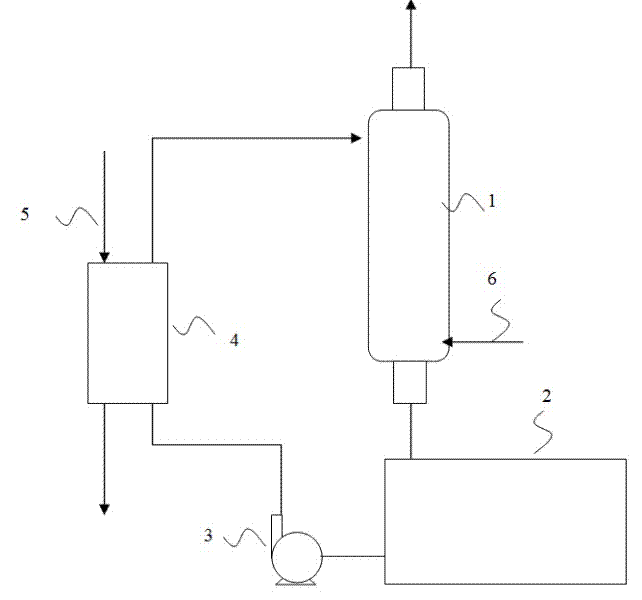

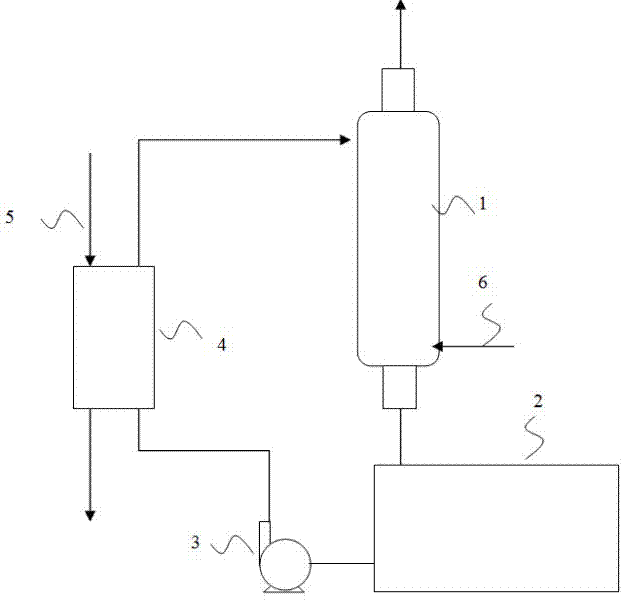

Anti-scabing method of aluminum oxide roasting furnace flue gas waste heat recovery process

A flue gas waste heat, roasting furnace technology, applied in furnaces, waste heat treatment, furnace components and other directions, can solve the problems affecting the normal operation cycle of the recovery system, equipment and pipeline blockage, unusable and other problems, to ensure normal operation, reduce scarring Speed, the effect of improving the operation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0011] Roasting furnace: the speed of the exhaust fan is 75%, and the feeding volume is 79t / h.

[0012] Waste heat recovery system: heat exchanger flue gas throughput 50%, flue gas inlet temperature 153°C, outlet temperature 48°C, feed water temperature 47°C, outlet water temperature 76°C, flow rate 450m 3 / h.

[0013] Indirect heat exchange equipment: the user's incoming water temperature is 44°C, and the outlet water temperature is 73°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com