Patents

Literature

614results about "Sulfate/bisulfate preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

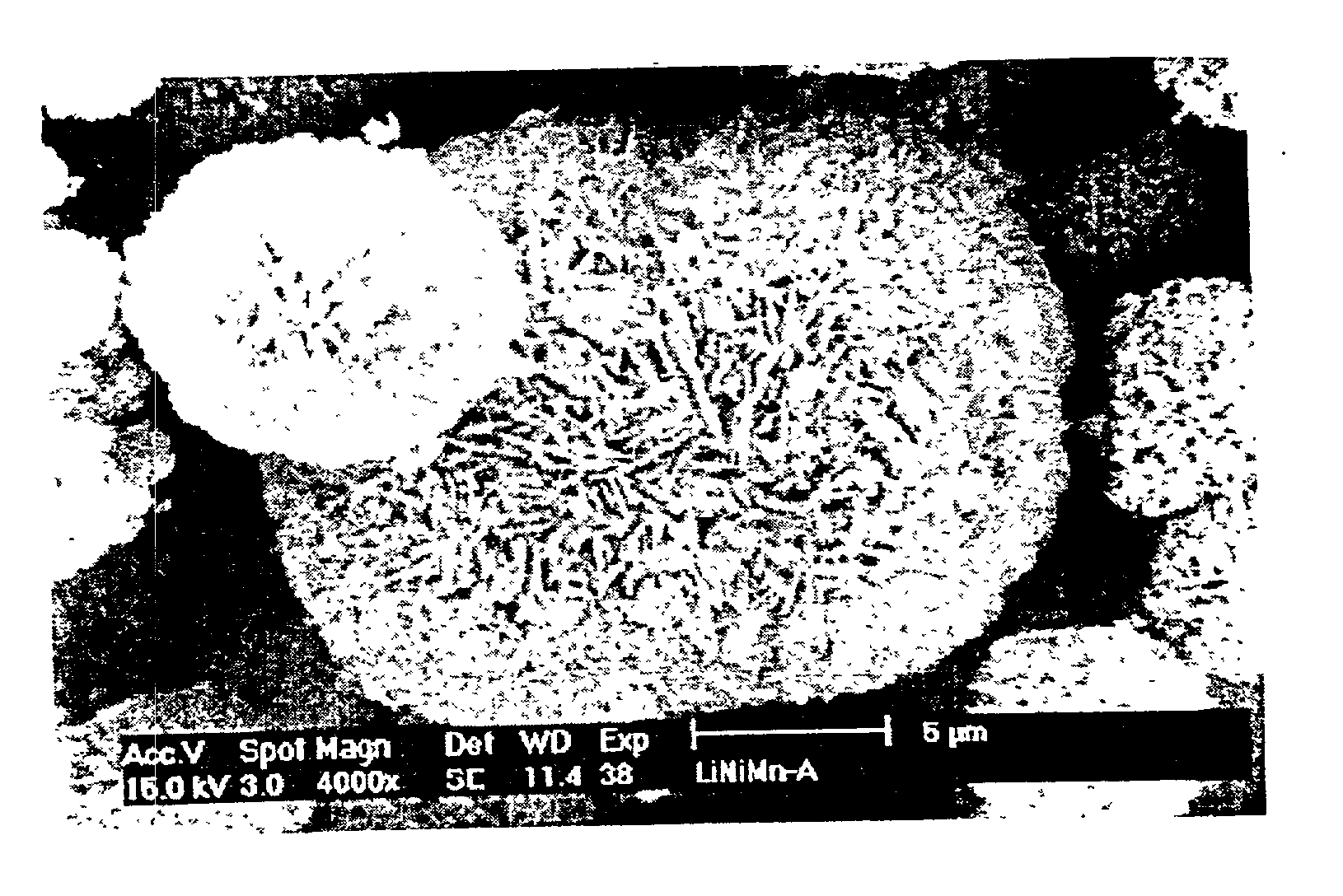

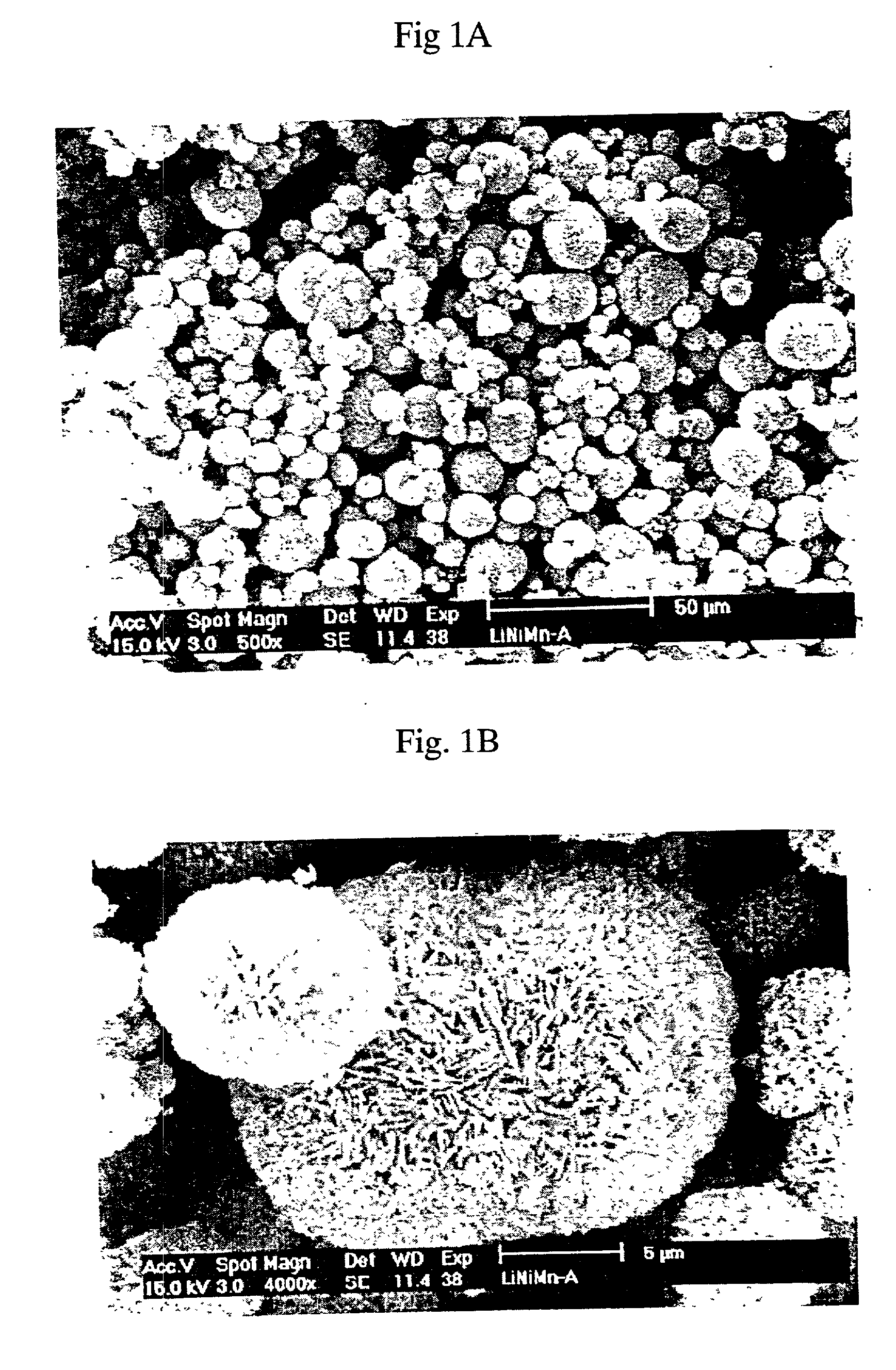

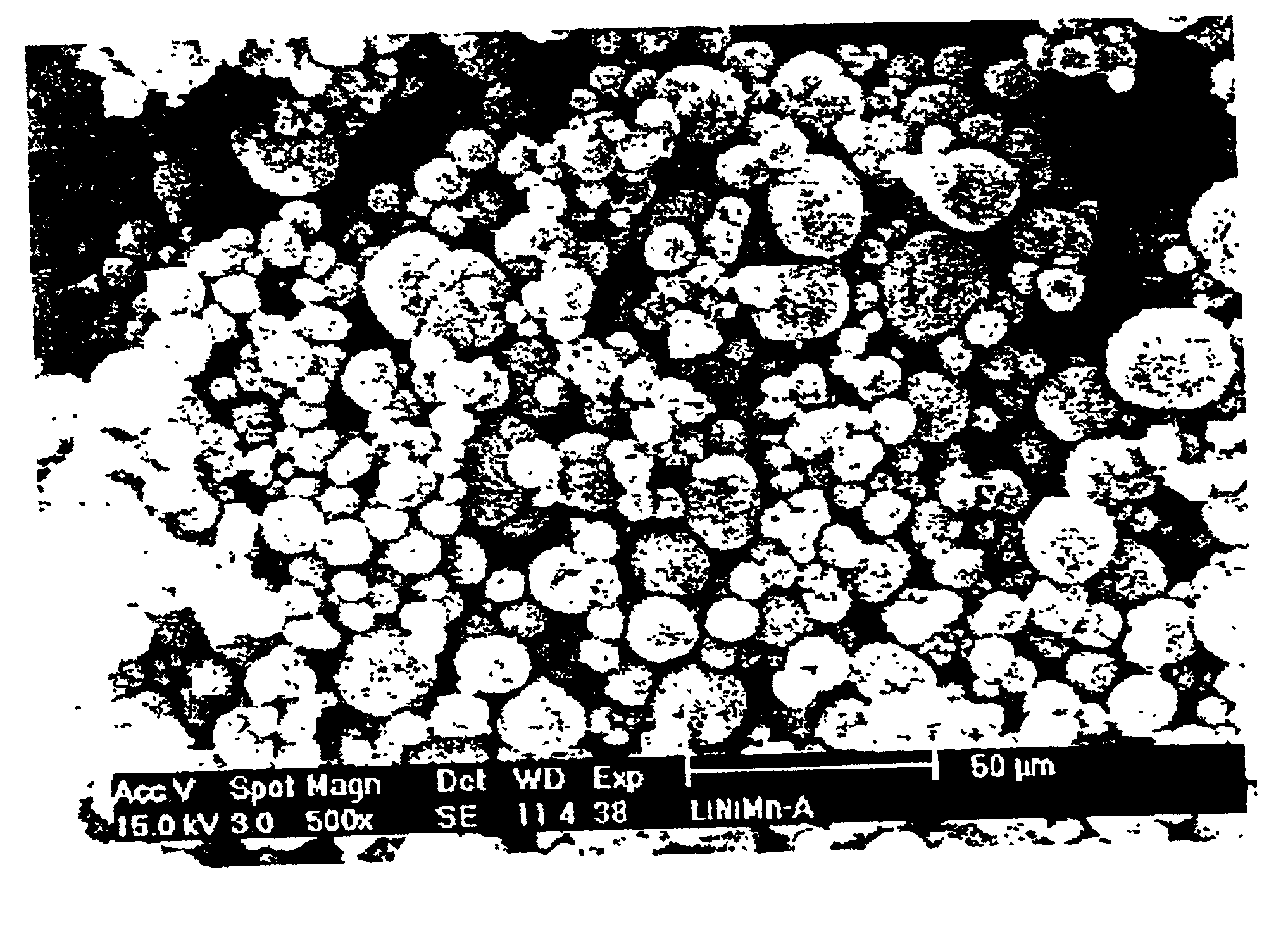

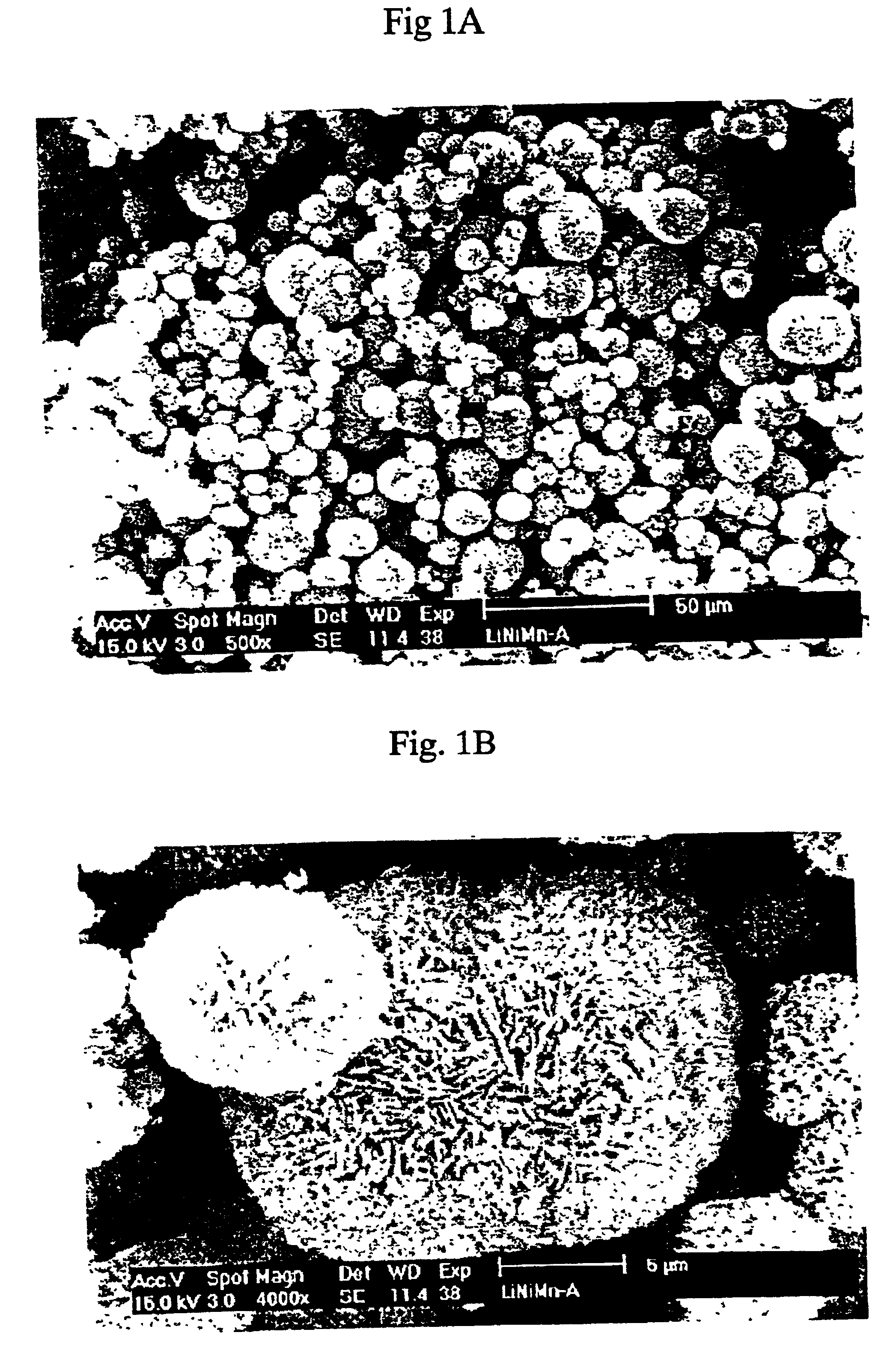

Positive active material for rechargeable lithium battery and method of preparing same

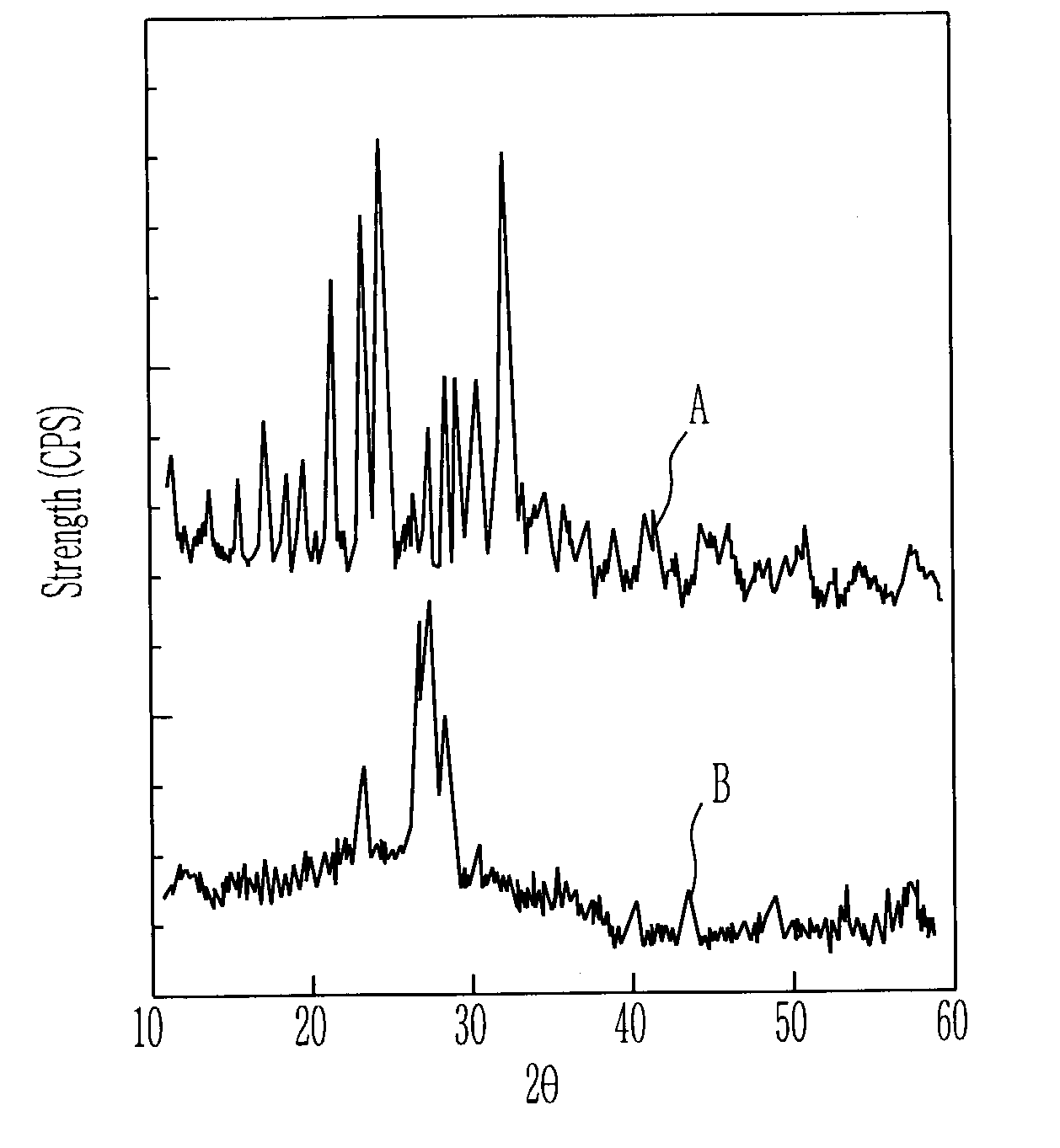

InactiveUS20020055042A1Improve thermal stabilityElectrode manufacturing processesZirconium compoundsPhysical chemistryLithium battery

