Patents

Literature

2385results about How to "Difficult to enter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

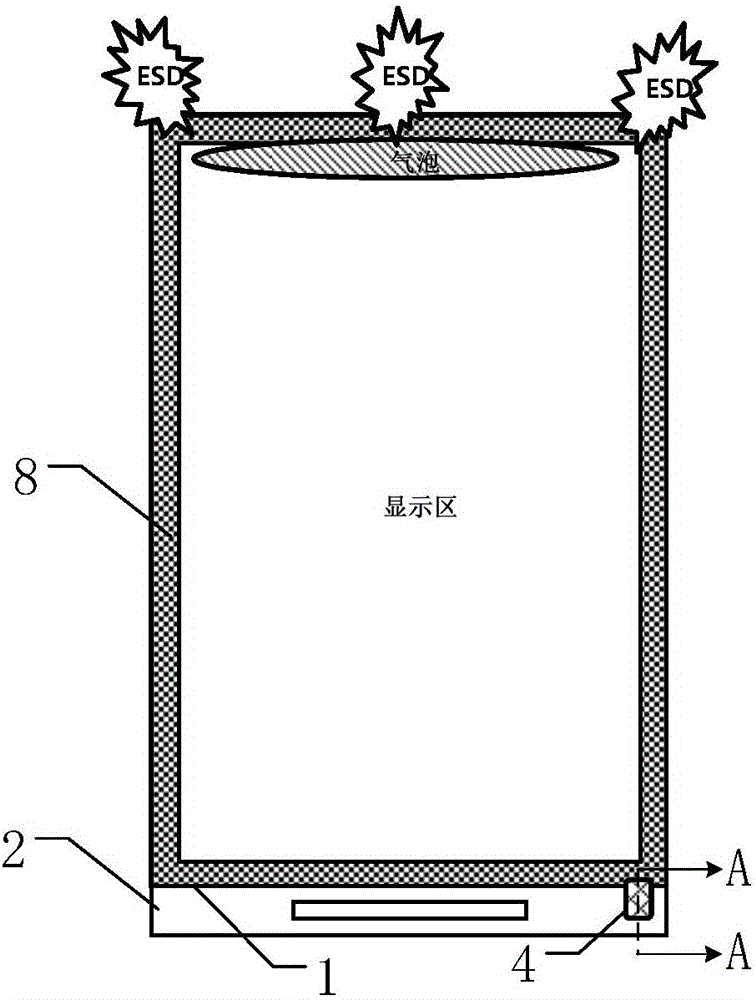

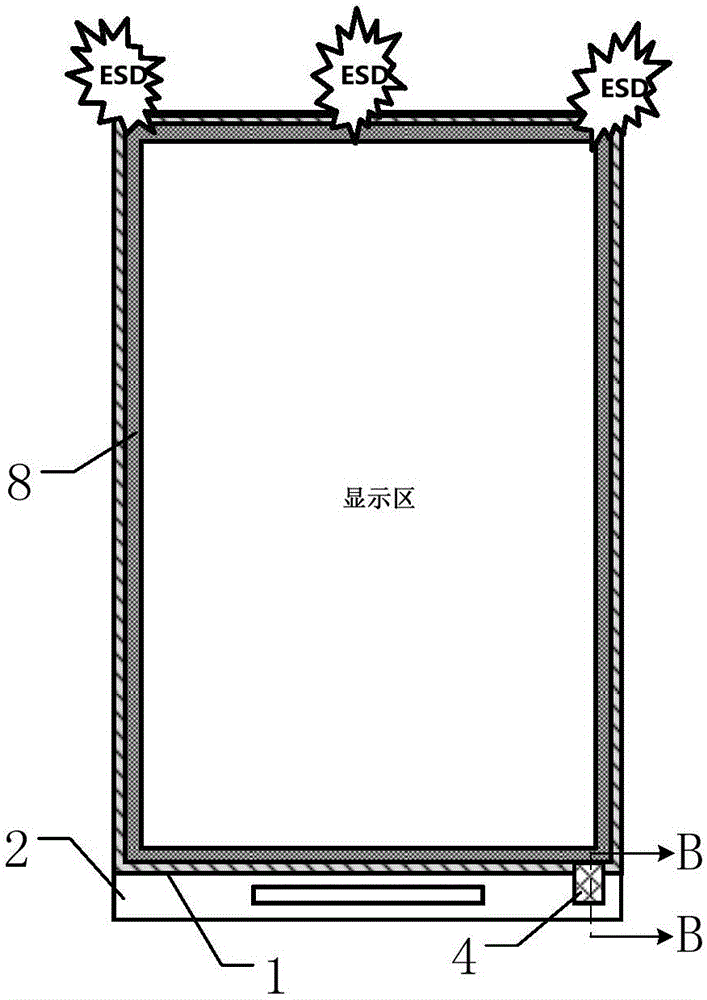

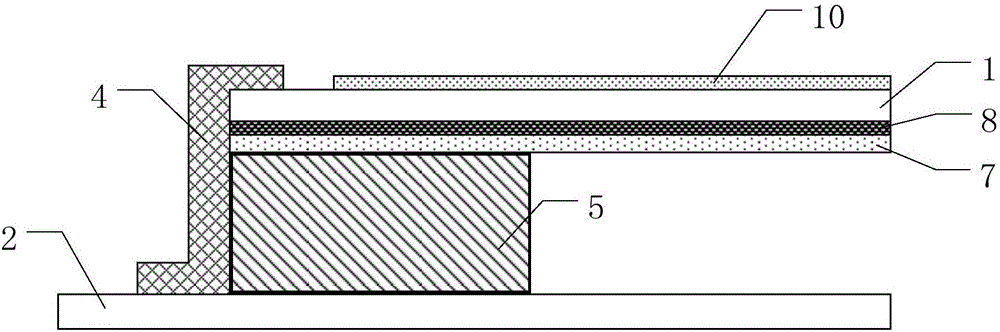

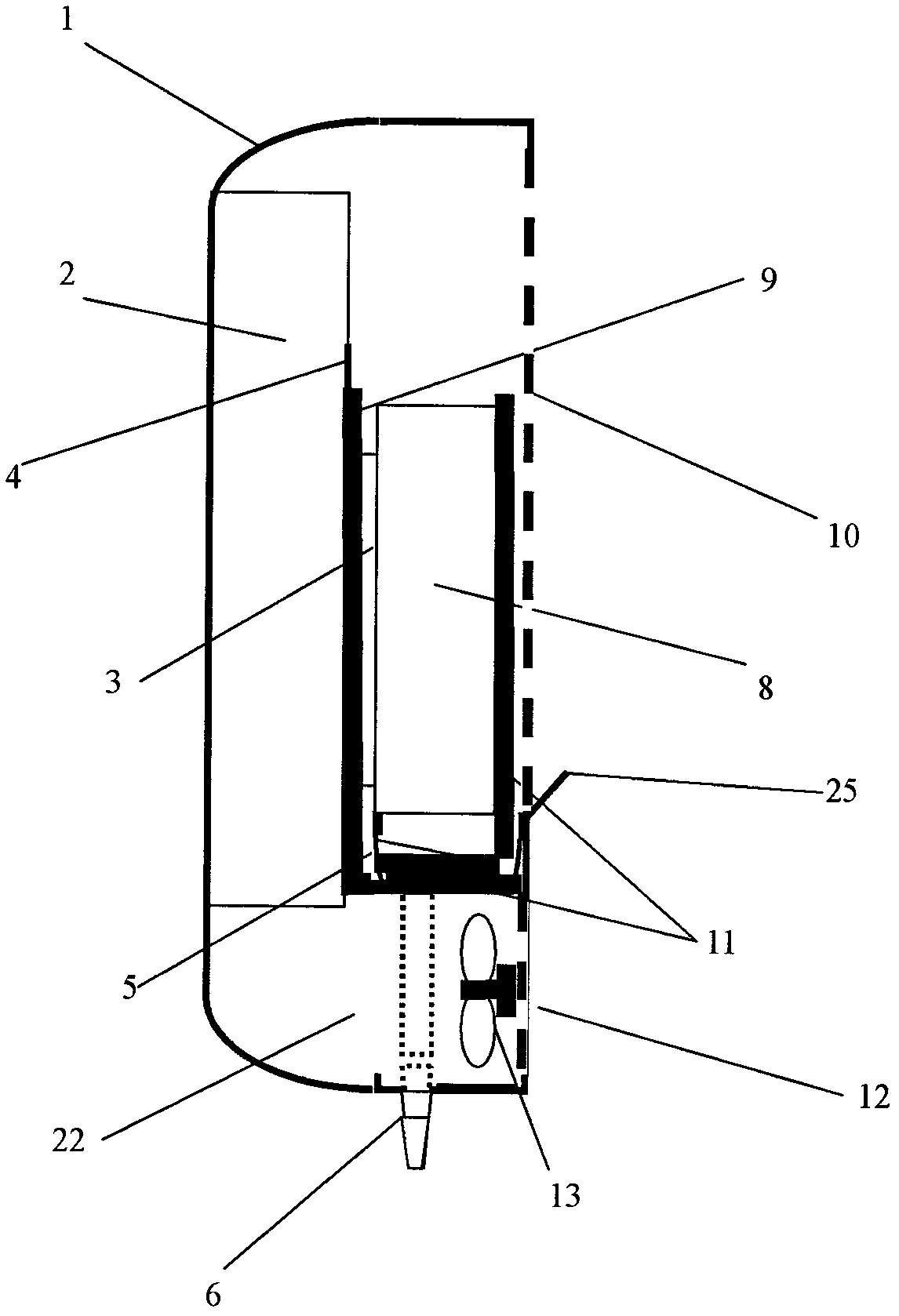

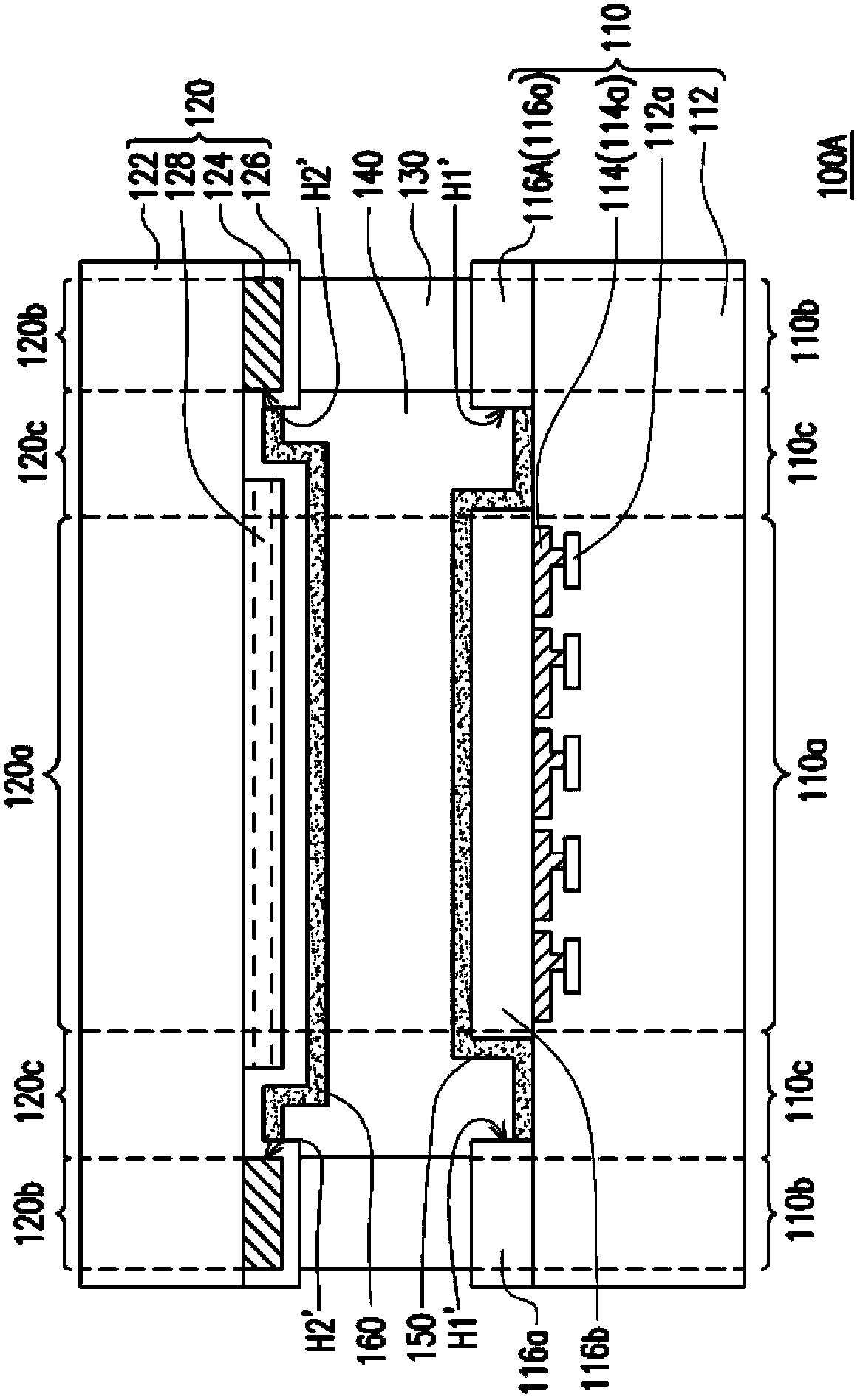

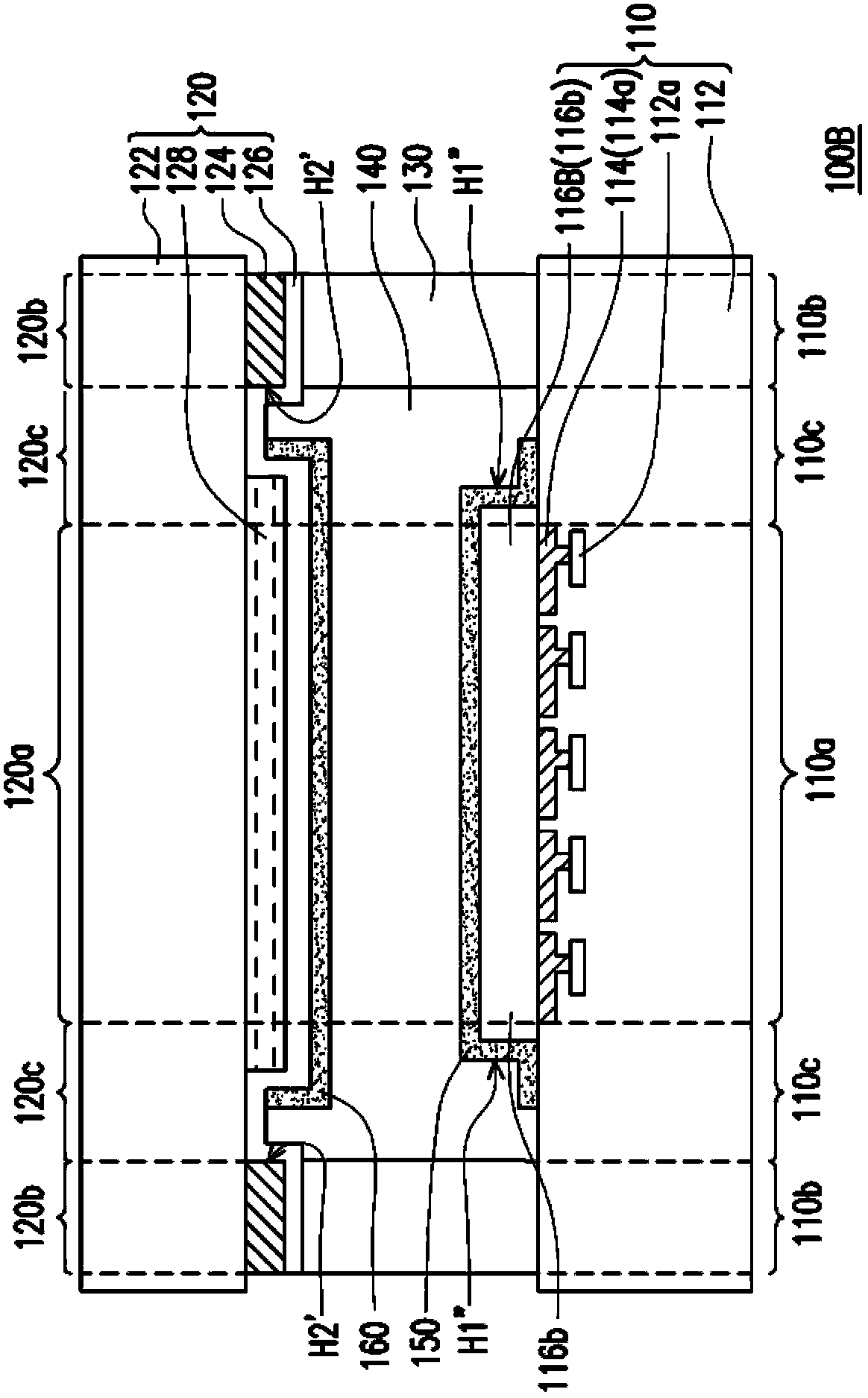

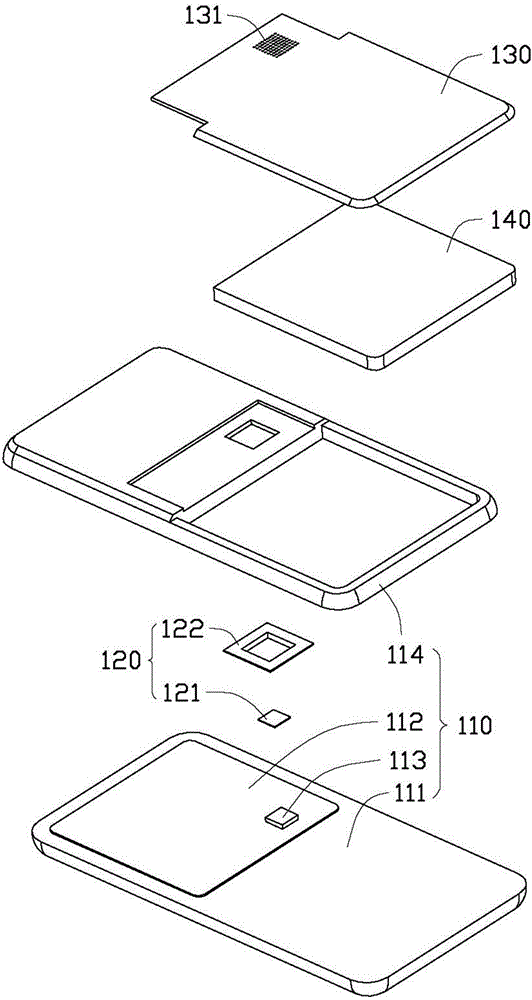

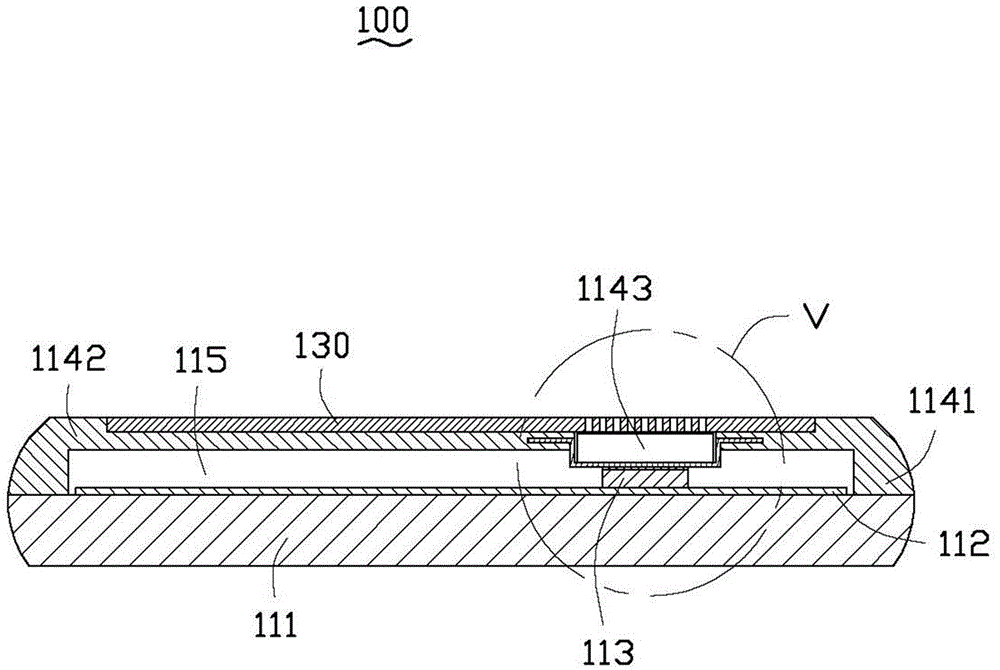

Display panel and display device

InactiveCN106154632AEasy accessAvoid enteringNon-linear opticsInput/output processes for data processingEngineeringStatic electricity

The invention provides a display panel and a display device. The display panel is provided with a display area and a frame area located on the periphery of the display area. The display panel comprises an array substrate, an opposite substrate opposite to the array substrate, frame sealing glue arranged in the frame area and making the array substrate and the opposite substrate oppositely arranged, and a black matrix layer arranged between the opposite substrate and the array substrate. The black matrix layer is provided with at least one opening in the frame area, the at least one opening comprises a first annular opening arranged between the frame sealing glue and the display area and surrounding the display area, and the black matrix layer is disconnected at the at least one opening. The display panel can reduce adverse static electricity.

