Patents

Literature

115results about How to "Eradicate pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fermented biofertilizer prepared from waste vegetables, straw and livestock and poultry feces and preparation method thereof

ActiveCN102531720AEradicate pollutionSave water in washing processBio-organic fraction processingOrganic fertiliser preparationBiotechnologyMicrobiology

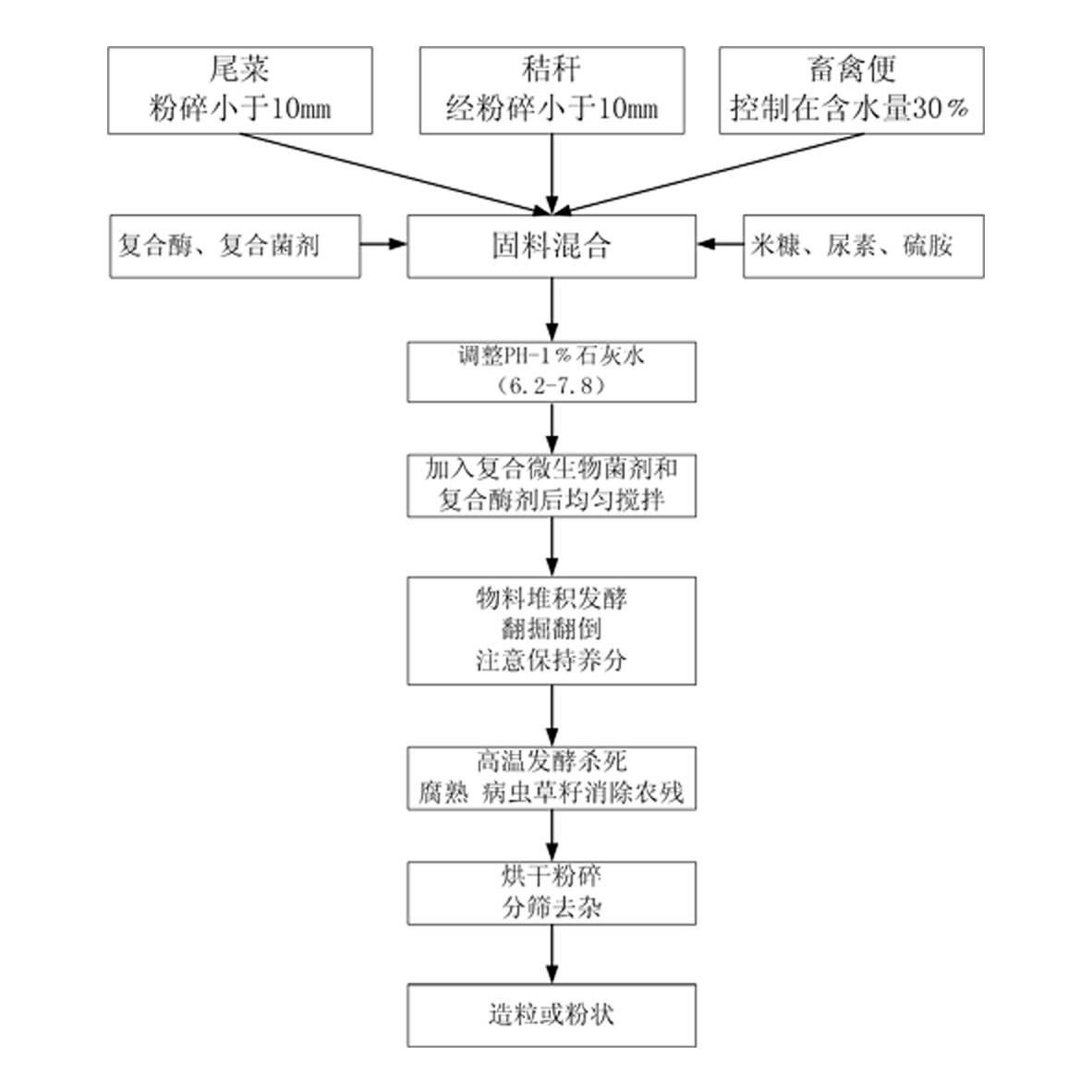

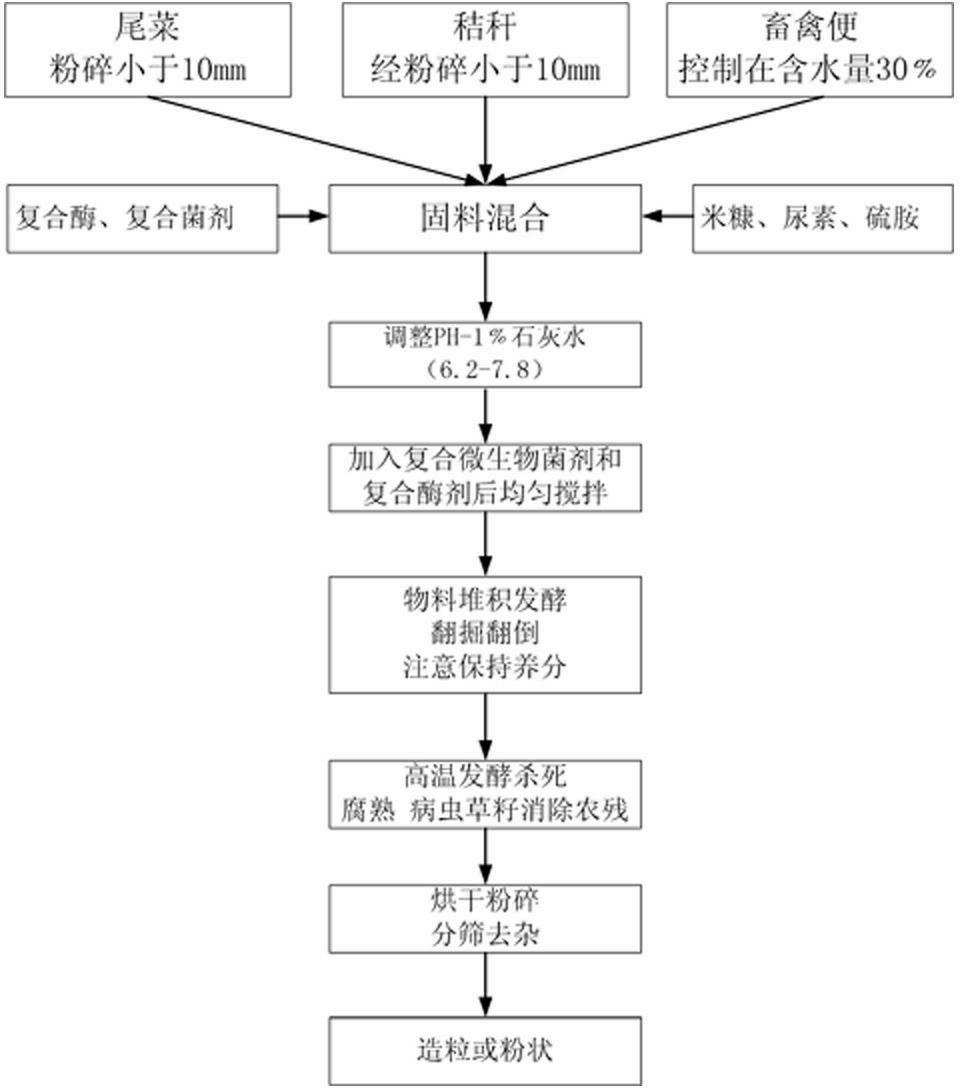

The invention relates to a method for preparing biofertilizer by fermenting waste vegetables, straw and livestock and poultry feces. The fermented biofertilizer is prepared from the following raw materials in parts by weight: 90-110 parts of waste vegetables, 45-55 parts of straw, 18-22 parts of livestock and poultry feces, 6-10 parts of rice bran, 1.7-2.0 parts of urea, and 1.7-2.0 parts of ammonium sulfate. The invention also provides a preparation method of the fermented biofertilizer prepared from waste vegetables, straw and livestock and poultry feces. The preparation method comprises the following steps of: crushing the waste vegetables till particle size is below 10 mm, crushing the straw till particle size is below 10 mm, adding 45-55 parts by weight of straw, 18-22 parts by weight of livestock and poultry feces, 6-10 parts by weight of rice bran, 1.7-2.0 parts by weight of urea, and 1.7-2.0 parts by weight of ammonium sulfate to 90-110 parts by weight of waste vegetables, mixing, adjusting the water content of the mixed material to 50-65%, adding 0.08-0.12% of composite microorganism agent and 0.008-0.010% of composite enzyme based on the weight of the mixed material, sufficiently and uniformly stirring, controlling water content of the fermentation material to be 50-65%, adjusting the pH to 6.2-7.8 with 1% lime water, and carrying out aerobic fermentation for 10-20 days to obtain the biofertilizer product.

Owner:甘肃明德伟业生物科技有限公司

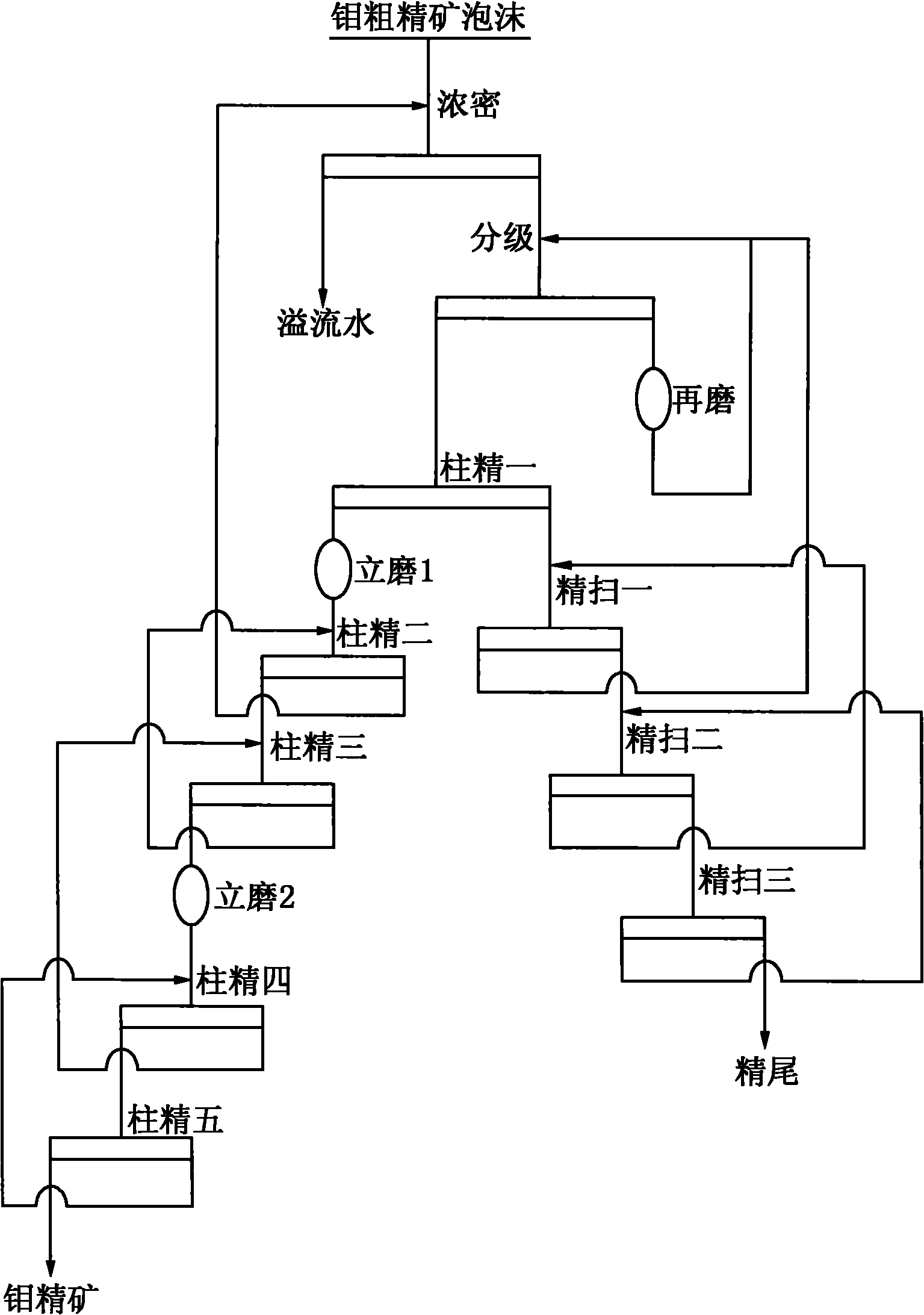

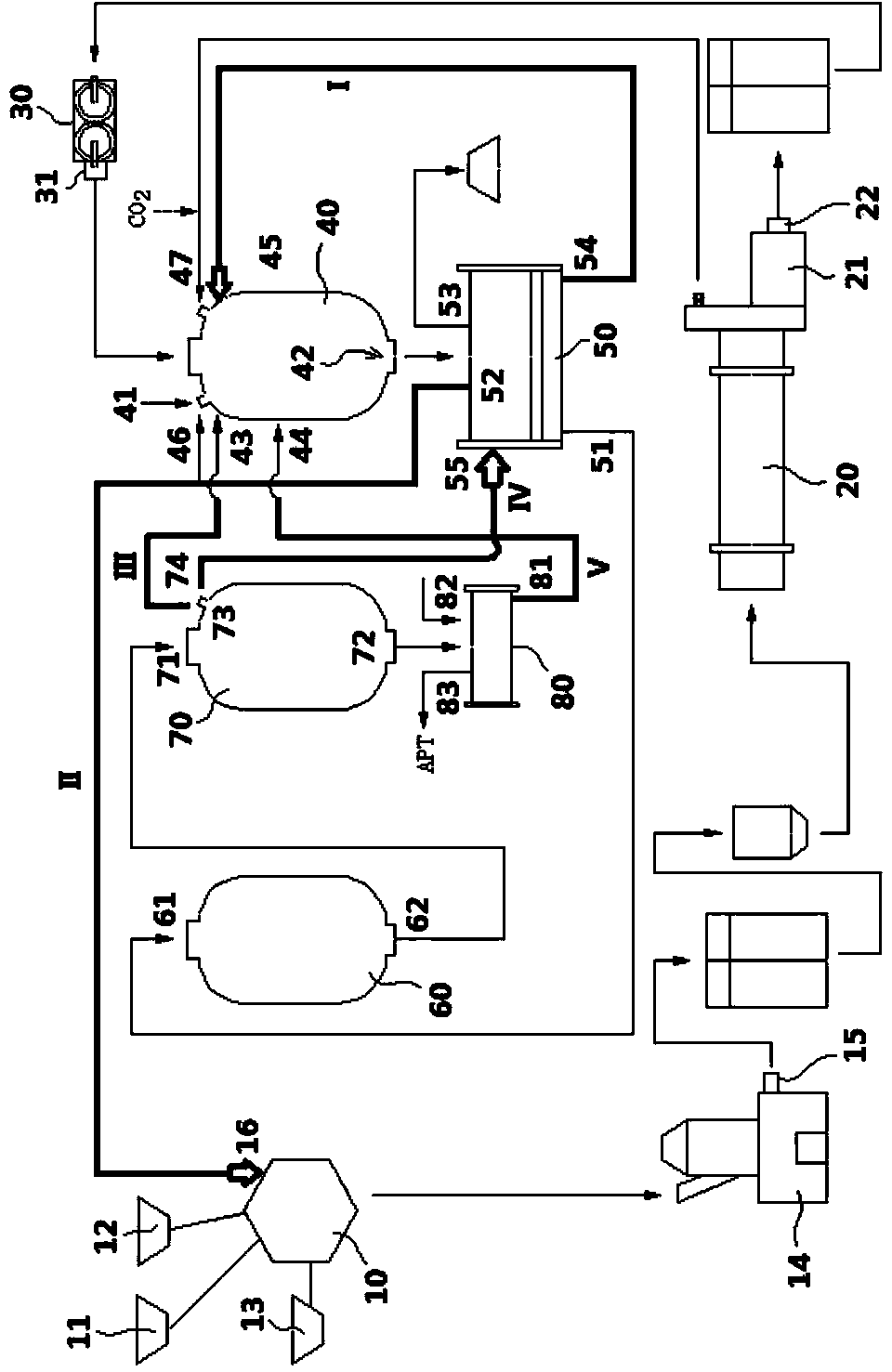

Production technology of high-grade molybdenum concentrate

ActiveCN101773871AReduce pollutionIncrease feed concentrationFlotationWet separationBall millReagent