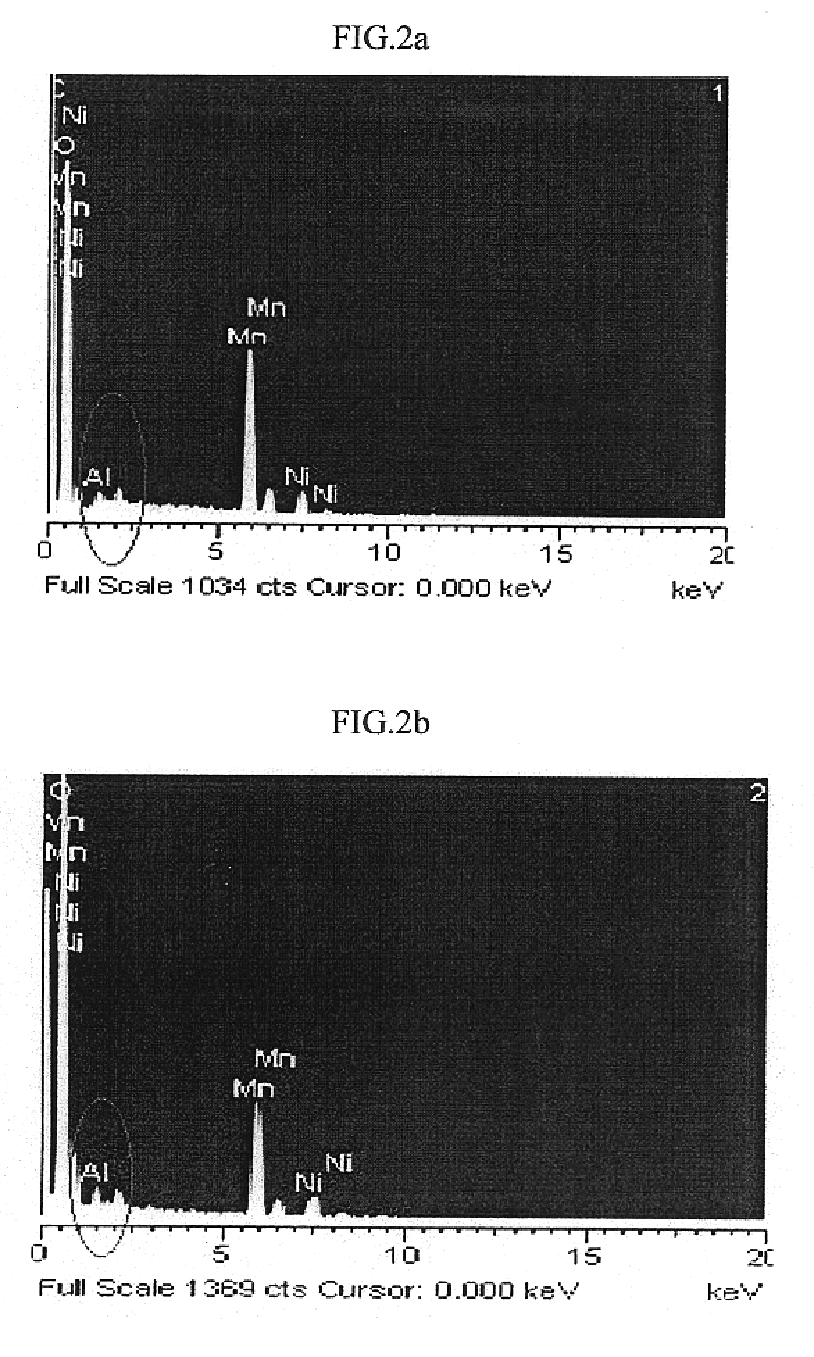

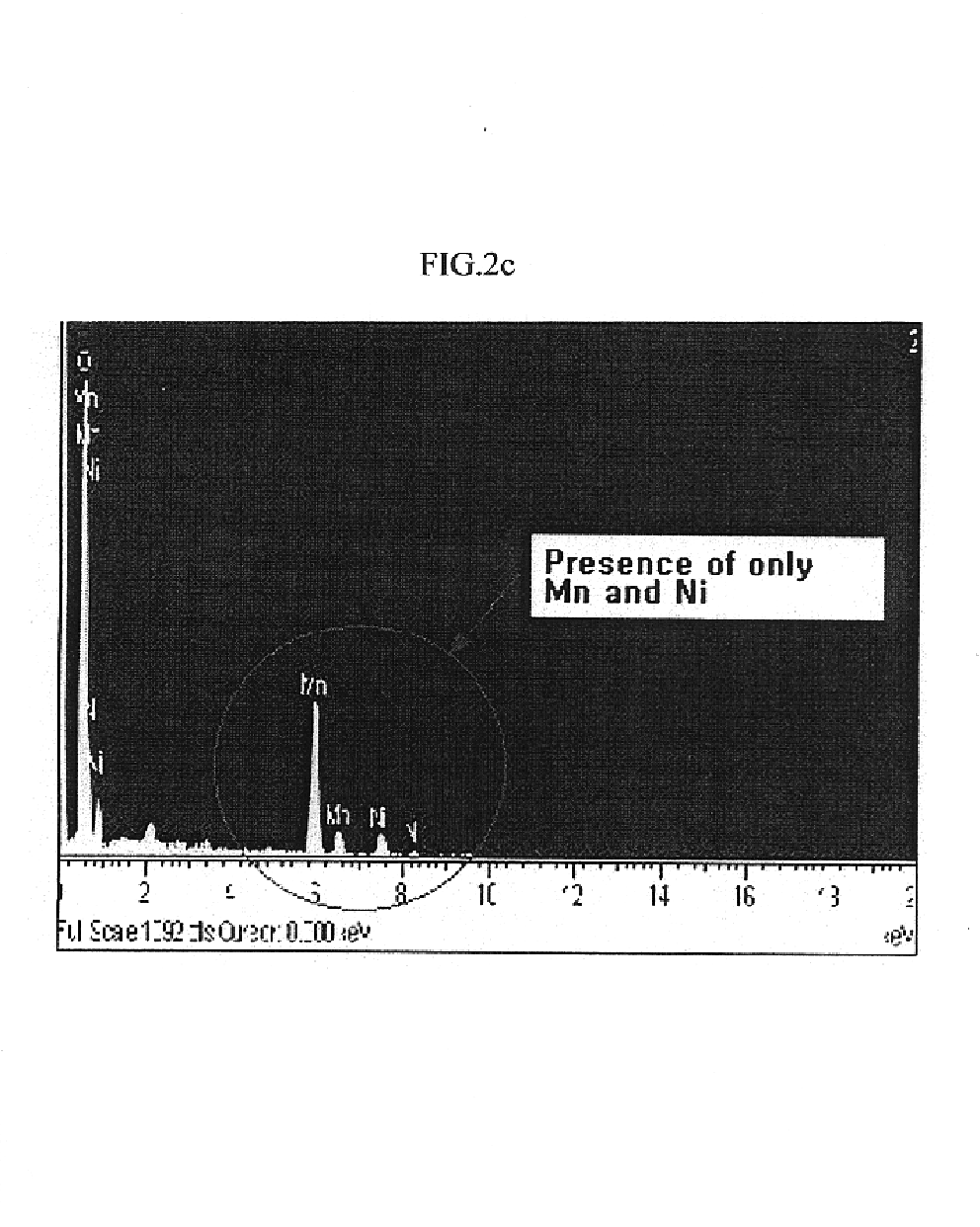

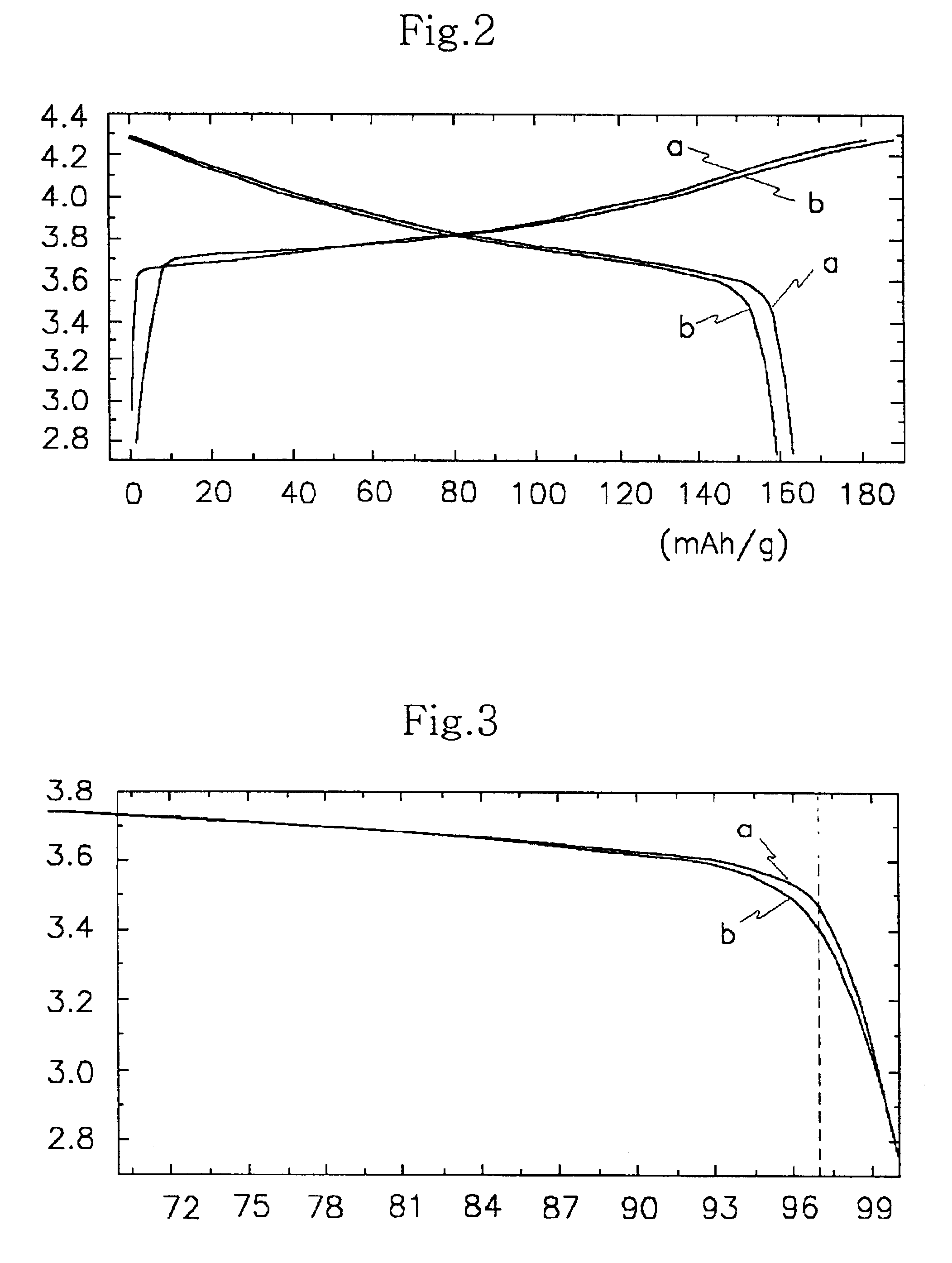

Disclosed is a positive active material for a rechargeable lithium battery. The positive active material includes at least one compound represented by formulas 1 to 4 andl a metal oxide or composite metal oxide layer formed on the compound. <table-cwu id="TABLE-US-00001"> <number>1< / number> <tgroup align="left" colsep="0" rowsep="0" cols="3"> <colspec colname="OFFSET" colwidth="42PT" align="left" / > <colspec colname="1" colwidth="77PT" align="left" / > <colspec colname="2" colwidth="98PT" align="center" / > <row> <entry>< / entry> <entry>< / entry> < / row> <row> <entry>< / entry> <entry namest="OFFSET" nameend="2" align="center" rowsep="1">< / entry> < / row> <row> <entry>< / entry> <entry>LixNi1-yMnyF2< / entry> <entry>(1)< / entry> < / row> <row> <entry>< / entry> <entry>LixNi1-yMnyS2< / entry> <entry>(2)< / entry> < / row> <row> <entry>< / entry> <entry>LixNi1-y-zMnyMzO2-aFa< / entry> <entry>(3)< / entry> < / row> <row> <entry>< / entry> <entry>LixNi1-y-zMnyMzO2-aSa< / entry> <entry>(4)< / entry> < / row> <row> <entry>< / entry> <entry namest="OFFSET" nameend="2" align="center" rowsep="1">< / entry> < / row> < / tgroup> < / table-cwu> (where M is selected from the group consisting of Co, Mg, Fe, Sr, Ti, B, Si, Ga, Al, Sc, Y, La, Ce, Pr, Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, Ac, Th, Pa, U, Np, IPu, Am, Cm, Bk, Cf, Es, Fm, Md, No and Lr, 0.95<=x<=1.1, 0<=y<=0.99, 0<=,z<=0.5, and 0<=a<=0.5)

Owner:SAMSUNG SDI CO LTD

Production of biodiesel

InactiveUS20060225341A1Fatty oils/acids recovery from wasteFatty acid esterificationBiodieselRefinery

A process for the production of biodiesel is disclosed. In a preferred embodiment, the process is based on the production of biodiesel using refinery soapstock where the process is performed in an alcoholic medium resulting in the insolubility of certain byproducts. Other valuable products can also be obtained from the process.

Owner:RESITEC PARTICIPACOES

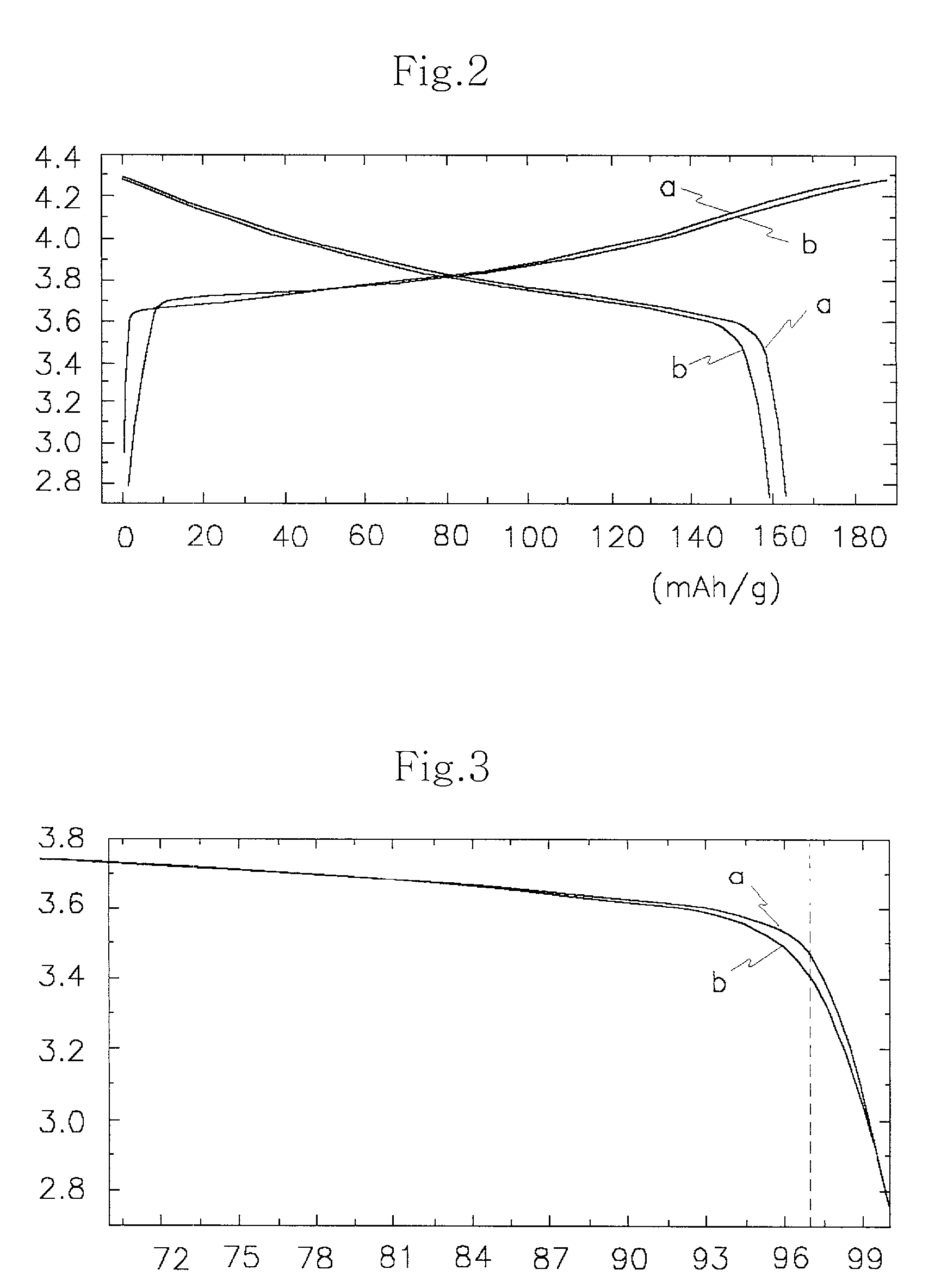

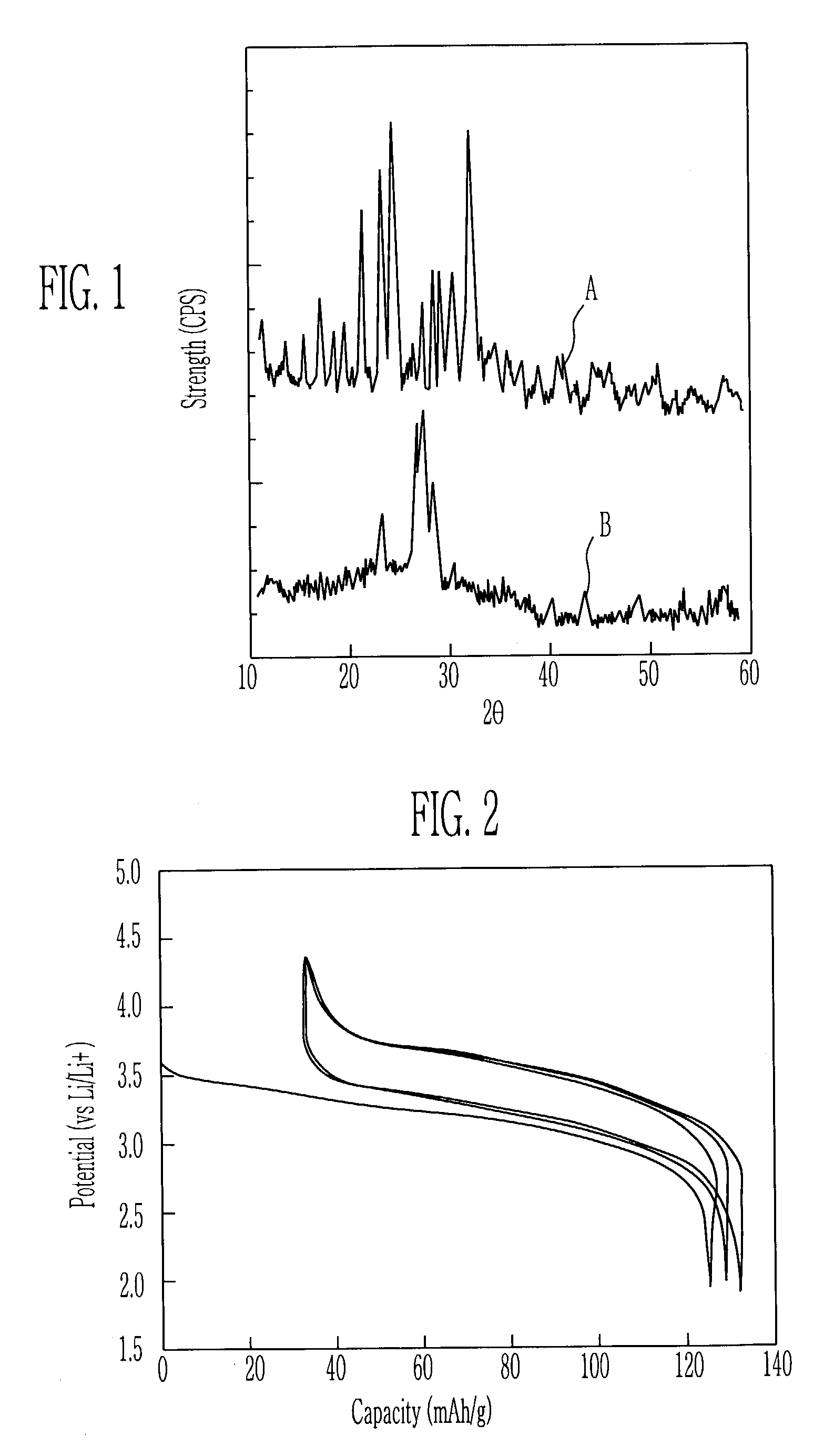

Method of preparing positive active material for rechargeable lithium batteries

InactiveUS6949233B2Improved cycle life characteristicsHigh discharge rateElectrode manufacturing processesPhosphatesPhysical chemistryHeat treated

Owner:SAMSUNG SDI CO LTD

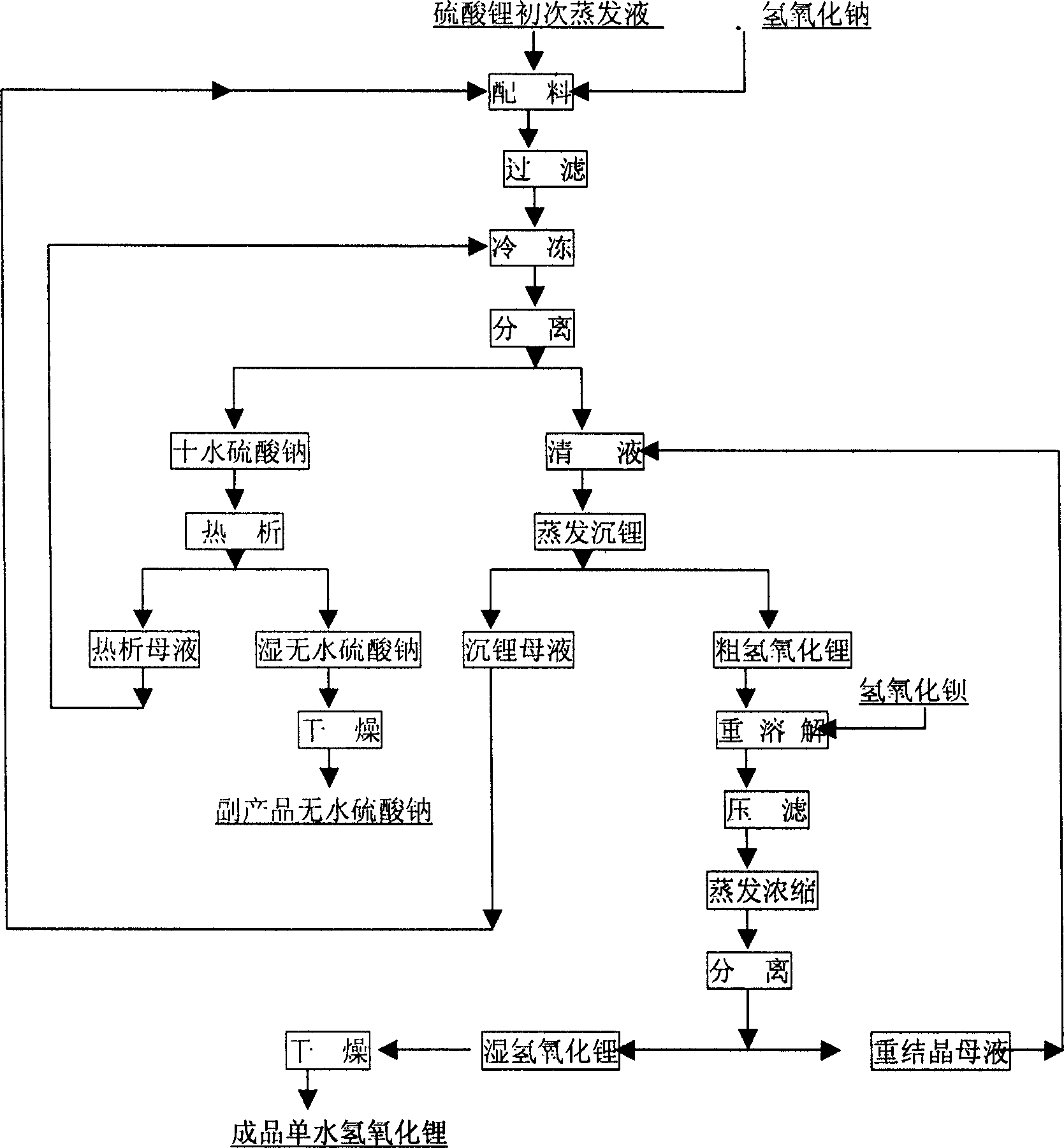

Production process of lithium hydroxide monohydrate

InactiveCN1486931AShort process routeHigh yieldSulfate/bisulfate preparationLithium oxides/hydroxidesSolubilityStrontium hydroxide octahydrate

In the production process of lithium hydroxide monohydrate, lithium sulfate solution and caustic soda are made to produce metathetic reaction to form mixture solution of sodium sulfate and lithium hydroxide, and sodium sulfate and lithium hydroxide monohydrate are then separated by means of the obvious difference in low temperature solubility. The production process includes the following steps: adding sodium hydroxide into lithium sulfate solution obtained through serial production steps to obtain mixture solution of sodium sulfate and lithium hydroxide; cooling to minus 10 deg.c to 5 deg.c for the crystallization and separation of sodium sulfate; heating to concentrate the separated clear liquid; crystallization and separation to obtain coarse lithium hydroxide monohydrate product; water dissolving coarse lithium hydroxide monohydrate, adding barium hydroxide to form insoluble barium sulfate, filtering, concentrating filtrate, crystallizing to separate wet lithium hydroxide monohydrate; and drying.