Owner:HEFEI BOE OPTOELECTRONICS TECH +1

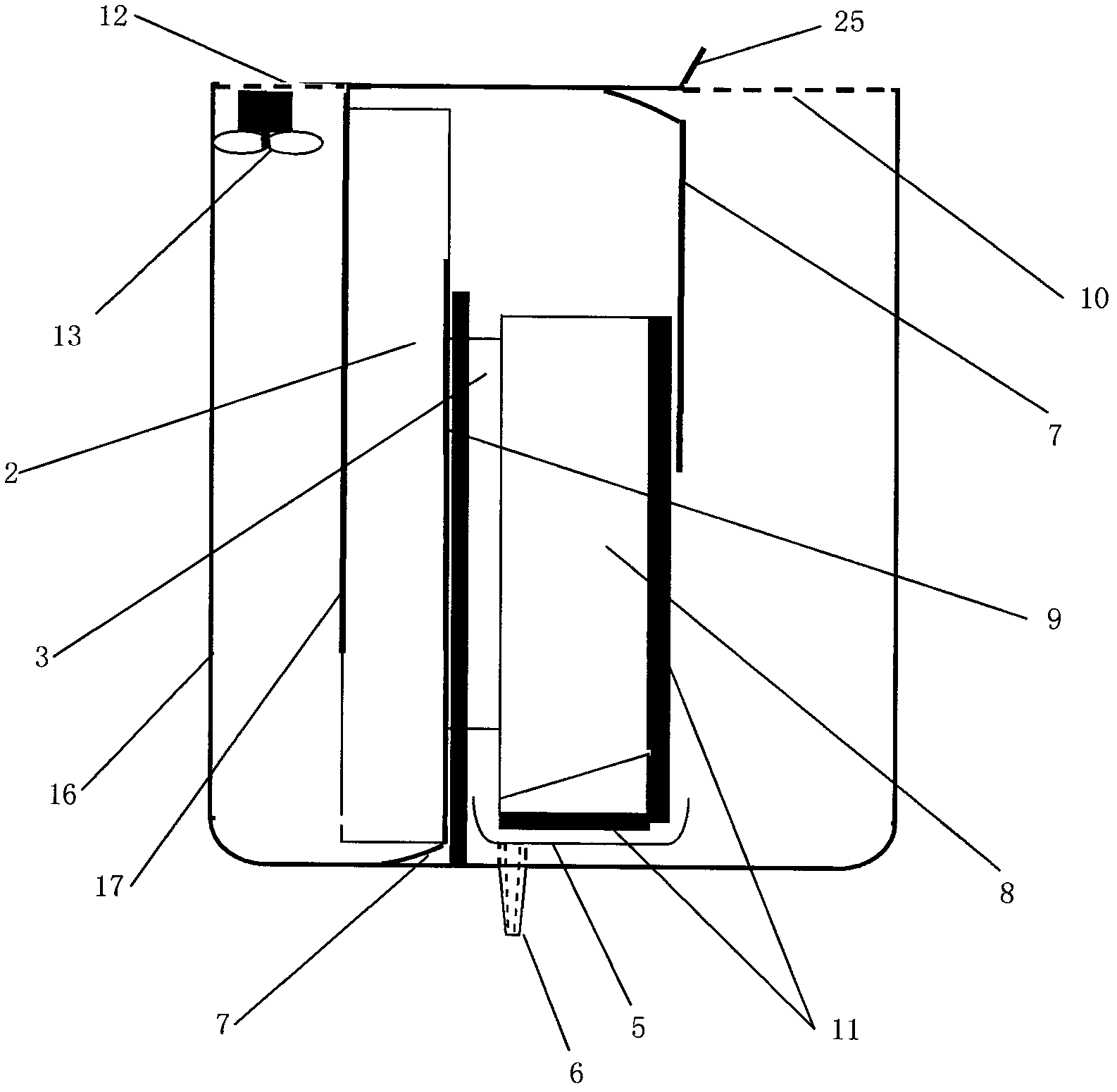

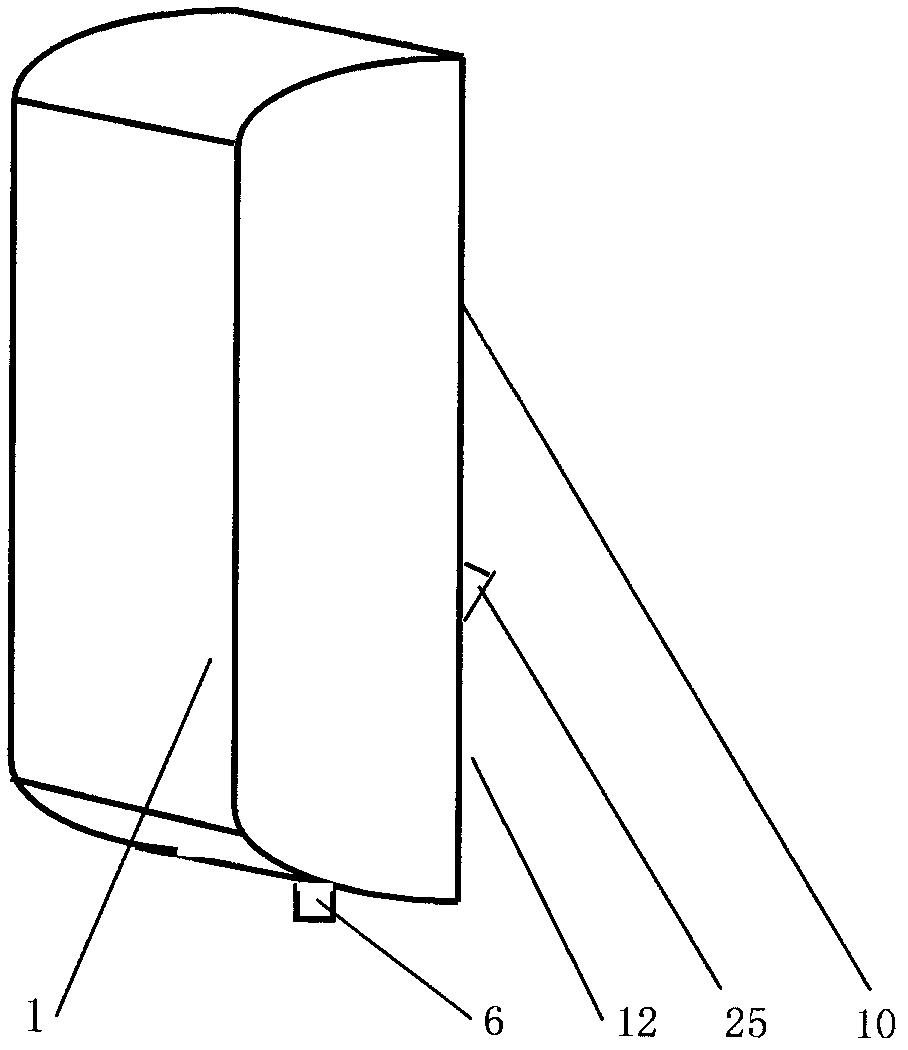

Sealed structure of mini-type electronic dehumidifying and cooling machine

InactiveCN102545080AEnsure safe operation and reliabilityReduce power consumptionSubstation/switching arrangement cooling/ventilationWater collectionWater pipe

The invention provides a sealed structure of a mini-type electronic dehumidifying and cooling machine. A heat radiation face and a refrigerating face of a vertical electronic refrigerating sheet are sealed to be a wet air heating channel and a wet air condensing channel, which are mutually independent and are provided with vertical communicated upper parts. One end of a wet air leading channel is communicated with the lower part of the wet air heating channel, and the other end of the wet air leading channel is provided with a mini-type blower. The lower end opening of the wet air condensing channel is sealed, and a refrigerating face of the wet air condensing channel aligns to a dried cool air discharge hole which is arranged at a vertical position. A water collection hopper is arranged below a condensing sheet of the refrigerating face. A drain pipe of the water collection hopper is communicated to the outside of a shell box of the sealed structure of the mini-type electronic dehumidifying and cooling machine through leading of the water collection hopper. The installation on the lateral face or the bottom face outside an indoor armor switch cabinet or various terminal bins of an electric system with a 6-kV or above voltage class is met. The inside spaces of the armor switch cabinet and the terminal bins are not occupied. No interferences of a high voltage and a strong magnetic field exist. The equipment operation inside the armor switch cabinet and the terminal bins is not influenced by the maintenance and repair of the mini-type electronic dehumidifying and cooling machine.

Owner:叶秋诗 +2

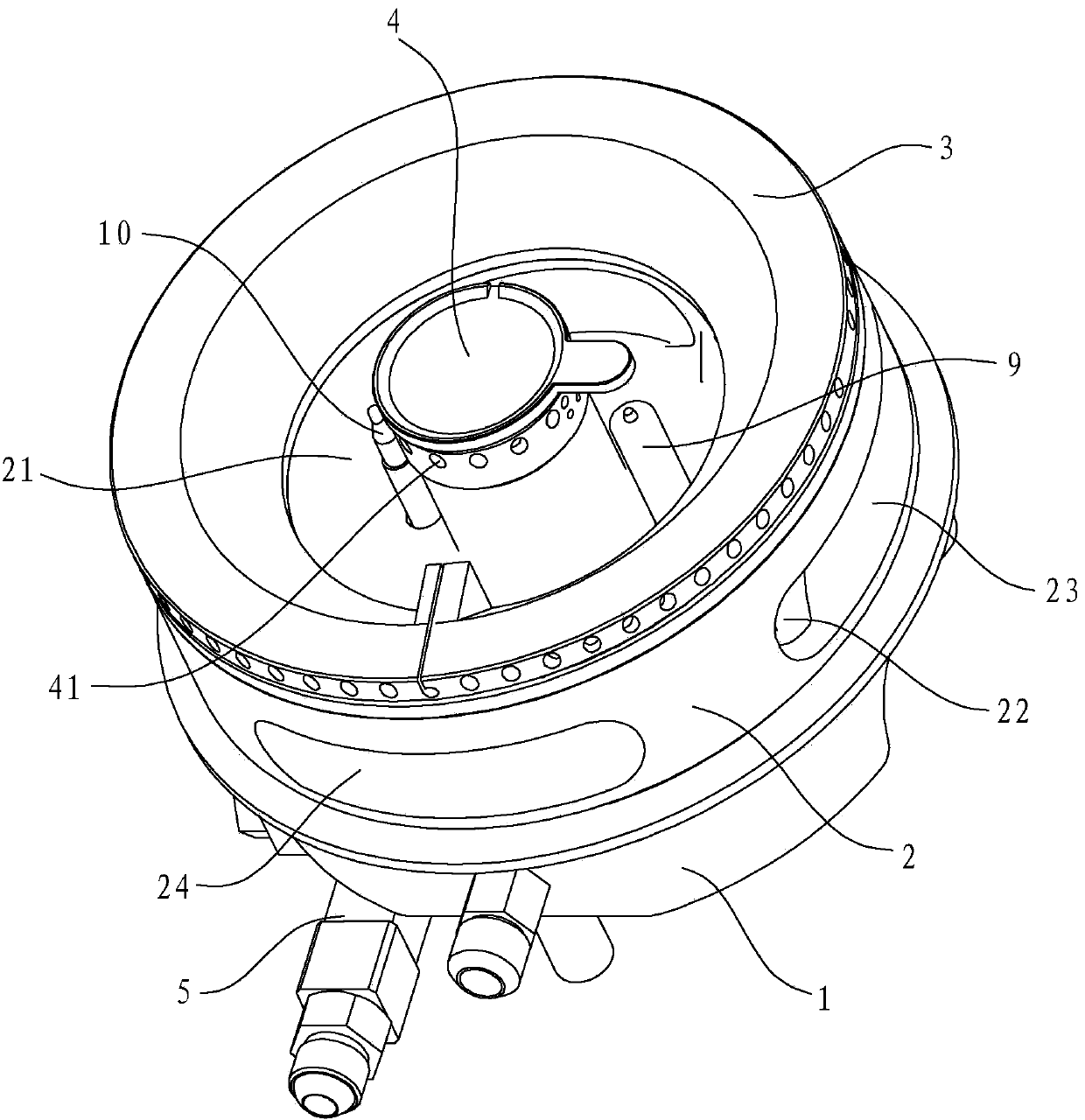

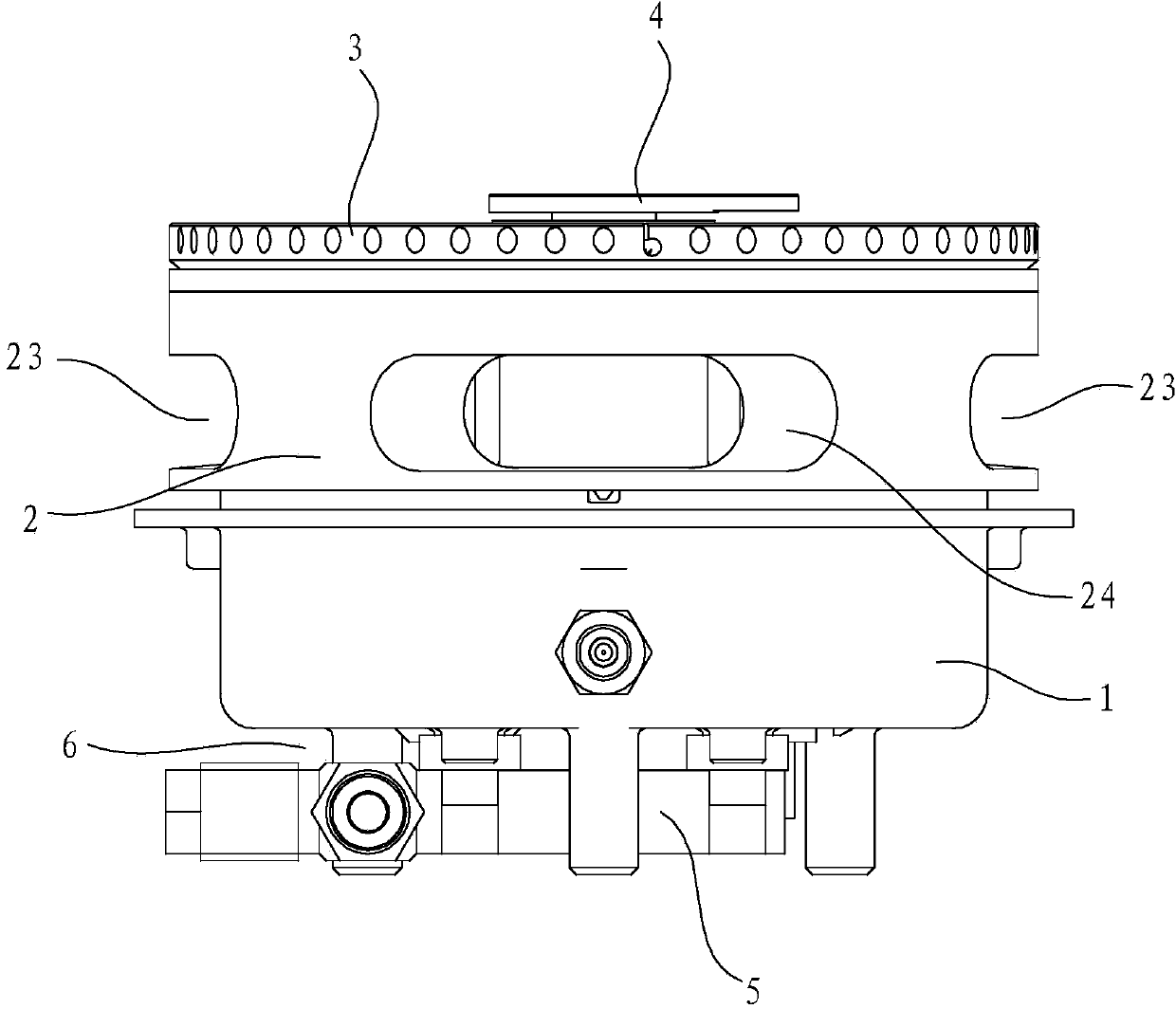

Upper air inlet type burner for gas stove

An upper air inlet type burner for a gas stove comprises a base, a gas mixing chamber, an outer ring fire cover and an inner ring fire cover. The base is provided with a cavity with an upward opening, the gas mixing chamber is arranged above the base and provided with an annular cavity, and the inner ring fire cover and the outer ring fire cover are arranged on the gas mixing chamber and located on the inner side and the outer side of the annular cavity respectively. The upper air inlet type burner is characterized in that the cavity is isolated from the annular cavity, the side portion of the gas mixing chamber is provided with a primary air hole and a secondary air hole, the primary air hole is communicated with the cavity to form a primary air channel, and the secondary air hole is communicated with the annular cavity to form a secondary air channel. The upper air inlet type burner has the advantages that due to the fact that the cavity of the base is isolated from the annular cavity of the gas mixing chamber, and the primary air hole is formed in the side portion of the gas mixing chamber, primary air supplement can be carried out without arranging a gap between the gas mixing chamber and the base, a panel screw can be hidden below the gas mixing chamber, and the structure of the burner can be simple; in addition, secondary air can be supplemented to the inner ring fire cover through the annular cavity via the secondary air hole, and therefore the inner ring fire combustion efficiency can be improved.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Building rubbish crusher

InactiveCN106925378ACause wasteImprove dust removal efficiencyCombination devicesGas treatmentArchitectural engineeringCrusher

The invention discloses a building rubbish crusher which comprises a rack and baffles. An electromotor is mounted at the upper end of the left side of the rack. A machine body is arranged at the upper end of the rack. A feeding opening is fixed to the upper end of the machine body. The lower end of the feeding opening is connected with the baffles through supporting rods. A sealing ring is arranged on the outer side of each baffle. Crushing rollers are mounted in the machine body. An exhaust opening is formed in the upper end of the right side in a cavity of the machine body and located below the crushing rollers. A filter screen is mounted in the exhaust opening. The upper end of an air suction motor is connected with the exhaust opening through an air outlet pipe. The machine body is mounted on the left side of the exhaust opening. A water tank is fixed below the air suction motor and located on the right side of the rack. A discharging opening is mounted below the machine body. A shock absorption mat is arranged at the upper end in the discharging opening. The building rubbish crusher is provided with the water tank, sucked-out building rubbish dust can be removed through water in the water tank, the dust removal efficiency is high, and water resources cannot be wasted.

Owner:THE FOURTH OF CHINA CONSTR SEVENTH ENG

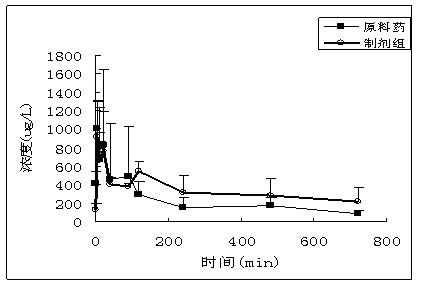

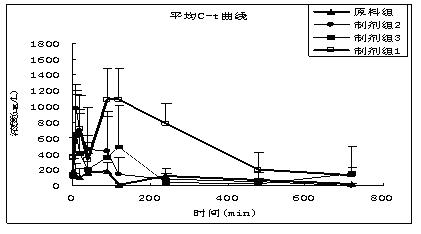

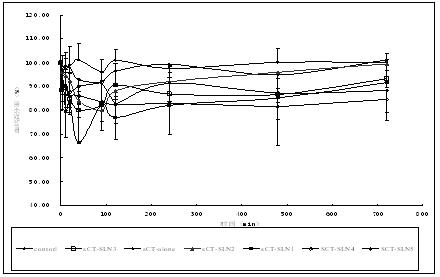

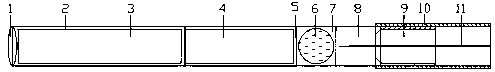

Novel solid lipid nanoparticle medicament delivery system for protein-loaded medicaments

ActiveCN102106821AHigh activityGuaranteed stabilityPowder deliveryAerosol deliveryActive agentBULK ACTIVE INGREDIENT

The invention provides novel solid lipid nanoparticles for protein medicaments and a preparation method thereof. Each solid lipid nanoparticle consists of two parts, namely a core and a shell, wherein the core is that a biosurfactant forms a micelle or an aggregate to wrap active ingredients, or / and the biosurfactant and the active ingredients form a synergic aggregate; and the shell is that a solid lipid material is adopted for encapsulating the core. A novel solid lipid nanoparticle medicament delivery system has extremely high safety, can effectively protect the biological activity of polypeptides and polypeptide medicaments and remarkably improve the stability of preparations of the polypeptides and the polypeptide medicaments at the same time, can be applied in multiple ways such as injection, non-injection and the like, and achieves better bioavailability.

Owner:SICHUAN UNIV

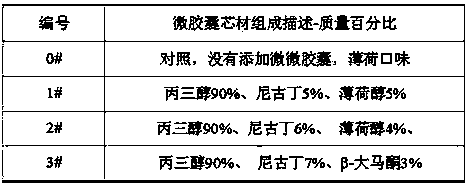

Electronic cigarette with microcapsule releasing device and microcapsule

ActiveCN104126878AImprove stabilityAvoid volatile lossTobacco treatmentTobacco devicesTarEngineering

The invention relates to an electronic cigarette with a microcapsule releasing device and a microcapsule. The electronic cigarette with the microcapsule releasing device comprises a cigarette-shaped cavity shell, a battery, an indicating lamp, a cigarette holder and an adsorbing material, an atomizer is arranged in the adsorbing material and is connected with the battery and a starting switch, the indicating lamp is located on one end face of the cigarette-shaped cavity shell, the battery and the adsorbing material are arranged at the end, close to the indicating lamp, in the cigarette-shaped cavity shell, a microcapsule cavity is formed in the other end of the adsorbing material and is internally provided with a microcapsule, the cigarette holder is arranged at the other end of the microcapsule cavity, and a piercing needle is arranged in the middle of the cigarette holder. The electronic cigarette with the microcapsule releasing device and the microcapsule have the advantages that releasing can be controlled, the stability of tobacco tar can be controlled, the microcapsule can be replaced, taste and smell can be shielded, other smells in the environment cannot enter the tobacco tar easily, and the ingredients of the tobacco tar are protected against contamination.

Owner:CHINA TOBACCO YUNNAN IND

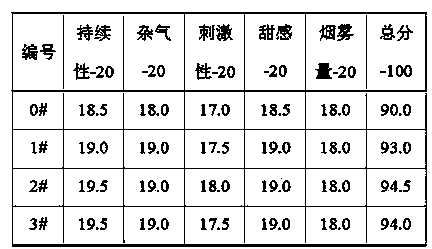

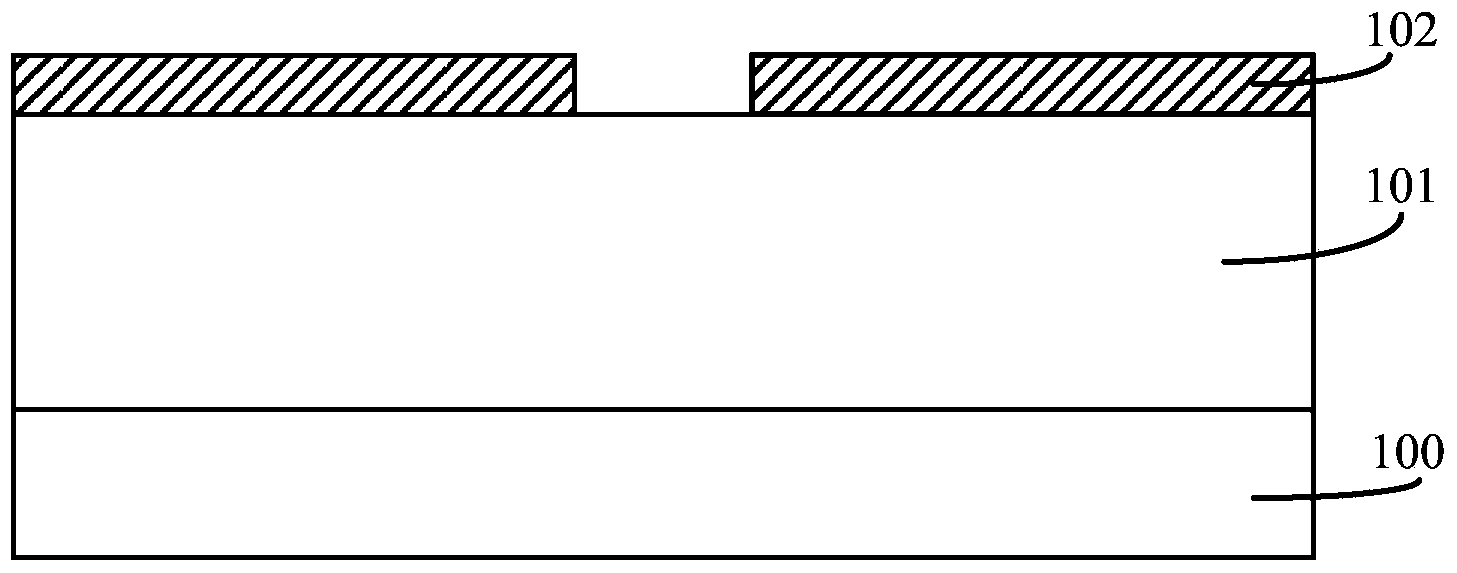

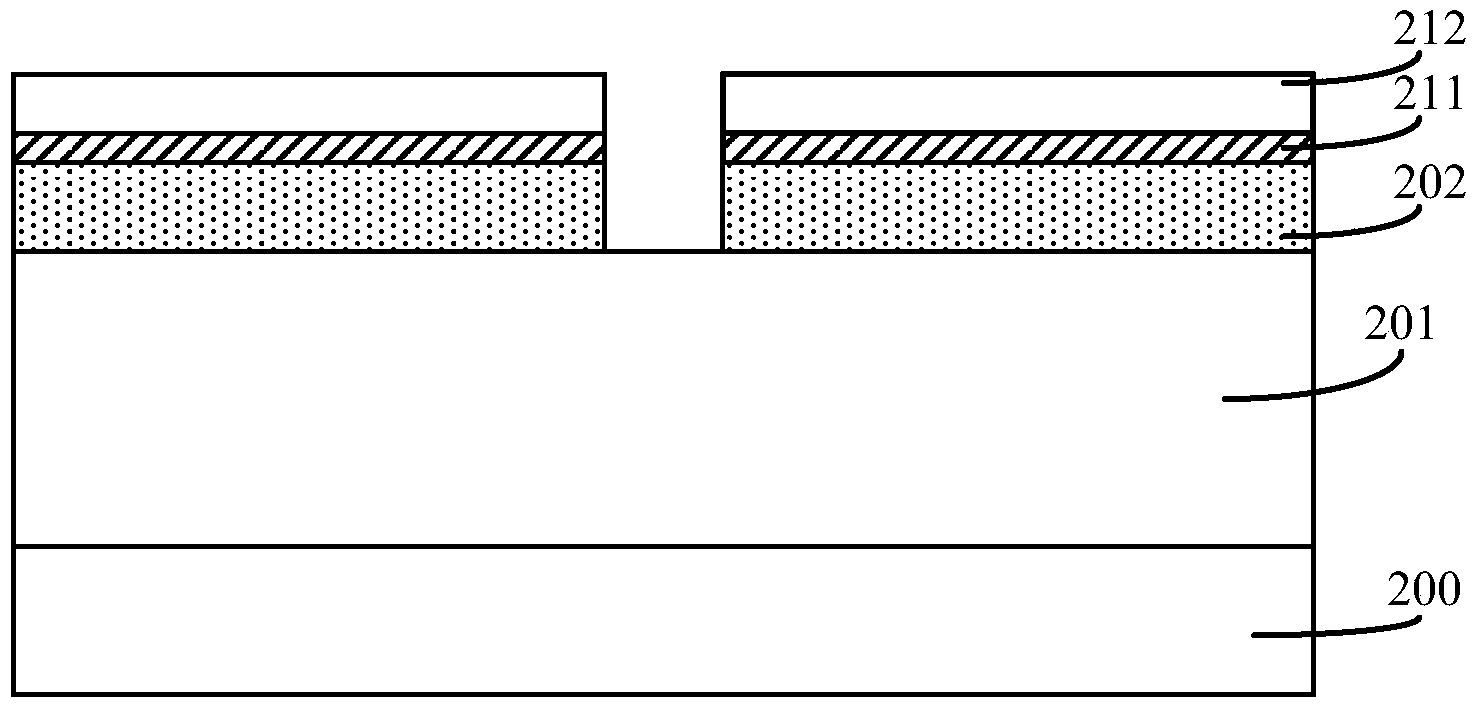

Method for forming semiconductor structure

ActiveCN103400762AReduce reactivityLow etch impactSemiconductor/solid-state device manufacturingSemiconductor structureRadio frequency signal

