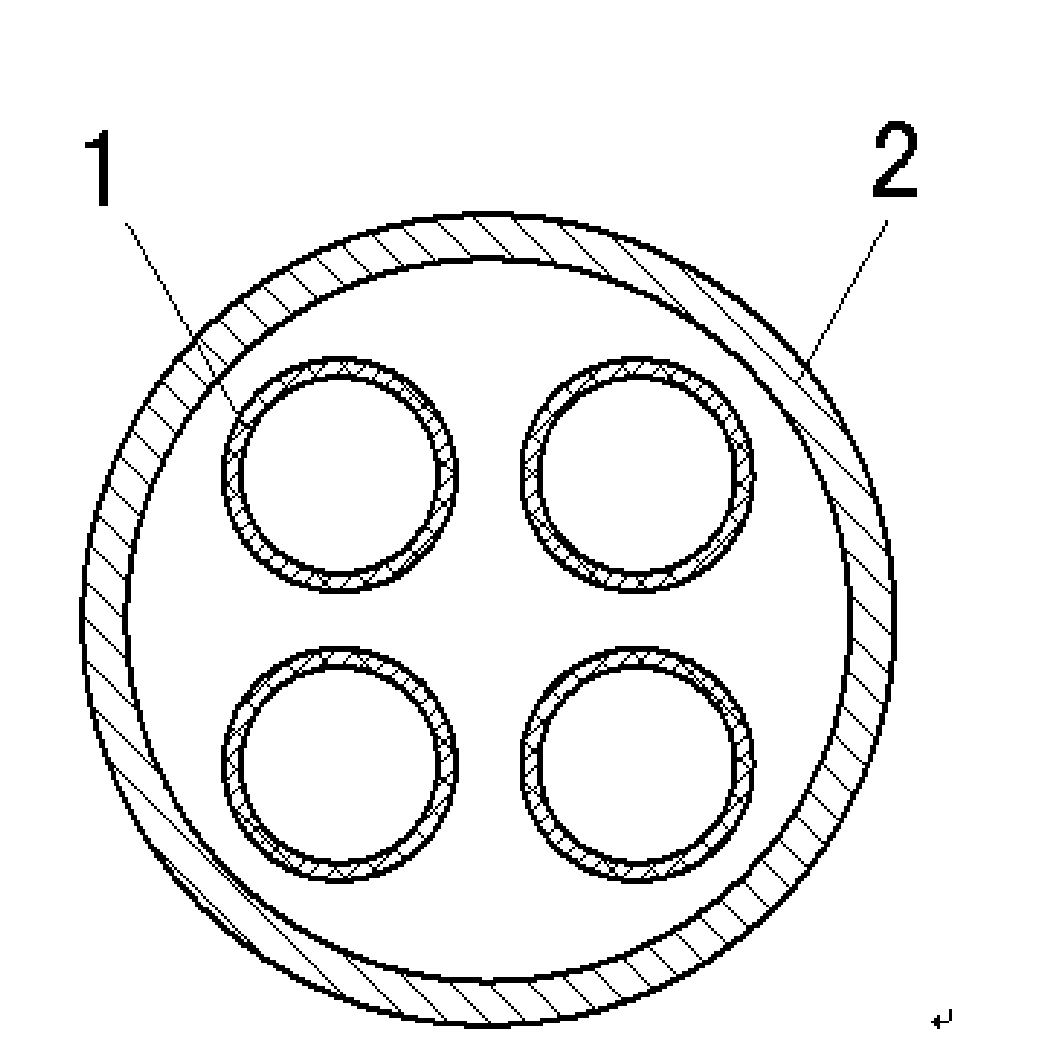

Alumina melting method

InactiveCN101671042AReduce scarring speedHigh heating temperatureAluminium oxides/hydroxidesAlkalinityRed mud

The invention discloses an alumina melting method. The melting method comprises the following steps: a. conveying primary ore pulp from a normal-pressure desiliconization process with the temperatureof 85-100 DEG C into a vapor preheater for preheating to 200-230 DEG C; b. conveying the ore pulp preheated by the vapor preheater into a molten salt heater for heating to 260-280 DEG C; c. conveyingthe ore pulp heated by the molten salt heater into an insulated melting tank for heat preservation for 30-45 minutes until a melting process is finished; d. conveying the melted ore pulp into a ore pulp self evaporator to decrease temperature and pressure; and e. conveying the ore pulp evaporated and concentrated in the self evaporator into a diluting tank, and diluting and mixing with a primary red mud washing fluid. The invention improves the heating temperature of the ore pulp to 280 DEG C, decreases the alkalinity of the primary ore pulp, saves the construction investment and equipment cost, reduces the energy consumption of an evaporation process, improves the utilization rate of secondary vapor heat, delays the scaring speed of a sleeve and decreases the equipment maintenance cost.