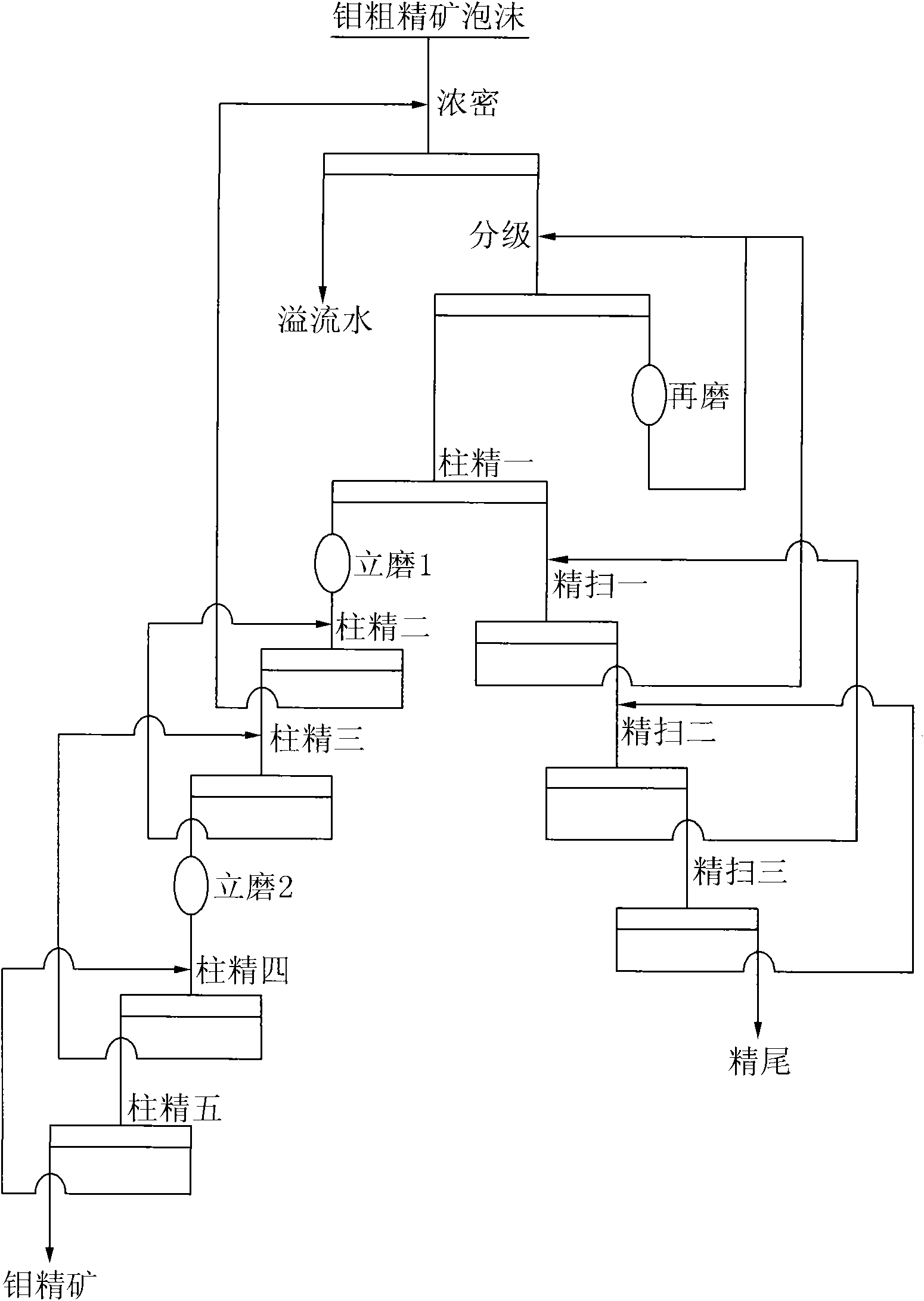

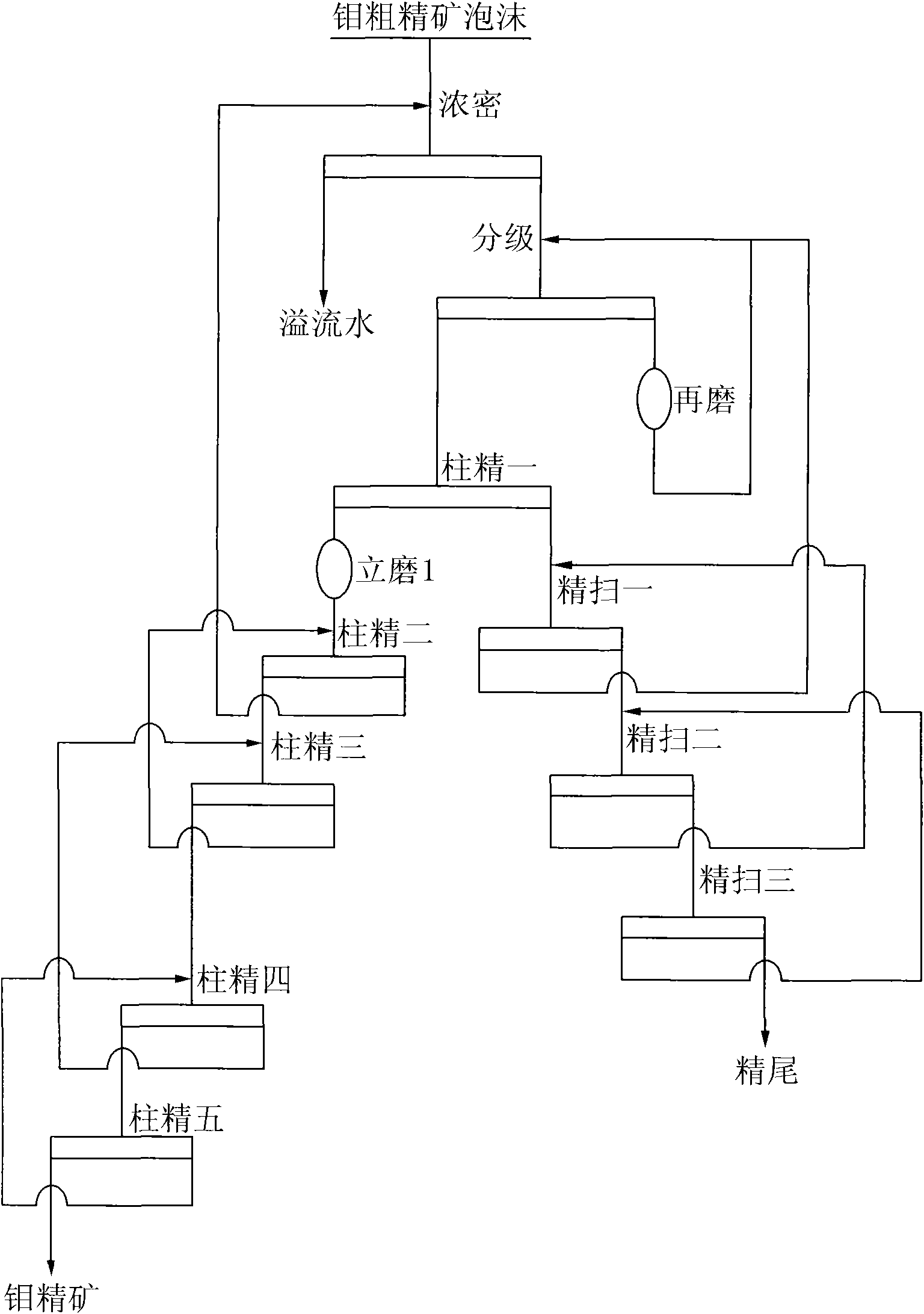

The invention discloses a production technology of high-grade molybdenum concentrate, which comprises the following steps: rough molybdenum concentrate is obtained by roughing crude molybdenum ore, the rough molybdenum concentrate is concentrated and removed reagent through a thickener, underflow enters a hydraulic swirler to be graded previously, overflow after the grading enters a primary flotation column to be selected, the underflow after the grading enters a horizontal ball grinding mill to be reground, and after the regrinding, the ore discharge enters the hydraulic swirler to be regraded; selected concentrate from the primary flotation column is cleaned by a vertical ore mill to enter a secondary and a tertiary flotation columns to be selected, and the selected concentrate from thetertiary flotation column directly enters or enters a quartic or a quintic flotation columns to be selected after being cleaned by a second section of the vertical ore mill to obtain the high-grade molybdenum concentrate; the selected tailings from the primary flotation column is tertiary scavenged by a flotation machine, and the scavenged concentrate tailings from the tertiary scavenging enters the next procedure. The technology adopts the flotation columns and the flotation machine, so the flow is short, the agent system is simple, the adaptability of the crude ore is strong, and the molybdenum concentration ratio is high, the molybdenum concentrate has high grade, large yield and high recycling rate so as to provide excellent raw material to the following molybdenum chemical engineering and further processing.

Owner:JINDUICHENG MOLYBDENUM CO LTD

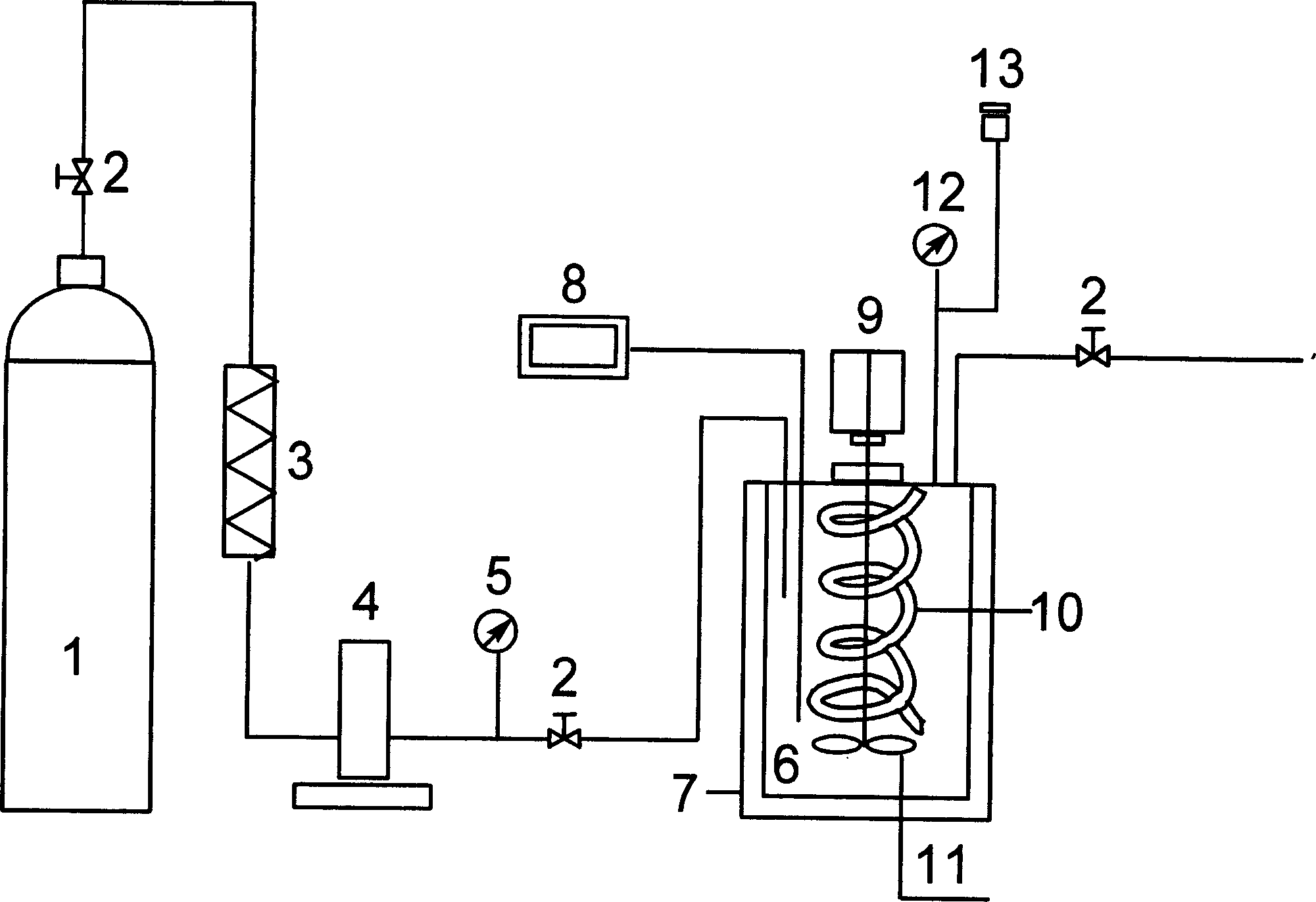

Technology for dyeing ramie fiber with overcritical carbon dioxide method

The invention relates to a new process of supercritical CO2 dyeing of ramie fiber, using ramie fiber as raw material, swelling by NaOH solution and modifying by benzoyl chloride, and dyeing with dispersive dye in supercritical CO2 medium by supercritical fluid technique. And its advantages: it is a clean producing process; the dyed ramie fiber has characters of bright color, short dyeing flow, dyeing uniformity, good color intensity, low synthetic cost, and remarkable economic and environmental protection benefits. And it also reveals a process device implementing the dyeing method, suitable to spread and apply in spinning and weaving, and printing and dyeing enterprises.

Owner:SHAANXI NORMAL UNIV

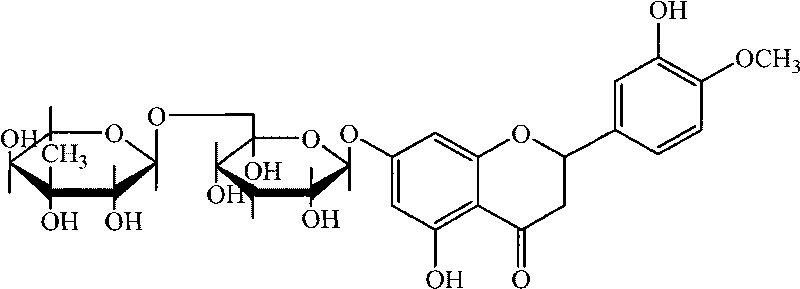

Method for extracting hesperidin from tangerine peel

ActiveCN101747394AReduce the impactGood choiceSugar derivativesSugar derivatives preparationDipotassium hydrogen phosphateSodium bicarbonate

The invention discloses a method for extracting hesperidin from tangerine peel. The method comprises: mixing tangerine peel with a solid-phase alkali reagent, wherein the tangerine peel is tangerine peel powder which is ground to have a powder particle size analysis result D90 between 10 and 200 mu m; adding water, stirring, centrifuging and taking supernatant; adding acid to regulate pH between 2.0 and 6.0; standing and then filtering the obtained product; drying a filter cake; and obtaining hesperidin. The solid-phase alkali reagent is one or arbitrary mixture of more than two of sodium hydroxide, aluminum hydroxide, calcium hydroxide, potassium hydroxide, sodium bicarbonate, potassium bicarbonate, sodium carbonate, potassium carbonate, calcium carbonate, sodium silicate, disodium hydrogen phosphate or dipotassium hydrogen phosphate. By adopting a mechanochemical technique to extract and separate the hesperidin, the method has the advantages of high extraction rate, high product purity, simple process, environment-friendly property, low cost and short production cycle, and is an extraction-separation route with broad industrialization prospects.