The invention discloses a method for forming a semiconductor structure, comprising the steps: providing a substrate, wherein the surface of the substrate is provided with a layer to be etched; forming a mark layer on the layer to be etched, wherein a part of the mark layer is exposed out of the surface of the layer to be etched; performing plasma etching on the layer to be etched by using the mark layer as a mark to form an opening in the layer to be etched, wherein a radio frequency signal output from a bias radio frequency power source in the plasma etching is a pulse signal, the duty cycle of the pulse signal is reduced along with the increasing of the etching depth, when the bias radio frequency power source is powered on, a part of the layer to be etched is etched to form an etching hole in which an etching byproduct is provided, and when the bias radio frequency power source is powered off, the etching byproduct diffuses from the etching hole. The size of the opening formed by the plasma etching process is precious and even, and the opening etching rate is high.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

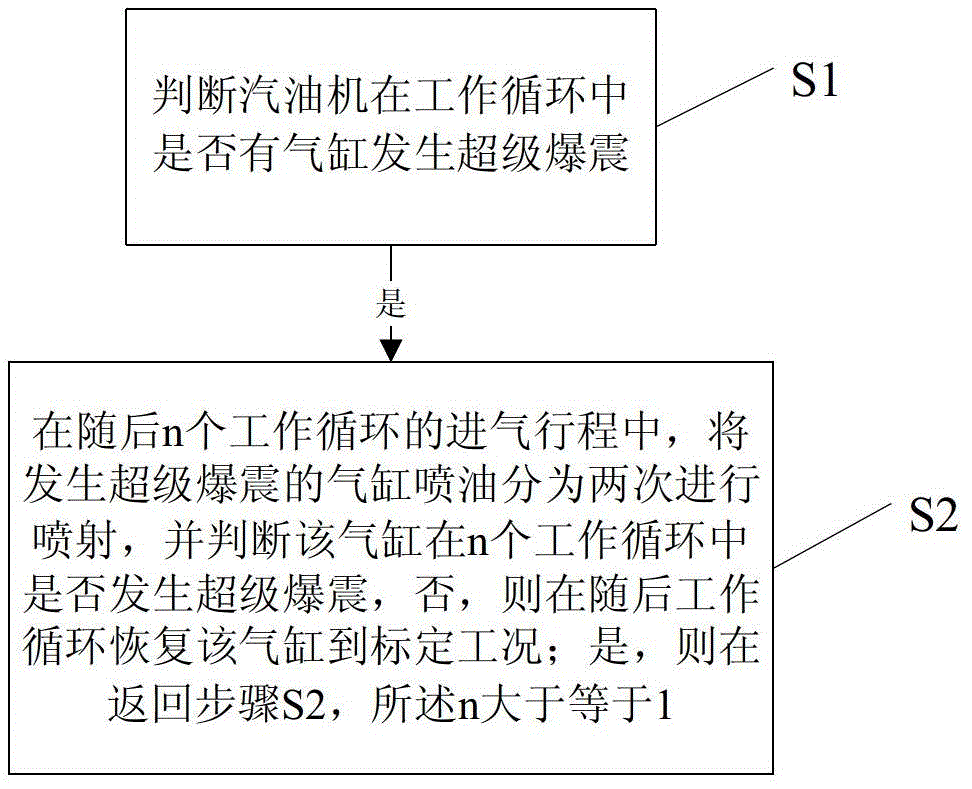

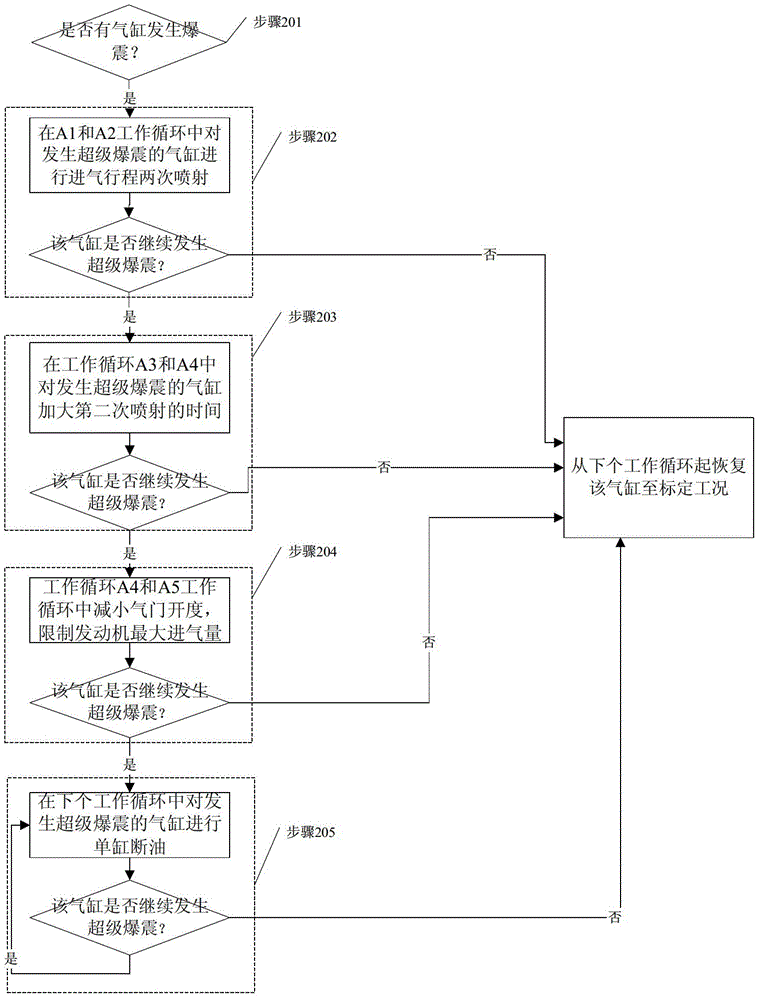

Method for judging and controlling super detonation

ActiveCN103334846AIncrease fuel consumptionEasy dischargeElectrical controlMachines/enginesDetonationWork cycle

The invention provides a method for judging and controlling super detonation. The method comprises the following steps of: S1, judging whether super detonation occurs to a cylinder of a gasoline engine in the working cycle and if yes, carrying out the step S2; and S2, in the gas inlet process of the following n working cycles, carrying out oil spraying for twice on the cylinder to which super detonation occurs, judging whether super detonation occurs to the cylinder in the n working cycles, recovering the cylinder to the declared working condition in the following working cycles if no, and returning to the step S2 if yes, wherein n is more than or equal to 1. By the method disclosed by the invention, continuous occurrence of super detonation can be effectively inhibited; any additional devices are not required; and cost is low.

Owner:TSINGHUA UNIV

Display

InactiveCN103576390AImprove reliabilitySimplified coating processNon-linear opticsLiquid-crystal displayDisplay device

The invention discloses a display which comprises a first substrate, a second substrate, frame rubber, a liquid crystal layer and a first alignment film. The first substrate is provided with a first display region, a first frame rubber coating region and first recessions. The first frame rubber coating region encircles the first display region. The first recessions are at least positioned in a region between the first display region and the first frame rubber coating region. The second substrate is opposite to the first substrate. The frame rubber is arranged in the frame rubber coating region and positioned between the first substrate and the second substrate. The first substrate, the second substrate and the frame rubber encircle the liquid crystal layer jointly. The first alignment film is arranged between the first substrate and the liquid crystal layer and filled in the first recessions.

Owner:HIMAX DISPLAY INC

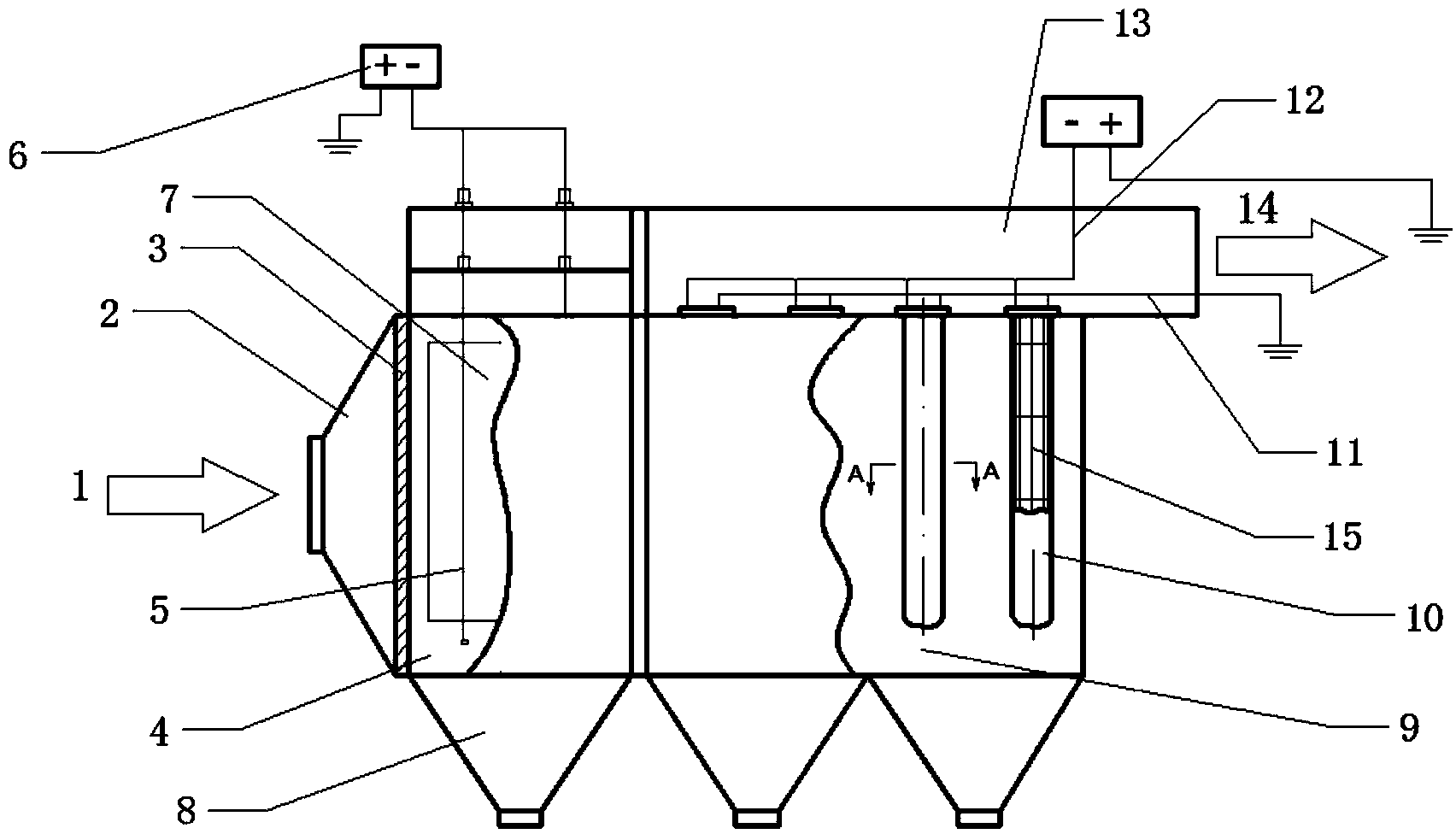

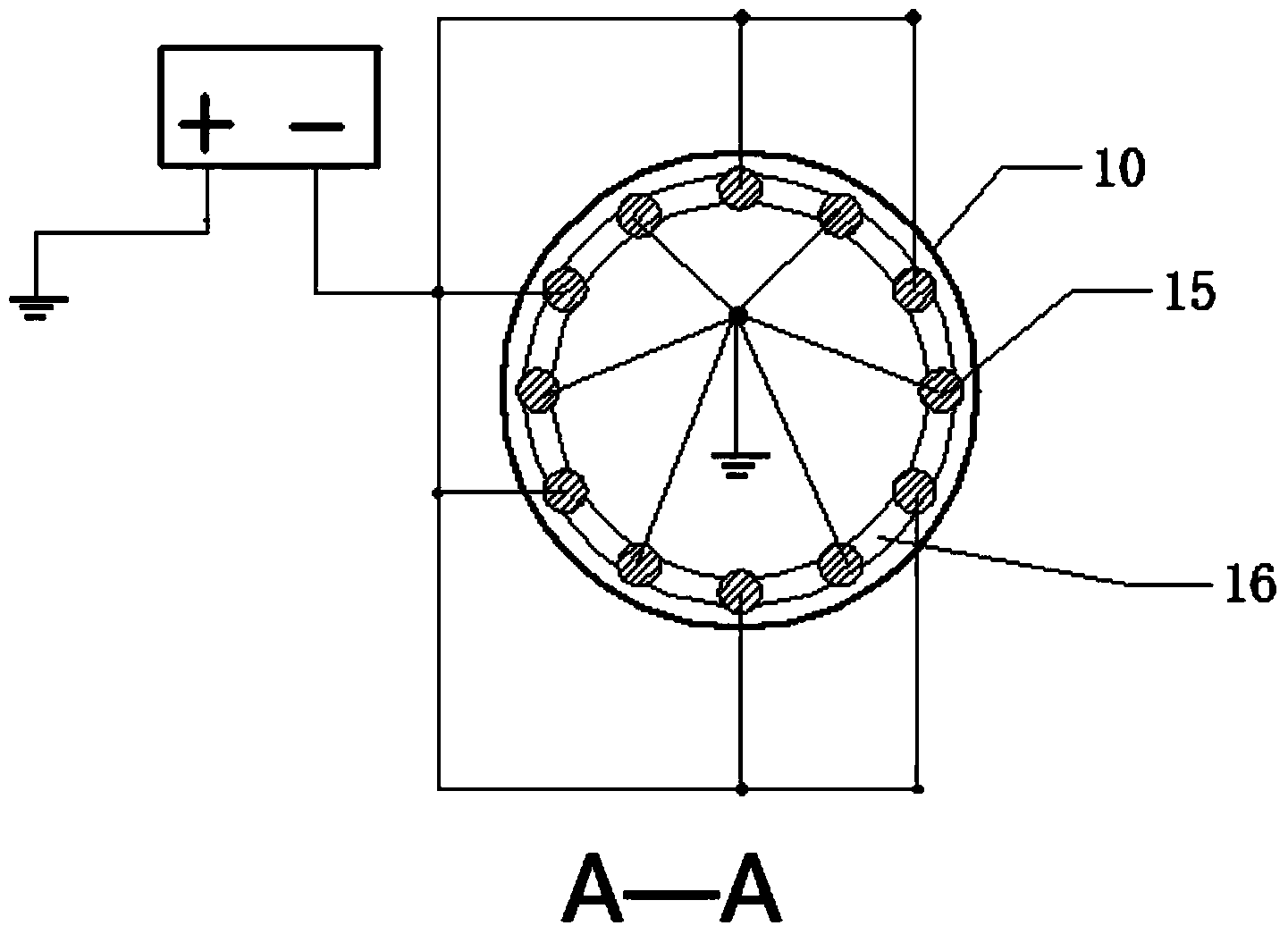

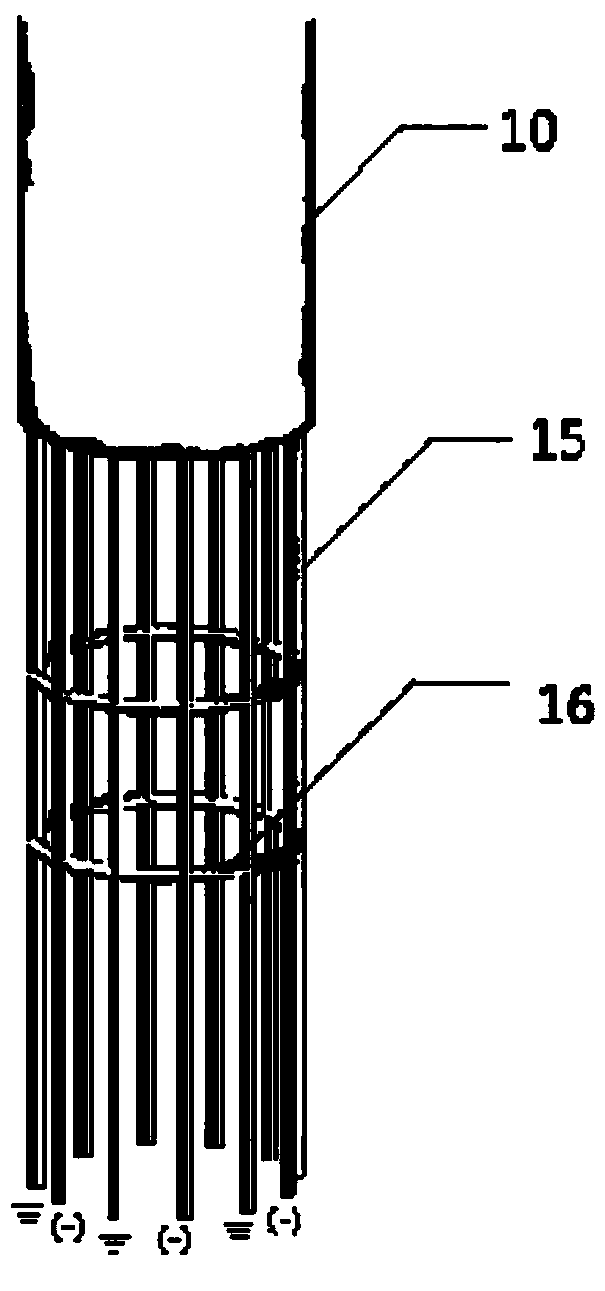

Electrostatically-enhanced electric-bag compound dust remover

ActiveCN103657316ADifficult to enterExtend your lifeCombination devicesFiltrationHigh-voltage direct current

An electrostatically-enhanced electric-bag compound dust remover comprises a high-voltage power supply arranged outside a casing and a compound dust removing area arranged in the casing; the compound dust removing area comprises a forestage electrostatic dust removing area and a rear-stage bag type dust removing area, wherein the forestage electrostatic dust removing area comprises a high-voltage discharge polar line and a dust collecting pole plate; filtering bags uniformly distributed are arranged in the bag type dust removing area; conductive cage bones are arranged in the filtering bags; vertical reinforcement bars in the conductive cage bones are connected with the ground and the negative pole of a high-voltage direct-current power supply, and each two adjacent vertical reinforcement bars are opposite in polarity; a plurality of insulating rings are arranged in the vertical direction; the vertical reinforcement bars are fixed on the insulating rings. The electrostatically-enhanced electric-bag compound dust remover has the characteristics that a non-uniform electric field is added in the bag type dust removing area, so that charged dust particles are distributed non-uniformly on the surfaces of the filtering bags; meanwhile, the particles are polarized into chains through the electric field, and then the probability of collecting the particles can be increased, so that the air-to-cloth ratio can be improved, the filtration resistance can be lowered at the same time, the soot cleaning frequency can be reduced, and the dust remover has the advantages of low energy consumption and long service life.