Owner:中铝国际技术发展有限公司

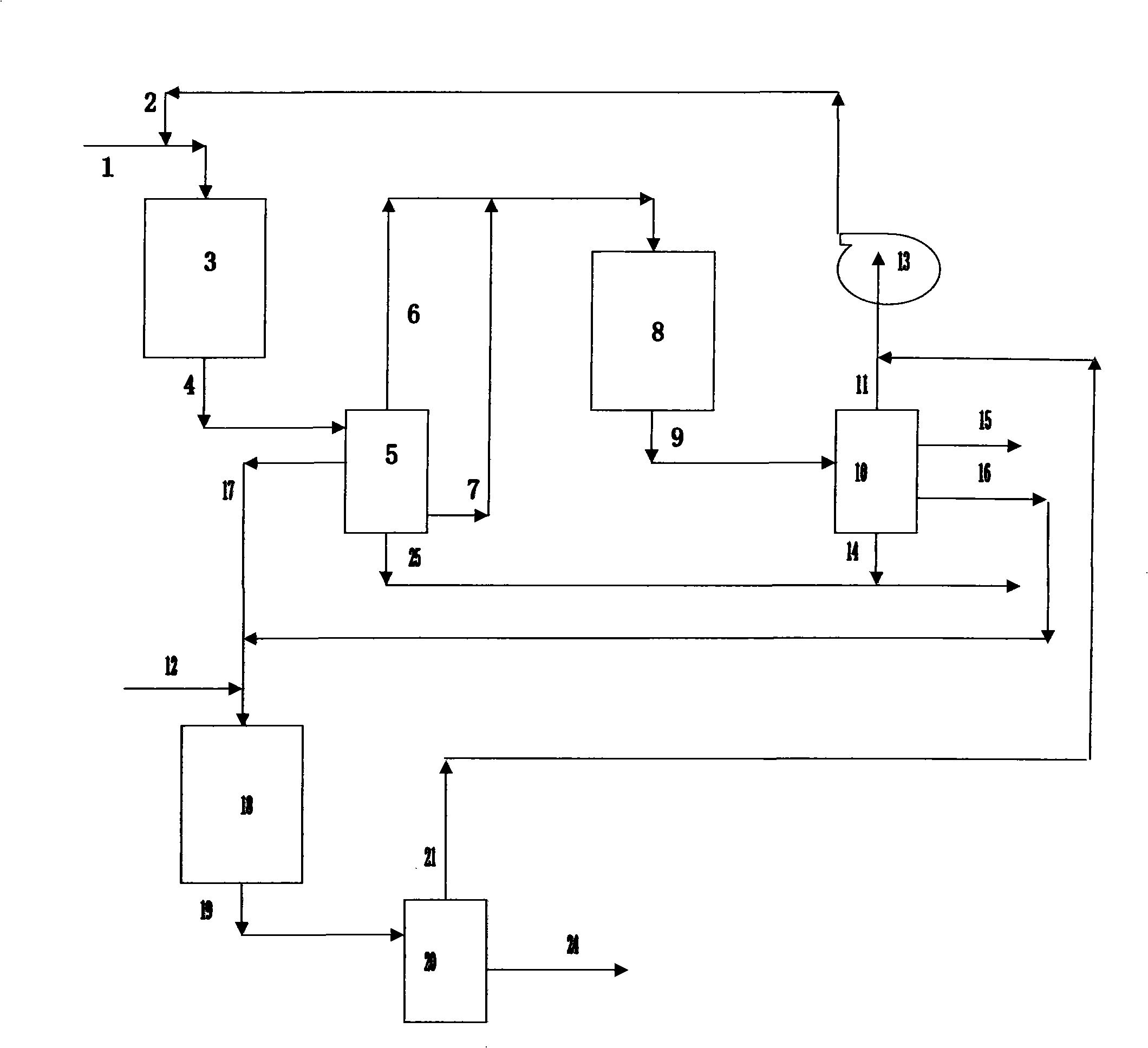

Combined process for treating residual oil

ActiveCN103059998ALess investmentHydrogenation Depth ModerationTreatment with hydrotreatment processesEngineeringHydrogen treatment

The invention discloses a combined process for treating residual oil. Boiling bed residual oil hydrotreatment, delayed coking, wax oil hydrotreatment and catalytic cracking are organically combined in the method. The method concretely comprises the following steps of: enabling a liquid-phase product obtained after residual oil raw materials are subjected to boiling bed hydrotreatment to directly enter a coking fractional distillation column to be in countercurrent contact with oil gas generated through coking, and then, carrying out fractional distillation to obtain a wax oil fraction, and enabling the wax oil fraction to enter a wax oil hydrotreatment device, wherein the liquid-phase product is not subjected to fractional distillation; enabling the obtained liquid-phase product as a raw material to enter a catalytic cracking unit for treating; enabling circulating oil obtained through the fractional distillation of the coking fractional distillation column to return to a delayed coking unit; generating gasoline and diesel products by the coking fractional distillation column; and carrying out catalytic cracking and fractional distillation to obtain liquefied gas, gasoline and diesel products. Compared with the prior art, the combined process has the advantages that a hydrogenization fractional distillation column can be omitted, the investment cost can be reduced, the coking and catalytic cracking raw material sources are expanded, and the coked and catalyzed light oil yield is increased; and meanwhile, the reaction heat energy is sufficiently utilized, and the production energy consumption is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Combined technique of hydrotreating and delay coking of residual oil

