Energy storage type passenger and freight transportation vertical conveyer

An energy storage and elevator technology, applied in the elevator field, can solve the problems of uneven load, energy waste, and load fluctuation of the power supply network, and achieve the effects of daytime load reduction, low operating cost, and stable power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Solution one embodiment

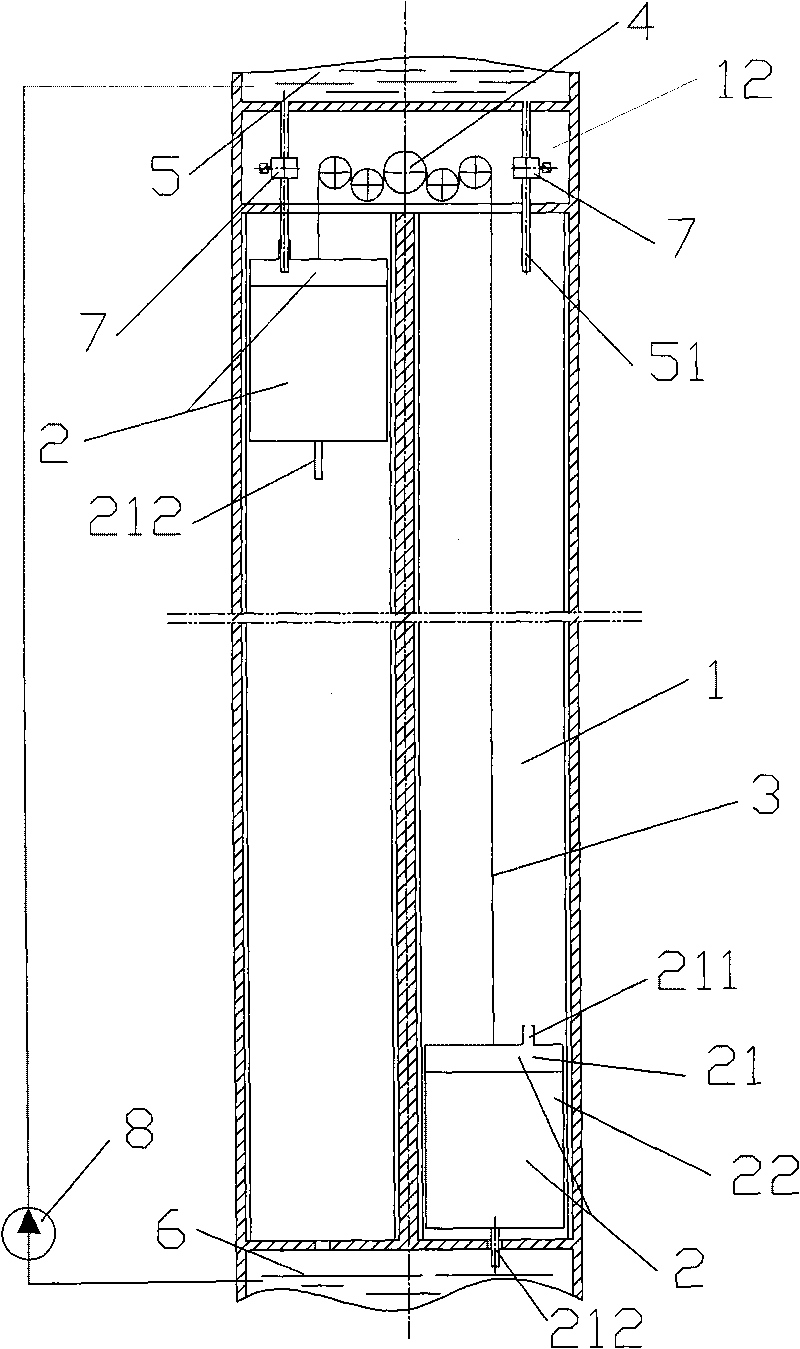

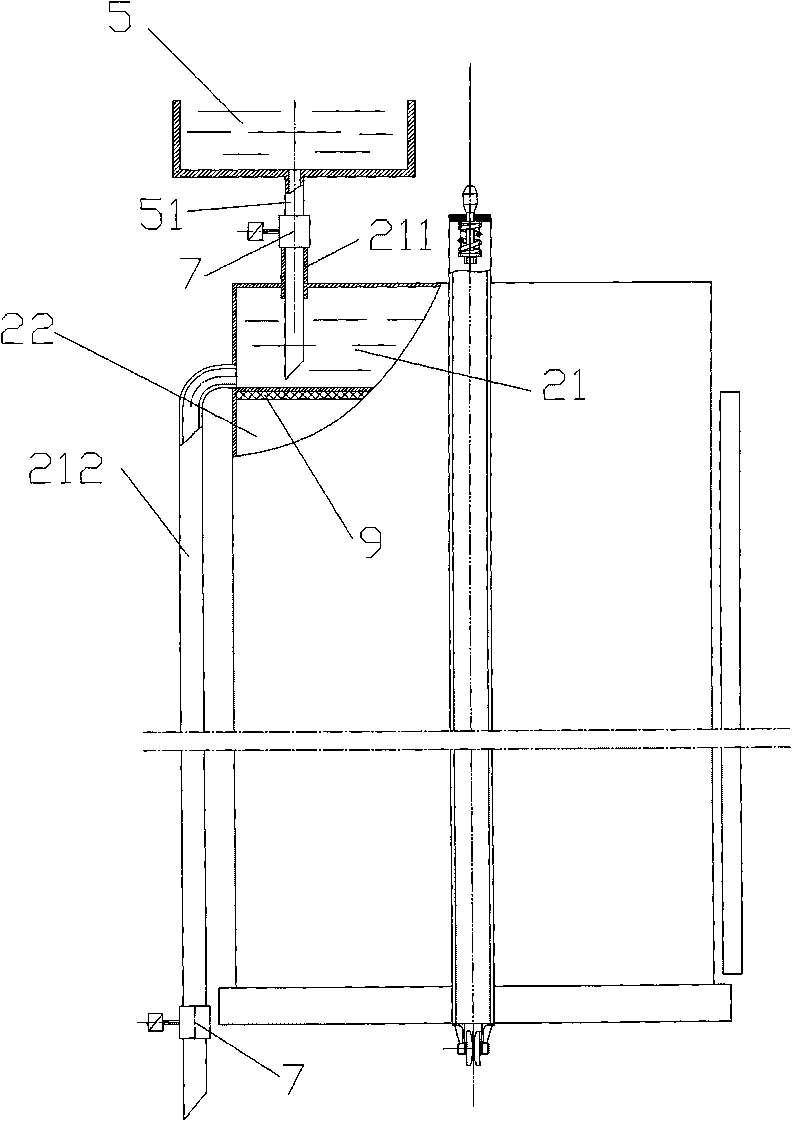