Owner:TSINGHUA UNIV

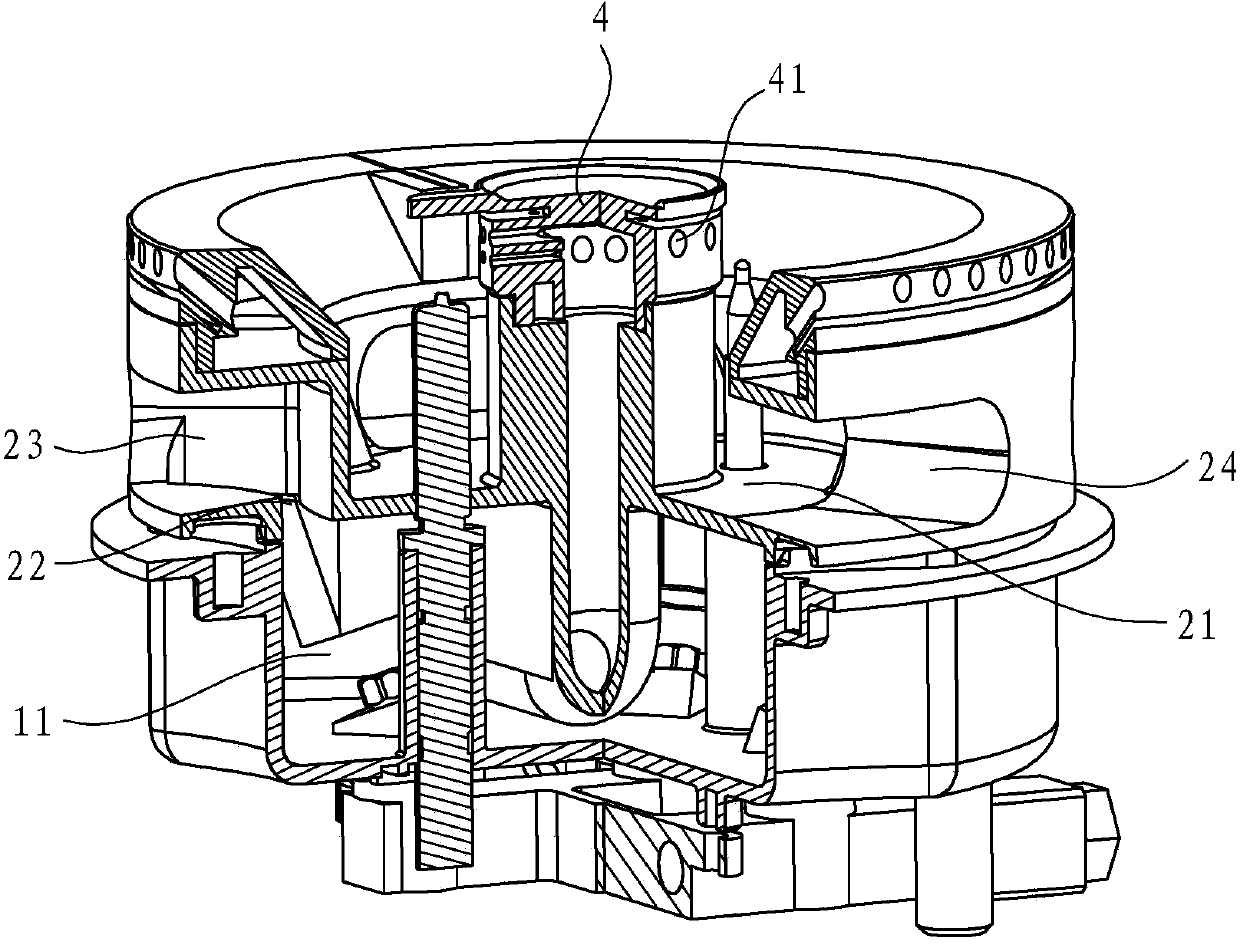

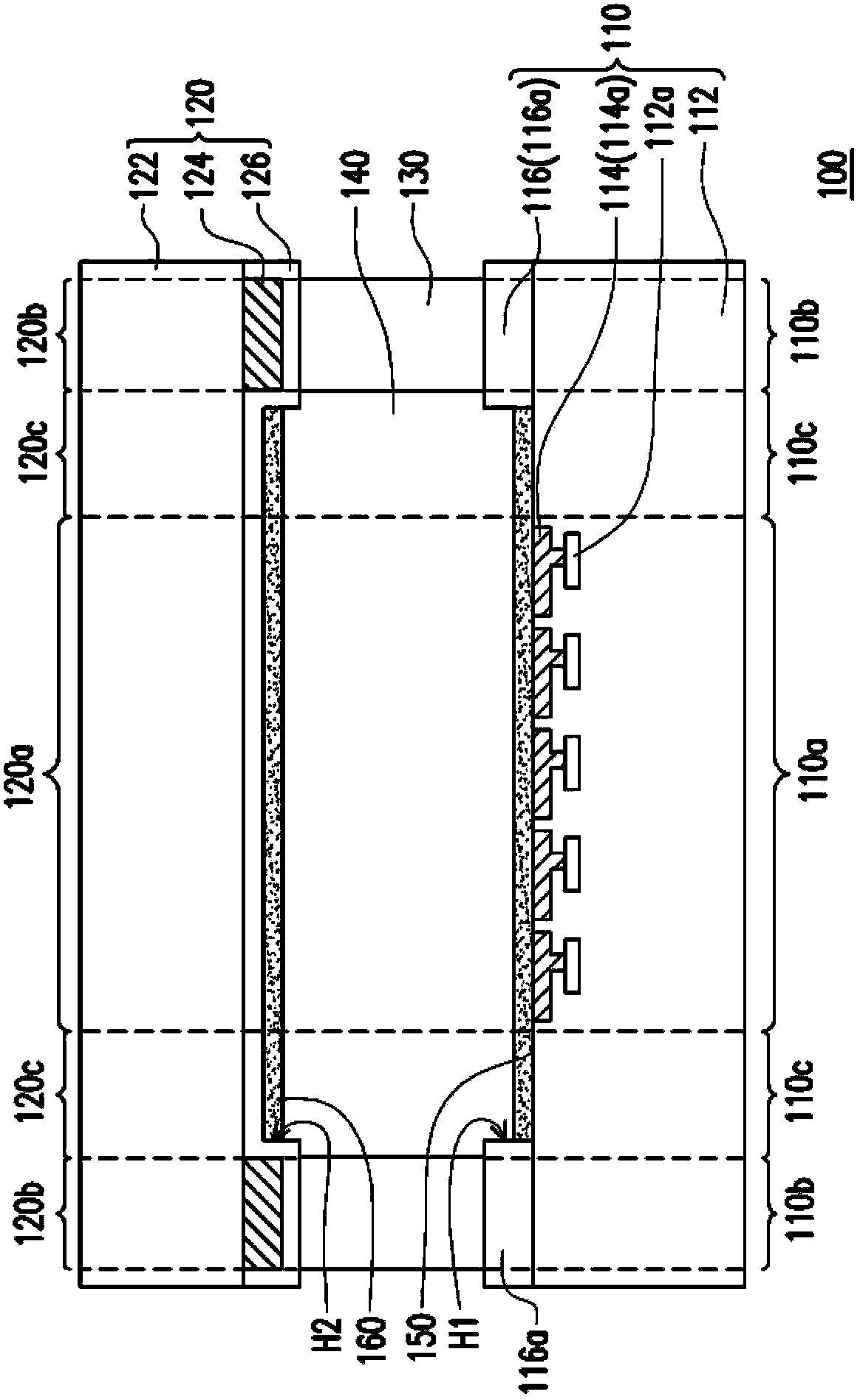

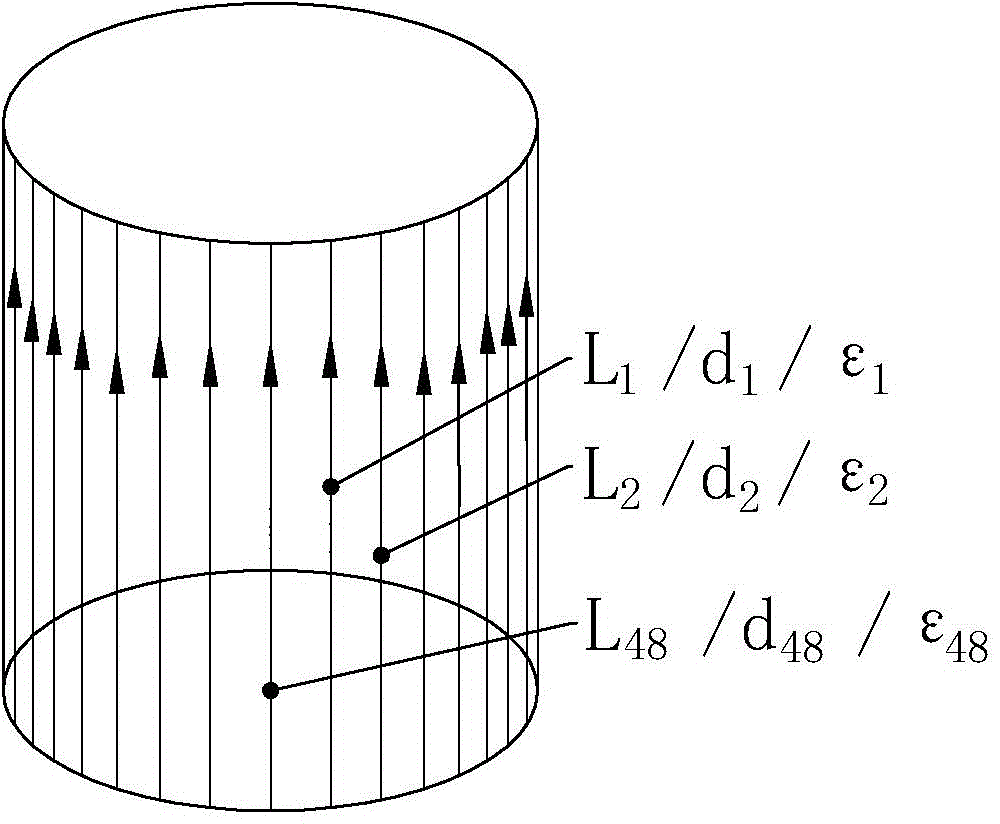

Direct drive permanent magnet wind generator, direct drive permanent magnet wind generator system and stator of direct drive permanent magnet wind generator

ActiveCN104600886AReduce risk of erosionGuaranteed insulation reliabilityMagnetic circuit rotating partsMagnetic circuit stationary partsEngineeringTurbine

The invention provides a direct drive permanent magnet wind generator, a direct drive permanent magnet wind generator system and a stator of the direct drive permanent magnet wind generator. The stator comprises a stator support, a stator iron core arranged on the peripheral wall of the stator support, and a paddle side tooth support, wherein the paddle side tooth support is arranged on the paddle side axial end face of the stator iron core, at least one air hole is formed in the peripheral wall of the stator support, and at least one second air hole is formed in the paddle side tooth support. The stator further comprises at least one air flow passageway used for communicating the first air holes with the second air holes, wherein the air flow passageways penetrate through the stator iron core. The micro-positive pressure technology is used in the stator and a rotor of the airborne wind turbine, and therefore a motor can dry itself in a self-adaption mode, external severe air flow is prevented from entering the motor, the service life of permanent magnet poles is prolonged, the insulation level reduction of devices inside the motor is prevented, the risk that the motor is corroded by severe air flow is lowered, and the insulation reliability is improved.

Owner:XINJIANG GOLDWIND SCI & TECH

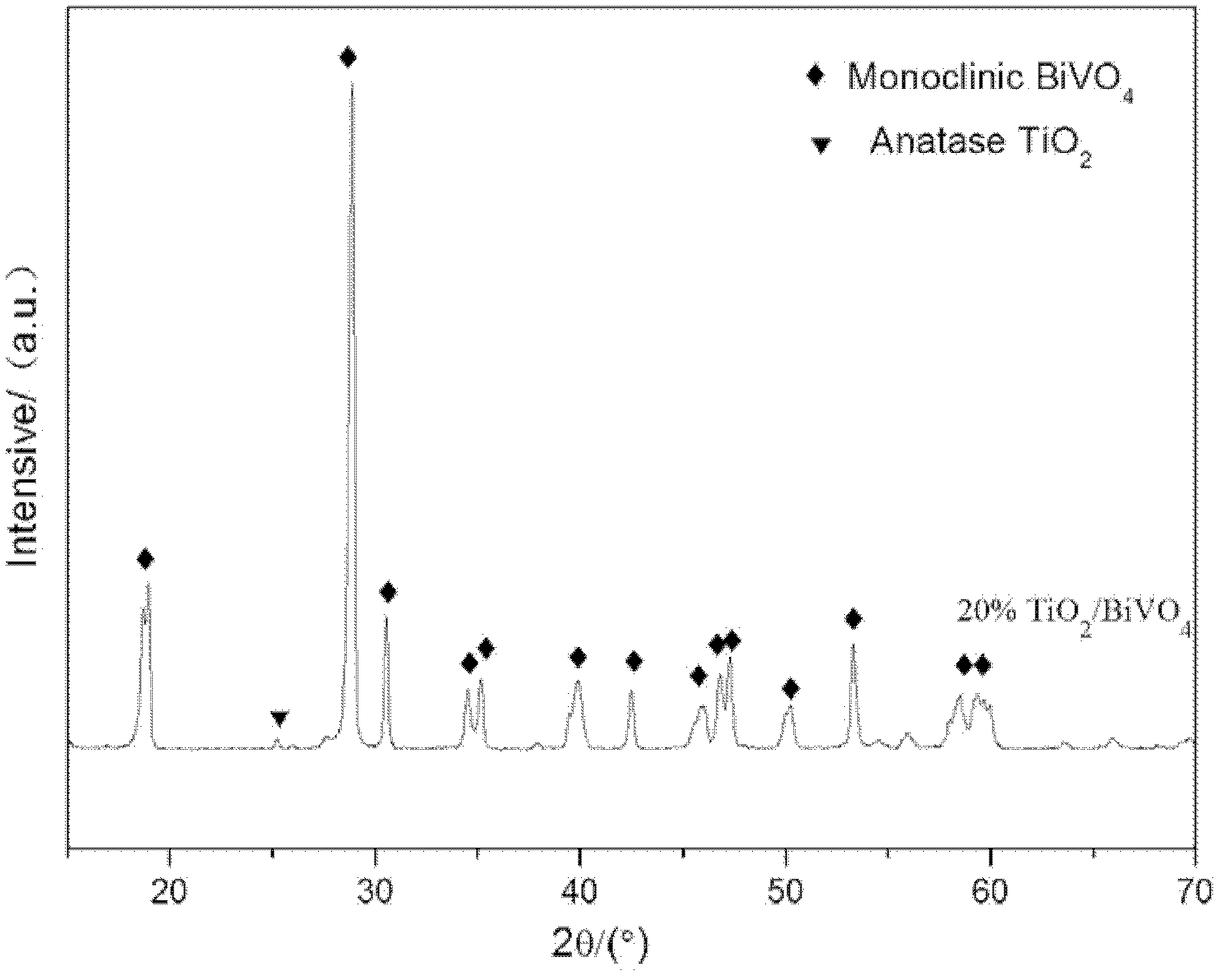

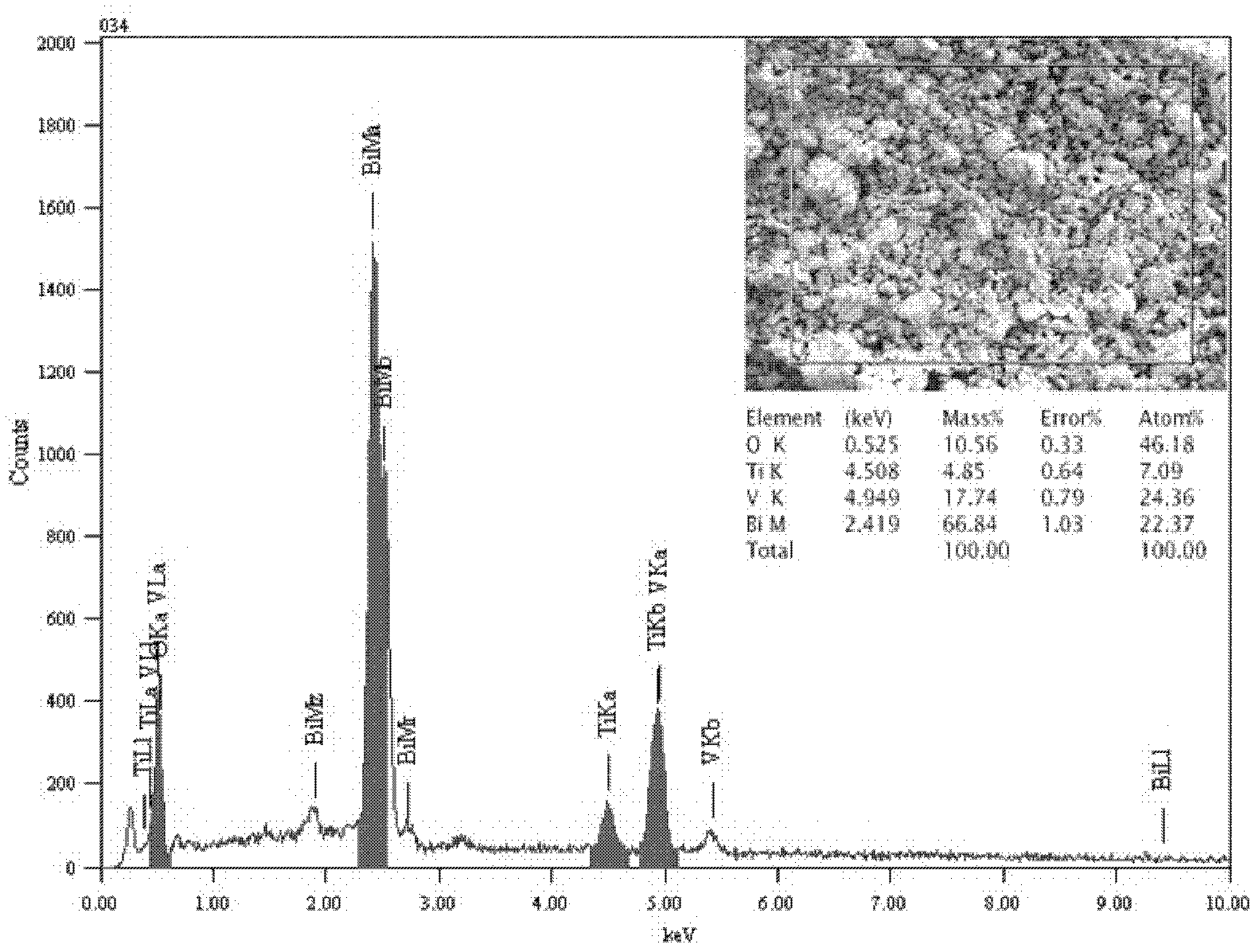

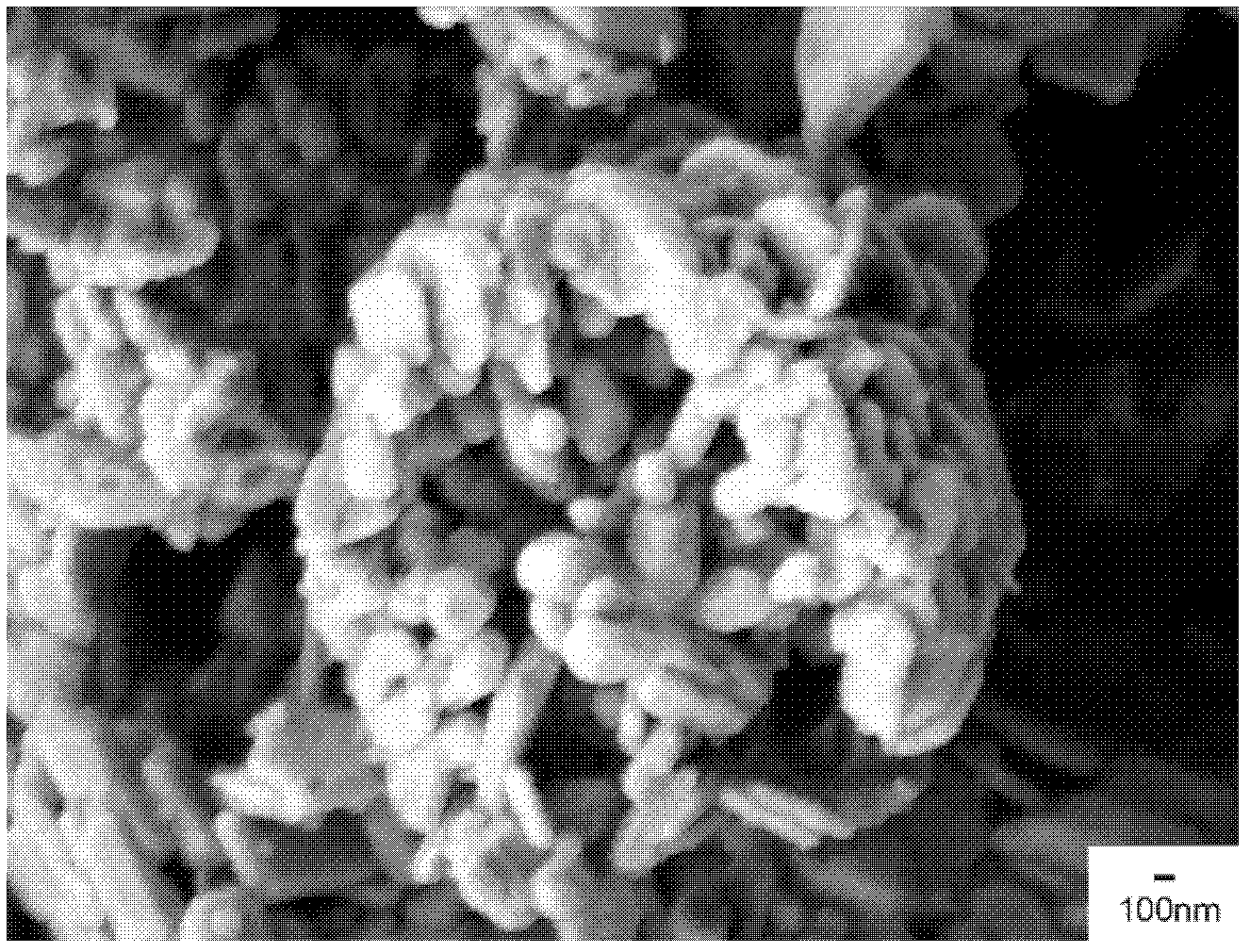

Method for preparing TiO2/BiVO4 composite photocatalyst by MH method

ActiveCN102580721AImprove photocatalytic performanceInhibitory complexWater/sewage treatment by irradiationCatalyst activation/preparationHydrothermal synthesisSalt solution

The invention discloses a method for preparing TiO2 / BiVO4 composite photocatalyst by a MH (microwave-hydrothermal) method. The method comprises the steps as follows: Bi(NO3)3 5H2O and (NH4)2TiF6 are resolved in HNO3 to form mother salt solution A, NH4VO3 is resolved in NaOH solution to form mother salt solution B, the mother salt solution A and the mother salt solution B are mixed uniformly to form precursor solution, the precursor solution is placed in a microwave hydrothermal reaction kettle for microwave hydrothermal reaction and is cooled after the reaction is over, and yellow sediment in the reaction kettle is taken out and is washed and dried. According to the invention, TiO2 / BiVO4 powder is synthesized quickly through a microwave-hydrothermal synthesis technology, and the photocatalysis performance of the powder is better because TiO2 particles are carried on the surface of BiVO4 to serve as an electron acceptor, and then compounding of a photon-generated carrier is inhibited, further the photocatalysis efficiency of pure-phase BiVO4 powder can be improved.

Owner:南通润能机械有限公司

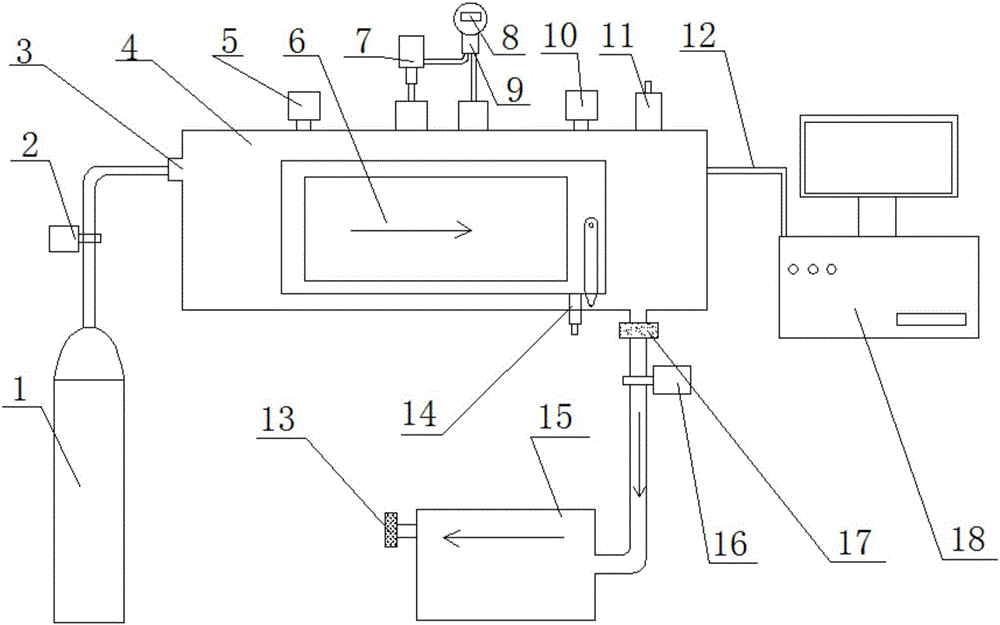

Device and method for stabilizing air pressure in sealed molding chamber for 3D printing of metal

InactiveCN105728726AReduced oxygen contentLower oxygen levelsAdditive manufacturing apparatusIncreasing energy efficiencyPositive pressurePressure sense

The invention discloses a device and method for stabilizing air pressure in a sealed molding chamber for 3D printing of metal. The device mainly comprises an oxygen content detecting device for detecting the content of oxygen in the molding chamber, a vacuumizing device for the molding chamber and a pressure sensing device for detecting air pressure in the molding chamber; and the oxygen content detecting device, the vacuumizing device and the pressure sensing device are controlled by the control device, and a way of simultaneously introducing inert gases into the molding chamber and vacuumizing is adopted, so that the content of oxygen in the molding chamber is kept to be reduced, and the air pressure is kept stable. Therefore, the stability and quality of an equipment molding process can be greatly improved, and the safety and reliability of a processing course can be ensured. The device and technical means of the method are simple, convenient and easy; the molding chamber works at positive pressure, so that oxygen in the atmosphere can be kept difficult to enter the sealed molding chamber; in addition, dust cannot be easily raised in the 3D printing process of the metal.