ActiveCN103059997ALess investmentHydrogenation Depth ModerationTreatment with hydrotreatment processesWaxThermal energy

The invention discloses a combined technique of hydrotreating and delay coking of residual oil. In the technique, the residual oil hydrotreating adopts an ebullated bed hydrogenation process which comprises the following steps: directly feeding a liquid phase product of residual oil subjected to an ebullated bed hydrogenation process into a coker fractionating tower without fractionation, performing countercurrent contact on the liquid phase product and an oil gas generated through coking, leaching coke powder in the oil gas at a high temperature, discharging a light component generated through hydrogenation and a light component generated through coking from a device together, and circulating wax oil and the fractions above the wax oil back to a delayed coking device. Comparing with the prior art, the combined technique disclosed by the invention can be used for omitting a hydrogenation fractionating tower, reducing the investment cost, enlarging the source of coking raw materials, improving the light oil yield from coking, meanwhile, fully utilizing reaction heat, and reducing the energy consumption in production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Waste water treatment apparatus for generating firedamp and self-circulating anaerobic reactor thereby

InactiveCN1907886AEasy to handleImprove efficiencyWaste based fuelTreatment with anaerobic digestion processesHigh concentrationLow load

This invention relates to a biogas production wastewater treatment device and a cycle anaerobic reactor used in the device, which is used for environmental engineering. The device invented consists of a new self-cycle anaerobic reactor and a computer control system. The core self-cycle anaerobic reactor comprises two overlapping anaerobic reaction zones in series, wherein the upper parts of the two reaction zone are established gas-solid-liquid three phase separators respectively. The lower reaction zone is at an extreme high load, while the upper reaction zone is at low load. The three-phase separator sludge can be separated and returned to the main separator by the separator and biogas is collected. Internal reactor is capable of forming self-circle liquid, and can strengthen mass transfer process of organism and granular sludge and improve handling capability. The floor place of the three phase separator is small, high concentration of organic wastewater can be treated and biogas as biological energy can be produced. The device can achieve the scale biogas technology and automated production, and is an ideal scale wastewater treatment and gas production equipment.

Owner:WUXI MASHENG ENVIRONMENT ENERGY TECH CO LTD

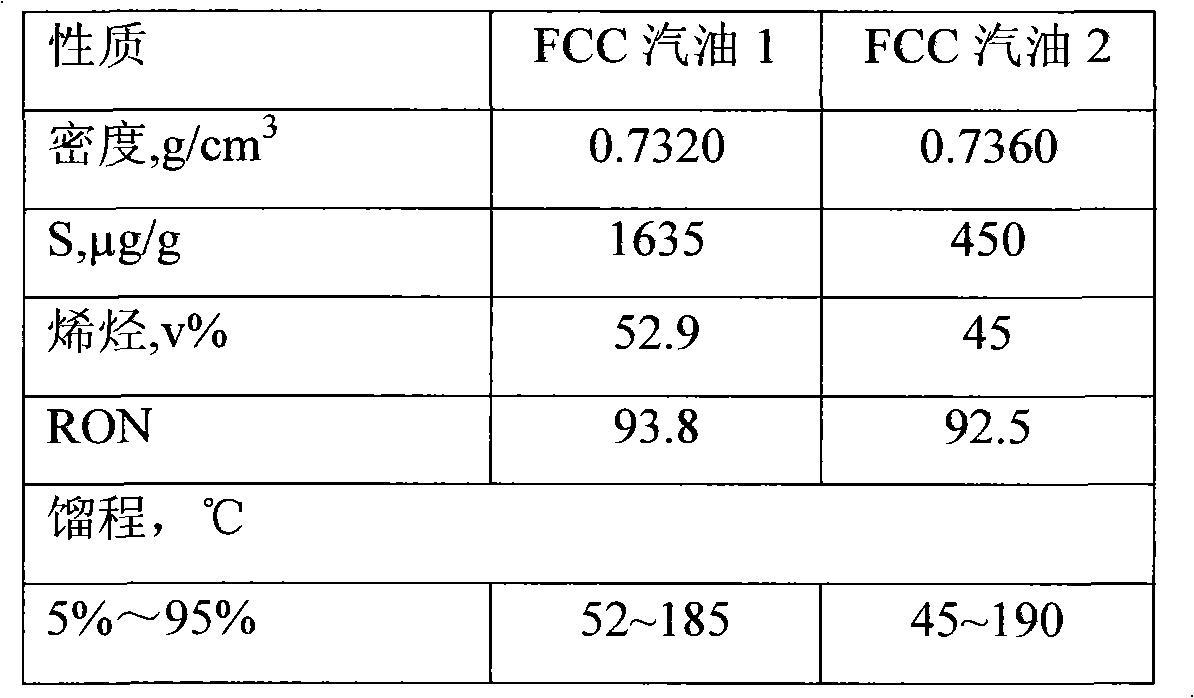

Hydrodesulphurization, olefin reduction method for gasoline

ActiveCN101343562AEasy to take outReduce saturationTreatment with hydrotreatment processesIsomerizationGas phase