Owner:ZHEJIANG UNIV OF TECH

Rare earth ore beneficiation method

ActiveCN103962232ACoarse granularityReduce manufacturing costWet separationRare earthSmall footprint

The invention relates to a rare earth ore beneficiation method which is characterized in that grading is carried out after ore grinding is carried out on raw ore; reselection is carried out on coarse fractions to obtain gravity concentrates and tailings; magnetic separation is carried out on fine fractions to obtain strong-magnetic separation concentrates and tailings; reselection is respectively carried out on gravity concentrates and strong-magnetic separation concentrates which are different in fraction through a table to obtain table concentrates, table middlings and table tailings; the table concentrates and the table middlings which are different in fraction are mixed, and wet-type high-gradient magnetic separation is carried out to obtain magnetic separation rare earth ore concentrates and magnetic separation middlings; the magnetic separation middlings and the table tailings are mixed, closed-loop flotation including primary rough concentration, secondary scavenging and secondary fine selection is carried out after ore regrinding is carried out, the middlings are returned in proper sequence, and flotation rare earth ore concentrates and flotation tailings are obtained. The magnetic separation rare earth ore concentrates and the flotation rare earth ore concentrates are total rare earth ore concentrates, the REO grade is higher than 65%, and the total recovery rate ranges from 80% to 87%. The rare earth ore beneficiation method is high in grading efficiency, small in occupied area, continuous in production and low in cost, full-wet dust-free operation is achieved, and industrialization is easy to achieve. The rare earth ore beneficiation method is suitable for beneficiation of light rare earth ore existing in the bastnaesite or parisite mode.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI +1

Novel method for extracting vanadic anhydride from stone coal vanadium ore

The invention discloses a novel method for extracting vanadium pentoxide from stone coal-vanadium ore, which comprises the following steps: the stone coal-vanadium ore is crushed, then is directly added with water for wet ball milling, and then is sent into a reaction kettle to stir to leach through acid adding and pressurization, leaching pulp is subjected to solid-liquid separation to obtain leachate, the leachate is pretreated and then is extracted, concentrated and purified, a strip liquor after the extraction is used to precipitate ammonium poly-vanadate, and then a vanadium pentoxide product is obtained through the thermolysis. The method has the advantages of high automation degree of production process, convenient operation, and steady and reliable operation; the yield of vanadium is more than 75 percent, the production cost is lower than those of a sodium method and a normal pressure acid leaching method, the consumption of sulfuric acid is only one third of that of the normal pressure acid leaching method, the grinding of ores adopts a wet ball mill; the method does not bake, has no pollution to the environment, fully utilizes mineral resources and thermal energy, shortens more than one time of leaching time, saves the thermal energy, and reduces the cost; the production process can not destroy the carbon content in the stone coal-vanadium ore, and leaching residue can be used for generating electricity, producing cement, baking bricks and tiles and so on.

Owner:湖南创大钒钨有限公司

Method for preparing granular hexamethylol melamine

The invention discloses a method for preparing granular hexamethylol melamine, which includes the following steps that: measured water and paraformaldehyde are poured into a reaction kettle, a moderate amount of inorganic base is added to regulate the pH value to 7 to 8, measured melamine is then added after 5 minutes of stirring, and the temperature is then increased to 40 DEG C to 50 DEG C, and is kept for about 15 minutes to 2 hours; a moderate amount of inorganic base is used to regulate the pH value to 8 to 10, and the temperature is then increased to 50 DEG C to 80 DEG C, kept for about 15 minutes to 2 hours and reduced to less than 40 DEG C; acid is used for regulating the pH value to neutral, centrifugal separation is carried out, so that waste water is separated, and after drying, the finished product is obtained; and the separated waste water can be recycled to replace part of water. The invention has the advantages of little pollution and easy operation, moreover, the synthesized hexamethylol melamine is sand-like granules, and can be easily separated and dried, and the hexamethylol melamine has good effect when being used in fields such as the synthesization of glue for rubber, the synthesization of amino resin for baked steel finish and waterproof coating for mineral wool boards.

Owner:奥仕集团有限公司

Process for producing protein feed by using alcohol full grains and stalk solid fermentation

InactiveCN1457668AEradicate degradationHigh nutritional valueFood processingAnimal feeding stuffMixed materialsMoisture

The present invention belongs to the fermented protein feed producing technology. Grain alcohol residue in 70-94 wt%, straw in 0.6-1.5 wt%, solidifying agent comprising wheat bran, urea and ammonium sulfate are mixture to regulate the moisture content of grain alcohol residue of 40-60 %; and after further mixing with composite enzyme and composite bacteria, the mixed material is fermented at 25-35 deg.c and under anaerobic condition for 1-5 days to produce the protein feed. The present invention has the advantages of saving in energy source, no pollution and the high protein content up to 28 % in the produced feed.

Owner:TIANJIN UNIV

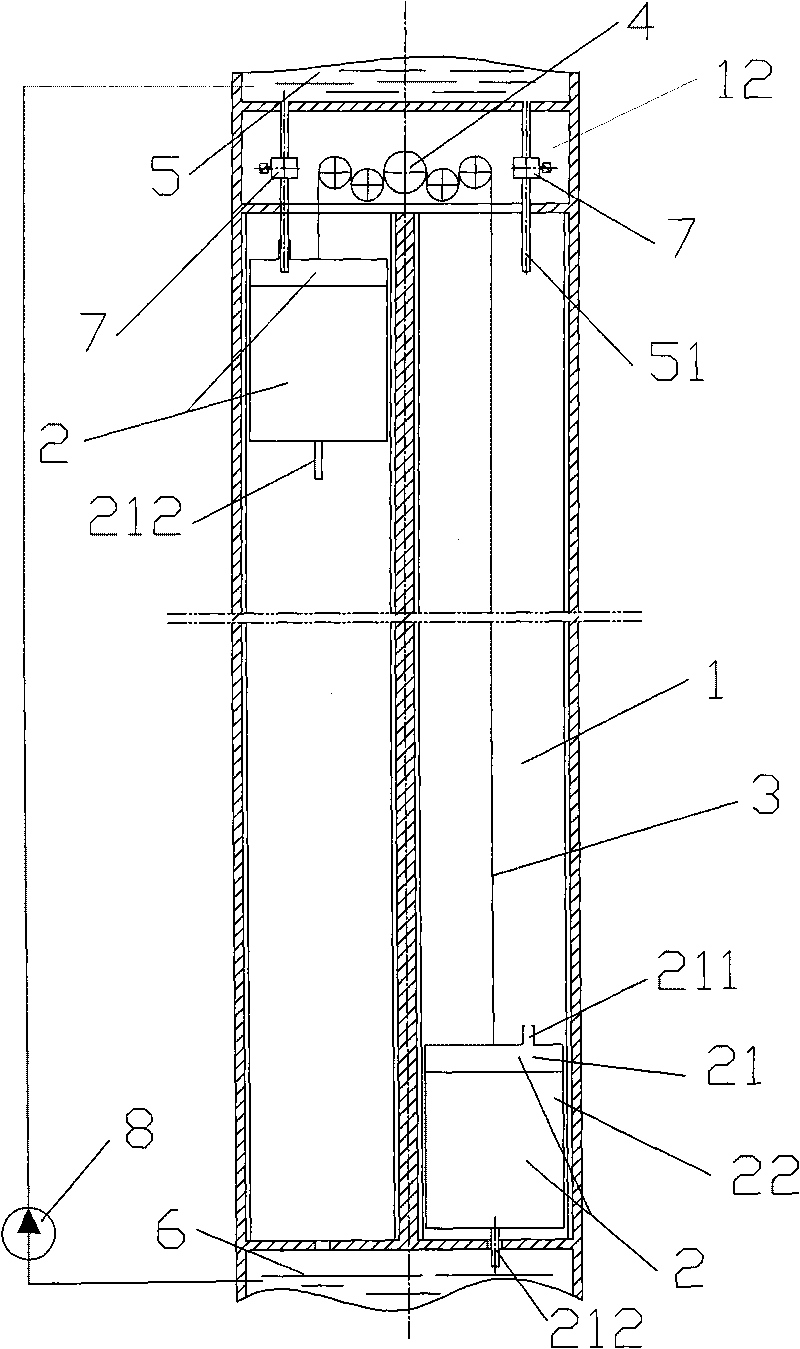

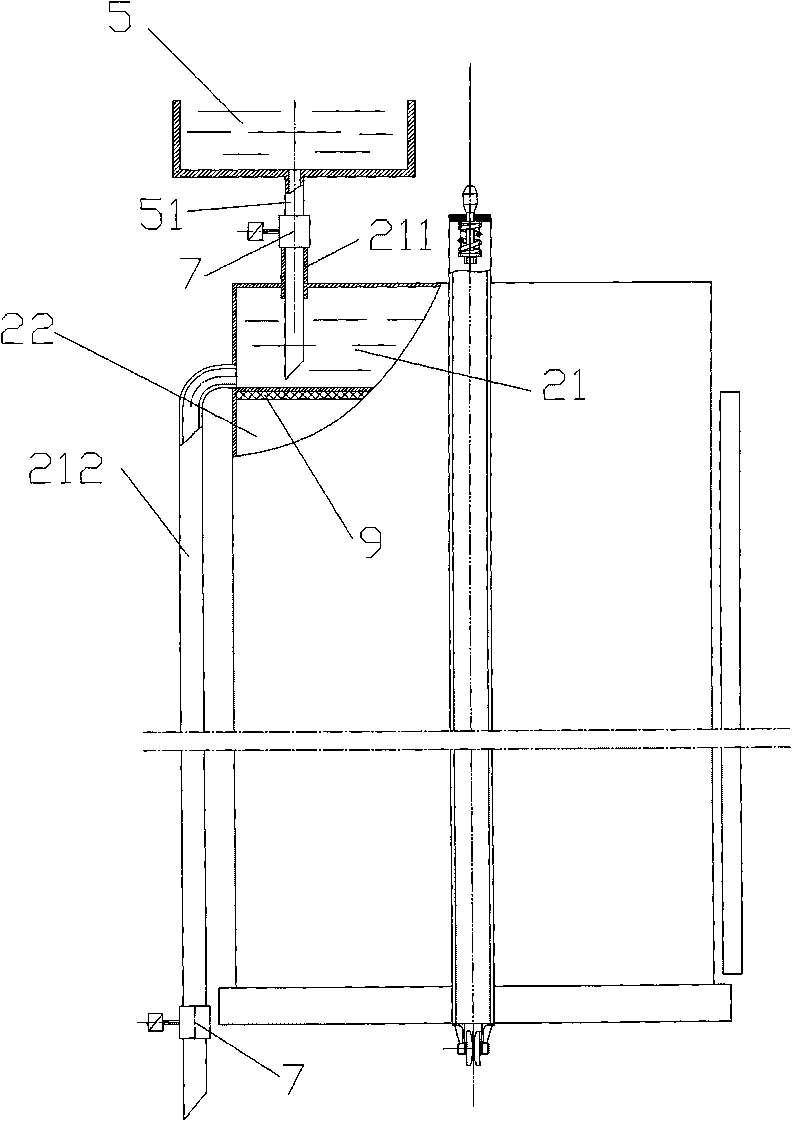

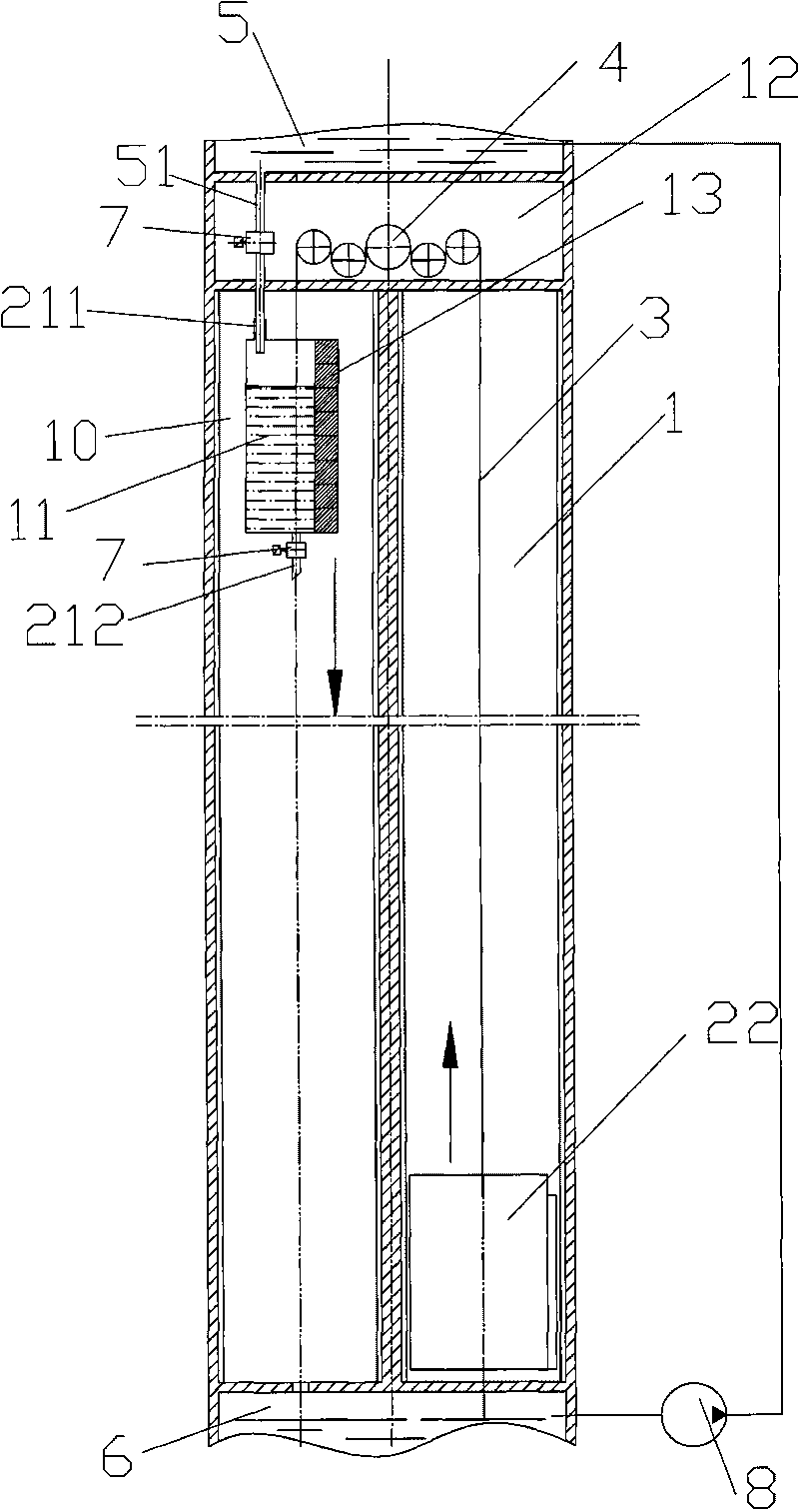

Energy storage type passenger and freight transportation vertical conveyer

InactiveCN101695981AWon't get stuckStable powerBuilding liftsEnergy efficiency in elevatorsTrappingEngineering

The invention discloses an energy storage type passenger and freight transportation vertical conveyer, comprising two driven wells and two ladder boxes. Each ladder box comprises a water box and a lift cage, the water box is arranged on the lift cage and is provided with a water intake pipe and a drainage pipe, the two ladder boxes are connected by steel wire ropes, the steel wire ropes are wound on a hub wheel set in a machine room, an impounding reservoir with a water injection pipe is arranged on the top of the machine room, and discharge bays are arranged in the bottoms of the driven wells. The invention also discloses an energy storage type passenger and freight transportation vertical conveyer, comprising a driven well, a balance weight well, a lift cage and a weight balance water box; a lift cage is arranged in the driven well, the balance weight water box is arranged in the balance weight well, wherein the balance weight water box is provided with a water intake pipe and a drainage pipe, the lift cage is connected with the balance weight water box through steel wire ropes, the steel wire ropes are wound on a hub wheel set in a machine room, an impounding reservoir with a water injection pipe is arranged on the top of the machine room, and a discharge bay is arranged at the bottom of the balance weight well. The invention has the advantages of completely avoiding trapping in the conveyer phenomenon caused by power failure, saving energy sources and reducing operating cost by utilizing the transformation of the potential energy of the water in the impounding reservoir into the kinetic energy used for driving the conveyer.