Owner:JIANGSU RONGHUI GENERAL LITHIUM IND CO LTD

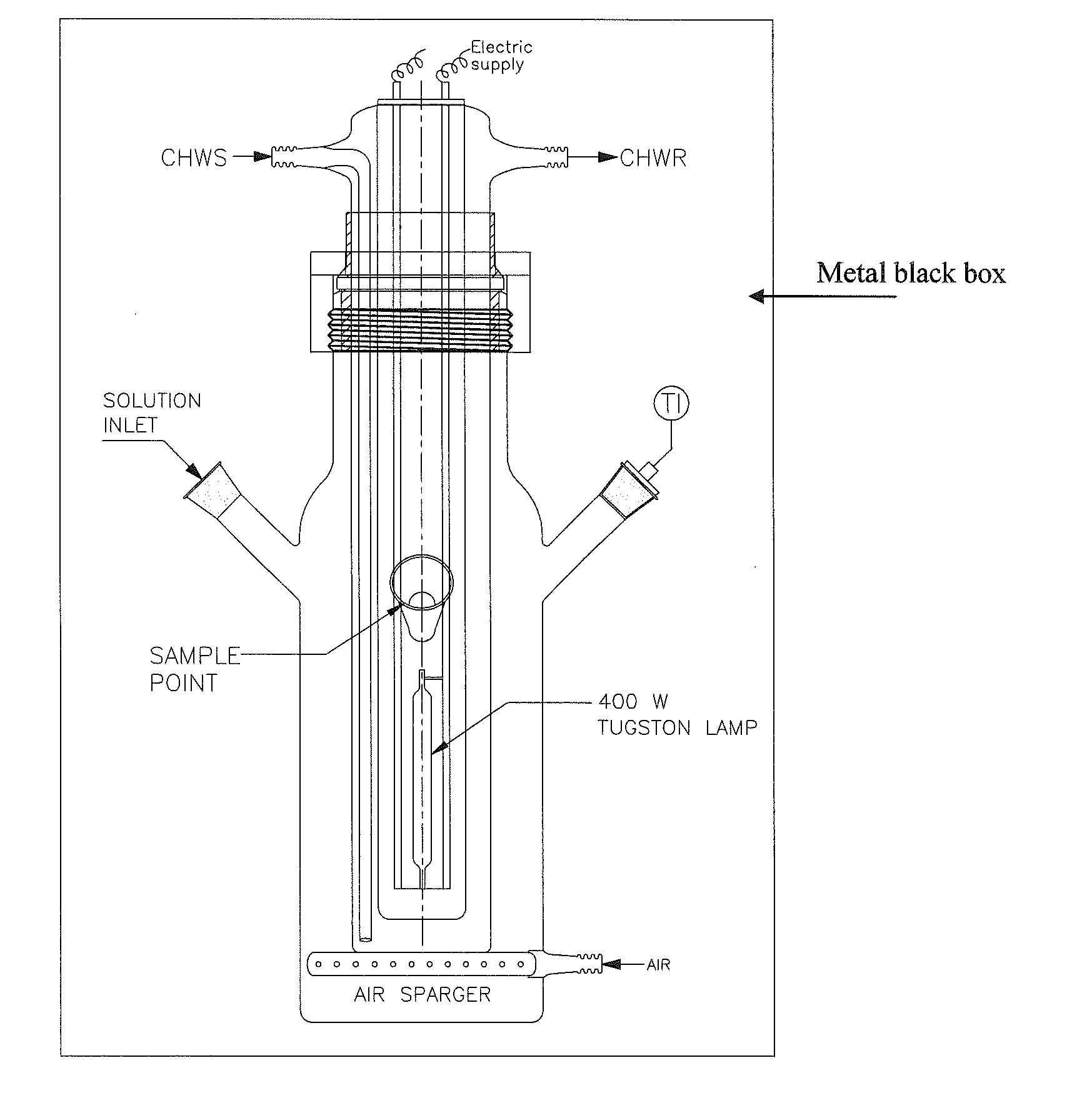

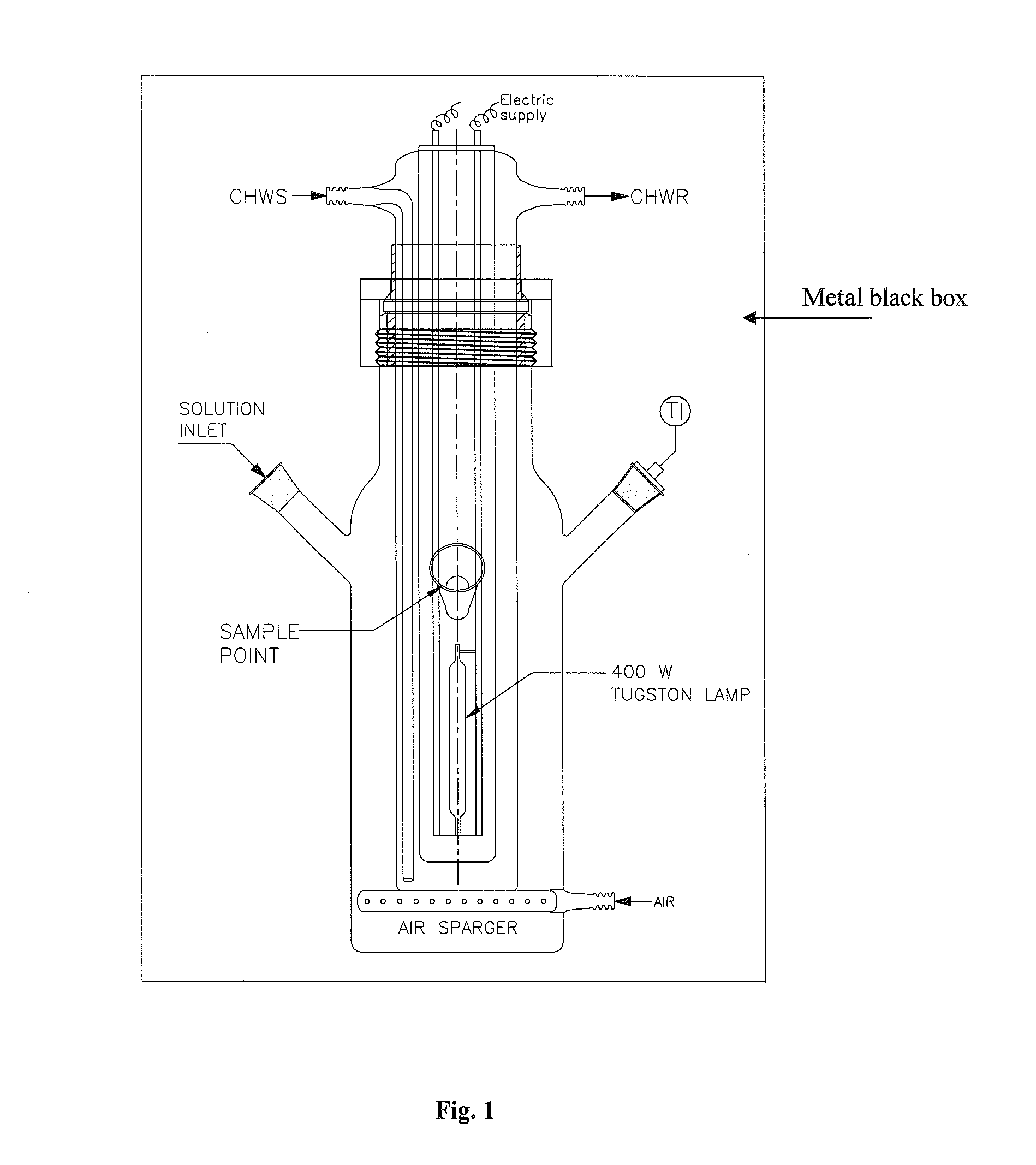

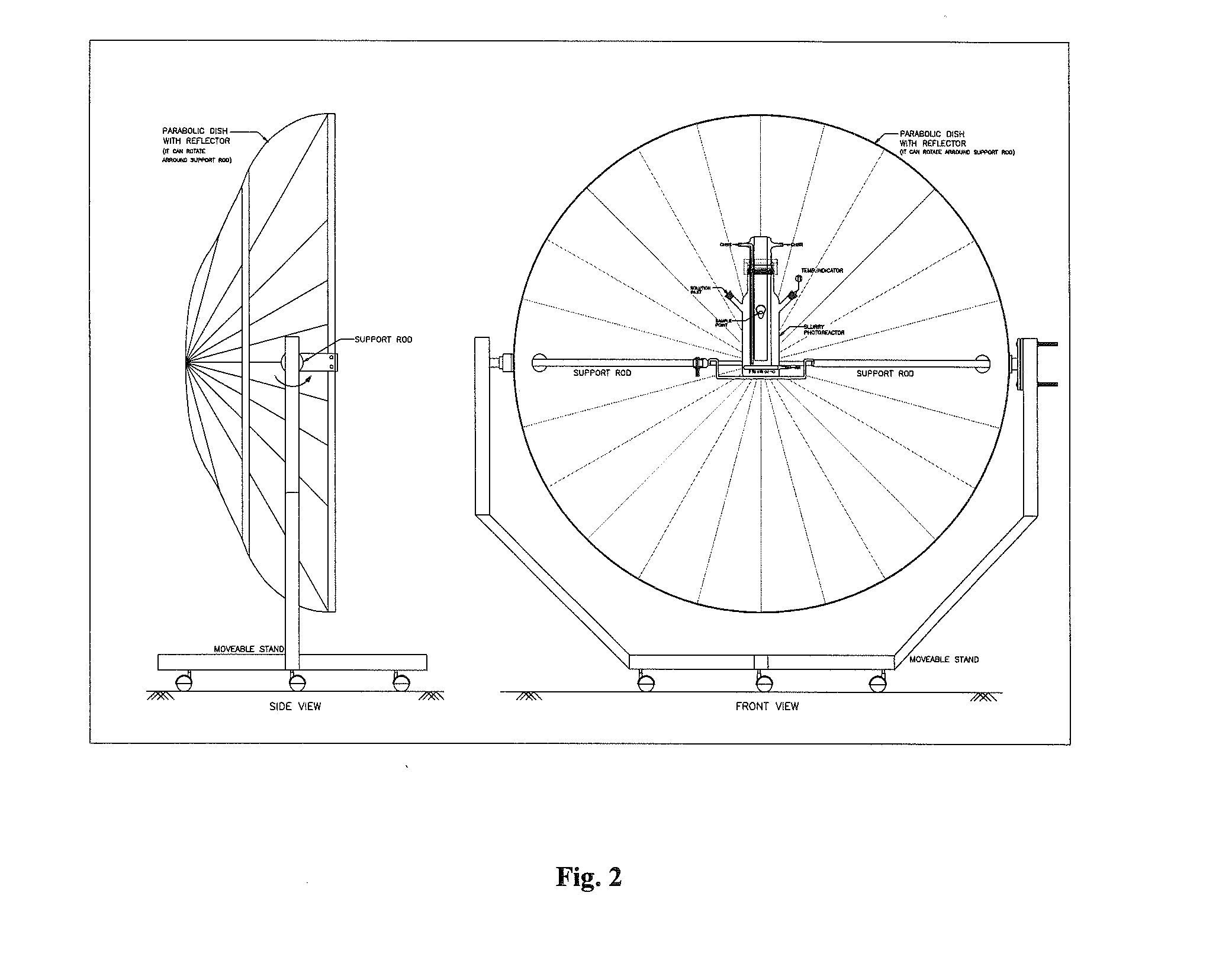

Photocatalytic degradation of pharmaceutical drugs and dyes using visible active biox photocatalyst

ActiveUS20160185615A1PhosphatesSulfate/bisulfate preparationPharmaceutical drugPhotocatalytic degradation

Provided is a visible active photocatalyst of formula BiOX wherein X=P or S and process of preparation and use thereof. Use of the catalyst is demonstrated in the photocatalytic degradation of pharmaceutical drug pollutants and pollutant dyes using solar radiation or artificial radiation.

Owner:COUNCIL OF SCI & IND RES

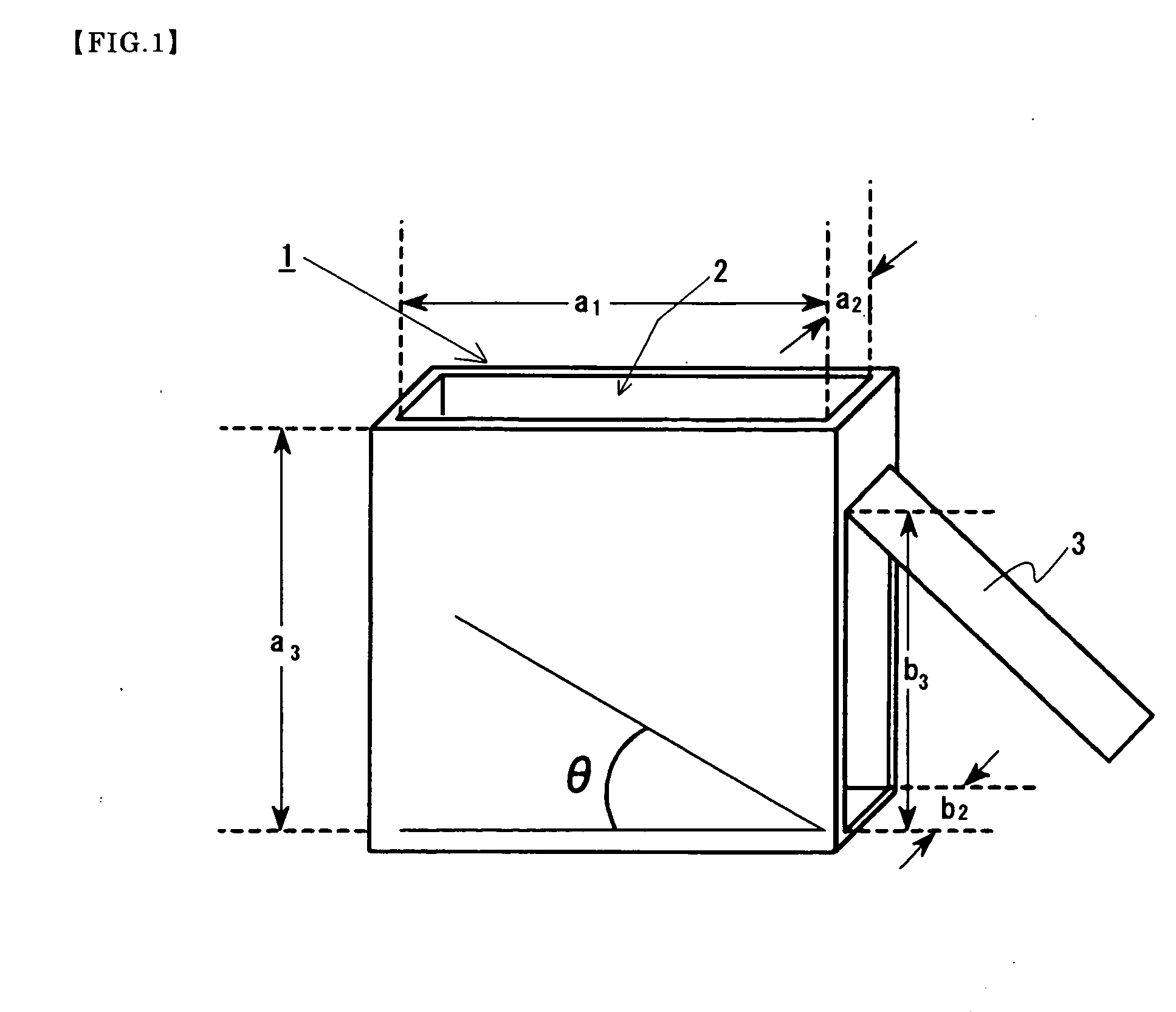

Scavenger for aldehyde(s) and a manufacturing method of a woody panel using the same

InactiveUS20090130474A1Ease of evaluationImprove trapping efficiencyOrganic chemistrySulfate/bisulfate preparationScavengerRoom temperature

Regarding the scavenger for aldehyde(s) used at the time of manufacturing a woody panel using woody materials and formaldehyde-based binders, the scavenger for aldehyde(s) without lowering of trapping properly even when a surface of said woody panel is sanded and having an excellent trapping property of trapping formaldehyde is provided. Further, the method of manufacturing a woody panel using a scavenger for aldehyde(s) and a woody panel are provided.At least one kind of compound for trapping aldehyde(s) being solid at a room temperature is included and said compound for trapping aldehyde(s) is defined to be a powdery scavenger for aldehyde(s) having a property of generating acidic gas, in particular, sulfurous acid gas by heating and said compound for trapping aldehyde(s) is added to a binder or woody materials followed by a hot press, thereby manufacturing a woody panel.