The invention discloses a lightweight hydrocarbon hydrogenising method, which adopts a countercurrent hydrogenising reactor and conventional co-current hydrogenising reactor combined technology. The raw material enters into a flash evaporation area of the countercurrent hydrogenising reactor at a lower temperature, gas-phase hydrocarbon flows upwards and performs a reaction of diene and mercaptan generating sulfide and a diene hydrogenising reaction at the upper part of the countercurrent hydrogenising reactor, high boiling sulfide generated by the upper part reaction and liquid-phase hydrocarbon after the raw material flash evaporation flow downwards together, and an alkylation reaction of thiophene sulfur and olefin is performed at the lower part of the countercurrent hydrogenising reactor. Liquid phase discharged at the bottom of the countercurrent hydrogenising reactor and new hydrogen are mixed and enter into the co-current hydrogenising reactor to perform the reactions, such as deep hydrodesulfurization, selective cracking or isomerization and the like after being heated. Effluent of the co-current reaction is performed for the gas-liquid countercurrent hydroprocessing of the moderate condition. The method has the advantages that the technological process is simple, the desulphurization effect is good, the octane value loss is low, the product yield is high, and the required equipment is few. The method is mainly used for the secondary processing the poor-quality gasoline, namely, the upgrading process of catalytic cracking gasoline, coking gasoline or thermal cracking gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

