Plastic fuel tank cover of engineering vehicle

A technology for fuel tank caps and engineering vehicles, which is applied to vehicle components, layout combined with internal combustion engine fuel supply, power units, etc. The effect of normal environment and fuel supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

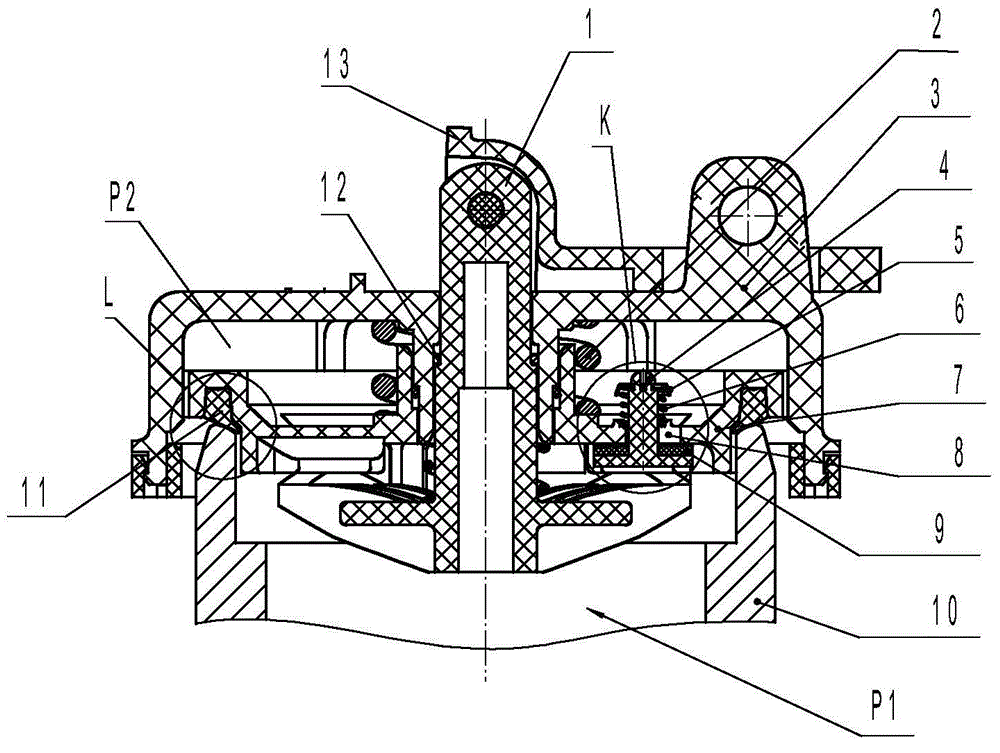

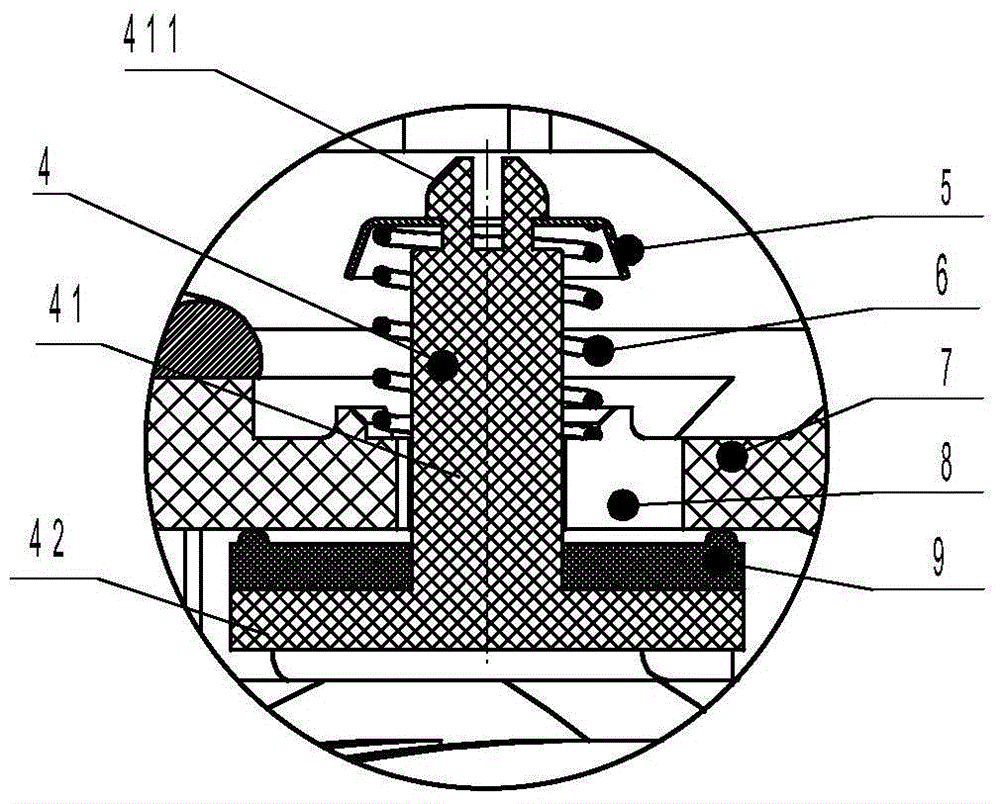

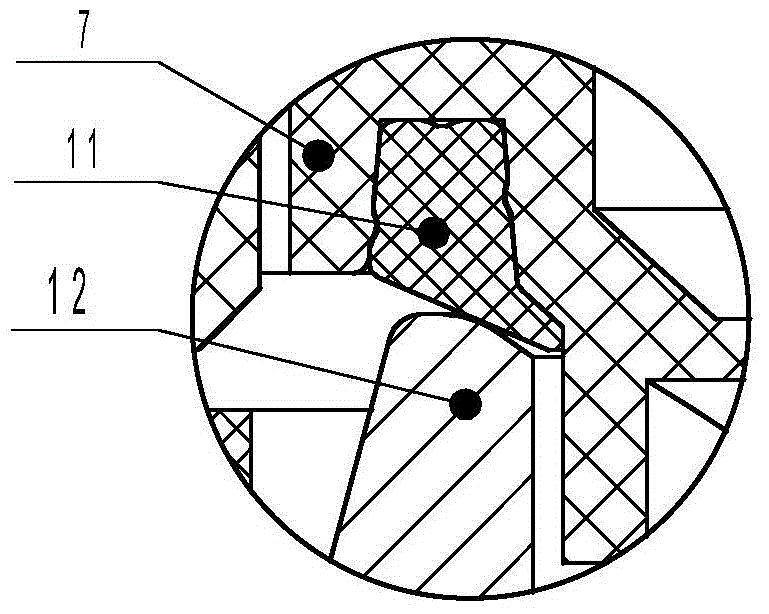

[0029] Embodiment 1: A plastic fuel tank cap for an engineering vehicle, comprising a fuel tank filling port 10, a pressure plate 7, a pressure spring 2, an air intake valve assembly, a plastic locking lever 1, a plastic shell cover 3 and a handle rod 13, the The handle bar 13 is movably connected with the plastic locking bar 1 through the horizontal pin 15, and the handle bar can rotate around the horizontal pin. The plastic shell cover 3 has a middle hole with a small upper part and a larger lower part. The plastic locking bar 1 is The upper part is small and the lower part is large, the plastic case cover 3 is set on the plastic lock rod 1 through the middle hole, and there is an annular groove 14 between the plastic lock rod and the plastic case cover, and the plastic lock rod and the plastic case cover 3 are installed by The O-shaped rubber ring 12 in the annular groove is interference fit and sealed, and the plastic shell cover 3 is provided with a boss 31 with a padlock ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com