Shot type gear ultrasonic shot peening strengthening device

A technology of ultrasonic peening and strengthening device, which is applied in the direction of improving process efficiency, etc., and can solve problems such as difficult to achieve processing effect, long distance between ultrasonic peening tool head and the surface of the processed gear, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

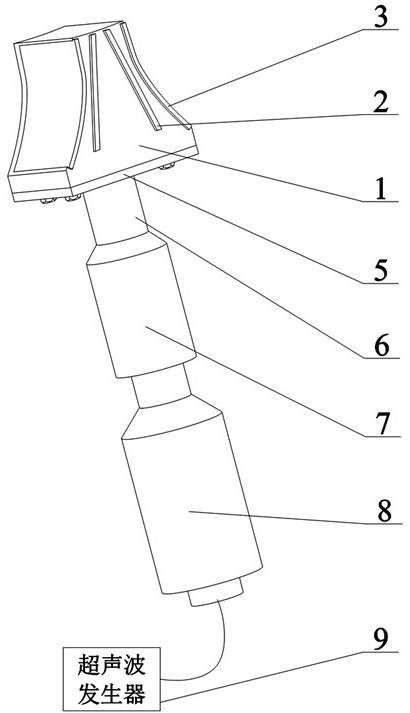

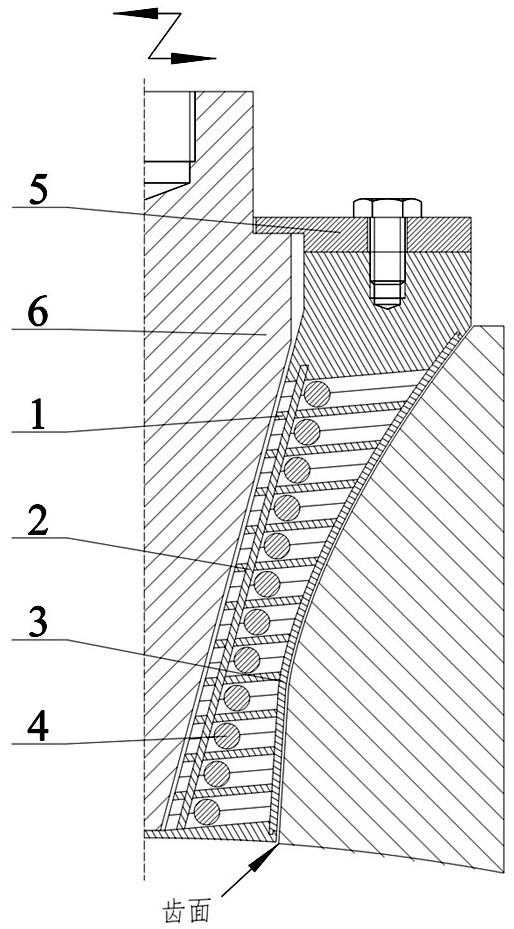

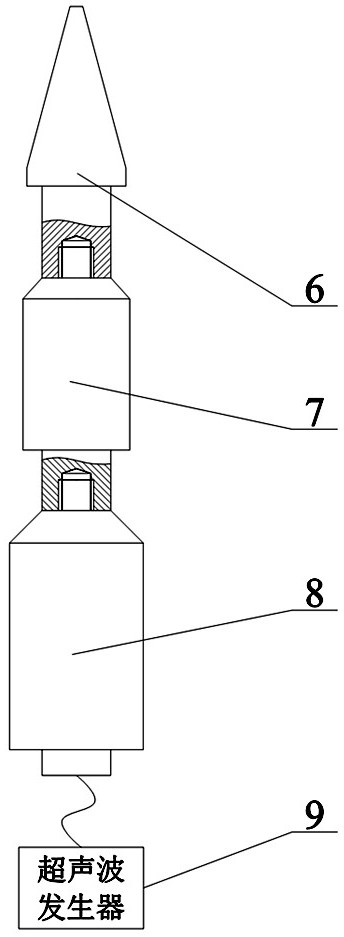

[0022] Embodiment 1, the present invention will be further described according to specific examples below, see Figure 1~Figure 6 , a projectile-type gear ultrasonic shot peening device, including an ultrasonic vibration device and a projectile impact mechanism, characterized in that the ultrasonic vibration device is composed of an ultrasonic generator 9, a transducer 8, a horn 7 and a vibrating head 6 , the cross-sectional shape of the working end of the vibrating head 6 is an isosceles trapezoid, the vibration mode is radial vibration, the amplitude of the vibrating head is 30 microns, and the vibration frequency is 20KHz. The projectile impact mechanism is composed of a housing 1, an upper cover plate 5, The inner baffle 2, the outer baffle 3 and the projectile 4 are composed. The housing 1 is provided with a cavity with the same shape as the vibrating head 6. The vibrating head 6 and the cavity of the housing 1 are in clearance fit, and the gap is smaller than that of the ...

Embodiment 2

[0024] Embodiment 2, the present invention will be further described according to the specific embodiment below, see Figure 1~Figure 6 , a projectile-type gear ultrasonic shot peening device, including an ultrasonic vibration device and a projectile impact mechanism, characterized in that the ultrasonic vibration device is composed of an ultrasonic generator 9, a transducer 8, a horn 7 and a vibrating head 6 , the cross-sectional shape of the working end of the vibrating head 6 is an isosceles trapezoid, the vibration mode is radial vibration, the amplitude of the vibrating head is 50 microns, and the vibration frequency is 30KHz. The projectile impact mechanism is composed of a housing 1, an upper cover plate 5, The inner baffle 2, the outer baffle 3 and the projectile 4 are composed. The housing 1 is provided with a cavity with the same shape as the vibrating head 6. The vibrating head 6 and the cavity of the housing 1 are in clearance fit, and the gap is smaller than that o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com