Alumina melting method

A technology of alumina and ore pulp, applied in alumina/aluminum hydroxide and other directions, can solve the problems of low secondary steam heat utilization, less self-evaporation stages, and large construction investment, so as to improve heat utilization rate and reduce pipeline length. , the effect of increasing the heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the examples, but it is not intended to limit the present invention.

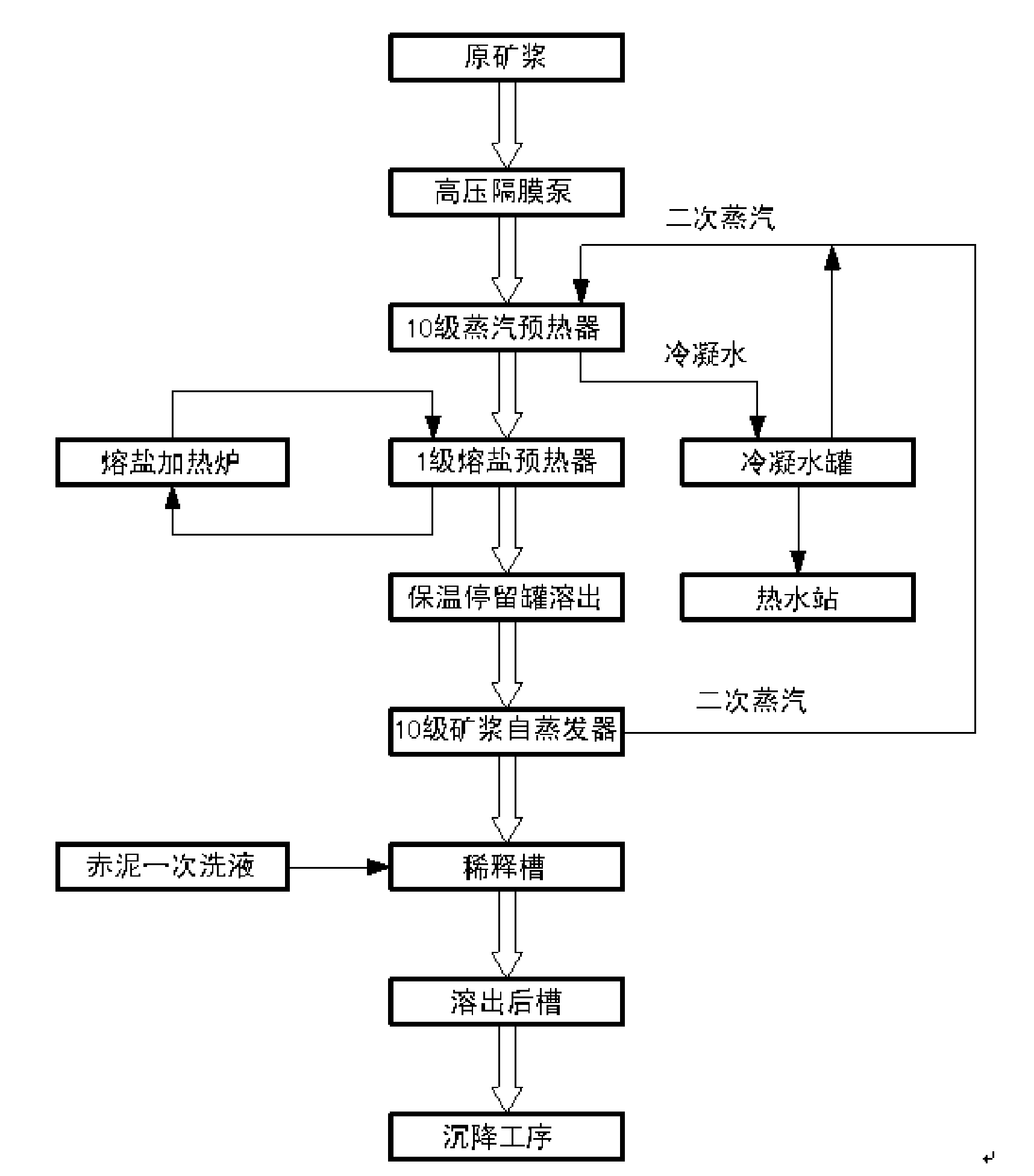

[0020] embodiments of the present invention. A kind of dissolution method of alumina, such as figure 1 shown. The method dissolves in the following steps:

[0021] a. The raw ore pulp with a temperature of 85-100°C from the atmospheric desiliconization process is sent to a steam preheater to be preheated to 200-230°C;

[0022] b. The slurry preheated by the steam preheater is sent to the molten salt heater to be heated to 260-280℃;

[0023] c. The ore pulp heated by the molten salt heater is sent into the thermal insulation dissolution tank and kept for 30-45 minutes until the dissolution process is completed;

[0024] d. The dissolved pulp is sent to the pulp to cool down and depressurize from the evaporator;

[0025] e. The ore slurry evaporated and concentrated from the evaporator is sent to the dilution tank,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com