Owner:舒先达

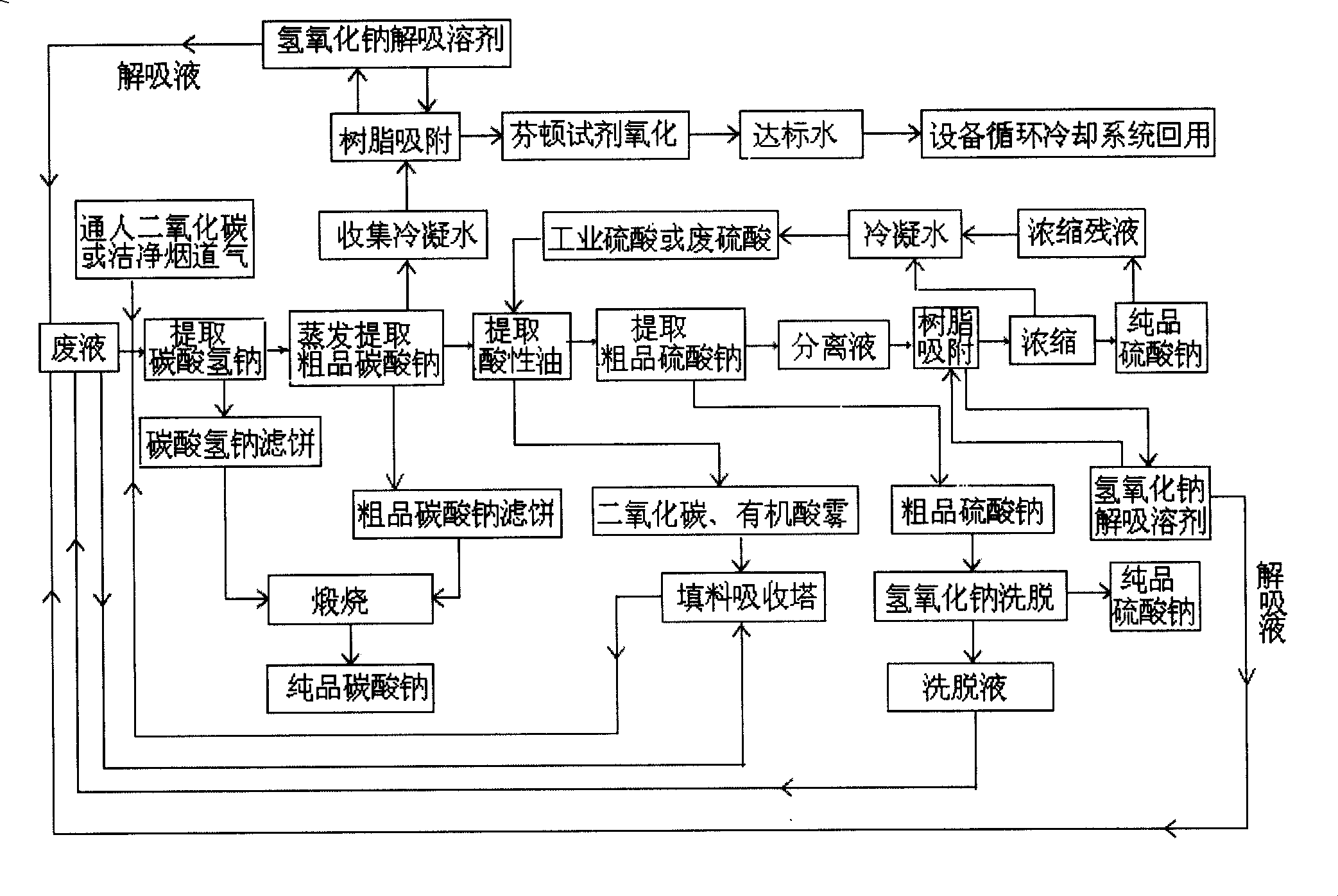

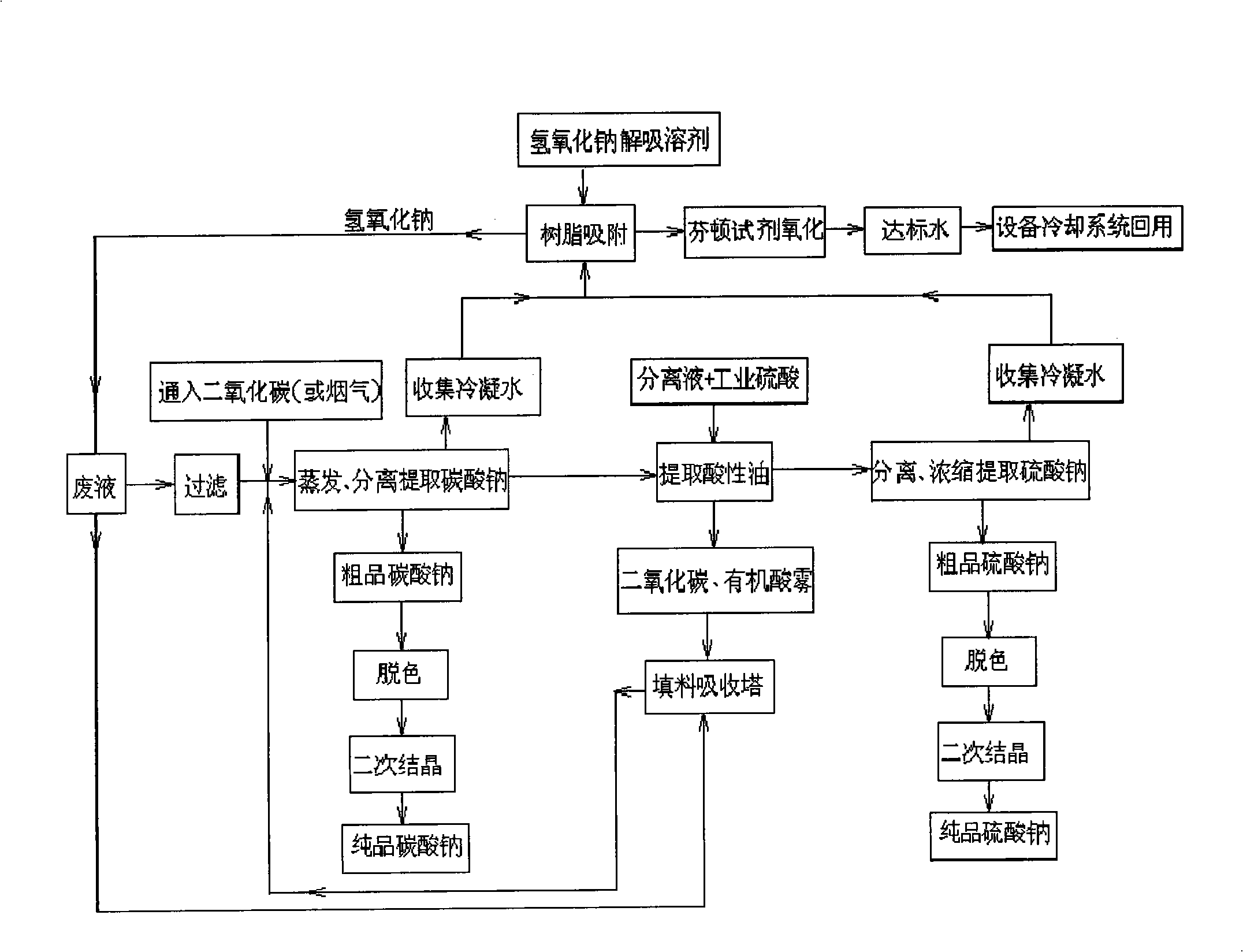

Method for zero discharge processing of waste saponification lye of cyclohexanone produced by cyclohexane oxidation technology

InactiveCN101428915AEradicate pollutionGood environmental benefitsMultistage water/sewage treatmentAlkali metal carbonatesCyclohexanoneEvaporation

The invention provides a method for zero discharge treatment of waste saponified lye generated during producing cyclohexanone by a cyclohexane oxidation technology. The method comprises the following technological steps: (1) the waste saponified lye is filtered, and simultaneously sufficient carbon dioxide gas is introduced into the waste saponified lye; (2) sodium carbonate is extracted after evaporation and separation; (3) acid oil is extracted after acid neutralization; and (4) sodium sulfate is extracted after separation and concentration. Moreover, the method also comprises the following technological steps: extraction of purified products, namely sodium carbonate, extraction of purified products, namely sodium sulfate, treatment of waste gas generated by acid neutralization, and treatment of condensed water. The method completely eliminates pollution of the waste saponified lye to the environment, has small investment of the adopted equipment and small energy consumption, can 'treat waste with processes of waste against one another', reclaims inorganic and organic chemical products from the waste saponified lye, and fully utilizes water resources of wastewater. Moreover, the method has simple technology, is suitable for industrial treatment of the waste saponified lye, has no secondary pollution emission during the treatment, really achieves zero discharge, and has obvious environmental benefit, social benefit and economic benefit.

Owner:赵志军

Method for zero discharge processing of waste saponification lye of cyclohexanone produced by cyclohexane oxidation technology

InactiveCN101323490AEradicate pollutionGood environmental benefitsMultistage water/sewage treatmentNature of treatment waterCyclohexanoneIndustrial scale

The invention provides a zero-emission method used for disposing the saponification waste lye generated during CYC production with a cyclohexane oxidation process. The method includes the following steps: (1) the saponification waste lye is filtered and sufficient carbon dioxide gas is injected into the lye; (2) the sodium carbonate is extracted through steaming, separating and extraction; (3) the acid oil is extracted through acid neutralization; (4) the sodium sulfate is extracted through separating and condensing. Besides, the method also comprises the extraction of pure sodium carbonate and sodium sulfate, the disposing of waste gas generated by acid neutralization and the disposal of condensed water, etc. steps. The invention completely avoids the contamination by the saponification waste lye to environment; the adopted apparatuses have low investment and the energy cost is low; the 'waste-disposal by wastes' can be actually realized; the inorganic and organic chemistry products can be recycled from the saponification waste lye; the water in the waste water can be thoroughly utilized. The invention has simple process and is suitable for the industrial scale disposal of saponification waste lye and the disposal process has no second-time contaminating emission so as to really reach zero-emission, with distinct environmental, social and economic benefits.

Owner:赵志军

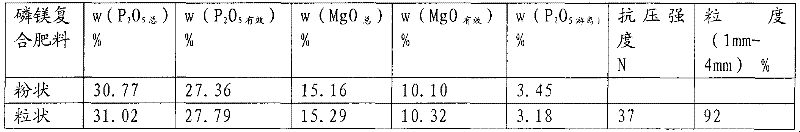

Method for preparing phosphorus-magnesium compound fertilizer by utilizing raffinate and phosphate tailings with high magnesium content

ActiveCN102161602AImprove decomposition rateEradicate pollutionSolid waste disposalFertilizer mixturesHigh magnesiumReaction temperature

Owner:WENGFU (GRP) CO LTD

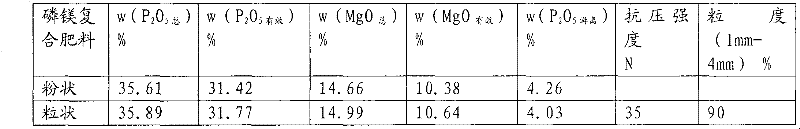

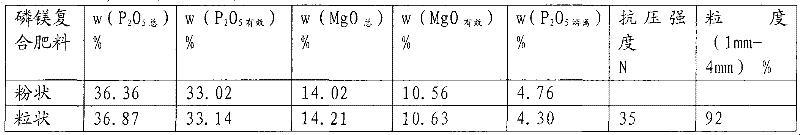

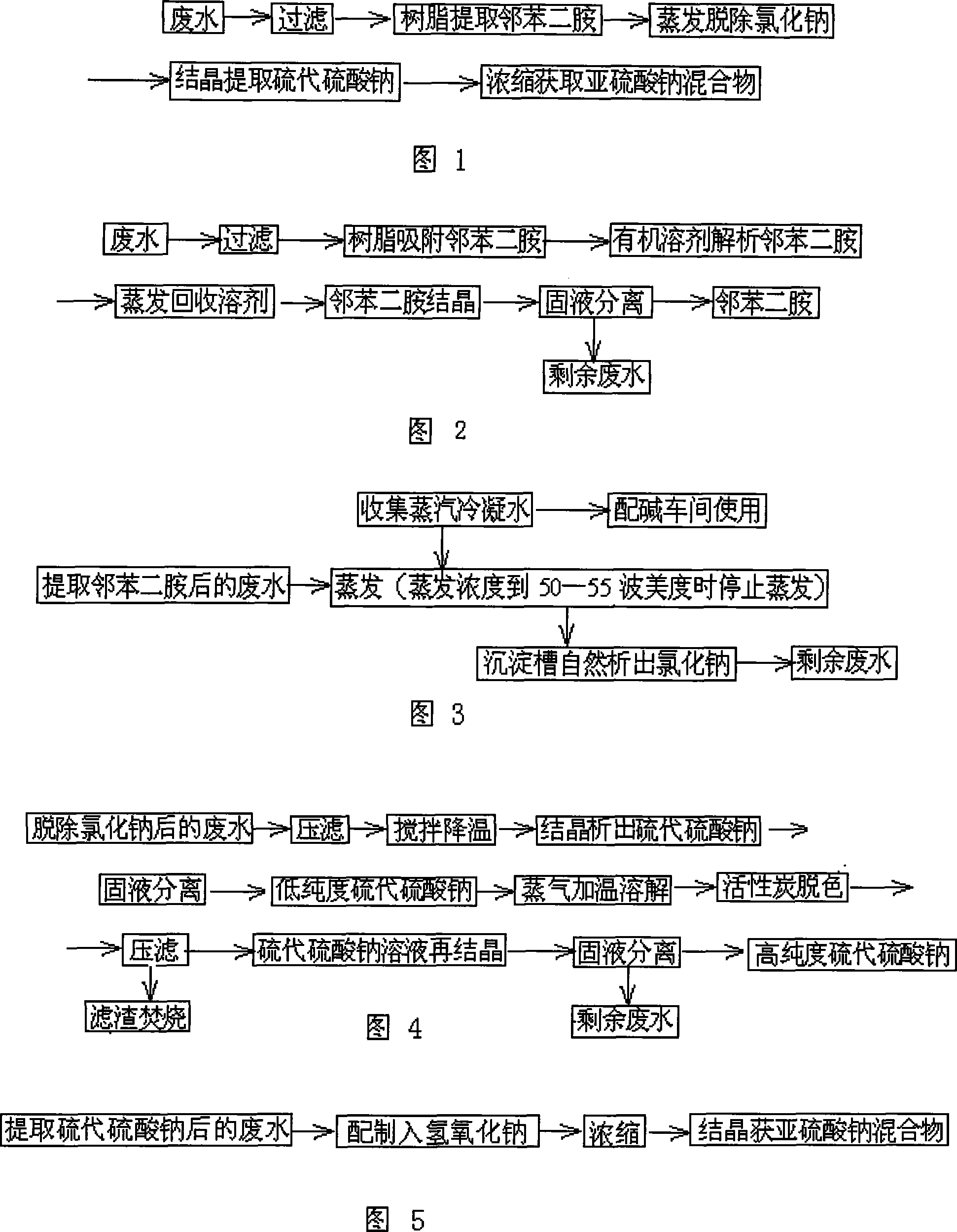

Process for zero-discharge treatment of o-phenylenediamine sodium sulfide reduction wastewater

InactiveCN101200336AEradicate pollutionGood environmental benefitsThiosulfates/dithionites/polythionitesWater/sewage treatment by ion-exchangeSulfite saltResource utilization

The invention relates to a zero-emission treatment process of O-phenylenediamine sodium sulfide reduction wastewater, which adopts the following steps in sequence: wastewater is filtered; O-phenylenediamine in the wastewater is absorbed and extracted by resin; the remained wastewater is vaporized and extracted to remove sodium chlorine; the wastewater that sodium chlorine is removed is filtered and crystallized to extract the sodium thiosulfate; the remained wastewater is concentrated to obtain sodium sulfite mixture. The invention can treat O-phenylenediamine sodium sulfide reduction wastewater with zero emission, so as to solve environmental pollution of wastewater thoroughly, thereby having obvious environmental benefit; simultaneously the wastewater is treated by the means of resource utilization, organic chemical product- O-phenylenediamine and inorganic product- sodium thiosulfate and sodium thiosulfate mixture are extracted from the wastewater; full process is a cleaning treatment process, not only secondary pollution is not generated but also energy is utilized circularly during process; the invention has small investment, simple process and practicality, and is applicable for popularization and utilization in the industry.

