Method for increasing capacity of flat type wet-method red mud disposal site by dry method

A red mud and wet process technology, applied in the field of red mud storage in alumina production, can solve the problems of only one-time construction of earth-rock dam storage, no mechanical strength, high operating costs, etc., saving investment and The effect of operating costs, increasing storage capacity, and large economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

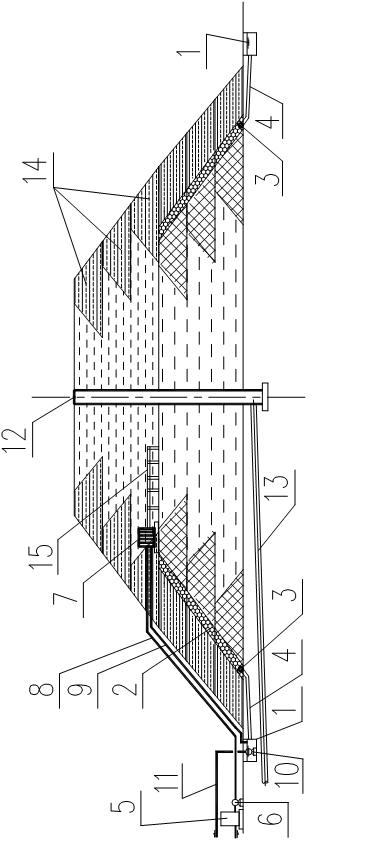

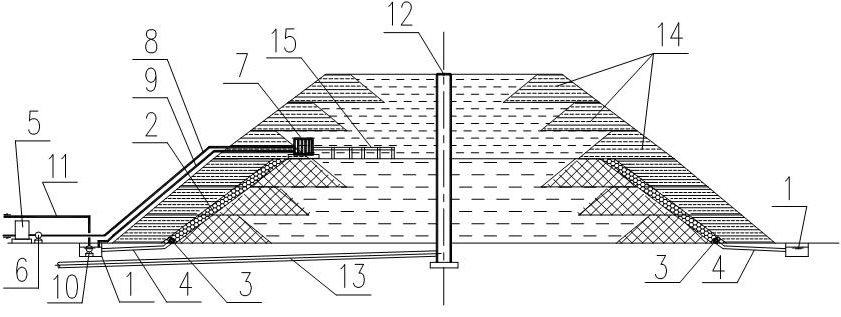

[0019] Embodiments of the present invention: as figure 1 As shown, the flat land type wet red mud stockpiling yard of the present invention carries out the method for dry process capacity increasing, implements according to the following steps:

[0020] According to the surrounding land conditions of the original wet-process red mud stockpile, the boundary of the stockpiling area is expanded, and intercepting ditches 1 are built around the new stockpiling boundary. A gravel layer 2 with a certain thickness is laid on the outer slopes of the initial dam and accumulation dam of the original wet-process red mud stockpile, and a perforated water collection pipe 3 is buried at the bottom. The perforated water collection pipe 3 is connected to the seepage pipe 4, and the seepage pipe 4 is connected to the intercepting ditch 1 with a certain slope. The surface of the gravel layer 2 is covered with a layer of geotextile.

[0021] Build several red mud slurry storage tanks 5 outside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com