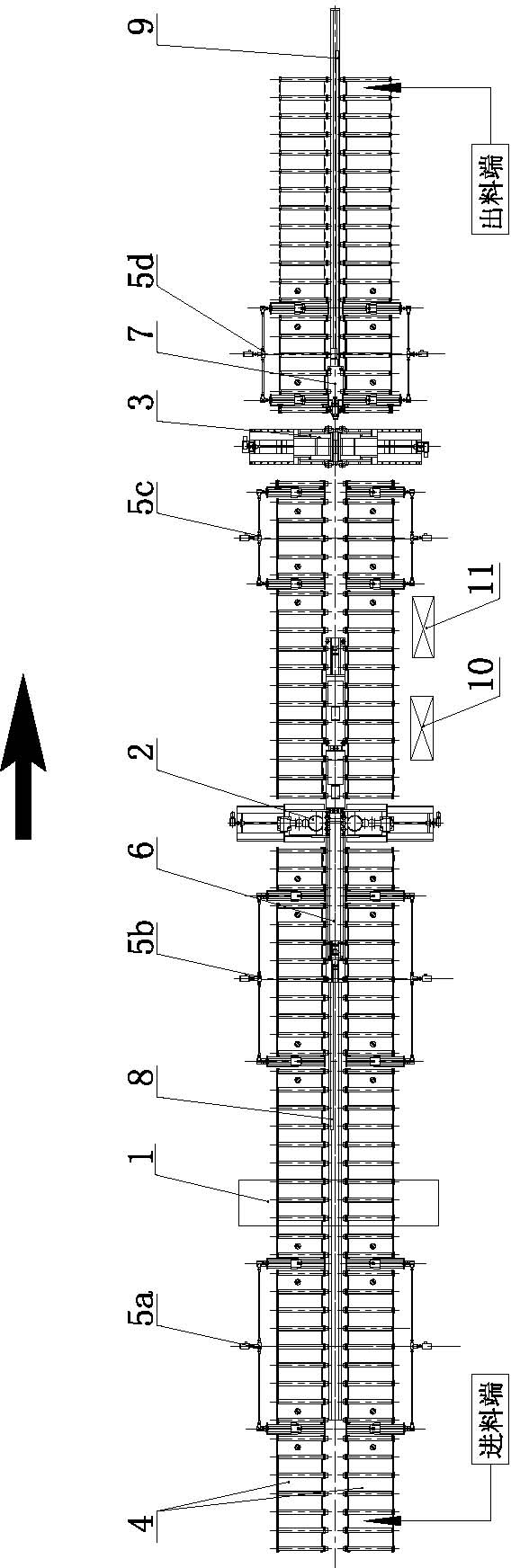

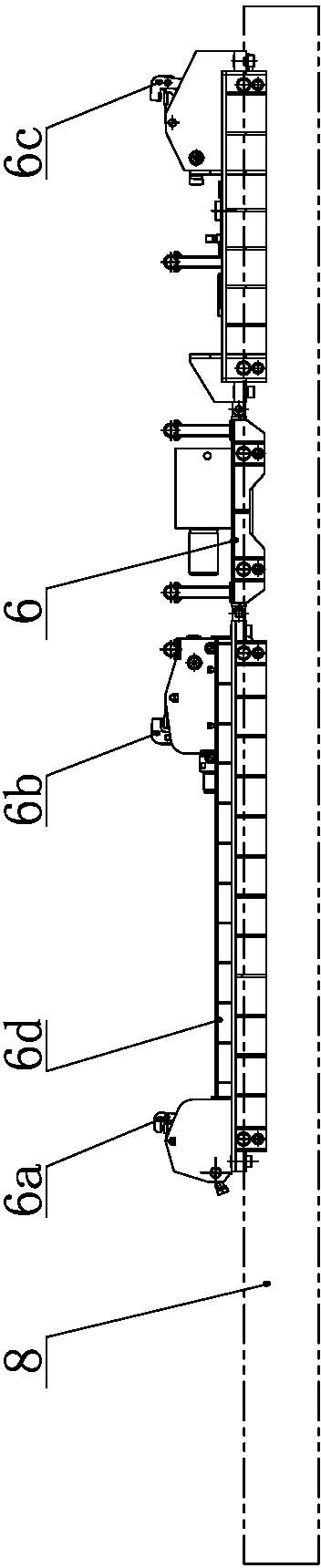

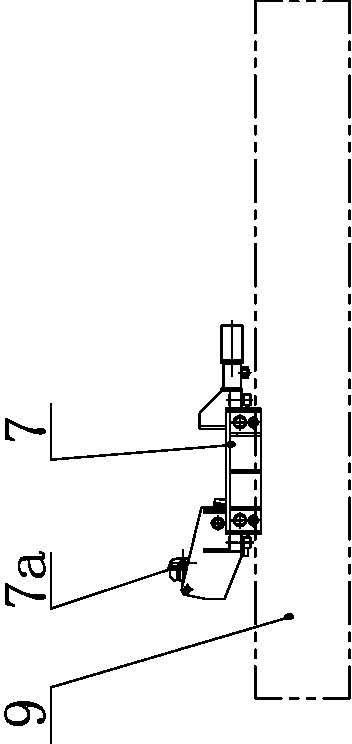

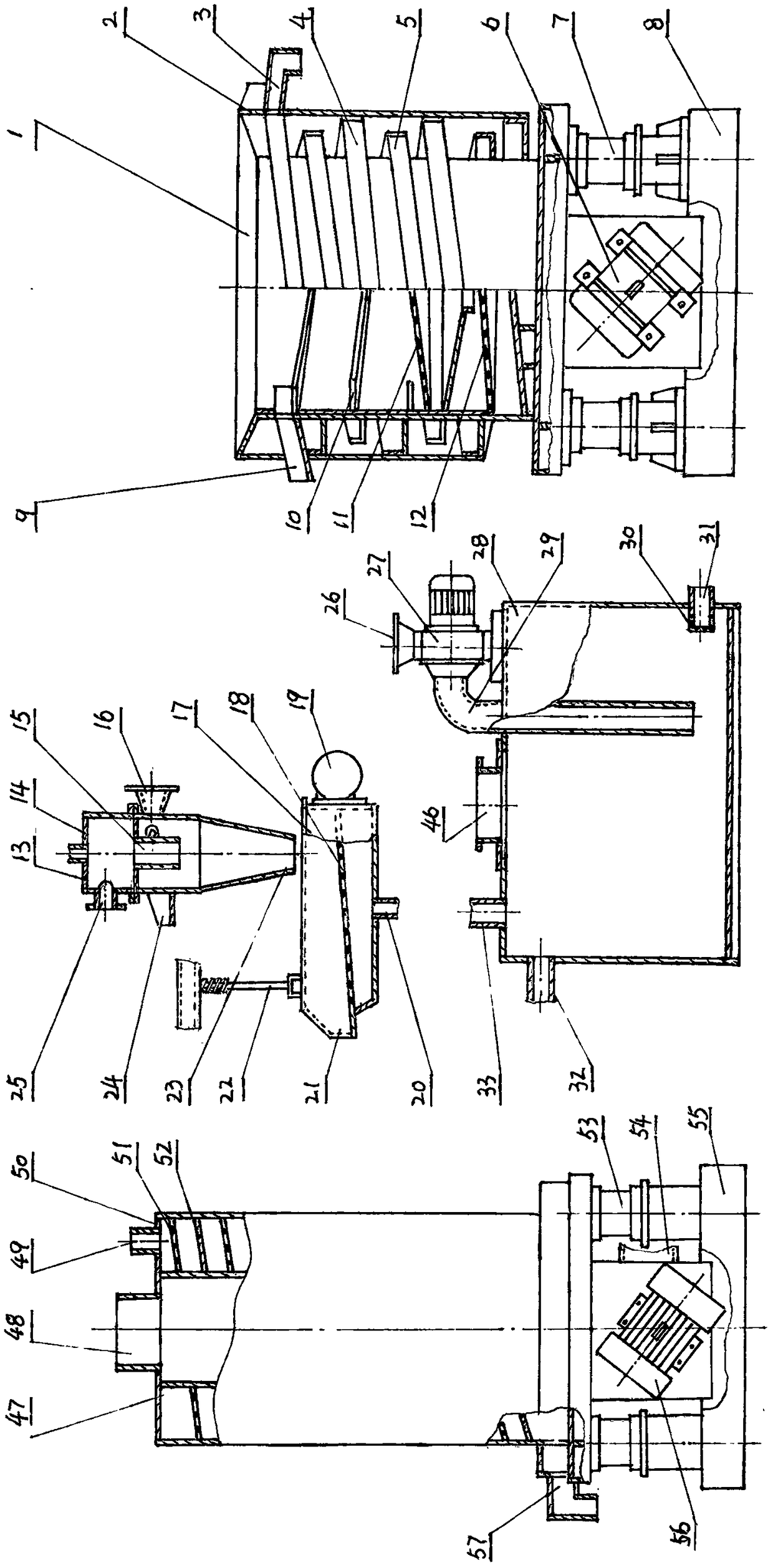

Flaw-detecting, edge-milling and pre-bending unit for straight slit steel pipe

InactiveCN102218660AImprove coordinationSave investment costsOther manufacturing equipments/toolsMetal working apparatusSheet steelAutomatic control