Owner:IPPOSHA OIL INDS

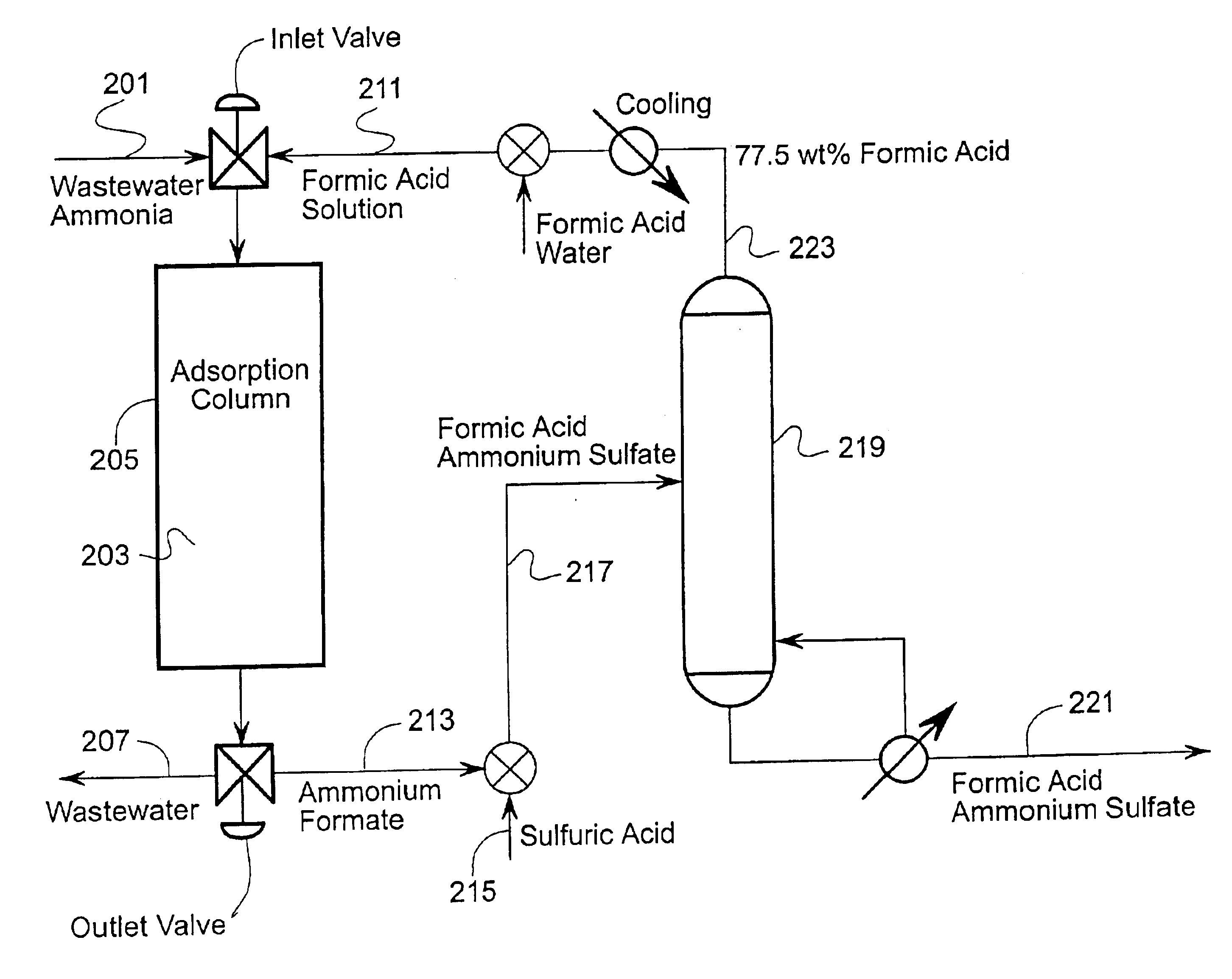

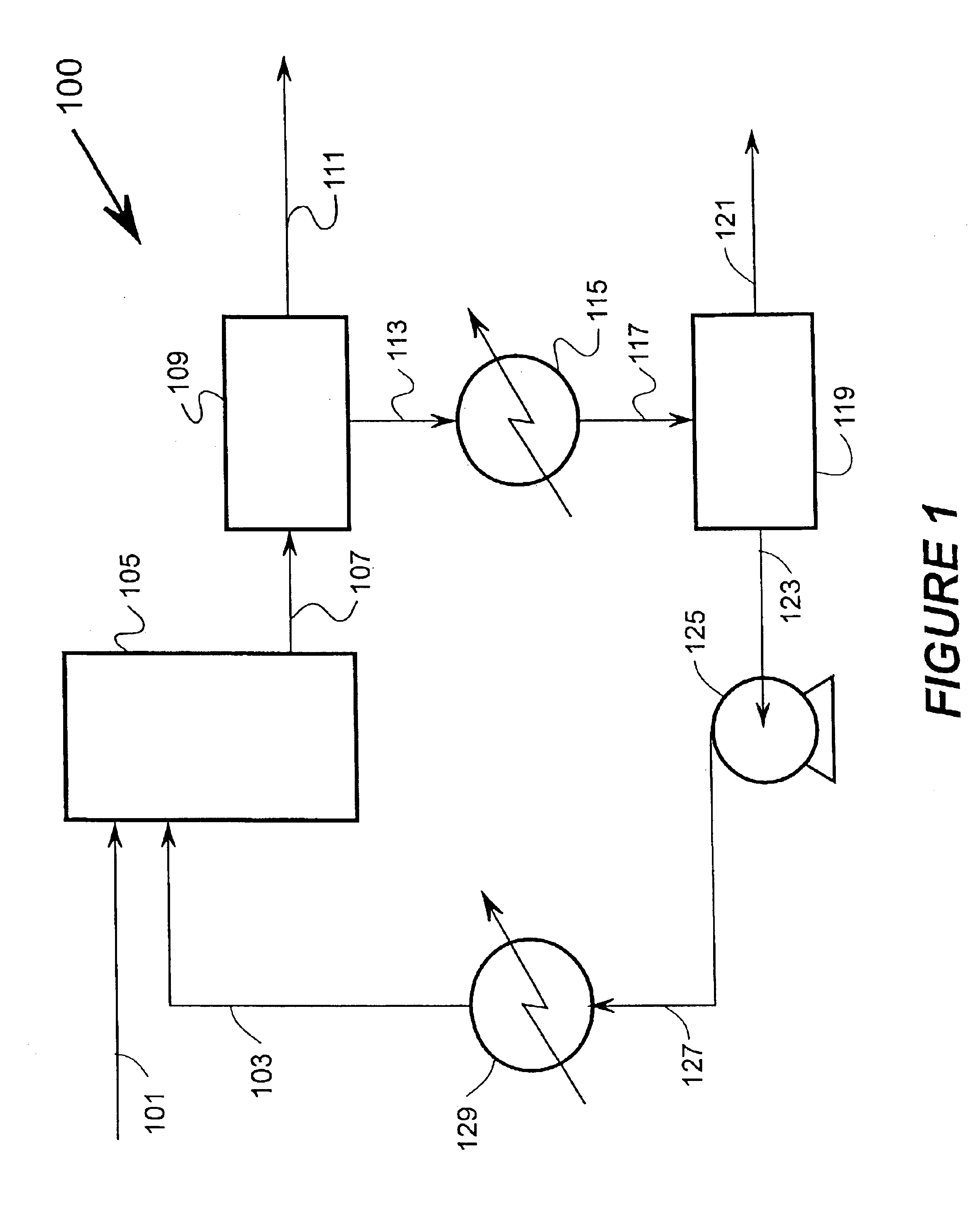

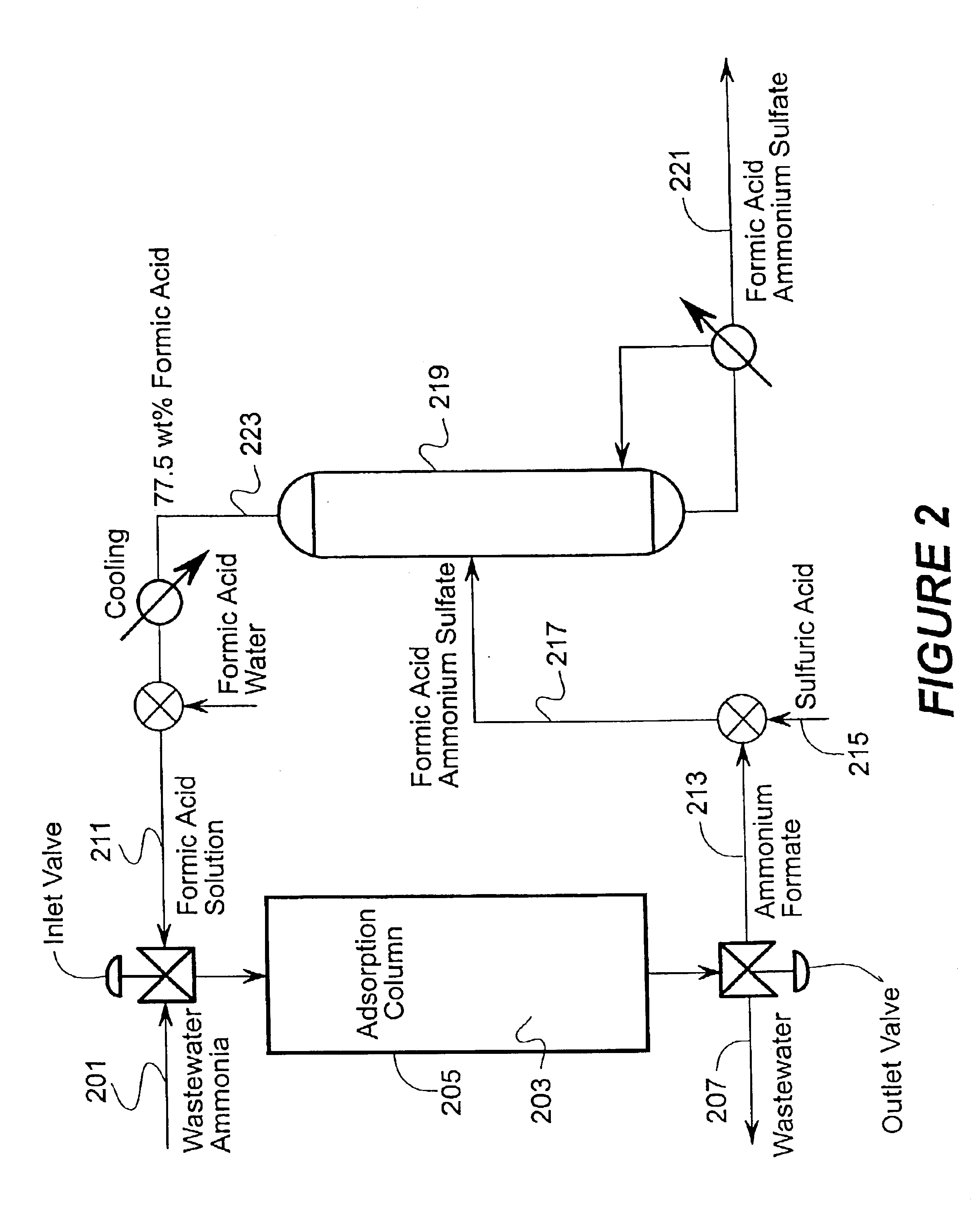

Apparatus and method for ammonia removal from waste streams

InactiveUS6838069B2Process economyCyanogen compoundsIon-exchanger regenerationZinc hydroxideDecomposition

Apparatus, materials, and methods for removing ammonia from fluid using metal hydroxides (e.g. zinc hydroxide) and metal cation loaded media (e.g. zinc loaded ion exchange resins); the metal hydroxides and metal cation loaded media may be regenerated with a weak acid (pKa between 3 and 7). Alternatively, ammonia is removed from fluids by using H2SO4 and ZnSO4 and metal cation loaded media; the metal cation loaded media may be regenerated with H2SO4 and ZnSO4; the ammonia containing H2SO4 and H2SO4 may be concentrated as necessary to form (NH4)2SO4.ZnSO4.6H2O (ammonium zinc sulfate hexahydrate) crystals. These crystals are removed from the mother liquor and heated to temperatures exceeding 200° C. releasing NH3 and H2O vapor upon the decomposition of the crystals.

Owner:BATTELLE MEMORIAL INST

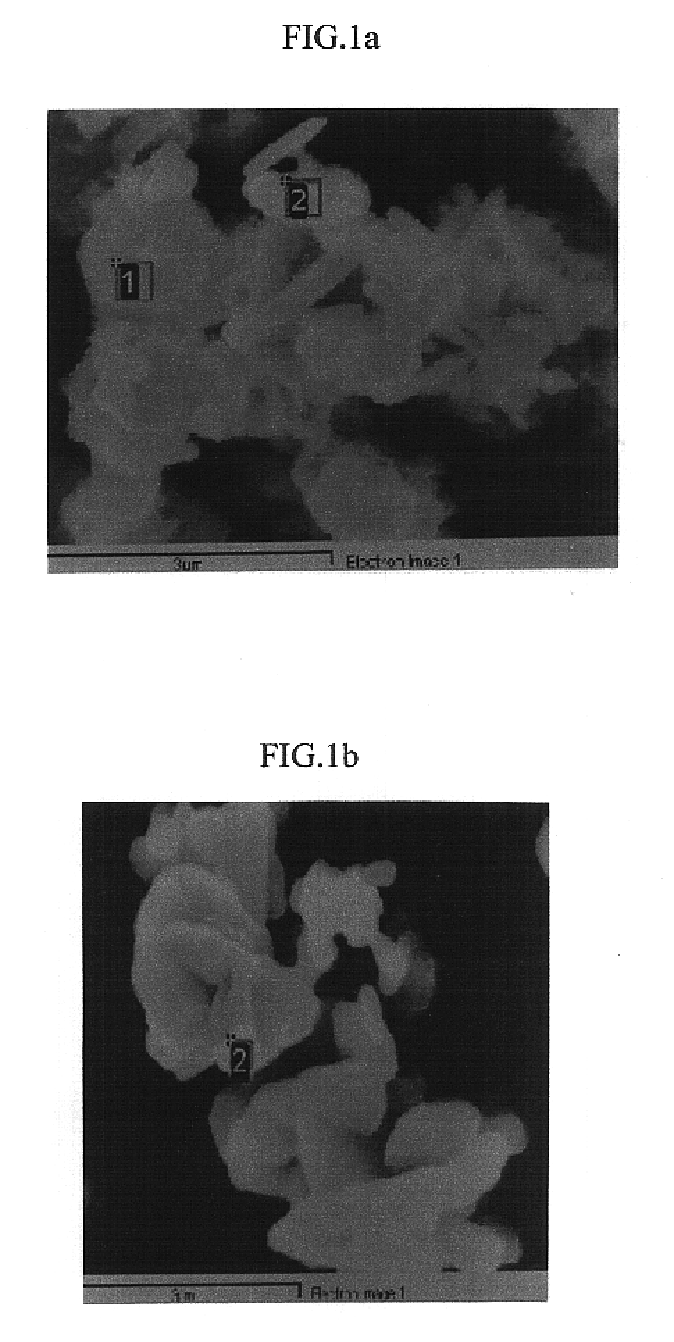

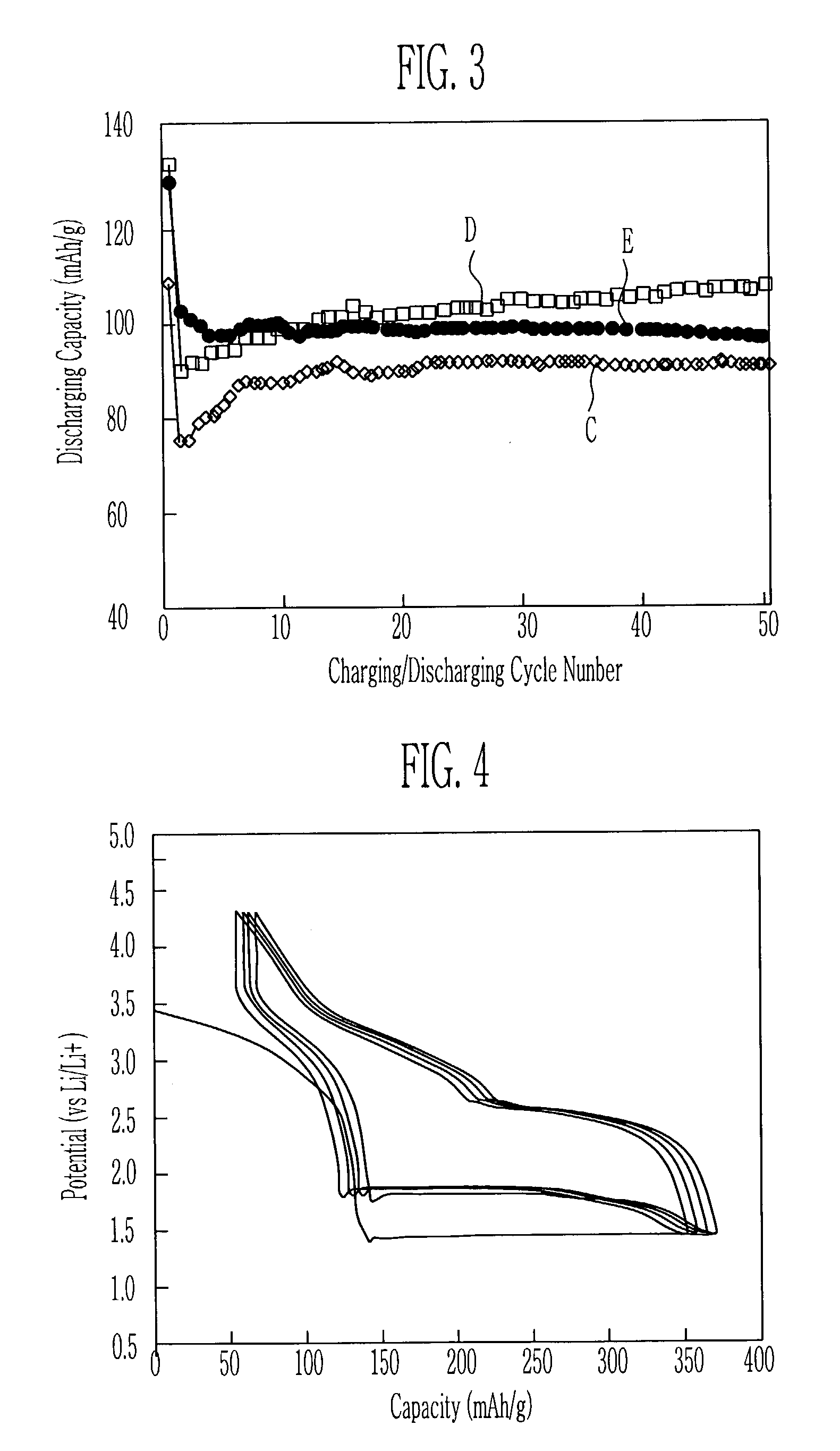

Cathode active material for lithium secondary cell and method for manufacturing the same

ActiveUS6986968B2Good electrochemical propertiesEasy to getPhosphatesSulfur compoundsChemical treatmentLithium

A cathode active material for a lithium secondary cell used in a cellular phone is disclosed. The cathode active material for the lithium secondary cell and the method the same having a high capacity and a long lifetime, different from LiCoO2 and LiMn2O4, Li(Ni, Co)O2, and V-system oxide that has been researched as the active material for substituting LiCoO2 are provided. The cathode active material for the lithium secondary cell in the next formula 1 is obtained by heating or chemically treating diadochite [Fe2(PO4)(SO4)(OH).6H2O] that is the mineral containing PO43−, SO42−, and OH−.LiaFebMc(PO4)x(SO4)y(OH)z (1)In the formula, M is at least one element selected from a radical consisting of Mg, Ti, Cr, Mn, Co, Ni, Cu, Zn, Al, and Si, with 0≦a, c≦0.5, 1≦b≦2, 0.5≦x, y, z≦1.5.

