Recycling method for waste cathode carbon blocks of electrolytic aluminum electrolysis cell

A waste cathode carbon block and electrolytic cell technology, which is applied in the preparation/purification of carbon, alumina/aluminum hydroxide, fluorine/hydrogen fluoride, etc., can solve the problems of HF pollution, secondary pollution, deterioration of production conditions, etc. Advanced technology, obvious advantages, and the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

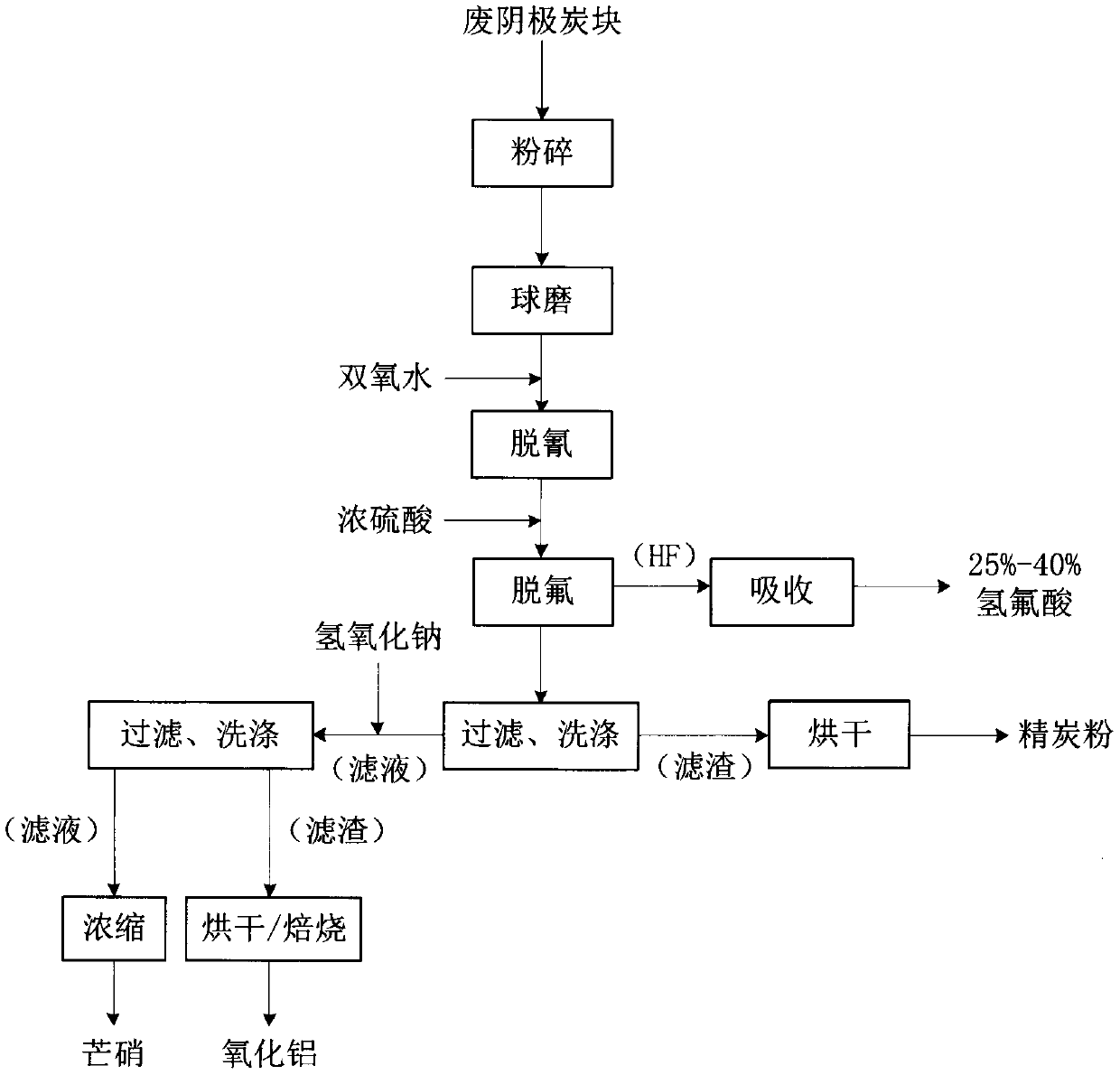

Method used

Image

Examples

Embodiment 1

[0013] A method for recycling waste and old cathode carbon blocks of electrolytic aluminum electrolytic cells, the processing process comprising the following steps: crushing and grinding the raw materials of waste and old cathode carbon blocks of electrolytic aluminum electrolytic cells to carbon powders smaller than 45 meshes; : 1 adding 10g concentration is 30wt% hydrogen peroxide, stirs 10min to decompose cyanide and excess hydrogen peroxide at 80 ℃, 50rpm; With the material that removes cyanide, add 50g concentration and be 95wt% thick Sulfuric acid, at 120°C and a stirring speed of 100rpm, generates HF gas; passes HF gas into the hydrogen fluoride condensation absorption tower, absorbs it with deionized water or low-concentration hydrofluoric acid cycle, and obtains high-concentration hydrogen fluoride with a concentration of 28.8wt% Acid; the carbon powder after removing fluorine is cooled to room temperature, and the concentration is 40wt% NaOH aqueous solution is added...

Embodiment 2

[0015] A method for recycling waste and old cathode carbon blocks of electrolytic aluminum electrolytic cells, the processing process comprising the following steps: crushing and grinding the raw materials of waste and old cathode carbon blocks of electrolytic aluminum electrolytic cells to carbon powders smaller than 45 meshes; : 1 add 10g concentration of hydrogen peroxide that is 30wt%, stir 20min at 80 ℃, 100rpm to decompose cyanide and excess hydrogen peroxide; With the material that removes cyanide, add 70g concentration and be 95wt% concentrated Sulfuric acid, at 120°C and a stirring speed of 150 rpm, generates HF gas; passes the HF gas into the hydrogen fluoride condensation absorption tower, and absorbs it with deionized water or low-concentration hydrofluoric acid to obtain high-concentration hydrogen with a concentration of 25.0 wt%. Fluoric acid: the carbon powder after removing fluorine is cooled to room temperature, and the concentration is 40wt% NaOH aqueous solu...

Embodiment 3

[0017]A method for recycling waste and old cathode carbon blocks of electrolytic aluminum electrolytic cells, the processing process comprising the following steps: crushing and grinding the raw materials of waste and old cathode carbon blocks of electrolytic aluminum electrolytic cells to carbon powders smaller than 45 meshes; : 1 add 10g concentration of 30wt% hydrogen peroxide, stir at 80°C and 100rpm for 30min to decompose cyanide and excess hydrogen peroxide; to remove the material of cyanide, add 60g concentration of 98wt% concentrated Sulfuric acid, at 120°C and a stirring speed of 200 rpm, generates HF gas; passes the HF gas into the hydrogen fluoride condensation absorption tower, and absorbs it with deionized water or low-concentration hydrofluoric acid to obtain high-concentration hydrogen with a concentration of 40.0wt% Fluoric acid: the carbon powder after removing fluorine is cooled to room temperature, and the concentration is 40wt% NaOH aqueous solution is added...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com