The invention discloses a flaw-detecting, edge-milling and pre-bending unit for a straight slit steel pipe, belonging to the field of a steel pipe production device. The flaw-detecting, edge-milling and pre-bending unit comprises two driven roller ways that are arranged in parallel, a hydraulic system and an electric automatic control system, wherein a flaw-detecting device, a milling device and a pre-bending device are sequentially arranged on the two driven roller ways from a feed end to a discharge end; four groups of centering devices are sequentially arranged on a roller way of the input end of the flaw-detecting device, a roller way of the input end of the milling device and roller ways of the input end and output end of the pre-bending device; a large trolley guideway and a small trolley guideway are sequentially arranged between the two driven roller ways from the feed end to the discharge end; a large trolley device is arranged on the large trolley guideway; a small trolley device is arranged on the small trolley guideway; the large trolley device is provided with three gripping clamps; and the small trolley device is provided with a gripping clamp. In the unit, a steel plate is dragged to move along the driven roller ways by the large trolley and the small trolley, therefore, the production cost is reduced, and the energy consumption is reduced; and the flaw-detecting, edge-milling and pre-bending unit can be directly used for the flaw-detecting, milling and pre-bending process of the straight slit steel pipes.

Owner:YANGZHOU METALLURGICAL MACHINERY

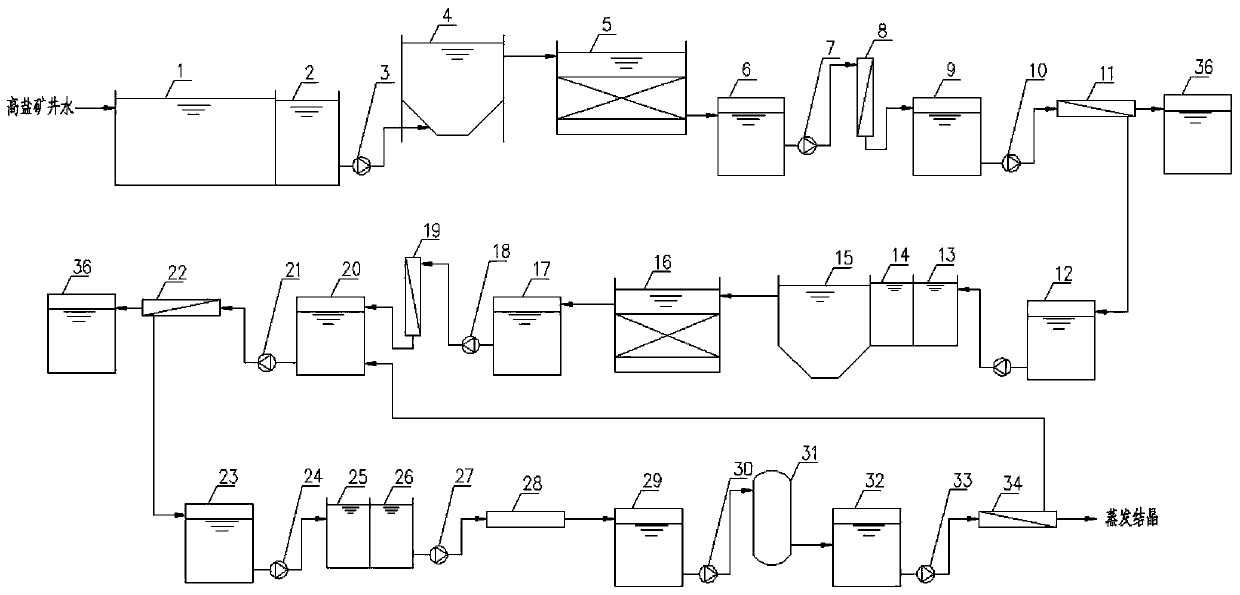

Stainless steel liquid waste regeneration system based on spray roasting method and control method thereof

ActiveCN105776385AHigh recovery rateImprove recycling effectGas treatmentUsing liquid separation agentLiquid wasteCooling tower

The invention discloses a stainless steel liquid waste regeneration system based on the spray roasting method.The system comprises an adsorption tower, a jet cleaning tower, a spray cooling tower, an oxidizing tower and a denitration device which are connected in sequence, wherein a spray liquid outlet of the jet cleaning tower is communicated with a first spray liquid inlet of the jet cleaning tower and a spray liquid inlet of the adsorption tower through pipelines, a spray liquid outlet of the spray cooling tower is communicated with a spray liquid inlet of the spray cooling tower and a second spray liquid inlet of the jet cleaning tower through pipelines, a spray liquid outlet of the oxidizing tower is communicated with a spray liquid inlet of the oxidizing tower and a chamber of the jet cleaning tower through pipelines, a jet cleaning pump is installed on a pipeline at the position of the spray liquid outlet of the jet cleaning tower, a spray cooling pump and a spray cooling circulating liquid cooler are installed on a pipeline at the position of the spray liquid outlet of the spray cooling tower, and an oxidizing tower pump and an oxidizing tower circulating liquid cooler are installed on a pipeline at the position of the spray liquid outlet of the oxidizing tower.By the adoption of the system, HNO3 recovery rate is increased.

