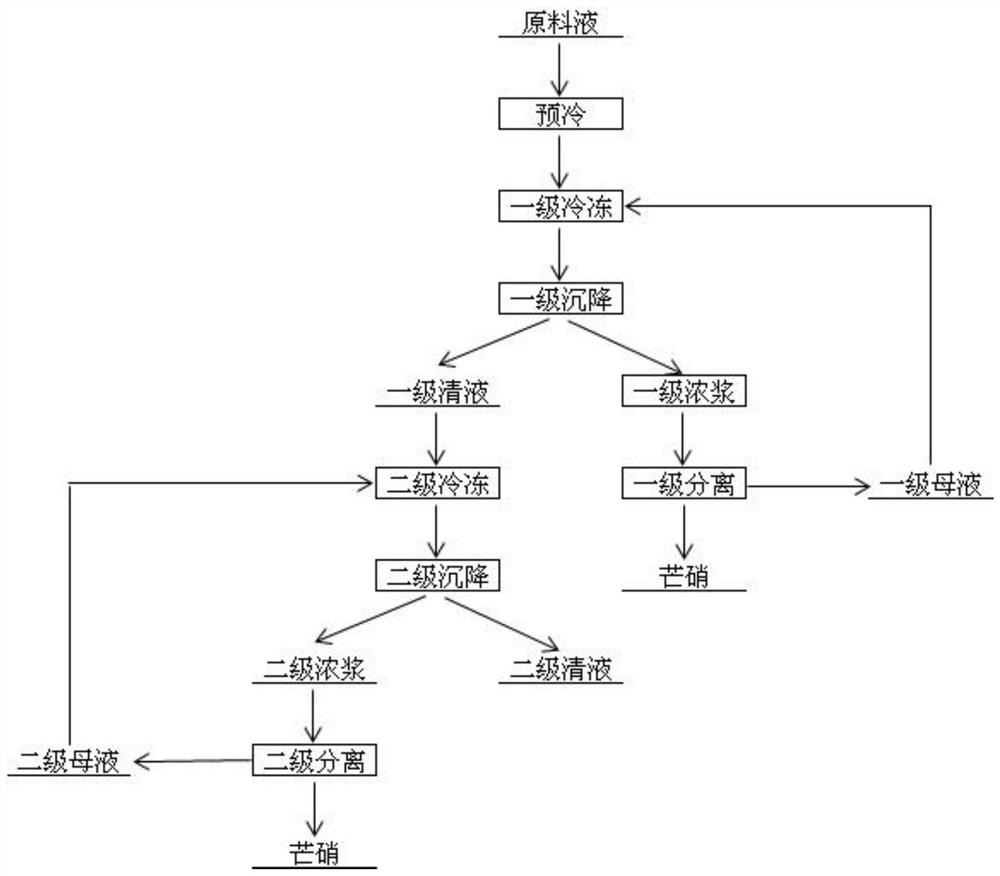

A kind of Glauber's salt continuous freezing crystallization process

A technology of freeze crystallization and freeze crystallizer, applied in solution crystallization, alkali metal sulfite/sulfite, inorganic chemistry, etc., can solve the problem of loss of heat exchange capacity of heat exchangers, unstable product quality, and large fluctuations in operating parameters and other problems to achieve the effect of reducing scarring, improving equipment utilization and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