Owner:SOUTH CHINA UNIV OF TECH

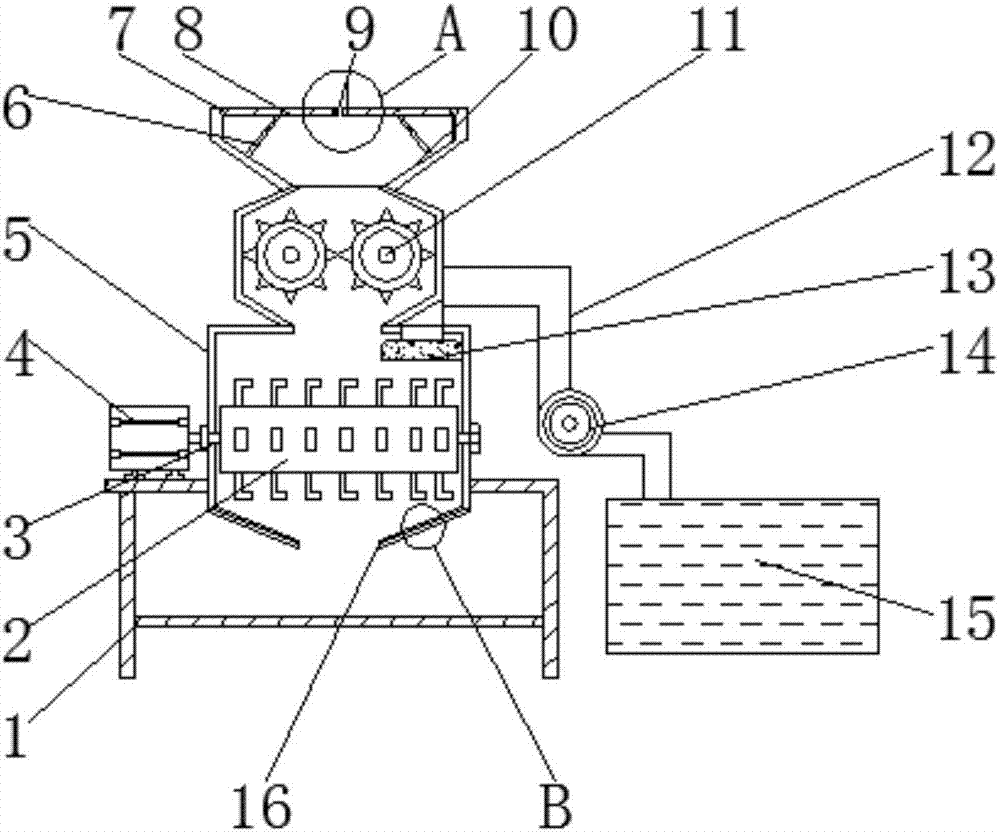

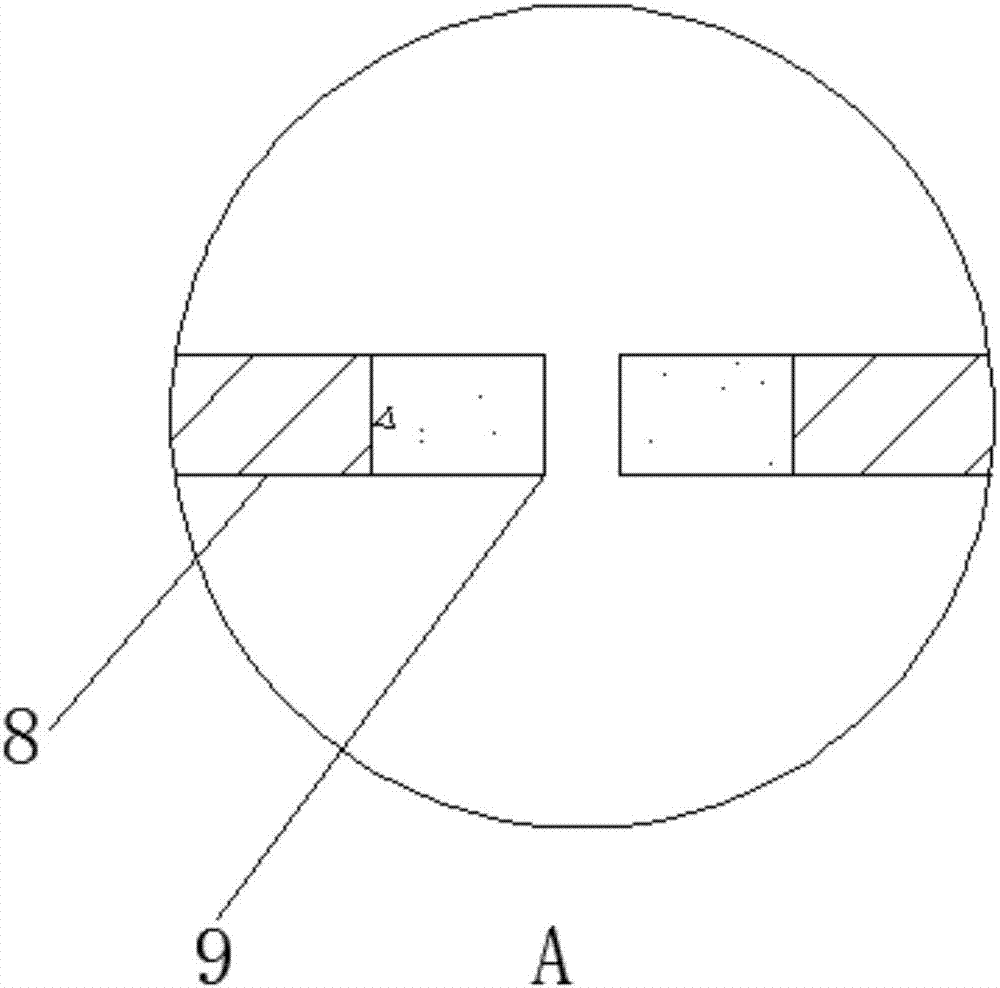

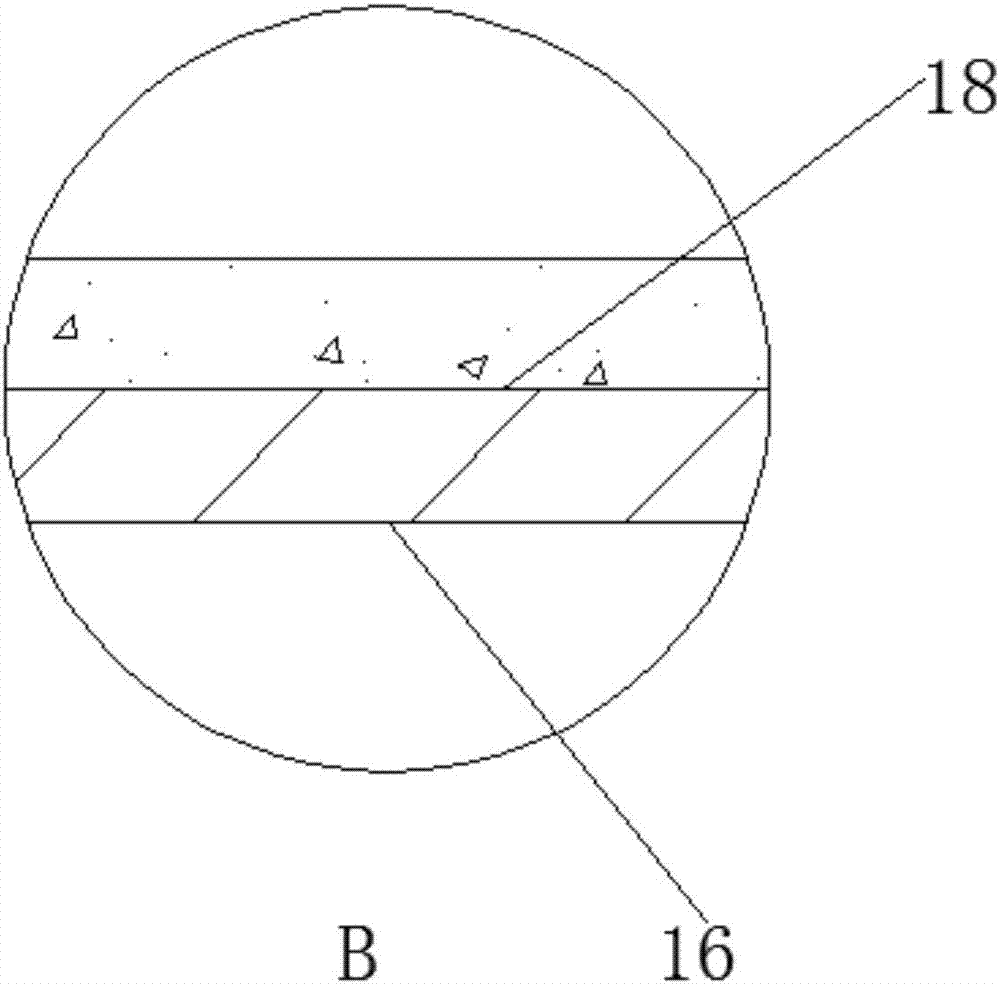

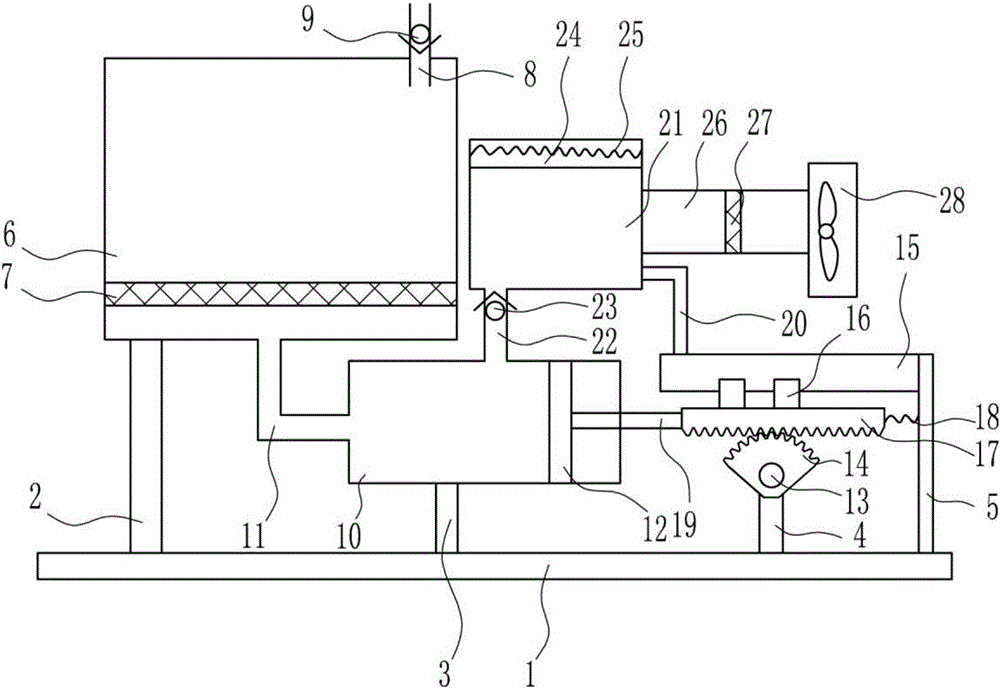

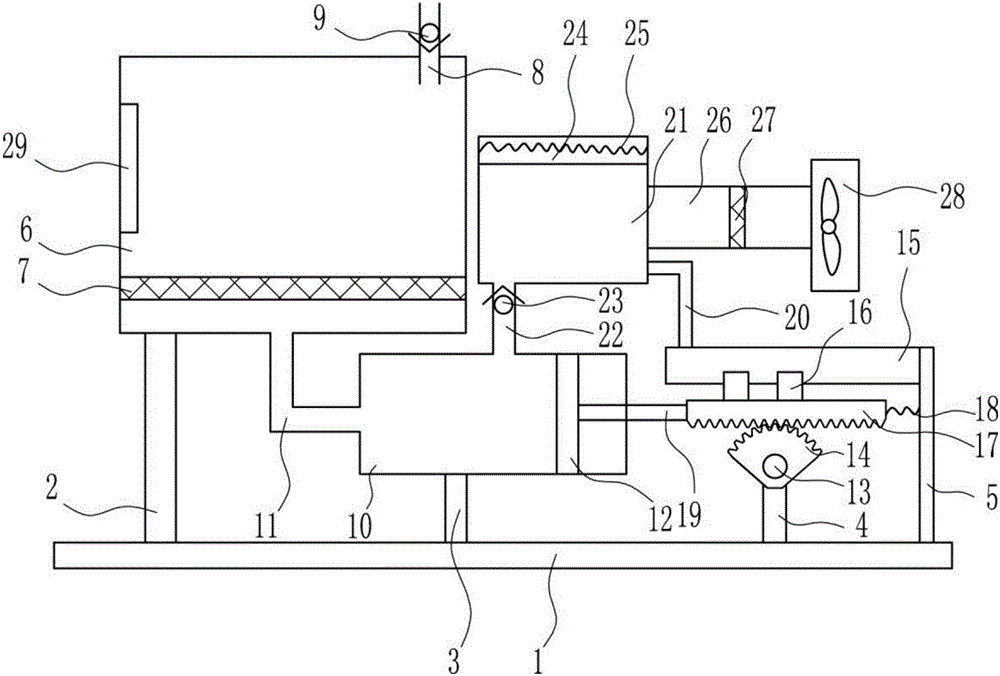

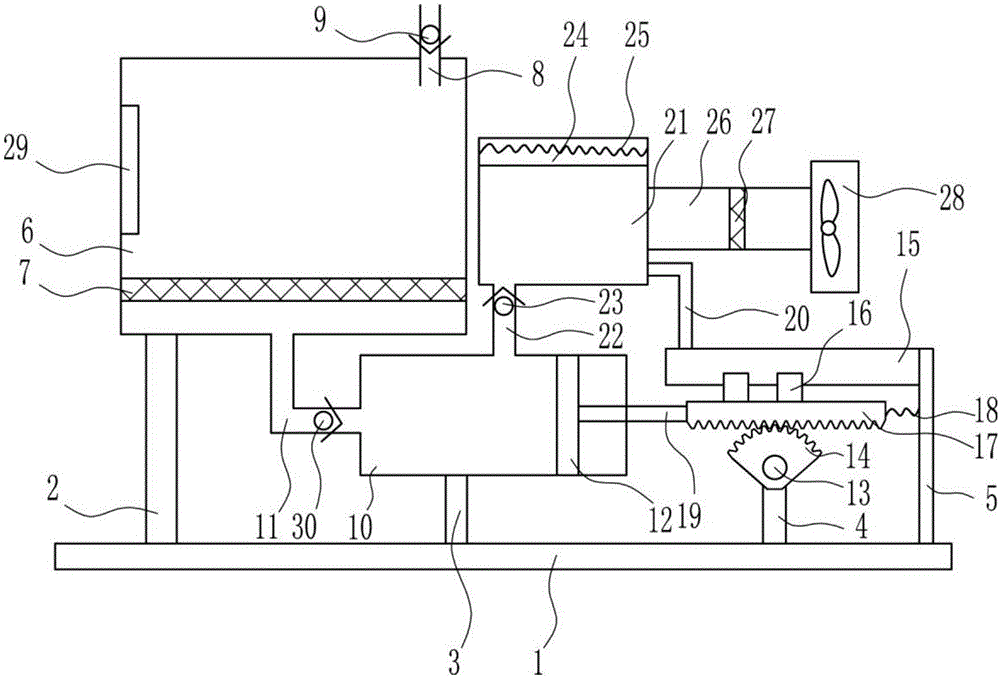

Efficient drying device for tea leaves

InactiveCN106643032AQuality assuranceEasy accessPre-extraction tea treatmentTea dryingEngineeringCheck valve

The invention relates to a drying device for tea leaves and especially relates to an efficient drying device for tea leaves. The technical problem to be solved by the invention is to provide the efficient drying device for the tea leaves, with the advantages of simple operation, dust prevention in the drying process of the tea leaves, capability of guaranteeing the quality of the tea leaves and high working efficiency. In order to solve the technical problem, the efficient drying device for the tea leaves provided by the invention comprises a base plate, a first support rod, a right bracket, a drying oven, a first filter screen, an exhaust pipe, a first check valve, a chamber, a first air inlet pipe, a piston, a motor, a fan-shaped gear, a slide rail, a slide block, a rack, a spring, a first connecting rod, an air collecting box, a shell, an electric heating wire, an air inlet pipe, a second filter screen and a fan, wherein the first support rod, a second support rod, a third support rod and the right bracket are successively arranged on the upper part of the base plate from left to right. The efficient drying device for the tea leaves can achieve the effects of simple operation, dust prevention in the drying process of the tea leaves, capability of guaranteeing the quality of the tea leaves and high working efficiency.

Owner:吴达君

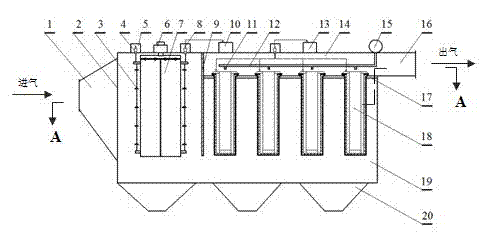

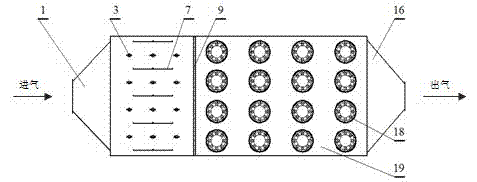

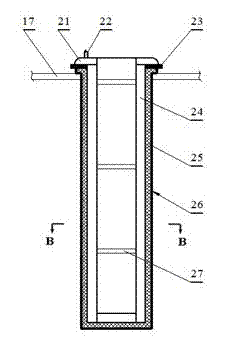

Electrostatic reinforcing bag type dust collector with reverse electric field

ActiveCN103084036AImprove breathabilityExtended service lifeCombination devicesExternal electric electrostatic seperatorBaghouseDust control

The invention relates to an electrostatic reinforcing bag type dust collector with a reverse electric field. The electrostatic reinforcing bag type dust collector adopts the technical scheme that an inlet box (1) and an outlet box (16) are correspondingly and fixedly connected with the inlet end and the outlet end of a dust collector body (2); the dust collector body (2) adopts a structure that the dust collector body (2) is divided into a dust precharging region and a dust filtering region by using a spoiler (9); the dust precharging region is arranged in the structure of the dust collector body (2) or in the middle part inside a shell of the dust collector body (2) along an air inlet direction; the dust filtering region is symmetrically arranged at two sides of the dust precharging region; corona electrode wires (3) of the dust precharging region and dust collection pole plates (7) are equidistantly arranged in parallel at intervals; the dust filtering region is divided into an air purifying chamber (14) and a filtering chamber (19) by a pattern plate (17) in the dust filtering region; a bag mouth of a filter bag unit (18) formed in the filtering chamber (19) is communicated with the air purifying chamber (14); and an outlet of the air purifying chamber (14) is the outlet end of the dust collector body (2). The electrostatic reinforcing bag type dust collector has the characteristics of high dust collection efficiency, good ash removal effect and no phenomenon of bag burning.

Owner:武汉景弘生态环境股份有限公司

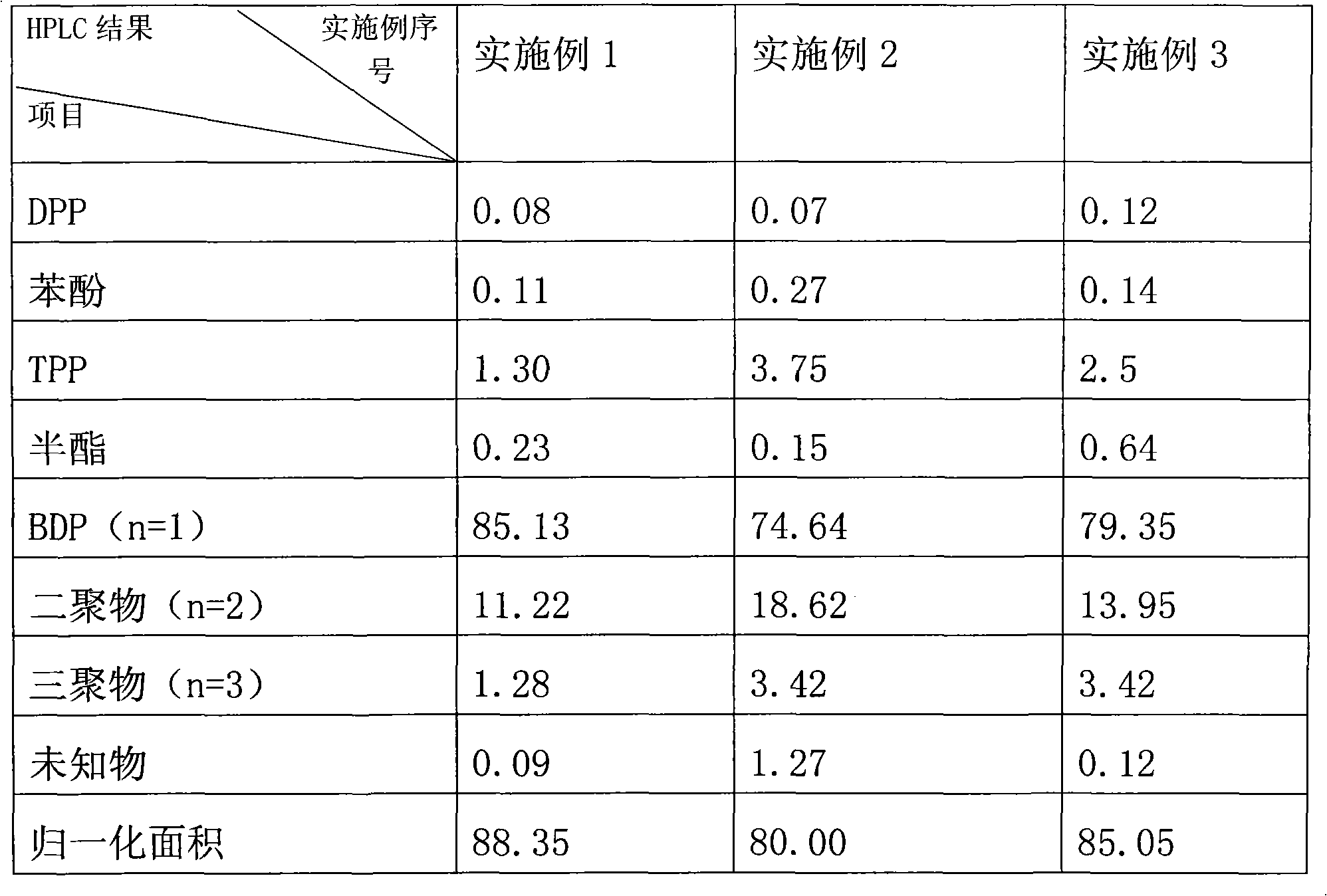

Preparation of bisphenol A bis(diphenyl phosphoester )

ActiveCN101348500AEasy accessNot easy to produceGroup 5/15 element organic compoundsDiphenyl phosphateSocial benefits

The invention provides a method for preparing bisphenol A bi-(diphenyl phosphate). The method is characterized in that the proper amount of bisphenol A and phosphorus oxychloride is added in a reactor, and subjected to heating and stirring until bisphenol A is completely dissolved, and dissolved materials are obtained; the proper amount of Lewis acid and phosphorus oxychloride is added in a reactor provided with a chlorine hydride absorption device and subjected to quick heating, the dissolved materials are added in the reactor, the excessive phosphorus oxychloride is distilled off after the reaction finishes, and the proper amount of phenol is added, the temperature is adjusted until the reaction finishes, and the finished product is obtained after washing and debenzolization. The product prepared by the process of the invention has the advantages of having good product quality, lowering labor intensity, improving working environment and having better economic and social benefits.