Owner:赵志军

Leather manufacturing process by pickling and tanning salt-free and chrome-free recycled waste liquid

ActiveCN102041321AEradicate pollutionSave saltTanning treatmentPre-tanning chemical treatmentChromiumProcess engineering

The invention provides a leather manufacturing process by pickling and tanning a salt-free and chrome-free recycled waste liquid. The process is characterized in that no chrome is used in the tanning process, thus the problem of chrome pollution is solved thoroughly; all the chrome tanning-free waste liquid is recycled, thus zero discharge of chrome tanning-free waste liquid is realized; and the process is suitable for the existing large production process of leather factories. In addition, no salt is added in the pickling process, a large amount of salt and other related chemical materials can be saved, wherein the salt can be saved by 100%, and the other related chemical materials can be saved by 40%-60%, and the energy can be saved by 25% approximately. Each performance index of the finished leather manufactured by the process meets the requirements, the rate of loose surface of the finished leather is decreased effectively, and the compactness of the finished leather is improved.

Owner:宝斯卡(商丘)化工有限公司

Method for thoroughly eradicating water source pollution of rivers and lakes

InactiveCN101613130APrevent collapseDrain controlWater/sewage treatmentBiological water/sewage treatmentLiquid wasteDifferential pressure

The invention relates to a method for thoroughly eradicating the water source pollution of rivers and lakes, which is the development of the field of environmental protection. The method has the technical characteristics that the rivers and the lakes are divided into five large functional zones, namely a river (lake) bed, an intertidal zone, a dam, a biological filtering and purifying zone as well as a farmland and a vegetable field outside the biological filtering and purifying zone. Crops such as pennisetum hydridum, mahonia fortunei, mulberry, salix psammophila, sea-buckthorn, papermulberry, and the like planted in the biological filtering and purifying zone, the dam, the intertidal zone, a water source conserving zone and a flood accumulating zone are respectively collected to be used as pulping raw materials. A spin coupling oxidation cleaning pulping mill and a sewage treatment plant are established in the position with intensive raw materials and convenient transportation, and the adjacent life and aquaculture sewage is intensively treated by a differential pressure filtering membrane device to be used for irrigating the crops inside and outside the dam so as to reduce the direct discharge of pollutants. Pulping waste liquor treated precipitates and sewage treated precipitates are mixed with leaves, skin, and the like to prepare methane, the electricity is generated by the methane, and the electricity and the methane are used by the mill and surrounding villages; and methane residues are made into a methyl ecological blanket for planting seedlings and seeds along the seacoast.

Owner:李朝旺

Method for extracting Gingko extract from ginkgo leaves

ActiveCN101449805AEradicate pollutionReduce the impactFood preparationGinkgo bilobaGinkgo leaf extract

The invention discloses a method for extracting ginkgo leaf extract from ginkgo leaves, which includes steps of: mixing ginkgo leaves and solid-phase reagent according to quality ratio of 1 to 0.1-2, fully grinding the mixture in a ball mill, fetching out the grinded powder, adding water to dissolve, filtering, adjusting pH value of supernatant to 2.0-6.0, separating and purifying. The invention has advantages of no pollution, high product purity, less solvent residue, convenient operation, short production period, low production cost, and better popularization and application prospect.

Owner:ZHEJIANG UNIV OF TECH

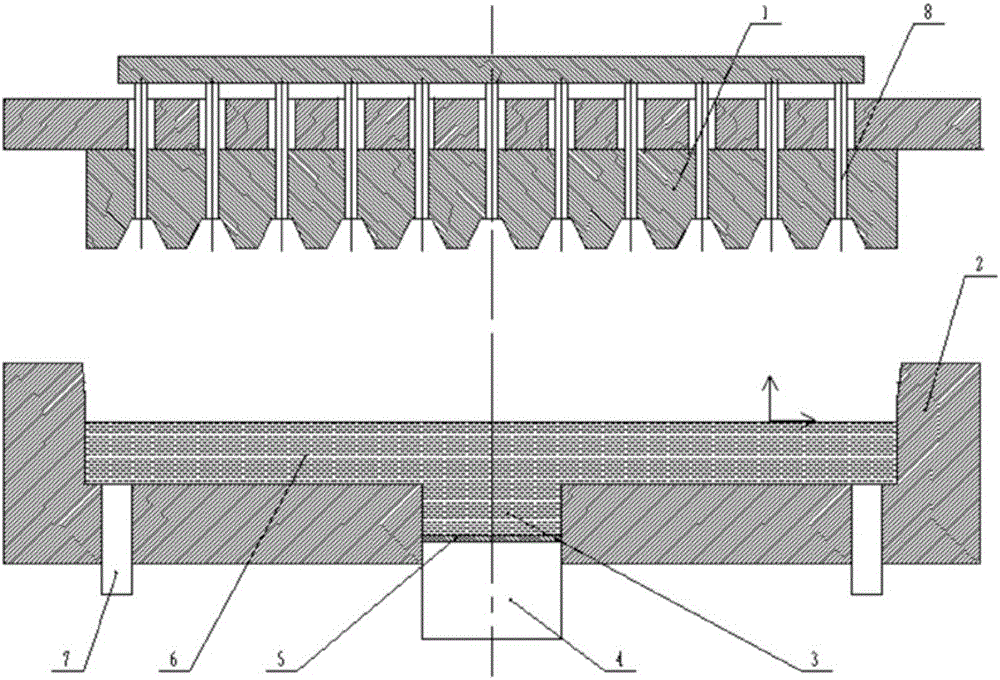

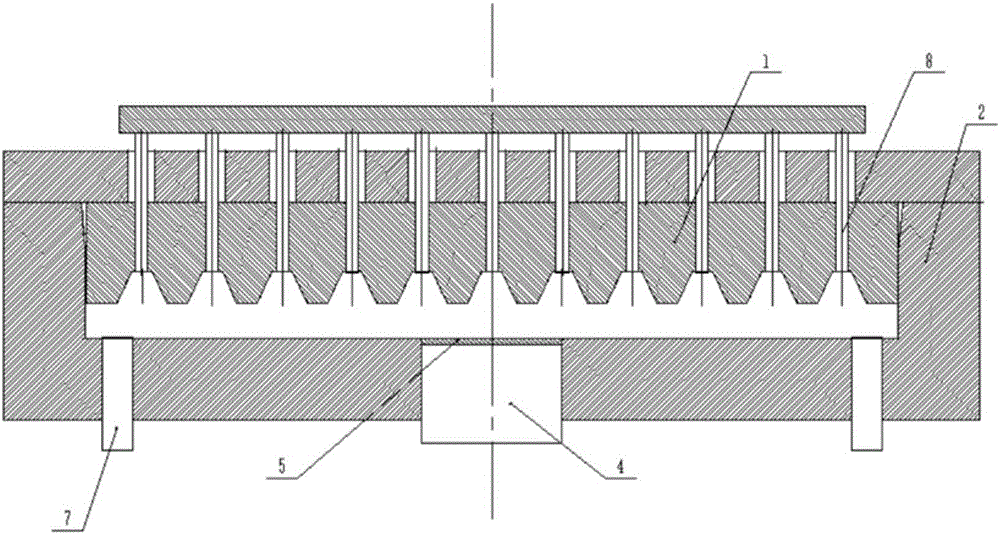

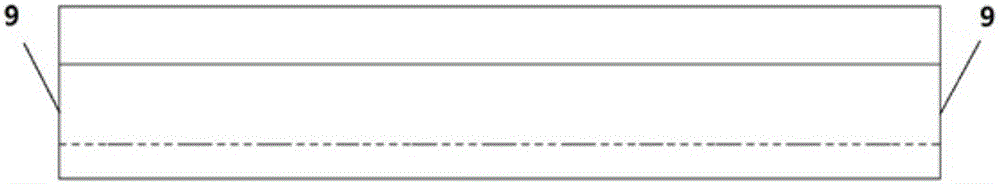

Liquid forging die and method for crusher jaw plates

The invention relates to a liquid forging die and method for crusher jaw plates. An upper pressure head and a lower pressure head pressurize molten metal of the jaw plates in three steps, mold filling of the molten metal is completed at lower pressure, solidifying and feeding of the molten metal are completed at higher pressure, plastic deformation of the molten metal is completed at highest pressure, the supercooling degree of solidification is improved, the microscopic structure is refined, the feeding capacity is improved, shrinkage shortcomings are eliminated, a plastic deformation layer with the thickness being 10 mm is generated on the work surface, the comprehensive mechanical property is excellent, the breakage danger of the jaw plates is thoroughly eliminated, the jaw plates compact in interior and free of shrinkage shortcomings can be obtained, and the material utilization rate is increased to be higher than 90% from 70% in the past. In addition, metal casting molds replace sand molds in the prior art, and therefore the obtained jaw plates are smooth and clean in appearance and accurate in size, and the pollution of waste sand is eliminated. In the pouring process, a buffering pit and a pouring pad are used, and therefore the high-temperature molten metal does not directly impact a die cavity, fusion welding faults of the die are avoided, and the service life is remarkably prolonged.

Owner:BEIJING JIAOTONG UNIV

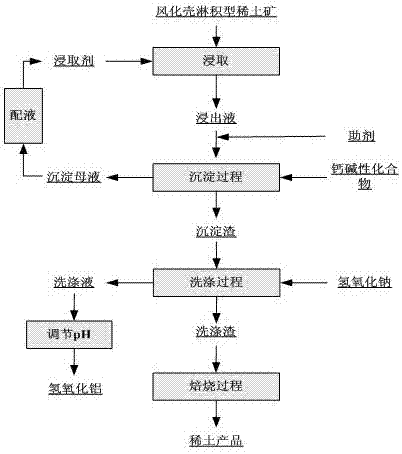

Method of recovering rare earth and aluminum from weathered elution-deposited rare earth ores

The invention discloses a method of recovering rare earth and aluminum from weathered elution-deposited rare earth ores. The method comprises the steps of leaching the weathered elution-deposited rare earth ores with a leaching agent to form rare earth leaching liquor, adding an assistant into the rare earth leaching liquor, and adding calcium oxide into the leaching liquor for precipitation. The concentration, temperature and pH (potential of hydrogen) of the assistant are controlled to achieve coordination of calcium ions and assistant molecules, so that the purpose of avoiding generating calcium sulfate is achieved; and the generating of calcium sulfate in a precipitation process is reduced. At the same time, the added assistant can return to be used for mineral leaching, exerts an effect of strengthening leaching under an acidic condition and increases a leaching rate of rare earth. No purification process is adopted in the method, and the loss of the rare earth in the purification process can be avoided. The method removes ammonia-nitrogen pollution, avoids the loss of the rare earth caused by the purification process of the traditional technology, increases a recovery rate of the rare earth, and comprehensively recovers an aluminum resource, and finally, a product with qualified purity is obtained.

Owner:JIANGXI UNIV OF SCI & TECH

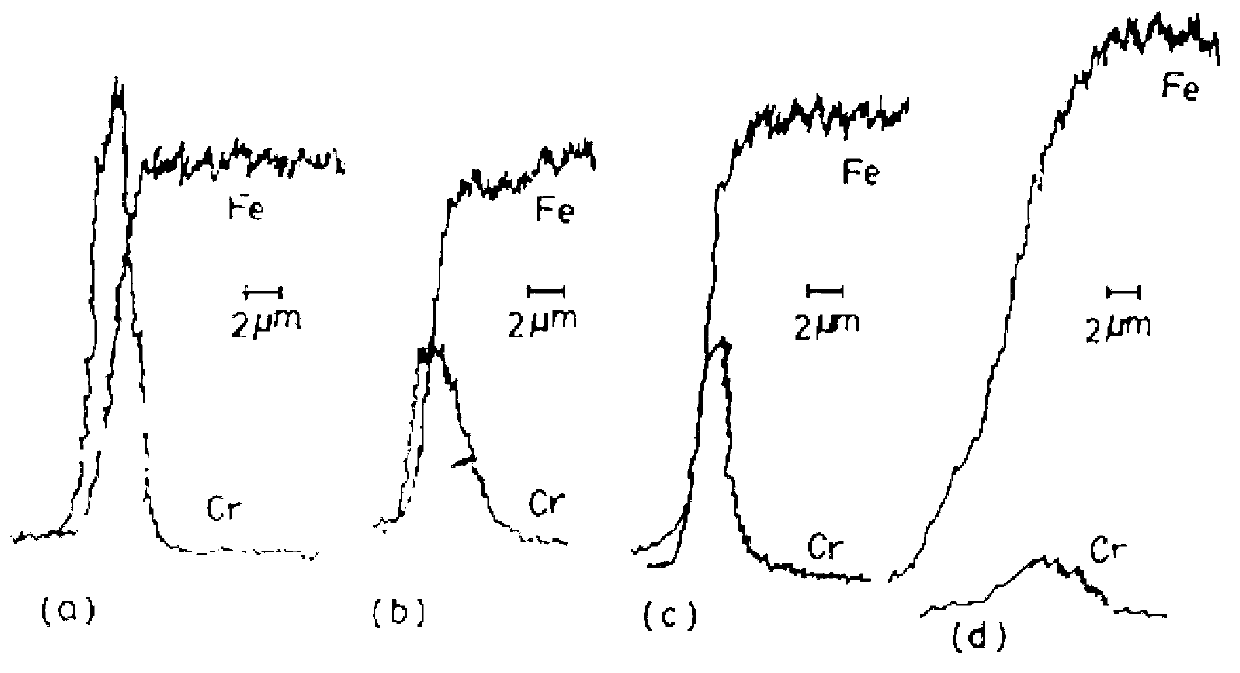

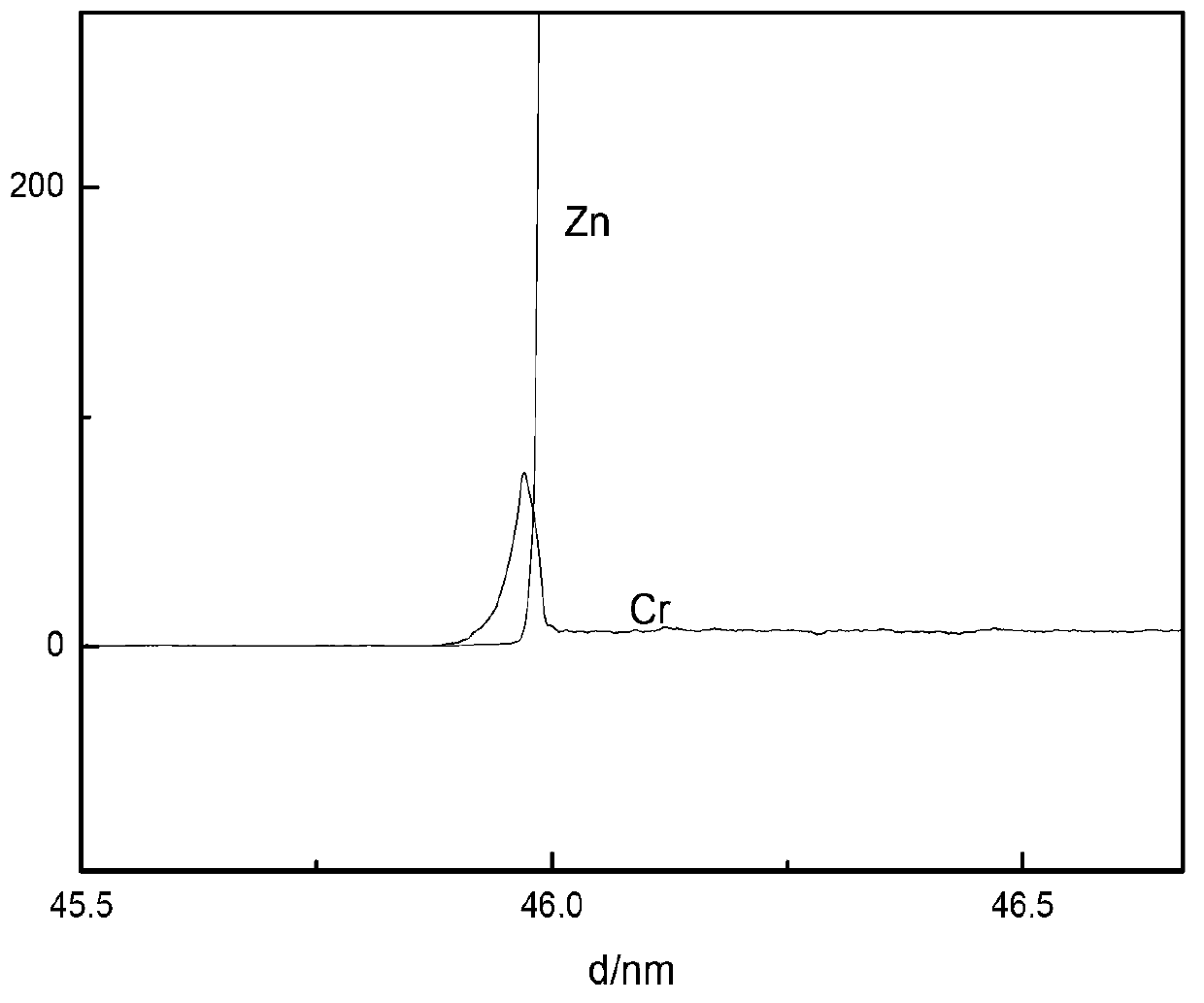

Steel and zinc based alloy vacuum ion chromium plating technology capable of substituting current chromium electroplating technologies

InactiveCN102787297ANo pollution in the processNo need to invest in pollution controlVacuum evaporation coatingSputtering coatingChromium coatingChromium nitride

A steel and zinc based alloy vacuum ion chromium plating technology capable of substituting current chromium electroplating technologies belongs to the field of material surface technologies. The ion chromium plating technology is characterized in that the ion chromium plating technology substitutes current chromium electroplate decoration technologies, and ion plated superhard chromium substitutes electroplated hard chromium. A pulse negative bias which has a voltage being 100-2000V is applied between a workpiece and a vacuum chamber, a transition layer having a thickness being 0.5-4mum is between a coating and the workpiece to improve the adhesiveness of the coating, and iron plated zirconium or chromium nitride substitutes an electroplated nickel coating in the current chromium electroplate decoration technologies; the ion plated chromium or cobalt substitutes an electroplated chromium coating in the chromium electroplate decoration technologies; and the ion plated superhard chromium substitutes the electroplated hard chromium, and an ion plated metal compound brightener, such as alumina or silica, enables the brightness of the ion coating to be improved. The ion chromium plating technology has the following effects and advantages: the coating does not have an Ni element, and is harmless to human bodies; three wastes which are not discharged are not treated; and the coating has the advantages of good adhesiveness, good compactness, strong corrosion resistance, high hardness and good abrasion resistance.