Owner:ELECTRONICS & TELECOMM RES INST

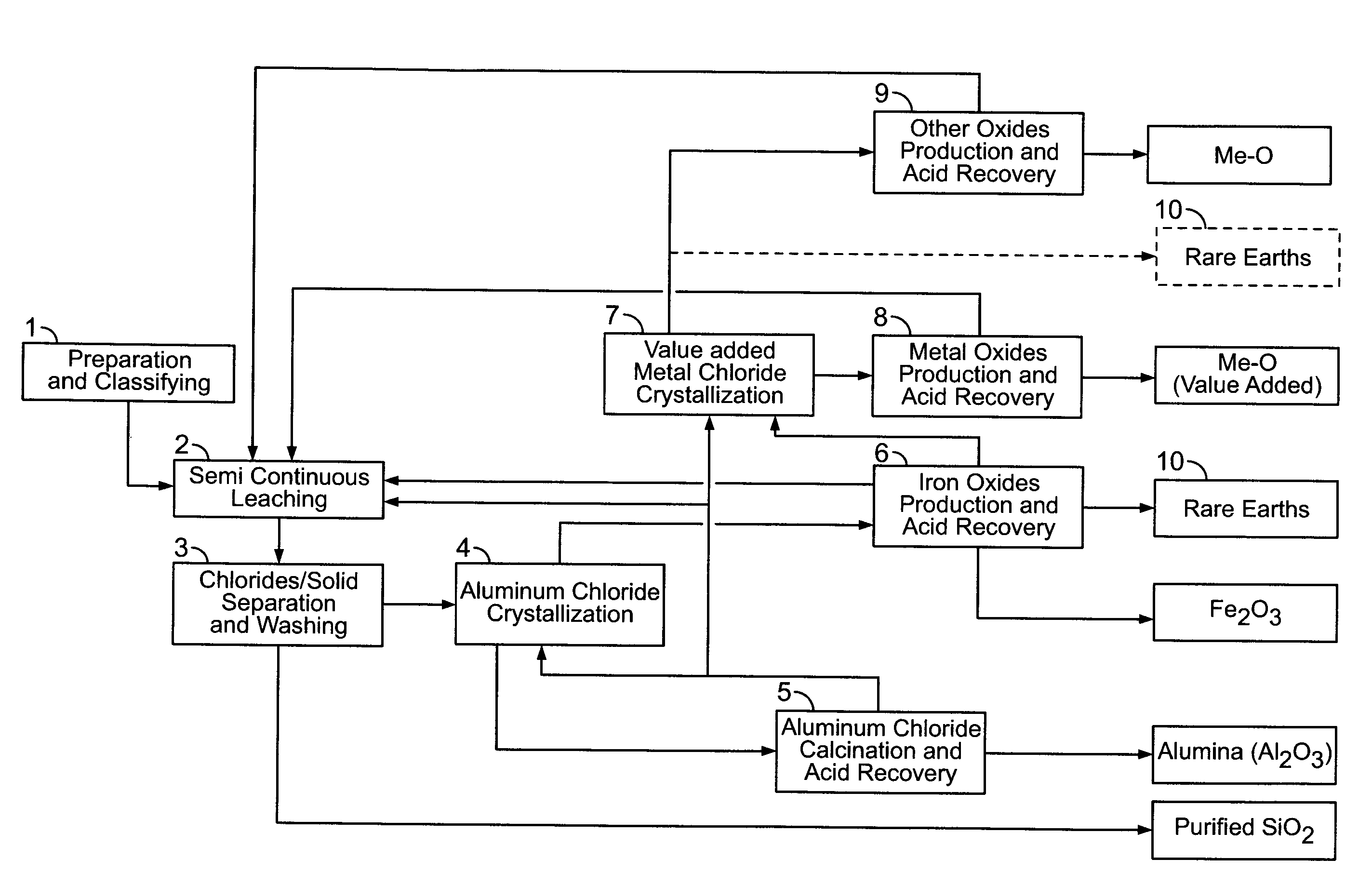

Processes for treating red mud

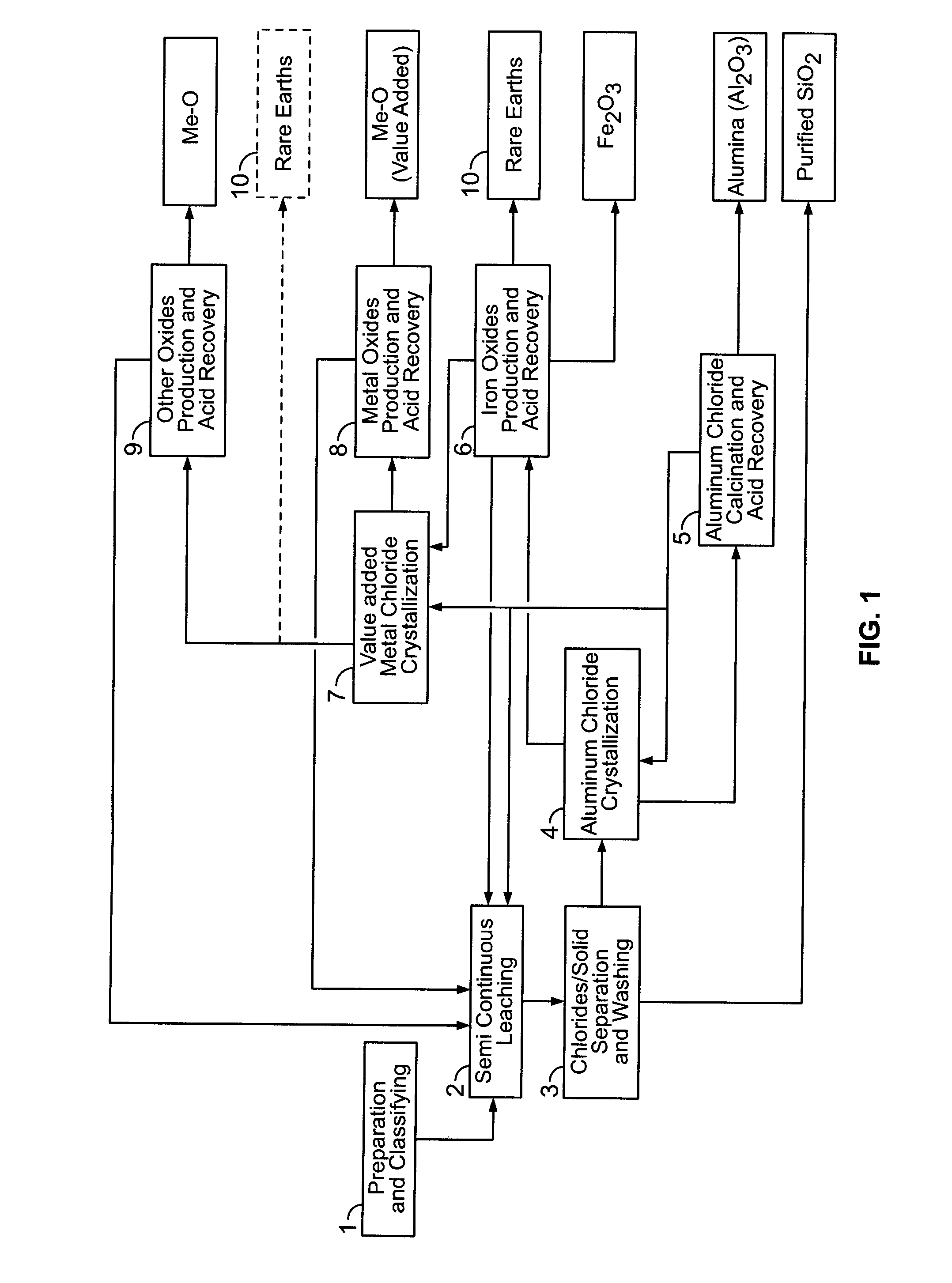

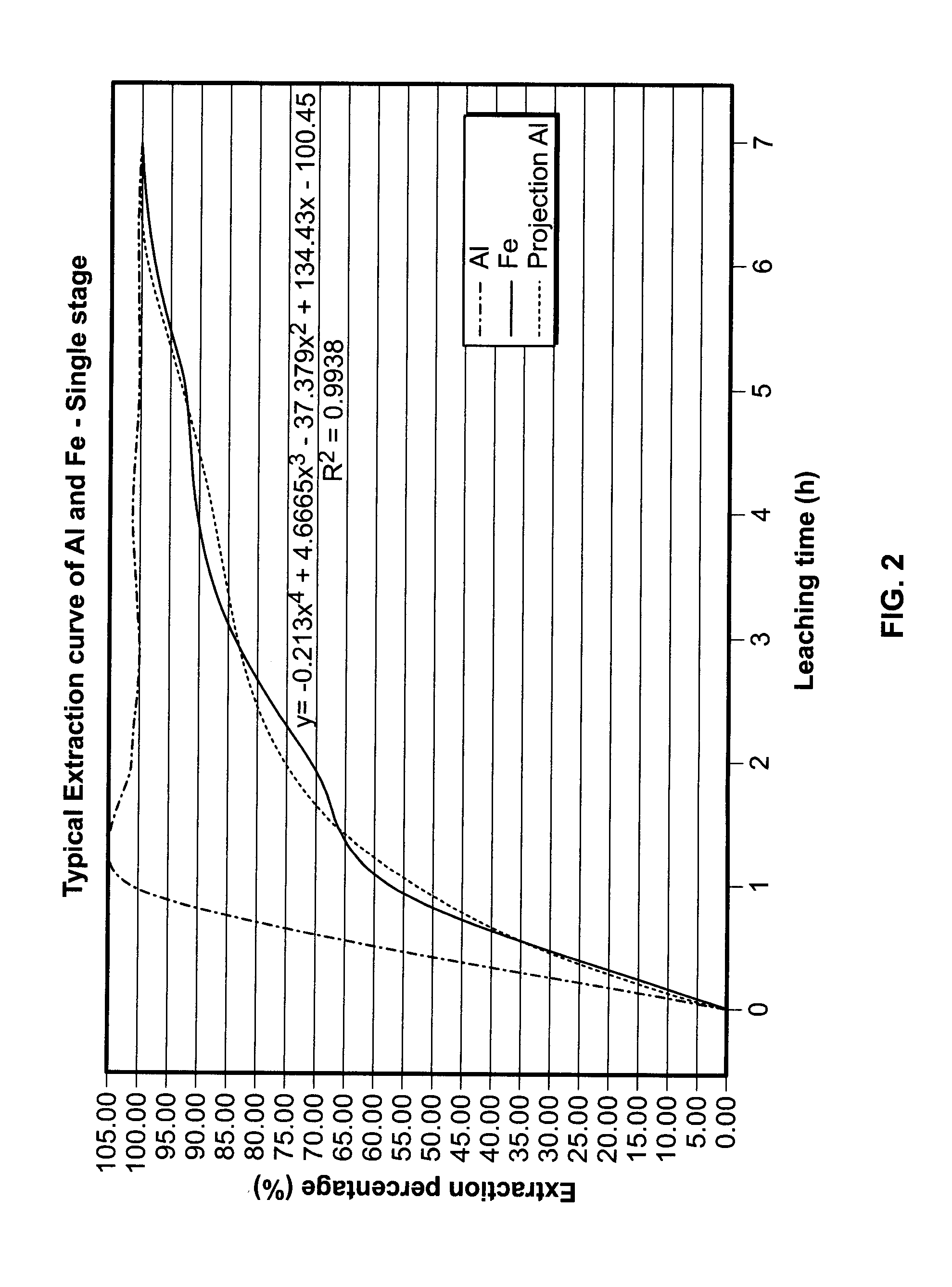

ActiveUS20140369907A1Simple and efficientLow costAluminium compoundsSolvent extractionPregnant leach solutionRare-earth element

There are provided processes for treating red mud. For example, the processes can comprise leaching red mud with HCl so as to obtain a leachate comprising ions of a first metal (for example aluminum) and a solid, and separating said solid from said leachate. Several other metals can be extracted from the leachate (Fe, Ni, Co, Mg, rare earth elements, rare metals, etc.). Various other components can be extracted from solid such as TiO2, SiO2 etc.

Owner:ORBITE ALUMINAE INC

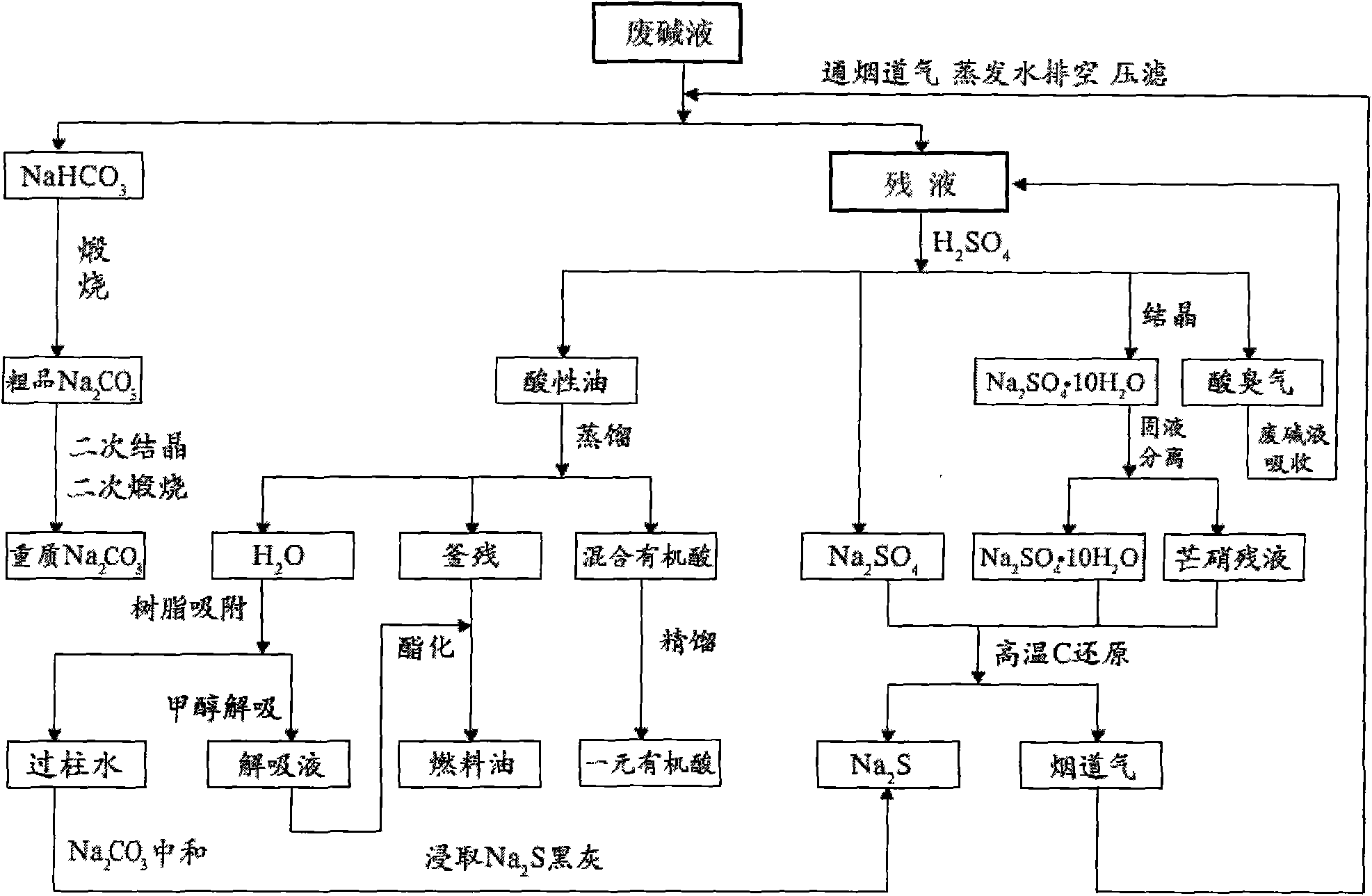

Method for high resource treatment of cyclohexanone waste saponification lye

InactiveCN101570370AIncrease added valueEradicate pollutionCarbon compoundsSulfate/bisulfate preparationSodium bicarbonateCyclohexanone

The invention relates to a method for high resource treatment of cyclohexanone waste saponification lye. The method is improvement on a method for performing zero emission treatment on waste saponification lye produced by producing cyclohexanone through cyclohexane oxidation technology. By using the method, a process is set that sodium sulfate and pulverized coal are calcined to obtain sodium sulfide and carbon dioxide flue gas on the basis of the prior art, carbon dioxide in flue gas reacts with sodium hydroxide and sodium carbonate in initial waste lye to generate sodium hydrogencarbonate, and partial moisture is evaporated in the waste lye by high-temperature heat in the flue gas. The method utilizes the joint production of the cyclohexanone waste saponification lye to obtain chemical resources with higher level such as sodium carbonate, sodium sulfide, monoprotic organic acid, clean fuel oil and the like, and has more remarkable economic benefit; the method achieves the zero emission through the treatment of a waste with another waste, completely roots up the pollution of the waste lye on the environment, and has remarkable social benefit; and waste resources are circularly utilized, so the method has low energy consumption and mature process, is suitable for the large-scale treatment on the cyclohexanone waste saponification lye, and is also used for industrialized production of the chemical resources in the waste lye.

Owner:赵志军

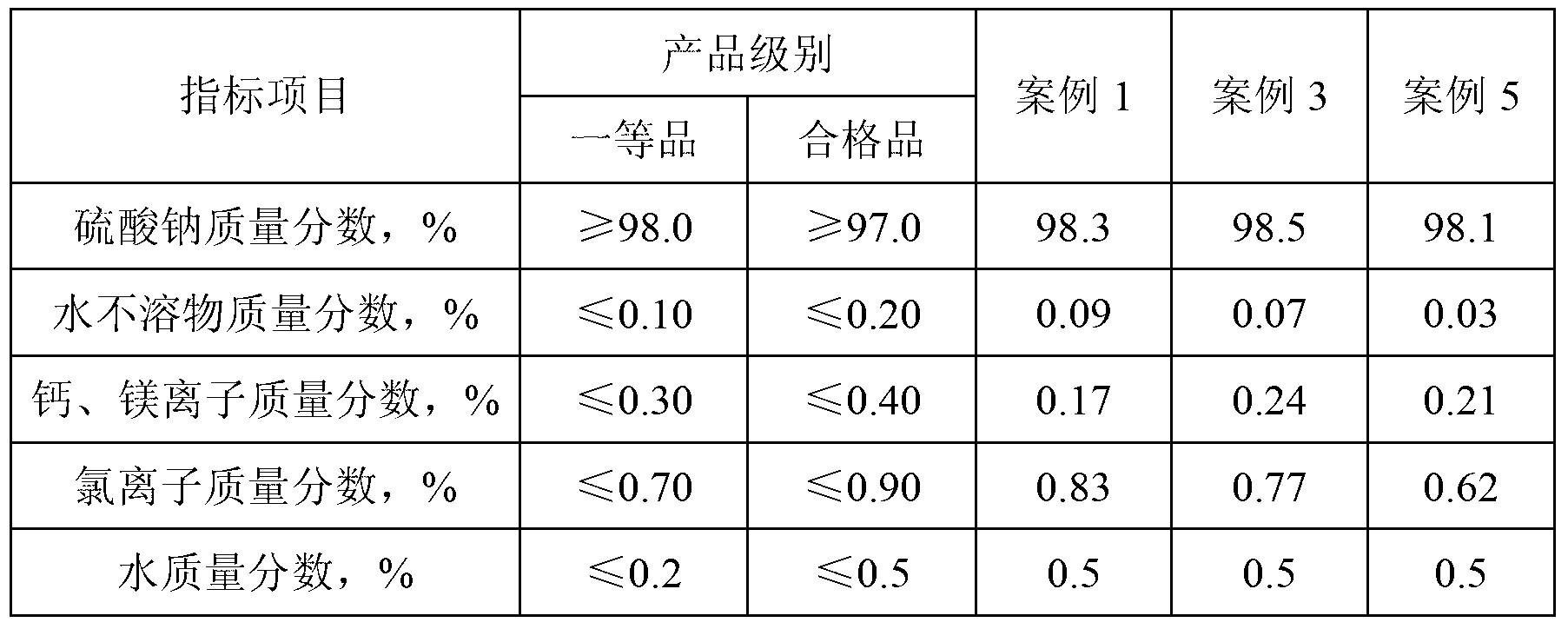

Production process of large grain anhydrous sodium sulfate with natural salt lake mirabilite

InactiveCN1986406AChange granularityControl the number of generatedSulfate/bisulfate preparationSalt lakeWarm water

The production process of large grain anhydrous sodium sulfate with natural salt lake mirabilite includes the steps of washing mirabilite, decomposing mirabilite, refining, settlement, neutralizing with sulfuric acid to obtain clear solution, evaporating, centrifuging to dewater, and drying with hot blast to obtain product. It features the addition of surfactant solution comprising sodium dodecyl benzene sulfonate, sodium ethoxy alkyl sulfate and warm water at about 40deg.c into the clear solution before evaporating. The production process can produce anhydrous sodium sulfate of granularity of 200-1000 microns and with high economic value.

Owner:乌鲁木齐市华高商贸有限公司

Method for separating lithium carbonate from electrolyte acidic leachate

InactiveCN107935015AEfficient extractionReduce energy consumptionMagnesium fluoridesCalcium/strontium/barium fluoridesEvaporationCarbonate

The invention discloses a method for separating lithium carbonate from electrolyte acidic leachate. The method comprises the following steps of: S1, adding a soluble salt solution to aluminum electrolyte acidic leachate while stirring and heating are performed, monitoring the acidity and the concentration of fluoride ions, and stopping the addition when the pH value is greater than 5 and the concentration of the fluoride ions is less than 0.01 g / L, wherein the soluble salt is one or more selected from MeSO4, MeNO3 and MeCl, and Me is metal which can produce precipitate with F<->; S2, performing filtration on reactants, performing washing and drying on filter residues to obtain a fluoride salt of the metal Me, adding a soluble carbonate solution into the obtained filtrate with stirring andheating, and terminating the reaction when the concentration of lithium ions is less than 0.08 g / L; S3, filter the filtrate, performing washing and drying on the filter cake to obtain lithium carbonate, and performing evaporation, crystallization, washing and drying on the filtrate to obtain inorganic salts. According to the method for separating lithium carbonate from the electrolyte acidic leachate, the reaction process is controlled by controlling the concentration of the fluoride ions and the acidity, so that the lithium ions are separated from other ions, lithium carbonate with high recovery rate is obtained, and meanwhile high-purity fluoride and inorganic salt products are obtained.

Owner:NORTHEASTERN UNIV

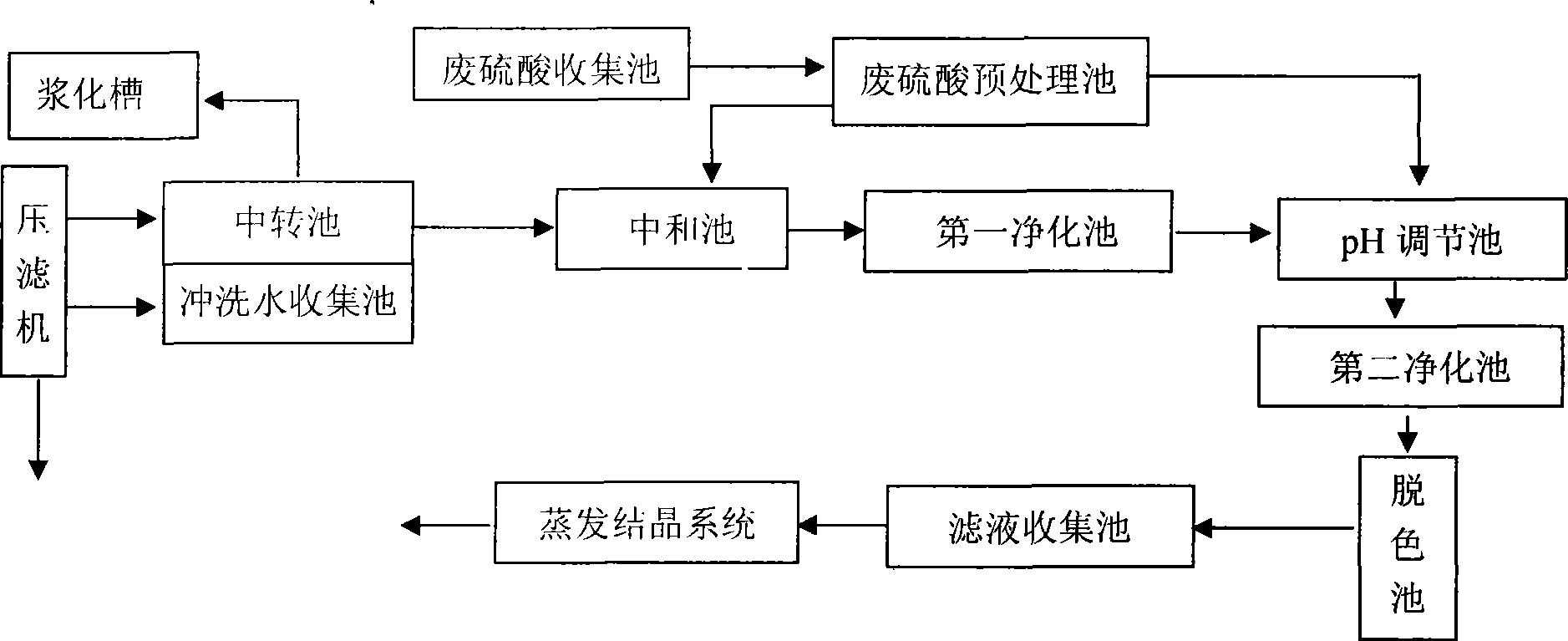

Method and device for recycling anhydrous sodium sulfate from desulfurization lead plaster filter liquor

ActiveCN101244831AEvaporative crystallizationGuaranteed Concentration RequirementsSulfate/bisulfate preparationAlkali metal sulfite/sulfate purificationFiltrationResource recovery

The invention relates to a method of recycling anhydrous sulfate sodium from de-sulfurized lead paste filtration, belonging to a resource recovery and utilization process, which avoids the disadvantages that waste sulfate is used and low concentration sulfate sodium is emitted into the environment. The method of the invention comprises: desulfurized lead paste filtration collection, sodium carbonate neutralization, first time heavy metal removal, filtration PH value adjustment, second-time heavy metal removal, decolorizing step, and vaporization and crystallization step; the device comprises a transfer tank, a neutralization tank, a first-stage purifying tank, a PH adjusting tank, a second-stage purifying tank, a decolorization tank, a filtration collection tank and a vaporization crystallization system; the waste sulfate collection tank is connected with a waste sulfate pre-processing tank, the waste sulfate pre-processing tank is respectively connected with the neutralization tank and the PH adjusting tank. The invention can directly recycle anhydrous sulfate sodium, the waste sulfate is used to neutralize the carbonate sodium remained in the filtration; the heavy metal ions and other ions in the filtration are removed according to two steps, so that the grade of obtained anhydrous sulfate sodium is equal to or larger than industrial grade.