Owner:山东旭锐新材股份有限公司

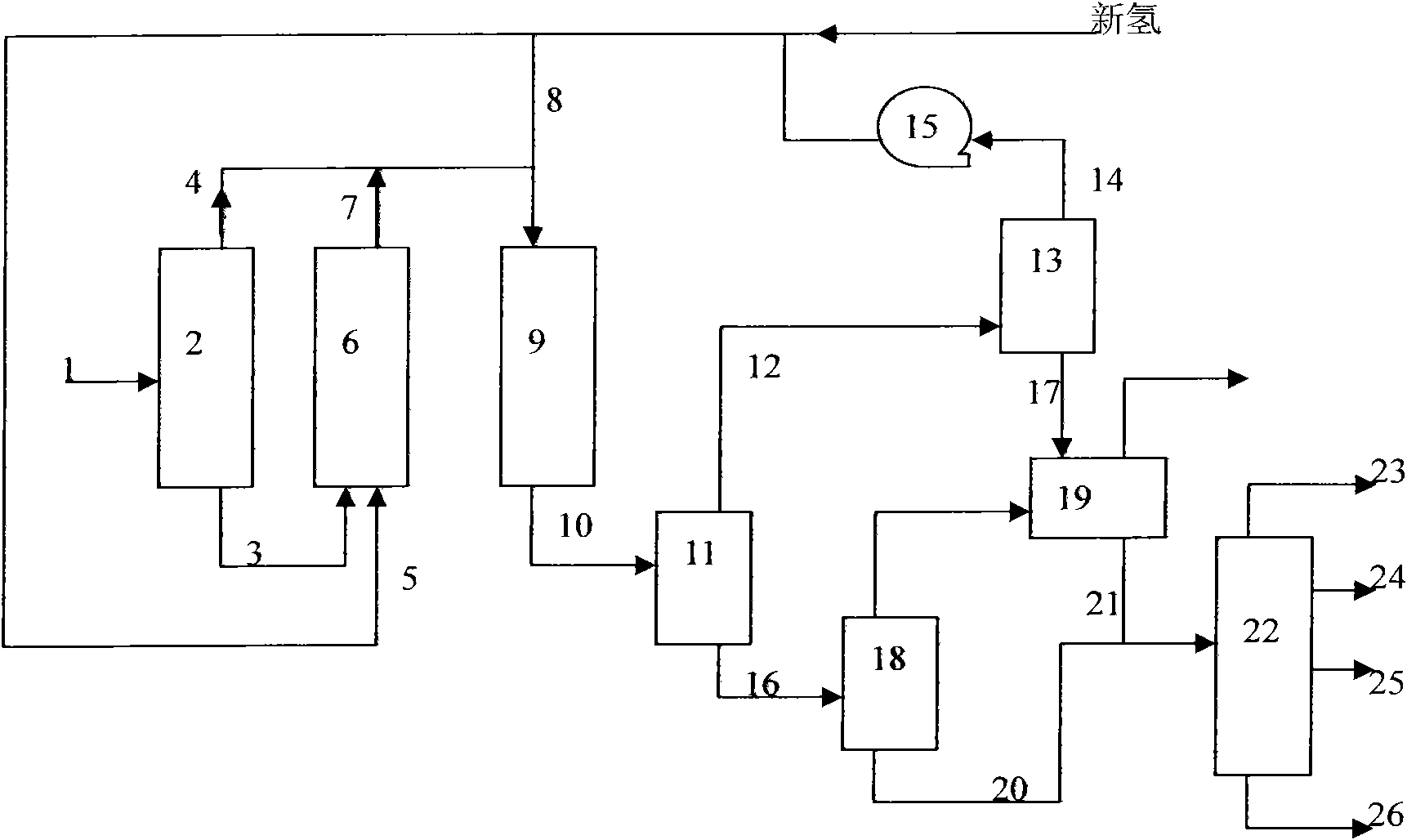

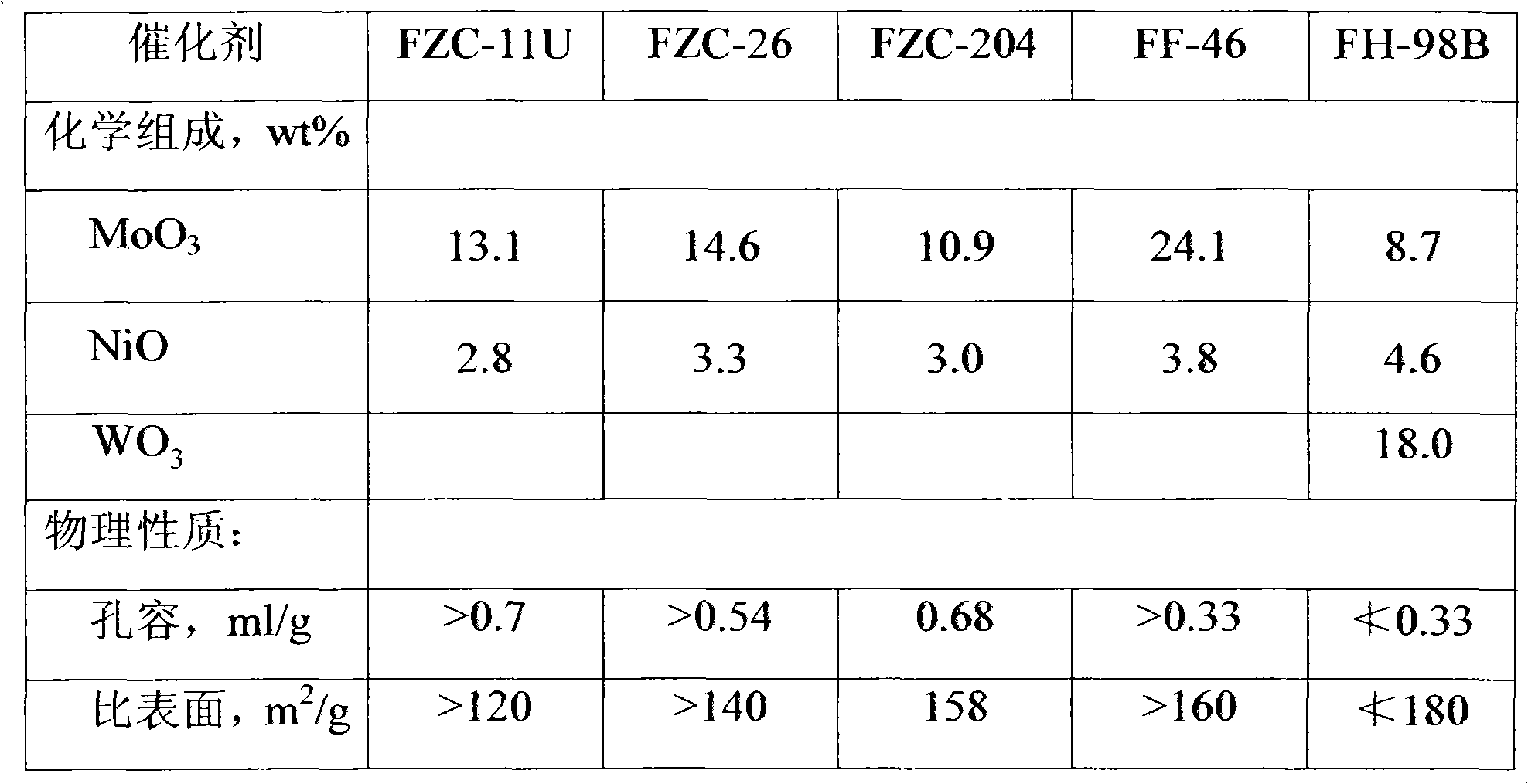

Shale oil processing method

ActiveCN102465015AEasy to settleDifficult to enterTreatment with hydrotreatment processesHydrogenSulfur

The invention discloses a shale oil processing method, comprising the steps of: segmenting shale oil into light components and heavy components, leading the heavy components and hydrogen to pass through an up-flow type hydrogenation reactor, leading an effluent and the light components as well as hydrogen to pass through a conventional hydrorefining reactor for reaction, and separating and distilling a hydrorefined effluent to obtain a light product. According to the method disclosed by the invention, the shale oil is firstly segmented into the light components and the heavy components so as to make metal, colloids and other easily precipitated impurities in the shale oil enter the heavy components, and then the characteristic of the up-flow type reactor is utilized to uniformly precipitate the colloids, the metal and other pollutants in a catalyst bed, so that the excessive increase of the pressure drop in the catalyst bed is effectively slowed down; a material flow in which most of impurities are removed is subjected to the conventional hydrorefining, on the one hand, sulfur, nitrogen and other impurities in the shale oil can be removed, on the other hand, the operating cycle of the hydrorefining catalyst can be prolonged, and thus, an ideal processing effect is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

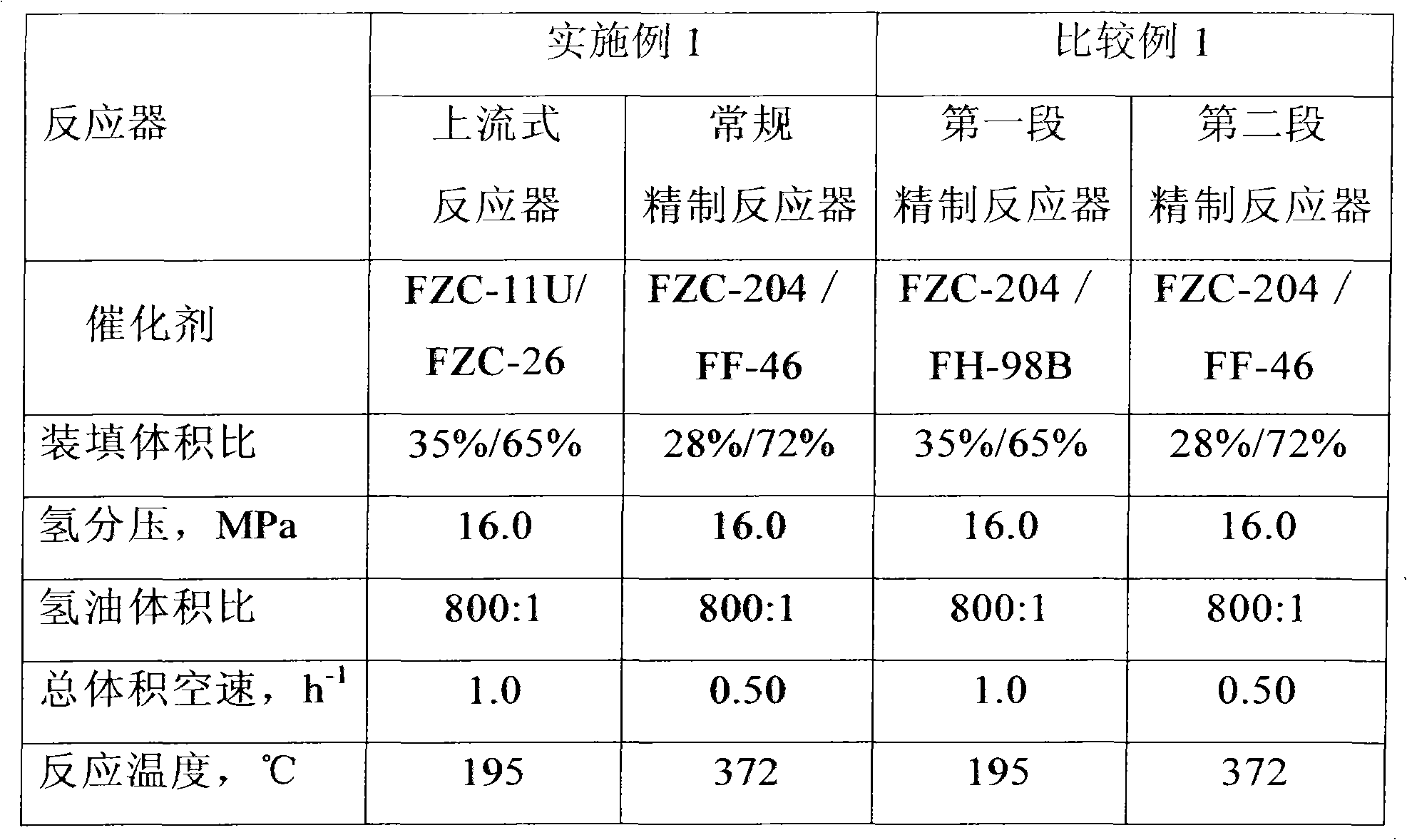

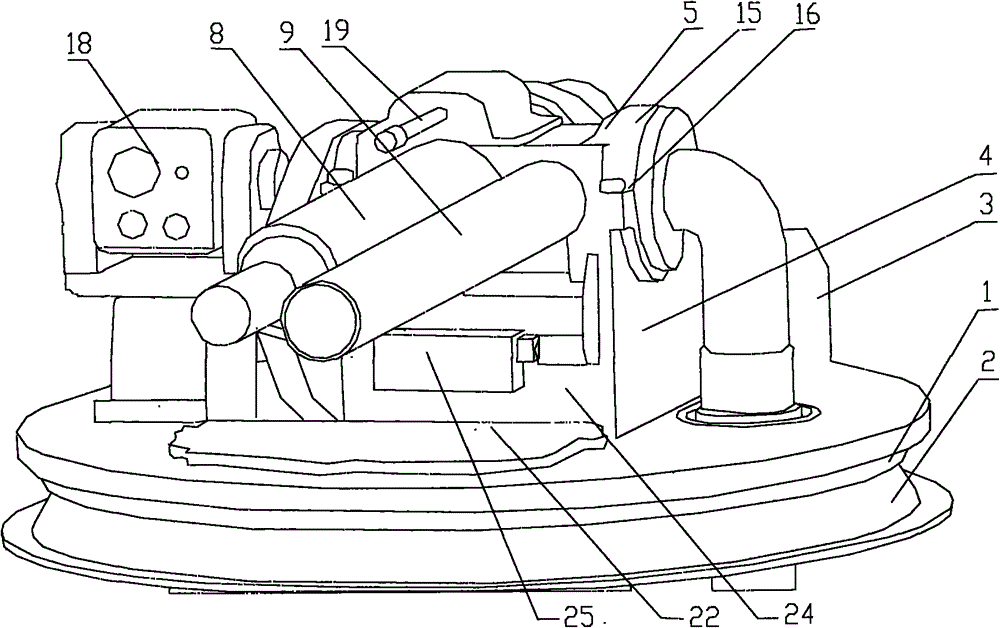

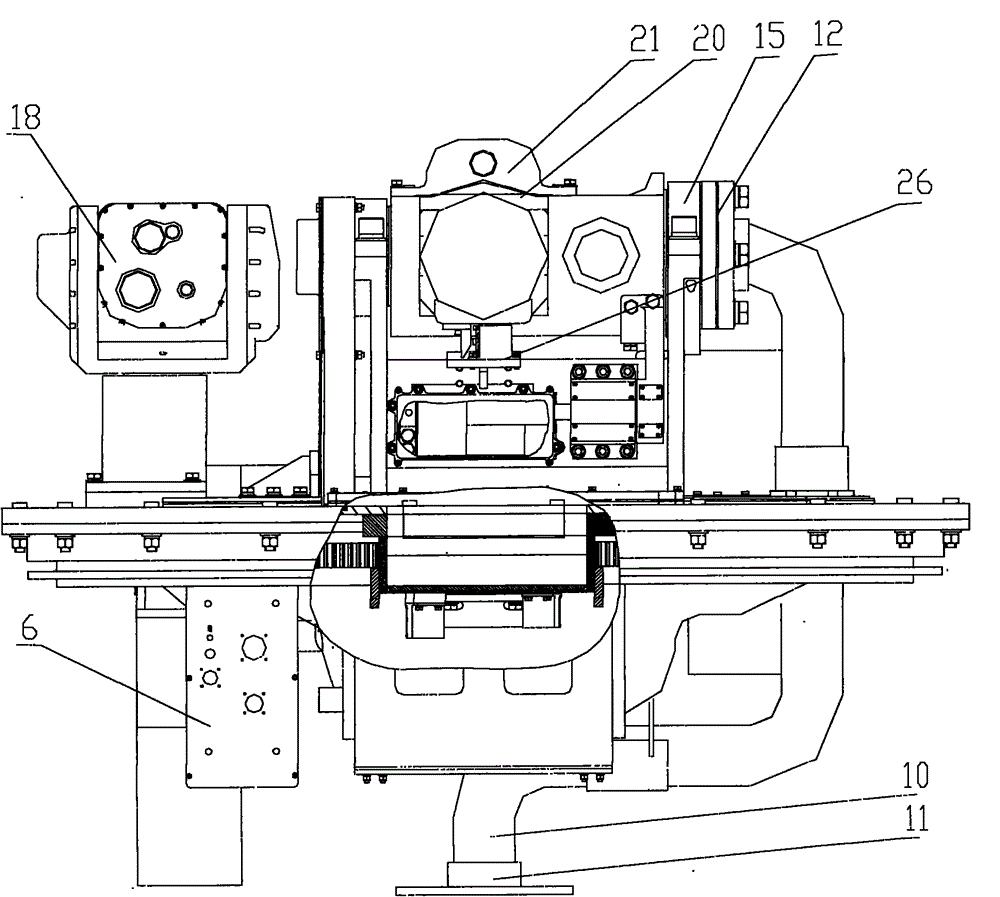

Fire extinguishing gun turret

InactiveCN104415485AHigh degree of automationPrecise aimingFire rescueSteering wheelShortest distance

The invention discloses a fire extinguishing gun turret, and belongs to the technical field of fire-fighting equipment. The fire extinguishing gun turret comprises a rotating gun adjusting module, a pitching gun adjusting module and a shooting module, wherein a compound motion of peripheral rotation and vertical pitching of the shooting module is achieved by virtue of the rotating gun adjusting module and the pitching gun adjusting module through electric control, so that automatic and accurate aiming of the shooting module is realized and automation degree is high; in addition, the shooting module not only can launch fire extinguishing bombs for long-distance fire extinguishing but also can jet high-pressure water for short-distance fire extinguishing by virtue of the common-frame setting of a pulse gun and a water gun, so that the application scope of the fire extinguishing gun is effectively extended; in addition, by virtue of the design of the installation structures of the pulse gun and the fire gun, the waterproof and dustproof structures of various important parts as well as the submerged design of a steering wheel and an electrical box body, and the like, the fire extinguishing gun turret is impact and reasonable in structure, good in assembling processing property and high in reliability; the fire extinguishing gun turret not only can be used for reducing production cost but also can be used for lowering the difficulty of later maintenance, and various properties reach advanced level in the field.

Owner:CHANGAN AUTOMOBILE (GRP) CO LTD

Antiseptic super-hydrophobic paint for electric power system fittings and preparation method

ActiveCN103642378AReduce manufacturing costSimple processAnti-corrosive paintsPolyurea/polyurethane coatingsBenzeneSolvent

The invention relates to an organic nano anticorrosion paint and its preparation method, and especially provides an antiseptic super-hydrophobic paint for an electric power system fittings and its preparation method, the antiseptic super-hydrophobic paint comprises the following components by weight: 11-20 parts of amino-modified nano fluorine silica, 40-50 parts of dispersant, 0.6-3 parts of carbon black. 3-6 parts of mica powder, 5-10 parts of titanium dioxide, 0.3-0.6 parts of antifoaming agent, 0.2-0.5 parts of wetting agent, 0.5-2 parts of zinc powder, 25-40 parts of membrane-forming substrate and 2-4 parts of curing agent; wherein the amino-modified nano fluorine silica accounts for 10-20% of total mass; the amino-modified nano fluorine silica takes nano silica, KH550, a fluorosilicone coupling agent, water and a solvent as raw materials, and the materials are charged according to the proportion of 5-10: 0.2-0.3: 0.5-0.8: 0.05-0.1: 20-25, the materials are performed with a stirring reaction for 5 hours at 75-85 DEG C, and filtered and dried to obtain the product. The solvent is acetone, ethanol or benzene. The preparation method has the advantages of no expensive equipment, simple process, low production cost and good hydrophobic anticorrosion effect.

Owner:CHONGQING UNIV +1

Multifunctional assembling and pouring type templated block, use method and use thereof

InactiveCN102444233ASpeed up and simplify construction proceduresUnified quality standardsWallsSound proofingWhole bodyEngineering

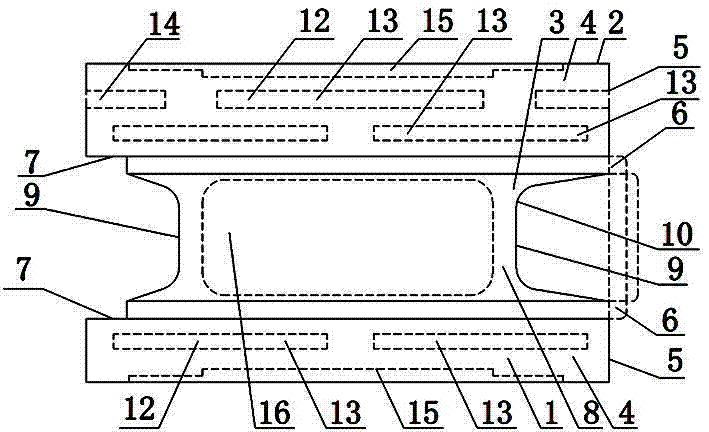

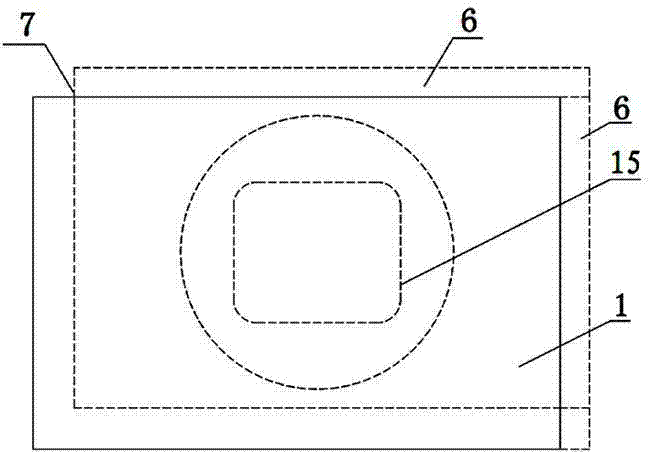

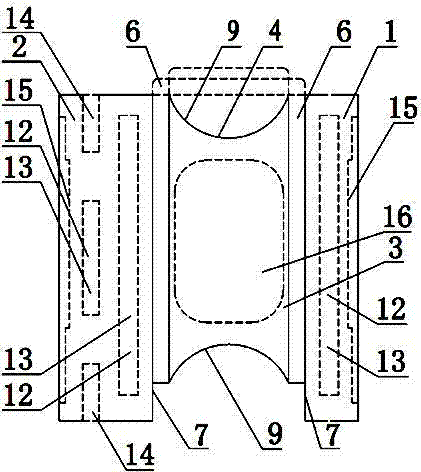

The present invention discloses a multifunctional assembling and pouring type templated block, a use method and a use thereof. The multifunctional assembling and pouring type templated block comprises a front panel (1) and a rear panel (2), wherein the front panel (1) and the rear panel (2) are parallel to the wall body. The front panel (1) and the rear panel (2) are connected by a middle plate (3) arranged between the two panels. The side surfaces of the front panel (1) and the rear panel (2) are provided with convex ribs (6) or notches (7). In the two relatively-arranged side surfaces of the middle plate (3), one side surface is arranged into a whole body groove (9), and the other side surface is arranged into a whole body groove (9) or a flat surface or a convex block. The block of the present invention has the following advantages that: the mutual clamping and assembling structure is adopted, the block can be applicable for a plurality of uses, the block has advantages of small volume, light weight, quick construction, insulation and water proofing, low construction cost, good earthquake-proof structure of the construction, energy saving, environmental protection, and quality standardization; with the block, the architectural industrialization is easily achieved.

Owner:王小松

Waterproof self-cleaning GRC (glass fiber reinforced concrete) product and preparation method thereof

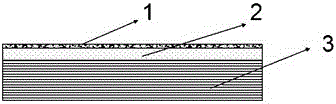

The invention relates to a building external wall decorative product, in particular to a waterproof self-cleaning GRC (glass fiber reinforced concrete) product.The waterproof self-cleaning GRC product comprises a self-cleaning coating (1), a GRC internally-doped waterproof decoration finish layer (2) and a GRC structural layer (3).The waterproof self-cleaning GRC product has the advantages that a hydrophobic protective agent is added into a GRC finish material and is distributed in voids produced after cement hydration reaction, so that moisture entering is prevented effectively; since the finish layer is applied with the contamination-resistant self-cleaning coating based on a waterborne inorganic binder, GRC has the waterproof, contamination-resistant and self-cleaning functions, the organic coating is prevented from being decomposed by a photocatalyst, and service life of the GRC is prolonged; the waterproof self-cleaning GRC product is simple in technology and high in economic and environmental benefits, thereby achieving high added-value resource utilization.