Owner:DALIAN UNIV OF TECH

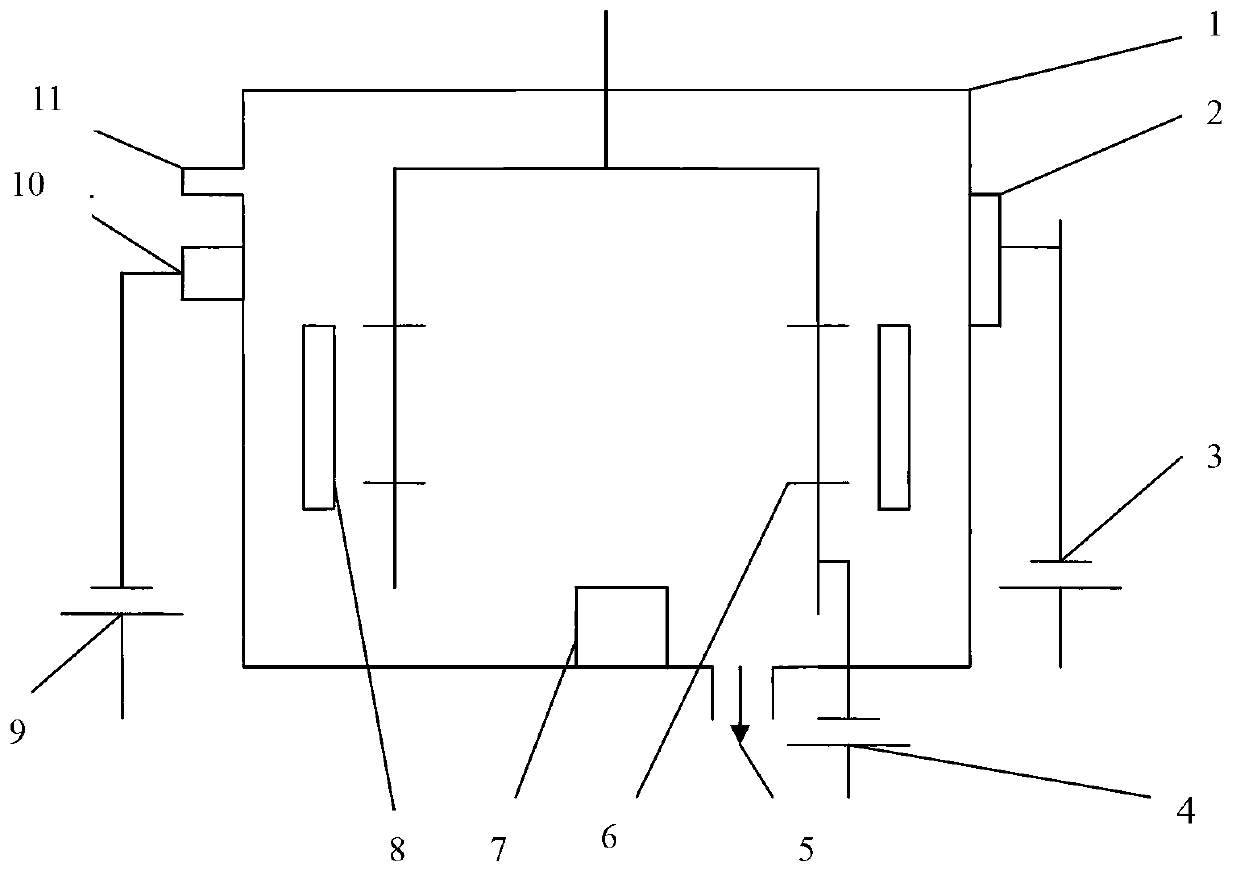

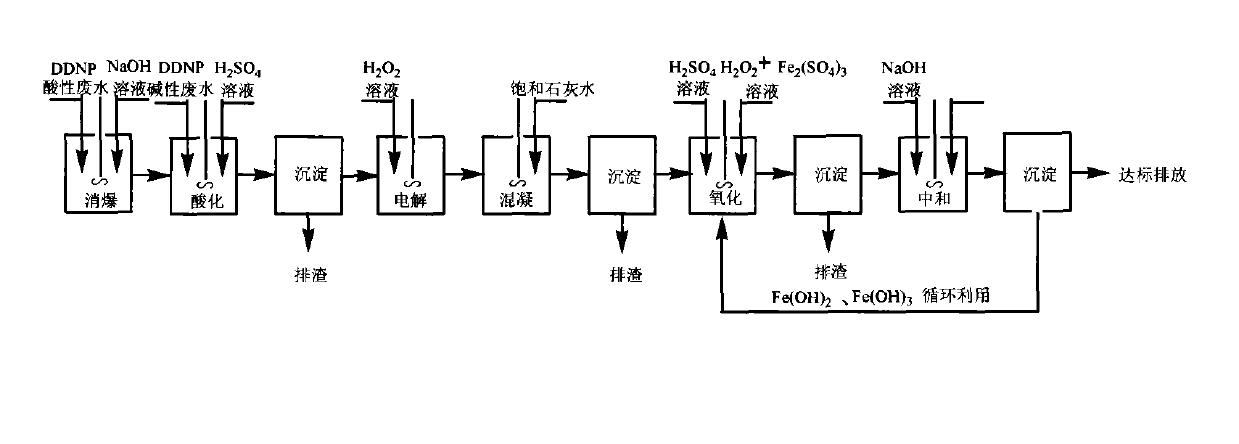

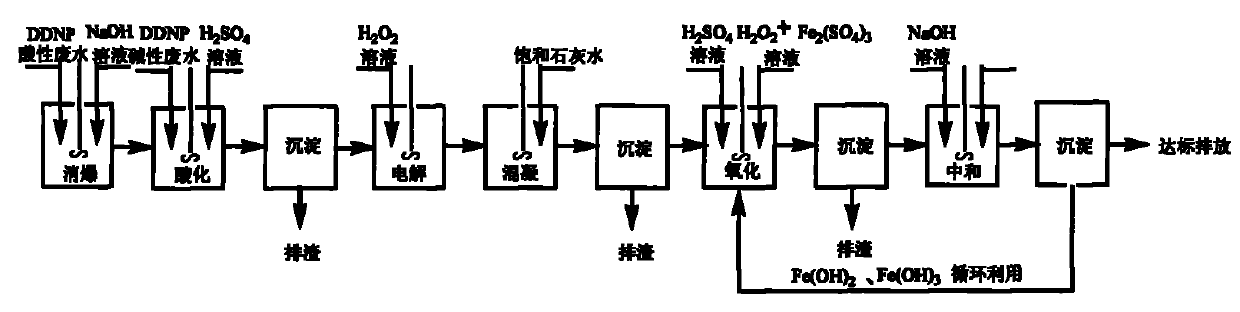

Treatment method of industrial waste water containing diazodinitrophenol

InactiveCN102020382AEffective destructionPromote oxidationMultistage water/sewage treatmentNature of treatment waterElectrolysisIndustrial waste water

The present invention provides a novel treatment method of industrial waste water containing diazodinitrophenol, which comprises the main steps of: explosion elimination, acidification, electrolysis, coagulation, oxidization and neutralization. Firstly DDNP acid waste water is subjected to explosion elimination and mixed with DDNP alkaline waste water, most nitrophenol compounds are precipitated under certain acidic condition, residual organic compounds are eliminated totally by electrolysis, coagulation and oxidizing degradation, after neutralization, the waste water can meet national emission standards without secondary pollution to environment.

Owner:SHANGRAO NORMAL UNIV

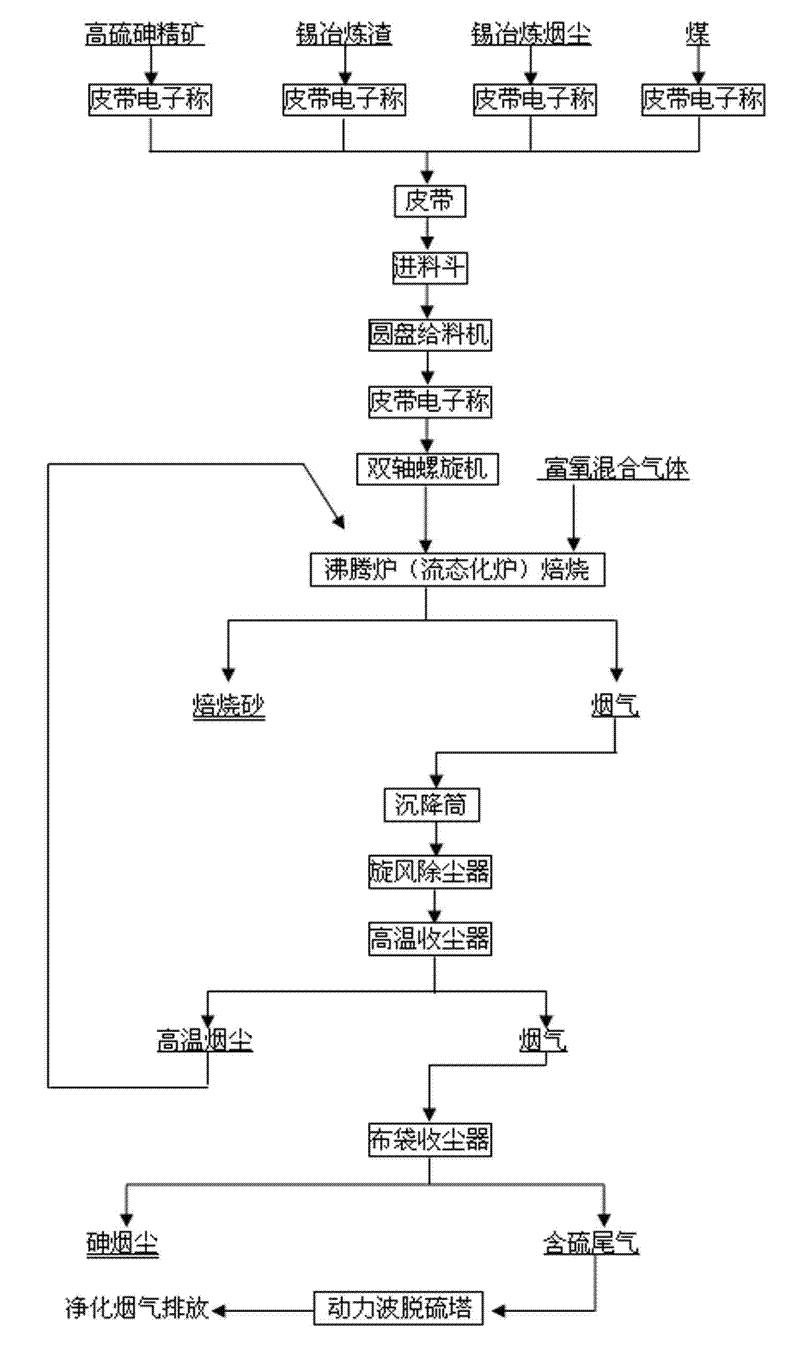

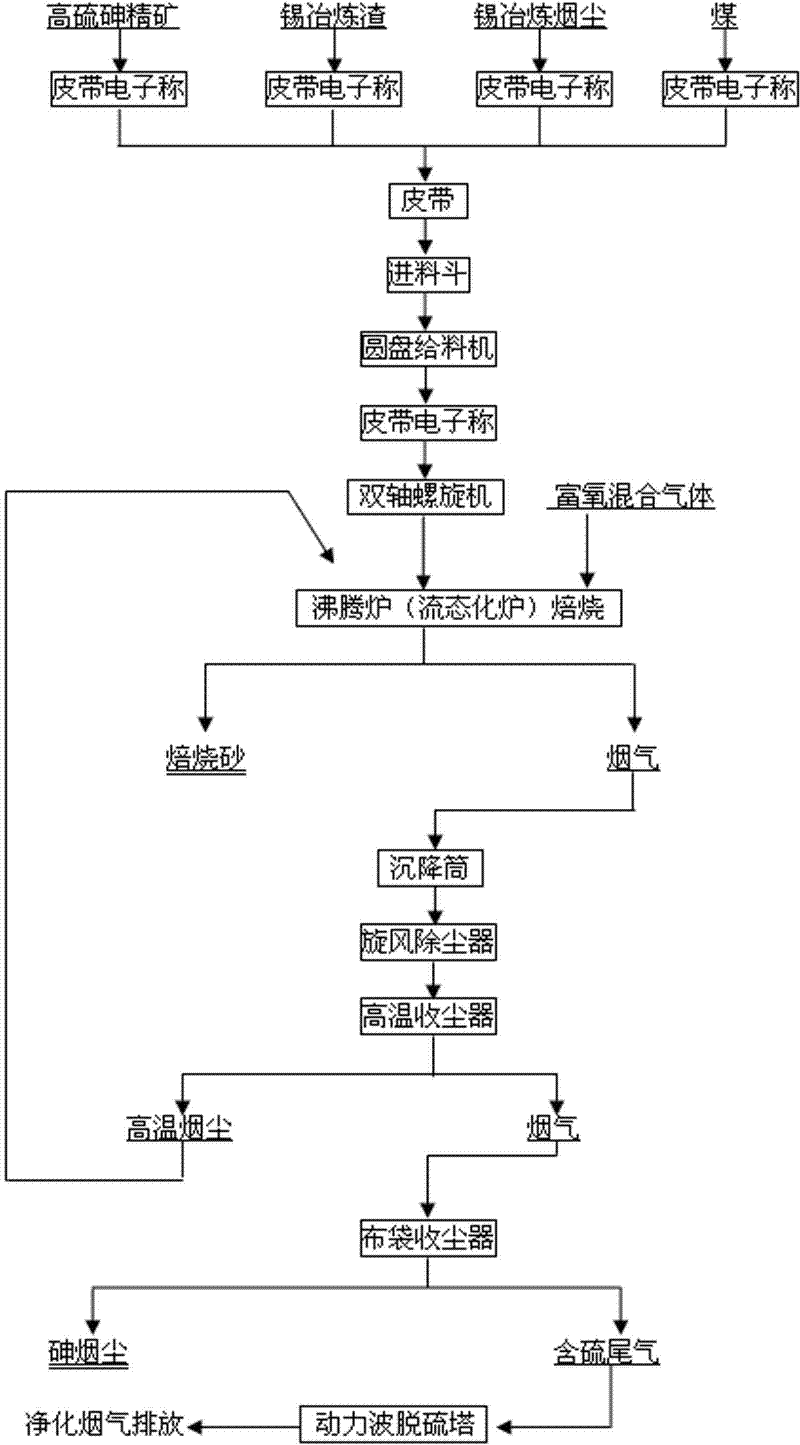

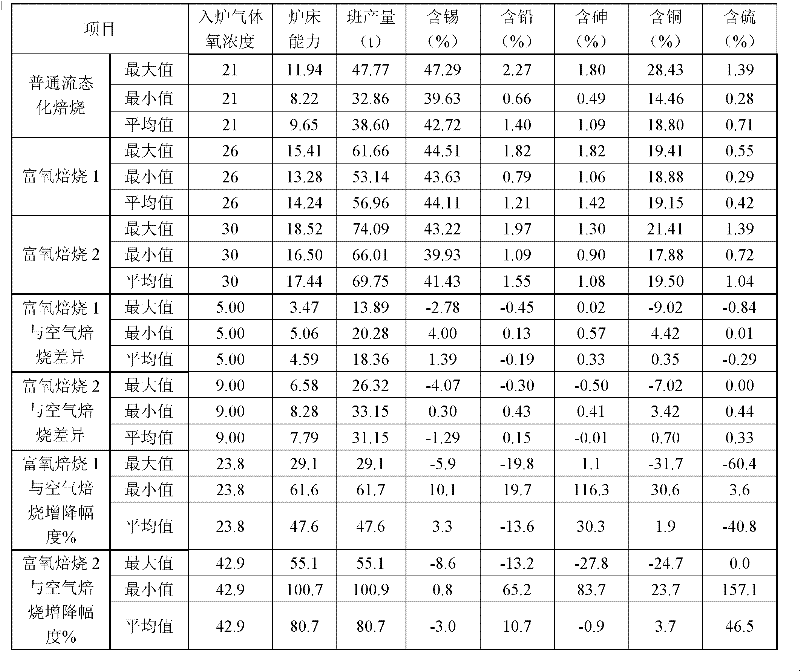

Method for roasting tin-containing high-arsenic and high-sulfur material by fluidized rich oxygen