Owner:WISDRI ENG & RES INC LTD

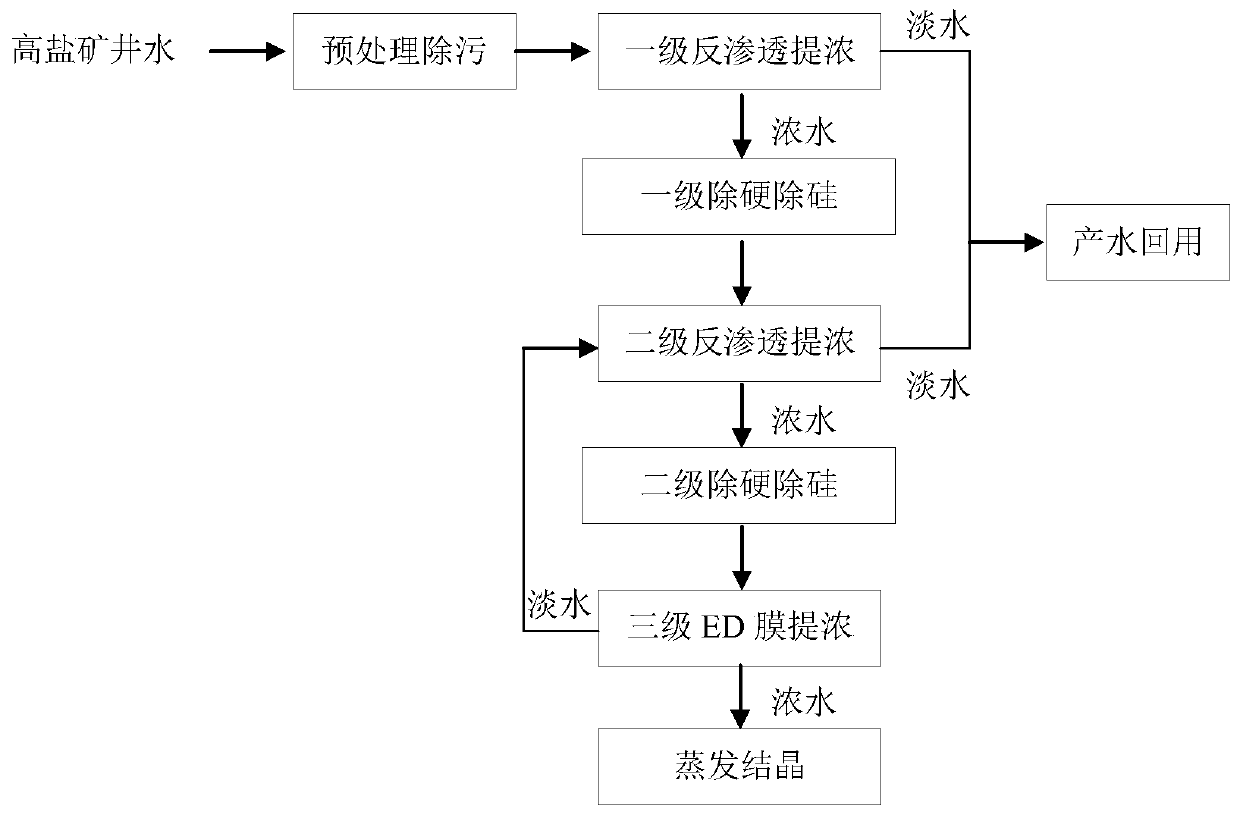

Method and system for concentrating high-salt mine well water

PendingCN111285531ASave investment costsSave running costsWaste water treatment from quariesMultistage water/sewage treatmentWater treatment systemReverse osmosis

The invention relates to a water treatment system, in particular to a method and a system for concentrating high-salt mine well water, and belongs to the technical field of coal mine water treatment.The method comprises the following steps: firstly, pretreating the high-salt mine well water to remove oil, suspended matters and colloid pollution factors; allowing effluent to enter a first-stage reverse osmosis system; feeding concentrated water of the first-stage reverse osmosis system to a first-stage hardness and silicon removal system to be subjected to hardness and silicon removal treatment; allowing effluent to enter a second-stage reverse osmosis system; feeding second-stage reverse osmosis concentrated water to a second-stage hardness and silicon removal system to be subjected to hardness and silicon removal treatment, and feeding effluent to an ED membrane system. The first-stage reverse osmosis system and the second-stage reverse osmosis system are both fed into a recycling water tank. According to the method, the recovery rate of the concentration section can reach 98%, the TDS of concentrated water after concentration can reach 150 g / L-200 g / L, compared with a conventional concentration mode, the method reduces the subsequent evaporative crystallization scale by 1 / 2-3 / 4, and the method has the advantages of being low in investment and low in operation cost.