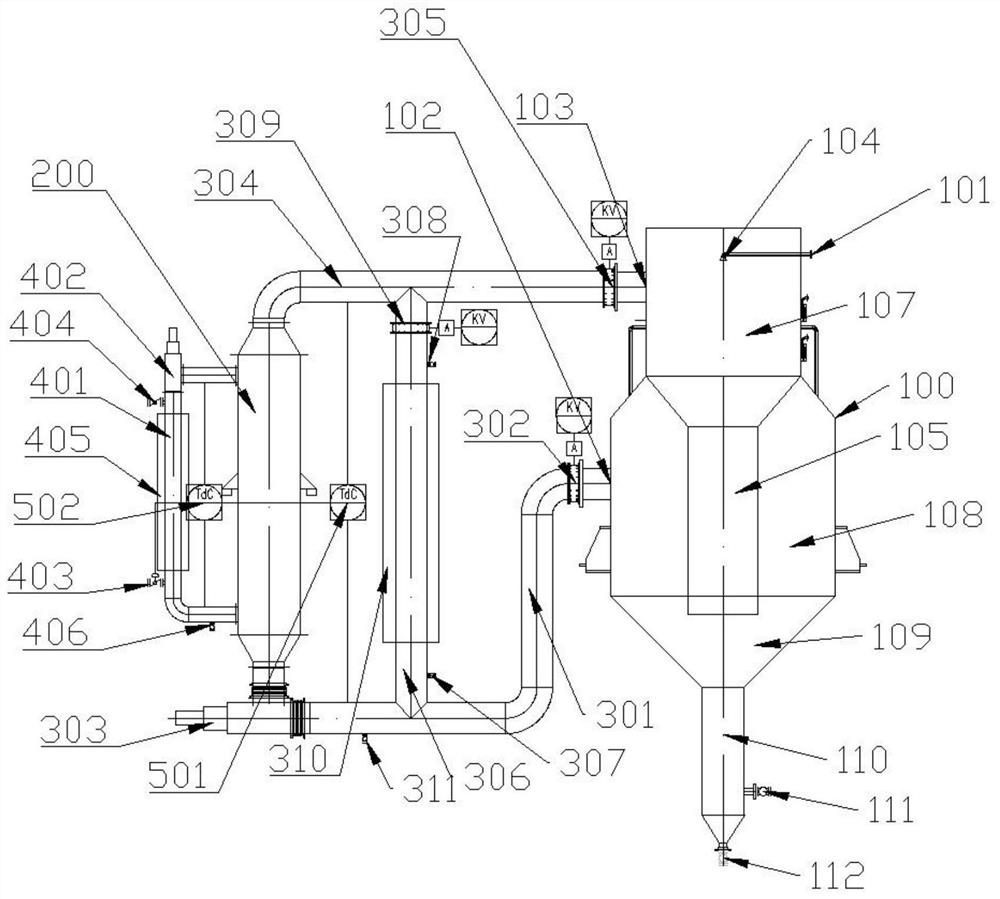

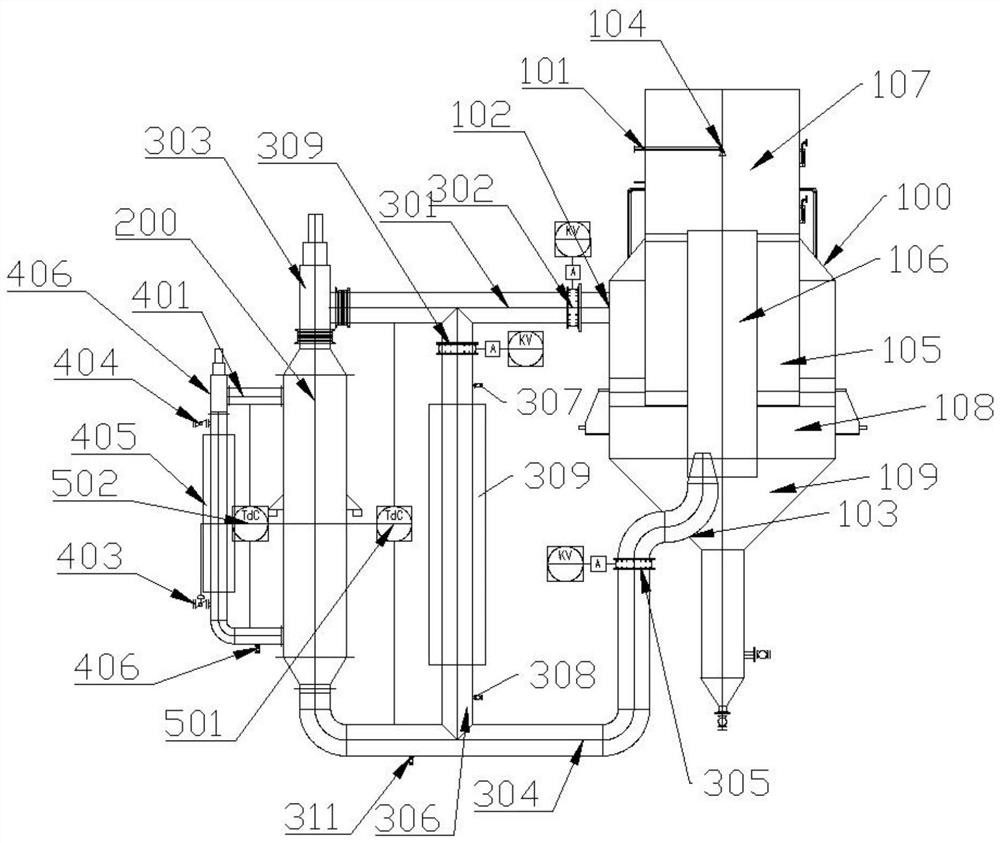

Method used

Image

Examples

Embodiment 1

[0055] Take the raw material solution containing sodium sulfate in the production process of lithium hydroxide monohydrate in an enterprise, wherein SO4 in the raw material solution 2- The content is 118.2g / L. The raw material liquid is subjected to freeze crystallization according to the above process, wherein, in step A, it is first cooled to 40°C, and then cooled to 25°C; SO4 in supernatant 2- The content is 44.0g / L, and the nitrate analysis rate is 82.5%; in step E, the secondary freezing and crystallization temperature is -6~-5°C; in step F, the SO4 in the secondary clear liquid 2- The content is 19.4g / L, and the nitrate analysis rate is 58.0%. The accumulative denitrification rate of primary freezing crystallization and secondary freezing crystallization is 92.7%.

Embodiment 2

[0057] Take the raw material solution containing sodium sulfate in the production process of lithium hydroxide monohydrate in an enterprise, wherein SO4 in the raw material solution 2- The content is 119.4g / L. The raw material liquid is subjected to freezing and crystallization according to the above process, wherein, in step A, it is first cooled to 40°C, and then cooled to 25°C; in step B, the first-stage freezing and crystallization temperature is 6-7°C; SO4 in supernatant 2- The content is 41.6g / L, and the nitrate analysis rate is 83.8%; in step E, the secondary freezing crystallization temperature is -7~-6°C; in step F, the secondary clear liquid SO4 2- The content is 16.2g / L, and the nitrate analysis rate is 63.0%. The accumulative nitrate removal rate of primary freezing crystallization and secondary freezing crystallization is 94.0%.

Embodiment 3

[0059] Take the raw material solution containing sodium sulfate in the production process of lithium hydroxide monohydrate in an enterprise, wherein, SO4 in the raw material solution 2- The content is 121.6g / L. The raw material solution is subjected to freezing and crystallization according to the above-mentioned process, wherein, in step A, it is first cooled to 40°C, and then cooled to 25°C; SO4 in supernatant 2- The content is 40.2g / L, and the nitrate analysis rate is 84.8%; in step E, the secondary freezing and crystallization temperature is -8~-7°C; in step F, the SO4 in the secondary clear liquid 2- The content is 15.5g / L, and the nitrate analysis rate is 63.3%. The accumulative denitrification rate of primary freezing crystallization and secondary freezing crystallization is 94.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com