Owner:NANJING BEILIDA NEW MATERIAL SYST ENG

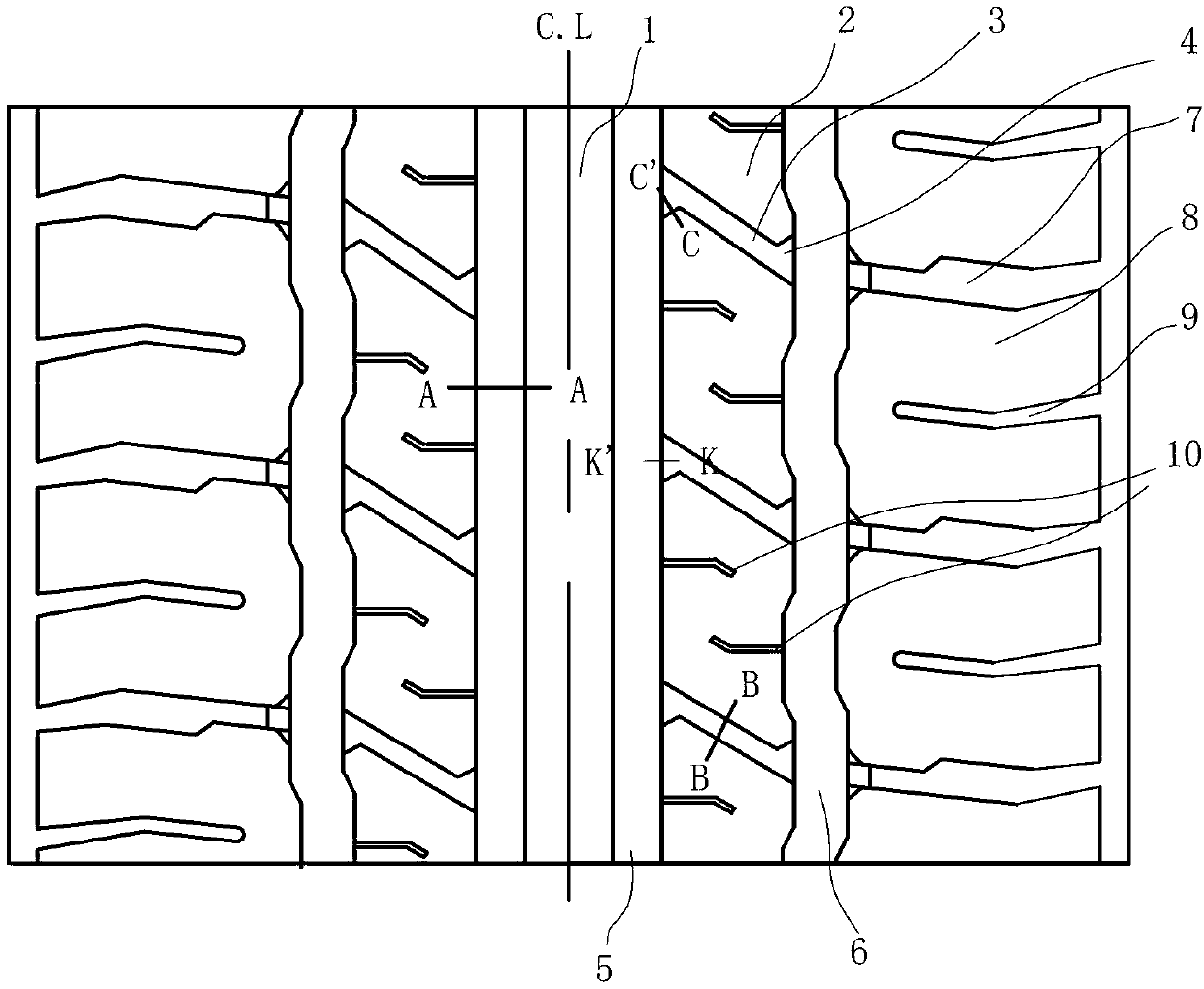

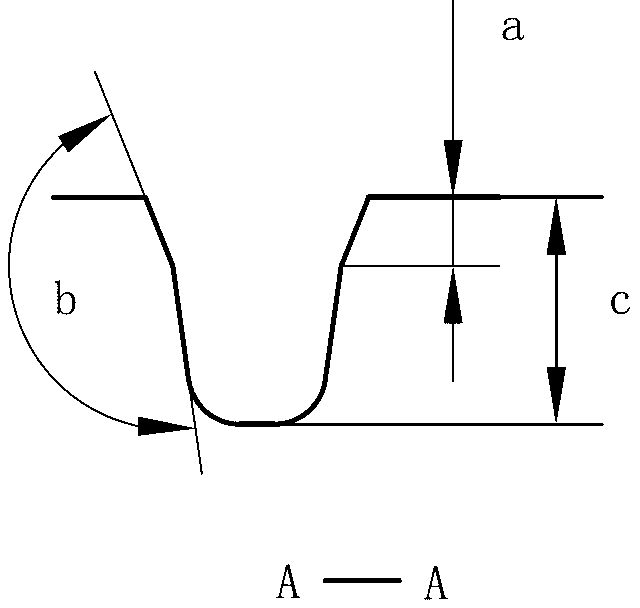

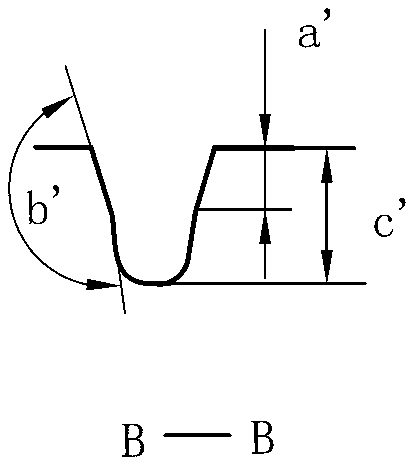

Stone-clamping preventing tyre

InactiveCN102887039AEasy to excludeImprove anti-rock performanceTyre tread bands/patternsSurface patternMain channel

Owner:CHENG SHIN RUBBER XIAMEN IND

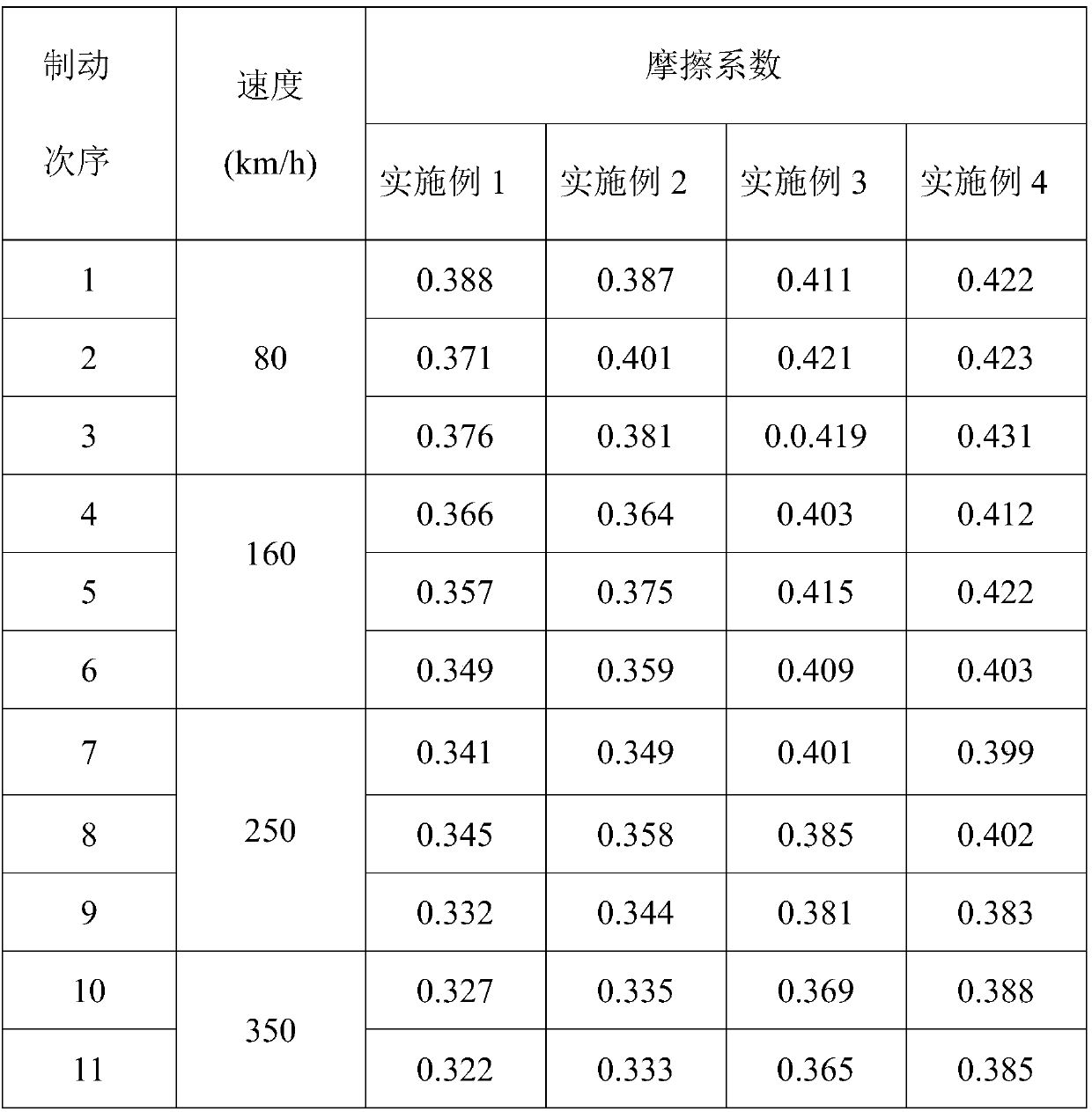

Powder metallurgy friction material for high-speed train braking and preparation method of powder metallurgy friction material

InactiveCN109518100AImprove high temperature friction performanceImprove self-shear strength and compressive strengthPowder metallurgyCopper plating

The invention relates to the technical field of brake materials, in particular to a powder metallurgy friction material for high-speed train braking and a preparation method of the powder metallurgy friction material. The powder metallurgy friction material is prepared from the following raw materials: copper powder, iron powder, copper-plated flake graphite, copper-plated graphite granules, chromium iron powder, molybdenum disulfide powder and alumina fiber through a powder metallurgy process. The powder metallurgy friction material has good mechanical properties, and is stable in friction coefficient, small in abrasion loss and good in thermal failure resistance; through the adopted raw materials and the ratio, the friction material with excellent properties can be prepared at the relatively-low sintering pressure and temperature, energy consumption is saved, a preparing process is simple and easy to control, the performance is excellent, and good application prospects are achieved.

Owner:BEIJING TIANRENDAOHE NEW MATERIAL CO LTD

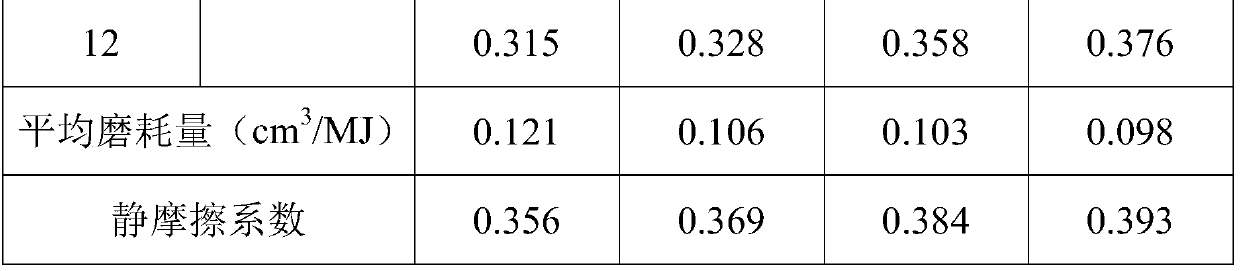

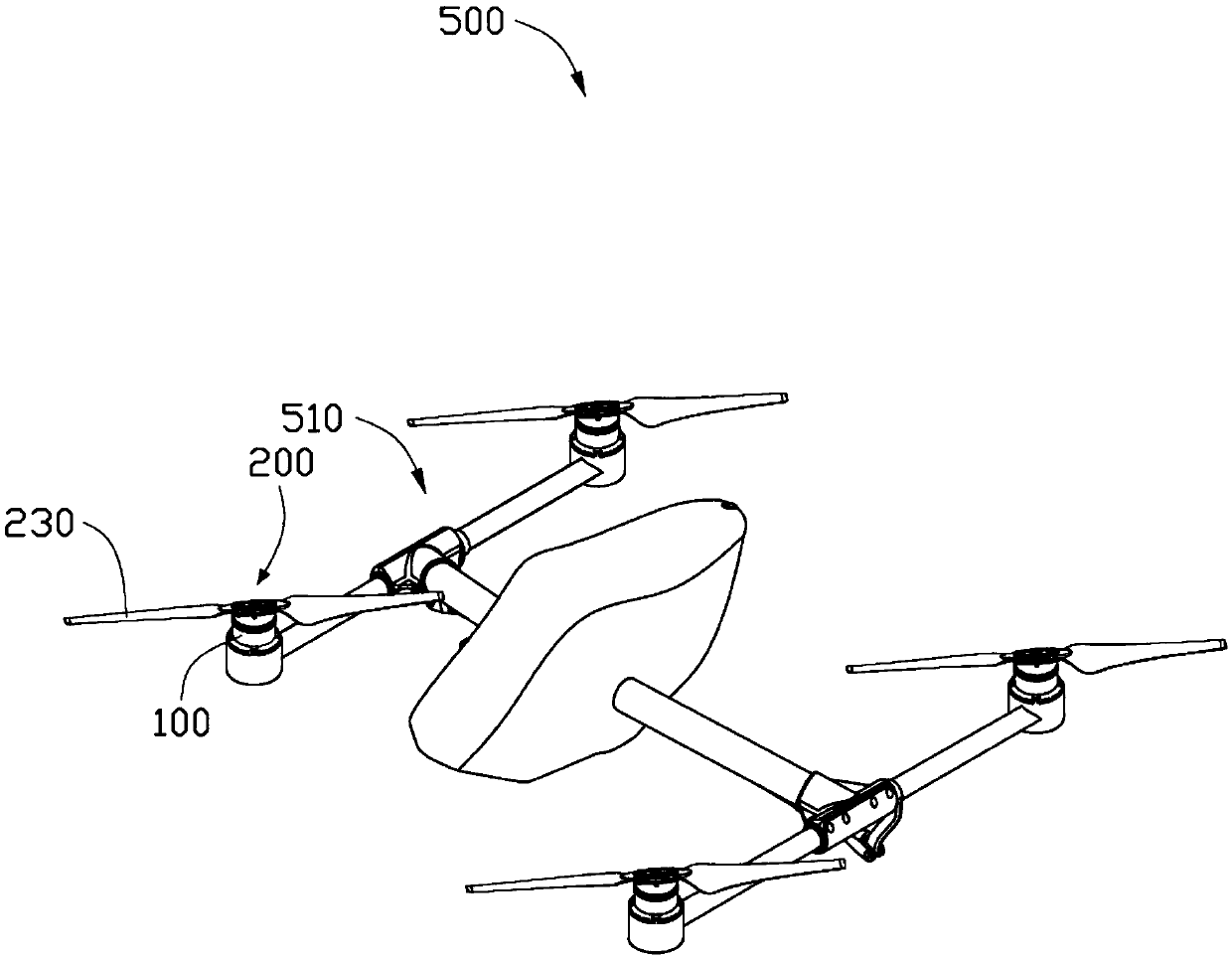

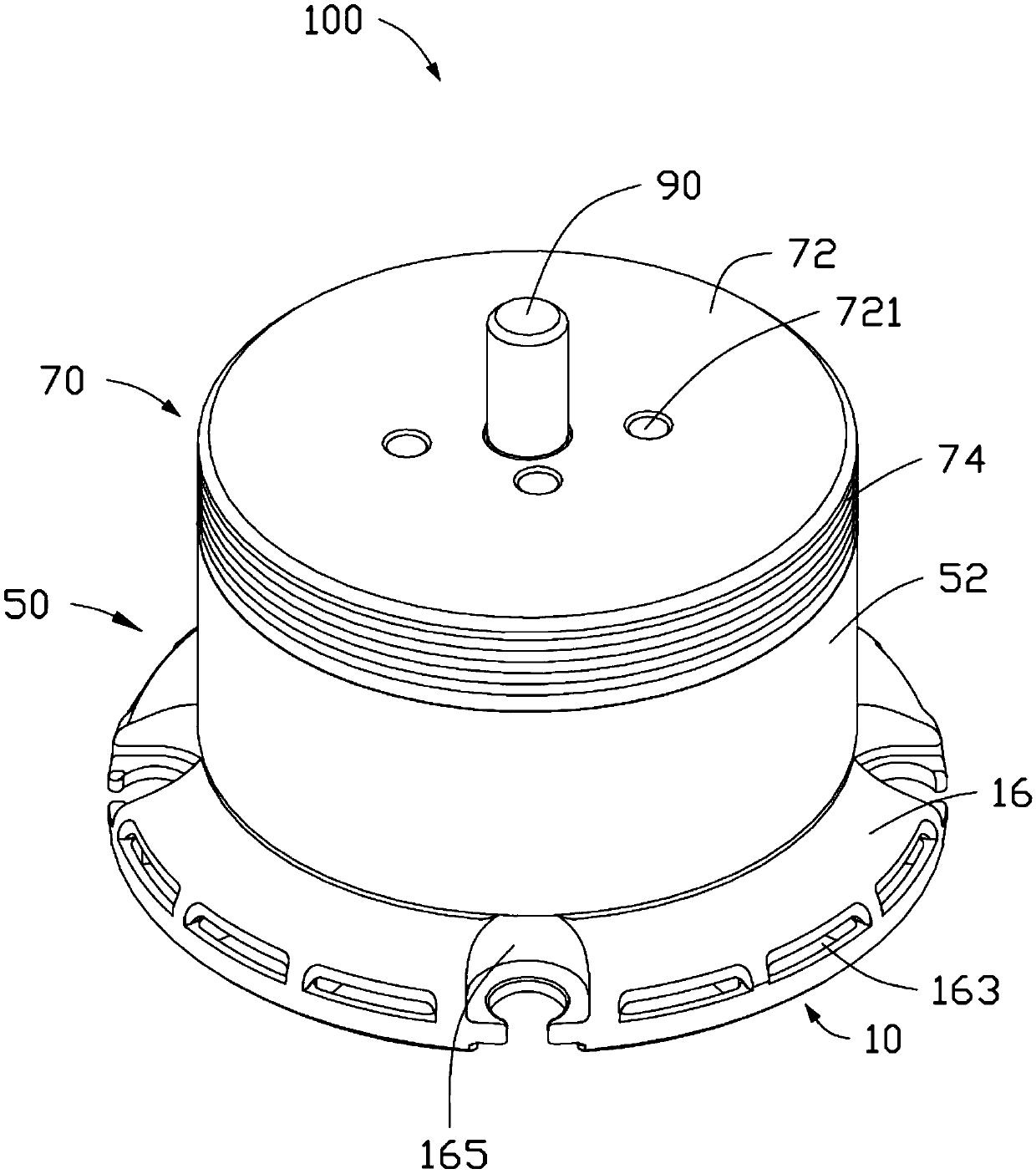

Motor, power device and aircraft using power device

ActiveCN105518980ASmooth runningImprove cooling efficiencyCooling/ventillation arrangementPower plant typePropellerMotive power

The invention relates to a motor, a power device and an aircraft using the power device. The aircraft comprises an aircraft body, a motor arranged on the aircraft body and propellers mounted on the motor, wherein the motor is formed by a stator arranged on the aircraft body, a rotor rotationally covering the stator and a cover body arranged on the rotor; the cover body has blades; and a slit is formed in the cover body. When the motor operates, the rotor drives the cover body to rotate; rotation of the blades enables air in the rotor to be discharged out of the slit and take away heat produced by the motor. The aircraft and the motor have high heat radiation efficiency and are dustproof.

Owner:SZ DJI TECH CO LTD

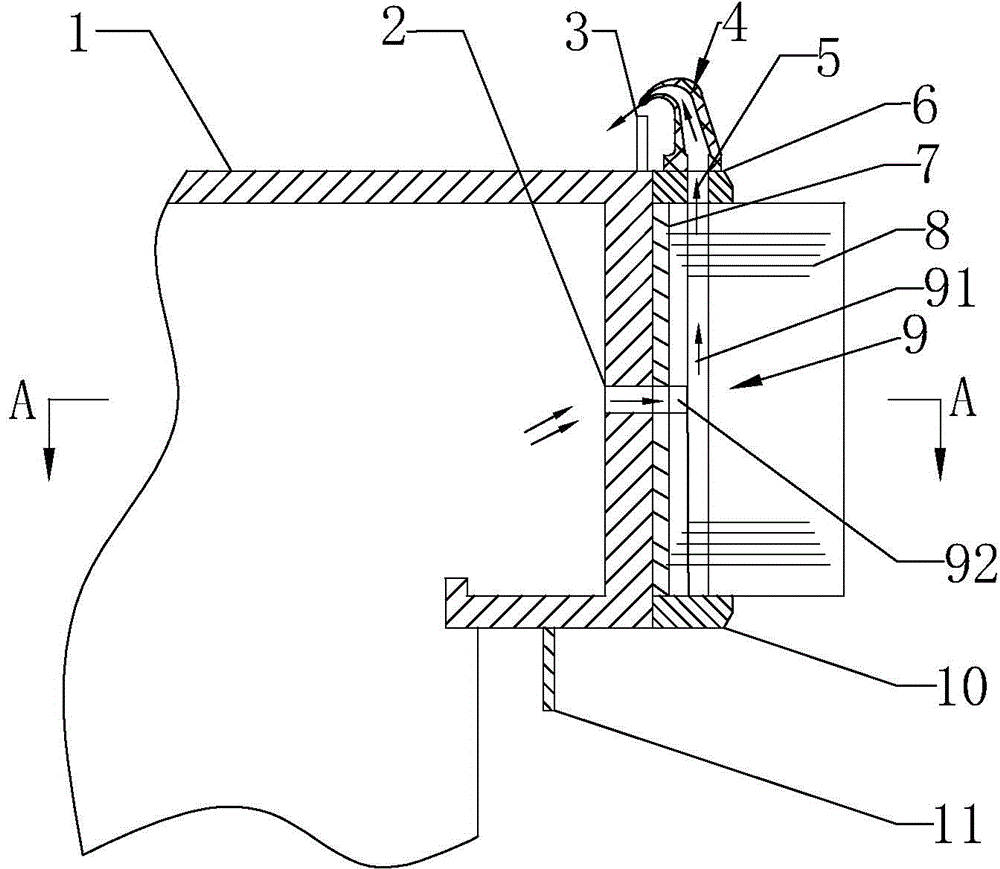

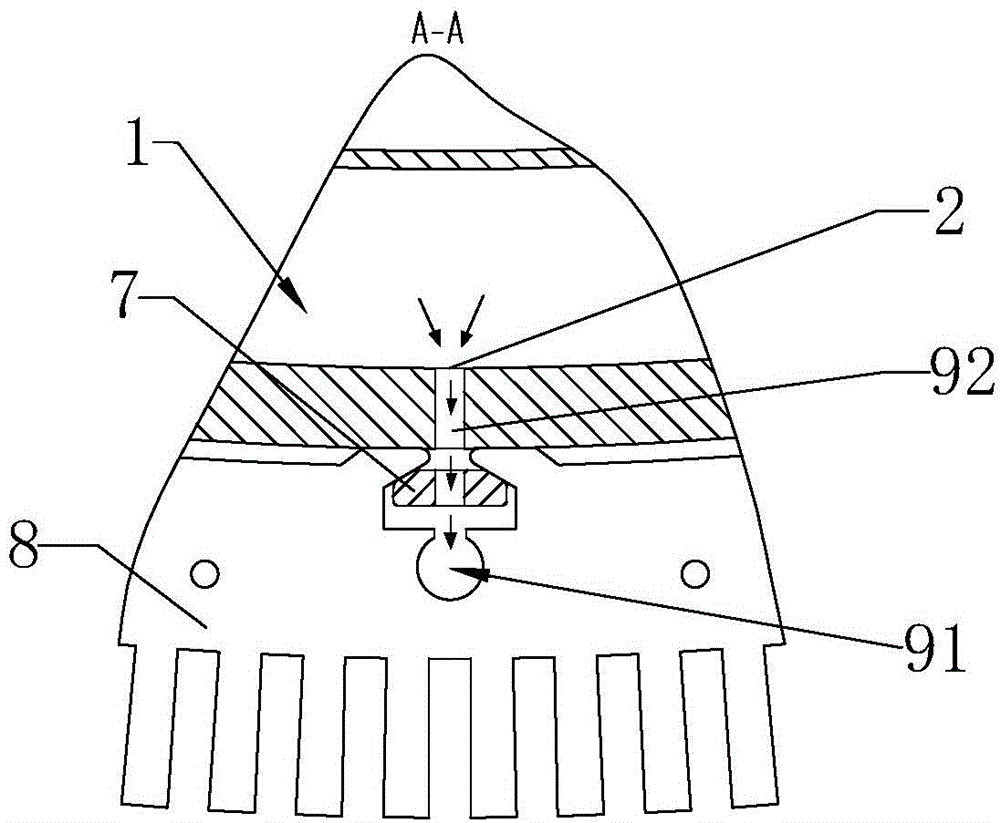

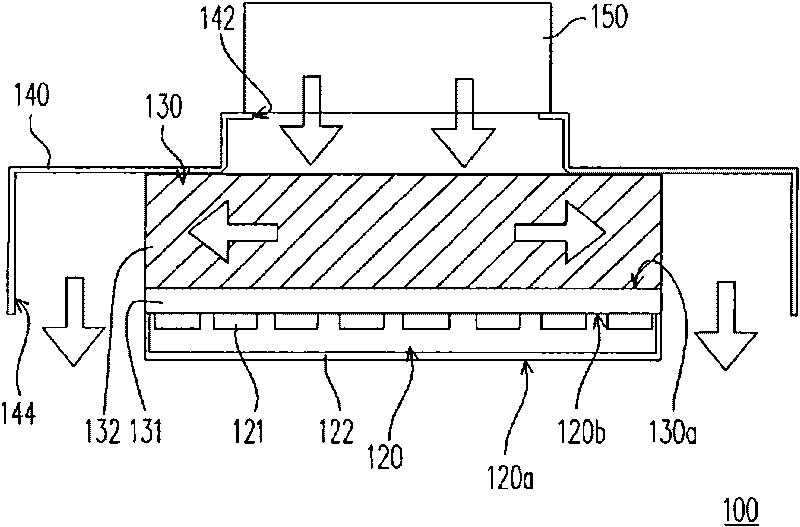

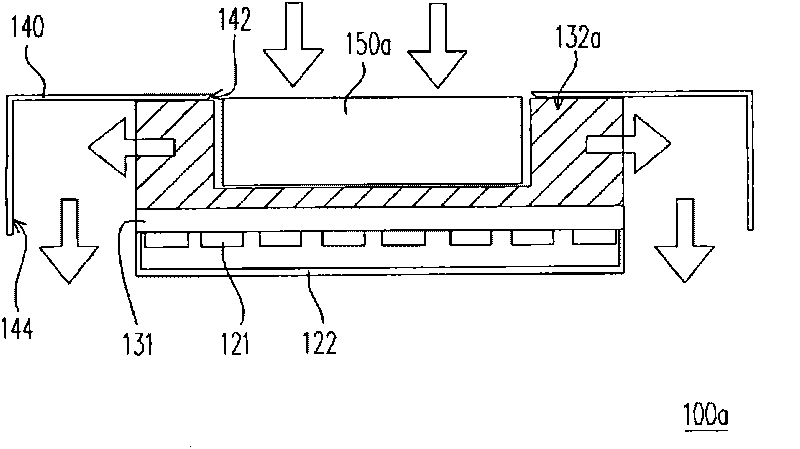

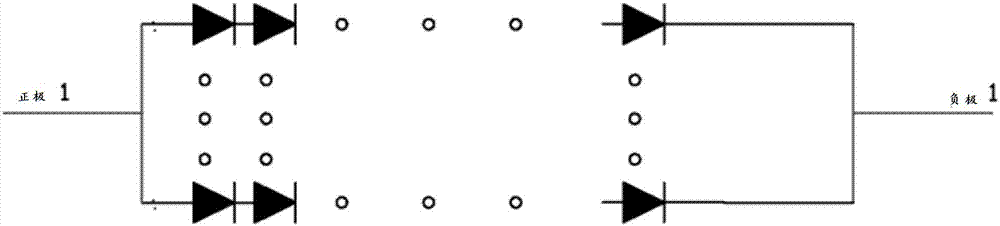

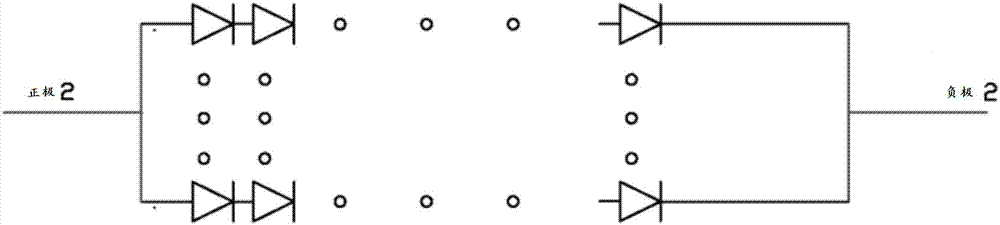

Lighting module and lighting system

InactiveCN101749555ADifficult to enterAvoid enteringPoint-like light sourceSemiconductor/solid-state device detailsEffect lightHeat sink