InactiveCN102230074AIncrease the furnace concentrationReduce the amount of furnaceProcess efficiency improvementExhaust gasArsenic

The invention belongs to the technical field of tin metallurgy, in particular relates to a novel method for roasting a tin-containing high-arsenic and high-sulfur material by fluidized rich oxygen. The method comprises the following steps of: mixing oxygen into a charged gas of a fluidized furnace; controlling the oxygen quantity to reach 22-45 wt% of the total charged gas; carrying out oxygen-enriched fluidized roasting on the material at 600-1000 DEG C; and adding the oxygen in such a way that the quantity of the charged air is gradually reduced and the oxygen quantity is gradually increased so that the total charged gas is invariable and the oxygen concentration satisfies the process parameters while a charging system is started for charging. According to the invention, the arsenic and sulfur removing rate can be effectively increased, the roasting quality can be improved, the smoke gas quantity generated by treatment of the unit material can be reduced, the heat loss can be reduced, the heat utilization rate can be increased, the furnace hearth capacity can be improved without increasing the area of the furnace hearth, the treatment quantity can be increased and the production efficiency can be enhanced; meanwhile, the concentration of SO2 in the smoke gas can be increased so that the problems of low SO2 concentration in the tail gas, unfavorable acid making and environment pollution can be solved to change the harm into the treasure in the tail gas acid making.

Owner:YUNNAN TIN GROUP HLDG

Hydroxyproline fermentation production technology

ActiveCN105837488AAchieving zero emissionsHigh yieldOrganic chemistryAccessory food factorsHydroxyprolineSeparation technology

The invention belongs to the technical field of separation and extraction of amino acids, and concretely relates to a hydroxyproline fermentation production technology. A technology for separating hydroxyproline from a special self-fermentation liquid is created through adopting a multi-stage series membrane separation technology and an electrodialysis technology in order to form the brand new hydroxyproline fermentation production technology. The hydroxyproline fermentation production technology can realize zero discharge of waste residues and wastewater in the hydroxyproline fermentation production process, thoroughly and radically solves the environment pollution problem in the hydroxyproline fermentation production process, improves the total yield of hydroxyproline to 70% or above, greatly improves the quality of the hydroxyproline product, and allows the hydroxyproline content of the hydroxyproline product to reach 99% or above.

Owner:TIANJIN JINGYE FINE CHEM

Friction material without asbestos and producing process

The friction material without asbestos consists of modified phenolic resin, iron ore powder, re-burnt magnesite, alumina, clinostrengite powder, silica, barytine, wollastonite, carbon black, calcium carbonate, graphite, tire powder, zinc stearate, plant fiber, sepiolite and steel fiber. Using plant fiber and sepiolite to replace asbestos and glass fiber separately can eliminate the harm of asbestos and glass fiber to human health. The friction material has the features of high tensile strength, high toughness, heat resistance, and stable heat decay performance, and may be used in friction wafer for common vehicle and heavy truck.

Owner:宋强 +1

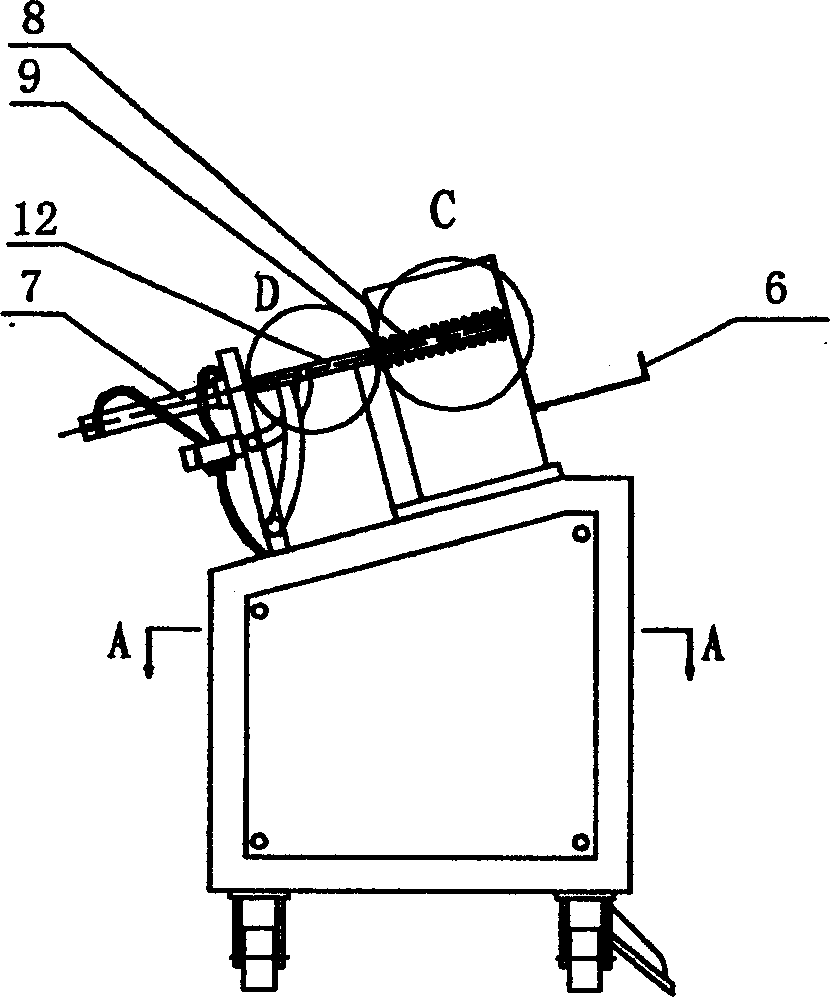

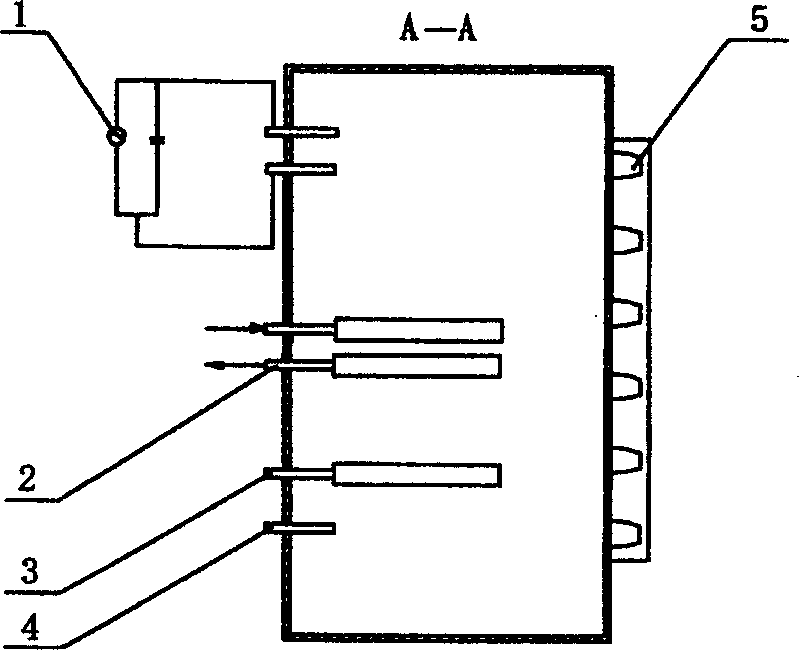

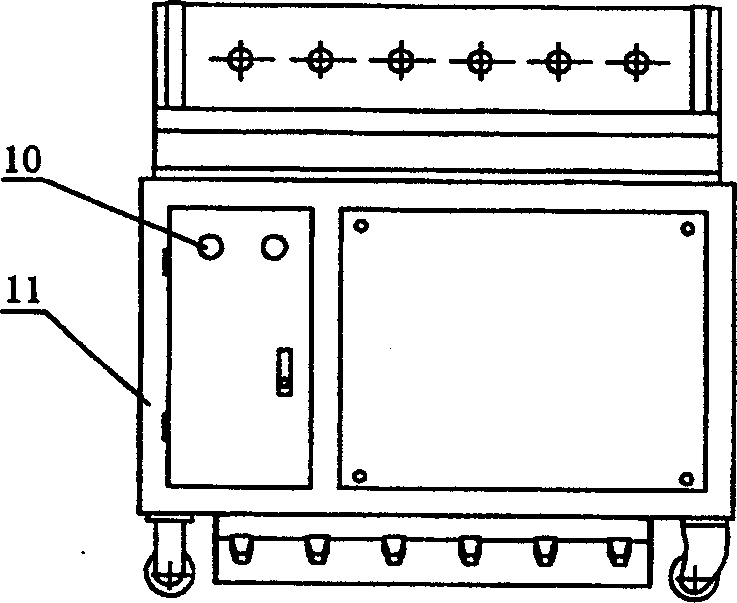

Electromagnetic induction rivet heater

InactiveCN1425516AEradicate pollutionImprove heating qualityInduction heating apparatusElectromagnetic inductionRivet

The electromagnetic induction rivet heater consists of one heater on the main body, one ejecting mechanism and one cooling system. The heater consists of lining and induction coil on the outer wall of the lining; the ejecting mechanism consists of one cylinder and one material ejecting pin capable of entering into or withdrawing from the lining in the same axis; and the cooling system has circulation water union communicated with the induction coil and the material ejecting pin. The lining is inclined and has material discharging end higher than the entering end of the material ejecting pin. The cooling system is equipped with low water pressure warning and water failure protecting system. The present invention has simple rivet heating process, low cost, high efficiency and other advantages.

Owner:JILIN UNIV

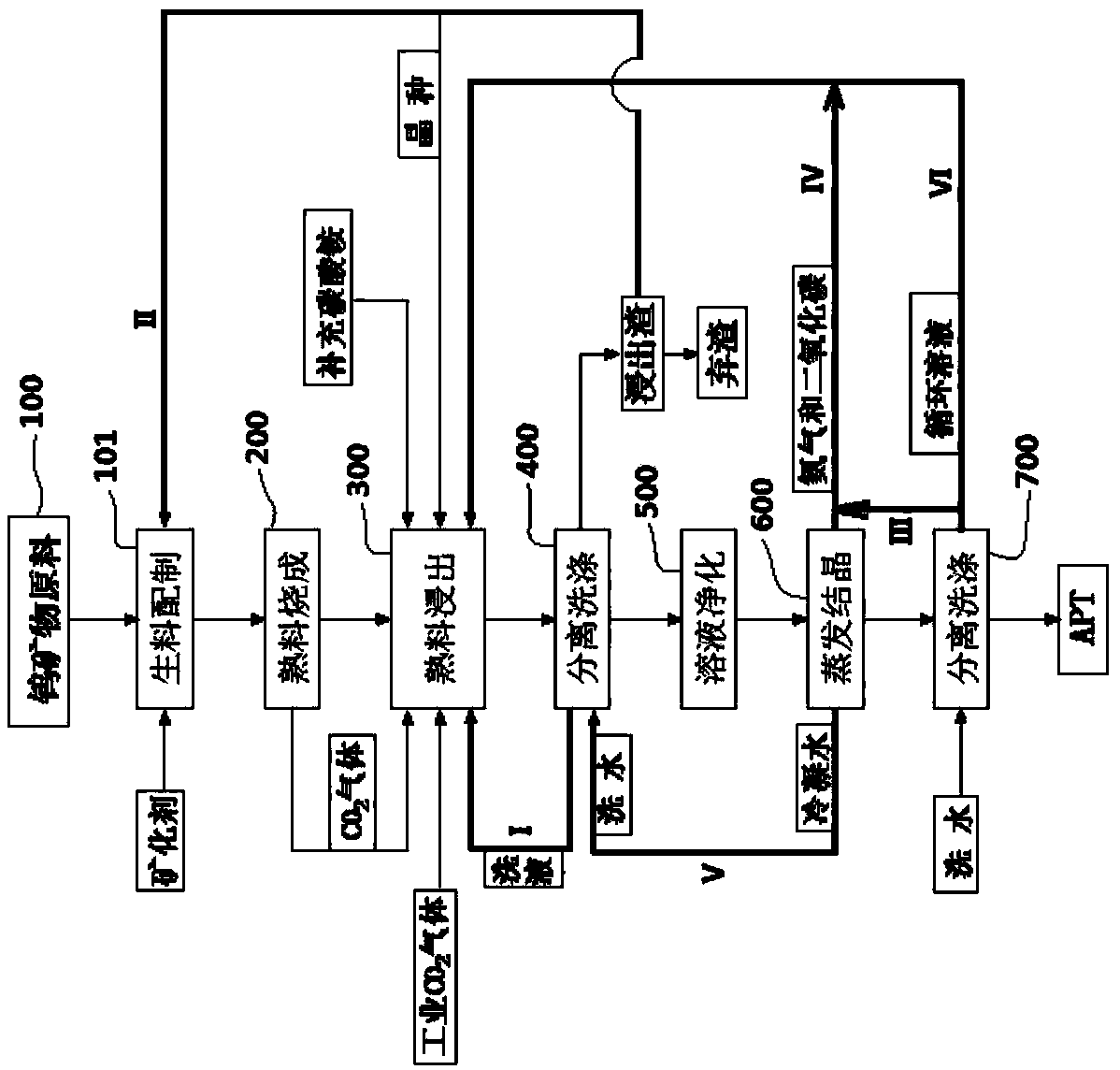

Metallurgical technology with multiple closed cycles for tungsten mineral raw materials

ActiveCN104263975ARealize closed loopEradicate pollutionProcess efficiency improvementWater dischargeAdditive ingredient

The invention discloses a metallurgical technology for tungsten mineral raw materials. The technology comprises the following steps: proportioning the mineral raw materials and ingredients to obtain raw materials; roasting the raw materials to enable the raw materials to be transformed into clinker; using a weak alkali solution to leach the clinker, and recovering solutions fed back from all the links; performing solid-liquid separation on leached slurry, washing leached residues, feeding back washing liquid to a clinker leaching link (a first closed cycle), and feeding back at least part of the leached residues to a raw material preparing link (a second closed cycle) as the ingredients; performing purification and residue-removing on crude solutions; evaporating and crystallizing the purified solutions; returning released gases to the clinker leaching step (a third closed cycle), and feeding back evaporated water to a solid-liquid separation link (a fourth closed cycle) of leaching the slurry; performing the solid-liquid separation on the crystallized slurry, washing a solid phase through water and / or an ammonium salt solution, and drying the washed solid phase to obtain a final product containing W elements; returning crystallized mother liquid to the clinker leaching step (a fifth closed cycle). Therefore, the technology disclosed by the invention comprises the multiple closed cycles, and the situation of zero waste water discharge in the whole process is realized.