Owner:HUAZHONG UNIV OF SCI & TECH

Application of elementary-substance selenium as catalyzer

ActiveCN102862962ABreak through the conditions of high temperature and high pressureHigh puritySulfate/bisulfate preparationSulfur preparation/purificationSulfurSulfite

The invention relates to an application of elementary-substance selenium as a catalyzer, and particularly, the elementary-substance selenium is applied in catalytic reaction of sulfite to prepare elementary-substance sulfur. According to the application of the elementary-substance selenium as the catalyzer, the elementary-substance selenium is applied as the catalyzer to prepare the high-purity elementary-substance sulfur, limits of high-temperature and high-pressure environments required by the elementary-substance sulfur preparation in traditional modes are broken; the catalyzer is stable in structure performance, can be recycled and used repeatedly; and the technology and the equipment are simple, the production cost is low, and the catalyzer is free of environmental pollution.

Owner:CENT SOUTH UNIV

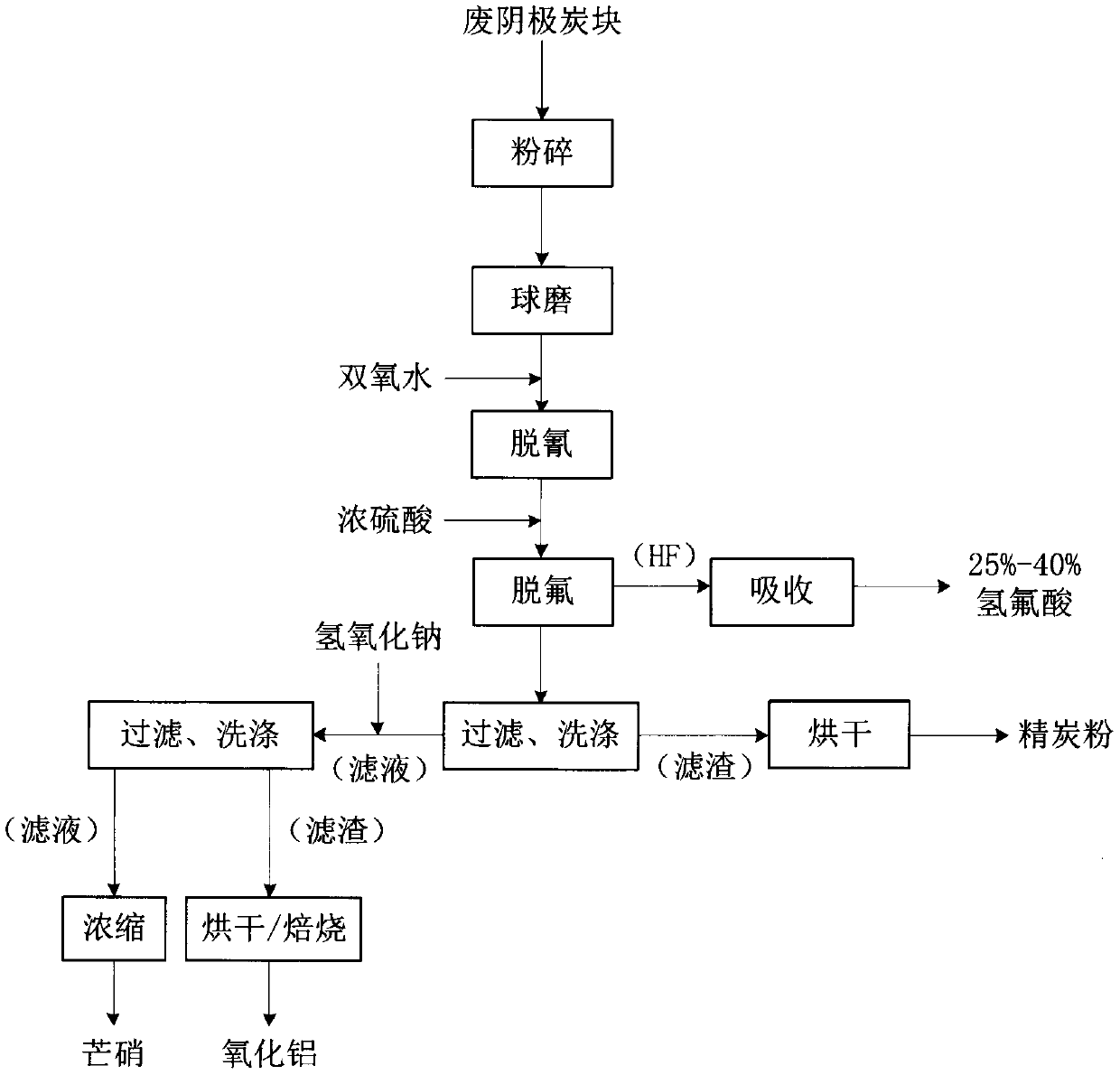

Recycling method for waste cathode carbon blocks of electrolytic aluminum electrolysis cell

ActiveCN110127649AAchieve recyclingAdvanced technologyHydrogen fluorideSulfate/bisulfate preparationElectrolysisBall mill

The invention discloses a recycling method of waste cathode carbon blocks of an aluminum electrolysis cell. The method comprises the following steps: breaking, crushing and ball milling the waste cathode carbon block raw material of the aluminum electrolysis cell to form powder, and then adding hydrogen peroxide to remove cyanide; adding concentrated sulfuric acid to react to generate hydrogen fluoride gas, introducing the hydrogen fluoride gas into a condensation absorption tower, and circularly absorbing the hydrogen fluoride gas with deionized water or a low-concentration hydrofluoric acidsolution to obtain a 25-40% hydrofluoric acid product; neutralizing carbon powder by adding NaOH, filtering and drying the carbon powder to use as a raw material for processing a new cathode for recycling; finally, concentrating a large amount of sodium sulfate contained in filtrate to obtain sodium sulfate crystals. The recycling method has the advantages of advanced technology and obvious advantages, and realizes zero emission of environmental pollutants in the recycling process. The treated waste cathode carbon blocks can be reused to process new cathode carbon blocks, and the main harmfulcomponent fluorine in the original waste cathode carbon blocks is converted into high side addition hydrogen fluoride to realize the recycling of fluorine.

Owner:广西田东曙光科技有限公司

Harmlessness and reclamation treatment method of aluminum scrap electrolyte

ActiveCN108677020AEfficient decompositionSolve environmental problemsSulfate/bisulfate preparationAlkali metal nitrate preparationAluminum fluorideElectrolysis

The invention discloses a harmlessness and reclamation treatment method of aluminum scrap electrolyte and belongs to the technical field of inorganic chemistry. The method comprises the main steps that 1, aluminum scraps are electrolyzed and subjected to crushing and screening, and aluminum electrolyte particles are obtained; 2, acid liquor with the concentration of 1 mol / L and an aluminum salt solution with the concentration of 1 mol / L are prepared for standby application; 3, the aluminum electrolyte particles obtained in the step 1 are placed in the acid liquor prepared in the step 2 and leached on the heating and stirring conditions, the PH of the solution is controlled to be smaller than 5, when the fluorinion leaching rate is higher than 94%, leaching is finished, impurities are filtered, and a leaching solution is obtained; 4, the aluminum salt solution prepared in the step 2 is added to the leaching solution in the step 3, the mixture is heated and stirred, Al3+ / Na+ is controlled to be larger than 0.3, when sediment is generated in the solution, the solution is filtered, filter residues and filter liquor are obtained, and the filter residues are washed and dried to obtain alkali type aluminum fluoride products; and 5, the filter liquor in the step 4 is evaporated and crystallized to obtain sodium salt products.

Owner:NORTHEASTERN UNIV

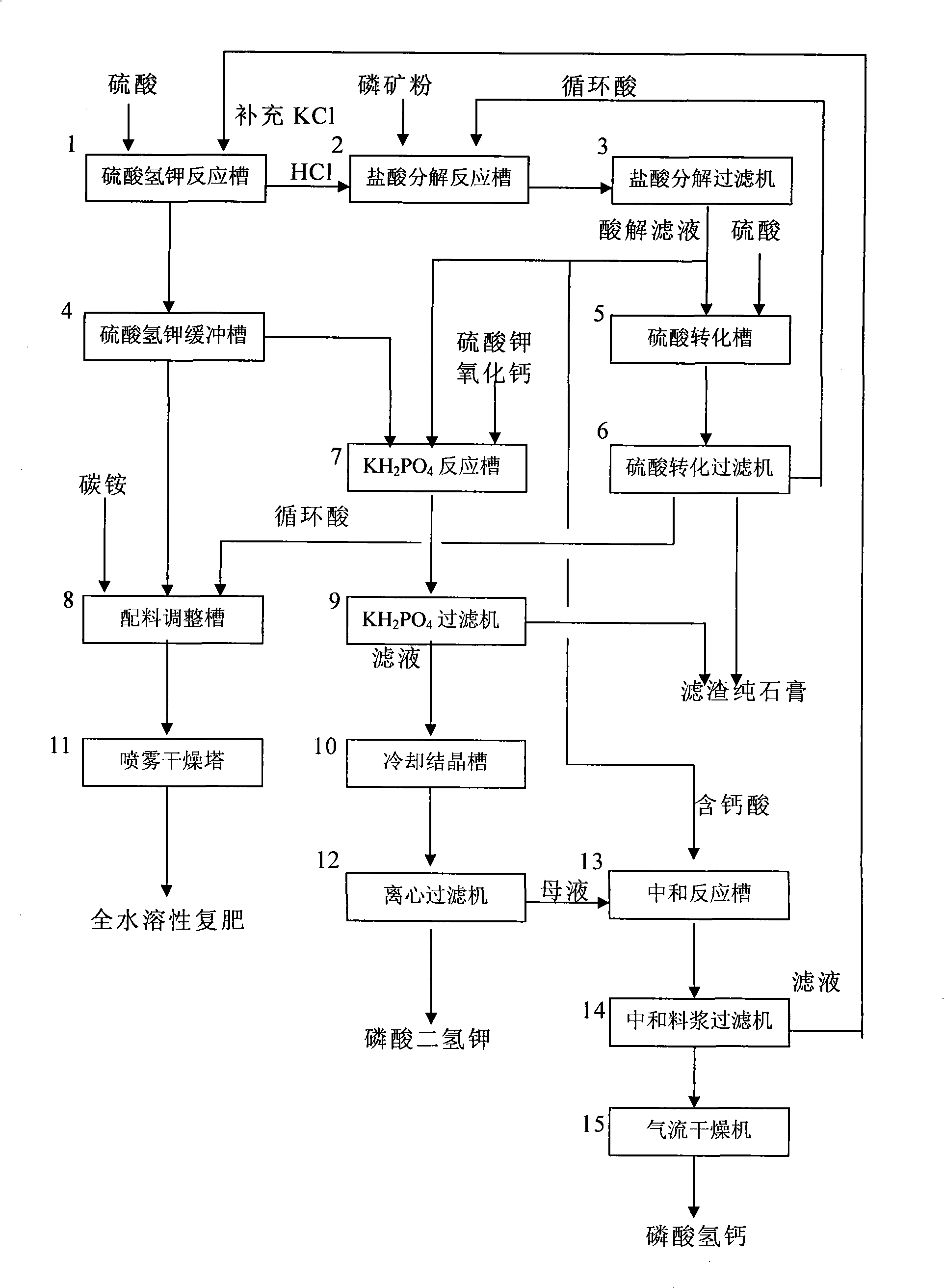

Process for disassembling phosphate ore by mixed acid and coproducing potassium dihydrogen phosphate, hydrogen phosphate and combined fertilizer

InactiveCN101337657ASolve processing problemsSolving Phosphogypsum ProblemsChlorine/hydrogen-chlorideSulfate/bisulfate preparationSolubilitySlurry

A method for the joint production of monopotassium phosphate, calcium hydrophosphate and compound fertilizers through by subjecting phosphorite to mixed acid resolution is characterized in that the method comprises the steps of taking sulphuric acid and potassium chloride to prepare chlorine hydride and acid potassium sulfate; conducting acidolysis reaction after phosphorite slurry absorbs chlorine hydride; preparing monopotassium phosphate through the reaction between an acidolysis filtrate and calcium oxide and lemery; agitating a mixture of the acidolysis fitrate with monopotassium phosphate crystallization mother liquor to neutralize and prepare calcium hydrophosphate; preparing recycle acid through the reaction between the acidolysis filtrate with sulphuric acid; preparing full water-solubility compound fertilizers through the reaction between recycle acid and an acid potassium sulfate solution and ammonium hydrogen carbonate or ammonia, etc. The method can successfully solve the impurity interference problem in the production of phosphate by using phosphorite of middle-low grade, and increase the reclaim rate of phosphorus pentoxide to approximate 100%. The method has the advantages of fully utilizing resources, simplifying process and devices, reducing corrosion, saving energy, reducing acid consumption and cost, eliminating pollution, and achieving good technical and economic effects.

Owner:黄明科 +1

Positive active material for rechargeable lithium battery and method of preparing same

InactiveUS6737195B2Improve thermal stabilityElectrode manufacturing processesZirconium compoundsMaterials scienceMetal

Disclosed is a positive active material for a rechargeable lithium battery. The positive active material includes at least one compound represented by formulas 1 to 4 and a metal oxide or composite metal oxide layer formed on the compound.(where M is selected from the group consisting of Co, Mg, Fe, Sr, Ti, B, Si, Ga, Al, Sc, Y, La, Ce, Pr, Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, Ac, Th, Pa, U, Np, Pu, Am, Cm, Bk, Cf, Es, Fm, Md, No and Lr, 0.95<=x<=1.1, 0<y<=0.99, 0<=z<=0.5, and 0<=A≤0.5).

Owner:SAMSUNG SDI CO LTD

Comprehensive utilization method of waste denitration catalyst

The invention relates to a comprehensive utilization method of an waste denitration catalyst, and belongs to the field of comprehensive utilization of waste catalysts. The method comprises the following steps: crushing a waste denitration catalyst, and then separating vanadium pentoxide out of the waste denitration catalyst by pickling reduction; carrying out the operations such as enrichment, oxidation, molybdenum precipitation, deamination and the like on the separated vanadium pentoxide, so as to reach the purification target. By adopting the method, the vanadium pentoxide in the waste denitration catalyst can be separated from other metal oxides and is further purified, the material left after the vanadium pentoxide is separated out is used for replacing ilmenite to serve as the raw material for producing titanium dioxide by a sulfuric acid method, thereby reaching the comprehensive utilization of the waste denitration catalyst.

Owner:LUOHE XINGMAO TITANIUM IND

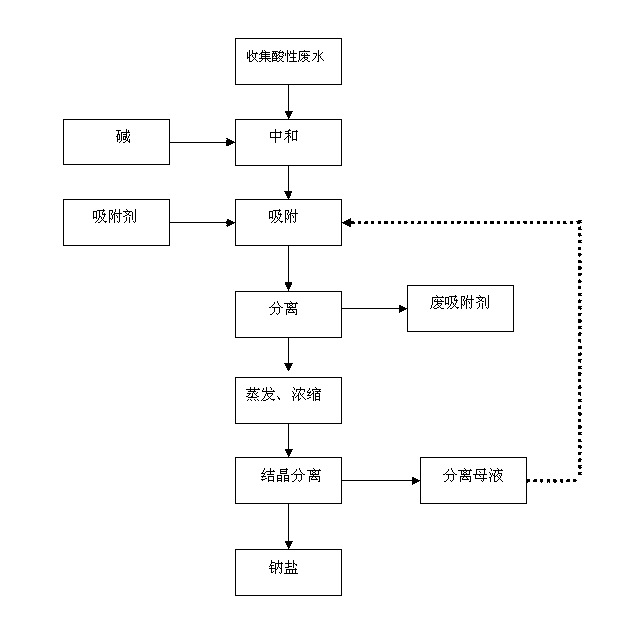

Method for treating acid waste water of disperse dye

InactiveCN103241885ALow costHigh removal rateSulfate/bisulfate preparationMultistage water/sewage treatmentActivated carbonDisperse dye

The invention relates to a method for treating acid waste water of disperse dye, belonging to the technical field of three-waste treatment in the dye industry. The method comprises the steps of: firstly, collecting sulfuric acid or hydrochloric acid waste water from industrial production; neutralizing the pH value of the acid waste water to 5.0-7.0; adding an adsorbent, namely activated carbon, kieselguhr or any mixture of the activated carbon and the kieselguhr to implement adsorption bleaching; filtering and separating the adsorbent; and finally evaporating, concentrating and crystallizing the waste water, thereby obtaining high-quality damp sodium sulfate or sodium chloride which can be reused after being dried. The method has the advantages of environment friendliness, high efficiency, good feasibility and the like.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

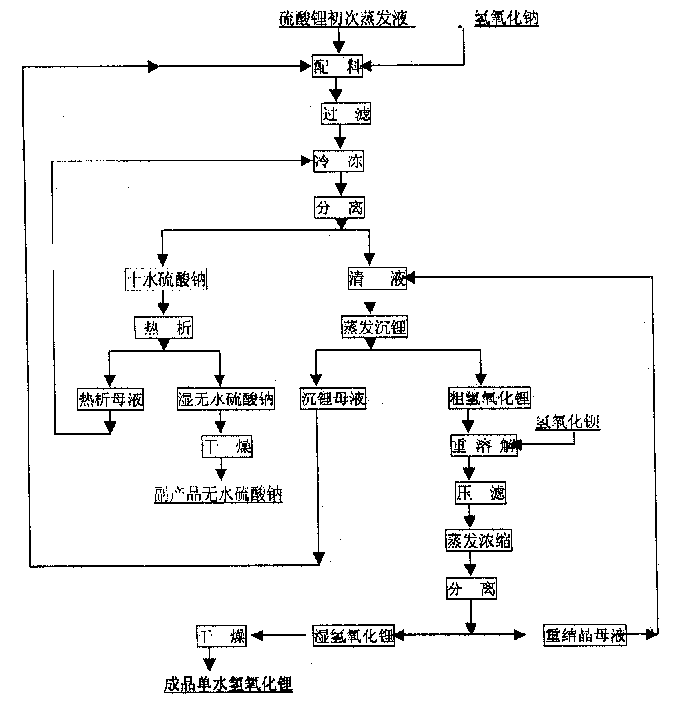

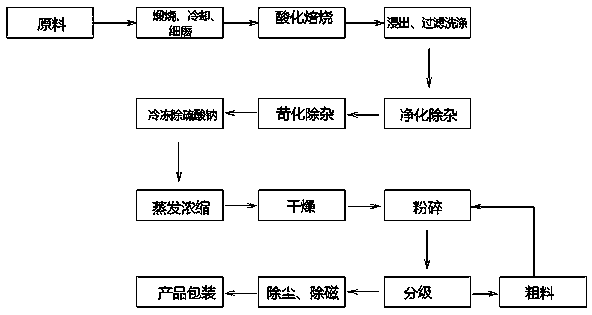

Production process of micro-powder-grade lithium hydroxide monohydrate

PendingCN111439760AMeet production needsAdequate responseSulfate/bisulfate preparationLithium oxides/hydroxidesPhysical chemistryProcess engineering

The invention discloses a production process of micro-powder-grade lithium hydroxide monohydrate. The production process comprises the following steps: (1) sequentially calcining spodumene, cooling the calcining product, finely grinding the calcining product, adding acid for reaction, and then mixing the obtained powder and the acid into slurry; (2) adding calcium salt into the slurry, and carrying out stirring and leaching; (3) filtering the filtered clear liquid again, and purifying the filtered clear liquid by using an alkaline solution; (4) filtering the causticized solution; (5) freezingthe filtered causticized liquid in a freezing workshop to separate out sodium sulfate decahydrate and a lithium hydroxide solution; (6) evaporating, concentrating and purifying the sodium sulfate decahydrate; (7) screening and weighing the sodium sulfate decahydrate; (8) carrying out shunting; (9) carrying out crushing; (10) carrying out grading; and (11) carrying out packaging.