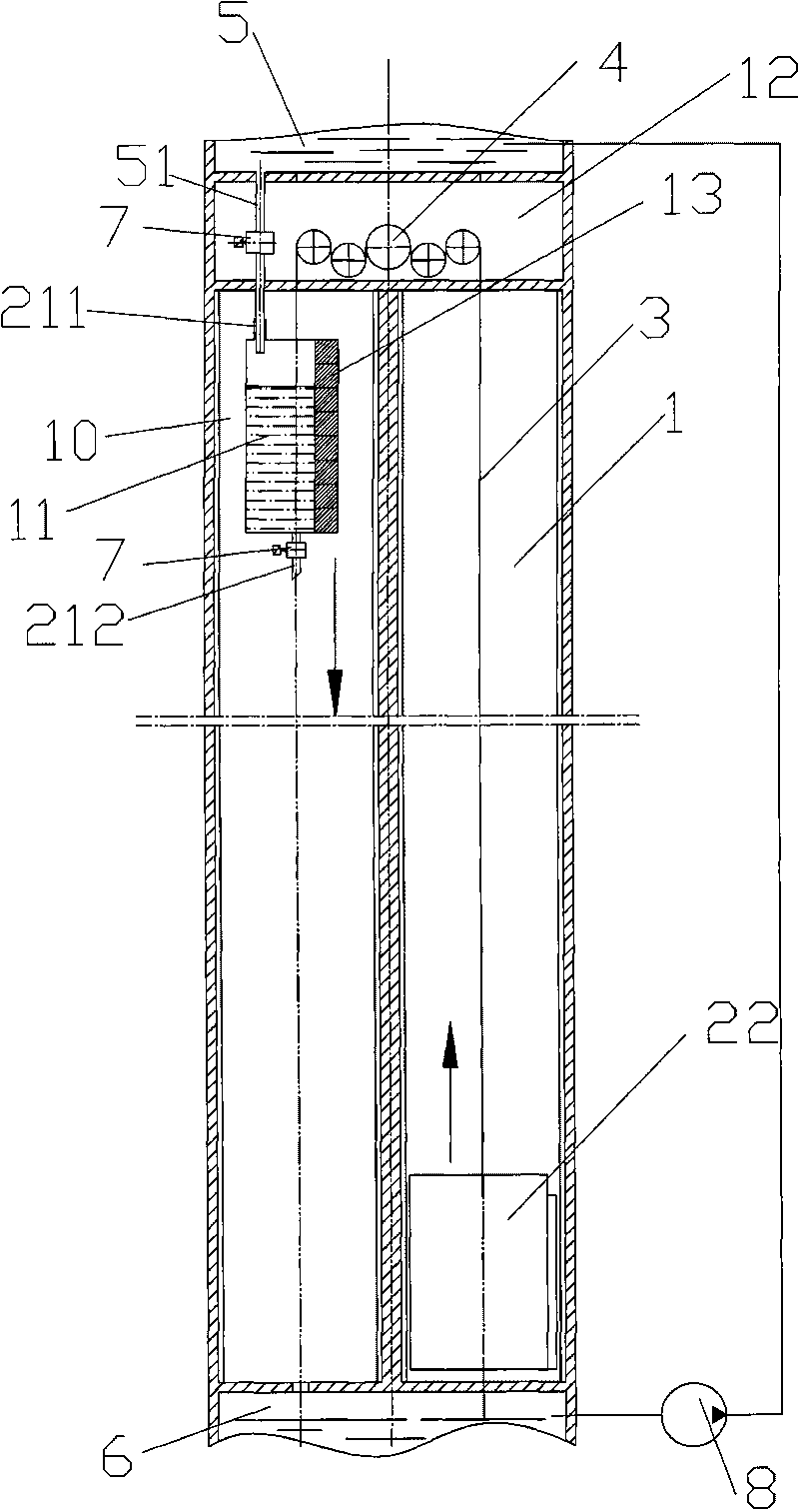

[0026] figure 1 and 2 As shown, the energy storage type vertical elevator for passenger and cargo transport of the present invention comprises a machine shaft 1, two elevator boxes 2 and a machine room 12 on the machine shaft 1, the elevator box 2 is composed of a water tank 21 and a car 22, and the water tank 21 is located on the car 22 , the water tank 21 is provided with a water inlet pipe 211 and a drain pipe 212, and the two elevator boxes 2 are connected by a steel wire rope 3, and the steel wire rope 3 is wound on the hub wheel group 4 in the machine room 12, and a water injection pipe is provided on the top of the machine room 12 The reservoir 5 of 51, the bottom of machine well 1 is provided with drain pool 6, is connected with electromagnetic valve 7 on water injection pipe 51 and drain pipe 212 respectively. A water pump 8 is provided between the water storage tank 5 and the drain tank 6 . Between the car 22 and the water tank 21,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com