Owner:JIANGXI RARE EARTH & RARE METALS TUNGSTEN GRP HLDG CO LTD +1

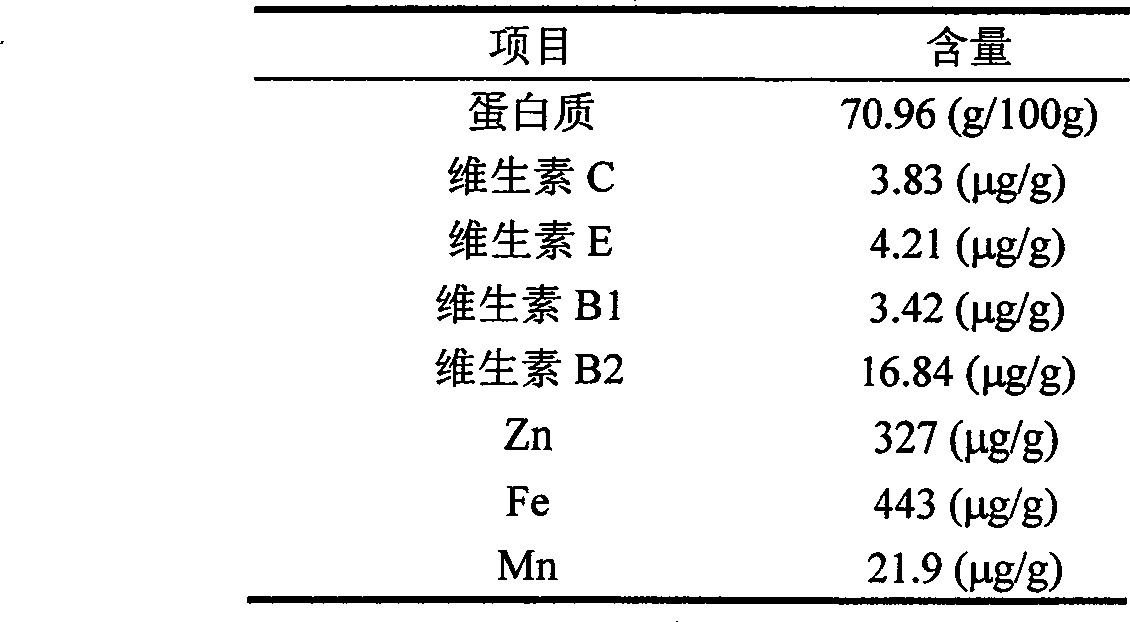

Clean production technology for separation and extraction of catalase

The invention relates to the technical field of separation and extraction of bioactive substances, in particular relates to a clean production technique for the separation and the extraction of catalase, and provides an environment-friendly technique for the separation and the extraction of catalase. The technique can realize zero-discharge of waste water and waste residue during the process of processing and producing catalase and radically solve the environment pollution problem in the prior technique of processing and producing catalase without influencing the yield and quality of catalase. The technique is suitable for the processing and the production of catalase by using the raw material of the liver of various animals such as pig, cattle, ship, chicken, duck, goose, fish, etc after autolysis treatment, and is also suitable for the processing and the production of catalase by using the catalase-containing fermentation liquid obtained through the fermentation and the cultivation of microbe. According to the invention, taking pig liver as an example, 2 kg of catalase liquid (50,000 U / ml) can be prepared from 1 kg of pig liver, the water consumption is reduced to lower than 2.2 kg, and 230 g of the solid substances with protein content being higher than 60% can be obtained at the same time.

Owner:江苏省江大绿康生物工程技术研究有限公司 +2

Method for fermentation production of hydroxyproline by adopting escherichia coli JL-HYP

ActiveCN107435057AHigh densityGrow fastOrganic chemistryMicroorganism based processesEscherichia coliHydroxyproline

The invention relates to a method for fermentation production of hydroxyproline by adopting escherichia coli JL-HYP. The method comprises the following steps that an escherichia coli JL-HYP strain is subjected to slant activation, the activated escherichia coli JL-HYP strain is subjected to gradient dilution, the diluent coats an LB culture medium, after culture, single colonies are selected and respectively inoculated to an LB slant culture medium, the LB slant culture medium is placed in a biochemical incubator, and culture is carried out for 12h at 30-36 DEG C; single colonies are selected from the LB slant culture medium and inoculated into a seed bottle filled with a seed culture medium to be cultured; the seed liquid is inoculated into a fermentation tank filled with a fermentation culture medium to be cultured for 30-45 h, and thus fermentation liquor containing hydroxyproline is obtained; and hydroxyproline in the fermentation liquor containing hydroxyproline is extracted. For the process, the fermentation period is short, the density of thallus is high, and the output and yield of hydroxyproline are high. The method has the advantages that the fermentation period is short, the density of thallus is high, and the output and yield of hydroxyproline are high.

Owner:河南巨龙生物医药有限公司

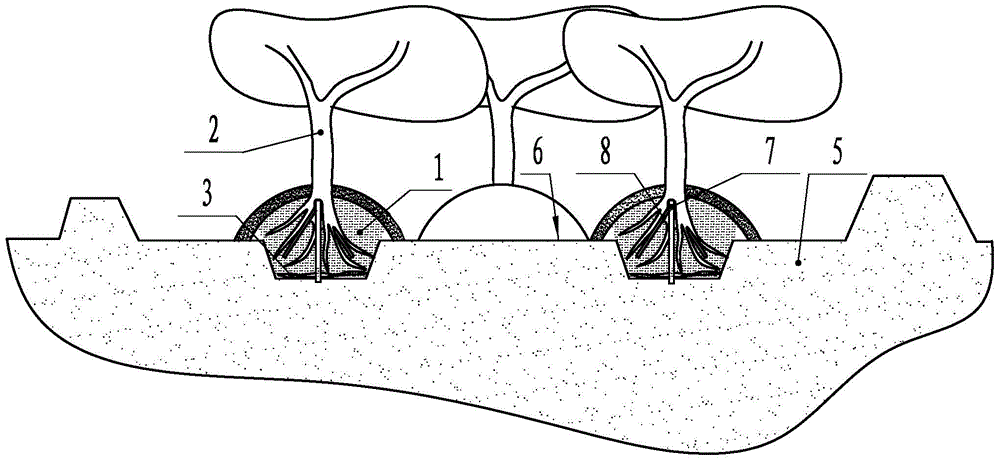

Method for forest planting by accumulating wastes in mounds

InactiveCN104584978AEradicate pollutionPollution suppressionClimate change adaptationCultivating equipmentsDecompositionLitter

The invention discloses a method for forest planting by accumulating wastes in mounds, relating to a forest planting method. A mode of planting trees in a refuse landfill is disadvantageous to root system development of trees and nutrient absorption, leads to poor growth of the trees and is not conductive to rapid decomposition and utilization of refuse since the soil covering thickness is small and the refuse is directly positioned below the soil. The method disclosed by the invention comprises the following steps: collecting refuse; digging a pit, to be specific: digging a pit, which has the diameter being larger than 2m and the depth being larger than 1m, on the ground; erecting a frame, to be specific: putting a vertical rod in the middle of the pit, and arranging in inclined rods around the vertical rod to form an umbrella-shaped framework; carrying out backfilling, to be specific: backfilling a soil mixture blended with the refuse into the pit till being leveled up, adding soil to the top of the pit to form a raised mound, and forming a ditch between every two every mounds; planting, to be specific: planting an arbor seedling in the middle of each mound, and planting shrub seedlings around the corresponding arbor seedling. According to the technical scheme, the refuse can be recycled, the potential of the ecological functions of soil is furthest excavated, and the planted trees are promoted to normally and vigorously grow to form the forest.

Owner:徐高财

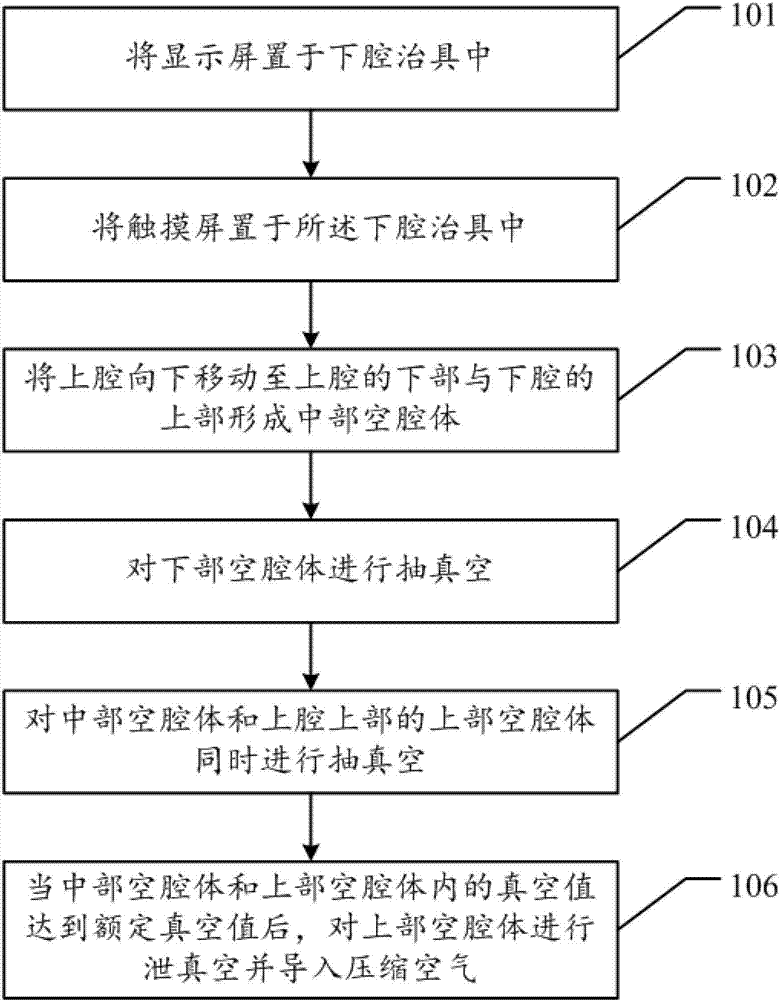

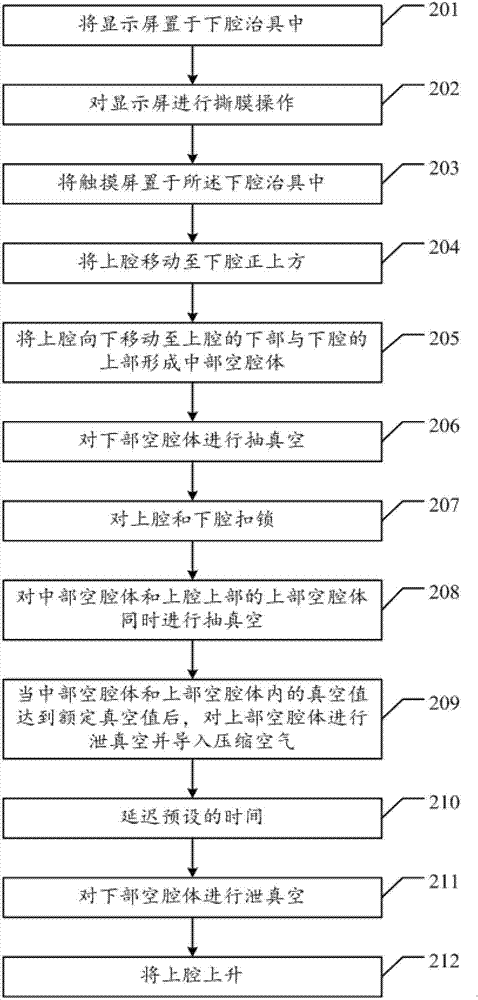

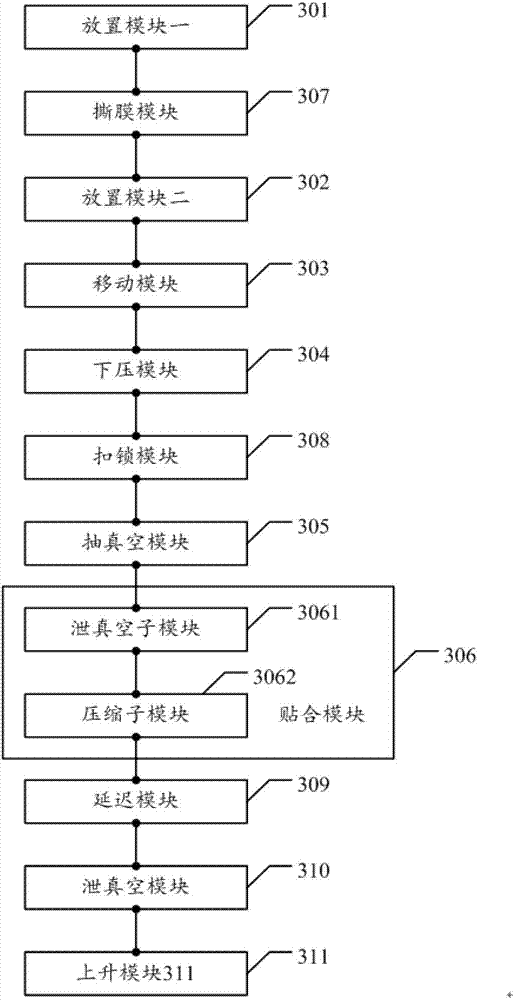

Device and method for fully bonding touch screen with display screen

ActiveCN103029410AImprove the display effectEradicate pollutionLaminationLamination apparatusTouchscreenComputer science

The invention discloses a device and a method for fully bonding a touch screen with a display screen. The device and the method can improve a display effect of the display screen effectively, reduce the thickness of a product, and eliminate dust and moisture pollution. The method comprises the steps that the display screen is placed in a lower cavity jig; a bonding face of the display screen faces upward; the display screen, the lower cavity jig and a lower part of a lower cavity form a lower part cavity body; the touch screen is placed in the lower cavity jig; a bonding face of the touch screen faces downward; an upper cavity is moved over the lower cavity; the upper cavity is moved downwards to the lower part of the upper cavity to form a middle cavity body with the upper part of the lower cavity; the lower part cavity body is vacuumized; the middle cavity body and an upper part cavity body at the upper part of the upper cavity are vacuumized simultaneously; when vacuum values in the middle cavity body and the upper part cavity body reach rated vacuum values, vacuum relief is conducted on the upper part cavity body; and compressed air is led in.

Owner:金龙机电(杭州)有限公司

Ceramic slag separator and gel injection molding manufacturing process thereof

The invention discloses a ceramic slag separator and a gel injection molding manufacturing process thereof, and belongs to the technical field of slag separators. The ceramic slag separator is characterized in that a ceramic slag separator main body is made from aluminum oxide ceramic; the inner wall of the slag separator is 0.01 to 0.1mu m in roughness; the aluminum oxide ceramic is prepared from the following raw materials in percentage by mass: 54 to 60 percent of aluminum oxide, 0.8 to 1.2 percent of chitosan, 0.7 to 0.85 percent of acetic acid, 0.015 to 0.027 percent of glutaraldehyde, 0.2 to 0.35 percent of polyacrylamide and 37.985 to 43.873 percent of water. The manufacturing process comprises the following steps: adding the aluminum oxide, the chitosan and the polyacrylamide into a ball mill in batches to perform ball milling, adding the acetic acid and the glutaraldehyde into a vacuum conical stirrer, and injecting slurry into a chromium-plated steel mold for curing and molding; placing a cured and molded product into a kiln for sintering to obtain the ceramic slag separator. The inner wall of the ceramic slag separator has a mirror effect, so that the problem of loss of accepted stock is solved, the recovery rate of the accepted stock is improved, and the equipment running utilization rate is high.

Owner:山东倍辰新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com