Owner:广西雅保锂业有限公司

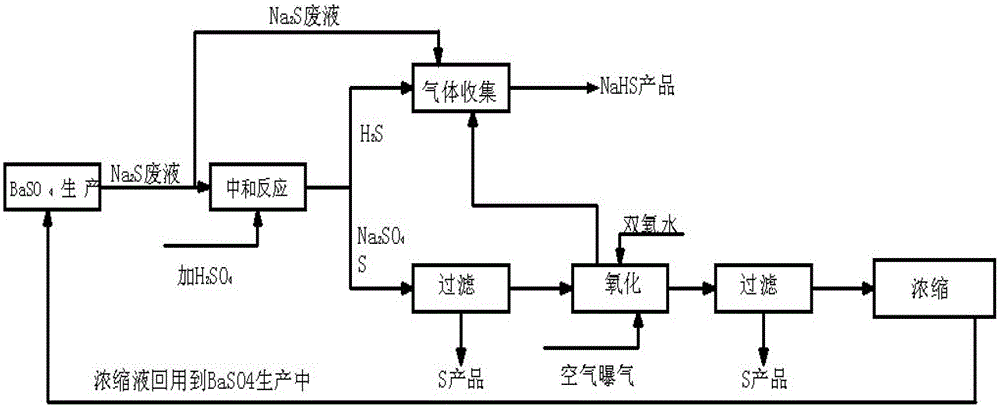

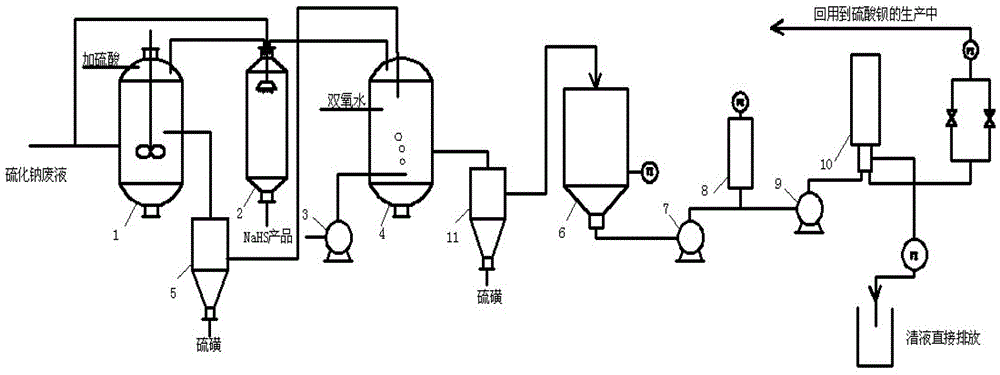

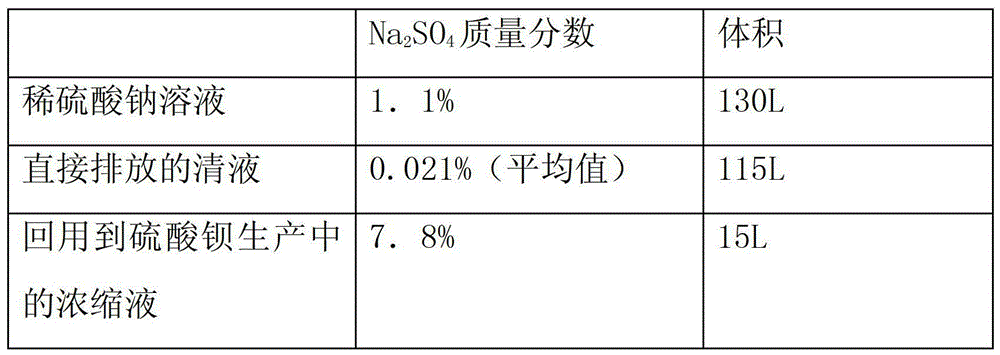

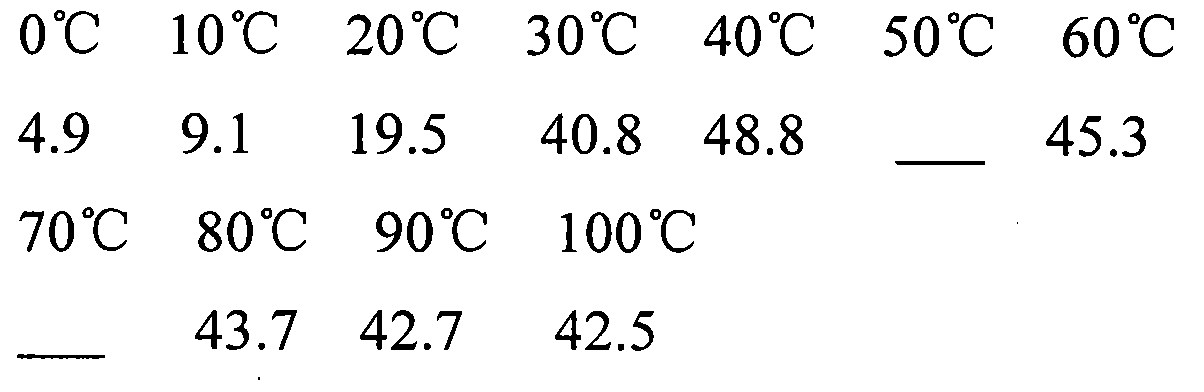

Process and device for recovering sodium sulphide wastewater in barium sulphate production

InactiveCN103058227AIncrease concentrationSulfate/bisulfate preparationSulfur preparation/purificationReverse osmosisHigh pressure

The invention discloses a process and a device for recovering sodium sulphide wastewater in barium sulphate production, belonging to the technical field of wastewater recovery. The process comprises the following steps performed by the corresponding devices: adding sulphuric acid to neutralize dilute sodium sulphide waste solution; absorbing hydrogen sulphide by a sodium sulphide spray tower; adding hydrogen peroxide in the sodium sulphate solution, so as to oxidize hydrogen sulphide which is dissolved in sodium sulphate solution into sulphur; filtering the sodium sulphate solution; and finally charging the sodium sulphate dilute solution in a disc-tube type reverse osmosis membrane system or a high-pressure flat-sheet membrane system, then concentrating, reusing the concentrate in barium sulphate production, and directly draining clear solution, so as to achieve the effect of turning waste into wealth.

Owner:BEIJING UNIV OF CHEM TECH

Resource recycling method of industrial phosphogypsum waste residues

ActiveCN104211099AResource conservationHigh chemical puritySulfate/bisulfate preparationCalcium/strontium/barium oxides/hydroxidesHydrogen SulfateSilicic acid

The invention discloses a resource recycling method of industrial phosphogypsum waste residues and relates to the technical field of inorganic chemical industry. The method comprises the following steps: carrying out a reaction on gypsum calcium sulfate and concentrated sulfuric acid to generate calcium hydrogen sulfate; carrying out a reaction on calcium hydrogen sulfate which is 1 time and a sodium hydroxide NaOH or potassium hydroxide KOH aqueous solution which is 4 times; filtering or precipitating and separating to recover calcium hydroxide, limonite, silicic acid and calcium fluoride and CaHPO4; and obtaining sodium sulfate / potassium sulfate, sodium aluminate or potassium aluminate and calcium acetate Ca(CH3COO)2. The method is mainly applied to resource recycling of industrial phosphogypsum waste residues.

Owner:济宁理工思源商务服务有限公司

Potassium sulfate extracted from sintering dust separation ash and method for producing the same

InactiveCN101428832AImprove resource utilizationHigh recovery rateSulfate/bisulfate preparationResource utilizationChemical products

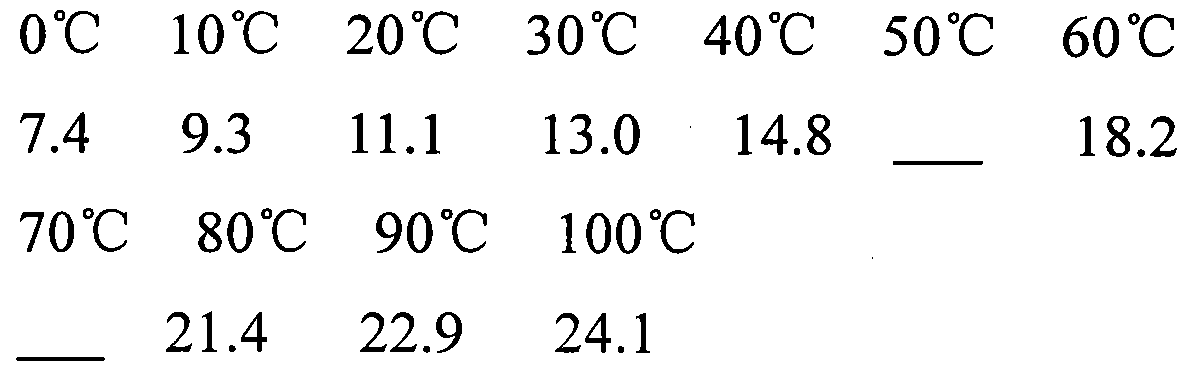

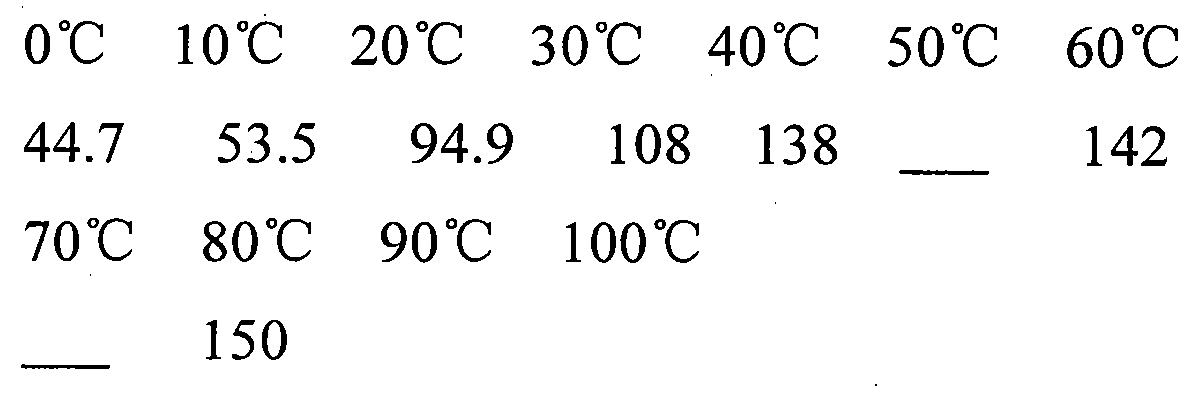

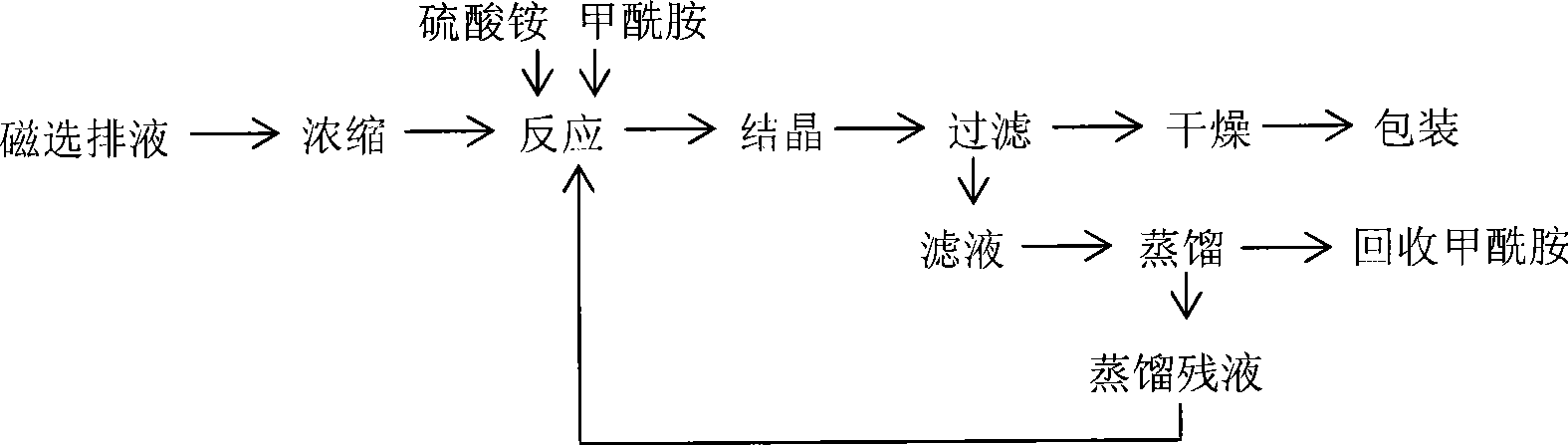

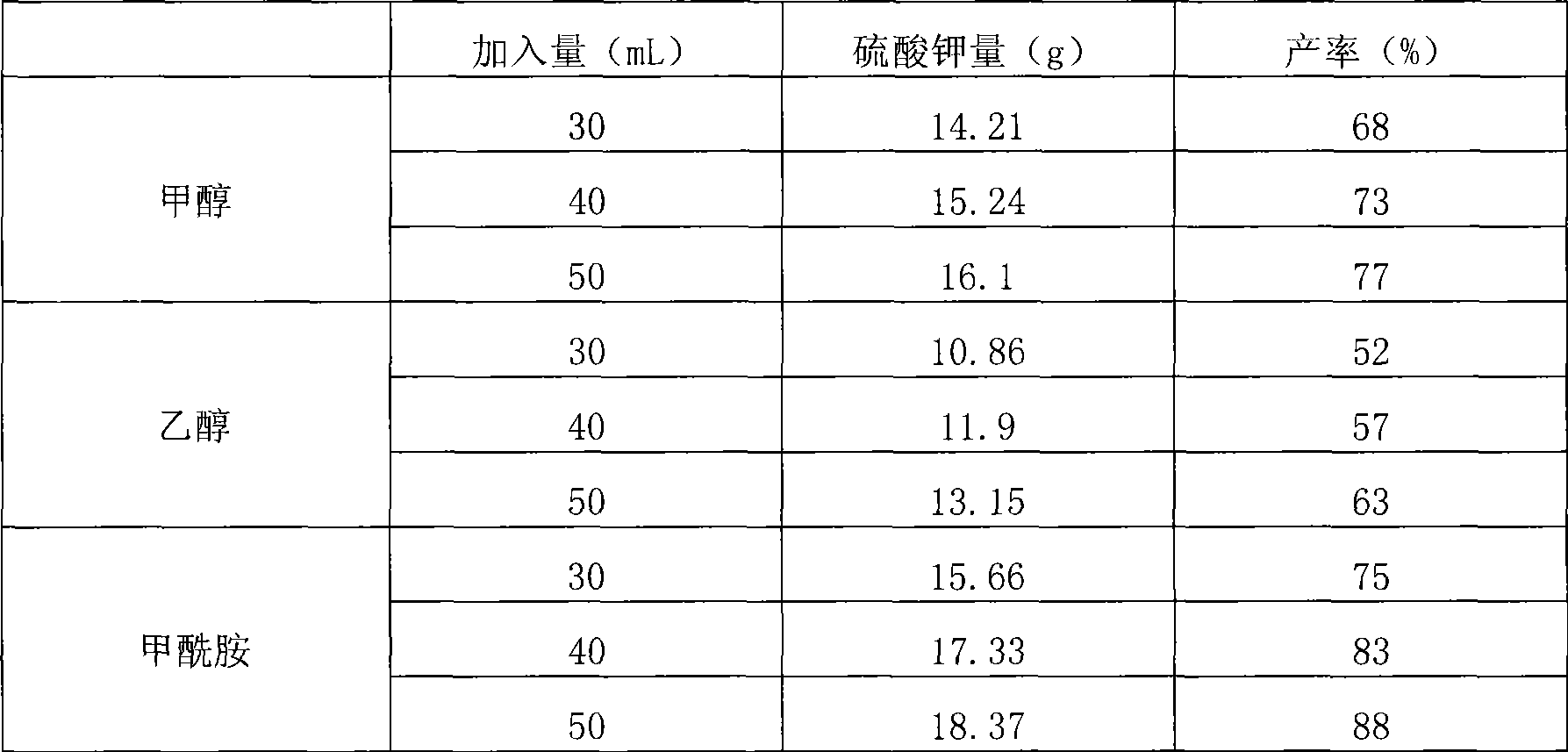

The invention relates to a potassium sulfate abstracted from sintered dust removing ash and a preparation method thereof, and belongs to the technical field of a chemical product. The preparation method comprises the following steps: weighing the dust removing ash, adding the dust removing ash in water with the weight being three times than that of the dust removing ash; dipping the dust removing ash for three days at the normal temperature; filtering the dust removing ash; concentrating filtrate to one tenth by adopting the reduced pressure distillation method; analyzing the content of K<+> in concentrated solution; adding ammonium sulfate in the concentrated solution, so that the K<+>: SO4<2+> is equal to 2.1:1 in the solution; adding formamide again; reacting for two hours at the temperature of 80 DEG C; and then obtaining potassium sulfate crystal. After the potassium sulfate crystal is filtered and dried, the potassium sulfate product can be obtained; the filtrate is distilled at the temperature of 90 DEG C; an organic solvent added is recovered; and distillation residue is returned to a potassium sulphate composite reaction system to be recycled. By utilizing the metallurgical sintered dust removing ash, the invention has the advantages of simple process, low energy consumption, high return rate of kali salt, not only improves the availability of high resources and protects the environment, but also has better economic benefit and is a green and environment-friendly recycling economy project.

Owner:SHANDONG IRON & STEEL CO LTD

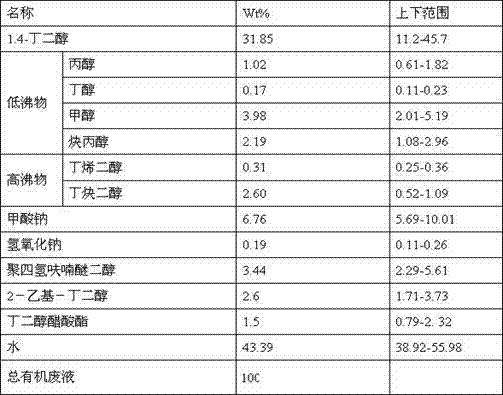

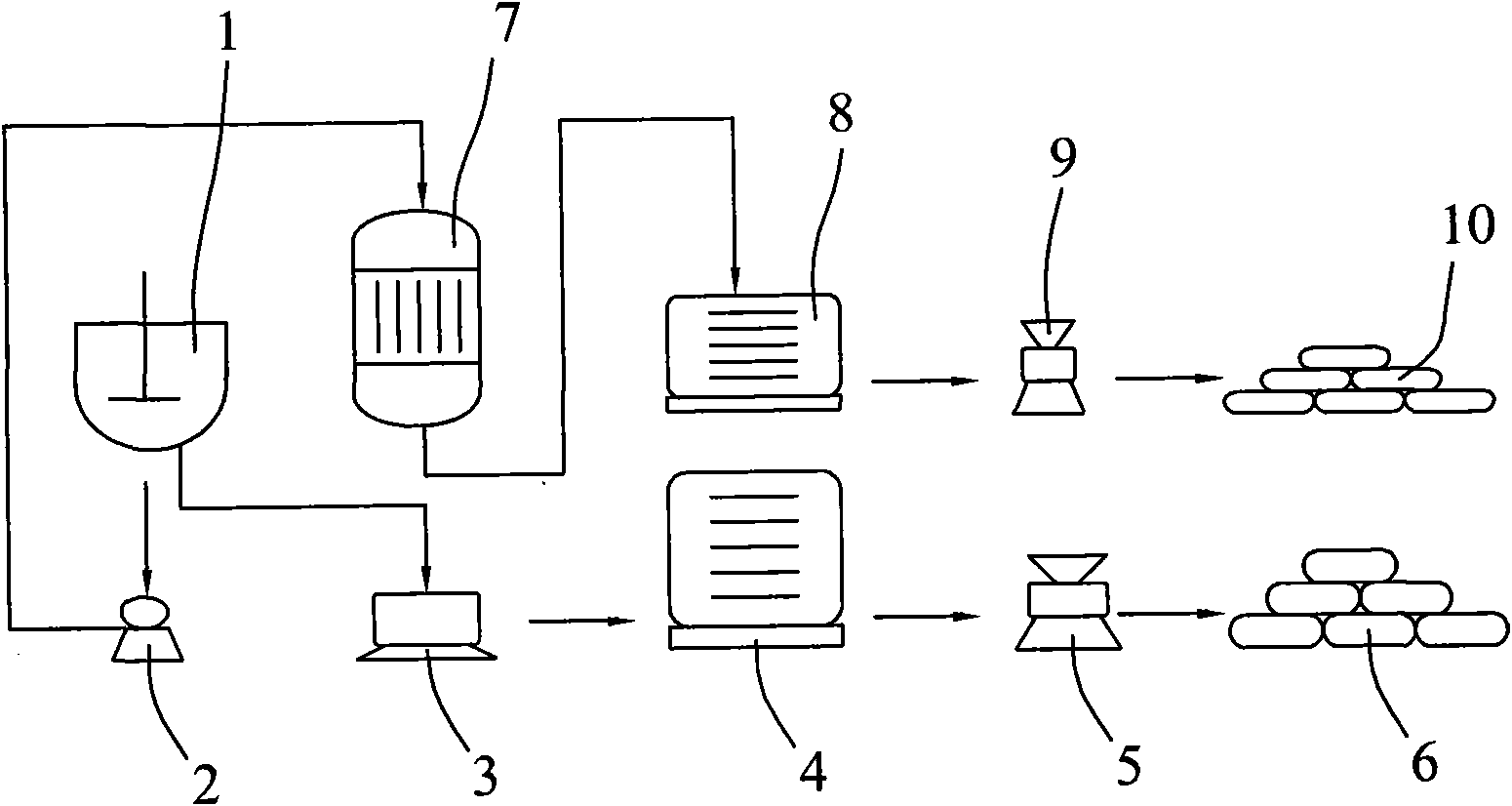

Method for innocently treating organic waste liquid generated in BDO production

ActiveCN105439820AHigh yieldReduce pollutionOrganic compound preparationPlastic recycling1,4-ButanediolAdditional values

The invention discloses a method for innocently treating an organic waste liquid generated in BDO production. According to the method, an organic waste liquid generated in BDO production is treated to obtain high-purity 1,4-butanediol (BDO), high-boiling residues, low-boiling residues, sodium nitrate and polyether polyol products, and innocent, recycling and zero emission treatment of the organic waste liquid generated in BDO production can be realized. The whole method is simple in process, easily controllable in condition and high in finished product yield, and all prepared products have high purity, little equipment investment, low production cost and energy consumption conservation. The method is applied to recycling treatment of organic waste liquid generated in BDO industrial production process to prepare products (industrial raw materials) which can be utilized in industrial production, meanwhile, innocent treatment and zero emission of pollutants can be realized. The method has extremely economic meaning and social meaning in the aspects of increasing production additional values, reducing environmental pollution and the like.