Owner:CHINA COAL TECH & ENG GRP HANGZHOU ENVIRONMENTAL PROTECTION INST

Dry and hot-wet combined old sand regenerating method and regeneration system thereof

InactiveCN108620529AQuality improvementStrong ability to remove inert film on the surface of old sand grainsMould handling/dressing devicesHeat flowThermal water

The invention relates to a dry and hot-wet combined old sand recycling method and a recycling system thereof, which can be used for casting production. According to the invention, organic fat-cured alkaline phenolic resin old sand is first placed in a centrifugal old sand recycling machine to remove a resin film on the surface of sand as much as possible, and then the sand is cleaned with hot water in a hot-flow old sand recycling machine, and under the action of high temperature and strong stirring, residual resin on the surface of the sand is dissolved in water; sewage discharged is filteredthrough a filter to obtain resin and fine powder, and remaining water is heated and then reused for sand washing; hot recycled sand is cleaned and dehydrated, then sent into a vacuum dryer to be dried, and sieved by a vibrating sieve to be used as new sand, and resin filtered is processed and then used for other purposes; waste hot water produced by cooling a metallurgical electric furnace in therecycling process is heated by a heat pump and then used as sand washing water. The dry and hot-wet combined old sand recycling method can not only produce high quality recycled sand but also realizezero discharge of sewage, avoids harmful smoke pollution caused by thermal regeneration of resin sand, and achieves energy conservation and environmental protection.

Owner:李江平

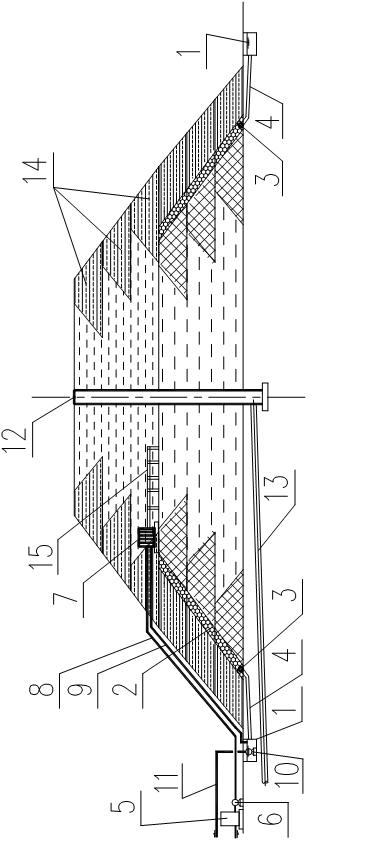

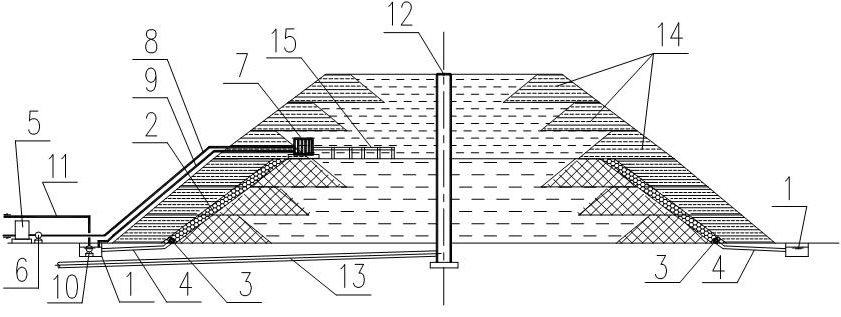

Method for increasing capacity of flat type wet-method red mud disposal site by dry method

ActiveCN101845817ASave investment costsSave operating costsClimate change adaptationEmbankmentsFiltrationRed mud

The invention discloses a method for increasing the capacity of a flat type wet-method red mud disposal site by a dry method, which comprises the following steps of: building an intercepting ditch (1) at the periphery of a new border; paving a rubble layer (2) on the outer sloping surface of the conventional wet-method red mud disposal site, and burying a perforated collector pipe (3) on the bottom of the wet-method red mud disposal site; connecting the perforated collector pipe (3) with a seepage pipe (4), and putting the seepage pipe (4) into the intercepting ditch (1); covering geotextile on the surface of the rubble layer (2); building a red mud storage tank (5) outside the intercepting ditch (1), connecting the red mud storage tank (5) with a feed pump (6), arranging a press filter (7) on the top of a fill dam of the conventional wet-method red mud disposal site, and arranging a water pump (10) at the lowest point of the intercepting ditch (1); heightening a flood discharge shaft (12) to the planned elevation; and performing press filtration on the red mud by using the press filter (7), conveying the red mud to a piling area for dry-method stockpiling, discharging flood by using the flood discharge shaft (12), collecting the rainwater, filtrate generated by the press filter (7) and seepage water on the outer slop of the conventional dam by using the intercepting ditch (1), and conveying back to a plant area by using a back water pump (10).

Owner:GUIYANG AL-MG DESIGN & RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com