The invention discloses a lighting module, which includes a light source, a heat sink, a diversion shell and a fan. The light source is provided with an extraction surface and a bottom surface relative to the extraction surface, and is suitable for providing beams emitted from the extraction surface. The heat sink is arranged at the bottom surface of the light source, and includes a heat radiation block which is provided with a heat radiation surface; wherein the heat radiation surface is opposite to the bottom surface. The diversion shell is arranged in the heat sink and is provided with a module inlet and a module outlet. The fan is arranged in the diversion shell or the heat sink, and is used for driving an air flow to pass through the module inlet, the heat sink and the module outlet in sequence. The diversion shell is suitable for leading the flowing direction of the air flow passing through the module outlet to be same with the extraction direction of the beams emitted from the extraction surface. The invention also discloses a lighting system using the lighting module.

Owner:YOUNG GREEN ENERGY

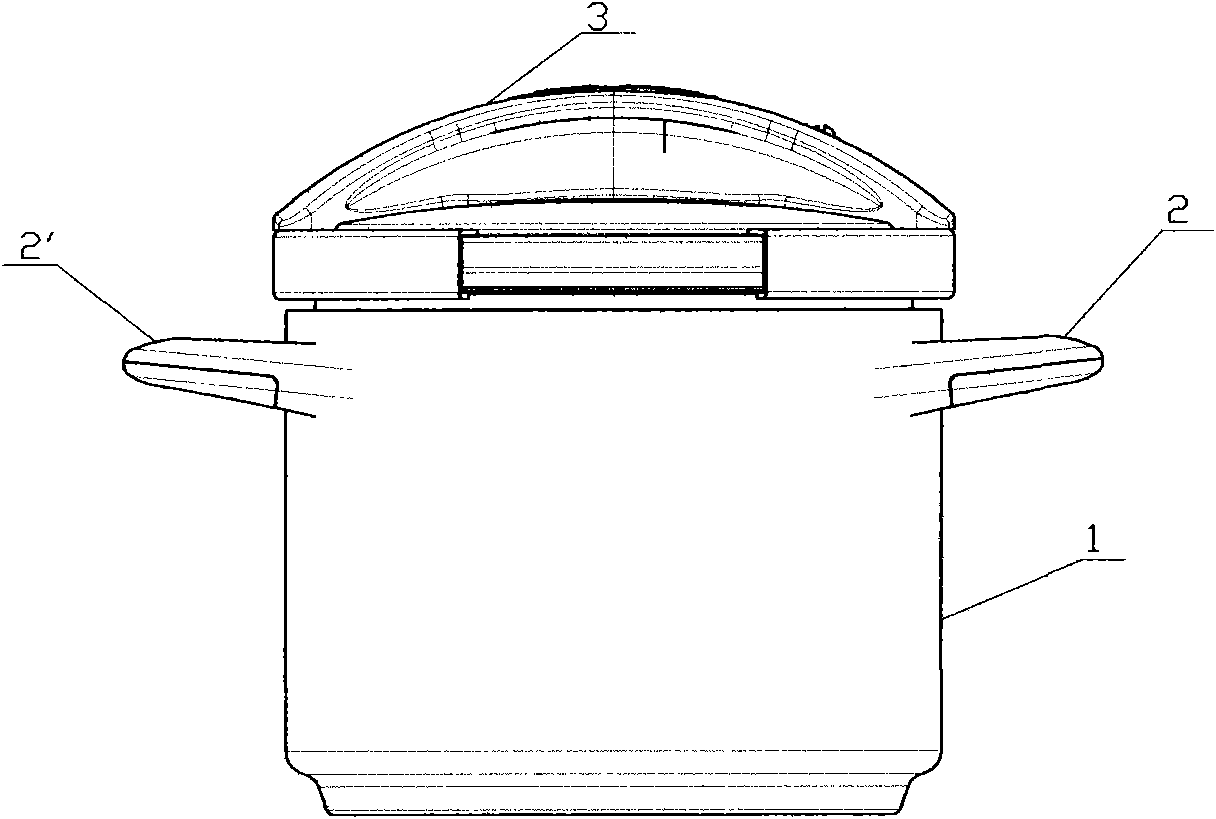

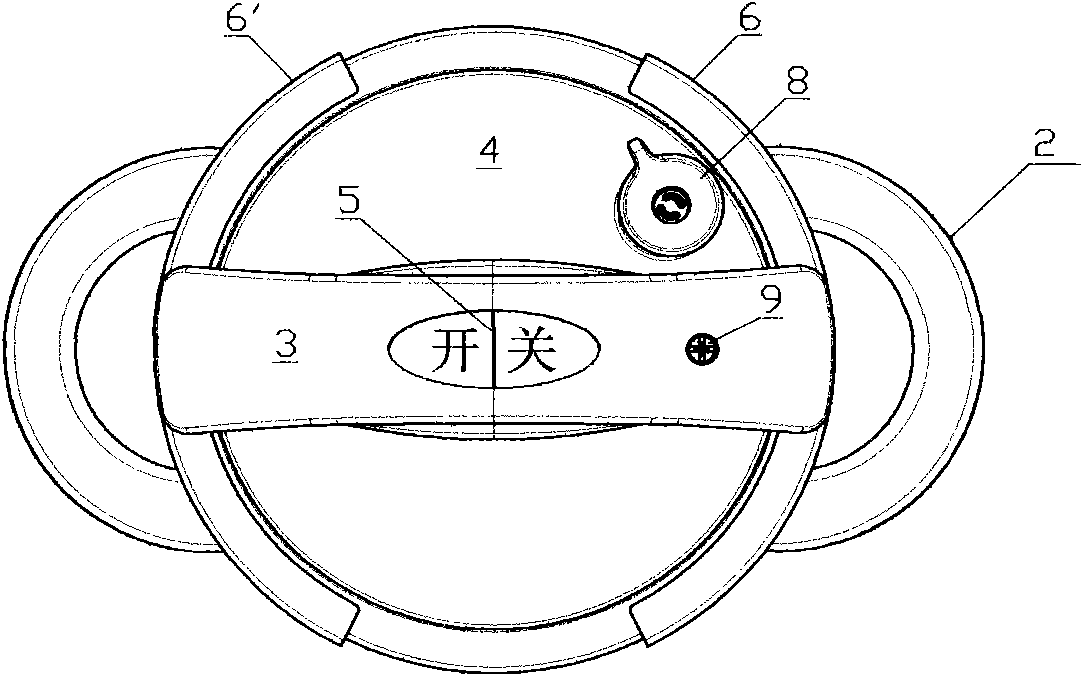

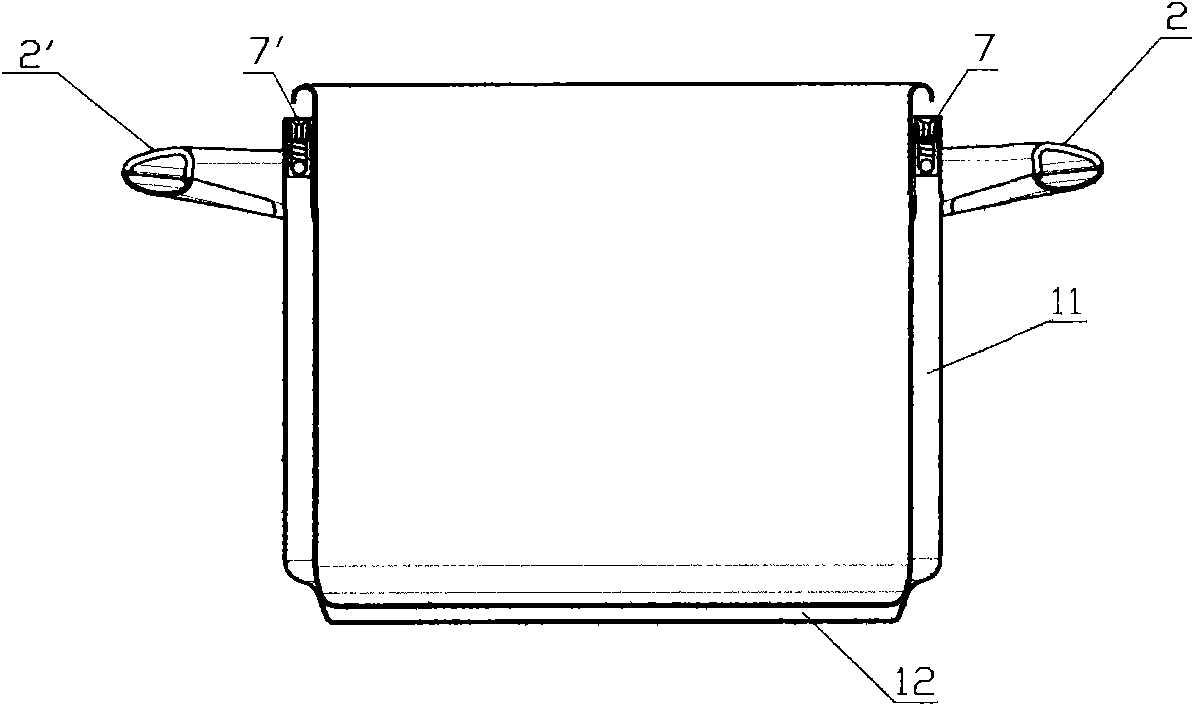

Button opening-closing type sandwich interlayer pressure pan

The invention relates to a button opening-closing type interlayersandwich pressure pan comprising a pan body, pan ears, a pan cover handle and a compound pan bottom. A regulating valve and a safety valve are arranged on a cover panel of the button opening-closing type sandwich pressure pan, a set of dragged opening and closing mechanism drives a pair of moving slide blocks on the cover panel, one ends of the slide blocks are welded with pressure opening-closing rings, a cover and the pan body are banded hooped by a pair of rings, the pressure cover is closed or opened along with the opposite or reverse movement of the opening-closing rings, a button is pressed to generated dragging force so that rocking bars are scratched up and down to drive a vertical side gear, and then the vertical side gear is meshed engaged with a circular gear through racks on the other ends of the slide blocks and is driven to the slide blocks to drag the opening-closing rings. A clip sleeve is arranged on the pan body in which a one-way valve is arranged, and the air pressure in the clip sleeve is 0.3 KPa-0.5 KPa; and the air pressure in the pan is controlled to 0-1 bar by the regulating valve. The sandwich interlayer pressure pan has the advantages of stable and firm structure, good safety, high efficiency, energy saving and convenient use, has the functions of smoldering, pressure maintaining and reboiling without fire and is suitable for various pressure pan cookers.

Owner:XINXING XIANFENG STAINLESS STEEL PROD MFGR CO LTD

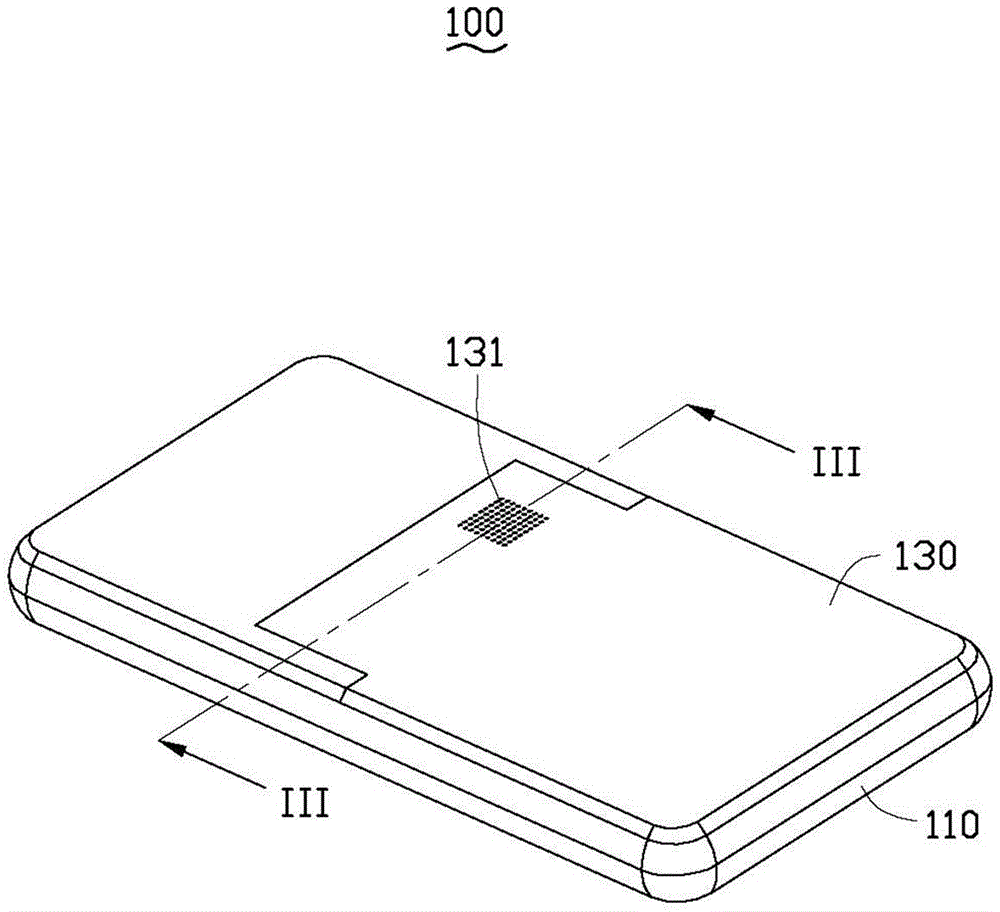

Mobile terminal

InactiveCN104640414AImprove securityEasy accessDigital data processing detailsTelephone set constructionsComputer terminalEngineering

Owner:FUTAIHUA PRECISION ELECTRONICS ZHENGZHOU +1

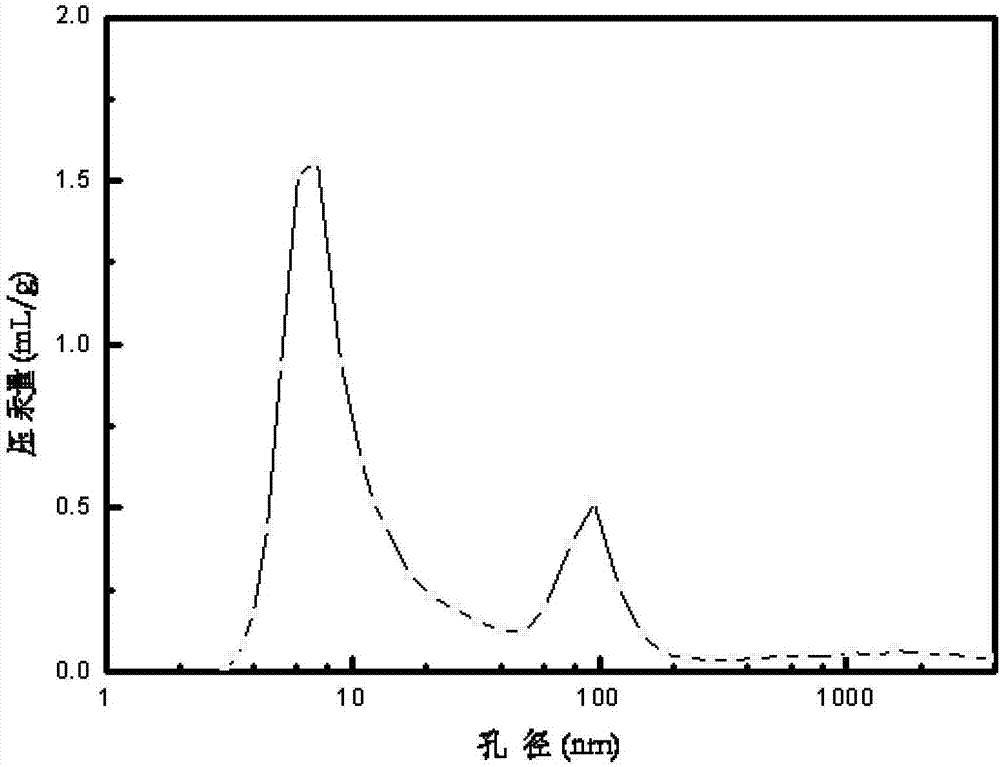

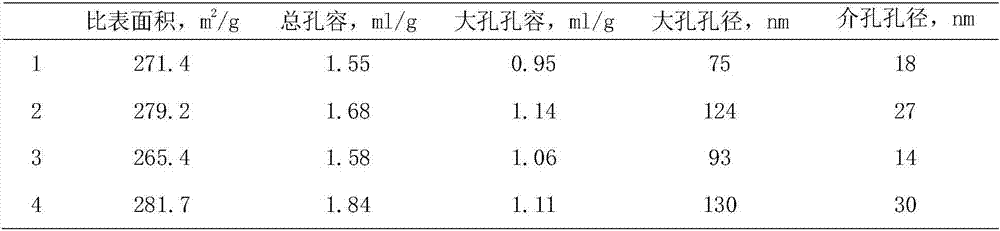

Catalyst for FCC gasoline sweetening and preparation method thereof

InactiveCN107096552ANot easy to coke and deactivateImprove stabilityCatalyst activation/preparationHydrocarbon oils treatment productsActive componentGasoline

The present invention relates to a catalyst for sweetening FCC gasoline. The catalyst comprises an alumina carrier having a macroporous structure and the metal active components nickel and molybdenum supported on the carrier, the alumina carrier having the macroporous structure is 66-91 wt% by weight percentage, the carrier contains auxiliary components phosphorus and magnesium, the pore size distribution is 60-180nm, the pore ratio is 2-75%, the pore volume 0.8-2.0 ml / g, and specific surface area is 250-300 m<2> / g. The content of nickel oxide is 5-19 wt%, and the molybdenum oxide content is 2-15wt%. The catalyst has the advantages of high sweetening activity, high hydrogenation selectivity of diolefin, and less loss of octane value.

Owner:QINZHOU UNIV

Treatment method of wood material

The invention discloses a method for processing a wood material, which is characterized in that the processing method is finished by fully soaking the wood material into silica sol and then drying the fully soaked wood material, wherein the silica sol is alkali silica sol which contains 10 to 31 percent of silicon dioxide. Because the silicon dioxide has the characteristics of difficult combustion, high strength and harness, corrosion resistance and the like, the wood material processed by the method also has the characteristics of difficult combustion, high strength and harness, corrosion resistance and the like; and the silica sol is only 2,000 Yuan per ton in the prior market, the used silica sol after the concentration of the silicon dioxide is reduced can be doped with the silica sol with higher concentration to be reused, so the method also has the characteristic of low processing cost. On the other hand, the silicon dioxide is a more environment-friendly substance, so the method also has the characteristic of environmental protection.

Owner:章浩龙

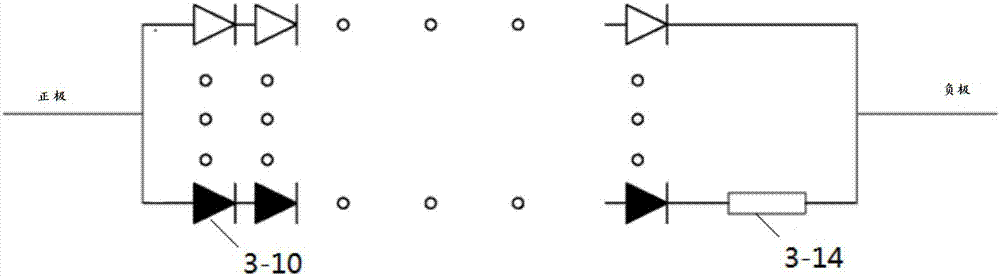

White-light LED COB with CSP chip andlip blue-light chip encapsulation and preparation method thereof

PendingCN107039411AImprove cooling effectIncrease Lumen DensitySolid-state devicesSemiconductor devicesPhosphorAdhesive

The invention discloses a structure of a white-light LED COB with CSP chip and a flip blue-light chip encapsulation and a preparation method thereof, so that problems of high difficulty of complexity of the color-tuning COB process can be solved and simple and efficient production of the customized color-tunable COB can be realized. The structure is formed by flip blue-light LED chips, low-color-temperature CSP light sources, and high-color-temperature phosphor silica gel; a plurality of strings of flip blue-light LED chips connected in parallel and a plurality of strings of low-color-temperature CSP light sources connected in parallel are connected to a positive electrode and a negative electrode jointly to form a dual-circuit structure; or a plurality of strings of flip blue-light LED chips connected in parallel and a plurality of strings of low-color-temperature CSP light sources connected in parallel are connected in parallel and then the parallel unit is connected to a positive electrode and a negative electrode jointly to form a single-circuit structure. The two kinds of circuit structures welded respectively are distributed on a COB substrate uniformly and are connected with corresponding electrodes respectively by lines on the COB substrate. A dam formed by a white dam adhesive is arranged around the two kinds of circuit structures and the blank area inside the dam is filled with the high-color-temperature phosphor silica gel, thereby forming a white-light LED COB structure.

Owner:SHINEON BEIJING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com