Owner:迪邦(泸州)化工有限公司

Method for preparing calcium carbonate and co-producing sodium sulfate by using phosphorus gypsum and soda ash

InactiveCN101850992AReasonable production processSimple production equipmentCalcium/strontium/barium carbonatesSulfate/bisulfate preparationChemical reactionDistillation

The invention discloses a method for preparing calcium carbonate and co-producing sodium sulfate by using phosphorus gypsum and soda ash. The method comprises the following steps of: (1) calculating pure calcium sulfate substance content of a phosphorus gypsum product, feeding the phosphorus gypsum and sodium carbonate solution into a reactor in a mass ratio of pure substances of the calcium sulfate and the sodium carbonate of 1: 0.58-0.78, and performing chemical reaction with slow stirring; (2) filtering a reaction product obtained in the step (1) in a filter to obtain clear sodium sulfate solution and calcium carbonate filter cakes; (3) washing the calcium carbonate filter cakes obtained in the step (2) by using water, centrifuging the solution through a centrifuge, separating solid and liquid, drying the solid through a dryer, and crushing the solid through a first crusher to obtain a calcium carbonate product; and (4) conveying the sodium sulfate solution obtained in the step (2) into a reduced pressure distiller to perform reduced pressure distillation, then cooling a reduced pressure distillation product in a cooler, and crushing the reduced pressure distillation product in a second crusher to obtain a powdery sodium sulfate product.

Owner:汪晋强

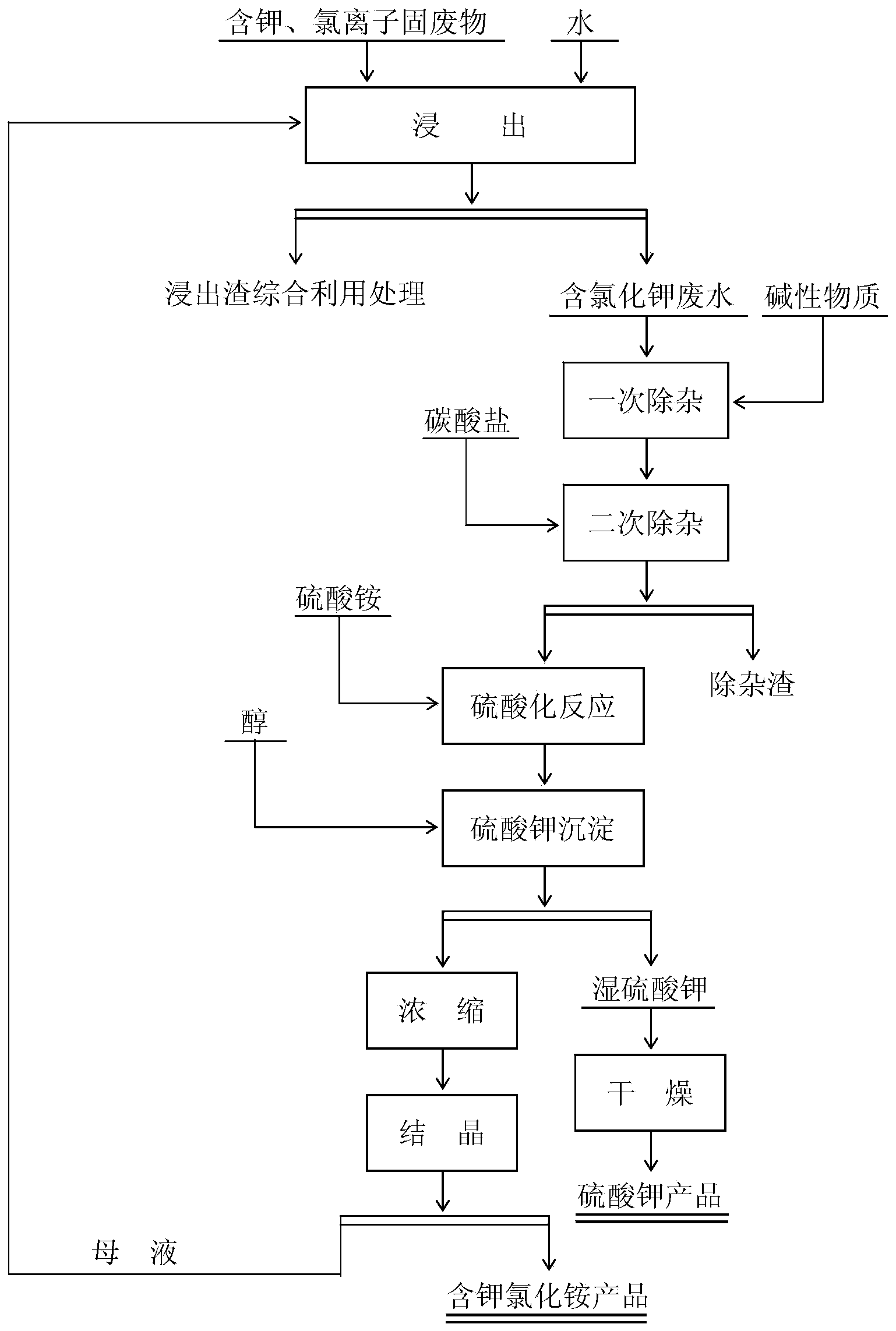

Method for producing potassium sulfate from potassium/chlorine-ion-containing solid waste

InactiveCN104261433AAchieving RecoveryImprove product qualitySulfate/bisulfate preparationAmmonium sulfateChloride potassium

The invention discloses a method for producing potassium sulfate from potassium / chlorine-ion-containing solid waste, which comprises the following steps: leaching potassium / chlorine-ion-containing solid waste with water, wherein the potassium / chlorine ions and other soluble impurity ions enter the water to form a potassium-chloride-containing mixed solution; adding an alkaline matter into the mixed solution to regulate the pH value of the solution, thereby performing primary impurity removal; adding soluble carbonate into the solution to perform secondary impurity removal; carrying out solid-liquid separation; adding ammonium sulfate into the filtrate; after the sulfating reaction, adding alcohol to precipitate potassium sulfate; after the potassium sulfate precipitation reaction, carrying out solid-liquid separation; drying the filter residue to obtain the potassium sulfate product; adding the filtrate into a concentration and crystallization device to perform concentration and crystallization, and carrying out solid-liquid separation, wherein the filter residue is the potassium-containing ammonium chloride product. By using the method, the recovery rate of K2O in the product is not less than 91% in the potassium-chloride-containing mixed solution.

Owner:XIANGTAN TIANZHI TECH

Comprehensive utilization method of serpentine and device used by method

Owner:NANYANG ORIENTAL APPL CHEM RES INST +1

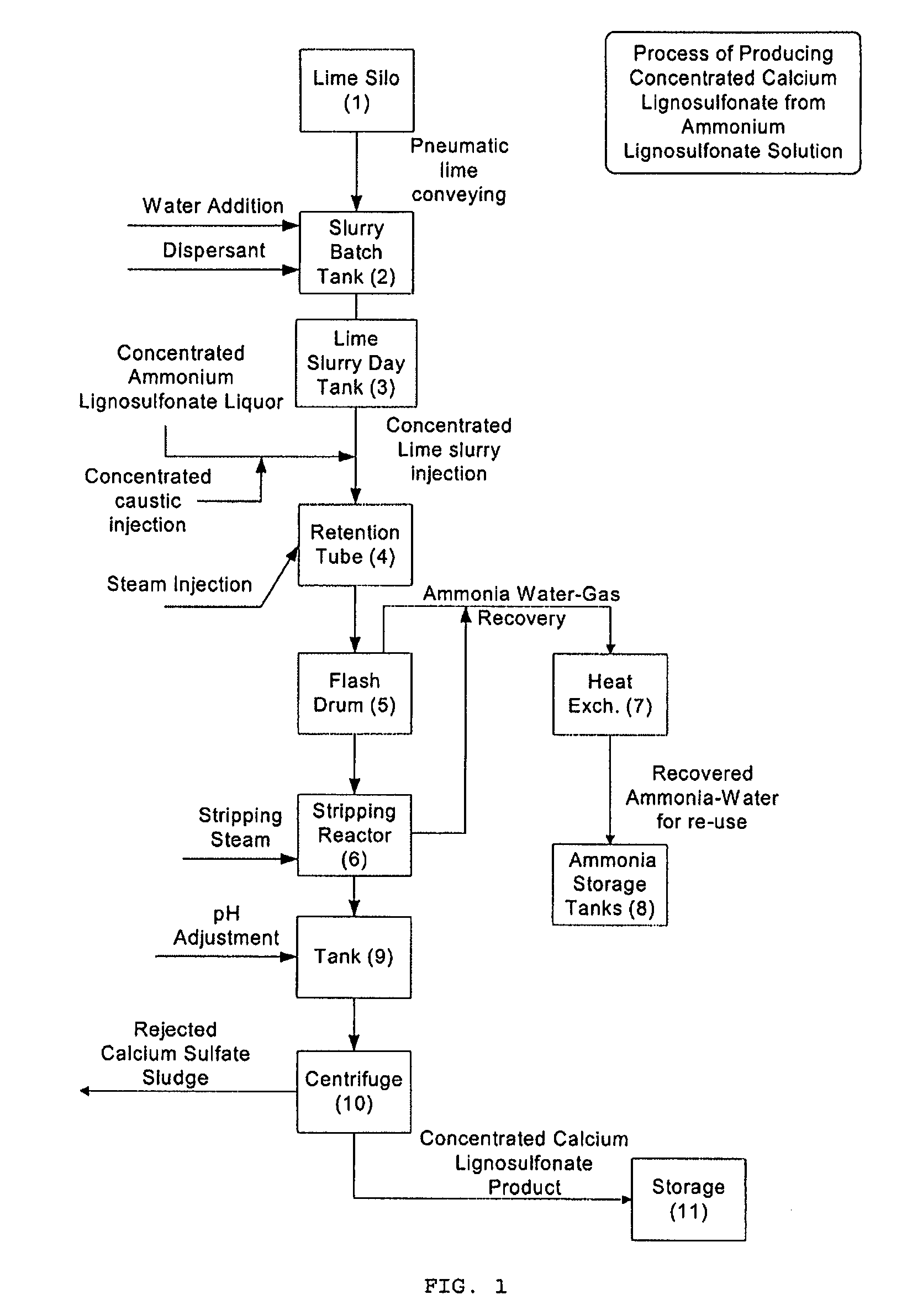

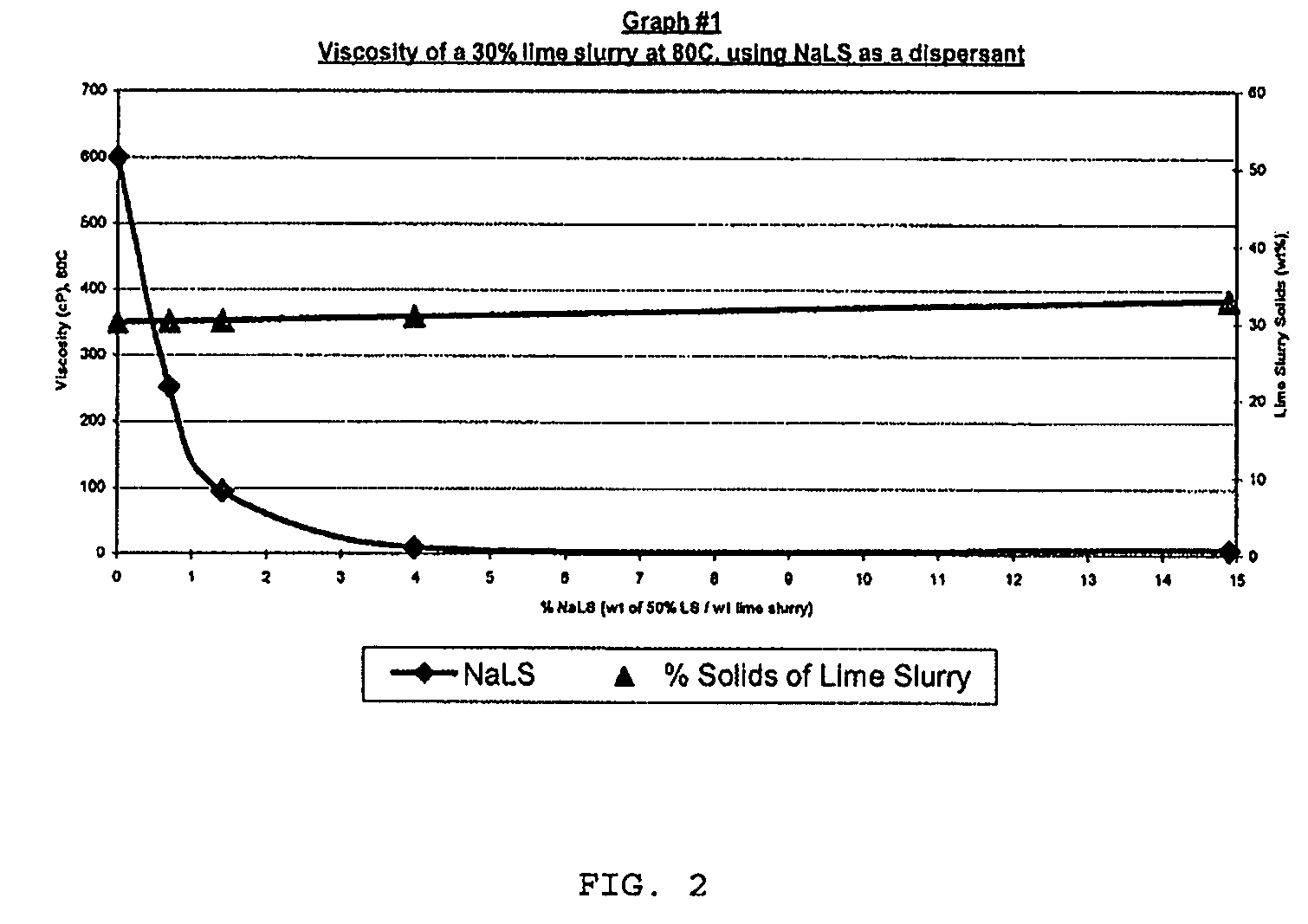

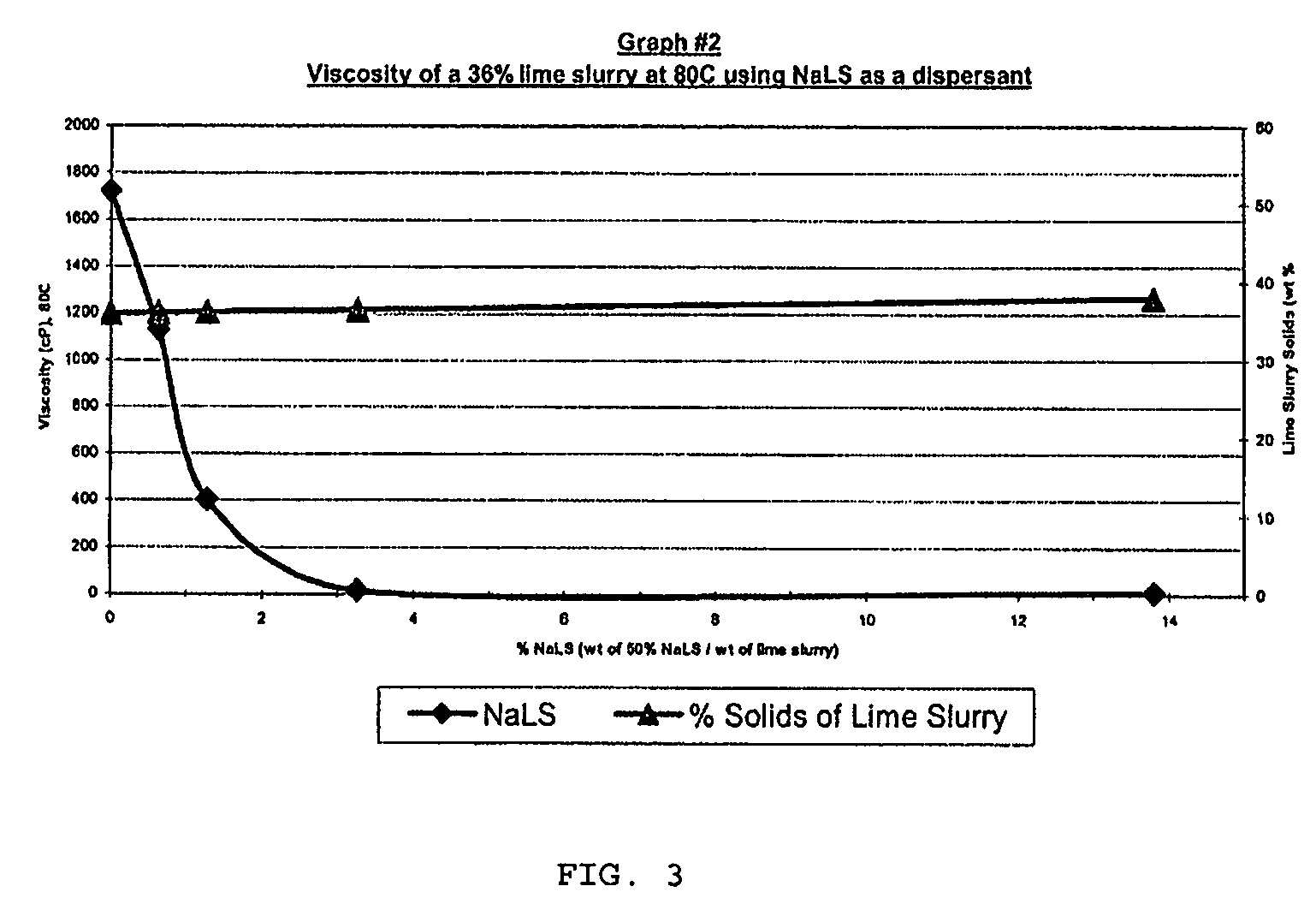

Higher than 30% concentration lime slurries, preparation and uses thereof

InactiveUS20080206126A1Reduced final product viscosityEliminate processingNon-fibrous pulp additionNatural cellulose pulp/paperCalcium hydroxideSulfate

The present invention relates to a composition comprising water, more than 30% w / w of calcium hydroxide, and >0.2% w / w dispersant. A process for preparing such a composition is also disclosed. The composition which can be in the form of a 45-55% concentration lime slurry is particularly useful for converting concentrated ammonium lignosulfonate into calcium lignosulfonate, for converting ammonium lignosulfonate into low sulfate calcium, potassium, sodium, or magnesium lignosulfonate and mixtures thereof, for removing soluble sulfate from concentrated sodium, potassium, ammonium or magnesium lignosulfonate or for treating a weak liquor obtained from the pulp and paper industry.

Owner:TEMBEC INC

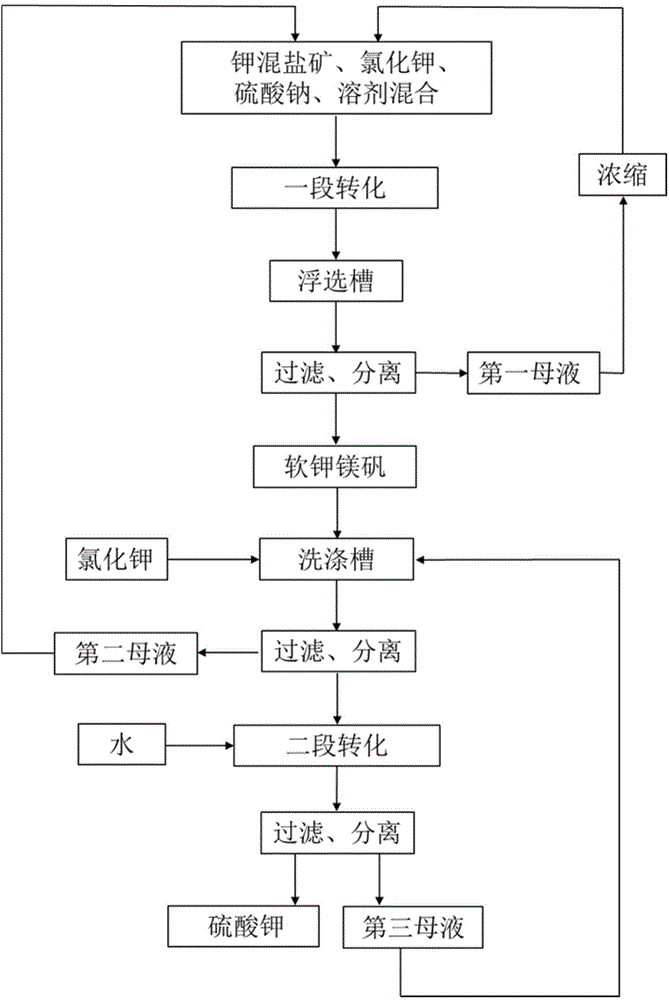

Method for preparing potassium sulfate

InactiveCN104477943AConserve fresh water resourcesShorten the growth cycleSulfate/bisulfate preparationFresh waterChloride

The invention discloses a method for preparing potassium sulfate. The method comprises the following steps: 1) mixing and stirring potassium mixed salt mine, potassium chloride, sodium sulfate and a solvent to obtain a solid-liquid mixture; 2) regulating the solid-liquid volume ratio of the solid-liquid mixture to 1:(3-5), adding a flotation medicament for flotation, and then filtering and separating obtained flotation foam to obtain soft leonite and first mother liquor; 3) mixing the obtained soft leonite and potassium chloride according to the mass ratio of (1.6-2.0): (0.8-1.2), adding a washing solution to basically clean Na<+> in the mixture, and then filtering and separating to obtain a solid phase and second mother liquor; and 4) adding the solid phase in the step 3) into fresh water according to the solid-water mass ratio of (1.0-1.5):1, converting for 1-1.5h at the temperature of 60-70 DEG C, and then cooling, filtering and separating to obtain a potassium sulfate product and third mother liquor. According to the method disclosed by the invention, a byproduct of a salt lake, namely sodium sulfate is fully utilized, fresh water resources are saved in the production process, the production period is shortened, the production efficiency is improved and the production cost is further reduced.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com